Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 71-00-02-400-014-A00 (A1-PPBU) - Install The Pneumatic Starter Ducts, The Pneumatic Starter And The Pneumatic Starter Valve, Installation-014

General

Fig/item numbers in parenthesis in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For the torque tightening procedures refer to the SPM TASK 70-41-00-400-501 and TASK 70-41-01-400-501.

Special torque data is identified with the symbol * after the torque value.

For lockwire data and procedures refer to the SPM TASK 70-42-05-400-501.

For safety cable data and procedures refer to the SPM TASK 70-42-08-400-501.

Safety the threaded fasteners in the ATA Chapter/Section/Subject 71-51-41 as applicable with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS unless other lubricants are to in procedure.

Transportation covers/blanks must be removed immediately before installation of the components.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to damaged surface protection, joint flanges and attach parts. Use the correct color of air drying enamel. Refer to the SPM TASK 70-38-12-380-501.

For data on electrical connectors refer to the SPM TASK 70-43-00-400-501 and TASK 70-43-01-400-501.

To identify, lubricate and install seal rings refer to the SPM TASK 70-44-00-400-501.

To install key washer (tab type) refer to the SPM TASK 70-42-03-400-501.

Do not remove the special plastic caps from the electrical connectors until immediately before they are installed. This will give protection from unwanted fluids or materials.

For the data on electrical connectors refer to the SPM TASK 70-43-00-400-501 and the SPM TASK 70-43-01-400-501.

NOTE

To identify the consumable materials refer to the PCI.

SBE 70-0813 : Announcement of introduction of safety cable as a preferred method to lockwire.

Safety the threaded fasteners in this TASK with safety cable for the ATA Chapter/Section/Subject detailed in 2. General.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Torque wrench, range 0 to 250 lbfin (0 to 20 Nm) | LOCAL | Torque Wrench 0-250 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-002 SOLVENT, DELETED. | 0AM53 | CoMat 01-002 | ||

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 02-274 SAFETY CABLE KIT | LOCAL | CoMat 02-274 | ||

| CoMat 02-275 SAFETY CABLE KIT | LOCAL | CoMat 02-275 | ||

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) | K6835 | CoMat 10-072 | ||

| CoMat 10-073 SYNTHETIC GREASE, MoDISULFIDE | 0AM53 | CoMat 10-073 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Preformed packing | 1 | |||

| Tab washer | 1 | |||

| Seal | 1 | |||

| Seal | 1 |

Safety Requirements

NONEProcedure

CAUTION

LUBRICATE ALL THE BOLT SHANKS IN THIS SUBTASK WITHCoMat 10-073 SYNTHETIC GREASE, MoDISULFIDE, MO DISULPHIDE. LUBRICATE ALL THE BOLT HOLES WITH CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE).NOTE

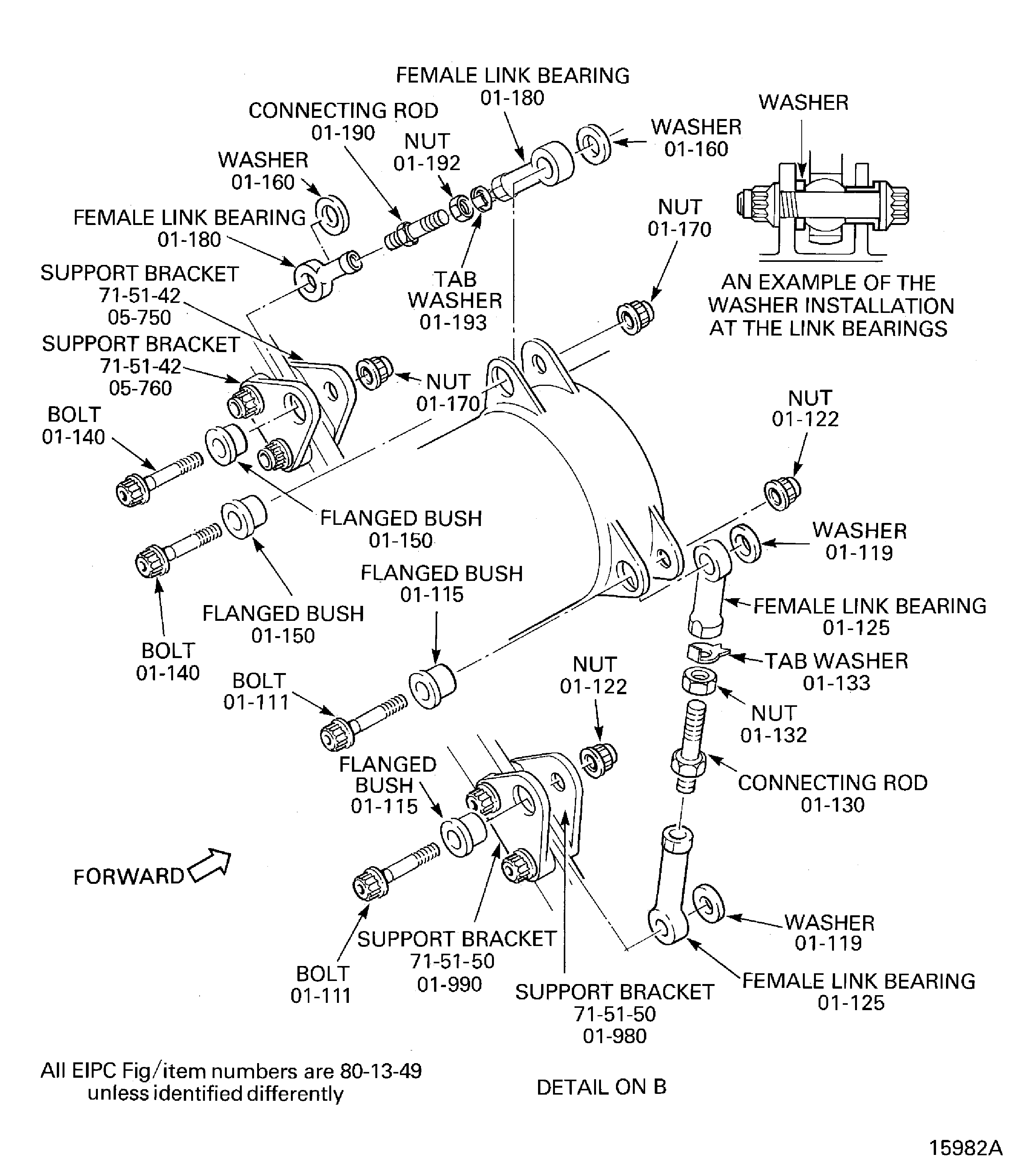

The pre-assembly dimension from the center of the two bearing links is 4.65 in. (118 mm).Assemble the nut STARTING-STARTER DUCT (80-13-49, 01-192), a new STARTING-STARTER DUCT (80-13-49, 01-193) tab washer 1 off, the two female link bearings STARTING-STARTER DUCT (80-13-49, 01-180) and the connecting rod STARTING-STARTER DUCT (80-13-49, 01-190) together. Install the assembly to the support brackets ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS and ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (05-760) with the bolt, the flanged bush, the washer and the nut STARTING-STARTER DUCT, STARTING-STARTER DUCT 01-150, STARTING-STARTER DUCT (01-160 and STARTING-STARTER DUCT (01-170). Refer to the detail on B. Make sure the washer is correctly installed.

Assemble the nut STARTING-STARTER DUCT (80-13-49, 01-132), a new STARTING-STARTER DUCT (80-13-49, 01-133) tab washer 1 off, the two female link bearings and the connecting rod STARTING-STARTER DUCT and STARTING-STARTER DUCT (01-130) together. Install the female link bearing/connecting rod assembly to the support brackets BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN and BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (01-990). Do the procedure as given in step (1). Make sure the washer is installed correctly.

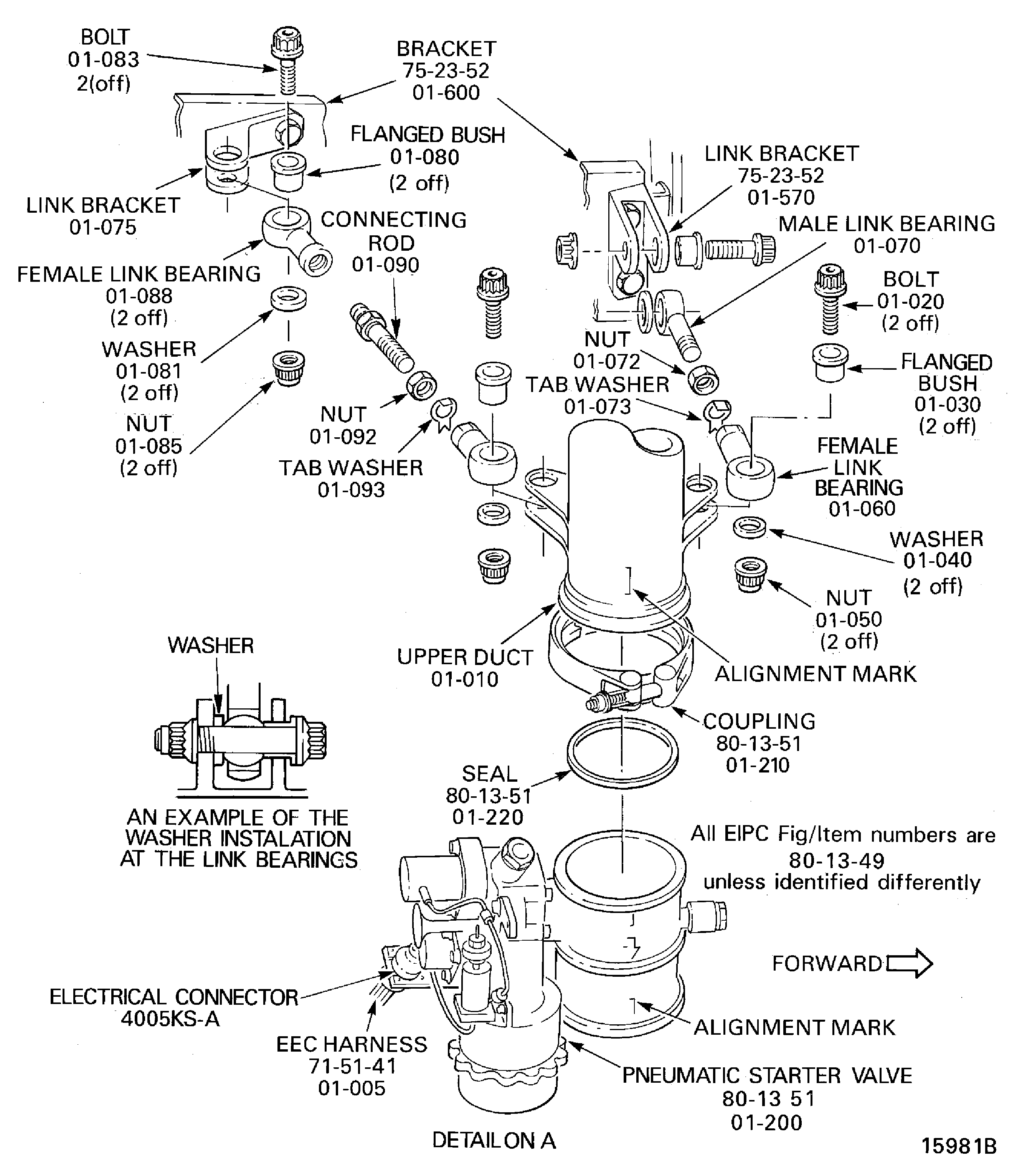

Assemble the male link bearing, the nut STARTING-STARTER DUCT and STARTING-STARTER DUCT 01-072) and a new STARTING-STARTER DUCT (80-13-49, 01-073) tab washer 1 off to the female link bearing STARTING-STARTER DUCT (80-13-49, 01-060). Install the assembly to the link bracket AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-570). Do the procedure as given in step (1). Refer to the detail on A.

Assemble the nut STARTING-STARTER DUCT (80-13-49, 01-092), a new STARTING-STARTER DUCT (80-13-49, 01-093) tab washer 1 off, the two female link bearings STARTING-STARTER DUCT (80-13-49, 01-088) and the connecting rod STARTING-STARTER DUCT (80-13-49, 01-090) together. Install the assembly to the link bracket STARTING-STARTER DUCT (80-13-49, 01-075). Do the procedure as given in step (1).

Torque the four nuts STARTING-STARTER DUCT, STARTING-STARTER DUCT (01-085, STARTING-STARTER DUCT (01-122 and STARTING-STARTER DUCT (01-170) to 85 to 105 lbf.in. (10 to 12 Nm).

Install the link bearings and the connecting rods.

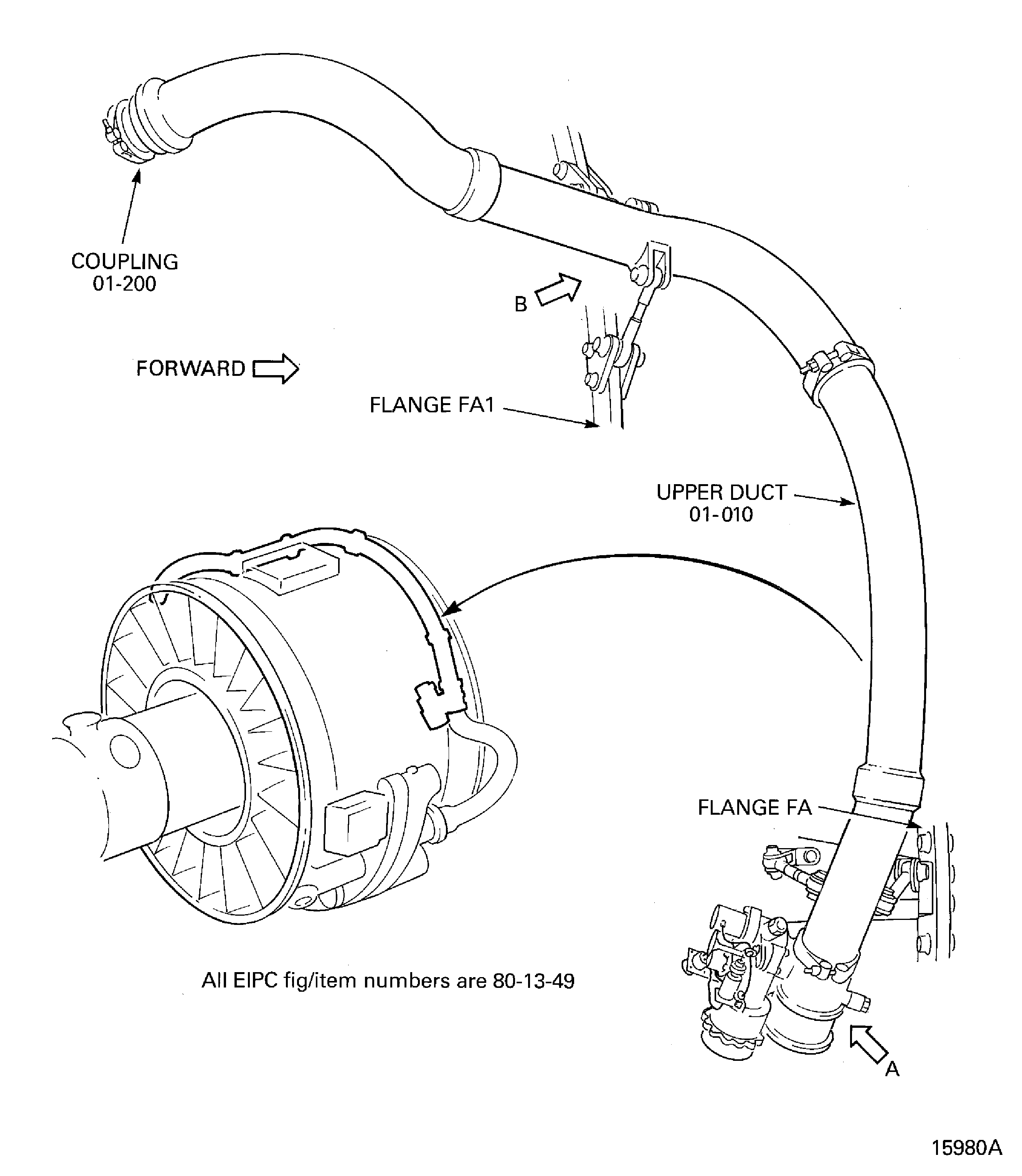

Attach the upper duct STARTING-STARTER DUCT (80-13-49, 01-010) to the two female link bearings STARTING-STARTER DUCT and STARTING-STARTER DUCT (01-180) with the two bolts STARTING-STARTER DUCT and STARTING-STARTER DUCT (01-140), the two flanged bushes STARTING-STARTER DUCT and STARTING-STARTER DUCT (01-150), the two washers STARTING-STARTER DUCT and STARTING-STARTER DUCT (01-160) and the two nuts STARTING-STARTER DUCT and STARTING-STARTER DUCT (01-170). Refer to the detail on B. Make sure the washers are installed correctly.

Attach the upper duct to the female link bearing STARTING-STARTER DUCT (80-13-49, 01-060) with the bolt STARTING-STARTER DUCT (80-13-49, 01-020), the flanged bush STARTING-STARTER DUCT (80-13-49, 01-030), the washer STARTING-STARTER DUCT (80-13-49, 01-040) and the nut STARTING-STARTER DUCT (80-13-49, 01-050). Lubricate the bolt with CoMat 10-077 APPROVED ENGINE OILS. Make sure the washer is installed correctly, refer to the detail on A.

Attach the upper duct to the female link bearing STARTING-STARTER DUCT (80-13-49, 01-088) with the bolt STARTING-STARTER DUCT (80-13-49, 01-083), the flanged bush STARTING-STARTER DUCT (80-13-49, 01-080), the washer STARTING-STARTER DUCT (80-13-49, 01-081) and the nut STARTING-STARTER DUCT (80-13-49, 01-085). Make sure the washer is installed correctly.

Torque the four nuts STARTING-STARTER DUCT, STARTING-STARTER DUCT (01-092, STARTING-STARTER DUCT (01-132 and STARTING-STARTER DUCT (01-192) to 170 * lbf.in. (19.20 Nm). Try to put CoMat 02-126 LOCKWIRE into the safety hole in the female link bearings. The safety holes must be blocked with the connecting rod threads, the safety wire must not go through the safety holes.

Torque the four nuts STARTING-STARTER DUCT, STARTING-STARTER DUCT 01-085, STARTING-STARTER DUCT 01-122 and STARTING-STARTER DUCT 01-170) to 85 to 105 lbf.in (10 to 12 Nm).

Install the upper duct.

SUBTASK 71-00-02-440-006 Install the Pneumatic Starter Upper Duct

CAUTION

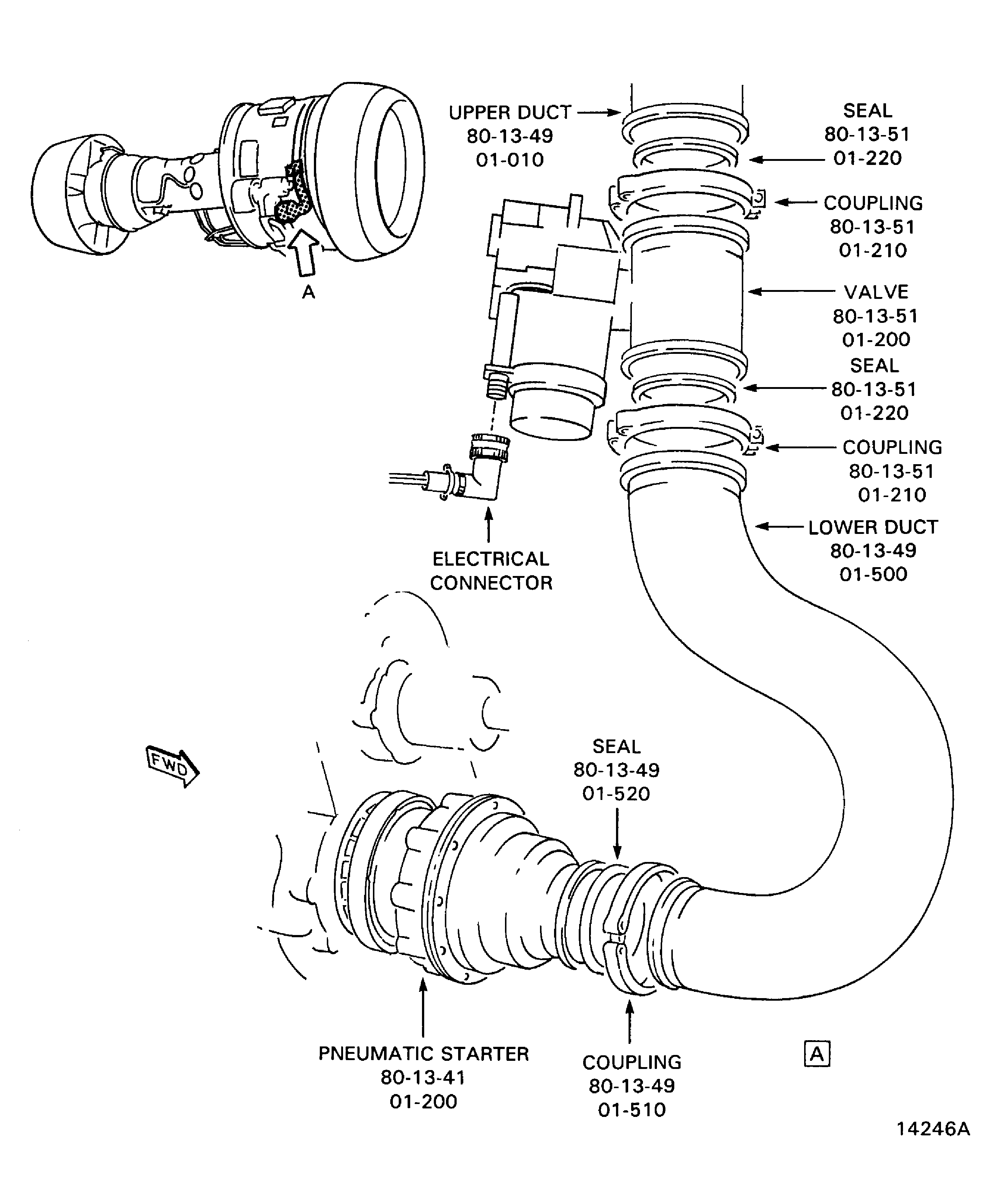

MAKE SURE THE VALVE IS INSTALLED CORRECTLY. THE DIRECTION-OF-FLOW ARROW ON THE VALVE BODY MUST POINT IN THE DIRECTION OF THE PNEUMATIC STARTER.Refer to Figure.

Put the new STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-220) seal 1 off, on the upper flange of the pneumatic starter valve STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-200), in the correct position for installation.

Hold the valve STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-200) and the seal STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-220) on the upper duct STARTING-STARTER DUCT (80-13-49, 01-010). Make sure that the marks on the pneumatic starter valve STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-200) and the upper duct STARTING-STARTER DUCT (80-13-49, 01-010) are aligned.

Install the coupling STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-210) to the connection of the pneumatic starter valve STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-200) and the upper duct STARTING-STARTER DUCT (80-13-49, 01-010). Torque the nut of the coupling STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-210) to between 75 and 85 lbf.in (8.5 and 9.6 Nm).

Install the electrical connector to the valve STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-200).

SUBTASK 71-00-02-440-013 Install the Pneumatic Starter Valve

Refer to Figure.

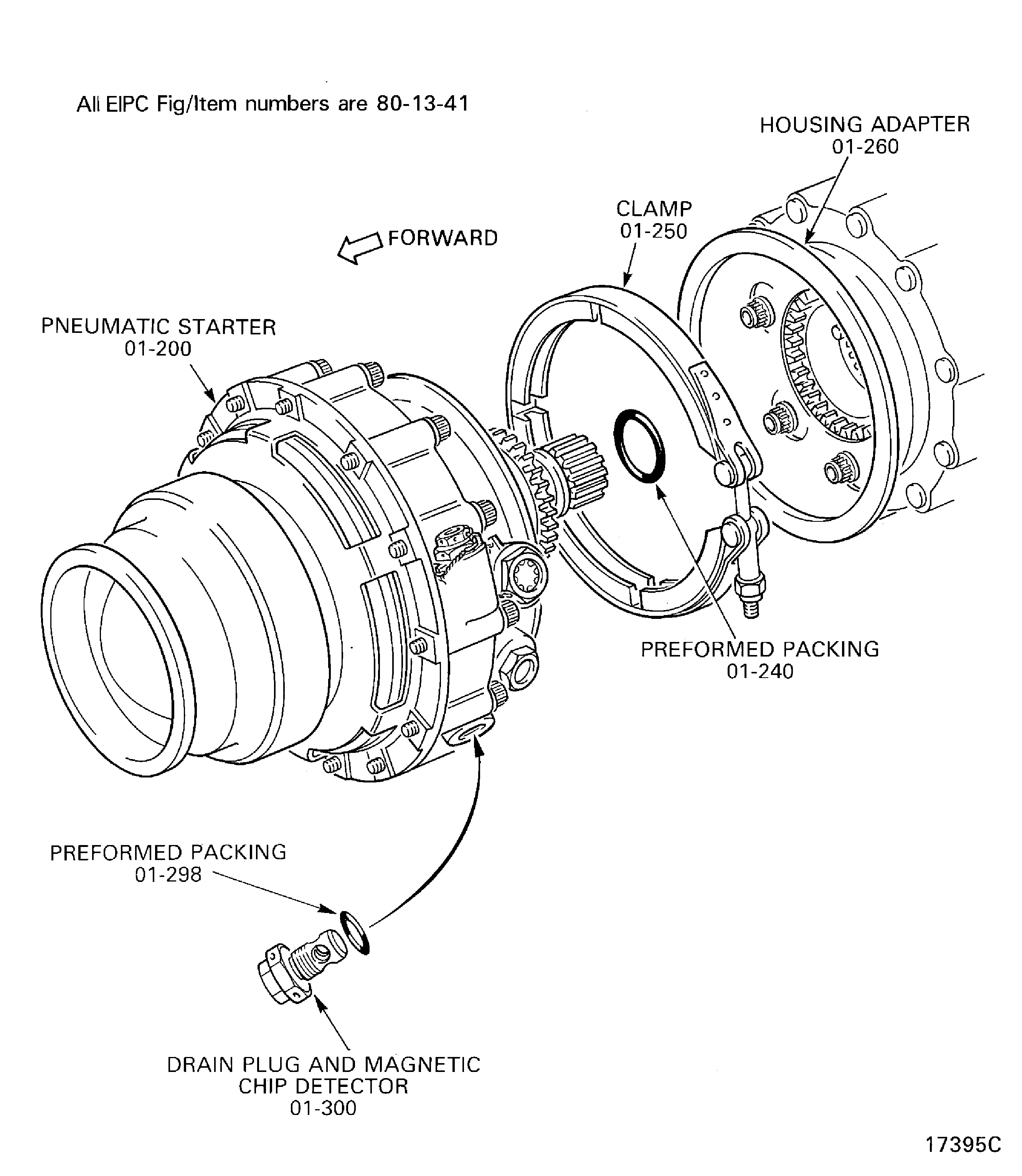

Lubricate the housing adapter studs with CoMat 10-077 APPROVED ENGINE OILS.

Install the housing adapter STARTING-PNEUMATIC STARTER (80-13-41, 01-260) on to the mounting pad. Attach with the six nuts STARTING-PNEUMATIC STARTER (80-13-41, 01-106).

Torque the six nuts STARTING-PNEUMATIC STARTER (80-13-41, 01-106) to 138 to 150 lbf.in (16 to 17 Nm).

WARNING

WHEN YOU USE CoMat 01-002 SOLVENT, DELETED.YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOUR CHANGES AND BECOMES TOXIC.Clean the mating faces of the pneumatic starter STARTING-PNEUMATIC STARTER (80-13-41, 01-200) with CoMat 01-002 SOLVENT, DELETED..

Lightly lubricate a new STARTING-PNEUMATIC STARTER (80-13-41, 01-240) preformed packing 1 off with CoMat 10-077 APPROVED ENGINE OILS and install it on the starter drive shaft.

Make sure the drain plug/magnetic chip detector STARTING-PNEUMATIC STARTER (80-13-41, 01-300) is installed and safetied with CoMat 02-126 LOCKWIRE.

Lubricate the starter drive shaft splines with CoMat 10-077 APPROVED ENGINE OILS.

Install the starter in the adapter housing and install the clamp STARTING-PNEUMATIC STARTER (80-13-41, 01-250). Torque the clamp to 60 to 65 * lbf.in (6.8 to 7.3 Nm).

CAUTION

INSTALL THE CLAMP WITH THE T-BOLT 90 DEGREES FROM THE TOP OF THE STARTER WITH THE STIFF NUT LOOKING DOWNWARD. IF YOU DO NOT THE CLAMP CAN TOUCH ADJACENT COMPONENTS AND CAN CAUSE DAMAGE.Install the starter.

SUBTASK 71-00-02-450-024 Install the Pneumatic Starter and Housing Adapter

Refer to Figure.

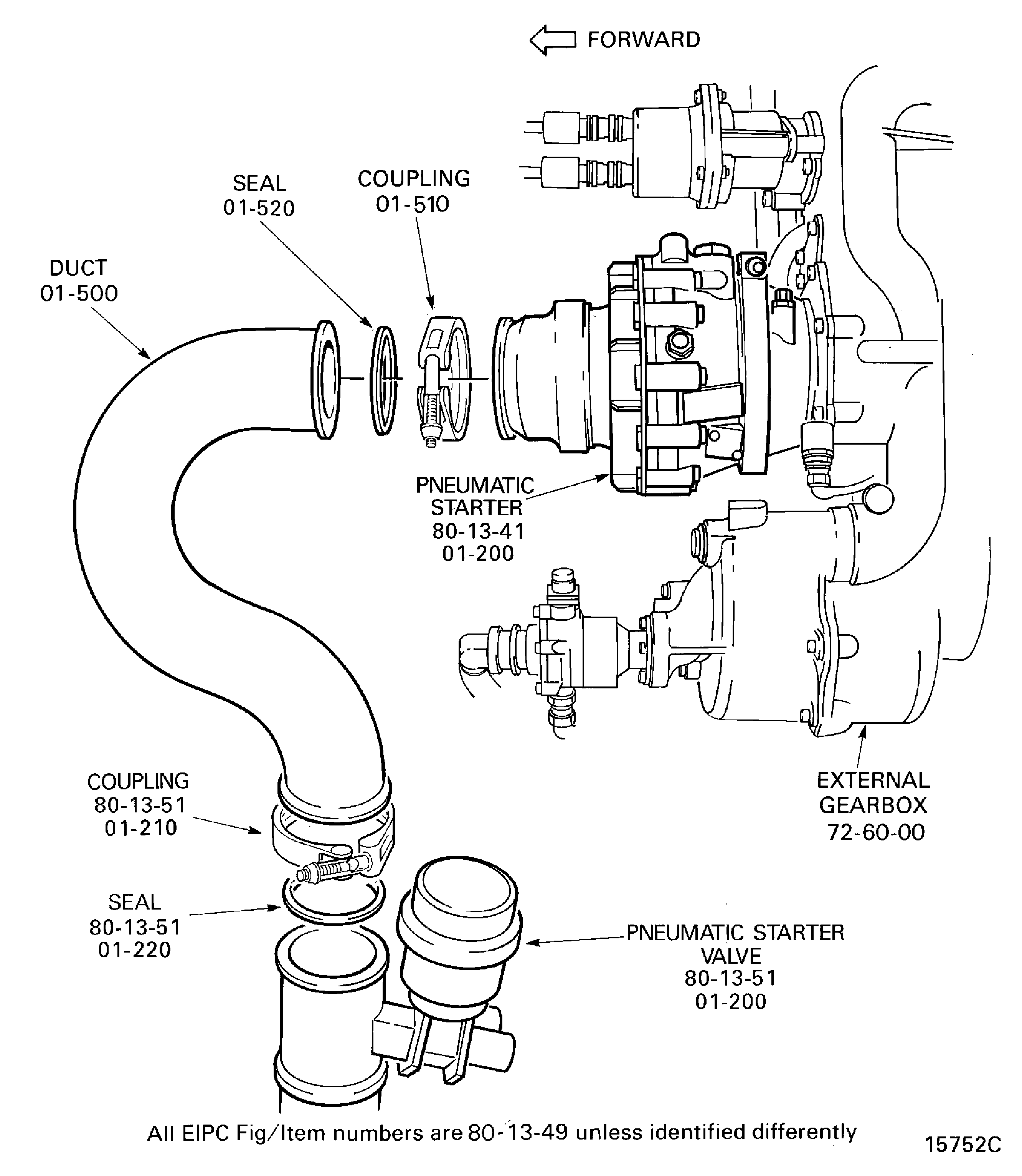

Hold the new STARTING-STARTER DUCT (80-13-49, 01-520) seal 1 off and the seal STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-220) and the lower air-starter duct STARTING-STARTER DUCT (80-13-49, 01-500) on to the pneumatic starter valve STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-200) and the pneumatic starter STARTING-PNEUMATIC STARTER (80-13-41, 01-200), in the correct position for installation. Make sure that the marks on the pneumatic starter valve STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-200) and the lower air-starter duct STARTING-STARTER DUCT (80-13-49, 01-500) are aligned.

Install the coupling STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-210) to the connection of the lower air-starter duct STARTING-STARTER DUCT (80-13-49, 01-500) and the pneumatic starter valve STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-200).

Install the coupling STARTING-STARTER DUCT (80-13-49, 01-510) to the connection of the lower air-starter duct STARTING-STARTER DUCT (80-13-49, 01-500) and the pneumatic starter STARTING-PNEUMATIC STARTER (80-13-41, 01-200).

Torque the nuts of the couplings STARTING-STARTER DUCT (80-13-49, 01-510) and STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-210) to between 75 and 85 lbf.in (8.5 and 9.6 Nm). Use a soft faced hammer and tap around the outside of the couplings.

SUBTASK 71-00-02-440-009 Install the Pneumatic Starter Lower Duct

Figure: Install the Pneumatic Starter Upper Duct

Sheet 1

Figure: Install the Pneumatic Starter Upper Duct

Sheet 2

Figure: Install the Pneumatic Starter Upper Duct

Sheet 3

Figure: Install the Pneumatic Starter Valve

Install the Pneumatic Starter Valve

Figure: Install the Pneumatic Starter

Install the Pneumatic Starter

Figure: Install the Pneumatic Starter Lower Duct

Install the Pneumatic Starter Lower Duct