Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

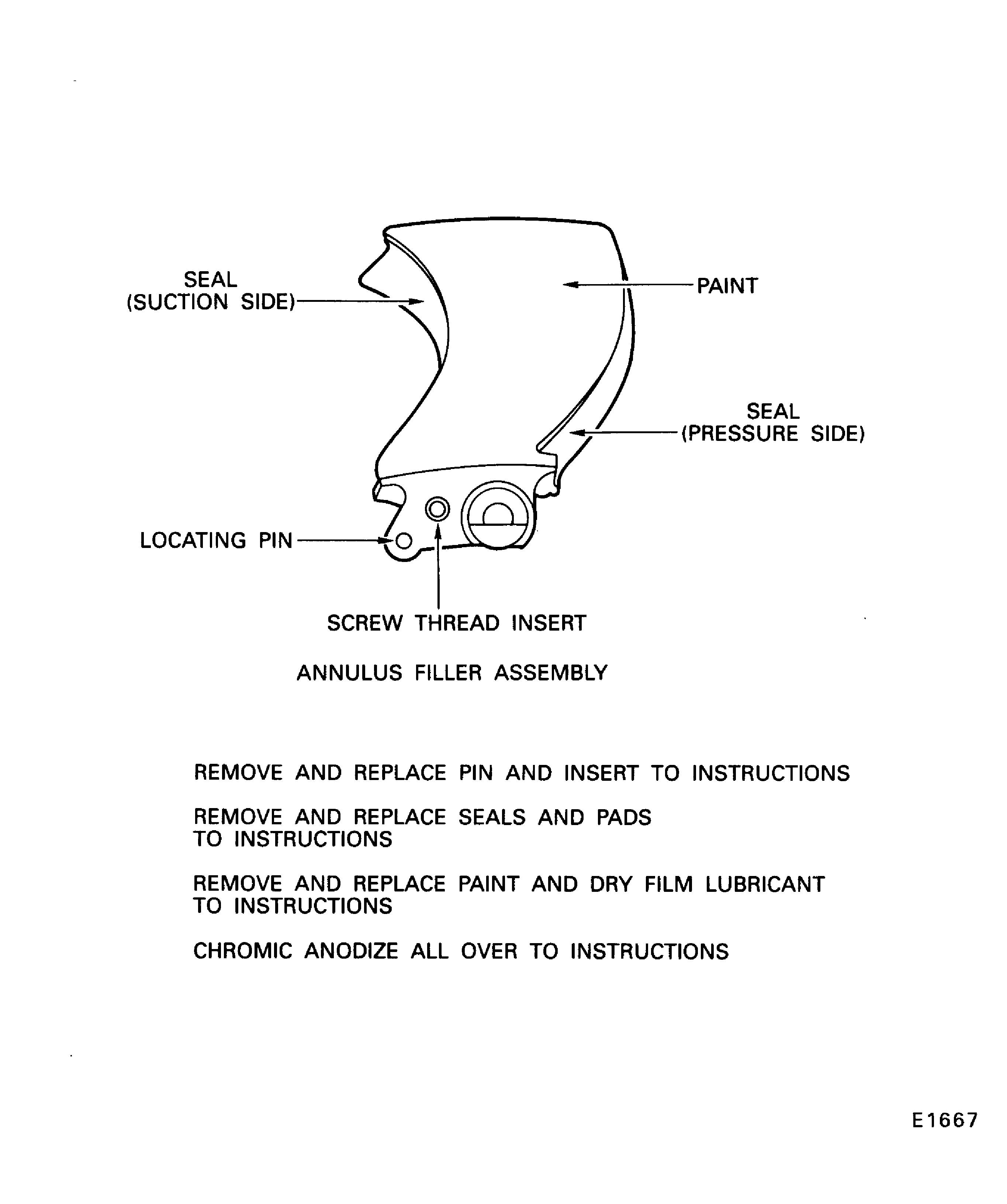

TASK 72-31-11-300-019 Annulus Filler - Replace The Anodized Coating, Repair-019 (VRS1019)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-100 | 5A0353 |

01-100 | 5A1459 |

01-100 | 5A1611 |

01-100 | 5A1638 |

01-100 | 5A1710 |

01-100 | 5A1750 |

01-100 | 5A1752 |

01-100 | 5A1753 |

01-100 | 5A6533 |

01-100 | 5A1854 |

General

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Price and availability - none

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chromic anodizing facility | LOCAL | Chromic anodizing facility | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 08-020 EPOXY PRIMER,RED | LOCAL | CoMat 08-020 | ||

| CoMat 02-002 ADHESIVE TAPE GENERALPURPOSE PAPER | LOCAL | CoMat 02-002 | ||

| CoMat 02-019 TAPE, ADHESIVE PAPER HEAT RESISTING MASKING | 94960 | CoMat 02-019 | ||

| CoMat 01-339 ALKALI CLEANER (GENERAL PURPOSE) | LOCAL | CoMat 01-339 | ||

| CoMat 01-023 CHROMIUM TRIOXIDE CrO3(CHROM.ACID) | LOCAL | CoMat 01-023 | ||

| CoMat 01-201 DISTILLED, DEIONIZED, DEMINERALIZED, OR REVERSE OSMOSIS (RO) WATER | LOCAL | CoMat 01-201 | ||

| CoMat 01-530 Nickel acetate (Mixture) | IE470 | CoMat 01-530 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Refer to VRS1010, TASK 72-31-11-300-005 (REPAIR-005).

Remove the locating pin.

Refer to VRS1018, TASK 72-31-11-300-022 (REPAIR-022) or VRS1007, TASK 72-31-11-300-003 (REPAIR-003).

Remove the seals and pads.

Refer to VRS1017, TASK 72-31-11-300-023 (REPAIR-023) or VRS1013, TASK 72-31-11-300-014 (REPAIR-014).

Remove the screw thread insert.

Refer to VRS1735, TASK 72-31-11-300-020 (REPAIR-020) or VRS1008, TASK 72-31-11-300-004 (REPAIR-004).

Remove the dry film lubricant.

Refer to VRS1009, TASK 72-31-11-300-002 (REPAIR-002).

Remove the heat resistant ES coating.

Refer to TASK 72-31-11-100-000 (CLEANING-000).

Remove the anodized coating.

SUBTASK 72-31-11-350-068 Prepare for Anodizing

Refer to TASK 72-31-11-200-000 (INSPECTION/CHECK-000).

Do a penetrant crack test.

SUBTASK 72-31-11-230-059 Examine the Annulus Filler for Cracks

Refer to the SPM TASK 70-33-20-300-503.

NOTE

This SUBTASK is an alternative to Step.Prepare the annulus filler to apply the anodized coating.

SUBTASK 72-31-11-330-051 Prepare the Annulus Filler for Anodizing

Use CoMat 01-339 ALKALI CLEANER (GENERAL PURPOSE) of 15 to 30 per cent.

Soak the part in solution for 10 to 30 minutes, at temperature of 122 to 140 deg F (50 to 60 deg C), as necessary.

NOTE

This SUBTASK is an alternative to Step.NOTE

All repairs and inspections must be completed, before anodizing.Prepare the annulus filler for anodizing.

SUBTASK 72-31-11-330-006 Prepare the Annulus Filler for Anodizing

Refer to the SPM TASK 70-33-20-300-503.

NOTE

This SUBTASK is an alternative to Step.Chromic anodize the annulus filler.

SUBTASK 72-31-11-330-007 Apply the Anodize Coating

The solution is made up of 6.6 to 14 oz/gal (50 to 105 g/l) CoMat 01-023 CHROMIUM TRIOXIDE CrO3(CHROM.ACID) in CoMat 01-201 DISTILLED, DEIONIZED, DEMINERALIZED, OR REVERSE OSMOSIS (RO) WATER.

Use the chromic anodizing facility.

WARNING

CHROMIC ACID SPRAY IS INJURIOUS IF INHALED, CAUSING ULCERS IN THE NOSE AND IN SOME CASES, PERFORATION OF THE NASAL SEPTUM. CHROMIC ACID SALTS AND SOLUTIONS IN CONTACT WITH THE SKIN MAY CAUSE CHROME SORES. ULCERS MAY BE FORMED IF CHROMIC ACID GETS INTO CUTS AND ABRASIONS.

WARNING

CHROMIC ACID SOLUTION MUST NEVER BE USED UNLESS THE FUME EXTRACTION PLANT IS IN OPERATION AND IS FULLY SERVICEABLE.

WARNING

BARRIER CREAM SHOULD BE APPLIED TO THE HANDS AND FOREARMS BEFORE STARTING WORK.

WARNING

PROTECTIVE GLOVES, OVERALLS, GOGGLES OR FACE VISOR AND SAFETY SHOES OR BOOTS MUST BE WORN.

WARNING

SMOKING AND THE CONSUMPTION OF FOOD NEAR THE CHROMIC ACID BATH ARE PROHIBITED.

WARNING

CUTS AND ABRASIONS, WHICH APPEAR NOT TO BE HEALING READILY SHOULD BE REPORTED, WITHOUT DELAY, TO THE MEDICAL DEPARTMENT.

WARNING

CHROMIC ACID IS STRONGLY OXIDIZING AND ENTAILS SOME FIRE RISK, POSSIBLE SPONTANEOUS COMBUSTION OF ORGANIC MATERIALS, SUCH AS RAGS AND SAWDUST, WHICH HAVE ABSORBED CHROMIC ACID SOLUTION. SUCH CONTAMINATED MATERIALS SHOULD BE IMMERSED IN A SOLUTION OF SODIUM BISULPHATED TO NEUTRALISE THE CHROMIC ACID, THE SOLUTION SHOULD THEN BE DISPOSED OF AS SPECIAL WASTE. THE SOLID MATERIAL SHOULD THEN BE RINSED WITH WATER PRIOR TO DISPOSAL.

WARNING

IT IS THE RESPONSIBILITY OF THE OPERATOR TO OBTAIN AND OBSERVE THE MANUFACTURERS MATERIAL SAFETY DATA SHEETS FOR CONSUMABLE MATERIALS INFORMATION SUCH AS, HAZARDOUS INGREDIENTS, PHYSICAL/CHEMICAL CHARACTERISTICS, FIRE, EXPLOSION, REACTIVITY, HEALTH HAZARD DATA, PRECAUTIONS FOR SAFE HANDLNG, USE AND CONTROL MEASURES AND ALSO TO TAKE LOCAL REGULATIONS IN TO CONSIDERATION.

CAUTION

THE ANODIZING PROCEDURE MUST BE CAREFULLY CONTROLLED, BECAUSE DAMAGE TO THE PARTS CAN BE CAUSED.NOTE

Step must be carried out within eight hours of anodizing.NOTE

This SUBTASK is an alternative to Step.Make up the chromic anodize solution.

NOTE

When the part as been installed, make sure that air bubbles can not occur.NOTE

The solution must be constantly mixed, by a pump or with clean compressed air, to make sure that temperature is kept constant, through the full bath.Install the part and connect to the positive pole of the DC electrical power supply.

The solution is made up of 0.93 oz/gal (7 g/l) of nickel acetate in CoMat 01-201 DISTILLED, DEIONIZED, DEMINERALIZED, OR REVERSE OSMOSIS (RO) WATER.

NOTE

Make sure that the pH value of solution is 5.3 to 6.0.NOTE

The pot life of sealing solution is about one week.Make up the nickel acetate sealing solution.

NOTE

Step must be carried out within eight hours of anodizing.Nickel acetate seal the part.

SUBTASK 72-31-11-330-008 Apply the Anodized Coating

Refer to the SPM TASK 70-33-20-300-503.

Make sure that the coating is continuous and even.

Visually examine the anodized coating.

SUBTASK 72-31-11-220-086 Examine the Anodized Coating

Refer to Figure.

Refer to TASK 72-31-11-200-000 (INSPECTION/CHECK-000).

Dimensionally inspect the trunnions (Dia E and Dia G).

SUBTASK 72-31-11-220-087 Examine the Annulus Filler Trunnions

Refer to VRS1735, TASK 72-31-11-300-020 (REPAIR-020) or VRS1008, TASK 72-31-11-300-004 (REPAIR-004).

Apply the dry film lubricant.

Refer to VRS1009, TASK 72-31-11-300-002 (REPAIR-002).

Apply the heat resistant ES coating.

SUBTASK 72-31-11-380-062 Apply the Dry Film Lubricant and the Heat Resistant ES Coating to the Annulus Filler

Refer to VRS1018, TASK 72-31-11-300-022 (REPAIR-022) or VRS1007, TASK 72-31-11-300-003 (REPAIR-003).

Install the seals and pads.

Refer to VRS1017, TASK 72-31-11-300-005 (REPAIR-023) or VRS1013, TASK 72-31-11-300-014 (REPAIR-014).

Install the screw thread insert.

SUBTASK 72-31-11-350-069 Install the Seals, Pad, Pin and Insert to the Annulus Filler

Use a Vibrating marking pencil.

Refer to the SPM TASK 70-09-00-400-501.

Vibro-engrave VRS1019 adjacent to the part number.

Refer to the SPM TASK 70-38-02-300-503, SUBTASK 70-38-02-300-002.

Apply chromate conversion coating to the marking letters.

SUBTASK 72-31-11-350-070 Make a Mark on the Annulus Filler

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions