Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-00-40-420-005-B00 HP System Module - Install The Components, Ducts, Electrical Harnesses, And Tubes To The HPC Case Vertical Splitline, Installation-008

General

This TASK gives the procedure to install the electrical harnesses, the tubes and the brackets on to the HP compressor/diffuser case assembly. Refer to the TASKs which follow for other related procedures.

TASK 72-00-40-420-004-B00 - Install the initial HP system module components and air off-take ducts.

TASK 72-00-40-420-006-B00 - Install and connect the components, the electrical harnesses and the tubes on the front of the HP compressor case.

TASK 72-00-40-420-007-B00 - Install the components, the electrical harnesses, tubes and brackets to the HP turbine.

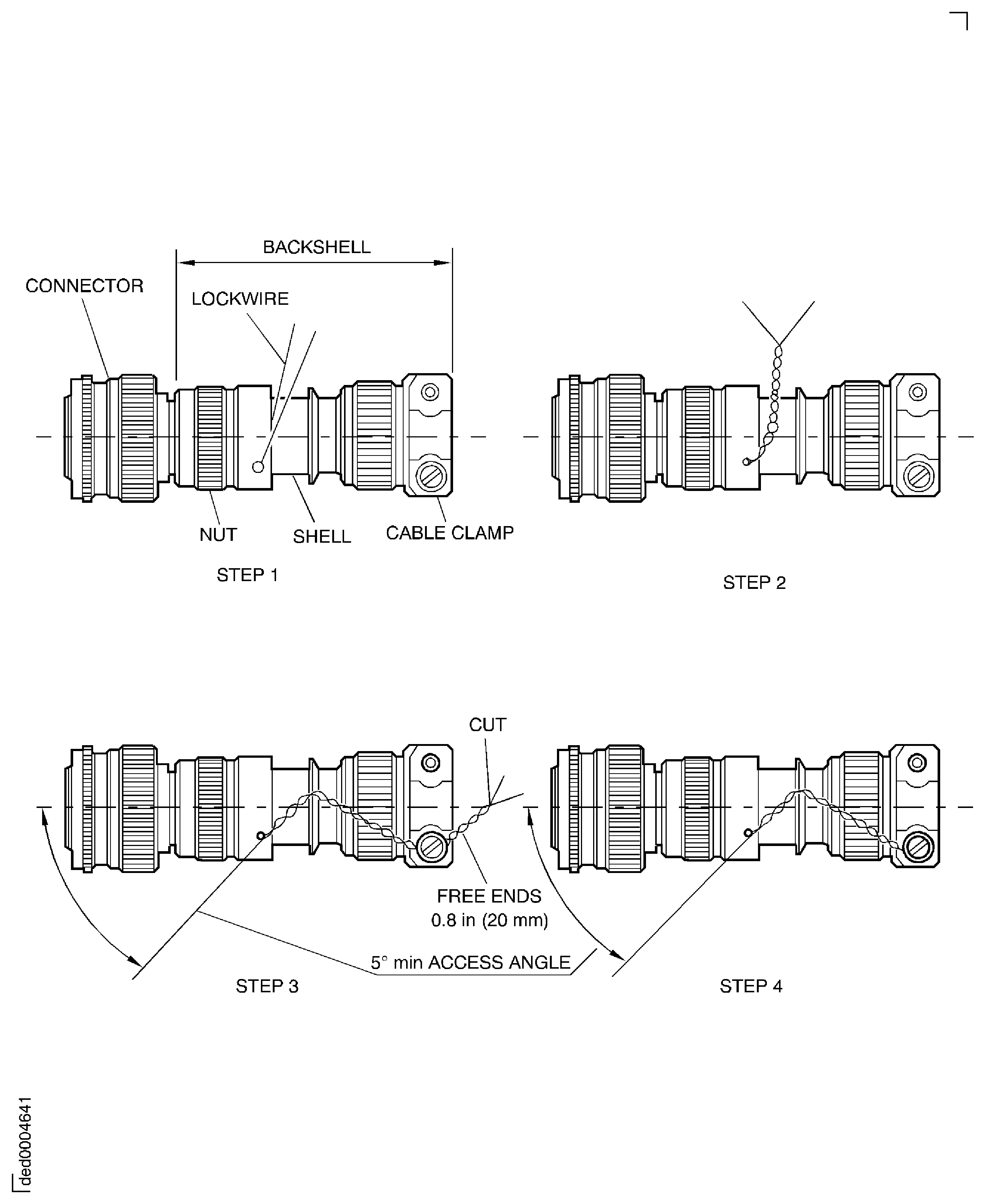

For lockwire data and procedures refer to the SPM TASK 70-42-05-400-501.

For safety cable data and procedures refer to the SPM TASK 70-42-08-400-501.

Safety the threaded fasteners in this TASK with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT for the ATA Chapter/Section/Subjects which follow:

A5 series engines: | ||

71-51-41 | 71-52-43 | 72-41-34 |

73-22-49 | 75-23-49 | 75-31-42 |

75-31-43 | 75-32-42 |

Transportation covers/blanks must be removed immediately before the installation of components and tubes.

Fig./item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the Service Bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig./item number.

For standard torque data and procedures refer to the SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data is identified with the symbol * after the torque value.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS approved engine oil unless other lubricants are referred to in the procedure.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of air drying enamel. Refer to the SPM TASK 70-38-21-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Refer to the V2500 Illustrated Tool and Equipment Manual (ITE-V2500-1IA) for the illustrations of the special tools given in this procedure.

Do not remove the special plastic caps from the electrical connectors until immediately before they are installed. This will give protection from unwanted fluids and materials.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| ACR Torq-Set bit 212-1/4-ACR | LOCAL | Torq-Set |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) | LOCAL | CoMat 02-148 | ||

| CoMat 02-274 SAFETY CABLE KIT | LOCAL | CoMat 02-274 | ||

| CoMat 02-275 SAFETY CABLE KIT | LOCAL | CoMat 02-275 | ||

| CoMat 04-005 JOINTING COMPOUND, MEDIUM GRADE | LOCAL | CoMat 04-005 | ||

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 10-031 ANTI-GALLING COMPOUND | 0AM53 | CoMat 10-031 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 | ||

| CoMat 10-129 ANTI-SEIZE PASTE | 34568 | CoMat 10-129 |

Spares

NONESafety Requirements

NONEProcedure

Torque the diffuser case adapter nut to 257 to 283 lbf.in (29 to 32 Nm). Safety with CoMat 02-126 LOCKWIRE.

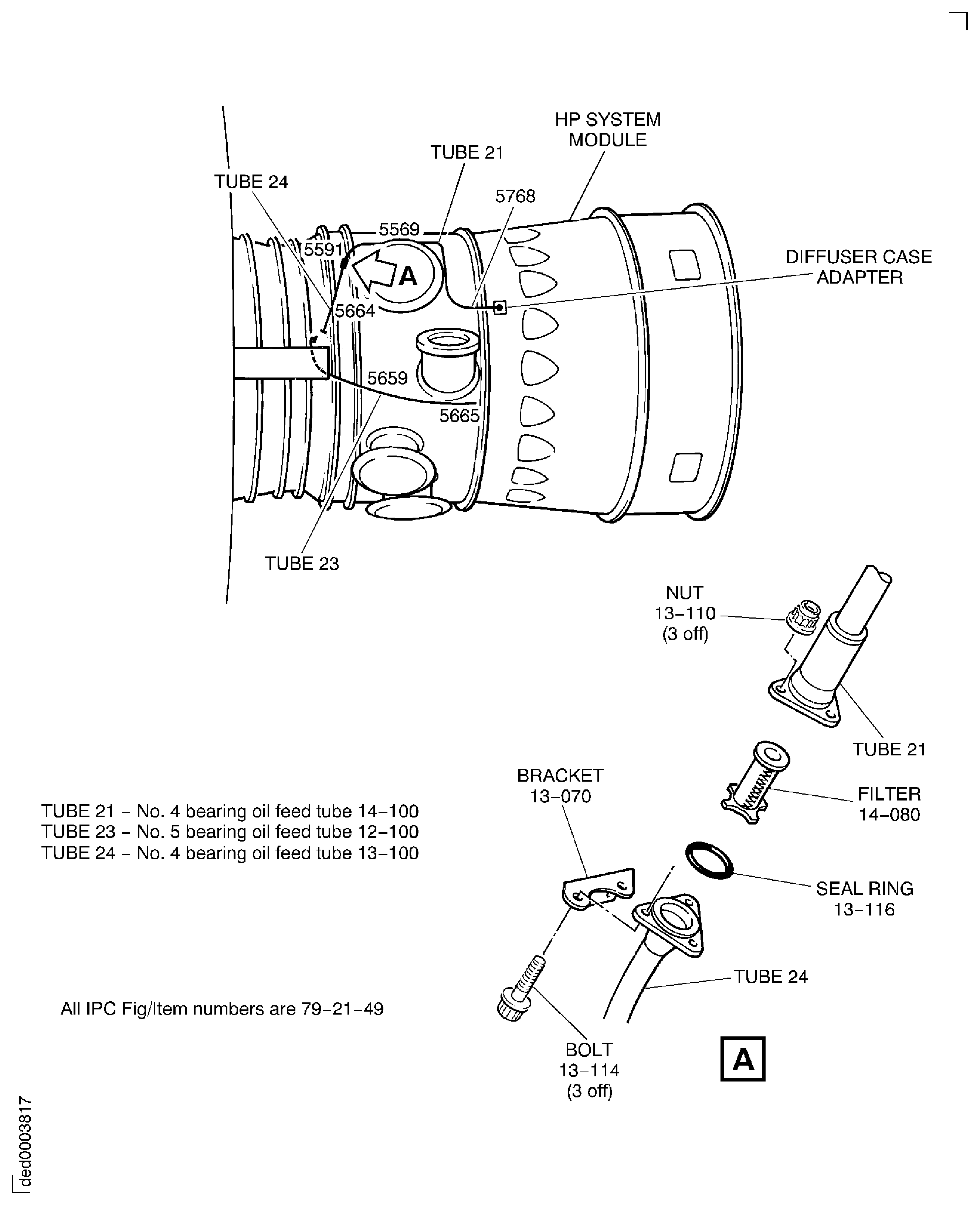

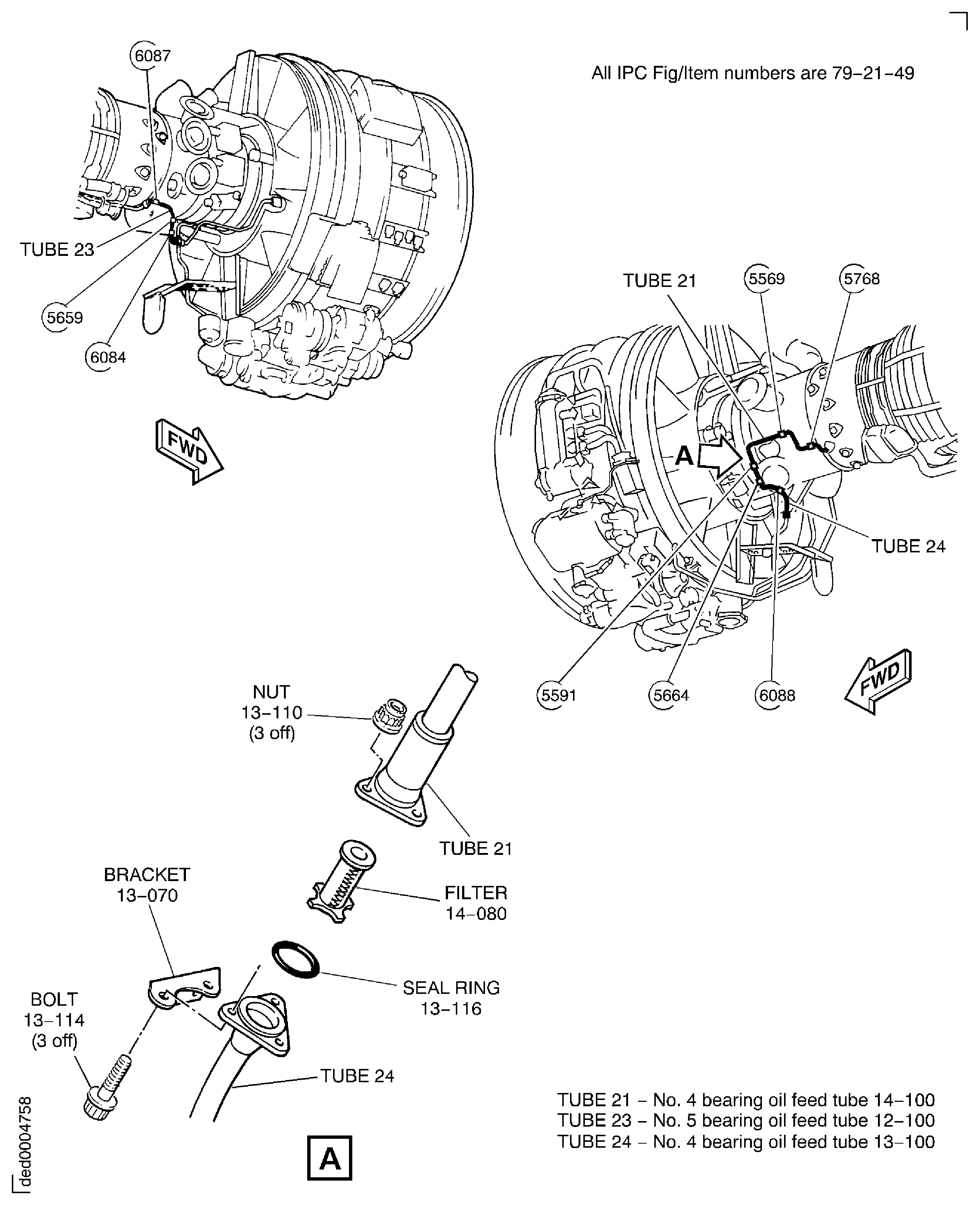

Install the tube 21 OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 14-100).

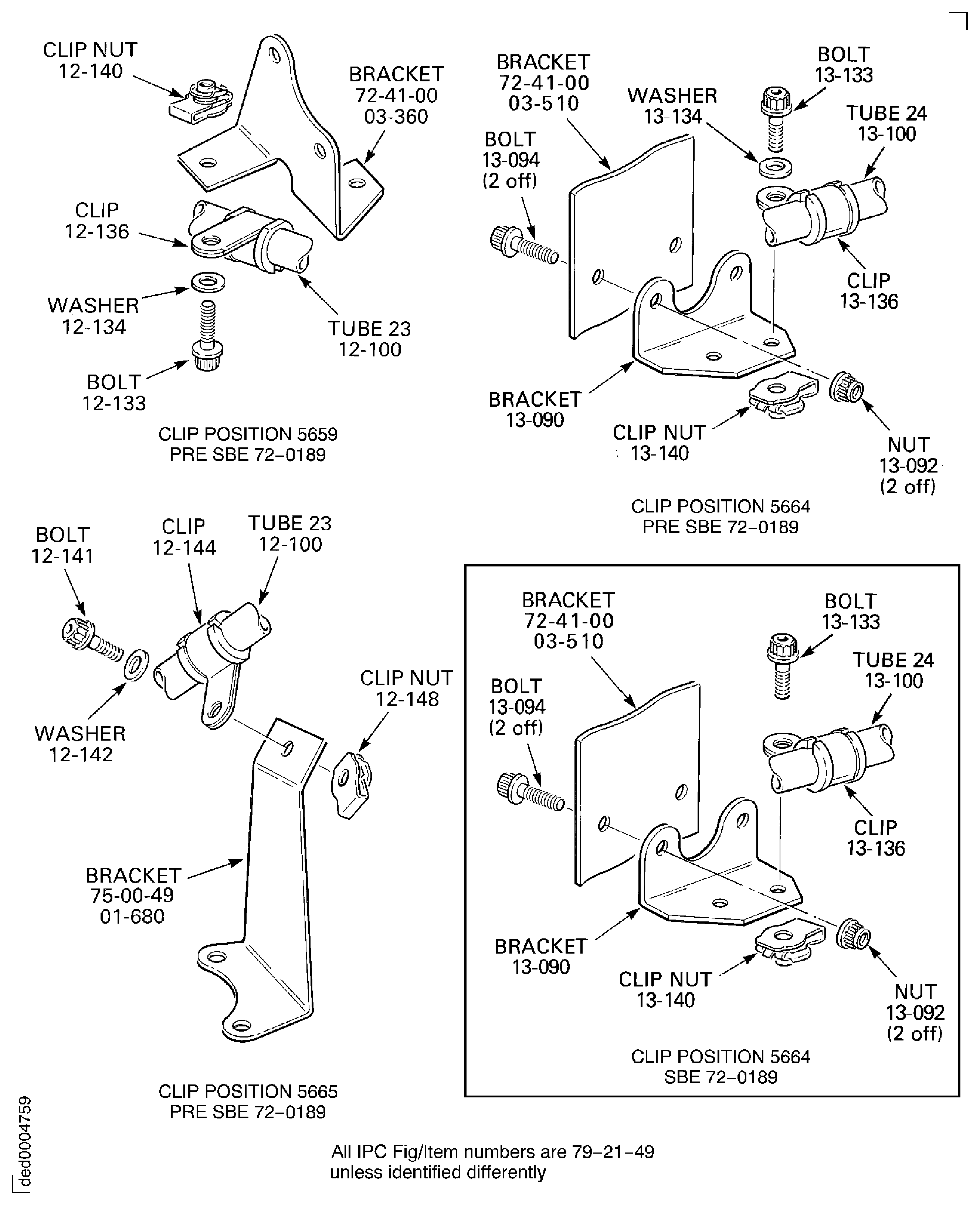

Attach the bracket OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-090) to the bracket HPC Assembly (72-41-00, 03-510) with the two bolts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-094) and the two nuts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-092) at clip position 5664. Torque the nuts to 36 to 45 lbf.in (4 to 5 Nm).

Lightly lubricate a new OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-116) seal ring with CoMat 10-077 APPROVED ENGINE OILS and install it on the tube 21.

Install the filter OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 14-080) in to the tube 21.

Put a thin layer of CoMat 04-005 JOINTING COMPOUND, MEDIUM GRADE on to the bracket OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-070) where it touches tube 24.

Attach the tube 24 to the tube 21 with the bracket, the three bolts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-114) and the three nuts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-110). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the tube 24 OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-100).

Install the tube 23 Engine Pressure Oil Tubes (79-21-49, 12-100).

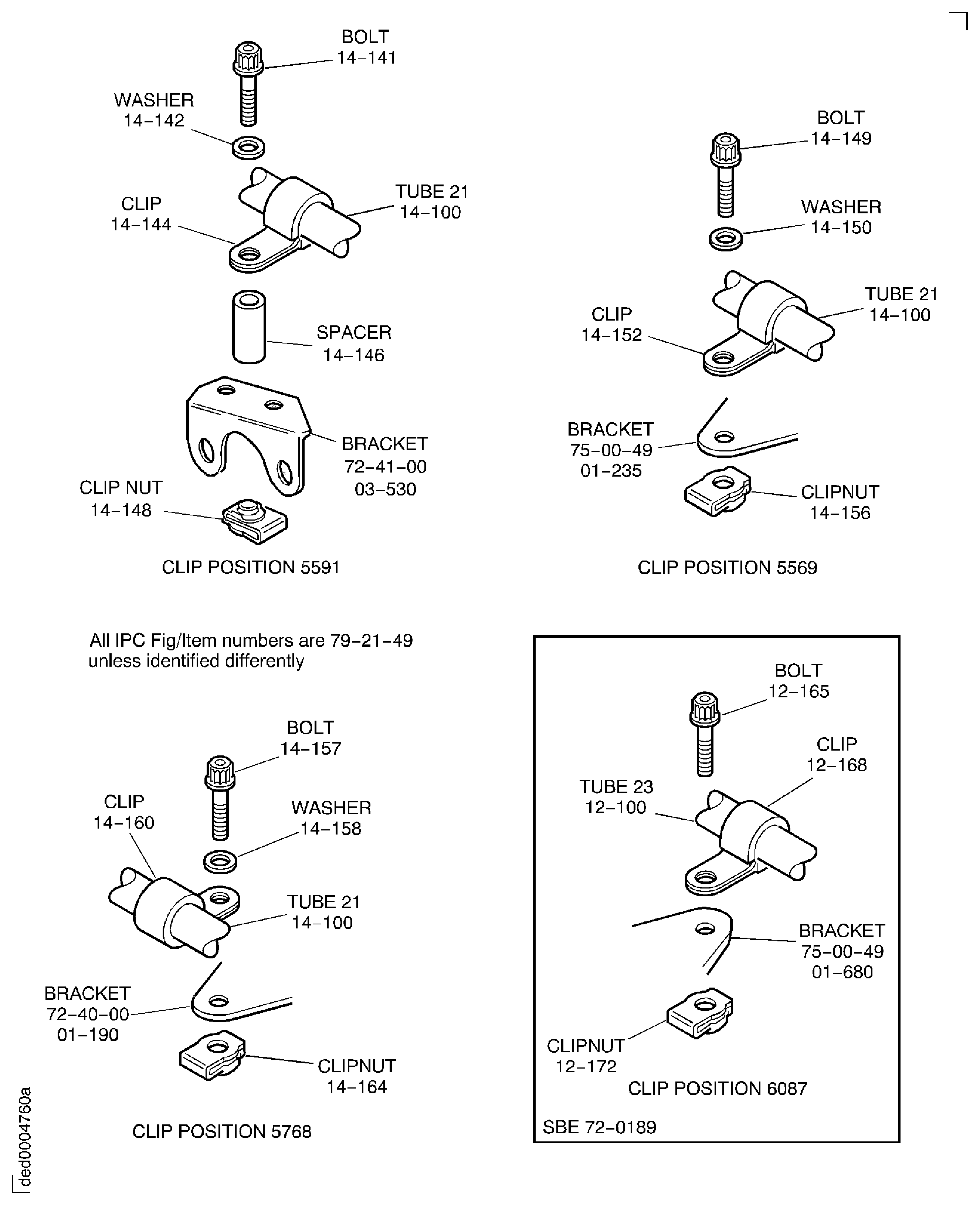

SUBTASK 72-00-40-420-219-A00 Install the Oil Feed Tubes (21, 23 and 24) (Pre SBE 72-0189)

Torque the diffuser case adapter nut to 257 to 283 lbf.in (29 to 32 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the tube 21 OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 14-100).

Attach the bracket OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-090) to the bracket HPC Assembly (72-41-00, 03-510) with the two bolts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-094) and the two nuts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-092) at clip position 5664. Torque the nuts to 36 to 45 lbf.in (4 to 5 Nm).

Lightly lubricate a new OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-116) seal ring with CoMat 10-077 APPROVED ENGINE OILS and install it on the tube 21.

Install the filter OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 14-080) in to the tube 21.

Put a thin layer of CoMat 04-005 JOINTING COMPOUND, MEDIUM GRADE on to the bracket OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-070) where it touches tube 24.

Attach the tube 24 to the tube 21 with the bracket, the three bolts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-114) and the three nuts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-110). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the tube 24 OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-100).

Install the clip, the clipnut and the bolt to the bracket Engine Air Off-Take Air Ducts (75-00-49, 01-680) at the clip position 6087.

Install the tube 23 Engine Pressure Oil Tubes (79-21-49, 12-100).

SUBTASK 72-00-40-420-219-B00 Install the Oil Feed Tubes (21, 23 and 24) (SBE 72-0189)

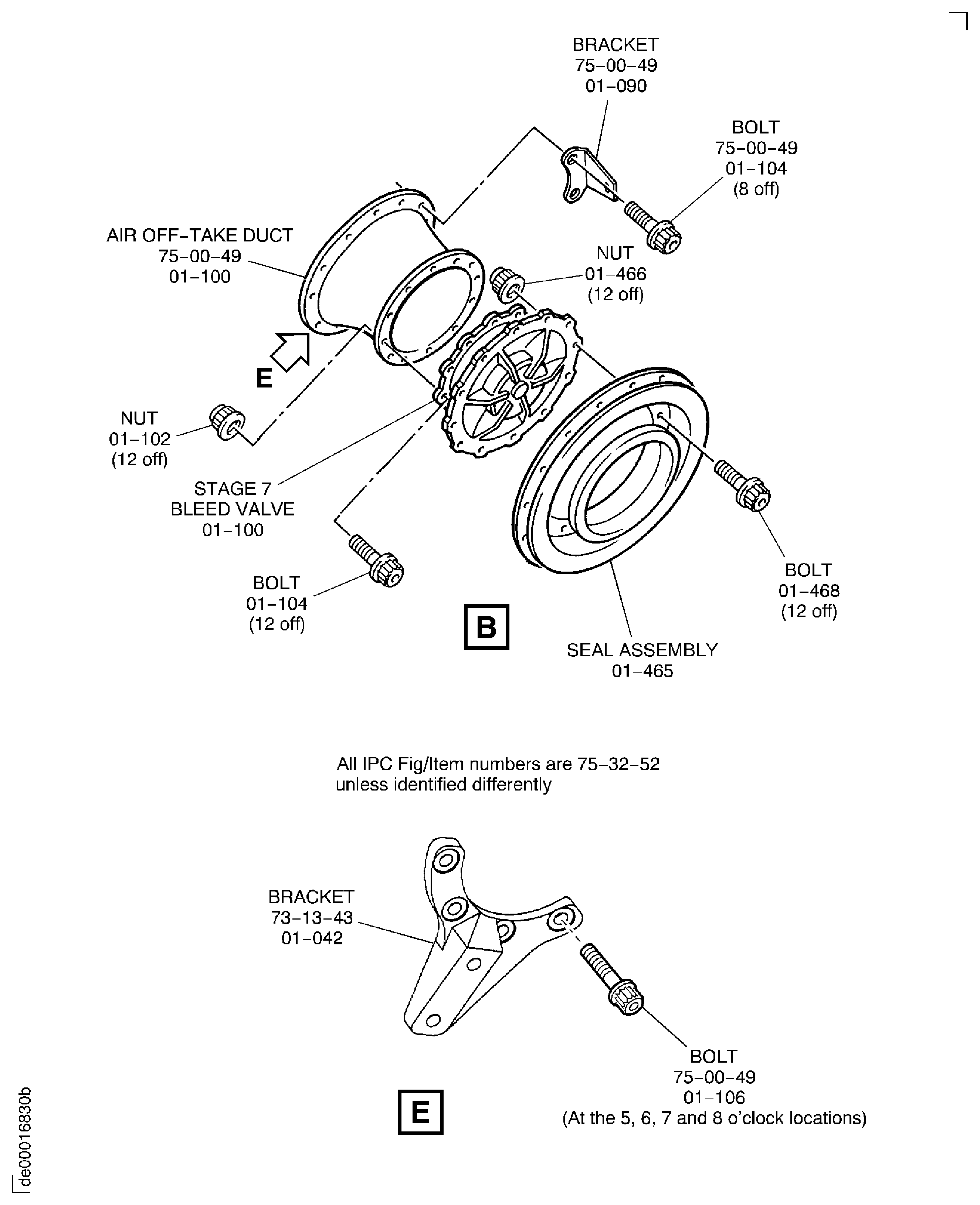

Install the 12 bolts Engine Air Off-Take Air Ducts (75-00-49, 01-252) together with the three brackets Engine Air Off-Take Air Ducts (75-00-49, 01-235), Engine Air Off-Take Air Ducts (75-00-49, 01-240) and Engine Air Off-Take Air Ducts (75-00-49, 01-242). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

Install the stage 7 air off-take duct Engine Air Off-Take Air Ducts (75-00-49, 01-250).

Install 12 of the bolts Engine Air Off-Take Air Ducts (75-00-49, 01-102) together with the brackets Engine Air Off-Take Air Ducts (75-00-49, 01-090). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

Install the bracket ENGINE FUEL AND CONTROL-FUEL DISTRIBUTION VALVE (73-13-43, 01-042) on the flange of the air offtake duct with the four bolts Engine Air Off-Take Air Ducts (75-00-49, 01-106) at the 5, 6, 7 and 8 o'clock locations. Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

Install the 8 bolts Engine Air Off-Take Air Ducts (75-00-49, 01-104) together with the bracket Engine Air Off-Take Air Ducts (75-00-49, 01-090) on the flange of the air offtake duct. Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

Install the two stage 7 air off-take ducts Engine Air Off-Take Air Ducts (75-00-49, 01-100).

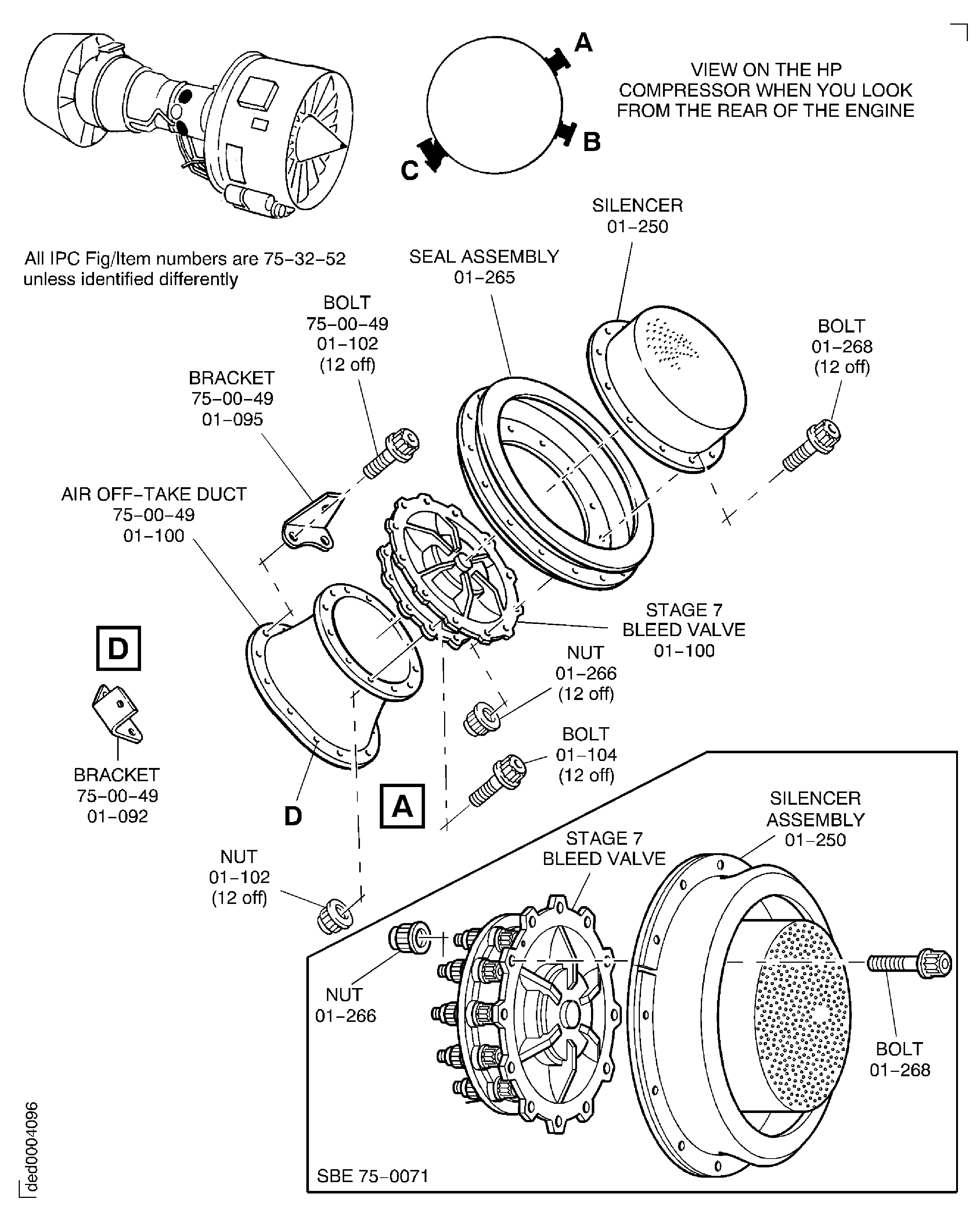

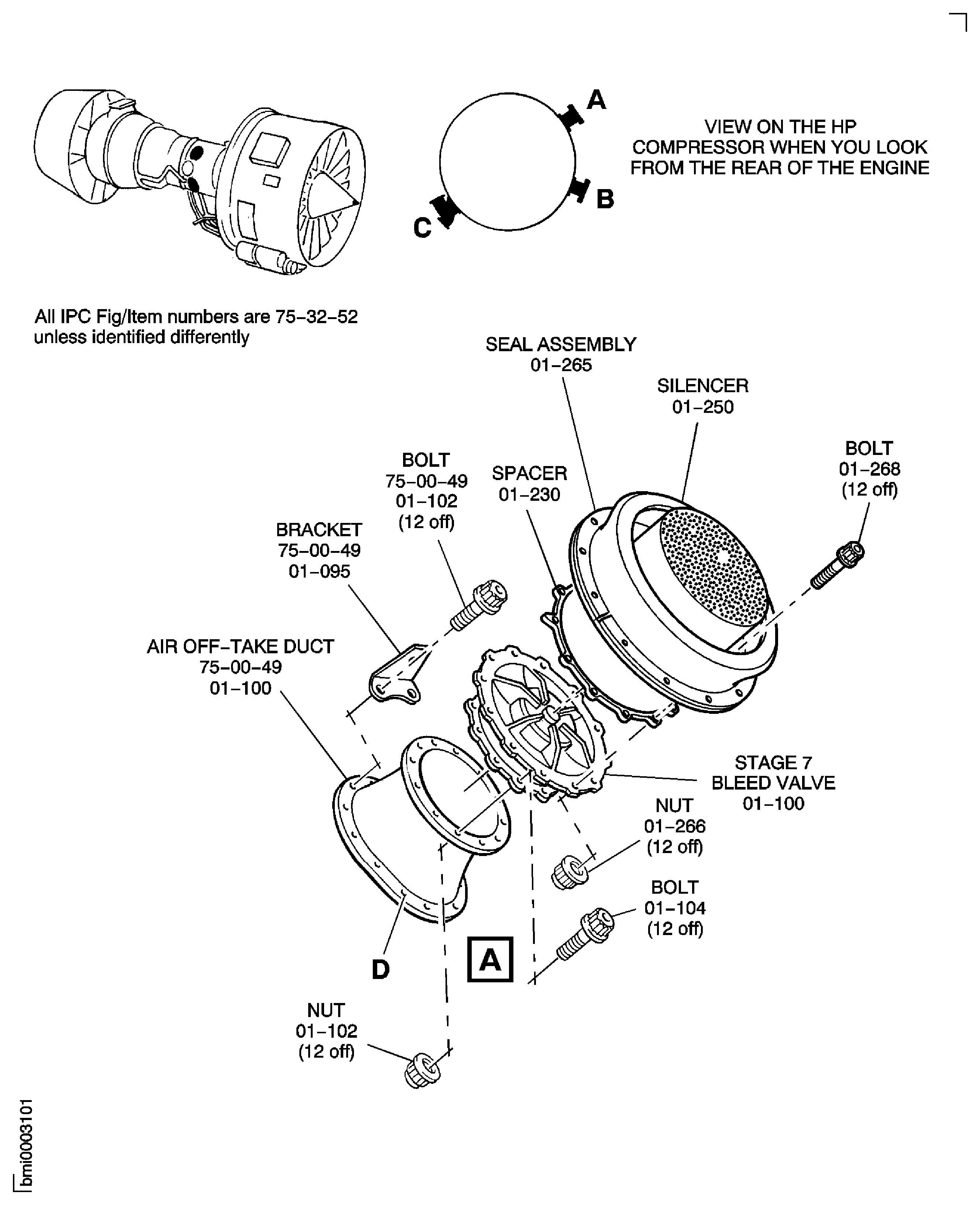

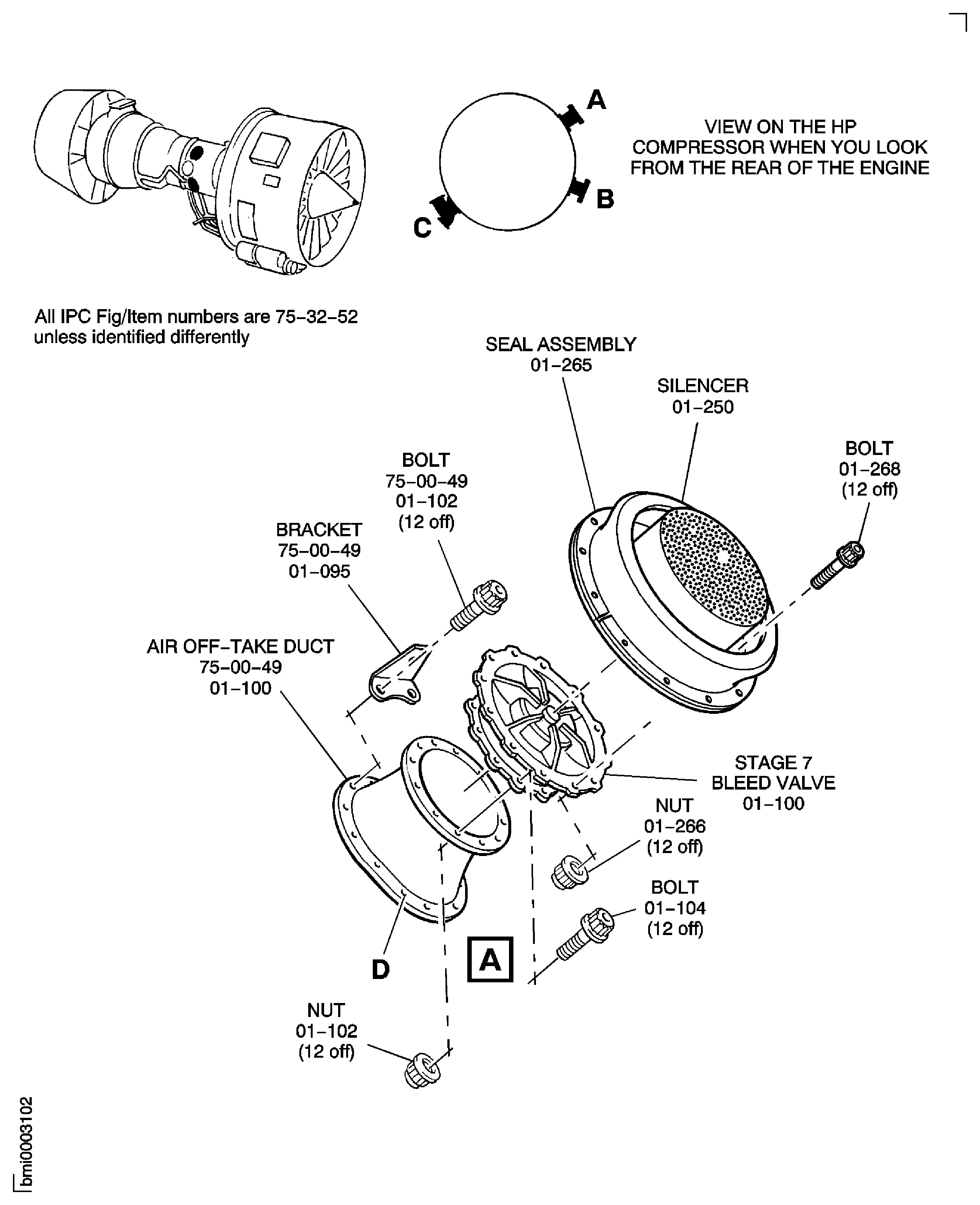

SUBTASK 72-00-40-420-220 Install the Stage 7 Air Off-Take Ducts

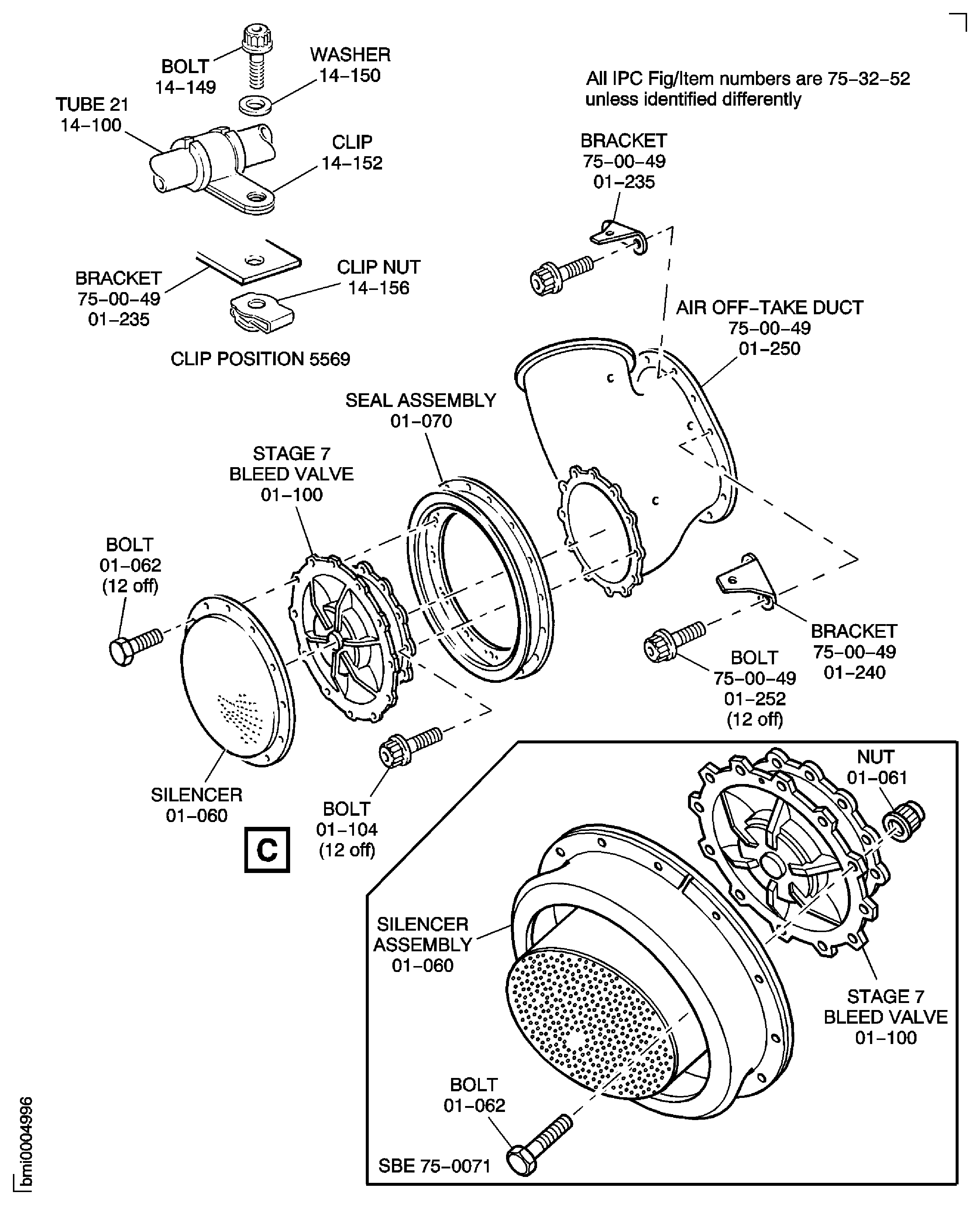

Put a bleed valve HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-100) in position on the air off-take duct Engine Air Off-Take Air Ducts (75-00-49, 01-100) at the 2 o'clock position. Make sure that bleed valve actuation connection is at the 4 o'clock position and align the bolt holes.

Install the 12 bolts HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-104) and the nuts HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-102) and torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Pre SBE 75-0071: Attach the silencer HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-250) and the seal assembly HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-265) to the bleed valve with the 12 bolts HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-268) and the 12 nuts HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-266). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

SBE 75-0071, Pre SBE 75-0092: Attach the silencer assembly HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-250) to the bleed valve with the 12 bolts HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-268) and the 12 nuts HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-266). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

SBE 75-0092, Pre SBE 75-0093: Attach the silencer assembly HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-250) and the spacer HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-230) to the bleed valve with the 12 bolts HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-268) and the 12 nuts HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-266). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

SBE 75-0093: Attach the silencer assembly HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-250) to the bleed valve with the 12 bolts HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-268) and the 12 nuts HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-266). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Put a bleed valve HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-100) in position on the air off-take duct Engine Air Off-Take Air Ducts (75-00-49, 01-100) at the 4 o'clock position. Make sure the bleed valve actuation connection is at the 10 o'clock position and align the bolt holes.

Install 12 of the bolts HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-104) and the nuts No. 2 Bearing (72-32-52, 01-102). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Attach the seal assembly HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-465) to the bleed valve with the 12 bolts HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-468) and the 12 nuts HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-466). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Put the remaining bleed valve No. 2 Bearing (72-32-52, 01-100) through the seal assembly HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-070) on to the air off-take duct Engine Air Off-Take Air Ducts (75-00-49, 01-250). Make sure the bleed valve actuation connection is at the 6 o'clock position and align the bolt holes.

Install the other 12 bolts HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-104) and torque them to 85 to 105 lbf.in (10 to 12 Nm).

Pre SBE 75-0071: Attach the silencer HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-060) and the seal assembly to the bleed valve with the 12 bolts HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-062). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

SBE 75-0071: Attach the silencer assembly HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-060) to the bleed valve with the 12 bolts HPC Stage 7 Bleed Outlet Duct, Seal Assembly And Silencer Assemblies (75-32-52, 01-062). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

.

SUBTASK 72-00-40-420-221 Install the Stage 7 Bleed Valves, the Seal Assemblies and the Silencers (Pre SBE 75-0071, Pre SBE 75-0092, Pre SBE 75-0093, SBE 75-0071, SBE 75-0092 and SBE 75-0093)

Torque the tube nuts in Step, Step and Step to 159 to 177 lbf.in (18 to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

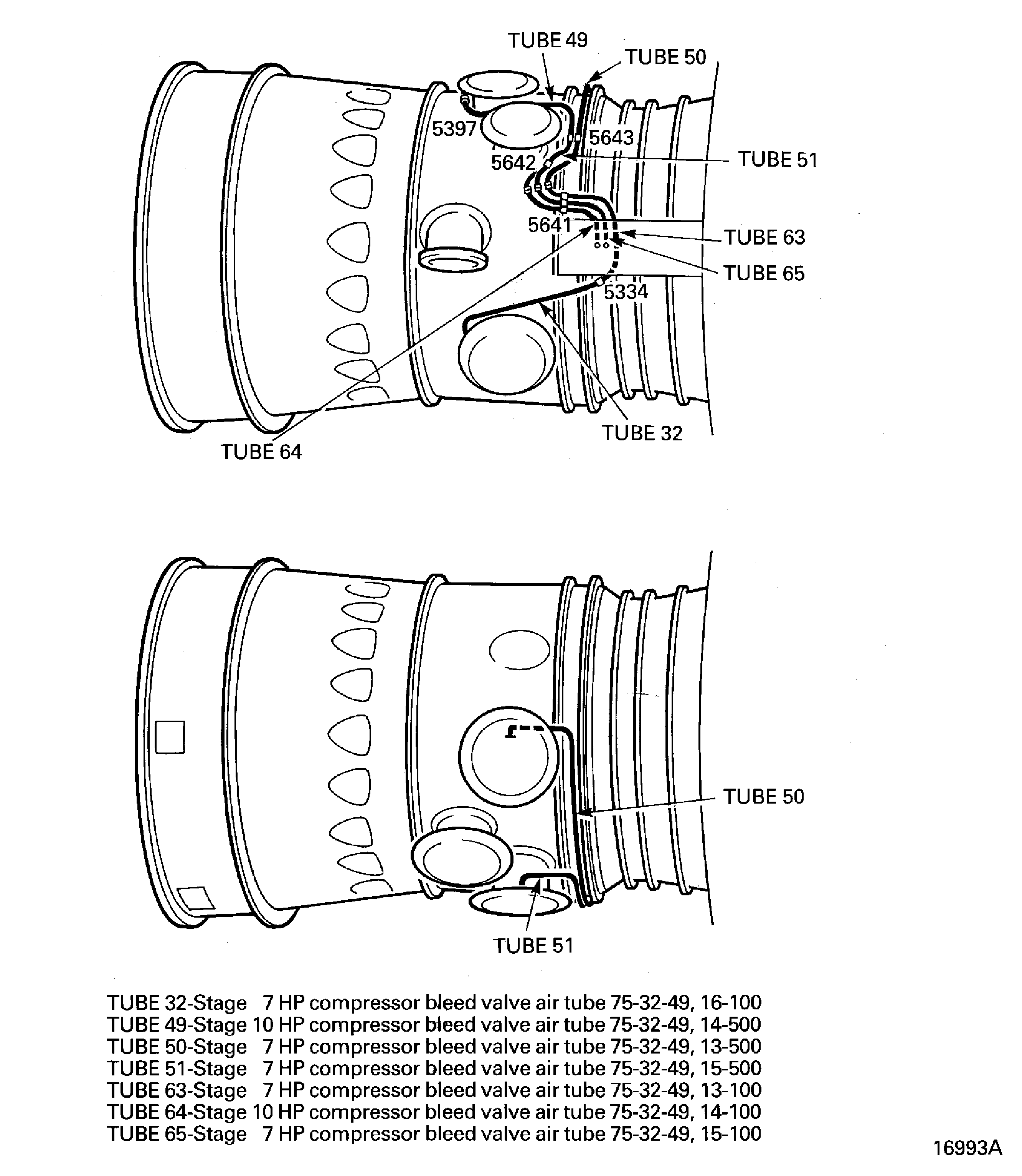

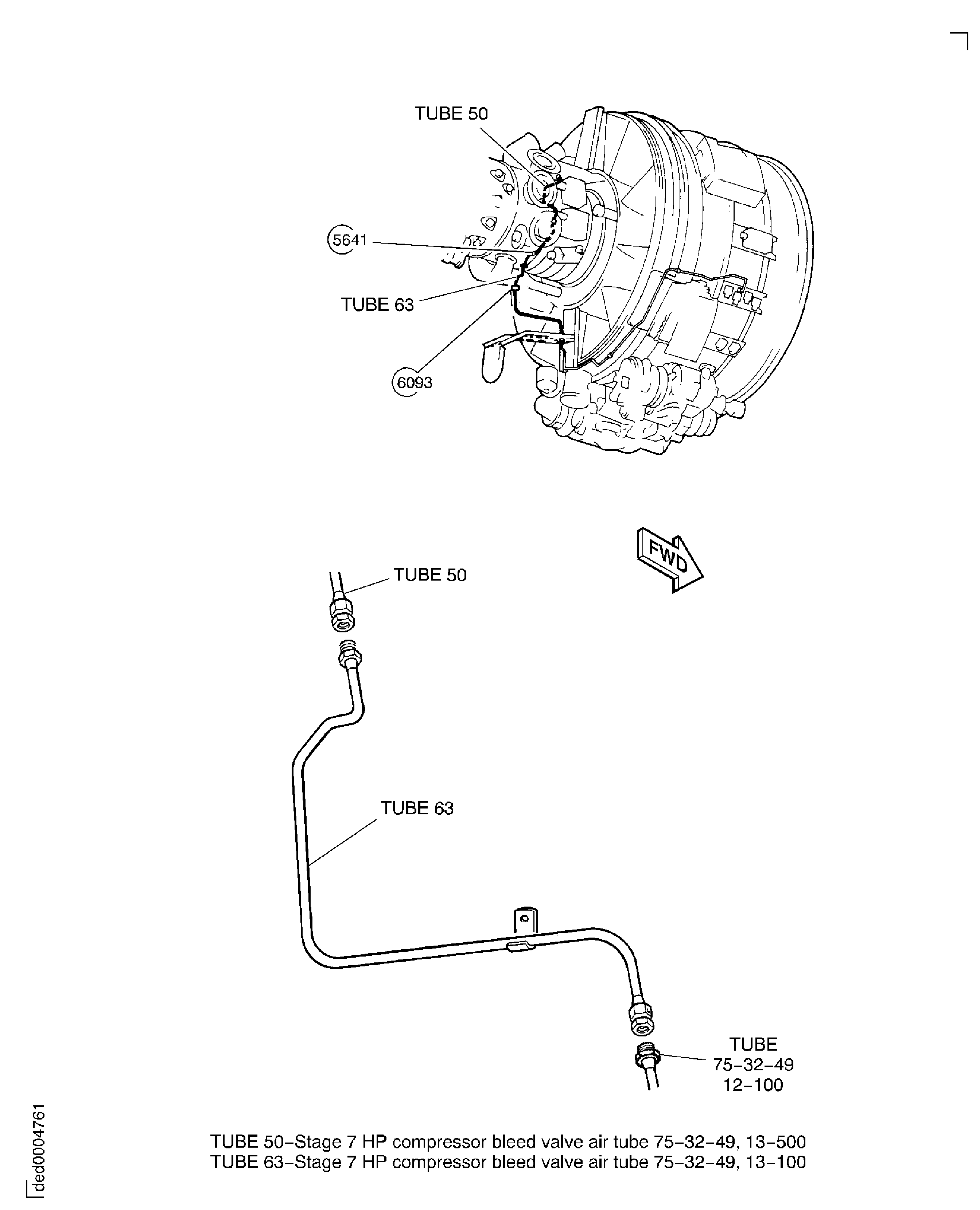

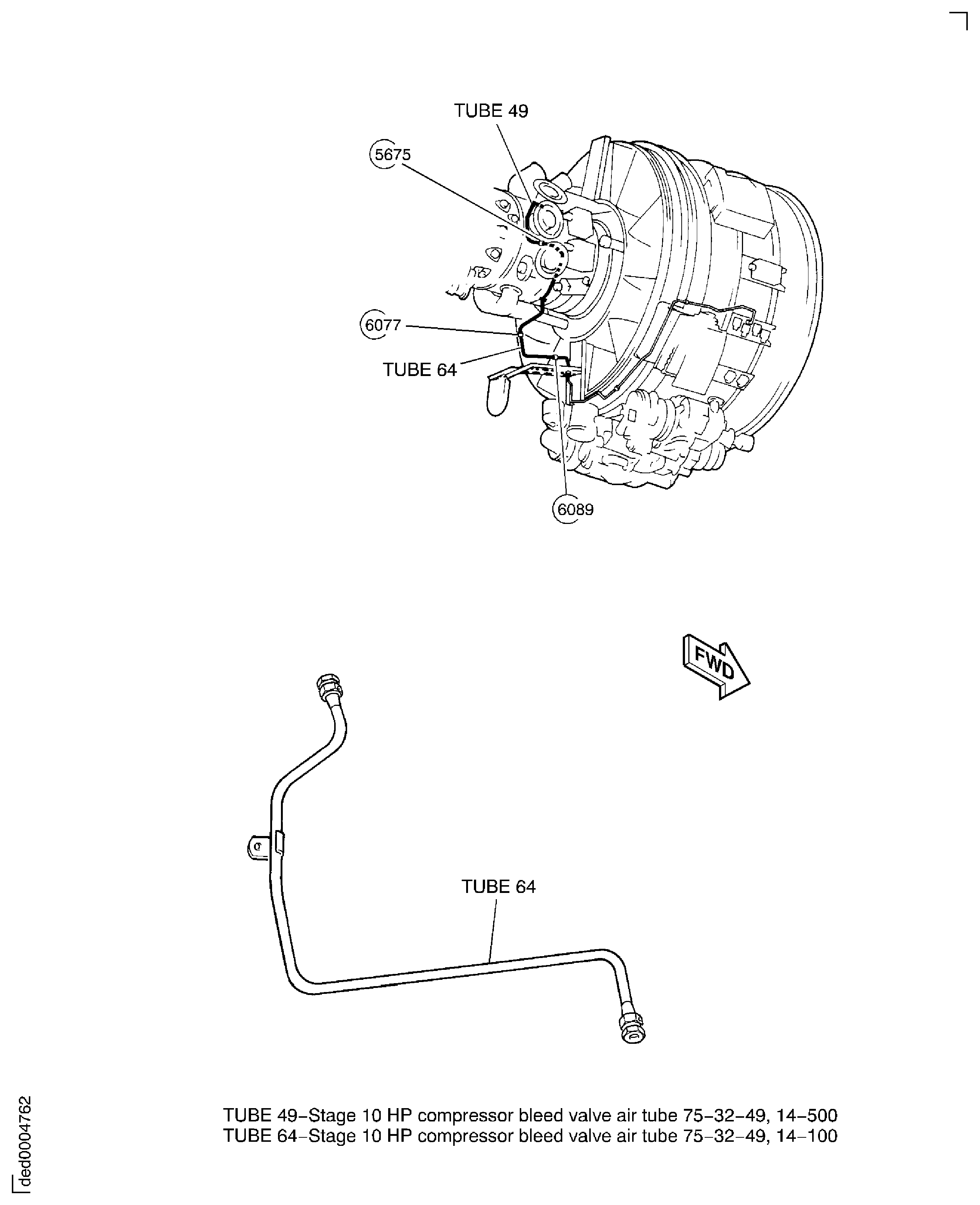

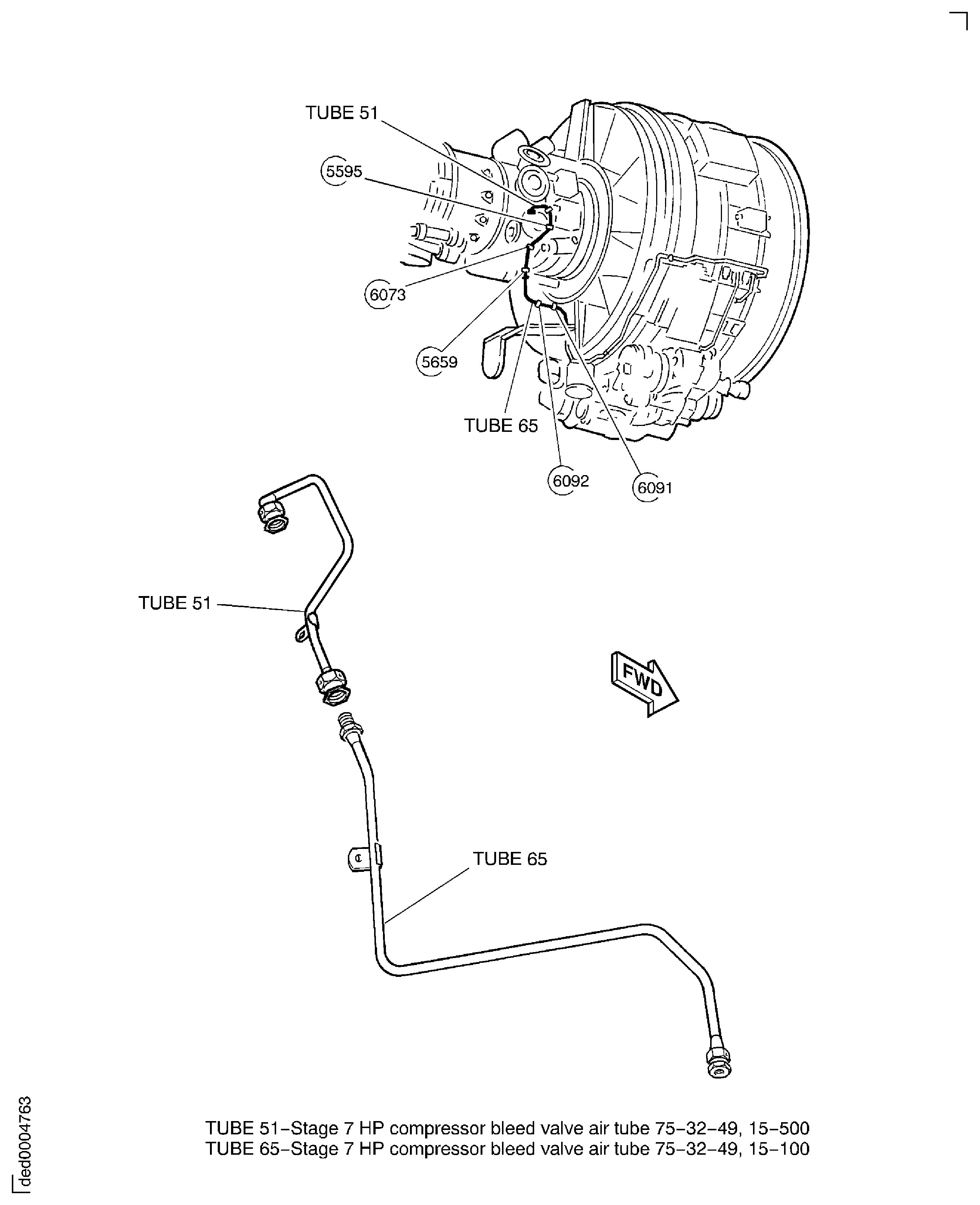

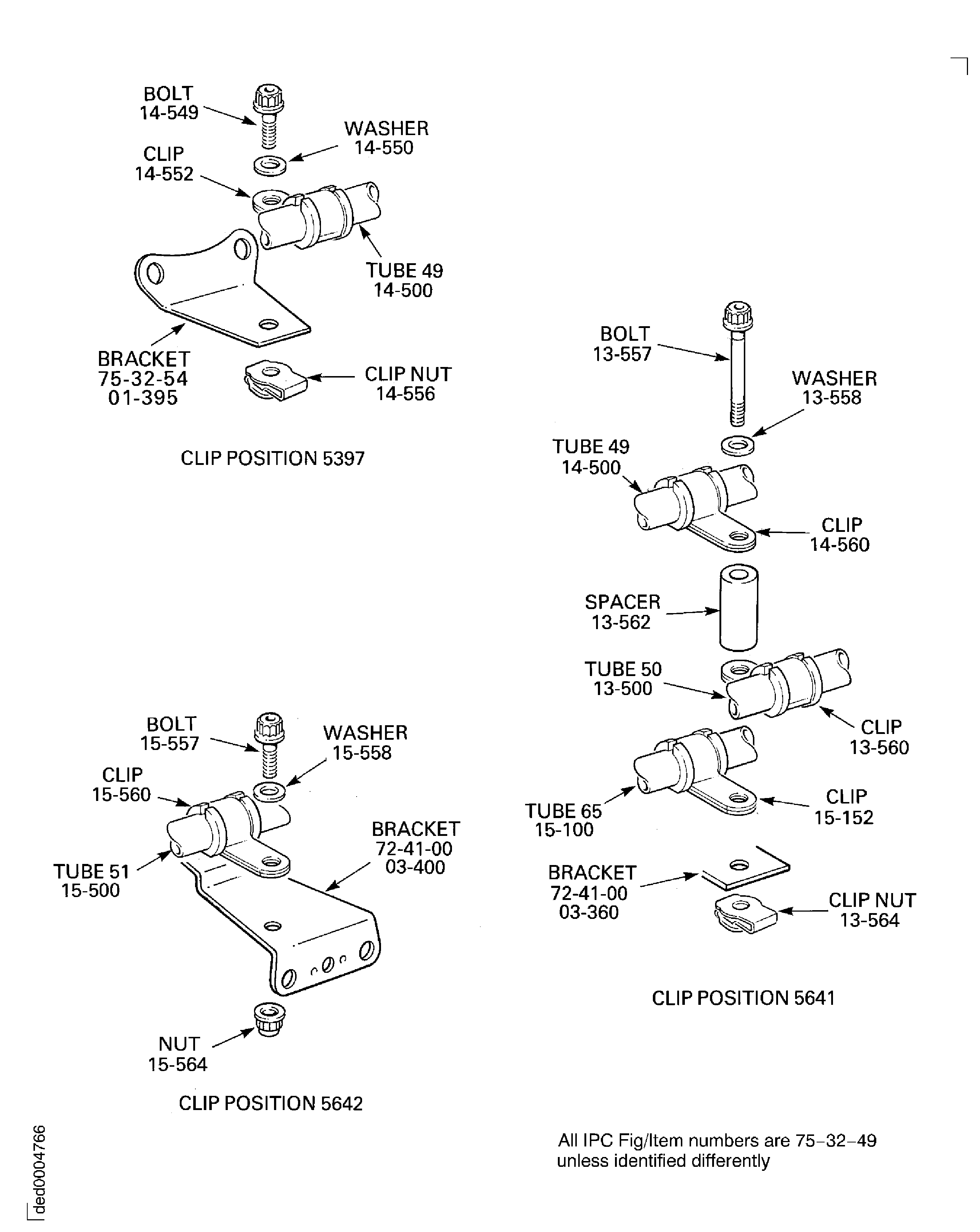

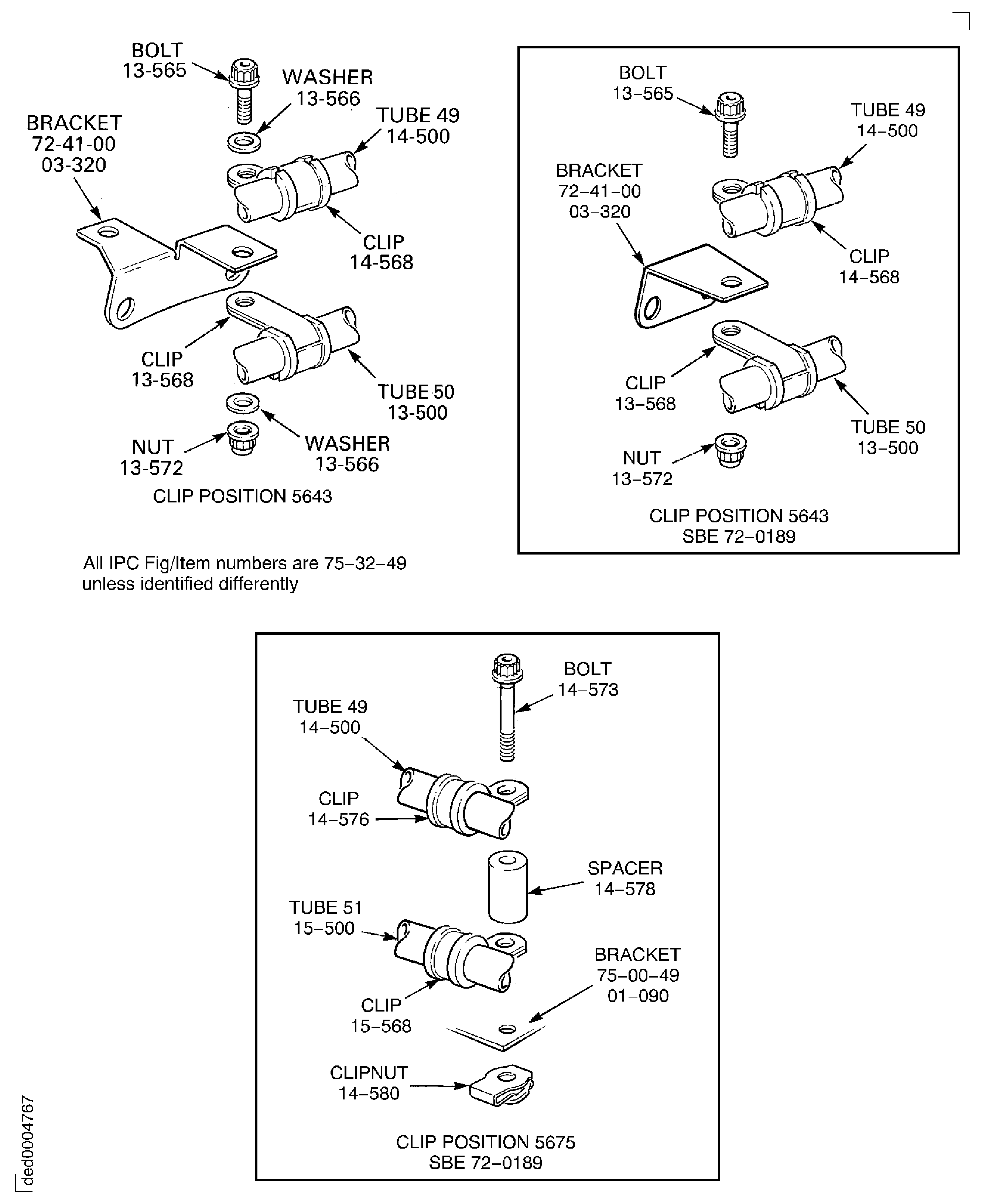

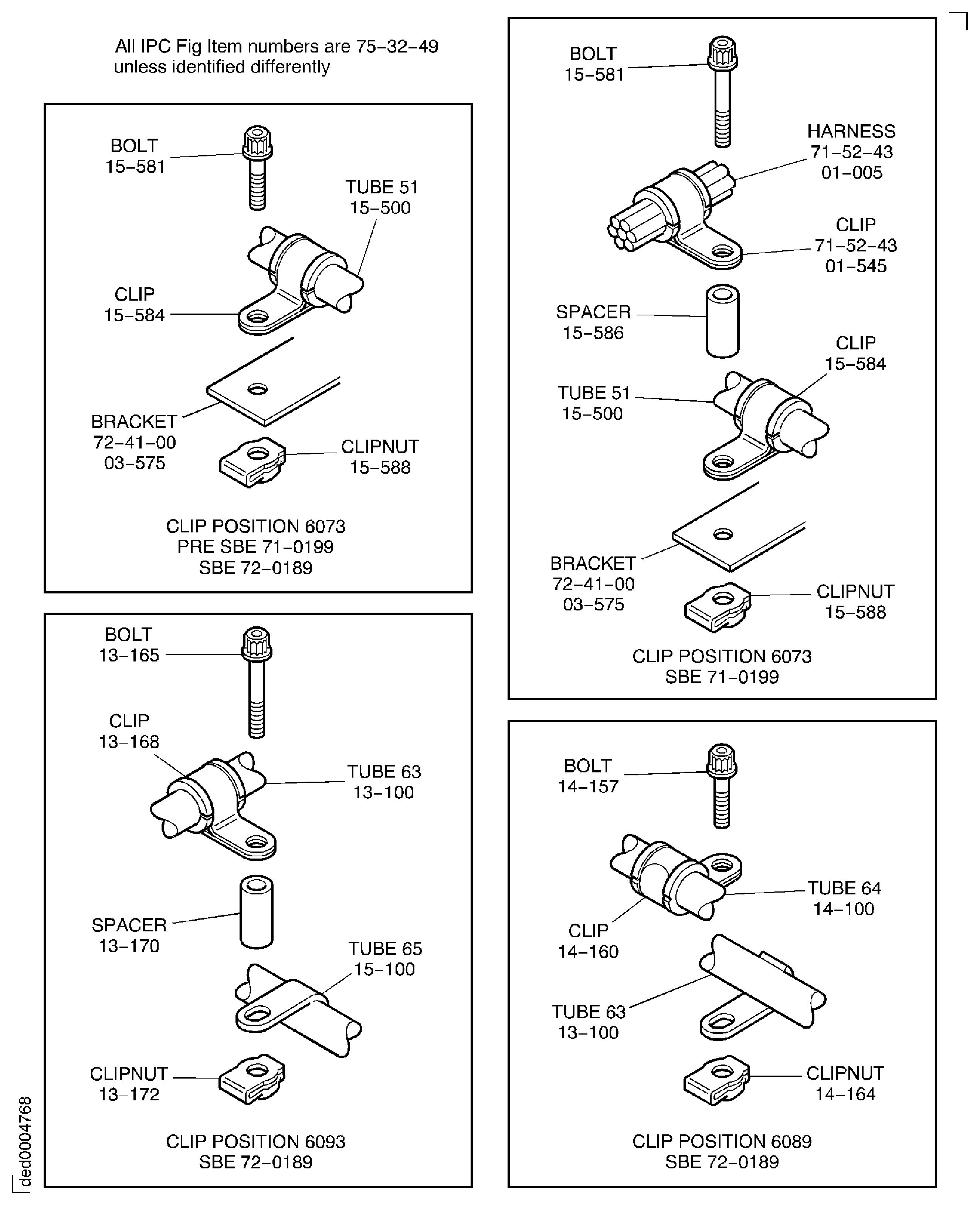

Install the tubes 49, 50 and 51 AIR-HP COMPRESSOR BLEED CONTROL TUBES (75-32-49, 14-500), HPC Bleed Control Air Tubes (75-32-49, 15-500) and HPC Bleed Control Air Tubes (75-32-49, 13-500).

Torque the tube nuts in Step, Step and Step to 159 to 177 lbf.in (18 to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the tubes 63, 64 and 65 HPC Bleed Control Air Tubes (75-32-49,13-100), AIR-HP COMPRESSOR BLEED CONTROL TUBES (75-32-49,14-100) and HPC Bleed Control Air Tubes (75-32-49,15-100).

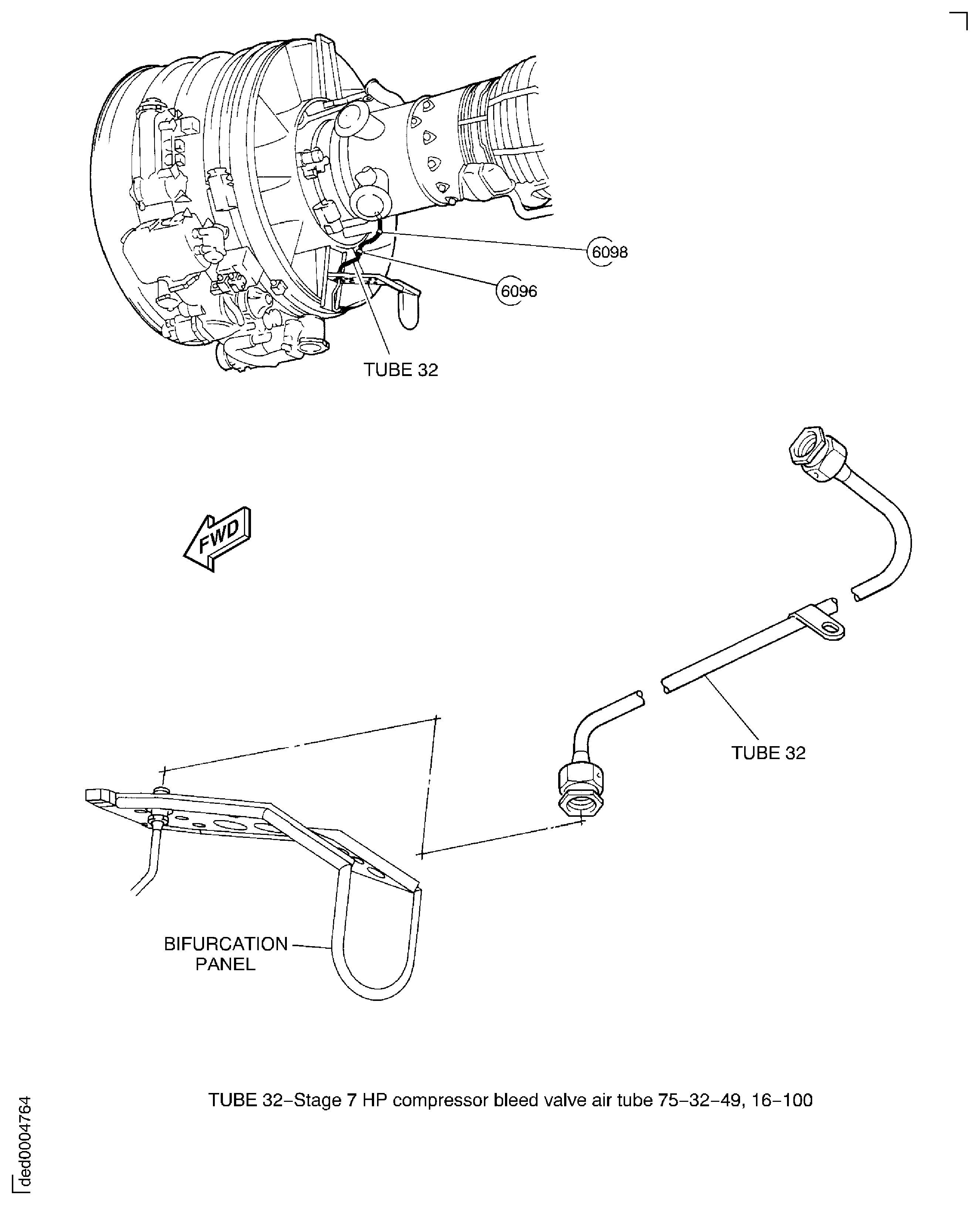

Attach the tube 32 to the stage 7 bleed valve at the 8 o'clock position. Torque the tube nut to 159 to 177 lbf.in (18 to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-40-420-222-A00 Install the HP Compressor Bleed Valve Air Tubes (Pre SBE 72-0189)

NOTE

The SBE 71-0199 clip position 6073 is assembled in TASK 72-00-40-420-006-C00.Pre SBE 71-0199: Install the clip, the clipnut and the bolt to the bracket HPC Assembly (72-41-00, 03-575) at the clip position 6073. Torque the bolt to 36 to 45 lbf.in (4 to 5 Nm).

Torque the tube nuts in Step, Step and Step to 159 to 177 lbf.in (18 to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the tubes 49, 50 and 51 AIR-HP COMPRESSOR BLEED CONTROL TUBES (75-32-49, 14-500), HPC Bleed Control Air Tubes (75-32-49, 15-500) and HPC Bleed Control Air Tubes (75-32-49, 13-500).

Torque the tube nuts in Step, Step and Step to 159 to 177 lbf.in (18 to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the tubes 63, 64 and 65 HPC Bleed Control Air Tubes (75-32-49, 13-100), AIR-HP COMPRESSOR BLEED CONTROL TUBES (75-32-49, 14-100) and HPC Bleed Control Air Tubes (75-32-49, 15-100).

Attach the tube 32 to the stage 7 bleed valve at the 8 o'clock position. Torque the tube nut to 159 to 177 lbf.in (18 to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-40-420-222-B00 Install the HP Compressor Bleed Valve Air Tubes (SBE 72-0189)

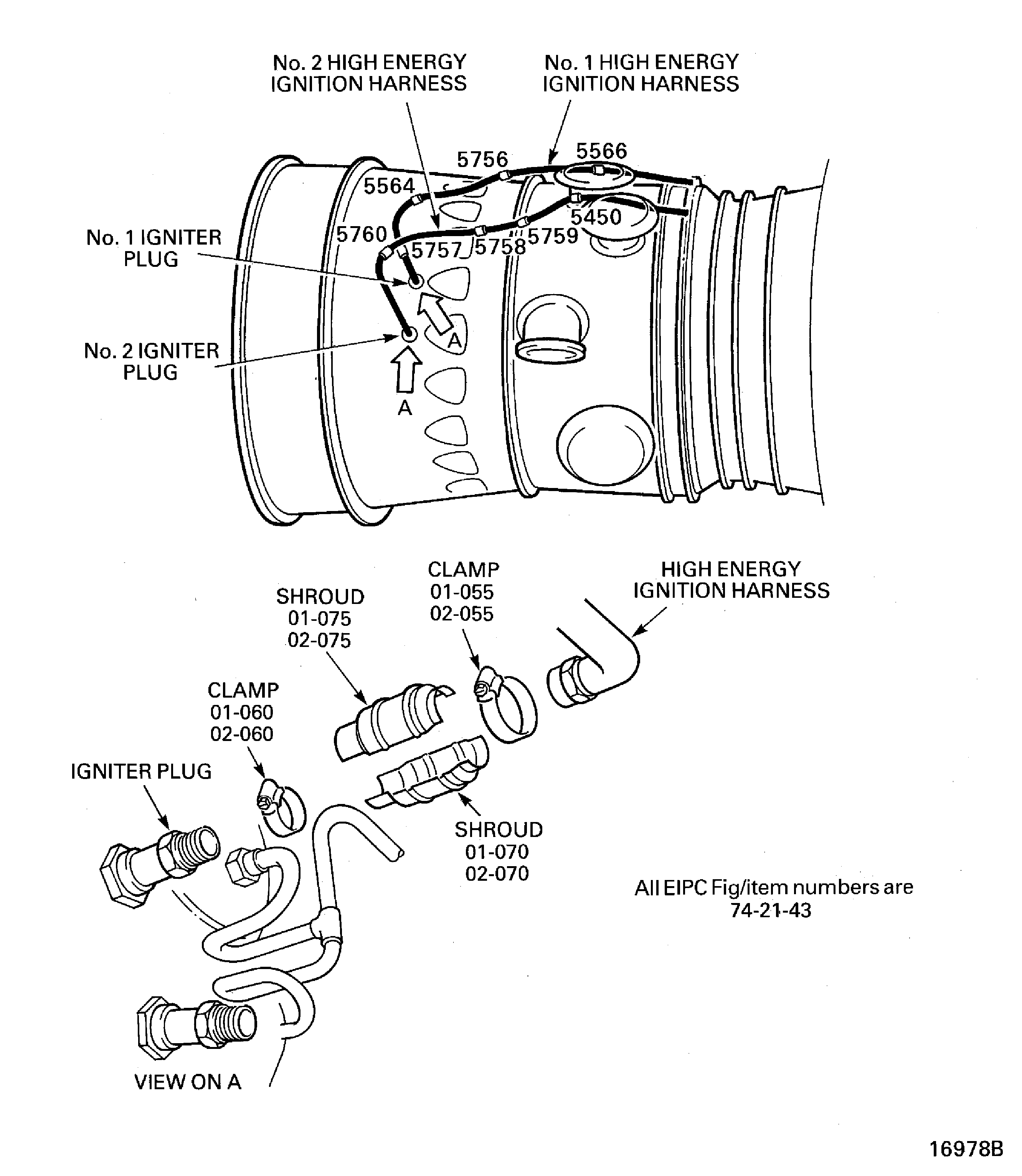

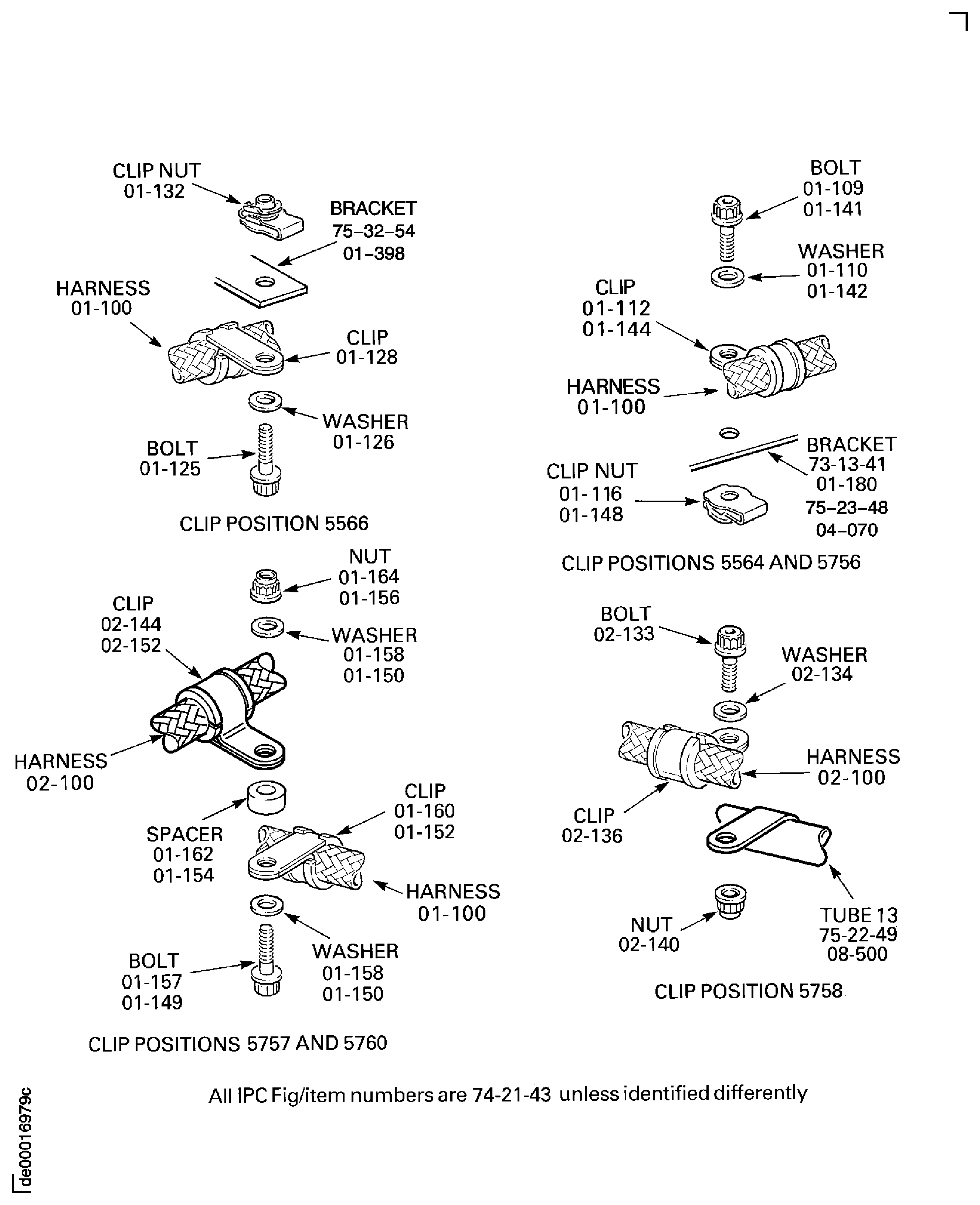

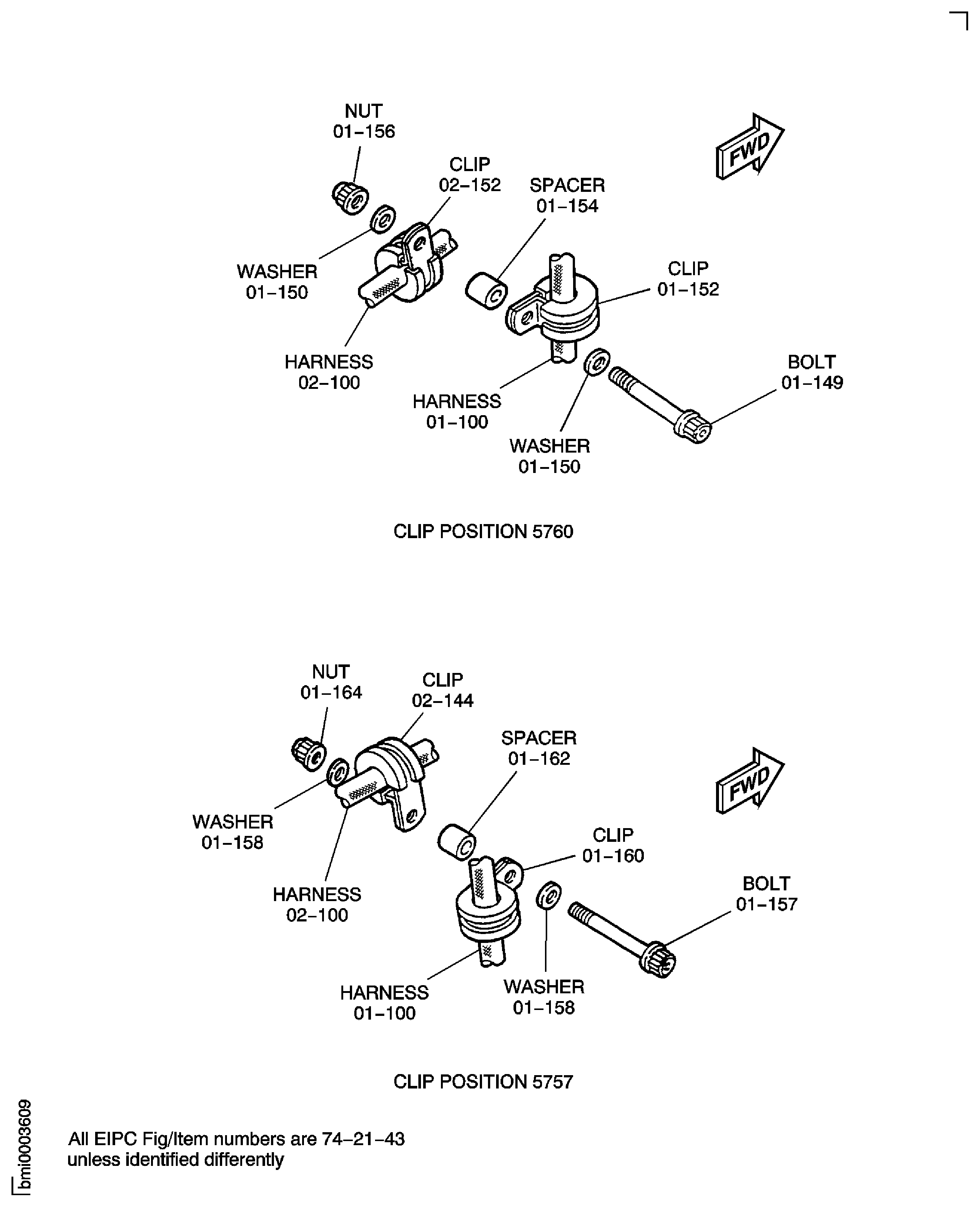

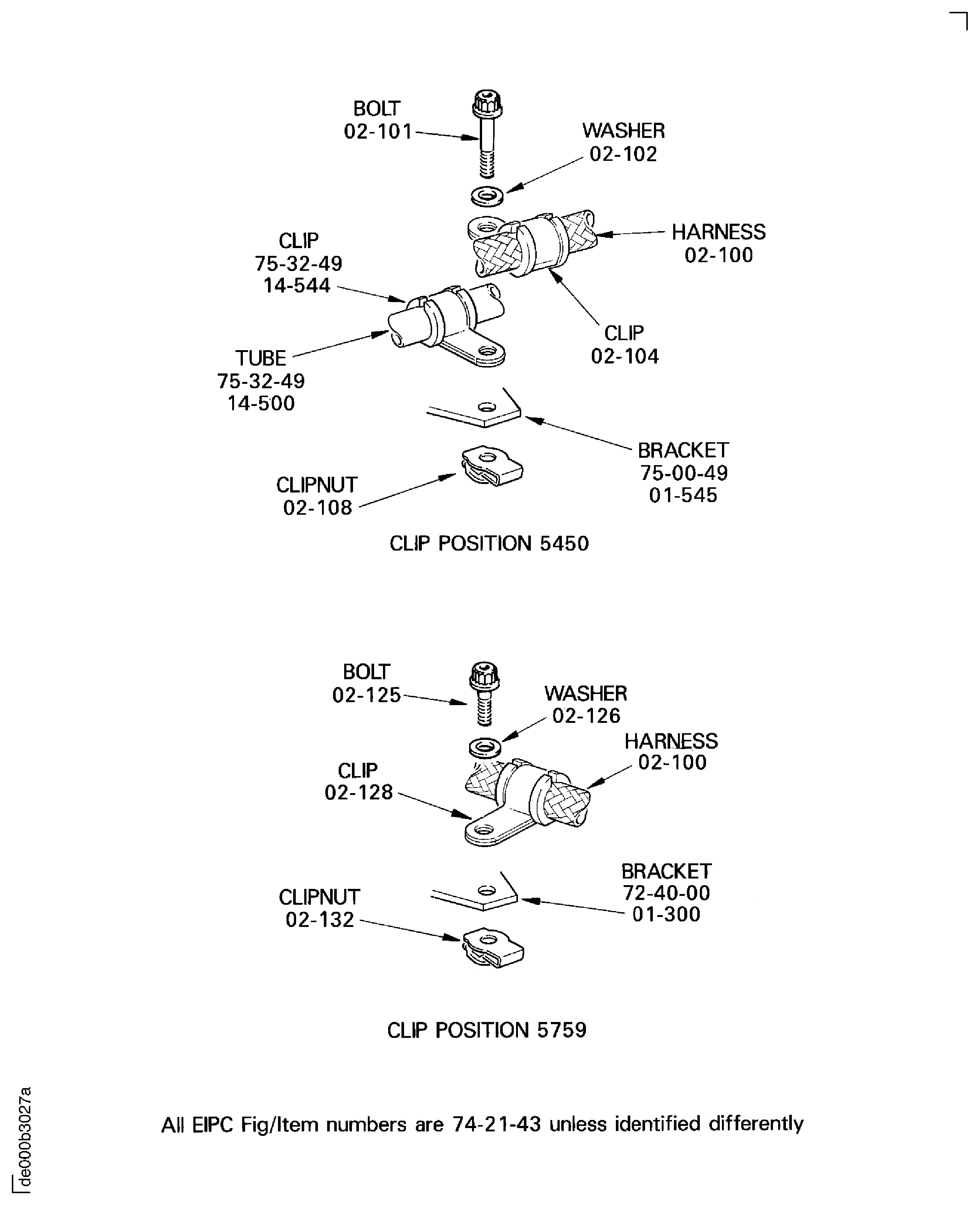

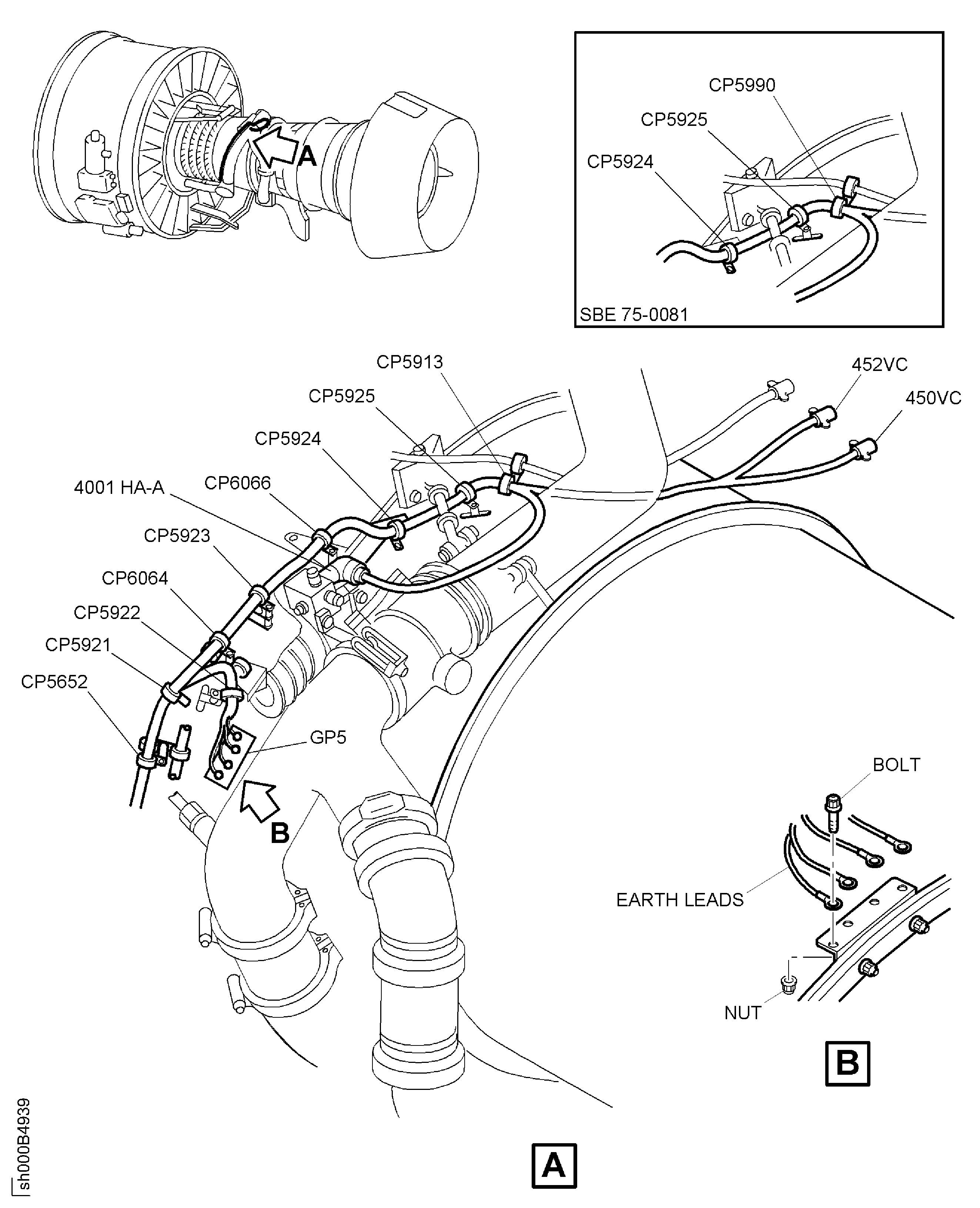

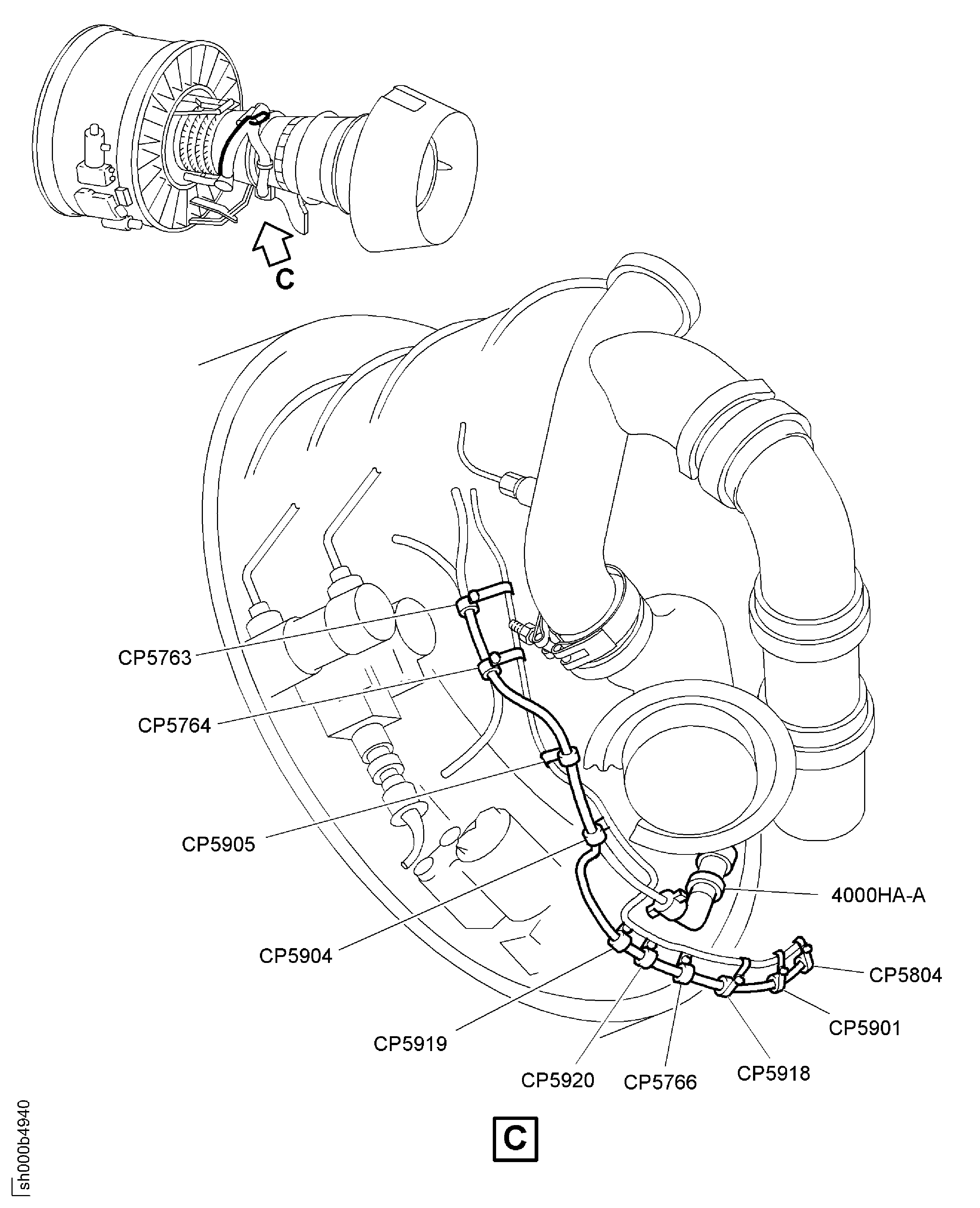

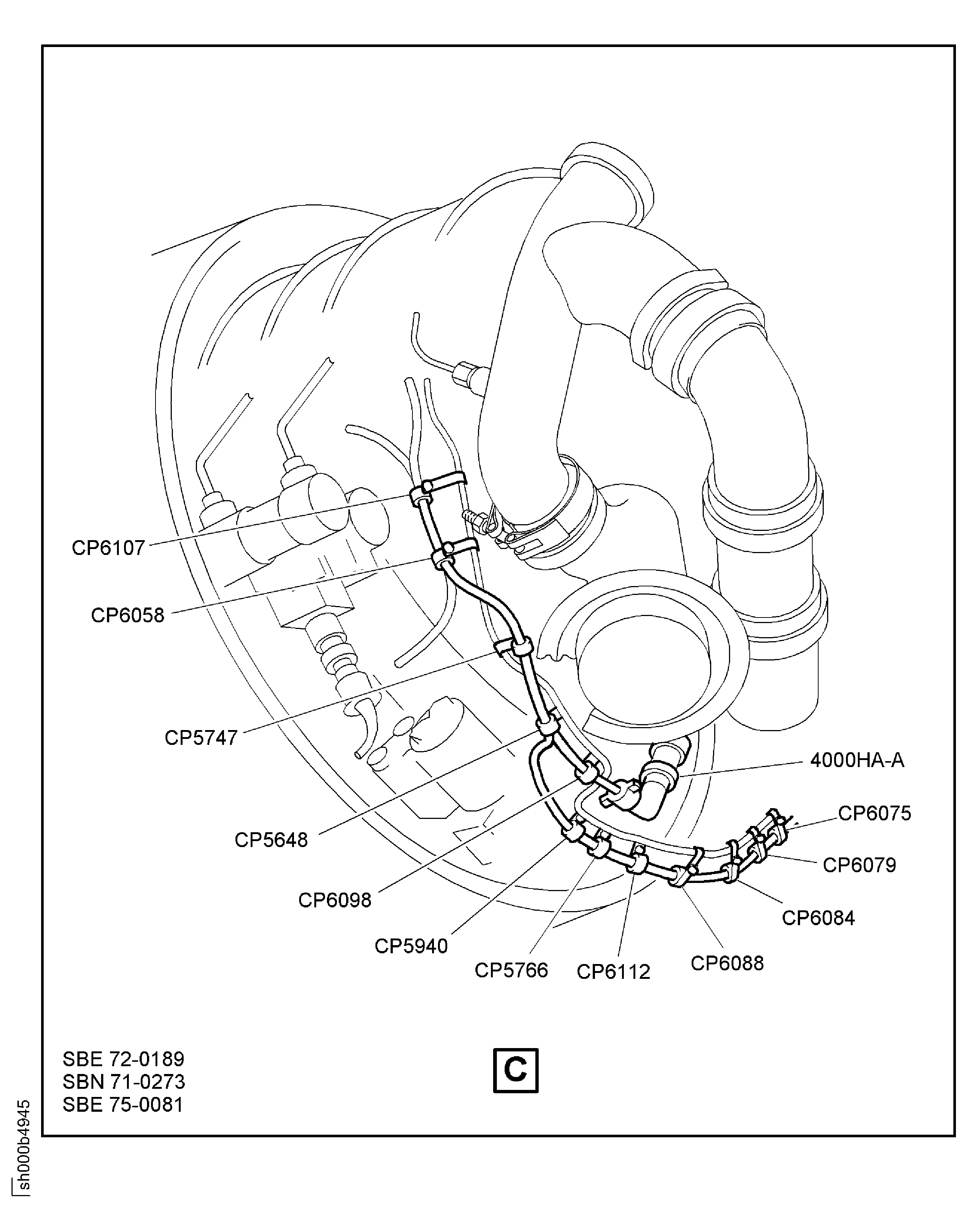

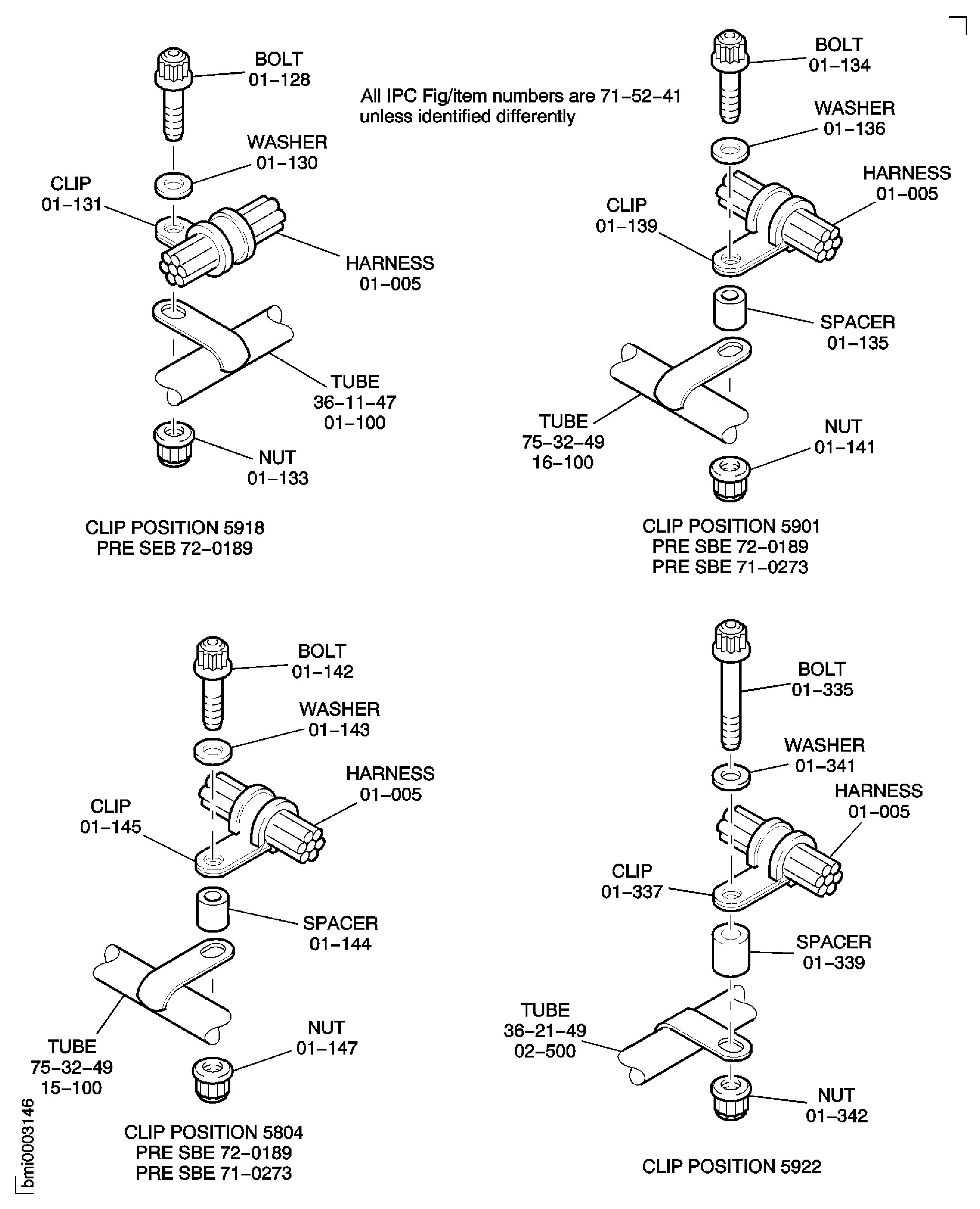

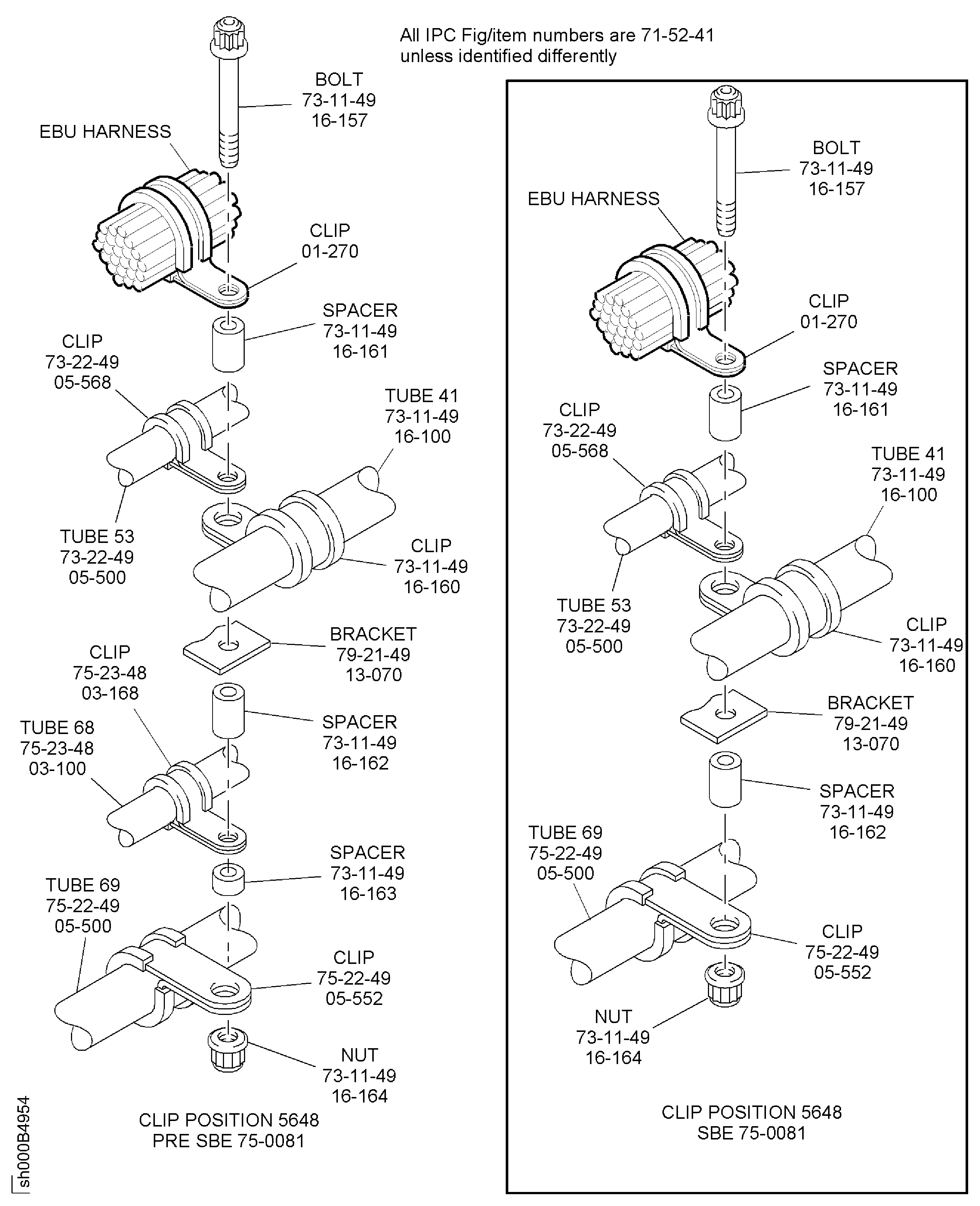

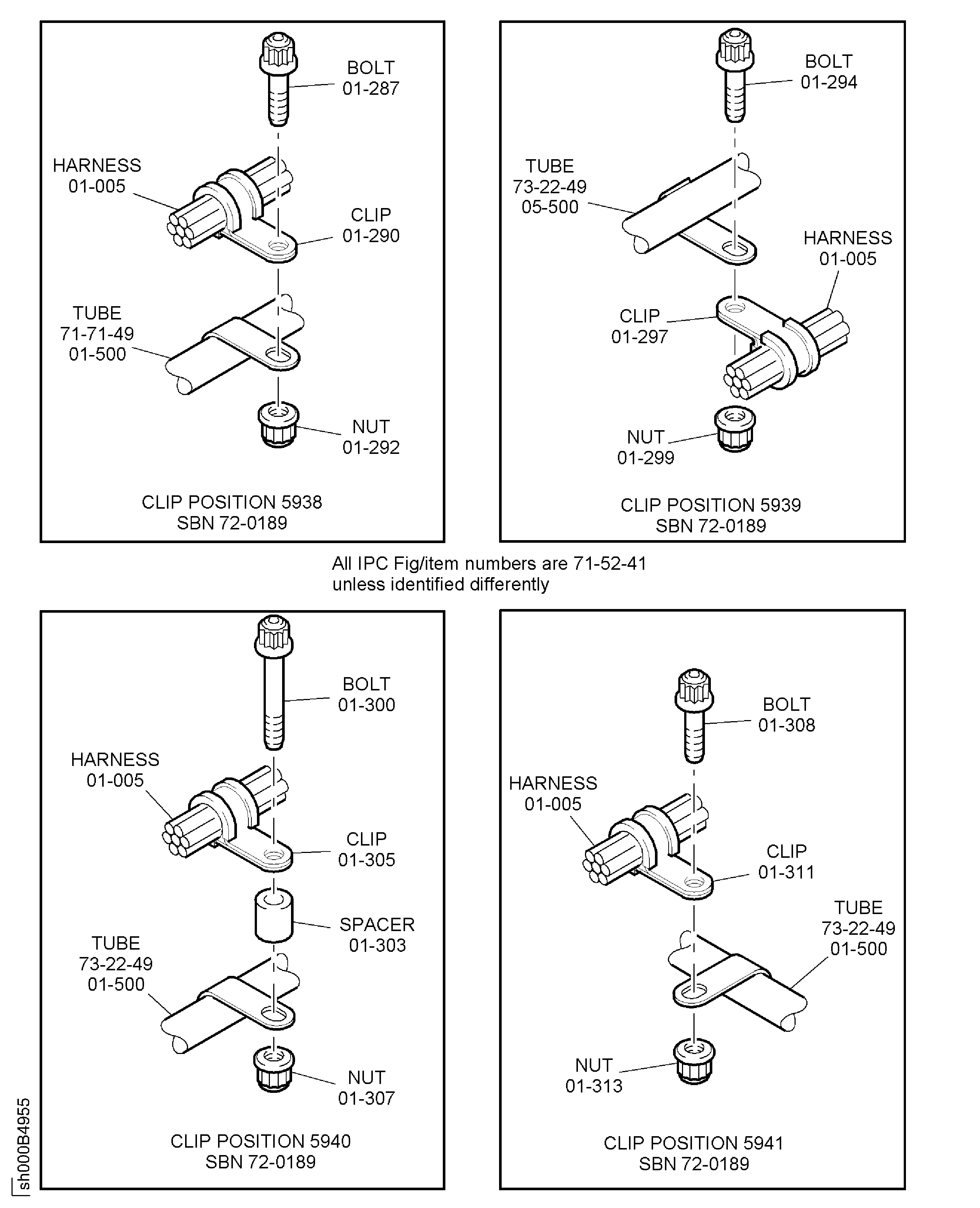

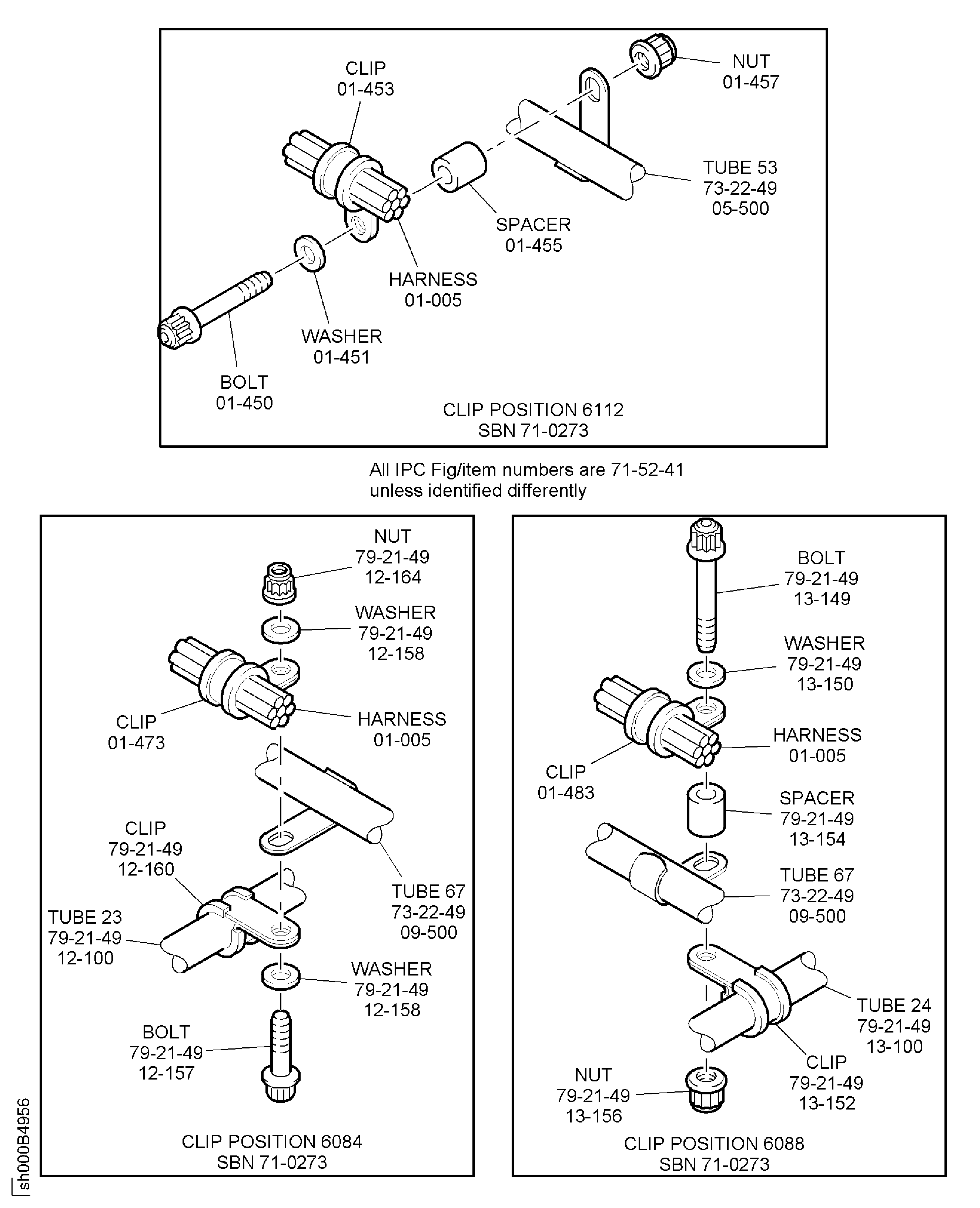

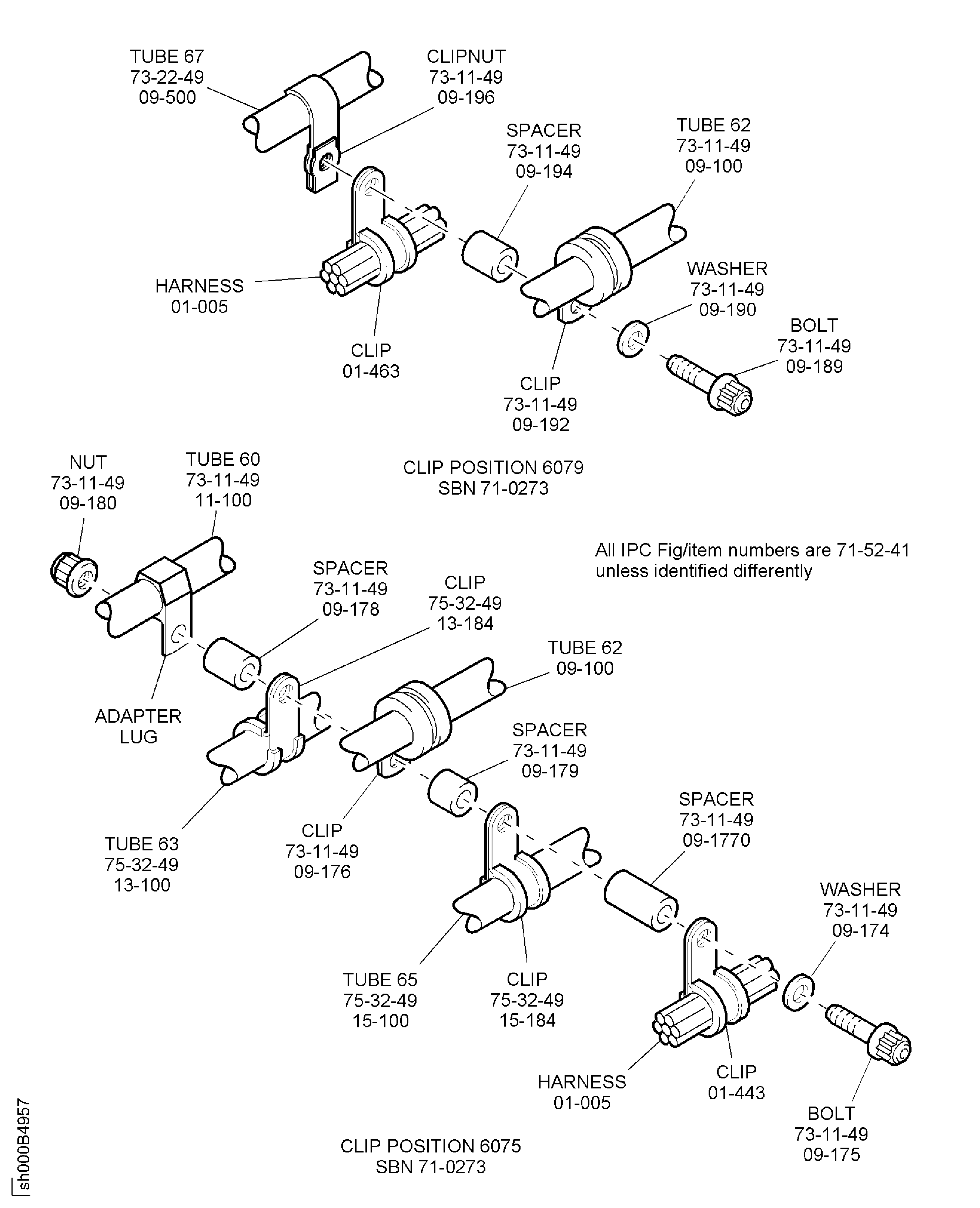

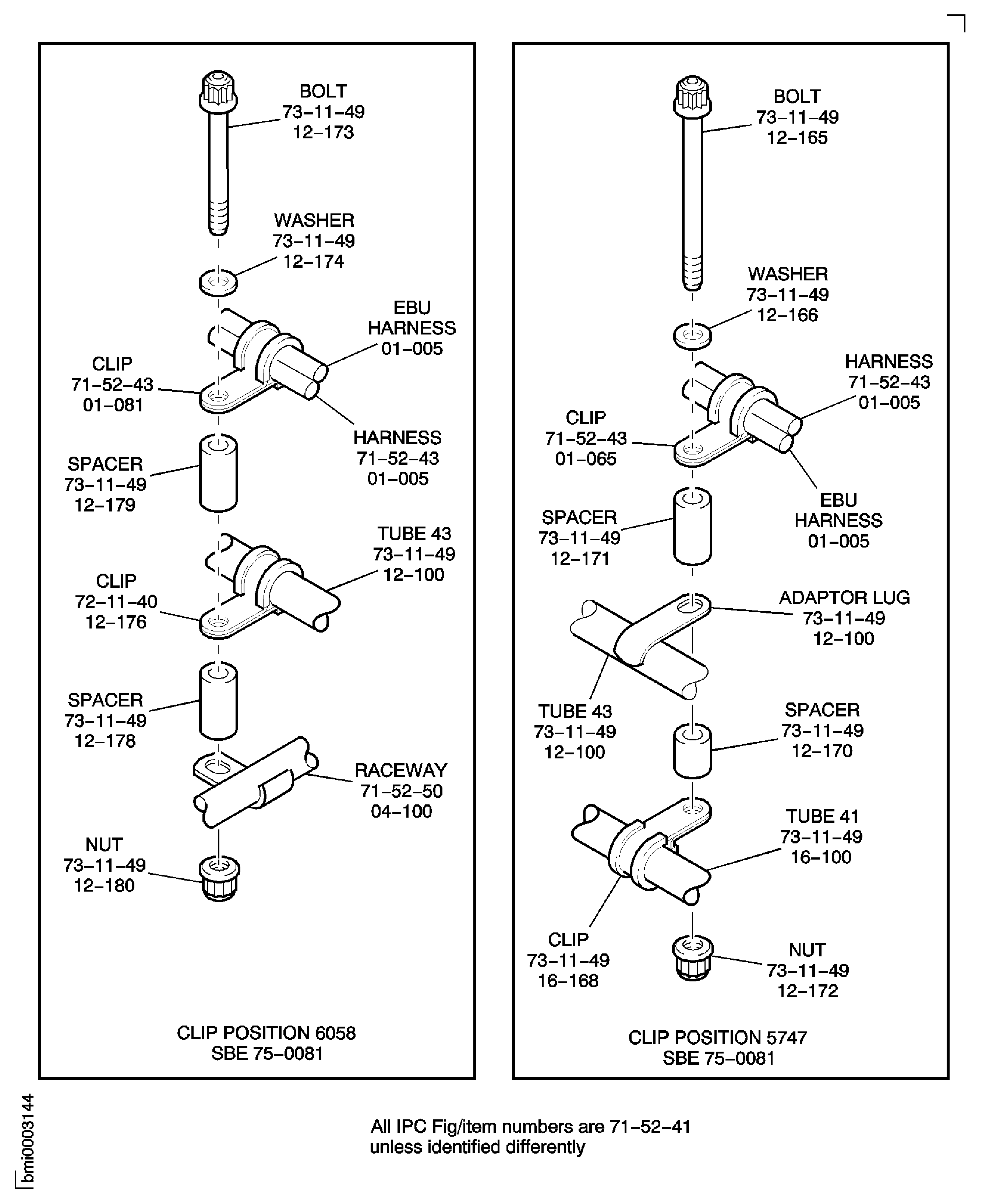

Refer to Figure.

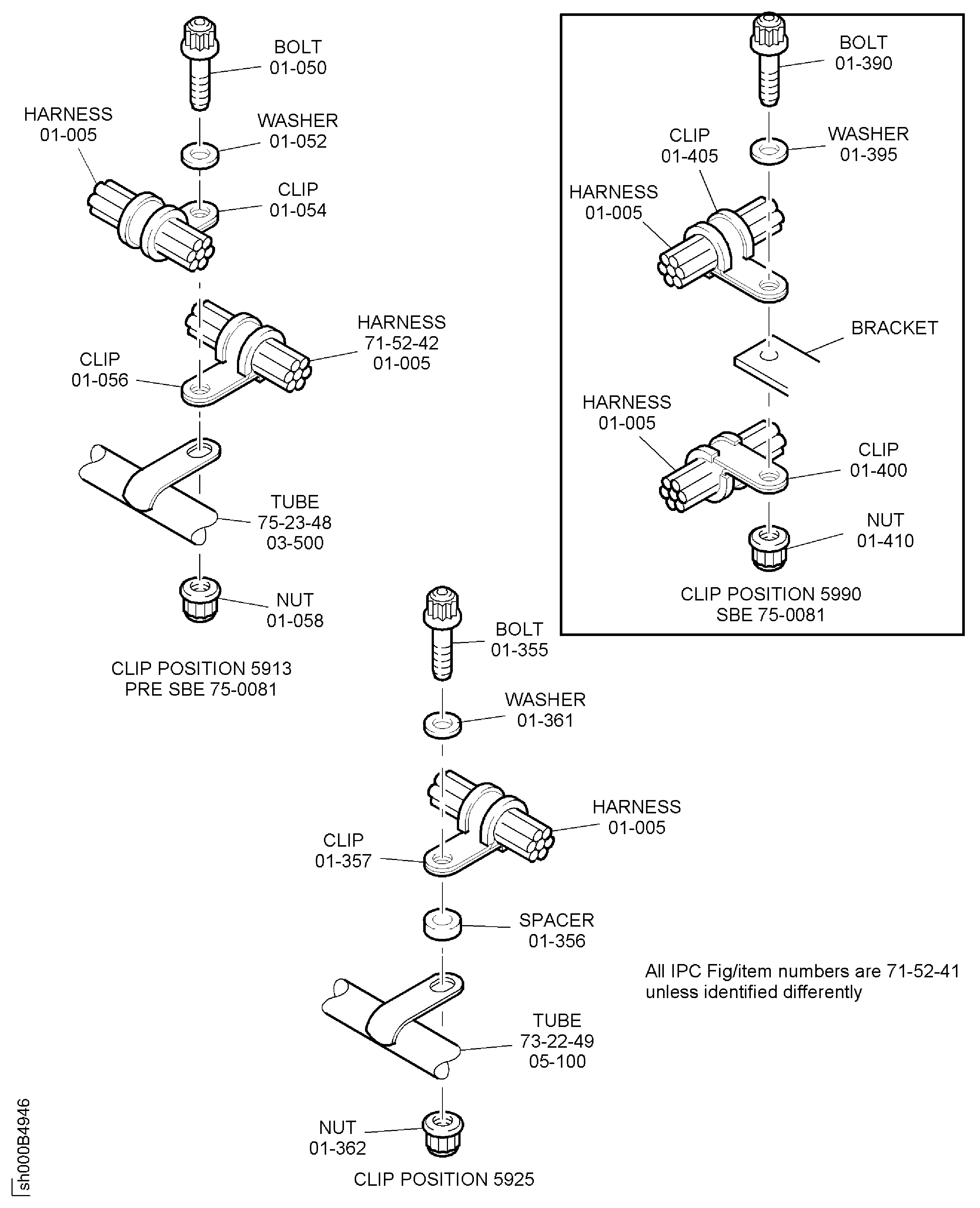

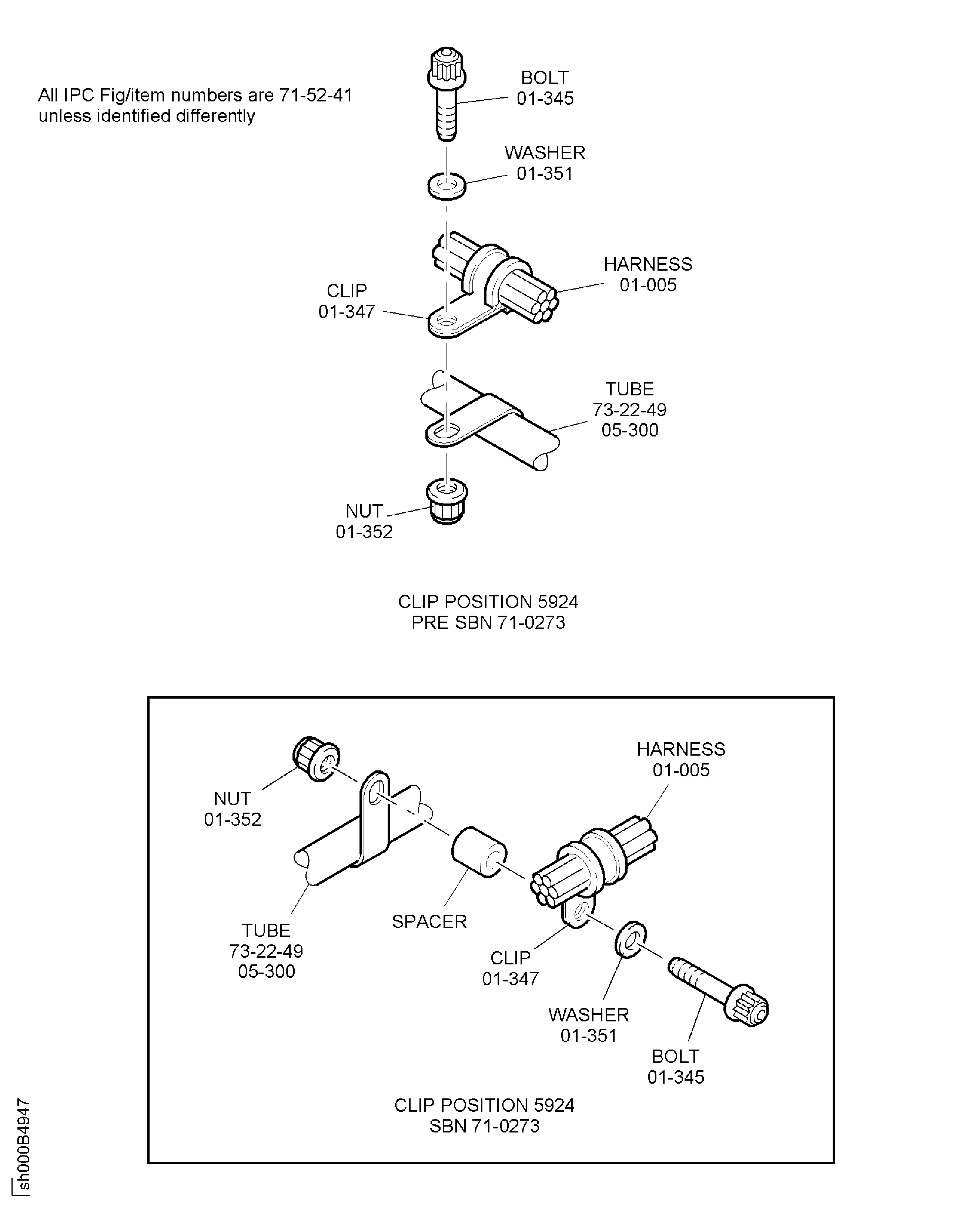

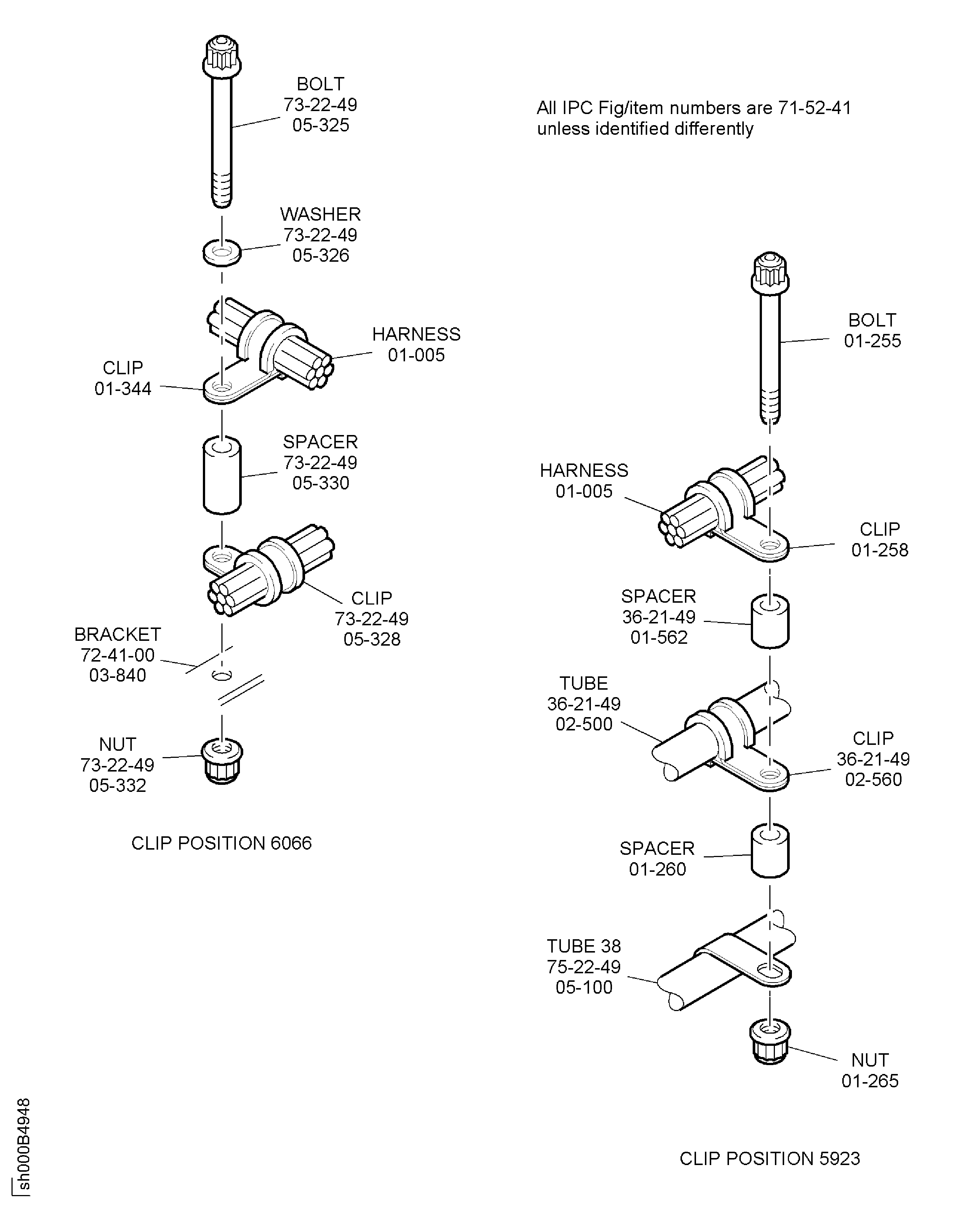

During the installation procedure make sure the harnesses are held temporarily along their different lengths. Always install the datum clip positions when you install each electrical connector. This will give correct installation of the different harnesses, prevent too much strain on the electrical connectors and give the necessary drip loops (the drip loop makes sure moisture or fluids do not go in to the electrical connector).

Because of the differences between the harness diameters, the specified clip could be too large or too small. You can use a clip from a range of six clips that have the same part numbers. If the harness diameter is between two of the clips in the range, use the larger clip. When you do this use CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) to increase the harness diameter.

For the data on the electrical connectors refer to the SPM TASK 70-43-00-400-501 and the SPM TASK 70-43-01-400-501.

SUBTASK 72-00-40-420-223 Electrical Harness Installation Procedure

Install the two shrouds (Ignition Leads (74-21-43, 02-070) and Ignition Leads (74-21-43, 02-075)) and the two clamps (Ignition Leads (74-21-43, 02-055) and Ignition Leads (74-21-43, 02-060)) on to the igniter plug end of the harness. Torque the clamp screws to 40 to 50 * lbf.in (4.52 to 5.65 Nm).

Install the No.2 high energy ignition harness Ignition Leads (74-21-43, 02-100).

Install the two shrouds (IGNITION-IGNITION LEADS (74-21-43, 01-070) and IGNITION-IGNITION LEADS (74-21-43, 01-075)) and the two clamps (IGNITION-IGNITION LEADS (74-21-43, 01-055) and IGNITION-IGNITION LEADS (74-21-43, 01-060)) on to the igniter plug end of the harness. Torque the clamp screws to 40 to 50 * lbf.in (4.52 to 5.65 Nm).

Install the No.1 high energy ignition harness IGNITION-IGNITION LEADS (74-21-43, 01-100).

SUBTASK 72-00-40-420-224 Install the High Energy Ignition Harness

CAUTION

DO NOT BEND THE HIGH ENERGY IGNITION HARNESS MORE THAN IS NECESSARY, YOU CAN DAMAGE THE CONDUIT.Attach the four earth leads to the bracket HPC Assembly (72-41-00, 03-760) with the four bolts and the four nuts. Torque the nuts to 36 to 45 lbf.in (4 to 5 Nm).

NOTE

Make sure there is sufficient length of harness to prevent a load on the harness connectors.Install the fire detection (system A), nacelle temperature and cabin services harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005).

SUBTASK 72-00-40-420-225-A00 Install the Fire Detection Harnesses, the Nacelle Temperature and Cabin Services Harnesses and the Core Overheat Detector (Pre SBE 72-0189 and Pre SBN 71-0273)

Attach the four earth leads to the bracket HPC Assembly (72-41-00, 03-760) with the four bolts and the four nuts. Torque the nuts to 36 to 45 lbf.in (4 to 5 Nm).

Install the fire detection (system A), nacelle temperature and cabin services harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005).

SUBTASK 72-00-40-420-225-B00 Install the Fire Detection Harnesses, the Nacelle Temperature and Cabin Services Harnesses and the Core Overheat Detector (Pre SBE 72-0189 and SBN 71-0273)

Attach the four earth leads to the bracket HPC Assembly (72-41-00, 03-760) with the four bolts and the four nuts. Torque the nuts to 36 to 45 lbf.in (4 to 5 Nm).

Install the fire detection (system A), nacelle temperature and cabin services harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005).

SUBTASK 72-00-40-420-225-C00 Install the Fire Detection Harnesses, the Nacelle Temperature and Cabin Services Harnesses and the Core Overheat Detector (SBE 72-0189, Pre SBE 75-0081 and Pre SBN 71-0273)

Attach the four earth leads to the bracket HPC Assembly (72-41-00, 03-760) with the four bolts and the four nuts. Torque the nuts to 36 to 45 lbf.in (4 to 5 Nm).

Install the fire detection (system A), nacelle temperature and cabin services harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005).

SUBTASK 72-00-40-420-225-D00 Install the Fire Detection Harnesses, the Nacelle Temperature and Cabin Services Harnesses and the Core Overheat Detector (SBE 72-0189, SBN 71-0273 and Pre SBE 75-0081)

Attach the four earth leads to the bracket HPC Assembly (72-41-00, 03-760) with the four bolts and the four nuts. Torque the nuts to 36 to 45 lbf.in (4 to 5 Nm).

Install the fire detection (system A), nacelle temperature and cabin services harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005).

SUBTASK 72-00-40-420-225-E00 Install the Fire Detection Harnesses, the Nacelle Temperature and Cabin Services Harnesses and the Core Overheat Detector (SBE 75-0081, SBE 72-0189 and Pre SBN 71-0273)

Attach the four earth leads to the bracket HPC Assembly(72-41-00,03-760) with the four bolts and the four nuts. Torque the nuts to 36 to 45 lbf.in (4 to 5 Nm).

Install the fire detection (system A), nacelle temperature and cabin services harness Fire Detection (System A) And Core Services Harness(71-52-41,01-005).

SUBTASK 72-00-40-420-225-F00 Install the Fire Detection Harnesses, the Nacelle Temperature and Cabin Services Harnesses and the Core Overheat Detector (SBE 75-0081, SBE 72-0189 and SBN 71-0273)

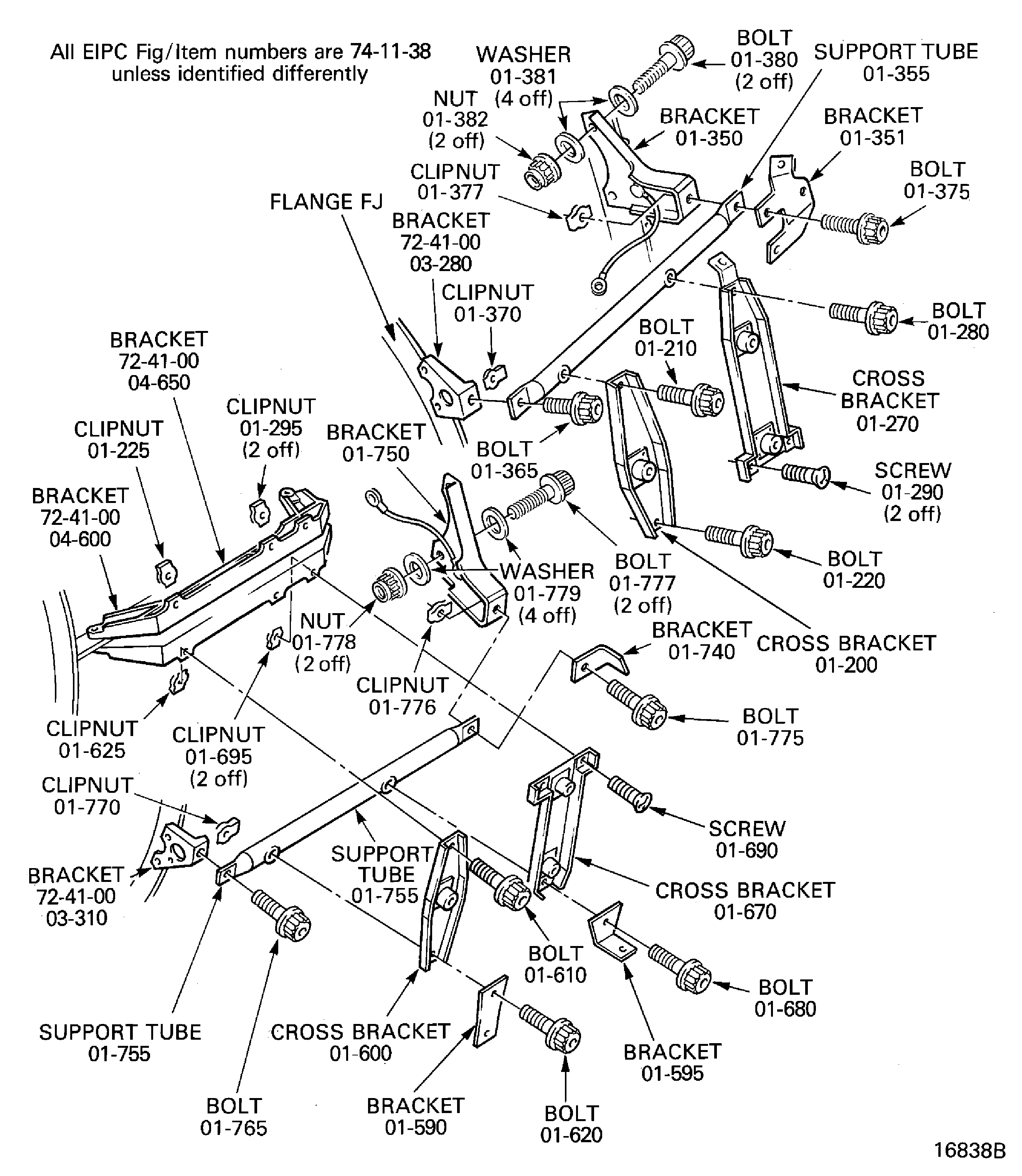

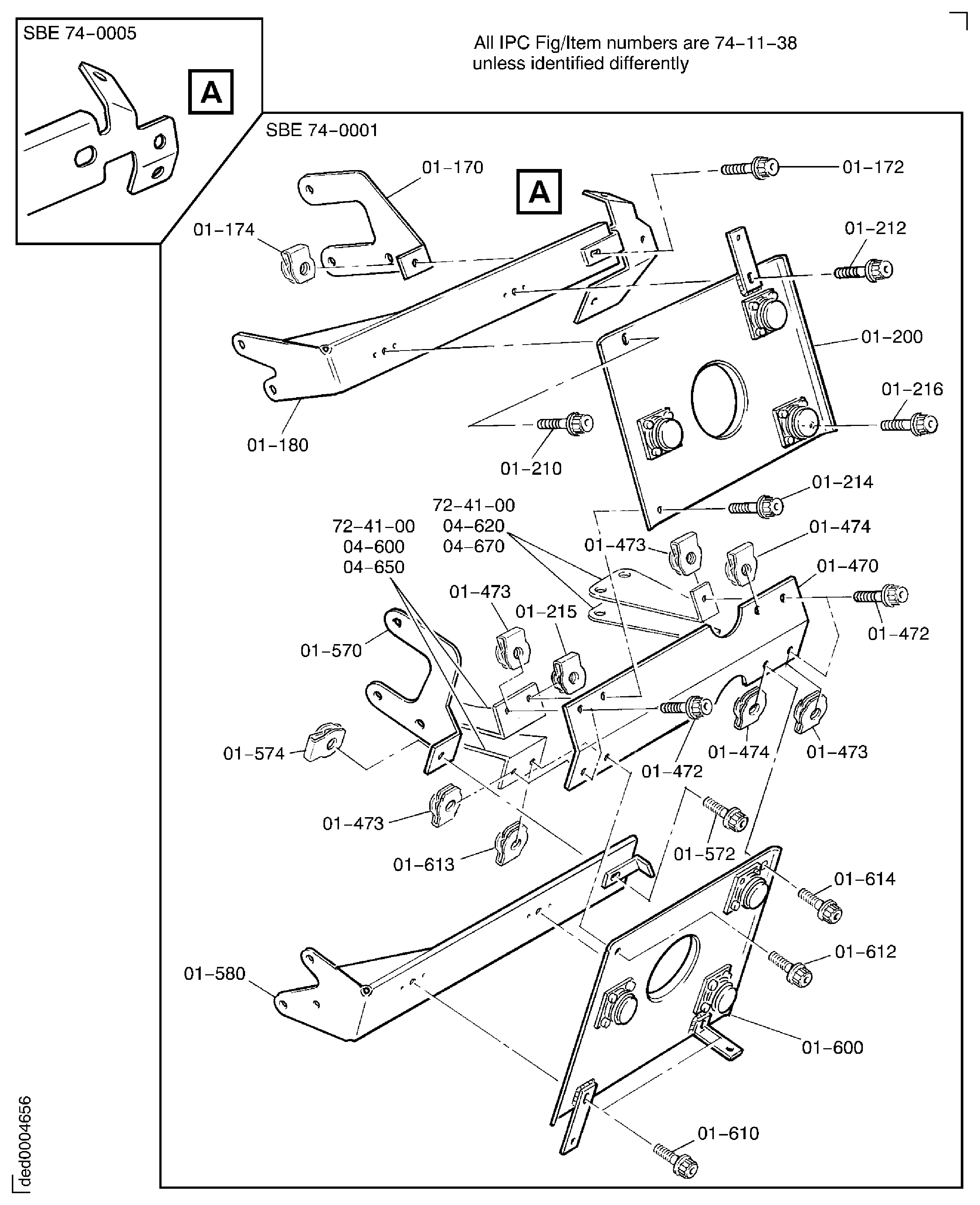

Refer to Figure.

Attach the support tube to the bracket HP SYSTEM MODULE (72-00-40, 01-280) with the bolt Ignition Exciters (74-11-38, 01-765) and the clipnut Ignition Exciters (74-11-38, 01-770).

Attach the support tube to the bracket HPC Assembly (72-41-00, 03-310) with the bolt Ignition Exciters (74-11-38, 01-765) and the clipnut Ignition Exciters (74-11-38, 01-770).

Install the lower support tube Ignition Exciters (74-11-38, 01-755).

Attach the support tube to the bracket HP SYSTEM MODULE (72-00-40, 01-310) with the bolt Ignition Exciters (74-11-38, 01-365) and the clipnut Ignition Exciters (74-11-38, 01-370).

Attach the support tube to the bracket HPC Assembly (72-41-00, 03-280) with the bolt Ignition Exciters (74-11-38, 01-365) and the clipnut Ignition Exciters (74-11-38, 01-370).

Install the upper support tube Ignition Exciters (74-11-38, 01-355).

Attach the cross bracket to the lower support bracket HPC Assembly (72-41-00, 04-650) with the two screws Ignition Exciters (74-11-38, 01-690) and the two clipnuts Ignition Exciters (74-11-38, 01-695). Use the ACR Torq-Set bit 212-1/4-ACR 1 off to install the two screws.

Attach the cross bracket to the support tube, together with the bracket Ignition Exciters (74-11-38, 01-595) with the bolt Ignition Exciters (74-11-38, 01-680).

Use the ACR Torq-Set bit 212-1/4-ACR 1 off to torque the screws to 85 to 105 lbf.in (10 to 12 Nm).

Install the lower, forward cross bracket Ignition Exciters (74-11-38, 01-670).

Attach the cross bracket to the lower support bracket HPC Assembly (72-41-00, 04-650) with the bolt Ignition Exciters (74-11-38, 01-610) and the clipnut Ignition Exciters (74-11-38, 01-625).

Attach the cross bracket to the support tube, together with the bracket Ignition Exciters (74-11-38, 01-590), with the bolt Ignition Exciters (74-11-38, 01-620).

Install the lower, rear cross bracket Ignition Exciters (74-11-38, 01-600).

Attach the cross bracket to the upper support bracket HPC Assembly (72-41-00, 04-600) with the two screws Ignition Exciters (74-11-38, 01-290) and the two clipnuts Ignition Exciters (74-11-38, 01-295). Use the ACR Torq-Set bit 212-1/4-ACR 1 off to install the two screws.

Attach the cross bracket to the support tube with the bolt Ignition Exciters (74-11-38, 01-280).

Use the ACR Torq-Set bit 212-1/4-ACR 1 off to torque the screws to 85 to 105 lbf.in (10 to 12 Nm).

Install the upper, forward cross bracket Ignition Exciters (74-11-38, 01-270).

Attach the cross bracket to the upper support bracket HPC Assembly (72-41-00, 04-600) with the bolt Ignition Exciters (74-11-38, 01-220) and the clipnut Ignition Exciters (74-11-38, 01-225).

Attach the cross bracket to the support tube with the bolt Ignition Exciters (74-11-38, 01-210).

Install the upper, rear cross bracket Ignition Exciters (74-11-38, 01-200).

SUBTASK 72-00-40-420-226-A00 Install the Support Tubes and the Cross Brackets for the Ignition Exciters (Pre SBE 74-0001)

Refer to Figure.

Attach the bracket Ignition Exciters (74-11-38, 01-470) to the brackets HPC Assembly (72-41-00, 04-620) and HPC Assembly (72-41-00, 04-670) installed in TASK 72-41-00-440-002-B00 with two bolts Ignition Exciters (74-11-38, 01-472) and two clipnuts Ignition Exciters (74-11-38, 01-473).

Attach the bracket Ignition Exciters (74-11-38, 01-470) to the brackets HPC Assembly (72-41-00, 04-600) and HPC Assembly(72-41-00,04-650) installed in TASK 72-41-00-440-002-B00 with two bolts Ignition Exciters (74-11-38, 01-472) and two clipnuts Ignition Exciters (74-11-38, 01-473).

Install the brackets Ignition Exciters (74-11-38, 01-470).

Attach the brackets Ignition Exciters (74-11-38, 01-170) and Ignition Exciters (74-11-38, 01-570) to the flange face using existing nuts, bolts and washers.

Install the brackets Ignition Exciters (74-11-38, 01-170) and Ignition Exciters (74-11-38, 01-570).

Attach the brackets Ignition Exciters (74-11-38, 01-180 and (74-11-38, 01-580) to the flange face using existing nuts and bolts.

Install the brackets Ignition Exciters (74-11-38, 01-180) and Ignition Exciters (74-11-38, 01-580).

Attach the bracket Ignition Exciters (74-11-38, 01-170) to the bracket Ignition Exciters (74-11-38, 01-180) with the bolts Ignition Exciters (74-11-38, 01-172) and the clipnuts Ignition Exciters (74-11-38, 01-174).

Attach the bracket Ignition Exciters (74-11-38, 01-570) to the bracket Ignition Exciters (74-11-38, 01-580) with the bolts Ignition Exciters (74-11-38, 01-572) and the clipnuts Ignition Exciters (74-11-38, 01-574).

Assemble the brackets Ignition Exciters (74-11-38, 01-170) and Ignition Exciters (74-11-38, 01-180) and Ignition Exciters (74-11-38, 01-570) and Ignition Exciters (74-11-38, 01-580).

Attach the bracket Ignition Exciters (74-11-38, 01-200) to the bracket Ignition Exciters (74-11-38, 01-470) with the two bolts Ignition Exciters (74-11-38, 01-214) and Ignition Exciters (74-11-38, 01-216) and the two clipnuts Ignition Exciters (74-11-38, 01-215 and (74-11-38, 01-474).

Attach the bracket Ignition Exciters (74-11-38, 01-600) to the bracket Ignition Exciters (74-11-38, 01-470) with the two bolts Ignition Exciters (74-11-38, 01-612) and Ignition Exciters (74-11-38, 01-614) and the two clipnuts Ignition Exciters (74-11-38, 01-613) and Ignition Exciters (74-11-38, 01-474).

Attach the bracket Ignition Exciters (74-11-38, 01-200) to the bracket Ignition Exciters (74-11-38, 01-180) with the two bolts Ignition Exciters (74-11-38, 01-210) and Ignition Exciters (74-11-38, 01-212).

Attach the bracket Ignition Exciters (74-11-38, 01-600) to the bracket Ignition Exciters (74-11-38, 01-580) with the two bolts Ignition Exciters (74-11-38, 01-610).

Install the brackets Ignition Exciters (74-11-38, 01-200) and Ignition Exciters (74-11-38, 01-600).

SUBTASK 72-00-40-420-226-B00 Install the Brackets for the Ignition Exciters (SBE 74-0001)

NOTE

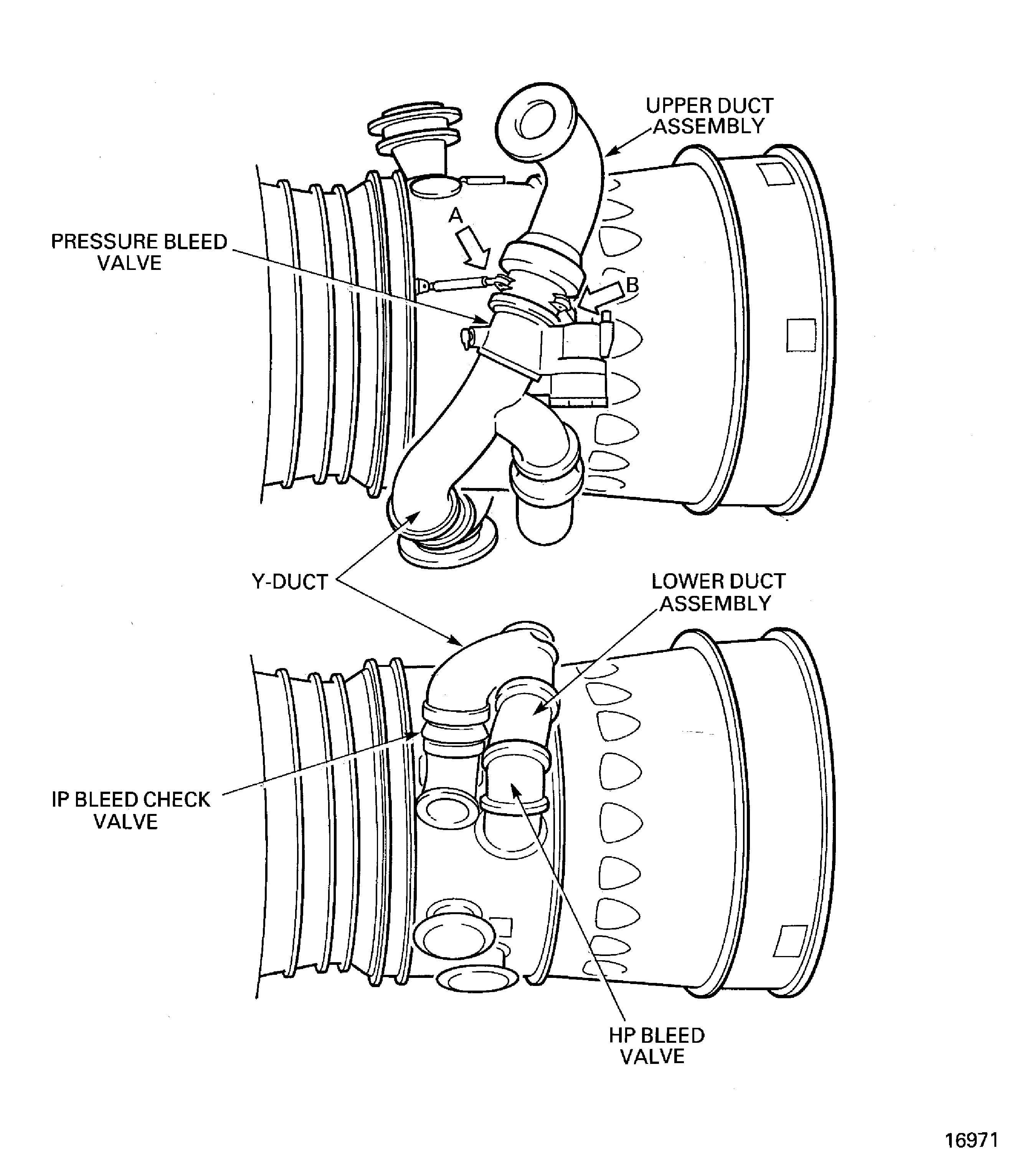

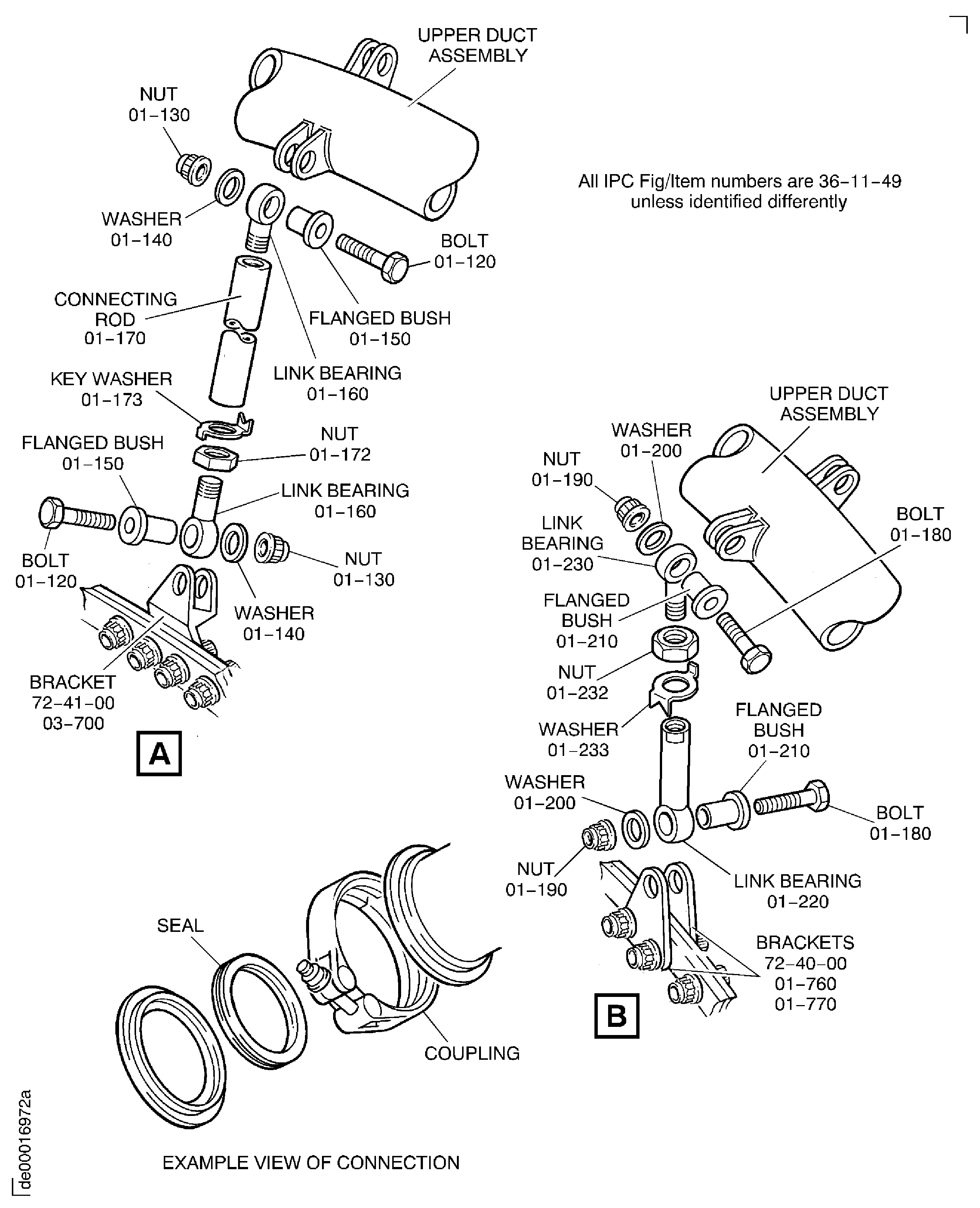

Refer to SPM TASK 70-47-01-470-501 for the procedure to install v-band couplings.Do not tighten or torque the duct v-band couplings until all the ducts, valves, couplings and tubes are installed in the correct position, refer to SUBTASK 72-00-40-420-228.

Install the seal PNEUMATIC-IP BLEED AIR CHECK VALVE (36-11-41, 01-110) onto the HP7 bleed valve/cabin air duct.

Attach the IP bleed check valve to the HP7 bleed valve/cabin air duct with the coupling PNEUMATIC-IP BLEED AIR CHECK VALVE (36-11-41, 01-100). Tighten the v-band coupling nut.

Install the IP bleed check valve PNEUMATIC-IP BLEED AIR CHECK VALVE (36-11-41, 01-050).

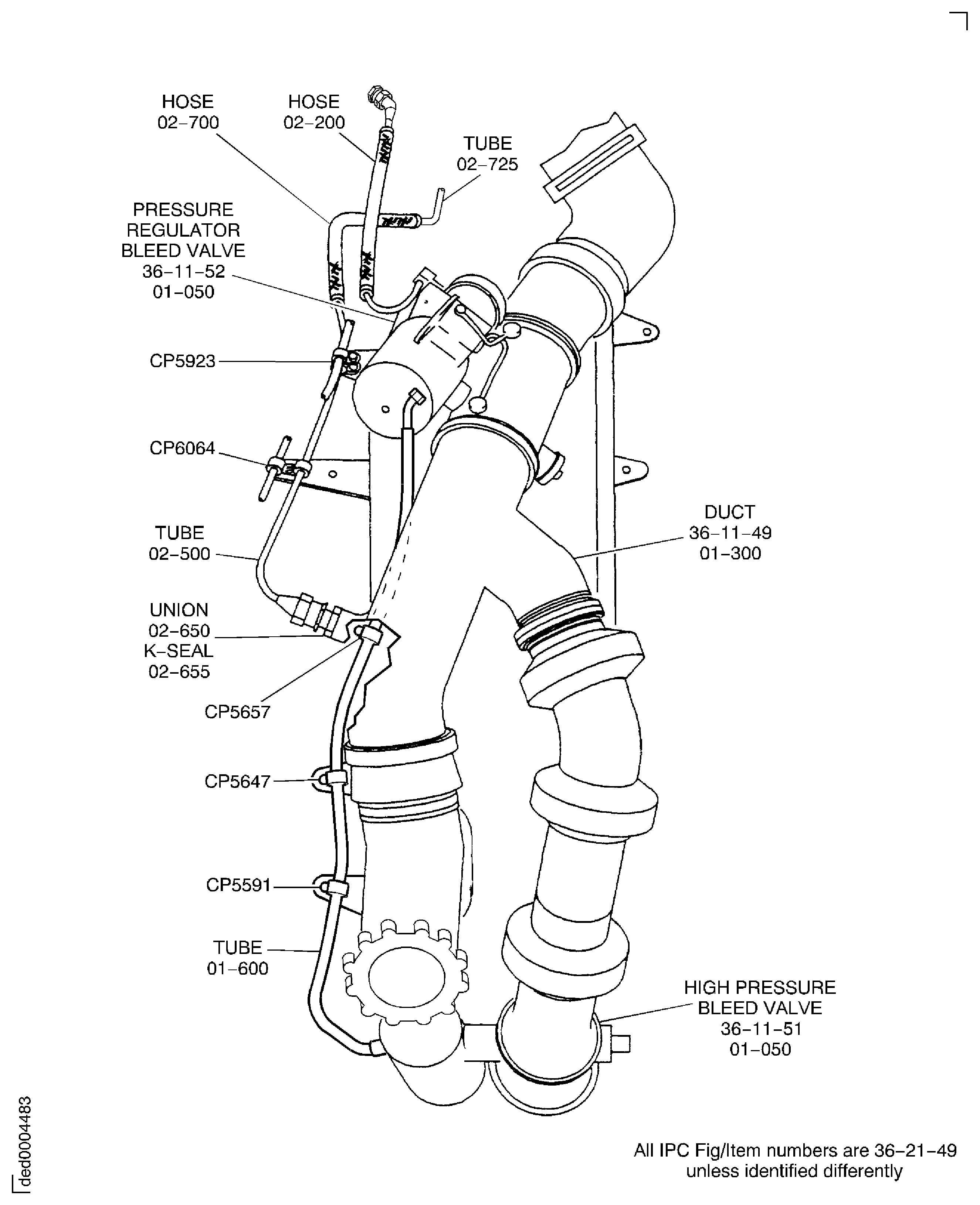

Install the seal PNEUMATIC-HP BLEED VALVE (36-11-51, 01-110) on to the HP10 cabin air duct.

Attach the HP bleed valve to the HP10 cabin air duct with the coupling PNEUMATIC-HP BLEED VALVE (36-11-51, 01-100). Tighten the v-band coupling nut.

Install the HP bleed valve PNEUMATIC-HP BLEED VALVE (36-11-51, 01-050).

Install the seal PNEUMATIC-HP BLEED VALVE (36-11-51, 01-110) on to the HP bleed valve.

Attach the lower duct assembly to the HP bleed valve with the coupling PNEUMATIC-HP BLEED VALVE (36-11-51, 01-100). Tighten the v-band coupling nut.

Install the lower duct assembly PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-500).

Install the seal PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-320) on to the lower duct assembly.

Install the seal PNEUMATIC-IP BLEED AIR CHECK VALVE (36-11-41, 01-110) on to the IP bleed check valve.

Attach the Y-duct to the IP bleed check valve with the coupling PNEUMATIC-IP BLEED AIR CHECK VALVE (36-11-41, 01-100) and the lower duct assembly with the coupling PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-310). Tighten the v-band coupling nut.

Install the Y-duct PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-300).

Install the seal Bleed Pressure Regulator Valve (36-11-52, 01-110) PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-340 on to the Y-duct.

Attach the pressure bleed valve to the Y-duct with the coupling Bleed Pressure Regulator Valve (36-11-52, 01-100), PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-330). Tighten the v-band coupling nut.

Install the pressure regulator bleed valve Bleed Pressure Regulator Valve (36-11-52, 01-050).

Install the seal Bleed Pressure Regulator Valve (36-11-52, 01-110) on to the pressure bleed valve.

Attach the upper duct assembly to the pressure bleed valve with the coupling Bleed Pressure Regulator Valve (36-11-52, 01-100). Tighten the v-band coupling nut.

Attach the link bearing PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-230), nut PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-232) and keywasher PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-233) to the link bearing PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-220). Adjust the length of the link bearing to align its holes with the holes in the upper duct assembly lugs and the brackets HPC Module - Attaching Parts (72-40-00, 01-760) and HPC Module - Attaching Parts (72-40-00, 01-770).

Attach the link bearings to the upper duct assembly lugs and the brackets with the two flanged bushes PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-210), the two bolts PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-180), the two washers PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-200) and the two nuts PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-190).

Attach the two link bearings PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-160), nut PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-172) and keywasher PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-173) to the connecting rod PNEUMATIC-BLEED AIR DUCTS (36-11-49 ,01-170). Adjust the length of the connecting rod assembly to align its holes with the holes in the upper duct assembly lugs and the bracket HPC Assembly (72-41-00, 03-770).

Attach the connecting rod assembly to the upper duct assembly lugs and the bracket with the two flanged bushings PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-150), the two bolts PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-120), the two washers PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-140) and the two nuts PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-130).

NOTE

Final adjust and secure the link assemblies when the engine is installed on the pylon.Install the upper duct assembly PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-100).

SUBTASK 72-00-40-420-227 Install the Cabin Bleed Air System Ducts and Valves

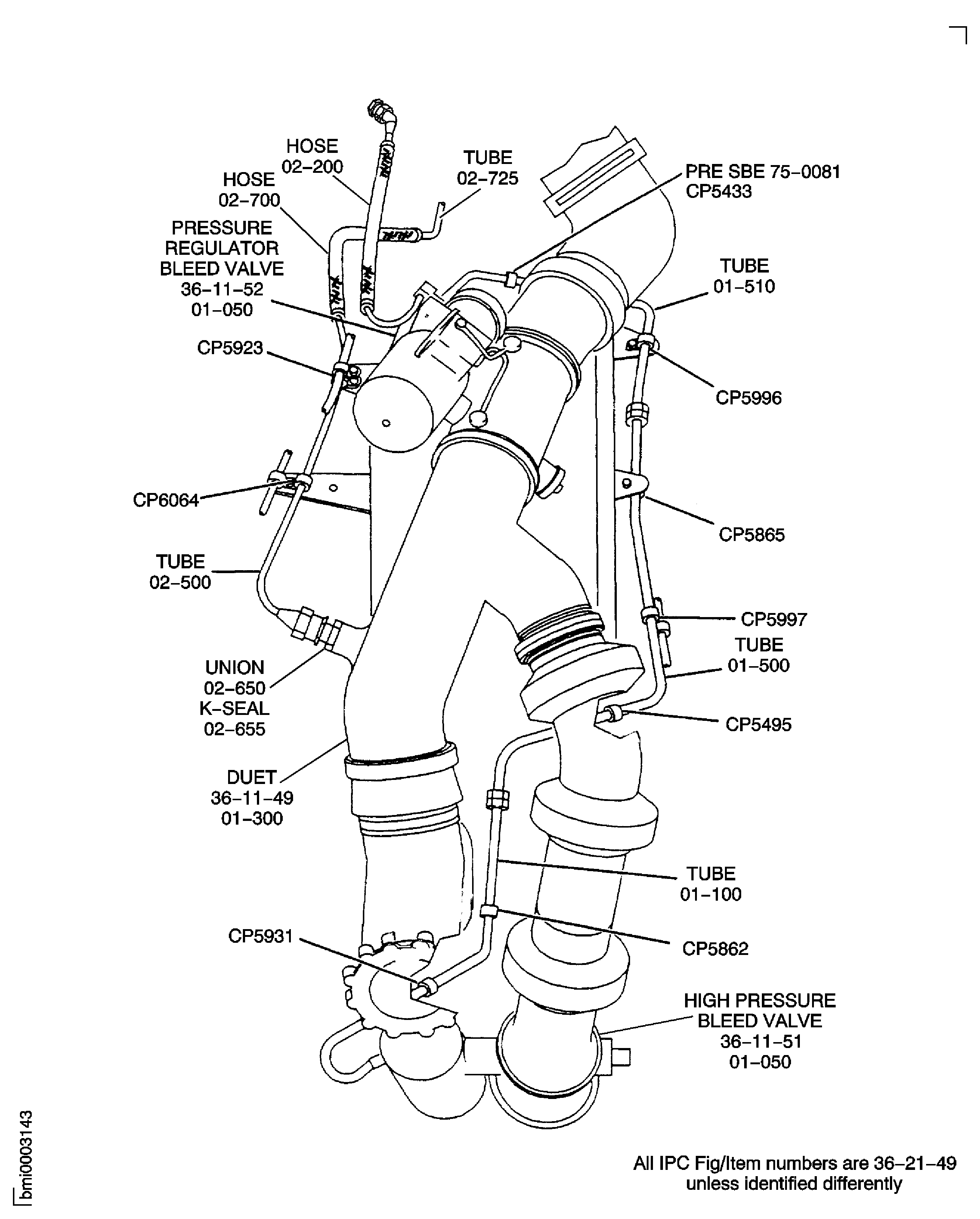

NOTE

Pre SBE 36-0007: It is quicker to loose install the two cabin bleed air system sense tubes PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) and PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500) before you install the cabin bleed air ducts.NOTE

Refer to the SPM TASK 70-41-02-400-501 for the torque loading procedures.Apply CoMat 10-129 ANTI-SEIZE PASTE to one of the mating thread surfaces of the pressure sense tubes, hoses and union before you connect the components, as follows:

Cabin Bleed Air System Sense Tubes (36-21-49)

IPC Fig./item

01-100

01-500

01-510

02-200

02-500

02-650

02-700

02-725

Install the K seal PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-655) and the union PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-650) in the duct PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-300). Torque the union to 168-181 lbf.in (19-20.50 Nm).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) to the union PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-650).

Connect the hose PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-700) to the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) and the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-725).

Attach the hose PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-200) to the tube connected to the pressure regulator bleed valve Bleed Pressure Regulator Valve (36-11-52, 01-050).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) and the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005) to the lug at the tube 38 at clip position 5923 with the bolt, spacer PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-562), spacer and the nut.

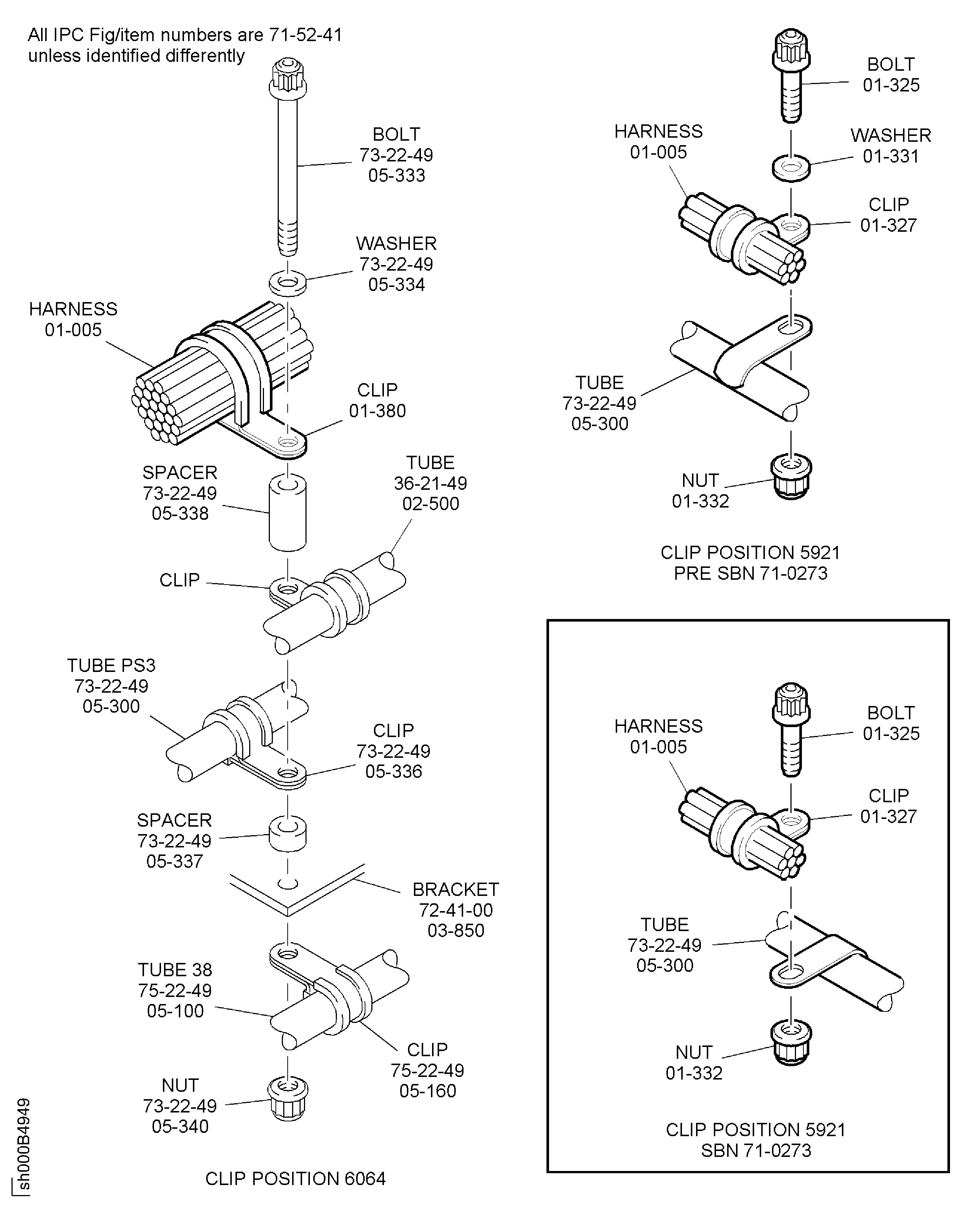

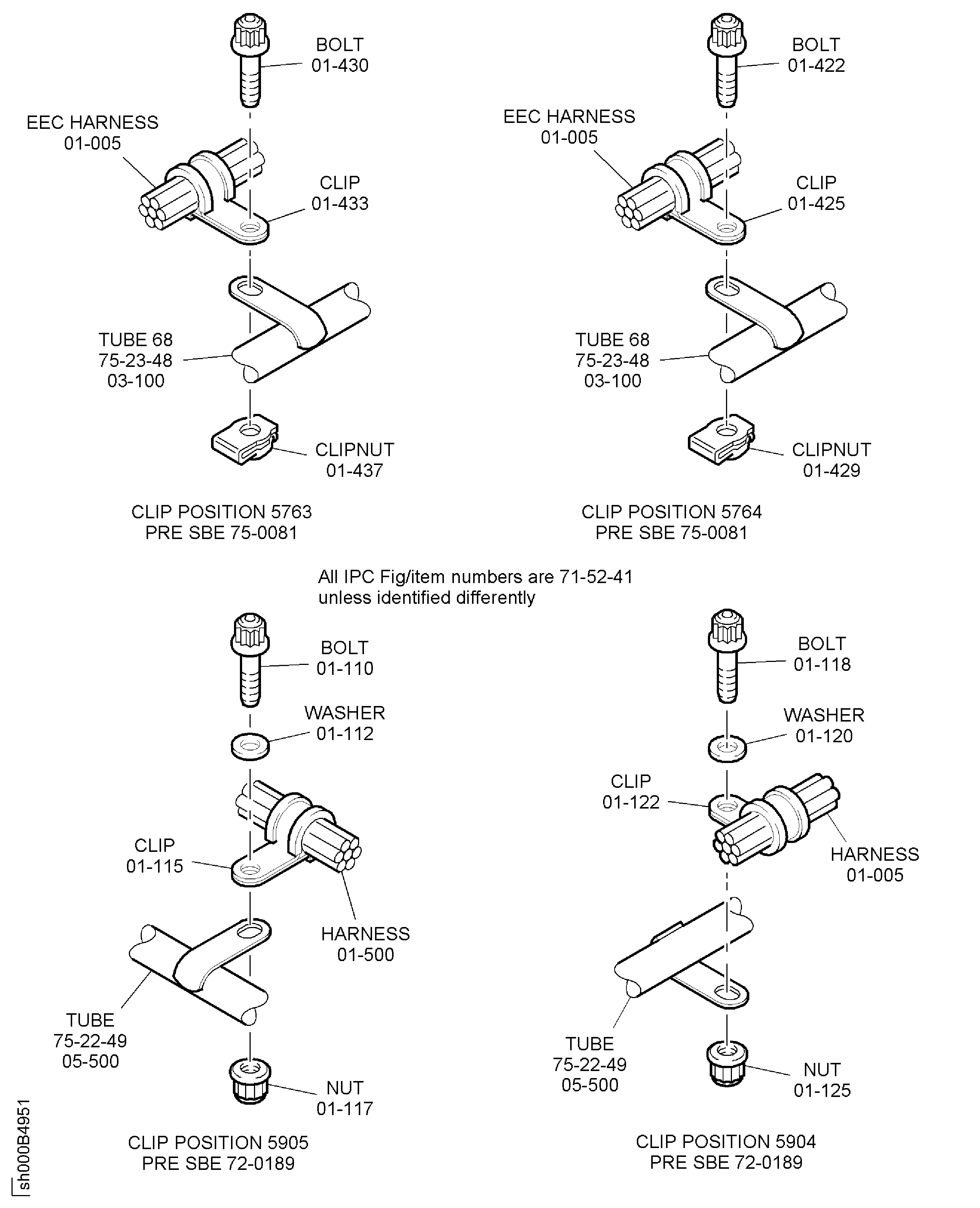

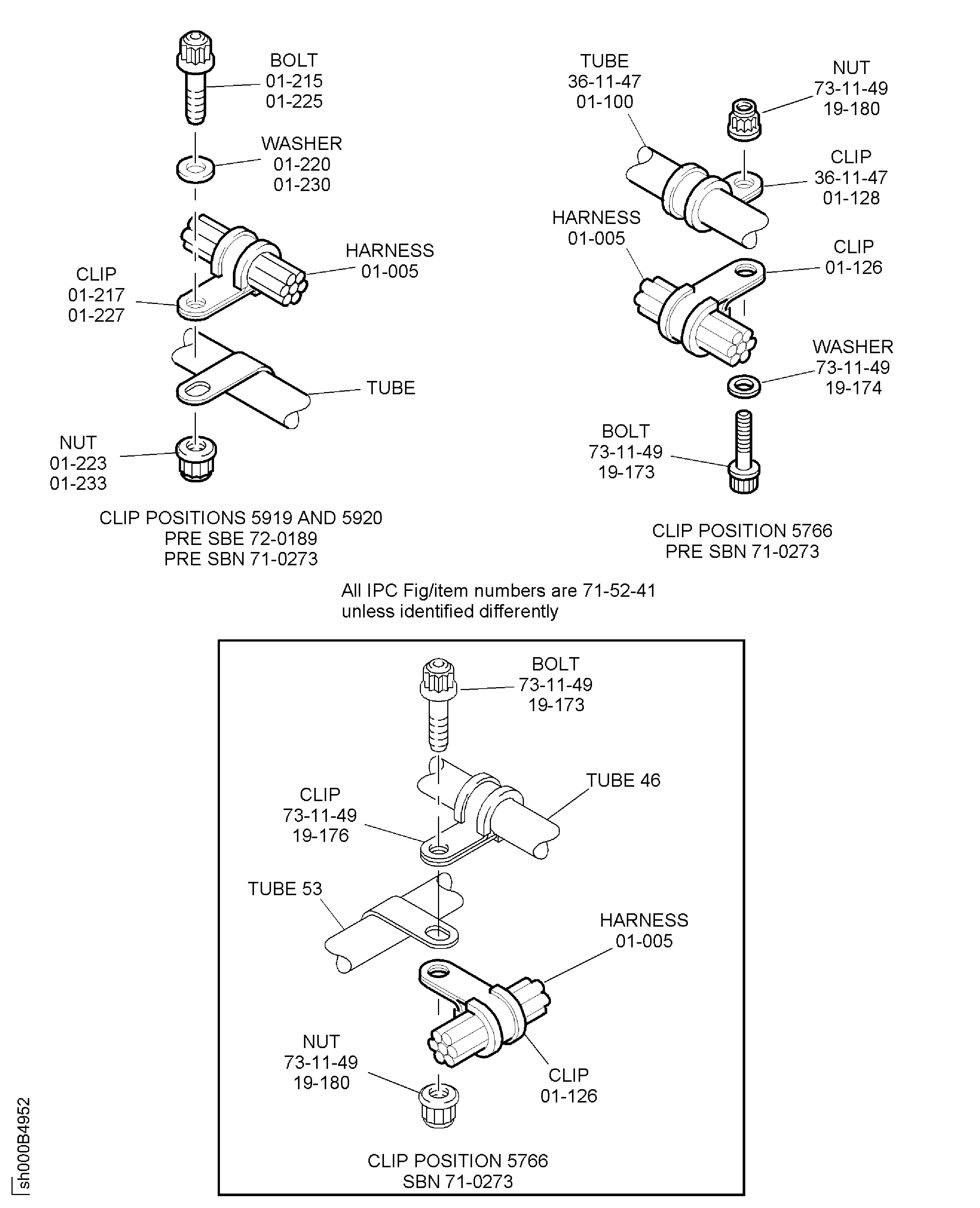

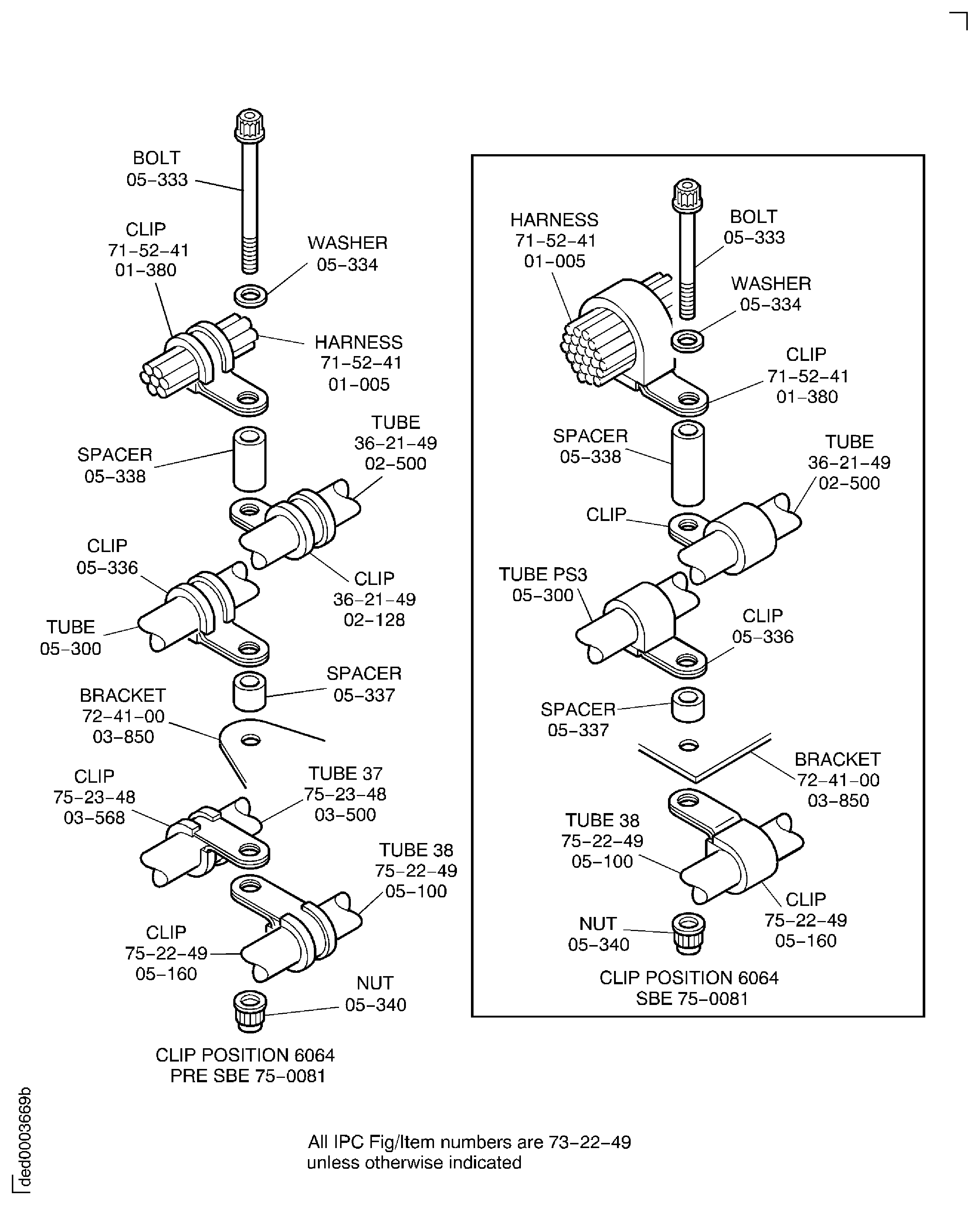

Pre SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-500), the clip Fuel System Air Tubes (73-22-49, 05-336) at the tube Fuel System Air Tubes (73-22-49, 05-300) and the clips Turbine Cooling Air (TCA) Controlled Air Tubes (75-23-48, 03-568) and Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 05-160) at tubes 37 and 38 to the bracket HPC Assembly (72-41-00, 03-850) at the clip position 6064 with the bolt Fuel System Air Tubes (73-22-49, 05-333), washer Fuel System Air Tubes (73-22-49, 05-334), spacer Fuel System Air Tubes (73-22-49, 05-338), spacer Fuel System Air Tubes (73-22-49, 05-337) and nut Fuel System Air Tubes (73-22-49, 05-340).

SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-500), the clip Fuel System Air Tubes (73-22-49, 05-336) at the tube Fuel System Air Tubes (73-22-49, 05-300) and the clip Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 05-160) at tube 38 to the bracket HPC Assembly (72-41-00, 03-850) at the clip position 6064 with the bolt Fuel System Air Tubes (73-22-49, 05-333), washer Fuel System Air Tubes (73-22-49, 05-334), spacer Fuel System Air Tubes (73-22-49, 05-338), spacer Fuel System Air Tubes (73-22-49, 05-337) and nut Fuel System Air Tubes (73-22-49, 05-340).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) to the pressure regulator bleed valve Bleed Pressure Regulator Valve (36-11-52, 01-050).

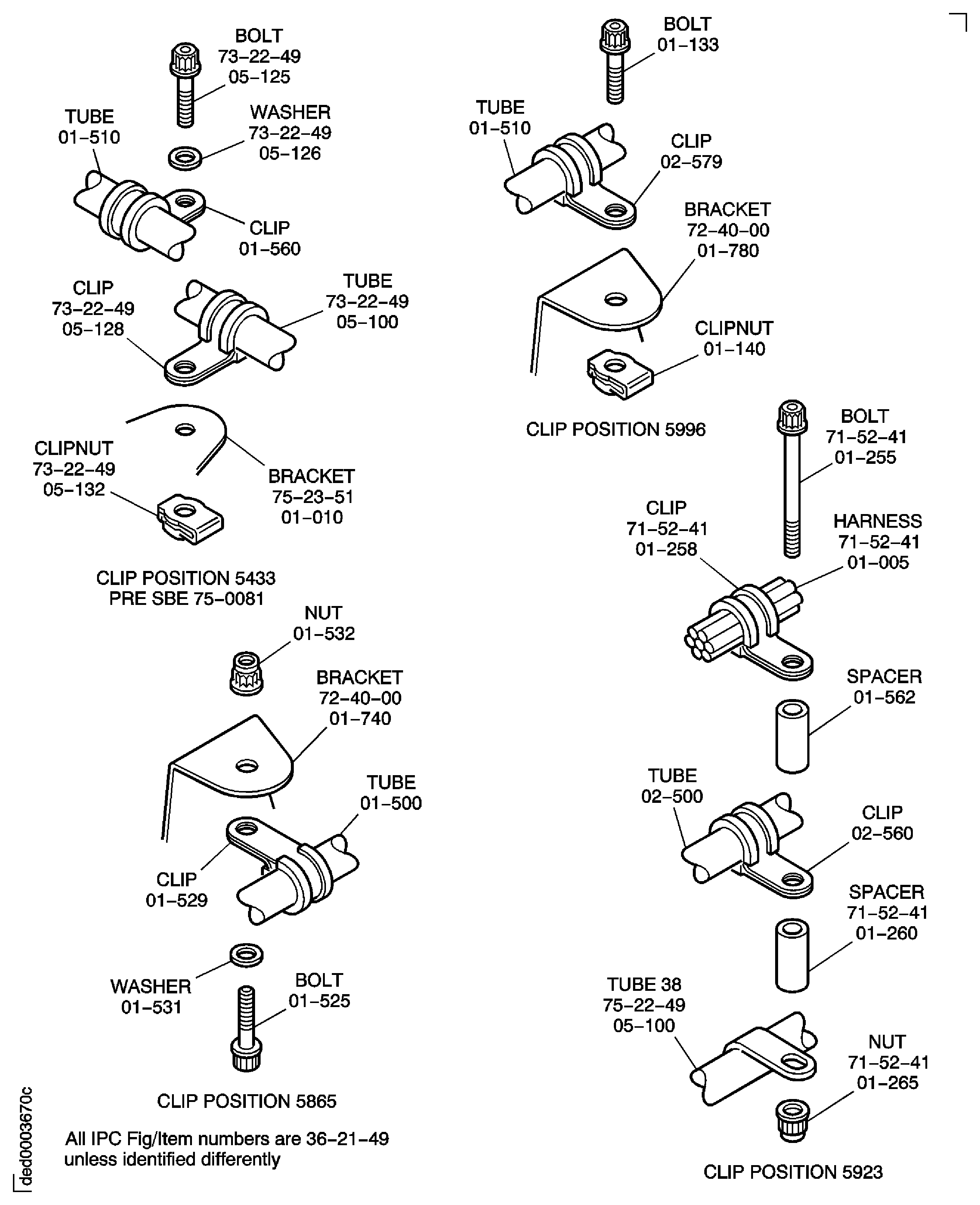

Pre SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) with the clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-560) and the tube 52 Fuel System Air Tubes (73-22-49, 05-100) with the clip Fuel System Air Tubes (73-22-49, 05-128) to the bracket AIR-STAGE 10 TO HPT AIR VALVE (75-23-51, 01-010) at the clip position 5433 with the bolt Fuel System Air Tubes (73-22-49, 05-125), the washer Fuel System Air Tubes (73-22-49, 05-126) and the clipnut Fuel System Air Tubes (73-22-49, 05-132).

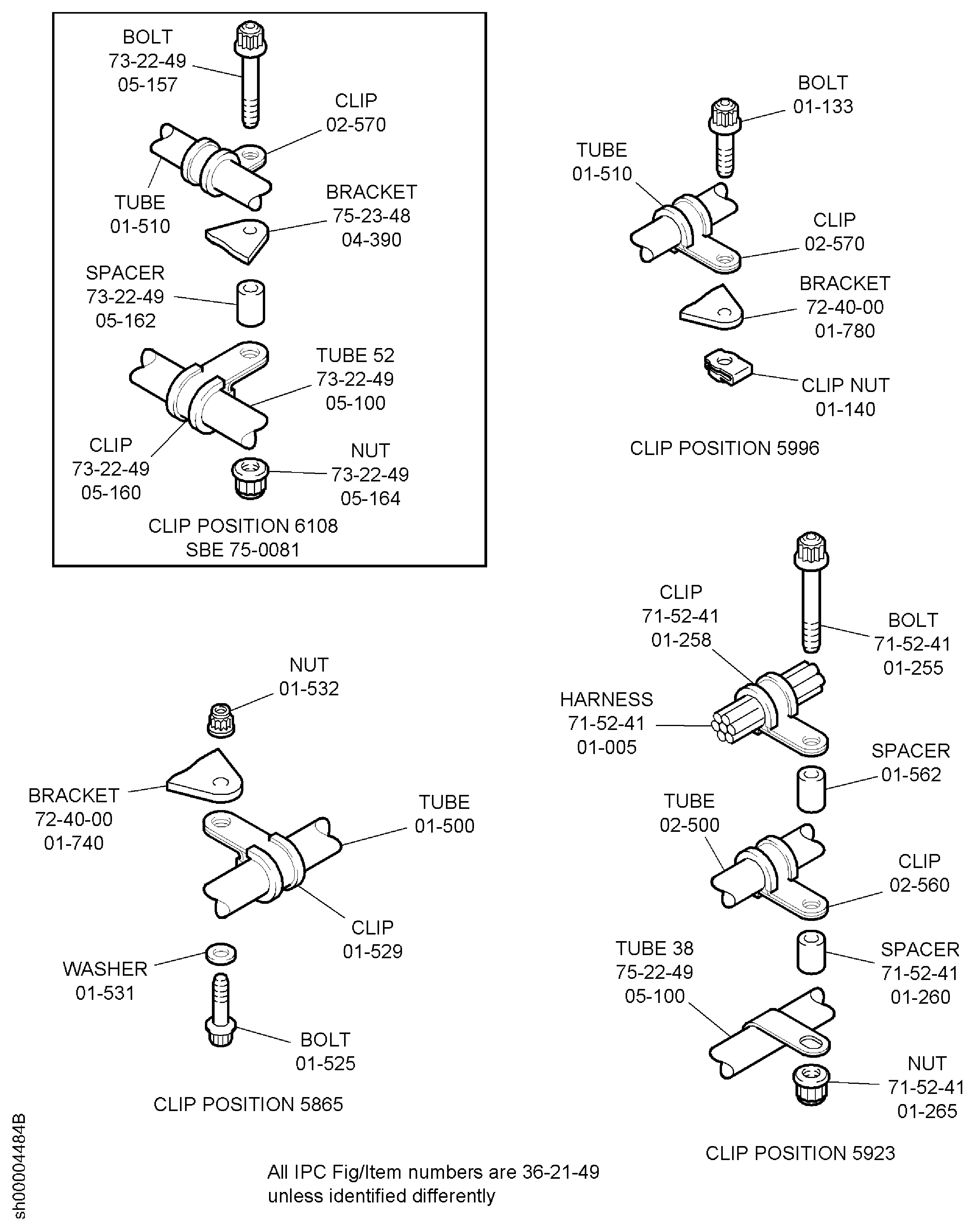

SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) with the clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-562) and the tube 52 Fuel System Air Tubes (73-22-49, 05-100) with the clip Fuel System Air Tubes (73-22-49, 05-160) to the bracket Turbine Cooling Air (TCA) Controlled Air Tubes (75-23-48, 04-390) at the clip position 6108 with the bolt Fuel System Air Tubes (73-22-49, 05-157), the spacer Fuel System Air Tubes (73-22-49 ,05-162) and the nut Fuel System Air Tubes (73-22-49 ,05-164).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) to the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500) to the bracket HPC Module - Attaching Parts (72-40-00, 01-740) at clip position 5865 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-525), washer PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-531), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-529) and the nut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-532).

NOTE

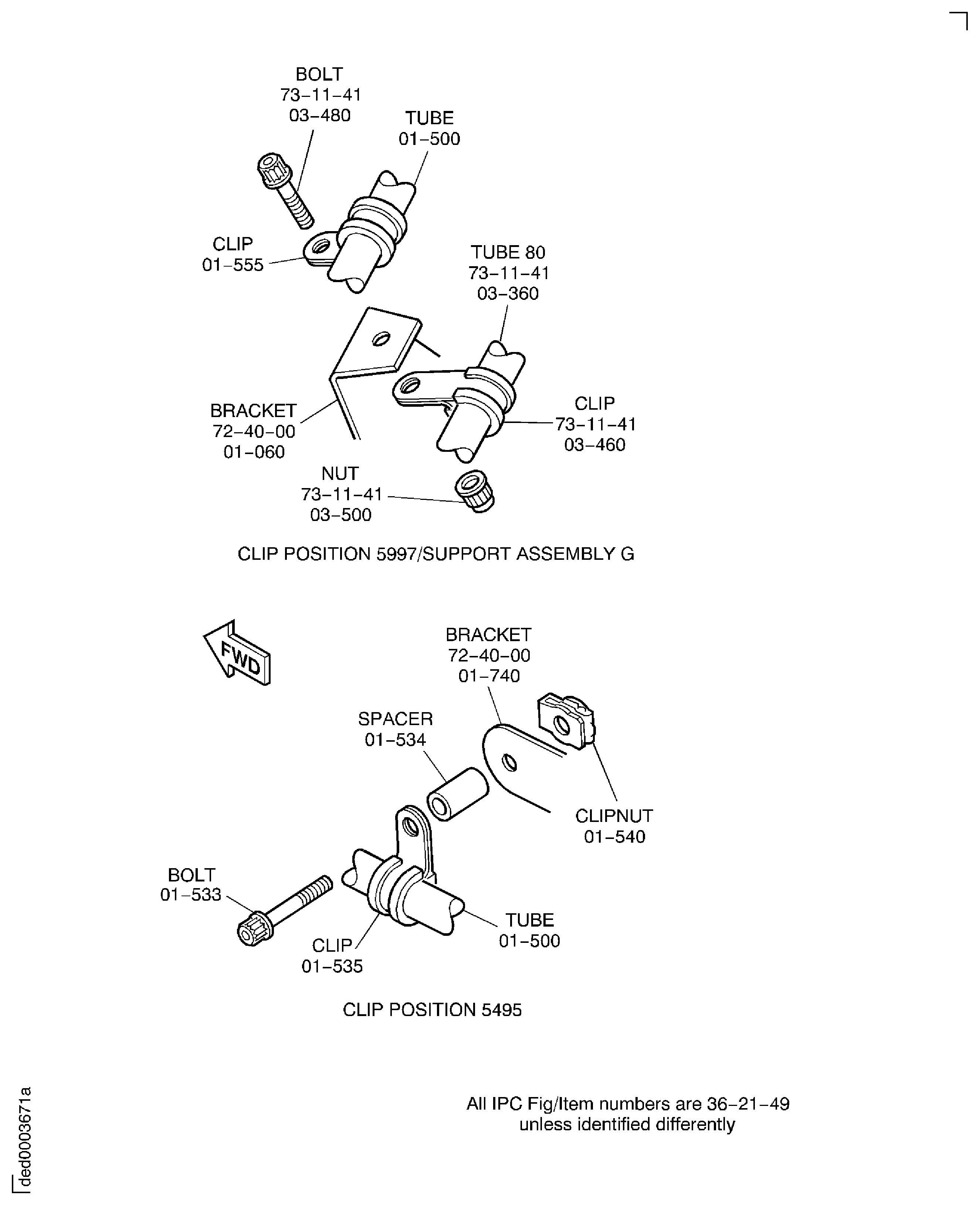

Refer to TASK 72-00-40-420-004 for the installation procedure for the tubes at support bracket G (clip position 5997).Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500), the clip Fuel Nozzle Supply Fuel Manifolds (73-11-41, 03-460) at the tube 80 at clip position 5997 to the bracket HPC Module - Attaching Parts (72-40-00, 01-060) with the bolt, clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-555) and the nut.

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500) to the bracket HPC Module - Attaching Parts (72-40-00, 01-740) at clip position 5495 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-532), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-535), spacer PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-534) and clipnut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-540).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) to the bracket HPC Module - Attaching Parts (72-40-00, 01-780) at clip position 5996 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-133), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-579) and clipnut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-140).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100) to the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500) and to the HP bleed valve PNEUMATIC-HP BLEED VALVE (36-11-51, 01-050).

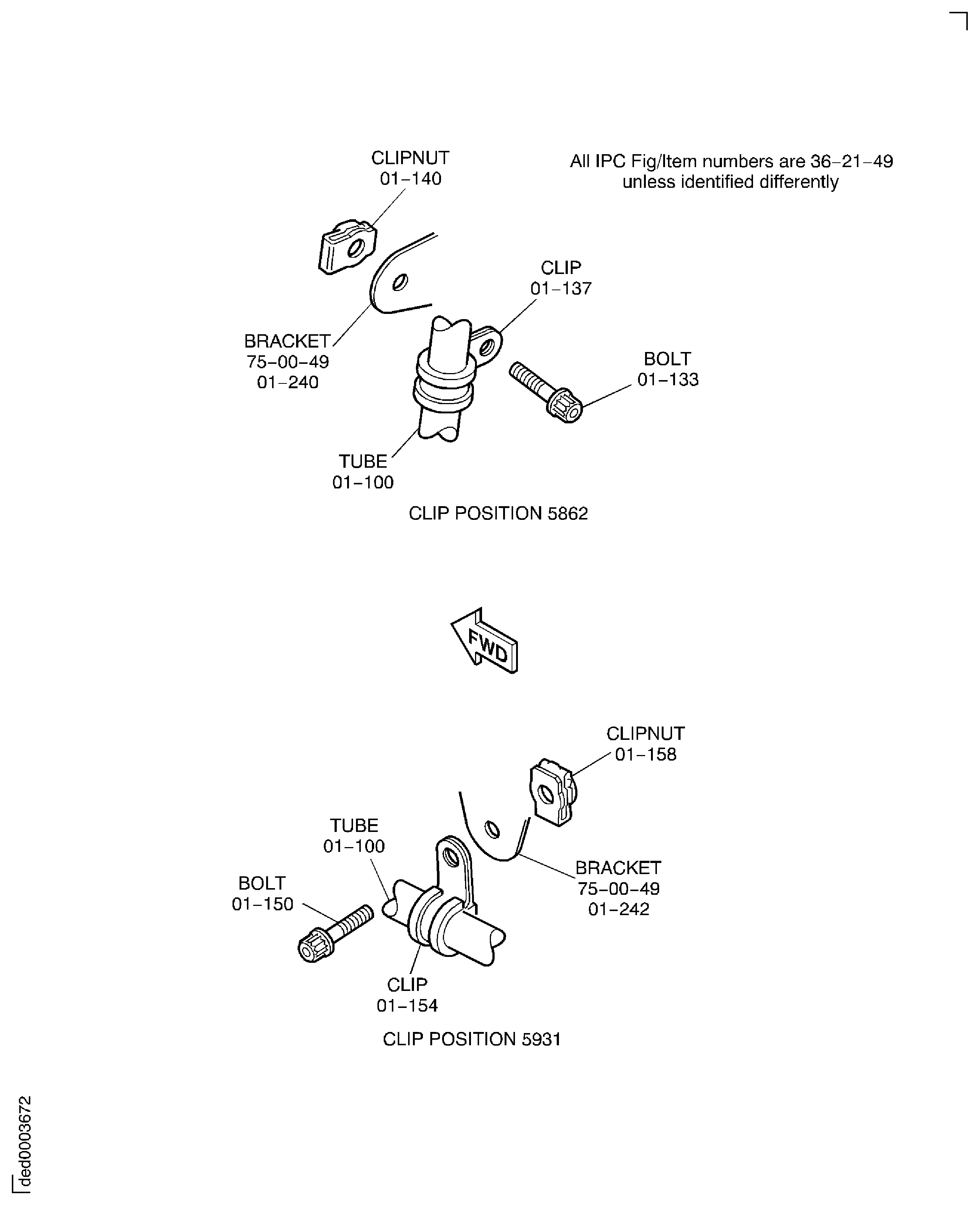

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100) to the bracket Engine Air Off-Take Air Ducts (75-00-49, 01-240) at clip position 5862 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-133), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-137) and the clipnut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-140).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100) to the bracket Engine Air Off-Take Air Ducts (75-00-49, 01-242) at clip position 5931 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-150), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-514) and the clipnut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-158).

Torque the tube nuts on the tubes PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49,02-510) and PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100) to 135-145 lbf.in (15-16 Nm).

Install the cabin bleed air system sense tubes (36-21-49).

Torque the couplings installed in Step: PNEUMATIC-IP BLEED AIR CHECK VALVE (36-11-41, 01-100), PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-310), PNEUMATIC-HP BLEED VALVE (36-11-51, 01-100), Bleed Pressure Regulator Valve (36-11-52, 01-100)) to 75-85 lbf.in (8.5-9.6 Nm). Use a soft faced hammer and tap around the outside of the couplings.

Keep the coupling PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-110) for installation of the cabin bleed air duct on the pylon.

NOTE

Refer to SPM TASK 70-47-01-470-501 for the procedure to install v-band couplings.Torque the cabin bleed air system duct couplings.

SUBTASK 72-00-40-420-228-A00 Install the Cabin Bleed Air System Sense Tubes (Pre SBE 36-0007, Pre SBN 70-0468, SBN 71-0273, Pre SBE 75-0081 and SBE 75-0081)

Apply CoMat 10-031 ANTI-GALLING COMPOUND to one of the mating thread surfaces of the pressure sense tubes, hoses and union before you connect the components, as follows:

NOTE

Refer to SPM TASK 70-41-02-400-501 for the torque loading procedures.Cabin Bleed Air System Sense Tubes (36-21-49)

IPC Fig./item

01-100

01-500

01-510

02-200

02-500

02-650

02-700

02-725

NOTE

Refer to SPM TASK 70-41-02-400-501 for the torque loading procedures.Do not tighten or torque the tube nuts or attaching parts until all the tubes are installed in their correct position.

Install the K seal PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-655) and the union PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-650) in the duct PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-300). Torque the union to 168-181 lbf.in (19-20.50 Nm).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) to the union PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-650).

Connect the hose PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-700) to the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) and the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-725).

Attach the hose PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-200) to the tube connected to the pressure regulator bleed valve Bleed Pressure Regulator Valve (36-11-52, 01-050).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) and the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005) to the lug at the tube 38 at clip position 5923 with the bolt, spacer PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-562), spacer and the nut.

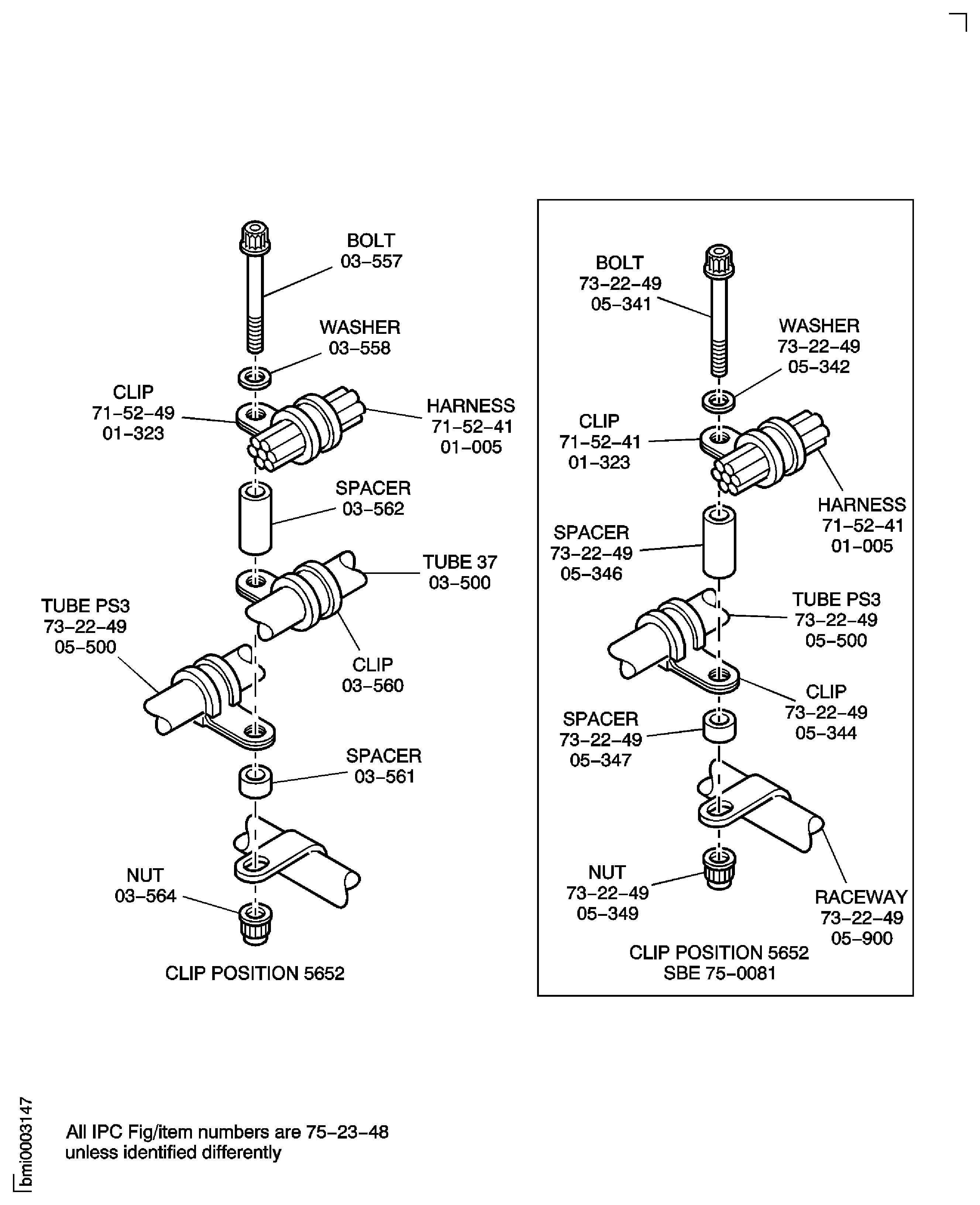

Pre SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-500), the clip Fuel System Air Tubes (73-22-49, 05-336) at the tube Fuel System Air Tubes (73-22-49, 05-300) and the clips Turbine Cooling Air (TCA) Controlled Air Tubes (75-23-48, 03-568) and Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 05-160) at tubes 37 and 38 to the bracket HPC Assembly (72-41-00, 03-850) at the clip position 6064 with the bolt Fuel System Air Tubes (73-22-49, 05-333), washer Fuel System Air Tubes (73-22-49, 05-334), spacer Fuel System Air Tubes (73-22-49, 05-338), spacer Fuel System Air Tubes (73-22-49, 05-337) and nut Fuel System Air Tubes (73-22-49, 05-340).

SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-500), the clip Fuel System Air Tubes (73-22-49, 05-336) at the tube Fuel System Air Tubes (73-22-49, 05-300) and the clip Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 05-160) at tube 38 to the bracket HPC Assembly (72-41-00, 03-850) at the clip position 6064 with the bolt Fuel System Air Tubes (73-22-49, 05-333), washer Fuel System Air Tubes (73-22-49, 05-334), spacer Fuel System Air Tubes (73-22-49, 05-338), spacer Fuel System Air Tubes (73-22-49, 05-337) and nut Fuel System Air Tubes (73-22-49, 05-340).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) to the pressure regulator bleed valve Bleed Pressure Regulator Valve (36-11-52, 01-050).

Pre SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) with the clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-560) and the tube 52 Fuel System Air Tubes (73-22-49, 05-100) with the clip Fuel System Air Tubes (73-22-49, 05-128) to the bracket AIR-STAGE 10 TO HPT AIR VALVE (75-23-51, 01-010) at the clip position 5433 with the bolt Fuel System Air Tubes (73-22-49, 05-125), the washer Fuel System Air Tubes (73-22-49, 05-126) and the clipnut Fuel System Air Tubes (73-22-49, 05-132).

SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) with the clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-562) and the tube 52 Fuel System Air Tubes (73-22-49, 05-100) with the clip Fuel System Air Tubes (73-22-49, 05-160) to the bracket Turbine Cooling Air (TCA) Controlled Air Tubes (75-23-48, 04-390) at the clip position 6108 with the bolt Fuel System Air Tubes (73-22-49, 05-157), the spacer Fuel System Air Tubes (73-22-49, 05-162) and the nut Fuel System Air Tubes (73-22-49, 05-164).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) to the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500) to the bracket HPC Module - Attaching Parts (72-40-00, 01-740) at clip position 5865 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-525), washer PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-531), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-529) and the nut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-532).

NOTE

Refer to TASK 72-00-40-420-004 for the installation procedure for the tubes at support bracket G (clip position 5997).Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500), the clip Fuel Nozzle Supply Fuel Manifolds (73-11-41, 03-460) at the tube 80 at clip position 5997 to the bracket HPC Module - Attaching Parts (72-40-00, 01-060) with the bolt, clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-555) and the nut.

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500) to the bracket HPC Module - Attaching Parts (72-40-00, 01-740) at clip position 5495 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-532), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-535), spacer PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-534) and clipnut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-540).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-510) to the bracket HPC Module - Attaching Parts (72-40-00, 01-780) at clip position 5996 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-133), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-579) and clipnut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-140).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100) to the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500) and to the HP bleed valve PNEUMATIC-HP BLEED VALVE (36-11-51, 01-050).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100) to the bracket Engine Air Off-Take Air Ducts (75-00-49, 01-240) at clip position 5862 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-133), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-137) and the clipnut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-140).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100) to the bracket Engine Air Off-Take Air Ducts (75-00-49, 01-242) at clip position 5931 with the bolt PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-150), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-514) and the clipnut PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-158).

Torque the tube nuts on the tubes PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-150) and PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100) to 135-145 lbf.in (15-16 Nm).

Install the cabin bleed air system sense tubes (36-21-49).

Torque the couplings installed in Step: PNEUMATIC-IP BLEED AIR CHECK VALVE (36-11-41, 01-100), PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-310), PNEUMATIC-HP BLEED VALVE (36-11-51, 01-100), Bleed Pressure Regulator Valve (36-11-52, 01-100) to 75-85 lbf.in (8.5-9.6 Nm). Use a soft faced hammer and tap around the outside of the couplings.

Keep the coupling PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-110) for installation of the cabin bleed air duct on the pylon.

NOTE

Refer to SPM TASK 70-47-01-470-501 for the procedure to install v-band couplings.Torque the cabin bleed air system duct couplings.

SUBTASK 72-00-40-420-228-B00 Install the Cabin Bleed Air System Sense Tubes (Pre SBE 36-0007, SBN 70-0468, SBN 71-0273, Pre SBE 75-0081 and SBE 75-0081)

Apply CoMat 10-031 ANTI-GALLING COMPOUND to one of the mating thread surfaces of the pressure sense tubes, hoses and union before you connect the components, as follows:

NOTE

Refer to the SPM TASK 70-41-02-400-501 for the torque loading procedures.NOTE

Refer to the SPM TASK 70-41-02-400-501 for the torque loading procedures.Cabin Bleed Air System Sense Tubes (36-21-49)

IPC Fig./item

01-100

01-500

01-510

02-200

02-500

02-650

02-700

02-725

Do not tighten or torque the tube nuts or attaching parts until all the tubes are installed in their correct position.

Install the K seal PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-655) and the union PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-650) in the duct PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-300). Torque the union to 168-181 lbf.in (19-20,50 Nm).

Connect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) to the union PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-650).

Connect the hose PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-700) to the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) and the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-725).

Attach the hose PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-050) to the tube connected to the pressure regulator bleed valve Bleed Pressure Regulator Valve (36-11-52, 01-050).

Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) and the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005) to the lug at the tube 38 at clip position 5923 with the bolt, spacer PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-562), spacer and the nut.

Pre SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-500), the clip Fuel System Air Tubes (73-22-49, 05-336) at the tube Fuel System Air Tubes (73-22-49, 05-300) and the clips Turbine Cooling Air (TCA) Controlled Air Tubes (75-23-48, 03-568) and Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 05-160) at tubes 37 and 38 to the bracket HPC Assembly (72-41-00, 03-850) at the clip position 6064 with the bolt Fuel System Air Tubes (73-22-49, 05-333), washer Fuel System Air Tubes (73-22-49, 05-334), spacer Fuel System Air Tubes (73-22-49, 05-338), spacer Fuel System Air Tubes (73-22-49, 05-337) and nut Fuel System Air Tubes (73-22-49, 05-340).

SBE 75-0081: Attach the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500), the clip at the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-500), the clip Fuel System Air Tubes (73-22-49, 05-336) at the tube Fuel System Air Tubes (73-22-49, 05-300) and the clip Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 05-160) at tube 38 to the bracket HPC Assembly (72-41-00, 03-850) at the clip position 6064 with the bolt Fuel System Air Tubes (73-22-49, 05-333), washer Fuel System Air Tubes (73-22-49, 05-334), spacer Fuel System Air Tubes (73-22-49, 05-338), spacer Fuel System Air Tubes (73-22-49, 05-337) and nut Fuel System Air Tubes (73-22-49, 05-340).

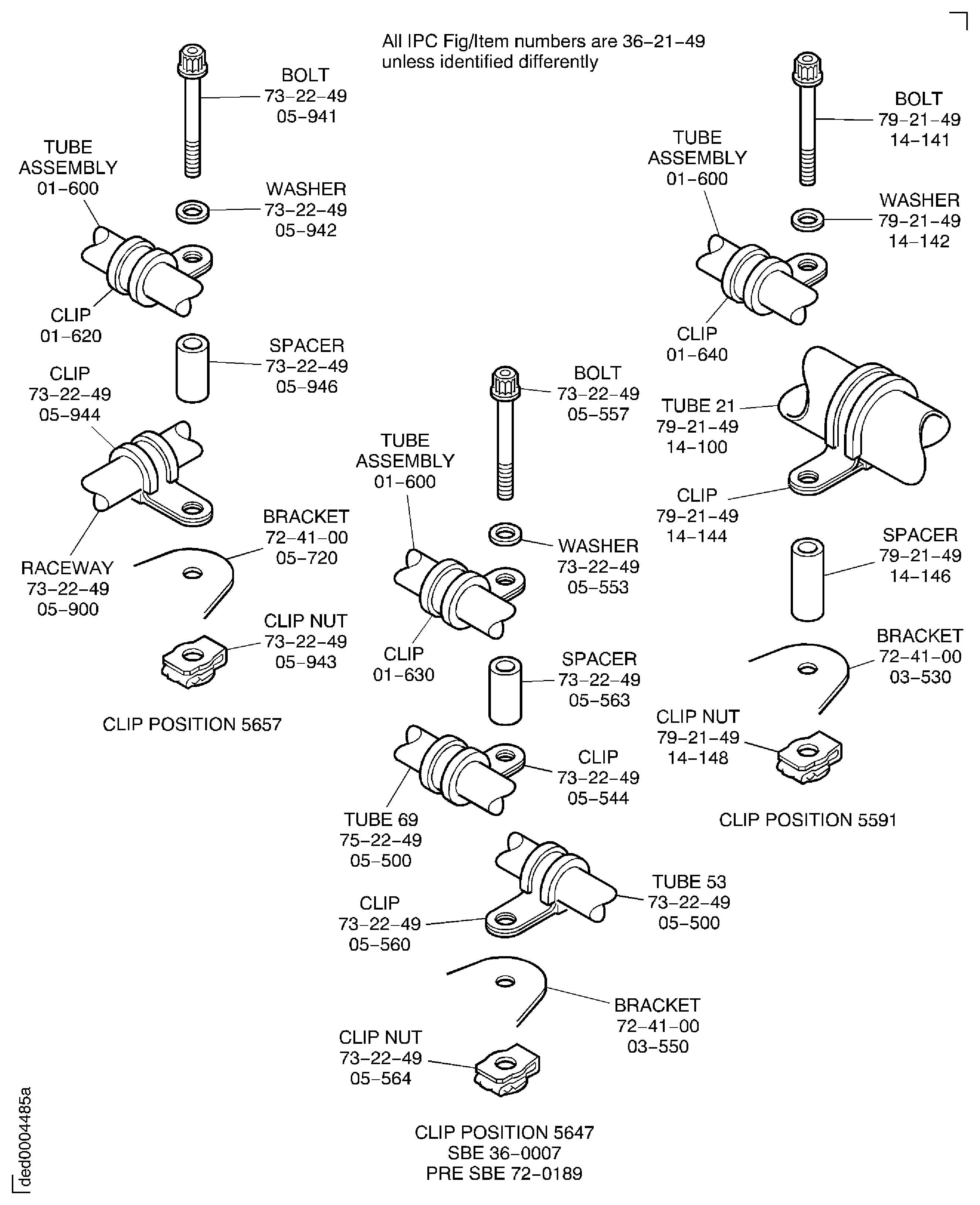

Attach the tube assembly PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-600), and the clip Fuel System Air Tubes (73-22-49, 05-944) at the raceway Fuel System Air Tubes (73-22-49, 05-900) to the bracket HPC Assembly (72-41-00, 03-720) at clip position 5657 with the bolt Fuel System Air Tubes (73-22-49, 05-941), washer Fuel System Air Tubes (73-22-49, 05-942), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-620), spacer Fuel System Air Tubes (73-22-49, 05-946) and clipnut Fuel System Air Tubes (73-22-49, 05-948).

Attach the tube assembly PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-600), the clip Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 05-544) at tube 69 Bearing Compartment Cooling And Sealing Air Tubes (75-22-49, 05-500) and the clip Fuel System Air Tubes (73-22-49, 05-560) at tube 53 Fuel System Air Tubes (73-22-49, 05-500) to the bracket HPC Assembly (72-41-00, 03-550) at clip position 5647 with the bolt Fuel System Air Tubes (73-22-49, 05-557), washer Fuel System Air Tubes (73-22-49, 05-558), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-630), spacer Fuel System Air Tubes (73-22-49, 05-563) and clipnut Fuel System Air Tubes (73-22-49, 05-564).

Attach the tube assembly PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-600), the clip OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 14-144) at tube 21 OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 14-100) to the bracket HPC Assembly (72-41-00, 03-530) at clip position 5591 with the bolt OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 14-141), washer OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 14-142), clip PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-640), spacer OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 14-146) and clipnut OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 14-148).

Torque the tube nuts on the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-600) to 135-145 lbf.in (15-16 Nm).

Install the cabin bleed air system sense tubes (36-21-49).

Torque the couplings installed in StepPNEUMATIC-IP BLEED AIR CHECK VALVE (36-11-41, 01-100), PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-310), PNEUMATIC-HP BLEED VALVE (36-11-51, 01-100), Bleed Pressure Regulator Valve (36-11-52, 01-100) to 75-85 lbf.in (8.5 - 9.6 Nm). Use a soft faced hammer and tap around the outside of the couplings.

Keep the coupling PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-110) for installation of the cabin bleed air duct on the pylon.

NOTE

Refer to SPM TASK 70-47-01-470-501 for the procedure to install v-band couplings.Torque the cabin bleed air system duct couplings.

SUBTASK 72-00-40-420-228-C00 Install the Cabin Bleed Air System Sense Tubes (Pre SBE 75-0081, SBE 36-0007 and SBE 75-0081)

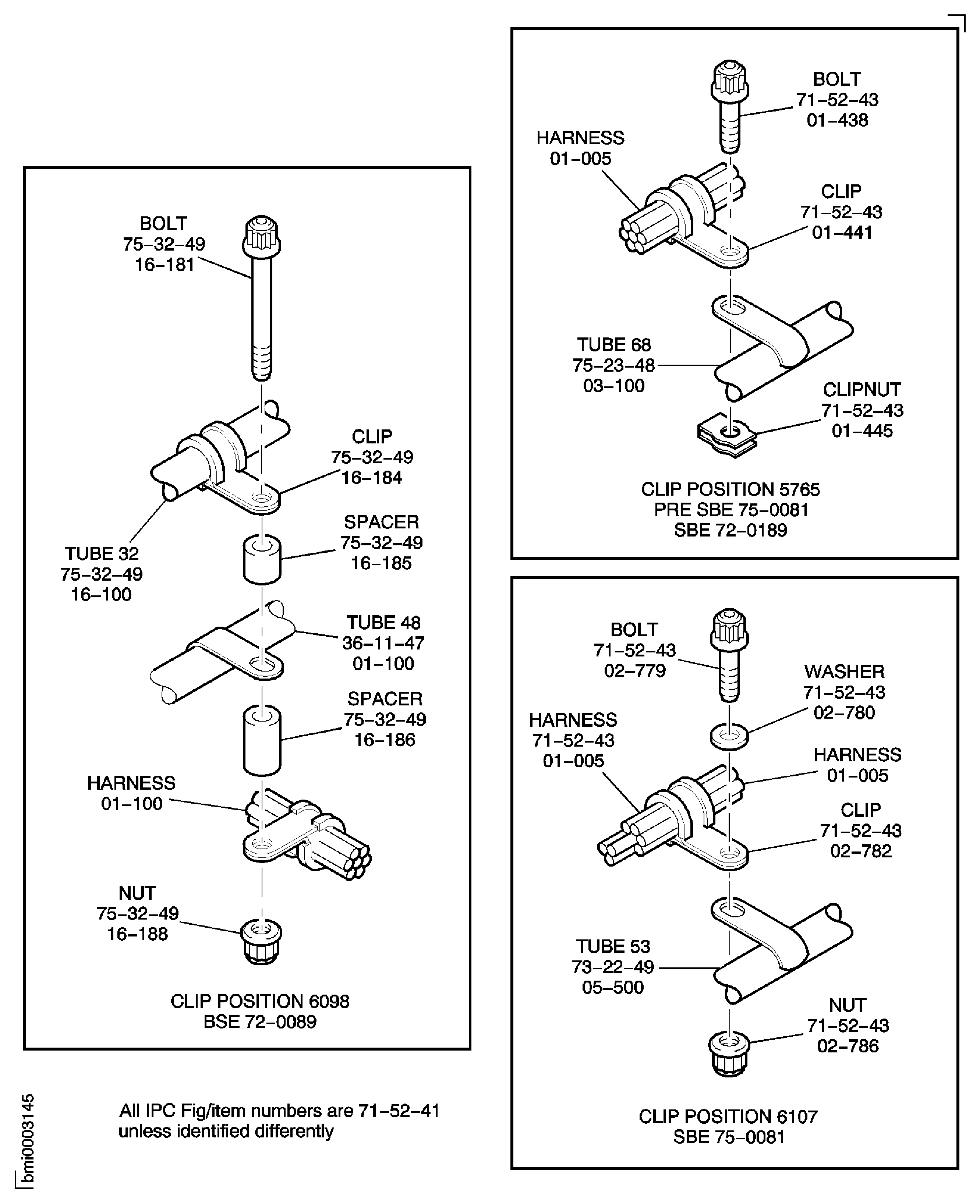

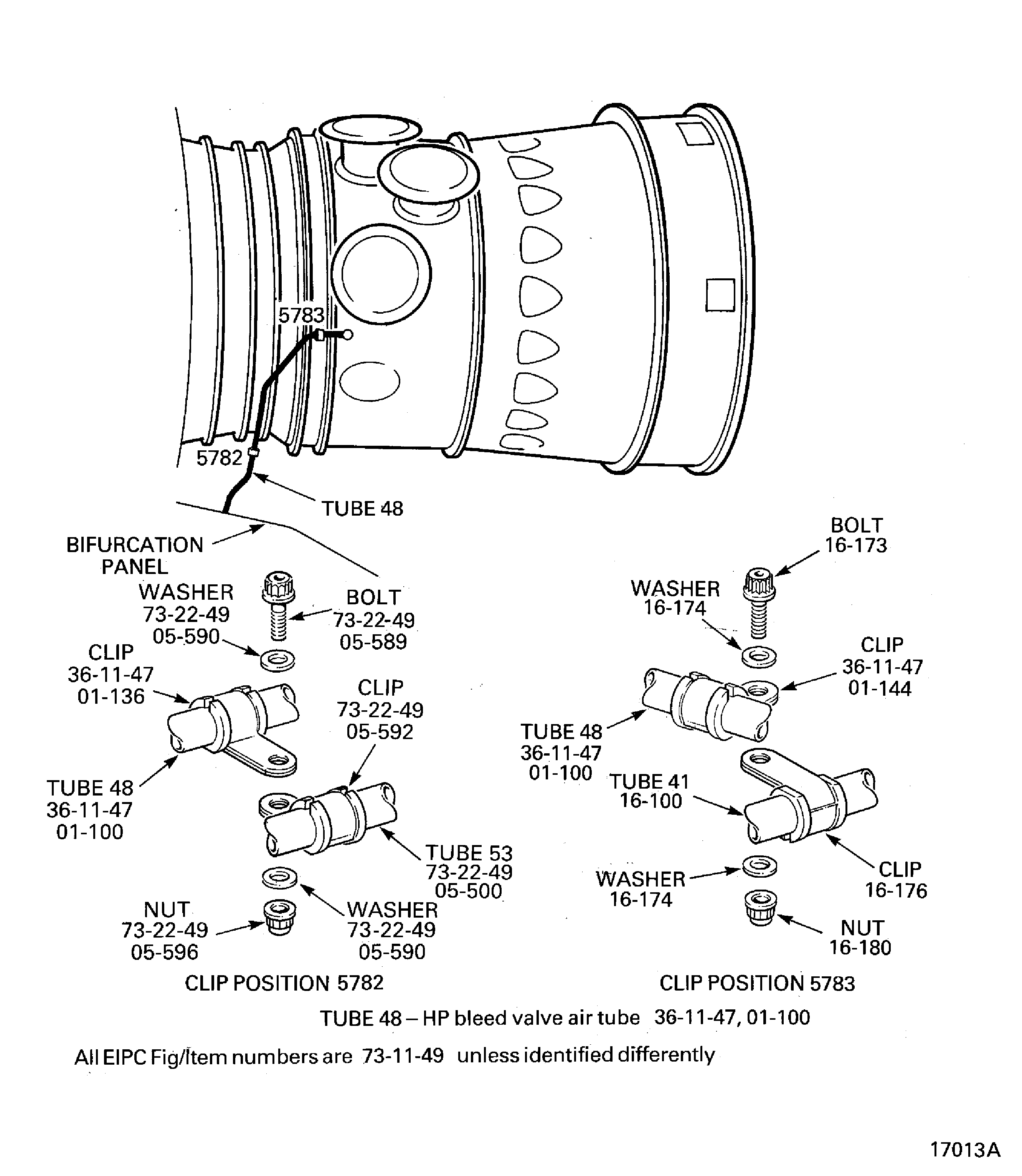

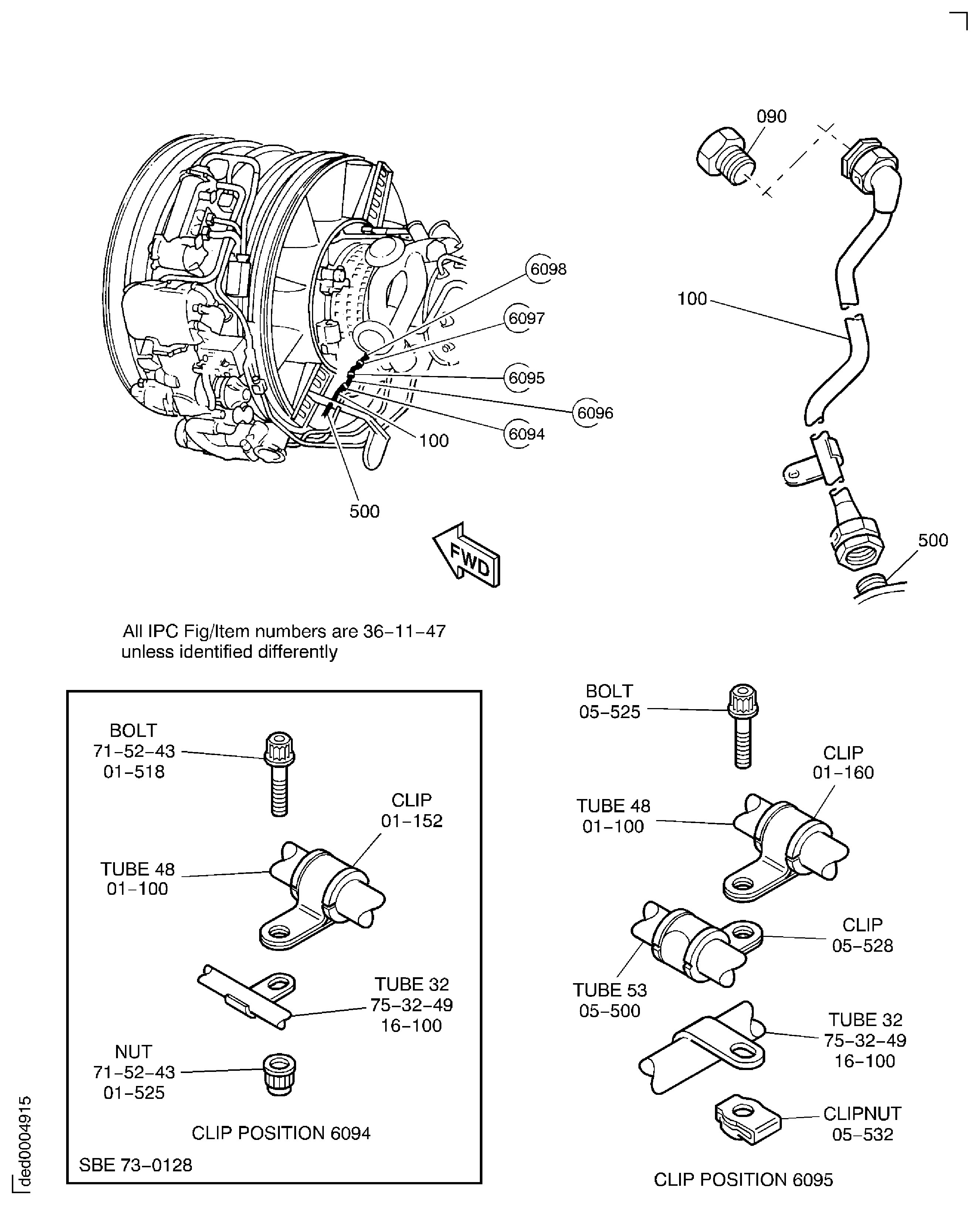

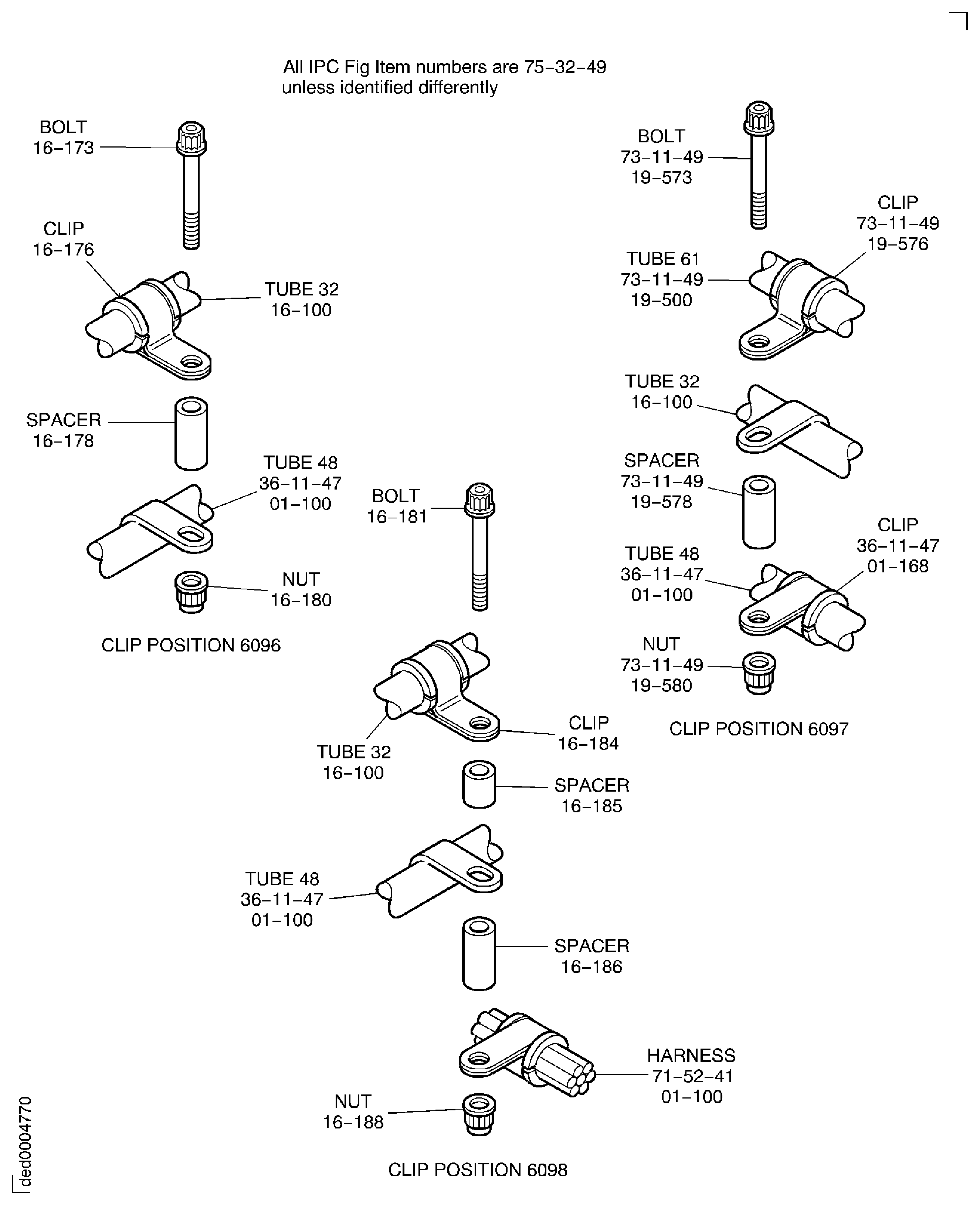

Refer to Figure.

SUBTASK 72-00-40-420-229-A00 Install the HP Bleed Control Air Tube (48) (Pre SBE 72-0189)

SBE 73-0128: Install the clips, the washers, the bolt and the nut at the clip positions 6094. Torque the nut and bolt to 36 to 45 lbfin (4 to 5 Nm).

NOTE

CP6097 is finally assembled in TASK 72-00-40-420-006-C00.Install the clips, the washers, the bolt and the nut at the clip positions, 6095, 6096 and 6098. Torque the nut and bolt to 36 to 45 lbf.in (4 to 5 Nm).

SUBTASK 72-00-40-420-229-B00 Install the HP Bleed Control Air Tube (48) (SBE 72-0189 and SBE 73-0128)

SBE 72-0189: Tube Assemblies Coupled to Bifurcation Panel Re-Run to Clear Cowl Door Hold Open Rods.

SBE 73-0128: Deletion of Harness Clip at CP6094.

Refer to Figure.

Make sure that all the applicable backshells and cable clamps are safetied with CoMat 02-126 LOCKWIRE. Refer to the SPM TASK 70-42-05-400-501.

SUBTASK 72-00-40-210-063 Visually Inspect the Electrical Backshells and Cable Clamps

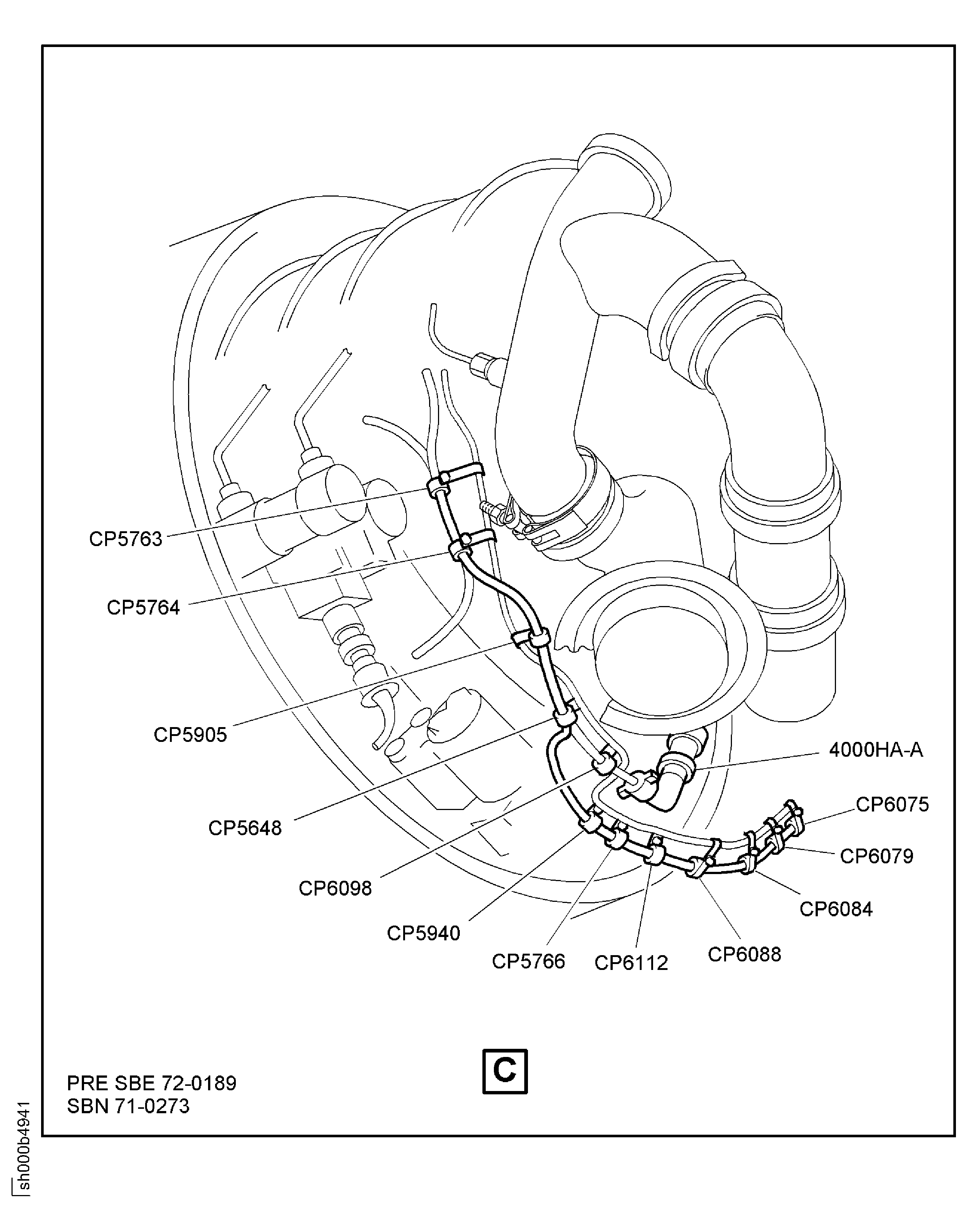

Figure: Pre SBE 72-0189: Install the Oil Feed Tubes

Sheet 1

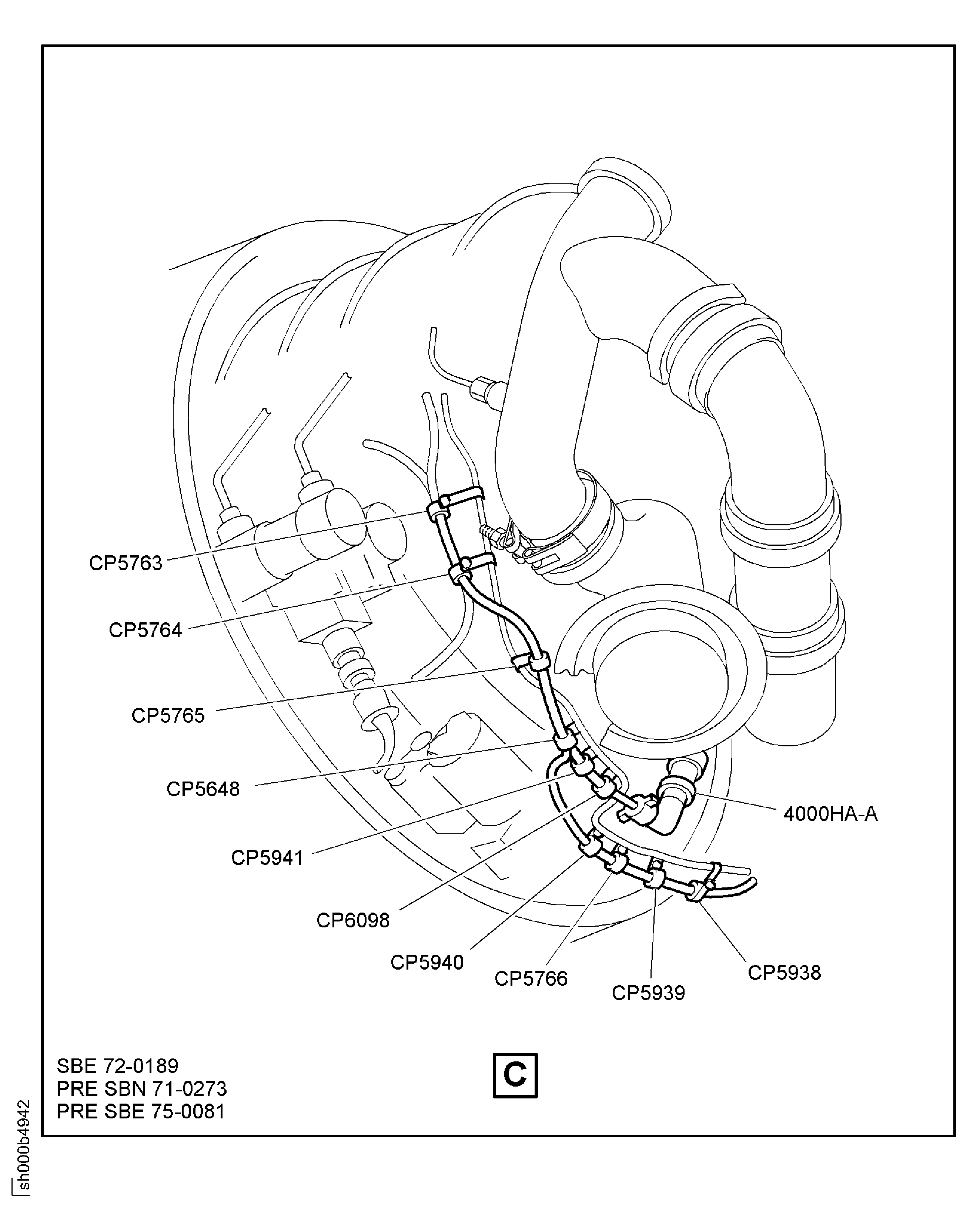

Figure: SBE 72-0189: Install the Oil Feed Tubes

Sheet 2

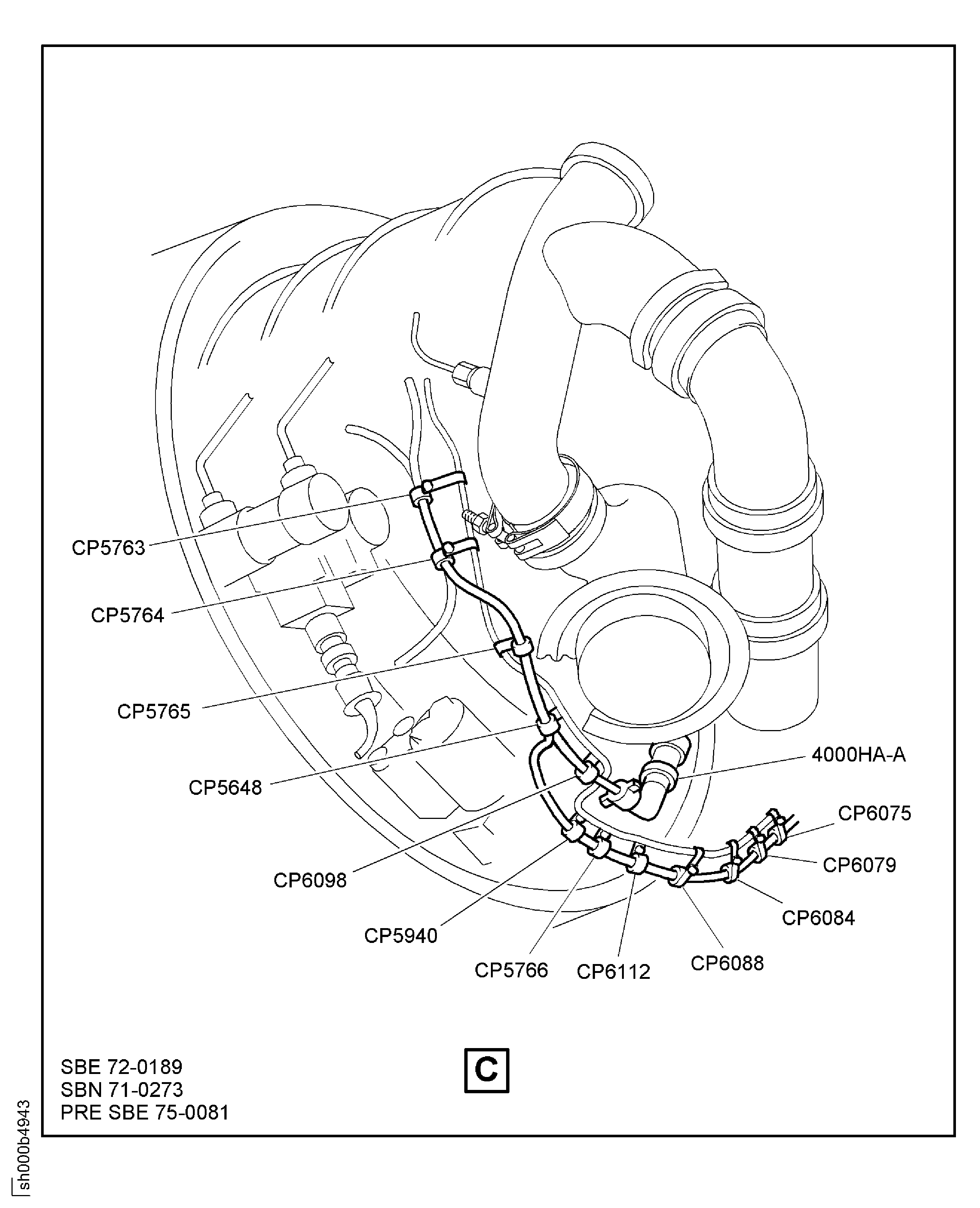

Figure: Install the Oil Feed Tubes

Sheet 3

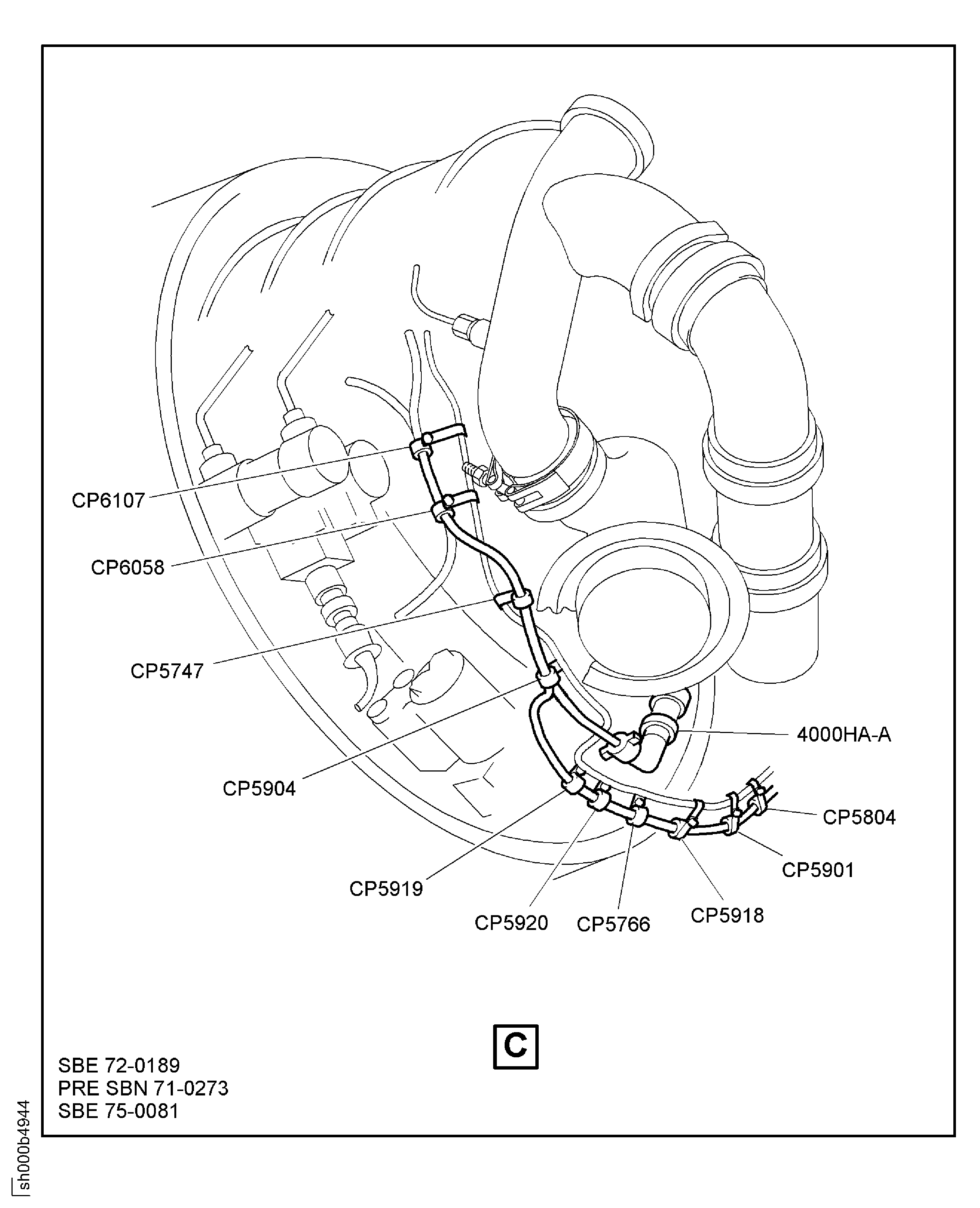

Figure: Install the Oil Feed Tubes

Sheet 4

Figure: Pre SBE 75-0092 and Pre SBE 75-0093: Install the Stage 7 HP Compressor Bleed Valve Assemblies and the Air Off-take Ducts

Sheet 1

Figure: Pre SBE 75-0093 and SBE 75-0092: Install the Stage 7 HP Compressor Bleed Valve Assemblies and the Air Off-take Ducts

Sheet 2

Figure: SBE 75-0093: Install the Stage 7 HP Compressor Bleed Valve Assemblies and the Air Off-take Ducts

Sheet 3

Figure: Install the Stage 7 HP Compressor Bleed Valve Assemblies and the Air Off-take Ducts

Sheet 4

Figure: Install the Stage 7 HP Compressor Bleed Valve Assemblies and the Air Off-take Ducts

Sheet 5

Figure: Pre SBE 72-0189: Install the HP Compressor Bleed Valve Air Tubes

Sheet 1

Figure: SBE 72-0189: Install the HP compressor bleed valve air tubes

Sheet 2

Figure: SBE 72-0189: Install the HP compressor bleed valve air tubes

Sheet 3

Figure: SBE 72-0189: Install the HP Compressor Bleed Valve Air Tubes

Sheet 4

Figure: SBE 72-0189: Install the HP compressor bleed valve air tubes

Sheet 5

Figure: Install the HP Compressor Bleed Valve Air Tubes

Sheet 6

Figure: Install the HP Compressor Bleed Valve Air Tubes

Sheet 7

Figure: Install the HP Compressor Bleed Valve Air Tubes

Sheet 8

Figure: Electrical Harness Installation

Electrical Harness Installation

Figure: Install the High Energy Ignition Harness

Sheet 1

Figure: Install the High Energy Ignition Harness

Sheet 2

Figure: Install the High Energy Ignition Harness

Sheet 3

Figure: Install the High Energy Ignition Harness

Sheet 4

Figure: Install the Fire Detection, the Nacelle Temperature and the Cabin Services Harnesses

Sheet 1

Figure: Install the Fire Detection, the Nacelle Temperature and the Cabin Services Harnesses

Sheet 2

Figure: Install the Fire Detection, the Nacelle Temperature and the Cabin Services Harnesses

Sheet 3

Figure: Install the Fire Detection, the Nacelle Temperature and the Cabin Services Harnesses

Sheet 4

Figure: Install the Fire Detection, the Nacelle Temperature and the Cabin Services Harnesses

Sheet 5

Figure: Install the Fire Detection Harnesses, the Nacelle Temperature and the Cabin Services Harness

Sheet 6

Figure: Install the Fire Detection Harnesses, the Nacelle Temperature and the Cabin Services Harness

Sheet 7

Figure: Install the Fire Detection Harnesses, the Nacelle Temperature and the Cabin Services Harness

Sheet 8

Figure: Install the Fire Detection Harnesses, the Nacelle Temperature and the Cabin Services Harness

Sheet 9

Figure: Install the Fire Detection Harnesses, the Nacelle Temperature and the Cabin Services Harness

Sheet 10

Figure: Install the Fire Detection Harnesses, the Nacelle Temperature and the Cabin Services Harness

Sheet 11

Figure: Install the Fire Detection Harnesses, the Nacelle Temperature and the Cabin Services Harness

Sheet 12

Figure: Install the Fire Detection Harnesses, the Nacelle Temperature and the Cabin Services Harness

Sheet 13

Figure: Install the Fire Detection Harnesses, the Nacelle Temperature and the Cabin Services Harness

Sheet 14

Figure: Install the Fire Detection Harnesses, the Nacelle Temperature and the Cabin Services Harness

Sheet 15

Figure: Install the Fire Detection Harnesses, the Nacelle Temperature and the Cabin Services Harness

Sheet 16

Figure: Install the Fire Detection Harnesses, the Nacelle Temperature and the Cabin Services Harness

Sheet 17

Figure: Install the Fire Detection Harnesses, the Nacelle Temperature and the Cabin Services Harness

Sheet 18

Figure: Install the Fire Detection Harnesses, the Nacelle Temperature and the Cabin Services Harness

Sheet 19

Figure: Install the Fire Detection Harnesses, the Nacelle Temperature and the Cabin Services Harness

Sheet 20

Figure: Install the Fire Detection Harnesses, the Nacelle Temperature and the Cabin Services Harness

Sheet 21

Figure: Pre SBE 74-0001: Install the Ignition Exciter Cross Brackets and the Support Tubes

Sheet 1

Figure: SBE 74-0001: Install the Ignition Exciter Support Brackets

Sheet 2

Figure: Install the Cabin Bleed Air System Ducts and the Valves

Sheet 1

Figure: Install the Cabin Bleed Air System Ducts and the Valves

Sheet 2

Figure: Pre SBE 36-0007, Pre SBE 75-0081 and SBN 71-0273: Install the Cabin Bleed Air System Sense Tubes

Sheet 1

Figure: SBE 36-0007: Install the Cabin Bleed Air System Sense Tubes

Sheet 2

Figure: Install the Cabin Bleed Air System Sense Tubes

Sheet 3

Figure: Pre SBE 36-0007, Pre SBE 75-0081: Install the Cabin Bleed Air System Sense Tubes

Sheet 4

Figure: SBE 75-0081: Install the Cabin Bleed Air System Sense Tubes

Sheet 5

Figure: Pre SBE 36-0007: Install the Cabin Bleed Air System Sense Tubes

Sheet 6

Figure: Pre SBE 36-0007, SBN 71-0273: Install the Cabin Bleed Air System SenseTtubes

Sheet 7

Figure: SBE 36-0007: Install the Cabin Bleed Air System Sense Tubes

Sheet 8

Figure: Pre SBE 72-0189: Install the HP Bleed Control Air Tube (48)

Sheet 1

Figure: SBE 72-0189: Install the HP Bleed Control Air Tube (48)

Sheet 2

Figure: SBE 72-0189: Install the HP Bleed Control Air Tube (48)

Sheet 3

Figure: Visually Inspect the Backshells and Cable Clamps

Visually Inspect the Backshells and Cable Clamps