Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 71-00-02-400-007-A00 (A1-PPBU) - Install The Drains Mast And The LP Compressor/Intermediate Case Module Drains, Installation-007

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

Special torque data is identified with the symbol * after the torque value.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILSunless other lubricants are referred to in the procedure.

Transportation covers/blanks must be removed immediately before installation of the components.

For lockwire data and procedures refer to the SPM TASK 70-42-05-400-501.

After assembly apply CoMat 07-032 ENAMEL, POLYURETHANE, AIR-DRYING, TWO-PART, GREY to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. Refer to the SPM TASK 70-38-07-380-501.

Loosely assemble the tubes together and the clip positions during the installation procedure. This will give flexibility and movement and not put strain on the tubes. Where access allows, fully torque the tube nuts and then the clip positions when all the tubes are connected and installed. Torque the nuts securing the tubes at the bifurcation panel after all the tubes have been installed. Refer to each specific step for the torque values and procedure at the point of application.

Torque the tube nuts and clips so that the tubes are free of preload and have a minimum clearance of 0.25 in. (6.4 mm) with adjacent components and structure. A minimum clearance of 0.02 in. (0.5 mm) is permitted between clip positions 0950 and 0951, between the gearbox and the air starter drain tube (221) and IDG drain tube (229). A minimum clearance of 0.06 in. (1.5 mm) is permitted between the gearbox and the FMU drain tube (225) on the collector plate assembly. Refer to the SPM TASK 70-42-01-400-501 to tighten tube end connectors. Make sure that the tubes always have support to prevent unwanted strain.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 02-147 LOCKWIRE | LOCAL | CoMat 02-147 | ||

| CoMat 07-032 ENAMEL, POLYURETHANE, AIR-DRYING, TWO-PART, GREY | LOCAL | CoMat 07-032 | ||

| CoMat 10-077 APPROVED ENGINE OILS | IAE00 | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| PIN - SHOULDER, HEADLESS, .0.1159 X 0.122 X 0.265 | LOCAL | 5306941 | 1 | |

| PIN - SHOULDER, HEADLESS, .0.1159 X 0.122 X 0.265 | LOCAL | 5306941 | 1 | |

| PIN - SHOULDER, HEADLESS, .0.1159 X 0.122 X 0.265 | LOCAL | 5306941 | 1 | |

| PIN - SHOULDER, HEADLESS, .0.1159 X 0.122 X 0.265 | LOCAL | 5306941 | 1 |

Safety Requirements

NONEProcedure

Refer to Figure.

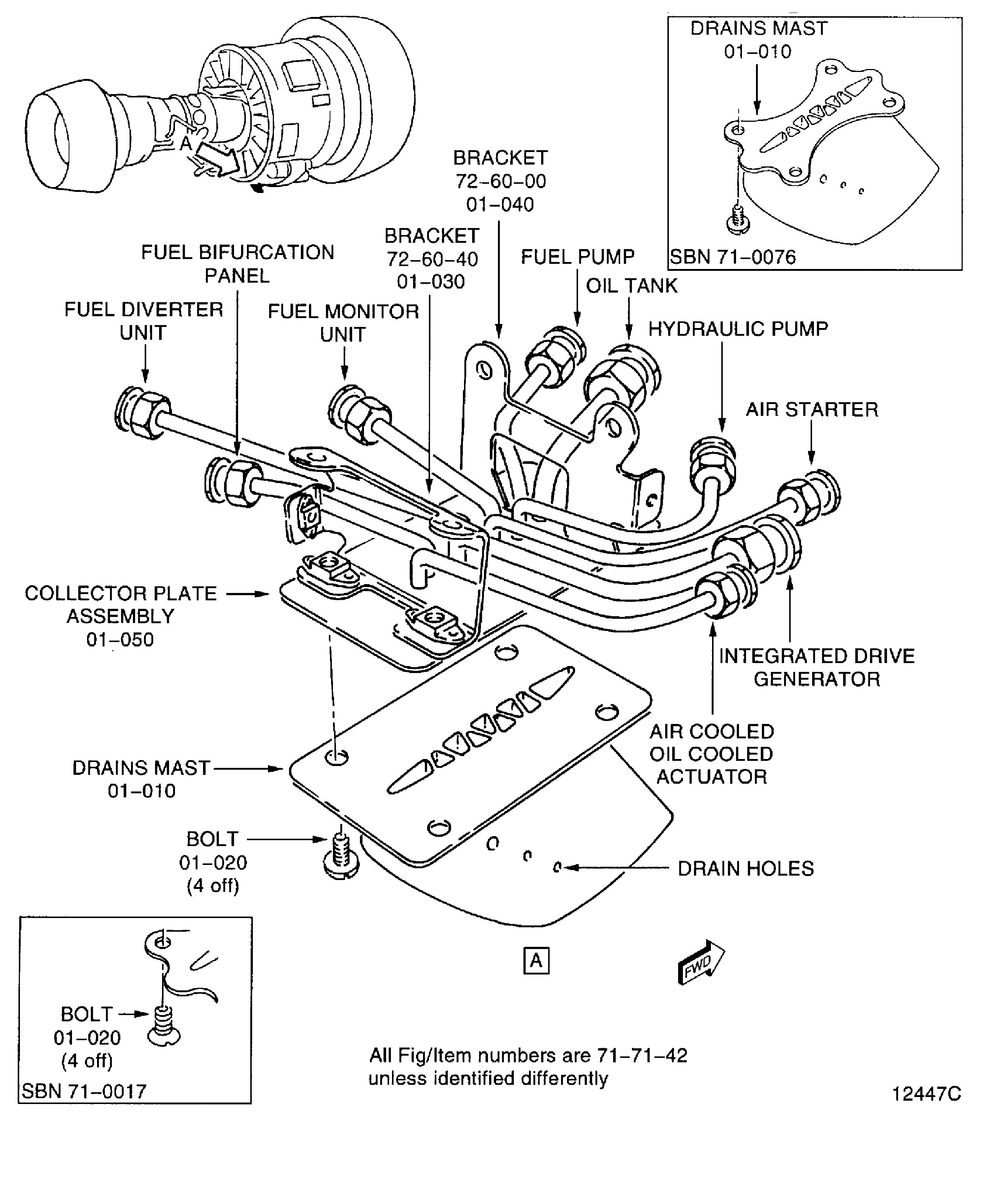

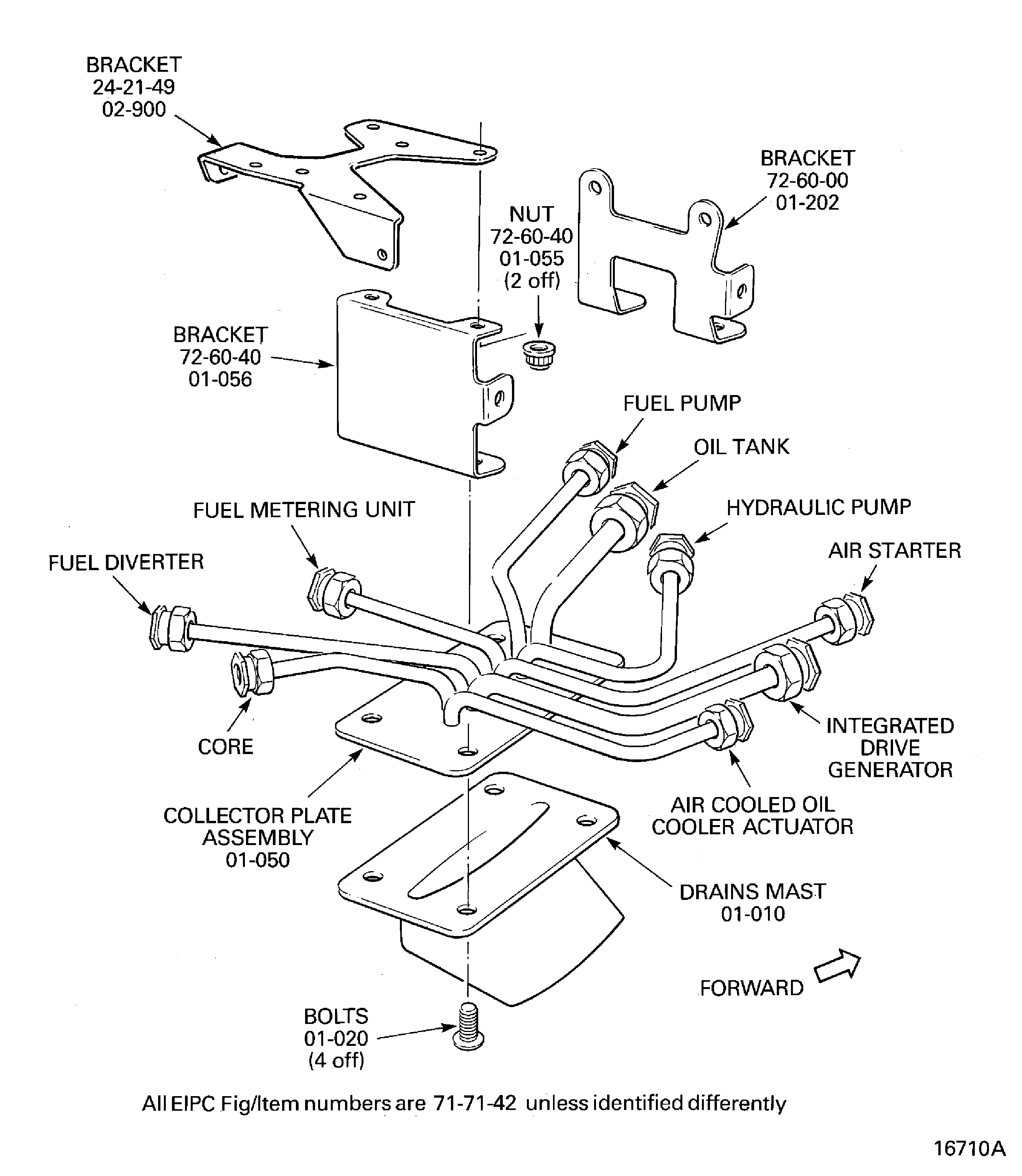

Hold the collector plate assembly POWER PLANT-DRAIN TUBE MAST (71-71-42, 01-050) and the drains mast POWER PLANT-DRAIN TUBE MAST (71-71-42, 01-010) on the engine in the correct position for installation.

Loosely install the four bolts POWER PLANT-DRAIN TUBE MAST (71-71-42, 01-020) to hold the drains mast assembly to the engine.

Oil tank/Drain tube "OIL,HYDRAULIC AND WATER DRAIN TUBES-POWER PLANT (71-73-48, 01-100).

Fuel pump/Drain tube POWER PLANT-FUEL DRAIN TUBES-POWER PLANT (71-71-48, 03-100).

Hydraulic pump/Drain tube "OIL,HYDRAULIC AND WATER DRAIN TUBES-POWER PLANT (71-73-48, 01-500).

Fuel monitor unit/Drain tube POWER PLANT-FUEL DRAIN TUBES-POWER PLANT (71-71-48, 02-500).

Air starter/Drain tube OIL,HYDRAULIC AND WATER DRAIN TUBES-POWER PLANT (71-73-48, 02-100).

Fuel diverter unit/Drain tube POWER PLANT-FUEL DRAIN TUBES-POWER PLANT (71-71-48, 02-100).

Integrated drive generator/Drain tube OIL,HYDRAULIC AND WATER DRAIN TUBES-POWER PLANT (71-73-48, 02-500).

Core drain (bifurcation panel)/Drain tube POWER PLANT-FUEL DRAIN TUBES-POWER PLANT (71-71-48, 03-700).

Air cooled oil cooler/Drain tube OIL,HYDRAULIC AND WATER DRAIN TUBES-POWER PLANT (71-73-48, 03-500).

Drain mast position/Connection.

Loosely attach the drain tubes to the appropriate connections as follows:

Torque tighten the bolts POWER PLANT-DRAIN TUBE MAST (71-71-42, 01-020) to 100 lbf-in. (11.3 Nm).

Safety the connection with CoMat 02-126 LOCKWIRE or CoMat 02-147 LOCKWIRE.

Tighten the tube connectors.

SUBTASK 71-00-02-440-011-000 Install the Drains Mast

Attach the drains mast POWER PLANT-DRAIN TUBE MAST (71-71-42, 01-010) and the collector plate assembly POWER PLANT-DRAIN TUBE MAST (71-71-42, 01-050) to the brackets ENGINE-ANGLE GEARBOX ASSEMBLY (72-60-40, 01-056) and ENGINE-EXTERNAL GEARBOX MODULE (72-60-00, 01-202) on the angle gearbox with the four bolts POWER PLANT-DRAIN TUBE MAST (71-71-42, 01-020). Torque the bolts to 85 lbf-in. to 105 lbf-in. (10 Nm to 12 Nm).

Lightly lubricate a new sealing ring OIL,HYDRAULIC AND WATER DRAIN TUBES-POWER PLANT (71-73-48, 02-505) 1 off with CoMat 10-077 APPROVED ENGINE OILS and install it on the banjo coupling OIL,HYDRAULIC AND WATER DRAIN TUBES-POWER PLANT (71-73-48, 02-501). Install the banjo coupling in the gearbox (adjacent to the IDG interface) and torque to 221 lbf-in. to 239 lbf-in. (25 Nm to 27 Nm). Safety with CoMat 02-126 LOCKWIRE.

Connect the tube 229 to the banjo coupling and the collector plate assembly. Torque the collector plate connector to 204 lbf-in. to 221 lbf-in. (23 Nm to 25 Nm) and the tube connector to 159 lbf-in. to 177 lbf-in. (18 Nm to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

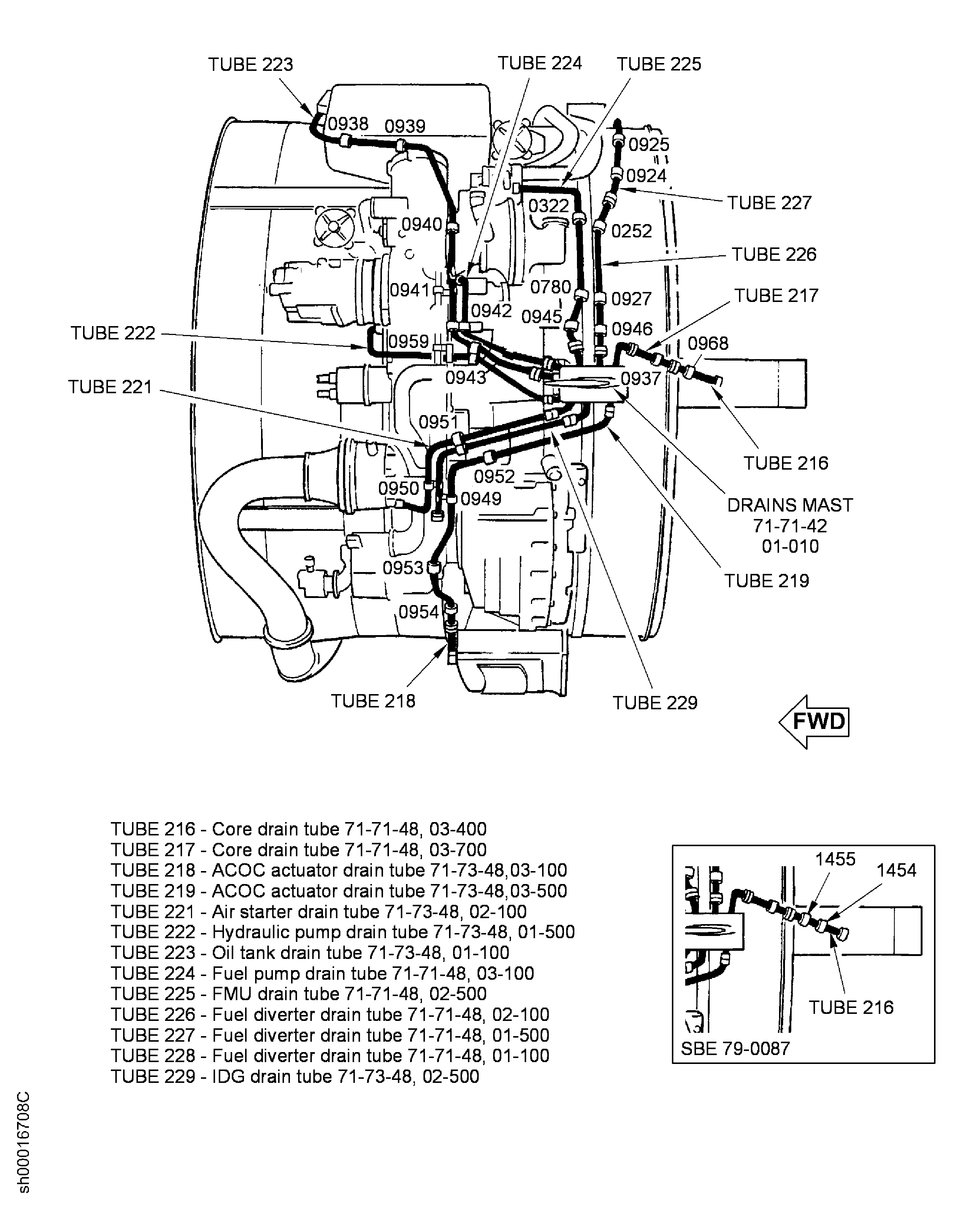

Install the Integrated Drive Generator (IDG) drain tube (229).

Torque the tube 218 connector to 142 lbf-in. to 150 lbf-in. (16 Nm to 17 Nm) and the tube 219 and collector plate connectors to 159 lbf-in. to 177 lbf-in. (18 Nm to 20 Nm). Safety the connectors with CoMat 02-126 LOCKWIRE.

Install the Air Cooled Oil Cooler (ACOC) actuator drain tubes (218 and 219).

Lightly lubricate a new "OIL,HYDRAULIC AND WATER DRAIN TUBES-POWER PLANT (71-73-48, 02-105) packing 1 off with CoMat 10-077 APPROVED ENGINE OILS and install it on the union "OIL,HYDRAULIC AND WATER DRAIN TUBES-POWER PLANT (71-73-48, 02-101).

Torque the tube connectors to 159 lbf-in. to 177 lbf-in. (18 Nm to 20 Nm) and safety with CoMat 02-126 LOCKWIRE.

NOTE

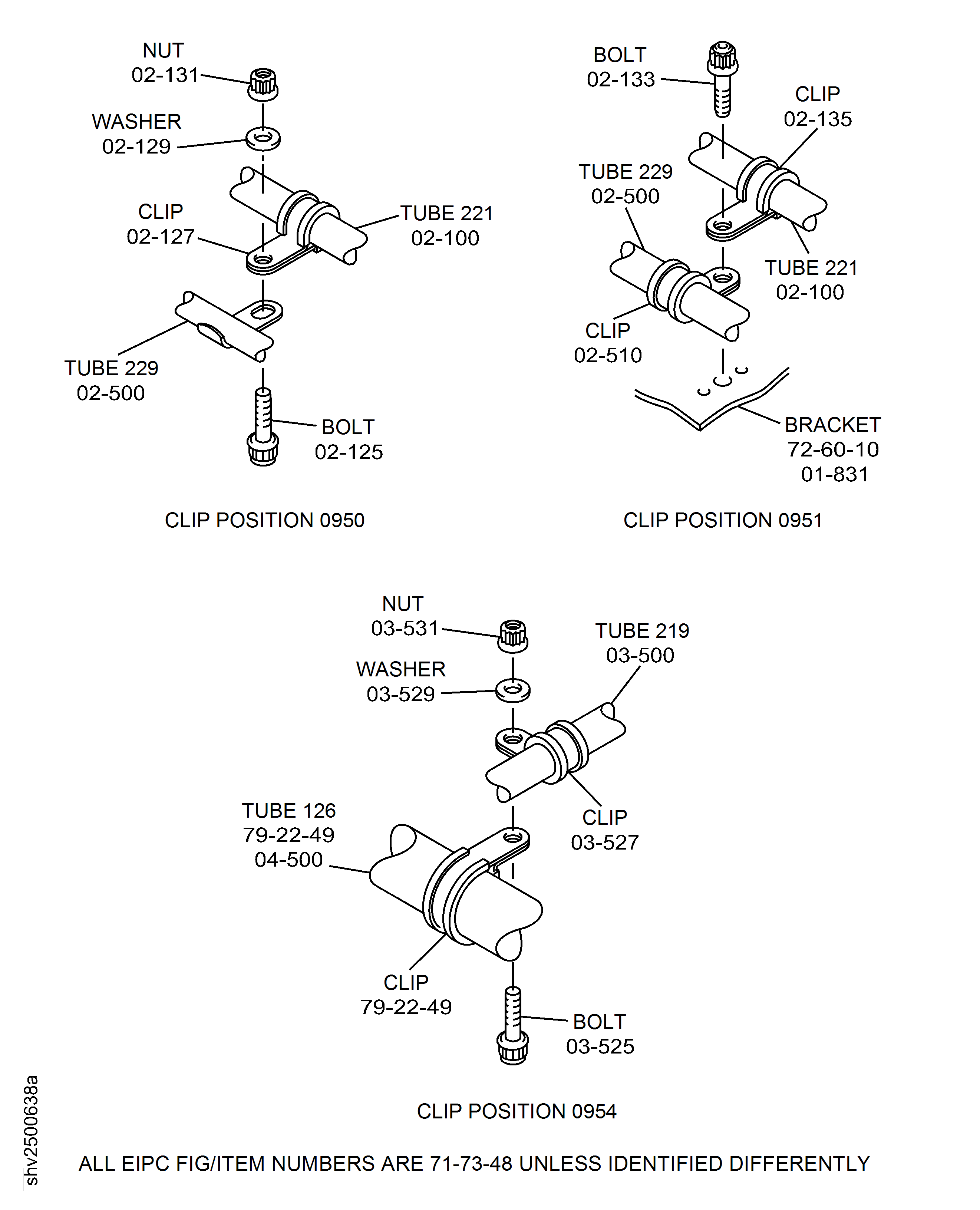

A minimum clearance of 0.02 in. (0.5 mm) is permitted between clip positions 0950 and 0951, between the gearbox and the air starter drain tube (221) and IDG drain tube (229).Install the air starter drain tube (221).

Lightly lubricate a new "OIL,HYDRAULIC AND WATER DRAIN TUBES-POWER PLANT (71-73-48, 01-505) packing 1 off with CoMat 10-077 APPROVED ENGINE OILS and install it on the union "OIL,HYDRAULIC AND WATER DRAIN TUBES-POWER PLANT (71-73-48, 01-501).

NOTE

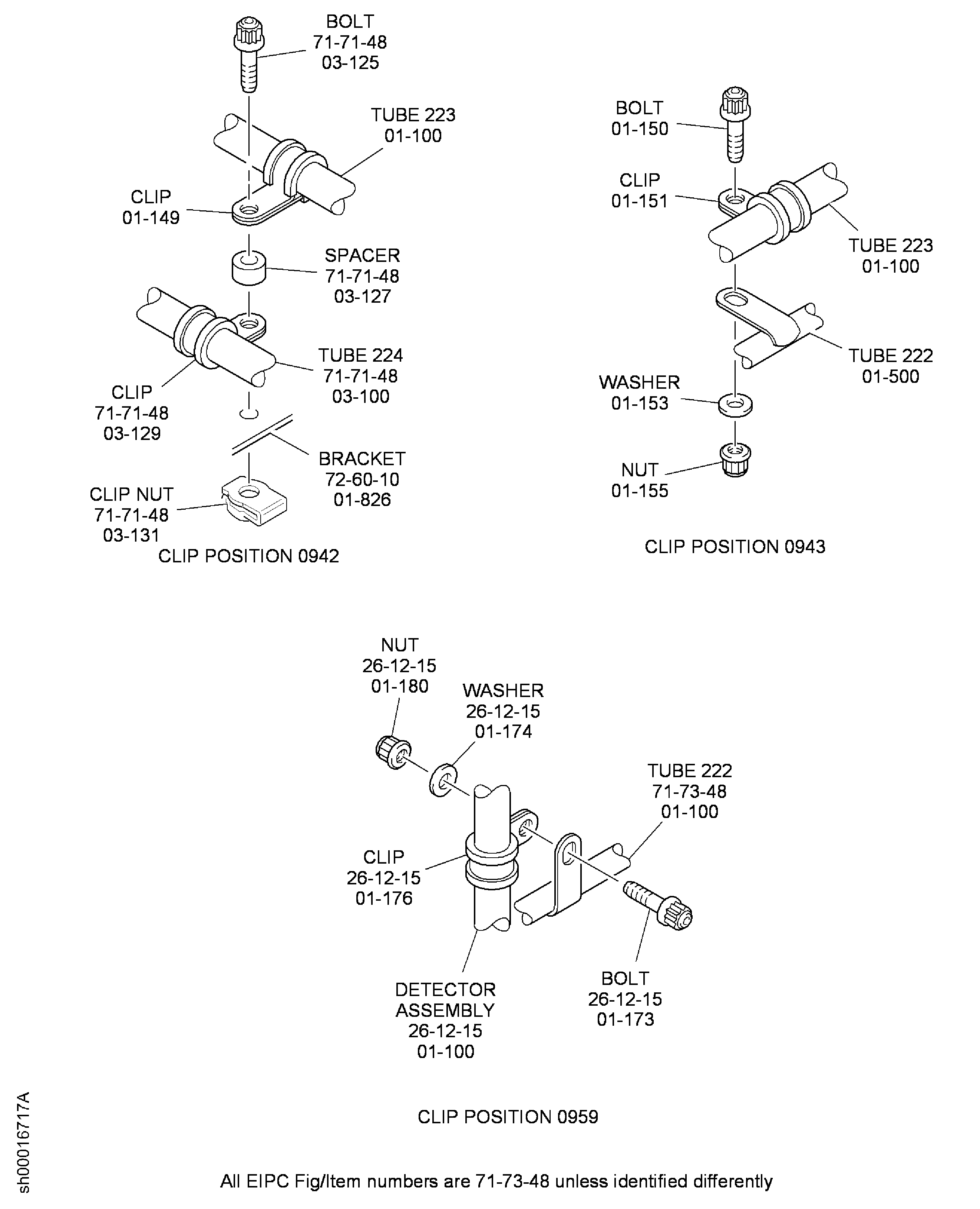

Tube 222 is attached at clip position 0943 when tube 223 is installed, and at clip position 0959 when the fire detector assembly is installed.Connect the tube 222 to the union and the collector plate assembly and torque the tube connectors to 159 lbf-in. to 177 lbf-in. (18 Nm to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the hydraulic pump drain tube (222).

Lightly lubricate a new "OIL,HYDRAULIC AND WATER DRAIN TUBES-POWER PLANT (71-73-48, 01-105) packing 1 off with CoMat 10-077 APPROVED ENGINE OILS and install it on the union "OIL,HYDRAULIC AND WATER DRAIN TUBES-POWER PLANT (71-73-48, 01-101).

Torque the tube connector to 159 to 177 lbf-in. (18 to 20 Nm) and the collector plate connector to 204 lbf-in. to 221 lbf-in. (23 Nm to 25 Nm). Safety the connectors with CoMat 02-126 LOCKWIRE.

Install the oil tank scupper drain tube (223).

Lightly lubricate a new POWER PLANT-FUEL DRAIN TUBES-POWER PLANT (71-71-48, 03-105) packing 1 off with CoMat 10-077 APPROVED ENGINE OILS and install it on the union POWER PLANT-FUEL DRAIN TUBES-POWER PLANT (71-71-48, 03-102).

Torque the tube connectors to 159 lbf-in. to 177 lbf-in. (18 Nm to 20 Nm) and safety with CoMat 02-126 LOCKWIRE.

Install the fuel pump drain tube (224).

NOTE

A minimum clearance of 0.06 in. (1.5 mm) is permitted between the gearbox and the FMU drain tube (225) on the collector plate assembly.Torque the tube connectors to 159 lbf-in.to 177 lbf-in. (18 Nm to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the Fuel Metering Unit (FMU) drain tube (225).

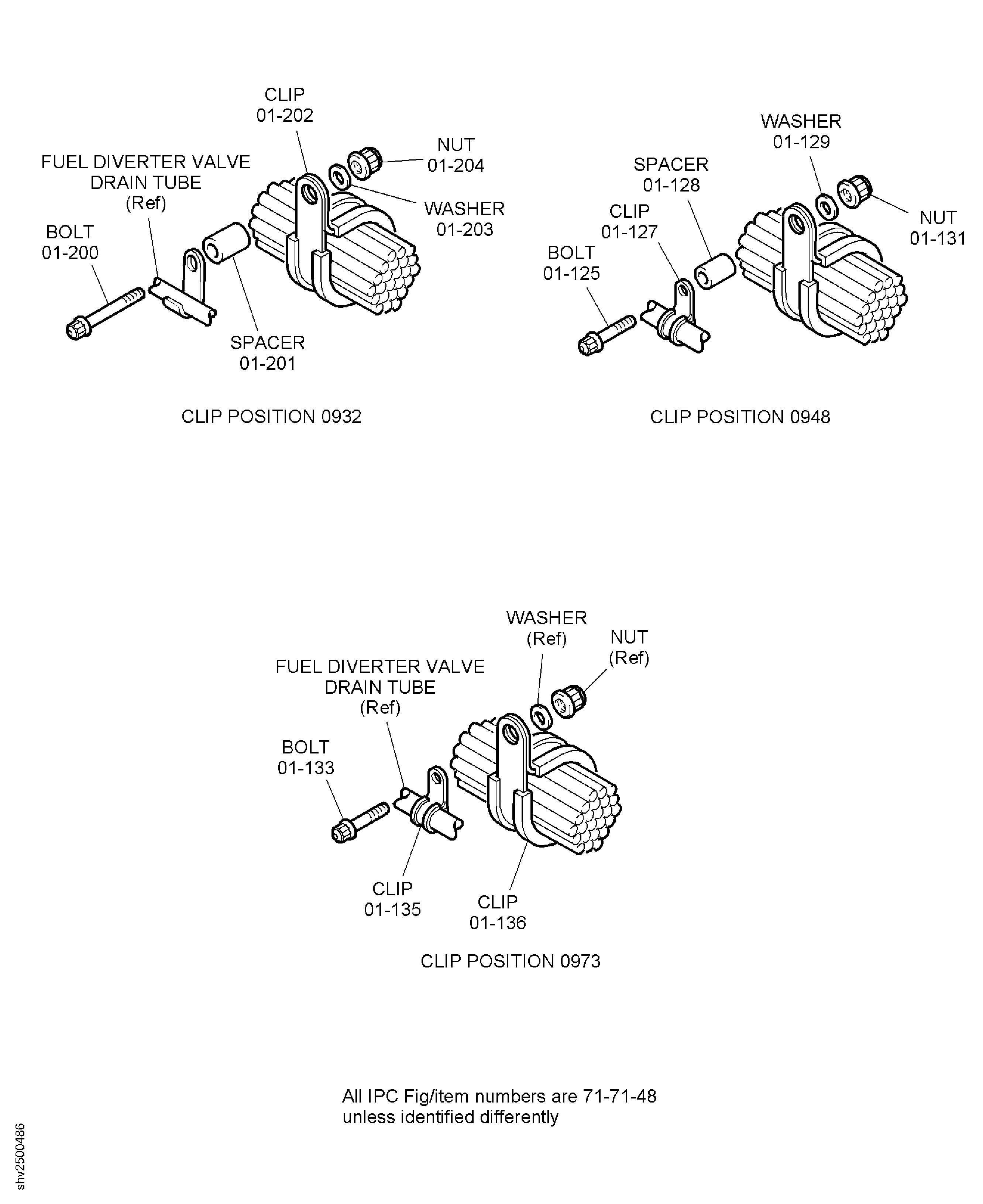

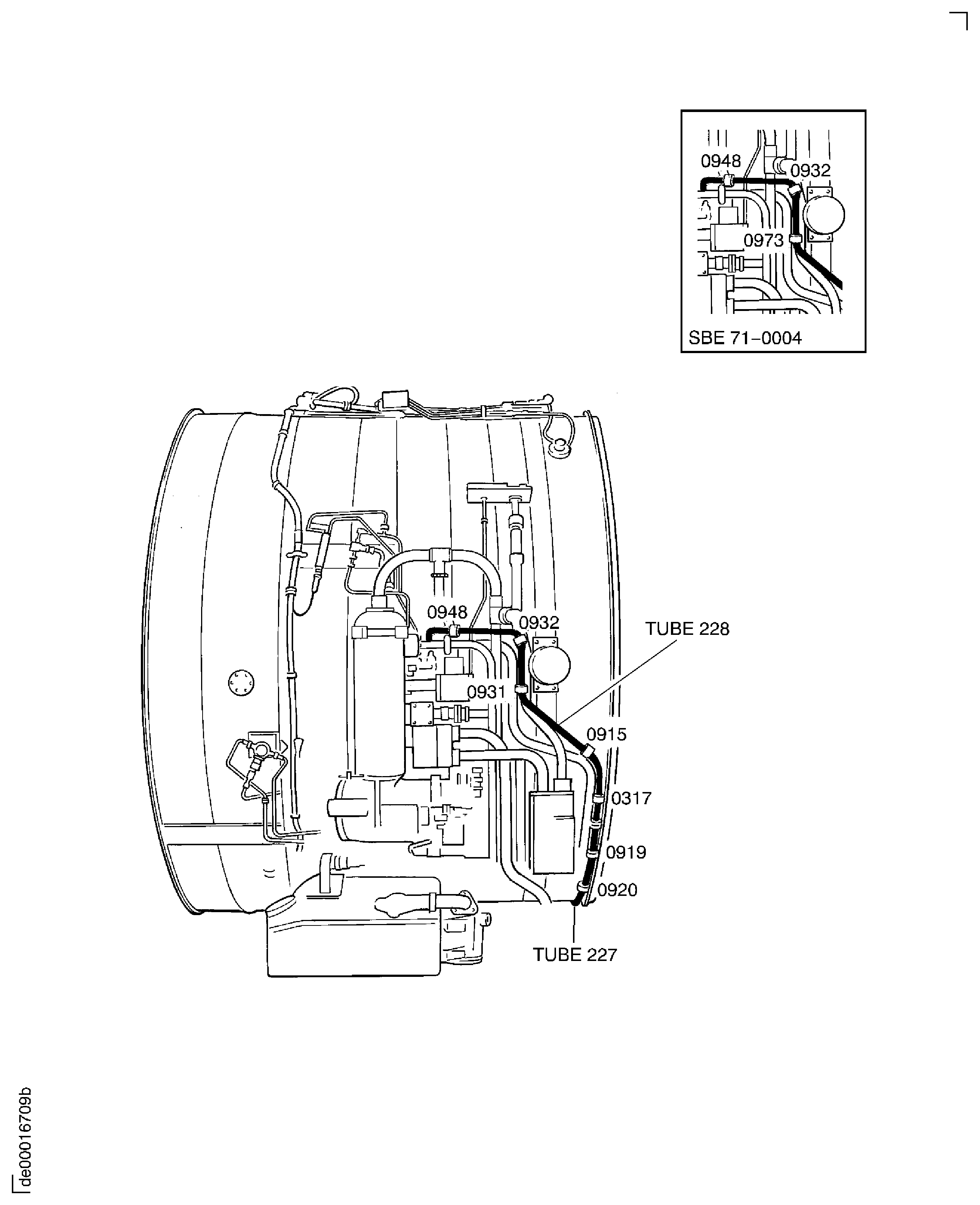

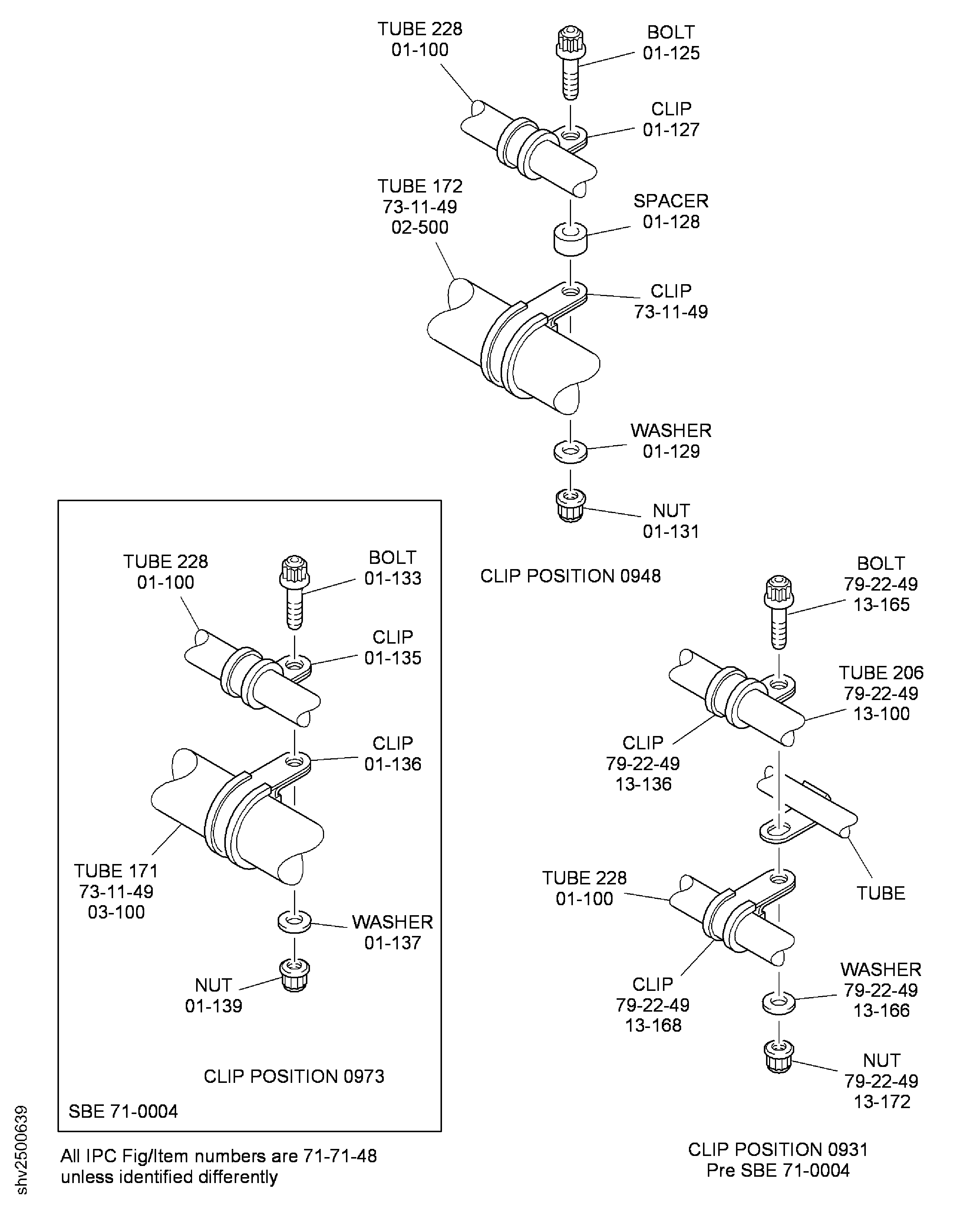

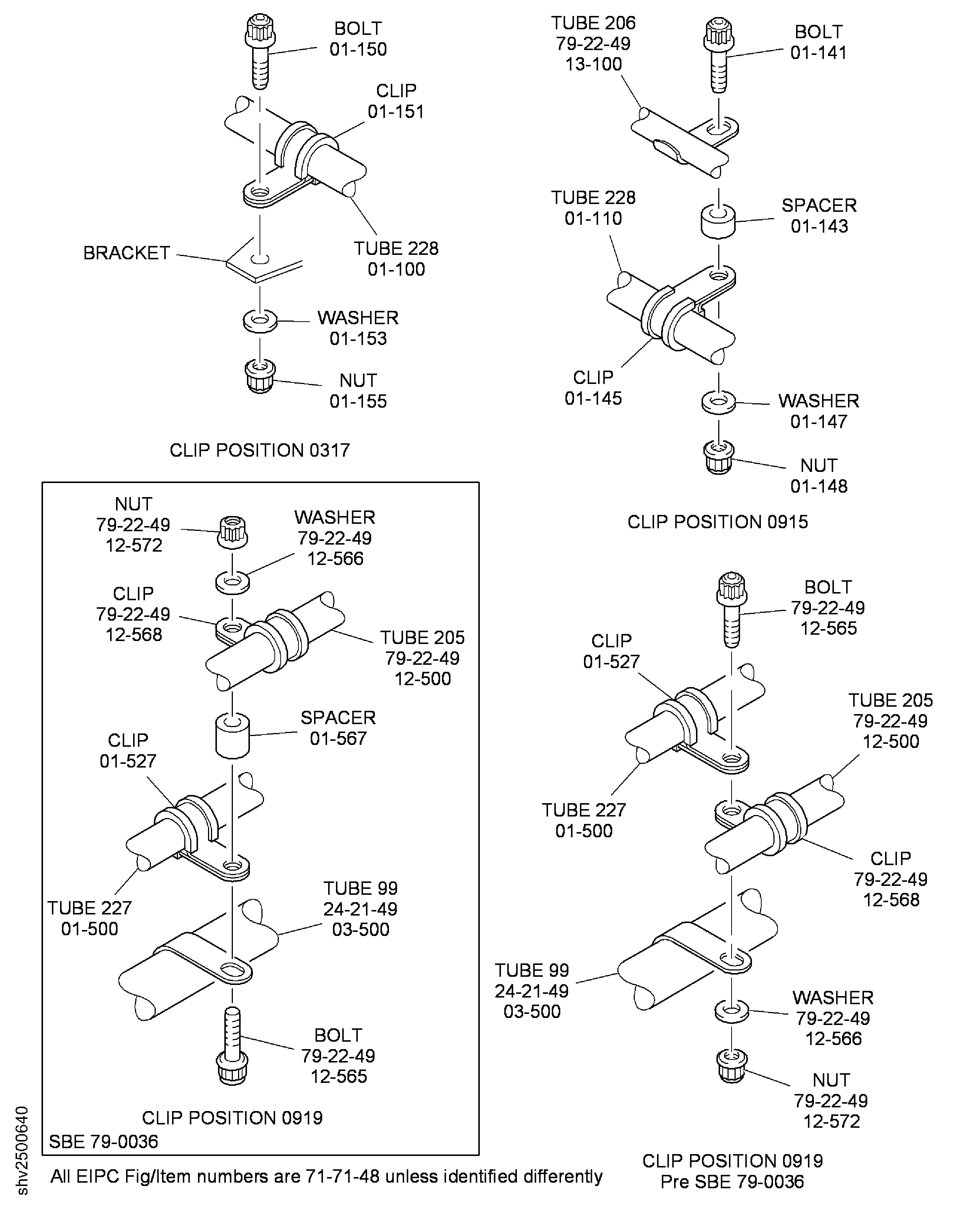

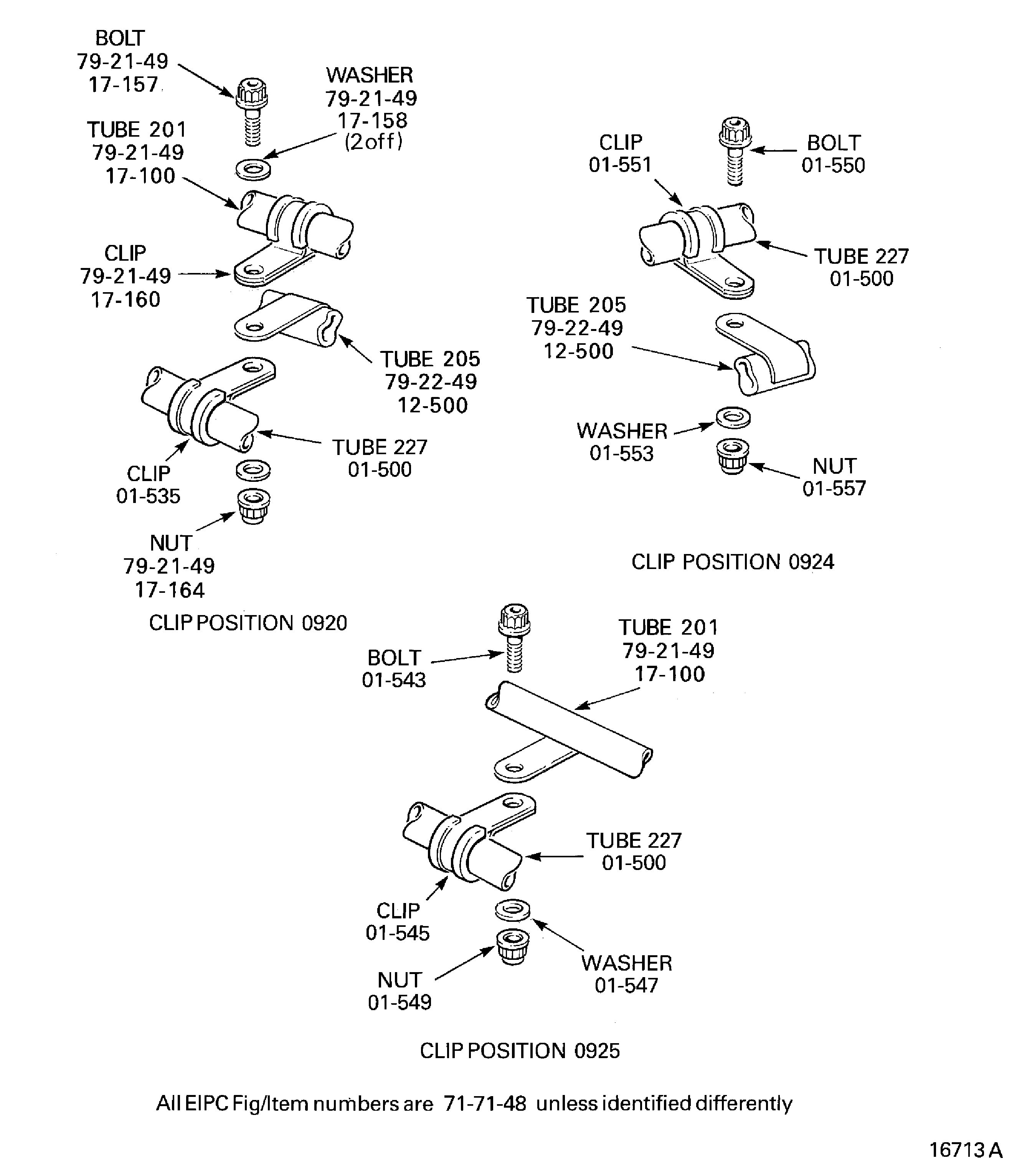

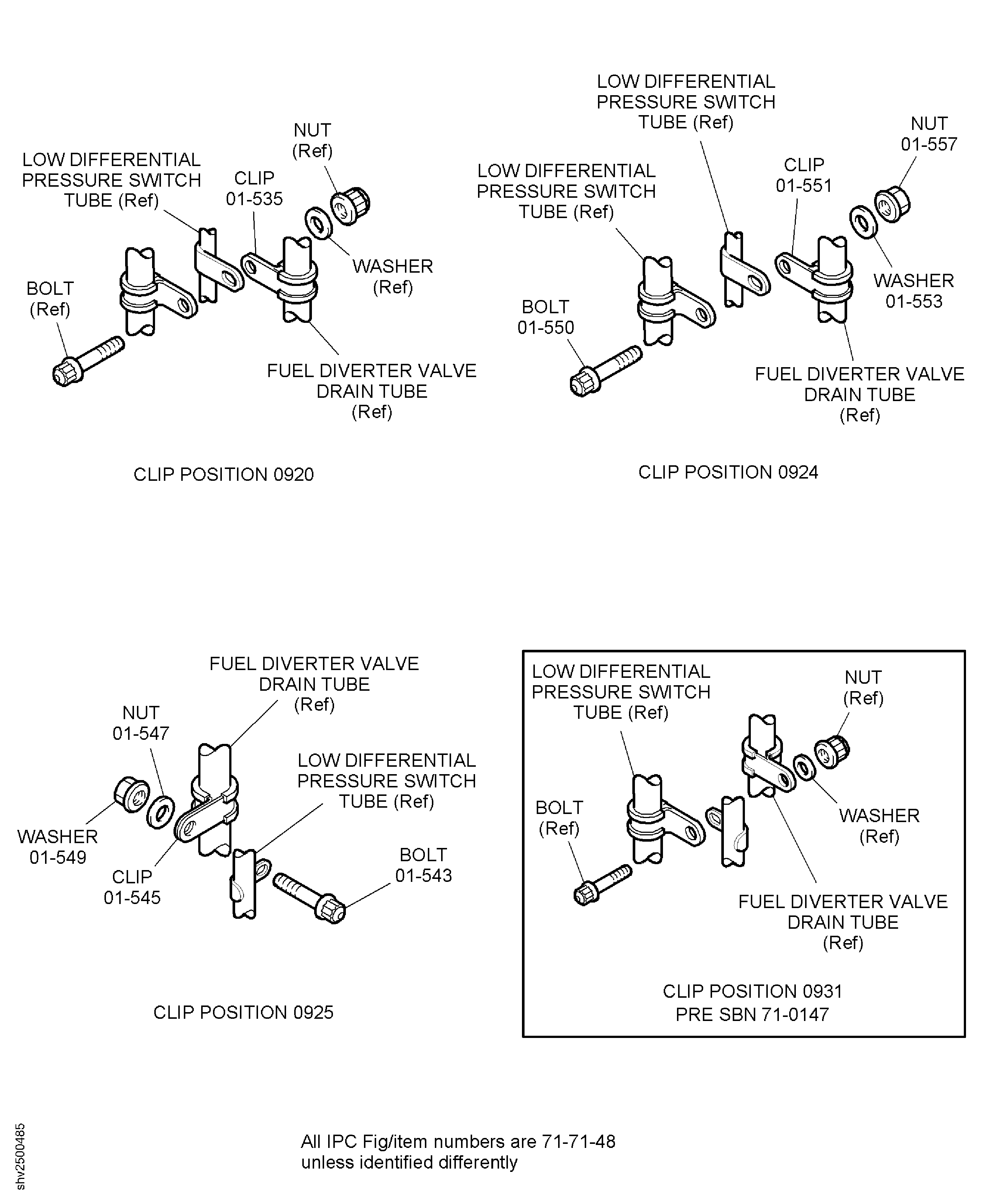

Pre SBE 71-0004: Assemble the clip positions 0948, 0932, 0931, 0915, 0317, 0919, 0920, 0925, 0924, 0252, 0927, and 0946. Torque the nuts to 36 to 45 lbf-in. (4 to 5 Nm).

SBE 71-0004: Assemble the clip positions 0948, 0932, 0973, 0915, 0317, 0919, 0920, 0925, 0924, 0252, 0927, and 0946. Torque the nuts to 36 to 45 lbf-in. (4 to 5 Nm).

Torque the tube connectors to 159 lbf-in. to 177 lbf-in. (18 Nm to 20 Nm) and safety with CoMat 02-126 LOCKWIRE.

Install the fuel diverter drain tubes (226, 227 and 228).

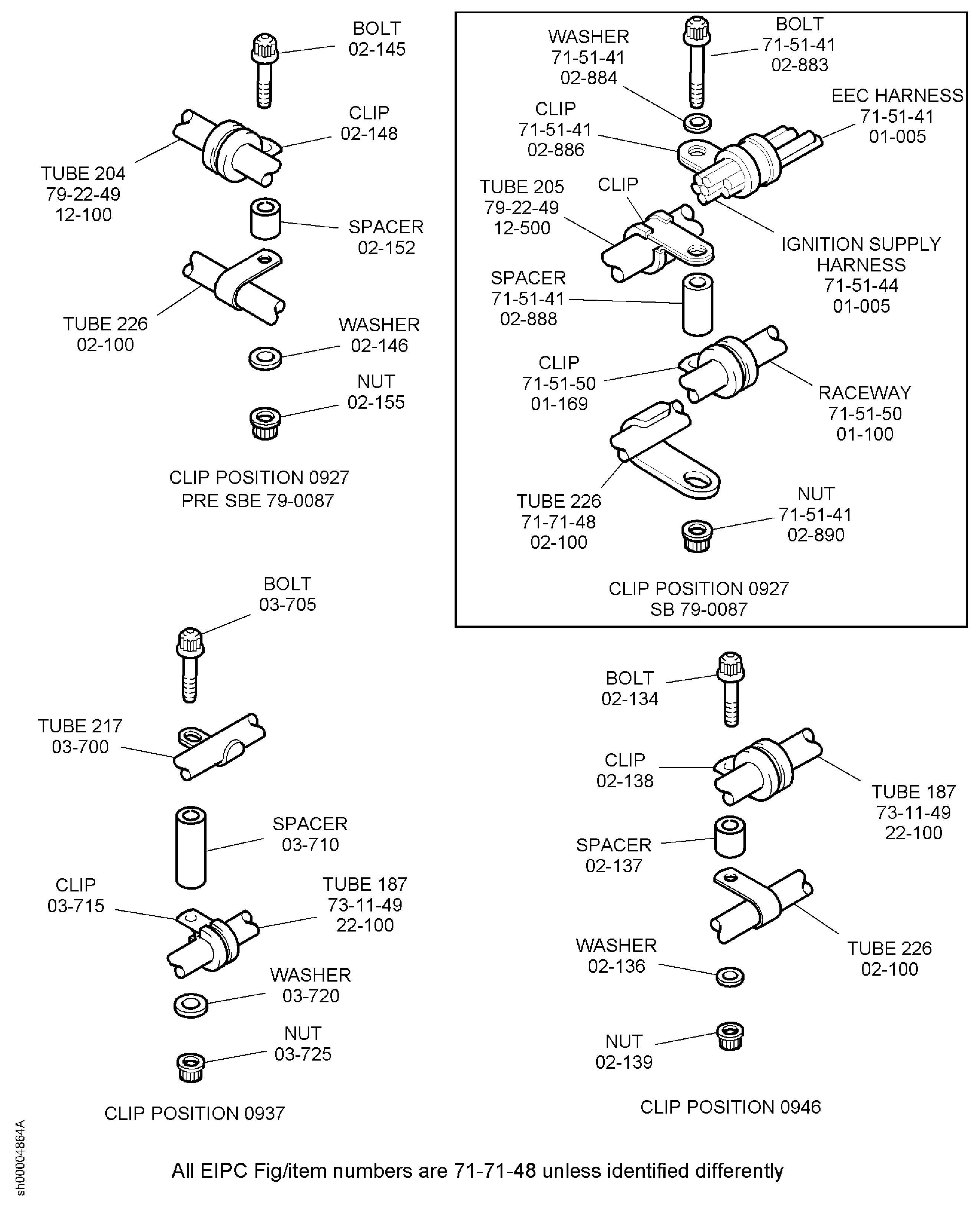

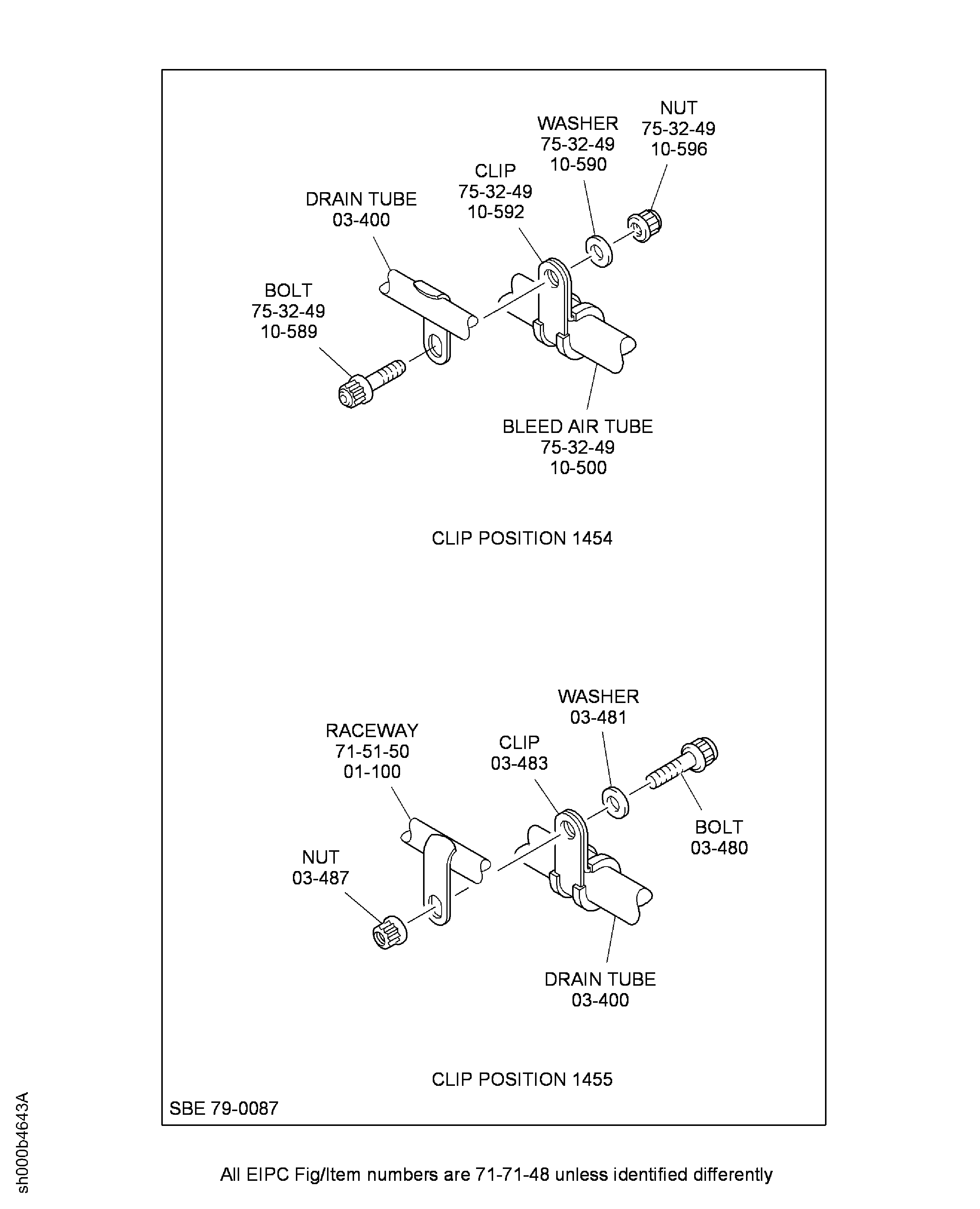

Pre SBE 79-0087: Assemble clip positions 0937 and 0968 and torque the nuts to 36 to 45 lbf-in. (4 to 5 Nm).

SBE 79-0087: Assemble clip positions 0937, 1454 and 1455 and torque the nuts to 36 lbf-in. to 45 lbf-in. (4 Nm to 5 Nm).

Install the two bolts POWER PLANT-FUEL DRAIN TUBES-POWER PLANT (71-71-48, 03-410) and nuts POWER PLANT-FUEL DRAIN TUBES-POWER PLANT (71-71-48, 03-415) that attach the tube 216 to the bifurcation panel and torque the nuts to 85 lbf-in. to 105 lbf-in. (10 Nm to 12 Nm).

Torque the tube connectors to 159 lbf-in. to 177 lbf-in. (18 Nm to 20 Nm) and safety with CoMat 02-126 LOCKWIRE.

Install the drain tubes (216 and 217) from the bifurcation panel.

SUBTASK 71-00-02-420-058-000 Install the LP Compressor/Intermediate Case Module Drains (Pre SBE 71-0004, Pre SBN 71-0147, Pre SBE 79-0087, SBE 71-0004, SBN 71-0147 and SBE 79-0087)

Figure: Install the Drains Mast

Install the Drains Mast

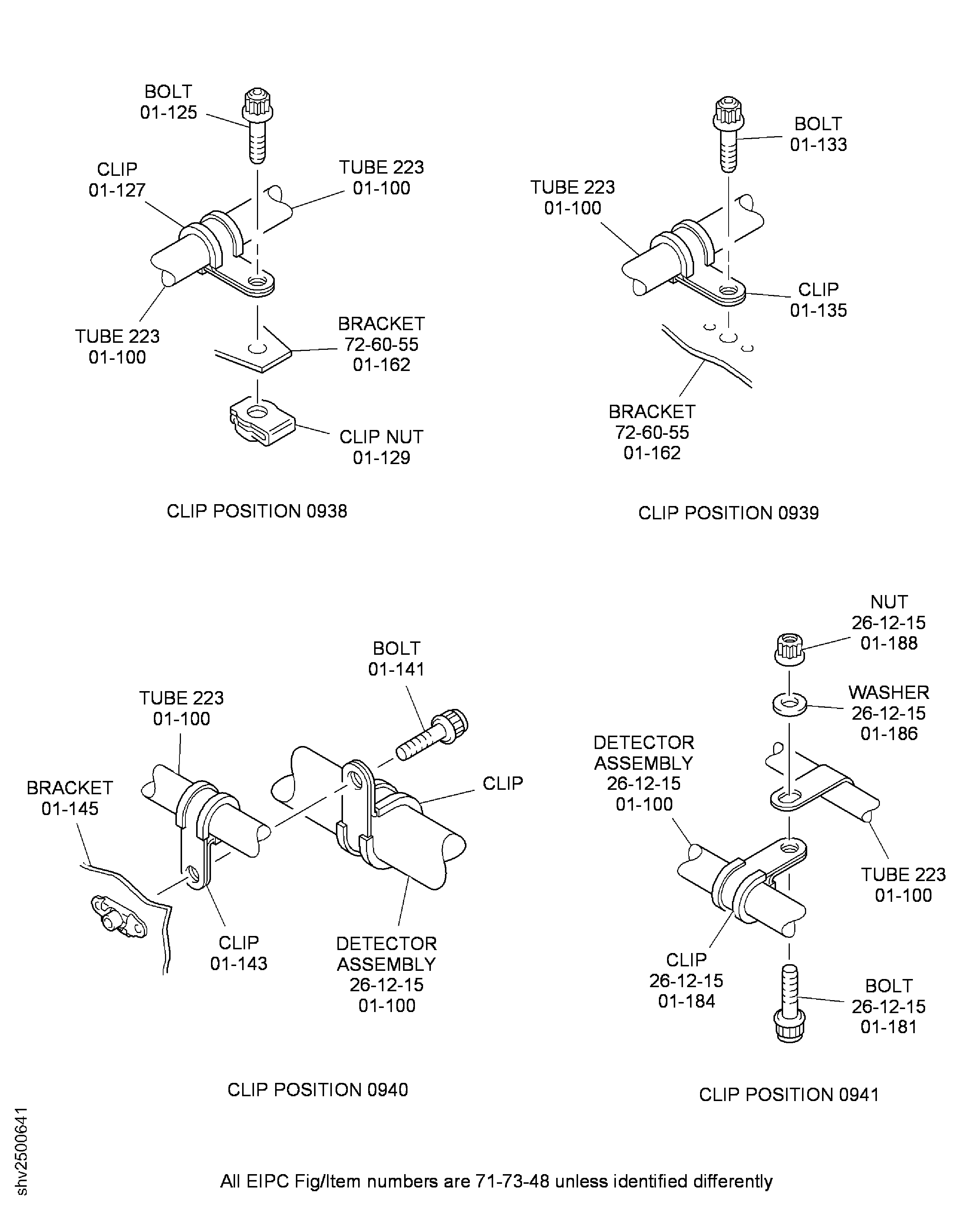

Figure: Install the LP Compressor/Intermediate Case Module Drains

Sheet 1

Figure: Install the LP Compressor/Intermediate Case Module Drains

Sheet 2

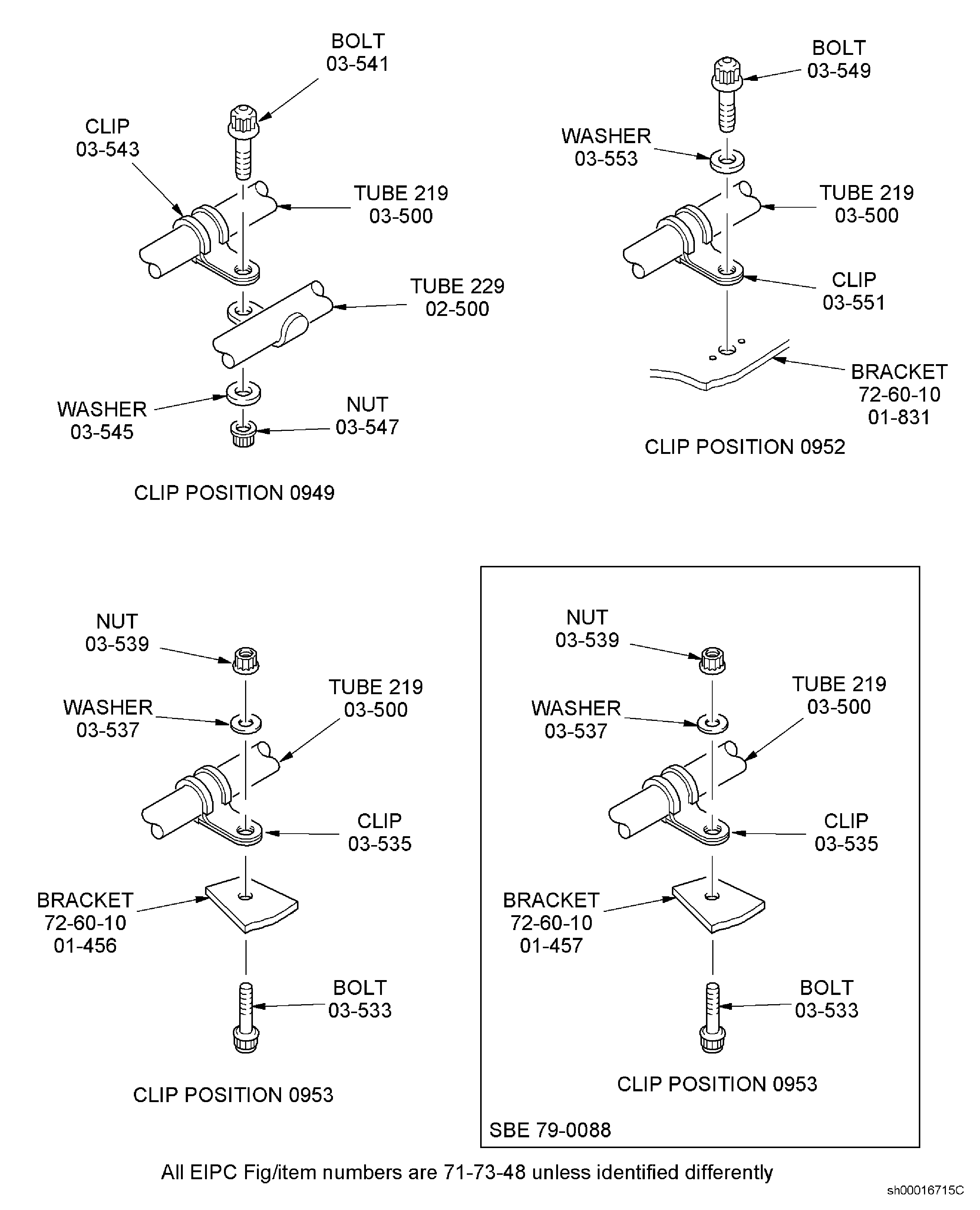

Figure: Install the LP Compressor/Intermediate Case Module Drains

Sheet 3

Figure: Install the LP Compressor/Intermediate Case Module Drains

Sheet 4

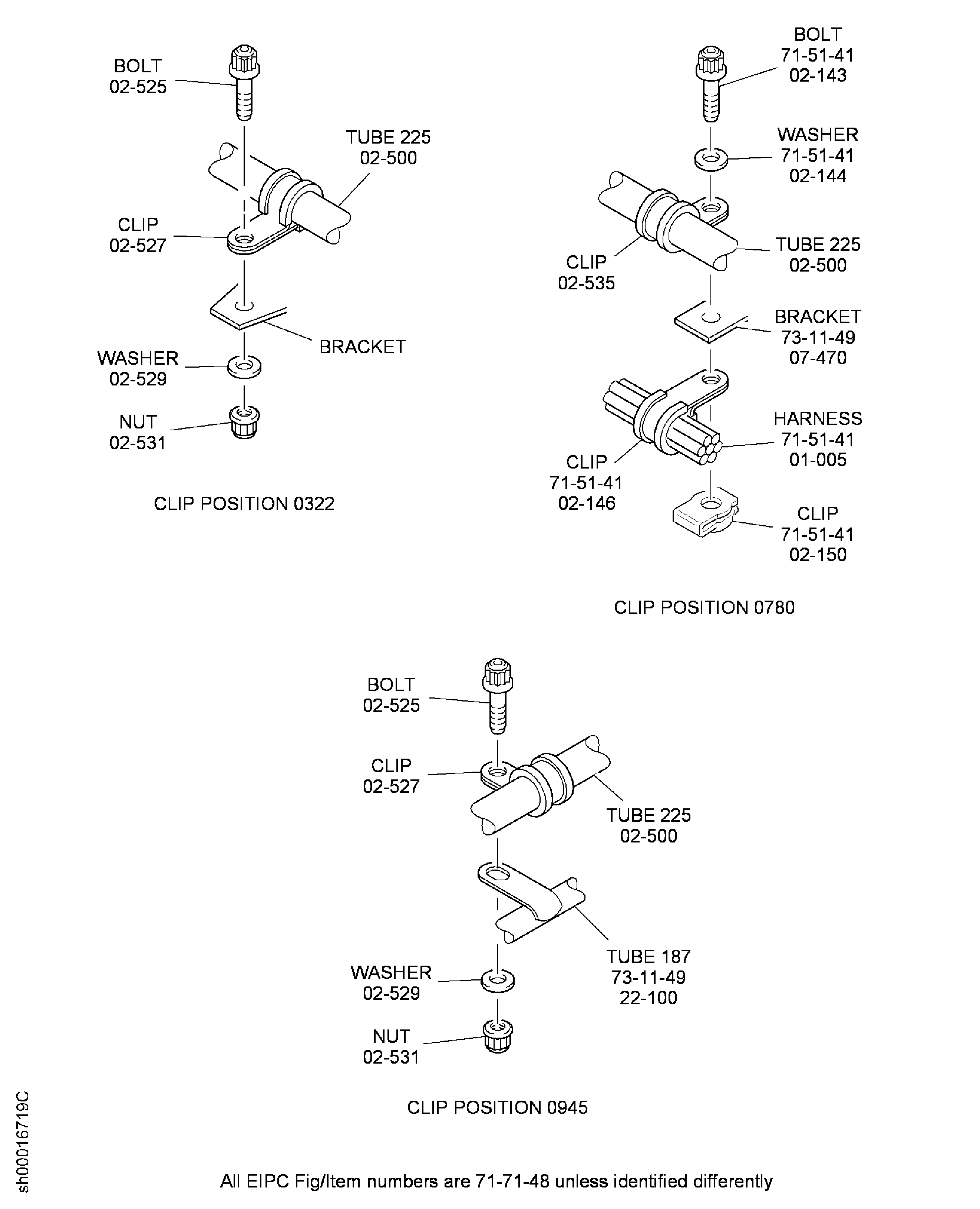

Figure: Install the LP Compressor/Intermediate Case Module Drains

Sheet 5

Figure: Install the LP Compressor/Intermediate Case Module Drains

Sheet 6

Figure: Install the LP Compressor/Intermediate Case Module Drains

Sheet 7

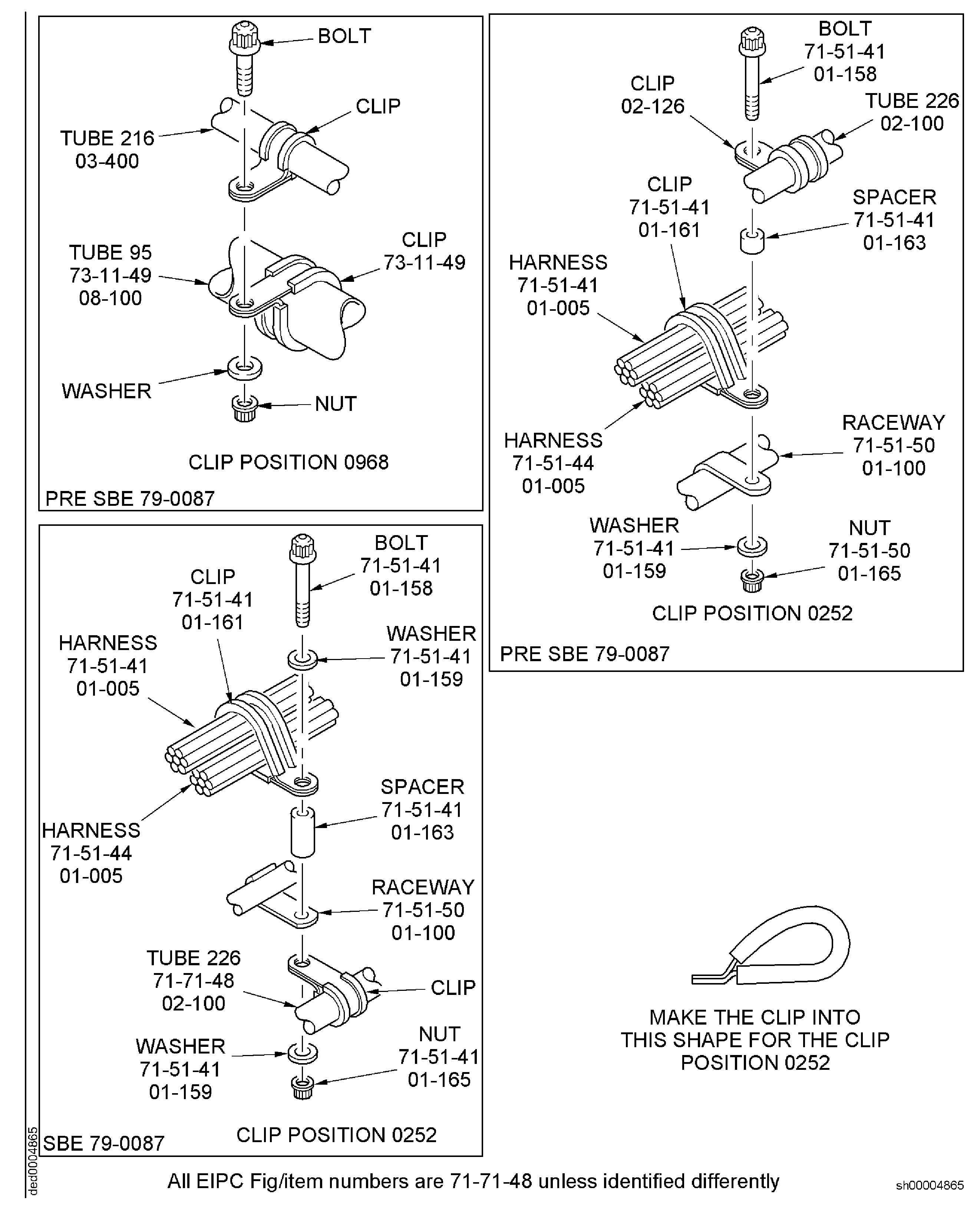

Figure: Install the LP Compressor/Intermediate Case Module Drains

Sheet 8

Figure: Install the LP Compressor/Intermediate Case Module Drains

Sheet 9

Figure: Install the LP Compressor/Intermediate Case Module Drains

Sheet 10

Figure: Install the LP Compressor/Intermediate Case Module Drains

Sheet 11

Figure: Install the LP Compressor/Intermediate Case Module Drains

Sheet 12

Figure: Install the LP Compressor/Intermediate Case Module Drains

Sheet 13

Figure: Install the LP Compressor/Intermediate Case Module Drains

Sheet 14

Figure: Install the LP Compressor/Intermediate Case Module Drains

Sheet 15

Figure: Install the LP Compressor/Intermediate Case Module Drains

Sheet 16