Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-44-10-300-019 HPT Stage 1 Support Assembly - Weld Repair Of Inner Wall/Flange Fretting, Repair-019 (VRS3559)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-010 | 2A1292 |

01-010 | 2A1358 |

01-010 | 2A1664 |

01-010 | 2A2703 |

01-010 | 2A3360 |

01-010 | 2A4027 |

01-010 | 2A3367 |

01-010 | 2A3896 |

01-010 | 2A4085 |

General

Price and availability - refer to IAE.

The practices and processes referred to in this procedure by the TASK numbers are in SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| Welding equipment | LOCAL | |||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-263 GRINDING WHEEL | LOCAL | CoMat 02-263 | ||

| CoMat 03-284 WELDING FILLER WIRE, NiBASE | LOCAL | CoMat 03-284 |

Spares

NONESafety Requirements

CAUTION

Procedure

Use grit blast, refer to SPM TASK 70-12-09-120-501.

Clean the repair areas.

Refer to SPM TASK 70-11-26-300-503 before weld.

Solvent wipe the repair areas.

SUBTASK 72-44-10-120-055 Clean the Worn/Fretted Repair Areas of Stage 1 HPT Support

Use manual gas tungsten arc method.

Use weld wire CoMat 03-284 WELDING FILLER WIRE, NiBASE.

It is recommended that a cooled copper chill block be used to minimize distortion during welding.

Refer to SPM TASK 70-31-02-310-501-001.

Weld buildup the repair surfaces.

SUBTASK 72-44-10-310-051 Weld Buildup the Repair Areas of the Stage 1 HPT Support

Refer to SPM TASK 70-23-03-230-501 or SPM TASK 70-23-08-230-501.

Fluorescent Penetrant Inspect the support.

SUBTASK 72-44-10-230-062 Fluorescent Penetrant inspect the Stage 1 HPT Support

Refer to SPM TASK 70-37-01-370-501.

Heat treat the Stage 1 HPT support.

SUBTASK 72-44-10-370-051 Heat Treat the Stage 1 HPT Support

Refer to SPM TASK 70-23-03-230-501 or SPM TASK 70-23-08-230-501.

Fluorescent Penetrant inspect the support.

SUBTASK 72-44-10-220-140 Inspect the Stage 1 HPT Support

Refer to Repair, VRS3272 TASK 72-44-10-300-002 (REPAIR-002).

Reinstall or replace the Stage 1 HPT support flange nuts.

Refer to TASK 72-44-10-440-001 (ASSEMBLY).

Reassemble the Stage 1 seal onto the Stage 1 HPT support.

Refer to Repair, VRS3129 TASK 72-44-10-300-007 (REPAIR-007).

If plasma coat was removed, apply plasma coat on the outside diameter bolt flange rear snap diameter.

Refer to Repair, VRS3270 TASK 72-44-10-300-008 (REPAIR-008).

If plasma coat was removed, apply plasma coat on the outside diameter bolt flange front snap diameter.

Refer to Repair, VRS3766 TASK 72-44-10-300-025 (REPAIR-025).

Additionally, for PN2A4085 apply plasma coat on the rear flange inner face.

Refer to Repair, VRS3771 TASK 72-44-10-300-027 (REPAIR-027).

Additionally, for PN2A4085 replace the brush seal.

SUBTASK 72-44-10-440-052 Postrequisite

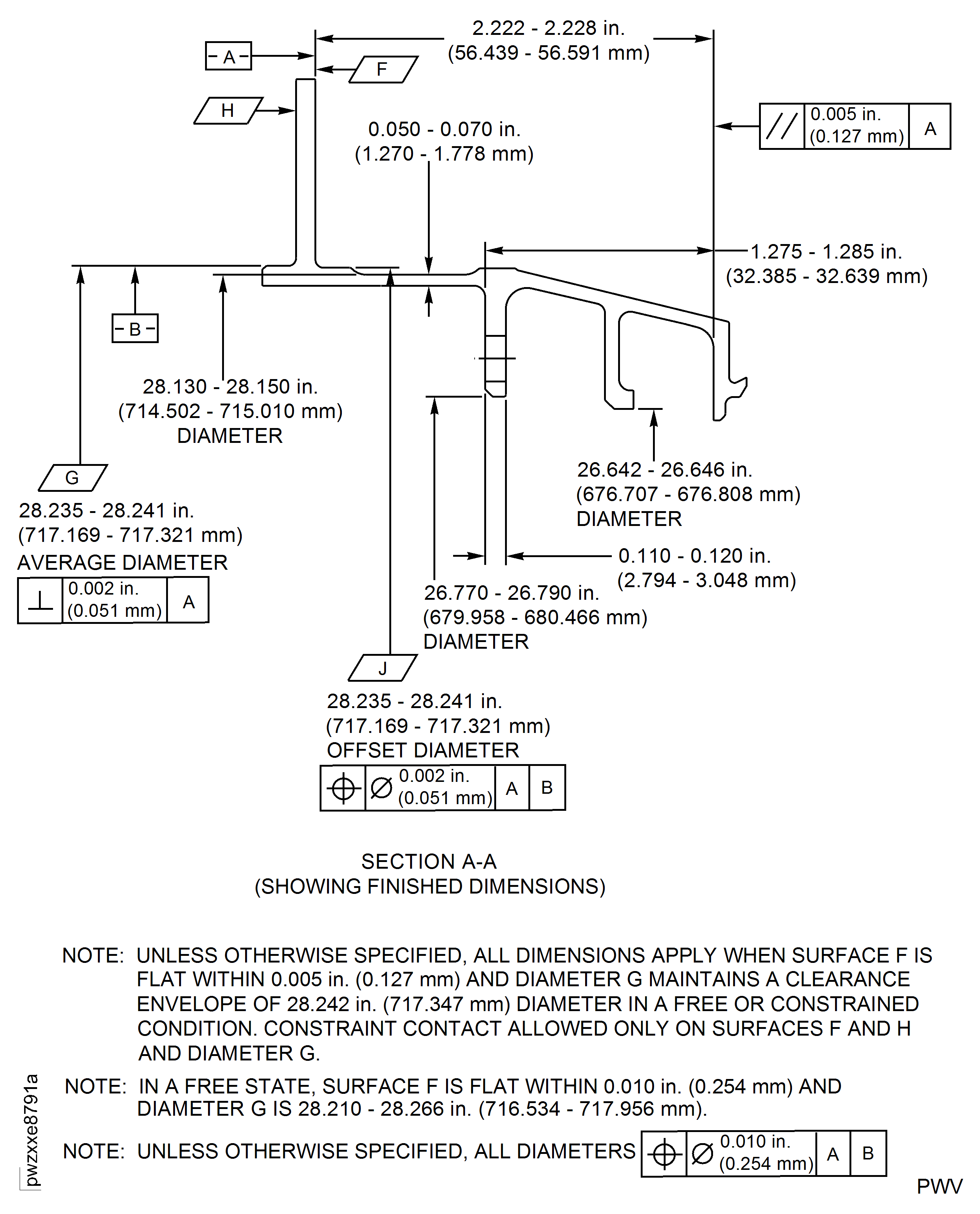

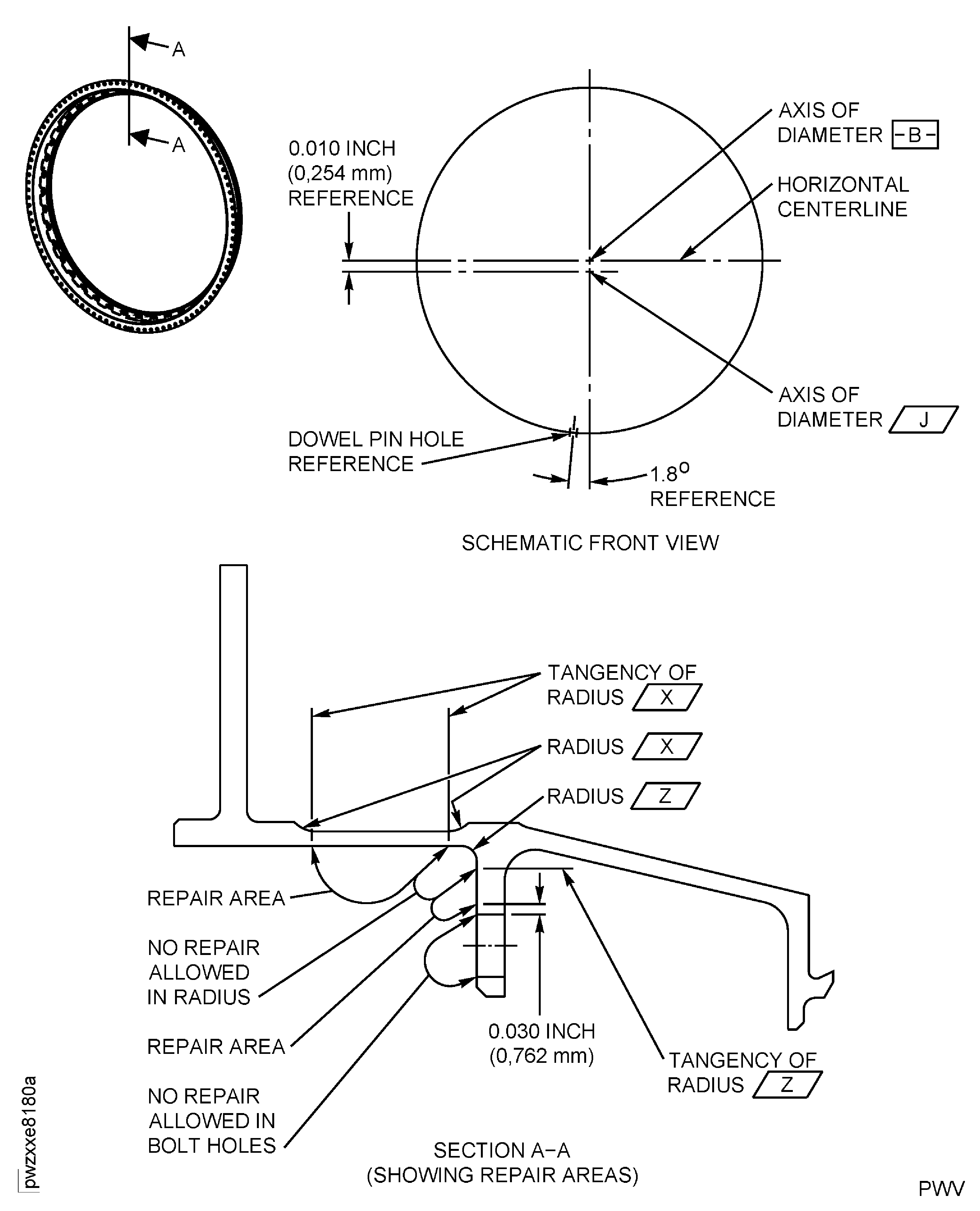

Figure: Repair Details and Dimensions (PN2A1292, 2A1358 and 2A1664)

Sheet 1

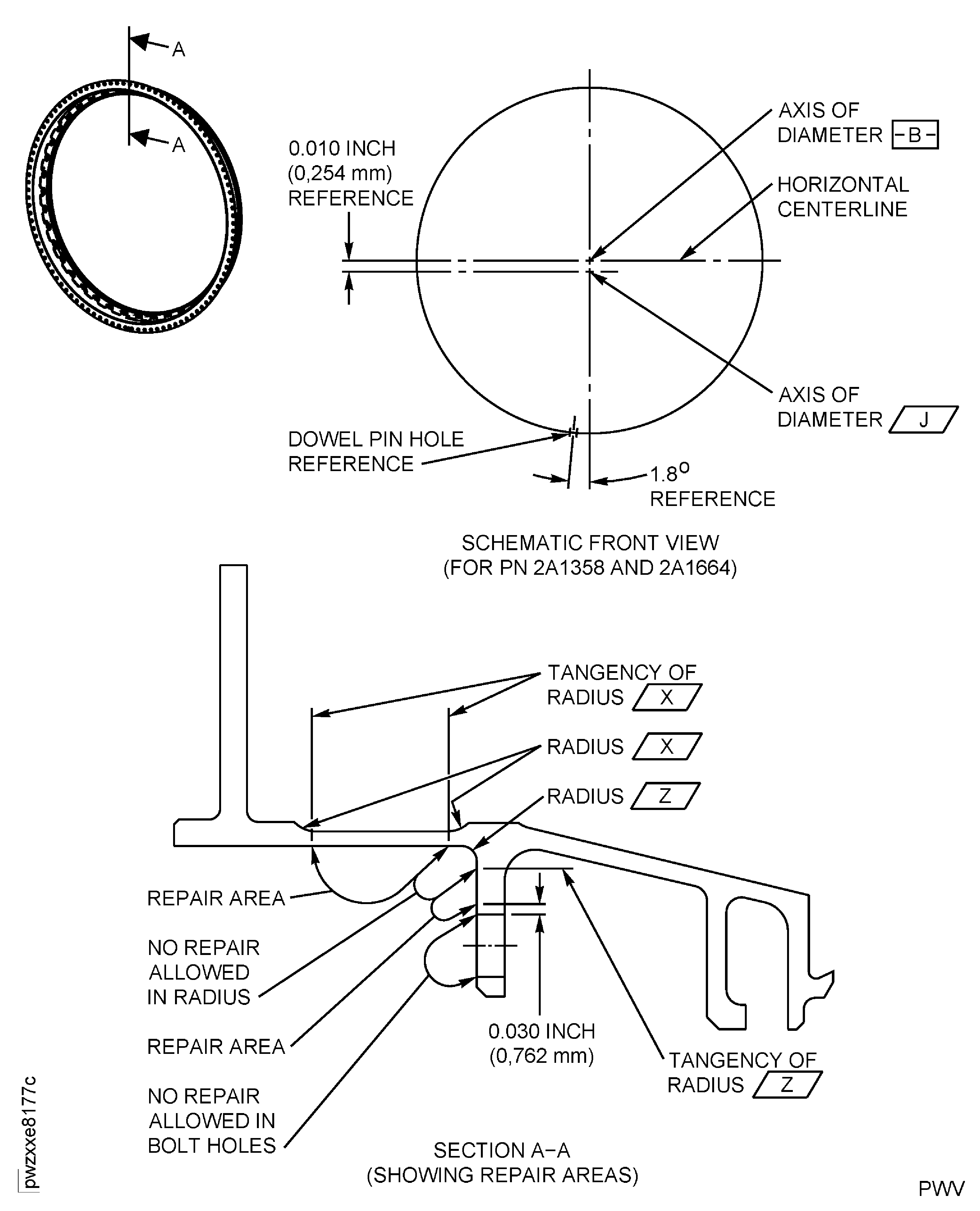

Figure: Repair Details and Dimensions (PN 2A1358 and 2A1664)

Sheet 2

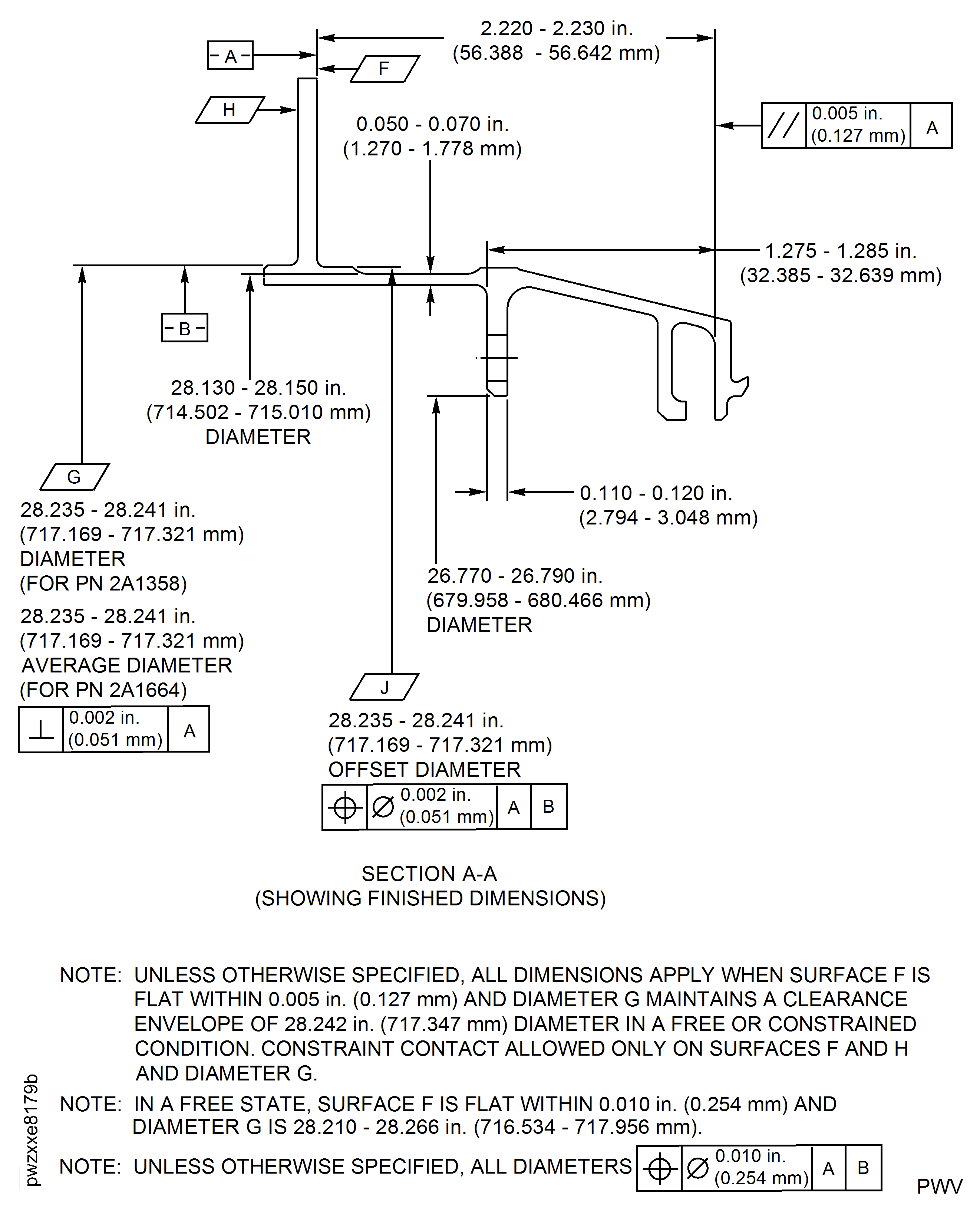

Figure: Repair Details and Dimensions (PN 2A1292)

Sheet 3

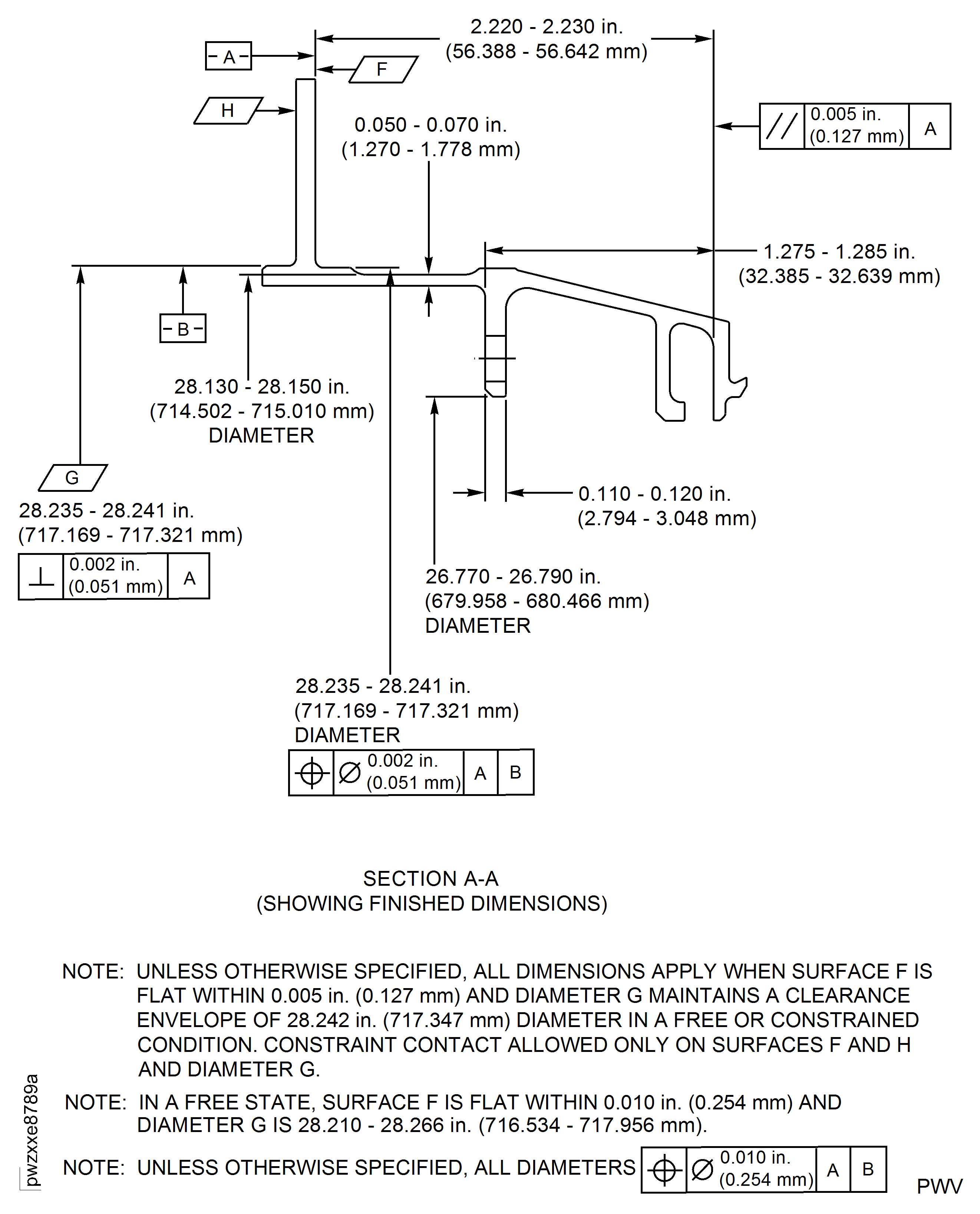

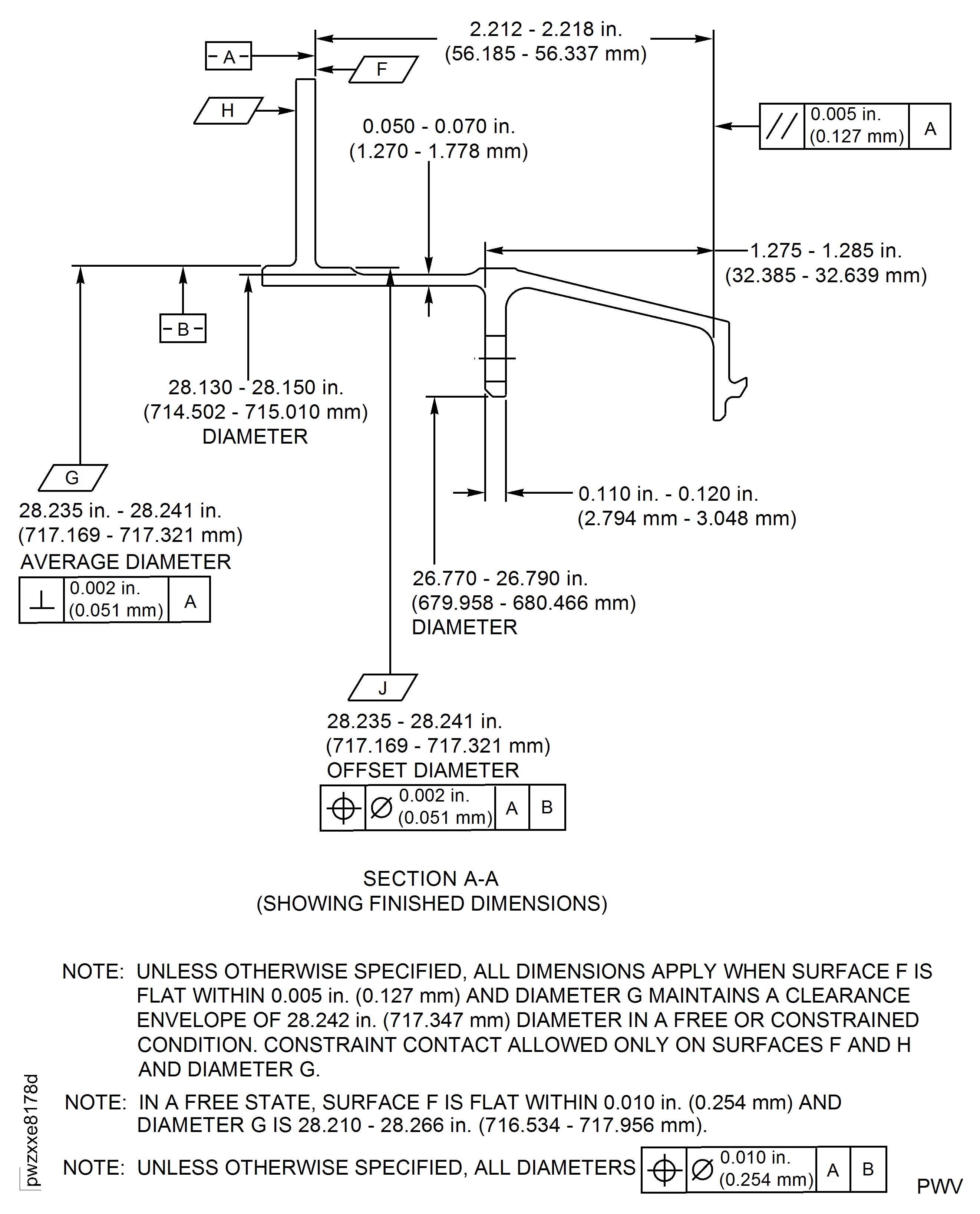

Figure: Repair Details and Dimensions (PN 2A2703, 2A4027, 2A3360, 2A3367 and 2A3896)

Sheet 1

Figure: Repair Details and Dimensions (PN 2A2703, 2A3360, 2A4027, 2A3367 and 2A3896)

Sheet 2

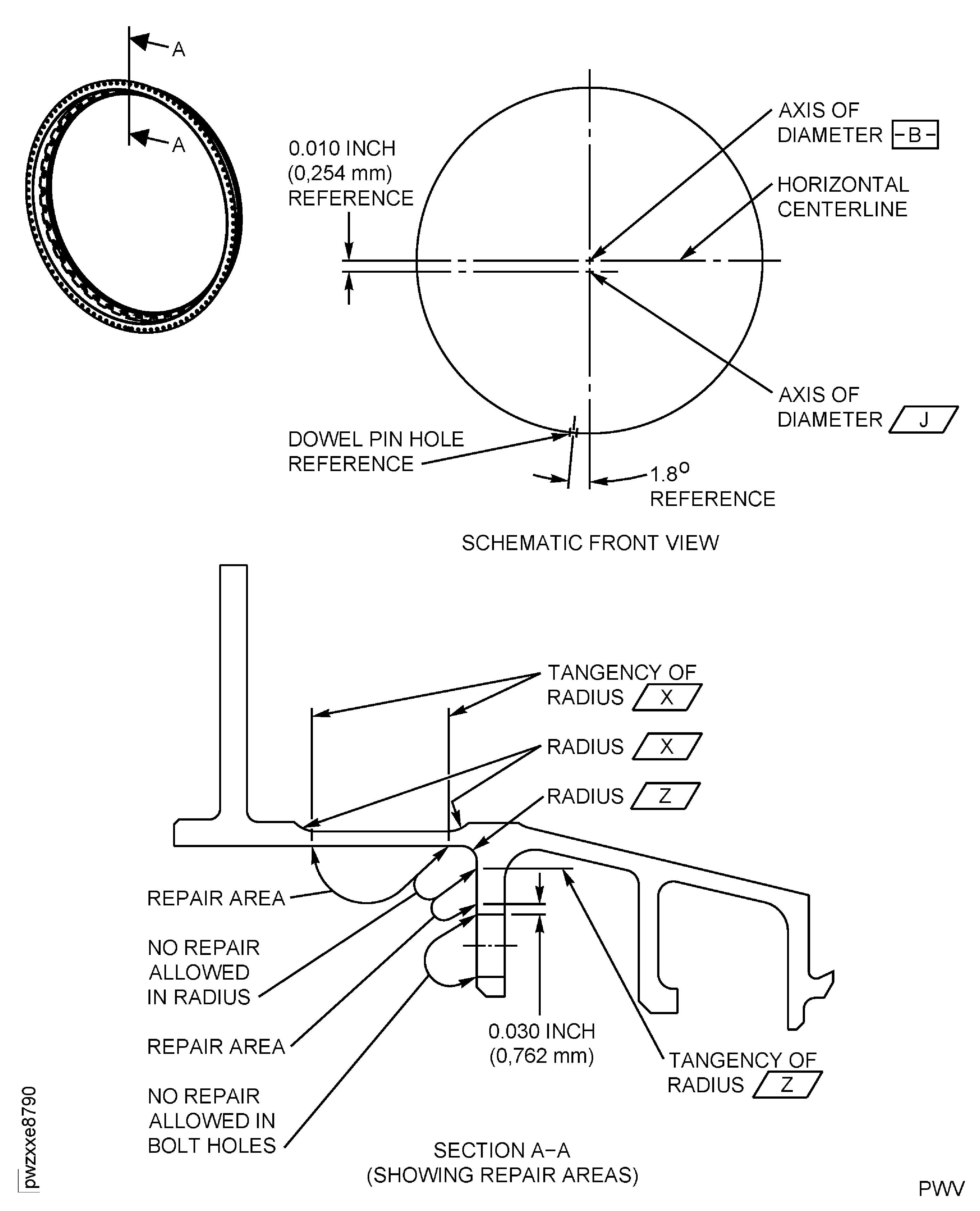

Figure: Repair Details Stagand Dimensions (PN 2A4085)

Sheet 1

Figure: Repair Details and Dimensions (PN 2A4085)

Sheet 2