Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

Post SBE 72-0560 AND Post SBE 72-0564 AND Post SBE 72-0571(SELECTONE PRODUCTION STANDARD)

Common Information

TASK 72-41-30-440-005-C00 HPC Front Case And Vane Assembly - Install The Stage 4 Variable Stator Vanes, Assembly-005 - SBE 72-0560 (Select One Retrofit And Production Standard), SBE 72-0564 And 72-0571 (Select One Production Standard)

General

This task gives the procedure to install the stage 4 variable stator vanes (VSV) for: The engines which have SBE 72-0560 (A5 Standard, SelectOne(TM) Retrofit Standard) incorporated or the engines which have SBE 72-0560, SBE 72-0564, SBE 72-0571 and SBE 72-0573 (SelectOne(TM) Production Standard) incorporated. The subsequent TASKS give the procedure to assemble the HP Compressor front cases.

Install the Stage 4 and 5 Rotor Path Rings and Stage 6 Rotor Ring Segments by TASK 72-41-30-440-001-C00 (ASSEMBLY-001).

Measure and then machine the Stage 6 Stator Vanes and the Stage 4, 5 and 6 Rotor Path Rings by TASK 72-41-30-440-002-B01 (ASSEMBLY-002).

Install the VIGV by TASK 72-41-30-440-003-C00 (ASSEMBLY-003).

Install the Stage 3 VSV by TASK 72-41-30-440-004-C00 (ASSEMBLY-004).

Install the Stage 5 VSV by TASK 72-41-30-440-006-C00 (ASSEMBLY-006).

Install the Stage 6 Stator Vanes by TASK 72-41-30-440-007-B00 (ASSEMBLY-007).

Install the VIGV and the Stage 3 to 5 Bridge Pieces by TASK 72-41-30-440-008-C00 (ASSEMBLY-008).

Measure the HP Compressor Front Cases by TASK 72-41-30-440-009-C00 (ASSEMBLY-009).

Disassemble the HP Compressor Front Cases by TASK 72-41-30-440-010-C00 (ASSEMBLY-010).

Check and Set VSV System with Optimised Build and Setting Clearances by TASK 72-41-30-440-011-C00 (ASSEMBLY-011).

Fig/item numbers in parentheses in the procedure agree with those used in the EIPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the EIPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and touch faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to SPM TASK 70-44-01-400-501.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and parts used to attach. Use the correct colour of the air drying enamel. Refer to SPM TASK 70-63-02-380-501.

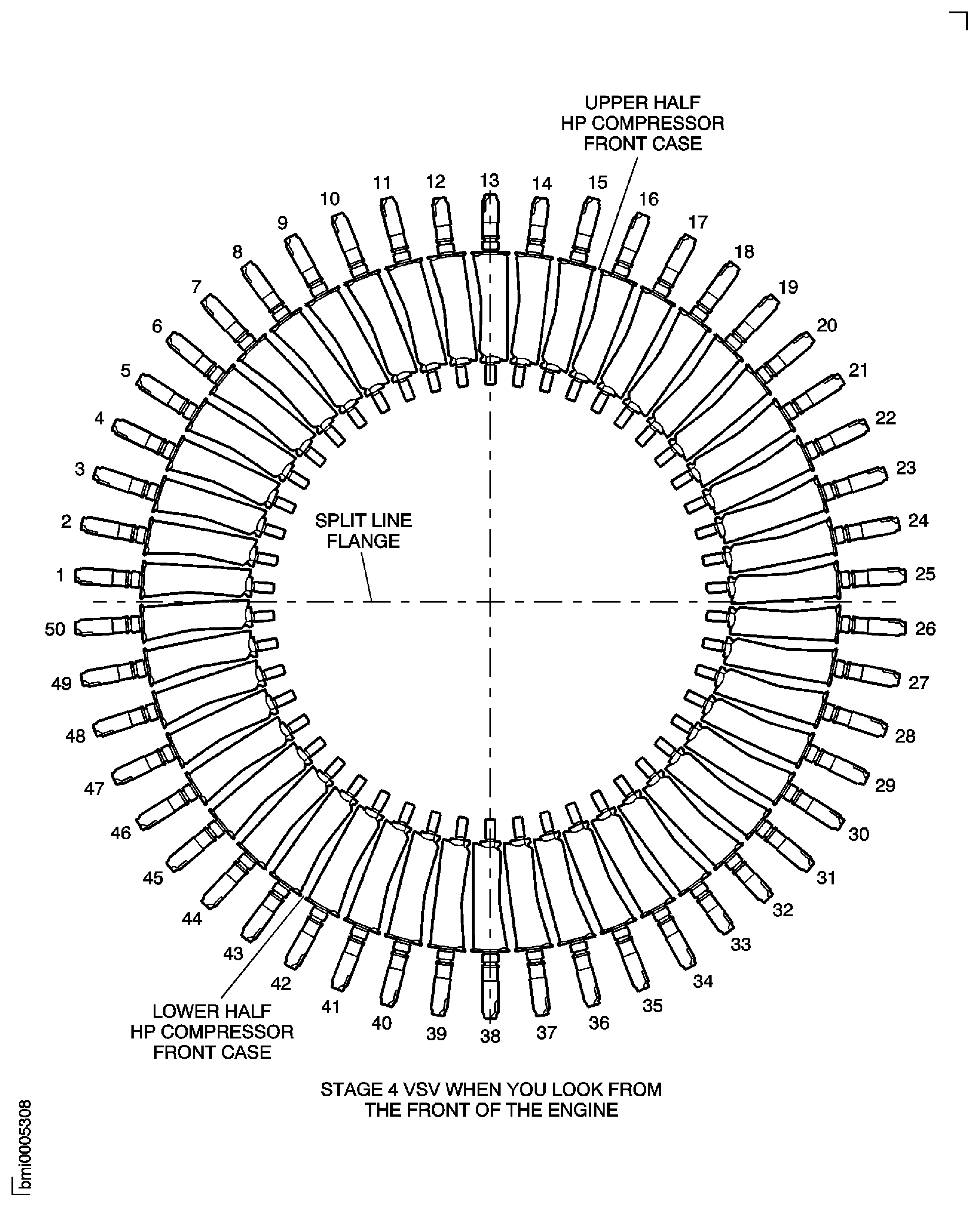

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

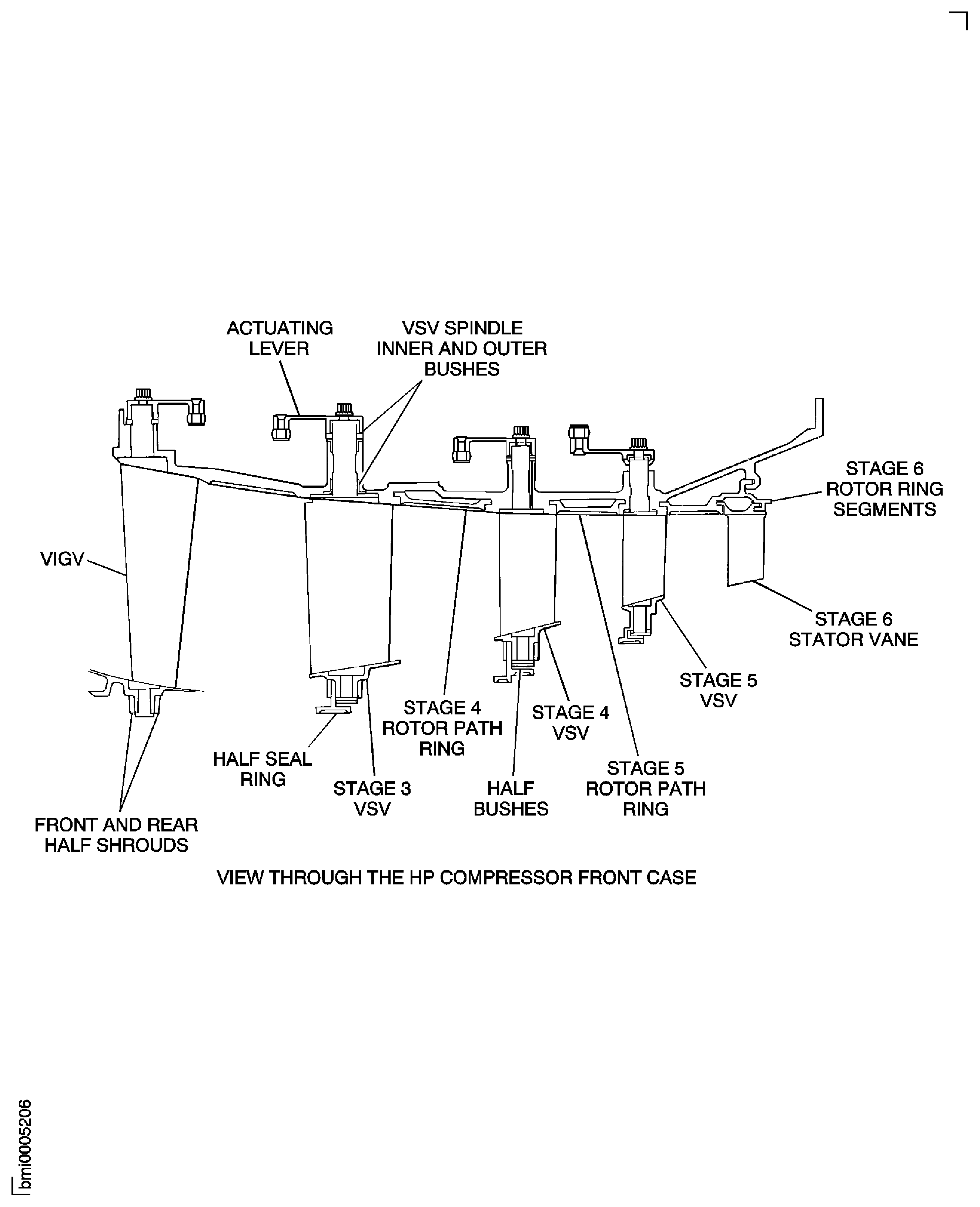

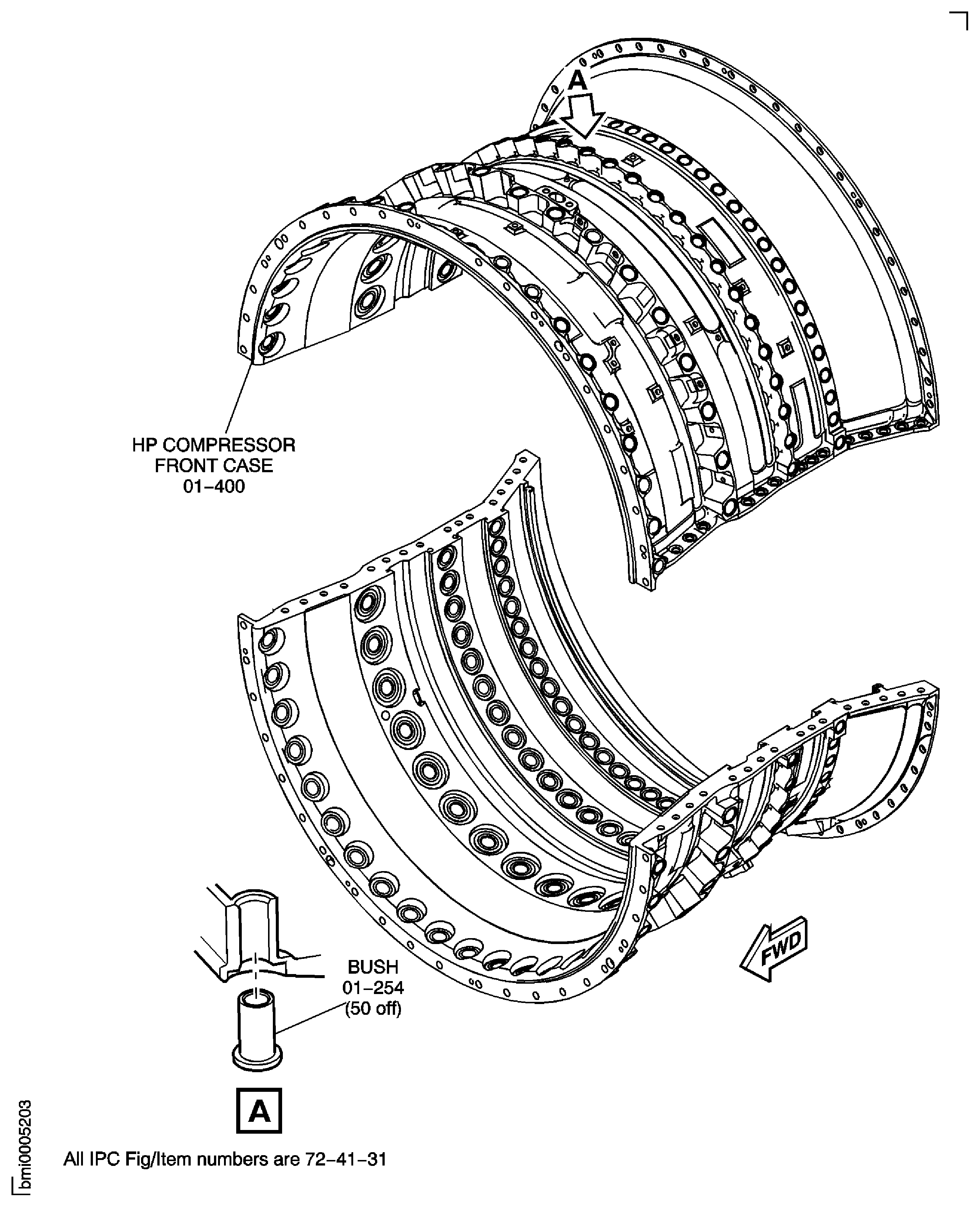

Refer to Figure for a sectional view of the HP Compressor front case.

The Fits and Clearances, NEW PART DIMENSIONS and REJECT IF MORE THAN columns will be used by most operators. This permits the full use of the maximum wear allowance and a reduction in the number of parts which are rejected, is possible.

As long as REJECT IF MORE THAN columns do not include reject values, NEW PART DIMENSIONS do not have to be measured before assembly, as there are no reject-if criteria. Values are only valid for new parts, not for worn parts.

The column WORN PART DIMENSIONS (Non-select) is included for operators who want to have full interchangeability. If this column is used an increase in the number of parts which are rejected is possible.

After the part has been in service for some time the REJECT IF MORE THAN and WORN PART DIMENSION could be changed. The operator must tell IAE and if agreed the manual will be changed.

The abbreviation Intf shows an interference or tight fit. This causes REJECT IF MORE THAN to become REJECT IF LESS THAN.

The abbreviation clear shows a clearance fit.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1R18423 Rigging pin | 0AM53 | IAE 1R18423 | 6 | |

| IAE 1R18894 Rigging pin | 0AM53 | IAE 1R18894 | 6 | |

| IAE 1R19823 Seal installation tool, Stage 4 IGV (short) | 0AM53 | IAE 1R19823 | 1 | |

| IAE 1R19824 Seal installation tool, Stage 4 IGV (long) | 0AM53 | IAE 1R19824 | 1 | |

| IAE 1R19832 Bushing installation tool | 0AM53 | IAE 1R19832 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 07-038 AIR DRYING ENAMEL | 00BB6 | CoMat 07-038 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 | ||

| CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R) | 39428 | CoMat 10-108 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| RING - SEALING, TOROIDAL | U1653 | AS43013-011 | 50 | 72-41-32, 03-495 |

Safety Requirements

NONEProcedure

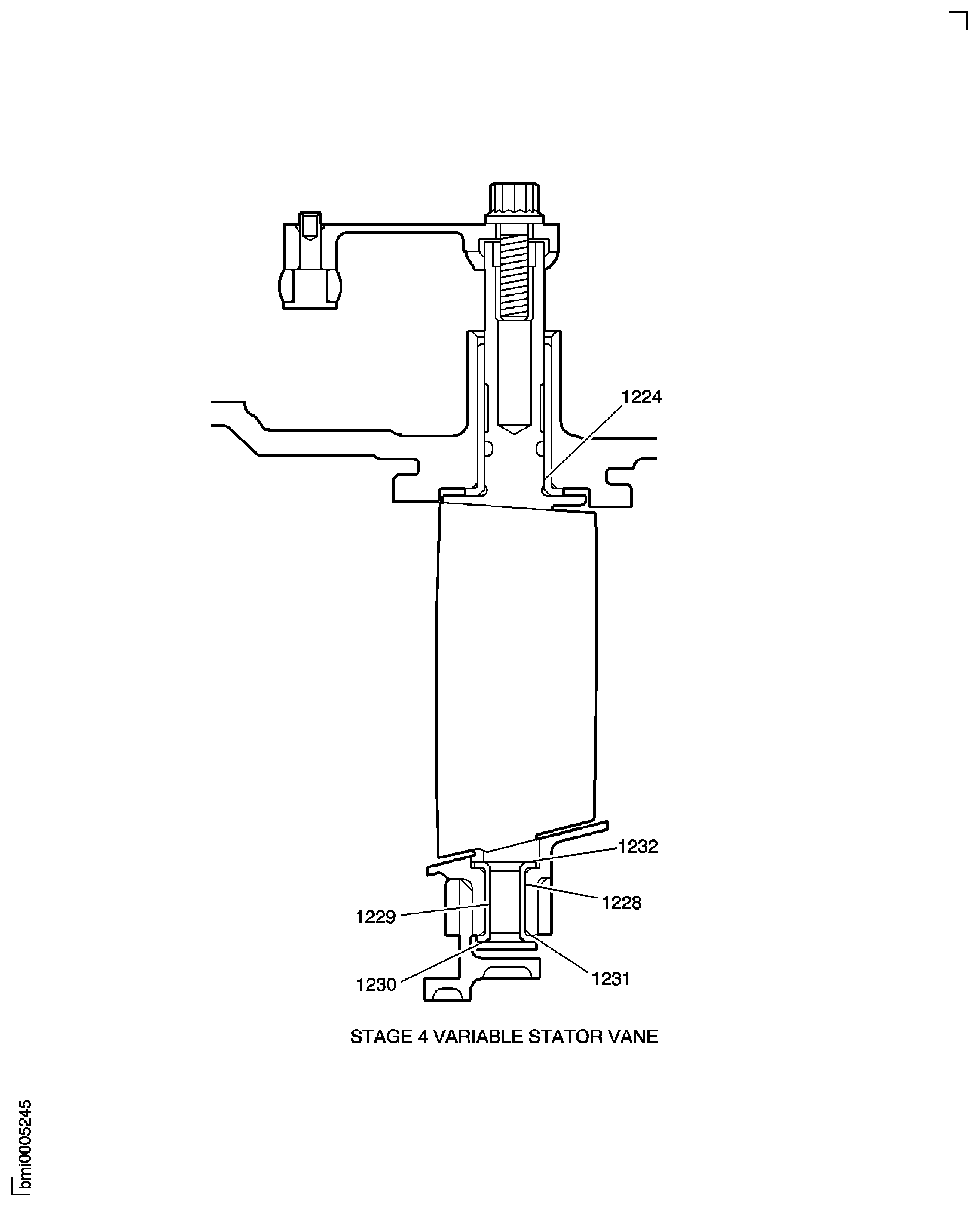

Refer to Figure.

Reference dimensions at location 1224. If necessary use the data written as a note in TASK 72-41-31-200-000 and TASK 72-41-32-200-000.

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1224

Stage 4 Bush HP COMPRESSOR SPLIT CASE (72-41-31, 01-254)

Locations At The Stage 4 VSV (HPC Variable Stator Vanes (72-41-32, 03-500 And 03-600).

Stage 4 Bush Internal Bore

0.476

0.477

0.0085

Stage 4 VSV Spindle Diameter

0.4685

0.005

0.471

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1224

Stage 4 BushHP COMPRESSOR SPLIT CASE (72-41-31, 01-254)

Locations At The Stage 4 VSV (HPC Variable Stator Vanes (72-41-32, 03-500 And 03-600).

Stage 4 Bush Internal Bore

12.08

12.12

0.22

Stage 4 VSV Spindle Diameter

11.900

0.12

11.96

SUBTASK 72-41-30-220-495 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1224

Refer to Figure.

Reference dimensions at location 1228. If necessary use the data written as a note in TASK 72-41-33-200-000.

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1228

Bush HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-190)

Location In The Stage 4 Half Shroud HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-200)

Bush Bore

0.411

0.421

0.03

Stage 4 Half Shroud Bush Location Diameter

0.394

Intf

0.3945

0.0165

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1228

Bush HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-190)

Location In The Stage 4 Half Shroud HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-200)

Bush Bore

10.44

10.7

0.7

Stage 4 Half Shroud Bush Location Diameter

10.0

Intf

10.022

0.418

SUBTASK 72-41-30-220-496 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1228

Refer to Figure.

Reference dimensions at location 1229. If necessary use the data written as a note in TASK 72-41-33-200-000.

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1229

Stage 4 VSV (HPC Variable Stator Vanes (72-41-32, 03-500 And 03-600)

Location At The Bush HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-190)

Stage 4 VSV Inner Spindle Diameter

0.270

0.273

0.0044

Bush Bore

0.2774

0.008

0.278

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1229

Stage 4 VSV (HPC Variable Stator Vanes (72-41-32, 03-500 And 03-600)

Location At The Bush HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-190)

Stage 4 VSV Inner Spindle Diameter

6.86

6.94

0.108

Bush Bore

7.048

0.21

7.07

SUBTASK 72-41-30-220-497 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1229

Refer to Figure.

Reference dimensions at location 1230. If necessary use the data written as a note in TASK 72-41-32-200-000 and TASK 72-41-33-200-000.

Table 7. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1230

Stage 4 VSV (HPC Variable Stator Vanes (72-41-32, 03-500 And 03-600)

Location At The Bush HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-190)

Stage 4 VSV Inner Spindle Length

6.4665

6.4703

0.0061

Bush Outer Length

6.4764

0.0107

6.4772

Table 8. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1230

Stage 4 VSV (HPC Variable Stator Vanes (72-41-32, 03-500 And 03-600)

Location At The Bush HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-190)

Stage 4 VSV Inner Spindle Length

164.250

164.347

0.173

Bush Outer Length

164.500

0.247

164.520

SUBTASK 72-41-30-220-498 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1230

Refer to Figure.

Reference dimensions at location 1231. If necessary use the data written as a note in TASK 72-41-33-200-000.

Table 9. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1231

Stage 4 Half Shroud HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-200)

Location At The Bush HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-190)

Stage 4 Half Shroud Internal Length

6.5315

6.5335

0.0034

Bush Inner Length

6.5230

0.0105

6.5281

Table 10. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1231

Stage 4 Half Shroud HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-200)

Location At The Bush HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-190)

Stage 4 Half Shroud Internal Length

165.900

165.950

0.087

Bush Inner Length

165.683

0.267

165.813

SUBTASK 72-41-30-220-499 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1231

Refer to Figure.

Reference dimensions at location 1232. If necessary use the data written as a note in TASK 72-41-32-200-000 and TASK 72-41-33-200-000.

Table 11. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1232

Stage 4 VSV (HPC Variable Stator Vanes (72-41-32, 03-500 And 03-600)

Location At The Bush HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-190)

Stage 4 VSV Inner Spindle Length

7.2006

7.2030

0.0116

Bush Inner Length

7.1838

0.0191

7.1889

Table 12. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1232

Stage 4 VSV (HPC Variable Stator Vanes (72-41-32, 03-500 And 03-600)

Location At The Bush HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-190)

Stage 4 VSV Inner Spindle Length

182.896

182.956

0.296

Bush Inner Length

182.470

0.486

182.600

SUBTASK 72-41-30-220-500 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1232

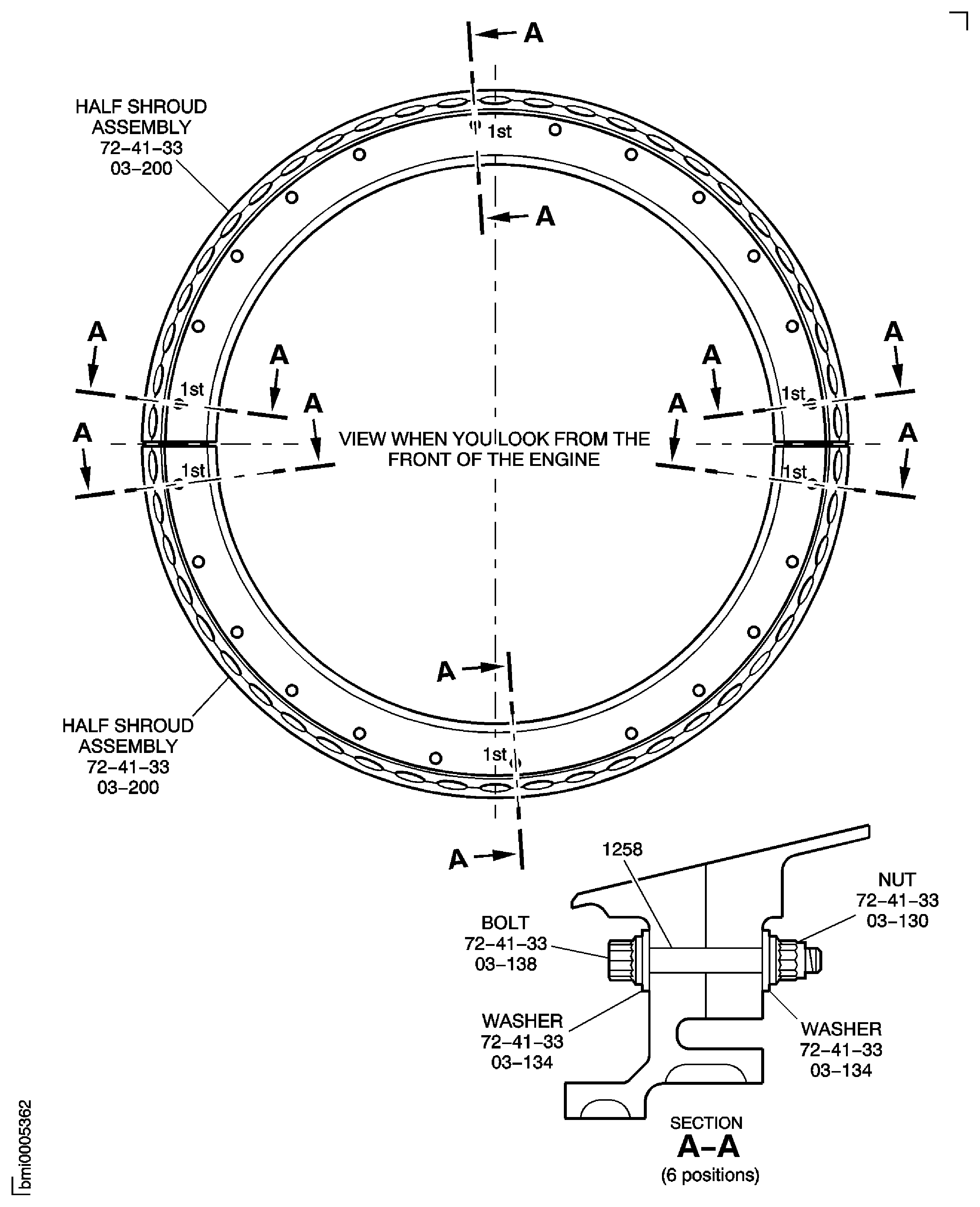

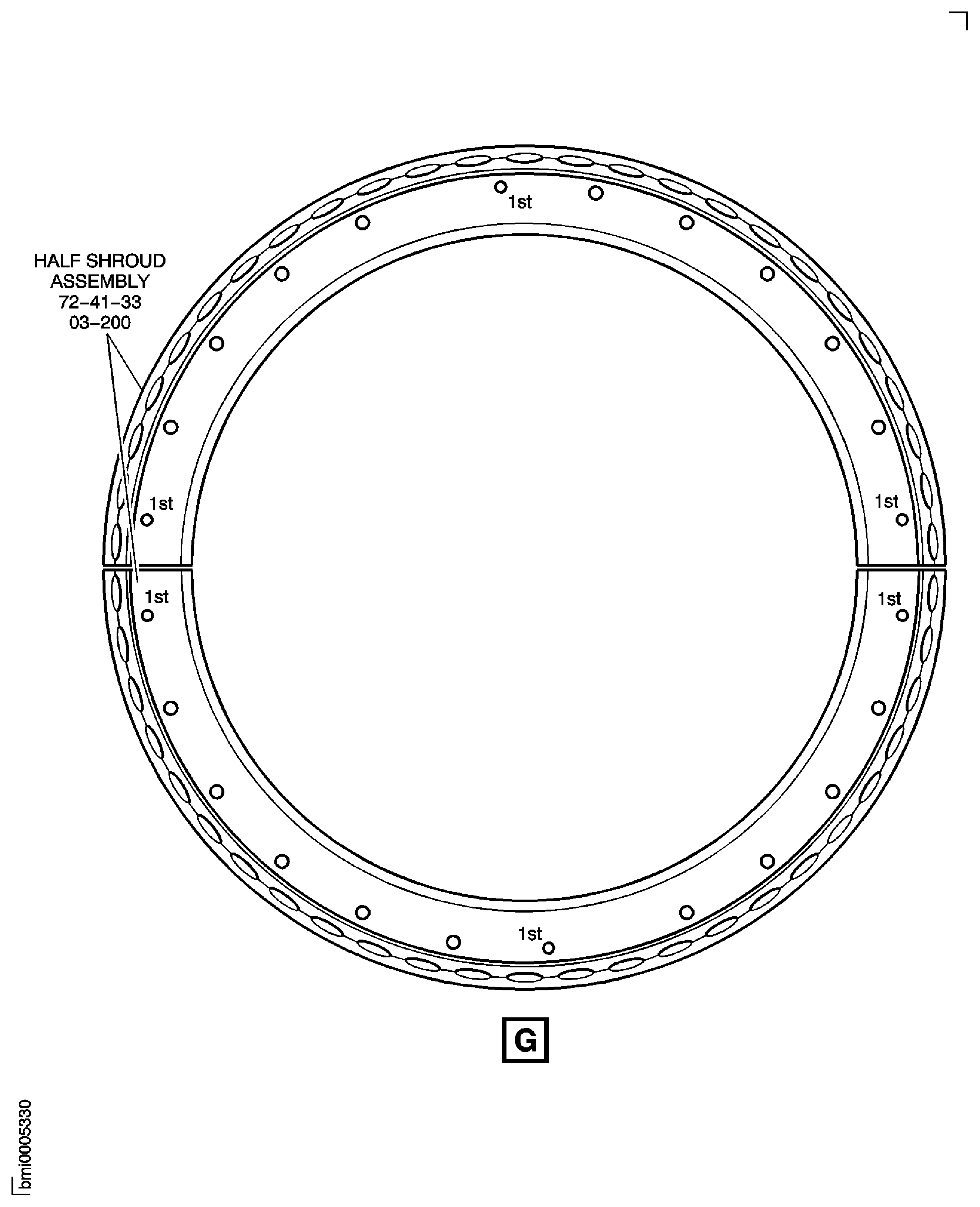

Refer to Figure.

Reference dimensions at location 1258. If necessary use the data written as a note in TASK 72-41-33-200-000.

Table 13. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1258

Stage 4 Half Shroud HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-200)

Location At The Bolthole Bore Marked 1st HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-138)

Stage 4 Half Shroud Location Bolthole Bore (Marked 1st)

0.220

0.232

0.043

Bolt Close Tolerance Diameter

0.1891

0.030

0.1896

Table 14. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1258

Stage 4 Half Shroud HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-200)

Location At The Bolthole Bore Marked 1st HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-138)

Stage 4 Half Shroud Location Bolthole Bore (Marked 1st)

5.60

5.90

1.10

Bolt Close Tolerance Diameter

4.803

0.78

4.816

SUBTASK 72-41-30-220-501 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1258

For the assembly procedure refer to TASK 72-41-30-440-005-B00.

NOTE

This subtask is applicable for engines which have A5 standard, SelectOne(TM) Retrofit Standard incorporated.

SUBTASK 72-41-30-440-281-001 Install the Stage 4 VSV Actuating Ring Centralizing Support Assemblies

SUBTASK 72-41-30-440-281-002 Install the Stage 4 VSV Actuating Ring Centralizing Support Assemblies (SBE 72-0564 only)

NOTE

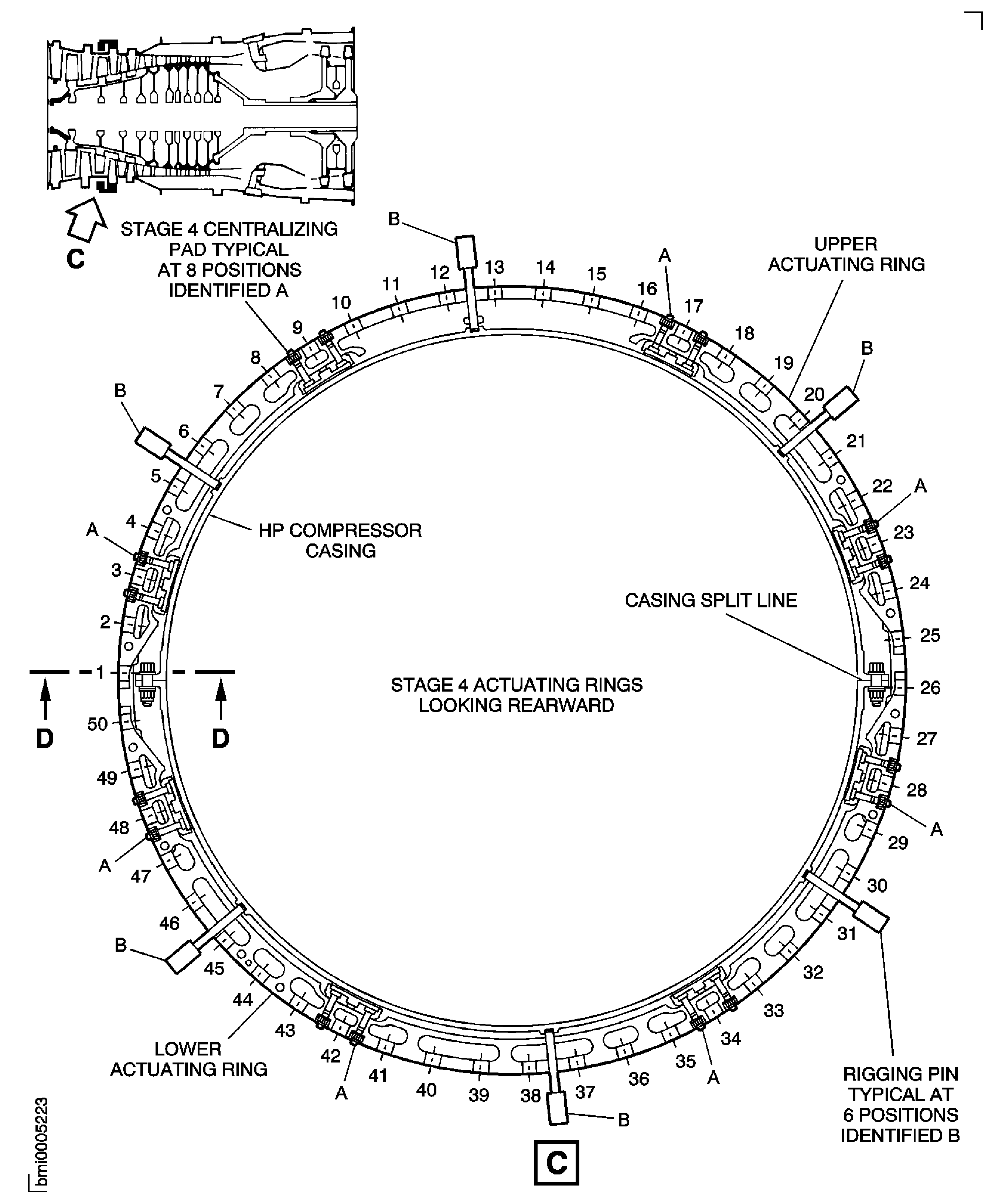

For accomplishment instructions that contain the content of SBE 72-0564 standard only, please refer to IAE Technical Services.Refer to Figure.

NOTE

This subtask is applicable for engines which have A5 standard, SelectOne(TM) Production Standard incorporated.Install the eight self locking nuts HPC Variable Stator Vane Actuation System (72-41-34, 04-698) to attach the four stage 4 centralizing support assemblies to the stage 4 upper actuating ring.

Install the four stage 4 centralizing support assemblies HPC Variable Stator Vane Actuation System (72-41-34, 04-680) on to the stage 4 stator vane upper actuating ring HPC Variable Stator Vane Actuation System (72-41-34, 04-440).

Install the four stage 4 centralizing support assemblies HPC Variable Stator Vane Actuation System (72-41-34, 04-680) on to the stage 4 stator vane lower actuating ring HPC Variable Stator Vane Actuation System (72-41-34, 04-540).

SUBTASK 72-41-30-440-281-003 Install the Stage 4 VSV Actuating Ring Centralizing Support Assemblies (SBE 72-0564 and SBE 72-0573)

For the assembly procedure refer to TASK 72-41-30-440-005-B00.

NOTE

This subtask is applicable for engines which have A5 standard, SelectOne(TM) Retrofit Standard incorporated.

SUBTASK 72-41-30-440-282-001 Install the Stage 4 VSV Spindle Bushes

SUBTASK 72-41-30-440-282-002 Install the Stage 4 VSV Spindle Bushes (SBE 72-0564 only)

NOTE

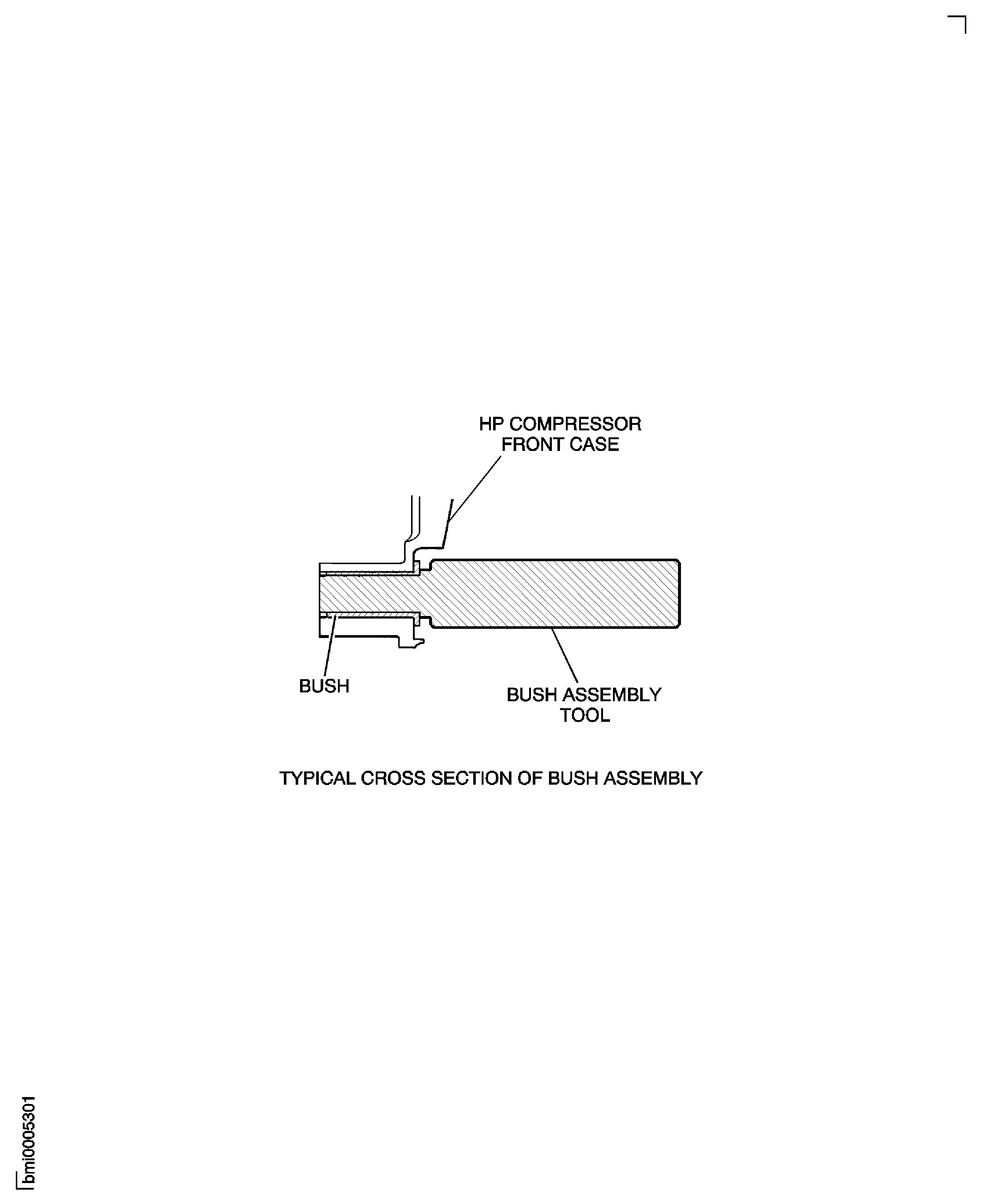

For accomplishment instructions that contain the content of SBE 72-0564 standard only, please refer to IAE Technical Services.Refer to Figure and Fig. 72-41-30-990-356-002.

NOTE

This subtask is applicable for engines which have A5 standard, SelectOne(TM) Production Standard incorporated.Put one of the bushes on the IAE 1R19832 Bushing installation tool. Make sure that the bush installation tool is correctly aligned to the spindle boss on the HPC front case assembly inner side.

Install the stage 4 VSV bushes HP COMPRESSOR SPLIT CASE (72-41-31, 01-254).

SUBTASK 72-41-30-440-282-003 Install the Stage 4 VSV Spindle Bushes (SBE 72-0564 and SBE 72-0573)

For the assembly procedure refer to TASK 72-41-30-440-005-B00.

NOTE

This subtask is applicable for engines which have A5 standard, SelectOne(TM) Retrofit Standard incorporated.

SUBTASK 72-41-30-440-283-001 Install the Stage 4 Variable Stator Vanes (VSV) in the HP Compressor Front Case (SBE 72-0560)

SUBTASK 72-41-30-440-283-002 Install the Stage 4 Variable Stator Vanes in the HP Compressor Front Case (SBE 72-0564 only)

NOTE

For accomplishment instructions that contain the content of SBE 72-0564 standard only, please refer to IAE Technical Services.Apply CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R) on the inner and mating faces of the stage 4 VSV spindle bushes.

Install IAE 1R19823 Seal installation tool, Stage 4 IGV (short) or IAE 1R19824 Seal installation tool, Stage 4 IGV (long) 1 off on to the spindle of one of the stage 4 stator vanes to be installed.

Install the 50 sealing rings HPC Variable Stator Vanes (72-41-32, 03-495) on to the 50 stage 4 stator vanes (HPC Variable Stator Vanes (72-41-32, 03-500) and HPC Variable Stator Vanes (72-41-32, 03-600)).

NOTE

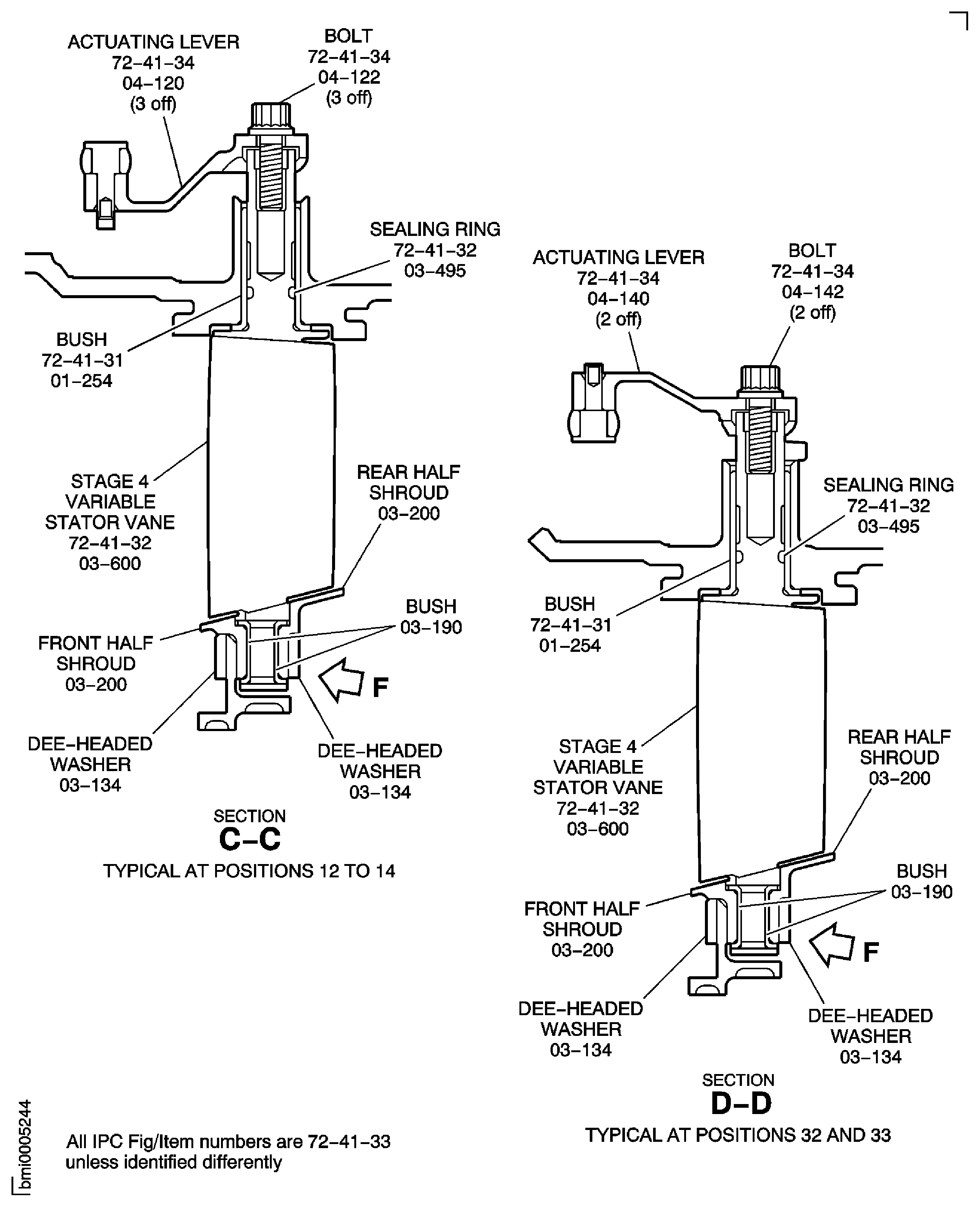

The tool IAE 1R19823 Seal installation tool, Stage 4 IGV (short) is applicable for the short spindle vanes. The tool IAE 1R19824 Seal installation tool, Stage 4 IGV (long) is applicable for the long spindle vanes.Install the 22 stage 4 stator vanes HPC Variable Stator Vanes (72-41-32, 03-500) and the three stage 4 stator vanes HPC Variable Stator Vanes (72-41-32, 03-600) into the bushes in the upper half HP Compressor front case.

The three stage 4 stator vanes HPC Variable Stator Vanes (72-41-32, 03-600) with the short spindles must be installed at the positions 12 to 14.

NOTE

The position information given in this procedure indicates that you must look from the front to the rear of the module.

Install the stage 4 stator vanes in the upper half HP Compressor front case.

Install the 23 stage 4 stator vanes HPC Variable Stator Vanes (72-41-32, 03-500) and the two stage 4 stator vanes HPC Variable Stator Vanes (72-41-32, 03-600) into the bushes in the lower half HP Compressor front case.

The two stage 4 stator vanes HPC Variable Stator Vanes (72-41-32, 03-600) with the short spindles must be installed at the positions 32 and 33.

Install the stage 4 stator vanes in the lower half HP Compressor front case.

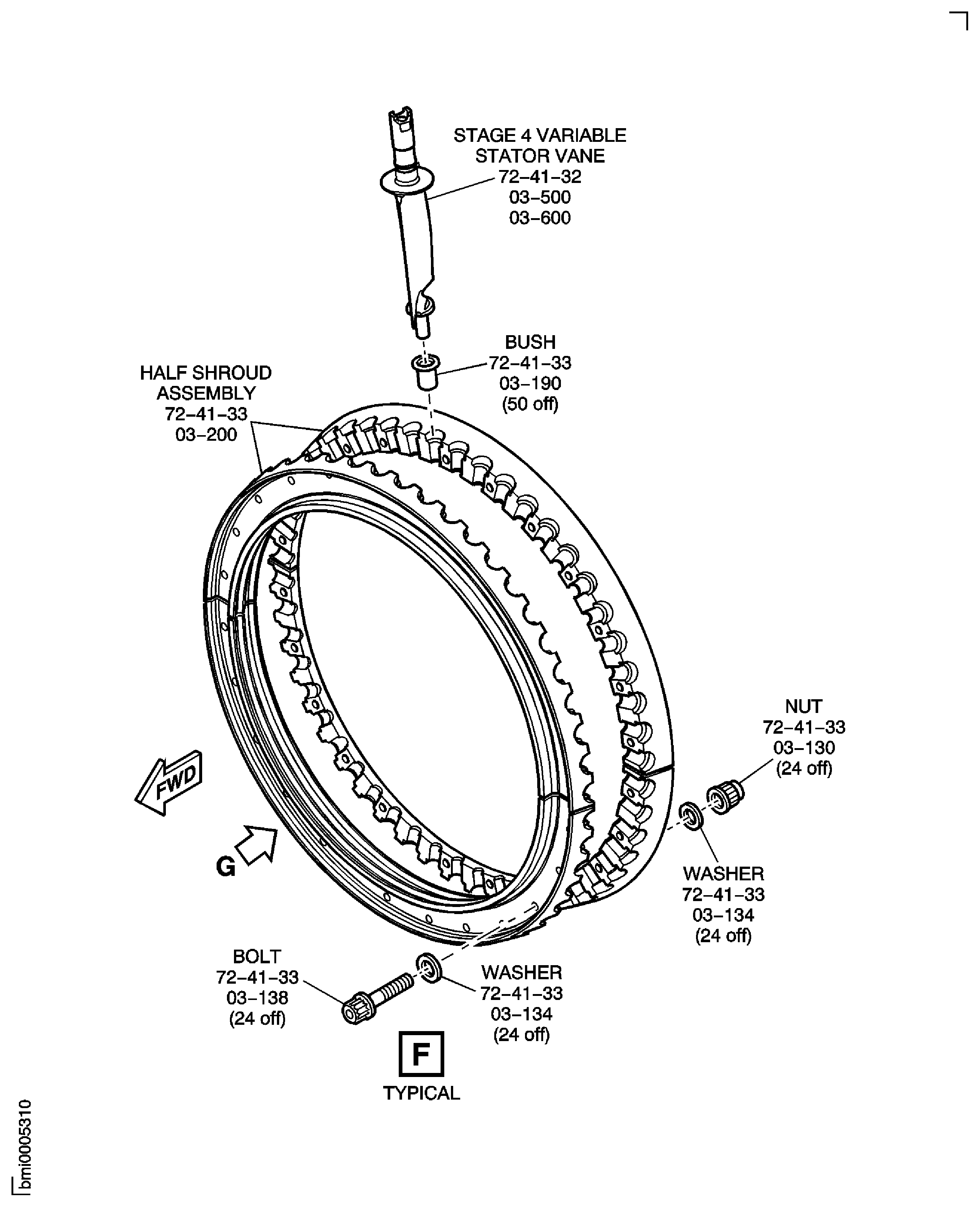

SUBTASK 72-41-30-440-283-003 Install the Stage 4 Variable Stator Vanes (VSV) in the HP Compressor Front Case (SBE 72-0571 and SBE 72-0573)

Apply CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R) teflon based lubricant on the inner vane spindles and mating faces of the inner bushes.

NOTE

The HP Compressor stage 4 half shroud assembly consists of the front half shroud and rear half shroud as a matched set. Check correlation markings on the front and rear half shrouds to ensure that the stage 4 half shroud assembly will be installed as a matched set.Install the 25 bushes HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-190) onto the stage 4 stator vanes.

Locate the stage 4 front half shroud with integral seal HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-200) on to the stage 4 stator vanes and bushes at the inner pivot point.

Install the three bolts HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-138), the six dee-headed washers HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-134) and the three nuts HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-130) to the stage 4 half shroud assembly at the position marked First (1st) and tighten them.

Install the remaining nine bolts HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-138), the 18 dee-headed washers HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-134) and the nine nuts HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-130) to the stage 4 half shroud assembly at the remaining positions.

CAUTION

MAKE SURE THAT THE BUSHES INSTALLED ON THE VANE INNER SPINDLES ARE ENGAGED CORRECTLY IN THE STAGE 4 HALF SHROUD ASSEMBLY AND THE INTEGRAL AIR SEAL IS FORWARD OF THE VANE SPINDLES. THIS WILL HELP TO PREVENT DAMAGE TO THE ENGINE.Install the stage 4 half shroud assembly HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-200) to the upper half HP Compressor front case.

Install the stage 4 half shroud assembly HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-200) to the lower half HP Compressor front case.

Install the stage 4 half shroud assemblies HPC Variable Stator Vane Shrouds And Related Part (72-41-33, 03-200) to the upper and lower half HP Compressor front case.

SUBTASK 72-41-30-440-285 Install the Stage 4 Variable Stator Vane Half Shroud (SBE 72-0560 and SBE 72-0573)

For the assembly procedure refer to TASK 72-41-30-440-005-B00.

NOTE

This subtask is applicable for the engine which have A5 standard, SelectOne(TM) Retrofit Standard incorporated.

SUBTASK 72-41-30-440-284-001 Install the Stage 4 Variable Stator Vane Actuating Rings

NOTE

This subtask is applicable for engines which have A5 standard, SelectOne(TM) Production Standard incorporated.NOTE

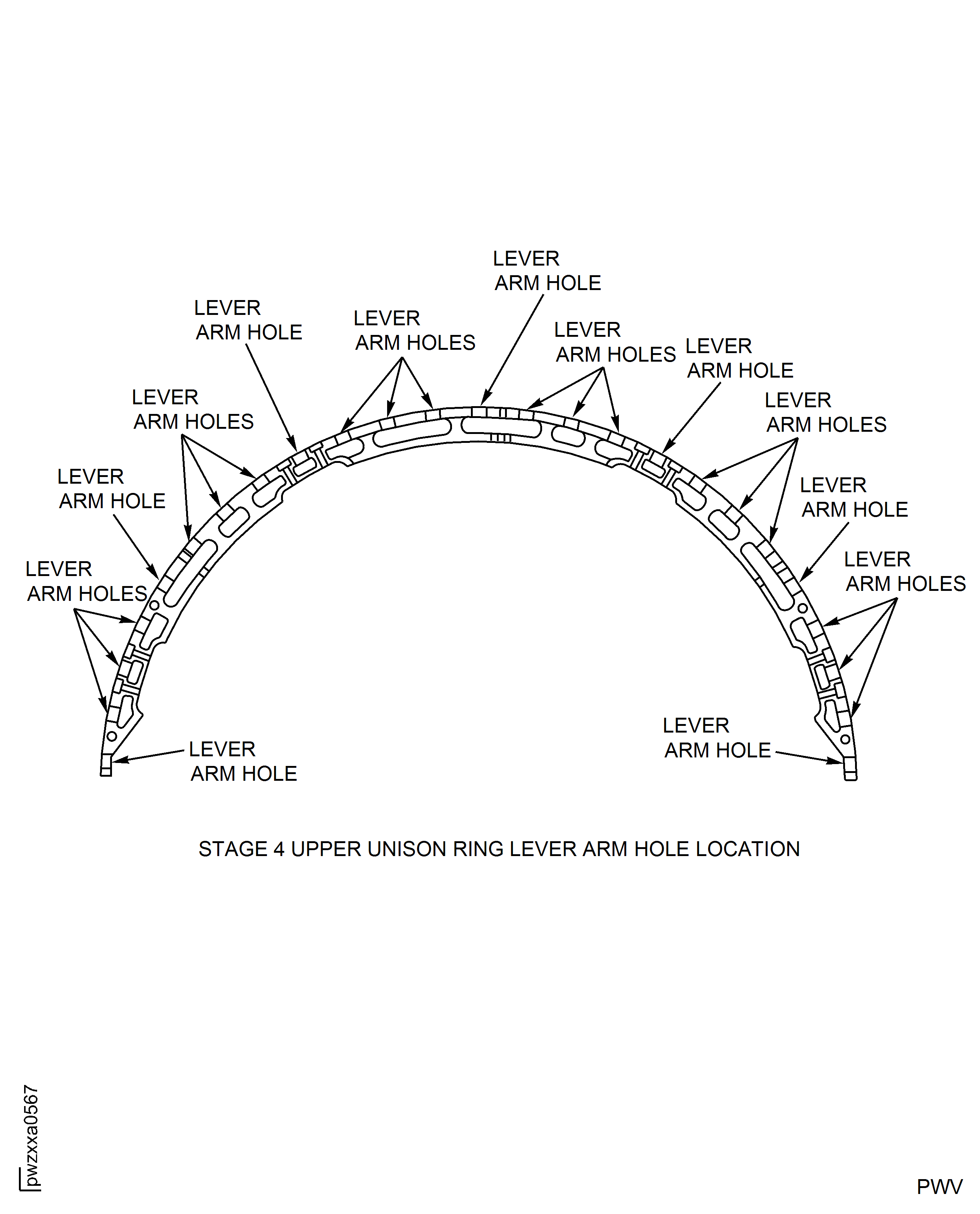

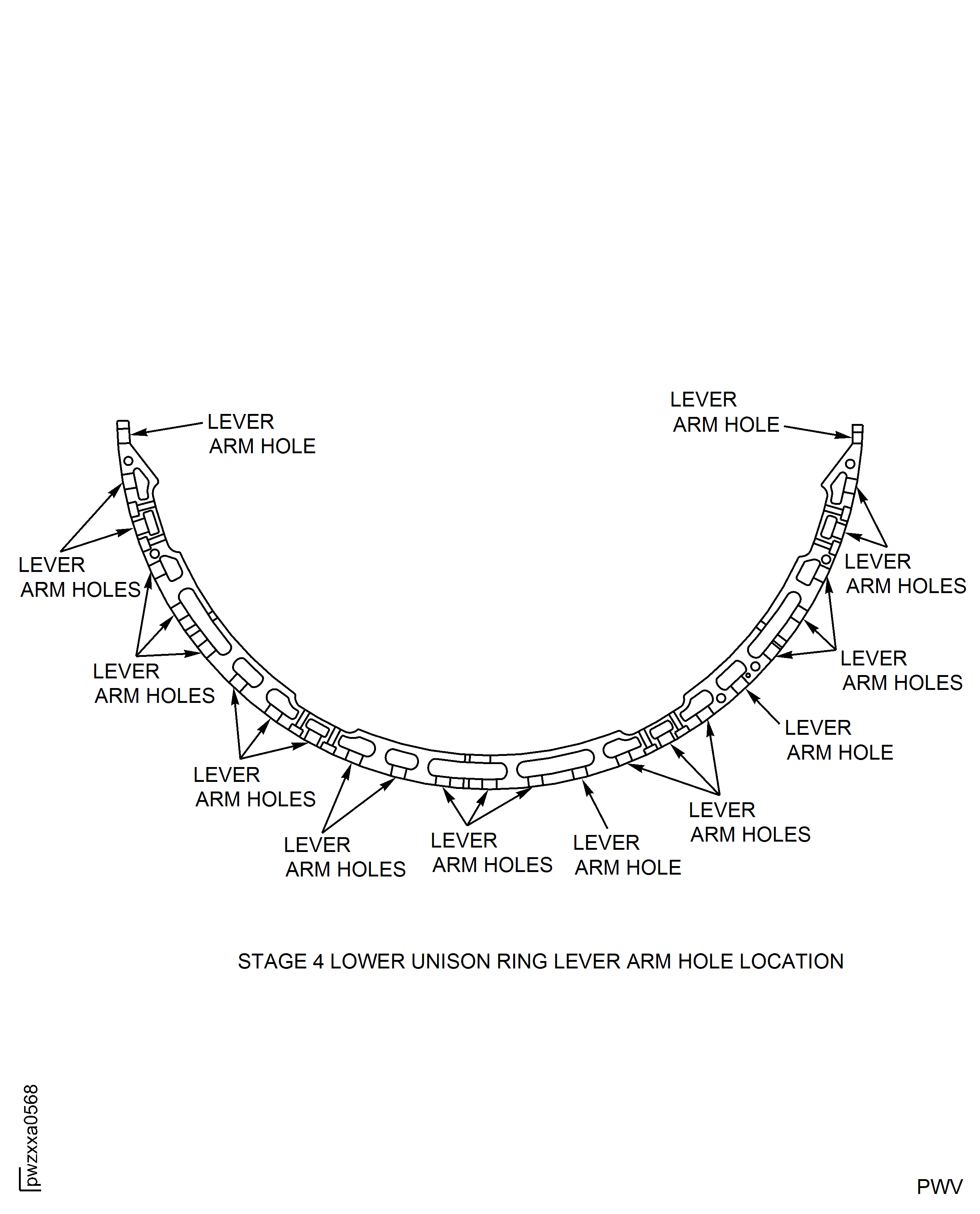

It is not necessary to lubricate the stage 4 locations with CoMat 10-108 HIGH PERFORMANCE PENETRATING LUBRICANT WITH TEFLON (R) during this SUBTASK.If all lever arm holes are within 0.4843 in. (12.300 mm) or less in the largest diameter, continue with Step.

If one or more lever arm hole is above the limits reject the part and continue with a serviceable part.

NOTE

"If the measurement has been previously accomplished or if a new part is installed then TASK 72-41-34-200-007-D00, Step 3.B can be skipped."

Measure the 25 lever arm holes in each of the upper or lower VIGV actuating rings.

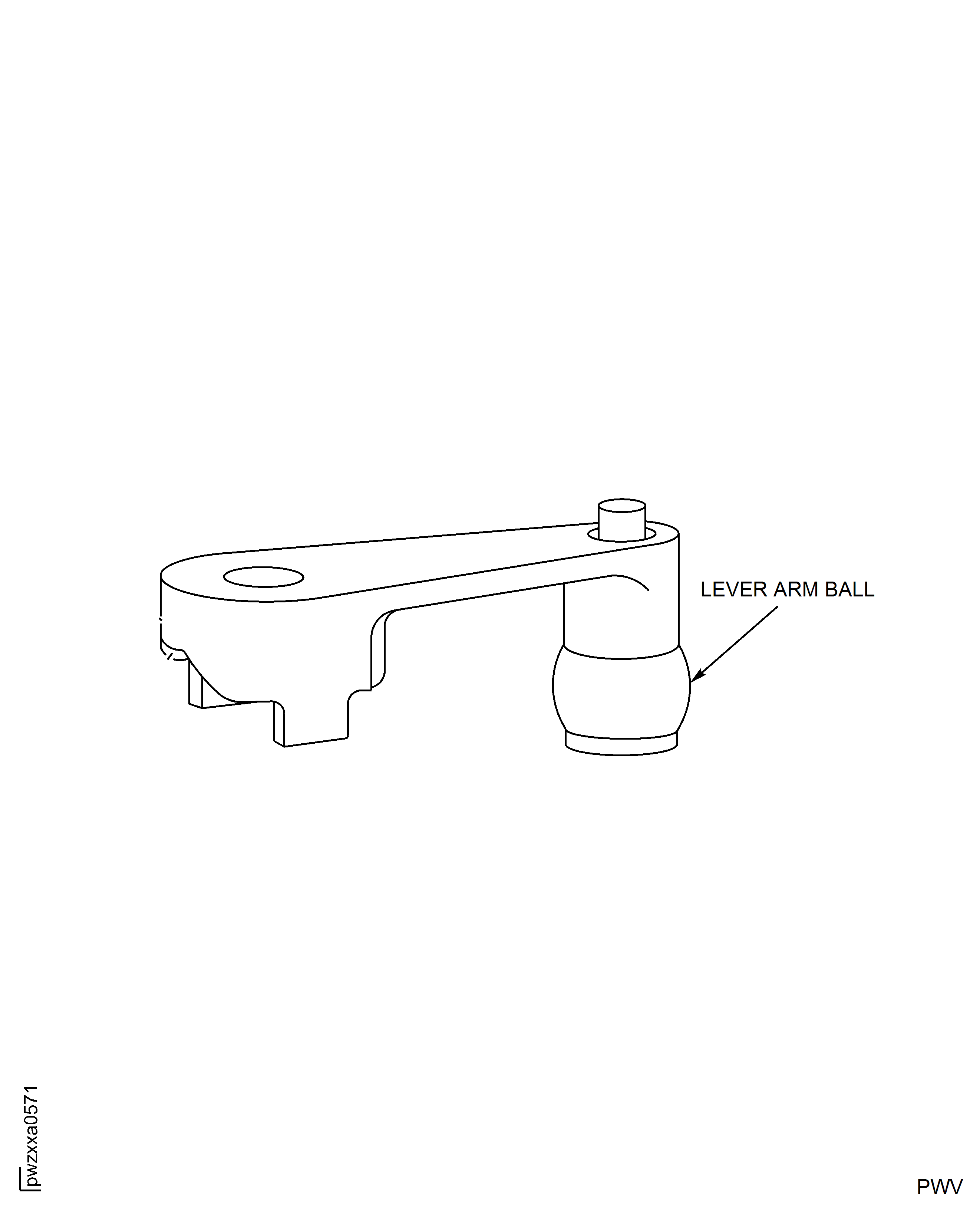

If all lever arm balls are within 0.4768 in. and 0.4787 in. (12.110 mm and 12.160 mm), continue with Step.

If any lever arm ball is above the limits reject the part and continue with a serviceable part.

NOTE

"If the measurement has been previously accomplished or if a new part is installed then TASK 72-41-34-200-004-B00, Step 15.C can be skipped."

Measure the 50 actuating lever arm balls.

Put the stage 4 upper actuating ring HPC Variable Stator Vane Actuation System (72-41-34, 04-440) into position on the upper half HP Compressor front case. Install three of IAE 1R18423 Rigging pin 3 off or IAE 1R18894 Rigging pin 3 off to attach the stage 4 upper actuating ring to the upper half HP Compressor front case.

Install the stage 4 upper actuating ring on to the upper half HP Compressor front case.

NOTE

The position information given in this procedure indicates that you must look from the front to the rear of the module.NOTE

Set the stage 4 upper actuating ring adjacent to the stage 4 stator vane at positions 1 to 25.Put the stage 4 lower actuating ring HPC Variable Stator Vane Actuation System (72-41-34, 04-540) into position on the lower half HP Compressor front case. Install three of IAE 1R18423 Rigging pin 3 off or IAE 1R18894 Rigging pin 3 off to attach the stage 4 lower actuating ring to the lower half HP Compressor front case.

Install the stage 4 lower actuating ring on to the lower half HP Compressor front case.

NOTE

The position information given in this procedure indicates that you must look from the front to the rear of the module.NOTE

Set the stage 4 lower actuating ring adjacent to the stage 4 stator vane at positions 26 to 50.Install the two stage 4 actuating levers HPC Variable Stator Vane Actuation System (72-41-34, 04-140) to the positions 32 and 33 and the two bolts HPC Variable Stator Vane Actuation System (72-41-34, 04-142) to the actuating levers.

Install the three stage 4 actuating levers HPC Variable Stator Vane Actuation System (72-41-34, 04-120) to the positions 12 to 14 and three two bolts HPC Variable Stator Vane Actuation System (72-41-34, 04-122) to the actuating levers.

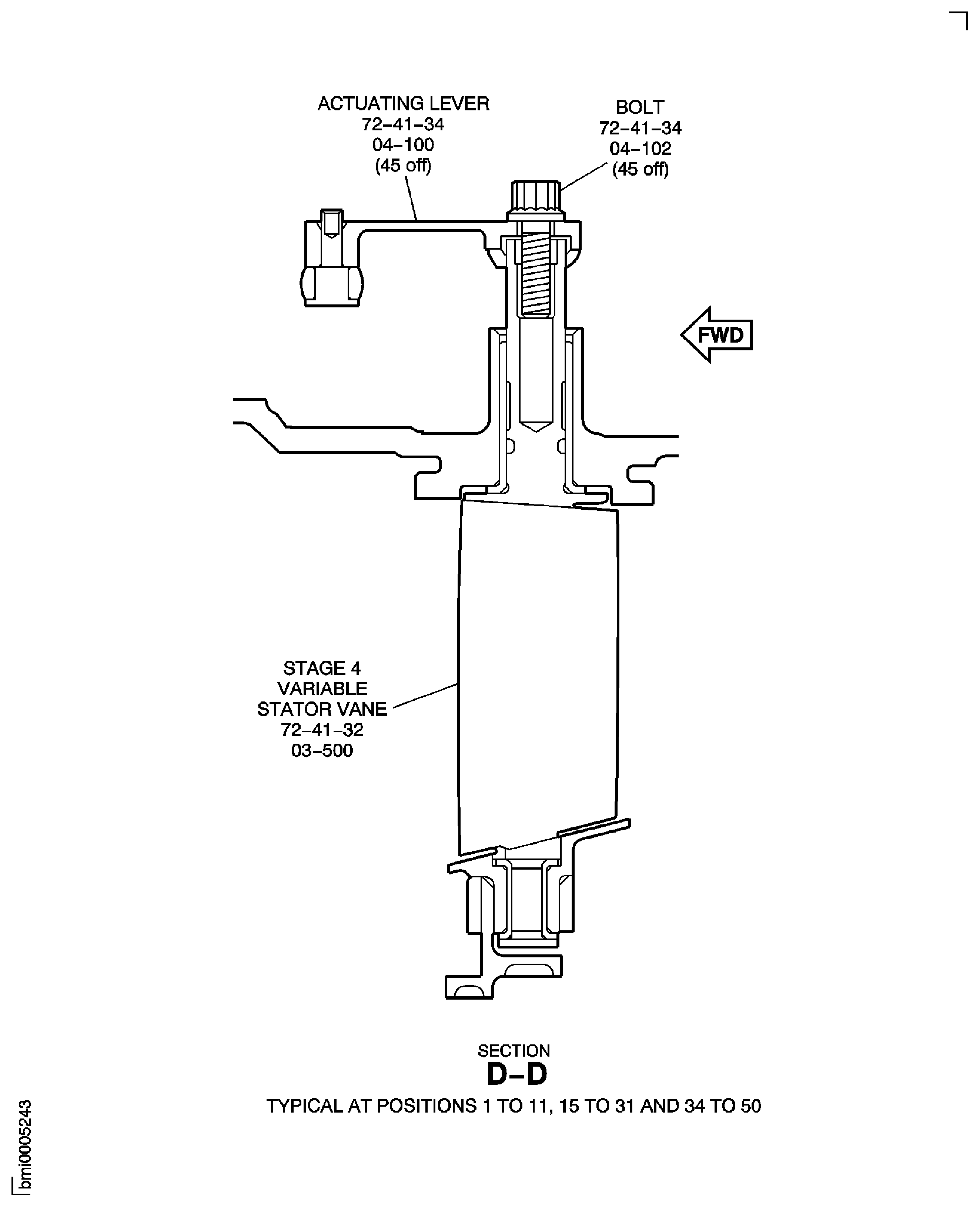

Install the 45 stage 4 actuating levers HPC Variable Stator Vane Actuation System (72-41-34, 04-100) to the positions 1 to 11, 15 to 31 and 34 to 50 and 45 bolts HPC Variable Stator Vane Actuation System (72-41-34, 04-102) to the actuating levers.

NOTE

The stage 4 actuating levers must be parallel with the casing center line when you torque the bolts. This is the null position.

CAUTION

MAKE SURE THAT THE VANE SPINDLE IS FULLY ENGAGED INTO THE LEVER AND THAT THE VANE TRAILING EDGE POINTS REARWARD. THIS WILL HELP TO PREVENT DAMAGE TO THE ENGINE.Install the 50 guide vane actuating levers on the spindles of the guide vanes and into their locations in the actuating ring.

NOTE

The position information given in this procedure indicates that you must look from the front to the rear of the module.

Install the stage 4 actuating levers.

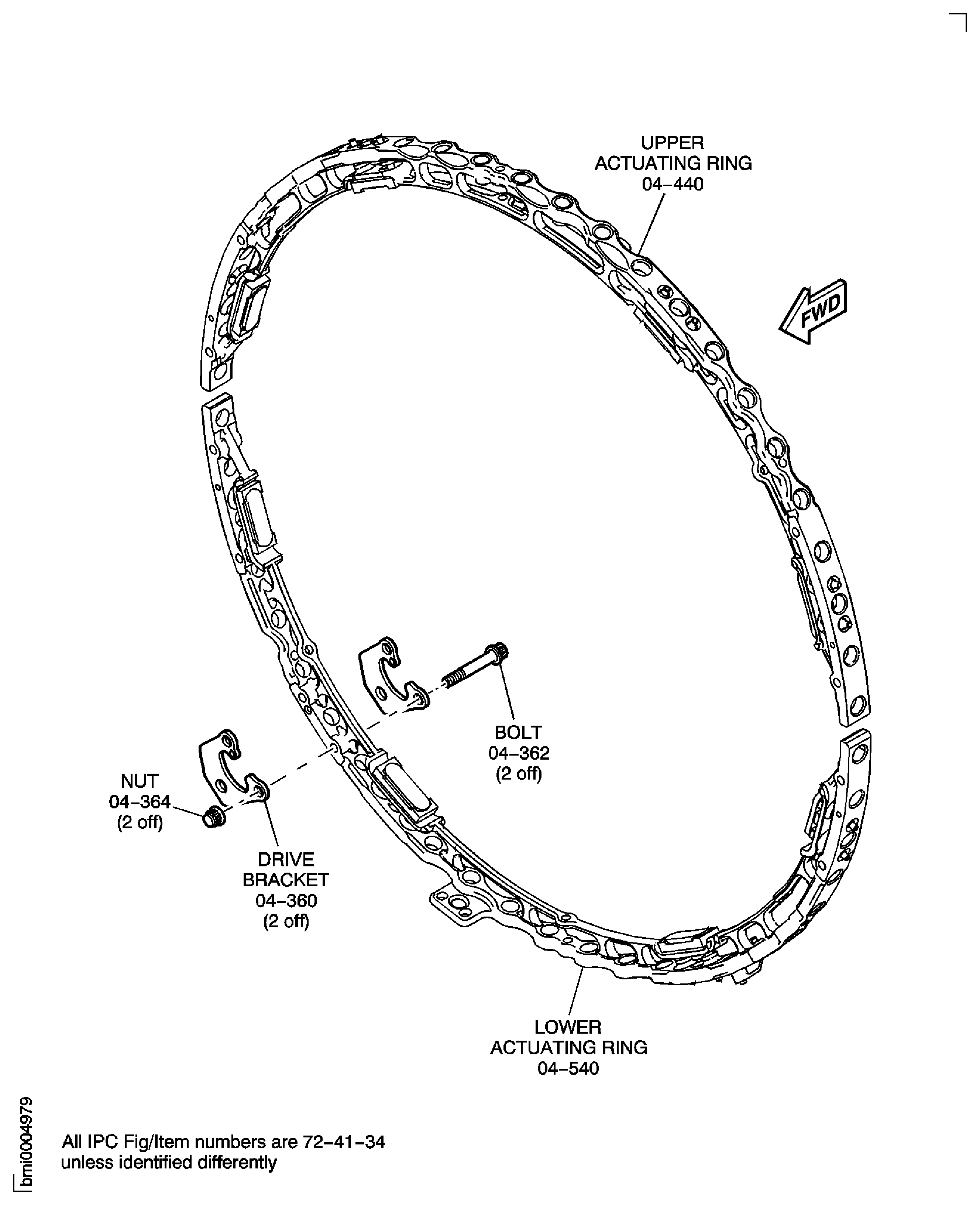

Put the two brackets HPC Variable Stator Vane Actuation System (72-41-34, 04-360) into position on the stage 4 lower actuating ring HPC Variable Stator Vane Actuation System (72-41-34, 04-540).

Install the two bolts HPC Variable Stator Vane Actuation System (72-41-34, 04-362) and two self locking nuts HPC Variable Stator Vane Actuation System (72-41-34, 04-364) to attach the two brackets to the stage 4 lower actuating ring.

Install the drive bracket.

SUBTASK 72-41-30-440-284-003 Install the Stage 4 Variable Stator Vane Actuating Rings (SBE 72-0564, SBE 72-0571 and SBE 72-0573)

Figure: SBE 72-0564 and SBE 72-0571: View through the HP Compressor Front Case

SBE 72-0564 and SBE 72-0571: View through the HP Compressor Front Case

Figure: Locations for the Fits and Clearances

Locations for the Fits and Clearances

Figure: SBE 72-0560: Locations for the Fits and Clearances

SBE 72-0560: Locations for the Fits and Clearances

Figure: SBE 72-0564: Install the Stage 4 Actuating Ring and Centralizing Support Assemblies

SBE 72-0564: Install the Stage 4 Actuating Ring and Centralizing Support Assemblies

Figure: SBE 72-0564: Install the Drive Brackets

SBE 72-0564: Install the Drive Brackets

Figure: SBE 72-0571: Install the Stage 4 Variable Stator Vanes

SBE 72-0571: Install the Stage 4 Variable Stator Vanes

Figure: SBE 72-0571: Install the Stage 4 Variable Stator Vanes

SBE 72-0571: Install the Stage 4 Variable Stator Vanes

Figure: SBE 72-0571: Install the Stage 4 Variable Stator Vanes

SBE 72-0571: Install the Stage 4 Variable Stator Vanes

Figure: SBE 72-0560 and SBE 72-0573: Install the Stage 4 Variable Stator Vane Half Shroud

SBE 72-0560 and SBE 72-0573: Install the Stage 4 Variable Stator Vane Half Shroud

Figure: SBE 72-0560 and SBE 72-0573: Install the Stage 4 Variable Stator Vane Half Shroud

SBE 72-0560 and SBE 72-0573: Install the Stage 4 Variable Stator Vane Half Shroud

Figure: SBE 72-0564: Install the Stage 4 Variable Stator Vane Spindle Bushes

SBE 72-0564: Install the Stage 4 Variable Stator Vane Spindle Bushes

Figure: SBE 72-0564: Install the Stage 4 Variable Stator Vane Spindle Bushes

SBE 72-0564: Install the Stage 4 Variable Stator Vane Spindle Bushes

Figure: Install the Seals on the Stage 4 Variable Stator Vane Spindles

Install the Seals on the Stage 4 Variable Stator Vane Spindles

Figure: SBE 72-0571: Install the Stage 4 Stator Vane Actuating Levers

SBE 72-0571: Install the Stage 4 Stator Vane Actuating Levers

Figure: Stage 4 Unison Ring Lever Arm Hole Location

Stage 4 Unison Ring Lever Arm Hole Location

Stage 4 Unison Ring Lever Arm Hole Location

Figure: Lever Arm Ball Location

Lever Arm Ball Location