Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-32-00-030-013-C00 LPC/Intermediate Case Module - Remove The No. 3 Bearing, Internal Gearbox And Support Assembly To Gain Access To FBC Area (Pre Surgical Strike Procedure For FBC Area), Disassembly-013

General

This TASK 72-32-00-030-013-C00 (DISASSEMBLY-013, CONFIG-003) gives the procedure to remove the No.3 bearing, internal gearbox and support assembly from the LP compressor/Intermediate case module to gain access to the front bearing compartment (FBC) area.

This procedure uses a method that does not require removal of the HP system module and the external gearbox module from the LP compressor/Intermediate case module.

Where this TASK 72-32-00-030-013-C00 (DISASSEMBLY-013, CONFIG-003) is used, it is recommended to use TASK 72-32-00-430-003-C00 (ASSEMBLY-003, CONFIG-003) for installation of the internal gearbox and support assembly.

Fig/Item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/Item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the item number.

Discard all rubber seal rings removed in this procedure.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1F10104 Hand wrench | 0AM53 | IAE 1F10104 | 1 | |

| IAE 1J12024 Special wrench | 0AM53 | IAE 1J12024 | 1 | |

| IAE 1J12105 Cantileer sling | 0AM53 | IAE 1J12105 | 1 | |

| IAE 1J12106 Aligning pin set | 0AM53 | IAE 1J12106 | 1 | |

| IAE 1J12108 Sling adapter | 0AM53 | IAE 1J12108 | 1 | |

| IAE 1J12117 TBD | 0AM53 | IAE 1J12117 | 1 | |

| IAE 1J12118 Storage stand | 0AM53 | IAE 1J12118 | 1 | |

| IAE 1J12119 Extension adapter | 0AM53 | IAE 1J12119 | 1 | |

| IAE 1J12182 Retaining protector | 0AM53 | IAE 1J12182 | ||

| IAE 1J12188 Puller bolt | 0AM53 | IAE 1J12188 | 1 | |

| IAE 1J12326 Vertical sling | 0AM53 | IAE 1J12326 | 1 | |

| IAE 1J12362 Work stand | 0AM53 | IAE 1J12362 | 1 | |

| IAE 1J12507 Guide pin | 0AM53 | IAE 1J12507 | 1 | |

| IAE 1P16046 Removal/Installation fixture | 0AM53 | IAE 1P16046 | 1 | |

| IAE 1P16285 Tie-rod adapter | 0AM53 | IAE 1P16285 | 1 | |

| IAE 1P16543 Removal/Installation fixture | 0AM53 | IAE 1P16543 | 1 | |

| IAE 1R18234 Support rod | 0AM53 | IAE 1R18234 | 2 | |

| IAE 1R19776 TBD | 0AM53 | IAE 1R19776 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 06-069 MARKER | IE207 | CoMat 06-069 |

Spares

NONESafety Requirements

NONEProcedure

Remove the booster stage assembly from the LP Compressor/Intermediate Case Module. Refer to TASK 72-32-00-030-006-D00 (DISASSEMBLY-006, CONFIG-004).

SUBTASK 72-32-00-030-272 Remove the Booster Stage Assembly

Remove the LP turbine module components, external harnesses and tubes from the engine. Refer to TASK 72-00-50-020-001-B00 (REMOVAL-001, CONFIG-002).

Remove the LP turbine module from the engine. Refer to TASK 72-00-50-020-002 (REMOVAL-002).

SUBTASK 72-32-00-030-273 Remove the LP Turbine Module

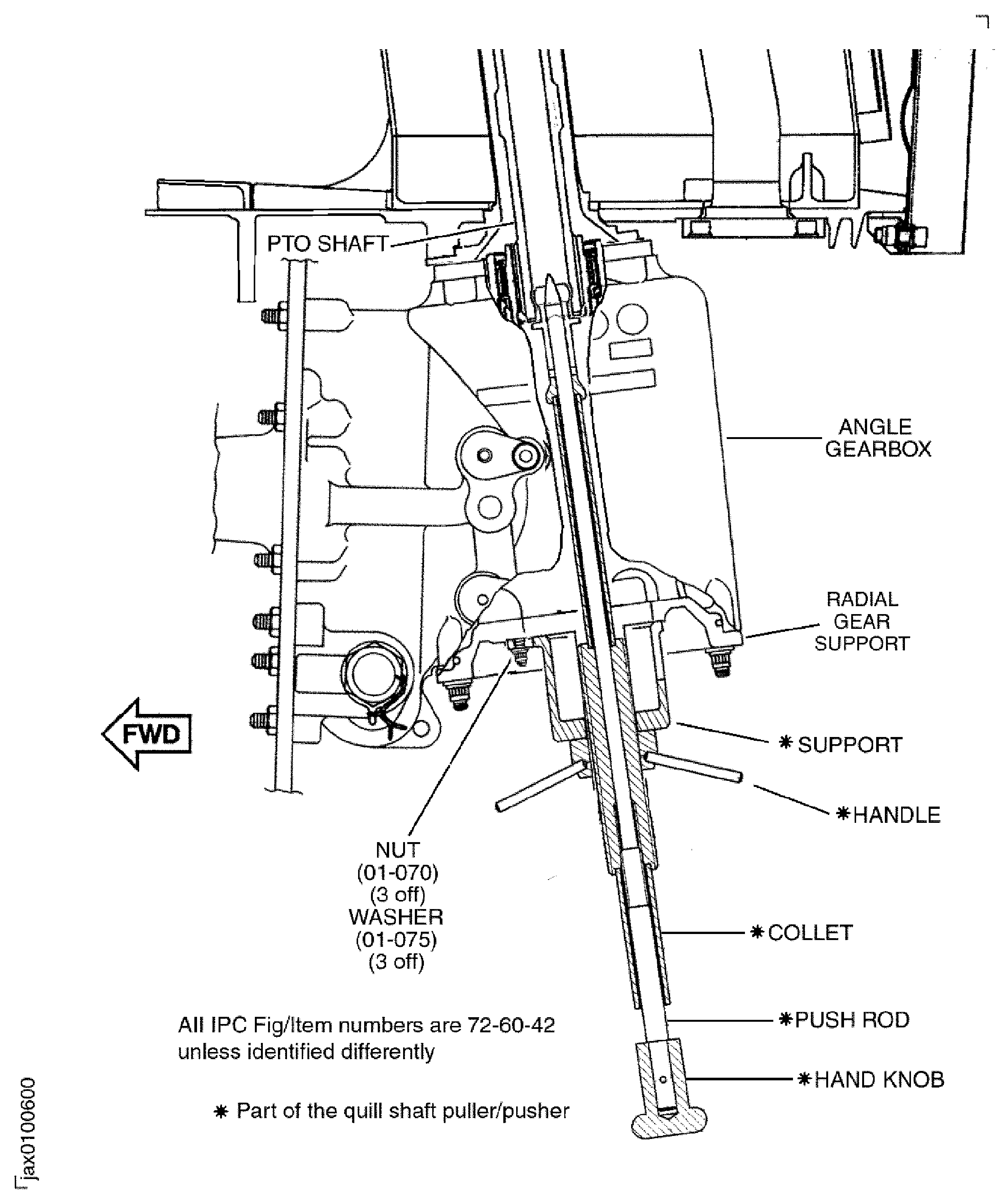

Refer to Figure.

Remove the plug from the lower flange of the angle gearbox. Refer to TASK 72-60-40-040-001 (DISASSEMBLY-001).

NOTE

It is not necessary to remove the oil nozzle Angle Gearbox Assembly (72-60-40, 01-240).Remove the oil nozzle Angle Gearbox Assembly (72-60-40, 01-400) from the angle gearbox. Refer to TASK 72-60-40-040-001 (DISASSEMBLY-001).

Remove the lock washer and the segment. Refer to TASK 72-60-42-040-001 (DISASSEMBLY-001).

Release and remove the nut from the radial gearshaft. Use IAE 1F10104 Hand wrench 1 off. Refer to TASK 72-60-42-040-001 (DISASSEMBLY-001).

Remove the radial coupling shaft and the oil duct from the radial gearshaft with IAE 1R19776 TBD 1 off.

Remove the radial coupling shaft and the oil duct.

Install the support (part of IAE 1J12117 TBD quill shaft puller/pusher 1 off) with the three nuts Angle Gearbox Driving Gearshaft Assembly (72-60-42, 01-070) and washers Angle Gearbox Driving Gearshaft Assembly (72-60-42, 01-075) removed in step 4.A. on the radial gearbox.

Remove the three nuts Angle Gearbox Driving Gearshaft Assembly (72-60-42, 01-070) and washers Angle Gearbox Driving Gearshaft Assembly (72-60-42, 01-075) which attach the support (part of quill shaft puller/pusher) to the radial gearbox.

Remove the quill shaft from the gearbox module with IAE 1J12117 TBD 1 off.

SUBTASK 72-32-00-030-274 Remove the Quill Shaft from the Fan Frame Strut through the Gearbox Module

Remove the No.1 bearing compartment scavenge oil tube. Refer to TASK 72-32-00-030-009-C00 (DISASSEMBLY-009, CONFIG-003).

SUBTASK 72-32-00-030-275 Remove the No. 1 Bearing Compartment Scavenge Oil Tube

Release the hydraulic seal assembly from the LPC stub shaft. Refer to TASK 72-32-00-030-010 (DISASSEMBLY-010).

SUBTASK 72-32-00-030-276 Release the Hydraulic Seal Assembly from the LPC Stub Shaft

NOTE

The retaining protector was installed in Step (step 3).Remove IAE 1J12182 Retaining protector from the stub shaft.

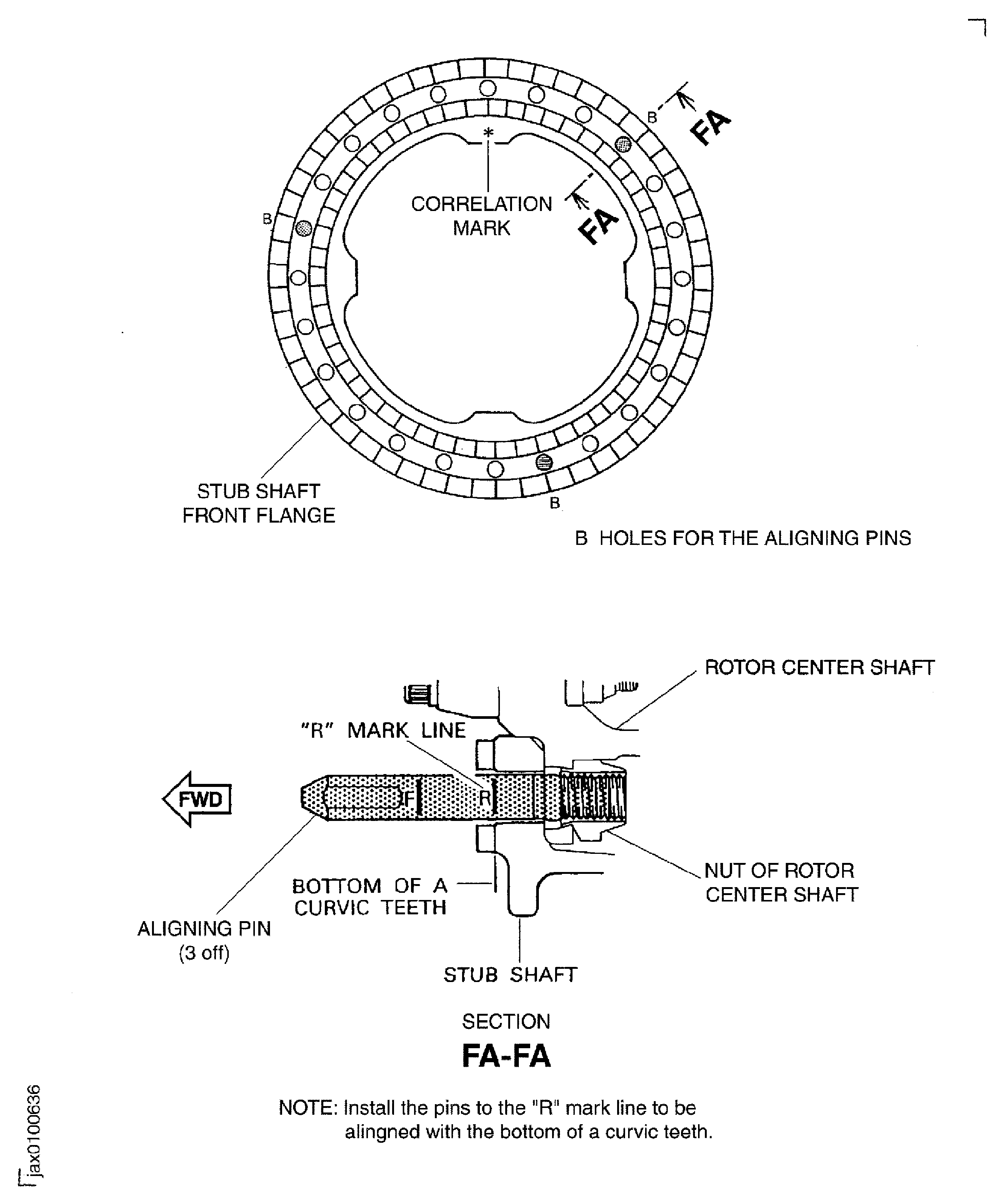

Install the three aligning pins (part of IAE 1J12106 Aligning pin set) in to three of the 24 nuts of the rotor center shaft through the holes B in the stub shaft front flange.

Remove the retaining protector and install the aligning pins.

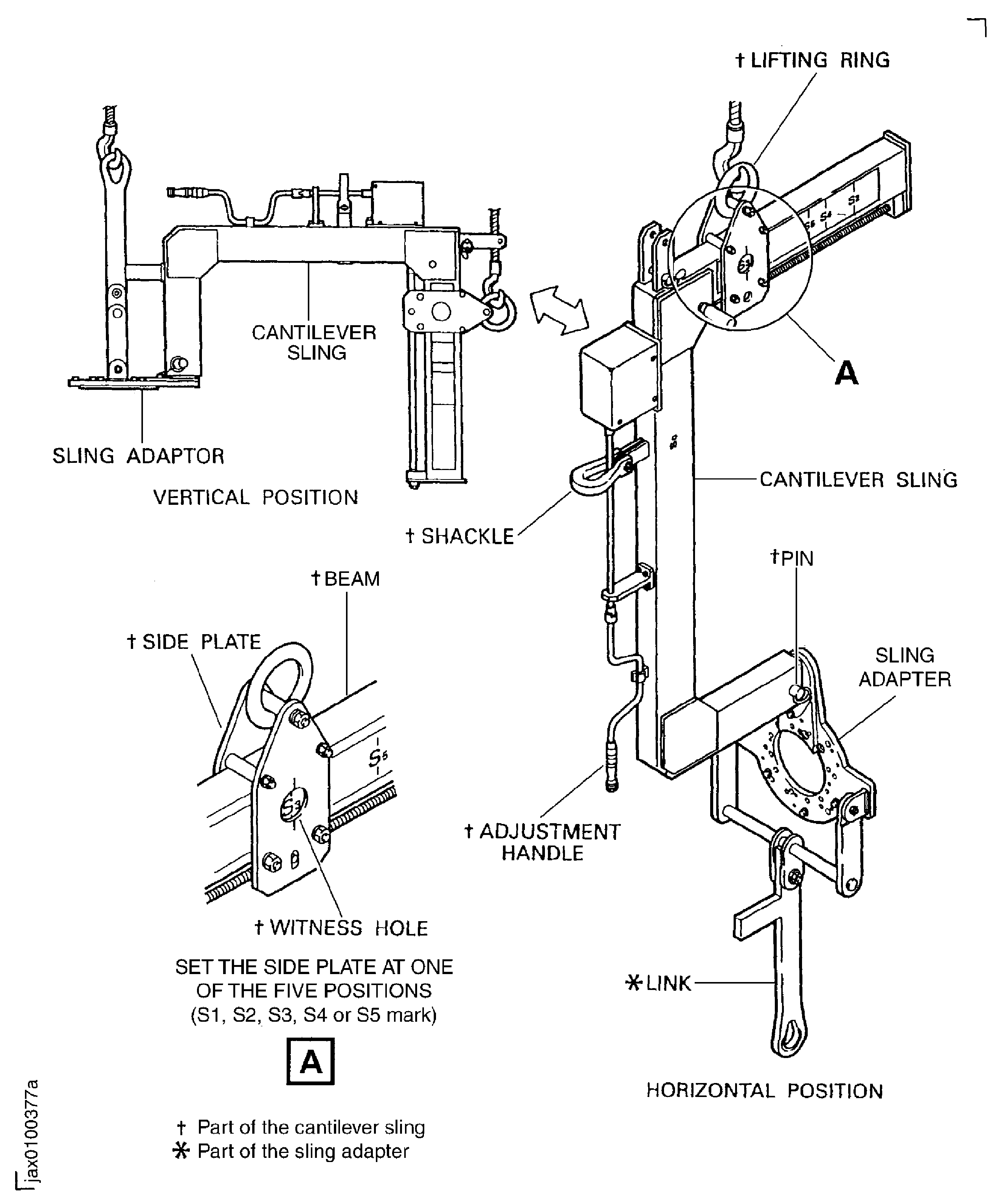

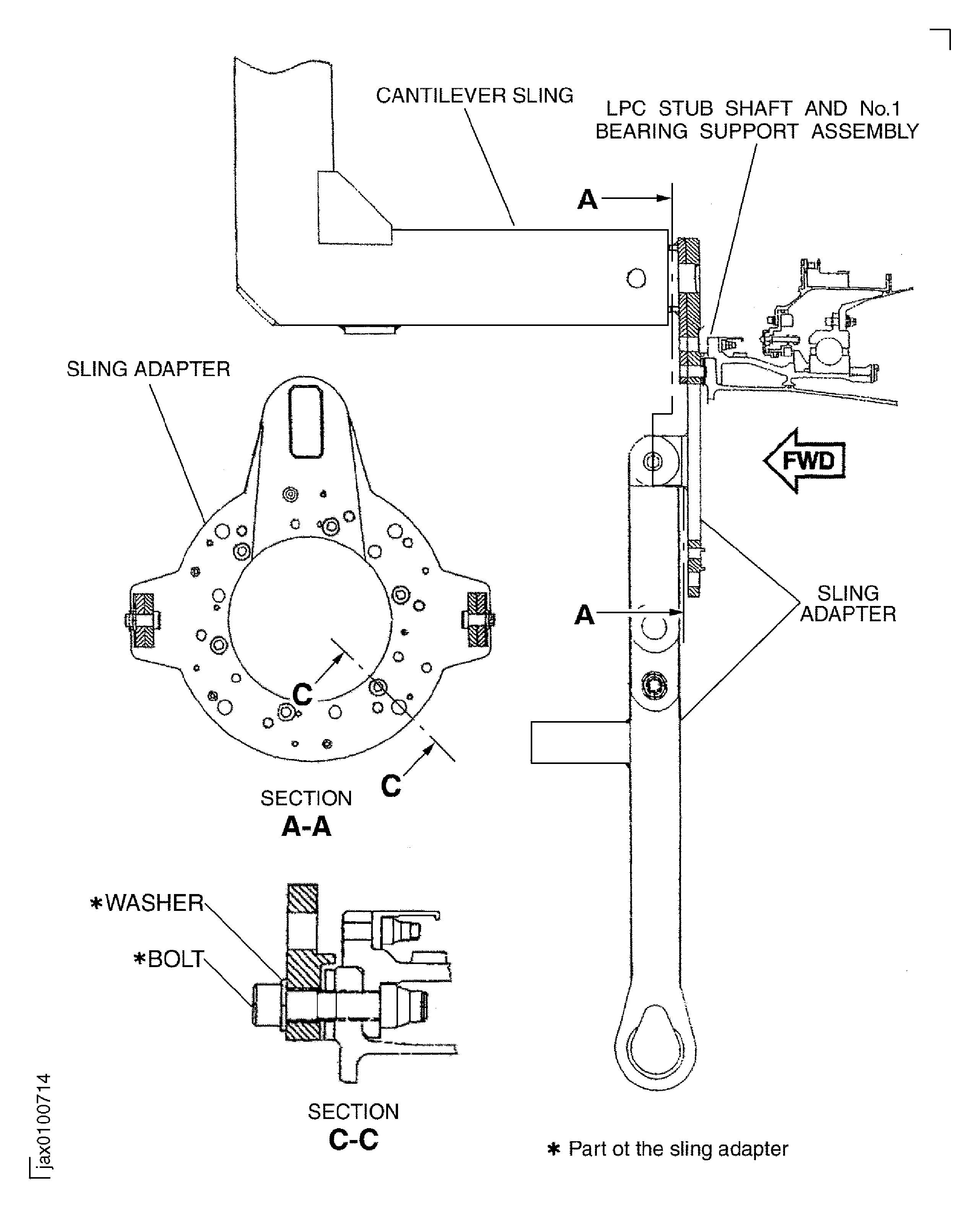

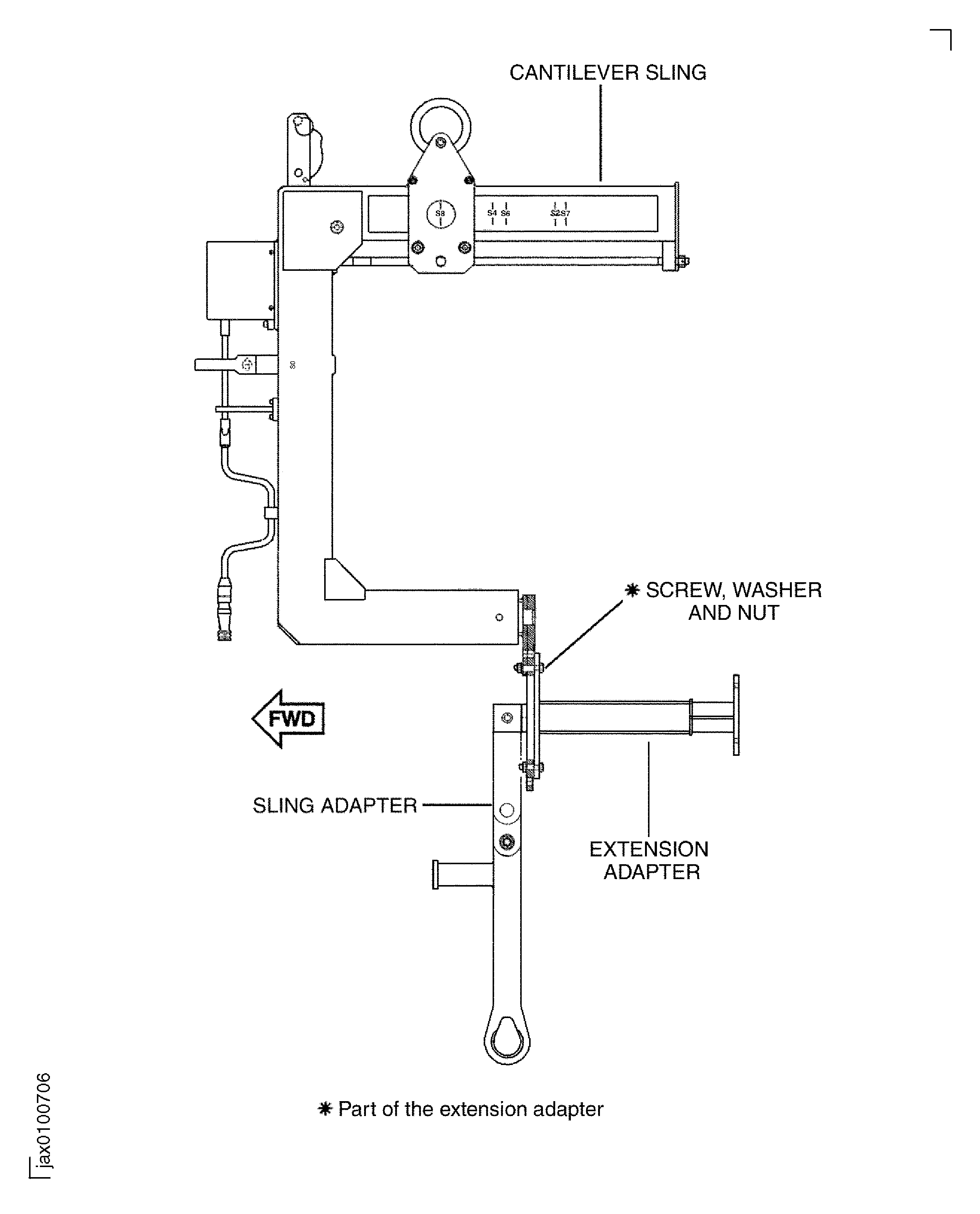

Assemble IAE 1J12105 Cantileer sling 1 off and IAE 1J12108 Sling adapter 1 off (sling assembly).

SUBTASK 72-32-00-030-277 Prepare the Tool for Removal of the Stub Shaft and No.1 Bearing Support Assembly

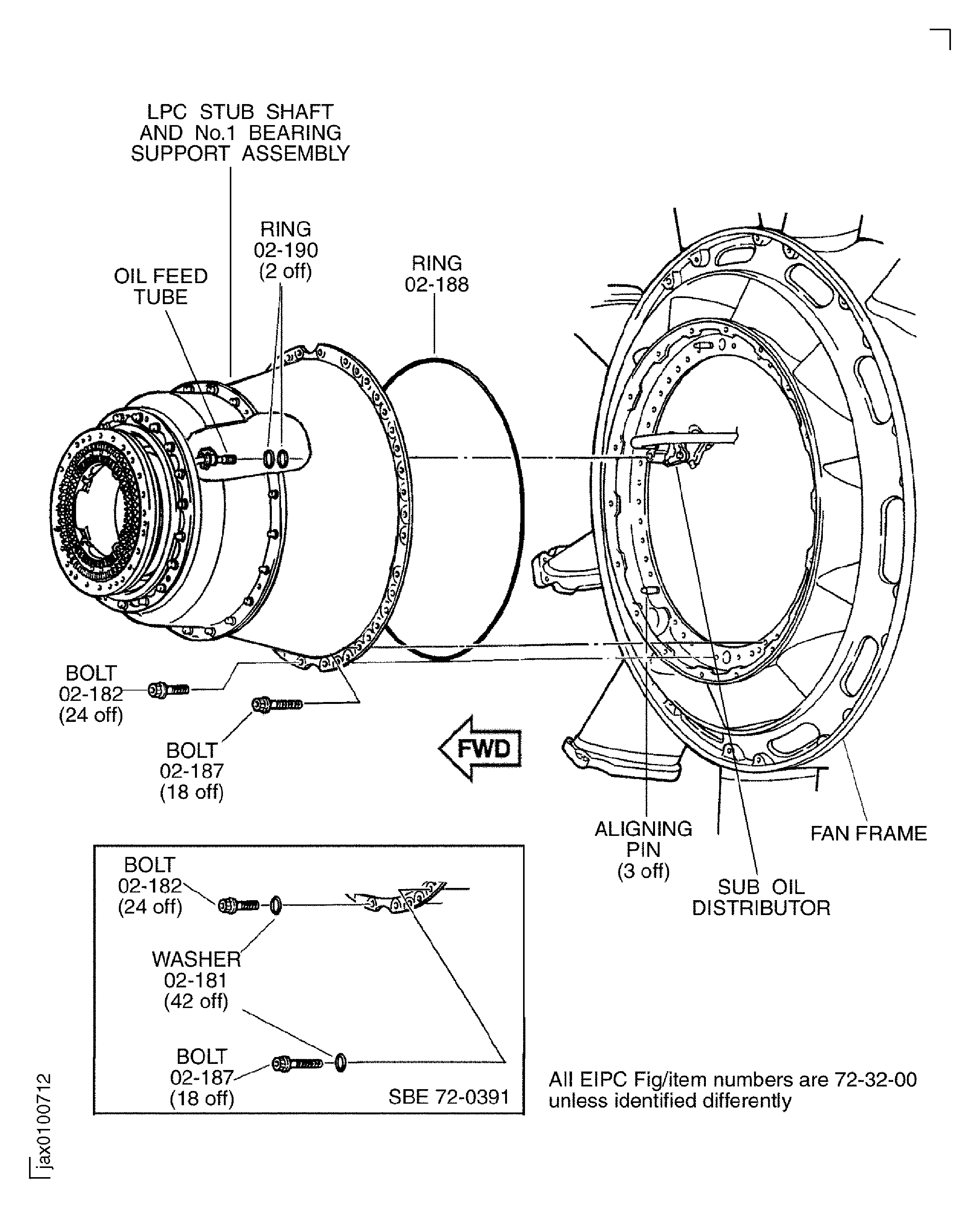

Pre SBE 72-0391: Remove the 42 bolts which attach the No. 1 bearing support rear flange of the No. 1 bearing support assembly to the fan frame.

SBE 72-0391: Remove the 42 bolts and washers, which attach the No. 1 bearing support rear flange of the No. 1 bearing support assembly to the fan frame.

Install the three aligning pins (part of IAE 1J12507 Guide pin 1 off) in to three of the 42 threaded holes in the fan frame flange. The three aligning pins must be installed at approximately 120 degrees apart from each other.

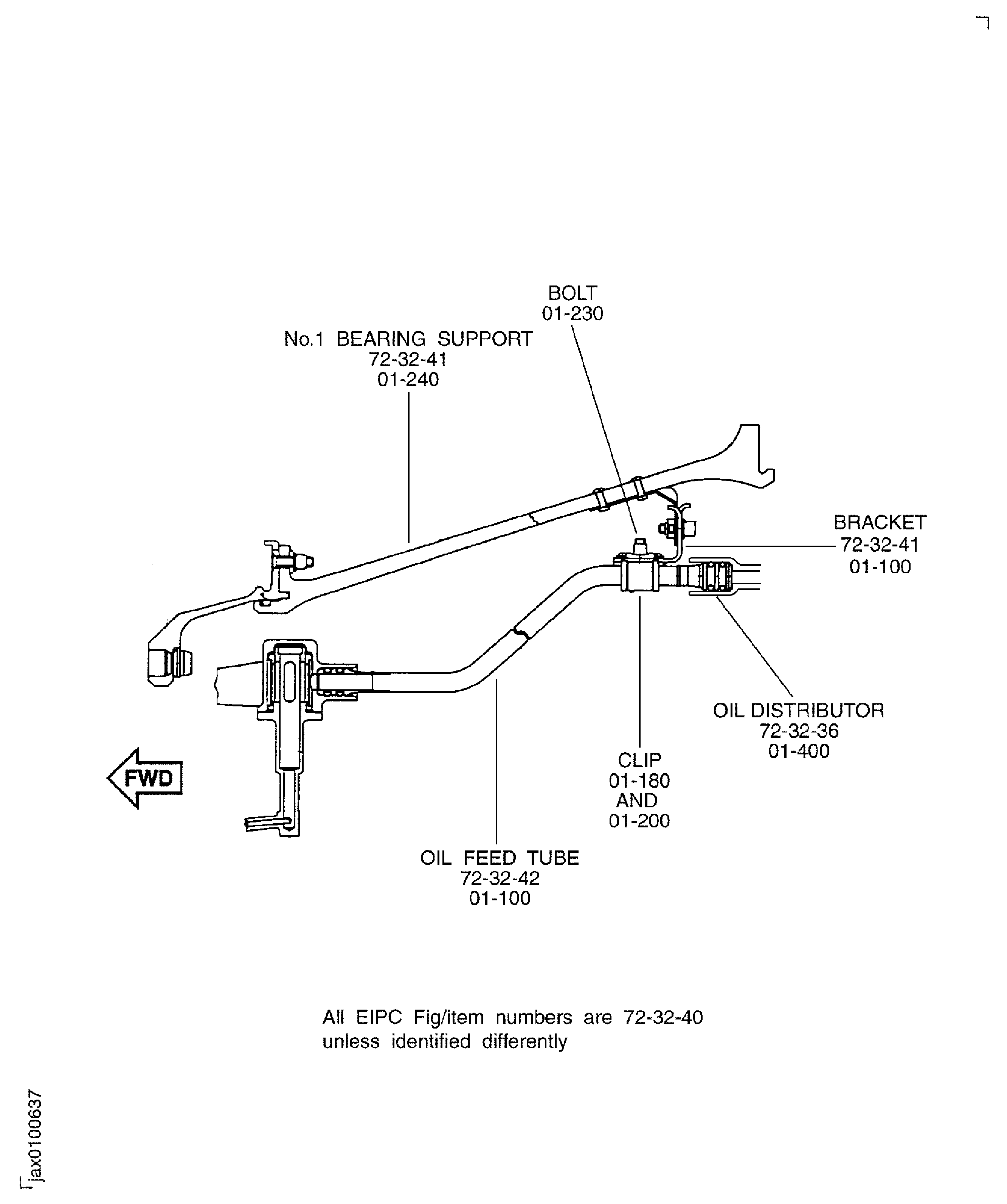

Tighten the four puller bolts equally until you can access to bolt ENGINE-NO.1 BEARING SUPPORT ASSEMBLY (72-32-40, 01-230) from clearance between the LPC stub shaft and No. 1 bearing support assembly and the fan frame.

CAUTION

REMOVE THE BOLT ENGINE-NO.1 BEARING SUPPORT ASSEMBLY (72-32-40, 01-230), CLIP ENGINE-NO.1 BEARING SUPPORT ASSEMBLY (72-32-40, 01-180) AND CLIP ENGINE-NO.1 BEARING SUPPORT ASSEMBLY (72-32-40, 01-200). IT CAN CAUSE DAMAGE TO THE OIL FEED TUBE ENGINE-OIL JET AND OIL SUPPLY TUBE (72-32-42, 01-100) WHEN YOU REMOVE THE LPC STUB SHAFT AND NO. 1 BEARING SUPPORT ASSEMBLY.Remove the bolt ENGINE-NO.1 BEARING SUPPORT ASSEMBLY (72-32-40,01-230), clip ENGINE-NO.1 BEARING SUPPORT ASSEMBLY (72-32-40, 01-180) and clip ENGINE-NO.1 BEARING SUPPORT ASSEMBLY (72-32-40, 01-200).

Use the four puller bolts (part of IAE 1J12188 Puller bolt 1 off) to release the LPC stub shaft and No.1 bearing support assembly from the fan frame.

Install LPC stub shaft and No. 1 bearing support assembly on IAE 1J12118 Storage stand 1 off.

SUBTASK 72-32-00-030-278 Remove the LPC Stub Shaft and No.1 Bearing Support Assembly from the Fan Frame (Pre SBE 72-0391 and SBE 72-0391)

SBE 72-0391: New separate type No. 1 bearing support assembly

Install IAE 1P16046 Removal/Installation fixture or IAE 1P16543 Removal/Installation fixture 1 off and IAE 1P16285 Tie-rod adapter 1 off to the HP system module rear flange to secure HPT rotor. Refer to TASK 72-00-40-020-006-B00 (REMOVAL-006, CONFIG-002).

Remove the LP compressor master bleed actuator to make a space for installation of the support rod (IAE 1R18234 Support rod 2 off) at 4 o'clock support rod (viewed from the front of the engine). Refer to TASK 72-00-40-020-002-B00 (REMOVAL-002, CONFIG-002).

Install IAE 1R18234 Support rod 2 off to keep radial location of HP compressor rotor at 4 and 8 o'clock positions (viewed from the front of the engine). Refer to TASK 72-00-40-020-006-B00 (REMOVAL-006, CONFIG-002).

SUBTASK 72-32-00-020-001 Hold the HP System Modules

Disconnect the eight harness terminals from the mounting pins on the fan speed proves and the trim balance prove. Refer to TASK 72-32-00-030-012 (DISASSEMBLY-012).

SUBTASK 72-32-00-030-279 Disconnect the NF Electrical Harness

Remove the No. 2 bearing oil feed tube from the sub oil distributor and the No. 2 bearing support. Refer to TASK 72-32-00-030-012 (DISASSEMBLY-012).

Remove the No. 3 bearing oil feed tube. Refer to TASK 72-32-00-030-012 (DISASSEMBLY-012).

SUBTASK 72-32-00-030-280 Remove the No. 2 and No. 3 Bearing Oil Feed Tube

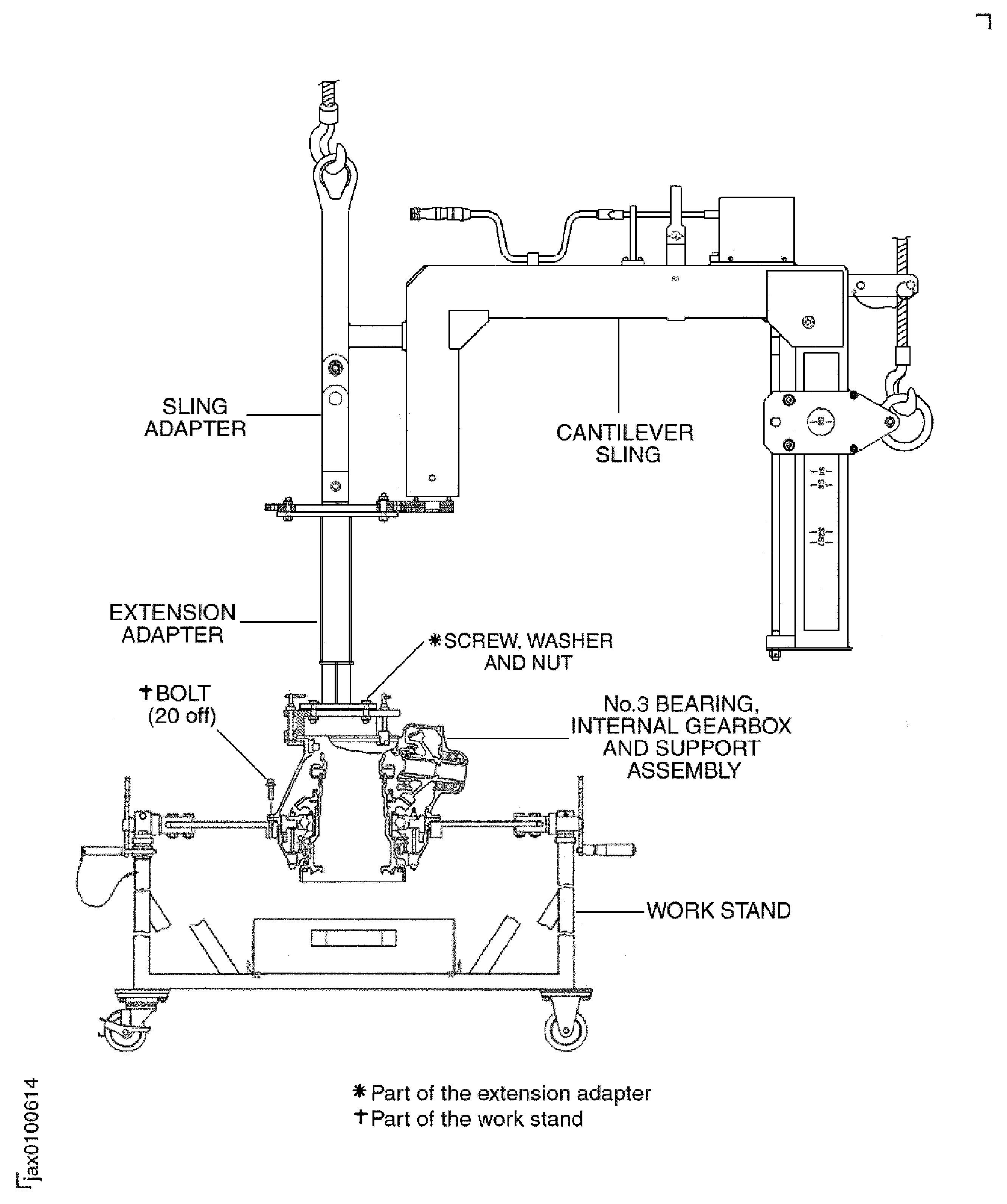

Install IAE 1J12119 Extension adapter 1 off to the sling assembly with the bolts, washers and nuts.

Install IAE 1J12326 Vertical sling 1 off to the No. 3 bearing, internal gearbox and support assembly.

SUBTASK 72-32-00-030-281 Prepare the Tools for Removal of the No.3 Bearing, Internal Gearbox and Support Assembly

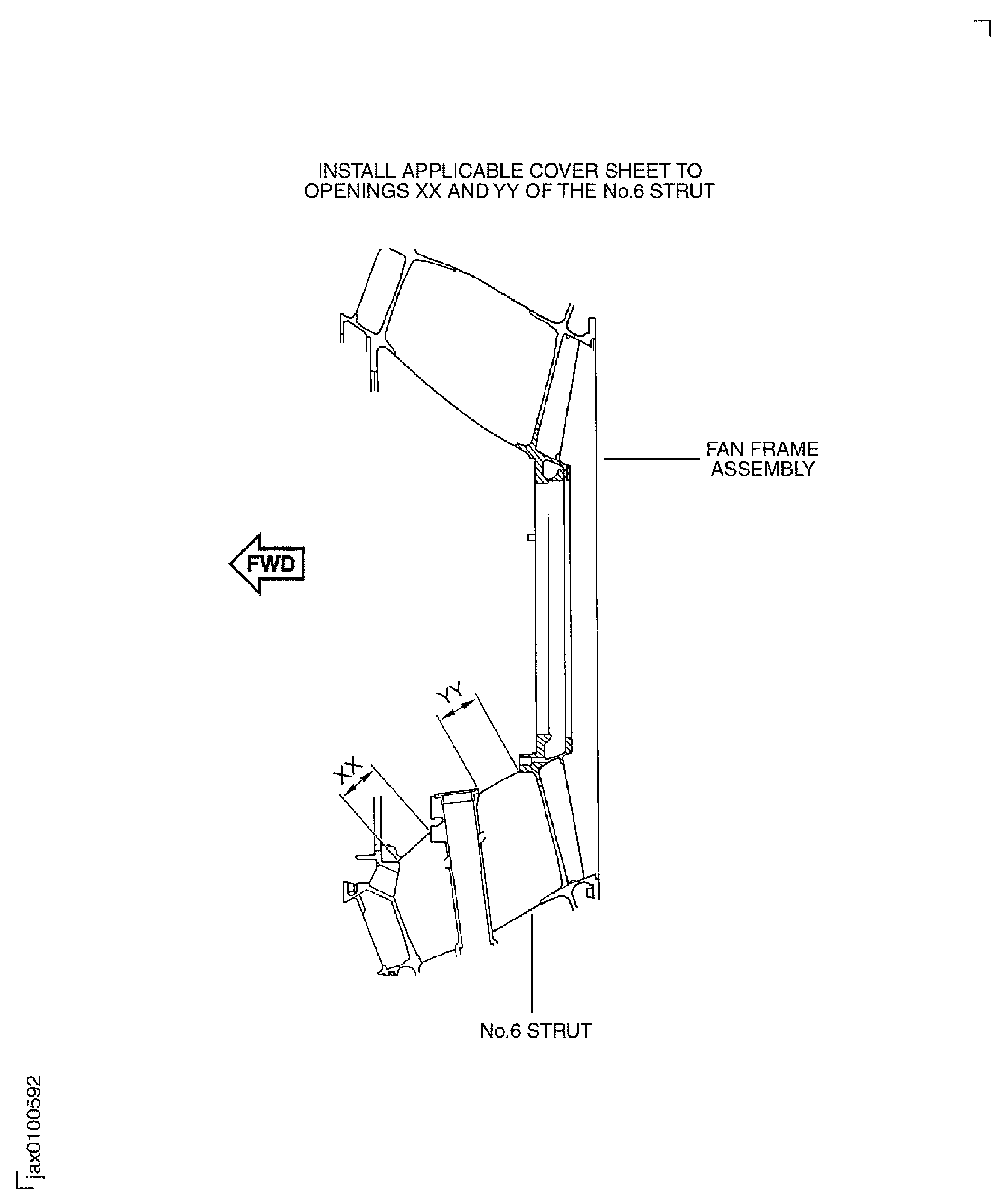

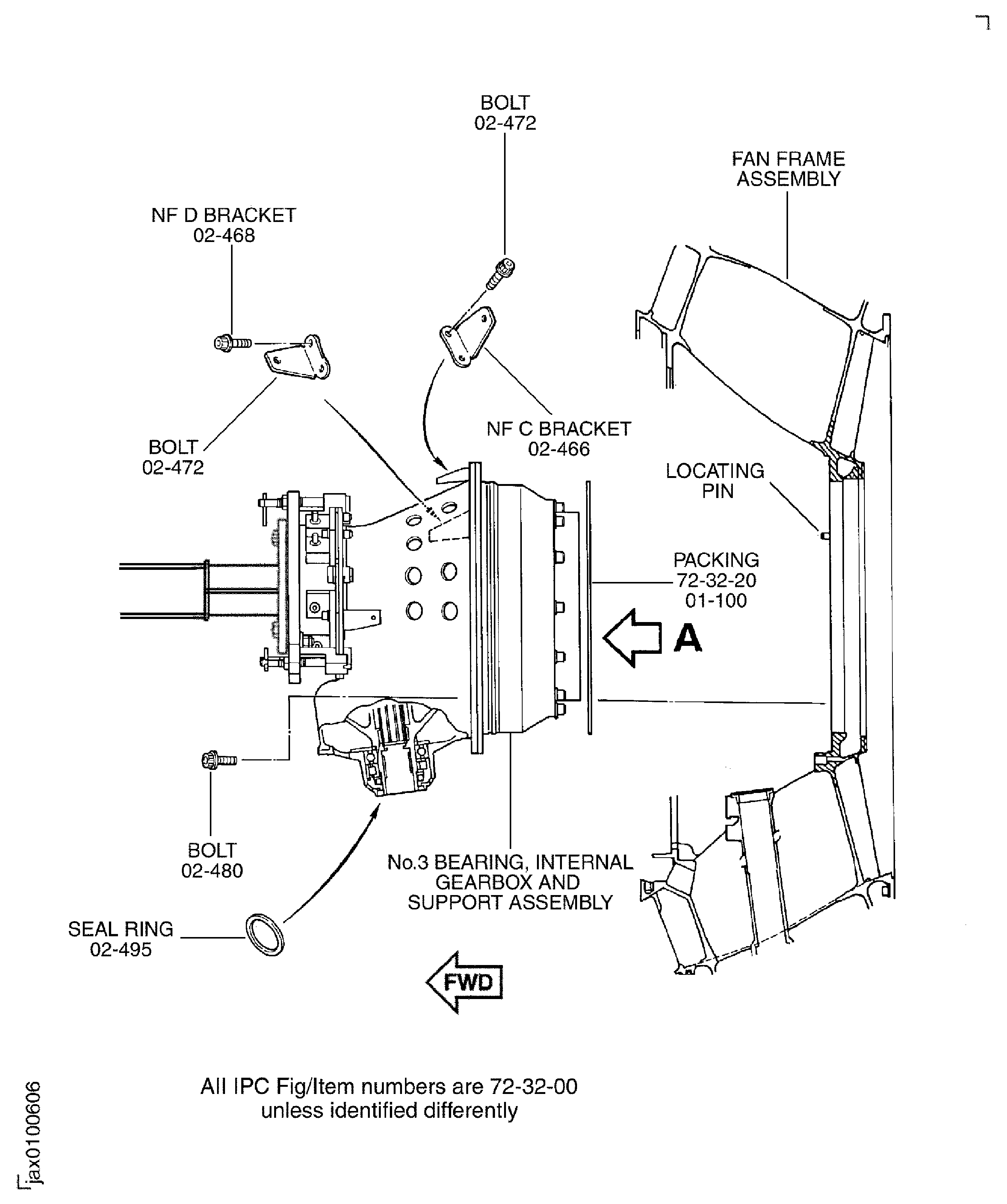

Remove the 18 bolts which attach the support assembly and the NF C and NF D brackets to the fan frame assembly. Use IAE 1J12024 Special wrench 1 off to remove the three bolts at position Z. Remove NF C and NF D brackets.

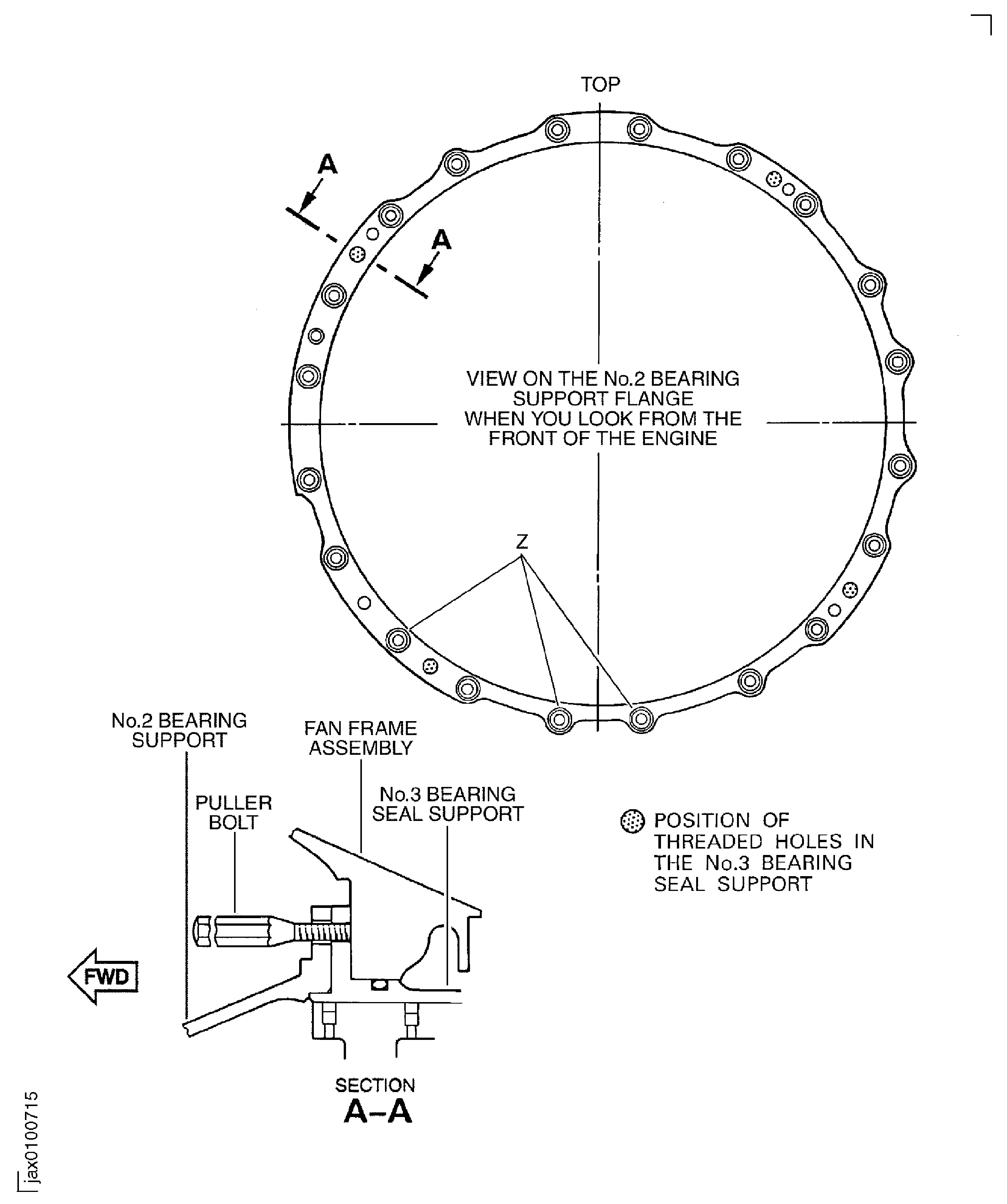

Install the three aligning pins (part of IAE 1J12507 Guide pin 1 off) in to the three of the 18 threaded holes in the fan frame thru the three of the 18 holes in the No. 2 bearing/No. 3 bearing support flanges.

Release the bolts from the HP compressor stage 3 disk curvic coupling. Refer to TASK 72-00-40-020-006-B00 (REMOVAL-006, CONFIG-002).

Use the four puller bolts (part of IAE 1J12188 Puller bolt puller bolt set 1 off) to release the No. 2 bearing/No. 3 bearing support from the fan frame assembly.

NOTE

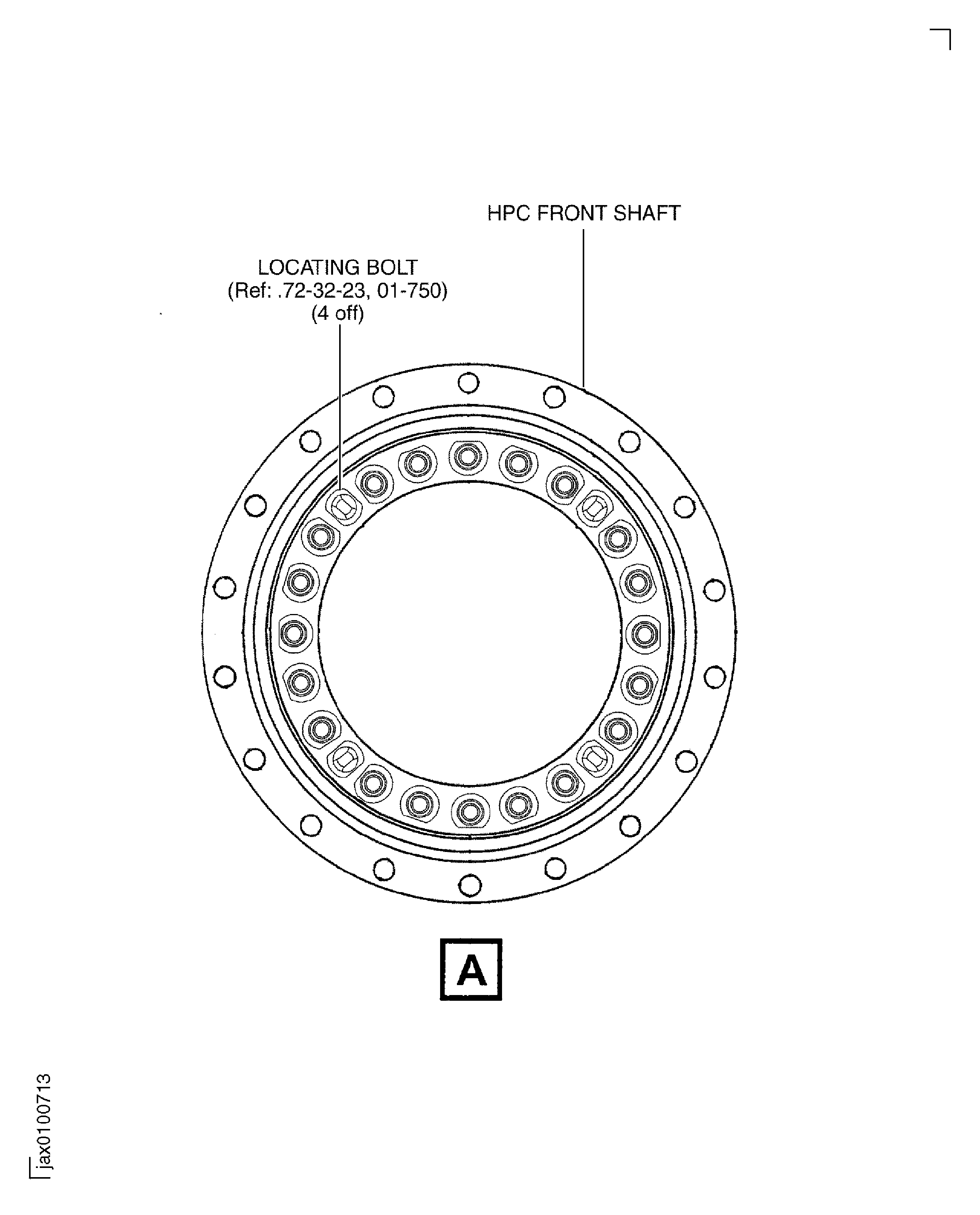

The correlation mark will be used when you install the HP compressor front shaft to the HP system in TASK 72-32-00-430-003-C00 (ASSEMBLY-003, CONFIG-003).Write a correlation mark on the No. 3 bearing support outer face with CoMat 06-069 MARKER at the same angular position as one of the four locating bolts HPC Front Shaft And Seal Carrier Assembly (72-32-23, 01-750) of the HP compressor front shaft.

Install the No. 3 bearing, internal gearbox and support assembly on to IAE 1J12362 Work stand 1 off.

SUBTASK 72-32-00-030-282 Remove the No. 3 Bearing, Internal Gearbox and Support Assembly

Figure: Remove the quill shaft from the fan frame strut through the gearbox module

Remove the quill shaft from the fan frame strut through the gearbox module

Figure: Remove the retaining protector

Remove the retaining protector

Figure: Install the aligning pins

Install the aligning pins

Figure: Assemble the cantilever sling and sling adapter

Assemble the cantilever sling and sling adapter

Figure: Turn the sling assembly to the horizontal position

Turn the sling assembly to the horizontal position

Figure: Attach the sling adapter to the front flange of the LPC stub shaft and No.1 bearing support assembly

Attach the sling adapter to the front flange of the LPC stub shaft and No.1 bearing support assembly

Figure: Remove the LPC stub shaft and No. 1 bearing support assembly from the fan frame

Sheet 1

Figure: Remove the LPC stub shaft and No. 1 bearing support assembly from the fan frame

Sheet 2

Figure: Install the LPC stub shaft and No. 1 bearing support assembly on to the storage stand

Install the LPC stub shaft and No. 1 bearing support assembly on to the storage stand

Figure: Install extension adapter to the sling assembly

Install extension adapter to the sling assembly

Figure: Install vertical sling to the No. 3 bearing, internal gearbox and support assembly

Install vertical sling to the No. 3 bearing, internal gearbox and support assembly

Figure: Install the extension adapter to the vertical sling

Install the extension adapter to the vertical sling

Figure: Install applicable cover sheet to openings XX and YY of the No. 6 strut

Install applicable cover sheet to openings XX and YY of the No. 6 strut

Figure: Remove the bolts which attach the support assembly and the NF C and NF D brackets to the fan frame assembly

Sheet 1

Figure: Remove the bolts which attach the support assembly and the NF C and NF D brackets to the fan frame assembly

Sheet 2

Figure: Use the puller bolts to release the No. 2 bearing/No. 3 bearing support from the fan frame assembly

Use the puller bolts to release the No. 2 bearing/No. 3 bearing support from the fan frame assembly

Figure: Move the No. 3 bearing, internal gearbox and support assembly forward until it is clear of the fan frame assembly

Move the No. 3 bearing, internal gearbox and support assembly forward until it is clear of the fan frame assembly

Figure: Install the No. 3 bearing, internal gearbox and support assembly on to the work stand

Install the No. 3 bearing, internal gearbox and support assembly on to the work stand

Figure: Remove the vertical sling from the No. 3 bearing, internal gearbox and support assembly

Remove the vertical sling from the No. 3 bearing, internal gearbox and support assembly