Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1 and Pre SBE 72-0063

Common Information

TASK 72-00-00-000-001-A00 Engine General - Replace The No. 5 Bearing Carbon Seal Assembly, Special Procedures-001 - Pre SBE 72-0063

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Special torque data is identified by the * symbol after the torque value.

Refer to SPM TASK 70-64-00-640-501 before the removal of threaded parts and parts with an interference fit. Let the parts soak before removal.

Discard all rubber seal rings, cotter pins and key washers removed in this procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to SPM TASK 70-64-02-640-501

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. Refer to SPM TASK 70-38-21-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Hot Air Gun | LOCAL | Hot Air Gun | ||

| IAE 1F10016 Mechanical wrench | 0AM53 | IAE 1F10016 | 1 | |

| IAE 1F10026 Hydraulic hand pump | 0AM53 | IAE 1F10026 | 1 | |

| IAE 1F10035 Hydraulic Removal puller | 0AM53 | IAE 1F10035 | 1 | |

| IAE 1F10036 Removal puller | 0AM53 | IAE 1F10036 | 1 | |

| IAE 1F10037 Wrench support | 0AM53 | IAE 1F10037 | 1 | |

| IAE 1F10038 Torque wrench | 0AM53 | IAE 1F10038 | 1 | |

| IAE 1F10039 Anti-torque adapter | 0AM53 | IAE 1F10039 | 1 | |

| IAE 1F10040 Anchor wrench plate | 0AM53 | IAE 1F10040 | 1 | |

| IAE 1F10074 Guide pogo stick | 0AM53 | IAE 1F10074 | 1 | |

| IAE 1F10075 Support pedestal | 0AM53 | IAE 1F10075 | 2 | |

| IAE 1F10153 Installation rod | 0AM53 | IAE 1F10153 | 1 | |

| IAE 2F10368 Plate, Vacuum check | 0AM53 | IAE 2F10368 | 1 | |

| IAE 6F10029 Air flow test cart | 0AM53 | IAE 6F10029 | 1 | |

| IAE 6F10030 Vacuum test cart | 0AM53 | IAE 6F10030 | 1 | |

| IAE 1J12221 Impact hammer | 0AM53 | IAE 1J12221 | 1 | |

| IAE 1J12243 Sizing sleeve | 0AM53 | IAE 1J12243 | 1 | |

| IAE 1J12259 Seal slider | 0AM53 | IAE 1J12259 | 1 | |

| IAE 1J12522 Seal slider | 0AM53 | IAE 1J12522 | 1 | |

| IAE 1P16354 Vacuum Test Adapter | 0AM53 | IAE 1P16354 | 1 | |

| IAE 1P16374 Wrench support | 0AM53 | IAE 1P16374 | 1 | |

| IAE 1F16426 remove/installation drier | 0AM53 | IAE 1F16426 | 1 | |

| IAE 1P17038 Slide puller | 0AM53 | IAE 1P17038 | 1 | |

| IAE 1P17523 Blank-off Plate | 0AM53 | IAE 1P17523 | 1 | |

| IAE 1F10034 Hydraulic installation pusher | 0AM53 | IAE 1F10034 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-119 LOCKWIRE | LOCAL | CoMat 02-119 | ||

| CoMat 02-141 LOCKWIRE | LOCAL | CoMat 02-141 | ||

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 10-045 LEAK CHECK FLUID, BUBBLES-TYPE | 03530 | CoMat 10-045 | ||

| CoMat 10-045A LEAK CHECK FLUID, BUBBLES-TYPE | LOCAL | CoMat 10-045A | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Sealing ring | 1 | |||

| Toroidal sealing ring | 2 | |||

| Metallic seal | 1 | |||

| Packing | 1 |

Safety Requirements

NONEProcedure

Refer to Figure.

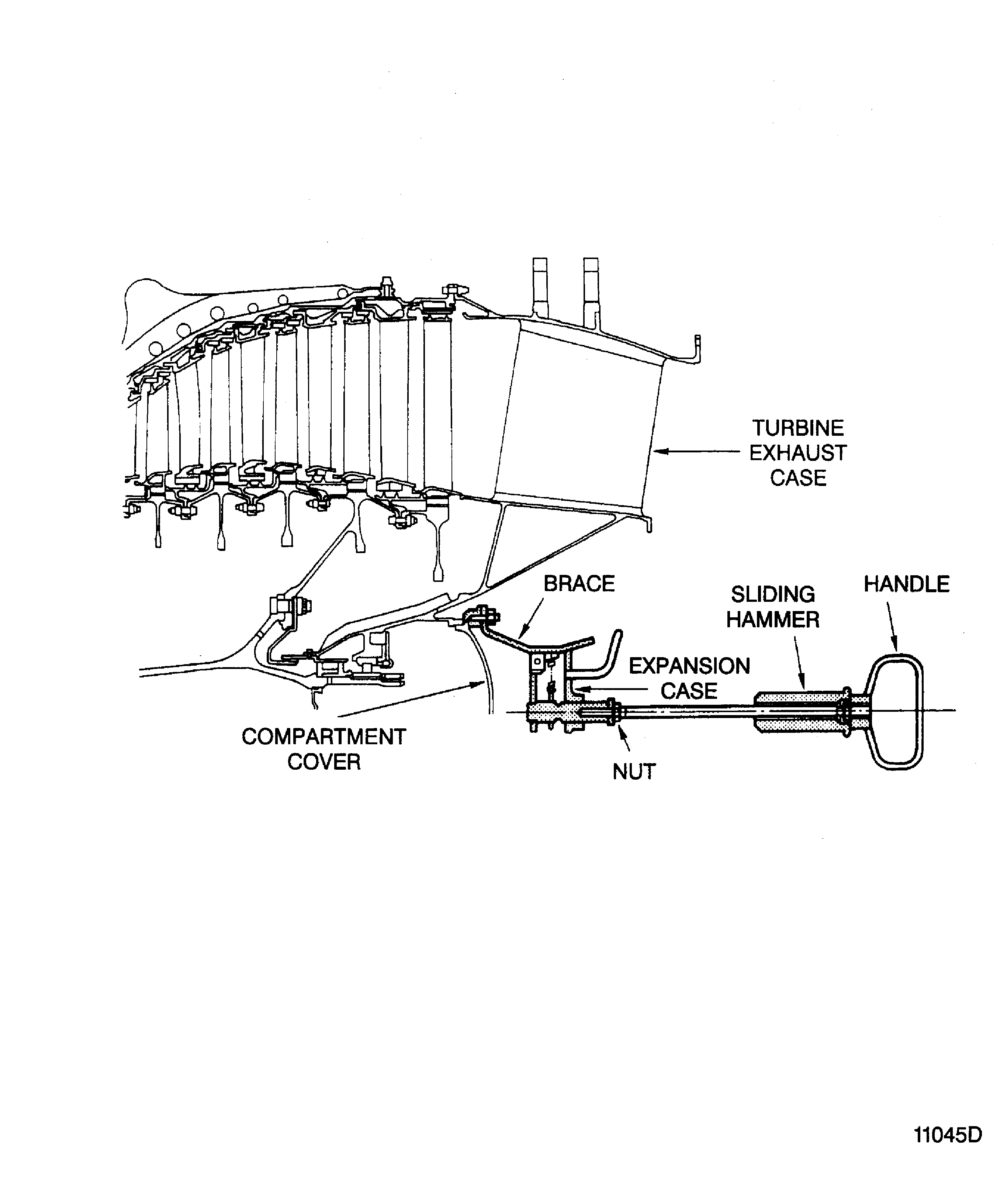

Make sure that the expansion case of the IAE 1F10036 Removal puller 1 off is in the rear position.

Do Step again until the compartment cover is free from the exhaust case.

SUBTASK 72-00-00-030-051-A00 Remove the No. 5 Bearing Compartment Cover (Pre SBE 72-0173)

Refer to Figure.

SBE 72-0173: Replace the No. 5 bearing rear cover packing with a new improved seal

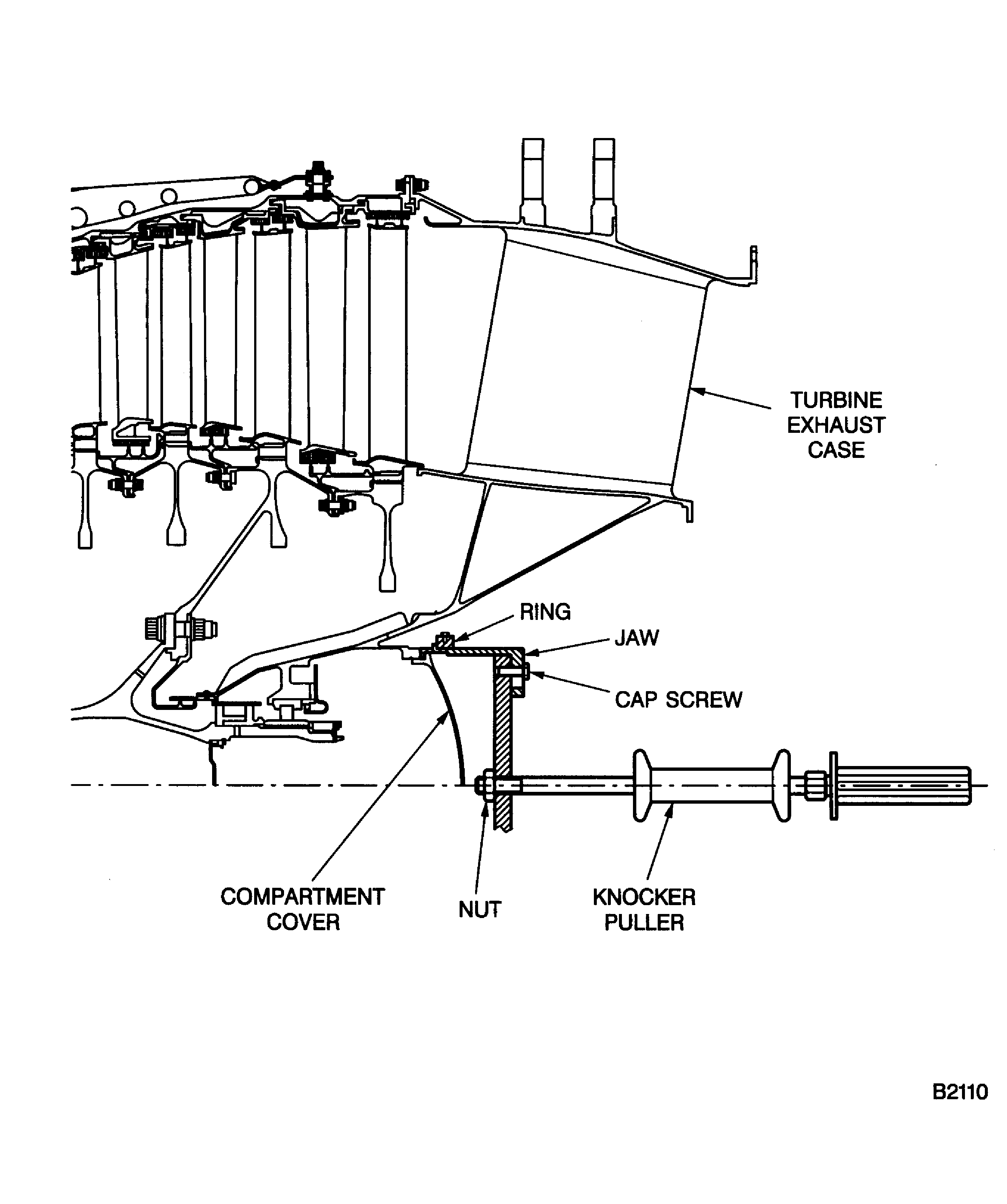

Make sure that the three jaws of the IAE 1P17038 Slide puller 1 off are in the outward position. Make sure that the three jaws are correctly engaged behind the flange at the compartment cover.

Do Step until the compartment cover is free from the exhaust case.

SUBTASK 72-00-00-030-051-B00 Remove the No. 5 Bearing Compartment Covers (SBE 72-0173)

Refer to Figure.

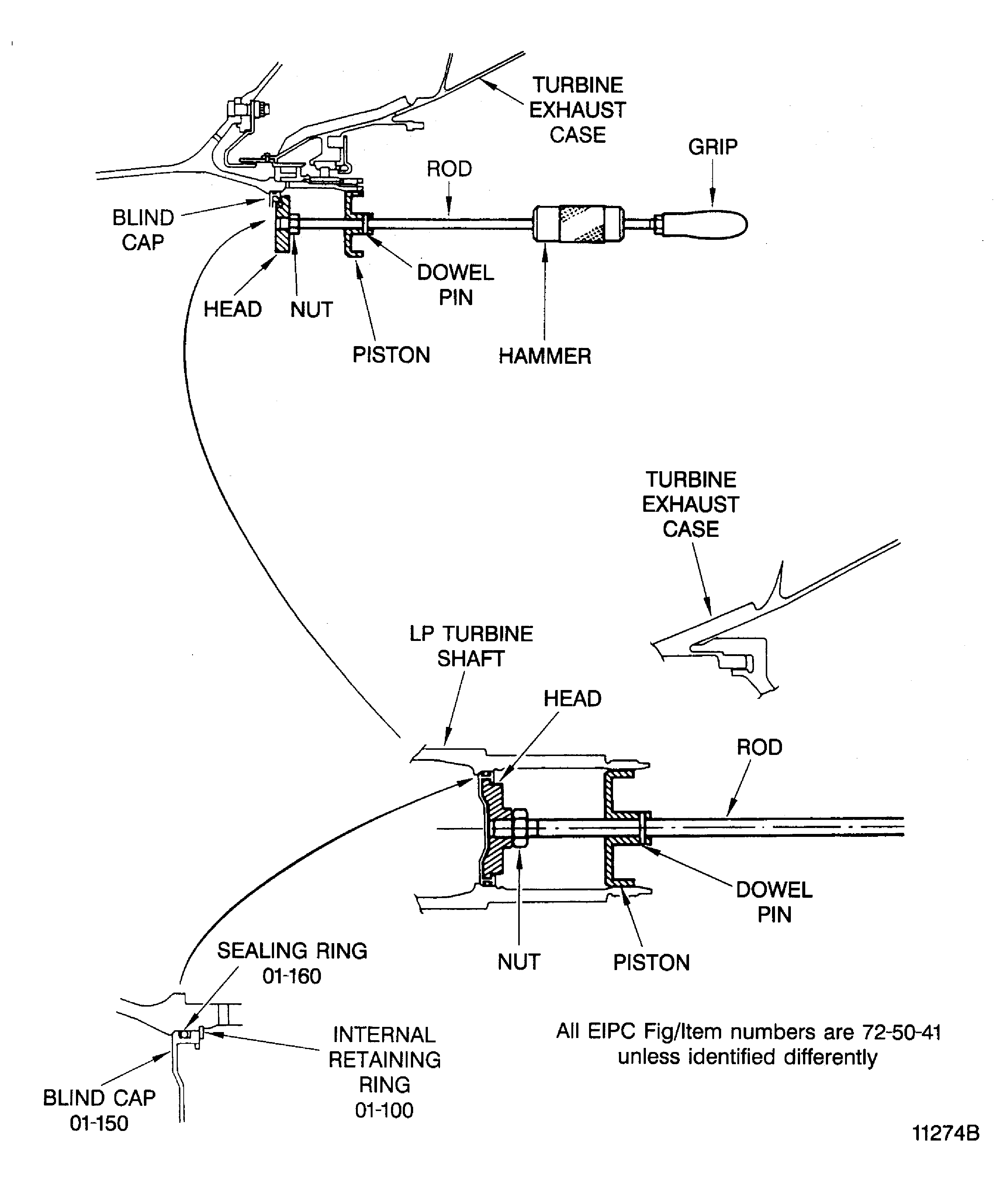

Install the IAE 1J12221 Impact hammer 1 off in to the turbine shaft. Make sure that the piston of the impact hammer is correctly aligned with the LP turbine shaft.

Do Step again until the blind cap is free from the turbine shaft.

SUBTASK 72-00-00-030-052 Remove the Blind Cap of the LP Turbine Shaft

Refer to Figure.

SUBTASK 72-00-00-030-053-A00 Disconnect the No. 5 Bearing Compartment Oil Feed and Scavenge Tubes (Pre SBE 79-0011)

Refer to Figure.

SBE 79-0011: Revise No. 5 bearing oil scavenge tube assembly attaching parts

SUBTASK 72-00-00-030-053-B00 Disconnect the No. 5 Bearing Compartment Oil Feed and Scavenge Tubes (SBE 79-0011)

Refer to Figure.

SUBTASK 72-00-00-030-054 Disconnect the Oil Feed Tube of the No. 5 Bearing

Refer to Figure.

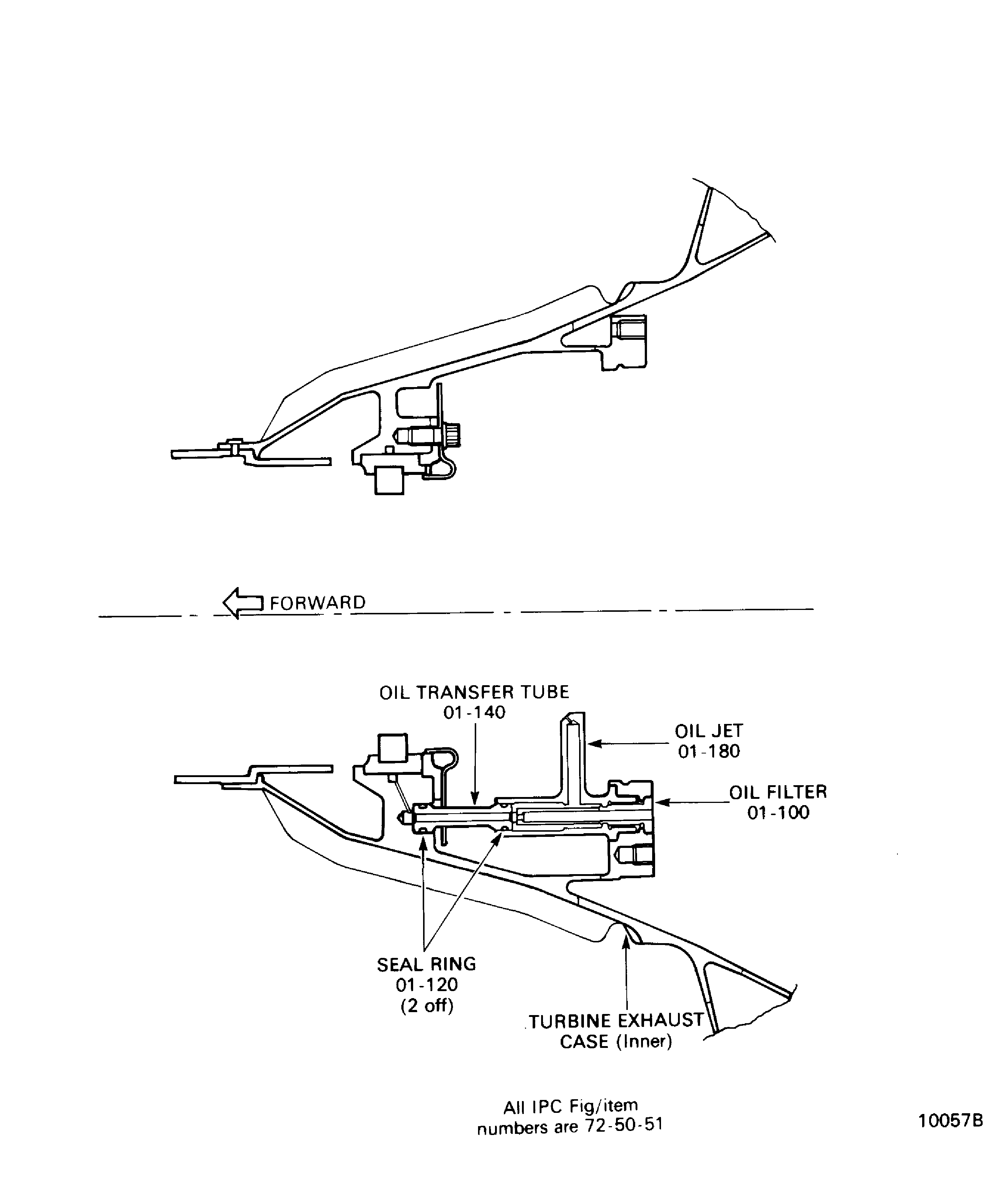

Release and remove the oil filter from the oil jet. Use the IAE 1F16426 remove/installation drier 1 off.

SUBTASK 72-00-00-030-055 Remove the Oil Jet and Oil Filter of the No. 5 Bearing

Refer to Figure.

Attach the IAE 1F10037 Wrench support 1 off to the inner rear flange of the TEC.

Install the IAE 1F10038 Torque wrench 1 off through the wrench support. Engage the torque wrench with the rear lock nut of the LP turbine shaft.

Install the IAE 1F10039 Anti-torque adapter 1 off through the torque wrench. Lock the anti-torque adapter to the LP turbine shaft.

Install the IAE 1F10016 Mechanical wrench 1 off to the torque wrench. Safety the anti-torque adapter to the mechanical wrench with the IAE 1F10040 Anchor wrench plate 1 off.

SUBTASK 72-00-00-030-056 Remove the Rear Lock Nut

Refer to Figure.

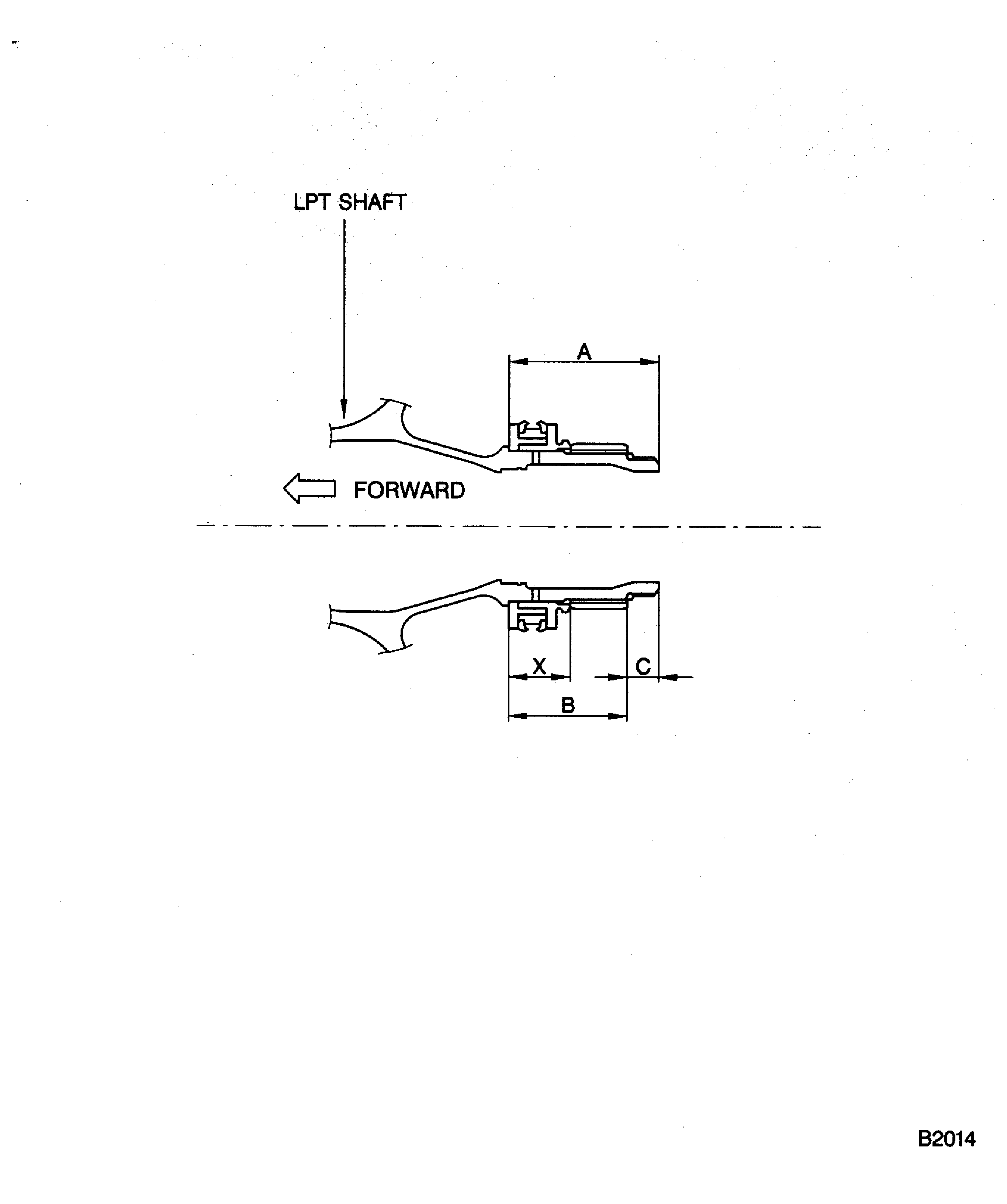

Measure dimension C at three equally spaced positions. Calculate the average and write it. Refer to Figure.

SUBTASK 72-00-00-030-057-A00 Remove the Deaerators and the Retaining Ring (Pre SBE 72-0142)

Refer to Figure.

SBE 72-0142: Provide a new carbon seal for the No.5 bearing compartment

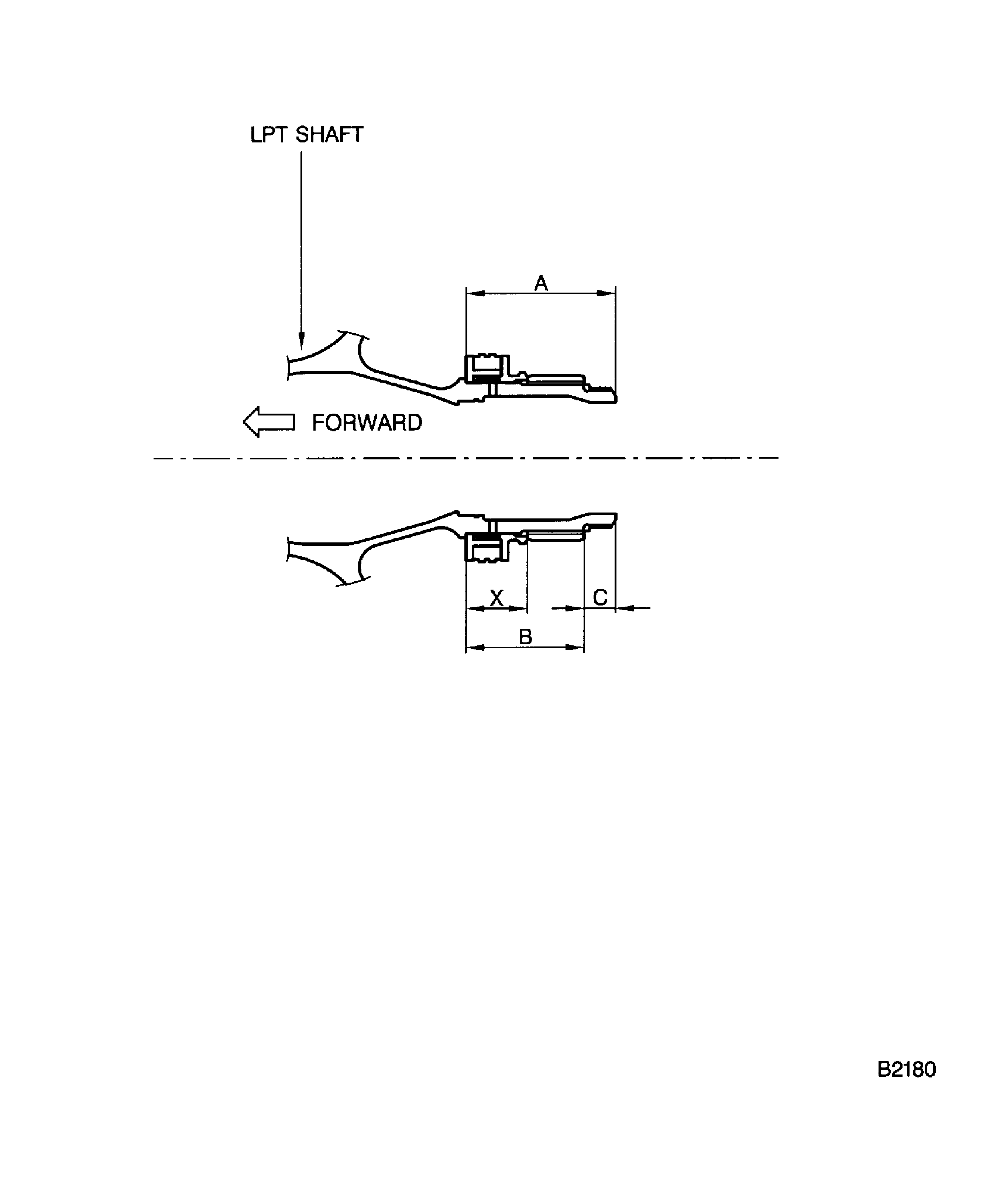

Measure dimension C at three equally spaced positions. Calculate the average and write it. Refer to Figure.

SUBTASK 72-00-00-030-057-B00 Remove the Deaerators and the Retaining Ring (SBE 72-0142)

Refer to Figure.

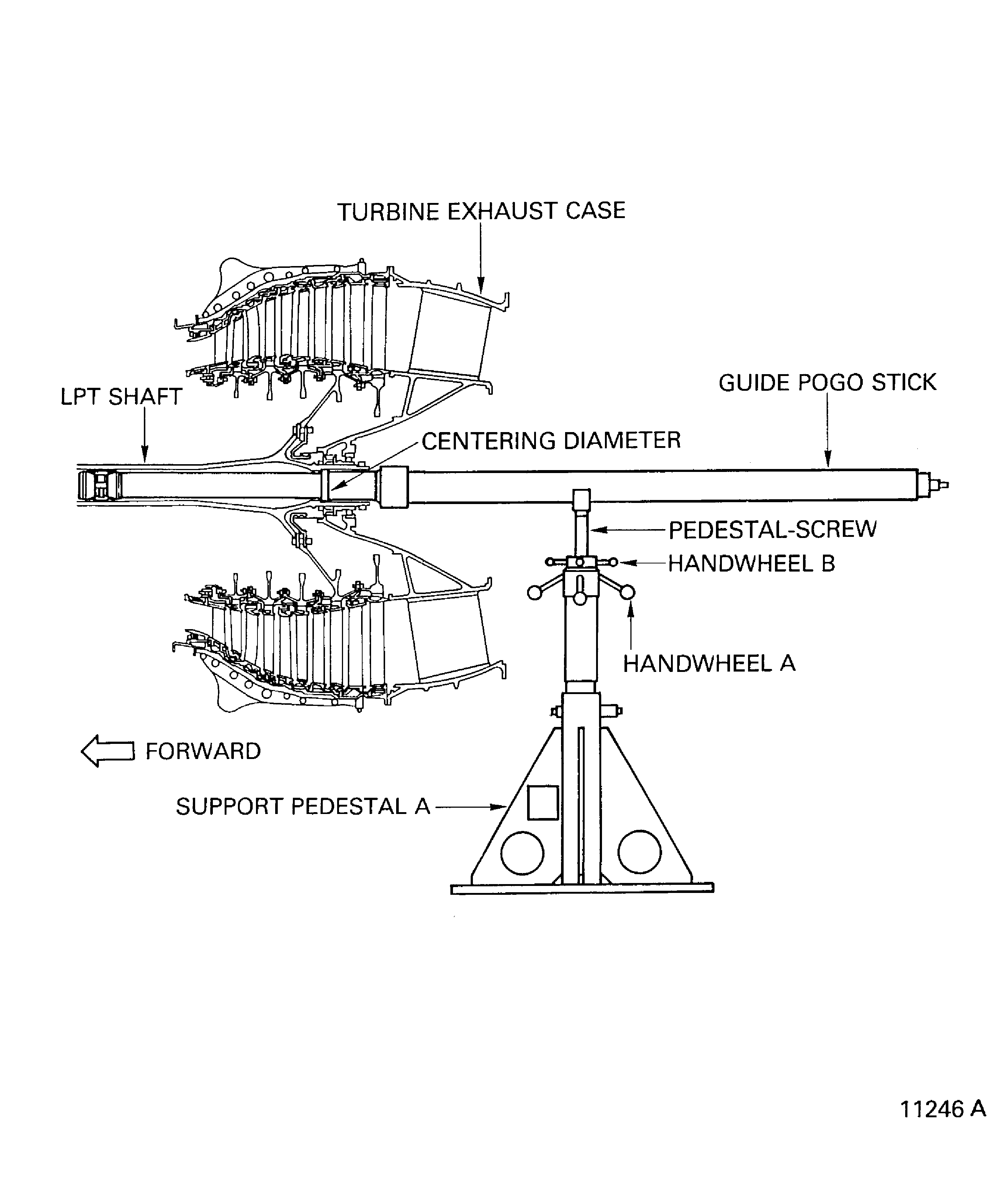

Install the IAE 1F10074 Guide pogo stick 1 off to the inner diameter of the LP turbine shaft. Use applicable webbing sling.

Put the IAE 1F10075 Support pedestal 1 off below the guide pogo stick. Move the support pedestal A near the rear flange of the TEC. Turn the handwheel A until the pedestal screw touches the guide pogo stick. Lift the LP turbine rotor so that the bearing outer race carries no load. Safety the pedestal-screw in that position with the handwheel B.

Release the handwheel B (part of the IAE 1F10075 Support pedestal support pedestal 1 off).

Remove the guide pogo stick.

SUBTASK 72-00-00-430-051 Install the Guide Pogo Stick to the LP Turbine Shaft

Refer to Figure.

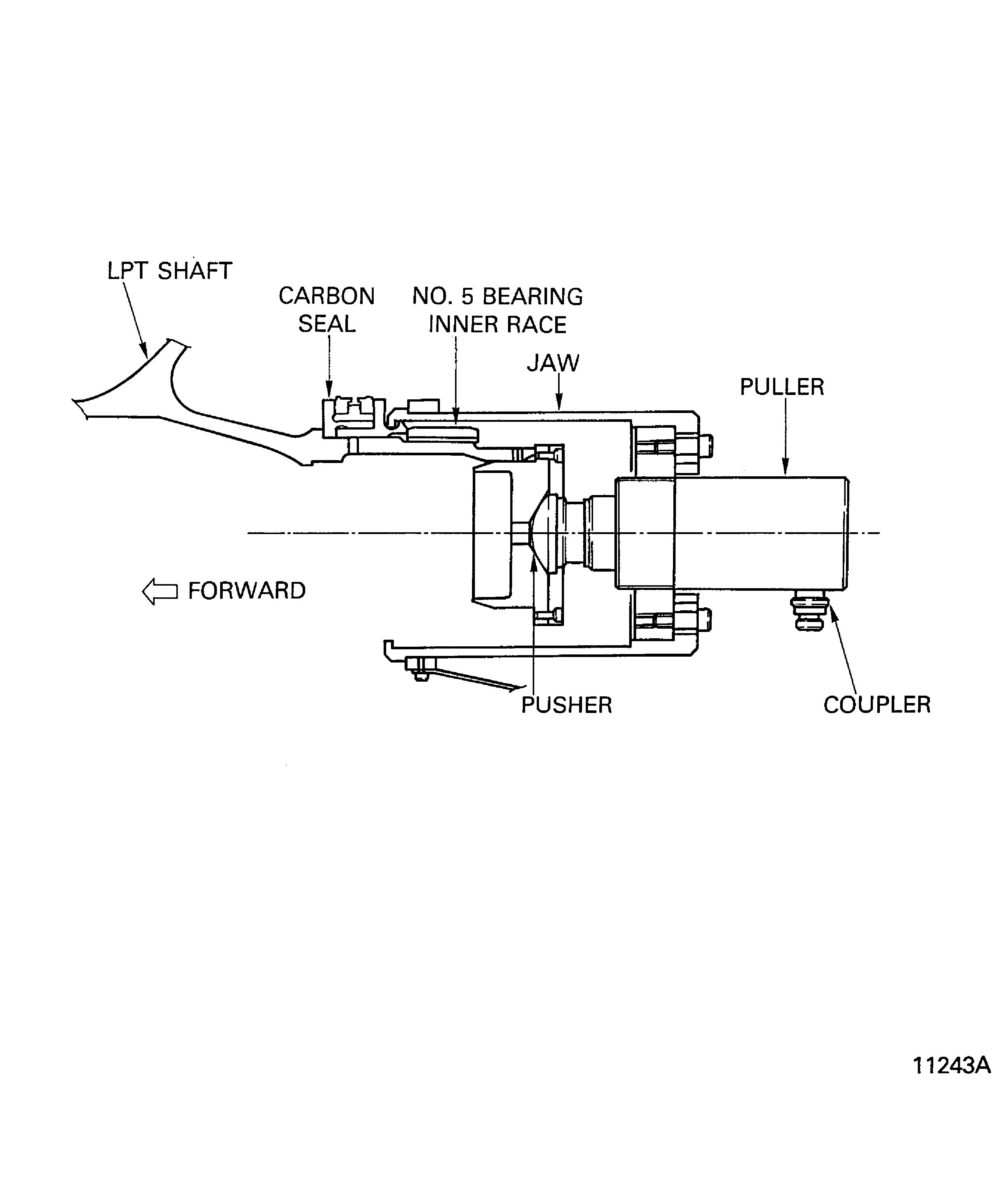

Make sure that the rear lock nut is removed. Install the IAE 1F10035 Hydraulic Removal puller 1 off to the rear face of the LP turbine shaft. Engage the jaws of the puller with the grooves of the carbon seal.

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the puller.

Operate the hydraulic pump until the No.5 bearing inner race and the carbon seal are free of the LP turbine shaft. Refer to Figure.

SUBTASK 72-00-00-030-058-A00 Remove the No. 5 Bearing Inner Race and the Carbon Seal (Pre SBE 72-0142)

NOTE

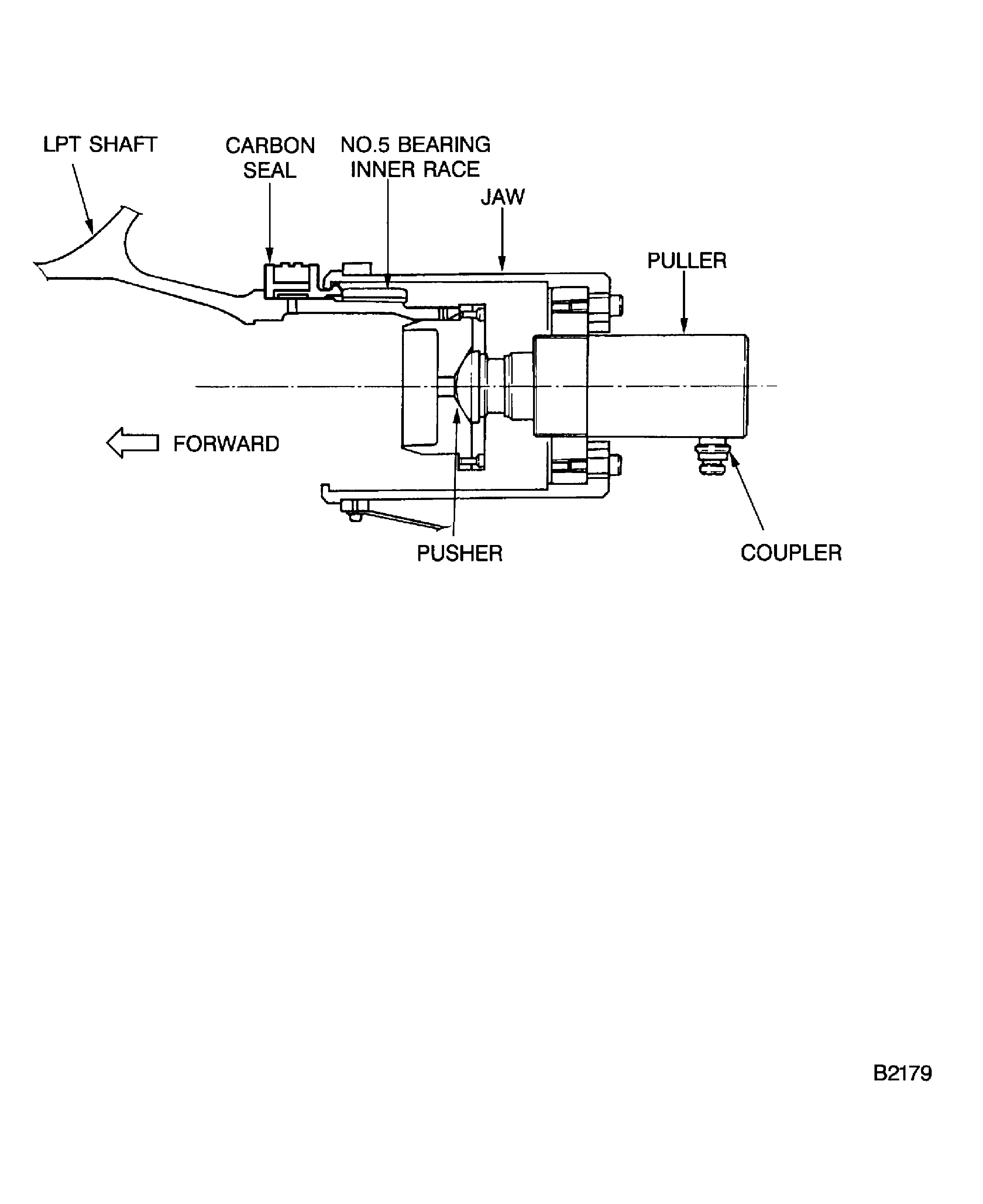

Do these steps as quickly as possible.Refer to Figure.

SBE 72-0142: Provide a new carbon seal for the No.5 bearing compartment

Make sure that the rear lock nut is removed. Install the IAE 1F10035 Hydraulic Removal puller 1 off to the rear face of the LP turbine shaft. Engage the jaws of the puller with the grooves of the carbon seal.

Connect IAE 1F10026 Hydraulic hand pump 1 off.

Operate the hydraulic pump until the No.5 bearing inner race and the carbon seal are free of the LP turbine shaft. Refer to Figure.

SUBTASK 72-00-00-030-058-B00 Remove the No. 5 Bearing Inner Race and the Carbon Seal, =002 (SBE 72-0142)

NOTE

Do these steps as quickly as possible.Refer to Figure.

Lubricate the new carbon seal with CoMat 10-077 APPROVED ENGINE OILS.

Install the new carbon seal to the IAE 1F10074 Guide pogo stick 1 off.

Measure dimension A and write it. Refer to Figure.

SUBTASK 72-00-00-430-052-A00 Install the Guide Pogo Stick (Pre SBE 72-0142)

Refer to Figure.

SBE 72-0142: Provide a new carbon seal for the No. 5 bearing compartment.

Lubricate the new carbon seal with CoMat 10-077 APPROVED ENGINE OILS.

Install the new carbon seal to the IAE 1F10074 Guide pogo stick 1 off.

Measure the dimension A and write it. Refer to Figure.

SUBTASK 72-00-00-430-052-B00 Install the Guide Pogo Stick (SBE 72-0142)

Install the carbon seal to the rear end of the LP turbine shaft. Refer to Figure. Make sure that the groove of the carbon seal points to the rear.

Release the handwheel B (part of the IAE 1F10075 Support pedestal).

Remove the IAE 1F10074 Guide pogo stick 1 off.

SUBTASK 72-00-00-430-053-A00 Install the Carbon Seal to the LP Turbine Shaft,.nd (Pre SBE 72-0142)

SBE 72-0142: Provide a new carbon seal for the No. 5 bearing compartment

Install the carbon seal to the rear end of the LP turbine shaft. Refer to Figure. Make sure that the groove of the carbon seal points to the rear.

Release the handwheel B (part of the IAE 1F10075 Support pedestal).

Remove the IAE 1F10074 Guide pogo stick 1 off.

SUBTASK 72-00-00-430-053-B00 Install the Carbon Seal to the LP Turbine Shaft (SBE 72-0142)

WARNING

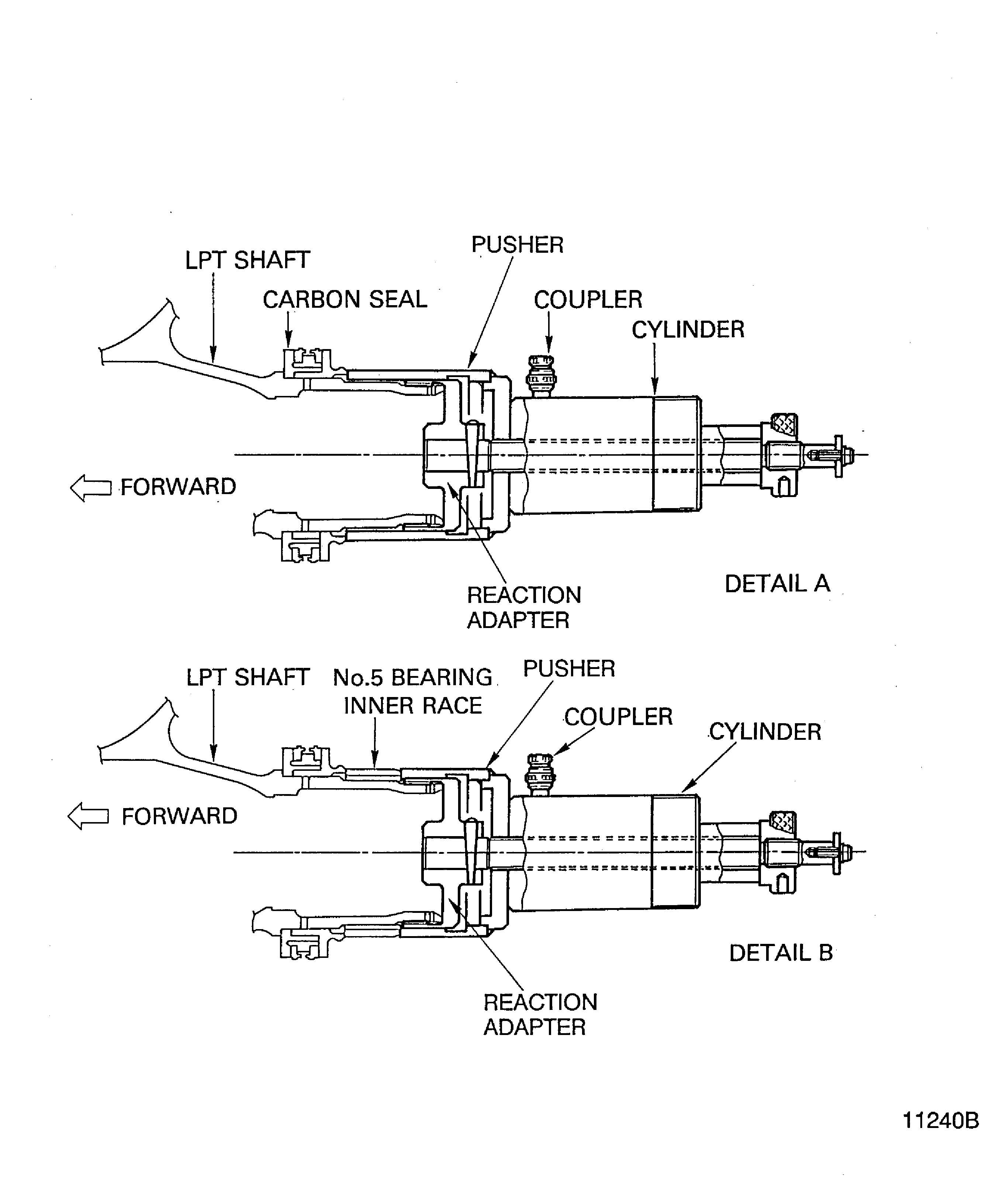

USE GLOVES TO INSTALL THE HOT INNER RACE OF THE NO. 5 BEARING.Install the inner race of the No. 5 bearing to the LP turbine shaft. Refer to Figure.

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the coupler of the pusher.

Measure the new dimension C and compare it with the dimension calculated C. The new dimension C must be equal to dimension calculated C. Refer to Figure.

SUBTASK 72-00-00-430-054-A00 Install the No. 5 Bearing Inner Race (Pre SBE 72-0142)

NOTE

Do these steps as quickly as possible.SBE 72-0142: Provide a new carbon seal for the No. 5 bearing compartment

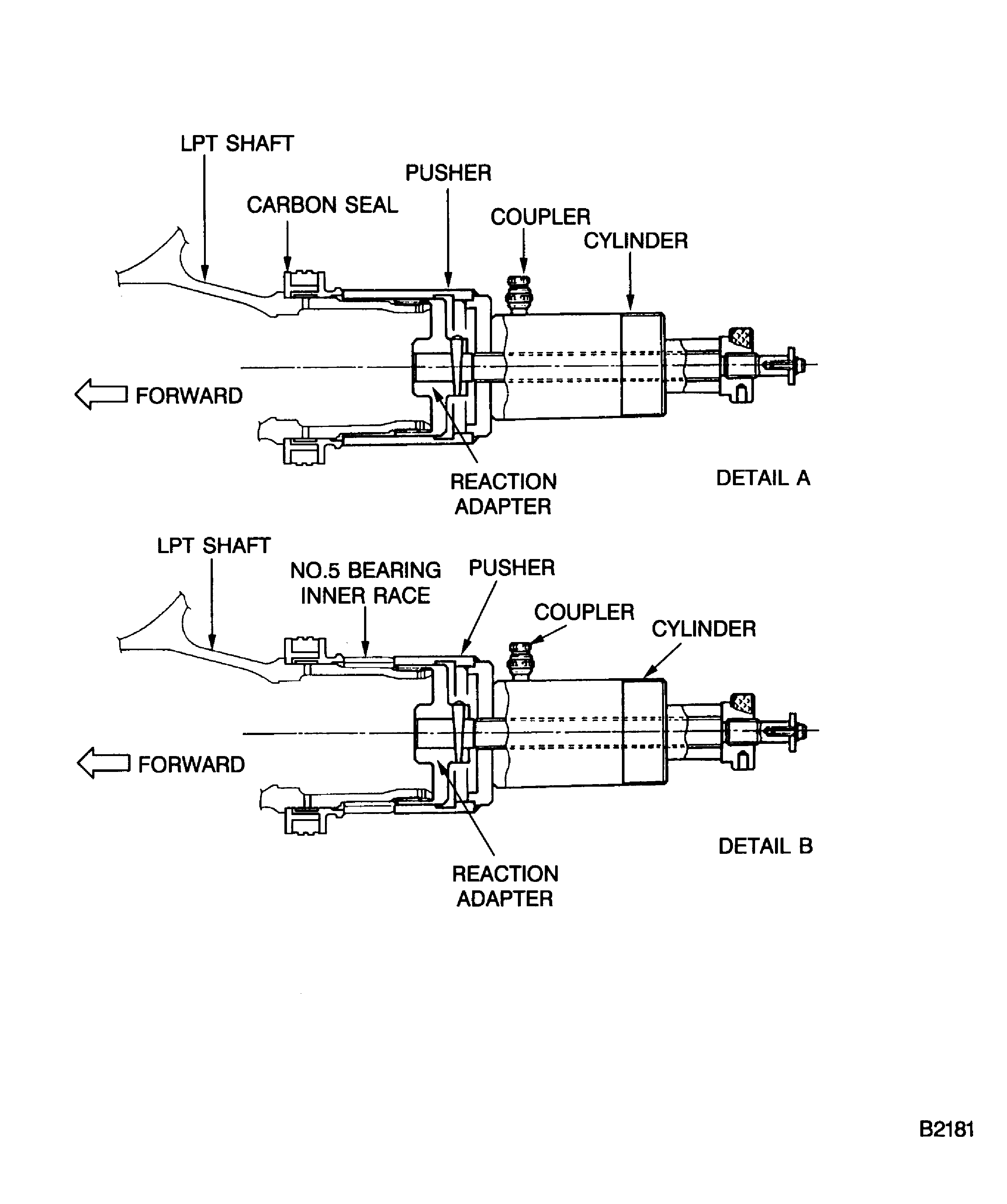

WARNING

USE GLOVES TO INSTALL THE HOT INNER RACE OF THE NO. 5 BEARING.Install the inner race of the No.5 bearing to the LP turbine shaft. Refer to Figure.

Install the IAE 1F10074 Guide pogo stick 1 off on the rear end of the LP turbine shaft. Attach the reaction adapter (part of the hydraulic installation pusher) to the rear thread of the LP turbine shaft.

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the coupler of the pusher.

SUBTASK 72-00-00-430-054-B00 Install the No. 5 Bearing Inner Race (SBE 72-0142)

NOTE

Do these steps as quickly as possible.Refer to Figure.

Install the bearing outer race on the IAE 1F10074 Guide pogo stick 1 off.

SUBTASK 72-00-00-430-055 Install the Bearing Outer Race

Refer to Figure.

SUBTASK 72-00-00-430-056 Install the Retaining Ring and the Deaerators

Refer to: Figure.

Attach the IAE 1F10037 Wrench support 1 off to the inner rear flange of the TEC.

Install the IAE 1F10038 Torque wrench 1 off through the wrench support. Engage the torque wrench with the rear lock nut.

Install the IAE 1F10039 Anti-torque adapter 1 off through the torque wrench. Lock the anti-torque adapter to the LP turbine shaft.

Install the IAE 1F10016 Mechanical wrench 1 off to the torque wrench. Safety the anti-torque adapter to the mechanical wrench with the IAE 1F10040 Anchor wrench plate 1 off.

Make a correlation mark between the IAE 1F10016 Mechanical wrench and the IAE 1F10038 Torque wrench.

Do Step again.

SUBTASK 72-00-00-430-057 Install the Rear Lock Nut to the Turbine Shaft

Refer to Figure.

Lubricate the ENGINE-NO.5 BEARING OIL JET AND FILTER (72-50-51, 01-120) toroidal sealing rings 2 off with CoMat 10-077 APPROVED ENGINE OILS and install the toroidal sealing rings on both ends of the oil transfer tube.

Push the transfer tube from the rear with the IAE 1F10153 Installation rod 1 off until it is fully installed in to the flange of the No. 5 bearing housing.

Install the oil filter in to the threaded hole of the oil jet. Torque the oil filter to 371.736 lbf.in (42.0 Nm). Use the IAE 1F16426 remove/installation drier 1 off.

SUBTASK 72-00-00-430-058 Install the Oil Jet of the No. 5 Bearing

Refer to Figure.

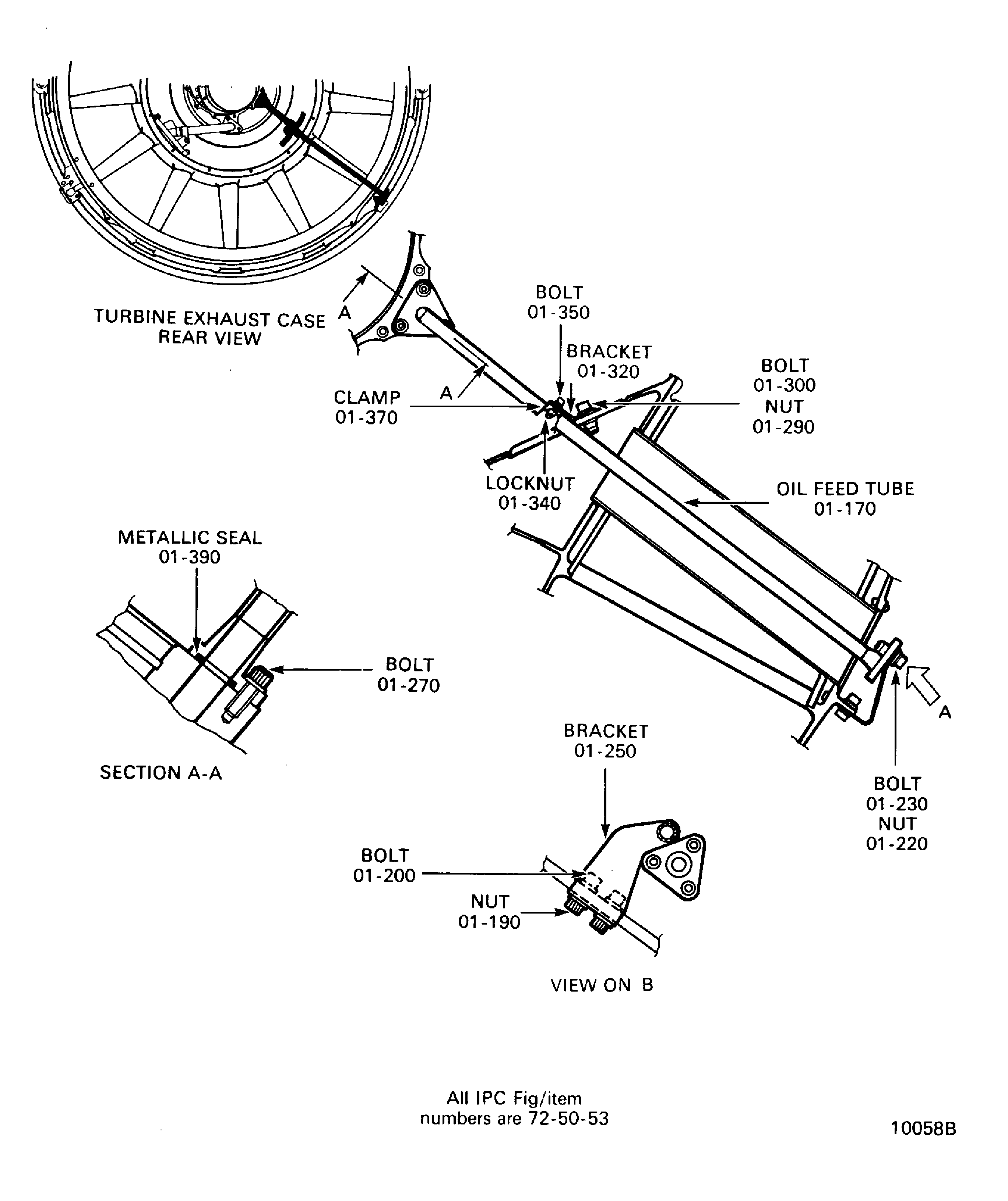

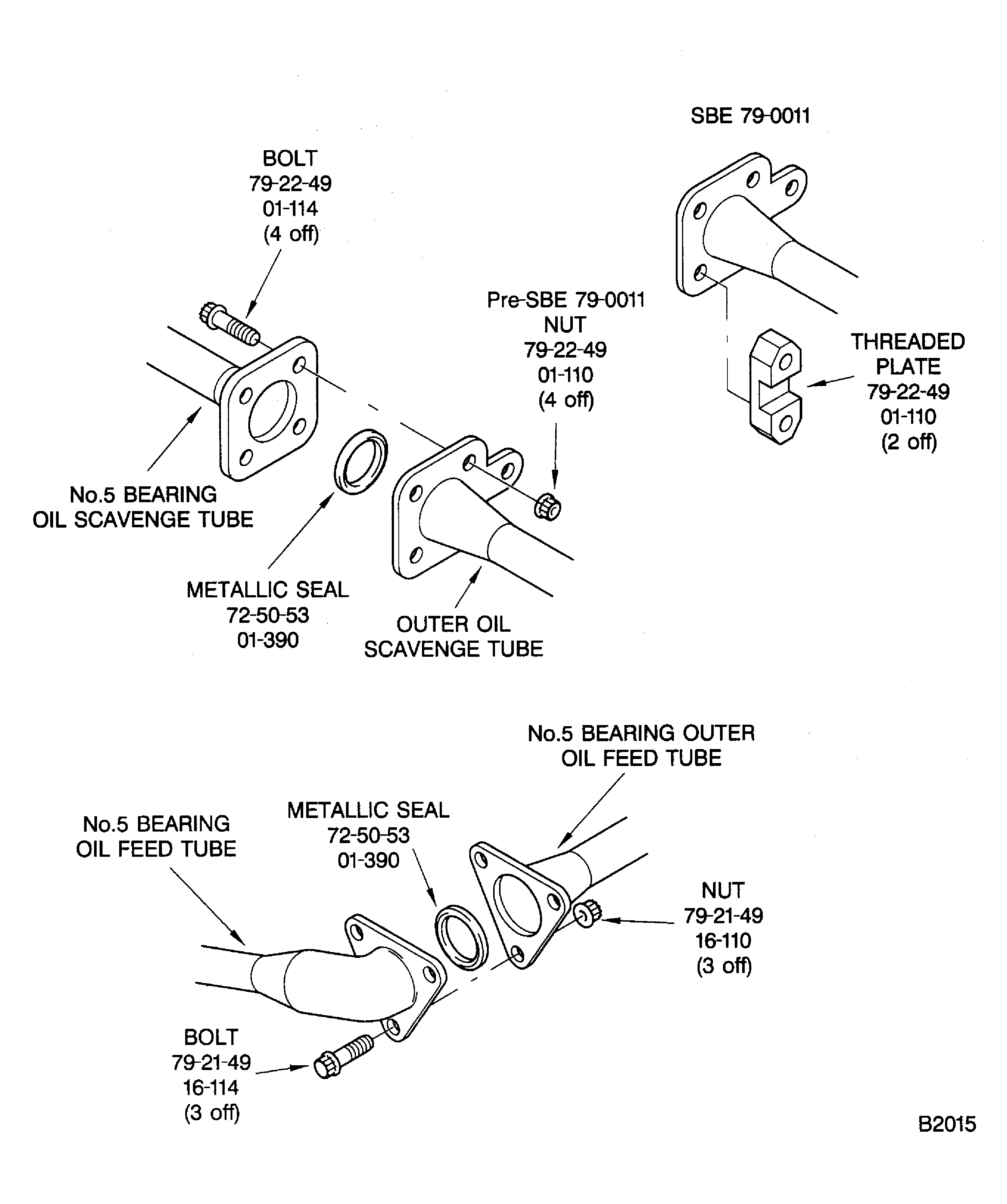

Install ENGINE-EXHAUST CASE AND FITTINGS (72-50-53, 01-390) metallic seal 1 off to the flange of the oil feed tube. Install the oil feed tube to the No. 5 bearing compartment.

SUBTASK 72-00-00-430-059 Connect the Oil Feed Tube of the No. 5 Bearing

SBE 72-0037: Replacement of the LP turbine shaft rear end sealing ring

NOTE

Use of IAE 1J12259 Seal slider seal slider without IAE 1J12243 Sizing sleeve sizing sleeve is not permitted.Refer to Figure.

Put the blind cap ENGINE-LP TURBINE SHAFT (72-50-41, 01-150) on to a work bench with rear end down.

Install the IAE 1J12259 Seal slider 1 off on to the blind cap.

Lubricate the new ENGINE-LP TURBINE SHAFT (72-50-41, 01-160) sealing ring with CoMat 10-077 APPROVED ENGINE OILS.

Lubricate the outer diameter faces of the seal slider and the blind cap with CoMat 10-077 APPROVED ENGINE OILS.

Extend the sealing ring and install it to the blind cap as follows. Refer to Figure.

Put the IAE 1J12243 Sizing sleeve 1 off on to the work bench with the front end down.

Lubricate the inner diameter face of the sizing sleeve and the outer diameter of the sealing ring with CoMat 10-077 APPROVED ENGINE OILS.

Put the blind cap in to the sizing sleeve. Diaphragm of the blind cap must be in down direction. Refer to Figure position A.

Slowly push down the blind cap until it touches the work bench. Refer to Figure position B.

Make the sealing ring diameter smaller as follows. Refer to Figure.

CAUTION

DO NOT CORRECT TWISTED CONDITION OF THE SEALING RING. DISCARD THE TWISTED SEALING RING.Make sure that the sealing ring is not twisted. Refer to Figure.

Examine the sealing ring.

Install the blind cap to the LP turbine shaft. Use the IAE 1J12221 Impact hammer 1 off.

Install the internal retaining ring ENGINE-LP TURBINE SHAFT (72-50-41, 01-100). Refer to Figure.

SUBTASK 72-00-00-430-061-B00 Install the Blind Cap to the LP Turbine Shaft (SBE 72-0037 and Pre SBE 72-0227)

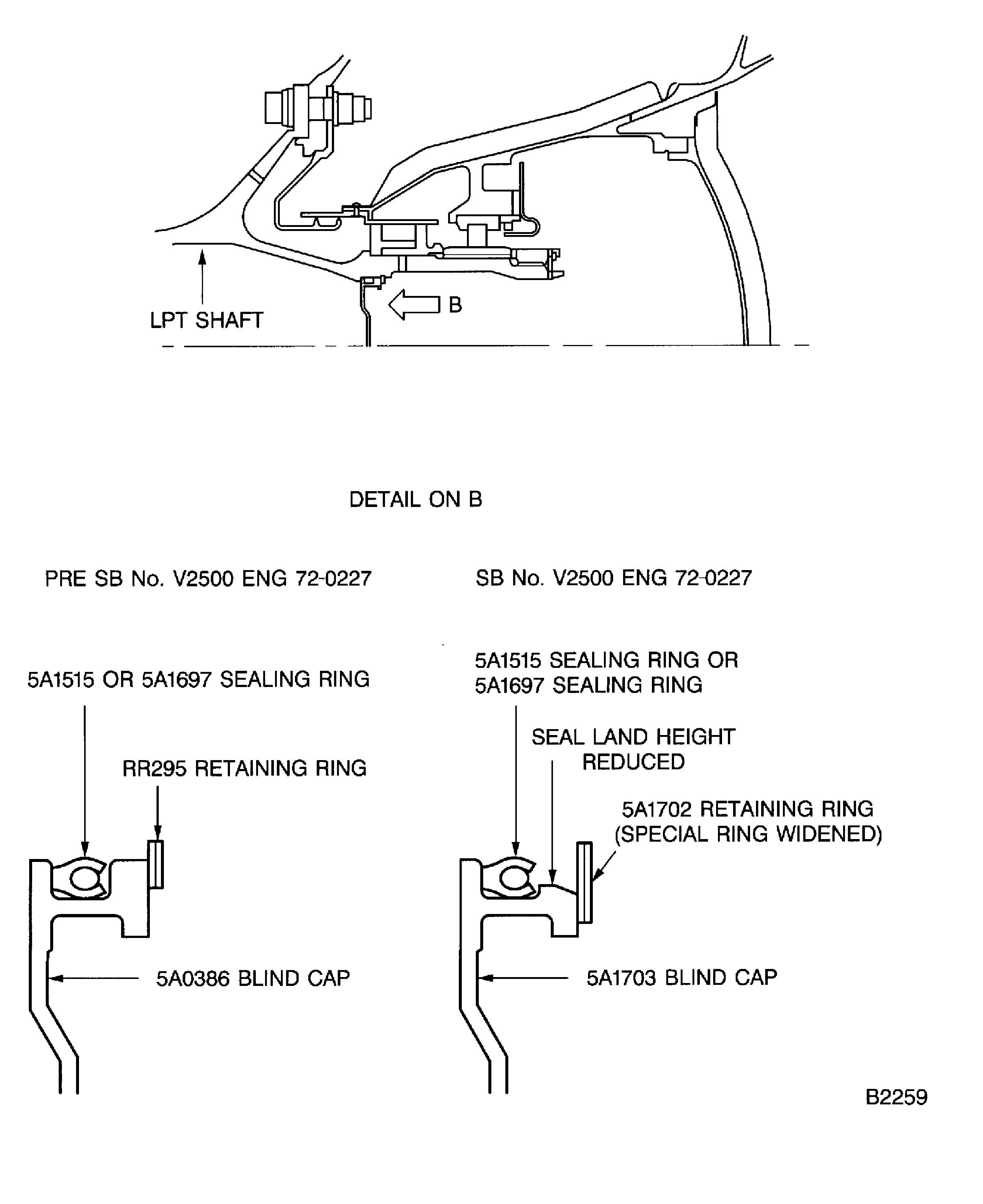

SBE 72-0227: Provide a new blind cap with decreased seal land height

Install IAE 1J12522 Seal slider 1 off on the blind cap.

Lubricate the sealing ring with CoMat 10-077 APPROVED ENGINE OILS.

Lubricate the outer diameter face of the blind cap with CoMat 10-077 APPROVED ENGINE OILS.

Install the new sealing ring ENGINE-LP TURBINE SHAFT (72-50-41, 01-160) to the blind cap ENGINE-LP TURBINE SHAFT (72-50-41, 01-150) as follows. Refer to Figure:

CAUTION

DO NOT CORRECT TWISTED CONDITION OF THE SEALING RING. DISCARD THE TWISTED SEALING RING.Make sure that the sealing ring is not twisted. Refer to Figure.

Examine the sealing ring.

CAUTION

DO NOT USE THE INTERNAL RETAINING RING P/N RR295 WITH THE BLIND CAP P/N 5A1703.Install the blind cap to the LP turbine shaft. Use the IAE 1J12221 Impact hammer.

Install the internal retaining ring ENGINE-LP TURBINE SHAFT (72-50-41, 01-100). Refer to Figure.

SUBTASK 72-00-00-430-061-D00 Install the Blind Cap to the LP Turbine Shaft (SBE 72-0227)

Refer to Figure.

Lubricate ENGINE-NO.5 BEARING COMPARTMENT COVER (72-58-01, 01-160) packing 1 off with CoMat 10-077 APPROVED ENGINE OILS. Install the packing on the groove of the compartment cover.

WARNING

IF YOU DO NOT SECURE THE COMPARTMENT COVER DURING THE LEAK TEST THERE IS A RISK OF PERSONAL INJURY FROM THE RELEASED COVER.Install 12 work bolts to the compartment cover. Tighten the bolts.

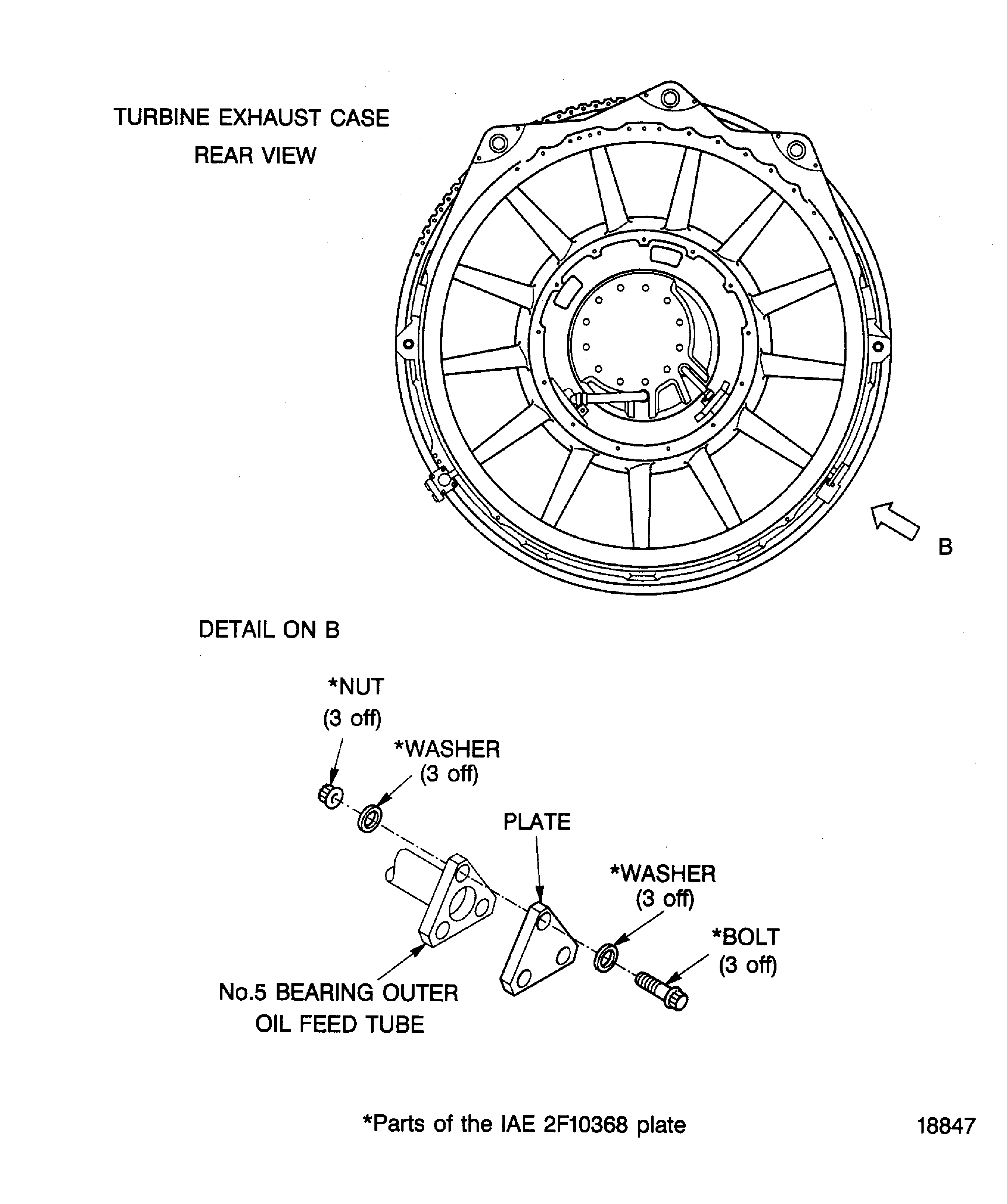

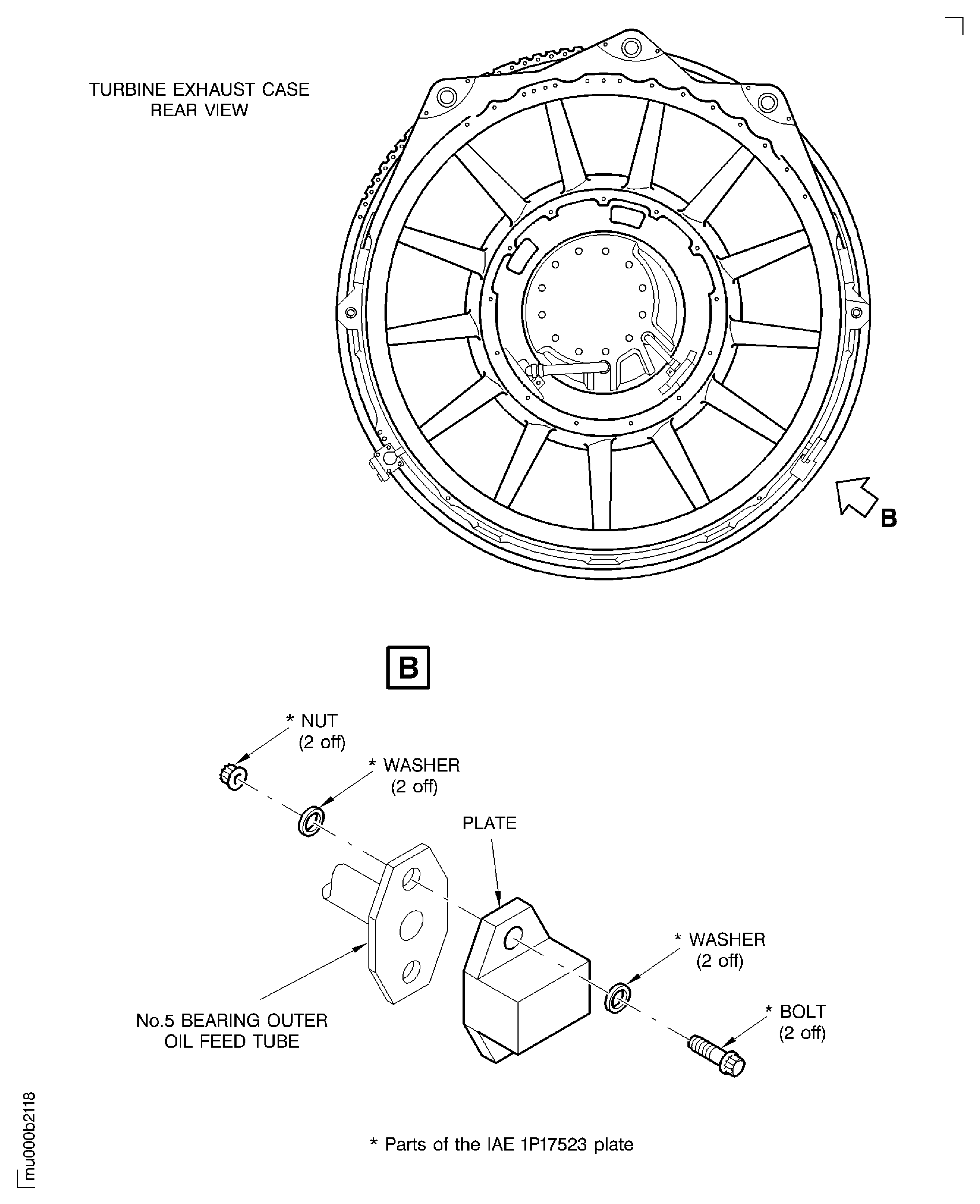

Install the IAE 1P17523 Blank-off Plate 1 off to the No. 5 bearing outer oil feed tube. Refer to Figure.

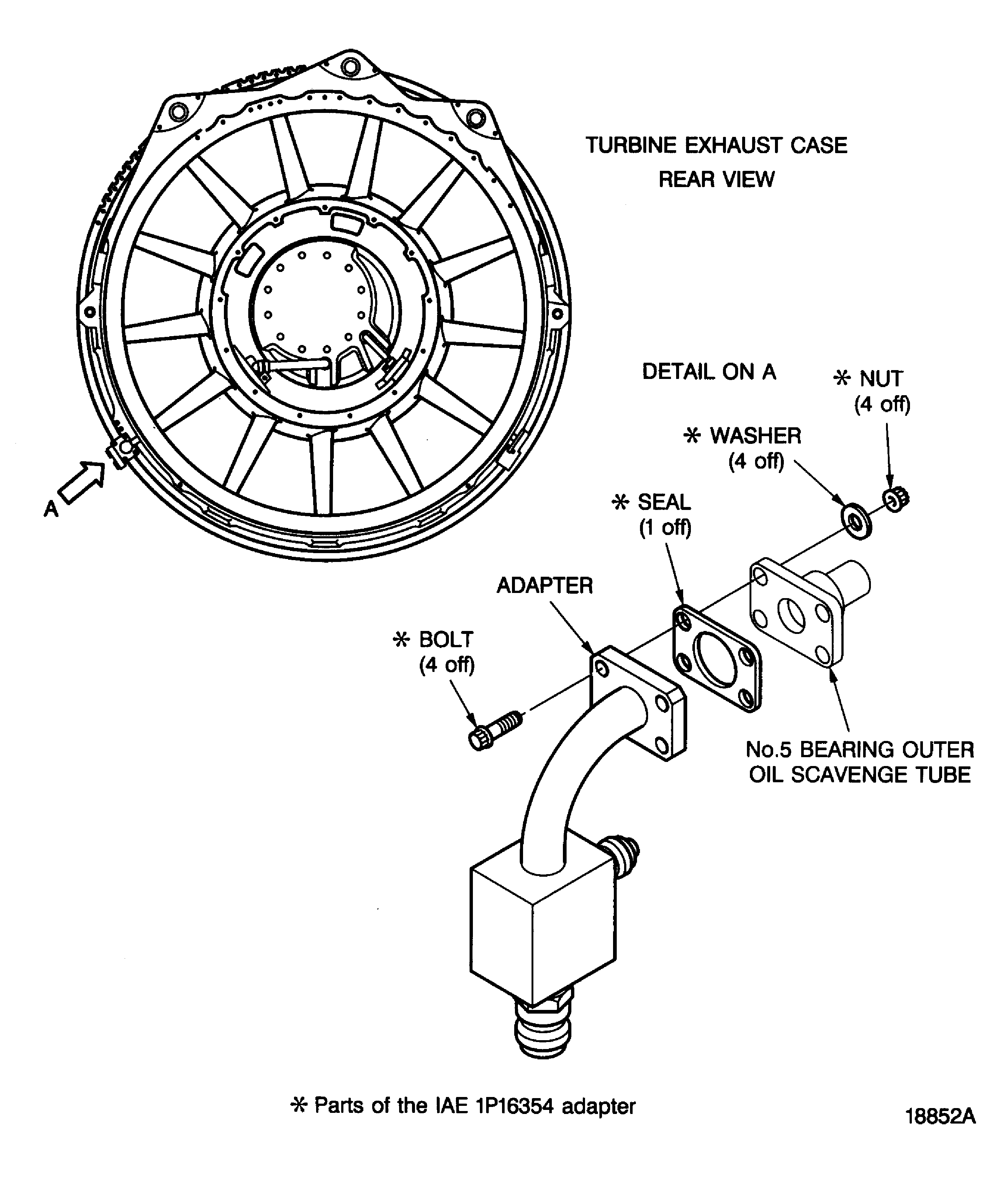

Install the IAE 1P16354 Vacuum Test Adapter 1 off to the No. 5 bearing oil scavenge tube outlet with three bolts (part of the adapter). Tighten the bolts. Refer to Figure.

Attach the hose on the IAE 6F10029 Air flow test cart 1 off to the adapter.

Control the air pressure to the adapter to 10 PSI (68.95 kPa).

Apply CoMat 10-045 LEAK CHECK FLUID, BUBBLES-TYPE or CoMat 10-045 LEAK CHECK FLUID, BUBBLES-TYPEA fluid around the cover and oil tube interfaces to check for leaks. Replace the seal of any leaking interface with a new seal.

Do the leak test again.

Remove the 12 work bolts.

Do a leak check of the compartment cover and oil tubes.

SUBTASK 72-00-00-430-062 Install the Compartment Cover

Lubricate the bolts, nuts and washers with CoMat 10-077 APPROVED ENGINE OILS.

Install the IAE 1P16354 Vacuum Test Adapter 1 off to No. 5 bearing outer oil scavenge tube. Figure.

Lubricate the bolts, nuts and washers with CoMat 10-077 APPROVED ENGINE OILS.

Install the IAE 2F10368 Plate, Vacuum check 1 off to No. 5 bearing outer oil feed tube. Figure.

SUBTASK 72-00-00-430-063 Install the Adapter and the Plate to the Turbine Exhaust Case

Refer to Figure.

Connect the hose of IAE 6F10030 Vacuum test cart 1 off to the nipple of the IAE 1P16354 Vacuum Test Adapter 1 off.

NOTE

Refer to manufacturer manual for the operation of the vacuum test cart.Attach the cart vacuum gage hose to the plug of the IAE 1P16354 Vacuum Test Adapter.

Set the air pressure at the test port to -20inHg (-508 mmHg gage). Based on the ambient pressure, refer to the table below for the vacuum pressure in psia.

Ambient Pressure of the Day (psia)

Vacuum Pressure (psia)

14.7

4.9

14.5

4.7

14.3

4.5

14.1

4.3

13.9

4.1

13.7

3.9

13.5

3.7

13.3

3.5

13.1

3.3

Vacuum pressure (psia) = Ambient pressure of the day (psia) - 9.8 psia

SUBTASK 72-00-00-430-064 Do an Evacuation Check for the No. 5 Bearing Compartment

Refer to: Figure

SUBTASK 72-00-00-430-065 Remove the Vacuum Test Cart, the Adapter and the Plate

Refer to: Figure

Put the OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-116) metallic oil seal in the correct position.

Install the OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 16-114) three bolts and the OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 16-110) three nuts.

Connect the oil feed tube flanges.

Put the OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 01-116) metallic oil seal in the correct position.

Connect the scavenge tube flanges.

SUBTASK 72-00-00-430-066-A00Connect the No. 5 Bearing Compartment Oil Feed and Scavenge Tube Flanges (Pre SBE 79-0011)

Refer to Figure.

SBE 79-0011: Revise No.5 bearing oil scavenge tube assembly attaching parts

Put the OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-116) metallic oil seal in correct position.

Install the OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 16-114) three bolts and the OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 16-110) three nuts.

Connect the oil feed tube flanges.

Put the OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 01-116) metallic oil seal in the correct position.

Safety the bolts with CoMat 02-119 LOCKWIRE.

Connect the scavenge tube flanges.

SUBTASK 72-00-00-430-066-B00 Connect the No. 5 Bearing Compartment Oil Feed and Scavenge Tube Flanges (SBE 79-0011)

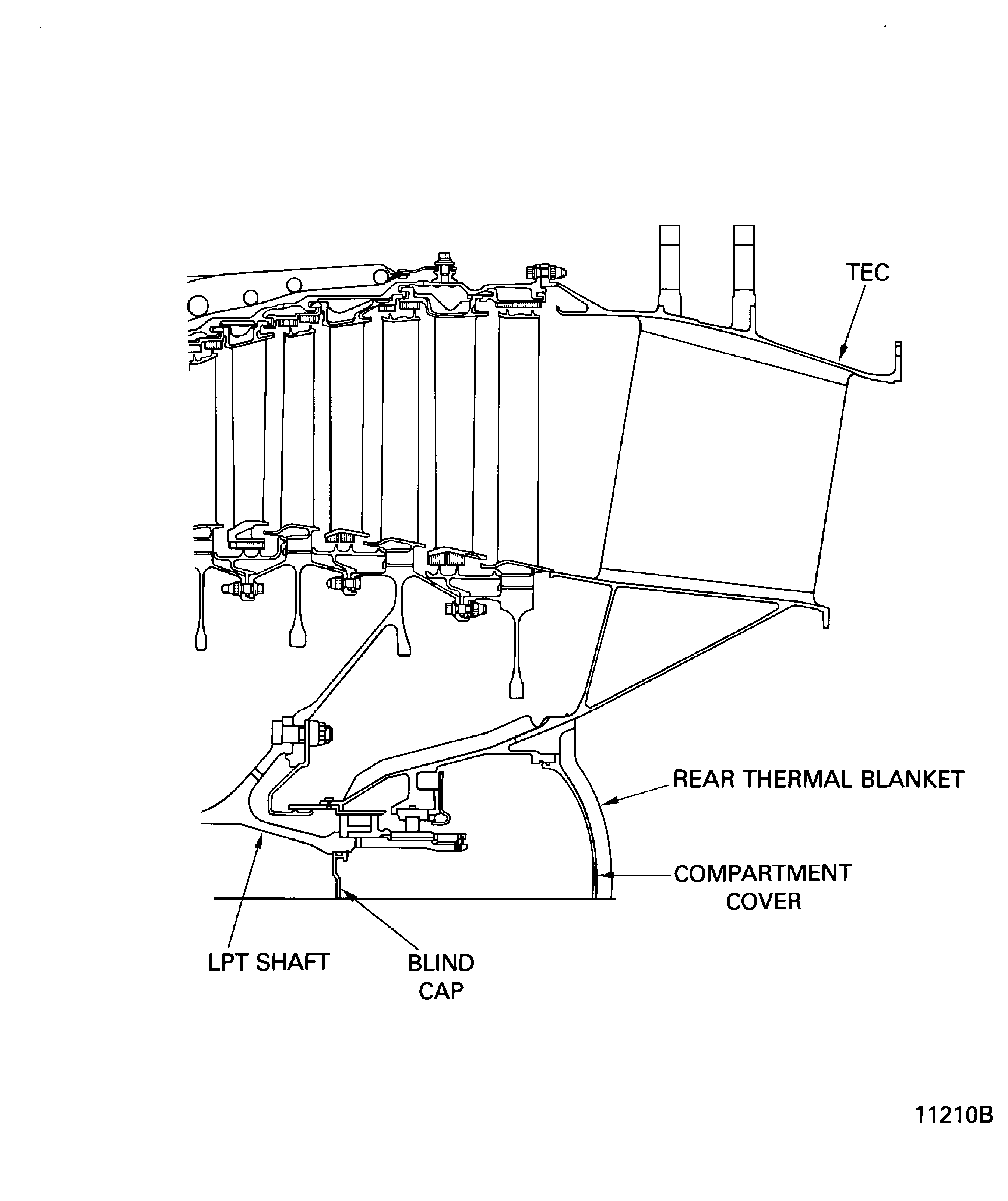

Figure: Pre SBE 72-0173 Removal of the No. 5 Bearing Compartment

Sheet 1

Figure: SBE 72-0173 Removal of the No. 5 Bearing Compartment

Sheet 2

Figure: Removal/Installation of the Blind Cap

Removal/Installation of the Blind Cap

Figure: Removal/Installation of the No. 5 Bearing Oil Feed

Removal/Installation of the No. 5 Bearing Oil Feed

Figure: Removal/Installation of the Oil Jet

Removal/Installation of the Oil Jet

Figure: Removal/Installation of the Rear Locknut

Removal/Installation of the Rear Locknut

Figure: Pre SBE 72-0142 Location of Dimensions

Sheet 1

Figure: SBE 72-0142 Location of Dimensions

Sheet 2

Figure: Removal/Installation of the Guide Pogo Stick

Removal/Installation of the Guide Pogo Stick

Figure: Pre SBE 72-0142 Removal of the Bearing Inner Race and Carbon Seal

Sheet 1

Figure: SBE 72-0142 Removal of the Bearing Inner Race and Carbon Seal

Sheet 2

Figure: Pre SBE 72-0142 Installation of the Inner Bearing Race

Sheet 1

Figure: SBE 72-0142 Installation of the Inner Bearing Race

Sheet 2

Figure: Installation of the Bearing Compartment Cover

Installation of the Bearing Compartment Cover

Figure: Installation of the Adapter to No. 5 Outer Oil Scavenge Tube

Installation of the Adapter to No. 5 Outer Oil Scavenge Tube

Figure: Installation of the Plate to No. 5 Bearing Outer Oil Feed Tube

Installation of the Plate to No. 5 Bearing Outer Oil Feed Tube

Figure: Connect the Fitting of the Vacuum Test Cart to the Adapter

Connect the Fitting of the Vacuum Test Cart to the Adapter

Figure: Pre SBE 79-0011 and SBE 79-0011: Connect/Disconnect the Oil Feed and Scavenge Tube Flange at the Turbine Exhaust Case

Pre SBE 79-0011 and SBE 79-0011: Connect/Disconnect the Oil Feed and Scavenge Tube Flange at the Turbine Exhaust Case

Figure: SBE 72-0037 and Pre SBE 72-0227: Installation of the Sealing Ring on to the Blind Cap

SBE 72-0037 and Pre SBE 72-0227: Installation of the Sealing Ring on to the Blind Cap

Figure: SBE 72-0037 and Pre SBE 72-0227: Installation of the Sealing Ring into the Sizing Sleeve

SBE 72-0037 and Pre SBE 72-0227: Installation of the Sealing Ring into the Sizing Sleeve

Figure: SBE 72-0037: Installed Condition of the Sealing Ring

SBE 72-0037: Installed Condition of the Sealing Ring

Figure: SBE 72-0037: Installation of the Sealing Ring on to the Blind Cap

SBE 72-0037: Installation of the Sealing Ring on to the Blind Cap

Figure: SBE 72-0037: Example of incorrect Installation of the Sealing Ring onto the Blind Cap

SBE 72-0037: Example of incorrect Installation of the Sealing Ring onto the Blind Cap

Figure: SBE 72-0037: Installation of Blind Cap and Retaining Ring

SBE 72-0037: Installation of Blind Cap and Retaining Ring

Figure: Installation of the Plate to No. 5 Bearing Outer Oil Feed Tube

Installation of the Plate to No. 5 Bearing Outer Oil Feed Tube

Figure: SBE 72-0227: Installation of the Sealing Ring on to the Blind Cap

SBE 72-0227: Installation of the Sealing Ring on to the Blind Cap