Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-32-420-002 LPC/Intermediate Case Module - Install The Components, Installation-002

General

Refer to the TASKs which follow for other related procedures:

TASK 72-00-32-420-001 Install the LP compressor/intermediate case brackets and the bifurcation panel.

TASK 72-00-32-420-003 Install the LP compressor/intermediate case tubes and electrical harness raceways.

TASK 72-00-32-420-004 Install the LP compressor/intermediate case electrical harnesses.

TASK 72-00-32-420-005 Install the LP compressor/intermediate case hydraulic tubes, the thermal anti-ice (TAI) duct, the pneumatic starter duct and the EEC cooling duct.

For lockwire data and procedures refer to SPM TASK 70-42-05-400-501.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures refer to SPM TASK 70-41-01-400-501 and the SPM TASK 70-41-02-400-501.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings refer to SPM TASK 70-64-02-640-501.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to damaged surface protection, joint flanges and attach parts. Use the correct color of air drying enamel. Refer to SPM TASK 70-38-21-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Transportation covers/blanks must not be removed until immediately before installation of the components.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Torque wrench with a 0 to 450 lbf.in range | LOCAL | Torque wrench 0 to 450 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-003 SOLVENT, DELETED | X111X | CoMat 01-003 | ||

| CoMat 01-076 METHYL ETHYL KETONE | LOCAL | CoMat 01-076 | ||

| CoMat 02-147 LOCKWIRE | LOCAL | CoMat 02-147 | ||

| CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE | LOCAL | CoMat 04-004 | ||

| CoMat 04-005 JOINTING COMPOUND, MEDIUM GRADE | LOCAL | CoMat 04-005 | ||

| CoMat 04-006 JOINTING COMPOUND, HEAVY GRADE | LOCAL | CoMat 04-006 | ||

| CoMat 07-038 AIR DRYING ENAMEL | 00BB6 | CoMat 07-038 | ||

| CoMat 10-038 PETROLEUM JELLY | LOCAL | CoMat 10-038 | ||

| CoMat 10-060 LIQUID PARAFFIN | LOCAL | CoMat 10-060 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Packing | 1 | |||

| Packing | 1 | |||

| Sealing ring | 1 | |||

| Sealing ring | 1 |

Safety Requirements

NONEProcedure

Refer to Figure.

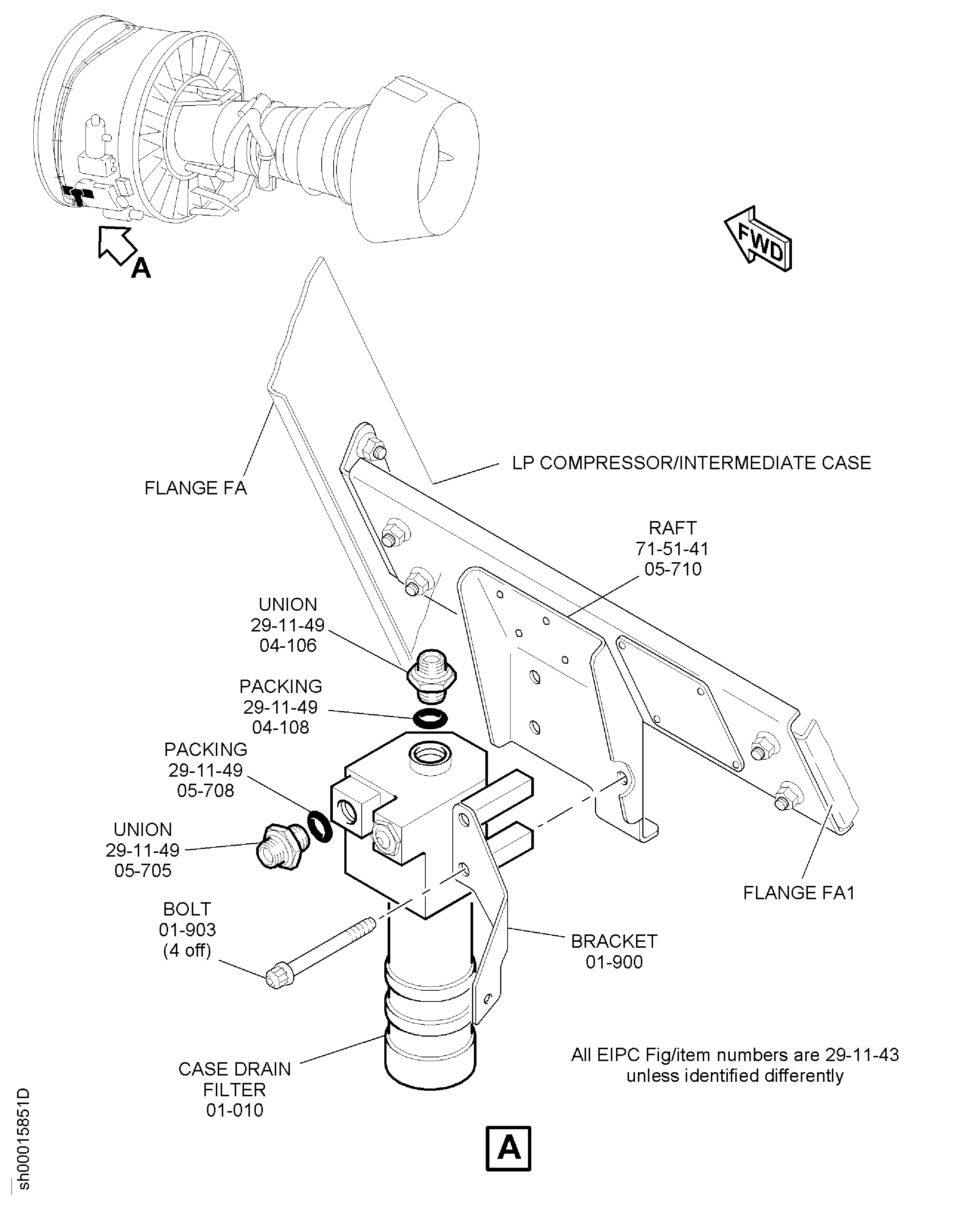

Install the union HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-106) and the new packing HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-108) to the case drain filter CASE DRAIN HYDRAULIC FILTER ASSEMBLY (29-11-43, 01-010). Torque the union to 155 to 165 lbf.in (17.5 to 18.5 Nm).

Install the union HYDRAULIC POWER - ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 05-705) and the new packing HYDRAULIC POWER - ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 05-708) to the case drain filter CASE DRAIN HYDRAULIC FILTER ASSEMBLY (29-11-43, 01-010). Torque the union to 155 to 165 lbf.in (17.5 to 18.5 Nm).

Attach the case drain filter CASE DRAIN HYDRAULIC FILTER ASSEMBLY (29-11-43, 01-010) and the bracket CASE DRAIN HYDRAULIC FILTER ASSEMBLY (29-11-43, 01-900) on the raft EEC Fan Harness (71-51-41, 05-710) with the four bolts CASE DRAIN HYDRAULIC FILTER ASSEMBLY (29-11-43, 01-903). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

SUBTASK 72-00-32-420-057 Install the Hydraulic Case Drain Filter Assembly

Refer to Figure.

WARNING

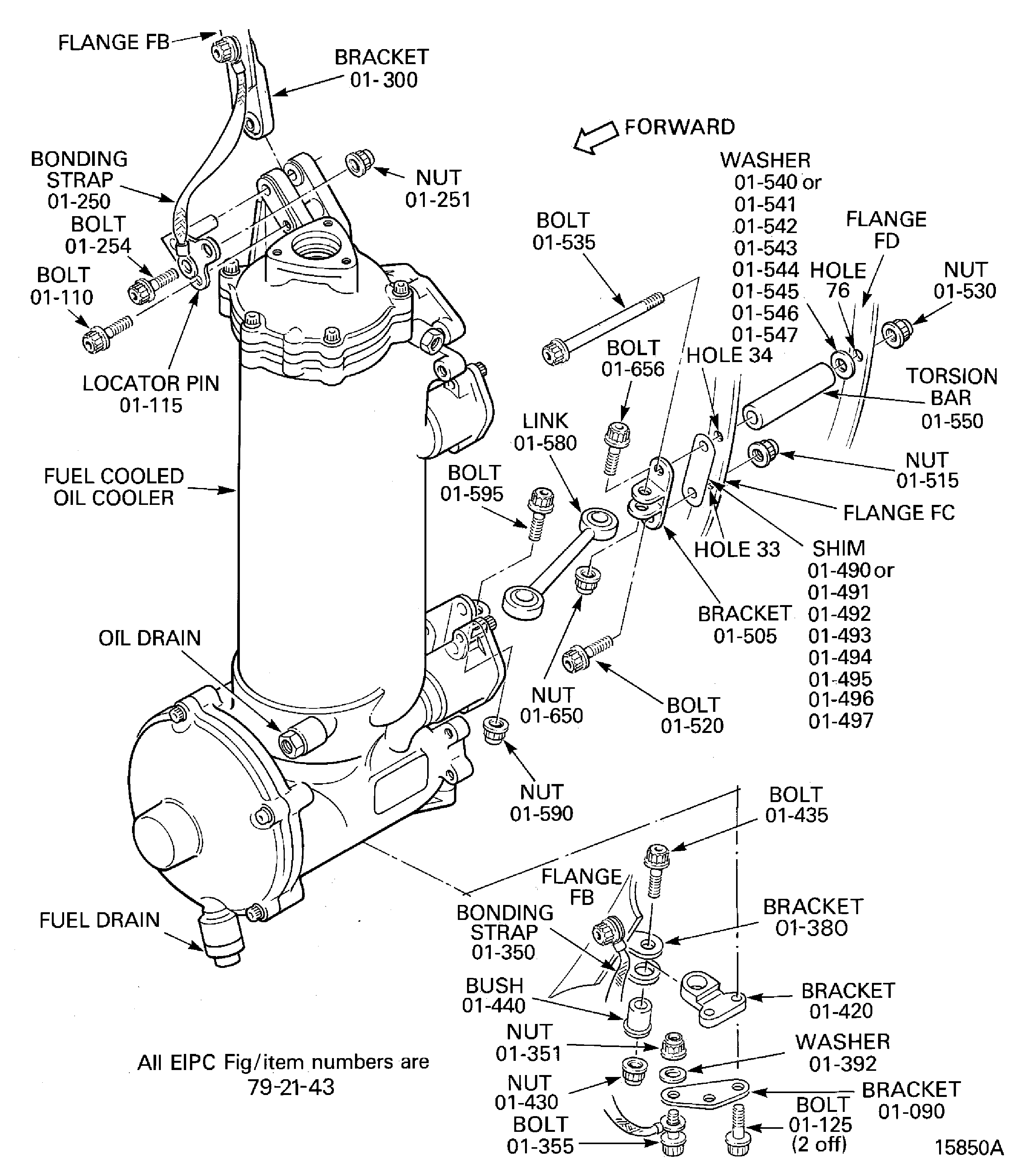

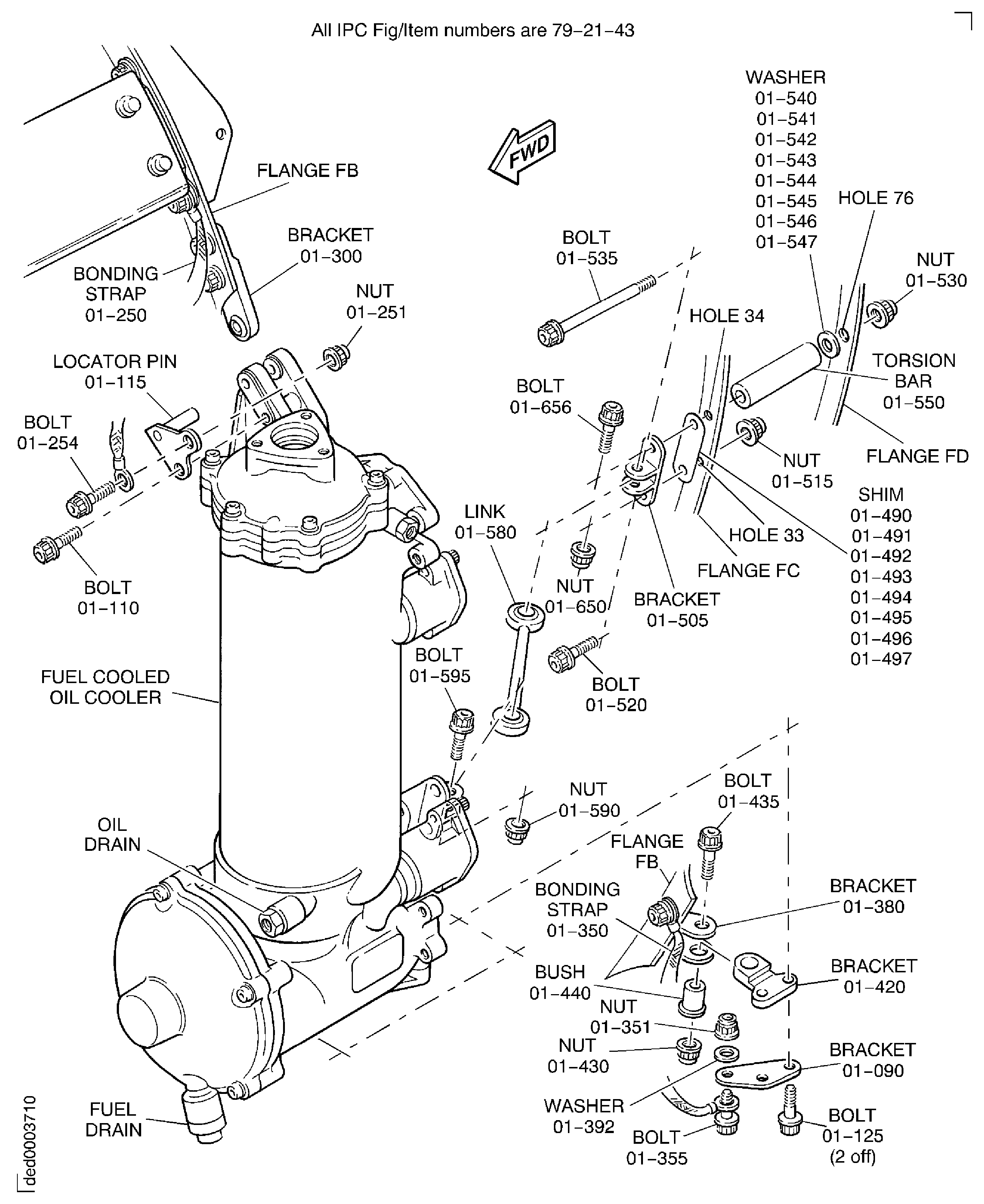

WHEN YOU USE CoMat 01-003 SOLVENT, DELETED YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Clean the locator pin Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-115), its mating faces on the FCOC and the connector of the bonding strap Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-250) with CoMat 01-003 SOLVENT, DELETED.

With the FCOC held in position; install the locator pin that attaches the FCOC and the bonding strap connector to the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-300) on flange FB and install the bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-110). Torque the bolt to 36 to 45 lbf.in (4 to 5 Nm).

Attach the bonding strap to the locator pin with the bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-254), the washer Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-253) and the nut Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-251). Torque the nut to 85 to 105 lbf.in (10 to 12 Nm).

Assemble the FCOC top mount.

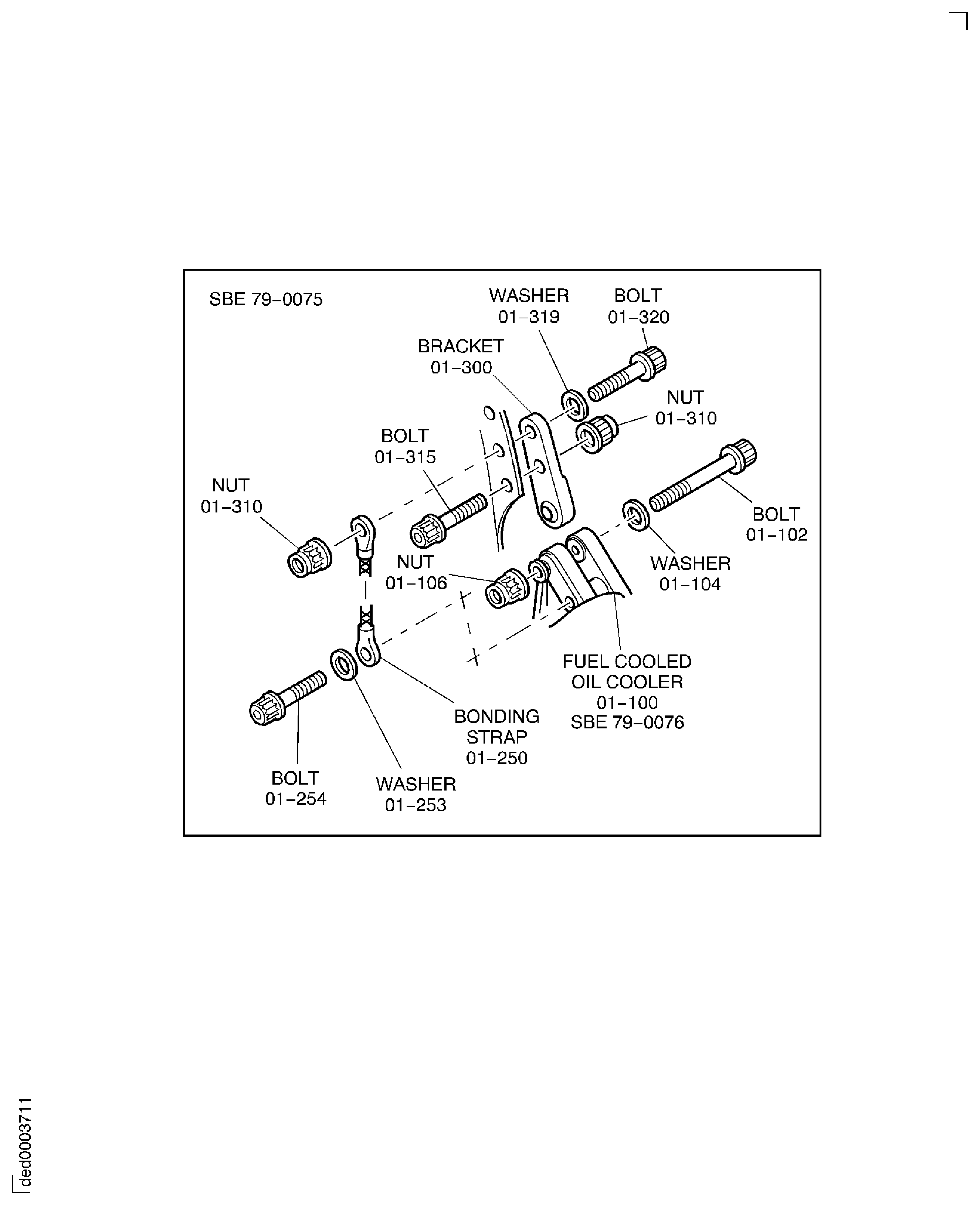

Pre SBE 79-0075 and 79-0076.

WARNING

WHEN YOU USE CoMat 01-003 SOLVENT, DELETED YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Clean the locator bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-102), and the nut Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-106), its mating faces on the FCOC and the connector of the bonding strap Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-250) with CoMat 01-003 SOLVENT, DELETED.

With the FCOC held in position; install the locator bolt that attaches the FCOC to the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-300) on flange FB. Torque the bolt to 285 lbf.in (32.2 Nm).

Attach the bonding strap to the FCOC with the bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-254), the washer Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-253) and the nut Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-251). Torque the nut to 85 to 105 lbf.in (10 to 12 Nm).

Assemble the FCOC top mount. Refer to Figure.

Remove the front bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-125) from the FCOC bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-420).

WARNING

WHEN YOU USE COMAT 01-003 INHIBITED AND STABILIZED TRICHLOROETHANE YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Clean the bonding strap connector, the surface it touches on the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-420), the bracket and FCOC mating faces and the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-090); with CoMat 01-003 SOLVENT, DELETED.

Attach the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-090) to the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-420) with the bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-125) and torque the bolt to 85 to 105 lbf.in (10 to 12 Nm).

Install the bracket of the FCOC into the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-380) on flange FB. Then install the bush Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-440), the bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-435) and the nut Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-430). Torque the nut to 180 to 220 lbf.in (20 to 25 Nm).

Attach the bonding strap to the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-090), with bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-355), the washer Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-392) and the nut Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-351). Torque the nut to 85 to 105 lbf.in (10 to 12 Nm).

Assemble the FCOC lower mount.

Attach the link Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-580) to the bracket on the FCOC with bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-595) and the nut Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-590). Torque the nut to 180 to 220 lbf.in (20 to 25 Nm).

From the range of shims Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-490 to Fuel Cooled Oil Cooler (FCOC) 01-497) get the shim that will align the three holes in the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-505) with holes 33 and 34 in flange FC and the hole in the link. With the bracket and the shim in position put the bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-535) together with the torsion bar Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-550) through hole 34 (flange FC) and hole 76 (flange FD). Measure the space remaining between the torsion bar and flange FD. From the range of washers Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-540 to Fuel Cooled Oil Cooler (FCOC) 01-547) get the largest washer which is less than that dimension. Remove the bolt and torsion bar.

Attach the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-505), with the shim, to flange FC with, the two bolts Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-520 and Fuel Cooled Oil Cooler (FCOC) 01-535), the torsion bar, the washer and the two nuts Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-515 and Fuel Cooled Oil Cooler (FCOC) 01-530). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Attach the link to the bracket with the bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-656) and the nut Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-650). Torque the nut to 180 to 220 lbf.in (20 to 25 Nm).

Assemble the center link assembly.

SUBTASK 72-00-32-420-058-A00 V2500-A1 Install the Fuel Cooled Oil Cooler (FCOC)

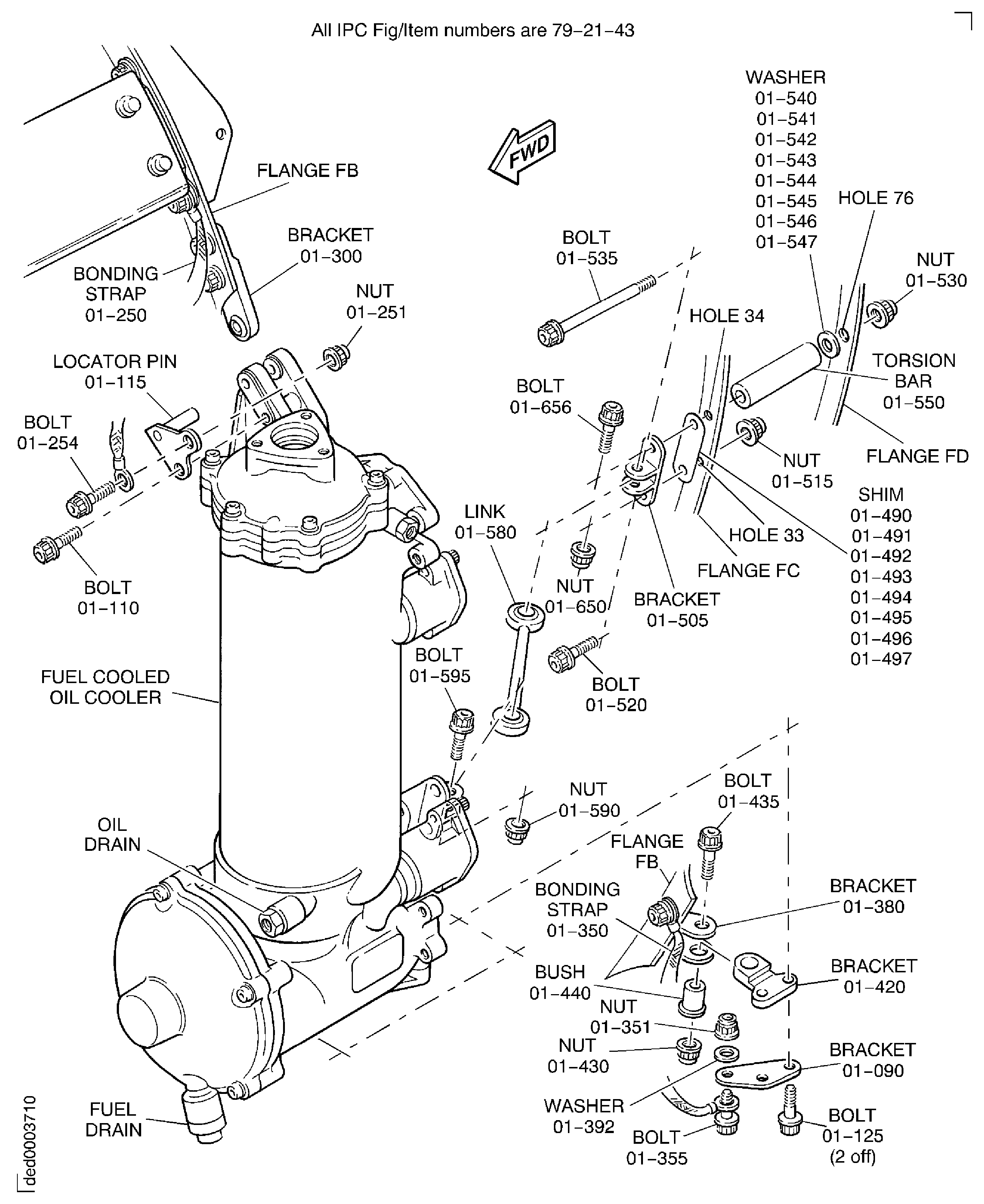

Refer to Figure.

WARNING

WHEN YOU USE CoMat 01-003 SOLVENT, DELETED YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Clean the locator pin Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-115), its mating faces on the FCOC and the connector of the bonding strap Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-250) with CoMat 01-003 SOLVENT, DELETED.

With the FCOC held in position; install the locator pin that attaches the FCOC and the bonding strap connector to the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-300) on flange FB and install the bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-110). Torque the bolt to 36 to 45 lbf.in (4 to 5 Nm).

Attach the bonding strap to the locator pin with the bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-254), the washer Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-253) and the nut Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-251). Torque the nut to 85 to 105 lbf.in (10 to 12 Nm).

Assemble the FCOC top mount.

Pre SBE 79-0075 and 79-0076.

WARNING

WHEN YOU USE COMAT 01-003 INHIBITED AND STABILIZED TRICHLOROETHANE YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Clean the locator bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-102), and the nut Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-106), its mating faces on the FCOC and the connector of the bonding strap Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-250) with CoMat 01-003 SOLVENT, DELETED.

With the FCOC held in position; install the locator bolt that attaches the FCOC to the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-300) on flange FB. Torque the bolt to 180 to 220 lbf.in ( 20 to 25 Nm).

Attach the bonding strap to the FCOC with the bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-254), the washer Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-253) and the nut Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-251). Torque the nut to 85 to 105 lbf.in (10 to 12 Nm).

Assemble the FCOC top mount.

SBE 79-0075: Oil - Fuel Cooled Oil Cooler - Introduction of revised FCOC upper mount. Refer to Figure.

Remove the front bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-125) from the FCOC bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-420).

WARNING

WHEN YOU USE CoMat 01-003 SOLVENT, DELETED YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Clean the bonding strap connector, the surface it touches on the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-420), the bracket and FCOC mating faces and the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-090); with CoMat 01-003 SOLVENT, DELETED.

Attach the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-090) to the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-420) with the bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-125) and torque the bolt to 85 to 105 lbf.in (10 to 12 Nm).

Install the bracket of the FCOC into the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-380) on flange FB. Then install the bush Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-440), the bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-435) and the nut Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-430). Torque the nut to 180 to 220 lbf.in (20 to 25 Nm).

Attach the bonding strap to the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-090), with bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-355), the washer Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-392) and the nut Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-351). Torque the nut to 85 to 105 lbf.in (10 to 12 Nm).

Assemble the FCOC lower mount.

Attach the link Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-580) to the bracket on the FCOC with bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-595) and the nut Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-590). Torque the nut to 180 to 220 lbf.in (20 to 25 Nm).

From the range of shims Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-490 to Fuel Cooled Oil Cooler (FCOC) 01-497) get the shim that will align the three holes in the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-505) with holes 33 and 34 in flange FC and the hole in the link. with the bracket and the shim in position put the bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-535) together with the torsion bar Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-550) through hole 34 (flange FC) and hole 74 (flange FD). Measure the space remaining between the torsion bar and flange FD. From the range of washers Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-540 to Fuel Cooled Oil Cooler (FCOC) 01-547) get the largest washer which is less than that dimension. Remove the bolt and torsion bar.

Attach the bracket Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-505), with the shim, to flange FC with, the two bolts Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-520 and Fuel Cooled Oil Cooler (FCOC) 01-535), the torsion bar, the washer and the two nuts Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-515 and Fuel Cooled Oil Cooler (FCOC) 01-530). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Attach the link to the bracket with the bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-656) and the nut Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-650). Torque the nut to 180 to 220 lbf.in (20 to 25 Nm).

Assemble the center link assembly.

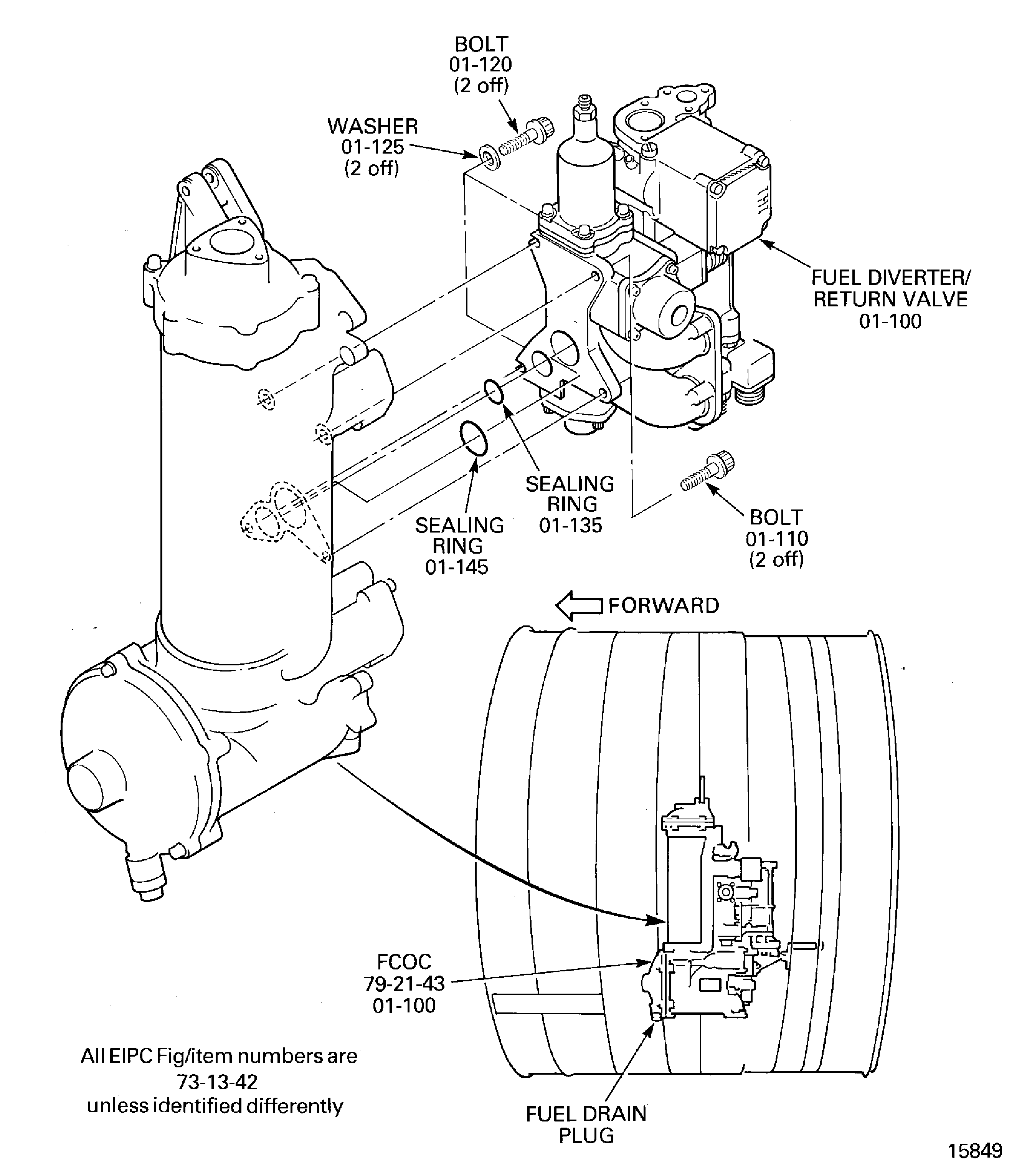

SUBTASK 72-00-32-420-058-B00 V2500-A5 Install the Fuel Cooled Oil Cooler (FCOC)

Refer to Figure.

Lightly lubricate a new sealing ring Fuel Diverter and Return Valve (73-13-42, 01-135) 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY.

Lightly lubricate a new sealing ring Fuel Diverter and Return Valve (73-13-42, 01-145) 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY.

Attach the FDRV to the FCOC with the four bolts Fuel Diverter and Return Valve (73-13-42, 01-110) and Fuel Diverter and Return Valve (73-13-42, 01-120) and the two washers Fuel Diverter and Return Valve (73-13-42, 01-125). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

SUBTASK 72-00-32-420-059 Install the Fuel Diverter and Return Valve (FDRV)

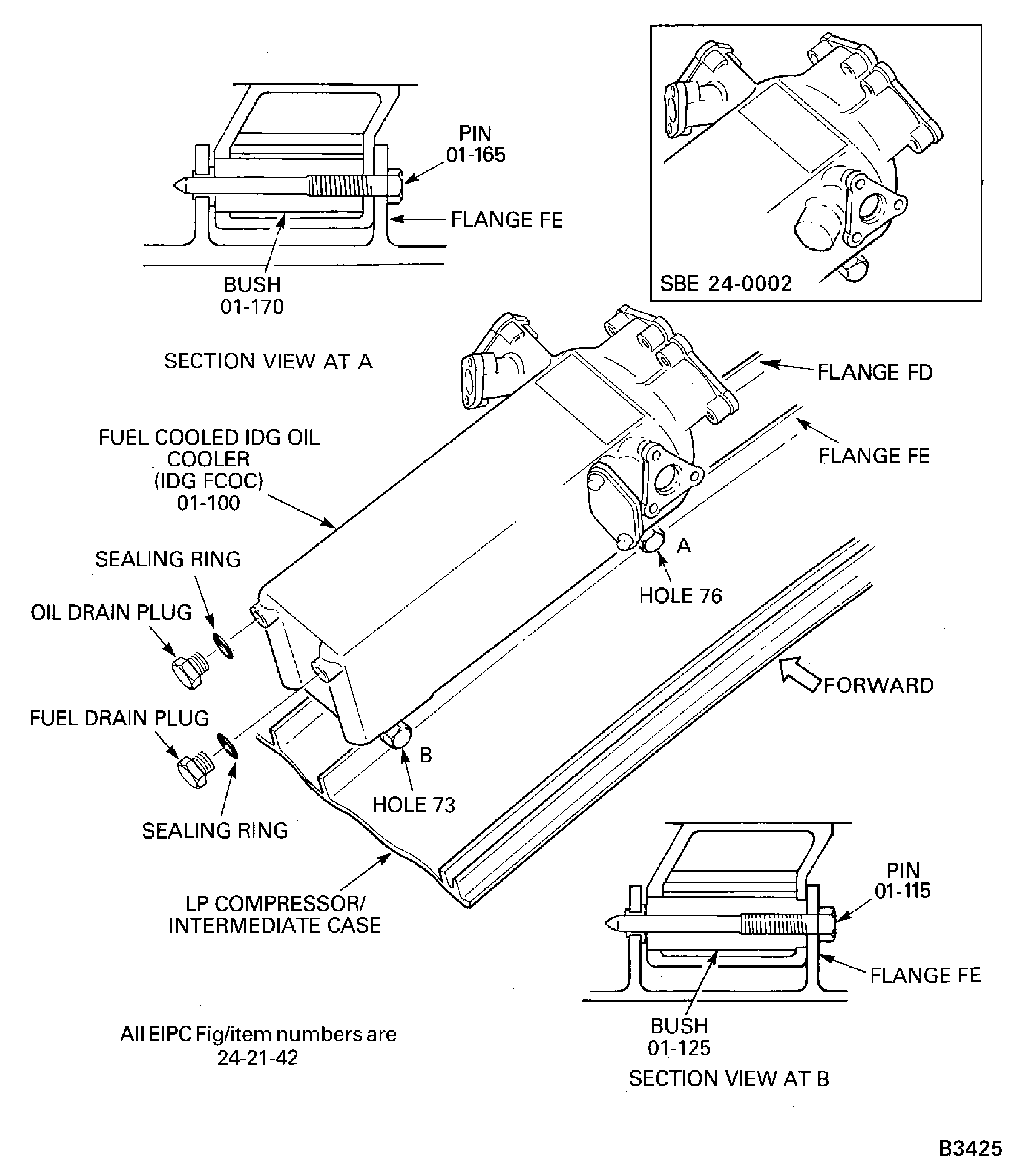

Refer to Figure.

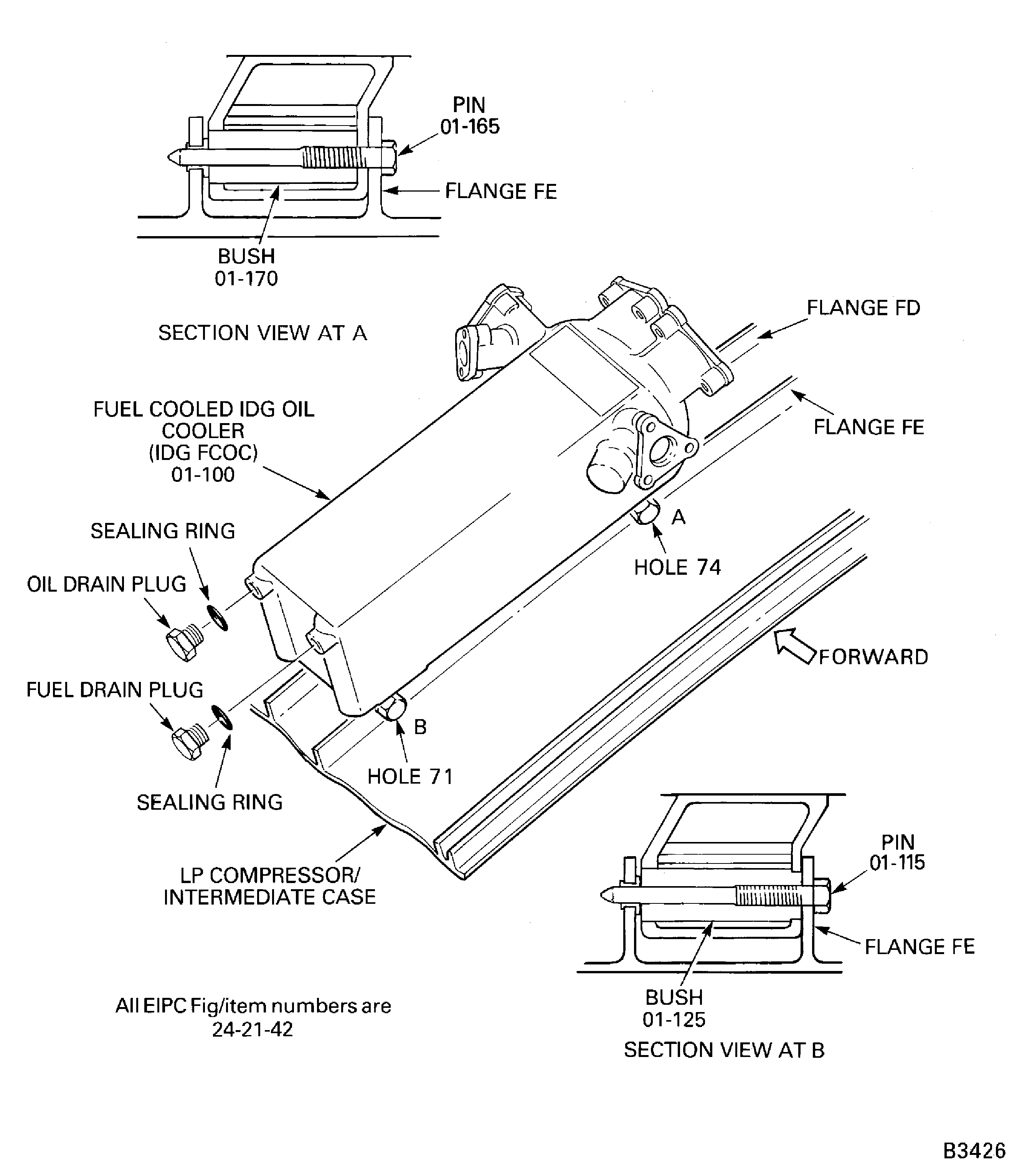

Install the bush Electrical Power-Fuel Cooled IDG Oil Cooler (24-21-42, 01-125) and the pin Electrical Power-Fuel Cooled IDG Oil Cooler (24-21-42, 01-115) to the mounting bracket at hole 73 of flange FE.

Attach the lower mounting bracket of the IDG oil cooler to flanges FD and FE.

Install the bush Electrical Power-Fuel Cooled IDG Oil Cooler (24-21-42, 01-170) and the pin Electrical Power-Fuel Cooled IDG Oil Cooler (24-21-42, 01-165) to the mounting bracket at hole 76 of flange FE.

Attach the top mounting bracket of the IDG oil cooler to flanges FD and FE.

SUBTASK 72-00-32-420-060-A00 V2500-A1 Install the Fuel Cooled IDG Oil Cooler

Refer to Figure

Install the bush Electrical Power-Fuel Cooled IDG Oil Cooler (24-21-42, 01-125) and the pin Electrical Power-Fuel Cooled IDG Oil Cooler (24-21-42, 01-115) to the mounting bracket at hole 71 of flange FE.

Attach the lower mounting bracket of the IDG oil cooler to flanges FD and FE.

Install the bush Electrical Power-Fuel Cooled IDG Oil Cooler (24-21-42, 01-170) and the pin Electrical Power-Fuel Cooled IDG Oil Cooler (24-21-42, 01-165) to the mounting bracket at hole 74 of flange FE.

Attach the top mounting bracket of the IDG oil cooler to flanges FD and FE.

SUBTASK 72-00-32-420-060-B00 V2500-A5 Install the Fuel Cooled IDG Oil Cooler

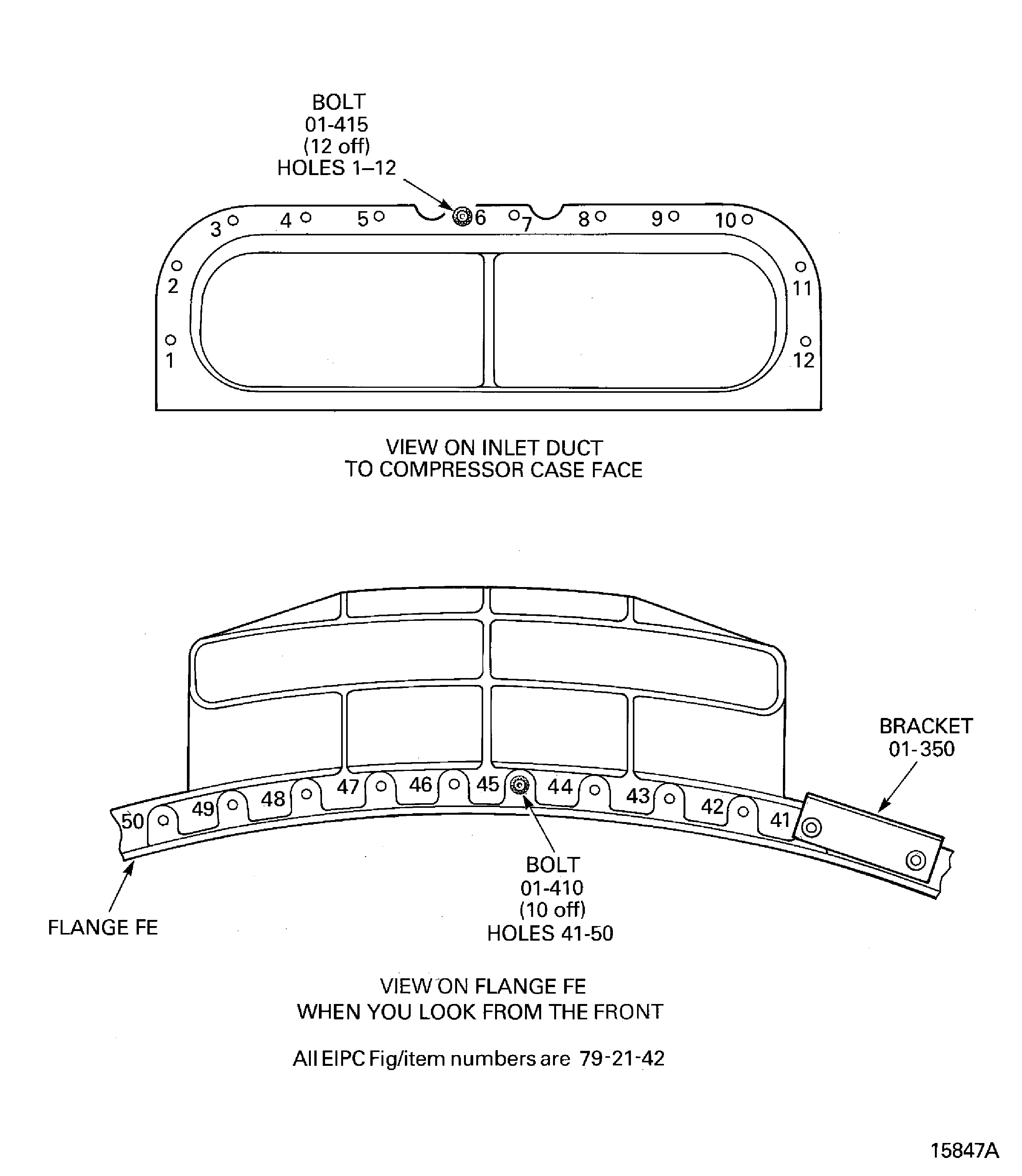

Refer to Figure.

WARNING

WHEN YOU USE COMAT 01-076 METHYL ETHYL KETONE YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Clean the mating faces of the air inlet duct and the LP compressor/intermediate case with CoMat 01-076 METHYL ETHYL KETONE.

Apply a layer, of equal thickness, of CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE or CoMat 04-005 JOINTING COMPOUND, MEDIUM GRADE or CoMat 04-006 JOINTING COMPOUND, HEAVY GRADE to the two faces. Let the faces become dry for ten minutes before installation of the air inlet duct.

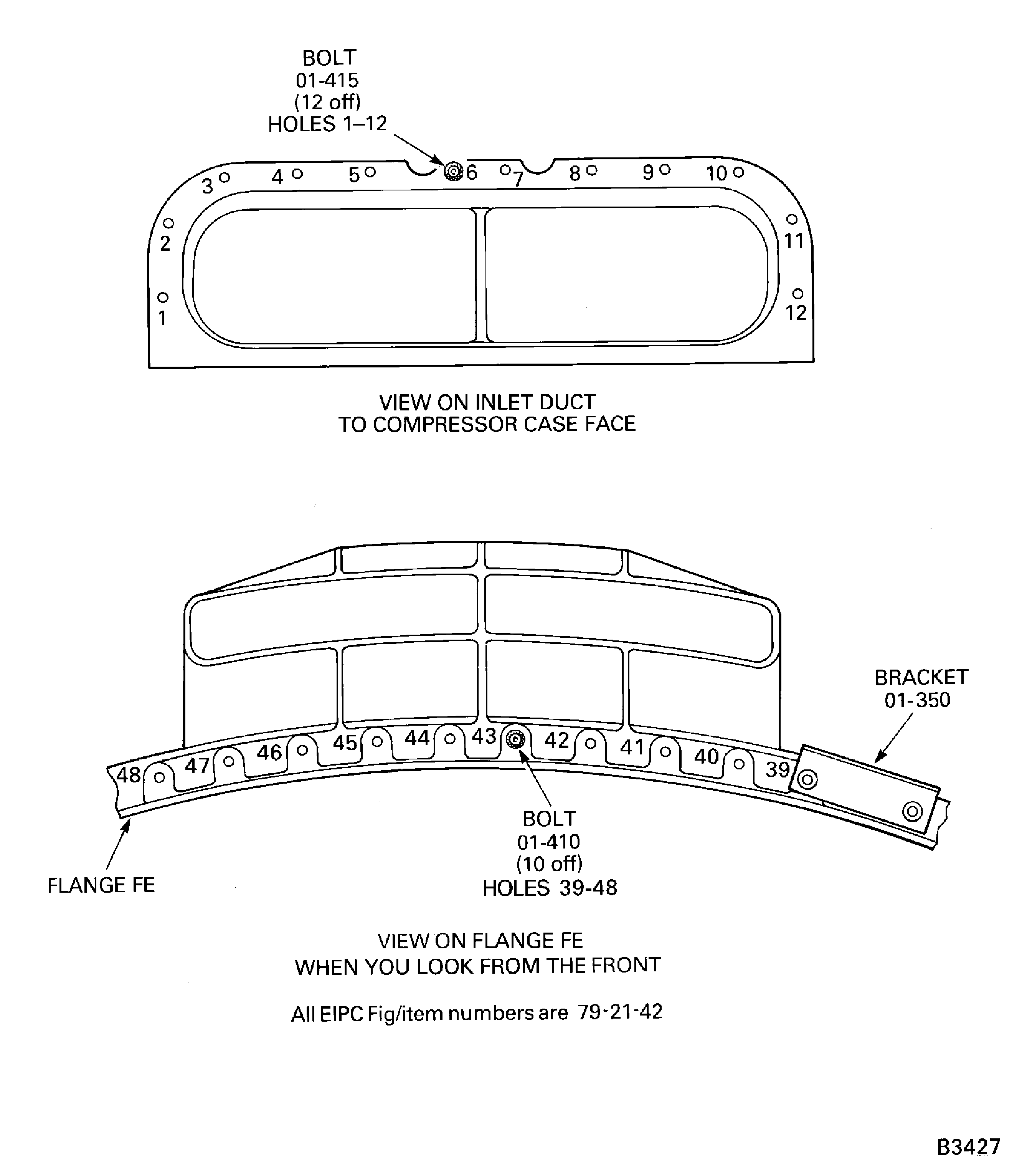

Step 1 - Install four bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-415) in holes 1, 6, 7 and 12.

Step 2 - Install four bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-410) in holes 41, 45, 46 and 50.

Step 3 - Install eight bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-415) in holes 2, 3, 4, 5, 8, 9, 10 and 11.

Step 4 - Install six bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-410) in holes 42, 43, 44, 47, 48 and 49.

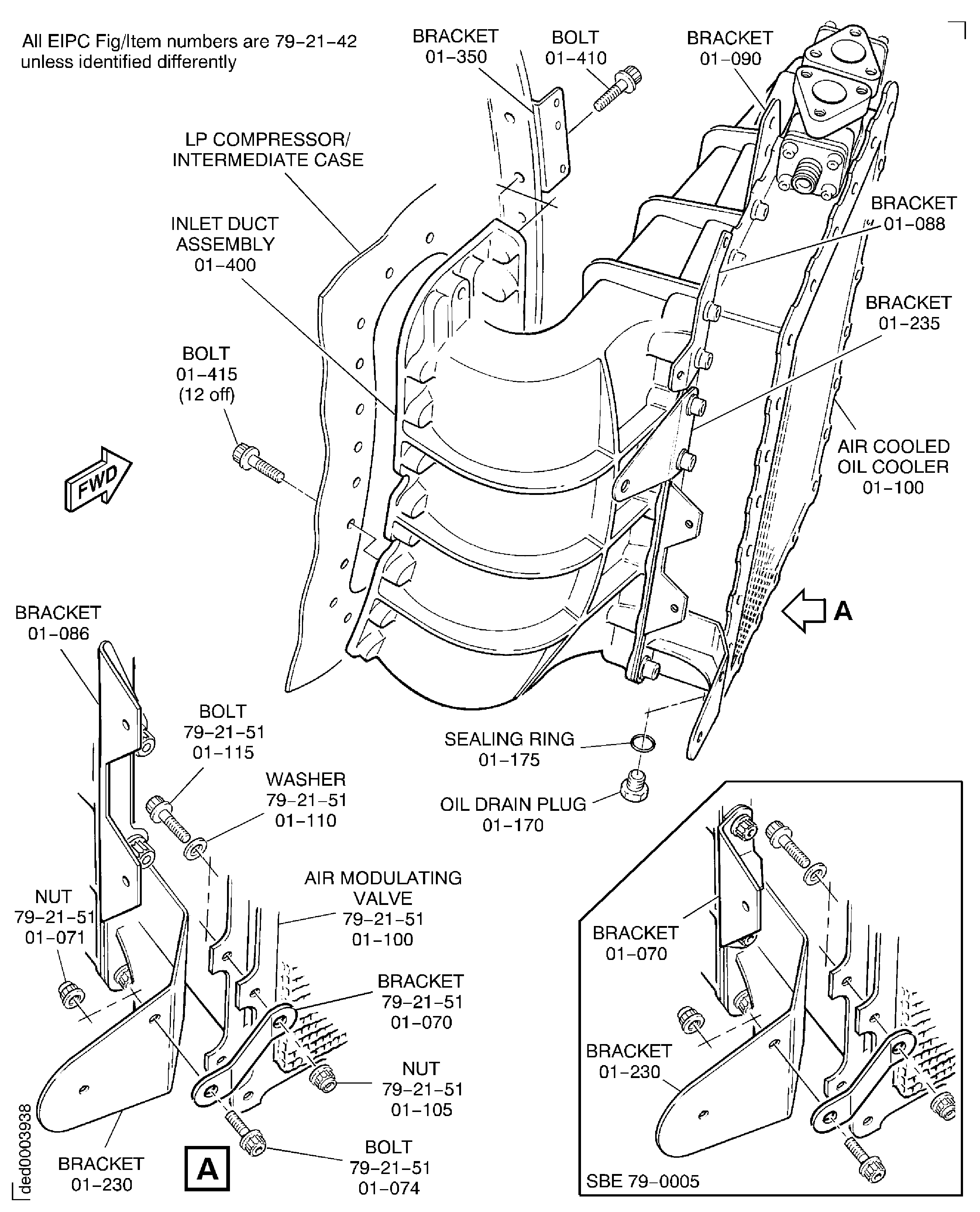

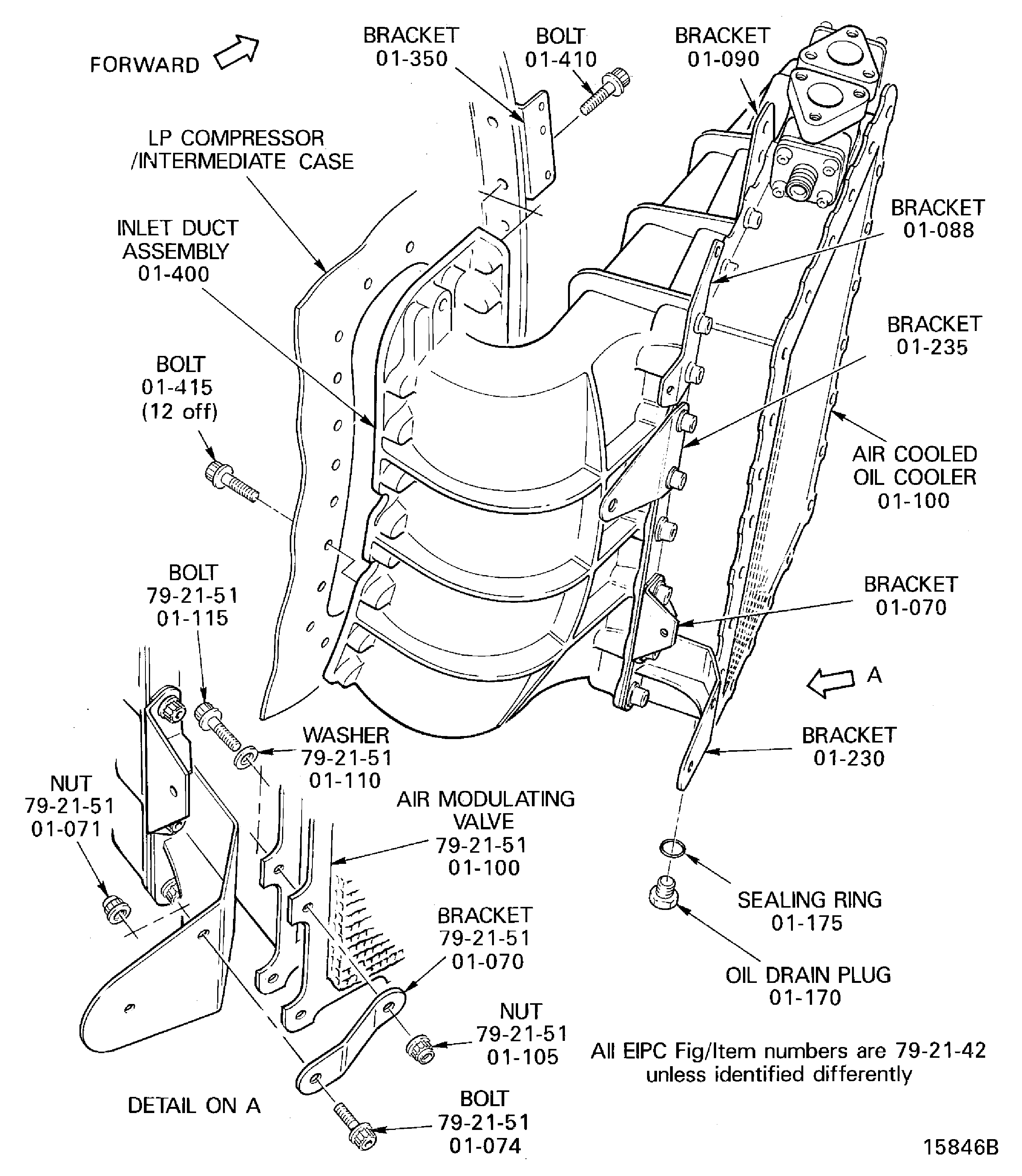

Put the ACOC in position. Then install the bolts that attach the ACOC to the LP compressor/intermediate case in the sequence that follows:

SUBTASK 72-00-32-420-061-A00 V2500-A1 Install the Air Inlet Duct Assembly

Refer to Figure

WARNING

WHEN YOU USE COMAT 01-076 METHYL ETHYL KETONE YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Clean the mating faces of the air inlet duct and the LP compressor/intermediate case with CoMat 01-076 METHYL ETHYL KETONE.

Apply a layer, of equal thickness, of CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE or CoMat 04-005 JOINTING COMPOUND, MEDIUM GRADE or CoMat 04-006 JOINTING COMPOUND, HEAVY GRADE to the two faces. Let the faces become dry for ten minutes before installation of the air inlet duct.

Step 1 - Install four bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-415) in holes 1, 6, 7 and 12.

Step 2 - Install four bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-410) in holes 39, 43, 44 and 50.

Step 3 - Install eight bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-415) in holes 2, 3, 4, 5, 8, 9, 10 and 11.

Step 4 - Install six bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-410) in holes 40, 41, 42, 45, 46 and 47.

Put the ACOC in position. Then install the bolts that attach the ACOC to the LP compressor/intermediate case in the sequence that follows:

SUBTASK 72-00-32-420-061-B00 V2500-A5 Install the Air Inlet Duct Assembly

Refer to Figure.

Clean the mating faces of the air inlet duct Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-400) and air cooled oil cooler (ACOC) Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-100), with CoMat 01-003 SOLVENT, DELETED.

Install the two boltsAir Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-150), washers Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-155) and bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-230) that attach the ACOC to the air inlet duct. Tighten the bolts by hand.

Install the two bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-150), washers Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-155) and bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-070) that attach the ACOC to the air inlet duct. Tighten the bolts by hand.

Install the two bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-150), washers Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-155) and bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-220) that attach the ACOC to the air inlet duct. Tighten the bolts by hand.

Install the two bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-150), washers Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-155) and bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-235) that attach the ACOC to the air inlet duct. Tighten the bolts by hand.

Install the two bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-150), washers Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-155) and bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-088) that attach the ACOC to the air inlet duct. Tighten the bolts by hand.

Install the two bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-150), washers Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-155) and bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-084) that attach the ACOC to the air inlet duct. Tighten the bolts by hand.

Install the two bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-150), washers Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-155) and bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-090) that attach the ACOC to the air inlet duct. Tighten the bolts by hand.

Install the remaining 10 bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-150) and washers Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-155). Tighten the bolts by hand.

WARNING

WHEN YOU USE CoMat 01-003 SOLVENT, DELETED YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Install the Air Cooled Oil Cooler Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-100).

SUBTASK 72-00-32-420-498 V2500-A1 Install the Air Cooled Oil Cooler

Refer to Figure.

Clean the mating faces of the air inlet duct Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-400) and air cooled oil cooler (ACOC) Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-100), with CoMat 01-003 SOLVENT, DELETED.

Install the two boltsAir Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-150), washers Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-155) and bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-230) that attach the ACOC to the air inlet duct. Tighten the bolts by hand.

Install the two bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-150), washers Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-155) and bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-070) that attach the ACOC to the air inlet duct. Tighten the bolts by hand.

Install the two bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-150), washers Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-155) and bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-220) that attach the ACOC to the air inlet duct. Tighten the bolts by hand.

Install the two bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-150), washers Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-155) and bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-235) that attach the ACOC to the air inlet duct. Tighten the bolts by hand.

Install the two bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-150), washers Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-155) and bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-088) that attach the ACOC to the air inlet duct. Tighten the bolts by hand.

Install the two bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-150), washers Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-155) and bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-084) that attach the ACOC to the air inlet duct. Tighten the bolts by hand.

Install the two bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-150), washers Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-155) and bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-090) that attach the ACOC to the air inlet duct. Tighten the bolts by hand.

Install the remaining 10 bolts Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-150) and washers Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-155). Tighten the bolts by hand.

WARNING

WHEN YOU USE CoMat 01-003 SOLVENT, DELETED YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Install the Air Cooled Oil Cooler Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-100).

SUBTASK 72-00-32-420-499 V2500-A5 Install the Air Cooled Oil Cooler

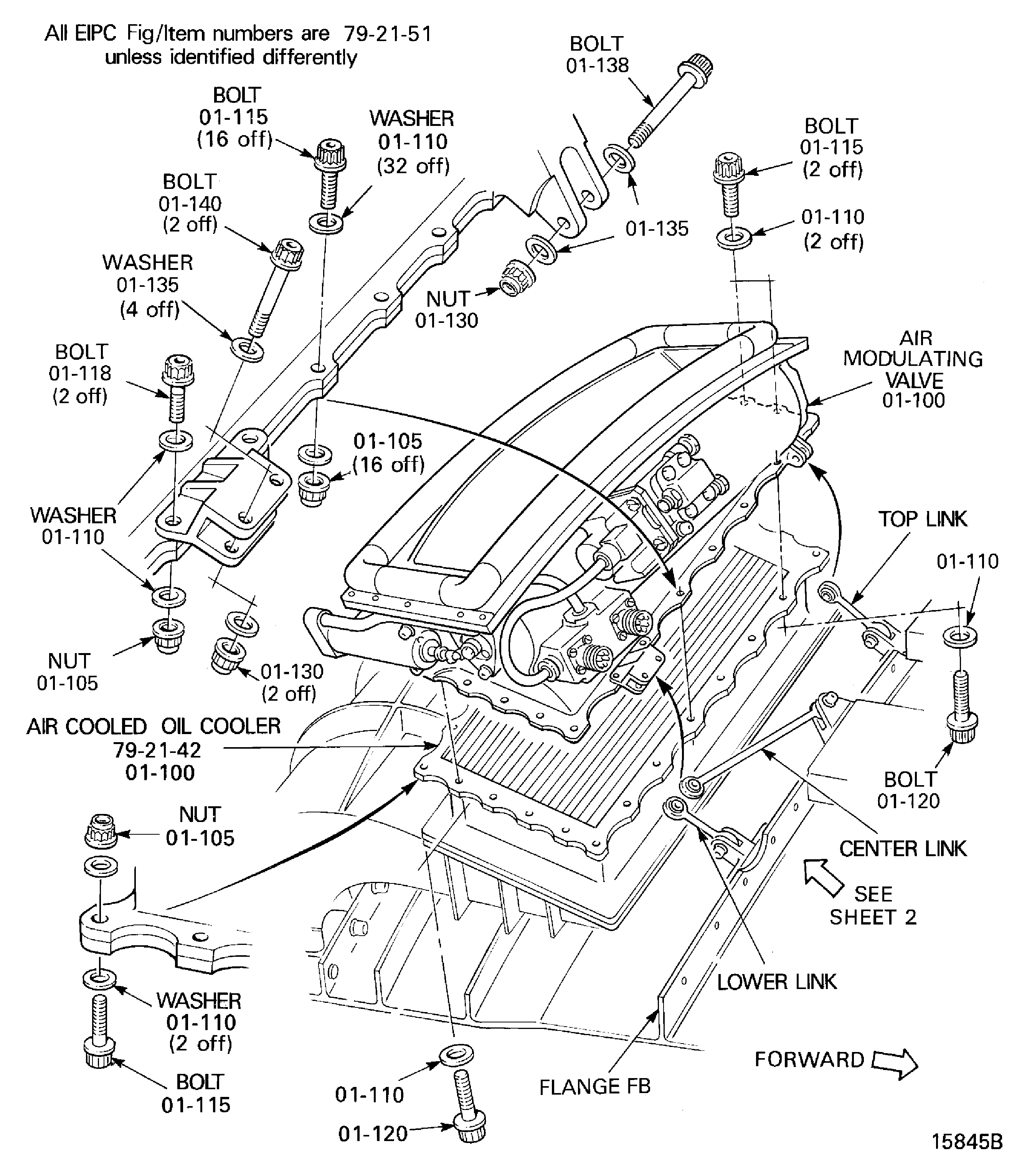

Clean the mating faces of the air modulating valve and the ACOC with CoMat 01-003 SOLVENT, DELETED. Use a clean lint free cloth moistened with the solvent.

Install the modulating valve to the ACOC flange with the four bolts and the four washers Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-120), Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-115) and Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-110). Tighten the bolts but do not torque them at this time.

Install the two bolts, the four washers and the two nuts Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-118), Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-110) and Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-105) which attach the modulating valve to the ACOC at the lower link bracket. Tighten the nuts.

Install the 16 bolts, the 32 washers and the 16 nuts Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-115), Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-110) and Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-105) which attach the modulating valve to the ACOC. Tighten the nuts.

Install the bolt, the two washers and the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-115),Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-110) and Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-105) which attach the modulating valve to the ACOC.

Attach the bracket Air Cooled Oil Cooler (ACOC) Modulating Valve(79-21-51, 01-070) to the modulating valve/ACOC flanges with the bolt, the washer and the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-115), Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-110) and Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-105) tighten the nut. Torque the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-071) which attaches the bracket to the bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42, 01-230) to 36 to 45 lbf.in (4 to 5 Nm).

Measure the electrical resistance between the modulating valve/ACOC flanges. Put an electrical current of 950 to 1050 milliamperes through the joint and measure the decrease in milli-volts across the joint. The electrical resistance must not be more than 0.0025 ohms. Clean the joint, if necessary, to get the correct electrical resistance.

Torque the four bolts Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-115) and Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-120) to 85 to 105 lbf.in (10 to 12 Nm) refer to Step.

Torque the 20 nuts Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-105) to 85 to 105 lbf.in (10 to 12 Nm) refer to Step to Step.

WARNING

WHEN YOU USE COMAT 01-003 INHIBITED AND STABILIZED TRICHLOROETHANE YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Install the modulating valve.

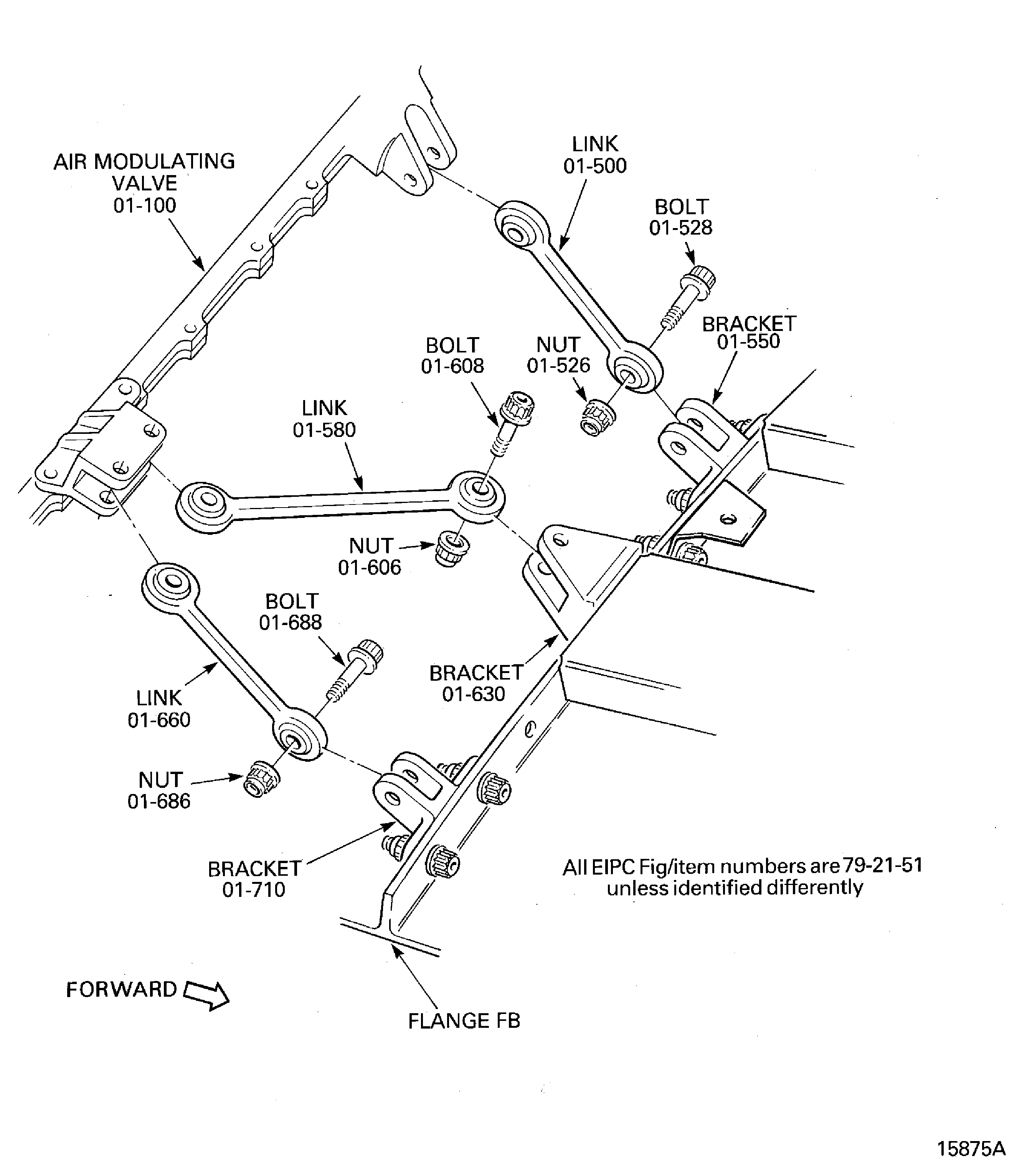

Attach the link to the air modulating valve with the bolt Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-138), the two washers Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-135) and the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-130).

Attach the link to the bracket Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51,01-550), on flange FB, with the bolt Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-528) and the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-526).

Install the top link Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-500).

Attach the link to the air modulating valve with the bolt Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-140), the two washers Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-135) and the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-130).

Attach the link to the bracket Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-630), on flange FB, with the bolt Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-608) and the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-606).

Install the center link Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-580).

Attach the link to the air modulating valve with the bolt Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-140), the two washers Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-135) and the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-130).

Attach the link to the bracket Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-710), on flange FB, with the bolt Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-688) and the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-686).

Install the lower link Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-660).

Install the three support link assemblies.

SUBTASK 72-00-32-420-062-A00 V2500-A1 Install the Air Modulating Valve

Clean the mating faces of the air modulating valve and the ACOC with CoMat 01-003 SOLVENT, DELETED. Use a clean lint free cloth moistened with the solvent.

Install the modulating valve to the ACOC flange with the four bolts and the four washers Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-120, Air Cooled Oil Cooler (ACOC) Modulating Valve 01-115 and Air Cooled Oil Cooler (ACOC) Modulating Valve 01-110). Tighten the bolts but do not torque them at this time.

Install the two bolts, the four washers and the two nuts Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-118 , Air Cooled Oil Cooler (ACOC) Modulating Valve 01-110 and Air Cooled Oil Cooler (ACOC) Modulating Valve 01-105) which attach the modulating valve to the ACOC at the lower link bracket. Tighten the nuts.

Install the 16 bolts, the 32 washers and the 16 nuts Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-115 , Air Cooled Oil Cooler (ACOC) Modulating Valve 01-110 and Air Cooled Oil Cooler (ACOC) Modulating Valve 01-105) which attach the modulating valve to the ACOC. Tighten the nuts.

Install the bolt, the two washers and the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-115 ,Air Cooled Oil Cooler (ACOC) Modulating Valve 01-110 and Air Cooled Oil Cooler (ACOC) Modulating Valve 01-105) which attach the modulating valve to the ACOC.

Attach the bracket Air Cooled Oil Cooler (ACOC) Modulating Valve(79-21-51,01-070) to the modulating valve/ACOC flanges with the bolt, the washer and the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-115 , Air Cooled Oil Cooler (ACOC) Modulating Valve 01-110 and Air Cooled Oil Cooler (ACOC) Modulating Valve 01-105) tighten the nut. Torque the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51,01-071) which attaches the bracket to the bracket Air Cooled Oil Cooler (ACOC) And Inlet Duct (79-21-42,01-230) to 36 to 45 lbf.in (4 to 5 Nm).

Measure the electrical resistance between the modulating valve/ACOC flanges. Put an electrical current of 950 to 1050 milliamperes through the joint and measure the decrease in milli-volts across the joint. The electrical resistance must not be more than 0.0025 ohms. Clean the joint, if necessary, to get the correct electrical resistance.

Torque the four bolts Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-115 and Air Cooled Oil Cooler (ACOC) Modulating Valve 01-120) to 85 to 105 lbf.in (10 to 12 Nm) refer to Step.

Torque the 20 nuts Air Cooled Oil Cooler (ACOC) Modulating Valve(79-21-51,01-105) to 85 to 105 lbfin (10 to 12 Nm) refer to Step to Step.

WARNING

WHEN YOU USE COMAT 01-003 INHIBITED AND STABILIZED TRICHLOROETHANE YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Install the modulating valve.

Attach the link to the air modulating valve with the bolt Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-138), the two washers Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-135) and the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-130).

Attach the link to the bracket Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51,01-550), on flange FB, with the bolt Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-528) and the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-526).

Install the top link Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-500).

Attach the link to the air modulating valve with the bolt Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-140), the two washers Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-135) and the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-130).

Attach the link to the bracket Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51,01-630), on flange FB, with the bolt Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-608) and the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-606).

Install the center link Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-580).

Attach the link to the air modulating valve with the bolt Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-140), the two washers Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-135) and the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-130).

Attach the link to the bracket Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51,01-710), on flange FB, with the bolt Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-688) and the nut Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-686).

Install the lower link Air Cooled Oil Cooler (ACOC) Modulating Valve (79-21-51, 01-660).

Install the three support link assemblies.

SUBTASK 72-00-32-420-062-B00 V2500-A5 Install the Air Modulating Valve

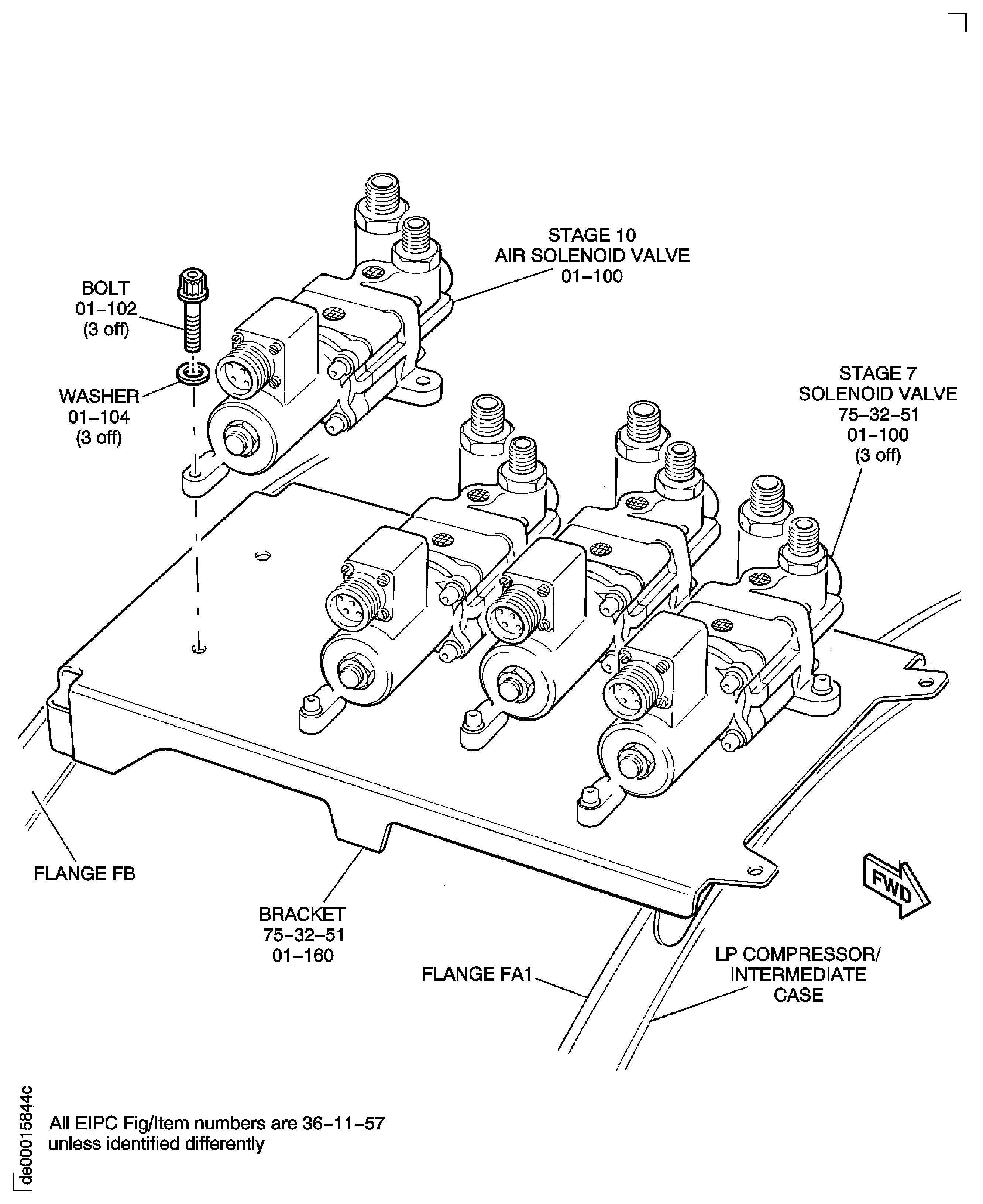

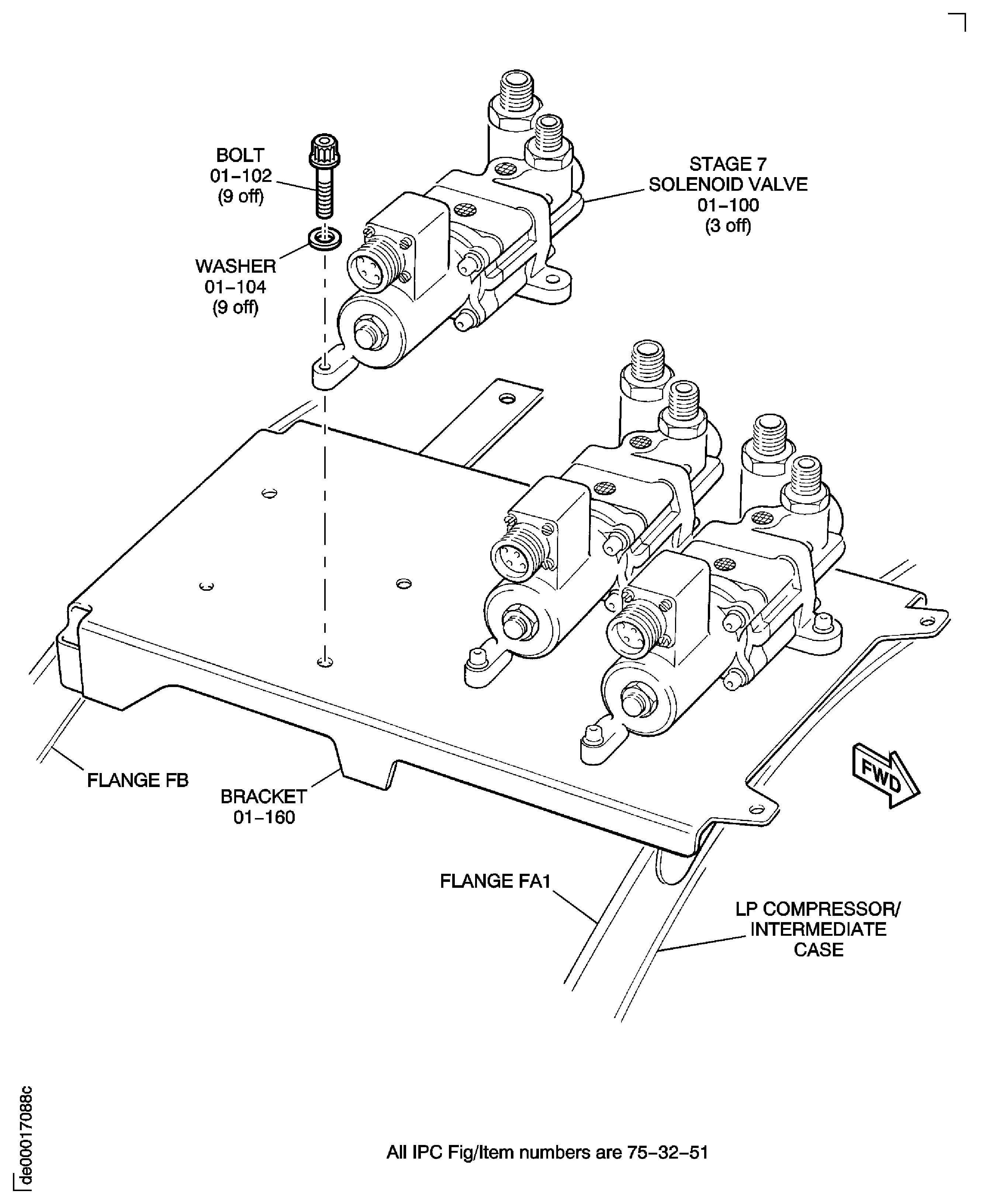

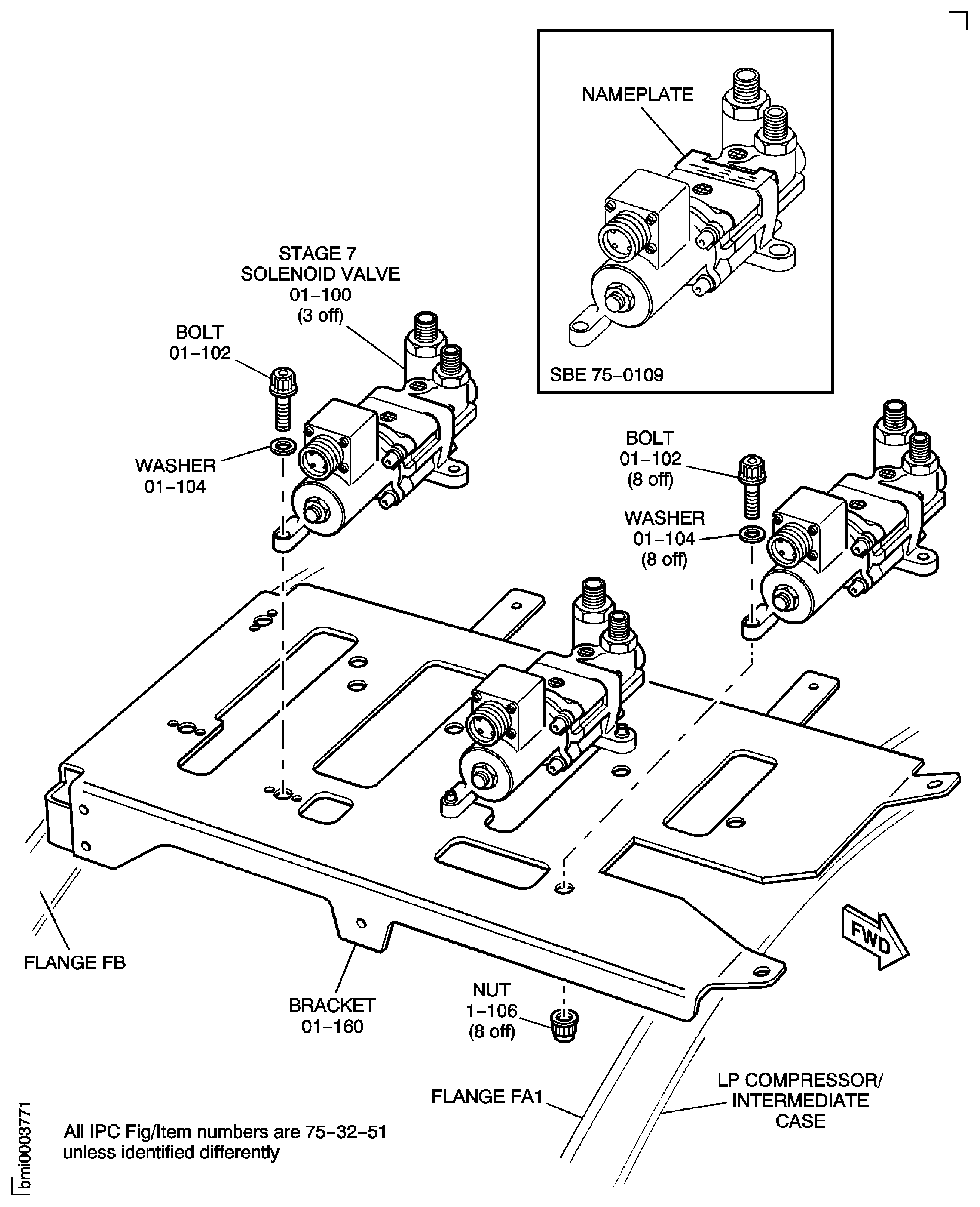

NOTE

The solenoid valves must have their maintenance completed, as given in the Dunlop Component Maintenance Manual (75-32-51).Pre SBE 75-0047: Install each of the three stage 7 HP compressor air solenoid valves HPC Stage 7 Solenoid Valve (75-32-51, 01-100) to the mounting bracket HPC Stage 7 Solenoid Valve (75-32-51, 01-160) with the three bolts HPC Stage 7 Solenoid Valve (75-32-51, 01-102) and the three washers HPC Stage 7 Solenoid Valve (75-32-51, 01-104).

NOTE

The solenoid valves must have their maintenance completed, as given in the Dunlop Component Maintenance Manual (75-32-51).SBE 75-0047: Install the three stage 7 HP compressor air solenoid valves HPC Stage 7 Solenoid Valve (75-32-51, 01-100) to the mounting bracket HPC Stage 7 Solenoid Valve (75-32-51, 01-160) with the nine bolts HPC Stage 7 Solenoid Valve (75-32-51, 01-102), the nine washers HPC Stage 7 Solenoid Valve (75-32-51, 01-104) and the eight nut HPC Stage 7 Solenoid Valve (75-32-51, 01-106).

SUBTASK 72-00-32-420-063 Install the Stage 7 HP Compressor Air Solenoid Valves (Pre SBE 75-0047 and SBE 75-0047)

NOTE

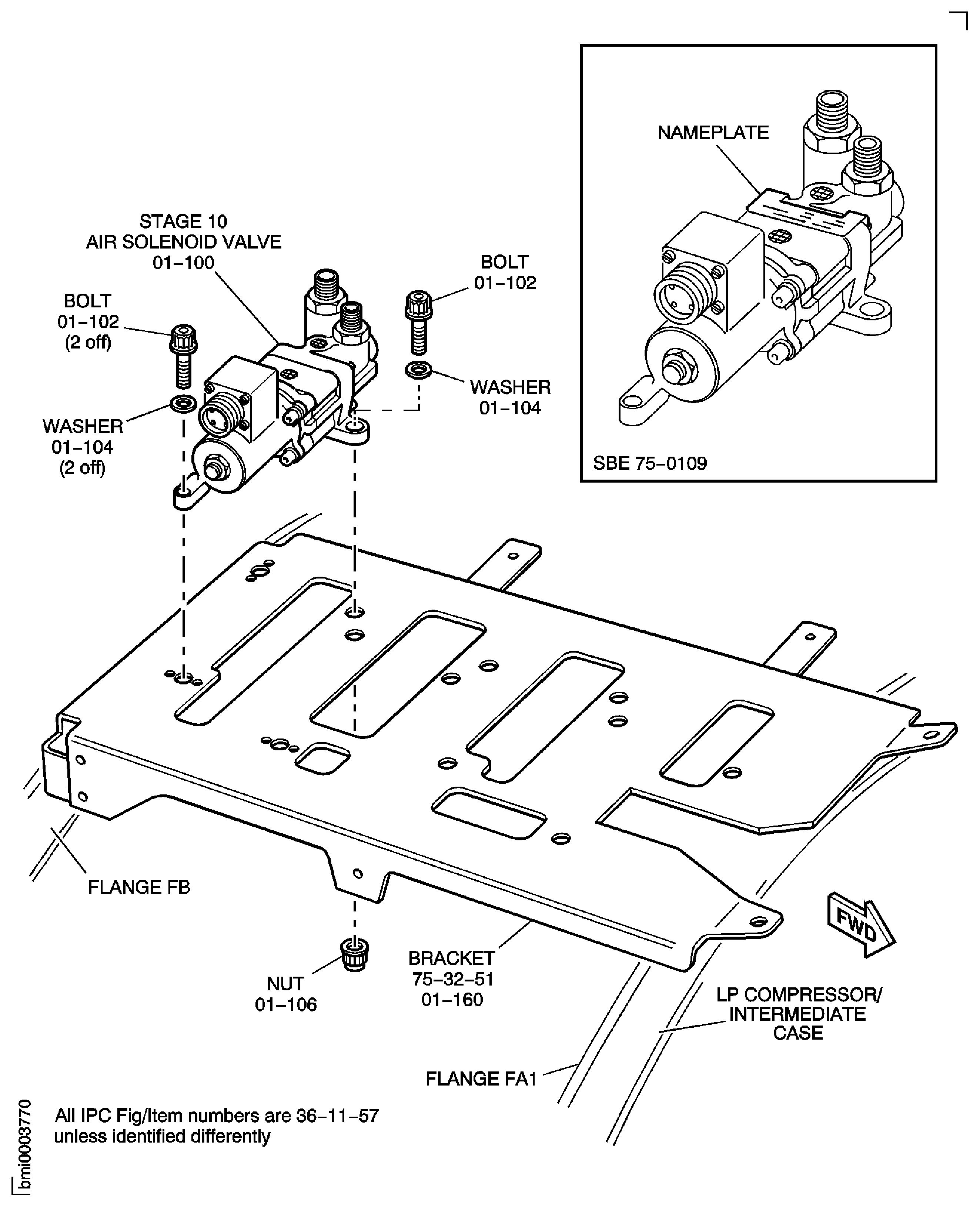

The solenoid valve must have its maintenance completed, as given in the Dunlop Component Maintenance Manual (36-11-57).Pre SBE 75-0047: Install the stage 10 air solenoid valve STAGE 10 AIR SOLENOID VALVE (36-11-57, 01-100) to the mounting bracket HPC Stage 7 Solenoid Valve (75-32-51, 01-160) with the three bolts STAGE 10 AIR SOLENOID VALVE (36-11-57, 01-102) and the three washers STAGE 10 AIR SOLENOID VALVE (36-11-57, 01-104).

NOTE

The solenoid valve must have its maintenance completed, as given in the Dunlop Component Maintenance Manual (36-11-57).SBE 75-0047: Install the stage 10 air solenoid valve STAGE 10 AIR SOLENOID VALVE (36-11-57, 01-100) to the mounting bracket HPC Stage 7 Solenoid Valve (75-32-51, 01-160) with the three bolts STAGE 10 AIR SOLENOID VALVE (36-11-57, 01-102), the three washers STAGE 10 AIR SOLENOID VALVE (36-11-57, 01-104) and the nut STAGE 10 AIR SOLENOID VALVE (36-11-57,01-106).

SUBTASK 72-00-32-420-109 Install the Stage 10 Air Solenoid Valve (Pre SBE 75-0047 and SBE 75-0047)

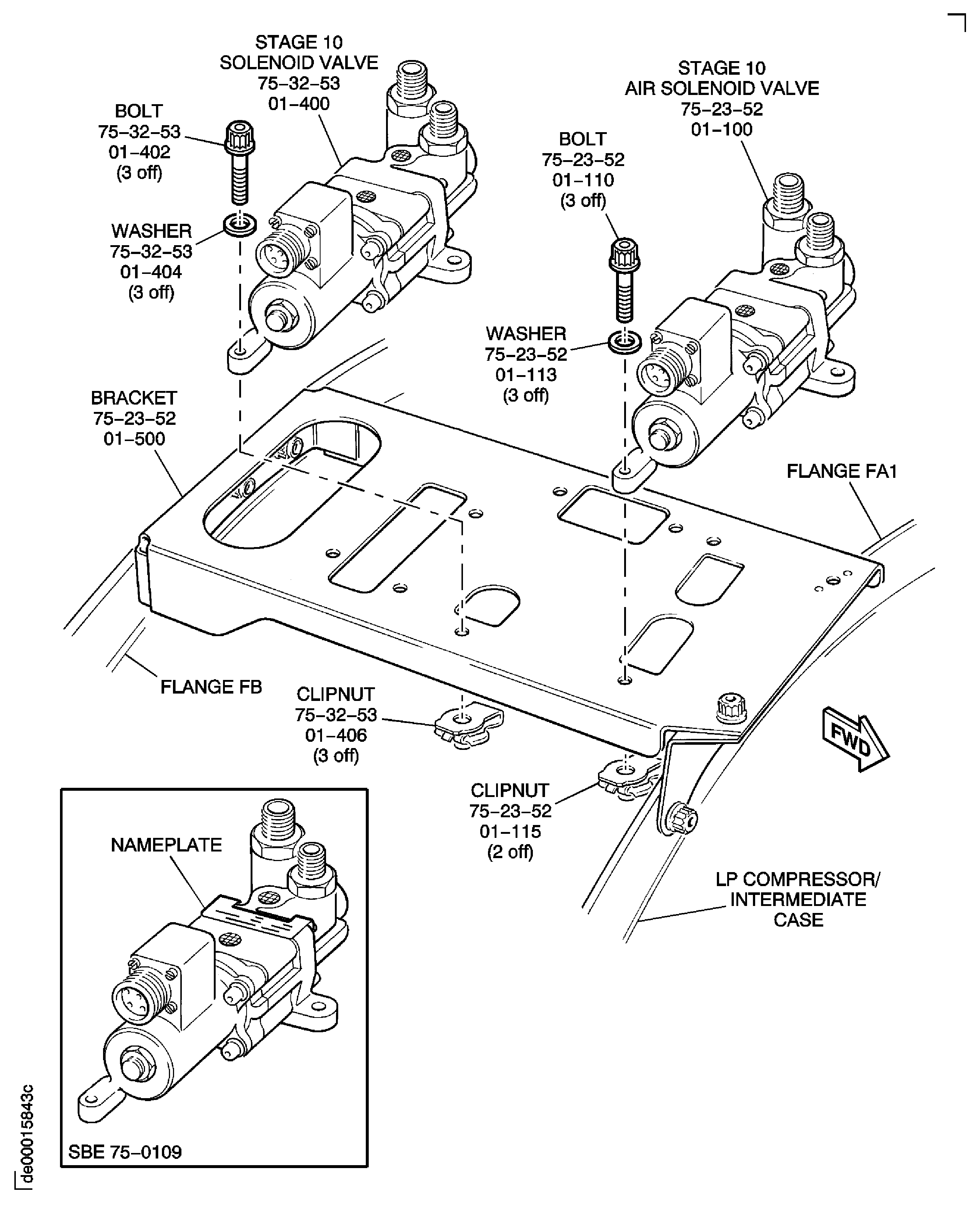

Refer to Figure

Install the stage 10 solenoid valve AIR-HPC STAGE 10 SOLENOID VALVE (75-32-53, 01-400) to the mounting bracket AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-500) with the three bolts AIR-HPC STAGE 10 SOLENOID VALVE (75-32-53, 01-402), the three washers AIR-HPC STAGE 10 SOLENOID VALVE (75-32-53, 01-404) and the three clipnuts AIR-HPC STAGE 10 SOLENOID VALVE (75-32-53, 01-406).

Install the stage 10 solenoid valve AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-100) to the mounting bracket with three bolts AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-110), the three washers AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-113) and the two clipnuts AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-115).

SUBTASK 72-00-32-420-064 Install the Stage 10 HP Compressor Air Solenoid Valves

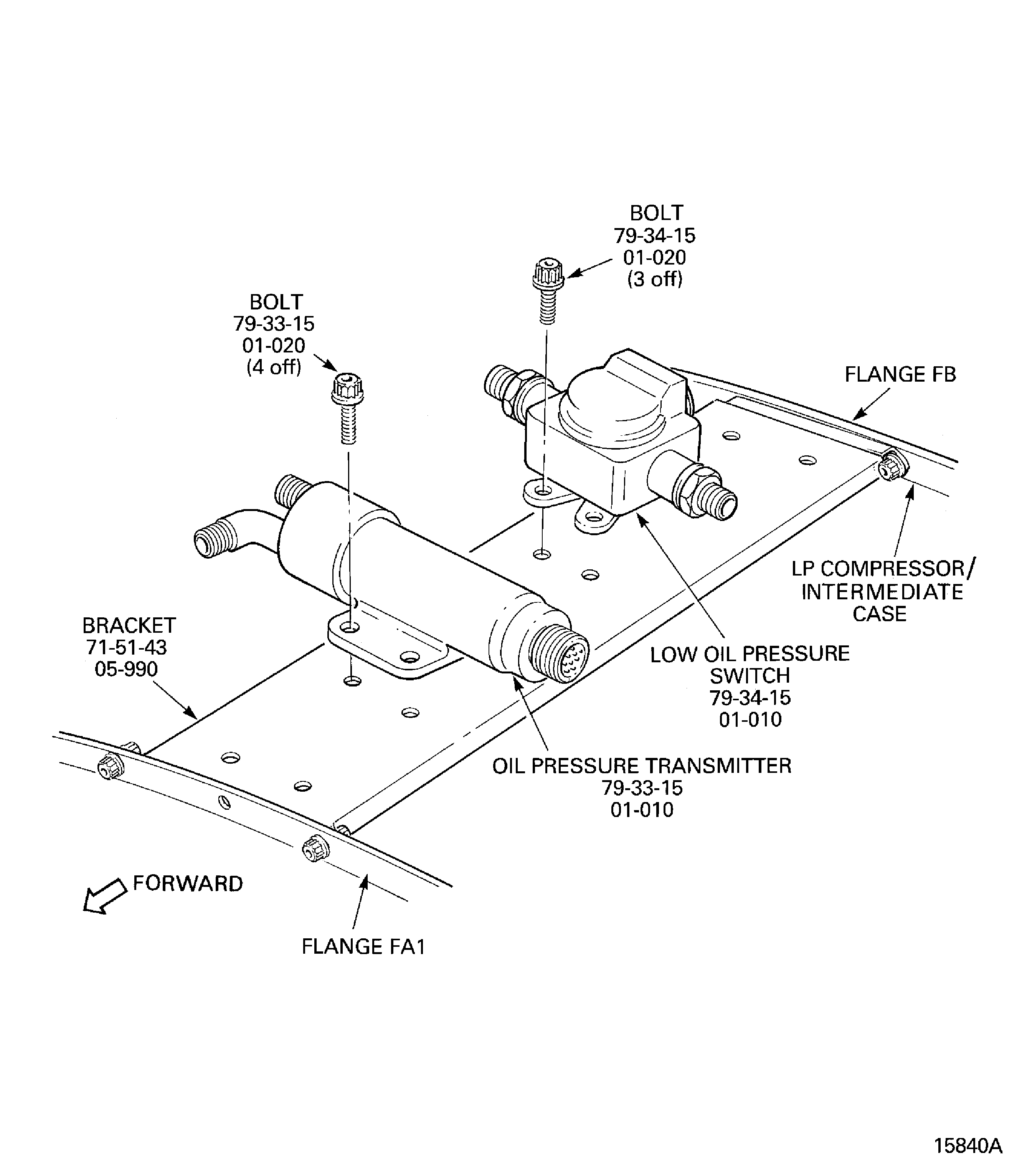

Refer to Figure.

Install the low oil pressure switch LOW OIL PRESSURE SWITCH (79-34-15, 01-010) to the mounting bracket General Services Harness (71-51-43, 05-990) with the three bolts LOW OIL PRESSURE SWITCH (79-34-15, 01-020). Torque the bolts to 36 to 45 lbf.in (4 to 5 Nm).

SUBTASK 72-00-32-420-065 Install the Low Oil Pressure Switch

Refer to Figure.

Install the oil pressure transmitter OIL-OIL PRESSURE TRANSMITTER (79-33-15, 01-010) to the mounting bracket General Services Harness (71-51-43, 05-990) with the four bolts OIL-OIL PRESSURE TRANSMITTER (79-33-15, 01-020). Torque the bolts to between 85 and 105 lbf.in (10 and 12 Nm).

SUBTASK 72-00-32-420-066 Install the Oil Pressure Transmitter

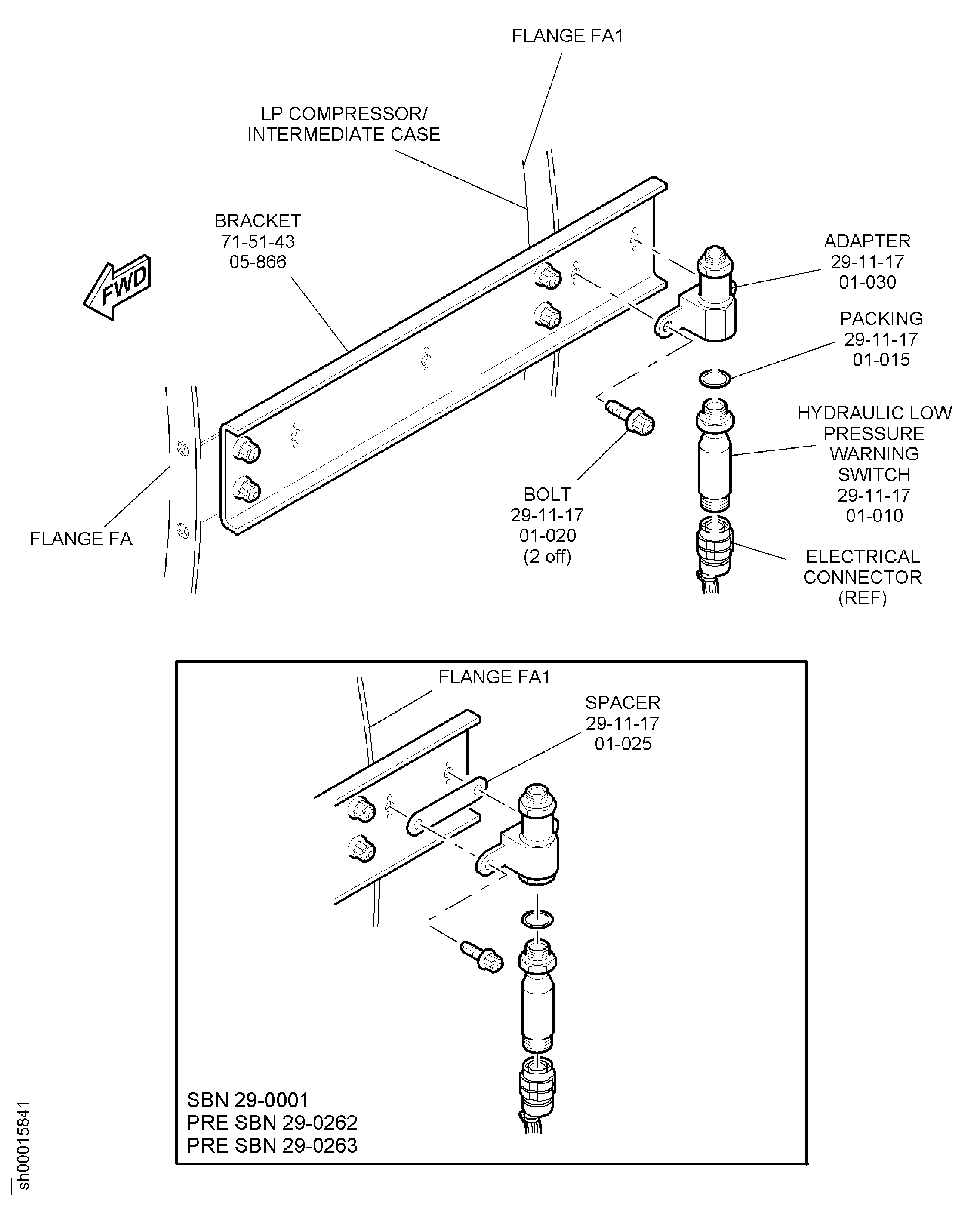

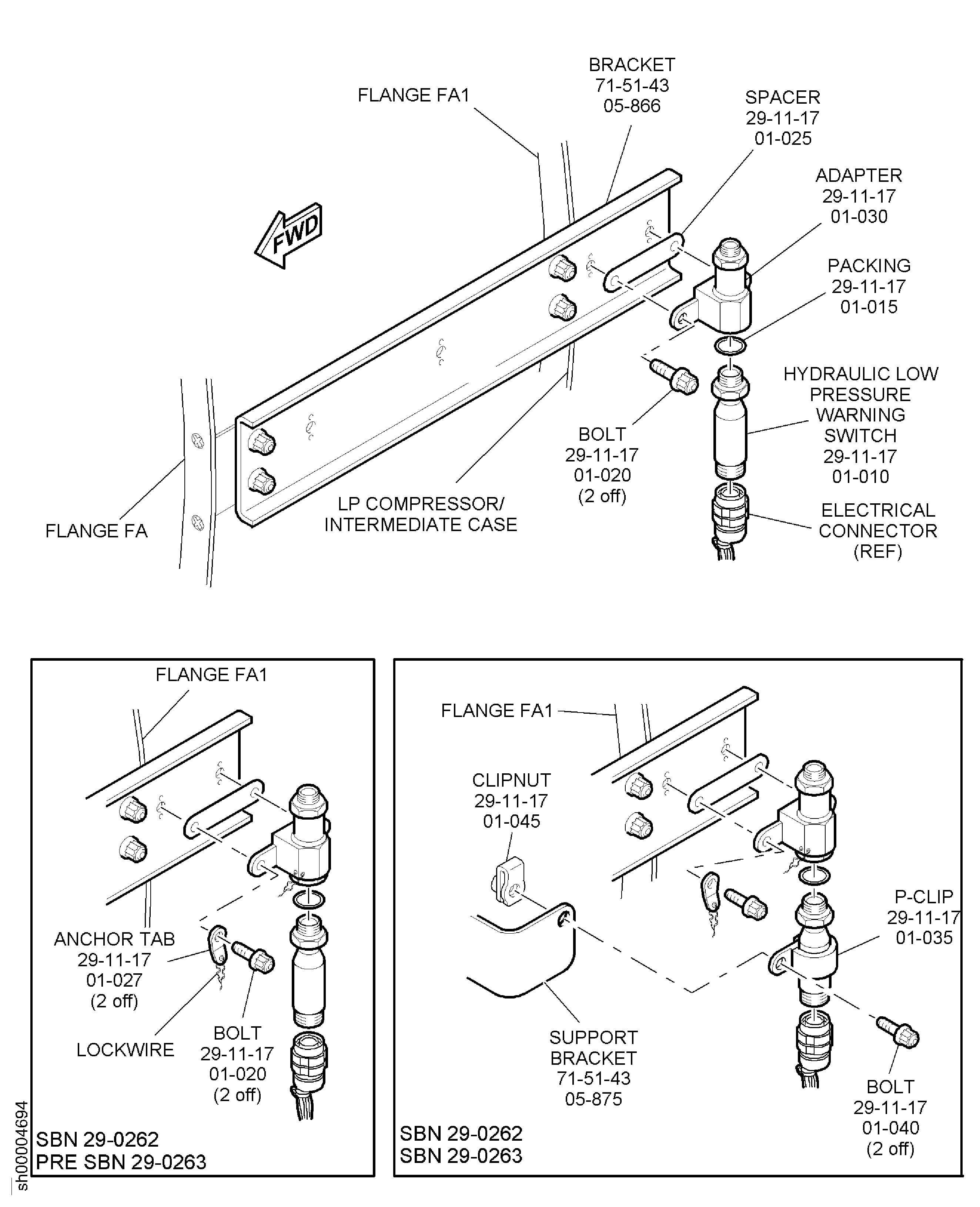

Refer to Figure.

Attach the hydraulic low pressure warning switch HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) with the packing HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-015) to the adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030). Torque the switch end HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) to 95 to 105 lbf.in (11 to 12 Nm) and the adapter end HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to 380 to 405 lbf.in (43 to 46 Nm).

Install the hydraulic low pressure warning switch assembly HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) and adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to the bracket General Services Harness (71-51-43, 05-866) with the two bolts HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-020). Torque the bolts to 36 to 45 lbf.in (4 to 5 Nm).

SUBTASK 72-00-32-420-067-A00 V2500-A1 Install the Hydraulic Low Pressure Warning Switch (Pre SBN 29-0001)

Refer to Figure.

Attach the hydraulic low pressure warning switch HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) with the packing HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-015) to the adapter (29-11-017,01-030). Torque the switch end HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) to 95 to 105 lbf.in (11 to 12 Nm) and the adapter end HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to 380-405 lbf.in (43 to 46 Nm).

Install the hydraulic low pressure warning switch assembly HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) and HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to the bracket HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-930) with the two bolts HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-020) and the spacer HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-025). Torque the bolts to 36 to 45 lbf.in (4 to 5 Nm).

SUBTASK 72-00-32-420-067-B00 V2500-A1 Install the Hydraulic Low Pressure Warning Switch (SBN 29-0001, Pre SBN 29-0262 and Pre SBN 29-0263)

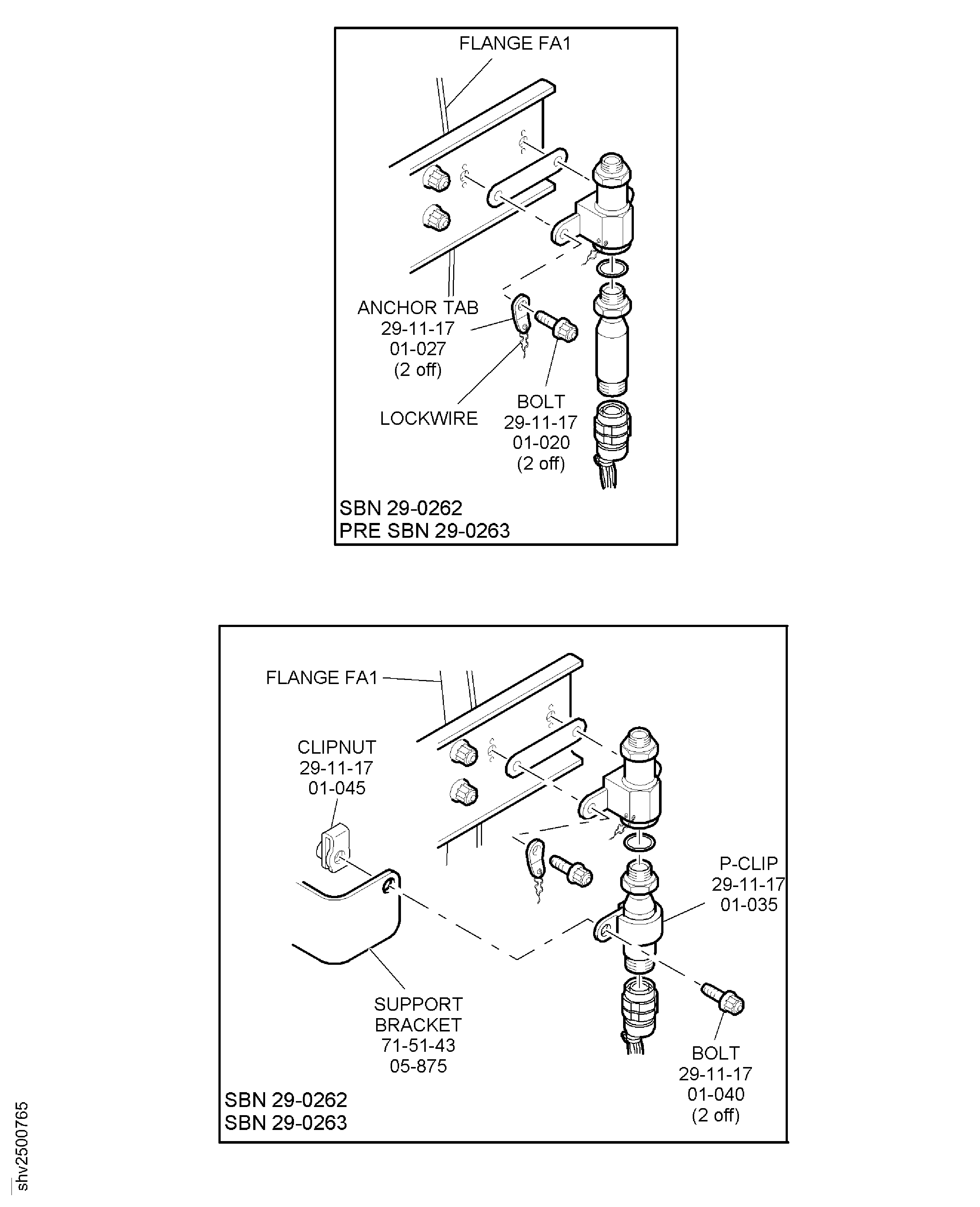

Refer to Figure.

Attach the hydraulic low pressure warning switch HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) with the packing HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-015) to the adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030). Hold the adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) with an applicable wrench and torque the switch end HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) to 95 to 105 lbf.in (11 to 12 Nm) and the adapter end HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to 380 to 405 lbf.in (43 to 46 Nm).

Install the hydraulic low pressure warning switch assembly HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) and adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to the bracket General Services Harness (71-51-43, 05-866) with the two bolts HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-020) the two anchor tabs HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-027) and the spacer HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-025). Torque the bolts to 36 to 45 lbf.in (4 to 5 Nm).

Safety the hydraulic low pressure warning switch assembly HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) and adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to the nearest anchor tab HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-027) with CoMat 02-147 LOCKWIRE.

SUBTASK 72-00-32-420-067-C00 V2500-A1 Install the Hydraulic Low Pressure Warning Switch (SBN 29-0001, SBN 29-0262 and Pre SBN 29-0263)

Refer to Figure.

Attach the hydraulic low pressure warning switch HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) with the packing HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-015) to the adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030). Torque the switch end HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) to 95 to 105 lbf.in (11 to 12 Nm) and the adapter end HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to 380 to 405 lbf.in (43 to 46 Nm).

Install the hydraulic low pressure warning switch assembly HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) and adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to bracket General Services Harness (71-51-43, 05-866) with the two bolts HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-020), the two anchor tabs HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-027) and the spacer HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-025). Torque the bolts to 36 to 45lbf.in (4 to 5 Nm).

Attach the hydraulic low pressure warning switch HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) to the support bracket General Services Harness (71-51-43, 05-875) with the P-clip HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-035), the bolt HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-040) and the clipnut HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-045), torque the bolt to 40 lbf.in (4.52 Nm).

Safety the hydraulic low pressure warning switch assembly HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) and adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to the nearest anchor tab HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-027) with CoMat 02-147 LOCKWIRE.

SUBTASK 72-00-32-420-067-D00 V2500-A1 Install the Hydraulic Low Pressure warning Switch (SBN 29-0001, SBN 29-0262 and SBN 29-0263)

Refer to Figure.

Attach the hydraulic low pressure warning switch HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) with the packing HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-015) to the adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030). Torque the switch end HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) to 95 to 105 lbf.in (11 to 12 Nm) and the adapter end HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to 380 to 405 lbf.in (43 to 46 Nm).

Install the hydraulic low pressure warning switch assembly HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) and adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to the bracket HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-930) with the two bolts HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-020) and the spacer HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-025). Torque the bolts to 36 to 45 lbf.in (4 to 5 Nm).

SUBTASK 72-00-32-420-067-E00 V2500-A5 Install the Hydraulic Low Pressure Warning Switch (Pre SBN 29-0262 and Pre SBN 29-0263)

Refer to Figure.

Attach the hydraulic low pressure warning switch HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) with the packing HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-015) to the adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030). Torque the switch end HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) to 95 to 105 lbf.in (11 to 12 Nm) and the adapter end HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to 380 to 405 lbf.in (43 to 46 Nm).

Install the hydraulic low pressure warning switch assembly HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) and adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to the bracket General Services Harness (71-51-43, 05-866) with the two bolts HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-020), the two anchor tabs HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-027) and the spacer HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-025). Torque the bolts to 36 to 45lbfin. (4 to 5 Nm).

Safety the hydraulic low pressure warning switch assembly HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) and adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to the nearest anchor tab HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-027) with CoMat 02-147 LOCKWIRE.

SUBTASK 72-00-32-420-067-F00 V2500-A5 Install the Hydraulic Low Pressure Warning Switch (SBN 29-0262 and Pre SBN 29-0263)

Refer to Figure.

Attach the hydraulic low pressure warning switch HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) with the packing HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-015) to the adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030). Torque the switch end HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) to 95 to 105 lbf.in (11 to 12 Nm) and the adapter end HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to 380 to 405 lbf.in (43 to 46 Nm).

Install the hydraulic low pressure warning switch assembly HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) and adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to the bracket General Services Harness (71-51-43, 05-866) with the two bolts HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-020), the two anchor tabs HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-027) and the spacer HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-025). Torque the bolts to 36 to 45 lbf.in (4 to 5 Nm).

Attach the hydraulic low pressure warning switch HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) to the support bracket General Services Harness (71-51-43, 05-875) with P-clip HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-035), the bolt HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-040) and the clipnut HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-045). Torque the bolt to 40 lbf.in (4.52 Nm).

Safety the hydraulic low pressure warning switch assembly HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-010) and adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030) to the nearest anchor tab HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-207) with CoMat 02-147 LOCKWIRE.

SUBTASK 72-00-32-420-067-G00 V2500-A5 Install the Hydraulic Low Pressure Warning Switch (SBN 29-0262 and SBN 29-0263)

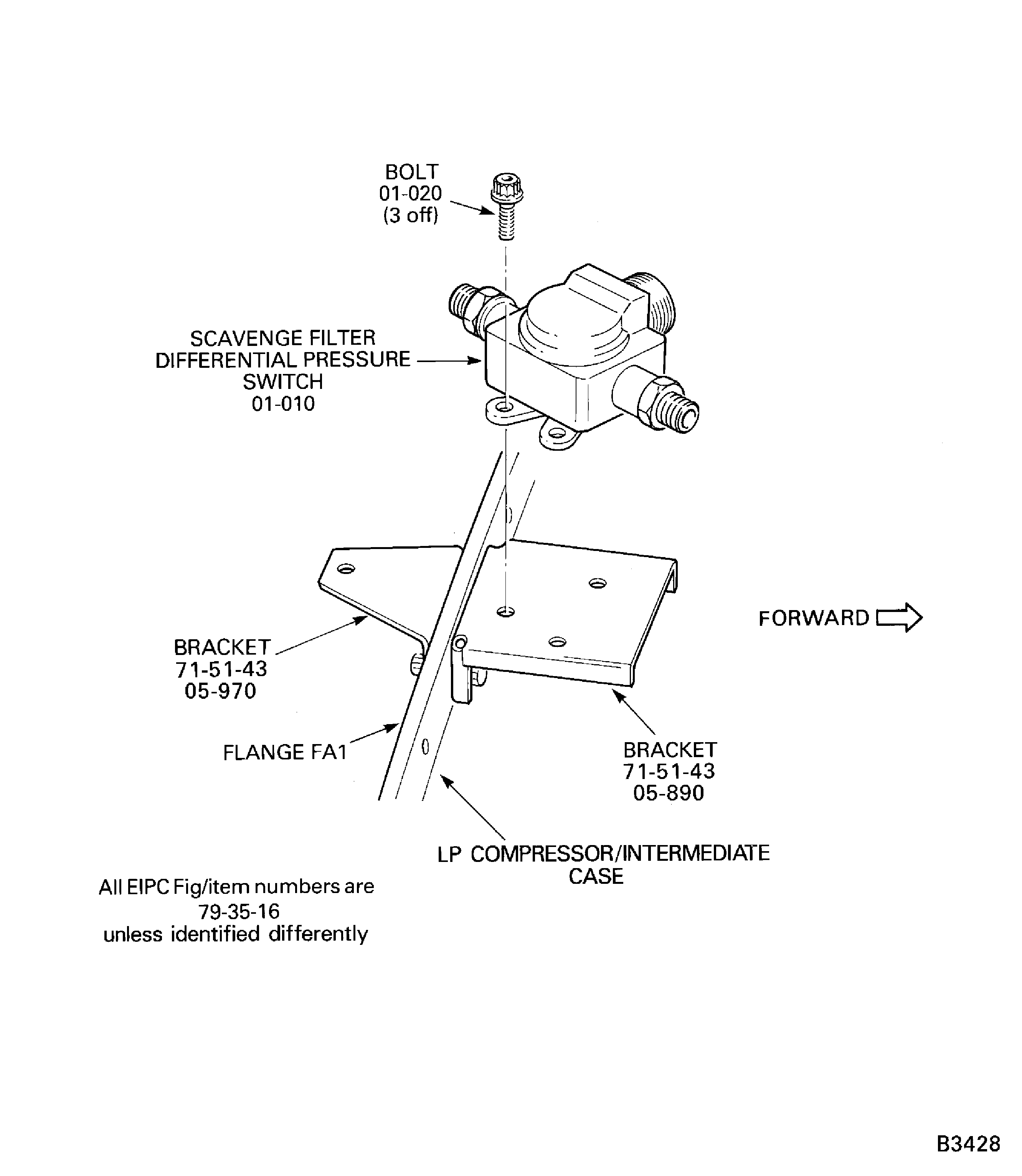

Refer to Figure.

Install the scavenge filter differential pressure switch OIL-SCAVENGE FILTER DIFFERENTIAL PRESSURE SWITCH (79-35-16, 01-010) to the bracket General Services Harness (71-51-43, 05-890) with the three bolts OIL-SCAVENGE FILTER DIFFERENTIAL PRESSURE SWITCH (79-35-16, 01-020). Torque the bolts to 36 to 45 lbf.in (4 to 5 Nm).

SUBTASK 72-00-32-420-068 Install the Scavenge Filter Differential Pressure Switch

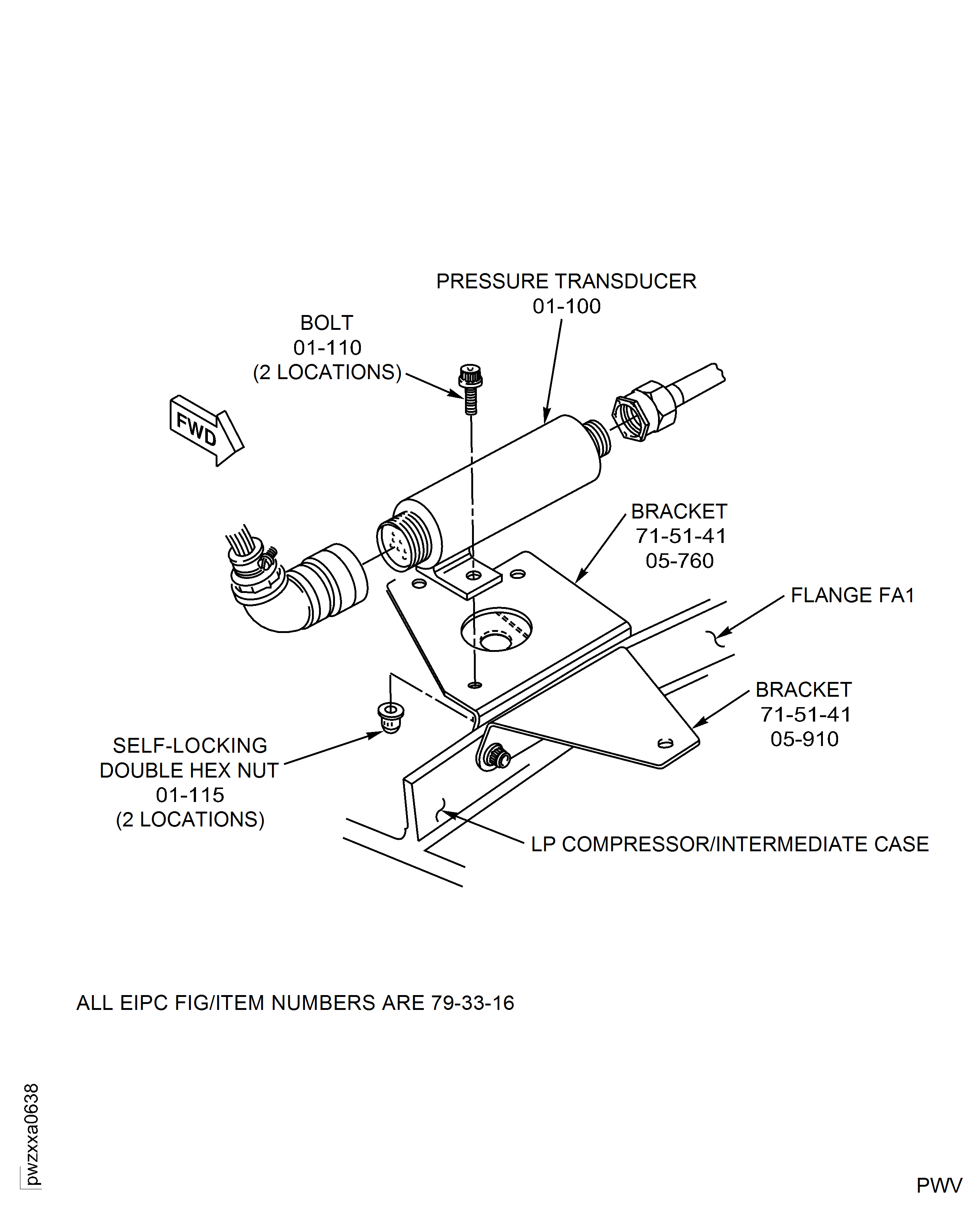

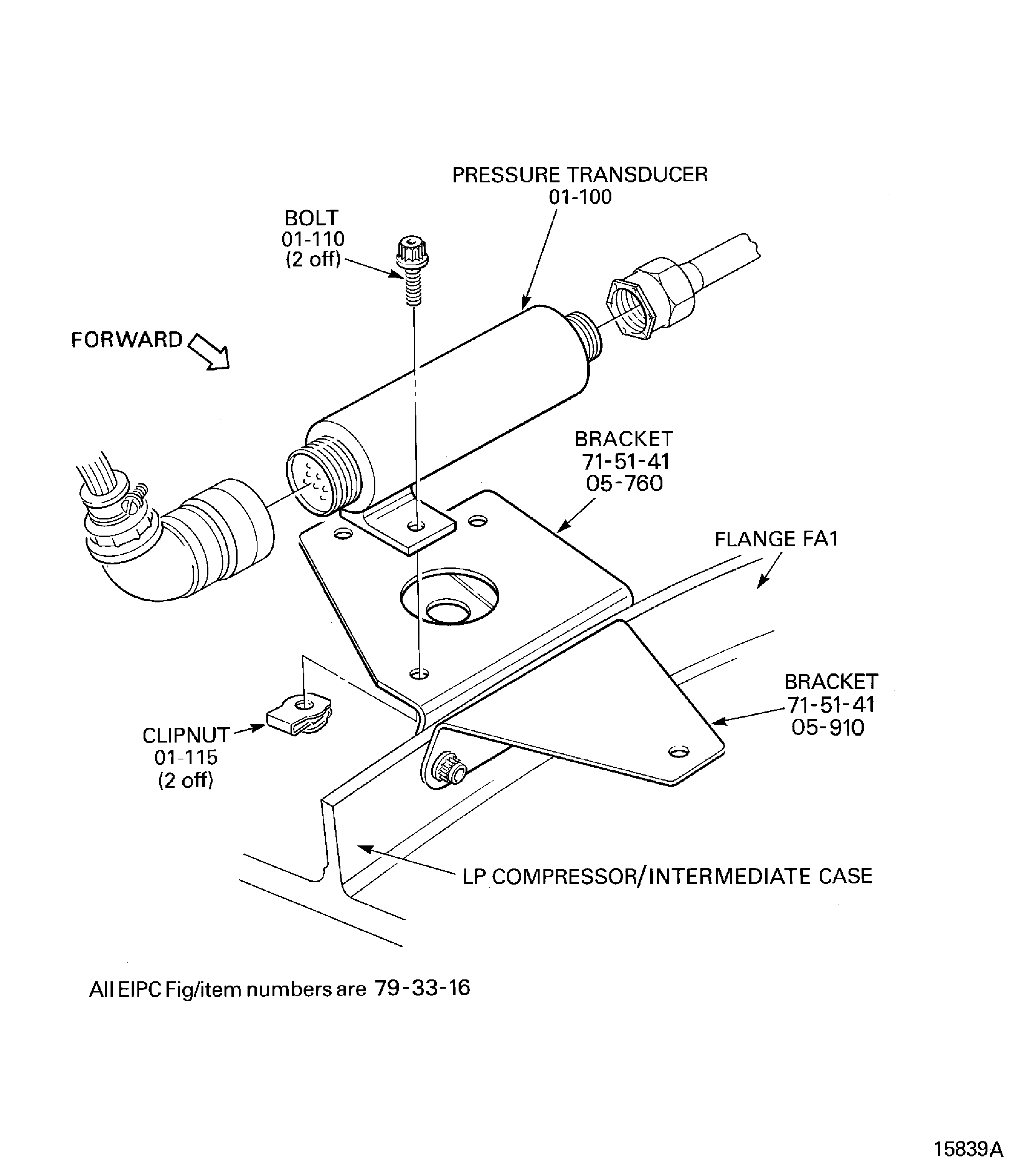

Pre SBE 71-0222: Install the No.4 bearing pressure transducer OIL-NO.4 BEARING PRESSURE TRANSDUCER (79-33-16, 01-100) to the bracket EEC Fan Harness (71-51-41, 05-760) with the two bolts OIL-NO.4 BEARING PRESSURE TRANSDUCER (79-33-16, 01-110) and the two clipnuts OIL-NO.4 BEARING PRESSURE TRANSDUCER (79-33-16, 01-115). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

Post SBE 71-0222: Install the No.4 bearing pressure transducer OIL-NO.4 BEARING PRESSURE TRANSDUCER (79-33-16, 01-100) to the bracket EEC Fan Harness (71-51-41, 05-760) with the two bolts OIL-NO.4 BEARING PRESSURE TRANSDUCER (79-33-16, 01-110) and the two self-locking double hex nut OIL-NO.4 BEARING PRESSURE TRANSDUCER (79-33-16, 01-115). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

SUBTASK 72-00-32-420-069 Install the No. 4 Bearing Pressure Transducer

Refer to Figure.

WARNING

WHEN YOU USE COMAT 01-003 INHIBITED AND STABILIZED TRICHLOROETHANE YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.NOTE

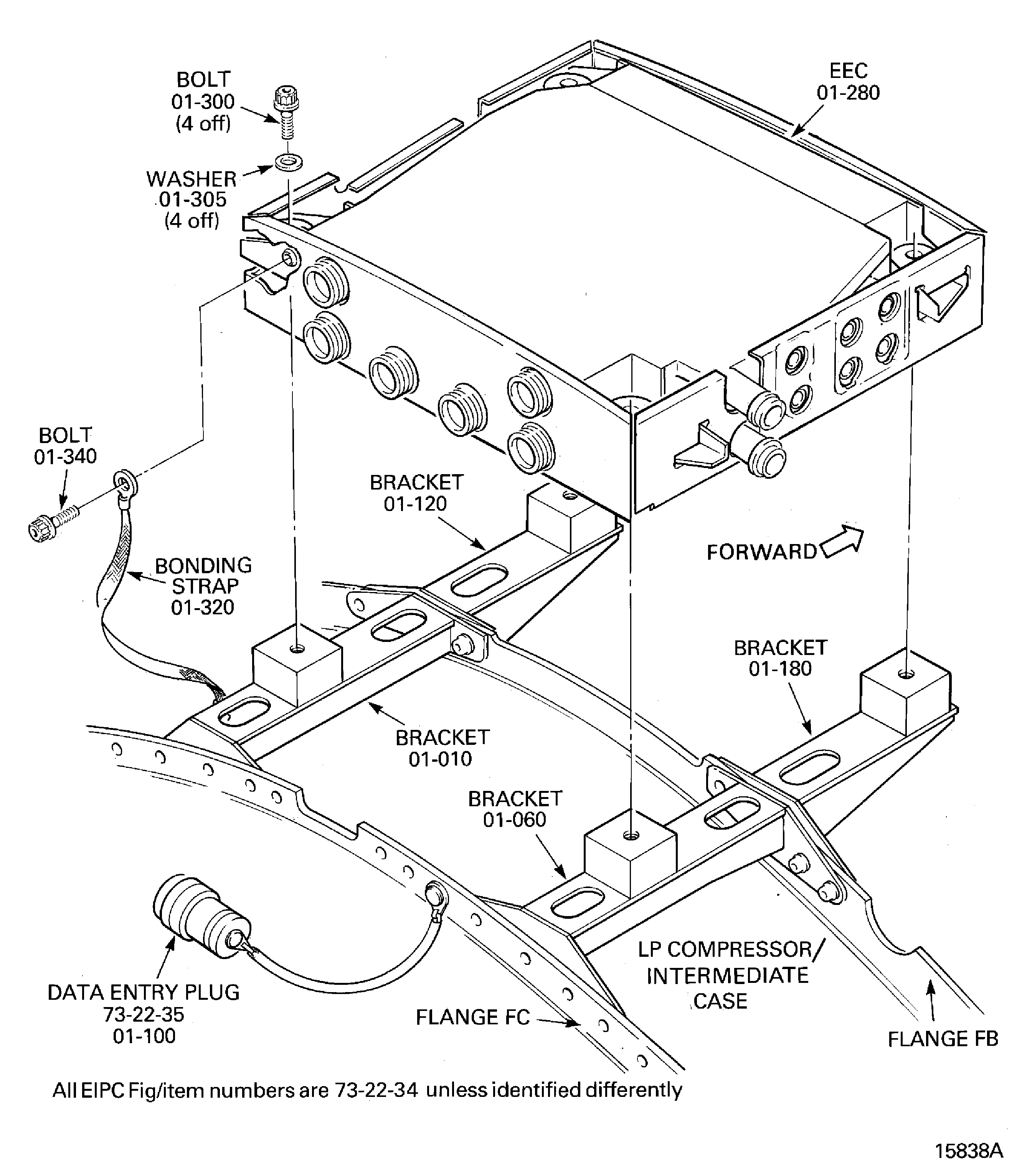

Installation of the data entry plug EEC Data Entry Plug (73-22-35, 01-100) is not necessary during this procedure.If the data entry plug was removed from the LP compressor/intermediate case flange, install the data entry plug to the flange by the procedure given in SPM TASK 72-00-32-450-023 Installation-30.The data entry plug will be connected to the electronic engine control (EEC) when the engine test is completed.Clean the bonding strap connector and its mating face on the EEC with CoMat 01-003 SOLVENT, DELETED. Attach the bonding strap V2500-A5-73-22-34-01A-941A-D (73-22-34, 01-320) to the EEC with the bolt V2500-A5-73-22-34-01A-941A-D (73-22-34, 01-340) and torque the bolt to 85 to 105 lbf.in (10 to 12 Nm).

SUBTASK 72-00-32-420-070 Install the Electronic Control Unit (EEC)

Refer to Figure.

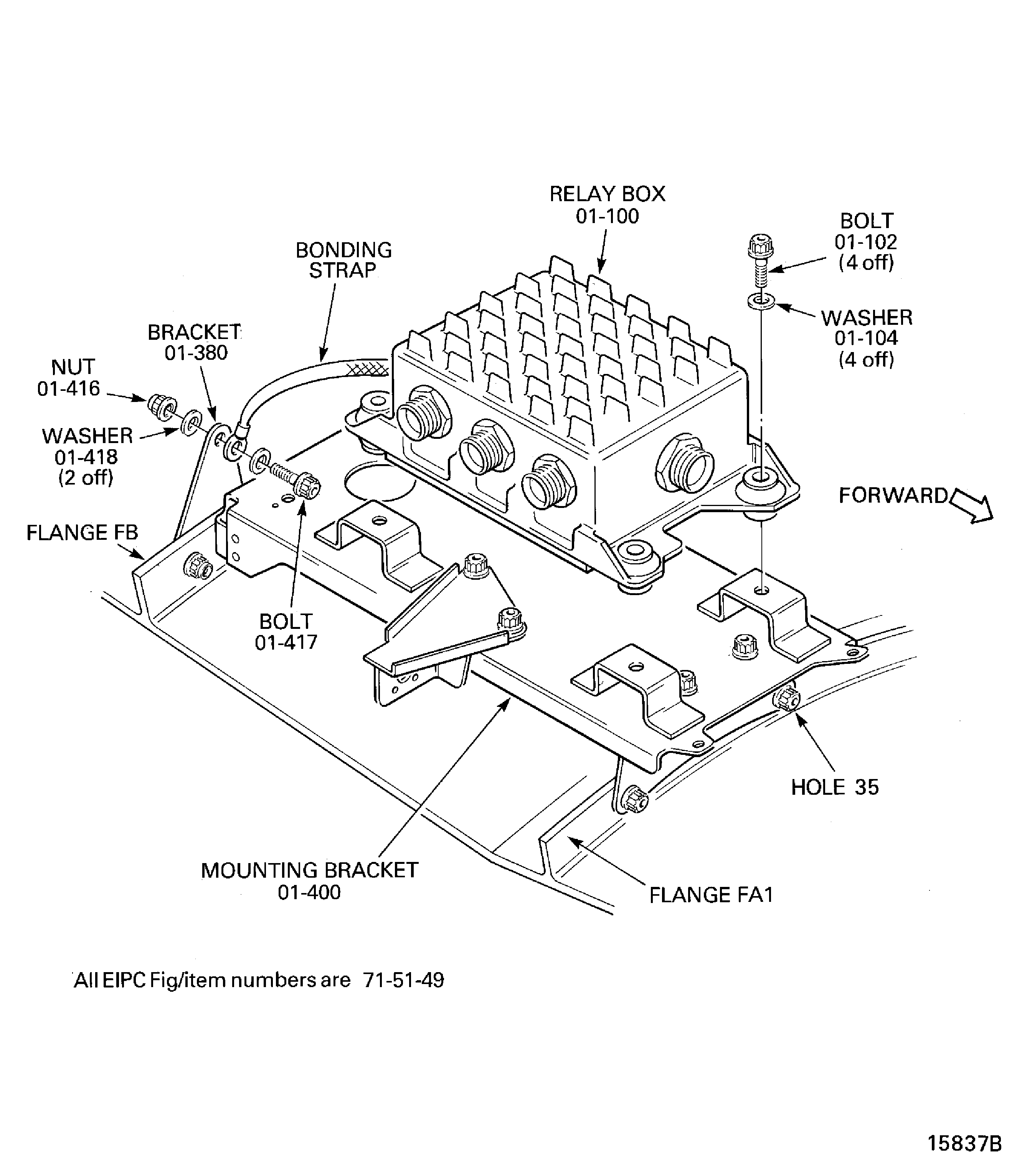

Put the relay box Ignition Relay Box (71-51-49, 01-100) in position on its mounting bracket pads and install the four bolts Ignition Relay Box (71-51-49, 01-102) and washers Ignition Relay Box (71-51-49, 01-104). Torque the bolts to 36 to 45 lbf.in (4 to 5 Nm).

WARNING

WHEN YOU USE COMAT 01-003 INHIBITED AND STABILIZED TRICHLOROETHANE YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Clean the bonding strap connector and its mating face on the bracket Ignition Relay Box (71-51-49, 01-380) with CoMat 01-003 SOLVENT, DELETED.

Attach the bonding strap to the bracket with the bolt Ignition Relay Box (71-51-49, 01-417), the two washers Ignition Relay Box (71-51-49, 01-418) and the nut Ignition Relay Box (71-51-49, 01-416). Torque the nut to 85 to 105 lbf.in (10 to 12 Nm).

If the impedance check result is not satisfactory do Step again. Make sure the bonding strap is not damaged and is installed correctly.

Install the bonding strap on flange FB.

SUBTASK 72-00-32-420-071 Install the Relay Box

Figure: Install the Hydraulic Case Drain Filter Assembly

Install the Hydraulic Case Drain Filter Assembly

Figure: V2500-A1, Pre SBE 79-0020: Install the Fuel Cooled Oil Cooler

Sheet 1

Figure: V2500-A1, SBE 79-0020: Install the Fuel Cooled Oil Cooler

Sheet 2

Figure: V2500-A5: Install the Fuel Cooled Oil Cooler

V2500-A5: Install the Fuel Cooled Oil Cooler

Figure: V2500-A1 and A5 SBE 79-0075 and 79-0076: Install the Fuel Cooled Oil Cooler Upper Mount

V2500-A1 and A5 SBE 79-0075 and 79-0076: Install the Fuel Cooled Oil Cooler Upper Mount

Figure: Install the Fuel Diverter and Return Valve

Install the Fuel Diverter and Return Valve

Figure: V2500-A1: Install the Fuel Cooled IDG Oil Cooler

V2500-A1: Install the Fuel Cooled IDG Oil Cooler

Figure: V2500-A5: Install the Fuel Cooled IDG Oil Cooler

V2500-A5: Install the Fuel Cooled IDG Oil Cooler

Figure: V2500-A1: Install the Air Cooled Oil Cooler

Sheet 1

Figure: V2500-A1: Install the Air Cooled Oil Cooler

Sheet 2

Figure: V2500-A5: Install the Air Cooled Oil Cooler

Sheet 1

Figure: V2500-A5: Install the Air Cooled Oil Cooler

Sheet 2

Figure: Install the Air Modulating Valve

Sheet 1

Figure: Install the Air Modulating Valve

Sheet 2

Figure: Pre SBE 75-0047: Install the Stage 10 Air Solenoid Valve

Sheet 1

Figure: SBE 75-0047: Install the Stage 10 Air Solenoid Valve

Sheet 2

Figure: Install the Stage 10 Air Solenoid Valves

Install the Stage 10 Air Solenoid Valves

Figure: Install the Low Oil Pressure Switch and Oil Pressure Transmitter

Install the Low Oil Pressure Switch and Oil Pressure Transmitter

Figure: V2500-A1: Install the Hydraulic Low Pressure Warning Switch

Sheet 1

Figure: V2500-A1: Install the Hydraulic Low Pressure Warning Switch

Sheet 2

Figure: V2500-A1: Install the Hydraulic Low Pressure Warning Switch

Sheet 3

Figure: Install the Scavenge Filter Differential Pressure Switch

Install the Scavenge Filter Differential Pressure Switch

Figure: Install the No. 4 Bearing Pressure Transducer (Pre SBE 71-0222)

Install the No. 4 Bearing Pressure Transducer (Pre SBE 71-0222)

Figure: Install the Electronic Control Unit (EEC)

Install the Electronic Control Unit (EEC)

Figure: Install the Relay Box

Install the Relay Box

Figure: Pre SBE 75-0047: Install the Stage 7 Air Solenoids

Sheet 1

Figure: SBE 75-0047: Install the Stage 7 Air Solenoids

Sheet 2

Figure: Install the No. 4 Bearing Pressure Transducer (Post SBE 71-0222)

Install the No. 4 Bearing Pressure Transducer (Post SBE 71-0222)