Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-50-420-002 LPT Module - Install The LPT Module Without Turbine Exhaust Case (TEC) (Horizontal) - Method 2, Installation-003

General

This TASK gives the procedure to install the LP Turbine Module without TEC in horizontal position. Other related TASKS are:

Install the LP Turbine Module (horizontal) - Method 1 by TASK 72-00-50-420-001-A00 (INSTALLATION-002), TASK 72-00-50-420-001-B00 (INSTALLATION-002) and TASK 72-00-50-420-001-C00 (INSTALLATION-002).

Install the LP Turbine Module (vertical) - Method 2 by TASK 72-00-50-420-004-A00 (INSTALLATION-005) and TASK 72-00-50-420-004-C00 (INSTALLATION-005).

Turn the LP Turbine Module from horizontal to vertical (front end down) by TASK 72-00-50-560-001 (REMOVAL-003).

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data is identified by the symbol * after the torque value.

Assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. Refer to SPM TASK 70-38-21-380-501.

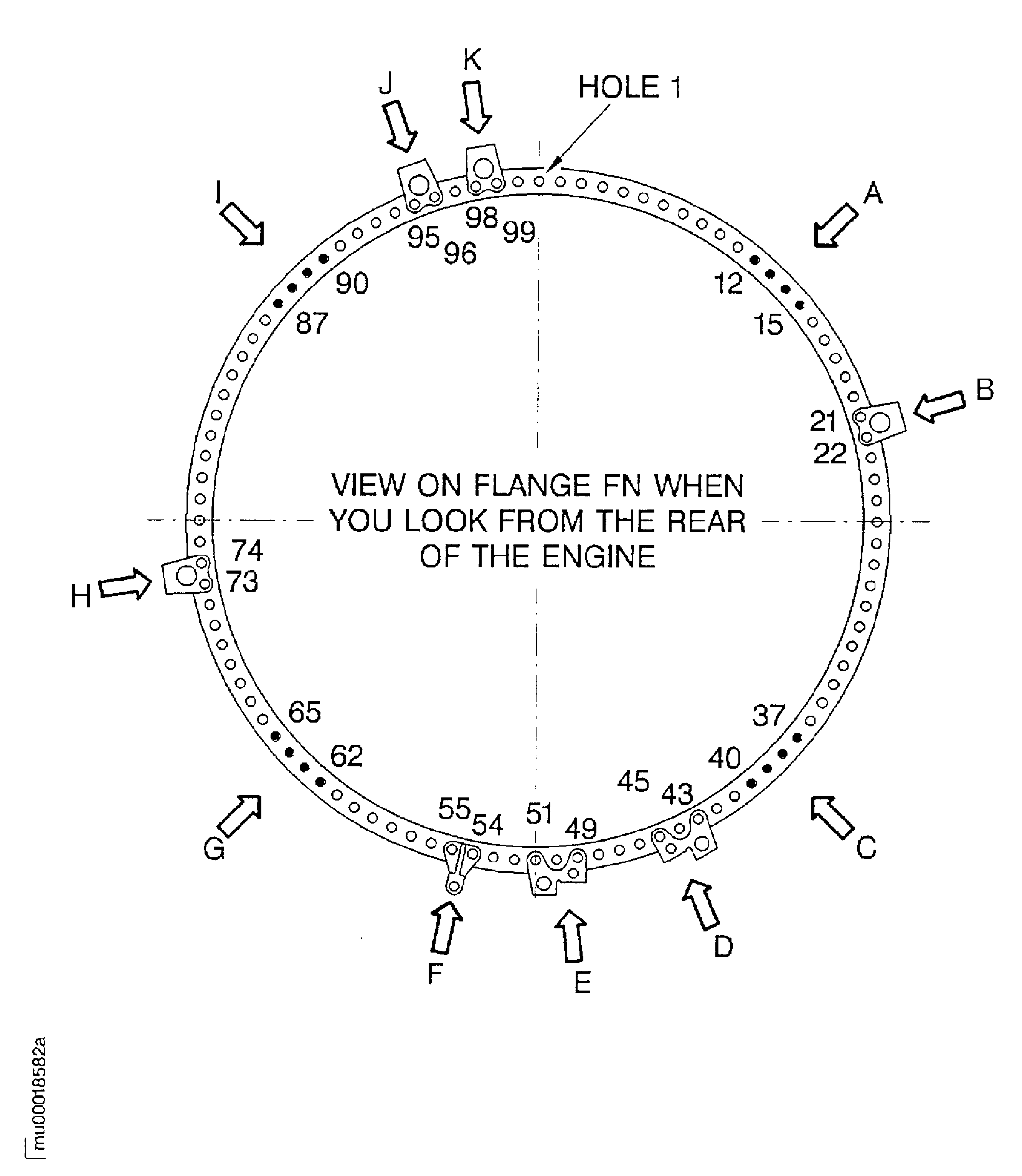

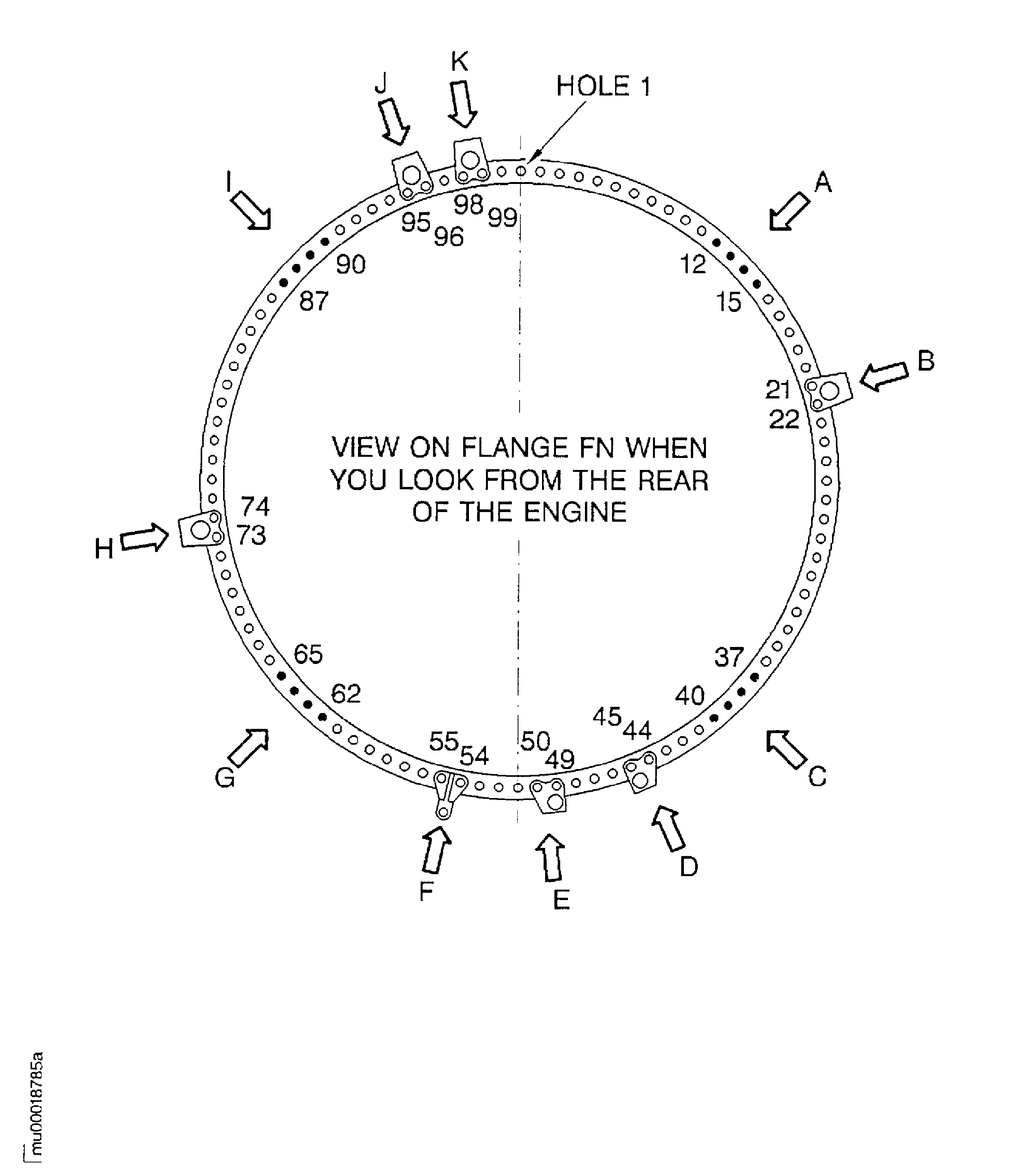

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Transportation covers/blanks must be removed immediately before the installation of the components.

For lockwire data and procedures, refer to SPM TASK 70-42-05-400-501.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Dial Gage | LOCAL | Dial Gage | ||

| Vernier depth gage | LOCAL | Vernier depth gage | ||

| IAE 1F10016 Mechanical wrench | 0AM53 | IAE 1F10016 | 1 | |

| IAE 1F10019 Mechanical wrench | 0AM53 | IAE 1F10019 | 1 | |

| IAE 1F10026 Hydraulic hand pump | 0AM53 | IAE 1F10026 | 1 | |

| IAE 1F10052 Two cables sling | 0AM53 | IAE 1F10052 | 1 | |

| IAE 1F10058 Handling fixture | 0AM53 | IAE 1F10058 | 1 | |

| IAE 1F10063 Expanding retainer | 0AM53 | IAE 1F10063 | 1 | |

| IAE 1F10074 Guide pogo stick | 0AM53 | IAE 1F10074 | 1 | |

| IAE 1F10075 Support pedestal | 0AM53 | IAE 1F10075 | 2 | |

| IAE 1F10080 Horizontal stand | 0AM53 | IAE 1F10080 | 1 | |

| IAE 2F10418 Length gage | 0AM53 | IAE 2F10418 | 1 | |

| IAE 2F10415 Loading fixture | 0AM53 | IAE 2F10415 | 1 | |

| IAE 6F10027 Heater control unit | 0AM53 | IAE 6F10027 | 1 | |

| IAE 1J12220 Hydraulic pusher/puller | 0AM53 | IAE 1J12220 | 1 | |

| IAE 1J12260 Spanner wrench | 0AM53 | IAE 1J12260 | 1 | |

| IAE 1J12270 Guide puller | 0AM53 | IAE 1J12270 | 1 | |

| IAE 1J12271 0AM53 heater | 0AM53 | IAE 1J12271 | 1 | |

| IAE 1J12279 Grinding fixture | 0AM53 | IAE 1J12279 | 1 | |

| IAE 1J12280 Guide bar | 0AM53 | IAE 1J12280 | 1 | |

| IAE 1J12281 0AM53 heater | 0AM53 | IAE 1J12281 | 1 | |

| IAE 1J12282 Expanding pliers | 0AM53 | IAE 1J12282 | 1 | |

| IAE 1M14000 Lifting fixture | 0AM53 | IAE 1M14000 | 1 | |

| IAE 1M14002 Support fixture | 0AM53 | IAE 1M14002 | 1 | |

| IAE 1M14003 Support arm | 0AM53 | IAE 1M14003 | 2 | |

| IAE 1M14005 Torque wrench | 0AM53 | IAE 1M14005 | 1 | |

| IAE 1M14006 Immobilizing fixture | 0AM53 | IAE 1M14006 | 1 | |

| IAE 1M14086 Supporting fixture | 0AM53 | IAE 1M14086 | 1 | |

| IAE 1M14127 Support plate | 0AM53 | IAE 1M14127 | 2 | |

| IAE 1M14139 Immobilizing fixture | 0AM53 | IAE 1M14139 | 1 | |

| IAE 1M14143 Support fixture | 0AM53 | IAE 1M14143 | 1 | |

| IAE 1M14461 Supporting fixture | LOCAL | IAE 1M14461 | ||

| IAE 1M14146 Support plate | 0AM53 | IAE 1M14146 | 2 | |

| IAE 1P16377 Guide support | 0AM53 | IAE 1P16377 | 1 | |

| IAE 1R18907 Expanding retainer | 0AM53 | IAE 1R18907 | 1 | |

| IAE 1R18908 Guide plug | 0AM53 | IAE 1R18908 | 1 | |

| IAE 1R18909 Guide plug | 0AM53 | IAE 1R18909 | 1 | |

| IAE 1M14114 Sizing gage | 0AM53 | IAE 1M14114 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-119 LOCKWIRE | LOCAL | CoMat 02-119 | ||

| CoMat 07-038 AIR DRYING ENAMEL | k3504 | CoMat 07-038 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Examine the HP System Module at interface D-45. Refer to TASK 72-00-45-220-001 (INSPECTION/CHECK-001).

Examine the front face of the LP Turbine Case and Rotor Assembly at interface D-50/10. Refer to TASK 72-00-50-220-001 (INSPECTION/CHECK-001).

Examine the LP Compressor/Intermediate Case Module at interface F-32. Refer to TASK 72-00-32-220-004 (INSPECTION/CHECK-004).

Examine the LP Turbine Module without TEC at interface F-50. Refer to TASK 72-00-50-220-005 (INSPECTION/CHECK-005).

Examine the LP Turbine Module without TEC at interface N-50/10. Refer to TASK 72-00-50-220-002 (INSPECTION/CHECK-002).

SUBTASK 72-00-50-210-053 Examine the Module Interfaces

Refer to Figure.

Calculate the fit at location 5624.

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 5624

LP Turbine Case (72-50-21, 01-010), Bore

HP Turbine Stage 2 Support Case ENGINE-STAGE 2 HPT SUPPORT ASSEMBLY (72-45-27, 01-010), Diameter

LP Turbine Case Bore

28.527

Intf

28.527

Intf

28.533

0.002

28.533

0.002

HP Turbine Support Case Diameter

28.535

0.014

28.529

0.014

28.541

28.541

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 5624

LP Turbine Case (72-50-21, 01-010), Bore

HP Turbine Stage 2 Support Case ENGINE-STAGE 2 HPT SUPPORT ASSEMBLY (72-45-27, 01-010), Diameter

LP Turbine Case Bore

724.586

Intf

724.586

Intf

724.738

0,050

724.738

0.050

HP Turbine Support Case Diameter

724.789

0.356

724.637

0.356

724.941

724.941

SUBTASK 72-00-50-220-114-A00 V2500-A1 Measure that the Fits and Clearances between the LP Turbine Module and the HP System Module are in the Limits given at Location 5624.

Refer to Figure

Calculate the fit at location 5624.

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 5624

LP Turbine Case (72-50-21, 01-010), Bore

HP Turbine Stage 2 Support Case (72-45-27, 01-010), Diameter

LP Turbine Case Bore

28.527

Intf

28.533

0.002

HP Turbine Support Case Diameter

28.535

0.014

28.541

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 5624

LP Turbine Case (72-50-21, 01-010), Bore

HP Turbine Stage 2 Support Case ENGINE-STAGE 2 HPT SUPPORT ASSEMBLY (72-45-27, 01-010), Diameter

LP Turbine Case Bore

724.586

Intf

724.738

0.050

HP Turbine Support Case Diameter

724.789

0.356

724.941

SUBTASK 72-00-50-220-114-B00 V2500-A5 Measure that the Fits and Clearances between the LP Turbine Module and the HP System Module are in the Limits Given at Location 5624

Refer to Figure.

Calculate the clearance at Location 5623.

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Select)

REJECT IF

MORE THAN

LOCATION 5623

Inner Duct Segment LPT Inner Diffuser Duct And Related Parts (72-50-24, 01-010), Honeycomb Surface

Stage 2 HPT Blade Retaining Plate HPT Stage 2 Blade Retaining Plate And Related Parts (72-45-33, 01-010), Knife Edge Outside Diameter

Inner Duct Segment Honeycomb Surface

19.896

0.118

19.896

0.118

19.925

Clear

19.925

Clear

Knife Edge Outside Diameter

19.807

Clear

19.797

Clear

19.812

0.084

19.812

0.084

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Select)

REJECT IF

MORE THAN

LOCATION 5623

Inner Duct Segment LPT Inner Diffuser Duct And Related Parts (72-50-24, 01-010), Honeycomb Surface

Stage 2 HPT Blade Retaining Plate HPT Stage 2 Blade Retaining Plate And Related Parts (72-45-33, 01-010), Knife Edge Outside Diameter

Inner Duct Segment Honeycomb Surface

505.36

3.00

505.36

3.00

506.10

Clear

506.10

Clear

Knife Edge Outside Diameter

503.10

Clear

502.84

Clear

503.22

2.13

503.22

2.13

SUBTASK 72-00-50-220-115 Measure that the Fits and Clearances between the LP Turbine Module and the HP System Module are in the Limits given at Location 5623 (Pre SBE 72-0028)

Refer to Figure.

Calculate the clearance at Location 5623.

Table 7. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Select)

REJECT IF

MORE THAN

LOCATION 5623

Inner Duct Segment LPT Inner Diffuser Duct And Related Parts (72-50-24, 01-010), Honeycomb Surface

Stage 2 HPT Blade Retaining Plate HPT Stage 2 Blade Retaining Plate And Related Parts (72-45-33, 01-010), Knife Edge Outside Diameter

Inner Duct Segment Honeycomb Surface

19.896

0.121

19.896

0.121

19.925

Clear

19.925

Clear

Knife Edge Outside Diameter

19.804

Clear

19.797

Clear

19.812

0.084

19.812

0.084

Table 8. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Select)

REJECT IF

MORE THAN

LOCATION 5623

Inner Duct Segment LPT Inner Diffuser Duct And Related Parts (72-50-24, 01-010), Honeycomb Surface

Stage 2 HPT Blade Retaining Plate HPT Stage 2 Blade Retaining Plate And Related Parts (72-45-33, 01-010), Knife Edge Outside Diameter

Inner Duct Segment Honeycomb Surface

505.36

3.07

505.36

3.07

506.10

Clear

506.10

Clear

Knife Edge Outside Diameter

503.02

Clear

502.84

Clear

503.22

2.13

503.22

2.13

SUBTASK 72-00-50-220-255 Measure that the Fits and Clearances between the LP Turbine Module and the HP System Module are in the Limits given at Location 5623 (SBE 72-0028)

Refer to Figure.

Calculate the fit at location 5620.

Table 9. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 5620

LP Stub Shaft ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-350), Bore

LP Turbine Shaft LPT Shaft And Related Parts (72-50-41, 01-200), Diameter

Stub Shaft Bore

3.5433

Intf

3.5447

0.0006

LP Turbine Shaft Diameter

3.5453

0.0029

3.5462

Table 10. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 5620

LP Stub Shaft ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-350), Bore

LP Turbine Shaft LPT Shaft And Related Parts (72-50-41, 01-200), Diameter

Stub Shaft Bore

90.000

90.035

Intf

0.016

LP Turbine Shaft Diameter

90.051

0.073

90,073

SUBTASK 72-00-50-220-116 Measure that the Fits and Clearances between the LP Turbine Module and the LP Compressor are in the Limits given at Location 5620

Refer to Figure.

Calculate the fit at location 5621.

Table 11. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 5621

LP Stub Shaft ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-350), Bore

LP Turbine Shaft LPT Shaft And Related Parts (72-50-41, 01-200), Diameter

Stub Shaft Bore

3.9370

Intf

3.9379

0.0006

LP Turbine Shaft Diameter

3.9385

0.0023

3.9393

Table 12. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 5621

LP Stub Shaft ENGINE-LP STUB SHAFT AND ROTOR CENTRE (72-32-51, 01-350), Bore

LP Turbine Shaft LPT Shaft And Related Parts (72-50-41, 01-200), Diameter

Stub Shaft Bore

100.000

Intf

100.022

0.015

LP Turbine Shaft Diameter

100.037

0.059

100.059

SUBTASK 72-00-50-220-117 Measure that the Fits and Clearances between the LP Turbine Module and the LP Compressor are in the Limits given at Location 5621.

Refer to Figure.

Calculate the clearance at location 5622.

Table 13. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 5622

Differential Seal (72-32-26, 01-110), Bore

LP Turbine Shaft LPT Shaft And Related Parts (72-50-41, 01-200), Diameter

Seal Bore

3.9410

3.9449

0.0017

LP Turbine Shaft Diameter

3.9385

0.0064

3.9393

Table 14. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 5622

Differential Seal (72-32-26, 01-110), Bore

LP Turbine Shaft LPT Shaft And Related Parts (72-50-41, 01-200), Diameter

Seal Bore

100.100

100.200

0.041

LP Turbine Shaft Diameter

100.037

0.163

100.059

SUBTASK 72-00-50-220-118 Measure that the Fits and Clearances between the LP Turbine Module and the LP Compressor are in the Limits given at Location 5622.

Refer to Figure.

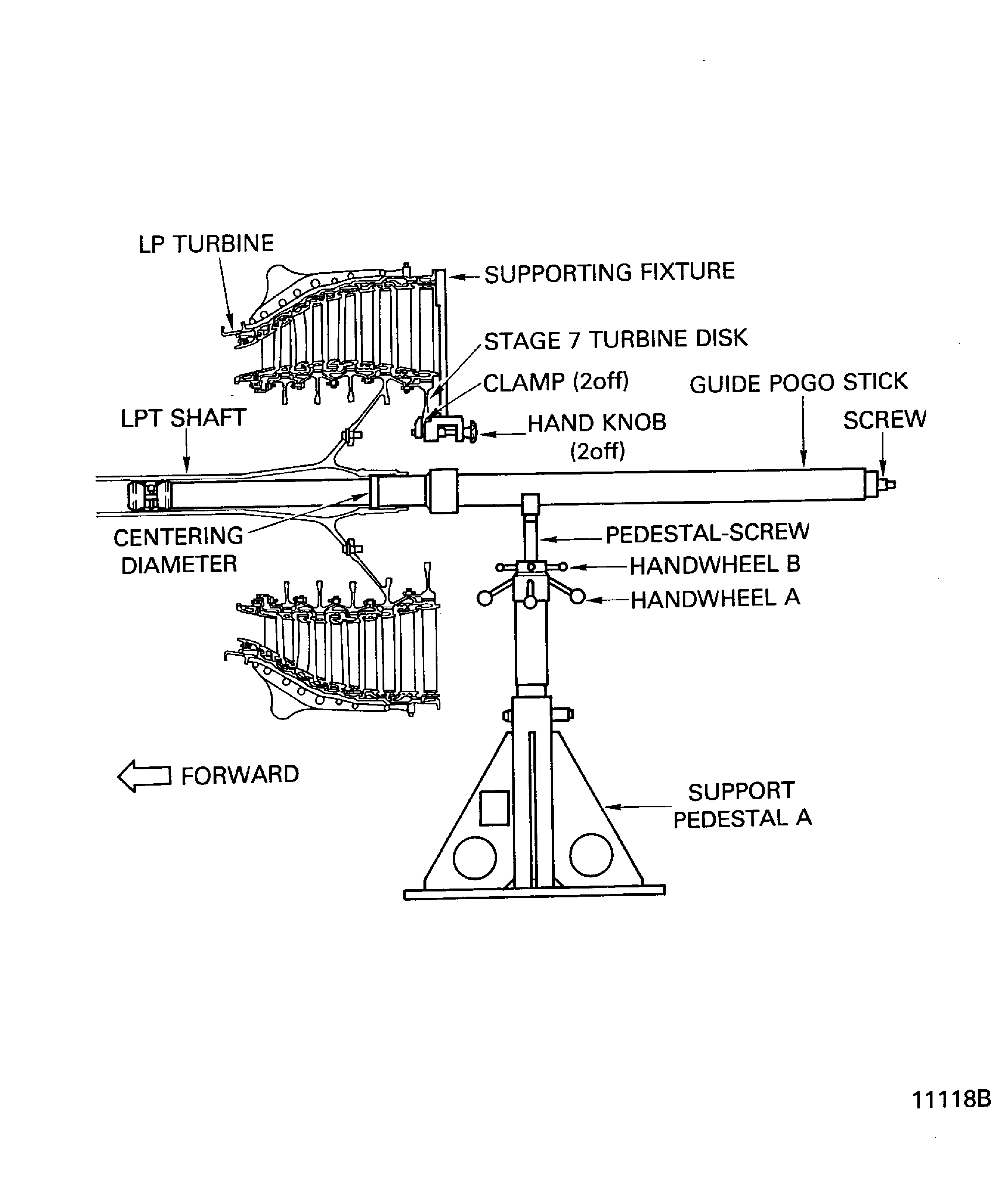

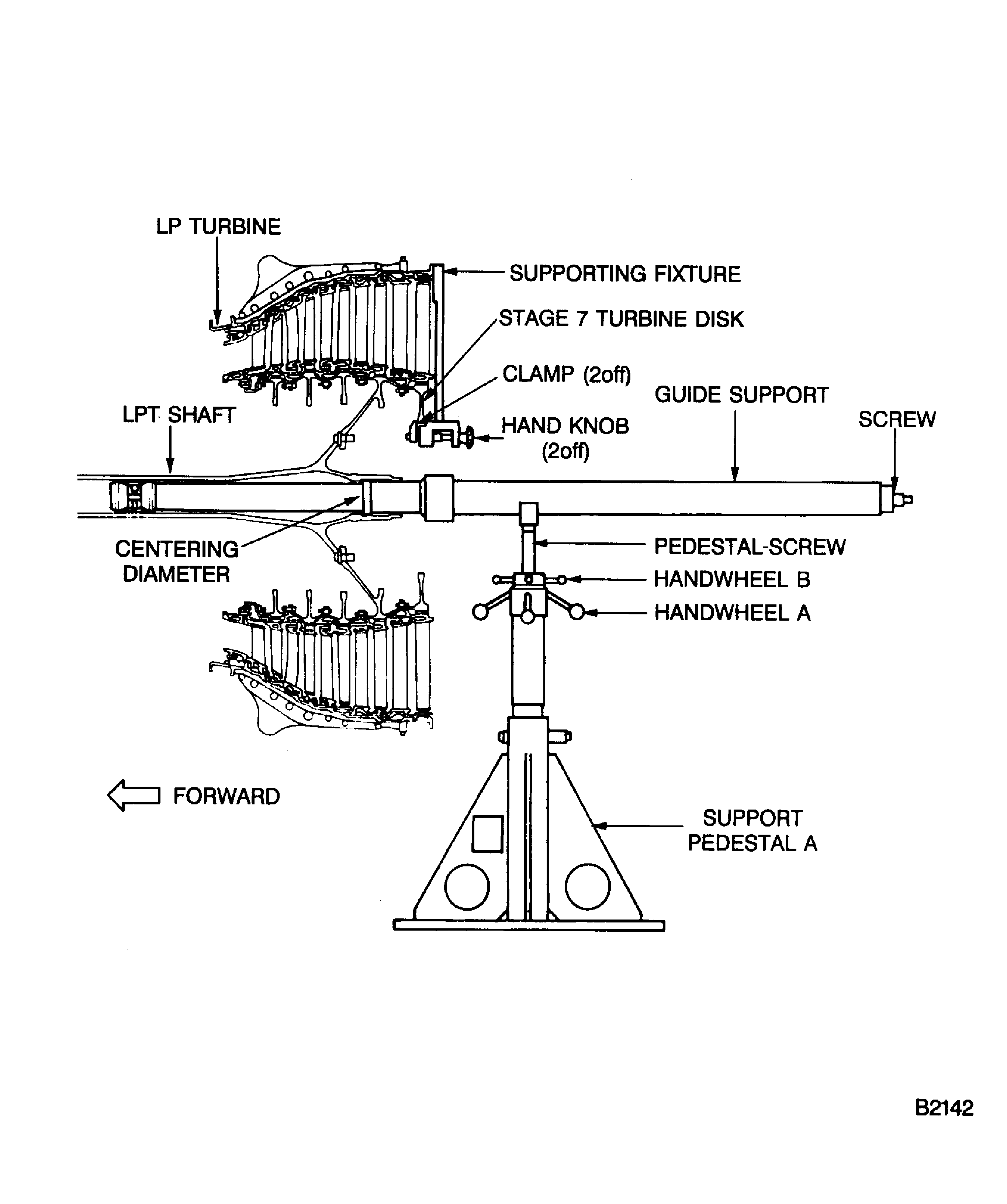

Install the IAE 1F10074 Guide pogo stick 1 off to the inner diameter of the LP Turbine Shaft. Use applicable webbing sling.

Put the IAE 1F10075 Support pedestal 1 off below the guide pogo stick. Move the support pedestal A near to the rear flange of the LP Turbine Case.

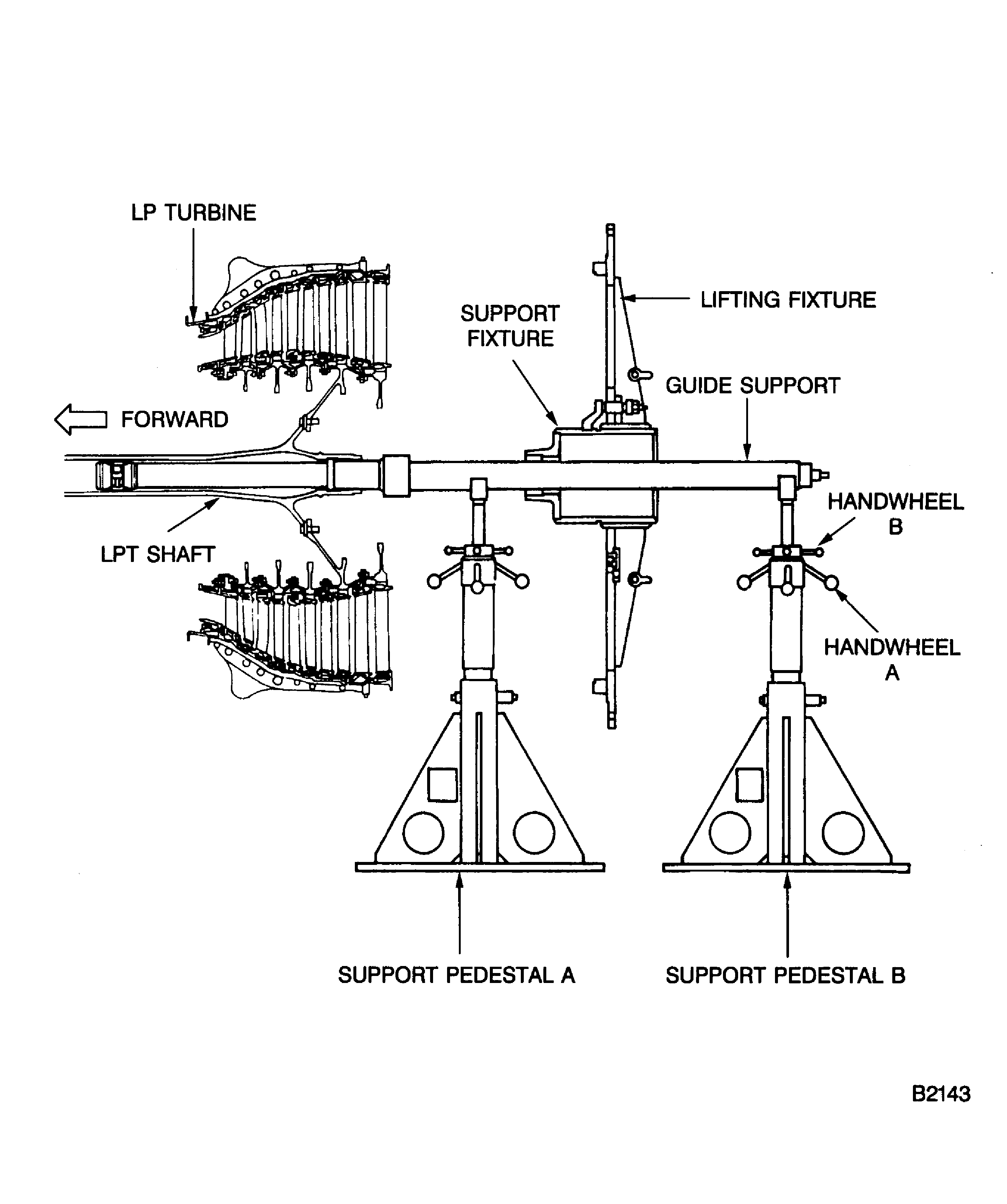

SUBTASK 72-00-50-420-079-A00 V2500-A1: Install the Guide Pogo Stick to the LP Turbine Shaft

Refer to Figure.

Install the IAE 1P16377 Guide support 1 off to the inner diameter of the LP Turbine Shaft. Use applicable webbing sling.

Put the IAE 1F10075 Support pedestal 1 off below the guide support. Move the support pedestal A near to the rear flange of the LP Turbine Case.

SUBTASK 72-00-50-420-079-B00 V2500-A5: Install the Guide Support to the LP Turbine Shaft

Refer to Figure.

Release the two hand knobs that attach the two clamps (part of the IAE 1M14086 Supporting fixture or of the IAE 1M14461 Supporting fixture) to the Stage 7 Turbine Disk.

SUBTASK 72-00-50-420-080-A00 V2500-A1: Remove the Supporting Fixture

Refer to Figure.

Release the two hand knobs that attach the two clamps (part of the IAE 1M14143 Support fixture or of the IAE 1M14461 Supporting fixture) 1 off to the Stage 7 Turbine Disk.

SUBTASK 72-00-50-420-080-B00 V2500-A5: Remove the Supporting Fixture

Refer to Figure.

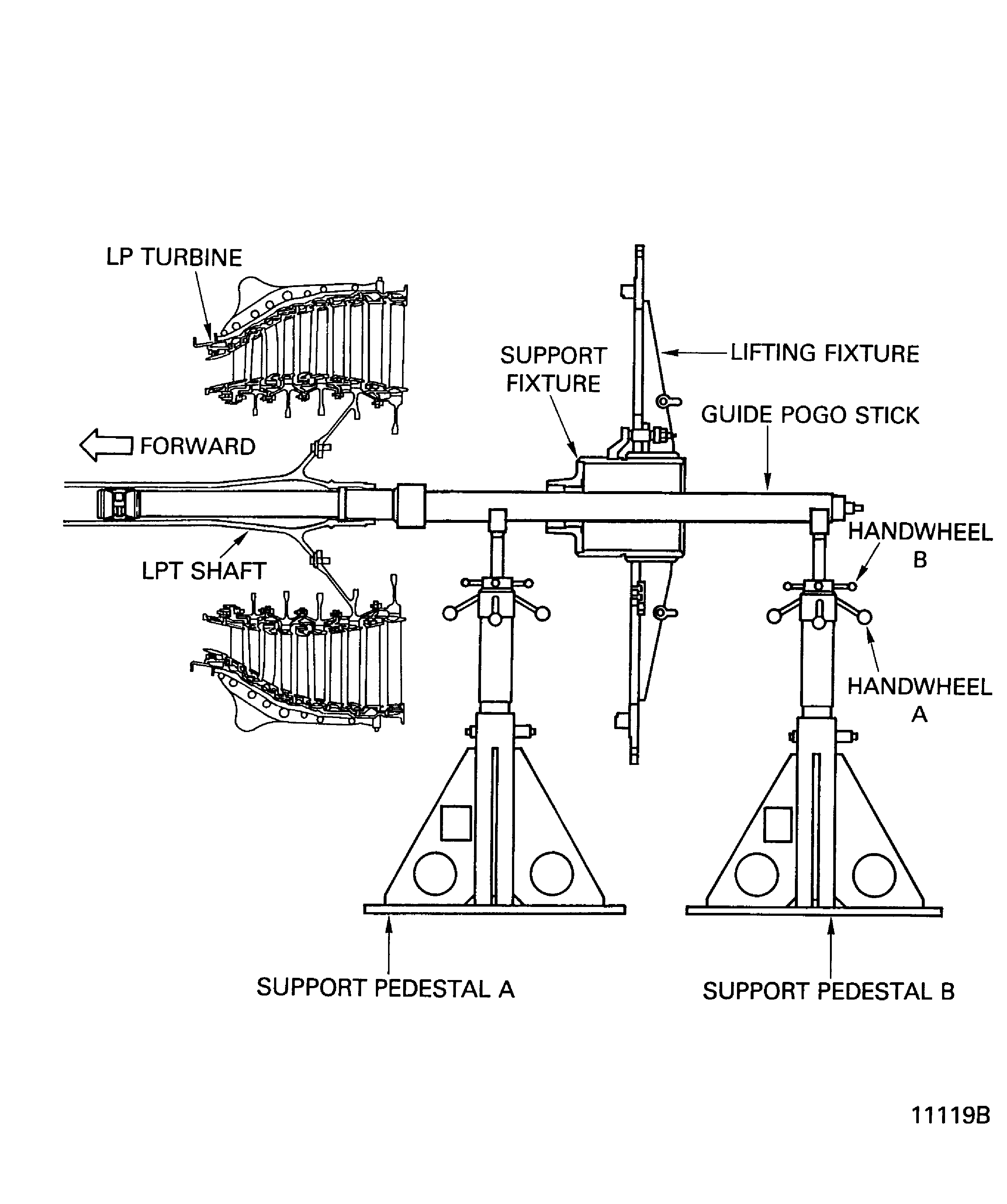

Engage the IAE 1M14000 Lifting fixture 1 off on to the IAE 1M14002 Support fixture 1 off. Turn back the three guide sleeves, part of the lifting fixture, until the support fixture touches the lifting fixture.

Install the IAE 1M14003 Support arm 2 off to the lifting fixture. Attach each support arm with the eight screws and washers.

Use hoist equipment to install the IAE 1F10052 Two cables sling 1 off to the rear spools of the support arms.

SUBTASK 72-00-50-420-124 Install the Support Fixture in to the Lifting Fixture

Refer to Figure.

Put the IAE 1F10075 Support pedestal 1 off below the rear end of the guide pogo stick. Refer to Step.

Remove the IAE 1F10075 Support pedestal A.

Loosen the three nuts that safety the guide sleeves (part of the IAE 1M14000 Lifting fixture). Turn the guide sleeves clockwise until the support fixture is correctly installed to the LP Turbine Shaft. Tighten the three nuts. Refer to Figure.

CAUTION

MAKE SURE THAT THE SUPPORT FIXTURE IS CORRECTLY INSTALLED AT THE LP TURBINE SHAFT AND LOCKED ON THE LIFTING FIXTURE. IF THE FIXTURES ARE NOT CORRECTLY LOCKED THE LP TURBINE CASE AND ROTOR PARTS CAN BE DAMAGED DURING HANDLING OF THE LP TURBINE CASE ASSEMBLY.Remove the support pedestal B. Remove the guide pogo stick through the support fixture.

SUBTASK 72-00-50-420-081-A00 V2500-A1: Install the Assembled Lifting Fixture and Remove the Guide Pogo Stick

Refer to Figure.

Put the IAE 1F10075 Support pedestal 1 off below the rear end of the guide support. Refer to Step.

Remove the IAE 1F10075 Support pedestal A.

Loosen the three nuts that safety the guide sleeves (part of IAE 1M14000 Lifting fixture 1 off). Turn the guide sleeves clockwise until the support fixture is correctly installed to the LP Turbine Shaft. Tighten the three nuts. Refer to Figure.

CAUTION

MAKE SURE THE SUPPORT FIXTURE IS CORRECTLY LOCKED ON THE LIFTING FIXTURE. IF THE FIXTURES ARE NOT CORRECTLY LOCKED THE LP TURBINE CASE AND ROTOR PARTS CAN BE DAMAGED DURING HANDLING OF THE LP TURBINE CASE ASSEMBLY.Remove the support pedestal B. Remove the guide support through the support fixture.

SUBTASK 72-00-50-420-081-B00 V2500-A5: Install the Assembled Lifting Fixture and Remove the Guide Support

Refer to Figure.

Install the ring nut (part of the IAE 1M14002 Support fixture) on to the rear end of the LP Turbine Shaft.

Install the IAE 1M14005 Torque wrench 1 off to the ring nut.

Assemble the IAE 1F10019 Mechanical wrench 1 off to the torque wrench.

Install the IAE 1M14006 Immobilizing fixture 1 off on to the rear end of the LP Turbine Shaft. Safety the immobilizing fixture to the mechanical wrench with the immobilizer plate.

SUBTASK 72-00-50-420-082-A00 V2500-A1: Safety the Assembled Lifting Fixture to the LP Turbine Module without Turbine Exhaust Case

Refer to Figure.

Install the ring nut (part of IAE 1M14002 Support fixture) on to the rear end of the LP Turbine Shaft.

Install the IAE 1M14005 Torque wrench 1 off to the ring nut.

Assemble the IAE 1F10019 Mechanical wrench 1 off to the torque wrench.

Install the IAE 1M14139 Immobilizing fixture 1 off on to the rear end of the LP Turbine Shaft. Safety the immobilizing fixture to the mechanical wrench with the immobilizer plate.

SUBTASK 72-00-50-420-082-B00 V2500-A5: Safety the Assembled Lifting Fixture to the LP Turbine Module without Turbine Exhaust Case

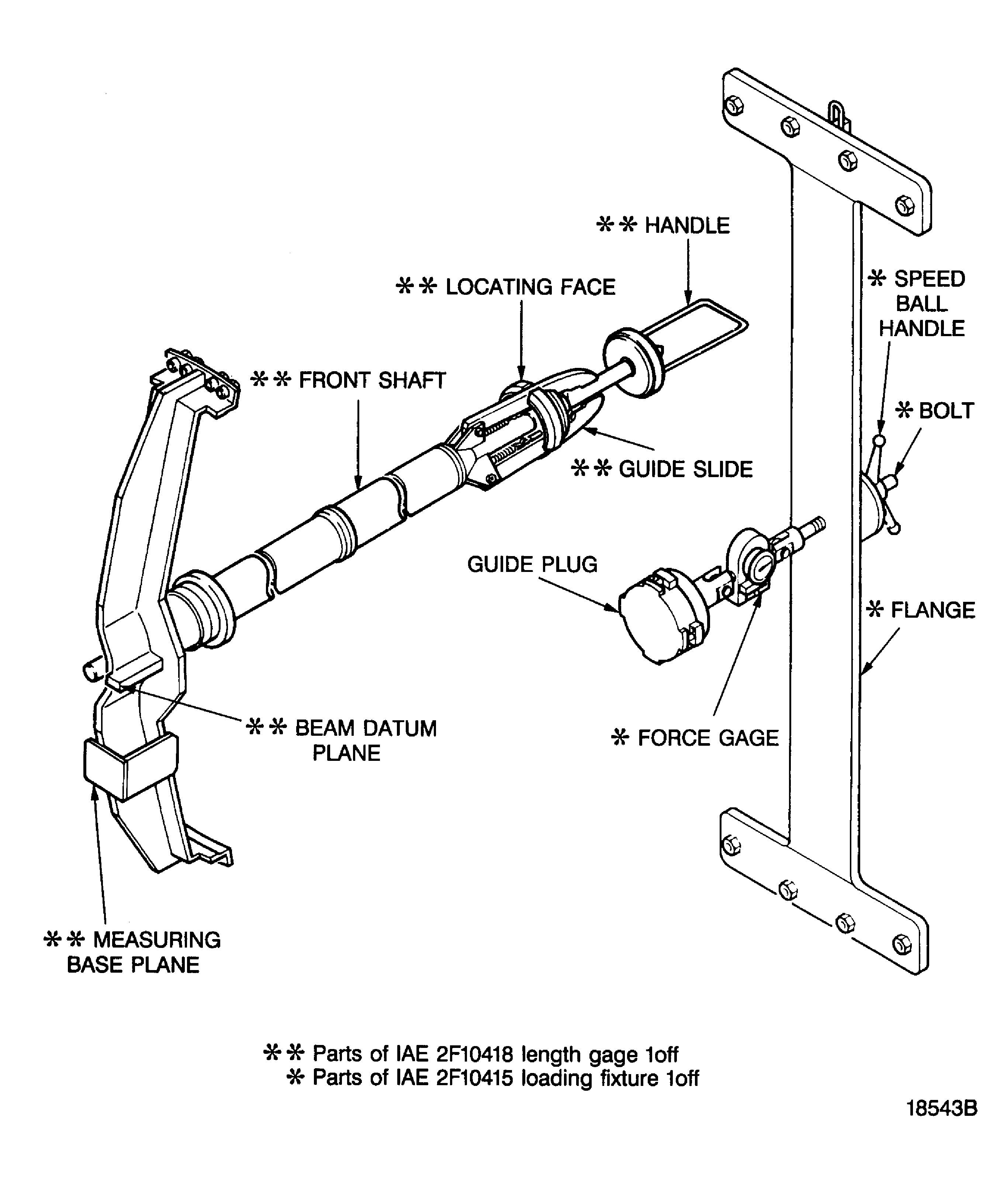

Refer to Figure.

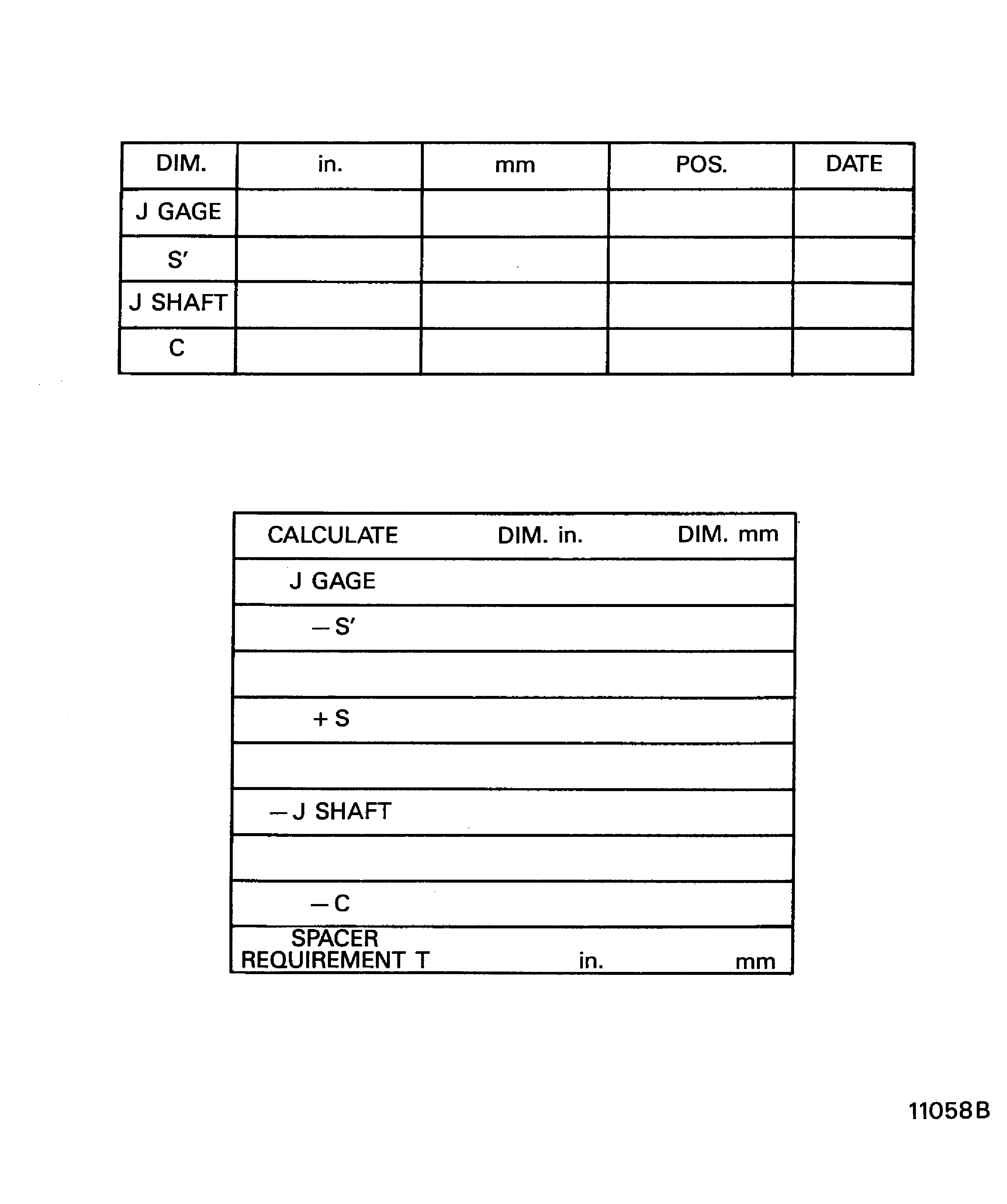

Connect the front shaft and the rear shaft of the IAE 2F10418 Length gage 1 off.

SUBTASK 72-00-50-420-085 Install the Length Gage into the Engine

Refer to Figure.

Install the beam (part of the IAE 2F10418 Length gage) to rear flange of the HP Turbine Case. Safety the beam to the HP Turbine Case with the eight bolts and nuts. The end of the rear shaft must be on the beam.

SUBTASK 72-00-50-420-086 Install the Beam of the Length Gage to the Rear Flange of the HP Turbine Case

Install the handle to the front end of the IAE 2F10418 Length gage.

SUBTASK 72-00-50-420-149 Install the Disk with Handle to the Length Gage

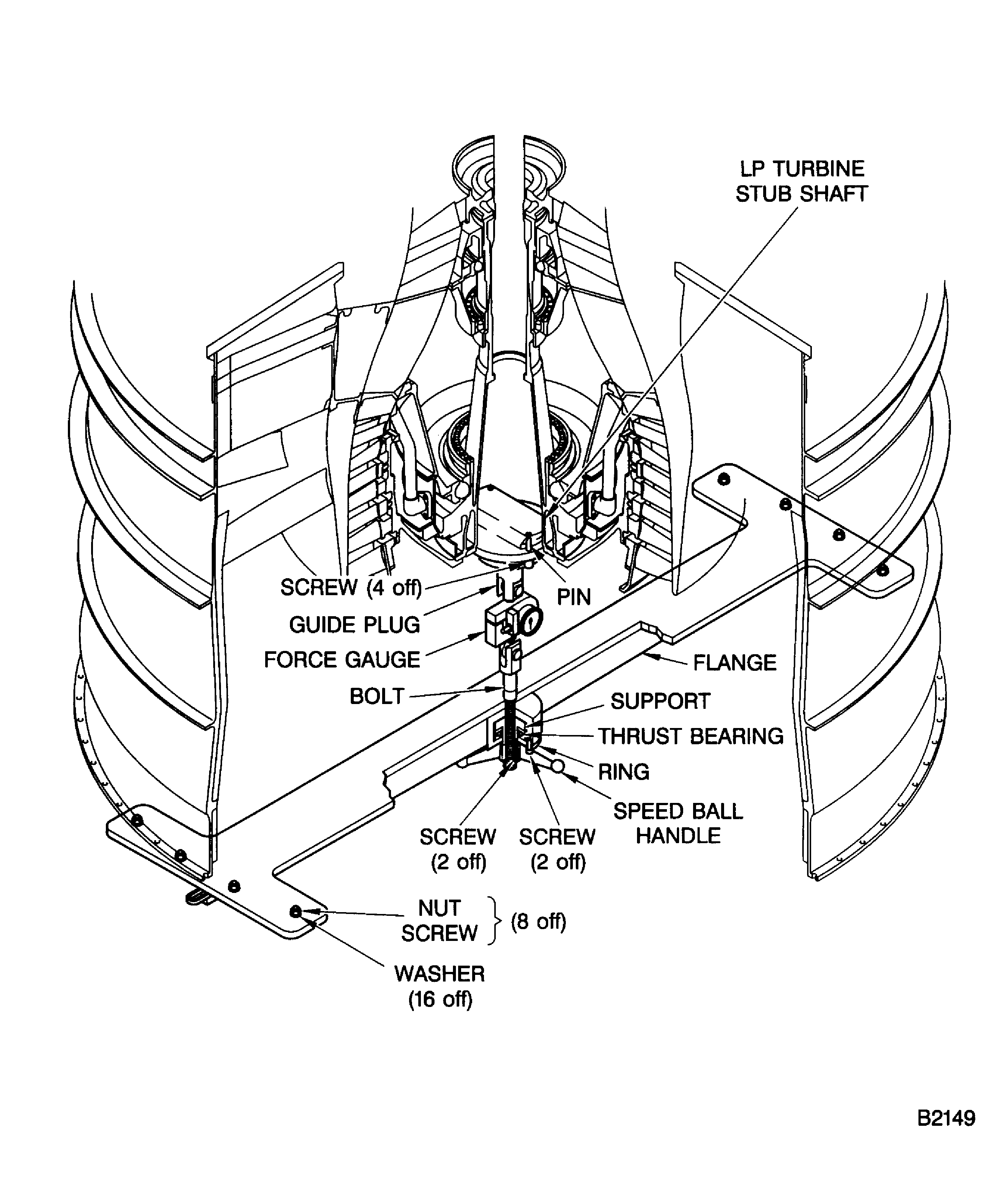

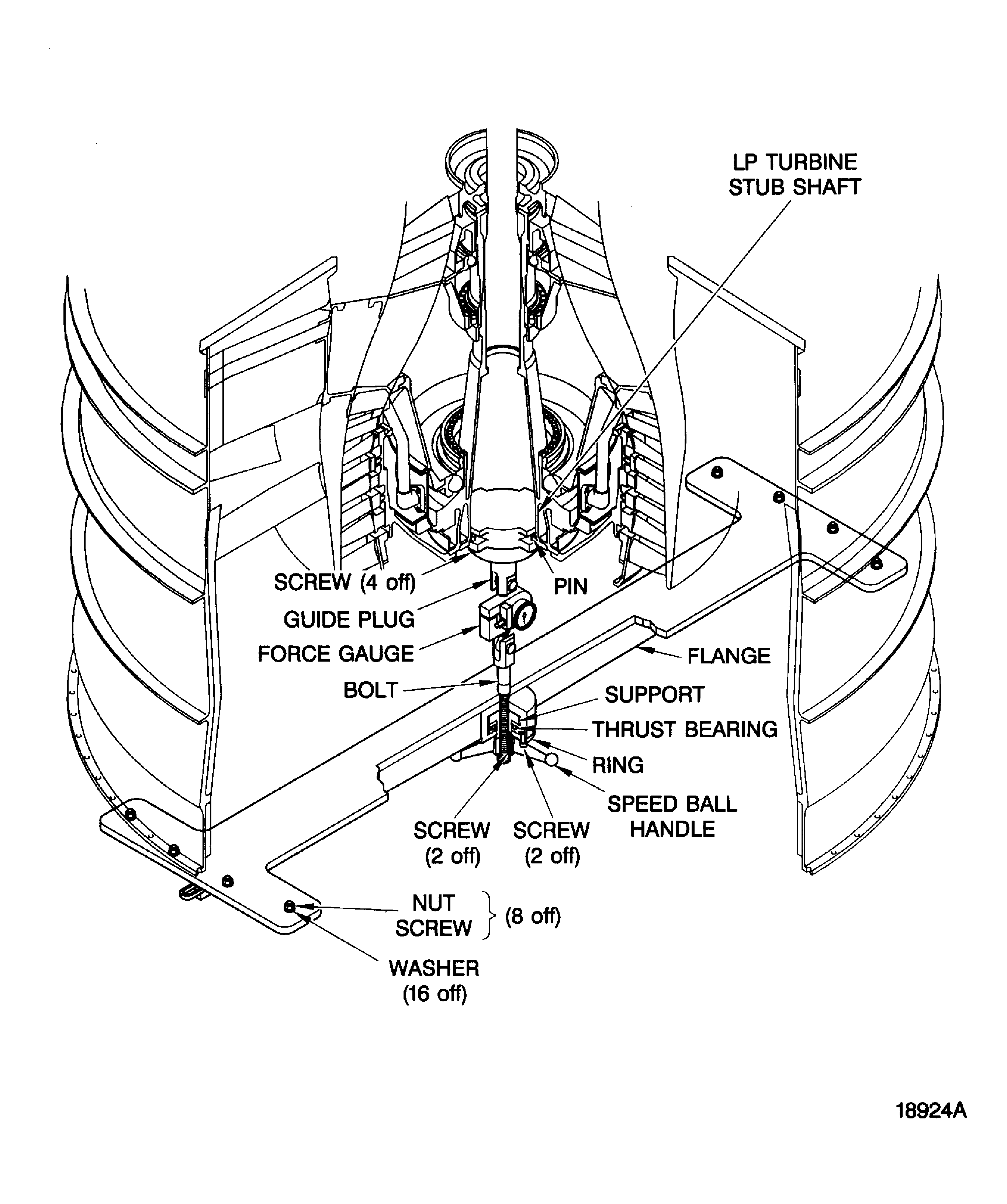

Refer to Figure.

Safety the guide plug to the LP Stub Shaft with the four pins (parts of the IAE 1R18908 Guide plug).

Safety the four pins to the guide plug with the four screws (parts of the IAE 1R18908 Guide plug).

Safety with the socket head cap screw and nut (parts of the IAE 2F10415 Loading fixture).

Safety with the socket head cap screw and nut (parts of the IAE 2F10415 Loading fixture).

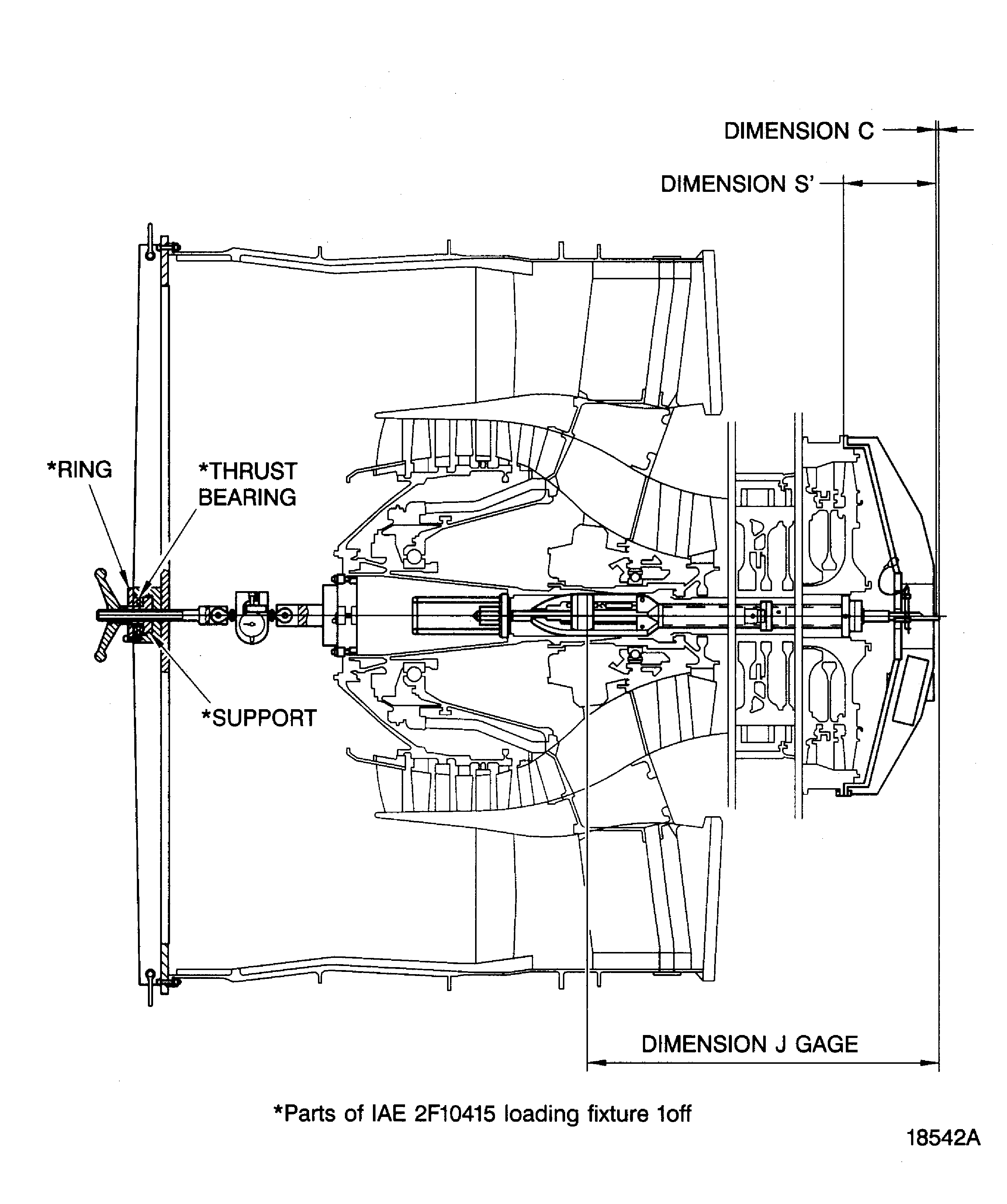

Install the IAE 1R18908 Guide plug 1 off with the force gage and the bolt (parts of the IAE 2F10415 Loading fixture 1 off) to the curvic coupling of the LP Stub Shaft as follows:

Install the flange (part of the IAE 2F10415 Loading fixture 1 off) to the front flange of the Fan Case. The bolt must come out through the center hole of the flange. Attach the flange to the Fan Case with eight screws, eight nuts and 16 washers.

Install the support (part of the IAE 2F10415 Loading fixture 1 off) to the bolt and the flange.

Install the thrust bearing (part of the IAE 2F10415 Loading fixture 1 off) on to the support. Safety all together with the ring and four screws.

Install the speed ball handle (part of the IAE 2F10415 Loading fixture 1 off). Safety it to the support with two screws.

SUBTASK 72-00-50-420-200-A00 V2500-A1: Install the Loading Fixture to the Front Flange of the Fan Case

Refer to Figure.

Safety with the socket head cap screw and nut (parts of the IAE 2F10415 Loading fixture).

Safety with the socket head cap screw and nut (parts of the IAE 2F10415 Loading fixture).

Install the IAE 1R18909 Guide plug 1 off with the force gage and the bolt (parts of the IAE 2F10415 Loading fixture 1 off) to the curvic coupling of the LP Stub Shaft as follows:

Install the flange (part of the IAE 2F10415 Loading fixture 1 off) to the front flange of the Fan Case. The bolt must come out through the center hole of the flange. Attach the flange to the fan case with eight screws, eight nuts and 16 washers.

Install the support (part of the IAE 2F10415 Loading fixture 1 off) to the bolt and the flange.

Install the thrust bearing (part of the IAE 2F10415 Loading fixture 1 off) on to the support safety all together with the ring and four screws.

Install the speed ball handle (part of the IAE 2F10415 Loading fixture 1 off). Safety it to the support with two screws.

SUBTASK 72-00-50-420-200-B00 V2500-A5: Install the Loading Fixture to the Front Flange of the Fan Case

Turn the speed ball handle of the IAE 2F10415 Loading fixture 1 off until the force gage shows the load of 900 lbf (4.0 kN).

SUBTASK 72-00-50-420-150 Load the No. 1 Bearing

NOTE

Load must be applied in a rearward direction.Refer to Figure.

Point the dial gage to the rear end of the IAE 2F10418 Length gage.

SUBTASK 72-00-50-420-091 Measure the Dimension C

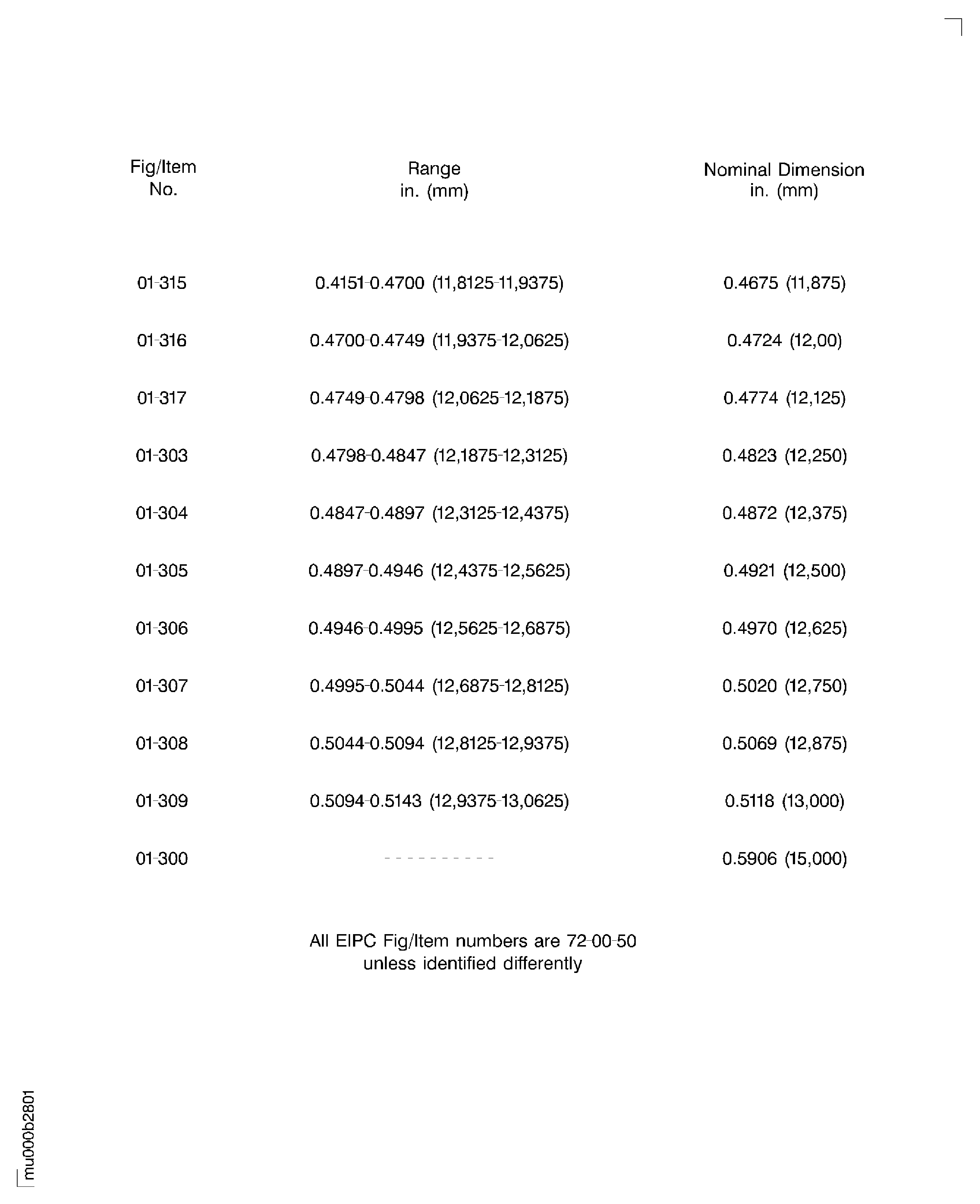

Calculated dimension T and Figure are necessary for selection of the required adjusting ring.

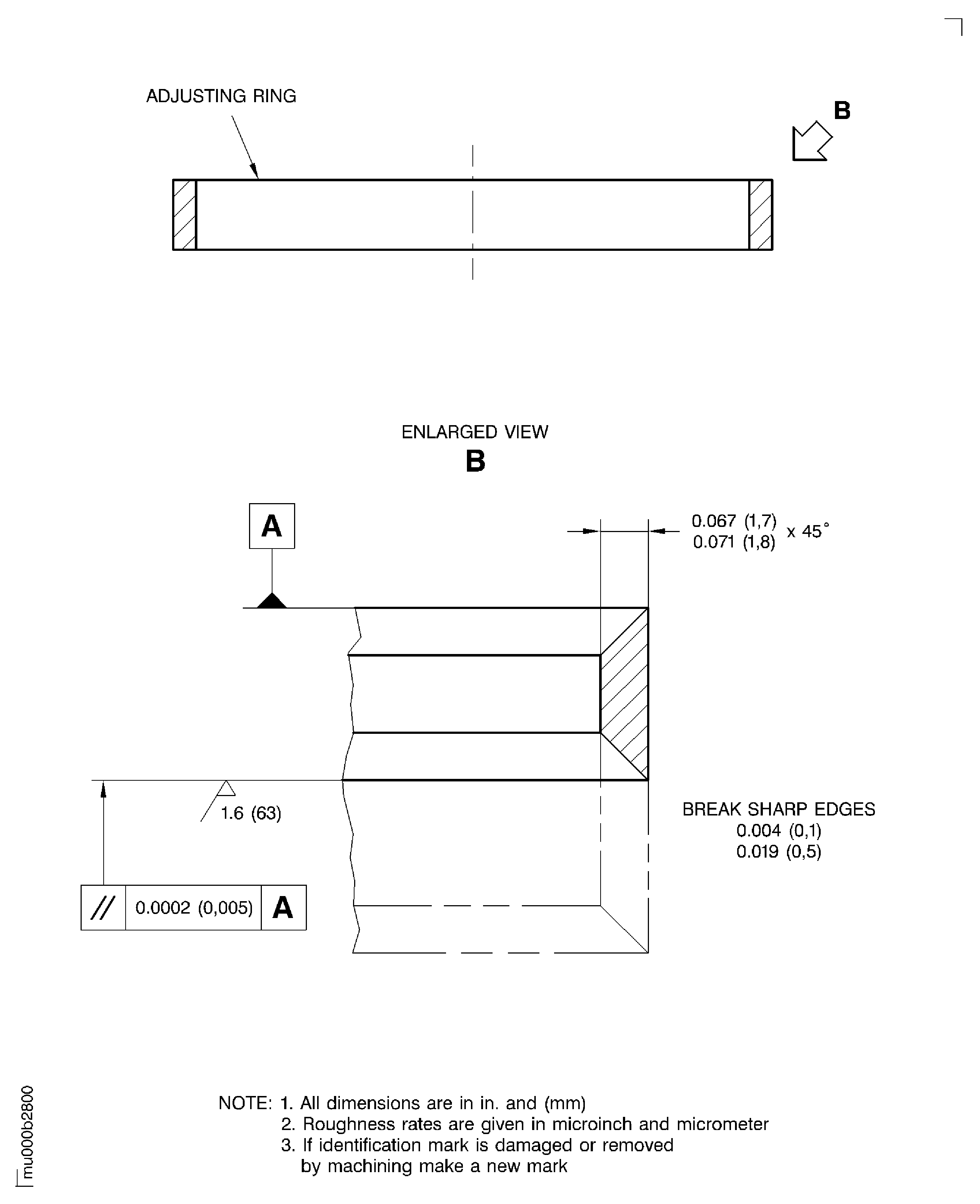

If the calculated dimension of T is out of the limits given in Figure the applicable adjusting ring must be machined to calculated dimension T. Refer to Figure. Use the grinding machine and IAE 1J12279 Grinding fixture 1 off.

SUBTASK 72-00-50-325-051 Adjust the Thickness of the Adjusting Ring

NOTE

Figure shows all the available adjusting rings and related thickness ranges.Refer to Figure.

Disassemble the speed ball handle, the ring, the thrust bearing and the support (parts of the IAE 2F10415 Loading fixture).

Remove the bolt, the force gage and the IAE 1R18908 Guide plug 1 off (V2500-A1) from the curvic coupling of the LP Stub Shaft.

SUBTASK 72-00-50-420-097-A00 V2500-A1: Remove the Loading Fixture from the Engine

Refer to Figure.

Disassemble the speed ball handle, the ring, the thrust bearing and the support (parts of the IAE 2F10415 Loading fixture 1 off).

Remove the bolt, the force gage and the IAE 1R18909 Guide plug 1 off from the curvic coupling of the LP Stub Shaft.

SUBTASK 72-00-50-420-097-B00 V2500-A5: Remove the Loading Fixture from the Engine

Remove the IAE 2F10418 Length gage 1 off from the engine.

SUBTASK 72-00-50-420-098 Remove the Length Gage from the Engine

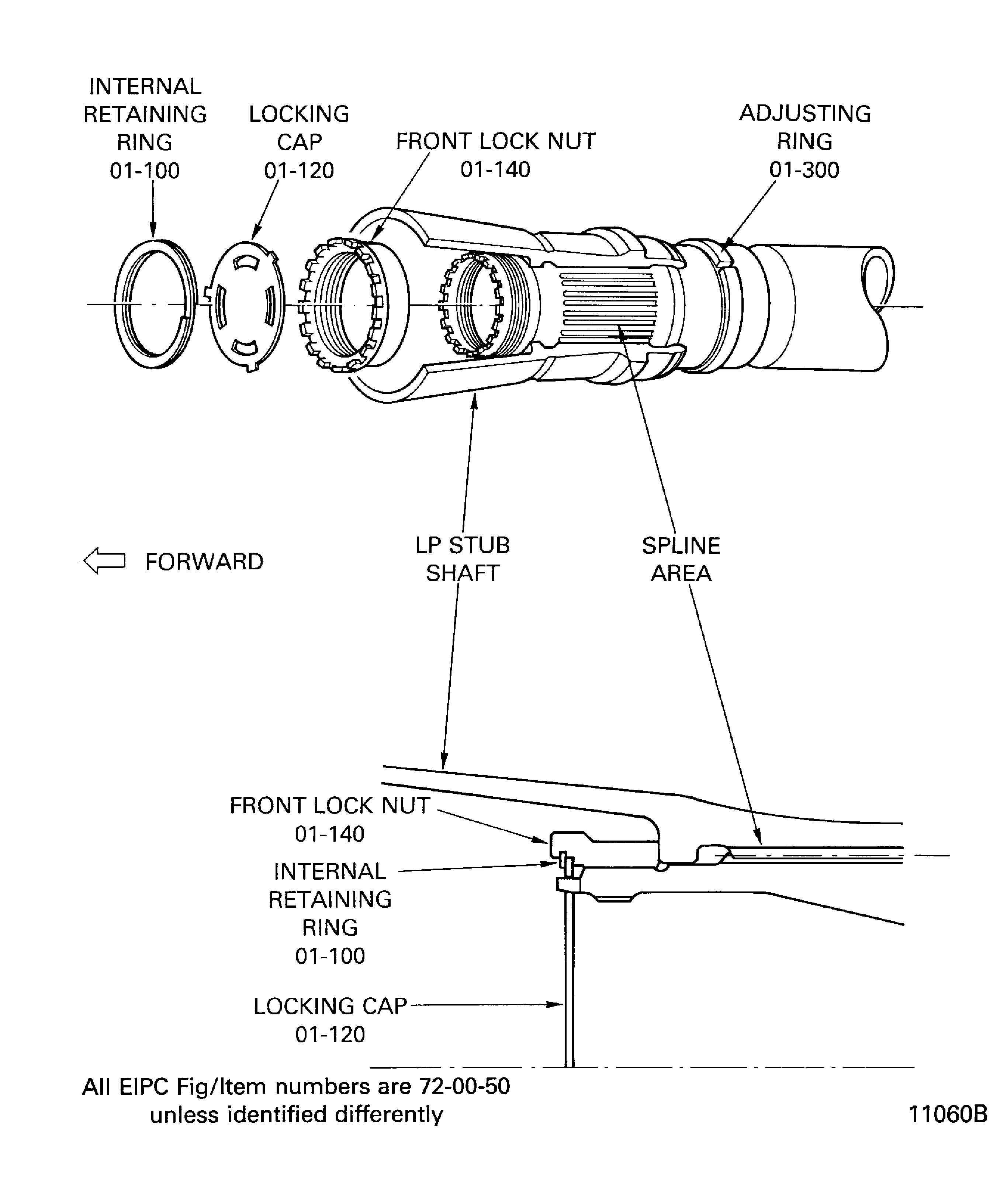

Remove the old adjusting ring from the LP Turbine Shaft and install the new adjusting ring. Use the IAE 1J12282 Expanding pliers 1 off.

SUBTASK 72-00-50-420-099 Install the Adjusting Ring to the LP Turbine Shaft

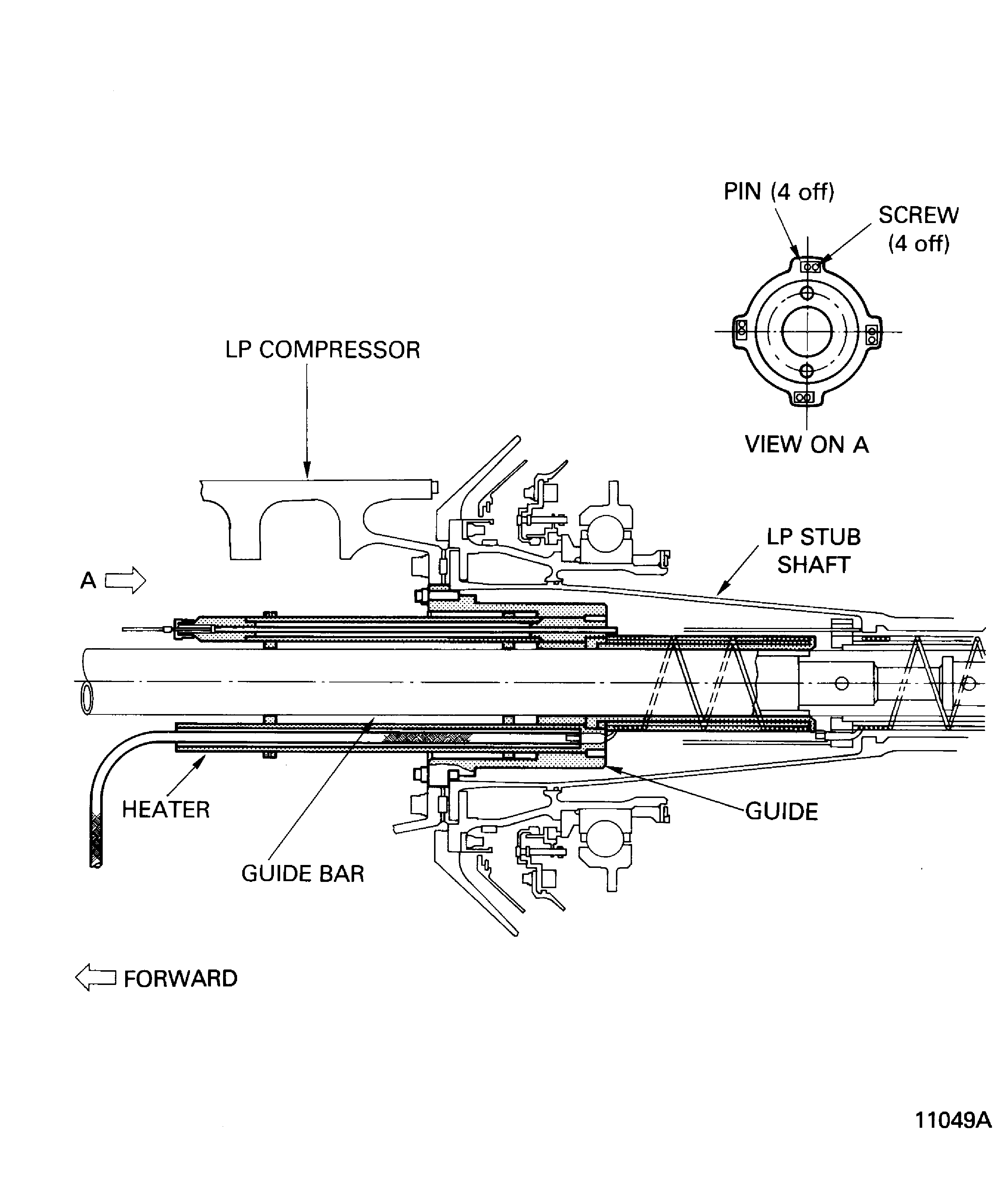

Install IAE 1J12281 0AM53 heater 1 off to the stub shaft front flange as follows. Refer to Figure.

Install the guide ring A1 (part of IAE 1J12280 Guide bar) on to the lock nut at the rear face of the Stage 2 Turbine Disk. Refer to Figure.

Connect the two guide bars (parts of the IAE 1J12280 Guide bar).

Install the IAE 1J12280 Guide bar 1 off.

SUBTASK 72-00-50-420-100-A00 V2500-A1: Prepare the Engine for the Installation of the LP Turbine Module without TEC

Align the four holes in the guide (part of the IAE 1J12271 0AM53 heater) with the four slots in the flange of the LP Stub Shaft.

Install IAE 1J12281 0AM53 heater 1 off together with IAE 1J12271 0AM53 heater 1 off to the Stub Shaft Front Flange as follows. Refer to Figure.

Install the guide ring A1 (part of the IAE 1J12280 Guide bar 1 off) on to the lock nut at the rear flange of the Stage 2 Turbine Disk. Refer to Figure.

Connect the two guide bars (parts of the IAE 1J12280 Guide bar).

Install the IAE 1J12280 Guide bar 1 off.

SUBTASK 72-00-50-420-100-B00 V2500-A5: Prepare the Engine for the Installation of the LP Turbine Module without TEC

Refer to Figure.

Attach the IAE 1F10052 Two cables sling 1 off to the front spool of the support arms which are installed at the LP Turbine Module without TEC.

Loosen the nut of the eye bolt (part of the IAE 1F10080 Horizontal stand). Refer to Figure.

SUBTASK 72-00-50-420-101 Remove the LP Turbine Module without TEC from the Horizontal Stand

Remove the guide ring A1 and install the guide rings A3 (part of IAE 1J12280 Guide bar1 off) on to the lock nut at the rear flange of the Stage 2 Turbine Disk. Refer to Figure.

SUBTASK 72-00-50-420-151 Remove the Guide Ring A1

Remove the guide ring A3 and install the guide ring A2 (part of the IAE 1J12280 Guide bar1 off) to the lock nut at the rear flange of the Stage 2 Turbine Disk. Refer to Figure.

Push the IAE 1J12281 0AM53 heater backwards, until it is against the stop position. Increase the temperature of the spline area of the LP Stub Shaft to the temperature of 275 deg F to 329 deg F (135 deg C to 165 deg C). Use the IAE 6F10027 Heater control unit 1 off.

During this time remove the IAE 1M14127 Support plate from the LP Turbine Case front flange and the LP Turbine Shaft. Refer to Figure.

Pull the local heater forwards. Move the LP Turbine Module in to the engine, until the LP Turbine Case front flange touches the HP Turbine Case rear flange. Refer to Figure.

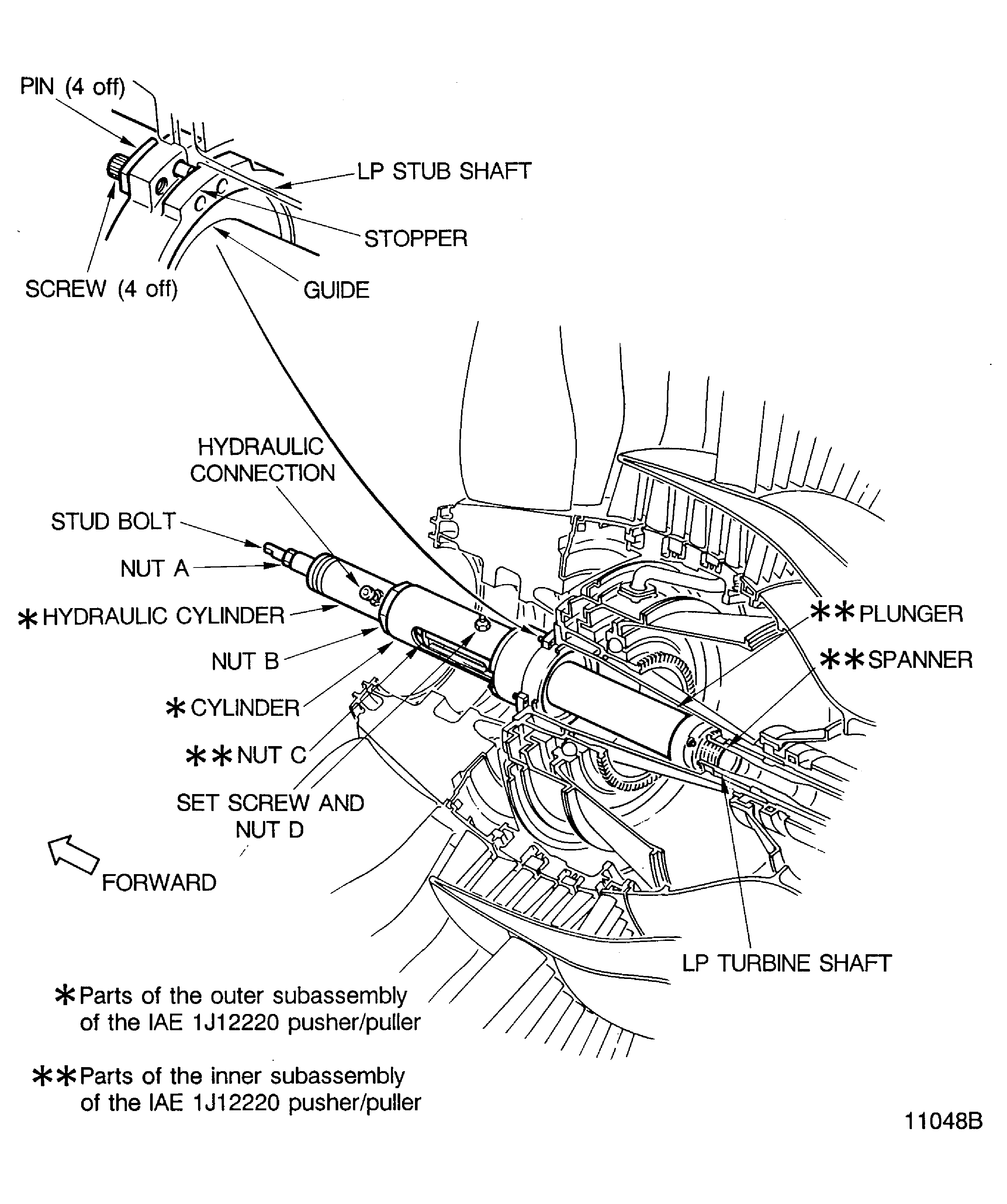

Attach the outer subassembly of the hydraulic pusher/puller (which has the guide, the cylinder and the hydraulic cylinder) to the front flange of the LP Stub Shaft. The four stoppers of the guide must be in line with the scallops of the LP Stub Shaft.

NOTE

Make sure that the hydraulic connection of the hydraulic cylinder is at the opposite side of the cylinder.

Install the IAE 1J12220 Hydraulic pusher/puller 1 off to the front flange of the LP Stub Shaft as follows: Refer to Figure.

Install the IAE IAE 1F10026 Hydraulic hand pump 1 off to the hydraulic connection of the hydraulic pusher/puller.

Pull the LP Turbine Module in correct position. Tighten the work nut pairs at the HP/LP Turbine Flanges in opposite sequence. Apply equal force all around the flange to pull them together. In the same time operate the hydraulic pump stepwise to connect the LP Turbine Shaft with the LP Stub Shaft.

NOTE

Tighten the work nuts, and operate the hydraulic pump at the same time to prevent overloading of the handling fixture.If the HP/LP Turbine Flanges are together, loosen the two nuts which secure the IAE IAE 1F10063 Expanding retainer 1 off to the IAE IAE 1F10058 Handling fixture 1 off.

Loosen and remove the four screws which safety the pins to the guide of the IAE IAE 1J12220 Hydraulic pusher/puller 1 off together with the IAE 1J12270 Guide puller.

Remove the hydraulic pusher/puller from the LP Stub Shaft as follows: Refer to Figure.

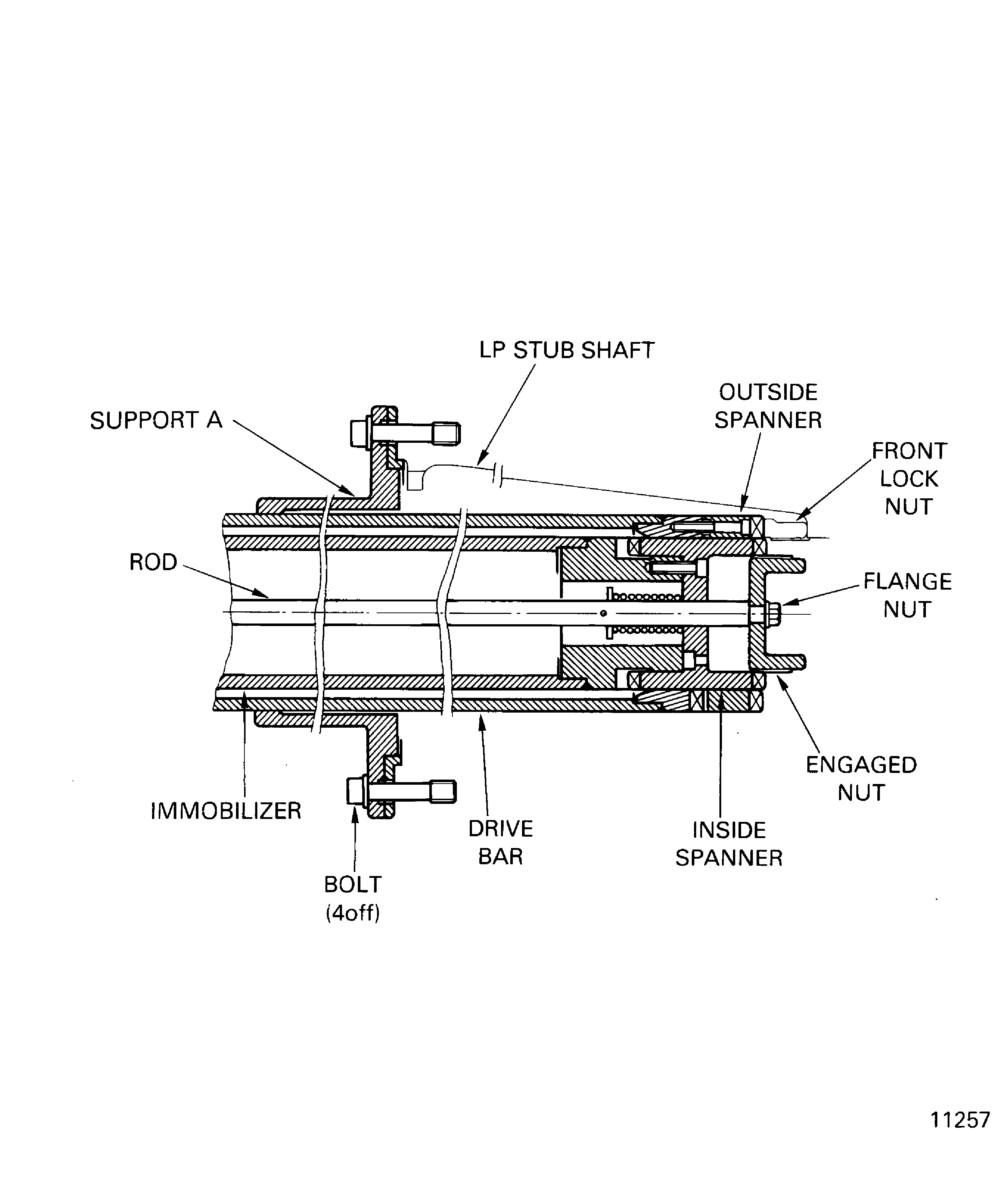

Install the support B (part of the IAE 1J12260 Spanner wrench 1 off) to the retaining ring of the LP Compressor Disk. Attach the support B with the four bolts. Refer to Figure.

Install the support A (part of the spanner wrench) to the curvic coupling of the LP Stub Shaft. Attach the support A with the four bolts. Refer to Figure.

Assemble the IAE 1F10016 Mechanical wrench 1 off to the spanner wrench.

Install the Turbine Shaft Front Lock Nut on to the front of the LP Turbine Shaft. Refer to Figure.

Safety the front lock nut of the LP Turbine Shaft with the locking cap and the internal retaining ring LPT Shaft And Related Parts (72-50-41, 01-100). Refer to Figure.

CAUTION

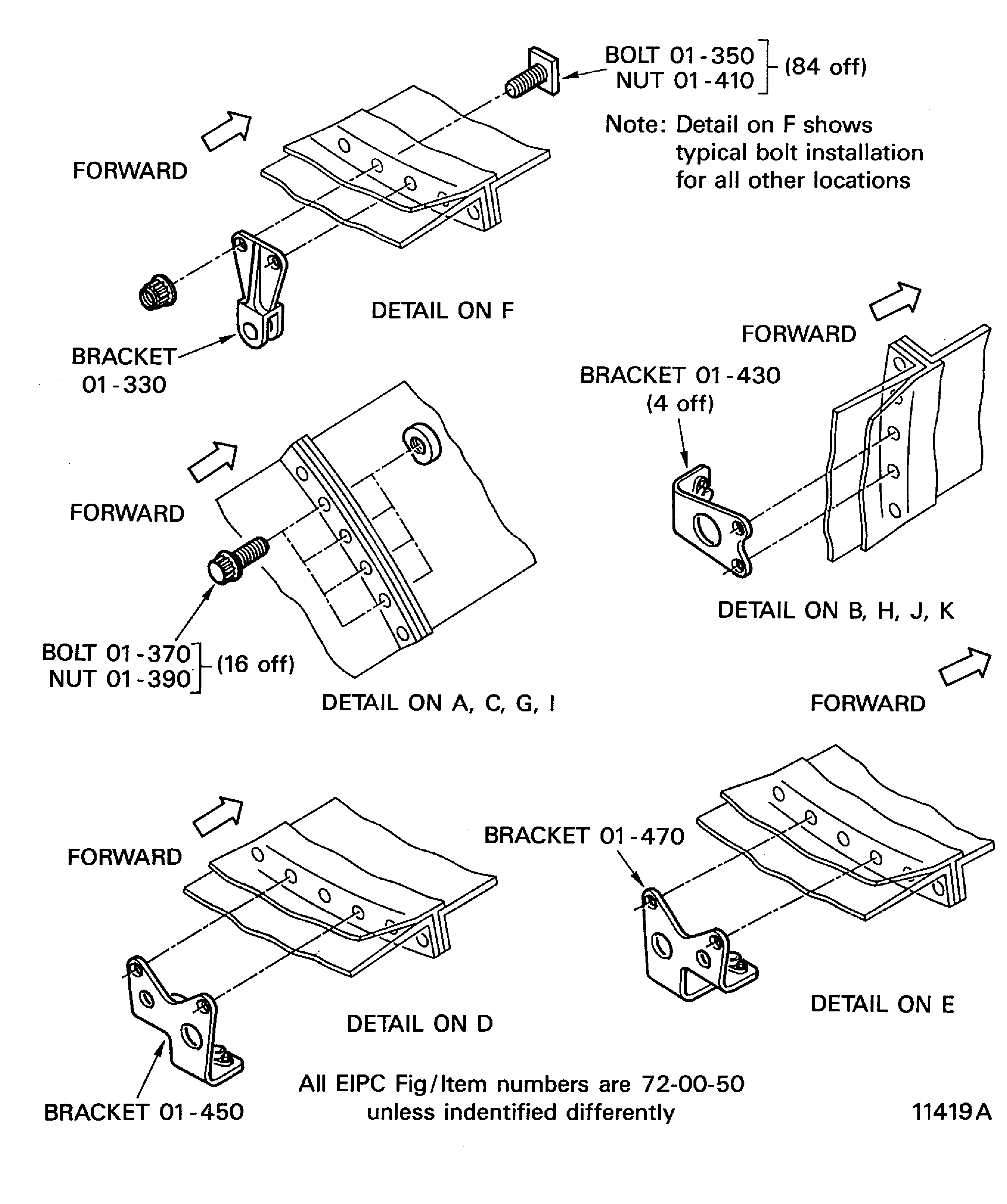

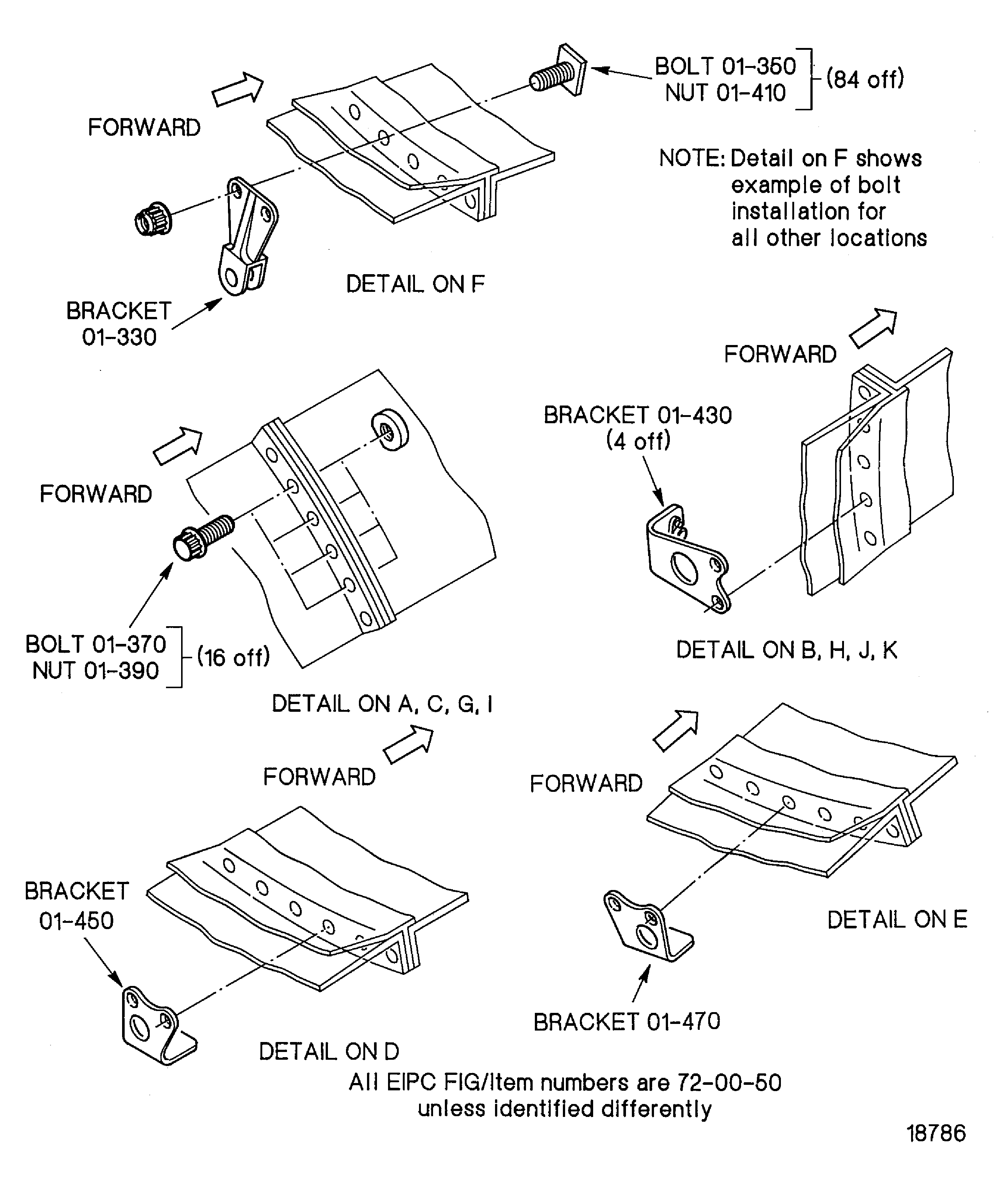

HOLD THE BOLTS IN THEIR POSITION WHEN YOU REMOVE THE NUTS FROM THE BOLTS. DO NOT TURN THE BOLTS OR MAKE TO-AND-FRO MOVEMENTS. THE LP TURBINE CASE/HP TURBINE CASE FLANGE AND/OR THE BOLTS CAN BE DAMAGED.Torque the 84 nuts installed on the bolts which have their heads located on the HP Turbine Flange from 180.0 lbfin to 220.0 lbfin (20.0 Nm to 25.0 Nm).

Torque the 16 bolts which have their heads located on the LP Turbine Flange from 180.0 lbfin to 220.0 lbfin (20.0 Nm to 25.0 Nm). Safety the bolts with CoMat 02-119 LOCKWIRE.

Install the seven brackets and attach the 100 bolts and nuts, which lock the LP Turbine Case to the HP Turbine Case. Refer to Figure.

SUBTASK 72-00-50-420-102-A00 V2500-A1: Install the LP Turbine Module without TEC

Remove the guide ring A3 and install the guide ring A2 (part of IAE 1J12280 Guide bar 1 off) to the lock nut at the rear flange of the Stage 2 Turbine Disk. Refer to Figure.

Push the IAE 1J12281 0AM53 heater 1 off together with the IAE 1J12271 0AM53 heater 1 off backwards, until it is against the stop position. Increase the temperature of the spline area of the LP Stub Shaft to the temperature of 275 deg F to 329 deg F (135 deg C to 165 deg C). Use the IAE 6F10027 Heater control unit 1 off.

During this time remove the IAE 1M14114 Sizing gage 2 off from the LP Turbine Case front flange and the LP Turbine Shaft. Refer to Figure.

Pull the local heater forwards. Move the LP Turbine Module in to the engine, until the LP Turbine Case front flange touches the HP turbine Case rear flange. Refer to Figure.

Attach the outer subassembly of the hydraulic pusher/puller (which has the guide, the cylinder and the hydraulic cylinder) to the front flange of the LP Stub Shaft. The four stoppers of the guide must be in line with the scallops of the LP Stub Shaft.

NOTE

Make sure that the hydraulic connection of the hydraulic cylinder is at the opposite side of the cylinder.

Install the IAE 1J12220 Hydraulic pusher/puller 1 off together with the IAE 1J12270 Guide puller 1 off to the front flange of the LP Stub Shaft as follows: Refer to Figure.

Install the IAE 1F10026 Hydraulic hand pump 1 off to the hydraulic connection of the hydraulic pusher/puller.

Pull the LP Turbine Module in correct position. Tighten the work nut pairs at the HP/LP Turbine Flanges in opposite sequence. Apply equal force all around the flange to pull them together. At the same time operate the hydraulic pump stepwise to connect the LP Turbine Shaft with the LP Stub Shaft.

NOTE

Tighten the work nuts, and operate the hydraulic pump at the same time to prevent overloading of the handling fixture.If the HP/LP Turbine Flanges are together, loosen the two nuts which secure the IAE 1R18907 Expanding retainer 1 off to the IAE 1F10058 Handling fixture 1 off.

Loosen and remove the four screws which safety the pins to the guide of the IAE 1J12220 Hydraulic pusher/puller 1 off.

Remove the hydraulic pusher/puller from the LP Stub Shaft as follows: Refer to Figure.

Install the support B (Part of the IAE 1J12260 Spanner wrench 1 off) to the retaining ring of the LP Compressor Disk. Attach the support B with four bolts. Refer to Figure.

Install the support A (part of the spanner wrench) to the curvic coupling of the LP Stub Shaft. Attach the support A with four bolts. Refer to Figure.

Assemble the IAE 1F10016 Mechanical wrench 1 off to the spanner wrench.

Install the Turbine Shaft Front lock nut on to the front of the LP Turbine Shaft. Refer to Figure.

Safety the front lock nut of the LP Turbine Shaft with the locking cap and the internal retaining ring LPT Shaft And Related Parts (72-50-41, 01-100). Refer to Figure.

CAUTION

HOLD THE BOLTS IN THEIR POSITION WHEN YOU INSTALL THE NUTS ON TO THE BOLTS. DO NOT TURN THE BOLTS OR MAKE TO-AND-FRO MOVEMENTS. THE LP TURBINE CASE/HP TURBINE CASE FLANGE AND/OR THE BOLTS CAN BE DAMAGED.Torque the 84 nuts installed on the bolts which have their heads located on the HP Turbine Flange from 180.0 lbfin to 220.0 lbfin (20.0 Nm to 25.0 Nm).

Torque the 16 bolts which have their heads located on the LP Turbine Flange from 180.0 lbfin to 220.0 lbfin (20.0 Nm to 25.0 Nm). Safety the bolts with CoMat 02-119 LOCKWIRE.

Install the seven brackets and attach the 100 bolts and nuts, which lock the LP Turbine Case to the HP Turbine Case. Refer to Figure.

SUBTASK 72-00-50-420-102-B00 V2500-A5: Install the LP Turbine Module without TEC

Refer to Figure.

Install the IAE 1M14005 Torque wrench 1 off to the ring nut (part of the IAE 1M14002 Support fixture).

Assemble the IAE 1F10019 Mechanical wrench 1 off to the torque wrench.

Install the IAE 1M14006 Immobilizing fixture 1 off on to the rear end of the LP Turbine Shaft. Safety the immobilizing fixture to the mechanical wrench with the immobilizer plate.

SUBTASK 72-00-50-420-125-A00 V2500-A1: Release the Assembled Lifting Fixture from the LP Turbine Module without TEC

Refer to Figure.

Install the IAE 1M14005 Torque wrench 1 off to the ring nut (part of the IAE 1M14002 Support fixture).

Assemble the IAE 1F10019 Mechanical wrench 1 off to the torque wrench.

Install the IAE 1M14139 Immobilizing fixture 1 off on to the rear end of the LP Turbine Shaft. Safety the immobilizing fixture to the mechanical wrench with the immobilizer plate.

SUBTASK 72-00-50-420-125-B00 V2500-A5: Release the Assembled Lifting Fixture from the LP Turbine Module without TEC

Install the IAE 2F10415 Loading fixture 1 off on to the front flange of the Fan Case. Refer to SUBTASK 72-00-50-420-200 .

SUBTASK 72-00-50-420-126 Install the Loading Fixture

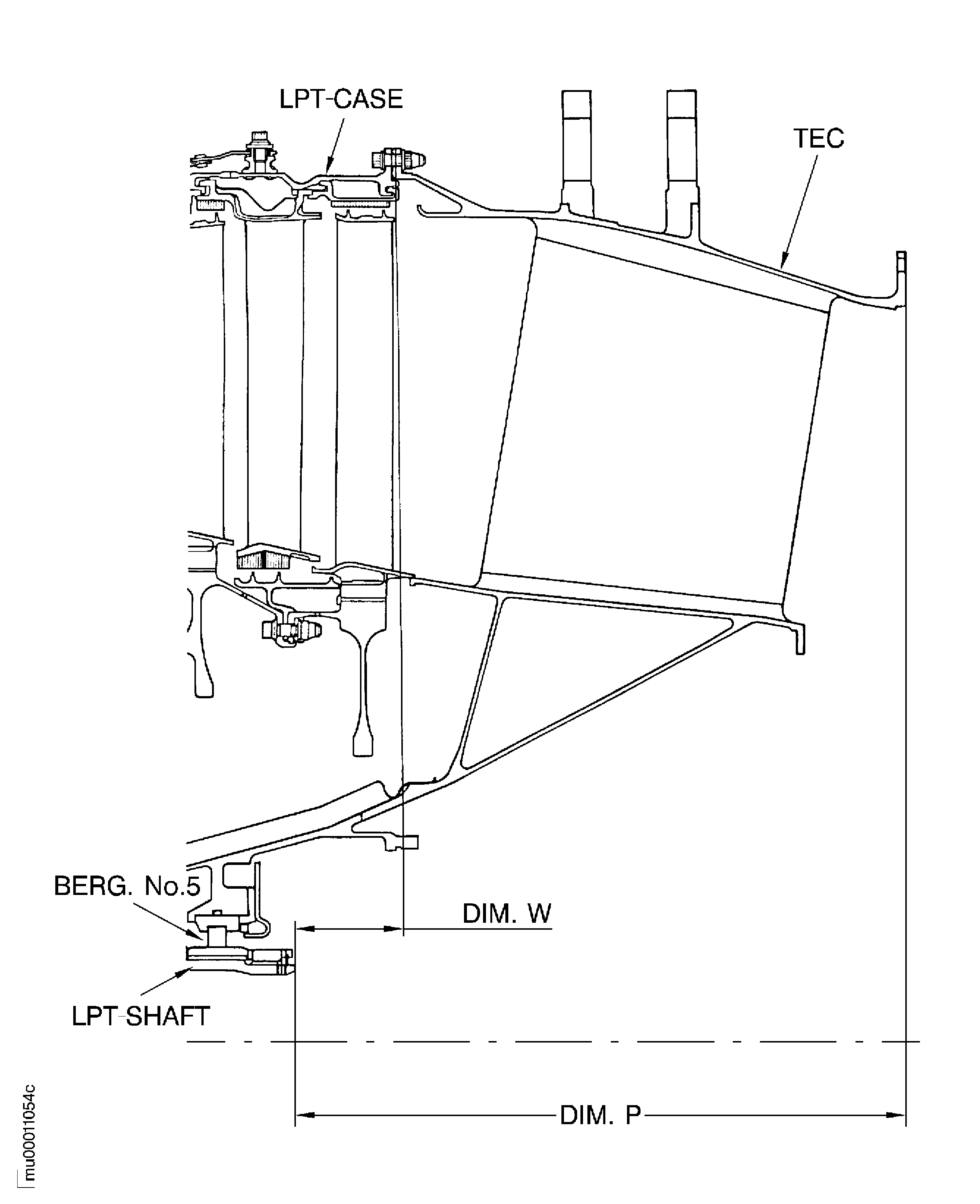

Use a suitable vernier depth gage to measure the dimension W (actual). Refer to Figure. DIM.W to be within 2.1988 in. to 2.2421 in. (55.85 mm to 56.95 mm).

SUBTASK 72-00-50-420-104 Measure the Dimension W after the Installation of the LP Turbine Case and Rotor Assembly

NOTE

Load must be applied in a rearward direction.Remove the IAE 2F10415 Loading fixture from the front flange of the Fan Case.

SUBTASK 72-00-50-420-127 Remove the Loading Fixture

Refer to Figure.

Install the IAE 1F10074 Guide pogo stick 1 off to the inner diameter of the LP Turbine Shaft. Use applicable webbing sling.

Put the IAE 1F10075 Support pedestal 1 off B below the guide pogo stick near to the rear end of the guide pogo stick.

Install the IAE 1F10075 Support pedestal 1 off between the rear flange of the LP Turbine Case and the lifting fixture.

SUBTASK 72-00-50-420-103-A00 V2500-A1: Install the Guide Pogo Stick and Remove the Lifting Fixture

Refer to Figure.

Install the IAE 1P16377 Guide support 1 off to the inner diameter of the LP Turbine Shaft. Use applicable webbing sling.

Put the IAE 1F10075 Support pedestal 1 off below the guide support near to the rear end of the guide support.

Install the IAE 1F10075 Support pedestal A 1 off between the rear flange of the LP Turbine Case and the lifting fixture.

SUBTASK 72-00-50-420-103-B00 V2500-A5: Install the Guide Support and Remove the Lifting Fixture

Refer to Figure.

Install the IAE 1M14086 Supporting fixture or the IAE 1M14461 Supporting fixture 1 off at the 12 o'clock position to LP Turbine Case. Attach the supporting fixture with the four screws.

SUBTASK 72-00-50-420-128-A00 V2500-A1: Install the Supporting Fixture

NOTE

Measure the inner hub diameter of Stage 7 Disk before you install the supporting fixture.NOTE

If the inner hub diameter is 12.595 in. (319.9 mm) use IAE 1M14086 Supporting fixtureIf the inner hub diameter is 12.441 in. (316 mm) use IAE 1M14461 Supporting fixtureRefer to Figure.

Install the IAE 1M14143 Support fixture or the IAE 1M14461 Supporting fixture 1 off at the 12 o'clock position to LP Turbine Case. Attach the supporting fixture with the four screws.

SUBTASK 72-00-50-420-128-B00 V2500-A5: Install the Supporting Fixture

NOTE

Measure the inner hub diameter of Stage 7 Disk before you install the supporting fixture.NOTE

If the inner hub diameter is 12.595 in. (319.9 mm) use IAE 1M14143 Support fixtureIf the inner hub diameter is 12.441 in. (316 mm) use IAE 1M14461 Supporting fixtureRemove the IAE 1F10075 Support pedestal.

Remove the IAE 1F10074 Guide pogo stick 1 off from the LP Turbine Shaft.

SUBTASK 72-00-50-420-129-A00 V2500-A1: Remove the Guide Pogo Stick

Refer to Figure.

Remove the three nuts of the guide sleeves part of the IAE 1M14002 Support fixture 1 off.

SUBTASK 72-00-50-420-130 Disassemble the Lifting Fixture and the Support Fixture

Install the Turbine Exhaust Case. Refer to TASK 72-00-50-420-003-A00 (INSTALLATION-004).

SUBTASK 72-00-50-420-105 Install the Turbine Exhaust Case

Install the module dressings. Refer to TASK 72-00-50-420-005-A00 (INSTALLATION-007).

SUBTASK 72-00-50-420-106 Install the Module Dressings

Install the Inlet Cone. Refer to TASK 72-38-11-420-001 (INSTALLATION-001).

SUBTASK 72-00-50-420-107 Install the Inlet Cone

Figure: Fits and Clearances at Interface D-45 and D-50/10

Fits and Clearances at Interface D-45 and D-50/10

Figure: Fits and Clearances at Interface F-32 and F-50

Fits and Clearances at Interface F-32 and F-50

Figure: V2500-A1: Install the Guide Pogo Stick to the LP Turbine

V2500-A1: Install the Guide Pogo Stick to the LP Turbine

Figure: V2500-A5: Install the Guide Support to the LP Turbine

V2500-A5: Install the Guide Support to the LP Turbine

Figure: V2500-A1: Install the Lifting Fixture and Remove the Guide Pogo Stick

V2500-A1: Install the Lifting Fixture and Remove the Guide Pogo Stick

Figure: V2500-A5: Install the Lifting Fixture and Remove the Guide Support

V2500-A5: Install the Lifting Fixture and Remove the Guide Support

Figure: Install the Lifting Fixture on to the LP Turbine

Install the Lifting Fixture on to the LP Turbine

Figure: Installation of the Heater and the Guide Bar

Installation of the Heater and the Guide Bar

Figure: Installation of the Guide Rrings

Installation of the Guide Rrings

Figure: V2500-A1: Calculate the Adjusting Ring Thickness

V2500-A1: Calculate the Adjusting Ring Thickness

Figure: V2500-A5: Calculate the Adjusting Ring Thickness

V2500-A5: Calculate the Adjusting Ring Thickness

Figure: Calculate the Adjusting Ring Thickness

Calculate the Adjusting Ring Thickness

Figure: V2500-A5: Calculate the Adjusting Ring Thickness

V2500-A5: Calculate the Adjusting Ring Thickness

Figure: Calculate the Adjusting Ring Thickness

Calculate the Adjusting Ring Thickness

Figure: Calculate the Adjusting Ring Thickness

Calculate the Adjusting Ring Thickness

Figure: Calculate the Adjusting Ring Thickness

Calculate the Adjusting Ring Thickness

Figure: Example of a Component Dimension Record Sheet

Example of a Component Dimension Record Sheet

Figure: Example of a Component Dimension Record Sheet

Example of a Component Dimension Record Sheet

Figure: Example of a Component Dimension Record Sheet

Example of a Component Dimension Record Sheet

Figure: Remove the LP Turbine Module from the Horizontal Stand

Remove the LP Turbine Module from the Horizontal Stand

Figure: Remove the LP Turbine Module from the Horizontal Stand

Remove the LP Turbine Module from the Horizontal Stand

Figure: Remove the Support Plates

Remove the Support Plates

Figure: V2500-A1: Connect the LP Shaft Front end with the LP Stub Shaft

V2500-A1: Connect the LP Shaft Front end with the LP Stub Shaft

Figure: V2500-A5: Connect the LP Shaft Front End with the LP Stub Shaft

V2500-A5: Connect the LP Shaft Front End with the LP Stub Shaft

Figure: Install the Turbine Shaft Front Lock Nut

Install the Turbine Shaft Front Lock Nut

Figure: Install the Turbine Shaft Front Lock Nut

Install the Turbine Shaft Front Lock Nut

Figure: Safety the Front Lock Nut of the LP Turbine Shaft

Safety the Front Lock Nut of the LP Turbine Shaft

Figure: V2500-A1 Pre-SBE 75-0013: Installation of the Bolts and the Brackets at the LP Turbine Module Front Flange

V2500-A1 Pre-SBE 75-0013: Installation of the Bolts and the Brackets at the LP Turbine Module Front Flange

Figure: V2500-A1 Pre-SBE 75-0013: Installation of the Bolts and the Brackets at the LP Turbine Module Front Flange

V2500-A1 Pre-SBE 75-0013: Installation of the Bolts and the Brackets at the LP Turbine Module Front Flange

Figure: V2500-A1 SBE 75-0013 and V2500-A5: Installation of the Bolts and the Brackets at the LP Turbine Module Front Flange

V2500-A1 SBE 75-0013 and V2500-A5: Installation of the Bolts and the Brackets at the LP Turbine Module Front Flange

Figure: V2500-A1 SBE 75-0013 and V2500-A5: Installation of the Bolts and the Brackets at the LP Turbine Module Front Flange

V2500-A1 SBE 75-0013 and V2500-A5: Installation of the Bolts and the Brackets at the LP Turbine Module Front Flange

Figure: V2500-A1: Install/Remove the Loading Fixture

V2500-A1: Install/Remove the Loading Fixture

Figure: V2500-A5: Install/Remove the Loading Fixture

V2500-A5: Install/Remove the Loading Fixture