Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-45-10-440-001-A00 HPT Stage 1 Rotor Assembly - Assemble The HPT Stage 1 Rotor Assembly, Assembly-001

General

Fig/Item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/Item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/Item number.

For standard torque data and procedures, refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

To identify, lubricate and install seal rings, refer to SPM TASK 70-44-01-400-501.

The number for each radial location must be identified in a clockwise direction. Use CoMat 06-153 FELT TIP MARKER, RAPID DRYING, CoMat 06-153X FELT TIP MARKER, RAPID DRYING, FINE POINT, BLACK, TRACE ELEMENT CERTIFIED or CoMat 06-158 MARKER, EXTRA FINE POINT(BLACK). These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

For temporary marking procedures, refer to SPM TASK 70-09-01-400-501.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Vertical balance machine | LOCAL | Vertical balance machine | ||

| IAE 1F10052 Two cables sling | 0AM53 | IAE 1F10052 | 1 | |

| IAE 1P16006 Fixture | 0AM53 | IAE 1P16006 | 1 | |

| IAE 1P16008 Fixture | 0AM53 | IAE 1P16008 | 1 | |

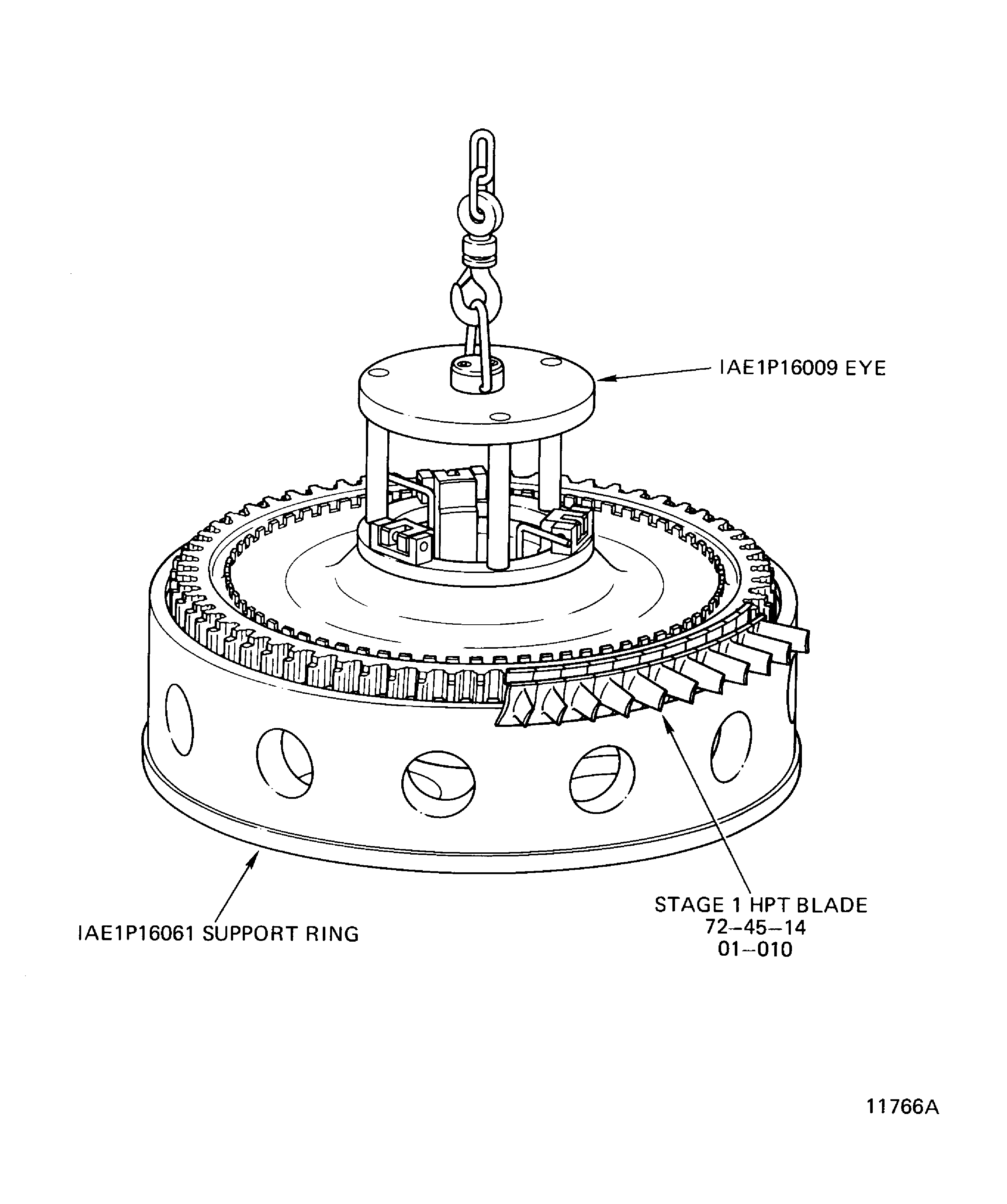

| IAE 1P16009 Lifting eye | 0AM53 | IAE 1P16009 | 1 | |

| IAE 1P16014 Fixture | 0AM53 | IAE 1P16014 | 1 | |

| IAE 1P16015 Adapter | 0AM53 | IAE 1P16015 | 1 | |

| IAE 1P16029 Drift | 0AM53 | IAE 1P16029 | 1 | |

| IAE 1P16032 Calibration weight | 0AM53 | IAE 1P16032 | 1 | |

| IAE 1P16038 Heater | 0AM53 | IAE 1P16038 | 1 | |

| IAE 1P16061 Support ring | 0AM53 | IAE 1P16061 | 1 | |

| IAE 1P16140 Support base | 0AM53 | IAE 1P16140 | 1 | |

| IAE 1P16442 Calibration weight | 0AM53 | IAE 1P16442 | 1 | |

| IAE 1P16494 Installation fixture | 0AM53 | IAE 1P16494 | 1 | |

| IAE 1P17750 Fixture | 0AM53 | IAE 1P17750 | 1 | |

| IAE 1P17763 Metering plug drift | 0AM53 | IAE 1P17763 | 1 | |

| IAE 6F10027 Heater control unit | 0AM53 | IAE 6F10027 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-573 WAX BLEND, PARAFFIN | 24269 | CoMat 01-573 | ||

| CoMat 06-153 FELT TIP MARKER, RAPID DRYING | LOCAL | CoMat 06-153 | ||

| CoMat 06-153X FELT TIP MARKER, RAPID DRYING, FINE POINT, BLACK, TRACE ELEMENT CERTIFIED | 86874 | CoMat 06-153X | ||

| CoMat 06-158 MARKER, EXTRA FINE POINT(BLACK) | 0AM53 | CoMat 06-158 |

Safety Requirements

NONEProcedure

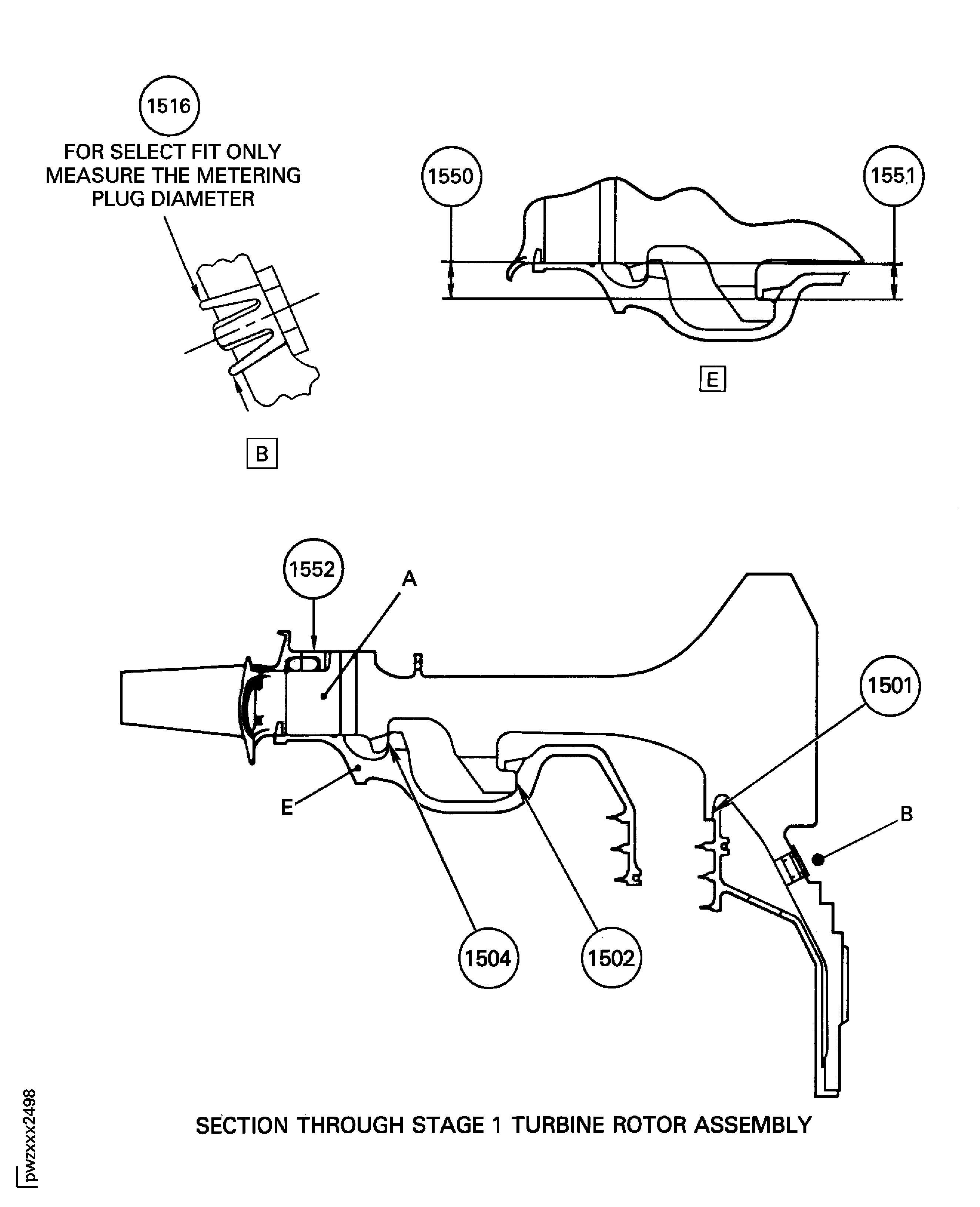

Refer to Figure.

Reference the interference at Location 1501. If required use the data written as a note in TASK 72-45-11-200-001-A00 (INSPECTION-001), TASK 72-45-11-200-001-B00 (INSPECTION-001) or TASK 72-45-11-200-001-C00 (INSPECTION-001) and TASK 72-45-13-200-001-A00 (INSPECTION-001) or TASK 72-45-13-200-001-B00 (INSPECTION-001).

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1501

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Seal Bore

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (INNER) (72-45-13, 01-020), Rear Outside Location Diameter

Hub Seal Bore

8.622

Intf

See applicable TASK 72-45-11-200-001-C00 (INSPECTION-001) for acceptable select fit limits.

Intf

8.618

0.017

0.017

Airseal Diameter

8.635

0.011

0.008

8.633

Intf

Intf

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1501

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Seal Bore

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (INNER) (72-45-13, 01-020), Rear Outside Location Diameter

Hub Seal Bore

218.998

Intf

See applicable TASK 72-45-11-200-001-C00 (INSPECTION-001) for acceptable select fit limits.

Intf

218.898

0.432

0.432

Airseal Diameter

219.329

0.279

0.203

219.279

Intf

Intf

SUBTASK 72-45-10-220-051 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1501

Refer to Figure.

Reference clearance/interference at Location 1502. If required use the data written as a note in TASK 72-45-11-200-001-A00 (INSPECTION-001), TASK 72-45-11-200-001-B00 (INSPECTION-001) or TASK 72-45-11-200-001-C00 (INSPECTION-001) and TASK 72-45-12-200-001-A00 (INSPECTION-001).

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1502

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Inside Lug Location Diameter

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Inside Lug Location Diameter

Hub Diameter

14.166

Clear

14.1665

Clear

14.162

0.001

14.1615

0.001

Airseal Diameter

14.167

0.005

14.1677

0.005

14.165

Intf

14.160

Intf

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1502

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Inside Lug Location Diameter

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Inside Lug Location Diameter

Hub Diameter

359.816

Clear

359.829

Clear

359.715

0.026

359.703

0.026

Airseal Diameter

359.841

0.127

359.860

0.127

359.791

Intf

359.664

Intf

SUBTASK 72-45-10-220-052-A00 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1502 (Pre SBE 70-0014 and Pre SBE 72-0013)

Refer to Figure.

SBE 70-0014: Stage 1 HPT Airseal (outer) new part number.

SBE 72-0013: Replacement of the Stage 1 HPT duct segment and the Stage 1 HPT Airseal.

Reference clearance/interference at Location 1502. If required use the data written as a note in TASK 72-45-11-200-001-A00 (INSPECTION-001), TASK 72-45-11-200-001-B00 (INSPECTION-001) or TASK 72-45-11-200-001-C00 (INSPECTION-001) and TASK 72-45-12-200-001-B00 (INSPECTION-001) or TASK 72-45-12-200-001-C00 (INSPECTION-001).

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1502

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Inside Lug Location Diameter

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Inside Lug Location Diameter

Hub Diameter

14.166

Intf

14.166

Intf

14.162

0.006

14.162

0.006

Airseal Diameter

14.168

0.002

14.1685

0.002

14.164

Clear

14.159

Clear

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1502

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Inside Lug Location Diameter

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Inside Lug Location Diameter

Hub Diameter

359.816

Intf

359.816

Intf

359.715

0.152

359.715

0.152

Airseal Diameter

359.867

0.051

359.880

0.051

359.766

Clear

359.639

Clear

SUBTASK 72-45-10-220-052-B00 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1502 (SBE 70-0014 and SBE 72-0013)

Refer to Figure.

SBE 72-0131: Provide new Stage 1 HPT Airseal.

Reference clearance/interference at Location 1502. If required use the data written as a note in TASK 72-45-11-200-001-A00 (INSPECTION-001), TASK 72-45-11-200-001-B00 (INSPECTION-001) or TASK 72-45-11-200-001-C00 (INSPECTION-001) and TASK 72-45-12-200-001-D00 (INSPECTION-001).

Table 7. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1502

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Inside Lug Location Diameter

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Lug Location Diameter

Hub Diameter

14.166

Intf

14.166

Intf

14.162

0.006

14.162

0.006

Airseal Diameter

14.168

0.002

14.168

0.002

14.164

Clear

14.159

Clear

Table 8. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1502

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Inside Lug Location Diameter

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040) Inside Lug Location Diameter

Hub Diameter

359.816

Intf

359.816

Intf

359.715

0.152

359.715

0.152

Airseal Diameter

359.867

0.051

359.867

0.051

359.766

Clear

359.639

Clear

SUBTASK 72-45-10-220-052-C00 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1502 (SBE 72-0131)

Refer to Figure.

Reference clearance at Location 1504. If required use the data written as a note in TASK 72-45-11-200-001-A00 (INSPECTION-001) or TASK 72-45-11-200-001-B00 (INSPECTION-001) and TASK 72-45-12-200-001-A00 (INSPECTION-001).

Table 9. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1504

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Outside Lug Location Diameter

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Outside Lug Location Diameter

Airseal Diameter

17.753

Clear

17.747

Clear

17.755

0.003

17.7564

0.003

Hub Diameter

17.758

0.009

17.753

0.009

17.762

Clear

17.7625

Clear

Table 10. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1504

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Outside Lug Location Diameter

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Outside Lug Location Diameter

Airseal Diameter

450.927

Clear

450.774

Clear

450.977

0.077

451.013

0.077

Hub Diameter

451.054

0.228

450.926

0.228

451.154

Clear

451.168

Clear

SUBTASK 72-45-10-220-053-A00 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1504 (Pre SBE 70-0014 and Pre SBE 72-0013)

Refer to Figure.

SBE 70-0014: Stage 1 HPT Airseal (outer) new part number.

SBE 72-0013: Replacement of the Stage 1 HPT duct segment and the Stage 1 HPT Airseal.

Reference clearance at Location 1504. If required use the data written as a note in TASK 72-45-11-200-001-C00 (INSPECTION-001) and TASK 72-45-12-200-001-B00 (INSPECTION-001) or TASK 72-45-12-200-001-C00 (INSPECTION-001).

Table 11. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1504

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Outside Lug Location Diameter

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Outside Lug Location Diameter

Airseal Diameter

17.752

Clear

17.747

Clear

17.756

0.007

17.7564

0.007

Hub Diameter

17.763

0.015

17.758

0.015

17.767

Clear

17.770

Clear

Table 12. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1504

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Outside Lug Location Diameter

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Outside Lug Location Diameter

Airseal Diameter

450.901

Clear

450.774

Clear

451.002

0.178

451.013

0.178

Hub Diameter

451.180

0.381

451.053

0.381

451.282

Clear

451.358

Clear

SUBTASK 72-45-10-220-053-B00 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1504 (SBE 70-0014 and SBE 72-0013)

Refer to Figure.

SBE 72-0131: Provide new Stage 1 HPT Airseal.

Reference clearance at Location 1504. If required use the data written as a note in TASK 72-45-11-200-001-C00 (INSPECTION-001) and TASK 72-45-12-200-001-D00 (INSPECTION-001).

Table 13. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1504

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Outside Lug Location Diameter

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Outside Lug Location Diameter

Airseal Diameter

17.752

Clear

17.747

Clear

17.756

0.007

17.756

0.007

Hub Diameter

17.763

0.015

17.758

0.0015

17.767

Clear

17.770

Clear

Table 14. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1504

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Outside Lug Location Diameter

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Outside Lug Location Diameter

Airseal Diameter

450.901

Clear

450.774

Clear

451.002

0.178

451.002

0.178

Hub Diameter

451.180

0.381

451.053

0.381

451.282

Clear

451.358

Clear

SUBTASK 72-45-10-220-053-C00 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1504 (SBE 72-0131)

Refer to Figure.

Reference clearance at Location 1504. If required use the data written as a note in TASK 72-45-11-200-001-C00 (INSPECTION-001) and TASK 72-45-12-200-001-D00 (INSPECTION-001).

Table 15. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1504

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Outside Lug Location Diameter

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Outside Lug Location Diameter

Airseal Diameter

17.753

Clear

Clear

17.755

0.003

0.003

Hub Diameter

17.758

0.009

0.009

17.762

Clear

Clear

Table 16. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1504

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Outside Lug Location Diameter

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Outside Lug Location Diameter

Airseal Diameter

450.926

Clear

Clear

450.977

0.077

0.077

Hub Diameter

451.053

0.228

0.228

451.155

Clear

Clear

SUBTASK 72-45-10-220-094 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1504

Refer to Figure.

SBE 72-0075: Provide new Stage 1 HPT Hub.

Reference clearance at Location 1504. If required use the data written as a note in TASK 72-45-11-200-001-C00 (INSPECTION-001) and TASK 72-45-12-200-001-D00 (INSPECTION-001).

Table 17. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1504

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Outside Lug Location Diameter

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Outside Lug Location Diameter

Airseal Diameter

17.753

Clear

Clear

17.755

0.008

0.008

Hub Diameter

17.763

0.014

0.014

17.767

Clear

Clear

Table 18. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1504

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Outside Lug Location Diameter

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Outside Lug Location Diameter

Airseal Diameter

450.926

Clear

Clear

450.977

0.203

0.203

Hub Diameter

451.180

0.356

0.356

451.282

Clear

Clear

SUBTASK 72-45-10-220-095 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1504 (SBE 72-0075)

Refer to Figure.

SBE 70-0014: Provide new HPT Stage 1 Airseal.

SBE 72-0013: Provide new HPT Stage 1 Airseal.

SBE 72-0131: Provide new HPT Stage 1 Airseal.

Reference clearance at Location 1504. If required use the data written as a note in TASK 72-45-11-200-001-C00 (INSPECTION-001) and TASK 72-45-12-200-001-D00 (INSPECTION-001).

Table 19. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1504

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Outside Lug Location Diameter

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Outside Lug Location Diameter

Airseal Diameter

17.752

Clear

Clear

17.756

0.002

0.002

Hub Diameter

17.758

0.010

0.010

17.762

Clear

Clear

Table 20. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1504

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Outside Lug Location Diameter

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Outside Lug Location Diameter

Airseal Diameter

450.901

Clear

Clear

451.002

0.051

0.051

Hub Diameter

451.053

0.254

0.254

451.155

Clear

Clear

SUBTASK 72-45-10-220-096 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1504 (SBE 70-0014, SBE 72-0013 and SBE 72-0131)

Refer to Figure.

SBE 72-0075: Provide new HPT Stage 1 Hub.

SBE 70-0014: Provide new HPT Stage 1 Airseal.

SBE 72-0013: Provide new HPTStage 1 Airseal.

SBE 72-0131: Provide new HPT Stage 1 Airseal.

Reference clearance at Location 1504. If required use the data written as a note in TASK 72-45-11-200-001-C00 (INSPECTION-001) and TASK 72-45-12-200-001-D00 (INSPECTION-001).

Table 21. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1504

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Outside Lug Location Diameter

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Outside Lug Location Diameter

Airseal Diameter

17.752

Clear

Clear

17.756

0.007

0.007

Hub Diameter

17.763

0.015

0.015

17.767

Clear

Clear

Table 22. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1504

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Outside Lug Location Diameter

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Outside Lug Location Diameter

Airseal Diameter

450.901

Clear

Clear

451.002

0.178

0.178

Hub Diameter

451.180

0.381

0.381

451.282

Clear

Clear

SUBTASK 72-45-10-220-097 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1504 (SBE 72-0075, SBE 70-0014, SBE 72-0013 and SBE 72-0131)

Refer to Figure.

SBE 72-0430: HPT Stage 1 disk metering plug replacement.

CAUTION

IF ONE HUB HOLE AT LOCATION 1516 DOES NOT MEET THE DIMENSIONAL REQUIREMENTS, THEN YOU MUST NOT INSTALL A METERING PLUG AT THAT LOCATION. WRITE THIS IN THE ENGINE BUILD RECORDS.

CAUTION

IF TWO OR MORE HOLES AT LOCATION 1516 DO NOT MEET THE DIMENSIONAL REQUIREMENTS, THEN CONTACT IAE. DO NOT ASSEMBLE THE ROTOR.Reference interference at Location 1516. If required use the data written as a note in TASK 72-45-11-200-001-C00 (INSPECTION-001).

Table 23. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1516

Stage 1 HPT Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-011), Hole Diameter

Stage 1 HPT Metering Plug ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-040), Outside Diameter Contact Surface

Hub Hole Diameter

0.383

Intf

0.387

Intf

0.377

0.004

0.384

0.004

Metering Plug Diameter

0.392

0.015

0.392

0.008

0.387

Intf

0.387

Intf

Table 24. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1516

Stage 1 HPT Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-011), Hole Diameter

Stage 1 HPT Metering Plug ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-040), Outside Diameter Contact Surface

Hub Hole Diameter

9.728

Intf

9.83

Intf

9.576

0.102

9.754

0.102

Metering Plug Diameter

9.957

0.381

9.957

0.203

9.83

Intf

9.83

Intf

SUBTASK 72-45-10-220-098 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1516 (SBE 72-0430)

Refer to Figure.

Reference interference at Location 1550. If required use the data written as a note in TASK 72-45-11-200-001-A00 (INSPECTION-001), TASK 72-45-11-200-001-B00 (INSPECTION-001) or TASK 72-45-11-200-001-C00 (INSPECTION-001) and TASK 72-45-12-200-001-A00 (INSPECTION-001).

Table 25. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1550

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Lug Axial Location

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Lug Axial Location

Hub Lug Axial Location

0.500

Intf

0.496

0.012

Airseal Lug Axial Location

0.522

0.026

0.512

Intf

NOTE

Look at the paperwork for the Stage 1 HPT Airseal to see if a worn dimension has been recorded. If part has worn dimension it can be used only if the mating part has a diameter that will result in fit of reference No. 1550.Table 26. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1550

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Lug Axial Location

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Lug Axial Location

Hub Lug Axial Location

12.700

Intf

12.599

0.30

Airseal Lug Axial Location

13.26

0.66

13.00

Intf

NOTE

Look at the paperwork for the Stage 1 HPT Airseal to see if a worn dimension has been recorded. If part has worn dimension it can be used only if the mating part has a diameter that will result in fit of reference No. 1550.

SUBTASK 72-45-10-220-054-A00 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1550 (Pre SBE 70-0014)

Refer to Figure.

SBE 70-0014: Stage 1 HPT Airseal (outer) new part number.

Reference interference at Location 1550. If required use the data written as a note in TASK 72-45-11-200-001-A00 (INSPECTION-001), TASK 72-45-11-200-001-B00 (INSPECTION-001) or TASK 72-45-11-200-001-C00 (INSPECTION-001) and TASK 72-45-12-200-001-C00 (INSPECTION-001).

Table 27. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1550

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Lug Axial Location

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Lug Axial Location

Hub Lug Axial Location

0.500

Intf

0.496

0.011

Airseal Lug Axial Location

0.527

0.031

0.511

Intf

NOTE

Fit is 0.006 in. to 0.012 in. tighter than actual fit No. 1551.Table 28. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1550

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Lug Axial Location

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Lug Axial Location

Hub Lug Axial Location

12.700

Intf

12.599

0.280

Airseal Lug Axial Location

13.39

0.790

12.98

Intf

NOTE

Fit is 0.153 to 0.304 mm tighter than actual fit No. 1551.

SUBTASK 72-45-10-220-054-B00 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1550 (SBE 70-0014, Pre SBE 72-0013 and Pre SBE 72-0131)

SBE 72-0013: Stage 1 HPT Airseal (outer) new part number.

SBE 72-0131: Stage 1 HPT Airseal (outer) new part number.

Refer to Figure.

Reference interference at Location 1550. If required use the data written as a note in TASK 72-45-11-200-001-A00 (INSPECTION-001), TASK 72-45-11-200-001-B00 (INSPECTION-001) or TASK 72-45-11-200-001-C00 (INSPECTION-001) and TASK 72-45-12-200-001-B00 (INSPECTION-001) or TASK 72-45-12-200-001-D00 (INSPECTION-001).

Table 29. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1550

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Lug Axial Location

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Lug Axial Location

Hub Lug Axial Location

0.500

Intf

0.496

0.0275

Airseal Lug Axial Location

0.5435

0.0475

0.5275

Intf

Table 30. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1550

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Lug Axial Location

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Lug Axial Location

Hub Lug Axial Location

12.700

Intf

12.599

0.70

Airseal Lug Axial Location

13.80

1.21

13.40

Intf

SUBTASK 72-45-10-220-054-C00 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1550 (SBE 72-0013 and SBE 72-0131)

Refer to Figure.

Reference interference at Location 1551. If required use the data written as a note in TASK 72-45-11-200-001-A00 (INSPECTION-001), TASK 72-45-11-200-001-B00 (INSPECTION-001) or TASK 72-45-11-200-001-C00 (INSPECTION-001) and TASK 72-45-12-200-001-A00 (INSPECTION-001).

Table 31. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1551

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Lug Axial Location

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Lug Axial Location

Hub Lug Axial Location

0.500

Intf

0.496

0.002

Airseal Lug Axial Location

0.523

0.027

0.502

Intf

Table 32. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1551

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Lug Axial Location

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Lug Axial Location

Hub Lug Axial Location

12.700

Intf

12.599

0.05

Airseal Lug Axial Location

13.28

0.686

12.75

Intf

SUBTASK 72-45-10-220-055-A00 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1551 (Pre SBE 70-0014 and Pre SBE 72-0013)

Refer to Figure.

SBE 70-0014: Stage 1 HPT Airseal (outer) new part number.

Reference the interference at Location 1551. If required use the data written as a note in TASK 72-45-11-200-001-A00 (INSPECTION-001), TASK 72-45-11-200-001-B00 (INSPECTION-001) or TASK 72-45-11-200-001-C00 (INSPECTION-001) and TASK 72-45-12-200-001-C00 (INSPECTION-001).

Table 33. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1551

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Lug Axial Location

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Lug Axial Location

Hub Lug Axial Location

0.500

Intf

0.496

0.005

Airseal Lug Axial Location

0.515

0.019

0.505

Intf

Table 34. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1551

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Lug Axial Location

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Lug Axial Location

Hub Lug Axial Location

12.700

Intf

12.599

0.130

Airseal Lug Axial Location

13.08

0.480

12.83

Intf

SUBTASK 72-45-10-220-055-B00 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1551 (SBE 70-0014 and Pre SBE 72-0131)

Refer to Figure.

SBE 72-0013: Replacement of the Stage 1 HPT duct segment and the Stage 1 HPT Airseal.

SBE 72-0131: To provide a new Stage 1 HPT Airseal.

Reference interference at Location 1551. If required use the data written as a note in TASK 72-45-11-200-001-A00 (INSPECTION-001), TASK 72-45-11-200-001-B00 (INSPECTION-001) or TASK 72-45-11-200-001-C00 (INSPECTION-001) and TASK 72-45-12-200-001-B00 (INSPECTION-001) or TASK 72-45-12-200-001-D00 (INSPECTION-001).

Table 35. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1551

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Lug Axial Location

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Lug Axial Location

Hub Lug Axial Location

0.500

Intf

0.496

0.018

Airseal Lug Axial Location

0.528

0.032

0.518

Intf

Table 36. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1521

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Lug Axial Location

Stage 1 HPT Airseal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Lug Axial Location

Hub Lug Axial Location

12.700

Intf

12.599

0.460

Airseal Lug Axial Location

13.410

0.810

13.160

Intf

SUBTASK 72-45-10-220-055-C00 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1551 (SBE 72-0013 and SBE 72-0131)

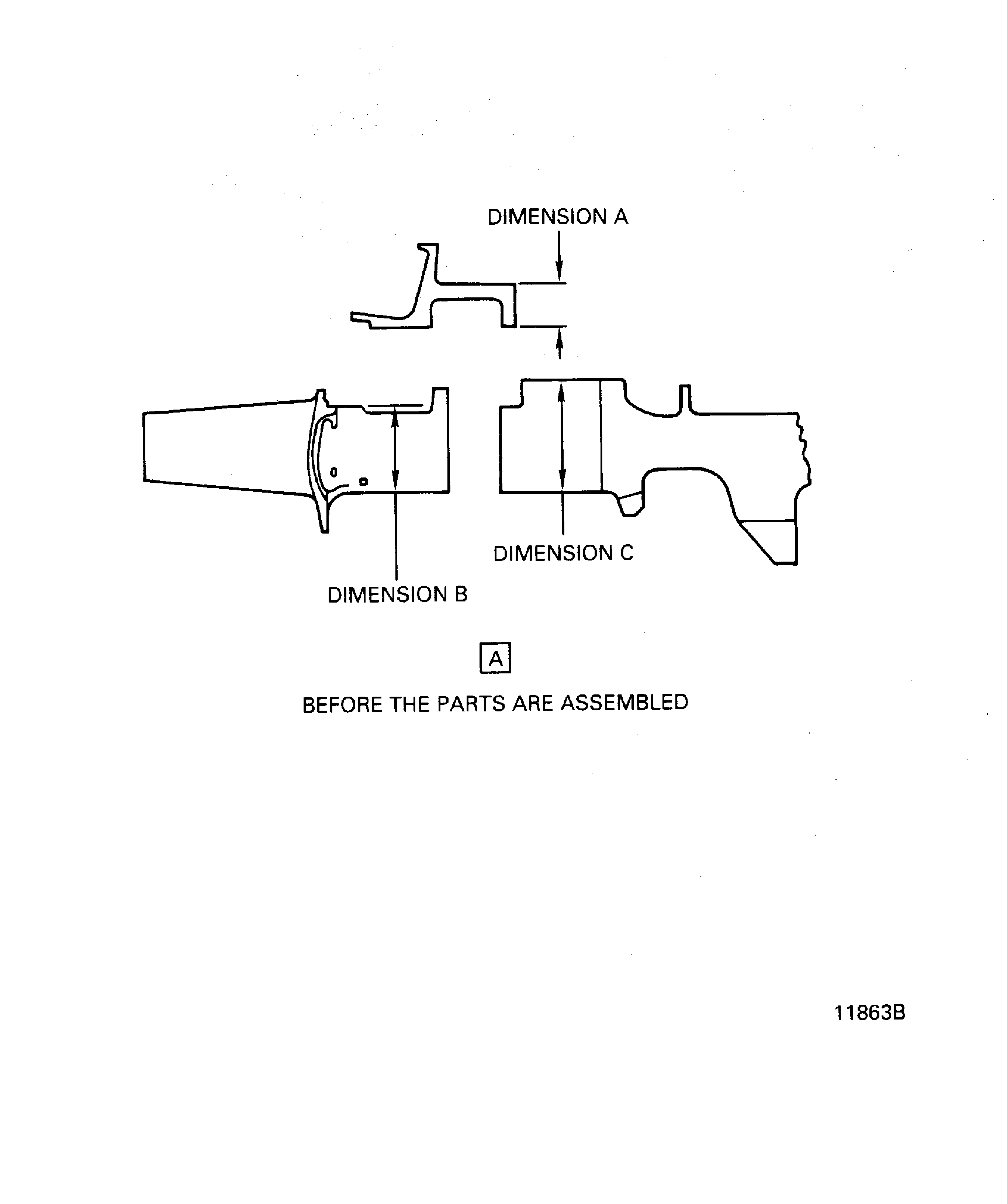

Refer to Figure.

Table 37. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Select

REJECT IF

MORE THAN

LOCATION 1552

Stage 1 HPT Airseal (Rear) ENGINE-STAGE 1 AIR SEAL (REAR) (72-45-15, 01-020), Dimension A

Stage 1 HPT Blade ENGINE-STAGE 1 HPT BLADE ASSEMBLY (72-45-14, 01-010), Dimension B

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Dimension C

Seal Dimension A

0.276

0.276

0.274

0.272

Blade Dimension B

0.888

0.890

0.884

Intf

0.882

Intf

Hub Dimension C

1.162

0.004

1.162

0.004

1.160

0.004

1.160

0.004

Clear

Clear

Table 38. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Select

REJECT IF

MORE THAN

LOCATION 1552

Stage 1 HPT Airseal (Rear) ENGINE-STAGE 1 AIR SEAL (REAR) (72-45-15, 01-020), Dimension A

Stage 1 HPT Blade ENGINE-STAGE 1 HPT BLADE ASSEMBLY (72-45-14, 01-010), Dimension B

Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Dimension C

Seal Dimension A

7.010

7.010

6.960

6.909

Blade Dimension B

22.555

Intf

22.606

22.454

0.102

22.403

Intf

Hub Dimension C

29.514

0.102

29.514

0.102

29.464

Clear

29.464

0.102

Clear

SUBTASK 72-45-10-220-056 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly at Location 1552

Refer to Figure.

Measure and make a record of the Stage 1 HPT Airseal (rear) ENGINE-STAGE 1 AIR SEAL (REAR) (72-45-15, 01-020) Dimension A.

Measure and make a record of the Stage 1 HPT blade ENGINE-STAGE 1 HPT BLADE ASSEMBLY (72-45-14, 01-010) Dimension B.

Measure and make a record of the Stage 1 Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010) Dimension C.

Make a record of the results. This is the fit you must have at Location 1552 when you install the Stage 2 HPT Airseal in TASK 72-45-00-430-001-A00 (ASSEMBLY, CONFIG-001).

Calculate the results as follows:

SUBTASK 72-45-10-220-057 Measure and Calculate the Stage 1 HPT Airseal (rear), Stage 1 HPT Blade and Stage 1 Turbine Hub Dimensions at Location 1552

Refer to Repair 002, TASK 72-45-11-300-002, VRS3187, for the required metering plug installation procedures.

SUBTASK 72-45-10-440-086-A00 Install the Stage 1 HPT Hub Metering Plugs (72-45-11, 01-040) (Pre SBE 72-0430)

SBE 72-0430: HPT Stage 1 disk metering plug replacement.

Install the new Stage 1 metering plugs into inner side of Stage 1 turbine hub holes. Refer to Repair, VRS3730 TASK 72-45-11-300-020 (REPAIR-020) for the required metering plug installation procedures.

Make sure the metering plug tangs touch the outer side of the hub hole.

Inspect the installed metering plugs.

SUBTASK 72-45-10-440-086-B00 Install the Stage 1 HPT Hub Metering Plugs (72-45-11, 01-040) (SBE 72-0430)

CAUTION

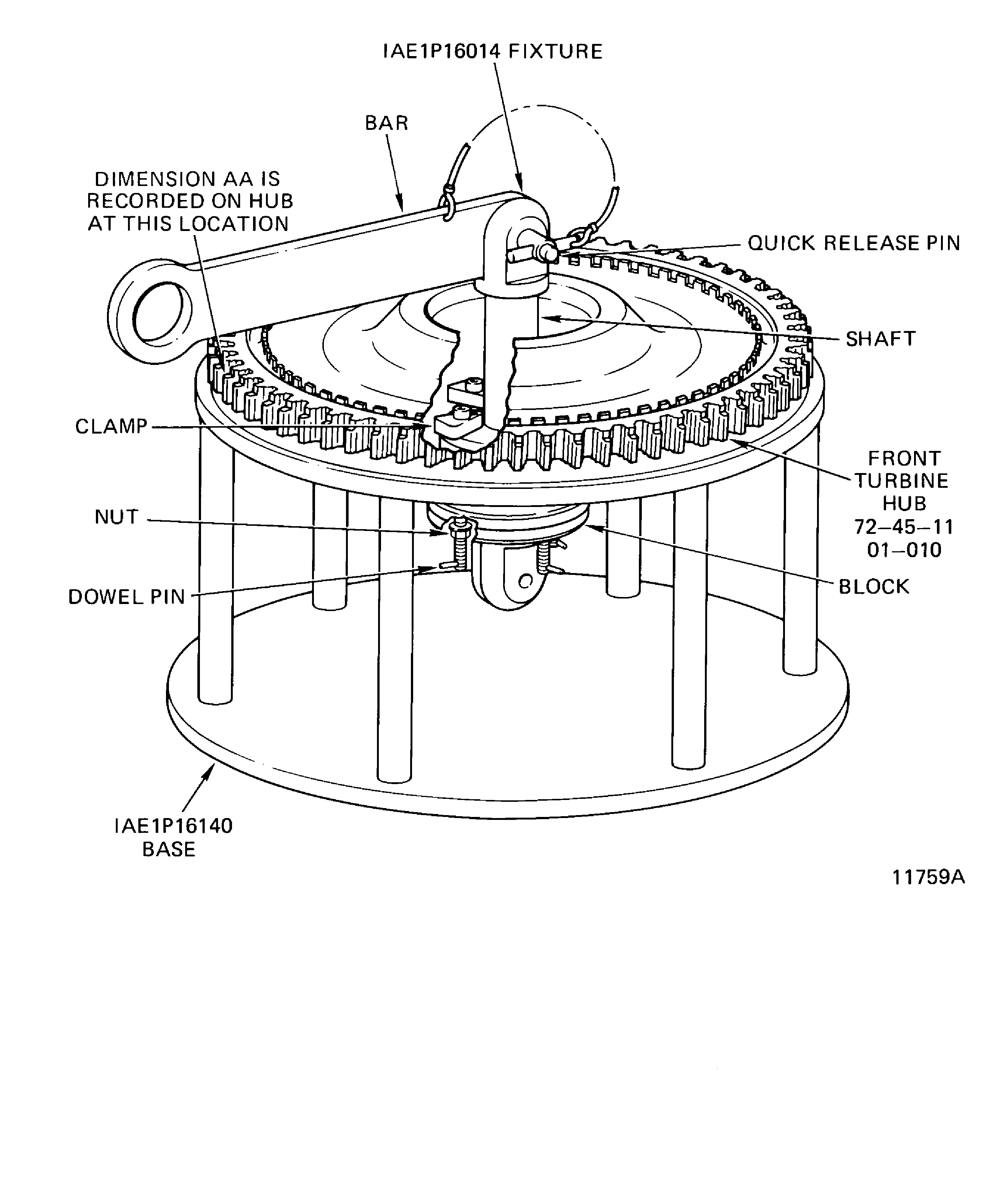

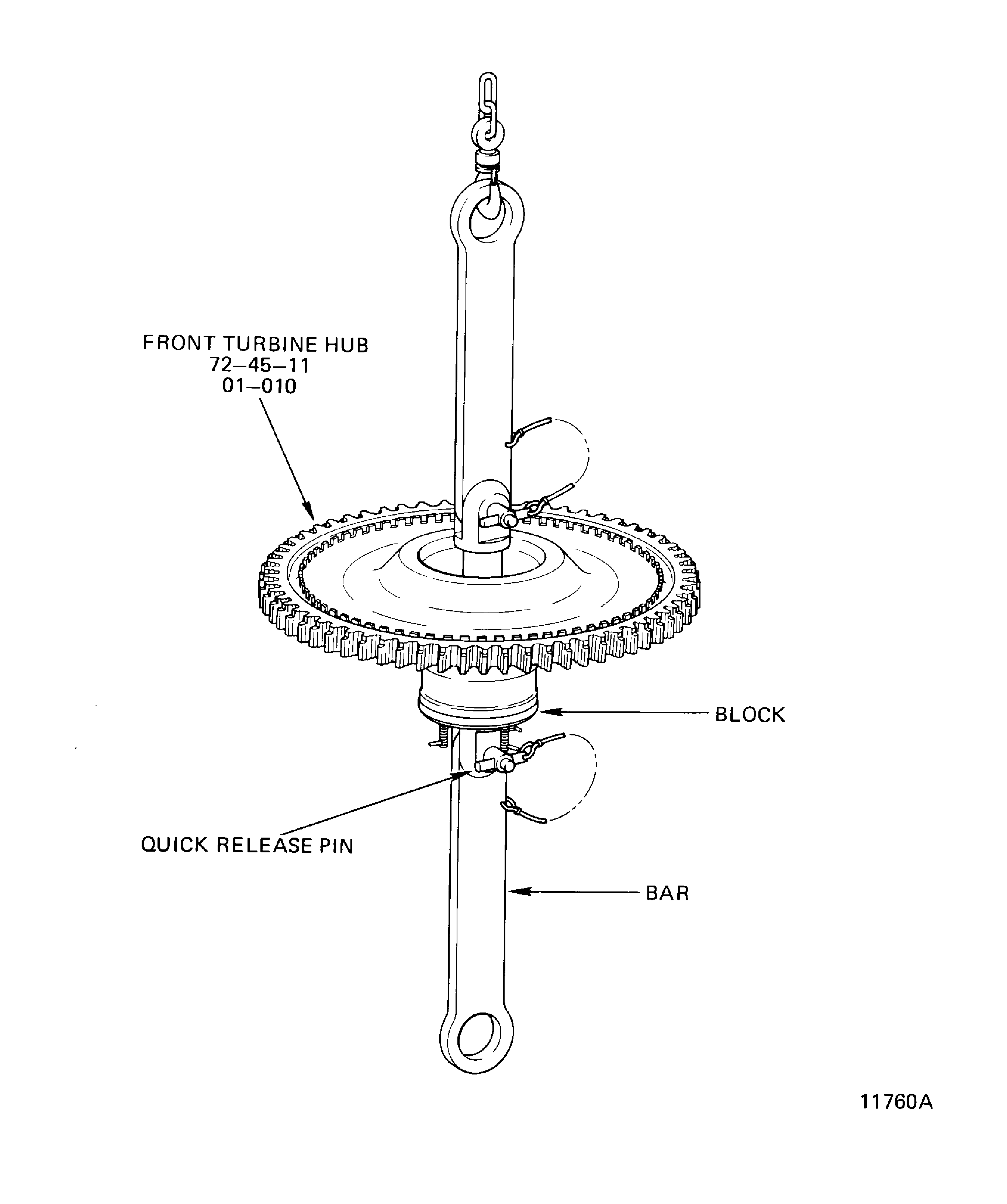

FAILURE TO CORRECTLY INSTALL STAGE 1 HPT METERING PLUGS CAN RESULT IN DAMAGE TO THE ENGINE.Remove the shaft from the block, Figure.

Remove the bar from the block, Figure.

Loosen the four nuts securing the clamps to the block, Figure.

Move the clamps out of the block until they can be turned, Figure.

Hold the block assembly against the front turbine hub front face and turn the dowel pin until the clamp threaded end is pointing away from the hub centerline, Figure.

Find and write dimension AA on the paperwork, Figure.

Attach the bar to the block with the quick release pin, Figure.

Install the IAE 1P16014 Fixture 1 off to the turbine front hub.

SUBTASK 72-45-10-440-051 Install the Fixture to the Turbine Hub (72-45-11, 01-010)

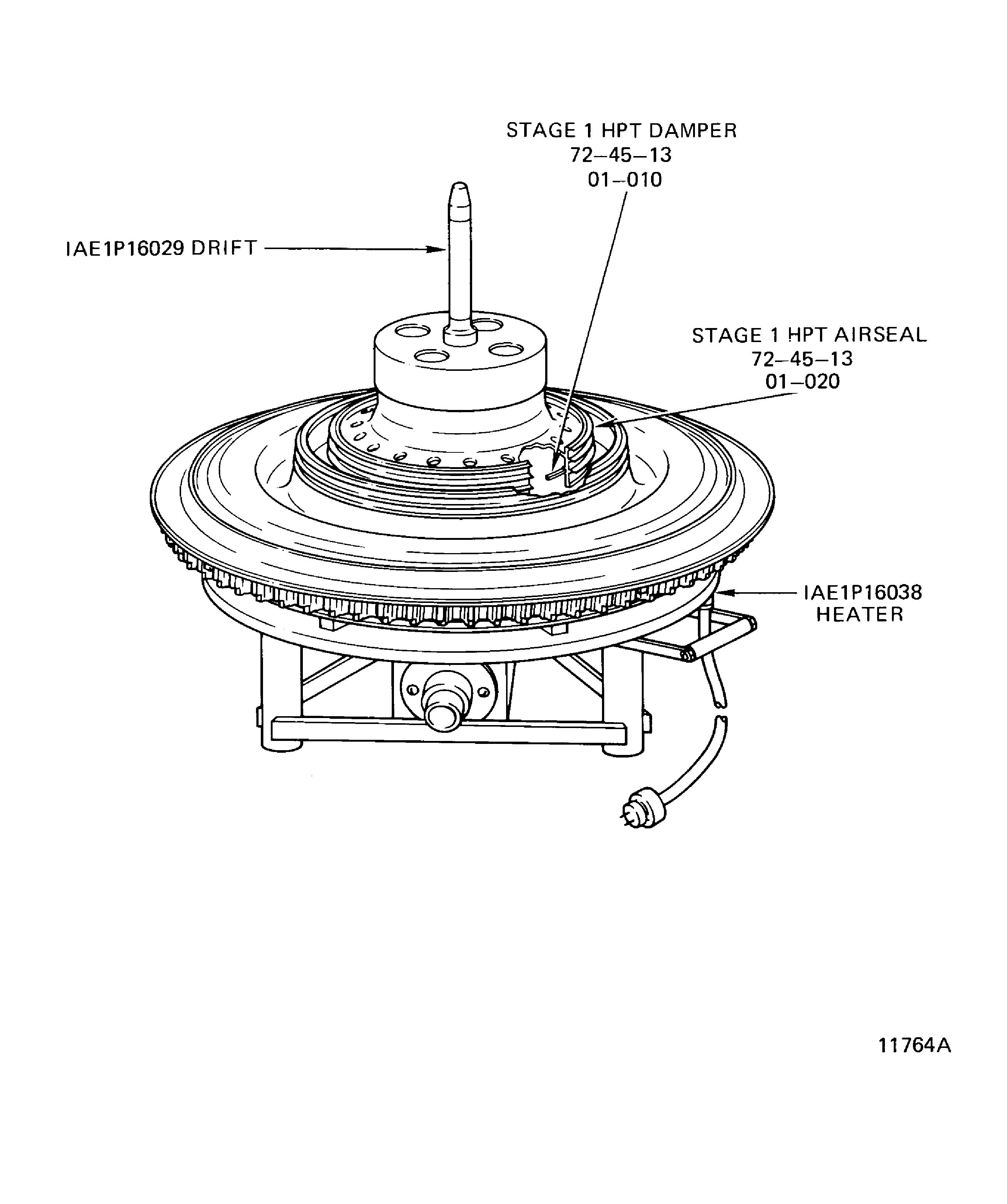

Refer to Figure.

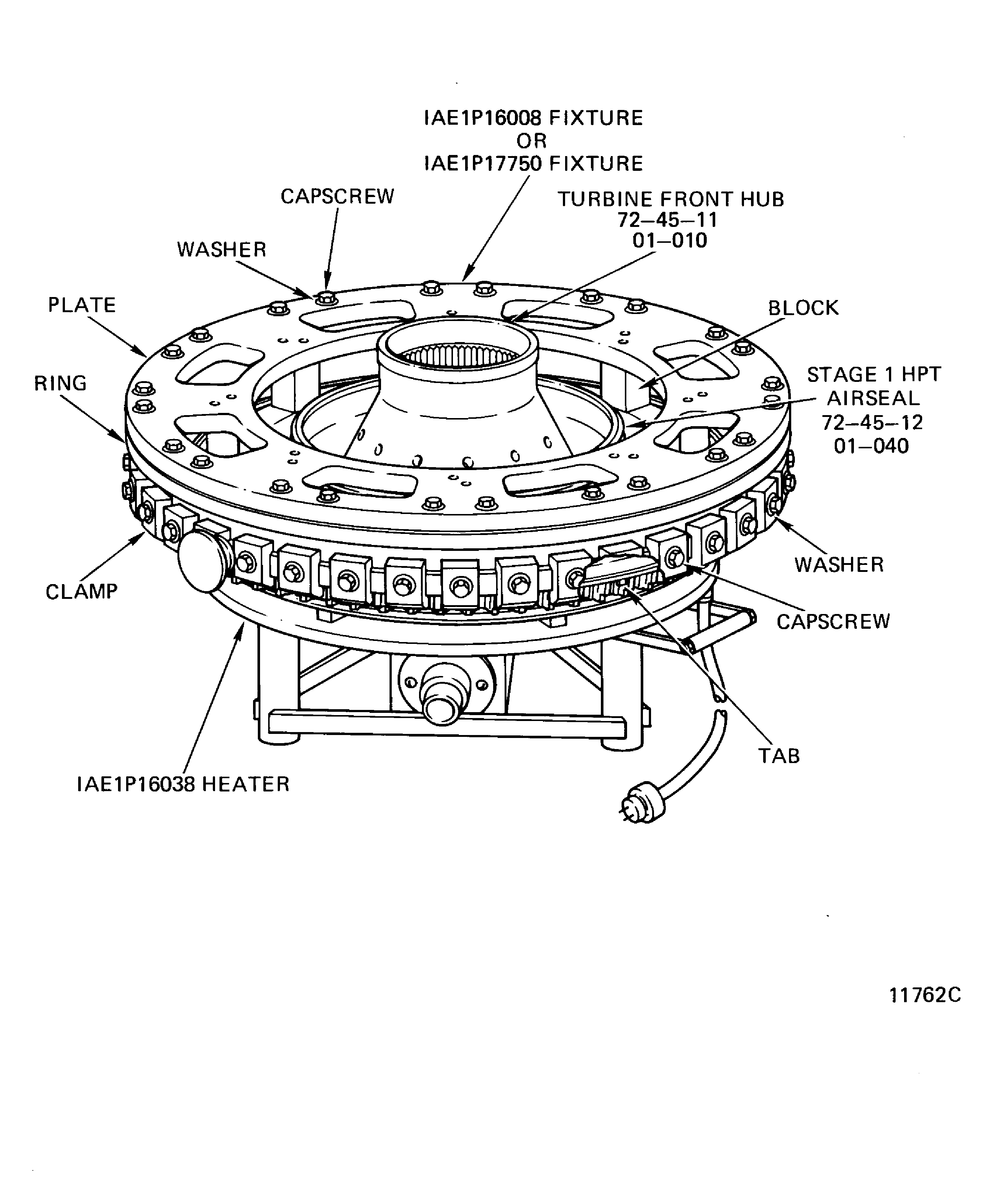

Lower the Turbine Front Hub in to the IAE 1P16038 Heater 1 off.

Connect the IAE 6F10027 Heater control unit 1 off to the heater.

Remove the IAE 1P16014 Fixture 1 off from the Turbine Hub.

SUBTASK 72-45-10-440-052 Install the Turbine Hub on to the Heater

Refer to Figure.

Put the ring slotted end up, on a bench with a hoist and IAE 1F10052 Two cables sling 1 off.

Install the Stage 1 HPT Airseal (outer) in the IAE 1P16008 Fixture 1 off or IAE 1P17750 Fixture 1 off.

SUBTASK 72-45-10-440-053 Install the Stage 1 HPT Airseal (Outer) (72-45-12, 01-040) in the Fixture

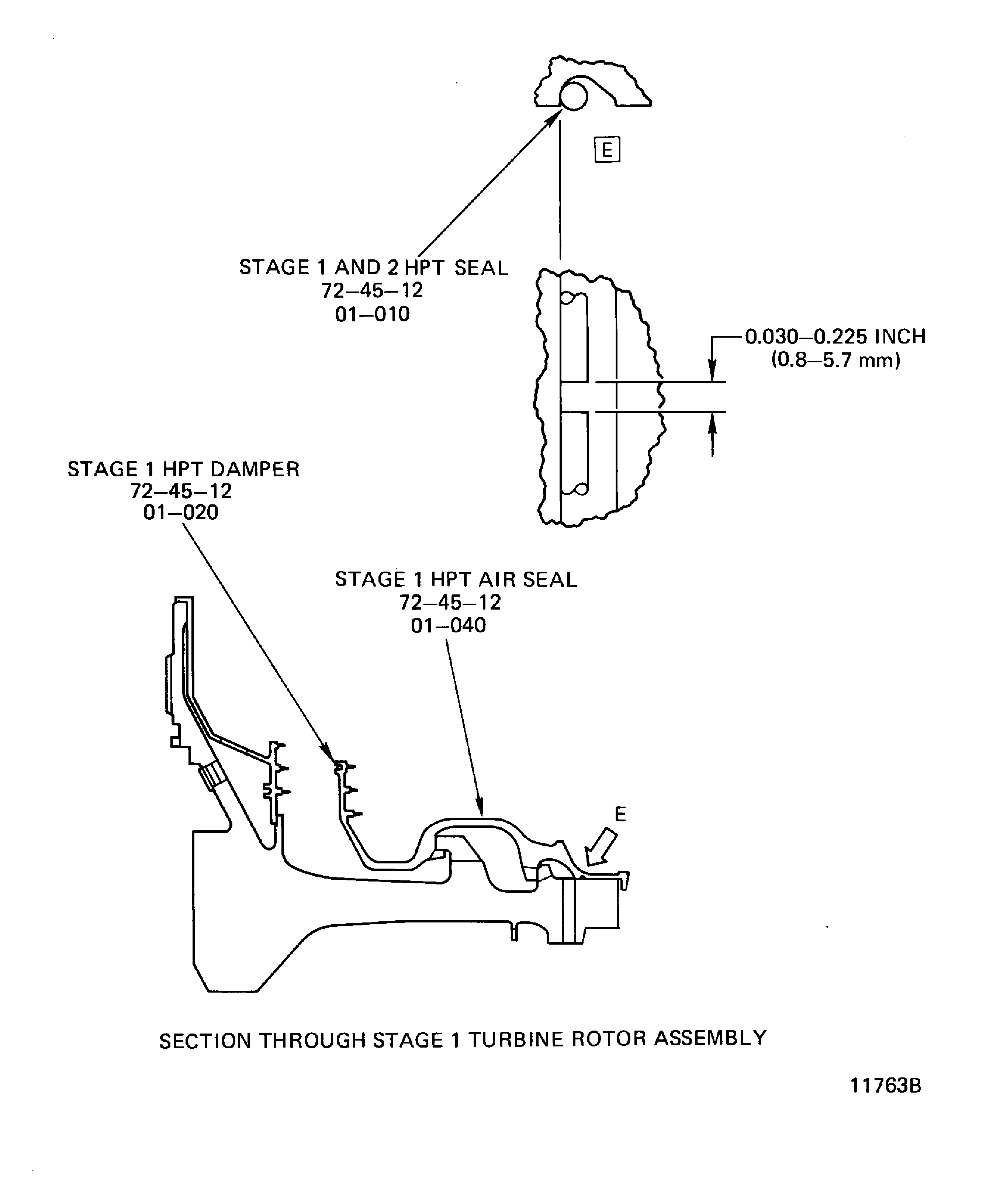

Install a new Stage 1 and 2 HPT seal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-010) in to the groove in the flange face of the Stage 1 HPT seal and do a check of the end gap, Figure.

Install the damper ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-020) in to the groove in the inner diameter of the Stage 1 HPT Airseal, Figure.

NOTE

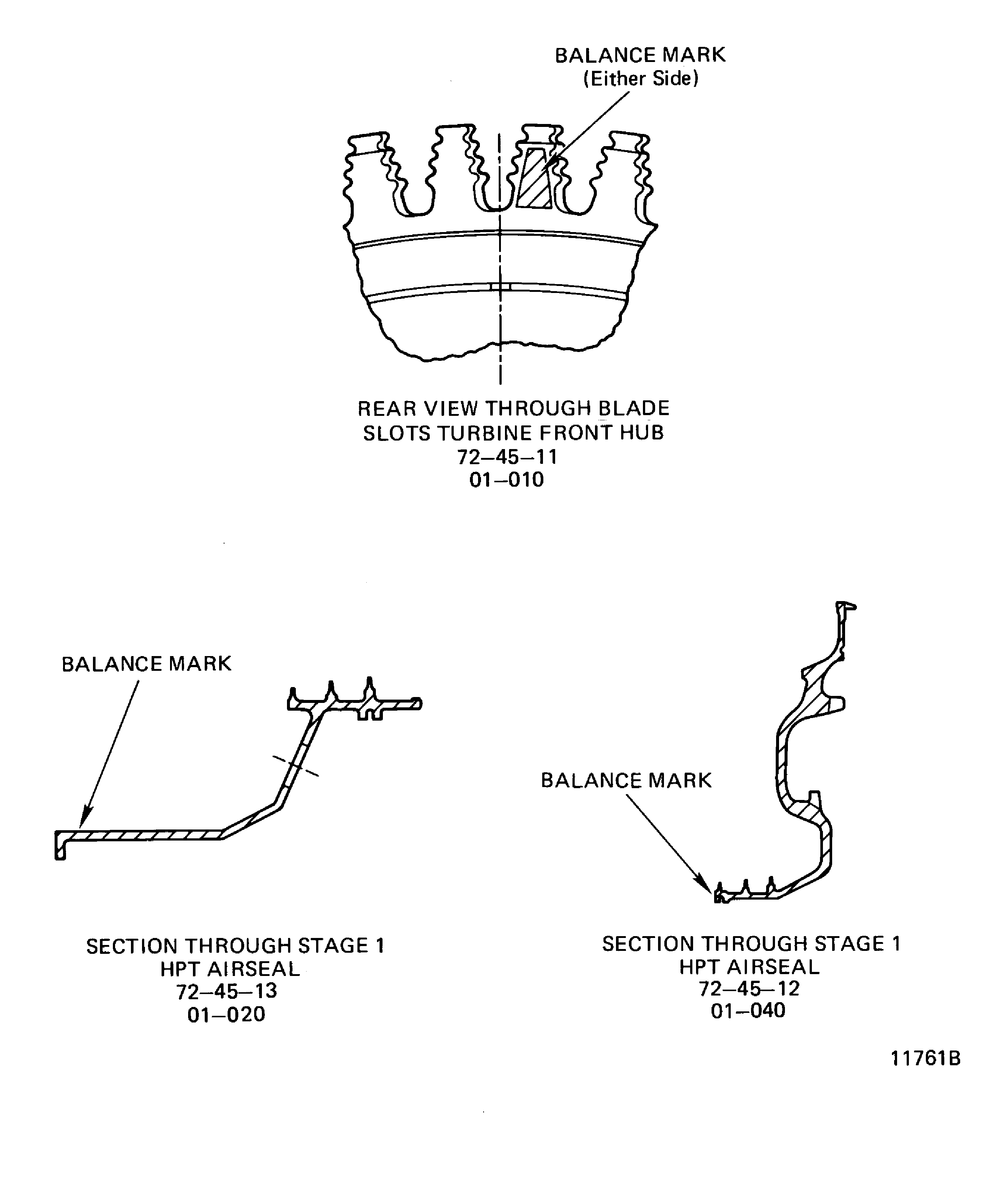

The rotor parts may be heated to 300 deg F (149 deg C) to permit assembly. Minimum difference in temperature between the parts must be 200 deg F (97 deg C).Use the balance marks to put the parts in position, Figure.

Put the Stage 1 HPT Airseal in position to a vector stack with respect to the Turbine Hub.

Install the two Stage 1 HPT blades ENGINE-STAGE 1 HPT BLADE ASSEMBLY (72-45-14, 01-010), with one of the blades in each of the blade slots adjacent to the antirotation tabs.

Make sure the position of the antirotation tabs is correct.

SUBTASK 72-45-10-440-054 Install the Stage 1 HPT Airseal (Outer) on to the Turbine Hub

Refer to Figure.

NOTE

The 2A1203 airseal must be used with the 2A1204-01 No. 4 Bearing heat shield assembly. The 2A0891-01 and 2A1205-01 No. 4 Rear Bearing cooling duct can be used with the 2A1203 Stage 1 HPT airseal.Install a Stage 1 HPT damper ENGINE-STAGE 1 HPT AIR SEAL (INNER) (72-45-13, 01-010) in the Stage 1 HPT Airseal.

Install the IAE 1P16029 Drift 1 off on the stage 1 HPT airseal.

SUBTASK 72-45-10-440-055 Install the Stage 1 HPT Airseal (Inner) (72-45-13, 02-010)

Install the IAE 1P16014 Fixture 1 off to the Turbine Hub. Refer to Step.

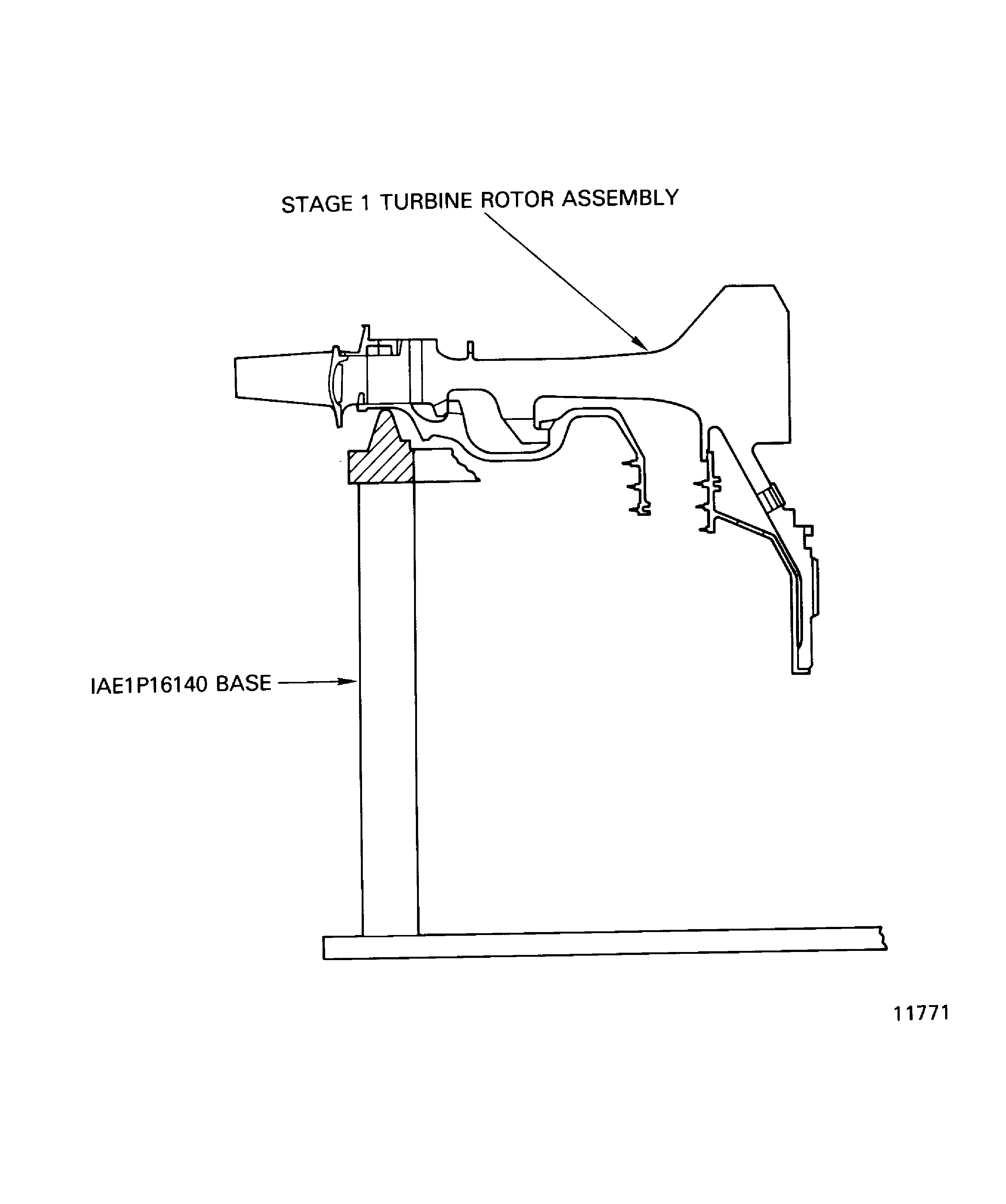

Lower the assembly in to the IAE 1P16140 Support base 1 off.

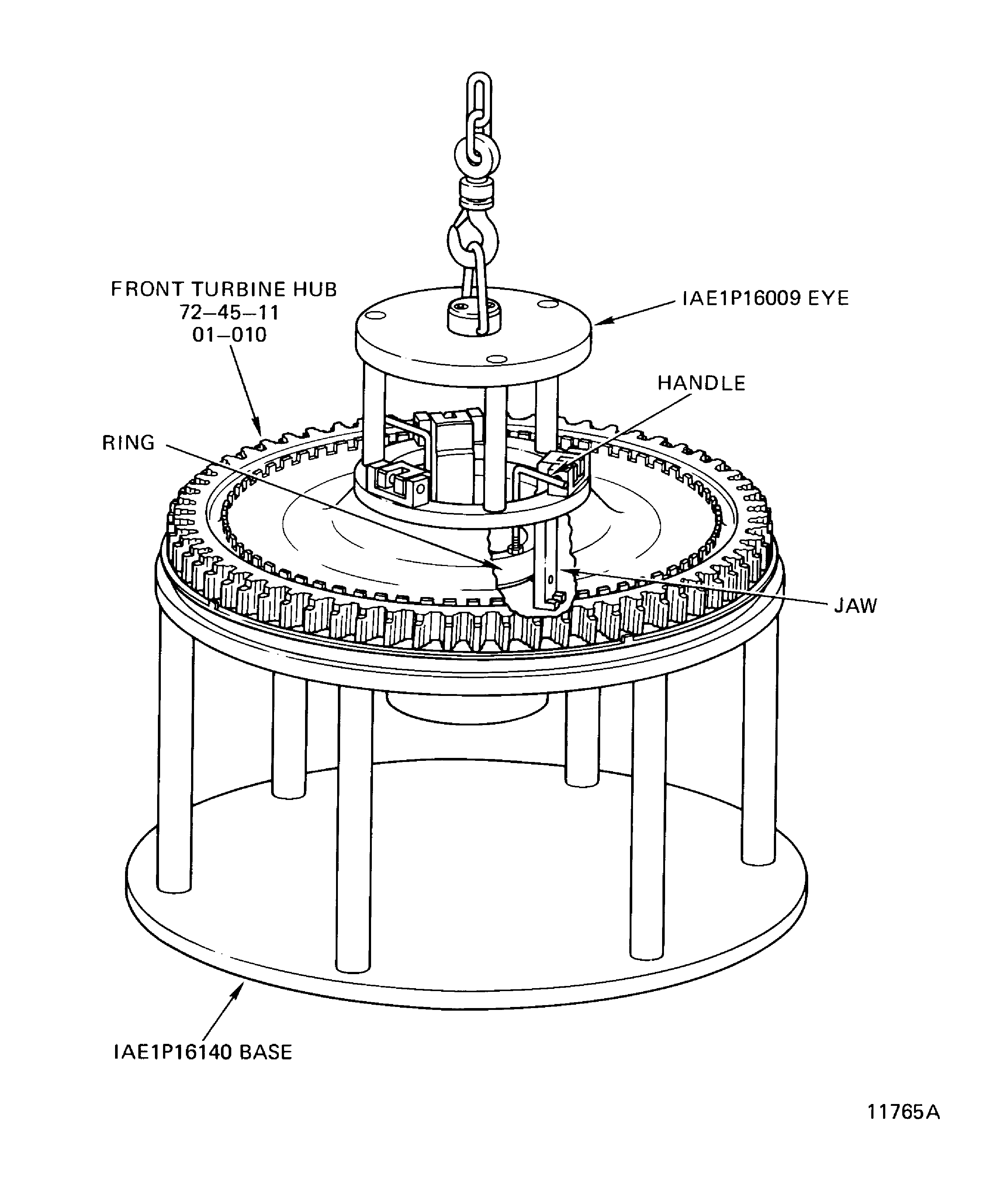

SUBTASK 72-45-10-440-056 Install the Turbine Hub in to the Support Base

Refer to Figure.

Loosen the two handles and retract ring so the jaws can be moved inward for clearance, Figure.

Install the IAE 1P16009 Lifting eye 1 off in the bore of the Turbine Hub.

SUBTASK 72-45-10-440-057 Install the Lifting Eye on the Turbine Hub

Refer to Figure.

Lift the assembly with the hoist and lower it on to the IAE 1P16061 Support ring 1 off.

SUBTASK 72-45-10-440-058 Install the Turbine Hub in to the Support Ring

Refer to Figure.

NOTE

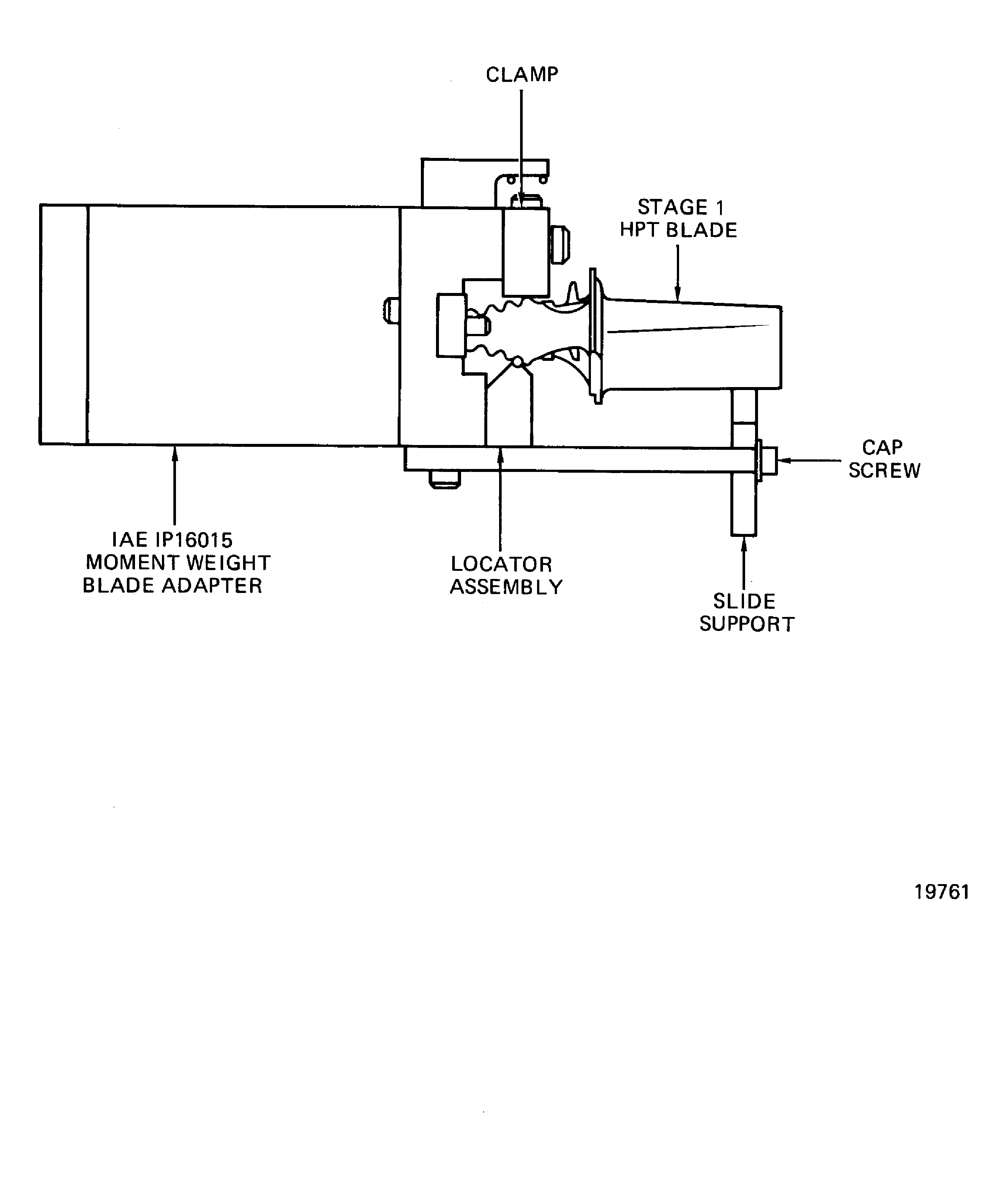

If new or fully repaired Stage 1 HPT Duct Segments (BOAS) are to be installed, two thirds of Stage 1 HPT blades must have fully repaired tips. One third of the blades can have complete, partial, or no tip coating.Install and attach the IAE 1P16015 Adapter 1 off to the lever arm on the moment weighing equipment.

Mark the moment weight on the concave side of the blade airfoil. Use CoMat 06-153 FELT TIP MARKER, RAPID DRYING, CoMat 06-153X FELT TIP MARKER, RAPID DRYING, FINE POINT, BLACK, TRACE ELEMENT CERTIFIED or CoMat 06-158 MARKER, EXTRA FINE POINT(BLACK). Refer to SPM TASK 70-09-01-400-501.

SUBTASK 72-45-10-440-067 Moment Weigh the Stage 1 HPT Blades (72-45-14, 01-010)

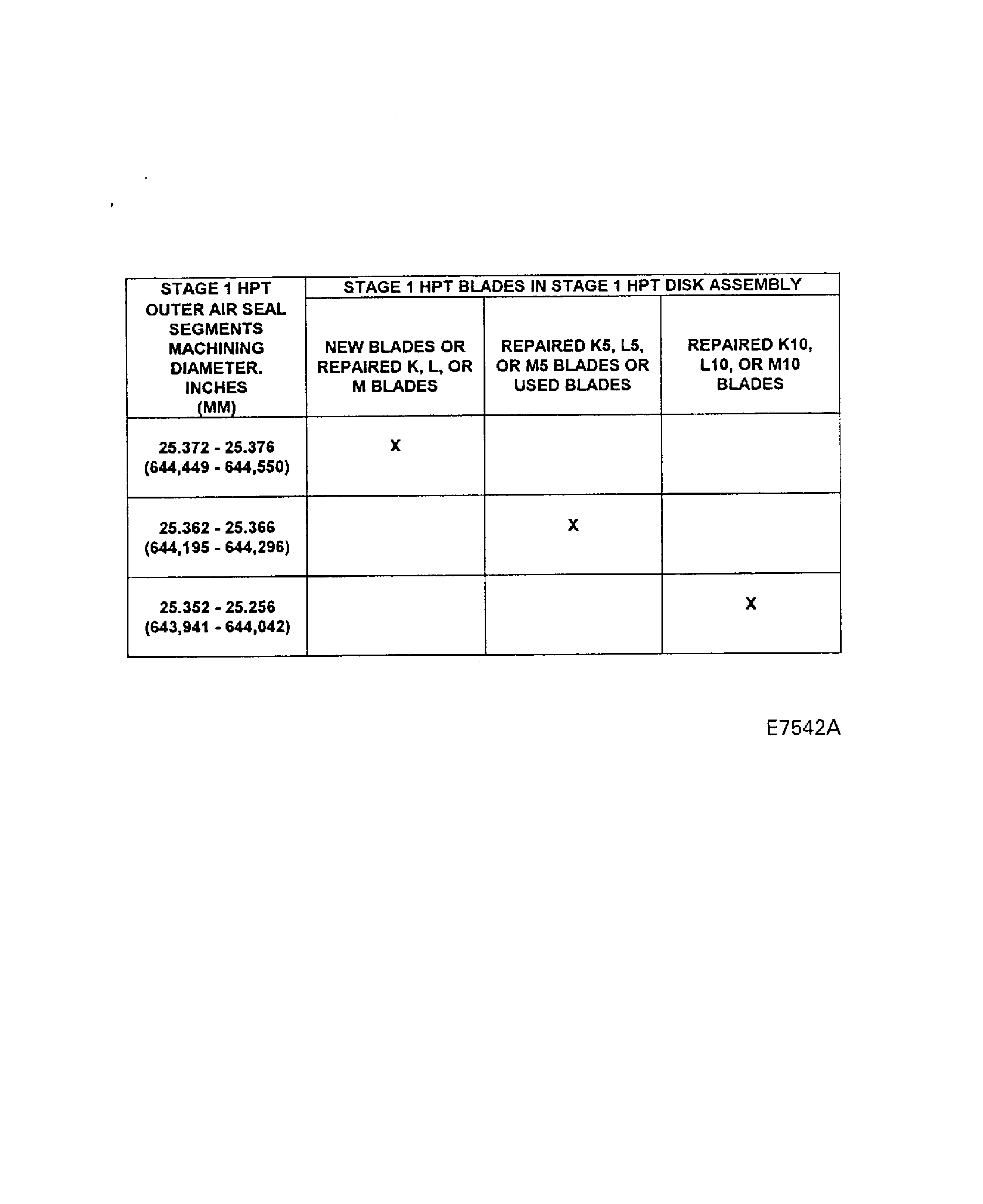

Use the table Figure to find the dimension that will be used to machine the diameter of the Stage 1 HPT Outer Airseal segments. Record this dimension.

NOTE

A blade set contains two blades of equal weight or as near as possible to the same weight.

Record the type and quantity of blades used in this Rotor Assembly and the diameter that will be used to machine the OAS, Figure.

Put the moment weighed Stage 1 HPT Blades ENGINE-STAGE 1 HPT BLADE ASSEMBLY (72-45-14, 01-010) in to 32 blade sets on a bench.

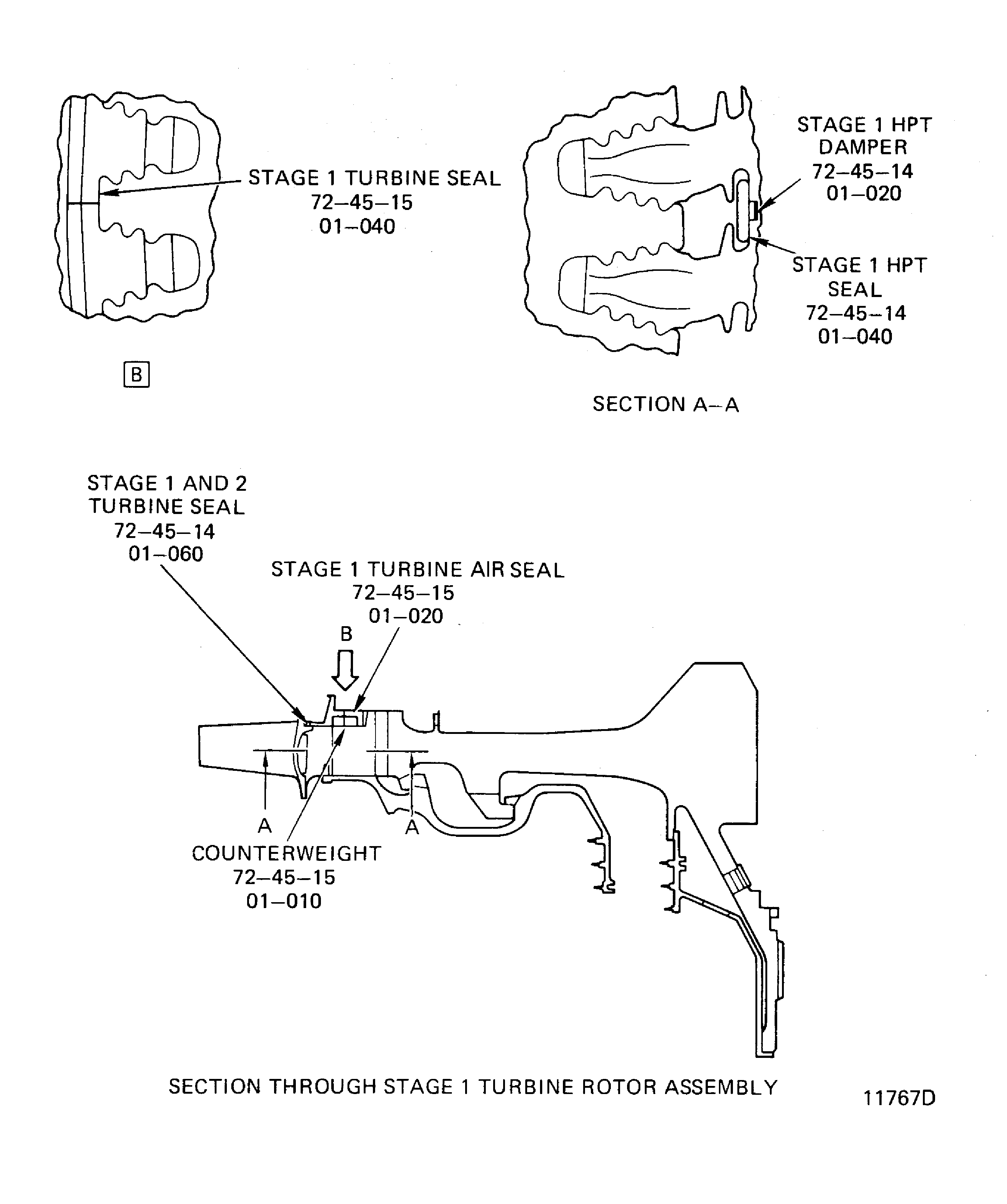

Install a Stage 1 Blade Seal ENGINE-STAGE 1 HPT BLADE ASSEMBLY (72-45-14, 01-040) and a Stage 1 Blade Damper ENGINE-STAGE 1 HPT BLADE ASSEMBLY (72-45-14, 01-020) in the No. 2 blade in row one by the steps that follow.

SUBTASK 72-45-10-440-059 Put the Stage 1 HPT Blades in to the Blade Slots in the Turbine Hub

CAUTION

REPAIRED BLADES CAN BE THREE DIFFERENT LENGTHS. THEY CAN BE THE SAME LENGTH AS NEW BLADES, 0.005 IN. (0.127 MM) UNDERSIZE OR 0.010 IN. (0.254 MM) UNDERSIZE. REPAIRED BLADE LENGTHS ARE IDENTIFIED BY MARKS ON THE BLADE ROOT OR THE UNDERSIDE OF THE BLADE PLATFORMS AS THE LETTER K, L OR M AND CAN BE FOLLOWED BY A NUMBER 5 OR 10. A LETTER K, L OR M WITH NO NUMBER MEANS THE BLADE IS THE SAME LENGTH AS A NEW BLADE. A LETTER FOLLOWED BY A 5 MEANS THE BLADE IS 0.005 IN. (0.127 MM) UNDERSIZE. A LETTER FOLLOWED BY A NUMBER 10 MEANS THE BLADE IS 0.010 IN. (0.254 MM) UNDERSIZE. YOU CAN INSTALL NEW, USED, OR REPAIRED BLADES, OR BLADES THAT ARE 0.005 IN. (0.127 MM) OR 0.010 IN. (0.254 MM) UNDERSIZE COMBINATIONS OF DIFFERENT BLADE LENGTHS IN THE SAME ROTOR ARE NOT PERMITTED. \ YOU MUST INSTALL BLADES OF THE SAME LENGTH IN A ROTOR.Put one end of seal in the center of any blade bottom radius. Use CoMat 06-158 MARKER, EXTRA FINE POINT(BLACK) to hold the seal in position. Remove any wax that is not needed.

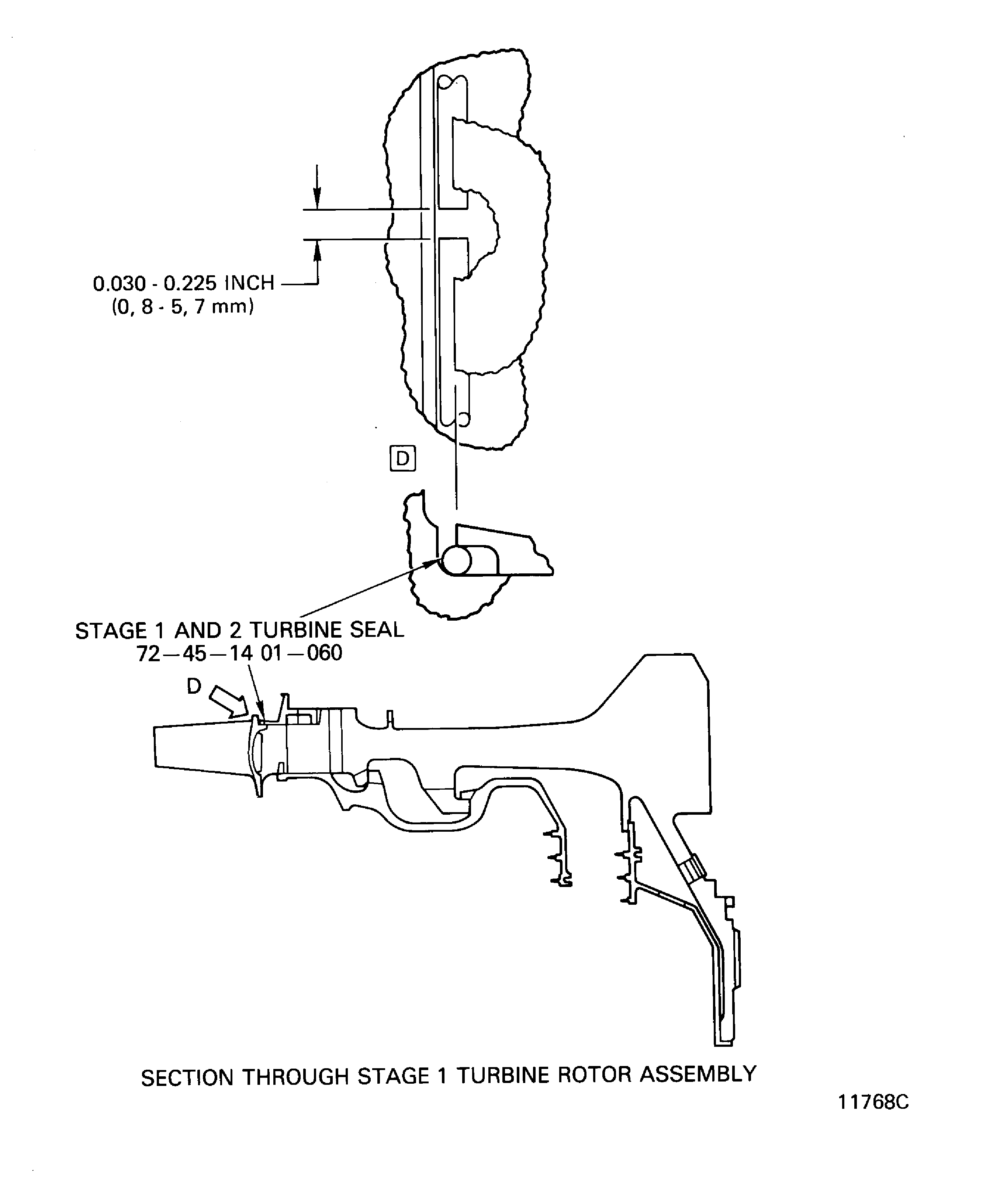

Do a check for the clearance between the two ends of the seal, Figure.

Install the Stage 1 and 2 Turbine seal into the bottom radius on the Stage 1 Blades.

SUBTASK 72-45-10-440-060 Install the Stage 1 and 2 Turbine Seal (72-45-14, 01-060)

Refer to Figure.

SUBTASK 72-45-10-440-061 Install the Stage 1 HPT Airseals (72-45-15, 01-020)

Refer to Figure.

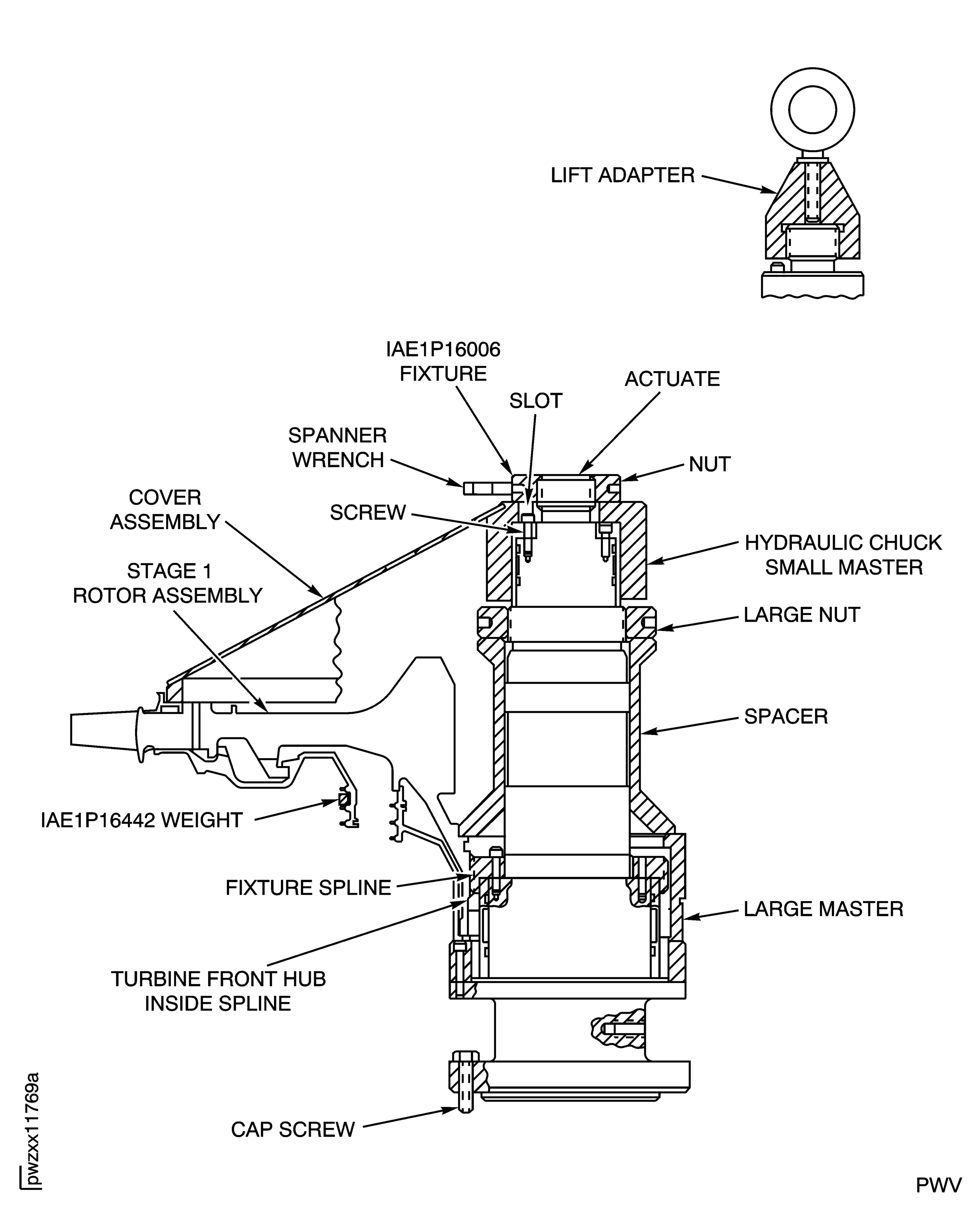

Remove the nut at the top of the IAE 1P16006 Fixture 1 off with the spanner wrench.

Remove the large nut with the spanner wrench, Figure.

SUBTASK 72-45-10-440-062 Install the Balance Fixture on a Vertical Balance Machine

Refer to Figure.

Install the IAE 1P16442 Calibration weight (calibration weight) 1 off at the OD radius between the second knife edge and the third knife edge flange.

Do a check for balance machine calibration as follows:

SUBTASK 72-45-10-440-063 Install the Stage 1 Turbine Rotor Assembly in to the Fixture

Correct unbalance to within 3 ozin (2160 gm mm) by moving stage 1 HPT blades (Figure) and/or stage 1 turbine seals ENGINE-STAGE 1 AIR SEAL (REAR) (72-45-15, 01-020), Figure.

Correct unbalance to within 0.5 ozin (360 gm mm) by adding up to six counterweights, Figure.

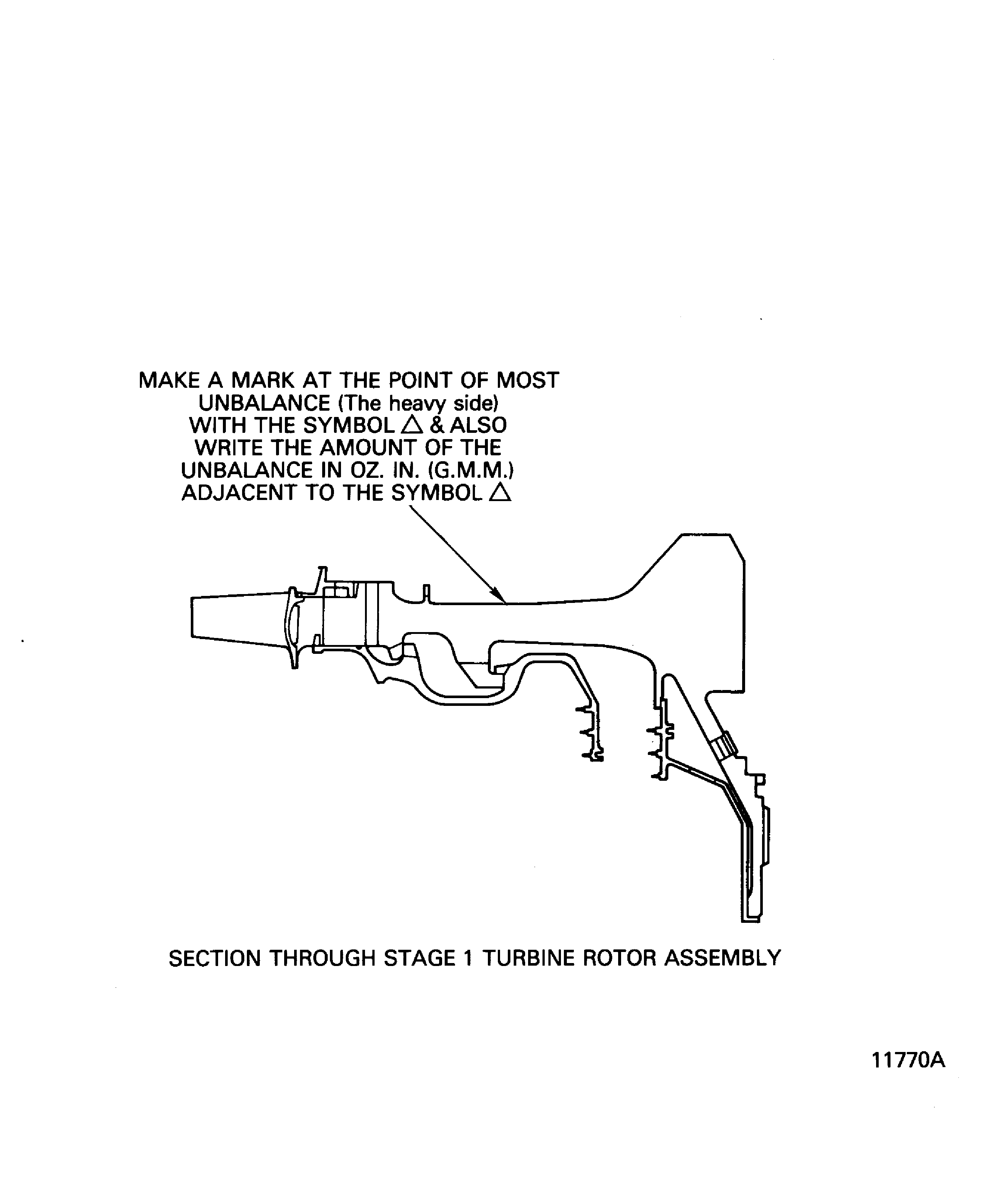

Make a mark for amount and location of unbalance with CoMat 06-153 FELT TIP MARKER, RAPID DRYING, CoMat 06-153X FELT TIP MARKER, RAPID DRYING, FINE POINT, BLACK, TRACE ELEMENT CERTIFIED or CoMat 06-158 MARKER, EXTRA FINE POINT(BLACK). Refer to SPM TASK 70-09-00-400-501 and Figure.

SUBTASK 72-45-10-440-064 Balance the Stage 1 Turbine Rotor Assembly

Remove the nut with the spanner wrench, Figure.

Install the IAE 1P16009 Lifting eye 1 off. Refer to Step.

SUBTASK 72-45-10-440-065 Prepare and Remove the Stage 1 Turbine Rotor Assembly from the Balance Fixture

Refer to Figure.

Lower the Stage 1 Turbine Rotor Assembly into the IAE 1P16140 Support base 1 off.

SUBTASK 72-45-10-440-066 Put the Stage 1 Turbine Rotor Assembly in to the Support Base

Refer to Figure.

Wax the seals in position with CoMat 06-158 MARKER, EXTRA FINE POINT(BLACK). Remove the wax that is not necessary.

Install the Stage 1 Turbine seals between the outer diameter of the turbine hub fir trees and the Stage 1 Turbine Airseals. The concave side of the seal must be pointed toward the Turbine Hub.

SUBTASK 72-45-10-440-087 Install the Stage 1 Turbine Seals (72-45-15, 01-040)

Figure: Install the IAE 1P16014 Fixture

Install the IAE 1P16014 Fixture

Figure: Install the Bar to the Block

Install the Bar to the Block

Figure: Install the Stage 1 HPT Airseal (Outer)

Install the Stage 1 HPT Airseal (Outer)

Figure: Check the Seal End Clearance

Check the Seal End Clearance

Figure: Location of the Balance Marks

Location of the Balance Marks

Figure: Install the Stage 1 HPT Airseal (Inner)

Install the Stage 1 HPT Airseal (Inner)

Figure: Install the IAE 1P16009 Lifting Eye

Install the IAE 1P16009 Lifting Eye

Figure: Install the Stage 1 Turbine Rotor Assembly in the IAE 1P16061 Support Ring

Install the Stage 1 Turbine Rotor Assembly in the IAE 1P16061 Support Ring

Figure: Install the Stage 1 HPT Dampers, Airseals, Seals and Counterweights

Install the Stage 1 HPT Dampers, Airseals, Seals and Counterweights

Figure: Check the Seal End Clearance

Check the Seal End Clearance

Figure: Install the Stage 1 Turbine Rotor Assembly in the IAE 1P16006 Fixture

Install the Stage 1 Turbine Rotor Assembly in the IAE 1P16006 Fixture

Figure: Mark the Stage 1 Turbine Rotor Assembly

Mark the Stage 1 Turbine Rotor Assembly

Figure: Install the Stage 1 Turbine Rotor Assembly in the IAE 1P16140 Support Base

Install the Stage 1 Turbine Rotor Assembly in the IAE 1P16140 Support Base

Figure: Stage 1 Turbine Rotor Assembly - Fits and Clearances

Sheet 1

Figure: Stage 1 Turbine Rotor Assembly - Fits and Clearances

Sheet 2

Figure: Stage 1 IAE 1P16015 Mount Weight Blade Adapter

Stage 1 IAE 1P16015 Mount Weight Blade Adapter

Figure: Stage 1 HPT Rotor Assembly, OAS Diameter Table

Stage 1 HPT Rotor Assembly, OAS Diameter Table