Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-20-440-004-C00 HPC Rear Cases And Vanes Assembly- Assemble The HPC Stage 10 Stator Vanes To The Cases, Assembly-004 SBE 72-0627

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the Service Bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures refer to SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and parts used to attach. Use the correct color of the air drying enamel. Refer to SPM TASK 70-63-02-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

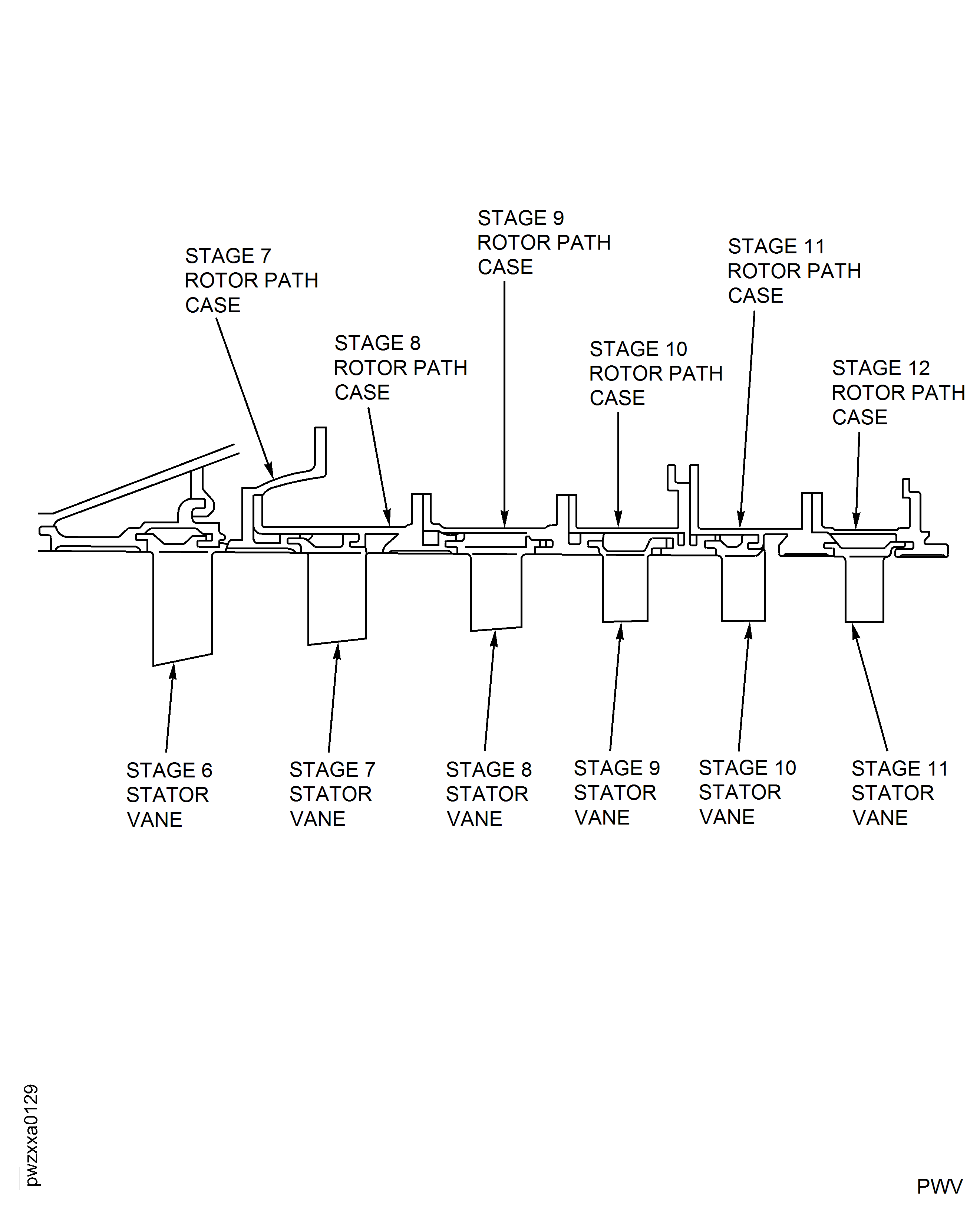

Refer to Figure for a sectional view of the HP compressor rear cases and vanes.

Make sure all the flange faces and tool faces that touch are very clean.

The Fits and Clearances, NEW PART DIMENSIONS and REJECT IF MORE THAN columns will be used by most operators. This permits the full use of the maximum wear allowance and a reduction in the number of parts which are rejected, is possible.

The column WORN PART DIMENSIONS (non-select) is included for operators who want to have full interchangeability. If this column is used an increase in the number of parts which are rejected is possible.

After the part has been in service for some time the REJECT IF MORE THAN and WORN PART DIMENSIONS could be changed. The operator must tell IAE and if agreed the manual will be changed.

The abbreviation lntf shows an interference or tight fit. This causes REJECT IF MORE THAN to become REJECT IF LESS THAN.

The abbreviation clear shows a clearance fit.

This TASK gives the procedures to assemble the HP Compressor Stage 10 Case, vanes, liners and stator vane stops. The subsequent TASKS give the procedures to assemble the remaining HP Compressor Rear Cases And Vanes.

Assemble the HP Compressor Stage 7 Cases and Stator Vanes by TASK 72-41-20-440-001-C00 (ASSEMBLY-001).

Assemble the HP Compressor Stage 8 Stator Vanes by TASK 72-41-20-440-002-C00 (ASSEMBLY-002).

Assemble the HP Compressor Stage 9 Stator Vanes by TASK 72-41-20-440-003-C00 (ASSEMBLY-003).

Assemble the HP Compressor Stage 11 Stator Vanes by TASK 72-41-20-440-005-C00 (ASSEMBLY-005).

Machine the Stator Vane Tips and the Rotor Path Ring Liners by TASK 72-41-20-440-006-C00 (ASSEMBLY-006).

Disassemble the HP Compressor Rear Cases and Vanes by TASK 72-41-20-440-007-C00 (ASSEMBLY-007).

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Heating blanket | LOCAL | |||

| IAE 1R18635 Spanner wrench | 0AM53 | IAE 1R18635 | 1 | |

| IAE 1R18636 Spanner Wrench | 0AM53 | IAE 1R18636 | 1 | |

| IAE 1R18637 Spanner Wrench | 0AM53 | IAE 1R18637 | 1 | |

| IAE 1R18827 Extractor | 0AM53 | IAE 1R18827 | 1 | |

| IAE 1R18864 Stop aligning tool | 0AM53 | IAE 1R18864 | 1 | |

| IAE 1R19686 Assembly tool | 0AM53 | IAE 1R19686 | ||

| IAE 1R19692 Assembly tool | 0AM53 | IAE 1R19692 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 07-038 AIR DRYING ENAMEL | k3504 | CoMat 07-038 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

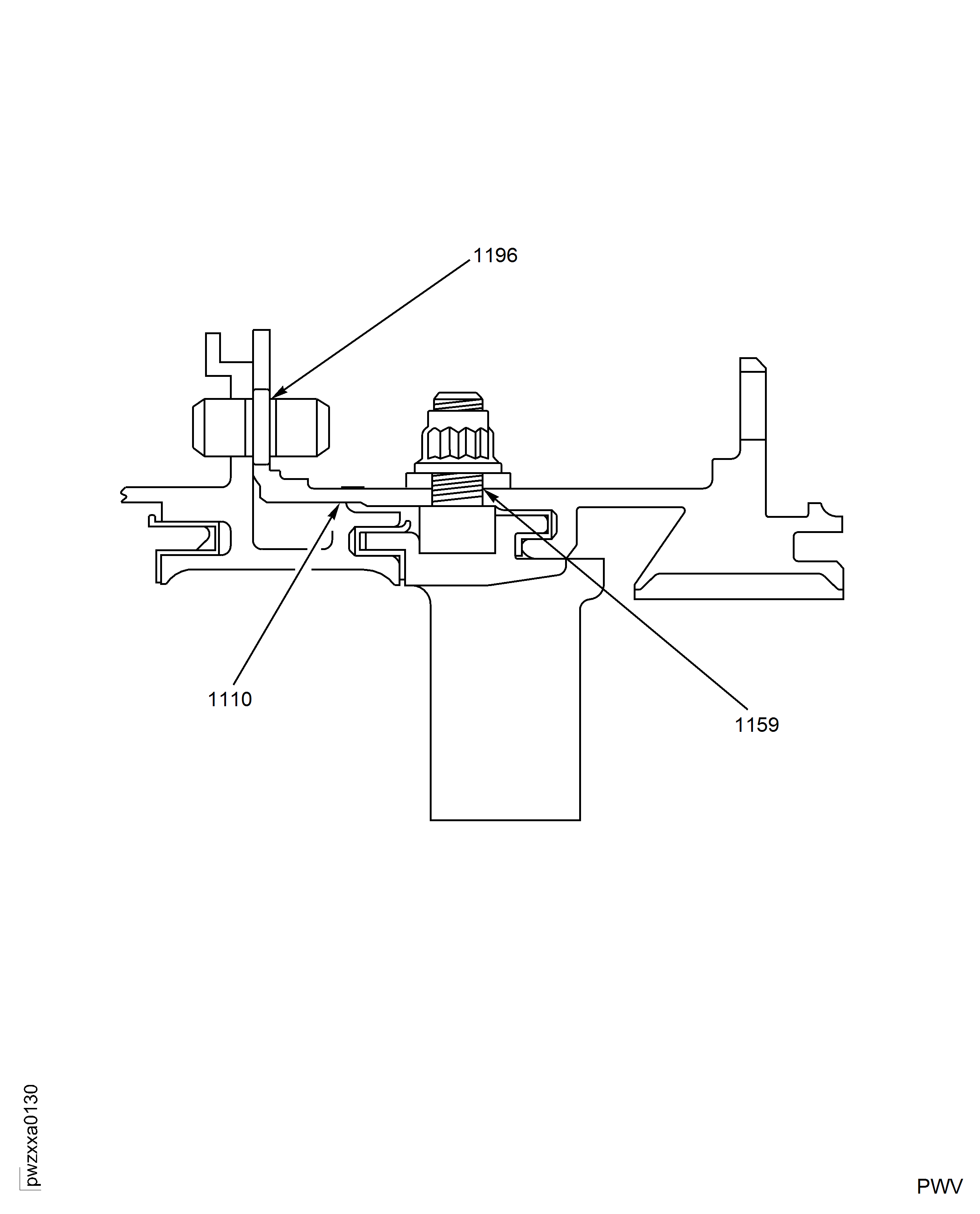

Refer to Figure.

Reference dimensions at Location 1159. If required use the data written as a Note in TASK 72-41-21-200-000.

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 1159

Stage 10 Stator Vane Stop HPC Ring Cases And Related Parts HPC Ring Cases And Related Parts (72-41-21, 04-330)

Location In The Stage 11 Case Rotor Path Case Assembly HPC Ring Cases And Related Parts HPC Ring Cases And Related Parts (72-41-21, 04-350)

Stage 10 Stator Vane Stop Shank Diameter

0.1872

Clear

0.1892

0.0067

Stage 11 Rotor Path Case Stop Location Bore

0.1959

0.0126

0.1998

Clear

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 1159

Stage 10 Stator Vane Stop HPC Ring Cases And Related Parts HPC Ring Cases And Related Parts (72-41-21, 04-330)

Location In The Stage 11 Rotor Path Case HPC Ring Cases And Related Parts HPC Ring Cases And Related Parts (72-41-21, 04-350)

Stage 10 Stator Vane Stop Shank Diameter

4.755

Clear

4.805

0.170

Stage 11 Rotor Path Case Stop Location Bore

4.975

0.320

5.075

Clear

SUBTASK 72-41-20-220-225-001 Reference Fits and Clearances of the HP Compressor Rear Cases and Vanes at Location 1159

Refer to Figure.

Reference dimensions at Location 1110. If required use the data written as a Note in TASK 72-41-21-200-000.

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 1110

Stage 10 Rotor Path Case Assembly HPC Ring Cases And Related Parts HPC Ring Cases And Related Parts (72-41-21, 03-800)

Location With The Stage 11 Rotor Path Case Assembly HPC Ring Cases And Related Parts HPC Ring Cases And Related Parts (72-41-21, 04-350)

Stage 10 Rotor Path Case Assembly Rear Flange Outer Diameter

21.3504

Intf

21.3551

0.0020

Stage 11 Rotor Path Case Assembly Front Bore

21.3437

0.0114

21.3484

Intf

Table 4. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 1110

Stage 10 Rotor Path Case Assembly HPC Ring Cases And Related Parts HPC Ring Cases And Related Parts (72-41-21, 03-800)

Location With The Stage 11 Rotor Path Case Assembly HPC Ring Cases And Related Parts HPC Ring Cases And Related Parts (72-41-21, 04-350)

Stage 10 Rotor Path Case Assembly Rear Flange Outer Diameter

542.30

lntf

542.42

0.050

Stage 11 Rotor Path Case Assembly Front Bore

542.13

0.290

542.25

lntf

SUBTASK 72-41-20-220-225-002 Reference Fits and Clearances of the HP Compressor Rear Cases and Vanes at Location 1110

Refer to Figure.

Reference dimensions at Location 1196. If required use the data written as a Note in TASK 72-41-21-200-000.

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 1196

Stage 11 Rotor Path Case Assembly HPC Ring Cases And Related Parts HPC Ring Cases And Related Parts (72-41-21, 04-350)

Location With The Stage 10 Rotor Path Case Assembly Location Pin HPC Ring Cases And Related Parts HPC Ring Cases And Related Parts (72-41-21, 03-825)

Stage 11 Rotor Path Case Assembly Location Pin Hole Bore

0.1638

Clear

0.1709

0.0054

Stage 10 Rotor Path Case Assembly Location Pin Outer Diameter

0.1580

0.0129

0.1584

Clear

Table 6. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 1196

Stage 11 Rotor Path Case Assembly HPC Ring Cases And Related Parts HPC Ring Cases And Related Parts (72-41-21, 04-350)

Location With The Stage 10 Rotor Path Case Assembly Location Pin HPC Ring Cases And Related Parts HPC Ring Cases And Related Parts (72-41-21, 03-825)

Stage 11 Rotor Path Case Assembly Location Pin Hole Bore

4.160

Clear

4.340

0.136

Stage 10 Rotor Path Case Assembly Location Pin Outer Diameter

4.012

0.328

4.024

Clear

SUBTASK 72-41-20-220-225-003 Reference Fits and Clearances of the HP Compressor Rear Cases and Vanes at Location 1196

Put the Stage 10 rotor path case front flange down on to a clean work surface.

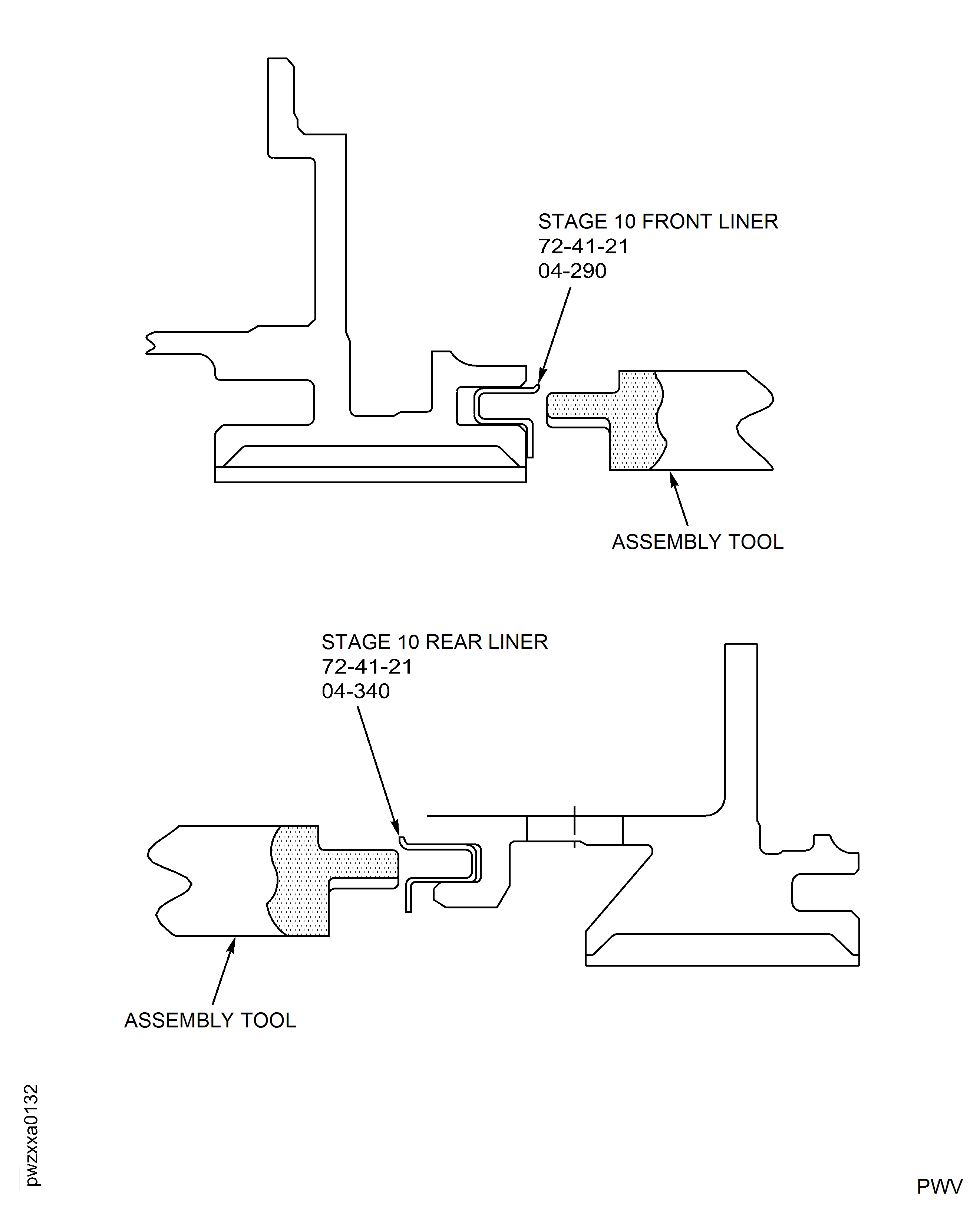

Use IAE 1R19686 Assembly tool 1 off to install the Stage 10 front liner. Make sure the liner touches the Stage 10 rotor path case rear face at Location B. Refer to Figure.

Measure and write down a record of the Stage 10 front liner split line clearance. The split line clearance must be 0.047 in. to 0.079 in. (1.20 mm to 2.00 mm).

Install the new HPC Ring Cases and related parts HPC Ring Cases And Related Parts (72-41-21, 04-290) Stage 10 front liner 1 off in to the slot in the Stage 10 rotor path case HPC Ring Cases And Related Parts HPC Ring Cases And Related Parts (72-41-21, 03-800).

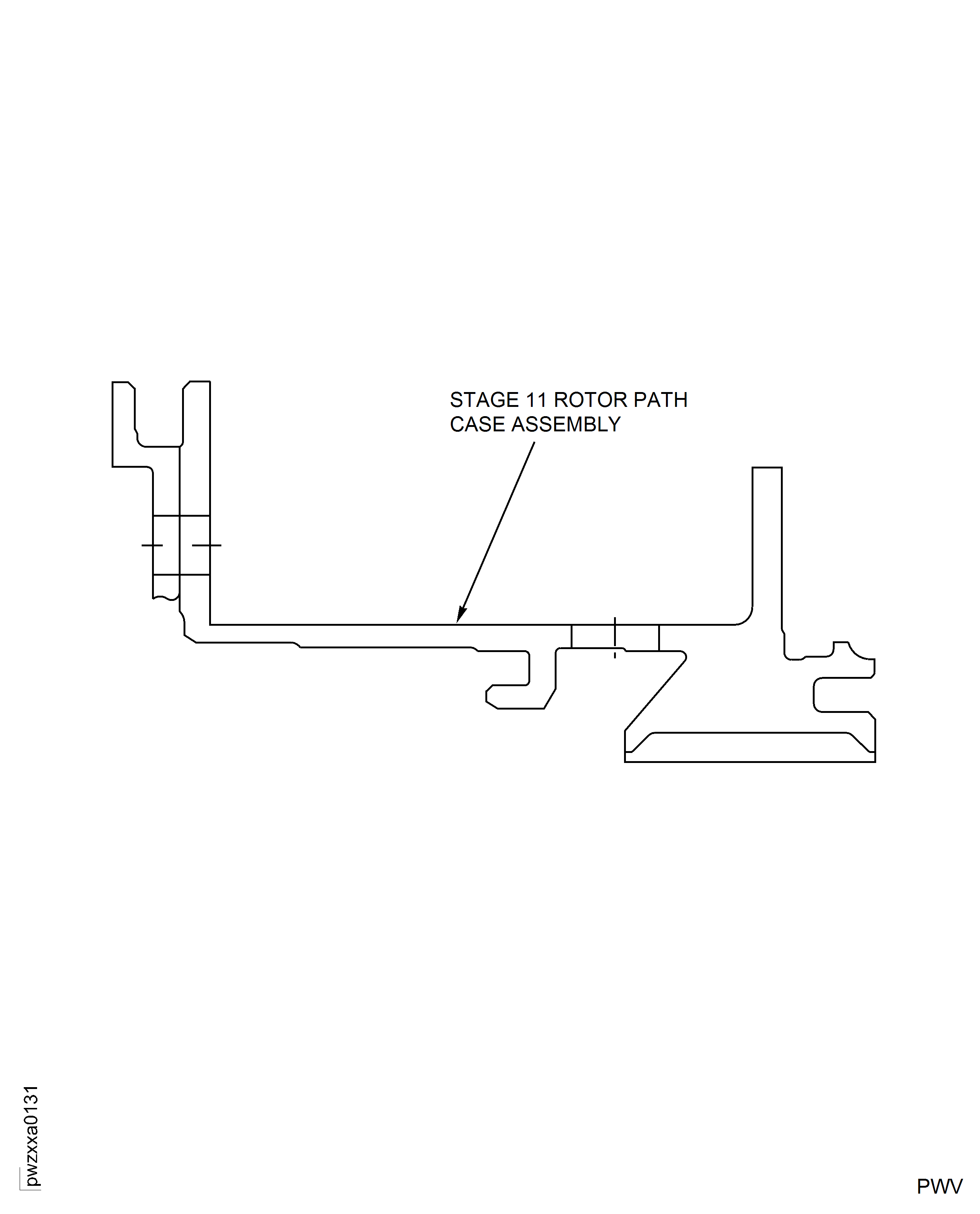

Put the Stage 11 Rotor Path Case Assembly rear flange down on a clean work surface.

Use IAE 1R19692 Assembly tool 1 off to install the Stage 10 rear liner. Make sure the liner touches the Stage 10 case at Location A. Refer to Figure.

Measure and write down a record of the Stage 10 rear liner split line clearance. The split line clearance must be 0.169 in. to 0.201 in. (4.30 mm to 5.10 mm).

Install the new HPC Ring Cases and related parts HPC Ring Cases And Related Parts (72-41-21, 04-280) Stage 10 rear liner 1 off, in to the slot in the Stage 11 Rotor Path Case Assembly HPC Ring Cases And Related Parts HPC Ring Cases And Related Parts (72-41-21, 04-350).

SUBTASK 72-41-20-440-280-001 Install the Stage 10 Stator Vane Rear Liner

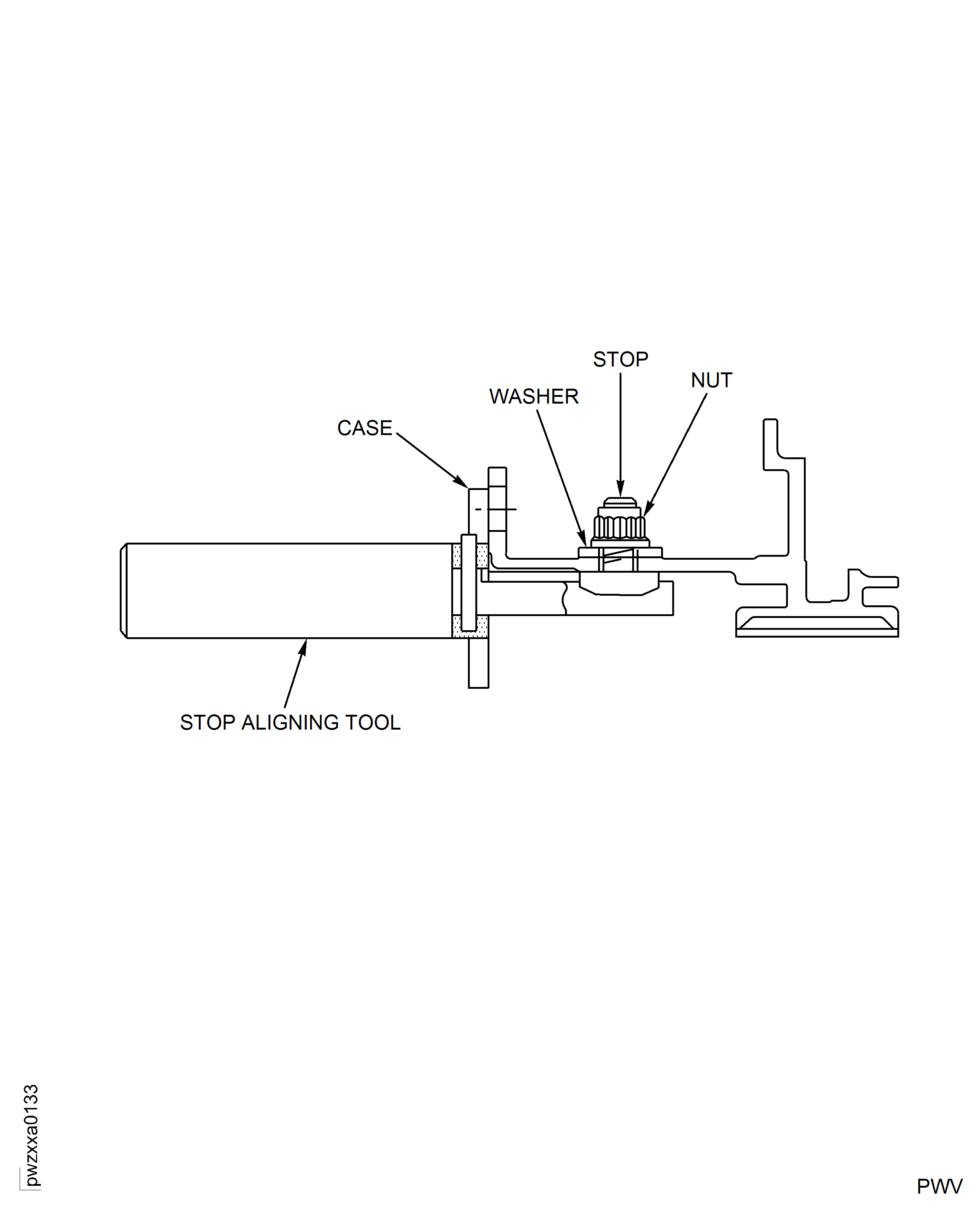

Refer to Figure.

Use the IAE 1R18864 Stop aligning tool 1 off and align the Stage 10 stator vane stop in the Stage 11 Rotor Path Case Assembly.

Install a washer HPC Ring Cases and related parts HPC Ring Cases And Related Parts (72-41-21, 04-329) and a nut HPC Ring Cases and related parts HPC Ring Cases And Related Parts (72-41-21, 04-328) on to the Stage 10 stator vane stop.

Torque the nut to 36 lbfin to 45 lbfin (4.00 Nm to 5.00 Nm).

Install the Stage 10 stator vane stops HPC Ring Cases and related parts HPC Ring Cases And Related Parts (72-41-21, 04-330) in the Stage 11 Rotor Path Case Assembly V2500-A5-72-41-20-04A-941A-D (72-41-20, 04-350).

SUBTASK 72-41-20-440-280-002 Install the Stator Vane Stops in the Stage 11 Rotor Path Case Assembly

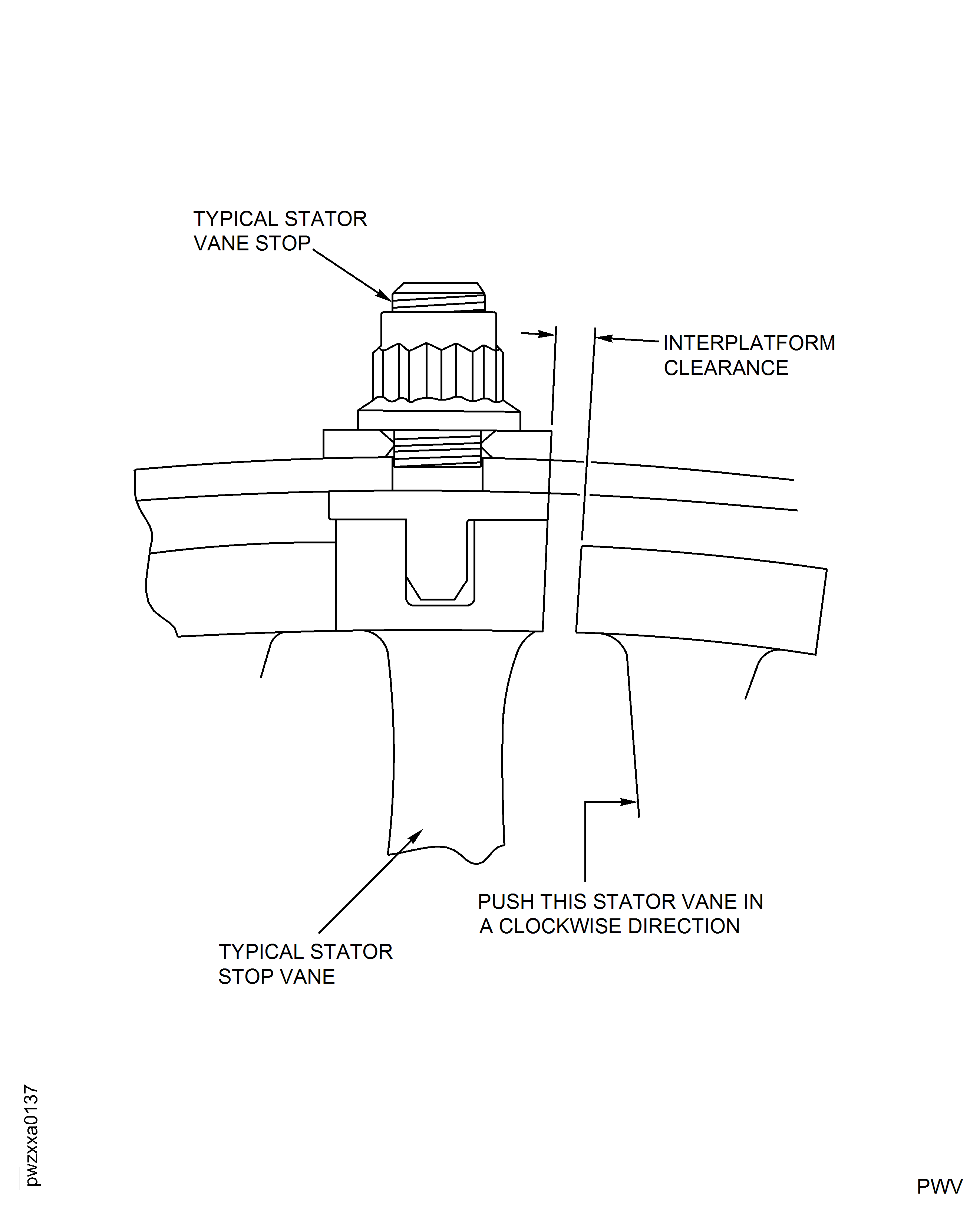

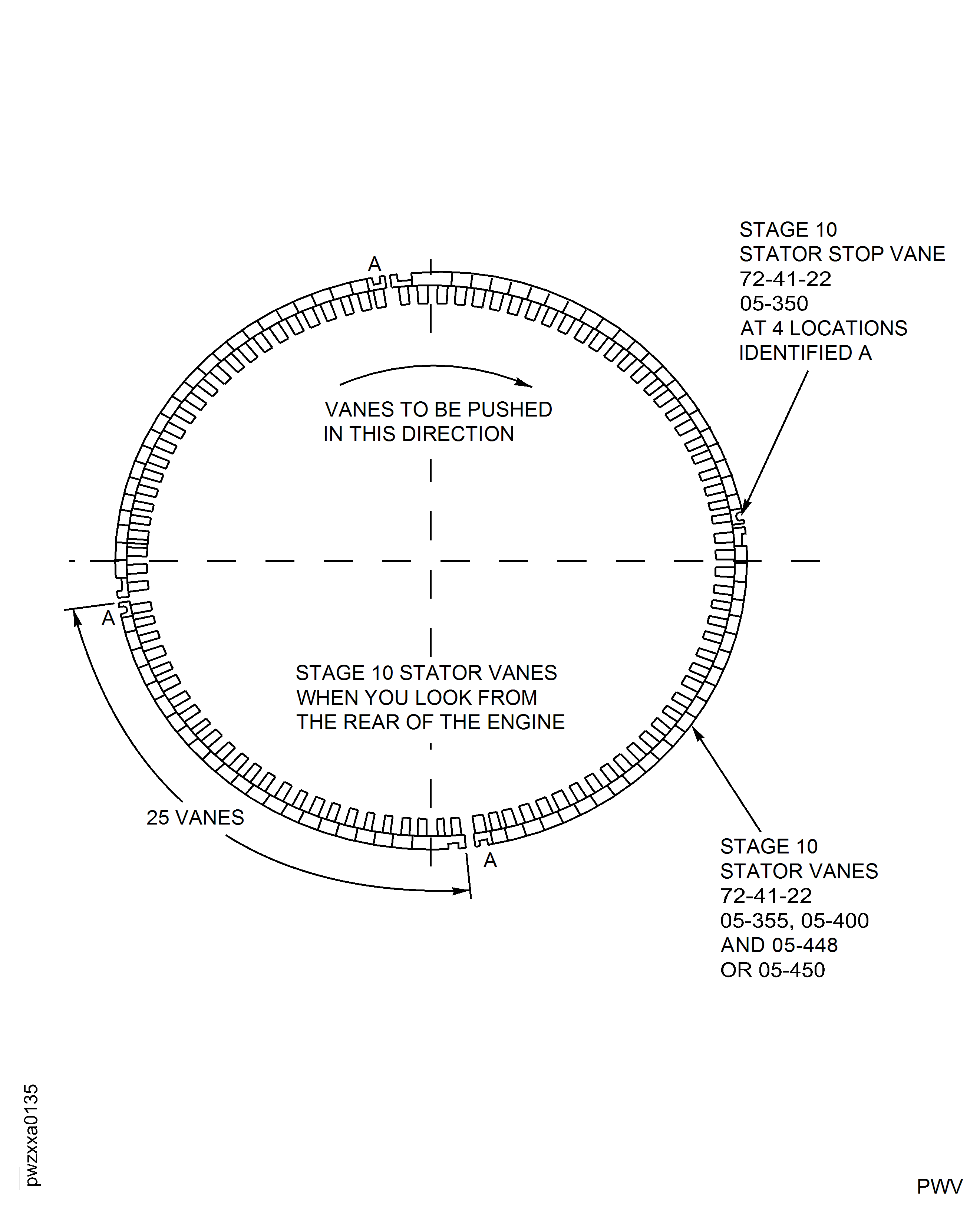

Install the four Stage 10 stop vanes in to the Stage 11 Rotor Path Case Assembly, at the Stage 10 stator vane stops. Engage the vanes in the Stage 10 rear liner HPC Ring Cases and related parts HPC Ring Cases And Related Parts (72-41-21,04-340). Make sure the Stage 10 stator vane stops are engaged in the slots in the Stage 10 stop vanes.

Push each of the Stage 10 stop vanes forward until the vane platform touches the Stage 10 front liner.

Push each Stage 10 stop vane in a clockwise direction, until the slot in the vane platform touches the Stage 10 stator vane stop.

Install the Stage 10 stop vanes HPC stator vanes HPC Stator Vanes (72-41-22, 05-350).

Install the vanes in a clockwise direction. Engage each of the vanes in the Stage 11 Rotor Path Case Assembly. Make sure the platform of the first vane that is installed touches the platform of the Stage 10 stop vane. Push each subsequent vane clockwise as it is installed until the vane platforms touch.

Push each vane forward until the vane platform touches the Stage 10 rear liner.

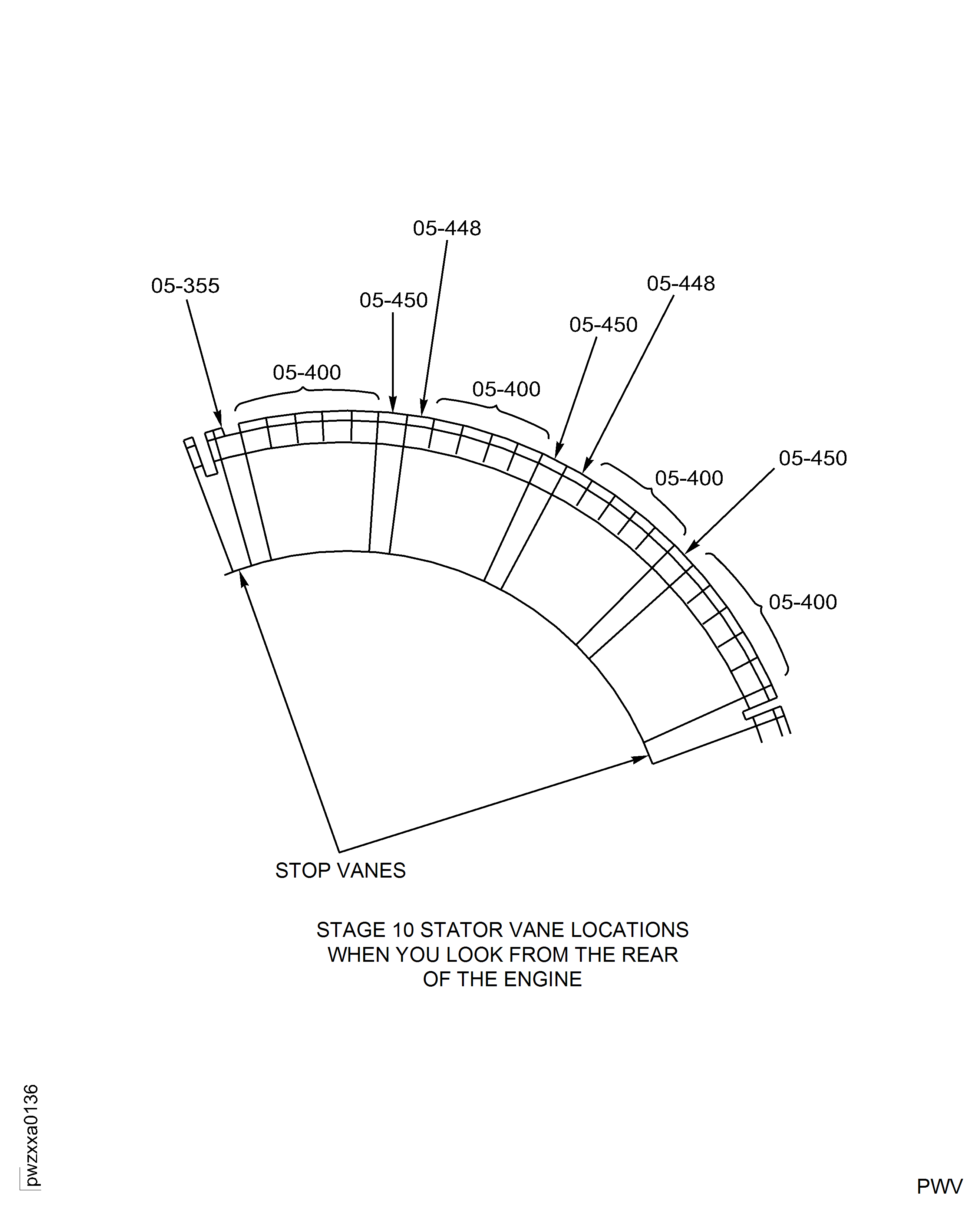

Install five Stage 10 stator vanes HPC Stator Vanes HPC Stator Vanes (72-41-22, 05-400).

Install one Stage 10 undersize stator vane HPC Stator Vanes HPC Stator Vanes (72-41-22, 05-450).

Install four Stage 10 stator vanes HPC Stator Vanes HPC Stator Vanes (72-41-22, 05-400).

Install one Stage 10 stator vane HPC Stator Vanes HPC Stator Vanes (72-41-22, 05-448).

Install one Stage 10 undersize stator vane HPC Stator Vanes HPC Stator Vanes (72-41-22, 05-450).

Install four Stage 10 stator vanes HPC Stator Vanes HPC Stator Vanes (72-41-22, 05-400).

Install one Stage 10 stator vane HPC Stator Vanes HPC Stator Vanes (72-41-22, 05-448).

Install one Stage 10 undersize stator Vane HPC Stator Vanes HPC Stator Vanes (72-41-22, 05-450).

Install five Stage 10 stator vanes HPC Stator Vanes HPC Stator Vanes (72-41-22, 05-400).

Install one Stage 10 retaining vane HPC Stator Vanes HPC Stator Vanes (72-41-22, 05-355).

Install the Stage 10 stator vanes between the two Stage 10 stop vanes adjacent to the 12 o'clock and 3 o'clock positions. Use the subsequent sequence.

Install the Stage 10 stator vanes HPC Stator Vanes HPC Stator Vanes (72-41-22, 05-355), HPC Stator Vanes HPC Stator Vanes (72-41-22, 05-400), HPC Stator Vanes HPC Stator Vanes (72-41-22, 05-480) and HPC Stator Vanes HPC Stator Vanes (72-41-22, 05-450) between the Stage 10 stop vanes in the remaining three segments. Use the sequence given in Step to Step.

Install the Stage 10 stator vanes.

SUBTASK 72-41-20-440-280-003 Install the Stage 10 Stator Vanes

Install the Seal Ring HPC Ring Cases And Related Parts (72-41-21, 04-406).

Put the Stage 11 Rotor Path Case Assembly HPC Ring Cases and related parts HPC Ring Cases And Related Parts (72-41-21, 04-350) front flange down on to a clean work surface.

Measure the clearance at Location 1106. The clearance between the sealing ring HPC Ring Cases and related parts HPC Ring Cases And Related Parts (72-41-21, 04-406) and the Stage 10 case must be 0.003 in. (0.08 mm).

Install the heating blanket on to the Stage 11 Rotor Path Case Assembly.

Heat the Stage 11 Rotor Path Case Assembly to 167 deg F to 212 deg F (75 deg C to 100 deg C).

Remove the heating blanket.

WARNING

YOU MUST PUT ON THE CORRECT PROTECTIVE GLOVES BEFORE YOU TOUCH THE STAGE 11 ROTOR PATH CASE ASSEMBLY.

WARNING

YOU MUST MAKE SURE THE STAGE 10 STATOR VANES ENGAGE CORRECTLY IN THE STAGE 11 ROTOR PATH CASE ASSEMBLY.Install the Stage 11 Rotor Path Case Assembly on to the Stage 10 Rotor Path Case Assembly and the Stage 10 stator vanes. Align the pin hole in the Stage 11 Rotor Path Case Assembly with the location pin in the Stage 10 Rotor Path Case Assembly.

Install eight slave nuts and bolts through the assembly joint flange. Space them at equal distances around the flange. Install the bolts from the Stage 11 Rotor Path Case Assembly Flange.

Tighten the nuts in the correct sequence to pull the Stage 11 Rotor Path Case Assembly on to the Stage 10 Rotor Path Case Assembly.

Let the assembly become cool.

Make sure that all the stator vanes can be moved in their locations. Any vanes which cannot be moved must be renewed.

SUBTASK 72-41-20-440-280-004 Install the Stage 11 Rotor Path Case Assembly

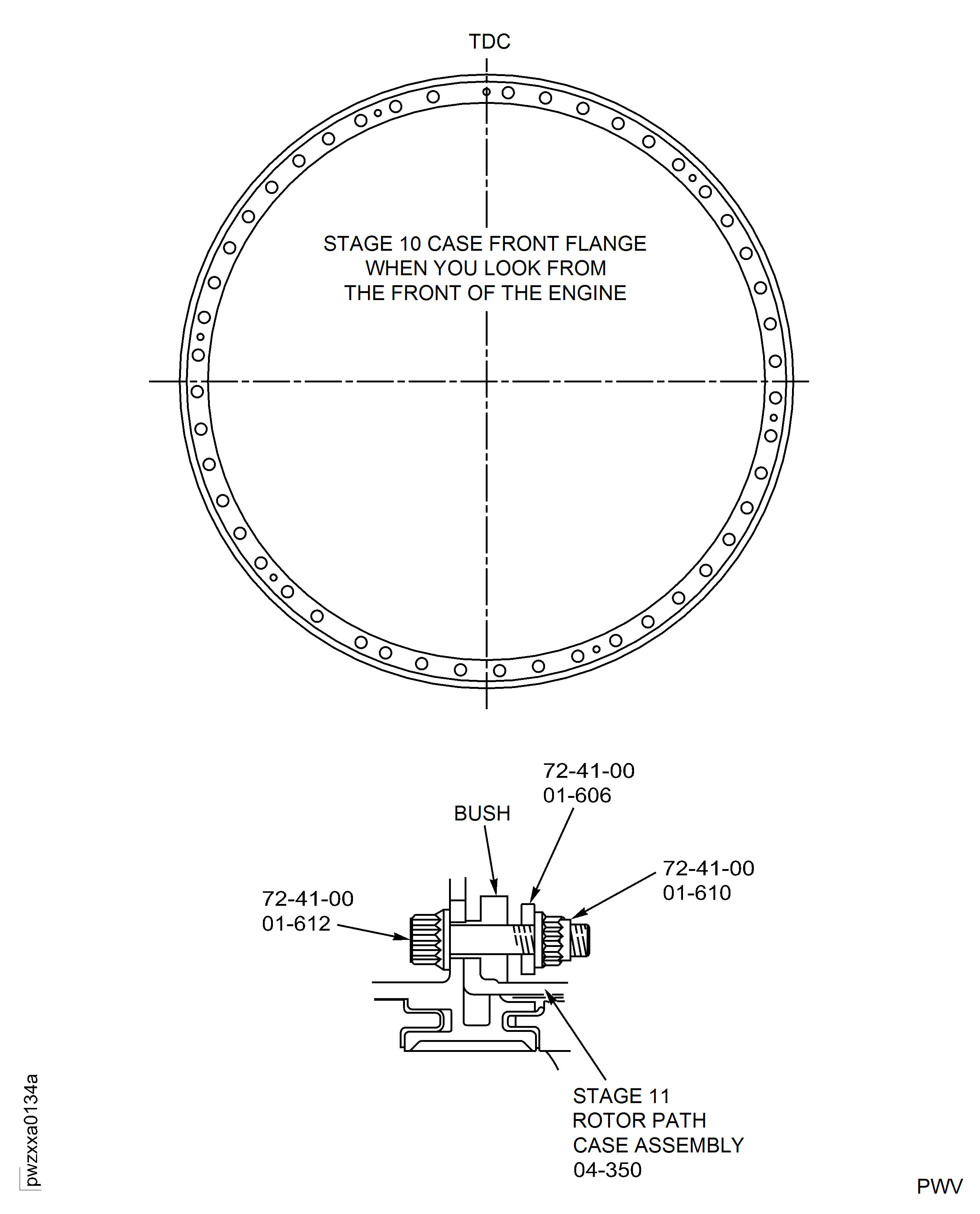

Refer to Figure.

Measure and write down a record of the interplatform clearances at the Stage 10 stop vanes. Measure all four clearances.

SUBTASK 72-41-20-440-280-005 Measure the lnterplatform Clearances

NOTE

To get the specified interplatform clearance at the four Stage 10 stop vanes HPC Stator Vanes HPC Stator Vanes (72-41-22, 05-350) use Stage 10 undersize vanes HPC Stator Vanes HPC Stator Vanes (72-41-22, 04-450) as necessary.NOTE

A maximum of eight undersize vanes can be used between two adjacent stop vanes. These must be set at equal distances between the stop vanes.Remove the eight slave nuts and bolts which attach the Stage 11 Rotor Path Case Assembly HPC Ring Cases and related parts HPC Ring Cases And Related Parts (72-41-21, 04-350) to the Stage 10 Rotor Path Case Assembly HPC Ring Cases and related parts HPC Ring Cases And Related Parts (72-41-21, 03-800).

Install the heating blanket on to the Stage 11 Rotor Path Case Assembly.

Heat the Stage 11 Rotor Path Case Assembly to 167 deg F to 212 deg F (75 deg C to 100 deg C).

Remove the heating blanket.

Use IAE 1R18827 Extractor 3 off to remove the Stage 11 Rotor Path Case Assembly.

Engage the pins of the extractors in the extraction holes in the Stage 11 Rotor Path Case Assembly front flange.

Adjust the bolts of the extractors until the plates touch the Stage 11 Rotor Path Case Assembly rear flange.

Continue to turn the bolts to remove the Stage 11 Rotor Path Case Assembly. Turn the bolts in sequence by a small equal quantity to remove the Stage 11 Rotor Path Case Assembly.

Remove the Stage 11 Rotor Path Case Assembly.

CAUTION

UNDERSIZE VANES MUST NOT BE INSTALLED ADJACENT TO THE STOP VANES OR OTHER UNDERSIZE VANES.Remove the Stage 10 stator vanes HPC Stator Vanes HPC Stator Vanes (72-41-22, 05-448) and install the Stage 10 undersize vanes as necessary. One Stage 10 undersize vane will give an increase in the interplatform clearance of 0.016 in. (0.40 mm).

Install the Stage Rotor Path Case Assembly as given in Step.

Measure and write down a record of the interplatform clearances at the four Stage 10 stop vanes as given in Step.

SUBTASK 72-41-20-440-280-006 Install the Stage 10 Undersize Vanes

Refer to Figure.

Install the 47 bolts HPC Assembly HPC Assembly (72-41-00, 01-612) from the Stage 10 Rotor Path Case Assembly HPC Ring Cases And Related Parts (72-41-21, 03-800), HPC Ring Cases and related parts HPC Ring Cases And Related Parts (72-41-21, 04-420) and Stage 11 Rotor Path Case Assembly HPC Ring Cases And Related Parts (72-41-21, 04-350) front flange. Make sure the bolts are correctly installed on the Stage 11 Rotor Path Case Assembly front flange.

Install the 47 washers HPC Assembly HPC Assembly (72-41-00, 01-606) and the 47 nuts HPC Assembly HPC Assembly (72-41-00, 01-610) on bolts.

Use the IAE 1R18636 Spanner Wrench 1 off to tighten the nuts.

Use the IAE 1R18637 Spanner Wrench 1 off to torque the nuts. Torque the nuts in the correct sequence to 36 lbfin to 45 lbfin (4.00 Nm to 5.00 Nm).

SUBTASK 72-41-20-440-280-007 Install the Stage 11 Rotor Path Case Assembly

Figure: View through the HP Compressor Rear Cases and Vanes

View through the HP Compressor Rear Cases and Vanes

Figure: Fits and Clearances Locations

Fits and Clearances Locations

Figure: Stage 11 Rotor Path Case Assembly

Stage 11 Rotor Path Case Assembly

Figure: Stage 10 Rotor Path Case Assembly

Stage 10 Rotor Path Case Assembly

Figure: Install the Stage 10 Stator Vane Stops

Install the Stage 10 Stator Vane Stops

Figure: Bolt Locations

Bolt Locations

Figure: HPC Stage 10 Stator Vanes

HPC Stage 10 Stator Vanes

Figure: HPC Stage 10 Stator Vane Positions

HPC Stage 10 Stator Vane Positions

Figure: Measure the Stator Vane lnterplatform Clearances

Measure the Stator Vane lnterplatform Clearances