Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-32-10-440-001-A00 No. 3 Bearing, Internal Gearbox, And Support Assembly - Assemble, Assembly-001

General

This TASK gives the procedure to assemble the No. 3 Bearing Internal Gearbox and Support Assembly.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

Special torque data is identified with the symbol * after the torque value.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to SPM TASK.

The abbreviation Intf shows an interference or tight fit. This causes REJECT IF MORE THAN to become REJECT IF LESS THAN. The abbreviation Clear shows a clearance fit.

For cupwasher installation, refer to the SPM TASK 70-42-04-400-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Digital depth gage | LOCAL | Digital depth gage | (Alternative to dial indicator (part of IAE 1J12356 Setting gage 1 off)) | |

| Arbor Press | LOCAL | Arbor Press | ||

| Oven | LOCAL | Oven | ||

| Heat protection gloves | LOCAL | Heat protection gloves | ||

| Thickness gage | LOCAL | Thickness gage | (feeler gage) | |

| IAE 1J12339 Spanner wrench | 0AM53 | IAE 1J12339 | 1 | |

| IAE 1J12343 PTO bearing pusher | 0AM53 | IAE 1J12343 | 1 | |

| IAE 1J12345 Base plate | 0AM53 | IAE 1J12345 | 1 | |

| IAE 1J12346 Spanner wrench | 0AM53 | IAE 1J12346 | 1 | |

| IAE 1J12347 PTO bearing pusher | 0AM53 | IAE 1J12347 | 1 | |

| IAE 1J12353 TBD | 0AM53 | IAE 1J12353 | 1 | |

| IAE 1J12355 Spanner wrench | 0AM53 | IAE 1J12355 | 1 | |

| IAE 1J12356 Setting gage | 0AM53 | IAE 1J12356 | 1 | |

| IAE 1J12357 Spigot holder | 0AM53 | IAE 1J12357 | 1 | |

| IAE 1J12362 Work stand | 0AM53 | IAE 1J12362 | 1 | |

| IAE 1J12364 Measuring holder | 0AM53 | IAE 1J12364 | 1 | |

| IAE 1J12365 PTO bearing pusher | 0AM53 | IAE 1J12365 | 1 | |

| IAE 1J12366 Spanner wrench | 0AM53 | IAE 1J12366 | 1 | |

| IAE 1J12367 Tab bender | 0AM53 | IAE 1J12367 | 1 | |

| IAE 1J12368 Oil sleeve pusher | 0AM53 | IAE 1J12368 | 1 | |

| IAE 1J12369 PTO bearing pusher | 0AM53 | IAE 1J12369 | 1 | |

| IAE 1J12371 Dummy phonic wheel | 0AM53 | IAE 1J12371 | 1 | |

| IAE 1J12381 Tab bender | 0AM53 | IAE 1J12381 | 1 | |

| IAE 1J12382 Hydraulic seal pusher | 0AM53 | IAE 1J12382 | 1 | |

| IAE 1J12385 Backlash fixture | 0AM53 | IAE 1J12385 | 1 | |

| IAE 1J12422 Gearshaft holder | 0AM53 | IAE 1J12422 | 1 | |

| IAE 1J12447 PTO housing holder | 0AM53 | IAE 1J12447 | 1 | |

| IAE 1J12448 Restraint holder | 0AM53 | IAE 1J12448 | 1 | |

| IAE 1J12449 Installation holder | 0AM53 | IAE 1J12449 | 1 | |

| IAE 1J12188 Puller bolt | 0AM53 | IAE 1J12188 | 1 | |

| IAE 1J12021 Lifting spacer | 0AM53 | IAE 1J12021 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 06-069 MARKER | IE207 | CoMat 06-069 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Seal ring | 1 | |||

| Seal ring | 1 | |||

| Cupwasher | 1 | |||

| Cupwasher | 1 | |||

| Seal ring | 1 | |||

| Seal ring | 1 | |||

| Seal ring | 1 | |||

| Seal ring | 1 | |||

| Seal ring | 1 | |||

| Seal ring | 1 | |||

| Seal ring | 1 | |||

| Seal ring | 1 | |||

| Lock plate | 1 |

Safety Requirements

NONEProcedure

Refer to Figure.

Reference dimensions at location 0501. If required, use the data noted in TASK 72-32-16-200-000 (INSPECTION-000).

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 0501

Bevel Gearshaft ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-750)

Inner Roller Bearing ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-300)

Bevel Gearshaft Outside Diameter

1.9689

Intf

1.9692

0.0004

Inner Roller Diameter Bore Diameter

1.9683

0.0009

1.9685

Intf

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 0501

Bevel Gearshaft ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-750)

Inner Roller Bearing ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-300)

Bevel Gearshaft Outside Diameter

50.009

Intf

50.020

0.009

Inner Roller Bearing Bore Diameter

49.994

0.026

50.000

Intf

SUBTASK 72-32-10-220-053 Reference Fits and Clearances of the Bevel Gearshaft and Inner Roller Bearing at Location 0501

Refer to Figure.

Reference dimensions at location 0505. If required, use the data noted in TASK 72-32-16-200-000 (INSPECTION-000).

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 0505

Bevel Gearshaft ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-750)

Inner Ball Bearing ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-600)

Bevel Gearshaft Outside Diameter

1.7720

Intf

1.7724

0.0004

Inner Ball Bearing Bore Diameter

1.7715

0.0009

1.7716

Intf

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 0505

Bevel Gearshaft ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-750)

Inner Ball Bearing ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-600)

Bevel Gearshaft Outside Diameter

45.009

Intf

45.020

0.009

Inner Ball Bearing Bore Diameter

44.994

0.026

45.000

Intf

SUBTASK 72-31-10-220-054 Reference Fits and Clearances of the Bevel Gearshaft and Inner Ball Bearing at Location 0505

Refer to Figure.

Reference dimensions at location 0507. If required, use the data noted in TASK 72-32-16-200-000 (INSPECTION-000).

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 0507

Bevel Gearshaft ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-750)

Inner Roller Bearing ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-500)

Bevel Gearshaft Outside Diameter

1.7720

Intf

1.7724

0.0004

Inner Roller Bearing Bore Diameter

1.7715

0.0009

1.7716

Intf

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 0507

Bevel Gearshaft ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-750)

Inner Roller Bearing ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-500)

Bevel Gearshaft Outside Diameter

45.009

Intf

45.020

0.009

Inner Roller Bearing Bore Diameter

44.994

0.026

45.000

Intf

SUBTASK 72-32-10-220-055 Reference Fits and Clearances of the Bevel Gearshaft and Inner Roller Bearing at Location 0507

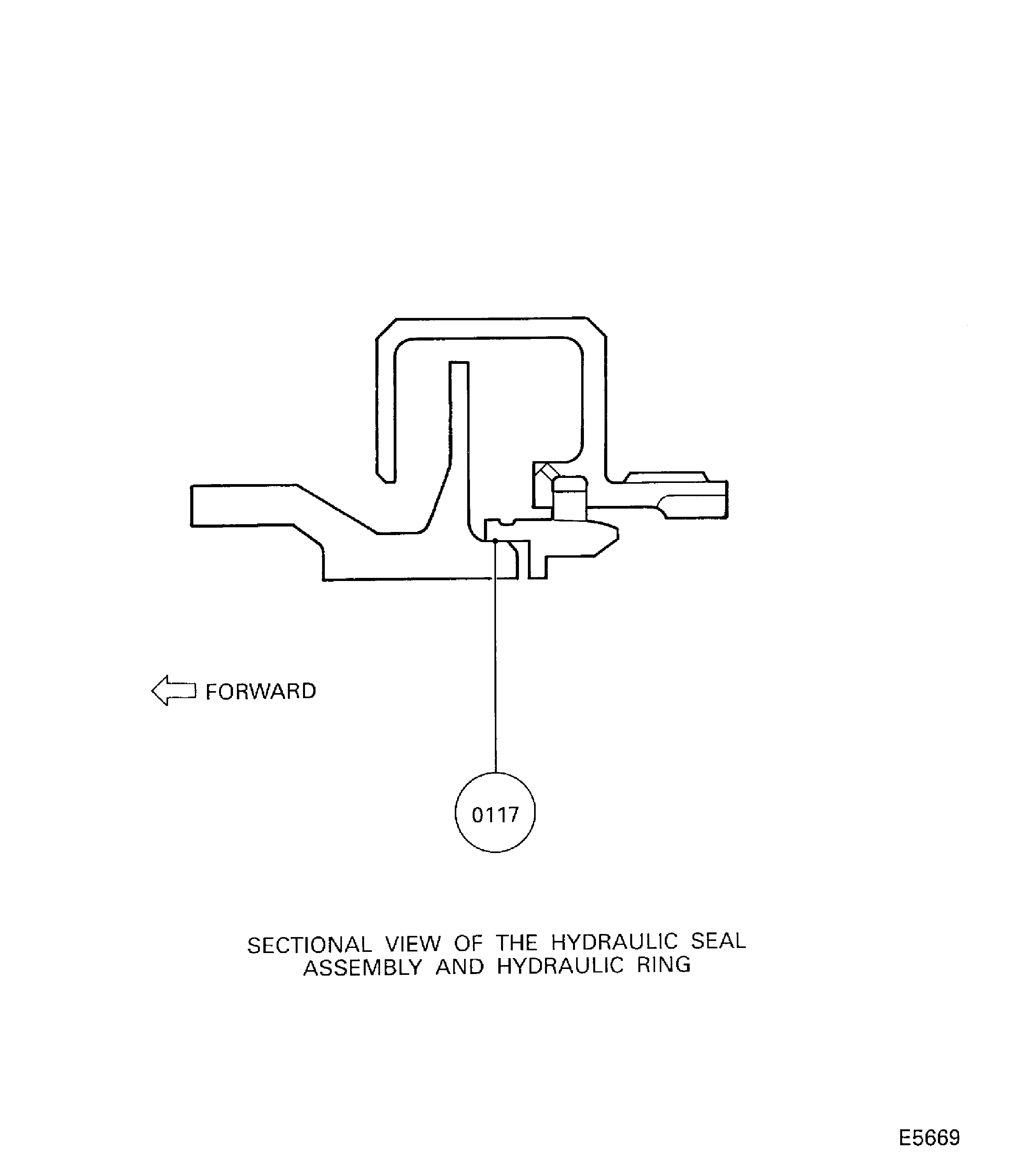

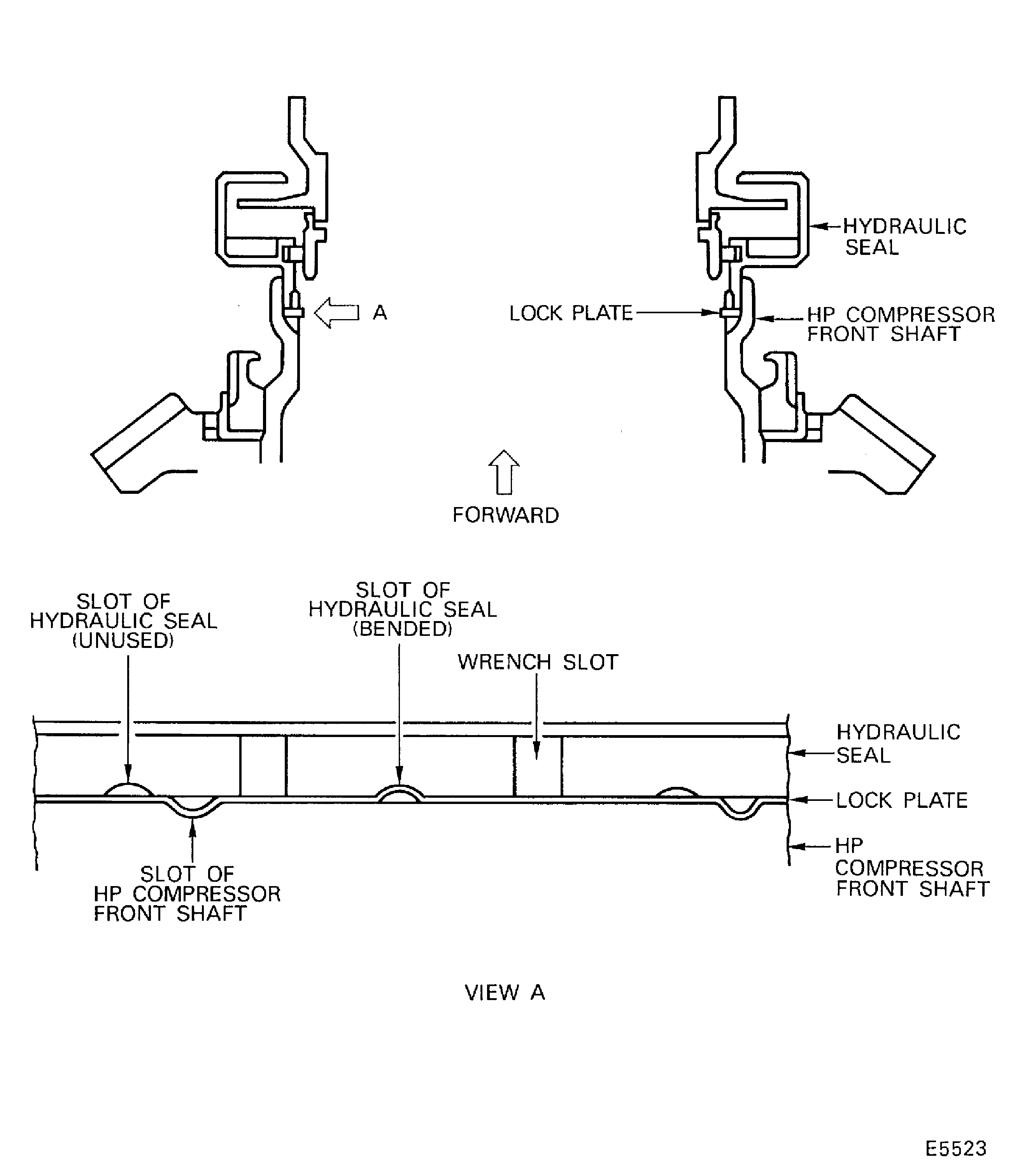

Refer to Figure.

Reference dimensions at location 0117. If required, use the data noted in TASK 72-32-19-200-000 (INSPECTION-000).

Table 7. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 0117

Hydraulic Ring ENGINE-HYDRAULIC SEAL ASSEMBLY (72-32-19, 01-140), Inner Diameter

Hydraulic Seal ENGINE-HYDRAULIC SEAL ASSEMBLY (72-32-19, 01-100), Outside Diameter

Hydraulic Ring Inner Diameter

4.2528

Intf

4.2520

0.0007

Hydraulic Seal Outside Diameter

4.2542

0.0022

4.2535

Intf

Table 8. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 0117

Hydraulic Ring ENGINE-HYDRAULIC SEAL ASSEMBLY (72-32-19, 01-140), Inner Diameter

Hydraulic Seal ENGINE-HYDRAULIC SEAL ASSEMBLY (72-32-19, 01-100), Outside Diameter

Hydraulic Ring Inner Diameter

108.020

Intf

108.000

0.017

Hydraulic Seal Outside Diameter

108.059

0.059

108.037

Intf

SUBTASK 72-32-10-220-060 Reference Fits and Clearances of the Hydraulic Ring and the Hydraulic Seal at Location 0117

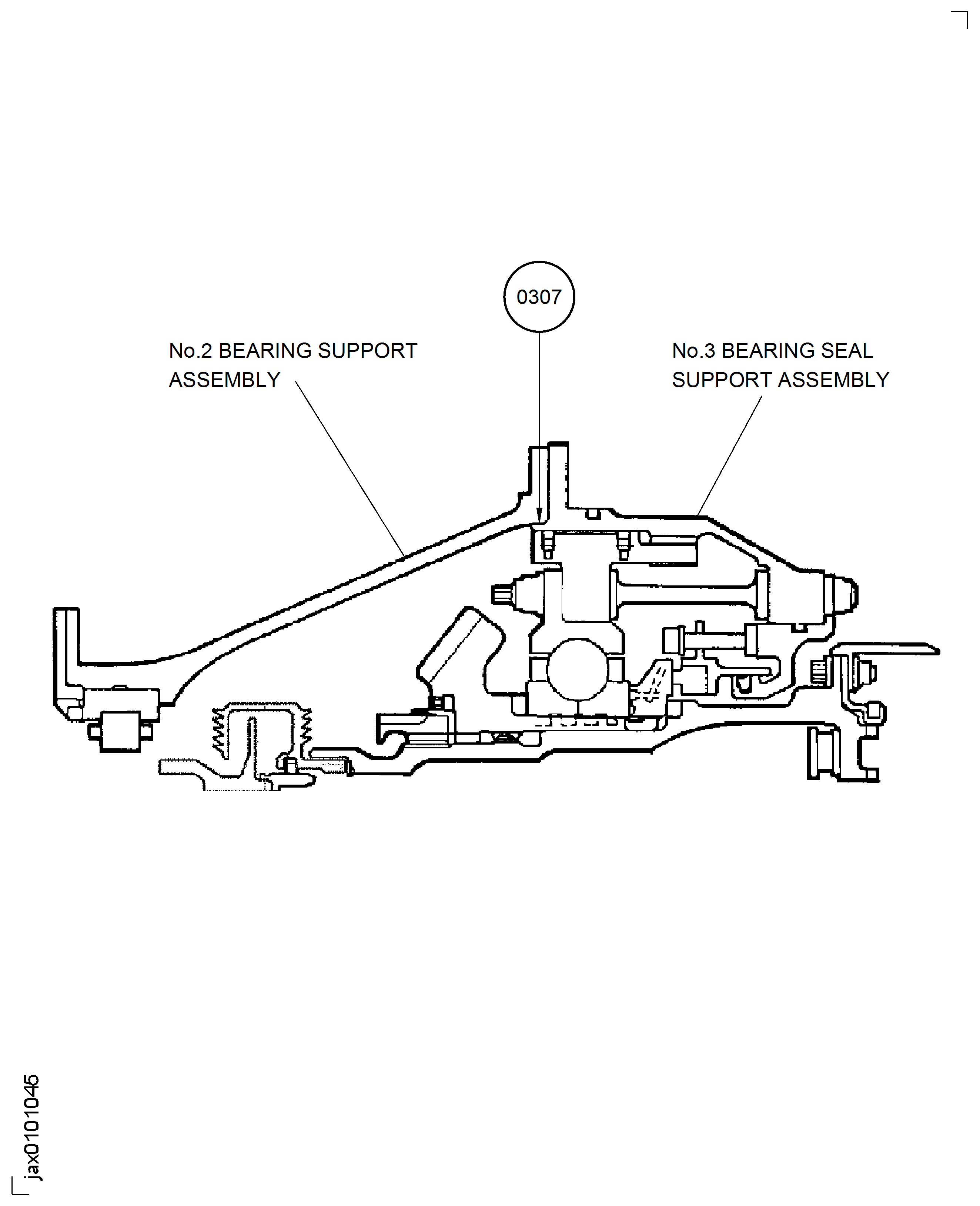

Refer to Figure.

Reference dimensions at Location 0307. If required, use the data noted in TASK 72-32-17-200-000 (INSPECTION-000) and TASK 72-32-22-200-000 (INSPECTION-000).

Table 9. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 0307

No. 2 Bearing Support ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-850)

No. 3 Bearing Seal Support ENGINE-NO.3 BEARING SEAL SUPPORT (72-32-22, 01-040)

No. 2 Bearing Support Inner Diameter

10.9798

Intf

10.9798

Intf

10.9807

0.0013

10.9807

0.0013

No. 3 Bearing Seal Support Outside Diameter

10.982

0.0062

10.982

0.0062

10.986

Intf

10.986

Intf

Table 10. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 0307

No. 2 Bearing Support ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-850)

No. 3 Bearing Seal Support ENGINE-NO.3 BEARING SEAL SUPPORT (72-32-22, 01-040)

No. 2 Bearing Support Inner Diameter

278.886

Intf

278.886

Intf

278.911

0.032

278.911

0.032

No. 3 Bearing Seal Support Outside Diameter

278.943

0.158

278.943

0.158

279.044

Intf

279.044

Intf

SUBTASK 72-32-10-220-072 Reference Fits and Clearances of the No. 2 Bearing Support and the No. 3 Bearing Seal Support at Location 0307

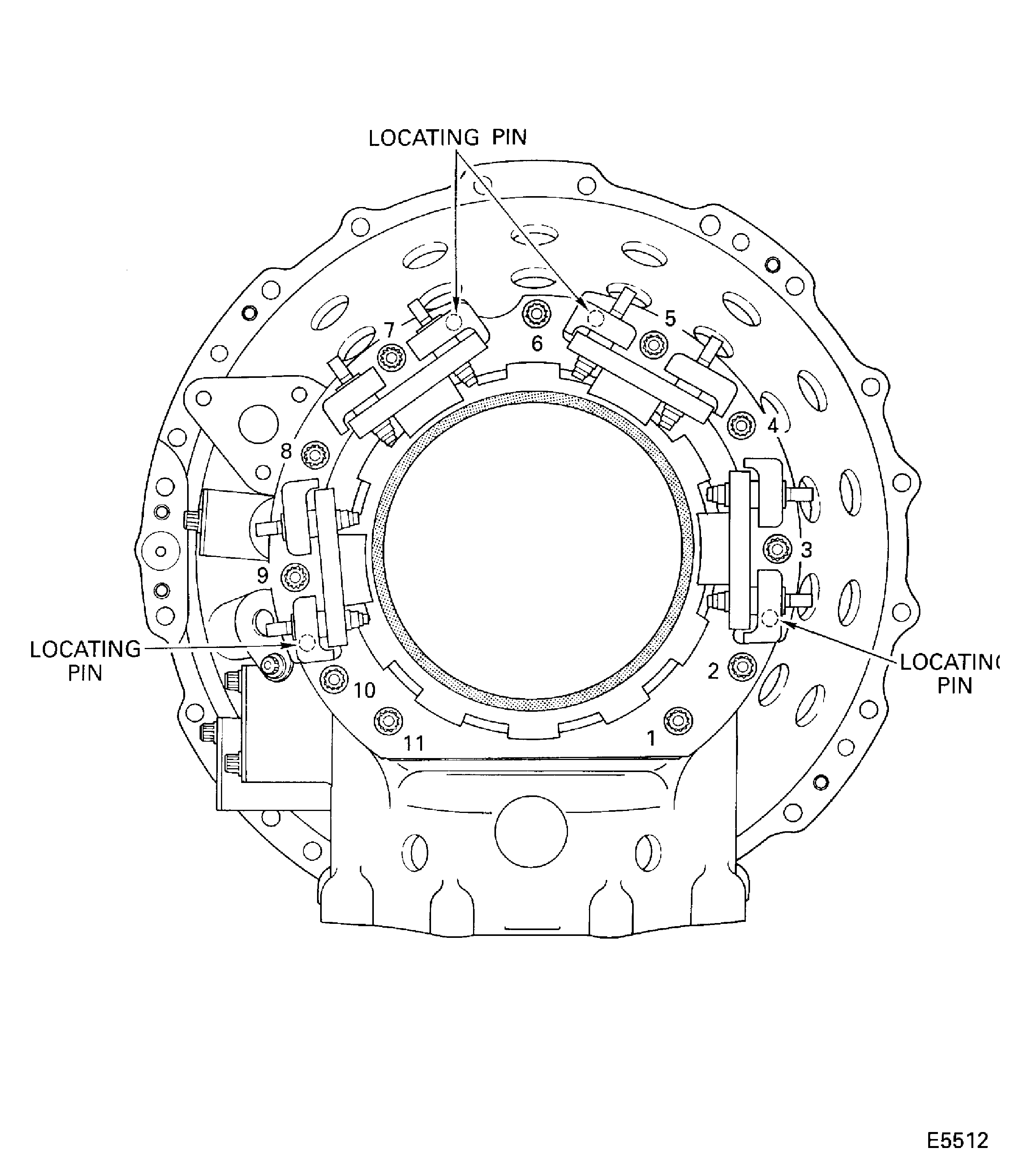

Refer to Figure.

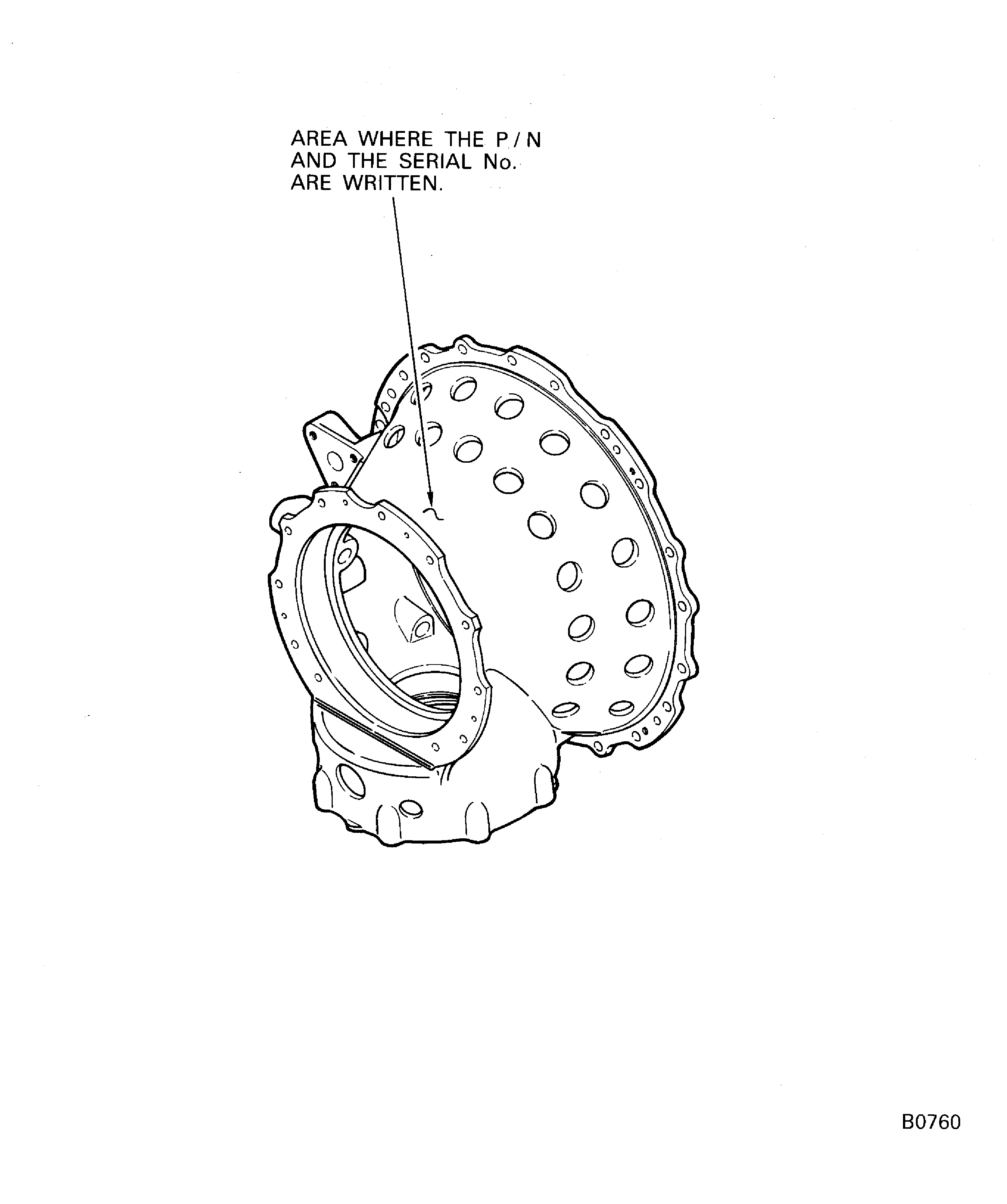

SUBTASK 72-32-10-440-119 Identify the No. 3 Bearing, Internal Gearbox and Support Assembly (Sub-Module)

Refer to Figure.

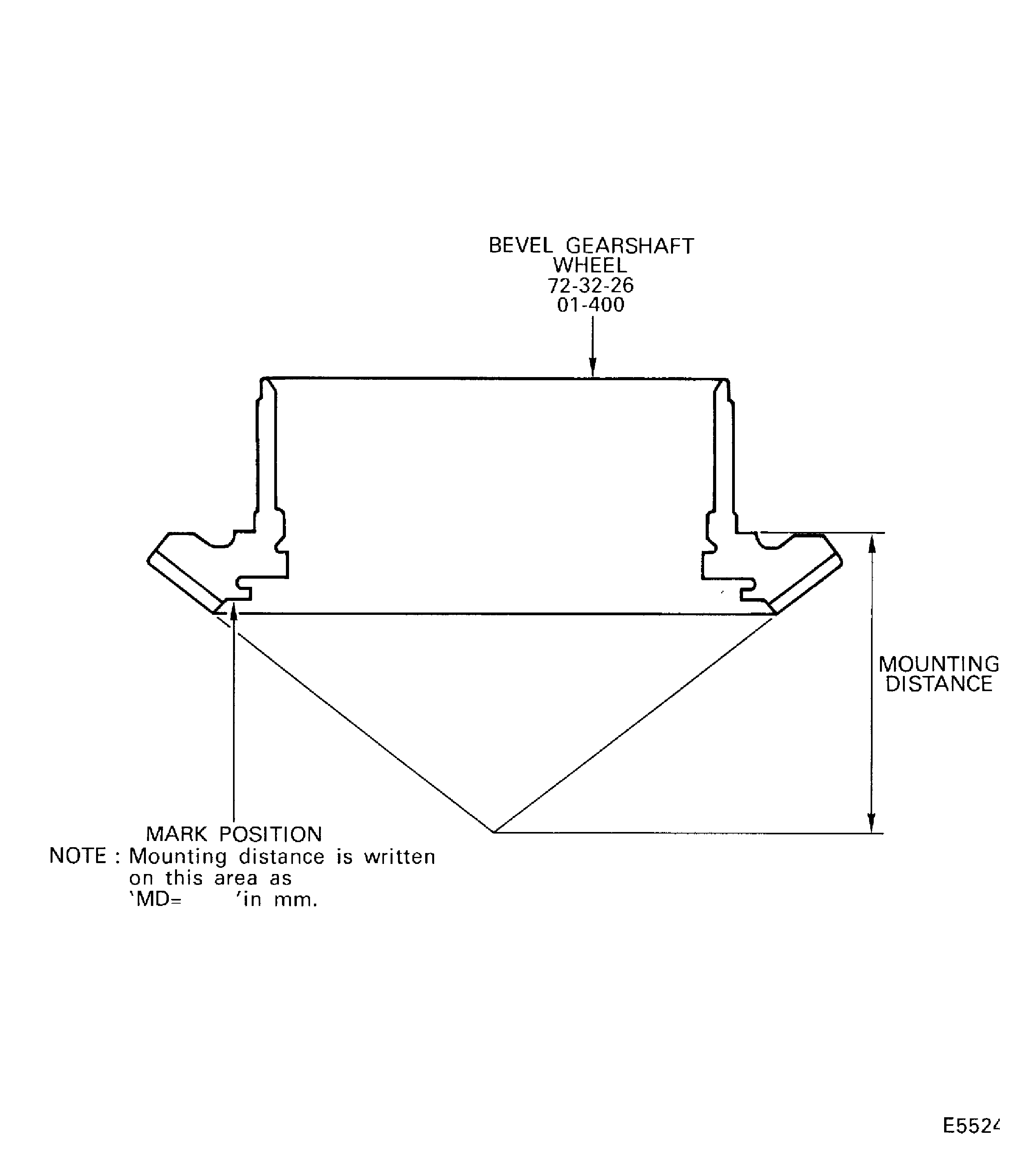

SUBTASK 72-32-10-220-061 Find the Value of the Mounting Distance of the Bevel Gearshaft Wheel (01-400)

Refer to Figure.

NOTE

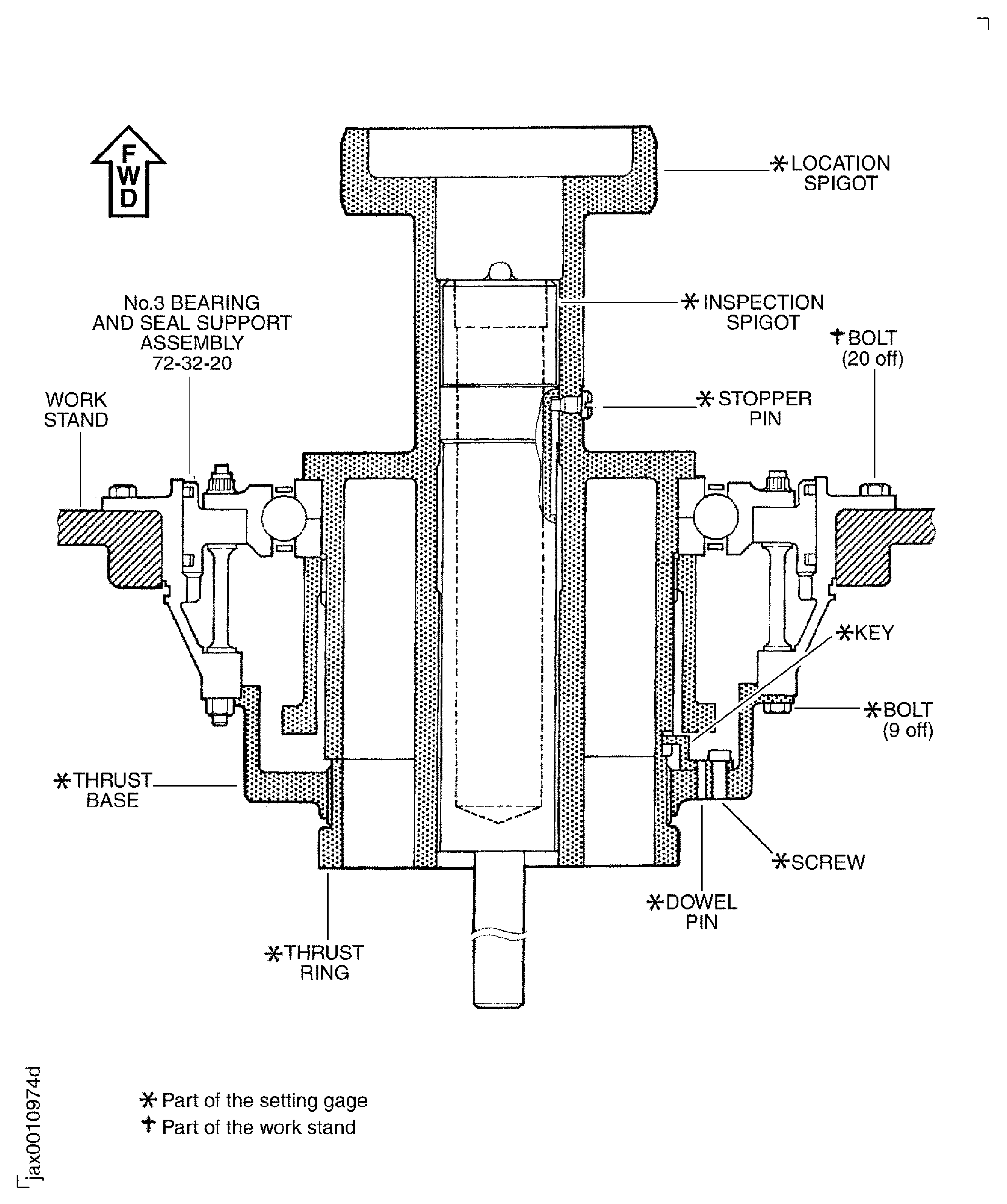

The No. 3 Bearing And support assembly is assembled in TASK 72-32-20-440-001-A00 (ASSEMBLY-001) and TASK 72-32-20-440-001-B00 (ASSEMBLY-001).The No. 3 Bearing And support assembly and No. 3 bearing inner races are temporarily installed to calculate the thickness of the adjusting washers.Attach IAE 1J12357 Spigot holder 1 off to IAE 1J12345 Base plate 1 off with the four bolts (part of the spigot holder).

Cover the threads of the location spigot with CoMat 02-001 ADHESIVE TAPE (MASKING) to prevent damage of the No. 3 Bearing.

NOTE

The inner race front half has a step at the inner diameter. The inner race rear half has a smaller step and oil slots.

Install the No. 3 Bearing inner race front half ENGINE-NO.3 BEARING (72-32-24, 01-100) to the location spigot, part of IAE 1J12356 Setting gage 1 off.

Install the No. 3 Bearing inner race rear half ENGINE-NO.3 BEARING (72-32-24, 01-100) through the location spigot on the inner race front half.

Put the No. 3 Bearing And Support Assembly on the location spigot.

NOTE

Hold the ball and cage assembly together by hand when you move the No. 3 Bearing And Support Assembly because the ball and cage can release from the outer race.

SUBTASK 72-32-10-440-051 Install the No. 3 Bearing And Support Assembly (72-32-20) to the Setting Gage

Install the assembly to IAE 1J12362 Work stand 1 off.

SUBTASK 72-32-10-440-052 Install the No. 3 Bearing And Support Assembly to the Work Stand

Refer to Figure.

Lubricate the front surface of the thrust ring with CoMat 10-077 APPROVED ENGINE OILS.

Install the thrust base (part of the setting gage) and the thrust ring (part of the setting gage) to the No. 3 Bearing And Support Assembly.

SUBTASK 72-32-10-440-053 Install the Inspection Spigot (Part of the Setting Gage) to the Location Spigot

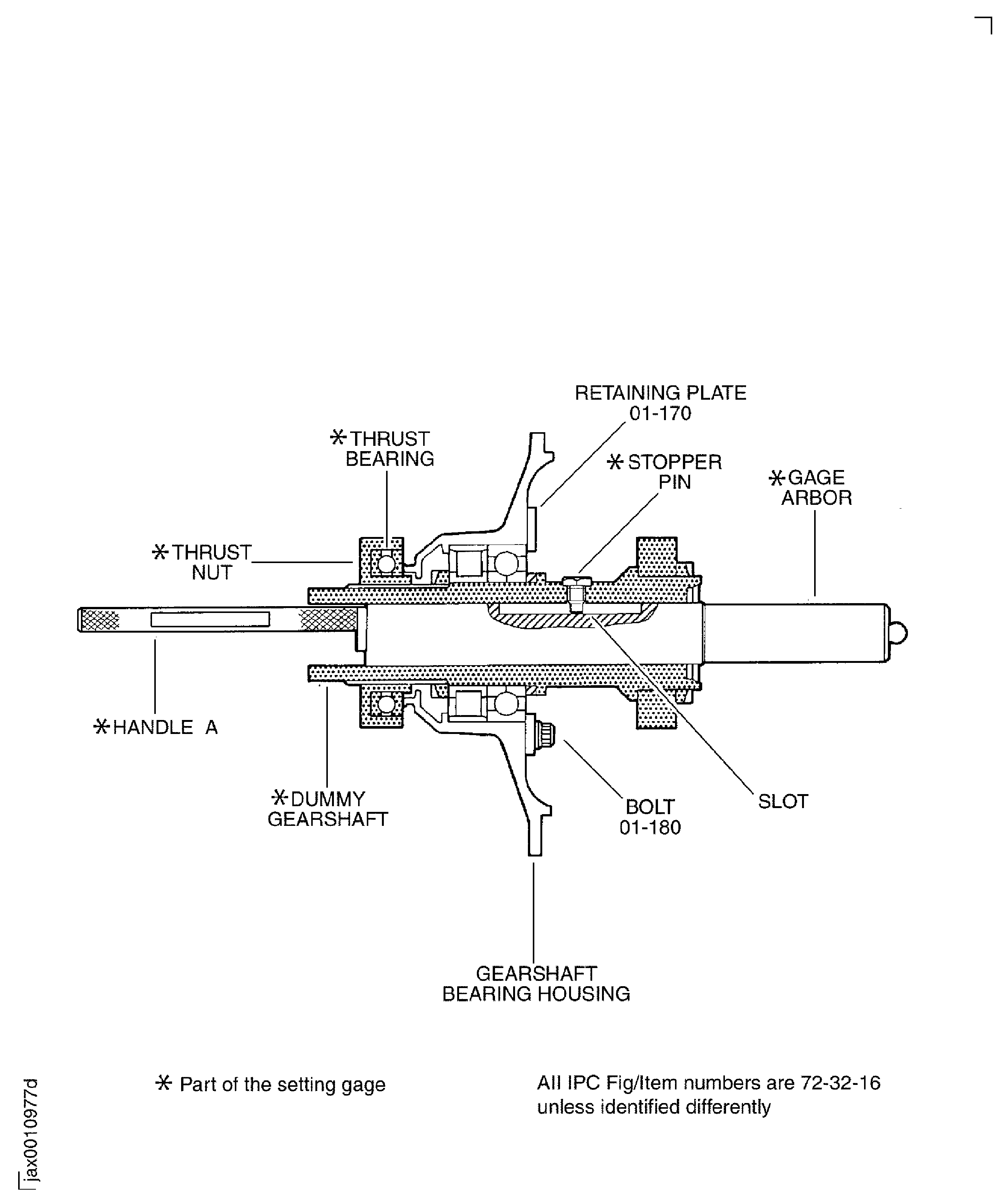

Refer to Figure.

Install the dummy gearshaft to IAE 1J12364 Measuring holder 1 off.

Lubricate the mating surface of the nut A (part of the setting gage) with the dummy bearing with CoMat 10-077 APPROVED ENGINE OILS.

Install the dummy bearing (part of the setting gage) on the dummy gearshaft.

Install the retaining plate ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-170) on the dummy gearshaft.

Lubricate the mating surface of the nut B (part of the setting gage) with the inner roller bearing with CoMat 10-077 APPROVED ENGINE OILS.

CAUTION

CAREFULLY INSTALL THE BEARING SO THAT THE THREADS OF THE DUMMY GEARSHAFT DO NOT CAUSE DAMAGE TO THE BEARING.Install the ball bearing ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-600) and the inner roller bearing ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-500) on the dummy gearshaft.

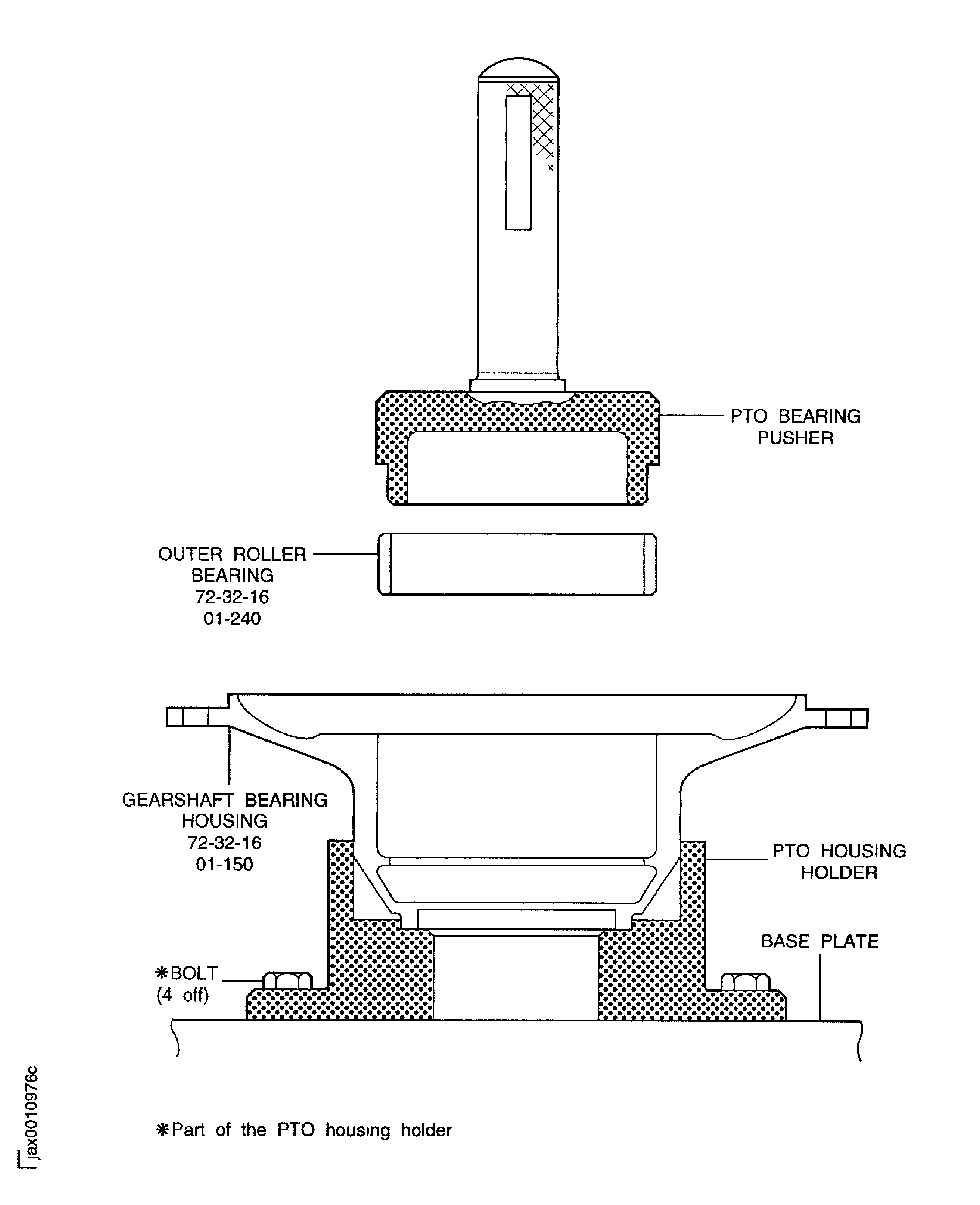

SUBTASK 72-32-10-440-054 Install the PTO Bearings and the Dummy Bearing to the Dummy Gearshaft (Part of the Setting Gage)

Refer to Figure.

Attach IAE 1J12447 PTO housing holder 1 off to base plate with the four bolts (part of the PTO housing holder).

Put IAE 1J12347 PTO bearing pusher 1 off on the bearing.

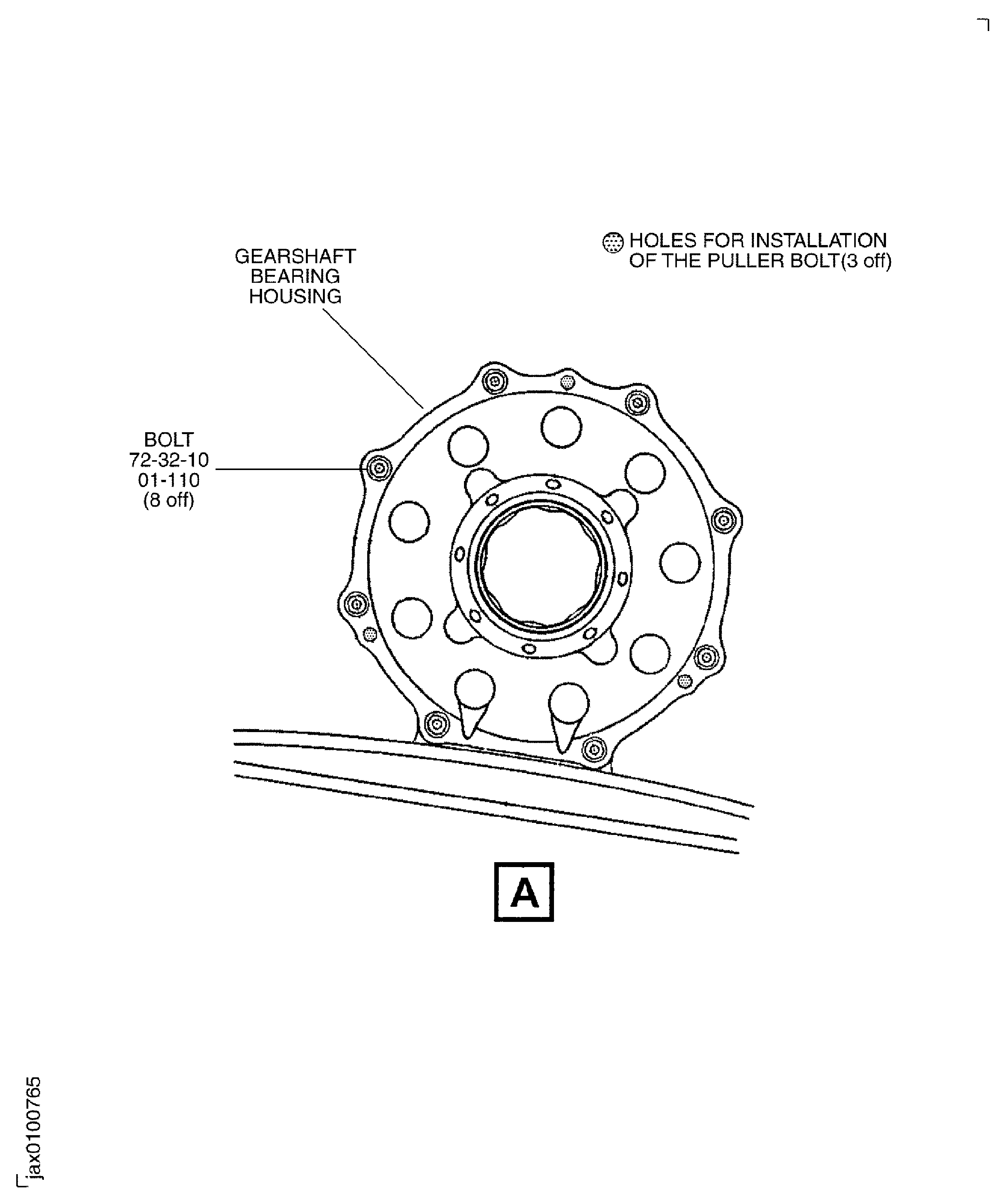

Install the outer roller bearing into the Gearshaft Bearing Housing.

SUBTASK 72-32-10-440-055 Install the Outer Roller Bearing (72-32-16,01-240) into the Gearshaft Bearing Housing (72-32-10,01-150)

Refer to Figure.

Attach the retaining plate ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-170) to the Gearshaft Bearing Housing with the four bolts ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-180) and torque the bolts to 85 lbfin to 105 lbfin (10.00 Nm to 12.00 Nm).

Lightly tighten the thrust nut with IAE 1J12366 Spanner wrench 1 off.

Install the thrust nut (part of the setting gage) on the dummy gearshaft.

SUBTASK 72-32-10-440-056 Install the Gearshaft Bearing Housing on the Dummy Gearshaft

Refer to Figure.

SUBTASK 72-32-10-440-057 Install the Gage Arbor (Part of the Setting Gage) to the Dummy Gearshaft

Refer to Figure.

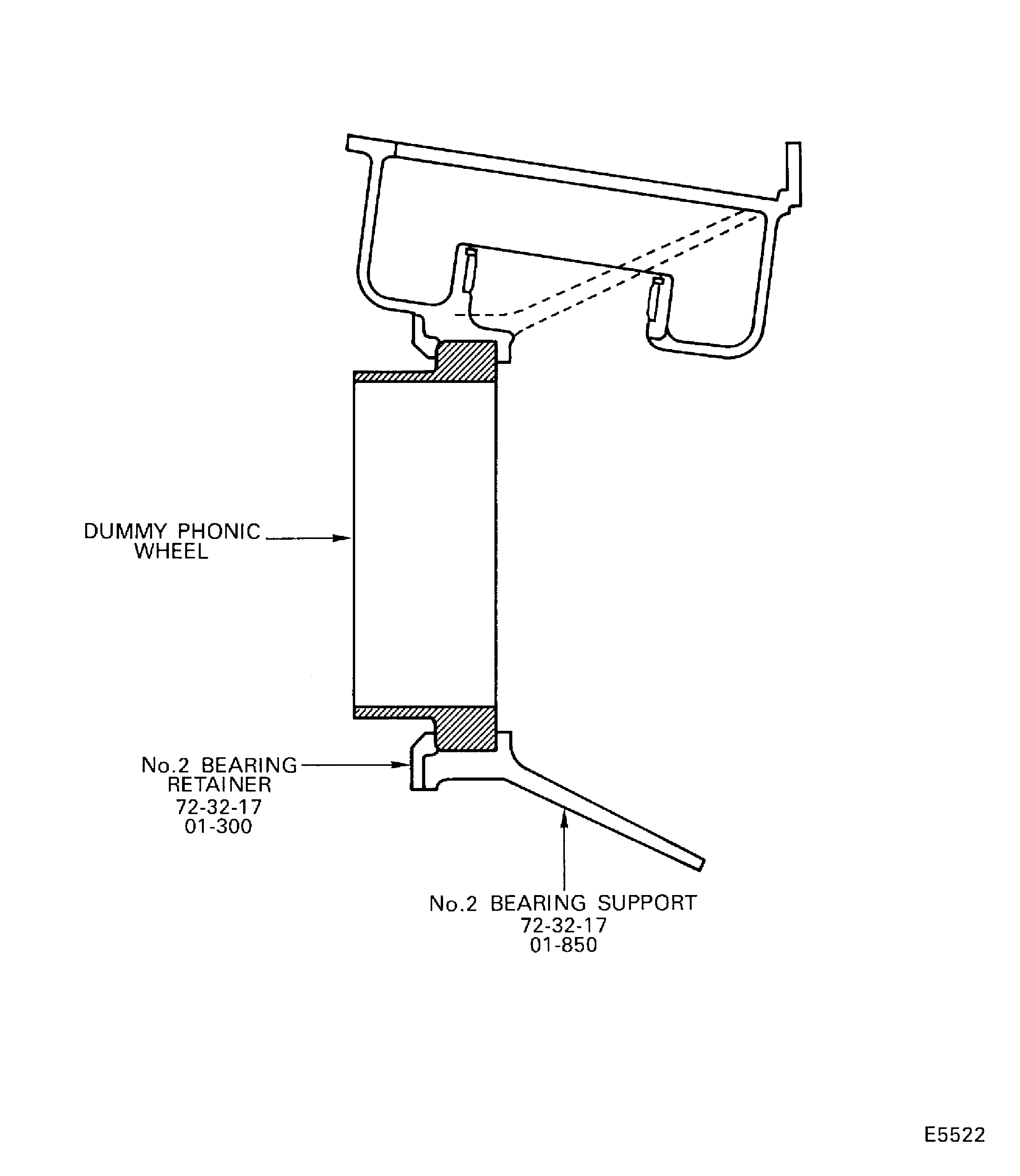

Put the No. 2 Bearing Support ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17,01-850) on a work bench with the rear end down.

Lubricate the outer diameter surface of the dummy outer race with CoMat 10-077 APPROVED ENGINE OILS.

Attach the No. 2 Bearing Retainer ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-300) to the No. 2 Bearing Support with the three bolts ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-320) and nuts ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-310). Torque the nuts to 80 lbfin to 105 lbfin (10.00 Nm to 12.00 Nm).

SUBTASK 72-32-10-440-058 Install the Dummy Outer Race (Part of the Setting Gage) into the No. 2 Bearing Support

Refer to Figure.

Lubricate the outer diameter surface of the dummy bearing on the dummy gearshaft with CoMat 10-077 APPROVED ENGINE OILS.

Attach the Gearshaft Bearing Housing to the flange of the No. 2 Bearing Support with the eight bolts NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-110) and torque the bolts to 85 lbfin to 105 lbfin (10.00 Nm to 12.00 Nm).

Install the Gearshaft Bearing Housing and dummy Gearshaft Assembly into the No. 2 Bearing Support.

SUBTASK 72-32-10-440-059 Assemble the Setting Gage

Calculate the thickness A2 of the adjusting washer as follows:

A2(mm) = L2 + R - WMD2 - S2 + 12.611.

A2(in.) = A2(mm)/25.4.

Where:

WMD2 - The mounting distances of the Bevel Gearshaft wheel. Refer to Step.

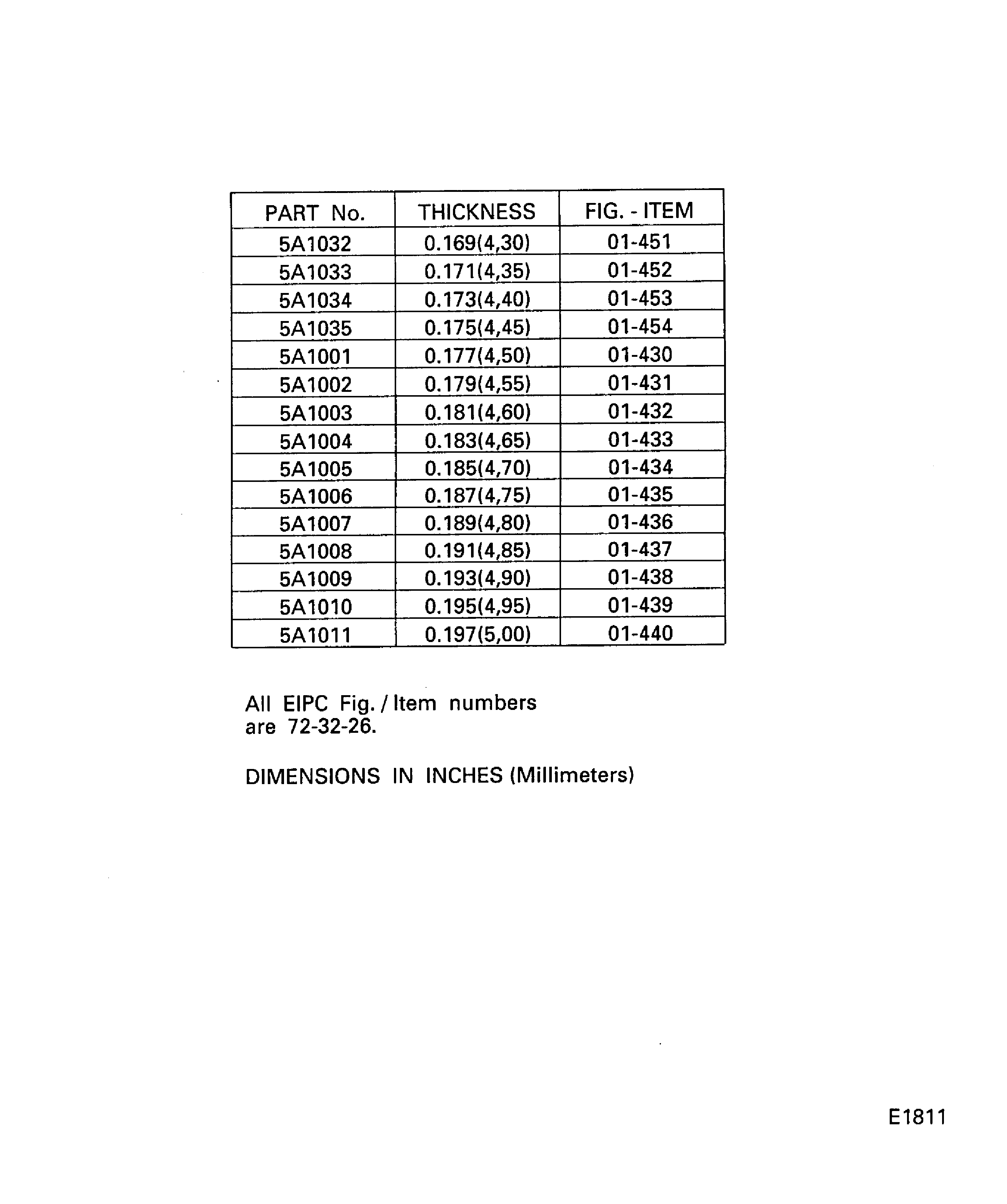

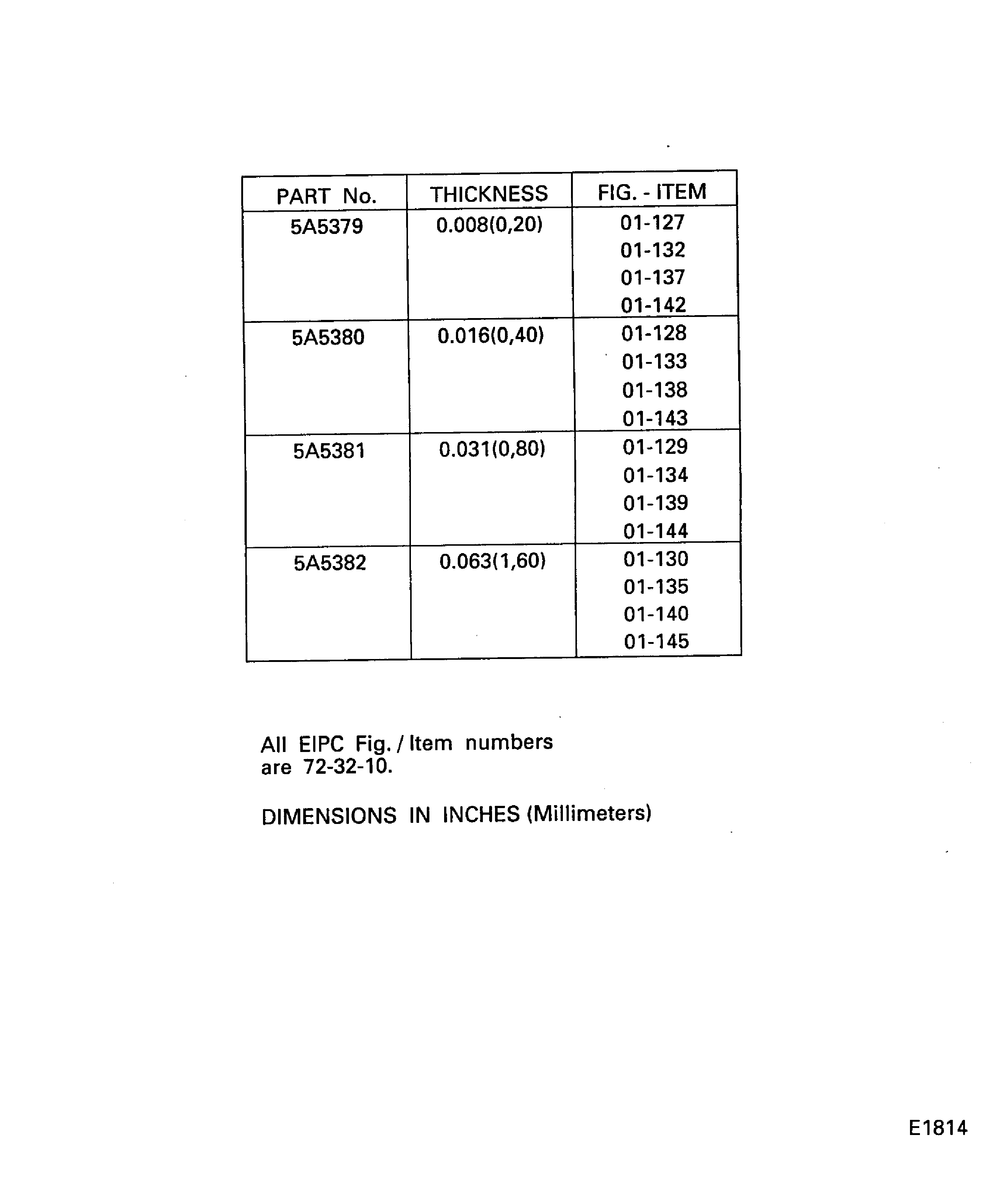

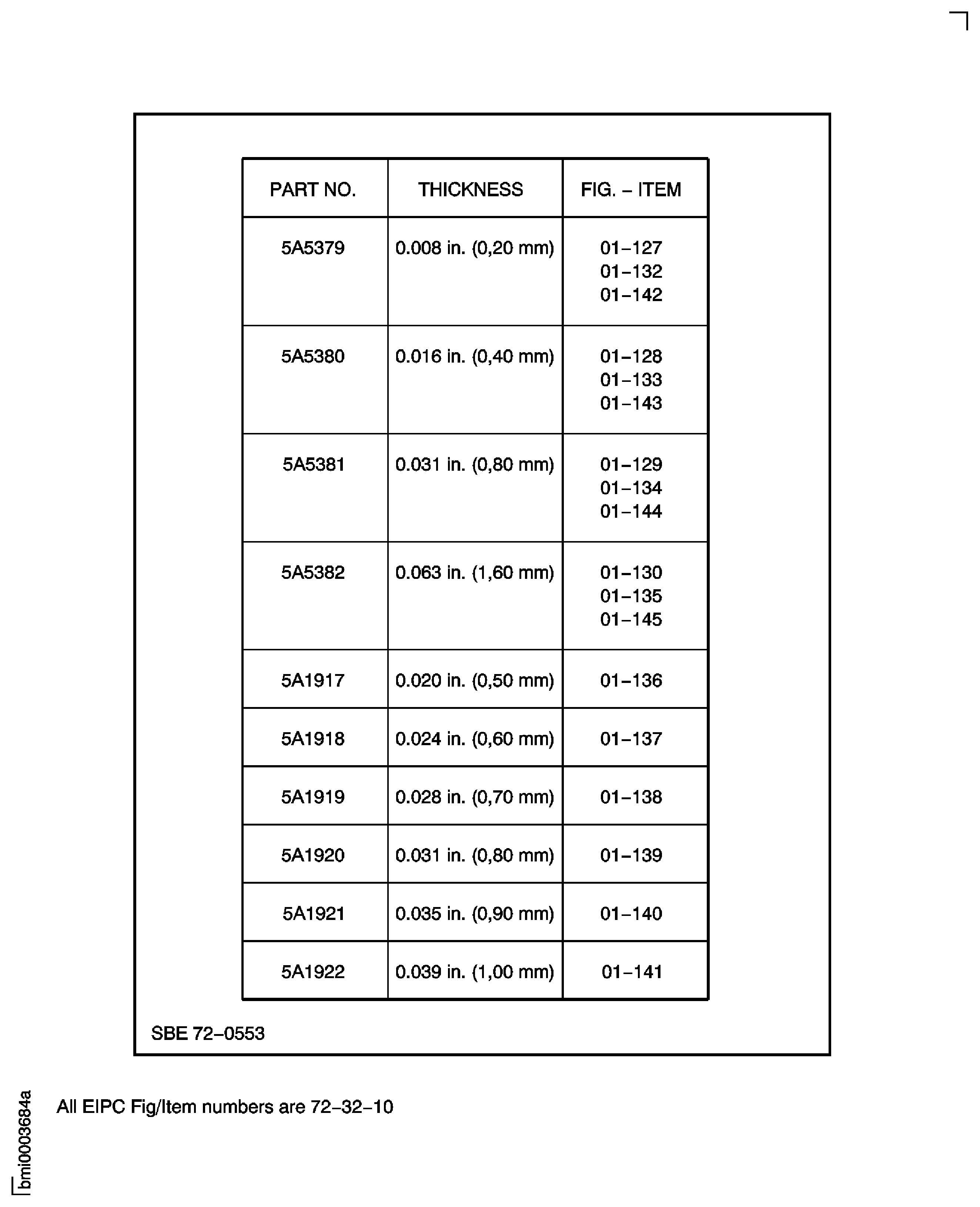

Find the adjusting washer of which thickness is nearest to A2. Refer to Figure.

Calculate the thickness of the adjusting washer.

Use the adjusting washer when you do SUBTASK 72-32-20-440-063, TASK 72-32-20-440-001-A00 (ASSEMBLY-001) and TASK 72-32-20-440-001-B00 (ASSEMBLY-001).

SUBTASK 72-32-10-440-060 Calculate the Thickness of the Adjusting Washer-PTO (72-32-26,01-430 to 01-440 and 01-451 to 01-454)

Calculate the thickness A1 of the adjusting washer as follows:

A1(mm) = L1 + Q - WMD1 - S1 + 24.190.

Al(in.) = A1(mm)/25.4.

Where:

WMD1 - The mounting distance of the Bevel Gearshaft. Refer to Step.

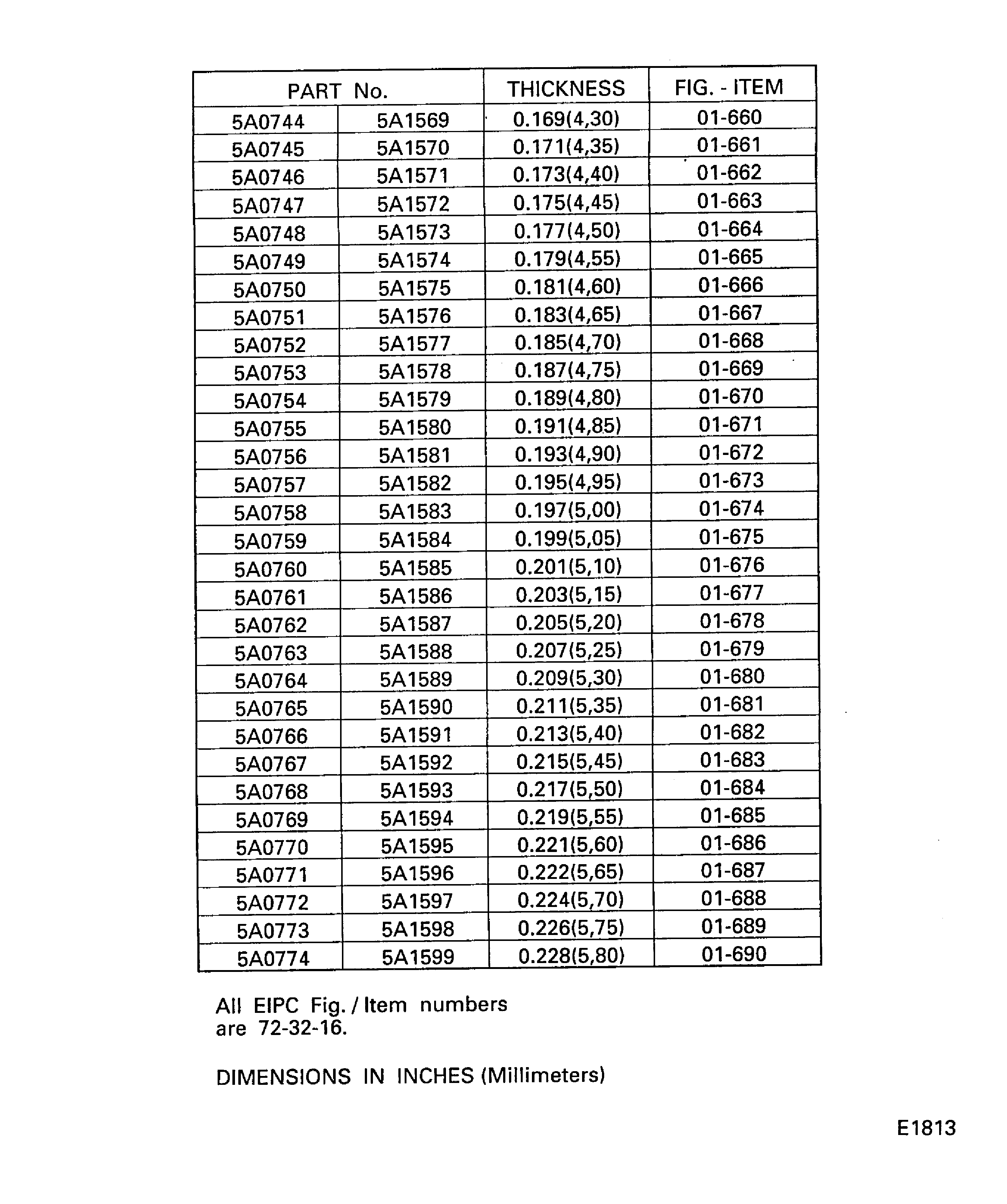

Find the adjusting washer of which thickness is nearest to A1. Refer to Figure.

Calculate the thickness of the adjusting washer.

SUBTASK 72-32-10-440-061 Calculate the Thickness of the Adjusting Washer (72-32-16,01-660 to 01-690)

Remove the eight bolts which attach the Gearshaft Bearing Housing to the No. 2 Bearing Support with IAE 1J12366 Spanner wrench 1 off.

Release the Gearshaft Bearing Housing from the No. 2 Bearing Support with the three puller bolts (part of IAE 1J12188 Puller bolt 1 off).

SUBTASK 72-32-10-440-062 Remove the Gearshaft Bearing Housing and the Dummy Gearshaft assembly from the No. 2 Bearing Support

Refer to Figure.

SUBTASK 72-32-10-440-064 Remove the No. 2 Bearing Support from the No. 3 Bearing And Support Assembly

Refer to Figure.

SUBTASK 72-32-10-440-065 Remove the Dummy Outer Race from the No. 2 Bearing Support

Refer to Figure.

SUBTASK 72-32-10-440-066 Remove the Thrust Ring and the Thrust Base from the No. 3 Bearing And Support Assembly

Refer to Figure.

Cover the threads of the location spigot with CoMat 02-001 ADHESIVE TAPE (MASKING) so as not to damage the No. 3 bearing.

Remove the No. 3 Bearing And Support Assembly from the location spigot.

Return the No. 3 Bearing And Support Assembly to TASK 72-32-20-440-001-A00 (ASSEMBLY-001) and TASK 72-32-20-440-001-B00 (ASSEMBLY-001).

SUBTASK 72-32-10-440-068 Remove the No. 3 Bearing from the Location Spigot

Attach IAE 1J12449 Installation holder 1 off to the base plate with the four bolts and tighten the bolts.

Install the Bevel Gearshaft ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-750) on to the installation holder.

Put IAE 1J12368 Oil sleeve pusher 1 off into the distributor and push the oil sleeve pusher with the arbor press. Push in the distributor until you can see the slot for the retaining ring of the gearshaft.

Engage the retaining ring ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-460) with the slot in the Bevel Gearshaft.

Install the distributor ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-450) to the Bevel Gearshaft.

Push the bearing with IAE 1J12365 PTO bearing pusher r 1 off.

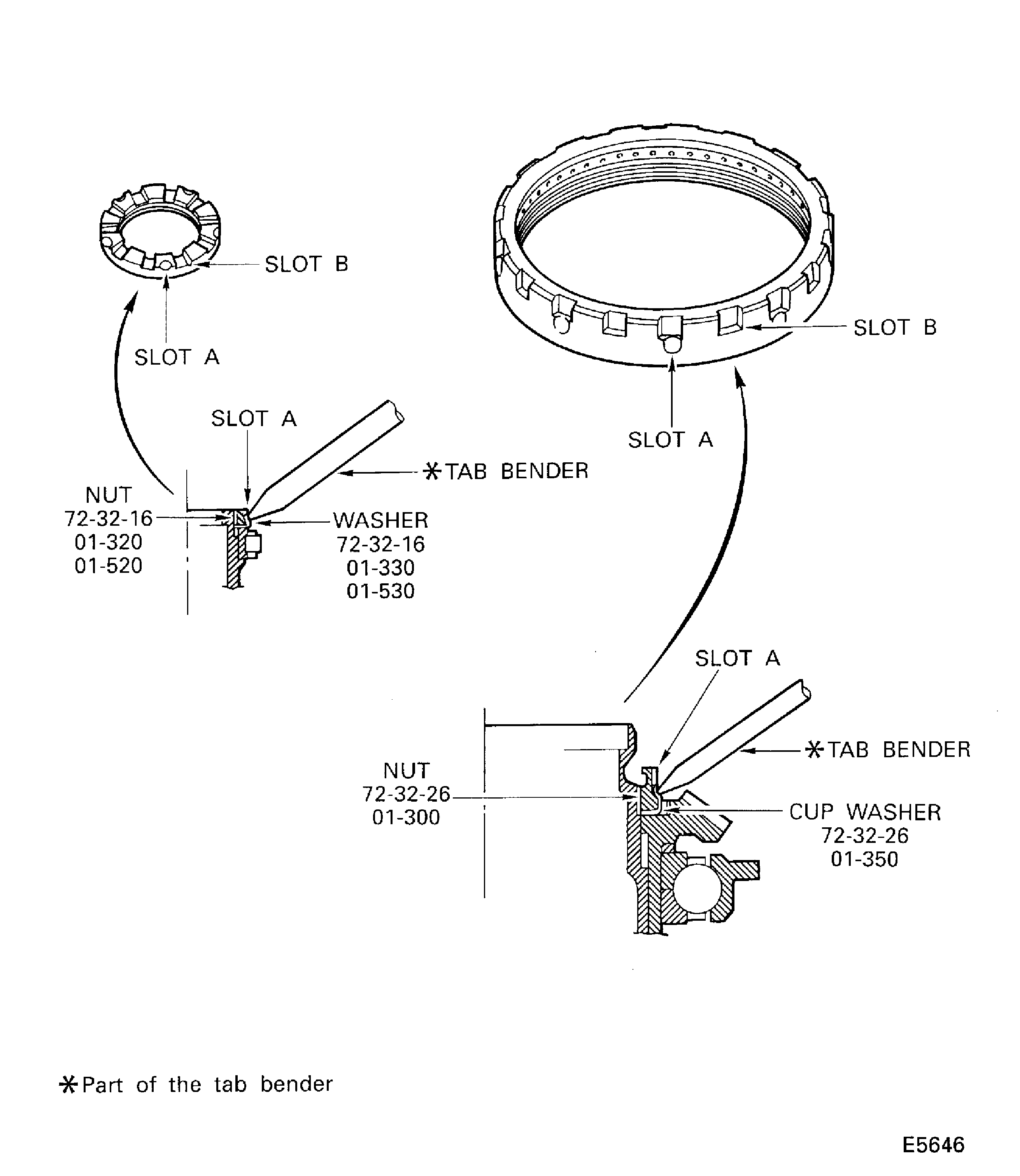

Put a new ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-330) 1 off and the round plain nut ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-320) on the Bevel Gearshaft.

Install the inner roller bearing ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-300) on to the Bevel Gearshaft.

Remove the Bevel Gearshaft from the installation holder and put on IAE 1J12422 Gearshaft holder 1 off.

Put IAE 1J12366 Spanner wrench 1 off on the nut.

Put a correlation mark on the Bevel Gearshaft and the nut with CoMat 06-069 MARKER.

Bend the rim of the cupwasher with IAE 1J12367 Tab bender 1 off to safety the nut.

Tighten the round plain nut.

Remove the Bevel Gearshaft from the gearshaft holder and install the Bevel Gearshaft to IAE 1J12448 Restraint holder 1 off.

Put the retaining plate ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-170) on the conical surface of the Bevel Gearshaft.

Put the selected flat adjusting washer on to the Bevel Gearshaft with IAE 1J12369 PTO bearing pusher 1 off. Refer to Step for the selection procedure.

Heat the inner races of the ball bearing ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-600) to a temperature of 302 deg F (150 deg C) in an oven for 20 minutes.

Lubricate the bearing journal of the Bevel Gearshaft which touches the inner races with CoMat 10-077 APPROVED ENGINE OILS.

WARNING

BE CAREFUL BECAUSE THE INNER RACES ARE HOT. USE APPROVED GLOVES WHEN YOU REMOVE THEM FROM THE OVEN.Remove the inner race upper half from the oven and install on to the Bevel Gearshaft.

NOTE

Refer to Step to identify the inner race halves.Heat the inner roller bearing ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-500) to a temperature of 302 deg F (150 deg C) in an oven for 20 minutes.

Lubricate the surface of the Bevel Gearshaft which touches the bearing with CoMat 10-077 APPROVED ENGINE OILS.

WARNING

BE CAREFUL BECAUSE THE INNER ROLLER BEARING IS HOT. USE APPROVED GLOVES WHEN YOU REMOVE IT FROM THE OVEN.Remove the inner roller bearing from the oven and install to the Bevel Gearshaft.

Lubricate the threads and the mating surface of the nut with CoMat 10-077 APPROVED ENGINE OILS.

Install a new ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-530) cupwasher1 off and the nut on to the Bevel Gearshaft.

Put IAE 1J12346 Spanner wrench 1 off on the nut.

Put correlation mark on the Bevel Gearshaft and the nut with CoMat 06-069 MARKER.

Install the round plain nut ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-520) on to the Bevel Gearshaft and tighten.

Lubricate the seal ring with CoMat 10-077 APPROVED ENGINE OILS.

Install a new ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-100) seal ring 1 off into the Bevel Gearshaft.

SUBTASK 72-32-10-440-069 Assemble the Bevel Gearshaft and Bearing Assembly

Make sure that the outer roller bearing ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-240) is installed to the Gearshaft Bearing Housing.

Lubricate the outer surface of the outer race of the ball bearing and the outer roller bearing with CoMat 10-077 APPROVED ENGINE OILS.

Attach the retaining plate to the Gearshaft Bearing Housing with the four bolts ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-180).

Install the Gearshaft Bearing Housing on to the Bevel Gearshaft and Bearing Assembly.

SUBTASK 72-32-10-440-070 Assemble the Internal Gearbox Driven Gear Assembly

Refer to Figure.

Lubricate the outer diameter surface of the bearing with CoMat 10-077 APPROVED ENGINE OILS.

Put the pressure pad (part of IAE 1J12343 PTO bearing pusher 1 off) in the bearing bore.

Engage the internal retaining ring ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-390) into the groove of the No. 2 Bearing Support.

Install the outer roller bearing ENGINE-INTERNAL GEARBOX DRIVEN GEAR ASSEMBLY (72-32-16, 01-400) into the No. 2 Bearing Support.

SUBTASK 72-32-10-440-071 Install the Outer Roller Bearing (72-32-16,01-240) to the No. 2 Bearing Support

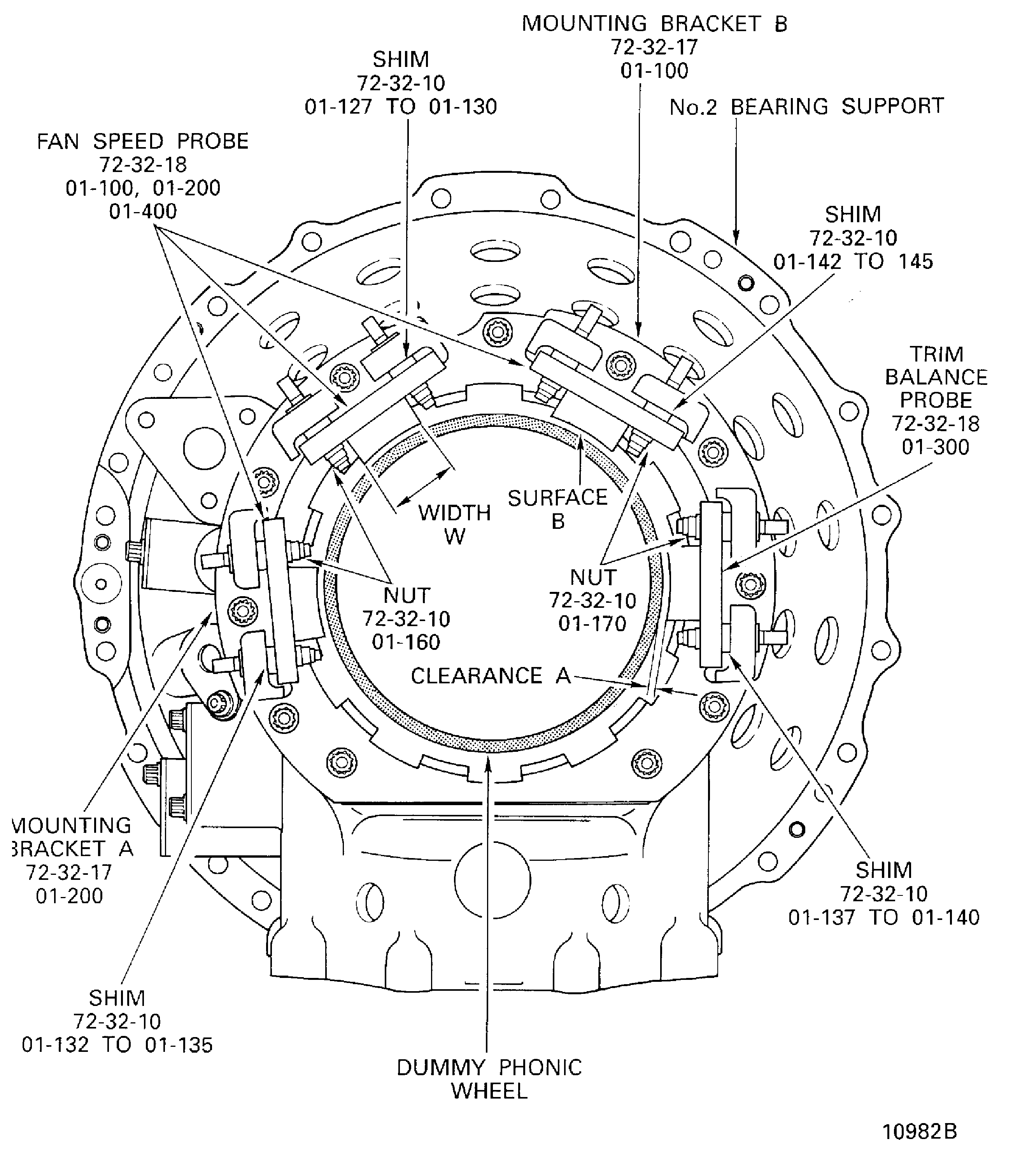

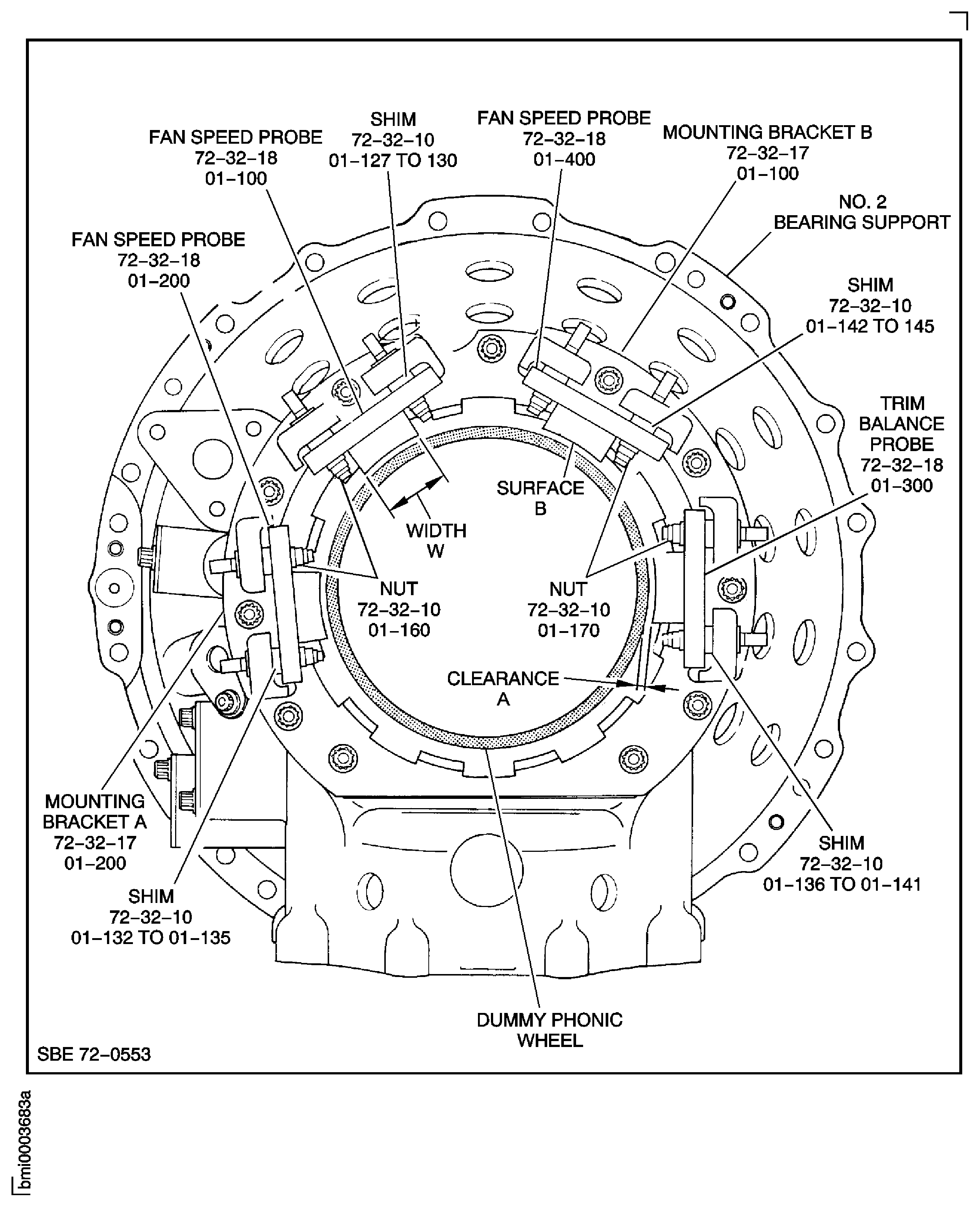

Pre SBE 72-0553: Put the shims (NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-127) to NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-130), NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-132) to NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-135) and NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-142) to NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-145)) for fan speed probe and shims (NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-137) to NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-140)) for trim balance probe.

SBE 72-0553: Put the shims (NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-127) to NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-130), NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-132) to NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-135) and NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-142) to NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-145)) for fan speed probe and shims (NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-136) to NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-141)) for trim balance probe.

Put the fan speed probes ENGINE-FAN SPEED/TRIM BALANCE PROBES (72-32-18, 01-100), ENGINE-FAN SPEED/TRIM BALANCE PROBES (72-32-18, 01-200) and ENGINE-FAN SPEED/TRIM BALANCE PROBES (72-32-18, 01-400) and the trim balance probe ENGINE-FAN SPEED/TRIM BALANCE PROBES (72-32-18, 01-300) on to the pins of the mounting brackets A ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17,01-200) and brackets B ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-100).

Attach the probes to the mounting brackets with the four nuts NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-160) and nuts NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-170). Torque the nuts to 36 lbfin to 45 lbfin (4.00 Nm to 5.00 Nm).

Install the probes on the mounting brackets.

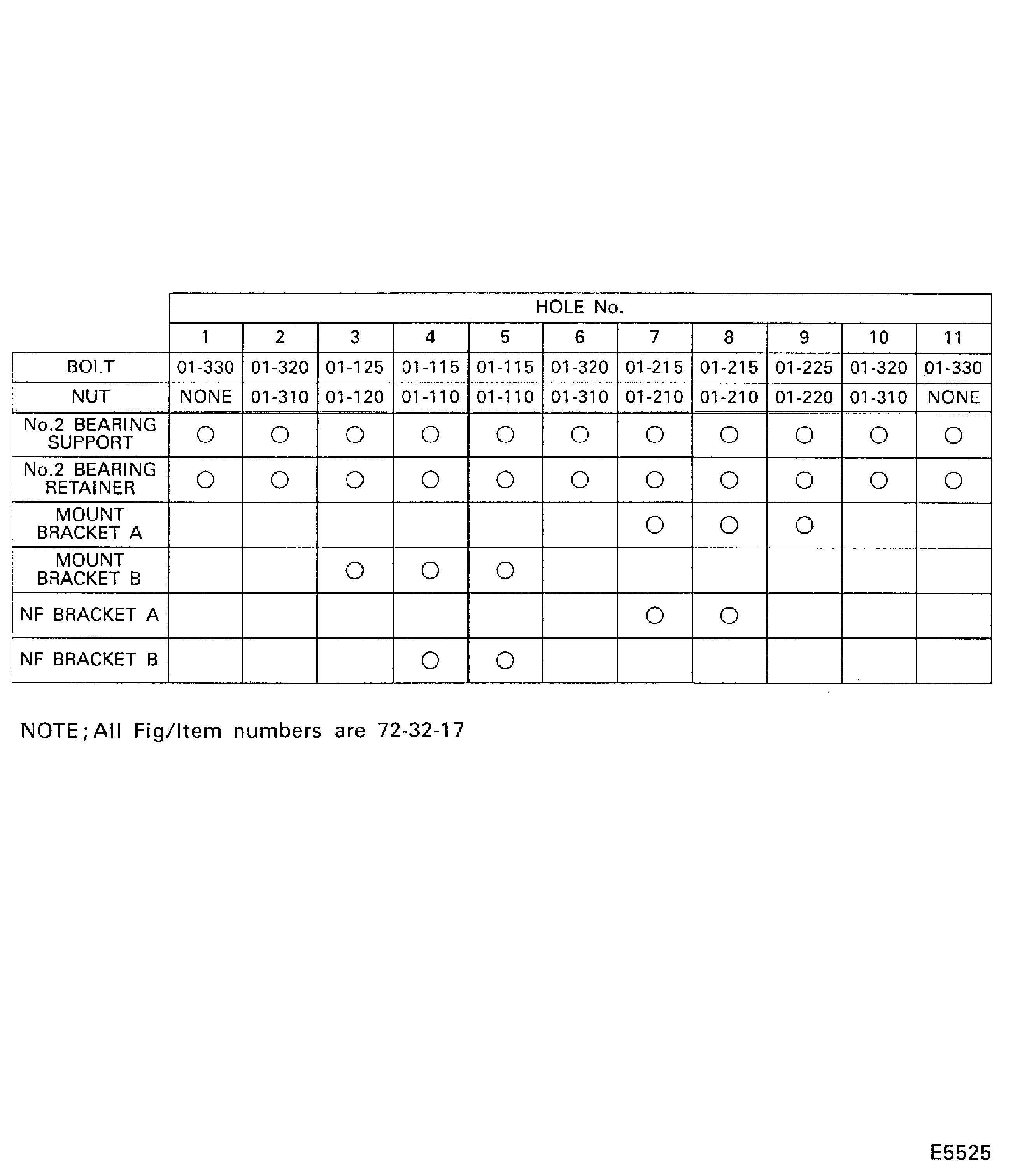

Attach the two mounting brackets and the No. 2 Bearing Retainer to the No. 2 Bearing Support with the bolt ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-115), the bolt ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-125), the two bolts ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-215), the bolt ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-225), the three bolts ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-320), the two bolts ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-330), the two nuts ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-110), the nut ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-120), the two nuts ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-210), the nut ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-220) and the three nuts ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-310). Torque the bolts and nuts to 85 lbfin to 105 lbfin (10.00 Nm to 12.00 Nm).

NOTE

Measure the clearances A over the width W of the probes.

Install IAE 1J12371 Dummy phonic wheel 1 off, the No. 2 Bearing Retainer ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-300) and the mounting brackets on to the No. 2 Bearing Support.

0.0236 in. (0.600 mm) to 0.0354 in. (0.900 mm).

Limit for the fan speed probes and the trim balance probe:

Pre SBE 72-0553: Make sure the clearance A is in the following limit:

0.0236 in. (0.600 mm) to 0.0354 in. (0.900 mm).

Limit for the fan speed probes:

0.067 in. (1.70 mm) to 0.075 in. (1.90 mm).

Limit for the trim balance probe:

SBE 72-0553: Make sure the clearance A is in the following limit:

SUBTASK 72-32-10-440-072 Select the Shim (Pre SBE 72-0553 and SBE 72-0553)

Find the necessary shim thickness from Step.

Attach the selected shims and the probes on to the mounting brackets.

NOTE

Pre SBE 72-0553: Do not install more than three shims onto each pin of the mounting bracket.NOTE

SBE 72-0553: Do not install more than two shims for the trim balance probe onto each pin of the mounting bracket.Do not install more than three shims for the fan speed probes onto the pin of the mounting bracket.Go to Step.

SUBTASK 72-32-10-440-073 Install the Shims on to the Mounting Brackets (Pre SBE 72-0553 and SBE 72-0553)

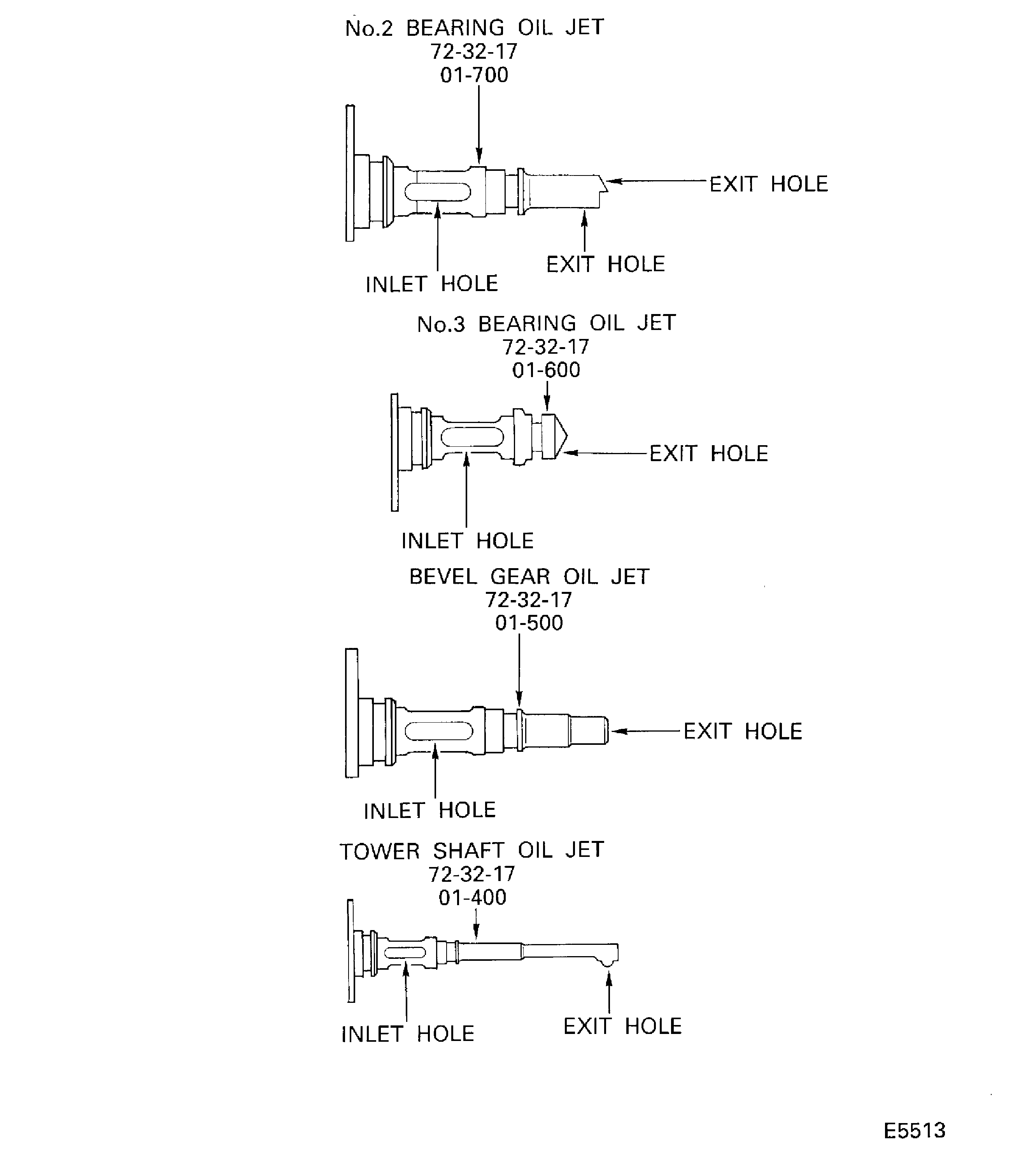

CAUTION

DO NOT APPLY PRESSURIZED AIR TO THE INLET HOLE IN THE OIL JET. PRESSURIZED AIR CAN PUSH UNWANTED MATERIAL INTO THE THROAT IN THE OIL JET. THE UNWANTED MATERIAL CAUSES A BLOCKAGE.DO NOT PUSH A HAND TOOL INTO THE EXIT HOLE TO EXAMINE ITS CLEARANCE. THE HAND TOOL CAN CAUSE DAMAGE TO THE HOLE.If the air does not flow at the inlet holes, reject the oil jet.

Do a clear passage test for the oil jets ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-400), ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-500), ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-600) and ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-700).

Lubricate a new ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-720) seal ring 1 off and a new ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-730) seal ring 1 off with CoMat 10-077 APPROVED ENGINE OILS. Put the seal rings into the grooves in the oil jet.

Put the oil jet strainer ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-760) on the oil jet.

Attach the seal rings and the strainer on to the No. 2 Bearing oil jet ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-700).

Lubricate a new ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-620) seal ring 1 off and a new ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-630) seal ring 1 off with CoMat 10-077 APPROVED ENGINE OILS. Put the seal rings into the grooves in the oil jet.

Put the oil jet strainer ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-660) on the oil jet.

Attach the seal rings and the strainer on to the No. 3 Bearing oil jet ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-600).

Lubricate a new ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-520) seal ring 1 off and a new ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-530) seal ring 1 off with CoMat 10-077 APPROVED ENGINE OILS. Put the seal rings into the grooves in the oil jet.

Put the oil jet strainer ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-560) on the oil jet.

Attach the seal rings and the strainer on to the bevel gear oil jet ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-500).

Lubricate a new ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-420) seal ring 1 off and a new ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-430) seal ring 1 off with CoMat 10-077 APPROVED ENGINE OILS. Put the seal rings into the grooves in the oil jet.

Put the oil jet strainer ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-460) on the oil jet.

Attach the seal rings and the strainer on to the tower shaft oil jet ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-400).

CAUTION

POINT THE EXIT HOLE OF THE TOWER SHAFT OIL JET IN THE CORRECT DIRECTION. IF THE HOLE IS IN AN INCORRECT DIRECTION, THE HOLE CAN NOT SUPPLY OIL TO THE BEARINGS. IT CAN CAUSE DAMAGE TO THE BEARINGS.Put the oil jets in the holes in the No. 2 Bearing Support. Exit hole of the tower shaft oil jet must point in direction X.

Attach the oil jets with the two bolts ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-410), the bolt ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-510), the bolt ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-610) and the bolt ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-710). Torque the bolts to 36 lbfin to 45 lbfin (4.00 Nm to 5.00 Nm).

Attach the No. 2 Bearing oil jet, the No. 3 Bearing oil jet, the bevel gear oil jet and the tower shaft oil jet to the No. 2 Bearing Support.

SUBTASK 72-32-10-440-074 Install the Oil Jets to the No. 2 Bearing Support

Lubricate the anti-torque lug with CoMat 10-077 APPROVED ENGINE OILS.

Install the No. 2 Roller Bearing Outer ENGINE-NO.2 BEARING (72-32-52, 01-100) into the No. 2 Bearing Support.

Safety the brackets and the retainer to the support with the bolt ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-115), the bolt ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-125), the two bolts ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-215), the bolt ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-225), the three bolts ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-320), the two bolts ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-330), the two nuts ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-110), the nut ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-120), the two nuts ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-210), the nut ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-220) and the three nuts ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-310). Torque the bolts and the nuts to 85 lbfin to 105 lbfin (10.00 Nm to 12.00 Nm).

Attach the No. 2 Bearing Retainer, the mounting brackets and the NF brackets ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-150) and ENGINE-NO.2 BEARING SUPPORT AND PROBE BRACKETS (72-32-17, 01-195) to the No. 2 Bearing Support.

SUBTASK 72-32-10-440-075 Assemble the No. 2 Bearing Support Assembly

Assemble the No. 3 Bearing Rotor Center and Support Assembly. Refer to TASK 72-32-20-440-001-A00 (ASSEMBLY-001) and TASK 72-32-20-440-001-B00 (ASSEMBLY-001).

SUBTASK 72-32-10-440-076 Assemble the No. 3 Bearing Rotor Center and Support Assembly

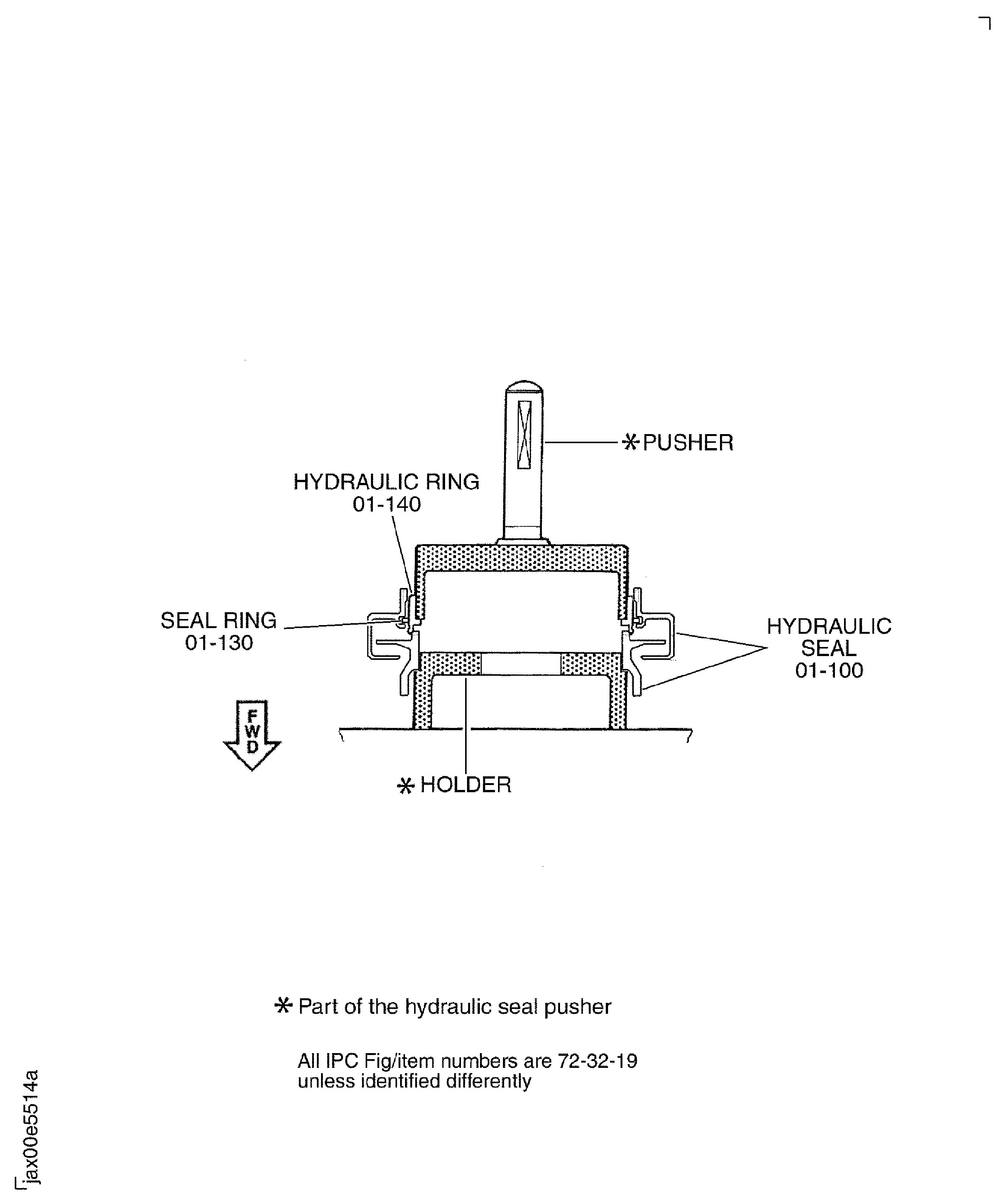

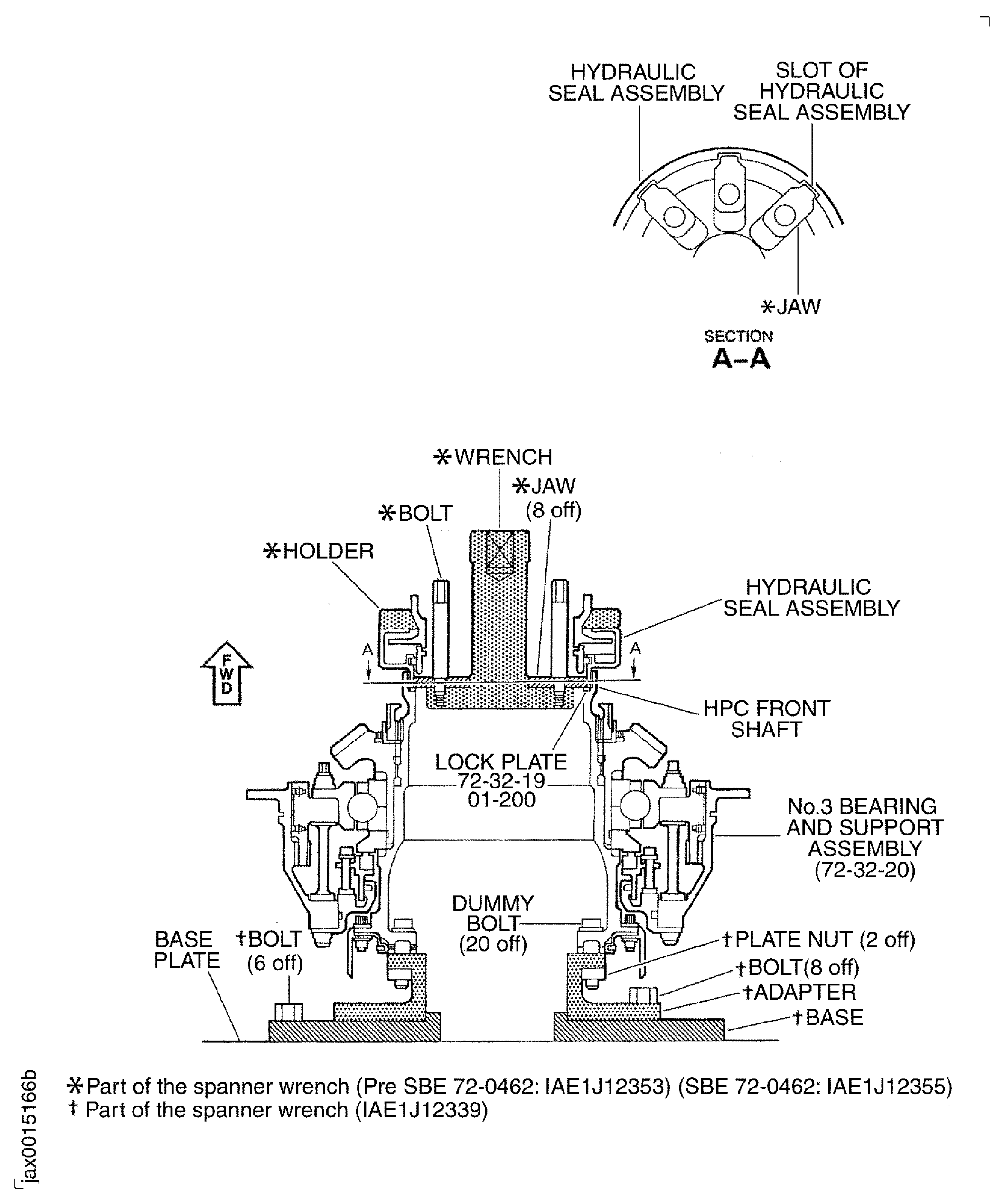

Refer to Figure.

Put the hydraulic seal ENGINE-HYDRAULIC SEAL ASSEMBLY (72-32-19, 01-100) on the holder (part of IAE 1J12382 Hydraulic seal pusher 1 off).

Put the seal ring ENGINE-HYDRAULIC SEAL ASSEMBLY (72-32-19, 01-130) into the groove in the hydraulic seal.

Heat the hydraulic ring ENGINE-HYDRAULIC SEAL ASSEMBLY (72-32-19, 01-140) to a temperature of 302 deg F (150 deg C) in an oven for 20 minutes.

SUBTASK 72-32-10-440-115 Assemble the Hydraulic Seal Assembly

Attach the base (part of the spanner wrench) on IAE 1J12345 Base plate 1 off with the six bolts (part of the spanner wrench).

Install No. 3 Bearing And Support Assembly to the adapter (part of IAE 1J12339 Spanner wrench1 off).

Install IAE 1J12353 TBD 1 off onto the hydraulic seal.

Prepare the No. 3 Bearing And Support Assembly and the Hydraulic Seal Assembly for installation.

Lubricate the threaded hole of the HPC front shaft with CoMat 10-077 APPROVED ENGINE OILS.

Attach the new ENGINE-HYDRAULIC SEAL ASSEMBLY (72-32-19, 01-200) lock plate 1 off to the assembly (72-32-20).

Lubricate the mating surface of the hydraulic seal and the lock plate with CoMat 10-077 APPROVED ENGINE OILS.

Install the hydraulic seal assembly into the threaded hole of the HPC front shaft.

Install a torque wrench into the hole in IAE 1J12353 TBD and torque hydraulic seal assembly to 2342 lbfin to 3045 lbfin (264.60 Nm to 343.80 Nm).

Install the Hydraulic Seal Assembly onto the HPC front shaft of the No. 3 Bearing And Support Assembly.

Put the spacer (part of IAE 1J12367 Tab bender 1 off) on the hydraulic seal.

Crimp the lock plate into the slots of the HPC front shaft.

Install the holder (part of the IAE 1J12367 Tab bender) on IAE 1J12345 Base plate with the four bolts (part of the tab bender).

Turn the No. 3 Bearing Support and Hydraulic Seal Assembly.

Crimp the lock plate into the four slots with the long tab bender (part of IAE 1J12367 Tab bender tab bender) and lock Hydraulic Seal Assembly.

Crimp the lock plate into the slots of the Hydraulic Seal Assembly.

SUBTASK 72-32-10-440-077-A00 Install the Hydraulic Seal Assembly on to the No. 3 Bearing And Support Assembly (Pre SBE 72-0462)

Attach the base (part of the spanner wrench) on IAE 1J12345 Base plate with the six bolts (part of the spanner wrench).

Install No. 3 Bearing And Support Assembly to the adapter (part of IAE 1J12339 Spanner wrench 1 off).

Install IAE 1J12355 Spanner wrench 1 off onto the hydraulic seal.

Prepare the No. 3 Bearing And Support Assembly and the Hydraulic Seal Assembly for installation.

Lubricate the threaded hole of the HPC front shaft with CoMat 10-077 APPROVED ENGINE OILS.

Attach the new ENGINE-HYDRAULIC SEAL ASSEMBLY (72-32-19, 01-200) lock plate 1 off to the assembly (72-32-20).

Lubricate the mating surface of the hydraulic seal and the lock plate with CoMat 10-077 APPROVED ENGINE OILS.

Install the Hydraulic Seal Assembly into the threaded hole of the HPC front shaft.

Install a torque wrench into the hole in IAE 1J12355 Spanner wrench and torque hydraulic seal assembly to 2342 lbfin to 3045 lbfin (264.60 Nm to 343.80 Nm).

Install the hydraulic seal assembly onto the HPC front shaft of the No. 3 Bearing And Support Assembly.

Put the spacer (part of IAE 1J12381 Tab bender 1 off) on the hydraulic seal.

Crimp the lock plate into the slots of the HPC front shaft.

Install the holder (part of the IAE 1J12381 Tab bender) on IAE 1J12345 Base plate with the four bolts (part of the tab bender).

Turn the No. 3 Bearing Support and Hydraulic Seal Assembly.

Crimp the lock plate into the four slots with the long tab bender (part of IAE 1J12381 Tab bender) and lock Hydraulic Seal Assembly.

Crimp the lock plate into the slots of the Hydraulic Seal Assembly.

SUBTASK 72-32-10-440-077-B00 Install the Hydraulic Seal Assembly on to the No. 3 Bearing And Support Assembly (SBE 72-0462)

Install the No. 3 Bearing Rotor Center and Support Assembly to IAE 1J12362 Work stand 1 off.

Lubricate a new NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-200) seal ring 1 off with CoMat 10-077 APPROVED ENGINE OILS.

Install the No. 2 Bearing Support Assembly to the No. 3 Bearing Rotor Center and Support Assembly.

Attach the assembly to the No. 2 Bearing Support with the eight bolts NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-110). Torque the bolts to 80 lbfin to 105 lbfin (10.00 Nm to 12.00 Nm).

Install the Internal Gearbox driven gear assembly into the No. 2 Bearing Support.

SUBTASK 72-32-10-440-078 Assemble the No. 3 Bearing, Internal Gearbox and support Assembly

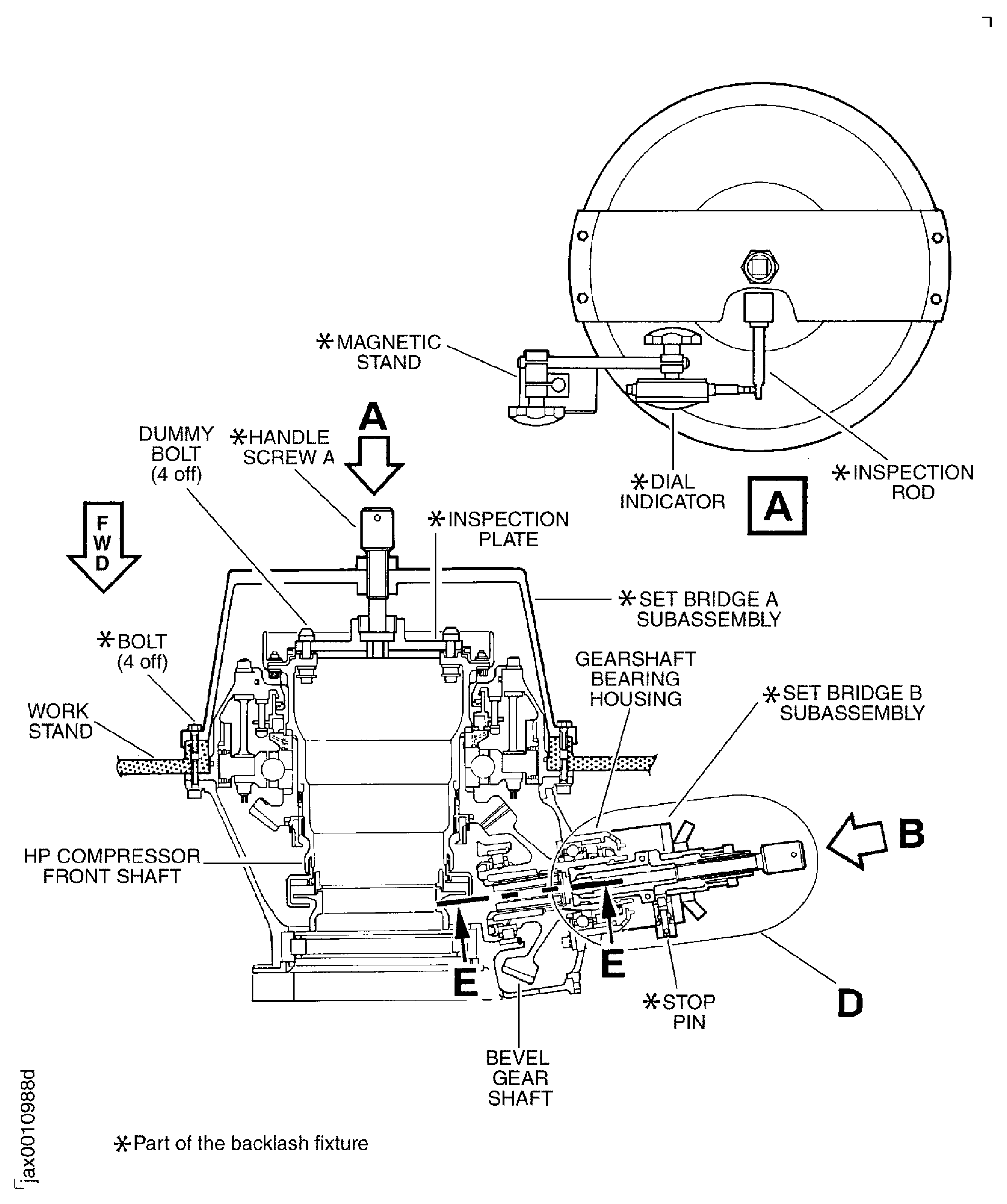

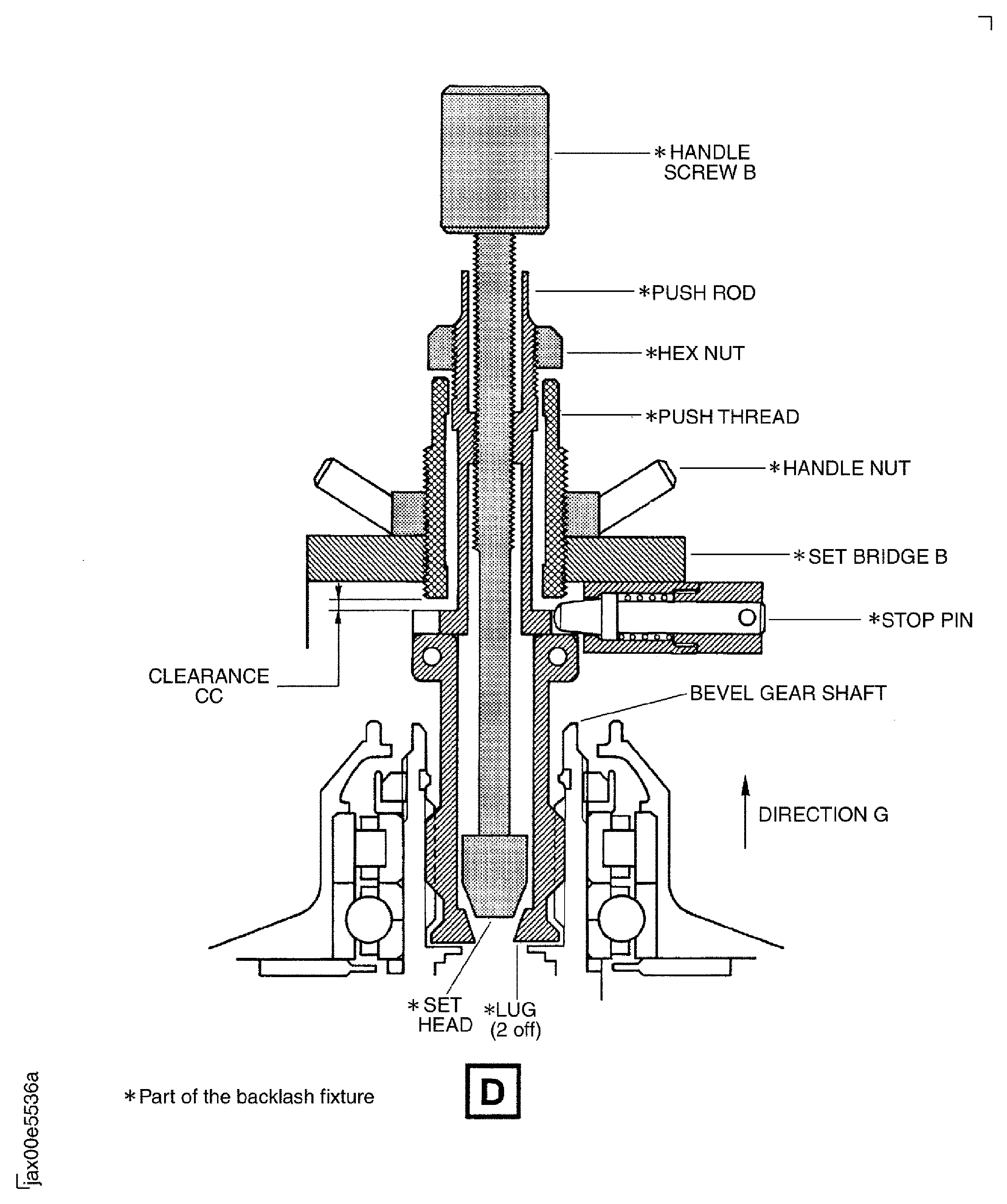

Loosen the hex nut (part of the backlash fixture) and the handle nut (part of the backlash fixture).

NOTE

It is needed that the clearance is at CC to pull the Bevel Gearshaft in direction G in Step.Install the three puller bolts (part of IAE 1J12188 Puller bolt 1 off) into the threaded holes in the No. 3 Bearing Seal Assembly.

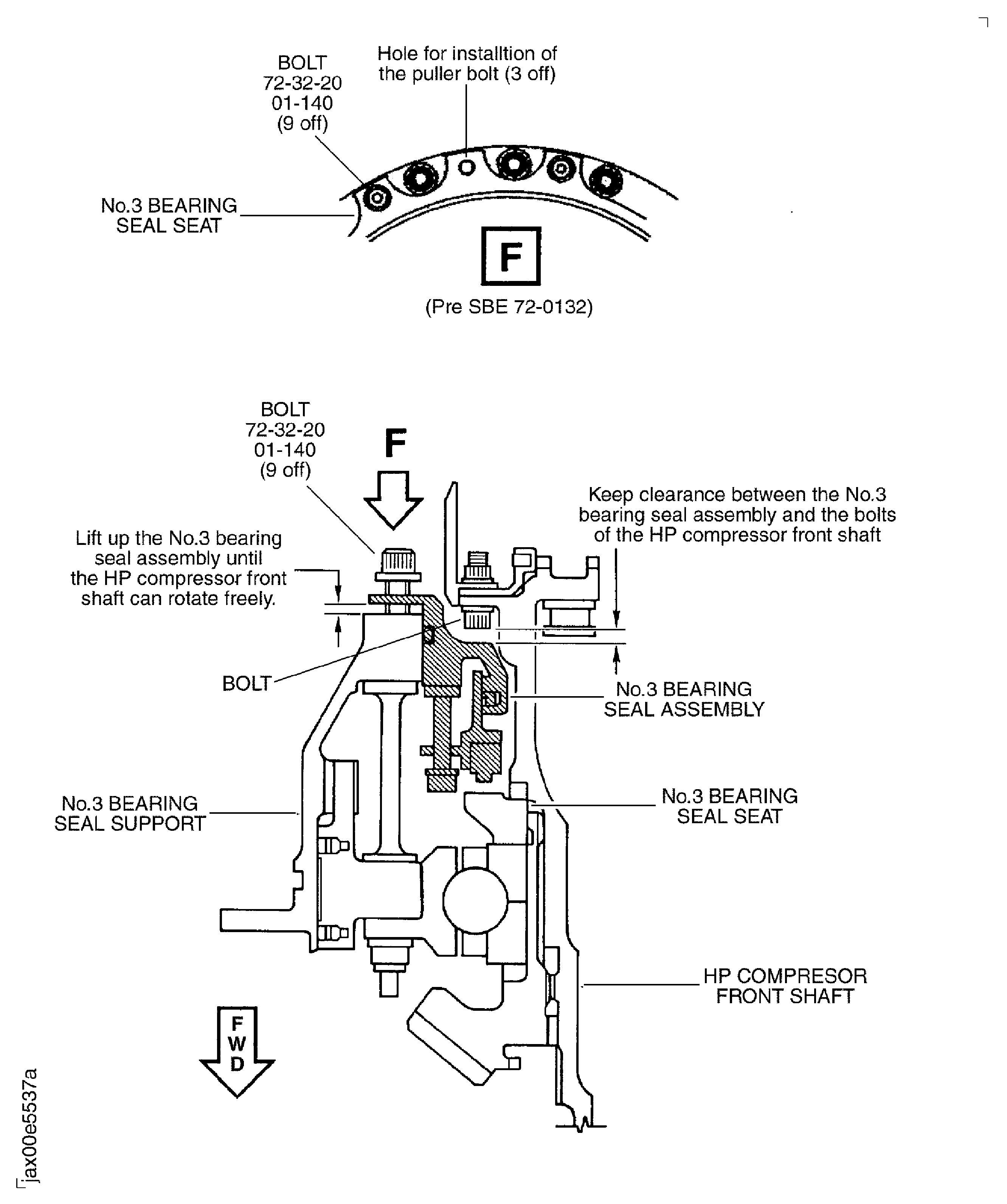

Pre SBE 72-0132: Move the No. 3 Bearing Seal Assembly rearward to make clearance between the No. 3 Bearing Seal Assembly and the No. 3 Bearing Seal Seat.

Loosen the nine bolts which attach the No. 3 Bearing Seal Assembly and IAE 1J12021 Lifting spacer to the No. 3 Bearing Seal Support.

SBE 72-0132: Move the No. 3 Bearing Seal Assembly rearward to make clearance between the No. 3 Bearing Seal Assembly and the No. 3 Bearing Seal Seat.

NOTE

The clearance lets you freely turn the HP Compressor front shaft by hand when you measure backlash of the bevel gears.NOTE

The lifting spacer is installed in TASK 72-32-20-440-001-A00 (ASSEMBLY-001) and TASK 72-32-20-440-001-B00 (ASSEMBLY-001).

Install IAE 1J12385 Backlash fixture 1 off to the assembly (72-32-10).

Prepare the tool to measure the backlash of the bevel gears.

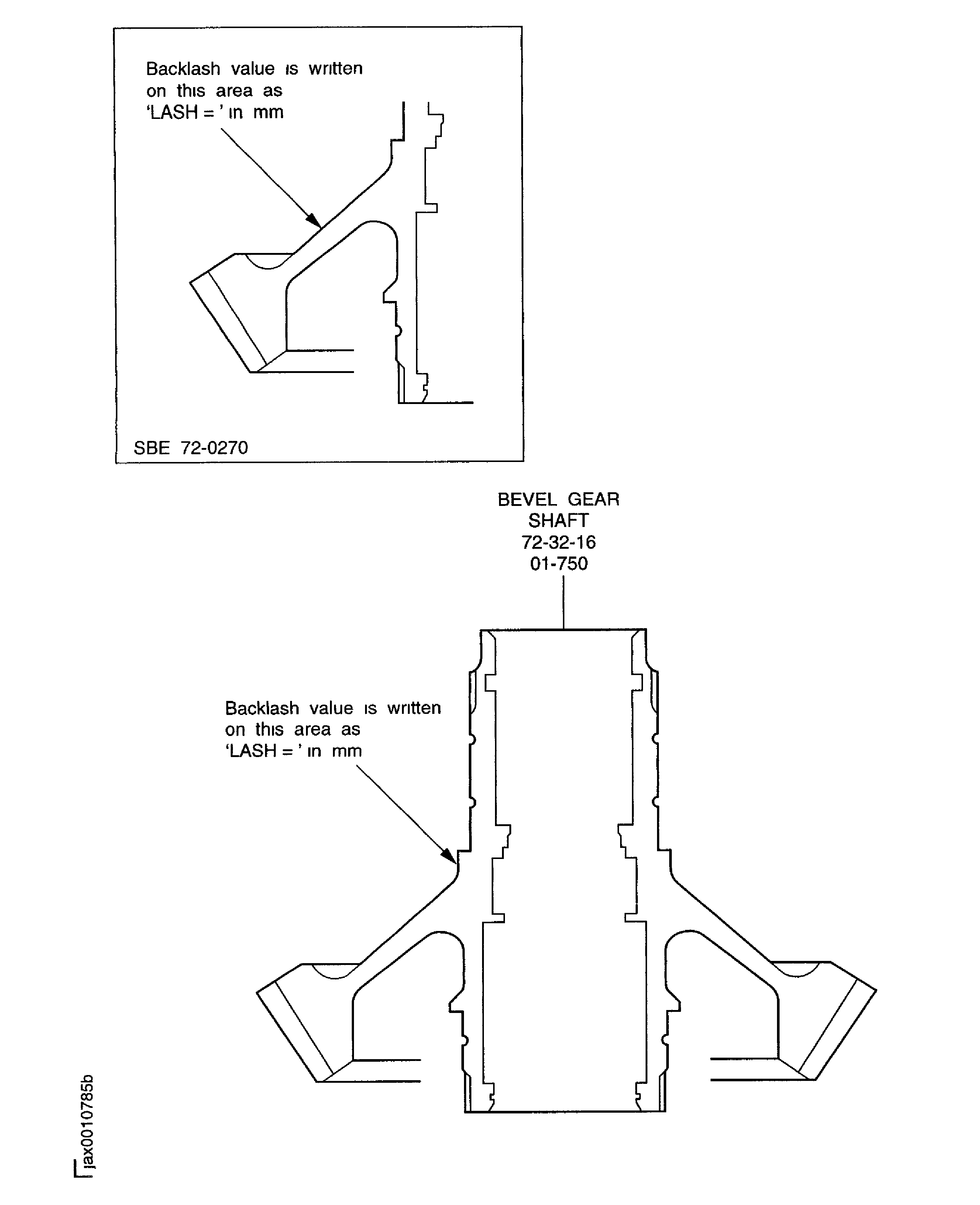

Calculate the minimum allowable backlash BL min and the maximum allowable backlash BL max.

BL min (mm) = (LASH A + LASH B + 0.46) x 1.4.

BL min (in.) = BL min (mm)/25.4.

BL max (mm) = (LASH A + LASH B + 0.56) x 1.4.

BL max (in.) = BL max (mm)/25.4.

Where:

LASH A - Refer to SUBTASK 72-32-20-220-051 in TASK 72-32-20-440-001-A00 (ASSEMBLY-001) and TASK 72-32-20-440-001-B00 (ASSEMBLY-001).

LASH B - Refer to Step.

Calculate the allowable backlash of the bevel gears.

Make sure that the backlash BLA measured in Step is between the minimum allowable backlash BL min. and the maximum allowable backlash BL max.

Attach the No. 3 Bearing Seal Assembly to the No. 3 Bearing Seal Support with the nine bolts "NO.3 BEARING,ROTOR CENTRE & SUPPORT ASSY (72-32-20, 01-140). Torque the bolts to 85 lbfin to 105 lbfin (10.00 Nm to 12.00 Nm).

Attach the Gearshaft Bearing Housing to the No. 2 Bearing Support with the four bolts NO.3 BEARING INT GEARBOX & SUPPORT ASSY (72-32-10, 01-110) which are removed in Step. Torque the bolts to 85 lbfin to 105 lbfin (10.00 Nm to 12.00 Nm).

SUBTASK 72-32-10-220-052 Do a Backlash Check of the Bevel Gears

Figure: Internal Gearbox Driven Gear Assembly - Fits and Clearances

Sheet 1

Figure: Reference Fits and Clearances of the Hydraulic Ring and the Hydraulic Seal at Location 0117

Sheet 2

Figure: Install the No. 3 Bearing And Support Assembly to the Setting Gage

Install the No. 3 Bearing And Support Assembly to the Setting Gage

Figure: Install the No. 3 Bearing And Support Assembly to the Work Stand

Install the No. 3 Bearing And Support Assembly to the Work Stand

Figure: Install the PTO Bearings and the Dummy Bearing to the Dummy Gearshaft

Install the PTO Bearings and the Dummy Bearing to the Dummy Gearshaft

Figure: Install the Outer Roller Bearing to the Gearshaft Bearing Housing

Install the Outer Roller Bearing to the Gearshaft Bearing Housing

Figure: Install the Gearshaft Bearing Housing to the Dummy Gearshaft

Install the Gearshaft Bearing Housing to the Dummy Gearshaft

Figure: Assemble the Setting Gage

Sheet 1

Figure: Assemble the Setting Gage

Sheet 2

Figure: Calculate the Thickness of the Adjusting Washer-PTO

Calculate the Thickness of the Adjusting Washer-PTO

Figure: Calculate the Thickness of the Adjusting Washer

Calculate the Thickness of the Adjusting Washer

Figure: Sectional View of the Internal Gearbox Driven Gear Assembly

Sectional View of the Internal Gearbox Driven Gear Assembly

Figure: Assemble the Bevel Gearshaft and Bearing Assembly

Sheet 1

Figure: Assemble the Bevel Gearschaft and Bearing Assembly

Sheet 2

Figure: Assemble the Bevel Gearshaft and Bearing Assembly

Sheet 3

Figure: Assemble the Bevel Gearshaft and Bearing Assembly

Sheet 4

Figure: Install the Outer Roller Bearing into the No. 2 Bearing Support

Sheet 5

Figure: Assemble the Bevel Gearshaft and Bearing Assembly

Sheet 6

Figure: Select the Shim

Sheet 1

Figure: Pre SBE 72-0553: Select the Shim

Sheet 2

Figure: SBE 72-0553: Select the Shim

Sheet 3

Figure: Pre SBE 72-0553: Replace the Shims on to the Mounting Brackets

Sheet 1

Figure: Pre SBE 72-0553: Replace the Shims on to the Mounting Brackets

Sheet 2

Figure: Install the Oil Jets to the No. 2 Bearing Support

Sheet 1

Figure: Install the Oil Jets to the No. 2 Bearing Support

Sheet 2

Figure: Assemble the Hydraulic Seal Assembly

Sheet 1

Figure: Install the Hydraulic Seal Assembly to the No. 3 Bearing And Support Assembly

Sheet 2

Figure: Install the Hydraulic Seal Assembly to the No. 3 Bearing And Support Assembly

Sheet 3

Figure: Pre SBE 72-0462: Install the Hydraulic Seal Assembly to the No. 3 Bearing And Support Assembly

Sheet 4

Figure: SBE 72-0462: Install the Hydraulic Seal Assembly to the No. 3 Bearing And Support Assembly

Sheet 5

Figure: Install the Hydraulic Seal Assembly to the No. 3 Bearing And Support Assembly

Sheet 6

Figure: Assemble the No. 3 Bearing, Internal Gearbox and Support Assembly

Assemble the No. 3 Bearing, Internal Gearbox and Support Assembly

Figure: Do a Backlash Check of the Bevel Gears

Sheet 1

Figure: Do a Backlash Check of the Bevel Gears

Sheet 2

Figure: Do a Backlash Check of the Bevel Gears

Sheet 3

Figure: Move the No. 3 Bearing Seal Assembly

Sheet 4

Figure: Find the Value of the LASH B and the Mounting Distance of the Bevel Gearshaft

Sheet 1

Figure: Find the Value of the LASH B and the Mounting Distance of the Bevel Gearshaft

Sheet 2

Figure: Find the Value of the LASH B and the Mounting Distance of the Bevel Gearshaft Wheel

Sheet 3

Figure: Assemble the No. 2 Bearing Support Assembly

Sheet 1

Figure: Assemble the No. 2 Bearing Support Assembly

Sheet 2

Figure: Assemble the No. 2 Bearing Support Assembly

Sheet 3

Figure: Identify the No. 3 Bearing, Internal Gearbox and Support Assembly (Sub-Module)

Identify the No. 3 Bearing, Internal Gearbox and Support Assembly (Sub-Module)

Figure: Reference Fits And Clearances Of The No. 2 Bearing Support And The No. 3 Bearing Seal Support At Location 0307

Reference Fits And Clearances Of The No. 2 Bearing Support And The No. 3 Bearing Seal Support At Location 0307