Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5 and Post SBE 75-0081

Common Information

TASK 72-00-32-020-002-C00 LPC/Intermediate Case Module - Remove The Electrical Harnesses, Removal-002 - SBE 75-0081

General

SBE 75-0081: Air - Stage 10 to HPT air valve - Deletion of the HPC stage 10 make-up air valve and associated hardware. Refer to the TASKS which follow for the other related procedures.

TASK 72-00-32-020-001-B00 (REMOVAL-001, CONFIG-002) remove the hydraulic tubes, the thermal anti-ice (TAI) duct and the pneumatic starter duct from the LP compressor/intermediate case module

TASK 72-00-32-020-003-B00 (REMOVAL-003, CONFIG-002) remove the LP compressor/intermediate case tubes and the electrical harness raceways

TASK 72-00-32-020-004 remove the LP compressor/intermediate case components

TASK 72-00-32-020-005 (REMOVAL-005, CONFIG-002) remove the LP compressor/intermediate case brackets and the bifurcation panel

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Remove and discard the lockwire before the component is disconnected.

Apply the approved CoMat 10-058 PENETRATING OIL before the removal of threaded parts. Let the parts soak before removal.

During the removal procedure make sure that the harnesses are held temporarily along their different lengths. This is to prevent too much strain on the harnesses, cables and electrical connectors.

During the removal procedure put the special plastic caps on the electrical connectors and receptacles. This is to give protection from unwanted fluids or materials.

During the removal procedure remove the lacing tape which attaches the different harnesses to each other.

Seal all openings when the tubes or components are disconnected to prevent contamination from unwanted material.

All the tubes, hoses and ducts removed in this procedure must have their maintenance completed, as given in the Component Maintenance Manual (CMM-THD-V2500-1IA).

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1R19416 EEC harness wrench | 0AM53 | IAE 1R19416 | 1 | |

| IAE 1J12018 EEC harness wrench | 0AM53 | IAE 1J12018 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 06-086 TIES | 18992 | CoMat 06-086 | ||

| CoMat 10-058 PENETRATING OIL | 0AM53 | CoMat 10-058 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

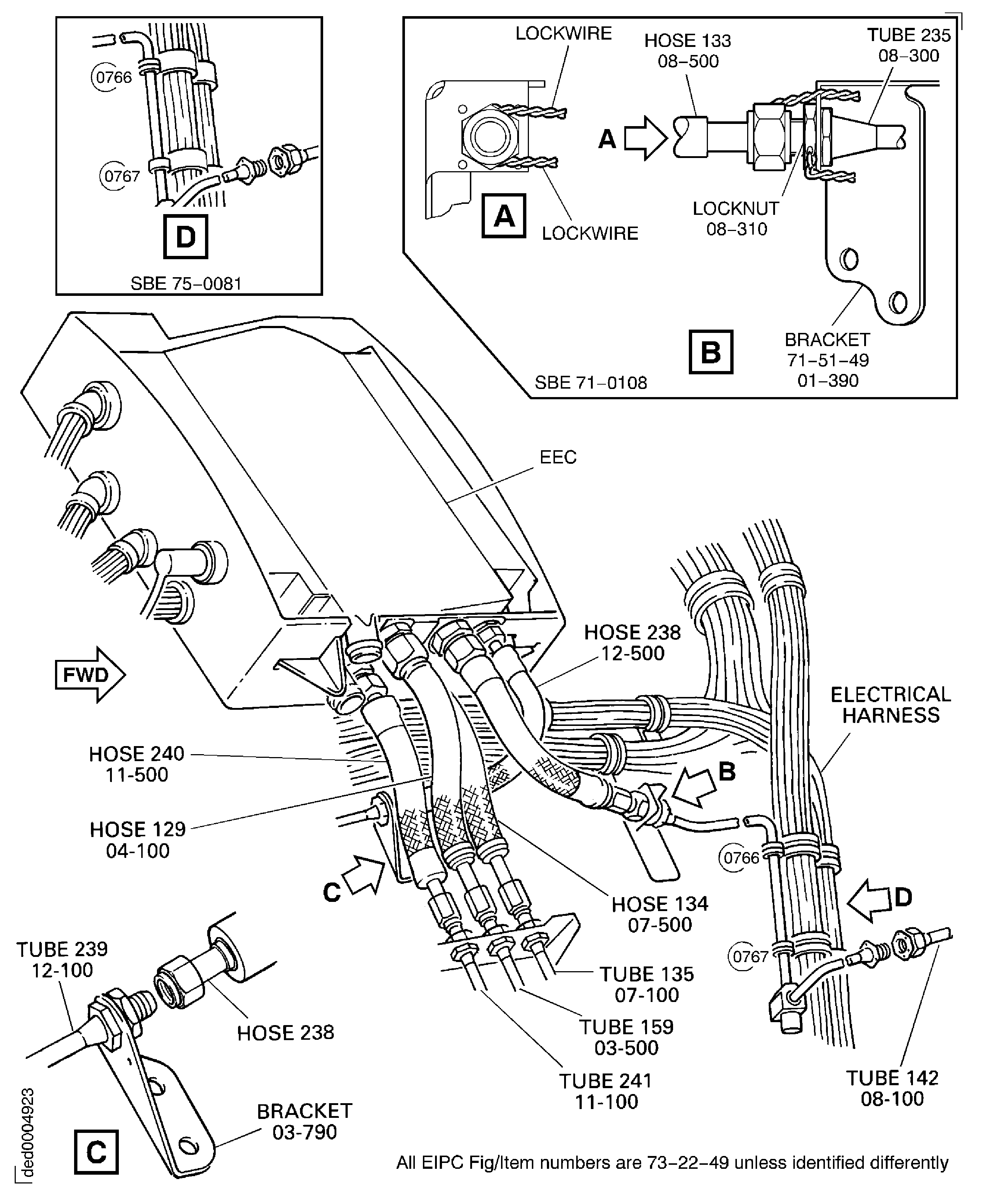

SUBTASK 72-00-32-020-246 Remove the EEC Flexible Hoses and the Tube 235

Refer to: Figure

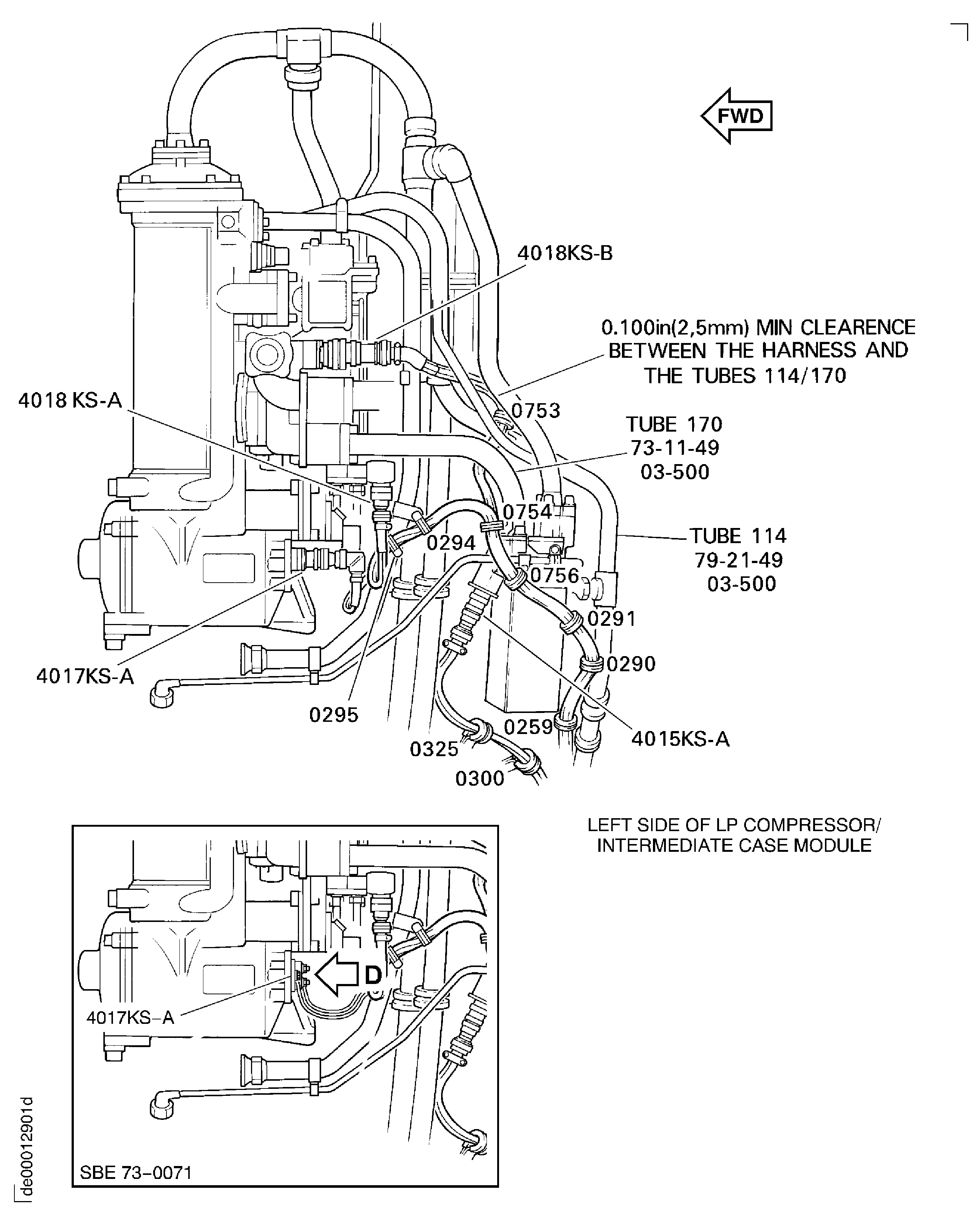

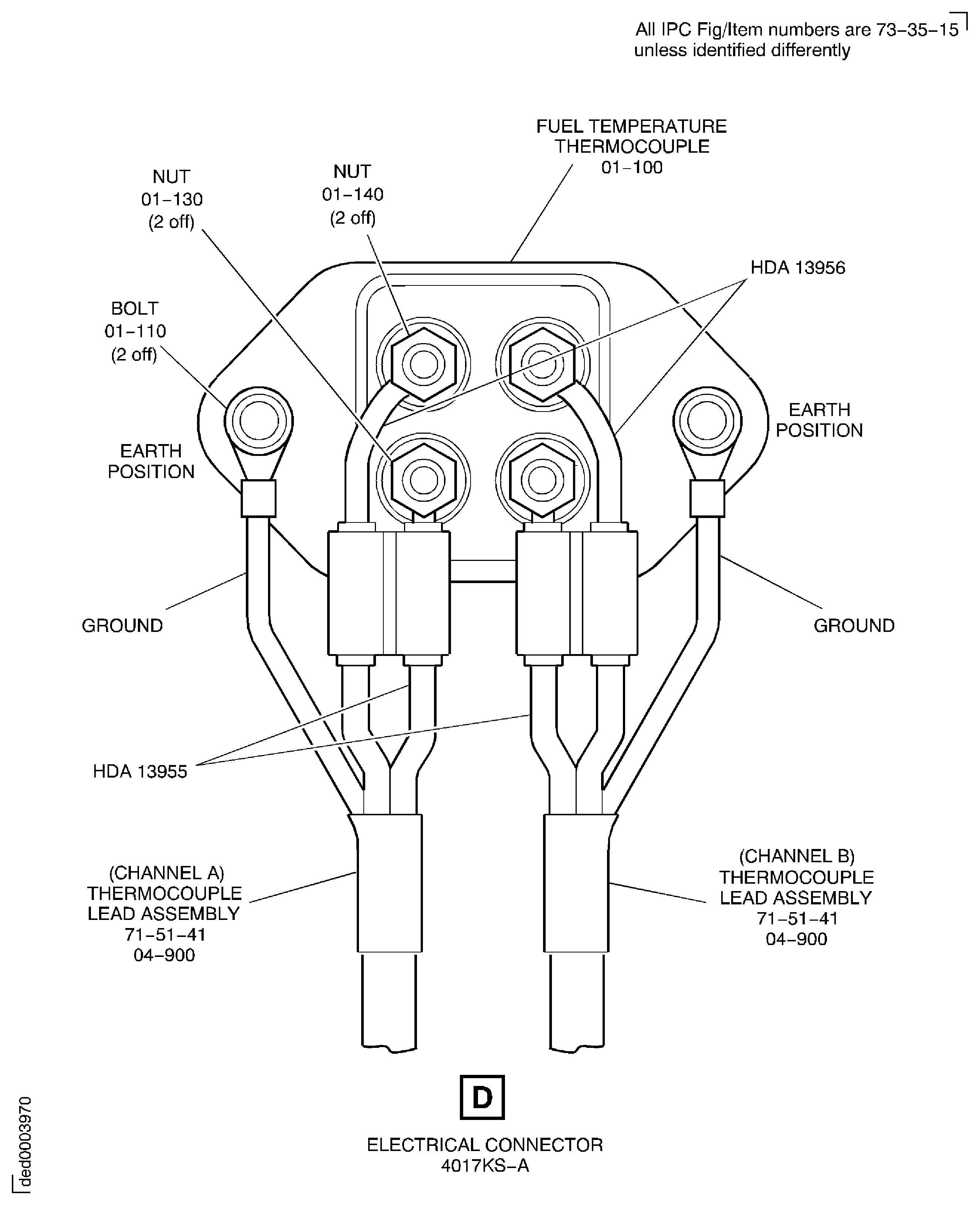

Disconnect the 4017KS-A from the fuel temperature thermocouple FUEL TEMPERATURE THERMOCOUPLE (73-35-15, 01-100).

SUBTASK 72-00-32-020-247-A00 Disconnect the EEC Harness Connector 4017KS-A (Pre SBE 73-0071 and Pre SBE 71-0183)

Remove the four nuts FUEL TEMPERATURE THERMOCOUPLE (73-35-15, 01-130 and FUEL TEMPERATURE THERMOCOUPLE 01-140) and disconnect the thermocouple harness from the thermocouple FUEL TEMPERATURE THERMOCOUPLE (73-35-15, 01-100).

Remove the two bolts FUEL TEMPERATURE THERMOCOUPLE (73-35-15, 01-110) that secure the thermocouple. Disconnect the harness ground connectors and refit the bolts.

Disconnect the terminal connectors from the FCOC fuel temperature thermocouple. Refer to Figure.

SUBTASK 72-00-32-020-247-B00 Disconnect the EEC Harness Terminal Connector 4017KS-A (SBE 73-0071 and SBE 71-0183)

NOTE

Remove the ignition supply harness with the EEC harness. Refer to SUBTASK 72-00-32-020-196.Disconnect the EEC harness EEC Fan Harness (71-51-41, 01-005) from the LP compressor/intermediate case module as follows:

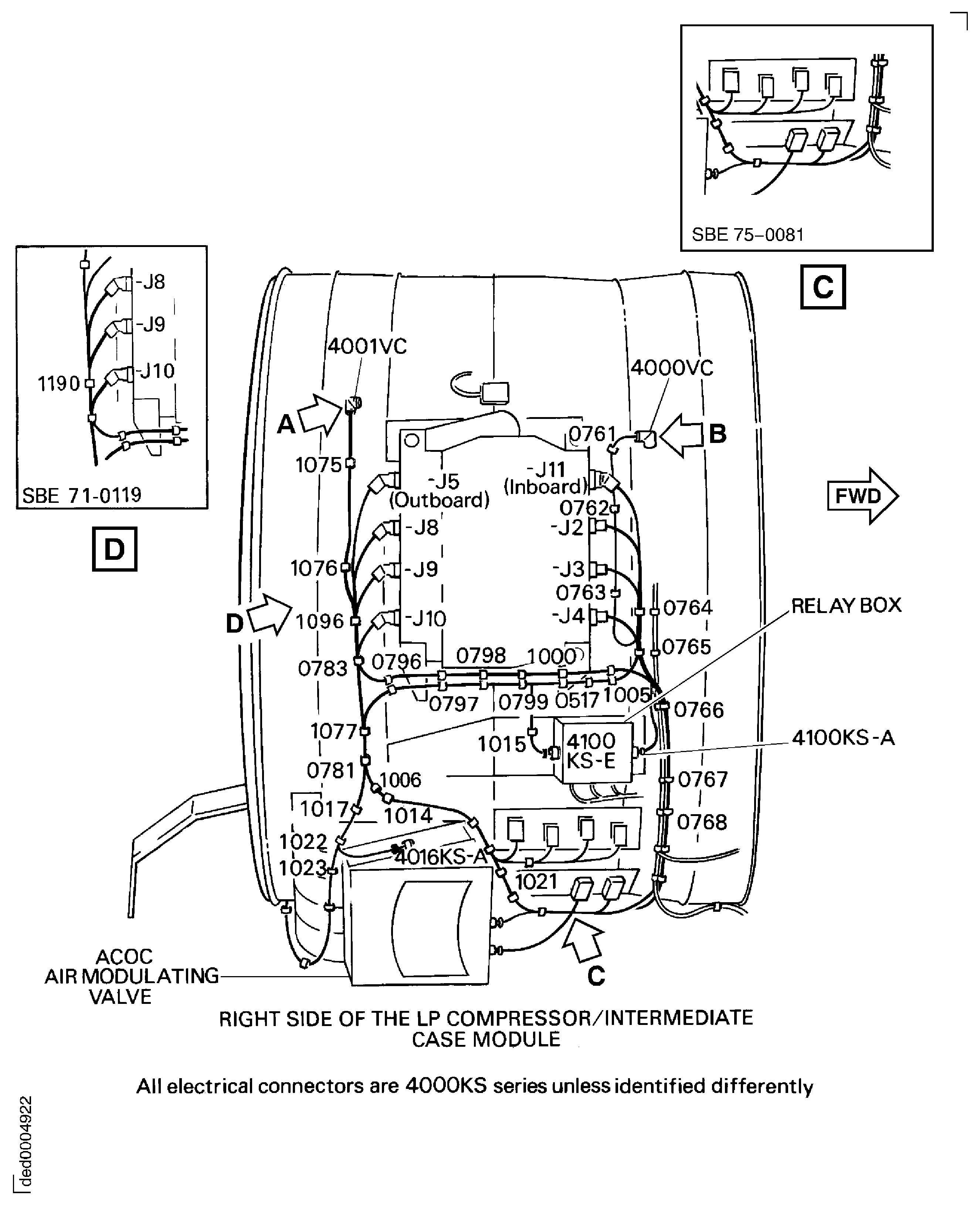

Disconnect the electrical connectors as follows:

4000KS-J2 to 4000KS-J5 and 4000KS-J8 to 4000KS-J11 from the EEC with the (IAE 1R19416 EEC harness wrench) 1 off.

4100KS-E and 4100KS-A from the relay box.

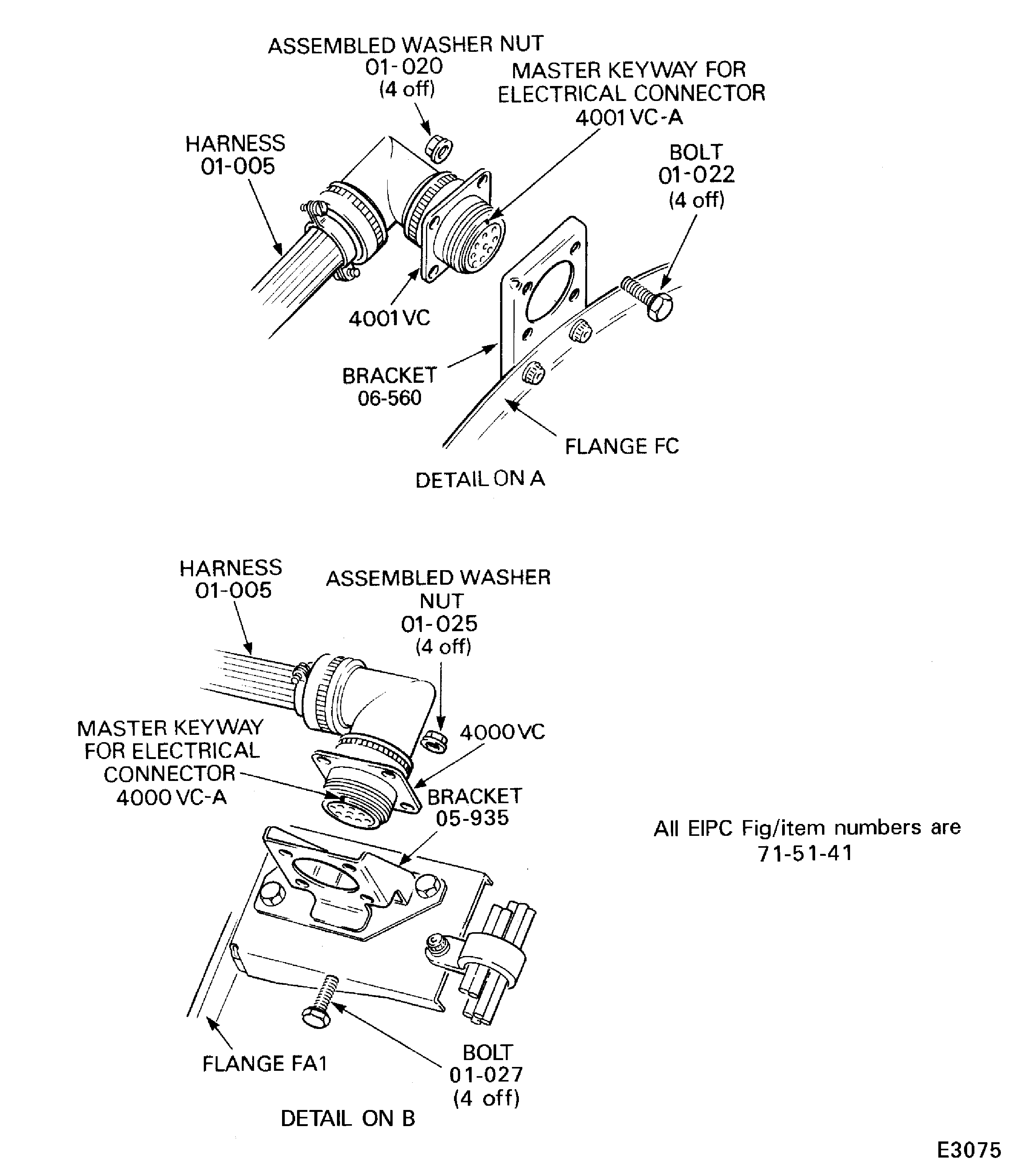

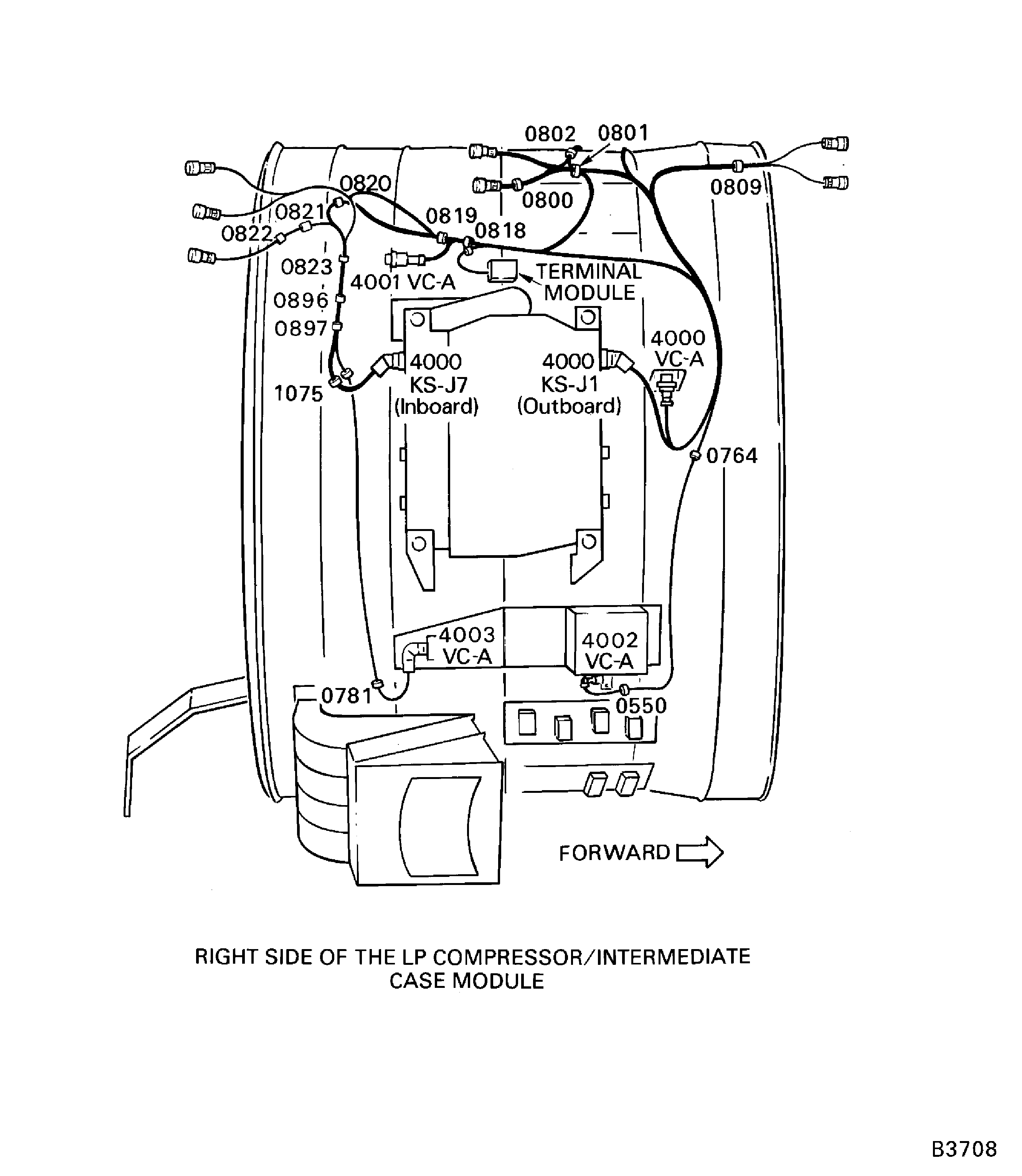

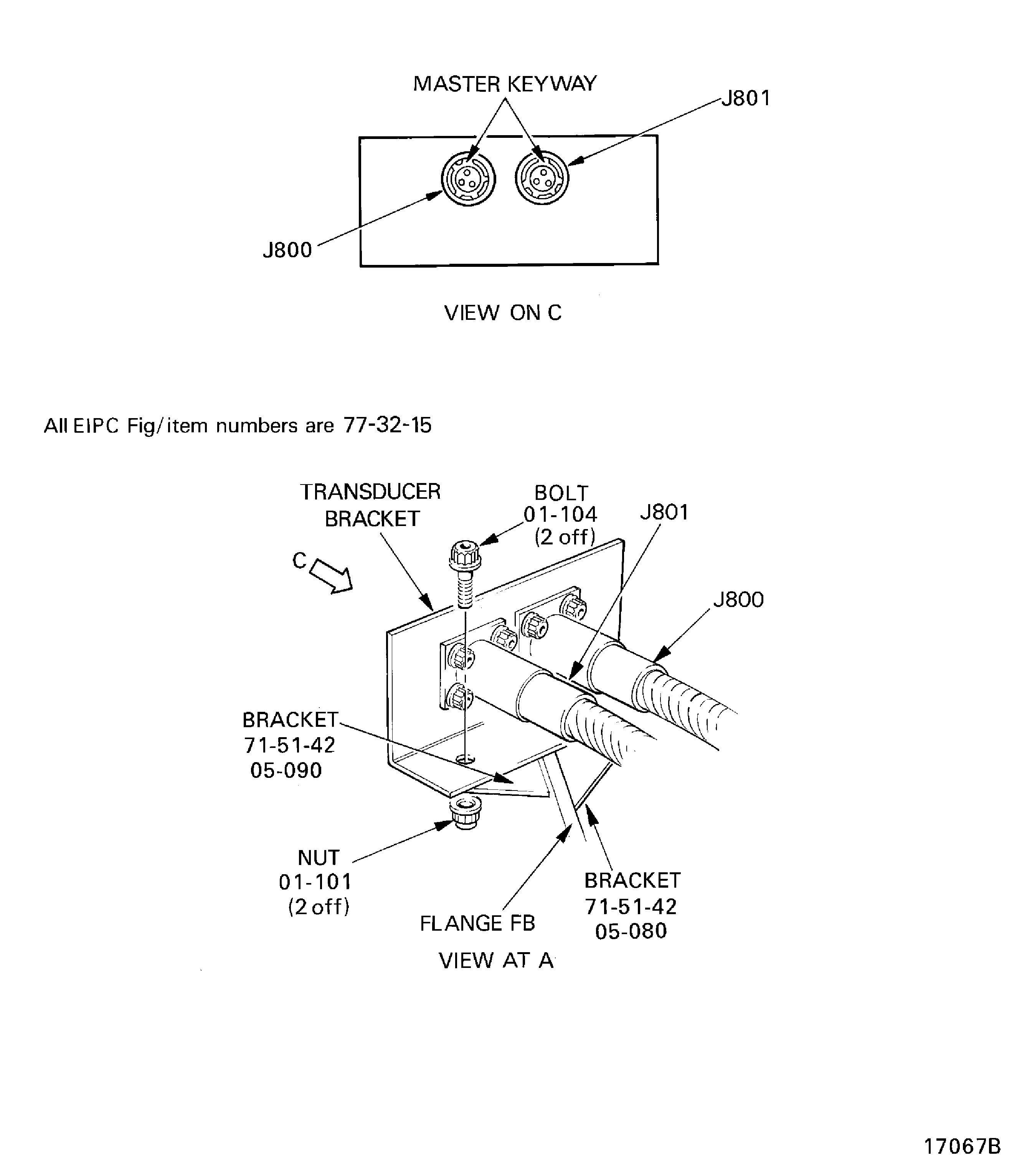

4000VC-A and 4001VC-A EEC Fan Harness And Ignition Supply Harness (71-51-42, 01-005) from the electrical harness receptacles attached to the flange brackets, refer to Figure.

4016KS-A from the ACOC oil temperature thermocouple.

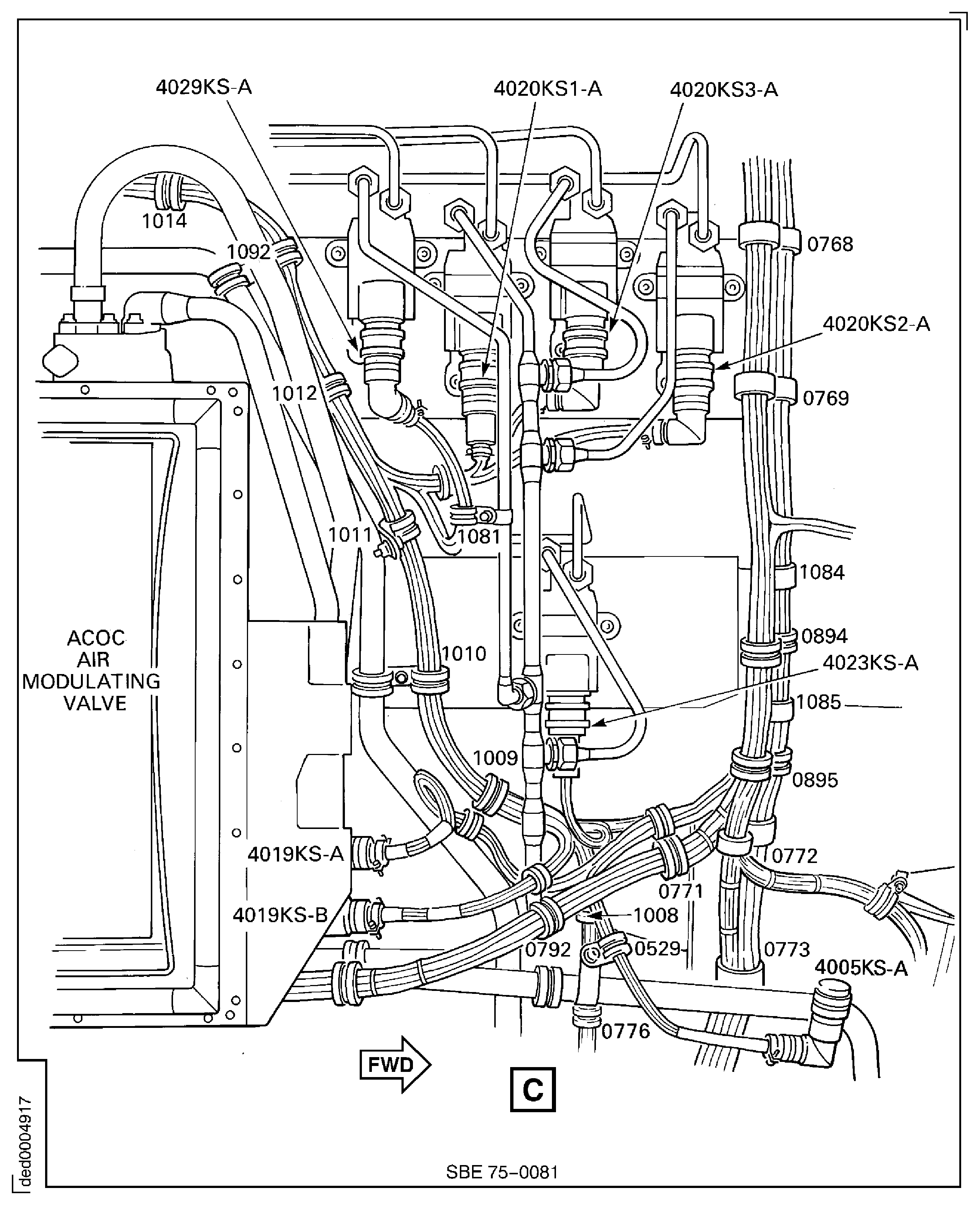

4020KS2-A from the HP compressor stage 7 solenoid valve (108.8 degrees).

4020KS3-A from the HP compressor stage 7 solenoid valve (228 degrees).

4020KS1-A from the HP compressor stage 7 solenoid valve (51.9 degrees).

4029KS-A from the HP stage 7 and 10 air solenoid valve STAGE 10 AIR SOLENOID VALVE (36-11-57, 01-100).

4023KS-A from the HP compressor stage 10 solenoid valve AIR-HPC STAGE 10 SOLENOID VALVE (75-32-53, 01-400).

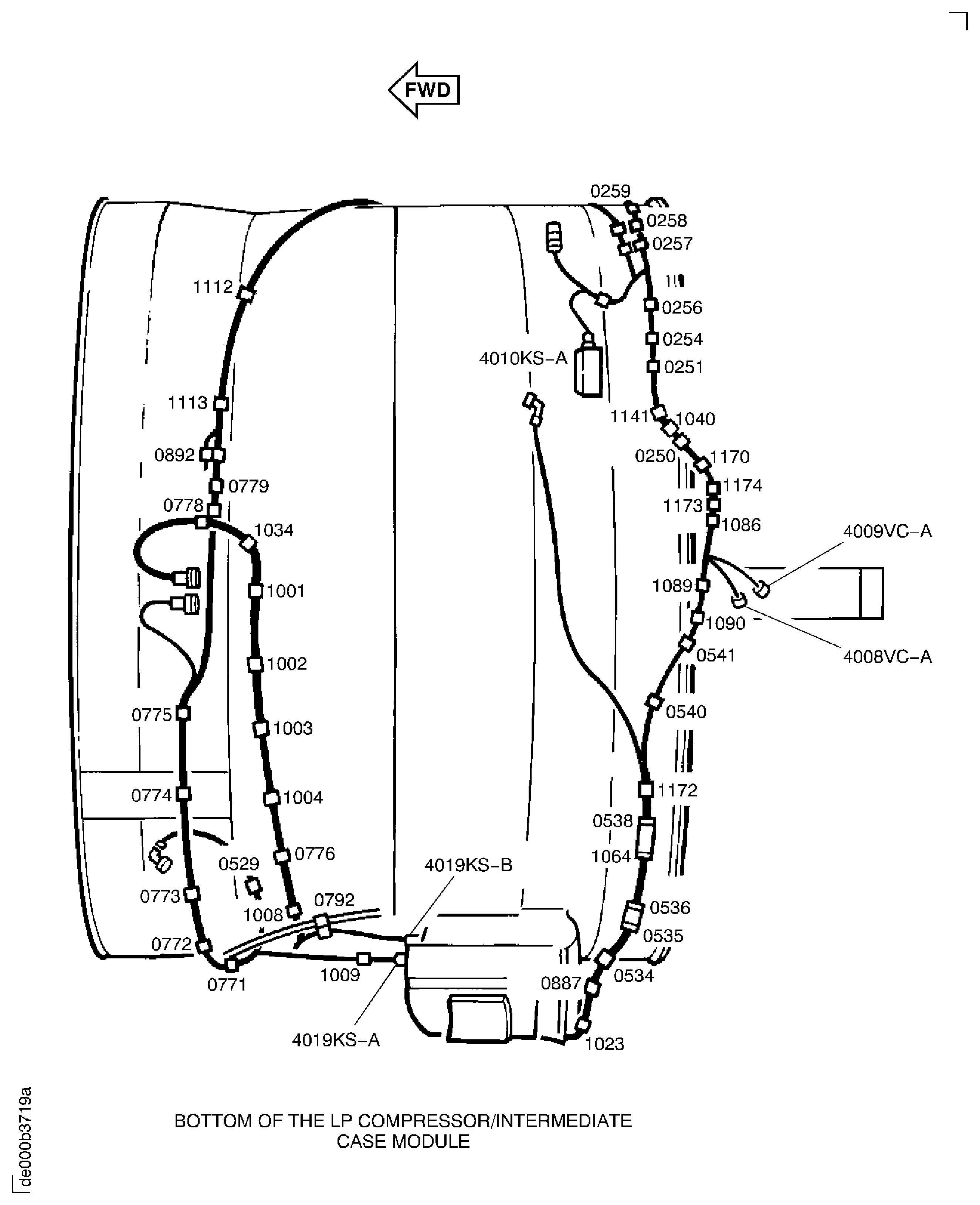

4019KS-A and 4019KS-B from the ACOC air modulating valve.

4010KS-A from the fuel flow transmitter.

4015KS-A from the IDG FCOC.

4018KS-A from the fuel diverter and return valve.

4018KS-B from the fuel diverter and return valve.

Remove the four bolts and the four assembled washer nuts which attach the receptacle 4001VC to the bracket. Refer to the detail on A, Figure.

Remove the two bolts and the two nuts which attach the tube 153 to the bifurcation panel, Figure.

NOTE

During this procedure do not disconnect the electrical harness receptacles from the LP compressor/intermediate case EEC harness.Disconnect the electrical harness receptacles.

SUBTASK 72-00-32-020-248 Remove the EEC Harness

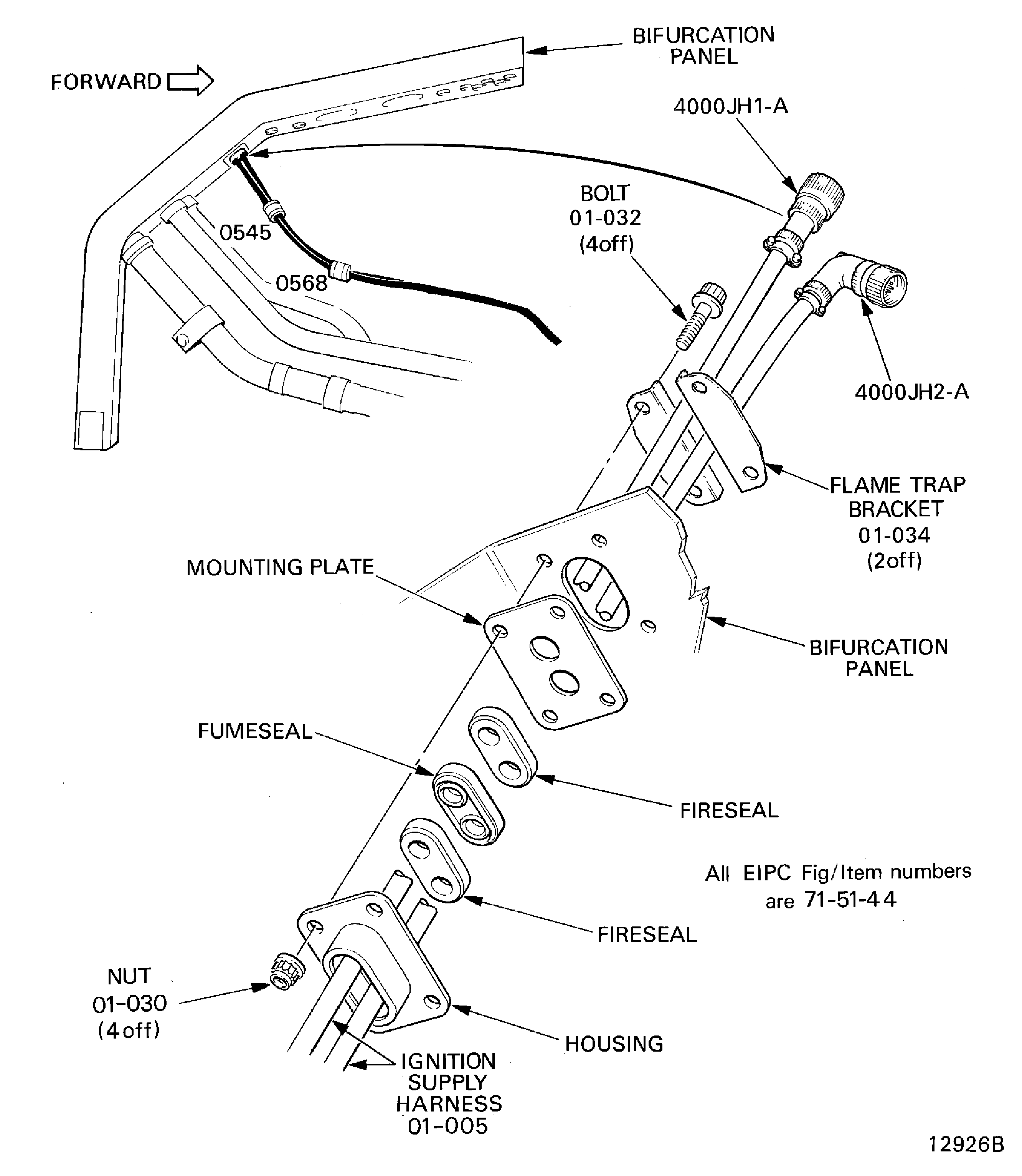

Disconnect the ignition supply harness Ignition Supply Harness (71-51-44, 01-005) as follows:

Disconnect the electrical connectors as follows:

4100KS-D and 4100KS-C from the relay box.

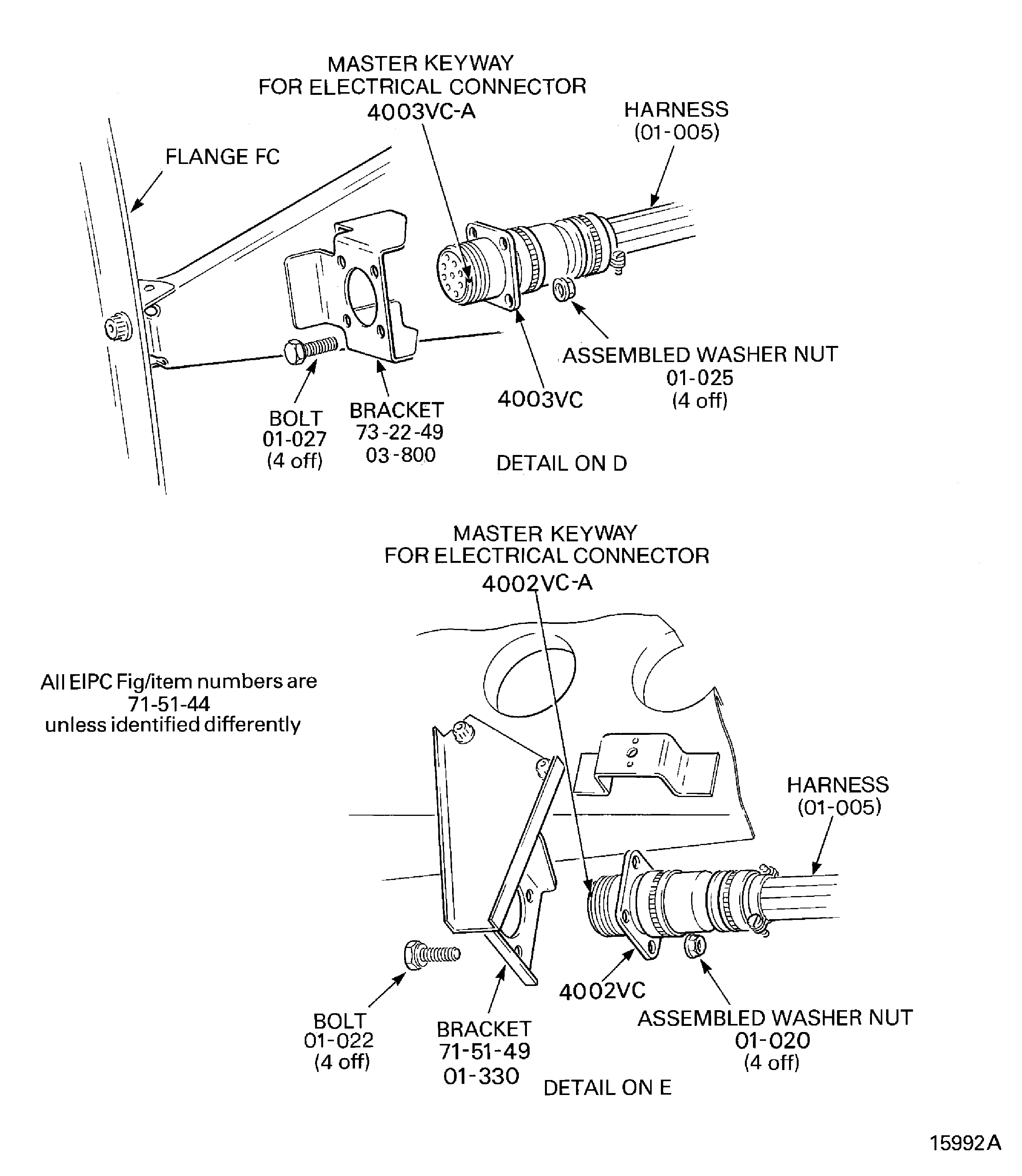

4002VC-A and 4003VC-A EEC Fan Harness And Ignition Supply Harness (71-51-42, 01-005) from the electrical harness receptacles attached to the brackets, refer to Figure.

Remove the four bolts and the four assembled washer nuts which attach the receptacle 4003VC to the bracket. Refer to the detail on D, Figure.

NOTE

During this procedure do not disconnect the electrical harness receptacles from the ignition supply harness.Disconnect the electrical harness receptacles.

Remove the four nuts, the four bolts and the two flame trap brackets which attach the combined fume and fireseal to the bifurcation panel. Remove the core engine part of the harness through the bifurcation panel. Safety the different parts of the combined fume and fireseal together with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-020-249 Remove the Ignition Supply Harness

NOTE

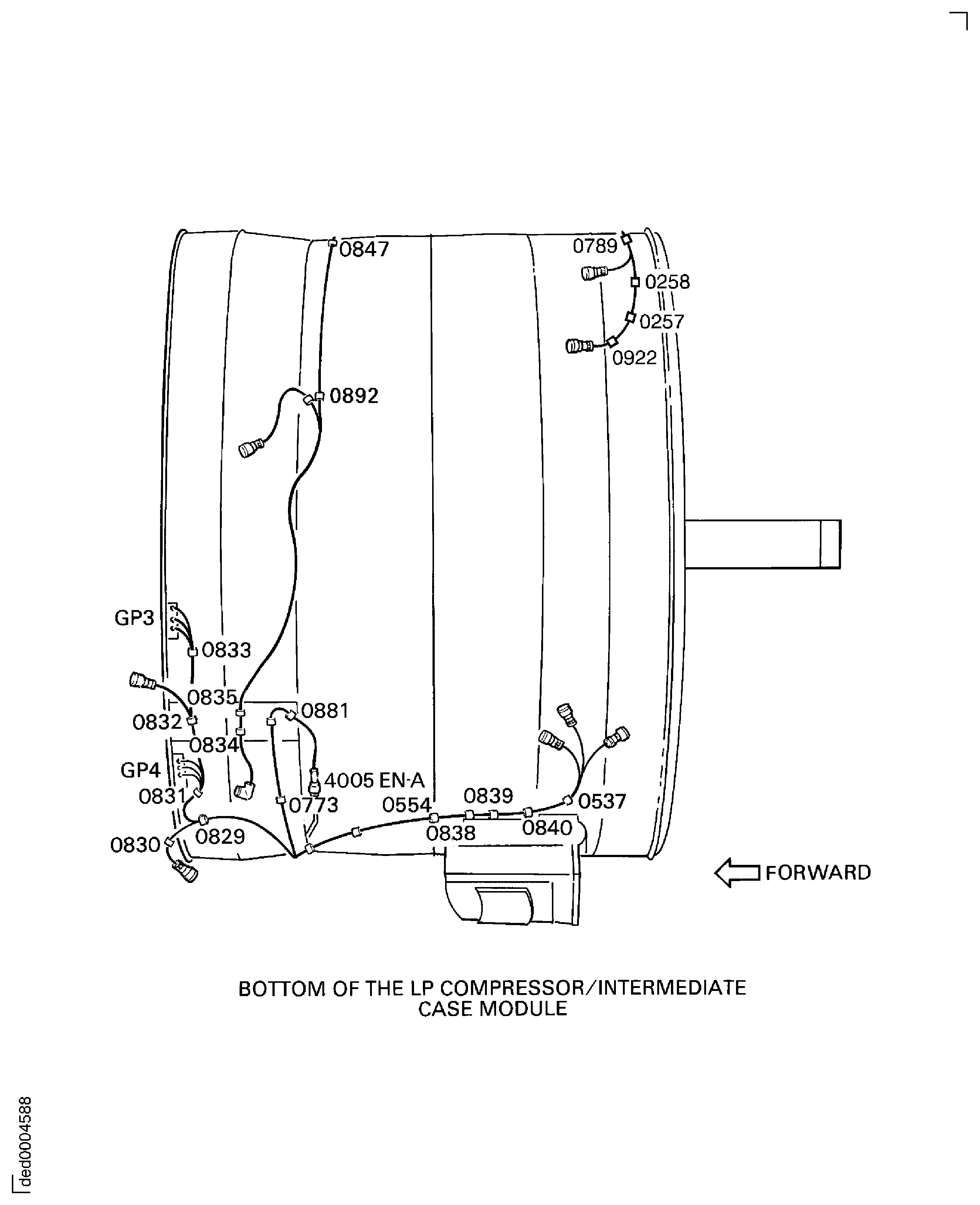

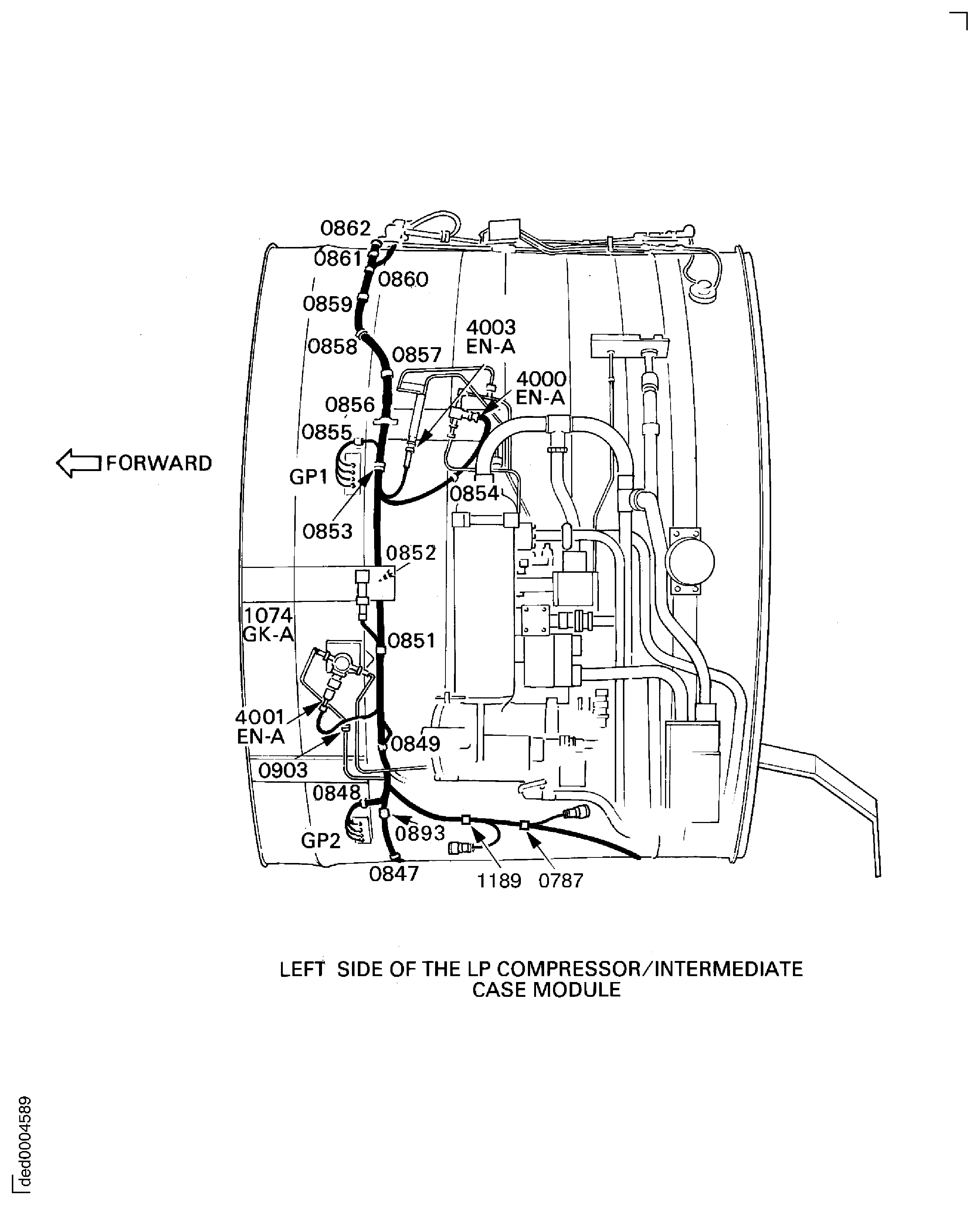

Remove the EEC and ignition supply harness with the general services harness. Refer to Step.Disconnect the general services harness General Services Harness (71-51-43, 01-005) as follows:

Disconnect the electrical connectors, as follows:

4001EN-A from the scavenge filter differential pressure switch.

1074GK-A from the hydraulic pressure switch.

4000EN-A from the low oil pressure switch.

4003EN-A from the oil pressure transmitter.

4100KS-B from from the relay box.

4005EN-A from the No.4 bearing pressure transducer.

SUBTASK 72-00-32-020-250 Remove the General Services Harness

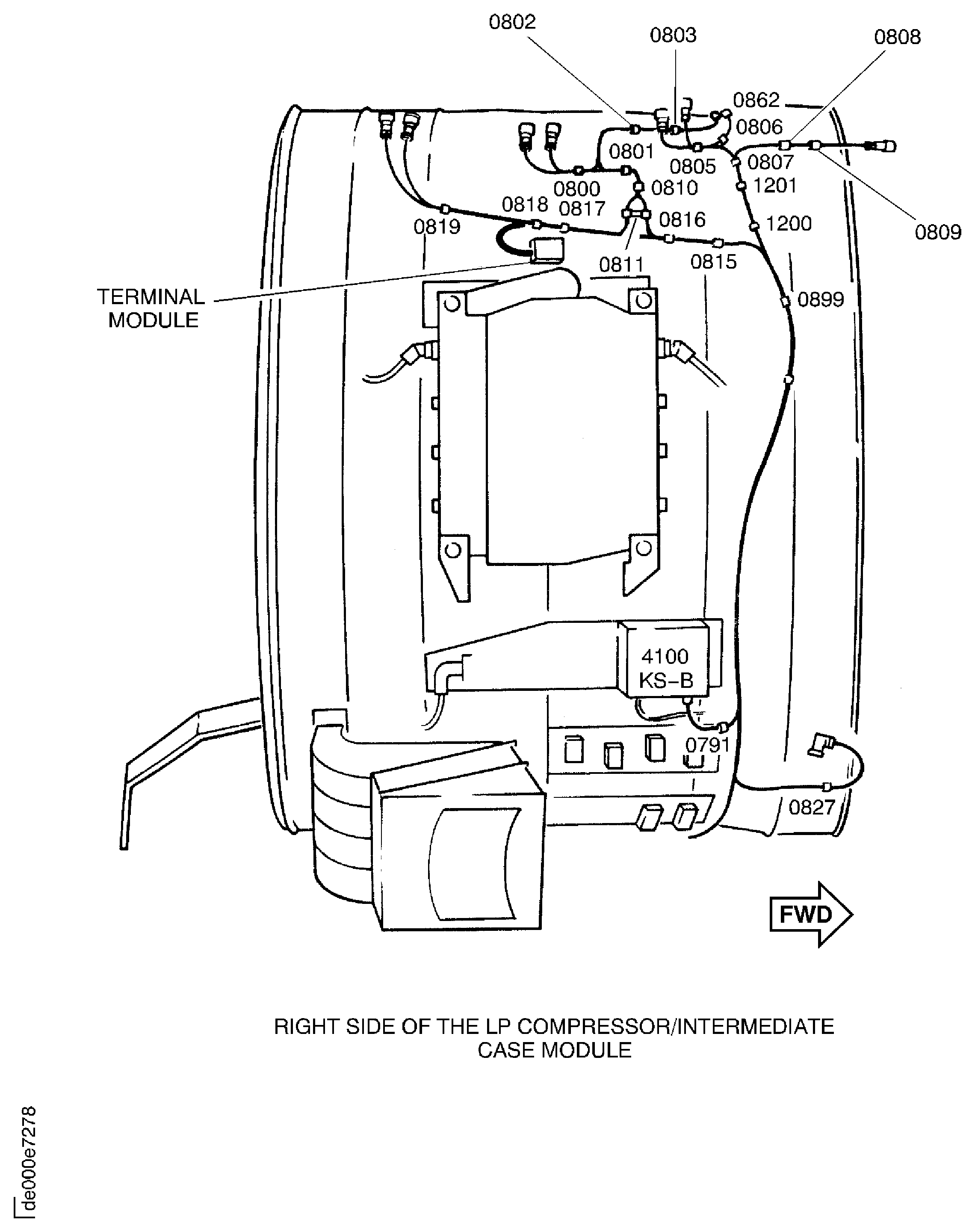

Disconnect the EEC and ignition supply harness EEC Fan Harness And Ignition Supply Harness (71-51-42, 01-005) as follows:

Disconnect the electrical connectors as follows:

4000KS-J1 and 4000KS-J7 from the EEC with theIAE 1J12018 EEC harness wrench 1 off.

NOTE

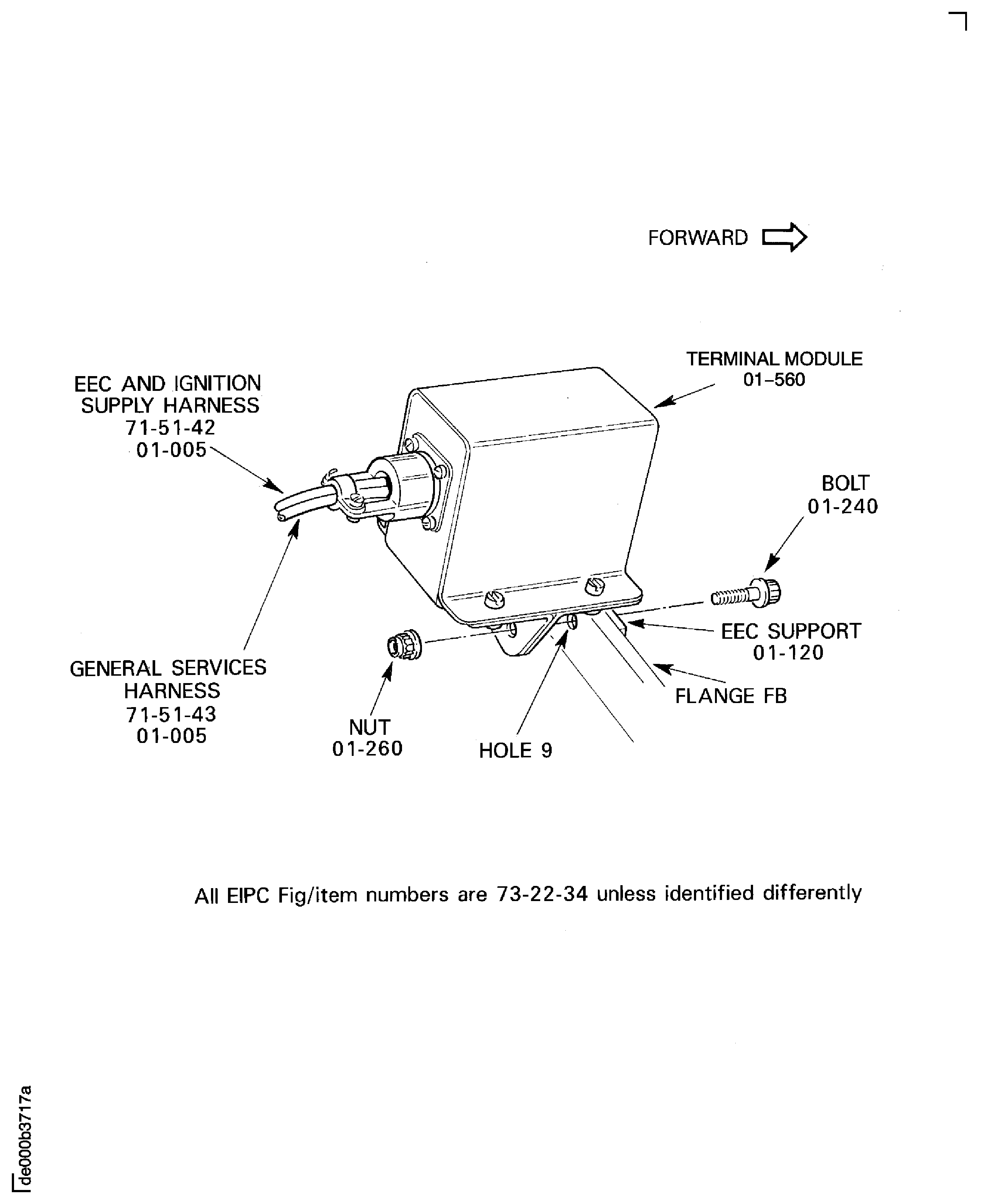

Hole No. 1 is at 12.5 degrees from the engine top position on the flange FB when you look from the rear of the engine.Remove the bolt and the nut which attaches the terminal module to the flange FB at the hole 9, Figure.

SUBTASK 72-00-32-020-251 Remove the EEC and Ignition Supply Harness (Pre SBE 71-0165 and SBE 71-0165)

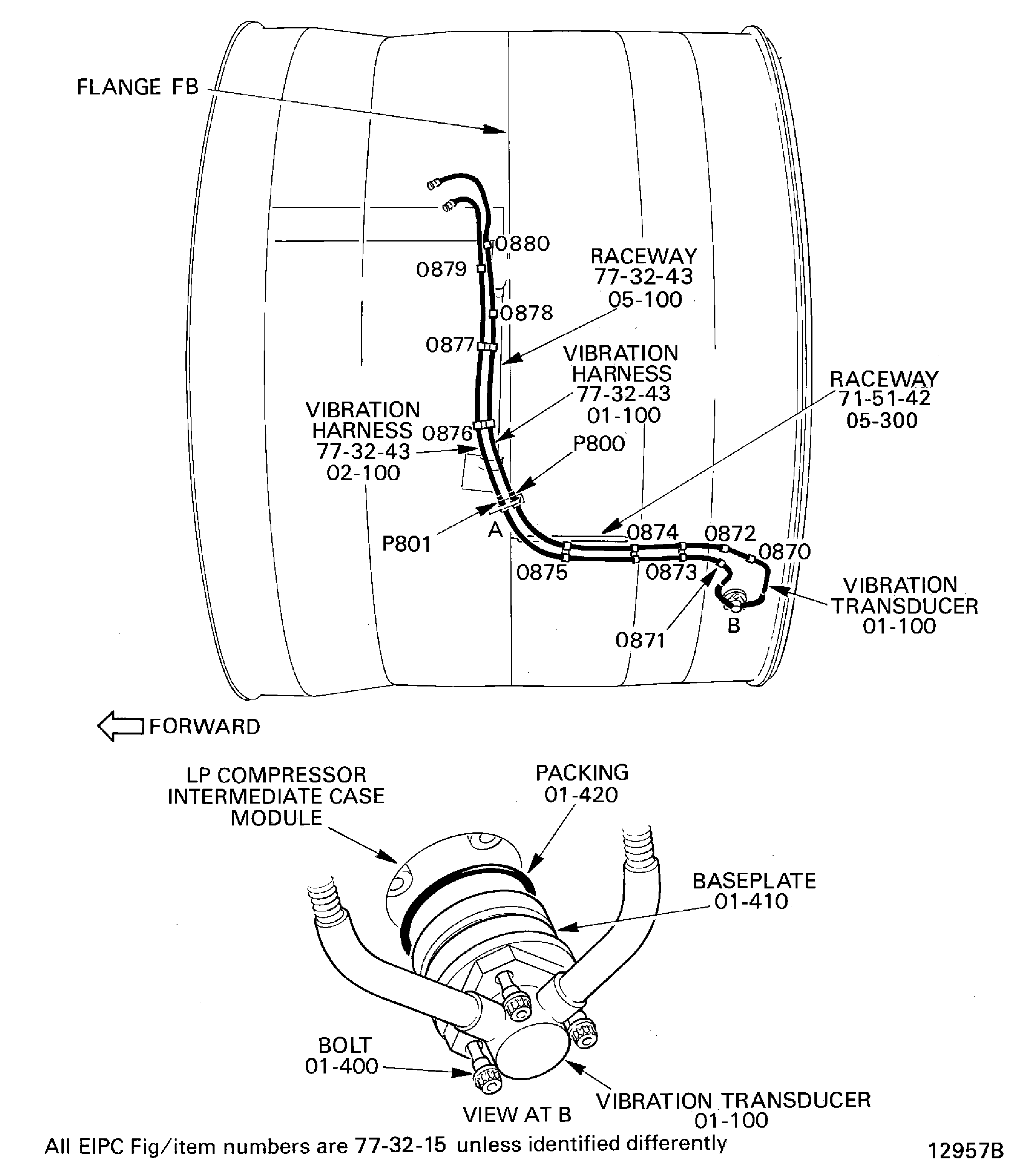

Disconnect the vibration harnesses Vibration Indication Harness (77-32-43, 01-100 and Vibration Indication Harness 02-100) as follows:

NOTE

The three bolts hold the transducer and the baseplate Vibration Transducer(77-32-15,01-410) together as a loose assembly.Loosen the three bolts Vibration Transducer (77-32-15, 01-400) which attach the transducer to the LP compressor/intermediate case.

Remove the transducer with the three bolts, the baseplate and the packing Vibration Transducer (77-32-15, 01-420). Discard the packing.

Disconnect the vibration transducer Vibration Transducer (77-32-15, 01-100) as follows:

SUBTASK 72-00-32-020-252 Remove the Vibration Harnesses/Transducer

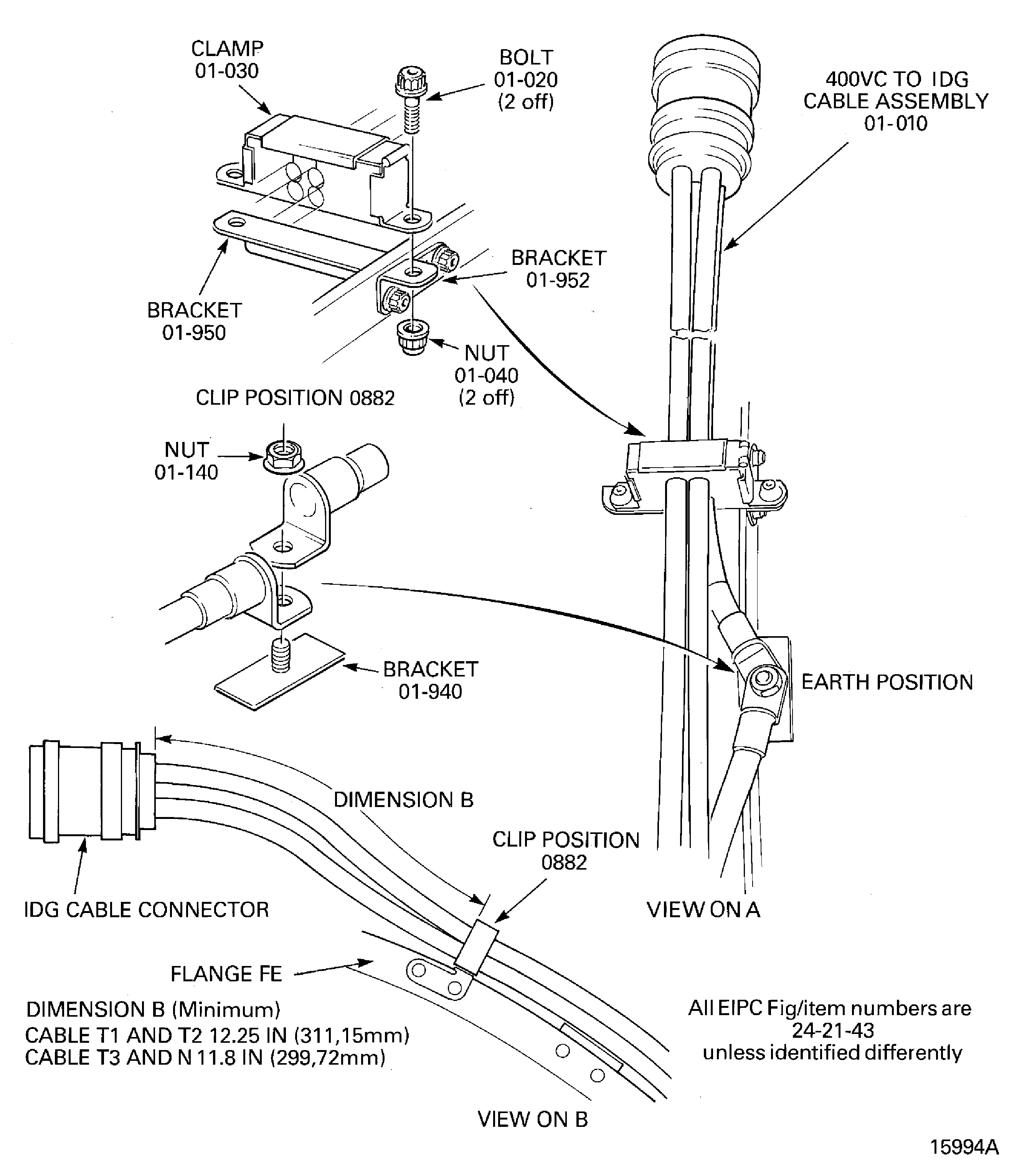

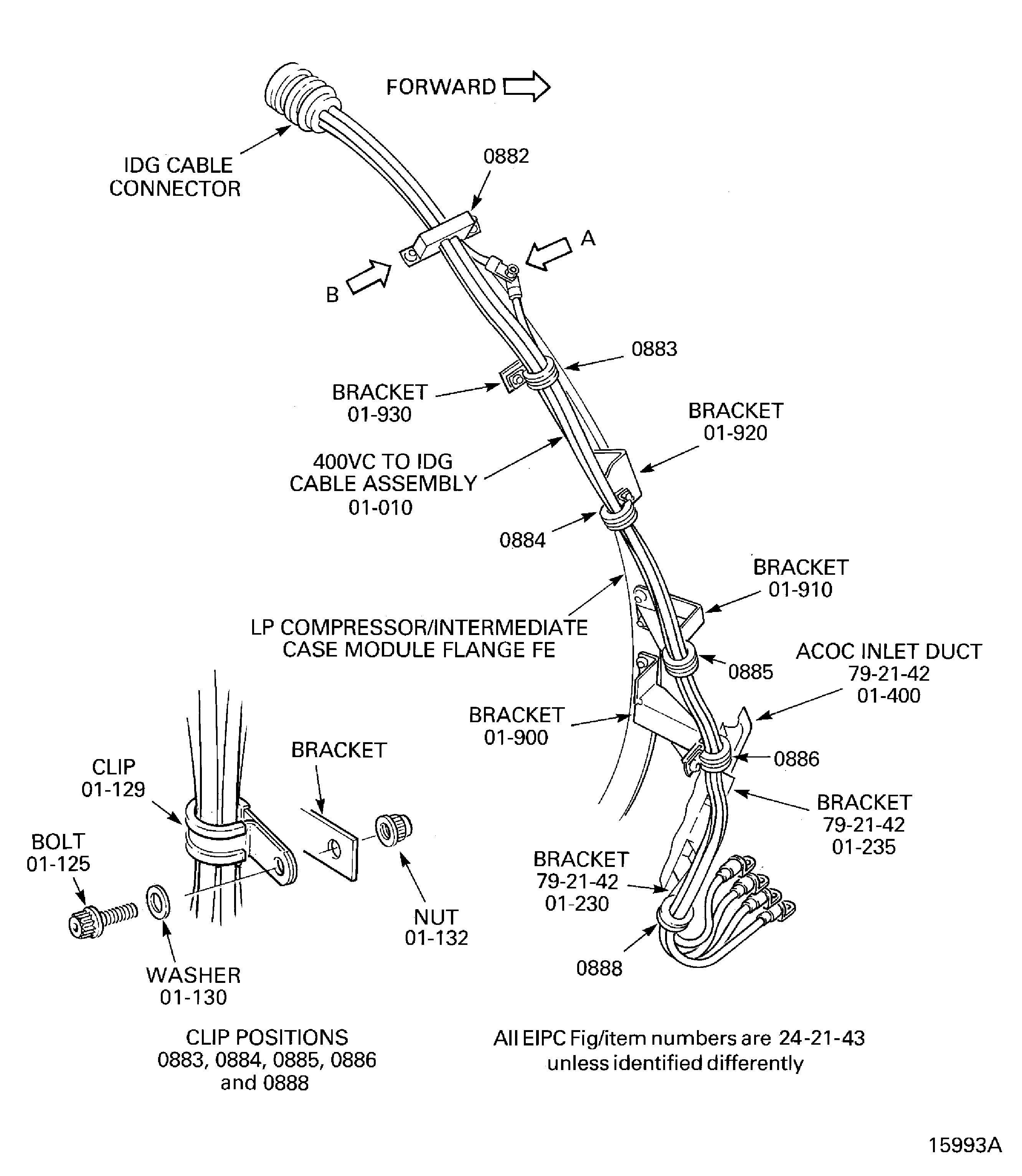

Temporarily attach the IDG cable connector to a safe position on the LP compressor/intermediate case with CoMat 06-086 TIES.

NOTE

The 400VC to IDG cable assembly removed in this procedure must have its maintenance completed, as given in the Component Maintenance Manual (CMM-EHC-V2500-1IA).Remove the CoMat 06-086 TIES which hold the IDG cable connector and remove remaining cable assembly.

SUBTASK 72-00-32-020-253 Remove the 400VC to IDG Cable Assembly

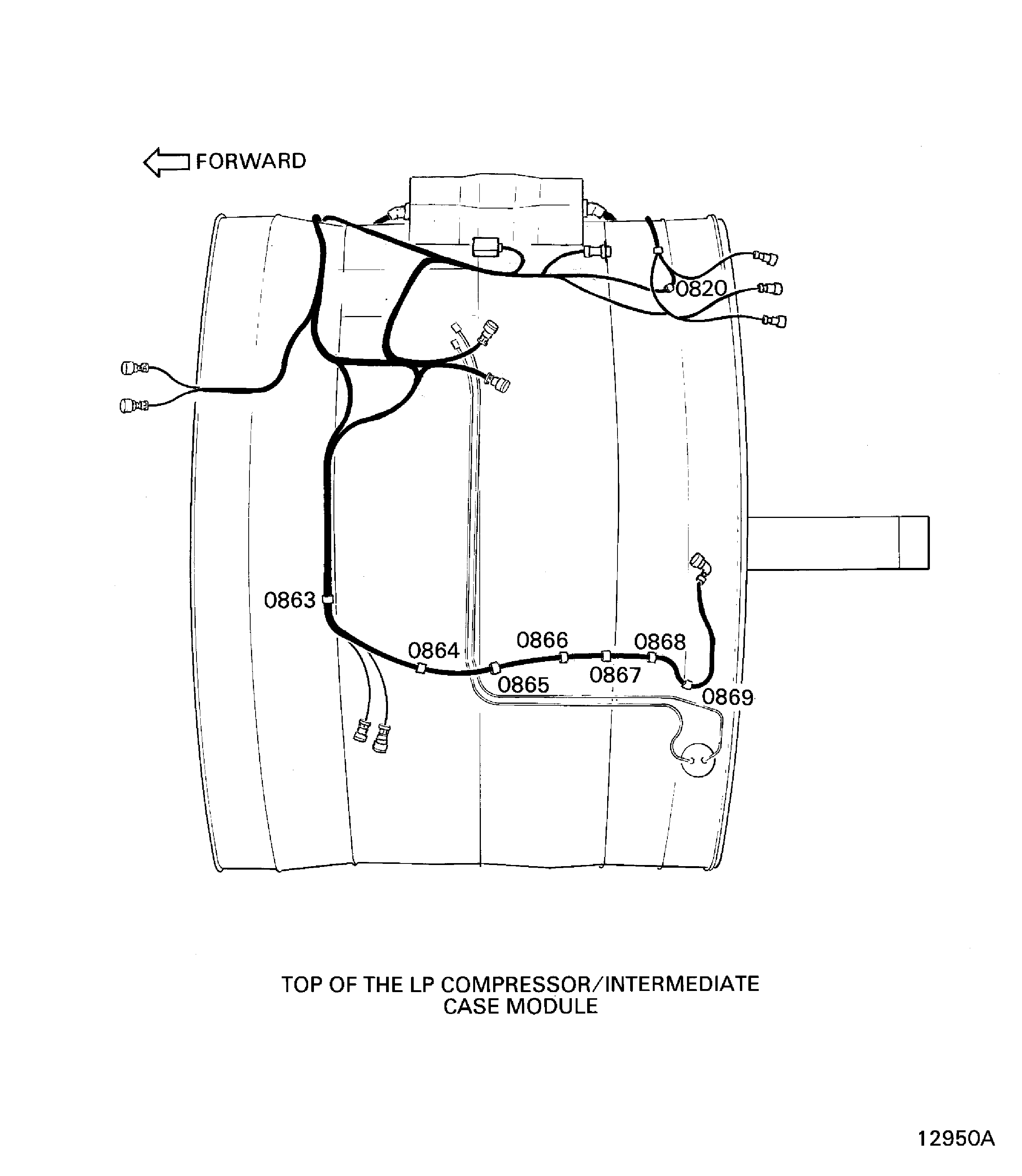

Figure: SBE 75-0081: Remove the EEC flexible hoses and the tube 235

SBE 75-0081: Remove the EEC flexible hoses and the tube 235

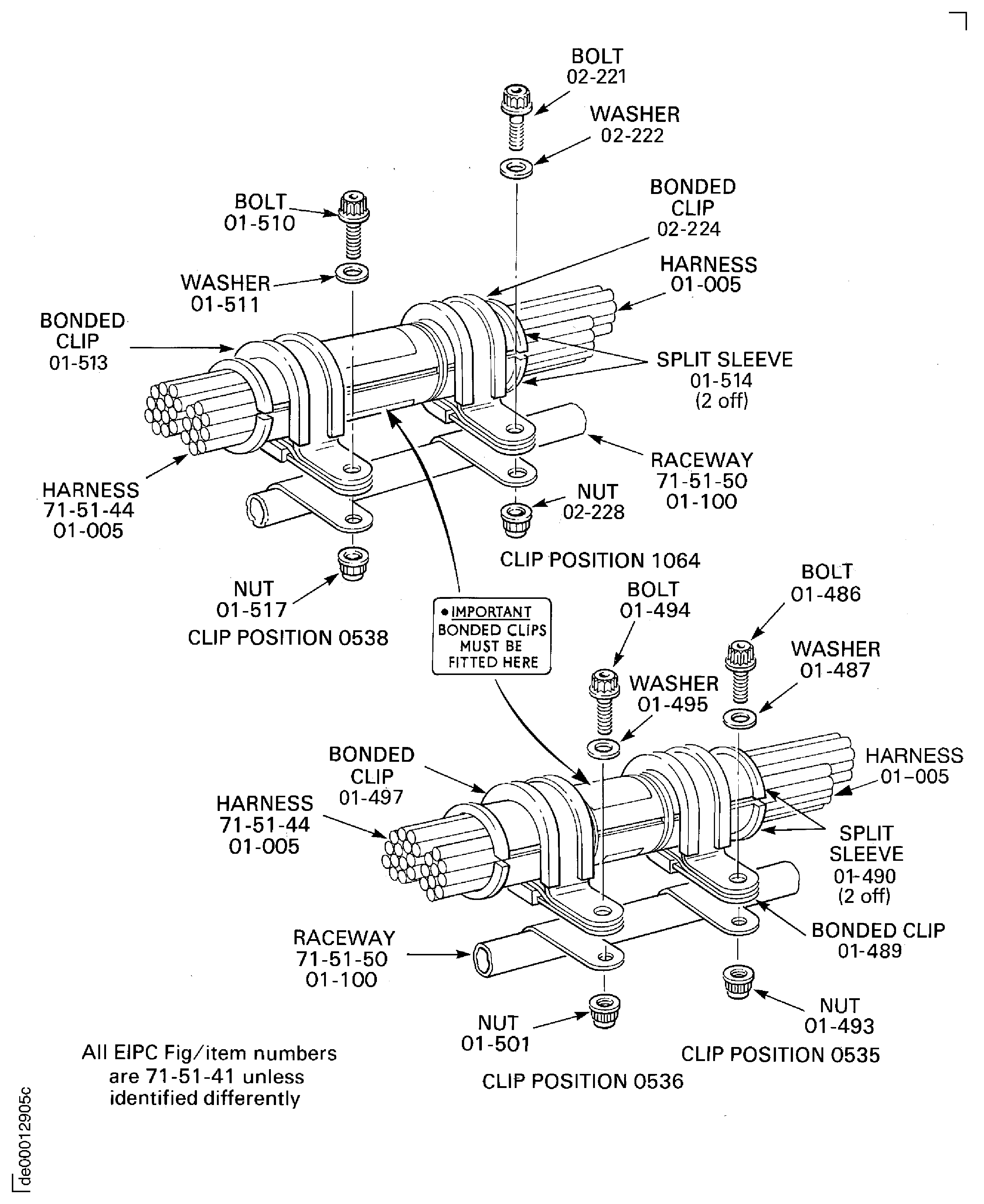

Figure: SBE 75-0081: Remove the EEC harness

SBE 75-0081: Remove the EEC harness

Figure: SBE 75-0081:Remove the EEC harness

SBE 75-0081:Remove the EEC harness

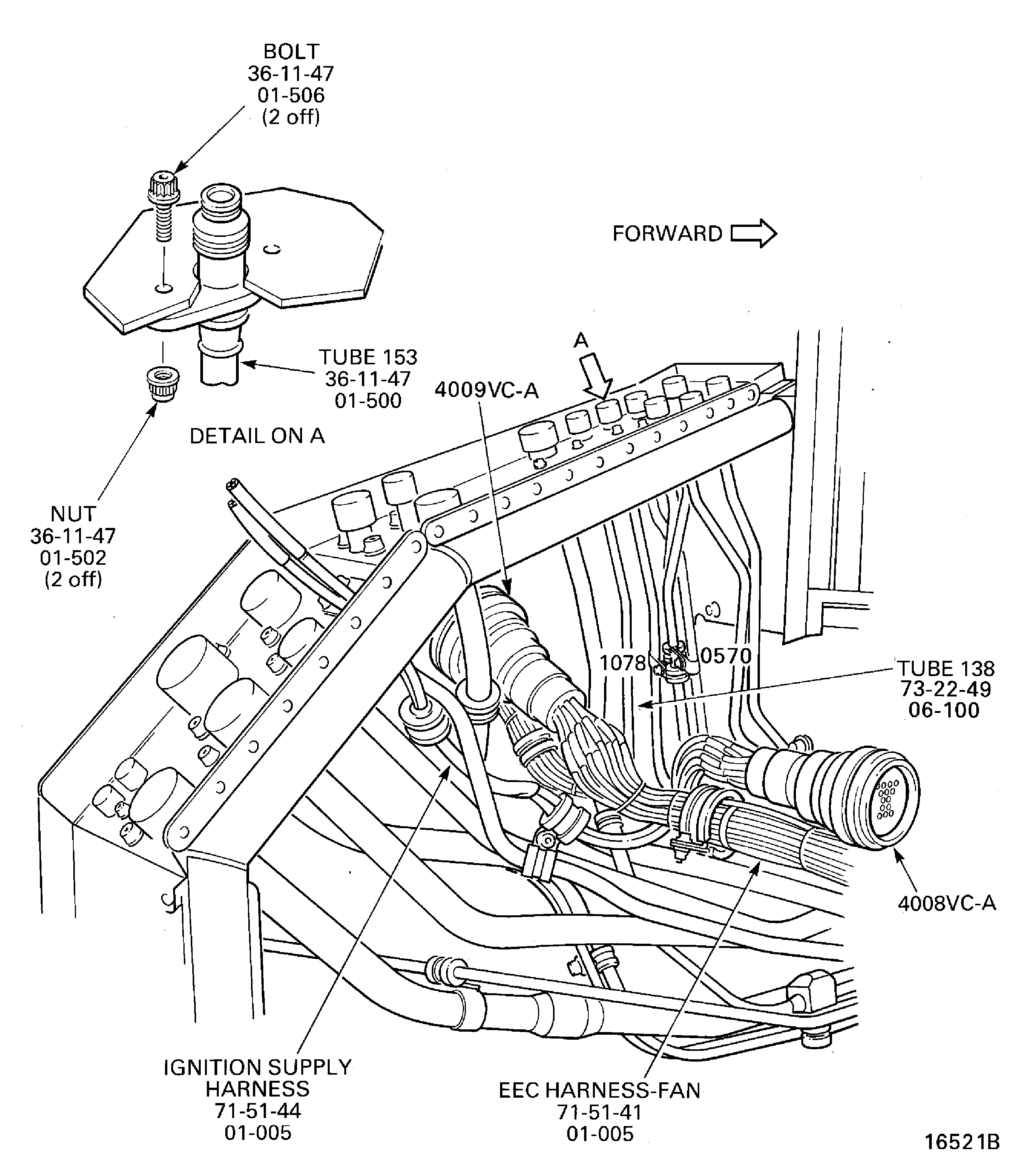

Figure: SBE 73-0071 and 75-0081: Remove the EEC harness

SBE 73-0071 and 75-0081: Remove the EEC harness

Figure: SBE 75-0081: Remove the EEC harness

SBE 75-0081: Remove the EEC harness

Figure: SBE 75-0081: Remove the EEC harness

SBE 75-0081: Remove the EEC harness

Figure: SBE 75-0081: Remove the EEC harness

SBE 75-0081: Remove the EEC harness

Figure: SBE 75-0081:Remove the EEC harness

SBE 75-0081:Remove the EEC harness

Figure: SBE 75-0081: Remove the EEC harness

SBE 75-0081: Remove the EEC harness

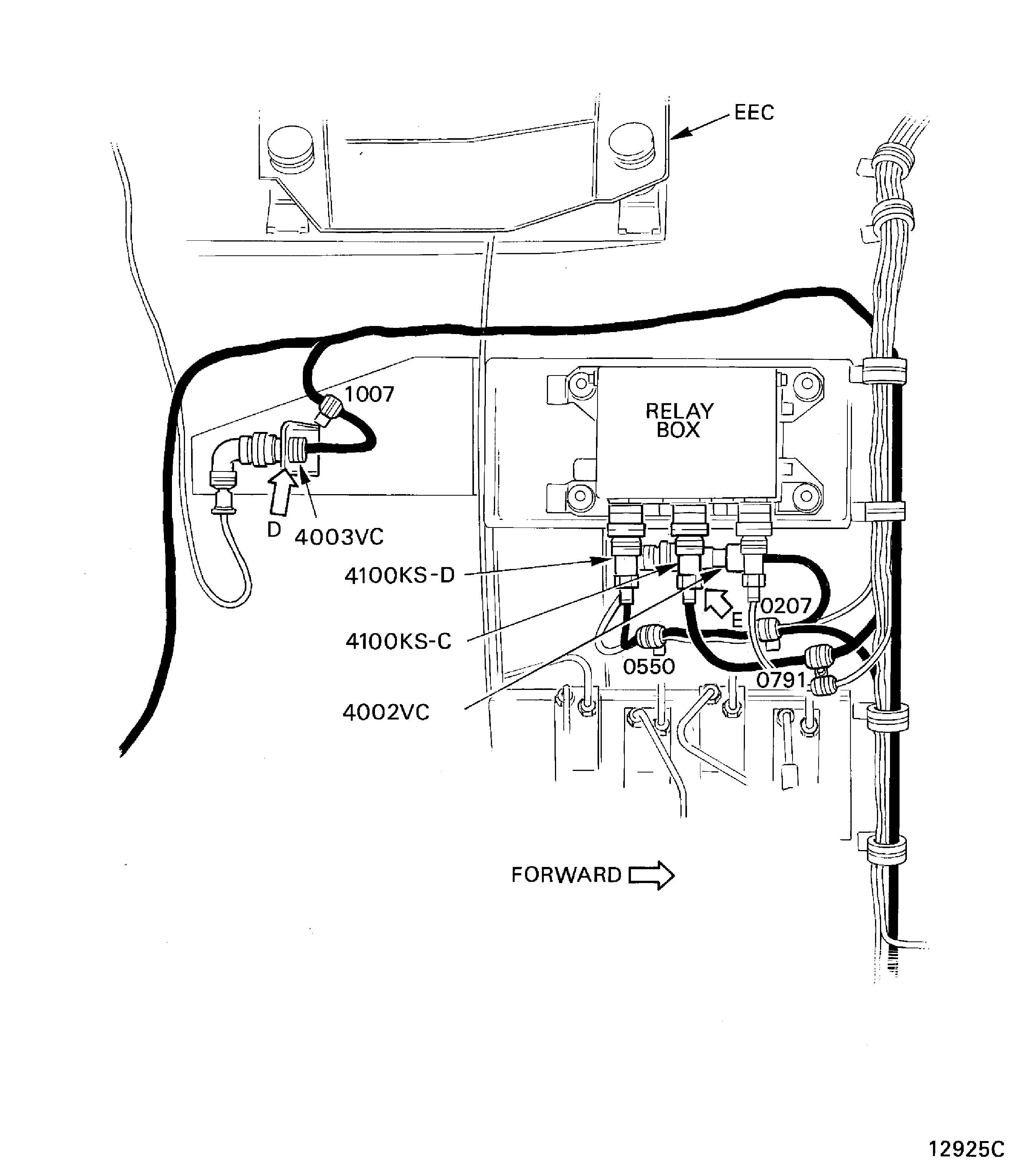

Figure: SBE 75-0081: Remove the ignition supply harness

SBE 75-0081: Remove the ignition supply harness

Figure: SBE 75-0081: Remove the ignition supply harness

SBE 75-0081: Remove the ignition supply harness

Figure: SBE 75-0081: Remove the ignition supply harness

SBE 75-0081: Remove the ignition supply harness

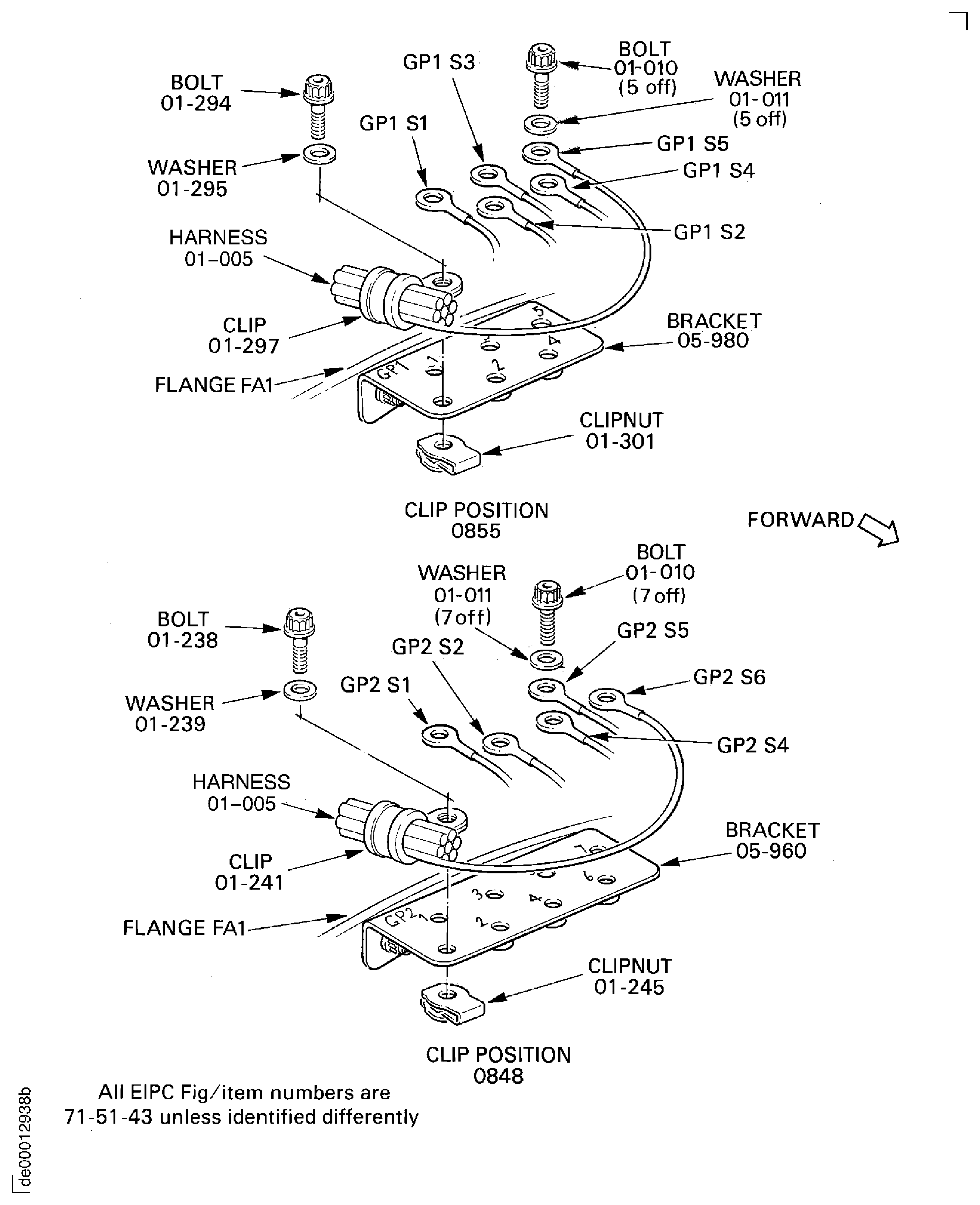

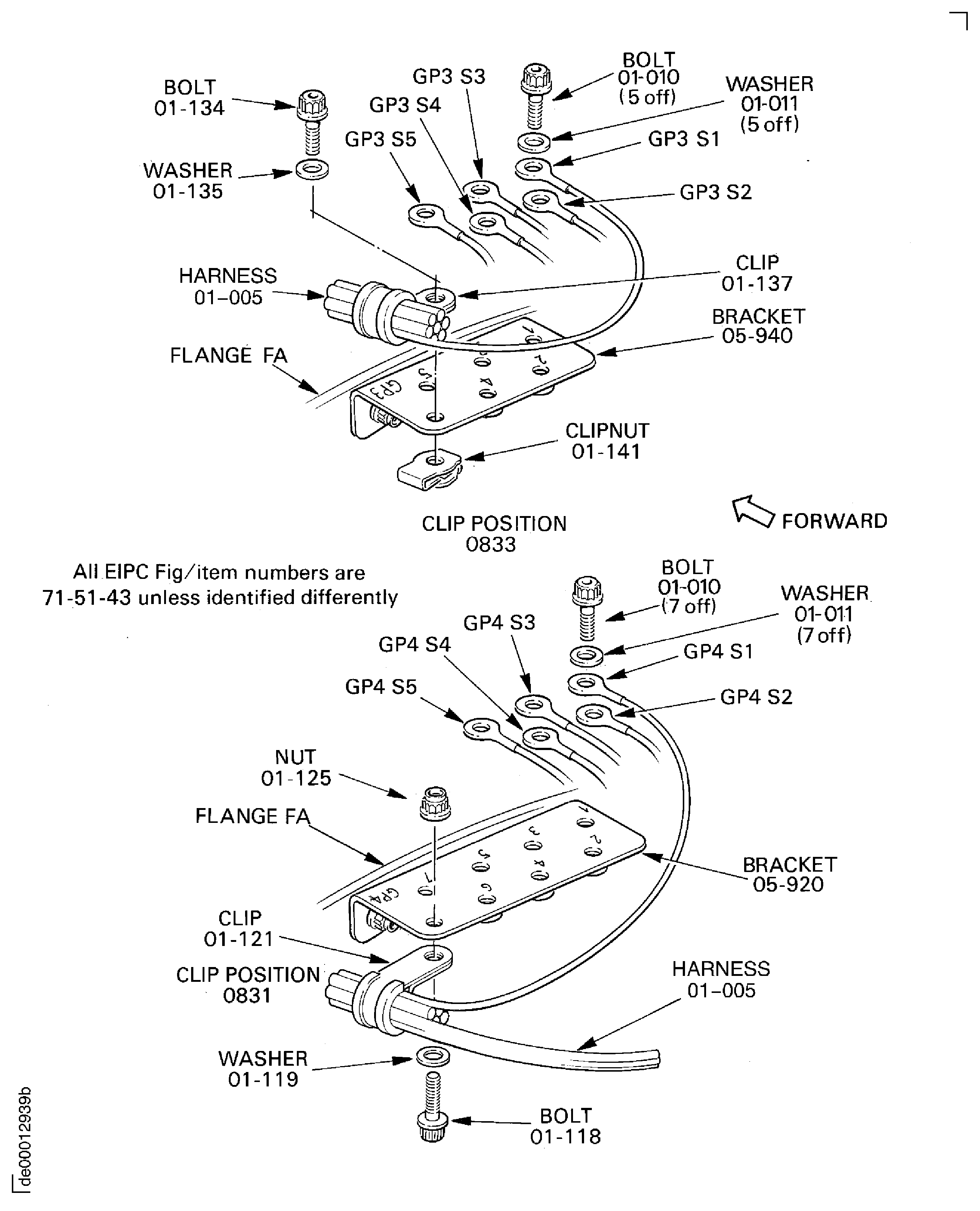

Figure: SBE 75-0081: Remove the general services harness

SBE 75-0081: Remove the general services harness

Figure: SBE 75-0081: Remove the general services harness

SBE 75-0081: Remove the general services harness

Figure: SBE 75-0081: Remove the general services harness

SBE 75-0081: Remove the general services harness

Figure: SBE 75-0081: Remove the general services harness

SBE 75-0081: Remove the general services harness

Figure: SBE 75-0081: Remove the general services harness

SBE 75-0081: Remove the general services harness

Figure: SBE 75-0081: Remove the terminal module

SBE 75-0081: Remove the terminal module

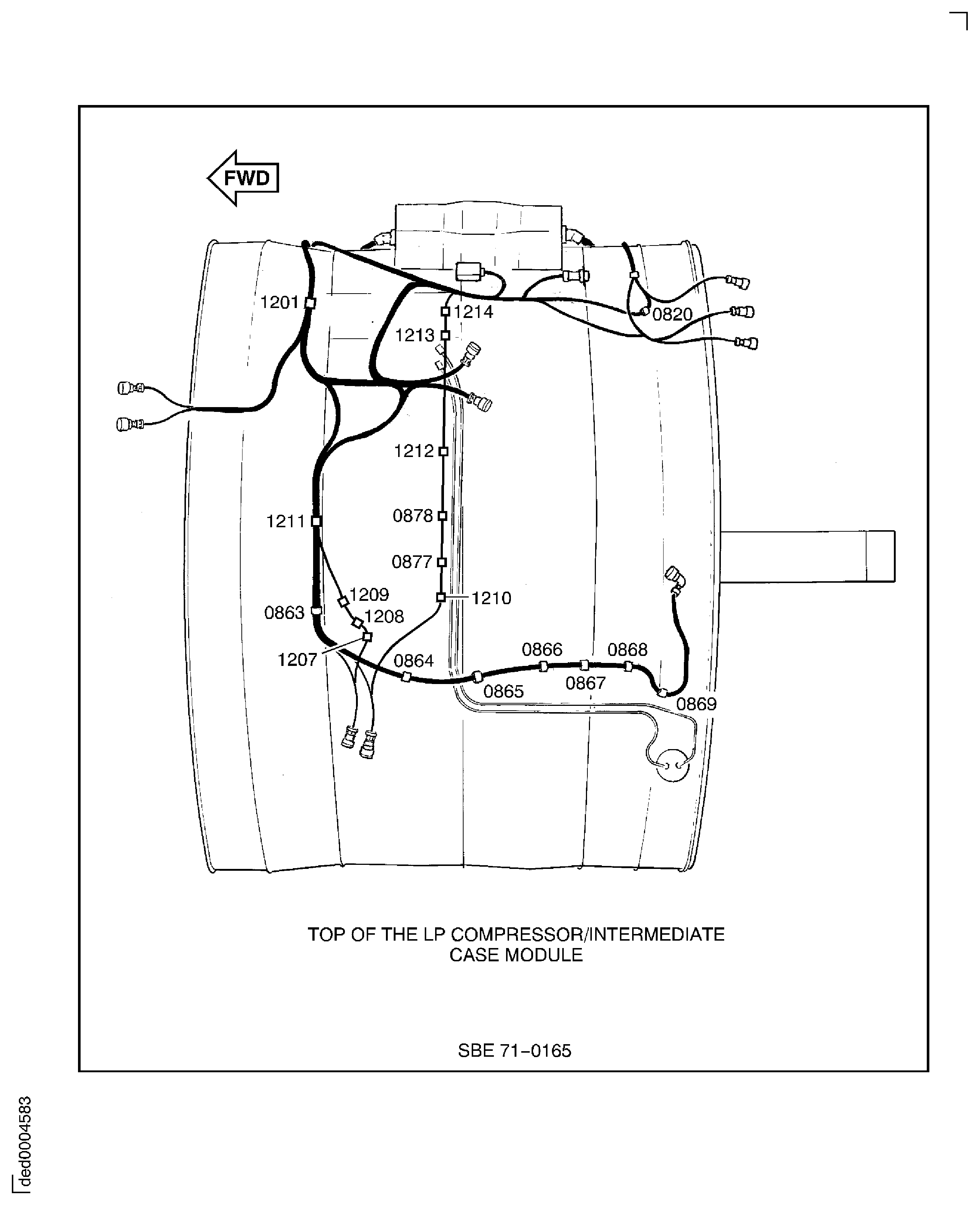

Figure: SBE 75-0081: Remove the EEC and ignition supply harness

SBE 75-0081: Remove the EEC and ignition supply harness

Figure: SBE 75-0081: Remove the EEC and ignition supply harness

SBE 75-0081: Remove the EEC and ignition supply harness

Figure: SBE 71-0165 and 75-0081: Remove the EEC and ignition supply harness

SBE 71-0165 and 75-0081: Remove the EEC and ignition supply harness

Figure: SBE 75-0081: Remove the vibration harnesses/transducer

SBE 75-0081: Remove the vibration harnesses/transducer

Figure: SBE 75-0081: Remove the vibration harnesses/transducer

SBE 75-0081: Remove the vibration harnesses/transducer

Figure: SBE 75-0081: Remove the 400VC to IDG cable assembly

SBE 75-0081: Remove the 400VC to IDG cable assembly

Figure: SBE 75-0081: Remove the 400VC to IDG cable assembly

SBE 75-0081: Remove the 400VC to IDG cable assembly