Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-44-30-200-001-A00 Inner Combustion Chamber Assembly - Examine, Inspection-001

General

This TASK gives the procedure for the inspection of the combustion chamber inner liner. For the other part of the combustion chamber inner liner, refer to TASK 72-44-30-200-000 (INSPECTION-000).

Fig/item numbers in parentheses in the procedure agree with those used in the IPC.

The policy that is necessary for inspection is given in SPM TASK 70-20-00-200-501.

All the parts must be cleaned before any part is examined. Refer to SPM TASK 70-10-00-100-501.

All parts must be visually examined for damage, corrosion and wear. Any defects that are not identified in the procedure must be referred to IAE.

Do not discard any part until you are sure there are no repairs available. Refer to the instructions in Repair before a discarded part is used again or oversize parts are installed.

Parts which should be discarded can be held although no repair is available. The repair of a discarded part could be shown to be necessary at a later date.

All parts must be examined to make sure that all the repairs have been completed satisfactorily.

The practices and processes referred to in the procedure by the TASK numbers are in SPM.

Use a bright light and a 3X magnifying glass to find surface cracks.

References

Refer to SPM for data on these items.

Definitions of Damage, SPM TASK 70-02-02-350-501.

Inspection of Parts, SPM TASK 70-20-01-200-501.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Repair, VRS3173 TASK 72-44-30-300-001 (REPAIR-001)

Other than (a)

Cracks.

Repair, VRS3173 TASK 72-44-30-300-001 (REPAIR-001)

Holes

Repair, VRS3173 TASK 72-44-30-300-001 (REPAIR-001)

Other than (a)

Burns.

Repair, VRS3173 TASK 72-44-30-300-001 (REPAIR-001)

Other than (a)

Distortion.

Examine the inner liner for cracks, holes, burns and distortion in the liner segments, rows 1 thru 5.

SUBTASK 72-44-30-220-051 Examine the Combustion Chamber Inner Liner (01-401) for Cracks, Holes, Burns and Distortion in the Liner Segments

Refer to Figure.

Repair, VRS3265 TASK 72-44-30-300-002 (REPAIR-002)

If the wear at the vane contact points is a maximum of 0.020 in. (0.51 mm) in depth

Repair, VRS3813 TASK 72-44-30-300-021 (72-4-30, REPAIR 021)

If the wear at the vane contact points is a maximum of 0.030 in. (0.76 mm) in depth

Wear that is not smooth.

Examine the inner liner shell at location 5 for wear that is not smooth on the rear flange-to-vane platform seal face.

SUBTASK 72-44-30-220-052 Examine the Combustion Chamber Inner Liner (01-401) for Wear that is Not Smooth on the Rear Flange-to-Vane Platform Seal Face

Refer to Figure.

Repair, VRS3264 V2500-A0-72-44-3001-00A-920A-C (REPAIR-003)

Nuts that are not there, cracks or pieces that are broken away

Examine the inner liner nut channel at location 6 for nuts that are not there, cracks and pieces that are broken away.

SUBTASK 72-44-30-220-053 Examine the Combustion Chamber Inner Liner (01-401) Nut Channel for Nuts that are Not There, Cracks and Pieces that are Broken Away

Refer to Figure.

Repair, VRS3170 TASK 72-44-30-300-004 (REPAIR-004)

Other than (a)

Wear.

Repair, VRS3170 TASK 72-44-30-300-004 (REPAIR-004)

Other than (a)

Chipped or spalled hardface.

Examine the inner liner at location 7 for wear and chipped or spalled hardface on the rear mount flange.

Repair, VRS3741 TASK 72-44-30-300-019 (REPAIR-019)

If the hole cracks go from the flange hole to the outside diameter of the flange

Cracks.

Examine the inner liner for hole cracks on the rear mount flange.

SUBTASK 72-44-30-220-054 Examine the Combustion Chamber Inner Liner (01-401) for Wear and Chipped or Spalled Hardface and for Hole Cracks on the Rear Mount Flange

Refer to Figure.

Repair, VRS3173 TASK 72-44-30-300-001 (REPAIR-001)

Nuts that are not there

Examine the inner liner at location 8 for nuts that are not there.

SUBTASK 72-44-30-220-055 Examine the Combustion Chamber Inner Liner (01-401) for Nuts that are Not There

Refer to Figure.

Replace washers by Repair, VRS3173 TASK 72-44-30-300-001 (REPAIR-001)

Loose washers

Examine the inner liner at location 9 for loose, oval-shaped washers.

SUBTASK 72-44-30-220-056 Examine the Combustion Chamber Inner Liner (01-401) for Loose, Oval-Shaped Washers

Refer to Figure.

Repair, VRS3174 TASK 72-44-30-300-005 (REPAIR-005).

Repair, VRS3174 TASK 72-44-30-300-005 (REPAIR-005).

Other than Step.

Cracks.

Repair, VRS3174 TASK 72-44-30-300-005 (REPAIR-005).

Burn holes.

Examine the inner liner at location 11 for cracks, dents, burn holes and blocked holes.

Repair, VRS3745 TASK 72-44-30-300-020 (REPAIR-020).

Axial cracks on the trailing edge of Row 5 that are not more than 0.125 in. (3.175 mm) long that are at least 0.100 in. (2.540 mm) apart, or look like they will go through each other and permit material to break off.

Examine the inner liner at Location 14 for cracks on the shell.

Repair, VRS3745 TASK 72-44-30-300-020 (REPAIR-020).

Cracks which extend from the boltholes.

Other than Step.

Examine the inner liner at Location 15 for cracks on the rear flange.

Repair, VRS3745 TASK 72-44-30-300-020 (REPAIR-020).

Axial cracks on the trailing edge of Row 5 that are not more than 0.125 in. (3.175 mm) long that are at least 0.100 in. (2.540 mm) apart, or look like they will go through each other and permit material to break off.

Examine the inner liner at Location 16 for cracks on the outer shell.

SUBTASK 72-44-30-220-057 Examine the Combustion Chamber Inner Liner (01-401) for Cracks, Dents, Burn Holes and Blocked Holes

Refer to Figure.

Repair, VRS3169 TASK 72-44-30-300-007 (REPAIR-007).

Other than (a).

Wear.

Repair, VRS3169 TASK 72-44-30-300-007 (REPAIR-007).

Other than (a).

Chipped or spalled hardface.

Examine the inner liner at location 12, for wear and chipped or spalled hardface on the front outside diameter seal.

SUBTASK 72-44-30-220-058 Examine the Combustion Chamber Inner Liner (01-401) for Wear and Chipped or Spalled Hardface on the Front Outside Diameter Seal

Refer to Figure.

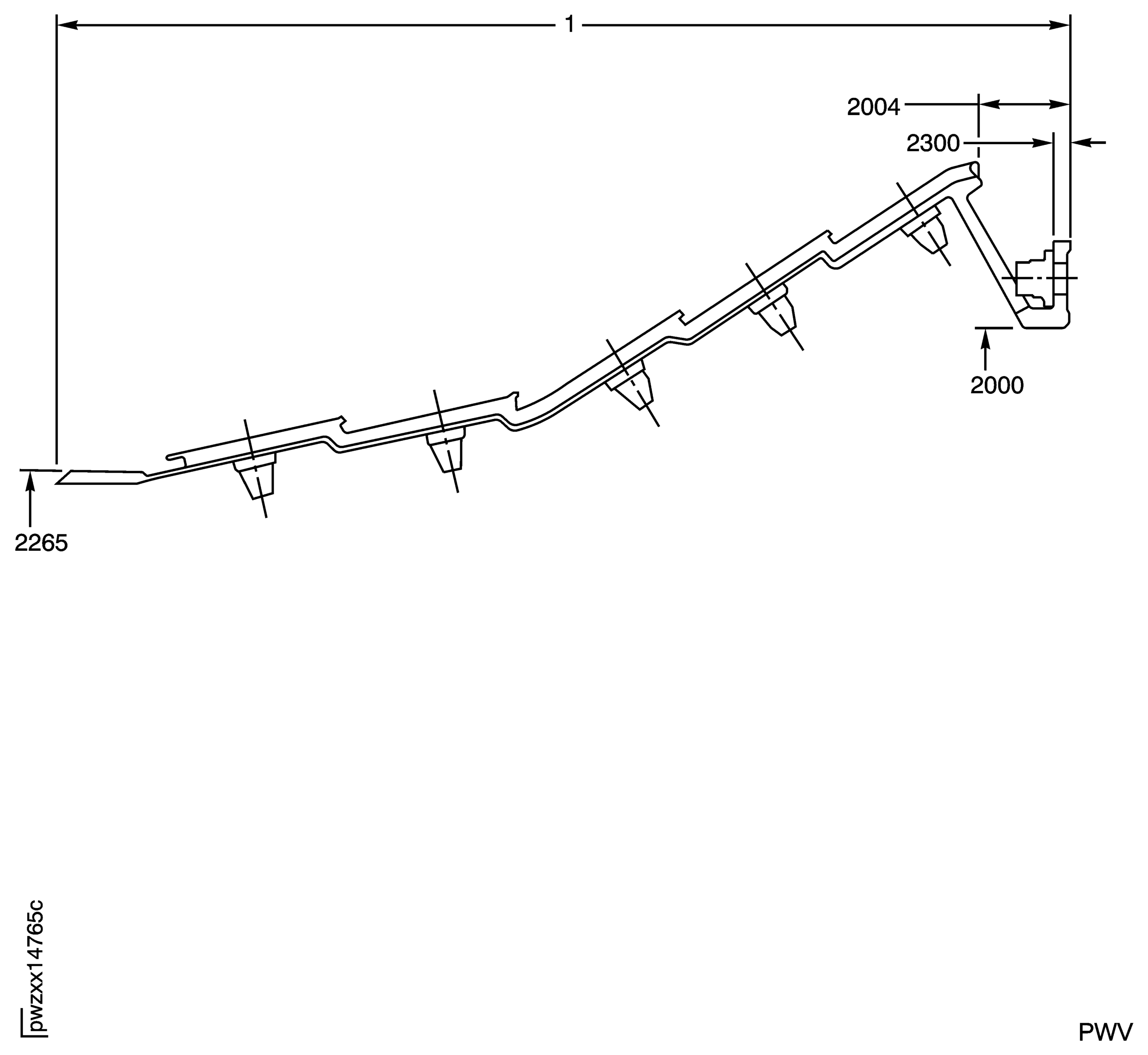

SUBTASK 72-44-30-220-059 Examine the Combustion Chamber Inner Liner (01-401) for the Length

Refer to Figure.

Repair, VRS3265 TASK 72-44-30-300-002 (REPAIR-002) or Repair, VRS3813 TASK 72-44-30-300-021 (REPAIR-021)

Other than (a)

Axial dimension.

Examine the inner liner for the axial dimension of the rear support at location 2004.

Repair, VRS3170 TASK 72-44-30-300-004 (REPAIR-004)

If the thickness is less than 0.156 in. (3.96 mm) and equal or more than 0.140 in. (3.56 mm)

Examine the inner liner for the thickness of the rear mount flange (Reference No. 2300).

SUBTASK 72-44-30-220-060 Examine the Combustion Chamber Inner Liner (01-401) for the Axial Dimension of the Rear Support and Thickness of the Rear Mount Flange

Refer to Figure.

Repair, VRS3266 TASK 72-44-30-300-008 (REPAIR-008)

More than 19.400 in. (492.760 mm)

Repair, VRS3628 TASK 72-44-30-300-017 (REPAIR-017)

Less than 19.392 in. (492.557 mm)

Diameter.

Examine the inner liner at location 3 for the rear inside diameter (Reference No. 2000).

SUBTASK 72-44-30-220-061 Examine the Combustion Chamber Inner Liner (01-401) for the Rear Inside Diameter

Refer to Figure.

Accept part for select fit only

NOTE

This part can be used only if the mating part has a diameter that will result in fit of reference No. 2265. Refer to TASK 72-00-44-420-001-001 (INSTALLATION-001) or TASK 72-40-00-430-005 (ASSEMBLY-005).

If the diameter is between 16.616 and 16.618 in. (422.05 and 422.10 mm)

Repair, VRS3306 TASK 72-44-30-300-009 (REPAIR-009)

Other than (1) or (2)

Examine the inner liner at location 4 for the diameter of the front outside diameter seal (Reference No. 2265).

Repair, VRS3306 TASK 72-44-30-300-009 (REPAIR-009)

Other than (a)

Out-of-roundness.

Examine the inner liner at location 4 for the out-of-roundness of the front outside diameter seal.

SUBTASK 72-44-30-220-062 Examine the Combustion Chamber Inner Liner (01-401) Front Outside Diameter Seal for the Diameter and Out-of-Roundness

Figure: Combustion Chamber Inner Liner Inspection Locations

Combustion Chamber Inner Liner Inspection Locations

Figure: Combustion Chamber Inner Liner Inspection Locations

Combustion Chamber Inner Liner Inspection Locations