Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-00-40-450-001-A00 HP System Module Components - Install The Variable Stator Vane (VSV) Actuator, Installation-011

General

Fig/item numbers in parenthesis in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures refer to the SPM TASK 70-41-01-400-501.

Special torque data is identified with the symbol * after the torque value.

Assembly tolerances are included in this procedure.

For lockwire data and procedures refer to the SPM TASK 70-42-05-400-501.

For safety cable data and procedures refer to the SPM TASK 70-42-08-400-501. | ||

Safety the threaded fasteners in this TASK with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT for the ATA Chapter/Section/Subjects which follow: | ||

A1 series engines: | ||

71-51-41 | 71-52-43 | 72-41-34 |

73-22-49 | 75-23-49 | 75-31-42 |

75-31-43 | 75-32-42 | 75-00-49 |

Refer to the V2500 Illustrated Tool and Equipment Manual (ITE-V2500-1IA) for the illustrations of the special tools used in this procedure.

Transportation covers/blanks must not be removed until immediately before installation of the components.

Do not remove the special plastic caps from electrical connections or tube connections which are not applicable in this procedure. This will give protection from unwanted material.

Lubricate all threads and abutment faces or nuts and bolts with CoMat 10-039 ENGINE OIL engine oil unless other lubricants are referred to in this procedure.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL damaged surface protection, joint flanges and attach parts. Use the correct color of air drying enamel. Refer to the SPM TASK 70-38-21-380-501.

NOTE

To identify the consumable materials refer to the PCI.

SBE 70-0813 : Announcement of introduction of safety cable as a preferred method to lockwire.

Safety the threaded fasteners in this TASK with safety cable for the ATA Chapter/Section/Subjects detailed in 2. General.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Crowsfoot spanner | LOCAL | Crowsfoot spanner | 0.937 in. (24 mm) | |

| IAE 1R18254 Rigging pin | 0AM53 | IAE 1R18254 | 1 | |

| IAE 1R18282 Rigging pin | 0AM53 | IAE 1R18282 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-001 SOLVENT, DELETED | 0AM53 | CoMat 01-001 | ||

| CoMat 02-119 LOCKWIRE | LOCAL | CoMat 02-119 | ||

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 02-274 SAFETY CABLE KIT | LOCAL | CoMat 02-274 | ||

| CoMat 02-275 SAFETY CABLE KIT | LOCAL | CoMat 02-275 | ||

| CoMat 04-005 JOINTING COMPOUND, MEDIUM GRADE | LOCAL | CoMat 04-005 | ||

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 10-038 PETROLEUM JELLY | LOCAL | CoMat 10-038 | ||

| CoMat 10-039 ENGINE OIL | LOCAL | CoMat 10-039 | ||

| CoMat 10-060 LIQUID PARAFFIN | LOCAL | CoMat 10-060 | ||

| CoMat 02-146 LOCKWIRE | LOCAL | CoMat 02-146 |

Safety Requirements

NONEProcedure

WARNING

WHEN YOU SEE CoMat 01-001 SOLVENT, DELETED INHIBITED AND STABILIZED TRICHLORETHANE YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.With CoMat 01-001 SOLVENT, DELETED inhibited and stabilized trichloroethane; clean the bolts AIR-HP COMPRESSOR VARIABLE STATOR VANE ACTUATOR (75-32-41,01-082), AIR-HP COMPRESSOR VARIABLE STATOR VANE ACTUATOR (75-32-41,01-102) and AIR-HP COMPRESSOR VARIABLE STATOR VANE ACTUATOR (75-32-41,01-112), the brackets AIR-HP COMPRESSOR VARIABLE STATOR VANE ACTUATOR (75-32-41,01-070) and AIR-HP COMPRESSOR VARIABLE STATOR VANE ACTUATOR (75-32-41,01-080) and the attachment faces of the VSV actuator and the HP compressor case. Then apply a layer of CoMat 04-005 JOINTING COMPOUND, MEDIUM GRADE to the surfaces and the bolts.

Attach the bracket AIR-HP COMPRESSOR VARIABLE STATOR VANE ACTUATOR (75-32-41,01-080) to the VSV actuator with the bolt AIR-HP COMPRESSOR VARIABLE STATOR VANE ACTUATOR (75-32-41,01-112) and tighten by hand.

Attach the VSV actuator to the HP compressor case with the four bolts AIR-HP COMPRESSOR VARIABLE STATOR VANE ACTUATOR (75-32-41, 01-102 and AIR-HP COMPRESSOR VARIABLE STATOR VANE ACTUATOR01-082), the two washers AIR-HP COMPRESSOR VARIABLE STATOR VANE ACTUATOR (75-32-41,01-104) and the bracket AIR-HP COMPRESSOR VARIABLE STATOR VANE ACTUATOR (75-32-41,01-070). Tighten by hand.

Torque the two bolts AIR-HP COMPRESSOR VARIABLE STATOR VANE ACTUATOR (75-32-41,01-102) to 180 to 220 lbfin (20 to 25 Nm).

Torque the two bolts AIR-HP COMPRESSOR VARIABLE STATOR VANE ACTUATOR (75-32-41,01-082) to 180 to 220 lbfin (20 to 25 Nm).

Torque the two bolts AIR-HP COMPRESSOR VARIABLE STATOR VANE ACTUATOR (75-32-41,01-112) to 180 to 220 lbfin (20 to 25 Nm).

Install IAE 1R18254 Rigging pin rigging pin 1 off through the bearing housing and locate in the crankshaft recess.

Install IAE 1R18282 Rigging pin rigging pin 1 off in the actuating ram.

If necessary adjust the length of the control rod such that the bolt HP COMP VARIABLE STATOR VANE ACTUATOR LINKAGE (75-32-42,01-084) can be installed. Do the steps that follow:

Install the washer HP COMP VARIABLE STATOR VANE ACTUATOR LINKAGE (75-32-42,01-083) and the nut HP COMP VARIABLE STATOR VANE ACTUATOR LINKAGE (75-32-42,01-082). Align the D-head of the bolt with the stepped section of the actuator fork. Torque the nut to 290 to 370 lbfin (33 to 42 Nm).

Safety the control rod locknuts with CoMat 02-119 LOCKWIRE.

Lock the control rod ends. Do the steps that follow:

Remove the two rigging pins.

Pre SBE 72-0132 : Assemble the clip positions 5745 and 5746 and torque the bolts to 36 to 45 lbfin (4 to 5 Nm).

SBE 72-0132: Assemble the clip positions 5745 and 5746 and torque the bolts to 36 to 45 lbfin (4 to 5 Nm).

SBE 75-0034: Clip position 5745 - make sure that the clip is aligned correctly with the lip on the bracket AIR-HP COMPRESSOR VARIABLE STATOR VANE ACTUATOR (75-32-41,01-070) to give a minimum clearance of 0.25 in (6.35 mm) between the master BSBVA actuator electrical connectors and the EEC harness.

Connect the VSV actuator to the actuating mechanism.

Connect the fuel drain tube 47 POWER PLANT-FUEL DRAIN TUBES-ENGINE (71-71-49,01-500) and torque the tube connector to 159 to 177 lbfin (18 to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

Lightly lubricate a new packing ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,12-496) 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY and install it on the VSV actuator.

Connect the fuel servo tube 44 ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,12-500) to the VSV actuator and with a 0.937 in. (24 mm) crowsfoot spanner torque the tube connector to 425 to 475 lbfin (48 to 53.7 Nm). Safety with CoMat 02-126 LOCKWIRE.

Lightly lubricate a new packing ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,19-096) 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY and install it on the VSV actuator.

Connect the fuel servo tube 46 ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,19-100) to the VSV actuator and torque the tube connector to 425 to 475 lbfin (48 to 53.7 Nm). Safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-40-450-051-A00 Install the VSV Actuator (Pre SBE 75-0055, SBE 72-0398, Pre SBE 72-0132, SBE 72-0132 and SBE 75-0034)

SUBTASK 72-00-40-450-051-B00 Install the VSV Actuator (SBE 75-0055)

NOTE

SBE 72-0398 has removed the requirement for SBE 75-0055.SBE 75-0055: Introduce a new setting procedure for the re-scheduling of the HP Compressor Variable Vanes

Refer to: Figure

SUBTASK 72-00-40-420-250-A00 Connect the EEC Harness Electrical Connectors to the VSV Actuator (Pre SBE 71-0063)

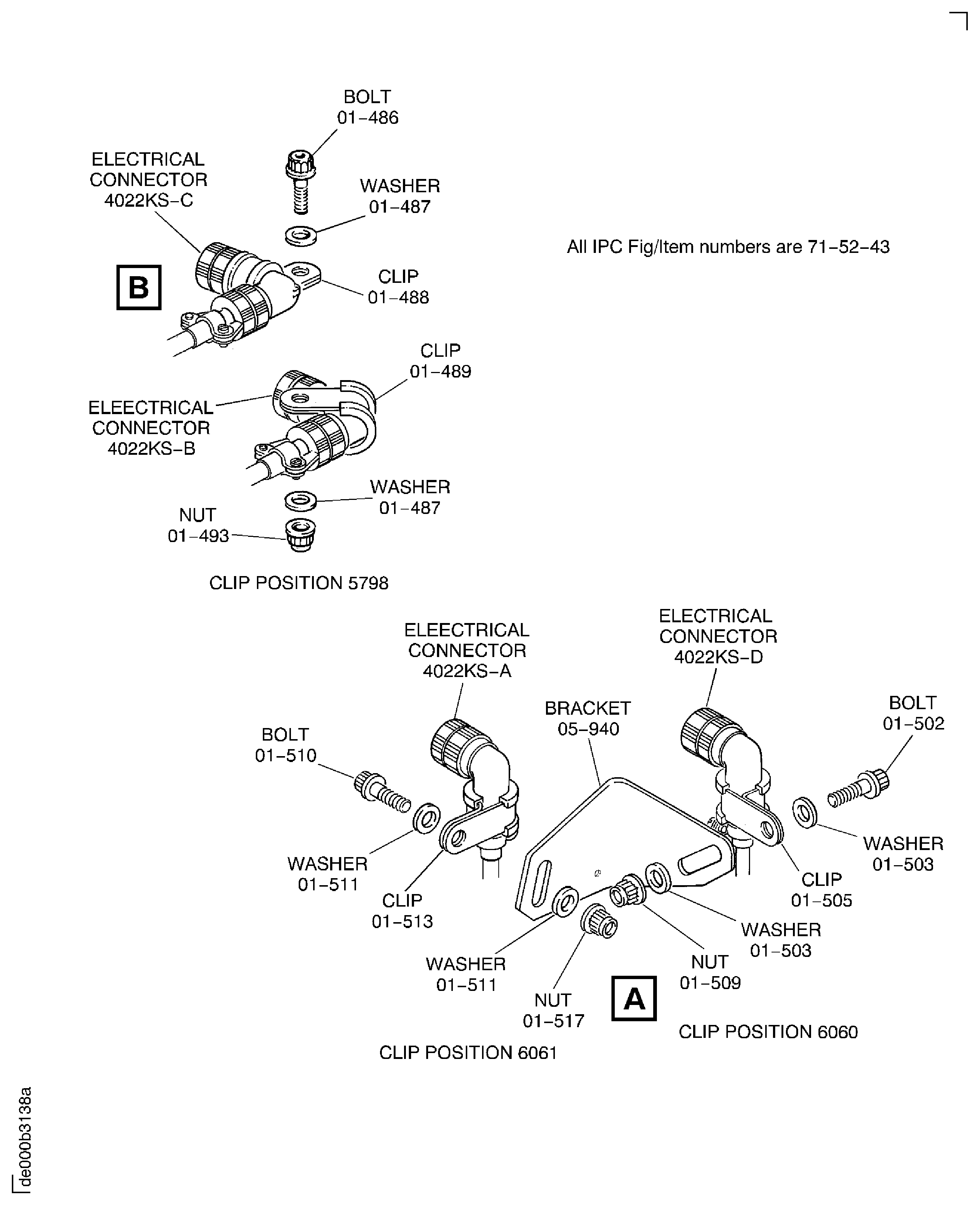

Install the two clips ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE (71-52-43, 01-488 and ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE01-489) on the backshells of the two connectors 4022KS-B and 4022KS-C.

Attach the two clips together with the bolt ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE (71-52-43, 01-486), the two washers ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE (71-52-43, 01-487) and the nut ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE (71-52-43, 01-493).

Assemble the clip position 5798.

Install the two clips ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE (71-52-43, 01-505 and ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE01-513) on the backshells of the two connectors 4022KS-A and 4022KS-D.

Put the bracket ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE (71-52-43, 05-940) in position. Attach the two clips to the bracket with the two bolts ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE (71-52-43, 01-502 and ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE01-510), the four washers ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE (71-52-43, 01-503 and ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE01-511) and the two nuts ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE (71-52-43, 01-509 and ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE01-517).

Safety the bracket to one of the connector backshells with CoMat 02-146 LOCKWIRE. Use the wire locking hole of the bracket and a wire locking hole in one of the backshell relief clamps.

Assemble the clip positions 6060 and 6061.

SUBTASK 72-00-40-420-250-B00 Connect the EEC Harness Electrical Connectors to the VSV Actuator (SBE 71-0063 and Pre SBE 71-0111)

Refer to: Figure

SBE 71-0111: EEC harness fan/core - Deletion of clipping at VSVA and PMA harness connectors and introduction of wire locking to secure connectors.

Safety the two connectors to each other with CoMat 02-126 LOCKWIRE.

Safety the two connectors to each other with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-40-420-250-C00 Connect the EEC Harness Electrical Connectors to the VSV Actuator (SBE 71-0111)

Refer to Figure.

Make sure that all the applicable backshells and cable clamps are safetied with CoMat 02-126 LOCKWIRE. Refer to the SPM TASK 70-42-05-400-501.

SUBTASK 72-00-40-210-061 Visually Inspect the Electrical Backshells and Cable Clamps

Refer to Figure.

Make sure that all the EEC harness backshells and cable clamps are safetied. Safety with CoMat 02-274 SAFETY CABLE KIT or with CoMat 02-275 SAFETY CABLE KIT. Refer to the SPM TASK 70-42-08-400-501.

SUBTASK 72-00-40-210-062 Visually Inspect the EEC Harness (01-005) Electrical Backshells and Cable Clamps (SBE 70-0813)

SBE 70-0813: Announcement of introduction of safety cable as a preferred method to lockwire.

NOTE

Use this procedure to safety the EEC harness backshells and cable clamps with safety cable.

Figure: Install the VSV Actuator

Sheet 1

Figure: Install the VSV Actuator

Sheet 2

Figure: Install the VSV actuator

sheet 3

Figure: Install the VSV Actuator

Sheet 4

Figure: Connect the electrical harness connectors

Sheet 1

Figure: Pre SBE 71-0111 : Connect the electrical harness

Sheet 2

Figure: Visually inspect the backshells and cable clamps

Visually inspect the backshells and cable clamps