Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5 and Post SBE 72-0627

Common Information

TASK 72-41-00-440-001-E00 HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly, Assembly-001 (SBE 72-0627)

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the Service Bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item numbers.

For standard torque data and procedures refer to SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-410-501.

Special torque data and assembly tolerances are included in this procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to SPM TASK 70-44-01-400-501.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanged and attach parts. Use the correct color of the CoMat 07-038 AIR DRYING ENAMEL. Refer to SPM TASK 70-63-02-380-501.

The number for each circumferential location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless otherwise specified in the procedure.

This TASK gives the procedure to assemble the HP compressor rear cases and vanes on to the HP compressor rotor assembly. TASK 72-41-00-440-002-B00 (ASSEMBLY-002) gives the procedure to install the HP compressor front cases on to the HP compressor rotor assembly.

The practices and processes referred to in the procedure by the TASK/SUBTASK number are in SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Heating blanket | LOCAL | Heating blanket | ||

| Heat protection gloves | LOCAL | Heat protection gloves | ||

| IAE 1R18090 Safety support stand | 0AM53 | IAE 1R18090 | 1 | |

| IAE 1R18091 Support stand | 0AM53 | IAE 1R18091 | 1 | |

| IAE 1R18213 Alignment checking pin | 0AM53 | IAE 1R18213 | 1 | |

| IAE 1R18214 Build stand | 0AM53 | IAE 1R18214 | 1 | |

| IAE 1R18217 Lift fixture | 0AM53 | IAE 1R18217 | 1 | |

| IAE 1R18401 Support stand | 0AM53 | IAE 1R18401 | 1 | |

| IAE 1R18635 Spanner wrench | 0AM53 | IAE 1R18635 | 1 | |

| IAE 1R18636 Spanner Wrench | 0AM53 | IAE 1R18636 | 1 | |

| IAE 1R18637 Spanner Wrench | 0AM53 | IAE 1R18637 | 1 | |

| IAE 1R18693 Support ring | 0AM53 | IAE 1R18693 | 1 | |

| IAE 1R18831 Support ring | 0AM53 | IAE 1R18831 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-002 SOLVENT, DELETED. | X111X | CoMat 01-002 | ||

| DELETED | LOCAL | DELETED | ||

| CoMat 02-271 ADHESIVE TAPE (DOUBLE SIDED) | LOCAL | CoMat 02-271 | ||

| CoMat 04-011 JOINTING COMPOUND | LOCAL | CoMat 04-011 | ||

| CoMat 07-038 AIR DRYING ENAMEL | k3504 | CoMat 07-038 | ||

| CoMat 08-013 COLD CURING SILICONE COMPOUND | X222X | CoMat 08-013 | ||

| CoMat 10-070 ANTI-SEIZE COMPOUND | LOCAL | CoMat 10-070 | ||

| CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) | K6835 | CoMat 10-072 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Corrujoint gasket | 3 | |||

| Corrujoint gasket | 1 |

Safety Requirements

CAUTION

Procedure

Install IAE 1R18091 Support stand on to the IAE 1R18090 Safety support stand. Refer to Figure.

Align the HP compressor rotor assembly above the IAE 1R18091 Support stand installed in the IAE 1R18401 Support stand.

Slowly lower the HP compressor rotor assembly on to the IAE 1R18401 Support stand. Make sure the front universal sling adapter goes through the hole in the middle of the IAE 1R18091 Support stand. Continue to lower the HP compressor rotor until the stage 3 disk touches the IAE 1R18091 Support stand.

Install the HP compressor rotor assembly on the IAE 1R18401 Support stand. Refer to Figure and Figure.

Remove the front universal sling adapter from dummy stub shaft. Refer to Figure.

Use the hoist installed in Step and vertically lift the HP compressor rotor assembly from the IAE 1R18401 Support stand.

Align the HP compressor rotor assembly above the IAE 1R18214 Build stand.

Slowly lower the HP compressor rotor assembly on to the IAE 1R18214 Build stand. Align the dummy stub shaft with the central housing in the IAE 1R18214 Build stand. Continue to lower the HP compressor rotor assembly until it is installed in the IAE 1R18214 Build stand.

Install the HP compressor rotor assembly in the IAE 1R18214 Build stand. Refer to Figure.

Remove the rear universal sling adapter. Refer to Figure.

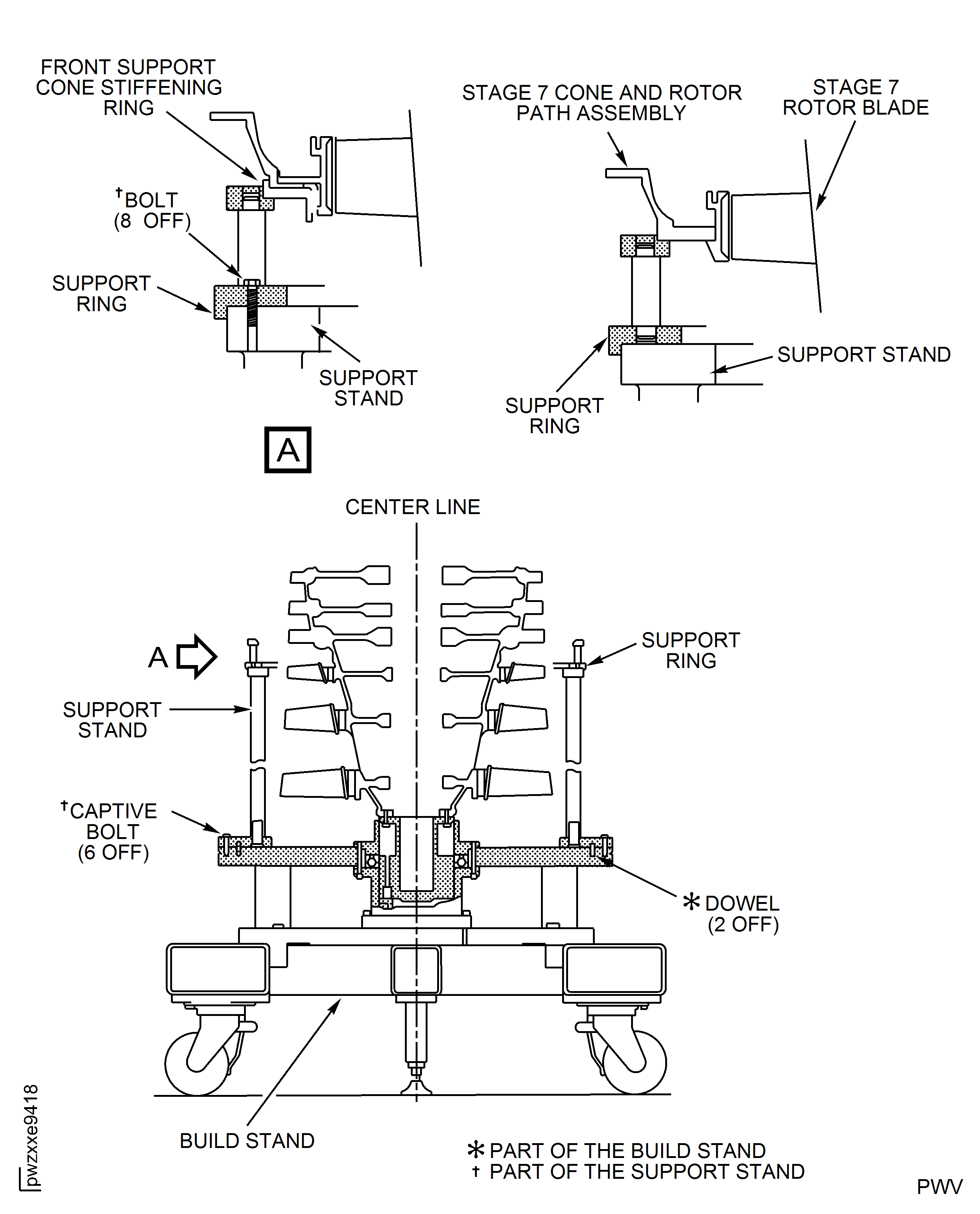

SUBTASK 72-41-00-440-268 Install the HP Compressor Rotor Assembly in the Build Stand

Refer to Figure.

Put the two halves of the IAE 1R18401 Support stand on to the IAE 1R18214 Build stand.

The two dowels in the IAE 1R18214 Build stand are to go between the IAE 1R18401 Support stand split lines.

Align the six captive bolts, part of the IAE 1R18401 Support stand, with the six boltholes in the IAE 1R18214 Build stand.

Install the six captive bolts to attach the IAE 1R18401 Support stand to the IAE 1R18214 Build stand.

Install the two halves of IAE 1R18401 Support stand.

Align the split line flanges of the IAE 1R18693 Support ring with the split lines on the IAE 1R18401 Support stand.

Align the four boltholes in each half of the IAE 1R18693 Support ring with the four bolt holes in the IAE 1R18401 Support stand.

Install the eight bolts, part of the IAE 1R18401 Support stand, to attach the IAE 1R18693 Support ring to the IAE 1R18401 Support stand.

Install IAE 1R18831 Support ring or IAE 1R18693 Support ring, on to the IAE 1R18401 Support stand.

SUBTASK 72-41-00-440-269 Prepare the Tools to Assemble the HP Compressor Assembly

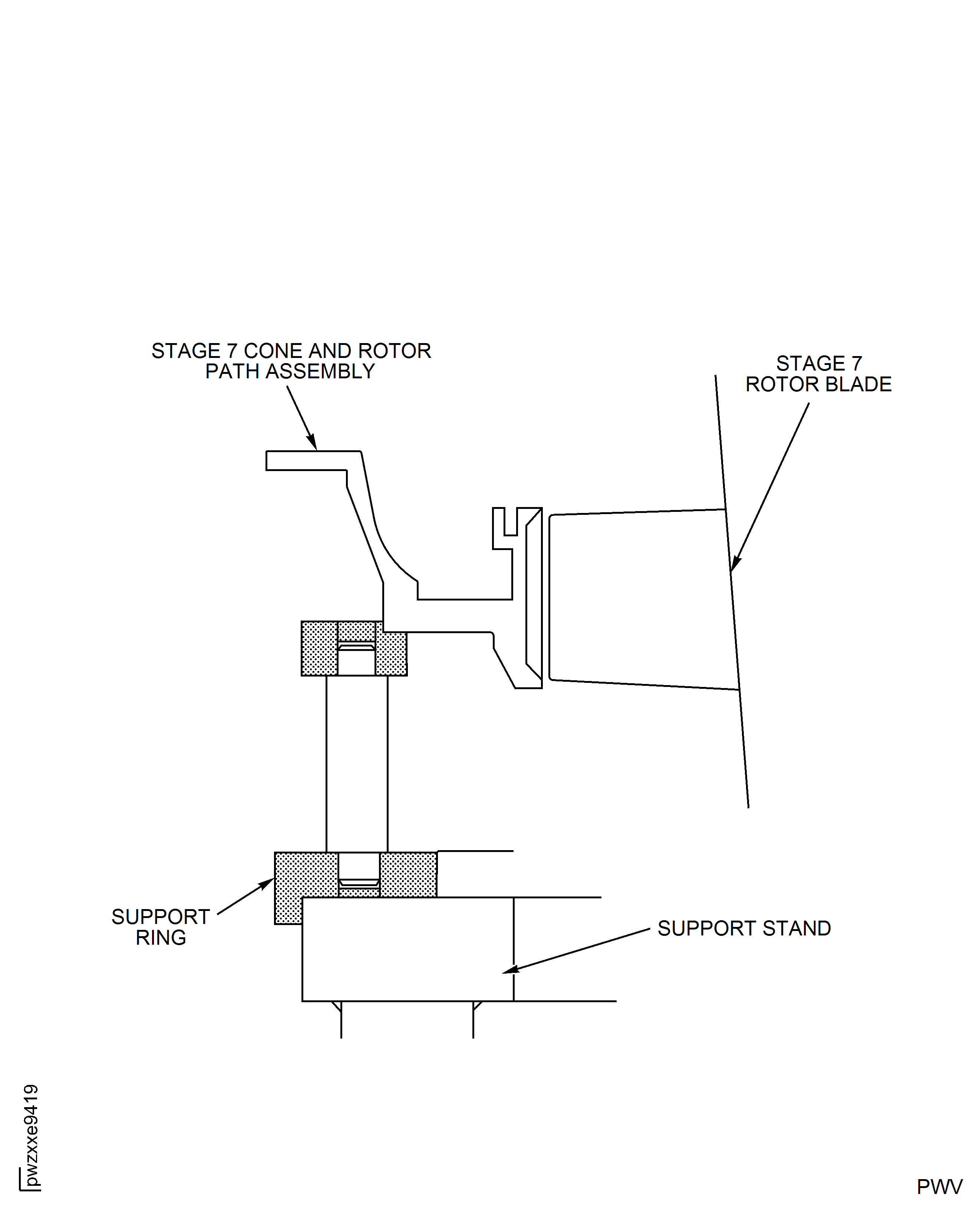

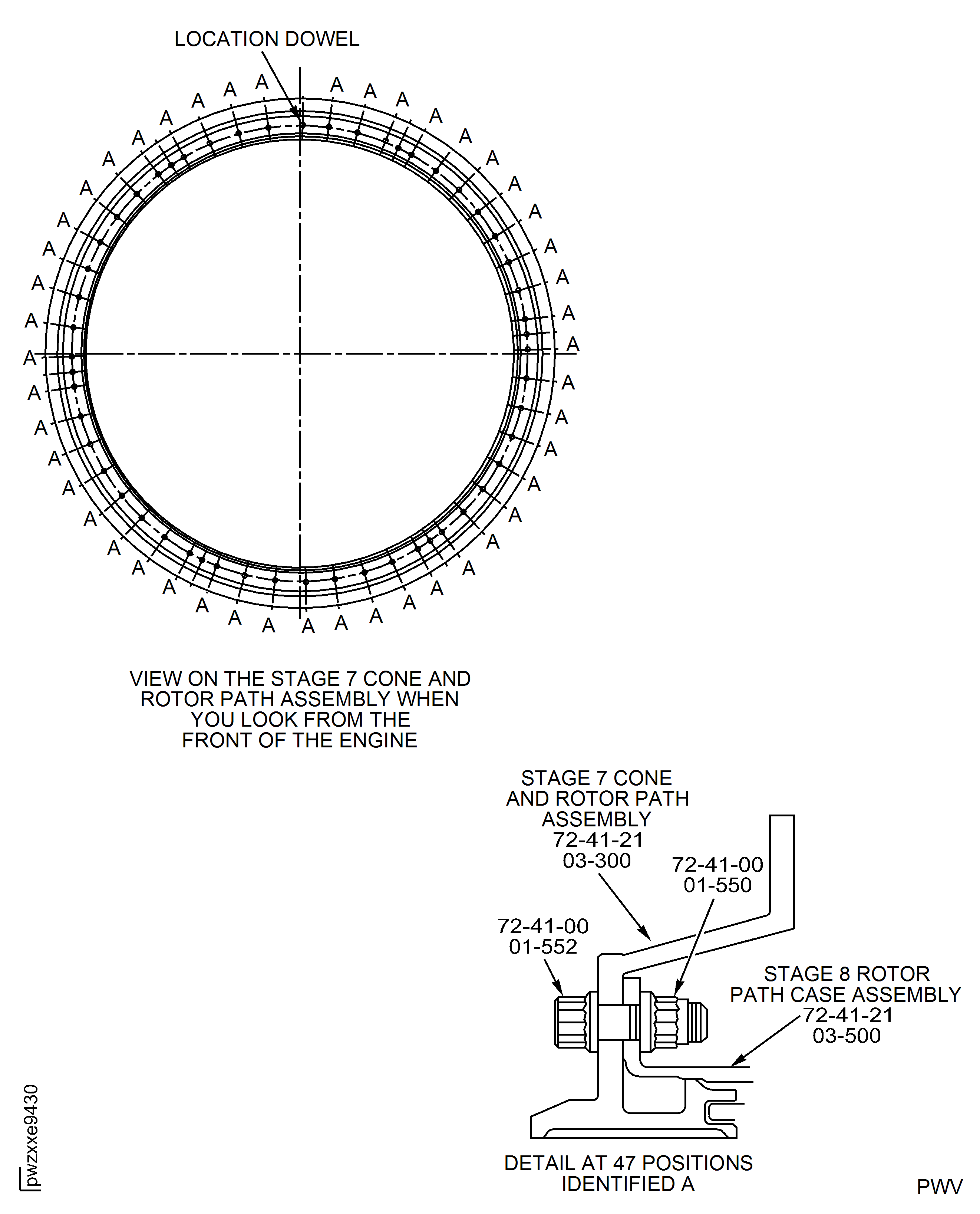

Refer to Figure.

Install the stage 7 cone and rotor path case assembly on to the support ring. The front flange of the stage 7 cone and rotor path case assembly must be correctly located on the IAE 1R18693 Support ring.

SUBTASK 72-41-00-440-270 Install the Stage 7 Cone and Rotor Path Case Assembly on to the Support Ring

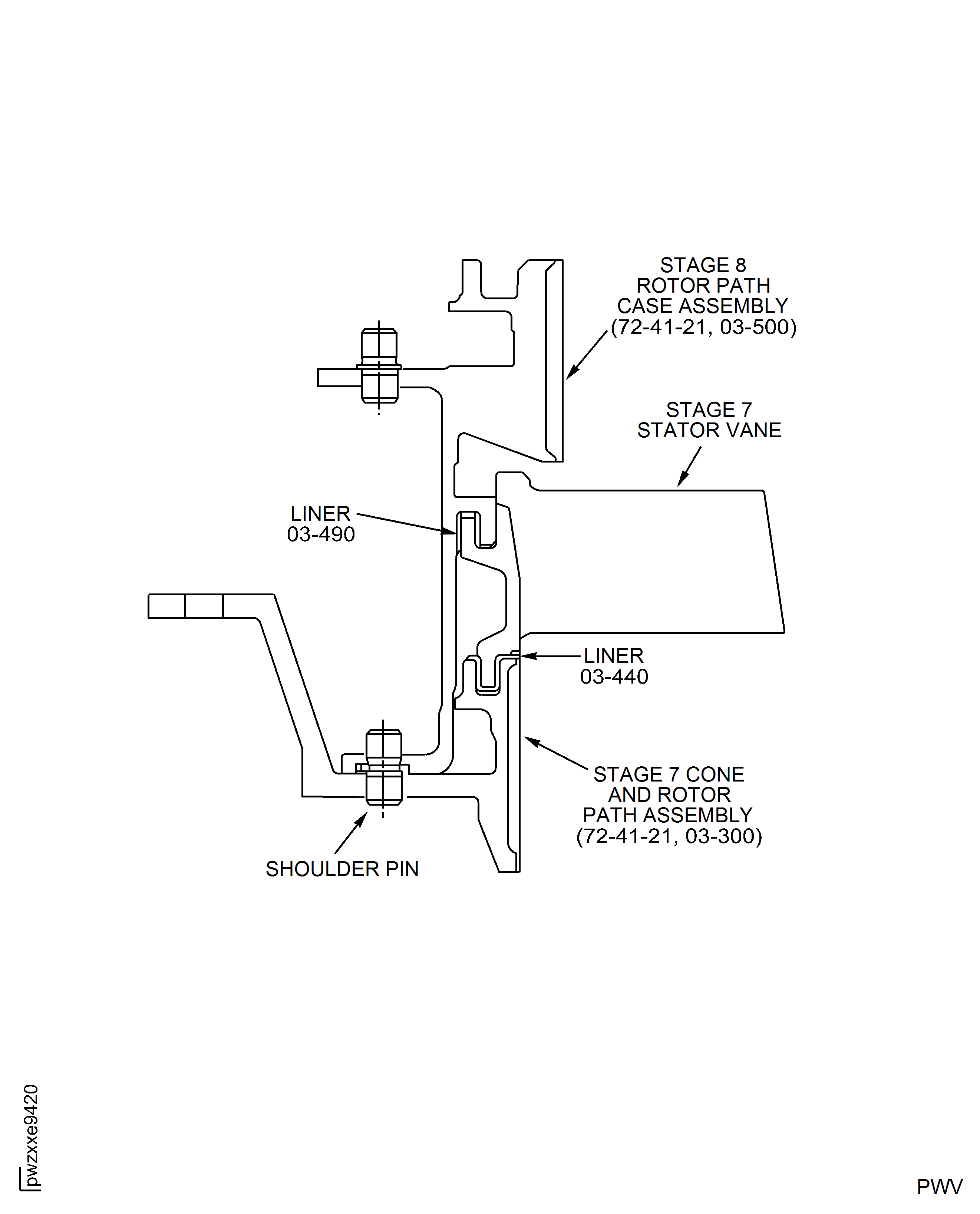

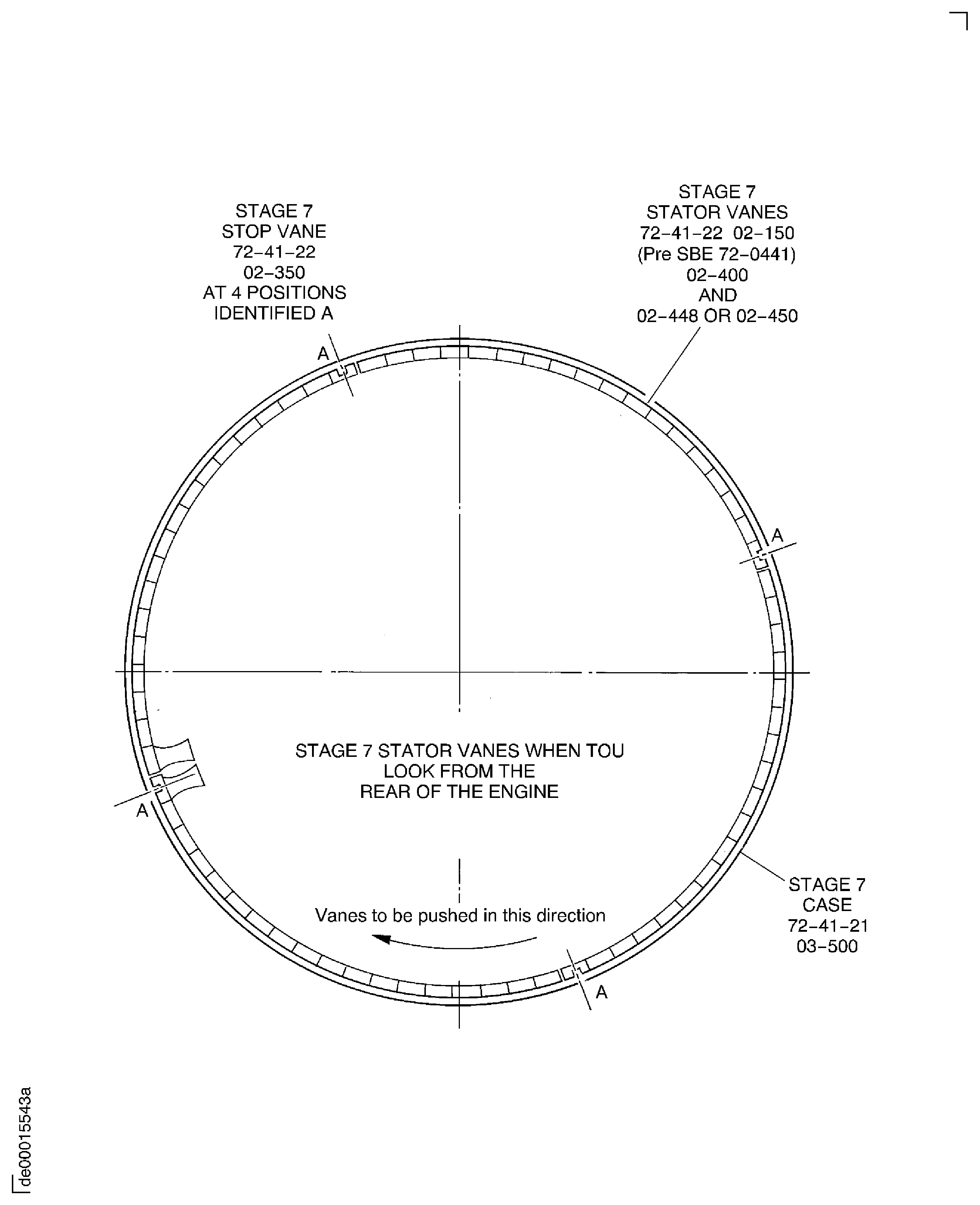

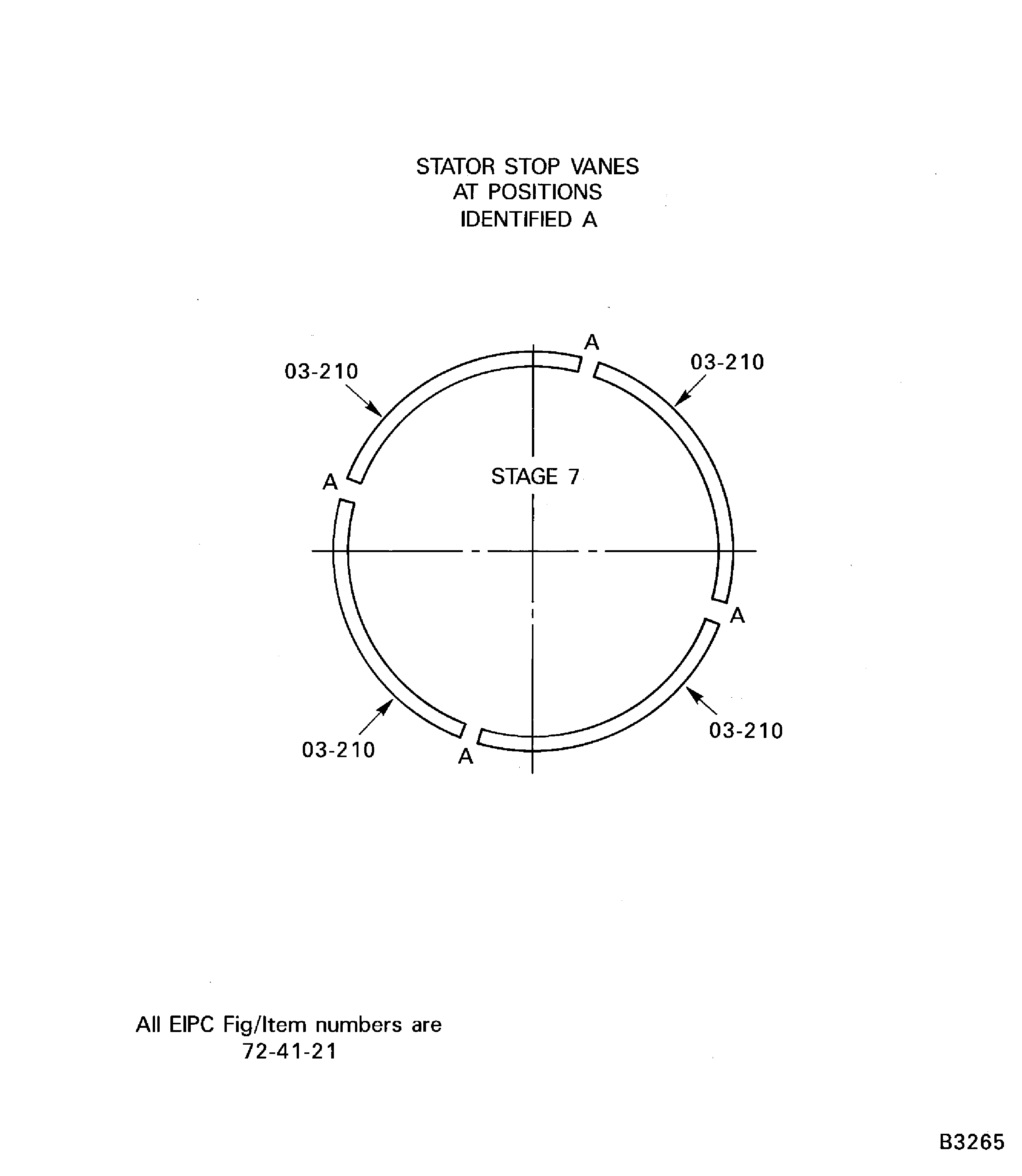

Install the four stage 7 stop vanes in to the stage 7 cone and rotor path case assembly HPC Ring Cases And Related Parts (72-41-21, 03-300) at the four stage 7 vane stops HPC Ring Cases And Related Parts (72-41-21, 03-480) positions. Engage the vanes in the stage 7 front liner HPC Ring Cases And Related Parts (72-41-21, 03-440). Make sure the four stop vanes are at the correct positions.

Install the stage 7 stop vanes HPC Stator Vanes (72-41-22, 02-350).

Install the other stage 7 stator vanes HPC Stator Vanes (72-41-22, 02-150) (Pre BE 72-0441), HPC Stator Vanes (72-41-22, 02-400) and HPC Stator Vanes (72-41-22, 02-448) or HPC Stator Vanes (72-41-22, 02-450).

WARNING

WHEN YOU USE CoMat 01-002 SOLVENT, DELETED. YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.NOTE

Use only CoMat 02-271 ADHESIVE TAPE (DOUBLE SIDED) to attach the insulation strips of SBE 72-0612 standard to the HP compressor vanes.Clean the stator vane outer platforms with CoMat 01-002 SOLVENT, DELETED..

Apply a thin layer of CoMat 08-013 COLD CURING SILICONE COMPOUND to the stator vane platforms.

Install the sealing strips on to the CoMat 08-013 COLD CURING SILICONE COMPOUND.

Install the insulation strips HPC Ring Cases And Related Parts (72-41-21, 03-210).

SUBTASK 72-41-00-440-271 Install the Stage 7 Stator Vanes (Pre SBE 72-0441, SBE 72-0441, Pre SBE 72-0612, SBE 72-0612)

Install the stage 8 rotor path case assembly HPC Ring Cases And Related Parts (72-41-21, 03-500) front flange down on to a clean work surface.

Install the Heating blanket on to the stage 8 rotor path case assembly.

Remove the Heating blanket.

WARNING

YOU MUST PUT ON THE CORRECT PROTECTIVE GLOVES BEFORE YOU TOUCH THE STAGE 8 ROTOR PATH CASE ASSEMBLY.

CAUTION

YOU MUST MAKE SURE THE STAGE 7 STATOR VANES ENGAGE CORRECTLY IN THE STAGE 8 ROTOR PATH CASE ASSEMBLY.Install the stage 7 cone and rotor path case assembly on to the stage 8 rotor path case assembly and stator vanes.

Remove the eight slave bolts installed in Step.

Install the 47 bolts HPC Assembly (72-41-00, 01-552) and nuts HPC Assembly (72-41-00, 01-550) to attach the stage 8 rotor path case assembly to the stage 7 cone and rotor path case assembly. Install the bolts from the front of the stage 7 cone and rotor path case assembly. Refer to Figure detail identified A for the position of the bolts.

SUBTASK 72-41-00-440-272 Install the Stage 7 Cone and Rotor Path Assembly to the Stage 8 Rotor Path Case Assembly

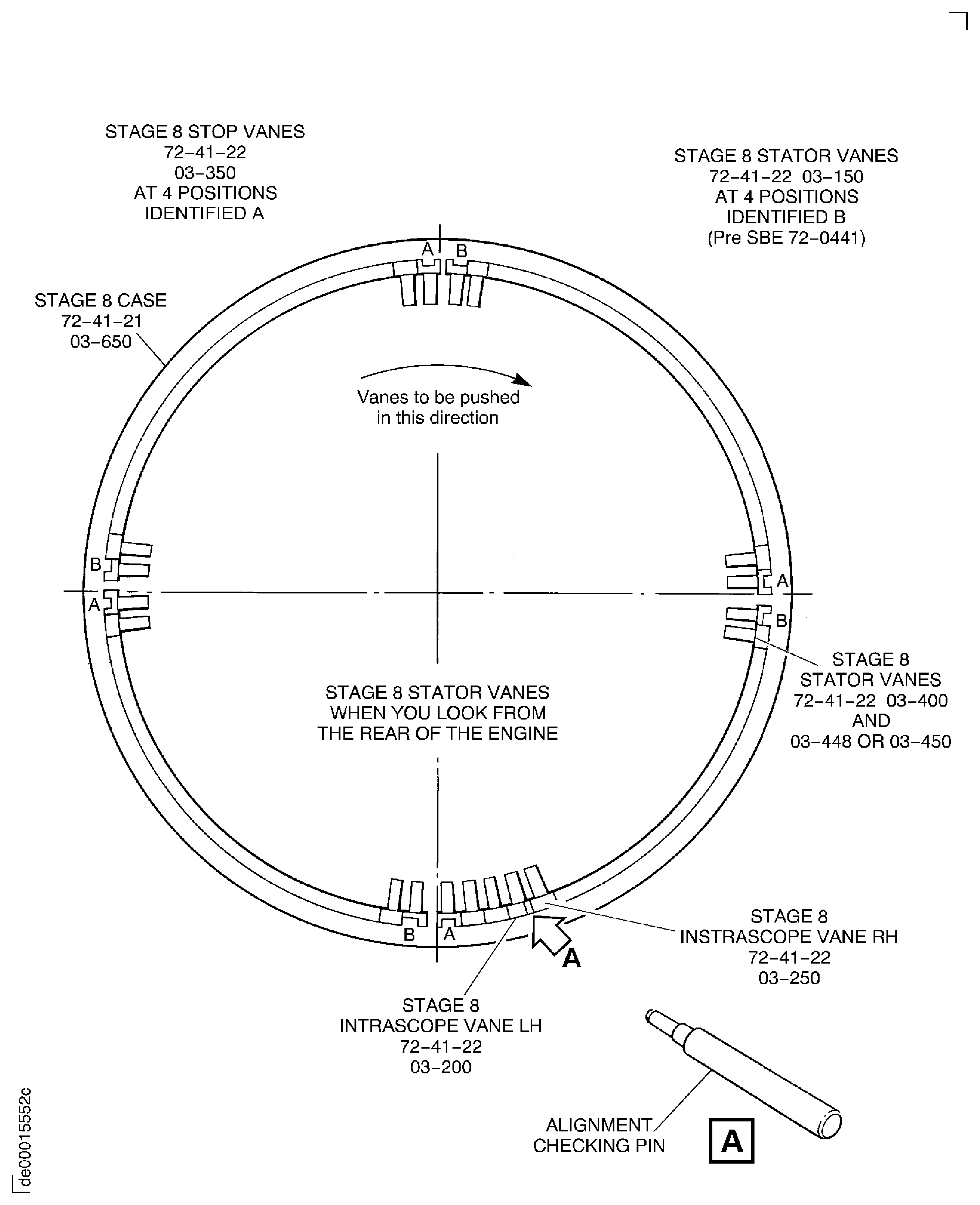

Install the four stage 8 stop vanes in to the stage 8 rotor path case assembly HPC Ring Cases And Related Parts (72-41-21, 03-500) at the four stage 8 stator vane stop HPC Ring Cases And Related Parts (72-41-21, 03-640) positions. Engage the vanes in the stage 8 front liner HPC Ring Cases And Related Parts (72-41-21, 03-590). Make sure the four stop vanes are at the correct positions.

Install the stage 8 stop vanes HPC Stator Vanes (72-41-22, 03-350).

Install the vanes referred to in Step to Step, in a clockwise direction. Engage each of the vanes in the stage 8 front liner. Make sure the platform of the first vane that is installed touches the platform of the stage 8 stop vane. Push each subsequent vane clockwise as it is installed until the vane platforms touch.

Install the 22 stage 8 stator vanes (HPC Stator Vanes (72-41-22, 03-150) (Pre SBE 72-0441)), HPC Stator Vanes (72-41-22, 03-400) and HPC Stator Vanes (72-41-22, 03-448) or HPC Stator Vanes (72-41-22, 03-450) between the two stage 8 stop vanes at the positions 12 o'clock and 3 o'clock.

Between the two stage 8 stop vanes at the 3 o'clock and 6 o'clock positions, install 20 stage 8 stator vanes (HPC Stator Vanes (72-41-22, 03-150) (Pre SBE 72-0441)), HPC Stator Vanes (72-41-22, 03-400) and HPC Stator Vanes (72-41-22, 03-448) or HPC Stator Vanes (72-41-22, 03-450) and the two stage 8 LH and RH intrascope vanes HPC Stator Vanes (72-41-22, 03-200) and HPC Stator Vanes (72-41-22, 03-250).

Install the 22 stage 8 stator vanes (HPC Stator Vanes (72-41-22, 03-150) (Pre SBE 72-0441)), HPC Stator Vanes (72-41-22, 03-400) and HPC Stator Vanes (72-41-22, 03-448) or HPC Stator Vanes (72-41-22, 03-450) between the two stage 8 stop vanes located at the 6 o'clock and 9 o'clock positions.

Install the 22 stage 8 stator vanes (HPC Stator Vanes (72-41-22, 03-150) (Pre SBE 72-0441)), HPC Stator Vanes (72-41-22, 03-400) and HPC Stator Vanes (72-41-22, 03-448) or HPC Stator Vanes (72-41-22, 03-450) between the two stage 8 stop vanes located at the 9 o'clock and 12 o'clock positions.

Install the stage 8 stator vanes.

WARNING

WHEN YOU USE CoMat 01-002 SOLVENT, DELETED. YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.NOTE

Use only CoMat 02-271 ADHESIVE TAPE (DOUBLE SIDED) to attach the insulation strips of SBE 72-0612 standard to the HP compressor vanes.Clean the stator vane outer platforms with CoMat 01-002 SOLVENT, DELETED..

Apply a thin layer of CoMat 08-013 COLD CURING SILICONE COMPOUND to the stator vane outer platforms.

Install the sealing strips on to the CoMat 08-013 COLD CURING SILICONE COMPOUND.

Install the insulation strips HPC Ring Cases And Related Parts (72-41-21, 03-154), HPC Ring Cases And Related Parts (72-41-21, 03-156) and HPC Ring Cases And Related Parts (72-41-21, 03-158).

SUBTASK 72-41-00-440-273 Install the Stage 8 Stator Vanes (Pre SBE 72-0441, SBE 72-0441, Pre SBE 72-0612, SBE 72-0612)

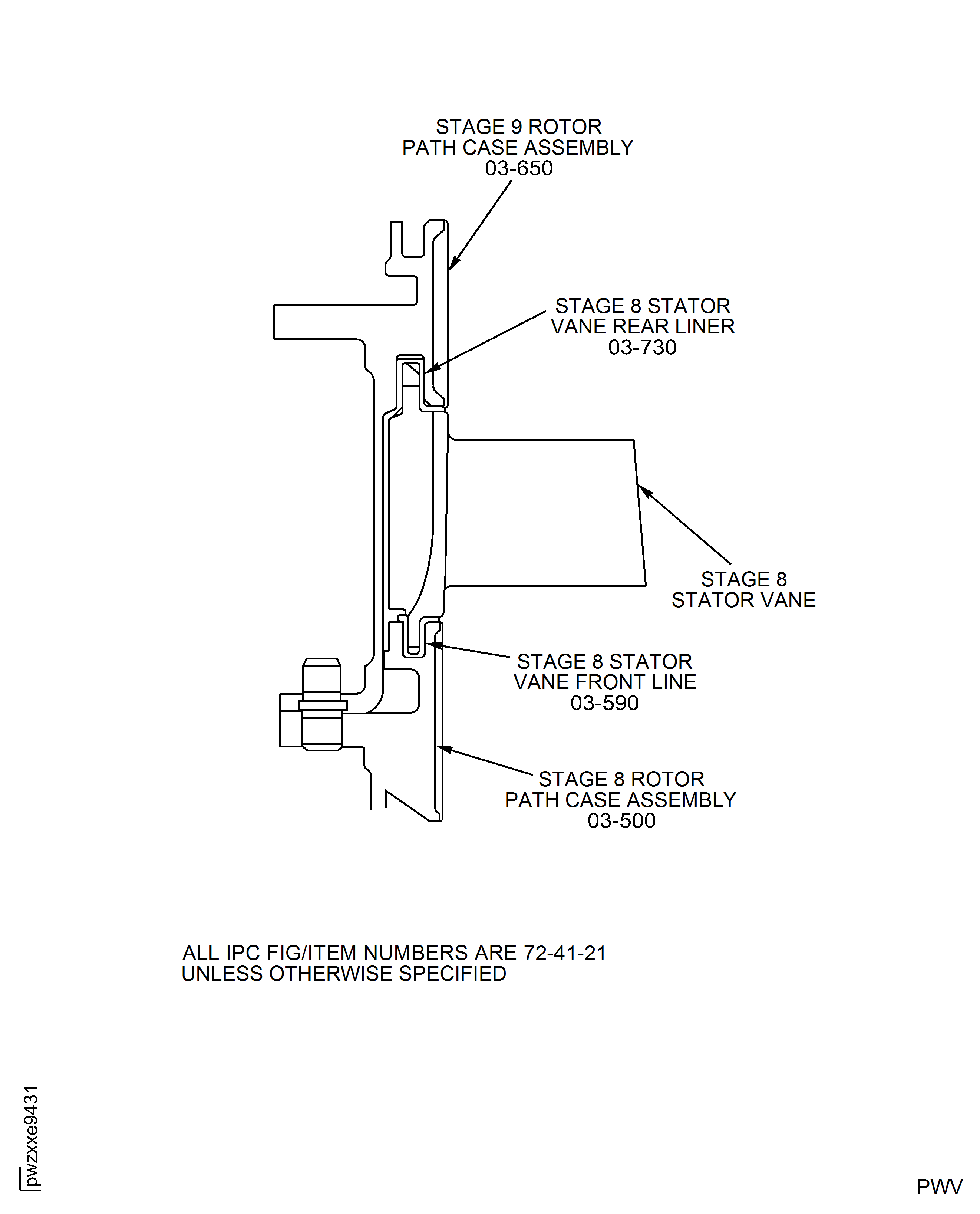

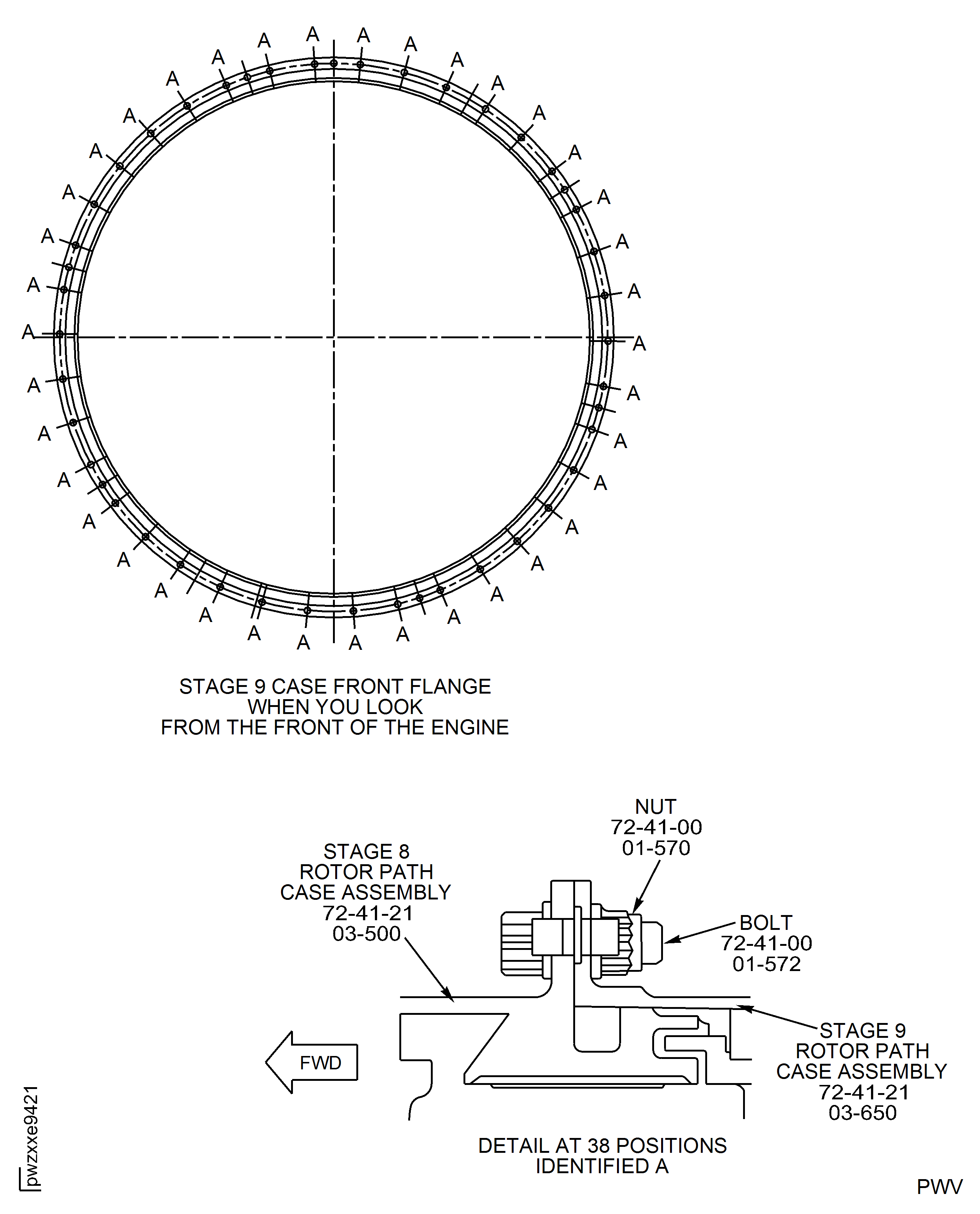

Put the stage 9 rotor path case assembly HPC Ring Cases And Related Parts (72-41-21, 03-650) front flange down on to a clean work surface.

Install a Heating blanket on to the stage 9 rotor path case assembly.

WARNING

YOU MUST PUT ON THE CORRECT PROTECTIVE GLOVES BEFORE YOU TOUCH THE STAGE 9 ROTOR PATH CASE ASSEMBLY.

CAUTION

YOU MUST MAKE SURE THE STAGE 8 STATOR VANES ENGAGE CORRECTLY IN THE STAGE 9 ROTOR PATH CASE ASSEMBLY.Remove the Heating blanket.

Engage the stage 8 stator vanes rear platform in the liner in the stage 9 rotor path case assembly.

Align the dowel hole in the stage 9 rotor path case assembly front flange with the location dowel in the stage 8 rotor path case assembly rear flange.

Align the four stage 8 stop vanes with the stage 8 stop vane slots.

Install the stage 9 rotor path case assembly on to the stage 8 rotor path case assembly.

Install IAE 1R18213 Alignment checking pin through the stage 9 case assembly borescope hole. Make sure the IAE 1R18213 Alignment checking pin easily goes in to the intrascope vanes hole.

Remove the IAE 1R18213 Alignment checking pin.

Install the 38 bolts HPC Assembly (72-41-00, 01-572) and nuts HPC Assembly (72-41-00, 01-570) to attach the stage 9 case to the rear of the stage 8 case. Refer to Figure detail identified at A. Make sure the bolts are correctly located on the stage 9 rotor path case assembly.

SUBTASK 72-41-00-440-274 Install the Stage 9 Rotor Path Case Assembly

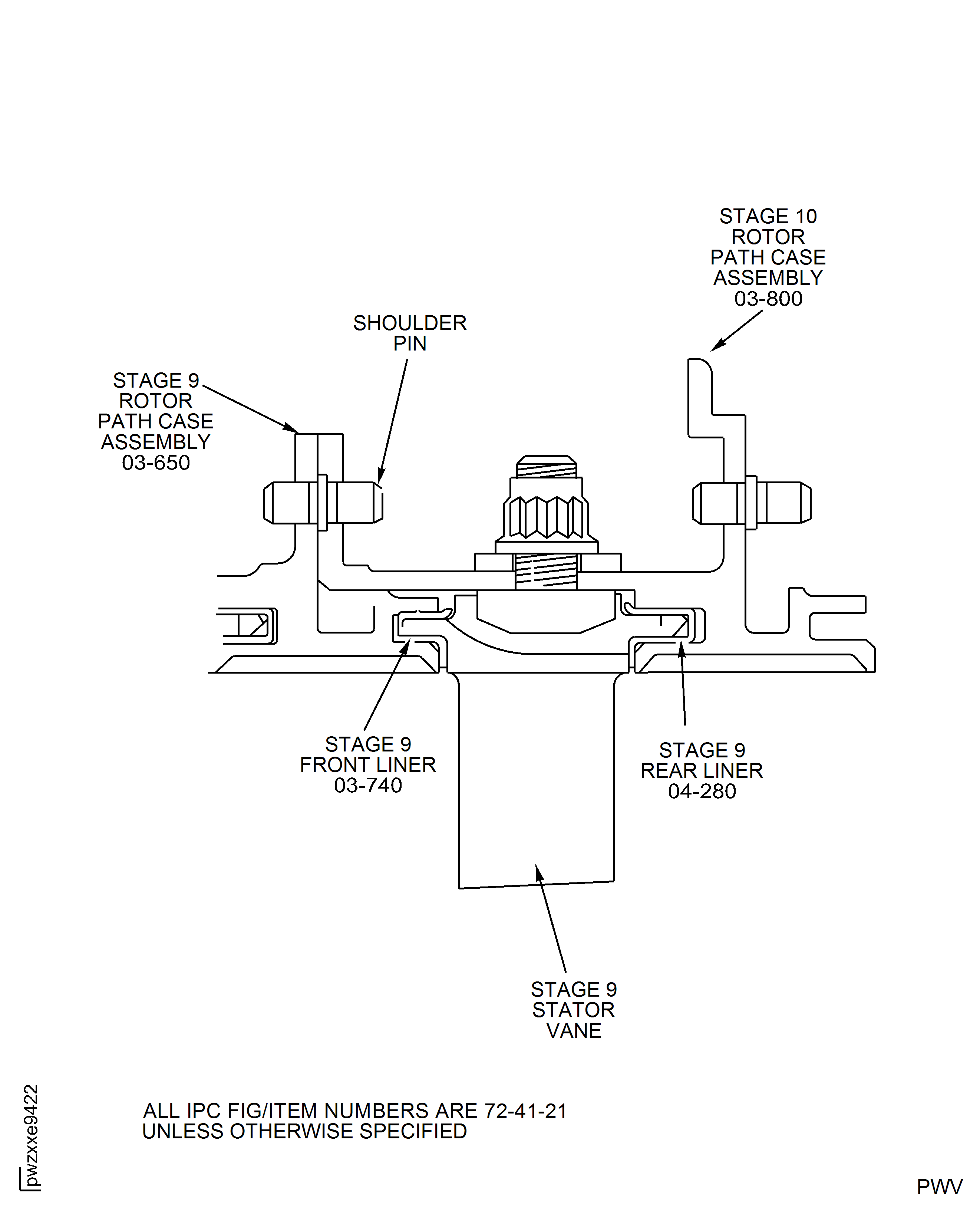

Install the eight stage 9 stop vanes in to the stage 9 rotor path case assembly, at the stage 9 stator vane stops HPC Ring Cases And Related Parts (72-41-21, 03-790). Engage the vanes in the stage 9 rotor path case assembly. Install two stage 9 stop vanes at each of the stage stator vane stops.

Push each stage 9 stop vane forward until the vane platform touches the stage 9 front liner HPC Ring Cases And Related Parts (72-41-21, 03-740).

Install the stage 9 stop vanes HPC Stator Vanes (72-41-22, 04-350).

Install the vanes referred to in Step to Step, in a clockwise direction. Engage each of the vanes in the stage 9 front liner. Make sure the platform of the first vane that is installed touches the platform of the stage 9 stop vane. Push each subsequent vane clockwise as it is installed until the vane platforms touch.

Install the 24 stage 9 stator vanes HPC Stator Vanes (72-41-22, 04-400) and HPC Stator Vanes (72-41-22, 04-448) or HPC Stator Vanes (72-41-22, 04-450) between the two stage 9 stop vanes located at the 12 o'clock and 3 o'clock positions.

Between the two stage 9 stop vanes located at the 3 o'clock and 6 o'clock positions, install 22 stage 9 stator vanes HPC Stator Vanes (72-41-22, 04-400) and HPC Stator Vanes (72-41-22, 04-448) or HPC Stator Vanes (72-41-22, 04-450) and the two stage 9 LH and RH intrascope vanes HPC Stator Vanes (72-41-22, 04-200) and HPC Stator Vanes (72-41-22, 04-250).

Install the 24 stage 9 stator vanes HPC Stator Vanes (72-41-22, 04-400) and HPC Stator Vanes (72-41-22, 04-448) or HPC Stator Vanes (72-41-22, 04-450) between the two stage 9 stop vanes located at the 6 o'clock and 9 o'clock positions.

Install the 24 stage 9 stator vanes HPC Stator Vanes (72-41-22, 04-400) and HPC Stator Vanes (72-41-22, 04-448) or HPC Stator Vanes (72-41-22, 04-450) between the two stage 9 stop vanes located at the 9 o'clock and 12 o'clock positions.

Install the stage 9 stator vanes.

WARNING

WHEN YOU USE CoMat 01-002 SOLVENT, DELETED. YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.NOTE

Use only CoMat 02-271 ADHESIVE TAPE (DOUBLE SIDED) to attach the insulation strips of SBE 72-0612 standard to the HP compressor vanes.Clean the stator vane outer platforms with CoMat 01-002 SOLVENT, DELETED..

Apply a thin layer of CoMat 08-013 COLD CURING SILICONE COMPOUND to the stator vane platforms.

Install the sealing strips on to the CoMat 08-013 COLD CURING SILICONE COMPOUND.

Install the insulation strips HPC Ring Cases And Related Parts (72-41-21, 03-094), HPC Ring Cases And Related Parts (72-41-21, 03-096) and HPC Ring Cases And Related Parts (72-41-21, 03-098).

SUBTASK 72-41-00-440-275 Install the Stage 9 Stator Vanes

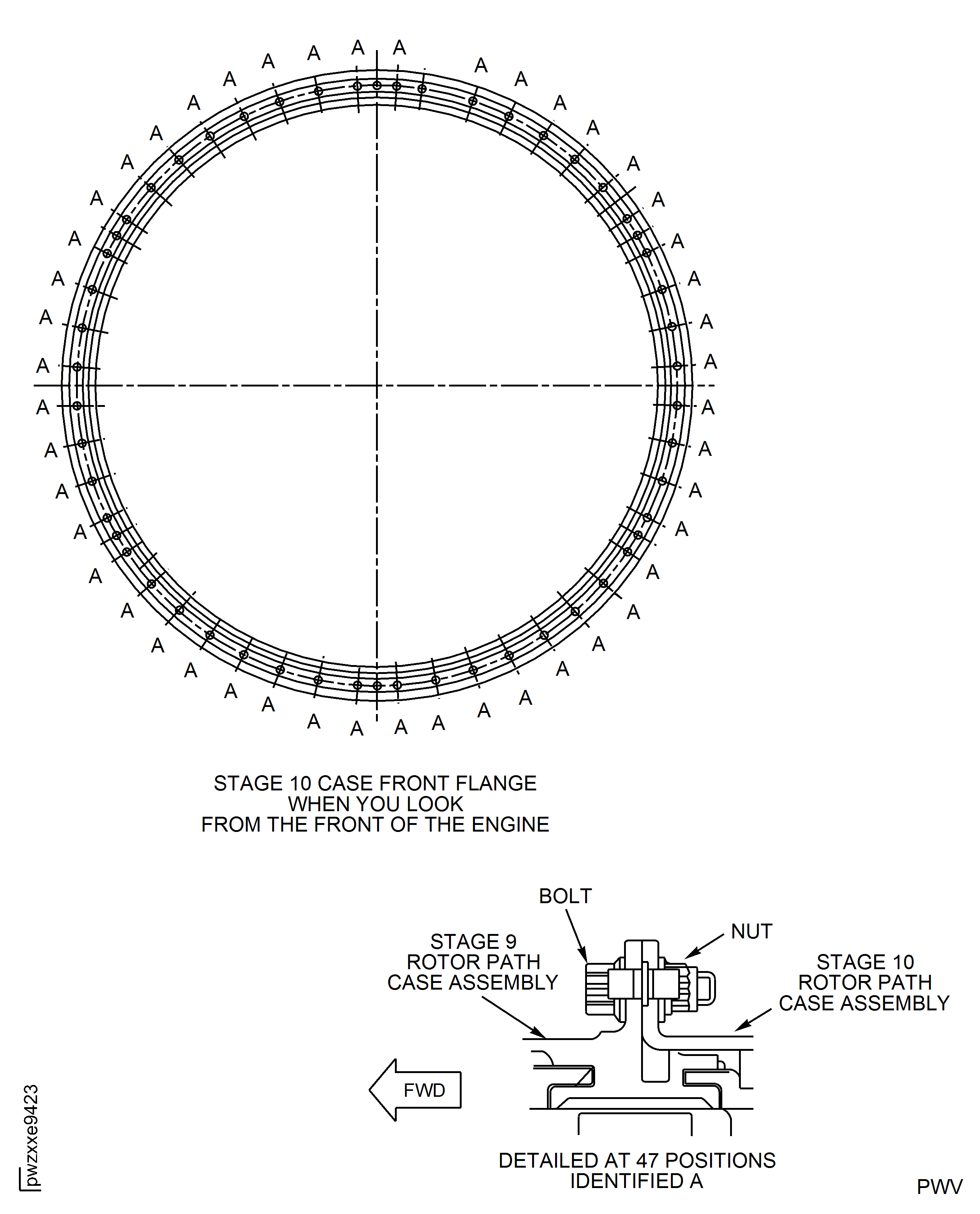

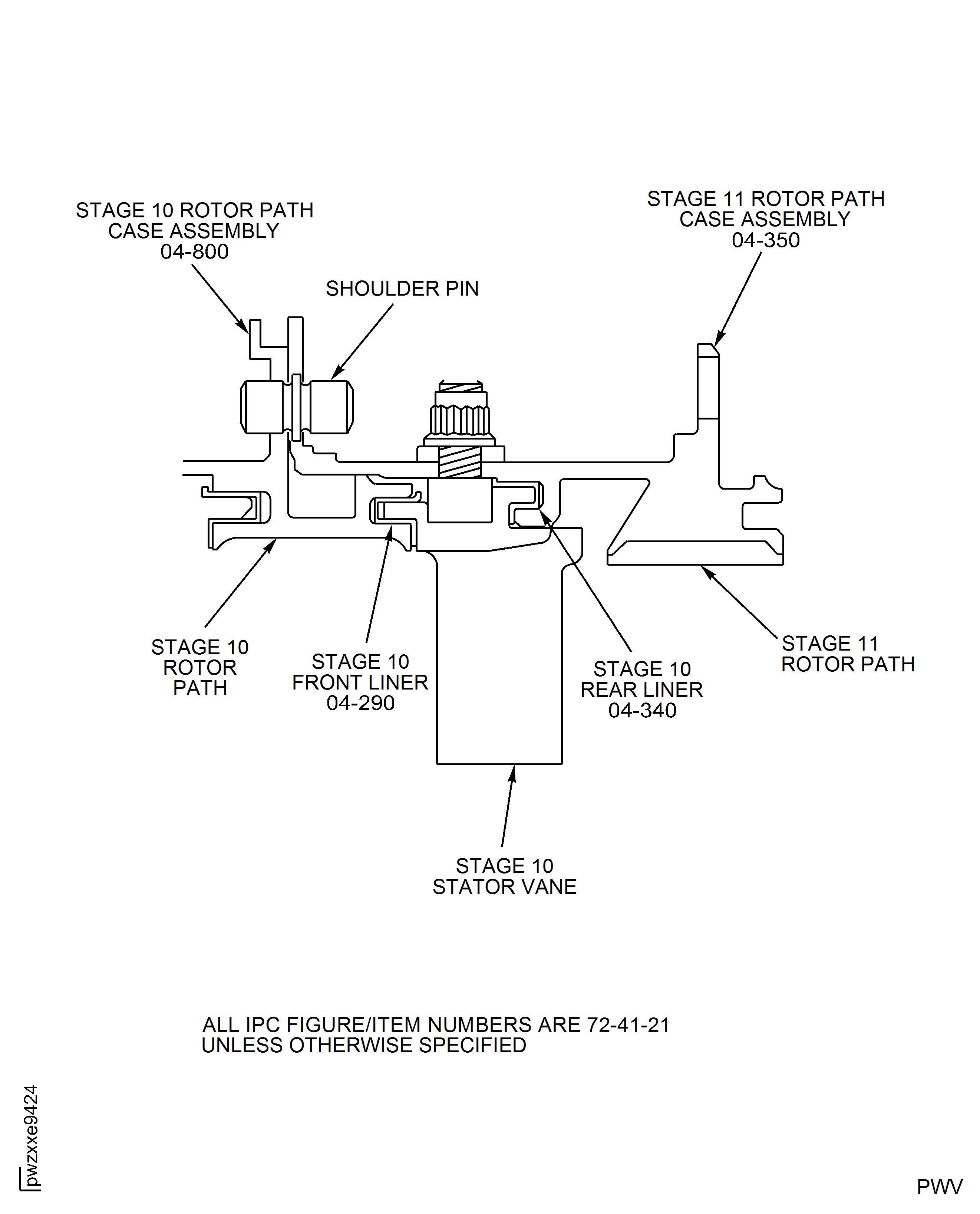

Install the stage 10 rotor path case assembly HPC Ring Cases And Related Parts (72-41-21, 03-800).

Install a Heating blanket on to the stage 10 rotor path case assembly.

WARNING

YOU MUST PUT ON THE CORRECT PROTECTIVE GLOVES BEFORE YOU TOUCH THE STAGE 10 ROTOR PATH CASE ASSEMBLY.

CAUTION

YOU MUST MAKE SURE THE STAGE 9 STATOR VANES ENGAGE CORRECTLY IN THE STAGE 10 ROTOR PATH CASE ASSEMBLY.Remove the Heating blanket.

Install IAE 1R18213 Alignment checking pin through the stage 10 case assembly borescope hole. Make sure the IAE 1R18213 Alignment checking pin easily goes in to the intrascope vanes hole.

Remove the IAE 1R18213 Alignment checking pin.

Install the 47 bi-hex bolts HPC Assembly (72-41-00, 01-592) and nuts HPC Assembly (72-41-00, 01-590) to attach the stage 10 rotor path case assembly to the stage 9 rotor path case assembly. Refer to Figure detail identified at A. Make sure the bolts are correctly located on the stage 10 rotor path case assembly.

SUBTASK 72-41-00-440-276 Install the Stage 8 Heatshield, Stage 10 Rotor Path Case Assembly and the Stage 9 Front Heatshield

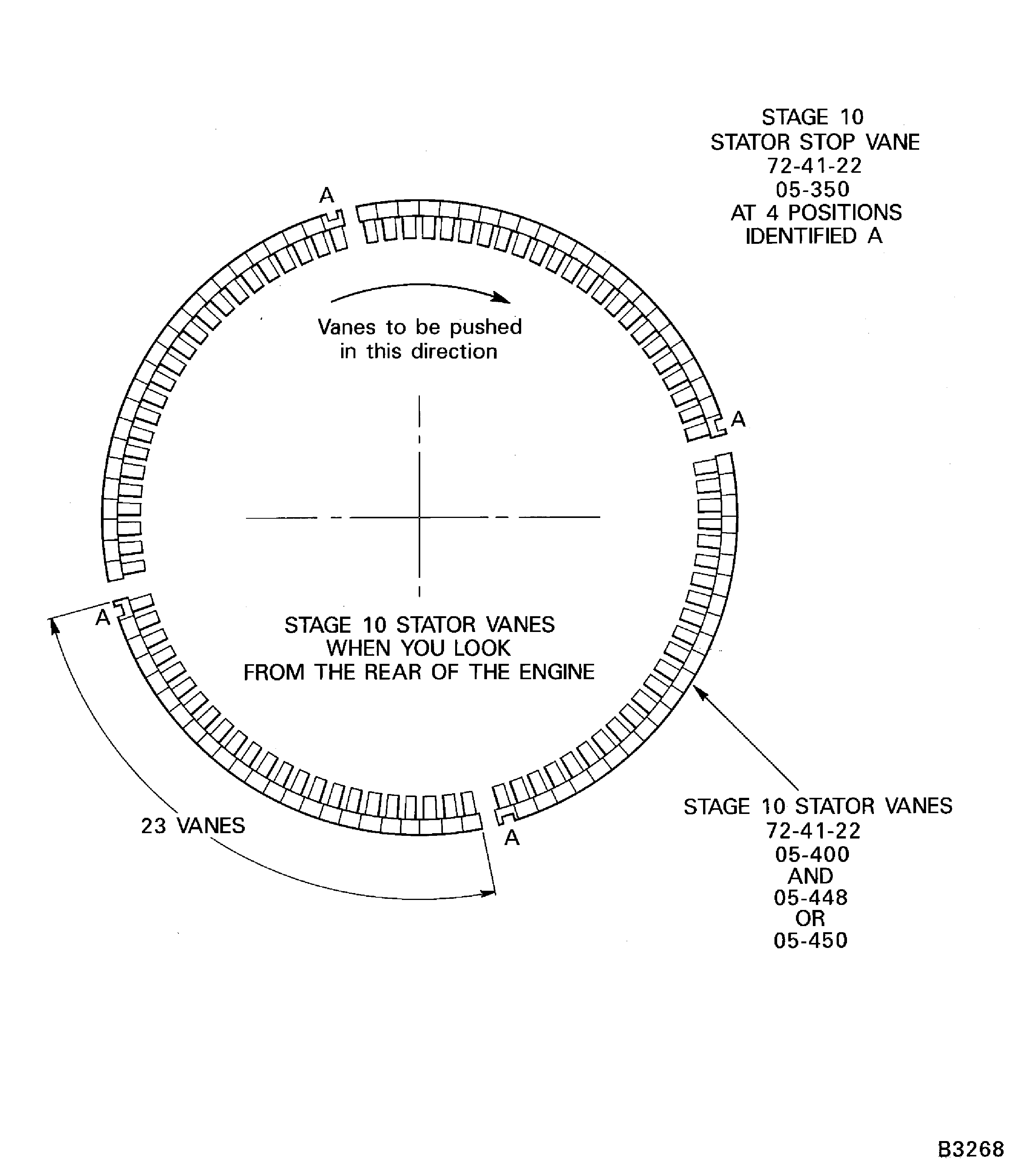

Install the four stage 10 stop vanes in to the stage 10 rotor path case assembly at the stage 10 stator vane stops. Engage the vanes in the stage 10 front liner HPC Ring Cases And Related Parts (72-41-21, 04-290). Make sure the stage 10 stator vane stops are engaged in the slots in the stage 10 stop vanes.

Install the stage 10 stop vanes HPC Stator Vanes (72-41-22, 05-350).

Install the vanes referred to in Step, in a clockwise direction. Engage each of the vanes in the stage 10 front liner. Make sure the platform of the first vane that is installed touches the platform of the stage 10 stop vane. Push each subsequent vane clockwise as it is installed until the vane platforms touch.

Install the stage 10 stator vanes HPC Stator Vanes (72-41-22, 05-400) and HPC Stator Vanes (72-41-22, 05-448) or HPC Stator Vanes (72-41-22, 05-450).

WARNING

WHEN YOU USE CoMat 01-002 SOLVENT, DELETED. INHIBITED AND STABILIZED TRICHLOROETHANEYOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.NOTE

Use only CoMat 02-271 ADHESIVE TAPE (DOUBLE SIDED) to attach the insulation strips of SBE 72-0612 standard to the HP compressor vanes.Clean the stator vane outer platforms with CoMat 01-002 SOLVENT, DELETED..

Apply a thin layer of CoMat 08-013 COLD CURING SILICONE COMPOUND to the stator platforms.

Install the sealing strips on to the CoMat 08-013 COLD CURING SILICONE COMPOUND.

Install the insulation strips HPC Ring Cases And Related Parts (72-41-21, 04-150).

SUBTASK 72-41-00-440-277 Install the Stage 10 Stator Vanes (Pre SBE 72-0612 and SBE 72-0612)

Refer to Figure.

Install the seal ring HPC Ring Cases And Related Parts (72-41-21, 04-420).

SUBTASK 72-41-00-440-278 Install the Seal Ring

Install the stage 11 rotor path case assembly HPC Ring Cases And Related Parts (72-41-21, 04-350) front flange down on to a clean work surface.

Install a Heating blanket on to the stage 11 rotor path case assembly.

WARNING

YOU MUST PUT ON THE CORRECT PROTECTIVE GLOVES BEFORE YOU TOUCH THE STAGE 11 ROTOR PATH CASE ASSEMBLY.

CAUTION

YOU MUST MAKE SURE THE STAGE 10 STATOR VANES ENGAGE CORRECTLY IN THE STAGE 11 ROTOR PATH CASE ASSEMBLY.Remove the Heating blanket.

Engage the stage 10 stator vanes rear platform in the liner in the stage 11 rotor path case assembly.

Align the dowel hole in the stage 11 rotor path case assembly front flange with the location dowel in the stage 10 rotor path case assembly rear flange.

Align the four stage 10 stop vanes with the stage 10 stop vane slots.

Install the stage 11 rotor path case assembly on to the stage 10 rotor path case assembly and the stage 10 stator vanes.

Install eight slave nuts and bolts through the assembly joint flange. Make sure that you keep them at equal distances around the flange. Install the bolts from the stage 11 rotor path case assembly flange. Tighten the nuts in the correct sequence to pull the stage 11 rotor path case assembly on to the stage 10 rotor path case assembly.

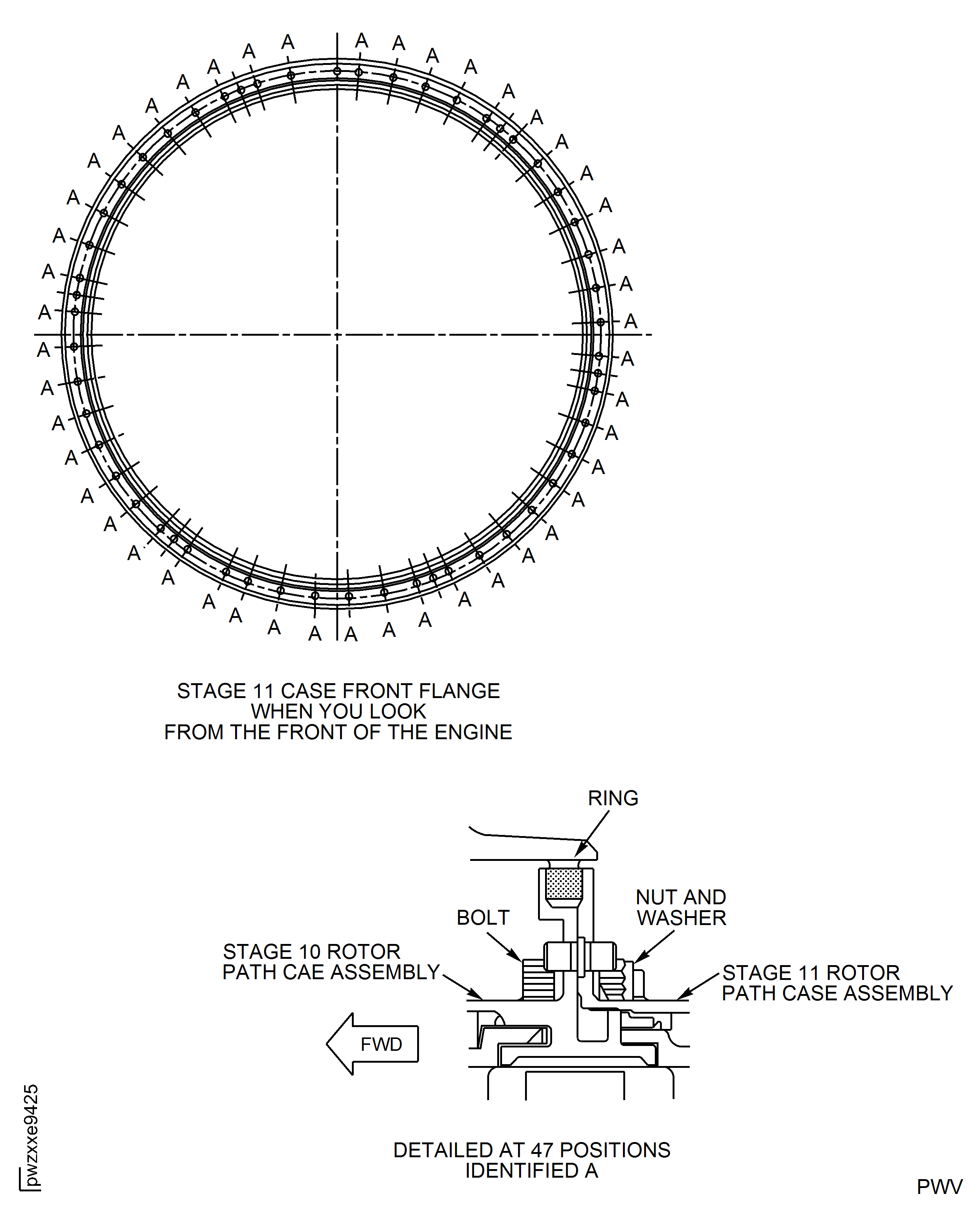

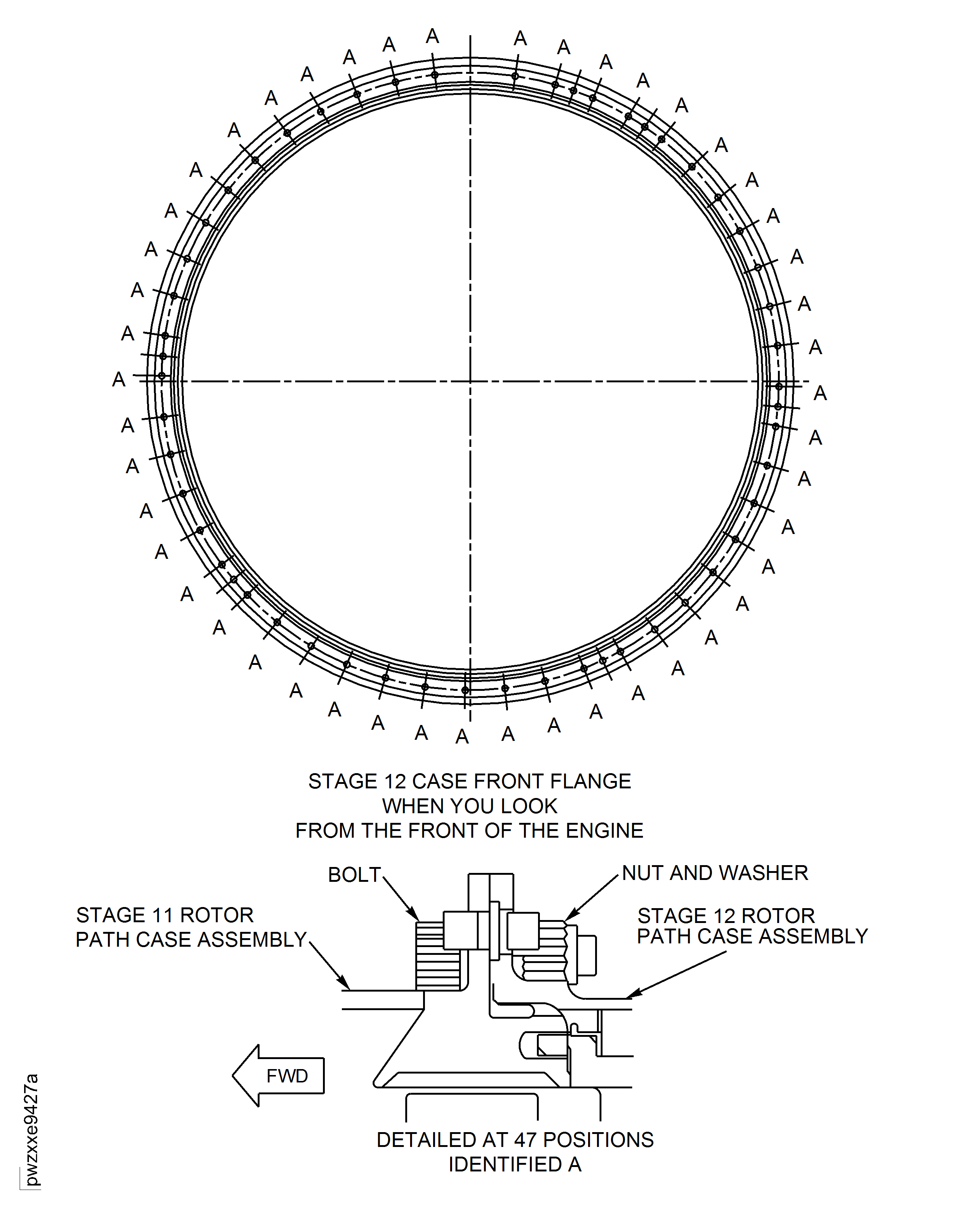

Install the 47 bolts HPC Assembly (72-41-00, 01-612), the washers HPC Assembly (72-41-00, 01-606) and nuts HPC Assembly (72-41-00, 01-610) which attach the stage 11 rotor path case assembly to the stage 10 rotor path case assembly. Refer to Figure, detail identified at A. Make sure the bolts are correctly located on the stage 10 case flange.

SUBTASK 72-41-00-440-279 Install the Stage 11 Rotor Path Case Assembly

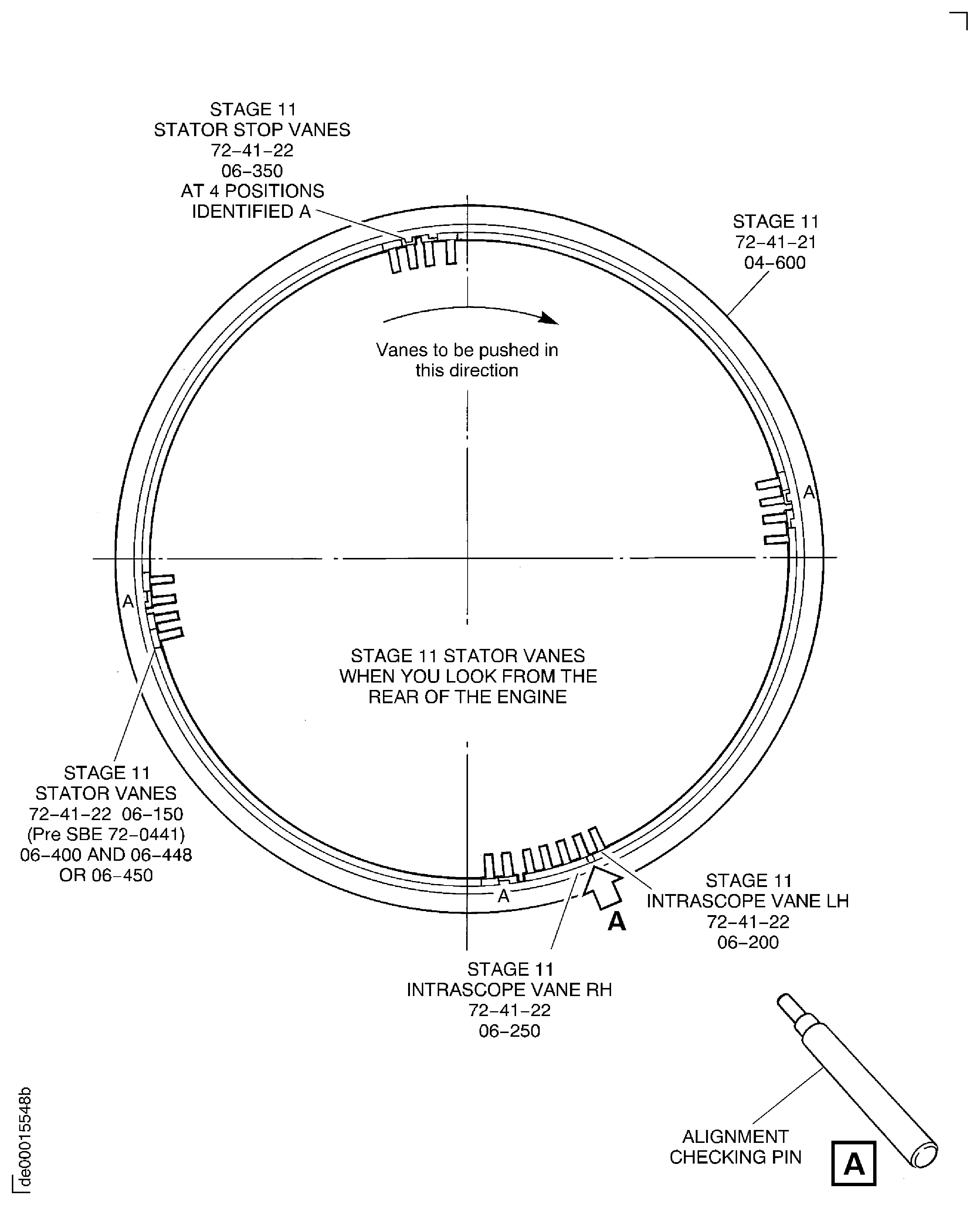

Install the four stage 11 stop vanes in to the stage 11 rotor path case assembly HPC Ring Cases And Related Parts (72-41-21, 04-350) at the stage 11 stator vane stops HPC Ring Cases And Related Parts (72-41-21, 04-590). Engage the vanes in the stage 11 rotor path case assembly. Make sure the stage 11 stator vane stops are engaged in the slots in the stage 11 stop vanes.

Install the stage 11 stop vanes HPC Stator Vanes (72-41-22, 06-350).

Install the vanes referred to in Step to Step, in a clockwise direction. Engage each of the vanes in the stage 11 front liner. Make sure the platform of the first vane that is installed touches the platform of the stage 11 stop vane. Push each subsequent vane clockwise as it is installed until the vane platforms touch.

Install the 26 stage 11 stator vanes (HPC Stator Vanes (72-41-22, 06-150) (Pre SBE 72-0441)), HPC Stator Vanes (72-41-22, 06-400) and HPC Stator Vanes (72-41-22, 06-448) or HPC Stator Vanes (72-41-22, 06-450) between the two stage 11 stop vanes located at the 12 o'clock and 3 o'clock positions.

Between the two stage 11 stop vanes located at the 3 o'clock and 6 o'clock positions, install 24 stage 11 stator vanes (HPC Stator Vanes (72-41-22, 06-150) (Pre SBE 72-0441)), HPC Stator Vanes (72-41-22, 06-400) and HPC Stator Vanes (72-41-22, 06-448) or HPC Stator Vanes (72-41-22, 06-450) and the two stage 11 LH and RH intrascope vanes HPC Stator Vanes (72-41-22, 06-200) and HPC Stator Vanes (72-41-22, 06-250).

Install the 26 stage 11 stator vanes (HPC Stator Vanes (72-41-22, 06-150) (Pre SBE 72-0441)), HPC Stator Vanes (72-41-22, 06-400) and HPC Stator Vanes (72-41-22, 06-448) or HPC Stator Vanes (72-41-22, 06-450) between the two stage 11 stop vanes located at the 6 o'clock and 9 o'clock positions.

Install the 26 stage 11 stator vanes (HPC Stator Vanes (72-41-22, 06-150) (Pre SBE 72-0441)), HPC Stator Vanes (72-41-22, 06-400) and HPC Stator Vanes (72-41-22, 06-448) or HPC Stator Vanes (72-41-22, 06-450) between the two stage 11 stop vanes located at the 9 o'clock and 12 o'clock positions.

Install the stage 11 stator vanes.

WARNING

WHEN YOU USE CoMat 01-002 SOLVENT, DELETED. YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.NOTE

Use only CoMat 02-271 ADHESIVE TAPE (DOUBLE SIDED) to attach the insulation strips of SBE 72-0612 standard to the HP compressor vanes.Clean the stator vanes outer platform with CoMat 01-002 SOLVENT, DELETED..

Apply a thin layer of CoMat 08-013 COLD CURING SILICONE COMPOUND to the stator vane platform.

Install the sealing strips on to the CoMat 08-013 COLD CURING SILICONE COMPOUND.

Install the insulation strips HPC Ring Cases And Related Parts (72-41-21, 04-094), HPC Ring Cases And Related Parts (72-41-21, 04-096) and HPC Ring Cases And Related Parts (72-41-21, 04-098).

SUBTASK 72-41-00-440-280 Install the Stage 11 Stator Vanes (Pre SBE 72-0441, SBE 72-0441, Pre SBE 72-0612 and SBE 72-0612)

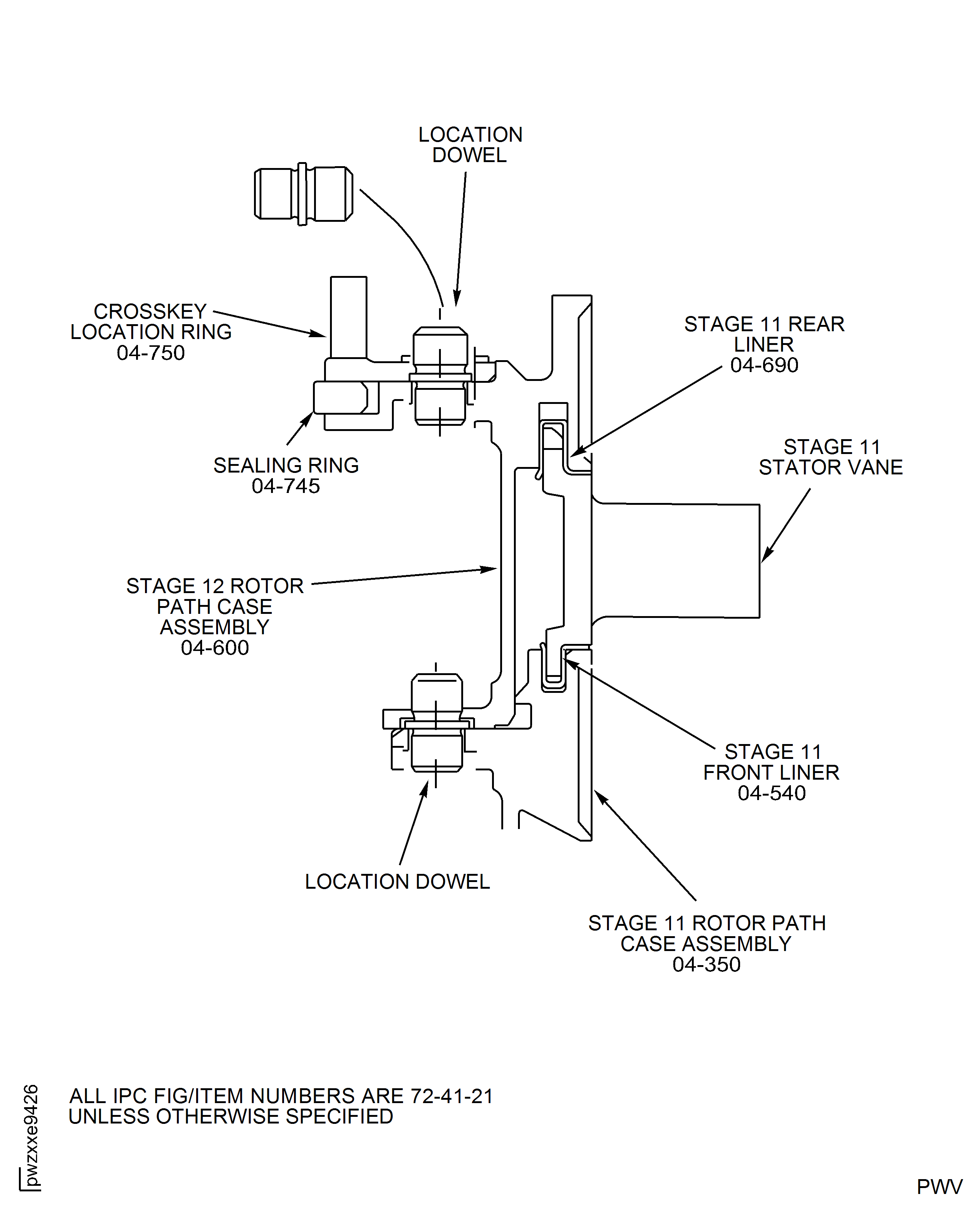

Install a Heating blanket on to the stage 12 rotor path case assembly.

WARNING

YOU MUST PUT ON THE CORRECT PROTECTIVE GLOVES BEFORE YOU TOUCH THE STAGE 12 ROTOR PATH CASE ASSEMBLY.

CAUTION

YOU MUST MAKE SURE THE STAGE 11 STATOR VANES ENGAGE CORRECTLY IN THE STAGE 12 ROTOR PATH CASE ASSEMBLY.Remove the Heating blanket.

Engage the stage 11 stator vanes rear platforms in the liner in the stage 12 rotor path case assembly.

Align the dowel hole in the stage 12 rotor path case assembly front flange with the location dowel in the stage 11 rotor path case assembly rear flange.

Align the four stage 11 stator stops with the stage 11 stop vanes.

Install the stage 12 rotor path case assembly on to the stage 11 rotor path case assembly.

Install eight slave nuts and bolts through the assembly joint flange. Space them at equal distances around the flange. Install the bolts from the stage 11 rotor path case assembly flange. Tighten the nuts in the correct sequence to pull the stage 12 rotor path case assembly on to the stage 11 rotor path case assembly.

Install IAE 1R18213 Alignment checking pin through the stage 12 rotor path case assembly borescope hole. Make sure the IAE 1R18213 Alignment checking pin easily goes into the intrascope vanes hole.

Remove the IAE 1R18213 Alignment checking pin.

Install the 47 bolts HPC Assembly (72-41-00, 01-632), the washers HPC Assembly (72-41-00, 01-625) and nuts HPC Assembly (72-41-00, 01-630) which attach the stage 12 rotor path case assembly to the stage 11 rotor path case assembly. Make sure the bolts are correctly located on the stage 12 rotor path case assembly rear flange. Refer to Figure, detail identified at A.

SUBTASK 72-41-00-440-281 Install the Stage 12 Rotor Path Case Assembly

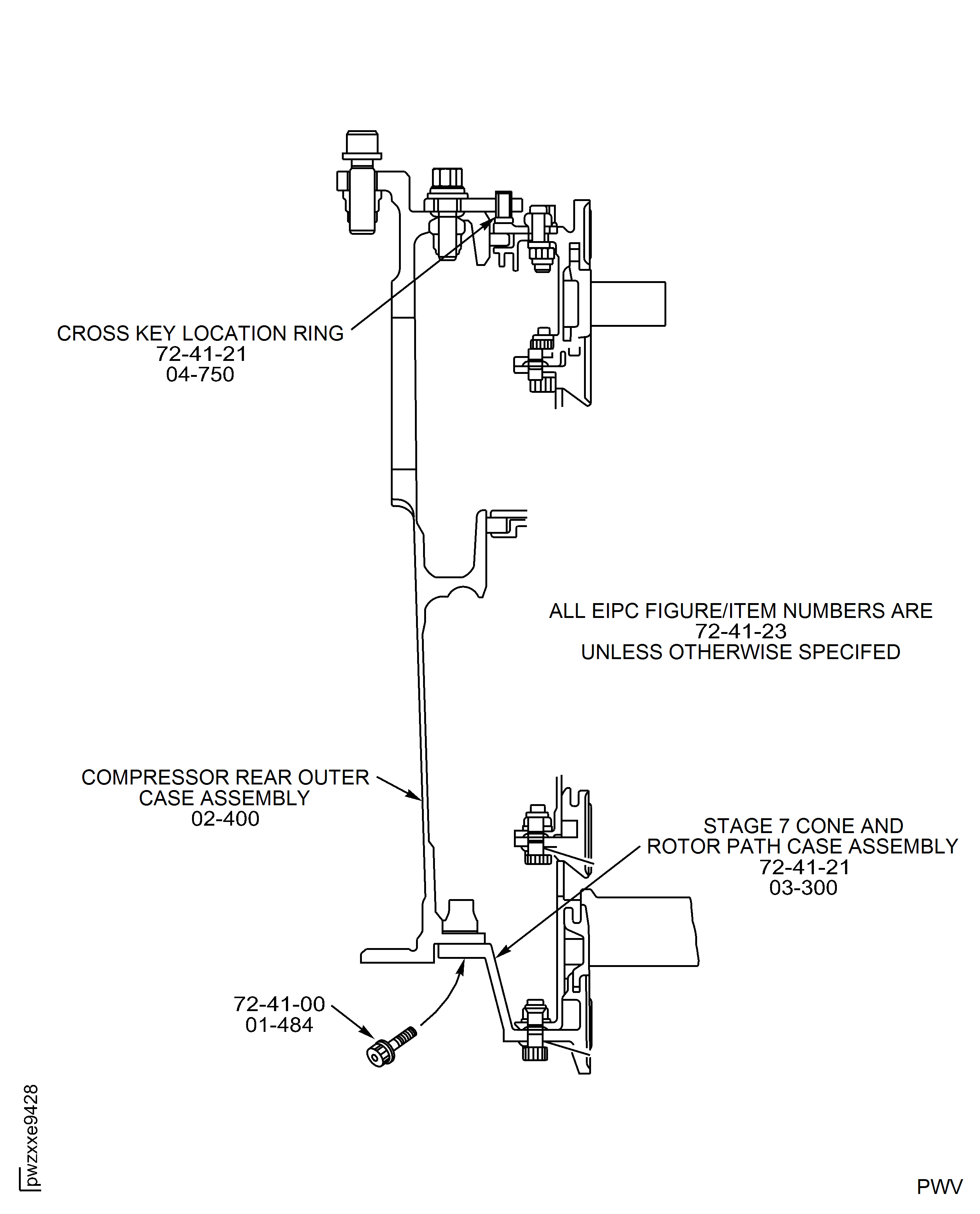

Refer to Figure.

Install the seal ring HPC Ring Cases And Related Parts (72-41-21, 04-745) on to the flange of the stage 12 rotor path case assembly.

Install a Heating blanket on to the cross key location ring.

WARNING

YOU MUST PUT ON THE CORRECT PROTECTIVE GLOVES BEFORE YOU TOUCH THE CROSS KEY LOCATION RING.Remove the Heating blanket.

Install the 47 bolts HPC Assembly (72-41-00, 01-644), the washers HPC Assembly (72-41-00, 01-646) and nuts HPC Assembly (72-41-00, 01-642) which attach the stage 12 rotor path case assembly cross key location ring.

Install the cross key location ring HPC Ring Cases And Related Parts (72-41-21, 04-750).

SUBTASK 72-41-00-440-282 Install the Stage 12 Rotor Path Ring and the Cross Key Location Ring Assembly

Install IAE 1R18217 Lift fixture on to the compressor rear outer case assembly HPC Rear Outer Case And Related Parts (72-41-23, 02-400).

Release the three thumbscrews on the IAE 1R18217 Lift fixture.

Adjust the three capscrews until the ring touches the main part of the IAE 1R18217 Lift fixture.

Use a suitable hoist and lift the IAE 1R18217 Lift fixture on to the rear flange of the compressor rear outer case.

Align the six holes in the IAE 1R18217 Lift fixture with six holes in the rear flange of the compressor rear outer case.

Install the six bolts, the 12 washers and the six nuts to attach the IAE 1R18217 Lift fixture to the compressor rear outer case.

Use the hoist, used in Step, and lift the compressor rear outer case above the HP compressor rear cases.

CAUTION

YOU MUST MAKE SURE THERE IS NO RESISTANCE WHEN YOU LOWER THE HP COMPRESSOR REAR OUTER CASE ASSEMBLY ONTO THE HP COMPRESSOR REAR INNER CASES OR YOU WILL DAMAGE THE INTERNAL COMPONENTS. IF THERE IS RESISTANCE REMOVE THE REAR OUTER CASE ASSEMBLY AND FIND THE CAUSE. DO Step. AGAIN, IF NECESSARY.Carefully lower the compressor rear outer case assembly on to the HP compressor rear inner cases.

Install the compressor rear outer case assembly on to the HP compressor rear cases while it is hot.

SUBTASK 72-41-00-440-283 Install the Compressor Rear Outer Case Assembly on to the HP Compressor Rear Cases

WARNING

WHEN YOU USE CoMat 01-002 SOLVENT, DELETED. YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Put the HP compressor rear outer case in a tank of CoMat 01-002 SOLVENT, DELETED. heated to 158 to 175 deg F (70 to 80 deg C) for 15 minutes.

Install IAE 1R18217 Lift fixture on to the compressor rear outer case assembly HPC Rear Outer Case And Related Parts (72-41-23, 02-400).

Release the three thumbscrews on the IAE 1R18217 Lift fixture.

Adjust the three capscrews until the ring touches the main part of the IAE 1R18217 Lift fixture.

Use a suitable hoist and lift the IAE 1R18217 Lift fixture on to the rear flange of the compressor rear outer case.

Align six holes in the IAE 1R18217 Lift fixture with six holes in the rear flange of the compressor rear outer case.

Install the six bolts, the 12 washers and the six nuts to attach the IAE 1R18217 Lift fixture to the compressor rear outer case.

Use the hoist, used in Step, and lift the compressor rear outer case above the HP compressor rear inner cases.

CAUTION

YOU MUST MAKE SURE THERE IS NO RESISTANCE WHEN YOU LOWER THE HP COMPRESSOR REAR OUTER CASE ASSEMBLY ONTO THE HP COMPRESSOR REAR CASES OR YOU WILL DAMAGE THE INTERNAL COMPONENTS. IF NECESSARY, IF THERE IS RESISTANCE REMOVE THE REAR OUTER CASE ASSEMBLY AND FIND THE CAUSE. DO Step AGAIN.Carefully lower the compressor rear outer case assembly on to the HP compressor rear inner cases.

Install the compressor rear outer case assembly on to the HP compressor rear cases, while it is hot.

SUBTASK 72-41-00-440-284 Install the Compressor Rear Outer Case Assembly on to the HP Compressor Rear Cases

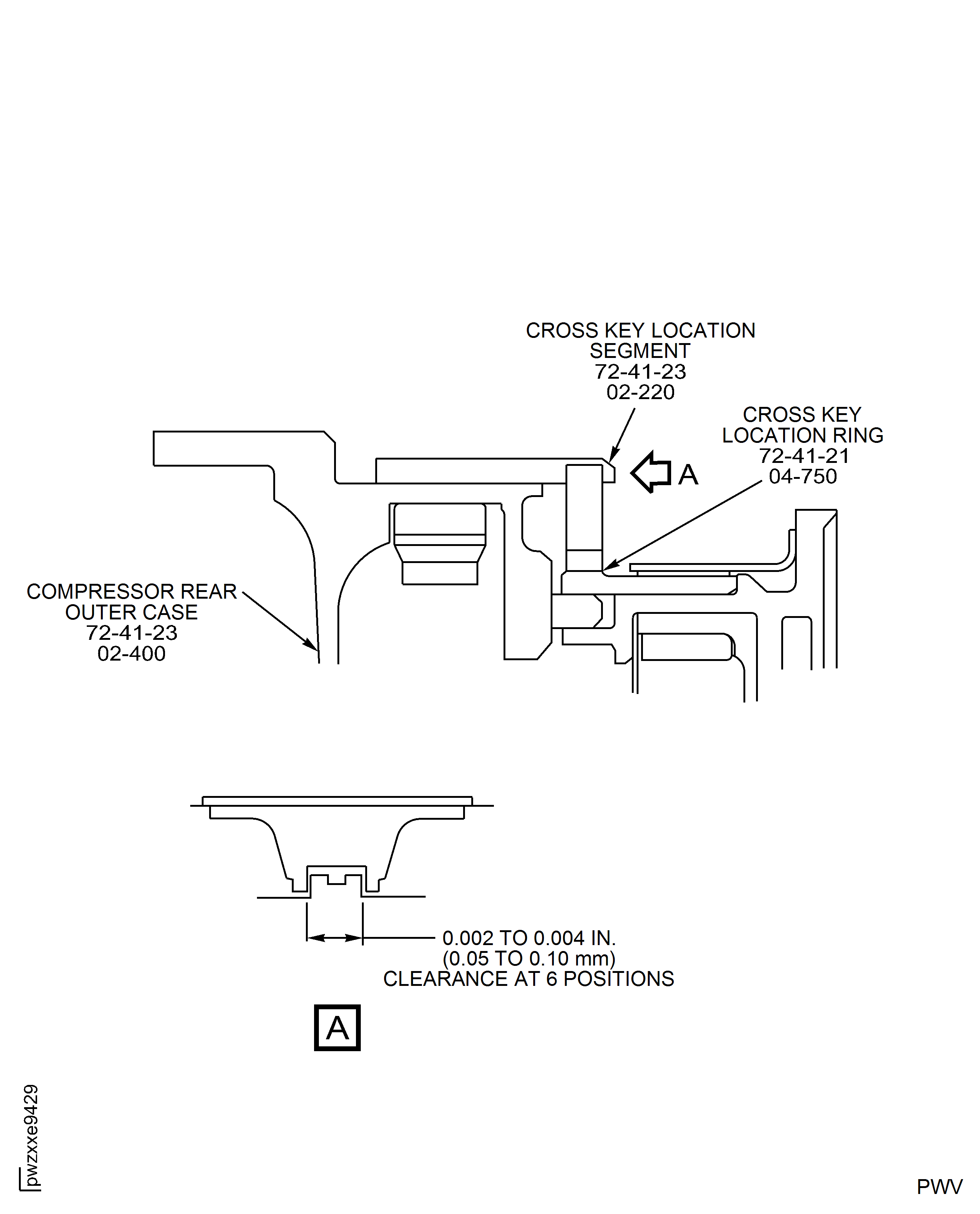

Refer to Figure.

Install the 6 cross key location segments HPC Rear Outer Case And Related Parts (72-41-23, 02-220) on the compressor rear outer case assembly HPC Rear Outer Case And Related Parts (72-41-23, 02-400).

SUBTASK 72-41-00-440-285 Install the Cross Key Location Segments

Refer to Figure.

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the three bolts HPC Rear Outer Case And Related Parts (72-41-23, 02-102) which hold the borescope access port cover onto the compressor rear outer case.

Install the borescope access port cover on the compressor rear outer case HPC Rear Outer Case And Related Parts (72-41-23, 02-400) with the HPC Rear Outer Case And Related Parts (72-41-23, 02-108) corrujoint gasket and the three bolts HPC Rear Outer Case And Related Parts (72-41-23, 02-102).

Install the stage 7 borescope access blank cover HPC Rear Outer Case And Related Parts (72-41-23, 02-100).

Refer to Figure.

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the three bolts ENGINE SECURING FEATURES-HP COMPRESSOR CASES ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-102) which hold the blanking plug to the compressor rear outer case.

Install one of the blanking plugs on the compressor rear outer case with the ENGINE SECURING FEATURES-HP COMPRESSOR CASES ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-108) corrujoint gasket and the three bolts ENGINE SECURING FEATURES-HP COMPRESSOR CASES ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-102).

Install the stage 8, 9 and 11 borescope access blanking plugs ENGINE SECURING FEATURES-HP COMPRESSOR CASES ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-102).

SUBTASK 72-41-00-440-286 Install the Borescope Access Blank Plugs and Cover TASK 72-41-00-990-132

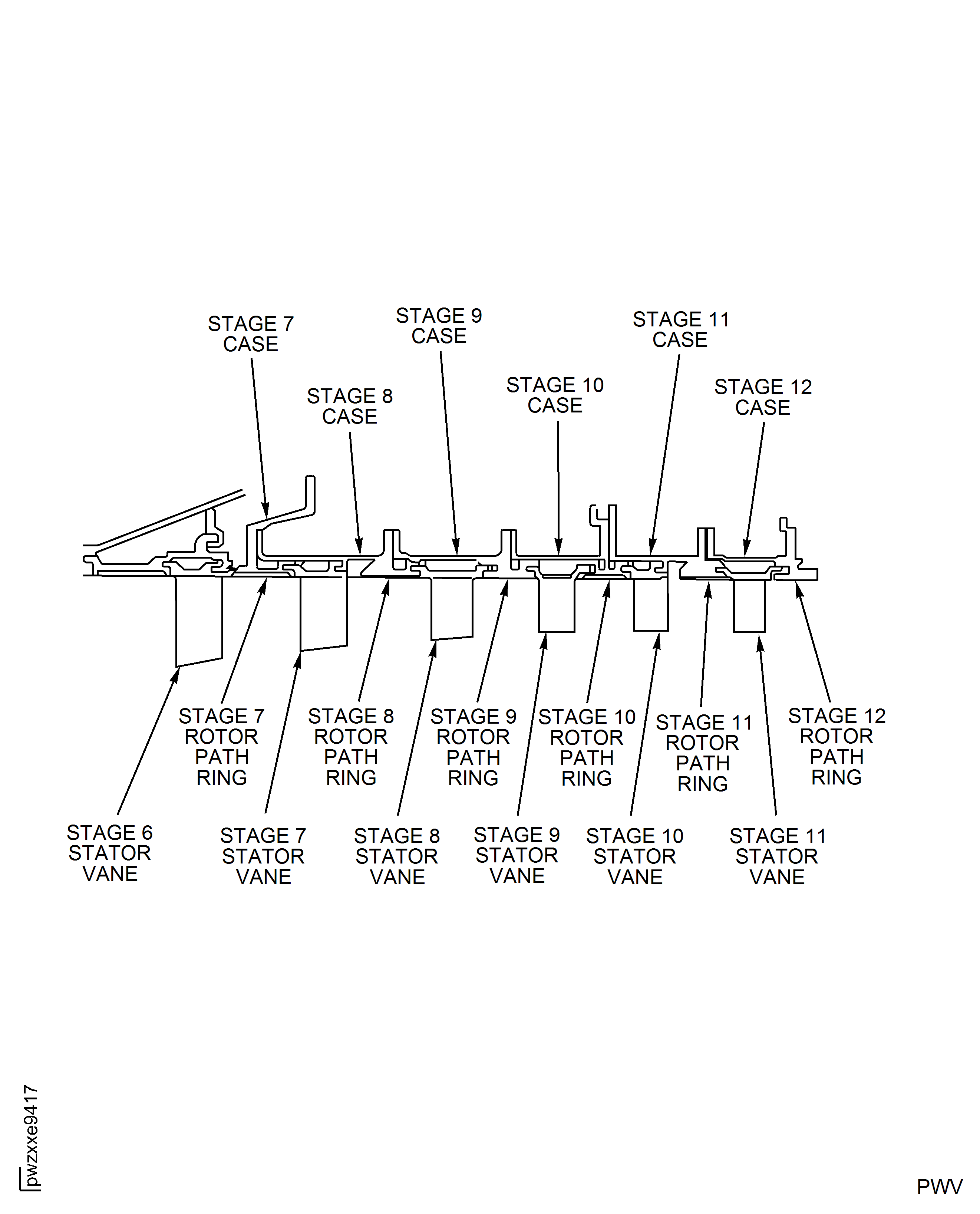

Figure: View Through The HP Compressor Assembly

View Through The HP Compressor Assembly

Figure: View Through The HP Compressor Assembly

View Through The HP Compressor Assembly

Figure: View Through The HP Compressor Assembly

View Through The HP Compressor Assembly

Figure: HP Compressor Rotor Assembly Installed In The Support Stand

HP Compressor Rotor Assembly Installed In The Support Stand

Figure: HP Compressor Rotor Installed In The Transport Trolley

HP Compressor Rotor Installed In The Transport Trolley

Figure: Remove And Install The Lifting Adapter And The Universal Sling Adapter

Remove And Install The Lifting Adapter And The Universal Sling Adapter

Figure: Prepare The Tools To Assemble The HP Compressor Assembly

Prepare The Tools To Assemble The HP Compressor Assembly

Figure: Assemble The Parts On The Support Ring

Assemble The Parts On The Support Ring

Figure: Install The Stage 7 Stator Vanes

Install The Stage 7 Stator Vanes

Figure: Install The Stage 7 Stator Vanes

Install The Stage 7 Stator Vanes

Figure: Install The Stage 7 Stator Vanes

Install The Stage 7 Stator Vanes

Figure: Install The Stage 7 Flange Parts

Install The Stage 7 Flange Parts

Figure: Install The Stage 7 Flange Parts

Install The Stage 7 Flange Parts

Figure: Install The Stage 8 Stator Vanes

Install The Stage 8 Stator Vanes

Figure: Install The Insulation Strips

Install The Insulation Strips

Figure: HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

Figure: HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

Figure: Install The Stage 9 Stator Vanes

Install The Stage 9 Stator Vanes

Figure: HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

Figure: HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

Figure: Install The Stage 10 Stator Vanes

Install The Stage 10 Stator Vanes

Figure: HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

Figure: HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

Figure: Install The Stage 11 Stator Vanes

Install The Stage 11 Stator Vanes

Figure: HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

Figure: Install The Lift Fixture On The Compressor Rear Outer Case Assembly

Install The Lift Fixture On The Compressor Rear Outer Case Assembly

Figure: HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

Figure: Install The Compressor Rear Outer Case Assembly

Install The Compressor Rear Outer Case Assembly

Figure: HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

HPC Assembly - Assemble The HPC Cases And Vanes To The Rotor Assembly

Figure: Install The Borescope Access Blank Plugs And The Cover

Install The Borescope Access Blank Plugs And The Cover