Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

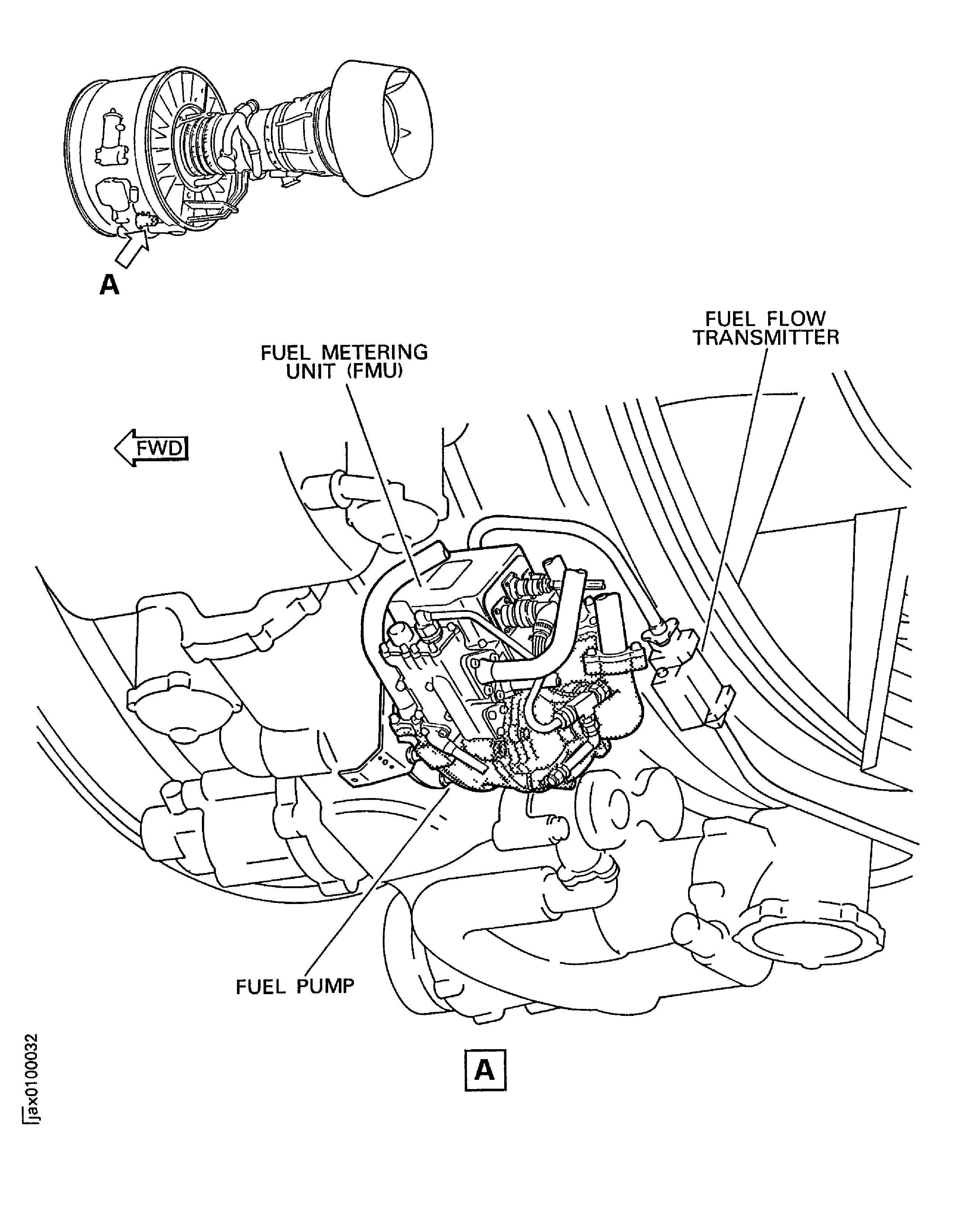

TASK 72-00-60-450-008-A00 External Gearbox Components - Install The LP/HP Fuel Pump, Installation-012

General

This TASK gives the procedure to install the LP/HP fuel pump to the engine.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha-variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the item number.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred in the procedure.

For the torque tightening procedures, refer to TASK 70-41-00-400-501 and TASK 70-41-01-400-501 .

Special torque data and assembly tolerances are included in the procedure.

Special torque data is identified with the symbol * after the torque value.

For the lockwire data and procedure refer to TASK 70-42-05-400-501 .

To identify, lubricate and install seal rings refer to TASK 70-44-01-400-501 .

For the data on the electrical connectors refer to TASK 70-43-00-400-501 and TASK 70-43-01-400-501 .

Make sure that there is a minimum distance of 0.500in. (12.7 mm) between the harness and an adjacent sharp edge; a part which can move or system with a flammable fluid.

The engine must be isolated from starting air supply, fuel supply and electrical power source while you do this procedure.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1R18003 Wrench | 0AM53 | IAE 1R18003 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 02-147 LOCKWIRE | LOCAL | CoMat 02-147 | ||

| CoMat 10-038 PETROLEUM JELLY | LOCAL | CoMat 10-038 | ||

| CoMat 10-060 LIQUID PARAFFIN | LOCAL | CoMat 10-060 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

Safety Requirements

NONEProcedure

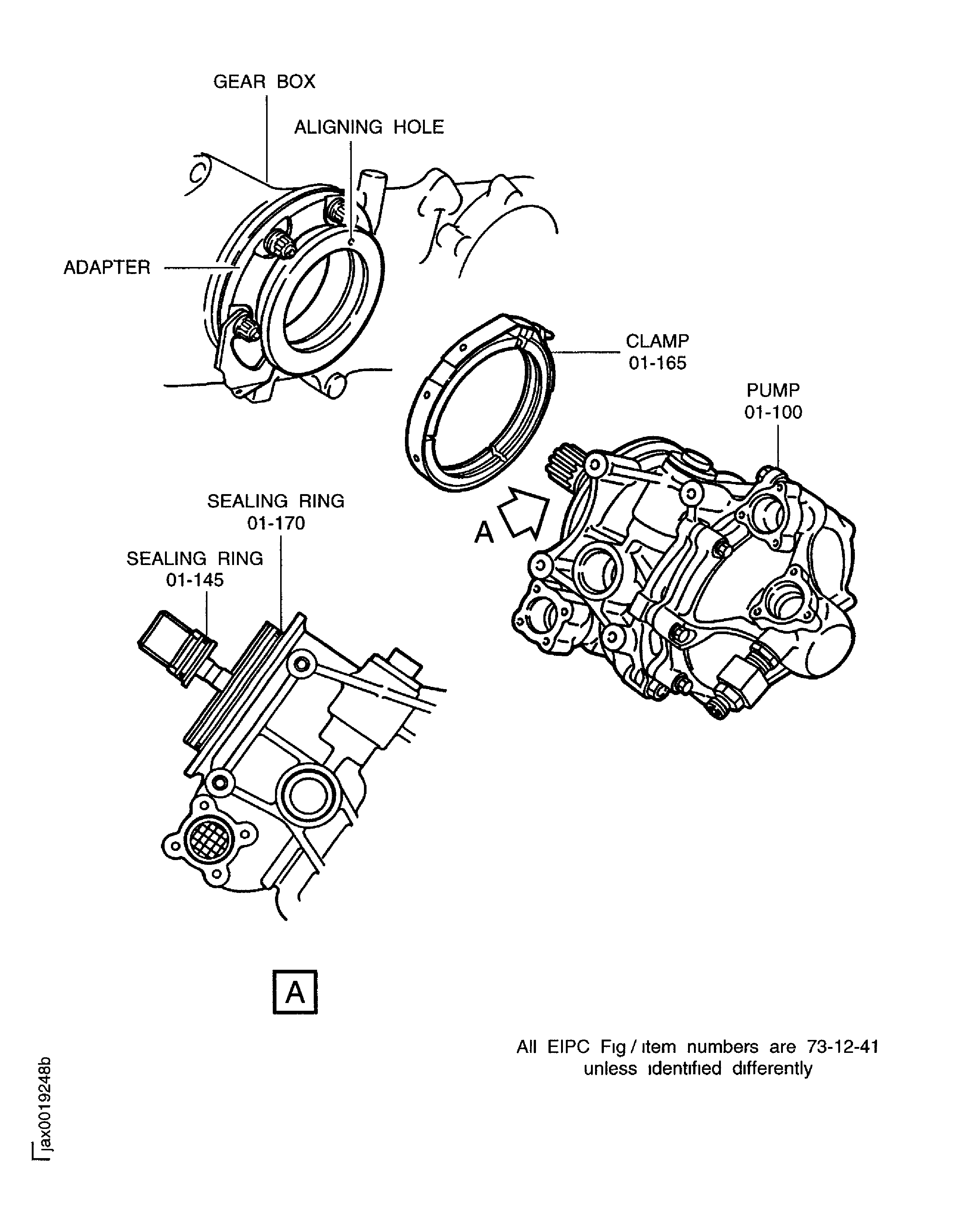

Lubricate the sealing rings with CoMat 10-077 APPROVED ENGINE OILS.

Install the new ENGINE FUEL AND CONTROL-LP & HP FUEL PUMPS (73-12-41,01-145) sealing ring1 off and the new ENGINE FUEL AND CONTROL-LP & HP FUEL PUMPS (73-12-41,01-170) sealing ring1 off.

SUBTASK 72-00-60-450-090 Install the LP/HP Fuel Pump

Refer to: Figure

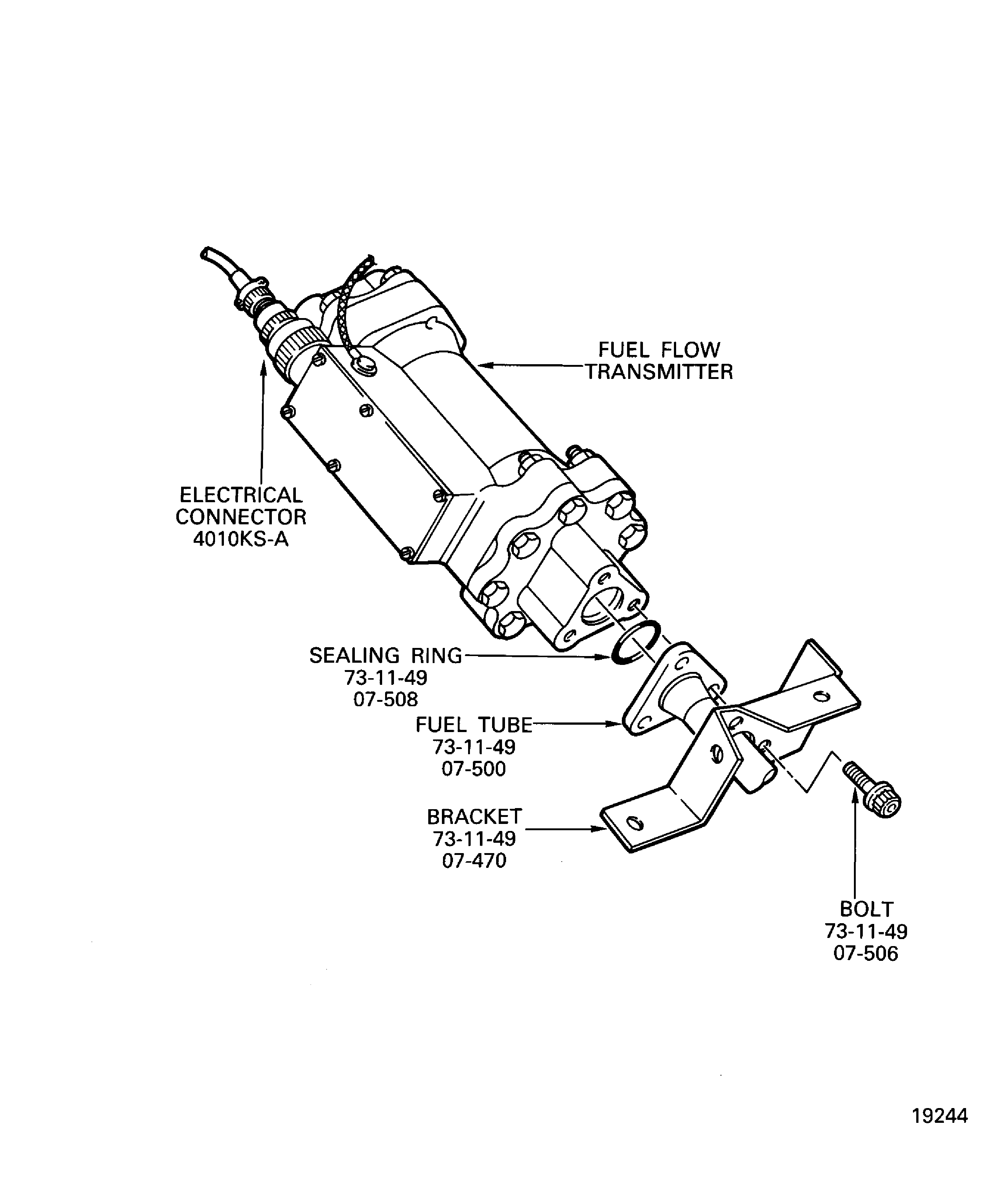

Lubricate the sealing ring with CoMat 10-060 LIQUID PARAFFINor CoMat 10-038 PETROLEUM JELLY.

Install the sealing ring in to the groove in the fuel tube ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,07-500).

Install the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,07-508) sealing ring 1 off.

Attach the fuel flow transmitter and the bracket to the fuel tube and safety with the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,07-506).

Attach the fuel flow transmitter and the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE(73-11-49,07-470) to the fuel tube ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,07-500).

SUBTASK 72-00-60-450-091 Install the Fuel Flow Transmitter

Refer to: Figure

Lubricate the sealing ring with CoMat 10-060 LIQUID PARAFFINor CoMat 10-038 PETROLEUM JELLY.

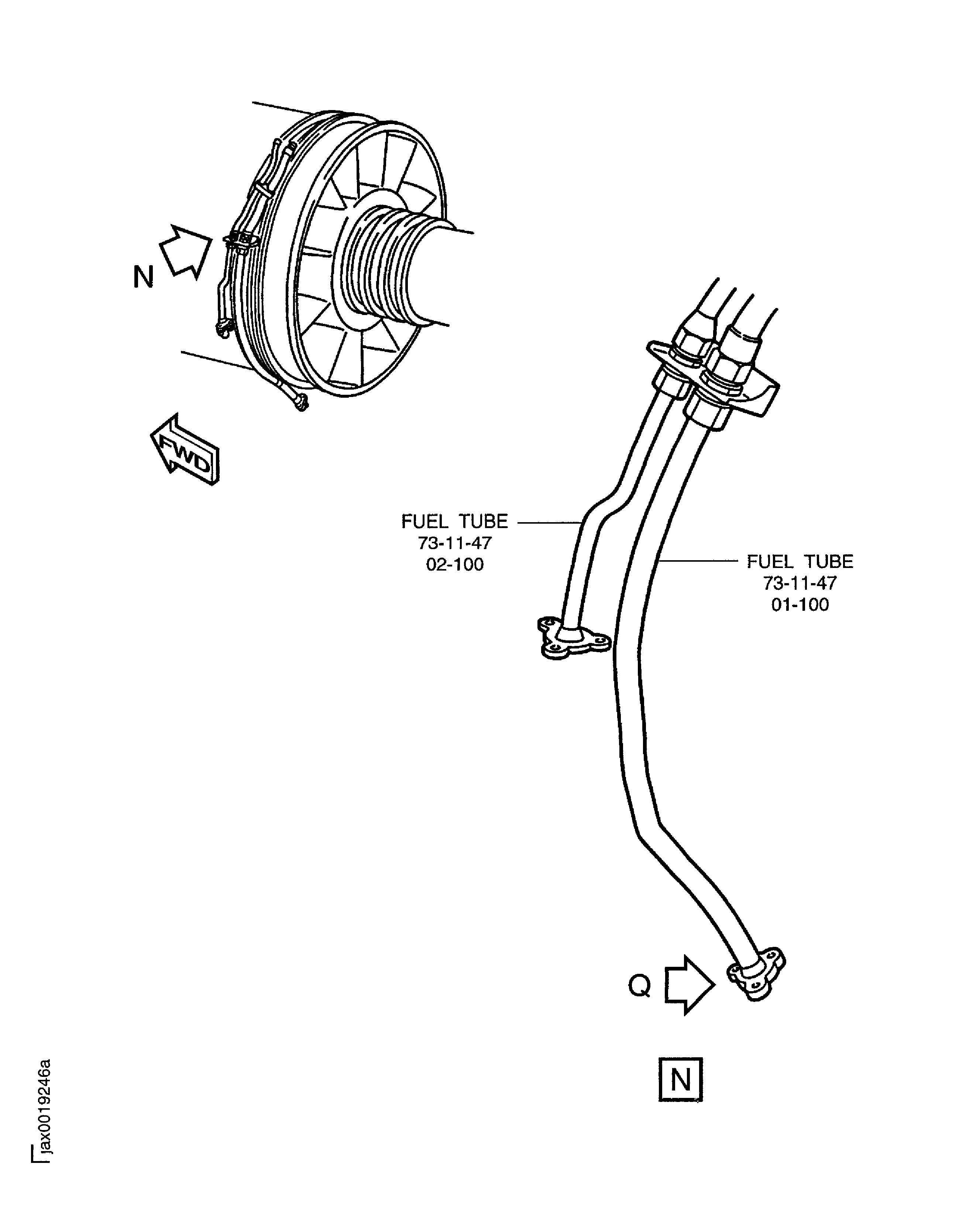

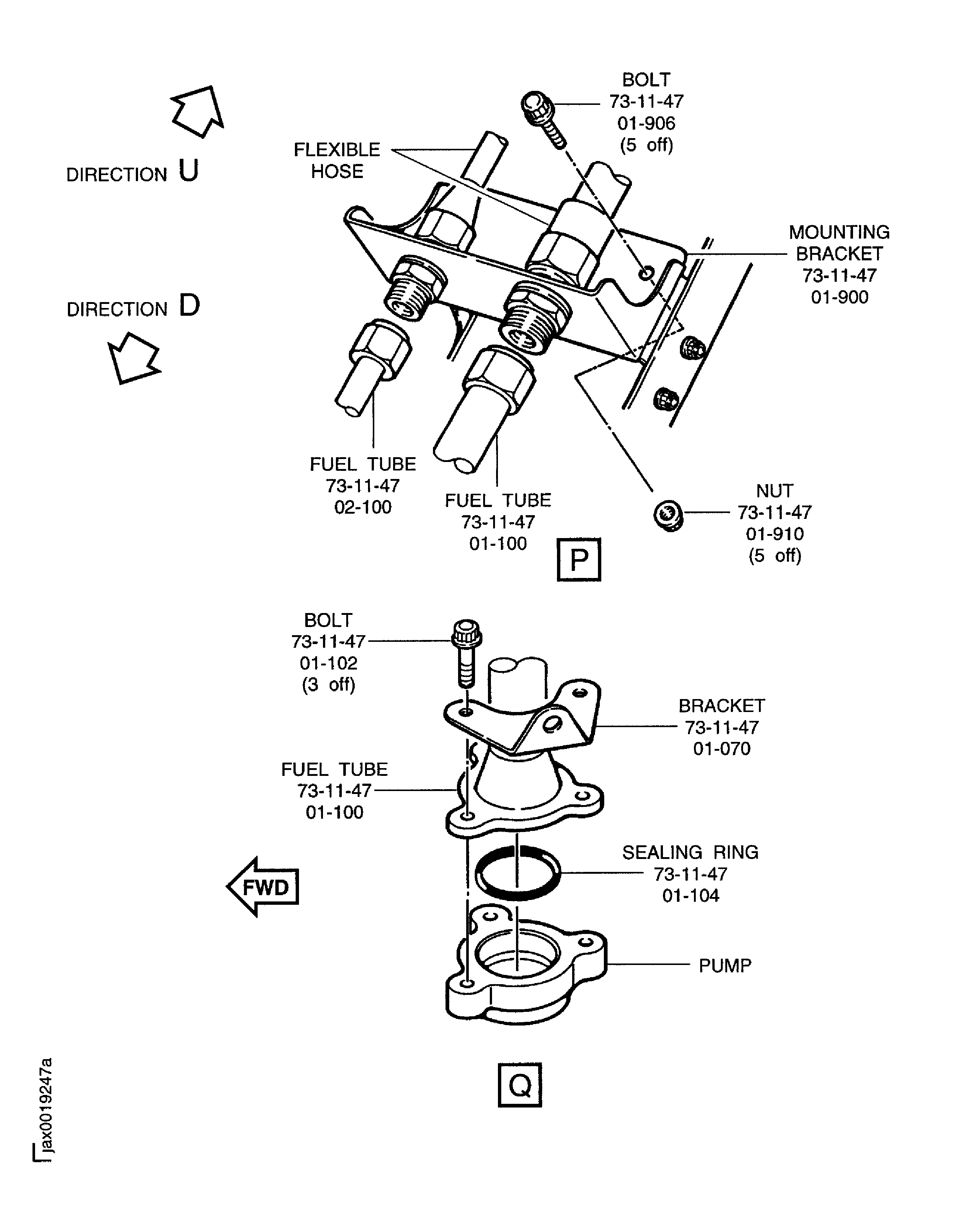

Install the sealing ring in to the groove in the fuel tube FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47,01-100).

Install the new FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47,01-104) sealing ring 1 off.

Attach the fuel tube and the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,07-070) to the pump with the three bolts FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47,01-102). Torque the bolts to 85 to 105 lbfin (10.00 to 12.00 Nm).

Connect the fuel tubes FUEL SYSTEM TUBES (RIGID)-POWER PLANT(73-11-47,01-100) and FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47,02-100) to the flexible hoses.

Safety the mounting bracket with the five bolts FUEL SYSTEM TUBES (RIGID)-POWER PLANT(73-11-47,01-906) and nuts FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47,01-910). Torque the bolts to 85 to 105 lbfin (10.00 to 12.00 Nm).

CAUTION

HOLD THE UNION OF THE FLEXIBLE HOSE DURING THE TORQUE PROCEDURE TO PREVENT DAMAGE TO THE FLEXIBLE HOSE.Torque the nut of the fuel tube FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47,01-100) to 1520 to 1680* lbfin (172 to 190* Nm).

CAUTION

HOLD THE UNION OF THE FLEXIBLE HOSE DURING THE TORQUE PROCEDURE TO PREVENT DAMAGE TO THE FLEXIBLE HOSE.Torque the nut of the fuel tube FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47,02-100) to 470 to 510* lbfin (53 to 58* Nm).

Safety the nuts of the fuel tubes with CoMat 02-147 LOCKWIRE.

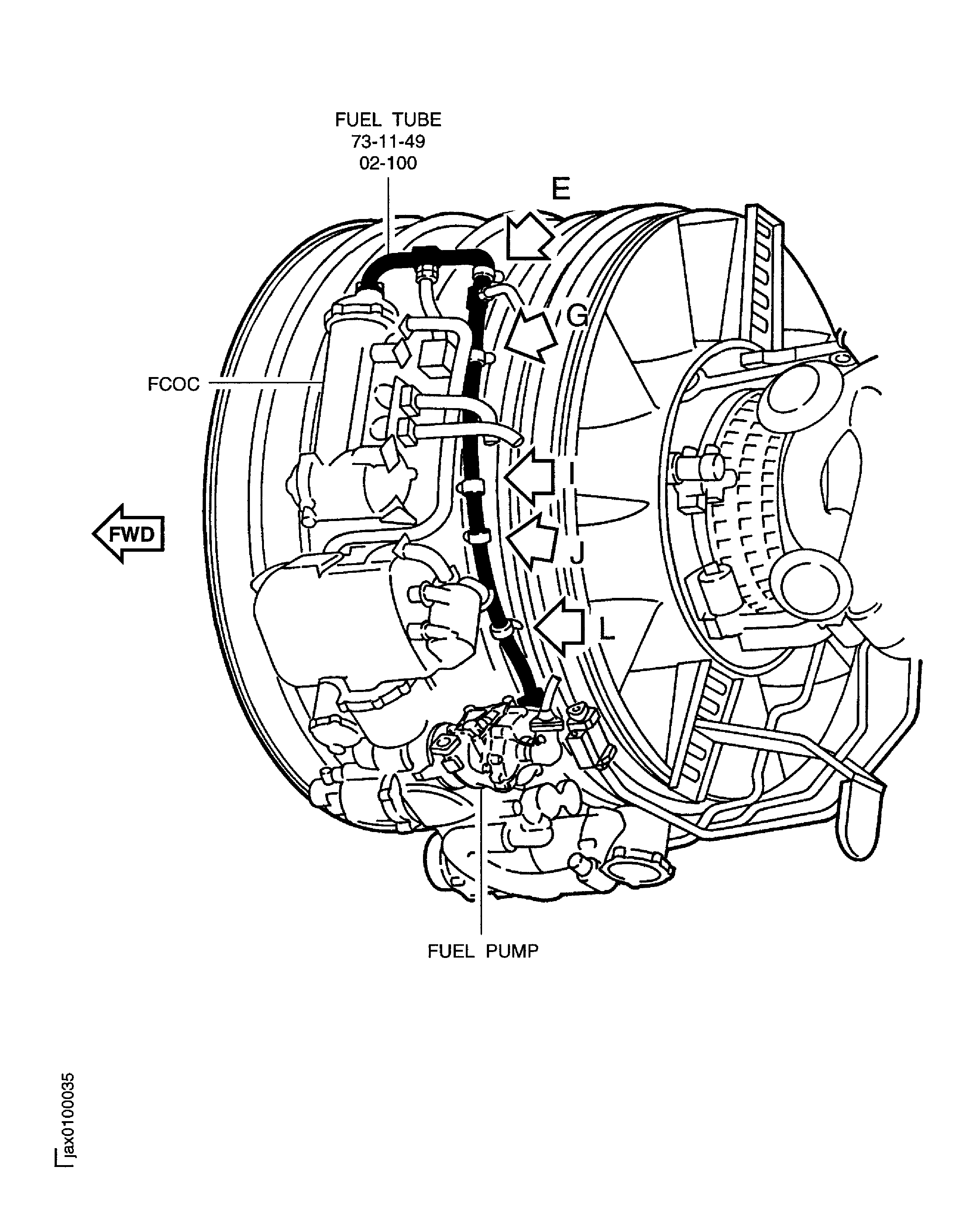

SUBTASK 72-00-60-450-092 Install the Fuel Tube (73-11-47,01-100) to the Flexible Hose and the Pump

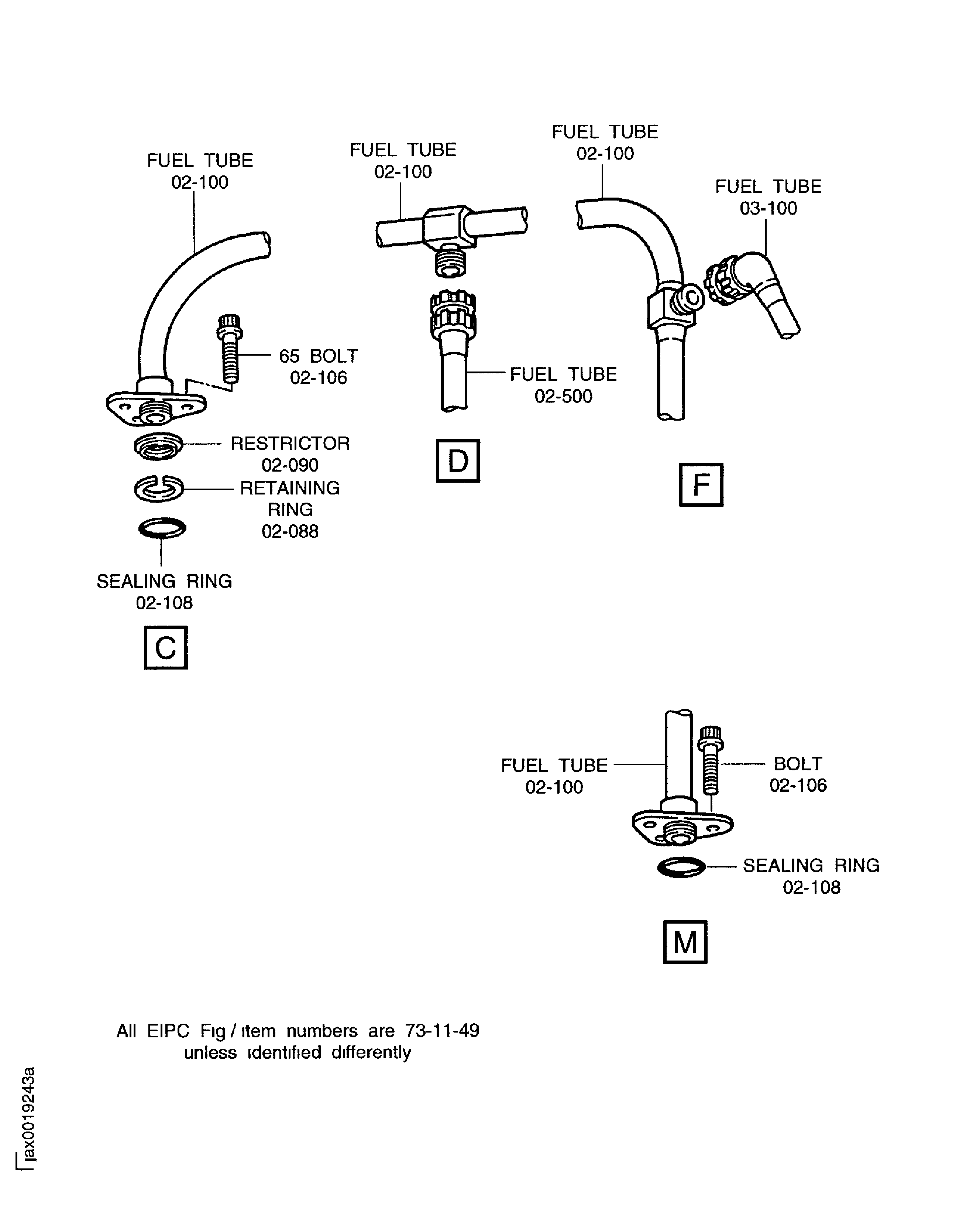

Install the restrictor ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-090) and the retaining ring ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-088) into the fuel tube.

Lubricate the sealing rings with CoMat 10-060 LIQUID PARAFFINor CoMat 10-038 PETROLEUM JELLY.

Install the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-108) sealing rings 2 off.

Safety the fuel tube with the six bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-106) and tighten the bolts lightly.

Connect the fuel tubes ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 03-100 an ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE02-500) to the fuel tube ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-100). Tighten the nuts of the fuel tubes lightly.

Torque the six bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-106) to 85 to 105 lbfin (10.00 to 12.00 Nm).

Torque the nuts of the fuel tubes ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 03-100 and ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE 02-500) to 566 to 611 lbfin (64 to 69 Nm) with IAE 1R18003 Wrench 1 off.

Safety the nuts of the fuel tubes with CoMat 02-147 LOCKWIRE.

Apply torque to the bolts and the fuel tube nuts.

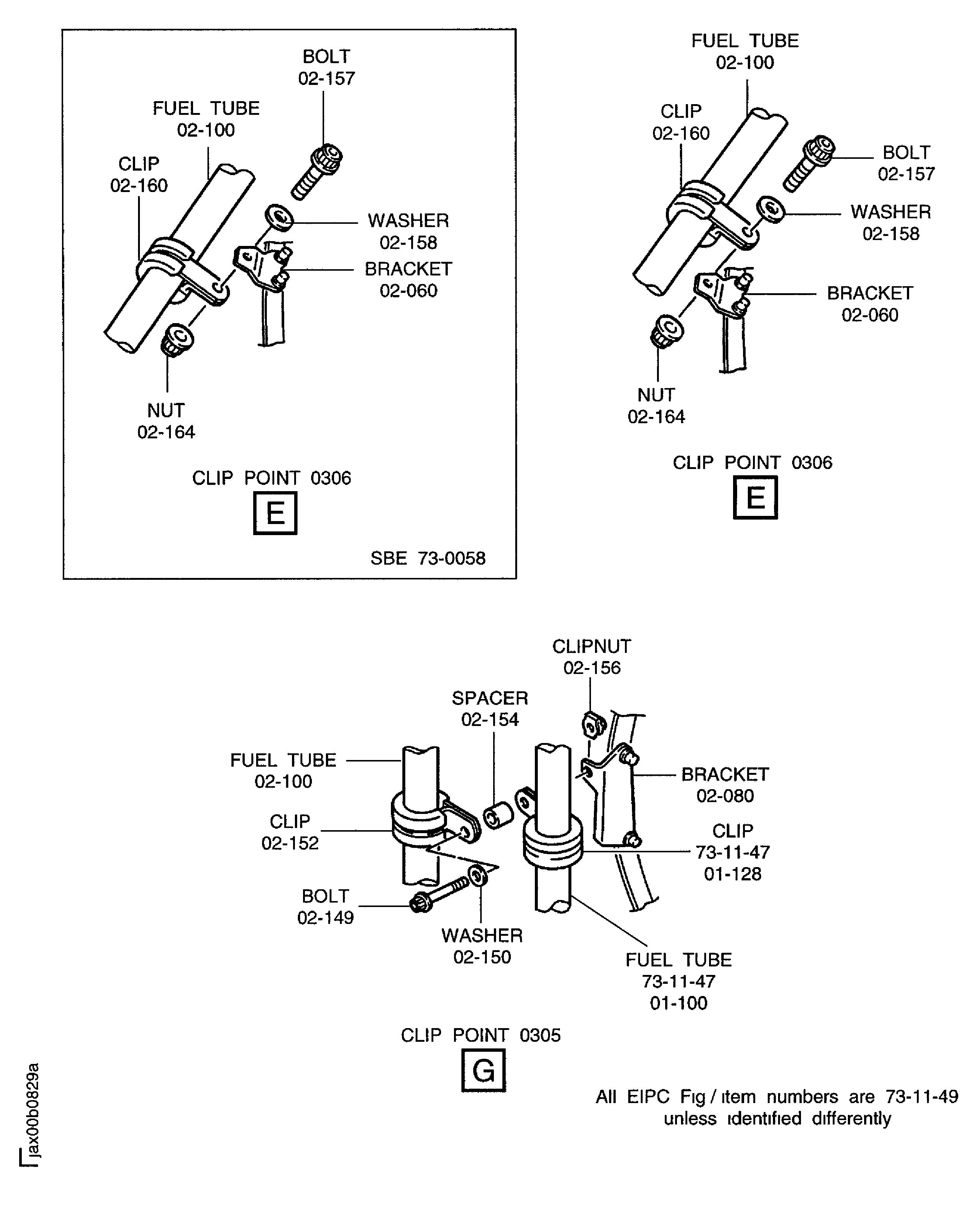

Install the clip ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-160), the washer ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-158), the bolt ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-157) and the nut ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-164) at the clip point 0306. Torque the bolt to 36 to 45 lbfin (4.00 to 5.00 Nm).

Install the clips ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-152 and FUEL SYSTEM TUBES (RIGID)-POWER PLANT 73-11-47, 01-128), the washer ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-150), the spacer ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-154), the bolt ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-149) and the clipnut ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-156) at the clip point 0305. Torque the bolt to 36 to 45 lbfin (4.00 to 5.00 Nm).

Install the clips ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-144 and OIL-PRESSURE OIL TUBES-ENGINE 79-21-49, 03-528), the washer ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-142), the bolt ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-141) and the nut ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-148) at the clip point 0304. Torque the bolt to 36 to 45 lbfin (4.00 to 5.00 Nm).

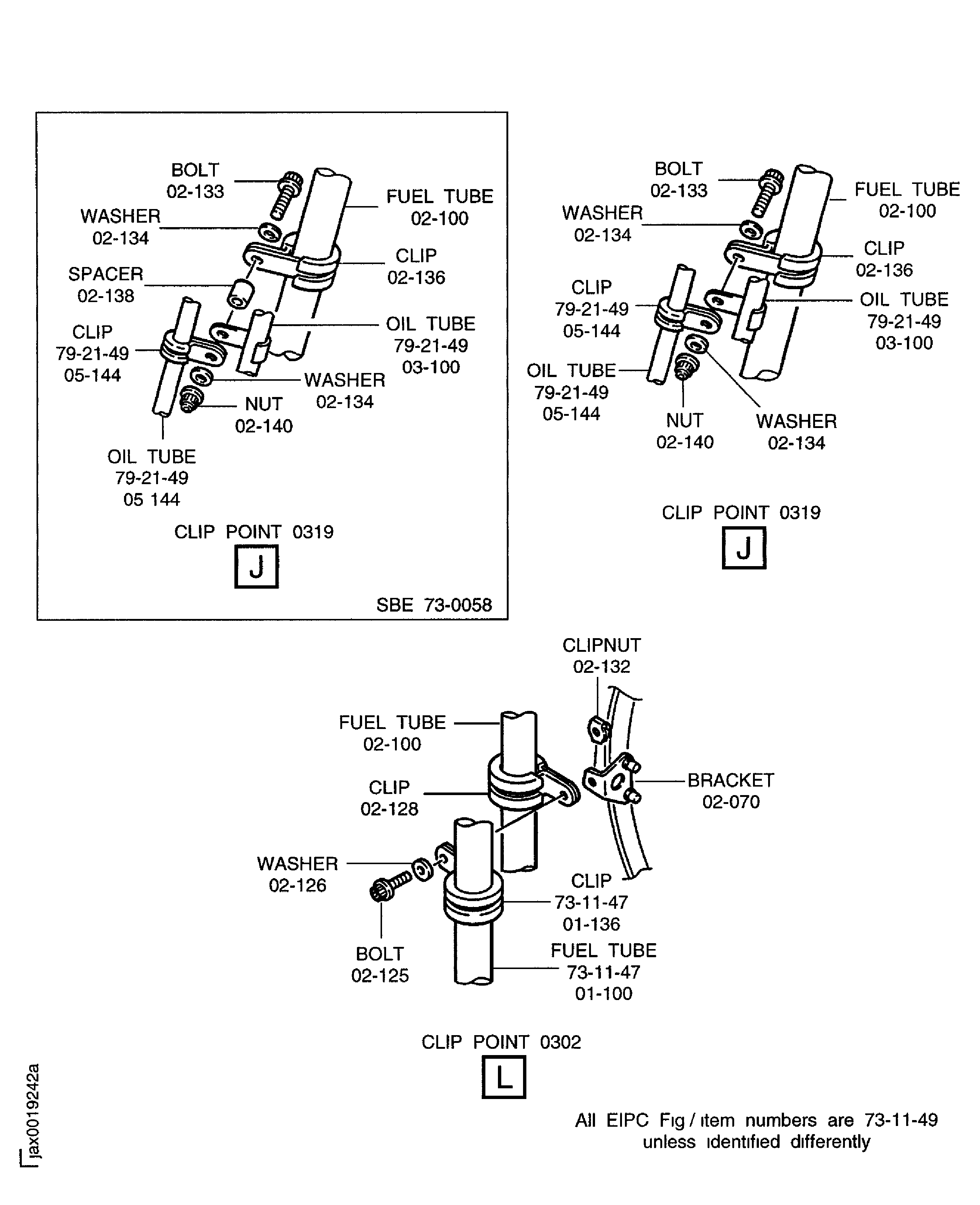

Install the clips ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-136 and OIL-PRESSURE OIL TUBES-ENGINE 79-21-49, 05-144), the two washers ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-134), the bolt ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-133) and the nut ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-140) at the clip point 0319. Torque the bolt to 36 to 45 lbfin (4.00 to 5.00 Nm).

Install the clips ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-128 and FUEL SYSTEM TUBES (RIGID)-POWER PLANT 73-11-47, 01-136), the washer ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-126), the bolt ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-125) and the clipnut ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-132) at the clip point 0302. Torque the bolt to 36 to 45 lbfin (4.00 to 5.00 Nm).

Assemble the clip points 0306, 0305, 0304, 0319 and 0302.

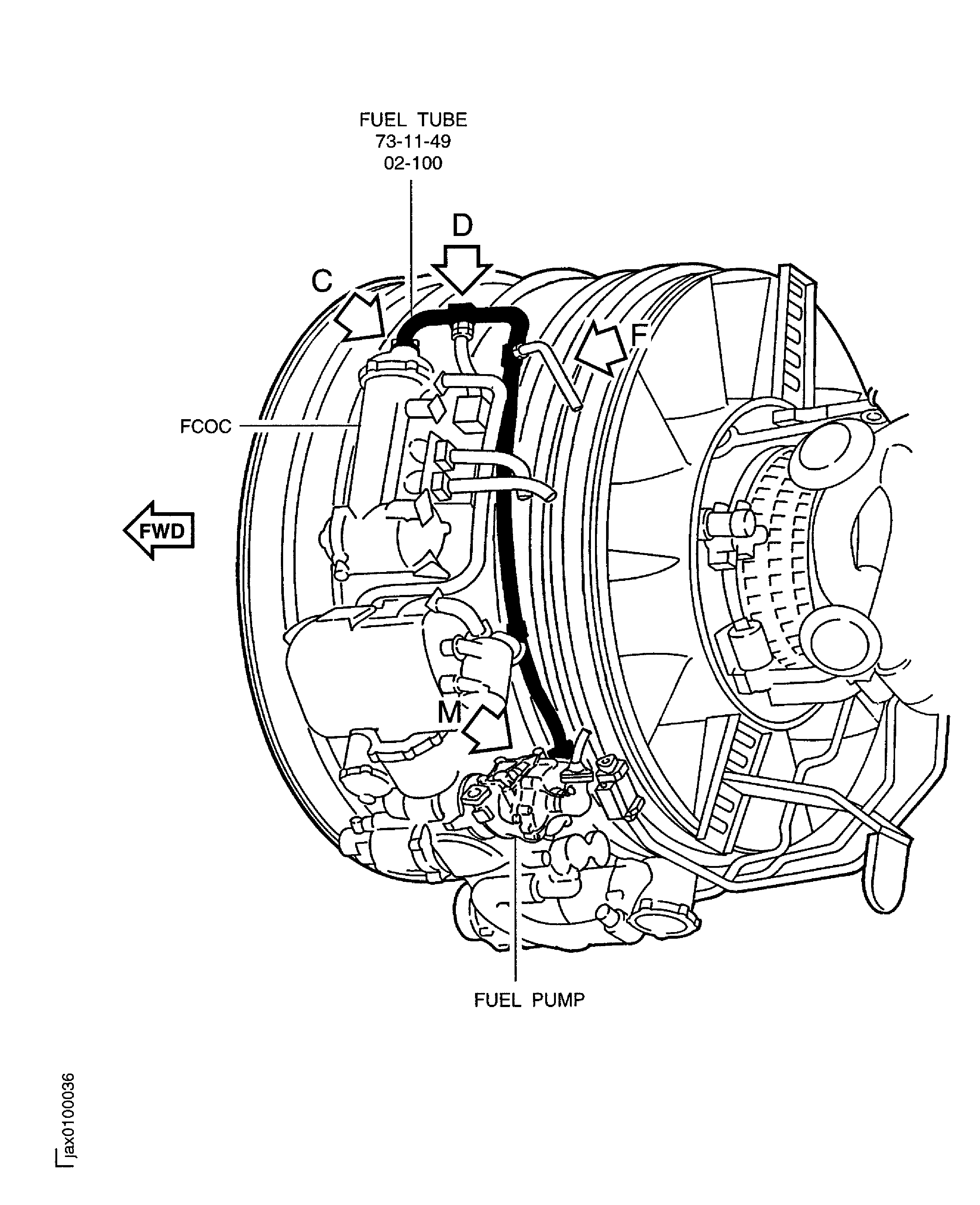

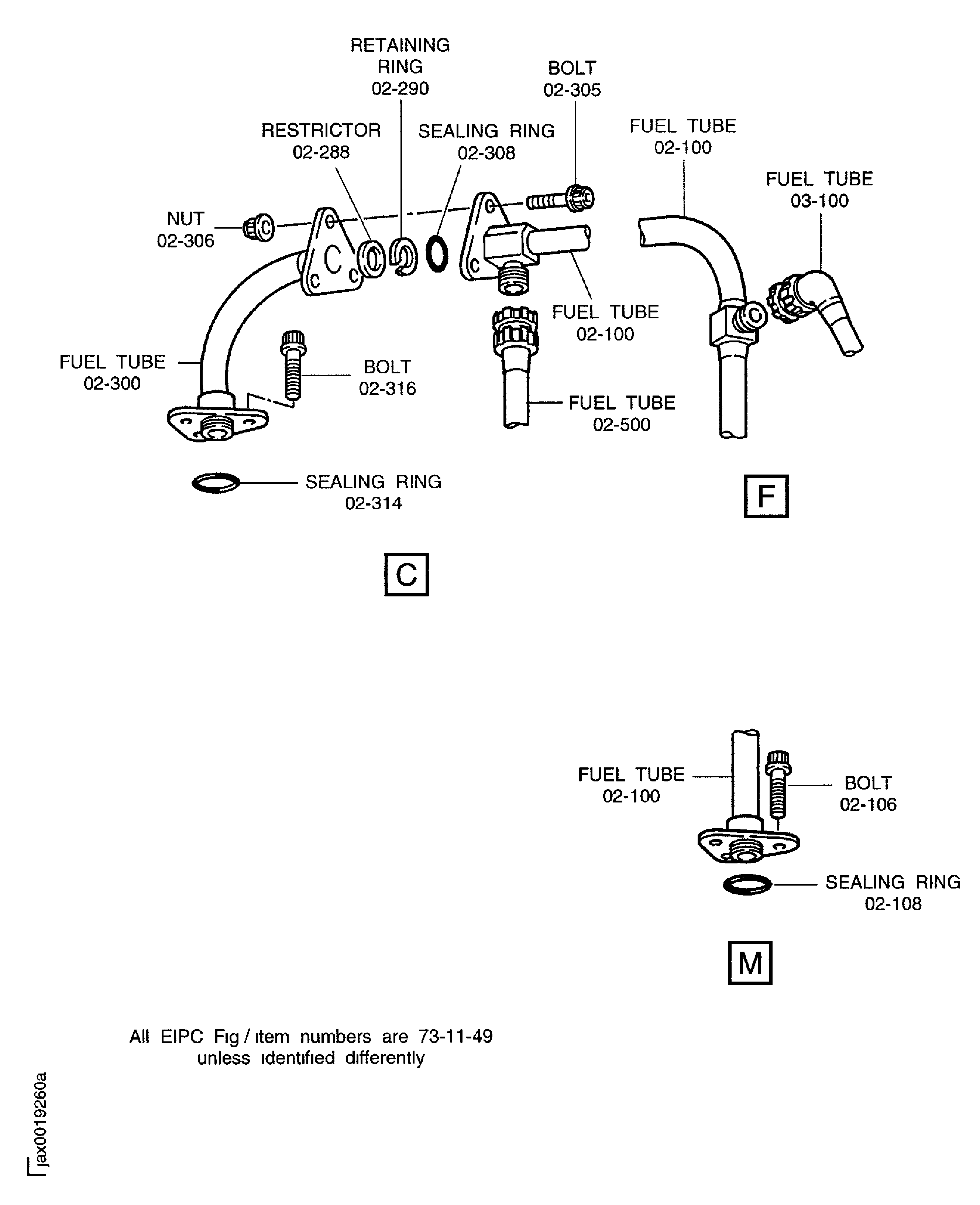

SUBTASK 72-00-60-450-093-A00 Install the Fuel Tube (73-11-49,02-100) to the FCOC and the Pump (Pre SBE 73-0058)

Install the restrictor ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-288) and the retaining ring ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-290) into the fuel tube.

Lubricate the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-308) sealing ring 1 off and ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-314) sealing ring 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the sealing rings into the grooves in the fuel tube.

Attach the fuel tube to the FCOC with the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-316). Tighten the bolts lightly.

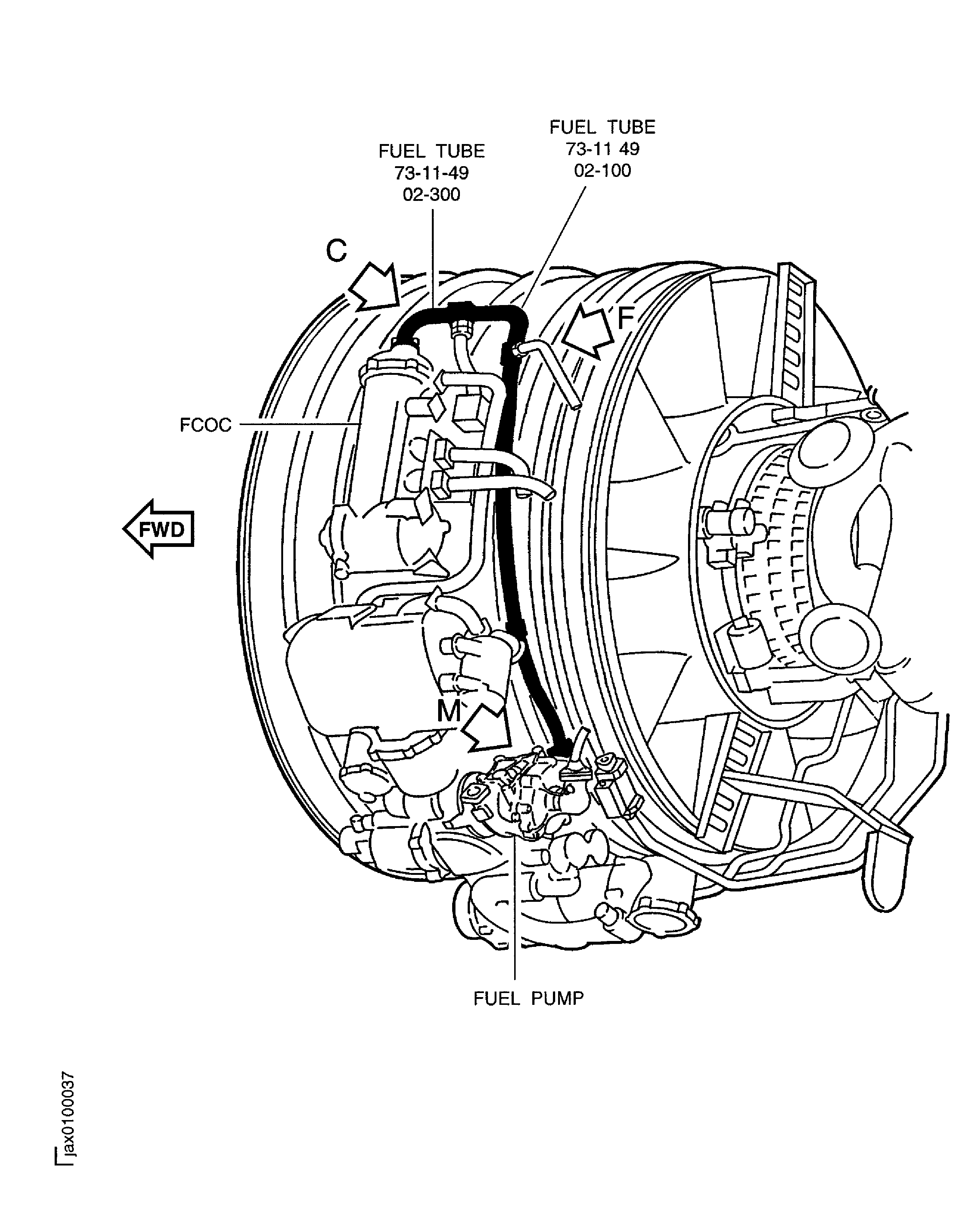

Install the fuel tube ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE(73-11-49,02-300) to the FCOC.

Lubricate the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-108) sealing ring 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the sealing ring into the groove in the fuel tube.

Attach the fuel tube to the fuel pump and the fuel tube ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-300) with the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-106) and the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-305). Tighten the bolts lightly.

Torque the bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-106 , ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE 02-305 and ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE 02-316) to 85 to 105 lbfin (10.00 to 12.00 Nm).

Install the fuel tube ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-100) to the pump.

Connect the fuel tubes ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-500 and ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE 03-100) to the fuel tube ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-100). Torque the nuts of the fuel tubes to 566 to 611 lbfin (64 to 69 Nm) with IAE 1R18003 Wrench wrench 1 off. Safety the nuts with CoMat 02-147 LOCKWIRE.

Install the clip ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-160), the washer ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE(73-11-49,02-158), the bolt ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-157) and the nut ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-164) at the clip point 0306. Torque the bolt to 36 to 45 lbfin (4.00 to 5.00 Nm).

Install the clips ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-152 and FUEL SYSTEM TUBES (RIGID)-POWER PLANT 73-11-47, 01-128), the washer ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-150), the spacer ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-154), the bolt ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-149) and the clipnut ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-156) at the clip point 0305. Torque the bolt to 36 to 45 lbfin (4.00 to 5.00 Nm).

Install the clips ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-144 and OIL-PRESSURE OIL TUBES-ENGINE 79-21-49, 03-528), the washer ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-142), the spacer ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-145), the bolt ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-141) and the nut ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-148) at the clip point 0304. Torque the bolt to 36 to 45 lbfin (4.00 to 5.00 Nm).

Install the clips ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-136 and OIL-PRESSURE OIL TUBES-ENGINE79-21-49, 05-144), the two washers ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-134), the spacer ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-138), the bolt ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-133) and the nut ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-140) at the clip point 0319. Torque the bolt to 36 to 45 lbfin (4.00 to 5.00 Nm).

Install the clips ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-128 and FUEL SYSTEM TUBES (RIGID)-POWER PLANT 73-11-47, 01-136), the washer ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-126), the bolt ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-125) and the clipnut ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,02-132) at the clip point 0302. Torque the bolt to 36 to 45 lbfin (4.00 to 5.00 Nm).

Assemble the clip points 0306, 0305, 0304, 0319 and 0302.

SUBTASK 72-00-60-450-093-B00 Install the Fuel Tubes (73-11-49,02-100 and 02-300) to the FCOC and the Pump (SBE 73-0058)

SBE 73-0058: New tubes with a repositioned restrictor orifice.

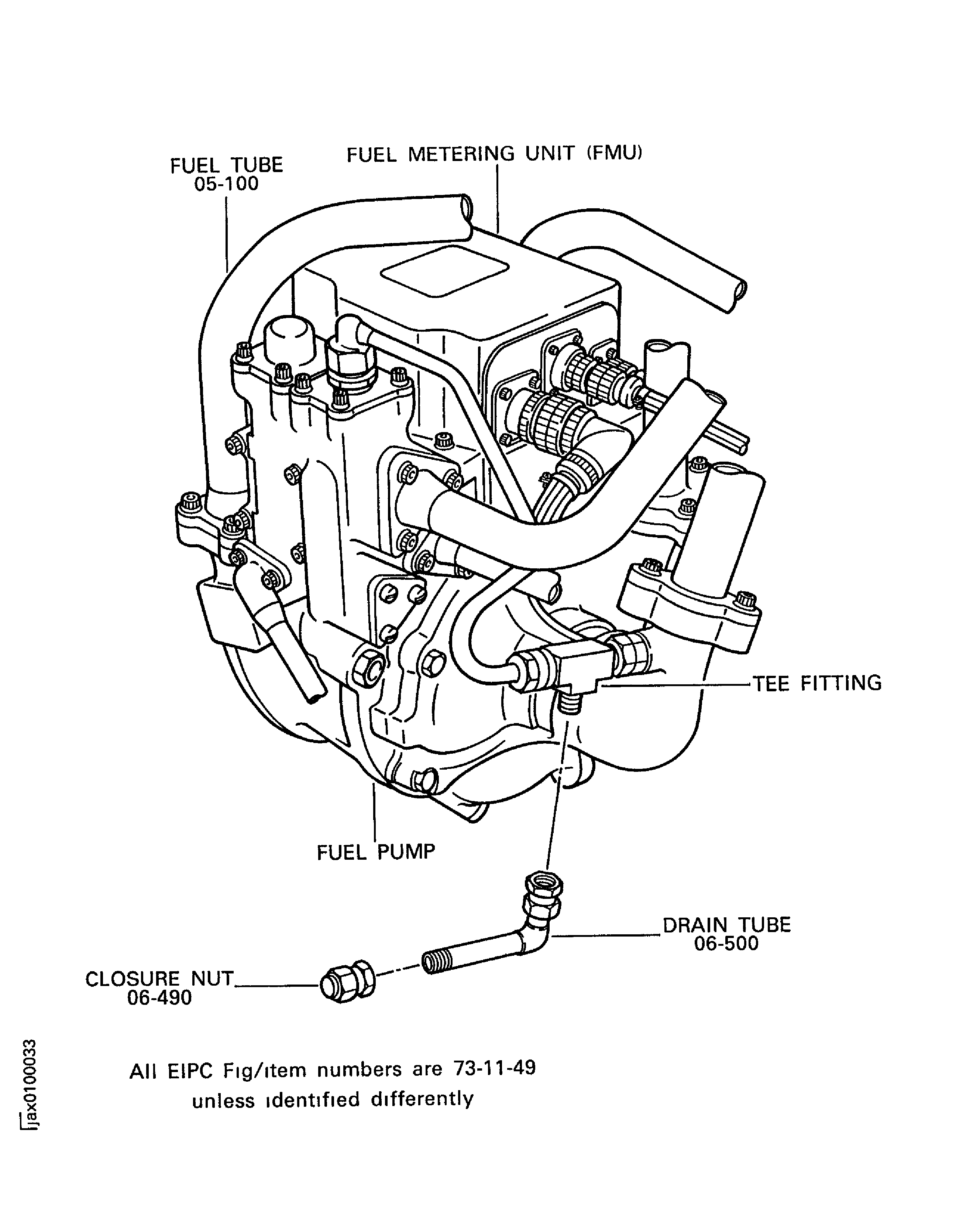

Install the FMU to the pump. Refer to TASK 72-00-60-450-002-A00 (INSTALLATION-006, CONFIG-001).

Install the drain tube ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE(73-11-49,06-500) and the fuel tube ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,05-100) to the pump. Refer to TASK 72-00-60-450-002-A00 (INSTALLATION-006, CONFIG-001).

Connect the electrical connectors and the tubes to the FMU. Refer to TASK 72-00-60-450-002-A00 (INSTALLATION-006, CONFIG-001).

SUBTASK 72-00-60-450-094 Install the Fuel Metering Unit (FMU) to the Pump

Refer to: Figure

Install the closure nut ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE(73-11-49, 06-490) on to the threads on the drain tube ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49,06-500). Torque the closure nut to 230 to 248 lbfin (26 to 28 Nm).

Safety the closure nut with CoMat 02-147 LOCKWIRE.

SUBTASK 72-00-60-450-101 Install the Closure Nut

Figure: Install the pump

Install the pump

Figure: Install the fuel flow transmitter

Install the fuel flow transmitter

Figure: Install the fuel tube to the flexible hose and the pump

Install the fuel tube to the flexible hose and the pump

Figure: Install the fuel tube to the flexible hose and the pump

Install the fuel tube to the flexible hose and the pump

Figure: Pre SBE 73-0058: Install the fuel tube to the FCOC and the pump

Pre SBE 73-0058: Install the fuel tube to the FCOC and the pump

Figure: Pre SBE 73-0058: Install the fuel tube to the FCOC and the pump

Pre SBE 73-0058: Install the fuel tube to the FCOC and the pump

Figure: SBE 73-0058: Install the fuel tube to the FCOC and the pump

SBE 73-0058: Install the fuel tube to the FCOC and the pump

Figure: SBE 73-0058: Install the fuel tube to the FCOC and the pump

SBE 73-0058: Install the fuel tube to the FCOC and the pump

Figure: Assemble the clip points

Assemble the clip points

Figure: Assemble the clip points

Assemble the clip points

Figure: Assemble the clip points

Assemble the clip points

Figure: Assemble the clip points

Assemble the clip points

Figure: LP/HP fuel pump

LP/HP fuel pump

Figure: LP/HP fuel pump

LP/HP fuel pump