Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-00-440-002-A00 HPC Assembly - Assemble The HPC Front Cases To The HPC Rotor Assembly, Assembly-002

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item numbers.

For standard torque data and procedures refer to the SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-410-501.

Special torque data and assembly tolerances are included in this procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to the SPM TASK 70-44-01-400-501.

For lockwire data and procedures refer to the SPM TASK 70-42-05-400-501.

For safety cable data and procedures refer to the SPM TASK 70-42-08-400-501. | ||

Safety the threaded fasteners in the ATA Chapter/Section/Subject 72-41-34 as applicable with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT. |

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flange and attach parts. Use the correct color of the air drying enamel. Refer to the SPM TASK 70-63-02-380-501.

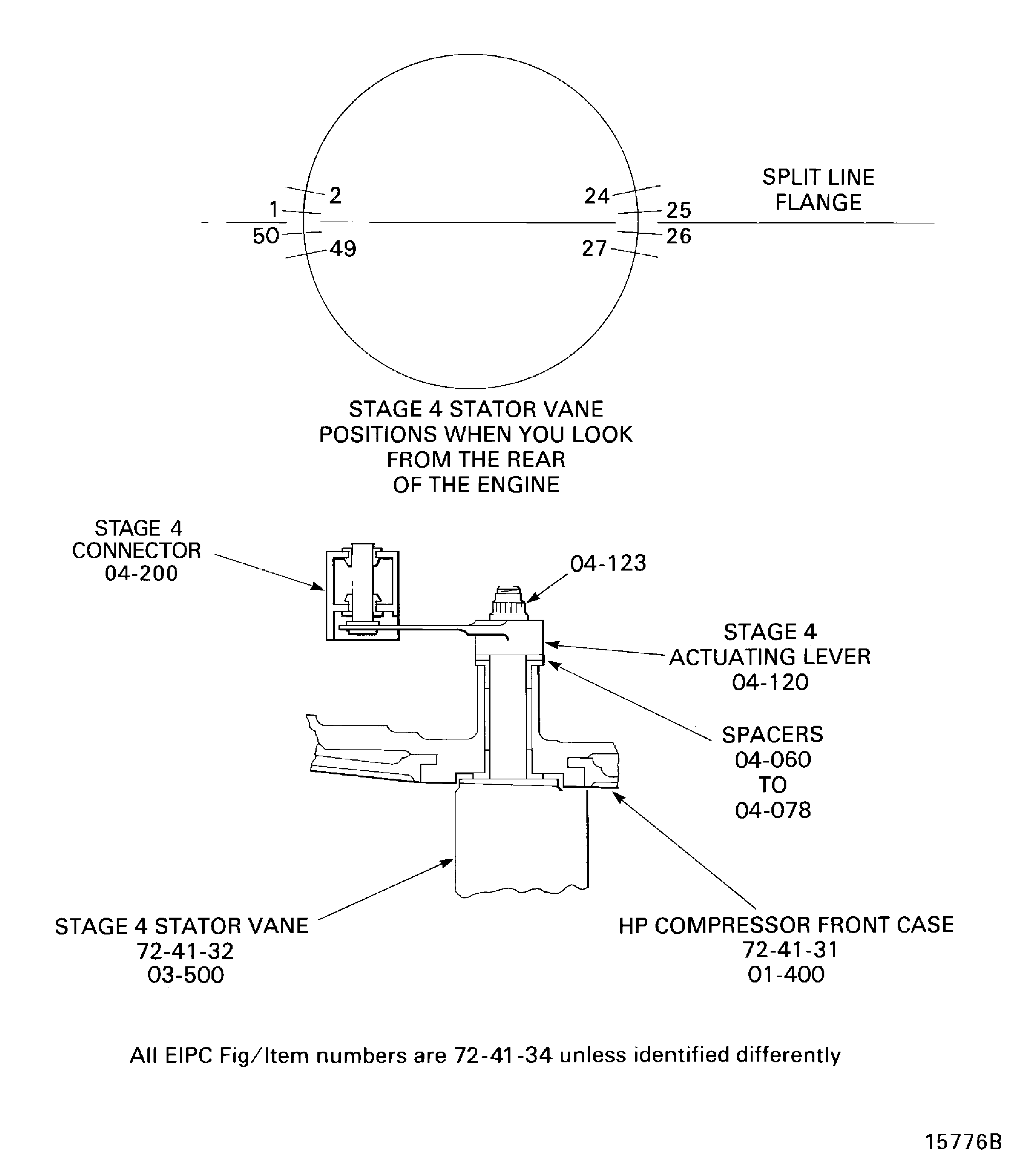

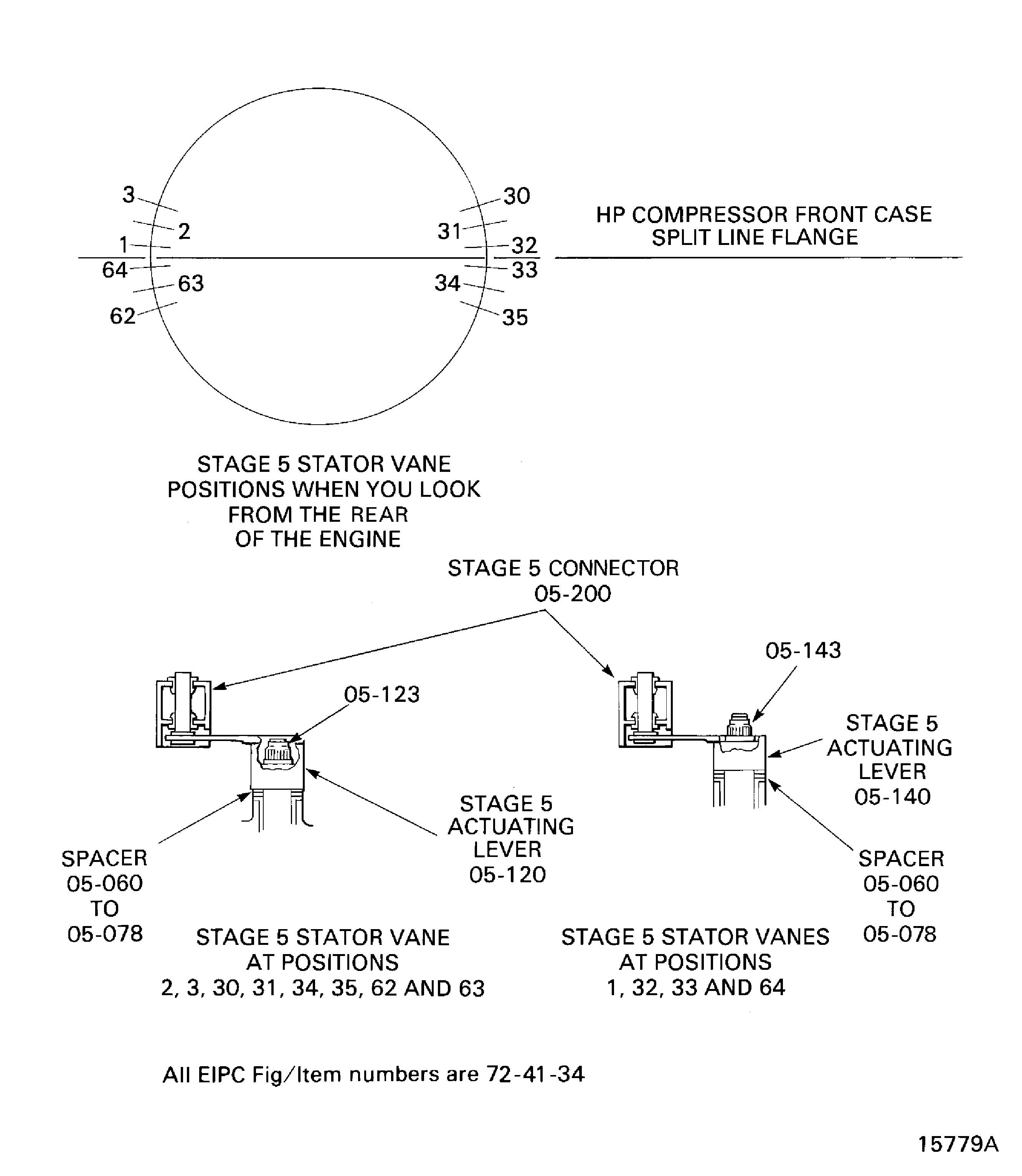

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

This TASK gives the procedure to assemble the HP compressor front cases on to the HP compressor rotor assembly. TASK 72-41-00-440-001-A00 (ASSEMBLY-001, CONFIG-001) gives the procedure to install the HP compressor rear cases and vanes on to the HP compressor rotor assembly.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1R18090 Safety support stand | 0AM53 | IAE 1R18090 | 1 | |

| IAE 1R18214 Build stand | 0AM53 | IAE 1R18214 | 1 | |

| IAE 1R18217 Lift fixture | 0AM53 | IAE 1R18217 | 1 | |

| IAE 1R18220 Holding fixture | 0AM53 | IAE 1R18220 | 1 | |

| IAE 1R18222 Support rod | 0AM53 | IAE 1R18222 | 2 | |

| IAE 1R18248 Rigging pin | 0AM53 | IAE 1R18248 | 2 | |

| IAE 1R18638 Rigging pin | 0AM53 | IAE 1R18638 | 2 | |

| IAE 1R18250 Split ring assembly | 0AM53 | IAE 1R18250 | 1 | |

| IAE 1R18251 Axial measuring fixture | 0AM53 | IAE 1R18251 | 1 | |

| IAE 1R18252 Protective cover | 0AM53 | IAE 1R18252 | 1 | |

| IAE 1R18254 Rigging pin | 0AM53 | IAE 1R18254 | 1 | |

| IAE 1R18294 Clock holder | 0AM53 | IAE 1R18294 | 1 | |

| IAE 1R18423 Rigging pin | 0AM53 | IAE 1R18423 | 15 | |

| IAE 1R18892 Rigging pin | 0AM53 | IAE 1R18892 | 6 | |

| IAE 1R18893 Riggingpin | 0AM53 | IAE 1R18893 | 6 | |

| IAE 1R18894 Rigging pin | 0AM53 | IAE 1R18894 | 6 | |

| IAE 1R18895 Rigging pin | 0AM53 | IAE 1R18895 | 6 | |

| IAE 1R18896 Rigging pin | 0AM53 | IAE 1R18896 | 6 | |

| IAE 1R18441 Lifting adapter | 0AM53 | IAE 1R18441 | 1 | |

| IAE 1R19552 Protective cover | 0AM53 | IAE 1R19552 | 1 | |

| IAE 1R19633 Split ring assembly | 0AM53 | IAE 1R19633 | 1 | |

| IAE 1R18219 Support ring | 0AM53 | IAE 1R18219 | ||

| IAE 1R18401 Support stand | 0AM53 | IAE 1R18401 | ||

| IAE 1R18247 Rigging pin | 0AM53 | IAE 1R18247 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 02-274 SAFETY CABLE KIT | LOCAL | CoMat 02-274 | ||

| CoMat 02-275 SAFETY CABLE KIT | X111X | CoMat 02-275 | ||

| CoMat 04-007 SILICONE GREASE | LOCAL | CoMat 04-007 | ||

| CoMat 07-038 AIR DRYING ENAMEL | 00BB6 | CoMat 07-038 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 | ||

| CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R) | 39428 | CoMat 10-108 | ||

| CoMat 08-013 COLD CURING SILICONE COMPOUND | X222X | CoMat 08-013 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Cotter pin | 1 | |||

| Cotter pin | 1 | |||

| Cotter pin | 1 | |||

| Cotter pin | 1 | |||

| Cotter pin | 1 |

Safety Requirements

CAUTION

Procedure

Refer to: Figure

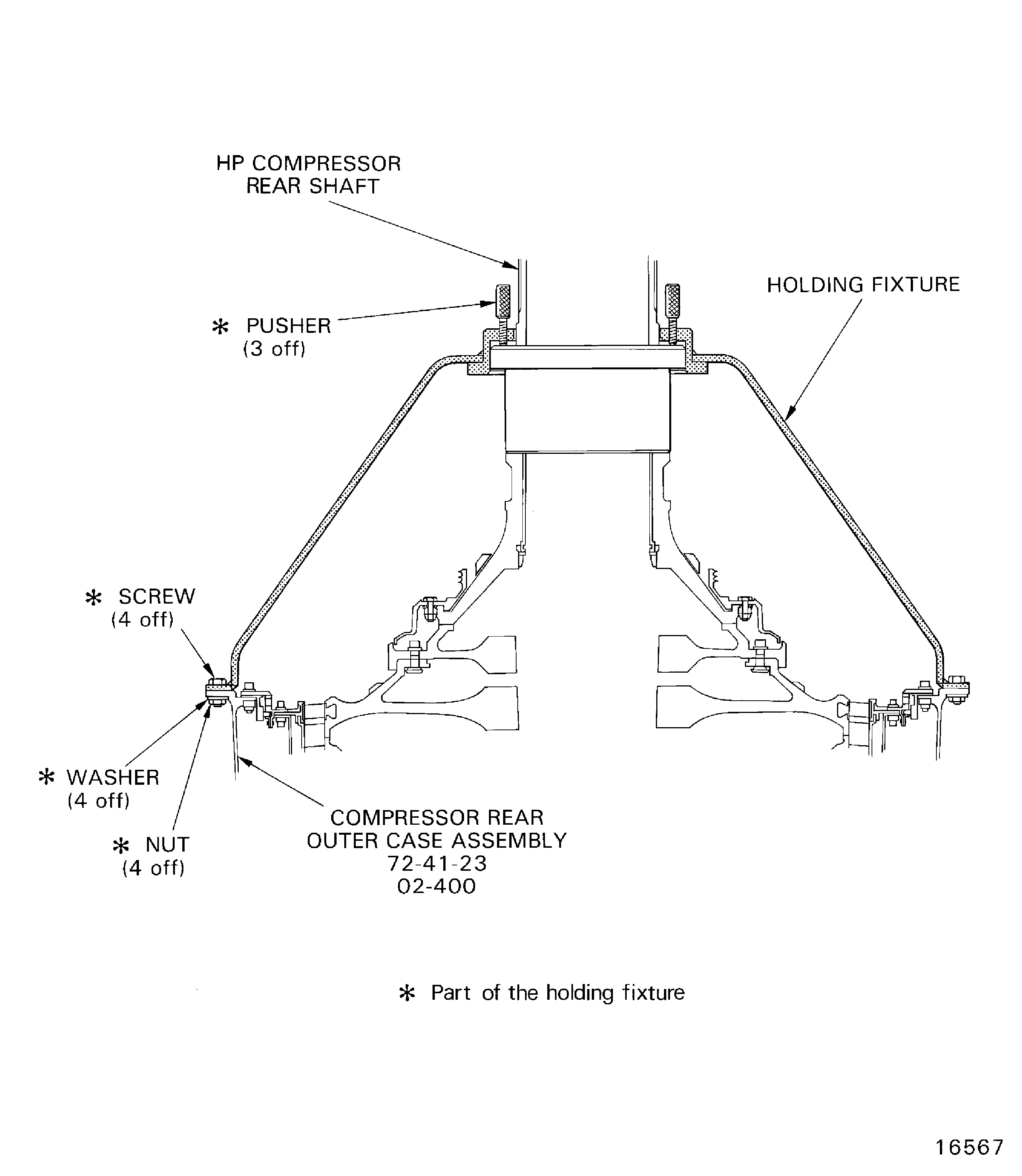

Install IAE 1R18220 Holding fixture 1 off on to the compressor rear outer case and the HP compressor rear shaft.

SUBTASK 72-41-00-440-067 Install the Holding Fixture on to the Compressor Rear Outer Case and the HP Compressor Rear Shaft

Adjust the position of IAE 1R18220 Holding fixture 1 off.

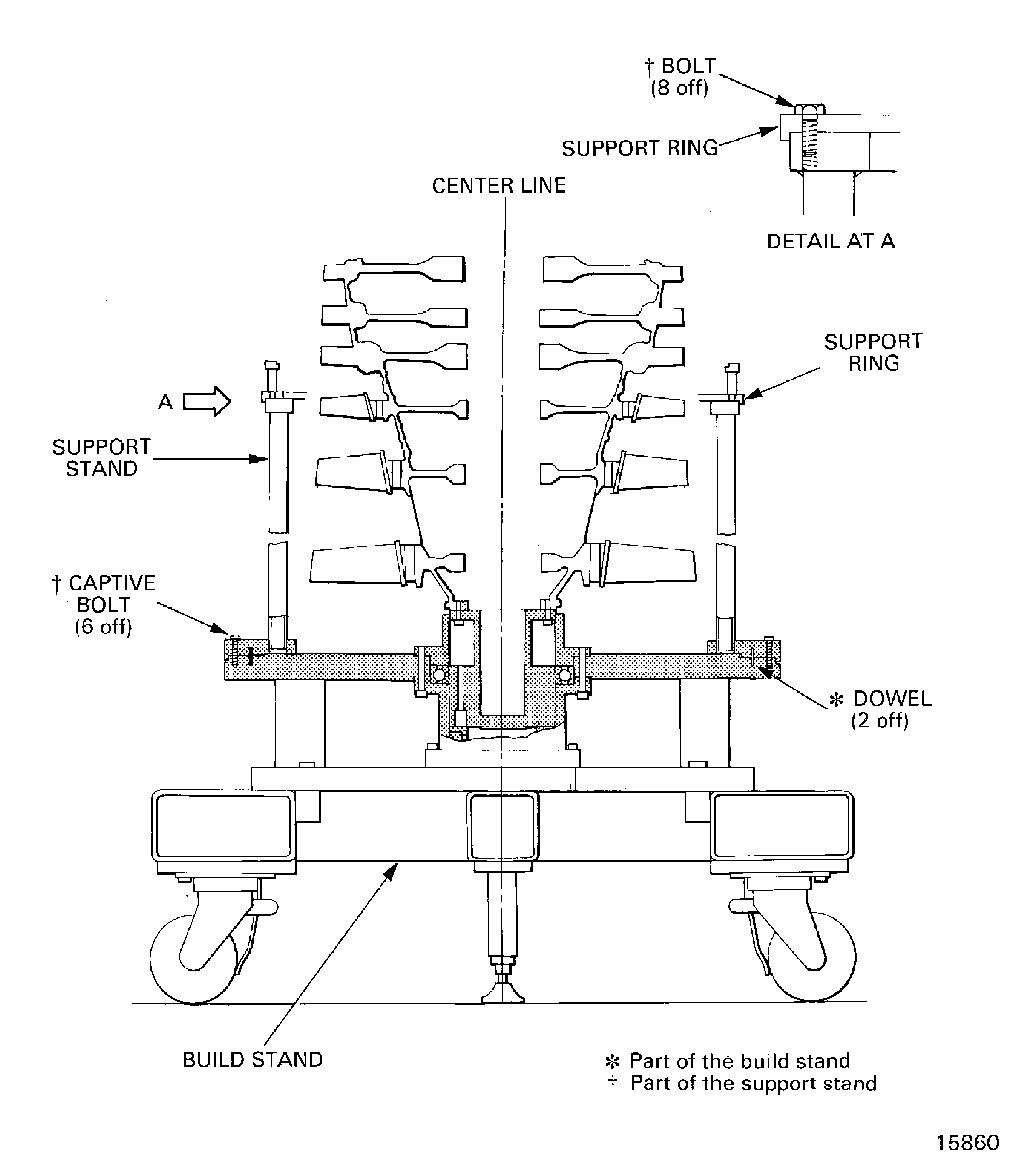

Remove IAE 1R18219 Support ring and IAE 1R18401 Support stand from IAE 1R18214 Build stand.

Install IAE 1R18222 Support rod 2 off on to the build stand. Refer to Figure.

SUBTASK 72-41-00-440-068 Install the Support Ring on the Build Stand

Install the two sealing strips HP COMPRESSOR SPLIT CASE (72-41-31, 01-677) at the stage 3 rotor path ring HP COMPRESSOR SPLIT CASE (72-41-31, 01-685). Install the sealing strips at the opposite split line flanges.

Install the two sealing strips HP COMPRESSOR SPLIT CASE (72-41-31, 01-678) at the stage 4 rotor path ring HP COMPRESSOR SPLIT CASE (72-41-31, 01-690). Install the sealing strips at the opposite split line flanges.

Install the two sealing strips HP COMPRESSOR SPLIT CASE (72-41-31, 01-679) at the stage 5 rotor path ring HP COMPRESSOR SPLIT CASE (72-41-31, 01-695). Install the sealing strips at the opposite split line flanges.

Install the two sealing strips HP COMPRESSOR SPLIT CASE (72-41-31, 01-680) at the stage 6 rotor path ring HP COMPRESSOR SPLIT CASE (72-41-31, 01-700). Install the sealing strips at the opposite split line flanges.

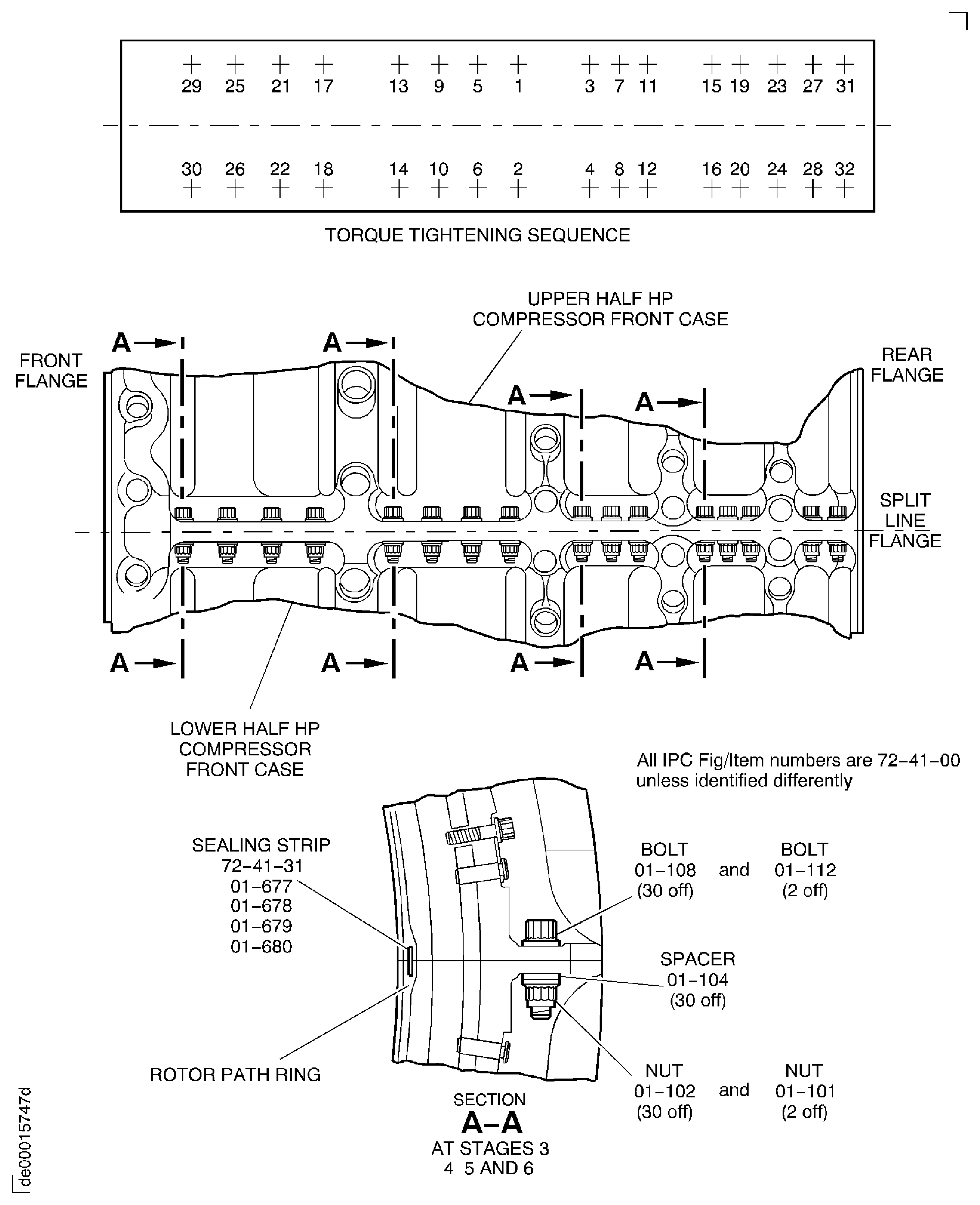

Install the stage 3, 4, 5 and 6 sealing strips. Refer to Figure.

Install the upper and lower half HP compressor front case HP COMPRESSOR SPLIT CASE (72-41-31, 01-400). Refer to Figure.

Install the 30 bolts HPC Assembly (72-41-00,01-108) the 30 spacers HPC Assembly (72-41-00, 01-104) and the 30 nuts HPC Assembly (72-41-00, 01-102) at the split line flanges.

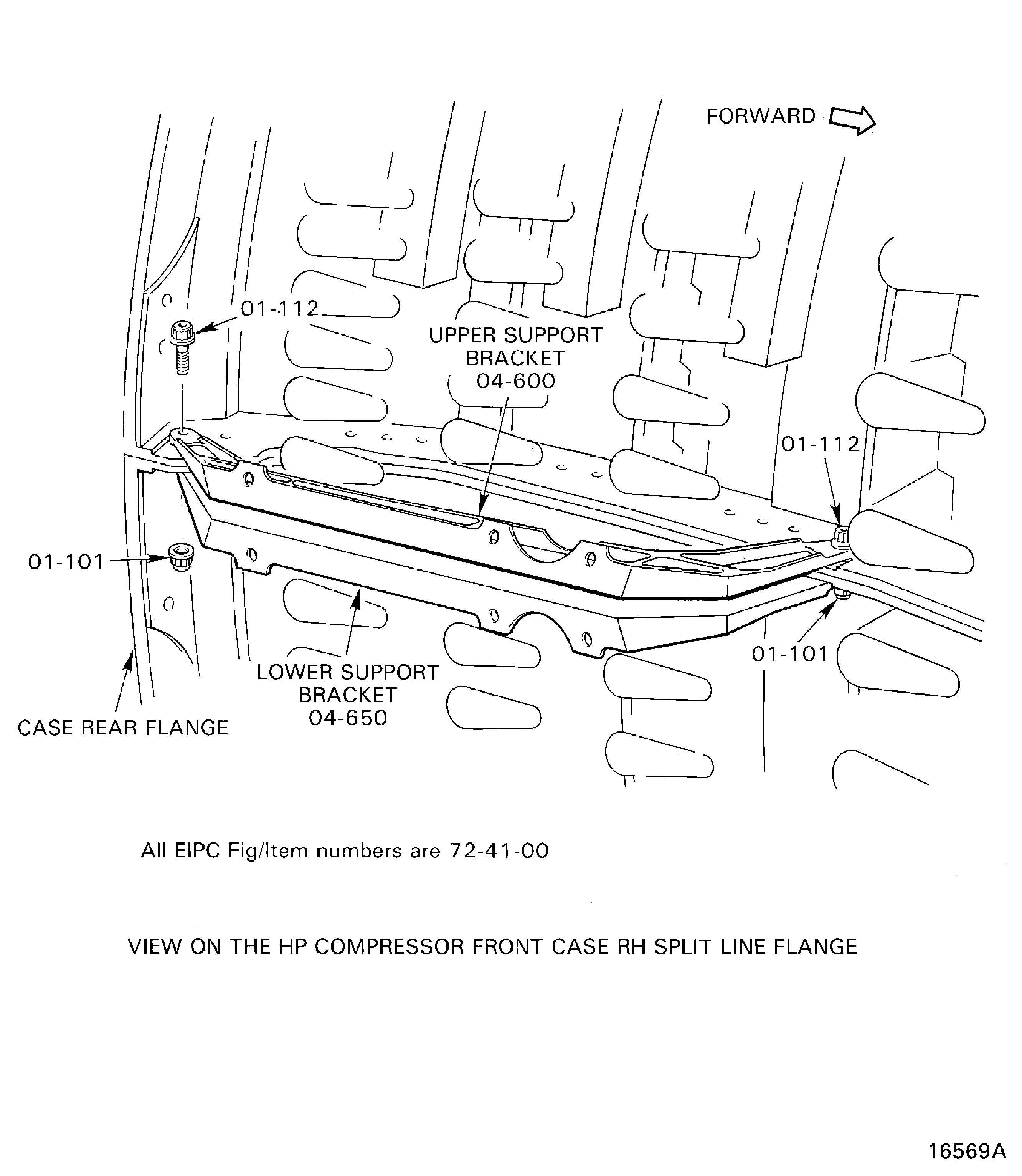

Install the bolts HPC Assembly (72-41-00, 01-112) through the upper and lower support brackets and the split line flange.

Install the nuts HPC Assembly (72-41-00, 01-101) on to the bolt.

At the bolts positions 13 and 31 install the upper and lower support brackets HPC Assembly (72-41-00, 04-600 and HPC Assembly04-650). Refer to Figure.

Release the three pushers on the holding fixture so that the HP compressor rear outer case touches the HP compressor front case. Make sure the dowel pin holes are aligned. Refer to Figure.

CAUTION

THE BOLTS ARE A CLOSE TOLERANCE FIT. THEY MUST NOT BE TURNED WHEN BEING INSTALLED.Install the HP compressor front case split line flange bolts, spacers and nuts. Refer to Figure.

NOTE

Do not install a bolt, nut and spacer at the bolt positions 13 and 31.

SUBTASK 72-41-00-440-069-A00 Install the HP Compressor Front Cases (Pre SBE 72-0027)

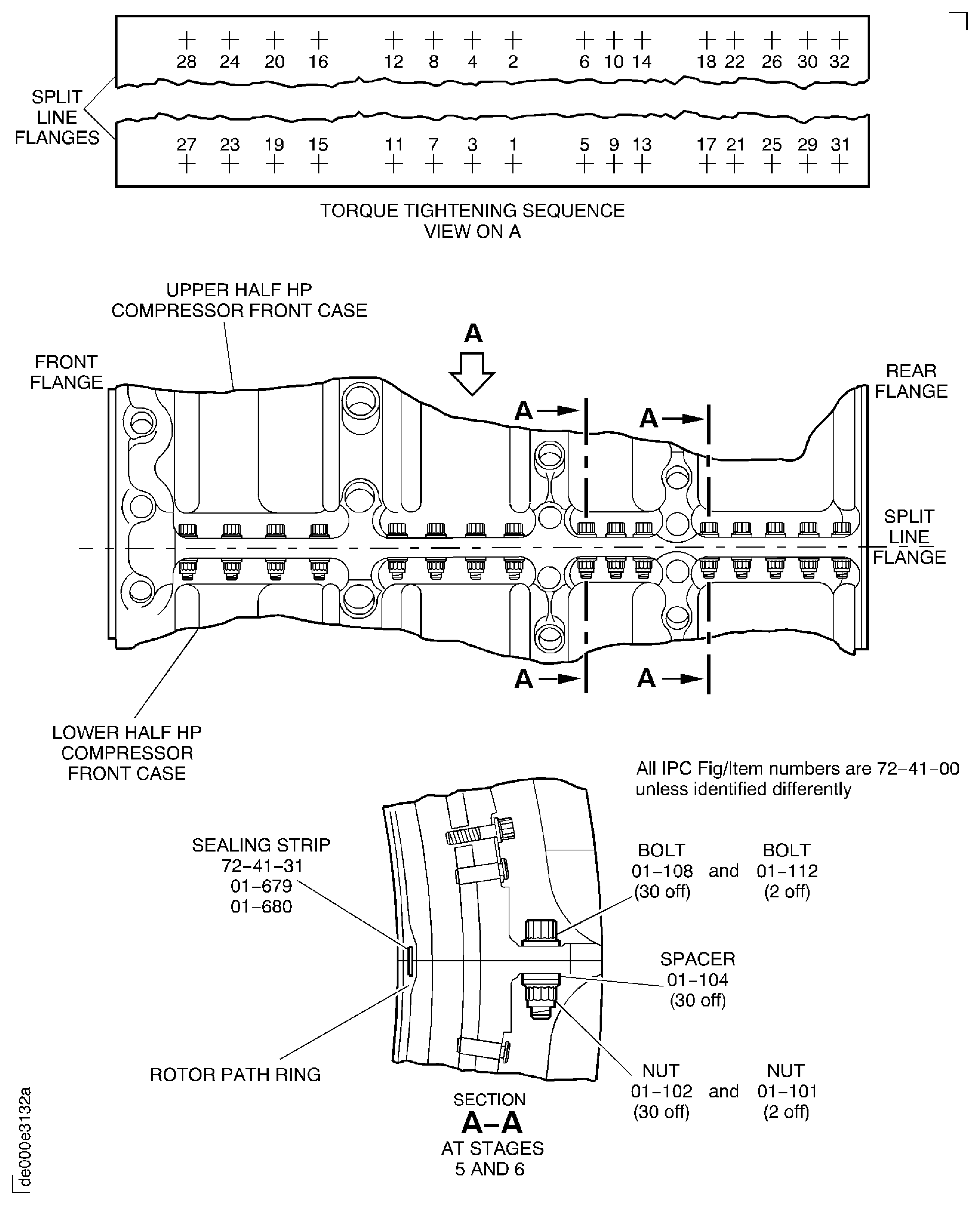

Install the two sealing strips HP COMPRESSOR SPLIT CASE (72-41-31, 01-679) at the stage 5 rotor path ring HP COMPRESSOR SPLIT CASE (72-41-31, 01-695). Install the sealing strips at the opposite split line flanges.

Install the two sealing strips HP COMPRESSOR SPLIT CASE (72-41-31, 01-680) at the stage 6 rotor path ring HP COMPRESSOR SPLIT CASE (72-41-31, 01-700). Install the sealing strips at the opposite split line flanges.

Install the stage 5 and 6 sealing strips. Refer to Figure.

Install the upper and lower half HP compressor front case HP COMPRESSOR SPLIT CASE (72-41-31, 01-400). Refer to Figure.

Install the 30 bolts HPC Assembly (72-41-00, 01-108) the 30 spacers HPC Assembly (72-41-00, 01-104) and the 30 nuts HPC Assembly (72-41-00, 01-102) at the split line flanges.

Install the bolts HPC Assembly (72-41-00, 01-112) through the upper and lower support brackets and the split line flange.

Install the nuts HPC Assembly (72-41-00, 01-101) on to the bolt.

At the bolts positions 12 and 32 install the upper and lower support brackets HPC Assembly (72-41-00, 04-600 and HPC Assembly 04-650). Refer to Figure.

Release the three pushers on the holding fixture so that the HP compressor rear outer case touches the HP compressor front case. Make sure the dowel pin holes are aligned. Refer to Figure.

CAUTION

THE BOLTS ARE A CLOSE TOLERANCE FIT. THEY MUST NOT BE TURNED WHEN BEING INSTALLED.Install the HP compressor front case split line flange bolts, spacers and nuts. Refer to Figure.

NOTE

Do not install a bolt, nut and spacer at the bolt positions 12 and 32.

SUBTASK 72-41-00-440-069-B00 Install the HP Compressor Front Cases (SBE 72-0027)

SBE 72-0027: Engine - HP compressor - Introduction of reduced weight front compressor casing

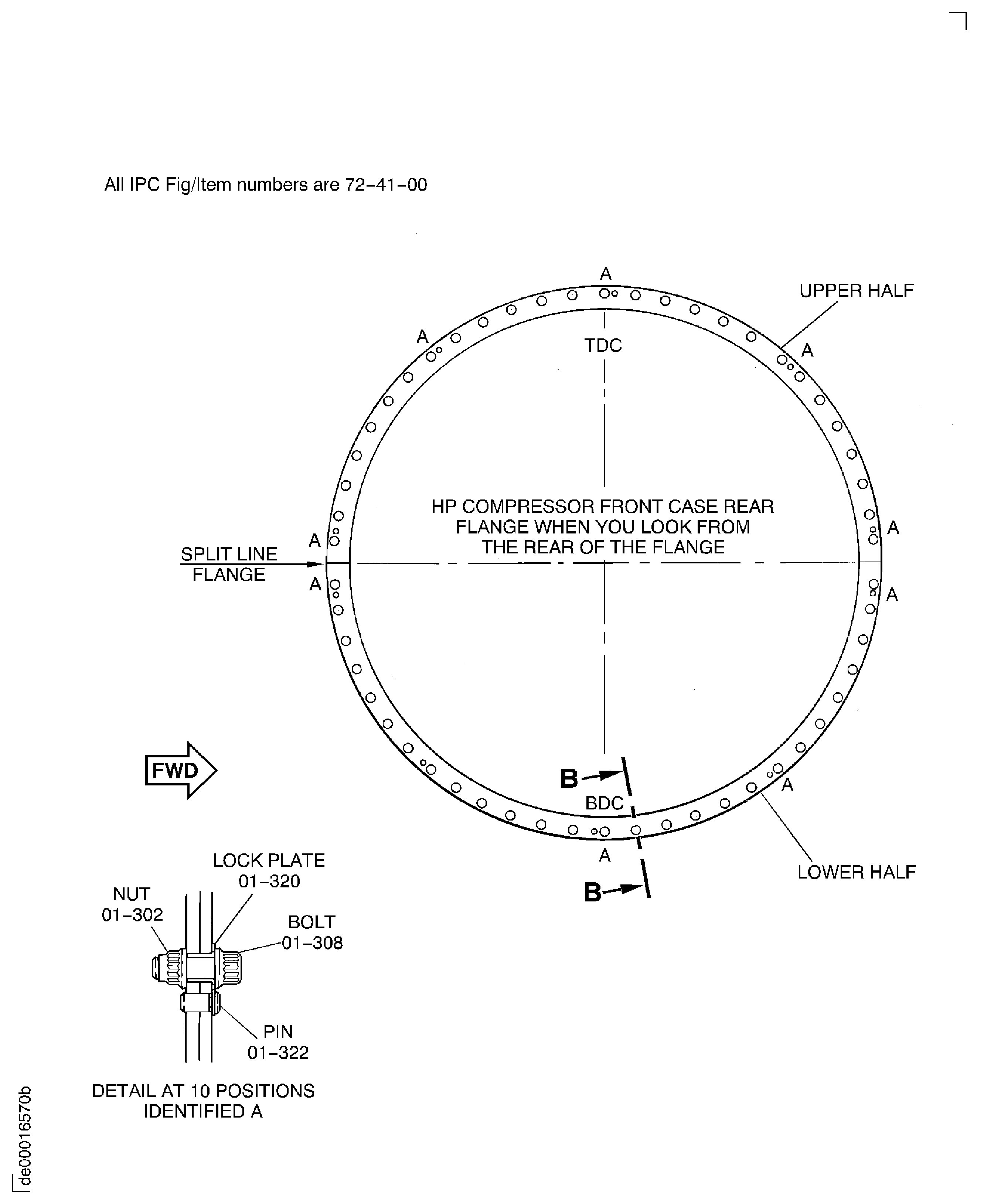

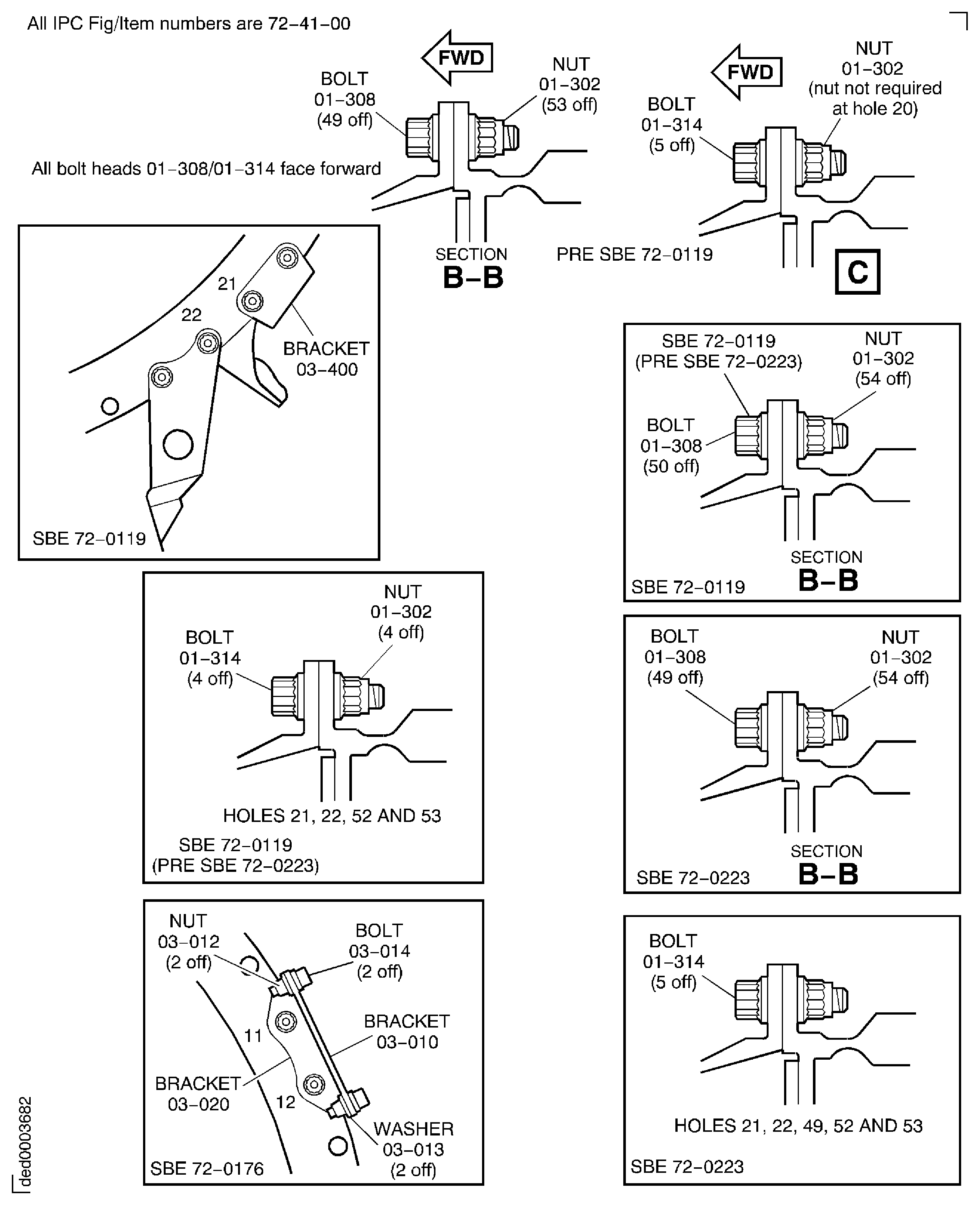

Install the 10 pins HPC Assembly (72-41-00, 01-322) and the 10 lock plates HPC Assembly (72-41-00, 01-320) together with 10 bolts HPC Assembly (72-41-00, 01-308) and the 10 nuts HPC Assembly (72-41-00, 01-302). Lightly tighten the nuts at the positions A.

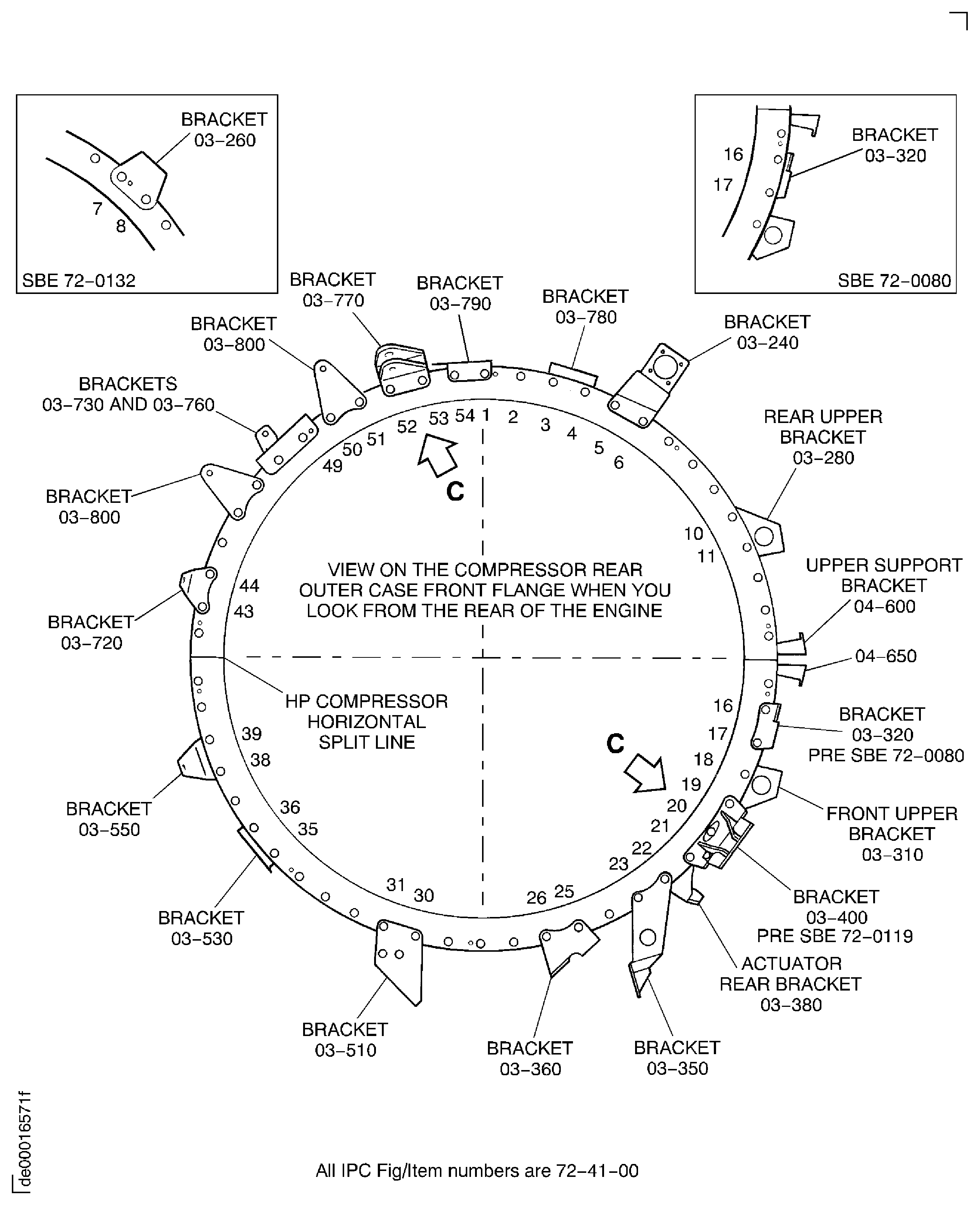

Install the two bolts HPC Assembly (72-41-00, 01-308) and the two nuts HPC Assembly (72-41-00, 01-302) to attach the bracket to the flange.

Install the bracket HPC Assembly (72-41-00, 03-780).

Install the two bolts HPC Assembly (72-41-00, 01-308) and the two nuts HPC Assembly (72-41-00, 01-302) to attach the bracket to the flange.

Install the bracket HPC Assembly (72-41-00, 03-240).

Install the two bolts HPC Assembly (72-41-00, 01-308) and the two nuts HPC Assembly (72-41-00, 01-302) to attach the bracket to the flange.

SBE 72-0132: Install the bracket HPC Assembly (72-41-00,03-260).

Install the two bolts HPC Assembly (72-41-00, 01-308) and the two nuts HPC Assembly (72-41-00, 01-302) to attach the bracket to the flange.

Install the rear upper bracket HPC Assembly (72-41-00, 03-280).

Apply CoMat 08-013 COLD CURING SILICONE COMPOUND to the identification plate HPC Assembly (72-41-00,03-010) and bond the plate to the bracket HPC Assembly (72-41-00,03-020). Refer to the SPM TASK 70-36-02-360-501, SUBTASK 70-36-02-360-020.

Attach the plate to the bracket with the two bolts HPC Assembly (72-41-00,03-014) the two washers HPC Assembly (72-41-00,03-013) and the two nuts HPC Assembly (72-41-00,03-012). Torque tighten the bolts 36 to 45 lbfin (4 to 5 Nm.).

NOTE

The bolt and nut at position 11 was installed during installation of bracket HPC Assembly (72-41-00,03-280).Install the two bolts HPC Assembly (72-41-00,01-308) and the two nuts HPC Assembly (72-41-00,01-302) to attach the assembly the the flange rear face.

SBE 72-0176: Install the HP system module serial number identification plate and bracket.

Pre SBE 72-0080: Put the bracket into position on the compressor rear outer case front flange at the bolt positions 16 and 17.

SBE 72-0080: Put the bracket into position on the HP compressor front case rear flange at the bolt positions 16 and 17.

Install the two bolts HPC Assembly (72-41-00, 01-308) and the two nuts HPC Assembly (72-41-00, 01-302) to attach the bracket to the flange.

Install the bracket HPC Assembly (72-41-00, 03-320).

Install the bolt HPC Assembly (72-41-00, 01-308) and the nut HPC Assembly (72-41-00, 01-302) at the bolt position 18.

Install the front upper bracket HPC Assembly (72-41-00, 03-310).

Install the bolt HPC Assembly (72-41-00, 01-308) and the nut HPC Assembly (72-41-00, 01-302) at the position 19. Install the bolt HPC Assembly (72-41-00, 01-308) at the bolt position 20.

Pre SBE 72-0119: Install the bracket HPC Assembly (72-41-00, 03-400).

Install the bolt HPC Assembly (72-41-00, 01-308) and the nut HPC Assembly (72-41-00, 01-302) at the position 20.

SBE 72-0119: Install the bracket HPC Assembly (72-41-00, 03-400).

Install the bolt HPC Assembly (72-41-00, 01-314) and the nut HPC Assembly (72-41-00, 01-302) at the position 21.

Install the actuator rear bracket HPC Assembly (72-41-00, 03-380).

Install the bolt HPC Assembly (72-41-00, 01-314) and the nut HPC Assembly (72-41-00, 01-302) at the bolt position 22. Install the bolt HPC Assembly (72-41-00, 01-308) and the nut HPC Assembly (72-41-00, 01-302) at the bolt position 23.

Install the bracket HPC Assembly (72-41-00, 03-350).

Install the two bolts HPC Assembly (72-41-00, 01-308) and the two nuts HPC Assembly (72-41-00, 01-302) to attach the bracket to the flange.

Install the bracket HPC Assembly (72-41-00, 03-360).

Install the two bolts HPC Assembly (72-41-00, 01-308) and the two nuts HPC Assembly (72-41-00, 01-302) to attach the bracket to the flange.

Install the bracket HPC Assembly (72-41-00, 03-510).

Install the two bolts HPC Assembly (72-41-00, 01-308) and the two nuts HPC Assembly (72-41-00, 01-302) to attach the bracket to the flange.

Install the bracket HPC Assembly (72-41-00, 03-530).

Install the two bolts HPC Assembly (72-41-00, 01-308) and the two nuts HPC Assembly (72-41-00, 01-302) to attach the bracket to the flange.

Install the bracket HPC Assembly (72-41-00, 03-550).

Install the two bolts HPC Assembly (72-41-00, 01-308) and the two nuts HPC Assembly (72-41-00, 01-302) to attach the bracket to the flange.

Install the bracket HPC Assembly (72-41-00, 03-720).

Install the two bolts HPC Assembly (72-41-00, 01-308) and the two nuts HPC Assembly (72-41-00, 01-302) to attach the bracket to the flange.

Install the bracket HPC Assembly (72-41-00, 03-800).

Put the two brackets into position on the compressor rear outer case front flange at the bolt holes 48 and 49. Bracket HPC Assembly (72-41-00, 03-760) goes on the rear of the flange.

Install the two bolts HPC Assembly (72-41-00, 01-308) and the two nuts HPC Assembly (72-41-00, 01-302) to attach the brackets to the flange.

Pre SBE 72-0223: Install the bracket HPC Assembly (72-41-00, 03-730 and HPC Assembly03-760).

Put the two brackets into position on the compressor rear outer case front flange at the bolt holes 48 and 49. Bracket HPC Assembly (72-41-00, 03-760) goes on the rear of the flange.

Install the bolt HPC Assembly (72-41-00, 01-308) and the nut HPC Assembly (72-41-00, 01-302) at the bolt position 48 and the bolt HPC Assembly (72-41-00,01-314) and the nut HPC Assembly (72-41-00,01-302) at the bolt position 49 to attach the brackets to the flange.

SBE 72-0223: Install the bracket HPC Assembly (72-41-00, 03-730 and HPC Assembly 03-760).

Install the two bolts HPC Assembly (72-41-00, 01-308) and the two nuts HPC Assembly (72-41-00, 01-302) to attach the bracket to the flange.

Install the bracket HPC Assembly (72-41-00, 03-800).

Install the two bolts HPC Assembly (72-41-00, 01-314) and the two nuts HPC Assembly (72-41-00, 01-302) to attach the bracket to the flange.

Install the bracket HPC Assembly (72-41-00, 03-770).

Install the two bolts HPC Assembly (72-41-00, 01-308) and the two nuts HPC Assembly (72-41-00, 01-302) to attach the bracket to the flange.

Install the bracket HPC Assembly (72-41-00, 03-790).

Install the remaining bolts HPC Assembly (72-41-00, 01-308) and the nuts HPC Assembly (72-41-00, 01-302) at the remaining bolt holes. Refer to Figure.

Pre SBE 72-0119: Torque the 53 nuts to 180 to 220 lbfin (20.00 to 25.00 Nm).

SBE 72-0119: Torque the 54 nuts to 180 to 220 lbfin (20.00 to 25.00 Nm).

Remove the IAE 1R18220 Holding fixture 1 off.

SUBTASK 72-41-00-440-070 Install the HP Compressor Front Case Rear Flange Attach Parts (Pre SBE 72-0080, Pre SBE 72-0119, Pre SBE 72-0132, Pre SBE 72-0223, SBE 72-0080, SBE 72-0119, SBE 72-0132, SBE 72-0176 and SBE 72-0223)

SBE 72-0080: HP compressor - Replace a bracket at flange FJ

SBE 72-0119: HP system module - Provide new brackets and clamping at flange K and a new fuel flow divider valve brackets

SBE 72-0132: LP compressor - Removal of stage 6 buffer air system

SBE 72-0176: HP compressor - Introduction of an HP system module serial number identification plate and bracket

SBE 72-0223: Securing features - HP compressor cases - increased bolt lengths

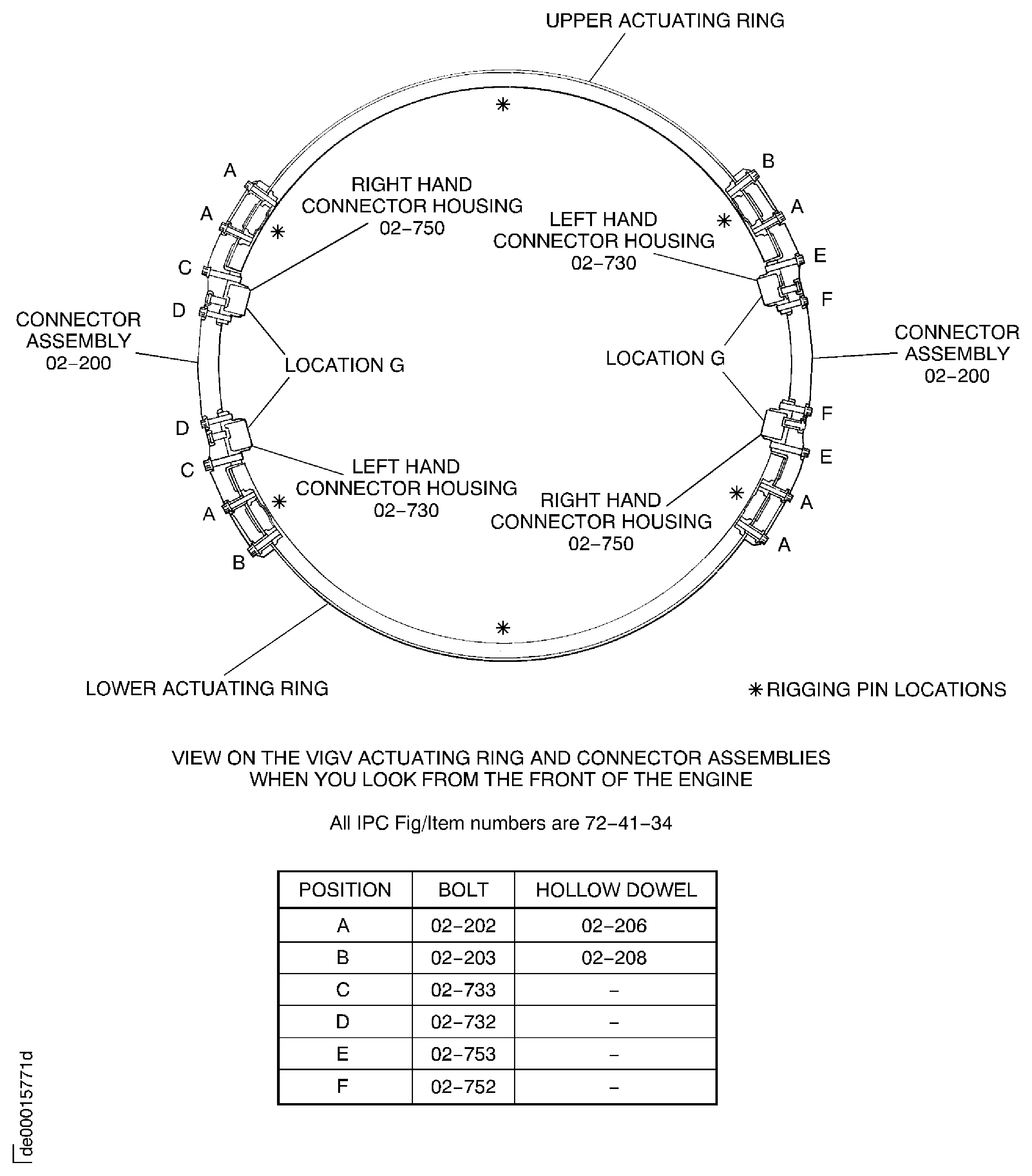

Install IAE 1R18423 Rigging pin 4 off or IAE 1R18892 Rigging pin 4 off and IAE 1R18248 Rigging pin 2 off or IAE 1R18638 Rigging pin 2 off into the upper and lower actuating rings (HPC Variable Stator Vane Actuation System (72-41-34,02-440) and HPC Variable Stator Vane Actuation System (72-41-34,02-540)). Install three rigging pins in each half of the actuating ring.

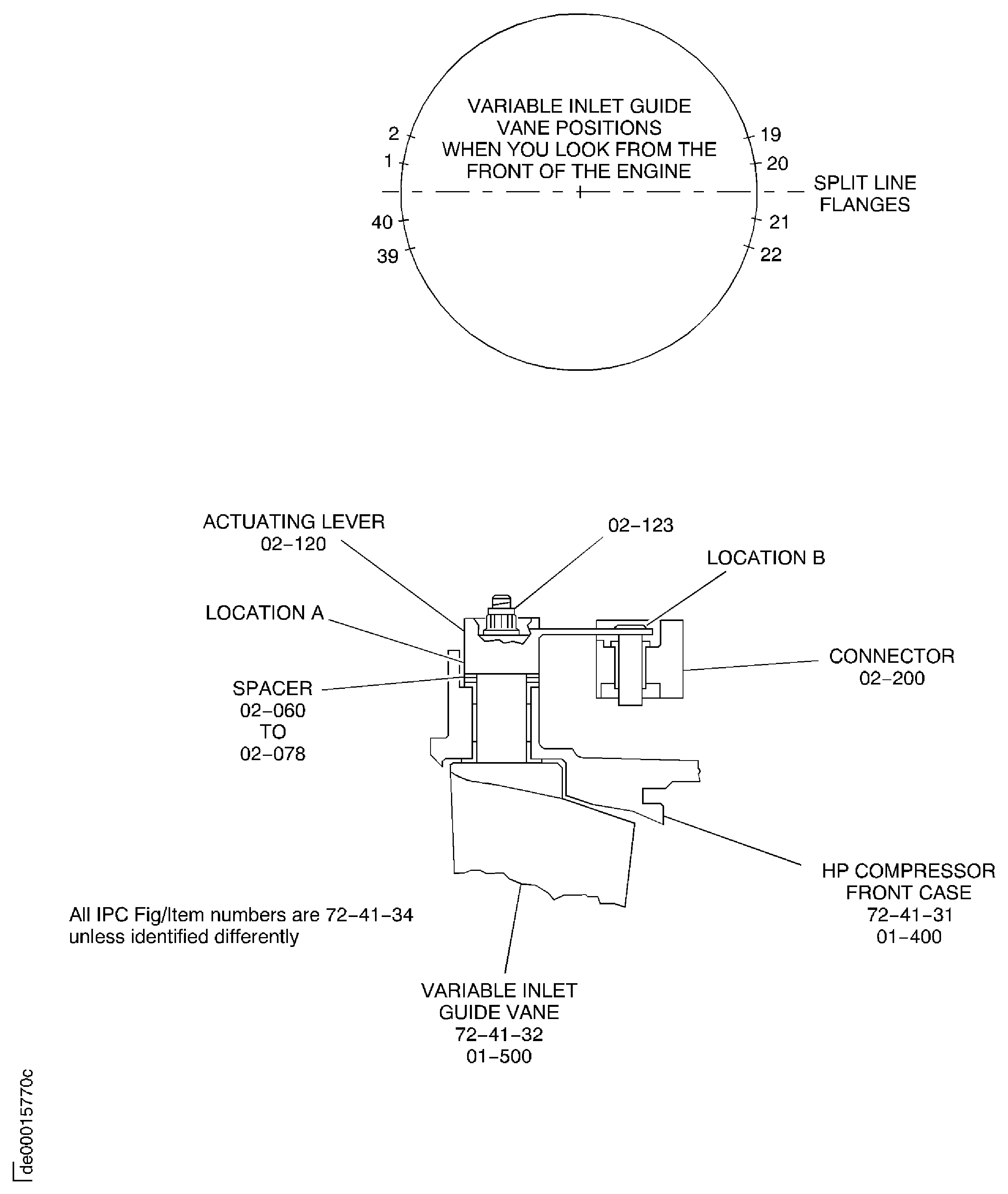

Remove the four nuts HPC Variable Stator Vane Actuation System (72-41-34,02-123) and the four actuating levers HPC Variable Stator Vane Actuation System (72-41-34,02-120) from the inlet guide vanes at the positions 1, 2, 39 and 40.

Pre SBE 72-0385 or SBE 72-0416: Install the three hollow dowels HPC Variable Stator Vane Actuation System (72-41-34,02-206) and the three bolts HPC Variable Stator Vane Actuation System (72-41-34,02-202), which attach the left hand VIGV connector to the upper and lower actuating rings. Torque the bolts to 85 to 105 lbfin (10.00 to 12.00 Nm).

SBE 72-0385: Install the three bolts HPC Variable Stator Vane Actuation System (72-41-34,02-202), which attach the left hand VIGV connector to the upper and lower actuating rings. Torque the bolts to 85 to 105 lbfin (10.00 to 12.00 Nm).

SBE 72-0416: Install the three bolts HPC Variable Stator Vane Actuation System (72-41-34,02-202) and the three washers HPC Variable Stator Vane Actuation System (72-41-34,02-205), which attach the left hand VIGV connector to the upper and lower actuating rings. Torque the bolts to 85 to 105 lbfin (10.00 to 12.00 Nm).

Pre SBE 72-0385 or SBE 72-0416: Install the hollow dowel HPC Variable Stator Vane Actuation System (72-41-34,02-208) and the bolt HPC Variable Stator Vane Actuation System (72-41-34,02-203), which attach the left hand VIGV connector to the lower actuating ring. Torque the bolt to 180 to 220 lbfin (20 to 25 Nm). Safety the bolt with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT or CoMat 02-126 LOCKWIRE.

SBE 72-0385: Install the bolt HPC Variable Stator Vane Actuation System (72-41-34,02-203), which attach the left hand VIGV connector to the lower actuating ring. Torque the bolt to 180 to 220 lbfin (20 to 25 Nm). Safety the bolt with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT or CoMat 02-126 LOCKWIRE.

SBE 72-0416: Install the bolt HPC Variable Stator Vane Actuation System (72-41-34,02-203) and the washer HPC Variable Stator Vane Actuation System (72-41-34,02-207) which attach the left hand VIGV connector to the lower actuating ring. Torque the bolt to 180 to 220 lbfin (20 to 25 Nm). Safety the bolt with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT or CoMat 02-126 LOCKWIRE.

Install the variable inlet guide vane connectors HPC Variable Stator Vane Actuation System (72-41-34,02-200).

SUBTASK 72-41-00-440-072-A00 Install the Variable Inlet Guide Vane Connectors (Pre SBE 72-0402, Pre SBE 72-0385 or SBE 72-0416 and SBE 72-0385 or SBE 72-0416)

NOTE

The following SUBTASK references are in TASK 72-41-30-440-011-A00.During the assembly procedure lubricate the applicable areas of the VSV mechanism for each stage with a thin layer of 10-108 teflon based lubricant, refer to TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-440-208.

Install the build pins, refer to TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-440-206.

Follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001) and this SUBTASK.

Remove the two rigging pins adjacent to the HP compressor front case right hand split line flange.

Remove the four nuts HPC Variable Stator Vane Actuation System (72-41-34, 02-123) and the four actuating levers HPC Variable Stator Vane Actuation System (72-41-34, 02-120) from the inlet guide vanes at the positions 1, 2, 39 and 40, Figure.

Pre SBE 72-0385 or SBE 72-0416: Install the three hollow dowels HPC Variable Stator Vane Actuation System (72-41-34, 02-206) and the three bolts HPC Variable Stator Vane Actuation System (72-41-34,02-202), which attach the left hand VIGV connector to the upper and lower actuating rings. Torque the bolts to 85 to 105 lbfin (10.00 to 12.00 Nm).

SBE 72-0385: Install the three bolts HPC Variable Stator Vane Actuation System (72-41-34,02-202), which attach the left hand VIGV connector to the upper and lower actuating rings. Torque the bolts to 85 to 105 lbfin (10.00 to 12.00 Nm).

SBE 72-0416: Install the three bolts HPC Variable Stator Vane Actuation System (72-41-34,02-202) and the three washers (72-41-34, 02-205), which attach the left hand VIGV connector to the upper and lower actuating rings. Torque the bolts to 85 to 105 lbfin (10.00 to 12.00 Nm).

Pre SBE 72-0385 or SBE 72-0416: Install the hollow dowel HPC Variable Stator Vane Actuation System (72-41-34, 02-208) and the bolt HPC Variable Stator Vane Actuation System (72-41-34, 02-203), which attach the left hand VIGV connector to the lower actuating ring. Torque the bolt to 180 to 220 lbfin (20 to 25 Nm). Safety the bolt with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT or CoMat 02-126 LOCKWIRE.

SBE 72-0385: Install the bolt HPC Variable Stator Vane Actuation System (72-41-34, 02-203), which attach the left hand VIGV connector to the lower actuating ring. Torque the bolt to 180 to 220 lbfin (20 to 25 Nm). Safety the bolt with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT or CoMat 02-126 LOCKWIRE.

SBE 72-0416: Install the bolt HPC Variable Stator Vane Actuation System (72-41-34, 02-203) and the washer HPC Variable Stator Vane Actuation System (72-41-34, 02-207) which attach the left hand VIGV connector to the lower actuating ring. Torque the bolt to 180 to 220 lbfin (20 to 25 Nm). Safety the bolt with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT or CoMat 02-126 LOCKWIRE.

Pre SBE 72-0385 or SBE 72-0416: After the installation of the connectors make sure that the dowels are correctly installed, refer to TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-220-445.

Install the variable inlet guide vane connectors HPC Variable Stator Vane Actuation System (72-41-34, 02-200).

SUBTASK 72-41-00-440-072-B00 Install the Variable Inlet Guide Vane Connectors (SBE 72-0402, Pre SBE 72-0385 or SBE 72-0416 and SBE 72-0385 or SBE 72-0416)

SBE 72-0402: HP compressor variable vanes - inlet guide vane and stages 3 to 6 with optimised build and setting instructions.

SBE 72-0385 or SBE 72-0416: Introduction of revised actuation ring connectors and unison ring assemblies.

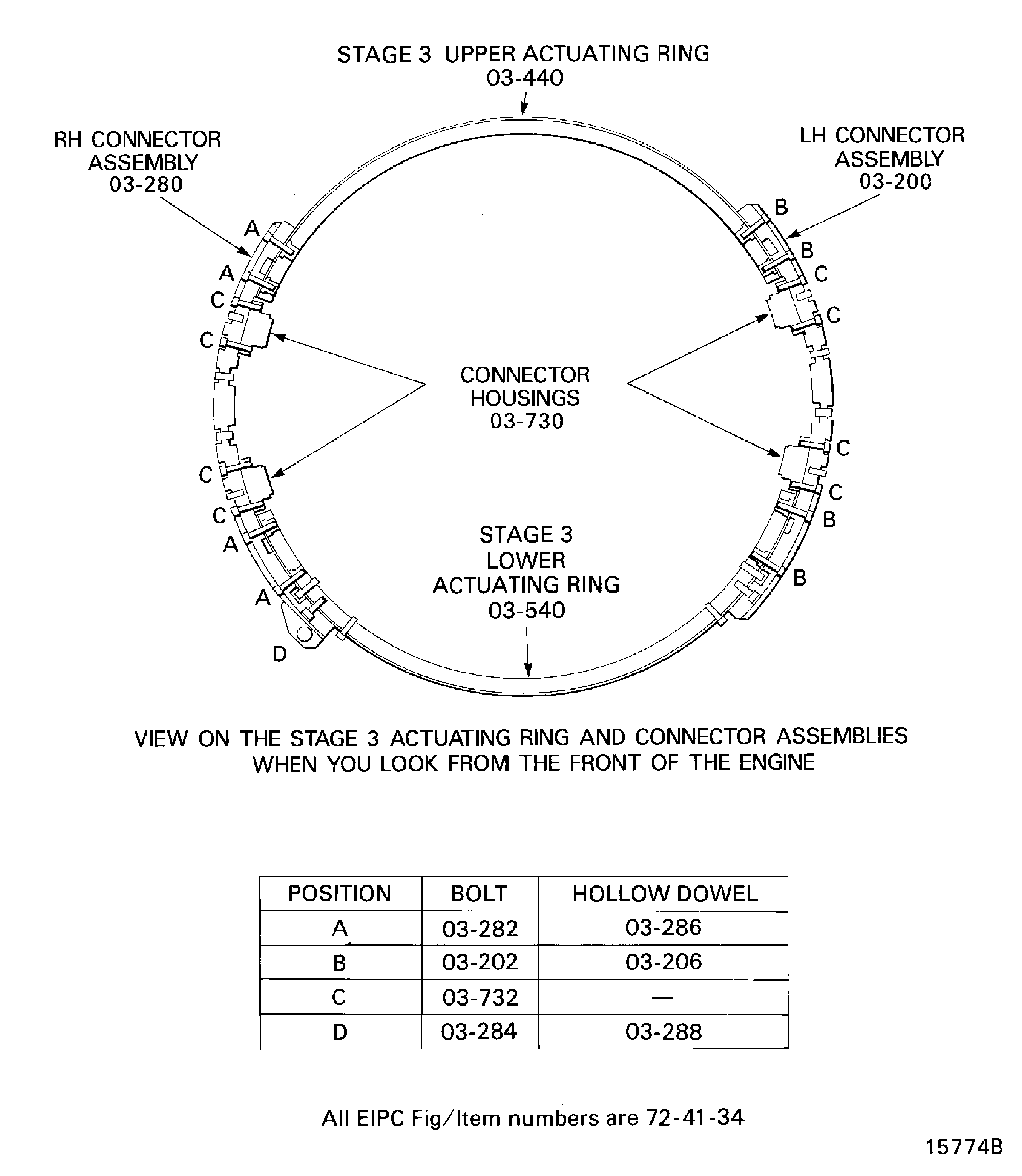

Install IAE 1R18423 Rigging pin 6 off or IAE 1R18893 Riggingpin 6 off into the upper and lower actuating rings (HPC Variable Stator Vane Actuation System (72-41-34,03-440) and HPC Variable Stator Vane Actuation System (72-41-34,03-540)).

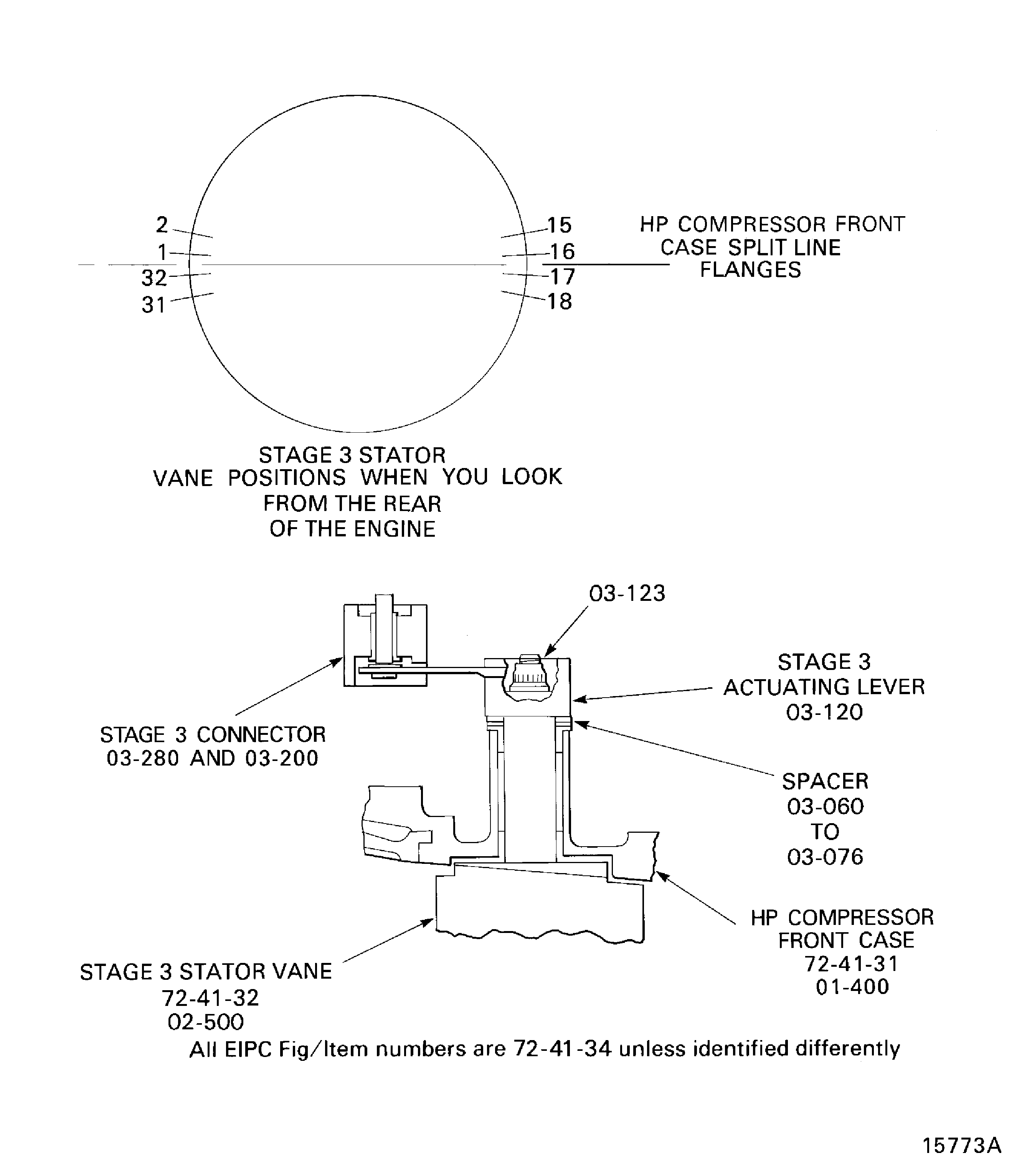

Put the right hand connectors HPC Variable Stator Vane Actuation System (72-41-34,03-280) in to position on the upper and lower actuating rings adjacent to the stator vanes at the positions 1, 2, 31 and 32. Engage the connector on the pins of the stator vanes actuating levers. Make sure the actuating levers pins are correctly engaged in the connector.

Pre SBE 72-0385 or SBE 72-0416: Install the four hollow dowels HPC Variable Stator Vane Actuation System (72-41-34,03-286) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34,03-282) which attach the RH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

SBE 72-0385: Install the four bolts HPC Variable Stator Vane Actuation System (72-41-34,03-282) which attach the RH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

SBE 72-0416: Install the four bolts HPC Variable Stator Vane Actuation System (72-41-34,03-282) and the four washers HPC Variable Stator Vane Actuation System (72-41-34,03-285) which attach the RH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

Pre SBE 72-0385 or SBE 72-0416: Install the bolt HPC Variable Stator Vane Actuation System (72-41-34,03-284) and dowel HPC Variable Stator Vane Actuation System (72-41-34,03-288) which attaches the RH stage 3 connector to the stator vane lower actuating rings.

SBE 72-0385 or SBE 72-0416: Install the bolt HPC Variable Stator Vane Actuation System (72-41-34,03-284) and washer HPC Variable Stator Vane Actuation System (72-41-34,03-287) which attaches the RH stage 3 connector to the stator vane lower actuating rings.

Install the left hand connector HPC Variable Stator Vane Actuation System (72-41-34,03-200) as given in steps below on to the actuating rings adjacent to the stage 3 stator vanes at the positions 15 to 18.

Pre SBE 72-0385 or SBE 72-0416: Install the four hollow dowels HPC Variable Stator Vane Actuation System (72-41-34,03-206) and four bolts HPC Variable Stator Vane Actuation System (72-41-34,03-202) which attach the LH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

SBE 72-0385: Install the four bolts HPC Variable Stator Vane Actuation System (72-41-34,03-202) which attach the LH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

SBE 72-0416: Install the four bolts HPC Variable Stator Vane Actuation System (72-41-34,03-202) and the four washers HPC Variable Stator Vane Actuation System (72-41-34,03-205) which attach the LH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

Install the two connectors (HPC Variable Stator Vane Actuation System (72-41-34,03-280) and HPC Variable Stator Vane Actuation System (72-41-34,03-200)).

SUBTASK 72-41-00-440-073-A00 Install the Stage 3 Actuating Ring Connectors (Pre SBE 72-0402, Pre SBE 72-0385 or SBE 72-0416 and SBE 72-0385 or SBE 72-0416)

NOTE

The following SUBTASK references are in TASK 72-41-30-440-011-A00.During the assembly procedure lubricate the applicable areas of the VSV mechanism for each stage with a thin layer of 10-108 teflon based lubricant, refer to TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-440-208.

Install the build pins, refer to TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-440-206.

Follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001) and this SUBTASK.

Put the right hand connectors HPC Variable Stator Vane Actuation System (72-41-34, 03-280) in to position on the upper and lower actuating rings adjacent to the stator vanes at the positions 1, 2, 31 and 32. Engage the connector on the pins of the stator vanes actuating levers. Make sure the actuating levers pins are correctly engaged in the connector.

Pre SBE 72-0385 or SBE 72-0416: Install the four hollow dowels HPC Variable Stator Vane Actuation System (72-41-34, 03-286) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34, 03-282). These attach the connector to the actuating rings.

SBE 72-0385: Install the four bolts HPC Variable Stator Vane Actuation System (72-41-34, 03-282) which attach the RH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

SBE 72-0416: Install the four bolts HPC Variable Stator Vane Actuation System (72-41-34, 03-282) and the four washers HPC Variable Stator Vane Actuation System (72-41-34, 03-285) which attach the RH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

Pre SBE 72-0385 or SBE 72-0416: Install the bolt HPC Variable Stator Vane Actuation System (72-41-34, 03-284) and dowel HPC Variable Stator Vane Actuation System (72-41-34, 03-288) which attaches the RH stage 3 connector to the stator vane lower actuating rings.

SBE 72-0385 or SBE 72-0416: Install the bolt HPC Variable Stator Vane Actuation System (72-41-34, 03-284) and washer HPC Variable Stator Vane Actuation System (72-41-34, 03-287) which attaches the RH stage 3 connector to the stator vane lower actuating rings.

Install the left hand connector HPC Variable Stator Vane Actuation System (72-41-34, 03-200) as given in steps below on to the actuating rings adjacent to the stage 3 stator vanes at the positions 15 to 18.

Pre SBE 72-0385 or SBE 72-0416: Install the four hollow dowels HPC Variable Stator Vane Actuation System (72-41-34,03-206) and four bolts HPC Variable Stator Vane Actuation System (72-41-34,03-202) which attach the LH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

SBE 72-0385: Install the four bolts HPC Variable Stator Vane Actuation System (72-41-34,03-202) which attach the LH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

SBE 72-0416: Install the four bolts HPC Variable Stator Vane Actuation System (72-41-34,03-202) and the four washers HPC Variable Stator Vane Actuation System (72-41-34, 03-205) which attach the LH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

Pre SBE 72-0385 or SBE 72-0416: After the installation of the connectors make sure that the dowels are correctly installed, refer to SUBTASK 72-41-30-220-445.

Install the two connectors HPC Variable Stator Vane Actuation System (72-41-34, 03-280) and HPC Variable Stator Vane Actuation System (72-41-34, 03-200).

SUBTASK 72-41-00-440-073-B00 Install the Stage 3 Actuating Ring Connectors (SBE 72-0402, Pre SBE 72-0385 or SBE 72-0416 and SBE 72-0385 or SBE 72-0416)

SBE 72-0402: HP compressor variable vanes - inlet guide vane and stages 3 to 6 with optimised build and setting instructions.

SBE 72-0385 or SBE 72-0416: Introduction of revised actuation ring connectors and unison ring assemblies.

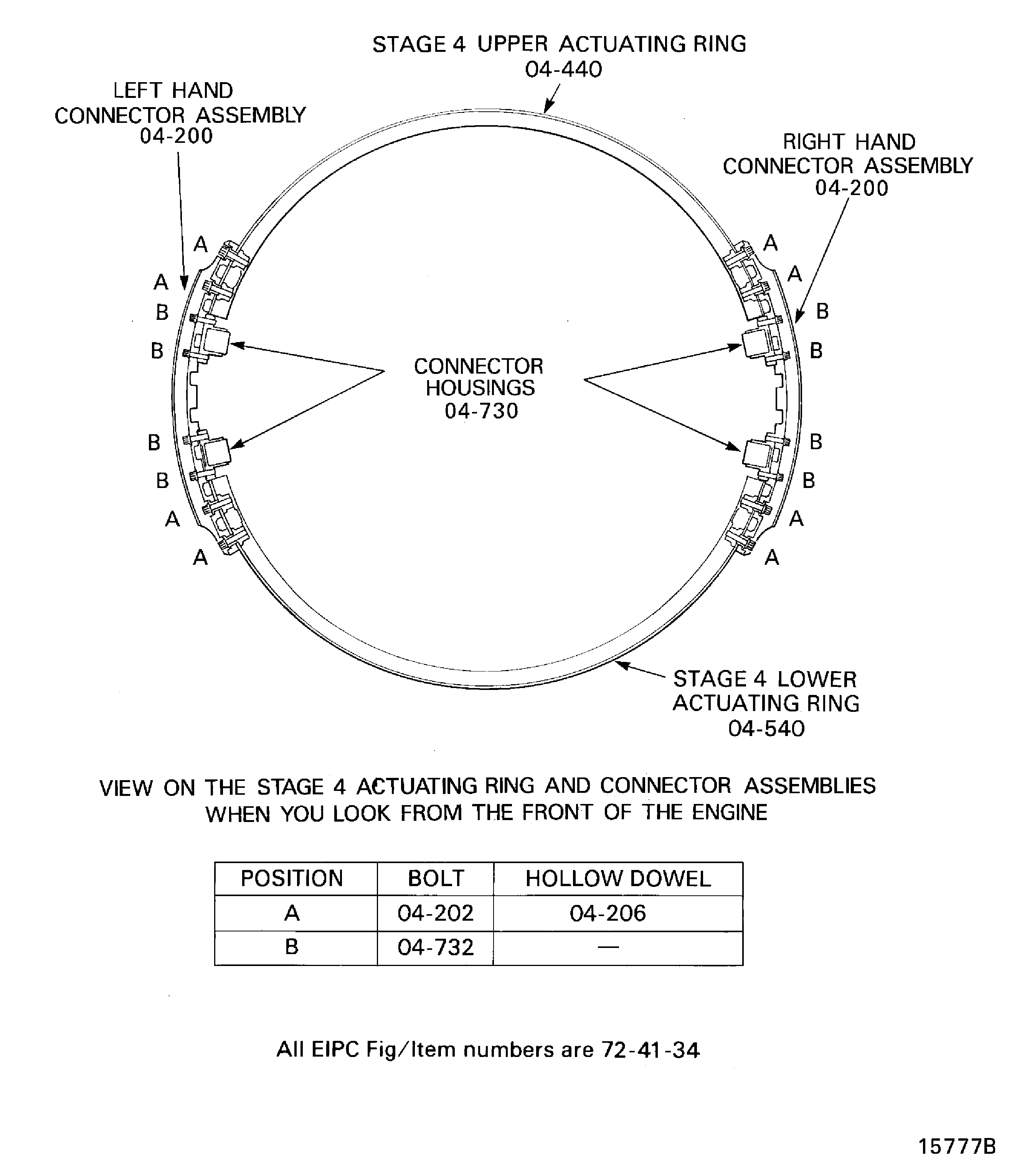

Install IAE 1R18423 Rigging pin 6 off or IAE 1R18894 Rigging pin 6 off into the upper and lower actuating rings (HPC Variable Stator Vane Actuation System (72-41-34,04-440) and HPC Variable Stator Vane Actuation System (72-41-34,04-540)).

Pre SBE 72-0348: Install the four hollow dowels HPC Variable Stator Vane Actuation System (72-41-34,04-206) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34,04-202), which attach the right hand stage 4 connector and connector housings to the stage 4 upper and lower actuating rings.

SBE 72-0348: Install the four washers HPC Variable Stator Vane Actuation System (72-41-34,04-204) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34,04-202), which attach the right hand stage 4 connector and connector housings to the stage 4 upper and lower actuating rings.

Pre SBE 72-0385 or SBE 72-0416: Install the four washers HPC Variable Stator Vane Actuation System (72-41-34,04-204) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34,04-202), which attach the right hand stage 4 connector and connector housings to the stage 4 upper and lower actuating rings.

SBE 72-0385 or SBE 72-0416: Install the two washers HPC Variable Stator Vane Actuation System (72-41-34,04-204) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34,04-202), which attach the right hand stage 4 connector and connector housings to the stage 4 upper and lower actuating rings.

Install the two connectors HPC Variable Stator Vane Actuation System (72-41-34,04-200).

SUBTASK 72-41-00-440-074-A00 Install the Stage 4 Actuating Ring Connectors (Pre SBE 72-0402, Pre SBE 72-0348, Pre SBE 72-0385 or SBE 72-0416, SBE 72-0348 and SBE 72-0385 or SBE 72-0416)

NOTE

The following SUBTASK references are in TASK 72-41-30-440-011-A00.During the assembly procedure lubricate the applicable areas of the VSV mechanism for each stage with a thin layer of 10-108 teflon based lubricant, refer to TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-440-208.

Install the build pins, refer to TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-440-206.

Follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001) and this SUBTASK.

Pre SBE 72-0348: Install the four hollow dowels HPC Variable Stator Vane Actuation System (72-41-34, 04-206) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34, 04-202), which attach the right hand stage 4 connector and connector housings to the stage 4 upper and lower actuating rings.

SBE 72-0348: Install the four washers HPC Variable Stator Vane Actuation System (72-41-34, 04-204) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34, 04-202), which attach the right hand stage 4 connector and connector housings to the stage 4 upper and lower actuating rings.

Pre SBE 72-0385 or SBE 72-0416: Install the four washers HPC Variable Stator Vane Actuation System (72-41-34, 04-204) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34, 04-202), which attach the right hand stage 4 connector and connector housings to the stage 4 upper and lower actuating rings.

SBE 72-0385 or SBE 72-0416: Install the two washers HPC Variable Stator Vane Actuation System (72-41-34, 04-204) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34, 04-202), which attach the right hand stage 4 connector and connector housings to the stage 4 upper and lower actuating rings.

Pre SBE 72-0385 or SBE 72-0416: After the installation of the connectors make sure that the dowels are correctly installed, refer to TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-220-445.

Install the two connectors HPC Variable Stator Vane Actuation System (72-41-34, 04-200).

SUBTASK 72-41-00-440-074-B00 Install the Stage 4 Actuating Ring Connectors (SBE 72-0402, Pre SBE 72-0348, Pre SBE 72-0385 or SBE 72-0416, SBE 72-0348 and SBE 72-0385 or SBE 72-0416)

SBE 72-0348: Introduction of revised actuation ring connectors.

SBE 72-0385 or SBE 72-0416: Introduction of revised actuation ring connectors and unison ring assemblies.

SBE 72-0402: HP compressor variable vanes - inlet guide vane and stages 3 to 6 with optimised build and setting instructions.

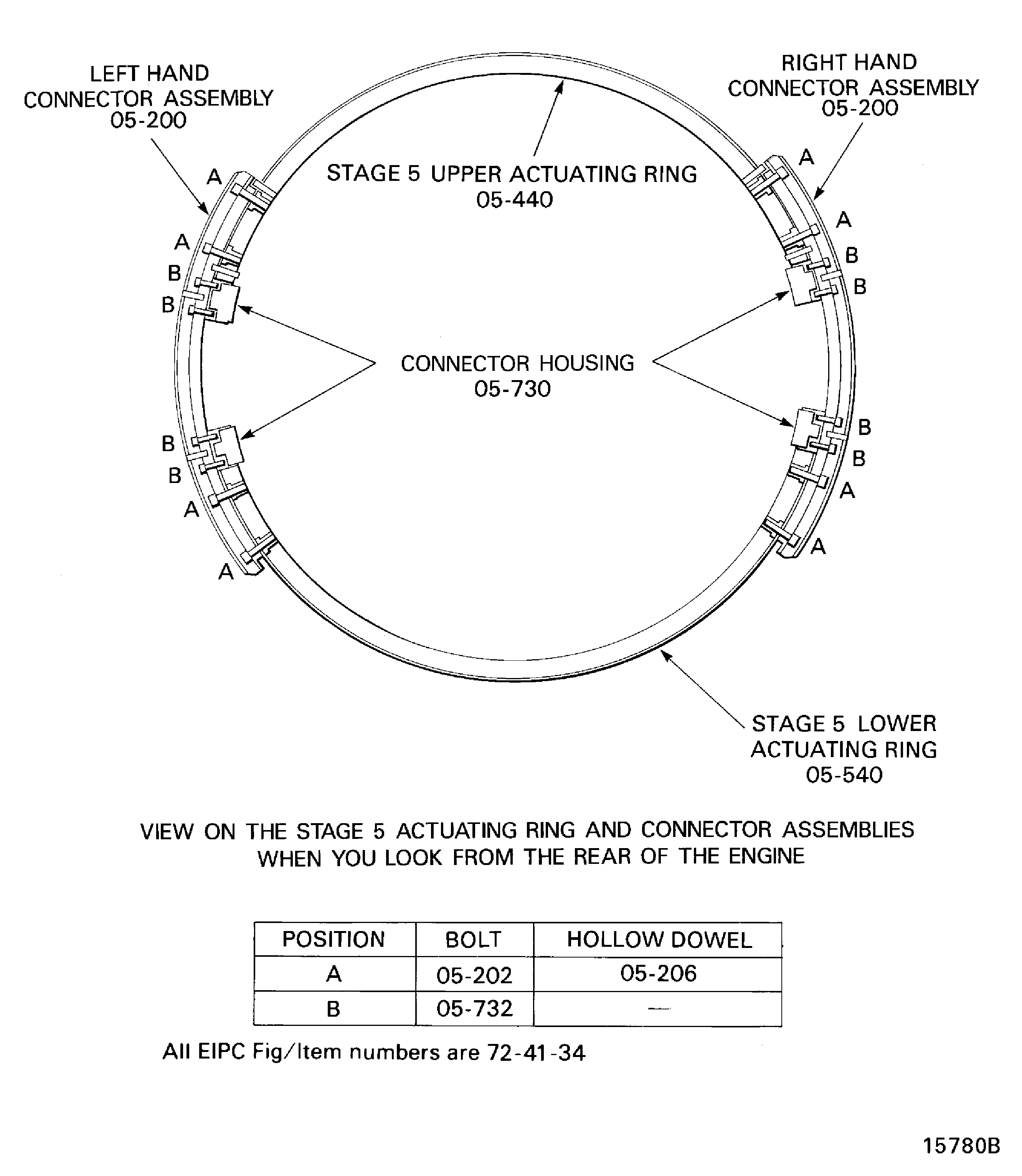

Install IAE 1R18423 Rigging pin rigging pin 6 off or IAE 1R18895 Rigging pin rigging pin 6 off into the stage 5 upper and lower actuating rings (HPC Variable Stator Vane Actuation System (72-41-34,05-440) and HPC Variable Stator Vane Actuation System (72-41-34,05-540)).

Pre SBE 72-0348: Install the four hollow dowels HPC Variable Stator Vane Actuation System (72-41-34,05-206) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34,05-202), which attach the right hand stage 5 connector and connector housings to the stage 5 upper and lower actuating ring.

SBE 72-0348: Install the four washers HPC Variable Stator Vane Actuation System (72-41-34,05-204) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34,05-202), which attach the right hand stage 5 connector and connector housings to the stage 5 upper and lower actuating ring.

Pre SBE 72-0385 or SBE 72-0416: Install the four washers HPC Variable Stator Vane Actuation System (72-41-34,05-204) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34,05-202), which attach the right hand stage 5 connector and connector housings to the stage 5 upper and lower actuating ring.

SBE 72-0385 or SBE 72-0416: Install the two washers HPC Variable Stator Vane Actuation System (72-41-34,05-204) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34,05-202), which attach the right hand stage 5 connector and connector housings to the stage 5 upper and lower actuating ring.

Install the two connectors HPC Variable Stator Vane Actuation System (72-41-34,05-200).

SUBTASK 72-41-00-440-075-A00 Install the Stage 5 Actuating Ring Connectors (Pre SBE 72-0402, Pre SBE 72-0348, Pre SBE 72-0385 or SBE 72-0416, SBE 72-0348 and SBE 72-0385 or SBE 72-0416)

NOTE

The following SUBTASK references are in TASK 72-41-30-440-011-A00.During the assembly procedure lubricate the applicable areas of the VSV mechanism for each stage with a thin layer of 10-108 teflon based lubricant, refer to TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-440-208.

Install the build pins, refer to TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-440-206.

Follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001) and this SUBTASK.

Pre SBE 72-0348: Install the four hollow dowels HPC Variable Stator Vane Actuation System (72-41-34, 05-206) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34, 05-202), which attach the right hand stage 5 connector and connector housings to the stage 5 upper and lower actuating.

SBE 72-0348: Install the four washers HPC Variable Stator Vane Actuation System (72-41-34, 05-204) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34, 05-202), which attach the right hand stage 5 connector and connector housings to the stage 5 upper and lower actuating ring.

Pre SBE 72-0385 or SBE 72-0416: Install the four washers HPC Variable Stator Vane Actuation System (72-41-34, 05-204) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34, 05-202), which attach the right hand stage 5 connector and connector housings to the stage 5 upper and lower actuating ring.

SBE 72-0385 or SBE 72-0416: Install the two washers HPC Variable Stator Vane Actuation System (72-41-34, 05-204) and the four bolts HPC Variable Stator Vane Actuation System (72-41-34, 05-202), which attach the right hand stage 5 connector and connector housings to the stage 5 upper and lower actuating ring.

After the installation of the connectors make sure that the dowels are correctly installed, refer to TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-220-445.

Install the two connectors HPC Variable Stator Vane Actuation System (72-41-34, 05-200).

SUBTASK 72-41-00-440-075-B00 Install the Stage 5 Actuating Ring Connectors (SBE 72-0402, Pre SBE 72-0348, Pre SBE 72-0385 or SBE 72-0416, SBE 72-0348 and SBE 72-0385 or SBE 72-0416)

SBE 72-0402: HP compressor variable vanes - inlet guide vane and stages 3 to 6 with optimised build and setting instructions.

SBE 72-0348: Introduction of revised actuation ring connectors.

SBE 72-0385or SBE 72-0416: Introduction of revised actuation ring connectors and unison ring assemblies.

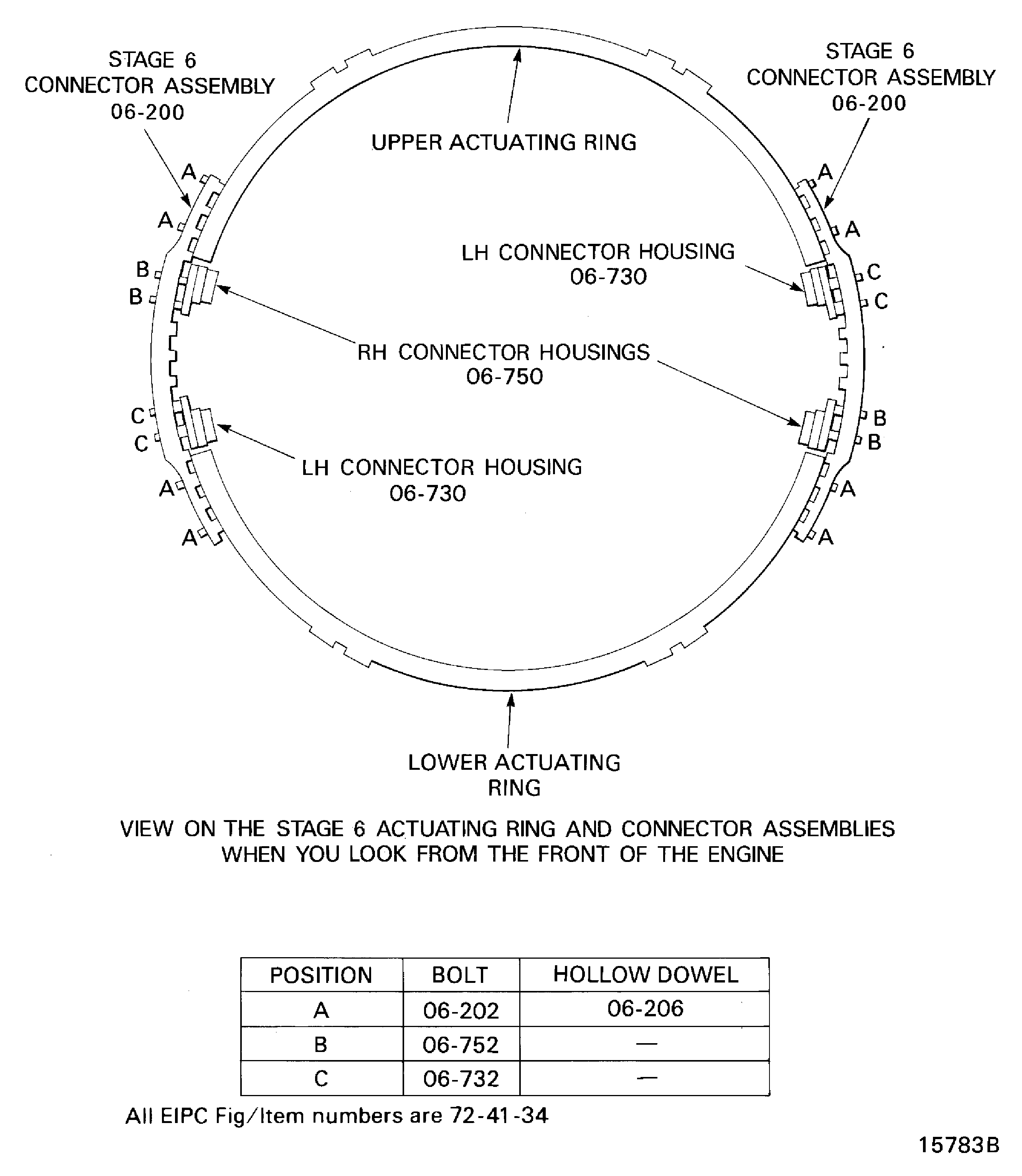

Install IAE 1R18423 Rigging pin 6 off or IAE 1R18896 Rigging pin 6 off into the upper and lower actuating rings V2500-A5-72-41-34-06A-941A-D (72-41-34,06-440) and V2500-A5-72-41-34-06A-941A-D (72-41-34,06-540).

Install the four hollow dowels V2500-A5-72-41-34-06A-941A-D (72-41-34,06-206) and the four bolts V2500-A5-72-41-34-06A-941A-D (72-41-34,06-202). These attach the connector to the actuating rings.

Install the stage 6 connectors V2500-A5-72-41-34-06A-941A-D (72-41-34,06-200).

SUBTASK 72-41-00-440-076-A00 Install the Stage 6 Actuating Ring Connectors (Pre SBE 72-0402)

NOTE

The following SUBTASK references are in TASK 72-41-30-440-011-A00.Install the build pins, refer to TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-440-206.

Follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001) and this SUBTASK.

Install the four hollow dowels V2500-A5-72-41-34-06A-941A-D (72-41-34, 06-206) and the four bolts V2500-A5-72-41-34-06A-941A-D (72-41-34, 06-202). These attach the connector to the actuating rings.

After the installation of the connectors make sure that the dowels are correctly installed, refer to TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-220-445.

Install the stage 6 connectors V2500-A5-72-41-34-06A-941A-D (72-41-34, 06-200).

SUBTASK 72-41-00-440-076-B00 Install the Stage 6 Actuating Ring Connectors (SBE 72-0402)

SBE 72-0402: HP compressor variable vanes - inlet guide vane and stages 3 to 6 with optimised build and setting instructions.

NOTE

The SUBTASK references which follow are in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001).During the clearance checking procedure it could be necessary to lubricate the applicable areas of a particular stage of the VSV mechanism. Use CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R), refer to TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-440-208.

Follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001) when specified and this SUBTASK.

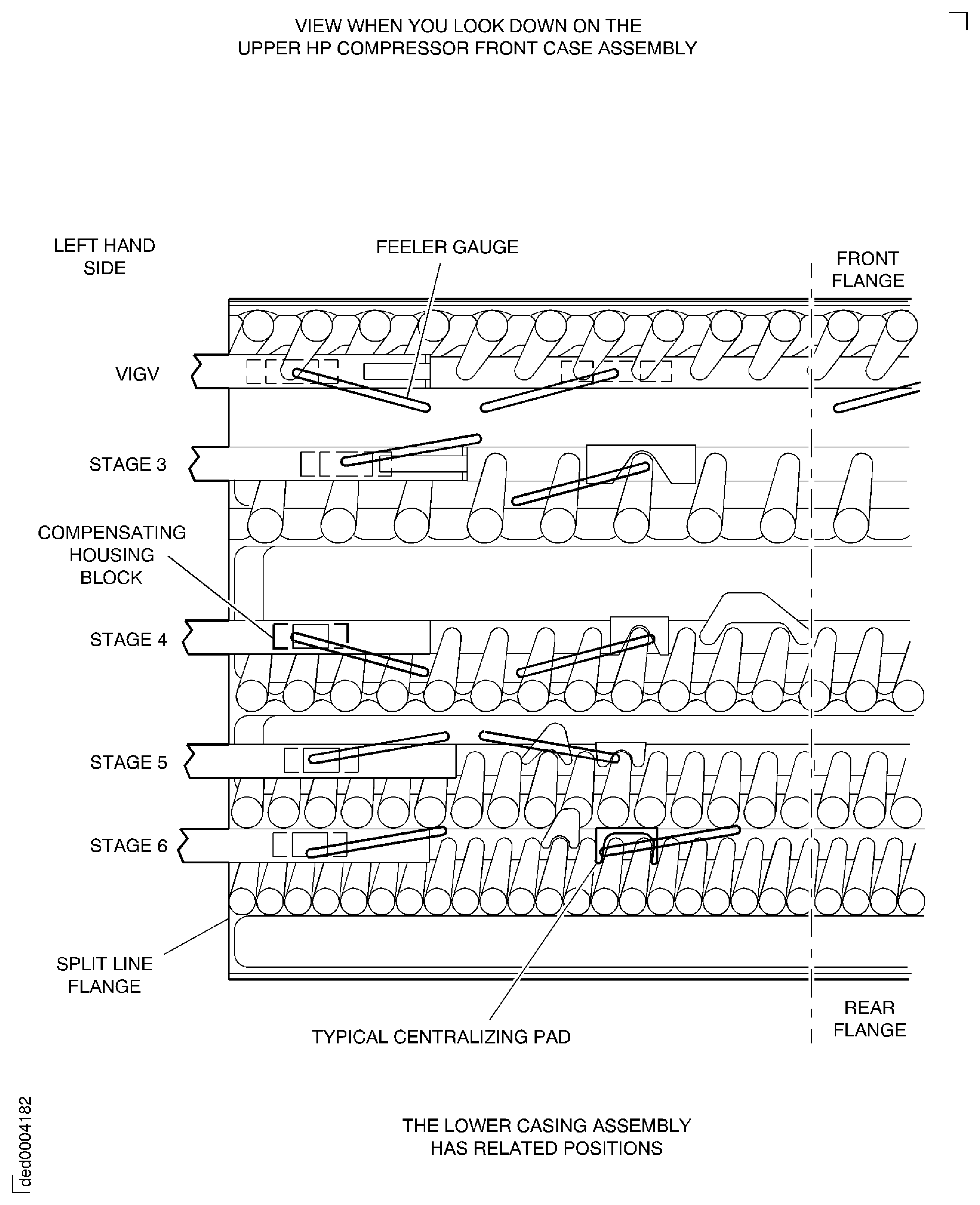

The clearances must agree with checking limits in Table 1.

Measure and make a record of the clearance and the location of each stage. During the procedure the feeler gauge(s) must stay in position as each stage is checked in turn. A clearance of zero is acceptable.

NOTE

If you check the clearance with a feeler gauge in an axial position it will give large errors.Add the eight clearances for each stage and refer to the limits below which gives the total clearance for each stage and for each maximum clearance.

NOTE

The procedure to set the pad clearances is given in TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-440-207.If the clearances for each stage are more than the limits given in the following table of limits (Table 1) then the particular connector must be removed and the actuating ring must be checked for misalignment marks. Refer to the checking procedure for the correct installation of the dowels given in TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-220-445.

If marks are seen then it could be possible to meet the limits in table 1 by re-installing the connectors and rechecking the clearances. Use the above procedure to re-check the clearances so they are within the limits of table 1.

If marks are not seen then the stage must have the pad clearances reset from the start of the procedure, that is, as given in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001).

TABLE OF LIMITS - VSV CLEARANCE CHECKING PROCEDURE

VSV SYSTEM

STAGE

MAXIMUM INDIVIDUAL CLEARANCE

MINIMUM TOTAL CLEARANCE

MAXIMUM TOTAL CLEARANCE

VIGV

0.016 in

(0.41 mm)

0.024 in

(0.61 mm)

0.042 in

(1.07 mm)

3

0.020 in

(0.51 mm)

0.032 in.

(0.81 mm)

0.050 in

(1.27 mm)

4

0.036 in.

(0.91 mm)

0.064 in

(1.63 mm)

0.082 in

(2.08 mm)

5

0.032 in.

(0.81 mm)

0.056 in

(1.42 mm)

0.074 in

(1.88 mm)

6

0.036 in.

(0.91 mm)

0.064 in

(1.63 mm)

0.082 in

(2.08 mm)

Measure the clearance for each stage between each centralizing pad, compensating block housing pad and the contact surface of the HP compressor front case.

SUBTASK 72-41-00-440-140 Do the HP Compressor Front Case VSV Clearance Checks (SBE 72-0402)

SBE 72-0402: HP compressor variable vanes - inlet guide vane and stages 3 to 6 with optimised build and setting instructions.

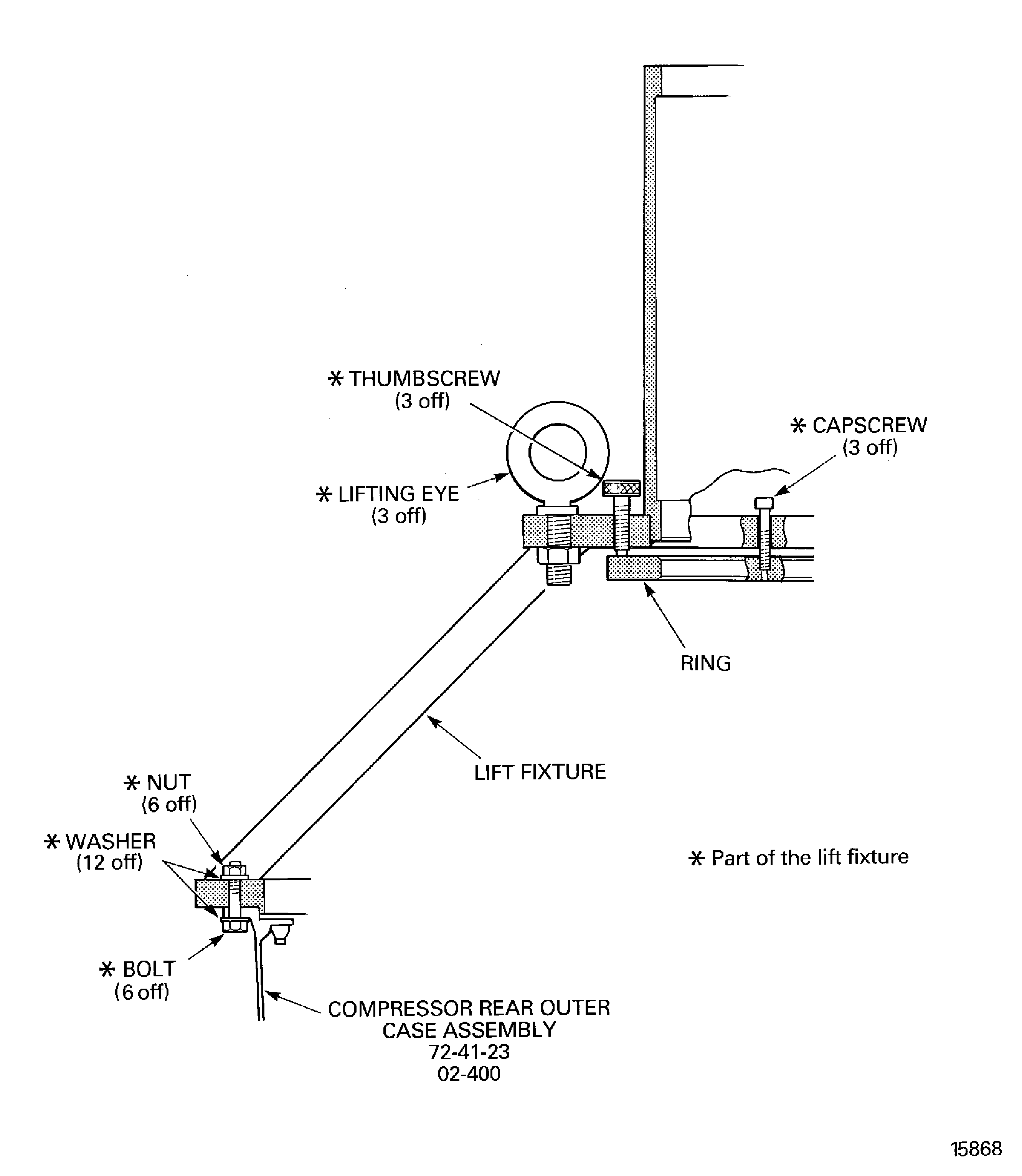

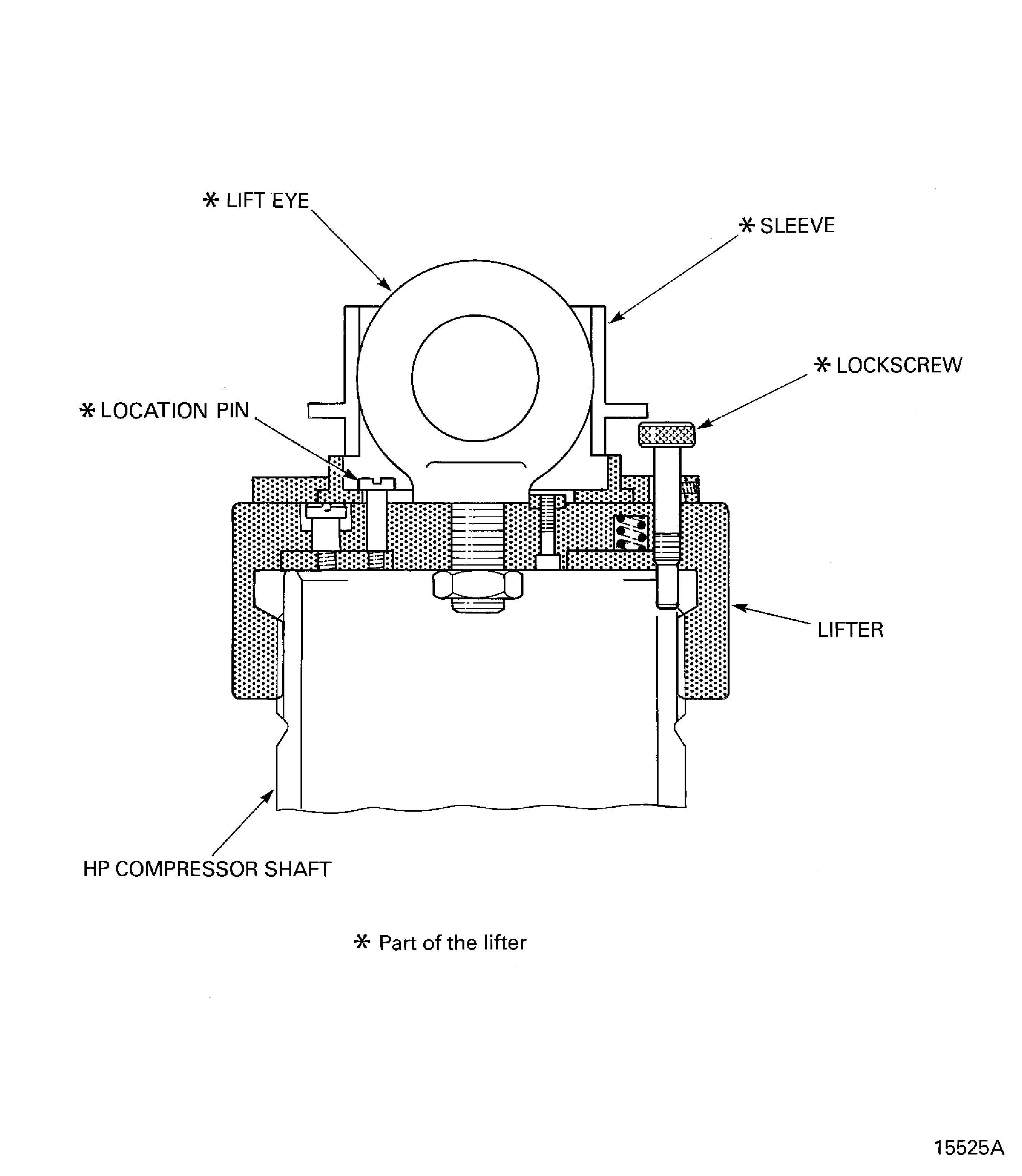

Install IAE 1R18217 Lift fixture 1 off on to the HP compressor assembly.

Install IAE 1R18441 Lifting adapter 1 off on to the compressor shaft.

SUBTASK 72-41-00-440-077 Install the Lift Fixture and the Lifter on to the HP Compressor Assembly

Refer to: Figure

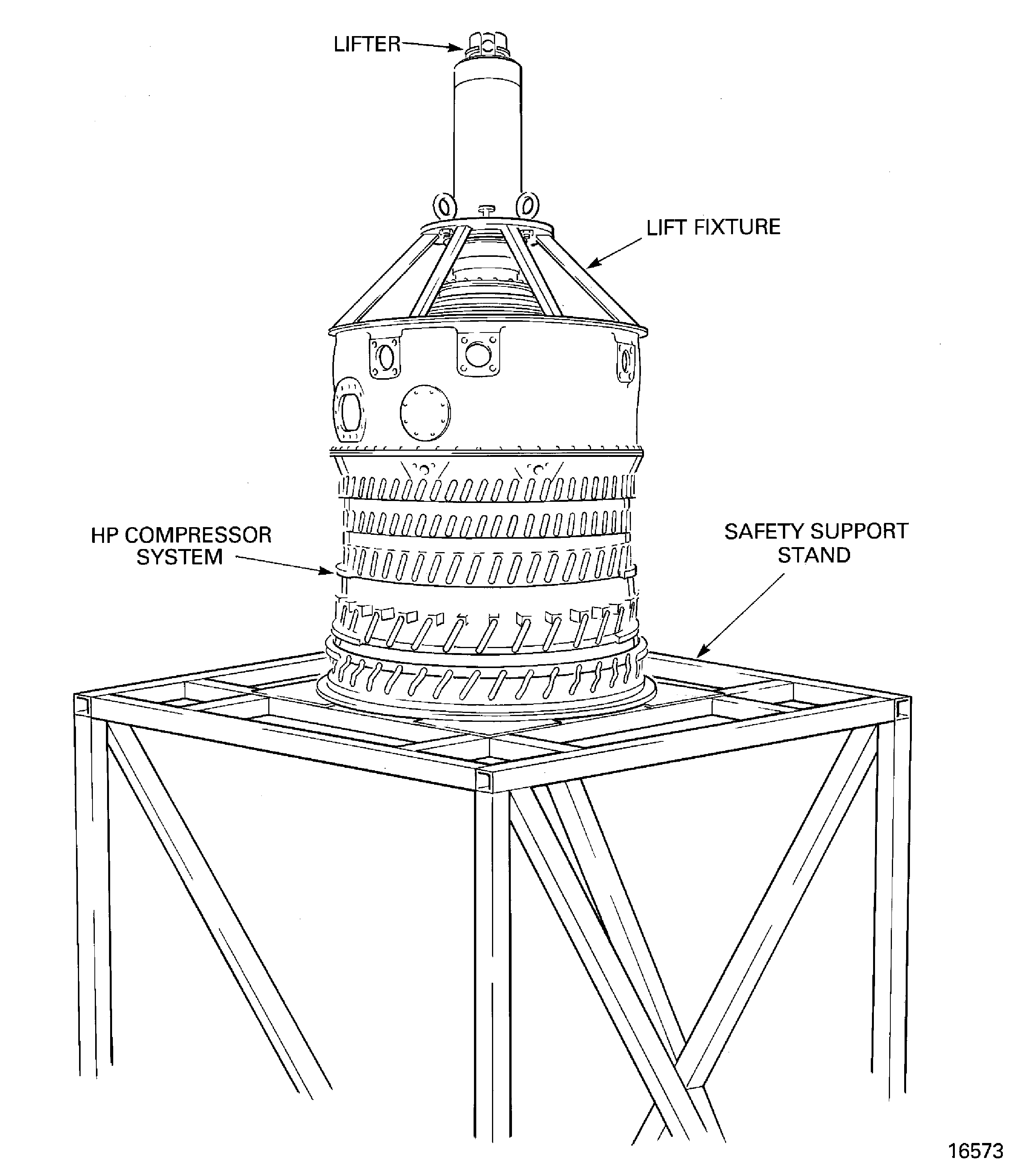

Use the hoist installed in Step and vertically lift the HP compressor assembly from the build stand.

NOTE

Do not remove the hoist.Install the HP compressor assembly on IAE 1R18090 Safety support stand 1 off. Only lower the HP compressor assembly sufficiently until it is on the safety support stand.

SUBTASK 72-41-00-440-078 Install the HP Compressor Assembly on the Safety Support Stand

Refer to: Figure

SBE 72-0422 Remove the two halves of the split ring assembly IAE 1R18250 Split ring assembly.

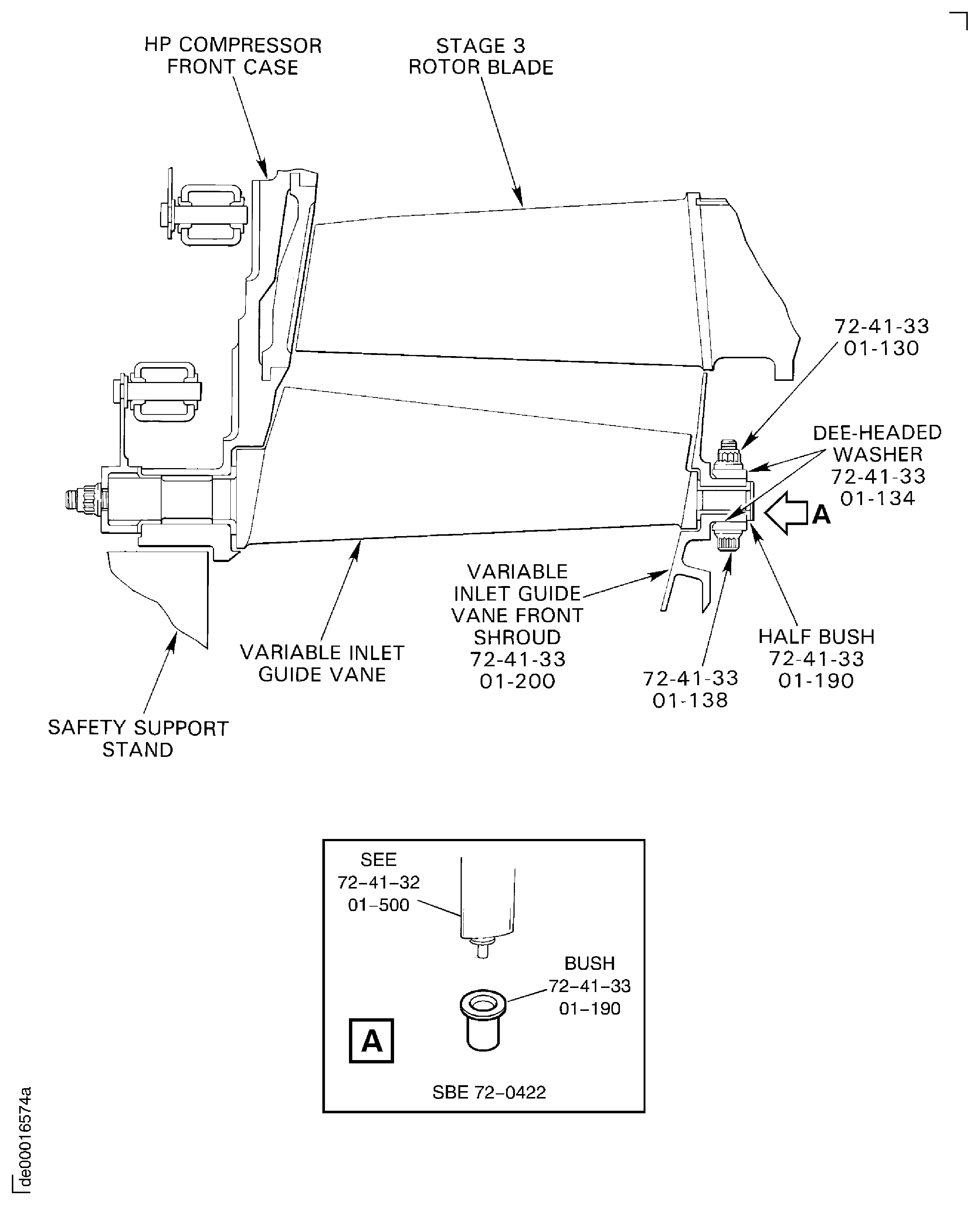

Apply a thin layer of CoMat 04-007 SILICONE GREASE to the 40 half bushes HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-190) outer surface.

Install the 20 bolts HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-138), the 40 dee-headed washers HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-134) and the 20 nuts HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-130). These attach the two halves of the inlet guide vane front shroud.

SBE 72-0422 Remove the two halves of the split ring assembly IAE 1R19633 Split ring assembly. Make sure the 40 one piece bushes are attached to the stator vanes.

Apply a thin layer of CoMat 04-007 SILICONE GREASE to the 40 bushes HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-190) outer surface.

NOTE

The inlet guide vane rear upper half shroud has four location dowels.Install the 20 bolts HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-138), the 40 dee-headed washers HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-134) and the 20 nuts HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-130). These attach the two halves of the inlet guide vane front shroud.

Install the variable inlet guide vane front half shroud HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-200).

SUBTASK 72-41-00-440-079-A00 Install the Variable Inlet Guide Vane Front Half Shroud (Pre SBE 72-0402, Pre SBE 72-0422 and SBE 72-0422)

SBE 72-0422: HP compressor variable inner shrouds - Introduction of revised one piece bushes

Refer to: Figure

During the assembly procedure lubricate the applicable areas of the VSV mechanism for the VIGV stage with a thin layer of 10-108 teflon based lubricant, refer to TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001) SUBTASK 72-41-30-440-208.

SBE 72-0422 Remove the two halves of the split ring assembly IAE 1R18250 Split ring assembly.

Apply a thin layer of CoMat 04-007 SILICONE GREASE to the 40 half bushes HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-190) outer surface.

Install the 20 bolts HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-138), the 40 dee-headed washers HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-134) and the 20 nuts HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-130). These attach the two halves of the inlet guide vane front shroud.

SBE 72-0422 Remove the two halves of the split ring assembly IAE 1R19633 Split ring assembly. Make sure the 40 one piece bushes are attached to the stator vanes.

Apply a thin layer of CoMat 04-007 SILICONE GREASE to the 40 bushes HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-190) outer surface.

NOTE

The inlet guide vane rear upper half shroud has four location dowels.Install the 20 bolts HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-138), the 40 dee-headed washers HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-134) and the 20 nuts HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-130). These attach the two halves of the inlet guide vane front shroud.

Install the variable inlet guide vane front half shroud HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 01-200).

SUBTASK 72-41-00-440-079-B00 Install the Variable Inlet Guide Vane Front Half Shroud (SBE 72-0402, Pre SBE 72-0422 and SBE 72-0422)

SBE 72-0402: HP compressor variable vanes - inlet guide vane and stages 3 to 6 with optimised build and setting instructions.

SBE 72-0422: HP compressor variable inner shrouds - Introduction of revised one piece bushes

Use the hoist installed in Step and lift the HP compressor assembly from the safety support stand.

Install the HP compressor assembly on to IAE 1R18214 Build stand 1 off.

SUBTASK 72-41-00-440-080 Install the HP Compressor Assembly in the Build Stand

Install IAE 1R18252 Protective cover or IAE 1R19552 Protective cover 1 off on to the HP compressor assembly. Make sure the protective cover is correctly installed on the compressor rear outer case rear flange.

SUBTASK 72-41-00-440-082 Install the Protective Cover on to the HP Compressor Assembly

Refer to: Figure

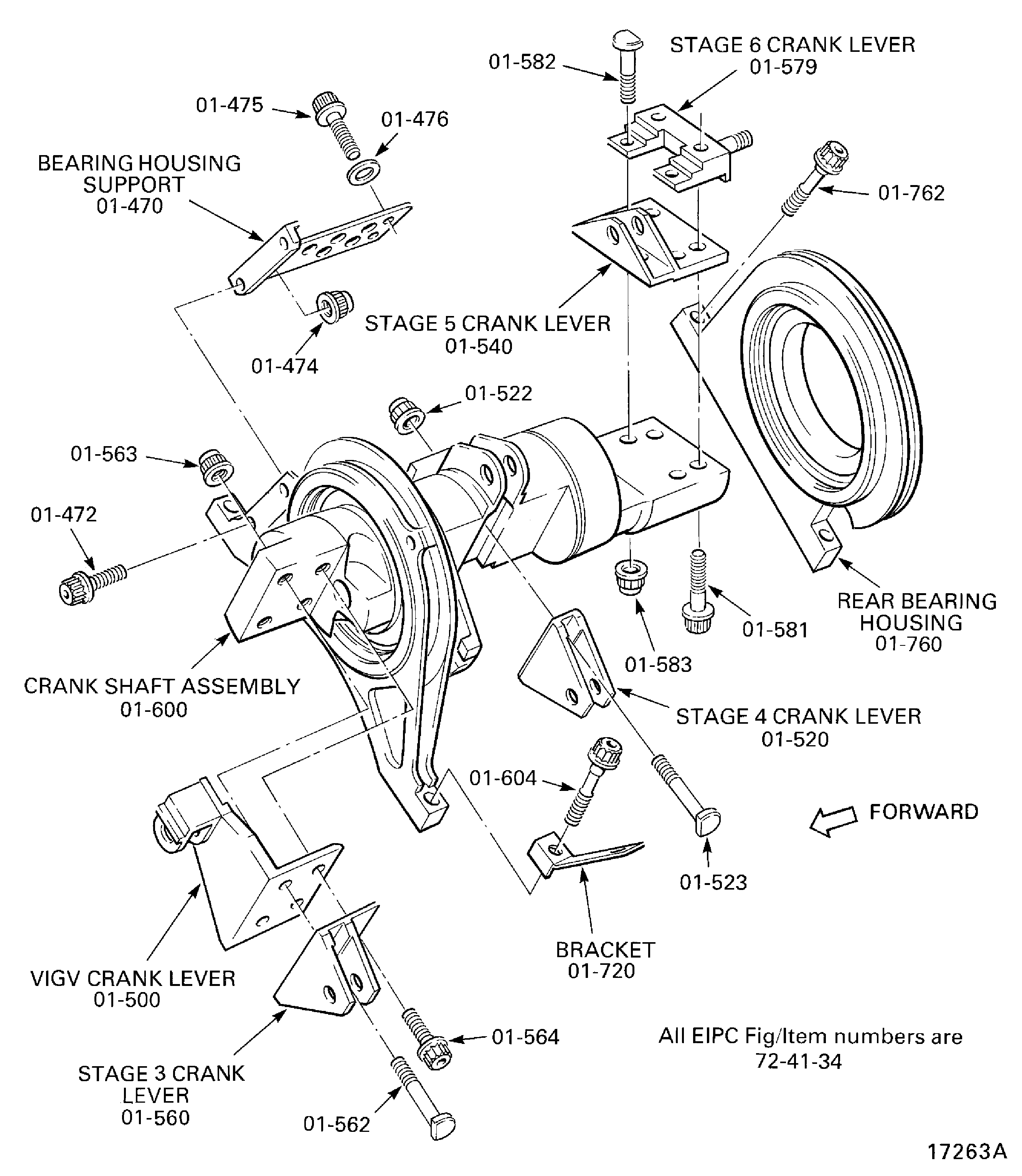

Install the crankshaft assembly on the HP compressor front case HP COMPRESSOR SPLIT CASE (72-41-31, 01-400).

SUBTASK 72-41-00-440-089 Install the Crankshaft Assembly on the Compressor Front Case

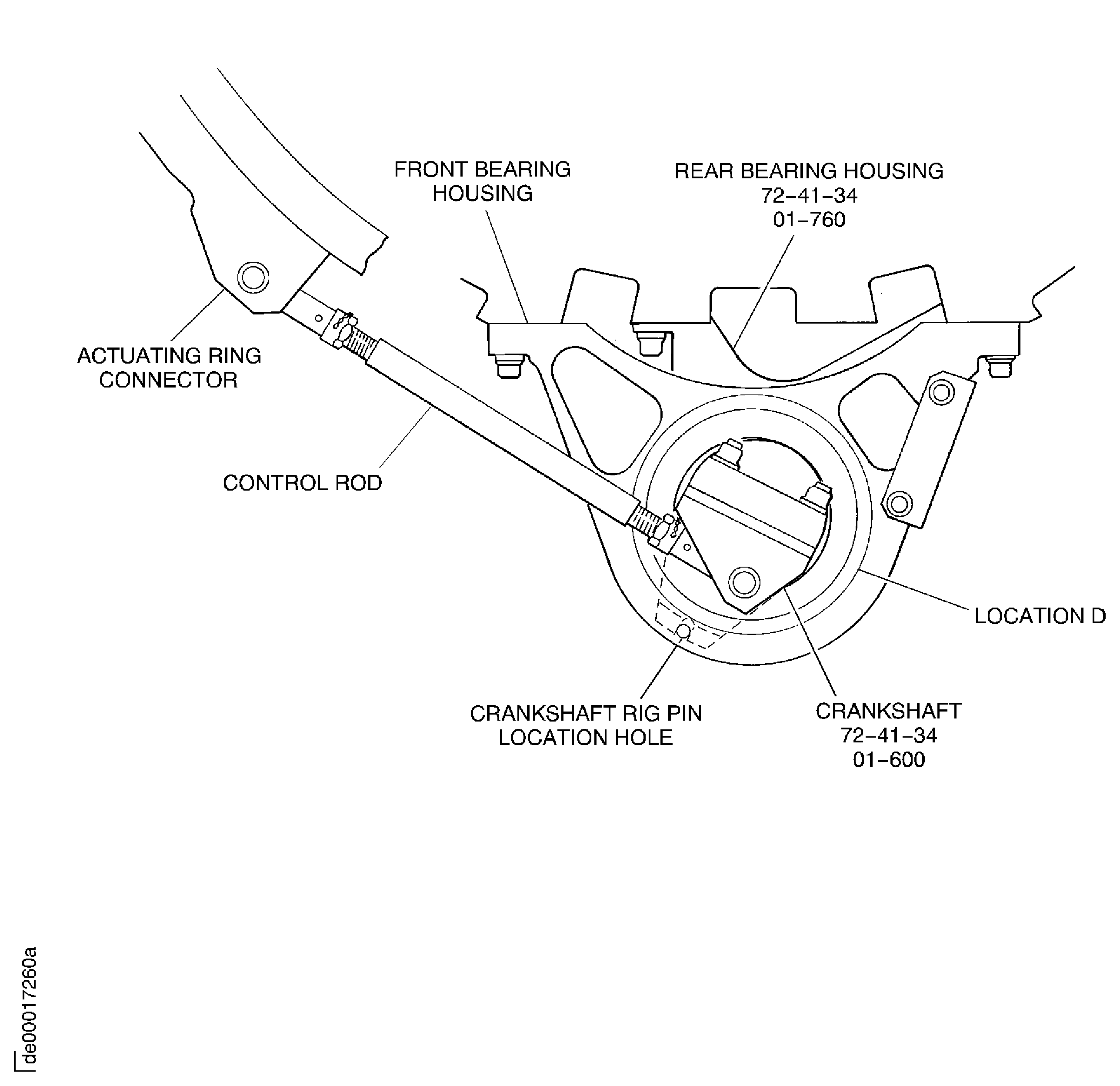

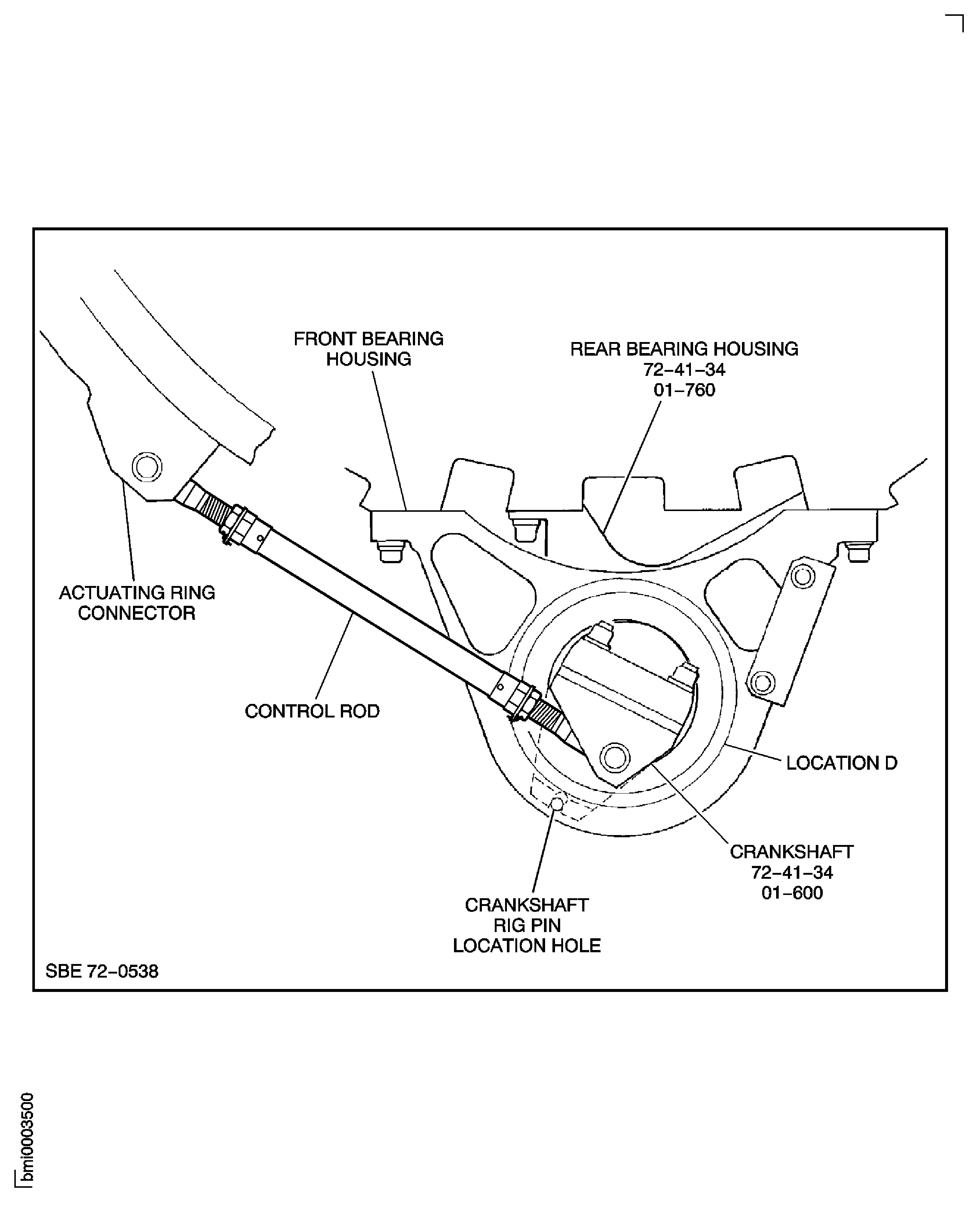

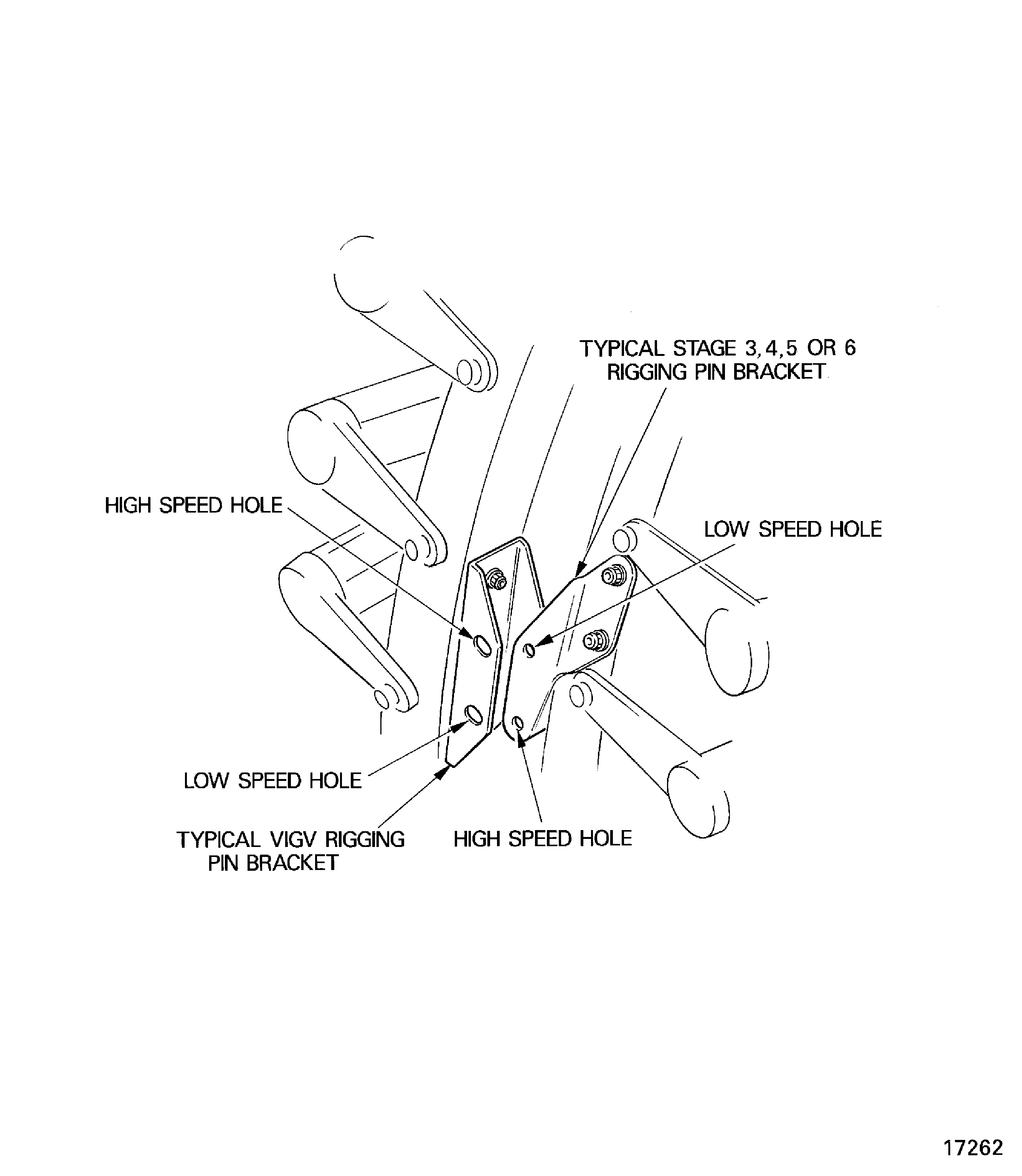

Install IAE 1R18254 Rigging pin 1 off through the front bearing housing in to the crankshaft assembly (72-41-34,01-600). This will set the crankshaft in the high speed position.

Install the IAE 1R18423 Rigging pin 15 off or three IAE 1R18892 Rigging pin 3 off, IAE 1R18893 Riggingpin 3 off, IAE 1R18894 Rigging pin 3 off, IAE 1R18895 Rigging pin 3 off and IAE 1R18896 Rigging pin 3 off in the VSV actuating ring brackets. Install three pins in each stage of the VSV. Install the rigging pins in the high speed positions.

SUBTASK 72-41-00-440-090 Install the Variable Stator Vane and Crankshaft Rigging Pins

Install the spacer (72-41-34,01-185) on to the spindle on the lower VIGV actuating ring HPC Variable Stator Vane Actuation System (72-41-34,02-540).

Install the nut (72-41-34,01-180) on to the spindle. Torque the nut to 290 to 370 lbfin (33 to 42 Nm). Install the cotter pin (72-41-34,01-178) through the nut and the spindle to safety the assembly. Follow the the procedure given in Step to install the cotter pin.

Torque the nut (72-41-34,01-182) to 170 to 210 lbfin (19 to 24 Nm) and install the cotter pin (72-41-34,01-181) through nut and the bolt to safety the assembly. Follow the the procedure given in Step to install the cotter pin.

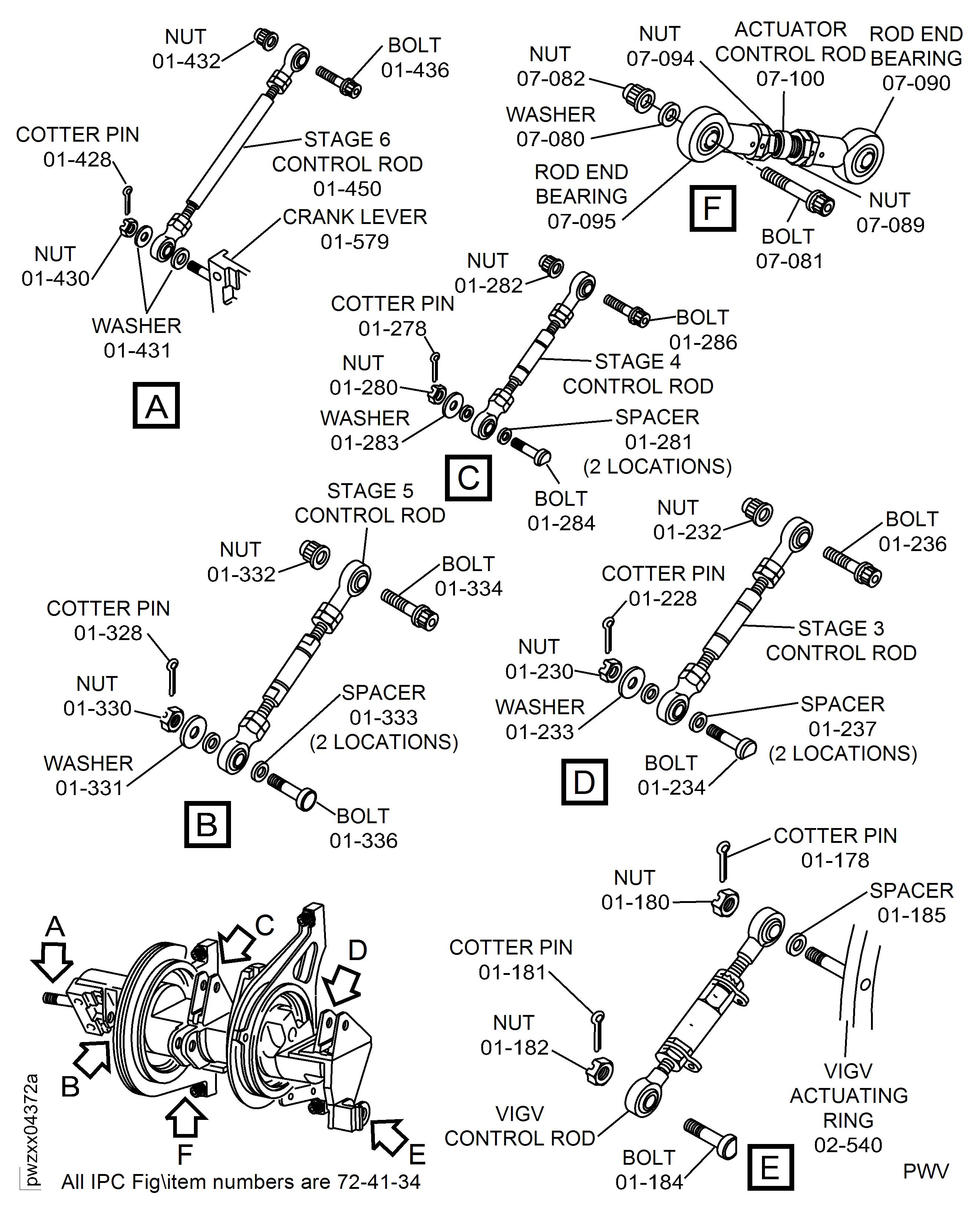

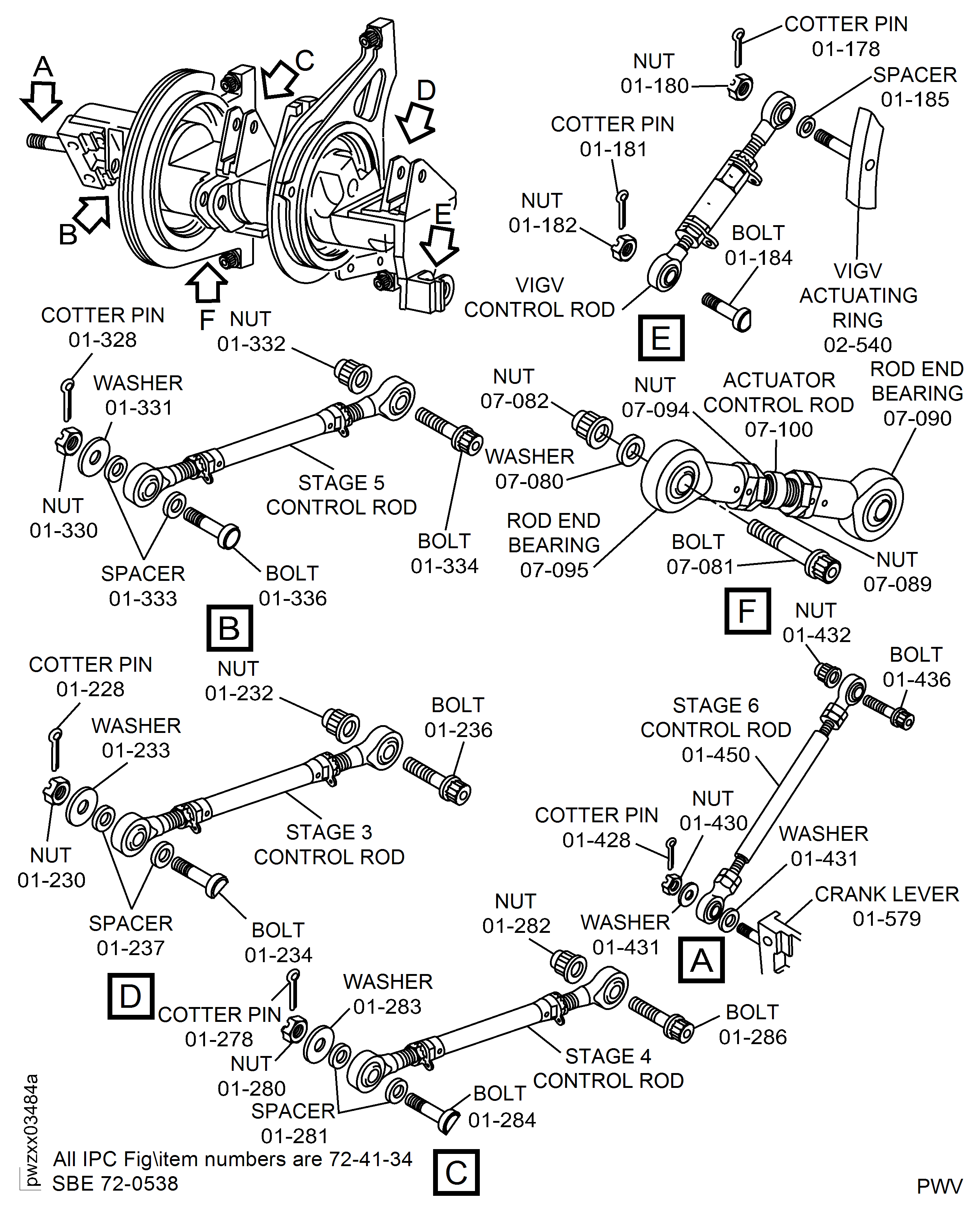

Install the VIGV control rod assembly (72-41-34,01-200).

Install the rigging pins removed in Step into the crankshaft and all stages except for the one being adjusted.

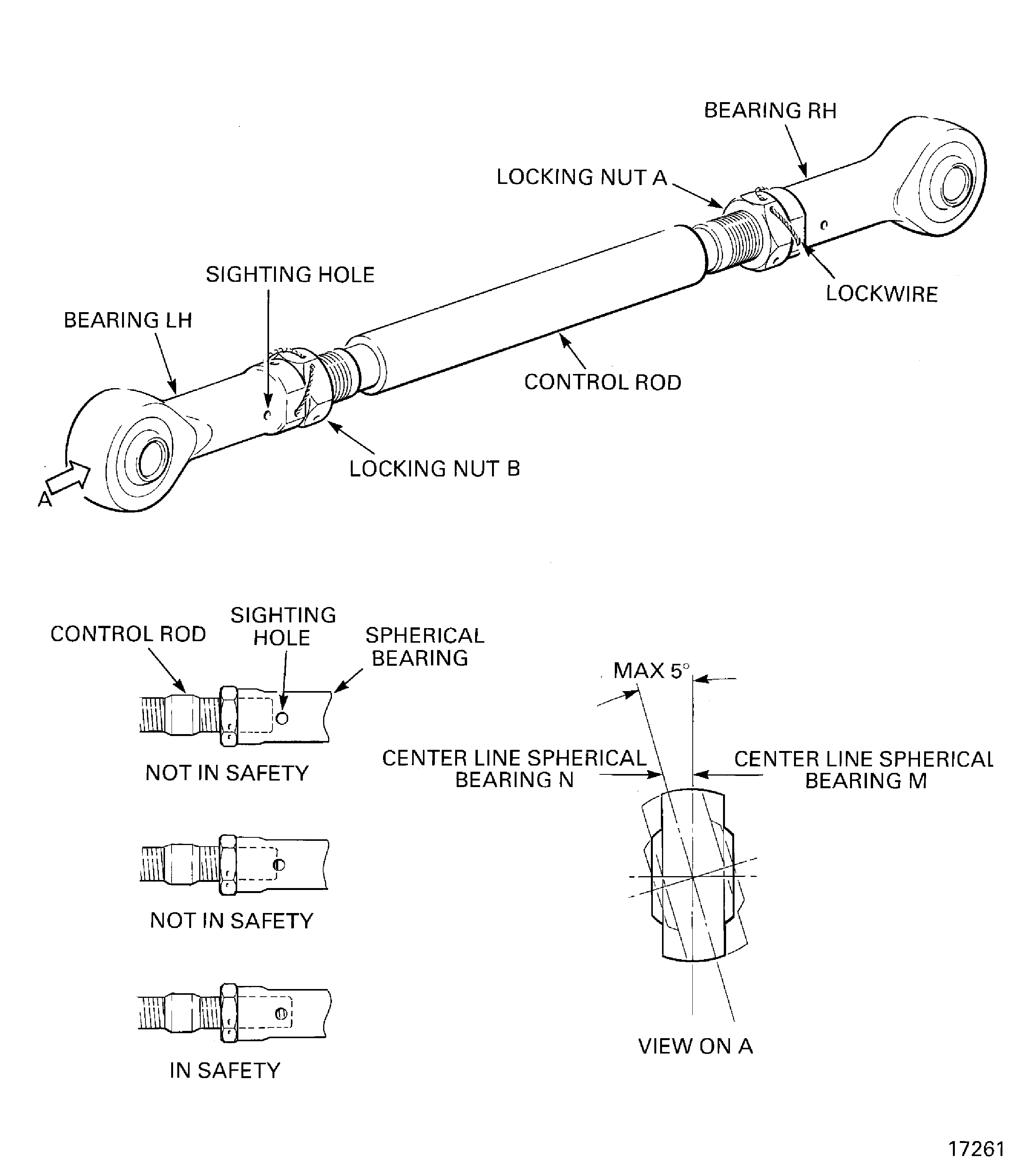

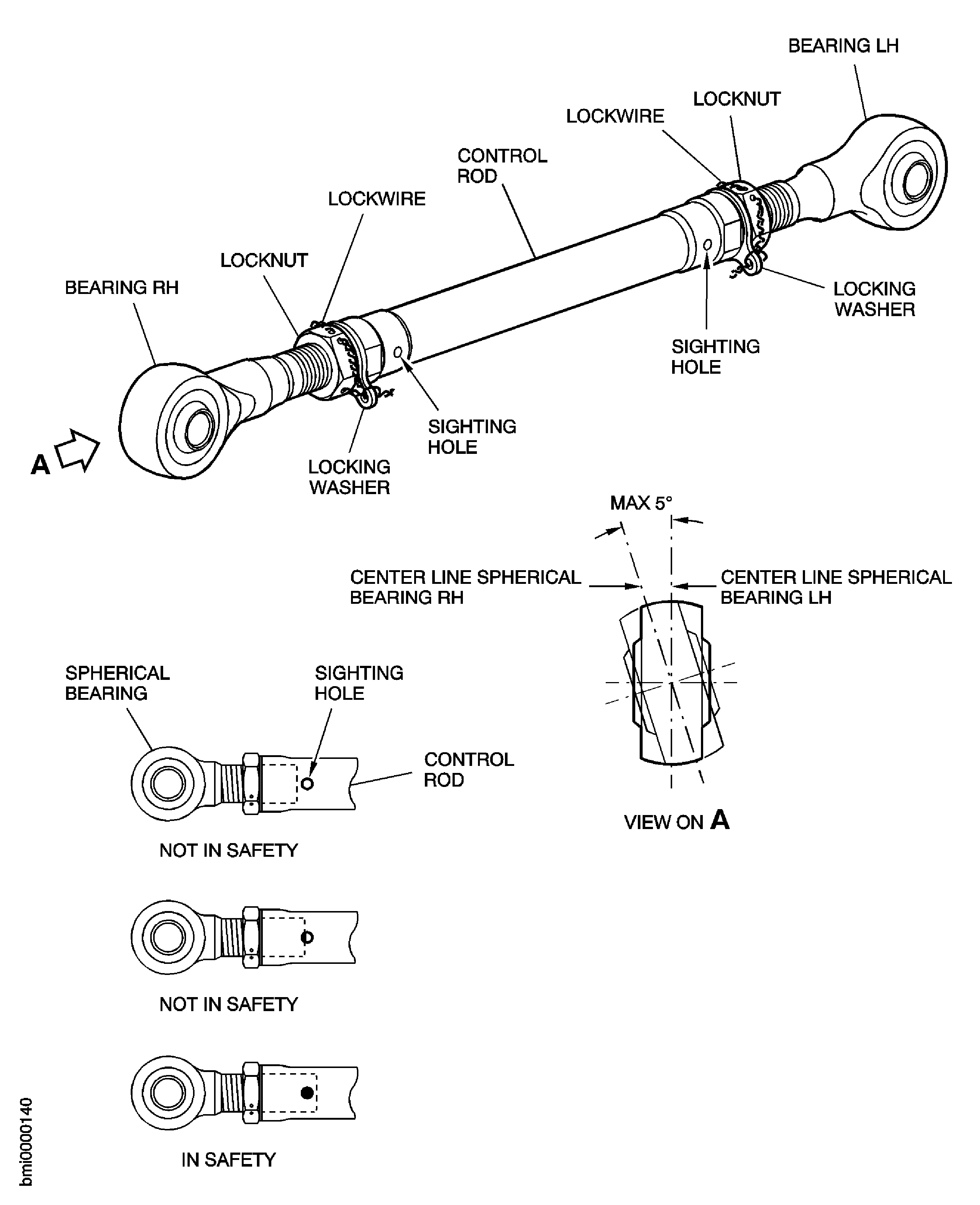

Safety the two locknuts with CoMat 02-126 LOCKWIRE. One of the two locking nuts has a left hand thread.

Procedure to adjust the length of a control rod.

Locate the left hand bearing (72-41-34,01-240) in the connector on the lower stage 3 actuating ring HPC Variable Stator Vane Actuation System (72-41-34,03-540).

Torque the nut to 170 to 210 lbfin (19 to 24 Nm). Install the cotter pin (72-41-34,01-228). Follow the the procedure given in Step to install the cotter pin.

If it is necessary to adjust the length of the control rod refer to the procedure given in Step.

Install the stage 3 control rod assembly (72-41-34,01-250).

Locate the left hand bearing (72-41-34,01-290) in the connector on the lower half stage 4 actuating ring HPC Variable Stator Vane Actuation System (72-41-34,04-540).

Torque the nut to 170 to 210 lbfin (19 to 24 Nm). Install the cotter pin (72-41-34,01-278) through the nut and bolt. Follow the the procedure given in Step to install the cotter pin.

If it is necessary to adjust the length of the control rod refer to the procedure given in Step.

Install the stage 4 control rod (72-41-34,01-300).

Locate the left hand bearing (72-41-34,01-340) in the connector on the lower stage 5 actuating ring HPC Variable Stator Vane Actuation System (72-41-34,05-540).

Torque the nut to 170 to 210 lbfin (19 to 24 Nm). Install the cotter pin (72-41-34,01-328) through the nut and bolt. Follow the the procedure given in Step to install the cotter pin.

If it is necessary to adjust the length of the control rod refer to the procedure given in Step.

Install the stage 5 control rod (72-41-34,01-350).

Locate the right hand bearing (72-41-34, 01-445) in the connector in the lower stage 6 actuating ring V2500-A5-72-41-34-06A-941A-D (72-41-34, 06-540).

Torque the nut to 290 to 370 lbfin (33 to 42 Nm). Install the cotter pin (72-41-34,01-428) through the nut and bolt. Follow the the procedure given in Step to install the cotter pin.

If it is necessary to adjust the length of the control rod refer to the procedure given in Step.

Install the stage 6 control rod (72-41-34,01-450).

Locate the right hand bearing ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 07-095) on the actuator control rod position on the crankshaft.

Install the bolt ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 07-081), the washer ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 07-080), and the nut ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 07-082).

Torque the nut to 290 to 370 lbf-in (33 to 42 N.m).

Install the actuator control rod ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 07-100).

SUBTASK 72-41-00-440-091 Install the Control Rods

Install the IAE 1R18247 Rigging pin 4 off to set the VIVGs in the correct position.

CAUTION

IT IS VERY IMPORTANT TO FULLY INSERT ALL BUILD PINS.Measure and write down the gap between the centralizing pads and compensating pads and the front casing, use feeler gauges. The feeler gauges must be inserted in a circumferential direction and towards the split line flange at the 3 o'clock and 9 o'clock positions. Do not remove the feeler gauges until all clearances have been measured.

If the clearances do not meet the values in Table A or Table B, the connector housings HPC Variable Stator Vane Actuation System (72-41-34, 02-200) may have been incorrectly assembled onto the unison ring HPC Variable Stator Vane Actuation System (72-41-34, 02-440 and HPC Variable Stator Vane Actuation System72-41-34, 02-540). The parts must be carefully checked to ensure that the dowels HPC Variable Stator Vane Actuation System (72-41-34, 02-206 and HPC Variable Stator Vane Actuation System72-41-34, 02-208) are correctly seated into the unison rings.

If the connector housings and unison rings are correctly assembled and the clearances do not meet those in Table A or Table B, the pad clearances must be reset. Use the procedure detailed in TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-440-206 and SUBTASK 72-41-30-440-207.

Check the VIVG pad clearances.

CAUTION

IT IS VERY IMPORTANT TO FULLY INSERT ALL BUILD PINS.Install the IAE 1R18247 Rigging pin 6 off to set the VSVs in the correct position.

Measure and write down the gap between the centralizing pads and the compensating pads and the front casing, using feeler gauges. The feeler gauges must be inserted in a circumferential direction and towards the split line flange at the 3 o'clock and 9 o'clock positions. Do not remove the feeler gauges until all clearances have been measured.

If the clearances do not meet the values in Table A or Table B, the connector housings HPC Variable Stator Vane Actuation System (72-41-34, 03-200 and HPC Variable Stator Vane Actuation System 72-41-34, 03-280) may have been incorrectly assembled onto the unison ring HPC Variable Stator Vane Actuation System (72-41-34, 03-440 and HPC Variable Stator Vane Actuation System 72-41-34, 03-540). The parts must be carefully checked to ensure that the dowels HPC Variable Stator Vane Actuation System (72-41-34, 03-206 , HPC Variable Stator Vane Actuation System 03-286 and HPC Variable Stator Vane Actuation System 03-288) are correctly seated into the unison rings.

If the connector housings and unison rings are correctly assembled and the clearances do not meet those in Table A or Table B, the pad clearances must be reset. Use the procedure detailed in TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-440-206 and SUBTASK 72-41-30-440-207.

Check the Stage 3 VSV pad clearances.

CAUTION

IT IS VERY IMPORTANT TO FULLY INSERT ALL BUILD PINS.Install the IAE 1R18247 Rigging pin 6 off to set the VSVs in the correct position.

Measure and write down the gap between the centralizing pads and compensating pads and the front casing, use feeler gauges. The feeler gauges must be inserted in a circumferential direction and towards the split line flange at the 3 o'clock and 9 o'clock positions. Do not remove the feeler gauges until all clearances have been measured.

If the clearances do not meet the values in Table A or Table B, the connector housings HPC Variable Stator Vane Actuation System (72-41-34, 04-200) may have been incorrectly assembled onto the unison rings HPC Variable Stator Vane Actuation System (72-41-34, 04-440 and HPC Variable Stator Vane Actuation System72-41-34, 04-540). The parts must be carefully checked to ensure that the dowels HPC Variable Stator Vane Actuation System (72-41-34, 04-206) are correctly seated into the unison rings.

If the connector housings and unison rings are correctly assembled and the clearances do not meet those in Table A or Table B, the pad clearances must be reset. Use the procedure detailed in TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-440-206 and SUBTASK 72-41-30-440-207.

Check the Stage 4 VSV pad clearances.

CAUTION

IT IS VERY IMPORTANT TO FULLY INSERT ALL BUILD PINS.Install the IAE 1R18247 Rigging pin 6 off to set the VSVs in the correct position.

Measure and write down the gap between the centralizing pads and the compensating pads and the front casing, use feeler gauges. The feeler gauges must be inserted in a circumferential direction and towards the split line flange at the 3 o'clock and 9 o'clock positions. Do not remove the feeler gauges until all clearances have been measured.

If the clearances do not meet the values in Table A or Table B, the connector housings HPC Variable Stator Vane Actuation System (72-41-34, 05-200) may have been incorrectly assembled onto the unison rings HPC Variable Stator Vane Actuation System (72-41-34, 05-440 and HPC Variable Stator Vane Actuation System72-41-34, 05-540). The parts must be carefully checked to ensure that the dowels HPC Variable Stator Vane Actuation System (72-41-34, 05-206) are correctly seated into the unison rings.

If the connector housings and unison rings are correctly assembled and the clearances do not meet those in Table A or Table B, the pad clearances must be reset. Use the procedure detailed in TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-440-206 and 72-41-30-440-207.

Check the Stage 5 VSV pad clearances.

CAUTION

IT IS VERY IMPORTANT TO FULLY INSERT ALL BUILD PINS.Install the IAE 1R18247 Rigging pin 6 off to set the VSVs in the correct position.

Measure and write down the gap between the centralizing pads and the compensating pads and the front casing, use feeler gauges. The feeler gauges must be inserted in a circumferential direction and towards the split line flange at the 3 o'clock and 9 o'clock positions. Do not remove the feeler gauges until all clearances have been measured.

If the clearances do not meet the values in Table A or Table B, the connector housings V2500-A5-72-41-34-06A-941A-D (72-41-34, 06-200) may have been incorrectly assembled onto the unison ring V2500-A5-72-41-34-06A-941A-D (72-41-34, 06-440 and V2500-A5-72-41-34-06A-941A-D72-41-34, 06-540). The parts must be carefully checked to ensure that the dowels V2500-A5-72-41-34-06A-941A-D (72-41-34, 06-206) are correctly seated into the unison rings.

If the connector housings and unison rings are correctly assembled and the clearances do not meet those in Table A or Table B, the pad clearances must be reset. Use the procedure detailed in TASK 72-41-30-440-011-A00, SUBTASK 72-41-30-440-206 and SUBTASK 72-41-30-440-207.

CAUTION

DO NOT USE THE LIMITS IN TABLE A AND TABLE B FOR SETTING. THESE LIMITS MUST ONLY BE USED AS A FINAL ASSEMBLY CHECK.NOTE

Maximum individual pad clearance is the maximum value allowable for 1 pad clearance per stage.Minimum total pad clearance is the minimum value for the sum total of all eight pad clearances per stage.Maximum total pad clearance is the maximum value for the sum total of all eight pad clearances per stage.A clearance of zero is acceptable provided that the individual maximum pad clearance and the minimum and maximum total pad clearances are within the values specified in the table.PRE SB72-0027

TABLE OF LIMITS - VSV PAD CLEARANCE LIMITS

VSV SYSTEM

STAGE

MAXIMUM INDIVIDUAL PAD CLEARANCE

MINIMUM TOTAL PAD CLEARANCE

MAXIMUM TOTAL PAD CLEARANCE

VIGV

0.016 in

(0.41 mm)

0.024 in

(0.61 mm)

0.042 in

(1.07 mm)

3

0.016 in

(0.41 mm)

0.024 in.

(0.61 mm)

0.042 in

(1.07 mm)

4

0.020 in.

(0.51 mm)

0.032 in

(0.82 mm)

0.050 in

(1.27 mm)

5

0.020 in.

(0.51 mm)

0.032 in

(0.82 mm)

0.050 in

(1.27 mm)

6

0.016 in.

(0.41 mm)

0.024 in

(0.61 mm)

0.042 in

(1.07 mm)

VSV SYSTEM

STAGE

MAXIMUM INDIVIDUAL PAD CLEARANCE

MINIMUM TOTAL PAD CLEARANCE

MAXIMUM TOTAL PAD CLEARANCE

POST SB72-0027

TABLE OF LIMITS - VSV PAD CLEARANCE LIMITS

VIGV

0.016 in

(0.41 mm)

0.024 in

(0.61 mm)

0.042 in

(1.07 mm)

3

0.020 in

(0.51 mm)

0.032 in.

(0.82 mm)

0.050 in

(1.27 mm)

4

0.036 in.

(0.91 mm)

0.064 in

(1.63 mm)

0.082 in

(2.08 mm)

5

0.032 in.

(0.82 mm)

0.056 in

(1.42 mm)

0.074 in

(1.88 mm)

6

0.036 in.

(0.91 mm)

0.064 in

(1.63 mm)

0.082 in

(2.08 mm)

Check the Stage 6 VSV pad clearances.

SUBTASK 72-41-00-440-213 Do a Check of the VSV Pad Clearances

Remove IAE 1R18252 Protective cover or IAE 1R19552 Protective cover protective cover from the HP compressor assembly.

SUBTASK 72-41-00-440-094 Remove the Protective Cover from the HP Compressor Assembly

Refer to: Figure

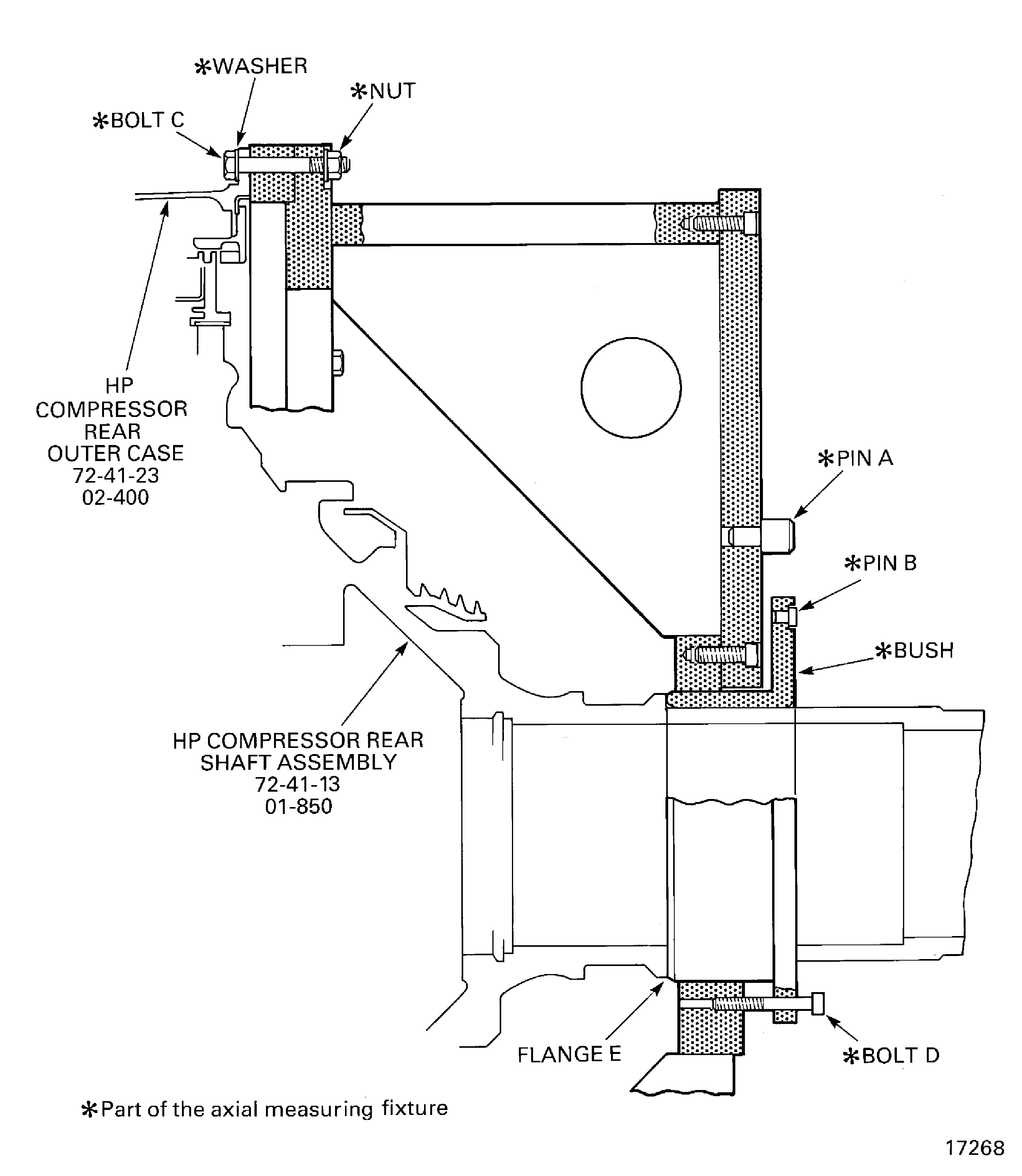

Install the IAE 1R18251 Axial measuring fixture 1 off on to the HP compressor assembly.

Install the IAE 1R18294 Clock holder 1 off on to the axial measuring fixture at pin A.

Measure the gap between the pins A and B.

Install the correct lifting equipment as given in Step.

Remove the axial measuring fixture.

SUBTASK 72-41-00-440-093 Measure the Position of the HP Compressor Rear Shaft

WARNING

YOU MUST USE THE CORRECT PERSONNEL PROTECTION EQUIPMENT WHEN HANDLING AND APPLYING THE LUBRICANT, CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R) TEFLON BASED LUBRICANT.

CAUTION

DO NOT APPLY LUBRICANT TO THE VSV ACTUATOR.

CAUTION

DO NOT LUBRICATE THE CRANKSHAFT BEARINGS.NOTE

These bearings are designed to run dry. Lubrication of the bearings shall cause "swelling" of the bearing fabroid material, resulting in tightness of operation.Apply CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R) to each variable stator vane lever spindle at location A for the VIGV stage thru to stage 6. Refer to Figureto illustrate the typical area.

WARNING

YOU MUST USE THE CORRECT PERSONNEL PROTECTION EQUIPMENT WHEN HANDLING AND APPLYING THE LUBRICANT, CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R) TEFLON BASED LUBRICANT.Apply the lubricant using an appropriately sized brush or hand pump spray. Not an aerosol.

Apply CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R) to each pin at location B that connects the VSV levers to the unison ring. Refer to Figure to illustrate the typical area.

WARNING

YOU MUST USE THE CORRECT PERSONNEL PROTECTION EQUIPMENT WHEN HANDLING AND APPLYING THE LUBRICANT, CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R) TEFLON BASED LUBRICANT.Apply the lubricant using an appropriately sized brush or hand pump spray. Not an aerosol.

Apply CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R) to the exposed areas of all unison ring centralizing pads, location G on the compressor cases.

SUBTASK 72-41-00-440-138 Lubricate the Variable Stator Vane Mechanism

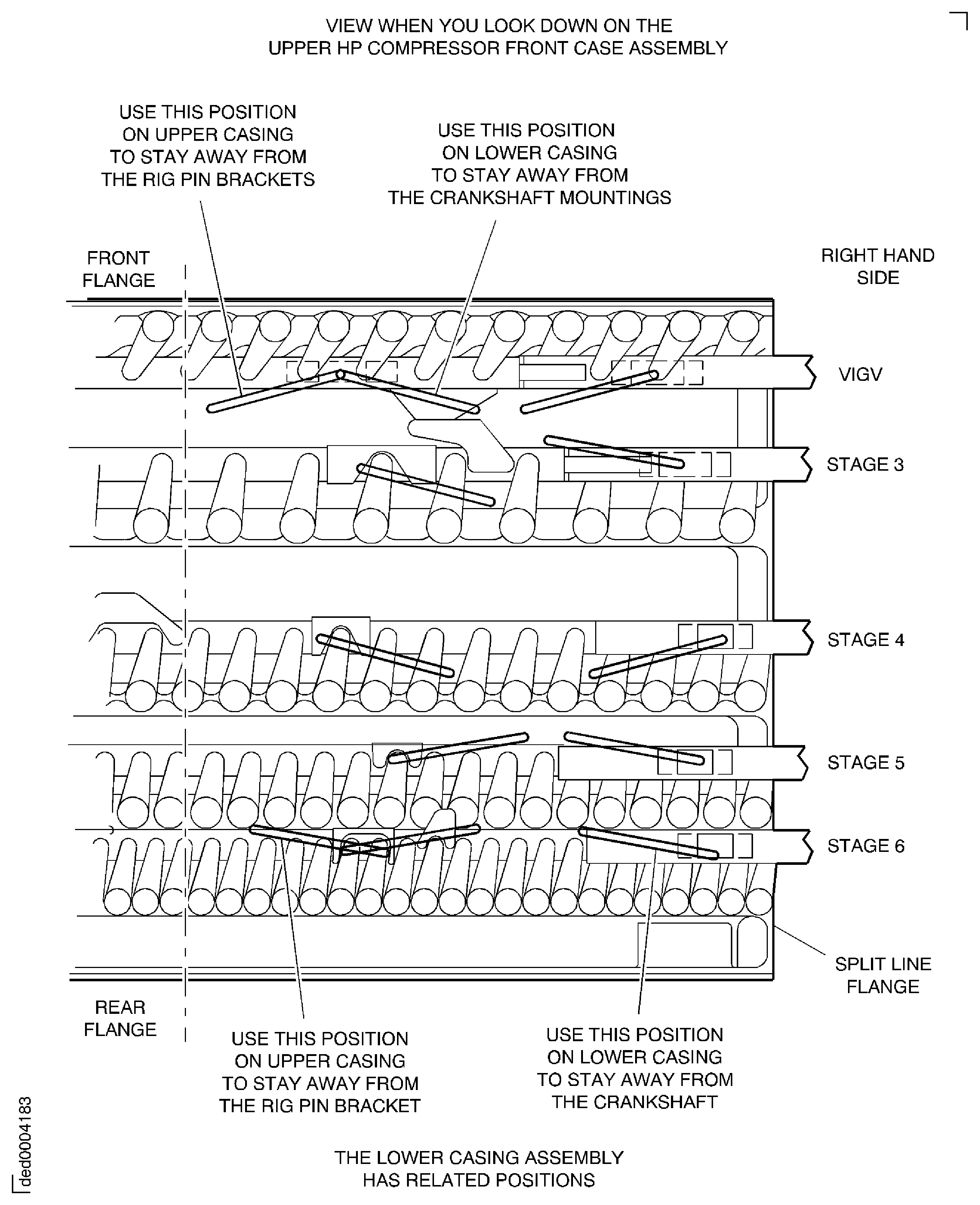

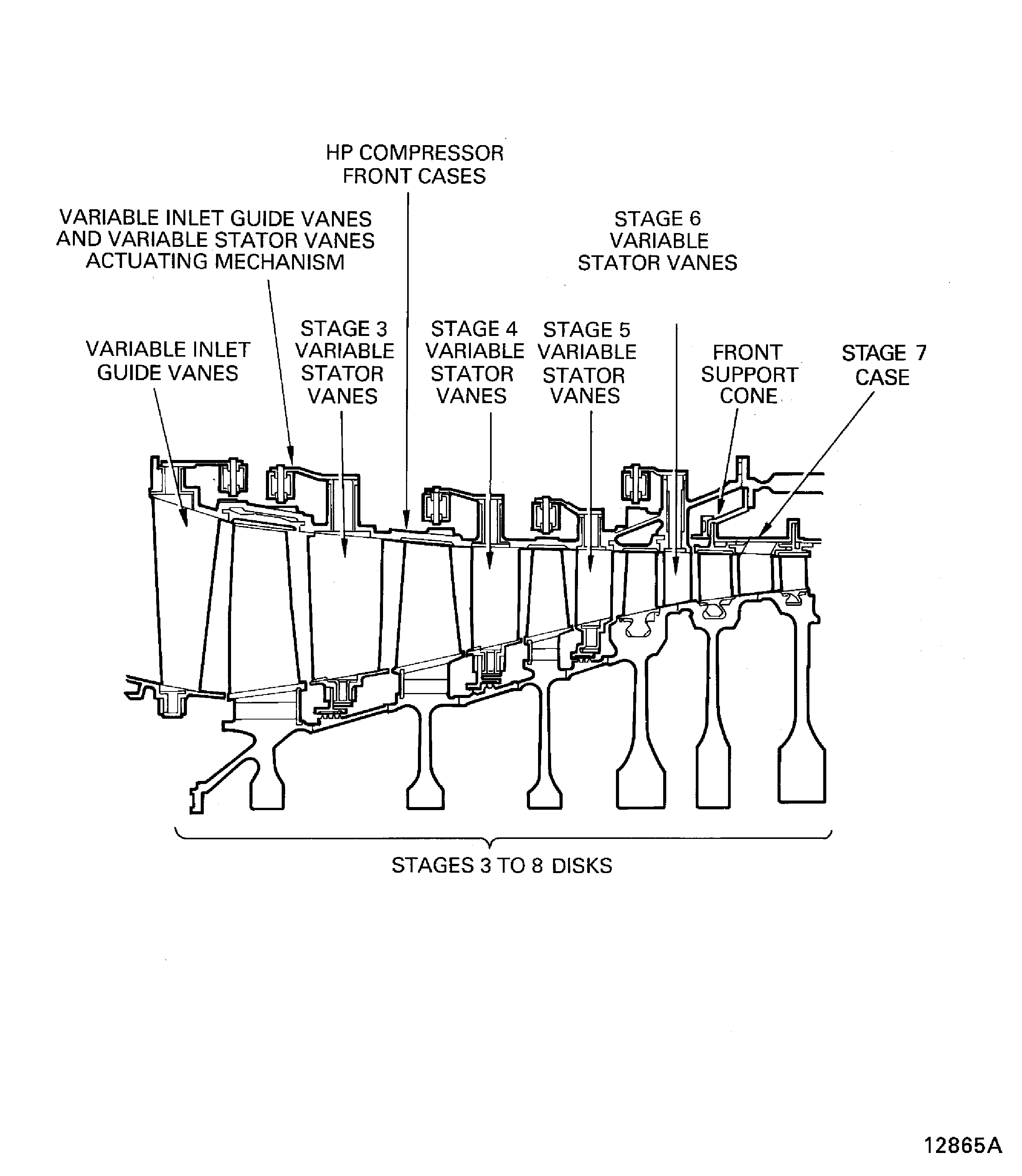

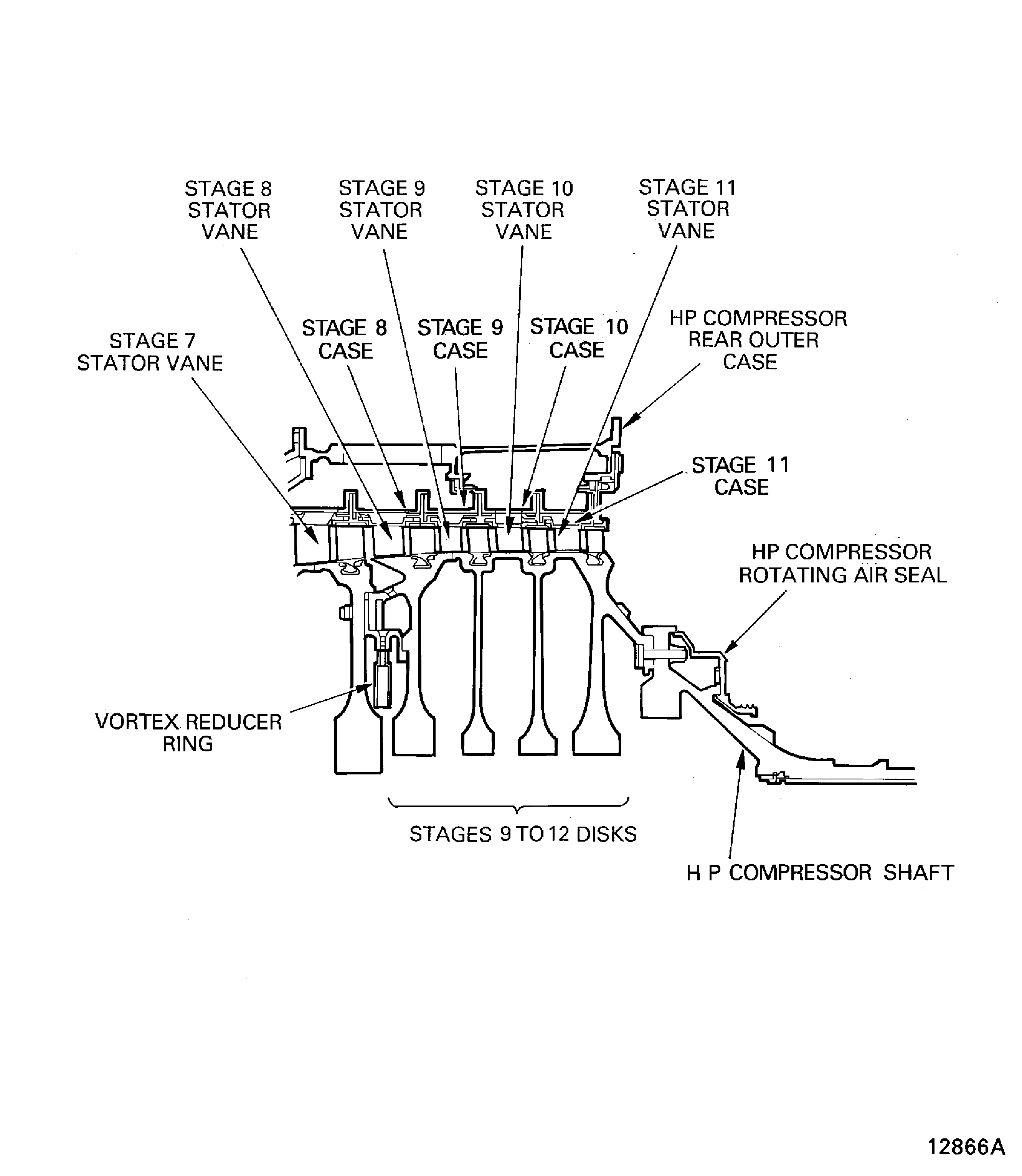

Figure: View through the HP compressor assembly

View through the HP compressor assembly

Figure: View through the HP compressor assembly

View through the HP compressor assembly

Figure: Install the holding fixture on the HP compressor assembly

Install the holding fixture on the HP compressor assembly

Figure: Remove the support stand and the support ring

Remove the support stand and the support ring

Figure: Install the support ring

Install the support ring

Figure: Install the support ring

Install the support ring

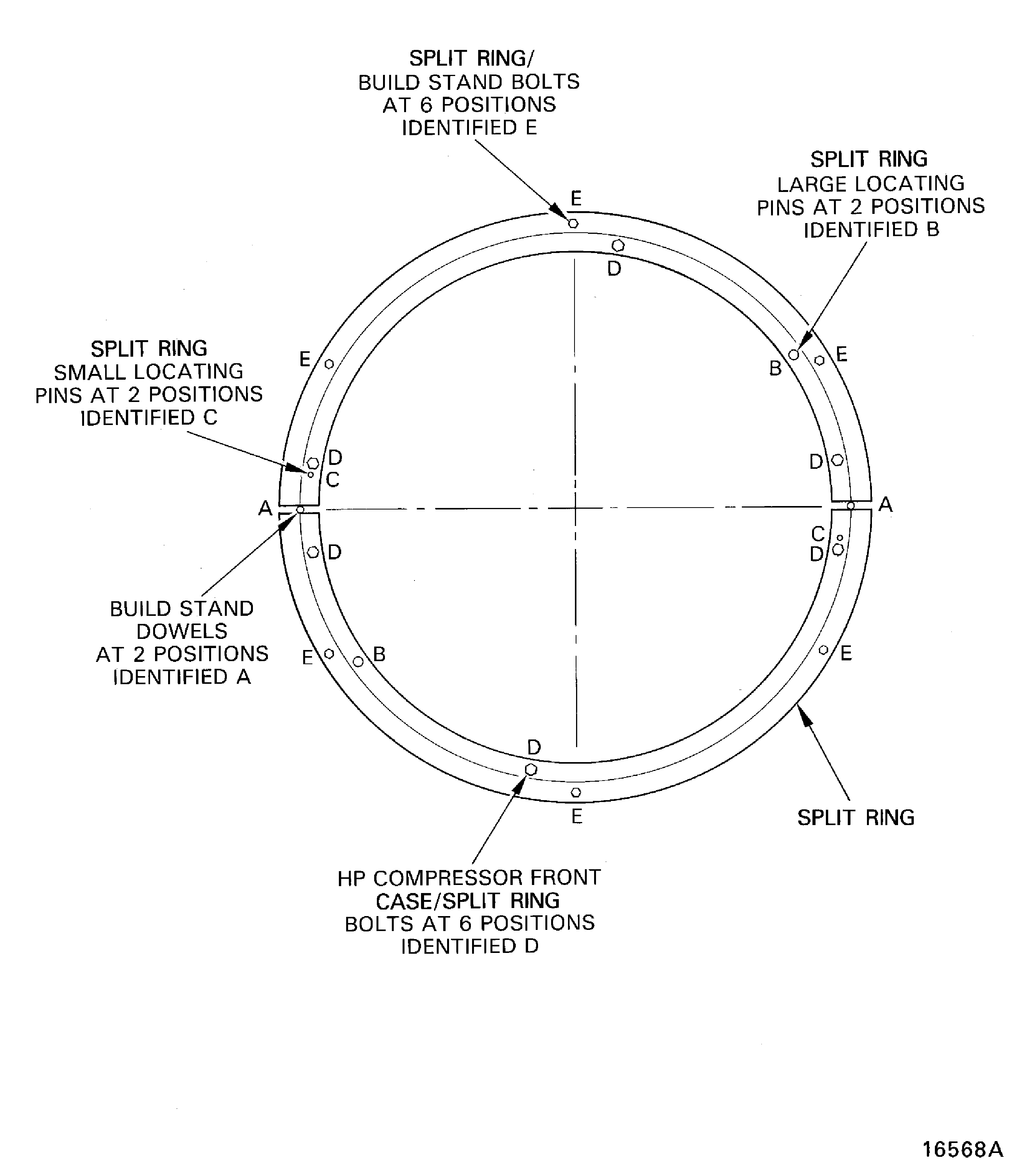

Figure: Pre SBE 72-0027: Install the HP compressor front case split line flange bolts

Pre SBE 72-0027: Install the HP compressor front case split line flange bolts

Figure: SBE 72-0027: Install the HP compressor front case split line flange bolts

SBE 72-0027: Install the HP compressor front case split line flange bolts

Figure: Install the HP compressor front case split line flange bolts

Install the HP compressor front case split line flange bolts

Figure: Install the brackets, the pins, the bolts and the nuts at the HP compressor front case to the compressor rear outer case flange

Install the brackets, the pins, the bolts and the nuts at the HP compressor front case to the compressor rear outer case flange

Figure: Install the brackets, the pins, the bolts and the nuts at the HP compressor front case to the compressor rear outer case flange

Install the brackets, the pins, the bolts and the nuts at the HP compressor front case to the compressor rear outer case flange

Figure: Install the brackets, the pins, the bolts and the nuts at the HP compressor front case to the compressor rear outer case flange

Install the brackets, the pins, the bolts and the nuts at the HP compressor front case to the compressor rear outer case flange

Figure: Install the inlet guide vane connectors

Install the inlet guide vane connectors

Figure: Install the inlet guide vane connectors

Install the inlet guide vane connectors

Figure: Install the stage 3 actuating ring connectors

Install the stage 3 actuating ring connectors

Figure: Install the stage 3 actuating ring connectors

Install the stage 3 actuating ring connectors

Figure: Install the stage 4 actuating ring connectors

Install the stage 4 actuating ring connectors

Figure: Install the stage 4 actuating ring connectors

Install the stage 4 actuating ring connectors

Figure: Install the stage 5 actuating ring connectors

Install the stage 5 actuating ring connectors

Figure: Install the stage 5 actuating ring connectors

Install the stage 5 actuating ring connectors

Figure: Install the stage 6 actuating ring connectors

Install the stage 6 actuating ring connectors

Figure: Install the stage 6 actuating ring connectors

Install the stage 6 actuating ring connectors

Figure: Install the lift fixture and the lifter on to the HP compressor assembly

Install the lift fixture and the lifter on to the HP compressor assembly

Figure: Install the lift fixture and the lifter on to the HP compressor assembly

Install the lift fixture and the lifter on to the HP compressor assembly

Figure: Install the HP compressor assembly on to the safety support stand

Install the HP compressor assembly on to the safety support stand

Figure: Install the inlet guide vane front shroud

Install the inlet guide vane front shroud

Figure: Install the crankshaft assembly

Install the crankshaft assembly

Figure: Pre SBE 72-0538 : Install the Variable Stator Vanes

Pre SBE 72-0538 : Install the Variable Stator Vanes

Figure: SBE 72-0538 : Install the Variable Stator Vanes

SBE 72-0538 : Install the Variable Stator Vanes

Figure: Install the rigging pins

Install the rigging pins

Figure: Pre SBE 72-0538 : Assemble/Install the Control Rods

Pre SBE 72-0538 : Assemble/Install the Control Rods

Figure: SBE 72-0538 : Assemble/Install the Control Rods

SBE 72-0538 : Assemble/Install the Control Rods

Figure: Pre SBE 0538 : Assemble/Install The Control Rods

Pre SBE 0538 : Assemble/Install The Control Rods

Figure: SBE 72-0538 : Assemble/Install The Control Rods

SBE 72-0538 : Assemble/Install The Control Rods

Figure: Install a Split Cotter Pin

Install a Split Cotter Pin

Figure: Measure the axial clearance

Measure the axial clearance

Figure: Set the HP compressor front case (left hand side) VSV pad clearances - recommended feeler gauge positions

Set the HP compressor front case (left hand side) VSV pad clearances - recommended feeler gauge positions

Figure: Set the HP compressor front case (right hand side) VSV pad clearances - recommended feeler gauge positions

Set the HP compressor front case (right hand side) VSV pad clearances - recommended feeler gauge positions