Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 73-13-41-200-201 Fuel Nozzle And Support Assembly - Examine The Fuel Nozzle and Support Assembly, Inspection-001

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-020 | 2A0994 |

01-020 | 2A0994-001 |

01-020 | 2A1637 |

01-020 | 2A1637-001 |

01-020 | 2A2250 |

01-020 | 2A2250-001 |

01-020 | 2A3448 |

01-020 | 2A3448-001 |

01-020 | 2A3453 |

01-020 | 2A3453-001 |

General

This TASK gives the procedure for the inspection of the Fuel Nozzle and Support Assembly.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC.

The policy that is necessary for inspection is given in SPM TASK 70-20-00-200-501.

All the parts must be cleaned before any part is examined. Refer to SPM TASK 70-10-00-100-501.

All parts must be visually examined for damage, corrosion and wear. Any defects that are not identified in the procedure must be referred to IAE.

The procedure for those parts which must have a crack test is given in Step. Do the test before the part is visually examined.

Do not discard any part until you are sure there are no repairs available. Refer to the instructions in Repair before a discarded part is used again or oversize parts are installed.

Parts which should be discarded can be held although no repair is available. The repair of a discarded part could be shown to be necessary at a later date.

All parts must be examined to make sure that all the repairs have been completed satisfactorily.

A ** following repair referenced in this inspection indicates that the repair is not yet published in the current revision of the manual and the part must be rejected. Contact IAE for additional information concerning FAA approved repair date.

The practices and processes referred to in the procedure by the TASK numbers are in SPM.

References

Refer to SPM for data on these items.

Definitions of damage, SPM TASK 70-02-02-350-501.

Inspection of parts, SPM TASK 70-20-01-200-501.

Some data on these items is contained in this TASK. For more data on these items refer to SPM.

Method of testing for crack indications.

Chemical processes.

Surface protection.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Magnifying Glass, 10x | LOCAL | Magnifying Glass, 10x |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Clean the part. Refer to Cleaning-000 TASK 73-13-41-100-200.

Repair, VRS3589 (Repair-009) .TASK 73-13-41-300-009.

Repair, VRS3032 (Repair-005) TASK 73-13-41-300-005.

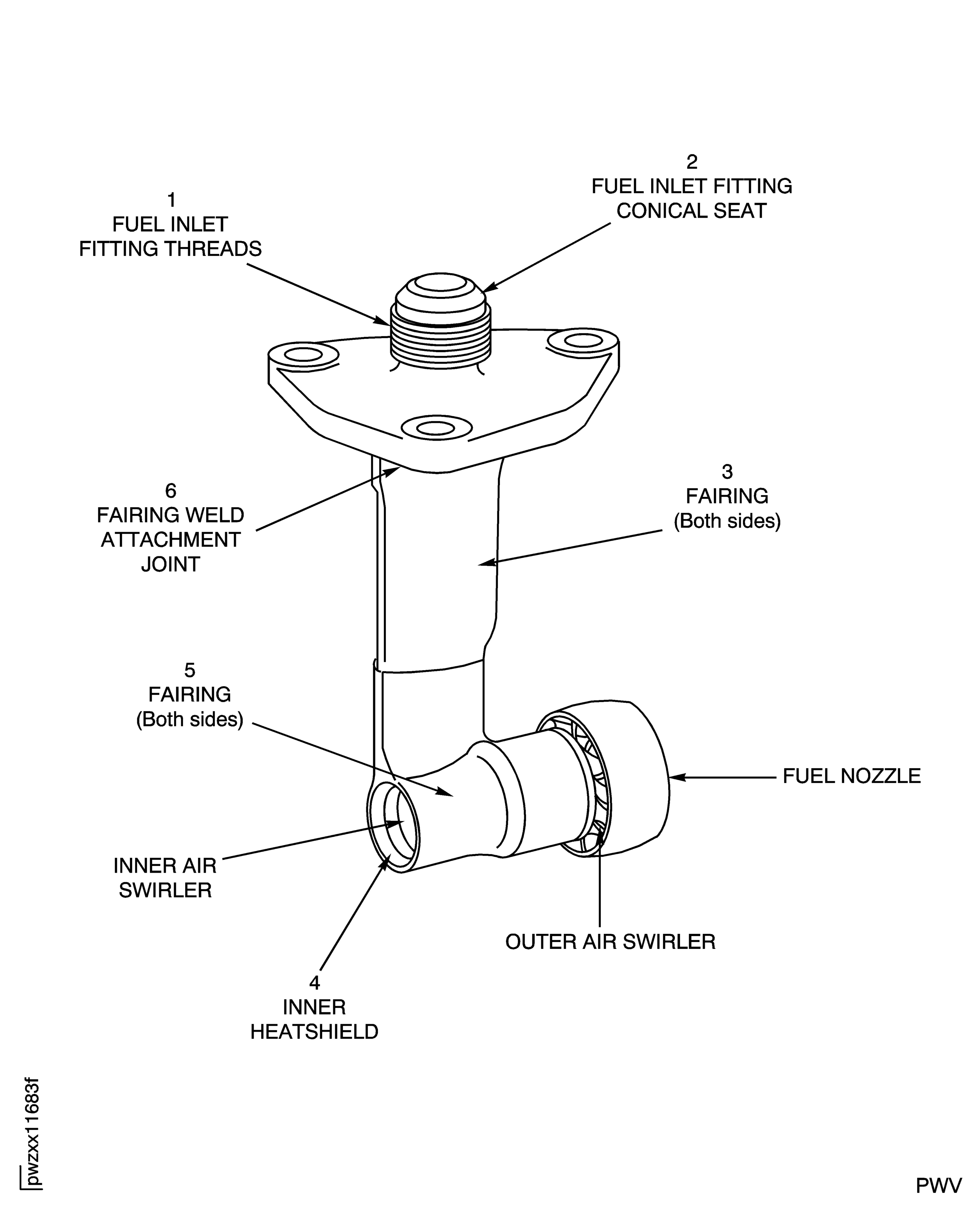

Fairing cracks not more than 1.000 in. (25.40 mm) at Location 6, Figure.

Repair, VRS3032 (Repair-005) TASK 73-13-41-300-005.

Fairing cracks not more than 0.500 in. (12.70 mm) at Location 3 and/or 5, Figure

Repair, VRS3583 (Repair-008) TASK 73-13-41-300-008.

Fairing cracks more than 1.000 in. (25.40 mm) at Location 6, Figure

Repair, VRS3583 (Repair-008) TASK 73-13-41-300-008.

Fairing cracks more than 0.500 in. (12.70 mm) at Locations 3 and/or 5, Figure

Do the crack test on the part that is given below. Use the applicable penetrant inspection procedure.

PART IDENT

TASK/SUBTASK

Fuel nozzle and support assembly

SUBTASK 73-13-41-230-054 Examine the Fuel Nozzle and Support Assembly (01-020) for Cracks

Repair, VRS3163 (Repair-006) TASK 73-13-41-300-006.

If the diameter is greater than or equal to 1.233 in. (31.318 mm).

Repair, VRS3589 (Repair-009) TASK 73-13-41-300-009.

Diameter

Examine the fuel nozzle and support assembly at location 4 for the swirler assembly spherical diameter.

SUBTASK 73-13-41-220-072 Examine the Fuel Nozzle and Support Assembly (01-020) for the Swirler Assembly Spherical Diameter

Repair, VRS3163 (Repair-006) TASK 73-13-41-300-006.

Other than Step.

Plasma wear

Examine the fuel nozzle and support assembly at location 7 for worn plasma spray coating on the swirler assembly.

SUBTASK 73-13-41-220-073 Examine the Fuel Nozzle and Support Assembly (01-020) for the Worn Plasma Spray Coating of the Swirler Assembly

Accept.

Radial cracks on the deflector lip of the nozzle swirler assembly radial cracks at location 6 not more than 0.075 in. (1.91 mm) long from the lip edge

Repair, VRS3483 (Repair-007) TASK 73-13-41-300-007 or Repair, VRS3807 (Repair-012) TASK 73-13-41-300-012 or Repair, VRS3589 (Repair-009) TASK 73-13-41-300-009.

Examine the fuel nozzle and support assembly at location 1 for burns, cracks, and damage on the inner and outer surfaces of the swirler assembly of the nozzle.

SUBTASK 73-13-41-220-074 Examine the Fuel Nozzle and Support Assembly (01-020) for Burns, Cracks, and Damage on the Inner and Outer Surface of the Swirler Assembly

Clean, Refer to Cleaning-001 TASK 73-13-41-100-201.

Carbon material

Examine the fuel nozzle and support assembly at location 3 for signs of carbon material. Use Magnifying Glass, 10x.

SUBTASK 73-13-41-220-075 Examine the Fuel Nozzle and Support Assembly (01-020) for Signs of Carbon Material on the Nozzle Face

Repair, VRS3589 (Repair-009) TASK 73-13-41-300-009.

Distortion, burns and cracks

Examine the fuel nozzle and support assembly at location 2 for distortion, burns and cracks of the annular orifice. Use Magnifying Glass, 10x.

SUBTASK 73-13-41-220-076 Examine the Fuel Nozzle and Support Assembly (01-020) for Distortion, Burns and Cracks of the Annular Orifice

Repair, VRS3483 (Repair-007) TASK 73-13-41-300-007 or Repair, VRS3807 (Repair-012) TASK 73-13-41-300-012.

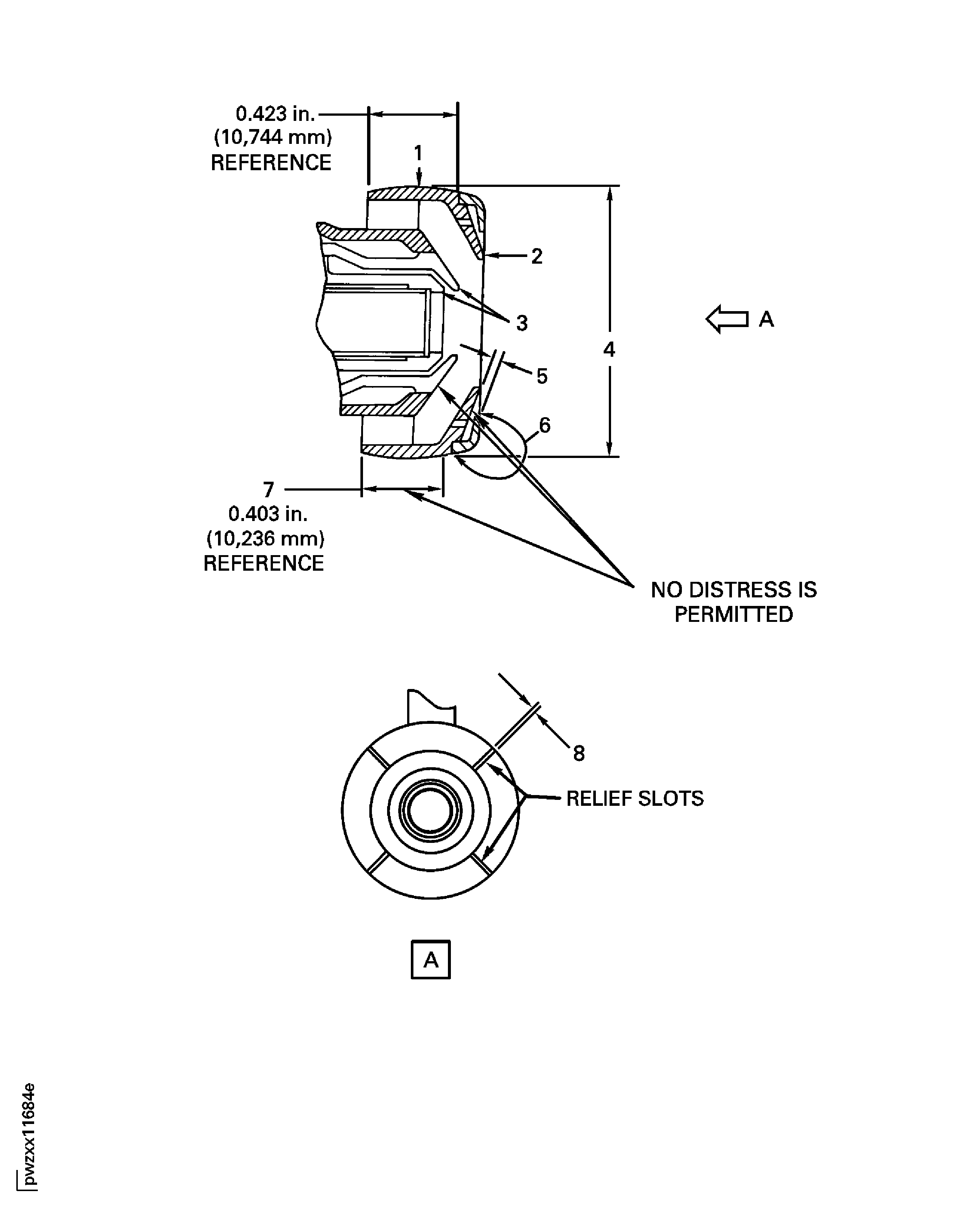

Gap between the end cap heatshield and the fuel nozzle is completely closed

Examine the end cap heatshield at location 5 for the gap.

Repair, VRS3483 (Repair-007) TASK 73-13-41-300-007 or Repair, VRS3807 (Repair-012) TASK 73-13-41-300-012).

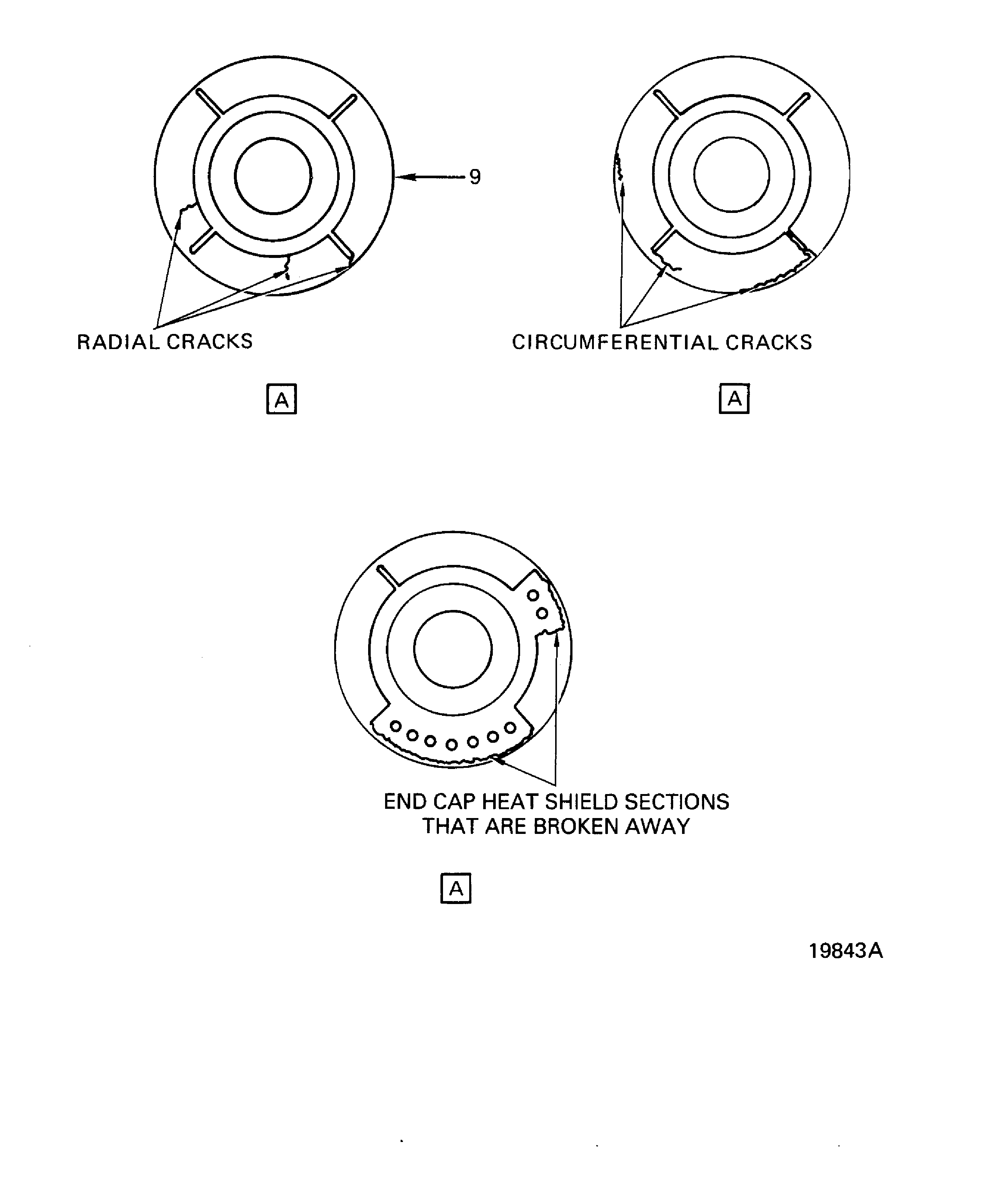

Radial cracks that extend beyond the relief slots are not acceptable.

Repair, VRS3589 (Repair-009) TASK 73-13-41-300-009.

Radial cracks that extend rearward beyond dimension 7 in the figure.

Repair, VRS3483 (Repair-007) TASK 73-13-41-300-007 or Repair, VRS3807 (Repair-012) TASK 73-13-41-300-012.

One or more of the end cap heatshield segments or pieces missing is not acceptable.

Repair, VRS3589 (Repair-009) TASK 73-13-41-300-009.

Distress (cracks, distortion or erosion) on areas adjacent to the end cap heatshield more than the limits permitted in the figure

Repair, VRS3483 (Repair-007) TASK 73-13-41-300-007 or Repair, VRS3807 (Repair-012) TASK 73-13-41-300-012.

Circumferential cracks that are longer than 0.050 in. (1.27 mm) are not acceptable

Examine the end cap heatshield at location 9 for damage.

SUBTASK 73-13-41-220-077 Examine the Fuel Nozzle and Support Assembly (01-020) for Damage to the End Cap Heatshield of the Nozzle

Refer to Figure.

Repair, VRS3590 (Repair-011) TASK 73-13-41-300-011.

Damage

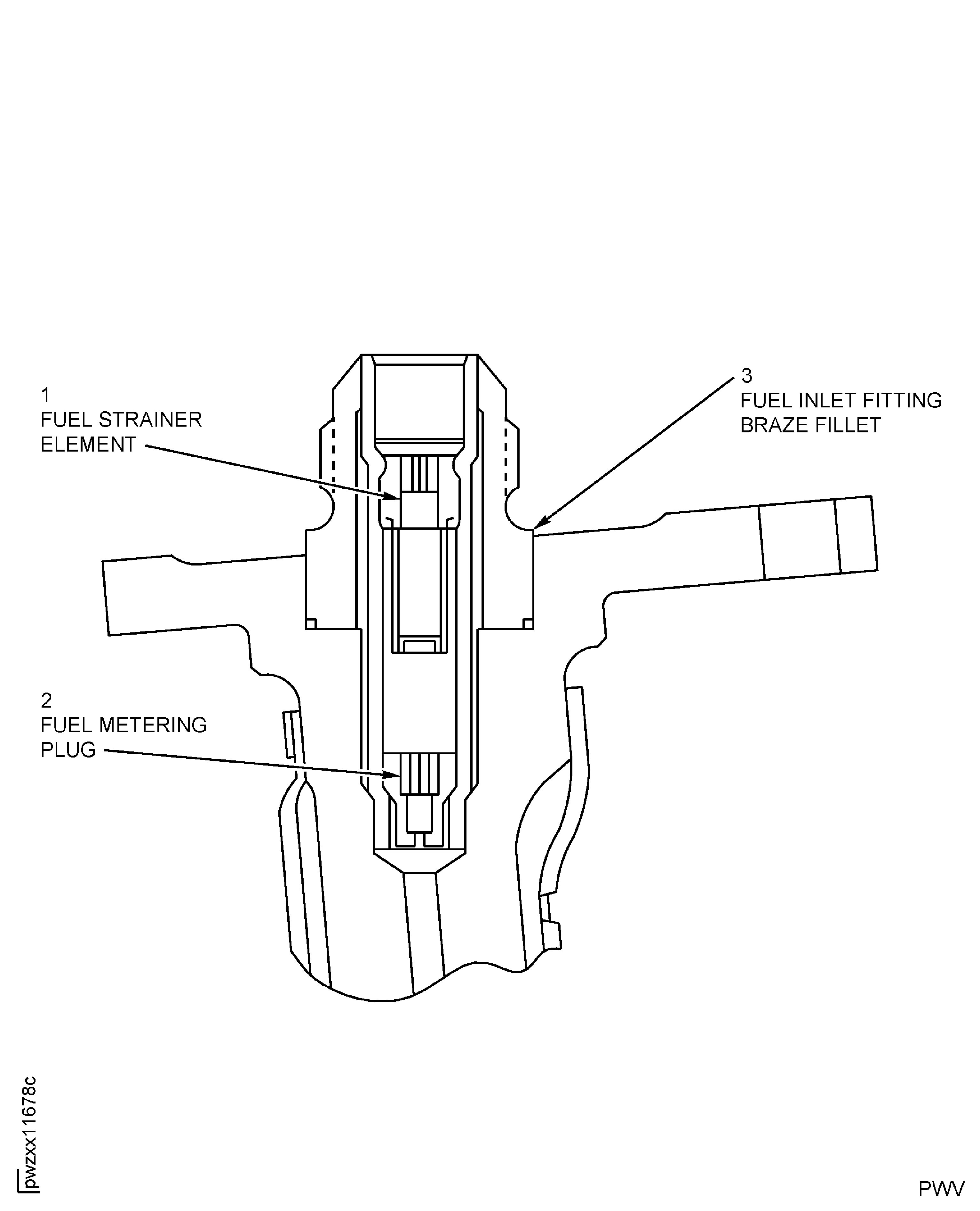

Examine the fuel inlet fitting threads at location 1 for damage.

SUBTASK 73-13-41-220-078 Examine the Fuel Nozzle and Support Assembly (01-020) for Damage on the Fuel Inlet Fitting Threads

Refer to Figure.

Repair, VRS3257 (Repair-004) TASK 73-13-41-300-004 or Repair, VRS3590 (Repair-011) TASK 73-13-41-300-011.

Radial scratches that extend more than half the width of the conical sealing surface.

Examine the fuel inlet fitting conical seat at location 2 for damage.

SUBTASK 73-13-41-220-079 Examine the Fuel Nozzle and Support Assembly (01-020) for Damage on the Fuel Inlet Fitting Conical Seat

Refer to Figure.

Accept.

NOTE

Fluorescent penetrant inspection is not necessary.Braze is 100 percent complete over full 360 degree circumference.

Repair, VRS3590 (Repair-011) TASK 73-13-41-300-011.

Cracks, incomplete braze or other damage.

Examine the fuel inlet fitting braze fillet at location 3 for cracks, damage or incomplete braze.

SUBTASK 73-13-41-220-103 For All Configurations Except PN 2A0994 and 2A0994-001: Examine the Fuel Nozzle and Support Assembly (01-020) for Cracks or Damage of the Fuel Inlet Fitting Braze Fillet

Refer to Figure.

Repair, VRS3458 (Repair-002) TASK 73-13-41-300-002 **.

Damage

Clean, Refer to Cleaning-005 TASK 73-13-41-100-205.

Carbon material

Examine the fuel strainer element at location 1 for damage or carbon material.

SUBTASK 73-13-41-220-080 Examine the Fuel Nozzle and Support Assembly (01-020) for Damage or Carbon Material on the Fuel Strainer Element

Refer to Figure.

Repair, VRS3458 TASK 73-13-41-300-002 (REPAIR-002).

Damage.

Clean, Refer to cleaning-005 TASK 73-13-41-100-205.

Carbon material.

Examine the fuel metering plug at location 2 for damage or carbon material. Use Magnifying Glass, 10x.

SUBTASK 73-13-41-220-081 Examine the Fuel Nozzle and Support Assembly (01-020) for Damage or Carbon Material on the Fuel Metering Plug

Refer to Figure.

Replace fairings. Refer to VRS3583 TASK 73-13-41-300-008 (REPAIR-008).

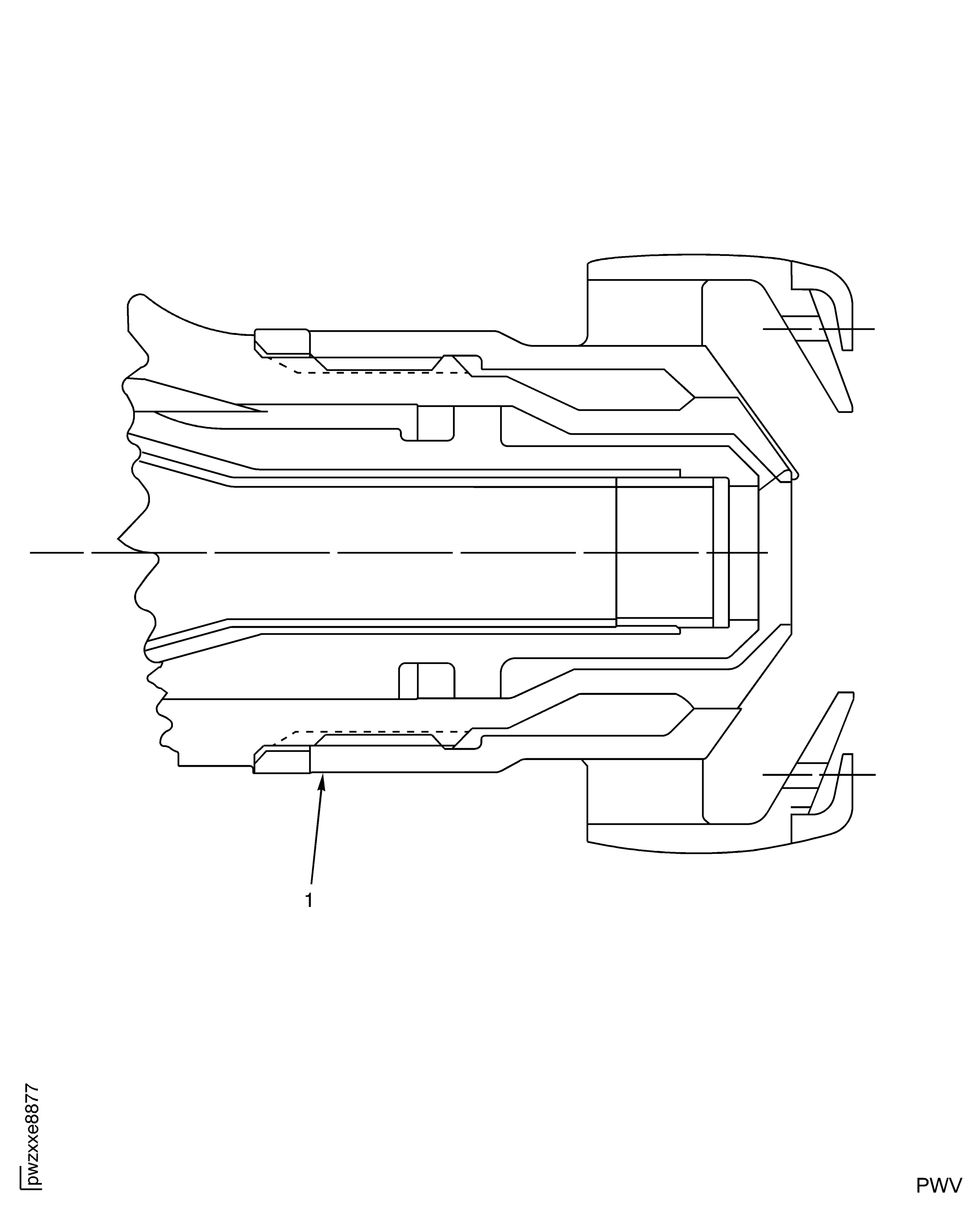

Burns, looseness or damage at locations 3 and 5.

Reject.

Burns or looseness at location 4.

Examine the fairings at locations 3 and 5 and heatshield at location 4 for burns, looseness or damage.

Accept.

Damage up to 0.050 in. (1.27 mm) deep.

Repair, VRS3583 TASK 73-13-41-300-008 (REPAIR-008).

Damage more than 0.050 in. (1.27 mm) deep.

Examine the fairings at location 3 and 5 for dents, scratches and physical damage.

Accept.

Damage up to 0.050 in. (1.27 mm) with smooth contours.

Reject.

Damage more than 0.050 in. (1.27 mm) or with sharp contours.

Cracks.

Repair, VRS3673 TASK 73-13-41-300-010 (REPAIR-010).

Examine the inner heatshield at location 4 for dents, cracks and physical damage.

Accept.

Damage up 0.010 in. (0.25 mm).

Reject.

Damage more than 0.010 in. (0.25 mm) or any cracking on the inner swirler.

Repair, VRS3589 TASK 73-13-41-300-009 (REPAIR-009).

Damage more than 0.010 in. (0.25 mm) on the outer swirler.

Examine the inner and outer swirler vanes for dents, scratches and physical damage.

SUBTASK 73-13-41-220-082 Examine the Fuel Nozzle and Support Assembly (01-020) for Burned, Loose or Damaged Fairings and Swirler Vanes

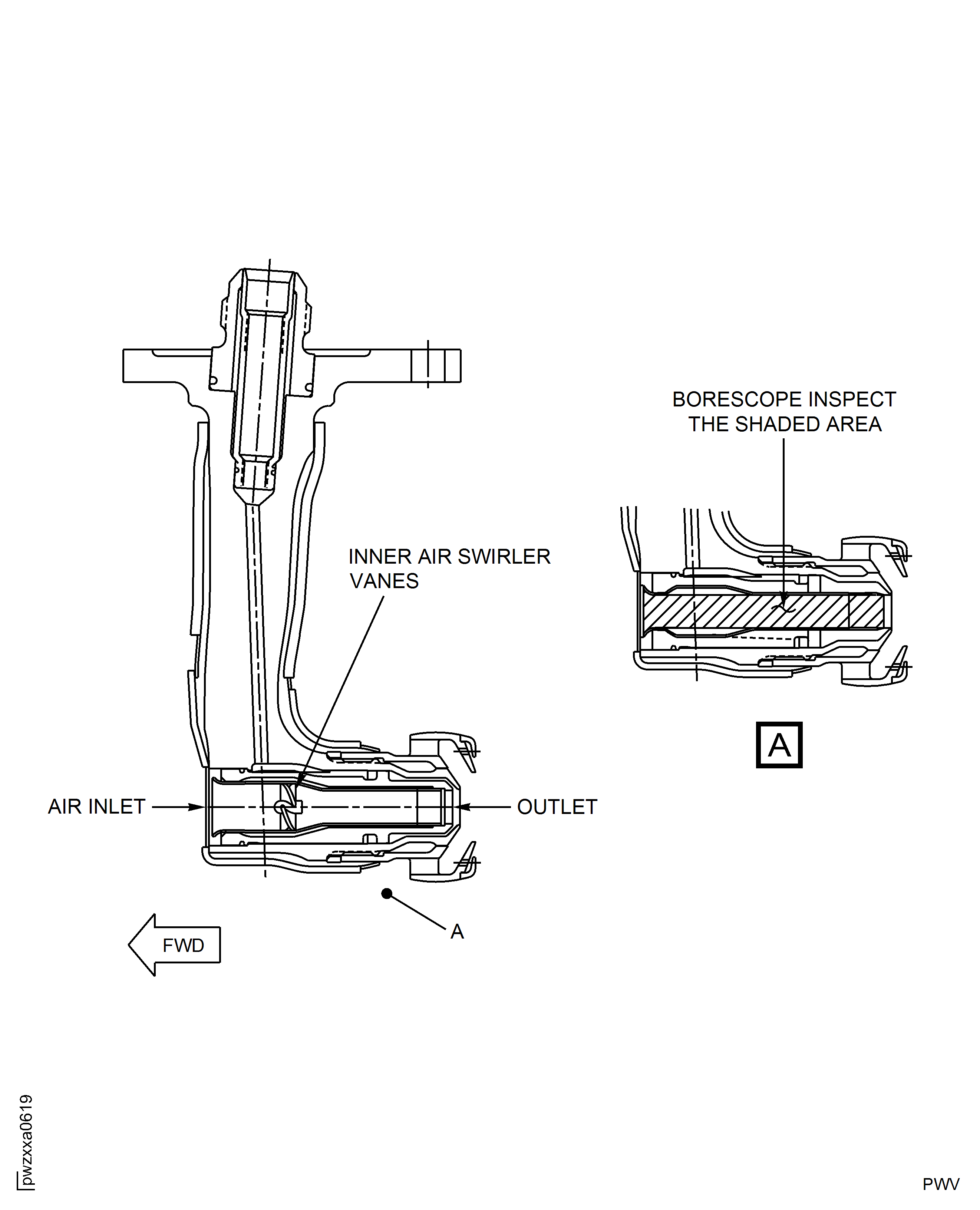

CAUTION

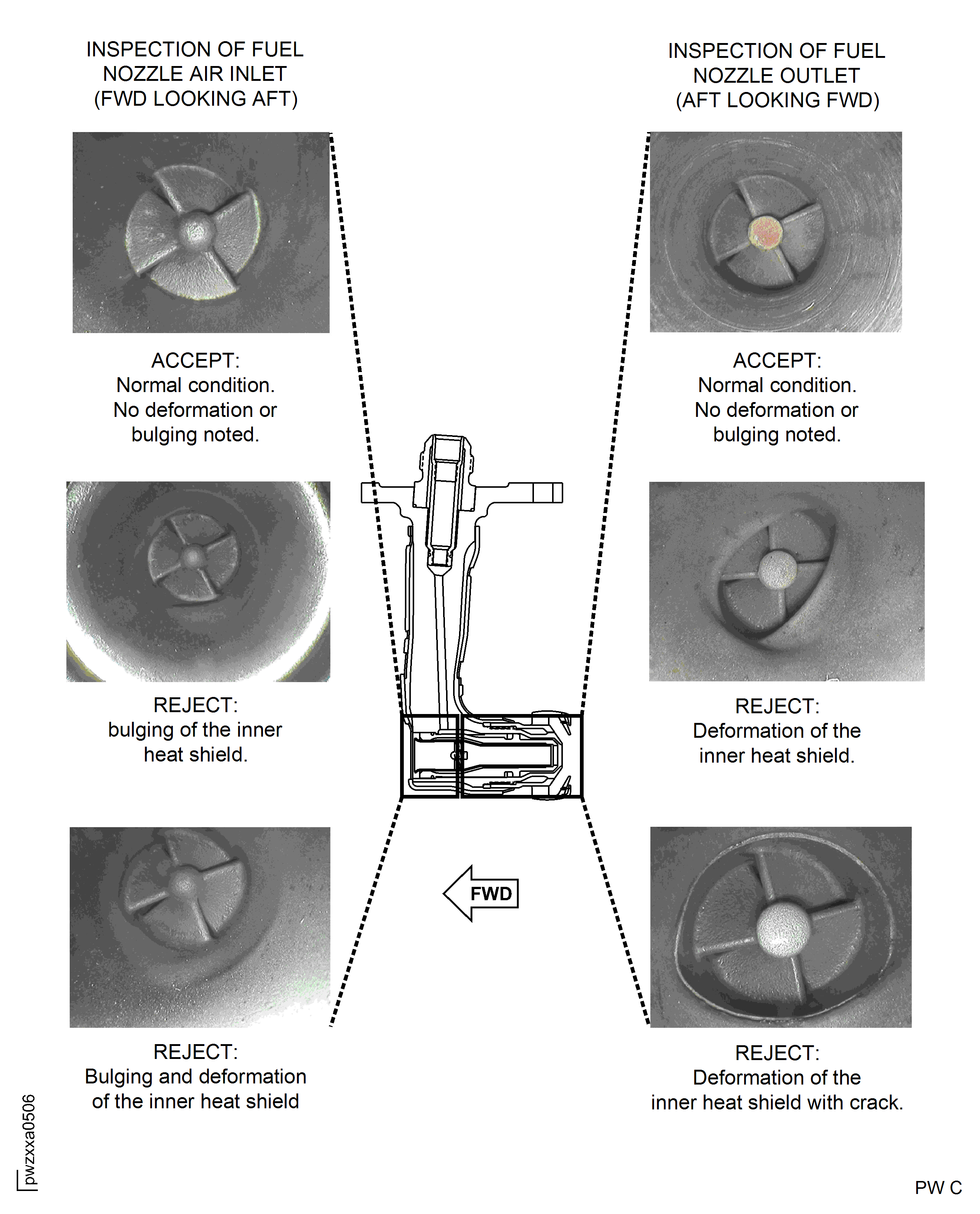

THE INNER HEATSHIELD AT LOCATION 4 IS A VERY IMPORTANT AREA WHERE DEFORMATION AND BULGING HAS BEEN OBSERVED. INSPECT THIS AREA CAREFULLY. IF YOU DO NOT OBEY THIS INSTRUCTION YOU CAN INCREASE THE POSSIBILITY OF NOT IDENTIFYING DEFORMATION OR BULGING THAT CAN RESULT IN GREATER DAMAGE.

CAUTION

THE INNER HEATSHIELD, INNER AIR SWIRLER, AND INNER AIR SWIRLER VANES ARE VERY IMPORTANT AREAS WHERE DEFORMATION AND BULGING HAVE BEEN OBSERVED. INSPECT THESE AREAS CAREFULLY. IF YOU DO NOT OBEY THESE INSTRUCTIONS YOU CAN INCREASE THE POSSIBILITY OF NOT IDENTIFYING DEFORMATION OR BULGING THAT CAN RESULT IN GREATER DAMAGE.Use a 0.158 in. (4 mm) or 0.237 in. (6 mm) borescope with a nearfield tip.

Accept.

Deformation or bulging up to 0.010 in. (0.250 mm).

Reject.

Deformation or bulging more than 0.010 in. (0.250 mm).

Examine the inner heatshield, inner air swirler and inner swirler vanes at the air inlet for deformation or bulging.

Accept.

Deformation or bulging up to 0.010 in. (0.250 mm).

Reject.

Deformation or bulging more than 0.010 in. (0.250 mm).

Examine the inner heatshield, inner air swirler and inner swirler vanes at the outlet for deformation or bulging.

SUBTASK 73-13-41-220-112 Borescope Examine the Fuel Nozzle Inner Air Swirler Vanes, Inner Air Swirler, and Inner Heatshield for Deformation or Bulging

Refer to Figure.

Repair, VRS3459 TASK 73-13-41-300-003 (REPAIR-003).

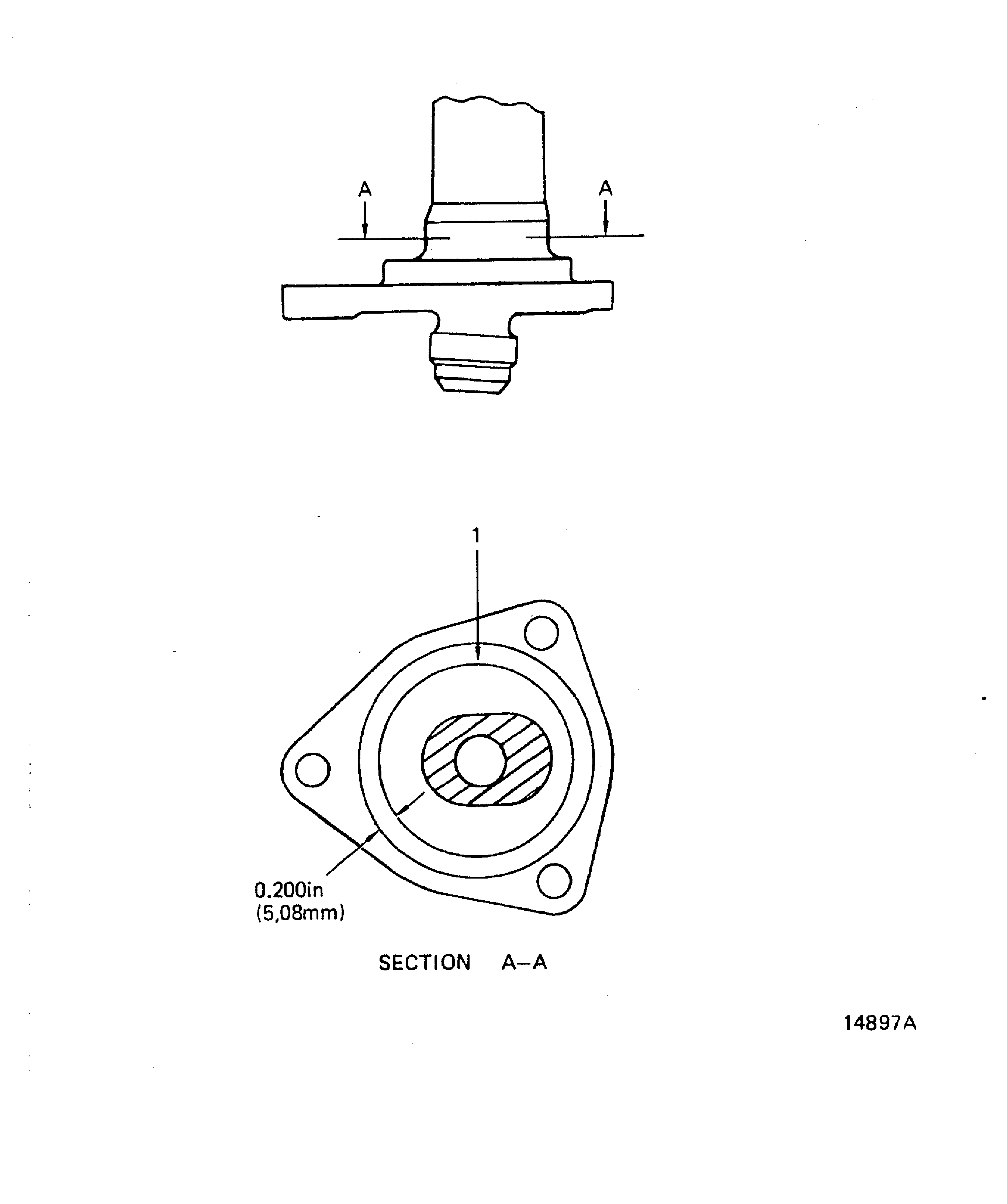

Examine the fuel nozzle and support assembly at location 1 for damage on the mounting flange sealing face.

SUBTASK 73-13-41-220-109 Examine the Fuel Nozzle and Support Assembly (01-020) for Damage on the Mounting Flange Sealing Face

Accept.

Suffix-001 is not present.

Use the vibration peening method. Mark out-001 and identify with VRS3483. Refer to SPM TASK 70-09-00-400-501.

The part is identified with suffix-001

Examine the fuel nozzle and support assembly for the suffix-001 following the basic part number.

SUBTASK 73-13-41-220-110 Examine the Fuel Nozzle and Support Assembly (01-020) for Part Number Marking

Refer to Figure.

Repair, VRS3589 (Repair-009) TASK 73-13-41-300-009.

Loose outer air swirler

Examine the fuel nozzle and support assembly at Location 1 for loose outer air swirler.

SUBTASK 73-13-41-220-111 Examine the Fuel Nozzle and Support Assembly (01-020) for Loose Outer Air Swirler

Figure: Fuel Nozzle and Support Assembly Inspection Locations

Fuel Nozzle and Support Assembly Inspection Locations

Fuel Nozzle and Support Assembly Inspection Locations

Figure: Fuel Nozzle and Support Assembly Inspection Locations

Fuel Nozzle and Support Assembly Inspection Locations

Figure: Fuel Nozzle and Support Assembly Inspection Locations

Fuel Nozzle and Support Assembly Inspection Locations

Figure: Fuel Nozzle and Support Assembly Inspection Locations

Fuel Nozzle and Support Assembly Inspection Locations

Figure: Fuel Nozzle and Support Assembly Inspection Locations

Fuel Nozzle and Support Assembly Inspection Locations

Figure: Borescope Inspection Area of the Fuel Nozzle

Borescope Inspection Area of the Fuel Nozzle

Figure: Borescope Inspection Examples

Borescope Inspection Examples