Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-31-200-002-C00 HPC Front Cases - Examine, Inspection-002

General

This TASK gives the procedure for the inspection of the HP compressor front cases. For the other parts of the HP compressor front cases, refer to TASK 72-41-31-200-000 (INSPECTION-000).

Fig./item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig./item numbers are used. For the Service Bulletin alpha variants refer to the IPC.

The policy that is necessary for inspection is given in the SPM TASK 70-20-01-200-501.

All the parts must be cleaned before any part is examined.

All the parts must be visually examined for damage, corrosion and wear. Any defects that are not identified in the procedure must be referred to IAE.

The procedure for the parts which must have a crack test is given in Step. Do the crack test before a part is visually examined.

Do not discard any part until you are sure there are no repairs available. Refer to the instructions in repair before a discarded part is used again or oversize parts are installed.

Parts which should be discarded can be held although no repair is available. The repair of a discarded part can be shown to be necessary at a subsequent date.

All the parts must be examined to make sure that all the repairs have been completed satisfactorily.

The practices and processes referred to in the procedure by the TASK/SUBTASK number are in SPM.

References

Refer to SPM for data on these items:

Definition of Damage, SPM TASK 70-02-02-350-501,

Inspection of Parts, SPM TASK 70-20-01-200-501.

Some data on these items is contained in this TASK. For more data on these items refer to the SPM.

Methods of Testing for Crack Indications,

Chemical Processes,

Surface Protection.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Clean the parts. Refer to TASK 72-41-31-100-000 (CLEANING-000).

SUBTASK 72-41-31-230-083 Examine the HP Compressor Front Cases for Cracks

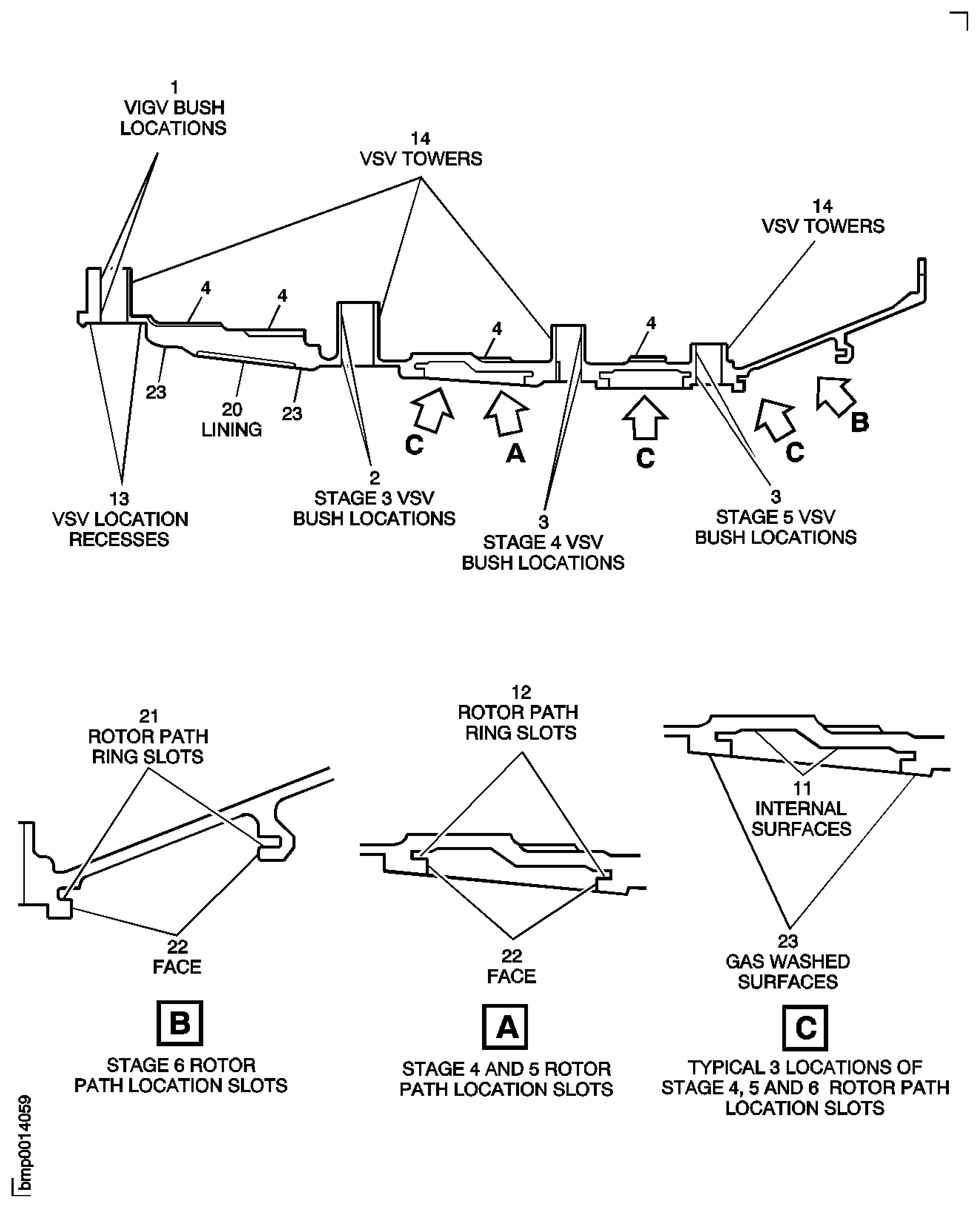

Refer to Figure.

Repair, VRS6634 TASK 72-41-31-300-028 (REPAIR-028)

In the limits given in Repair, VRS6634 TASK 72-41-31-300-028 (REPAIR-028)

Repair, VRS6105 TASK 72-41-31-300-001 (REPAIR-001).

NOTE

The circumferential length of damage repairable using VRS6105 at the stage 6 rotor path groove bottom (location 21) is a cumulative limit for each half case.

In the limits given in Repair, VRS6105 TASK 72-41-31-300-001 (REPAIR-001).

Scored/Scratched/Fretted.

Repair, VRS6661 TASK 72-41-31-300-029 (Repair-029).

In the limits given in Repair VRS6661.

More than in Step.

Cracked.

SUBTASK 72-41-31-220-250 Examine the Stage 6 HP Compressor Front Cases Rotor Path Ring Slots at Location 21

Refer to Figure.

Repair, VRS6105 TASK 72-41-31-300-001 (REPAIR-001)

Scored or with burred edges

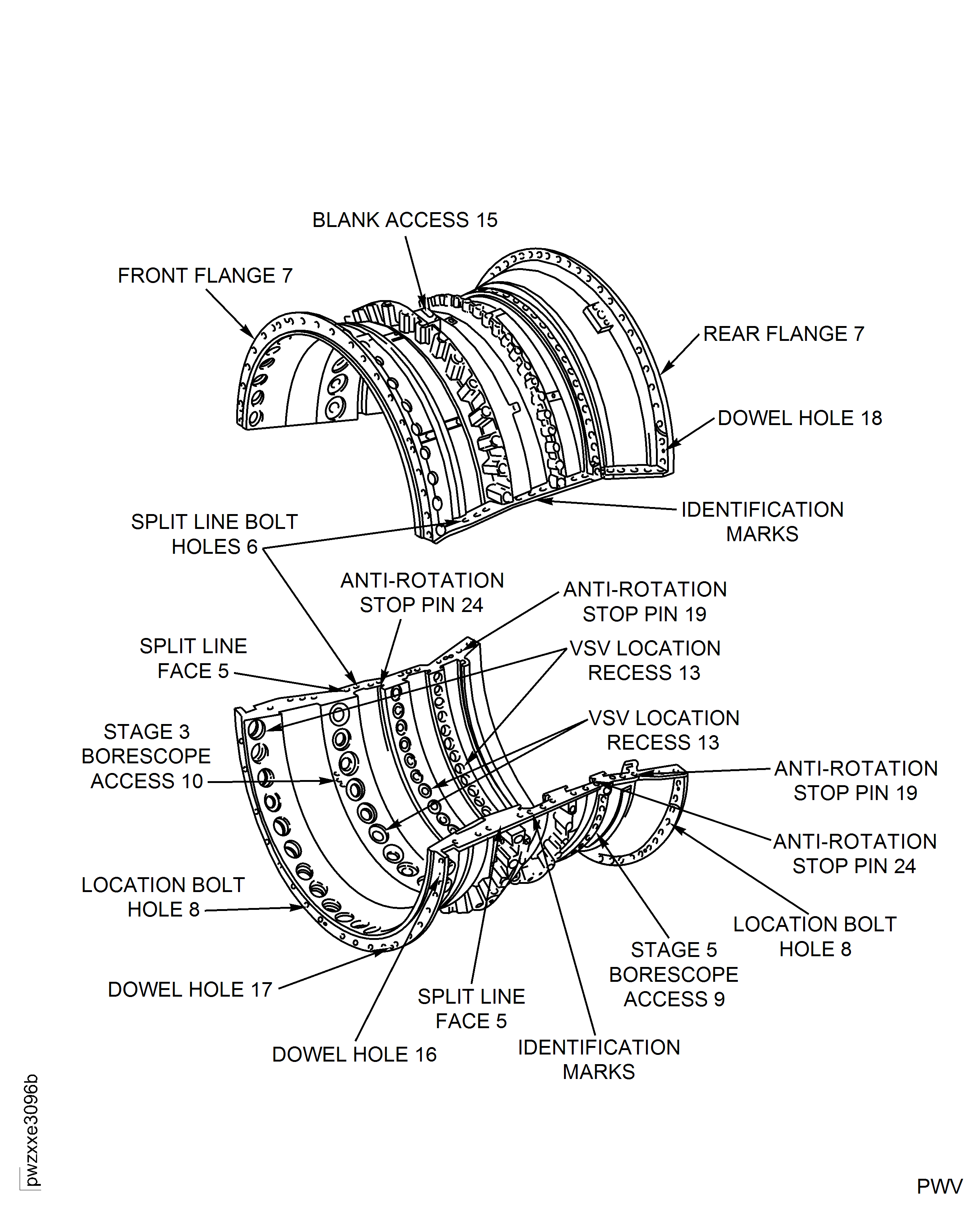

SUBTASK 72-41-31-220-181 Examine the HP Compressor Front Cases Split Line Bolt Holes at Location 6

Refer to Figure.

Repair, VRS6105 TASK 72-41-31-300-001 (REPAIR-001)

More than Step.

Scored/Scratched/Galled.

SUBTASK 72-41-31-220-182 Examine the HP Compressor Front Cases Front and Rear Flanges at Location 7

Refer to Figure.

Repair, VRS6105 TASK 72-41-31-300-001 (REPAIR-001)

Scored or with burred edges

SUBTASK 72-41-31-220-183 Examine the HP Compressor Front Cases Location Bolt Holes at Location 8

Refer to Figure.

Repair, VRS6105 TASK 72-41-31-300-001 (REPAIR-001)

More than Step in bore.

Repair, VRS6511 TASK 72-41-31-300-022 (REPAIR-022)

More than Step around inner surface edge.

Scored/Scratched.

SUBTASK 72-41-31-220-184 Examine the HP Compressor Front Cases Blank Access, Stage 3 and 5 Borescope Access at Locations 9, 10 and 15

Refer to Figure.

SUBTASK 72-41-31-220-185 Examine the Stage 4 and 5 HP Compressor Front Cases Rotor Path Ring Slots at Location 12

Refer to Figure.

Repair, VRS6517 TASK 72-41-31-300-030 (REPAIR-030).

Not more than 0.040 in. (1.02 mm) in depth over a localised arc of not more than 0.650 in. (16.51 mm) at no more than 3 locations in each half casing

Repair, VRS6661 TASK 72-41-31-300-029 (REPAIR-029)

Not more than 0.080 in. (2.03 mm) in depth over a localised arc of not more than 0.650 in. (16.51 mm) at no more than 3 locations in each half casing

Repair, VRS6634 TASK 72-41-31-300-028 (REPAIR-028).

For 6th stage only: Within the limits given in Repair, VRS6634 TASK 72-41-31-300-028 (REPAIR-028).

Scored, Scratched and frettage.

SUBTASK 72-41-31-220-239 Examine the HP Compressor Front Cases Rotor Path Ring Slot Faces at Location 22

Repair, VRS6511 TASK 72-41-31-300-022 (REPAIR-022)

Not more than 0.078 in. (1.98 mm) in depth radially from the bore

More than Step.

VIGV and stages 3, 4 and 5 VSV location recess and adjacent wall area - Scored/Nicked/Worn.

SUBTASK 72-41-31-220-186 Examine the HP Compressor Front Cases VSV Location Recesses at the VIGV and Stages 3, 4 and 5 at Location 13

Repair, VRS6345 TASK 72-41-31-300-011 (REPAIR-011)

Broken, loose, worn, crossed or stripped thread

Examine the screw thread inserts at the support tool blank, stage 6 off- takes and the stage 3 and 5 borescope blank mounts.

Repair, VRS6345 TASK 72-41-31-300-011 (REPAIR-011)

Broken, loose, worn, crossed or slipped thread

Examine the remaining screw thread inserts.

SUBTASK 72-41-31-220-187 Examine the HP Compressor Front Cases Screw Thread Inserts

Refer to Figure.

Repair, VRS6105 TASK 72-41-31-300-001 (REPAIR-001)

Nicked/Dented/Scored

SUBTASK 72-41-31-220-188 Examine the HP Compressor Front Cases VSV Towers at Location 14

Refer to Figure.

Repair, VRS6105 TASK 72-41-31-300-001 (REPAIR-001)

More than Step.

Scored/Scratched

SUBTASK 72-41-31-220-189 Examine the HP Compressor Front Cases Surface Finish at Location 4

Repair, VRS6321 TASK 72-41-31-300-012 (REPAIR-012)

Loose or with burred edges

Repair, VRS6321 TASK 72-41-31-300-012 (REPAIR-012).

Less than 0.2367 in. (6.01 mm).

Worn.

Active clearance control actuator location dowels.

Repair, VRS6321 TASK 72-41-31-300-012 (REPAIR-012)

Loose or with burred edges

Crankshaft location dowels.

Repair, VRS6321 TASK 72-41-31-300-012 (REPAIR-012)

Less than in 0.2367 in. (6.012 mm)

Worn.

Larger dowels.

Repair, VRS6321 TASK 72-41-31-300-012 (REPAIR-012)

Less than 0.1973 in. (5.011 mm)

Worn.

Small dowels.

SUBTASK 72-41-31-220-190 Examine the HP Compressor Front Cases Dowels

Refer to Figure.

Repair, VRS6105 TASK 72-41-31-300-001 (REPAIR-001).

Burred edges.

Blend smooth to remove damage by Repair, VRS6105 TASK 72-41-31-300-001 (REPAIR-001).

Not more than 0.375 in. (9.53 mm) in circumferential length, 0.055 in. (1.40 mm) in axial width, and 0.032 in. (0.81 mm) in radial depth.

Location 16.

Remove raised material and burrs only by Repair, VRS6105 TASK 72-41-31-300-001 (REPAIR-001).

Not more than 0.225 in. (5.72 mm) in circumferential length, 0.055 in. (1.40 mm) in axial width, and 0.032 in. (0.81 mm) in radial depth.

Location 17.

Blend smooth to remove damage by Repair, VRS6105 TASK 72-41-31-300-001 (REPAIR-001).

Not more than 0.370 in. (9.40 mm) in circumferential length, 0.135 in. (3.43 mm) in axial width, and 0.032 in. (0.81 mm) in radial depth.

Location 18.

Repair, VRS9343 TASK 72-41-31-300-017 (REPAIR-017).

More than Step.

Scored/nicked/dented/gouged in the dowel pin holes and/or on hole edges extending onto the flange face.

Repair, VRS9343 TASK 72-41-31-300-017 (REPAIR-017).

More than 0.237 in. (6.02 mm)

Location 18.

Worn.

SUBTASK 72-41-31-220-191 Examine the HP Compressor Front Cases Dowel Holes at Locations 16, 17 and 18

Refer to Figure.

Repair, VRS6105 TASK 72-41-31-300-001 (REPAIR-001)

More than in Step

Scored/Scratched/Worn at location 11.

Repair, VRS6105 TASK 72-41-31-300-001 (REPAIR-001)

Not more than 0.005 in. (0.13 mm) in depth

Repair, VRS6511 TASK 72-41-31-300-022 (REPAIR-022)

Not more than 0.050 in. (1.27 mm)

More than Step.

Scored/Scratched/Nicked/Worn at location 23.

SUBTASK 72-41-31-220-192 Examine the HP Compressor Front Cases Gas Washed Surfaces at Location 23 and Internal Surfaces at Location 11

Refer to Figure.

Repair, VRS6500 TASK 72-41-31-300-020 (REPAIR-020)

More than 11.150 in. (283.21 mm)

Rotor path ring lining radius. Use the data written as a note in TASK 72-41-00-040-001. (DISASSEMBLY, CONFIG-001).

Repair, VRS6500 TASK 72-41-31-300-020 (REPAIR-020).

Gouged

Repair, VRS6500 TASK 72-41-31-300-020 (REPAIR-020).

More than Step.

Chipped

Repair, VRS6500 TASK 72-41-31-300-020 (REPAIR-020).

More than Step.

Scored.

SUBTASK 72-41-31-220-193 Examine the Stage 3 Rotor Path Lining at Location 20

Refer to Figure.

Repair, VRS6624 TASK 72-41-31-300-026 (REPAIR-026).

Damaged

SUBTASK 72-41-31-220-194 Examine the HP Compressor Front Cases Stage 6 and Stage 4 Segment Anti-Rotation Stop Pins at Location 19 and Location 24

Refer to Figure.

Repair, VRS6501 TASK 72-41-31-300-021 (REPAIR-021).

Apply dry film lubricant.

SUBTASK 72-41-31-380-054 Reprotect the HP Compressor Front Cases at Location 4

Figure: HP Compressor Front Cases - Inspection Locations

Sheet 1

Figure: HP Compressor Front Cases - Inspection Locations

Sheet 2