Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-32-20-440-001-B00 No. 3 Bearing, Seal, HPC Shaft, And Gearshaft Assembly - Assemble, Assembly-001

General

This TASK gives the procedure to assemble the No. 3 Bearing Rotor Center and Support Assembly.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

Special torque data and assembly tolerances are included in the procedure.

Special torque data is identified with the symbol * after the torque value.

Lubricate all threads and abutment faces of nuts and bolts with approved engine oils, unless other lubricants are referred to in the procedure. For the approved engine oils and procedures, refer to the SPM TASK 70-64-00-640-501.

To identify, lubricate and install seal rings, refer to the SPM TASK 70-44-01-400-501.

For cup washer installation, refer to the SPM TASK 70-42-04-400-501.

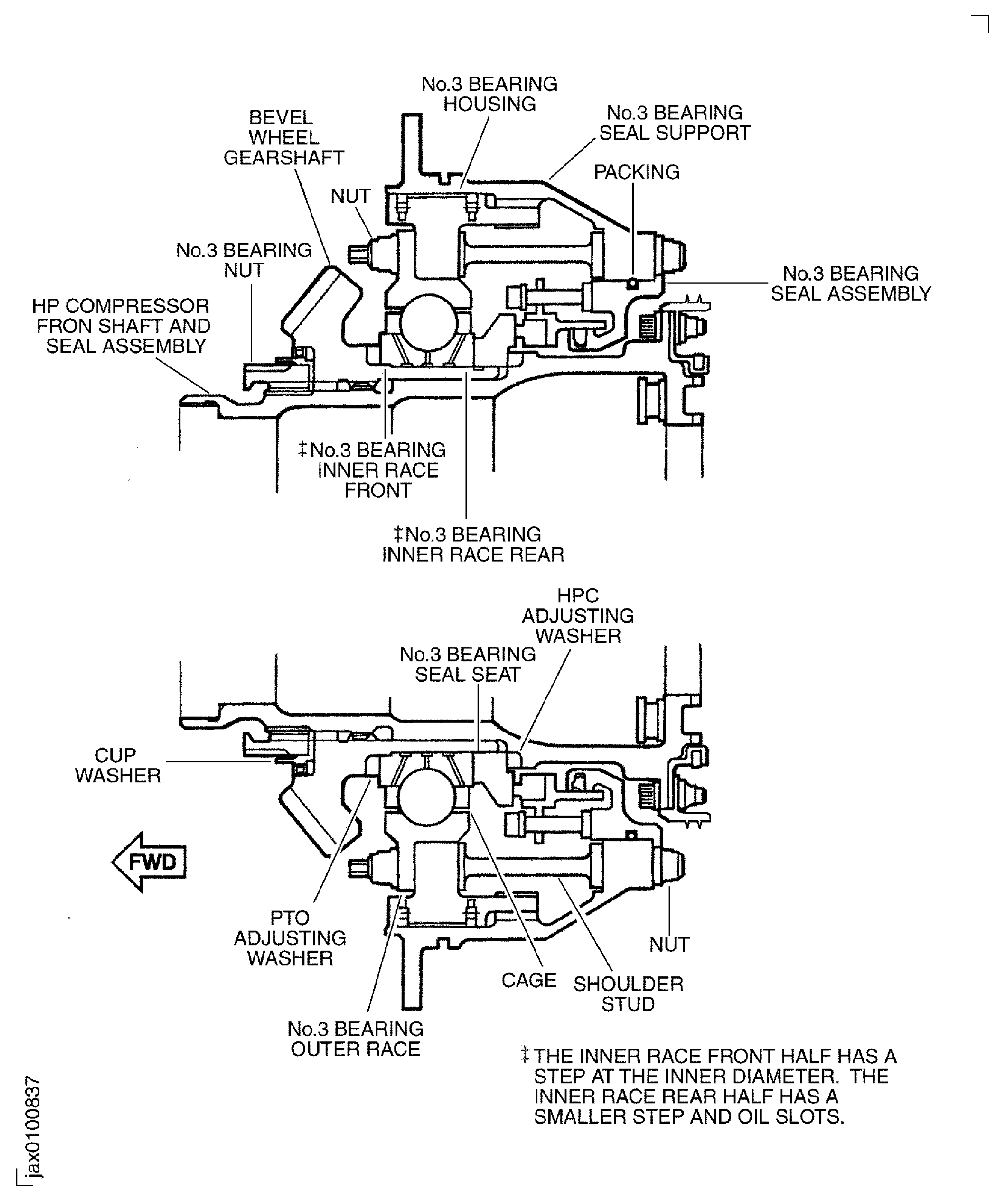

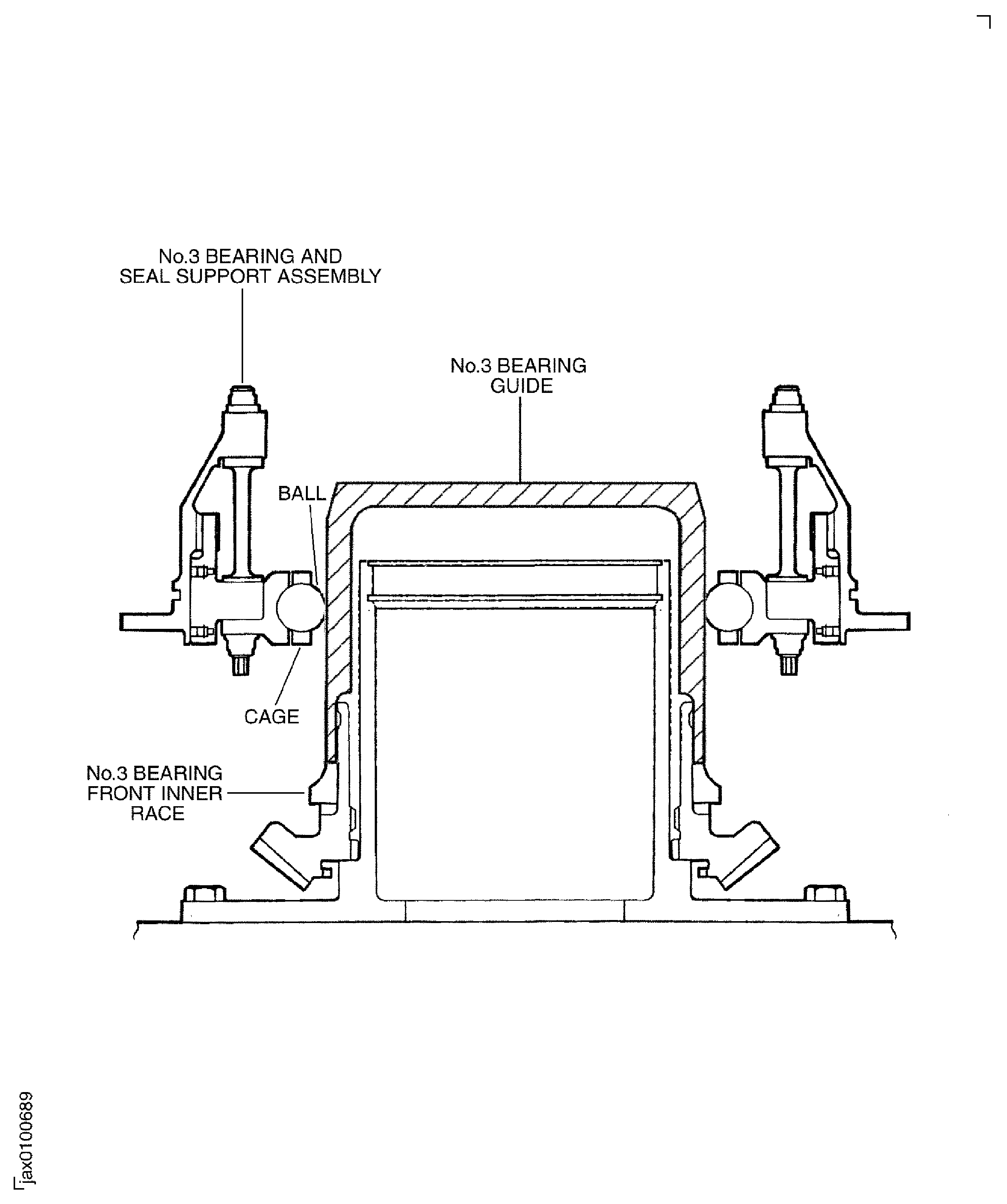

Refer to Figure for a sectional view of a No. 3 Bearing Rotor Center and Support Assembly.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Oven | LOCAL | |||

| Torque multiplier | LOCAL | SWEENEY 8200 | ||

| Hot Oil Tank | LOCAL | |||

| Feeler gage | LOCAL | |||

| Protection cover | LOCAL | |||

| Hydraulic hand pump | LOCAL | |||

| Digital depth gage | LOCAL | |||

| IAE 1J12021 Lifting spacer | 0AM53 | IAE 1J12021 | 1 | |

| IAE 1J12188 Puller bolt | 0AM53 | IAE 1J12188 | 1 | |

| IAE 1J12339 Spanner wrench | 0AM53 | IAE 1J12339 | 1 | |

| IAE 1J12359 Inspection bridge | 0AM53 | IAE 1J12359 | 1 | |

| IAE 1J12367 Tab bender | 0AM53 | IAE 1J12367 | 1 | |

| IAE 1J12374 Oil flow test stand | 0AM53 | IAE 1J12374 | 1 | |

| IAE 1J12375 Oil flow check box | 0AM53 | IAE 1J12375 | 1 | |

| IAE 1J12376 Oil feed adapter | 0AM53 | IAE 1J12376 | 1 | |

| IAE 1J12378 Ratchet wrench | 0AM53 | IAE 1J12378 | 1 | |

| IAE 1J12379 Hydraulic pusher | 0AM53 | IAE 1J12379 | 1 | |

| IAE 1J12380 Hydraulic pusher | 0AM53 | IAE 1J12380 | 1 | |

| IAE 1J12383 Swash check fixture | 0AM53 | IAE 1J12383 | 1 | |

| IAE 1J12384 Swash check ring | 0AM53 | IAE 1J12384 | 1 | |

| IAE 1J12387 Work stand | 0AM53 | IAE 1J12387 | 1 | |

| IAE 1J12421 Base holder | 0AM53 | IAE 1J12421 | 1 | |

| IAE 1J12469 Leak test fixture | 0AM53 | IAE 1J12469 | 1 | |

| IAE 1J12477 Base holder | 0AM53 | IAE 1J12477 | 1 | |

| IAE 1J12478 Hydraulic pusher/puller | 0AM53 | IAE 1J12478 | 1 | |

| IAE 1J12502 No.3 bearing guide | 0AM53 | IAE 1J12502 | 1 | |

| IAE 1J12504 Ring holder | 0AM53 | IAE 1J12504 | 1 | |

| IAE 1J12505 0AM53 heater | 0AM53 | IAE 1J12505 | 1 | |

| IAE 1J12529 Measuring stretch | 0AM53 | IAE 1J12529 | 1 | |

| IAE 1J12556 Measuring block | 0AM53 | IAE 1J12556 | 1 | |

| IAE 1F10026 Hydraulic hand pump | 0AM53 | IAE 1F10026 | 1 | |

| IAE 6F10027 Heater control unit | 0AM53 | IAE 6F10027 | 1 | |

| IAE 6F10030 Vacuum test cart | 0AM53 | IAE 6F10030 | 1 | |

| IAE 1P17526 Torque sequence locator | 0AM53 | IAE 1P17526 | 1 | |

| IAE 1P17043 Knocker puller | 0AM53 | IAE 1P17043 | 1 | |

| IAE 1P17507 Spacer ring | 0AM53 | IAE 1P17507 | 1 | |

| IAE 1P17508 Build fixture | 0AM53 | IAE 1P17508 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 06-069 MARKER | IE207 | CoMat 06-069 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 | ||

| CoMat 02-130 POLAR GRAPH PAPER | LOCAL | CoMat 02-130 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| PACKING - PREFORMED | 77445 | ST1946-265 | 1 | |

| WASHER - CUP | 0AM53 | 5A0242 | 1 |

Safety Requirements

NONEProcedure

Refer to Figure.

Reference the interference at location 2400. If required, use the data written as a note in TASK 72-32-21-200-000 (INSPECTION-000) and TASK 72-32-22-200-000 (INSPECTION-000).

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2400

Shoulder Stud ENGINE-NO.3 BEARING HOUSING (72-32-21, 01-080)

No. 3 Bearing Seal Support Assembly ENGINE-NO.3 BEARING SEAL SUPPORT (72-32-22, 01-040)

Inside Diameter Seal Support Hole

0.2795

Intf

0.2785

0.000

Stud Outside Diameter

0.2801

0.0016

0.2795

Intf

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2400

Shoulder Stud ENGINE-NO.3 BEARING HOUSING (72-32-21, 01-080)

No. 3 Bearing Seal Support Assembly ENGINE-NO.3 BEARING SEAL SUPPORT (72-32-22, 01-040)

Inside Diameter Seal Support Hole

7.099

Intf

7.074

0.000

Stud Outside Diameter

7.114

0.041

7.099

Intf

SUBTASK 72-32-20-220-060 Reference Fits and Clearances of the No. 3 Bearing Damper Assembly at Location 2400

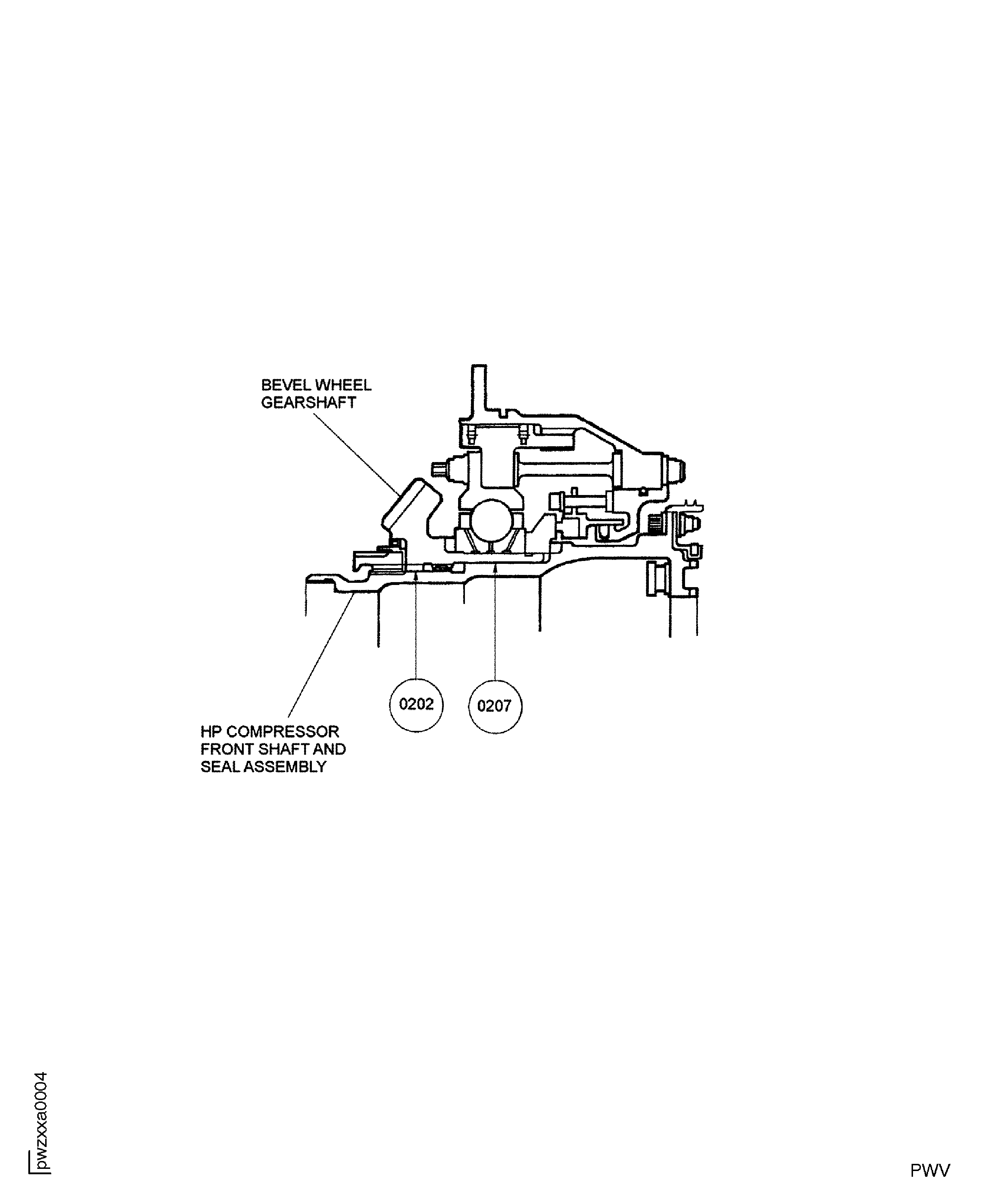

Refer to Figure.

Reference dimensions at location 0202. If required, use the data written as the note in TASK 72-32-23-200-000 (INSPECTION-000) and TASK 72-32-26-200-000 (INSPECTION-000).

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 0202

Bevel Wheel Gearshaft ENGINE-INTERNAL GEARBOX DRIVING GEAR (72-32-26, 01-400)

And

HP Compressor Front Shaft Assembly ENGINE-NO.3 BEARING ROTOR CENTRE (72-32-23, 01-745)

Gearshaft Inside Diameter

5.2363

Intf

5.2363

Intf

5.2369

-0.0041

5.2369

-0.0041

Shaft Outside Diameter

5.2410

-0.0051

5.2410

-0.0051

5.2414

Intf

5.2414

Intf

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 0202

Bevel Wheel Gearshaft ENGINE-INTERNAL GEARBOX DRIVING GEAR (72-32-26, 01-400)

And

HP Compressor Front Shaft Assembly ENGINE-NO.3 BEARING ROTOR CENTRE (72-32-23, 01-745)

Gearshaft Inside Diameter

133.000

Intf

133.000

Intf

133.018

-0.104

133.018

-0.104

Shaft Outside Diameter

133.122

-0.134

133.122

-0.134

133.134

Intf

133.134

Intf

SUBTASK 72-32-20-220-068 Reference Fits and Clearances of the Bevel Wheel Gearshaft and the HP Compressor Front Shaft and Seal Assembly at Location 0202

Refer to Figure.

Reference dimensions at location 0207. If required, use the data written as the note in TASK 72-32-23-200-000 (INSPECTION-000) and TASK 72-32-26-200-000 (INSPECTION-000).

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 0207

Bevel Wheel Gearshaft ENGINE-INTERNAL GEARBOX DRIVING GEAR (72-32-26, 01-400)

And

HP Compressor Front Shaft Assembly ENGINE-NO.3 BEARING ROTOR CENTRE (72-32-23, 01-745)

Gearshaft Inside Diameter

5.5521

Intf

5.5521

Intf

5.5527

-0.0026

5.5527

-0.0026

Shaft Outside Diameter

5.5553

-0.0037

5.5553

-0.0037

5.5558

Intf

5.5558

Intf

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 0207

Bevel Wheel Gearshaft ENGINE-INTERNAL GEARBOX DRIVING GEAR (72-32-26, 01-400)

And

HP Compressor Front Shaft Assembly ENGINE-NO.3 BEARING ROTOR CENTRE (72-32-23, 01-745)

Gearshaft Inside Diameter

141.021

Intf

141.021

Intf

141.039

-0.066

141.039

-0.066

Shaft Outside Diameter

141.105

-0.096

141.105

-0.096

141.117

Intf

141.117

Intf

SUBTASK 72-32-20-220-069 Reference Fits and Clearances of the Bevel Wheel Gearshaft and the HP Compressor Front Shaft and Seal Assembly at Location 0207

Refer to Figure.

SUBTASK 72-32-20-220-061 Find the Value of the LASH of the Bevel Wheel Gearshaft (Gearshaft) (72-32-26, 01-400)

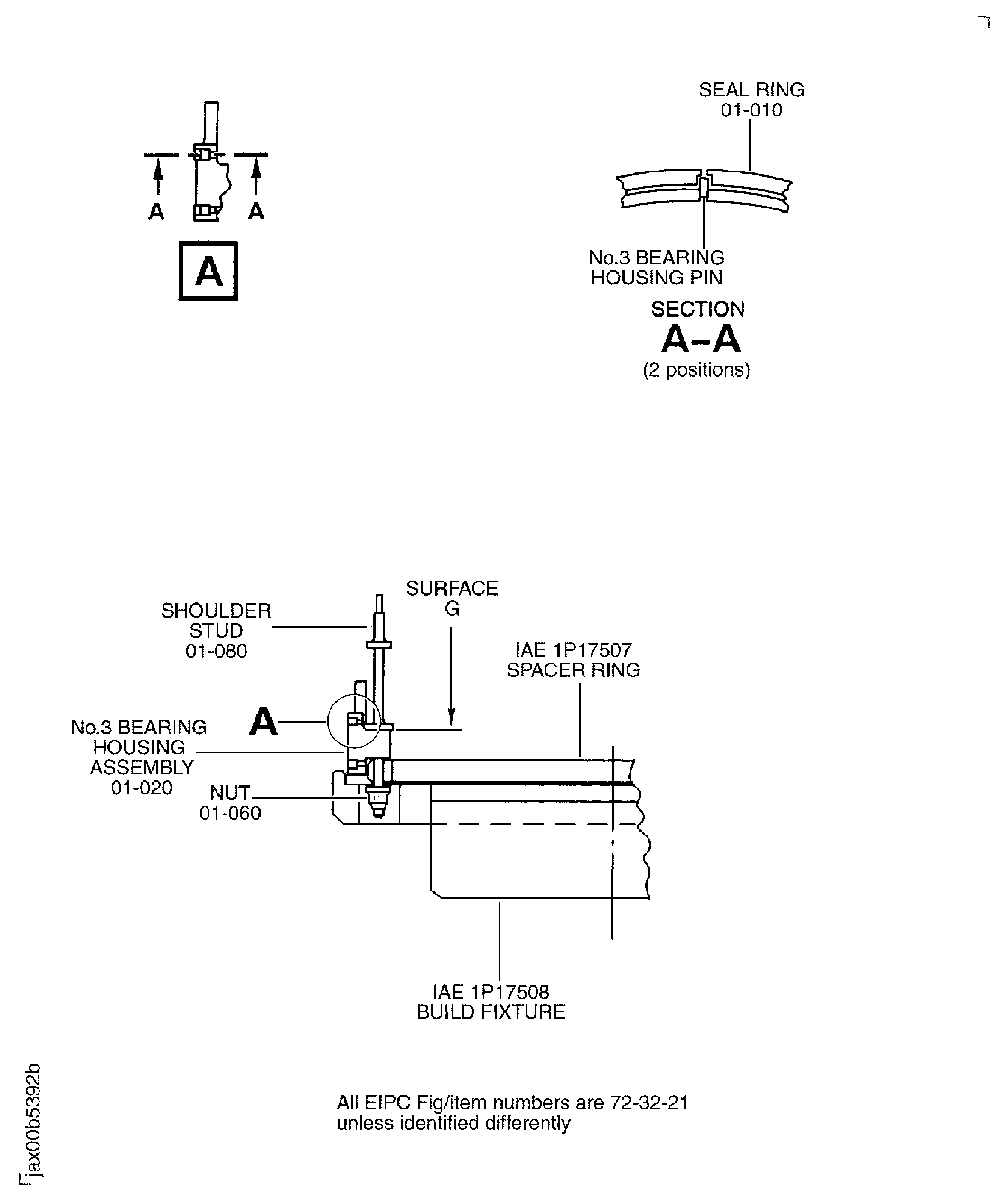

Install IAE 1P17508 Build fixture 1 off in a suitable vise.

Install IAE 1P17507 Spacer ring 1 off in the build fixture.

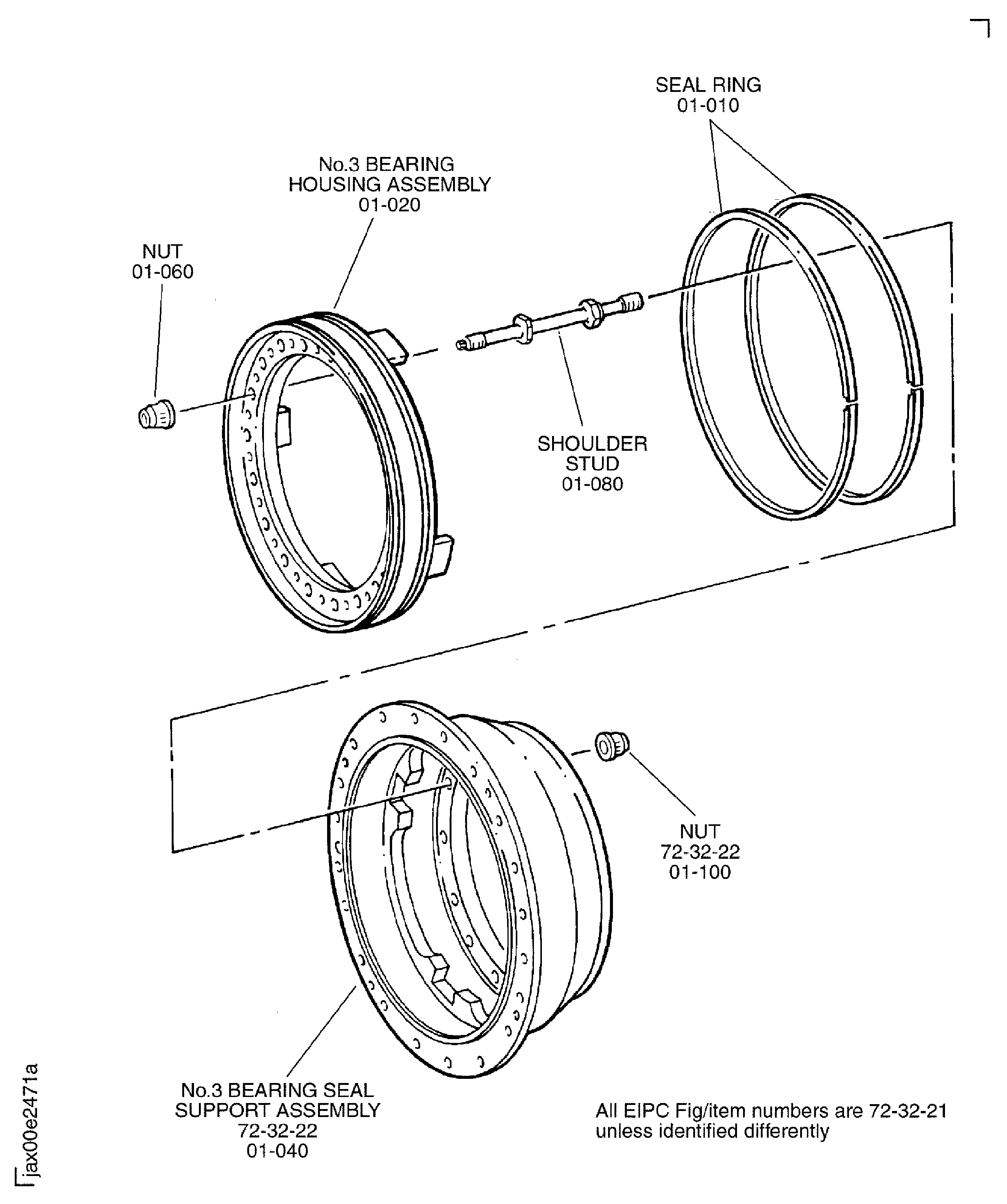

Install one nut ENGINE-NO.3 BEARING HOUSING (72-32-21, 01-060) on the shoulder stud and tighten it with your hand.

SUBTASK 72-32-20-440-071 Install the Shoulder Studs (72-32-21, 01-080) in to the No. 3 Bearing Housing Assembly (72-32-21, 01-020)

Refer to Figure.

SUBTASK 72-32-20-220-062 Do the Clearance Check on the Shoulder Stud

Install the two seal rings ENGINE-NO.3 BEARING HOUSING (72-32-21, 01-010) into the grooves on the OD of the No. 3 Bearing Housing Assembly. Put the seal ring ends over the pins in the Housing Assembly.

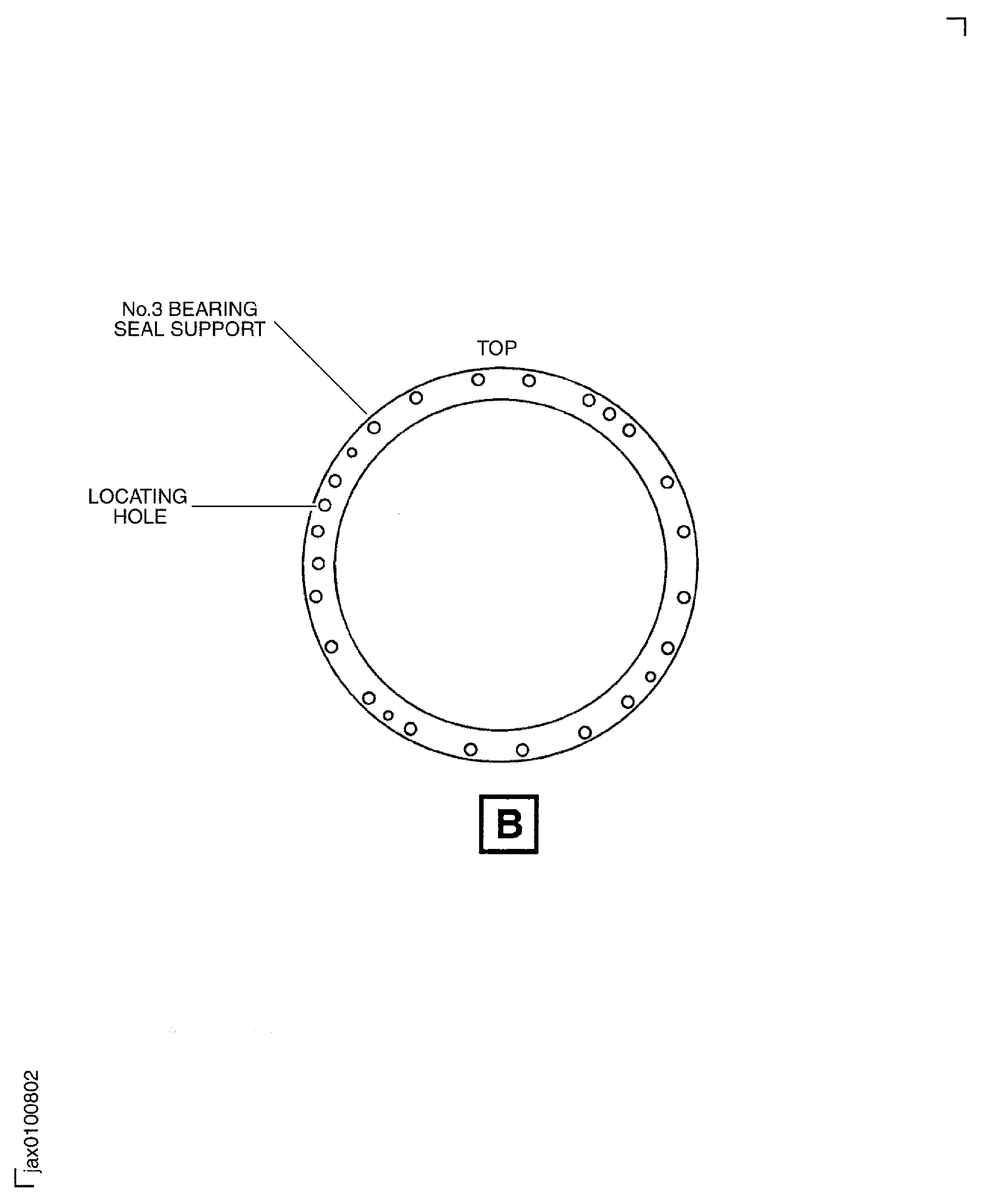

SUBTASK 72-32-20-440-072 Install the No. 3 Bearing Seal Support Assembly (72-32-22, 01-040) on to the No. 3 Bearing Housing Assembly

Refer to Figure.

Install IAE 1P17526 Torque sequence locator 1 off to the No. 3 Bearing Seal Support Assembly.

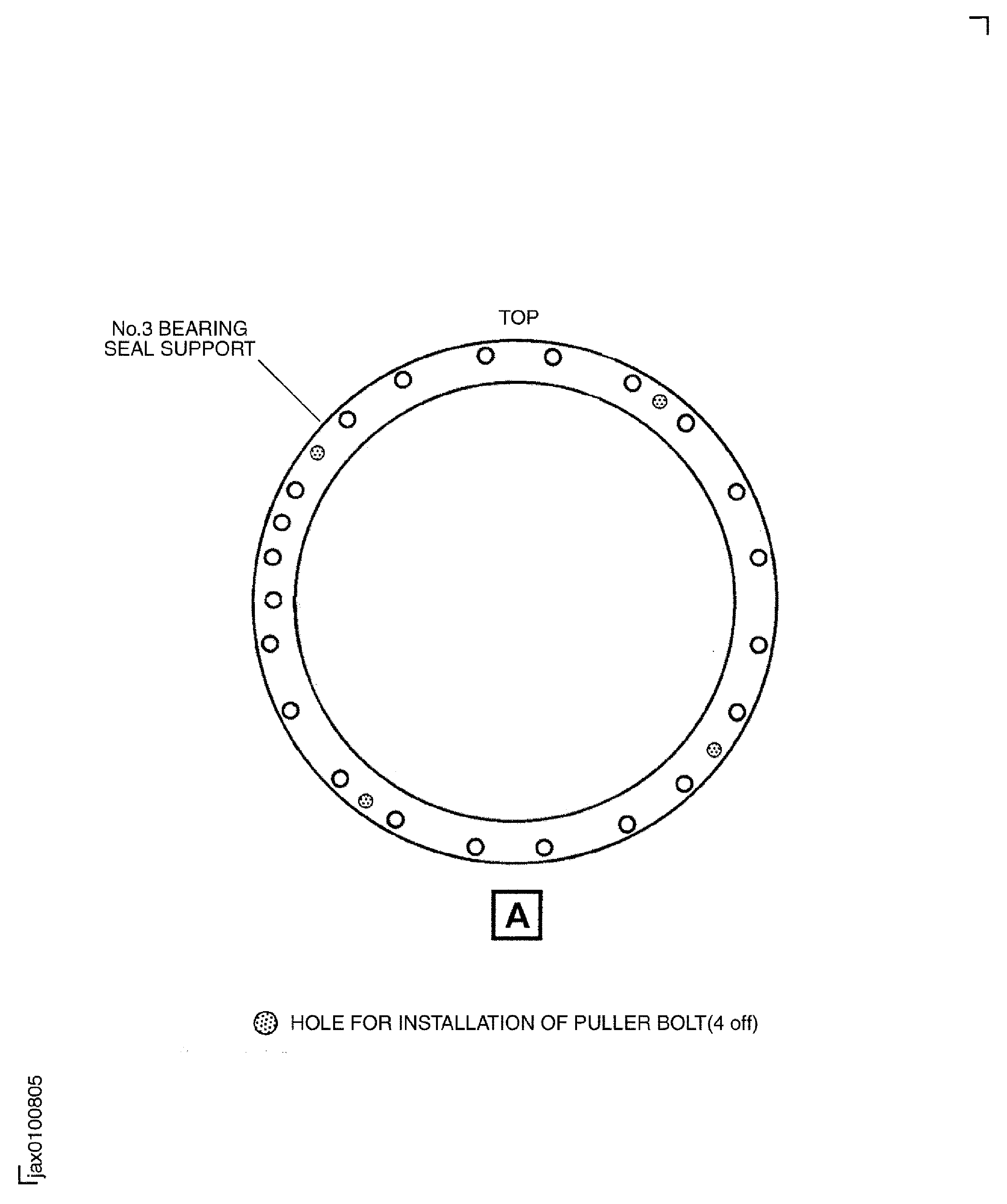

Torque the nuts in the sequence given in Figure and as follows:

Remove all the nuts ENGINE-NO.3 BEARING HOUSING (72-32-21, 01-060) and the spacer ring from the ends of the shoulder studs that go through the No. 3 Bearing Housing Assembly.

SUBTASK 72-32-20-440-073 Install and Torque the Nuts (72-32-22, 01-100)

Refer to Figure.

SUBTASK 72-32-20-220-063 Do the Clearance Check on the Shoulder Stud

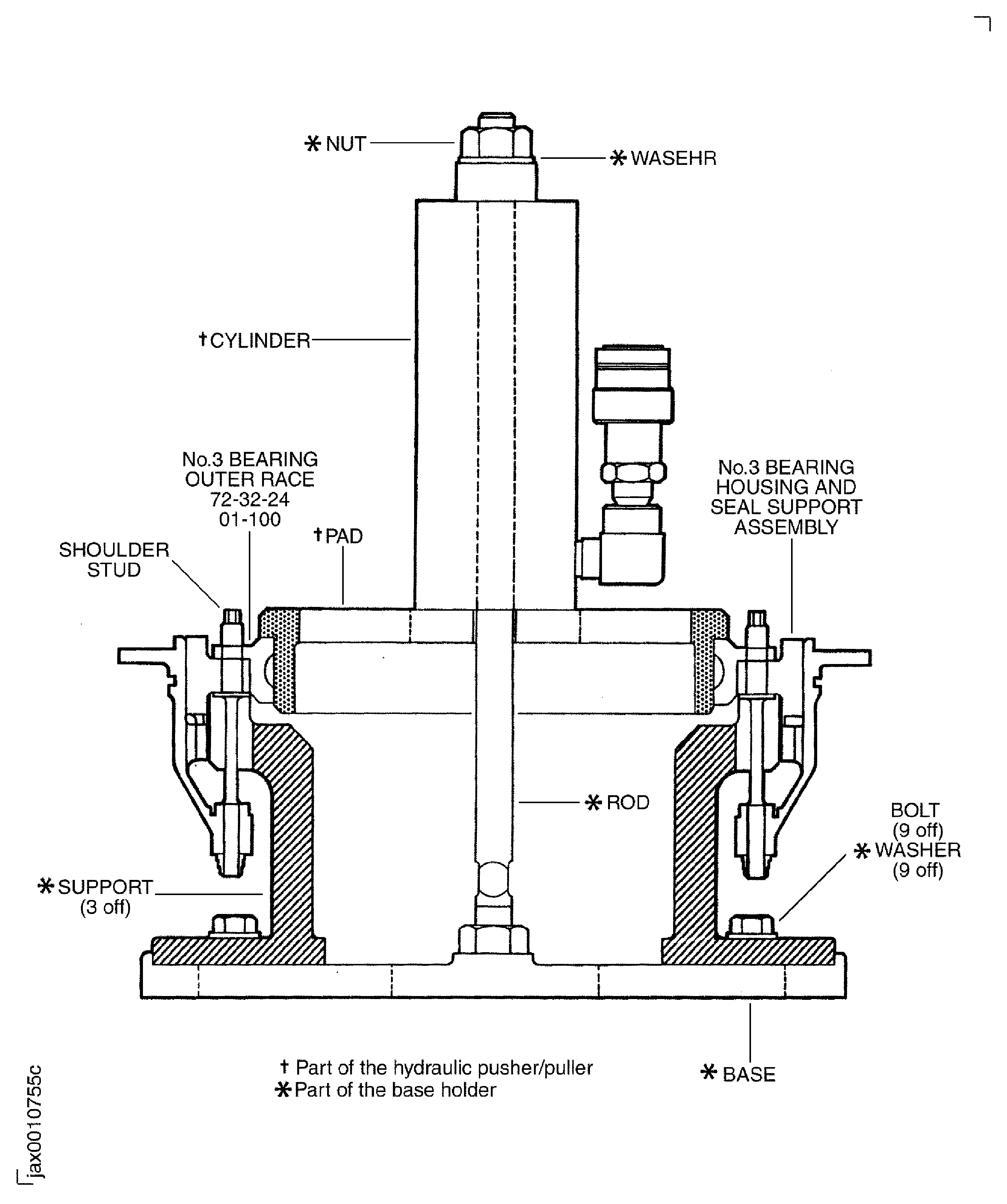

Move IAE 1J12477 Base holder 1 off and IAE 1J12478 Hydraulic pusher/puller 1 off to the work area.

Connect the hose (part of IAE 1F10026 Hydraulic hand pump 1 off) to the cylinder.

Put the No. 3 Bearing outer race into the No. 3 Bearing Housing and Seal Support Assembly.

Tighten the nuts with IAE 1J12378 Ratchet wrench 1 off.

Torque the nuts to 54* lbfin to 60* lbfin (6.101* Nm to 6.779* Nm) in the sequence shown in the Figure.

Torque the nuts to 54* lbfin to 60* lbfin (6.101* Nm to 6.779 Nm) in the sequence shown in the Figure.

Install the No. 3 Bearing outer race to the No. 3 Bearing Housing and Seal Support Assembly with the 18 nuts ENGINE-NO.3 BEARING HOUSING (72-32-21, 01-060).

Refer to TASK 72-32-10-440-001-B00 (ASSEMBLY-001) for the selection of the PTO adjusting washer. On completion of the selection, continue assembly in accordance with the next SUBTASK within this TASK.

SUBTASK 72-32-20-440-074 Install the No. 3 Bearing Outer Race (72-32-24, 01-100) into the No. 3 Bearing Housing and Seal Support Assembly

Refer to Figure.

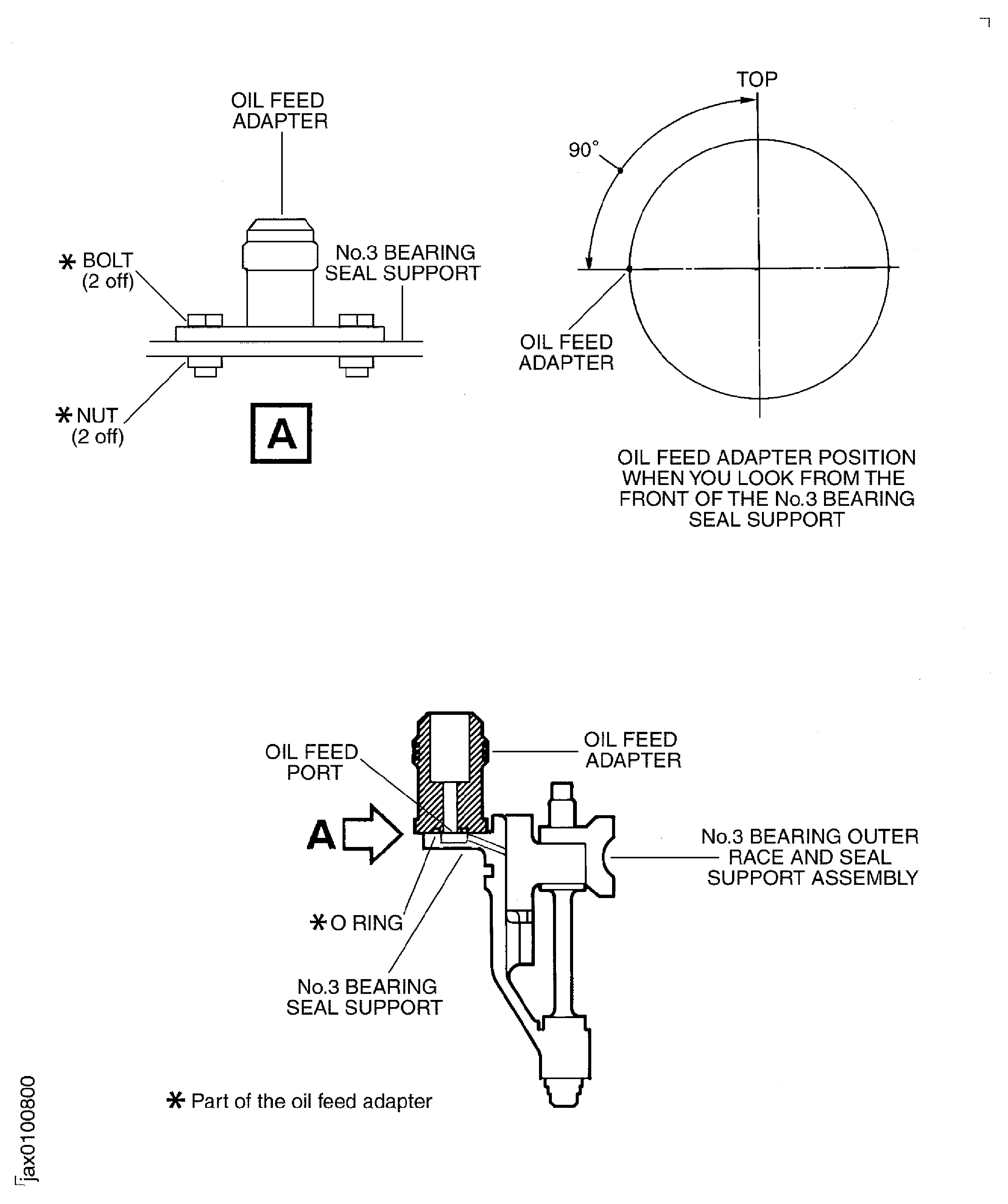

Move IAE 1J12374 Oil flow test stand 1 off and IAE 1J12375 Oil flow check box 1 off to the work area.

Install the O-ring (part of IAE 1J12376 Oil feed adapter) to IAE 1J12376 Oil feed adapter 1 off.

Reject the No. 3 Bearing outer race and Seal Support Assembly and do further inspection to find the cause, if the oil flow rate is out of the range in Step.

Examine the oil flow of the No. 3 Bearing outer race and Seal Support Assembly. Fully close the stop valve and fully open the relief valve of the test stand.

SUBTASK 72-32-20-710-054 Examine the Oil Flow in the No. 3 Bearing Outer Race and Seal Support Assembly

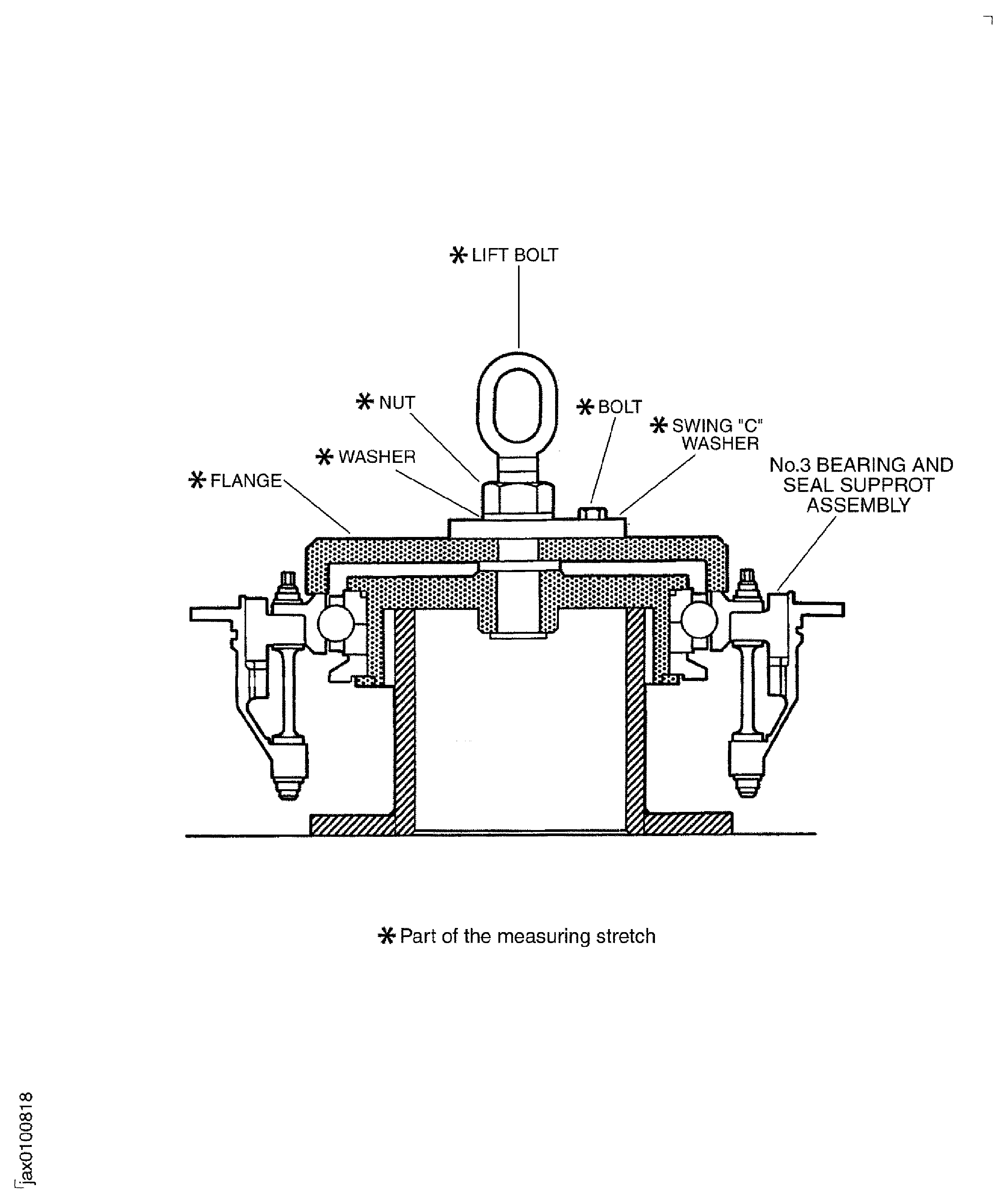

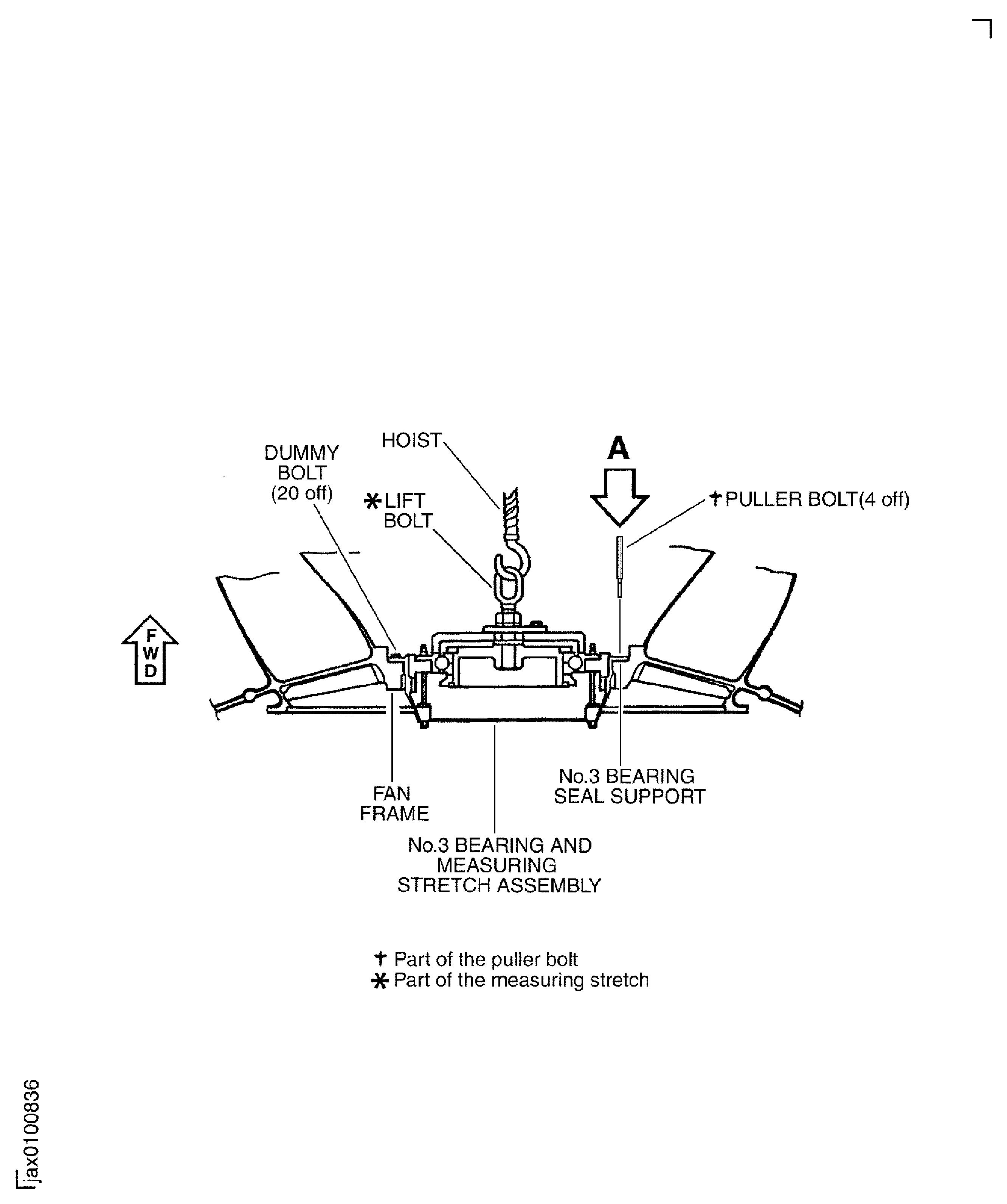

Move IAE 1J12529 Measuring stretch 1 off, IAE 1J12504 Ring holder 1 off and IAE 1J12502 No.3 bearing guide 1 off to work a bench.

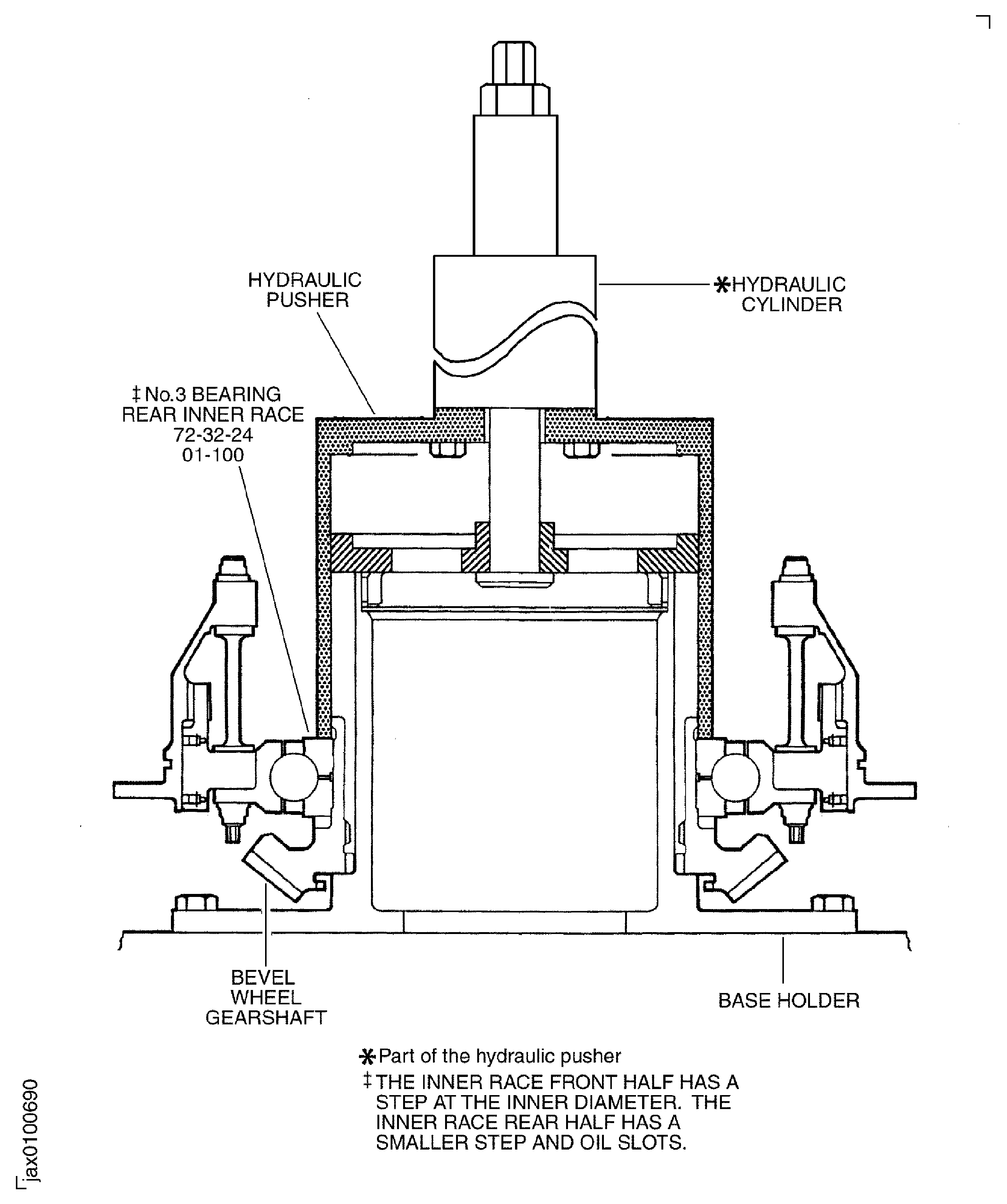

Install the No. 3 Bearing rear inner race No. 3 Bearing (72-32-24, 01-100) on the guide.

Install the No. 3 Bearing Seal Seat and the No. 3 Bearing and No. 3 Seal Support Assembly on the guide.

NOTE

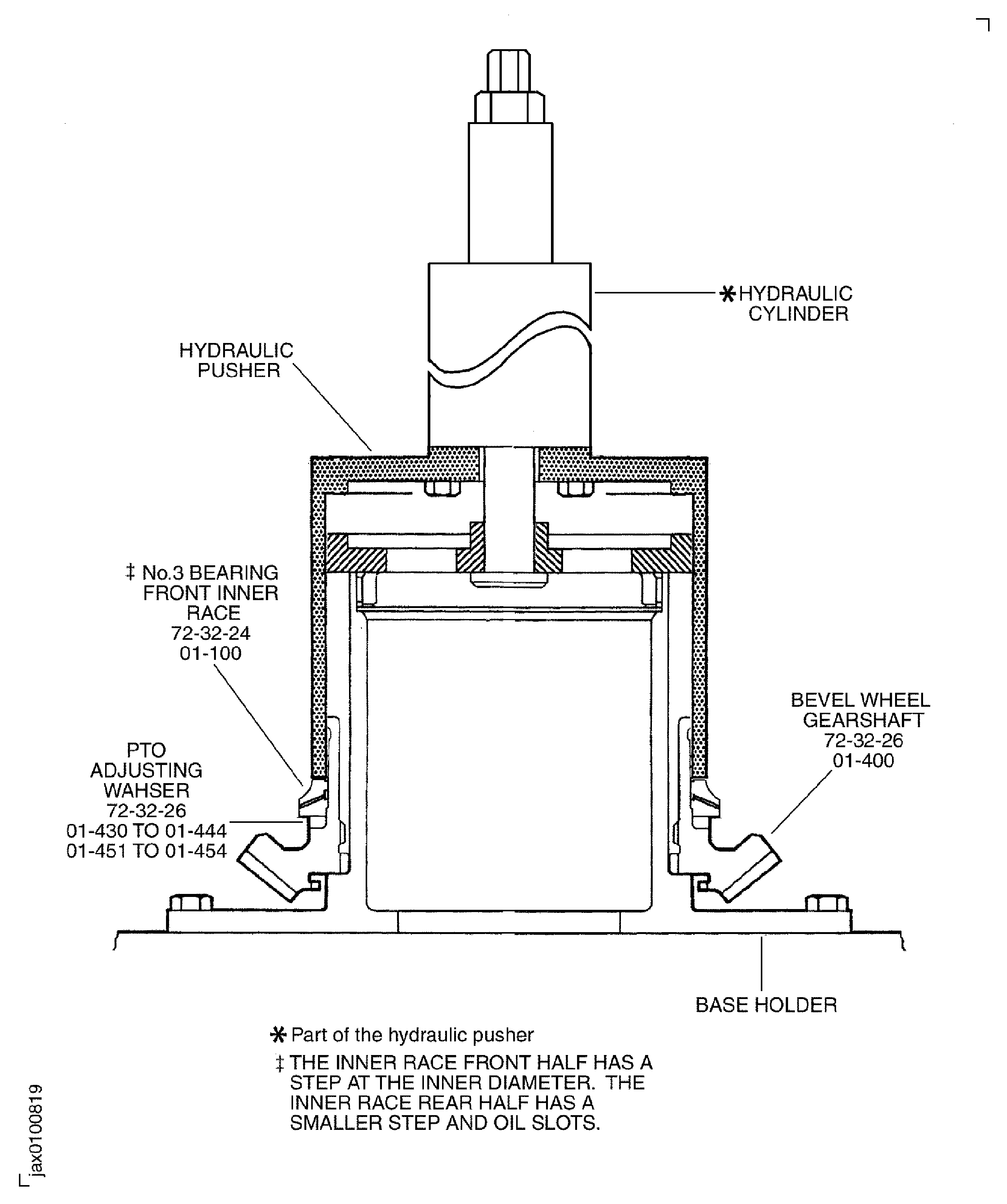

The inner race front half has a step at the inner diameter. The inner race rear half has a smaller step and oil slots. Refer to Fig. 72-32-20-990-037.

SUBTASK 72-32-20-440-075 Install the No. 3 Bearing Seal Seat (72-32-25, 02-400) and the No. 3 Bearing and Seal Support Assembly to the Measuring Stretch

Refer to the TASK 72-32-00-430-001 (ASSEMBLY-001).

SUBTASK 72-32-20-440-076 Install the Fan Frame on to the Turnover Stand

Turn the Fan Frame with the front end up. Refer to the TASK 72-32-00-430-001 (ASSEMBLY-001).

SUBTASK 72-32-20-440-077 Turn the Fan Frame

Install IAE 1J12505 0AM53 heater 1 off on to the rear-inner flange.

Connect the cables of the local heater to IAE 6F10027 Heater control unit 1 off.

Increase the temperature of the bore of the rear-inner flange of the Fan Frame.

SUBTASK 72-32-20-440-078 Install the No. 3 Bearing Measuring Stretch Assembly into the Fan Frame

Refer to Figure.

Turn the Fan Frame with the rear end up. Refer to TASK 72-32-00-430-001 (ASSEMBLY-001).

Install the dial gage into the gage (part of IAE 1J12359 Inspection bridge 1 off) into the clock holder (part of the inspection bridge).

Install the clocking pin into the hole which is 90 degrees apart from the initial hole. Measure the distance X. Refer to Step.

Install the clocking pin into the hole which is 180 degree apart from the initial hole. Measure the distance X. Refer to Step.

Install the clocking pin into the hole which is 270 degree apart from the initial hole. Measure the distance X. Refer to Step.

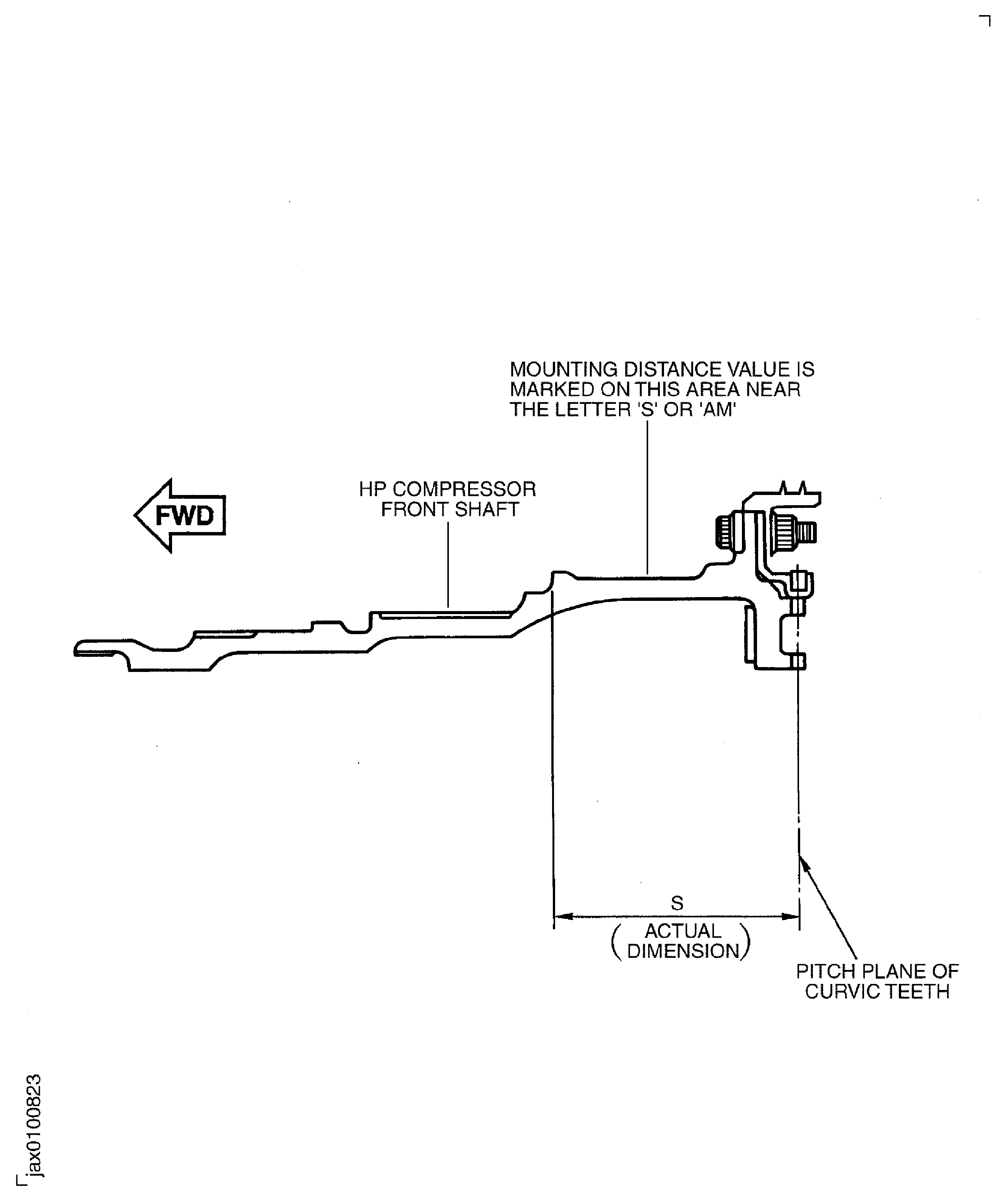

SUBTASK 72-32-20-220-064 Measure the Distance X to find the HPC Adjusting Washer Thickness

NOTE

The HPC adjusting washer is found as an initial selection in this SUBTASK. The last selection of the adjusting washer is done in TASK 72-32-00-430-011-B00 (ASSEMBLY-011).Find the average distance X measured in Step.

Calculate the minimum valve E1 and the maximum value E2 for selection of the adjusting washer as follows:

E1 (mm)

=

=

=

K2 + X - K1 - S - H + 28.70 - 0.13

K2 + X - K1 - S - 0.08 + 28.70 - 0.13

K2 + X - K1 - S + 28.49

E2 (mm)

=

=

=

K2 + X - K1 - S - H + 28.70 + 0.13

K2 + X - K1 - S - 0.08 + 28.70 + 0.13

K2 + X - K1 - S + 28.75

E1 (in.) = E (mm)/25.4.

E2 (in.) = E (mm)/25.4.

Where:

H = The effect of the No. 3 Bearing fit condition difference between the clearance fit on the measuring stretch and the interference fit on the gearshaft.

SUBTASK 72-32-20-440-079 Find the HPC Adjusting Washer (72-32-26, 01-500 to 72-32-26, 01-510)

Install the four puller bolts (part of IAE 1J12188 Puller bolt 1 off) into the thread holes in the outer flange of the No. 3 Bearing Seal Support.

SUBTASK 72-32-20-440-080 Remove the No. 3 Bearing and Measuring Stretch Assembly from the Fan Frame

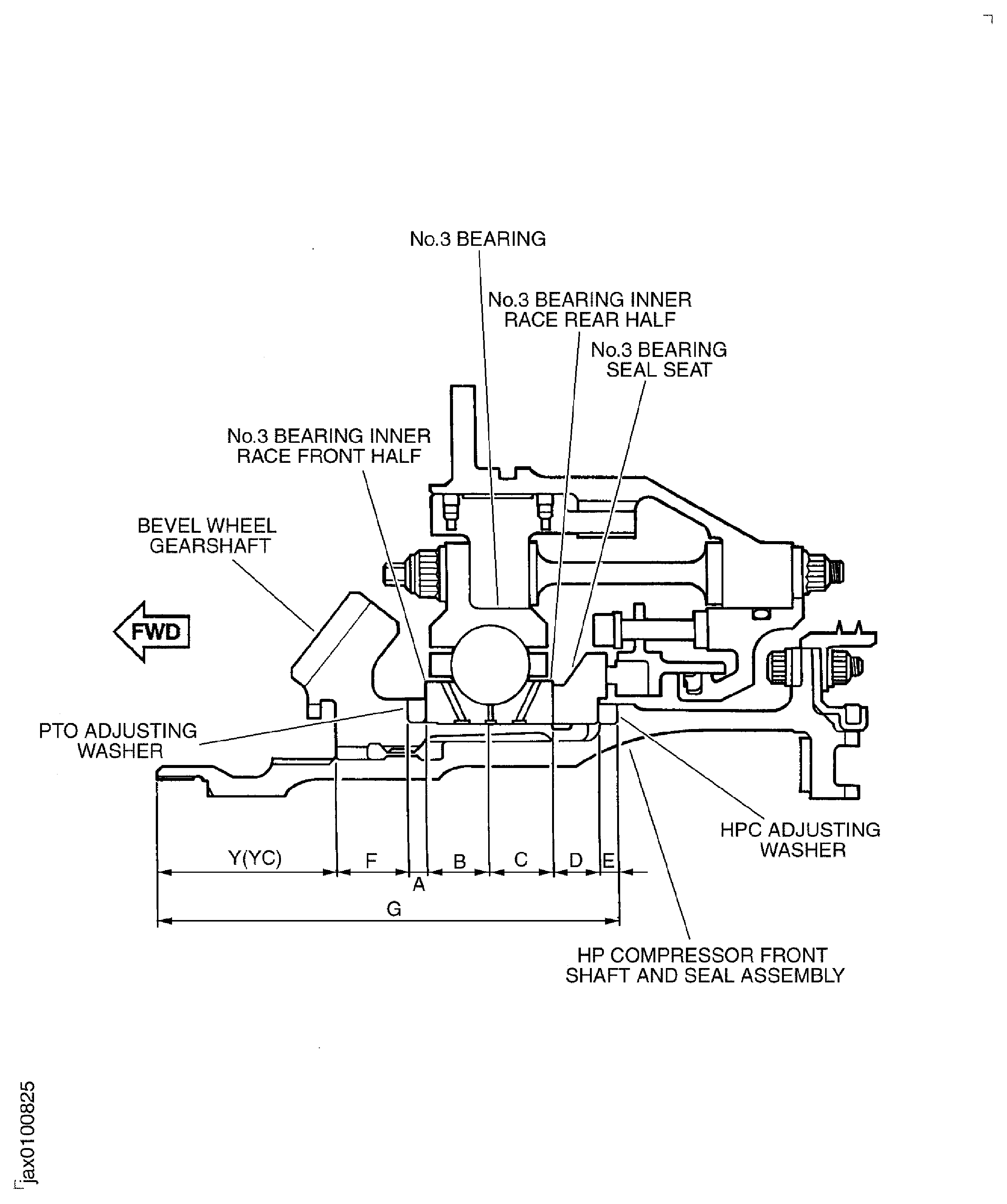

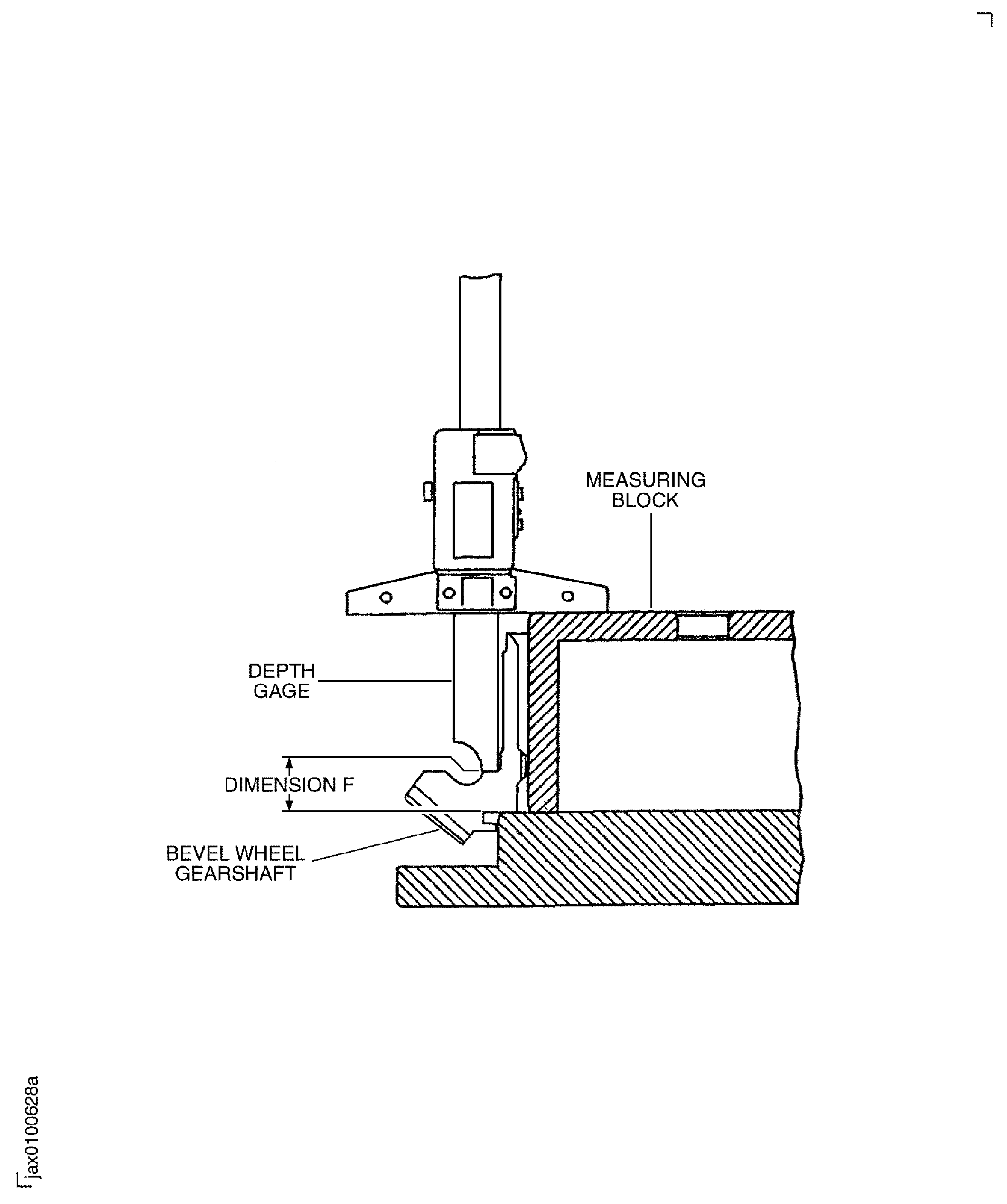

Dimension F - axial dimension between mating surfaces of the gearshaft. Use IAE 1J12556 Measuring block 1 off and the depth gage when you measure the dimension F.

Measure the axial dimensions of the No. 3 Bearing and the related parts to make sure that they are assembled correctly. Use an applicable micrometer to do this. Write the axial dimensions on an applicable record sheet.

NOTE

Use the PTO adjusting washer found in TASK 72-32-10-440-001-B00 (ASSEMBLY-001).

SUBTASK 72-32-20-220-065 Measure the Axial Dimensions of the No. 3 Bearing and the Related Parts

NOTE

The PTO adjusting washer is found in TASK 72-32-10-440-001-B00 (ASSEMBLY-001).Move IAE 1J12421 Base holder 1 off and IAE 1J12379 Hydraulic pusher 1 off to the work area.

CAUTION

DO NOT LET THE BEARINGS TOUCH THE BOTTOM OF THE HOT OIL TANK. A HEAVY SCREEN OR SOME RODS ATTACHED 3 IN. (76 MM) ABOVE THE BOTTOM OF THE TANK WILL KEEP HOT OIL ON ALL SIDES OF THE BEARING.Increase the temperature of the No. 3 Bearing inner races to 300 deg F (149 deg C) with an oven or a hot oil tank. Heat the No. 3 Bearing inner races for 20 minutes.

WARNING

THE NO. 3 BEARING INNER RACES FRONT HALF ARE HOT. USE APPROVED GLOVES WHEN YOU REMOVE THEM FROM THE OVEN OR HOT OIL TANK.Remove the No. 3 Bearing inner race front half from the oven and install it on to the gearshaft.

NOTE

The inner race front half has a step at the inner diameter. The inner race rear half has a smaller step and oil slots.Put the hydraulic pusher on the base holder and the No. 3 Bearing inner race front half and connect the hose (part of IAE 1F10026 Hydraulic hand pump 1 off) to the cylinder (part of the hydraulic pusher).

WARNING

THE NO. 3 BEARING INNER RACES FRONT HALF ARE HOT. USE APPROVED GLOVES WHEN YOU REMOVE THEM FROM THE OVEN OR HOT OIL TANK.

CAUTION

YOU MUST MAKE SURE THAT THE NO. 3 BEARING BALLS ARE IN THE CORRECT POSITION BEFORE YOU INSTALL THE REAR INNER RACE. INCORRECT POSITION CAN CAUSE DAMAGE TO THE BALLS WHEN YOU PUSH THE REAR INNER RACE.Remove the No. 3 Bearing inner race rear half from the oven and install it on the gearshaft.

SUBTASK 72-32-20-440-082 Install the PTO Adjusting Washer and the No. 3 Bearing and Seal Support Assembly on to the Gearshaft

Refer to Figure.

NOTE

The No. 3 Bearing Seal Assembly is assembled in TASK 72-32-25-440-001 (ASSEMBLY-001).Move IAE 1J12469 Leak test fixture 1 off to the work area.

Install the No. 3 Bearing Seal Seat No. 3 Bearing Rear Seal Assembly (72-32-25, 02-400) onto the gearshaft and the No. 3 Bearing.

Lubricate the new No. 3 Bearing Rear Seal Assembly (72-32-25, 02-350) packing 1 off with CoMat 10-077 APPROVED ENGINE OILS.

Attach the No. 3 Bearing Seal Assembly No. 3 Bearing Rear Seal Assembly (72-32-25, 02-100) on the No. 3 Bearing Seal Support Assembly rear flange with the nine bolts "NO.3 BEARING,ROTOR CENTRE & SUPPORT ASSY (72-32-20, 01-140).

SUBTASK 72-32-20-440-083 Install the No. 3 Bearing, Gearshaft, Support and Seal Assembly on to the Leak Test Fixture

Refer to Figure.

Move IAE 6F10030 Vacuum test cart 1 off to the work area.

Set the pressure to 20 inHg (500 mmHg) and measure the volume of the leak air. Make sure that the leakage is not more than 5 ppH. Based on the ambient pressure, refer to the table below for the vacuum pressure in psia.

Ambient Pressure of the Day (psia)

Vacuum Pressure (psia)

14.7

4.9

14.5

4.7

14.3

4.5

14.1

4.3

13.9

4.1

13.7

3.9

13.5

3.7

13.3

3.5

13.1

3.3

Vacuum pressure (psia) = Ambient pressure of the day (psia) - 9.8 psia

SUBTASK 72-32-20-790-052 Do the Leak Test on the No. 3 Bearing Seal Assembly

Put a clean soft mat on the work bench and put the No. 3 Bearing, Gearshaft, Support and Seal Assembly onto the mat with the bevel gear end down.

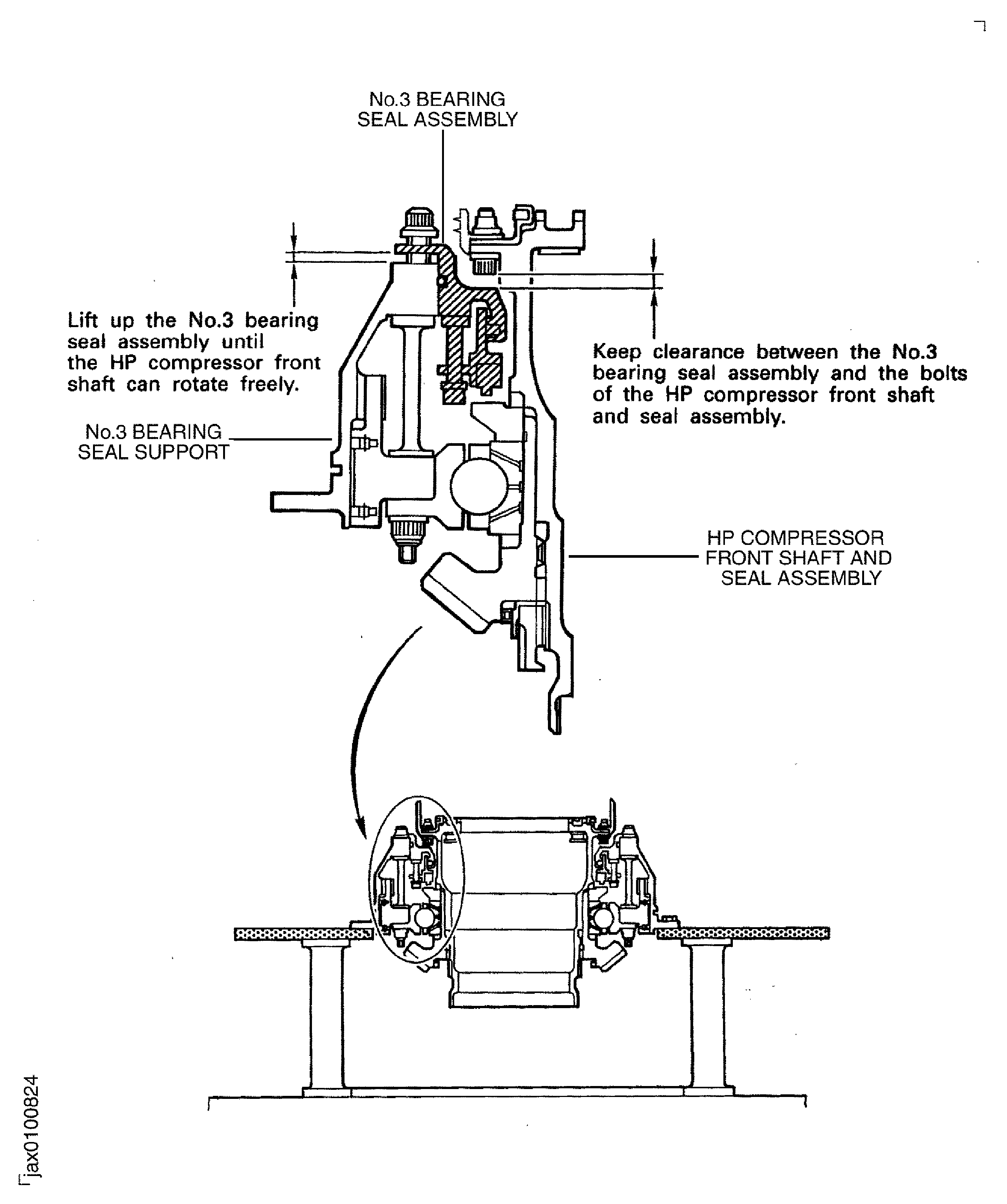

NOTE

IAE 1J12021 Lifting spacer 1 off keeps the clearance between the flanges of the No. 3 Bearing Seal Assembly and the No. 3 Bearing Seal Support Assembly to permit the installation of a tool when you lift the No. 3 Bearing Seal Assembly.Install IAE 1P17043 Knocker puller 1 off to the No. 3 Bearing Seal Assembly.

Pull out the No. 3 Bearing Seal Assembly from the No. 3 Bearing Seal Support.

SUBTASK 72-32-20-440-084 Install IAE 1J12021 Lifting Spacer between the No. 3 Bearing Seal Support and No. 3 Bearing Seal Assembly

Refer to Figure.

NOTE

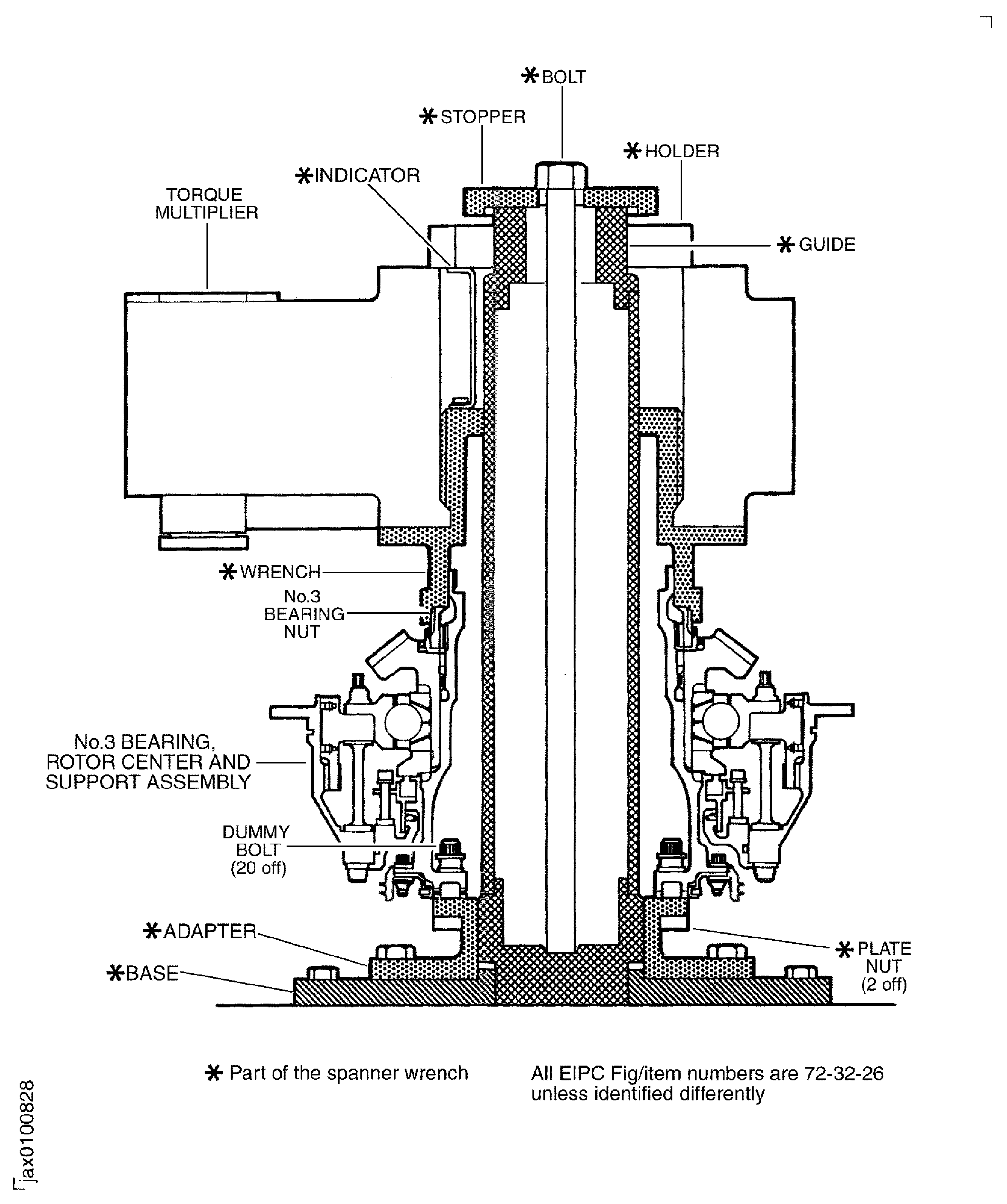

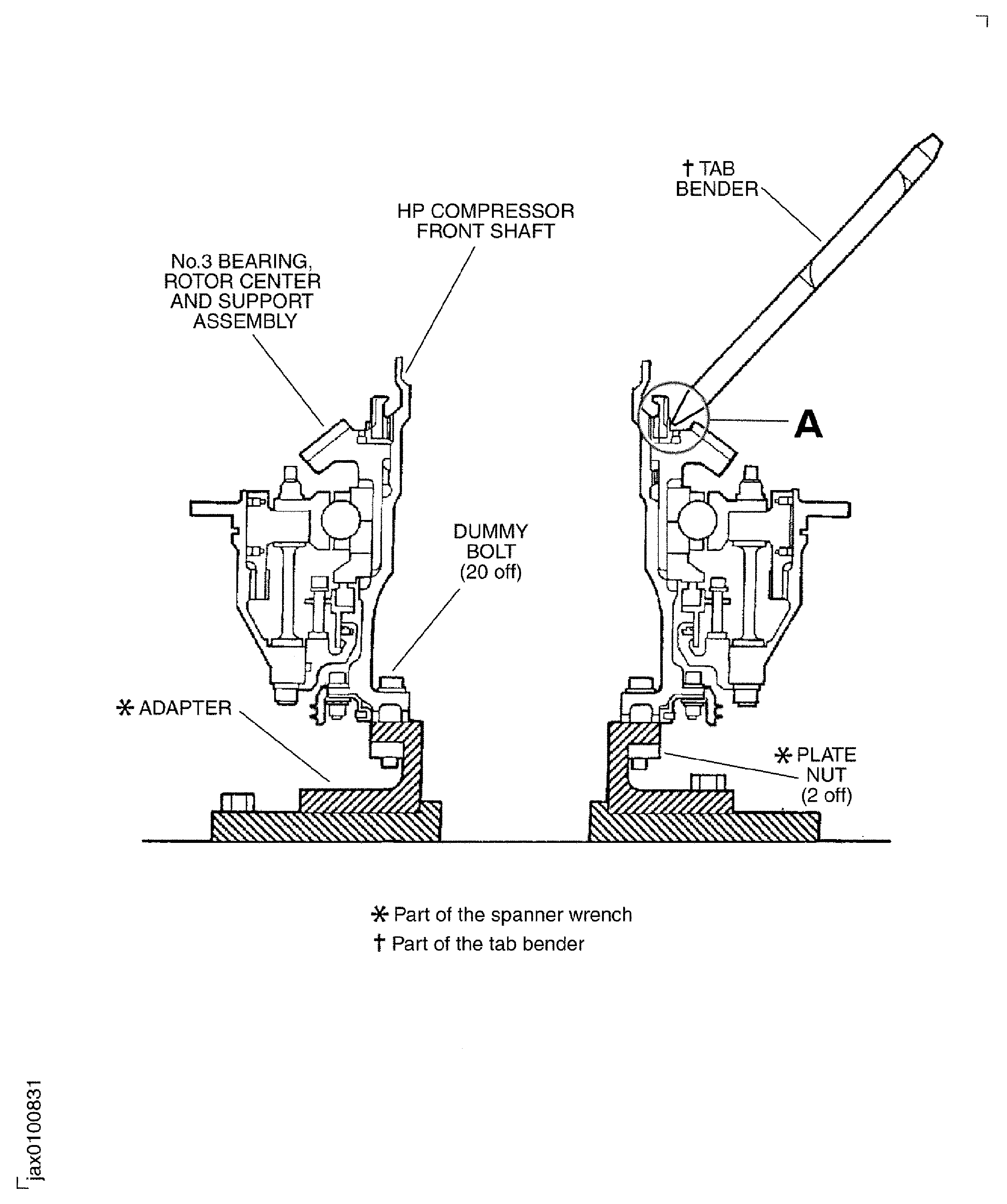

The HP Compressor front shaft and Seal Assembly is assembled in TASK 72-32-23-440-001-A00 (ASSEMBLY-001).Move IAE 1J12339 Spanner wrench 1 off and IAE 1J12387 Work stand 1 off to the work area.

Prepare the tools for installation of the No. 3 Bearing, Gearshaft, Support and Seal Assembly.

Install the HPC adjusting washer on the HP Compressor front shaft. The adjusting washer thickness was found in the Step.

Install IAE 1J12380 Hydraulic pusher 1 off on the HP Compressor front shaft and the No. 3 Bearing, Gearshaft, Support and Seal Assembly.

WARNING

BE CAREFUL BECAUSE THE No. 3 BEARING, GEARSHAFT, SUPPORT AND SEAL ASSEMBLY ARE HOT. USE APPROVED GLOVES WHEN YOU REMOVE IT FROM THE HOT OIL TANK OR OVEN.

CAUTION

DO NOT LET THE NO. 3 BEARING, GEARSHAFT AND SEAL ASSEMBLY TOUCH THE BOTTOM OF THE HOT OIL TANK. A HEAVY SCREEN OR SOME RODS ATTACHED 3IN. (76 MM) ABOVE THE BOTTOM OF THE TANK WILL KEEP HOT OIL ON ALL SIDES OF THE NO. 3 BEARING, GEARSHAFT AND SEAL ASSEMBLY.Install the No. 3 Bearing, Gearshaft, Support and Seal Assembly on the HP Compressor front shaft and Seal Assembly.

SUBTASK 72-32-20-440-085 Install the No. 3 Bearing, Gearshaft, Support and Seal Assembly to the HP Compressor Front Shaft and Seal Assembly (72-32-23, 01-700)

Refer to Figure.

Calculate the assembled dimension YC from the individual parts dimensions A, B, C, D, E, F and G. Refer to the Step.

YC = G - A - B - C - D - E - F.

Examine the difference between the sum of the dimensions of the individual parts and the assembled dimension.

If the difference is more than 0.00079 in. (0.0200 mm), disassemble the assembly and return to Step. For the disassembly procedure, refer to TASK 72-32-20-040-001 (DISASSEMBLY-001).

SUBTASK 72-32-20-220-066 Examine the Dimension to Make Sure that the No. 3 Bearing and the Related Parts Assembled Correctly

Align the tang of the new Gearbox Driving Bevel Gearshaft And Related Parts (72-32-26, 01-350) cup washer 1 off with the slot of the gearshaft.

Install the No. 3 Bearing nut Gearbox Driving Bevel Gearshaft And Related Parts (72-32-26, 01-300) in the cup washer.

Torque the No. 3 Bearing nut to 14500 lbfin (1640 Nm). Mark the turning angle of the torque multiplier output shaft on the indicator (parts of the spanner wrench).

NOTE

The output torque of the SWEENEY 8200 torque multiplier is 10.7 times of the input torque, as follows: input torque 1762 lbfin (199 Nm) output torque 18850 lbfin (2130 Nm) or, input torque 1355 lbfin (153 Nm) output torque 14500 lbfin (1640 Nm).Check the angular position of the output shaft of the torque multiplier and confirm it is within 1 degree from the mark made in Step.

Torque the No. 3 Bearing nut.

SUBTASK 72-32-20-440-086 Assemble the No. 3 Bearing, Gearshaft, Support and Seal Assembly to the HP Compressor Front Shaft and Seal Assembly with the No. 3 Bearing Nut

Move IAE 1J12383 Swash check fixture 1 off and IAE 1J12384 Swash check ring 1 off to the work area.

Check the clearance between the mating surfaces of the No. 3 Bearing Seal Support Assembly and the swash check fixture with a 0.0008 in. (0.02 mm) feeler gage. The feeler gage must not fit between the two flanges.

NOTE

You cannot turn the HP Compressor front shaft by hand if the No. 3 Bearing Seal Assembly contacts the No. 3 Bearing Seal Seat.Clean the curvic coupling teeth on the swash check ring and the HP Compressor front shaft with a clean cloth made moist with CoMat 01-124 ISOPROPYL ALCOHOL.

Torque the bolts to 65 lbfin to 75 lbfin (7.3 Nm to 8.5 Nm) in the sequence shown in the Figure.

Attach the swash check ring with the 20 dummy bolts and nuts.

SUBTASK 72-32-20-440-087 Prepare the Swash and Concentricity Check of the Curvic Coupling of the HP Compressor Front Shaft

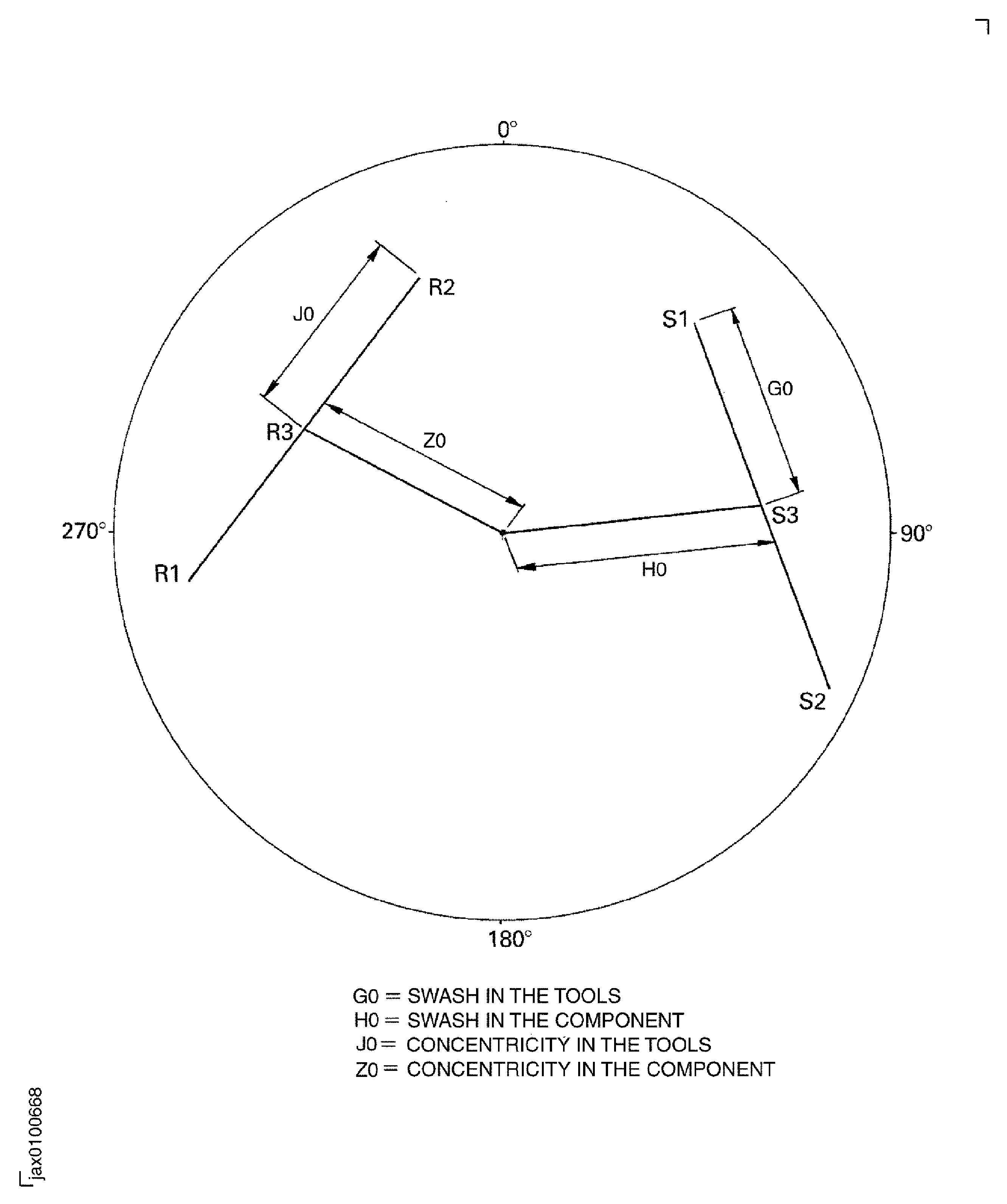

Use CoMat 06-069 MARKER to identify the position of the HP Compressor front shaft in relation to the swash check ring. Make a correlation mark between the HP Compressor front shaft and the swash check ring curvic couplings inner diameters. Refer to TASK 70-09-01-400-501.

Calculate the FIR and the angle of the swash. Make a mark on CoMat 02-130 POLAR GRAPH PAPER to show the FIR and angle and identify it as S1.

Use a dial indicator and a magnetic base to measure the swash of face B1 and the concentricity of diameter A1.

NOTE

When you turn the swash check ring, turn the inner diameter of the ring to prevent unwanted movement of the swash check ring.Install the swash check ring on to the HP Compressor front shaft. Refer to Step.

Turn the swash check ring 180 degrees in relation to the HP Compressor front shaft.

Measure the swash and concentricity, refer to Step. Identify the swash as S2 and the concentricity as R2 on the polar graph paper.

SUBTASK 72-32-20-220-067 Examine the Swash and the Concentricity of the Curvic Coupling of the HP Compressor Front Shaft

Install the three spacers (part of the lifting spacer) into the clearance at every 120 degrees. Align the slots of the three spacers with the bolts which attach the No. 3 Bearing Seal Assembly to the No. 3 Bearing Seal Support.

NOTE

The lifting spacer must remain in the No. 3 Bearing Rotor Center and Support Assembly until the backflash check of the bevel gears is completed in TASK 72-32-20-440-001-B00 (ASSEMBLY-001).

SUBTASK 72-32-20-440-088 Attach the No. 3 Bearing Seal Assembly to the No. 3 Bearing Seal Support Assembly

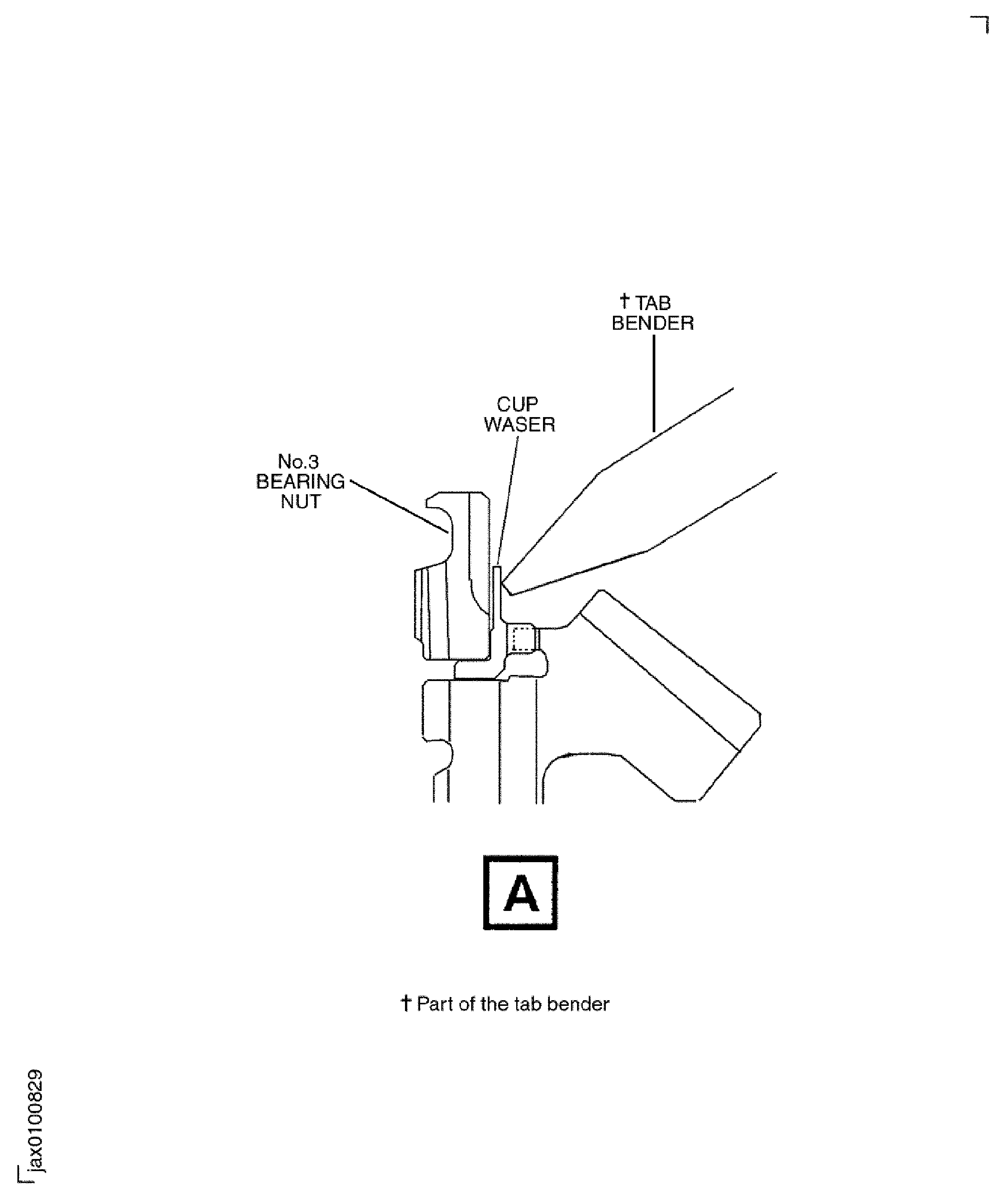

Bend the front part of the cup washer into the groove of the No. 3 Bearing nut with the tab bender (Part of IAE 1J12367 Tab bender 1 off).

SUBTASK 72-32-20-440-089 Bend the Cup Washer into the Groove of the No. 3 Bearing Nut

Figure: Sectional View of the No. 3 Bearing Rotor Center and Support Assembly

Sectional View of the No. 3 Bearing Rotor Center and Support Assembly

Figure: Reference Fits and Clearances of the No. 3 Bearing Damper Assembly at Location 2400

Reference Fits and Clearances of the No. 3 Bearing Damper Assembly at Location 2400

Figure: Reference Fits and Clearances of the Bevel Wheel Gearshaft and the HP Compressor Front Shaft and Seal Assembly at Location 0202 and 0207

Reference Fits and Clearances of the Bevel Wheel Gearshaft and the HP Compressor Front Shaft and Seal Assembly at Location 0202 and 0207

Figure: Find the Value of the LASH of the Bevel Wheel Gearshaft

Find the Value of the LASH of the Bevel Wheel Gearshaft

Figure: Install the Shoulder Studs in to the No. 3 Bearing Housing

Install the Shoulder Studs in to the No. 3 Bearing Housing

Figure: Install the Shoulder Studs in to the No. 3 Bearing Housing

Install the Shoulder Studs in to the No. 3 Bearing Housing

Figure: Torque the Nuts which Hold the Shoulder Studs to the No. 3 Bearing Seal Support Assembly

Torque the Nuts which Hold the Shoulder Studs to the No. 3 Bearing Seal Support Assembly

Figure: Install the No. 3 Bearing Outer Race in to the No. 3 Bearing Housing and Seal Support Assembly

Install the No. 3 Bearing Outer Race in to the No. 3 Bearing Housing and Seal Support Assembly

Figure: Install the No. 3 Bearing Outer Race in to the No. 3 Bearing Housing and Seal Support Assembly

Install the No. 3 Bearing Outer Race in to the No. 3 Bearing Housing and Seal Support Assembly

Figure: Examine the Oil Flow in the No. 3 Bearing Outer Race and Seal Support Assembly

Examine the Oil Flow in the No. 3 Bearing Outer Race and Seal Support Assembly

Figure: Install the No. 3 Bearing and Seal Seat to the Measuring Stretch

Sheet 1

Figure: Install the No. 3 Bearing and Seal Seat to the Measuring Stretch

Sheet 2

Figure: Install the No. 3 Bearing and Seal Seat to the Measuring Stretch

Sheet 3

Figure: No. 3 Bearing and Support Assembly

No. 3 Bearing and Support Assembly

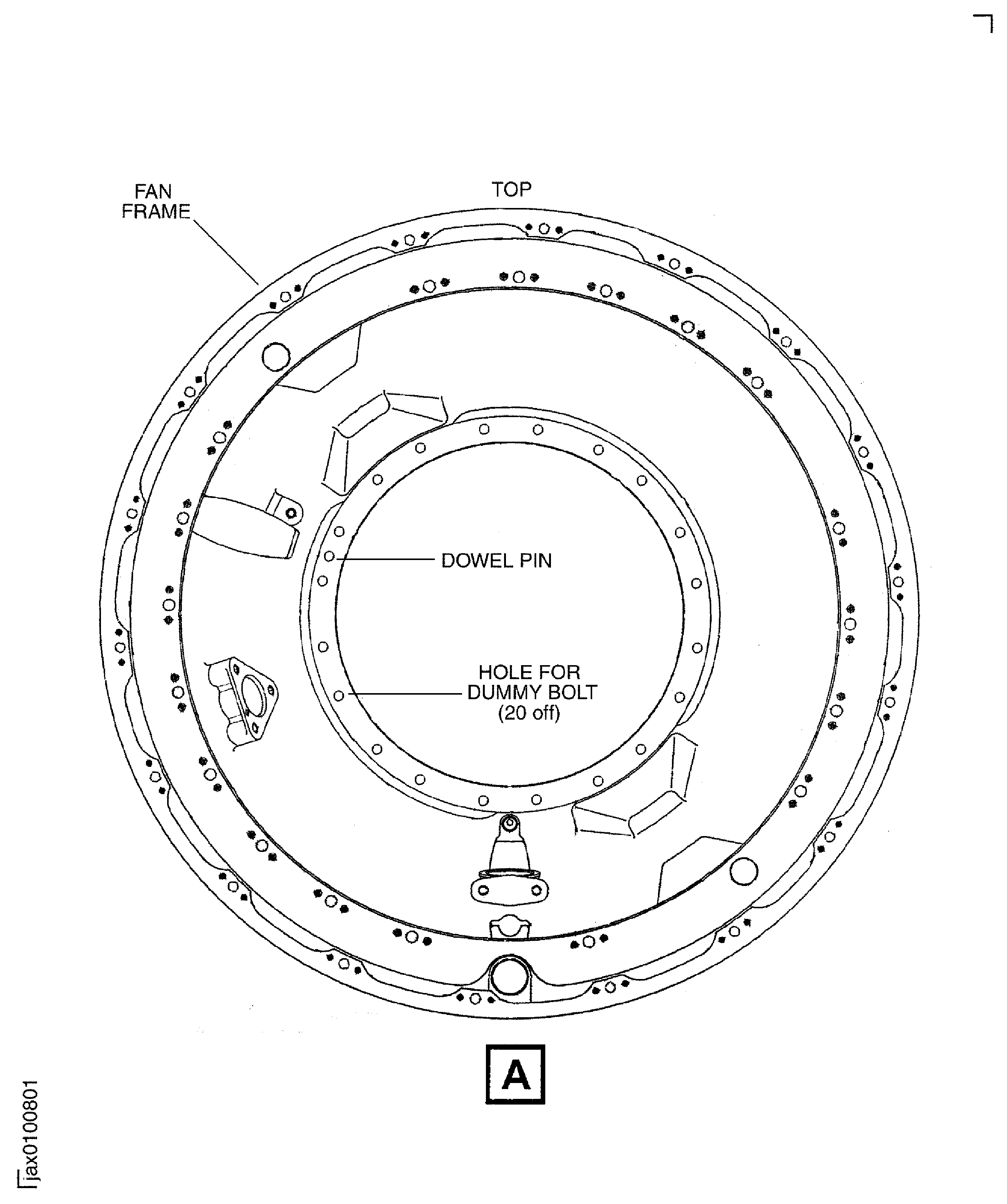

Figure: Install the No. 3 Bearing and Measuring Stretch Assembly in to the Fan Frame Assembly

Install the No. 3 Bearing and Measuring Stretch Assembly in to the Fan Frame Assembly

Figure: Install the No. 3 Bearing and Measuring Stretch Assembly in to the Fan Frame Assembly

Sheet 1

Figure: Install the No. 3 Bearing and Measuring Stretch Assembly in to the Fan Frame Assembly

Sheet 2

Figure: Install the No. 3 Bearing and Measuring Stretch Assembly in to the Fan Frame

Sheet 3

Figure: Measure the Distance X to Find the Adjusting Washer Thickness

Measure the Distance X to Find the Adjusting Washer Thickness

Figure: Find the HPC Adjusting Washer

Find the HPC Adjusting Washer

Figure: Find the HPC Adjusting Washer

Find the HPC Adjusting Washer

Figure: Find the HPC Adjusting Washer

Find the HPC Adjusting Washer

Figure: Remove the No. 3 Bearing and Measuring Stretch Assembly from the Fan Frame

Sheet 1

Figure: Remove the No. 3 Bearing and Measuring Stretch Assembly from the Fan Frame

Sheet 2

Figure: Measure the Axial Dimensions of the No. 3 Bearing and the Related Parts

Measure the Axial Dimensions of the No. 3 Bearing and the Related Parts

Figure: Measure the Axial Dimension F between Mating Surfaces of the Bevel Wheel Gearshaft

Measure the Axial Dimension F between Mating Surfaces of the Bevel Wheel Gearshaft

Figure: Install the No. 3 Bearing and Seal Support Assembly on the Bevel Wheel Gearshaft

Sheet 1

Figure: Install the No. 3 Bearing and Seal Support Assembly on the Bevel Wheel Gearshaft

Sheet 2

Figure: Install the No. 3 Bearing and Seal Support Assembly on the Bevel Wheel Gearshaft

Sheet 3

Figure: Install the No. 3 Bearing and Bevel Gear Assembly on to the Leak Test Fixture

Install the No. 3 Bearing and Bevel Gear Assembly on to the Leak Test Fixture

Figure: Install the No. 3 Bearing, Gearshaft, Support and Seal Assembly on the HP Compressor Front Shaft and Seal Assembly

Install the No. 3 Bearing, Gearshaft, Support and Seal Assembly on the HP Compressor Front Shaft and Seal Assembly

Figure: Assemble the No. 3 Bearing, Gearshaft, Support and Seal Assembly to the HP Compressor Front Shaft and Seal Assembly with the No. 3 Bearing Nut

Sheet 1

Figure: Assemble the No. 3 Bearing, Gearshaft, Support and Seal Assembly to the HP Compressor Front Shaft and Seal Assembly with the No. 3 Bearing Nut

Sheet 2

Figure: Assemble the No. 3 Bearing, Gearshaft, Support and Seal Assembly to the HP Compressor Front Shaft and Seal Assembly with the No. 3 Bearing Nut

Assemble the No. 3 Bearing, Gearshaft, Support and Seal Assembly to the HP Compressor Front Shaft and Seal Assembly with the No. 3 Bearing Nut

Figure: Swash and Concentricity Check on the Curvic Coupling

Sheet 1

Figure: Swash and Concentricity Check on the Curvic Coupling

Sheet 2

Figure: Calculate the Correct Swash and Concentricity Values

Calculate the Correct Swash and Concentricity Values

Figure: Bend the Cup Washer into the Groove of the No. 3 Bearing Nut

Bend the Cup Washer into the Groove of the No. 3 Bearing Nut

Figure: Bend the Cup Washer into the Groove of the No. 3 Bearing Nut

Bend the Cup Washer into the Groove of the No. 3 Bearing Nut