Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

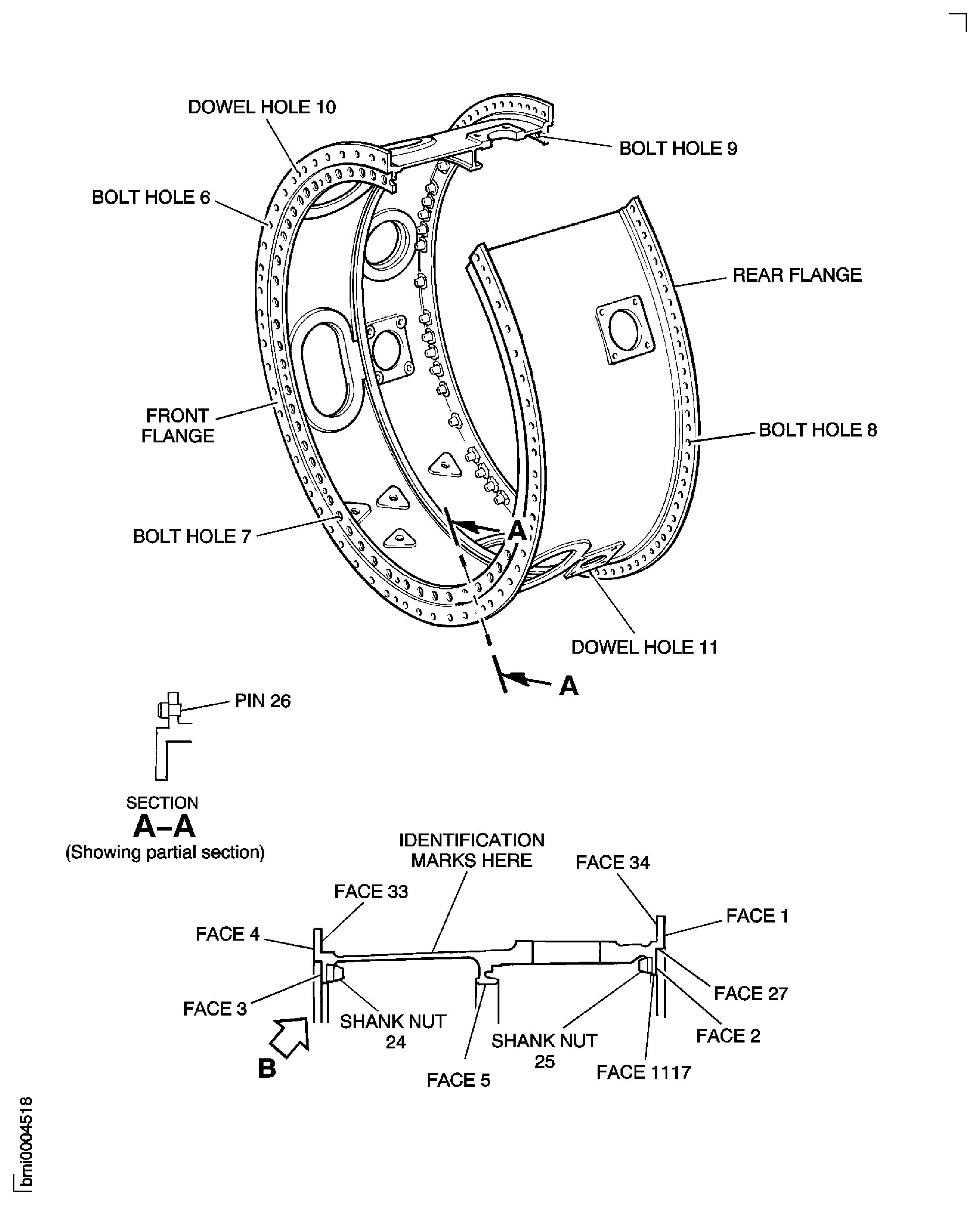

TASK 72-41-23-200-001-C00 HPC Rear Outer Case - Examine, Inspection-001

General

This TASK gives the procedure for the inspection of the rear outer case.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For service bulletin alpha variants refer to the IPC.

The policy that is necessary for inspection is given in SPM TASK 70-20-01-200-501.

All the parts must be cleaned before any part is examined.

All the parts must be visually examined for damage, corrosion and wear. Any defects that are not identified in the procedure must be referred to IAE.

The procedure for the parts which must have a crack test is given in Step. Do the crack test before the part is visually examined.

Do not discard any part until you are sure there are no repairs available. Refer to the instructions in repair before a discarded part is used again or oversize parts are installed.

Parts which should be discarded can be held although no repair is available. The repair of a discarded part can be shown to be necessary at a subsequent date.

All the parts must be examined to make sure that all the repairs have been completed satisfactory.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in SPM.

References

Refer to SPM for data on these items:

Definition of Damage, SPM TASK 70-02-02-350-501,

Inspection of Parts, SPM TASK 70-20-01-200-501.

Some data on these items are contained in this TASK. For more data on these items refer to SPM:

Methods of Testing for Crack Indications,

Chemical Processes,

Surface Protection.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Remove shank nuts. Refer to Repair, VRS6279 TASK 72-41-23-300-011 (REPAIR-011).

Clean the parts. Refer to TASK 72-41-23-100-000 (CLEANING-000).

Repair, VRS6530 TASK 72-41-23-300-024 (REPAIR-024).

Cracked at rear flange face 1.

Repair, VRS9537 TASK 72-41-23-300-028 (REPAIR-028).

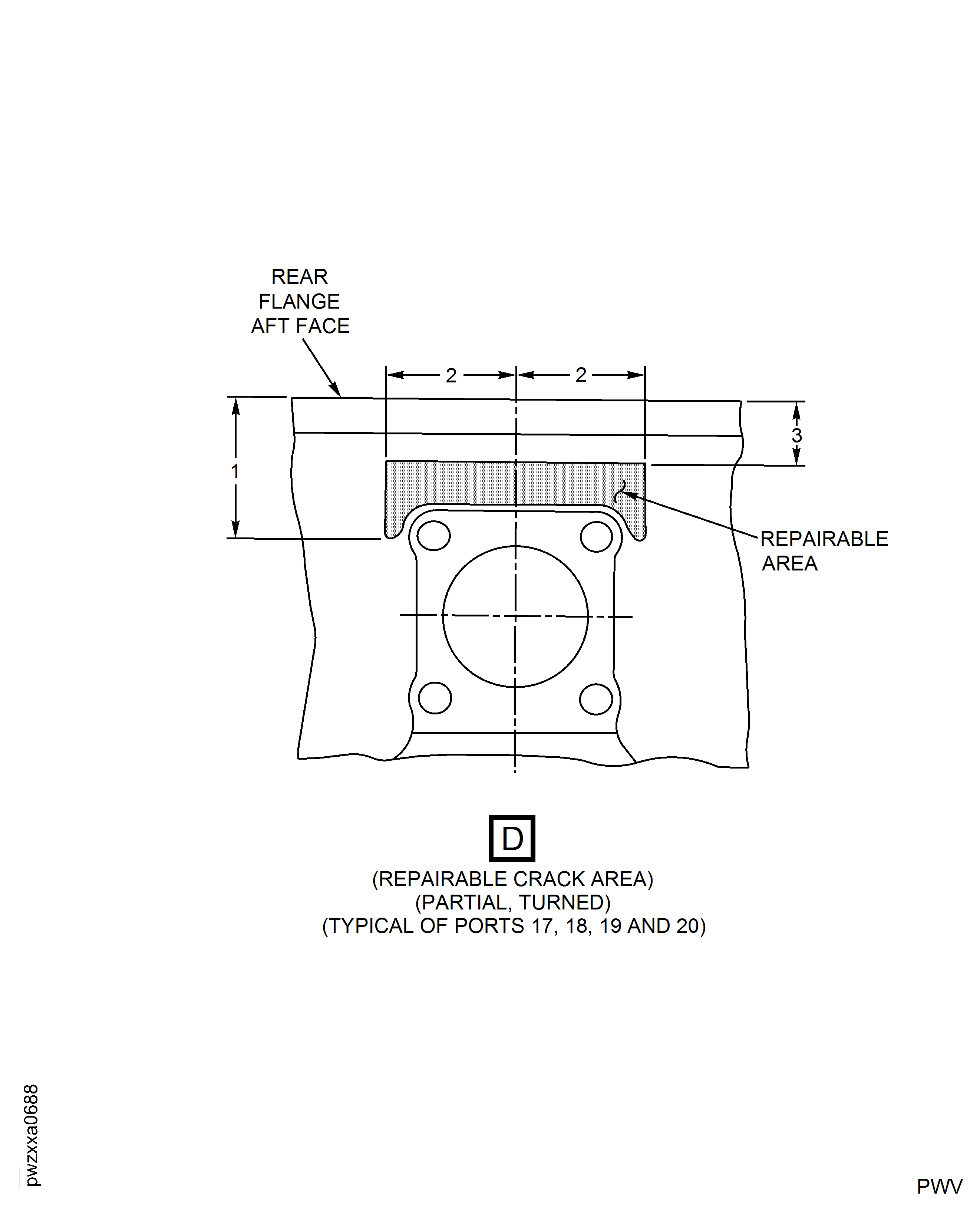

Cracked at outer wall cooling ports 17, 18, 19, and 20.

Do the test for cracks on the parts that is given below.

PART IDENT

TASK/SUBTASK

Rear outer case

SUBTASK 72-41-23-230-079 Examine the Rear Outer Case for Cracks

Refer to Figure.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001).

More than in Step.

Galled.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001).

More than in Step.

Worn.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001).

More than in Step.

Scored.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001).

More than in Step with local damage not more than 0.008 in. (0.20 mm) in depth, separated by more than 1.772 in. (45.00 mm) between damage area centres.

Repair VRS6528, TASK 72-41-23-300-023 (REPAIR-023).

More than in Step with general damage not more than 0.008 in. (0.20 mm) in depth separated by less than 1.772 in. (45.00 mm) between damage area centres.

Faces 1 and 4.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001).

More than in Step and not more than 0.010 in. (0.25 mm) in depth, with damage segregation not necessary.

Faces 2 and 3.

Pitted and surface damaged.

SUBTASK 72-41-23-220-150 Examine the Rear Outer Case Front and Rear Flanges at Face Locations 1 to 4

Refer to Figure.

Repair VRS6179, TASK 72-41-23-300-002 (REPAIR-002).

More than in Step.

Scored.

Repair VRS6179, TASK 72-41-23-300-002 (REPAIR-002).

More than in Step.

Scratched.

Repair VRS6179, TASK 72-41-23-300-002 (REPAIR-002).

Chipped.

Repair VRS6179, TASK 72-41-23-300-002 (REPAIR-002).

More than in Step.

Worn.

Repair VRS6179, TASK 72-41-23-300-002 (REPAIR-002).

If cracks are found.

Cracked.

SUBTASK 72-41-23-220-151 Examine the Rear Outer Case (72-41-23,02-400) Coated Face at Location 5

Refer to Figure.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

Burred edges

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

Repair VRS6528, TASK 72-41-23-300-023 (REPAIR-023)

More than in (a) and not more than 0.027 in. (0.68 mm) in depth

Hole 6 - bore surface.

Repair VRS6528, TASK 72-41-23-300-023 (REPAIR-023)

More than in (a) and not more than 0.020 in. (0.50 mm) in depth

Hole 7 - counter bore surface.

Repair VRS6528, TASK 72-41-23-300-023 (REPAIR-023)

More than in (a) and not more than 0.020 in. (0.50 mm) in depth

Hole 8 - bore surface.

Pitted and surface damaged.

Scratched

SUBTASK 72-41-23-220-152 Examine the Rear Outer Case Bolt Holes at Locations 6 to 9

Refer to Figure.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

From impact damage not more than 0.041 in. (1.04 mm) in depth in dowel hole axial direction

Burred and/or raised edges.

SUBTASK 72-41-23-220-153 Examine the Rear Outer Case Dowel Holes at Locations 10 and 11

Refer to Figure.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

More than in (1)

Galled surfaces.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

More than in (1)

Scored surfaces.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

More than in (a) with local pitting not more than 0.030 in. (0.75 mm) in depth, separated by more than 1.772 in. (45.00 mm) between damage area centres

Repair VRS6528, TASK 72-41-23-300-023 (REPAIR-023)

More than in (a) with general pitting not more than 0.030 in. (0.75 mm) in depth, separated by less than 1.772 in. (45.00 mm) between damage area centres

External boss surfaces.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

More than in (a) and not more than 0.012 in. (0.30 mm) in depth and in radius 0.236 in. (6.00 mm) of hole centre

Internal casing surface local to fastener holes.

Pitted surfaces.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

Burred edges

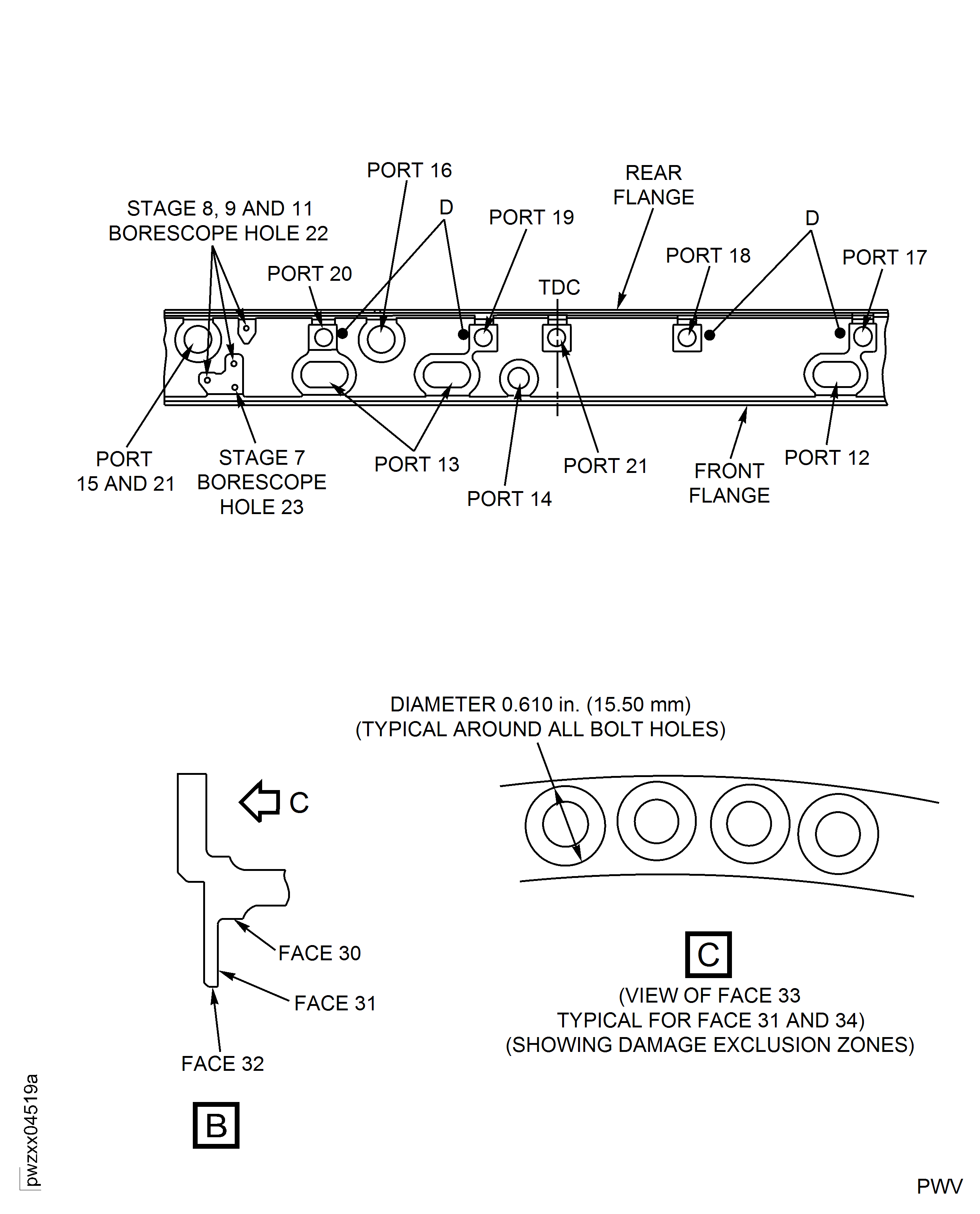

SUBTASK 72-41-23-220-154 Examine the Rear Outer Case Bleed Ports at Locations 12 to 16 and Cooling Air Ports at Locations 17 to 21

Refer to Figure.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

More than in (1)

Scored.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

More than in (1)

Galled.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

More than in (a) with local pitting not more than 0.030 in. (0.75 mm) in depth, separated by more than 1.772 in. (45.00 mm) between damage area centres

Repair VRS6528, TASK 72-41-23-300-023 (REPAIR-023)

More than in (a) with general pitting not more than 0.030 in. (0.75 mm) in depth, separated by less than 1.772 in. (45.00 mm) between damage area centres

External boss surfaces.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

More than in (a) and not more than 0.012 in. (0.30 mm) in depth and in radius 0.236 in. (6.00 mm) of hole centre

Internal casing surface local to fastener holes.

Refer to Repair, VRS6528 TASK 72-41-23-300-023 (REPAIR-023).

More than in Step.

Borescope bores.

Pitted and surface damaged.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001).

Burred edges.

SUBTASK 72-41-23-220-156 Examine the Rear Outer Case Stage 7 to 11 Borescope Holes at Locations 22 and 23

Refer to Figure.

Repair VRS6279, TASK 72-41-23-300-011 (REPAIR-011)

Loose

Repair VRS6279, TASK 72-41-23-300-011 (REPAIR-011)

Damaged

SUBTASK 72-41-23-220-157 Examine the Rear Outer Case Shank Nuts at Locations 24 and 25

Refer to Figure.

Repair VRS6278, TASK 72-41-23-300-021 (REPAIR-021)

Burred

Repair VRS6278, TASK 72-41-23-300-021 (REPAIR-021)

Scored

Repair VRS6278, TASK 72-41-23-300-021 (REPAIR-021)

Loose

SUBTASK 72-41-23-220-158 Examine the Rear Outer Case Pins at Location 26

Repair, VRS6306, TASK 72-41-23-300-019 (REPAIR-019)

Broken

Repair, VRS6306, TASK 72-41-23-300-019 (REPAIR-019)

Loose

Repair, VRS6306, TASK 72-41-23-300-019 (REPAIR-019)

Worn

Repair, VRS6306, TASK 72-41-23-300-019 (REPAIR-019)

Crossed thread

Repair, VRS6306, TASK 72-41-23-300-019 (REPAIR-019)

Stripped thread

SUBTASK 72-41-23-220-159 Examine the Rear Outer Case Screw Thread Inserts

Repair, VRS6526 TASK 72-41-23-300-022 (REPAIR-022).

Worn.

Repair, VRS6526 TASK 72-41-23-300-022 (REPAIR-022).

Missing threads/serrations.

Repair, VRS6526 TASK 72-41-23-300-022 (REPAIR-022).

Damaged

Repair, VRS6540 72-41-23-300-026 (REPAIR-026).

Damaged due to oversized inserts.

Repair, VRS6526 TASK 72-41-23-300-022 (REPAIR-022).

Inspect for KEENSERTS.

SUBTASK 72-41-23-220-176 Examine the Rear Outer Case Screw Thread Insert Holes

Repair, VRS6178 TASK 72-41-23-300-003 (REPAIR-003).

Damaged

SUBTASK 72-41-23-220-160 Examine the Rear Outer Case Surface Protection

Refer to Figure.

Repair VRS6179, TASK 72-41-23-300-002 (REPAIR-002)

More than in (1)

Scored.

Repair VRS6179, TASK 72-41-23-300-002 (REPAIR-002)

More than in (1)

Worn.

Repair VRS6179, TASK 72-41-23-300-002 (REPAIR-002)

Chipped

Repair VRS6179, TASK 72-41-23-300-002 (REPAIR-002)

More than in (1)

Scratched.

Repair VRS6179, TASK 72-41-23-300-002 (REPAIR-002)

If cracks are found

Cracked.

SUBTASK 72-41-23-220-161 Examine the Rear Outer Case Face at Location 1117

Refer to Figure.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

More than in (1)

Scored.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

More than in (1)

Galled.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

Not more than 0.002 in. (0.05 mm) in depth for an arc length of 1.968 in. (50.00 mm) in 7.874 in. (200.00 mm) circumferential length

Repair VRS6339, TASK 72-41-23-300-013 (REPAIR-013)

More than in (1)

Worn.

SUBTASK 72-41-23-220-162 Examine the Rear Outer Case Face at Location 27

Refer to Figure.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

More than in (a) with local pitting not more than 0.013 in. (0.33 mm) in depth, separated by more than 1.772 in. (45.00 mm) between damage area centres and not in the damage exclusion zone diameter 0.610 in. (15.50 mm) centred on fastener hole

Repair VRS6528, TASK 72-41-23-300-023 (REPAIR-023)

More than in (a) with general pitting not more than 0.016 in. (0.40 mm) in depth or pitting in the exclusion zone

Face 33.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

More than in (a) with local pitting not more than 0.013 in. (0.33 mm) in depth, separated by more than 1.772 in. (45.00 mm) between damage area centres and not in the damage exclusion zone diameter 0.610 in. (15.50 mm) centred on fastener hole

Repair VRS6528, TASK 72-41-23-300-023 (REPAIR-023)

More than in (a) with general pitting not more than 0.020 in. (0.50 mm) in depth or pitting in the exclusion zone

Face 34.

Pitted and surface damaged.

SUBTASK 72-41-23-220-196 Examine the Rear Outer Case Front Flange Rear Face and Rear Flange Front Face at Locations 33 and 34

Refer to Figure.

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

More than in (a) with local pitting not more than 0.012 in. (0.30 mm) in depth, separated by more than 1.772 in. (45.00 mm) between damage area centres and not in the damage exclusion zone diameter 0.630 in. (16.00 mm) centred on fastener hole

Repair VRS6528, TASK 72-41-23-300-023 (REPAIR-023)

More than in (a) with general pitting not more than 0.024 in. (0.60 mm) in depth

Face 30 (recess diameter).

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

More than in (a) with local pitting not more than 0.010 in. (0.25 mm) in depth

Repair VRS6528, TASK 72-41-23-300-023 (REPAIR-023)

More than in (a) with heavy pitting not more than 0.017 in. (0.43 mm) in depth or pitting in the exclusion zone

Face 31 (rear face).

Repair VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

More than in (a) with light pitting not more than 0.030 in. (0.75 mm) in depth

Repair VRS6528, TASK 72-41-23-300-023 (REPAIR-023)

More than in (a) with heavy pitting not more than 0.045 in. (1.15 mm) in depth

Face 32 (inner diameter).

Pitted and surface damaged.

SUBTASK 72-41-23-220-197 Examine the Rear Outer Case Front Inner Flange Recess Diameter, Rear Face and Internal Diameter at Locations 30, 31 and 32

Repair, VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

More than in step A.(1)

Nicked, dented and scratched.

SUBTASK 72-41-23-220-163 Examine the Rear Outer Case all Remaining Machined Surfaces

Repair, VRS6104, TASK 72-41-23-300-001 (REPAIR-001)

More than in step A.(1)

Nicked, dented and scratched.

SUBTASK 72-41-23-220-164 Examine the Rear Outer Case all Remaining Cast Surfaces

Repair VRS6178, TASK 72-41-23-300-003 (REPAIR-003)

Apply surface protection

Repair VRS6279, TASK 72-41-23-300-011 (REPAIR-011)

Replace shank nuts

SUBTASK 72-41-23-350-122 Replace Surface Protection and Shank Nuts

Figure: Rear Outer Case - Inspection Locations

Rear Outer Case - Inspection Locations

Figure: Rear Outer Case - Inspection Locations

Rear Outer Case - Inspection Locations

Rear Outer Case - Inspection Locations