Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 71-00-00-700-012-A00 Test No. 12 - Functional Test, Testing-012

General

CAUTION

For general information refer to Engine Safety Precautions and Engine Operation Limits, Guidelines, and Special Procedures. Refer to TASK 71-00-00-700-050-A00 (TESTING-000, CONFIG-001) and TASK 71-00-00-700-051-A00 (TESTING-000, CONFIG-001).

Use this test to get the performance data on an in-service engine when a module/section is removed and installed without overhaul, rework, repair or replacement, except when that module/section is part of the engine low pressure system where overhaul, rework or repair is permitted.

If you did not operate the engine before, do Test No.3, the Idle Leak Check before you do this test. Refer to TASK 71-00-00-700-003 (TESTING-003).

You can do other tests which are not done in the functional test, during engine operation before this test.

The applicable test data must be corrected by the specified test cell correction (before you use the curves given in the test procedure).

Refer to TEST No. 20 for the installation of the seal drain bottles needed for this test.

Refer to TEST No. 22 if the plugs on ACC valve are not correct.

Necessary Information

The engine must have instrumentation at the locations which follow:

N1

N2

P2.5 (P25)

PB or PS3

P4.9 (P49)

Delta Manifold Oil Pressure (MOP)

Main Oil Temperature

Oil Filter Differential Pressure

Fuel Pump Inlet Pressure

PAMB

T2.5

T3

Vibration: Fan Case

T4.9 Harness Average (EEC output)

Thrust

Fuel Flow

P12.5

T Fuel

No.4 Bearing Compartment Scavenge Pressure (P4SCAV)

Oil Tank Temperature

Specific Ratings

The thrust and the thrust specific fuel consumption (TSFC) ratings at sea level standard conditions are:

NOTE

Take-off

Corrected Jet thrust - 24.290 lbs (108.047 N)

TSFC - 0.3525

Maximum continuous

Corrected Jet thrust - 21.840 lbs (97.149 N)

TSFC - 0.3462

40 percent take-off

Corrected Jet thrust - 9.716 lbs (43.219 N)

Definitions

Operation Procedures - General

Do all the tests on the engine with a data entry plug in the Electronic Engine Control (EEC) with the correct class.

There is logic in the EEC for operation of the engine in one of two modes:

EPR - The primary control mode.

N1 - An alternative mode which lets you have faults in the EPR mode.

Do all intentional channel failures/resets at idle power.

Make sure that all instrumentation was calibrated by the necessary procedures given in Electronic Engine Control (EEC) and Test Cell Interface Requirements. Refer to TASK 71-00-00-700-063-A00 (TESTING-000, CONFIG-001).

Do a comparison of the engine flowmeter to the test facility flowmeters. The engine mass fuel flowmeter must be compared to the test facility flowmeters for all steady-state points of three minute stabilization or more, above APPROACH IDLE. The engine flowmeter must agree with the facility flowmeters within plus or minus 150 pph. The engine flowmeter must be repaired if it is not within these limits.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

CAUTION

CAUTION

Procedure

If the plugs on the ACC vane are not correct, do the procedure given in TASK 71-00-00-700-022 (TESTING-022).

NOTE

Do all the thrust lever movements by the instructions given in the Engine Safety Precautions unless specified differently. Refer to TASK 71-00-00-700-050-A00 (71-00-00, TESTING-00, CONFIG-01, Page 1301).

Make sure the part number of the ACC valve and the location of the vane plugs are the same as given in SBE 75-0021.

NOTE

The plugs should only be in the plug storage plate and not in the vanes if action was taken to restore the in-service EGT margin.If the engine is new or the HP turbine module is rework, make sure the vane plugs of the ACC valve are installed in the vane and the ACC valve part number is the same as given in SBE 75-0021, parts one and three.

If the plugs on the ACC valve are not correct, do the procedure given in TASK 71-00-00-700-022 (TESTING-022).

NOTE

Do all the thrust lever movements by the instructions given in the Engine Safety Precautions unless specified differently. Refer to TASK 71-00-00-700-051-B00

Examine the engine records and see if the engine is new or the HP turbine module is reworked.

CAUTION

HEAVY HIGH PRESSURE TURBINE (HPT) BLADE TIP RUB CAN OCCUR WHEN YOU OPERATE AN ENGINE WITH A CONFIGURATION THAT IS NOT CORRECT FOR THE REMOVABLE VANE PLUGS ON THE APPLICABLE ACTIVE CLEARANCE CONTROL (ACC) VALVE THAT IS GIVEN IN SBE 75-0021.Examine the removable plugs on the vane of the active clearance control (ACC) valve for the correct configuration as given in SBE 75-0021.

Do the necessary steps by the instructions in Pre-Rig the Engine for Testing. Refer to TASK 71-00-00-700-020 (TESTING-020).

Prepare and start the engine by the Normal Engine Automatic Start Procedure or the Normal Engine Manual Start Procedure. Refer to TASK 71-00-00-700-053-A01 (TESTING-000, CONFIG-001) or TASK 71-00-00-700-053-A02 (TESTING-000, CONFIG-001).

Let the engine become stable at MIN IDLE for three minutes.

Do not continue to operate the engine if any indications are unusual.

Make a record of the EEC status. Refer to the Fault Isolation V2500-A0-71-00-0000-01A-009A-B (FAULT ISOLATION-000) for more information on faults.

Do a shutdown of the engine by the Discontinued Start and Shutdown Procedure. Refer to TASK 71-00-00-700-054-A00 (TESTING-000, CONFIG-001).

Do not add oil during the functional test.

Fill the oil tank to the top of the overflow (5-25 minutes after shutdown) to find the engine oil consumption after the test. Record the oil tank temperature. Refer to TASK 71-00-00-700-064-A00 (TESTING-000, CONFIG-001).

If necessary, make sure all the seal drain bottles are empty for the functional test.

Operation of the Engine Before the Functional Test

The date of the engine functional test.

The engine serial number.

The serial number of the modules (to use for module history analysis).

The fuel specific gravity.

The fuel lower heat value (you can do this after the test).

The ambient atmospheric conditions (the true barometer wet and dry bulb temperature).

Make a record of the information which follows before you do the functional test.

Time

* Observed and corrected N1 and N2 speeds

Observed and corrected thrust (FN)

Observed and corrected fuel flow (WF)

* Engine inlet total temperature (T2)

* Fan inlet total pressure (P2)

** Turbine discharge total temperature (T4.9 harness average) Channels A and B

* Turbine discharge total pressure (P4.9)

* Calculated engine pressure ratio (P4.9/P2)

* Engine pressure ratio from EEC (EPR-O)

Fuel inlet pressure

Delta main oil pressure

Oil temperature

Vibration amplitude

* Burner pressure (PB or PS3) (Optional)

* HPC inlet pressure (P2.5) (Optional)

Ambient temperature (TAMB)

Ambient pressure (PAMB)

* HPC inlet temperature (T2.5) (Optional)

* HPC exit temperature T3

* Fan exit pressure (P12.5) (Optional)

* 2.5 bleed valve position indicator

No.4 bearing Compartment Scavenge Pressure (P4SCAV)

* ARINC data

Fuel temperature (T fuel)

* EEC outputs

** As a guideline it is recommended that the EGT level between channels A and B be within 10 deg F ( 5.6 deg C) of each other. Differences that are greater than this level should be investigated to ensure that no indication problems exist. If, after replacing the individual EGT probes and wiring harness to the probes, the EGT level is still greater than 10 deg F (5.6 deg C) between channel A and B, as determined by the engine test, than you may accept the engine data.

Make a record of and/or calculate all of the indications that follow, but the EEC outputs.

Be prepared to make a record of the data at all the test points when the engine is stable (before you move the thrust lever to the subsequent point).

If the scavenge pressure limit is exceeded at any time, you must shut down the engine as given in TASK 71-00-00-700-054-A00 (TESTING-000, CONFIG-001).

Disconnect the No. 4 bearing compartment external scavenge elbow.

Check and record signs of leaks from the gasket.

Replace the gasket. Refer to TASK 72-42-00-430-001 (ASSEMBLY).

Do the Performance Test again to check for correct No. 4 bearing compartment scavenge pressure. Refer to TASK 71-00-00-700-010-A00 (TESTING-0010, CONFIG-001) or TASK 71-00-00-700-010-A01 (TESTING-010, CONFIG-002).

Inspect the gasket for leaks at the interface between the No. 4 bearing compartment external scavenge elbow and internal scavenge line. (This potential cause more likely will increase P4SCAV in between 130 to 160 psig (896.3 to 1103.2 kPa).

Do the checks that follow if the P4SCAV limit is exceeded:

If the vacuum check is more than 17 pph, disassemble, inspect and reassemble No. 4 Bearing compartment.

If the vacuum check is less than 17 pph, contact IAE Technical Services for instructions.

If the scavenge pressure is still not normal, do a No. 4 Bearing Compartment Vacuum Check. Refer to TASK 72-00-43-420-001 (INSTALLATION).

Make sure at all power conditions that the No. 4 bearing compartment scavenge pressure is not more than the limits that follow:

Maximum Allowable Transient Limit:

All testing conditions: 205 psig (1413.4 kPa)

Maximum Allowable Steady-State Limit (3 Minutes Stabilization Or More):

Idle and Approach Idle: 9 psig (62.1 kPa)

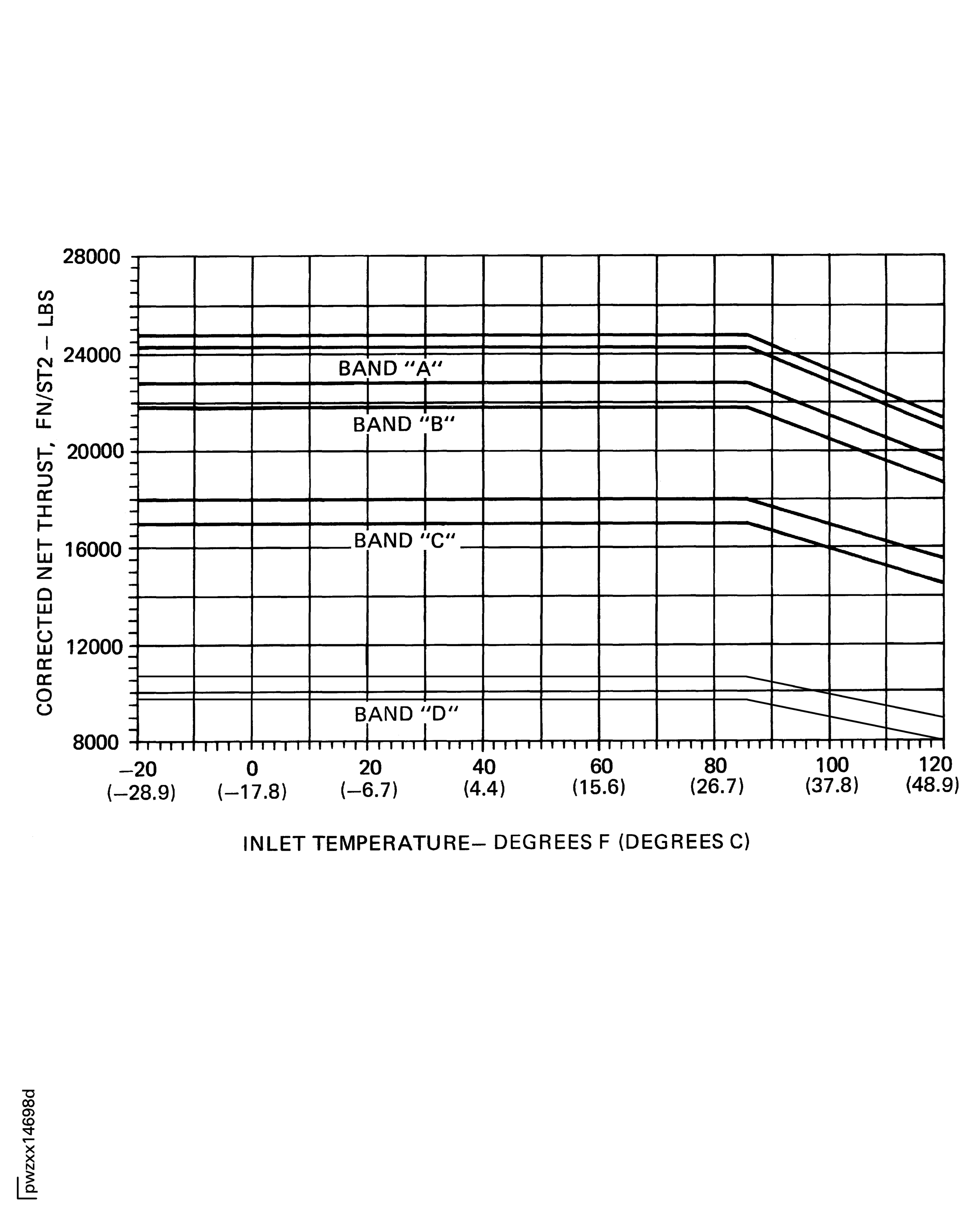

Table 2. Band D:

17 psig (117.2 kPa)

Band B and C:

145 psig (999.7 kPa)

Band A:

Minimum: 55 psig (379.2 kPa)

Maximum: 145 psig (999.7 kPa)

Do the Normal Engine Automatic Start Procedure or the Normal Engine Manual Start Procedure. Refer to TASK 71-00-00-700-053-A01 (TESTING-000, CONFIG-001) and TASK 71-00-00-700-053-A02 (TESTING-000, CONFIG-001).

Make a record of the data after five minutes at MIN IDLE.

Make sure that there are no faults in the EEC in Channel A and Channel B.

Refer to Test No.8 (Vibration Survey) or Testing-00 (Engine operating limits).

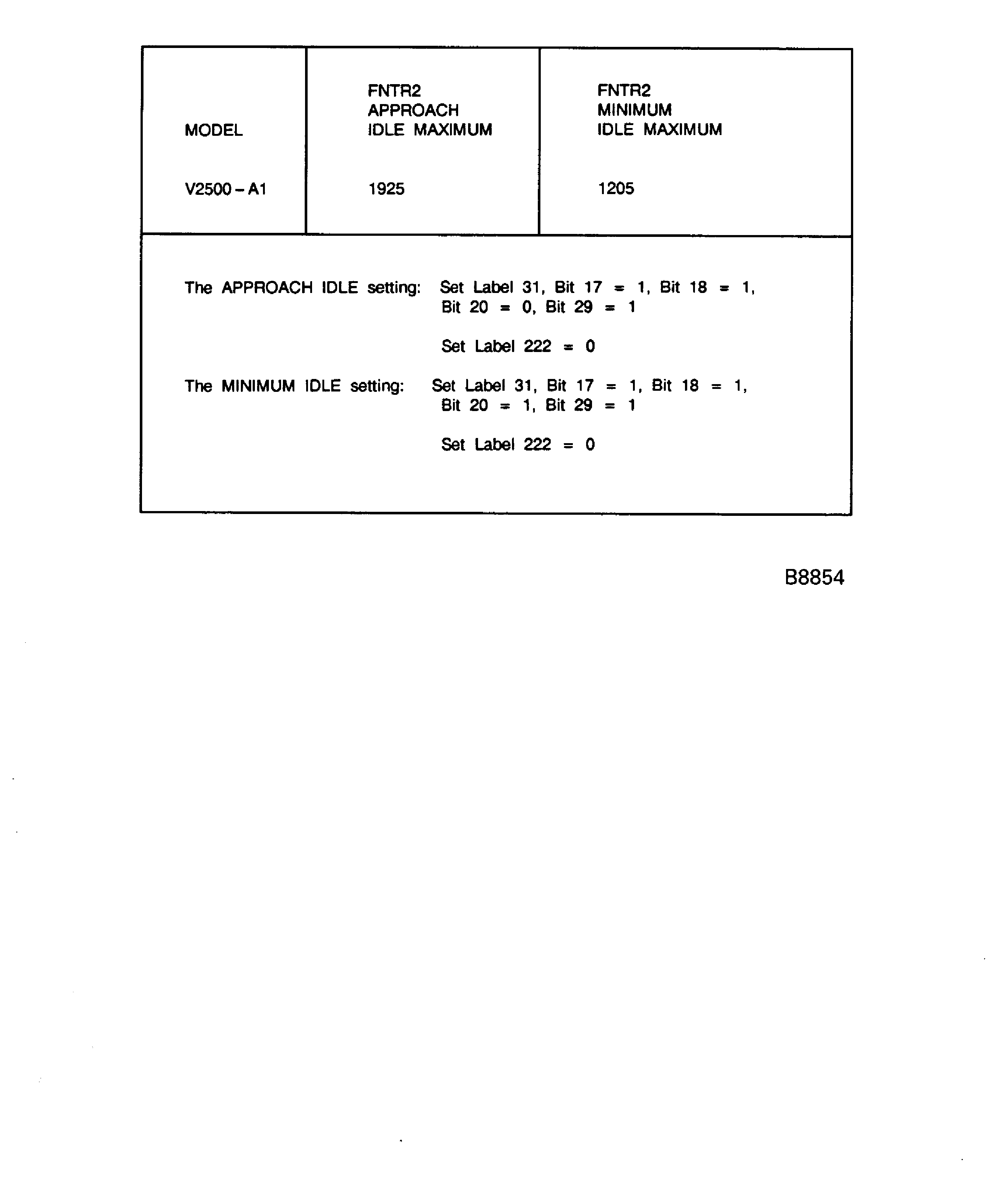

Make a selection of APPROACH IDLE and operate at APPROACH IDLE for 3 minutes. Refer to Figure to set APPROACH IDLE.

Make sure that the EEC operates in the EPR mode.

Make a record of the time to go from the start of the thrust lever movement to 90 percent of the lower line of Band A thrust. Refer to Figure.

The acceleration time cannot be more than 6.2 seconds or less than 4.9 seconds.

Let the engine become stable for one minute before you continue.

Do a snap acceleration (as quickly as the thrust lever will move) from APPROACH IDLE to Band A. Refer to Figure

Make a record of the time from the start of the thrust lever movement to a corrected thrust of 6976 plus or minus 30 lbs.

The deceleration time cannot be more than seven seconds.

NOTE

During subsequent acceleration and deceleration (steps (11) thru (15)), check and record the position of the No.4 bearing scavenge valve for correct operation. Refer to Figure.

Do a snap deceleration (as quickly as the thrust lever will move) from Band A to MIN IDLE. Refer to Figure

Operate the engine for five minutes with the thrust lever set in one position. Make a record of the data.

If the minimum required corrected take-off thrust or EPR for Band A is not shown at full TLA and PAMB is more than 14.696 PSIA, the correction method that follws must be used:

FNTR2 (Modified Band A) = (FNTR2 Band A)/(PAMB/14.696), where FNTR2 is obtained from Figure.

If you do not get the minimum required take-off thrust (after you apply the correction if necessary), stop the test and tell the test engineer.

Slowly increase the engine speed and set the thrust of Band A. Refer to Figure.

Operate the engine for three minutes with the thrust lever set in one position.

Make a record of the data.

Set the thrust of Band B. Refer to Figure.

Operate the engine for three minutes with the thrust lever in one position.

Make a record of the data.

Set the thrust lever of Band C. Refer to Figure.

Operate the engine for three minutes with the thrust lever set in one position.

Make a record of the data.

Set the thrust of Band D. Refer to Figure.

Let the engine become stable for five minutes.

Make a record of the data.

During the five minutes, do a check of the EEC fault messages.

Decrease the engine speed to MIN IDLE.

Do a shutdown by the Discontinued Start and Shutdown Procedure. Refer to TASK 71-00-00-700-054-A00 (TESTING-000, CONFIG-001).

The information which follows gives the instructions for operation of the engine during the performance test.

Functional Test

Fill the oil tank to the top of the overflow. Refer to TASK 71-00-00-700-064-A00 (TESTING-000, CONFIG-001).

Use a device with graduations to measure the quantity of oil added.

Make a record of the quantity of oil added.

Find the oil consumption in gal/hr (1 hr) and make a record of the quantity used during the functional test.

After shutdown, look at the oil tank temperature until it is within 15 deg F of the temperature recorded in step 7.H.

Compare the quantity to the following limits:

LOCATION: Fuel Pump Seal Drain, LIMIT 30 cc/hr

LOCATION: Hydraulic Pump Seal Drain, LIMIT 10 cc/hr

LOCATION: Starter Seal Drain, LIMIT 10 cc/hr

LOCATION: IDG Seal Drain, LIMIT 10 cc/hr

LOCATION: Common Core Seal Drain, LIMIT 10 cc/hr

LOCATION: All Others, Limit 0 cc/hr

Check the seal drain hole on the fuel-cooled oil cooler (FCOC). Leaks of fuel or oil are not allowed.

Check all the seal drain bottles and make a record of the quantity of oil collected.

Do a borescope inspection. Refer to TASK 72-00-00-200-000 (INSPECTION/CHECK-000).

Remove all of the chip detectors, do an inspection of them and install them. Refer to TASK 72-00-00-200-008 (INSPECTION/CHECK-008).

Remove the scavenge oil filter, inspect it, and install it.

Remove the pressure oil filter, inspect it, and install it.

Remove the fuel filter, inspect it and install it.

After you complete the engine operation do the Engine Preservation and Inhibiting Procedure. Refer to TASK 72-00-00-550-001 (STORAGE-001).

Do the necessary steps by the instructions in De-Rig the Engine after Testing. Refer to TASK 71-00-00-700-021 (TESTING-021).

Procedure to be Done After Completion of the Functional Test

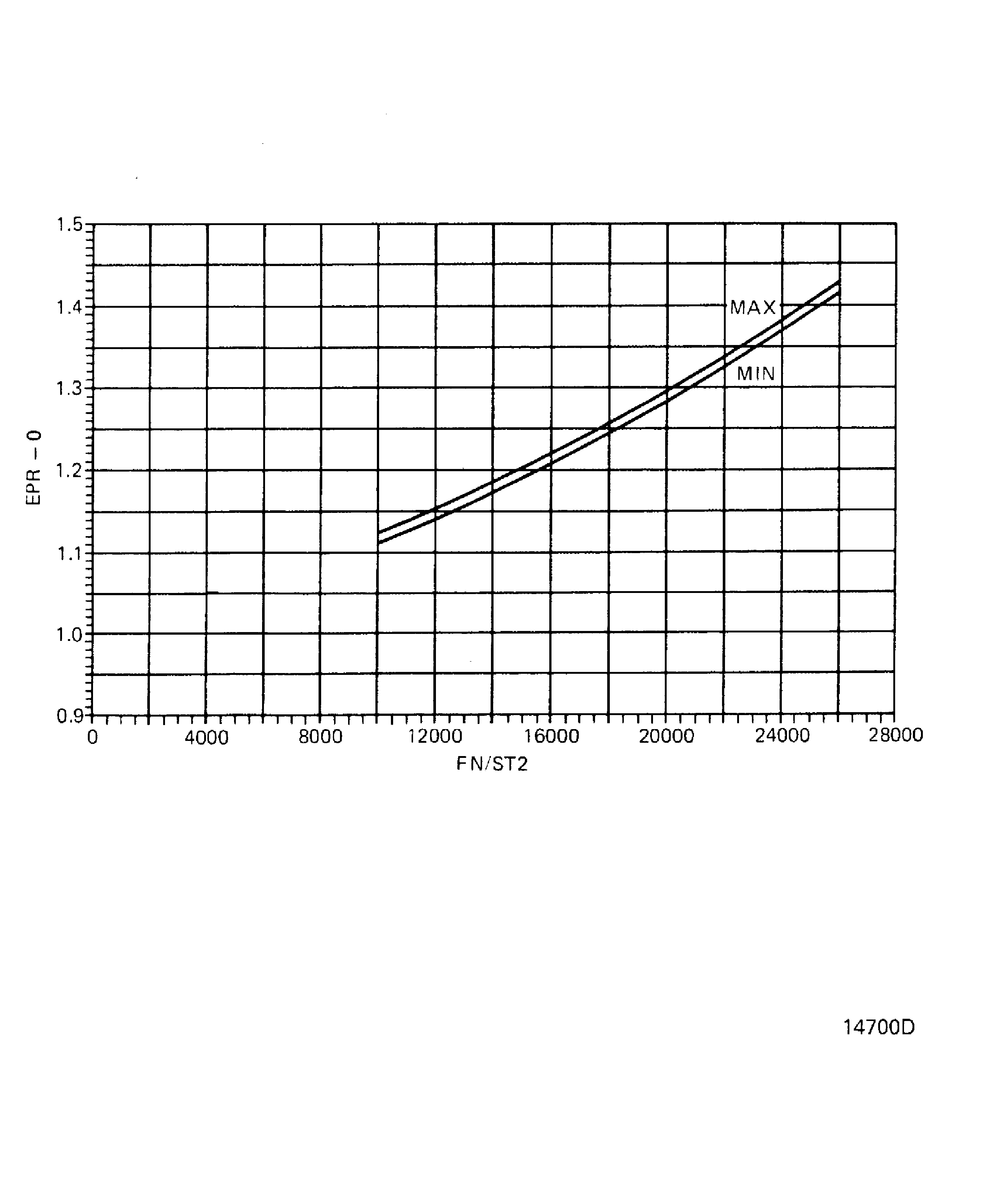

The reference lines are when EPR-O is the EEC EPR indication with a null class data entry plug installed.

The lines on this figure are only to be used as guidelines and are not limits.

If possible the values of FN/ST2 versus corrected EPR-O will be between the reference lines in the limits of the figures. Refer to Figure.

Do a check of corrected thrust specific fuel consumption (TSFC) by the specific rates given.

Check the vibration for the correct operating limits.

Do a Check of the Corrected Data

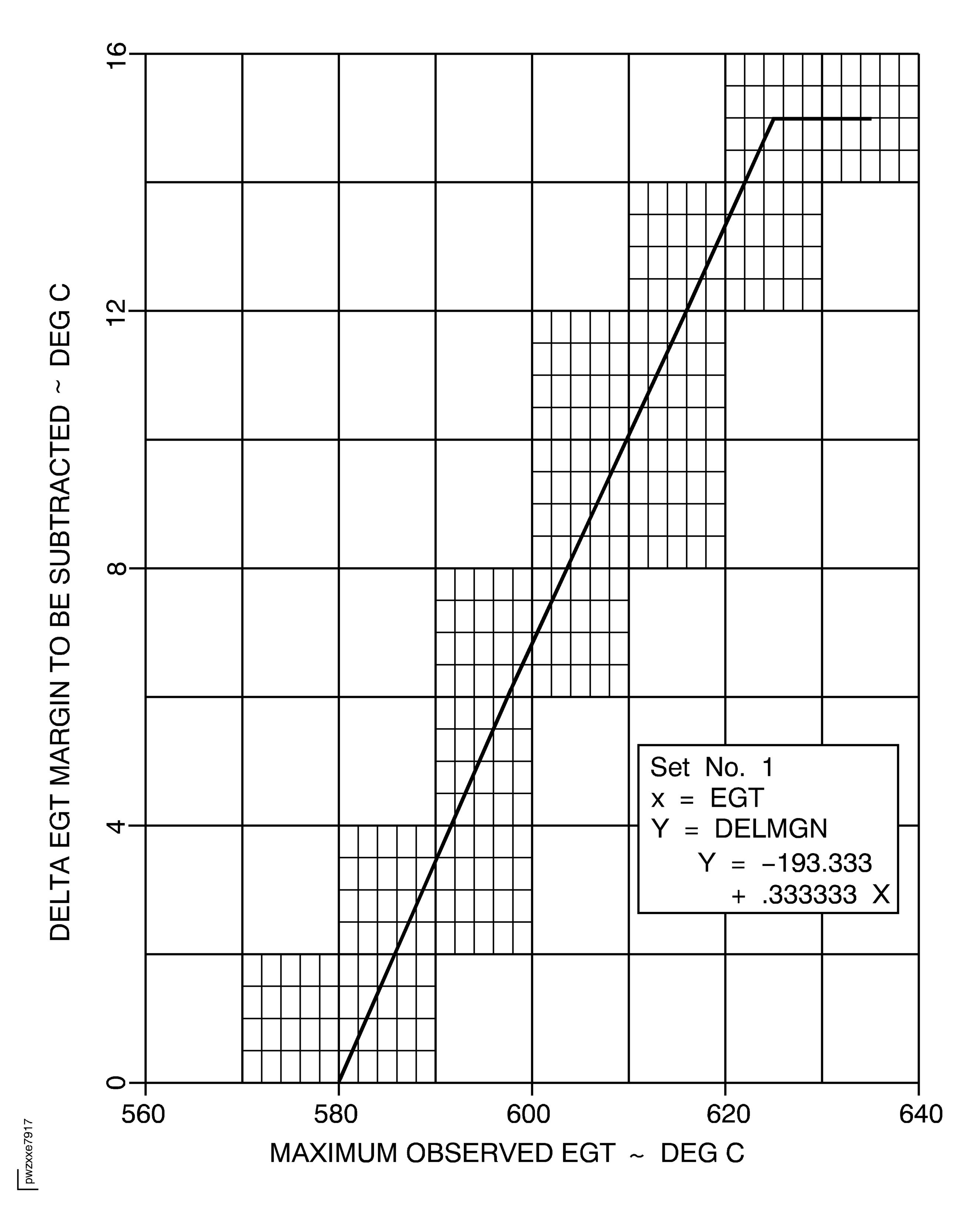

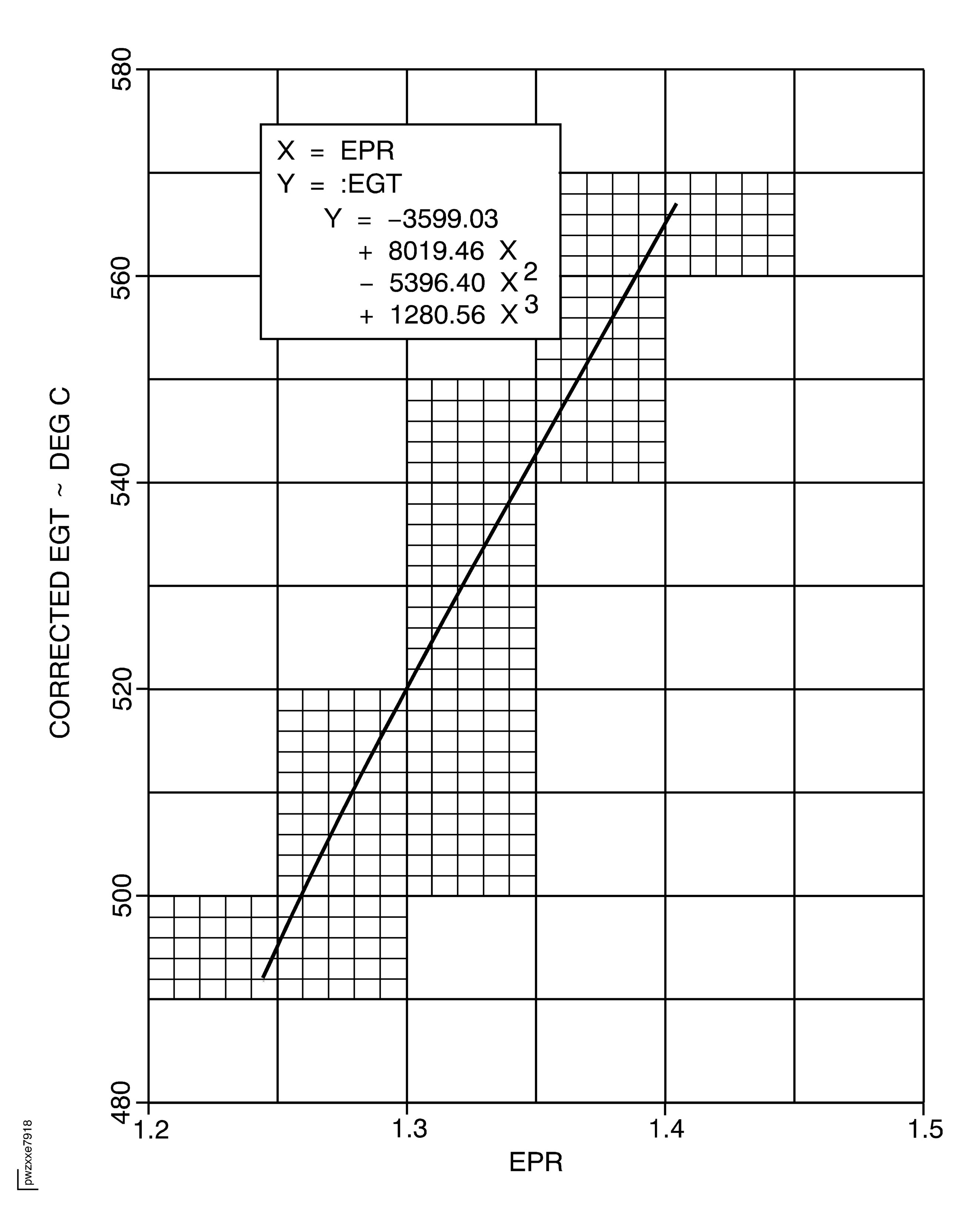

The EGT level can be compared to Figure to take advantage of the 15 deg C shunt associated with SCN12C or greater configurations. If it is necessary to determine the EGT margin at conditions other than 5000 feet/45 degrees C which are contained in Figure, then refer to SIL-057. You must use the delta EGT margin curve, Figure with Figure if the maximum observed EGT is more than 580 deg C and adjust the EGT margin downward for a shunted EGT margin that has been used before.

The lines on these figures are only reference lines. The lines are not limits.

Tell the engine test engineer if the data is above these reference lines.

Do a Corrected Data Reference Check

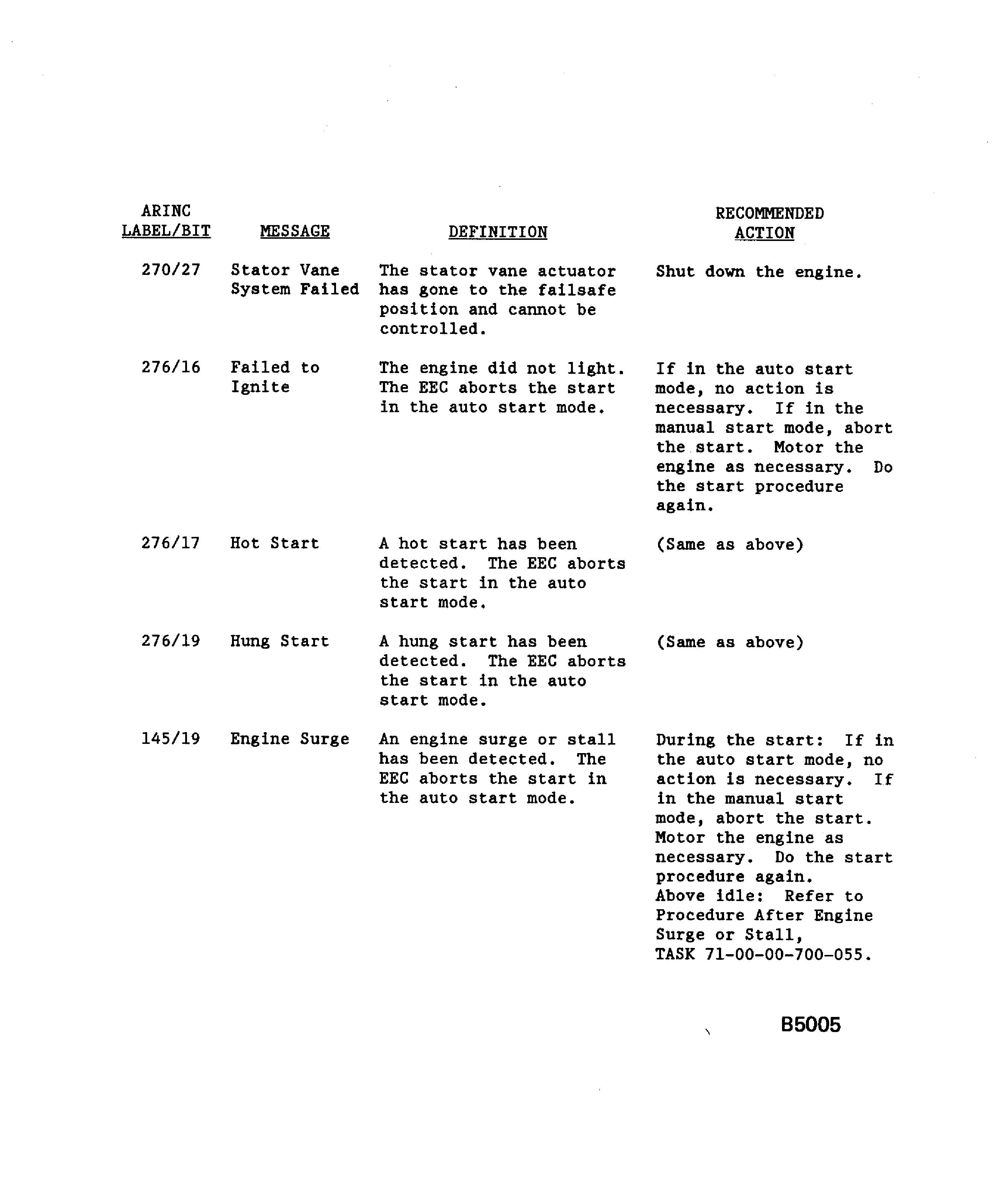

Figure: EEC Output Status Messages

Sheet 1

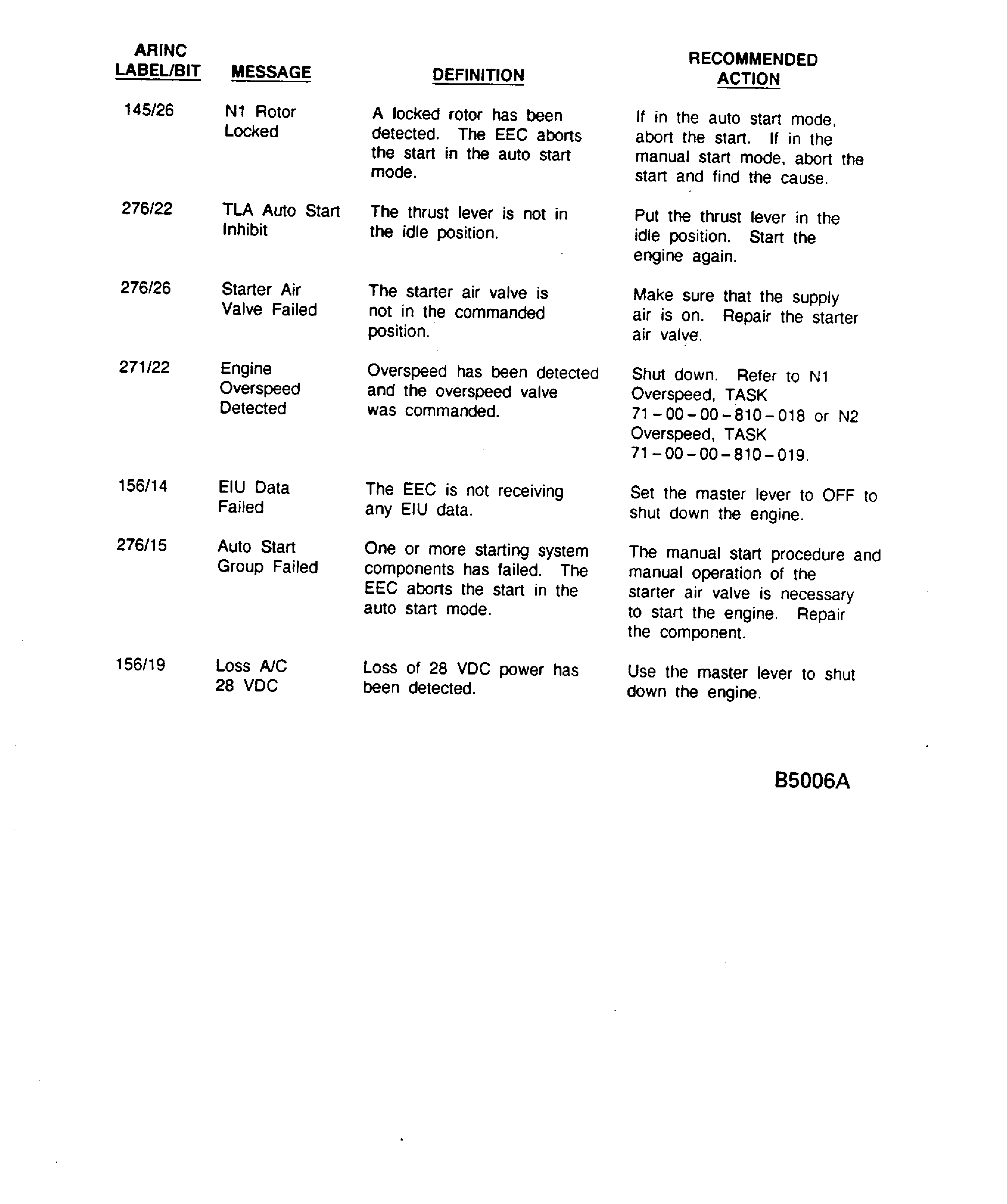

Figure: EEC Output Status Messages

Sheet 2

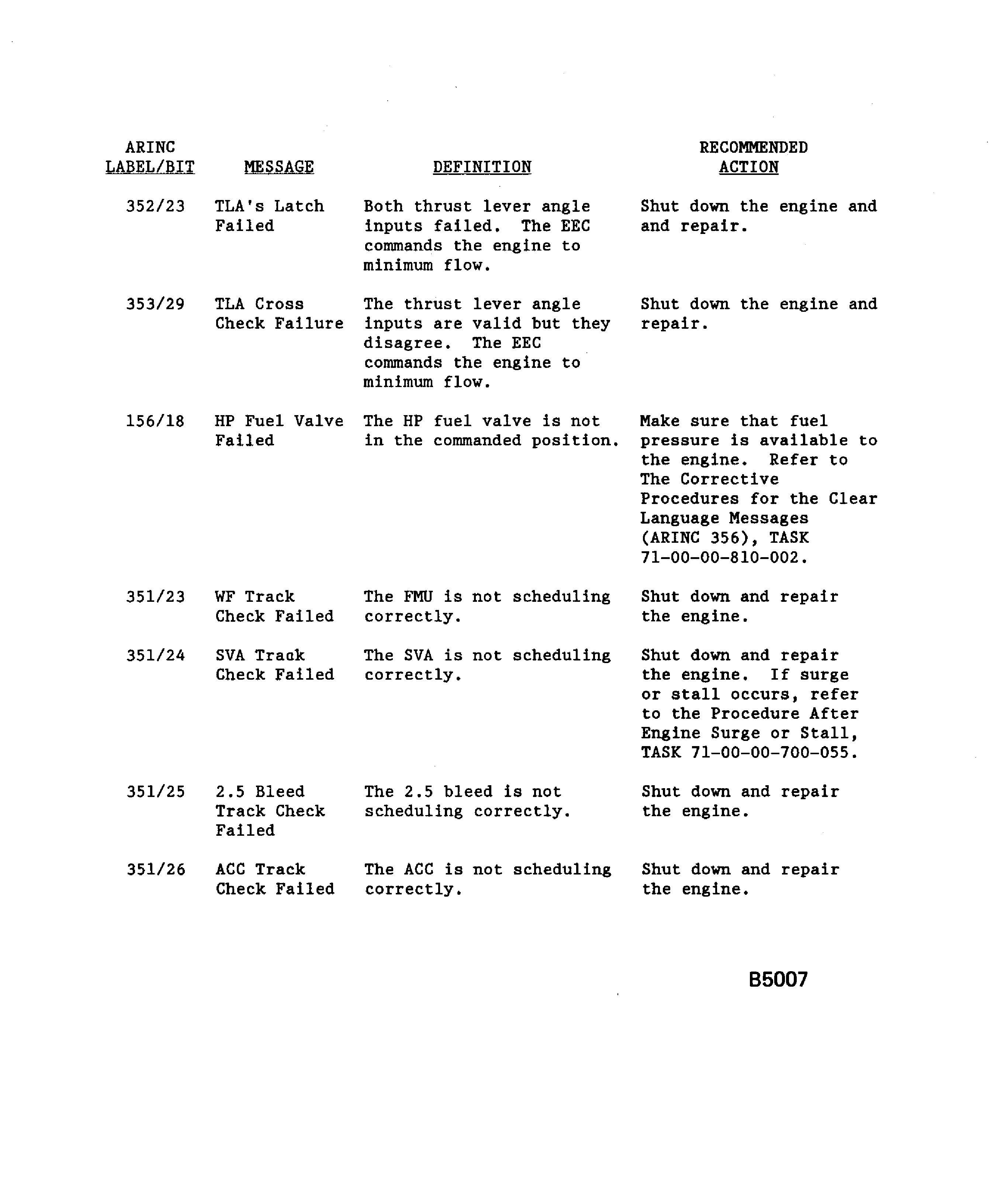

Figure: EEC Output Status Messages

Sheet 3

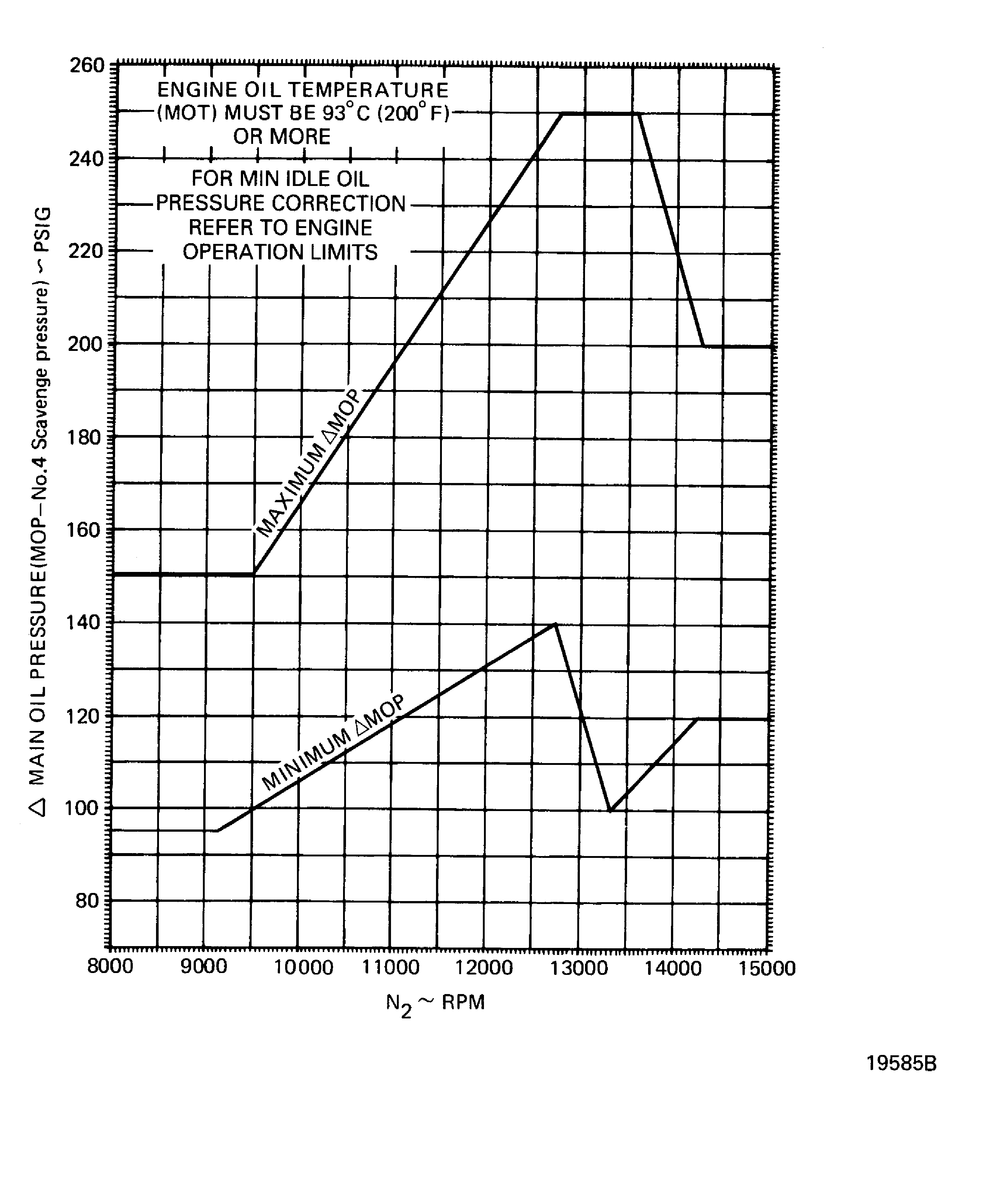

Figure: Main Oil Pressure (MOP) Limits During Operation Above Idle

Main Oil Pressure (MOP) Limits During Operation Above Idle

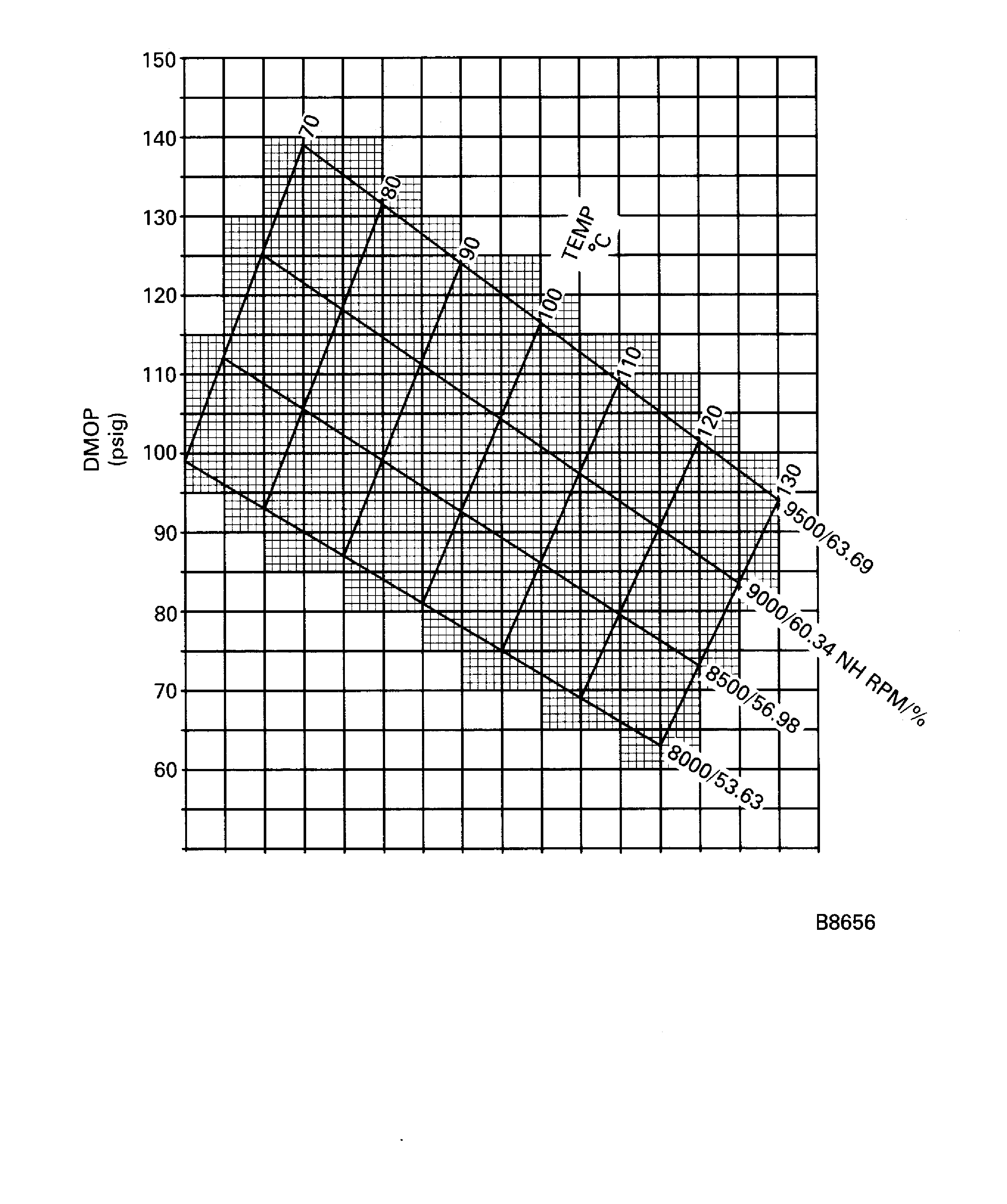

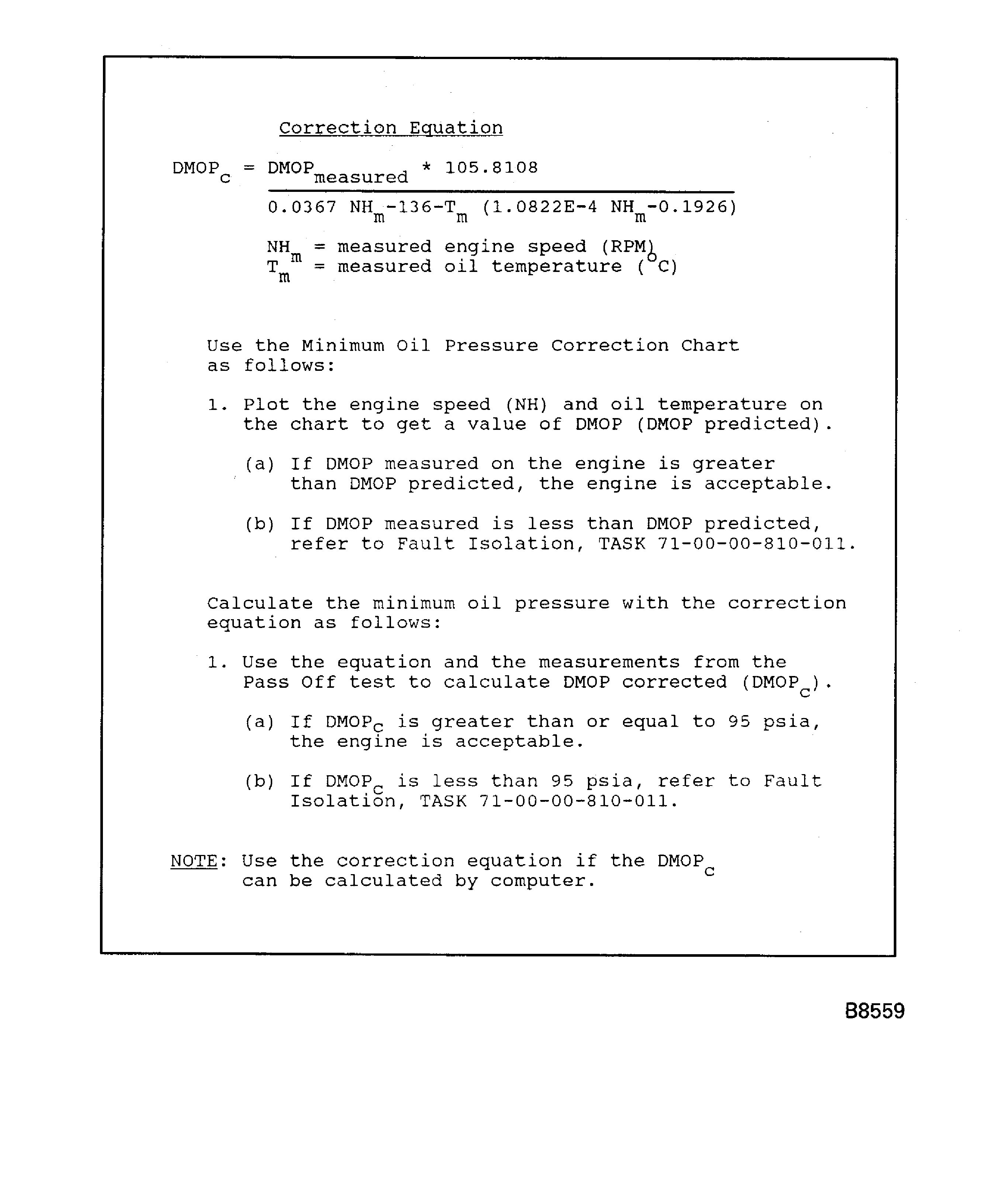

Figure: Main Oil Pressure (MOP) Limits During Operation at Idle

Sheet 1

Figure: Main Oil Pressure (MOP) Limits During Operation at Idle

Sheet 2

Figure: Approach and Minimum Idle Thrust Settings

Approach and Minimum Idle Thrust Settings

Figure: Thrust Setting Curve

Thrust Setting Curve

Figure: No.4 Bearing Scavenge Valve Position

No.4 Bearing Scavenge Valve Position

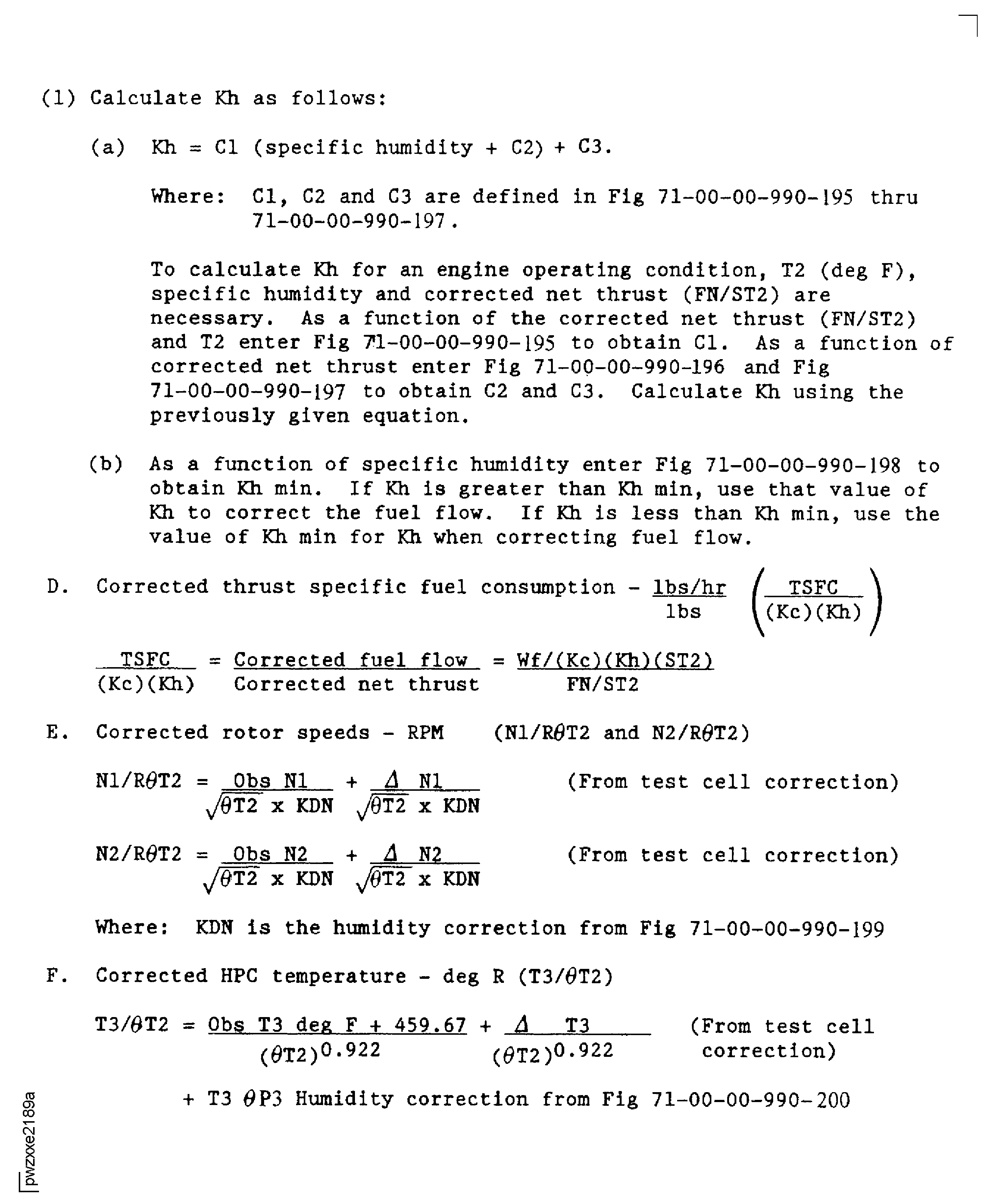

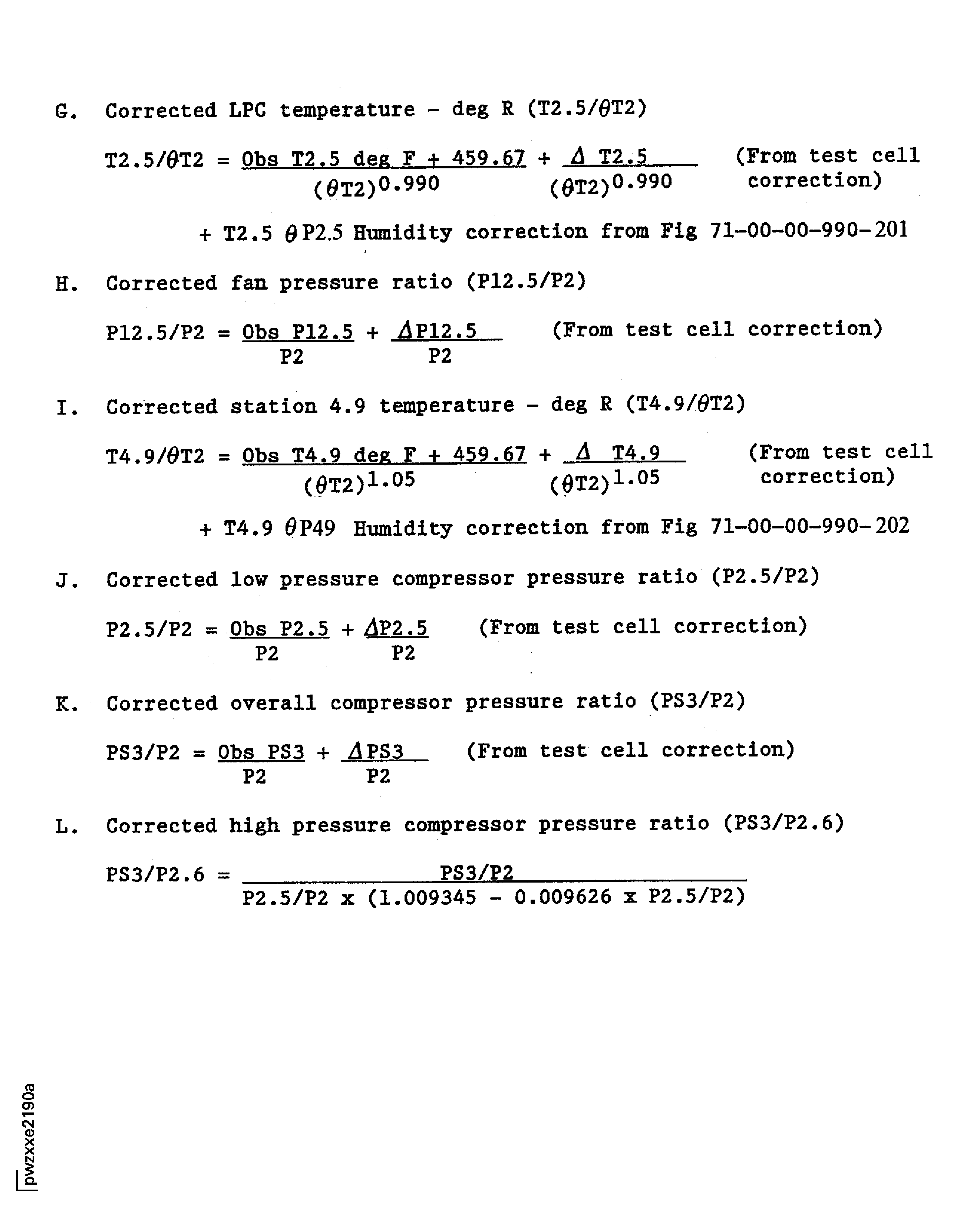

Figure: Data Calculation and Correction

Sheet 1

Figure: Data Calculation and Correction

Sheet 2

Figure: Data Calculation and Correction

Sheet 3

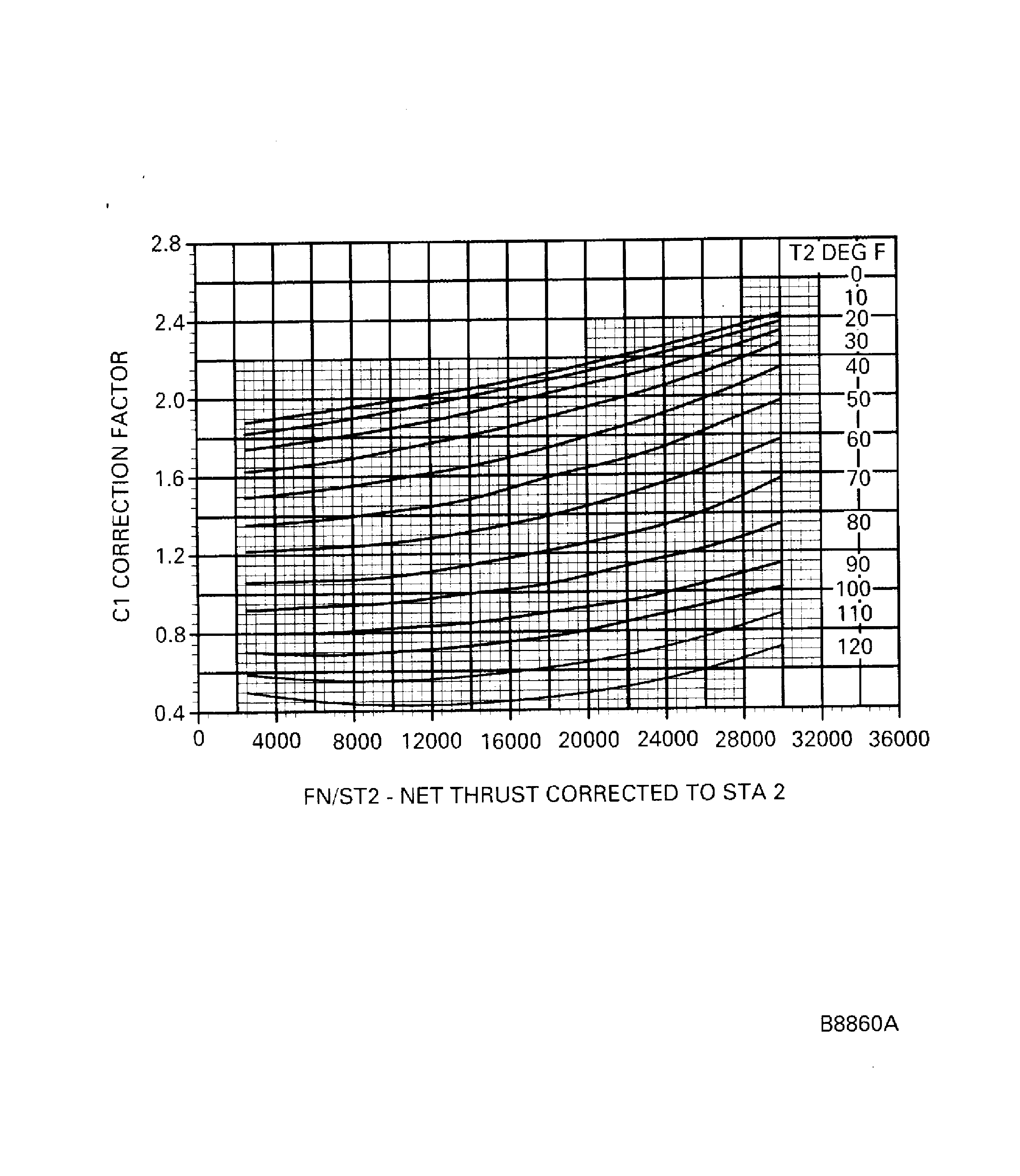

Figure: C1 Humidity/Condensation Correction Factor for WF

C1 Humidity/Condensation Correction Factor for WF

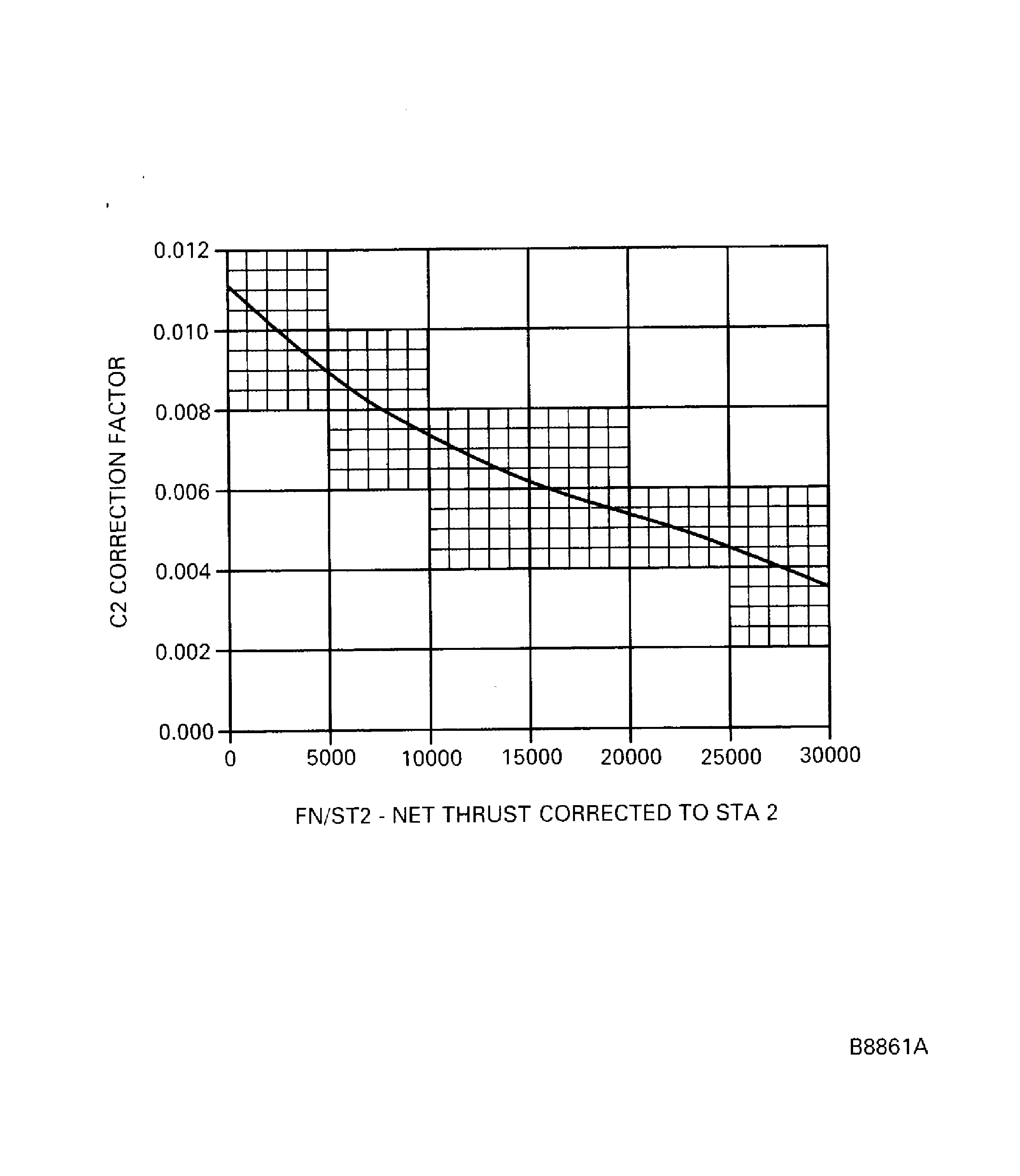

Figure: C2 Humidity/Condensation Correction Factor for WF

C2 Humidity/Condensation Correction Factor for WF

Figure: C3 Humidity/Condensation Correction Factor for WF

C3 Humidity/Condensation Correction Factor for WF

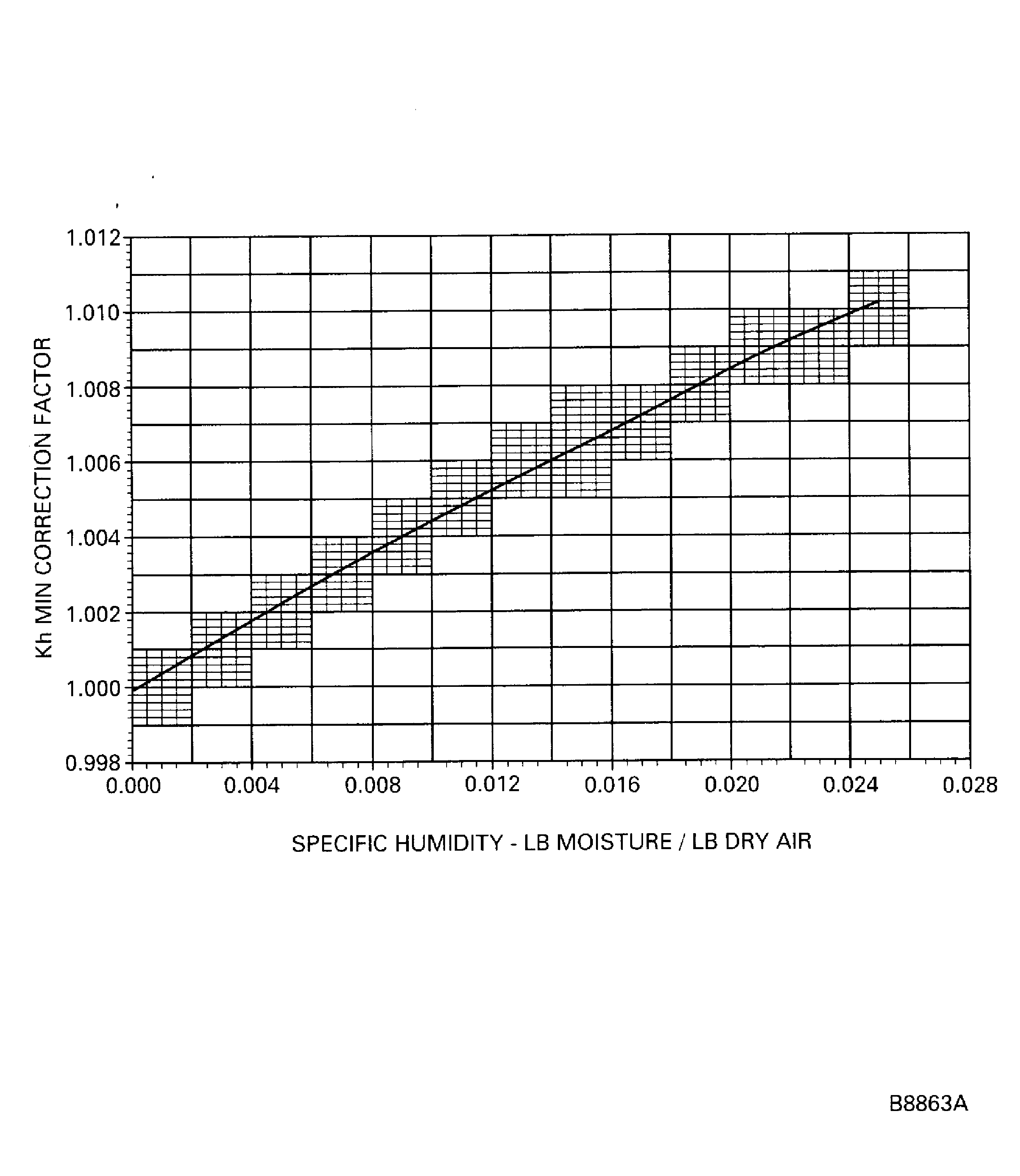

Figure: Kh MIN - Humidity/Condensation Correction Factor for WF

Kh MIN - Humidity/Condensation Correction Factor for WF

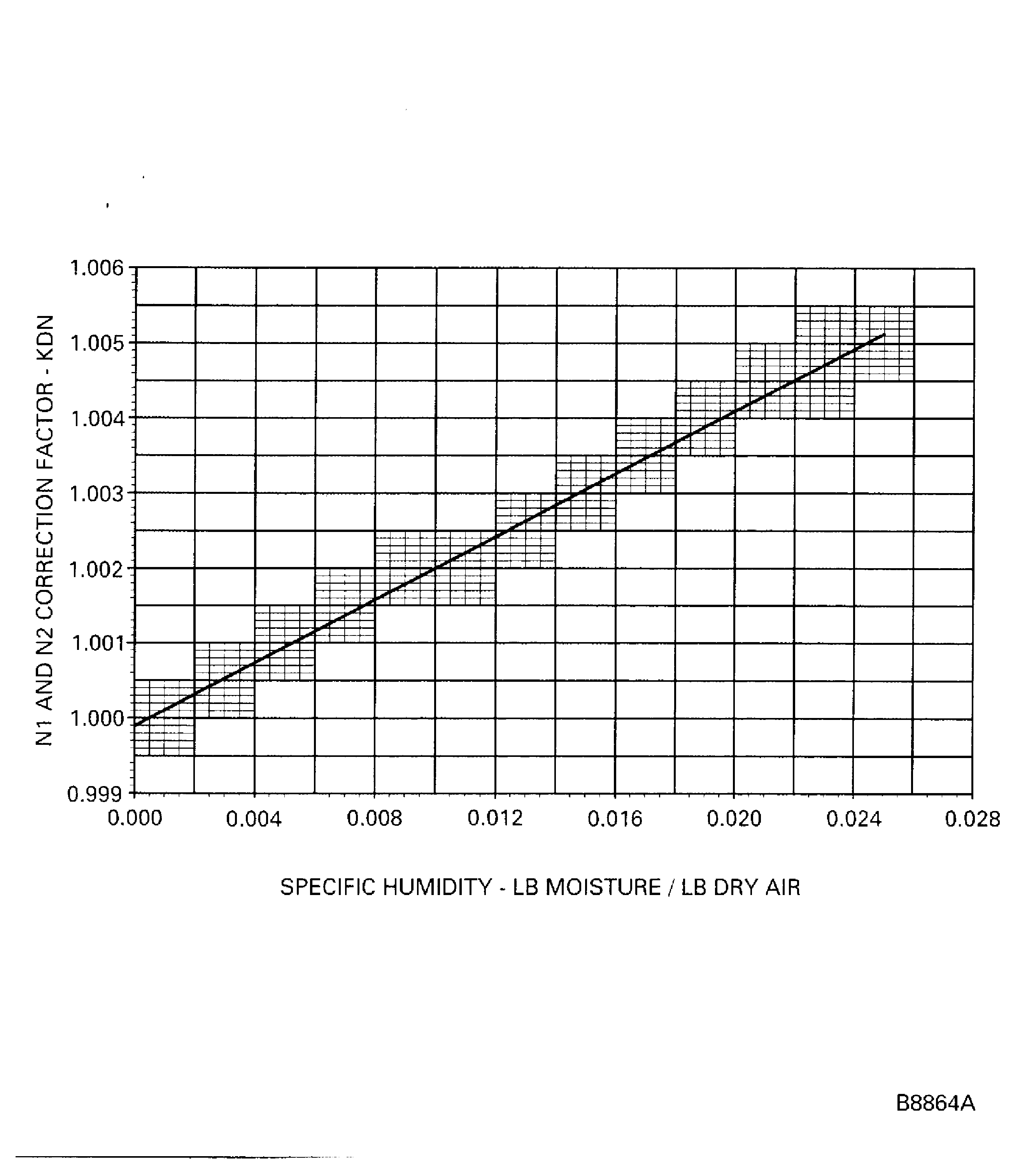

Figure: Humidity Correction Factor for N1 and N2 Rotor Speeds

Humidity Correction Factor for N1 and N2 Rotor Speeds

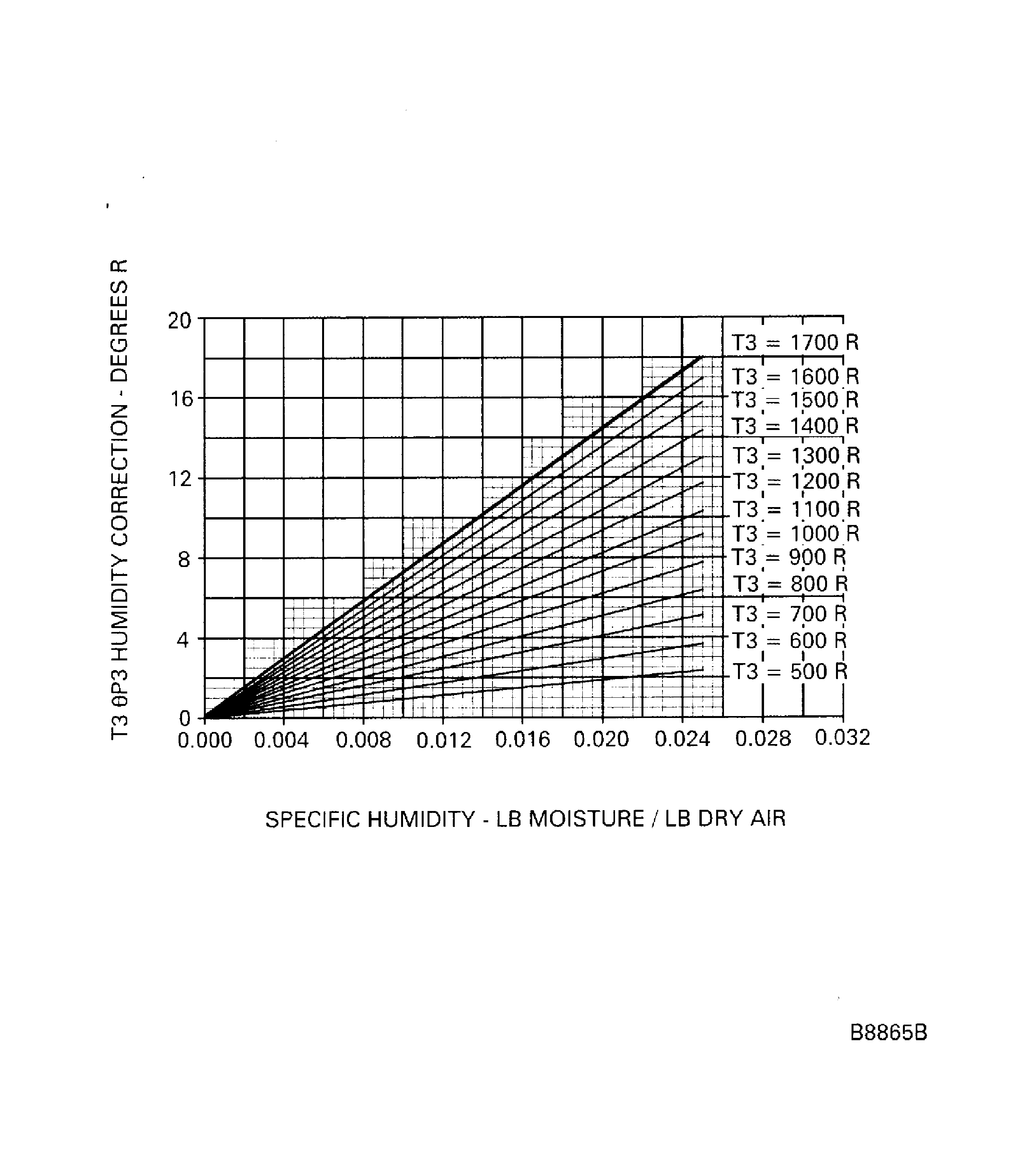

Figure: Humidity Correction Factor for T3

Humidity Correction Factor for T3

Figure: Humidity Correction Factor for T2.5

Humidity Correction Factor for T2.5

Figure: Humidity Correction Factor for T4.9

Humidity Correction Factor for T4.9

Figure: Gas Generator Check Curve

Gas Generator Check Curve

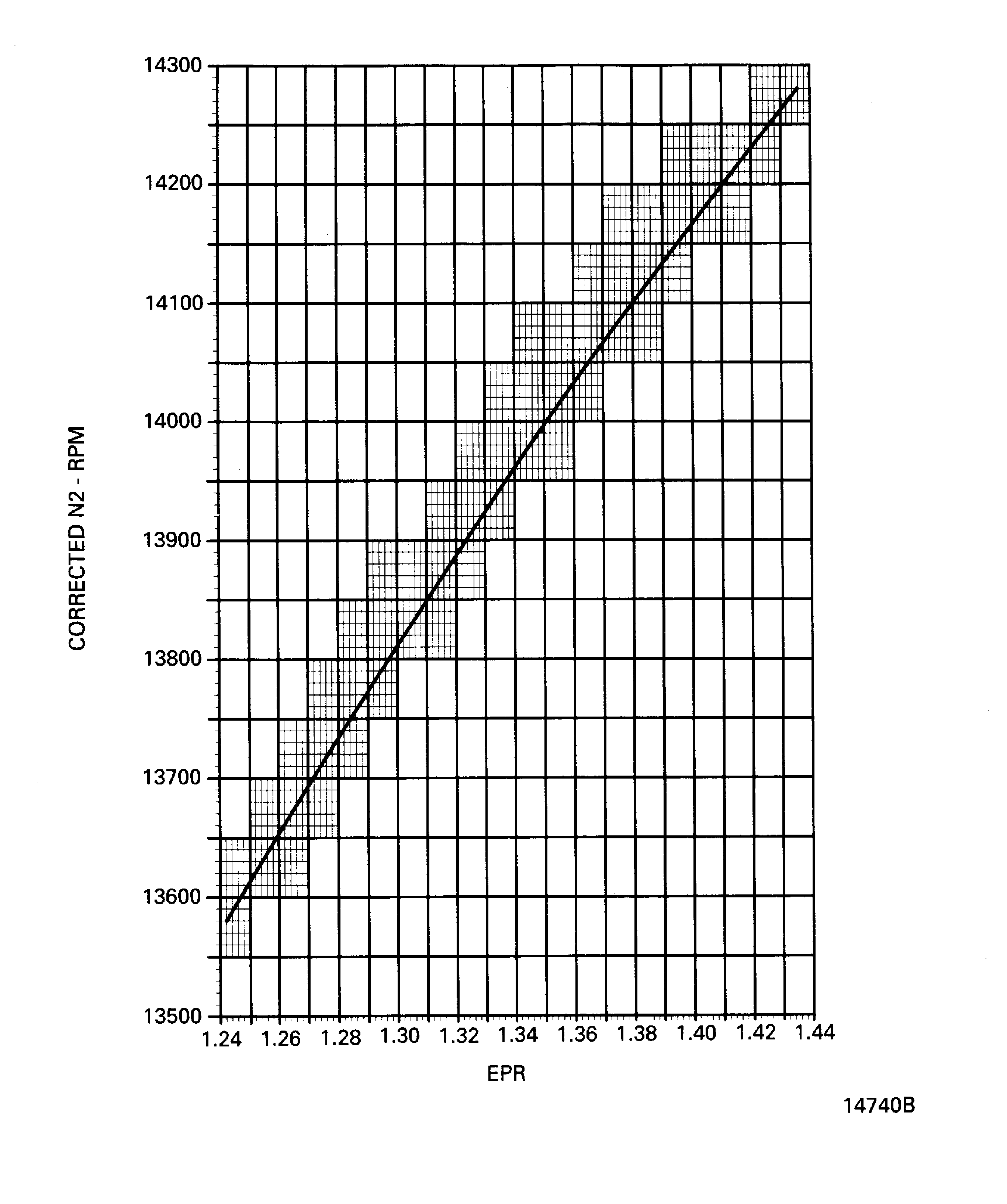

Figure: N2 Rotor Speed Level Curve

N2 Rotor Speed Level Curve

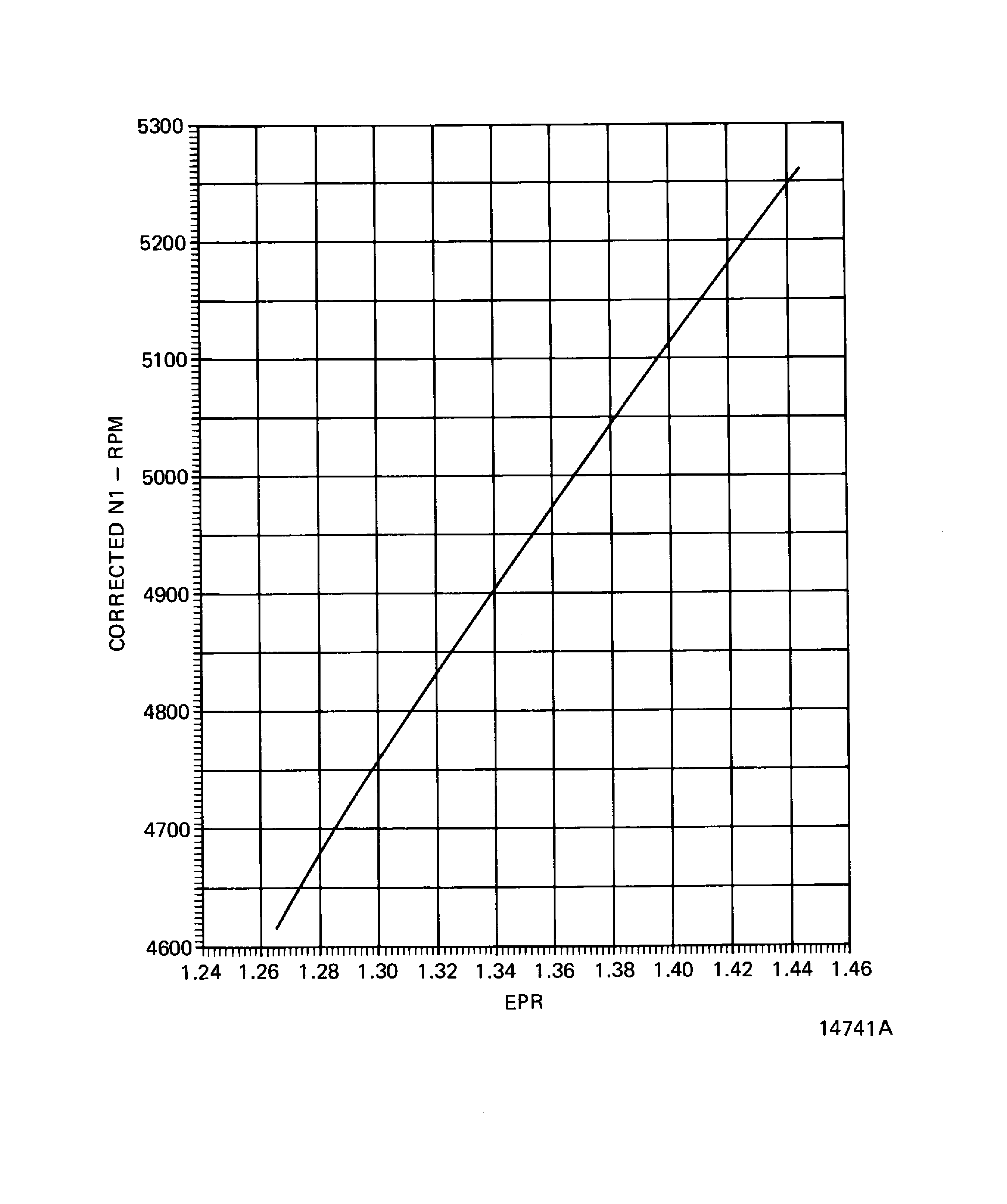

Figure: Corrected N1 Rotor Speed Level Curve

Corrected N1 Rotor Speed Level Curve

Figure: EGT Level Curve (for Engines to be Installed on Wing with an EEC which has SCN12C or Higer Software)

EGT Level Curve (for Engines to be Installed on Wing with an EEC which has SCN12C or Higer Software)

Figure: Delta EGT Margin Curve (for Engines to be Installed on Wing with an EEC which has SCN12C or Higer Software)

Delta EGT Margin Curve (for Engines to be Installed on Wing with an EEC which has SCN12C or Higer Software)