Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-44-30-300-021 Rear Flange-to-Vane Platform Seal Face - Weld Repair, Repair-021 (VRS3813)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-401 | 2A0549-01 |

01-401 | 2A1374 |

01-401 | 2A1398 |

01-401 | 2A1617 |

01-401 | 2A2034 |

01-401 | 2A2034-001 |

01-401 | 2A2722-01 |

01-401 | 2A2838-01 |

01-401 | 2A3344-01 |

01-401 | 2A3344-001 |

01-401 | 2A3344-002 |

01-401 | 2A3351-01 |

01-401 | 2A3351-003 |

01-401 | 2A3351-004 |

01-420 | 2A2718-01 |

Material of component

DESCRIPTION | MATERIAL |

|---|---|

Combustion chamber inner liner | Wrought non-hardenable nickel base alloy |

General

Price and availability - refer to IAE.

The practices and processes referred to in the procedure by the TASK numbers are in SPM.

To identify the consumable materials refer to the PCI.

Prerequisites

Make sure that the cleaning and inspection procedures are done before this repair. Refer to TASK 72-44-30-100-001 (CLEANING-001) and TASK 72-44-30-200-001-A00 or TASK 72-44-30-200-001-B00 (INSPECTION-001).

Make sure the liner segments are removed and remove the gangnut channels. Refer to TASK 72-44-30-040-001 (ASSEMBLY-001) and Repair, VRS 3264 TASK 72-44-30-300-003 (REPAIR-003).

Remove existing coating on the rear mounting flange. Refer to Repair, VRS3170 TASK 72-44-30-300-004 (REPAIR-004).

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Rotary austenitic stainless steel brush | LOCAL | |||

| Silicon carbide wheel | LOCAL | |||

| Welding equipment | LOCAL |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-287 WELDING FILLER WIRE | LOCAL | CoMat 03-287 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Refer to the SPM TASK 70-33-79-300-503.

Remove plasma coat by stripping.

Refer to the SPM TASK 70-15-01-160-501.

Remove plasma coat by high pressure water blast stripping.

Remove all wear and/or existing coating from the rear flange-to-vane platform seal face to the limits by one or more of the methods that follow:

SUBTASK 72-44-30-350-106 Remove Wear and/or Existing Coating from the Rear Flange-to-Vane Platform Seal Face

Refer to the SPM TASK 70-11-03-300-503.

Clean the part by aqueous degrease.

SUBTASK 72-44-30-110-068 Clean the Combustion Chamber Inner Liner Assembly

Refer to SPM TASK 70-37-24-370-501.

Use argon or vacuum.

Air cool or faster.

NOTE

Use appropriate heat fixture.

Do a solution heat treament of the part.

SUBTASK 72-44-30-370-063 Do a Solution Heat Treatment of the Combustion Chamber Inner Liner Assembly (For PN 2A1374, 2A1398, 2A1617, 2A2034, 2A2034-001 and 2A3351-004 only)

Refer to SPM TASK 70-23-03-230-501 or SPM TASK 70-23-08-230-501.

Do a fluorescent penetrant inspection of the part.

SUBTASK 72-44-30-230-066 Fluorescent Penentrant Examine the Combustion Chamber Inner Liner Assembly (For PN 2A1374, 2A1398, 2A1617, 2A2034, 2A2034-001 and 2A3351-004 only)

Refer to Figure.

Refer to the SPM TASK 70-11-26-300-503.

Wipe the repair area with isopropyl alcohol.

SUBTASK 72-44-30-120-001 Prepare the Repair Area for Weld

Refer to Figure.

Refer to the SPM TASK 70-31-13-310-501.

Weld build-up the repair area by IAE 16-33. Use manual gas tungsten arc weld (GTAW-MA) method. Use CoMat 03-287 WELDING FILLER WIRE.

SUBTASK 72-44-30-310-057 Weld Build-up the Repair Area

CAUTION

WELDING AT THIS REPAIR AREA CAN DISTORT THE PART. IT IS RECOMMENDED TO USE APPROPRIATE WELD FIXTURES TO MINIMIZE PART DISTORTION.Refer to the SPM TASK 70-37-24-370-501. Use argon or vacuum.

Refer to the SPM TASK 70-37-16-370-501. Use argon or vacuum.

Refer to one of the TASKs that follow.

NOTE

Use appropriate heat fixture.

Do a heat treatment of the part.

SUBTASK 72-44-30-370-064 Heat Treat the Combustion Chamber Inner Liner Assembly

Refer to the SPM TASK 70-11-03-300-503.

Clean the part by aqueous degrease.

SUBTASK 72-44-30-110-069 Clean the Combustion Chamber Inner Liner Assembly

Refer to the SPM TASK 70-23-03-230-501 or SPM TASK 70-23-08-230-501.

Do a fluorescent penetrant inspection of the part.

SUBTASK 72-44-30-230-067 Fluorescent Penetrant Examine the Combustion Chamber Inner Liner Assembly

Refer to Repair, VRS3170 TASK 72-44-30-300-004 (REPAIR-004).

Apply plasma coating on the rear mounting flange.

Refer to TASK 72-44-30-200-001-A00 (INSPECTION/CHECK-001) or TASK 72-44-30-200-001-B00 (INSPECTION/CHECK-001).

Do an inspection of the combustion chamber inner liner assembly.

Refer to TASK 72-44-30-440-001 (ASSEMBLY-001) and Repair, VRS3264 TASK 72-44-30-300-003 (REPAIR-003).

Install the liner segments and the gangnut channels.

SUBTASK 72-44-30-340-058 Postrequisites

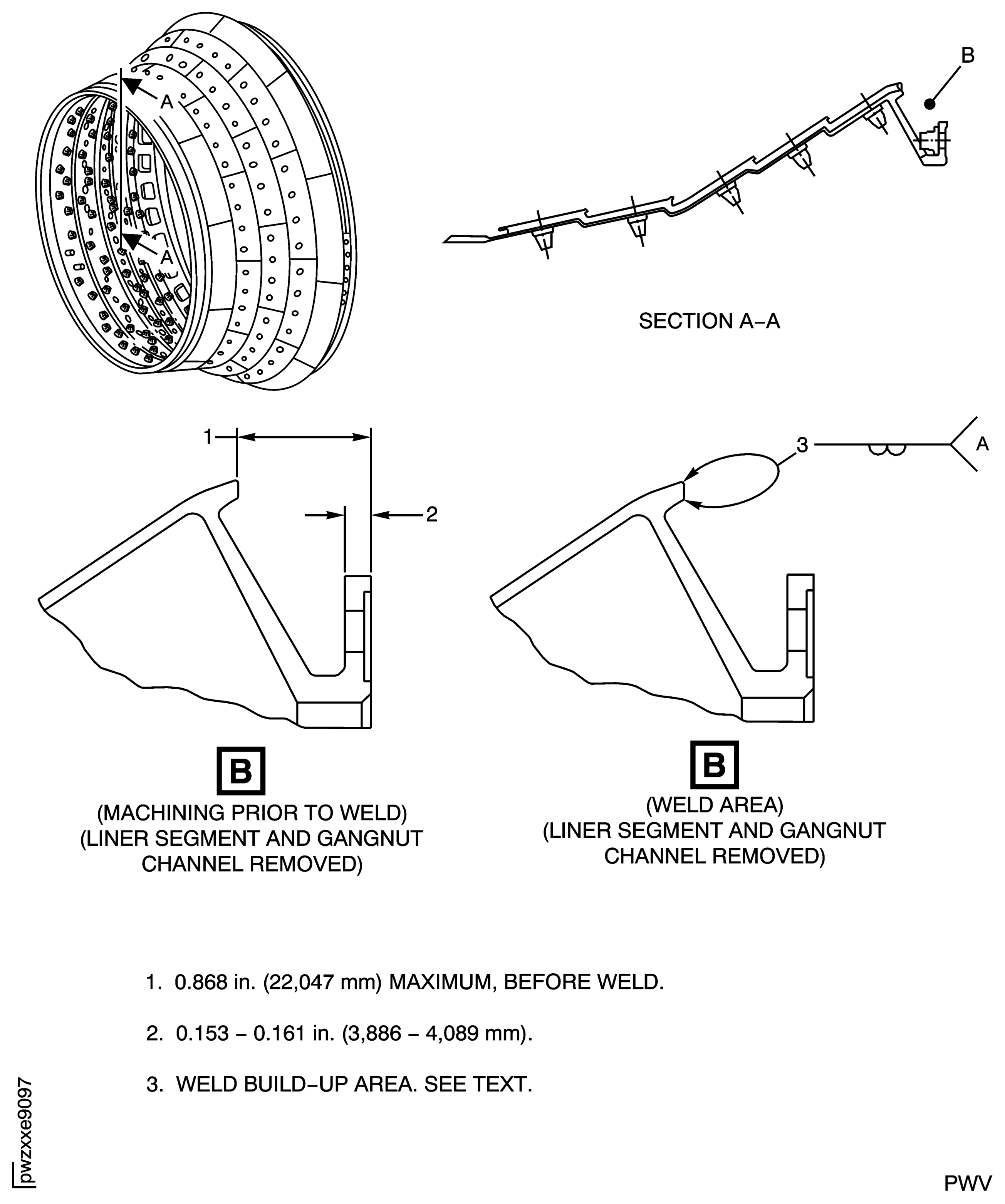

Figure: Repair details and dimensions

Repair details and dimensions

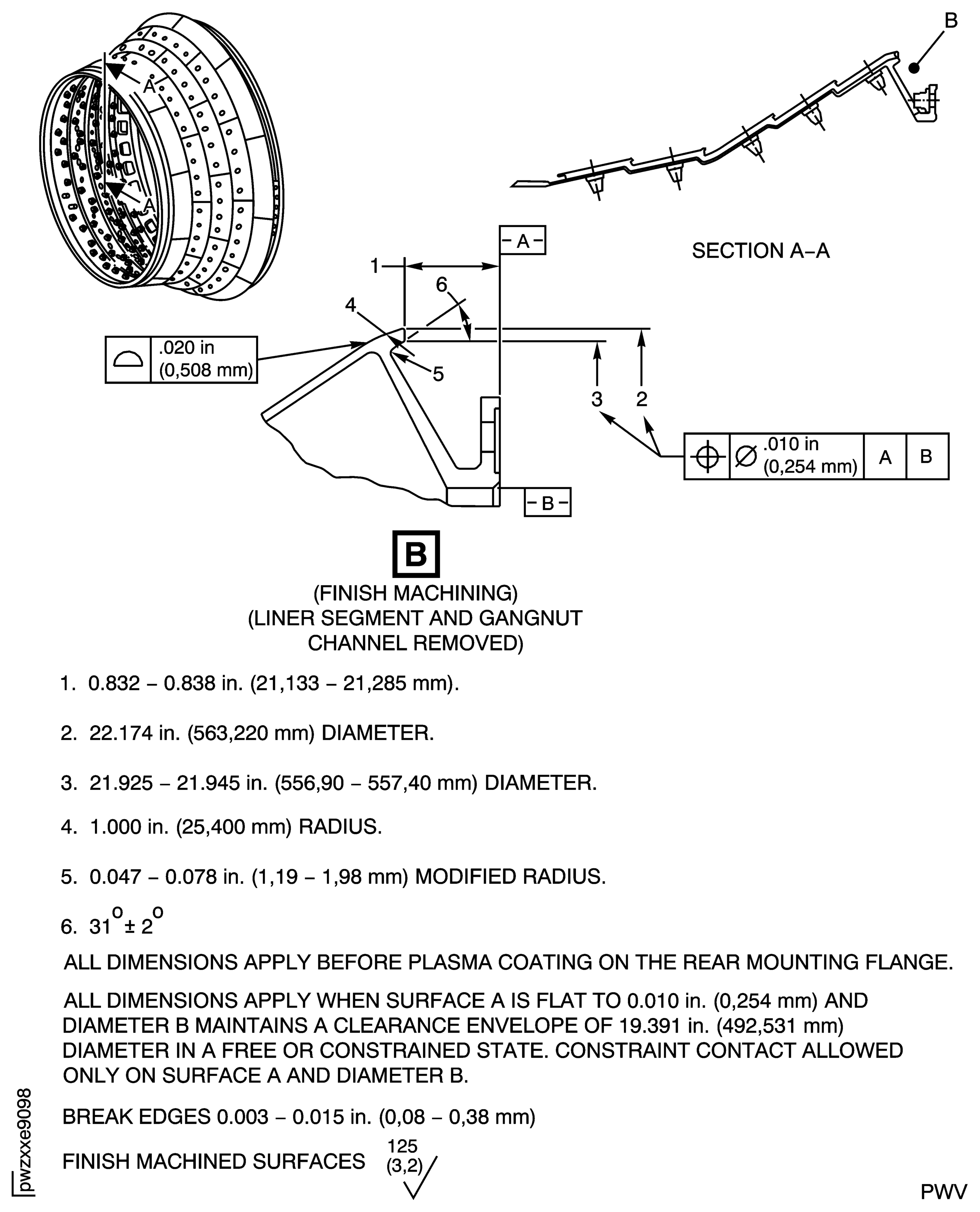

Figure: Repair Details and Dimensions (For PNs 2A1374, 2A1398, 2A1617, 2A2034, 2A2034-001 and 2A3351-004 only)

Repair Details and Dimensions (For PNs 2A1374, 2A1398, 2A1617, 2A2034, 2A2034-001 and 2A3351-004 only)

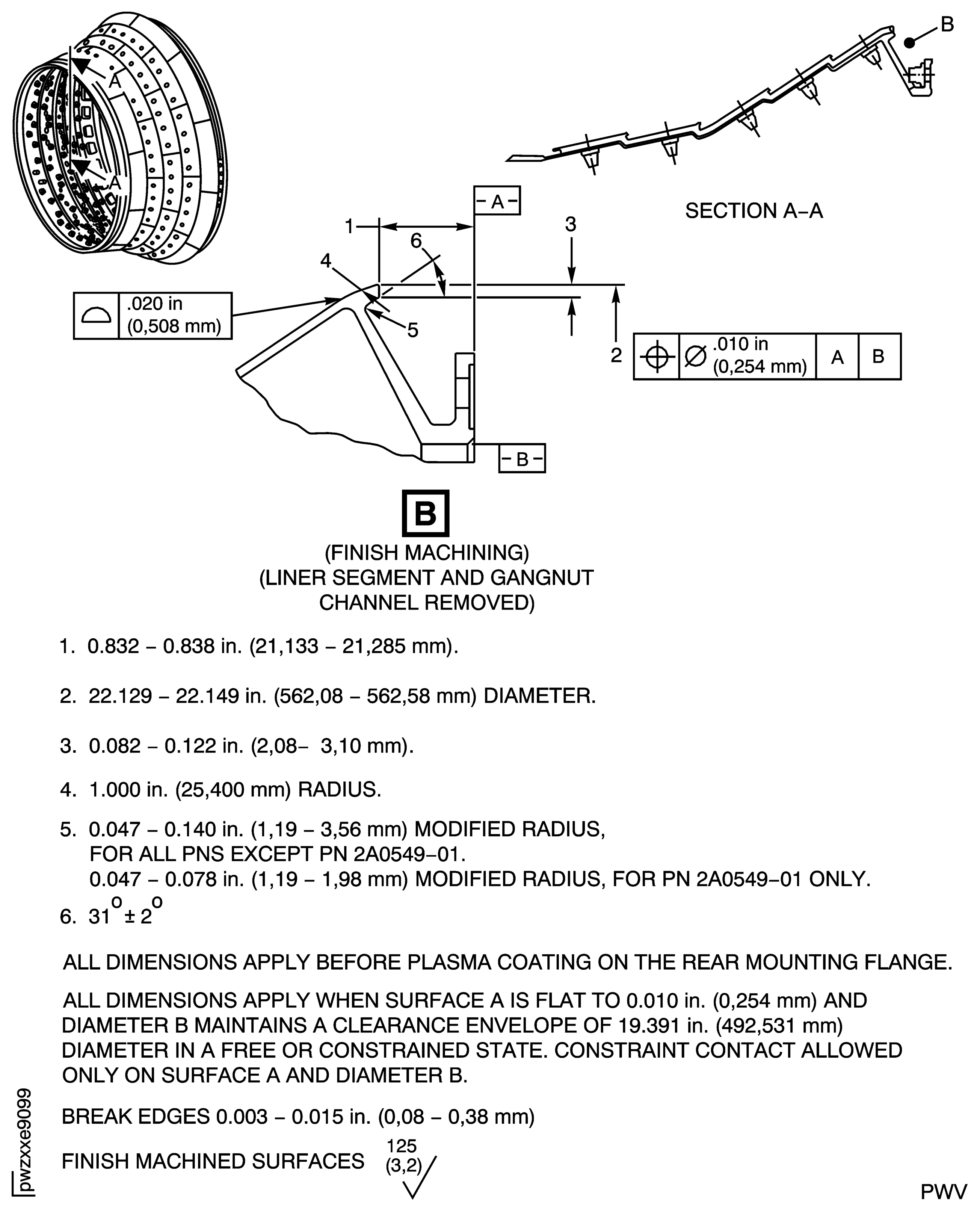

Figure: Repair Details and Dimensions (For all PNs except 2A1374, 2A1398, 2A1617, 2A2034, 2A2034-001 and 2A3351-004)

Repair Details and Dimensions (For all PNs except 2A1374, 2A1398, 2A1617, 2A2034, 2A2034-001 and 2A3351-004)