Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 71-00-02-400-002-A00 (A1-PPBU) - Install The EBU Fan Case Brackets, Installation-002

General

Fig/item numbers in parentheses in the procedure agree with those used in the EIPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the EIPC.

For all parts identified in a different ATA Chapter/Section/Subject, the applicable ATA Chapter/Section/Subject comes before the Fig/item number.

Lubricate all the bolt shanks given in this procedure with CoMat 10-073 SYNTHETIC GREASE, MoDISULFIDE. Lubricate all the bolt holes with CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE), unless other lubricants are referred to in the procedure.

Refer to TASK 72-00-32-420-001 for the position on a raft or bracket of a particular clip position.

For lockwire data and procedures refer to SPM TASK 70-42-05-400-501.

SBE 70-0813: Announcement of introduction of safety cables as a preferred method to lockwire.

For safety cable data and procedures refer to SPM TASK 70-42-08-400-501.

Safety the threaded fasteners in the ATA Chapter/Section/Subject 71-51-41 as applicable with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT.

To identify, lubricate and install seal rings, refer to SPM TASK 70-44-00-400-501.

For the torque tightening procedures, refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

To install key washer (tab type) refer to SPM TASK 70-42-03-400-501.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. Refer to SPM TASK 70-38-21-380-501.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| ACR Torq-Set bit 212-10-ACR | LOCAL | Torq Set | ||

| ACR Torq-Set bit 212-1/4-ACR | LOCAL | Torq-Set |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-003 SOLVENT, DELETED | LOCAL | CoMat 01-003 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 02-274 SAFETY CABLE KIT | LOCAL | CoMat 02-274 | ||

| CoMat 02-275 SAFETY CABLE KIT | LOCAL | CoMat 02-275 | ||

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 10-058 PENETRATING OIL | 0AM53 | CoMat 10-058 | ||

| CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) | K6835 | CoMat 10-072 | ||

| CoMat 10-073 SYNTHETIC GREASE, MoDISULFIDE | 0AM53 | CoMat 10-073 | ||

| CoMat 01-076 METHYL ETHYL KETONE | LOCAL | CoMat 01-076 |

Spares

NONESafety Requirements

NONEProcedure

WARNING

WEAR APPLICABLE PERSONAL PROTECTIVE EQUIPMENT (PPE) WHEN YOU DO THIS TASK. BEFORE YOU USE PPE, READ , UNDERSTAND AND OBEY ALL INSTRUCTIONS FOR ITS USE. THESE INSTRUCTIONS INCLUDE INSTRUCTIONS FROM THE MANUFACTURER, YOUR EMPLOYER AND GOVERNMENT REGULATIONS. YOU CAN GET INJURED IF YOU DO NOT USE PPE. GET INSTRUCTIONS FROM YOUR EMPLOYER ON WHICH PPE IS NECESSARY.

WARNING

BEFORE YOU USE CHEMICALS, READ, UNDERSTAND, AND OBEY ALL SAFETY INSTRUCTIONS FOR THE CHEMICALS. THESE INSTRUCTIONS INCLUDE INSTRUCTIONS FROM THE MANUFACTURER, THE MATERIAL SAFETY DATA SHEET (MSDS), AND GOVERNMENT REGULATIONS. CHEMICALS MAY CAUSE INJURY TO YOU OR MAKE YOU SICK WHEN SAFETY INSTRUCTIONS ARE NOT OBEYED. AN MSDS GIVES INSTRUCTIONS ON HOW YOU MUST SAFELY USE, KEEP, AND DISCARD CHEMICALS. GET INSTRUCTIONS FROM YOUR EMPLOYER ON HOW YOU MUST SAFELY USE, KEEP, AND DISCARD CHEMICALS.NOTE

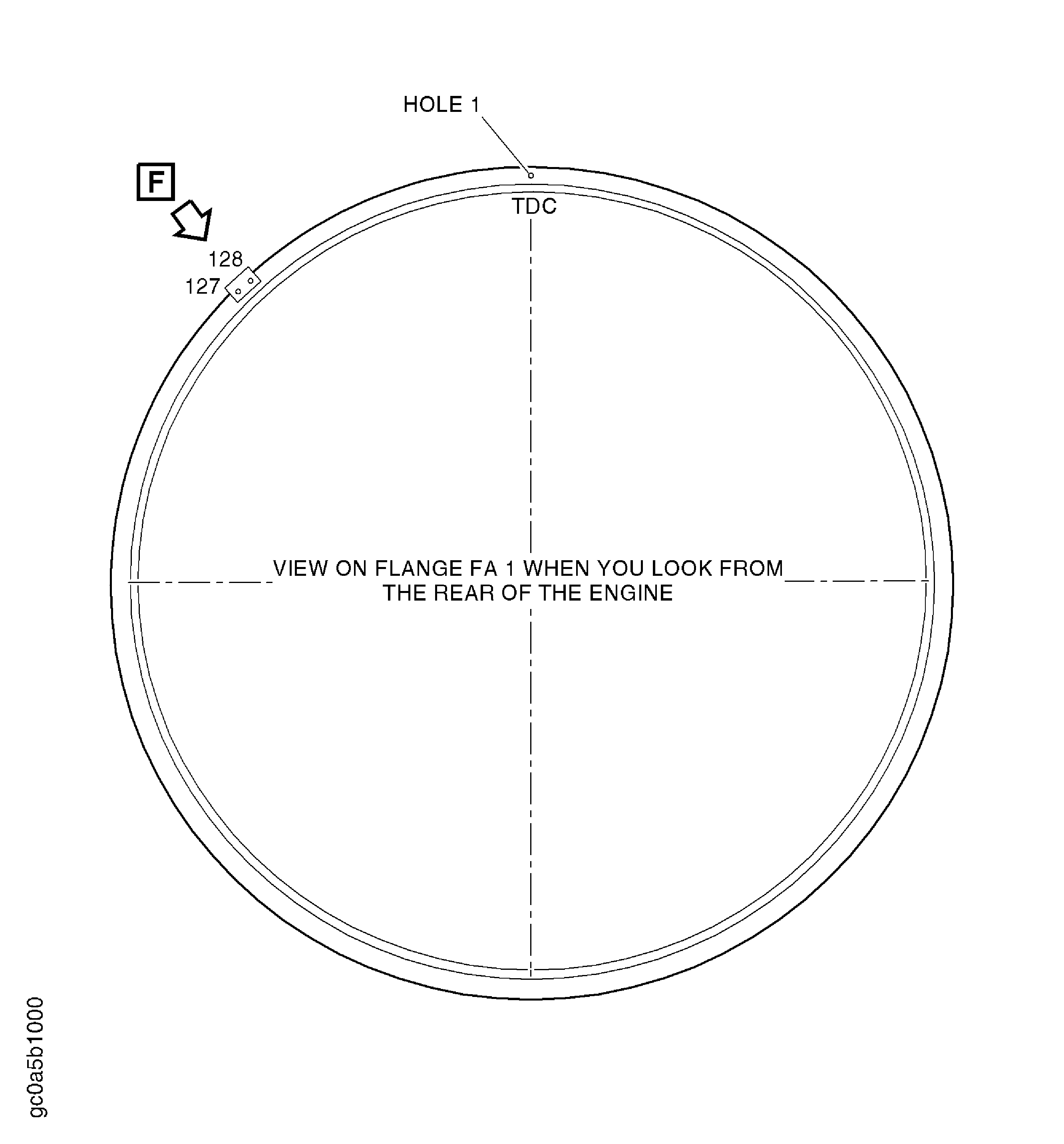

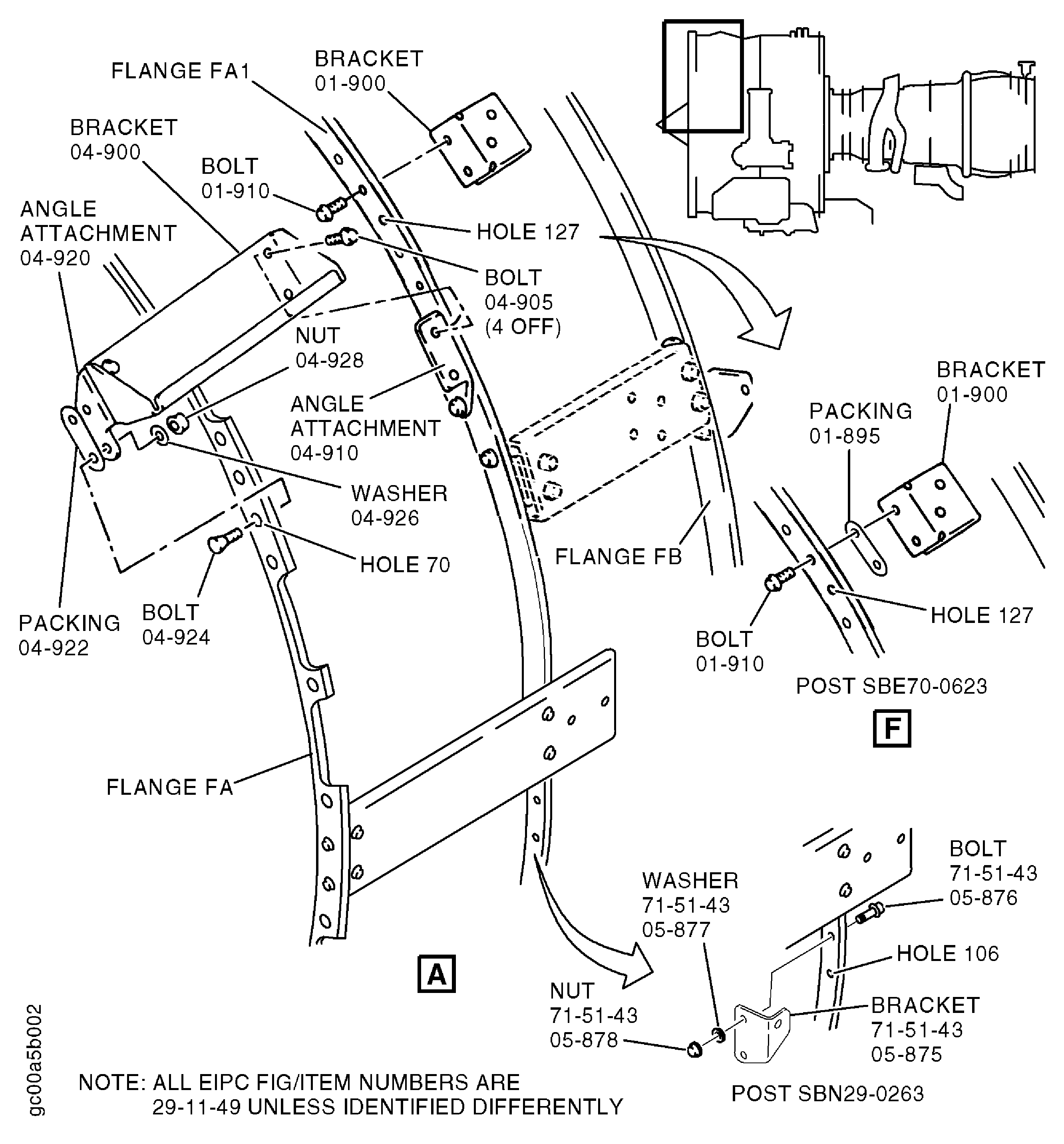

Clean the mating surfaces of the brackets, packing piece and flange with an application of CoMat 01-003 SOLVENT, DELETED with a CoMat 02-099 LINT-FREE CLOTH. Clean an area on the flange that is 1 1/2 times larger than the mating surface of the bracket.Put the bracket HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-900) in position at the holes 127 and 128 on the aft side of flange FA1. Point the bracket HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-900) angle in the aft direction. Attach with two bolts HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-910). Torque the bolts to 75 to 90 lbf.in (8 to 10 Nm).

NOTE

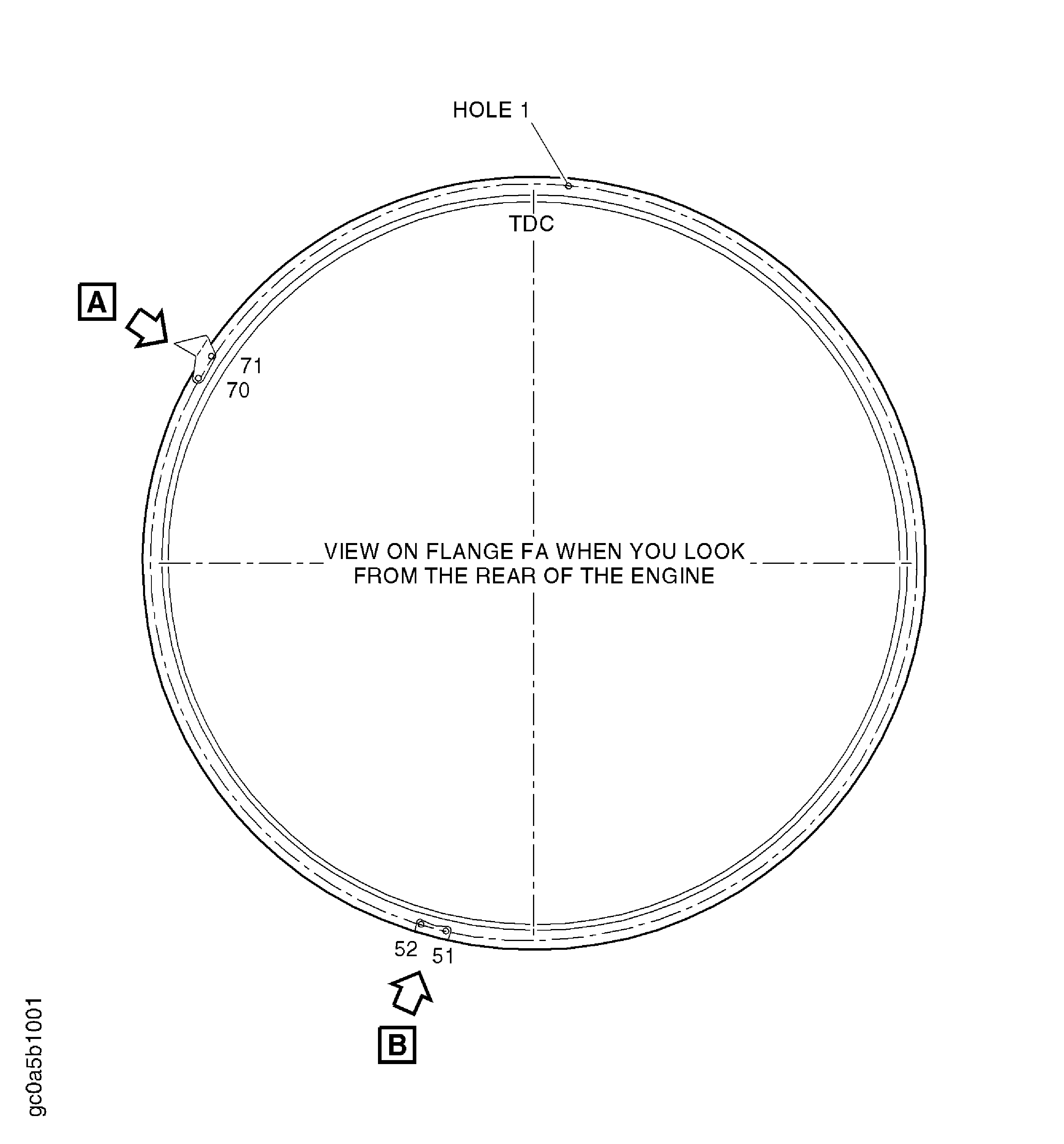

There are two types of nuts for HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-928) bihexagon and hexagon. The hexagon nut has a dry film lubricant, it is not necessary to lubricate their bolts.Put the attachment angle HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-920) and the packing HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-922) in position at the holes 70 and 71 on the aft side of flange FA. Point the attachment angle HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-920) in the aft direction. Attach with two bolts HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-924), two washers HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-926) and two nuts HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-928). Torque the bolts to 60 to 70 lbf.in (7 to 8 Nm).

Install the mounting bracket HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-900) with four bolts HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-905) on the angle attachments HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-920) and HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-910) at holes 70 and 71 on flange FA and at holes 123 and 124 on the forward side of flange FA1. Torque the nuts to 75 to 90 lbf.in (8 to 10 Nm).

SUBTASK 71-00-02-420-067-A00 Install the Upper Fan Case Brackets, Left Side (Pre SBN 29-0263 and Pre SBE 70-0623)

WARNING

WEAR APPLICABLE PERSONAL PROTECTIVE EQUIPMENT (PPE) WHEN YOU DO THIS TASK. BEFORE YOU USE PPE, READ , UNDERSTAND AND OBEY ALL INSTRUCTIONS FOR ITS USE. THESE INSTRUCTIONS INCLUDE INSTRUCTIONS FROM THE MANUFACTURER, YOUR EMPLOYER AND GOVERNMENT REGULATIONS. YOU CAN GET INJURED IF YOU DO NOT USE PPE. GET INSTRUCTIONS FROM YOUR EMPLOYER ON WHICH PPE IS NECESSARY.

WARNING

BEFORE YOU USE CHEMICALS, READ, UNDERSTAND, AND OBEY ALL SAFETY INSTRUCTIONS FOR THE CHEMICALS. THESE INSTRUCTIONS INCLUDE INSTRUCTIONS FROM THE MANUFACTURER, THE MATERIAL SAFETY DATA SHEET (MSDS), AND GOVERNMENT REGULATIONS. CHEMICALS MAY CAUSE INJURY TO YOU OR MAKE YOU SICK WHEN SAFETY INSTRUCTIONS ARE NOT OBEYED. AN MSDS GIVES INSTRUCTIONS ON HOW YOU MUST SAFELY USE, KEEP, AND DISCARD CHEMICALS. GET INSTRUCTIONS FROM YOUR EMPLOYER ON HOW YOU MUST SAFELY USE, KEEP, AND DISCARD CHEMICALS.NOTE

Clean the mating surfaces of the brackets, packing piece and flange with an application of CoMat 01-003 SOLVENT, DELETED with a CoMat 02-099 LINT-FREE CLOTH. Clean an area on the flange that is 1 1/2 times larger than the mating surface of the bracket.Put the packing HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-895) and the bracket HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-900) in position at the holes 127 and 128 on the aft side of flange FA1. Point the bracket HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-900) angle in the aft direction. Attach with two bolts HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-910). Torque the bolts to 75 to 90 lbf.in (8 to 10 Nm).

NOTE

There are two types of nuts for HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-928) bihexagon and hexagon. The hexagon nut has a dry film lubricant, it is not necessary to lubricate their bolts.Put the attachment angle HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-920) and the packing HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-922) in position at the holes 70 and 71 on the aft side of flange FA. Point the attachment angle HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-920) in the aft direction. Attach with two bolts HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-924), two washers HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-926) and two nuts HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-928). Torque the bolts to 60 to 70 lbf.in (7 to 8 Nm).

Install the mounting bracket HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-900) with four bolts HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-905) on the angle attachments HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-920) and HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-910) at holes 70 and 71 on flange FA and at holes 123 and 124 on the forward side of flange FA1. Torque the nuts to 75 to 90 lbf.in (8 to 10 Nm).

Put the bracket ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-875) in position at the holes 106 and 107 on the forward side of flange FA1. Point the angle in the aft direction. Attach with two bolts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-876), two washers ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-877) and two nuts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-878). Torque the nuts to 75 to 90 lbf.in (8 to 10 Nm).

SUBTASK 71-00-02-420-067-B00 Install the Upper Fan Case Brackets, Left Side (SBN 29-0263 and SBE 70-0623)

WARNING

WEAR APPLICABLE PERSONAL PROTECTIVE EQUIPMENT (PPE) WHEN YOU DO THIS TASK. BEFORE YOU USE PPE, READ , UNDERSTAND AND OBEY ALL INSTRUCTIONS FOR ITS USE. THESE INSTRUCTIONS INCLUDE INSTRUCTIONS FROM THE MANUFACTURER, YOUR EMPLOYER AND GOVERNMENT REGULATIONS. YOU CAN GET INJURED IF YOU DO NOT USE PPE. GET INSTRUCTIONS FROM YOUR EMPLOYER ON WHICH PPE IS NECESSARY.

WARNING

BEFORE YOU USE CHEMICALS, READ, UNDERSTAND, AND OBEY ALL SAFETY INSTRUCTIONS FOR THE CHEMICALS. THESE INSTRUCTIONS INCLUDE INSTRUCTIONS FROM THE MANUFACTURER, THE MATERIAL SAFETY DATA SHEET (MSDS), AND GOVERNMENT REGULATIONS. CHEMICALS MAY CAUSE INJURY TO YOU OR MAKE YOU SICK WHEN SAFETY INSTRUCTIONS ARE NOT OBEYED. AN MSDS GIVES INSTRUCTIONS ON HOW YOU MUST SAFELY USE, KEEP, AND DISCARD CHEMICALS. GET INSTRUCTIONS FROM YOUR EMPLOYER ON HOW YOU MUST SAFELY USE, KEEP, AND DISCARD CHEMICALS.NOTE

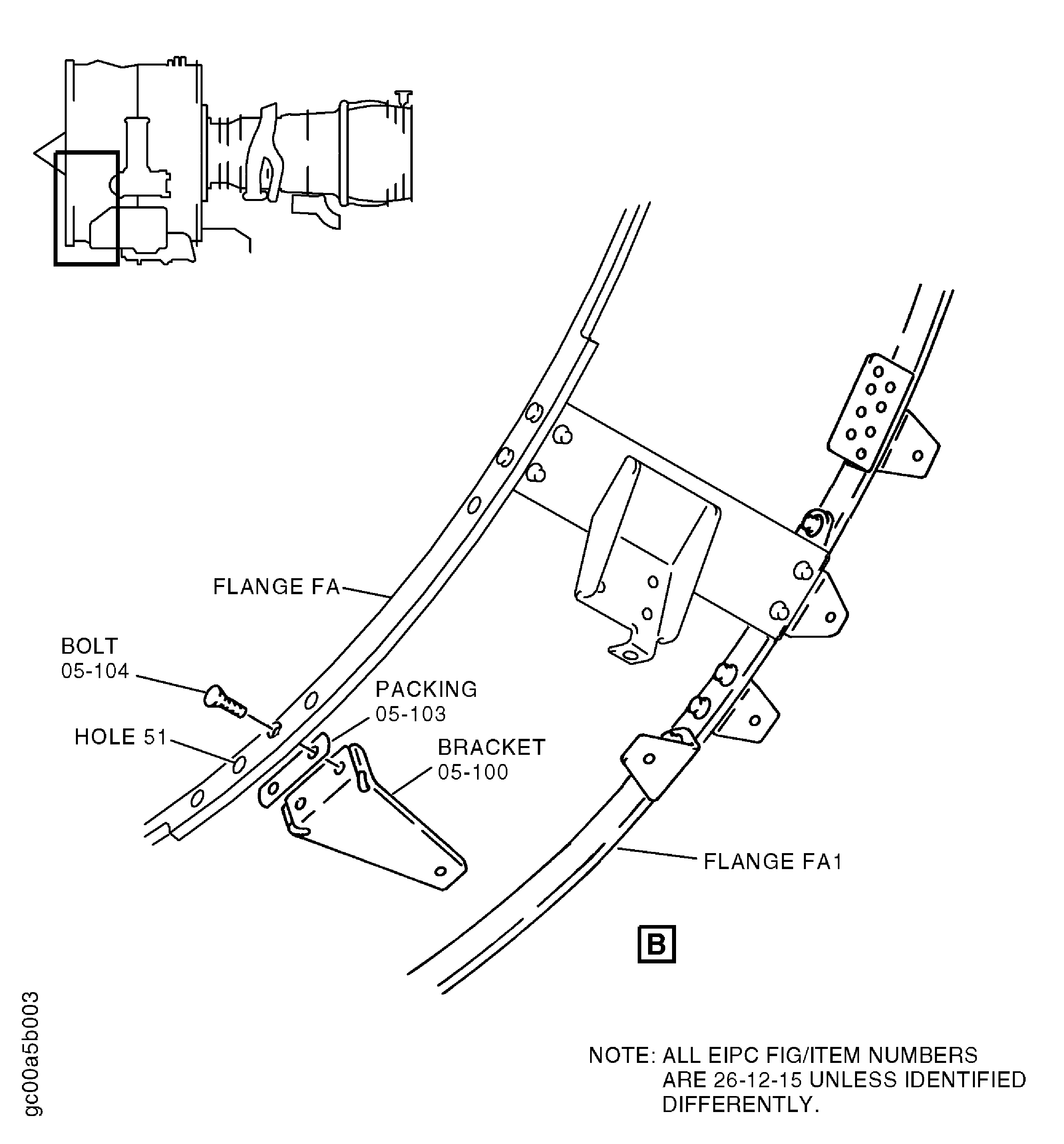

Clean the mating surfaces of the brackets, packing piece and flange with an application of CoMat 01-003 SOLVENT, DELETED with a CoMat 02-099 LINT-FREE CLOTH. Clean an area on the flange that is 1 1/2 times larger than the mating surface of the bracket.Put the packing ACCESSORY ZONE FIRE DETECTOR-RIGHT (26-12-15, 05-103) and the bracket ACCESSORY ZONE FIRE DETECTOR-RIGHT (26-12-15, 05-100) in position at holes 51 and 52 on the aft side of flange FA. Point the bracket ACCESSORY ZONE FIRE DETECTOR-RIGHT (26-12-15, 05-100) angle on the aft direction. Attach with two bolts ACCESSORY ZONE FIRE DETECTOR-RIGHT (26-12-15, 05-104). Torque the bolts to 75 to 90 lbf.in (8 to 10 Nm).

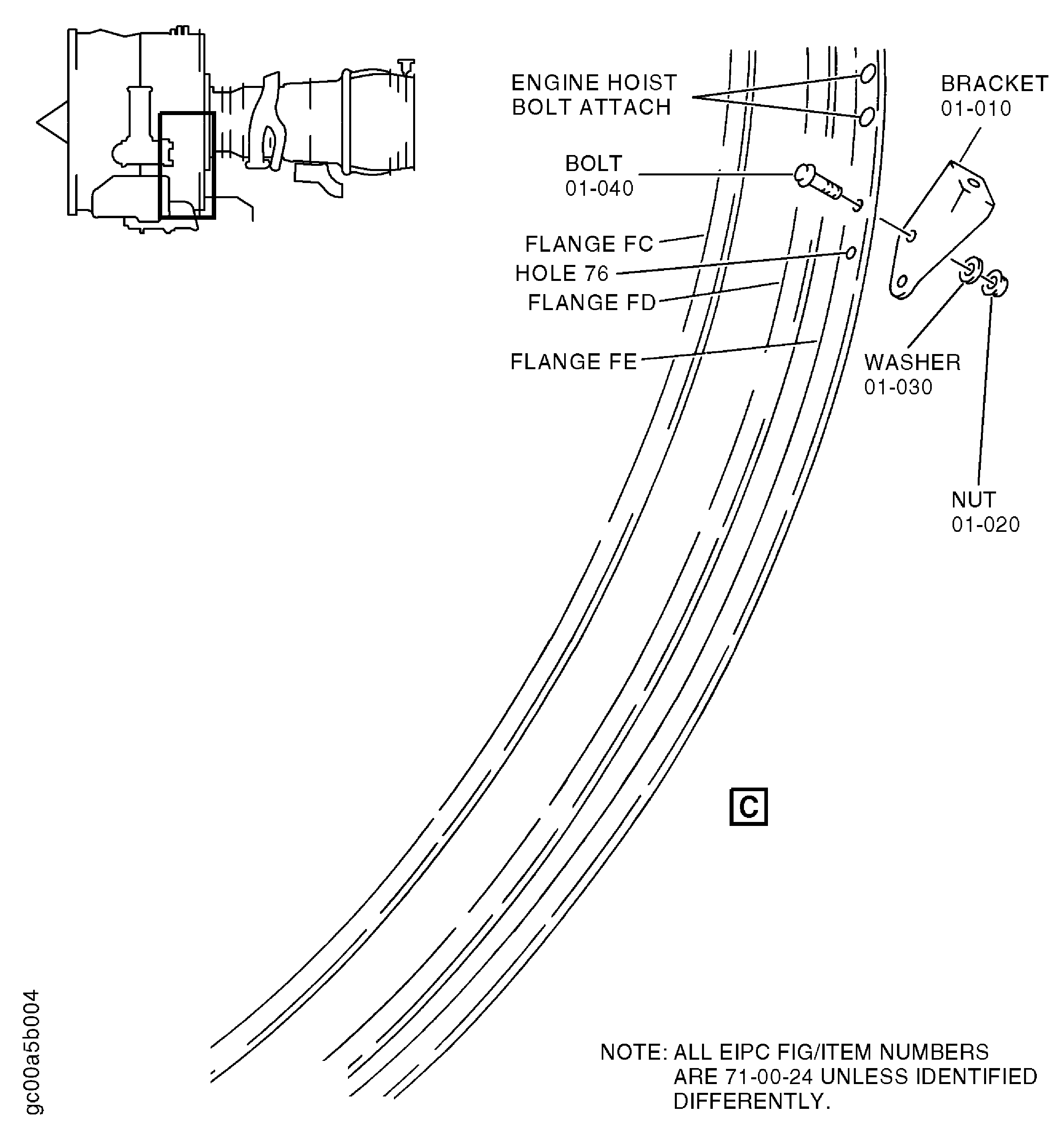

Lubricate the holes 76 and 77 with CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE).

Put the bracket POWER PLANT-F/C ROD SUPPORT BKTS (71-00-24, 01-010) in position at holes 76 and 77 on the aft side of flange FE. Point the bracket POWER PLANT-F/C ROD SUPPORT BKTS (71-00-24, 01-010) angle on the aft direction. Attach with two bolts POWER PLANT-F/C ROD SUPPORT BKTS (71-00-24, 01-040), two washers POWER PLANT-F/C ROD SUPPORT BKTS (71-00-24, 01-030) and two nuts POWER PLANT-F/C ROD SUPPORT BKTS (71-00-24, 01-020). Torque the bolts to 75 to 90 lbf.in (8 to 10 Nm).

SUBTASK 71-00-02-420-068 Install the Lower Fan Case Brackets, Left Side

WARNING

WEAR APPLICABLE PERSONAL PROTECTIVE EQUIPMENT (PPE) WHEN YOU DO THIS TASK. BEFORE YOU USE PPE, READ, UNDERSTAND AND OBEY ALL INSTRUCTIONS FOR ITS USE. THESE INSTRUCTIONS INCLUDE INSTRUCTIONS FROM THE MANUFACTURER, YOUR EMPLOYER AND GOVERNMENT REGULATIONS. YOU CAN GET INJURED IF YOU DO NOT USE PPE. GET INSTRUCTIONS FROM YOUR EMPLOYER ON WHICH PPE IS NECESSARY.

WARNING

BEFORE YOU USE CHEMICALS, READ, UNDERSTAND, AND OBEY ALL SAFETY INSTRUCTIONS FOR THE CHEMICALS. THESE INSTRUCTIONS INCLUDE INSTRUCTIONS FROM THE MANUFACTURER, THE MATERIAL SAFETY DATA SHEET (MSDS), AND GOVERNMENT REGULATIONS. CHEMICALS MAY CAUSE INJURY TO YOU OR MAKE YOU SICK WHEN SAFETY INSTRUCTIONS ARE NOT OBEYED. AN MSDS GIVES INSTRUCTIONS ON HOW YOU MUST SAFELY USE, KEEP, AND DISCARD CHEMICALS. GET INSTRUCTIONS FROM YOUR EMPLOYER ON HOW YOU MUST SAFELY USE, KEEP, AND DISCARD CHEMICALS.NOTE

Clean the mating surfaces of the brackets, packing piece and flange with an application of CoMat 01-003 SOLVENT, DELETED with a CoMat 02-099 LINT-FREE CLOTH. Clean an area on the flange that is 1 1/2 times larger than the mating surface of the bracket.Apply a thin layer of compound to the existing IAE fasteners. Refer to TASK 72-00-32-420-001-A00, SUBTASK 72-00-32-420-127.

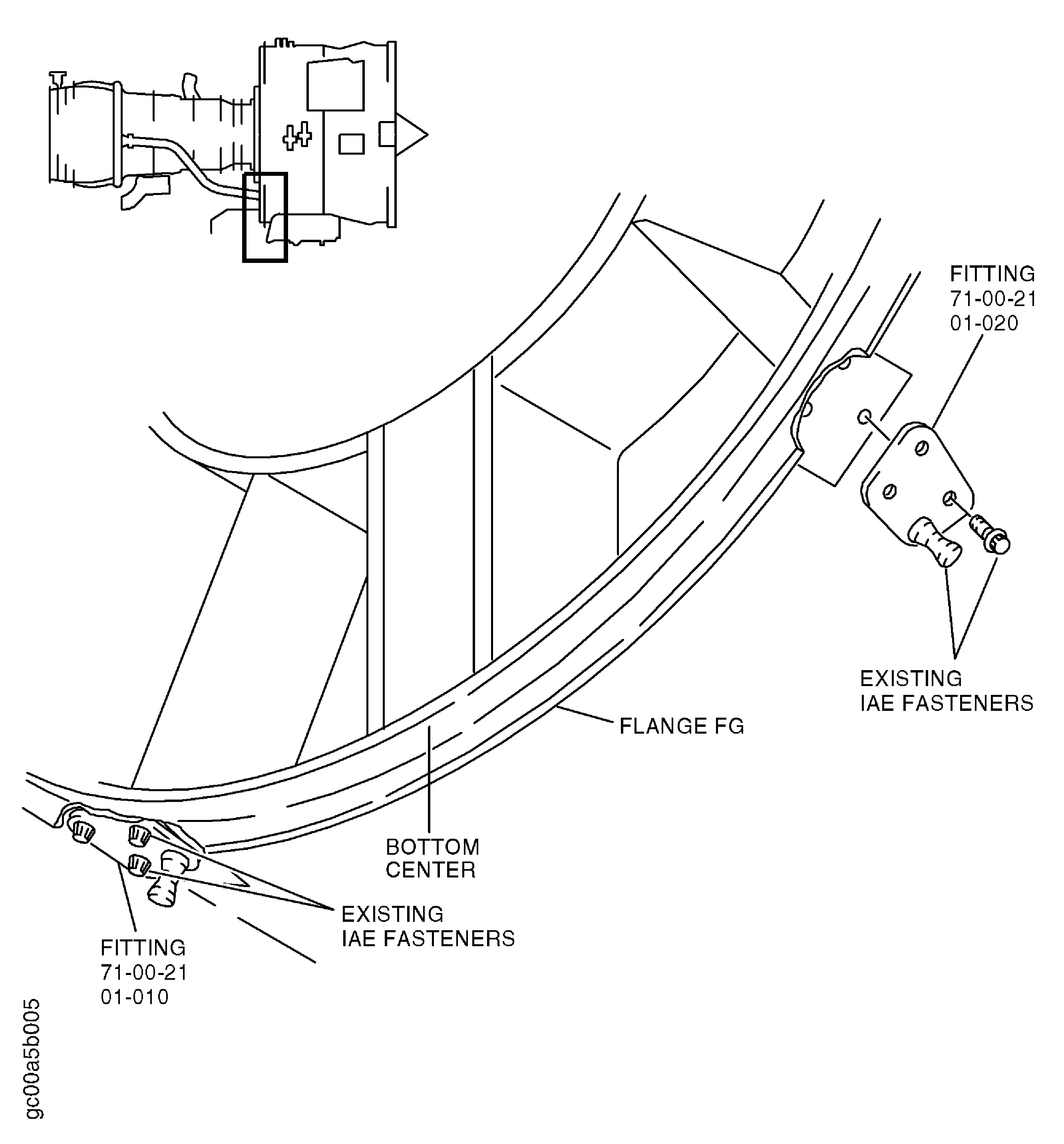

Install the right side bracket THRUST REVERSER HOLD OPEN ROD SUPPORT BRACKET (71-00-21, 01-020) on the LP compressor/intermediate case at 216 degree position on the forward side of the flange FG. Point the bracket THRUST REVERSER HOLD OPEN ROD SUPPORT BRACKET (71-00-21, 01-020) angle forward. Attach with the existing IAE fasteners. Do these while the bolts are wet with the compound. Torque the existing parts to a standard torque. Refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

Install the left side bracket THRUST REVERSER HOLD OPEN ROD SUPPORT BRACKET (71-00-21, 01-010) on the LP compressor/intermediate case at 216 degrees position on the forward side of the flange FG. Point the bracket THRUST REVERSER HOLD OPEN ROD SUPPORT BRACKET (71-00-21, 01-010) angle forward. Attach with the existing IAE fasteners. Do this while the bolts are wet with the compound. Torque the existing parts to a standard torque. Refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

SUBTASK 71-00-02-420-069 Install the Lower Fan Case Brackets, Aft

WARNING

WEAR APPLICABLE PERSONAL PROTECTIVE EQUIPMENT (PPE) WHEN YOU DO THIS TASK. BEFORE YOU USE PPE, READ , UNDERSTAND AND OBEY ALL INSTRUCTIONS FOR ITS USE. THESE INSTRUCTIONS INCLUDE INSTRUCTIONS FROM THE MANUFACTURER, YOUR EMPLOYER AND GOVERNMENT REGULATIONS. YOU CAN GET INJURED IF YOU DO NOT USE PPE. GET INSTRUCTIONS FROM YOUR EMPLOYER ON WHICH PPE IS NECESSARY.

WARNING

BEFORE YOU USE CHEMICALS, READ, UNDERSTAND, AND OBEY ALL SAFETY INSTRUCTIONS FOR THE CHEMICALS. THESE INSTRUCTIONS INCLUDE INSTRUCTIONS FROM THE MANUFACTURER, THE MATERIAL SAFETY DATA SHEET (MSDS), AND GOVERNMENT REGULATIONS. CHEMICALS MAY CAUSE INJURY TO YOU OR MAKE YOU SICK WHEN SAFETY INSTRUCTIONS ARE NOT OBEYED. AN MSDS GIVES INSTRUCTIONS ON HOW YOU MUST SAFELY USE, KEEP, AND DISCARD CHEMICALS. GET INSTRUCTIONS FROM YOUR EMPLOYER ON HOW YOU MUST SAFELY USE, KEEP, AND DISCARD CHEMICALS.NOTE

Clean the mating surfaces of the brackets, packing piece and flange with an application of CoMat 01-003 SOLVENT, DELETED with a CoMat 02-099 LINT-FREE CLOTH. Clean an area on the flange that is 1 1/2 times larger than the mating surface of the bracket.NOTE

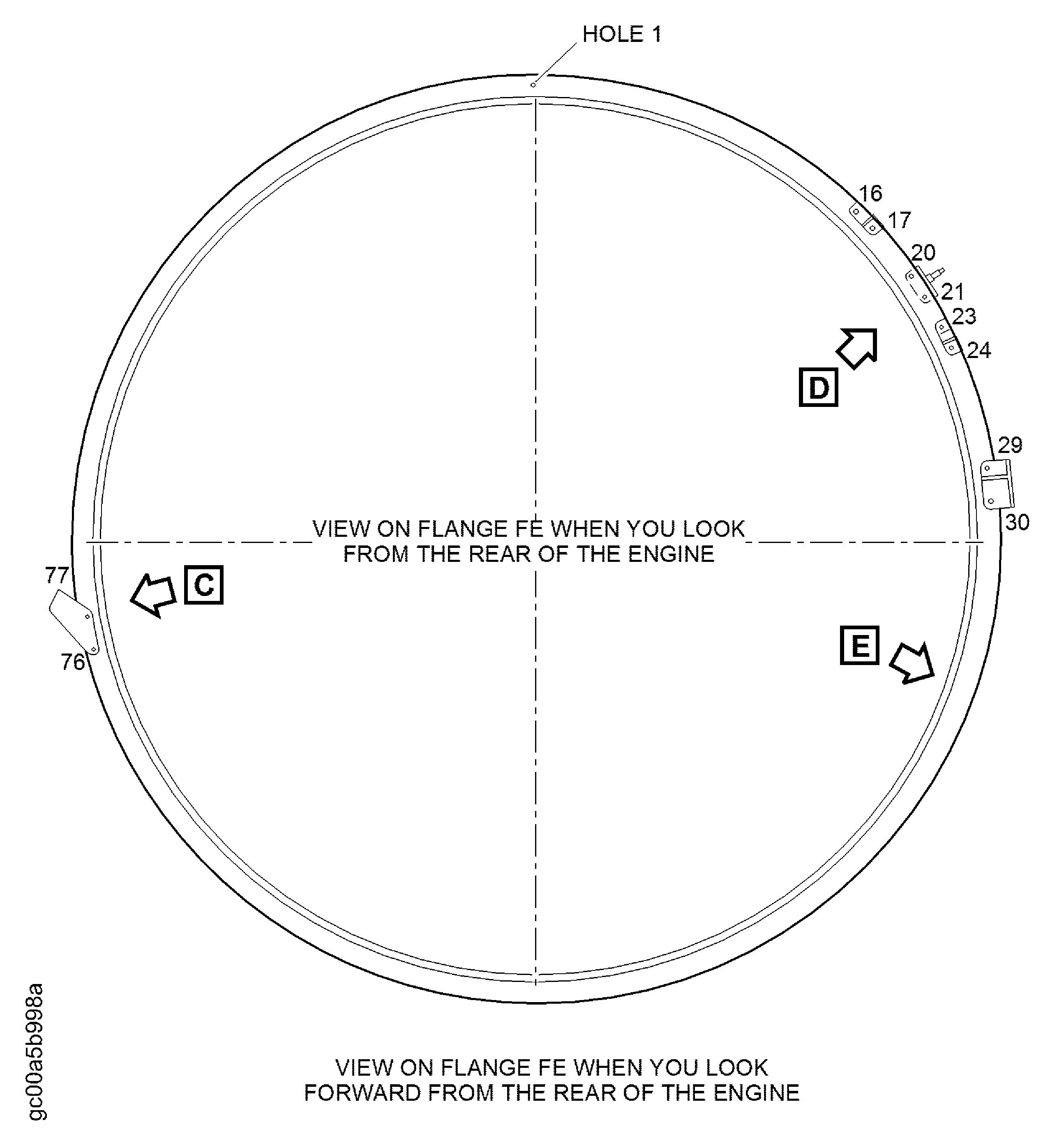

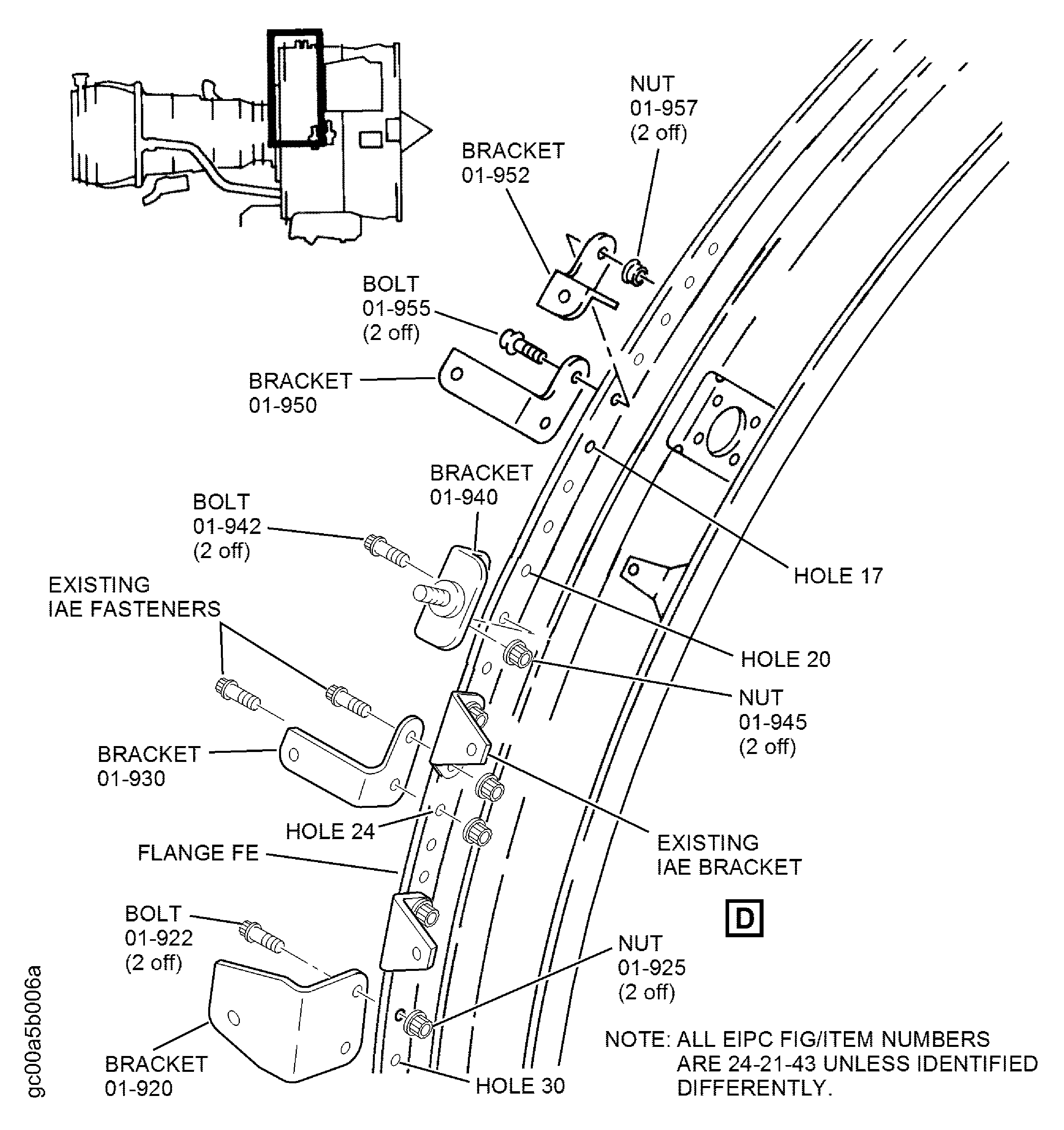

Flange FE hole number taken from top dead center. The two large holes at 90 degrees, engine hoist bolt attach holes must not be counted when the brackets are installed.Put the brackets ELECTRICAL POWER-IDG CABLES (24-21-43, 01-952) and ELECTRICAL POWER-IDG CABLES (24-21-43, 01-950) in position at the holes 16 and 17 on the forward and aft side of the flange FE. Point the bracket ELECTRICAL POWER-IDG CABLES (24-21-43, 01-952) angle forward and the bracket ELECTRICAL POWER-IDG CABLES (24-21-43, 01-950) in the aft direction. Attach with the two bolts ELECTRICAL POWER-IDG CABLES (24-21-43, 01-955) and the two nuts ELECTRICAL POWER-IDG CABLES (24-21-43, 01-957). Torque the nuts to 75 to 90 lbf.in (8 to 10 Nm).

NOTE

Clean the mating surfaces of the bracket and flange FE packing piece with CoMat 02-099 LINT-FREE CLOTH made moist with CoMat 01-076 METHYL ETHYL KETONE. Clean an area on the flange that is 1 1/2 times larger than the mating surface of the bracket. Rub the surface dry before the solvent becomes dry.NOTE

Do a check of the electrical resistance between the bracket and the flange. The resistance must be less than 0.005 ohms.Put the ground stud bracket ELECTRICAL POWER-IDG CABLES (24-21-43, 01-940) in position at the holes 20 and 21 on the forward side of the flange FE. Point the bracket ELECTRICAL POWER-IDG CABLES (24-21-43, 01-940) angle forward. Attach with the two bolts ELECTRICAL POWER-IDG CABLES (24-21-43, 01-942) and the two nuts ELECTRICAL POWER-IDG CABLES (24-21-43, 01-945). Torque the nuts to 75 to 90 lbf.in (8 to 10 Nm).

Put the bracket ELECTRICAL POWER-IDG CABLES (24-21-43, 01-930) in position at the holes 23 and 24 on the aft side of flange FE. Point the bracket ELECTRICAL POWER-IDG CABLES (24-21-43, 01-930) angle forward. Attach with the existing IAE fasteners. Torque the existing parts to a standard torque. Refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

Put the bracket ELECTRICAL POWER-IDG CABLES (24-21-43, 01-920) in position at the holes 29 and 30 on the aft side of the flange FE. Point the bracket ELECTRICAL POWER-IDG CABLES (24-21-43, 01-920) angle in the aft direction. Attach with the two bolts ELECTRICAL POWER-IDG CABLES (24-21-43, 01-922) and the two nuts ELECTRICAL POWER-IDG CABLES (24-21-43, 01-925). Torque the nuts to 75 to 90 lbf.in (8 to 10 Nm).

SUBTASK 71-00-02-420-070 Install the Upper Fan Case Brackets, Right Side

WARNING

WEAR APPLICABLE PERSONAL PROTECTIVE EQUIPMENT (PPE) WHEN YOU DO THIS TASK. BEFORE YOU USE PPE, READ, UNDERSTAND AND OBEY ALL INSTRUCTIONS FOR ITS USE. THESE INSTRUCTIONS INCLUDE INSTRUCTIONS FROM THE MANUFACTURER, YOUR EMPLOYER AND GOVERNMENT REGULATIONS. YOU CAN GET INJURED IF YOU DO NOT USE PPE. GET INSTRUCTIONS FROM YOUR EMPLOYER ON WHICH PPE IS NECESSARY.

WARNING

BEFORE YOU USE CHEMICALS, READ, UNDERSTAND, AND OBEY ALL SAFETY INSTRUCTIONS FOR THE CHEMICALS. THESE INSTRUCTIONS INCLUDE INSTRUCTIONS FROM THE MANUFACTURER, THE MATERIAL SAFETY DATA SHEET (MSDS), AND GOVERNMENT REGULATIONS. CHEMICALS MAY CAUSE INJURY TO YOU OR MAKE YOU SICK WHEN SAFETY INSTRUCTIONS ARE NOT OBEYED. AN MSDS GIVES INSTRUCTIONS ON HOW YOU MUST SAFELY USE, KEEP, AND DISCARD CHEMICALS. GET INSTRUCTIONS FROM YOUR EMPLOYER ON HOW YOU MUST SAFELY USE, KEEP, AND DISCARD CHEMICALS.NOTE

Clean the mating surfaces of the brackets, packing piece and flange with an application of CoMat 01-003 SOLVENT, DELETED with a CoMat 02-099 LINT-FREE CLOTH. Clean an area on the flange that is 1 1/2 times larger than the mating surface of the bracket.NOTE

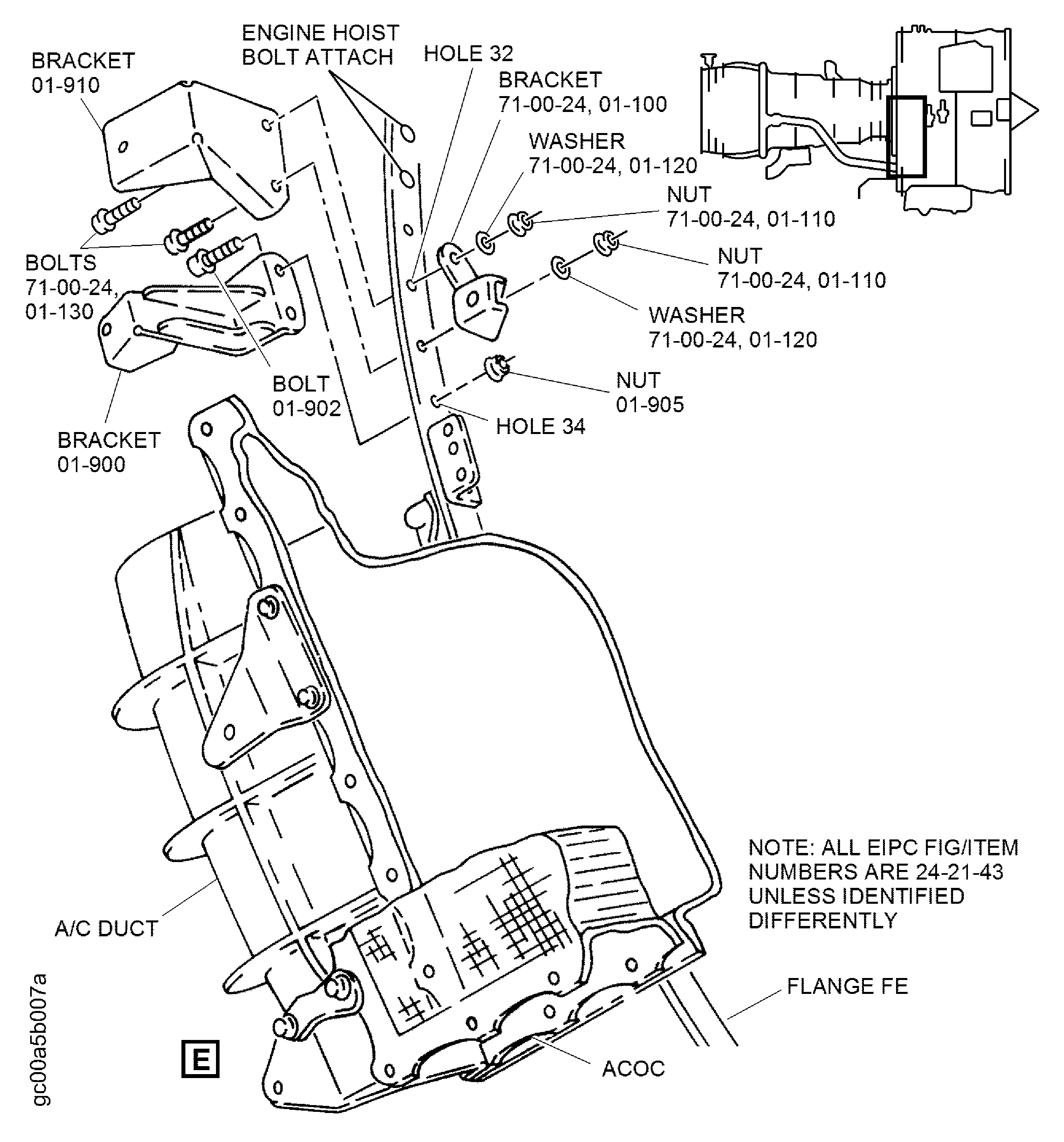

Flange FE hole number taken from top dead center. The two large holes at 90 degrees, engine hoist bolt attach holes must not be counted when the brackets are installed.Position the two brackets ELECTRICAL POWER-IDG CABLES (24-21-43, 01-910) and POWER PLANT-F/C ROD SUPPORT BKTS (71-00-24, 01-100) at the holes 32 and 33 on the forward and aft side of the flange FE. Point the bracket angle ELECTRICAL POWER-IDG CABLES (24-21-43, 01-910) in the aft direction and the bracket POWER PLANT-F/C ROD SUPPORT BKTS (71-00-24, 01-100) angle in the forward direction. Attach with the two bolts POWER PLANT-F/C ROD SUPPORT BKTS (71-00-24, 01-130), two washers POWER PLANT-F/C ROD SUPPORT BKTS (71-00-24, 01-120) and two nuts POWER PLANT-F/C ROD SUPPORT BKTS (71-00-24, 01-110). Torque the nuts to 75 to 90 lbf.in (8 to 10 Nm).

NOTE

The remaining bolt OIL-AIR COOLED OIL COOLER (79-21-42, 01-354) and nut OIL-AIR COOLED OIL COOLER(79-21-42, 01-351) for the installation of the bracket ELECTRICAL POWER-IDG CABLES(24-21-43, 01-900) at hole 38 is installed during. Refer to TASK 72-00-32-420-001-A00, SUBTASK 72-00-32-420-129 (Procedure D. Install Bracket at F).Put the bracket ELECTRICAL POWER-IDG CABLES (24-21-43, 01-900) in position at the holes 34 and 35 on the aft side of the flange FE. Point the bracket ELECTRICAL POWER-IDG CABLES (24-21-43, 01-900) angle in the aft direction. Attach with the bolt ELECTRICAL POWER-IDG CABLES (24-21-43, 01-902) and the nuts ELECTRICAL POWER-IDG CABLES (24-21-43, 01-905) at hole 37. Torque the nuts to 75 to 90 lbf.in (8 to 10 Nm).

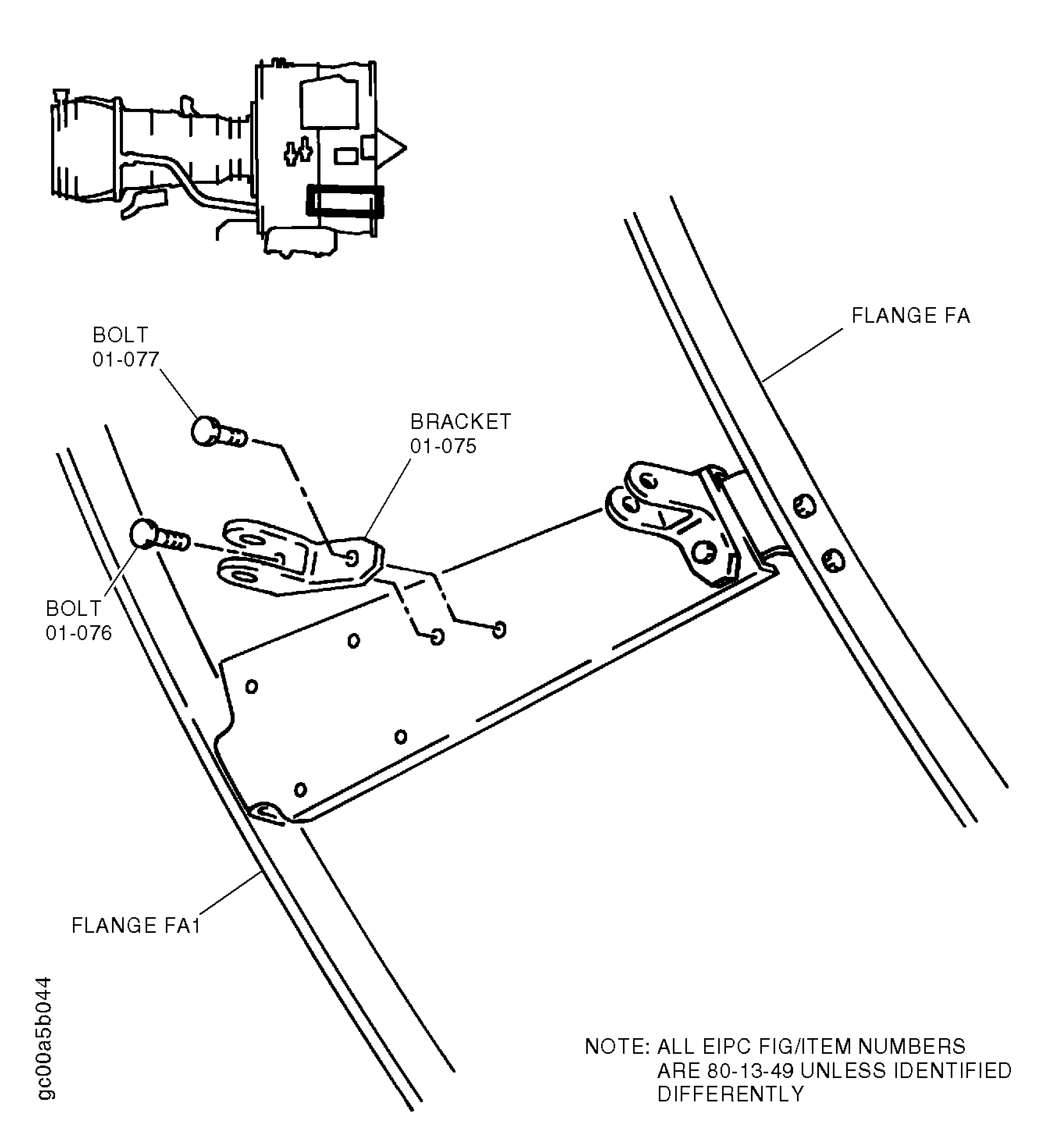

Install the bracket STARTING-STARTER DUCT (80-13-49, 01-075) with the bolt STARTING-STARTER DUCT (80-13-49, 01-076) and STARTING-STARTER DUCT (80-13-49, 01-077) on the raft AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-600) at flange FA and FA1. Torque the bolts to 75 to 90 lbf.in (8 to 10 Nm).

SUBTASK 71-00-02-420-071 Install the Lower Fan Case Brackets, Right Side

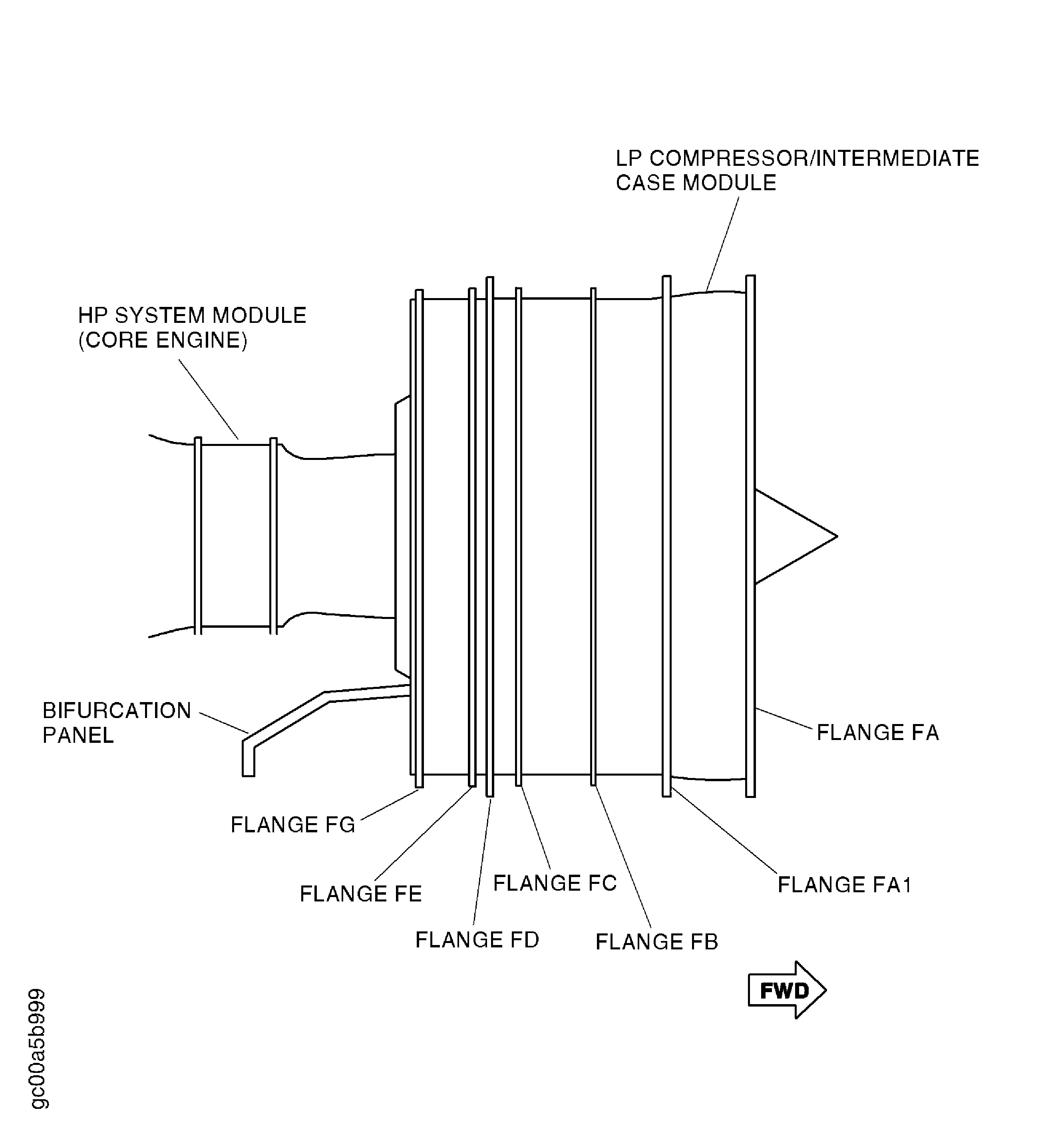

Figure: Install the LP Compressor/Intermediate Case Module Flanges

Install the LP Compressor/Intermediate Case Module Flanges

Figure: Install the Brackets at the Flange FA

Install the Brackets at the Flange FA

Figure: Install the Brackets at the Flange FA1

Install the Brackets at the Flange FA1

Figure: Install the Brackets at the Flange FE

Install the Brackets at the Flange FE

Figure: Install Upper Fan Case Brackets - Left Side

Install Upper Fan Case Brackets - Left Side

Figure: Install the Lower Fan Case Brackets - Left Side

Install the Lower Fan Case Brackets - Left Side

Figure: Install the Lower Fan Case Brackets - Left Side

Install the Lower Fan Case Brackets - Left Side

Figure: Install the Lower Fan Case Bracket - Aft

Install the Lower Fan Case Bracket - Aft

Figure: Install the Upper Fan Case Brackets - Right Side

Install the Upper Fan Case Brackets - Right Side

Figure: Install the Lower Fan Case Brackets - Right Side

Install the Lower Fan Case Brackets - Right Side

Figure: Install the Lower Fan Case Brackets - Right Side

Install the Lower Fan Case Brackets - Right Side