Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-60-10-440-001 Main Gearbox Assembly - Assemble The Main Gearbox Assembly, Assembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to SPM TASK 70-64-02-640-501.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. Refer to SPM TASK 70-63-02-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Transportation covers/blanks must be removed immediately before installation of the components.

Make sure that the outer race has the same serial number of the related bearing.

Lubricate the cages of the roller bearings with CoMat 10-077 APPROVED ENGINE OILS before the installation.

Refer to TASK 72-60-00-030-001 to install the main gearbox on the build stand if necessary.

Operate by hand the installed gearshafts to make easier subsequent installations.

Note

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1F10003 Pusher | 0AM53 | IAE 1F10003 | 1 | |

| IAE 1F10004 Pusher | 0AM53 | IAE 1F10004 | 1 | |

| IAE 1F10031 Pusher | 0AM53 | IAE 1F10031 | 1 | |

| IAE 1F10032 Pusher | 0AM53 | IAE 1F10032 | 1 | |

| IAE1F10070 Pusher | 0AM53 | IAE 1F10070 | 1 | |

| IAE 1F10072 Pusher | 0AM53 | IAE 1F10072 | 1 | |

| IAE 1F10082 Guide Pin | 0AM53 | IAE 1F10082 | 2 | |

| IAE 1F10155 Drift | 0AM53 | IAE 1F10155 | 1 | |

| IAE 1F10156 Drift | 0AM53 | IAE 1F10156 | 1 | |

| IAE 1F10157 IAE 1F10157 Drift | 0AM53 | IAE 1F10157 | 1 | |

| IAE 1F10221 Drift | 0AM53 | IAE 1F10221 | 1 | |

| IAE 1F10222 Pin | 0AM53 | IAE 1F10222 | 1 | |

| IAE 1F10223 Drift | 0AM53 | IAE 1F10223 | 1 | |

| IAE 1F10224 Drift | 0AM53 | IAE 1F10224 | 1 | |

| IAE 1F10225 Drift | 0AM53 | IAE 1F10225 | 1 | |

| IAE 1F10227 Drift | 0AM53 | IAE 1F10227 | 1 | |

| IAE 2F10229 Rotating handwheel | 0AM53 | IAE 2F10229 | 1 | |

| IAE 2F10257 Storage box | 0AM53 | IAE 2F10257 | 1 | |

| IAE 2F10266 Backlash kit | 0AM53 | IAE 2F10266 | 1 | |

| IAE 2F10267 Clamping fixture | 0AM53 | IAE 2F10267 | 1 | |

| IAE 2F10268 Backlash gage tip | 0AM53 | IAE 2F10268 | 1 | |

| IAE 2F10269 Comparator support | 0AM53 | IAE 2F10269 | 1 | |

| IAE 2F10270 Clamping fixture | 0AM53 | IAE 2F10270 | 1 | |

| IAE 2F10271 Clamping fixture | 0AM53 | IAE 2F10271 | 1 | |

| IAE 2F10272 Backlash gage tip | 0AM53 | IAE 2F10272 | 1 | |

| IAE 2F10273 Comparator support | 0AM53 | IAE 2F10273 | 1 | |

| IAE 2F10274 Clamping fixture | 0AM53 | IAE 2F10274 | 1 | |

| IAE 2F10275 Backlash gage tip | 0AM53 | IAE 2F10275 | 1 | |

| IAE 2F10276 Clamping fixture | 0AM53 | IAE 2F10276 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 07-038 AIR DRYING ENAMEL | 00BB6 | CoMat 07-038 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

Safety Requirements

NONEProcedure

Refer to Figure.

Calculate the interference at Location 4002. Use the data made as a note in TASK 72-60-21-200-002.

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4002

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Roller Bearing Deoiler Gear, Impeller, And Housing Assembly (72-60-29, 01-490) Of The Deoiler Gear Drive

Gearbox Casing Location Bore For The Roller Bearing

2.7560

Clear

2.7553

0.0005

Roller Bearing Outer Diameter

2.7559

Intf

2.7555

0.0006

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4002

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Roller Bearing Deoiler Gear, Impeller, And Housing Assembly (72-60-29, 01-490) Of The Deoiler Gear Drive

Gearbox Casing Location Bore For The Roller Bearing

70, 004

Clear

69.985

0.013

Roller Bearing Outer Diameter

70.000

Intf

69.991

0.015

SUBTASK 72-60-10-220-051 Make sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4002

Refer to Figure.

Calculate the interference at Location 4004. Use the data made as a note in TASK 72-60-29-200-003 and TASK 72-60-29-200-001.

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4004

Deoiler Gearshaft Deoiler Gear, Impeller, And Housing Assembly (72-60-29, 01-290)

Journal Of The Rotating Ring Deoiler Gear, Impeller, And Housing Assembly (72-60-29, 01-110)

Deoiler Gearshaft Journal Of The Rotating Ring

1.2991

1.9281

0.0010

Rotating Ring Inner Diameter

1.9311

0.0030

1.9303

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4004

Deoiler Gearshaft Deoiler Gear, Impeller, And Housing Assembly (72-60-29, 01-290)

Journal Of The Rotating Ring Deoiler Gear, Impeller, And Housing Assembly (72-60-29, 01-110)

Deoiler Gearshaft Journal Of The Rotating Ring

49.000

48.975

0.030

Rotating Ring Inner Diameter

49.050

0.075

49.030

SUBTASK 72-60-10-220-052 Make Sure the Fits and Clearances of the Deoiler Gearshaft are in the Limits given at Location 4004

Refer to Figure.

Calculate the interference at Location 4006. Use the data made as a note in TASK 72-60-29-200-002.

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4006

Deoiler Housing Deoiler Gear, Impeller, And Housing Assembly (72-60-29, 01-390)

Location For The Deoiler Casing ENGINE-DEOILER CASE AND COVER (72-60-31, 01-170)

Deoiler Housing Location For The Deoiler Casing

7.2834

7.2816

0.0008

Deoiler Casing Bore

7.2862

0.0046

7.2842

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4006

Deoiler Housing Deoiler Gear, Impeller, And Housing Assembly (72-60-29, 01-390)

Location For The Deoiler Casing ENGINE-DEOILER CASE AND COVER (72-60-31, 01-170)

Deoiler Housing Location For The Deoiler Casing

185.000

184.954

0.020

Deoiler Casing Bore

185.070

0.116

185.020

SUBTASK 72-60-10-220-053 Make Sure the Fits and Clearances of the Deoiler Housing are in the Limits given at Location 4006

Refer to Figure.

Calculate the interference at Location 4007. Use the data made as a note in TASK 72-60-21-200-002.

Table 7. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4007

Gearbox casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Deoiler Housing Deoiler Gear, Impeller, And Housing Assembly (72-60-29, 01-390)

Gearbox Casing Location Bore For The Deoiler Housing

6.9307

6.9291

0.0032

Deoiler Housing Outer Diameter

6.9291

0.0000

6.9275

Table 8. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4007

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Deoiler Housing Deoiler Gear, Impeller, And Housing Assembly (72-60-29, 01-390)

Gearbox Casing Location bore For The Deoiler Housing

176.040

176.000

0.080

Deoiler Housing Outer Diameter

176.000

0.000

175.960

SUBTASK 72-60-10-220-054 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4007

Refer to Figure.

Calculate the interference at Location 4010. Use the data made as a note in TASK 72-60-21-200-002.

Table 9. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4010

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Roller Bearing Generator Drive Gear And Housing Assembly (72-60-28, 01-590) Of The IDG Gear Drive Gearbox Casing

Location Bore For The Roller Bearing

2.7560

Clear

2.7553

0.0005

Roller Bearing Outer Diameter

2.7559

Intf

2.7555

0.0006

Table 10. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4010

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Roller Bearing Generator Drive Gear And Housing Assembly (72-60-28, 01-590) Of The IDG Gear Drive

Gearbox Casing Location Bore For The Roller Bearing

70.004

Clear

69.985

0.013

Roller Bearing Outer Diameter

70.000

Intf

69.991

0.015

SUBTASK 72-60-10-220-055 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4010

Refer to Figure.

Calculate the interference at Location 4012. Use the data made as a note in TASK 72-60-28-200-003 and TASK 72-60-28-200-001.

Table 11. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4012

IDG Gear Drive Generator Drive Gear And Housing Assembly (72-60-28, 01-410)

Journal Of The Rotating Ring Generator Drive Gear And Housing Assembly (72-60-28, 01-350)

2.0866

IDG Gear Drive Journal Of The Rotating Ring

2.0854

0.0012

Rotating Ring Inner Diameter

2.0885

0.0031

2.0878

Table 12. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4012

IDG Gear Drive Generator Drive Gear And Housing Assembly (72-60-28, 01-410)

Journal Of The Rotating Ring Generator Drive Gear And Housing Assembly (72-60-28, 01-350)

IDG Gear Drive Journal Of The Rotating Ring

53.000

52.970

0.030

Rotating Ring Inner Diameter

53.050

0.080

53.030

SUBTASK 72-60-10-220-056 Make Sure the Fits and Clearances of the IDG Gear Drive are in the Limits given at Location 4012

Refer to Figure.

Calculate the interference at Location 4014. Use the data made as a note in TASK 72-60-21-200-002 and TASK 72-60-28-200-002.

Table 13. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4014

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Smaller Location For The IDG Housing Generator Drive Gear And Housing Assembly (72-60-28, 01-450)

Gearbox Casing Location Bore For The Housing

7.0094

7.0078

0.0035

Housing Outer Diameter

7.0074

0.0004

7.0059

Table 14. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4014

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Smaller Location For The IDG Housing Generator Drive Gear And Housing Assembly (72-60-28, 01-450)

Gearbox Casing Location Bore For The Housing

178.040

178.000

0.090

Housing Outer Diameter

177.990

0.010

177.950

SUBTASK 72-60-10-220-057 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4014

Refer to Figure.

Calculate the interference at Location 4015. Use the data made as a note in TASK 72-60-21-200-002 and TASK 72-60-28-200-002.

Table 15. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4015

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Larger Location For The IDG Housing Generator Drive Gear And Housing Assembly (72-60-28, 01-450)

Gearbox Casing Location Bore For The Housing

7.0925

7.0886

0.0098

Housing Outer Diameter

7.0866

0.0020

7.0827

Table 16. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4015

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Larger Location For The IDG Housing Generator Drive Gear And Housing Assembly (72-60-28, 01-450)

Gearbox Casing Location Bore For The Housing

180.150

180.050

0.250

Housing Outer Diameter

180.000

0.050

179.900

SUBTASK 72-60-10-220-058 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4015

Refer to Figure.

Calculate the interference at Location 4018. Use the data made as a note in TASK 72-60-21-200-002.

Table 17. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4018

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Roller Bearing Starter Drive Gear And Housing Assembly (72-60-22, 01-500) Of The Starter Gear Drive

Gearbox Casing Location Bore For The Roller Bearing

2.9529

Clear

2.9521

0.0005

Roller Bearing Outer Diameter

2.9527

Intf

2.9524

0.0006

Table 18. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4018

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Roller Bearing Starter Drive Gear And Housing Assembly (72-60-22, 01-500) Of The Starter Gear Drive

Gearbox Casing Location Bore For The Roller Bearing

75.004

Clear

74.985

0.013

Roller Bearing Outer Diameter

75.000

Intf

74.991

0.015

SUBTASK 72-60-10-220-059 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4018

Refer to Figure.

Calculate the interference at Location 4020. Use the data made as a note in TASK 72-60-22-200-003 and TASK 72-60-22-200-001.

Table 19. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4020

Starter Gear Drive Starter Drive Gear And Housing Assembly (72-60-22, 01-260)

Journal Of The Rotating Ring Starter Drive Gear And Housing Assembly (72-60-22, 01-200)

Starter Gear Drive Journal Of The Rotating Ring

1.6535

1.6525

0.0012

Rotating Ring Inner Diameter

1.6555

0.0030

1.6547

Table 20. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4020

Starter Gear Drive Starter Drive Gear And Housing Assembly (72-60-22, 01-260)

Journal Of The Rotating Ring Starter Drive Gear And Housing Assembly (72-60-22, 01-200)

Starter Gear Drive Journal Of The Rotating Ring

42.000

41.975

0.030

Rotating Ring Inner Diameter

42.050

0.075

42.030

SUBTASK 72-60-10-220-060 Make Sure the Fits and Clearance of the Starter Gear Drive are in the Limits given at Location 4020

Refer to Figure.

Calculate the interference at Location 4022. Use the data made as a note in TASK 72-60-21-200-002 and TASK 72-60-22-200-002.

Table 21. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4022

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Starter Drive Housing Starter Drive Gear And Housing Assembly (72-60-22, 01-300)

Gearbox Casing Location Bore For The Housing

7.4033

7.4015

0.0036

Housing Outer Diameter

7.4015

0.0000

7.3997

Table 22. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4022

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Starter Drive Housing Starter Drive Gear And Housing Assembly (72-60-22, 01-300)

Gearbox Casing Location Bore For The Housing

188.046

188.000

0.092

Housing Outer Diameter

188.000

0.000

187.954

SUBTASK 72-60-10-220-061 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given in Location 4022

Refer to Figure.

Calculate the interference at Location 4023. Use the data made as a note in TASK 72-60-32-200-001.

Table 23. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4023

Angle Gearbox Support ENGINE-ANGLE GEARBOX SUPPORT (72-60-32, 01-300)

Location For The Roller Bearing Starter Idler Gear And Bearing Assembly (72-60-27, 01-100) Of The Starter Idler Gear

Angle Gearbox Support Location Bore Of The Roller Bearing

3.0316

Clear

3.0309

0.0005

Roller Bearing Outer Diameter

3.0315

Intf

3.0311

0.0006

Table 24. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4023

Angle gearbox support ENGINE-ANGLE GEARBOX SUPPORT (72-60-32, 01-300)

Location For The Roller Bearing Starter Idler Gear And Bearing Assembly (72-60-27, 01-100) Of The Starter Idler Gear

Angle Gearbox Support Location Bore Of The Roller Bearing

77.004

Clear

76.985

0.013

Roller Bearing Outer Diameter

77.000

Intf

76.991

0.150

SUBTASK 72-60-10-220-062 Make Sure the Fits and Clearance of the Angle Gearbox Support are in the Limits given at Location 4023

Refer to Figure.

Calculate the interference at Location 4025. Use the data made as a note in TASK 72-60-21-200-002.

Table 25. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4025

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Roller Bearing Starter Idler Gear And Bearing Assembly (72-60-27, 01-220) Of The Starter Idler Gear

Gearbox Casing Location Bore Of The Roller Bearing

3.0316

Clear

3.0309

0.0005

Roller Bearing Outer Diameter

2.0315

Intf

3.0311

0.0006

Table 26. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4025

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Roller Bearing Starter Idler Gear And Bearing Assembly (72-60-27, 01-220) Of The Starter Idler Gear

Gearbox Casing Location Bore Of The Roller Bearing

77.004

Clear

76.985

0.013

Roller Bearing Outer Diameter

77.000

Intf

76.991

0.015

SUBTASK 72-60-10-220-063 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4025

Refer to Figure.

Calculate the interference at Location 4027. Use the data made as a note in TASK 72-60-21-200-002 and TASK 72-60-32-200-001.

Table 27. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4027

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Pilot Starter Idler Gear Of The Angle Gearbox Support ENGINE-ANGLE GEARBOX SUPPORT (72-60-32, 01-300)

Gearbox Casing Location Bore

6,8562

6.8524

0.0117

Pilot Starter Idler Gear Outer Diameter

6.8445

6.8465

0.0059

Table 28. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4027

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Pilot Starter Idler Gear Of The Angle Gearbox Support ENGINE-ANGLE GEARBOX SUPPORT (72-60-32, 01-300)

Gearbox Casing Location Bore

174.150

174.050

0.300

Pilot Starter Idler Gear Outer Diameter

173.850

173.900

0.150

SUBTASK 72-60-10-220-064 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4027

Refer to Figure.

Calculate the interference at Location 4030. Use the data made as a note in TASK 72-60-21-200-002.

Table 29. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4030

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Roller Bearing Extension Layshaft Gear And Bearing Assembly (72-60-24, 01-280) Of The Layshaft Extension Gear

Gearbox Casing Location Bore Of The Roller Bearing

3.5434

Clear

3.5426

0.0004

Roller Bearing Outer Diameter

3.5433

Intf

3.5430

0.0007

Table 30. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4030

Gearbox casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Roller Bearing Extension Layshaft Gear And Bearing Assembly (72-60-24, 01-280) Of The Layshaft Extension Gear

Gearbox Casing Location Bore Of The Roller Bearing

90.004

Clear

89.982

0.012

Roller Bearing Outer Diameter

90.000

Intf

89.992

0.018

SUBTASK 72-60-10-220-065 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4030

Refer to Figure.

Calculate the interference at Location 4032. Use the data made as a note in TASK 72-60-21-200-002 and TASK 72-60-32-200-001.

Table 31. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4032

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Pilot Layshaft Extension Gear Of The Angle Gearbox Support ENGINE-ANGLE GEARBOX SUPPORT (72-60-32, 01-300)

Gearbox Casing Location Bore

3.3129

3.3091

0.0117

Pilot Layshaft Extension Gear Outer Diameter

3.3012

0.0059

3.3032

Table 32. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4032

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Pilot Layshaft Extension Gear Of The Angle Gearbox Support ENGINE-ANGLE GEARBOX SUPPORT (72-60-32, 01-300)

Gearbox Casing Location Bore

84.150

84.050

0.300

Pilot Layshaft Extension Gear Outer Diameter

83.850

0.150

83.900

SUBTASK 72-60-10-220-066 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4032

Refer to Figure.

Calculate the interference at Location 4033. Use the data made as a note in TASK 72-60-21-200-002 and TASK 72-60-24-200-001.

Table 33. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4033

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The PMA Drive Housing Extension Layshaft Gear And Bearing Assembly (72-60-24, 01-180)

Gearbox Casing Location Bore Of The PMA Drive Housing

4.3320

4.3307

0.0027

PMA Drive Housing Outer Diameter

4.3307

0.0000

4.3293

Table 34. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4033

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The PMA Drive Housing Extension Layshaft Gear And Bearing Assembly (72-60-24, 01-180)

Gearbox Casing Location Bore Of The PMA Drive Housing

110.035

110.000

0.070

PMA Drive Housing Outer Diameter

110.000

0.000

109.965

SUBTASK 72-60-10-220-067 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4033

Refer to Figure.

Calculate the interference at Location 4034. Use the data made as a note in TASK 72-60-32-200-001.

Table 35. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4034

Angle Gearbox Support ENGINE-ANGLE GEARBOX SUPPORT (72-60-32, 01-300)

Location For The Roller Bearing Oil Scavenge Pump Drive Gear And Bearing Assembly (72-60-26, 01-100) Of The Oil Scavenge Pump Gear Drive

Angle Gearbox Support Location Bore Of The Roller Bearing

2.7560

Clear

2.7553

0.0005

Roller Bearing Outer Diameter

2.7559

Intf

2.7555

0.0006

Table 36. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4034

Angle gearbox support ENGINE-ANGLE GEARBOX SUPPORT (72-60-32, 01-300)

Location For The Roller Bearing Oil Scavenge Pump Drive Gear And Bearing Assembly (72-60-26, 01-100) Of The Oil Scavenge Pump Gear Drive

Angle Gearbox Support Location Bore Of The Roller Bearing

70.004

Clear

69.985

0.013

Roller Bearing Outer Diameter

70.000

Intf

69.991

0.015

SUBTASK 72-60-10-220-068 Make Sure the Fits and Clearances of the Angle Gearbox Support are in the Limits given at Location 4034

Refer to Figure.

Calculate the interference at Location 4036. Use the data made as a note in TASK 72-60-21-200-002.

Table 37. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4036

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Roller Bearing Oil Scavenge Pump Drive Gear And Bearing Assembly (72-60-26, 01-180) Of The Oil Scavenge Pump Gear Drive

Gearbox Casing Location Of The Roller Bearing

2.9529

Clear

2.9521

0.0008

Roller Bearing Outer Diameter

2.9527

Intf

2.9521

0.0006

Table 38. Fits and Clearances (all dimensions are in millimeters) DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4036

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Roller Bearing Oil Scavenge Pump Drive Gear And Bearing Assembly (72-60-26, 01-180) Of The Oil Scavenge Pump Gear Drive

Gearbox Casing Location Bore Of The Roller Bearing

75.004

Clear

74.985

0.019

Roller Bearing Outer Diameter

75.000

Intf

74.985

0.015

SUBTASK 72-60-10-220-069 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4036

Refer to Figure.

Calculate the interference at Location 4038. Use the data made as a note in TASK 72-60-21-200-002 and TASK 72-60-32-200-001.

Table 39. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4038

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Pilot Of The Angle Gearbox Support ENGINE-ANGLE GEARBOX SUPPORT (72-60-32, 01-300)

Gearbox Casing Location Bore

6.8562

6.8524

0.0117

Pilot Oil Scavenge Pump Gear Drive Outer Diameter

6.8445

6.8465

0.0059

Table 40. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4038

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Pilot Of The Angle Gearbox Support ENGINE-ANGLE GEARBOX SUPPORT (72-60-32, 01-300)

Gearbox Casing Location Bore

174.150

174.050

0.300

Pilot Oil Scavenge Pump Gear Drive Outer Diameter

173.850

173.900

0.150

SUBTASK 72-60-10-220-070 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4038

Refer to Figure.

Calculate the interference at Location 4041. Use the data made as a note in TASK 72-60-21-200-002.

Table 41. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4041

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Roller Bearing Hydraulic Pump Drive Gear And Housing Assembly (72-60-23, 01-640) Of The Hydraulic Pump Gear Drive

Gearbox Casing Location Bore Of The Roller Bearing

2.7560

Clear

2.7553

0.0005

Roller Bearing Outer Diameter

2.7559

Intf

2.7555

0.0006

Table 42. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4041

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Roller Bearing Hydraulic Pump Drive Gear And Housing Assembly (72-60-23, 01-640) Of The Hydraulic Pump Gear Drive

Gearbox Casing Location Bore Of The Roller Bearing

70.004

Clear

69.985

0.013

Roller Bearing Outer Diameter

70.000

Intf

69.991

0.015

SUBTASK 72-60-10-220-071 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4041

Refer to Figure.

Calculate the interference at Location 4043. Use the data made as a note in TASK 72-60-23-200-002.

Table 43. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4043

Hydraulic Pump Gear Drive Hydraulic Pump Drive Gear And Housing Assembly (72-60-23, 01-440)

Journal Of The Rotating Ring Hydraulic Pump Drive Gear And Housing Assembly (72-60-23, 01-360)

Hydraulic Pump Gear Drive Journal Of The Rotating Ring

1.6535

1.6525

0.0012

Rotating Ring Inner Diameter

1.6555

0.0030

1.6547

Table 44. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4043

Hydraulic Pump Gear Drive Hydraulic Pump Drive Gear And Housing Assembly (72-60-23, 01-440)

Journal Of The Rotating Ring Hydraulic Pump Drive Gear And Housing Assembly (72-60-23, 01-360)

Hydraulic Pump Gear Drive Journal Of The Rotating Ring

42.000

41.975

0.030

Rotating Ring Inner Diameter

42.050

0.075

42.030

SUBTASK 72-60-10-220-072 Make Sure the Fits and Clearance of the Hydraulic Pump Gear Drive are in the Limits given at Location 4043

Refer to Figure.

Calculate the interference at Location 4045. Use the data made as a note in TASK 72-60-21-200-002 and TASK 72-60-23-200-001.

Table 45. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4045

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Hydraulic Pump Housing Hydraulic Pump Drive Gear And Housing Assembly (72-60-23, 01-460)

Gearbox Casing Location Bore Of The Housing

6.9700

6.9685

0.0031

Housing Outer Diameter

6.9685

0.0000

6.9669

Table 46. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4045

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Hydraulic Pump Housing Hydraulic Pump Drive Gear And Housing Assembly (72-60-23, 01-460)

Gearbox Casing Location Bore Of The Housing

177.040

177.000

0.080

Housing Outer Diameter

177.000

0.000

176.960

SUBTASK 72-60-10-220-073 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4045

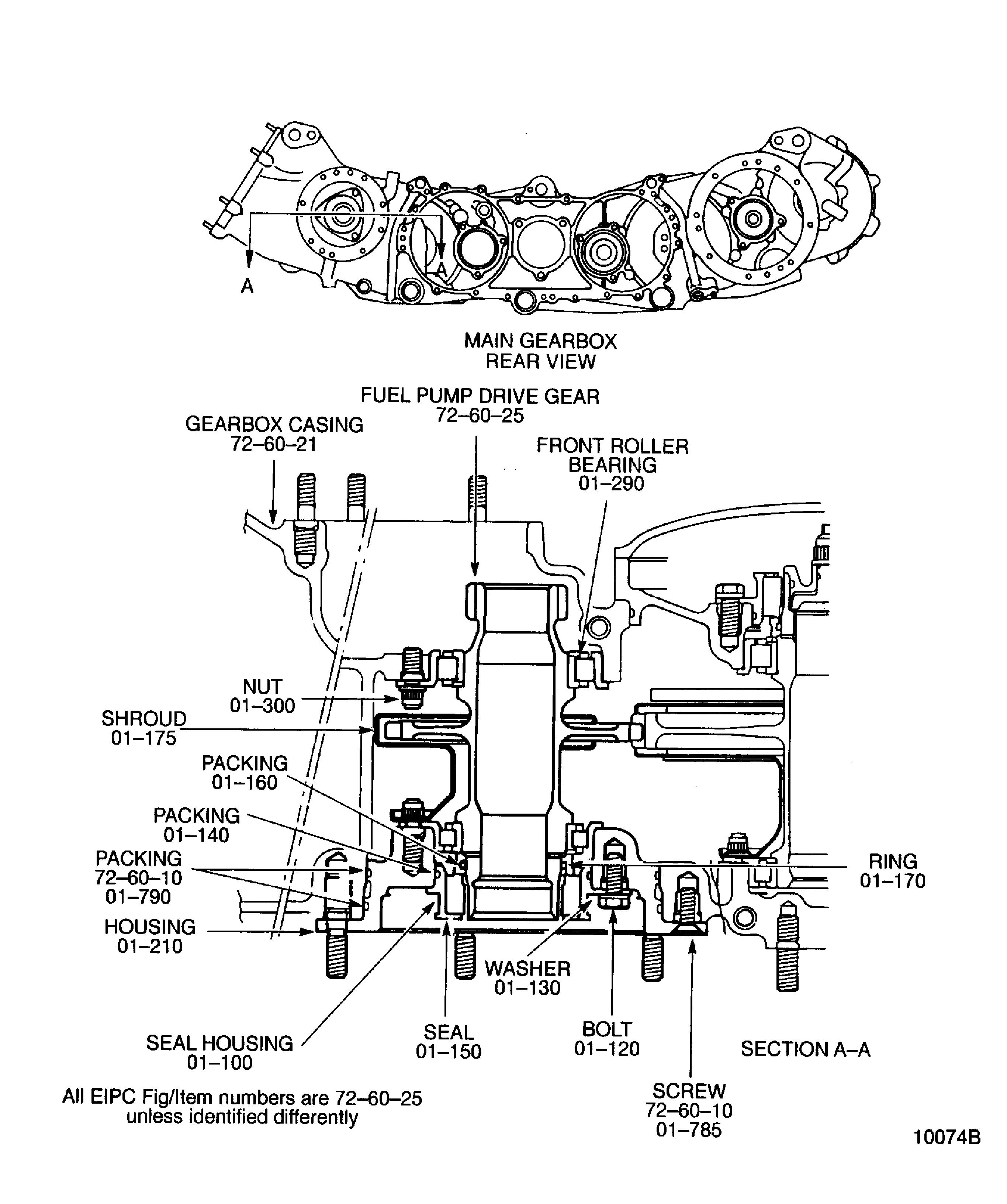

Refer to Figure.

Calculate the interference at Location 4049. Use the data made as a note in TASK 72-60-10-200-002.

Table 47. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4049

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Roller Bearing Fuel Pump Drive Gear And Housing Assembly (72-60-25, 01-290) Of The Fuel Pump Gear Drive

Gearbox Casing Location Bore Of The Roller Bearing

2.9529

Clear

2.9521

0.0007

Roller Bearing Outer Diameter

2.9527

Intf

2.9521

0.0006

Table 48. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4049

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Location For The Roller Bearing Fuel Pump Drive Gear And Housing Assembly (72-60-25, 01-290) Of The Fuel Pump Gear Drive

Gearbox Casing Location Bore Of The Roller Bearing

75.004

Clear

74.985

0.019

Roller Bearing Outer Diameter

75.000

Intf

74.985

0.015

SUBTASK 72-60-10-220-074 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4049

Refer to Figure.

Calculate the interference at Location 4051. Use the data made as a note in TASK 72-60-25-200-002.

Table 49. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4051

Fuel Pump Gear Drive Extension Layshaft Gear And Bearing Assembly (72-60-24, 01-200)

Journal Of The Rotating Ring Fuel Pump Drive Gear And Housing Assembly (72-60-25, 01-170)

Fuel Pump Gear Drive Journal Of The Rotating Ring

1.6535

1.6525

0.0012

Rotating Ring Inner Diameter

1.6555

0.0030

1.6547

Table 50. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4051

Fuel Pump Gear Drive Extension Layshaft Gear And Bearing Assembly (72-60-24, 01-200)

Journal Of The Rotating Ring Fuel Pump Drive Gear And Housing Assembly (72-60-25, 01-170)

Fuel Pump Gear Drive Journal Of The Rotating Ring

42.000

41.975

0.030

Rotating Ring Inner Diameter

42.050

0.075

42.030

SUBTASK 72-60-10-220-075 Make Sure the Fits and Clearances of the Fuel Pump Gear Drive are in the Limits given at Location 4051

Refer to Figure.

Calculate the interference at Location 4053. Use the data made as a note in TASK 72-60-21-200-002 and TASK 72-60-25-200-001.

Table 51. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4053

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Smaller Location For The Fuel Pump Drive Housing Fuel Pump Drive Gear And Housing Assembly (72-60-25, 01-210)

Gearbox Casing Location Bore For The Housing

5.0409

5.0393

0.0031

Housing Outer Diameter

5.0389

0.0004

5.0378

Table 52. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4053

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Smaller Location For The Fuel Pump Drive Housing Fuel Pump Drive Gear And Housing Assembly (72-60-25, 01-210)

Gearbox Casing Location Bore For The Housing

128.040

128.000

0.080

Housing Outer Diameter

127.990

0.010

127.960

SUBTASK 72-60-10-220-076 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4053

Refer to Figure.

Calculate the interference at Location 4054. Use the data made as a note in TASK 72-60-21-200-002 and TASK 72-60-24-200-001.

Table 53. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4054

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Larger Location For The Fuel Pump Drive Housing Extension Layshaft Gear And Bearing Assembly (72-60-24, 01-210)

Gearbox Casing Location Bore For The Housing

5.1240

5.1201

0.0098

Housing Outer Diameter

5.1181

0.0020

5.1142

Table 54. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4054

Gearbox Casing Main Gearbox Casing And Fittings (72-60-21, 02-050)

Larger Location For The Fuel Pump Drive Housing Extension Layshaft Gear And Bearing Assembly (72-60-24, 01-210)

Gearbox Casing Location Bore For The Housing

130.150

130.050

0.250

Housing Outer Diameter

130.000

0.050

129.900

SUBTASK 72-60-10-220-077 Make Sure the Fits and Clearances of the Gearbox Casing are in the Limits given at Location 4054

Refer to Figure.

Calculate the interference at Location 4055. Use the data made as a note in TASK 72-60-32-200-001 and TASK 72-60-21-200-002.

Table 55. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4055

Angle Gearbox Support ENGINE-ANGLE GEARBOX SUPPORT (72-60-32, 01-300)

Locations For The Pins ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-360) (2 Off) On The Angle Gearbox Casing

Angle Gearbox Support Location Bore For The Pin

0.3141

0.3128

0.0019

Pin Outer Diameter

0.3127

0.0001

0.3122

Table 56. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4055

Angle Gearbox Support ENGINE-ANGLE GEARBOX SUPPORT (72-60-32, 01-300)

Locations For The Pins ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-360) (2 Off) On The Angle Gearbox Casing

Angle Gearbox Support Location Bore For The Pin

7.980

7.945

0.050

Pin Outer Diameter

7.943

0.002

7.930

SUBTASK 72-60-10-220-078 Make Sure the Fits and Clearances of the Angle Gearbox Support are in the Limits given at Location 4055

Refer to Figure.

Calculate the interference at Location 4062. Use the data made as a note in TASK 72-60-24-200-001 and TASK 72-60-33-200-003.

Table 57. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4062

PMA Drive Housing Extension Layshaft Gear And Bearing Assembly (72-60-24, 01-180)

Location For The PMA Support PMA Shaft, Rotor, and Housing Assembly (72-60-33, 01-420)

PMA Drive Housing Location Bore For The PMA Support

3.1890

3.1876

0.0000

PMA Support Outer Diameter

3.1904

0.0028

3.1890

Table 58. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION 4062

PMA Drive Housing Extension Layshaft Gear And Bearing Assembly (72-60-24, 01-180)

Location For The PMA Support PMA Shaft, Rotor, and Housing Assembly (72-60-33, 01-420)

PMA Drive Housing Location Bore For The PMA Support

81.000

80.965

0.000

PMA Support Outer Diameter

81.035

0.070

81.000

SUBTASK 72-60-10-220-079 Make Sure the Fits and Clearances of the PMA Drive Housing are in the Limits given at Location 4062

Refer to Figure.

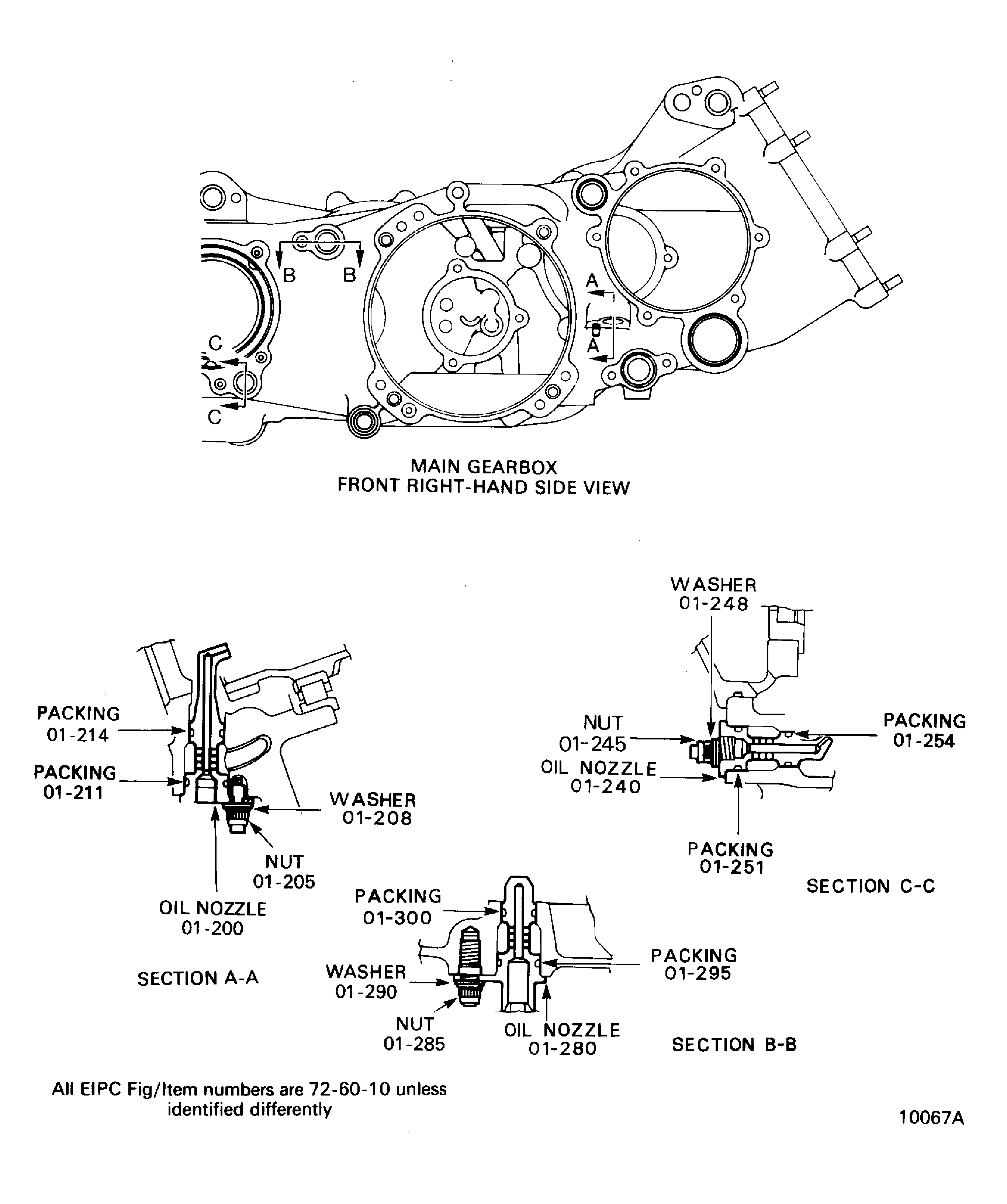

Install Main Gearbox Assembly(72-60-10, 01-211) and Main Gearbox Assembly (72-60-10, 01-214) packing 1 off each in to the grooves of the oil nozzle.

Install the oil nozzle of the fuel pump drive gear.

Install Main Gearbox Assembly (72-60-10, 01-295) and Main Gearbox Assembly (72-60-10, 01-300) packing 1 off each in to the grooves of the oil nozzle.

Install the oil nozzle of the hydraulic pump drive gear and the oil scavenge pump drive gear.

Install Main Gearbox Assembly (72-60-10, 01-251) and Main Gearbox Assembly (72-60-10, 01-254) packing 1 off each in to the grooves of the oil nozzle.

Install the oil nozzle of the extension layshaft gear.

SUBTASK 72-60-10-440-051 Install the Oil Nozzles on the Front Right-hand Side of the Main Gearbox

Refer to Figure.

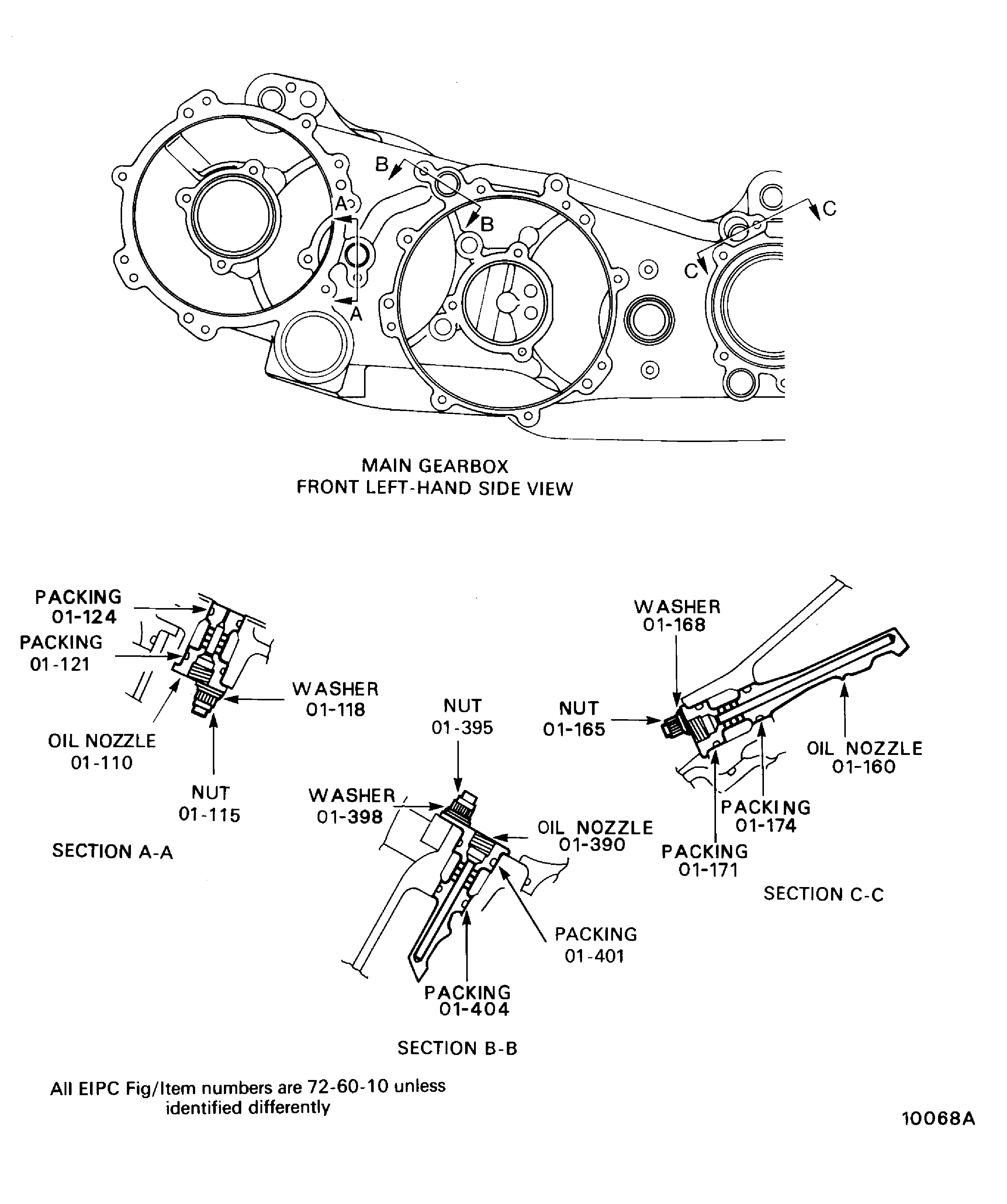

Install Main Gearbox Assembly (72-60-10, 01-121) and Main Gearbox Assembly (72-60-10, 01-124) packing 1 off each in to the grooves of the oil nozzle.

Install the oil nozzle of the IDG gear drive.

Install Main Gearbox Assembly (72-60-10, 01-401) and Main Gearbox Assembly (72-60-10, 01-404) packing 1 off each in to the grooves of the oil nozzle.

Install the oil nozzle of the spline of the starter drive gear and the IDG drive gear.

Install Main Gearbox Assembly (72-60-10, 01-171) and Main Gearbox Assembly (72-60-10, 01-174) packing 1 off each in to the grooves of the oil nozzle.

Install the oil nozzle of the extension layshaft gear.

SUBTASK 72-60-10-440-052 Install the Oil Nozzles on the Front Left-hand Side of the Main Gearbox

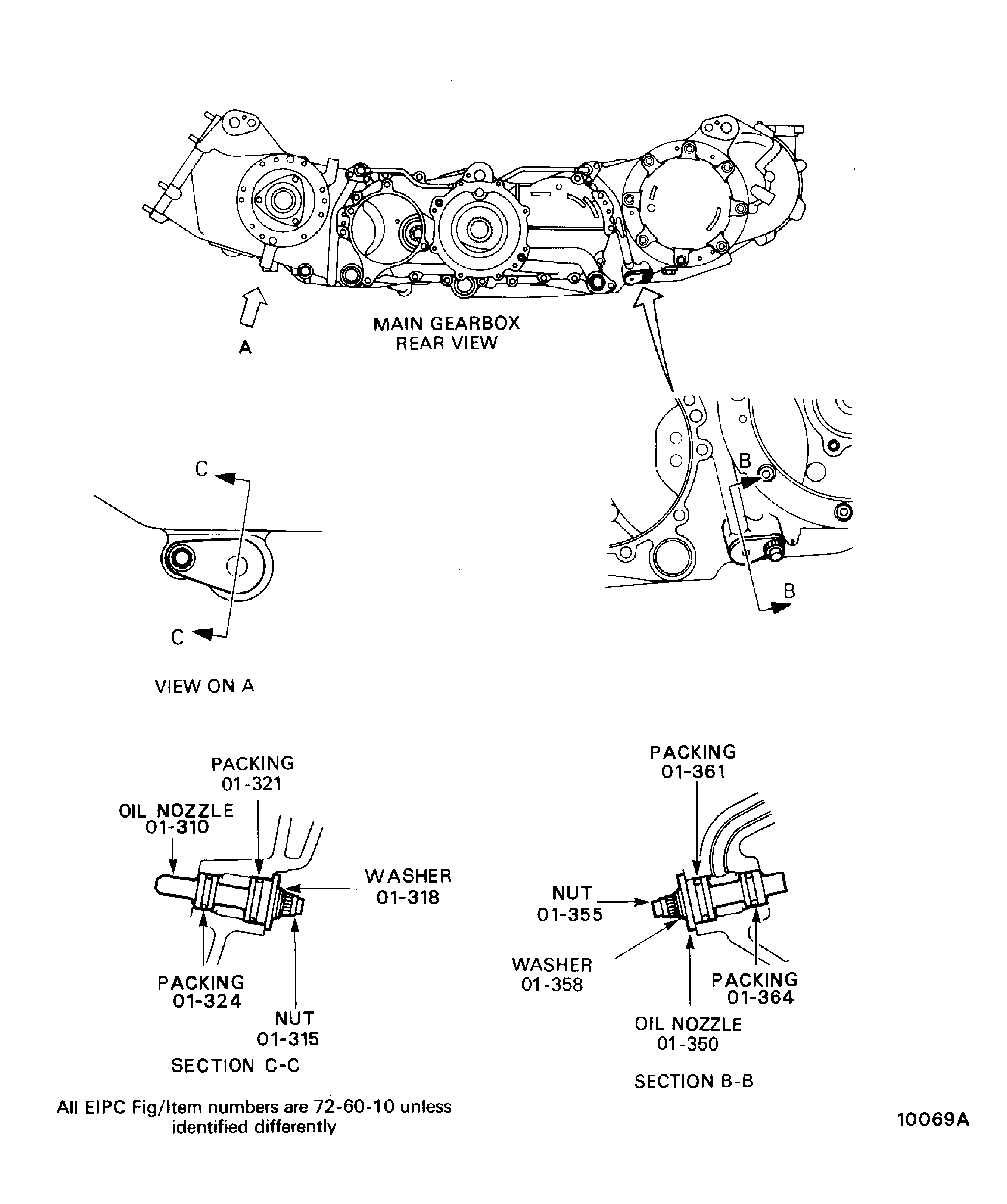

Refer to Figure.

Install Main Gearbox Assembly (72-60-10, 01-321) and Main Gearbox Assembly (72-60-10, 01-324) packing 1 off each in to the grooves of the oil nozzle.

Install the oil nozzle of the gear drives of the fuel pump and the hydraulic pump.

Install Main Gearbox Assembly (72-60-10, 01-361) and Main Gearbox Assembly (72-60-10, 01-364) packing 1 off each in to the grooves of the oil nozzle.

Install the oil nozzle of the starter idler gear.

SUBTASK 72-60-10-440-053 Install the Oil Nozzle on the Rear Side of the Main Gearbox

Refer to Figure.

Install the outer race of the front roller bearing in to the seat in the internal of the gearbox casing. Align the holes on the outer race flange with the studs on the gearbox casing. Use IAE 1F10157 IAE 1F10157 Drift drift.

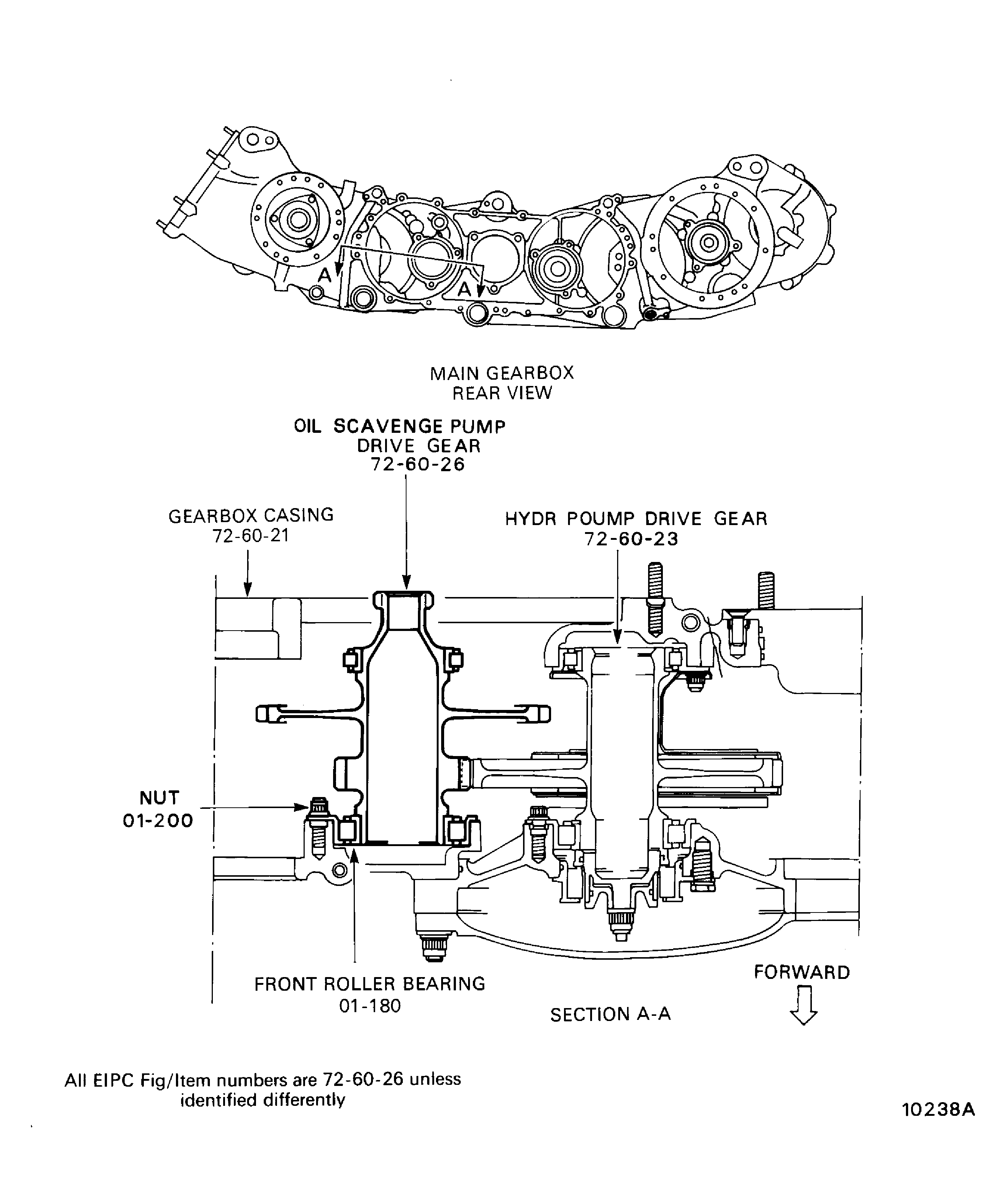

SUBTASK 72-60-10-440-054 Install the Oil Scavenge Pump Drive Gear

Refer to Figure.

Install the outer race of the front roller bearing in to the seat in the internal of the gearbox casing. Align the holes on the outer race flange with the studs on the gearbox casing. Use IAE 1F10157 IAE 1F10157 Drift drift to easy the installation.

Install Main Gearbox Assembly (72-60-10, 01-790) packings 2 off in to the grooves on the housing.

Push the housing and the drive gear in position. Use IAE 1F10223 Drift drift.

Install the fuel pump drive gear with the housing.

SUBTASK 72-60-10-440-055 Install the Fuel Pump Drive Gear

Refer to Figure.

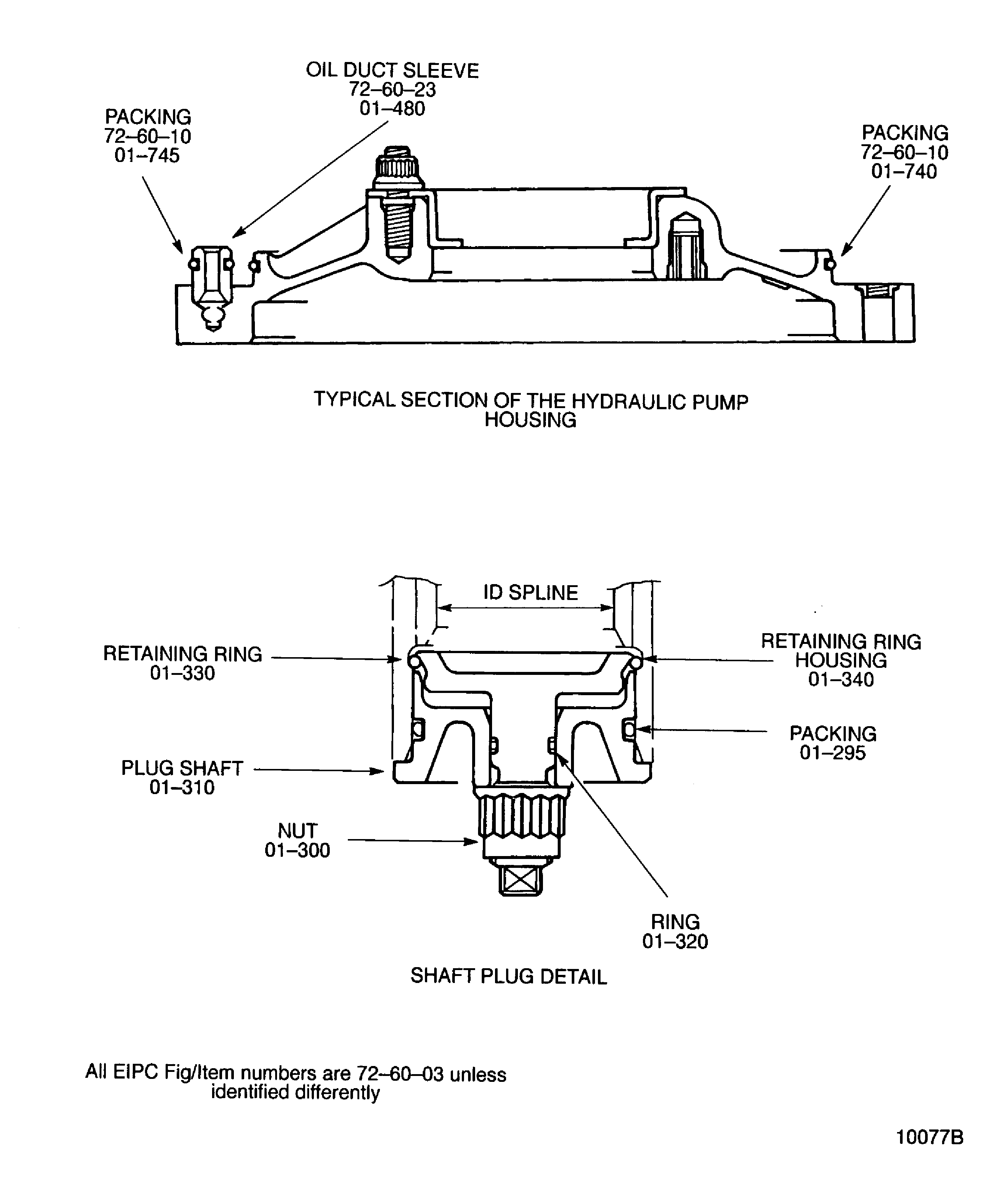

Install Main Gearbox Assembly (72-60-10, 01-745) packing off in to the groove of the oil duct sleeve.

Install Main Gearbox Assembly (72-60-10, 01-740) packing off in to the groove of the housing.

Align the housing holes with the studs and the oil duct sleeve with the seat on the gearbox casing flange. Align the outer race with the rear roller bearing. Put the housing over the hydraulic pump gear drive and install in the pad on the gearbox casing. Use IAE 1F10225 Drift drift.

Install the hydraulic pump housing on the gearbox casing.

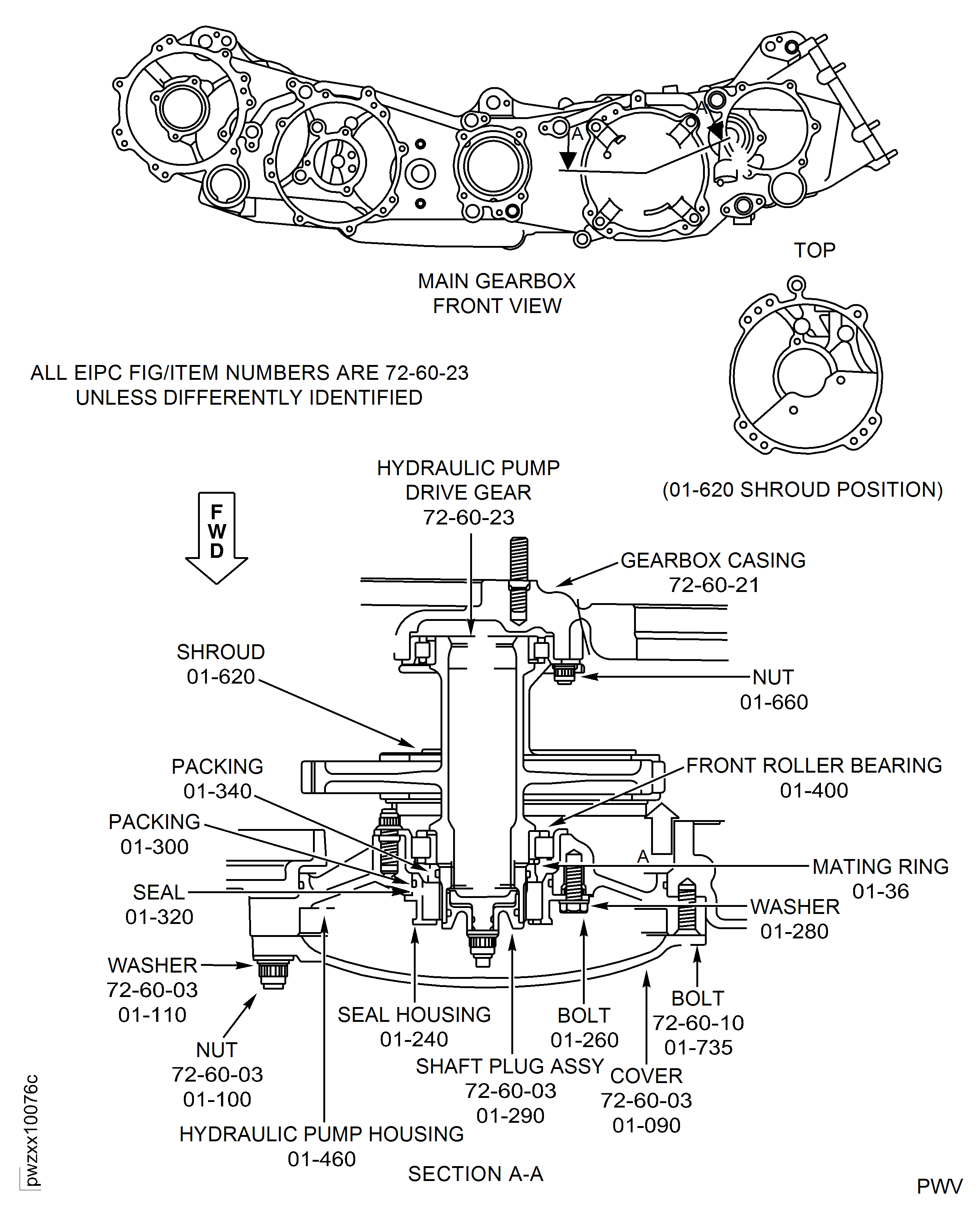

SUBTASK 72-60-10-440-056 Install the Hydraulic Pump Drive Gear (Pre SBE 72-0264)

Refer to Figure.

Align the holes on the shroud Hydraulic Pump Drive Gear And Housing Assembly (72-60-23, 01-620) with the studs that attach the bearing outer race to the gearbox casing.

Install the shroud Hydraulic Pump Drive Gear And Housing Assembly (72-60-23, 01-620) and the three nuts which attach the outer race to the gearbox casing. Torque to 85 lbfin to 95 lbfin (9.604 Nm to 10.734 Nm).

Put the hydraulic pump drive gear in the gearbox casing. Make sure that the inner diameter splined end points towards the front of the gearbox.

Install the rear roller bearing and the hydraulic gearshaft into the outer race installed in the gearbox casing.

Remove the three nuts that secure the bearing outer race to the hydraulic pump housing.

Align and install the shroud Hydraulic Pump Drive Gear And Housing Assembly (72-60-23, 01-410) on to the outer race. Install the nuts and torque to 85 lbfin to 95 lbfin (9.604 Nm to 10.734 Nm).

Install the hydraulic pump drive gear and the shroud.

Install Main Gearbox Assembly Main Gearbox Assembly (72-60-10, 01-745) packing into the groove of the oil duct sleeve.

Install Main Gearbox Assembly Main Gearbox Assembly (72-60-10, 01-740) packing into the groove of the housing.

Align the housing holes with the studs and the oil duct sleeve with the seat on the gearbox casing flange. Align the outer race with the rear roller bearing. Put the housing over the hydraulic pump gear drive and install in the pad on the gearbox casing. Use IAE 1F10225 Drift.

Install the two bolts which attach the housing to the gearbox casing. Torque to 85 lbfin to 95 lbfin (9.604 Nm to 10.734 Nm).

Install the hydraulic pump housing on the gearbox casing.

Measure the axial travel of the hydraulic pump drive gear which must be 0.0039 in. to 0.0315 in. (0.10 mm to 0.80 mm).

SUBTASK 72-60-10-440-081 Install the Hydraulic Pump Drive Gear (Post SBE 72-0264)

Refer to Figure.

Install IAE 1F10082 Guide Pin guide pin 2 off in to the boltholes near the seat of the outer race.

Align the holes on the outer race flange with the guide pins. Install the outer race in to the seat in the internal of the gearbox casing. Use IAE 1F10155 Drift drift to easy the installation. Remove the three guide pins.

Install the outer race of the rear roller bearing.

Install Main Gearbox Assembly (72-60-10, 01-685) packing in to the groove on the housing.

Install the PMA drive housing.

NOTE

Torque these nuts only after the installation of the PMA drive gear. Refer to Step.Release again the two nuts.

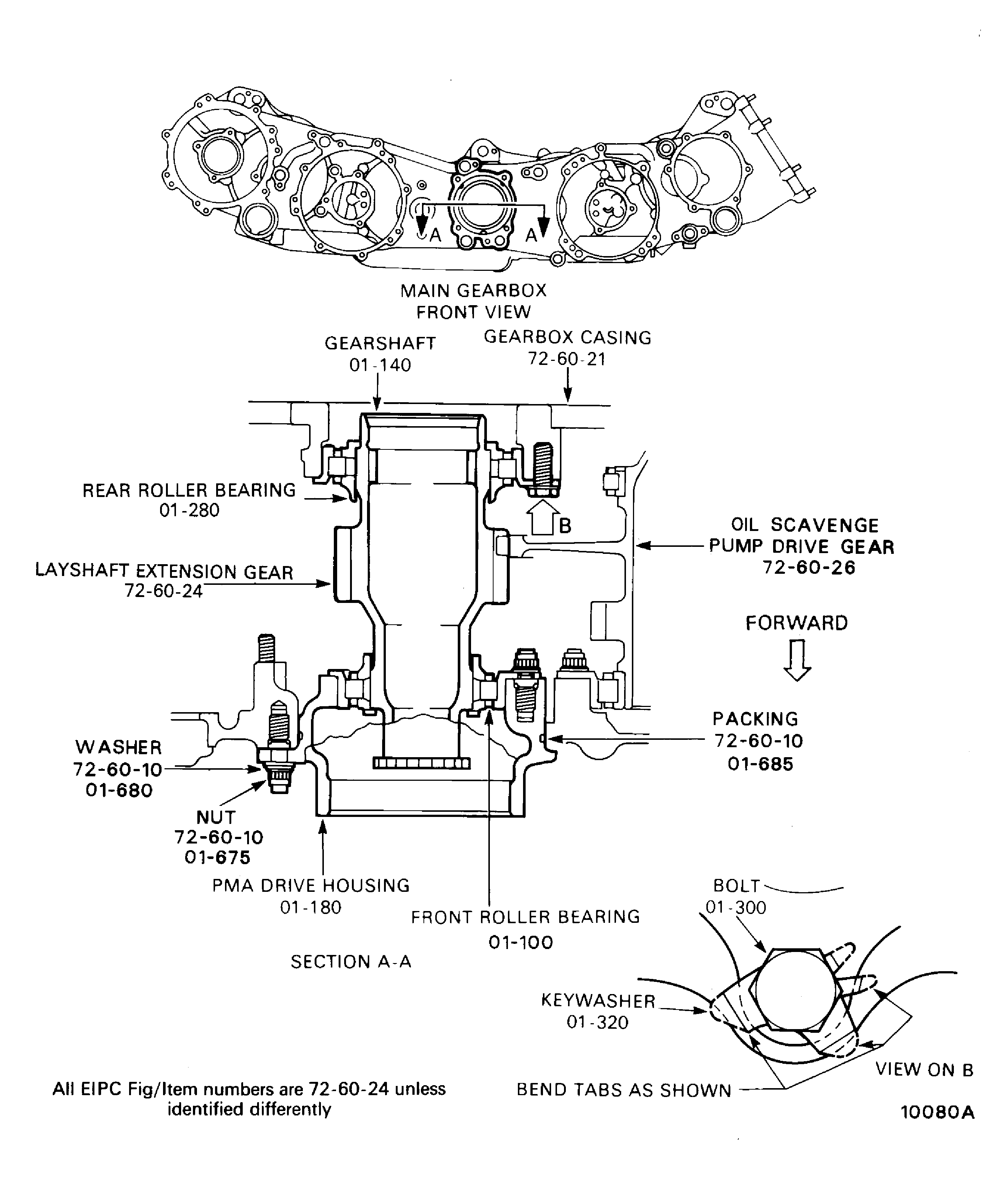

SUBTASK 72-60-10-440-057 Install the Extension Layshaft Gear

Install the outer race of the front roller bearing in to the seat in the internal of the gearbox casing. Align the holes on the outer race flange with the studs on the gearbox casing. Use IAE 1F10157 IAE 1F10157 Drift drift to easy the installation.

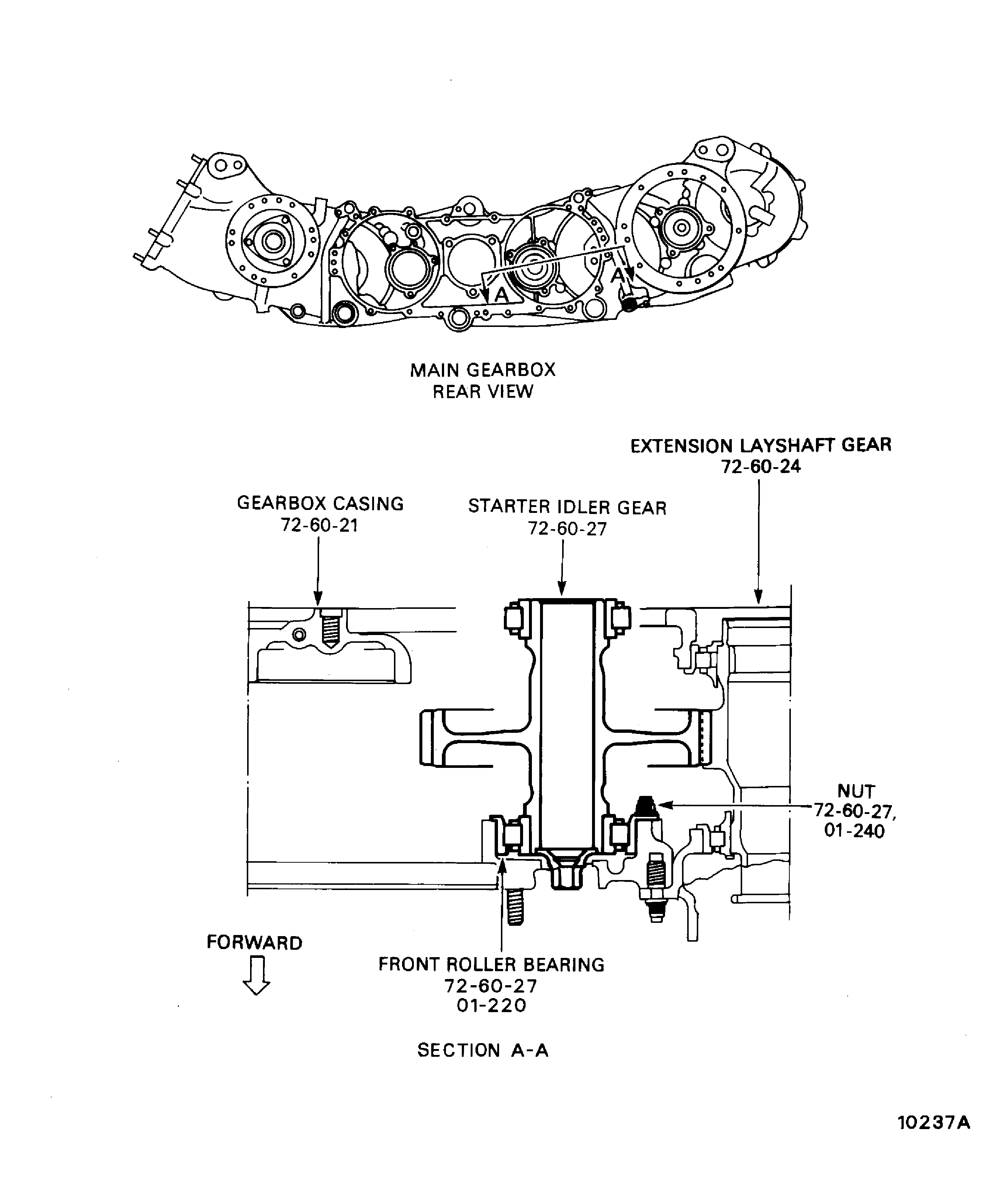

SUBTASK 72-60-10-440-058 Install the Starter Idler Gear

Refer to Figure.

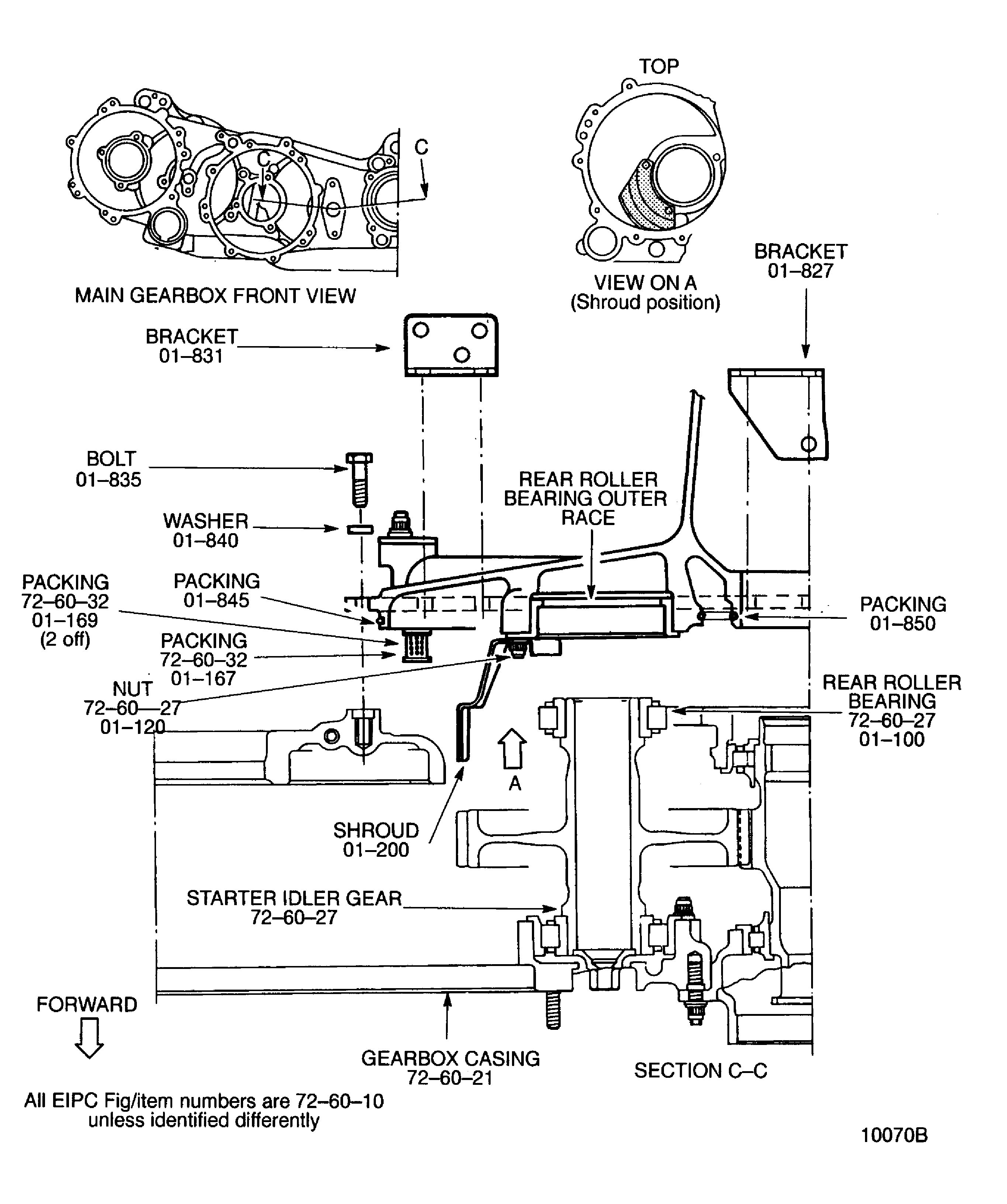

Install Main Gearbox Assembly (72-60-10, 01-845) packings off into the grooves on the external spigots of the angle gearbox support.

Install Main Gearbox Assembly (72-60-10, 01-850) packing off into the groove on the central spigot of the angle gearbox support.

Install ENGINE-ANGLE GEARBOX SUPPORT (72-60-32, 01-169) packing off and ENGINE-ANGLE GEARBOX SUPPORT (72-60-32, 01-167) packing off into the strainer suction.

Install the bracket Main Gearbox Assembly (72-60-10, 01-831), bracket Main Gearbox Assembly (72-60-10, 01-826), and the bracket Main Gearbox Assembly (72-60-10, 01-827) on the studs.

Install the 16 washers Main Gearbox Assembly (72-60-10, 01-830) and nuts Main Gearbox Assembly (72-60-10, 01-825) on the studs.

Install the washer Main Gearbox Assembly (72-60-10, 01-840) and the bolts Main Gearbox Assembly (72-60-10, 01-835).

Install the angle gearbox support on the rear side of the gearbox casing.

Install ENGINE-ANGLE GEARBOX SUPPORT (72-60-32, 01-167) packing 1 off and ENGINE-ANGLE GEARBOX SUPPORT (72-60-32, 01-169) packing 2 off into the groove of the strainer suction.

Install Transportation Fittings (72-60-03, 01-960) packing 1 off, into the groove of the transportation plug. Install, if required, the Transportation Fittings (72-60-03, 01-970) transportation plug on the strainer suction.

Install the strainer suction on the angle gearbox.

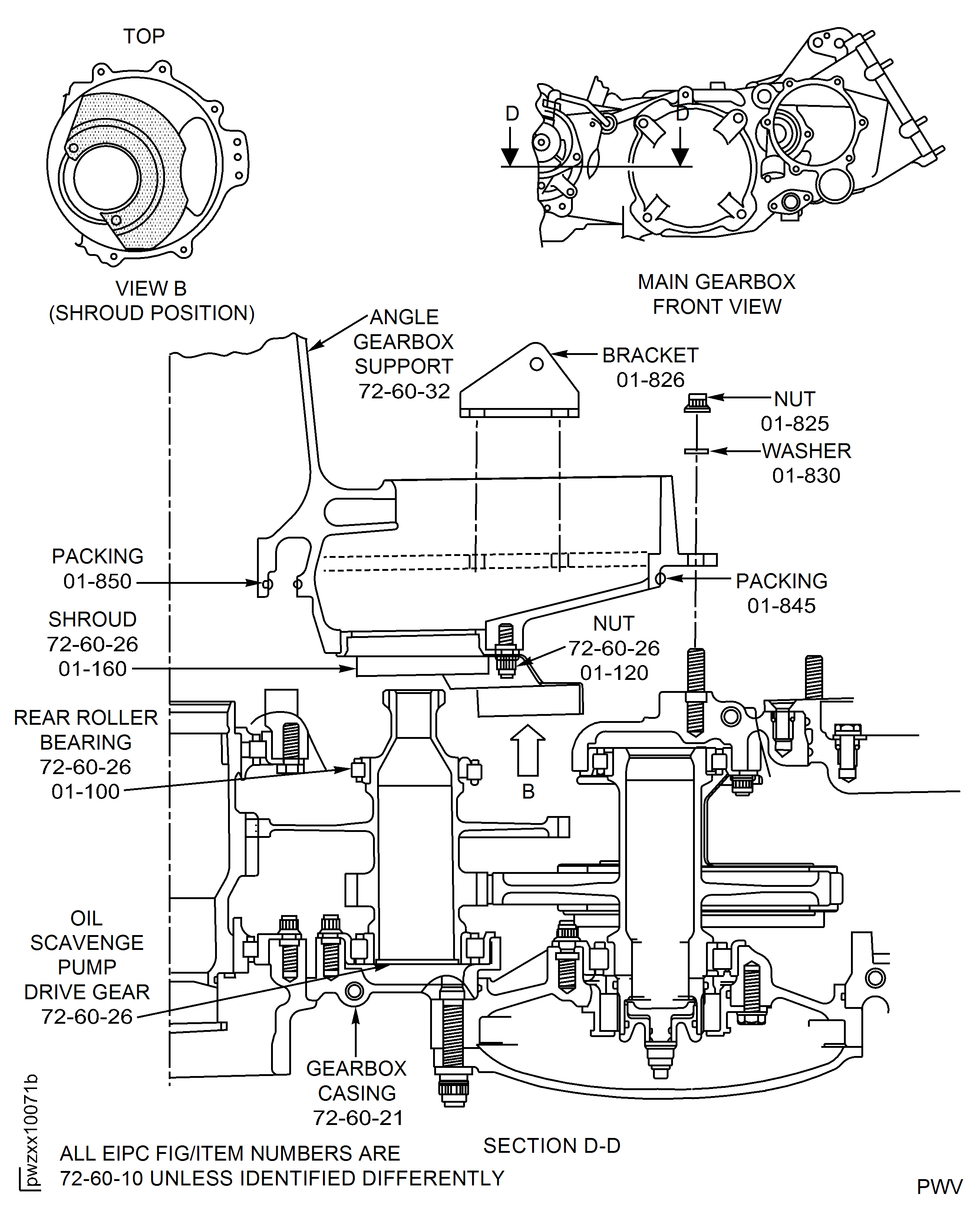

SUBTASK 72-60-10-440-059 Install the Angle Gearbox Support

Refer to Figure.

Install the outer race of the rear roller bearing in to the seat in the internal of the gearbox casing. Align the holes on the outer race flange with the studs on the gearbox casing. Use IAE 1F10157 IAE 1F10157 Drift drift to make easier the installation.

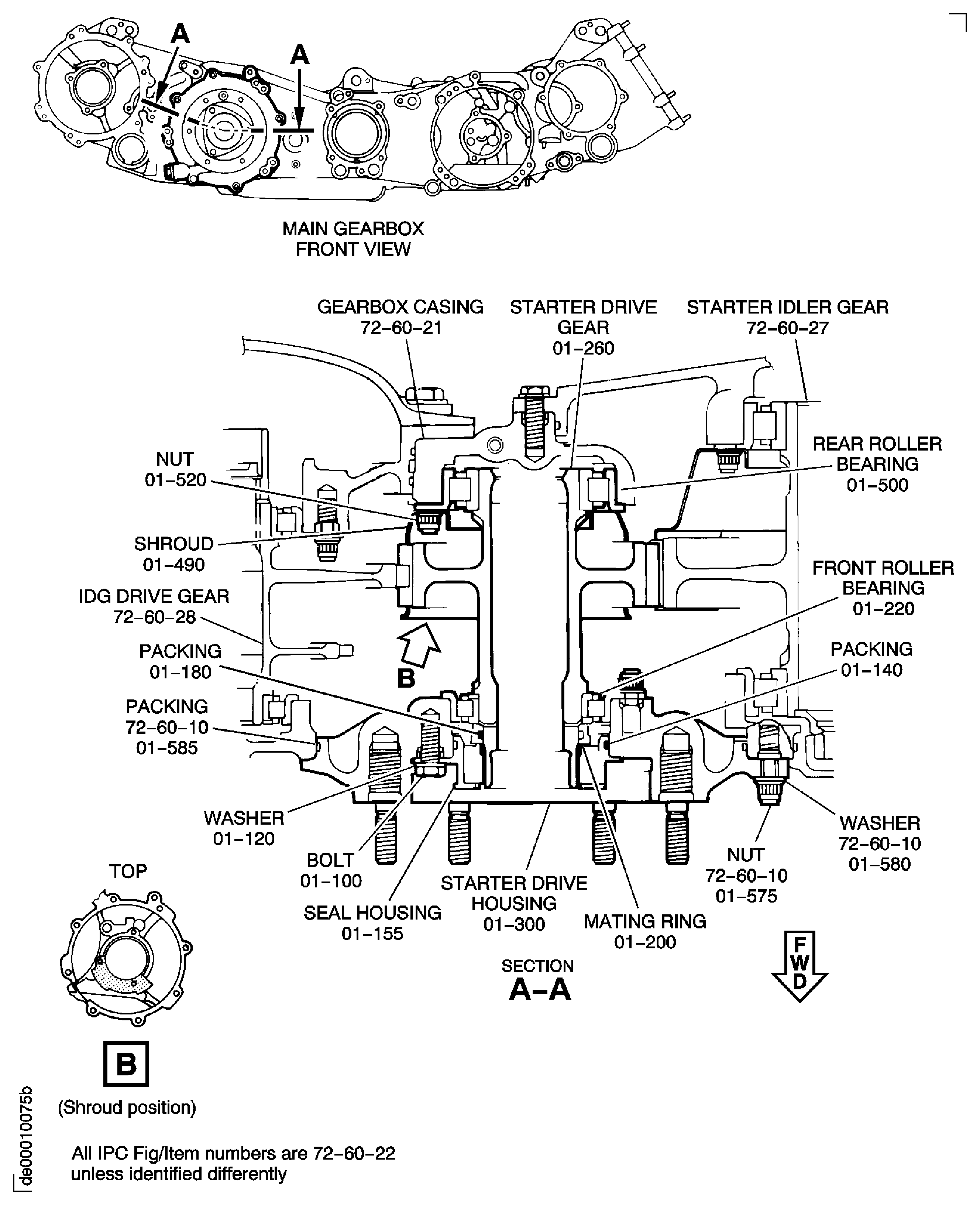

SUBTASK 72-60-10-440-060 Install the Starter Drive Gear

Refer to Figure.

Install the outer race of the front roller bearing in to the seat in the internal of the gearbox casing. Align the holes on the outer race flange with the studs on the gearbox casing. Use IAE 1F10156 Drift drift to easy the installation.

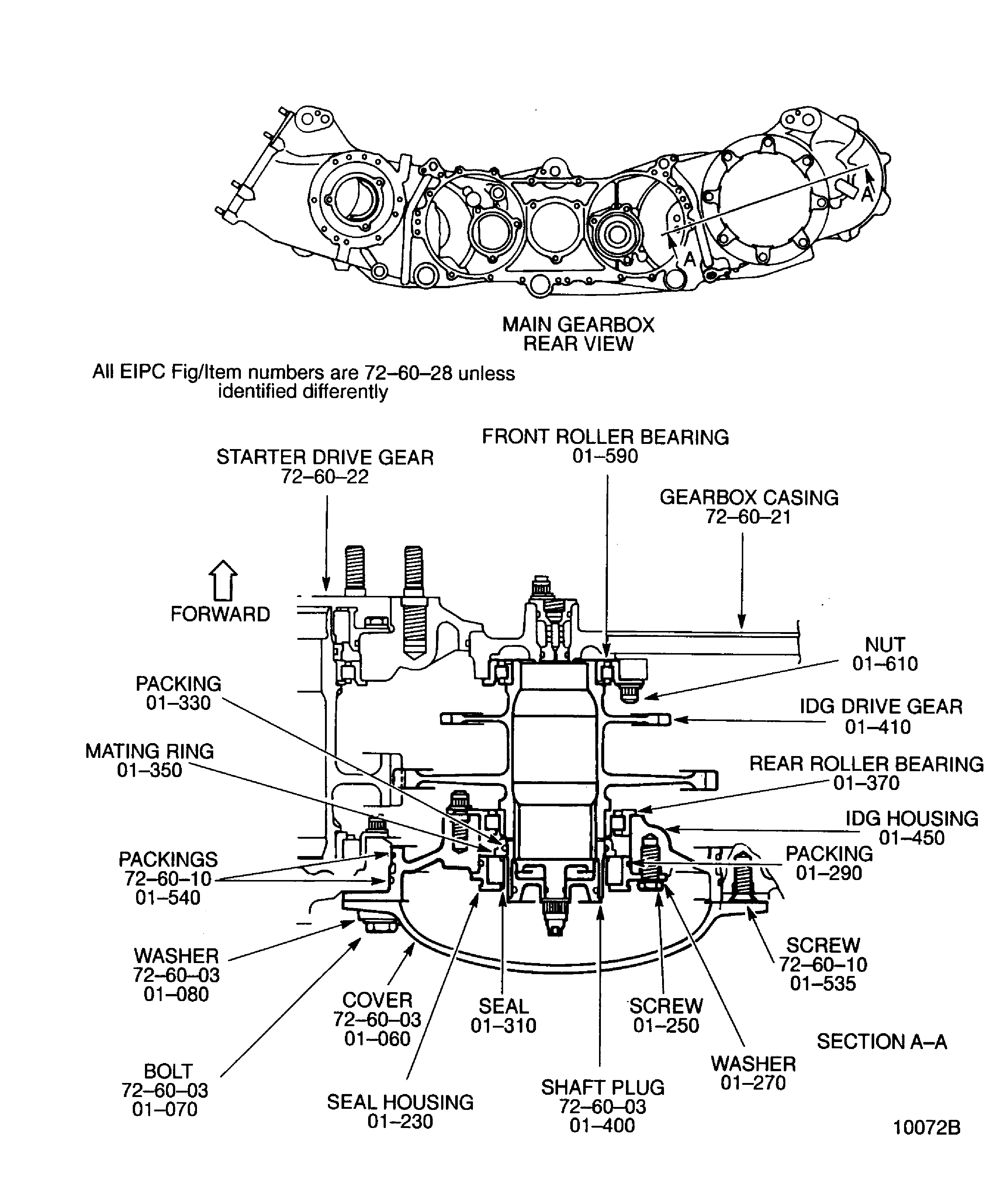

SUBTASK 72-60-10-440-061 Install the IDG Drive Gear

Refer to Figure.

Install Main Gearbox Assembly (72-60-10, 01-585) packing off in to the groove of the housing.

Align the housing holes with the studs on the gearbox casing. Align the outer race with the rear roller bearing. Put the housing over the starter drive gear and install in the pad on the gearbox casing. Use IAE 1F10224 Drift drift.

SUBTASK 72-60-10-440-062 Install the Starter Drive Housing

Refer to Figure.

Install Main Gearbox Assembly (72-60-10, 01-540) packings 2 off in to the grooves of the housing.

Install IAE 1F10222 Pin guide pins in to the bolthole on the gearbox casing at the mating flange of the housing.

Align the housing holes with the guide pins. Align the outer race with the rear roller bearing. Put the housing over the IDG drive gear and install in the pad on the gearbox casing. Use IAE 1F10221 Drift drift.

SUBTASK 72-60-10-440-063 Install the IDG Housing

Refer to Figure.

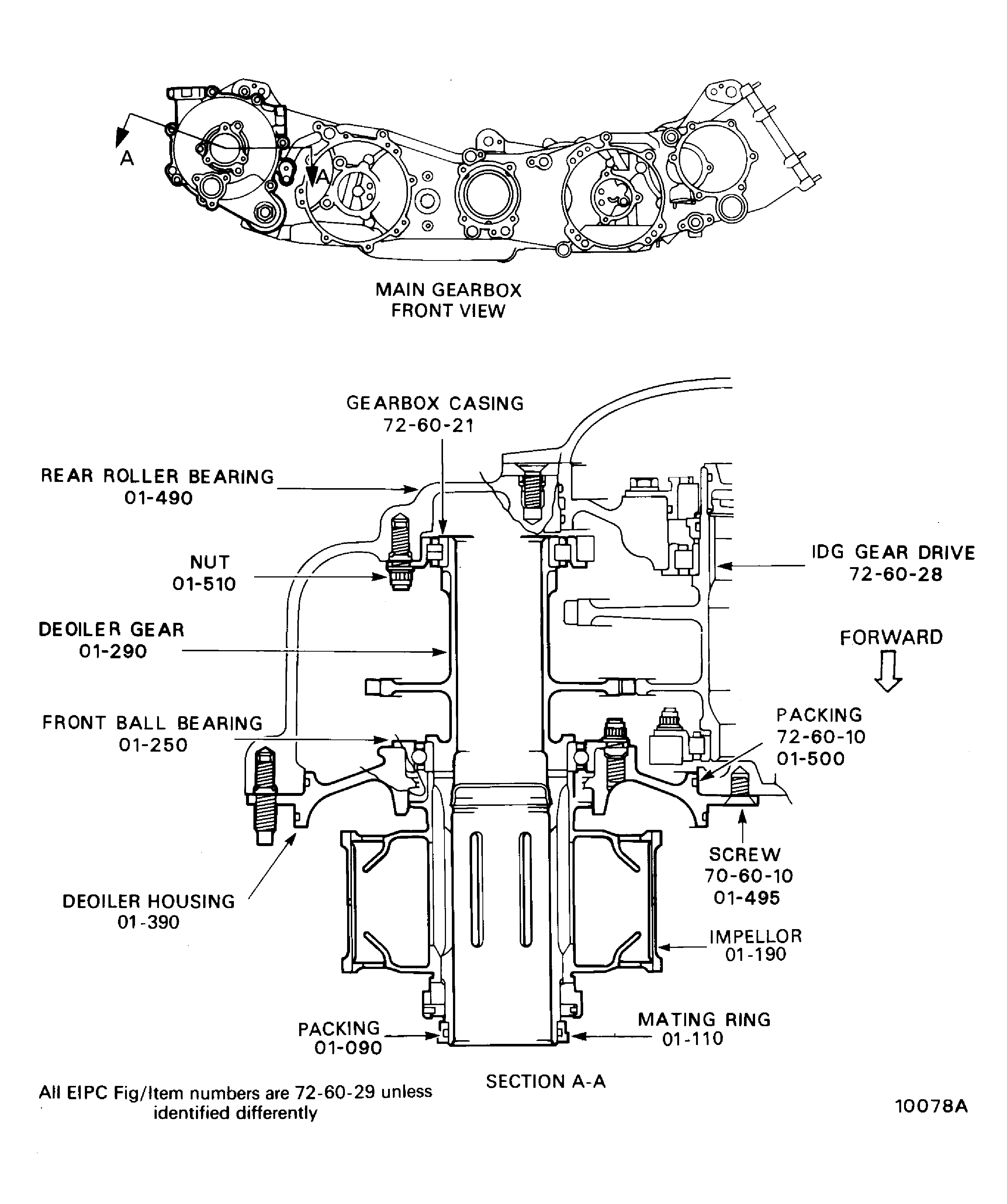

Install the outer race of the rear roller bearing in to the seat in the internal of the gearbox casing. Align the holes on the outer race flange with the studs on the gearbox casing. Use IAE 1F10156 Drift off to make easier the installation.

Install Main Gearbox Assembly (72-60-10, 01-500) off in to the groove on the rear flange of the deoiler housing.

Install the deoiler gear and impellor and the deoiler housing.

Install Deoiler Gear, Impeller, And Housing Assembly (72-60-29, 01-090) off in to the internal groove of the mating ring.

Put the mating ring on the guide bush of IAE1F10070 Pusher off, with the large contact face against the slide pusher.

Install the mating ring on the deoiler gearshaft.

SUBTASK 72-60-10-440-064 Install the Deoiler Gear and Impellor

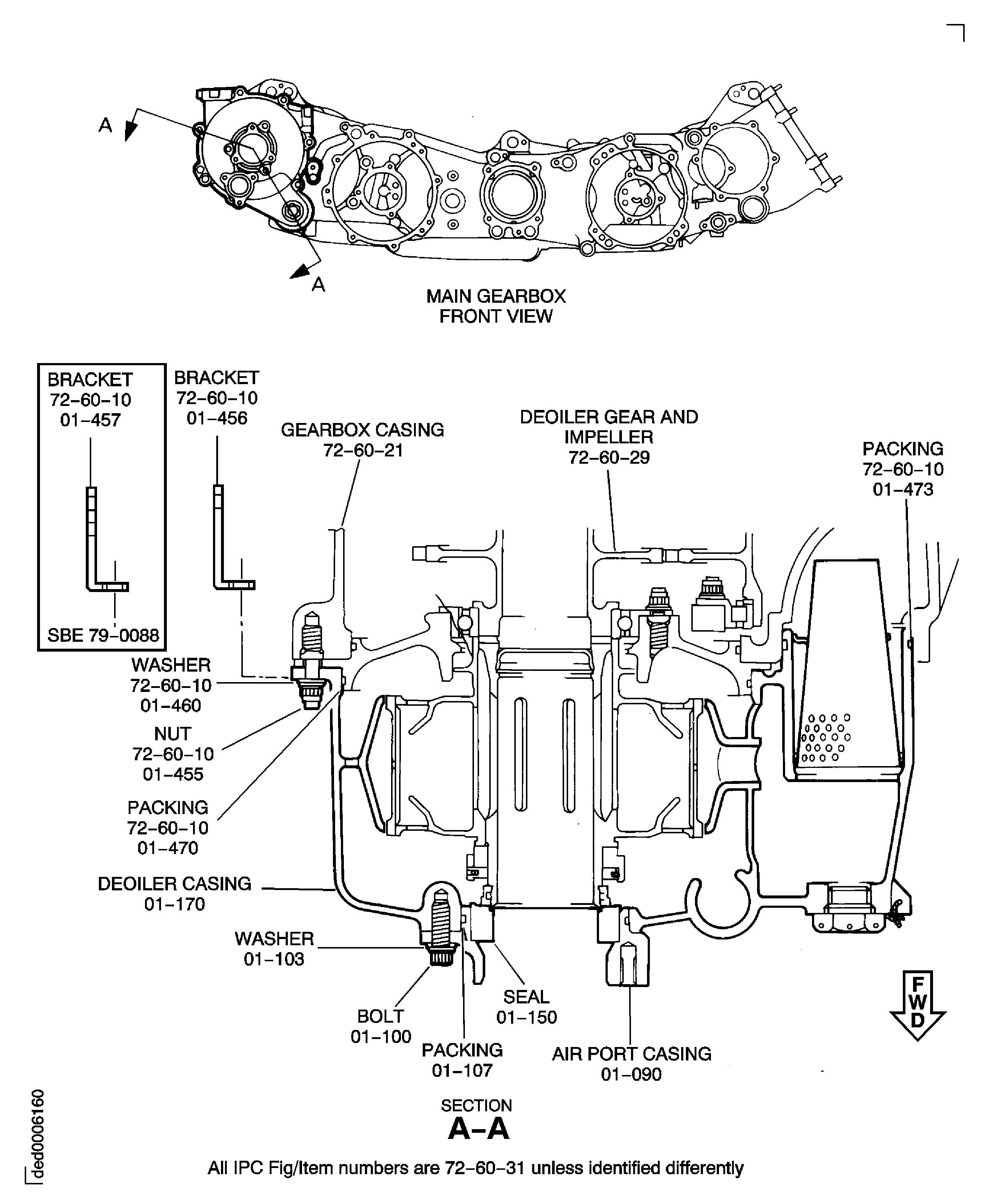

Refer to Figure and SBE 79-0088.

Install Main Gearbox Assembly (72-60-10, 01-470) off in to the groove of the deoiler casing.

Install Main Gearbox Assembly (72-60-10, 01-473) off in to the groove on the filter housing.

Pre SBE 79-0088: Install the bracket Main Gearbox Assembly (72-60-10, 01-456), and install the five washers and the seven nuts which attach the deoiler casing to the gearbox casing. Torque to 85 lbfin to 95 lbfin (9.604 Nm to 10.734 Nm).

SBE 79-0088: Install the bracket Main Gearbox Assembly (72-60-10, 01-457), and install the four washers and the seven nuts which attach the deoiler casing to the gearbox casing. Torque to 85 to 95 lbfin (9.604 to 10.734 Nm).

SUBTASK 72-60-10-440-065 Install the Deoiler Casing (Pre SBE 79-0088, SBE 79-0088)

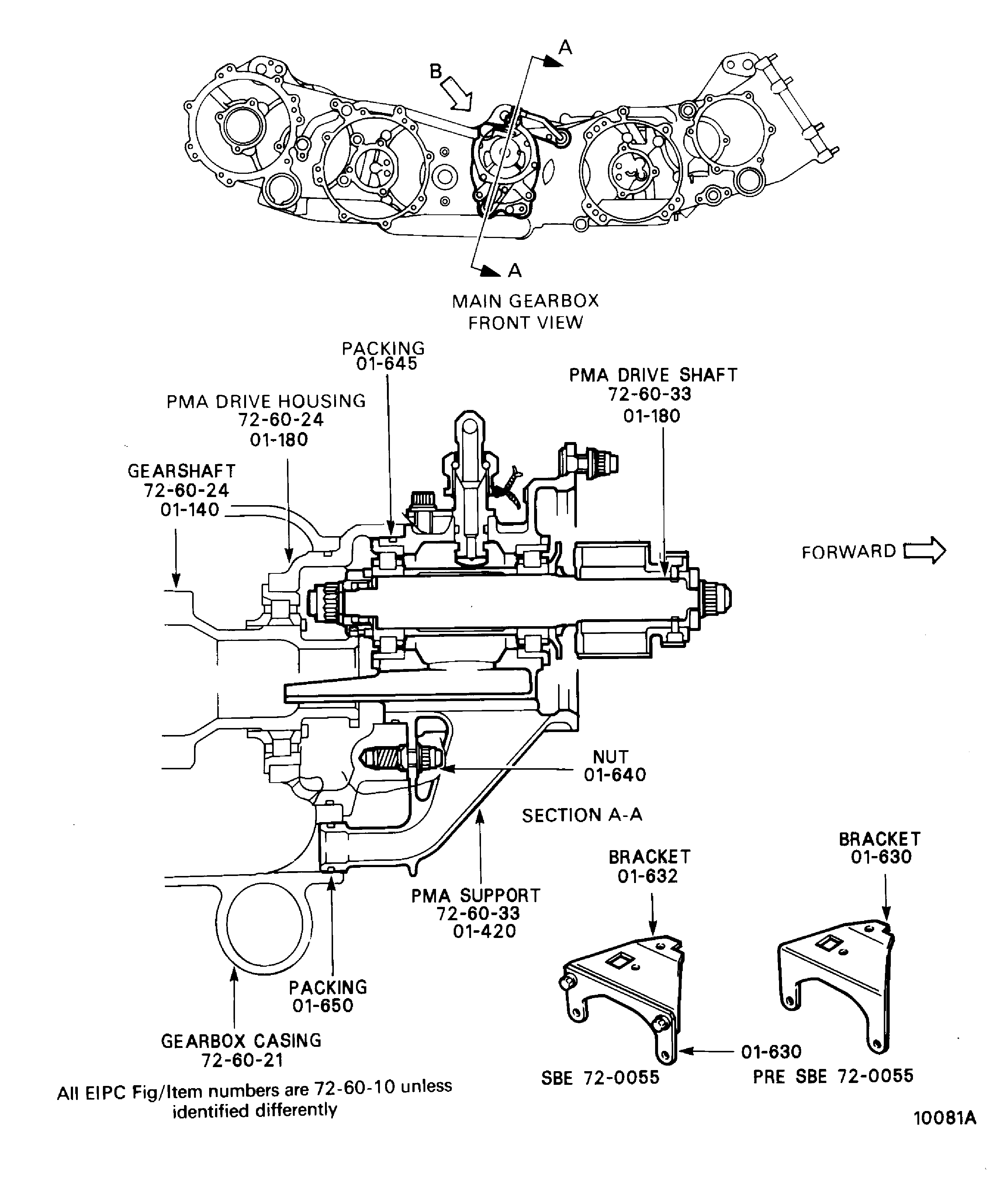

Refer to Figure.

Install Main Gearbox Assembly (72-60-10, 01-645) off in to the groove on the mounting flange of the PMA support.

Install Main Gearbox Assembly (72-60-10, 01-650) off in to the groove on the end of the manifold.

CAUTION

MAKE SURE THAT THE GEARS OF THE PMA DRIVE GEAR ASSEMBLY AND THE LAYSHAFT ARE CORRECTLY ENGAGED BEFORE THE USE OF THE DRIFT. DAMAGE TO THE PMA GEARS CAN OCCUR IF THE ENGAGEMENT IS FORCED.Align the PMA support with the studs and the manifold with the seat on the gearbox casing. Install the PMA support on the PMA housing. Engage the gear of the PMA shaft with the gear of extension layshaft. Use IAE 1F10227 Drift off.

SUBTASK 72-60-10-440-066 Install the PMA Drive Gear

Install IAE 2F10229 Rotating handwheel off on the starter idler gear and manually turn the gear train. Check that the gears are free to turn.

SUBTASK 72-60-10-210-051 Check the Free Rotation of the Gear Train

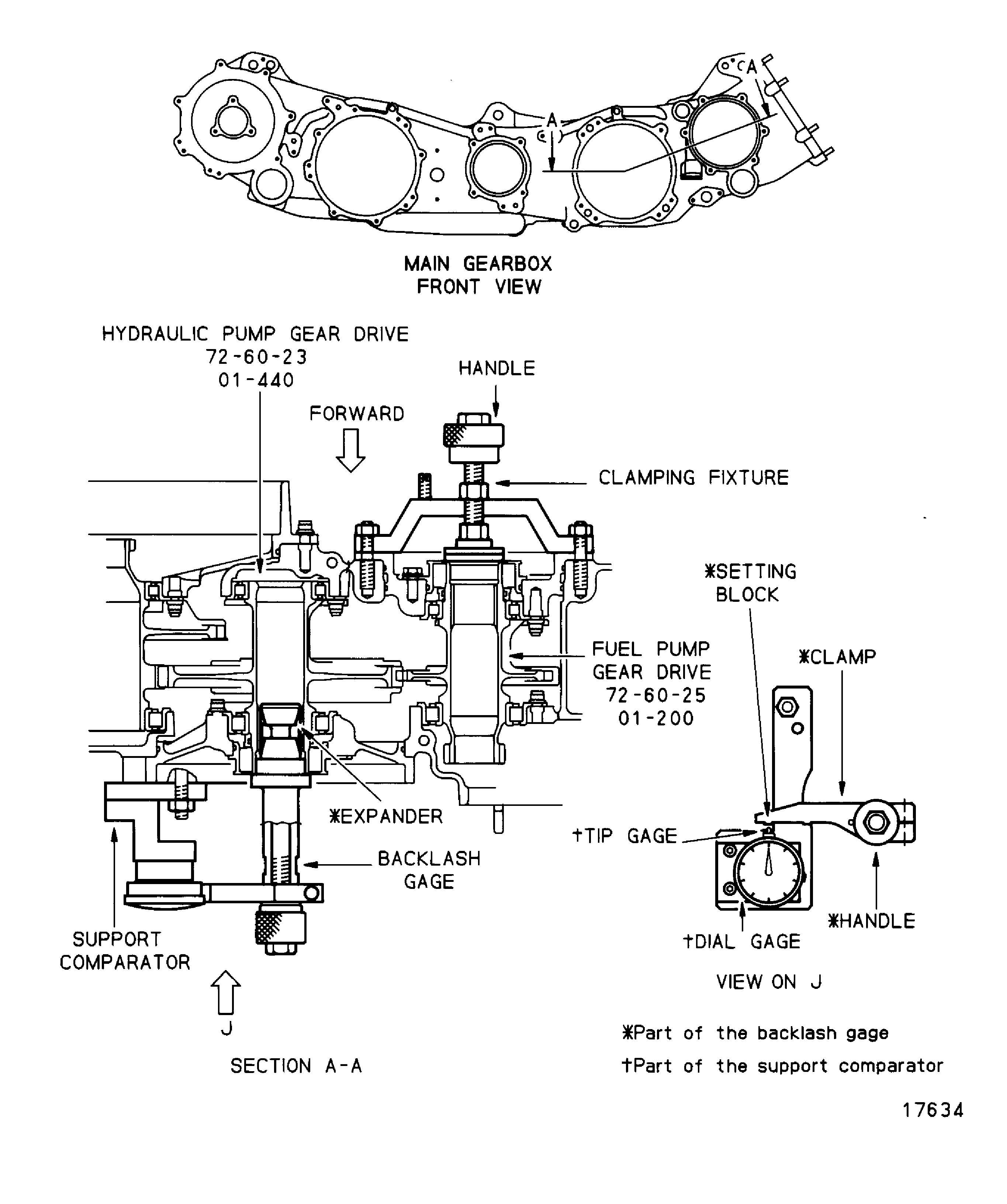

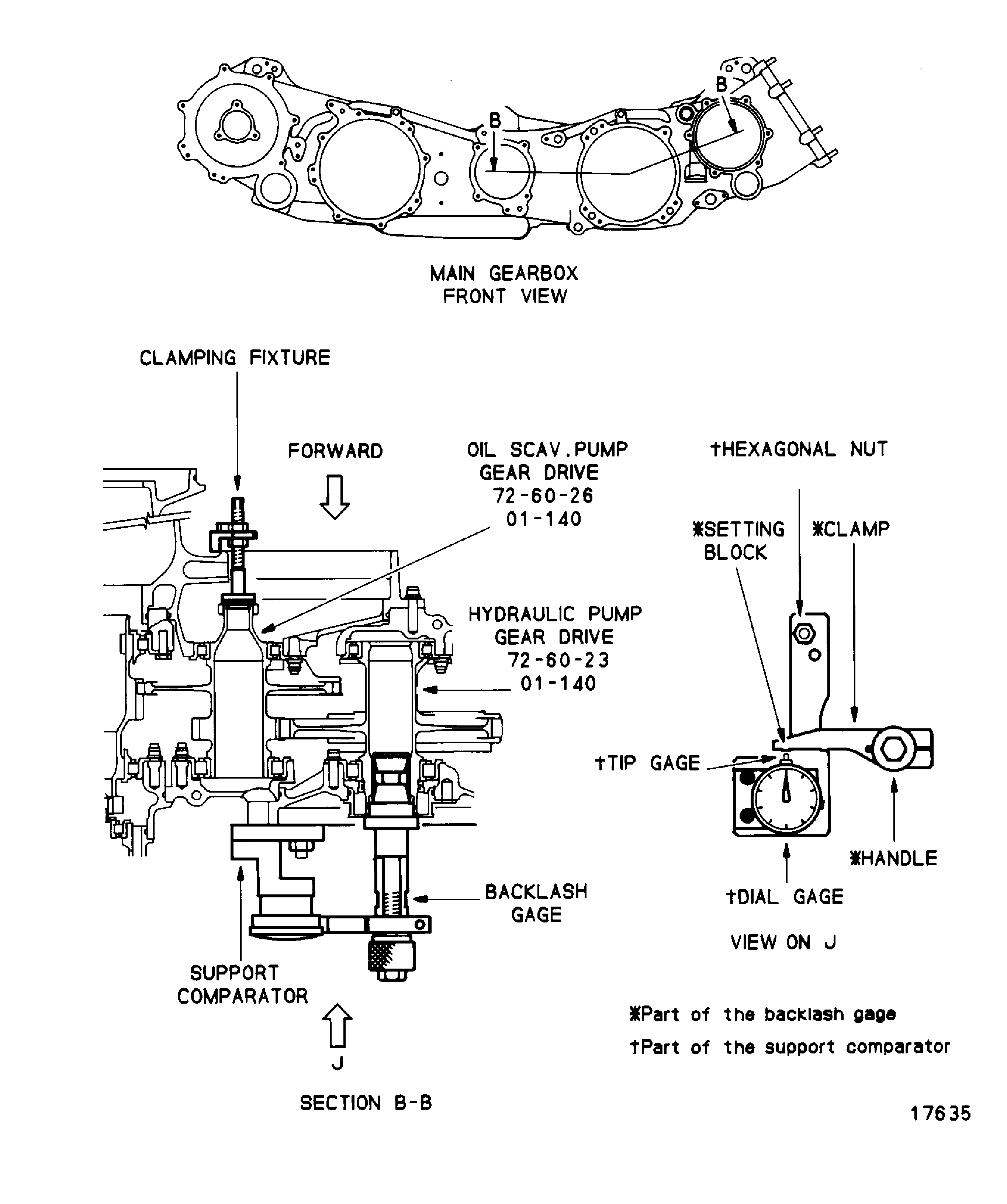

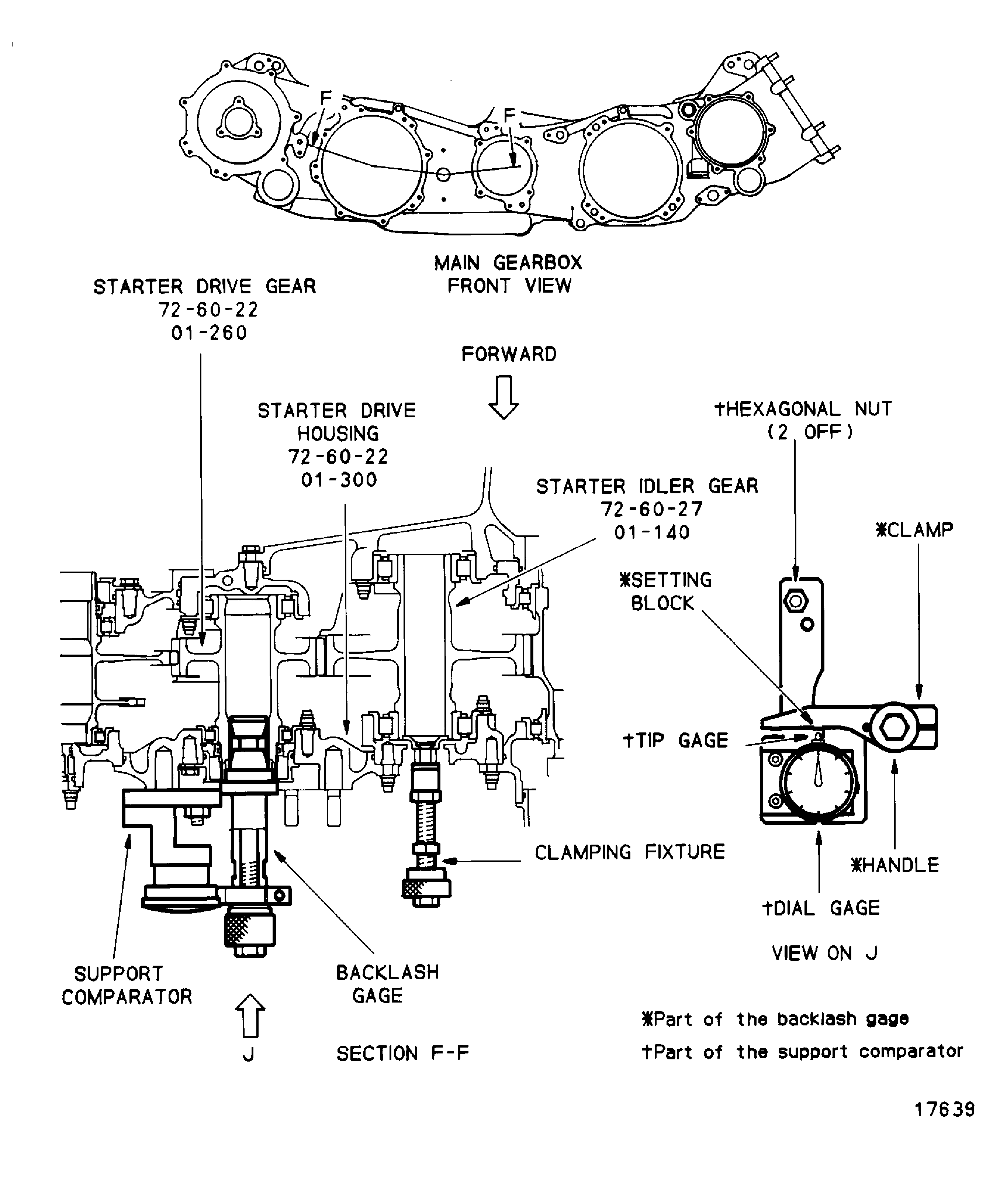

Refer to Fig-72-60-10-990-032-001.

NOTE

The backlash kit IAE 2F10266 Backlash kit includesInstall IAE 2F10267 Clamping fixture clamping fixture 1 off.

Install IAE 2F10269 Comparator support comparator support 1 off.

Install IAE 2F10268 Backlash gage tip backlash gage 1 off.

SUBTASK 72-60-10-440-067 Set the Tools to Measure the Circumferential Backlash between the Fuel Pump Drive Gear and the Hydraulic Pump Drive Gear

Refer to Figure.

Remove IAE 2F10267 Clamping fixture clamping fixture 1 off.

Keep IAE 2F10269 Comparator support comparator support 1 off and IAE 2F10268 Backlash gage tip backlash gage on place for the next measure.

SUBTASK 72-60-10-220-080 Measure the Circumferential Backlash between the Fuel Pump Drive Gear and the Hydraulic Pump Drive Gear

Refer to Figure.

Install IAE 2F10276 Clamping fixture clamping fixture 1 off.

SUBTASK 72-60-10-440-068 Set the Tools to Measure the Circumferential Backlash between the Oil Scavenge Pump Drive Gear and the Hydraulic Pump Drive Gear

Refer to Figure.

Remove IAE 2F10268 Backlash gage tip backlash gage 1 off and IAE 2F10269 Comparator support support comparator.

Keep IAE 2F10276 Clamping fixture clamping fixture on place for the next measure.

SUBTASK 72-60-10-220-081 Measure the Circumferential Backlash between the Oil Scavenge Pump Drive Gear and the Hydraulic Pump Drive Gear

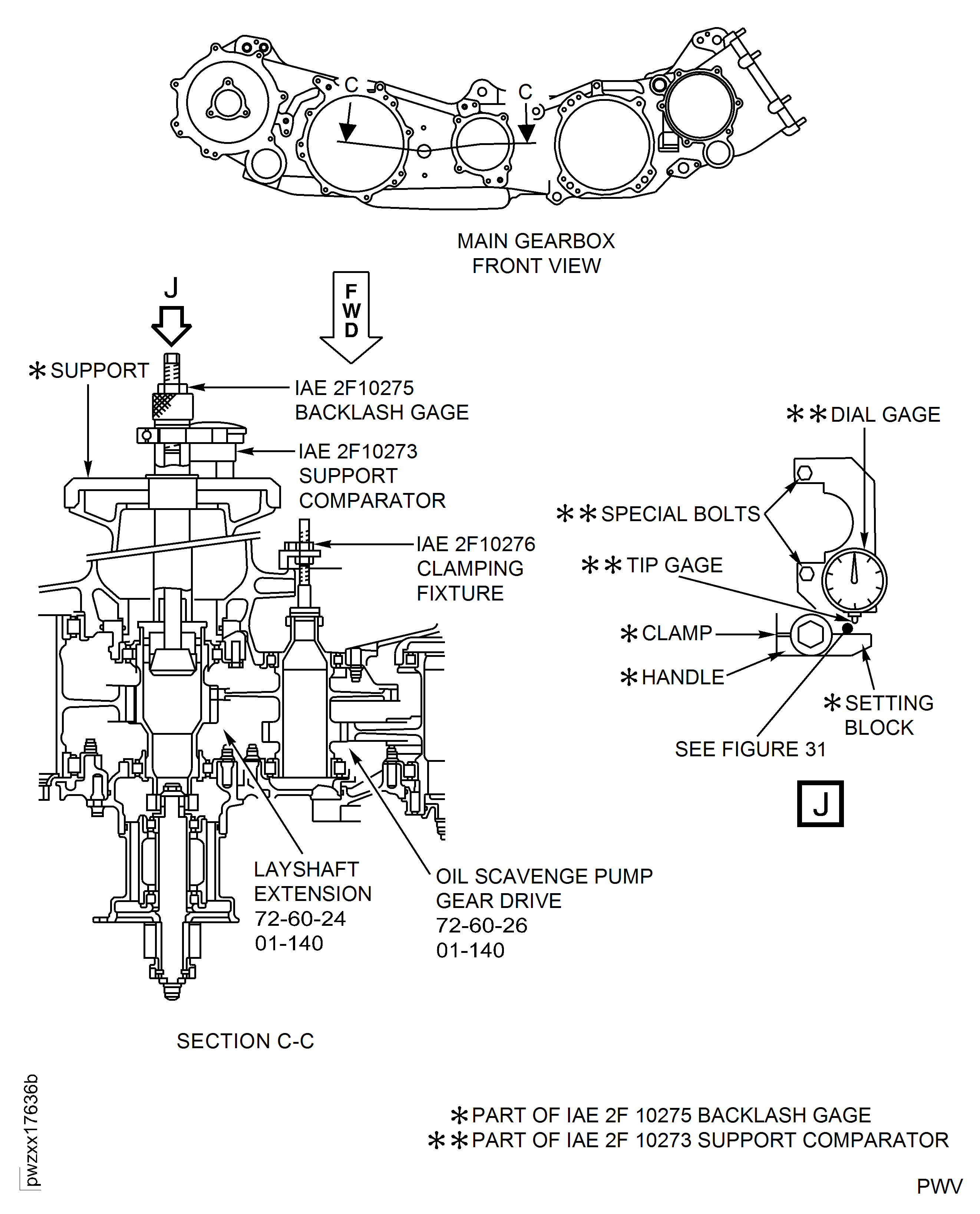

Refer to Figure.

Install IAE 2F10275 Backlash gage tip backlash gage 1 off.

Install IAE 2F10273 Comparator support off.

NOTE

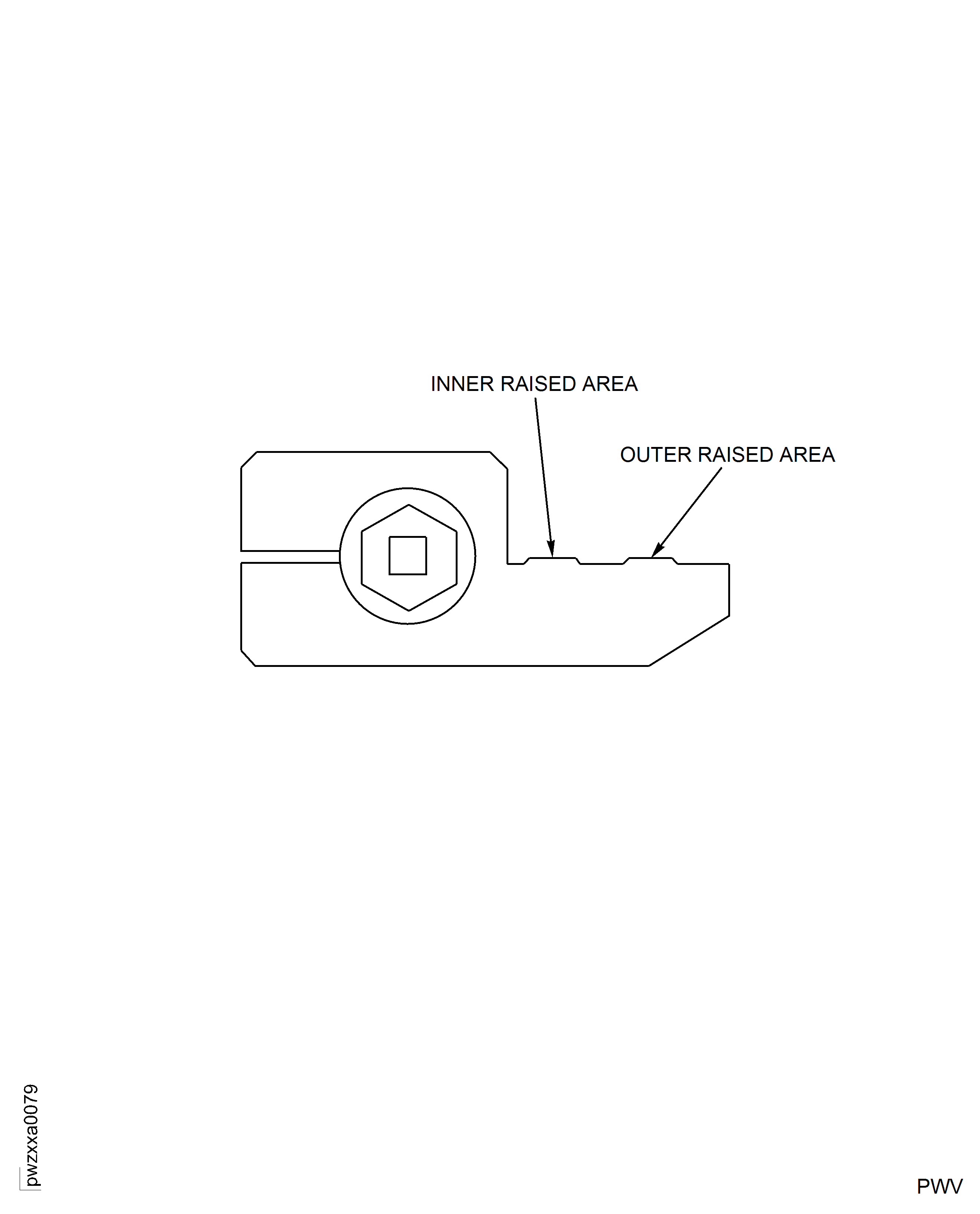

The IAE 2F10275 Backlash gage tip 1 off has two smooth raised areas on the setting block. Use the outer raised area to measure the circumferential backlash between the oil scavenge pump drive gear and the extension layshaft drive gear.Turn clockwise the handle of the backlash gage by hand and set to zero the dial gage.

SUBTASK 72-60-10-440-069 Set the Tools to Measure the Circumferential Backlash between the Oil Scavenge Pump Drive Gear and the Extension Layshaft Drive Gear

Refer to Figure.

Remove IAE 2F10276 Clamping fixture clamping fixture 1 off.

Keep IAE 2F10275 Backlash gage tip backlash gage and IAE 2F10273 Comparator support support comparator in place for the next measurement.

SUBTASK 72-60-10-220-082 Measure the Circumferential Backlash between the Oil Scavenge Pump drive Gear and the Extension Layshaft Drive Gear

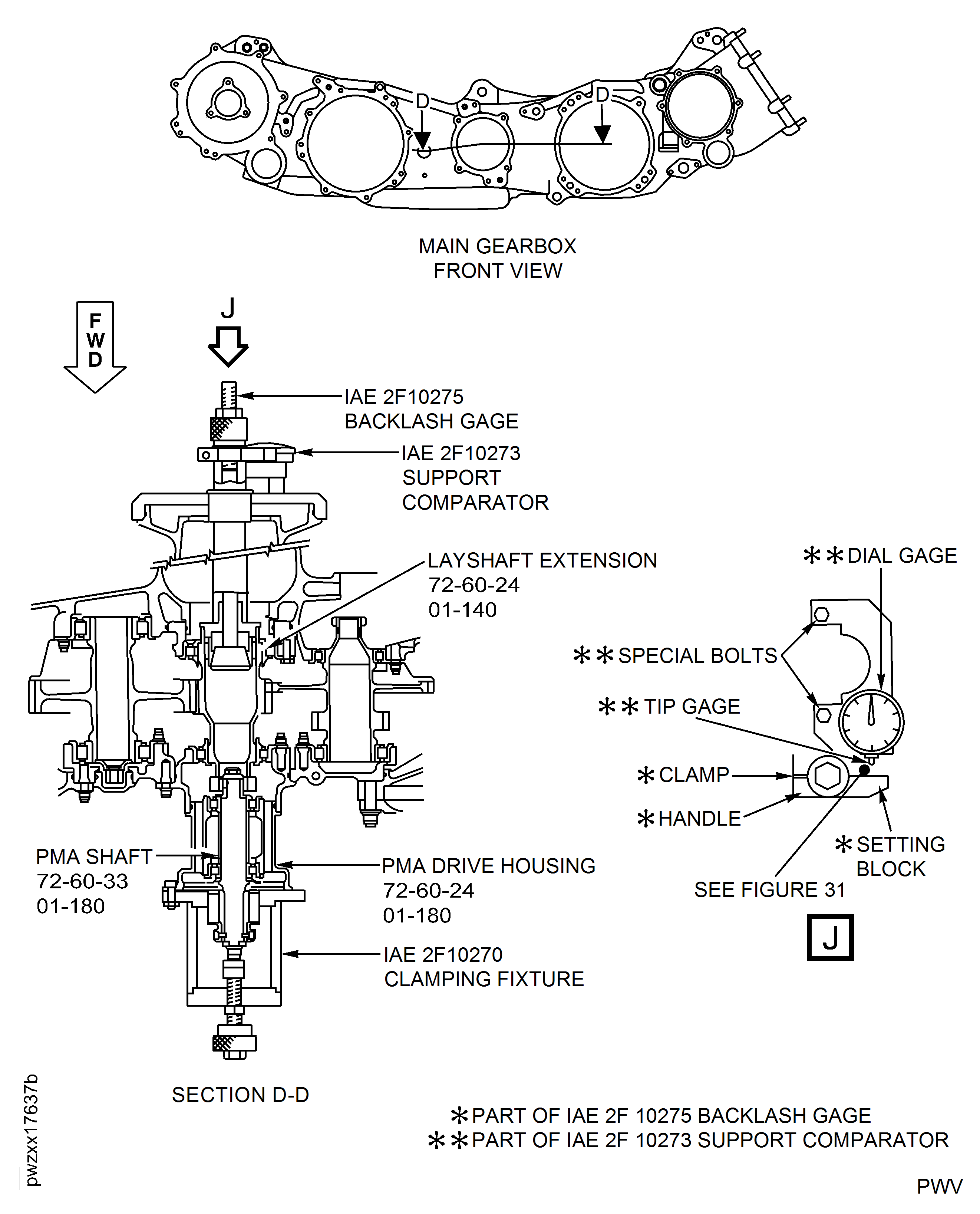

Refer to Figure.

Install IAE 2F10270 Clamping fixture off.

NOTE

The IAE 2F10275 Backlash gage tip 1 off has two smooth raised areas on the setting block. Use the inner raised area to measure the circumferential backlash between the PMA shaft and the extension layshaft drive gear.Turn clockwise the handle of the backlash gage by hand and set to zero the dial gage.

SUBTASK 72-60-10-440-070 Set the Tools to Measure the Circumferential Backlash between the PMA Shaft and the Extension Layshaft, Drive Gear

Refer to Figure and SBE 72-0048.

NOTE

Make sure all tool faces that touch are clean and not damaged.Turn counterclockwise the handle of the backlash gage by hand and read the value of backlash on the dial gage.

The value must be:

Pre SBE 72-0048: 0.0059 in. (0.15 mm) minimum 0.0102 in. (0.26 mm) maximum.

SBE 72-0048: 0.0098 in. (0.25 mm) minimum 0.0137 in. (0.35 mm) maximum.

Remove IAE 2F10270 Clamping fixture clamping fixture 1 off.

Keep IAE 2F10275 Backlash gage tip backlash gage and IAE 2F10273 Comparator support support comparator in place for the next measurement.

SUBTASK 72-60-10-220-083 Measure the Circumferential Backlash between the PMA Gear Shaft and the Extension Layshaft Drive Gear (SBE 72-0048, Pre SBE 72-0048)

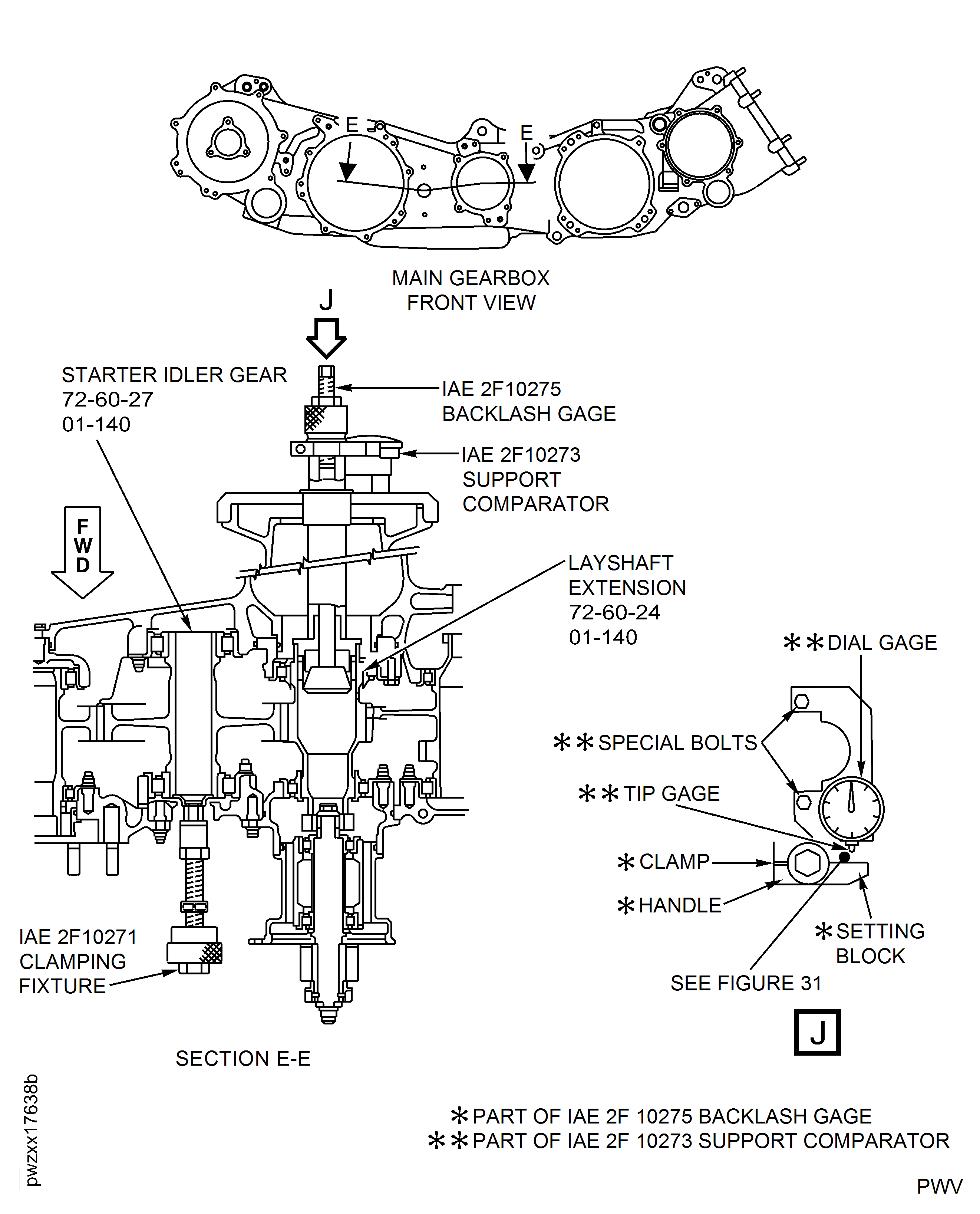

Refer to Figure.

Install IAE 2F10271 Clamping fixture off.

NOTE

The IAE 2F10275 Backlash gage tip 1 off has two smooth raised areas on the setting block. Use the outer raised area to measure the circumferential backlash between the starter idler gear and the extension layshaft drive gear.Turn clockwise the handle of the backlash gage by hand and set to zero the dial gage.

SUBTASK 72-60-10-440-071 Set the Tools to Measure the Circumferential Backlash between the Starter Idler Gear and the Extension Layshaft, Gear

Refer to Figure.

Remove IAE 2F10273 Comparator support clamping fixture 1 off and IAE 2F10275 Backlash gage tip backlash gage 1 off.

Keep IAE 2F10271 Clamping fixture clamping fixture in place for the next measurement.

SUBTASK 72-60-10-220-084 Measure the Circumferential Backlash between the Starter Idler Gear and the Extension Layshaft Gear

Refer to Figure.

Install IAE 2F10268 Backlash gage tip backlash gage 1 off.

Install IAE 2F10269 Comparator support comparator support 1 off.

SUBTASK 72-60-10-440-072 Set the Tools to Measure the Circumferential Backlash between the Starter Drive Gear and the Starter Idler Gear

Refer to Figure.

Remove IAE 2F10271 Clamping fixture clamping fixture 1 off.

Keep IAE 2F10269 Comparator support comparator support and IAE 2F10268 Backlash gage tip backlash gage in place for the next measurement.

SUBTASK 72-60-10-220-085 Measure the Circumferential Backlash between the Starter Drive and the Starter Idler Gear

Refer to Figure.

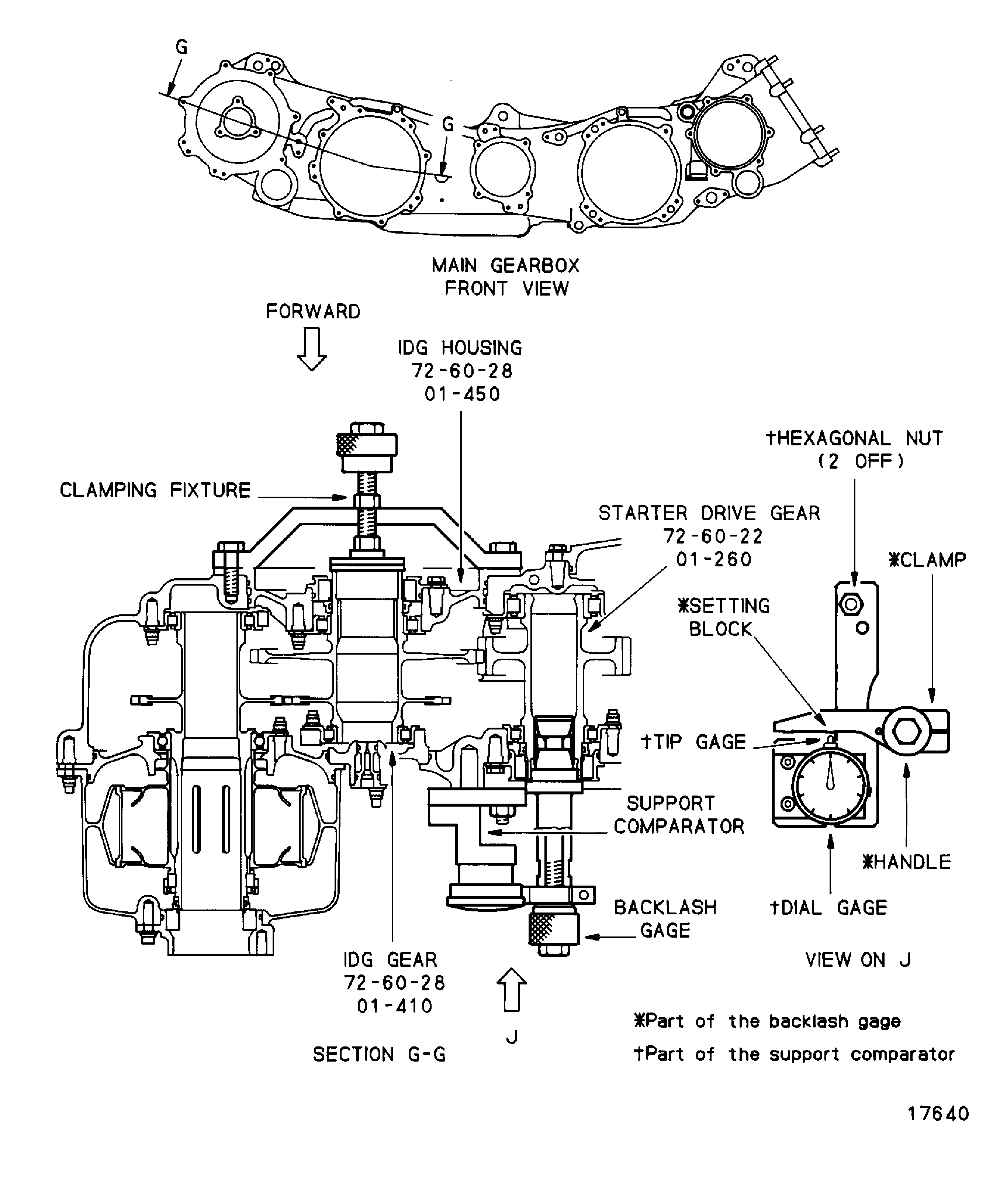

Install IAE 2F10274 Clamping fixture clamping fixture 1 off.

SUBTASK 72-60-10-440-073 Set the Tools to Measure the Circumferential Backlash between the IDG Gear and the Starter Drive Gear

Refer to Figure.

Remove IAE 2F10269 Comparator support comparator support and IAE 2F10268 Backlash gage tip backlash gage.

Keep IAE 2F10274 Clamping fixture clamping fixture in place for the next measurement.

SUBTASK 72-60-10-220-086 Measure the Circumferential Backlash between the IDG Gear and the Starter Drive Gear

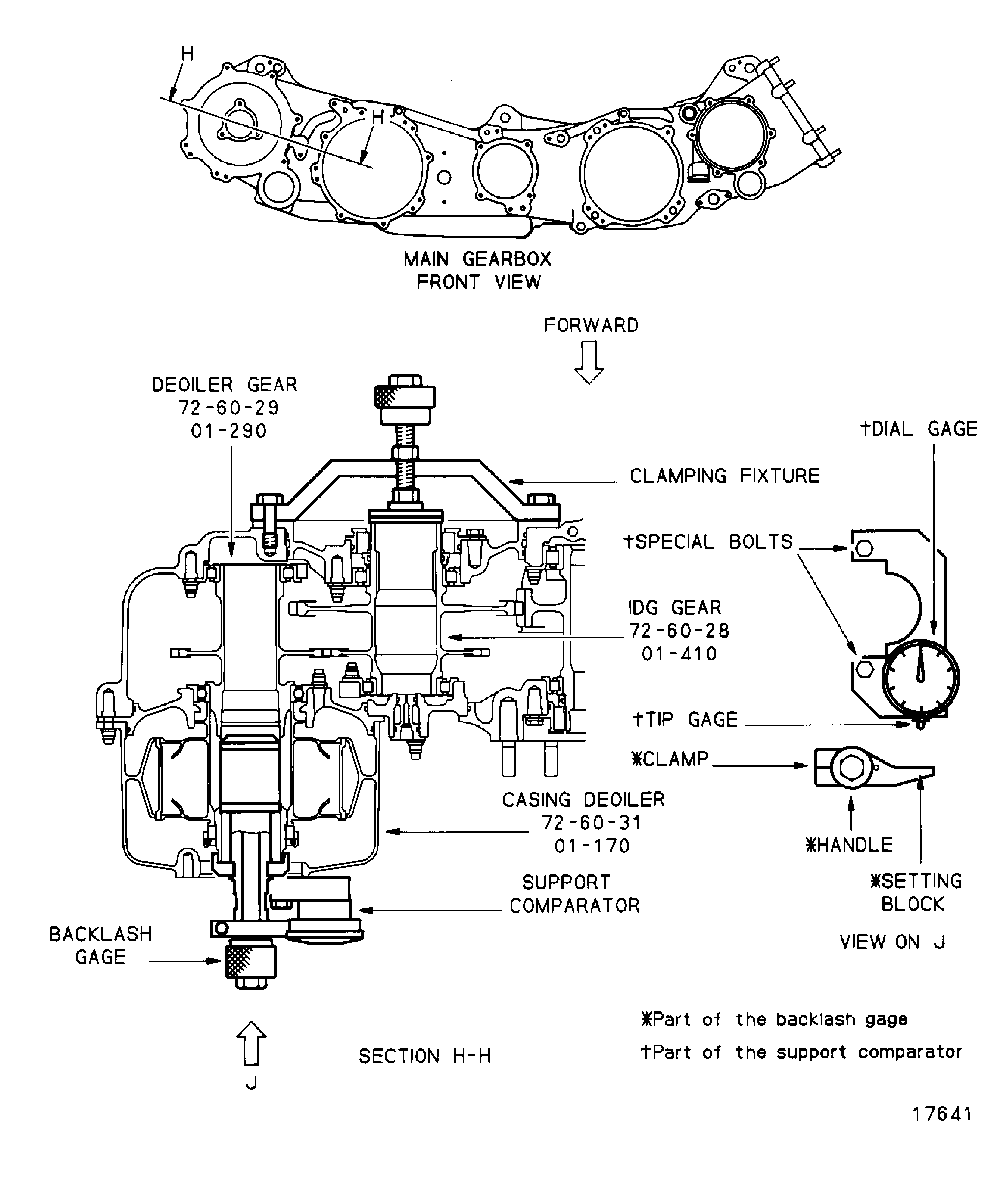

Refer to Figure.

Install IAE 2F10272 Backlash gage tip backlash gage 1 off.

Install IAE 2F10273 Comparator support comparator support 1 off.

SUBTASK 72-60-10-440-074 Set the Tools to Measure the Circumferential Backlash between the Deoiler Gear and the IDG Gear

Refer to Figure.

Remove IAE 2F10274 Clamping fixture clamping fixture 1 off, IAE 2F10272 Backlash gage tip backlash gage 1 off and IAE 2F10273 Comparator support comparator support 1 off.

SUBTASK 72-60-10-220-087 Measure the Circumferential Backlash between the Deoiler Gear and the IDG Gear

Refer to Figure.

Install Hydraulic Pump Drive Gear And Housing Assembly (72-60-23, 01-340) off in the internal groove of the mating ring.

Push the rotating ring against the inner race of the front roller bearing. Use IAE 1F10031 Pusher off.

Install the mating ring on the hydraulic pump drive gear.

NOTE

The carbon seal must have the free axial movement during its full travel in the seal housing.Put the seal housing with the carbon seal fully in to the CoMat 10-077 APPROVED ENGINE OILS before the installation. Make sure the free movement of the carbon seal.

Install Hydraulic Pump Drive Gear And Housing Assembly (72-60-23, 01-300) off in to the OD groove of the seal housing.

Remove the guide pin from the IAE 1F10003 Pusher off and install in to one of the bolts on the hydraulic pump housing.

Align one of the holes on the seal housing flange with the guide pin. Install the seal housing with the carbon seal over the hydraulic pump drive gear. Push the seal housing in position. Use IAE 1F10003 Pusher pusher 1 off.

Install the seal housing on the hydraulic pump drive gear.

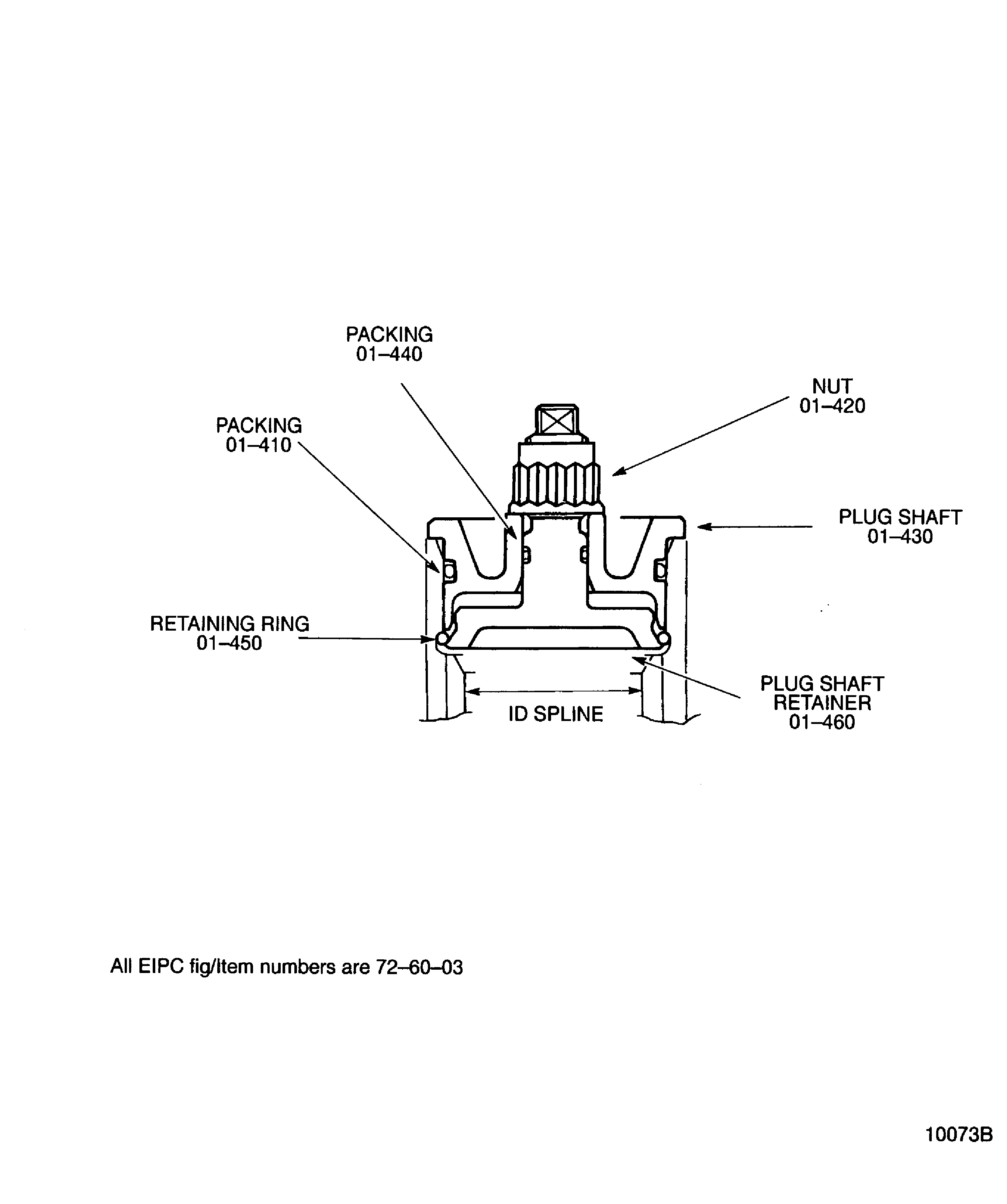

Install Transportation Fittings (72-60-03, 01-295) off in to the groove of the retaining ring housing. Install the retaining ring housing in to the end of the drive gear until it touches the end of the ID spline. Install the retaining ring.

Install Transportation Fittings (72-60-03, 01-320) off in to the groove of the plug shaft. Install the plug shaft in the retaining ring housing.

Install the plug shaft on the hydraulic pump drive gear.

SUBTASK 72-60-10-440-075 Complete the Installation of the Hydraulic Pump

Refer to Figure.

Install Fuel Pump Drive Gear And Housing Assembly (72-60-25, 01-160) off in the internal groove of the mating ring.

Push the mating ring against the inner race of the rear roller bearing. Use IAE 1F10031 Pusher off.

Install the mating ring on the fuel pump drive gear.

NOTE

The carbon seal must have the free axial movement during its full travel in the seal housing.Put the seal housing with the carbon seal fully in to CoMat 10-077 APPROVED ENGINE OILS before the installation. Make sure the free movement of the carbon seal.

Install Fuel Pump Drive Gear And Housing Assembly (72-60-25, 01-140) off in to the groove on the seal housing.

Remove the guide pin from the IAE 1F10003 Pusher off and install in to the one of the boltholes on the fuel pump housing.

Align one of the holes on the seal housing flange with the guide pin. Install the seal housing with the carbon seal over the fuel pump drive gear. Push the seal housing in position. Use IAE 1F10003 Pusher pusher 1 off.

Install the seal housing on the fuel pump drive gear.

SUBTASK 72-60-10-440-076 Complete the Installation of the Fuel Pump Drive Gear,

Refer to Figure.

Install Starter Drive Gear And Housing Assembly (72-60-22, 01-180) packing 1 off in the internal groove of the mating ring.

Push the mating ring against the inner race of the front roller bearing. Use IAE 1F10031 Pusher pusher 1 off.

Install the mating ring on the starter drive gear.

NOTE

The carbon seal must have the free axial movement during its full travel in the seal housing.Put the seal housing with the carbon seal fully in to CoMat 10-077 APPROVED ENGINE OILS before the installation. Make sure the free movement of the carbon seal.

Install Starter Drive Gear And Housing Assembly (72-60-22, 01-140) packing 1 off in to the groove on the seal housing.

Remove the guide pin from the IAE 1F10003 Pusher pusher 1 off and install in to one of the boltholes on the starter drive housing.

Align one of the holes on the seal housing flange with the guide pin. Install the seal housing with the carbon seal over the starter drive gear. Push the seal housing in position. Use IAE 1F10003 Pusher pusher 1 off.

Install the seal housing on the starter drive gear.

SUBTASK 72-60-10-440-077 Complete the Installation of the Starter Drive Gear

Refer to Figure.

Install Generator Drive Gear And Housing Assembly (72-60-28, 01-330) off in to the internal groove of the mating ring.

Push the mating ring against the inner race of the rear roller bearing. Use IAE 1F10032 Pusher off.

Install the mating ring on the IDG drive gear.

NOTE

The carbon seal must have the free axial movement during its fully travel in the seal housing.Put the seal housing with the carbon seal fully in to CoMat 10-077 APPROVED ENGINE OILS before the installation. Make sure the free movement of the carbon seal.

Install Generator Drive Gear And Housing Assembly (72-60-28, 01-290) off in to the groove of the seal housing.

Remove the IAE 1F10004 Pusher guide pin from the pusher and install into one of the boltholes on the IDG housing.

Align one of the holes on the seal housing flange with the guide pin. Install the seal housing with the carbon seal over the IDG drive gear. Push the housing in position. Use IAE 1F10004 Pusher off.

Install the seal housing on the IDG drive gear.

Install Transportation Fittings (72-60-03, 01-440) off in to the groove of the plug shaft retainer. Install the plug shaft retainer in to the end of the drive gear until it touches the end of the ID spline. Install Transportation Fittings (72-60-03, 01-450) retaining ring 1 off.

Install Transportation Fittings (72-60-03, 01-410) off in to the groove of the plug shaft. Install the plug shaft in to the drive gear, over the plug shaft retainer.

Install the plug shaft on the IDG drive gear.

SUBTASK 72-60-10-440-078 Complete the Installation of the IDG Drive Gear

Refer to Figure.

NOTE

The carbon seal must have the free axial movement during its full travel in the air port casing.Put the air port casing with the carbon seal fully in to the CoMat 10-077 APPROVED ENGINE OILS before the installation. Make sure the free movement of the carbons seal.

Install ENGINE-DEOILER CASE AND COVER (72-60-31, 01-107) off in to the OD groove of the air port casing.

Install the air port casing on the deoiler casing. Align the holes on the air port casing with the holes on the deoiler casing. Use IAE 1F10072 Pusher pusher to make easier the installation.

Install the air port casing.

SUBTASK 72-60-10-440-079 Complete the Installation of the Deoiler Casing

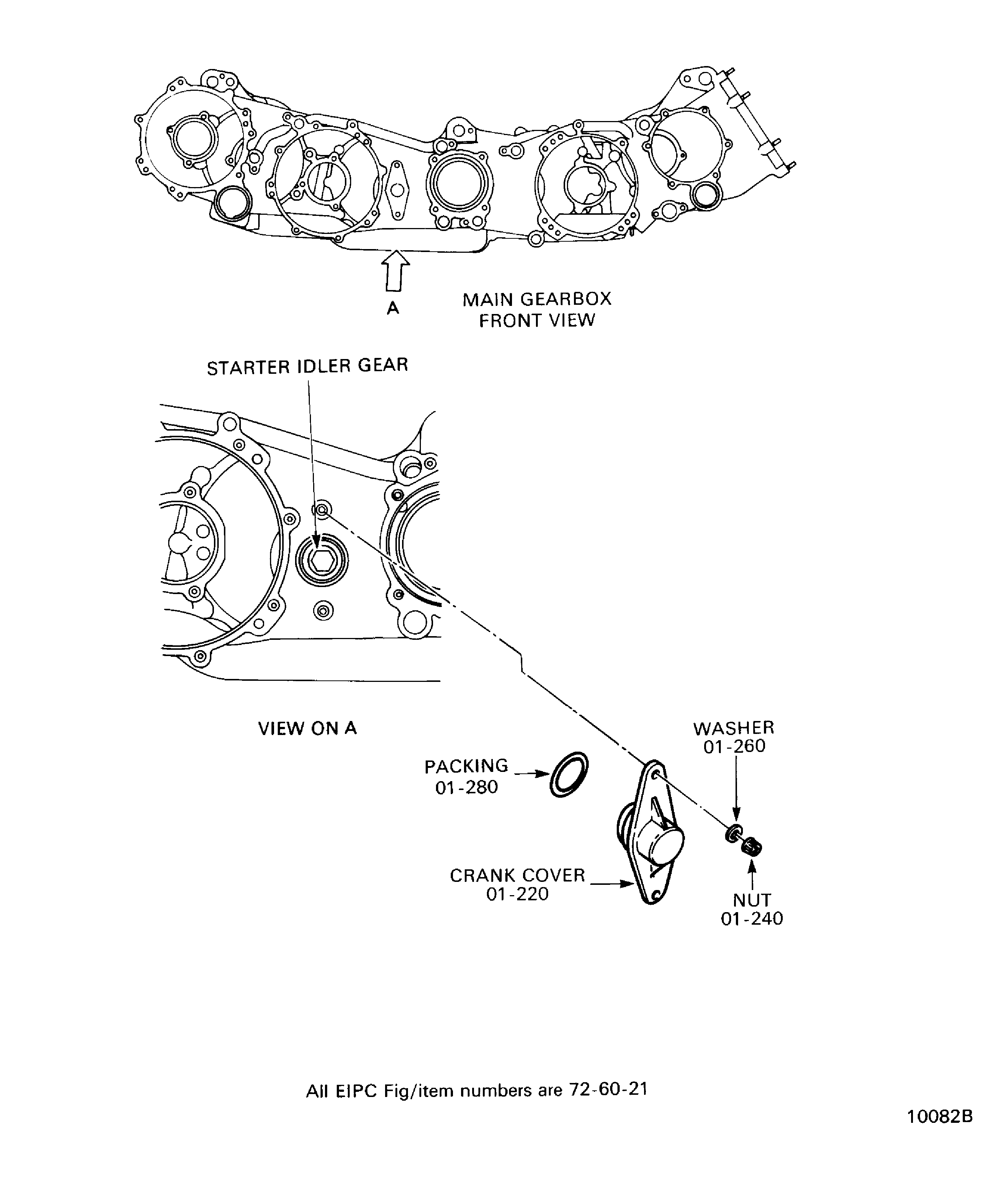

Install ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-280) packing 1 off in to the grooves on the cover crank.

SUBTASK 72-60-10-440-080 Install the Crank Cover

Refer to Figure.

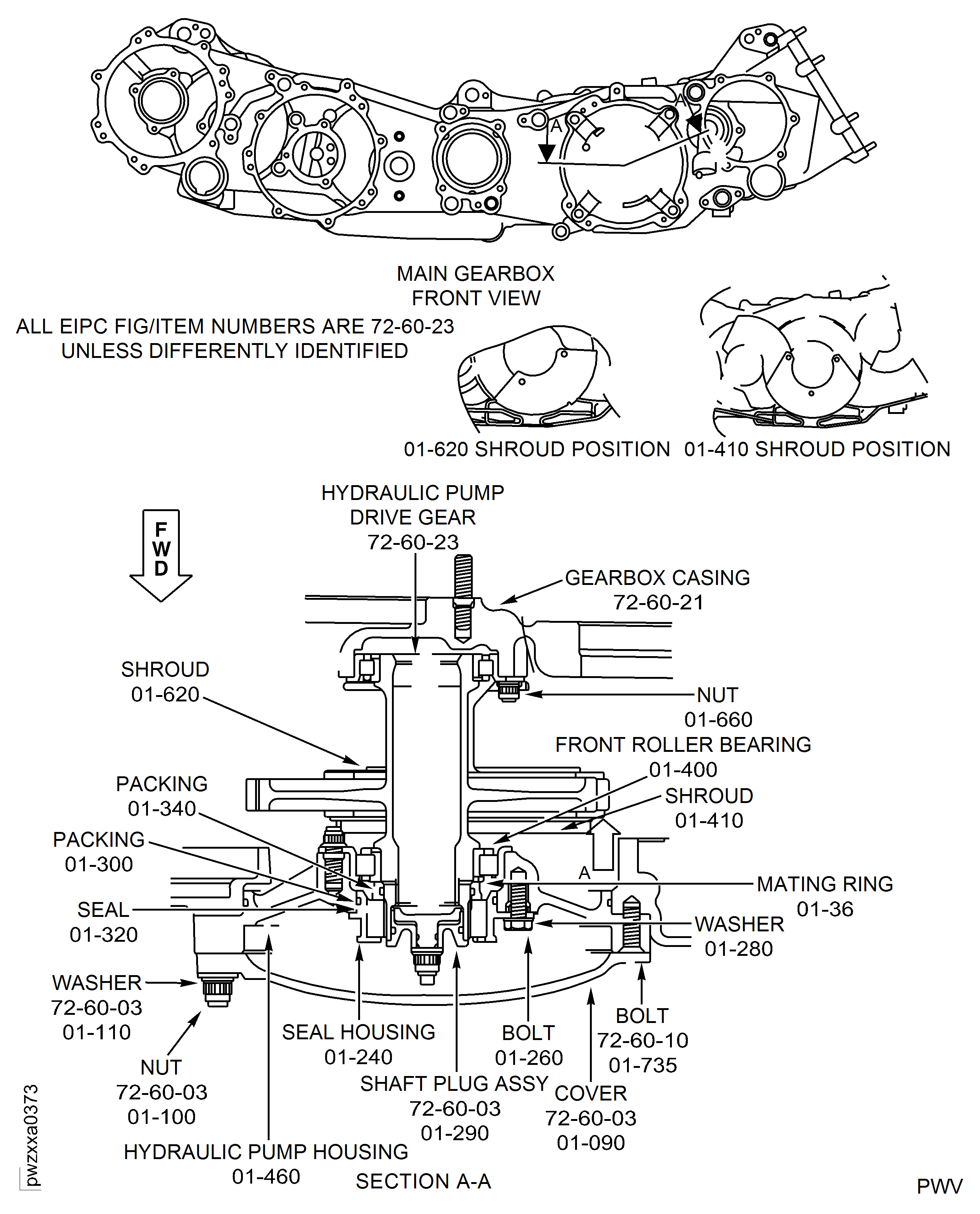

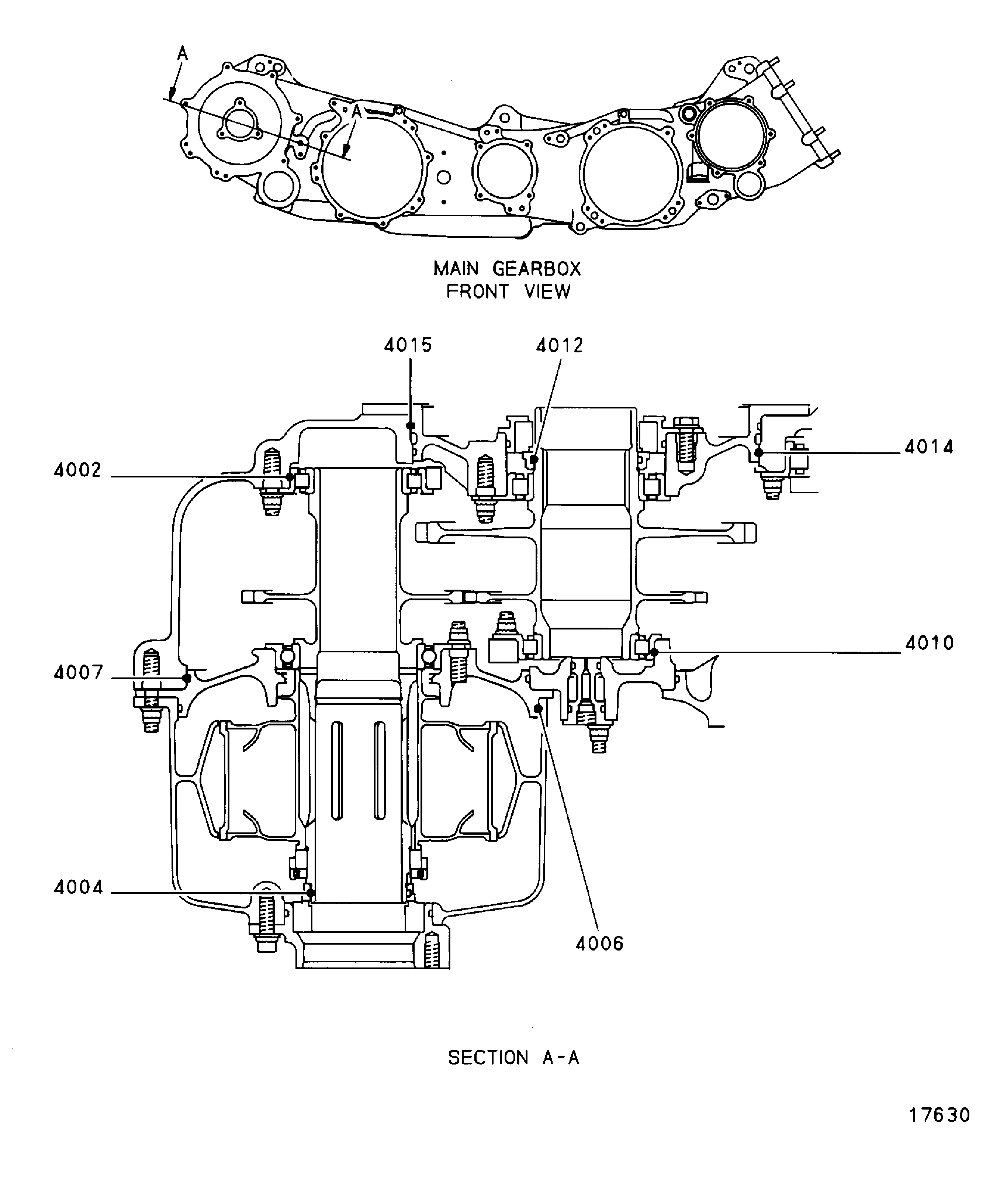

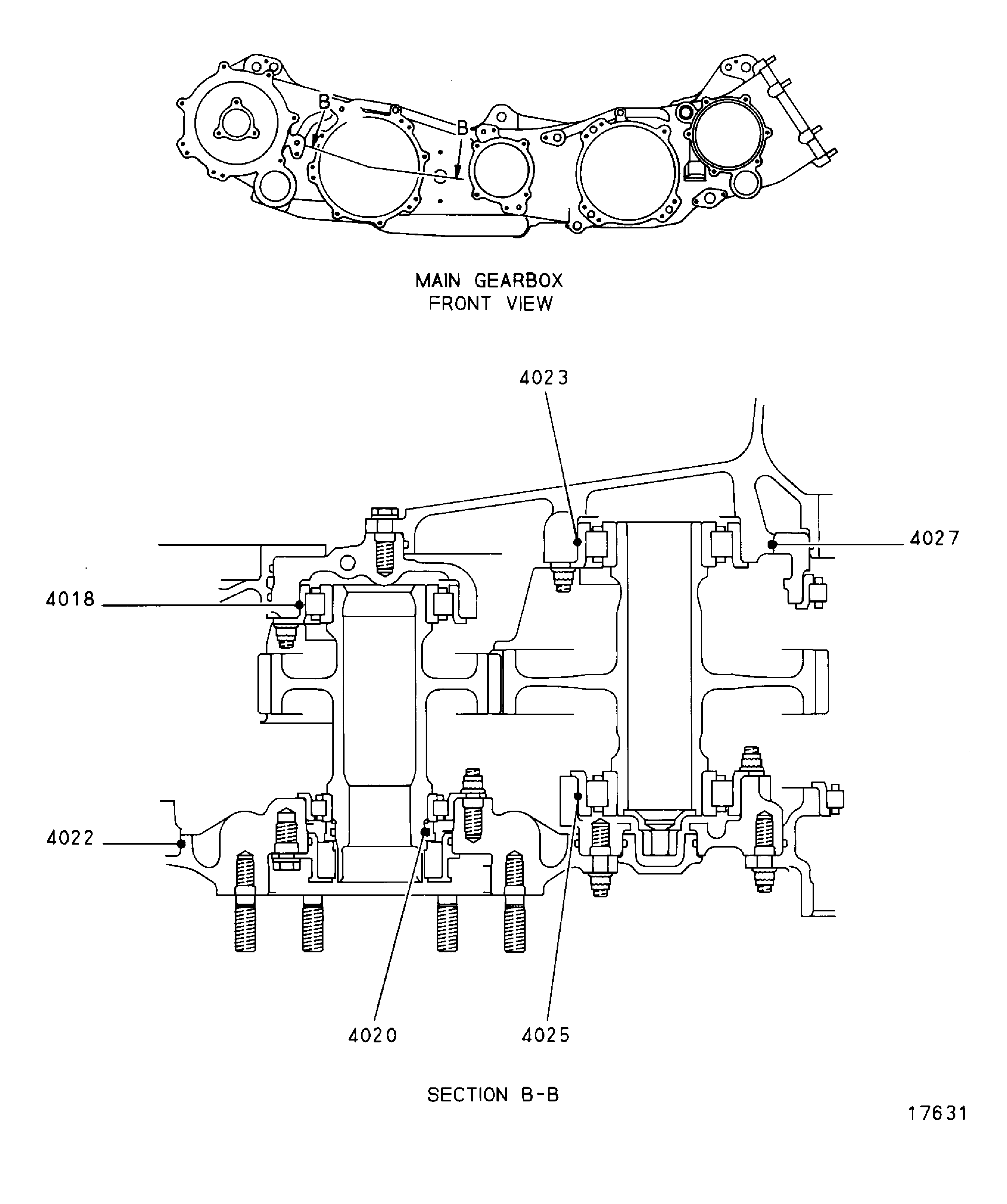

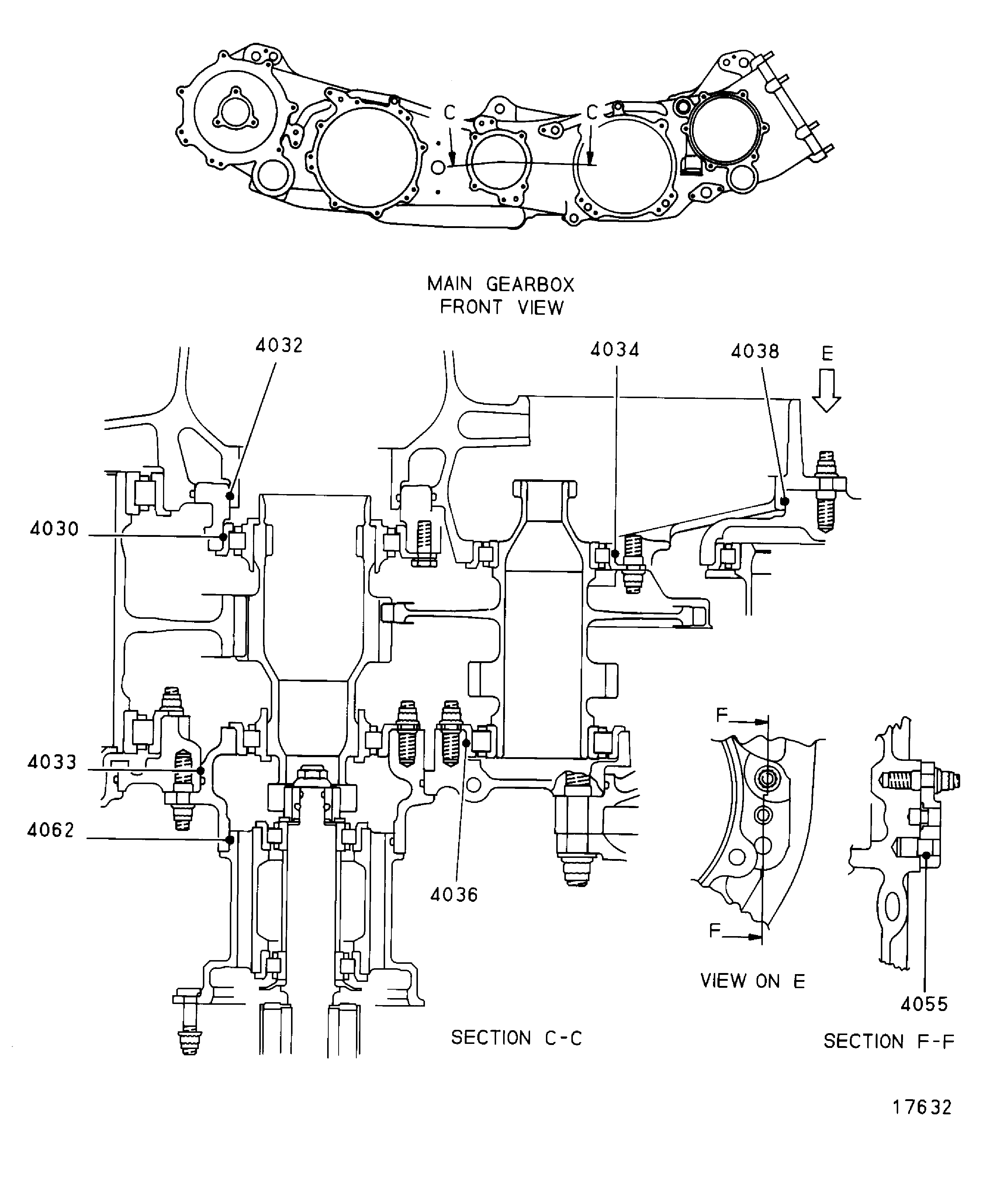

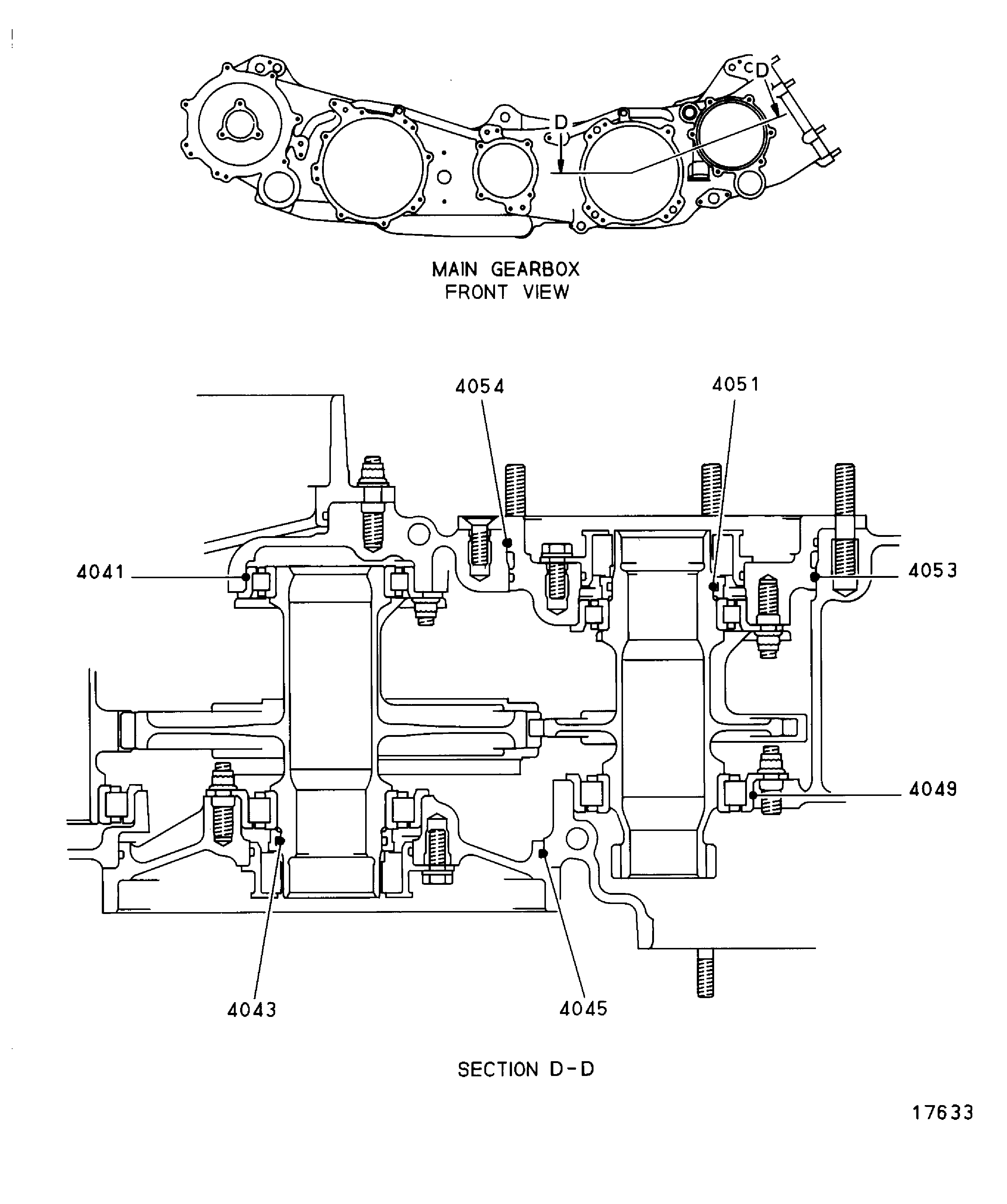

Figure: Main Gearbox Assembly - Fits and Clearances

Main Gearbox Assembly - Fits and Clearances

Figure: Main Gearbox Assembly - Fits and Clearances

Main Gearbox Assembly - Fits and Clearances

Figure: Main Gearbox Assembly - Figs and Clearances

Main Gearbox Assembly - Figs and Clearances

Figure: Main Gearbox Assembly - Fits and Clearances

Main Gearbox Assembly - Fits and Clearances

Figure: Oil Nozzles on the Front Right-Hand Side of the Main Gearbox

Oil Nozzles on the Front Right-Hand Side of the Main Gearbox

Figure: Oil Nozzles on the Front Left-Hand Side of the Main Gearbox

Oil Nozzles on the Front Left-Hand Side of the Main Gearbox

Figure: Oil Nozzle on the Rear Side of the Main Gearbox

Oil Nozzle on the Rear Side of the Main Gearbox

Figure: Install the Hydraulic Pump Drive Gear (Pre SB 72-0264)

Install the Hydraulic Pump Drive Gear (Pre SB 72-0264)

Figure: Install the Hydraulic Pump Drive Gear

Install the Hydraulic Pump Drive Gear

Figure: Install the Fuel Pump Drive Gear

Install the Fuel Pump Drive Gear

Figure: Install the Oil Scavenge Pump Drive Gear

Install the Oil Scavenge Pump Drive Gear

Figure: Install the Extension Layshaft Gear

Install the Extension Layshaft Gear

Figure: Install the Starter Idler Gear

Install the Starter Idler Gear

Figure: Install the Angle Gearbox Support

Install the Angle Gearbox Support

Figure: Install The Angle Gearbox Support

Install The Angle Gearbox Support

Figure: Install the Starter Drive Gear

Install the Starter Drive Gear

Figure: Install the IDG Drive Gear

Install the IDG Drive Gear

Figure: Install the IDG Drive Gear

Install the IDG Drive Gear

Figure: Install the Deoiler Gearshaft

Install the Deoiler Gearshaft

Figure: Install the Deoiler Casing

Install the Deoiler Casing

Figure: Install the PMA Drive Gear

Install the PMA Drive Gear

Figure: Install the Crank Cover

Install the Crank Cover

Figure: Measure the Circumferential Backlash Between the Fuel Pumpdrive Gear and the Hydraulic Pump Drive Gear

Measure the Circumferential Backlash Between the Fuel Pumpdrive Gear and the Hydraulic Pump Drive Gear

Figure: Measure the Circumferential Backlash Between the Oil Scavenge Pumpdrive Gear and the Hydraulic Pump Drive Gear

Measure the Circumferential Backlash Between the Oil Scavenge Pumpdrive Gear and the Hydraulic Pump Drive Gear

Figure: Measure the Circumferential Backlash Between the Oil Scavenge Pumpdrive Gear and the Extension Layshaft Drive Gear

Measure the Circumferential Backlash Between the Oil Scavenge Pumpdrive Gear and the Extension Layshaft Drive Gear

Figure: Measure the Circumferential Backlash Between the PMA Shaftand the Extension Layshaft Drive Gear

Measure the Circumferential Backlash Between the PMA Shaftand the Extension Layshaft Drive Gear

Figure: Measure the Circumferential Backlash Between the Starter Idler Gearand the Extension Layshaft Gear

Measure the Circumferential Backlash Between the Starter Idler Gearand the Extension Layshaft Gear

Figure: Measure the Circumferential Backlash Between the Starter Drive Gear and the Starter Idler Gear

Measure the Circumferential Backlash Between the Starter Drive Gear and the Starter Idler Gear

Figure: Measure the Circumferential Backlash Between the IDG Gearand the Starter Drive Gear

Measure the Circumferential Backlash Between the IDG Gearand the Starter Drive Gear

Figure: Measure the Circumferential Backlash Between the Deoiler Gear and the IDG Gear

Measure the Circumferential Backlash Between the Deoiler Gear and the IDG Gear

Figure: Setting Block of Backlash Gage IAE 2F10275

Setting Block of Backlash Gage IAE 2F10275

Figure: Install the Hydraulic Pump Drive Gear (Post SB 72-0264)

Install the Hydraulic Pump Drive Gear (Post SB 72-0264)