Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-00-32-020-003-B00 LPC/Intermediate Case Module - Remove The Tubes And Electrical Harness Raceways, Removal-003 - Pre SBE 79-0088

General

SBE 75-0081: Air - Stage 10 to HPT air valve - Deletion of the HPC stage 10 make-up air valve and associated hardware.

Refer to the TASKs which follow for the other related procedures.

TASK 72-00-32-020-001-B00 Remove the hydraulic tubes, the thermal anti-ice (TAI) duct, the pneumatic starter duct and the EEC cooling ducts from the LP compressor/intermediate case module

TASK 72-00-32-020-002-B00 Remove the LP compressor/intermediate case electrical harnesses

TASK 72-00-32-020-004 Remove the LP compressor/intermediate case components

TASK 72-00-32-020-005-B00 Remove the LP compressor/intermediate case brackets and the bifurcation panel

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For service bulletin alpha variants refer to the IPC.

Apply the approved CoMat 10-058 PENETRATING OIL before the removal of threaded parts. Let the parts soak before removal.

Discard all rubber seal rings, split cotter pins, keywashers and gaskets removed in this procedure.

Remove and discard the lockwire before the tube or connector is disconnected.

All the tubes, hoses and ducts removed in this procedure must have their maintenance completed, as given in the Component Maintenance Manual (CMM-THD-V2500-1IA).

Seal all openings when the tubes are disconnected to prevent contamination from unwanted material.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1R18001 Wrench | 0AM53 | IAE 1R18001 | 1 | |

| IAE 1R18002 Wrench | 0AM53 | IAE 1R18002 | 1 | |

| IAE 1R18003 Wrench | 0AM53 | IAE 1R18003 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-058 PENETRATING OIL | X222X | CoMat 10-058 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

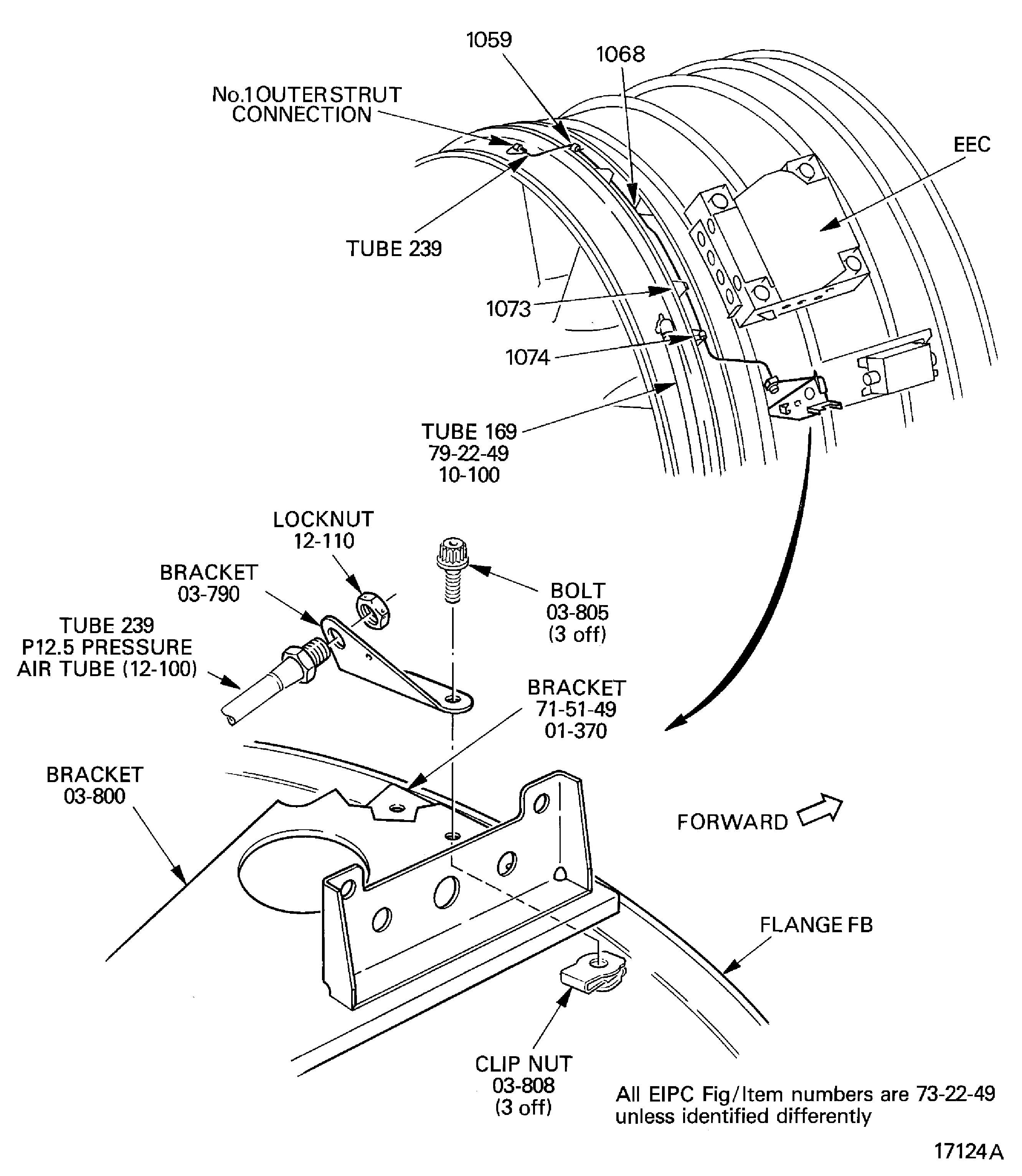

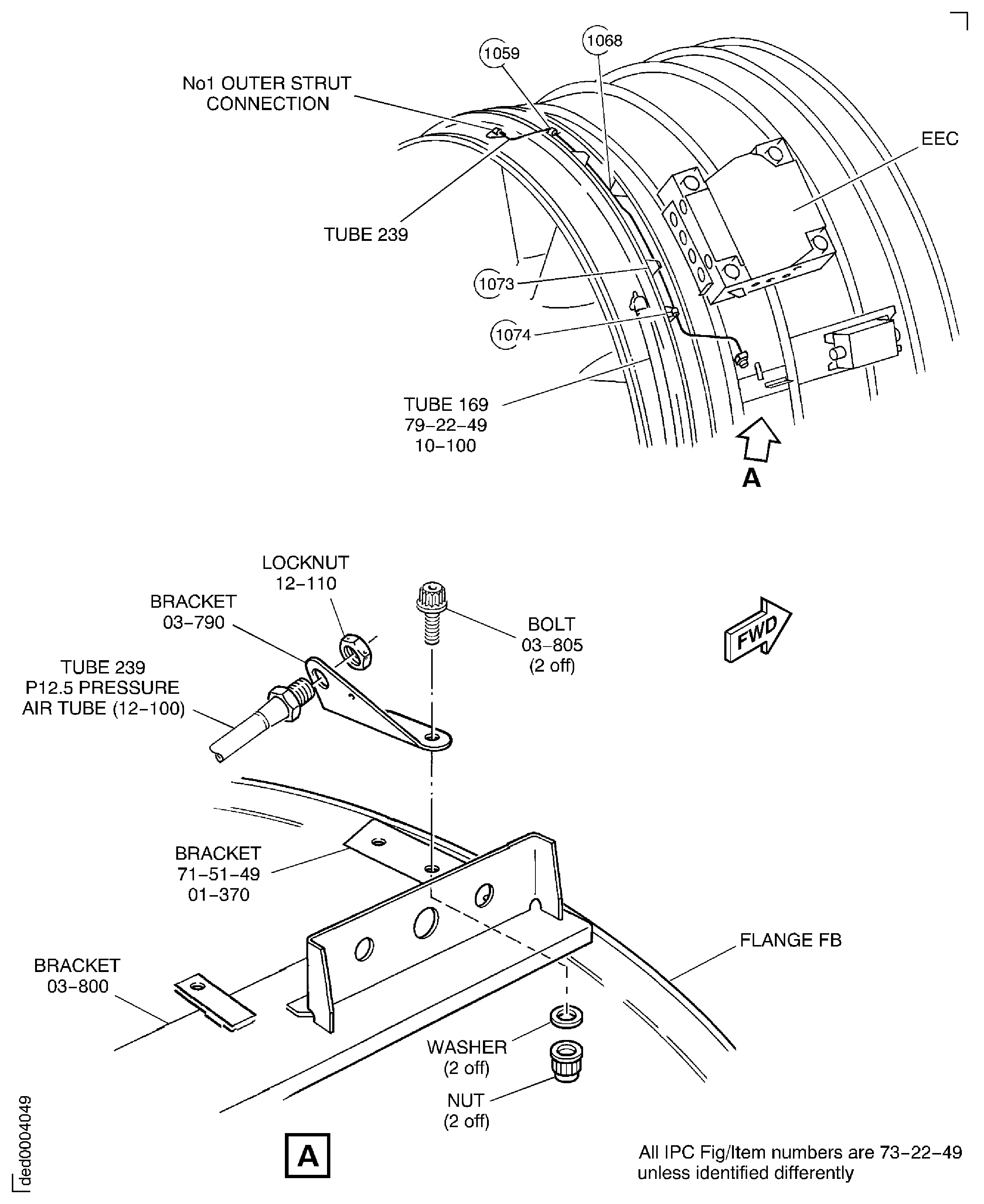

Remove the locknut which attaches the tube 239 to the bracket Fuel System Air Tubes (73-22-49, 03-790).

Remove the two bolts and the bracket Fuel System Air Tubes (73-22-49, 03-790). Temporarily install and tighten the two bolts in the two bracket clipnuts.

SUBTASK 72-00-32-020-158-A00 Remove the Tube 239, the Fuel System Air Tube (Pre SBE 73-0140)

Refer to Figure.

Remove the locknut which attaches the tube 239 to the bracket Fuel System Air Tubes (73-22-49, 03-790).

Remove the two bolts and the bracket Fuel System Air Tubes (73-22-49, 03-790). Temporarily install and tighten the two bolts and two washers in the two bracket nuts.

SUBTASK 72-00-32-020-158-B00 Remove the Tube 239, the Fuel System Air Tube (SBE 73-0140)

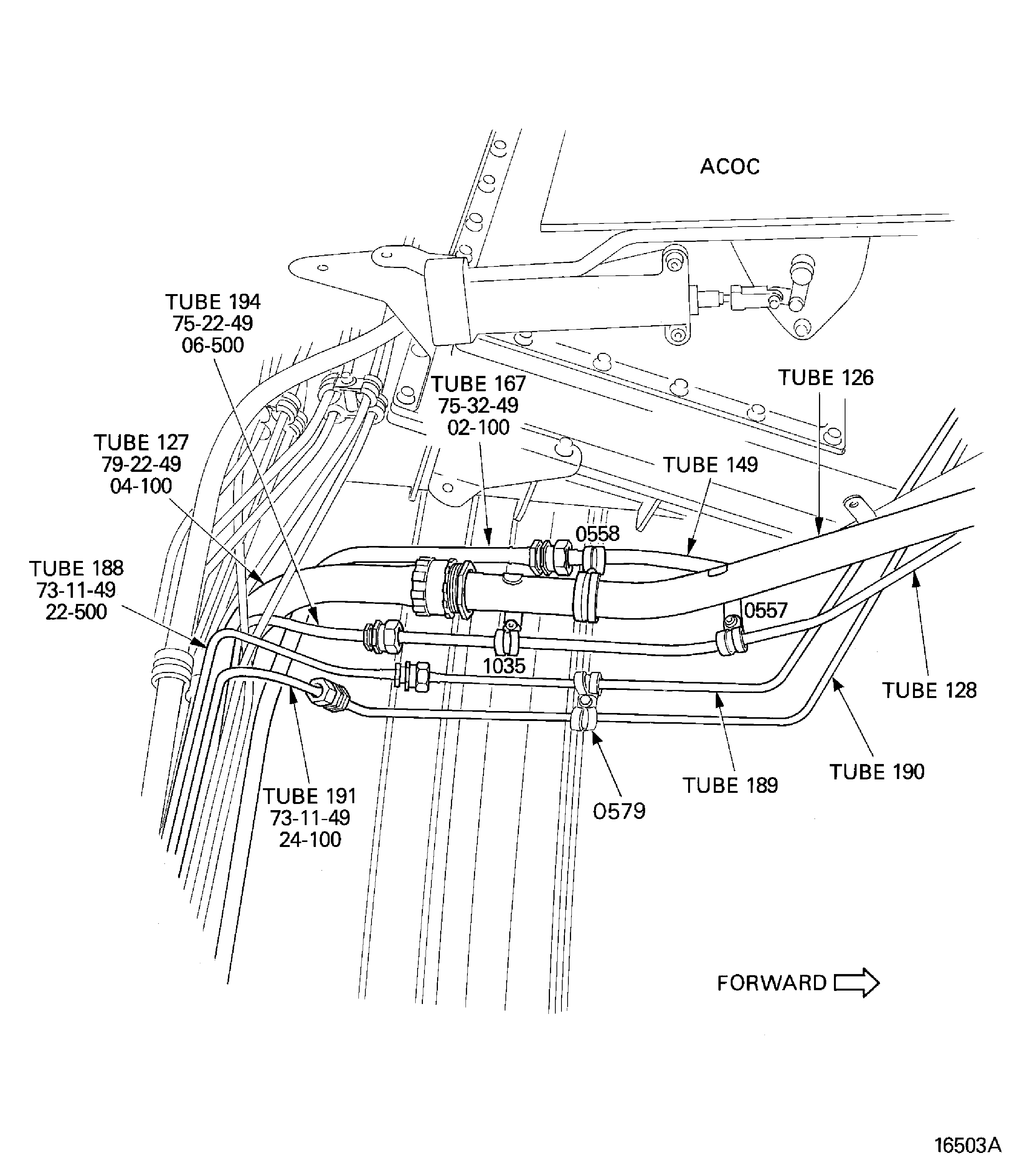

Disconnect the tube 127 from the tube 126 with the IAE 1R18003 Wrench 1 off.

SUBTASK 72-00-32-020-159 Remove the Tubes 193, 126 and 128 the Right Side Tubes

Refer to Figure.

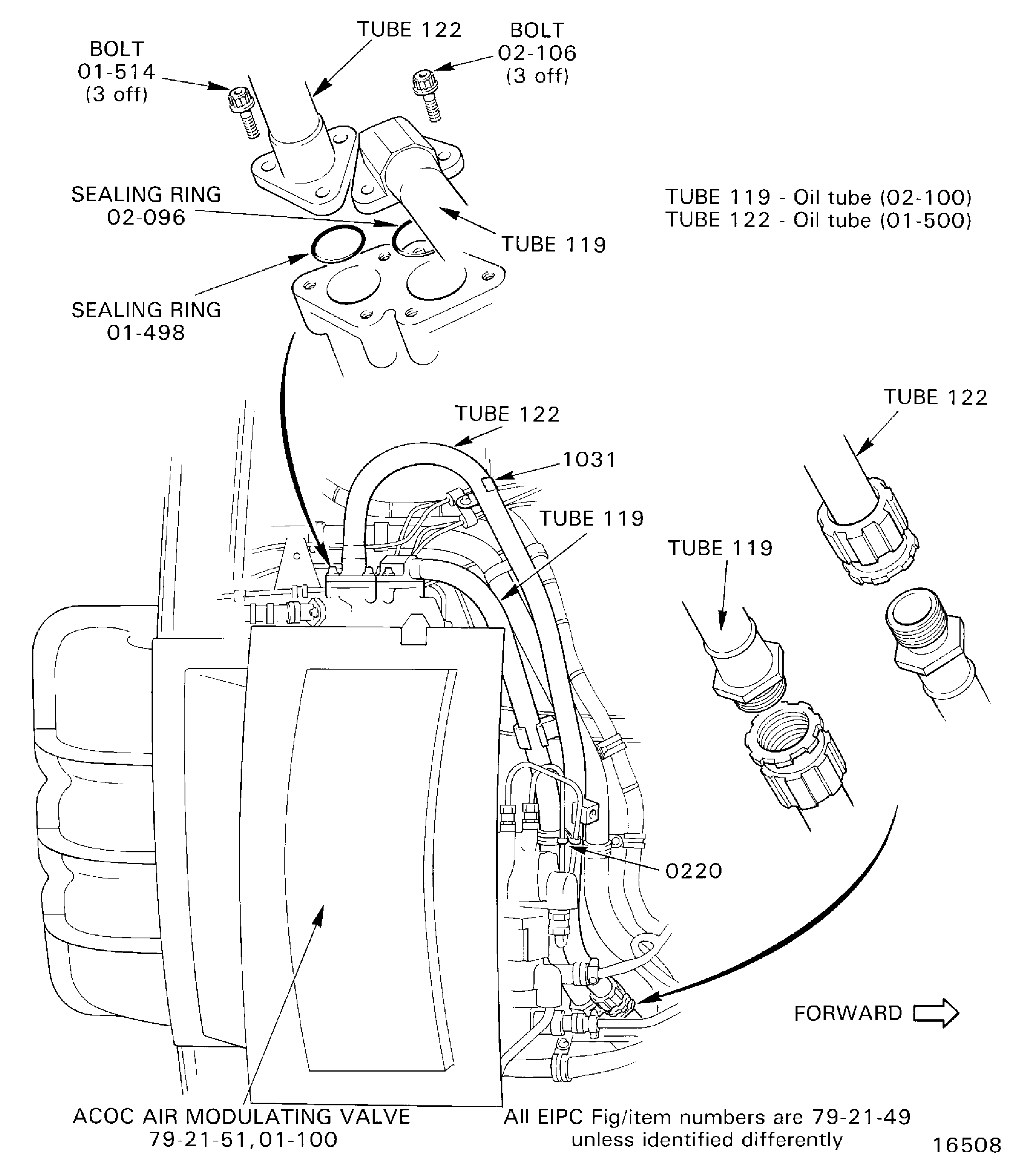

SUBTASK 72-00-32-020-160 Remove the Tubes 122 and 119, the Pressure Oil Tubes

Remove the bolt, the washer, the nut and the clip at the clip position 1025.

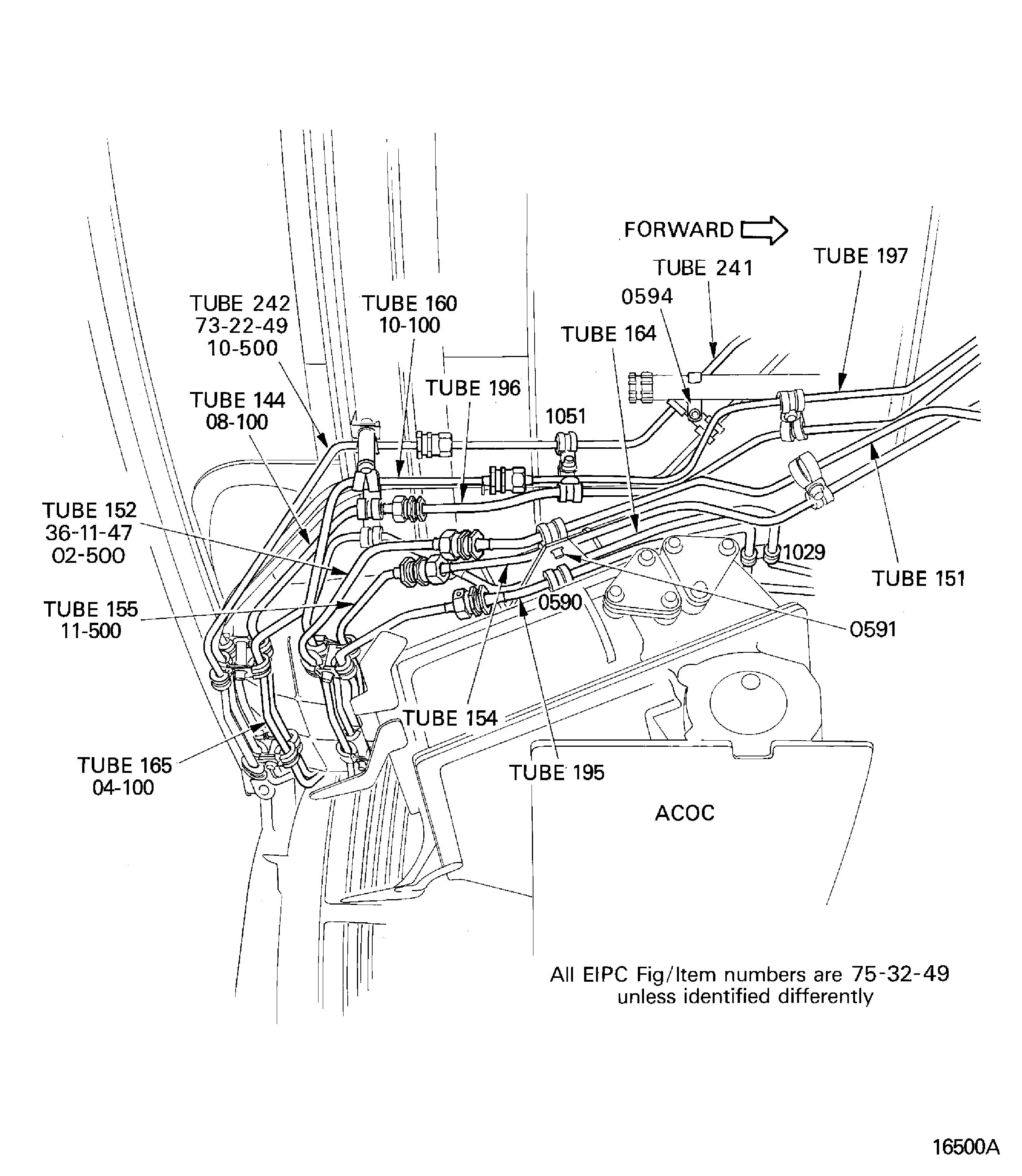

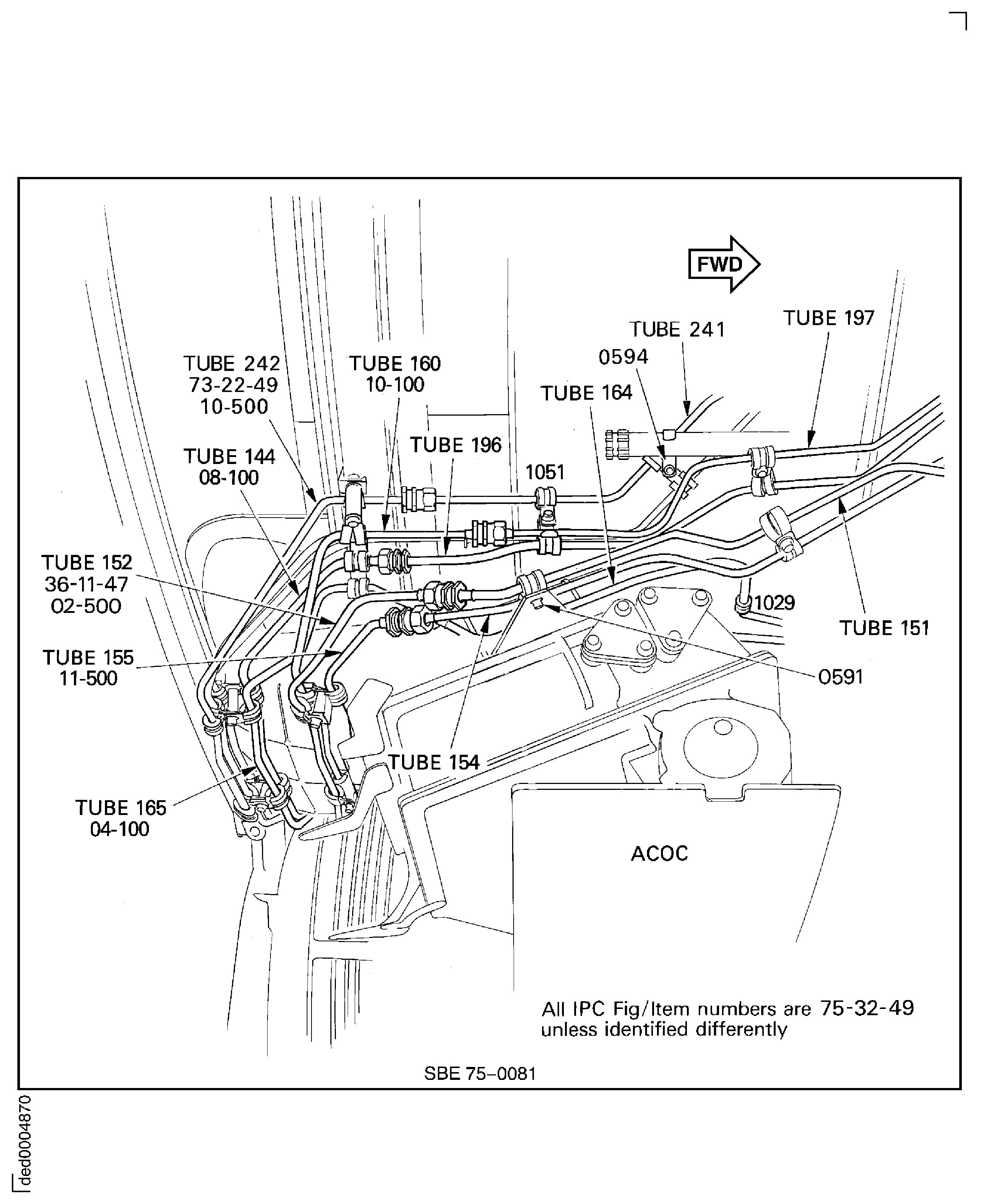

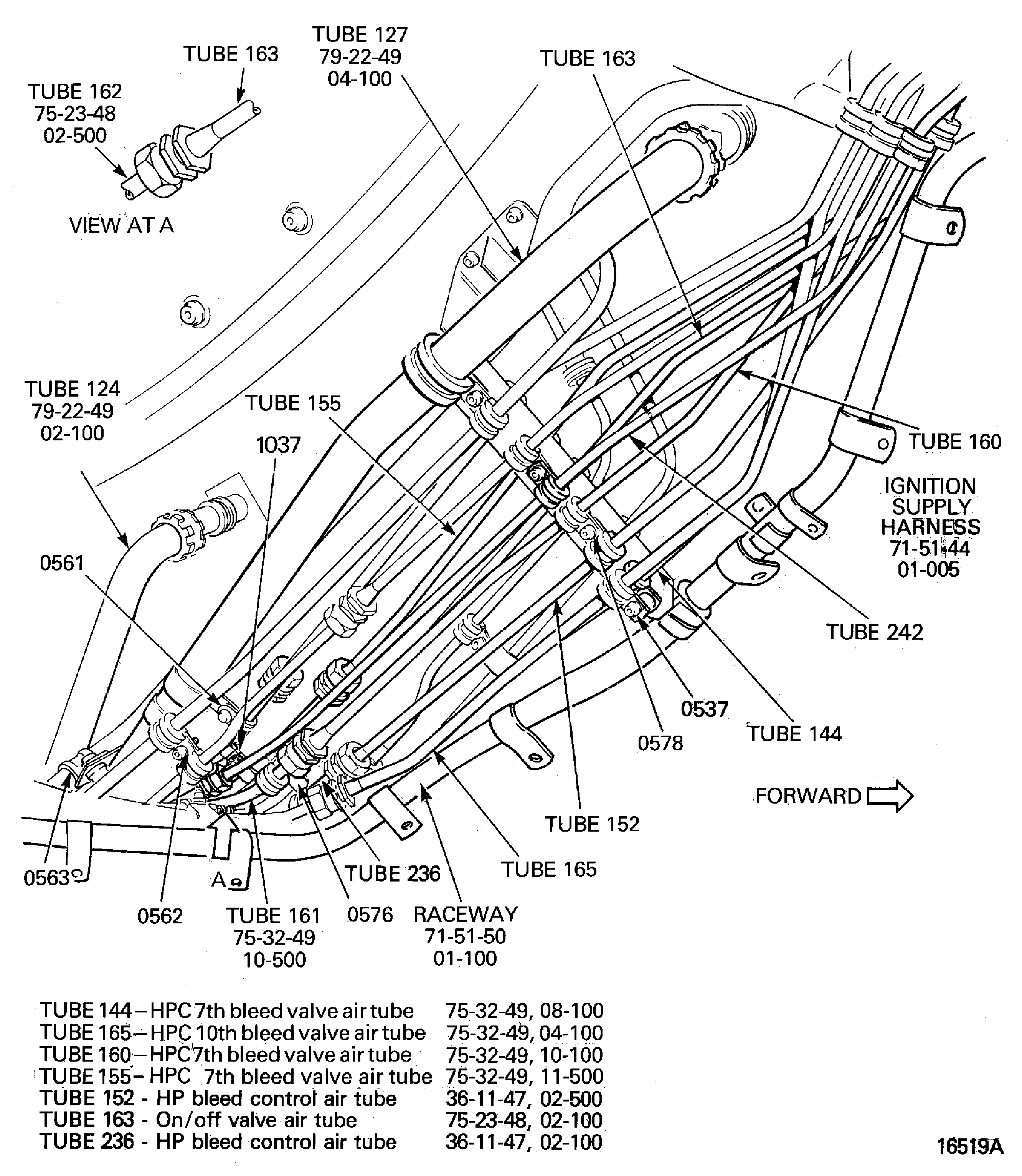

Pre SBE 75-0081: Refer to Figure.

SBE 75-0081: Refer to Figure.

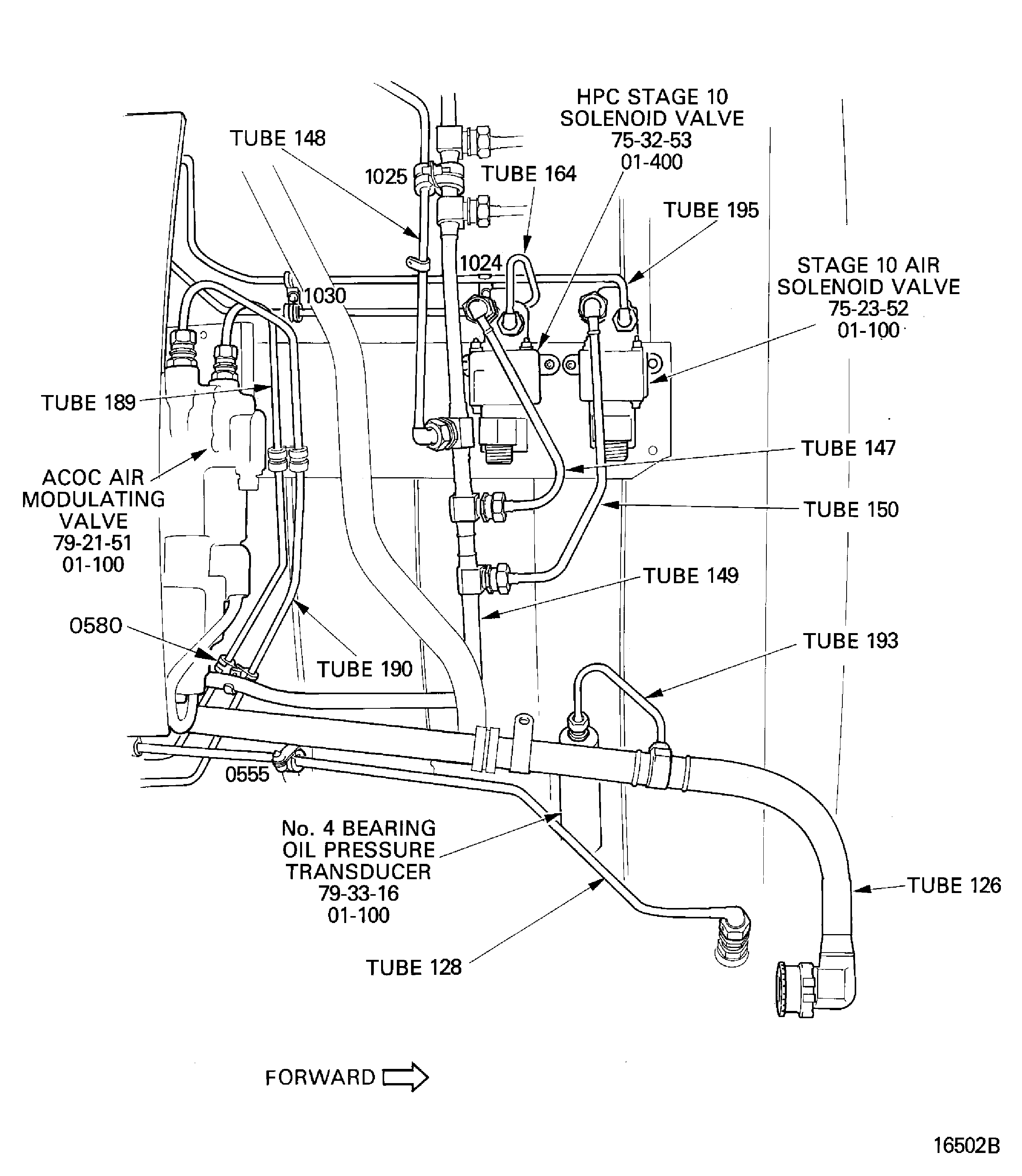

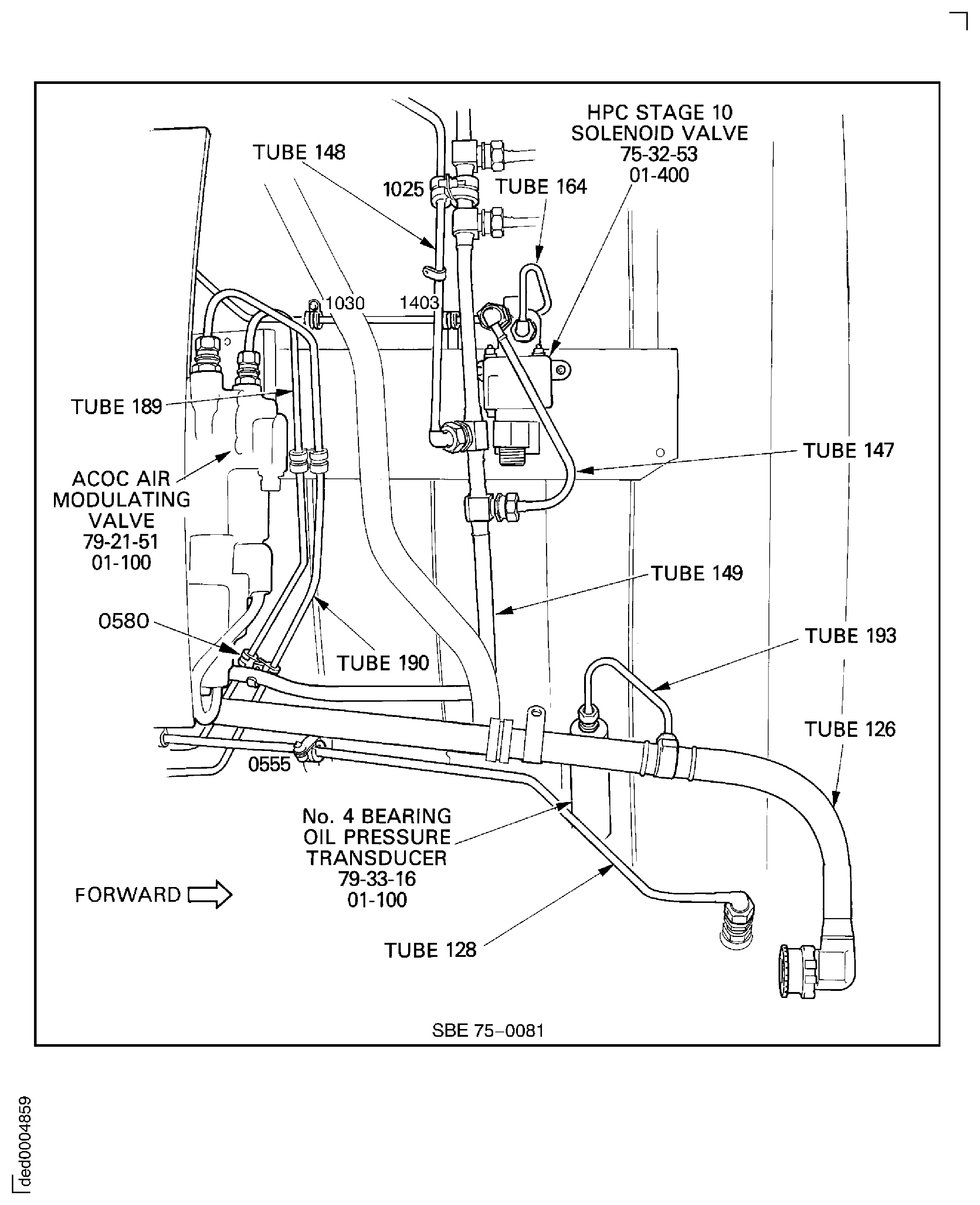

Disconnect the tube 148 from the HPC stage 7 and 10 air solenoid valve STAGE 10 AIR SOLENOID VALVE (36-11-57, 01-100) and the tube 149. Remove the tube 148.

Disconnect the tube 147 from the HPC stage 10 solenoid valve AIR-HPC STAGE 10 SOLENOID VALVE (75-32-53, 01-400) and the tube 149. Remove the tube 147.

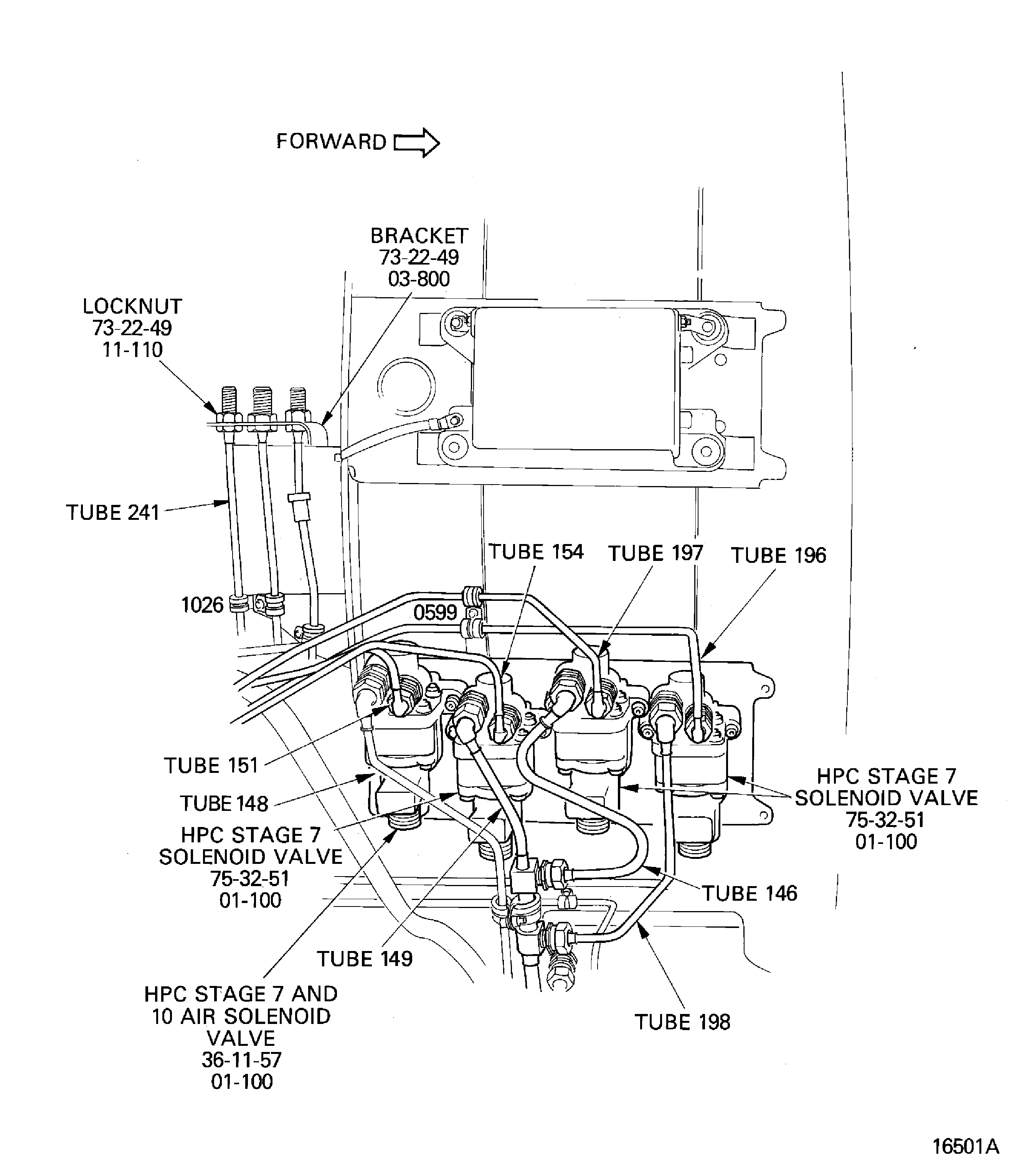

SUBTASK 72-00-32-020-161 Remove the Tubes 146 to 148 and the Tube 198, the HP Compressor (HPC) Bleed Air Tubes

Refer to Figure.

Disconnect the tube 150 from the stage 10 air solenoid valve AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-100) and the tube 149. Remove the tube 150.

SUBTASK 72-00-32-020-162 Remove the Tube 150 from the Turbine Cooling Controlled Air Tube System (Pre SBE 75-0081)

Remove the bolt, the washer, the clips and the nut at the clip position 0580.

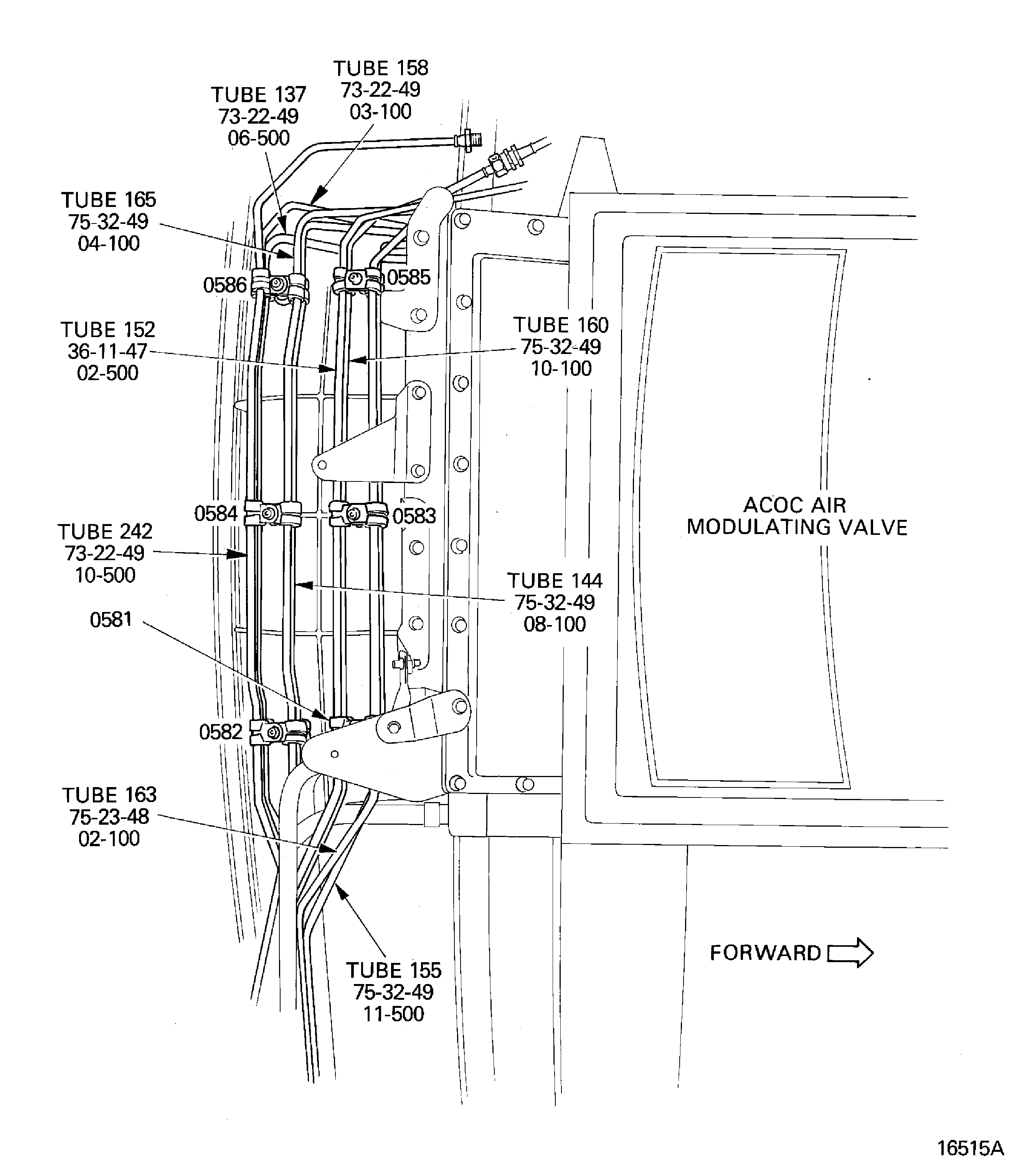

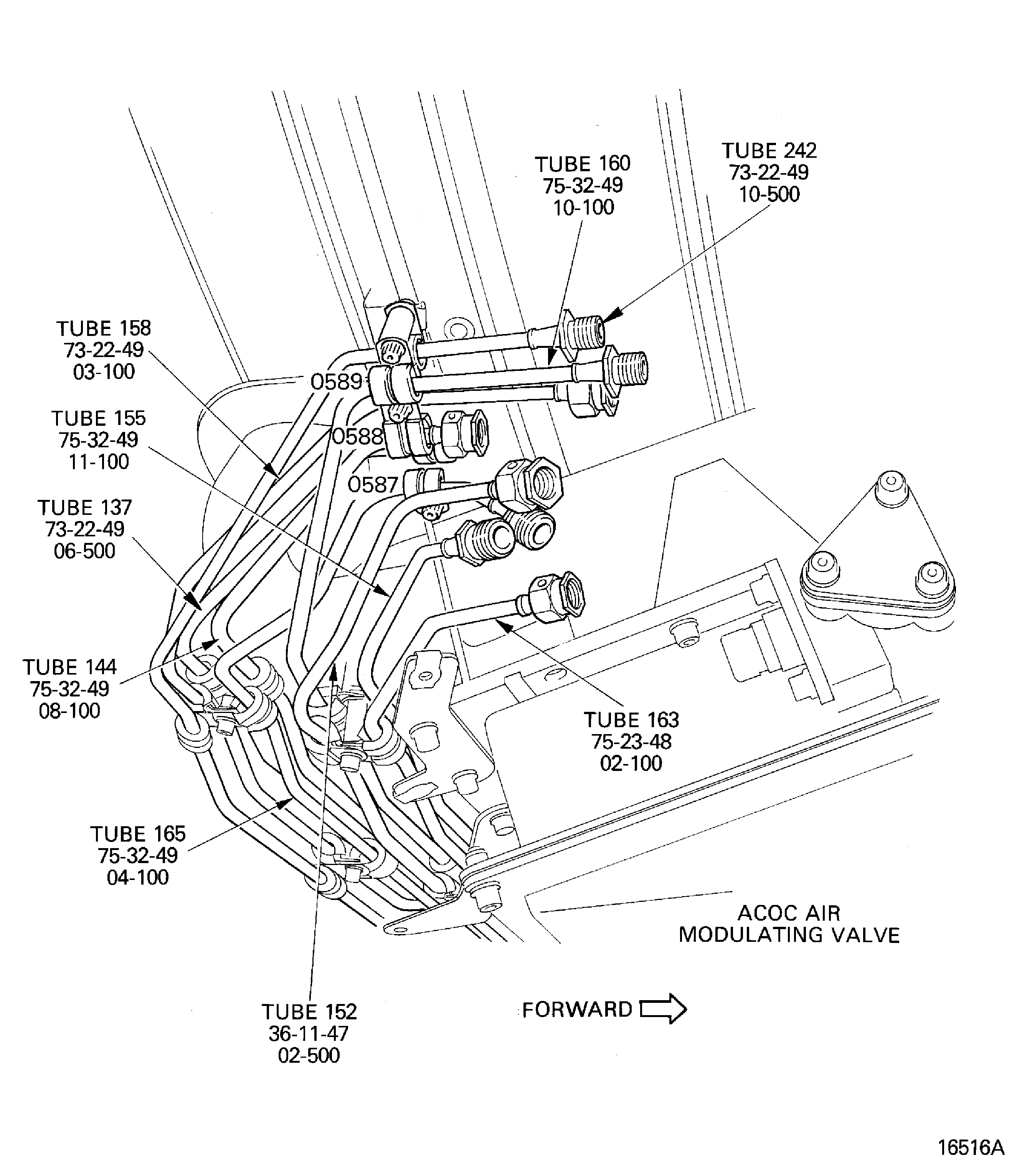

Pre SBE 75-0081: Refer to Figure.

SBE 75-0081: Refer to Figure.

SUBTASK 72-00-32-020-163 Remove the Tube 149, from the HP Compressor (HPC) Bleed Air Tube System

Disconnect the tube 190 from the ACOC air modulating valve. Disconnect the tube 191 from the tube 190. Remove the tube 190.

Pre SBE 75-0081: Refer to Figure.

SBE 75-0081: Refer to Figure.

SUBTASK 72-00-32-020-164 Remove the Tubes 190 and 189, the Fuel System Tubes

Remove the bolts, the washers, the nuts and the clipnut at the clip positions 1051, 0594 and 1026. Remove the tube 241.

Pre SBE 75-0081: Refer to Figure and Figure.

SBE 75-0081: Refer to Figure and Figure.

Remove the bolt, the washer, the clips and the nut at the clip position 0591.

Pre SBE 75-0081: Refer to Figure.

SBE 75-0081: Refer to Figure.

Disconnect the tube 151 from the HPC stage 7 and 10 air solenoid valve STAGE 10 AIR SOLENOID VALVE (36-11-57, 01-100). Disconnect the tube 152 from the tube 151. Remove the tube 151.

Disconnect the tube 154 from the HPC stage 7 solenoid valve (51.9 degrees) and the tube 155. Remove the tube 154.

Pre SBE 75-0081: Refer to Figure.

SBE 75-0081: Refer to Figure.

Disconnect the tube 195 (the turbine cooling controlled air tube) from the stage 10 air solenoid valve AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-100). Disconnect the tube 163 from the tube 195.

SUBTASK 72-00-32-020-165 Remove the Right Side Tubes

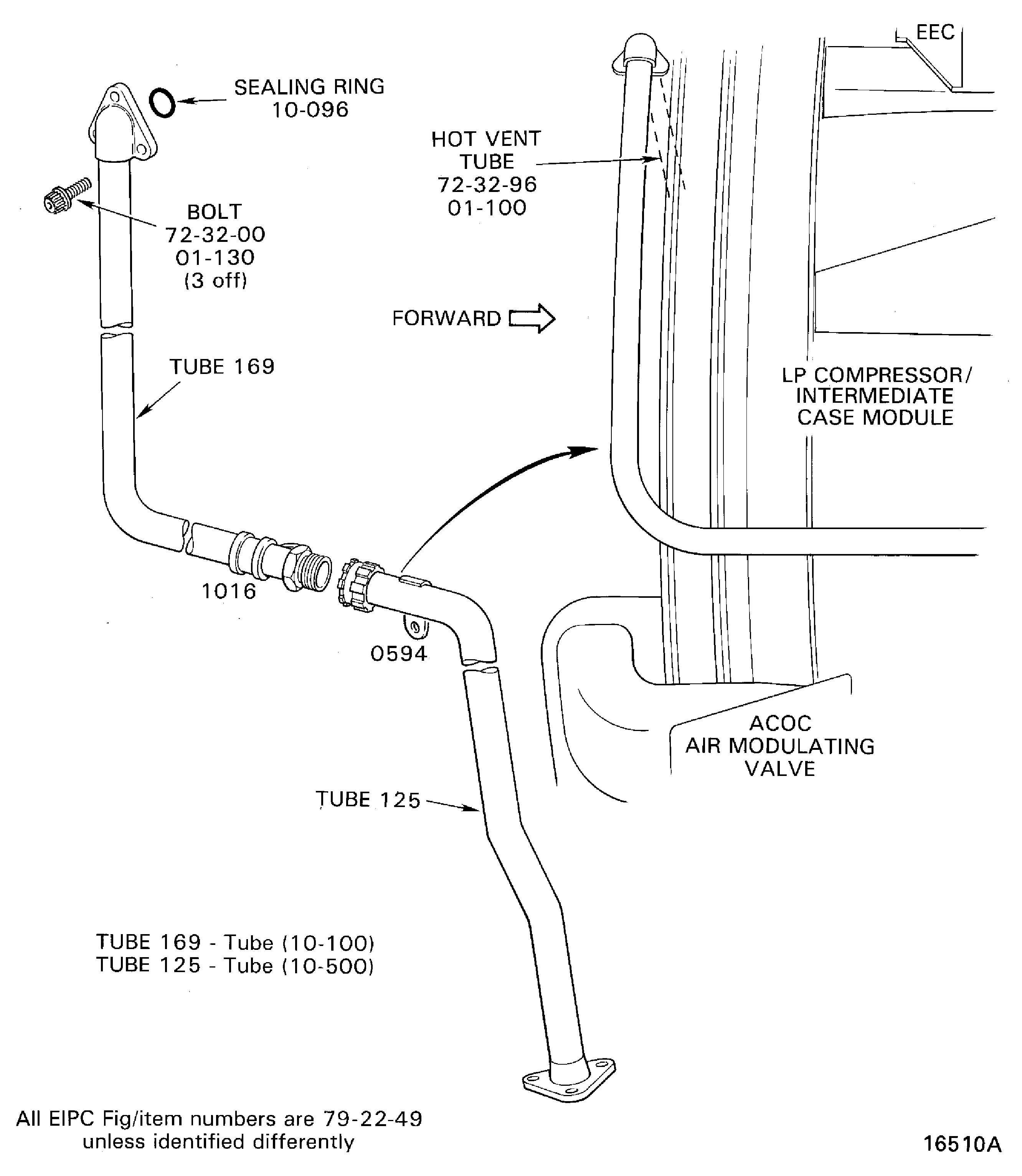

Refer to Figure.

Disconnect and remove the tube 125 from the tube 169 with the IAE 1R18003 Wrench 1 off.

Remove the three bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-130) which attach the tube 169 to the LP compressor/intermediate case module and the hot vent tube INTERMEDIATE STRUCTURE OIL & AIR TRANSFER TUBES (72-32-96, 01-100). Remove the tube 169 and the sealing ring.

Lubricate the three bolts (removed in the previous step) with CoMat 10-077 APPROVED ENGINE OILS. Install and tighten the three bolts in the module.

SUBTASK 72-00-32-020-166 Remove the Tubes 125 and 169, the Oil Scavenge Tubes

NOTE

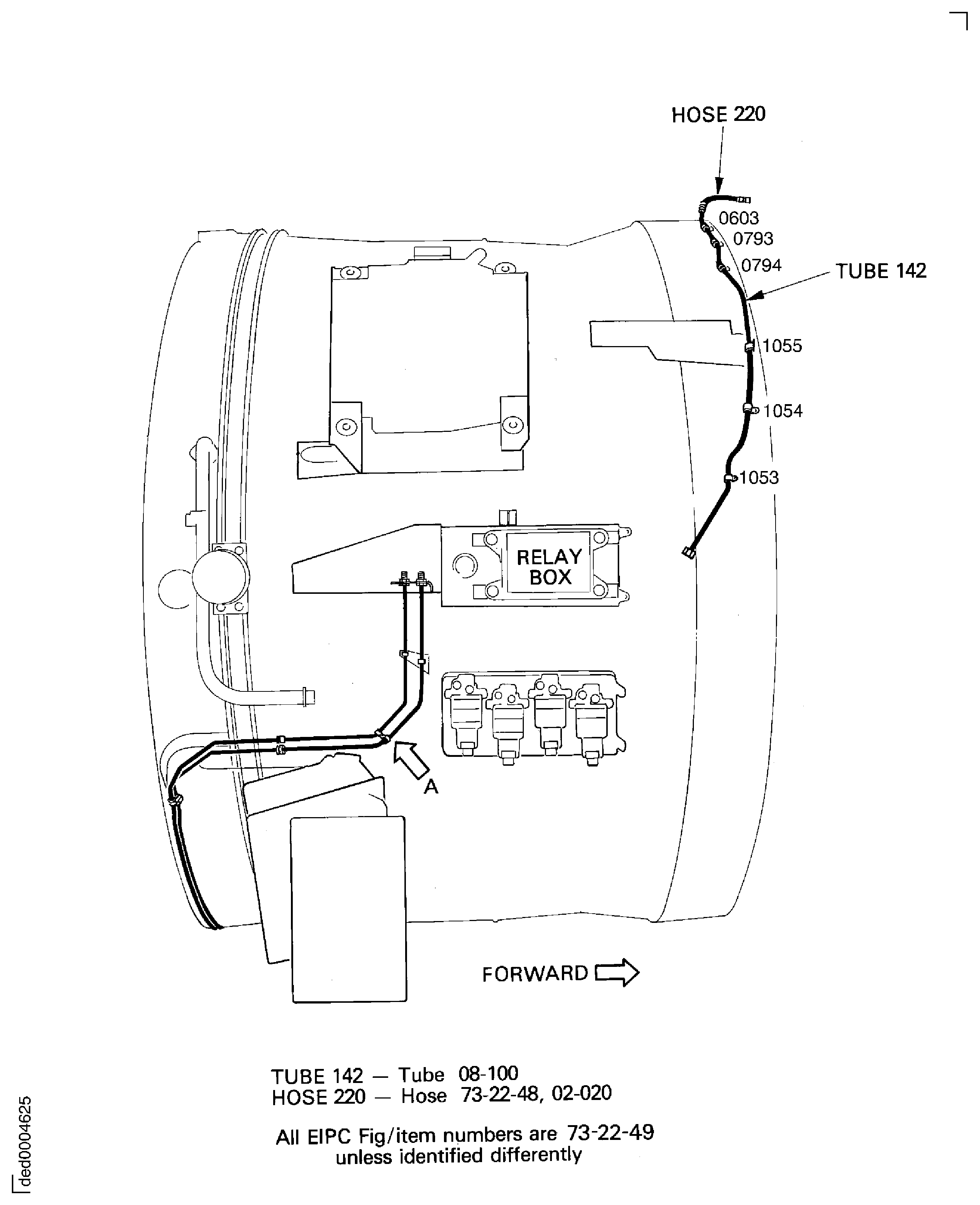

The clip position 0793 is temporarily installed during TASK 72-00-32-020-001-B00 to attach the tube 142 to the flange FA bracket.Remove the bolts, the washers, the nuts, the clipnuts and the clips at the clip positions 1053, 1054, 1055, 0603, 0793 and 0794. Remove the tube 142 and the hose 220.

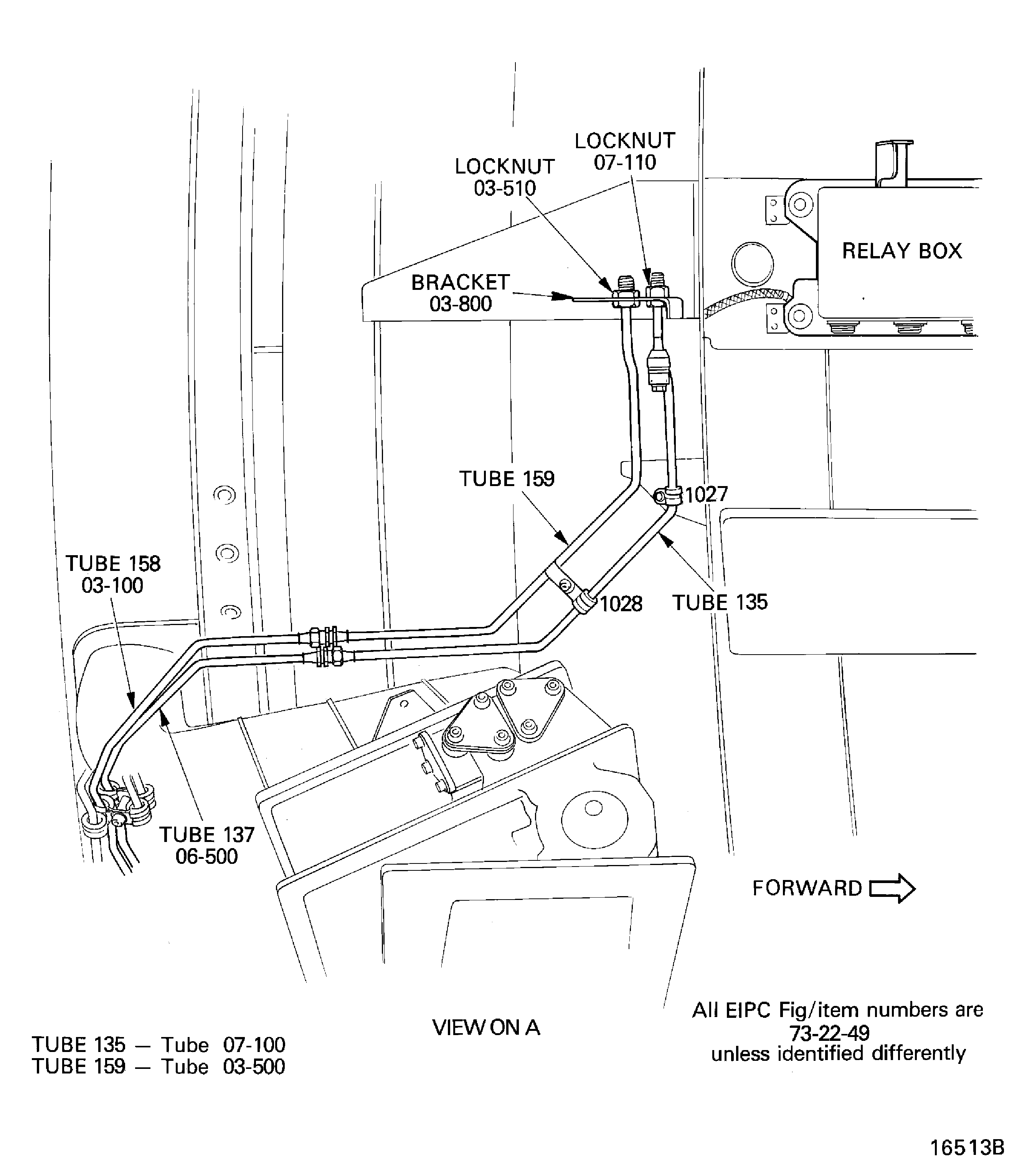

SUBTASK 72-00-32-020-167 Remove the Tubes 159, 135 and 142, the Fuel System Air Tubes and the Hose 220

Refer to Figure.

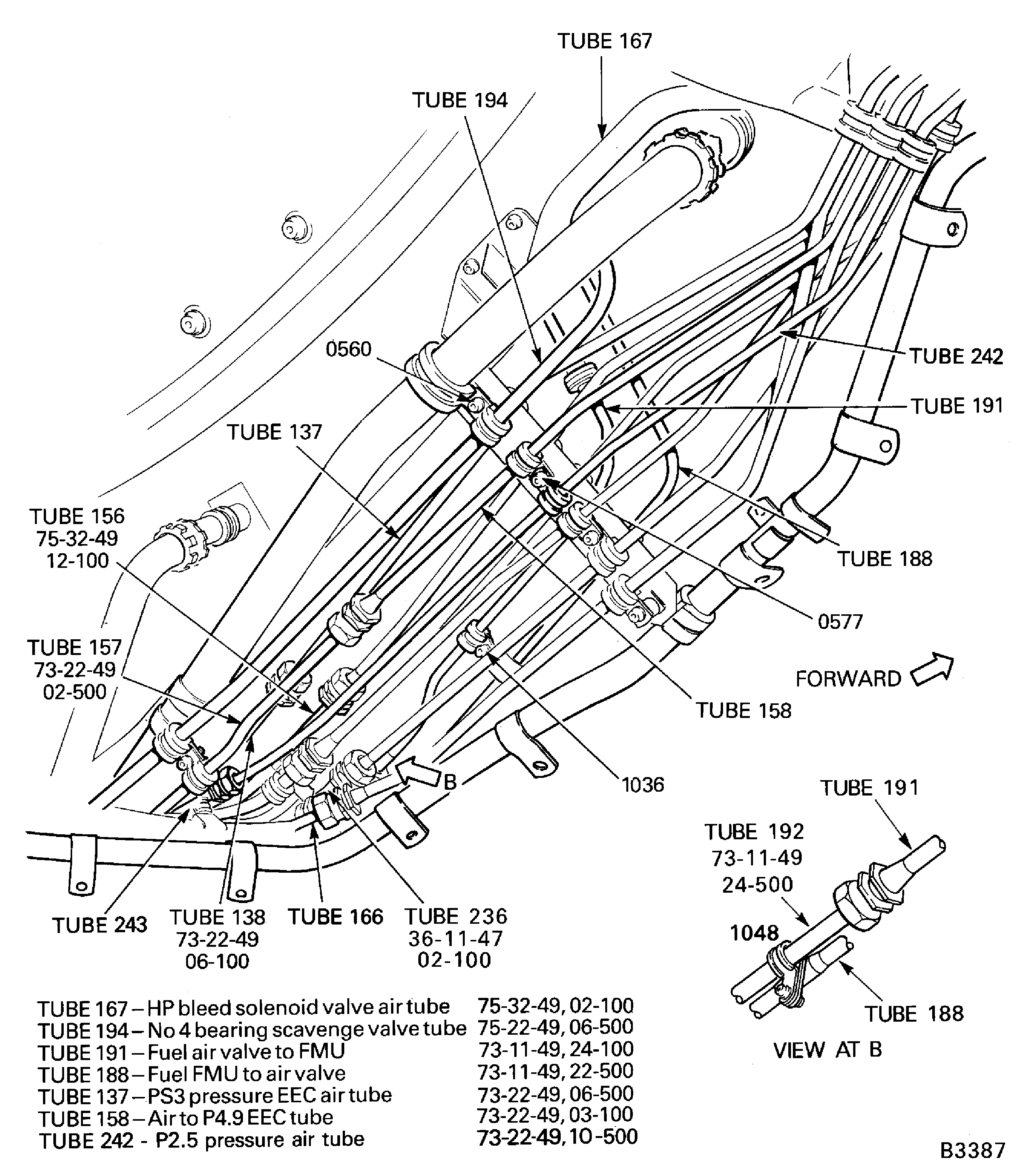

SUBTASK 72-00-32-020-168 Remove the Clip Position 1048

Refer to Figure.

Remove the bolt, the washers, the nut and the clips at the clip position 0560. Temporarily attach the tubes 127 and 167 to the bracket Control Fuel Tubes (73-11-49, 22-470) at the clip position 0560.

SUBTASK 72-00-32-020-170 Remove the Tubes 137 and 194, the Bottom Right Side Tubes

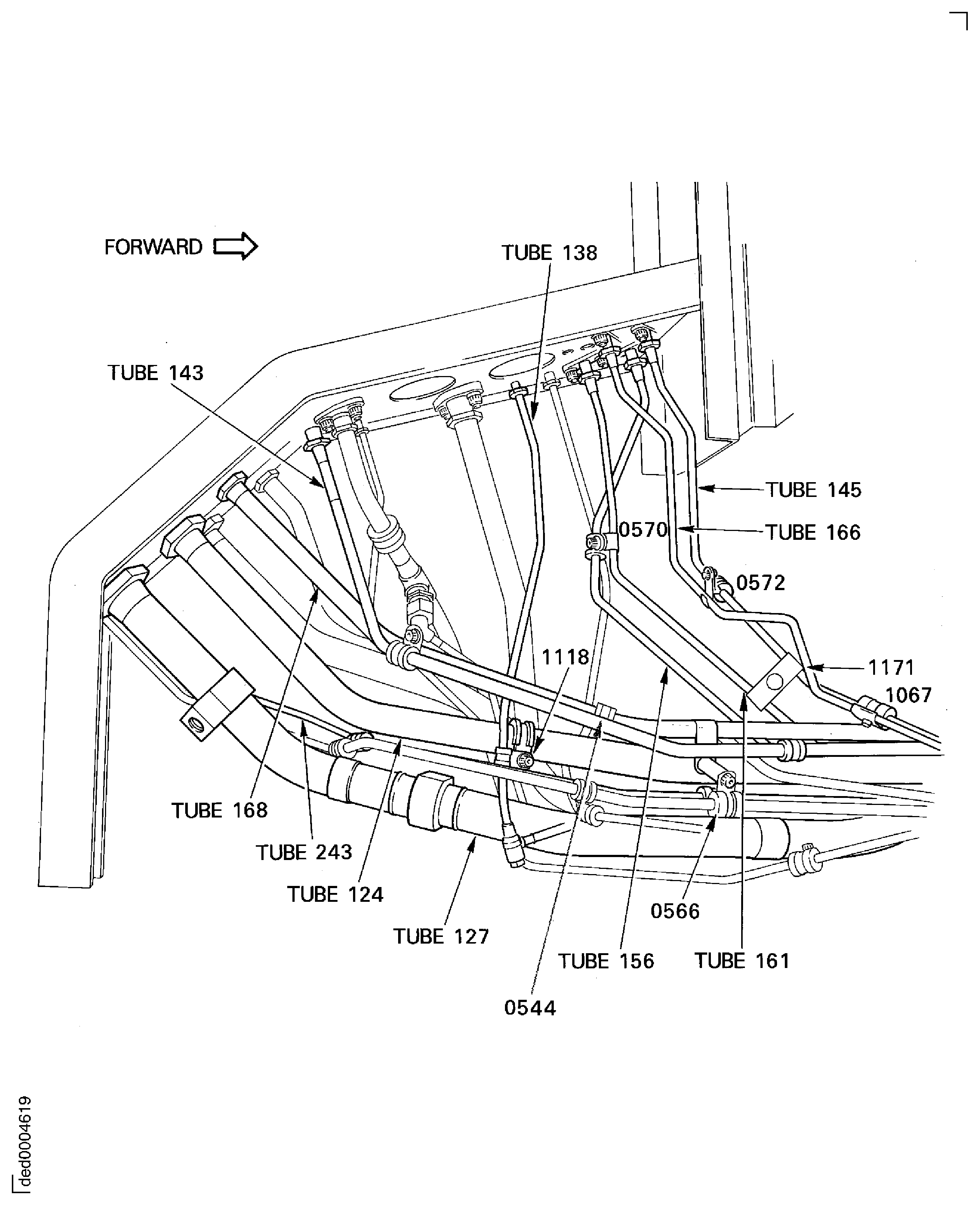

Remove the bolts, the washers, the nuts and the clips at the clip position 0574, 0572, 1067 and 1171.

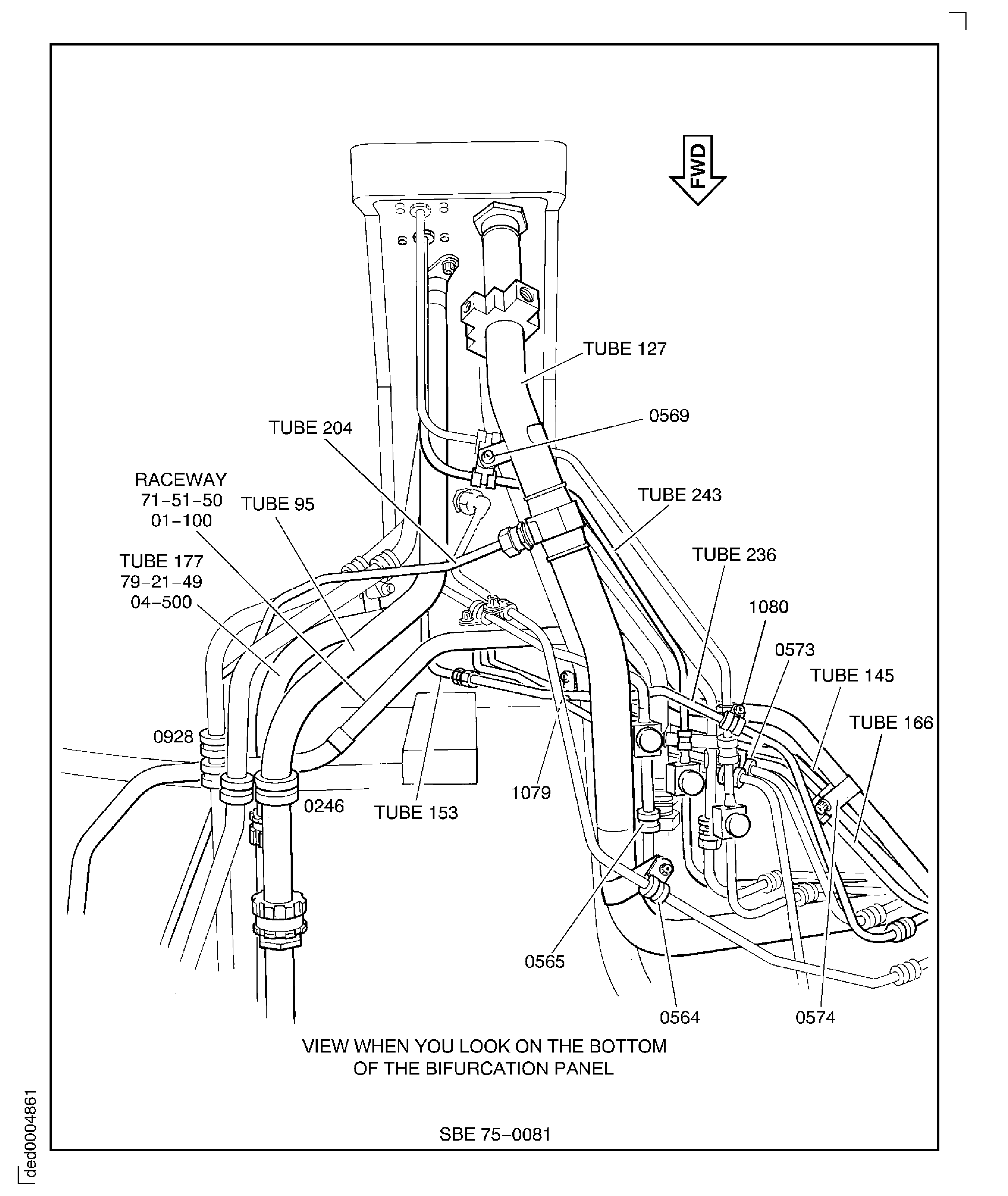

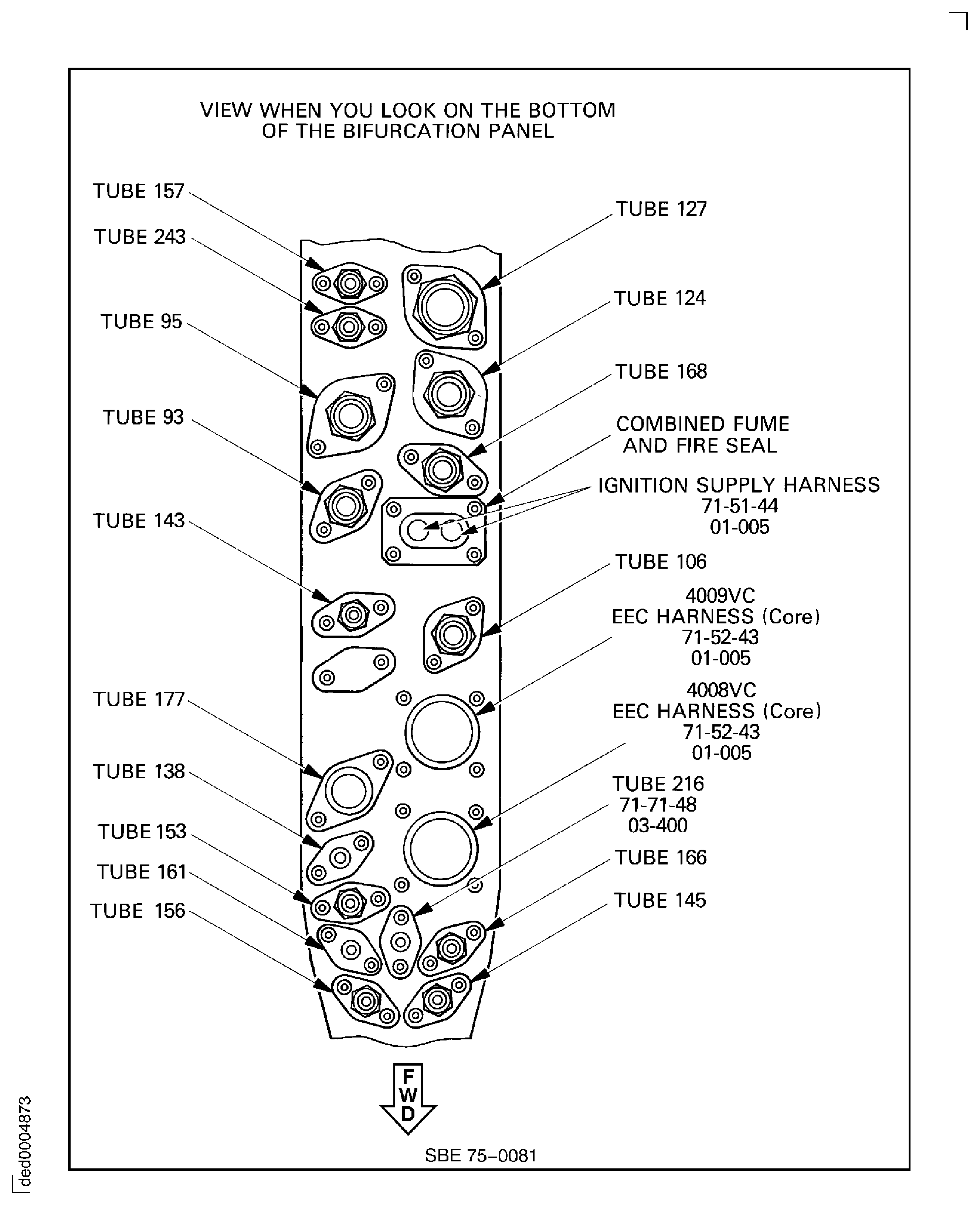

Pre SBE 75-0081: Refer to Figure and Figure.

SBE 75-0081: Refer to Figure and Figure.

SUBTASK 72-00-32-020-171 Remove the Bifurcation Panel Tubes

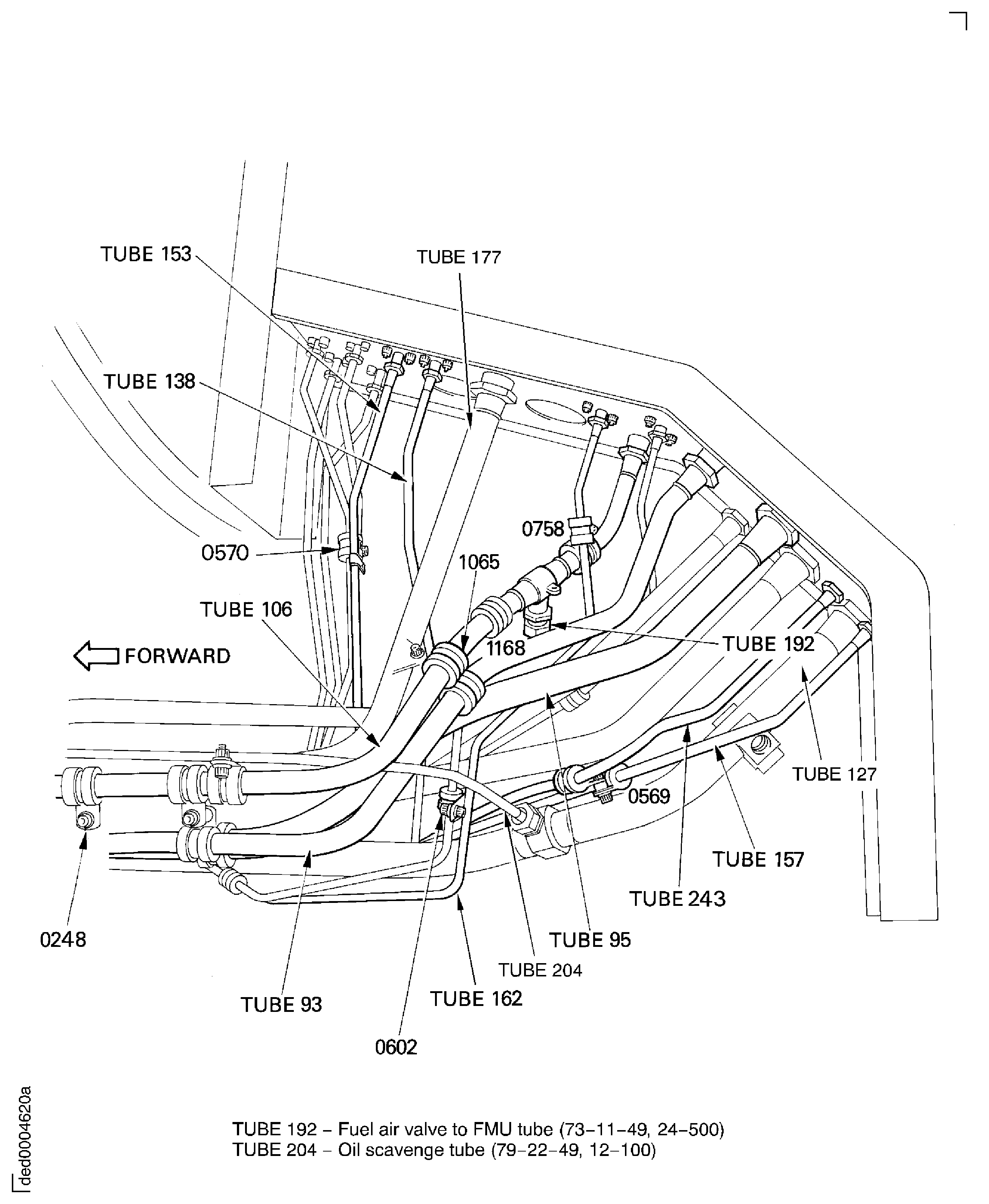

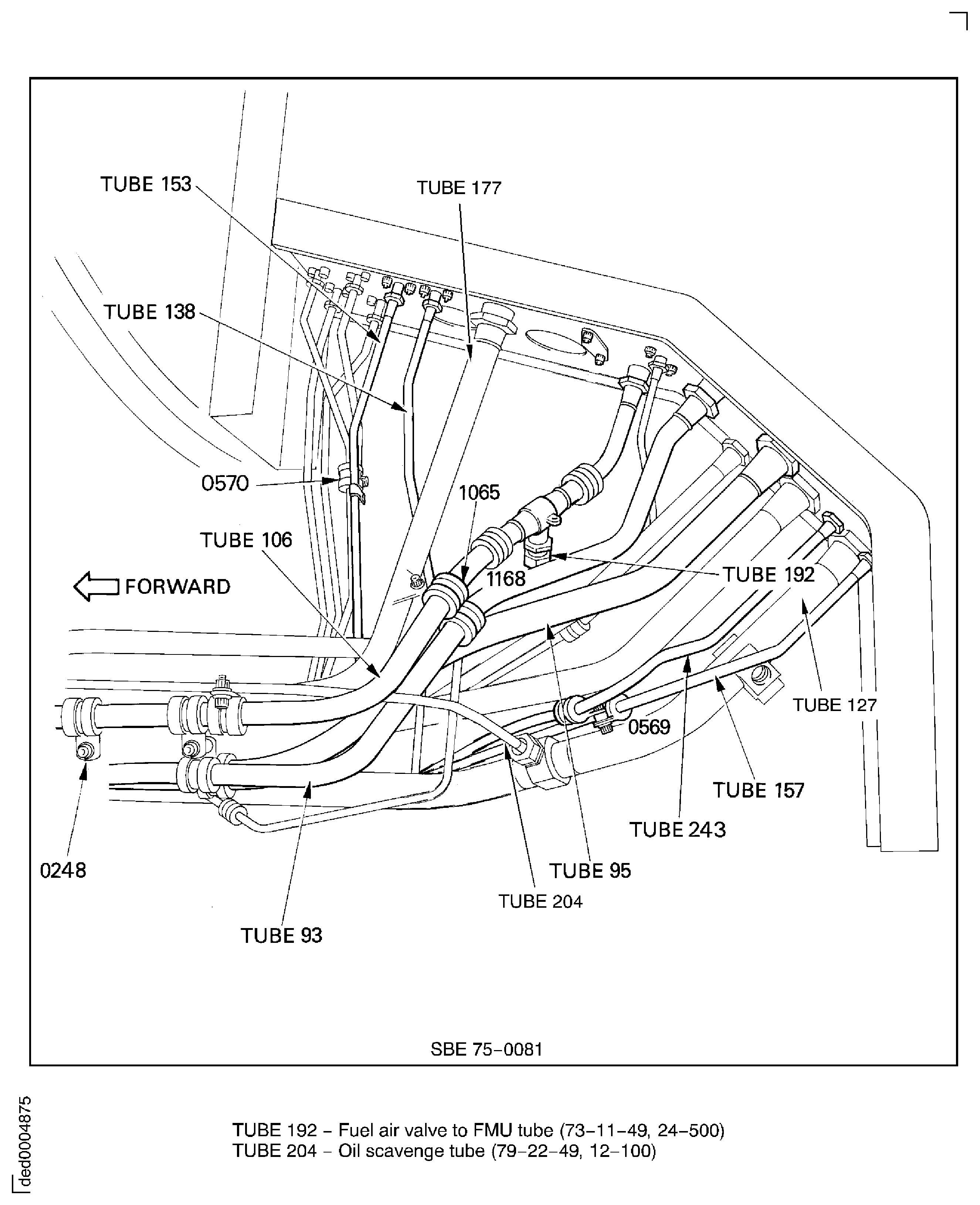

Pre SBE 75-0081: Remove the bolts, the washers, the nuts and the clips at the clip positions 0248, 0758, 0928, 0602, 0564 and 1168 remove the tube 192. Temporarily attach the tube 162 to the tube 127 at the clip position 0564.

SBE 75-0081: Remove the bolts, the washers, the nuts and the clips at the clip positions 0248, 0758, 0928, 0602, 0564 and 1168 remove the tube 192.

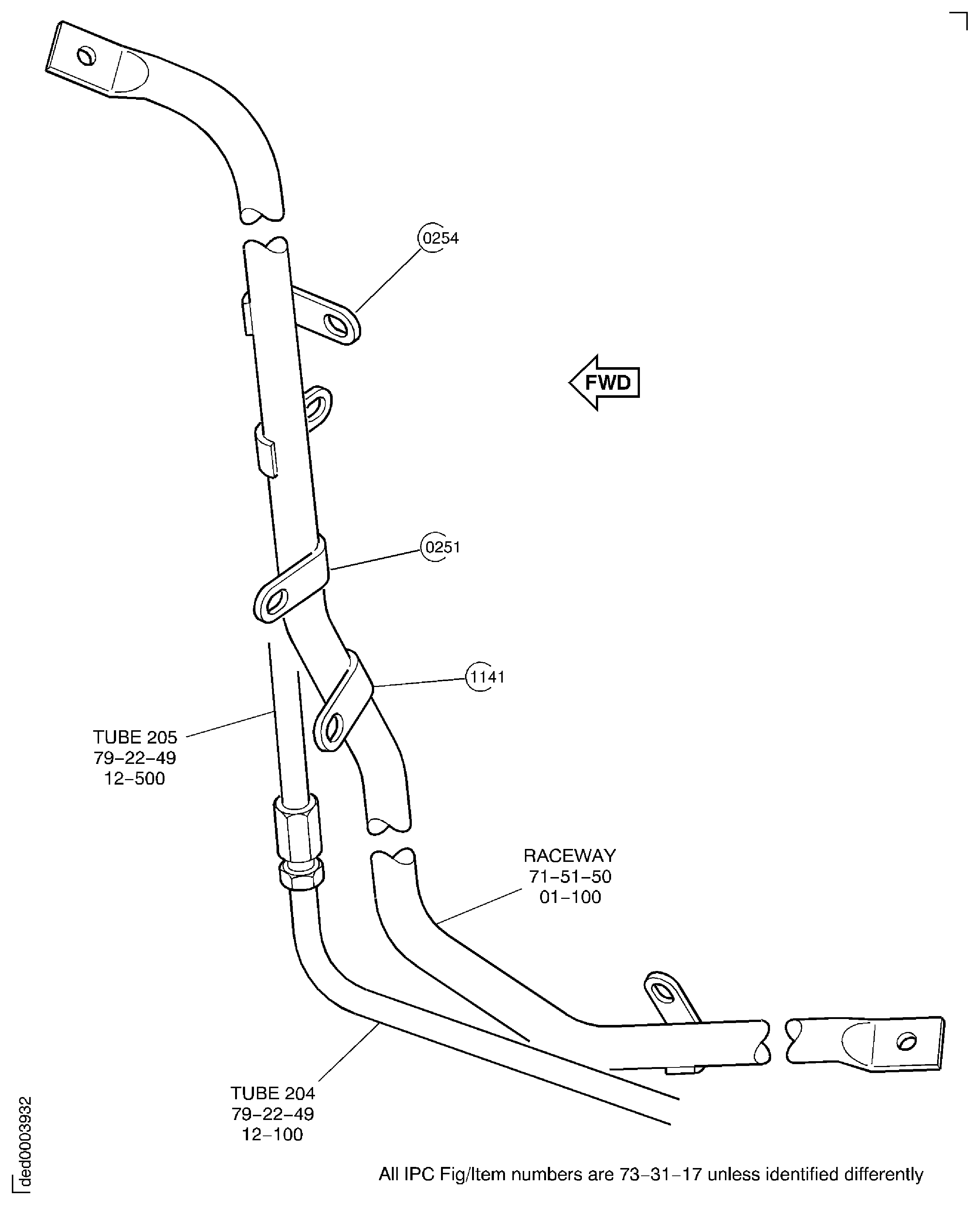

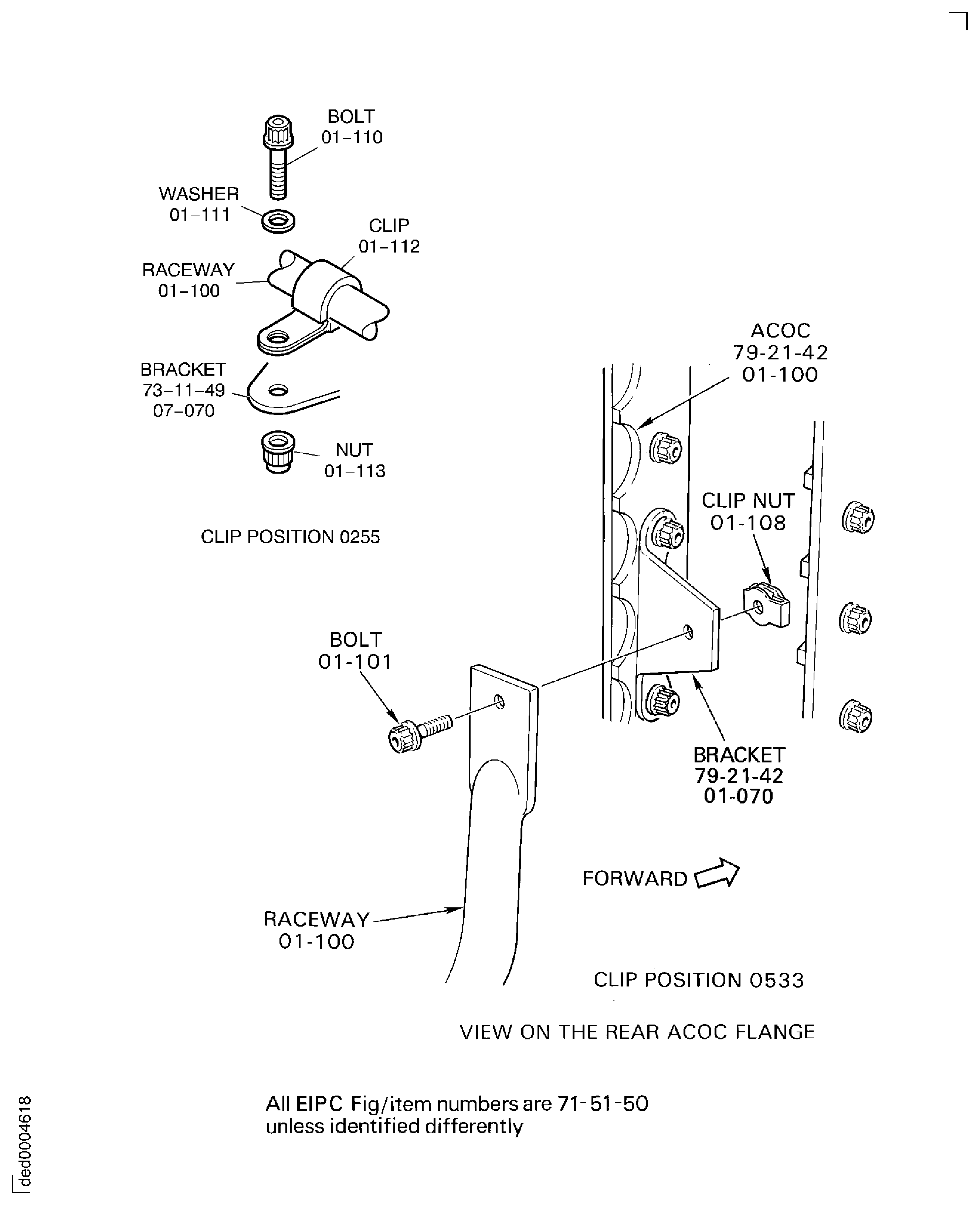

Remove the bolts, the washers, the spacers, the nuts and the clips at the clip positions 1065 and 0246. Temporarily attach the raceway Fan Harness Support Raceways (71-51-50, 01-100) to the tube 177 clip with the bolt, the washer and the nut at the clip position 0246.

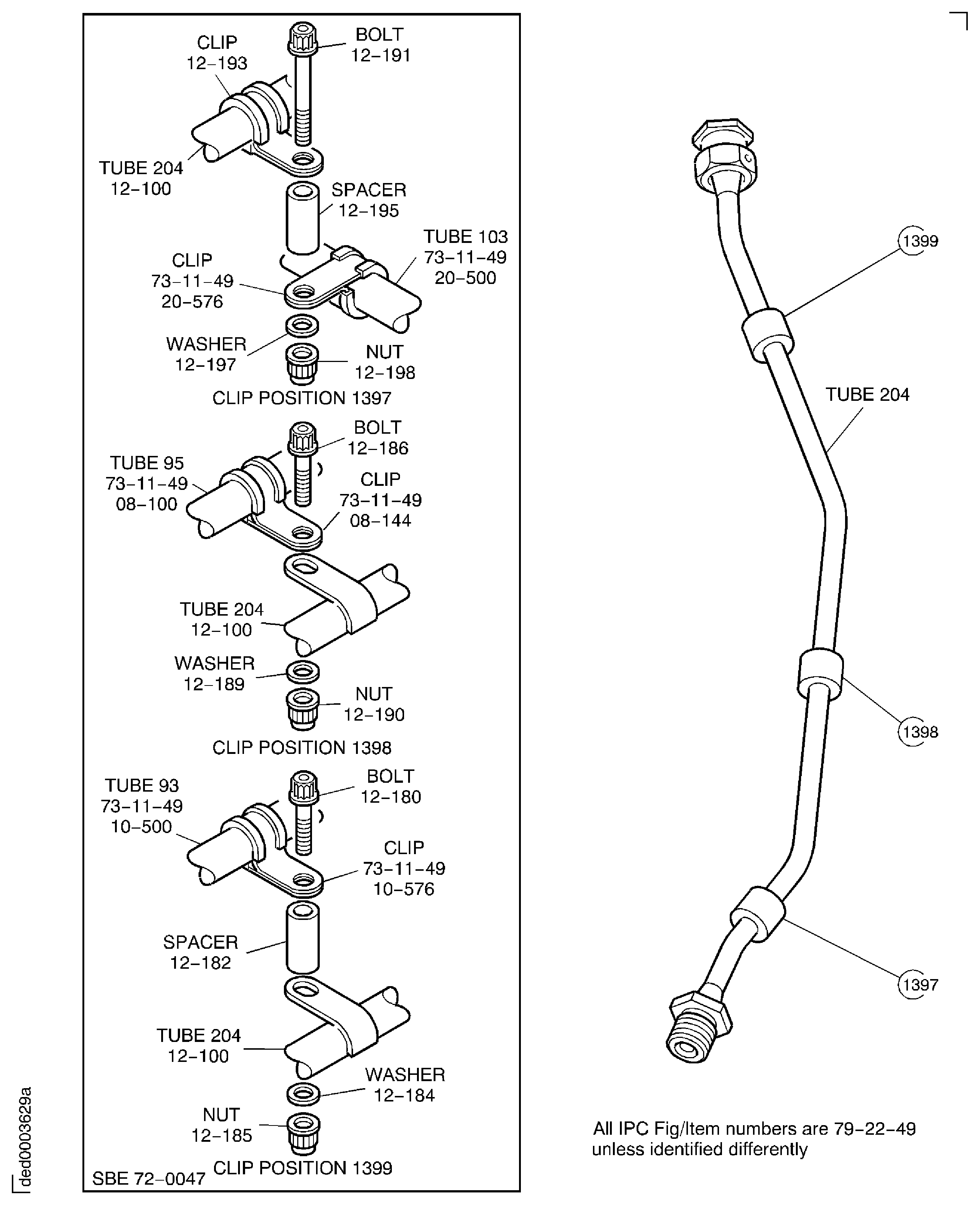

SUBTASK 72-00-32-020-172-A00 Remove the Tubes 192, 93 and 106 from the Fuel System (Pre SBE 79-0047)

Pre SBE 75-0081: Remove the bolts, the washers, the nuts and the clips at the clip positions 0758,1399, 0602 and 0564 remove the tube 192. Temporarily attach the tube 162 to the tube 127 at the clip position 0564.

SBE 75-0081: Remove the bolts, the washers, the nuts and the clips at the clip positions 1399 and 0564 remove the tube 192.

Remove the bolts, the washers, the spacers, the nuts and the clips at the clip positions 1065 and 0246. Temporarily attach the raceway Fan Harness Support Raceways (71-51-50, 01-100) to the tube 177 clip with the bolt, the washer and the nut at the clip position 0246.

SUBTASK 72-00-32-020-172-B00 Remove the Tubes 192, 93 and 106 from the Fuel System (SBE 79-0047)

SUBTASK 72-00-32-020-173-A00 Remove the Tube 204 from the Oil Scavenge System (Pre SBE 79-0047)

SUBTASK 72-00-32-020-173-B00 Remove the Tube 204 from the Oil Scavenge System (SBE 79-0047)

NOTE

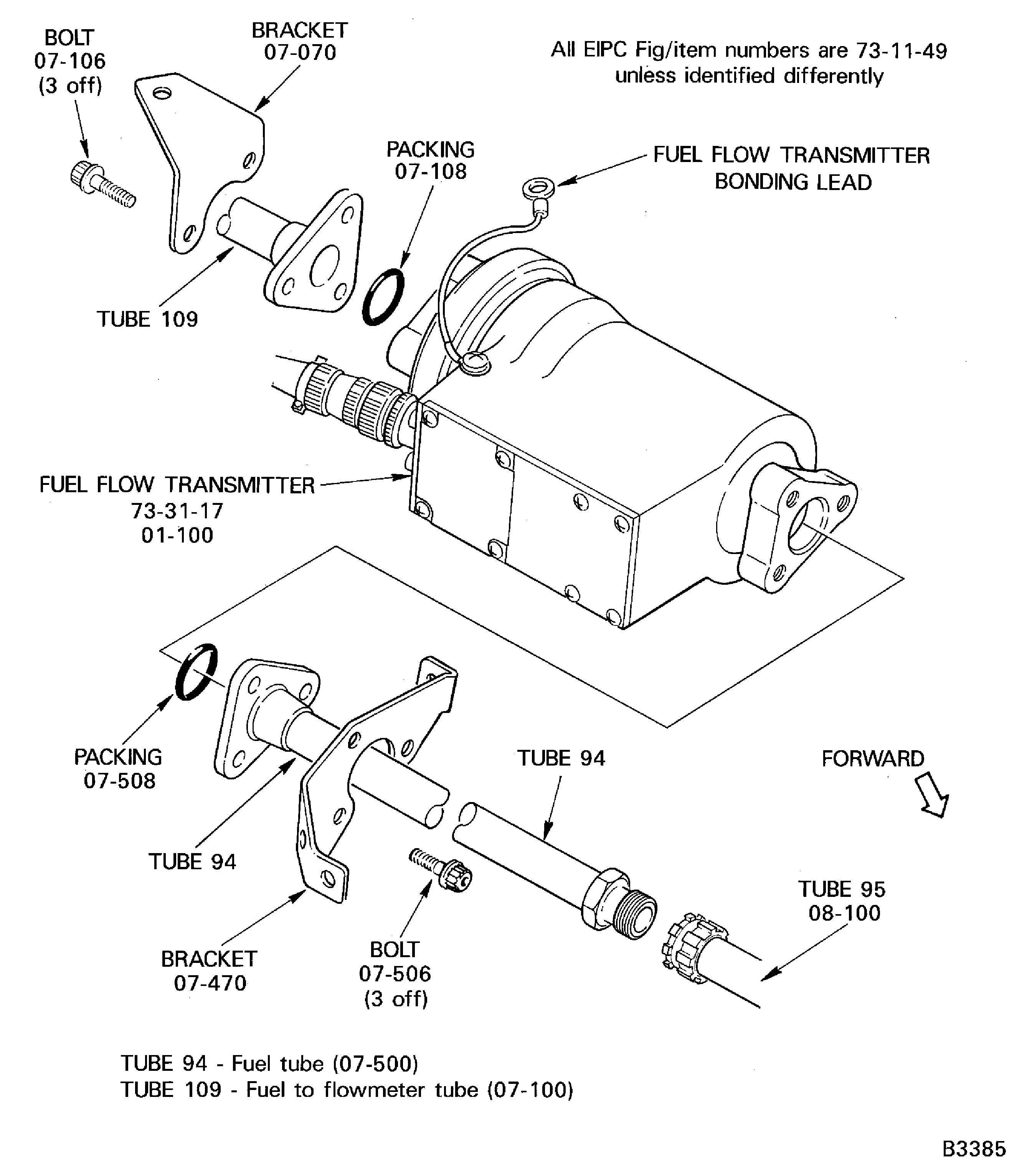

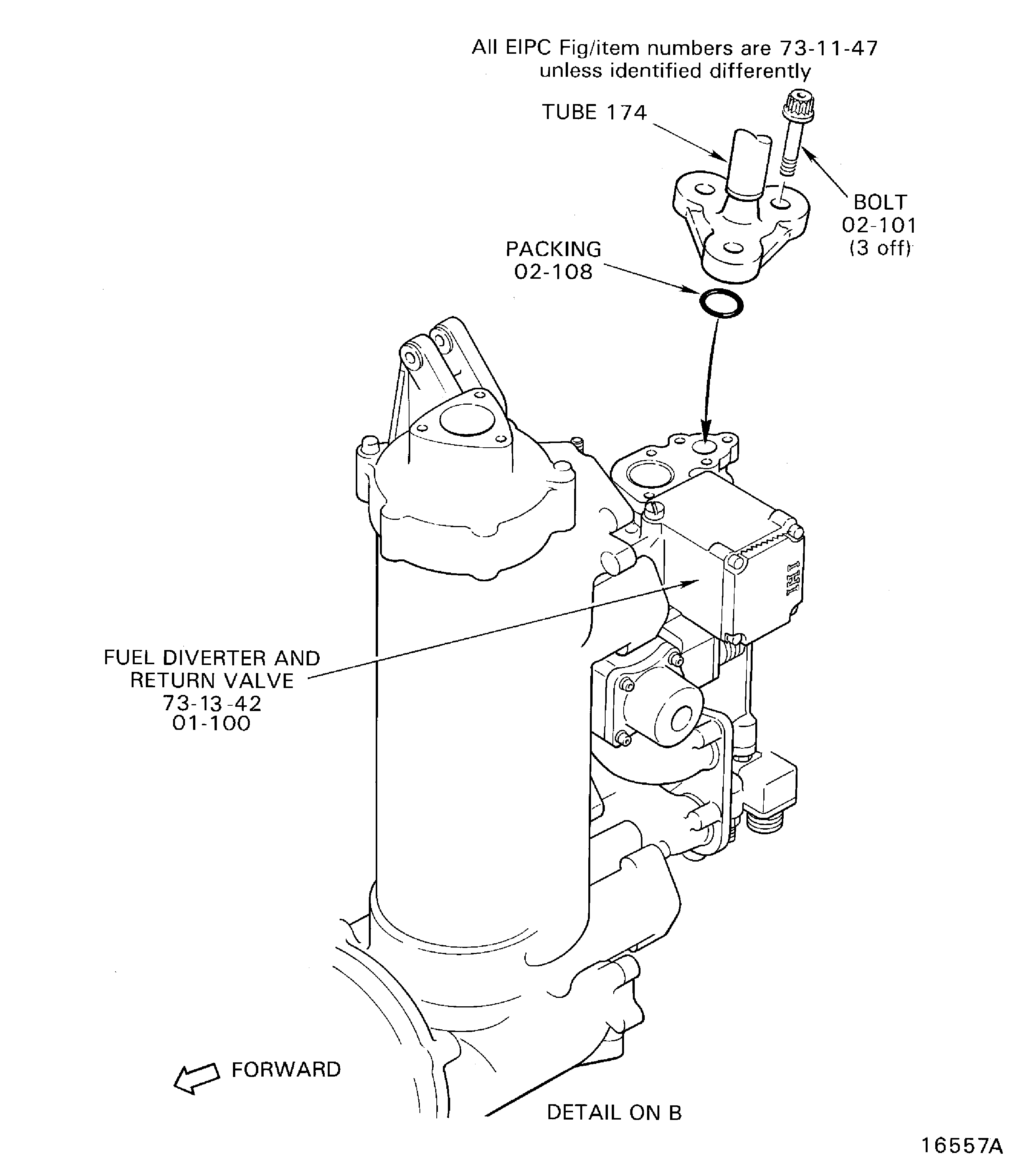

The fuel flow transmitter bonding lead which is attached to the raceway bonding lug at clip position 1141 is removed during TASK 72-00-32-020-003-B00 (REMOVAL-003, CONFIG-002).Remove the three bolts which attach the tube 109 to the fuel flow transmitter. Remove the bracket, the tube 109 and the packing.

Remove the tube 109 and the fuel flow transmitter.

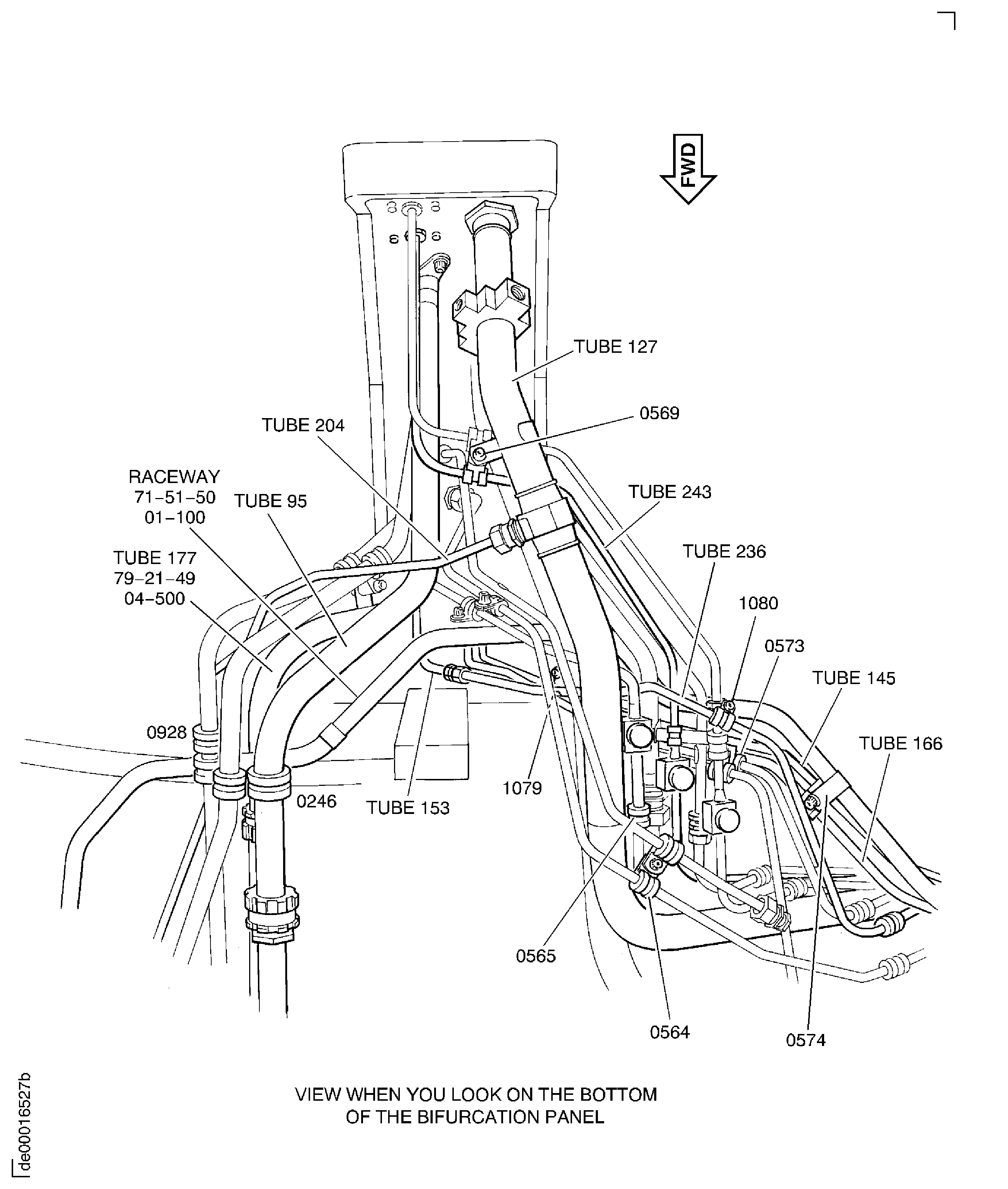

Disconnect the tube 95 from the tube 94 with the IAE 1R18001 Wrench. Remove the two bolts and the two nuts which attach the tube 95 to the bifurcation panel. Remove the tube 95.

SUBTASK 72-00-32-020-174 Remove the Tubes 109, 94, 95 and the Fuel Flow Transmitter from the Fuel System

NOTE

Some fuel drainage could occur during this procedure. It is recommended that an applicable container is available.Pre SBE 75-0081: Remove the two bolts and the two nuts which attach the tube 162 to the bifurcation panel. Remove the temporary clip position 0564 and remove the tube 162.

Disconnect the tube 236 from the tube 153. Remove the two bolts and the two nuts temporarily installed in TASK 72-00-32-020-002-B00. Remove the tube 153.

SUBTASK 72-00-32-020-175 Remove the Bifurcation Panel Tubes (Pre SBE 75-0081 and SBE 75-0081)

Refer to Figure.

Remove the two bolts and the two nuts which attach the tube 127 to the bifurcation panel. Remove the temporary clip position 0560 which attaches the tube 127 to the bracket Control Fuel Tubes (73-11-49, 22-470). Remove the tube 127.

SUBTASK 72-00-32-020-176 Remove the Tubes 124 and 127, the Scavenge Oil Tubes

NOTE

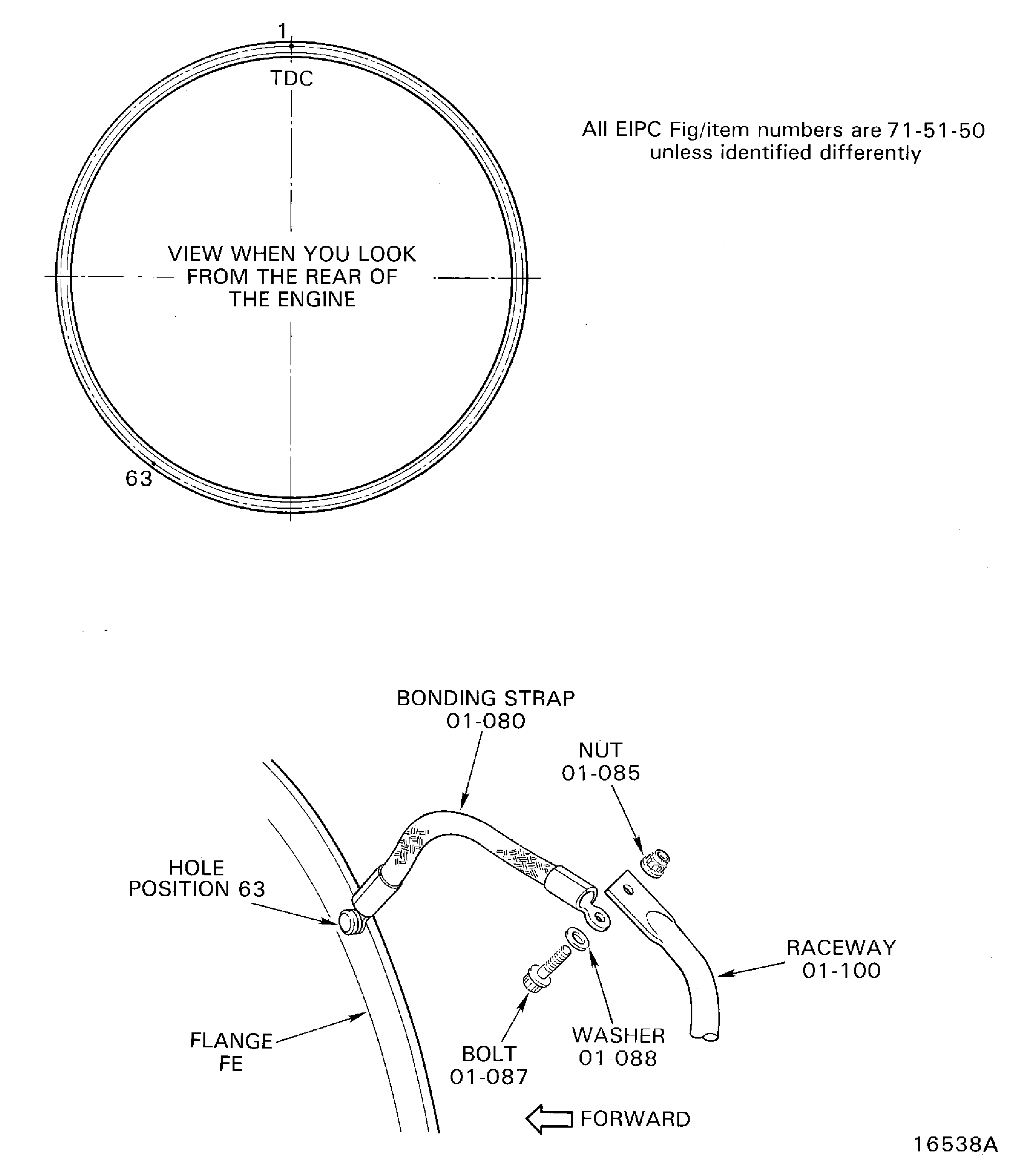

The bonding strap (and the nut and the bolt which attaches it) is permanently installed on the LP compressor/intermediate case module flange. It is not necessary to remove the bonding strap in this procedure.Remove the bolt, the washer and the nut which attaches the bonding strap to the raceway.

SUBTASK 72-00-32-020-177 Remove the Electrical Harness Raceway (71-51-50, 01-100)

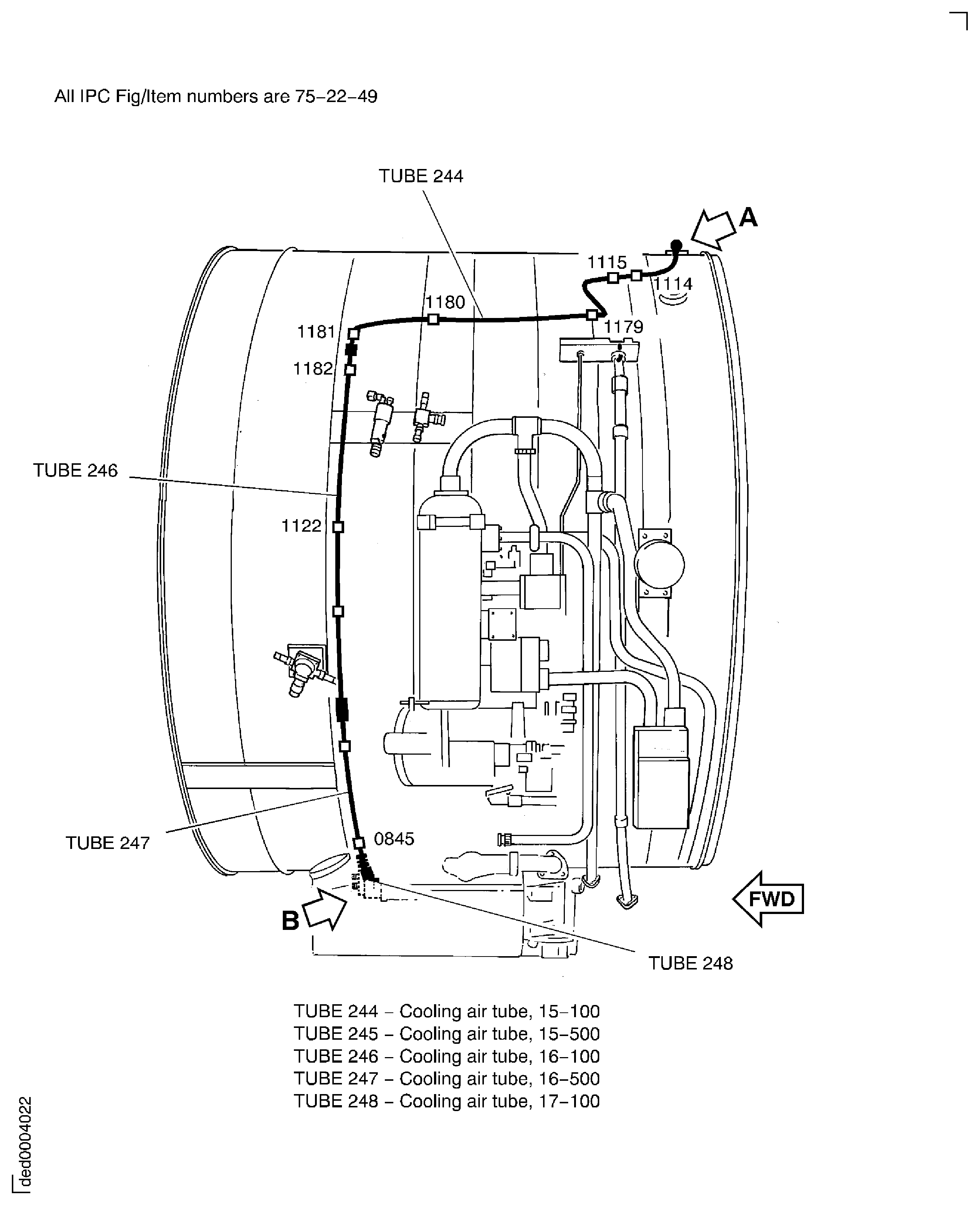

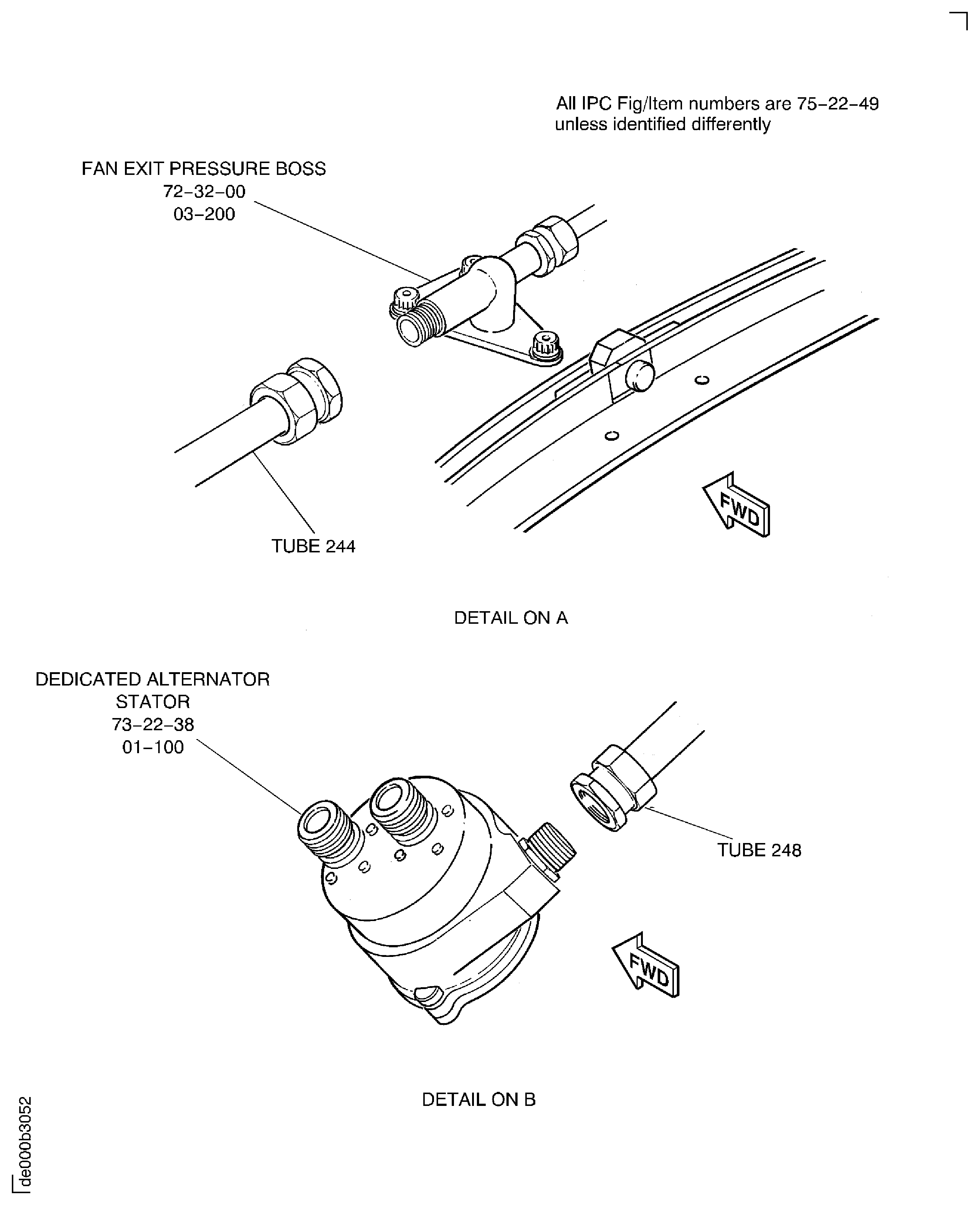

SUBTASK 72-00-32-020-180-A00 Remove the Tubes 244, 245, 246, 247 and 248, the Dedicated Alternator Cooling Air Tubes (SBE 75-0010 and Pre SBE 72-0160)

SUBTASK 72-00-32-020-180-B00 Remove the Tubes 244, 246, 247 and 248, the Dedicated Alternator Cooling Air Tubes (SBE 72-0160)

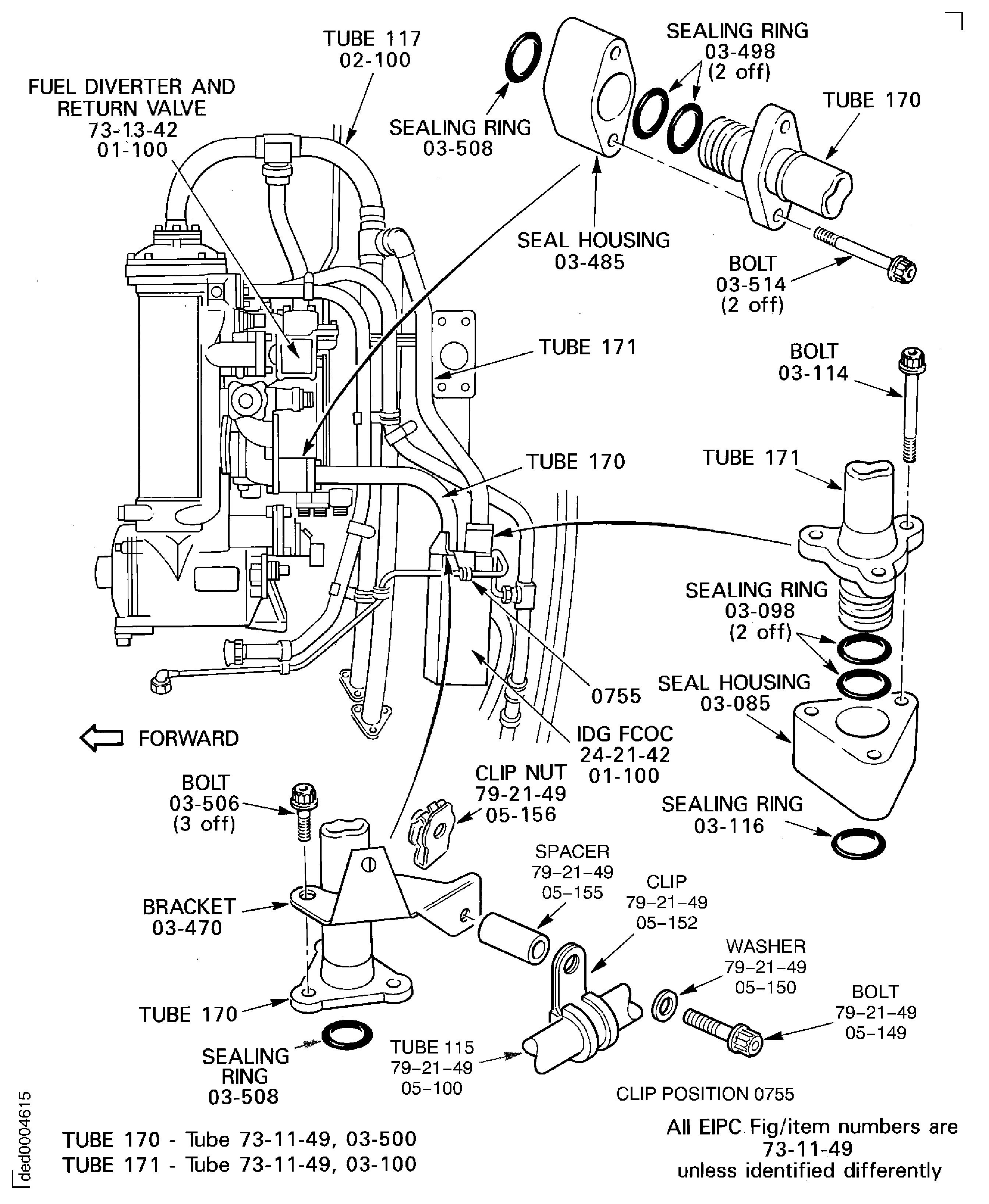

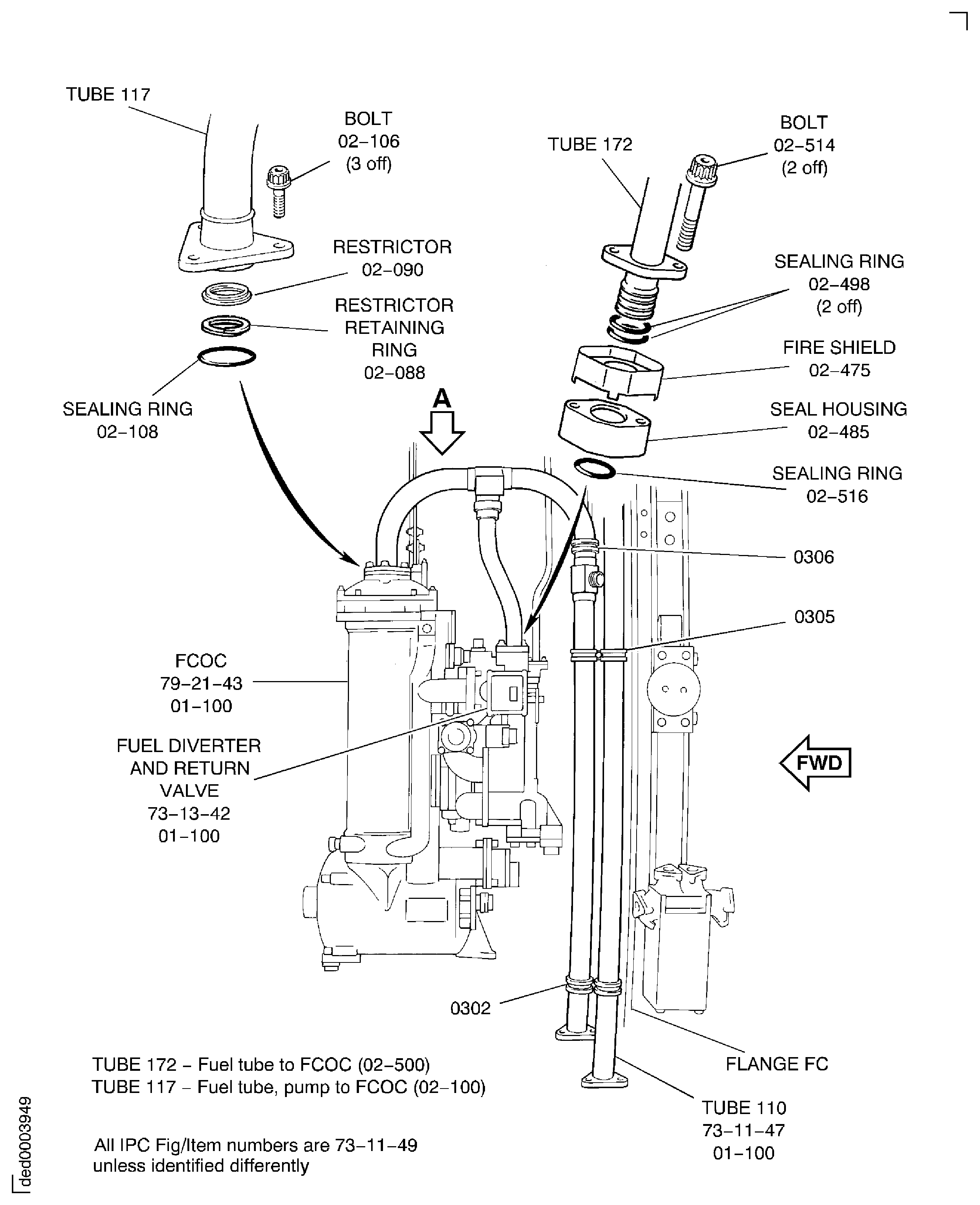

Refer to Figure.

Disconnect the tube 171 from the tube 117 with the IAE 1R18003 Wrench 1 off. Remove the tube 171, the seal housing and the three sealing rings.

SUBTASK 72-00-32-020-181 Remove the Tubes 171 and 170, the Fuel System Tubes

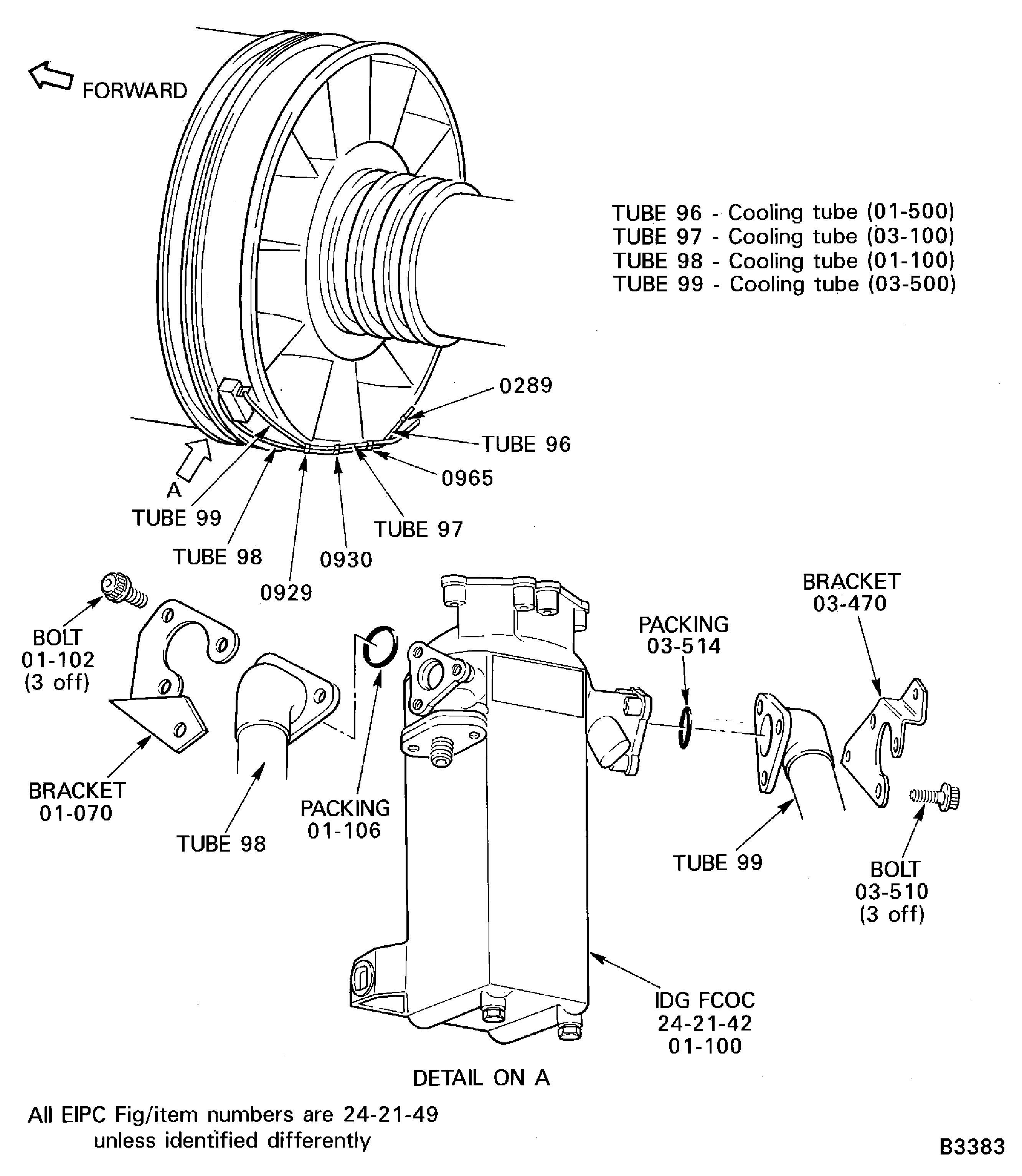

Refer to Figure.

SUBTASK 72-00-32-020-182 Remove the Tubes 98, 99, 97 and 96, the IDG Oil Cooling Tubes

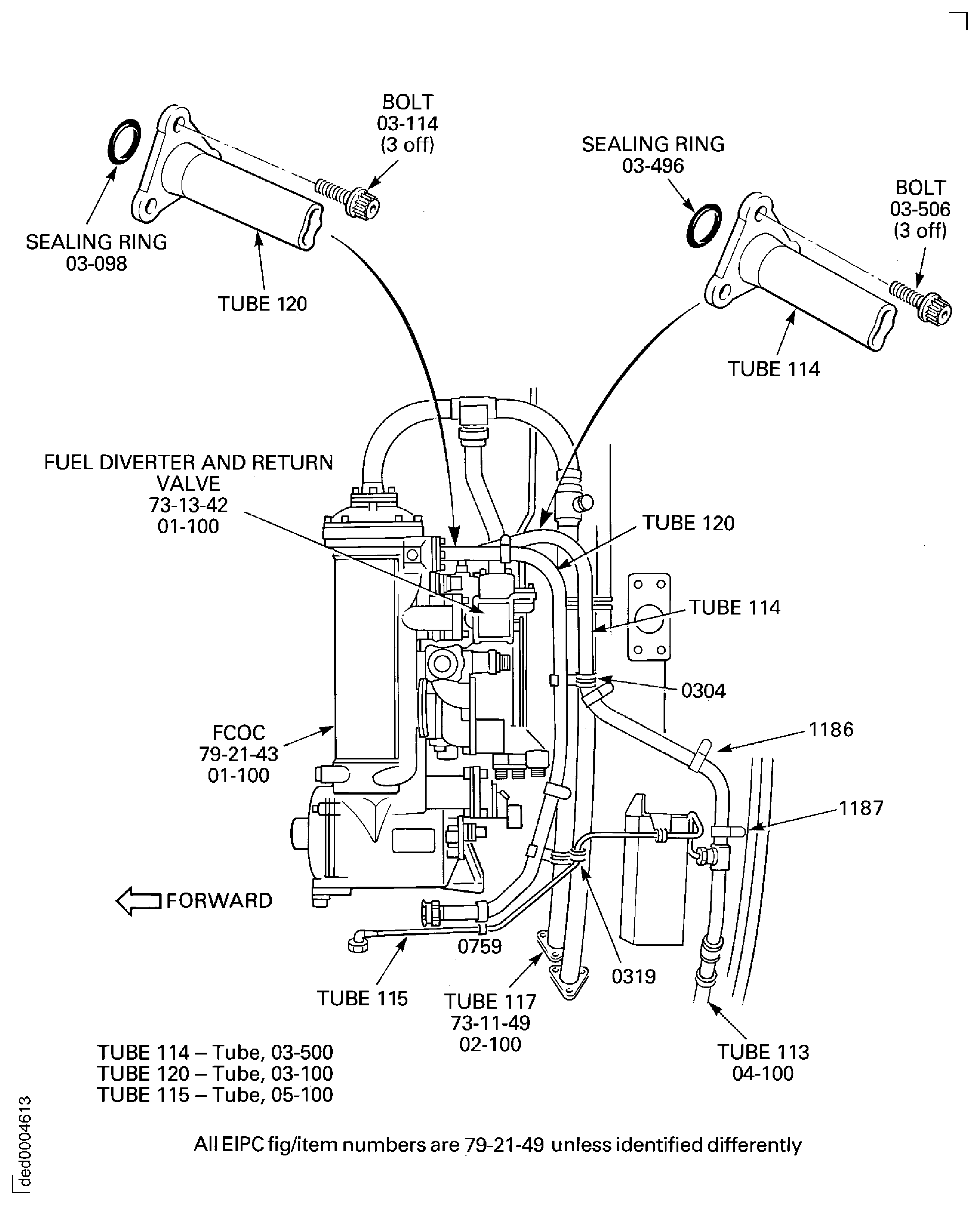

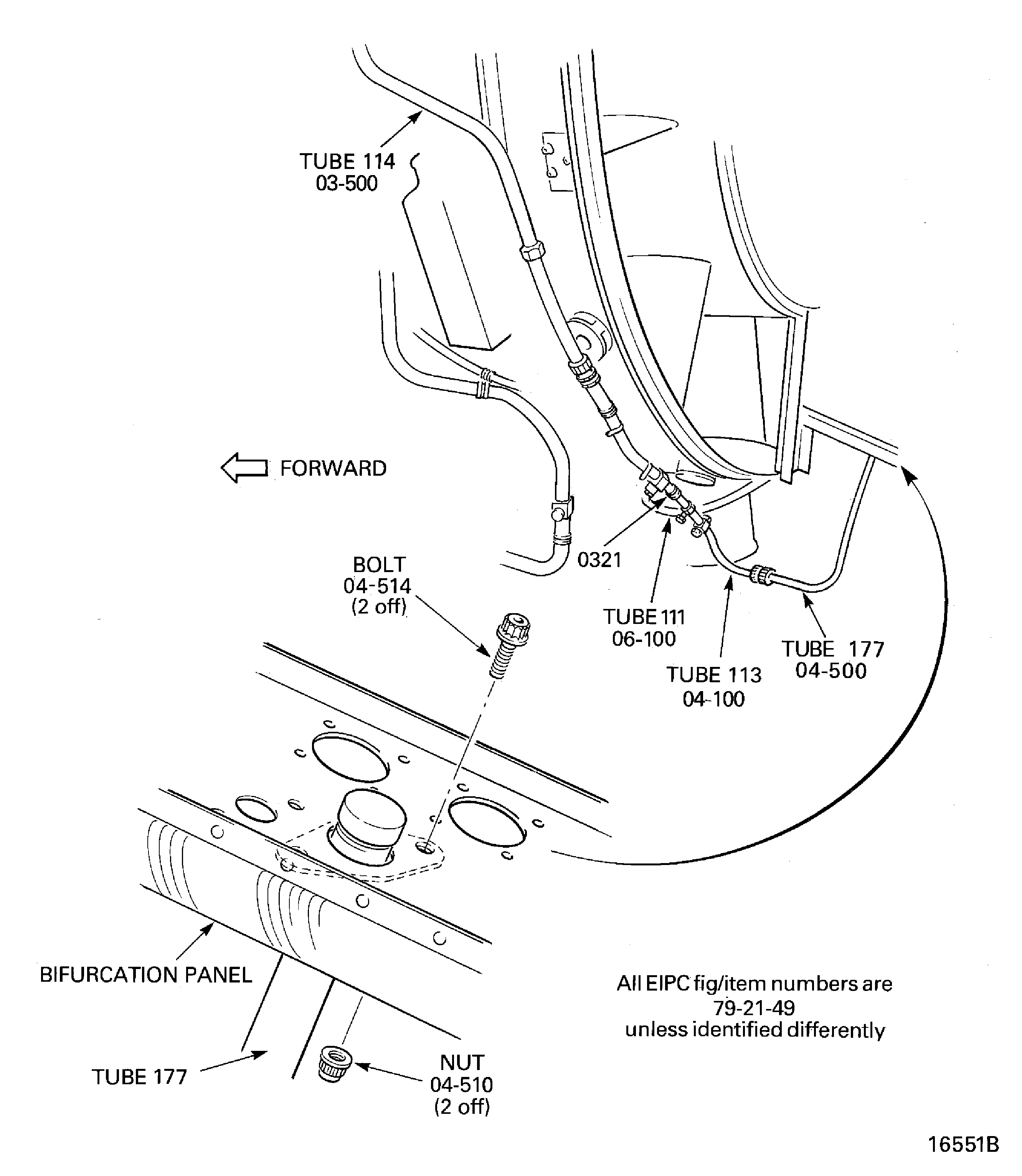

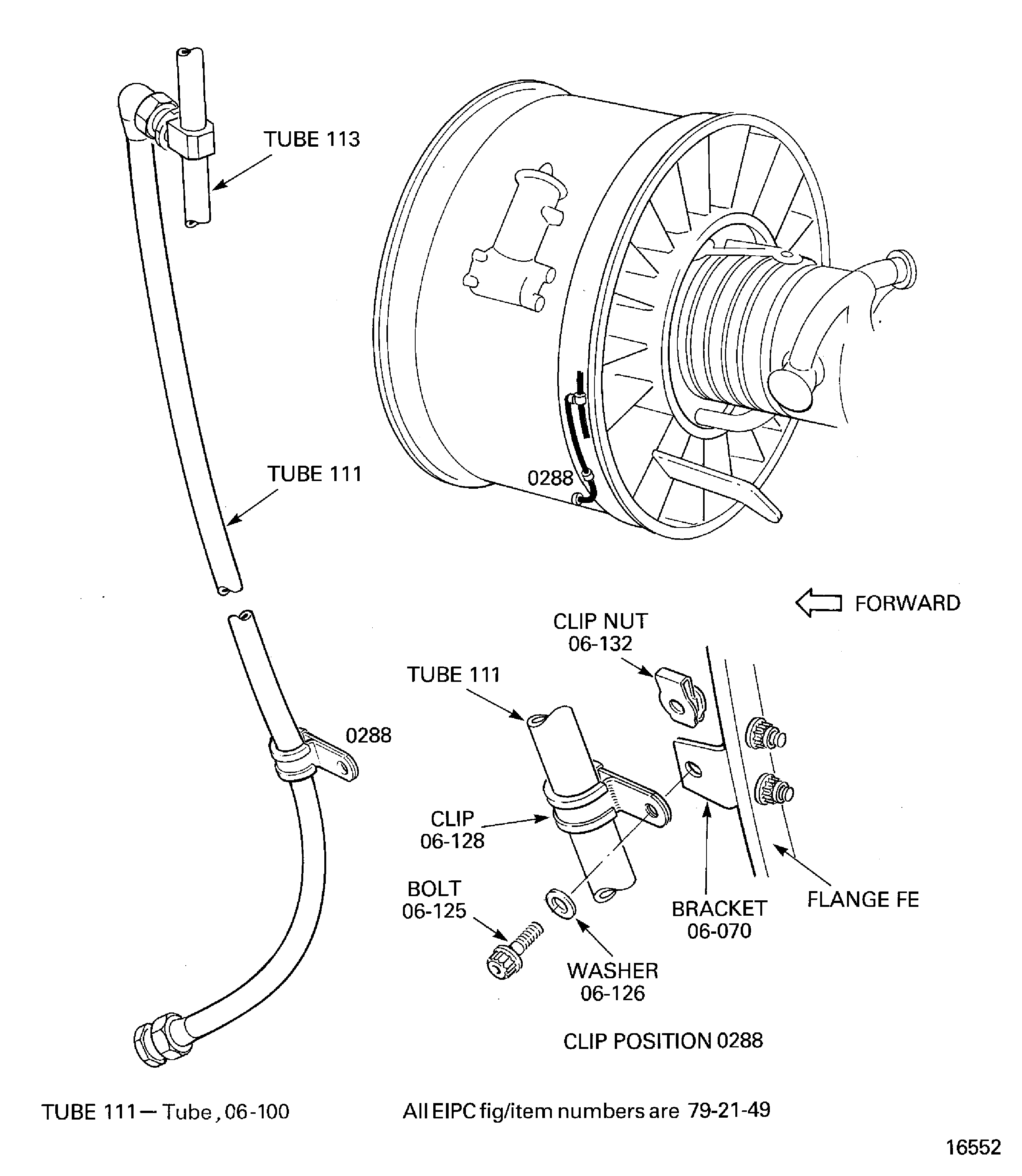

Disconnect the tube 114 from the tube 113 with the IAE 1R18002 Wrench 1 off. Remove the tube 114 and the sealing ring.

Disconnect the tube 113 from the tube 177 with the IAE 1R18001 Wrench 1 off. Remove the bolt, the washer, the clipnut and the clip at the clip position 0321. Remove the tube 113.

SUBTASK 72-00-32-020-183 Remove the Tubes 114, 115, 111, 113, 177 and 120, the Pressure Oil Tubes

NOTE

Some oil drainage could occur during this procedure. It is recommended than an applicable container is available.Refer to Figure.

Disconnect the tube 172 from the tube 117 with the IAE 1R18003 Wrench 1 off.

SUBTASK 72-00-32-020-184-A00 Remove the Tubes 117 and 172, the Fuel System Tubes (Pre SBE 73-0078)

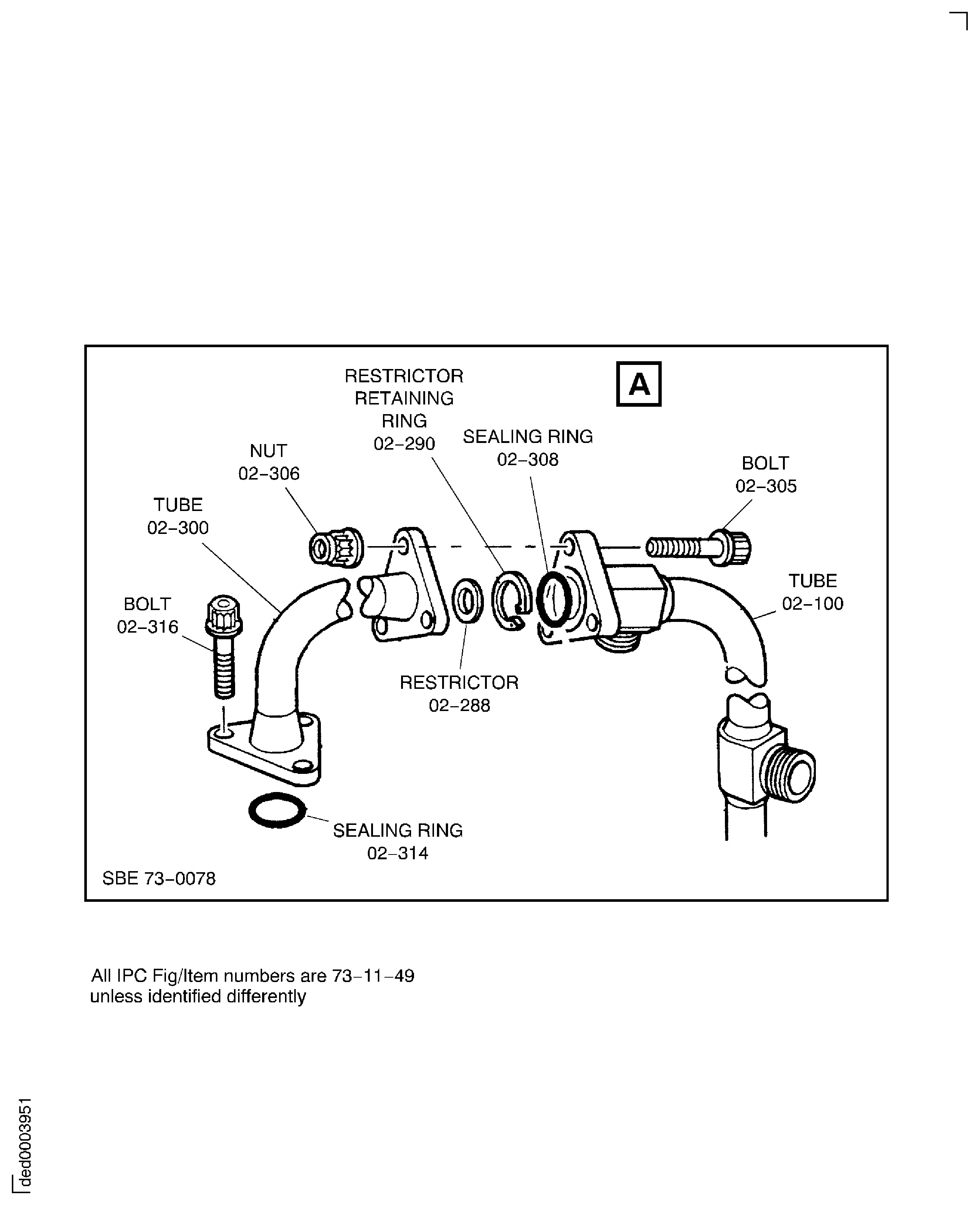

Disconnect the tube 172 from the tube 117 with the IAE 1R18003 Wrench 1 off.

Remove the three bolts which attach the tube Control Fuel Tubes (73-11-49, 02-300) to the FCOC. Remove the nuts and bolts that attach the tube Control Fuel Tubes (73-11-49, 02-300) to the tube 117.

Remove the restrictor and the restrictor retainer ring from the tube Control Fuel Tubes (73-11-49, 02-300).

SUBTASK 72-00-32-020-184-B00 Remove the Tubes 172, 117 and (73-11-49,02-300) the Fuel System Tubes (SBE 73-0078)

Refer to Figure.

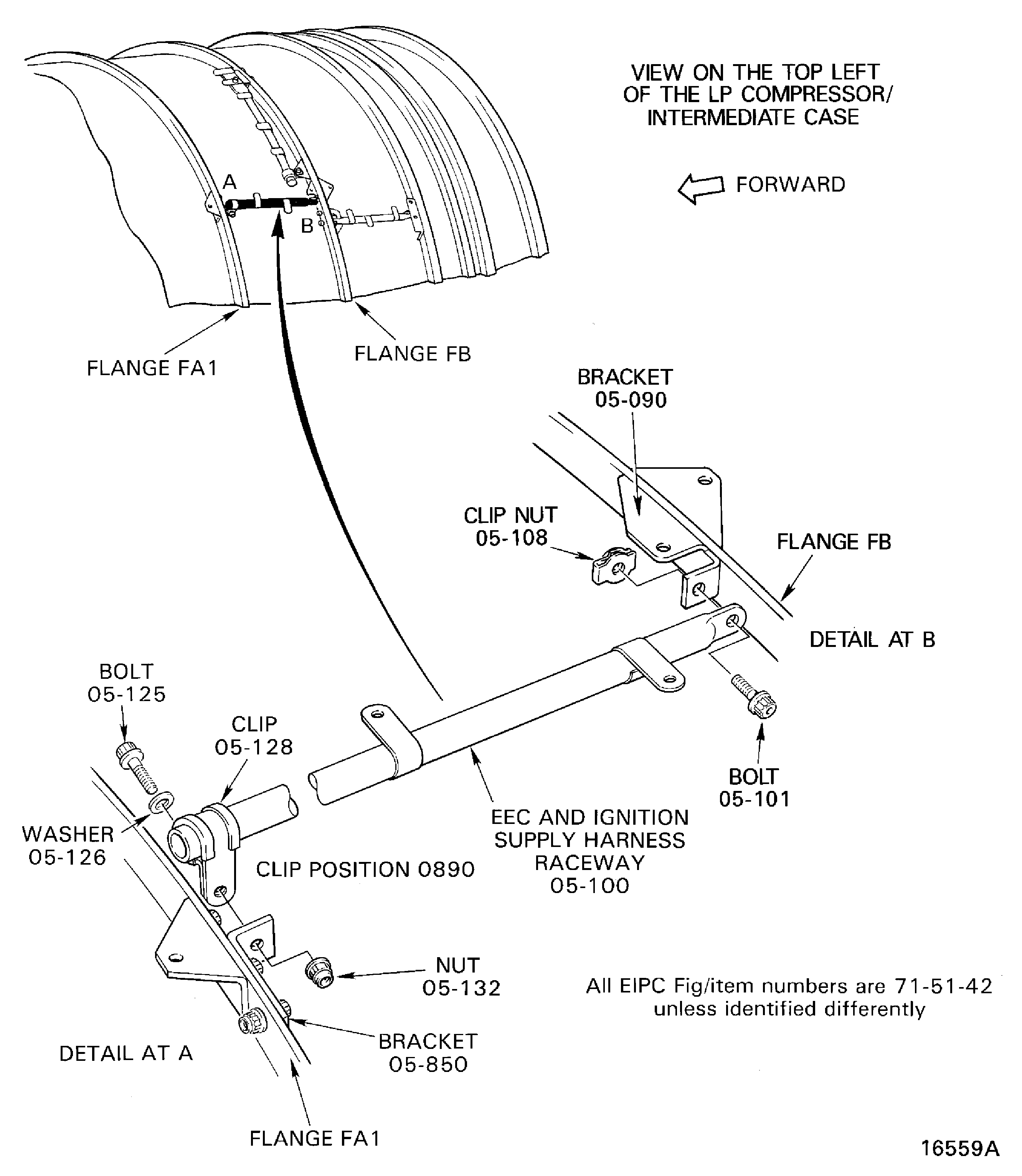

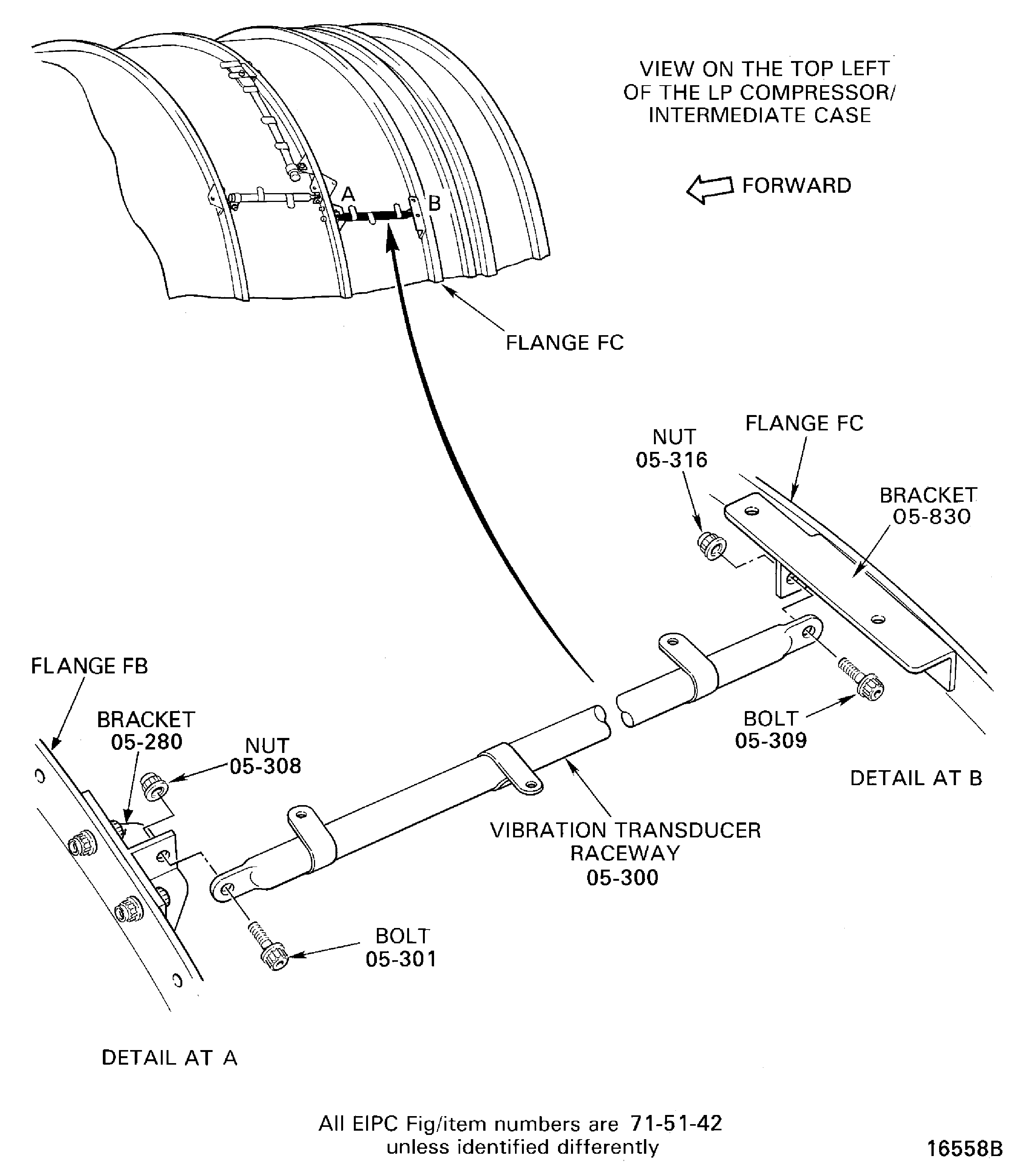

SUBTASK 72-00-32-020-186 Remove the Vibration Transducer Raceway (71-51-42, 05-300)

Refer to Figure.

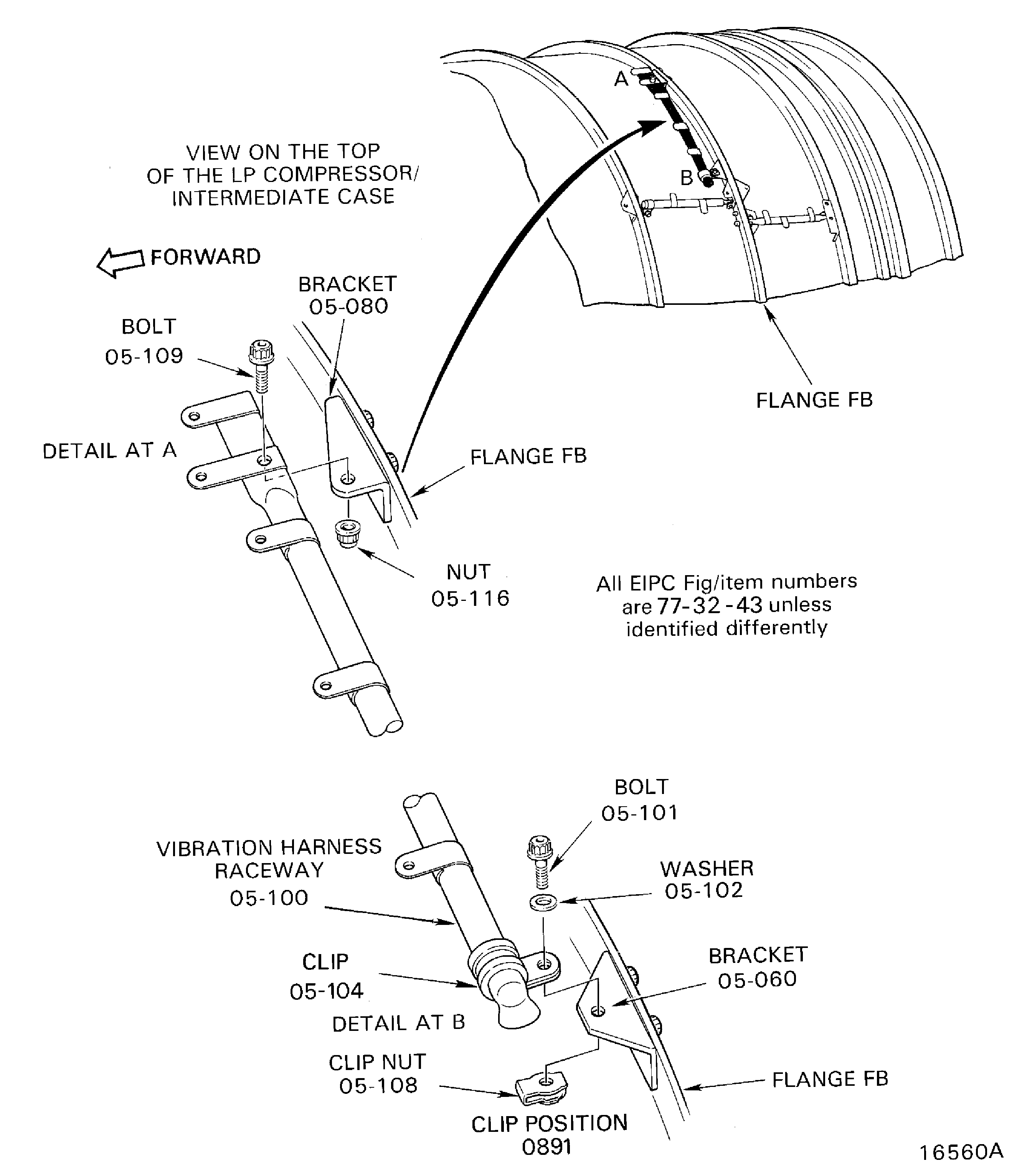

SUBTASK 72-00-32-020-187 Remove the Vibration Harness Raceway (77-32-43, 05-100)

Refer to Figure.

SUBTASK 72-00-32-020-188 Remove the EEC and Ignition Supply Harness Raceway (05-100)

Figure: Pre SBE 73-0140: Remove the Tube 239, the Fuel System Air Tube

Sheet 1

Figure: SBE 73-0140: Remove the Tube 239, the Fuel System Air Tube

Sheet 2

Figure: Pre SBE 75-0081: Remove the LP Compressor/Intermediate Case Right Side Tubes

Sheet 1

Figure: Remove the LP Compressor/Intermediate Case Right Side Tubes

Sheet 2

Figure: Pre SBE 75-0081: Remove the LP Compressor/Intermediate Case Right Side Tubes

Sheet 3

Figure: Remove the LP Compressor/Intermediate Case Right Side Tubes

Sheet 4

Figure: SBE 75-0081: Remove the LP Compressor/Intermediate Case Right Side Tubes

Sheet 5

Figure: SBE 75-0081: Remove the LP Compressor/Intermediate Case Right Side Tubes

Sheet 6

Figure: Remove the Tubes 119 and 122, the Pressure Oil Tubes

Remove the Tubes 119 and 122, the Pressure Oil Tubes

Figure: Remove the Tubes 125 and 169, the Oil Scavenge Tubes

Remove the Tubes 125 and 169, the Oil Scavenge Tubes

Figure: Remove the Tubes 159, 135 and 142, the Fuel System Air Tubes and the Hose 220

Sheet 1

Figure: Remove the Tubes 159, 135 and 142, the Fuel System Air Tubes and the Hose 220

Sheet 2

Figure: Remove the LP Compressor/Intermediate Case Right Rear Side Tubes

Sheet 1

Figure: Remove the LP Compressor/Intermediate Case Right Rear Side Tubes

Sheet 2

Figure: Remove the LP Compressor/Intermediate Case Bottom Right Side Tubes

Sheet 1

Figure: Remove the LP Compressor/Intermediate Case Bottom Right Side Tubes

Sheet 2

Figure: Remove the Tubes at the Bifurcation Panel

Sheet 1

Figure: Pre SBE 75-0081: Remove the Tubes at the Bifurcation Panel

Sheet 2

Figure: Pre SBE 75-0081: Remove the Tubes at the Bifurcation Panel

Sheet 3

Figure: Remove the Tubes at the Bifurcation Panel

Sheet 4

Figure: Pre SBE 75-0081: Remove the Tubes at the Bifurcation Panel

Sheet 5

Figure: SBE 75-0081: Remove the Tubes at the Bifurcation Panel

Sheet 6

Figure: SBE 75-0081: Remove the Tubes at the Bifurcation Panel

Sheet 7

Figure: SBE 75-0081: Remove the Tubes at the Bifurcation Panel

Sheet 8

Figure: Remove the Tubes and the Fuel Flow Transmitter from the Bottom of the LP Compressor/Intermediate Case

Sheet 1

Figure: Remove the Tubes and the Fuel Flow Transmitter from the Bottom of the LP Compressor/Intermediate Case

Sheet 2

Figure: Remove the Electrical Harness Raceway

Sheet 1

Figure: Remove the Electrical Harness Raceway

Sheet 2

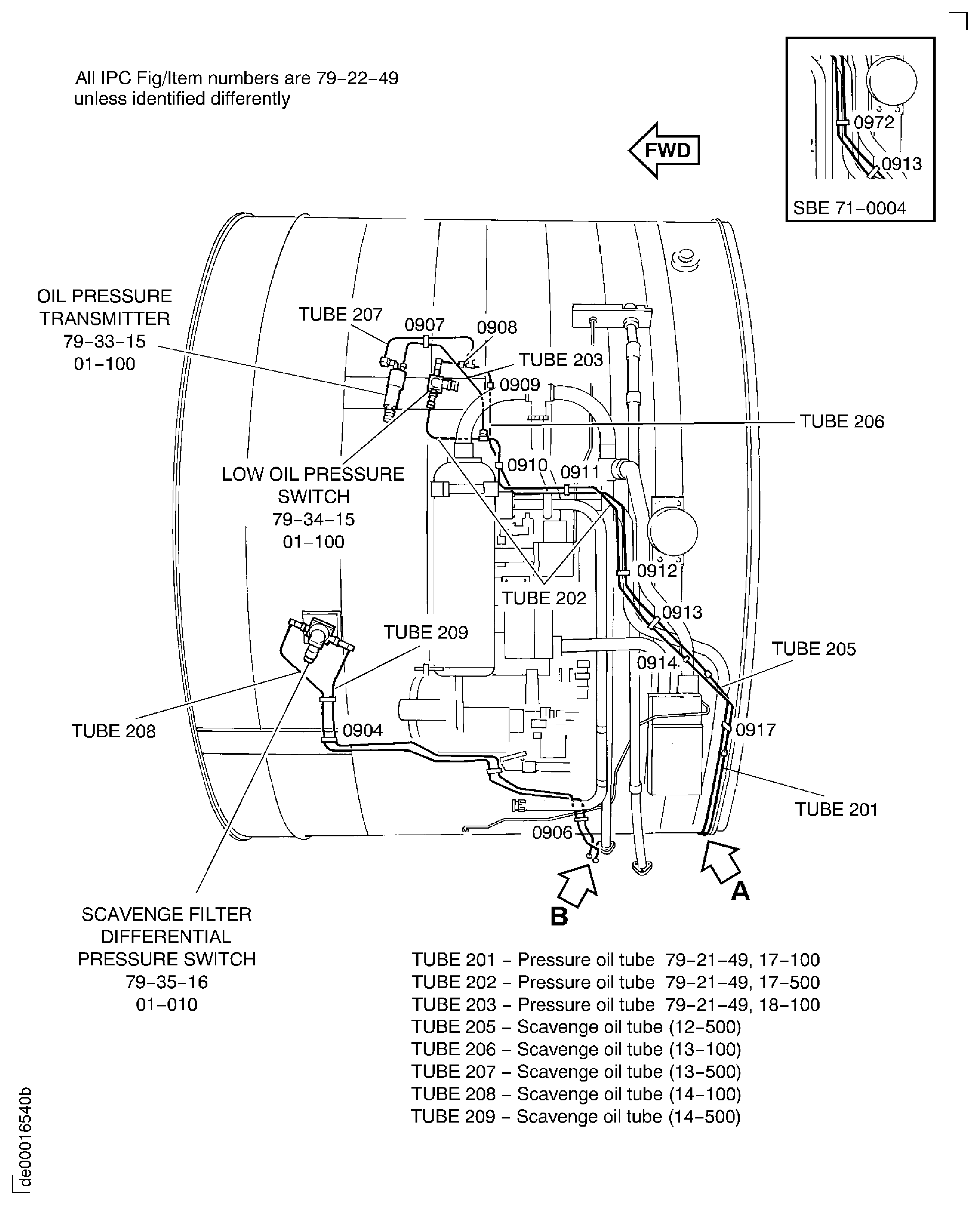

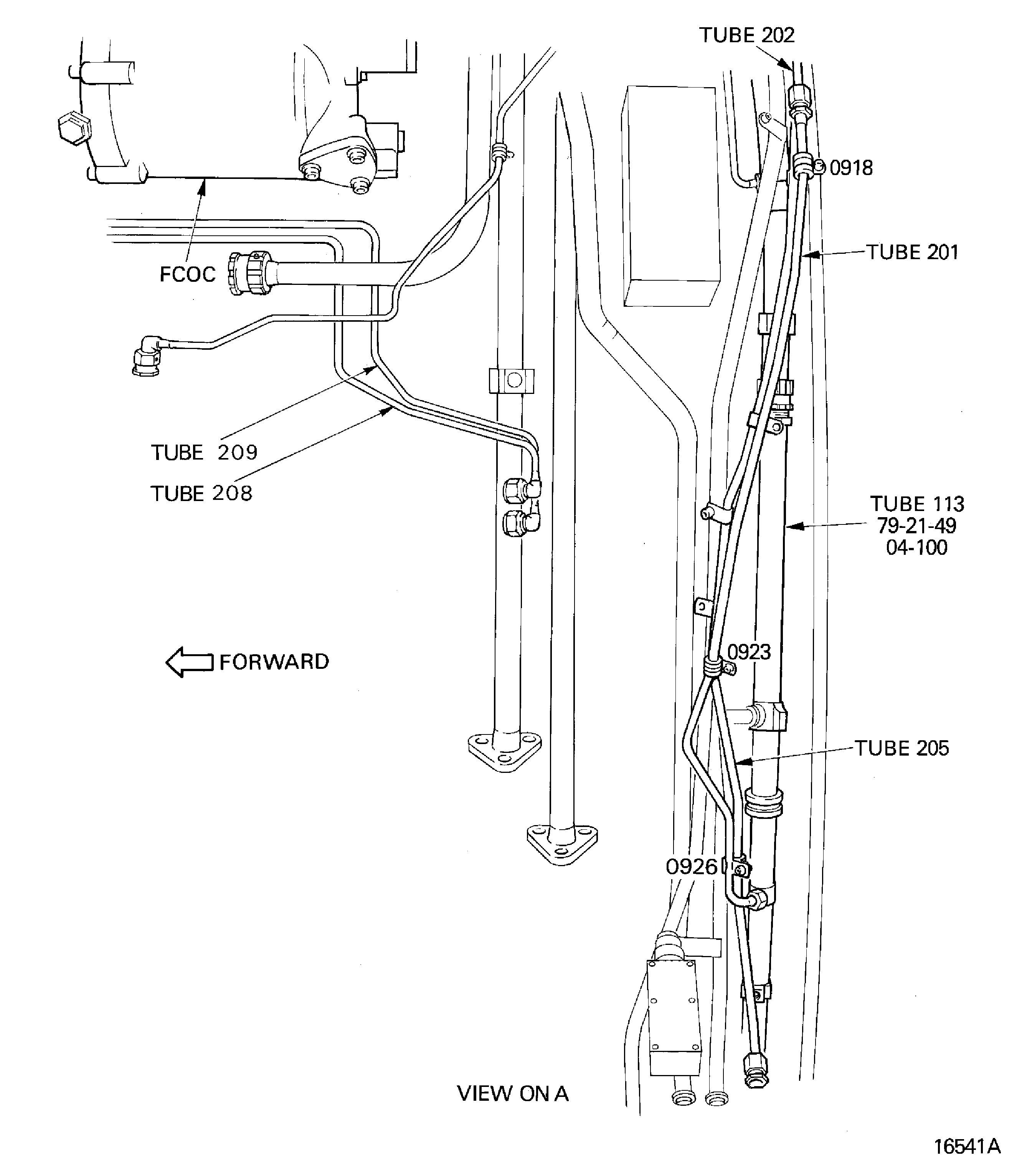

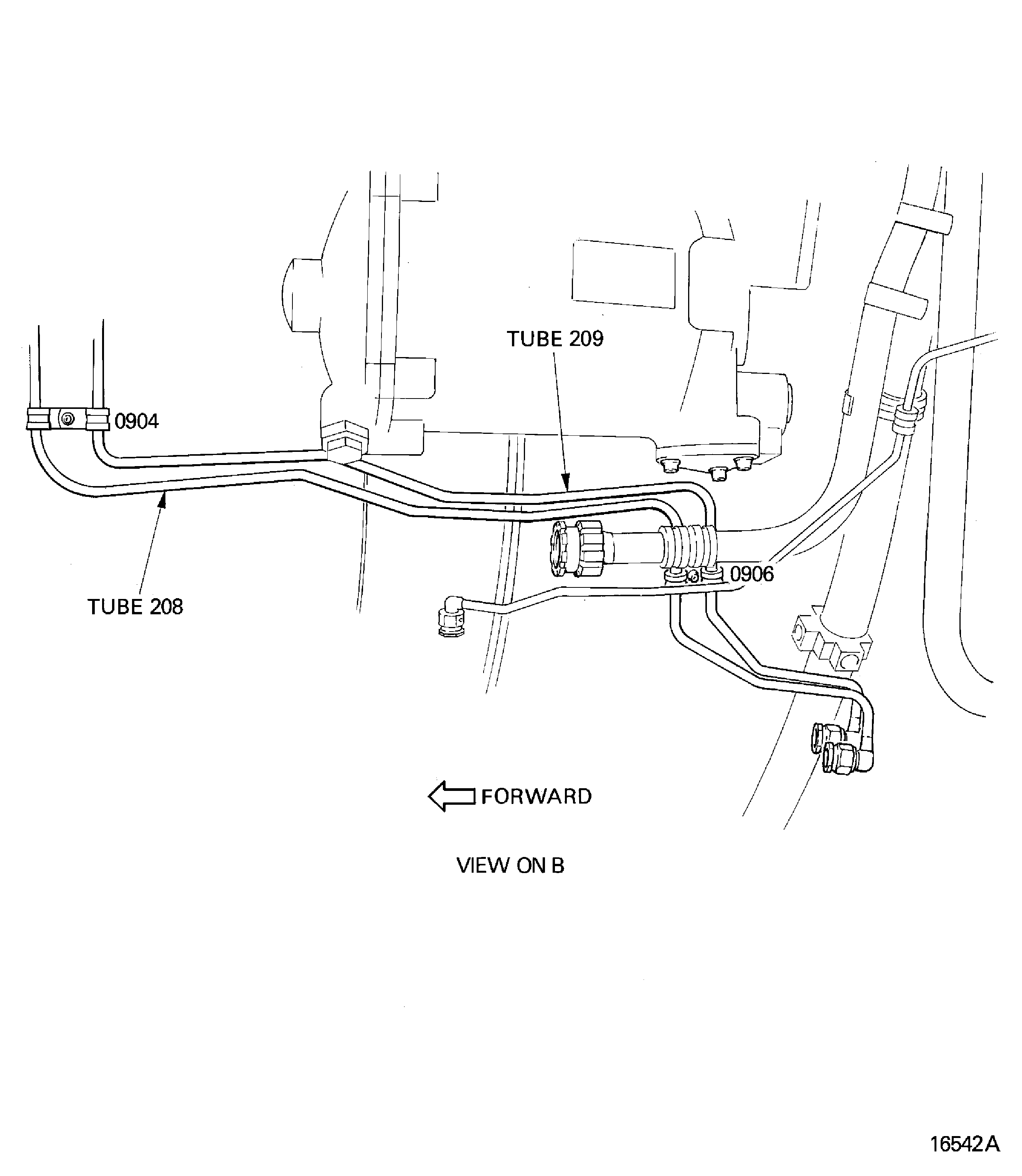

Figure: Remove the Pressure/Scavenge Oil Tubes from the Left Side of the LP Compressor/Intermediate Case

Sheet 1

Figure: Remove the Pressure/Scavenge Oil Tubes from the Left Side of the LP Compressor/Intermediate Case

Sheet 2

Figure: Remove the Pressure/Scavenge Oil Tubes from the Left Side of the LP Compressor/Intermediate Case

Sheet 3

Figure: Pre SBE 72-0160: Remove the Dedicated Alternator Cooling Air Tubes

Sheet 1

Figure: SBE 72-0160: Remove the Dedicated Alternator Cooling Air Tubes

Sheet 2

Figure: Remove the Dedicated Alternator Cooling Air Tubes

Sheet 3

Figure: Remove the Tubes 170 and 171, the Fuel System Tubes

Remove the Tubes 170 and 171, the Fuel System Tubes

Figure: Remove the Tubes 96 to 98, the IDG Cooling Tubes

Remove the Tubes 96 to 98, the IDG Cooling Tubes

Figure: Remove the Tubes 114, 115, 111, 113, 177 and 120, the Pressure Oil Tubes

Sheet 1

Figure: Remove the Tubes 114, 115, 111, 113, 177 and 120, the Pressure Oil Tubes

Sheet 2

Figure: Remove the Tubes 114, 115, 111, 113, 177 and 120, the Pressure Oil Tubes

Sheet 3

Figure: Remove the Tubes 117 and 172, the Fuel System Tubes

Sheet 1

Figure: Remove the Tubes 117 and 172, the Fuel System Subes

Remove the Tubes 117 and 172, the Fuel System Subes

Figure: Remove the Tubes 174 to 176 and 110, the Power Plant Fuel Tubes

Remove the Tubes 174 to 176 and 110, the Power Plant Fuel Tubes

Figure: Remove the Tubes 174 to 176 and 110, the Power Plant Fuel Tubes

Remove the Tubes 174 to 176 and 110, the Power Plant Fuel Tubes

Figure: Remove the Vibration Transducer Raceway

Remove the Vibration Transducer Raceway

Figure: Remove the Vibration Harness Raceway

Remove the Vibration Harness Raceway

Figure: Remove the EEC and Ignition Supply Harness Raceway

Remove the EEC and Ignition Supply Harness Raceway