Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-45-00-430-001-C00 HP Turbine (HPT) Rotor And Stator Assembly - Assemble The HPT Rotor And Stator Assembly, Assembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to SPM TASK 70-41-00-400-501, SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to SPM TASK 70-64-02-640-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1F10026 Hydraulic hand pump | 0AM53 | IAE 1F10026 | 1 | |

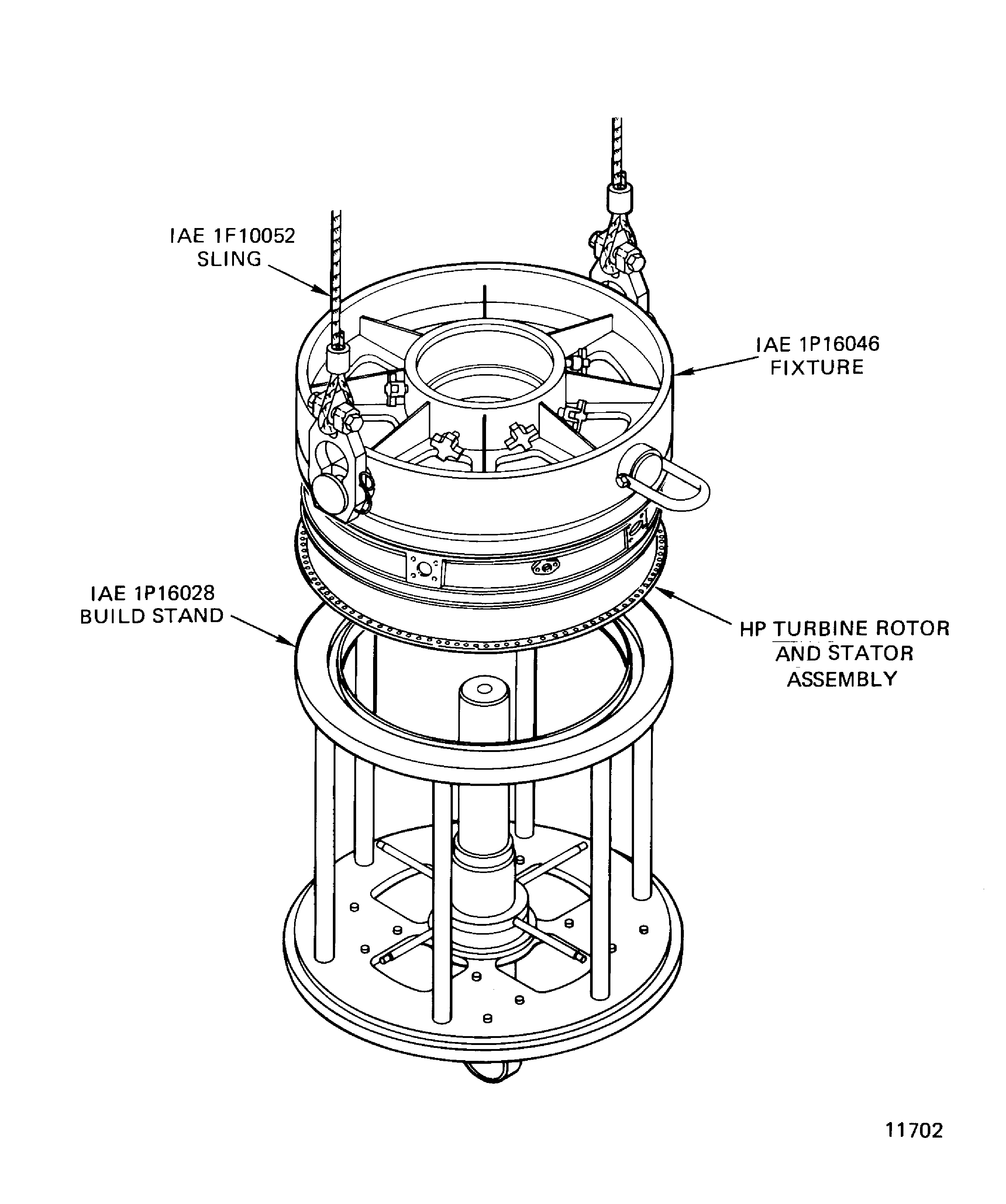

| IAE 1F10052 Two cables sling | 0AM53 | IAE 1F10052 | 1 | |

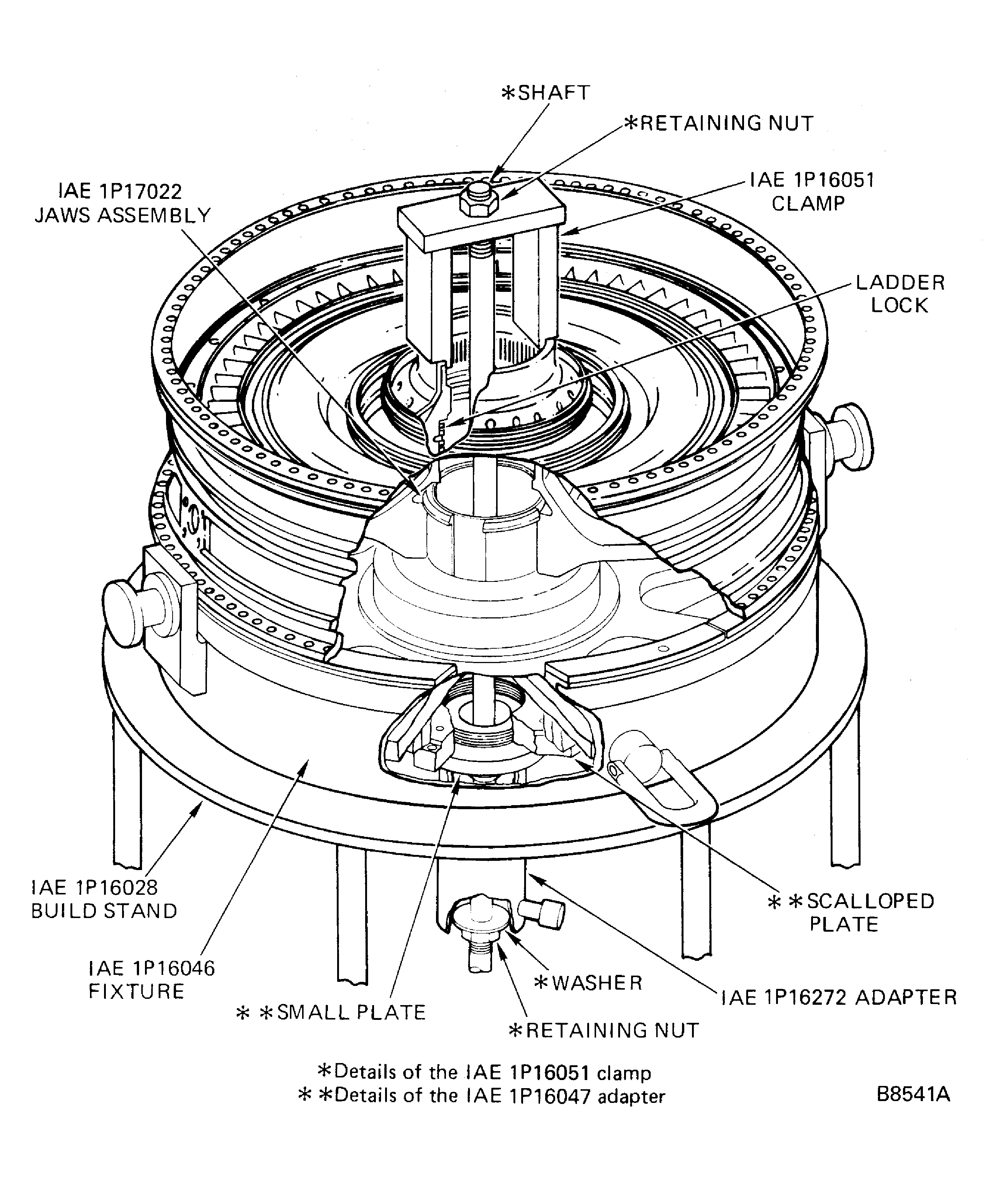

| IAE 1P16028 Build stand | 0AM53 | IAE 1P16028 | 1 | |

| IAE 1P16046 Removal/Installation fixture | 0AM53 | IAE 1P16046 | 1 | |

| IAE 1P16047 Hydraulic adapter | 0AM53 | IAE 1P16047 | 1 | |

| IAE 1P16051 Clamp | 0AM53 | IAE 1P16051 | 1 | |

| IAE 1P16052 Spline aligner | 0AM53 | IAE 1P16052 | 1 | |

| IAE 1P16063 Fixture | 0AM53 | IAE 1P16063 | 1 | |

| IAE 1P16173 Lift sling | 0AM53 | IAE 1P16173 | 1 | |

| IAE 1P16220 Heater | 0AM53 | IAE 1P16220 | 1 | |

| IAE 1P16543 Removal/Installation fixture | 0AM53 | IAE 1P16543 | 1 | |

| IAE 1P17022 Removal/installation jaws assembly | 0AM53 | IAE 1P17022 | 1 | |

| IAE 1P17026 Lift fixture | 0AM53 | IAE 1P17026 | 1 | |

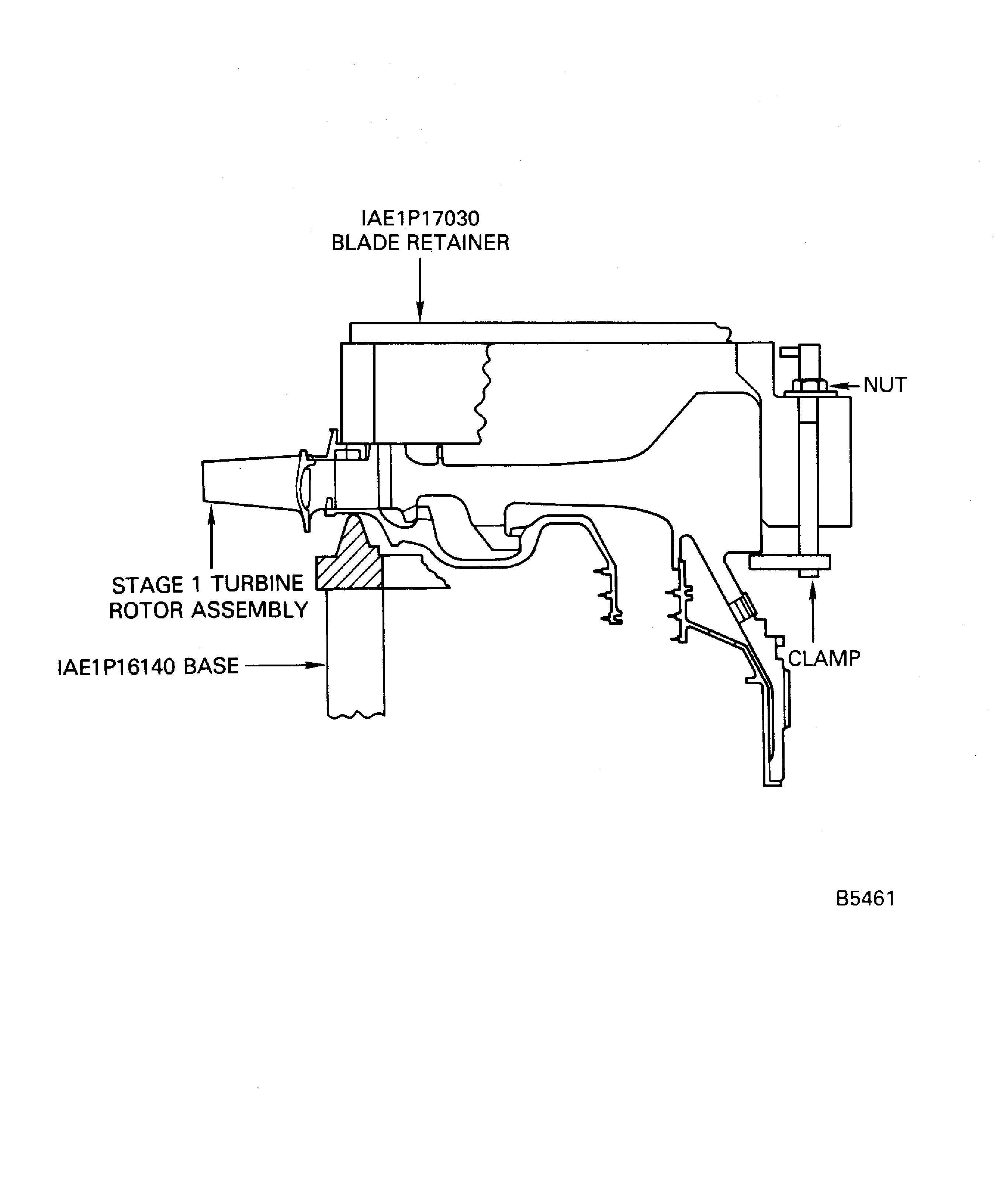

| IAE 1P17030 Blade retainer | 0AM53 | IAE 1P17030 | 1 | |

| IAE 1P17758 Protective cover | 0AM53 | IAE 1P17758 | 1 | |

| IAE 6F10027 Heater control unit | 0AM53 | IAE 6F10027 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-573 WAX BLEND, PARAFFIN | 24269 | CoMat 01-573 | ||

| CoMat 06-073 INK, METAL MARKING | LOCAL | CoMat 06-073 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 | ||

| DELETED | LOCAL | DELETED |

Safety Requirements

NONEProcedure

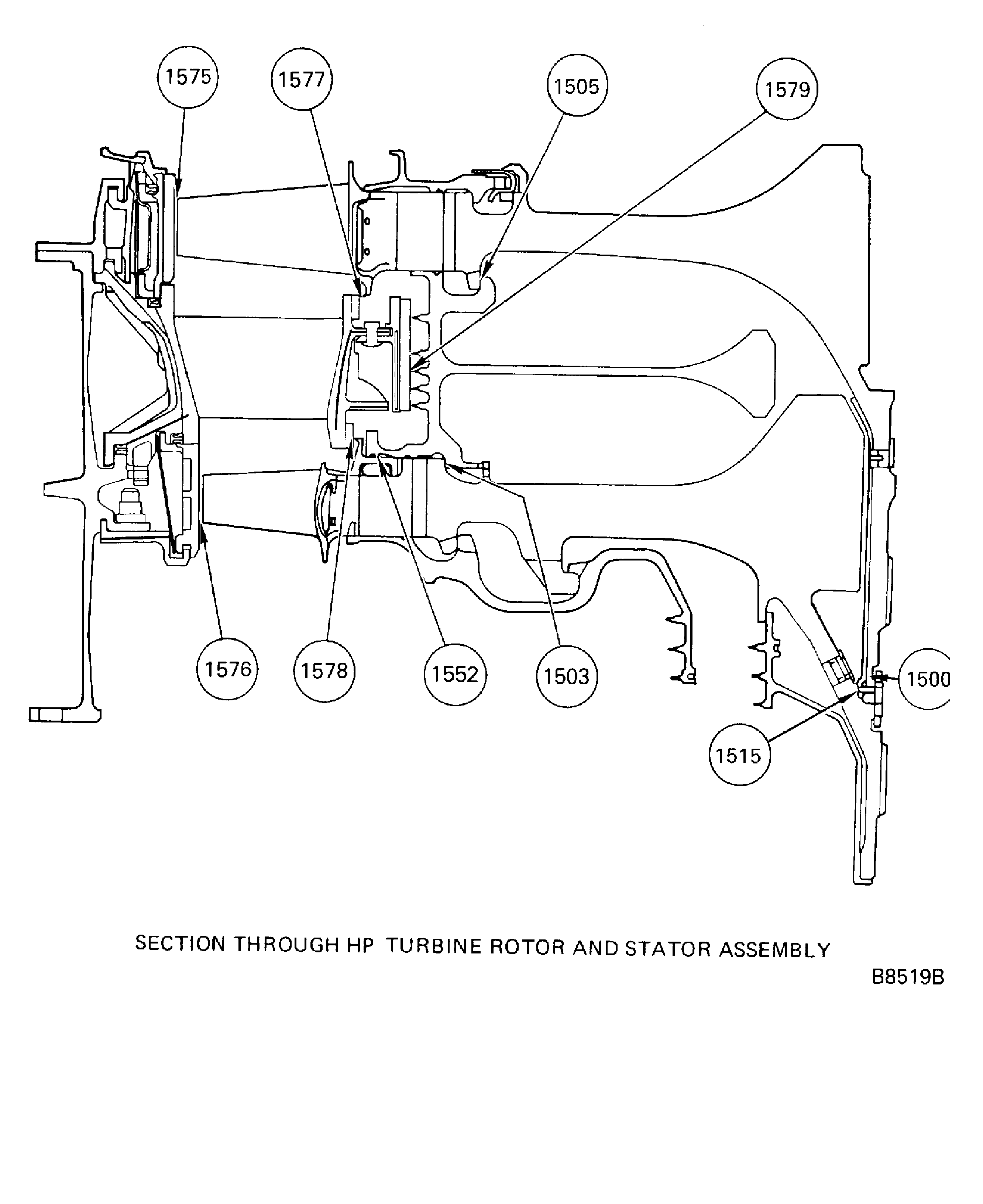

Refer to Figure.

Reference clearance at location 1500. If required use the data written as a note in TASK 72-45-31-200-000 (INSPECTION/CHECK).

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1500

Stage 2 Turbine Hub ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-011), Location Diameter

Stage 2 HPT Heatshield ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-020), Bore

Stage 2 Turbine Hub Location Diameter

5.520

Clear

Clear

5.524

0.002

0.002

Stage 2 HPT Heatshield Bore

5.526

0.012

0.012

5.532

Clear

Clear

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1500

Stage 2 Turbine Hub ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-011), Location Diameter

Stage 2 HPT Heatshield ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-020), Bore

Stage 2 Turbine Hub Location Diameter

140.208

Clear

Clear

140.310

0.050

0.050

Stage 2 HPT Heatshield Bore

140.360

0.300

0.300

140.513

Clear

Clear

SUBTASK 72-45-00-220-117 Reference Fits and Clearances of the Stage 1 Turbine Hub and the Stage 2 HPT Heatshield at Location 1500

Refer to Figure.

Reference clearance/interference at location 1503. If required, use the data written as a note in TASK 72-45-11-200-000 (INSPECTION-000) and TASK 72-45-00-200-000 (INSPECTION-000).

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1503

Stage 1 Turbine Hub HPT Stage 1 Hub (72-45-11, 01-011), Location Diameter

Stage 2 HPT Air Seal HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-080), Location Diameter

Stage 1 Turbine Hub Location Diameter

18.122

Intf

Intf

18.118

0.008

0.008

Stage 2 HPT Air Seal Location Diameter

18.126

0.000

0.000

18.122

Clear

Clear

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1503

Stage 1 Turbine Hub HPT Stage 1 Hub (72-45-11, 01-011), Location Diameter

Stage 2 HPT Air Seal HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-080), Location Diameter

Stage 1 Turbine Hub Location Diameter

460.298

Intf

Intf

460.198

0.203

0.203

Stage 2 HPT Air Seal Location Diameter

460.400

0.000

0.000

460.298

Clear

Clear

SUBTASK 72-45-00-220-103-A00 Reference Fits and Clearances of the Stage 1 Turbine Hub and Stage 2 HP Turbine Air Seal at Location 1503 (Pre SBE 72-0207)

SBE 72-0207: New Stage 2 HPT Airseal.

Refer to Figure.

Reference clearance/interference at location 1503. If required, use the data written as a note in TASK 72-45-11-200-000 (INSPECTION-000) and TASK 72-45-00-200-000 (INSPECTION-000).

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1503

Stage 1 Turbine Hub HPT Stage 1 Hub (72-45-11, 01-011), Location Diameter

Stage 2 HPT Air Seal HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-080), Location Diameter

Stage 1 Turbine Hub Location Diameter

18.122

Intf

Intf

18.118

0.008

0.0085

Stage 2 HPT Air Seal Location Diameter

18.126

0.000

0.0005

18.122

Clear

Clear

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1503

Stage 1 Turbine Hub HPT Stage 1 Hub (72-45-11, 01-011), Location Diameter

Stage 2 HPT Air Seal HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-080), Location Diameter

Stage 1 Turbine Hub Location Diameter

460.298

Intf

Intf

460.198

0.203

0.216

Stage 2 HPT Air Seal Location Diameter

460.400

0.000

0.0127

460.298

Clear

Clear

SUBTASK 72-45-00-220-103-B00 Reference Fits and Clearances of the Stage 1 Turbine Hub and Stage 2 HP Turbine Air Seal at Location 1503 (SBE 72-0207)

Refer to Figure.

Reference clearance/interference at location 1505. If required, use the data written as a note in TASK 72-45-00-200-000 (INSPECTION-000) and TASK 72-45-31-200-000 (INSPECTION-000).

Table 7. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1505

Stage 2 HPT Air Seal HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-080), Location Diameter

Stage 2 Turbine Hub ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-011), Location Diameter

Stage 2 HPT Air Seal Location Diameter

17.131

Intf

Intf

17.135

0.001

0.001

Stage 2 Turbine Hub Location Diameter

17.134

0.010

0.010

17.138

Clear

Clear

Table 8. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1505

Stage 2 HPT Air Seal HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-080), Location Diameter

Stage 2 Turbine Hub ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-011), Location Diameter

Stage 2 HPT Air Seal Location Diameter

435.127

Intf

Intf

435.229

0.025

0.025

Stage 2 Turbine Hub Location Diameter

435.204

0.254

0.254

435.305

Clear

Clear

SUBTASK 72-45-00-220-104-A00 Reference Fits and Clearances of the Stage 2 HP Turbine Air Seal and Stage 2 Turbine Hub at Location 1505 (Pre SBE 72-0145 and Pre SBE 72-0207)

Refer to Figure.

SBE 72-0145: Provide New Stage 2 Turbine Rotor Hub with Increased Front Mating Diameter.

Reference clearance at location 1505. If required, use the data written as a note in TASK 72-45-00-200-000 (INSPECTION-000) and TASK 72-45-31-200-000 (INSPECTION-000).

Table 9. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1505

Stage 2 HPT Air Seal HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-080), Location Diameter

Stage 2 Turbine Hub ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-011), Location Diameter

Stage 2 HPT Air Seal Location Diameter

17.131

Clear

Clear

17.135

0.011

0.011

Stage 2 Turbine Hub Location Diameter

17.146

0.019

0.020

17.150

Clear

Clear

Table 10. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1505

Stage 2 HPT Air Seal HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-080), Location Diameter

Stage 2 Turbine Hub ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-011), Location Diameter

Stage 2 HPT Air Seal Location Diameter

435.127

Clear

Clear

435.229

0.279

0.279

Stage 2 Turbine Hub Location Diameter

435.509

0.483

0.508

435.610

Clear

Clear

SUBTASK 72-45-00-220-104-B00 Reference Fits and Clearances of the Stage 2 HP Turbine Air Seal and Stage 2 Turbine Hub at Location 1505 (SBE 72-0145 and Pre SBE 72-0207)

Refer to Figure.

SBE 72-0207: New Stage 2 HPT Airseal.

Reference clearance/interference at location 1505. If required, use the data written as a note in TASK 72-45-00-200-000 (INSPECTION-000) and TASK 72-45-31-200-000 (INSPECTION-000).

Table 11. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1505

Stage 2 HPT Air Seal HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-080), Location Diameter

Stage 2 Turbine Hub ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-011), Location Diameter

Stage 2 HPT Air Seal Location Diameter

17.131

Intf

Intf

17.135

0.001

0.0015

Stage 2 Turbine Hub Location Diameter

17.134

0.010

0.010

17.138

Clear

Clear

Table 12. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1505

Stage 2 HPT Air Seal HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-080), Location Diameter

Stage 2 Turbine Hub ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-011), Location Diameter

Stage 2 HPT Air Seal Location Diameter

435.127

Intf

Intf

435.229

0.025

0.038

Stage 2 Turbine Hub Location Diameter

435.204

0.254

0.254

435.305

Clear

Clear

SUBTASK 72-45-00-220-104-C00 Reference Fits and Clearances of the Stage 2 HP Turbine Air Seal and Stage 2 Turbine Hub at Location 1505 (Pre SBE 72-0145 and SBE 72-0207)

SBE 72-0207: New Stage 2 HPT Airseal.

SBE 72-0145: Provide New Stage 2 Turbine Rotor Hub with Increased Front Mating Diameter.

Refer to Figure.

Reference clearance at location 1505. If required, use the data written as a note in TASK 72-45-00-200-000 (INSPECTION-000) and TASK 72-45-31-200-000 (INSPECTION-000).

Table 13. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1505

Stage 2 HPT Air Seal HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-080), Location Diameter

Stage 2 Turbine Hub ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-011), Location Diameter

Stage 2 HPT Air Seal Location Diameter

17.131

Clear

Clear

17.135

0.011

0.0105

Stage 2 Turbine Hub Location Diameter

17.146

0.019

0.020

17.150

Clear

Clear

Table 14. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1505

STAGE 2 HPT Air Seal HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-080), Location Diameter

Stage 2 Turbine Hub ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-011), Location Diameter

Stage 2 HPT Air Seal Location Diameter

435.127

Clear

Clear

435.229

0.279

0.267

Stage 2 Turbine Hub Location Diameter

435.509

0.483

0.508

435.610

Clear

Clear

SUBTASK 72-45-00-220-104-D00 Reference Fits and Clearances of the Stage 2 HP Turbine Air Seal and Stage 2 Turbine Hub at Location 1505 (SBE 72-0145 and SBE 72-0207)

Refer to Figure.

Reference clearance at location 1515. If required, use the data written as a note in TASK 72-45-11-200-001-C00 (INSPECTION-001) and TASK 72-45-31-200-001-C00 (INSPECTION-001).

Table 15. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1515

Stage 2 HPT Heatshield ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-020), Location Diameter

Stage 1 HPT Hub HPT Stage 1 Hub (72-45-11, 01-011), Location Diameter

Stage 2 HPT Heat Shield Location Diameter

5.735

Clear

Clear

5.745

0.008

0.008

Stage 1 HPT Hub Location Diameter

5.753

0.028

0.028

5.763

Clear

Clear

Table 16. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

Stage 2 HPT Heatshield ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-020), Location Diameter

Stage 1 Hub HPT Stage 1 Hub (72-45-11, 01-011), Location Diameter

Stage 2 HPT Heat Shield Location Diameter

145.669

Clear

Clear

145.923

0.203

0.203

Stage 1 Hub Location Diameter

146.126

0.711

0.711

146.380

Clear

Clear

SUBTASK 72-45-00-220-105 Reference Fits and Clearances of the Stage 2 HPT Heat Shield and Stage 1 HPT Hub at Location 1515.

Refer to Figure.

NOTE

The fit at this location has been calculated. Parts were measured before they were assembled to get this fit. Refer to TASK 72-45-10-440-001-C00 (ASSEMBLY, CONFIG-003).

SUBTASK 72-45-00-220-106 Reference Fits and Clearances of the Stage 1 HP Turbine Air Seal (Rear) Stage 1 HP Turbine Blade and Stage 1 Turbine Hub at Location 1552

Refer to Figure.

Measure the clearance at location 1575 after assembly.

Table 17. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1575

Stage 2 Turbine Rotor Assembly Blade Tip

Clearance

0.050 To 0.059 Average Clearance

NOTE

Axis of Turbine Case and Vane Assembly is 0.010 below the engine centerline.Table 18. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1575

Stage 2 Turbine Rotor Assembly Blade Tip

Clearance

1.270 To 1.499 Average Clearance

NOTE

Axis of Turbine Case and Vane Assembly is 0.254 below the engine centerline.

SUBTASK 72-45-00-220-107 Reference Fits and Clearances of the Stage 2 Turbine Rotor Assembly Blade Tip at Location 1575

Refer to Figure.

Measure the clearance at location 1576 after assembly.

Table 19. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1576

Stage 1 Turbine Rotor Assembly Blade Tip

Clearance

0.030 to 0.061 average clearance

NOTE

Axis Of Turbine Case And Vane Assembly Is 0.010 Below The Engine Centerline.Table 20. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1576

Stage 1 Turbine Rotor Assembly Blade Tip

Clearance

0.760 to 1.550 average clearance

NOTE

Axis Of Turbine Case And Vane Assembly Is 0.254 Below The Engine Centerline.

SUBTASK 72-45-00-220-108 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly Blade Tip at Location 1576

Refer to Figure.

Reference clearance at location 1577. If required, use the data written as a note in TASK 72-45-32-200-000 (INSPECTION-000) and TASK 72-45-20-200-000 (INSPECTION-000).

Table 21. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1577

Stage 2 Turbine Rotor Assembly

Seal Tip Radial Clearance

Clear

0.010

0.064

Clear

NOTE

Axis Of Turbine Case And Vane Assembly Is 0.010 Below The Engine Centerline.Table 22. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1577

Stage 2 Turbine Rotor Assembly

Seal Tip Radial Clearance

Clear

0.254

1.626

Clear

NOTE

Axis Of Turbine Case And Vane Assembly Is 0.254 Below The Engine Centerline.

SUBTASK 72-45-00-220-109 Reference Fits and Clearances of the Stage 2 Turbine Rotor Assembly Seal Tip at Location 1577

Refer to Figure.

Reference clearance at location 1578. If required, use the data written as a note in TASK 72-45-14-200-000 (INSPECTION-000) and TASK 72-45-20-200-000 (INSPECTION-000).

Table 23. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1578

Stage 1 Turbine Rotor Assembly

Seal Tip Radial Clearance

Clear

0.026

0.076

Clear

NOTE

Axis Of Turbine Case And Vane Assembly Is 0.010 Below The Engine Centerline.Table 24. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1578

Stage 1 Turbine Rotor Assembly

Seal Tip Radial Clearance

Clear

0.66

1.93

Clear

NOTE

Axis Of Turbine Case And Vane Assembly Is 0.254 Below The Engine Centerline.

SUBTASK 72-45-00-220-110 Reference Fits and Clearances of the Stage 1 Turbine Rotor Assembly Seal Tip at Location 1578

Refer to Figure.

Reference clearance at location 1579. If required, use the data written as a note in TASK 72-45-00-200-000 (INSPECTION-000) and Measure the stage 2 vane inner honeycomb seal diameter. To find the clearance subtract the stage 2 knife-edge seal diameter from the stage 2 vane inner honeycomb seal diameter.

Table 25. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1579

Stage 2 HPT Air Seal Tip Radial

Clearance

Clear

Clear

0.026

0.026

0.063

0.069

Clear

Clear

NOTE

Axis Of Turbine Case And Vane Assembly Is 0.010 Below The Engine Centerline.Table 26. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 1579

Stage 2 HPT Air Seal Tip Radial

Clearance

Clear

Clear

0.66

0.66

1.60

1.753

Clear

Clear

NOTE

Axis Of Turbine Case And Vane Assembly Is 0.254 Below The Engine Centerline.

SUBTASK 72-45-00-220-111 Reference Fits and Clearances of the Stage 2 HP Turbine Air Seal Tip at Location 1579

Refer to Figure.

Remove the IAE 1P17030 Blade retainer 1 off from the rear side of the turbine rotor assembly.

SUBTASK 72-45-00-430-087 Remove the Blade Retainer from the Stage 1 Turbine Rotor Assembly

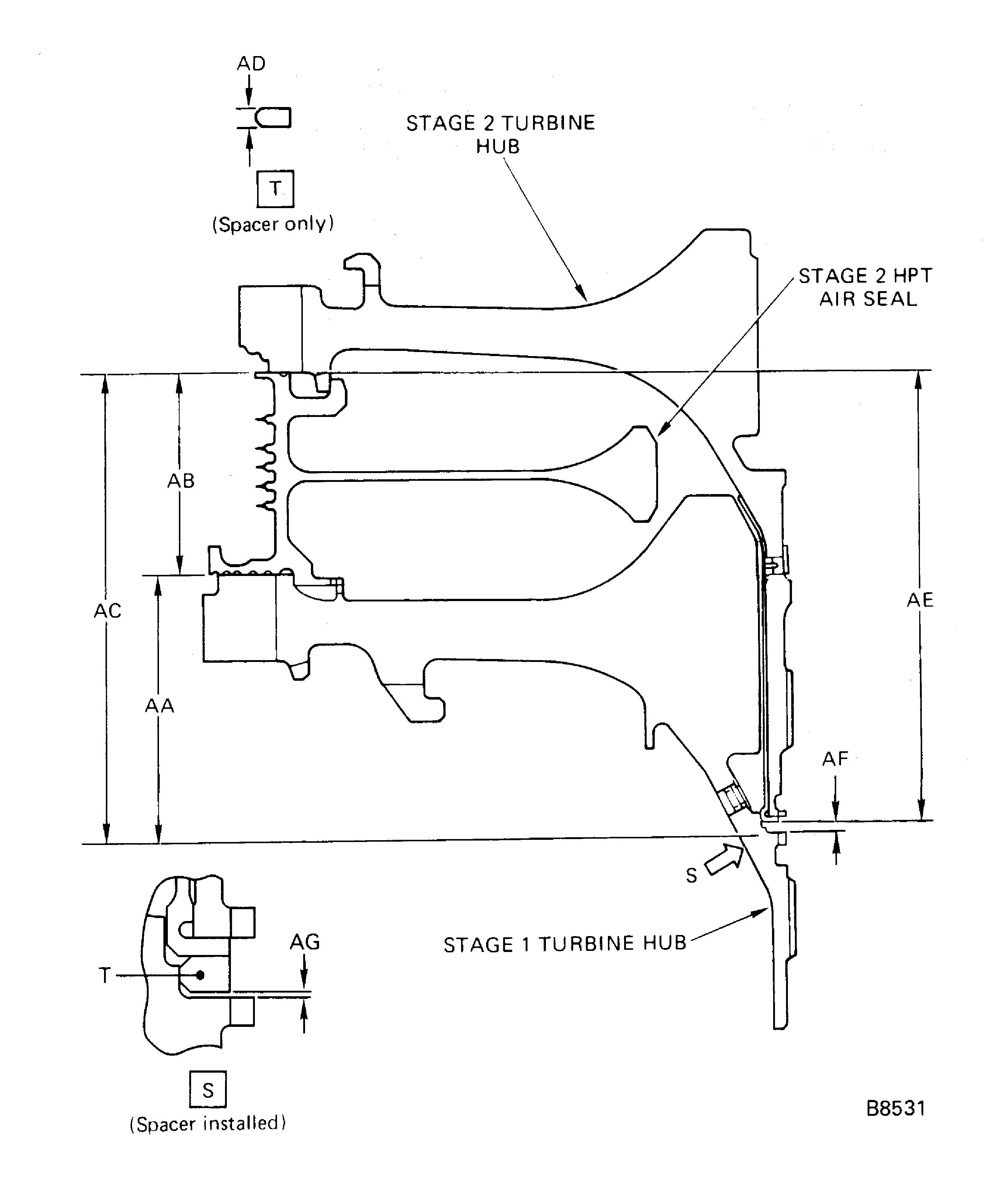

Get dimension AA from the Stage 1 Turbine Rotor Assembly paperwork.

NOTE

You must inspect the Stage 2 HP Turbine airseal for bore axial position before you install it again. Refer to TASK 72-45-00-200-000 (INSPECTION/CHECK-000).

Find dimension AC by these steps:

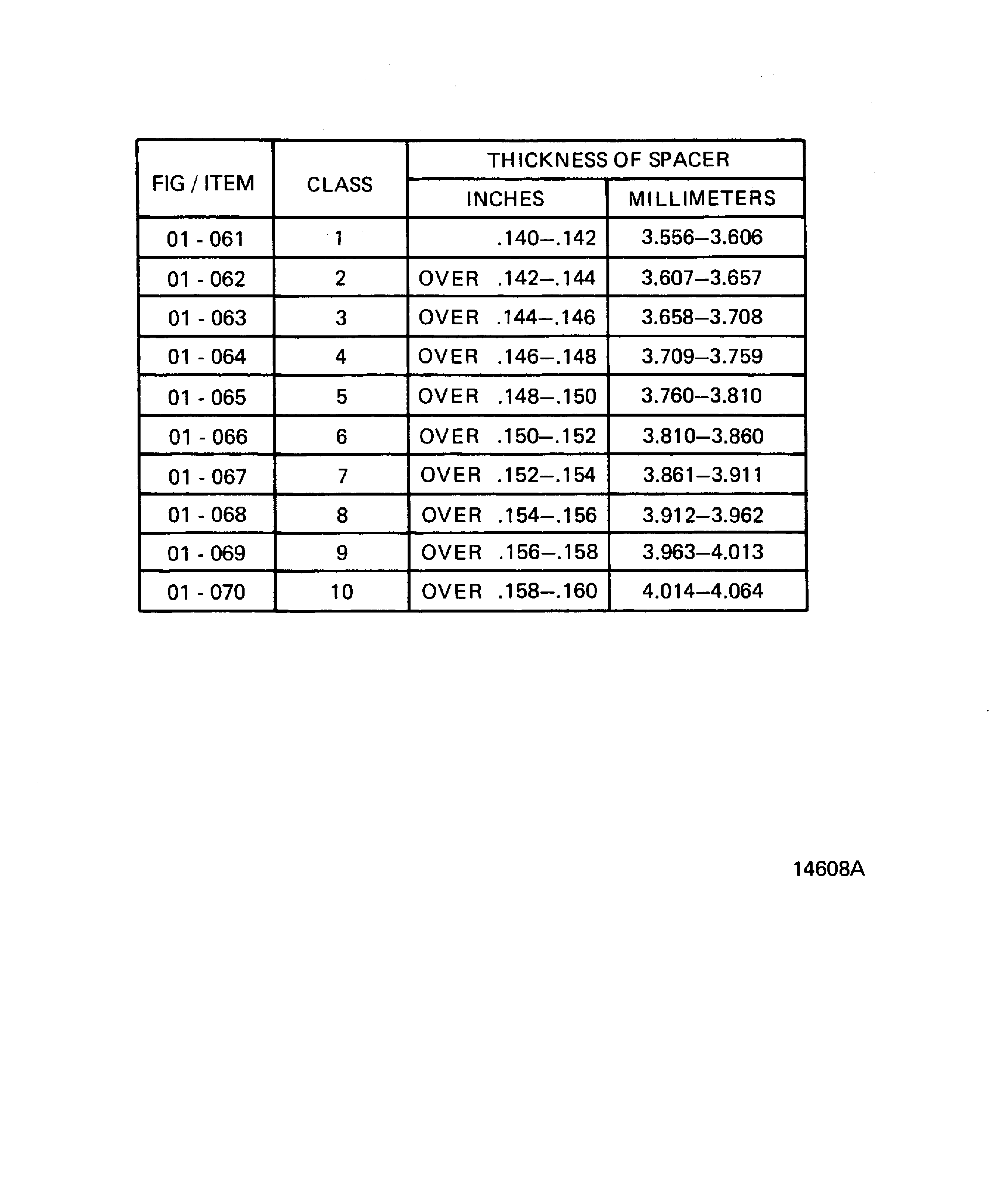

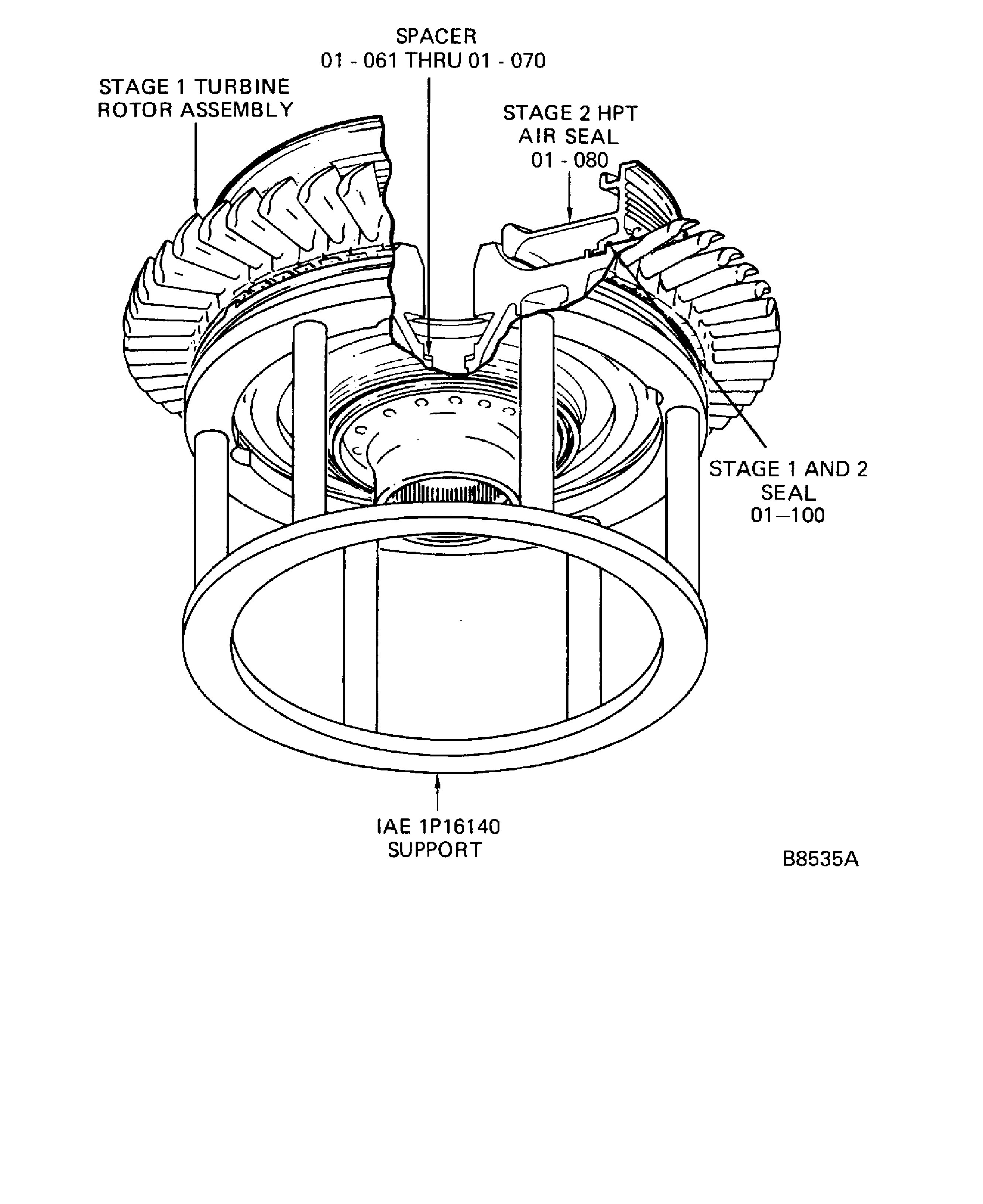

Find the No. 4 bearing spacer HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-061 thru HP Turbine (HPT) Rotor And Stator Assembly 01-070) thickness and get the correct class.

Use dimension AD and make a selection from the table given in Figure for the No. 4 bearing spacer class.

NOTE

This procedure is not necessary if the engine number is marked on the spacer.Mark V and the five numbers (V-XXXXX) of the engine number on the spacer adjacent to the part number. Use the vibration peen method. Refer to SPM TASK 70-09-00-400-501.

SUBTASK 72-45-00-430-088 Find the Thickness of the Spacer (Dimension AD)

Make a temporary mark with CoMat 06-073 INK, METAL MARKING on the Stage 2 HPT air seal and on the Stage 1 Turbine Rotor Assembly. Refer to SPM TASK 70-09-00-400-501.

SUBTASK 72-45-00-430-089 Find the Locations for the Stack of the Stage 1 Turbine Rotor Assembly, the Stage 2 HP Air Seal and the Stage 2 Turbine Rotor Assembly

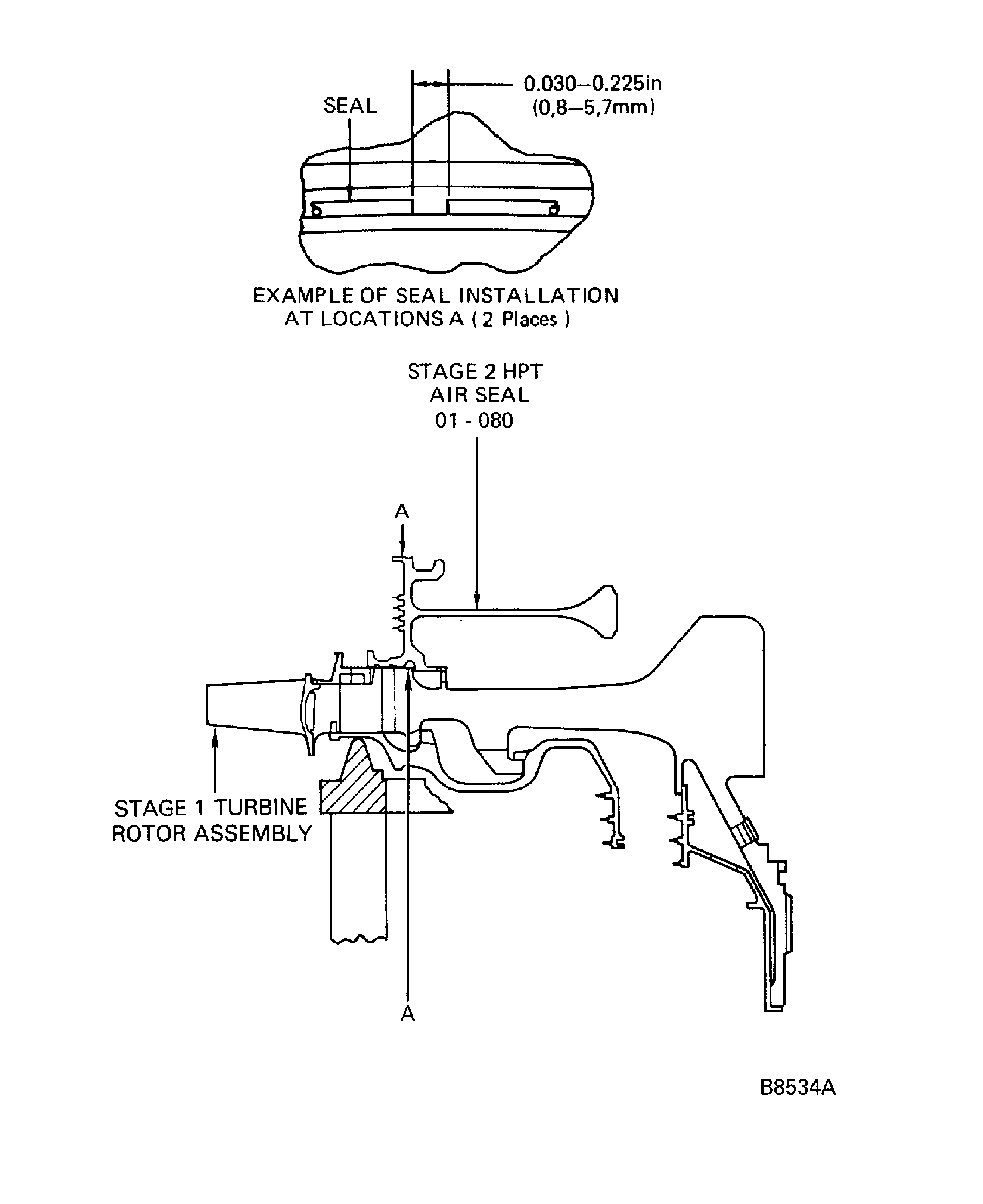

Put the stage 2 HPT air seal HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-080) on a work bench with the larger outer diameter flange up.

Hold the seal in position with CoMat 01-573 WAX BLEND, PARAFFIN. Remove the wax that is not necessary.

Install the stage 1 and 2 seal HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-100).

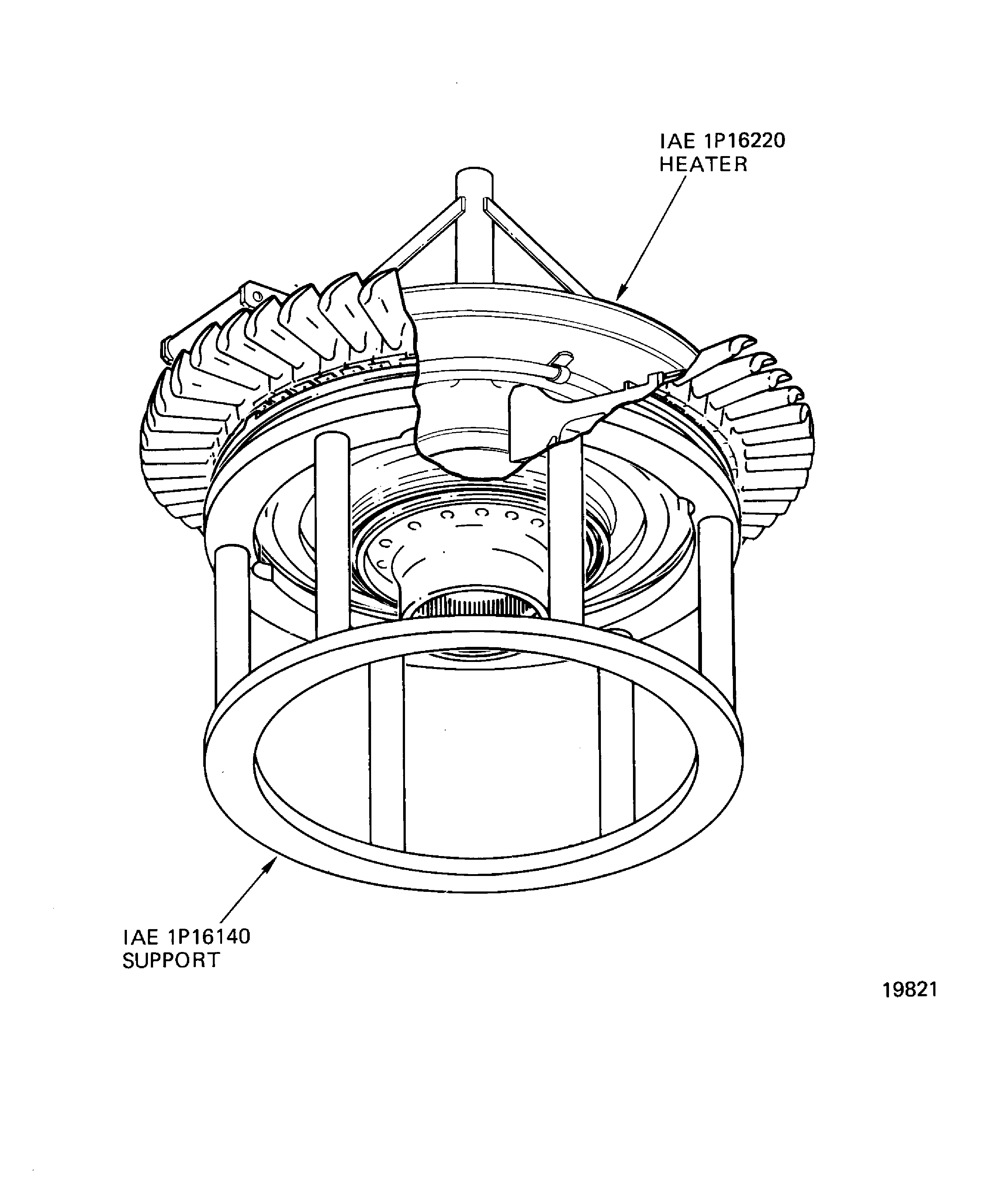

Install the IAE 1P16220 Heater 1 off on the rear side of the stage 1 turbine rotor assembly, Figure.

Connect the IAE 6F10027 Heater control unit 1 off to the heater.

SUBTASK 72-45-00-430-090 Install the Stage 2 HPT Air Seal

NOTE

If ten or more of the HPT Stage 2 vane ring inner segments HPT Stage 2 Ring Segment And Vane Cluster (72-45-24, 02-120 and/or HPT Stage 2 Ring Segment And Vane Cluster72-45-24, 02-320) have new honeycomb, the stage 2 air seal must be new or have the knife edge coating reapplied (per VRS3209) to prevent knife edge cracking.Refer to Figure.

SUBTASK 72-45-00-430-091 Do a Check to Make Sure the Stage 2 HPT Air Seal is Installed Correctly

Refer to Figure.

SUBTASK 72-45-00-430-092 Install the No. 4 Bearing Spacer

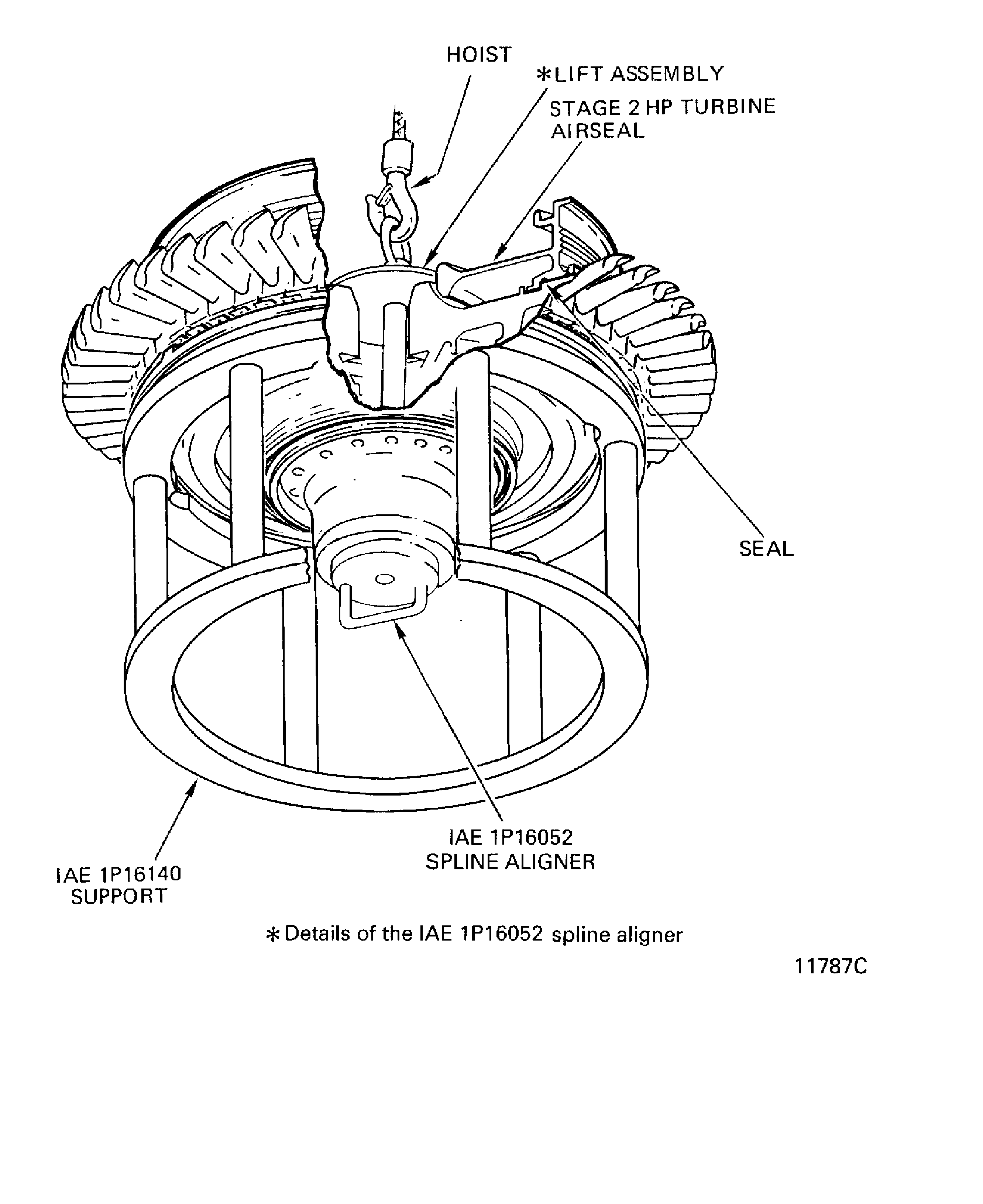

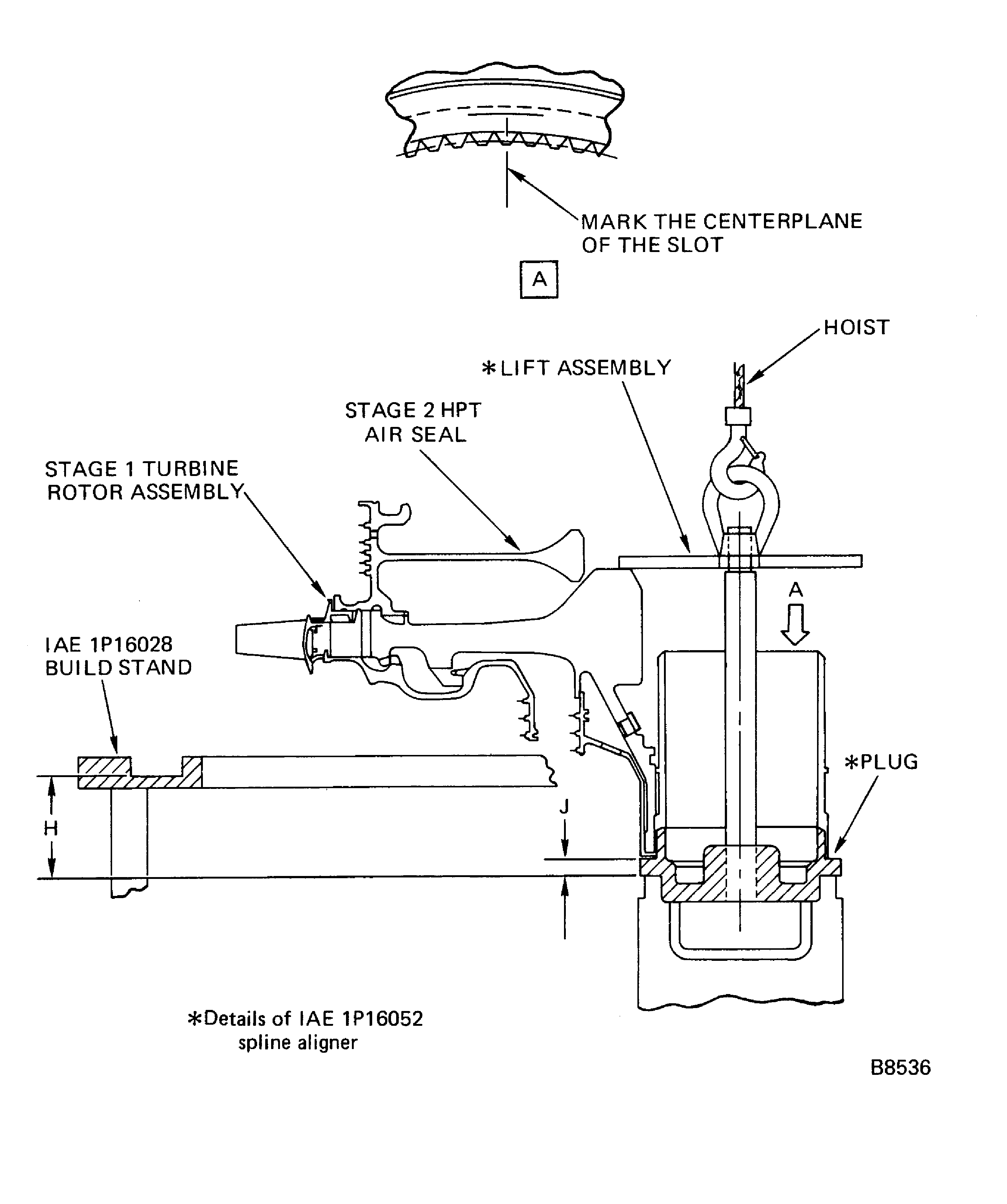

Measure the thickness of the plug flange at dimension J on the IAE 1P16052 Spline aligner 1 off.

Adjust the center adapter on the build stand to set dimension H plus or minus 0.005 in. (0.127 mm), Figure.

Adjust the center adapter on the IAE 1P16028 Build stand 1 off.

NOTE

Measure the thickness in three locations and average.

SUBTASK 72-45-00-430-093 Set the Stage 1 Turbine Rotor Assembly Build Stand

Install the plug of the IAE 1P16052 Spline aligner 1 off to the inner diameter of the Stage 1 Turbine Rotor Assembly at the small end. Thread the lift assembly in to the opposite end until the bar is tight against the rear face of the rotor hub.

Attach a hoist to the lift assembly. Lift the Stage 1 Rotor Assembly from the support and install the Stage 1 Rotor Assembly into the IAE 1P16028 Build stand 1 off with the plug detail positioned in to the center adapter on the stand.

Make a mark on the front surface of the spline plug to show the centerline location of one of the 14 internal slots. Use CoMat 06-073 INK, METAL MARKING. Refer to SPM TASK 70-09-00-400-501, Figure.

SUBTASK 72-45-00-430-094 Install the Stage 1 Turbine Rotor Assembly with the Airseal to the Build Stand

Refer to Figure.

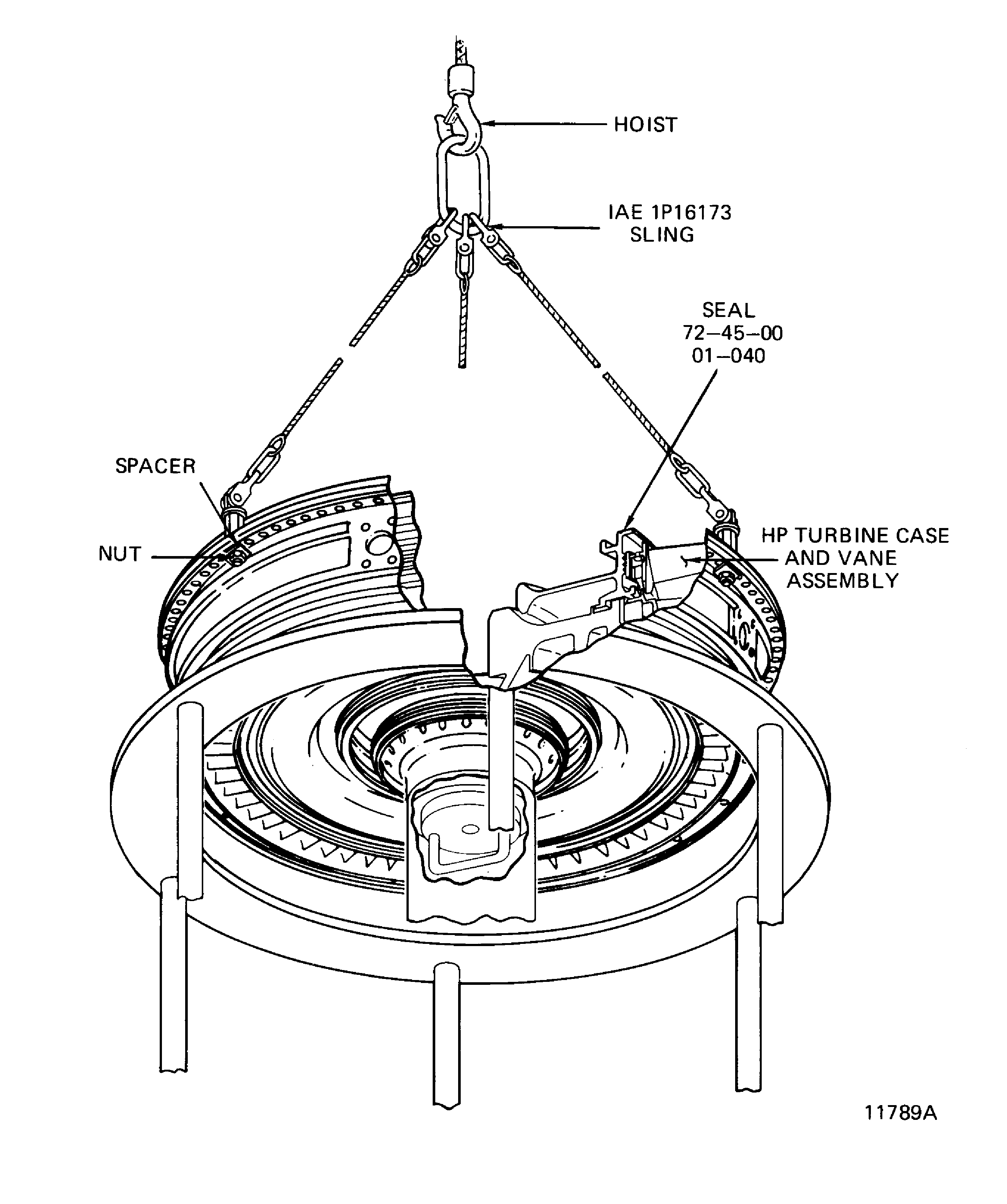

Remove the IAE 1P17758 Protective cover 1 off from the rear flange of the case and Vane Assembly.

Attach the IAE 1P16173 Lift sling 1 off to the rear flange of the HP Turbine Case and Vane Assembly. Secure with the spacers and the nuts.

CAUTION

BE CAREFUL WHEN YOU INSTALL THE CASE AND VANE ASSEMBLY OVER THE STAGE 1 TURBINE ROTOR ASSEMBLY. DAMAGE TO THE KNIFE-EDGE SEALS ON THE STAGE 2 HPT AIR SEAL AND STAGE 1 HPT BLADE TIPS COULD OCCUR.Lower the case and vane assembly in to position over the Stage 1 Rotor Assembly. Remove the sling and the hoist from the case and vane assembly.

SUBTASK 72-45-00-430-095 Install the HP Turbine Case and Vane Assembly

Hold the seal in position with CoMat 01-573 WAX BLEND, PARAFFIN. Remove the wax that is not necessary.

Install the stage 1 and 2 seal HP Turbine (HPT) Rotor And Stator Assembly (72-45-00, 01-040).

SUBTASK 72-45-00-430-096 Install the Stage 1 and 2 Seal on the Stage 2 HPT Air Seal

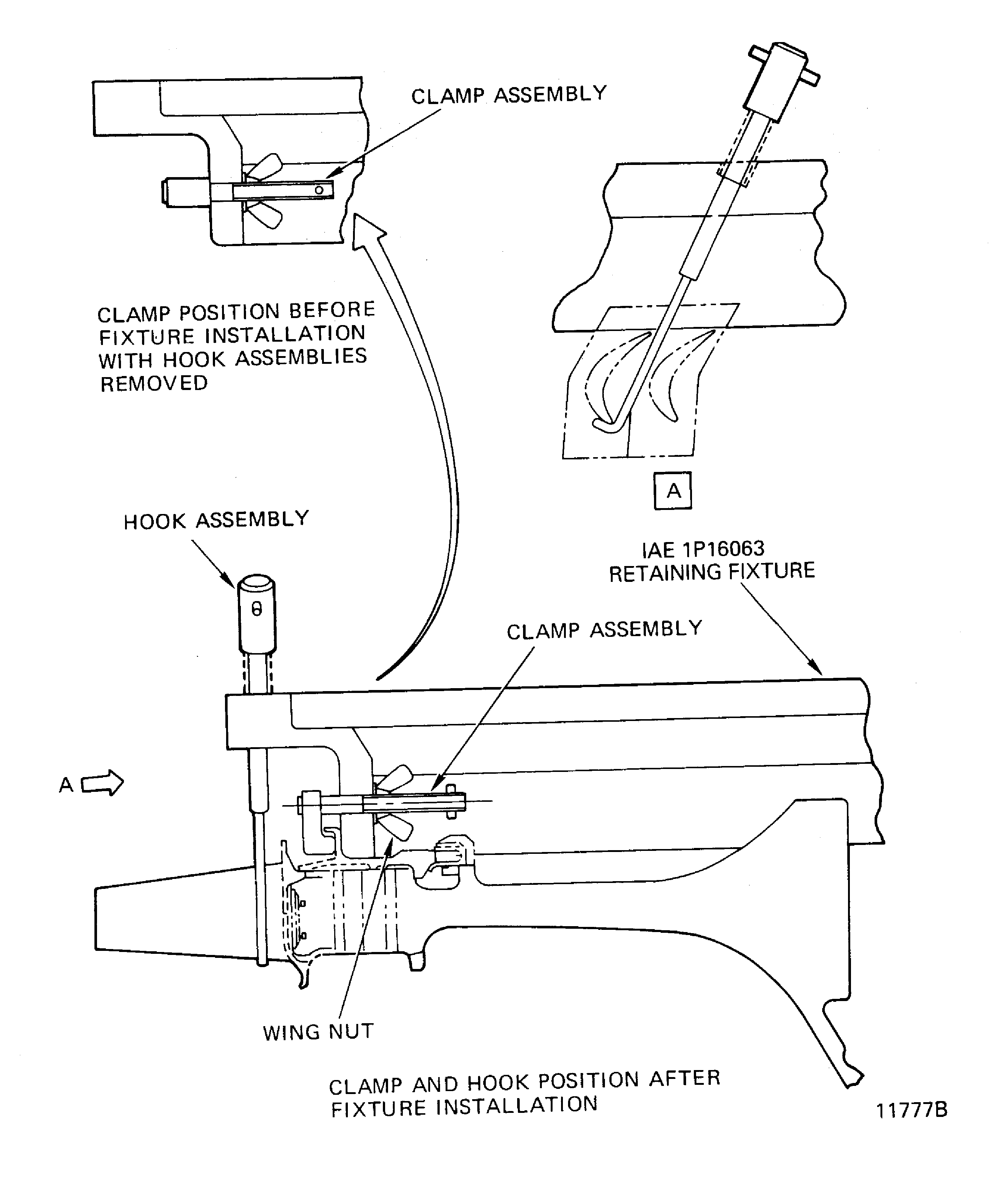

Refer to Figure.

Install the hook assemblies that remain by the procedure given in Step.

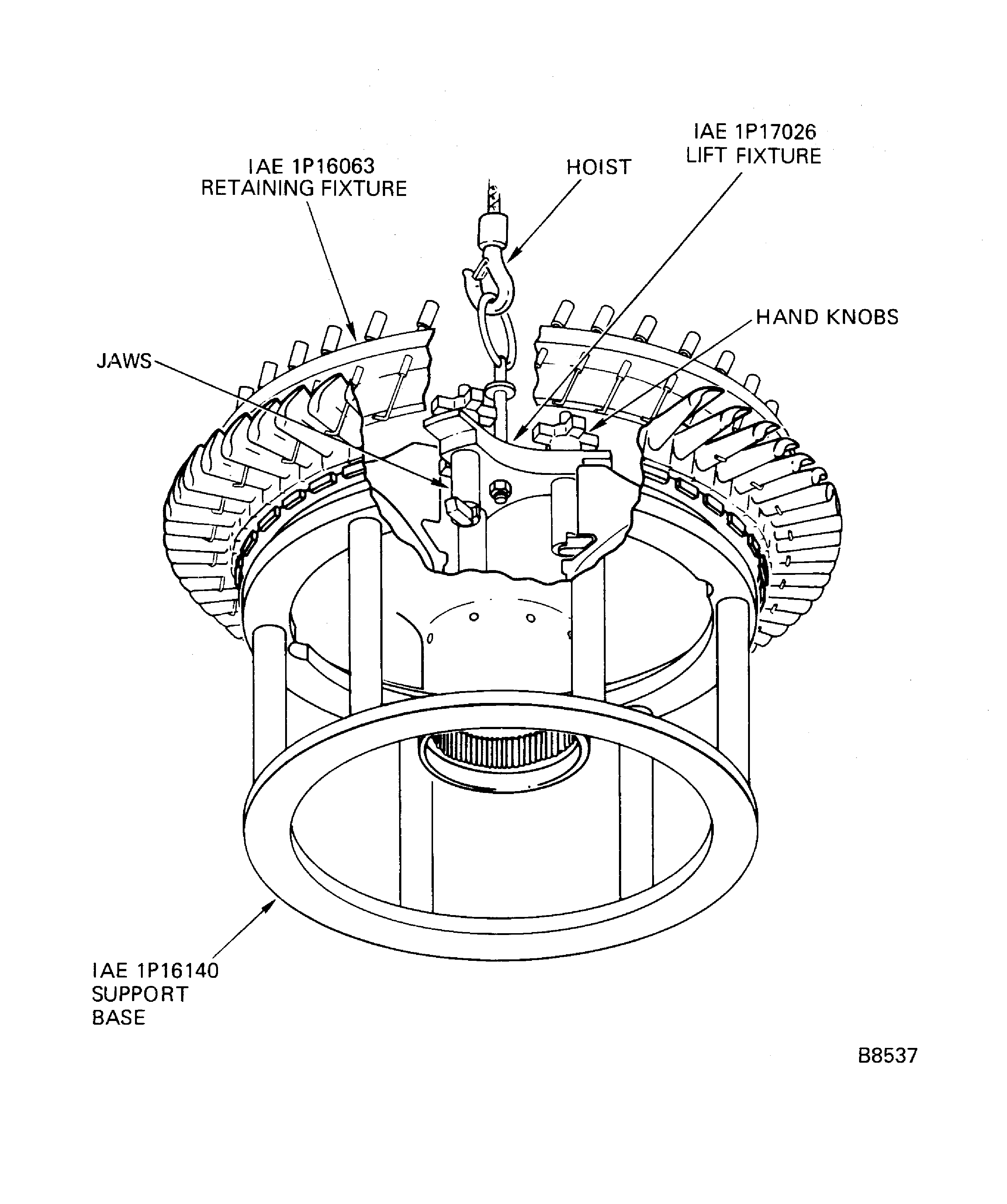

Prepare the IAE 1P16063 Fixture 1 off.

SUBTASK 72-45-00-430-097 Install the Retaining Fixture to the Stage 2 Turbine Rotor Assembly

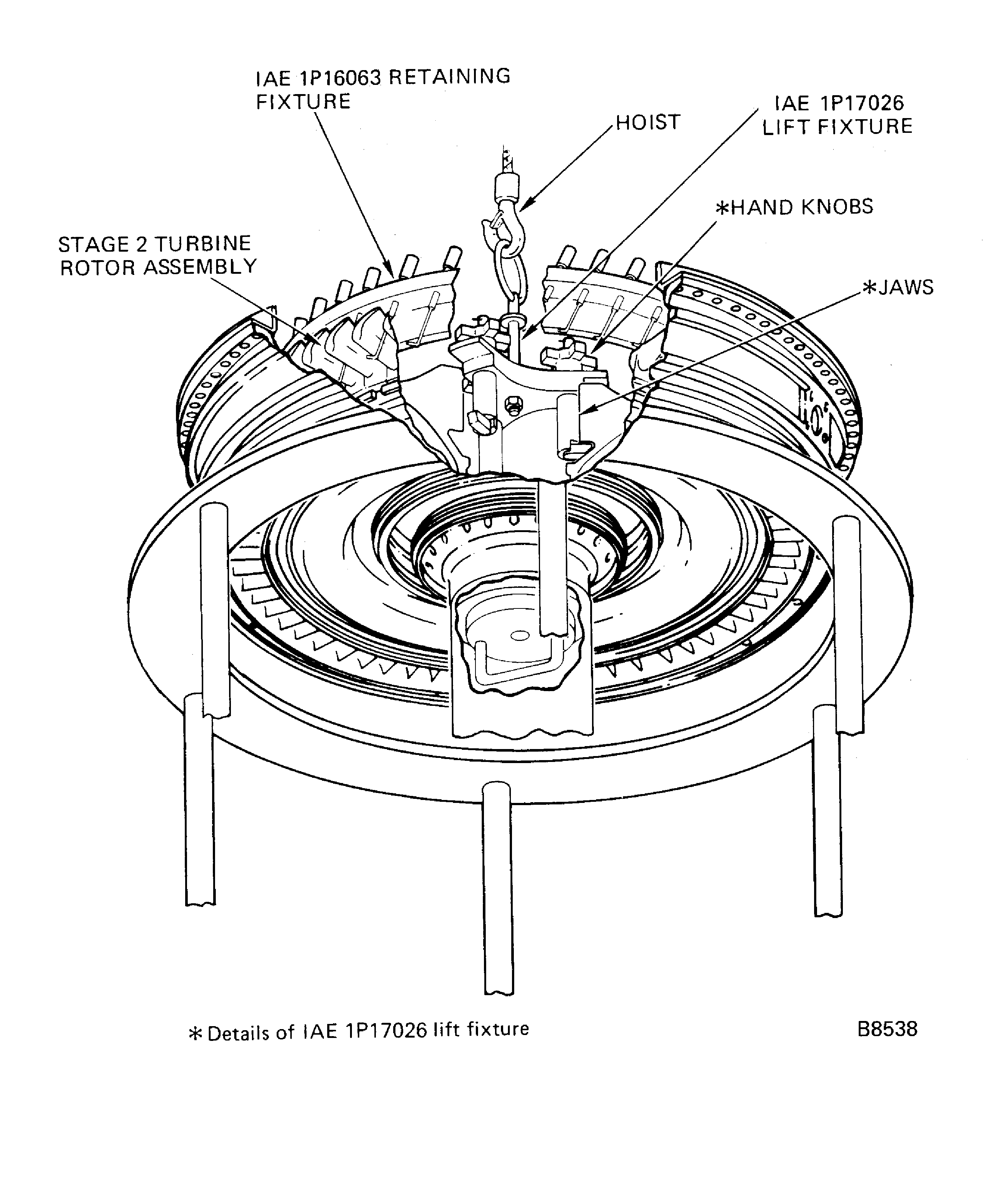

Turn the three jaws on the IAE 1P17026 Lift fixture 1 off inward.

SUBTASK 72-45-00-430-098 Install the Lift Fixture to the Rear of the Stage 2 HP Turbine Rotor

Refer to Figure.

SUBTASK 72-45-00-430-099 Install the Stage 2 Turbine Rotor Assembly

Refer to Figure.

SUBTASK 72-45-00-430-100 Remove the Lift Fixture

Refer to Figure.

SUBTASK 72-45-00-430-101 Remove the Retaining Fixture

Refer to Figure.

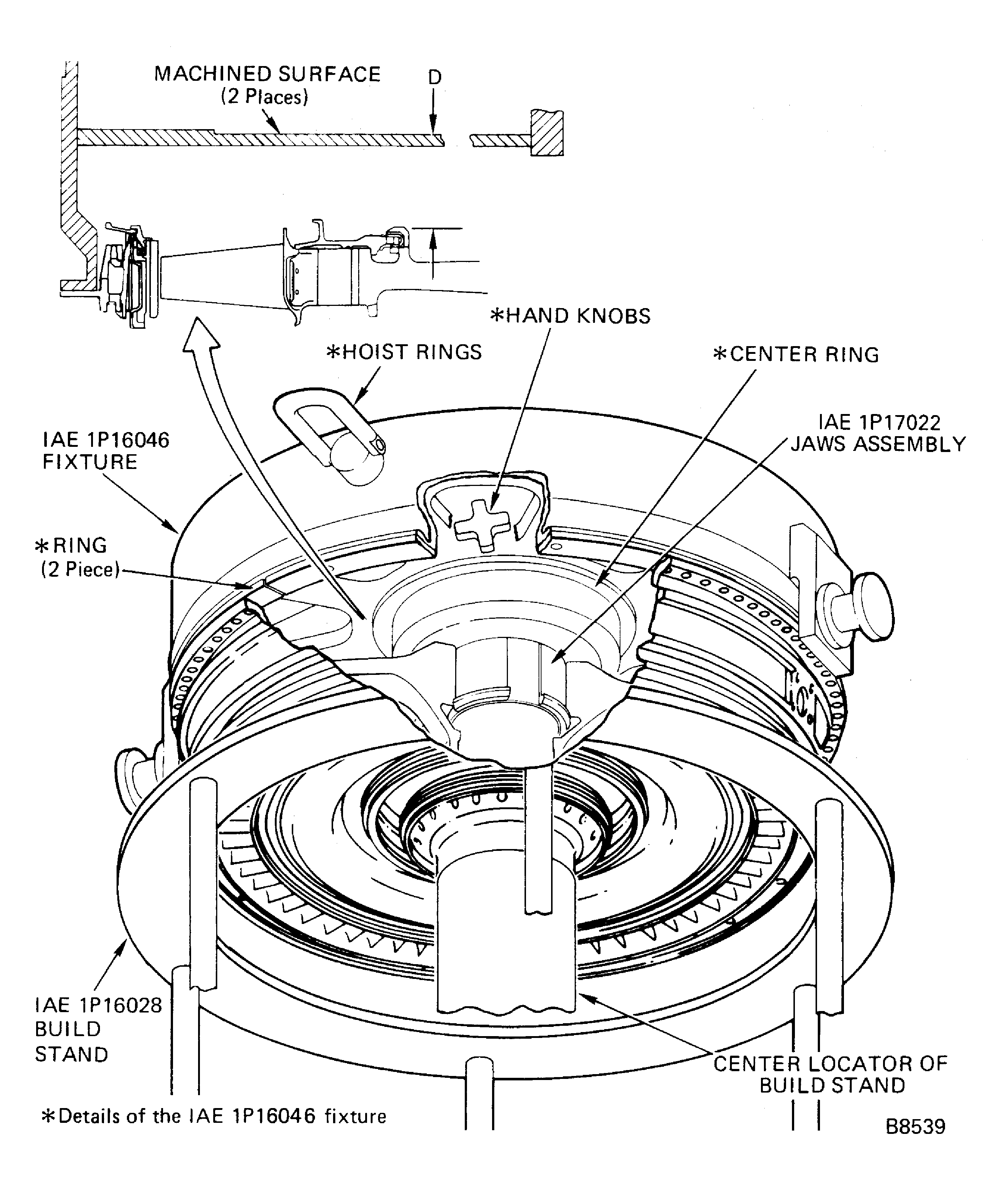

Install the IAE 1P16046 Removal/Installation fixture or IAE 1P16543 Removal/Installation fixture 1 off.

Install the IAE IAE 1P17022 Removal/installation jaws assembly 1 off.

SUBTASK 72-45-00-430-102 Install the Tooling to Position the HP Turbine Rotor and Stator Assembly

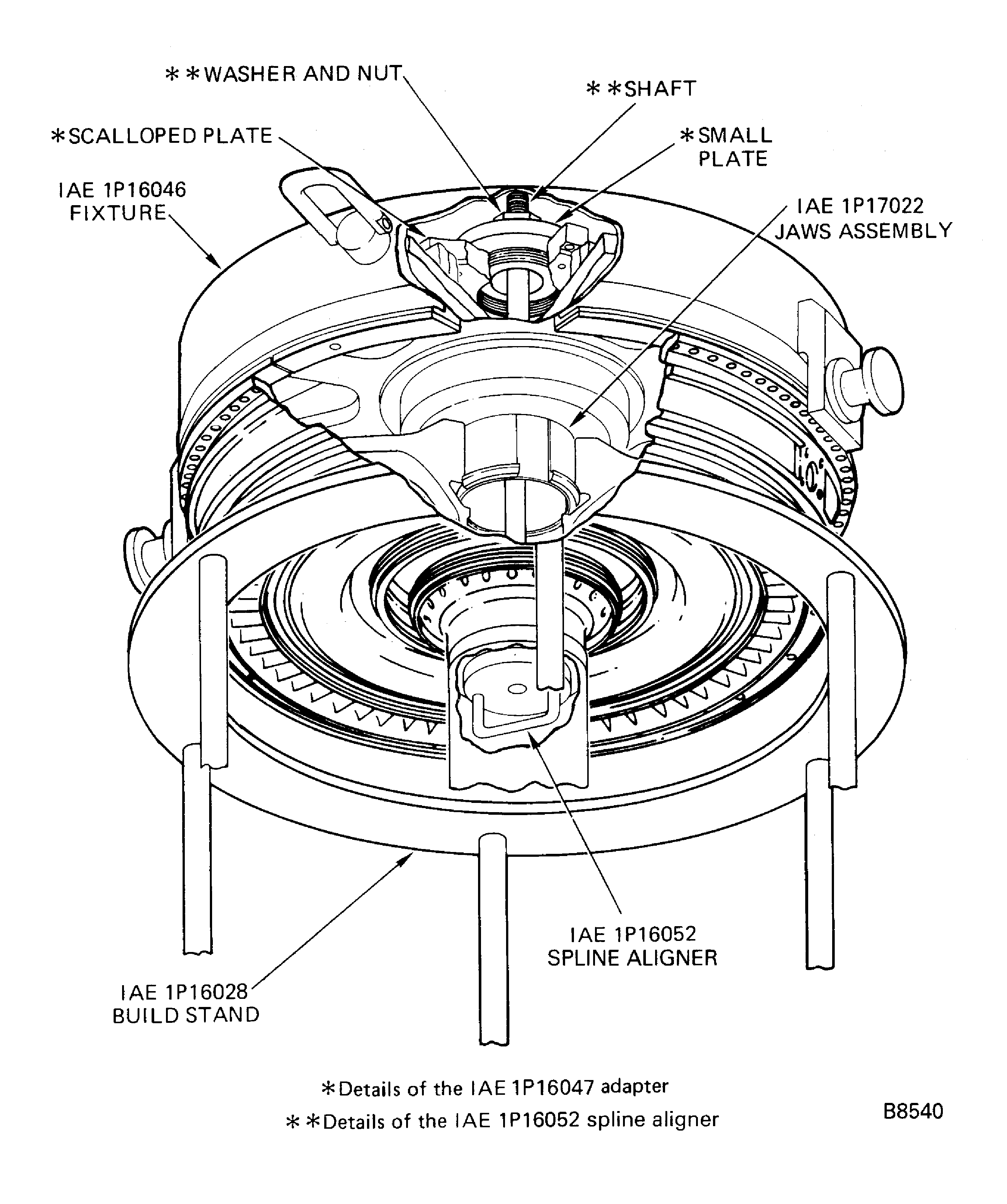

Install the shaft of the IAE 1P16047 Hydraulic adapter 1 off into the plug of the spline aligner in the center locator of the build stand, Figure.

Attach the IAE 1F10052 Two cables sling 1 off to a hoist and to the lifting spools on the fixture, Figure.

SUBTASK 72-45-00-430-103 Turn the HP Turbine Rotor and Stator Assembly to the Front End Up Position

Refer to Figure.

Install the IAE 1P16047 Hydraulic adapter 1 off over the clamp shaft with the threaded end down and attach with a washer and retaining nut.

Attach the IAE 1F10026 Hydraulic hand pump 1 off to the hydraulic cylinder and operate to move the hubs together.

Install the IAE 1P16051 Clamp 1 off and the hydraulic cylinder.

SUBTASK 72-45-00-430-104 Install the Ladder Lock

Refer to Figure

If the dimension AG is not in limits the turbine must be disassembled. Refer to TASK 72-45-00-030-001-B00 (DISASSEMBLY-0001).

SUBTASK 72-45-00-430-105 Dimension Check to Make Sure the Spacer is the Correct Thickness

Figure: HP Turbine Rotor and Stator Assembly - Fits and Clearances

HP Turbine Rotor and Stator Assembly - Fits and Clearances

Figure: Remove the IAE 1P17030 Blade Retainer

Remove the IAE 1P17030 Blade Retainer

Figure: Dimensions Necessary to Find the Thickness of the Spacer

Dimensions Necessary to Find the Thickness of the Spacer

Figure: Thickness of No. 4 Bearing Spacer

Thickness of No. 4 Bearing Spacer

Figure: Installation of the Stage 2 HPT Air Seal

Installation of the Stage 2 HPT Air Seal

Figure: Stage 1 HP Turbine Rotor Heater Installation

Stage 1 HP Turbine Rotor Heater Installation

Figure: Install the Stage 2 HPT Air Seal

Install the Stage 2 HPT Air Seal

Figure: Stage 1 Turbine Rotor Assembly and Stage 2 HPT Air Seal

Stage 1 Turbine Rotor Assembly and Stage 2 HPT Air Seal

Figure: Install the Stage 1 Turbine Rotor Assembly and the Stage 2 HPT Air Seal in to the Build Stand

Install the Stage 1 Turbine Rotor Assembly and the Stage 2 HPT Air Seal in to the Build Stand

Figure: Install the HP Turbine Case and Vane Assembly

Install the HP Turbine Case and Vane Assembly

Figure: IAE 1P16063 Retaining Fixture Installation

IAE 1P16063 Retaining Fixture Installation

Figure: IAE 1P17026 Lift Fixture Installation

IAE 1P17026 Lift Fixture Installation

Figure: Install the Stage 2 Turbine Rotor Assembly

Install the Stage 2 Turbine Rotor Assembly

Figure: Installation Tooling for the HP Turbine Rotor and Stator Assembly

Installation Tooling for the HP Turbine Rotor and Stator Assembly

Figure: Prepare to Turn the HP Turbine Rotor and Stator Assembly

Prepare to Turn the HP Turbine Rotor and Stator Assembly

Figure: Turn the HP Turbine Rotor and Stator Assembly

Turn the HP Turbine Rotor and Stator Assembly

Figure: HP Turbine Rotor and Stator Assembly Clamp Installation

HP Turbine Rotor and Stator Assembly Clamp Installation