Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-32-450-022 LPC/Intermediate Case Module Components - Install The Fuel Cooled Oil Cooler (FCOC), Installation-029

General

This TASK gives the procedure to install the Fuel Cooled Oil Cooler (FCOC).

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha-variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-039 ENGINE OIL, unless other lubricants are referred to in the procedure.

For the torque tightening procedures, refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. Refer to the SPM TASK 70-38-21-380-501.

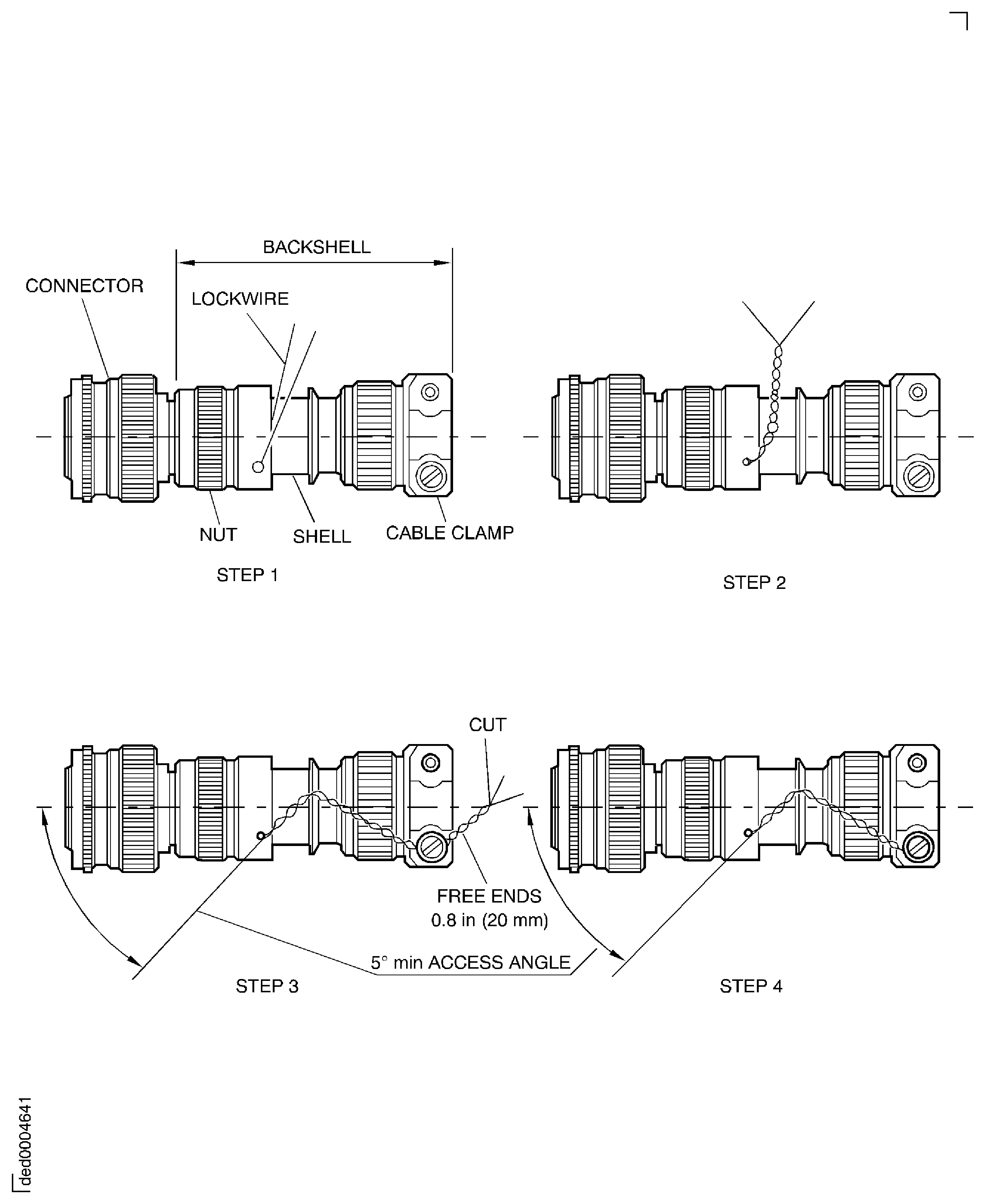

For lockwire data and procedures refer to the SPM TASK 70-42-05-400-501.

For safety cable data and procedures refer to the SPM TASK 70-42-08-400-501.

Safety the threaded fasteners in the ATA Chapter/Section/Subject 71-51-41 as applicable with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT.

To identify, lubricate and install seal rings refer to the SPM TASK 70-64-02-640-501.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-002 SOLVENT, DELETED. | X111X | CoMat 01-002 | ||

| CoMat 02-119 LOCKWIRE | LOCAL | CoMat 02-119 | ||

| CoMat 02-126 LOCKWIRE | K6835 | CoMat 02-126 | ||

| CoMat 02-274 SAFETY CABLE KIT | LOCAL | CoMat 02-274 | ||

| CoMat 02-275 SAFETY CABLE KIT | X111X | CoMat 02-275 | ||

| CoMat 07-038 AIR DRYING ENAMEL | 00BB6 | CoMat 07-038 | ||

| CoMat 10-039 ENGINE OIL | LOCAL | CoMat 10-039 |

Spares

Safety Requirements

NONEProcedure

NOTE

Do not install the FCOC, or FDRV separately to the engine. Install the assembly of the FCOC and the FDRV to the engine.Install the FDRV to the FCOC, refer to TASK 72-00-32-450-013.

SUBTASK 72-00-32-450-062 Install the Fuel Diverter and Return Valve (FDRV) to the Fuel Cooled Oil Cooler (FCOC)

CAUTION

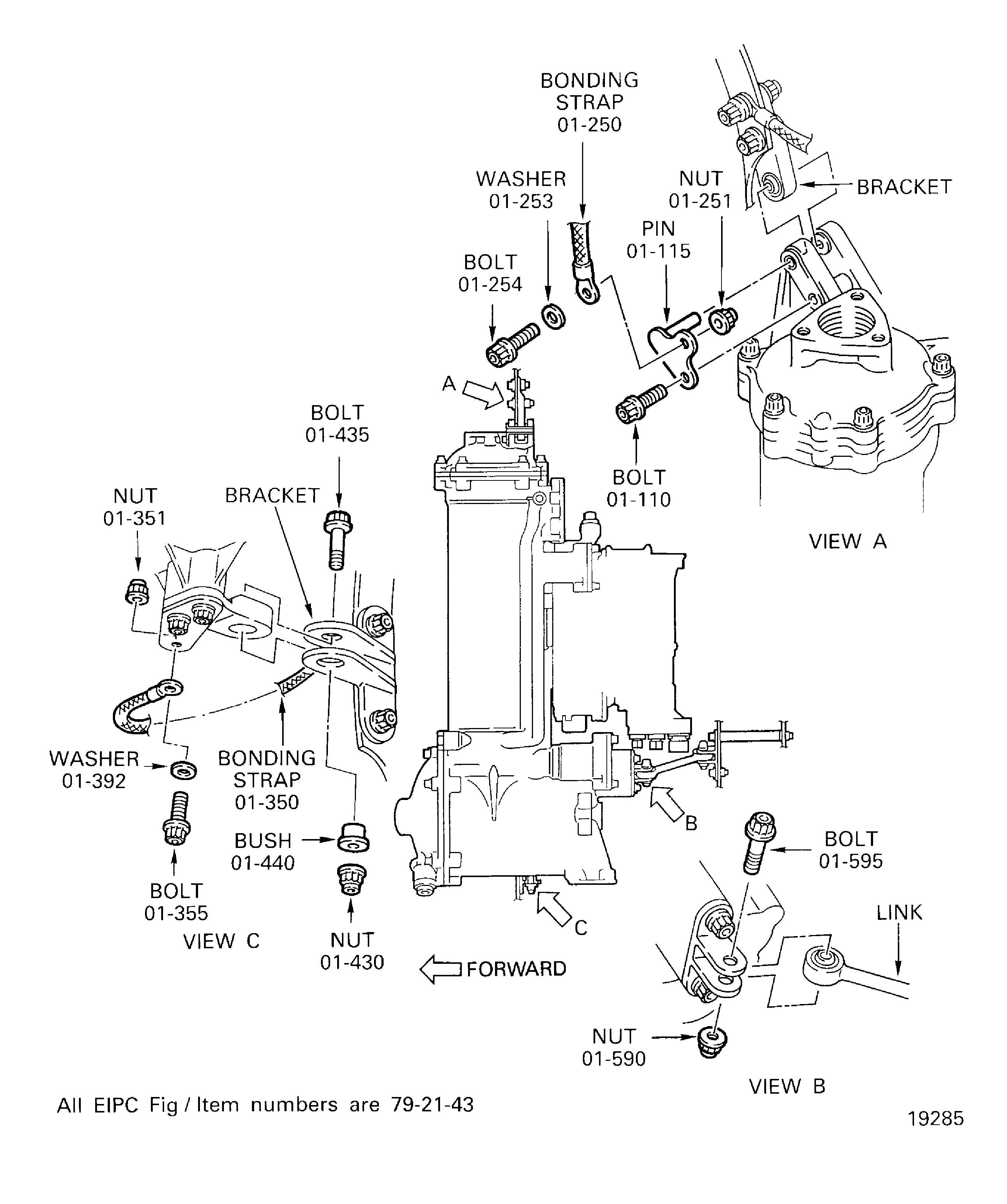

MAKE SURE THAT THE FUEL FILTER IS INSTALLED INTO THE FCOC. OPERATION OF THE ENGINE WITHOUT THE FUEL FILTER INSTALLED CAN DAMAGE THE ENGINE AND ITS COMPONENTS. LOCKWIRE AT THE FUEL FILTER END CAP BOLTS DOES NOT INDICATE THE PRESENCE OF THE FUEL FILTER.Install the FCOC and attach it with the bolts Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-595) and Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-435), the nuts Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-590) and Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-430) and the bush Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-440).

Pre SBE 79-0075 and 79-0076.

Refer to Figure.

Install the pin Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-115) and attach it with the bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-110).

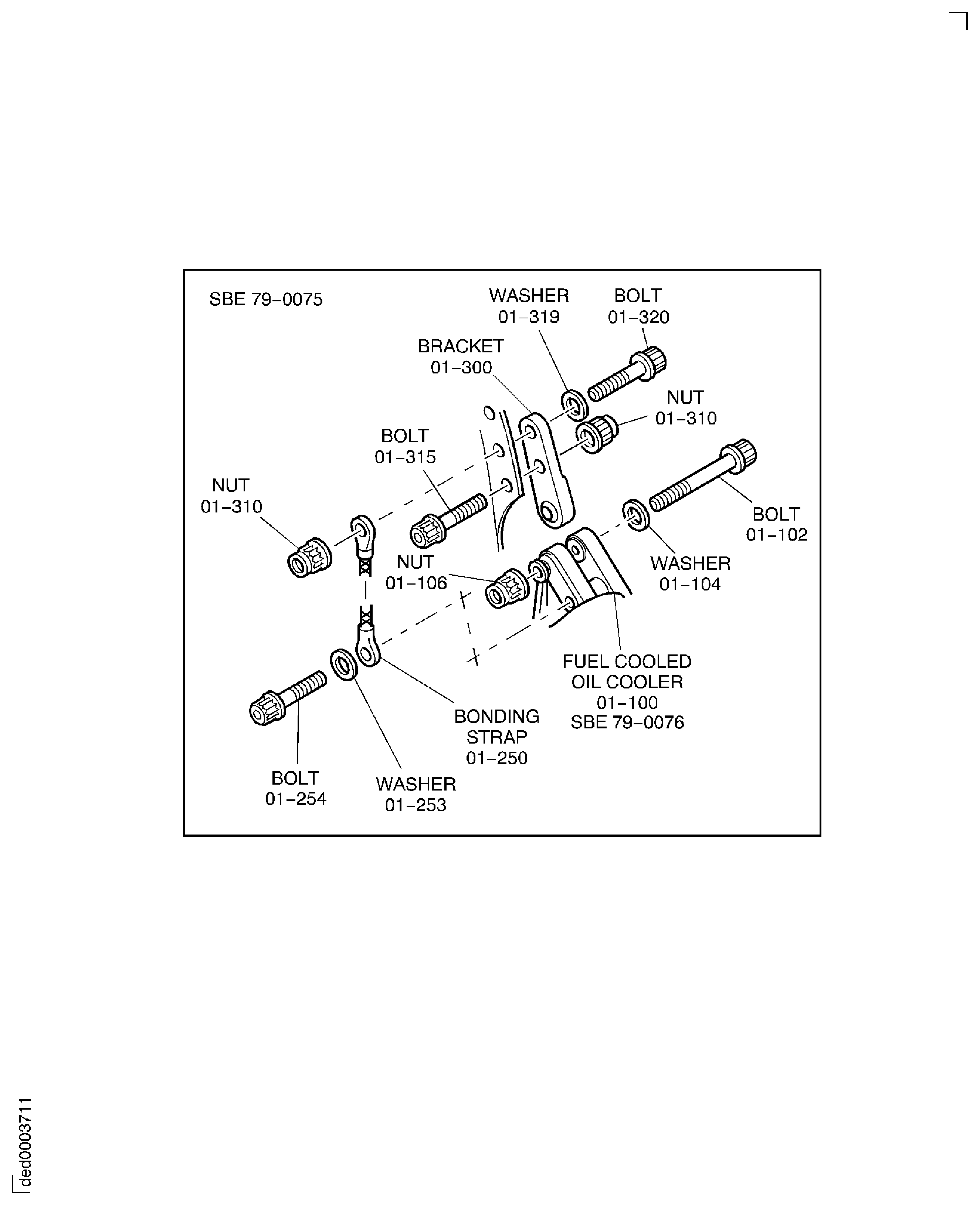

SBE 79-0075 and 79-0076.

Refer to Figure.

Install the precision bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-102) and nut Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-106).

NOTE

Make sure the FCOC is in the correct position on the fan case. If it is not in the correct position, you can not install the oil/fuel tubes.Install the bonding strap Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-250) and Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-350) with the bolts Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-254) and Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-355), the washers Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-253) and Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-392) and the nuts Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-251) and Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-351).

Torque the nuts Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-590) and Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-430) to between 150 and 170 lbf.in (1.69 and 1.92 mdaN).

Pre SBE 79-0075 and 79-0076.

Refer to Figure.

Torque the bolt Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-110) to between 32 and 36 lbf.in (0.36 and 0.41 mdaN).

SBE 79-0075 and 79-0076.

Refer to Figure.

Torque the nut Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-106) to 285 lbf.in (32.2 Nm).

Torque the nuts Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-251) and Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-351) to between 75 and 85 lbf.in (0.85 and 0.96 mdaN).

SUBTASK 72-00-32-450-063 Install the FCOC

Refer to Figure.

Connect the fuel drain tube POWER PLANT-FUEL DRAIN TUBES-POWER PLANT (71-71-48, 01-100) to the FDRV.

Torque the union nut of the drain tube POWER PLANT-FUEL DRAIN TUBES-POWER PLANT (71-71-48, 01-100) to between 105 and 115 lbf.in (1.19 and 1.30 mdaN).

SUBTASK 72-00-32-440-051 Connect the Fuel Drain Tube (71-71-48,01-100) to the FDRV

Refer to Figure.

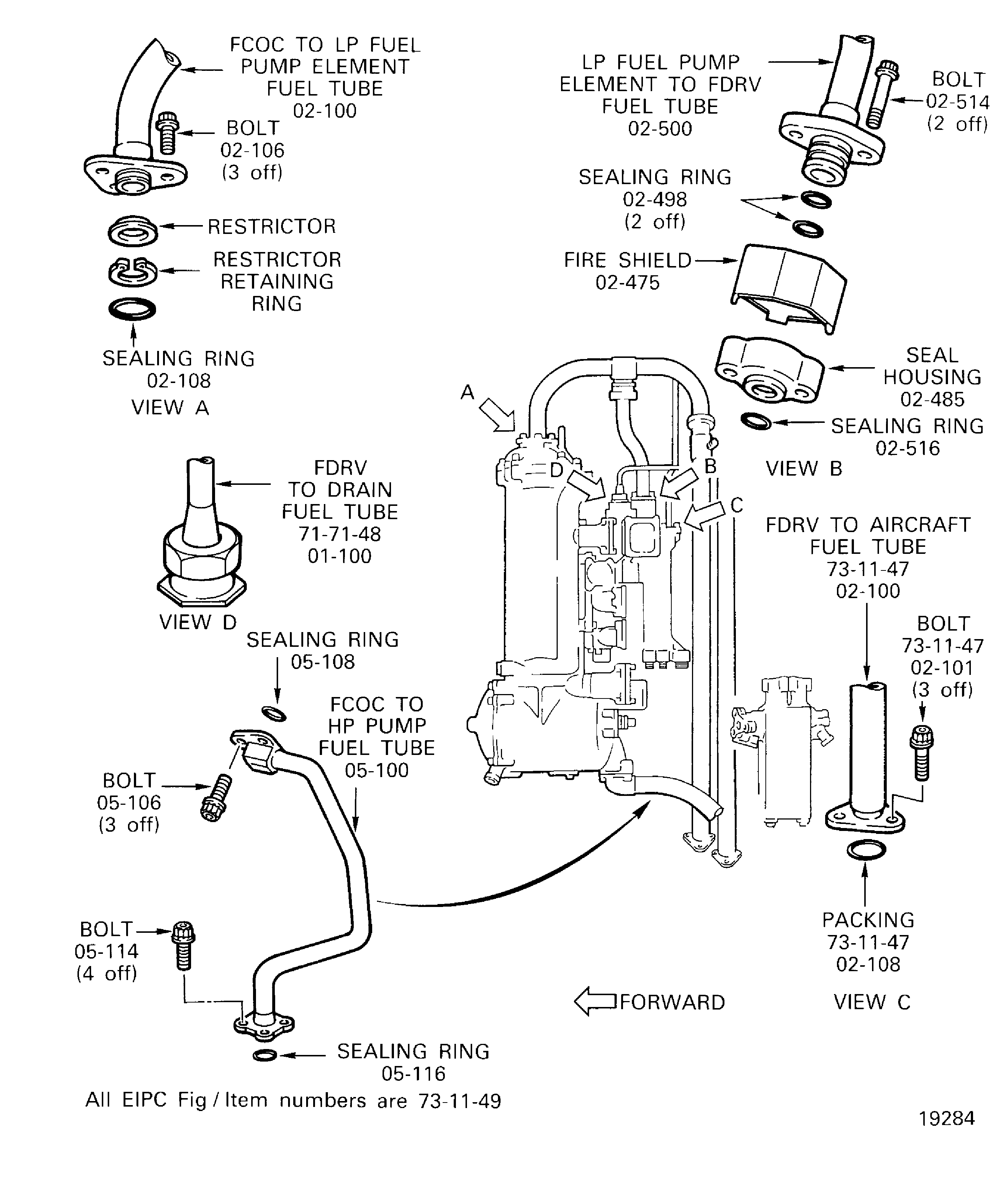

Install the new Control Fuel Tubes (73-11-49, 05-116) sealing ring 1 off and the new Control Fuel Tubes (73-11-49, 05-108) sealing ring 1 off, on to the tube Control Fuel Tubes (73-11-49, 05-100).

Attach the tube Control Fuel Tubes (73-11-49, 05-100) to the FCOC and HP fuel pump with the bolts Control Fuel Tubes (73-11-49, 05-114) and Control Fuel Tubes (73-11-49, 05-106).

Torque the bolts Control Fuel Tubes (73-11-49, 05-114) and Control Fuel Tubes (73-11-49, 05-106) to between 85 and 105 lbf-in (10 and 12 N.m).

SUBTASK 72-00-32-440-052 Install the Fuel Tube (73-11-49,05-100)

Refer to Figure.

Install the new FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47,02-108) packing 1 off, on to the tube FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-100).

Attach the tube FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-100) to the FDRV with the bolts FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-101).

Torque the bolts FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-101) to between 75 and 85 lbf.in (0.85 and 0.96 mdaN).

SUBTASK 72-00-32-440-053 Install the Fuel Tube (73-11-47,02-100)

Refer to Figure.

Install the new Control Fuel Tubes (73-11-49, 02-498) sealing ring 2 off and the new Control Fuel Tubes (73-11-49, 02-516) sealing ring 1 off, on to the tube Control Fuel Tubes (73-11-49, 02-500) and the seal housing Control Fuel Tubes (73-11-49, 02-485).

Attach the tube Control Fuel Tubes (73-11-49, 02-500), the fire shield Control Fuel Tubes (73-11-49, 02-475) and the seal housing Control Fuel Tubes (73-11-49, 02-485) to the FDRV with the bolts Control Fuel Tubes (73-11-49, 02-514).

Torque the bolts Control Fuel Tubes (73-11-49, 02-514) to between 75 and 85 lbf.in (0.85 and 0.96 mdaN).

SUBTASK 72-00-32-440-054 Install the Fuel Tube (73-11-49,02-500)

Refer to Figure.

Install the new Control Fuel Tubes (73-11-49, 02-108) sealing ring 2 off, on to the tube Control Fuel Tubes (73-11-49, 02-100).

Attach the tube Control Fuel Tubes (73-11-49, 02-100) to the FDRV with the bolts Control Fuel Tubes (73-11-49, 02-106).

Torque the bolts Control Fuel Tubes (73-11-49, 02-106) to between 75 and 85 lbf.in (0.85 and 0.96 mdaN).

SUBTASK 72-00-32-440-055 Install the Fuel Tube (73-11-49,02-100)

Refer to Figure.

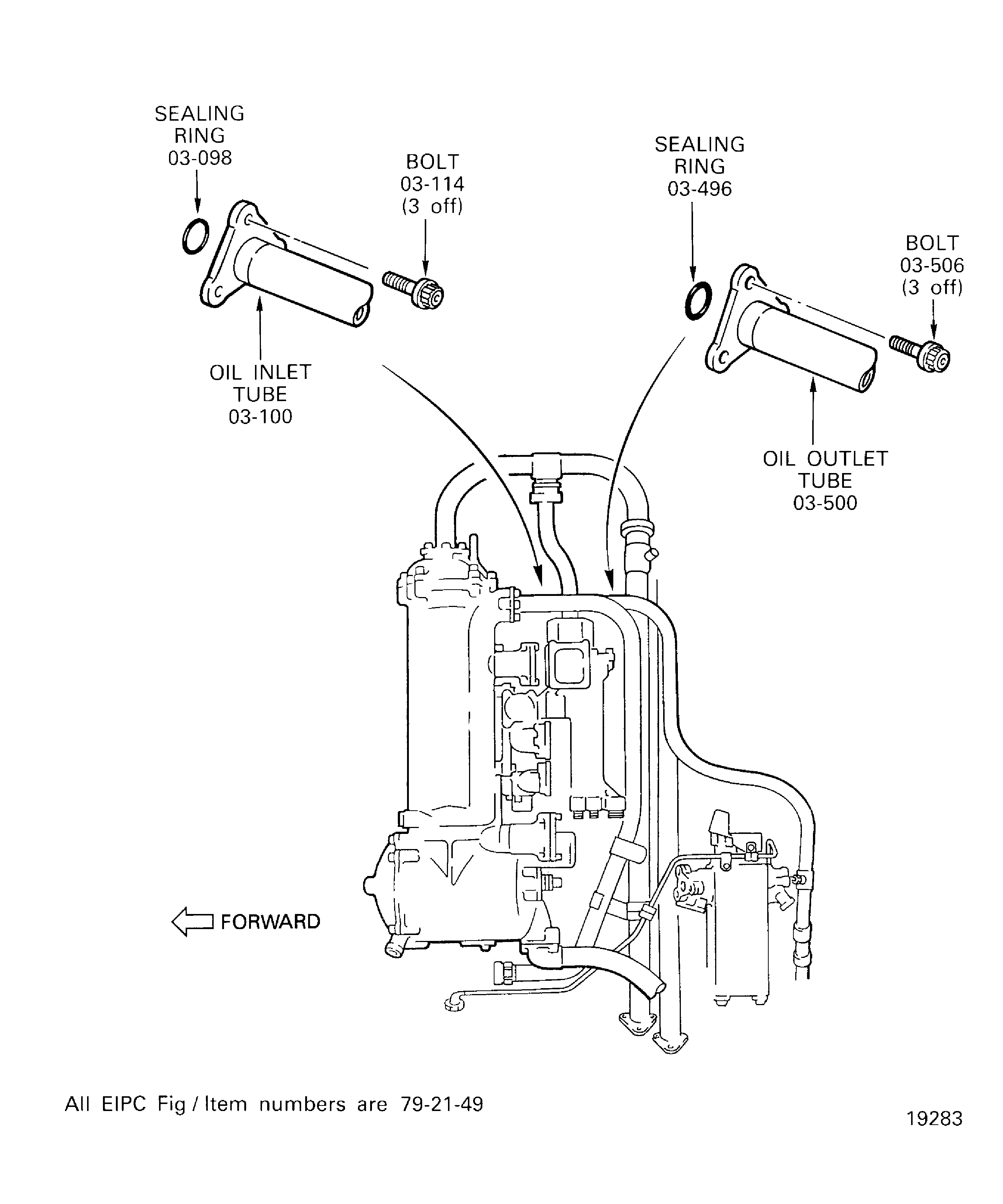

Install the new OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 03-098) sealing ring 1 off and the new OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 03-496) sealing ring 1 off, on to the tubes OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 03-100) and OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 03-500).

Attach the tubes OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 03-100) and OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 03-500) to the FCOC with the bolts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 03-114) and OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 03-506).

Torque the bolts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 03-114) and OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 03-506) to between 75 and 85 lbf.in (0.85 and 0.96 mdaN).

SUBTASK 72-00-32-440-056 Install the Oil Tubes (79-21-49, 03-100) and (79-21-49, 03-500)

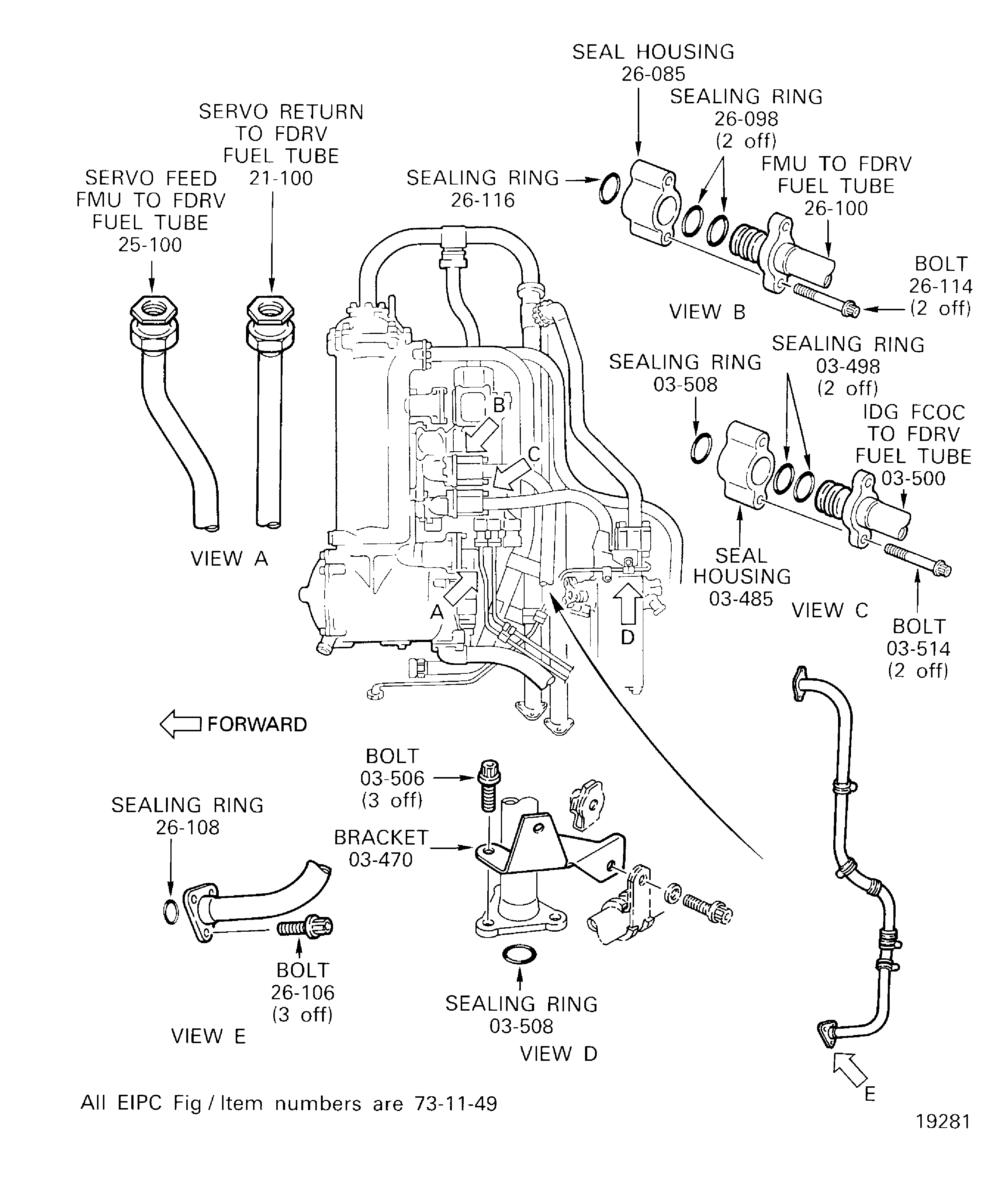

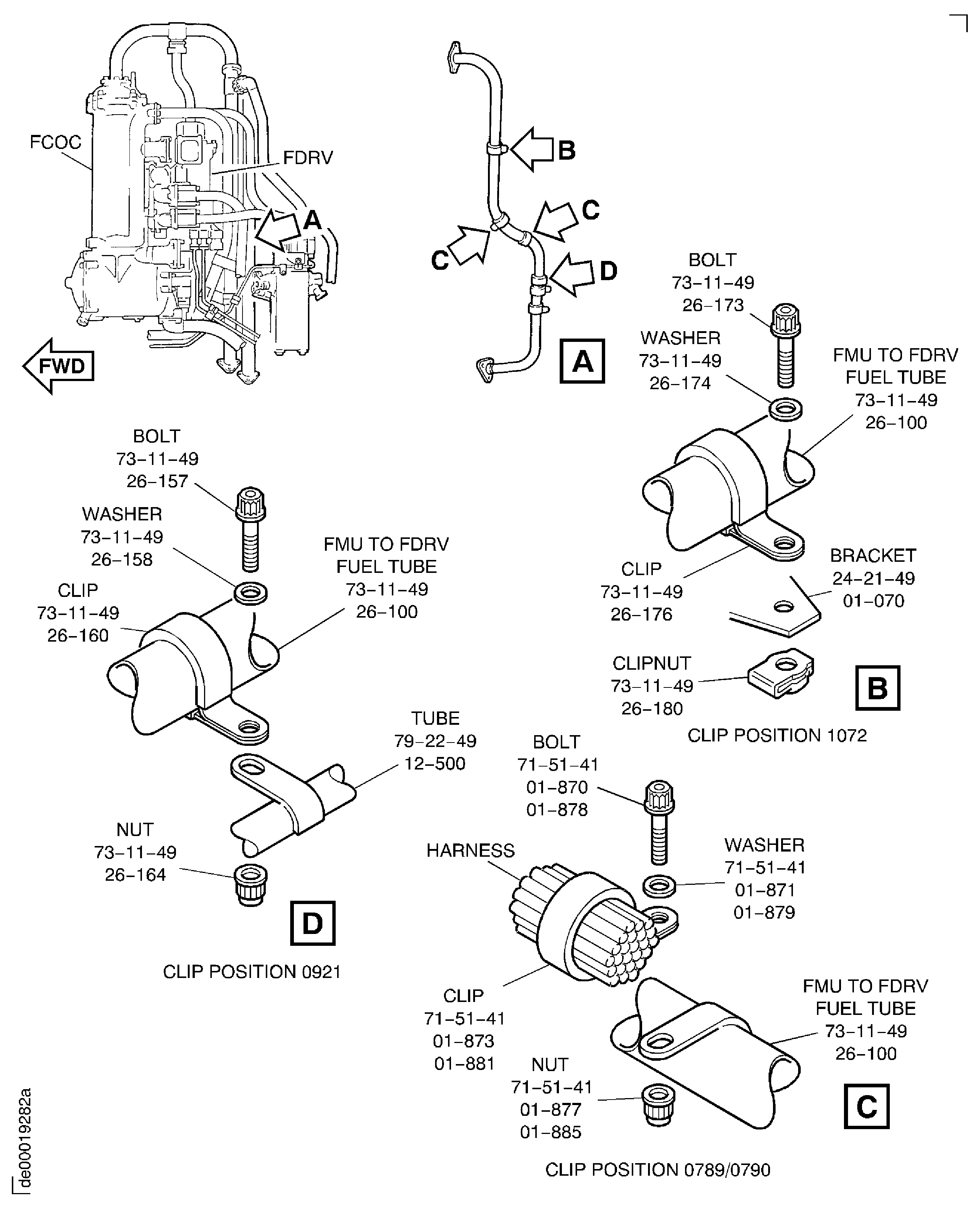

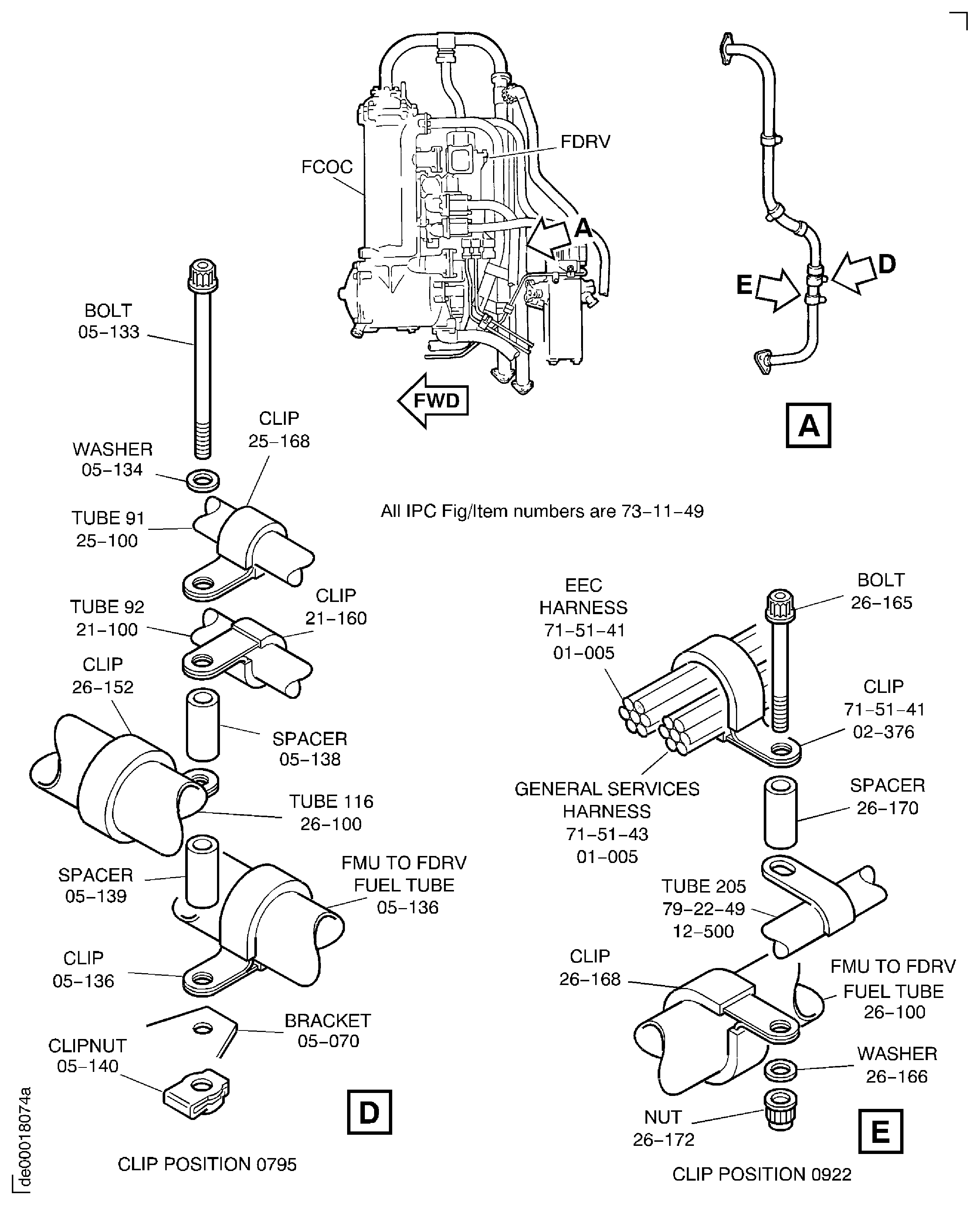

Install the new Control Fuel Tubes (73-11-49, 26-116) sealing ring 1 off and the new Control Fuel Tubes (73-11-49, 26-098) sealing ring 2 off and the new Control Fuel Tubes (73-11-49, 26-108) sealing ring 1 off, on to the tube Control Fuel Tubes (73-11-49, 26-100) and the seal housing Control Fuel Tubes (73-11-49, 26-085).

Attach the tube Control Fuel Tubes (73-11-49, 26-100) and the seal housing Control Fuel Tubes (73-11-49, 26-085) to the FDRV and the FMU with the bolts Control Fuel Tubes (73-11-49, 26-114) and Control Fuel Tubes (73-11-49, 26-106).

Torque the bolts Control Fuel Tubes (73-11-49, 26-114) to between 75 to 85 lbf.in (0.85 and 0.96 mdaN).

Assemble clipping point 1072 with the bolt Control Fuel Tubes (73-11-49, 26-173) and the washer Control Fuel Tubes (73-11-49, 26-174).

Assemble clipping point 0922 with the bolt Control Fuel Tubes (73-11-49, 26-165), the washer Control Fuel Tubes (73-11-49, 26-166), the nut Control Fuel Tubes (73-11-49, 26-172) and the spacer Control Fuel Tubes (73-11-49, 26-170).

Assemble clipping point 0921 with the bolt Control Fuel Tubes (73-11-49, 26-157) and the washer Control Fuel Tubes (73-11-49, 26-158) and the nut Control Fuel Tubes (73-11-49, 26-164).

Assemble clipping points 0789 and 0790 with the bolts EEC Fan Harness (71-51-41, 01-870) and EEC Fan Harness (71-51-41, 01-878), the washers EEC Fan Harness (71-51-41, 01-871) and EEC Fan Harness (71-51-41, 01-879) and the nuts EEC Fan Harness (71-51-41, 01-877) and EEC Fan Harness (71-51-41, 01-885).

Assemble clipping point 0795 with the bolt Control Fuel Tubes (73-11-49, 05-133) the washer Control Fuel Tubes (73-11-49, 05-134) and the spacers Control Fuel Tubes (73-11-49, 05-138).

Torque the bolts Control Fuel Tubes (73-11-49, 26-173) and Control Fuel Tubes (73-11-49, 05-133) and the nuts Control Fuel Tubes (73-11-49, 26-172)Control Fuel Tubes (73-11-49, 26-164) and EEC Fan Harness (71-51-41, 01-877) and EEC Fan Harness (71-51-41, 01-885) to between 32 and 36 lbf.in (0.36 and 0.41 mdaN).

SUBTASK 72-00-32-440-057 Install the Fuel Tube (73-11-49, 26-100)

Refer to Figure.

Install the new Control Fuel Tubes (73-11-49, 03-508) sealing ring 2 off and the new Control Fuel Tubes (73-11-49, 03-498) sealing ring 2 off, on to the tube Control Fuel Tubes (73-11-49, 03-500) and the seal housing Control Fuel Tubes (73-11-49, 03-485).

Attach the tube Control Fuel Tubes (73-11-49, 03-500), the seal housing Control Fuel Tubes (73-11-49, 03-485) and the bracket Control Fuel Tubes (73-11-49, 03-470) to the FDRV and the IDG FCOC with the bolts Control Fuel Tubes (73-11-49, 03-514) and Control Fuel Tubes (73-11-49, 03-506).

Torque the bolts Control Fuel Tubes (73-11-49, 03-514) and Control Fuel Tubes (73-11-49, 03-506) to between 85 and 105 lbf.in (10 and 12 Nm).

SUBTASK 72-00-32-440-058 Install the Fuel Tube (73-11-49, 03-500)

Refer to Figure.

Connect the fuel tubes V2500-A5-73-11-49-21A-941A-D (73-11-49, 21-100) and Control Fuel Tubes (73-11-49, 25-100) to the FDRV.

Safety the nuts of tubes with CoMat 02-119 LOCKWIRE.

SUBTASK 72-00-32-440-059 Install the Fuel Tube (73-11-49, 21-100) and (73-11-49, 25-100)

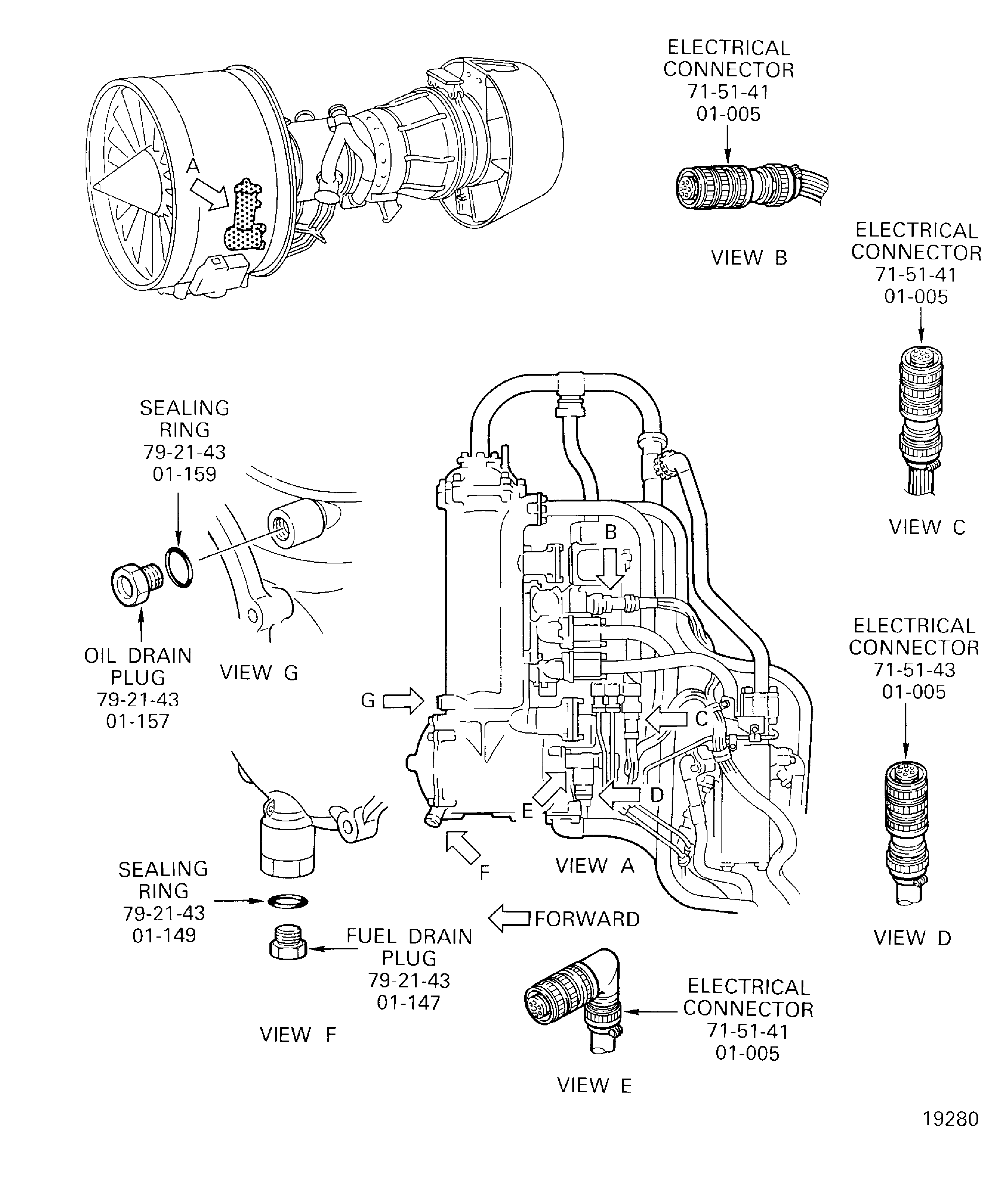

Refer to Figure.

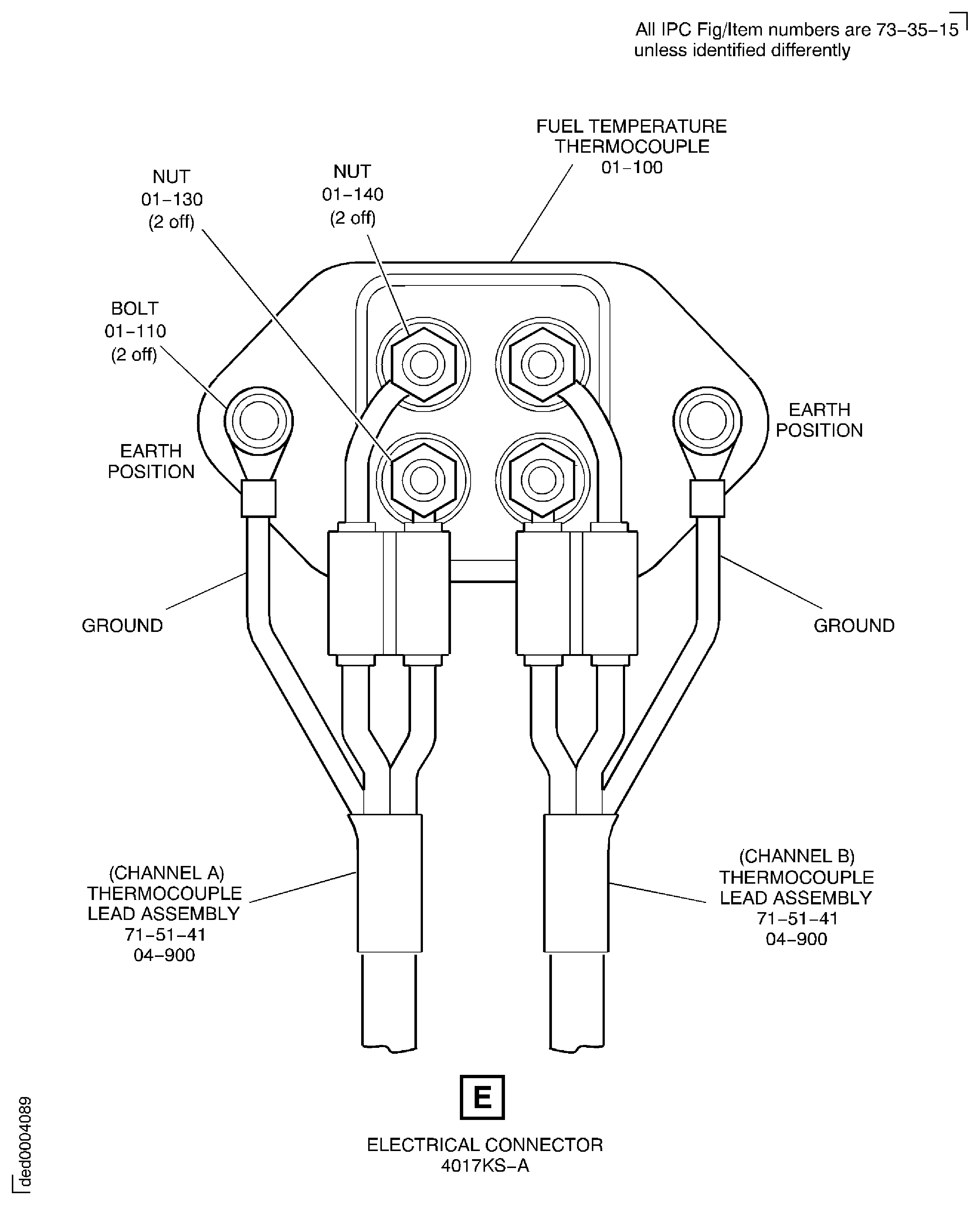

Connect the electrical connector 4017KS-A EEC Fan Harness (71-51-41, 01-005) to the fuel temperature thermocouple FUEL TEMPERATURE THERMOCOUPLE (73-35-15, 01-100) and torque the connector to 18 * lbf.in (1.6 Nm), refer to the view at E.

Connect the electrical connector 4000 EL-A General Services Harness (71-51-43, 01-005) to the fuel filter differential pressure switch FUEL FILTER DIFF PRESSURE SWITCH (73-34-15, 01-010) and torque the connector to 14 * lbf.in (1.6 Nm), refer to the view at D.

SUBTASK 72-00-32-440-060-A00 -A1 Series : Connect the Electrical Connectors (71-51-41, 01-005) and (71-51-43, 01-005)

Refer to Figure.

Connect the electrical connector 4017KS-A EEC Fan Harness (71-51-41, 01-005) to the fuel temperature thermocouple FUEL TEMPERATURE THERMOCOUPLE (73-35-15, 01-100) and torque the connector to 18 * lbf.in (1.6 Nm), refer to the view at E.

Connect the electrical connector 4000 EL-A General Services Harness (71-51-43, 01-005) to the fuel filter differential pressure switch FUEL FILTER DIFF PRESSURE SWITCH (73-34-15, 01-010) and torque the connector to 14 * lbf.in (1.6 Nm), refer to the view at D.

SUBTASK 72-00-32-440-060-B00 -A5 Series : Connect the Electrical Connectors (71-51-41, 01-005) and (71-51-43, 01-005) (Pre SBE 73-0071 and Pre SBE 71-0183)

Connect the electrical connector 4000 EL-A General Services Harness (71-51-43, 01-005) to the fuel filter differential pressure switch FUEL FILTER DIFF PRESSURE SWITCH (73-34-15, 01-010) and torque the connector to 14 * lbf.in (1.6 Nm), refer to the view at D.

Remove the two bolts FUEL TEMPERATURE THERMOCOUPLE (73-35-15, 01-110) that secure the thermocouple to the FCOC Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-100).

WARNING

WHEN YOU USE CoMat 01-002 SOLVENT, DELETED. YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Remove the grease, the fingerprints and the unwanted material from the mating surfaces of the ground terminals and thermocouple earth positions with CoMat 01-002 SOLVENT, DELETED.. Use a clean lint free cloth moistened with the solvent.

CAUTION

YOU MUST NOT EXCEED THE RECOMMENED TORQUE VALUES. OVER TORQUING CAN RESULT IN FRACTURE OF THE THERMOCOUPLE STUDS.Install channel A and B thermocouple lead assemblies EEC Fan Harness (71-51-41, 04-900) to the fuel temperature thermocouple studs. Install the two nuts FUEL TEMPERATURE THERMOCOUPLE (73-35-15, 01-140) to the top studs and torque to between 18 and 22 * lbf.in (2.03 to 2.48 Nm). Install the two nuts FUEL TEMPERATURE THERMOCOUPLE (73-35-15, 01-130) to the bottom studs and torque to between 15 and 18 * lbf.in (1.69 to 2.03 Nm).

Adjust the harness in the datumn clip position 0295 as necessary to obtain the correct clearance and drip loop. Torque the clip bolt to 36 to 45 lbf.in (4 to 5 Nm). Refer to TASK 72-00-32-420-004-B00.

Connect the electrical connector 4017KS-A terminal connectors EEC Fan Harness (71-51-41, 04-900) to the fuel temperature thermocouple FUEL TEMPERATURE THERMOCOUPLE (73-35-15, 01-100), refer to the view at E, Figure.

SUBTASK 72-00-32-440-060-C00 -A5 Series : Connect the Electrical Connectors (71-51-41, 01-005) and (71-51-43, 01-005) (SBE 73-0071 and SBE 71-0183)

SBE 73-0071: Fuel and Control - Replacement of fuel temperature thermocouple with stud and nut terminations

SBE 71-0183: Power Plant - Electrical harnesses - Introduction of production standard EEC harness to suit FCOC fuel temperature thermocouple with stud type thermocouple

Refer to Figure.

Install the new Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-149) sealing ring 1 off on to the fuel drain plug V2500-A5-70-21-43-01A-941A-D (70-21-43, 01-147).

Install the drain plug Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-147) to the FCOC.

Torque the fuel drain plug Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-147) to between 110 and 120 lbf.in (1.24 and 1.35 mdaN).

Safety the drain plug Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-147) with CoMat 02-119 LOCKWIRE.

SUBTASK 72-00-32-440-061 Install the Drain Plug (79-21-43, 01-147)

Refer to Figure.

Install the new Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-159) sealing ring 1 off, on to the oil drain plug Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-157).

Install the drain plug Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-157) to the FCOC.

Torque the oil drain plug Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-157) to between 110 and 120 lbf.in (1.24 and 1.35 mdaN).

Safety the drain plug Fuel Cooled Oil Cooler (FCOC) (79-21-43, 01-157) with CoMat 02-119 LOCKWIRE.

SUBTASK 72-00-32-440-062 Install the Oil Drain Plug (79-21-43, 01-157)

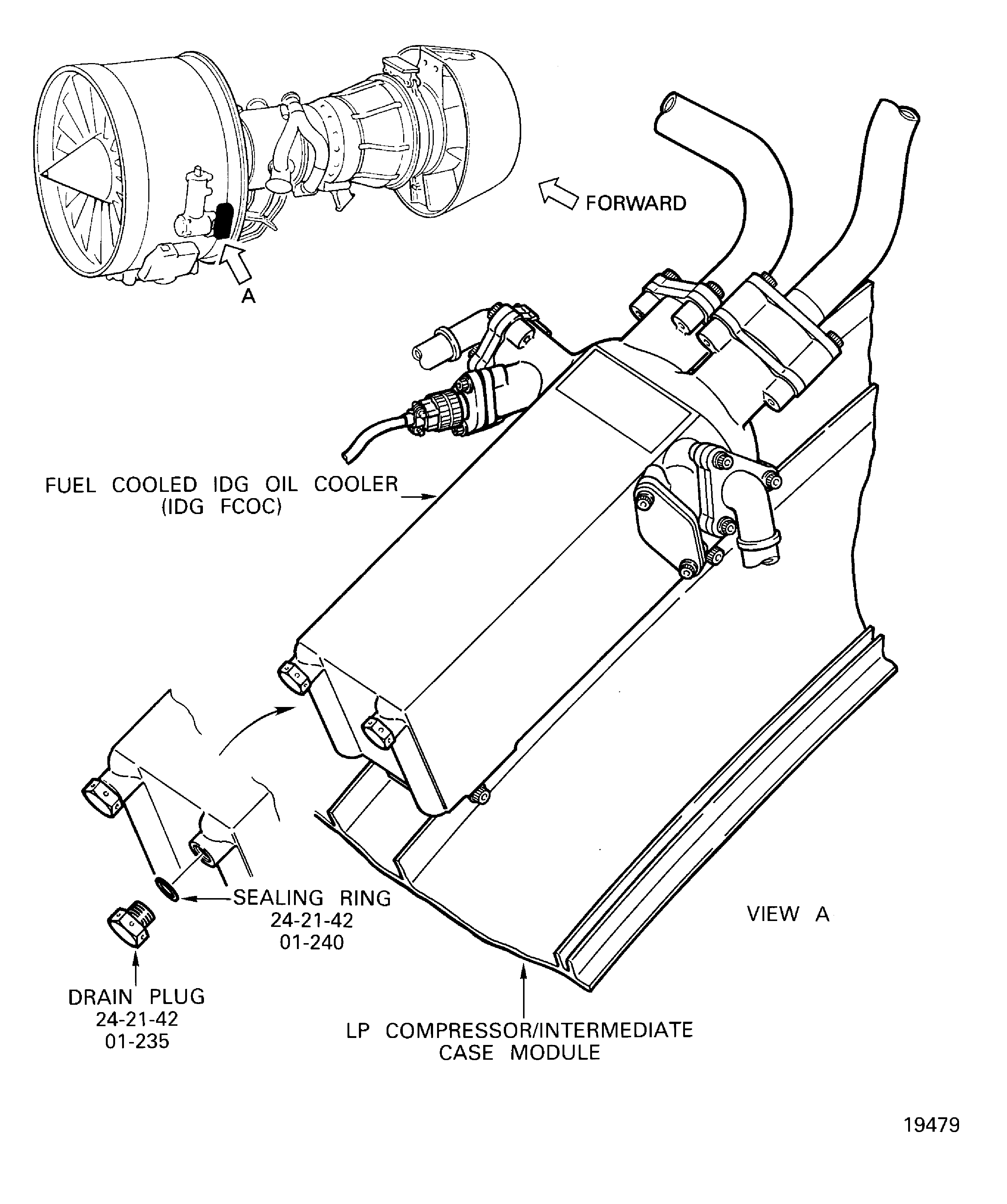

Refer to Figure.

Lubricate the new sealing ring Electrical Power-Fuel Cooled IDG Oil Cooler (24-21-42, 01-240) with clean CoMat 10-039 ENGINE OIL and install it to the fuel drain plug Electrical Power-Fuel Cooled IDG Oil Cooler (24-21-42, 01-235).

Safety the fuel drain plug to the fuel cooled IDG oil cooler with CoMat 02-119 LOCKWIRE.

SUBTASK 72-00-32-440-067 Install the fuel Drain Plug (24-21-42, 01-235)

Do an idle leak check of the FCOC and FDRV, refer to TASK 71-00-00-700-003.

SUBTASK 72-00-32-710-051 Oil Leak Check

Do an EEC system static test of the FCOC and FDRV, refer to TASK 71-00-00-700-005.

SUBTASK 72-00-32-750-052 EEC System Test

Refer to Figure.

Make sure that all the applicable backshells and cable clamps are safetied with CoMat 02-126 LOCKWIRE. Refer to the SPM TASK 70-42-05-400-501.

SUBTASK 72-00-32-210-075 Visually Inspect the Electrical Backshells and Cable Clamps

NOTE

Use this procedure to safety the EEC harness backshells and cable clamps with safety cable.Refer to Figure.

Make sure that all the EEC harness backshells and cable clamps are safetied. Safety with CoMat 02-274 SAFETY CABLE KIT or with CoMat 02-275 SAFETY CABLE KIT. Refer to the SPM TASK 70-42-08-400-501.

SUBTASK 72-00-32-210-076 Visually Inspect the EEC Harness (01-005) Electrical Backshells and Cable Clamps (SBE 70-0813)

SBE 70-0813: Announcement of introduction of safety cable as a preferred method to lockwire.

Figure: Drain plugs and electrical connectors

Drain plugs and electrical connectors

Figure: Drain plugs and electrical connectors SBE 73-0071 : (A5 Series) Install the electrical connecter 4017KS-A

Drain plugs and electrical connectors SBE 73-0071 : (A5 Series) Install the electrical connecter 4017KS-A

Figure: Fuel cooled oil cooler

Fuel cooled oil cooler

Figure: Fuel cooled oil cooler

Fuel cooled oil cooler

Figure: Fuel cooled oil cooler

Fuel cooled oil cooler

Figure: Fuel cooled oil cooler

Fuel cooled oil cooler

Figure: Fuel cooled oil cooler

Fuel cooled oil cooler

Figure: Fuel cooled oil cooler

Fuel cooled oil cooler

Figure: Fuel cooled oil cooler

Fuel cooled oil cooler

Figure: Fuel cooled IDG oil cooler

Fuel cooled IDG oil cooler

Figure: Visually inspect the backshells and cable clamps

Visually inspect the backshells and cable clamps