Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 71-00-02-400-013-B00 (A5-PPBU) - Install The Cabin Bleed Air System Ducts, Valves And Air System Sense Tubes, Installation-013

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Transportation covers/blanks must be removed immediately before the installation of components and tubes.

For standard torque data and procedures refer to the SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data is identified with the symbol * after the torque value.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS unless other lubricants are referred to in the procedure.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of air drying enamel. Refer to SPM TASK 70-38-21-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Do not remove the special plastic caps from the electrical connectors until immediately before they are installed. This will give protection from unwanted fluids and materials.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 10-130 ANTIGALLING COMPOUND | 8F024 | CoMat 10-130 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

NOTE

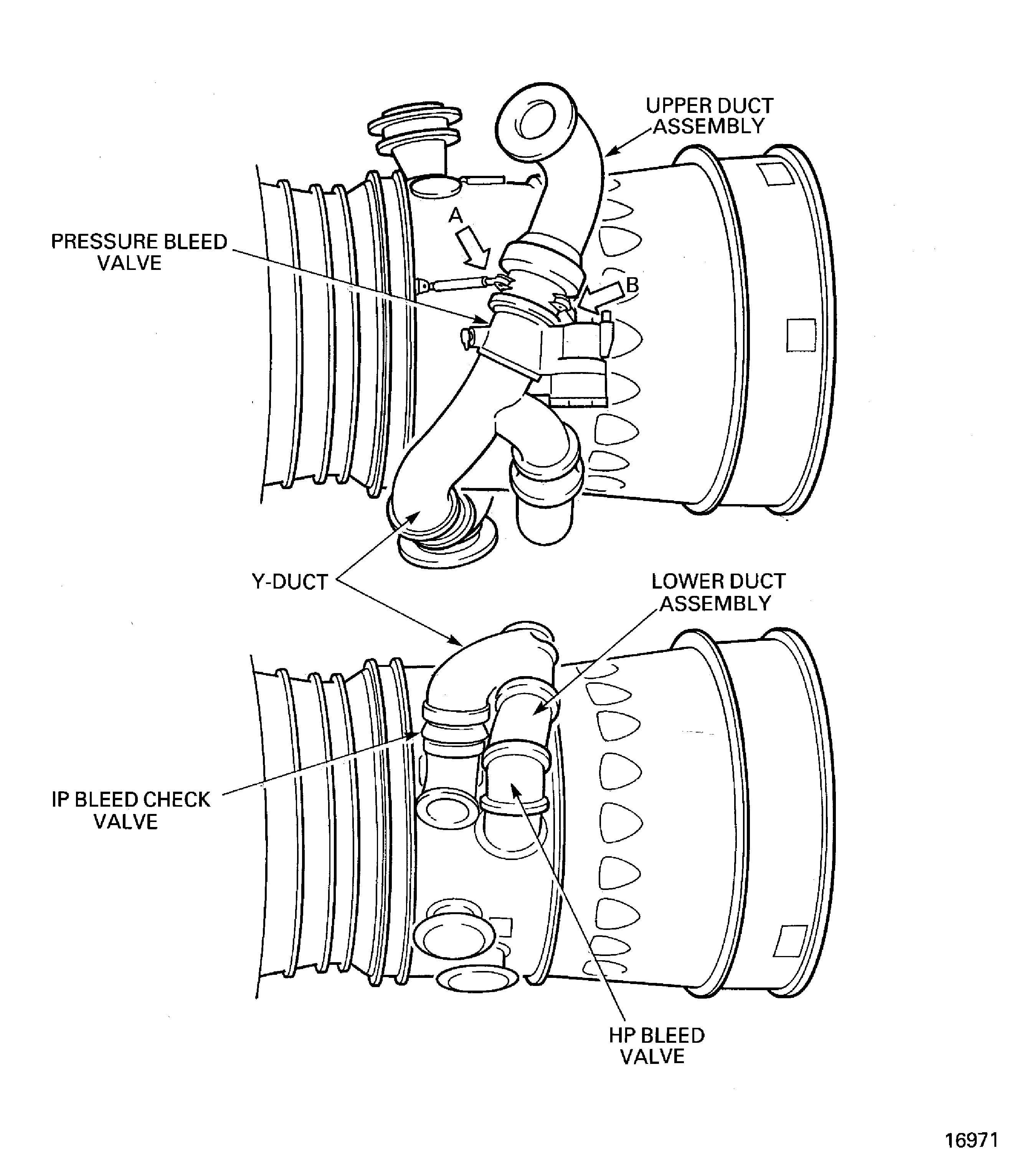

Refer to SPM TASK 70-47-01-470-501 for the procedure to install v-band couplings.Install the seal PNEUMATIC-IP BLEED AIR CHECK VALVE (36-11-41, 01-110) onto the HP7 bleed valve/cabin air duct.

Attach the IP bleed check valve to the HP7 bleed valve/cabin air duct with the coupling PNEUMATIC-IP BLEED AIR CHECK VALVE (36-11-41, 01-100). Tighten the v-band coupling nut.

Install the IP bleed check valve PNEUMATIC-IP BLEED AIR CHECK VALVE (36-11-41, 01-050).

Install the seal PNEUMATIC-HP BLEED VALVE (36-11-51, 01-110) on to the HP10 cabin air duct.

Attach the HP bleed valve to the HP10 cabin air duct with the coupling PNEUMATIC-HP BLEED VALVE (36-11-51, 01-100). Tighten the v-band coupling nut.

Install the HP bleed valve PNEUMATIC-HP BLEED VALVE (36-11-51, 01-050).

Install the seal PNEUMATIC-HP BLEED VALVE (36-11-51, 01-110) on to the HP bleed valve.

Attach the lower duct assembly to the HP bleed valve with the coupling PNEUMATIC-HP BLEED VALVE (36-11-51, 01-100). Tighten the v-band coupling nut.

Install the lower duct assembly PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-500).

Install the seal PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-320) on to the lower duct assembly.

Install the seal PNEUMATIC-IP BLEED AIR CHECK VALVE (36-11-41, 01-110) on to the IP bleed check valve.

Attach the Y-duct to the IP bleed check valve with the coupling PNEUMATIC-IP BLEED AIR CHECK VALVE (36-11-41, 01-100) and the lower duct assembly with the coupling PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-310). Tighten the v-band coupling nut.

Install the Y-duct PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-300).

Install the seal Bleed Pressure Regulator Valve (36-11-52, 01-110) and PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-340) on to the Y-duct.

Attach the pressure bleed valve to the Y-duct with the coupling Bleed Pressure Regulator Valve (36-11-52, 01-100), and PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-330). Tighten the v-band coupling nut.

Install the pressure regulator bleed valve Bleed Pressure Regulator Valve (36-11-52, 01-050).

Install the seal Bleed Pressure Regulator Valve (36-11-52, 01-110) on to the pressure bleed valve.

Attach the upper duct assembly to the pressure bleed valve with the coupling Bleed Pressure Regulator Valve (36-11-52, 01-100). Tighten the v-band coupling nut.

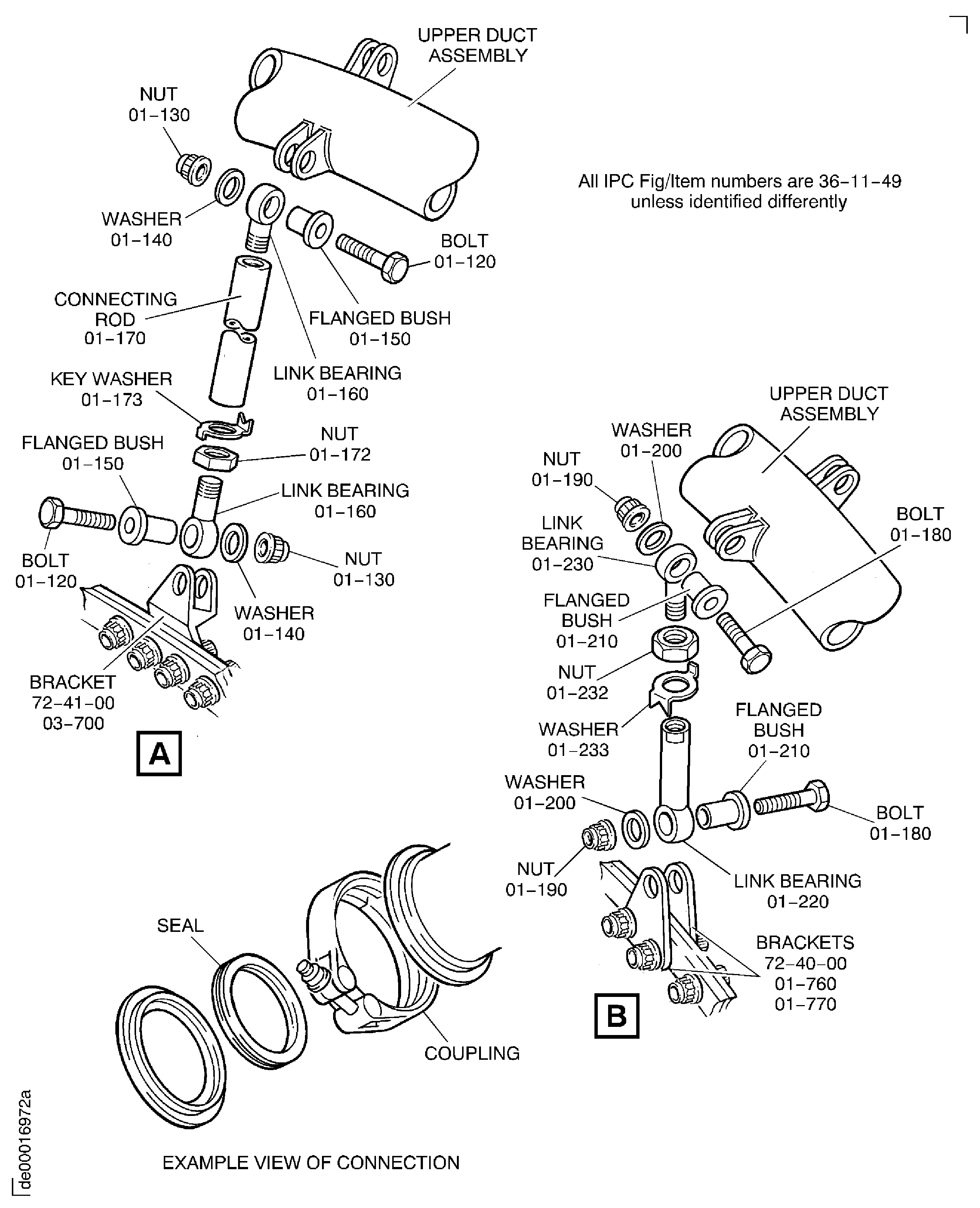

Attach the link bearing PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-230), nut PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-232) and keywasher PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-233) to the link bearing PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-220). Adjust the length of the link bearing to align its holes with the holes in the upper duct assembly lugs and the brackets HPC Module - Attaching Parts (72-40-00, 01-760 and HPC Module - Attaching Parts 01-770).

Attach the link bearings to the upper duct assembly lugs and the brackets with the two flanged bushes PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-210), the two bolts PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-180), the two washers PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-200) and the two nuts PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-190).

Attach the two link bearings PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-160), nut PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-172) and keywasher PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-173) to the connecting rod PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-170). Adjust the length of the connecting rod assembly to align its holes with the holes in the upper duct assembly lugs and the bracket HPC Assembly (72-41-00, 03-770).

Attach the connecting rod assembly to the upper duct assembly lugs and the bracket with the two flanged bushings PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-150), the two bolts PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-120), the two washers PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-140) and the two nuts PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-130).

NOTE

Final adjust and secure the link assemblies when the engine is installed on the pylon.Install the upper duct assembly PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-100).

SUBTASK 71-00-02-420-047 Install the Cabin Bleed Air System Ducts and Valves

NOTE

Pre SBE 36-0007: It is quicker to loose install the two cabin bleed air system sense tubes PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510 and PNEUMATIC-PRESSURE INDICATING TUBES 36-21-49, 01-500) before you install the cabin bleed air ducts.Apply CoMat 10-130 ANTIGALLING COMPOUND to one of the mating thread surfaces of the pressure sense tubes, hoses and union before you connect the components, as follows:

Cabin Bleed Air System Sense Tubes

IPC Fig./item

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-200)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-700)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-725)

NOTE

Refer to SPM TASK 70-41-02-400-501 for the torque loading procedures.Do not tighten or torque the tube nuts or attaching parts until all the tubes are installed in their correct position.

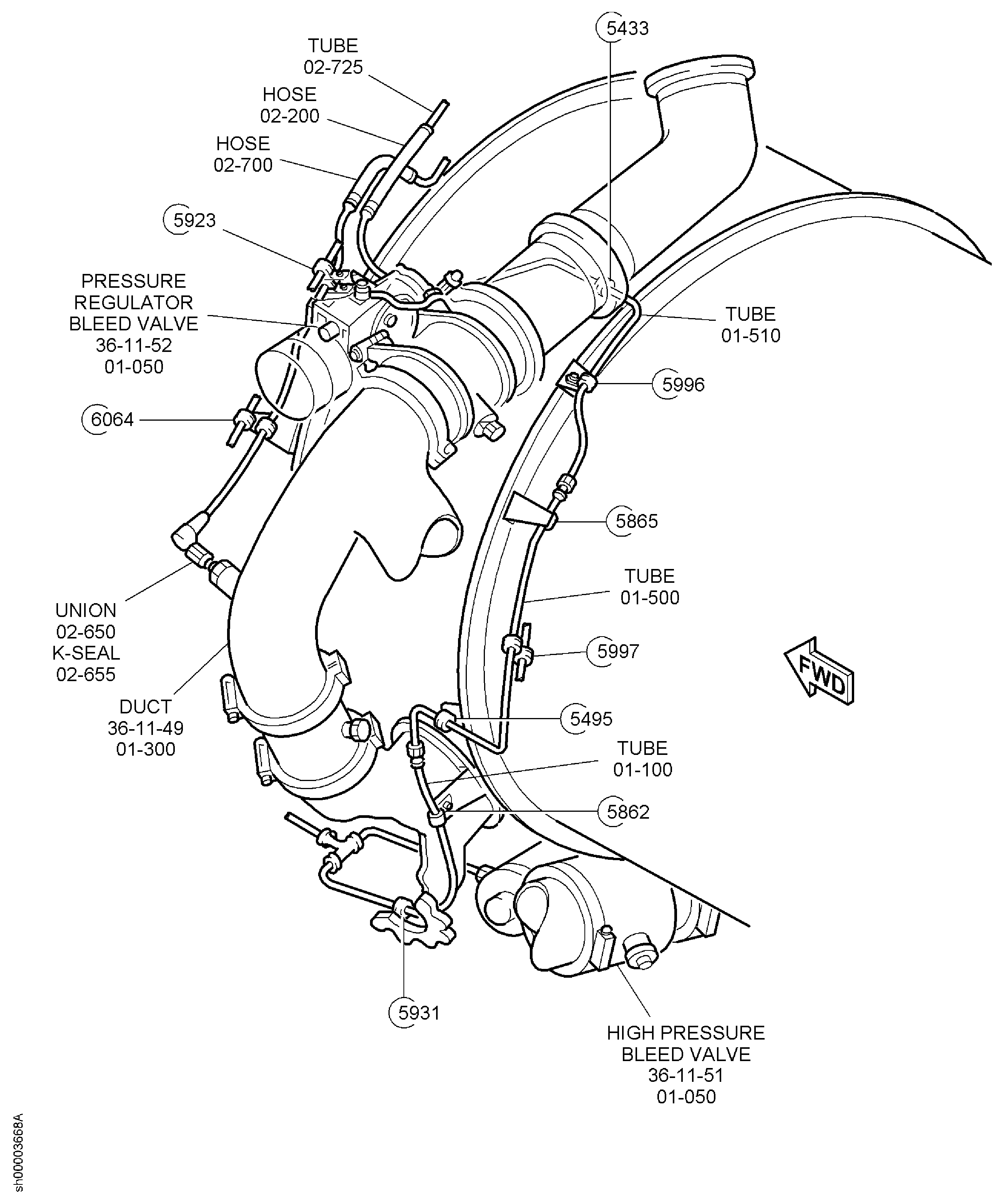

Install the K seal PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-655) and the union PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-650) in the duct PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-300). Torque the union to 168 to 181 lbf.in (19 to 20.50 Nm).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) to the union PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-650).

Connect the hose PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-700) to the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) and the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-725).

Attach the hose PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-200) to the tube connected to the pressure regulator bleed valve Bleed Pressure Regulator Valve (36-11-52, 01-050).

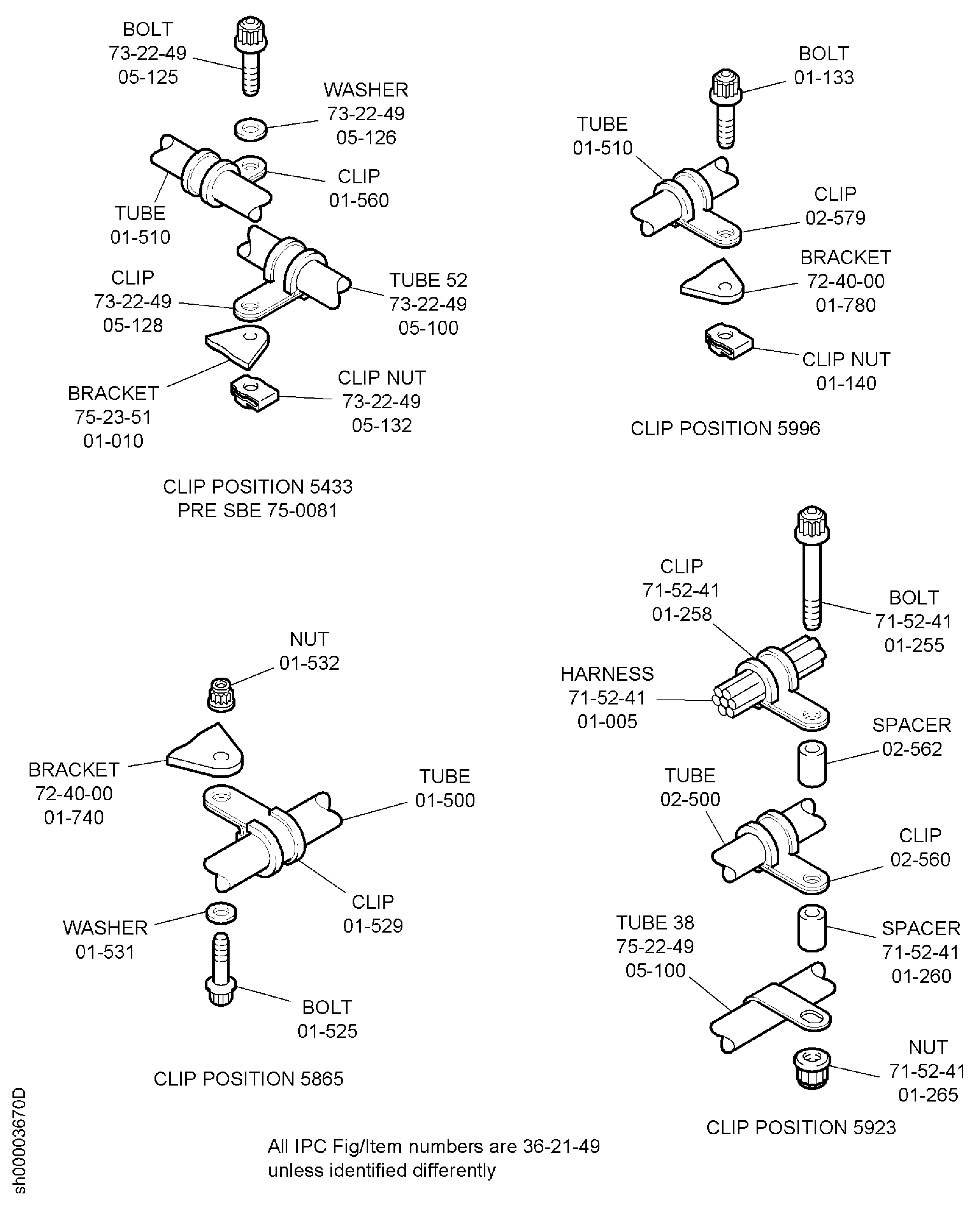

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) and the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005) to the lug at the tube 38 at clip position 5923 with the bolt, spacer PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-562), spacer and the nut.

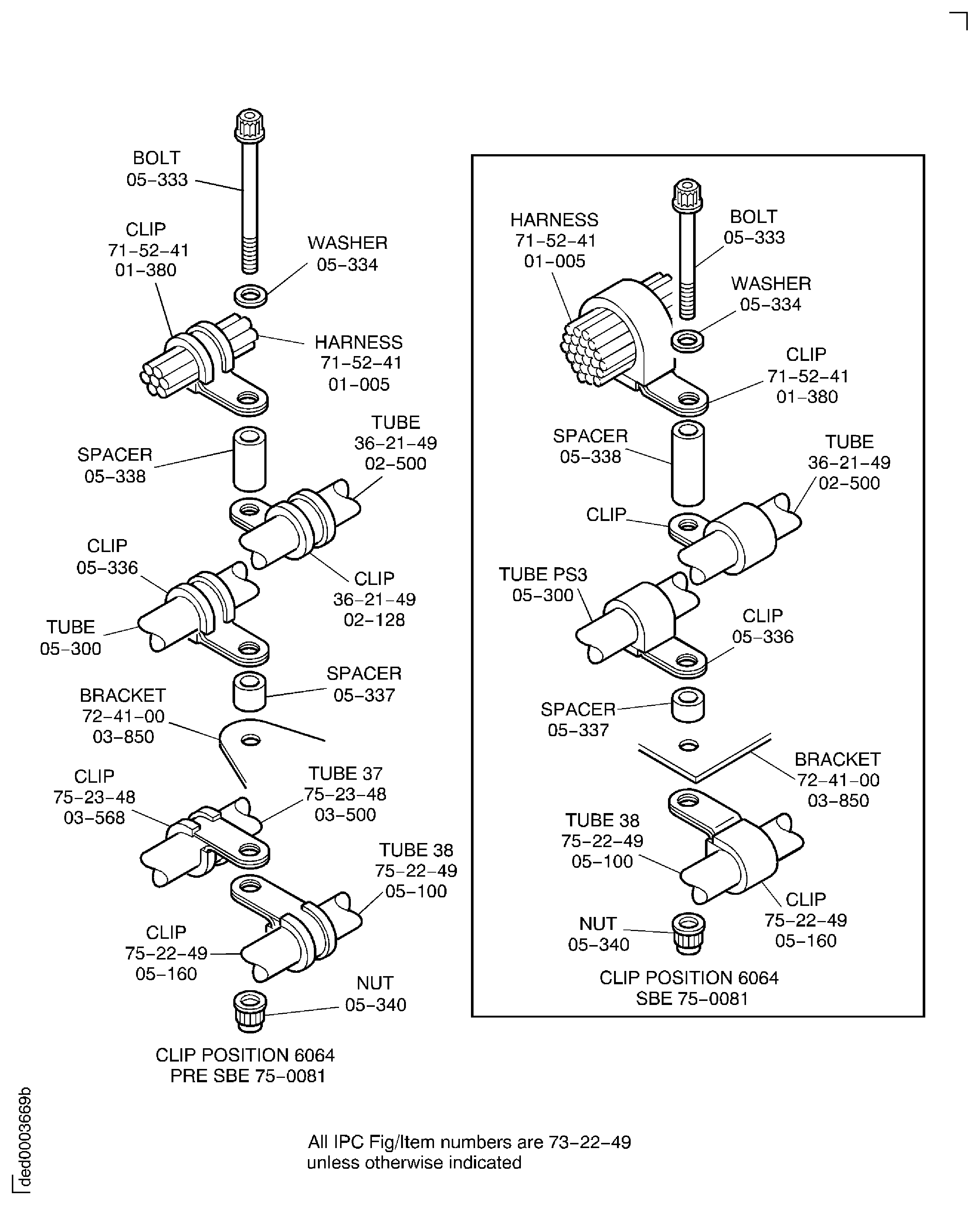

Pre SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005), the clip Fuel System Air Tubes (73-22-49, 05-336) at the tube Fuel System Air Tubes (73-22-49, 05-300) and the clips Turbine Cooling Air (TCA) Controlled Air Tubes (75-23-48, 03-568) and Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 05-160) at tubes 37 and 38 to the bracket HPC Assembly (72-41-00, 03-850) at the clip position 6064 with the bolt Fuel System Air Tubes (73-22-49, 05-333), washer Fuel System Air Tubes (73-22-49, 05-334), spacer Fuel System Air Tubes (73-22-49, 05-338), spacer Fuel System Air Tubes (73-22-49, 05-337) and nut Fuel System Air Tubes (73-22-49, 05-340).

SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005), the clip Fuel System Air Tubes (73-22-49, 05-336) at the tube Fuel System Air Tubes (73-22-49, 05-300) and the clip Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 05-160) at tube 38 to the bracket HPC Assembly (72-41-00, 03-850) at the clip position 6064 with the bolt Fuel System Air Tubes (73-22-49, 05-333), washer Fuel System Air Tubes (73-22-49, 05-334), spacer Fuel System Air Tubes (73-22-49, 05-338), spacer Fuel System Air Tubes (73-22-49, 05-337) and nut Fuel System Air Tubes (73-22-49, 05-340).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) to the pressure regulator bleed valve Bleed Pressure Regulator Valve (36-11-52, 01-050).

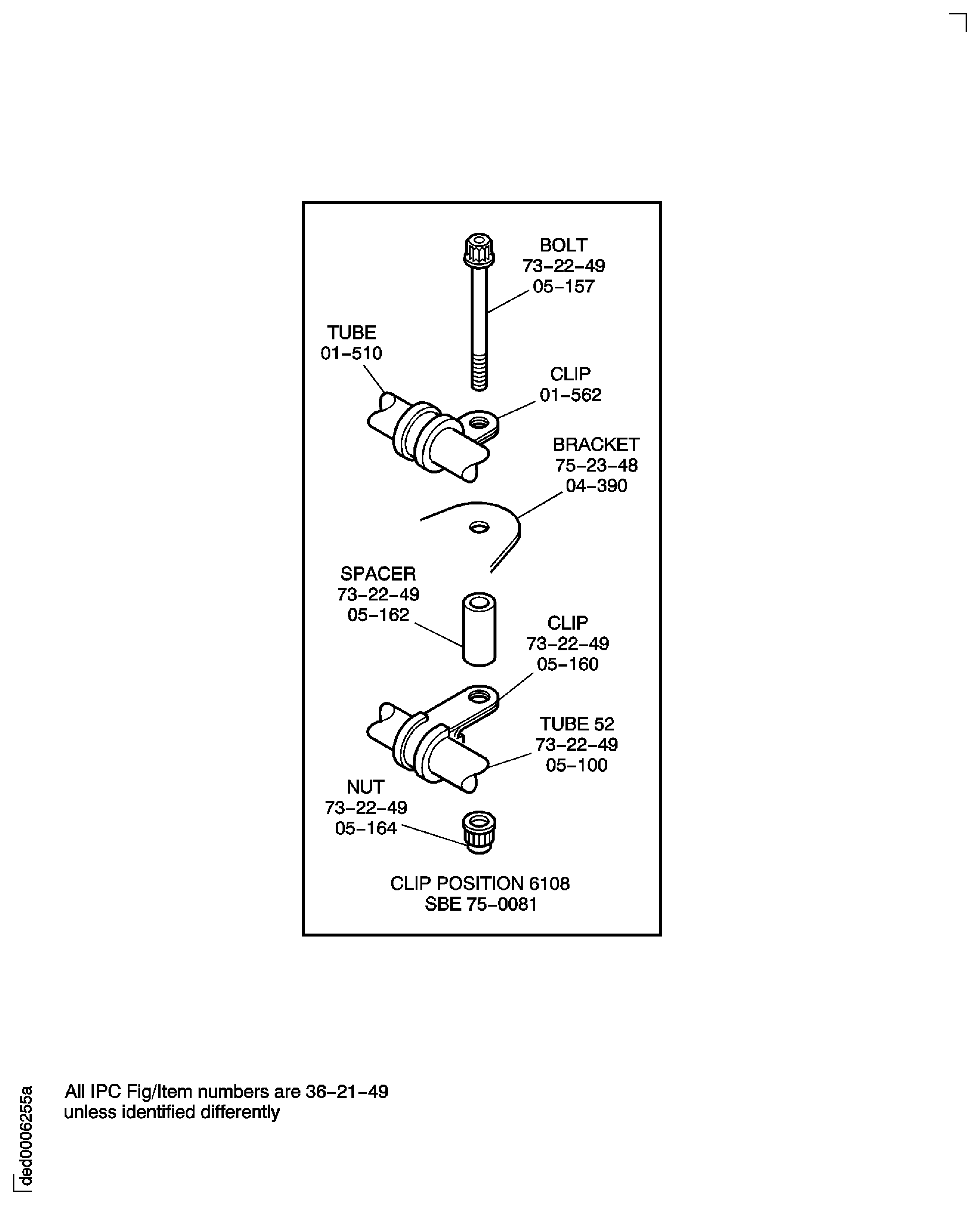

SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) with the clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-562) and the tube 52 Fuel System Air Tubes (73-22-49, 05-100) with the clip Fuel System Air Tubes (73-22-49, 05-160) to the bracket Turbine Cooling Air (TCA) Controlled Air Tubes (75-23-48, 04-390) at clip position 6108 with the bolt Fuel System Air Tubes (73-22-49, 05-157), the spacer Fuel System Air Tubes (73-22-49, 05-162) and the nut Fuel System Air Tubes (73-22-49, 05-164).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) to the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500) to the bracket HPC Module - Attaching Parts (72-40-00, 01-740) at clip position 5865 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-525), washer PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-531), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-529) and the nut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-532).

NOTE

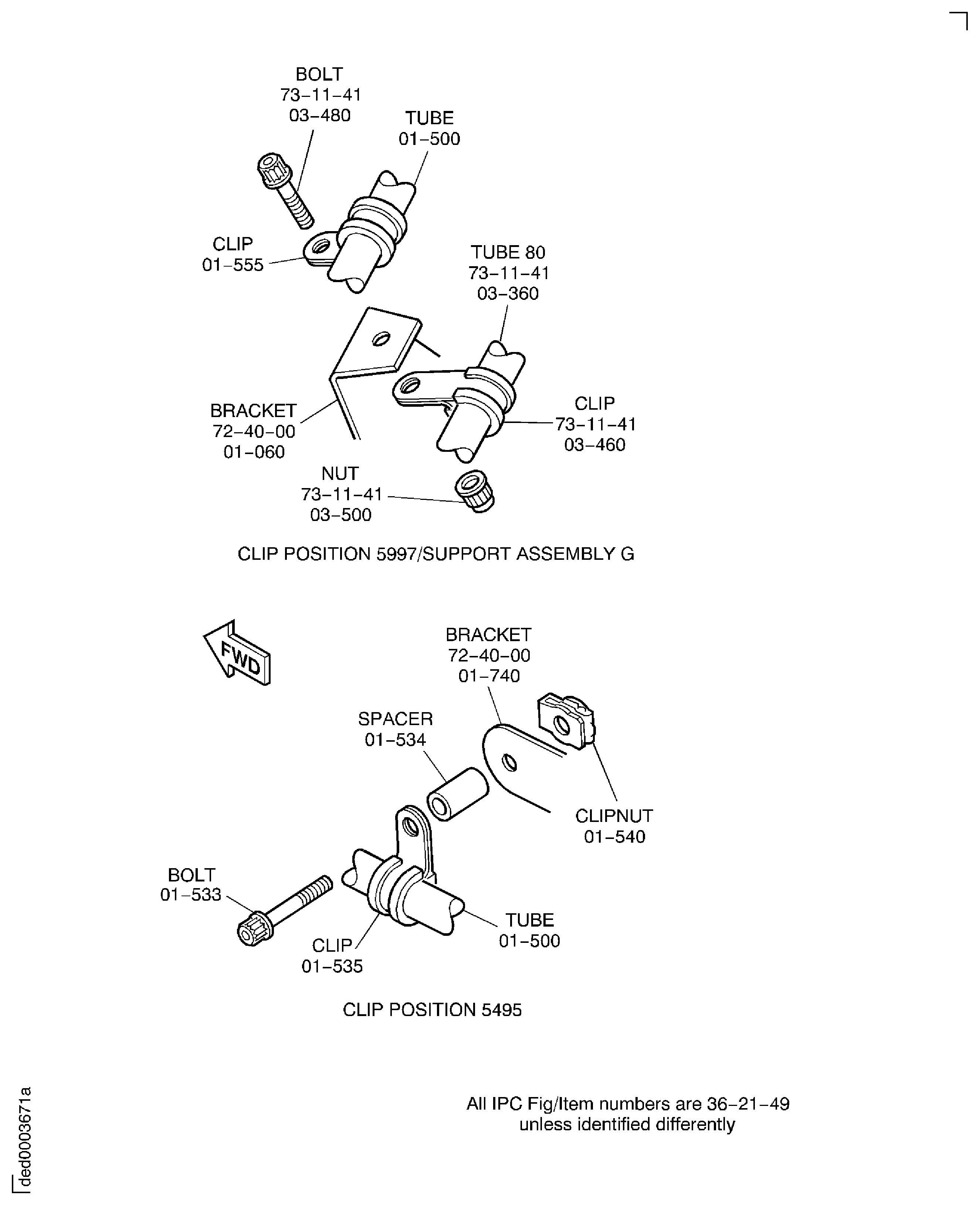

Refer to TASK 72-00-40-420-004 for the installation procedure for the tubes at support bracket G (clip position 5997).Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500), the clip Fuel Nozzle Supply Fuel Manifolds (73-11-41, 03-460) at the tube 80 at clip position 5997 to the bracket HPC Module - Attaching Parts (72-40-00, 01-060) with the bolt, clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-555) and the nut.

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500) to the bracket HPC Module - Attaching Parts (72-40-00, 01-740) at clip position 5495 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-532), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-535), spacer PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-534) and clipnut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-540).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) to the bracket HPC Module - Attaching Parts (72-40-00, 01-780) at clip position 5996 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-133), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-579) and clipnut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-140).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100) to the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500) and to the HP bleed valve PNEUMATIC-HP BLEED VALVE (36-11-51, 01-050).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100) to the bracket Engine Air Off-Take Air Ducts (75-00-49, 01-240) at clip position 5862 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-133), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-137) and the clipnut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-140).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100) to the bracket Engine Air Off-Take Air Ducts (75-00-49, 01-242) at clip position 5931 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-150), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-154) and the clipnut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-158).

Torque the tube nuts on the tubes PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-110) and PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100) to 135 to 145 lbf.in (15 to 16 Nm).

Torque the tube nuts on the tubes PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-700) and PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-725) to 135 to 145 lbf.in (15 to 16 Nm).

Install the cabin bleed air system sense tubes (36-21-49).

Torque the couplings installed in StepPNEUMATIC-IP BLEED AIR CHECK VALVE (36-11-41, 01-100), PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-310), PNEUMATIC-HP BLEED VALVE (36-11-51, 01-100), Bleed Pressure Regulator Valve (36-11-52, 01-100) to 75 to 85 lbf.in (8.5 to 9.6 Nm). Use a soft faced hammer and tap around the outside of the couplings.

Keep the coupling PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-110) for installation of the cabin bleed air duct on the pylon.

NOTE

Refer to SPM TASK 70-47-01-470-501 for the procedure to install v-band couplings.Torque the cabin bleed air system duct couplings.

SUBTASK 71-00-02-420-048-A00 Install the Cabin Bleed Air System Sense Tubes (Pre SBN 70-0468, Pre SBE 36-0007, Pre SBE 75-0081, SBE 75-0081 and SBN 71-0273)

Apply CoMat 10-130 ANTIGALLING COMPOUND to one of the mating thread surfaces of the pressure sense tubes, hoses and union before you connect the components, as follows:

Cabin Bleed Air System Sense Tubes

IPC Fig./item

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-200)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-700)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-725)

NOTE

Refer to SPM TASK 70-41-02-400-501 for the torque loading procedures.Do not tighten or torque the tube nuts or attaching parts until all the tubes are installed in their correct position.

Install the K seal PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-655) and the union PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-650) in the duct PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-300). Torque the union to 168 to 181 lbf.in (19 to 20.50 Nm).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) to the union PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-650).

Connect the hose PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-700) to the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) and the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-725).

Attach the hose PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-200) to the tube connected to the pressure regulator bleed valve Bleed Pressure Regulator Valve (36-11-52, 01-050).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) and the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005) to the lug at the tube 38 at clip position 5923 with the bolt, spacer PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-562), spacer and the nut.

Pre SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005), the clip Fuel System Air Tubes (73-22-49, 05-336) at the tube Fuel System Air Tubes (73-22-49, 05-300) and the clips Turbine Cooling Air (TCA) Controlled Air Tubes (75-23-48, 03-568) and Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 05-160) at tubes 37 and 38 to the bracket HPC Assembly (72-41-00, 03-850) at the clip position 6064 with the bolt Fuel System Air Tubes (73-22-49, 05-333), washer Fuel System Air Tubes (73-22-49, 05-334), spacer Fuel System Air Tubes (73-22-49, 05-338), spacer Fuel System Air Tubes (73-22-49,05-337) and nut Fuel System Air Tubes (73-22-49, 05-340).

SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005), the clip Fuel System Air Tubes (73-22-49, 05-336) at the tube Fuel System Air Tubes (73-22-49, 05-300) and the clip Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 05-160) at tube 38 to the bracket HPC Assembly (72-41-00, 03-850) at the clip position 6064 with the bolt Fuel System Air Tubes (73-22-49, 05-333), washer Fuel System Air Tubes (73-22-49, 05-334), spacer Fuel System Air Tubes (73-22-49, 05-338), spacer Fuel System Air Tubes (73-22-49, 05-337) and nut Fuel System Air Tubes (73-22-49, 05-340).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) to the pressure regulator bleed valve Bleed Pressure Regulator Valve (36-11-52, 01-050).

Pre SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) with the clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-560) and the tube 52 Fuel System Air Tubes (73-22-49, 05-100) with the clip Fuel System Air Tubes (73-22-49, 05-128) to the bracket AIR-STAGE 10 TO HPT AIR VALVE (75-23-51, 01-010) at clip position 5433 with the bolt Fuel System Air Tubes (73-22-49, 05-125), washer Fuel System Air Tubes (73-22-49, 05-126) and the clipnut Fuel System Air Tubes (73-22-49, 05-132).

SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) with the clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-562) and the tube 52 Fuel System Air Tubes (73-22-49, 05-100) with the clip Fuel System Air Tubes (73-22-49, 05-160) to the bracket Turbine Cooling Air (TCA) Controlled Air Tubes (75-23-48, 04-390) at clip position 6108 with the bolt Fuel System Air Tubes (73-22-49, 05-157), the spacer Fuel System Air Tubes (73-22-49, 05-162) and the nut Fuel System Air Tubes (73-22-49, 05-164).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) to the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500) to the bracket HPC Module - Attaching Parts (72-40-00, 01-740) at clip position 5865 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-525), washer PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-531), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-529) and the nut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-532).

NOTE

Refer to TASK 72-00-40-420-004 for the installation procedure for the tubes at support bracket G (clip position 5997).Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500), the clip Fuel Nozzle Supply Fuel Manifolds (73-11-41, 03-460) at the tube 80 at clip position 5997 to the bracket HPC Module - Attaching Parts (72-40-00, 01-060) with the bolt, clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-555) and the nut.

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500) to the bracket HPC Module - Attaching Parts (72-40-00, 01-740) at clip position 5495 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-532), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-535), spacer PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-534) and clipnut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-540).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) to the bracket HPC Module - Attaching Parts (72-40-00, 01-780) at clip position 5996 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-133), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-579) and clipnut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-140).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100) to the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500) and to the HP bleed valve PNEUMATIC-HP BLEED VALVE (36-11-51, 01-050).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100) to the bracket Engine Air Off-Take Air Ducts (75-00-49, 01-240) at clip position 5862 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-133), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-137) and the clipnut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-140).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100) to the bracket Engine Air Off-Take Air Ducts (75-00-49, 01-242) at clip position 5931 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-150), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-154) and the clipnut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-158).

Torque the tube nuts on the tubes PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500, PNEUMATIC-PRESSURE INDICATING TUBES 36-21-49, 02-110 and PNEUMATIC-PRESSURE INDICATING TUBES 36-21-49, 01-100) to 135 to 145 lbf.in (15 to 16 Nm).

Torque the tube nuts on the tubes PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-700) and PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-725) to 135 to 145 lbf.in (15 to 16 Nm).

Install the cabin bleed air system sense tubes (36-21-49).

Torque the couplings installed in StepPNEUMATIC-IP BLEED AIR CHECK VALVE (36-11-41, 01-100), PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-310), PNEUMATIC-HP BLEED VALVE (36-11-51, 01-100), Bleed Pressure Regulator Valve (36-11-52, 01-100) to 75 to 85 lbf.in (8.5 to 9.6 Nm). Use a soft faced hammer and tap around the outside of the couplings.

Keep the coupling PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-110) for installation of the cabin bleed air duct on the pylon.

NOTE

Refer to SPM TASK 70-47-01-470-501 for the procedure to install v-band couplings.Torque the cabin bleed air system duct couplings.

SUBTASK 71-00-02-420-048-B00 Install the Cabin Bleed Air System Sense Tubes (SBN 70-0468, Pre SBE 36-0007, Pre SBE 75-0081, SBE 75-0081 and SBN 71-0273)

Apply CoMat 10-130 ANTIGALLING COMPOUND to one of the mating thread surfaces of the pressure sense tubes, hoses and union before you connect the components, as follows:

NOTE

Refer to SPM TASK 70-41-02-400-501 for the torque loading procedures.Cabin Bleed Air System Sense Tubes

IPC Fig./item

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-200)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-700)

PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-725)

Do not tighten or torque the tube nuts or attaching parts until all the tubes are installed in their correct position.

Install the K seal PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-655) and the union PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-650) in the duct PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-300). Torque the union to 168 to 181 lbf.in (19 to 20.50 Nm).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) to the union PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-650).

Connect the hose PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-700) to the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) and the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-725).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) and the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005) to the lug at the tube 38 at clip position 5923 with the bolt, spacer PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-562), spacer and the nut.

Pre SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005), the clip Fuel System Air Tubes (73-22-49, 05-336) at the tube Fuel System Air Tubes (73-22-49, 05-300) and the clips Turbine Cooling Air (TCA) Controlled Air Tubes (75-23-48, 03-568) and Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 05-160) at tubes 37 and 38 to the bracket HPC Assembly (72-41-00, 03-850) at the clip position 6064 with the bolt Fuel System Air Tubes (73-22-49, 05-333), washer Fuel System Air Tubes (73-22-49, 05-334), spacer Fuel System Air Tubes (73-22-49, 05-338), spacer Fuel System Air Tubes (73-22-49, 05-337) and nut Fuel System Air Tubes (73-22-49, 05-340).

SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005), the clip Fuel System Air Tubes (73-22-49, 05-336) at the tube Fuel System Air Tubes (73-22-49, 05-300) and the clip Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 05-160) at tube 38 to the bracket HPC Assembly (72-41-00, 03-850) at the clip position 6064 with the bolt Fuel System Air Tubes (73-22-49, 05-333), washer Fuel System Air Tubes (73-22-49, 05-334), spacer Fuel System Air Tubes (73-22-49, 05-338), spacer Fuel System Air Tubes (73-22-49, 05-337) and nut Fuel System Air Tubes (73-22-49, 05-340).

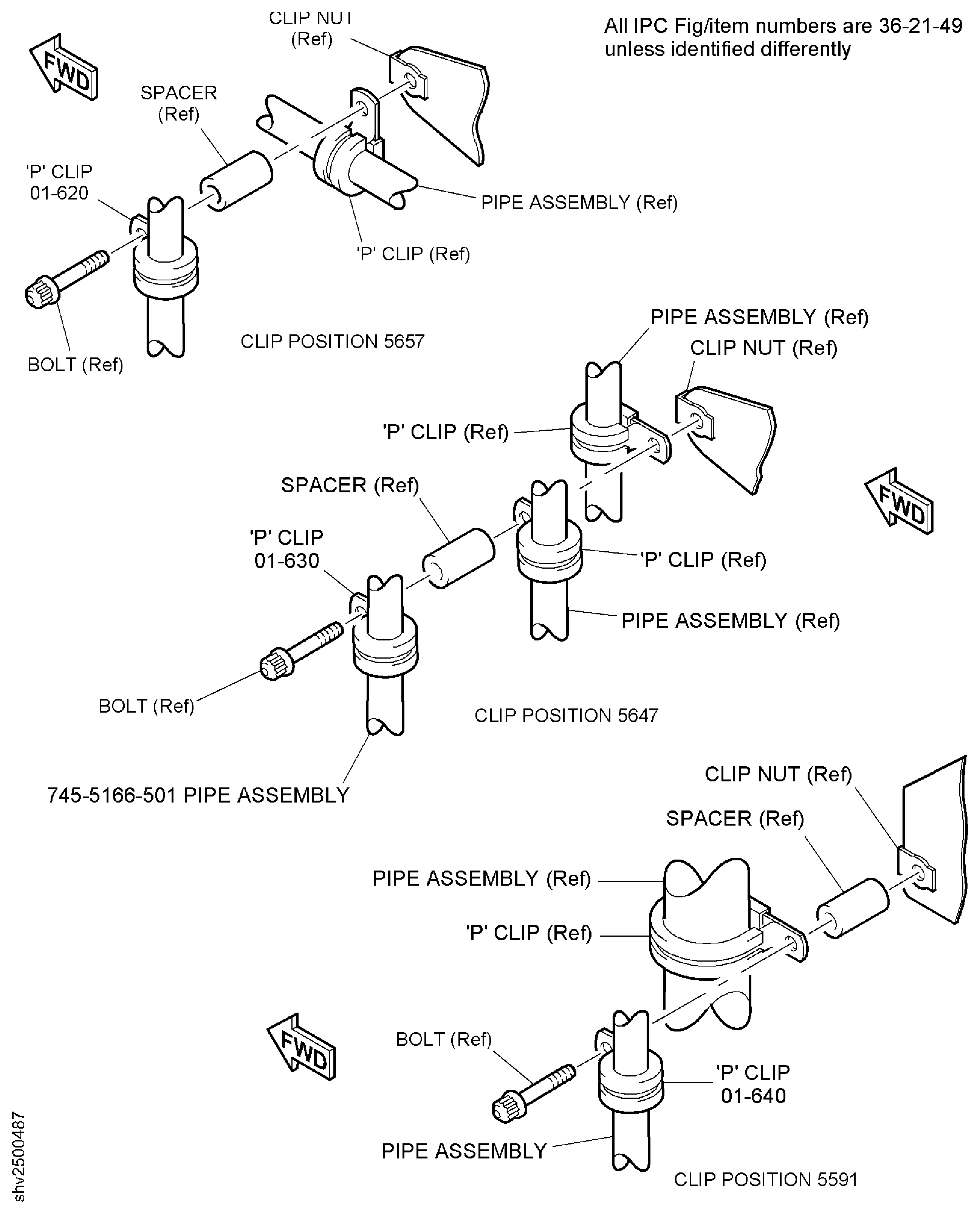

Attach the tube assembly PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-600), and the clip Fuel System Air Tubes (73-22-49, 05-944) at the raceway Fuel System Air Tubes (73-22-49, 05-900) to the bracket HPC Assembly (72-41-00, 03-720) at clip position 5657 with the bolt Fuel System Air Tubes (73-22-49, 05-941), washer Fuel System Air Tubes (73-22-49, 05-942), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-620), spacer Fuel System Air Tubes (73-22-49, 05-946) and clipnut Fuel System Air Tubes (73-22-49, 05-948).

Attach the tube assembly PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-600), the clip Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 05-544) at tube 69 Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 05-500) and the clip Fuel System Air Tubes (73-22-49, 05-560) at tube 53 Fuel System Air Tubes (73-22-49, 05-500) to the bracket HPC Assembly (72-41-00, 03-550) at clip position 5647 with the bolt Fuel System Air Tubes (73-22-49, 05-557), washer Fuel System Air Tubes (73-22-49, 05-558), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-630), spacer Fuel System Air Tubes (73-22-49, 05-563) and clipnut Fuel System Air Tubes (73-22-49, 05-564).

Attach the tube assembly PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-600), the clip OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 14-144) at tube 21 OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 14-100) to the bracket HPC Assembly (72-41-00, 03-530) at clip position 5591 with the bolt OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 14-141), washer OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 14-142), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-640), spacer OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 14-146) and clipnut OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 14-148).

Torque the tube nuts on the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-600) to 135-145 lbf.in (15-16 Nm).

Torque the tube nuts on the tubes PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-700) and PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-725) to 135 to 145 lbf.in (15 to 16 Nm).

Install the cabin bleed air system sense tubes (36-21-49).

Torque the couplings installed in StepPNEUMATIC-IP BLEED AIR CHECK VALVE (36-11-41, 01-100), PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-310), PNEUMATIC-HP BLEED VALVE (36-11-51, 01-100), Bleed Pressure Regulator Valve (36-11-52, 01-100) to 75 to 85 lbf.in (8.5 to 9.6 Nm). Use a soft faced hammer and tap around the outside of the couplings.

Keep the coupling PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-110) for installation of the cabin bleed air duct on the pylon.

NOTE

Refer to SPM TASK 70-47-01-470-501 for the procedure to install v-band couplings.Torque the cabin bleed air system duct couplings.

SUBTASK 71-00-02-420-048-C00 Install the Cabin Bleed Air System Sense Tubes (Pre SBE 75-0081, SBE 75-0081 and SBE 36-0007)

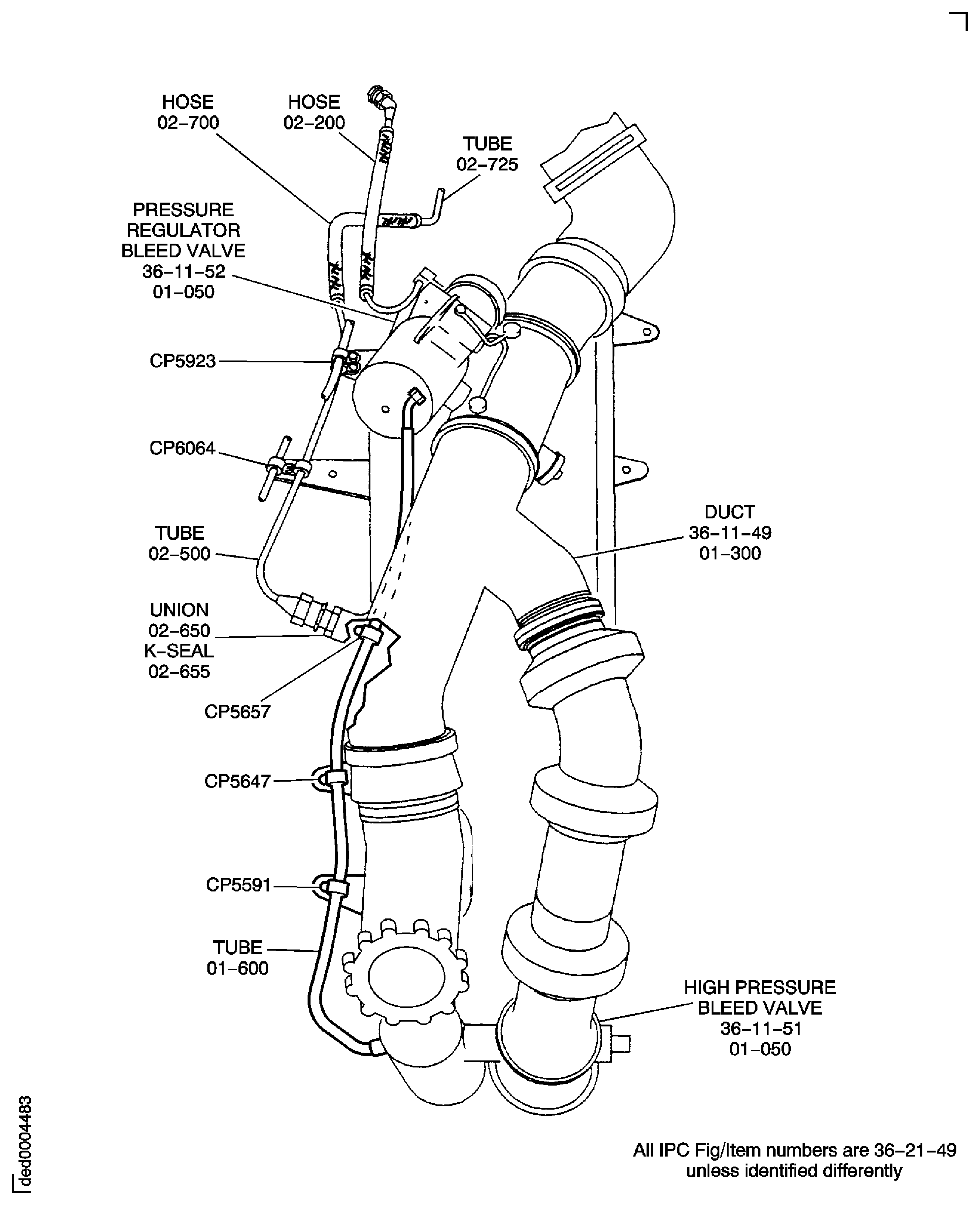

Figure: Install the Cabin Bleed Air System Ducts and the Valves

Sheet 1

Figure: Install the Cabin Bleed Air System Ducts and the Valves

Sheet 2

Figure: Pre SBE 75-0081, Pre SBE 36-0007 and SBN 71-0273: Install the Cabin Bleed Air System Sense Tubes

Sheet 1

Figure: SBE 36-0007: Install the Cabin Bleed Air System Sense Tubes

Sheet 2

Figure: Install the Cabin Bleed Air System Sense Tubes

Sheet 3

Figure: Pre SBE 36-0007, Pre SBE 75-0081: Install the Cabin Bleed Air System Sense Tubes

Sheet 4

Figure: SBE 75-0081: Install the Cabin Bleed Air System Sense Tubes

Sheet 5

Figure: Pre SBE 36-0007: Install the Cabin Bleed Air System Sense Tubes

Sheet 6

Figure: Pre SBE 36-0007, SBN 71-0273: Install the Cabin Bleed Air System Sense Tubes

Sheet 7