Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-32-00-430-003-C00 LPC/Intermediate Case Module - Install The No. 3 Bearing, Internal Gearbox And Support Assembly (Post Surgical Strike Procedure For FBC Area), Assembly-003

General

This TASK gives the procedure to assemble the No. 3 bearing, internal gearbox and support assembly (internal gearbox assembly) and install the assembly on to the LP compressor/Intermediate case module on which the HP system module and the external gearbox module are installed.

Where TASK 72-32-00-030-013-C00 (DISASSEMBLY-013, CONFIG-003) is used for removal of the internal gearbox assembly, it is recommended to use this TASK for assembly and installation of the assembly.

Fig/Item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/Item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

Special torque data is identified with the symbol * after the torque value.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILSs, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to the SPM TASK 70-64-02-640-501.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Vernier depth gage | LOCAL | Vernier depth gage | ||

| Electric heat gun | LOCAL | Electric heat gun | (Alternative to IAE 1J12505 Local heater 1 off) | |

| IAE 1J12005 Leak test fixture | 0AM53 | IAE 1J12005 | 1 | |

| IAE 1J12024 Special wrench | 0AM53 | IAE 1J12024 | 1 | |

| IAE 1J12102 Blanking Rod | 0AM53 | IAE 1J12102 | 1 | |

| IAE 1J12105 Cantileer sling | 0AM53 | IAE 1J12105 | 1 | |

| IAE 1J12108 Sling adapter | 0AM53 | IAE 1J12108 | 1 | |

| IAE 1J12117 TBD | 0AM53 | IAE 1J12117 | 1 | |

| IAE 1J12118 Storage stand | 0AM53 | IAE 1J12118 | ||

| IAE 1J12119 Extension adapter | 0AM53 | IAE 1J12119 | 1 | |

| IAE 1J12120 TBD | 0AM53 | IAE 1J12120 | 1 | |

| IAE 1J12182 Retaining protector | 0AM53 | IAE 1J12182 | ||

| IAE 1J12326 Vertical sling | 0AM53 | IAE 1J12326 | 1 | |

| IAE 1J12470 Leak check fixture | 0AM53 | IAE 1J12470 | 1 | |

| IAE 1J12502 No.3 bearing guide | 0AM53 | IAE 1J12502 | 1 | |

| IAE 1J12504 Ring holder | 0AM53 | IAE 1J12504 | 1 | |

| IAE 1J12505 0AM53 heater | 0AM53 | IAE 1J12505 | 1 | (Alternative to an electric heat gun) |

| IAE 1J12507 Guide pin | 0AM53 | IAE 1J12507 | 1 | |

| IAE 1J12508 Measuring stretch | 0AM53 | IAE 1J12508 | 1 | |

| IAE 1J12527 Setting master | 0AM53 | IAE 1J12527 | 1 | |

| IAE 1J12529 Measuring stretch | 0AM53 | IAE 1J12529 | 1 | |

| IAE 1P16046 Removal/Installation fixture | 0AM53 | IAE 1P16046 | ||

| IAE 1P16285 Tie-rod adapter | 0AM53 | IAE 1P16285 | ||

| IAE 1P16543 Removal/Installation fixture | 0AM53 | IAE 1P16543 | ||

| IAE 1R18234 Support rod | 0AM53 | IAE 1R18234 | ||

| IAE 6F10027 Heater control unit | 0AM53 | IAE 6F10027 | 1 | |

| IAE 6F10030 Vacuum test cart | 0AM53 | IAE 6F10030 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Safety Requirements

NONEProcedure

Refer to Figure.

If the internal gearbox assembly is not disassembled and returned to the initial module, selection of the HPC adjusting washer Gearbox Driving Bevel Gearshaft And Related Parts (72-32-26, 01-501 to Gearbox Driving Bevel Gearshaft And Related Parts 01-512) is not necessary. Go to Step.

If the internal gearbox assembly is disassembled and the specified parts, which have effect on the HP compressor rotor location, are not replaced, selection of the new HPC adjusting washer Gearbox Driving Bevel Gearshaft And Related Parts (72-32-26, 01-501 to Gearbox Driving Bevel Gearshaft And Related Parts 01-512) is not necessary. Go to Step.

If the internal gearbox assembly is disassembled and the specified parts are replaced, selection of the HPC adjusting washer Gearbox Driving Bevel Gearshaft And Related Parts (72-32-26, 01-501 to Gearbox Driving Bevel Gearshaft And Related Parts 01-512) is necessary. Go to Step.

Disassemble the internal gearbox assembly (72-32-10). Refer to TASK 72-32-10-040-001 (DISASSEMBLY).

Disassemble the No. 3 bearing, rotor center and support assembly (72-32-20). Refer to TASK 72-32-20-040-001 (DISASSEMBLY).

Go to Step.

If the internal gearbox assembly is replaced, disassembly of the internal gearbox assembly and selection of the new HPC adjusting washer Gearbox Driving Bevel Gearshaft And Related Parts (72-32-26, 01-501 to Gearbox Driving Bevel Gearshaft And Related Parts 01-512) is necessary.

SUBTASK 72-32-00-430-370 Find the Condition of the No.3 Bearing, Internal Gearbox and Support Assembly (Internal Gearbox Assembly)

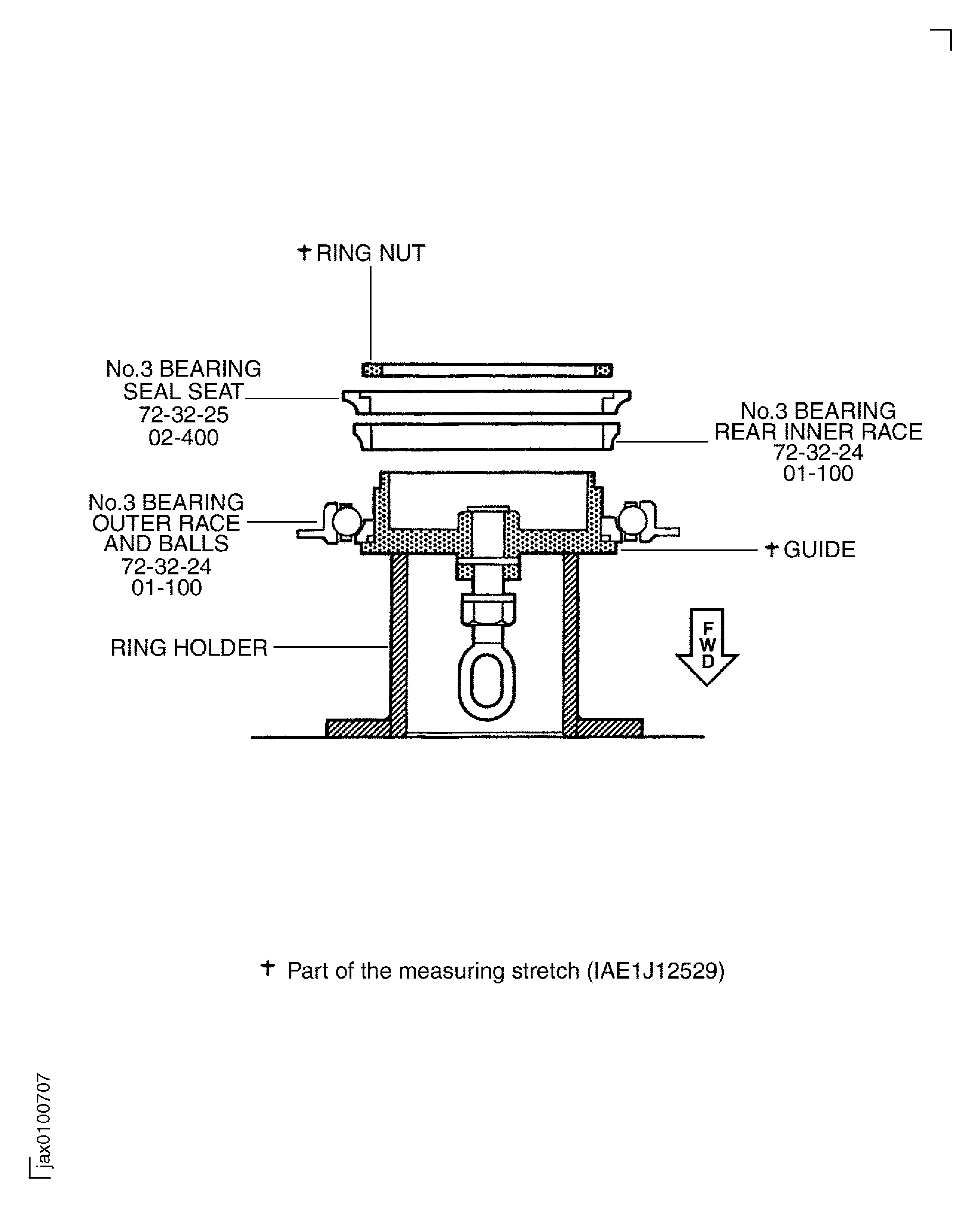

Put the guide (part of IAE 1J12529 Measuring stretch 1 off) on IAE 1J12504 Ring holder 1 off.

NOTE

The inner race of the No. 3 bearing front half has the marking FRONT on the front face.Put the No. 3 bearing front inner race No. 3 Bearing (72-32-24, 01-100) on the guide. The No. 3 bearing is a matched part. The inner race front and rear halves, the cage and the outer race must all have the same serial number.

Install the rear inner race No. 3 Bearing (72-32-24, 01-100) of the No. 3 bearing on the guide.

Install the No. 3 bearing seal seat No. 3 Bearing Rear Seal Assembly (72-32-25, 02-400) on the guide.

Attach the No. 3 bearing seal seat with the ring nut (part of IAE 1J12529 Measuring stretch). Tighten the ring nut.

Install the No. 3 bearing seal seat and the No. 3 bearing on IAE 1J12502 No.3 bearing guide No. 3 bearing guide 1 off.

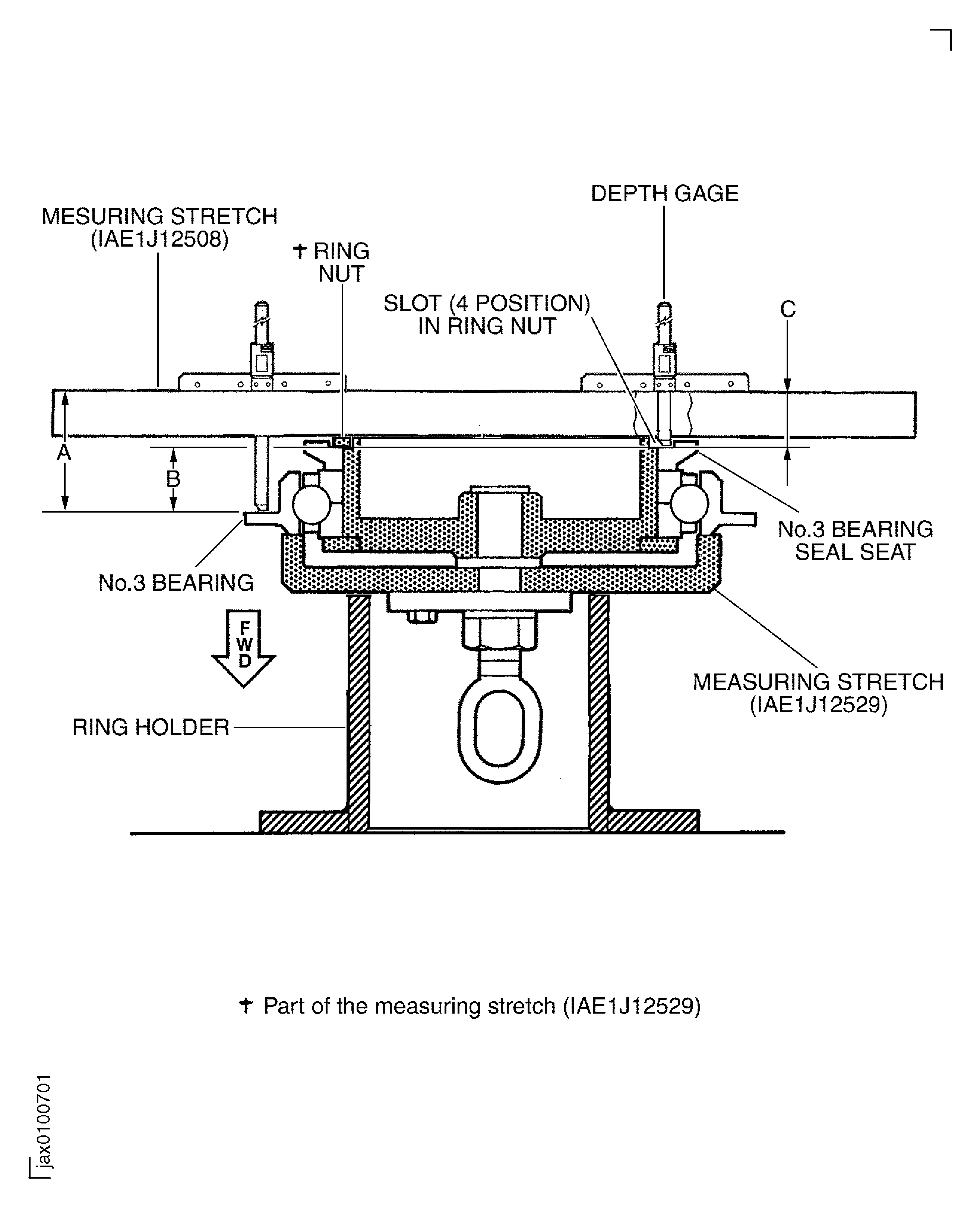

Turn IAE 1J12529 Measuring stretch, the No. 3 bearing and the No. 3 bearing seal seat and put them with the rear end down on the ring holder.

Align the hole in the flange with the lift bolt (part of IAE 1J12529 Measuring stretch). Install the flange on the No. 3 bearing outer race front face.

Loosen the lock nut and lift the plain washer (part of IAE 1J12529 Measuring stretch) along the lift bolt to make enough clearance for the swing C washer.

Install the flange (part of IAE 1J12529 Measuring stretch ) on the No. 3 bearing outer race front face.

Turn IAE 1J12529 Measuring stretch, the No. 3 bearing and the No. 3 bearing seal seat and put them with the front end down on the ring holder.

Put the stretch (part of IAE 1J12508 Measuring stretch) on IAE 1J12529 Measuring stretch.

Prepare the No. 3 bearing seal seat No. 3 Bearing Rear Seal Assembly (72-32-25, 02-400) and the No. 3 bearing No. 3 Bearing (72-32-24, 01-100) for measurement of the axial dimensions.

Find the mounting distance S (in millimeters) of the HPC front shaft and seal assembly. Refer to TASK 72-32-20-440-001-B00 (ASSEMBLY, CONFIG-002).

Find the HPC adjusting washer whose thickness is in the limits E. Refer to TASK 72-32-20-440-001-B00 (ASSEMBLY, CONFIG-002).

Remove the stretch (part of IAE 1J12508 Measuring stretch) and the measuring stretch (IAE 1J12529 Measuring stretch) and the ring holder from the No. 3 bearing and seal seat assembly.

SUBTASK 72-32-00-430-371 Find the HPC Adjusting Washer (01-501 to-001-512)

Assemble the No. 3 bearing, rotor center and support assembly. Refer to TASK 72-32-20-440-001-B00 (ASSEMBLY, CONFIG-002).

Assemble the internal gearbox assembly. Refer to TASK 72-32-10-440-001-B00 (ASSEMBLY, CONFIG-002).

SUBTASK 72-32-00-430-372 Assemble the Internal Gearbox Assembly

Install the three pins (part of IAE 1J12120 TBD 1 off) into the bushes of HP compressor front shaft.

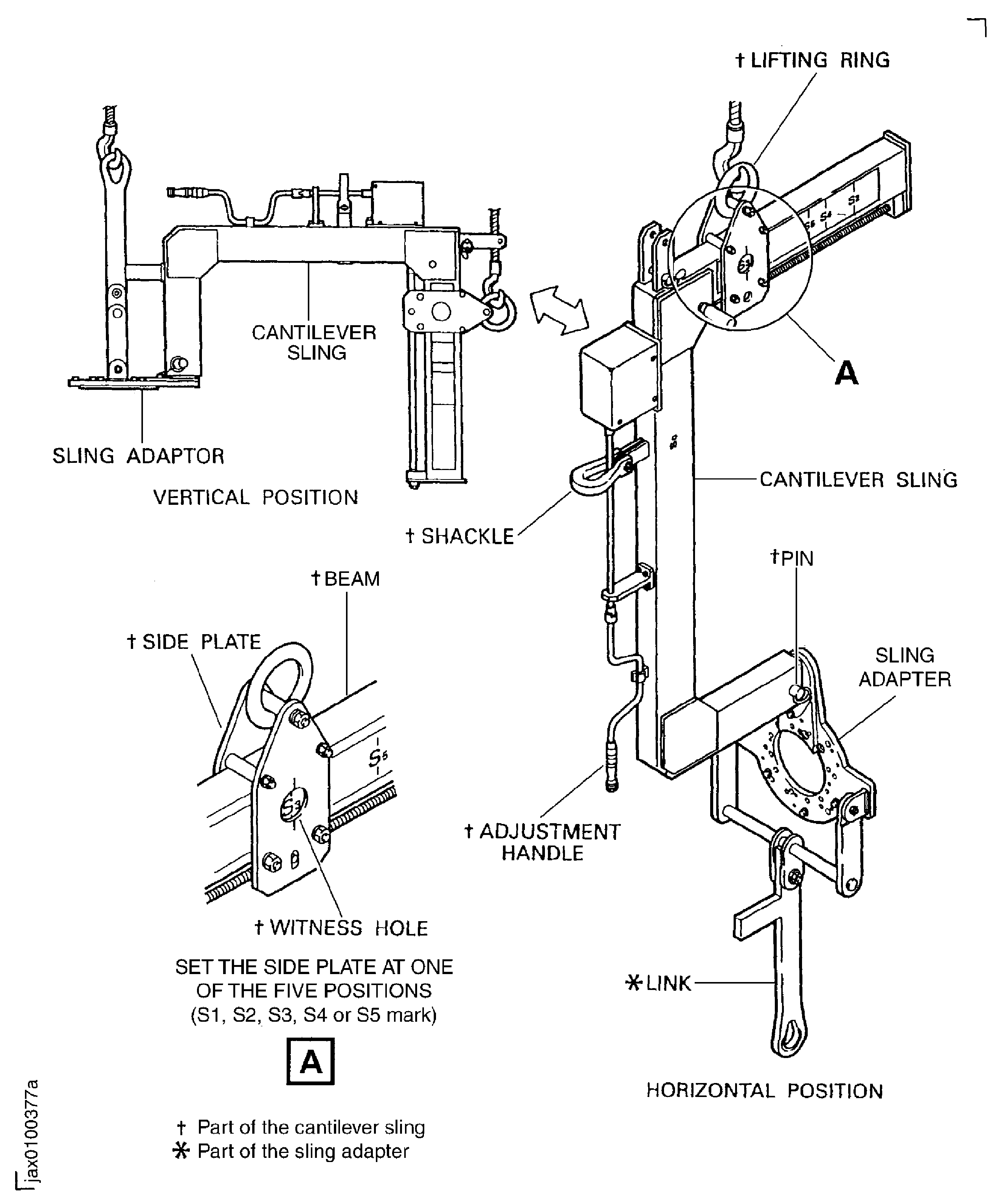

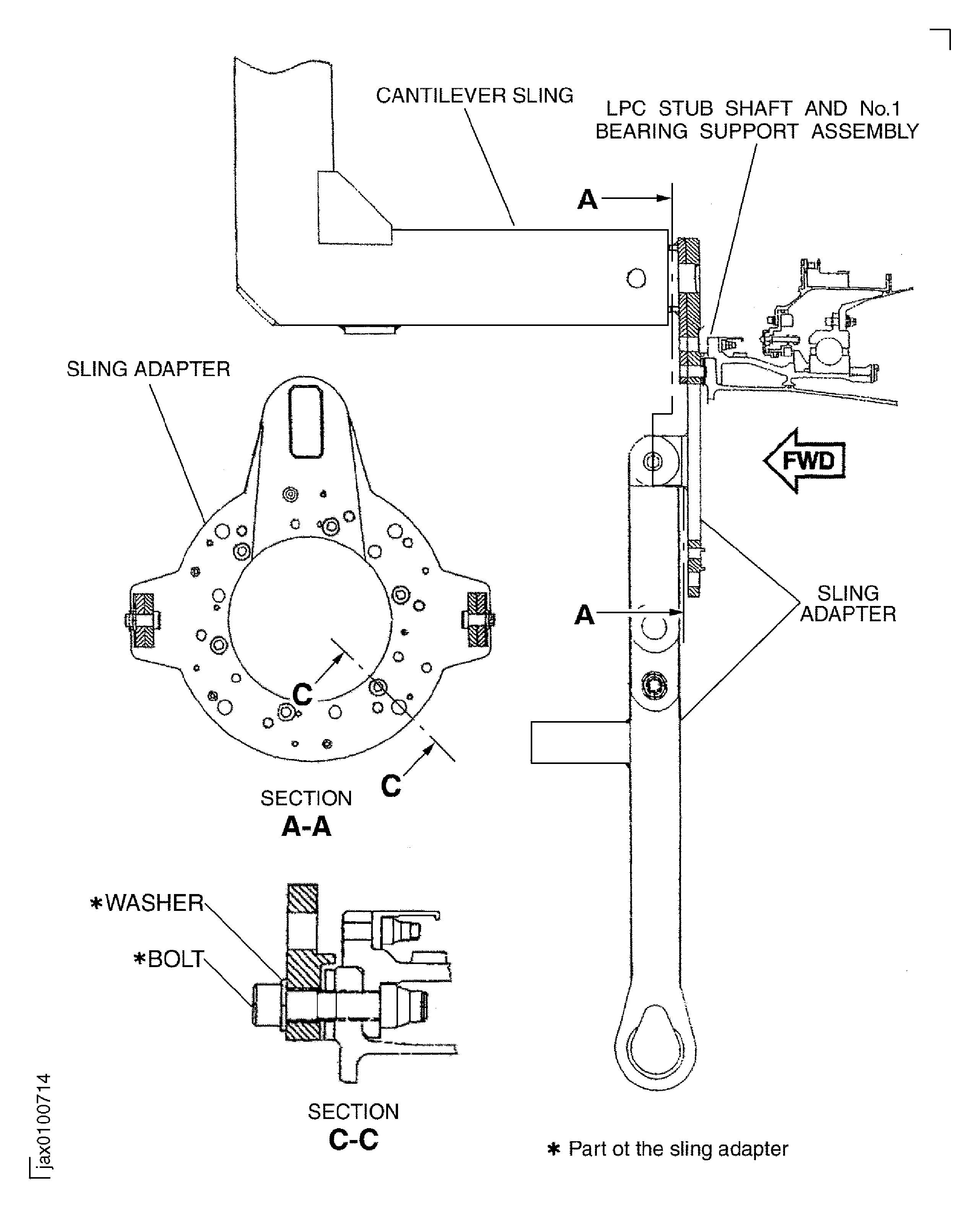

Assemble IAE 1J12105 Cantileer sling 1 off and IAE 1J12108 Sling adapter 1 off (sling assembly).

Install IAE 1J12119 Extension adapter 1 off to the sling assembly with the bolts, washers and nuts.

Install IAE 1J12326 Vertical sling 1 off to the internal gearbox assembly.

SUBTASK 72-32-00-430-373 Prepare the Tools for Installation of the Internal Gearbox Assembly

Install IAE 1J12505 0AM53 heater to the mounting flange.

Connect the cable of the local heater to IAE 6F10027 Heater control unit 1 off.

NOTE

You can use an electric heat gun as alternative to the IAE J12505 heater 1 off. Refer to SPM TASK 70-46-04-400-501.Increase the temperature of the mounting flange on the fan frame assembly.

Install the seal ring LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-495) into the internal gearbox assembly.

Lubricate the new "NO.3 BEARING,ROTOR CENTRE & SUPPORT ASSY (72-32-20, 01-100) packing 1 off with CoMat 10-077 APPROVED ENGINE OILS. Install the packing into the groove in the internal gearbox assembly.

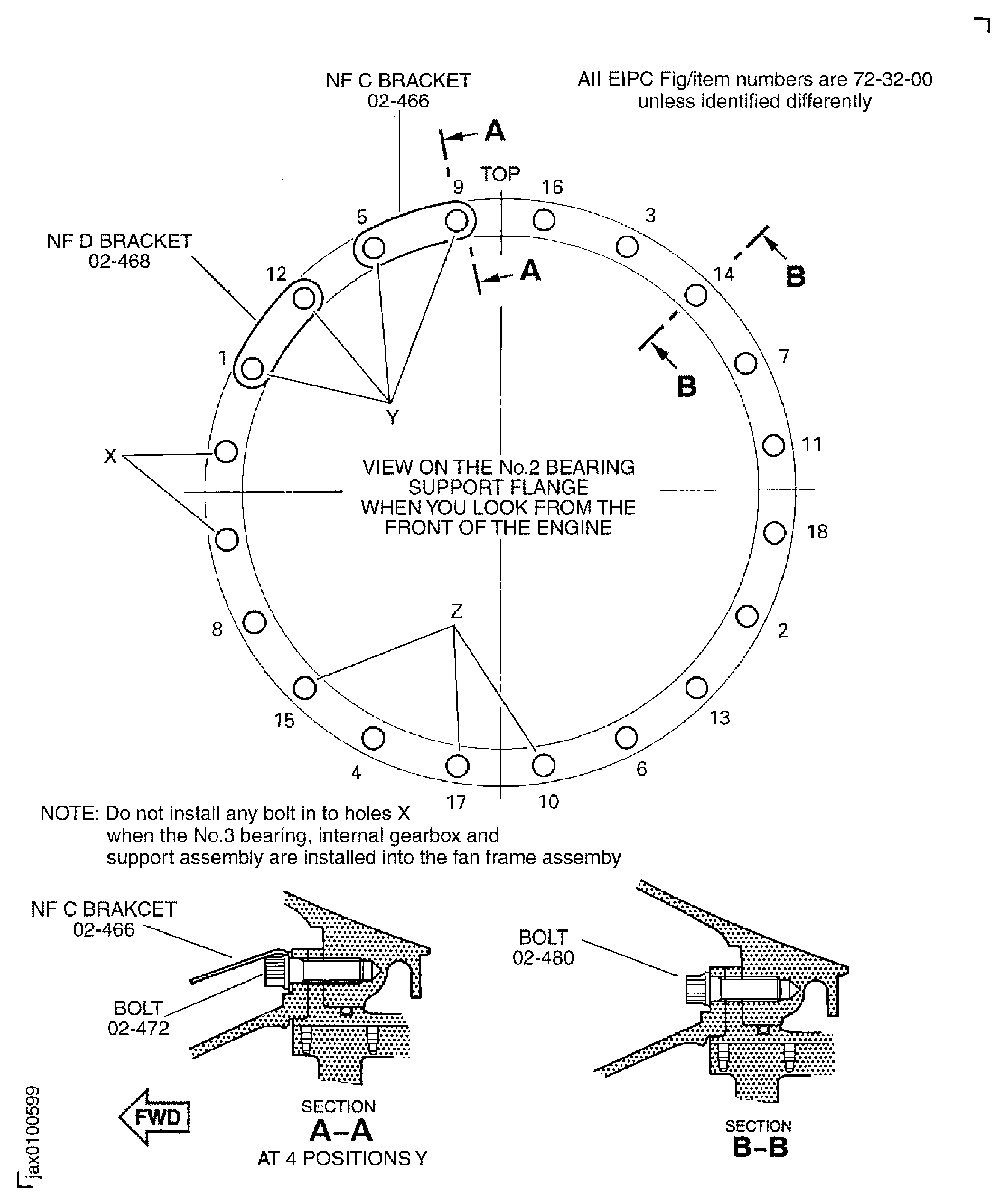

Install three aligning pins (part of IAE 1J12507 Guide pin 1 off) into three of the 14 holes for bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-480) of fan frame.

Turn the HP compressor front shaft and align one of the four locating bolts with the correlation mark on the No.3 bearing support outer face which was written in TASK 72-32-00-030-013-C00 (DISASSEMBLY-013, CONFIG-003).

Make sure that the three guide pins (part of IAE 1J12120 TBD) in the HP compressor front shaft are aligned with the shank nut holes in the HP compressor stage 3-8 disks.

Align the HP compressor front shaft with the HP compressor stage 3-8 disks.

Remove the three aligning pins (part of IAE 1J12507 Guide pin 1 off) from three of the 14 holes for bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-480) of fan frame.

NOTE

Use IAE 1J12024 Special wrench special wrench 1 off to tighten the three bolts at the holes Z.

The two bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-350) that attach the oil filter housing are installed into the holes X in SUBTASK 72-32-00-430-375.

Put the 14 bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-480) into the holes of the mounting flange of the internal gearbox assembly, but not into holes X and Y. Tighten the bolts lightly.

Install the NF C and NF D brackets LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-466 and LP Compressor (LPC) - Intermediate Structure Module 02-468) on to the mounting flange of the internal gearbox assembly with the four bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-472) at holes Y. Tighten the bolts lightly.

NOTE

Use the special wrench (IAE 1J12024 Special wrench) to torque the three bolts at holes Z.Torque the 18 bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-480 and LP Compressor (LPC) - Intermediate Structure Module 02-472) to 180 to 220 lbfin (22.00 to 25.00 Nm) for the bolt torque sequence.

Attach the internal gearbox assembly to the fan frame assembly.

Remove the tie-rod adapter (IAE 1P16285 Tie-rod adapter) from the install/removal fixture (IAE 1P16046 Removal/Installation fixture or IAE 1P16543 Removal/Installation fixture).

NOTE

The tie-rod adapter (IAE 1P16285 Tie-rod adapter) and the install/removal fixture (IAE 1P16046 Removal/Installation fixture or IAE 1P16543 Removal/Installation fixture) were installed in TASK 72-32-00-030-013-C00 (DISASSEMBLY-013, CONFIG-003).Torque the No.3 bearing rotor center and the HP compressor stage 3 disk curvic coupling bolts. Refer to TASK 72-00-40-420-002-B00 (INSTALLATION-002, CONFIG-002).

Install the internal gearbox assembly into the fan frame assembly.

SUBTASK 72-32-00-430-374 Install the Internal Gearbox Assembly in to the Fan Frame Assembly

NOTE

The support rods (IAE 1R18234 Support rod) were installed in TASK 72-32-00-030-013-C00 (DISASSEMBLY-013, CONFIG-003).Remove the two (IAE 1R18234 Support rod) from the HP compressor. Refer to TASK 72-00-40-420-002-B00 (INSTALLATION-002, CONFIG-002).

Remove (IAE 1P16046 Removal/Installation fixture or IAE 1P16543 Removal/Installation fixture). Refer to TASK 72-00-40-420-002-B00 (INSTALLATION-002, CONFIG-002).

Install the LP compressor master bleed actuator LPC Bleed Master Actuator(75-31-42,01-100). Refer to TASK 72-00-40-420-006-B00 (INSTALLATION-006, CONFIG-002).

Check the HP turbine assembly running distance. Refer to TASK 72-00-45-420-001-B01 (INSTALLATION-001, CONFIG-002).

SUBTASK 72-32-00-220-154 Check the HP Turbine Running Distance to Make Sure of the Correct Calculation of the HPC Adjusting Washer

NOTE

If the internal gearbox assembly and the specified parts, which have effect on the HP compressor rotor location, are not replaced nor repaired, it is not necessary to do this SUBTASK. Refer to Step.Install the No. 2 and the No. 3 bearing oil feed tubes. Refer to TASK 72-32-00-430-004 (ASSEMBLY-004).

Connect the eight harness terminals to the mounting pins on the fan speed probes and the trim balance probe. Refer to TASK 72-32-00-430-004 (ASSEMBLY-004).

SUBTASK 72-32-00-430-375 Connect the NF Electrical Harness and Install the No. 2 and No. 3 Bearing Oil Feed Tube

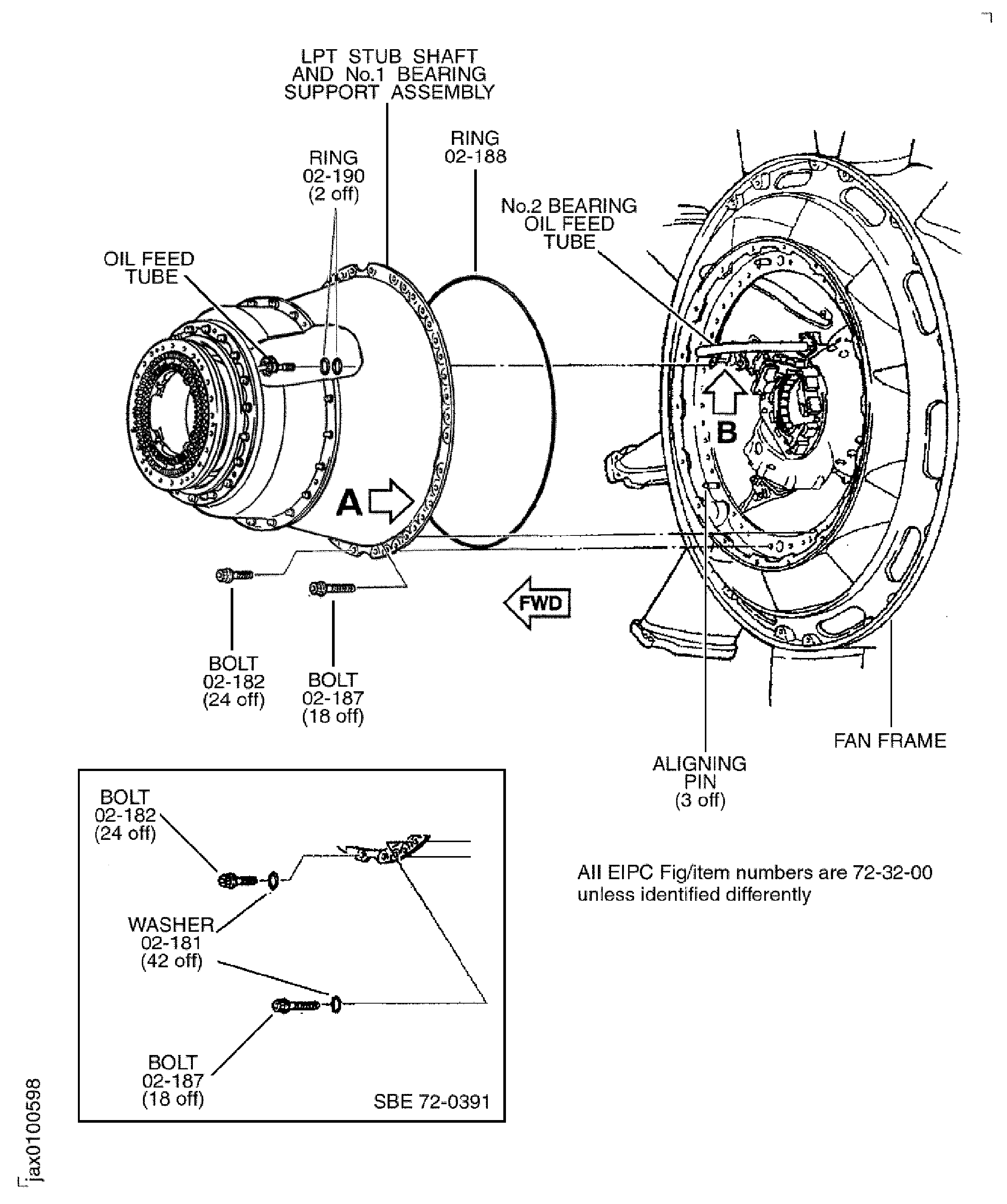

SBE 72-0391: New separate type No. 1 bearing support assembly

NOTE

The retaining protector (IAE 1J12182 Retaining protector) was installed in TASK 72-32-00-030-013-C00 (DISASSEMBLY-013, CONFIG-003).Remove the retaining protector (IAE 1J12182 Retaining protector) from the LPC stub shaft.

NOTE

The storage stand (IAE 1J12118 Storage stand) was installed in TASK 72-32-00-030-013-C00 (DISASSEMBLY-013, CONFIG-003).Remove the eight screws and washers (part of IAE 1J12118 Storage stand storage stand) which attach the LPC stub shaft and No.1 bearing support assembly to the storage stand.

Lubricate the new LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-188) sealing ring 1 off with engine oil. Install the ring into the groove in the No.1 bearing support.

Lubricate the new LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-190) sealing rings 2 off with engine oil. Install them on the oil feed tube in the No. 1 bearing support assembly.

Install the three aligning pins (part of IAE 1J12507 Guide pin aligning pin set 1 off) into three of the 42 threaded holes in the mounting flange. The three aligning pins must be installed at approximately 120 degrees apart from each other.

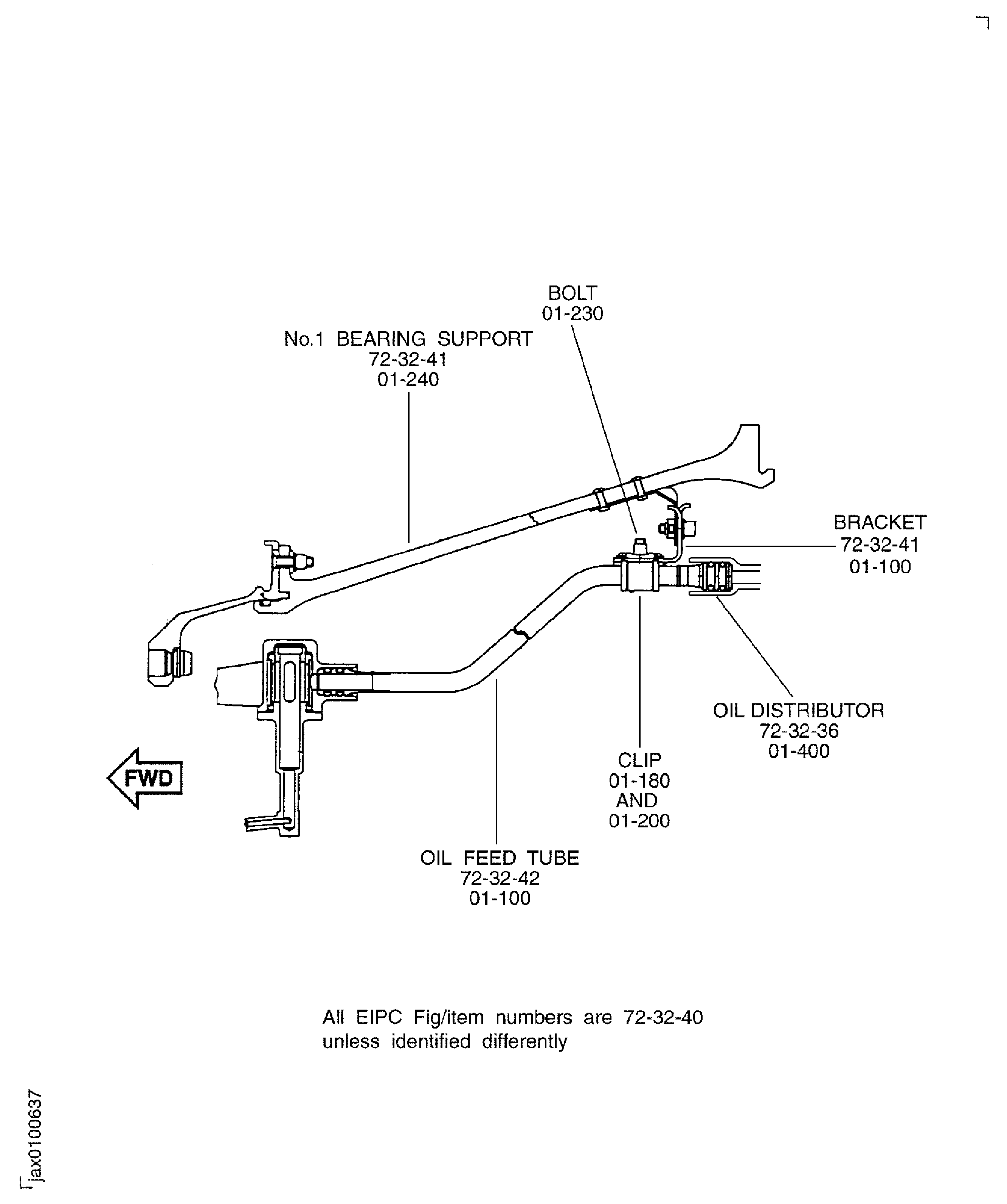

Install the oil feed tube to the bracket with the bolt ENGINE-NO.1 BEARING SUPPORT ASSEMBLY (72-32-40, 01-230), clip ENGINE-NO.1 BEARING SUPPORT ASSEMBLY (72-32-40, 01-180) and clip ENGINE-NO.1 BEARING SUPPORT ASSEMBLY (72-32-40, 01-200).

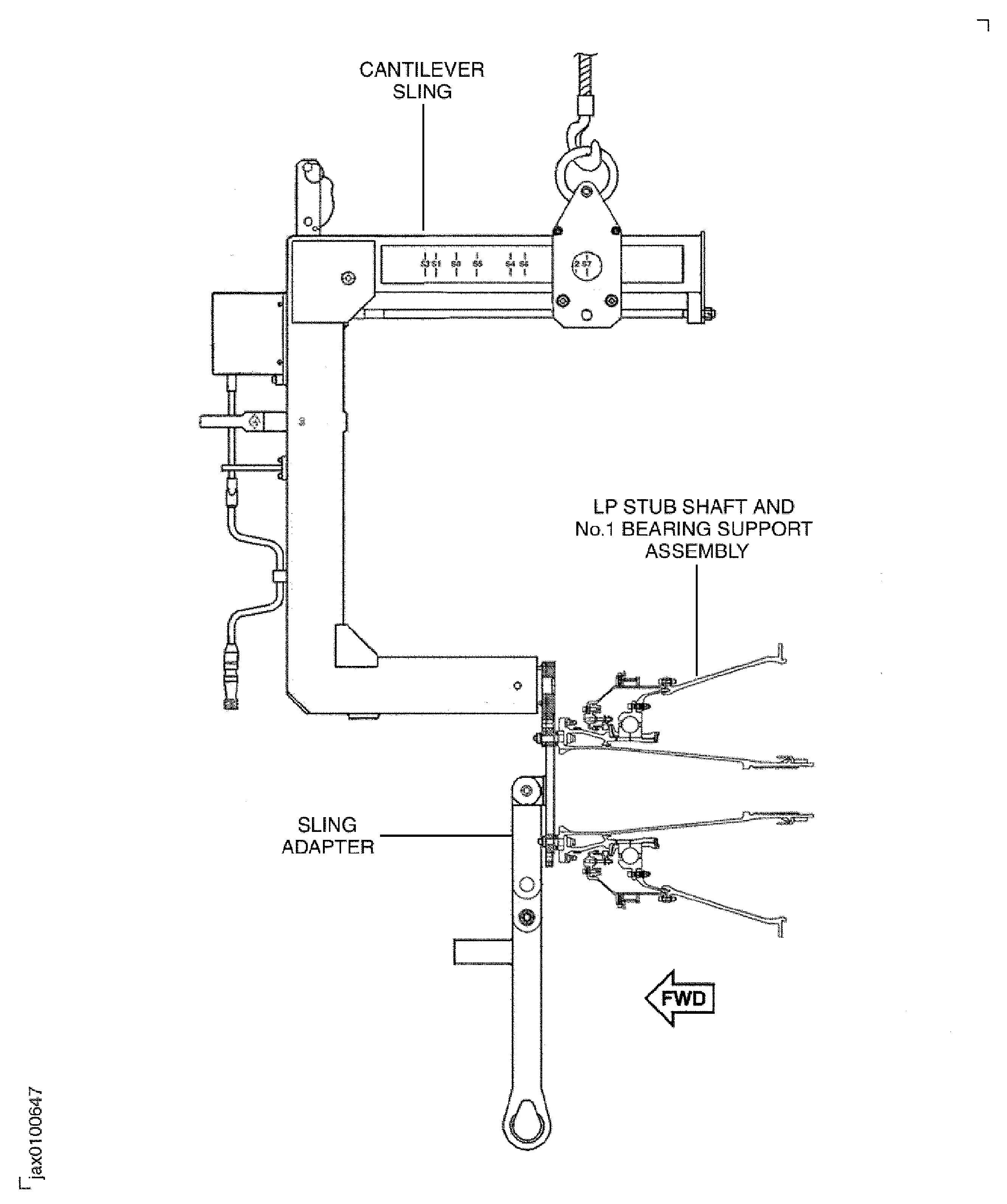

Install the LP shaft and the No. 1 bearing support assembly to the fan frame assembly.

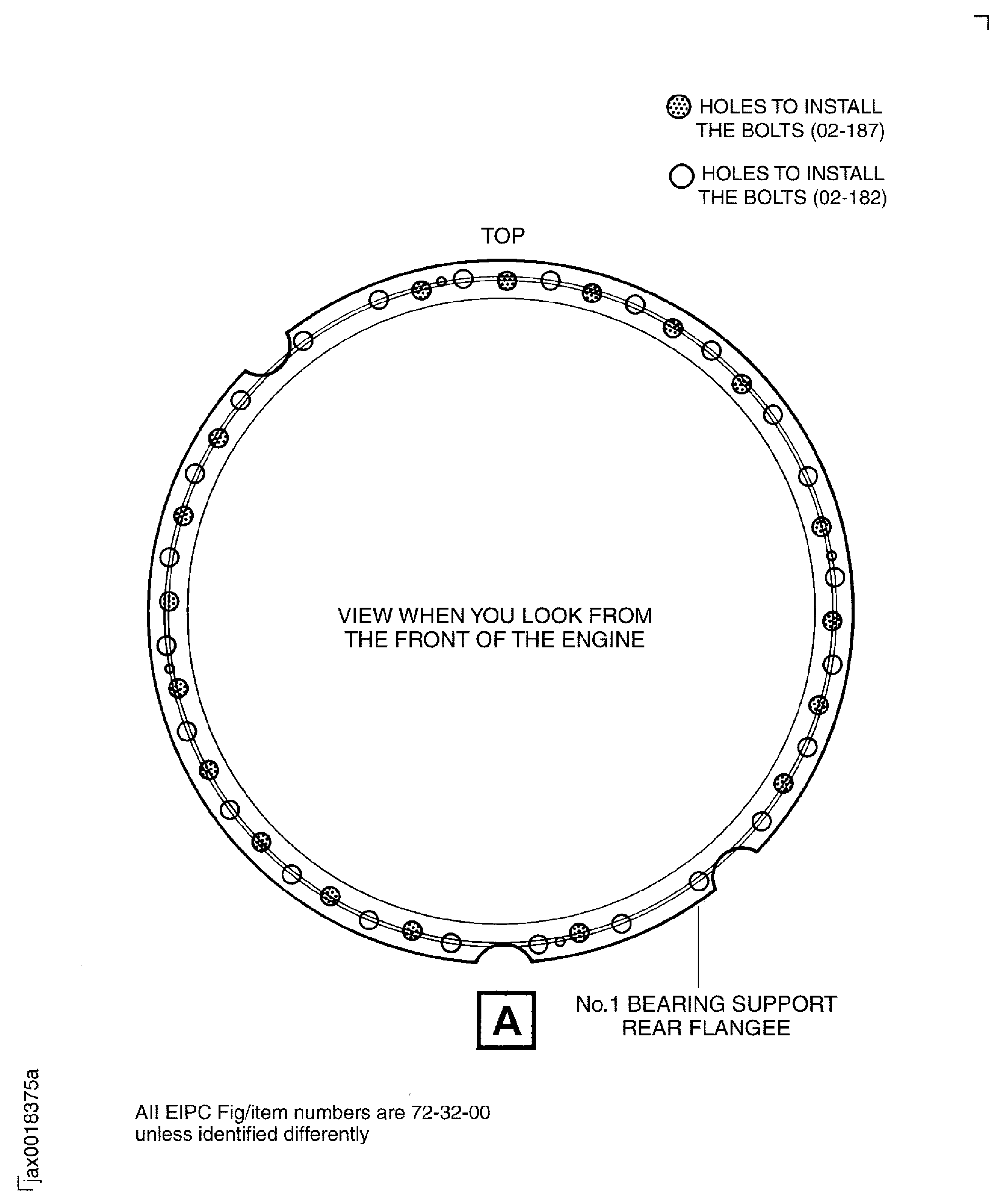

NOTE

You must identify the bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-187) and the bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-182) by their length. The bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-187) is longer than the bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-182).Pre SBE 72-0391: Attach the No. 1 bearing support assembly with the 18 bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-187) and 24 bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-182). Torque the bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-182 and LP Compressor (LPC) - Intermediate Structure Module 02-187) to 180 to 220 lbfin (20.00 to 25.00 Nm).

NOTE

You must identify the bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-187) and the bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-182) by their length. The bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-187) is longer than the bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-182).SBE 72-0391: Attach the No. 1 bearing support assembly with the 18 bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-187), 24 bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-182) and 42 washers LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-181). Torque the bolts to 180 to 220 lbfin (20.00 to 25.00 Nm).

Remove the IAE 1J12105 Cantileer sling and the IAE 1J12108 Sling adapter from the front flange of the LPC stub shaft.

Install the LPC stub shaft and No. 1 bearing support assembly to the fan frame assembly.

Do an air flow check for the oil feed tubes of the front bearing compartment. Refer to TASK 72-32-00-430-005 (ASSEMBLY-005).

SUBTASK 72-32-00-430-376 Install the LPC Stub Shaft and No. 1 Bearing Support Assembly to the Fan Frame Assembly (Pre SBE 72-0391 and SBE 72-0391)

Engage the hydraulic seal assembly with the LPC stub shaft. Refer to TASK 72-32-00-430-006 (ASSEMBLY-006).

Make sure that the hydraulic seal assembly and the hydraulic ring are in the correct locations. Refer to TASK 72-32-00-430-006 (ASSEMBLY-006).

SUBTASK 72-32-00-430-377 Engage the Hydraulic Seal Assembly with the LPC Stub Shaft

Install the No. 1 bearing compartment scavenge oil tube. Refer to TASK 72-32-00-430-007-C00 (ASSEMBLY-007, CONFIG-003).

SUBTASK 72-32-00-430-378 Install the No. 1 Bearing Compartment Scavenge Oil Tube

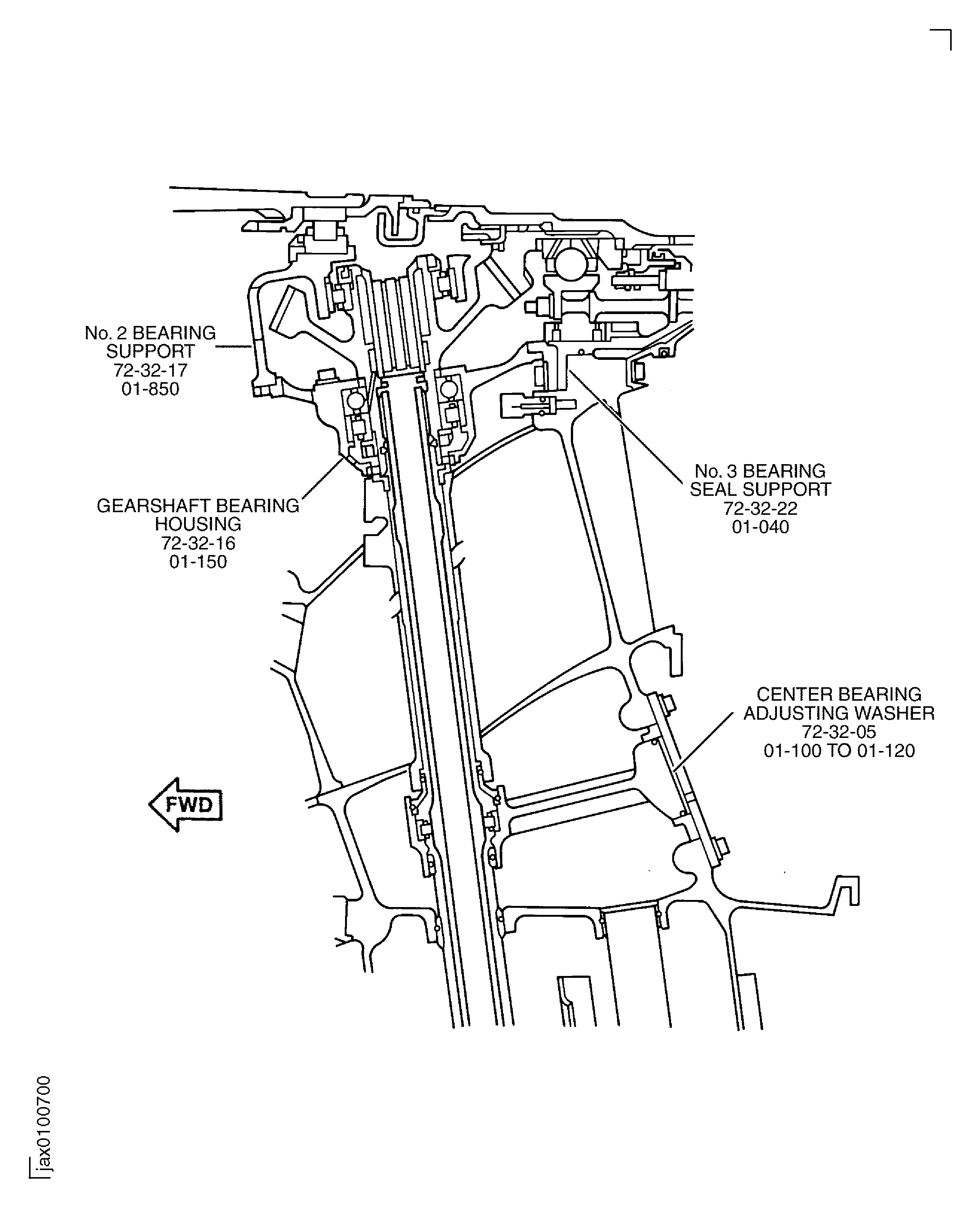

Refer to Figure.

Gearshaft bearing housing Gearbox Driven Gearshaft And Housing Assembly (72-32-16, 01-150).

No. 2 bearing support No. 2 Bearing Support And Related Parts (72-32-17, 01-850).

No. 3 bearing seal support ENGINE-NO.3 BEARING SEAL SUPPORT (72-32-22, 01-040).

Make sure that the following parts are not replaced.

If the parts shown in step B. are not replaced, use the initial adjusting washer. Go to Step.

Remove the external gearbox module. Refer to TASK 72-00-60-020-003-001 (REMOVAL-003).

Use IAE 1J12527 Setting master 1 off to make sure that the center bearing is in the correct location. Refer to TASK 72-32-00-430-011-B00 (ASSEMBLY-011, CONFIG-002).

NOTE

If the center bearing is in the correct location, use the initial adjusting washer.If the center bearing is not in the correct location, replace the existing adjusting washer with the found adjusting washer. Refer to TASK 72-32-00-430-011-B00 (ASSEMBLY-011, CONFIG-002).

If one or more parts are replaced, do a check for location of the center bearing. Replace the adjusting washer as necessary.

Install the external gearbox module. Refer to TASK 72-00-60-420-001-001 (INSTALLATION-001).

SUBTASK 72-32-00-430-379 Replace the Center Bearing Adjusting Washer as Necessary

Remove the three nut Angle Gearbox Driving Gearshaft Assembly (72-60-42, 01-070) and washers Angle Gearbox Driving Gearshaft Assembly (72-60-42, 01-075) which attach the plug Angle Gearbox Driving Gearshaft Assembly (72-60-42, 01-060) to the radial gear support. Refer to TASK 72-60-40-040-001 (DISASSEMBLY).

Remove the plug. Refer to TASK 72-60-40-040-001 (DISASSEMBLY).

Lubricate the two o-rings (part of the blanking rod) with CoMat 10-077 APPROVED ENGINE OILS.

Install the blanking rod into PTO oil seal tube through the angle gearbox with the removed three nuts Angle Gearbox Driving Gearshaft Assembly (72-60-42, 01-070).

Install IAE 1J12102 Blanking Rod 1 off in the PTO oil seal tube.

Remove the No. 1, 2 and 3 bearing compartment scavenge tube assembly (Tubes 107 and 108). Refer to TASK 72-00-60-020-002-B00 (REMOVAL-002, CONFIG-002).

Install the plug D on the scavenge tube. Refer to TASK 72-32-00-430-011-B00 (ASSEMBLY-011, CONFIG-002).

Install the plug D (part of IAE 1J12470 Leak check fixture 1 off) on the No. 1, 2 and 3 bearing scavenge tube flange in No. 6 strut.

Remove the oil tube cover and install the plug A (part of the leak check fixture 1 off) on to the oil feed adapter in the No. 4 strut. Refer to TASK 72-32-00-430-011-B00 (ASSEMBLY-011, CONFIG-002).

Turn the coupling nut (part of the leak test fixture) counterclockwise and remove it from the cylinder (part of IAE 1J12005 Leak test fixture).

Insert IAE 1J12005 Leak test fixture in the LPC stub shaft from the front side.

Install IAE 1J12005 Leak test fixture 1 off.

SUBTASK 72-32-00-790-055 Prepare for Evacuation Check

Refer to Figure.

Disconnect the tube 169 from the hot vent tube. Refer to TASK 72-00-32-020-003 (REMOVAL-003).

Install the joint (part of IAE 1J12470 Leak check fixture 1 off) on to the hot vent tube. Attach the adapter (part of IAE 6F10030 Vacuum test cart 1 off) to on joint on hot vent tube. Refer to TASK 72-32-00-430-011-B00 (ASSEMBLY-011, CONFIG-002).

Connect IAE 6F10030 Vacuum test cart 1 off to the electrical power. Refer to TASK 72-32-00-430-011-B00 (ASSEMBLY-011, CONFIG-002).

Connect IAE 1J12005 Leak test fixture to shop air supply source.

Inflate the ballon (part of IAE 1J12005 Leak test fixture) to the pressure between 7.0 (48.0 kPa) and 7.5 psig (52.0 kPa).

Operate IAE 6F10030 Vacuum test cart. Set the air pressure at the test port (part of vacuum test cart) at -20 in.Hg gage (-508 mmHg).

SUBTASK 72-32-00-790-056 Do a Evacuation Check for Leaks

Remove the IAE 1J12005 Leak test fixture.

Remove the IAE 6F10030 Vacuum test cart.

SUBTASK 72-32-00-790-057 Remove the Special Tools for Evacuation Check

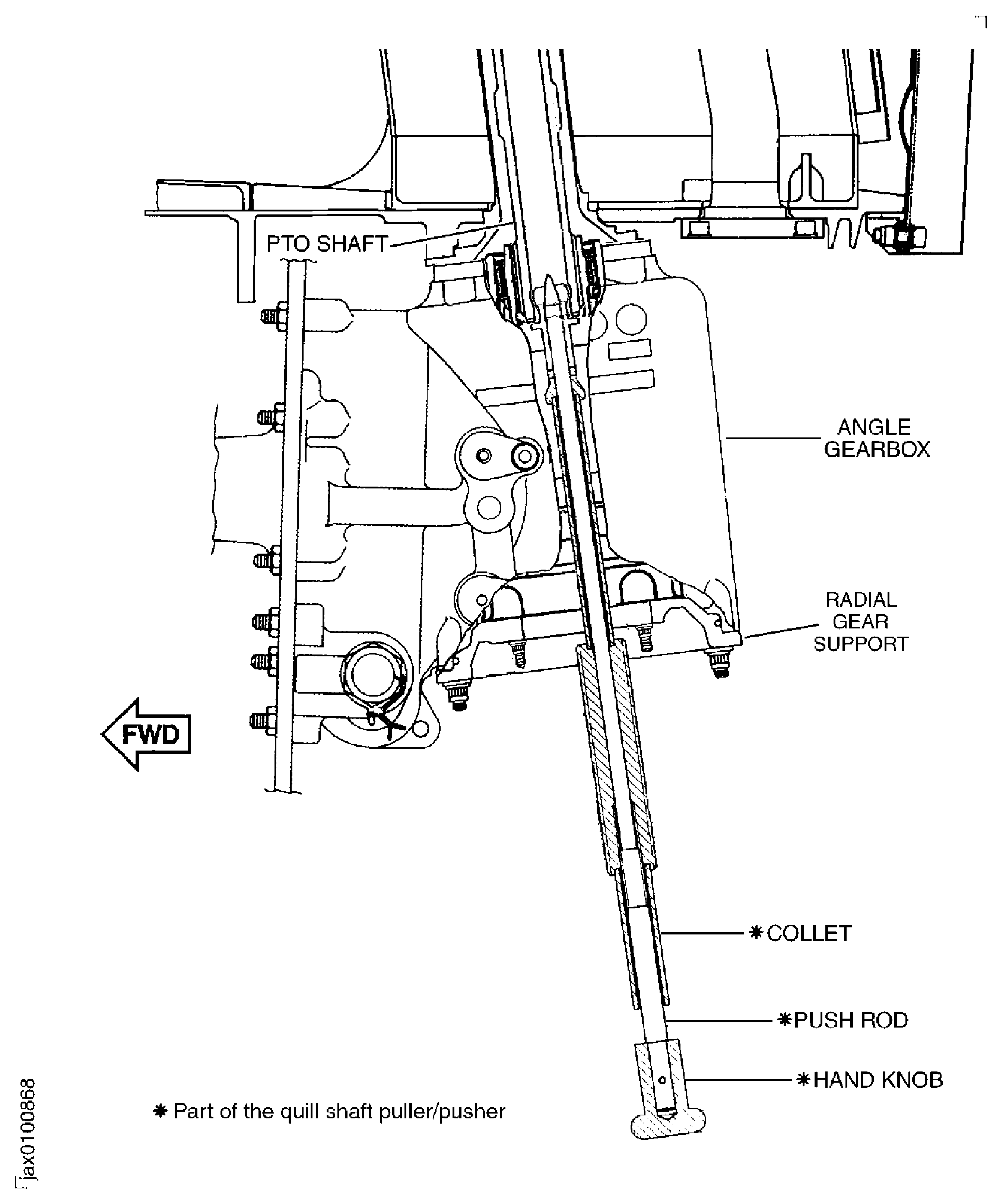

Refer to Figure.

Lubricate the outer faces and spline teeth on the shaft with CoMat 10-077 APPROVED ENGINE OILS.

Install the collet (part of IAE 1J12117 TBD 1 off) and the rod (part of the quill shaft puller/pusher) into the end, which has 28 spline teeth and four scallops, of the shaft.

NOTE

The shaft moves lightly before it touches the sealing ring Gearbox Driven Gearshaft And Housing Assembly (72-32-16, 01-100). When the shaft touches the ring , the movement of the shaft becomes hard.Insert the shaft, collet and rod through the angle gear box slowly to prevent the damage to the bearing ENGINE-PTO DRIVE SHAFT BEARING AND SUPPORT (72-32-05, 01-250) in the center bearing housing ENGINE-PTO DRIVE SHAFT BEARING AND SUPPORT (72-32-05, 01-300).

Engage the spline of the shaft with the spline of the bevel shaft gear Gearbox Driven Gearshaft And Housing Assembly (72-32-16, 01-750).

NOTE

The shaft has spline teeth at two ends of the shaft. The end, which has 24 spline teeth, must be installed in to the oil seal tube. The end, which has 28 spline teeth and four scallops, must be out of the oil seal tube.Install the quill shaft ENGINE-PTO SHAFT (72-32-95, 01-100) into the oil seal tube through the gearbox module.

Install the coupling shaft and the oil duct in to the internal of the radial gearshaft. Refer to TASK 72-60-40-440-001 (ASSEMBLY-001).

Install the nut Angle Gearbox Driving Gearshaft Assembly (72-60-42, 01-120) which attach the oil duct to the radial gearshaft. Refer to TASK 72-60-40-440-001 (ASSEMBLY).

Install the lock washer Angle Gearbox Driving Gearshaft Assembly (72-60-42, 01-110) and the segment Angle Gearbox Driving Gearshaft Assembly (72-60-42, 01-100) to lock the nut. Refer to TASK 72-60-40-440-001 (ASSEMBLY).

Install the oil nozzle Angle Gearbox Assembly (72-60-40, 01-400) and the plug Angle Gearbox Driving Gearshaft Assembly (72-60-42, 01-060) to the angle gearbox. Refer to TASK 72-60-40-440-001 (ASSEMBLY).

Install the plug Angle Gearbox Driving Gearshaft Assembly (72-60-42, 01-060), the oil duct Angle Gearbox Driving Gearshaft Assembly (72-60-42, 01-130) and the coupling shaft Angle Gearbox Driving Gearshaft Assembly (72-60-42, 01-210).

SUBTASK 72-32-00-430-380 Install the Quill Shaft in the Fan Frame Strut Through the Gearbox Module

Install the LP turbine module to the engine. Refer to TASK 72-00-50-420-001-C00 (INSTALLATION-001, CONFIG-003).

Install the LP turbine module components, external harnesses and tubes to the engine. Refer to TASK 72-00-50-420-005-B00 (INSTALLATION-005, CONFIG-002).

SUBTASK 72-32-00-430-381 Install the LP Turbine Module

Install the LPC booster stage assembly. Refer to TASK 72-32-00-430-010-D00 (ASSEMBLY-010, CONFIG-004).

SUBTASK 72-32-00-430-382 Install the LPC Booster Stage Assembly (Booster Assembly)

Figure: Sectional View of the No. 3 Bearing, Internal Gearbox and Support Assembly

Sectional View of the No. 3 Bearing, Internal Gearbox and Support Assembly

Figure: Set up the Measuring Stretch and the No. 3 Bearing Seal Seat and the No. 3 Bearing for Finding the HPC Adjusting Washer

Sheet 1

Figure: Install the No. 3 Bearing Seal Seat and the No. 3 Bearing on the No. 3 Bearing Guide

Sheet 2

Figure: Install the Flange on the No. 3 Bearing Outer Race Front Face

Sheet 3

Figure: Measure the Dimensions at the Positions Equally Apart

Sheet 4

Figure: Find the HPC Adjusting Washer

Find the HPC Adjusting Washer

Figure: Install the Guide Pin into the Bushes of HPC Front Shaft

Install the Guide Pin into the Bushes of HPC Front Shaft

Figure: Assemble Cantilever Sling and Sling Adapter

Assemble Cantilever Sling and Sling Adapter

Figure: Adjust the Two Hoists to Turn the Sling Assembly to Horizontal Position

Adjust the Two Hoists to Turn the Sling Assembly to Horizontal Position

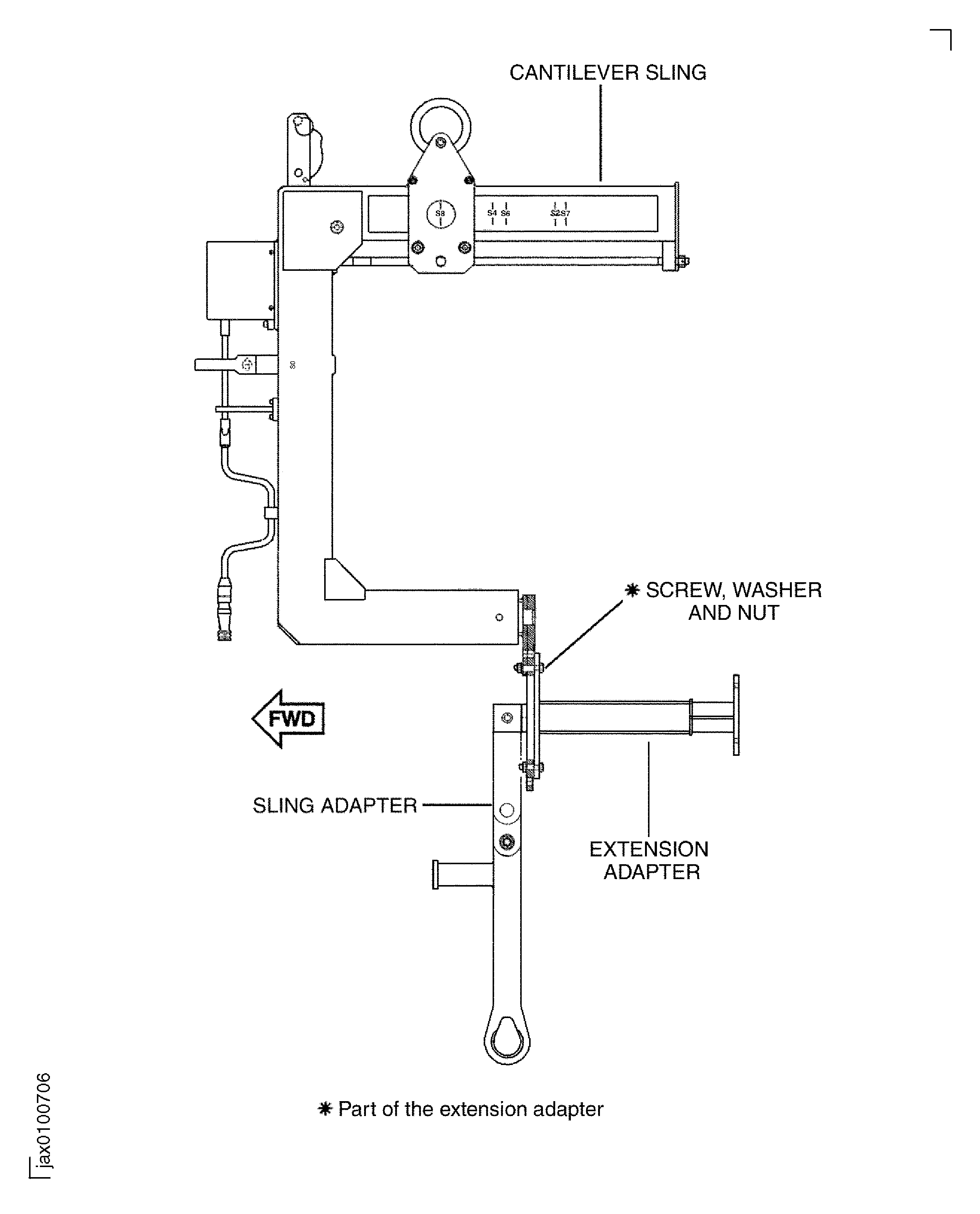

Figure: Install the Extension Adapter to the Sling Assembly

Install the Extension Adapter to the Sling Assembly

Figure: Install the Vertical Sling to the No.3 Bearing, Internal Gearbox and Support Assembly

Install the Vertical Sling to the No.3 Bearing, Internal Gearbox and Support Assembly

Figure: Adjust the Two Hoists to Turn the Sling Assembly and the Extension Adapter to Vertical Position

Adjust the Two Hoists to Turn the Sling Assembly and the Extension Adapter to Vertical Position

Figure: Install the Extension Adapter to the Vertical Sling

Install the Extension Adapter to the Vertical Sling

Figure: Adjust the Two Hoists to Turn the Tools and the No.3 Bearing, Internal Gearbox and Support Assembly to Horizontal Position

Adjust the Two Hoists to Turn the Tools and the No.3 Bearing, Internal Gearbox and Support Assembly to Horizontal Position

Figure: Install the Local Heater to Mount Flange on the Fan Frame Assembly

Install the Local Heater to Mount Flange on the Fan Frame Assembly

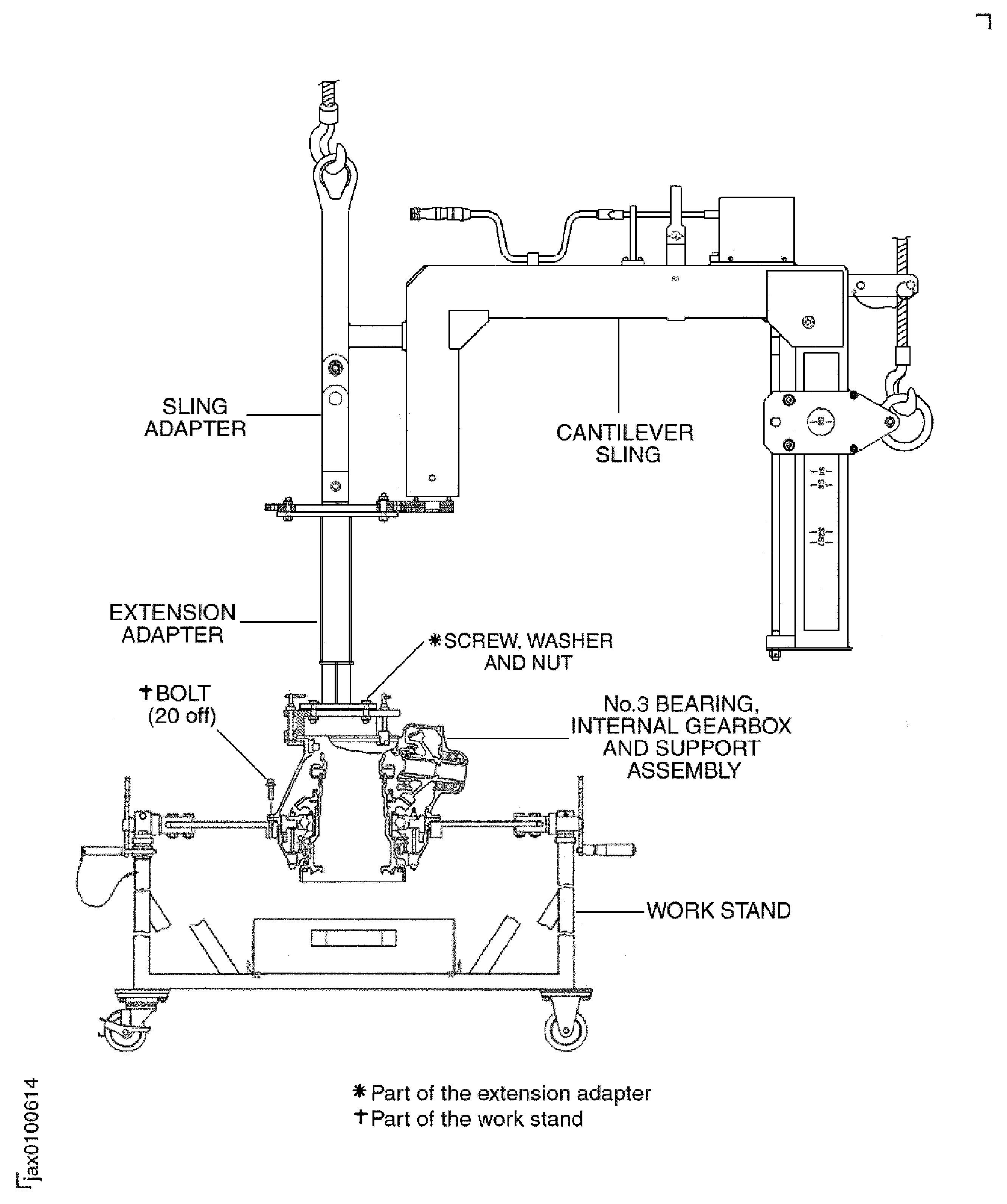

Figure: Install the No.3 Bearing, Internal Gearbox and Support Assembly into the Fan Frame Assembly

Install the No.3 Bearing, Internal Gearbox and Support Assembly into the Fan Frame Assembly

Figure: Remove the Extension Adapter from the Vertical Sling

Remove the Extension Adapter from the Vertical Sling

Figure: Remove the Vertical Sling from the No.3 Bearing, Internal Gearbox and Support Assembly

Remove the Vertical Sling from the No.3 Bearing, Internal Gearbox and Support Assembly

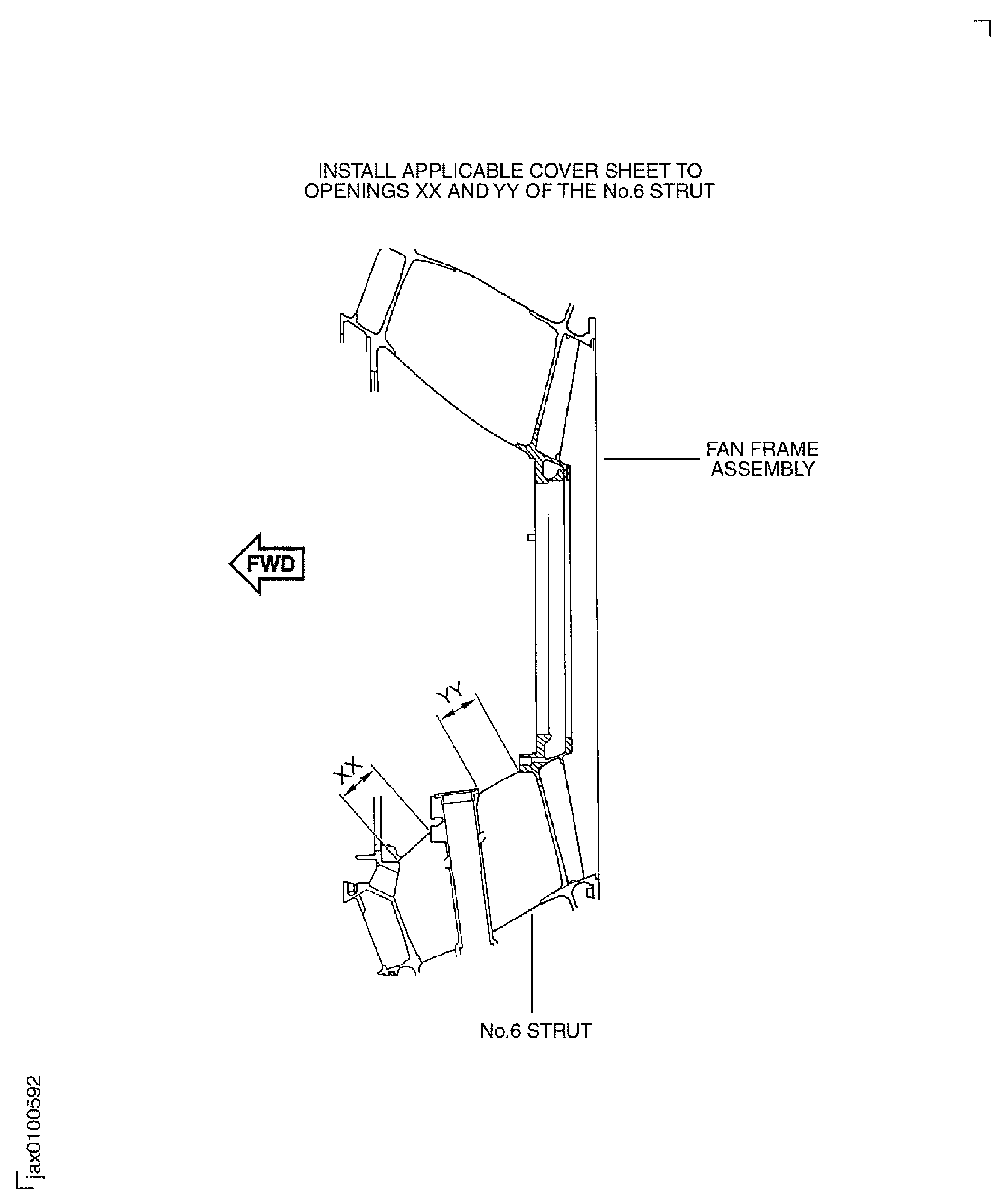

Figure: Install an Applicable Cover Sheet over the Openings XX and YY of the No.6 Strut

Install an Applicable Cover Sheet over the Openings XX and YY of the No.6 Strut

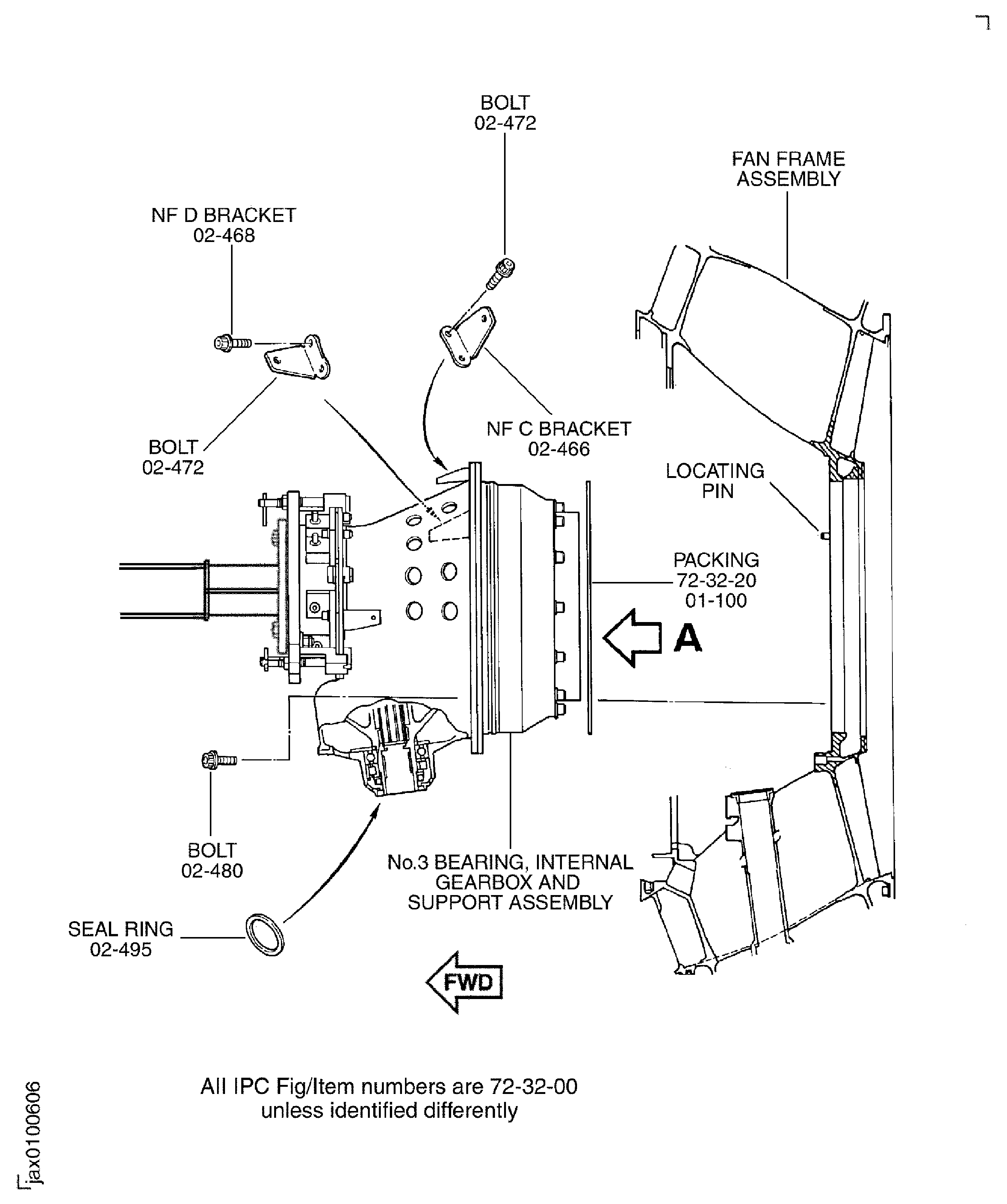

Figure: Attach the Support Assembly to the Fan Frame Assembly

Attach the Support Assembly to the Fan Frame Assembly

Figure: Remove the Retaining Protector from the LPC Stub Shaft

Remove the Retaining Protector from the LPC Stub Shaft

Figure: Attach the Sling Adapter to the Front Flange of the LPC Stub Shaft and No.1 Bearing Support Assembly

Sheet 1

Figure: Attach the Sling Adapter to the Front Flange of the LPC Stub Shaft and No.1 Bearing Support Assembly

Sheet 2

Figure: Adjust the Two Hoists to Turn the Sling Assembly and the LPC Stub Shaft and No.1 Bearing Support Assembly to Horizontal Position

Adjust the Two Hoists to Turn the Sling Assembly and the LPC Stub Shaft and No.1 Bearing Support Assembly to Horizontal Position

Figure: Install the LP Shaft and the No.1 Bearing Support Assembly to the Fan Frame Assembly

Sheet 1

Figure: Install the LP Shaft and the No.1 Bearing Support Assembly to the Fan Frame Assembly

Sheet 2

Figure: Install the LP Shaft and the No.1 Bearing Support Assembly to the Fan Frame Assembly

Sheet 3

Figure: Install the Oil Feed Tube on to the No.1 Bearing Support

Install the Oil Feed Tube on to the No.1 Bearing Support

Figure: Parts which have Effect on Location of the Center Bearing

Parts which have Effect on Location of the Center Bearing

Figure: Install the Blanking Rod in the PTO Oil Seal Tube

Install the Blanking Rod in the PTO Oil Seal Tube

Figure: Leak Test Fixture

Leak Test Fixture

Figure: Install the Quill Shaft into the Fan Frame Strut

Install the Quill Shaft into the Fan Frame Strut