Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1 AND Post SBE 72-0304

Common Information

TASK 72-41-10-440-003-E00 HPC Rotor Assembly - Do A Balance Check Of The Rotor Assembly And Install The Blades, Assembly-003 - SBE 72-0304

General

This TASK gives the procedure to do a balance check of the HP compressor rotor assembly (SBE 72-0304 standard) and install the blades.

The procedure to measure, assemble and balance the HP compressor rotor assembly is given in the subsequent TASKS.

TASK 72-41-10-440-001 (ASSEMBLY-001, CONFIG-001) Measure the HP compressor rotor assembly parts.

TASK 72-41-10-440-002 (ASSEMBLY-002, CONFIG-001) Assemble the HP compressor rotor assembly.

TASK 72-41-10-440-004 (ASSEMBLY-004, CONFIG-001) Grind the tips of the HP compressor blades.

TASK 72-41-10-440-005 (ASSEMBLY-005, CONFIG-001) Final balance the HP compressor rotor assembly.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item numbers.

Overhaul processes referred to in the procedure by the TASK/SUBTASK number are in SPM.

For standard torque data and procedure refer to SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data is identified with the symbol * after the torque value.

Special assembly tolerances are included in this procedure.

Lubricate all threads and mating faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

All the curvic teeth and mating faces must be cleaned with CoMat 01-001 SOLVENT, DELETEDor CoMat 01-002 SOLVENT, DELETED.before assembly. Refer to SPM TASK 70-11-01-300-503. They must also be dry assembled unless told differently in the procedure.

All the temporary marks made in this procedure must be removed before the engine is started.

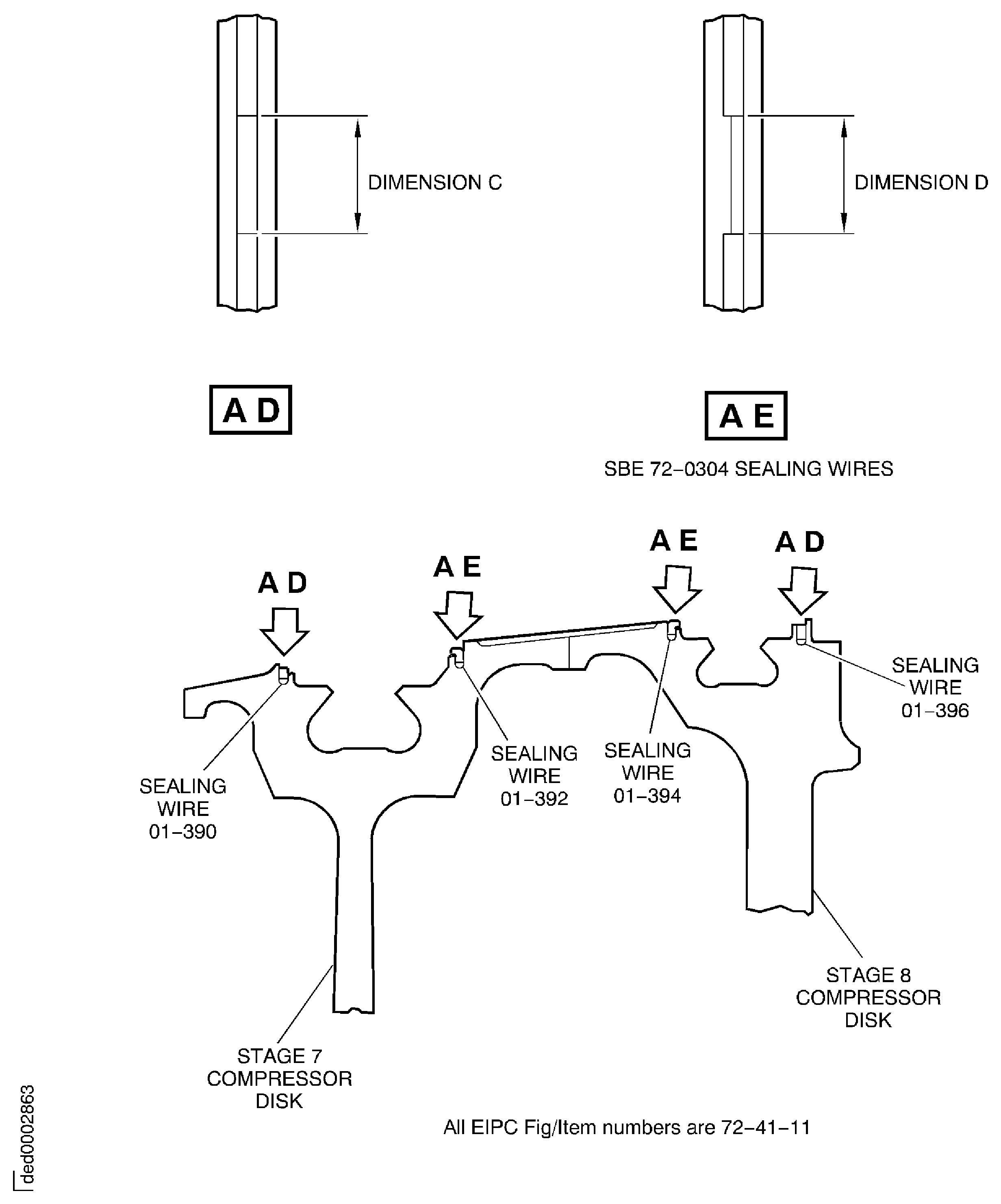

When stage 7 and stage 8 blades are installed in the disk, the L shaped stage 7 rear and stage 8 front sealing wires ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-392 and ENGINE-HP COMPRESSOR DISCS (STAGES 3-8)01-394) and stage 7 front and stage 8 rear sealing wires ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-390 and ENGINE-HP COMPRESSOR DISCS (STAGES 3-8)01-396) must be installed during all build procedures, that is gapping, balancing and rotor-tip grind. This is because the height of the wire retainer tip of the drum is decreased so that the L shaped wire can be installed. If the wire is not installed, the amount of movement of the blades is increased.

Data to balance.

The tools used in this procedure are used to adapt the HP compressor rotor assembly to the 'Schenck HL5' dynamic balancing machine. A balancing speed between 650 and 1000 RPM that gives stable and repeatable results is recommended. The best speed to use will be different for different machines. The correct RPM will usually agree with the gear ratios available. The balancing machine must turn the HP compressor rotor assembly in a clockwise direction (direction of engine turn) when seen from the rear of the engine.

Data to select and install the stages 6 thru 12 compressor blades.

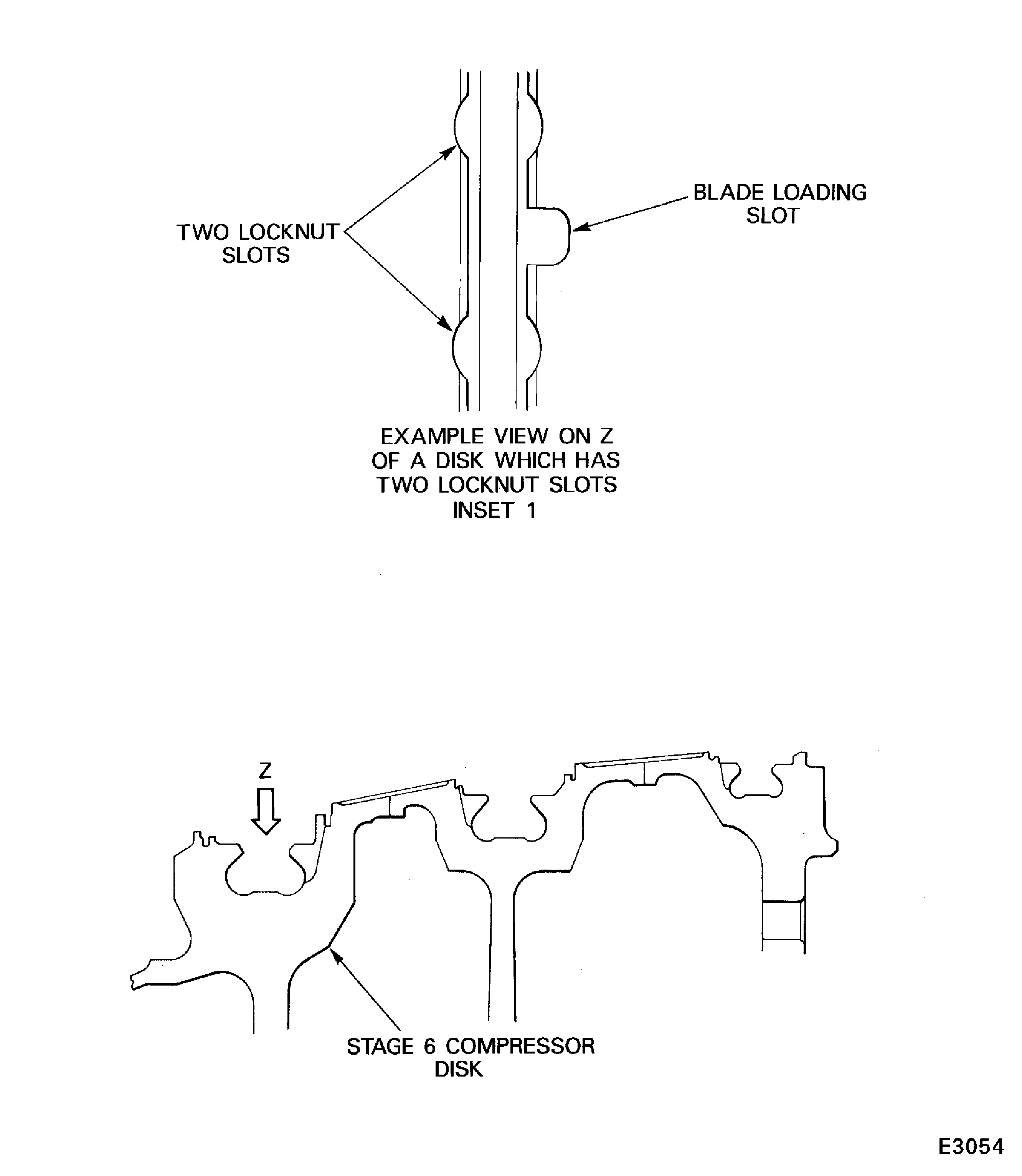

There are two different types of stage 3 thru 8 and 9 thru 12 compressor disks. One type has two locknut slots, the other has four locknut slots. The method to select and install the compressor blades is different for each type. This TASK gives the procedure to select and install the stage 3 to 8 blades and stage 9 to 12 blades for the two locknut type disks. Refer to TASK 72-41-10-440-003-A00 (ASSEMBLY-03, CONFIG-01) for the procedure to select and install the stage 3 to 8 blades and stage 9 to 12 blades for the 4 locknut slot type disks. To select the correct method it will be necessary to look at the disks to find which type are installed.

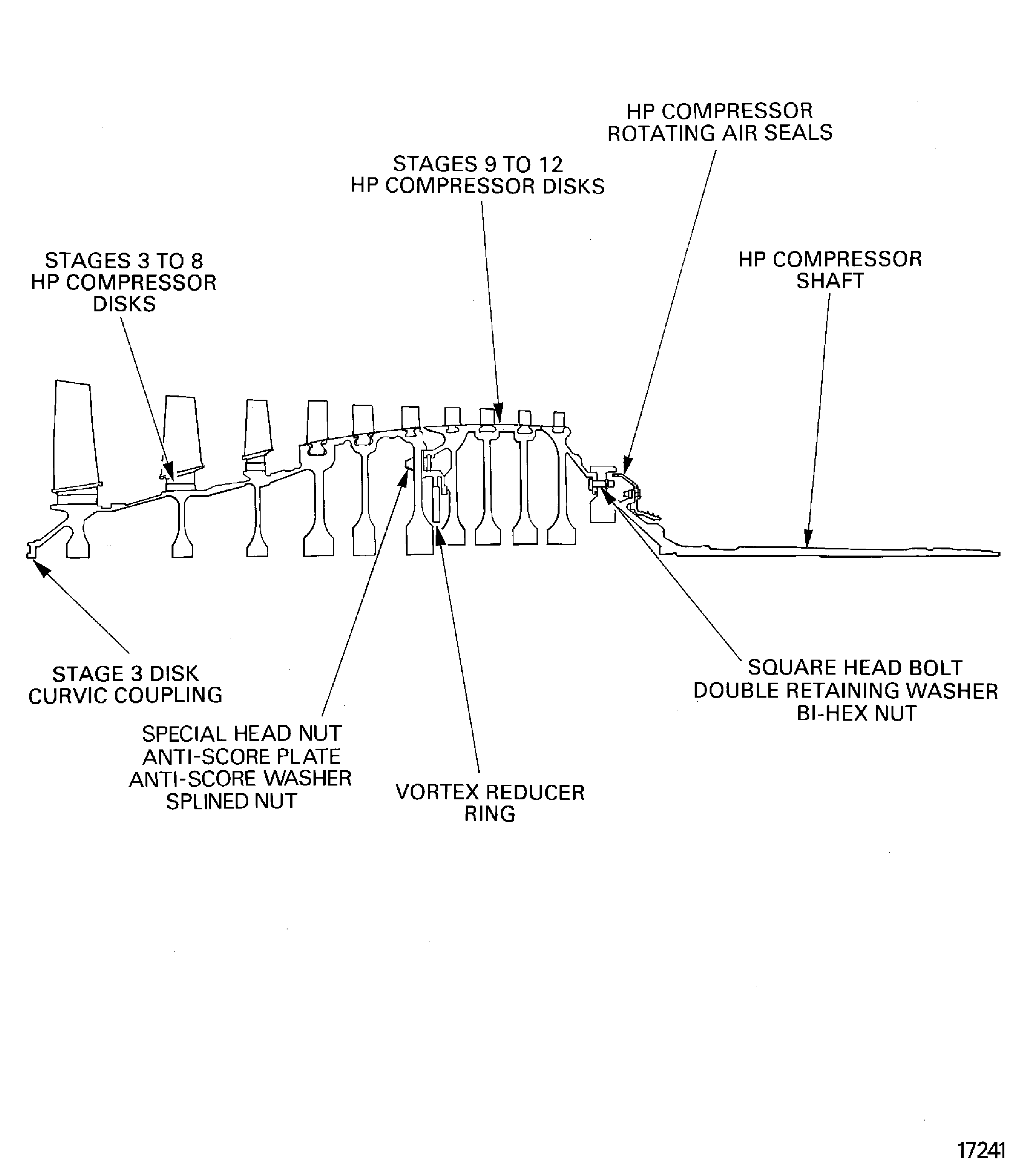

Refer to Figure for an example view of the HP compressor rotor assembly.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Dynamic balancing machine | LOCAL | Schenck HL-5U | ||

| End drive | LOCAL | Schenk 022748 | ||

| IAE 1R8060 Mounting foot | 0AM53 | IAE 1R8060 | 4 | |

| IAE 1R18058 Protective cover | 0AM53 | IAE 1R18058 | 1 | |

| IAE 1R18059 Trolley | 0AM53 | IAE 1R18059 | ||

| IAE 1R18060 Mounting foot | 0AM53 | IAE 1R18060 | ||

| IAE 1R18061 Rail | 0AM53 | IAE 1R18061 | ||

| IAE 1R18069 Rear anvil | 0AM53 | IAE 1R18069 | 1 | |

| IAE 1R18070 Front anvil | 0AM53 | IAE 1R18070 | 1 | |

| IAE 1R18071 Rear anvil | 0AM53 | IAE 1R18071 | 1 | |

| IAE 1R18072 Front anvil | 0AM53 | IAE 1R18072 | 1 | |

| IAE 1R18075 Support pedestal | 0AM53 | IAE 1R18075 | 1 | |

| IAE 1R18076 Slave lock plates | 0AM53 | IAE 1R18076 | 3 | |

| IAE 1R18079 Drift | 0AM53 | IAE 1R18079 | 1 | |

| IAE 1R18080 Drift | 0AM53 | IAE 1R18080 | 1 | |

| IAE 1R18081 Beam sling | 0AM53 | IAE 1R18081 | 1 | |

| IAE 1R18082 Pliers | 0AM53 | IAE 1R18082 | 1 | |

| IAE 1R18083 Hydraulic tool | 0AM53 | IAE 1R18083 | 1 | |

| IAE 1R18084 Pliers | 0AM53 | IAE 1R18084 | 1 | |

| IAE 1R18089 Lifting adapter | 0AM53 | IAE 1R18089 | ||

| IAE 1R18090 Safety support stand | 0AM53 | IAE 1R18090 | 1 | |

| IAE 1R18091 Support stand | 0AM53 | IAE 1R18091 | 1 | |

| IAE 1R18095 Universal slinging adapter | 0AM53 | IAE 1R18095 | ||

| IAE 1R18097 Drift | 0AM53 | IAE 1R18097 | 1 | |

| IAE 1R18245 Adapter | 0AM53 | IAE 1R18245 | 1 | |

| IAE 1R18590 Socket end | 0AM53 | IAE 1R18590 | 1 | |

| IAE 1R18629 Protective cover | 0AM53 | IAE 1R18629 | ||

| IAE 1R18683 Caliper adapter | 0AM53 | IAE 1R18683 | 1 | |

| IAE 1R19812 Filing fixture | 0AM53 | IAE 1R19812 | 1 | |

| IAE 1R19813 Filing fixture | 0AM53 | IAE 1R19813 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-001 SOLVENT, DELETED | LOCAL | CoMat 01-001 | ||

| CoMat 01-002 SOLVENT, DELETED. | LOCAL | CoMat 01-002 | ||

| CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON | IE304 | CoMat 02-121 | ||

| CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON | K6835 | CoMat 02-122 | ||

| CoMat 02-130 POLAR GRAPH PAPER | LOCAL | CoMat 02-130 | ||

| CoMat 02-181 MODELLING CLAY | LOCAL | CoMat 02-181 | ||

| CoMat 07-075 HIGH-HEAT RESISTING STOVING ENAMEL | k3504 | CoMat 07-075 | ||

| CoMat 10-070 ANTI-SEIZE COMPOUND | LOCAL | CoMat 10-070 | ||

| CoMat 10-077 APPROVED ENGINE OILS | IAE00 | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| PIN - SHOULDER, HEADLESS, .0.1159 X 0.122 X 0.265 | LOCAL | 5306941 | 3 | |

| PIN - SHOULDER, HEADLESS, .0.1159 X 0.122 X 0.265 | LOCAL | 5306941 | 3 |

Safety Requirements

CAUTION

CAUTION

Procedure

Do Step again with the other three mounting feet.

WARNING

MAKE SURE THAT THE PROTECTIVE COVER IS CLOSED AND THE KNOBS ARE IN THE SAFETY POSITION.NOTE

The protective cover must be between the No. 1 and No. 2 pedestals.Lift the protective cover and put it above the mounting feet. Lower the protective cover until it is approximately one inch above the tops of the mounting feet.

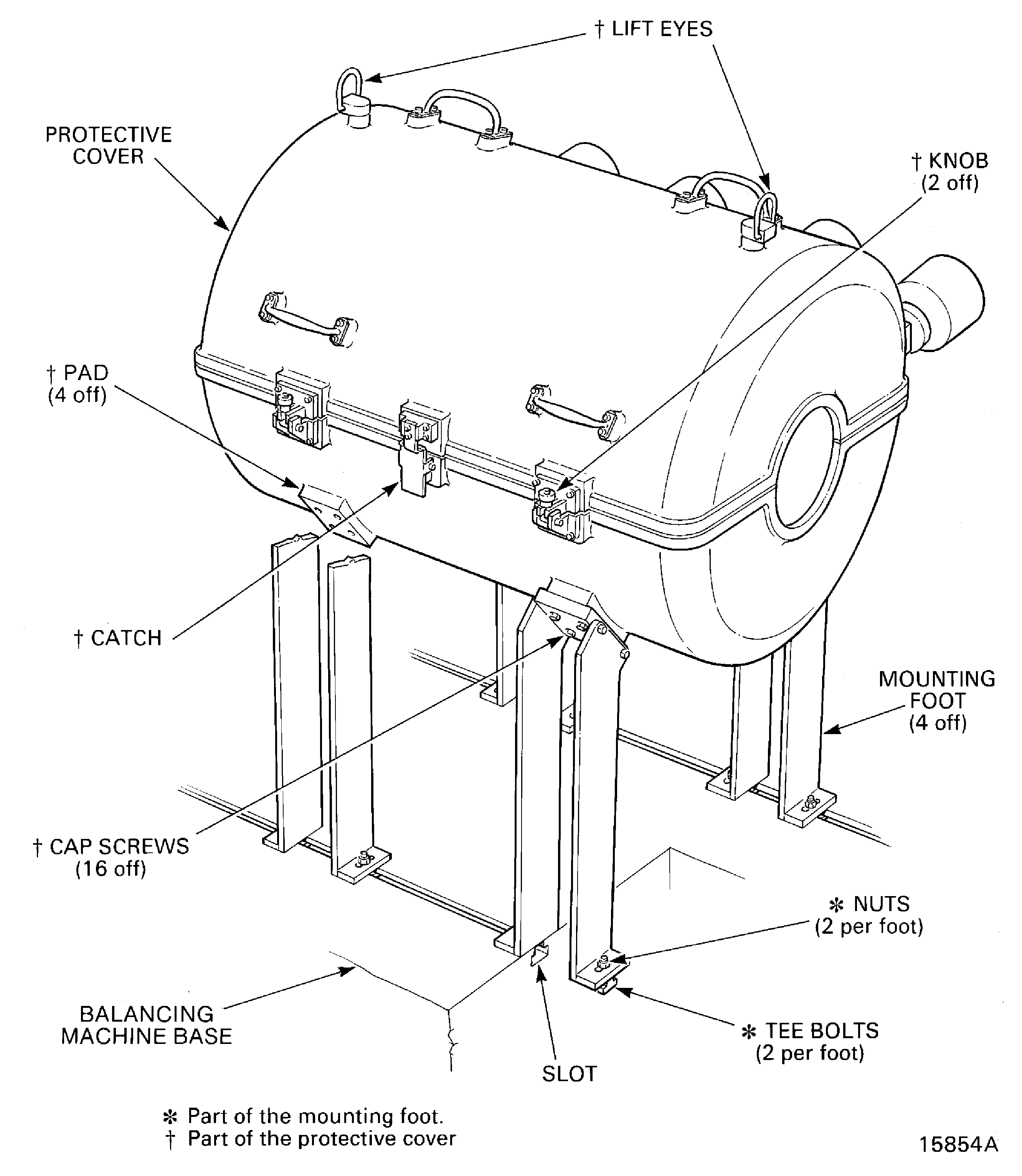

Install IAE 1R18060 Mounting foot 4 off and IAE 1R18058 Protective cover 1 off on to the balancing machine. Refer to Figure.

SUBTASK 72-41-10-440-206 Prepare the Balancing Machine for Use

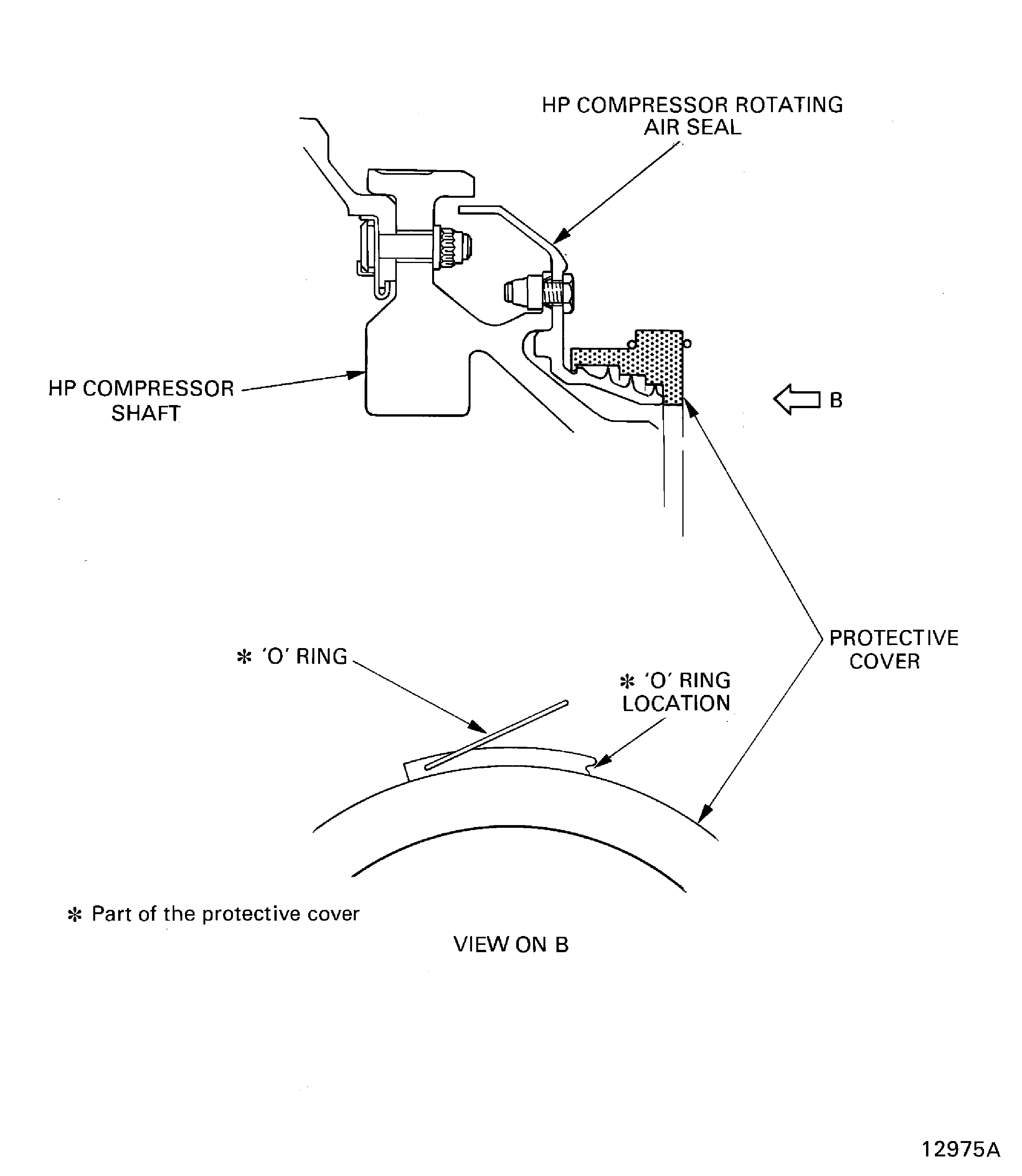

Remove IAE 1R18629 Protective cover protective cover from the compressor rotating air seals. Refer to Figure.

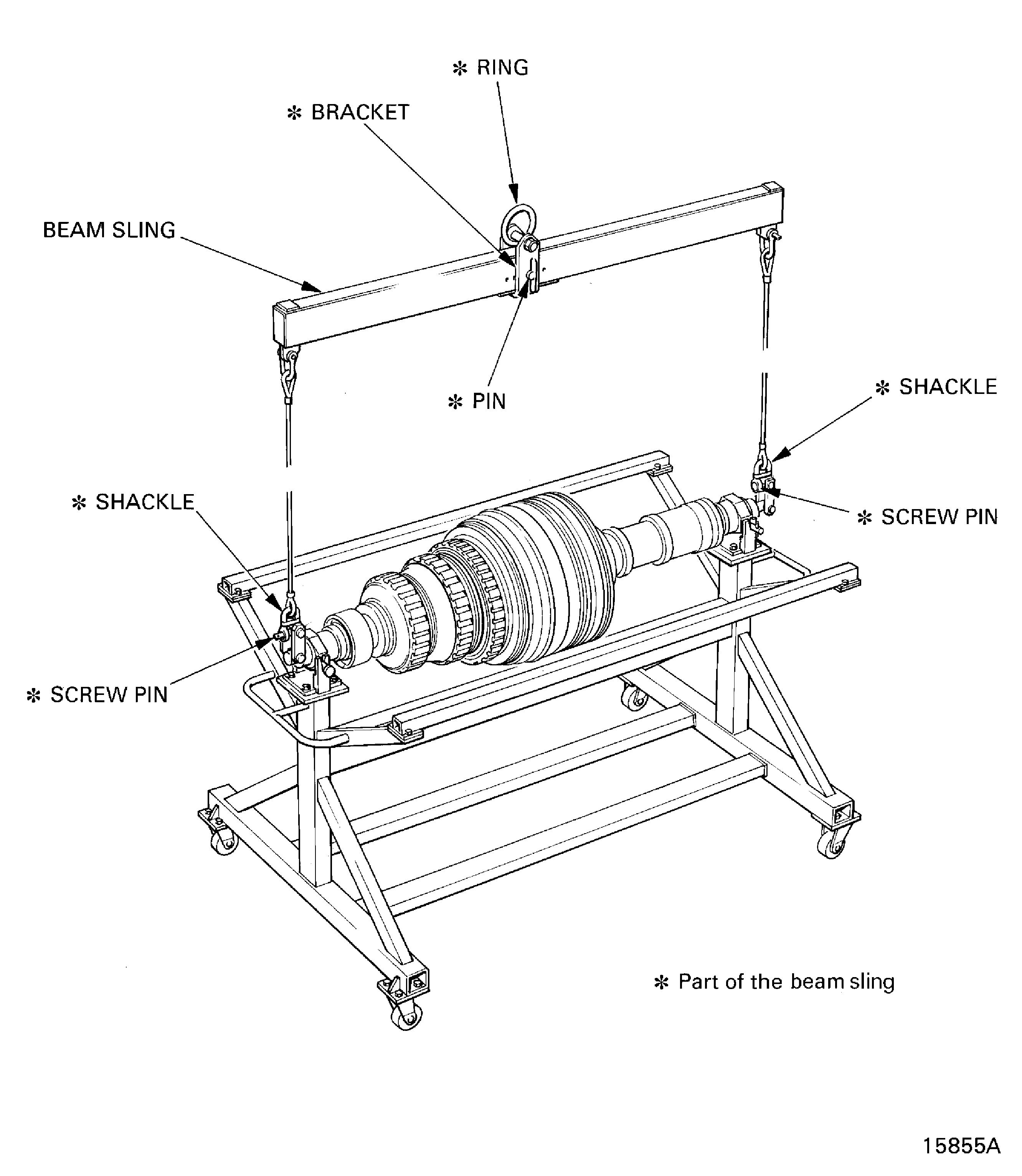

Install IAE 1R18081 Beam sling 1 off on to the compressor rotor assembly. Refer to Figure.

CAUTION

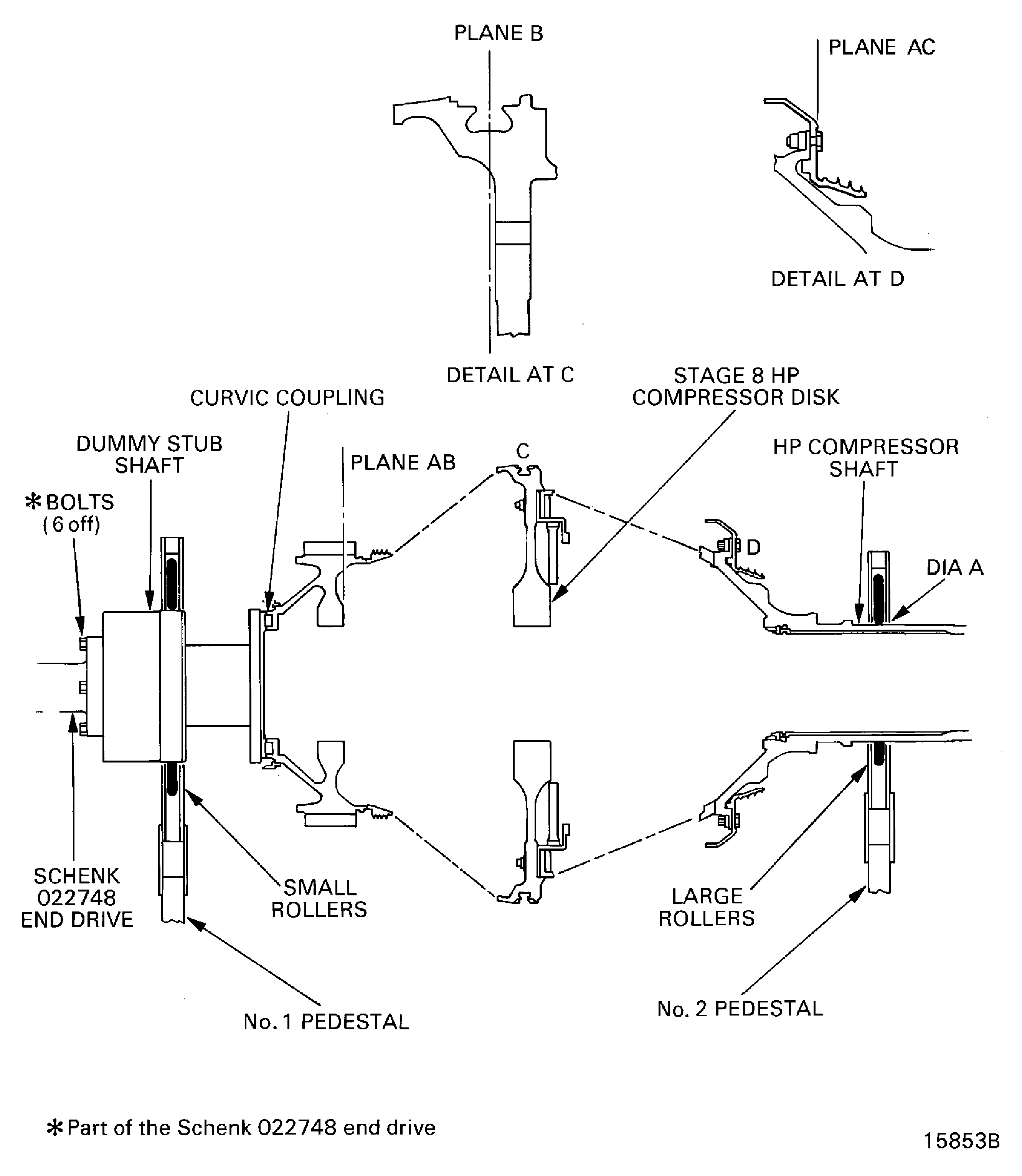

YOU MUST NOT LET THE COMPRESSOR ROTOR ASSEMBLY HIT THE BALANCING MACHINE.Carefully lower the compressor rotor assembly on to the balancing machine. Make sure the dummy stub shaft touches the No. 1 pedestal and the bearing location diameter (Diameter A) touches the No. 2 pedestal. Refer to Figure.

Remove the beam sling from the compressor rotor assembly. Refer to Figure.

Remove the universal sling adapters. Refer to Figure.

SUBTASK 72-41-10-440-207 Install the HP Compressor Rotor Assembly in to the Balancing Machine

NOTE

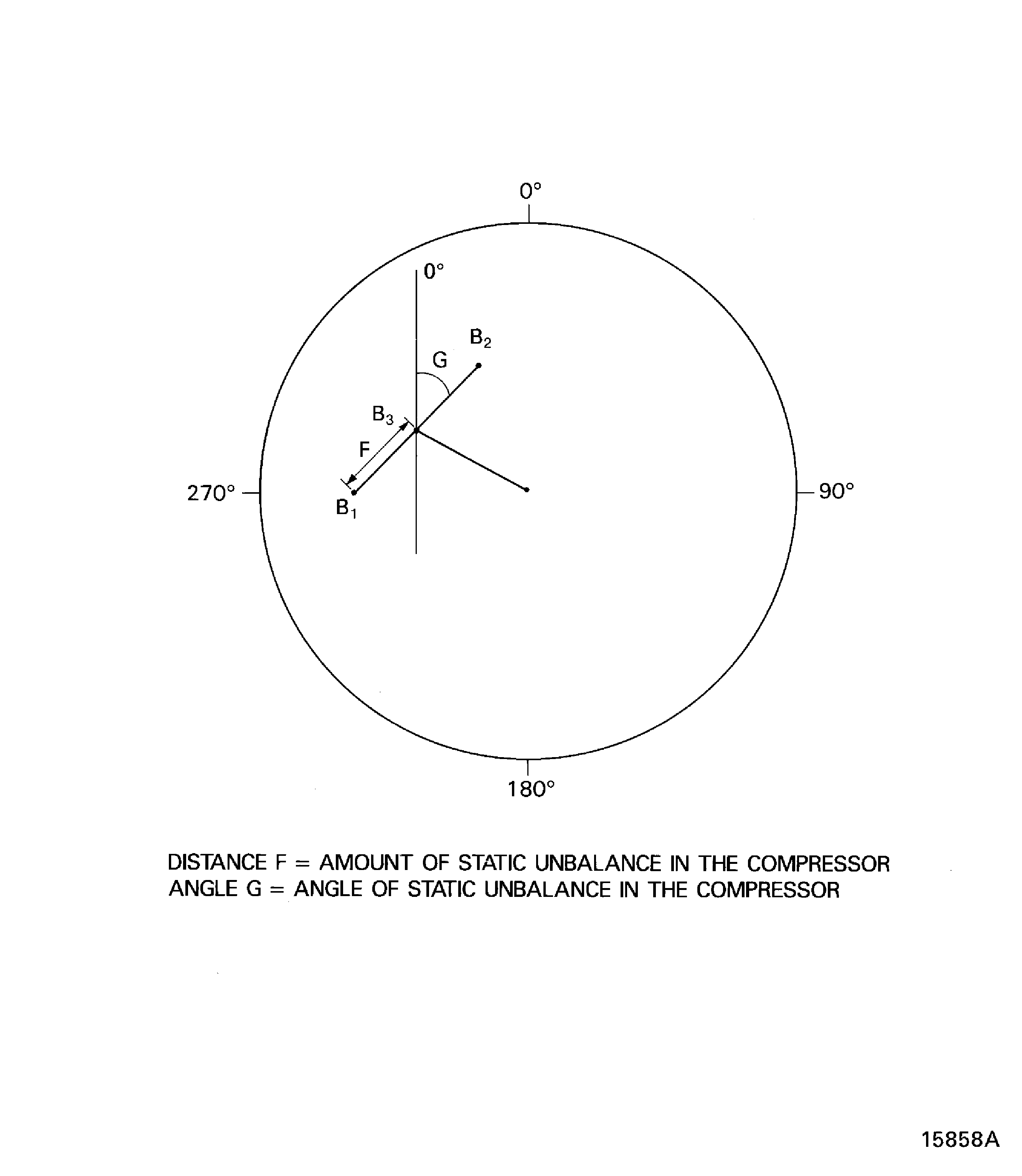

The HP compressor rotor assembly is installed in IAE 1R18059 Trolley trolley.Plane separate and calibrate the balancing machine to read static unbalance. Measure and record the quantity and angular position of the unbalance. Refer to Figure.

Make a mark on CoMat 02-130 POLAR GRAPH PAPERto show the position and quantity of the unbalance. Identify this point as B1. Refer to Figure.

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON to make a mark that identifies the position of the dummy stub shaft in relation to the balancing machine drive head.

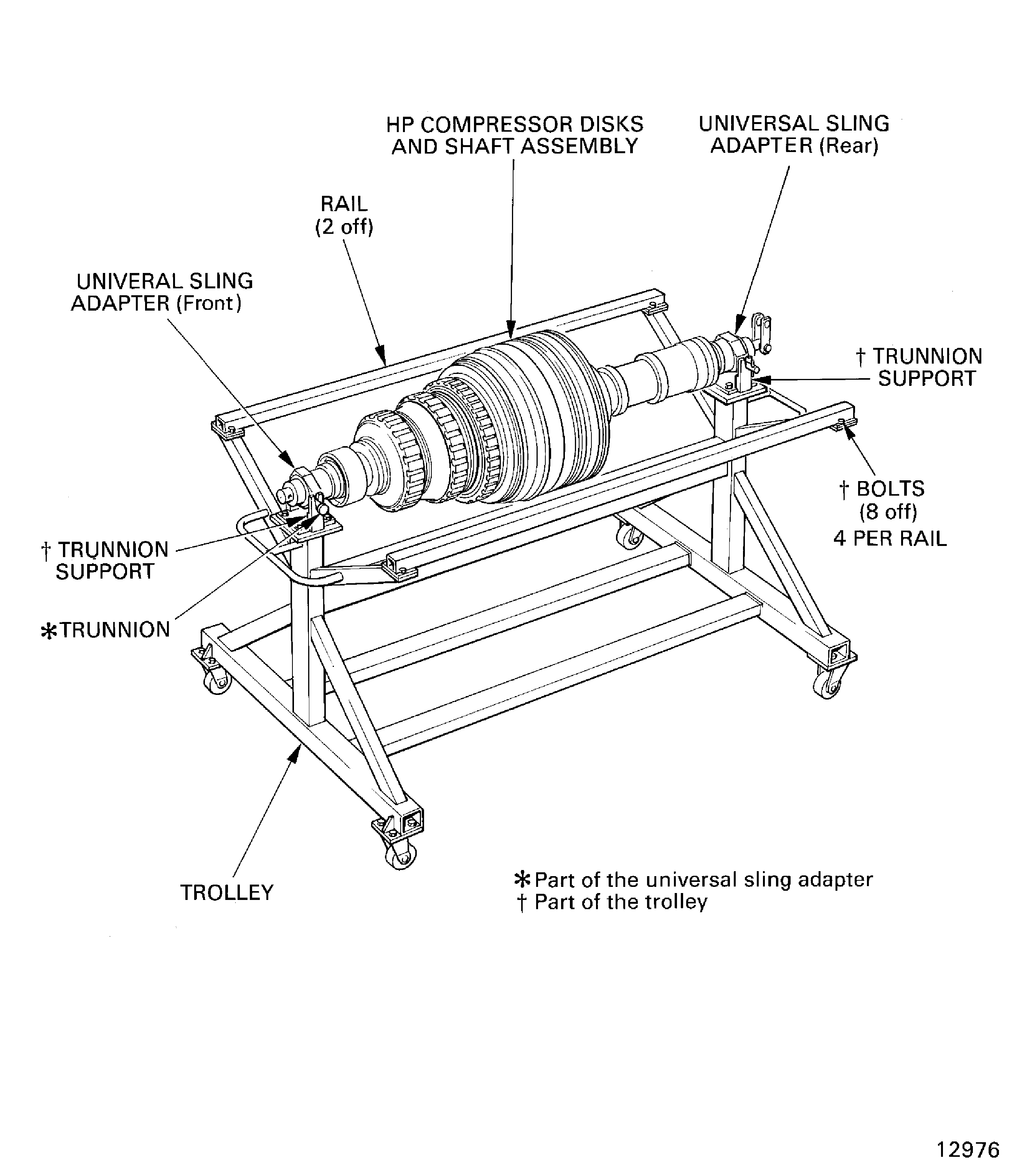

Remove the HP compressor rotor assembly from the balancing machine and install it in IAE 1R18059 Trolley. Refer to Step.

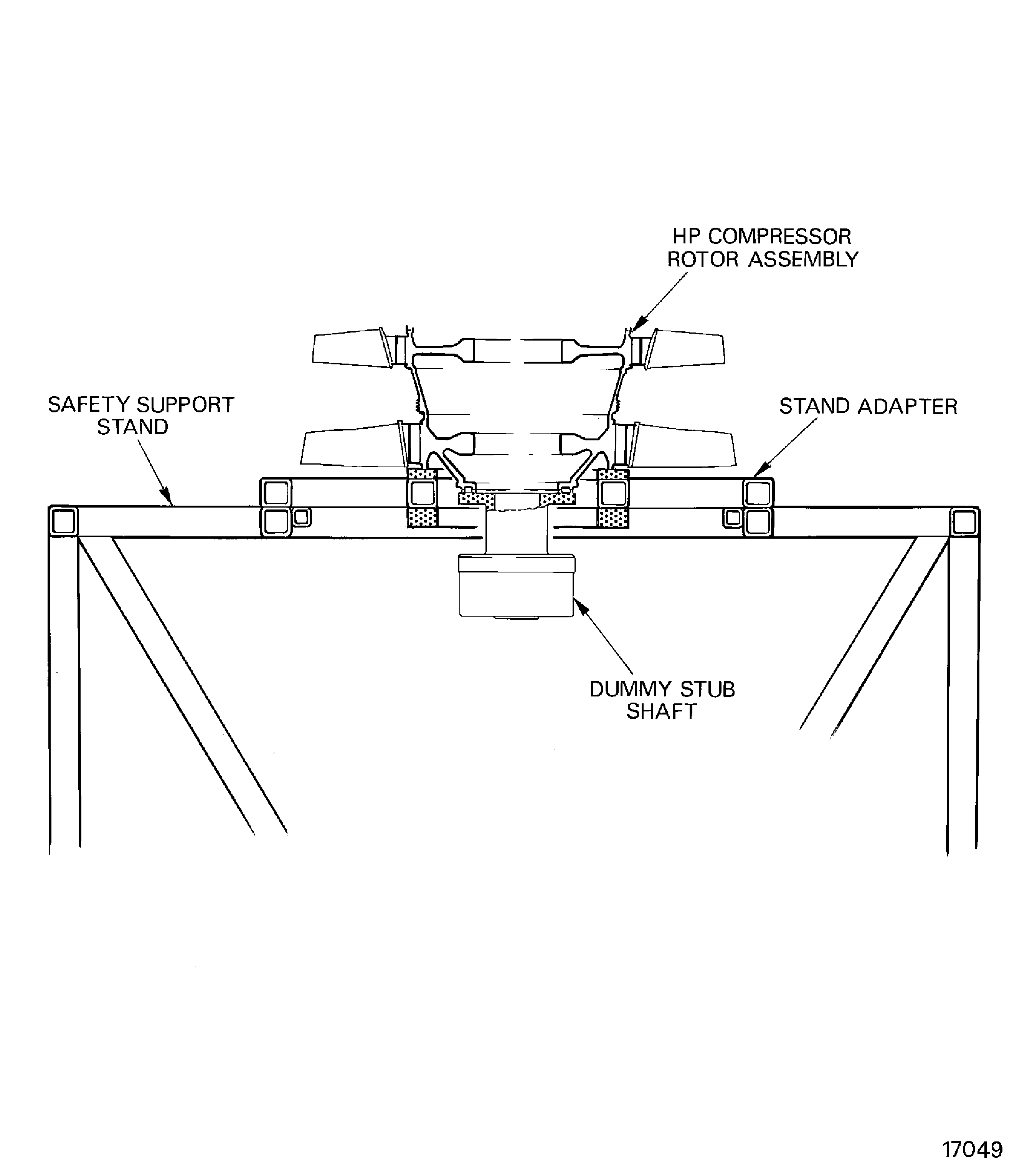

Install IAE 1R18091 Support stand 1 off on to the top of IAE 1R18090 Safety support stand 1 off. Make sure that the stand adapter is correctly engaged in the safety support stand.

Install the HP compressor rotor assembly in to IAE 1R18090 Safety support stand. Refer to Figure.

Remove the front universal sling adapter from the dummy stub shaft. Refer to Figure.

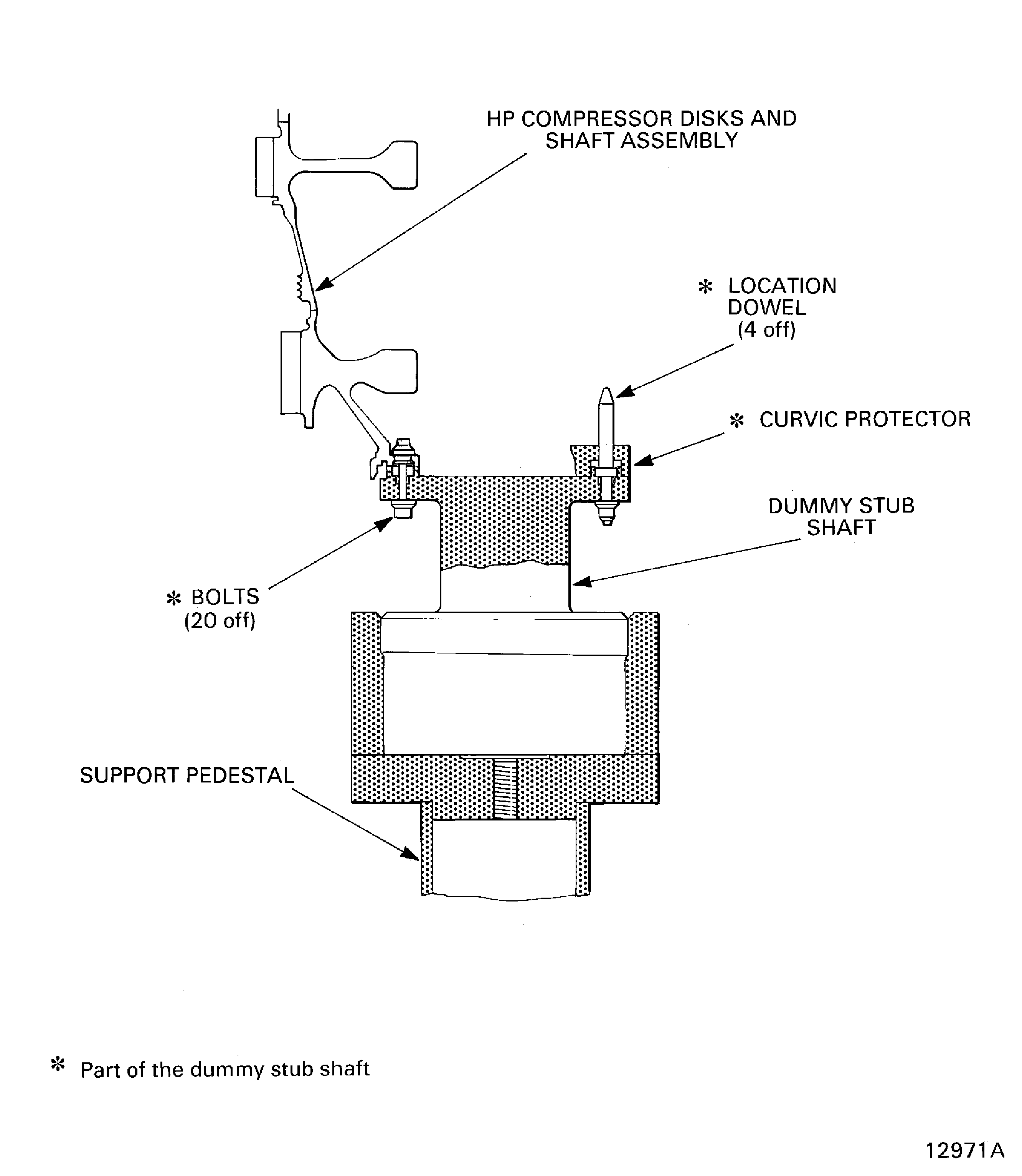

Use the hoist to lift the compressor rotor assembly off the safety support stand and put it above IAE 1R18075 Support pedestal 1 off.

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYONor CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYONto make a mark that identifies the position of the dummy stub shaft in relation to the stage 3 disk curvic coupling. Refer to TASK 70-09-01-400-501 .

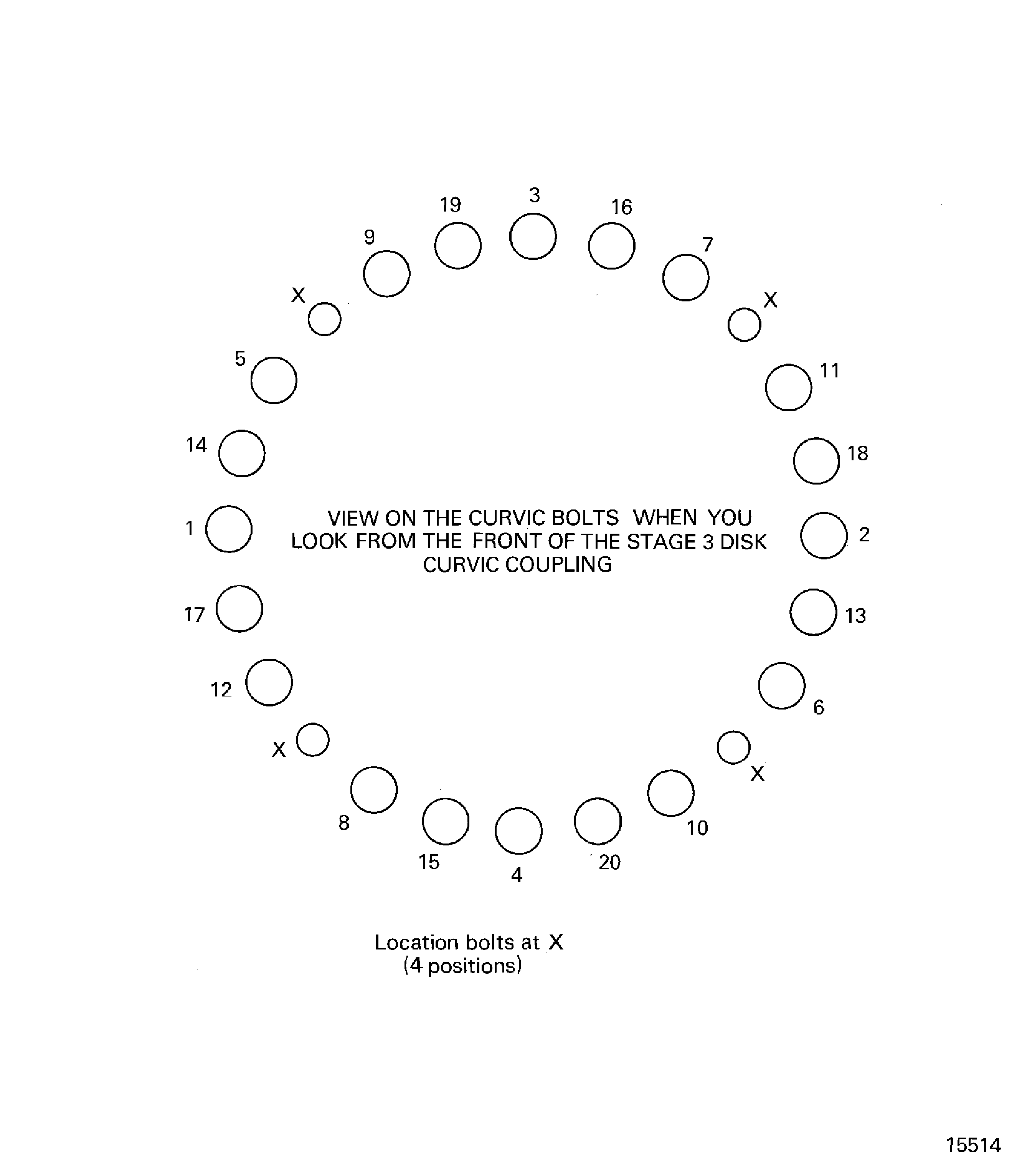

Torque all of the bolts in sequence to 18 lbfin (2.034 Nm). Refer to Figure.

Remove the HP compressor rotor assembly from the dummy stub shaft and turn the assembly 180 degrees. Refer to Figure.

Install the HP compressor rotor assembly in to IAE 1R18090 Safety support stand. Refer to Figure.

Install IAE 1R18095 Universal slinging adapter 1 off on to the dummy stub shaft. Refer to Figure.

Install the compressor rotor assembly in to IAE 1R18059 Trolley. Refer to Figure.

Install the compressor rotor assembly in to the balancing machine. Refer to Step. Make sure the temporary mark on the dummy stub shaft is aligned with the temporary mark on the balancing machine drive head.

NOTE

The 180 degree turn of the compressor rotor assembly is necessary so that the tool unbalance can be removed (calculated).Install the compressor rotor assembly on to the dummy stub shaft, 180 degrees from the original position.

Make a mark on the polar graph paper to show the position of the unbalance. Identify this as B2. Refer to Figure.

NOTE

The angle and amount of static unbalance can be checked by the temporary addition of CoMat 02-181 MODELLING CLAYon the stage 8 disk. This will move point B2 to point B3.Make a vertical line thru point B3. The angle (angle G) measured clockwise from 0 (Zero) degrees to B2 indicates the angle of static unbalance in the compressor. Write down this value.

If the static unbalance is more than 5.972 ozin (4300 gmm) then disassemble the compressor rotor assembly (refer to TASK 72-41-10-040-001) and examine the problem.

Calculate the correct unbalance in plane B. Refer to Figure.

SUBTASK 72-41-10-440-208 Do a Check Balance of the HP Compressor Rotor Assembly

NOTE

You must let the balancing machine run for a short time so that it can become stable, before balance values are read.Open IAE 1R18058 Protective cover protective cover.

Put IAE 1R18629 Protective cover 1 off on to the end of the compressor shaft. Move the protective cover along the compressor shaft until it is adjacent to the No. 2 pedestal.

Install IAE 1R18089 Lifting adapter 1 off on to the end of the compressor shaft. Tighten the lifting adapter.

Attach one of IAE 1R18095 Universal slinging adapter 2 off on to the lifting adapter. Refer to Figure.

Install IAE 1R18081 Beam sling 1 off on to the compressor rotor.

Install IAE 1R18629 Protective cover on to the compressor rotating air seals. Refer to Figure.

Put the compressor rotor assembly above IAE 1R18059 Trolley 1 off. Make sure that the trunnions on the universal sling adapters are above the trunnion supports.

Install the compressor rotor assembly in to the trolley. Refer to Figure.

Install IAE 1R18061 Rail 2 off on to the trolley.

SUBTASK 72-41-10-440-209 Install the HP Compressor Rotor Assembly in to the Trolley

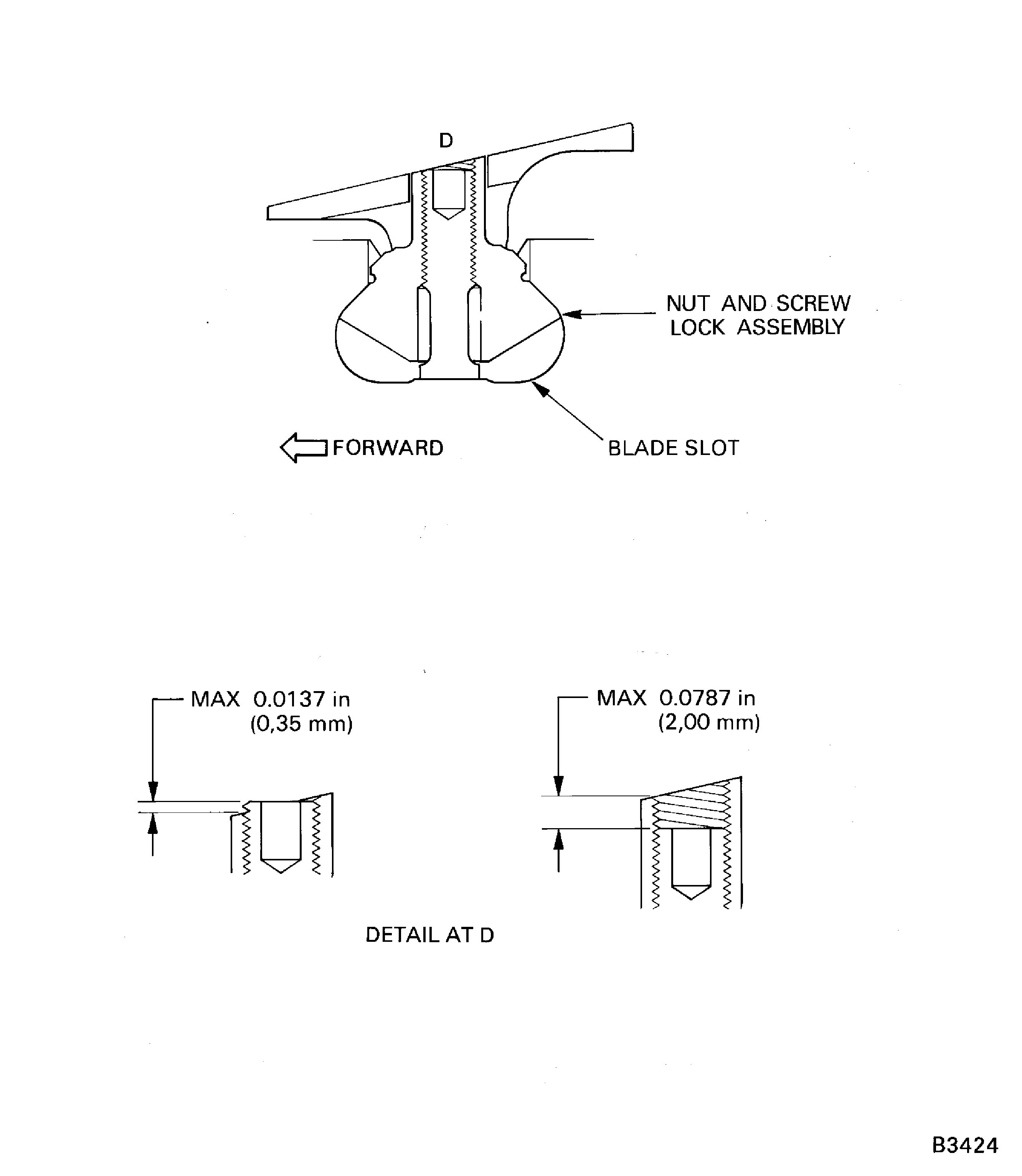

This method is used if the compressor disks have only two locking slots for the nut and screw lock assemblies. Refer to Figure Inset 1.

Make sure each nut and screw lock assembly is kept as a set.

CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON to make a mark on the nut and screw lock assembly and on the stage 6 thru 12 compressor disks so that they can be installed in the same positions.

SBE 72-0161: HP disks and blades - Stages 7 and 8 rotor blades with damping wires and stages 6, 7 and 8 blades with anti-fret coating.

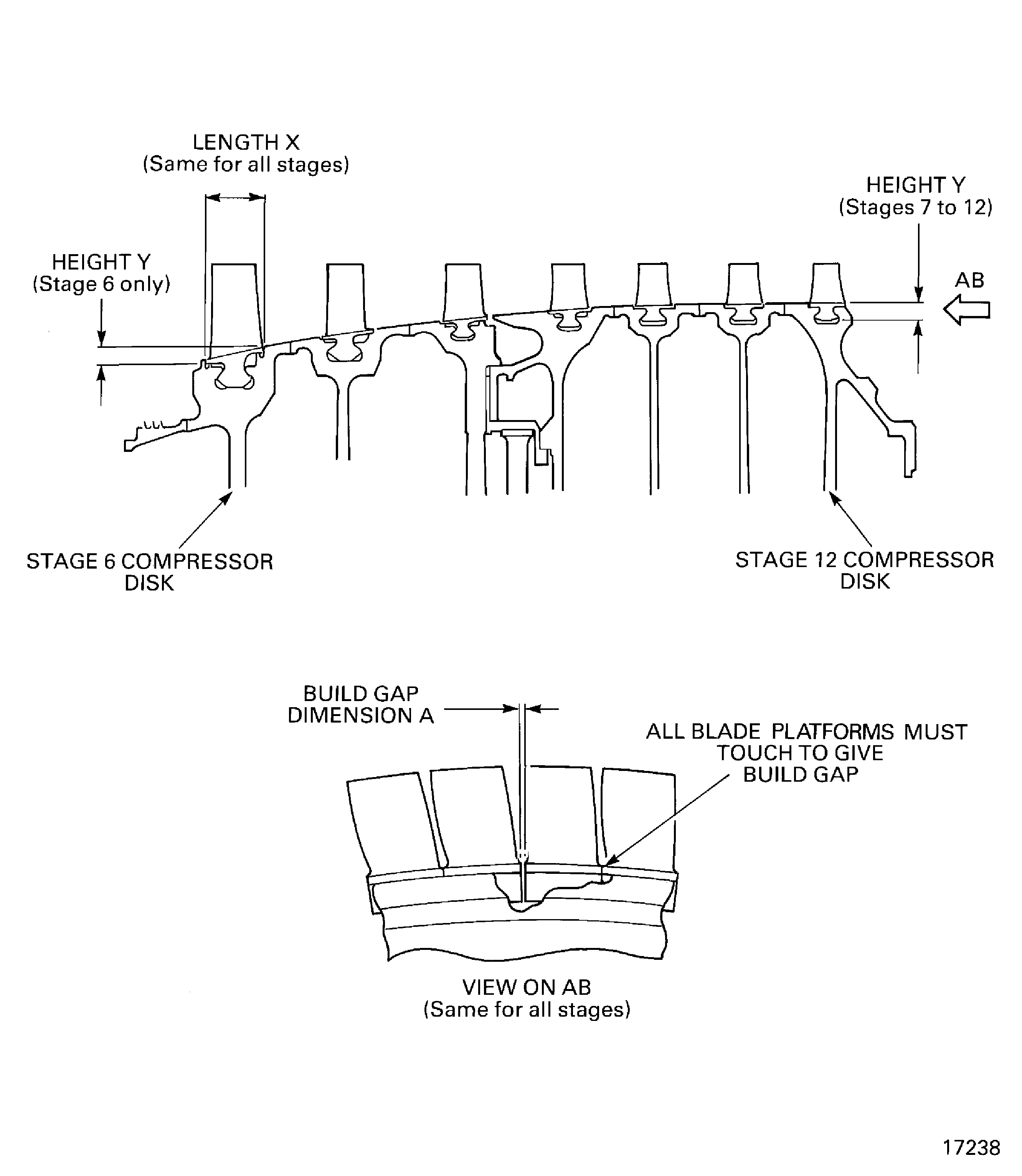

A selection of the 26 standard and the 26 undersize blades is used to get the correct platform build clearance.

A maximum of 26 undersize blades is permitted.

Install all of the standard blades in to the disk through the blade loading slot. Use IAE 1R18097 Drift 1 off positioned against the blade roots to move them around the disk in a counterclockwise direction when you look from the rear.

CAUTION

YOU MUST NOT USE THE DRIFT ON THE AIRFOIL SURFACES.Install the blades in to the disk. Refer to Figure.

Measure the platform build clearance, dimension A. Refer to Figure.

NOTE

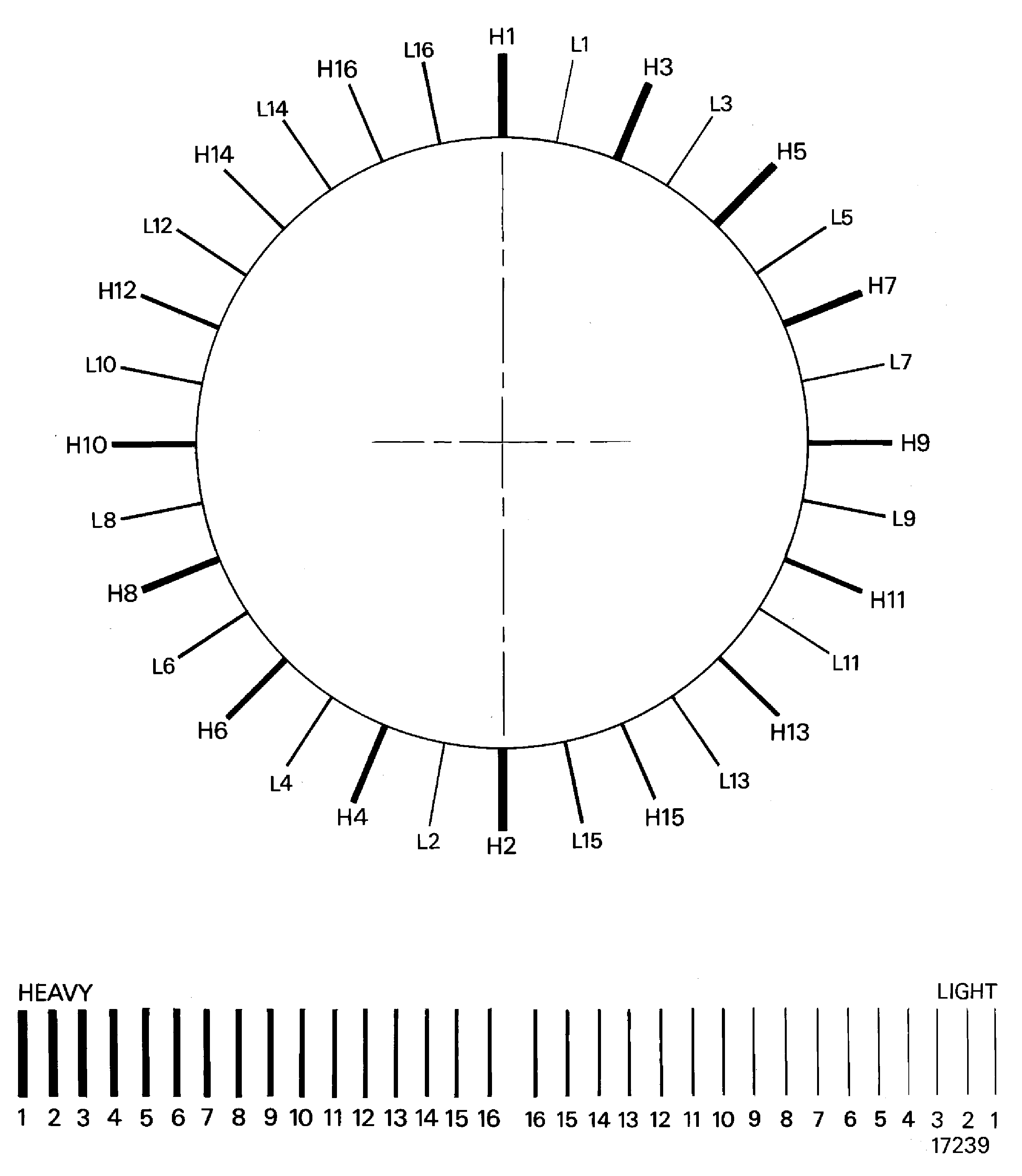

Do not include the LH and RH locking blades.Put the selection of standard and undersize blades on a suitable work surface in a light to heavy sequence. Refer to Figure.

NOTE

Undersize blades must not be installed adjacent to each other on assembly.Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON to identify the blades in a light-heavy-light sequence ready for assembly. Refer to Figure for an example of a light-heavy-light sequence.

NOTE

Find the correct selection of stage 6 compressor blades.

A full set of stage 6 compressor blades includes the IPC Fig/item numbers that follow:

2 LH locking blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-170).

2 RH locking blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-185).

59 Standard blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-200).

26 Standard blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-215).

26 Undersize blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-217).

SUBTASK 72-41-10-440-210 Find the Correct Selection of Stages 6 Compressor Blades (SBE 72-0161)

NOTE

Refer to Figure

SBE 72-0161: HP disks and blades - Stages 7 and 8 rotor blades with damping wires and stages 6, 7 and 8 blades with anti-fret coating.

SBE 72-0304: HP disks - Introduction of a reworked stage 3 to 8 disk assembly with revised L shaped sealing wires

Install the stage 7 front sealing wire ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-390) in the groove in the front of the stage 7 disk. The gap in the sealing wire must be 180 degrees from the blade loading slot.

Install the stage 7 rear sealing wire ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-392) in the groove in the rear of the stage 7 disk. The gap in the sealing wire must be 180 degrees from the blade loading slot.

SUBTASK 72-41-10-440-211 Install the Stage 7 Disk Sealing Wires (SBE 72-0161 and SBE 72-0304)

CAUTION

SBE72-0304 STAGE 3-8 DISKS AND SEALING WIRES ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-392 AND ENGINE-HP COMPRESSOR DISCS (STAGES 3-8)01-394) ARE NOT INTERCHANGEABLE WITH OTHER SERVICE BULLETIN STANDARDS.

CAUTION

WHEN INSTALLING THE DAMPER WIRES, POSITION THE DAMPER WIRE SO THAT THE SPLIT LINE IS AS FAR AWAY AS POSSIBLE FROM BOTH THE BLADE LOADING SLOT AND THE LOCATION OF THE MAXIMUM LOCAL WEAR TO THE DAMPER WIRE GROOVE.

CAUTION

SBE 72-0304 SEALING WIRES ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-392 AND ENGINE-HP COMPRESSOR DISCS (STAGES 3-8)01-394) MUST BE INSTALLED DURING ALL STAGE 7 AND 8 BLADE BUILD OPERATIONS WHEN THE STAGE 7 AND 8 BLADES ARE INSTALLED IN THE DISK.

CAUTION

STAGE 7 FRONT AND STAGE 8 REAR SEALING WIRES ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-390 AND ENGINE-HP COMPRESSOR DISCS (STAGES 3-8)01-396) MUST BE INSTALLED DURING ALL STAGE 7 AND STAGE 8 BLADE BUILD OPERATIONS FOR SBE 72-0304 STANDARD STAGE 3 TO 8 HP COMPRESSOR ROTOR ASSEMBLIES.This method is used if the compressor disks have only two locking slots for the nut and screw lock assemblies. Refer to FigureInset 1.

Make sure each nut and screw lock assembly is kept as a set.

CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON to make a mark on the nut and screw lock assembly and on the stage 6 thru 12 compressor disks so that they can be installed in the same positions.

SBE 72-0161: HP disks and blades - Stages 7 and 8 rotor blades with damping wires and stages 6, 7 and 8 blades with anti-fret coating.

SBE 72-0304: HP disks - Introduction of a reworked stage 3 to 8 disk assembly with revised L shaped sealing wires

Release and remove the stage 6 thru 12 jacking screw and locknut assemblies from the disks, as given in Step.

A selection of the 27 standard blades and the 27 undersize blades is used to get the correct platform build clearance.

A maximum of 27 undersize blades is permitted.

CAUTION

YOU MUST MAKE SURE THE MEASURED GAP IS NOT MORE THAN 0.236IN. (6,00MM) TO MAKE SURE THAT THE STAGE 7 REAR SEALING WIRE ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-392) IS INSTALLED IN THE CORRECT POSITION AND IS NOT INSTALLED IN THE STAGE 8 GROOVE IN THE FRONT OF THE DISK.NOTE

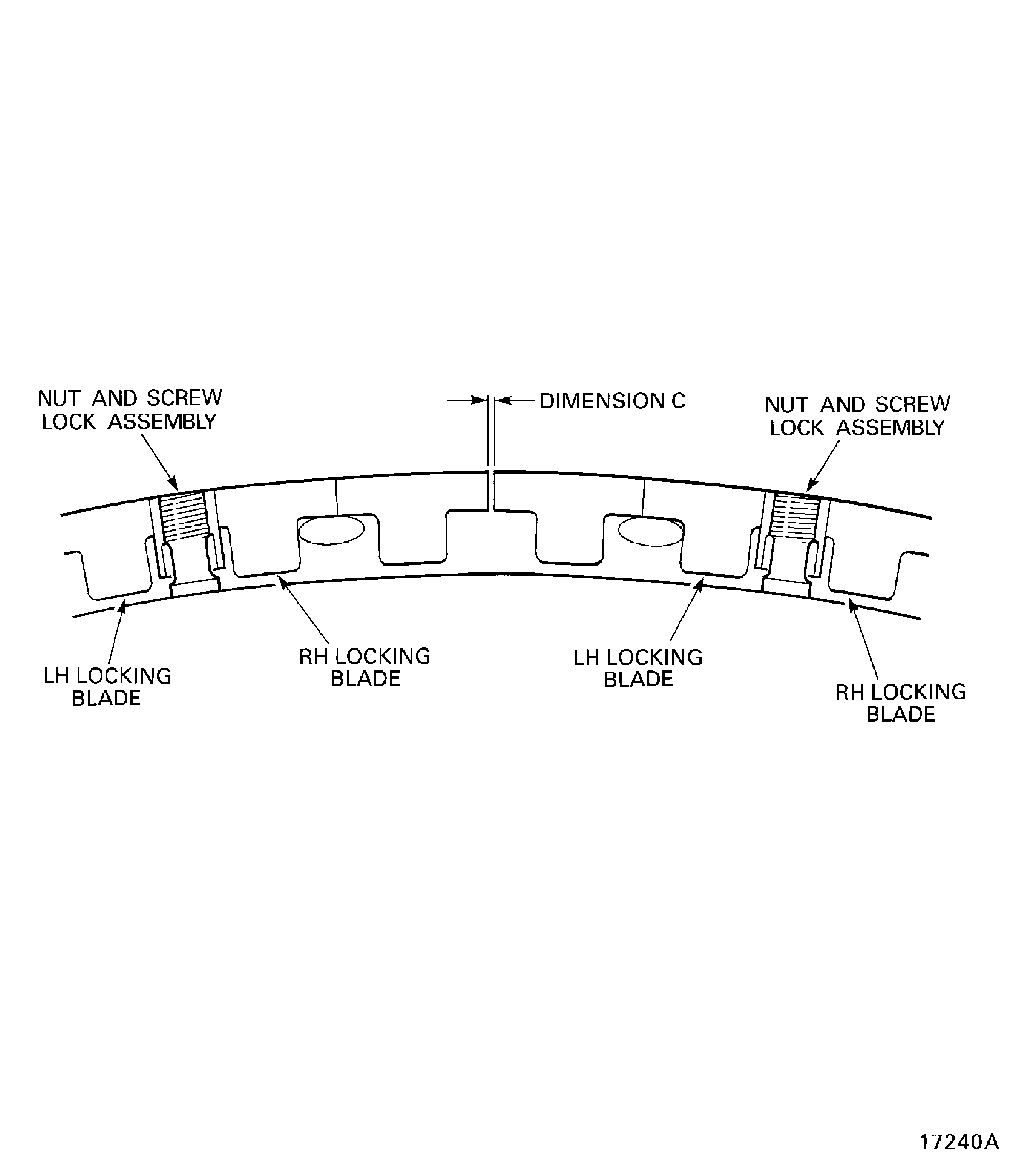

Do not mark the stage 7 blades in a light-heavy-light sequence.Do Step thru Step given in Step again to get the correct selection of stage 7 blades. During this procedure and before installing the last three blades, measure the gap (dimension C and dimension D) in the stage 7 front and rear sealing wires, refer to Figure. The gap must not be more than 0.236 in. (6mm).

NOTE

Find the correct selection of stage 7 compressor blades.

A full set of stage 7 compressor blades includes the IPC Fig/item numbers that follow:

2 LH locking blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-270).

2 RH locking blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-285).

62 Standard blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-300).

27 Standard blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-315).

27 Undersize blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-317).

SUBTASK 72-41-10-440-212 Find the Correct Selection of Stage 7 Compressor Blades (SBE 72-0161 and SBE 72-0304)

NOTE

Refer to Figure.

SBE 72-0161: HP disks and blades - Stages 7 and 8 rotor blades with damping wires and stages 6, 7 and 8 blades with anti-fret coating.

SBE 72-0304: HP disks - Introduction of a reworked stage 3 to 8 disk assembly with revised L shaped sealing wires

Install the stage 8 front sealing wire ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-394) in the groove in the front of the stage 8 disk. The gap in the sealing wire must be 180 degrees from the blade loading slot.

Install the stage 8 rear sealing wire ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-396) in the groove in the rear of the stage 8 disk. The gap in the sealing wire must be 180 degrees from the blade loading slot.

SUBTASK 72-41-10-440-213 Install the Stage 8 Disk Sealing Wires (SBE 72-0161 and SBE 72-0304)

CAUTION

SBE72-0304 STAGE 3-8 DISKS AND SEALING WIRES ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-392 AND ENGINE-HP COMPRESSOR DISCS (STAGES 3-8)01-394) ARE NOT INTERCHANGEABLE WITH OTHER SERVICE BULLETIN STANDARDS.

CAUTION

WHEN INSTALLING THE DAMPER WIRES, POSITION THE DAMPER WIRE SO THAT THE SPLIT LINE IS AS FAR AWAY AS POSSIBLE FROM BOTH THE BLADE LOADING SLOT AND THE LOCATION OF THE MAXIMUM LOCAL WEAR TO THE DAMPER WIRE GROOVE.

CAUTION

SBE 72-0304 SEALING WIRES ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-392 AND ENGINE-HP COMPRESSOR DISCS (STAGES 3-8)01-394) MUST BE INSTALLED DURING ALL STAGE 7 AND 8 BLADE BUILD OPERATIONS WHEN THE STAGE 7 AND 8 BLADES ARE INSTALLED IN THE DISK.

CAUTION

STAGE 7 FRONT AND STAGE 8 REAR SEALING WIRES ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-390 AND ENGINE-HP COMPRESSOR DISCS (STAGES 3-8)01-396) MUST BE INSTALLED DURING ALL STAGE 7 AND STAGE 8 BLADE BUILD OPERATIONS FOR SBE 72-0304 STANDARD STAGE 3 TO 8 HP COMPRESSOR ROTOR ASSEMBLIES.This method is used if the compressor disks have only two locking slots for the nut and screw lock assemblies. Refer to Figure Inset 1.

Make sure each nut and screw lock assembly is kept as a set.

CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON to make a mark on the nut and screw lock assembly and on the stage 6 thru 12 compressor disks so that they can be installed in the same positions.

SBE 72-0161: HP disks and blades - Stages 7 and 8 rotor blades with damping wires and stages 6, 7 and 8 blades with anti-fret coating.

SBE 72-0304: HP disks - Introduction of a reworked stage 3 to 8 disk assembly with revised L shaped sealing wires

Release and remove the stage 6 thru 12 jacking screw and locknut assemblies from the disks, as given in Step.

A selection of the 26 standard blades and the 26 undersize blades is used to get the correct platform build clearance.

A maximum of 26 undersize blades is permitted.

CAUTION

YOU MUST MAKE SURE THE MEASURED GAP IS NOT MORE THAN 0.236IN. (6,00MM) TO MAKE SURE THAT THE STAGE 7 REAR SEALING WIRE ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-392) IS INSTALLED IN THE CORRECT POSITION AND IS NOT INSTALLED IN THE STAGE 8 GROOVE IN THE FRONT OF THE DISK.Do Step thru Step given in Step again to get the correct selection of stage 8 blades. During this procedure and before installing the last three blades, measure the gap (dimension C and dimension D) in the stage 8 front and rear sealing wires, refer to Figure. The gap must not be more than 0.236 in. (6mm).

NOTE

Find the correct selection of stage 8 compressor blades.

A full set of stage 8 compressor blades includes the IPC Fig/item numbers that follow:

2 LH locking blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-370).

2 RH locking blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-385).

59 Standard blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-400).

26 Standard blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-415).

26 Undersize blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-417).

SUBTASK 72-41-10-440-214 Find the Correct Selection of Stage 8 Compressor Blades. 72-41-10-990-325and (SBE 72-0161 and SBE 72-0304)

NOTE

Refer to Figure

CAUTION

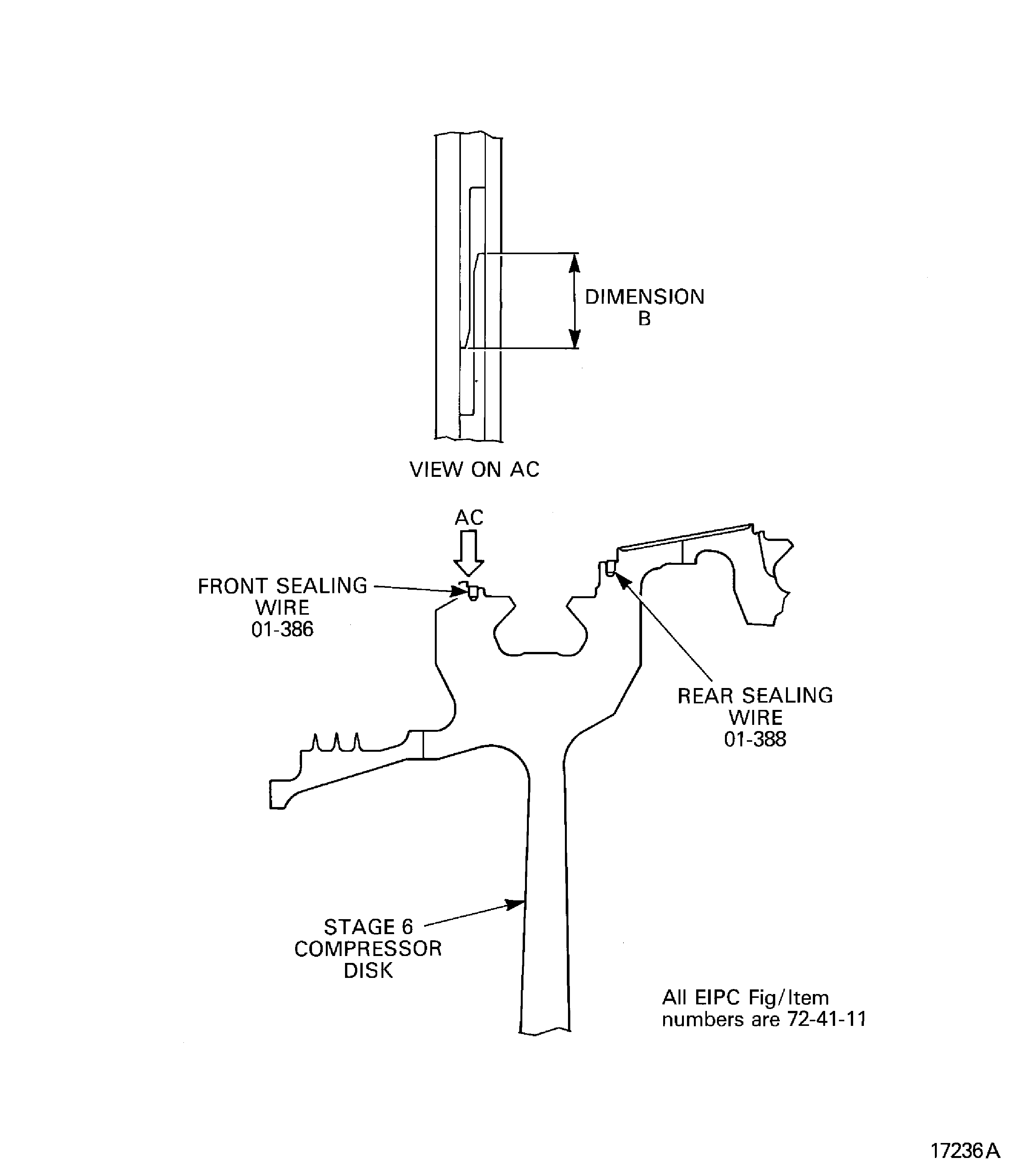

WHEN INSTALLING THE DAMPER WIRES, POSITION THE DAMPER WIRE SO THAT THE SPLIT LINE IS AS FAR AWAY AS POSSIBLE FROM BOTH THE BLADE LOADING SLOT AND THE LOCATION OF THE MAXIMUM LOCAL WEAR TO THE DAMPER WIRE GROOVE.Install the stage 6 front sealing wire ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-386) in to the stage 6 disk front groove.

Install the stage 6 rear sealing wire ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-388) in to the stage 6 disk rear groove. The front and rear sealing wire joints must be 180 degrees apart.

Do Step again for the rear sealing wire.

SUBTASK 72-41-10-440-215 Install the Stage 6 Disk Sealing Wires

CAUTION

YOU MUST NOT USE THE DRIFT ON THE AIRFOIL SURFACES.Install the stage 6 standard and undersize blades which were selected in Step in to the disk in the identified light-heavy-light sequence. Use IAE 1R18097 Drift 1 off to move the blades around the disk in a counterclockwise direction when you look from the rear.

WARNING

WHEN YOU USE CoMat 01-001 SOLVENT, DELETED OR CoMat 01-002 SOLVENT, DELETED. YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Use CoMat 01-001 SOLVENT, DELETED or CoMat 01-002 SOLVENT, DELETED. and a cloth to clean the threads of the jacking screw and locknut assemblies removed in Step.

Use a brush to apply CoMat 10-070 ANTI-SEIZE COMPOUND to the threads of the stage 6 jacking screw and locknut lock assemblies.

Prepare the jacking screw and locknut assemblies.

NOTE

A blade platform joint will be in line with the center of the blade loading slot.Continue to move the blades in a clockwise direction until the jacking scrw and locknut assemblies are in their correct positions. Refer to Figure.

Use IAE 1R18590 Socket end 1 off to torque the screws to between 4 lbfin and 5 lbfin (0.45 Nm and 0.56 Nm) above the applicable locking torque.

Use IAE IAE 1R18683 Caliper adapter 1 off to make sure that the jacking screws are correctly installed.

NOTE

The jacking screws and locknuts assemblies must be installed in the positions they were removed from. Refer to Step.Install the LH and RH locking blades and jacking screw and locknut assemblies.

SUBTASK 72-41-10-440-216 Install the Correct Selection of Stage 6 Blades

NOTE

This method is used if the compressor disk has only two locking slots for the nut and screw lock assembly. Refer to Figure Inset 1.A selection of the 26 standard blades and the 26 undersize blades is used to get the correct platform build clearance.

A maximum of 26 undersize blades is permitted.

The procedure to get the correct selection of stage 9 blades is the same as the procedure for stage 6 blades given in Step.

NOTE

Find the correct selection of stage 9 compressor blades.

A full set of stage 9 compressor blades includes the IPC Fig/item numbers that follow:

2 LH locking blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-470).

2 RH locking blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-485).

63 Standard blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-500).

26 Standard blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-515).

26 Undersize blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-517).

A selection of the 27 standard blades and the 27 undersize blades is used to get the correct platform build clearance.

A maximum of 27 undersize blades is permitted.

The procedure to get the correct selection of stage 10 blades is the same as the procedure for stage 6 blades given in Step.

NOTE

Find the correct selection of stage 10 compressor blades.

A full set of stage 10 compressor blades includes the IPC Fig/item numbers that follow:

2 LH locking blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-570).

2 RH locking blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-585).

66 Standard blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-600).

27 Standard blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-615).

27 Undersize blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-617).

A selection of the 24 standard blades and the 24 undersize blades is used to get the correct platform build clearance.

A maximum of 24 undersize blades is permitted.

The procedure to get the correct selection of stage 11 blades is the same as the procedure for stage 6 blades given in Step.

NOTE

Find the correct selection of stage 11 compressor blades.

A full set of stage 11 compressor blades includes the IPC Fig/item numbers that follow:

2 LH locking blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-670).

2 RH locking blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-685).

57 Standard blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-700).

24 Standard blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-715).

24 Undersize blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-717).

A selection of the 25 standard blades and the 25 undersize blades is used to get the correct platform build clearance.

A maximum of 25 undersize blades is permitted.

The procedure to get the correct selection of stage 12 blades is the same as the procedure for stage 6 blades given in Step.

NOTE

Find the correct selection of stage 12 compressor blades.

A full set of stage 12 compressor blades includes the IPC Fig/item numbers that follow:

2 LH locking blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-770).

2 RH locking blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-785).

60 Standard blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-800).

25 Standard blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-815).

25 Undersize blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 02-817).

SUBTASK 72-41-10-440-217 Find the Correct Selection of Stages 9 thru 12 Compressor Blades

NOTE

This method is used if the compressor disks have only two locking slots for the jacking screw and locknut assemblies Refer to Figure Inset 1.Refer to Figure

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYONor CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYONto identify the blades in a light-heavy-light sequence ready for assembly. Refer to Figurefor an example of a light-heavy-light sequence.

Weigh the stage 4 compressor blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-500).

Weigh the stage 5 compressor blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-800).

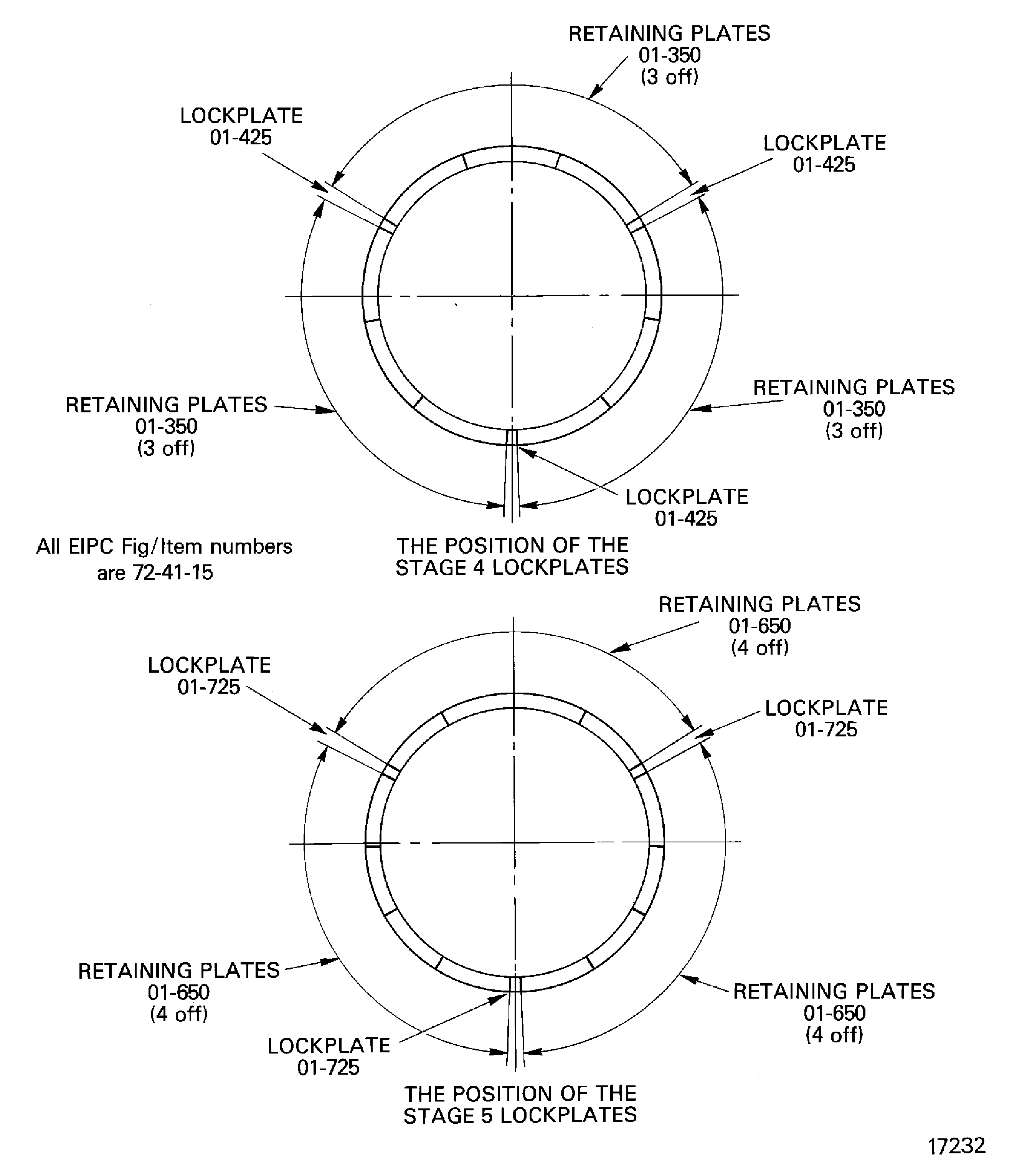

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON pencil/crayon temporary marker to identify the plates in a light-heavy-light sequence ready for assembly. Refer to Figure.

Weigh the 9 stage 4 retaining plates ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-350).

Weigh the 12 stage 5 retaining plates ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-650).

SUBTASK 72-41-10-440-219 Weigh the Stages 4 and 5 Compressor Blades and Retaining Plates

Apply CoMat 07-075 HIGH-HEAT RESISTING STOVING ENAMEL to the mating surfaces of the retaining plates.

Position the retaining plate centrally over area(s) of material removed; refer to Repair, VRS6630 Task TASK 72-41-11-300-023 (REPAIR-023).

Use IAE 1R18080 Drift 1 off to move the retaining plate around the disk in to the next blade groove.

Install the stage 5 retaining plates.

NOTE

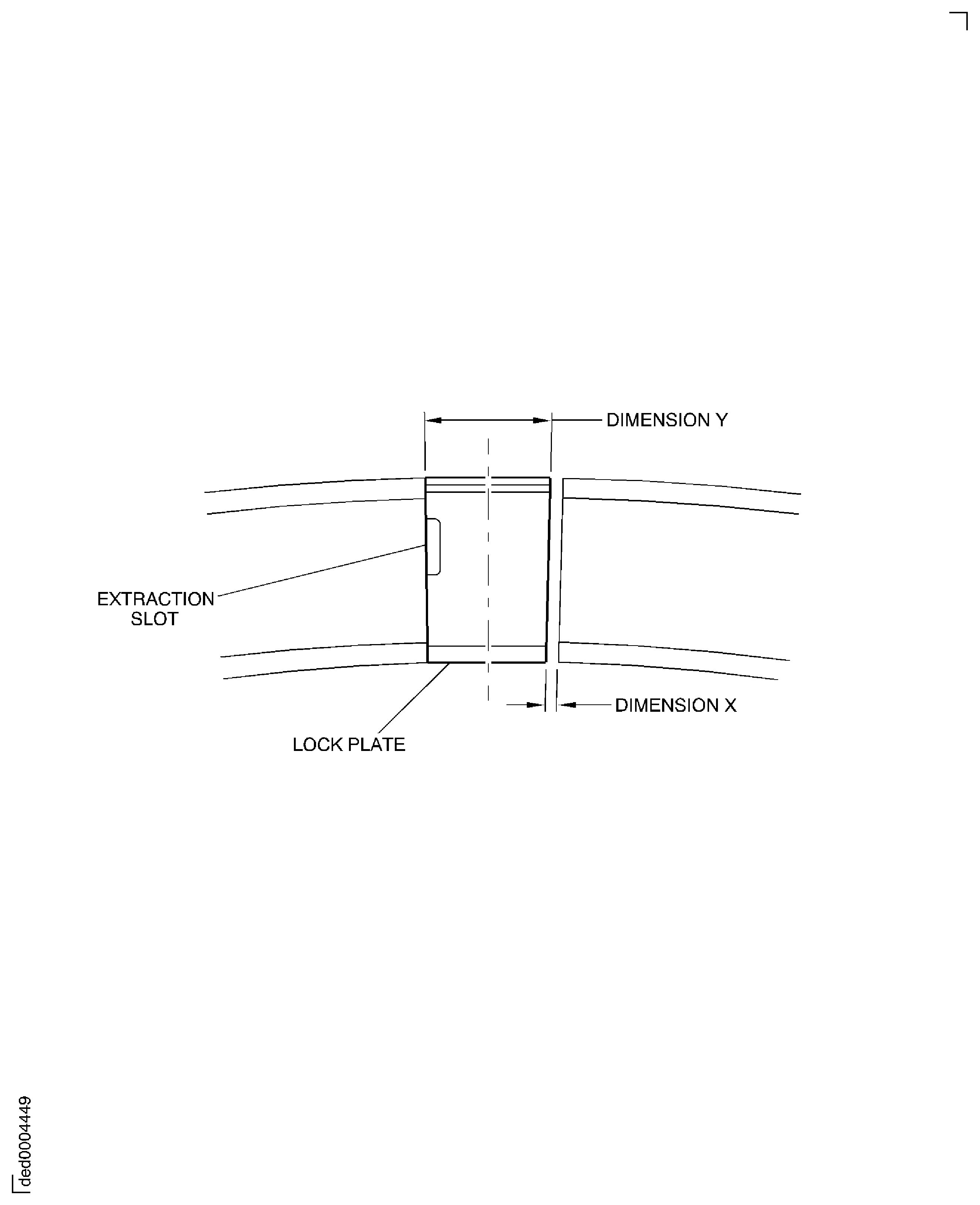

If the last lockplate overlaps a retaining plate go to Step.Install the three stage 5 lockplates in position between the retaining plates. Refer to Figure. Use IAE 1R18080 Drift to move the lockplates and retaining plates around the disk until they touch. Collect the total clearance (dimension X) between a lockplate and a retaining plate. Refer to Figure.

Use feeler gauges to measure the total clearance (dimension X). The total clearance (dimension X) must not exceed 0.010 in. (0.25 mm). Refer to Figure.

Install a lockplate in to IAE 1R19813 Filing fixture 1 off and use a file to remove metal. The minimum permitted width (dimension Y) of the stage 5 lockplate after filing is 0.297 in. (7.64 mm). Refer to Figure.

NOTE

Remove metal from the minimum number of lockplates.Remove metal from the edge opposite the extraction slot.

If it is necessary to remove metal from a lockplate to get the correct plate clearance do the steps that follow:

Apply CoMat 07-075 HIGH-HEAT RESISTING STOVING ENAMEL to the mating surfaces of the disk and the lockplates.

Install the lockplates in position. Refer to Figure. The lockplates must be in line with a blade root.

Position the retaining plate centrally over area(s) of material removed; refer to Repair, VRS6630 Task TASK 72-41-11-300-023 (REPAIR-023).

Install ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-725) stage 5 lockplates 3 off in to the blade and disk grooves. Refer to Figure.

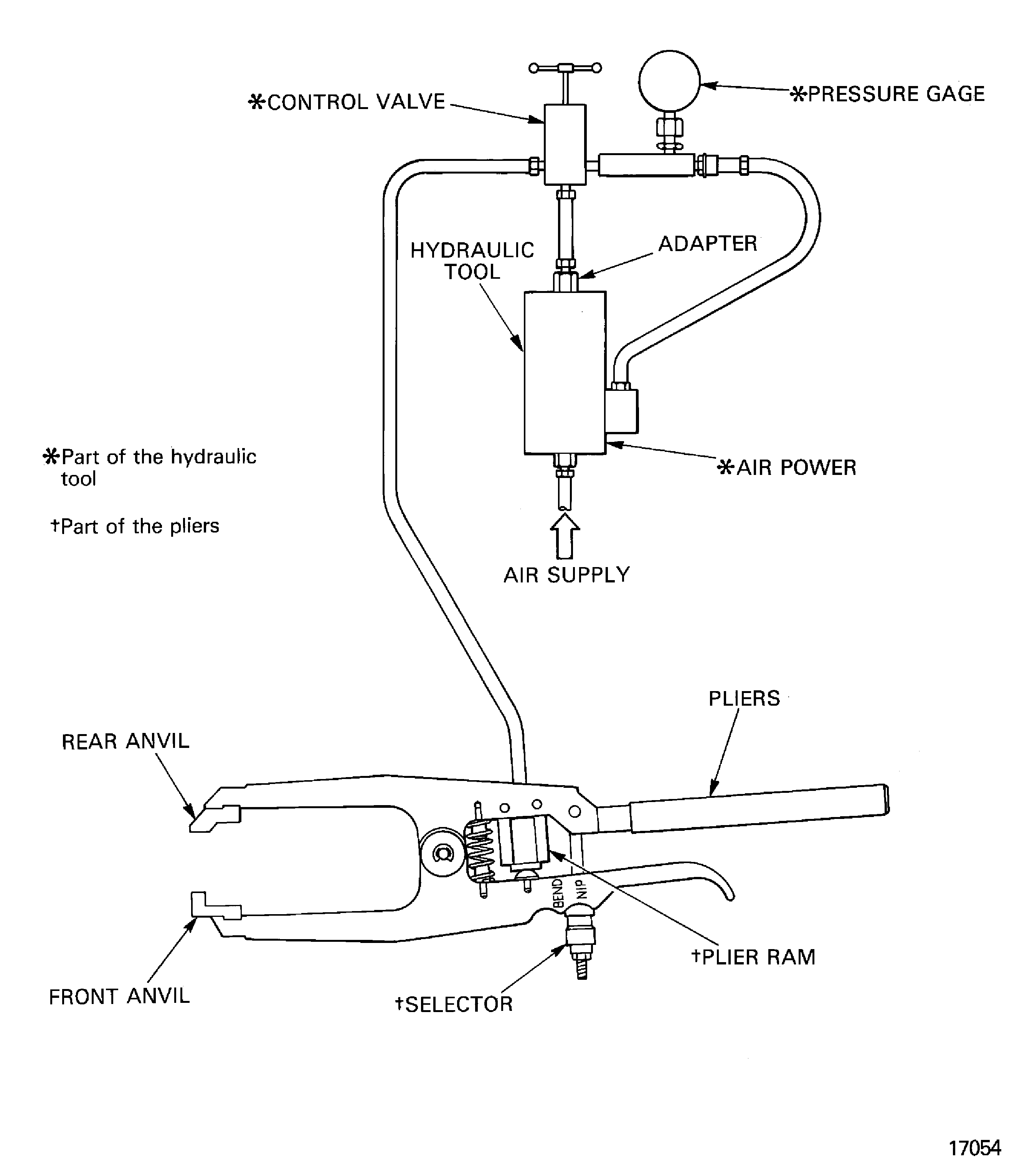

Install IAE 1R18070 Front anvil 1 off and IAE 1R18069 Rear anvil 1 off in to IAE 1R18082 Pliers 1 off.

Install IAE 1R18245 Adapter 1 off between the pressure control valve and IAE 1R18083 Hydraulic tool 1 off.

CAUTION

YOU MUST USE THE CORRECT ANVILS AND PLIERS FOR EACH STAGE WHEN LOCKING THE LOCKPLATES.

CAUTION

LOCKPLATES THAT ARE DAMAGED IN ANY WAY DURING INSTALLATION, FOR EXAMPLE: OVER BENT, TWISTED OR NICKED SHOULD BE REPLACED WITH NEW PARTS. CORRECT ENGAGEMENT OF THE LOCKPLATES IS ESSENTIAL.Lock the lockplates in position. Refer to Figure.

NOTE

Install the heaviest blade at the No. 1 blade slot position.Install the stage 4 blades to the disk in the sequence found in Step. Start from the No. 1 blade slot and install the blades in a clockwise direction when you look from the rear.

Install the stage 4 compressor blades.

Do the same procedure as given in Step.

Install the stage 4 retaining plates.

Do the procedure given in Step thru Step but use IAE 1R19812 Filing fixture 1 off. The minimum permitted width (dimension Y) of the stage 4 lockplate after filing is 0.402 in. (10.20 mm). Refer to Figure.

Do Do Step thru Step again to install the stage 4 lockplates. If it is necessary to remove metal from the lockplate in Step do the step that follows:

Install ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-425) stage 4 lockplates 3 off in to the grooves of the blades and the disk.

Install IAE 1R18072 Front anvil 1off and IAE 1R18071 Rear anvil 1 off in to IAE 1R18084 Pliers 1 off.

CAUTION

YOU MUST USE THE CORRECT ANVILS AND PLIERS FOR EACH STAGE WHEN LOCKING THE LOCKPLATES.

CAUTION

LOCKPLATES THAT ARE DAMAGED IN ANY WAY DURING INSTALLATION, FOR EXAMPLE: OVER BENT, TWISTED OR NICKED SHOULD BE REPLACED WITH NEW PARTS. CORRECT ENGAGEMENT OF THE LOCKPLATES IS ESSENTIAL.Lock the stage 4 lockplates in position. Figure.

SUBTASK 72-41-10-440-220 Install the Stages 4 and 5 Compressor Blades in the Disk Assembly

Refer to Figure

Install the compressor rotor assembly in to the balancing machine. Refer to Step.

Do a check balance of the HP compressor rotor. Refer to Step. Make a record of the quantity and angle of static unbalance in plane B.

Remove the blades. Refer to TASK 72-41-10-040-001.

If the static unbalance is more than 5.000 ozin (3600 gmm) do the steps that follow:

Install the compressor rotor in to the trolley. Refer to Step.

SUBTASK 72-41-10-440-221 Do a Check Balance of the HP Compressor Rotor Assembly

SBE 72-0161: HP disks and blades - stages 7 and 8 rotor blades with damping wires and stages 6, 7 and 8 blades with anti-fret coating.

SBE 72-0304: HP disks - Introduction of a reworked stage 3 to 8 disk assembly with revised L shaped sealing wires

Make sure the stage 8 front sealing wire ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-394) is correctly installed in the groove in the front of the stage 8 disk. The gap in the sealing wire must be 180 degrees from the blade loading slot.

Make sure the stage 8 rear sealing wire ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-396) is correctly installed in the groove in the rear of the stage 8 disk. The gap in the sealing wire must be 180 degrees from the blade loading slot.

CAUTION

SBE72-0304 STAGE 3-8 DISKS AND SEALING WIRES ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-392 AND ENGINE-HP COMPRESSOR DISCS (STAGES 3-8)01-394) ARE NOT INTERCHANGEABLE WITH OTHER SERVICE BULLETIN STANDARDS.

CAUTION

WHEN INSTALLING THE DAMPER WIRES, POSITION THE DAMPER WIRE SO THAT THE SPLIT LINE IS AS FAR AWAY AS POSSIBLE FROM BOTH THE BLADE LOADING SLOT AND THE LOCATION OF THE MAXIMUM LOCAL WEAR TO THE DAMPER WIRE GROOVE.

CAUTION

SBE 72-0304 SEALING WIRES ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-392 AND ENGINE-HP COMPRESSOR DISCS (STAGES 3-8)01-394) MUST BE INSTALLED DURING ALL STAGE 7 AND 8 BLADE BUILD OPERATIONS WHEN THE STAGE 7 AND 8 BLADES ARE INSTALLED IN THE DISK.

CAUTION

STAGE 7 FRONT AND STAGE 8 REAR SEALING WIRES ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-390 AND ENGINE-HP COMPRESSOR DISCS (STAGES 3-8)01-396) MUST BE INSTALLED DURING ALL STAGE 7 AND STAGE 8 BLADE BUILD OPERATIONS FOR SBE 72-0304 STANDARD STAGE 3 TO 8 HP COMPRESSOR ROTOR ASSEMBLIES.Make sure the stage 8 sealing wires are correctly installed.

Use the IAE 1R18097 Drift 1 off to move the blades around the disk in a counterclockwise direction when you look from the rear.

Install the stage 8 compressor blades.

WARNING

WHEN YOU USE CoMat 01-001 SOLVENT, DELETED OR CoMat 01-002 SOLVENT, DELETED. YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Use CoMat 01-001 SOLVENT, DELETED or CoMat 01-002 SOLVENT, DELETED. and a cloth to clean the threads of the jacking screw and locknut assemblies removed in Step.

Use a brush to apply CoMat 10-070 ANTI-SEIZE COMPOUND to the threads of the stage 8 jacking screw and locknut assemblies.

Prepare the jacking screw and locknut assemblies.

CAUTION

YOU MUST MAKE SURE THE MEASURED GAP IS NOT MORE THAN 0.236IN. (6.00MM) TO MAKE SURE THAT THE STAGE 7 REAR SEALING WIRE ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-392) IS INSTALLED IN THE CORRECT POSITION AND IS NOT INSTALLED IN THE STAGE 8 GROOVE IN THE FRONT OF THE DISK.Measure the gaps in the sealing wires. The gaps must not be more than 0.236in. (6.00 mm.) in each sealing wire. Refer to dimension C and D on Figure.

NOTE

A blade platform joint will be in line with the center of the blade loading slot.Continue to move the blades in a clockwise direction until the jacking screw and locknut assemblies are in their correction positions. Ref to Figure.

Use the IAE 1R18590 Socket end 1 off to torque the screws to 4 lbfin to 5 lbfin. (0.45 Nm to 0.56 Nm) above the locking torque.

Use IAE IAE 1R18683 Caliper adapter 1 off to make sure that the jacking screws are correctly installed.

Install the LH and RH locking blades and lock assemblies.

Make sure the stage 7 front sealing wire ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-390) is correctly installed in the groove in the front of the stage 7 disk. The gap in the sealing wire must be 180 degrees from the blade loading slot.

Make sure the stage 7 rear sealing wire ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-392) is correctly installed in the groove in the rear of the stage 7 disk. The gap in the sealing wire must be 180 degrees from the blade loading slot.

CAUTION

SBE72-0304 STAGE 3-8 DISKS AND SEALING WIRES ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-392 AND ENGINE-HP COMPRESSOR DISCS (STAGES 3-8)01-394) ARE NOT INTERCHANGEABLE WITH OTHER SERVICE BULLETIN STANDARDS.

CAUTION

WHEN INSTALLING THE DAMPER WIRES, POSITION THE DAMPER WIRE SO THAT THE SPLIT LINE IS AS FAR AWAY AS POSSIBLE FROM BOTH THE BLADE LOADING SLOT AND THE LOCATION OF THE MAXIMUM LOCAL WEAR TO THE DAMPER WIRE GROOVE.

CAUTION

SBE 72-0304 SEALING WIRES ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-392 AND ENGINE-HP COMPRESSOR DISCS (STAGES 3-8)01-394) MUST BE INSTALLED DURING ALL STAGE 7 AND 8 BLADE BUILD OPERATIONS WHEN THE STAGE 7 AND 8 BLADES ARE INSTALLED IN THE DISK.

CAUTION

STAGE 7 FRONT AND STAGE 8 REAR SEALING WIRES ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-390 AND ENGINE-HP COMPRESSOR DISCS (STAGES 3-8)01-396) MUST BE INSTALLED DURING ALL STAGE 7 AND STAGE 8 BLADE BUILD OPERATIONS FOR SBE 72-0304 STANDARD STAGE 3 TO 8 HP COMPRESSOR ROTOR ASSEMBLIES.Make sure the stage 7 sealing wires are correctly installed.

CAUTION

DO NOT USE THE DRIFT ON THE AIRFOIL SURFACES.Install the stage 7 compressor blades that were identified in Step. Use the drift to move the blades around the disk in a counterclockwise direction when you look from the rear.

NOTE

It is possible to correct up to approximately 2.500 ozin (1800 gmm) of the rotor static unbalance if you get the correct installation sequence of the blades.Install the stage 7 blades into the disk in a sequence that will get the static unbalance aimpoint. The static unbalance aimpoint is 50 per cent of the value recorded in Step and is at the same angle that was recorded.

CAUTION

YOU MUST MAKE SURE THE MEASURED GAP IS NOT MORE THAN 0.236IN. (6,00MM) TO MAKE SURE THAT THE STAGE 7 REAR SEALING WIRE ENGINE-HP COMPRESSOR DISCS (STAGES 3-8) (72-41-11, 01-392) IS INSTALLED IN THE CORRECT POSITION AND IS NOT INSTALLED IN THE STAGE 8 GROOVE IN THE FRONT OF THE DISK.Use the procedure in steps C. and D. to install the locking blades and the jacking screw and locknut assemblies and to measure the stage 7 front and rear sealing wire gaps.

Install the stage 7 compressor blades.

SUBTASK 72-41-10-440-222 Install the Stages 7 and 8 Rotor Blades in to the Disks (SBE 72-0161 and SBE 72-0304)

NOTE

This method is used if the compressor disks have only two locking slots for the jacking screw and locknut assemblies. Refer to Figure Inset 1.Refer to Figure

Install the compressor rotor assembly in to the balancing machine. Refer to Step.

Do a check balance of the compressor rotor assembly. Refer to Step.

NOTE

The static unbalance aimpoint is 50 per cent of the value recorded in Step and is at the same angle as recorded.If the static unbalance aimpoint has been achieved within 0.210 ozin (150 gmm) go to the next SUBTASK.

SUBTASK 72-41-10-440-223 Do a Check Balance of the HP Compressor Rotor Assembly

Refer to Figure

Plane separate and calibrate the balancing machine through planes AB and AC. Measure and record the quantity and angular positions of the unbalance in both planes. Refer to Figure.

Install the compressor rotor assembly on to the dummy stub shaft, 180 degrees from the original position. Refer to Step.

Install the compressor rotor in to the trolley. Refer to Step.

SUBTASK 72-41-10-440-224 Dynamic Balance the HP Compressor Rotor Assembly

NOTE

You must let the balancing machine run for a short time so that it can become stable, before balance values are read.Weigh the stage 3 compressor blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-200).

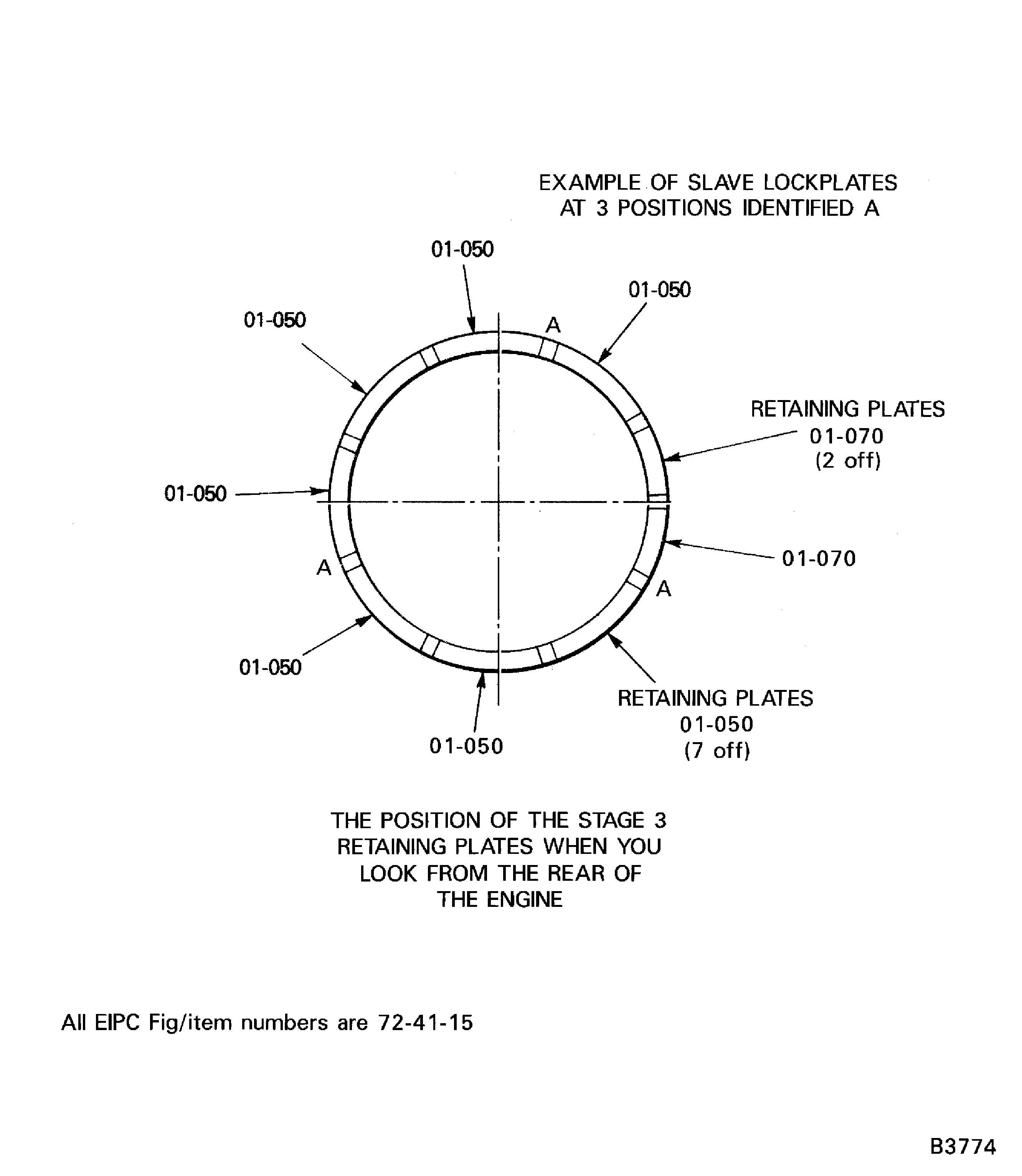

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYONor CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYONto identify the retaining plates ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-050) in a light-heavy-light sequence ready for assembly. Refer to Figure.

Weigh the stage 3 retaining plates ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-050 and ENGINE-HP COMPRESSOR BLADES01-070).

SUBTASK 72-41-10-440-225-A01 Weigh the Stage 3 Compressor Blades and Retaining Plates (Pre SBE 70-0068)

SBE 70-0068: HP compressor - to announce revised quantities of stage 3 compressor retaining plates

Weigh the stage 3 compressor blades ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-200).

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYONor CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYONto identify the retaining plates ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-050) in a light-heavy-light sequence ready for assembly. Refer to Figure.

Weigh the stage 3 retaining plates ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-050 and ENGINE-HP COMPRESSOR BLADES01-070).

SUBTASK 72-41-10-440-225-B01 Weigh the Stage 3 Compressor Blades and Retaining Plates (SBE 70-0068)

Install the stage 3 blades to the disk in a sequence to correct as much of the unbalance in plane AB as possible. The unbalance in plane AB was recorded in Step. Start at the No. 1 blade slot and install the blades in a clockwise direction when you look from the rear.

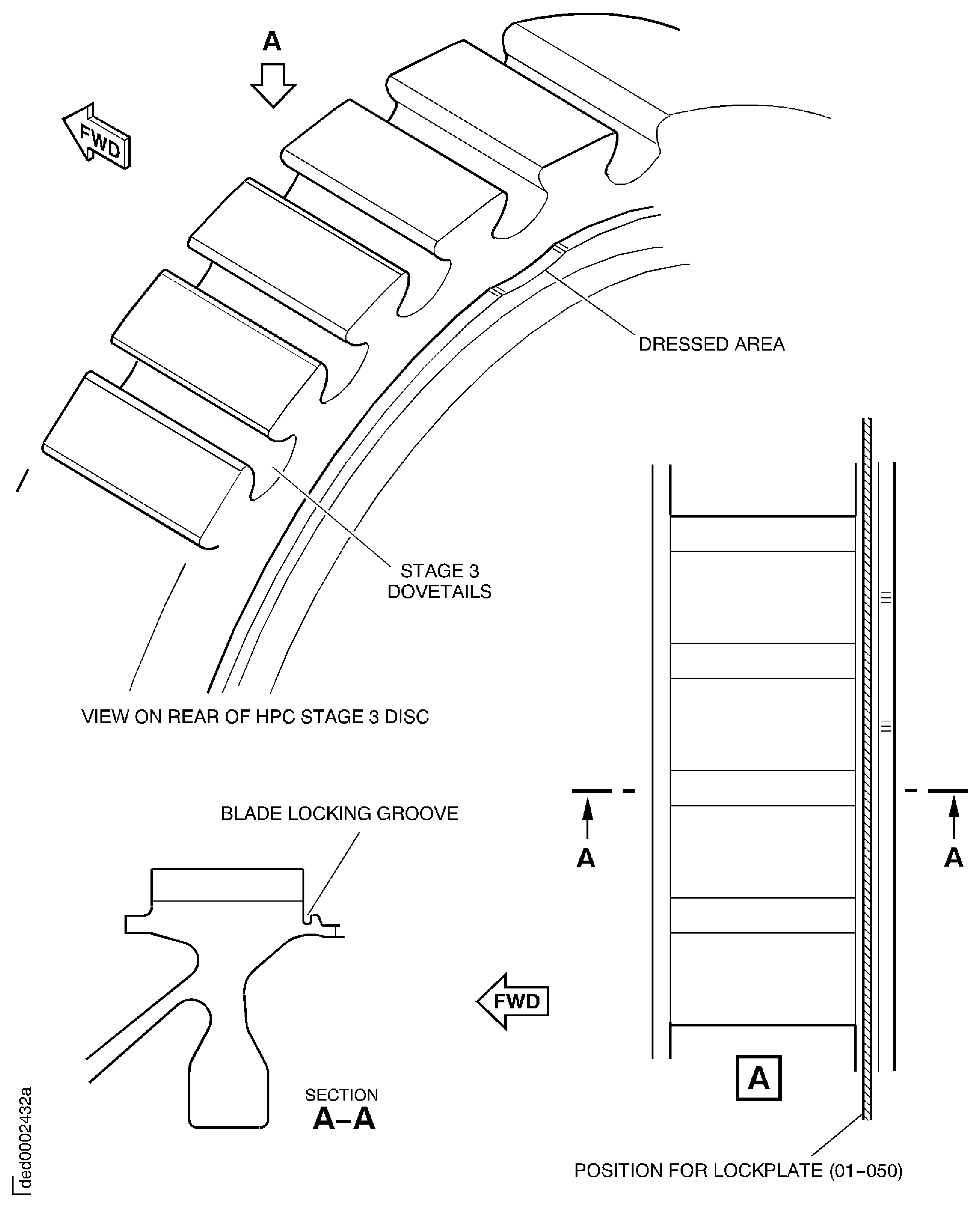

During installation of the retaining plates to a Stage 3 disk, which has a repaired area on the lockplate groove, make sure that you install the blade retaining plate V2500-A5-72-41-10-01A-941A-D (72-41-10, 01-050) centrally over the dressed area. Do not install the blade retaining plate (01-070) and locking plate ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-125) adjacent to the dressed area. Refer to Figure.

Apply CoMat 07-075 HIGH-HEAT RESISTING STOVING ENAMEL to the mating surfaces of the retaining plates.

Install one of the plates ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-050) into the two grooves.

Position the retaining plate centrally over area(s) of material removal, refer to Repair, VRS6300, TASK 72-41-11-300-016 (REPAIR-016) or Repair, VRS9300, TASK 72-41-11-300-026 (REPAIR-026).

Use IAE 1R18079 Drift 1 off to move the retaining plate around the disk in to the next blade groove.

Do steps B.(4) thru B.(7) to install the remaining plates in to the disk and blades grooves. The retaining plates ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-050) must be installed in the light-heavy-light sequence identified in SUBTASK 72-41-10-440-225. The 2 retaining plates ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-070) must be installed after the larger retaining plates and in the sequence shown in Figure.

Install the stage 3 retaining plates.

SUBTASK 72-41-10-440-226-A01 Install the Stage 3 Compressor Blades in to the Disk Assembly (Pre SBE 70-0068)

SBE 70-0068: HP compressor - to announce revised quantities of stage 3 compressor retaining plates

Install the stage 3 blades to the disk in a sequence to correct as much of the unbalance in plane AB as possible. The unbalance in plane AB was recorded in Step. Start at the No. 1 blade slot and install the blades in a clockwise direction when you look from the rear.

During installation of the retaining plates to a Stage 3 disk, which has a repaired area on the lockplate groove, make sure that you install the blade retaining plate V2500-A5-72-41-10-01A-941A-D (72-41-10, 01-050) centrally over the dressed area. Do not install the blade retaining plate (01-070) and locking plate ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-125) adjacent to the dressed area. Refer to to Figure.

Apply CoMat 07-075 HIGH-HEAT RESISTING STOVING ENAMELto the mating surfaces of the retaining plates.

Install one of the plates ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-050) into the two grooves.

Position the retaining plate centrally over area(s) of material removed; refer to Repair, VRS6630 Task TASK 72-41-11-300-023 (REPAIR-023).

Use IAE 1R18079 Drift 1 off to move the retaining plate around the disk in to the next blade groove.

Do steps B.(4) thru B.(7) to install the remaining plates in to the disk and blades grooves. The retaining plates ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-050) must be installed in the light-heavy-light sequence identified in SUBTASK 72-41-10-440-225. The 2 retaining plates ENGINE-HP COMPRESSOR BLADES (72-41-15, 01-070) must be installed after the larger retaining plates and in the sequence shown in Figure.

Install the stage 3 retaining plates.

SUBTASK 72-41-10-440-226-B01 Install the Stage 3 Compressor Blades in to the Disk Assembly (SBE 70-0068)

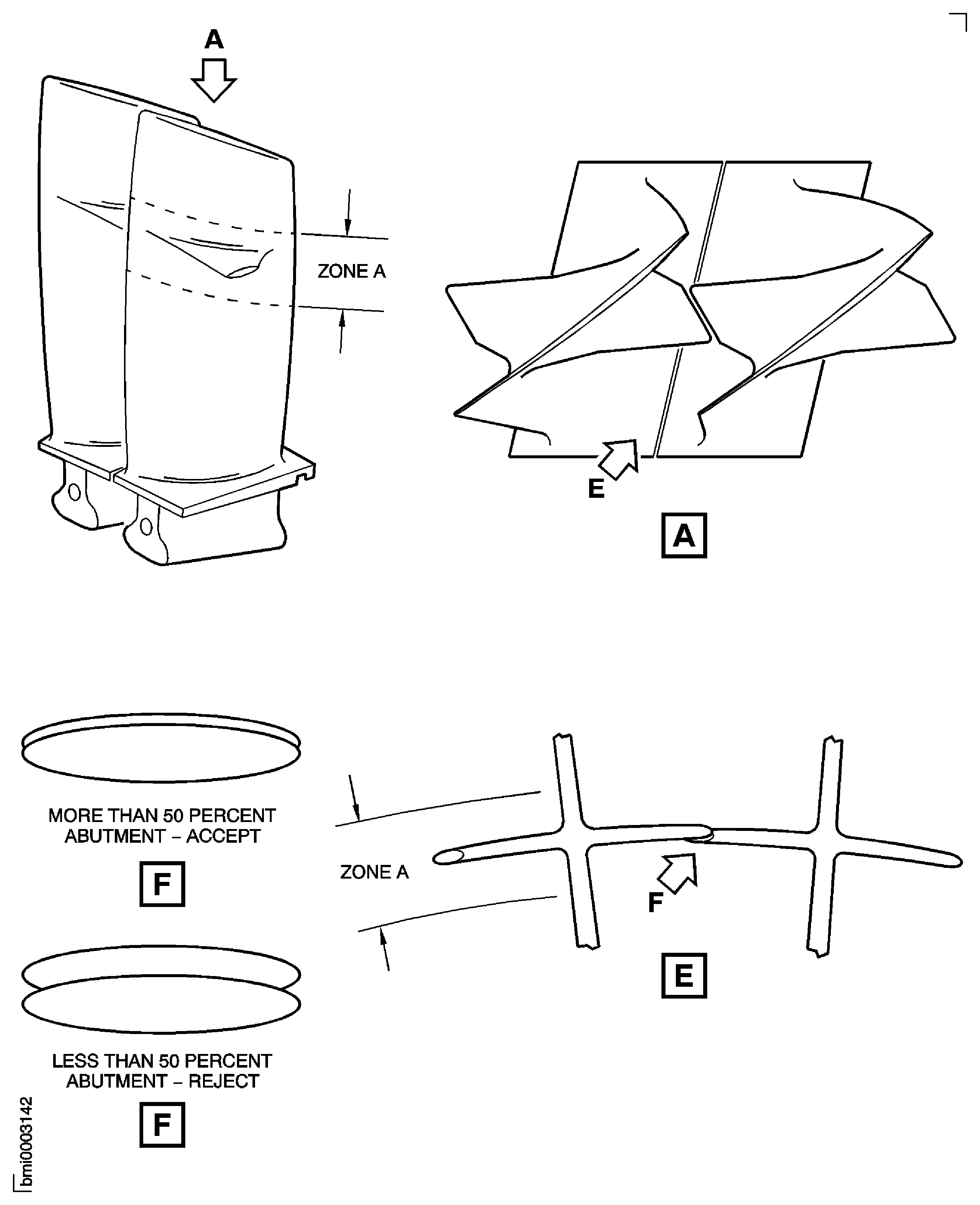

Refer to Zone A Figure.

SUBTASK 72-41-10-220-088 Examine the Clapper Abutment Faces

Install the slave lockplates in position between the retaining plates at equal distances around the disk. Refer to Figure for an example of the slave lockplates positions.

Position the retaining plate centrally over area(s) of material removed; refer to Repair, VRS6630 Task TASK 72-41-11-300-023 (REPAIR-023).

Install IAE 1R18076 Slave lock plates 3 off in to the grooves of the disk and blades.

SUBTASK 72-41-10-440-295-A00 Install the Stage 3 Compressor Blade Lockplates (Pre SBE 70-0068)

SBE 70-0068: HP compressor - to announce revised quantities of stage 3 compressor retaining plates

Install the slave lockplates in position between the retaining plates at equal distances around the disk. Refer to Figure for an example of the slave lockplates positions.

Position the retaining plate centrally over area(s) of material removed; refer to Repair, VRS6630 Task TASK 72-41-11-300-023 (REPAIR-023).

Install IAE 1R18076 Slave lock plates 3 off in to the grooves of the disk and blades.

SUBTASK 72-41-10-440-295-B00 Install the Stage 3 Compressor Blade Lockplates (SBE 70-0068)

Figure: Example view of the HP compressor rotor assembly

Example view of the HP compressor rotor assembly

Figure: Measure the stage 6 sealing wires overlap

Measure the stage 6 sealing wires overlap

Figure: Install the HP compressor rotor assembly in to the balancing machine

Install the HP compressor rotor assembly in to the balancing machine

Figure: Install the protective cover

Install the protective cover

Figure: Remove/install the HP compressor rotating air seal protective cover

Remove/install the HP compressor rotating air seal protective cover

Figure: Install the beam sling on to the HP compressor rotor assembly

Install the beam sling on to the HP compressor rotor assembly

Figure: Remove/install the universal sling adapters

Remove/install the universal sling adapters

Figure: Calculate the static unbalance

Calculate the static unbalance

Figure: Install the HP compressor rotor assembly in to the safety support stand

Install the HP compressor rotor assembly in to the safety support stand

Figure: Remove/install the dummy stub shaft

Remove/install the dummy stub shaft

Figure: Stage 3 disk curvic coupling bolt torque sequence

Stage 3 disk curvic coupling bolt torque sequence

Figure: Remove/install the HP compressor rotor assembly from/to the trolley

Remove/install the HP compressor rotor assembly from/to the trolley

Figure: Example of stages 6 thru 12 blade loading slot and locknut slots

Example of stages 6 thru 12 blade loading slot and locknut slots

Figure: SBE 72-0161 and SBE 72-0304: Measure the stage 7 and 8 sealing wire gaps

SBE 72-0161 and SBE 72-0304: Measure the stage 7 and 8 sealing wire gaps

Figure: Measure the stages 6 thru 12 platform build clearance

Measure the stages 6 thru 12 platform build clearance

Figure: Example of a light-heavy-light sequence

Example of a light-heavy-light sequence

Figure: Install the nut and screw lock assemblies in to the stages 6 thru 12 disks

Install the nut and screw lock assemblies in to the stages 6 thru 12 disks

Figure: Measure the clearance (dimension C) between the undersize blade and the standard blade

Measure the clearance (dimension C) between the undersize blade and the standard blade

Figure: Pre-SBE70-0068 Install the stage 3 retaining plates and lockplates

Pre-SBE70-0068 Install the stage 3 retaining plates and lockplates

Figure: SBE70-0068 Install the stage 3 retaining plates and lockplates

SBE70-0068 Install the stage 3 retaining plates and lockplates

Figure: Install the stages 4 and 5 retaining plates and lockplates

Install the stages 4 and 5 retaining plates and lockplates

Figure: Position of retaining plates following dressing repair

Position of retaining plates following dressing repair

Figure: Lock the lockplates in position

Lock the lockplates in position

Figure: Measure Blade Lockplate clearance

Measure Blade Lockplate clearance

Figure: Examine the Clapper Abutment Faces

Examine the Clapper Abutment Faces