Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1 Pre SB 72-0339 and SB 72-0341

Common Information

TASK 72-44-00-440-001-A01 HP Turbine (HPT) Stage 1 Nozzle Assembly - Assemble The Nozzle, Assembly-001 - Pre SB 72-0339 And SB 72-0341

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to SPM TASK 70-44-01-400-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

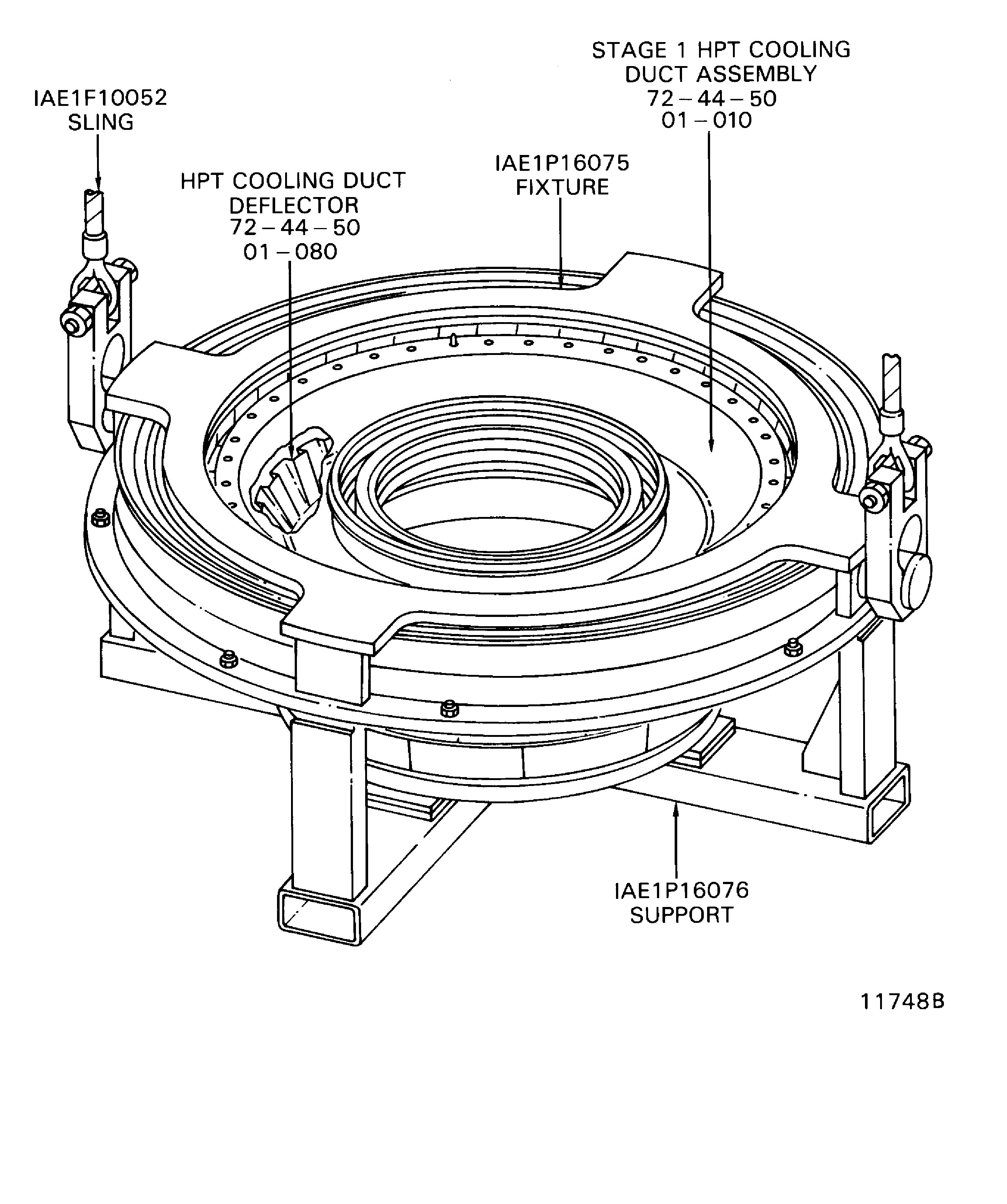

| IAE 1F10052 Two cables sling | 0AM53 | IAE 1F10052 | 1 | |

| IAE 1P16075 Fixture | 0AM53 | IAE 1P16075 | 1 | |

| IAE 1P16076 Support | 0AM53 | IAE 1P16076 | 1 | |

| IAE 1P16077 Fixture | 0AM53 | IAE 1P16077 | 1 | |

| IAE 1P16078 Alignment pin | 0AM53 | IAE 1P16078 | 4 | |

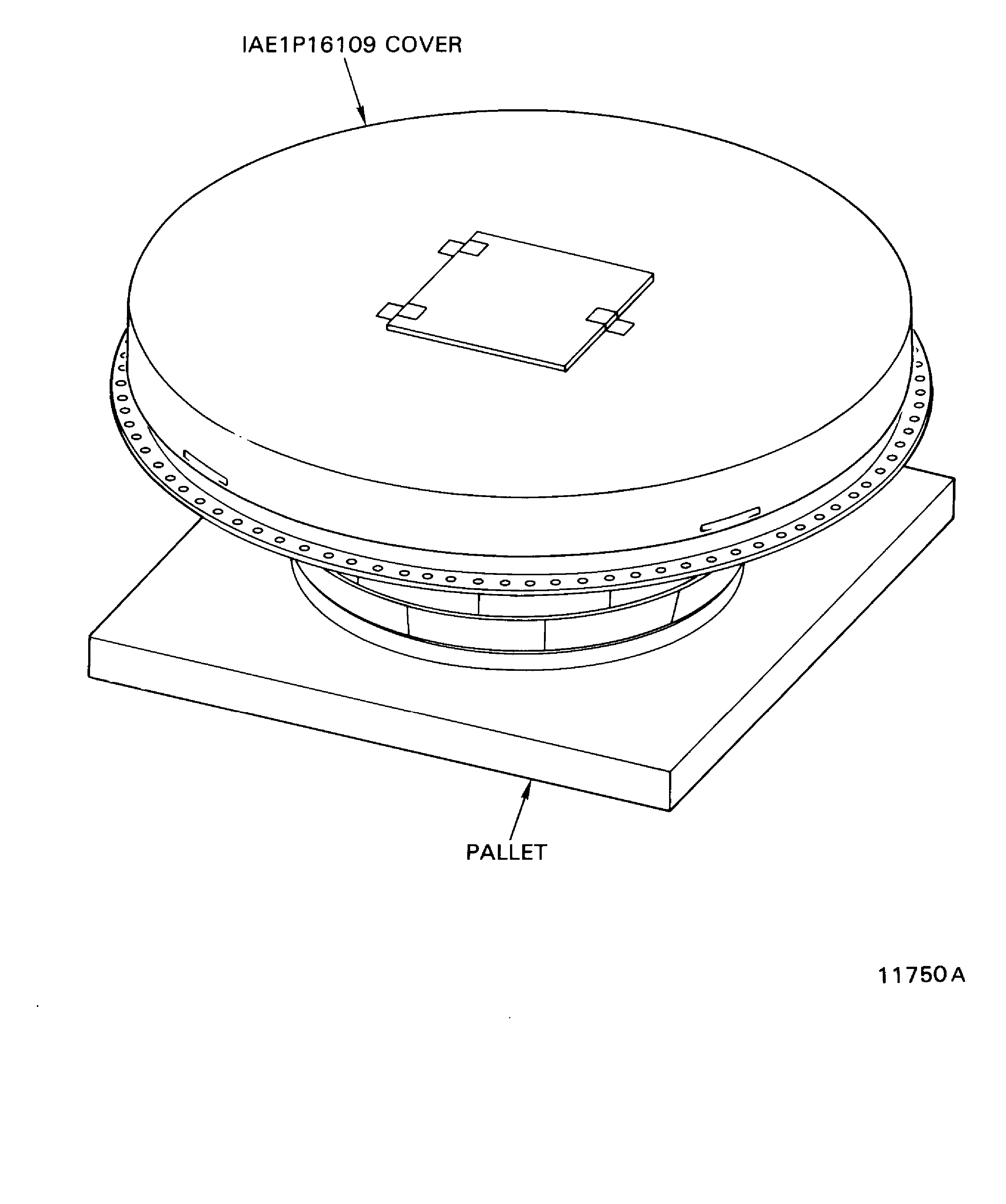

| IAE 1P16109 cover | 0AM53 | IAE 1P16109 | 1 | |

| IAE 1P16226 Alignment fixture | 0AM53 | IAE 1P16226 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| DELETED | LOCAL | DELETED | ||

| CoMat 01-573 WAX BLEND, PARAFFIN | 24269 | CoMat 01-573 | ||

| CoMat 08-041 CYANOACRYLATE ADHESIVE | LOCAL | CoMat 08-041 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

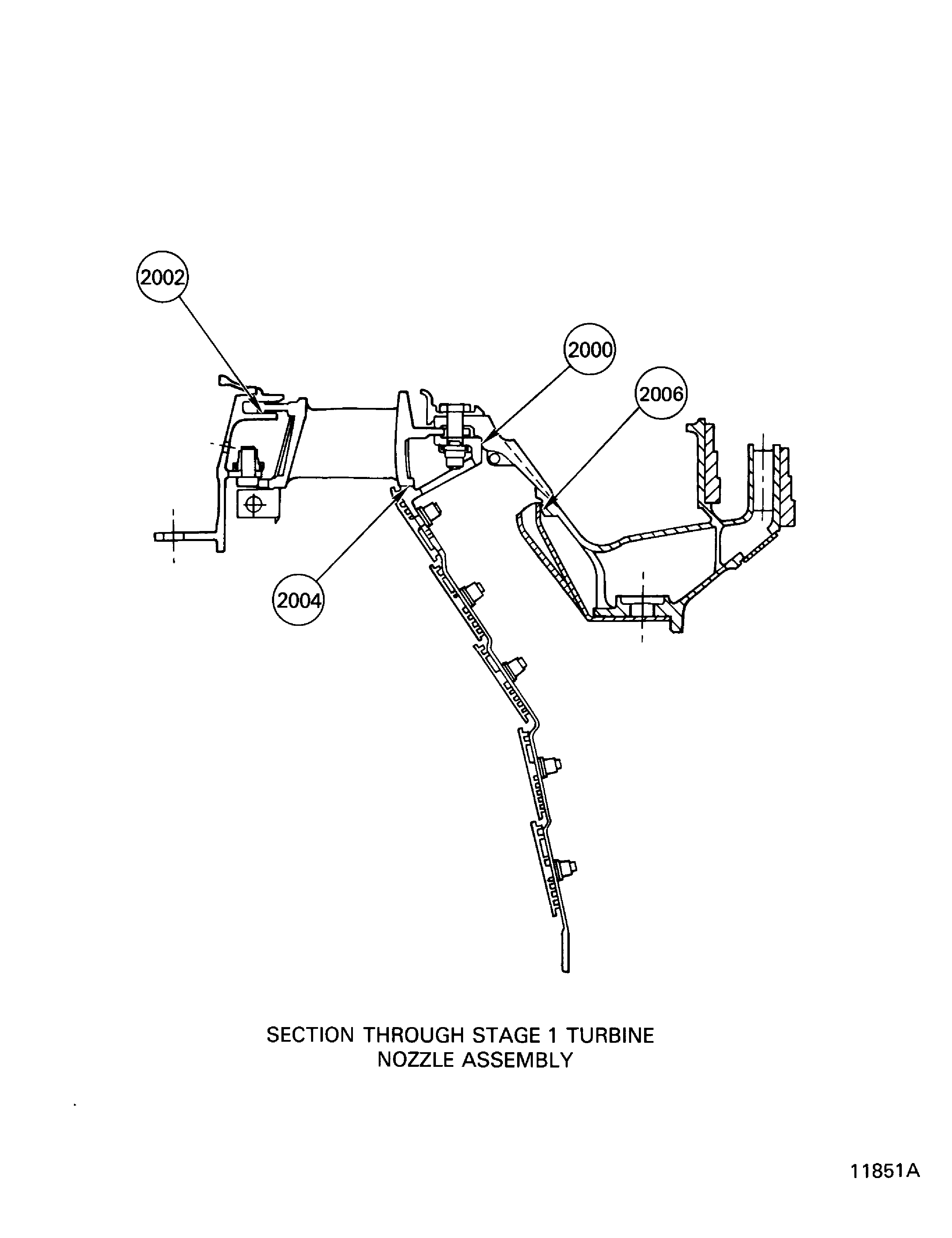

Reference the clearance at location 2002. If required, use the data written as a note in TASK 72-44-10-200-000 (INSPECTION-000) and TASK 72-44-20-200-000 (INSPECTION-000).

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2002

Stage 1 HPT Support Assembly ENGINE-STAGE 1 HPT SUPPORT ASSEMBLY (72-44-10, 01-010), Gap (Between Rear Flanges)

Stage 1 HPT Vane Cluster Assembly (72-44-20, 01-250 thru 01-278), Rear Flange Thickness

Support Assembly Gap

0.202

Clear

0.202

Clear

0.208

0.004

0.213

0.004

Vane Flange Thickness

0.192

0.016

0.192

0.021

0.198

Clear

0.198

Clear

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2002

Stage 1 HPT Support Assembly ENGINE-STAGE 1 HPT SUPPORT ASSEMBLY (72-44-10, 01-010), Gap (Between Rear Flanges)

Stage 1 HPT Vane Cluster Assembly (72-44-20, 01-250 Thru 01-278), Rear Flange Thickness

Support Assembly Gap

5.131

Clear

5.131

Clear

5.283

0.10

5.410

0.10

Vane Flange Thickness

4.877

0.41

4.877

0.53

5.029

Clear

5.029

Clear

SUBTASK 72-44-00-220-052 Reference Fits and Clearances of the Stage 1 HPT Support Assembly and the Stage 1 HPT Vane Cluster Assembly at Location 2002

Refer to Figure.

Reference the clearance/interference at location 2004. If required, use the data written as a note in TASK 72-44-30-200-000 (INSPECTION-000) and TASK 72-44-20-200-000 (INSPECTION-000).

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2004

Inner Combustion Chamber Assembly ENGINE-COMBUSTION CHAMBER INNER LINER (72-44-30, 01-010), Axial Distance (Between Mount Flanges)

Stage 1 HPT Vane Cluster Assembly (72-44-20, 01-250 Thru 01-278), Axial Distance (Front Flange Front Face To Rear Flange Rear Face)

Chamber Distance

0.843

Clear

0.845

Clear

0.835

0.001

0.830

0.003

Vane Cluster Distance

0.852

0.017

0.852

0.022

0.842

Intf

0.842

Intf

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2004

Inner Combustion Chamber Assembly ENGINE-COMBUSTION CHAMBER INNER LINER (72-44-30, 01-010), Axial Distance (Between Mount Flanges)

Stage 1 HPT Vane Cluster Assembly (72-44-20, 01-250 Thru 01-278), Axial Distance (Front Flange Front Face To Rear Flange Rear Face)

Chamber Distance

21.412

Clear

21.463

Clear

21.209

0.030

21.082

0.076

Vane Cluster Distance

21.640

0.430

21.640

0.559

21.390

Intf

21.390

Intf

SUBTASK 72-44-00-220-053 Reference Fits and Clearances of the Stage 1 HPT Support Assembly and the Stage 1 HPT Vane Cluster Assembly at Location 2004

Refer to Figure.

Reference the clearance/interference at location 2000. If required, use the data written as a note in TASK 72-44-30-200-000 (INSPECTION-000) and TASK 72-44-50-200-000 (INSPECTION-000).

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2000

Inner Combustion Chamber Assembly ENGINE-COMBUSTION CHAMBER INNER LINER (72-44-30, 01-010), Rear Location Bore

Stage 1 HPT Cooling Air DuctENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-010), Rear Location Diameter

Chamber Assembly Bore

19.398

Intf

19.400

Clear

19.392

0.000

19.392

0.002

Air Duct Diameter

19.402

0.010

19.402

0.010

19.398

Intf

19.398

Intf

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2000

Inner Combustion Chamber Assembly ENGINE-COMBUSTION CHAMBER INNER LINER (72-44-30, 01-010), Rear Location Bore

Stage 1 HPT Cooling Air Duct ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-010), Rear Location Diameter

Chamber Assembly Bore

492.709

Intf

492.760

Clear

492.557

0.000

492.557

0.051

Air Duct Diameter

492.810

0.250

492.811

0.254

492.710

Intf

492.710

Intf

SUBTASK 72-44-00-220-054 Reference Fits and Clearances of the Inner Combustion Chamber Assembly and the Stage 1 HPT Cooling Air Duct at Location 2000

Refer to Figure.

NOTE

Must maintain tight fit. Reject HPT cooling duct if loose.NOTE

Must maintain tight fit. Reject HPT cooling duct if loose.Reference the interference at location 2006. If required, use the data written as a note in TASK 72-44-50-200-000 (INSPECTION-000).

Table 7. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2006 (Reference only)

HPT Cooling Duct Deflector ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-080), Location Diameter

Stage 1 HPT Cooling Duct Assembly (72-44-50, 01-010), Location Diameter

Deflector Location Diameter

17.360

Untf

Intf

17.340

0.000

0.000

Duct Location Diameter

17.370

0.030

0.050

17.360

Intf

Intf

Table 8. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 2006 (Reference only)

HPT Cooling Duct Deflector ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-080), Location Diameter

Stage 1 HPT Cooling Duct Assembly ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-010), Location Diameter

Deflector Location Diameter

440.94

Intf

Intf

440.44

0.00

0.00

Duct Location Diameter

441.20

0.76

1.27

440.94

Intf

Intf

SUBTASK 72-44-00-220-055 Reference Fits and Clearances of the Stage 1 Turbine Nozzle Assembly at Location 2006.

Refer to Figure.

Put the IAE 1P16075 Fixture 1 off dowel pin up, on the bench.

Put the Stage 1 HPT Support Assembly, ENGINE-STAGE 1 HPT SUPPORT ASSEMBLY (72-44-10, 01-010) small end down in the fixture.

SUBTASK 72-44-00-440-051 Install the Stage 1 HPT Support Assembly on the Fixture

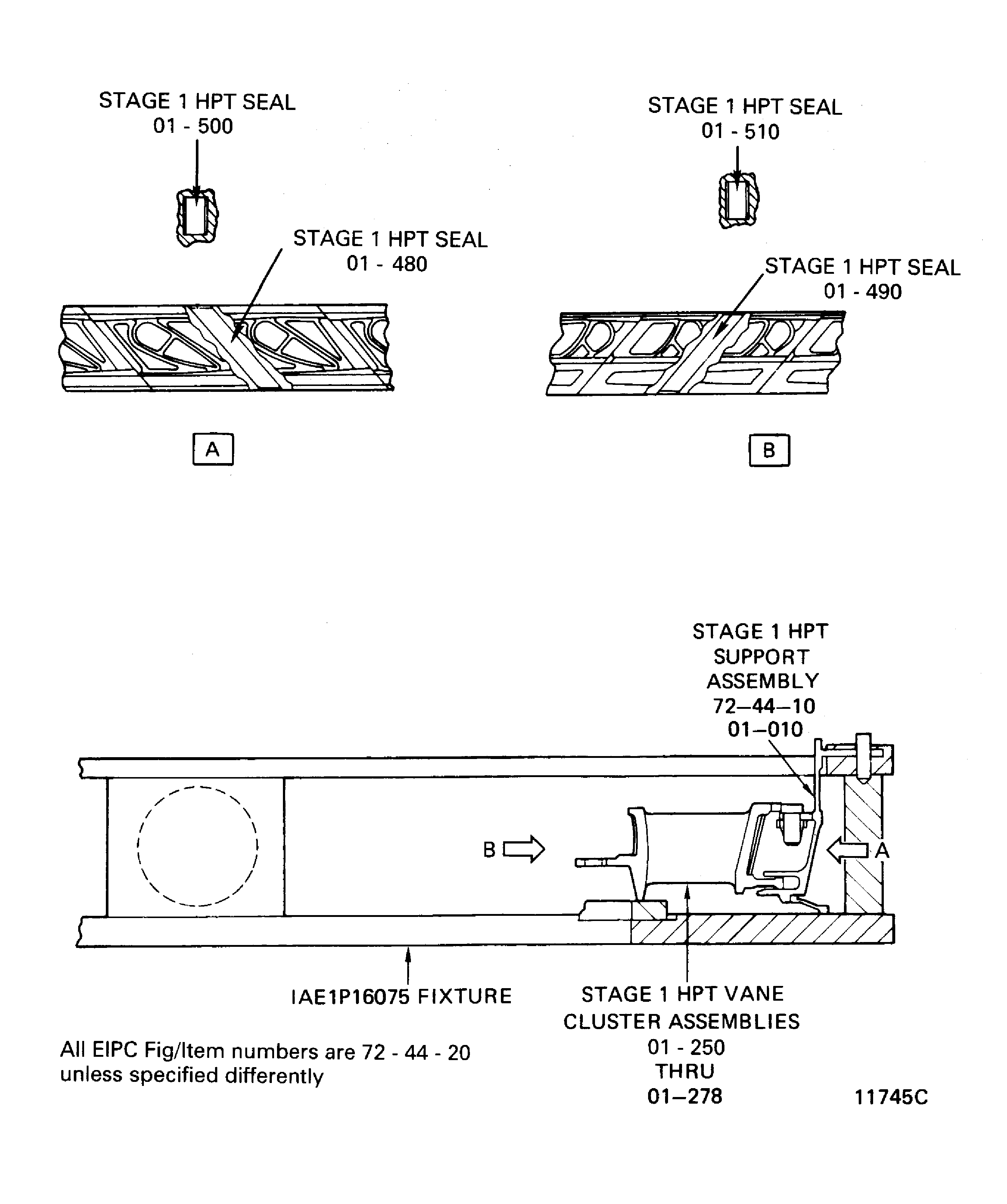

Refer to Figure.

Put the Stage 1 HPT Vane Cluster Assemblies ENGINE-STAGE 1 HPT VANE CLUSTER ASSEMBLY (72-44-20, 01-250) thru ENGINE-STAGE 1 HPT VANE CLUSTER ASSEMBLY (72-44-20, 01-278) on the work bench with the leading edge of the vane assembly up.

SUBTASK 72-44-00-440-052 Get the Stage 1 HPT Vane Cluster Assemblies Correct Nozzle Area Requirements

Refer to Figure.

Use CoMat 01-573 WAX BLEND, PARAFFIN to hold the seals in position. Remove any wax that is not needed.

Install the stage 1 HPT seals (01-490 and 01-510) in the outer vane platform slots.

Use CoMat 01-573 WAX BLEND, PARAFFIN to hold the seals in position. Remove any wax that is not needed.

Install the Stage 1 HPT seals (01-480 and 01-500) in the inner vane platform slots.

Install the stage 1 HPT seals in the slots that are located on the left side of the vane cluster assemblies.

SUBTASK 72-44-00-440-057 Install the Stage 1 HPT Seals in the slots of the Stage 1 HPT Vane Cluster Assemblies

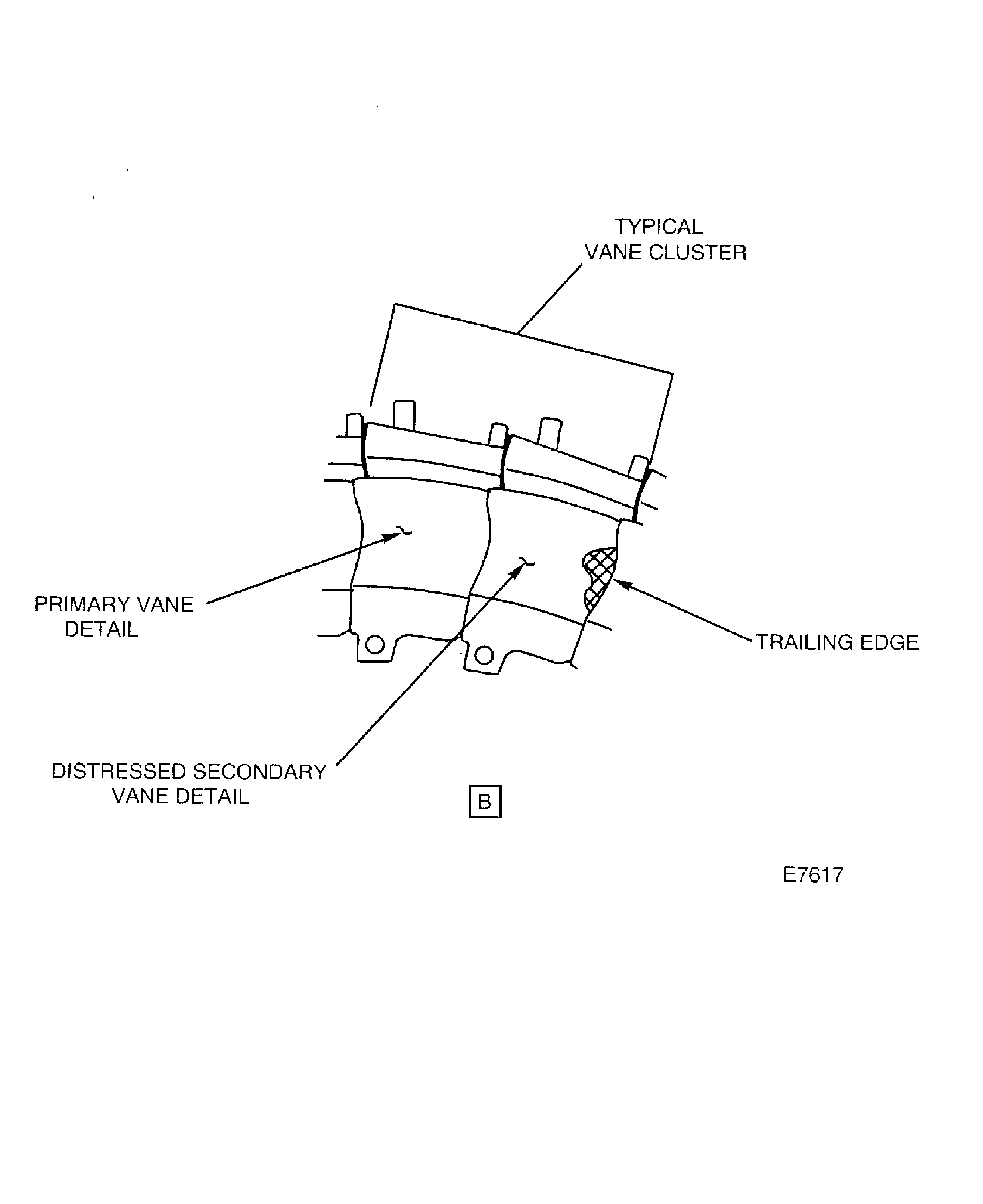

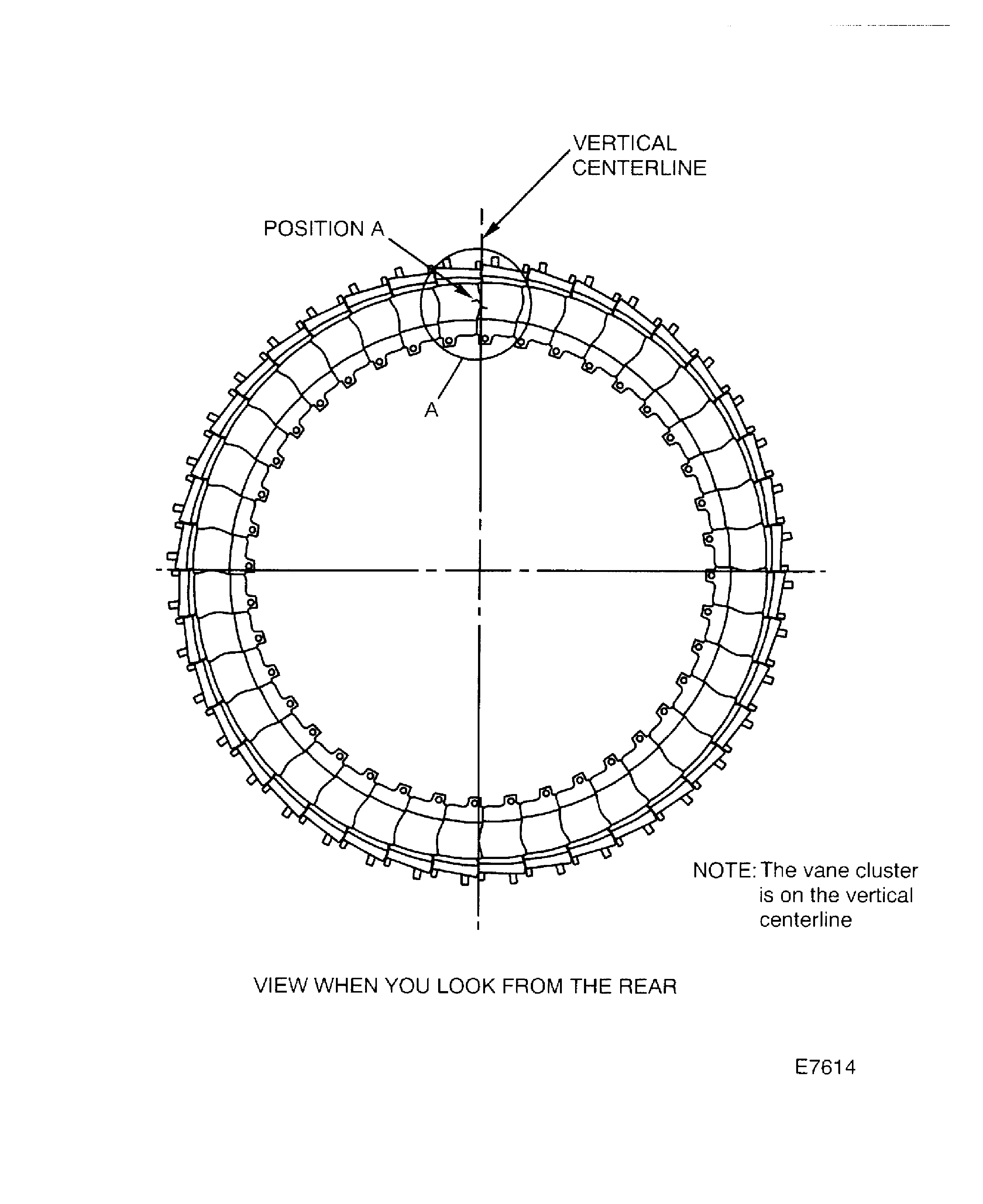

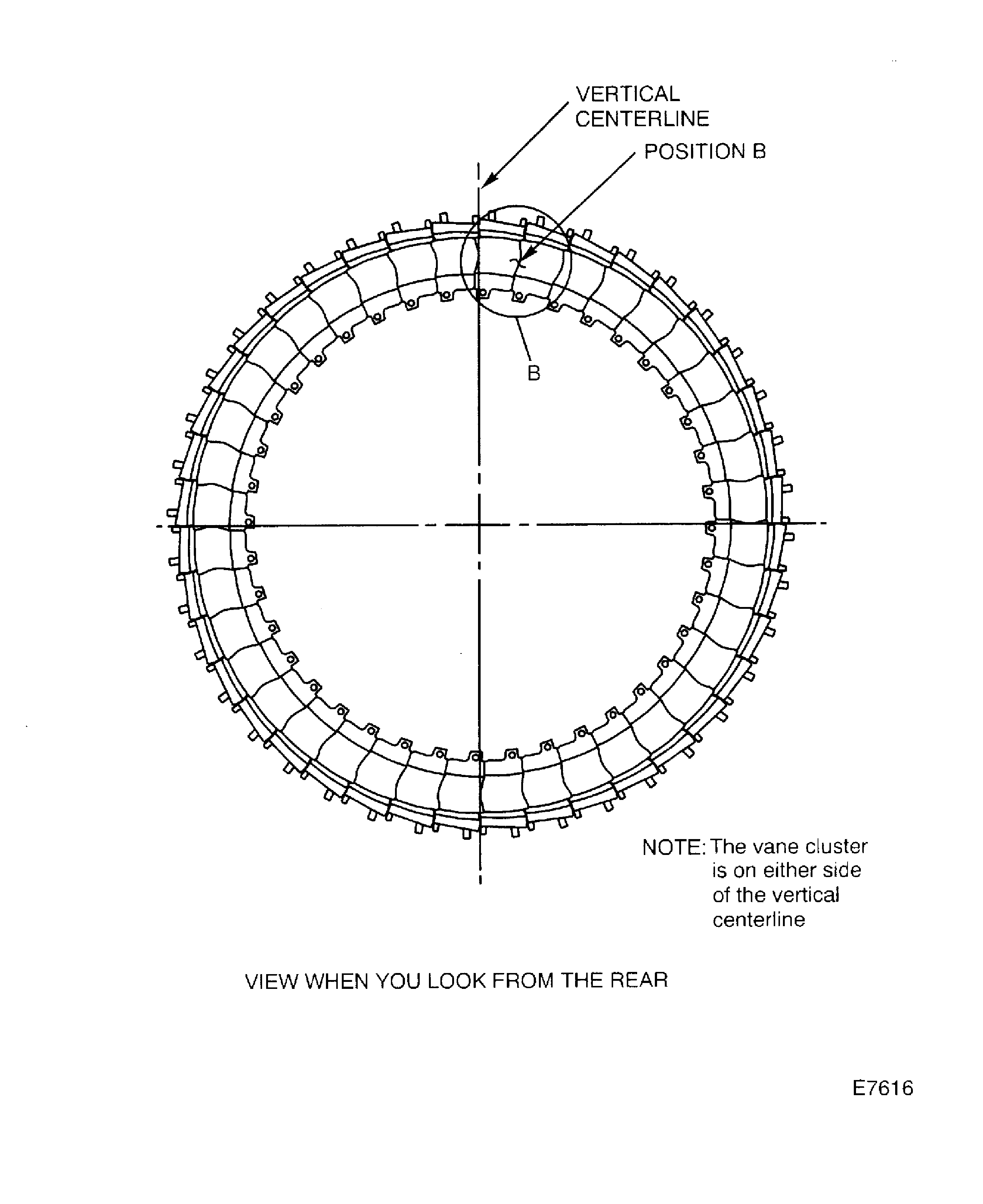

Do not use vane clusters again which have distress that is more than the limits given in TASK 72-00-44-220-001 (INSPECTION-001).

Look for the most vane distress to find the position of used Stage 1 HPT Vane Cluster Assemblies ENGINE-STAGE 1 HPT VANE CLUSTER ASSEMBLY (72-44-20, 01-250 thru 72-44-20, 01-278).

SUBTASK 72-44-00-440-065 Find the Position of Used Stage 1 HPT Vane Cluster Assemblies

Refer to Figure.

SUBTASK 72-44-00-440-058 Install the Stage 1 HPT Vane Cluster Assemblies in the Stage 1 HPT Support Assembly

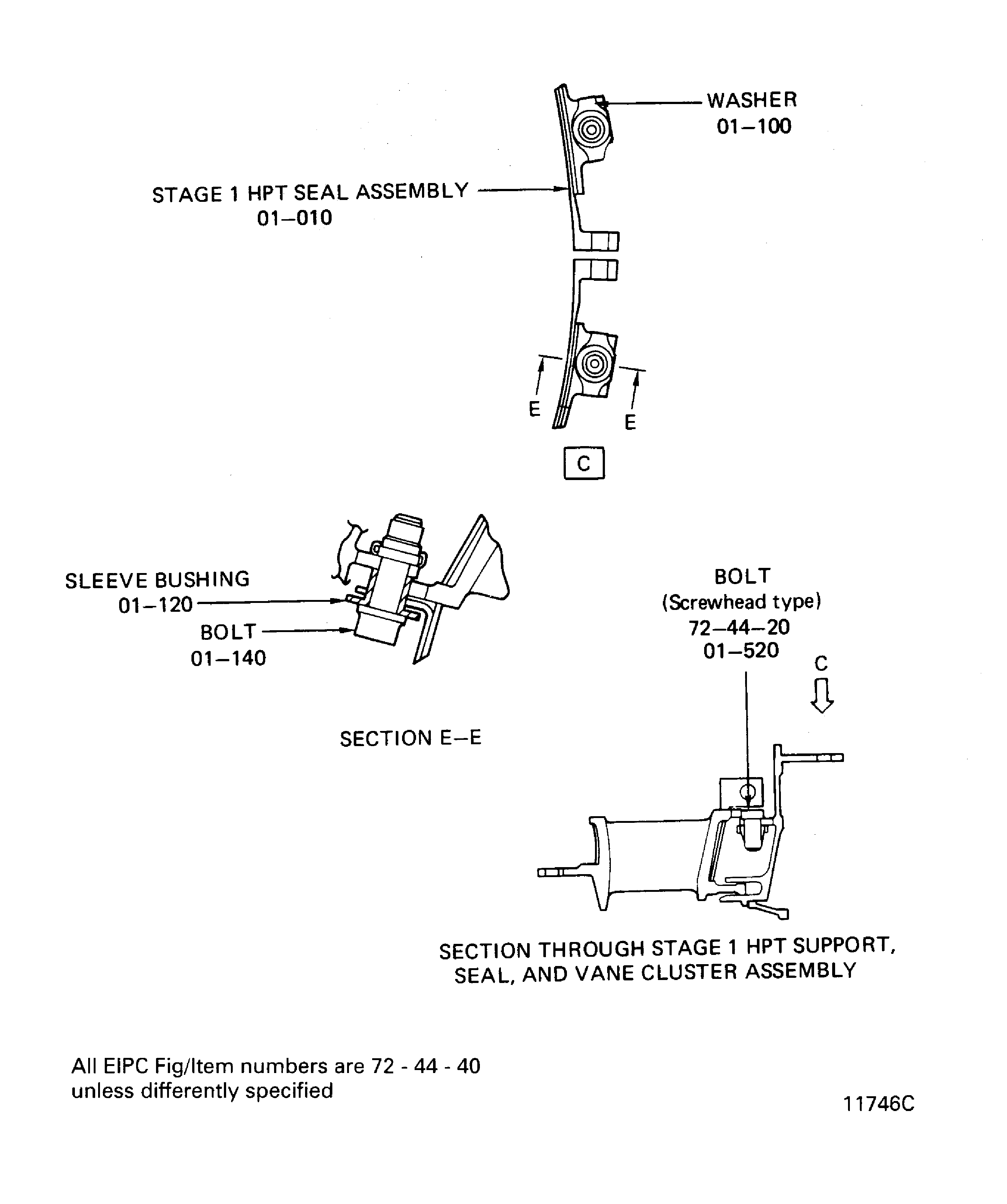

Refer to Figure.

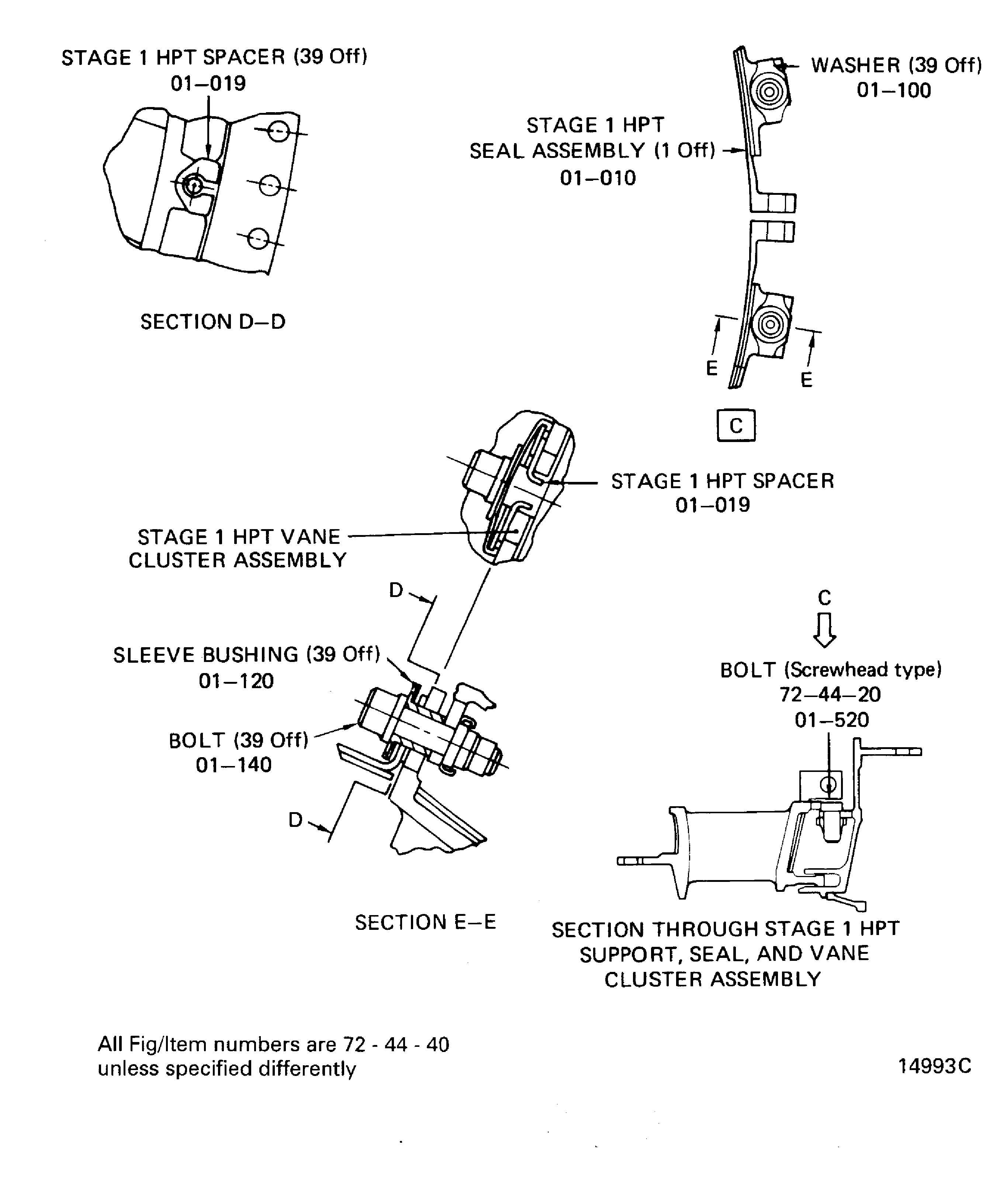

Install the one bolt ENGINE-STAGE 1 HPT VANE CLUSTER ASSEMBLY (72-44-20, 01-520), screw head type, at the location approximately 180 degrees from the offset hole in the Stage 1 HPT Support Assembly.

NOTE

This bolt is under the Stage 1 HPT Seal Assembly flanges when the seal is installed.Install the Stage 1 HPT Seal Assembly ENGINE-STAGE 1 HPT OUTER SEAL ASSEMBLY (72-44-40, 01-010).

Install the washers ENGINE-STAGE 1 HPT OUTER SEAL ASSEMBLY (72-44-40, 01-100), the sleeve bushings ENGINE-STAGE 1 HPT OUTER SEAL ASSEMBLY (72-44-40, 01-120) and the bolts ENGINE-STAGE 1 HPT OUTER SEAL ASSEMBLY (72-44-40, 01-140) which hold the Stage 1 HPT Seal Assembly. Tighten the bolts by hand.

NOTE

The bolts will be torqued when the classified spacer is installed. Refer to TASK 72-00-44-420-001-001 (INSTALLATION-001) or TASK 72-40-00-430-005 (ASSEMBLY-005).

SUBTASK 72-44-00-440-054-001 Install the Stage 1 HPT Seal Assembly (Pre SBE 72-0029)

Refer to Figure.

Install the bolt 1 off ENGINE-STAGE 1 HPT VANE CLUSTER ASSEMBLY (72-44-20, 01-520), screw head type at the location approximately 180 degrees from the offset hole in the Stage 1 HPT Support Assembly.

NOTE

This bolt is under two flanges where Stage 1 HPT Seal Assembly and the classified spacer connect when the seal assembly is installed.Install the stage 1 HPT spacers 39 off ENGINE-STAGE 1 HPT OUTER SEAL ASSEMBLY (72-44-40, 01-019) in the recesses around the boltholes (with the tangs positioned to the outside diameter).

Install the Stage 1 HPT Seal Assembly 1 off ENGINE-STAGE 1 HPT OUTER SEAL ASSEMBLY (72-44-40, 01-010).

Install the spring tension washers 39 off ENGINE-STAGE 1 HPT OUTER SEAL ASSEMBLY (72-44-40, 01-100).

Install the sleeve bushings 39 off ENGINE-STAGE 1 HPT OUTER SEAL ASSEMBLY (72-44-40, 01-120).

Install the bolts ENGINE-STAGE 1 HPT OUTER SEAL ASSEMBLY (72-44-40, 01-140) which hold the Stage 1 HPT Seal Assembly in position.

Tighten the bolts with your hand.

NOTE

The bolts will be torqued when the classified spacer is installed. Refer to TASK 72-00-44-420-001-001 (INSTALLATION-001) or TASK 72-40-00-430-005 (ASSEMBLY-005).

SUBTASK 72-44-00-440-054-002 Install the Stage 1 HPT Seal Assembly (72-44-40, 01-010) (SBE 72-0029)

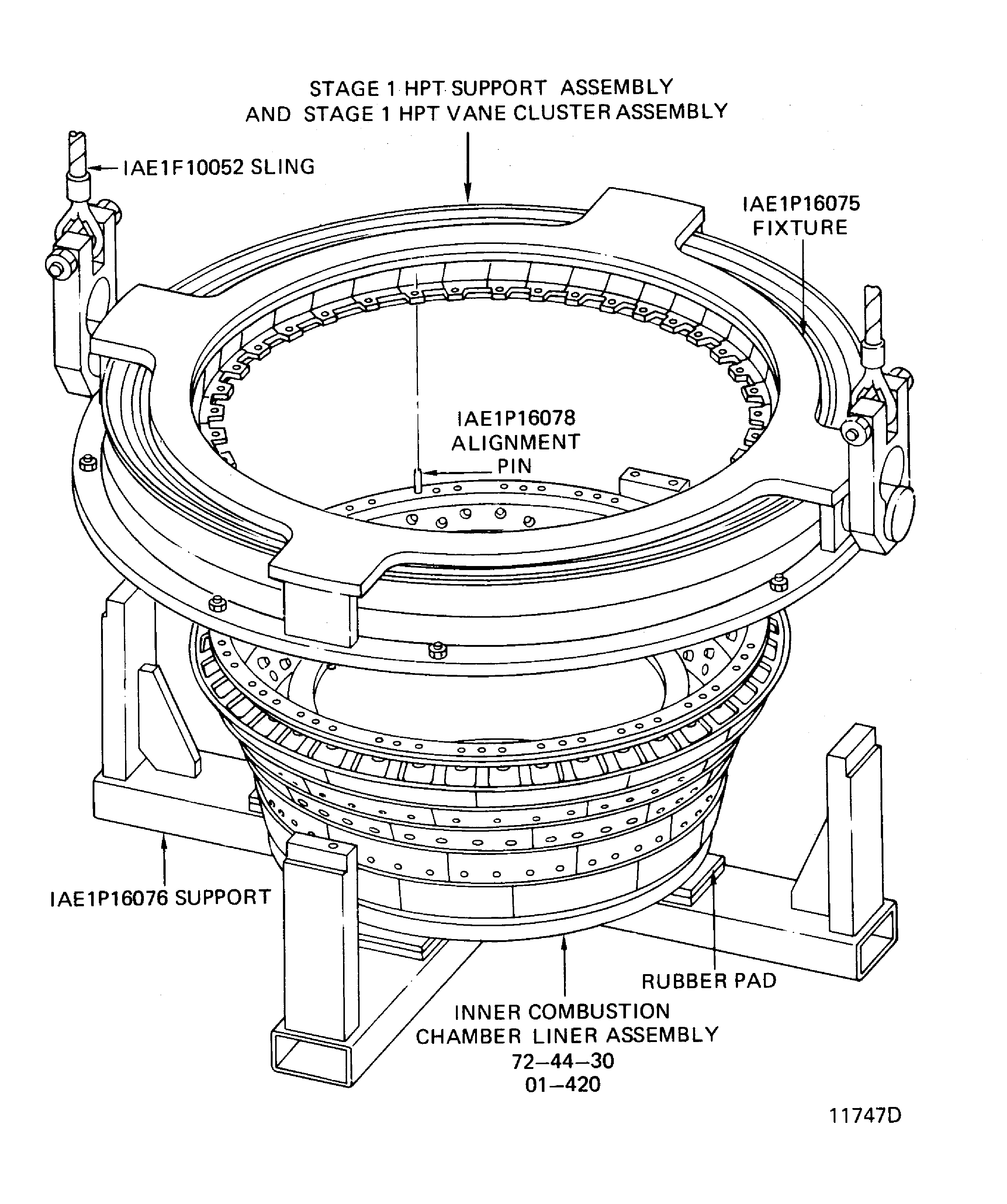

Install the Inner Combustion Chamber Liner Assembly ENGINE-COMBUSTION CHAMBER INNER LINER (72-44-30, 01-420) in the IAE 1P16076 Support 1 off, Figure.

Install the IAE 1P16078 Alignment pin 4 off at equal spaces around the flange and in the captured nuts on the Inner Combustion Chamber Liner Assembly.

Put the Stage 1 HPT Cooling Duct Assembly ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-010) with the small hole in the inner flange on the dowel pin on the fixture ring, Figure.

Turn the Combustion Chamber as necessary to locate the IAE 1P16078 Alignment pin through the holes in the Stage 1 HPT Cooling Duct Assembly flange.

Attach the IAE 1F10052 Two cables sling 1 off to the spools on the IAE 1P16075 Fixture.

Put the dowel pin on the IAE 1P16075 Fixture 1 off so it goes in the offset hole in the IAE 1P16076 Support 1 off.

NOTE

The four IAE 1P16078 Alignment pin should locate in the vane inner flange slots.

Lower the Stage 1 HPT Support Assembly and the Stage 1 HPT Vane Cluster Assemblies on to the Inner Combustion Chamber Liner Assembly.

Remove the IAE 1P16075 Fixture from the Stage 1 HPT Vane Cluster Assemblies.

SUBTASK 72-44-00-440-055 Install the Inner Combustion Chamber Liner Assembly

NOTE

You can use the PN 2A1271 stage 1 HPT air seal with the PN 2A0087 or PN 2A1198 Stage 1 HPT Duct Segments.NOTE

The PN 2A0488 Stage 1 HPT Air Seal cannot be used with PN 2A1198 Stage 1 HPT Duct segments because there will be interference.NOTE

You can use CoMat 08-041 CYANOACRYLATE ADHESIVE, Permabond 910, as required to retain the HPT Cooling Duct Deflector to the Stage 1HPT Cooling Duct Assembly during assembly. Alternative adhesives shall not be applied without written approval of IAE Engineering.Install the HPT cooling duct deflector ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-080) on the stage 1 HPT cooling duct assembly, Figure.

Lower the Stage 1 HPT Cooling Duct Assembly and put the small hole in the inner flange on the dowel pin in the ring.

NOTE

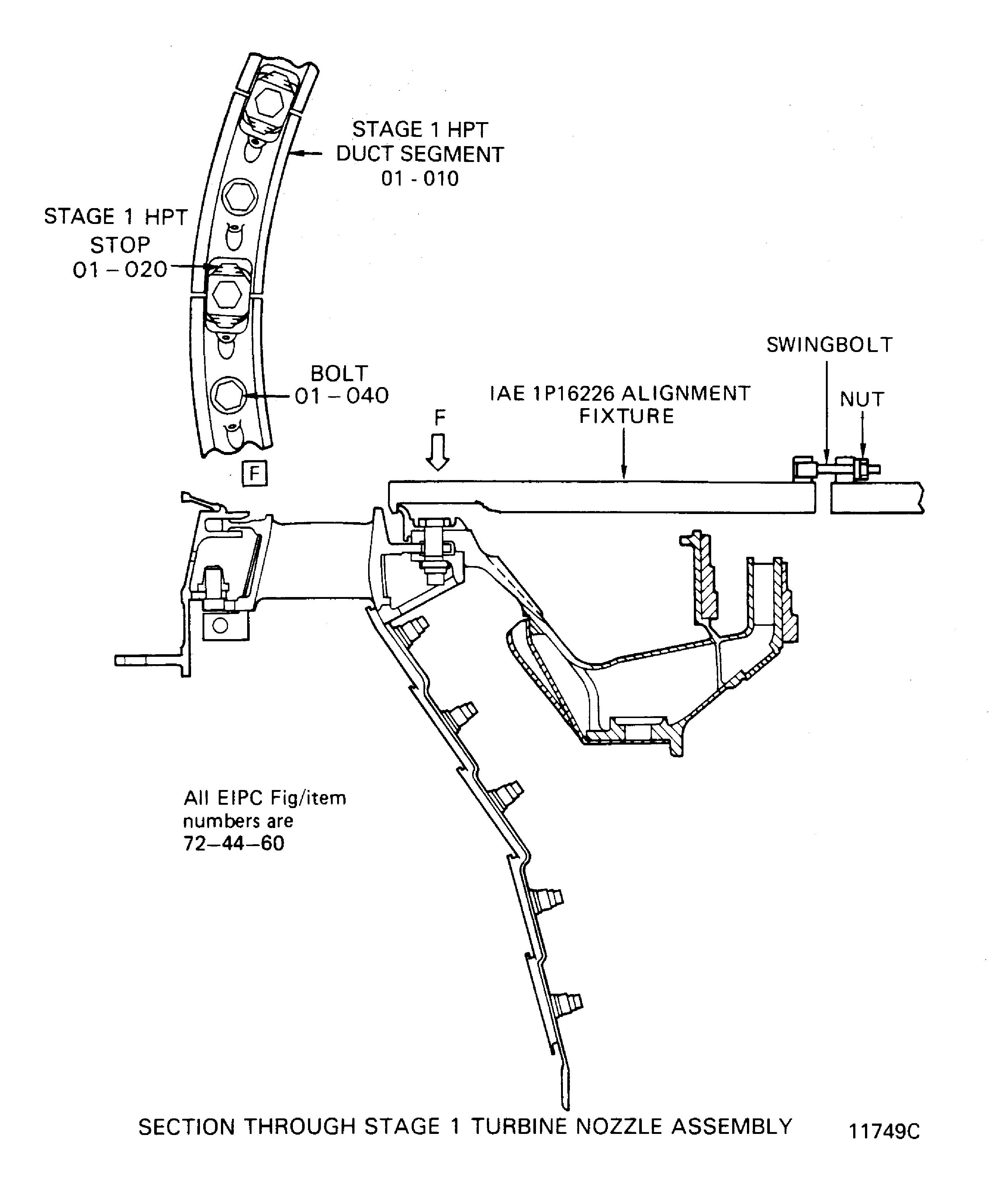

The four IAE 1P16078 Alignment pin should locate in the Cooling Duct Assembly outer flange.Install the 20 stage 1 HPT duct segments ENGINE-STAGE 1 HPT SEGMENT (72-44-60, 01-010), Figure.

Install the stops ENGINE-STAGE 1 HPT SEGMENT (72-44-60, 01-020) and the bolts ENGINE-STAGE 1 HPT SEGMENT (72-44-60, 01-040), except at the alignment pin locations.

Loosen the nut and the swing bolt on IAE 1P16226 Alignment fixture 1 off. Install the fixture to round out the Duct Assembly and secure with the swing bolt and nut.

Install the IAE 1P16077 Fixture 1 off on the assembly.

Install the IAE 1P16109 cover 1 off over the Stage 1 HPT Support Assembly, Figure.

SUBTASK 72-44-00-440-056 Install the HPT Cooling Duct Deflector the Stage 1 HPT Cooling Duct Assembly and the Stage 1 HPT Duct Segments

Figure: Install the Stage 1 HPT Vane Cluster Assemblies and the Stage 1 HPT Support Assembly in the IAE 1P16075 Fixture

Install the Stage 1 HPT Vane Cluster Assemblies and the Stage 1 HPT Support Assembly in the IAE 1P16075 Fixture

Figure: Install the Stage 1 HPT Support Assembly

Install the Stage 1 HPT Support Assembly

Figure: Install the Stage 1 HPT Support Assembly and the Stage 1 HPT Vane Cluster Assemblies

Install the Stage 1 HPT Support Assembly and the Stage 1 HPT Vane Cluster Assemblies

Figure: Install the HPT Cooling Duct Assembly and the Cooling Duct Deflector

Install the HPT Cooling Duct Assembly and the Cooling Duct Deflector

Figure: Install the Stage 1 HPT Duct Segments

Install the Stage 1 HPT Duct Segments

Figure: Install the IAE 1P16109 Cover

Install the IAE 1P16109 Cover

Figure: Stage 1 Turbine Nozzle Assembly Fits and Clearances

Stage 1 Turbine Nozzle Assembly Fits and Clearances

Figure: Install the Stage 1 HPT Seal Assembly and Stage 1 HPT Spacers

Install the Stage 1 HPT Seal Assembly and Stage 1 HPT Spacers

Figure: Stage 1 HPT Vane Cluster Installed in Position A

Sheet 1

Figure: Stage 1 HPT Vane Clusters Installed in Position A

Sheet 2

Figure: Stage 1 HPT Vane Clusters Installed in Position B

Sheet 1

Figure: Stage 1 HPT Vane Clusters Installed in Position B

Sheet 2