Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-45-14-200-001-A00 HPT Stage 1 Blade - Examine, Inspection-001

Effectivity

FIG/ITEM PART NO. | |

|---|---|

01-010 | 2A1221 |

01-010 | 2A1221-001 |

01-010 | 2A1221-002 |

01-010 | 2A1721 |

01-010 | 2A1721-001 |

01-010 | 2A1721-002 |

01-010 | 2A2421 |

01-010 | 2A2421-001 |

01-010 | 2A3001 |

01-010 | 2A3001-001 |

01-010 | 2A3001-002 |

01-010 | 2A8601 |

01-010 | 2A8901 |

General

This TASK gives the procedure for the inspection of the stage 1 HPT blade. For the other part of the stage 1 HPT blade assembly, refer to TASK 72-45-14-200-000 (INSPECTION/CHECK-000).

Fig/item numbers in parentheses in the procedure agree with those used in the IPC.

The policy that is necessary for inspection is given in the SPM TASK 70-20-00-200-501.

All the parts must be cleaned before any part is examined. Refer to the SPM TASK 70-10-00-100-501.

All parts must be visually examined for damage, corrosion and wear. Any defects that are not identified in the procedure must be referred to IAE.

The procedure for those parts which must have a crack test is given in SUBTASK 72-45-14-230-052. Do the test for cracks only if the visual examination of the blade is unsatisfactory.

A ** following repair referenced in this inspection indicates that the repair is not yet published in the current revision of the manual and the part must be rejected. Contact IAE for additional information concerning FAA approved repair date.

Do not discard any part until you are sure there are no repairs available. Refer to the instructions in Repair before a discarded part is used again or oversize parts are installed.

Parts which should be discarded can be held although no repair is available. The repair of a discarded part could be shown to be necessary at a later date.

All parts must be examined to make sure that all the repairs have been completed satisfactorily.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

References

Refer to the SPM for data on these items.

Definitions of Damage, SPM TASK 70-02-02-350-501

Metal Temperature Analysis (Nickel Base Alloys), SPM TASK 70-02-03-220-501

Vapor degrease, SPM TASK 70-11-01-300-503

Procedure to Moderately Clean, SPM TASK 70-11-03-300-503

Cleaning, SPM TASK 70-12-09-120-501

Fluorescent Penetrant Inspection, SPM TASK 70-23-08-230-501

Shotpeening, SPM TASK 70-38-13-380-501

Radiograph Inspection Procedure, SPM TASK 70-26-01-260-501

Airflow - Turbine Blades and Vanes, SPM TASK 70-72-01-720-501

Ultrasonic Clean all Metal (But not Magnesium), SPM TASK 70-13-01-100-501

Inspection of Parts, SPM TASK 70-20-01-200-501

Precipitation Heat Treatment of Nickel Castings, SPM TASK 70-37-27-370-501

Some data on these items is contained in this TASK. For more data on these items refer to the SPM.

Method of Testing for Crack Indications

Chemical Processes

Surface Protection

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Oven | LOCAL | Oven | ||

| Oven | LOCAL | Oven | (Air furnace) | |

| IAE 2P16101 Airflow base | 0AM53 | IAE 2P16101 | 1 | |

| IAE 2P16113 Airflow fixture | 0AM53 | IAE 2P16113 | 1 | |

| IAE 2P16114 Airflow insert | 0AM53 | IAE 2P16114 | 1 | |

| IAE 2P16115 Airflowmaster | 0AM53 | IAE 2P16115 | 1 | |

| IAE 2P16116 Airflowmaster | 0AM53 | IAE 2P16116 | 1 | |

| IAE 2P16117 Airflowmaster | 0AM53 | IAE 2P16117 | 1 | |

| IAE 2P16118 Airflowmaster | 0AM53 | IAE 2P16118 | 1 | |

| IAE 2P16360 Airflowmaster | 0AM53 | IAE 2P16360 | 1 | |

| IAE 2P16361 Airflowmaster | 0AM53 | IAE 2P16361 | 1 | |

| IAE 2P16362 Airflowmaster | 0AM53 | IAE 2P16362 | 1 | |

| IAE 2P16371 Stage 1 HPT Blade Length Gage | 0AM53 | IAE 2P16371 | 1 | |

| IAE 2P16508 Reference card | 0AM53 | IAE 2P16508 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-010 ARGON GAS | LOCAL | CoMat 03-010 | ||

| CoMat 03-117 ARGON GAS | 0AM53 | CoMat 03-117 | ||

| CoMat 03-118 ARGON GAS | 0AM53 | CoMat 03-118 | ||

| CoMat 05-029 CAST STEEL SHOT, S110 | LOCAL | CoMat 05-029 | ||

| CoMat 05-030 CAST STEEL SHOT DELETED | 0AM53 | CoMat 05-030 | ||

| CoMat 05-031 CAST STEEL SHOT DELETED | 0AM53 | CoMat 05-031 | ||

| CoMat 05-032 CAST STEEL SHOT, S170 | 42736 | CoMat 05-032 | ||

| CoMat 05-033 CAST STEEL SHOT DELETED | 0AM53 | CoMat 05-033 | ||

| CoMat 05-034 CAST STEEL SHOT DELETED | 0AM53 | CoMat 05-034 | ||

| CoMat 05-138 SHOT, CAST STEEL, S110 | 81349 | CoMat 05-138 | ||

| CoMat 05-176 CAST STEEL SHOT, S170 | 42736 | CoMat 05-176 | ||

| CoMat 05-177 CUT WIRE SHOT,CW-14 | LOCAL | CoMat 05-177 | ||

| CoMat 05-178 CUT WIRE SHOT, CW-20 | LOCAL | CoMat 05-178 | ||

| CoMat 05-187 STAINLESS STEEL CUT WIRE SHOT, SCW-20 | LOCAL | CoMat 05-187 | ||

| CoMat 05-188 STAINLESS STEEL CUT WIRE SHOT, SPECIAL CONDITIONED, SCW-20 | LOCAL | CoMat 05-188 | ||

| CoMat 05-234 CAST STEEL SHOT, HIGH HARDNESS, S110 | LOCAL | CoMat 05-234 |

Spares

NONESafety Requirements

NONEProcedure

Refer to: Figure

Repairs, VRS3202 TASK 72-45-14-300-001 (REPAIR-001), VRS3203 TASK 72-45-14-300-002 (REPAIR-002), VRS3204 TASK 72-45-14-300-003 (REPAIR-003), VRS3495 TASK 72-45-14-300-007 (REPAIR-007), or VRS3493 TASK 72-45-14-300-008 (REPAIR-008)

Other than (1)

Examine the blade platform area for corrosion and burned areas.

Repairs, VRS3202 TASK 72-45-14-300-001 (REPAIR-001), VRS3203 TASK 72-45-14-300-002 (REPAIR-002), VRS3204 TASK 72-45-14-300-003 (REPAIR-003), VRS3495 TASK 72-45-14-300-007 (REPAIR-007), or VRS3493 TASK 72-45-14-300-008 (REPAIR-008)

Other than (1), (2) and (3)

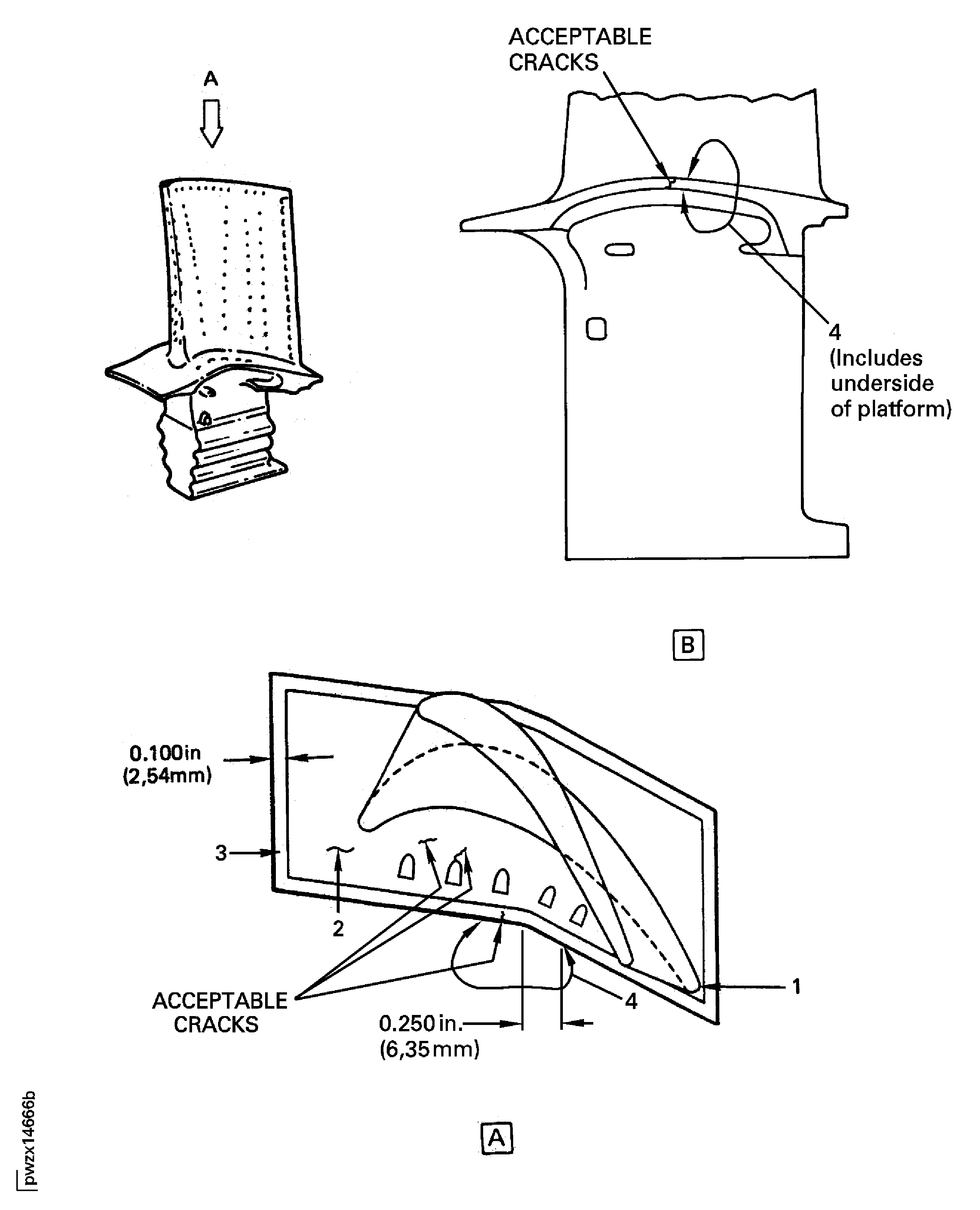

Examine the blade platform area for cracks, nicked coating, cracked coating and chipped coating. Use a white light and 10X magnification to examine for cracks.

Repairs, VRS3202 TASK 72-45-14-300-001 (REPAIR-001), VRS3203 TASK 72-45-14-300-002 (REPAIR-002), VRS3204 TASK 72-45-14-300-003 (REPAIR-003), VRS3495 TASK 72-45-14-300-007 (REPAIR-007) or VRS3493 TASK 72-45-14-300-008 (REPAIR-008)

Other than (1)

Examine the blade platform area for dents at locations 2 and 3.

SUBTASK 72-45-14-220-053 Examine the Stage 1 HPT Blade (01-010) Blade Platform Area

NOTE

To find if the base metal is shown, use the heat tint examination in Step.Repairs, VRS3202 TASK 72-45-14-300-001 (REPAIR-001), VRS3203 TASK 72-45-14-300-002 (REPAIR-002), VRS3204 TASK 72-45-14-300-003 (REPAIR-003), VRS3495 TASK 72-45-14-300-007 (REPAIR-007), or VRS3493 TASK 72-45-14-300-008 (REPAIR-008)

Other than (1)

Examine the blade airfoil surfaces for burned areas, corrosion and erosion.

Repairs, VRS3202 TASK 72-45-14-300-001 (REPAIR-001), VRS3203 TASK 72-45-14-300-002 (REPAIR-002), VRS3204 TASK 72-45-14-300-003 (REPAIR-003), VRS3495 TASK 72-45-14-300-007 (REPAIR-007), or VRS3493 TASK 72-45-14-300-008 (REPAIR-008)

Nicked or chipped coating

Examine the blade airfoil surfaces for nicked and chipped coating.

Remove the coating, VRS3204 TASK 72-45-14-300-003 (REPAIR-003)

Other than (a)

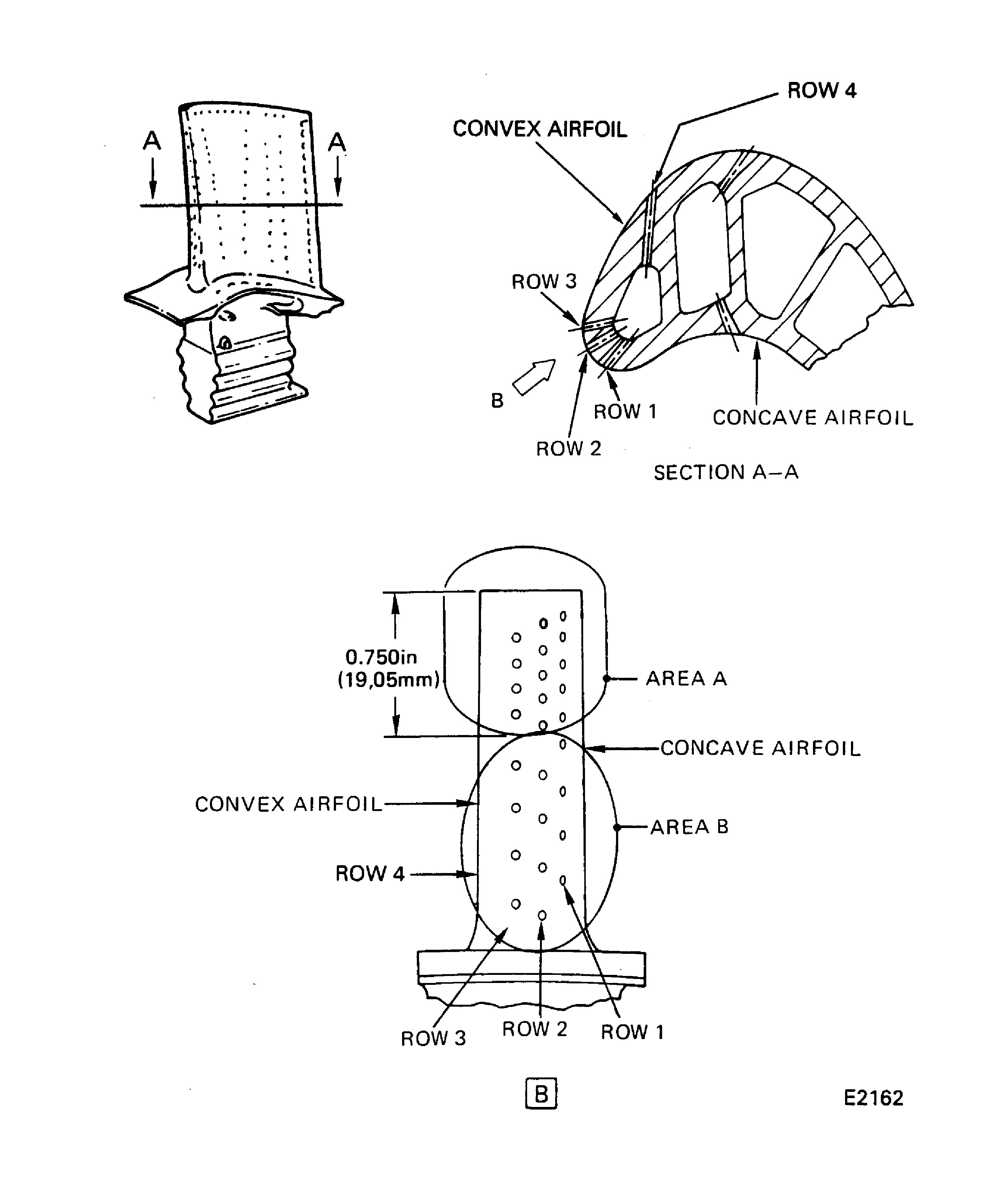

Cracks in Area A.

Remove the coating, VRS3204 TASK 72-45-14-300-003 (REPAIR-003)

Other than (a)

Cracks in Area B.

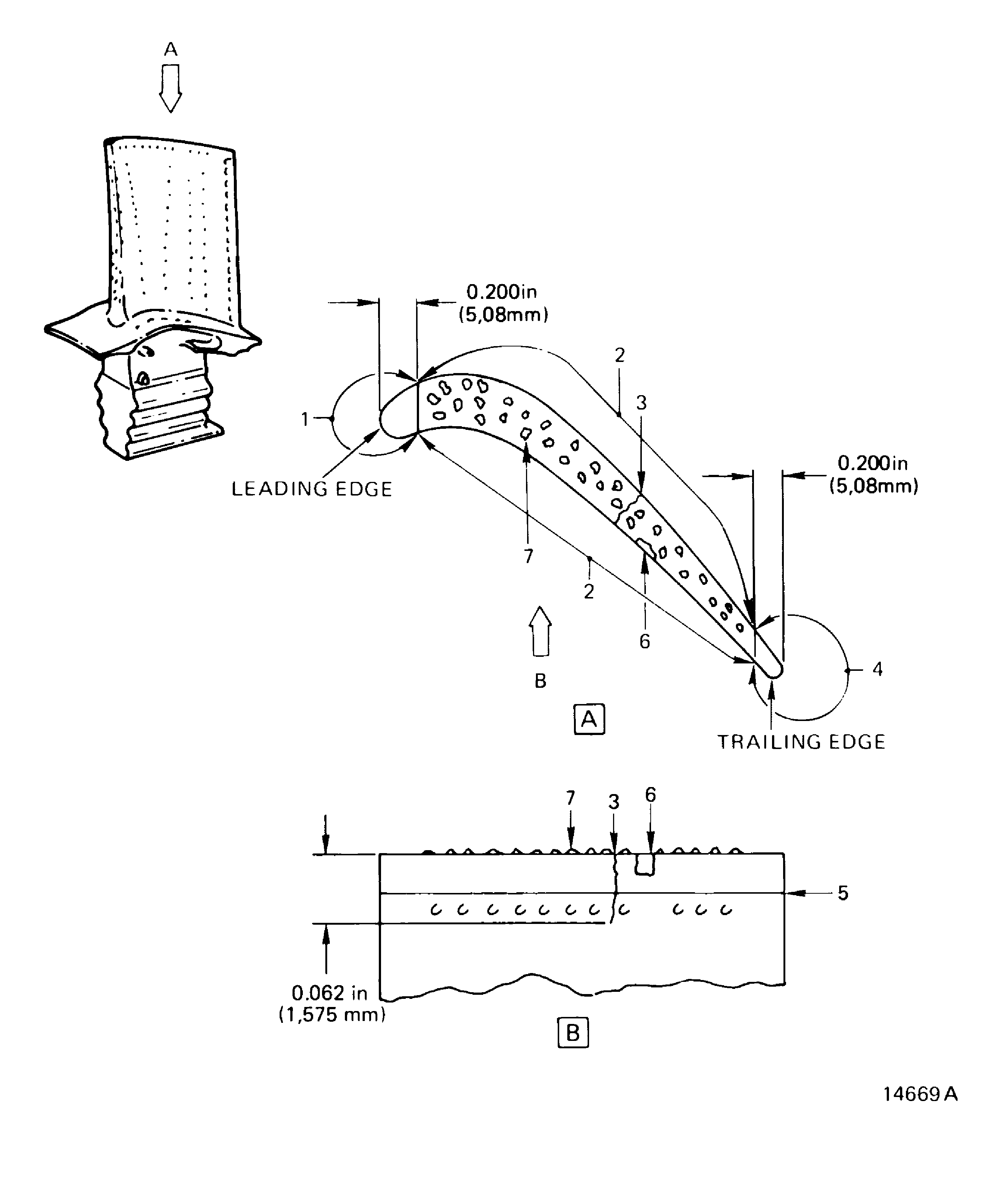

Examine the blade concave and convex surfaces and the leading edge cooling air holes for cracks. Use a white light and a 10X magnification, Figure.

Repairs, VRS3202 TASK 72-45-14-300-001 VRS3203 TASK 72-45-14-300-002 (REPAIR-002), VRS3204 TASK 72-45-14-300-003 (REPAIR-003), VRS3495 TASK 72-45-14-300-007 (REPAIR-007) or VRS3493 TASK 72-45-14-300-008 (REPAIR-008)

Other than (1) and (2), including nicks

Examine the blade concave and convex surfaces for dents, Figure.

SUBTASK 72-45-14-220-054 Examine the Stage 1 HPT Blade (01-010) Airfoil

NOTE

To find if the base metal is shown, use the heat tint examination in Step.Refer to: Figure

Repair, VRS3495 TASK 72-45-14-300-007 (REPAIR-007) VRS3493 TASK 72-45-14-300-008 (REPAIR-008) or VRS3204 TASK 72-45-14-300-003 (REPAIR-003)

NOTE

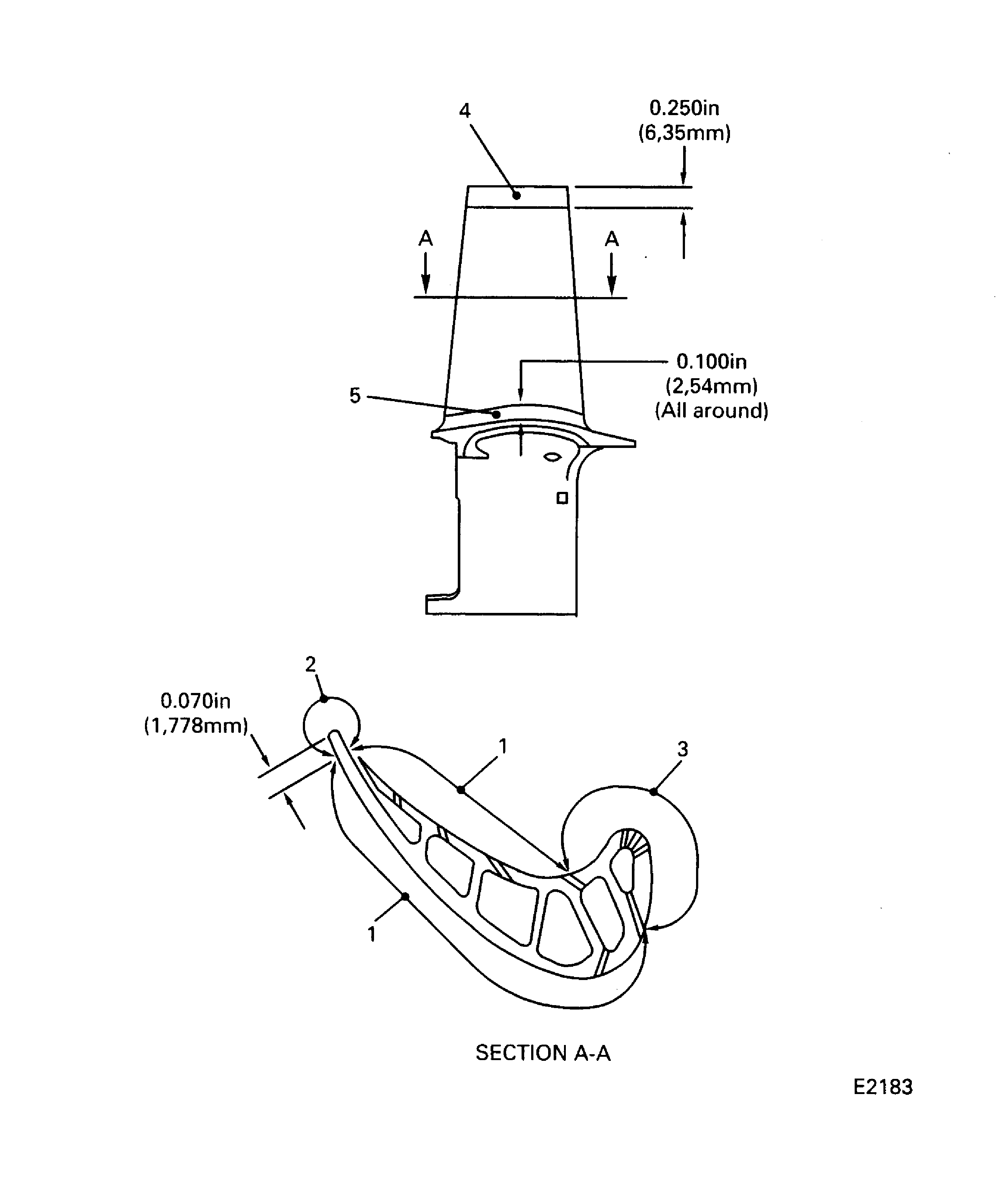

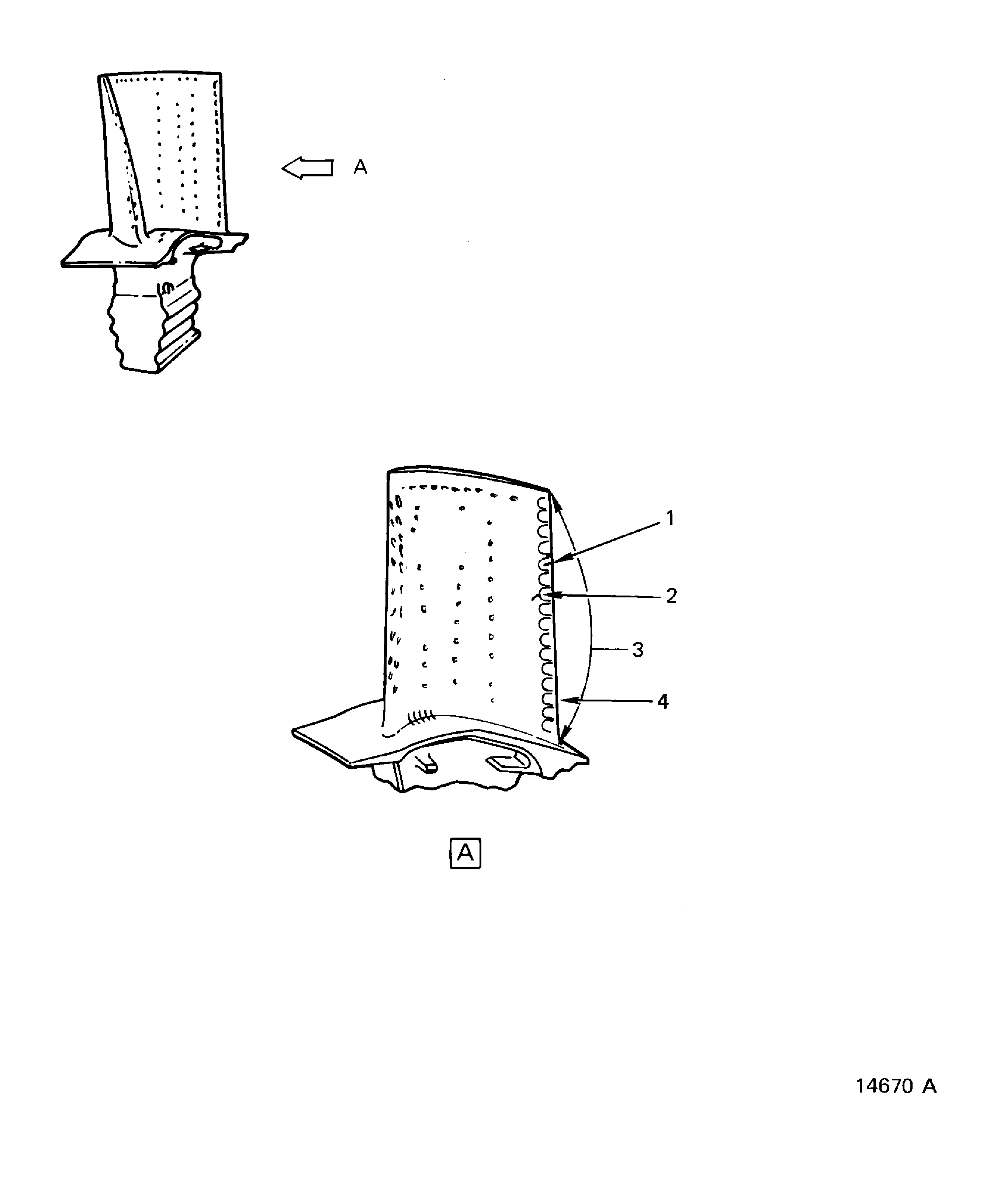

The base metal/tip interface is shown at location 5.

There is base metal that shows on the base metal/tip interface at location 2

Repair, VRS3495 TASK 72-45-14-300-007 (REPAIR-007) or VRS3493 TASK 72-45-14-300-008 (REPAIR-008)

Other than (3)

Examine the blade abrasive tip for base metal that shows.

SUBTASK 72-45-14-220-055 Examine the Stage 1 HPT Blade (01-010) Abrasive Tip

Install the blade assembly into the IAE 2P16371 Stage 1 HPT Blade Length Gage 1 off.

Repair, VRS3495 TASK 72-45-14-300-007 (REPAIR-007), VRS3493 TASK 72-45-14-300-008 (REPAIR-008) or VRS3204 TASK 72-45-14-300-003 (REPAIR-003)

Other than (a) thru (d)

Measure the distance from the end surface of the gage to the surface of the middle pin.

Repair, VRS3495 TASK 72-45-14-300-007 (REPAIR-007), VRS3493 TASK 72-45-14-300-008 (REPAIR-008) or VRS3204 TASK 72-45-14-300-003 (REPAIR-003)

Other then (a) thru (d)

Measure the distance for the end surface of the gage to the surface of the trailing edge pin.

Examine the blade assembly at location 1 for the blade length dimension.

SUBTASK 72-45-14-220-068 Examine the Stage 1 HPT Blade Assembly (01-010) Blade Length

NOTE

If the blades were repaired before, a repair code will be marked on the blade root area. These codes will have one, two, three or four characters. In some cases there will be a vendor-processing code before the repair code. The vendor-processing code will have ten or more digits and may be identified as (X-XXXXX-XX), or an approved supplier code (a heart inside a circle).These repair codes will indicate how the blade was repaired. More than one repair code can be shown on the blade root.Only the latest repair codes will not have a straight line through them.Refer to: Figure

NOTE

The tip of the trailing edge may have a blend no more than 0.060 in. (0.24 mm) deep, extending from the tip to the middle of the third trailing edge window. Reference VRS3685, TASK 72-45-14-300-021. This condition is acceptable.Repairs, VRS3202 TASK 72-45-14-300-001 (REPAIR-001), VRS3203 TASK 72-45-14-300-002 VRS3204 TASK 72-45-14-300-003 72-45-14-300-007 (REPAIR-007) or VRS3493 TASK 72-45-14-300-008 (REPAIR-008) or VRS3685 TASK 72-45-14-300-021 (REPAIR-021)

NOTE

Example of a crack is shown at location 1.

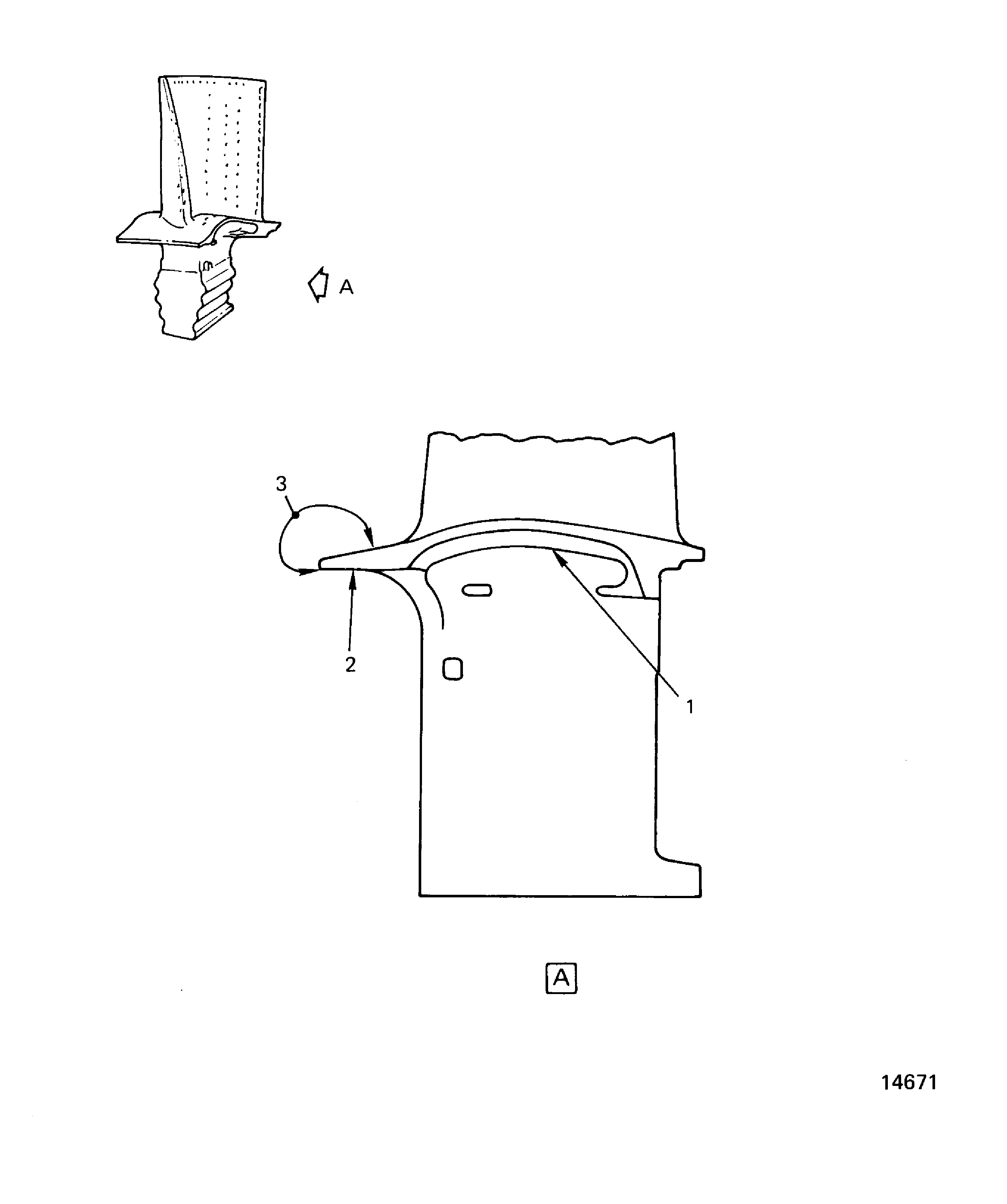

Cracks at the trailing edge at location 3

Examine the blade trailing edge for cracks. Use a white light and a 10X magnification.

Use a wire probe and power flush or pencil grit blast and high pressure air blast or Repair, VRS3357 TASK 72-45-14-300-005 (REPAIR-005)

NOTE

Example of a cooling air slot is shown at location 4.

Plugging

Examine the blade trailing edge cooling air slots at location 3, for plugging.

SUBTASK 72-45-14-220-056 Examine the Stage 1 HPT Blade (01-010) Trailing Edge

Refer to: Figure

SUBTASK 72-45-14-220-057 Examine the Stage 1 HPT Blade (01-010) Leading Edge Platform

Refer to: Figure

Repair, VRS3594 TASK 72-45-14-300-019 (REPAIR-019)

Other than (1)

Examine the blade damper contact area for wear at location 1.

SUBTASK 72-45-14-220-058 Examine the Stage 1 HPT Blade (01-010) Damper Contact Area

Refer to: Figure

Repair, VRS3203 TASK 72-45-14-300-002 (REPAIR-002) or Repair, VRS3594 TASK 72-45-14-300-019 (REPAIR 019)

Other than (1)

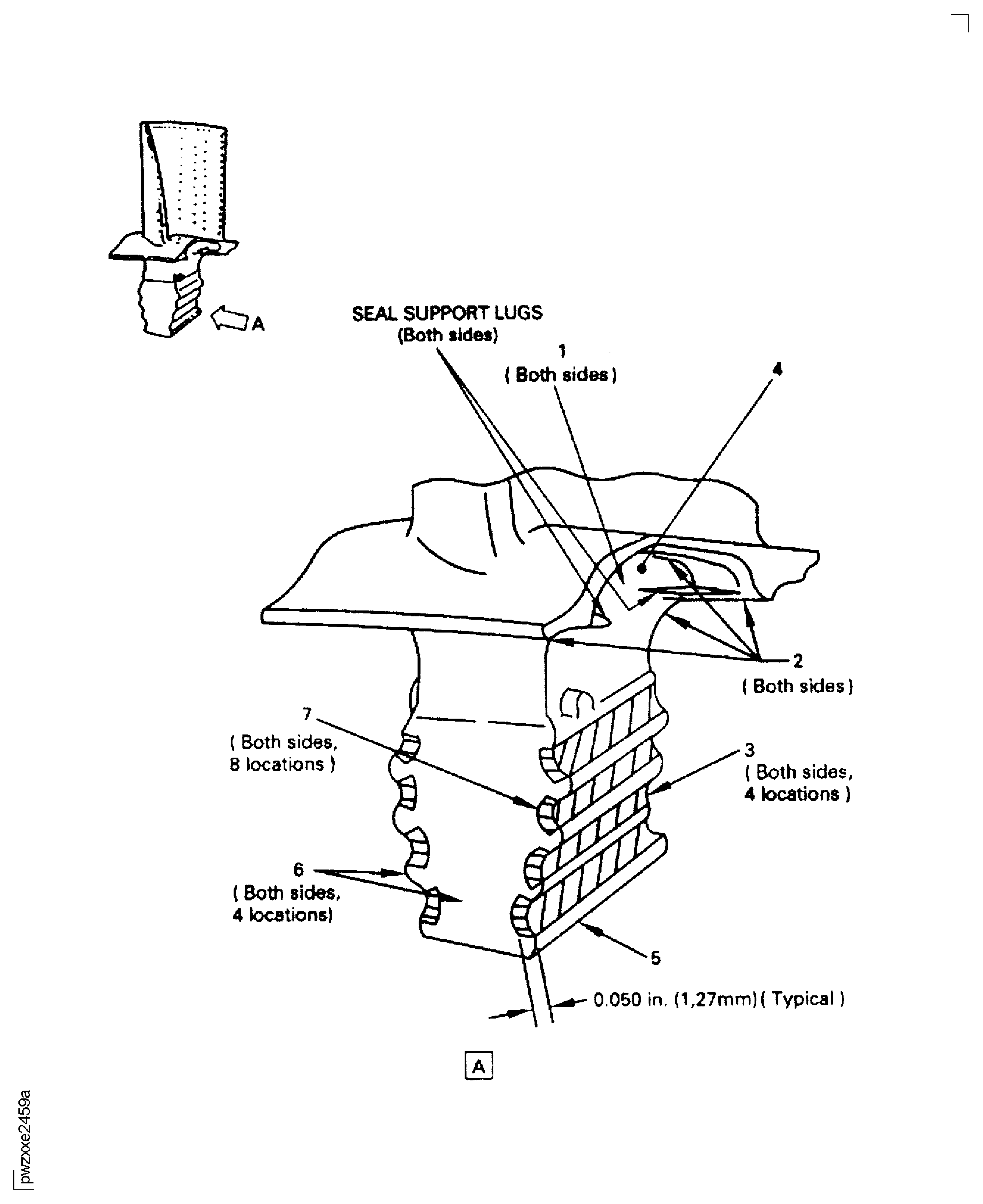

Examine the blade root attachment area for erosion and corrosion at locations 1, 5 and 6.

Repair, VRS3594 TASK 72-45-14-300-019 (REPAIR 019)

Other than (1)

Examine the blade root attachment area for fretting and galling at location 3.

Repair, VRS3594 TASK 72-45-14-300-019 (REPAIR-019)

Cracks, nicks or pitting

Examine the blade root attachment area for pitting, nicks and cracks at locations 2, 3 and 7. Use a white light and a 10X magnification to examine for cracks.

SUBTASK 72-45-14-220-059 Examine the Stage 1 HPT Blade (01-010) Root Attachment Area

Refer to: Figure

Repair, VRS3203 TASK 72-45-14-300-002 (REPAIR-002)

Cracks or nicks

Examine the blade root area for nicks and cracks at location 1, 5 and 6. Use a white light and a 10X magnification to examine for cracks.

Repair, VRS3594 TASK 72-45-14-300-019 (REPAIR-019)

Other than (1) or (2)

Examine the blade root area for pitting.

Repair, VRS3203 TASK 72-45-14-300-002 (REPAIR-002)

Other than (1), (2) or (3)

Examine the blade root area for blends and dents.

SUBTASK 72-45-14-220-060 Examine the Stage 1 HPT Blade (01-010) Root Area

Refer to Figure.

NOTE

Blades that were at temperatures more than the limit of 2000 deg F (1093 deg C) for a short time will cause a change in the alloy microstructure of the blade.

In the case of an EGT overtemperature, such that the AMM requires metallurgical analysis, the stage 2 HPT blades must be examined for overtemperature even if the stage 1 HPT blades are not rejected for overtemperature.

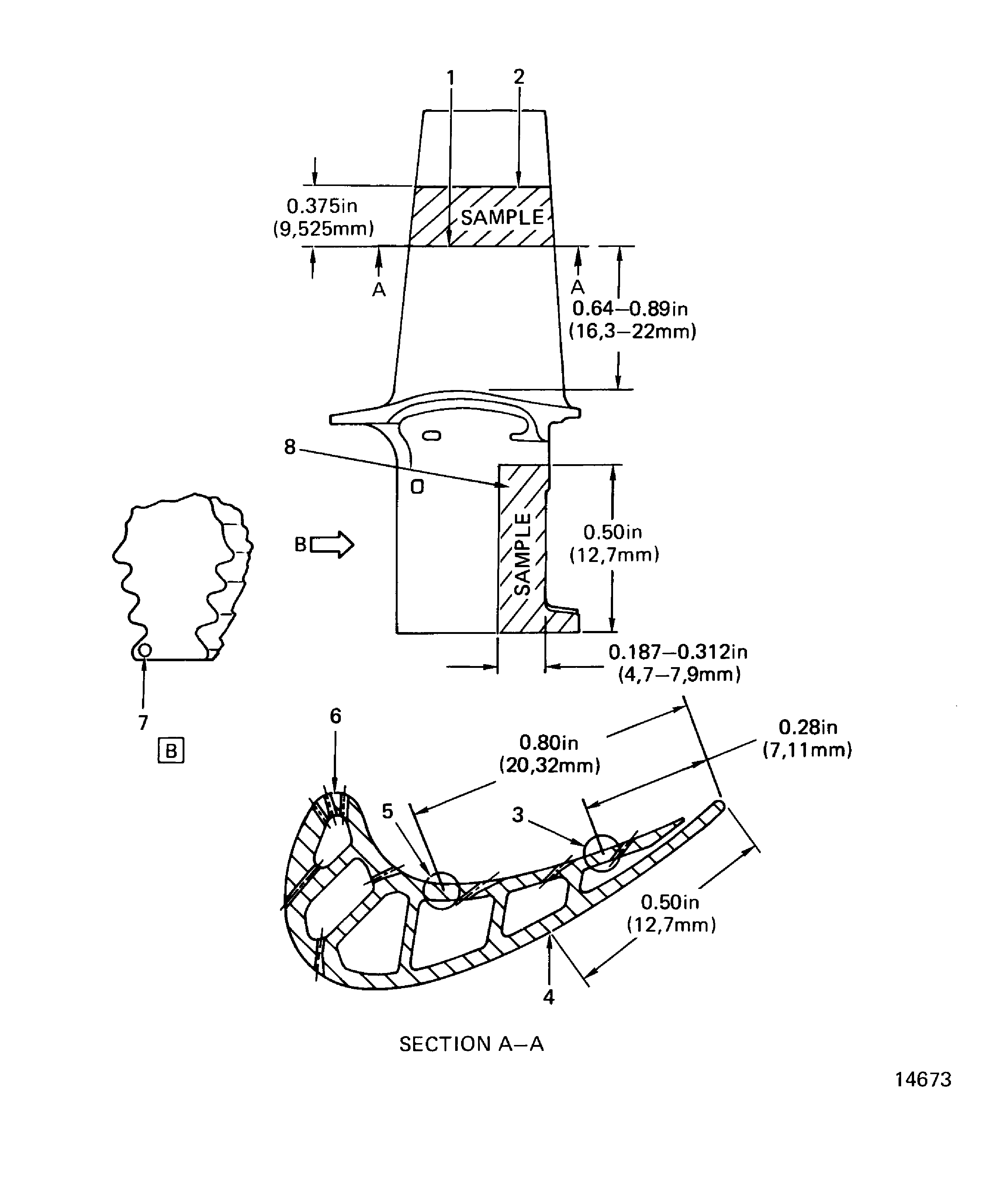

Cut the blade at location 1 to get the airfoil sample to be analyzed. Refer to the SPM TASK 70-02-03-220-501.

NOTE

The small vee shaped groove will make a mark for the blade airfoil sample surface to be analyzed.Attach and polish the blade samples by the SPM TASK 70-02-03-220-501 as follows:

Examine the microstructure of the blade samples, refer to the SPM TASK 70-02-03-220-501.

SUBTASK 72-45-14-280-051 Examine the Stage 1 HPT Blade (01-010) for Overtemperature

Refer to Figure.

NOTE

Do this procedure only if the visual examination of the blade is unsatisfactory.If you cannot do this procedure, do the procedure given in SUBTASK 72-45-14-230-052-003.

CAUTION

FAILURE TO STRESS RELIEVE THE BLADE BEFORE FLUORESCENT PENETRANT EXAMINATION CAN CAUSE DAMAGE TO THE BLADE.Heat the blade to between 1950 and 2000 deg F (1066 and 1093 deg C) in an oven and hold for 30 minutes minimum to four hours in a vacuum or argon protected atmosphere. Use CoMat 03-010 ARGON GAS, CoMat 03-117 ARGON GAS or CoMat 03-118 ARGON GAS. Refer to the SPM TASK 70-37-26-370-501.

WARNING

IT IS THE RESPONSILIBILTY OF THE OPERATOR TO OBTAIN AND OBSERVE THE MANUFACTURERS MATERIAL SAFETY SHEETS FROM THE CONSUMABLE MATERIALS INFORMATION SUCH AS HAZARDOUS INGREDIENTS, PHYSICAL/CHEMICAL CHARACTERISTICS, FIRE, EXPLOSION, REACTIVITY, HEALTH HAZARD DATA, PRECAUTIONS FOR SAFE HANDLING, USE AND CONTROL MEASURES AND ALSO TO TAKE LOCAL REGULATIONS INTO CONSIDERATION.Stress relief the blade.

If you find any crack indications, make a temporary mark on the indications with one of the approved temporary markers in the SPM TASK 70-09-00-400-501.

Heat the blade assembly (PN 2A1221, 2A1721 and 2A2421) to between 1575 and 1625 deg F (857 to 885 deg C) in an oven and keep at this temperature for 32 hours. PHT is optional for these part numbers. Refer to the SPM TASK 70-37-27-370-501.

Heat the blade assembly (PN 2A3001, 2A8601 and 2A8901) to between 1575 and 1625 deg F (857 and 885 deg C) in an oven and keep at this temperature for 8, 12 or 32 hours. Refer to the SPM TASK 70-37-27-370-501.

Precipitation heat treat (PHT) the blade assembly.

Use CoMat 05-029 CAST STEEL SHOT, S110, CoMat 05-030 CAST STEEL SHOT DELETED, CoMat 05-031 CAST STEEL SHOT DELETED, CoMat 05-032 CAST STEEL SHOT, S170, CoMat 05-033 CAST STEEL SHOT DELETED, CoMat 05-034 CAST STEEL SHOT DELETED, CoMat 05-138 SHOT, CAST STEEL, S110, CoMat 05-176 CAST STEEL SHOT, S170, CoMat 05-234 CAST STEEL SHOT, HIGH HARDNESS, S110 or CoMat 05-177 CUT WIRE SHOT,CW-14, CoMat 05-178 CUT WIRE SHOT, CW-20 or CoMat 05-187 STAINLESS STEEL CUT WIRE SHOT, SCW-20, CoMat 05-188 STAINLESS STEEL CUT WIRE SHOT, SPECIAL CONDITIONED, SCW-20. Peen with an intensity of 6A. Refer to the SPM TASK 70-38-13-380-501, SUBTASK 70-38-13-380-006.

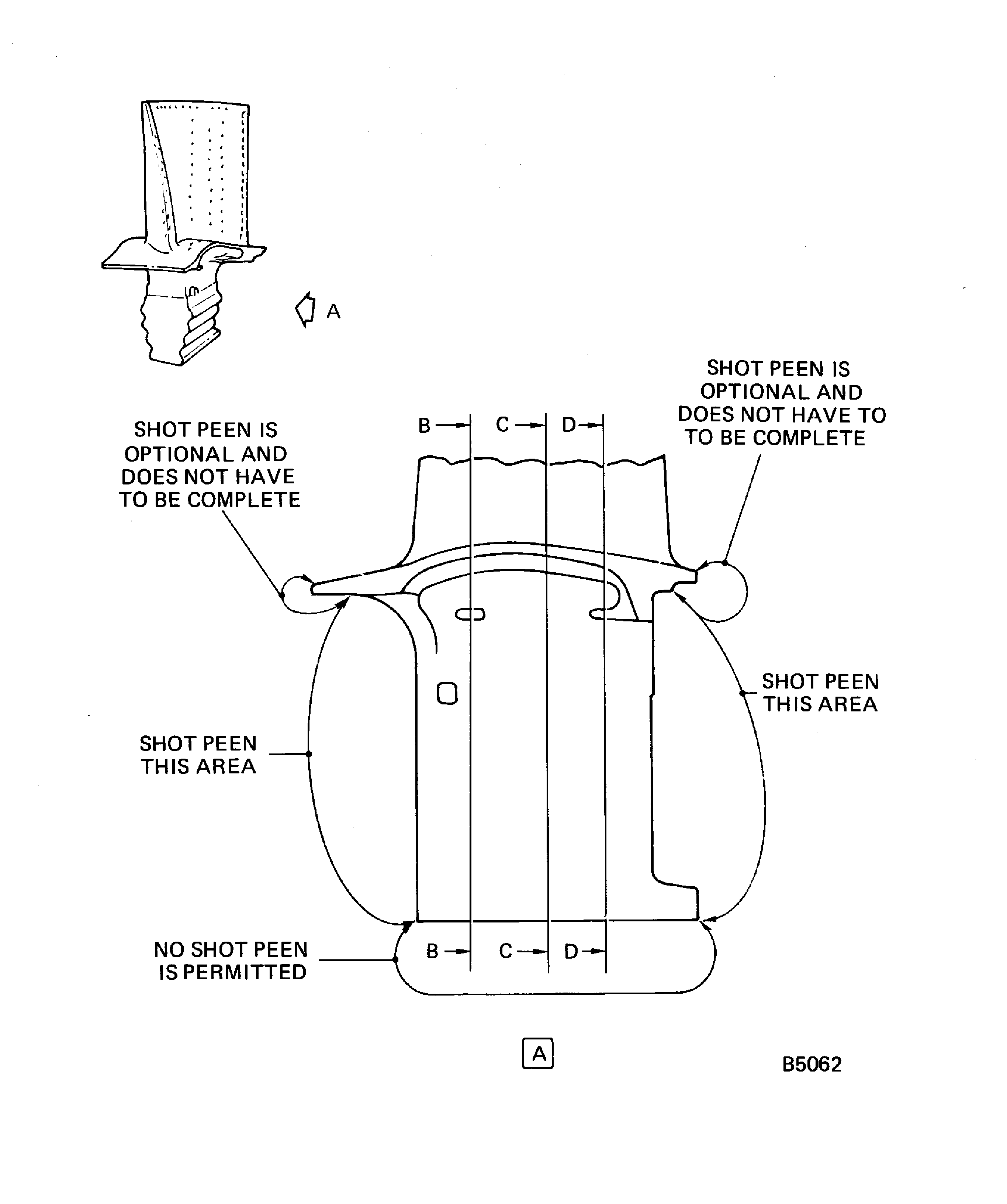

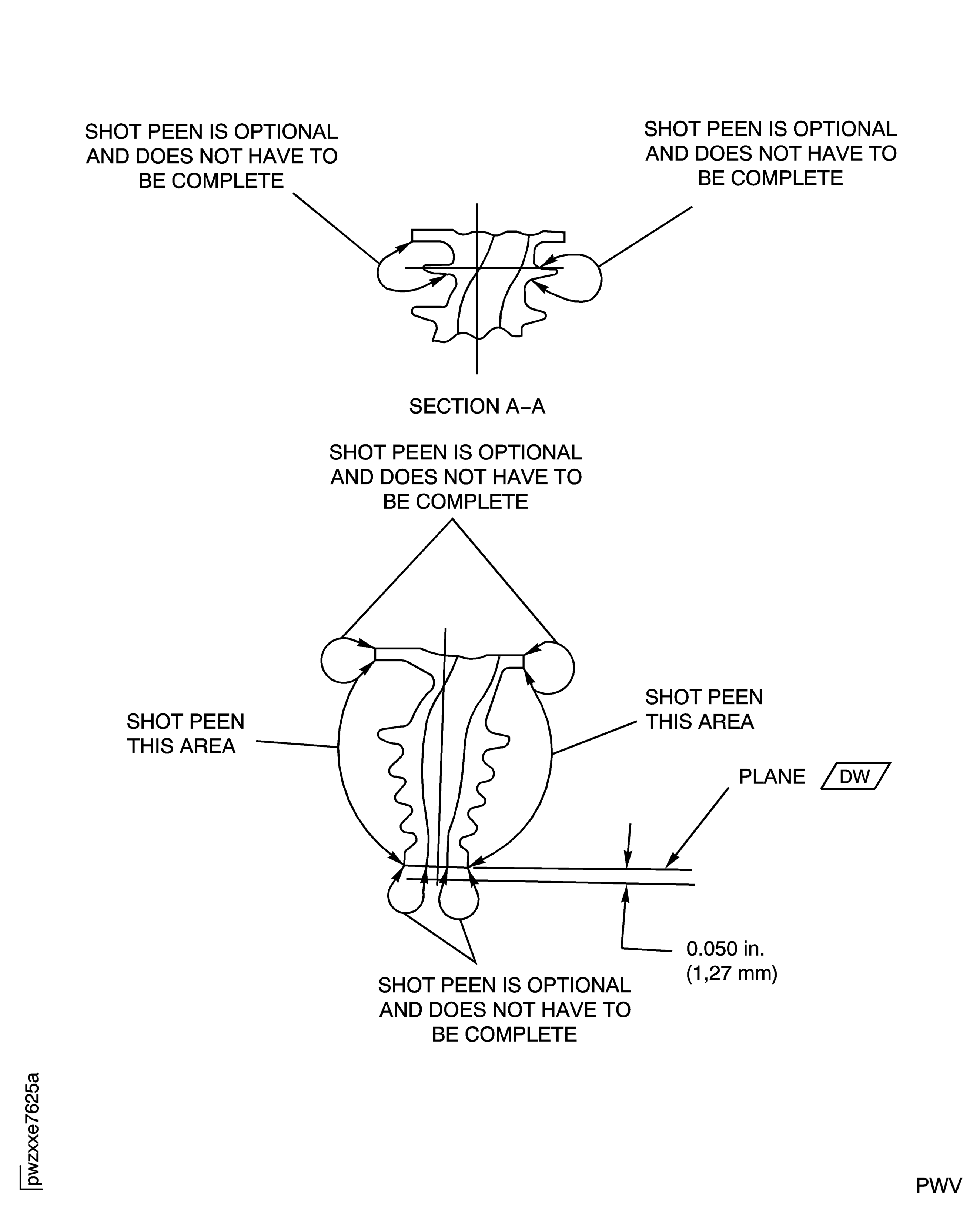

Shot peen the blade root area by the SPM TASK 70-38-13-380-501. Refer to Figure.

SUBTASK 72-45-14-230-052-001 Examine the Stage 1 HPT Blade (01-010) for Cracks

CAUTION

FAILURE TO STRESS RELIEVE THE BLADE BEFORE FLUORESCENT PENETRANT EXAMINATION CAN CAUSE DAMAGE TO THE BLADE.When you cannot stress relieve the blade, you must send the blade to one of the approved sources that follows:

PRATT and WHITNEY AFTERMARKET SERVICES (PWAS)

Connecticut Airfoil Repair Operations

400 Main St., Well 11

East Hartford, CT 06108-0969 USA

Tel: (860) 565-3922

Fax: (860) 557-8247

Sequa Corp.,

Chromalloy Research and Technology Div.

108 Blaisdell Road

Orangeburg, New York 10962 USA

Tel: (845) 359-4700

Fax: (845) 359-4409

SUBTASK 72-45-14-230-052-002 Examine the Stage 1 HPT Blade (01-010) for Cracks

NOTE

Do this procedure only if the visual examination of the blade is unsatisfactory.If you cannot do Step do this procedure.Moderately clean the blade by the SPM TASK 70-11-03-300-503 or vapor degrease the blade by the SPM TASK 70-11-01-300-503.

CAUTION

DO NOT DRY BLAST THE BLADE COATED AREA TOO MUCH. THIS CAUSES THE COATING TO BE REMOVED.Clean the blade by the SPM TASK 70-12-09-120-501.

Repair, VRS3203 TASK 72-45-14-300-002 (REPAIR-002), VRS3204 TASK 72-45-14-300-003 (REPAIR-003) VRS3495 TASK 72-45-14-300-007 (REPAIR-007) or VRS3493 TASK 72-45-14-300-008 (REPAIR-008)

Blue color that is not shiny shows the blade has no coating

Heat tint.

Examine the blade coating for heat tint.

SUBTASK 72-45-14-280-052 Examine the Stage 1 HPT Blade (01-010) Coating by Heat Tint

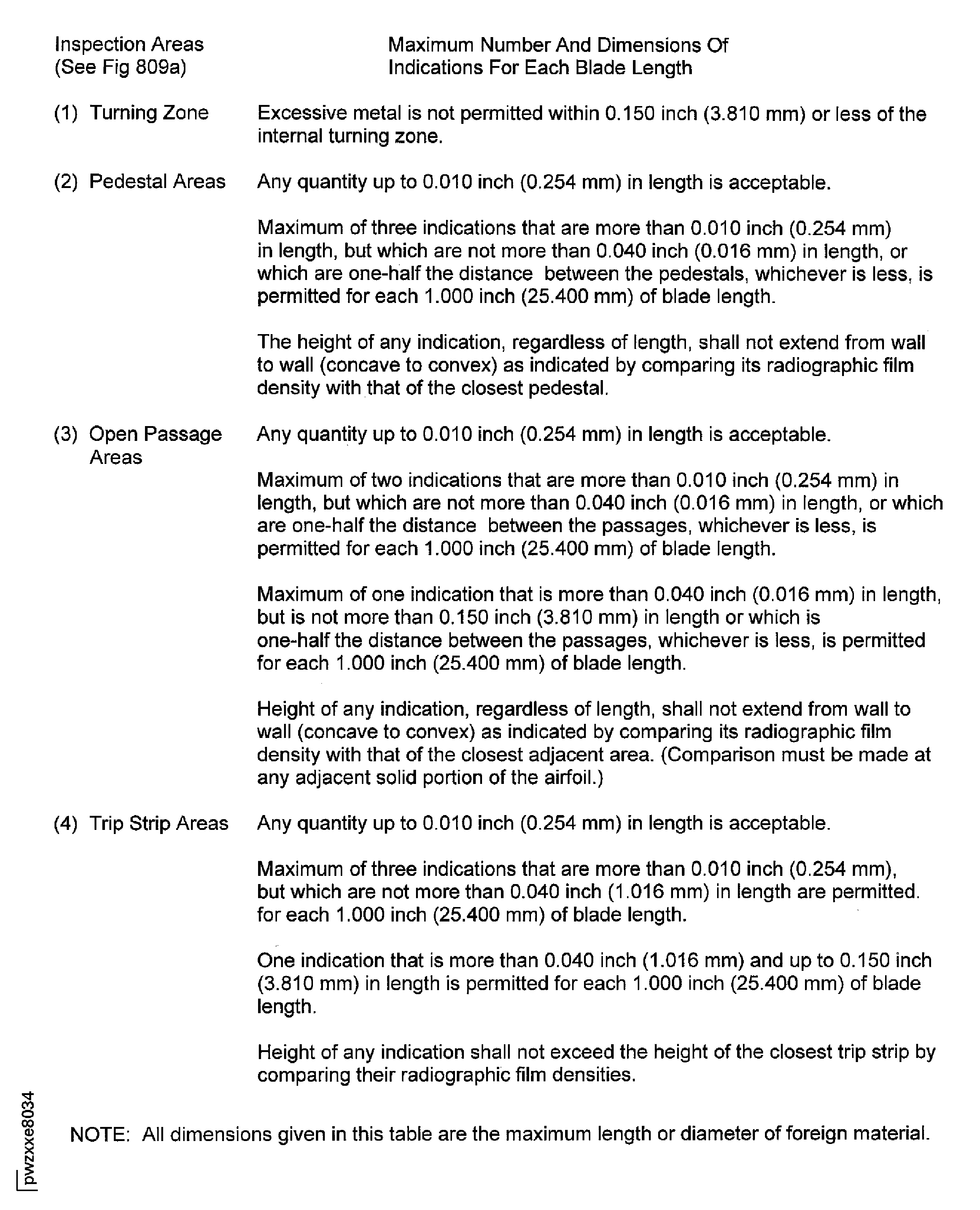

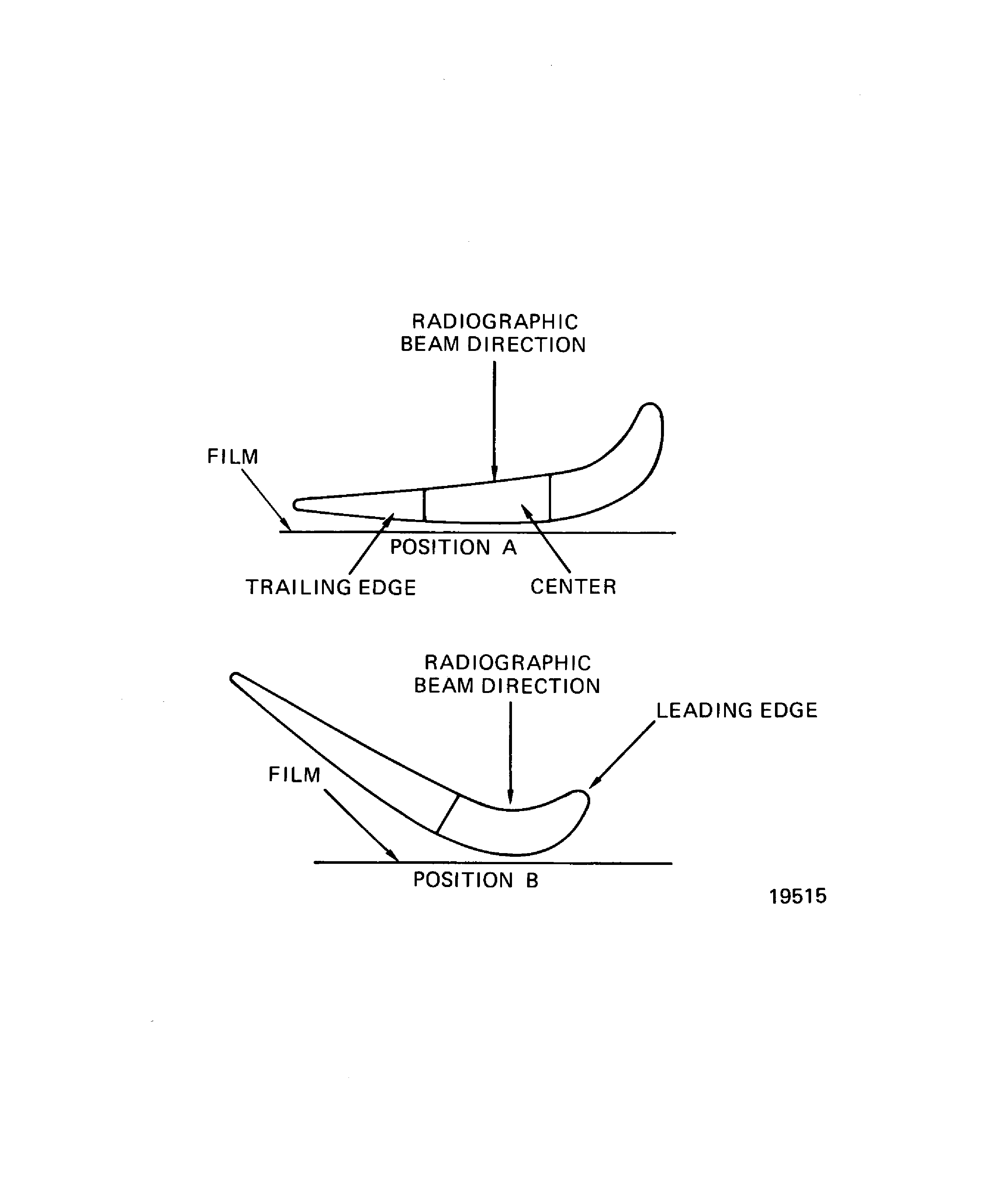

Do a radiographic inspection in Positions A and B, Figure by the SPM TASK 70-26-01-260-501.

NOTE

Surface indications that are acceptable to the visual inspection is not cause to be rejected by radiographic inspection.Power flush or Repair, VRS3357 TASK 72-45-14-300-005 (REPAIR-005)

NOTE

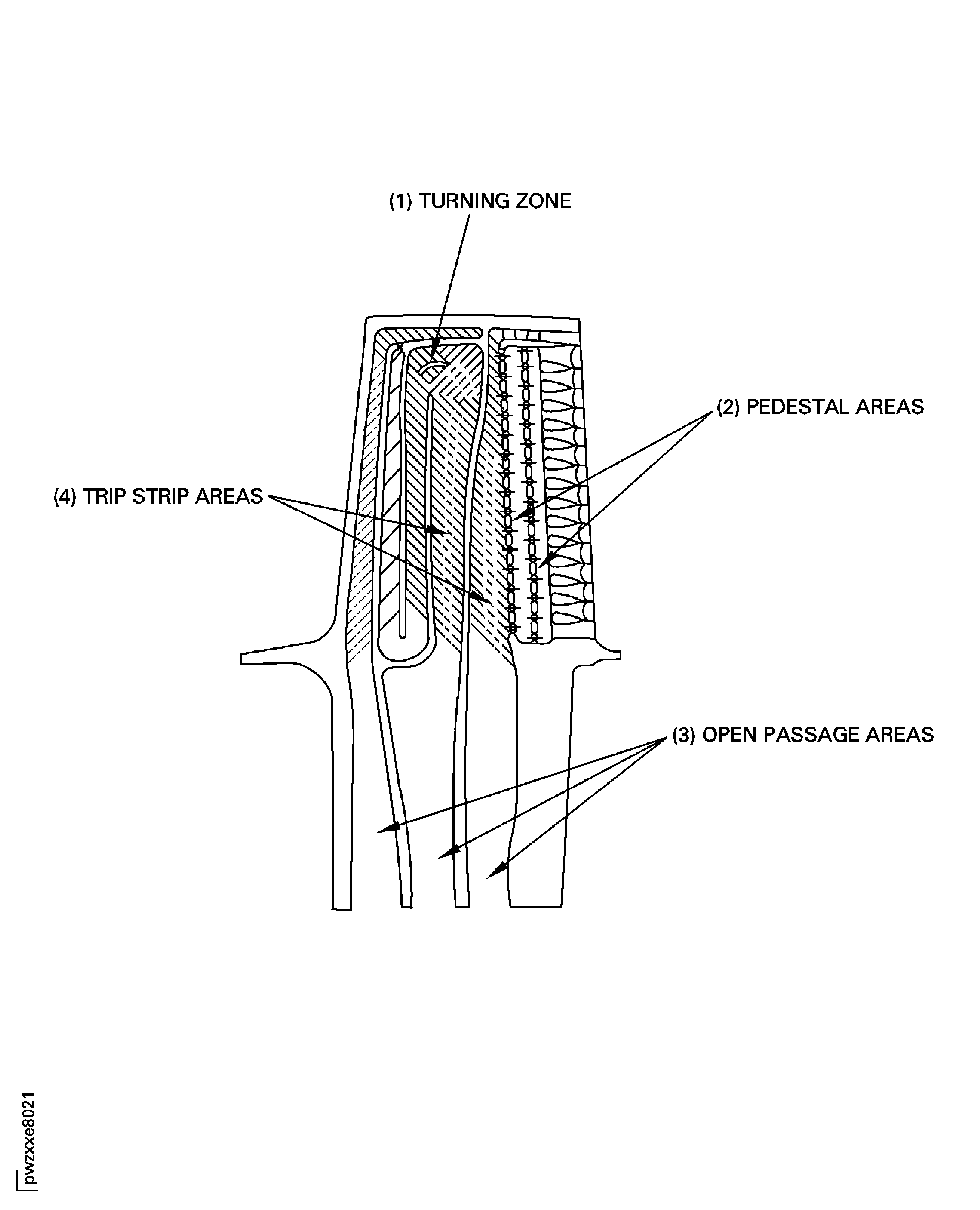

If there are any indications of shot peen and/or other forms of foreign material. e.g. metal chips or broken wire that are distinguishable by there shape, form or density, the parts shall be rejected.After cleaning the internal cavities refer to VRS3357 TASK 72-45-14-300-005 (REPAIR-005), unwanted metal and materials are acceptable provided the size, density and location of the indication(s) has remained unchanged from step (2) (b). Refer to the limits in Figure and Table 801.

Unwanted material in the internal cavities

Make an analysis on the radiographic indications.

Examine the blade for internal cracks and unwanted material by radiographic inspection.

SUBTASK 72-45-14-260-051 Examine the Stage 1 HPT Blade (01-010) for Internal Cracks and Unwanted Material by Radiographic Inspection

Do the airflow procedure for the stage 1 HPT blade assembly by the procedure given in VRS3710 TASK 72-45-14-300-031 (PEPAIR-031).

SUBTASK 72-45-14-280-066 Examine the Stage 1 HPT Blade Assembly (01-010) by Airflow Check

NOTE

Do all inspections and repairs on the blade assembly before you do the airflow check.Refer to Figure.

Do steps (1), (2) and (3) of the waterflow check again.

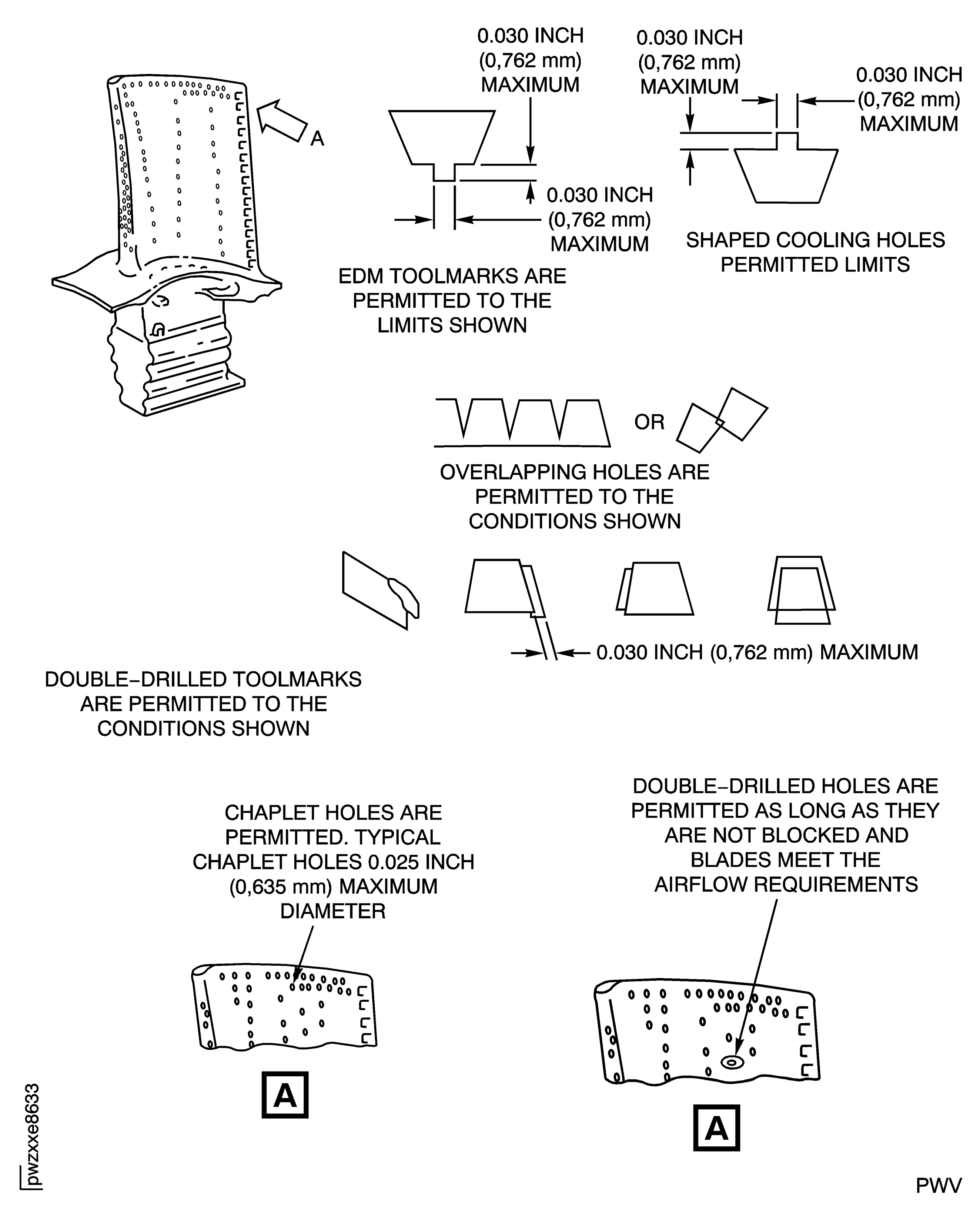

NOTE

Casting chaplet holes that are not mismatched or double drilled holes are acceptable. Chaplet holes may or may not exist. EDM toolmarks and/or double drilled holes are acceptable if they are not blocked and the blades meet airflow requirements. Refer to Figure for typical chaplet and double drilled holes.

Do the waterflow check to examine the blade.

SUBTASK 72-45-14-280-070 Examine the Stage 1 HPT Blade Assembly (01-010) by Waterflow Check

Examine the base of the underplatform damper pins for casting voids by visual inspection with a white light and a minimum of 3X magnification. These voids must be smooth, shallow in depth, and flat-bottomed. IAE 2P16508 Reference card 1 off shows an example of an acceptable casting void. These casting voids are a maximum of 0.030 in. (0.762 mm) in diameter. Any quantity of voids is permitted.

Examine the base of the underplatform damper pins for anomalies by visual inspection with a white light and a minimum of 10X magnification. Acceptable anomalies have a length of 0.070 in. (1.778 mm) or less. Indications that go from the centerline of the damper pin radius to the blade root, are not acceptable. Indications on the blade root are not acceptable. Any quantity of linear anomalies is permitted. IAE 2P16508 Reference card 1 off shows examples of acceptable linear anomalies. Cracks inside or which start from linear anomalies are not permitted. Fluorescent penetrant inspect questionable indications. Acceptable linear anomalies will not retain fluorescent penetrant fluid.

SUBTASK 72-45-14-230-057 Examine the Stage 1 HPT Blade (01-010) For Casting Flow Lines and Imperfections

Refer to Figure.

SUBTASK 72-45-14-230-058 Examine the Stage 1 HPT Blade (01-010) For Porosity and Shrinkage

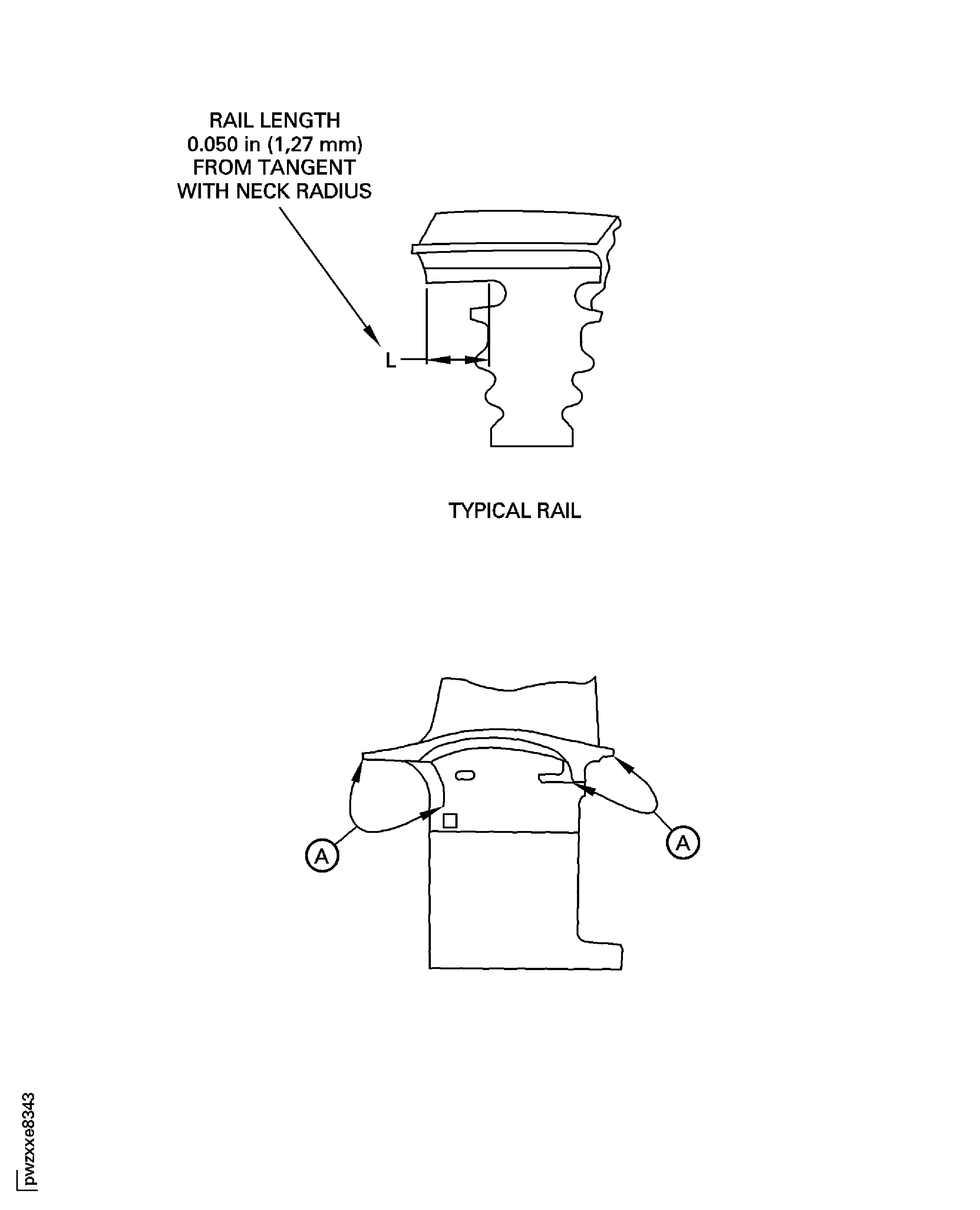

Figure: Stage 1 HPT Blade Platform Inspection Locations

Stage 1 HPT Blade Platform Inspection Locations

Figure: Stage 1 HPT Blade Cooling Air Holes Inspection Locations

Stage 1 HPT Blade Cooling Air Holes Inspection Locations

Figure: Stage 1 HPT Blade Airfoil Inspection Locations

Stage 1 HPT Blade Airfoil Inspection Locations

Figure: Stage 1 HPT Blade Abrasive Tip Inspection Locations

Stage 1 HPT Blade Abrasive Tip Inspection Locations

Figure: Stage 1 HPT Blade Trailing Edge Inspection Locations

Stage 1 HPT Blade Trailing Edge Inspection Locations

Figure: Stage 1 HPT Blade Platform Surfaces Inspection Locations

Stage 1 HPT Blade Platform Surfaces Inspection Locations

Figure: Stage 1 HPT Blade Root and Attachment Area Inspection Locations

Stage 1 HPT Blade Root and Attachment Area Inspection Locations

Figure: Stage 1 HPT Blade Metal Temperature Analysis Locations

Stage 1 HPT Blade Metal Temperature Analysis Locations

Figure: Excess Metal and Foreign Material Limits (After Cleaning)

Excess Metal and Foreign Material Limits (After Cleaning)

Figure: Stage 1 HPT Blade Radiographic Positions Inspection Locations

Stage 1 HPT Blade Radiographic Positions Inspection Locations

Figure: X-Ray Inspection Internal Cavity

X-Ray Inspection Internal Cavity

Figure: Stage 1 HPT Blade Assembly Shot Peen Locations

Sheet 1

Figure: Stage 1 HPT Blade Assembly Shot Peen Locations

Sheet 2

Figure: Stage 1 HPT Blade Assembly Airfoil Cooling Hole Inspection

Sheet 3

Figure: Stage 1 HPT Blade Assembly Casting Flow Line Inspection

Stage 1 HPT Blade Assembly Casting Flow Line Inspection

Figure: Stage 1 HPT Blade Assembly Inspection for Porosity and Shrinkage

Stage 1 HPT Blade Assembly Inspection for Porosity and Shrinkage