Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-31-200-006-B00 LPC Fan Module - Examine The Inlet Cone, The Inlet Cone Fairing, And The LPC Fan Module (Level 2 Inspection Limits), Inspection-006

General

This TASK gives the procedure for the inspection of LP compressor (fan) module below soft time as given in the engine management program.

A ** following repair referenced in this inspection indicates that the repair is not yet published in the current revision of the manual and the part must be rejected. Contact IAE for additional information concerning FAA approved repair date.

Where applicable these inspections are to be carried out in conjunction with those given in the interface inspections. Refer to TASK 72-00-00-200-000.

The module will be sufficiently disassembled for the components to be examined as specified in accordance with this procedure. Refer to TASK 72-31-00-030-001.

The policy that is necessary for inspection is given in the SPM TASK 70-20-01-200-501.

The practices and processes referred to in the procedure by the TASK/SUBTASK number are in the SPM.

Clean the inlet cone assembly. Refer to TASK 72-38-11-100-000. Degrease the inlet cone assembly, make sure that all dirt and debris have been removed before doing the inspection. Refer to SPM TASK 70-11-03-300-503.

Clean the inlet cone fairing assembly. Refer to TASK 72-38-11-100-000. Degrease the front cone retaining ring, make sure that all dirt and debris have been removed before doing the inspection. Refer to SPM TASK 70-11-03-300-503.

Clean the front blade retaining ring. Refer to TASK 72-31-13-100-001. Degrease the front blade retaining ring, make sure that all dirt and debris have been removed before doing the inspection. Refer to SPM TASK 70-11-03-300-503.

Clean the annulus filler. Degrease the annulus filler, make sure that all dirt and debris have been removed before doing the inspection. Refer to SPM TASK 70-11-03-300-503.

Clean the fan blades. Refer to Step.

Clean the fan disc. Refer to Step.

Clean the rear blade retaining ring. Refer to TASK 72-31-12-100-001. Degrease the rear blade retaining ring, make sure that all dirt and debris have been removed before doing the inspection. Refer to SPM TASK 70-11-03-300-503.

It is not necessary to separate the rear retaining ring from the fan disc to carry out this inspection, unless it has already been done.

Reference

Refer to the SPM for data on these items:

Definition of Damage, SPM TASK 70-02-02-350-501.

Inspection of Parts, SPM TASK 70-20-01-200-501.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 |

Spares

NONESafety Requirements

NONEProcedure

CAUTION

YOU MUST DO THE INSPECTIONS THAT FOLLOW IN CONJUNCTION WITH THE INTERFACE INSPECTIONS DEFINED IN TASK 72-38-11-200-000.Refer to Figure.

Repair, VRS1458 TASK 72-38-11-300-010 (REPAIR-010)

Varnish coating colored black with white spiral

Eroded.

More than in Step

Scored, gouged or grooved.

Repair, VRS1473 TASK 72-38-11-300-008 (REPAIR-008)

Not more than 0.315 sq in. (2.03 sqcm) per missing coating area and within five places area

Repair, VRS1458TASK 72-38-11-300-010 (REPAIR-010)

More than in Step

Missing coating (polyurethane and/or varnish coating).

Examine the outer surface at location 1.

More than in Step

Scored.

Repair, VRS1461TASK 72-38-11-300-015 (REPAIR-015)

Around pin holes

More than in Step

Around bolt holes.

Delaminated.

Examine the outer surface at location 5.

Repair, VRS1462 TASK 72-38-11-300-002 (REPAIR-002)

Missing

Repair, VRS1462 TASK 72-38-11-300-002(REPAIR-002)

Loss of bond securing tip

Repair, VRS1462 TASK 72-38-11-300-002 (REPAIR-002)

Tip securely bonded to inlet cone with filler missing

Examine the tip at location 3.

Repair, VRS1467 TASK 72-38-11-300-003 (REPAIR-003)

Cracked

Repair, VRS1467 TASK 72-38-11-300-003 (REPAIR-003)

More than in Step

Galled.

Examine the flange face at location 4.

Repair, VRS1431 TASK 72-38-11-300-013 (REPAIR-013)

All quantities

Depression.

Examine the fairing mating surface at location 6.

SUBTASK 72-00-31-220-155 Examine the Inlet Cone

Refer to Figure.

Repair, VRS1460 TASK 72-38-11-300-006 (REPAIR-006)

Edge burred

Examine the pin holes at location 3.

Repair, VRS1459 TASK 72-38-11-300-007 (REPAIR-007)

Delamination of glass fabric

Repair, VRS1459 TASK 72-38-11-300-007TASK 72-38-11-300-007 (REPAIR-007)

Disengagement of the balance weights

Examine the balance weight at location 4.

Repair, VRS1057 TASK 72-38-11-300-014 (REPAIR-014)

Unbonded

Repair, VRS1057 TASK 72-38-11-300-014 (REPAIR-014)

Torn

SBE 72-0318: Examine the strip seal at location 5.

SUBTASK 72-00-31-220-156 Examine the Inlet Cone Fairing

CAUTION

YOU MUST DO THE INSPECTIONS THAT FOLLOW IN CONJUNCTION WITH THE INTERFACE INSPECTIONS DEFINED IN TASK 72-00-31-220-002.Refer to Figure.

More than in Step

Galled.

Examine the blade abutment face at location 1.

More than in Step

Galled.

Examine the filler abutment face at location 2.

More than in Step

Galled.

Examine the disc abutment face at location 3.

More than in Step

Galled.

Examine the inlet cone abutment face at location 4.

More than in Step

Galled.

Examine the front face at location 5.

More than in Step

Scored.

Examine the snap diameter at location 8.

More than in Step

Scored.

Examine the snap diameter at location 9.

More than in Step

Nicks, dents or scratches.

Examine the outside diameter at location 10.

More than in Step

Scored.

Examine the pin holes at location 11.

Other than in Step

Examine the shank nuts at location 14.

More than in Step

Nicked, dented, scratched or gouged.

Examine the shank nut anti rotation land at location 19.

More than in Step

Gouged or rubbed.

Examine the locating pin holes at location 20.

SUBTASK 72-00-31-220-157 Examine the Front Blade Retaining Ring

CAUTION

YOU MUST DO THE INSPECTIONS THAT FOLLOW IN CONJUNCTION WITH THE INTERFACE INSPECTIONS DEFINED IN TASK 72-00-31-220-002.More than in Step

Examine the seals for wear.

Examine the seals at location 1.

Repair, VRS1060 TASK 72-00-31-300-006 (REPAIR-006)

Missing dry film lubricant

Examine the trunnion surface at location 3.

SUBTASK 72-00-31-220-158 Examine the Annulus Fillers

Do not soak. Use a soft bristle brush or swab. Refer to the SPM TASK 70-11-26-300-503

Remove the soft dirt and the dust

Use clean dry air blast or CoMat 02-099 LINT-FREE CLOTH.

Dry

NOTE

It is not necessary to remove existing dry film lubricant or the chocking pads from the blade root.Remove the soft dirt and dust from the fan blade.

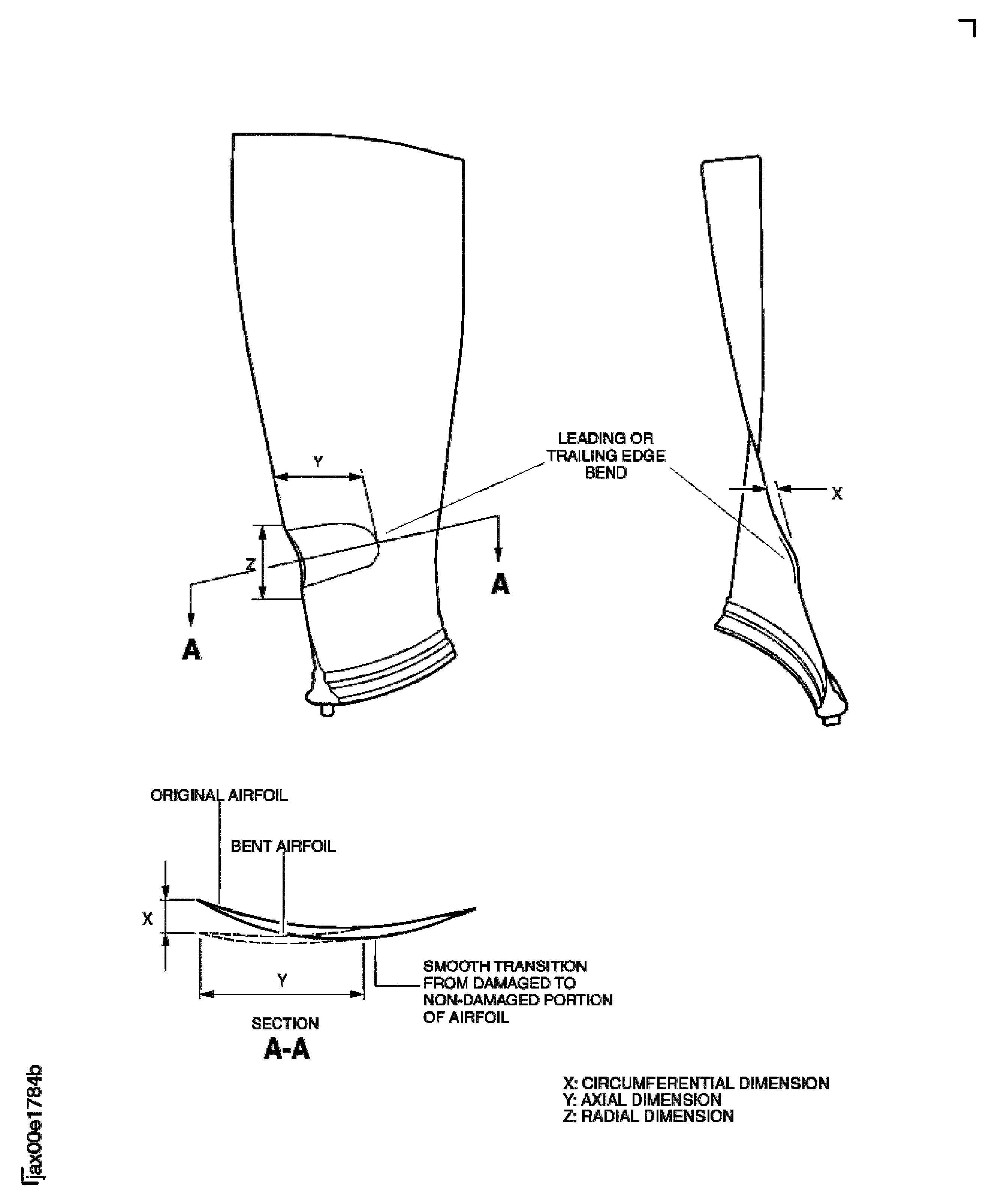

Examine the fan blade for bends. Refer to Figure.

Surface texture smoother than CoMat 05-021 WATERPROOF SILICON CARBIDE

More than in Step

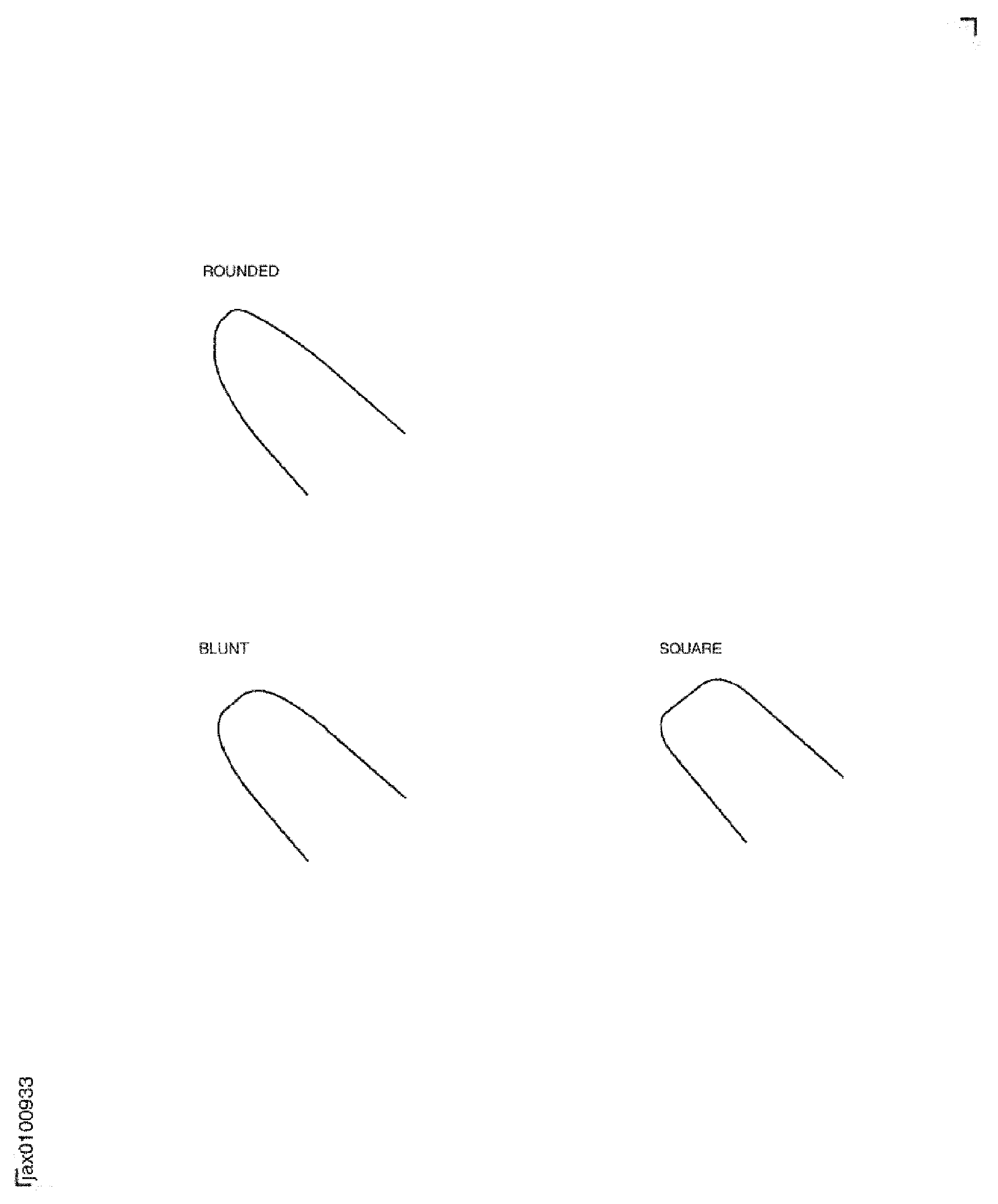

Leading edge condition.

Examine the leading edge profile. Refer to Figure.

Examine the fan blade at area Cr. Refer to Figure.

More than in Step

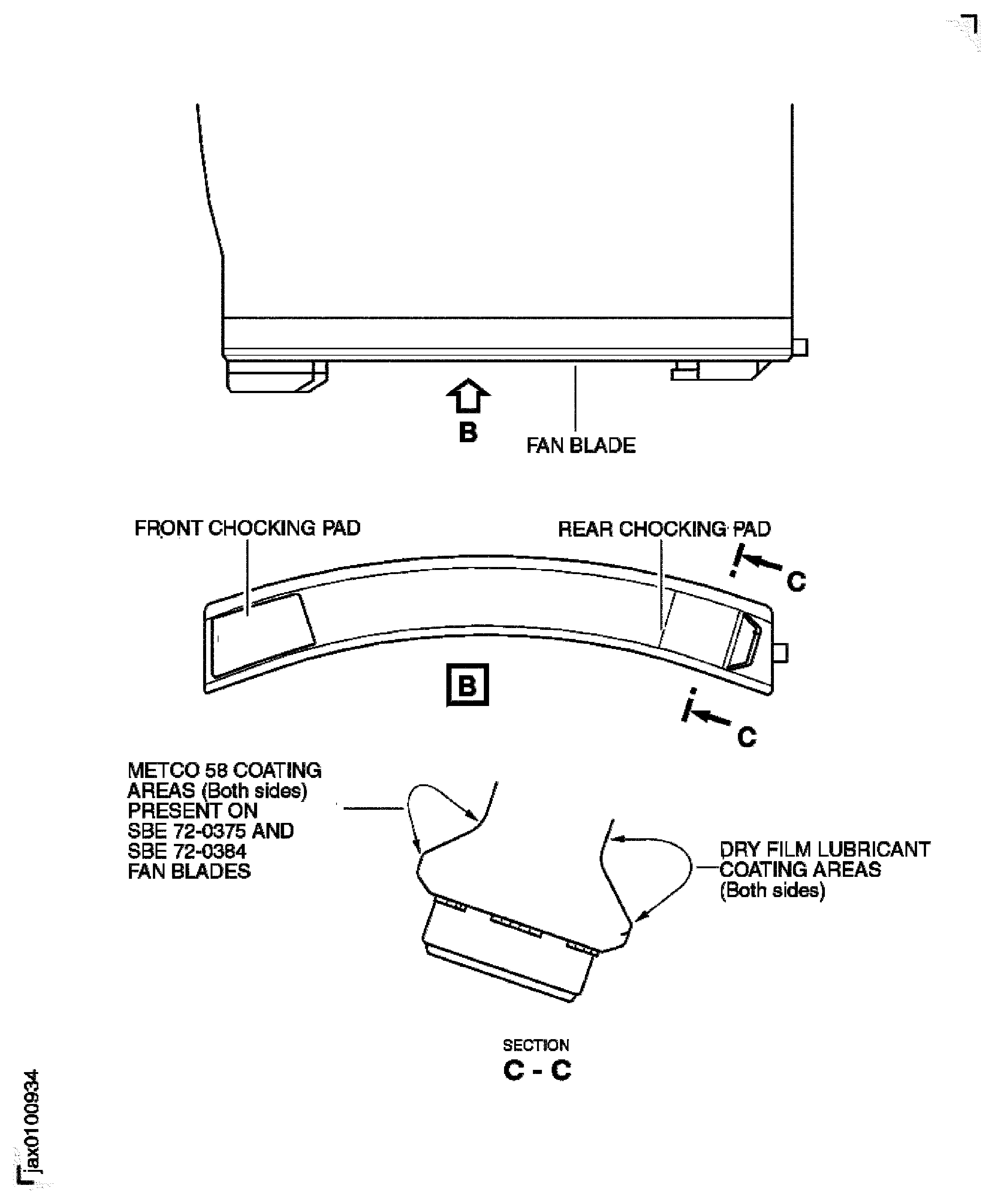

SBE 72-0375 or SBE 72-0384: Examine the root of the fan blade for Metco 58 coating of the dovetail root flank at location 6. Refer to Figure and Figure.

More than in Step

SBE 72-0375 or SBE 72-0384: Localised gouges and chips in Metco 58 coating.

SBE 72-0375 or SBE 72-0384: Flaking or debond of Metco 58 coating from the root flange

NOTE

Make sure that SBE 72-0386 is complied with appropriate intervals.Examine the fan blade roots. Refer to Figure.

SUBTASK 72-00-31-220-159 Examine the LP Compressor Blades (Fan Blades)

Refer to Figure.

More than in Step

Galled.

Repair, VRS1134 TASK 72-00-31-300-008 (REPAIR-008)

Missing dry film lubricant

Examine the dovetail sides at location 1.

More than in Step

Corrosion pitting.

Examine the curvic teeth at location 2.

Other than in Step

Do the torque check for reuse of the shank nuts. Refer to the SPM TASK 70-42-01-400-501.

SUBTASK 72-00-31-220-160 Examine the Stage 1 Fan Disc (Fan Disc)

Refer to Figure.

More than in Step

Worn.

Repair, VRS1135 TASK 72-00-31-300-009 (REPAIR-009)**

Missing of dry film lubricant

Examine the locating holes at location 2.

More than in Step

Worn.

Examine the pin holes at location 3.

Repair, VRS1135 TASK 72-00-31-300-009 (REPAIR-009)**

Missing dry film lubricant

NOTE

This inspection is only required if the rear retaining ring has been removed from the fan disc which exposes the inner area for the front face.Examine the front face at location 6.

SUBTASK 72-00-31-220-161 Examine the Rear Blade Retaining Ring

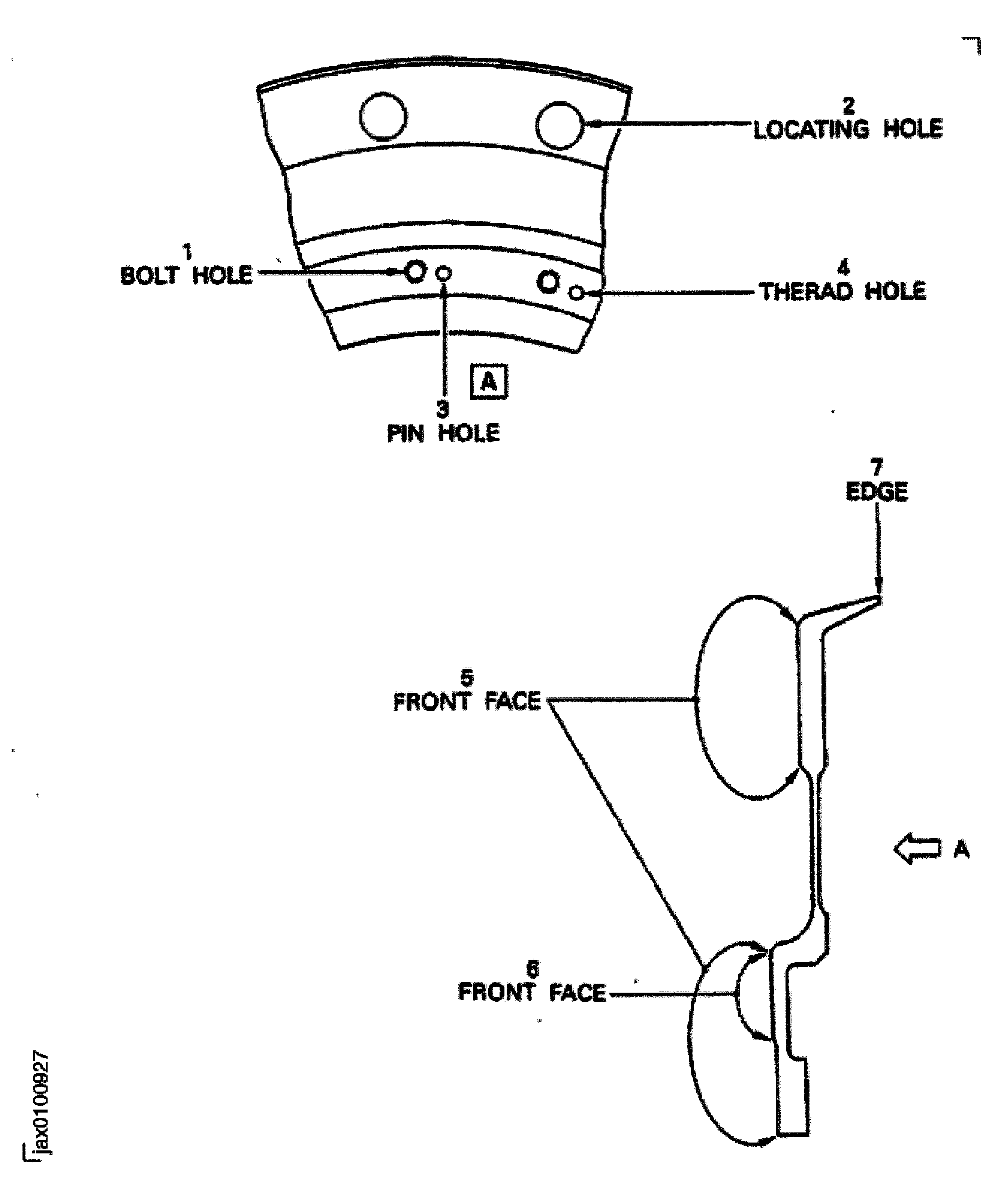

Figure: Location on the Inlet Cone Assembly

Location on the Inlet Cone Assembly

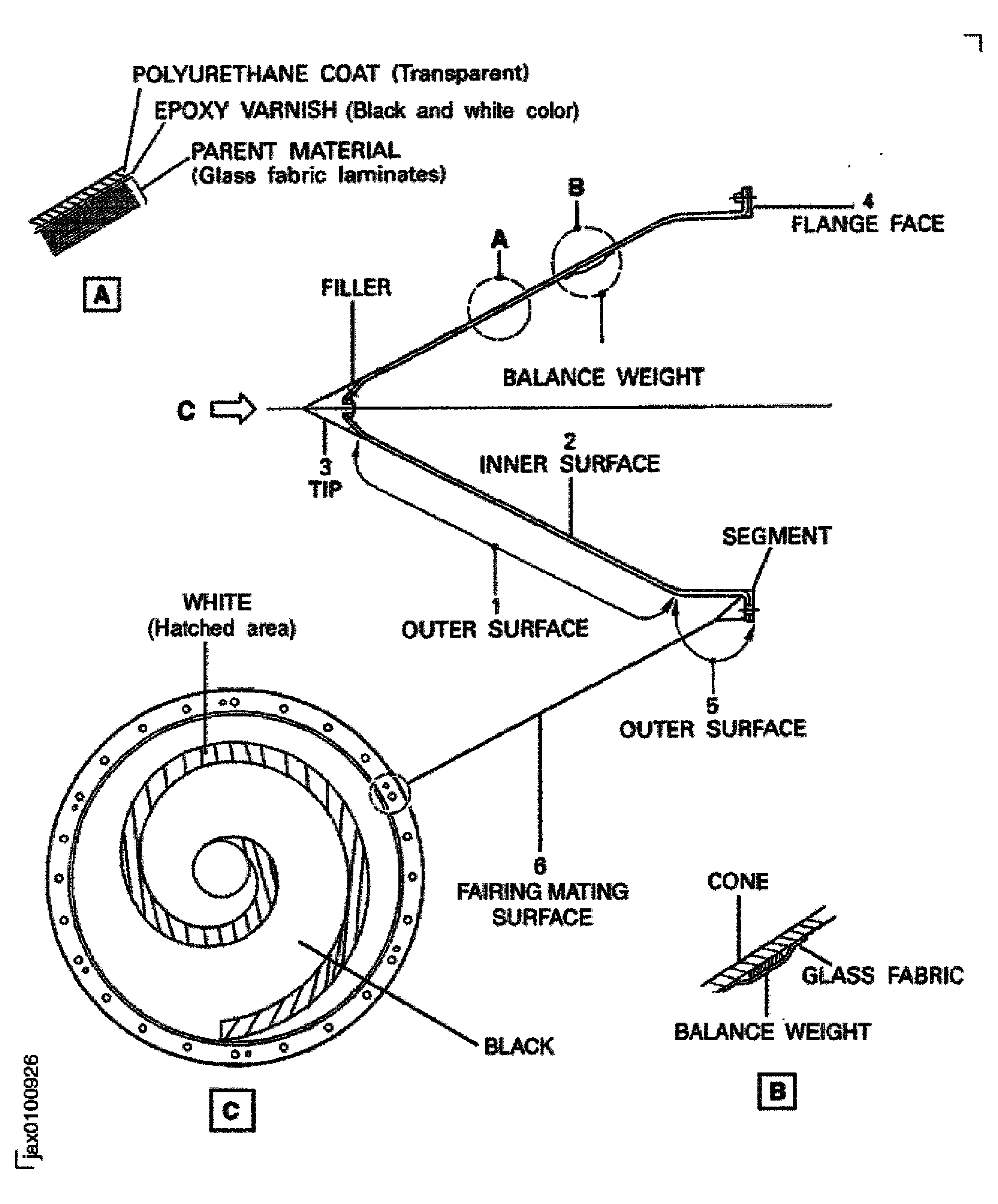

Figure: Location on the Inlet Cone Fairing

Location on the Inlet Cone Fairing

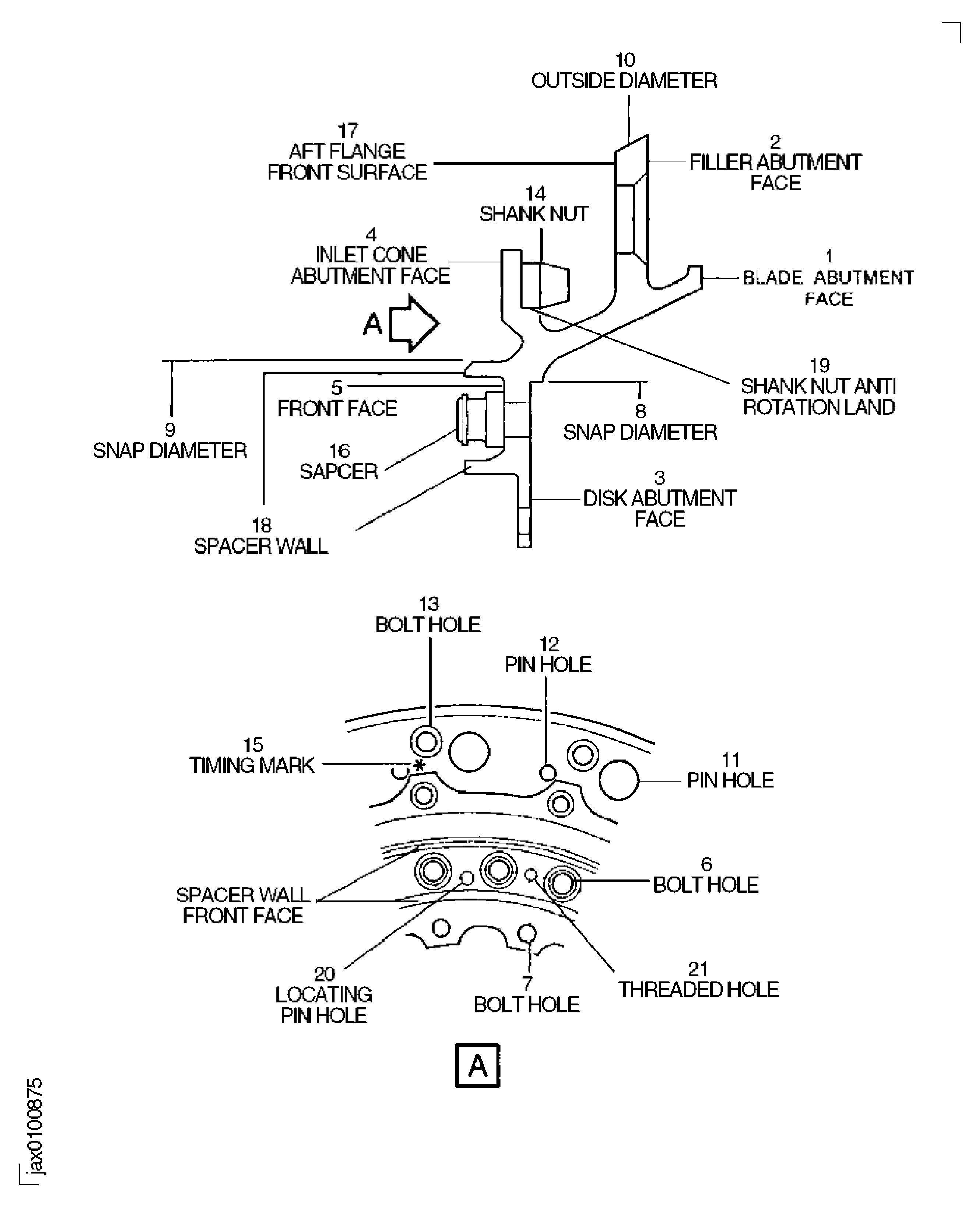

Figure: Location on the Front Blade Retaining Ring

Location on the Front Blade Retaining Ring

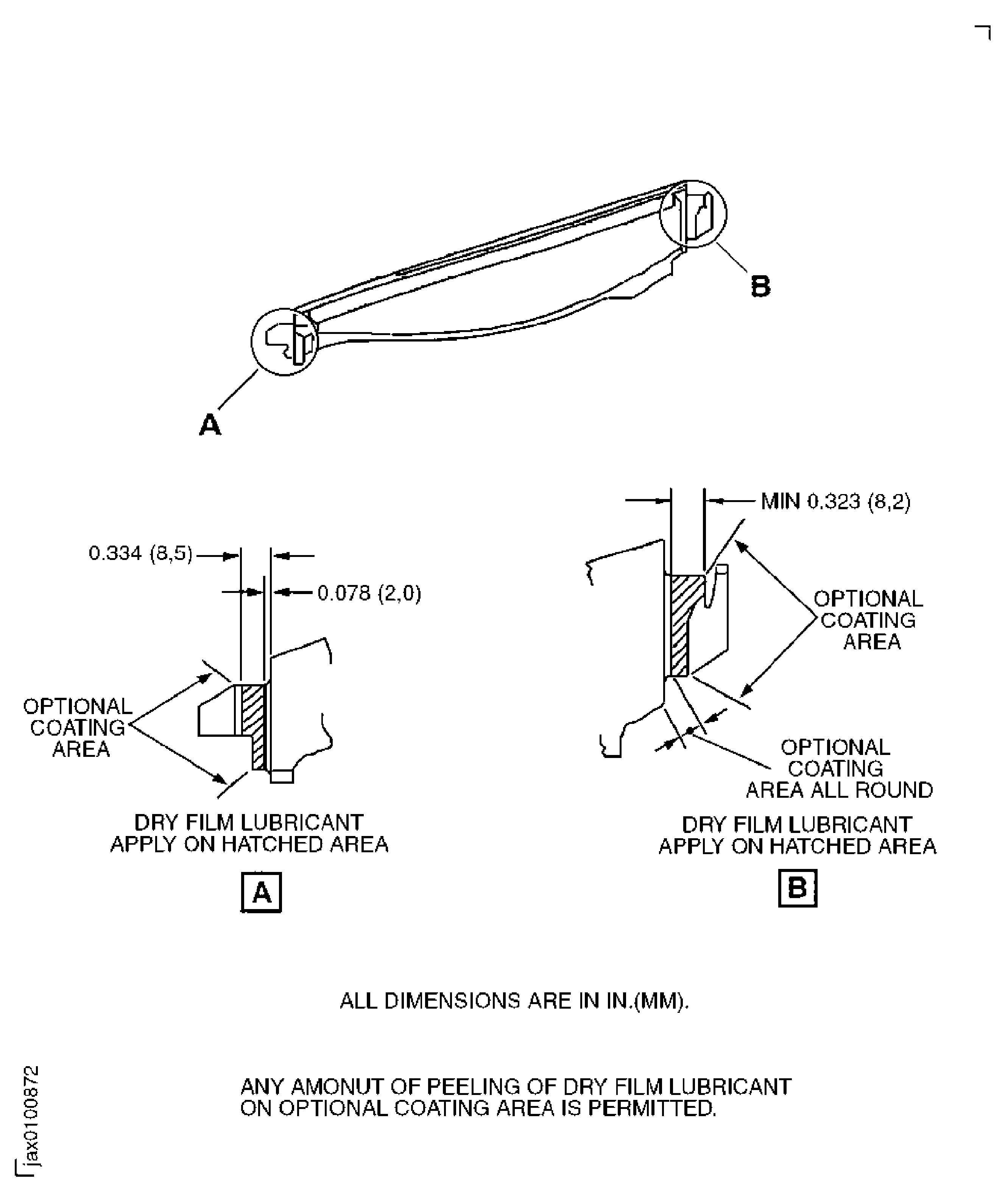

Figure: Location of Dry Film Lubricant on the Annulus Filler

Sheet 1

Figure: Location of Dry Film Lubricant on the Annulus Filler

Sheet 2

Figure: Locations on the Fan Blade Assembly

Locations on the Fan Blade Assembly

Figure: Fan Blade Damage

Fan Blade Damage

Figure: Area F - Feather Tip Feature

Area F - Feather Tip Feature

Figure: Maximum Serviceable Limits

Maximum Serviceable Limits

Figure: Fan Blade Typical Leading Edge Profiles

Fan Blade Typical Leading Edge Profiles

Figure: Dry Film Lubricant Areas

Dry Film Lubricant Areas

Figure: Fan Disc Inspection Locations

Fan Disc Inspection Locations

Figure: Location on the Rear Blade Retaining Ring

Location on the Rear Blade Retaining Ring