Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5 and Post SBE 79-0088

Common Information

TASK 72-00-40-420-006-C00 HP System Module - Install And Connect The Components, Electrical Harnesses, And Tubes On The Front Of The HPC Case, Installation-009 - SBE 79-0088

General

This TASK gives the procedure to install and connect the components, the electrical harnesses and the tubes at the front of the HP system module. Refer to the TASKs which follow for other related procedures.

TASK 72-00-40-420-004-B00 (INSTALLATION) - Install the initial components, the air off-take ducts and the tubes to the HP system module.

TASK 72-00-40-420-005-C00 (INSTALLATION) - Install the components, the ducts, the electrical harnesses and the tubes at the HP compressor vertical splitline.

TASK 72-00-40-420-007-B00 (INSTALLATION) - Install the components, the electrical harnesses, the tubes and the brackets on the HP turbine.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Assembly tolerances are included in this procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS approved engine oils, unless other lubricants are referred to in the procedure.

Special torque data is identified with the symbol * after the torque value.

For the torque tightening procedures refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

To identify, lubricate and install seal rings refer to the SPM TASK 70-44-01-400-501.

For lockwire data and procedures refer to the SPM TASK 70-42-05-400-501.

For safety cable data and procedures refer to SPM TASK 70-42-08-400-501.

Safety the threaded fasteners in this TASK with CoMat 02-274 SAFETY CABLE KIT safety cable or CoMat 02-275 SAFETY CABLE KIT safety cable for the ATA Chapter/Section/Subjects which follow:

A5 series engines: | ||

71-51-41 | 71-52-43 | 72-41-34 |

73-22-49 | 75-23-49 | 75-31-42 |

75-31-43 | 75-32-42 |

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attachment parts. Use the correct color of air drying enamel. Refer to the SPM TASK 70-38-21-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Transportation covers/blanks must not be removed until immediately before installation of the components.

Do not remove the special plastic caps from electrical connections until immediately before installation. This will give protection from unwanted material.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| 0.937 in. (24.00 mm) crowsfoot spanner | LOCAL | 0.937 in. (24.00 mm) crowsfoot spanner | ||

| IAE 1N20014 Forward engine mount sling | 0AM53 | IAE 1N20014 | 1 | |

| IAE 1R18000 Wrench | 0AM53 | IAE 1R18000 | 1 | |

| IAE 1R18001 Wrench | 0AM53 | IAE 1R18001 | 1 | |

| IAE 1R18003 Wrench | 0AM53 | IAE 1R18003 | 1 | |

| IAE 1R18254 Rigging pin | 0AM53 | IAE 1R18254 | 1 | |

| IAE 1R18282 Rigging pin | 0AM53 | IAE 1R18282 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-060 LIQUID PARAFFIN | LOCAL | CoMat 10-060 | ||

| CoMat 10-038 PETROLEUM JELLY | LOCAL | CoMat 10-038 | ||

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 02-274 SAFETY CABLE KIT | LOCAL | CoMat 02-274 | ||

| CoMat 02-275 SAFETY CABLE KIT | LOCAL | CoMat 02-275 | ||

| CoMat 01-001 SOLVENT, DELETED | 0AM53 | CoMat 01-001 | ||

| CoMat 04-005 JOINTING COMPOUND, MEDIUM GRADE | LOCAL | CoMat 04-005 | ||

| CoMat 02-119 LOCKWIRE | LOCAL | CoMat 02-119 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 | ||

| CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) | LOCAL | CoMat 02-148 | ||

| CoMat 02-141 LOCKWIRE | LOCAL | CoMat 02-141 | ||

| CoMat 02-159 LACING TAPE | LOCAL | CoMat 02-159 | ||

| CoMat 05-016 GARNET PAPER, 80-GRIT | LOCAL | CoMat 05-016 | ||

| CoMat 05-017 GARNET PAPER, 60 GRIT | LOCAL | CoMat 05-017 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 08-013 COLD CURING SILICONE COMPOUND | LOCAL | CoMat 08-013 | ||

| CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT | 0AM53 | CoMat 08-014 | ||

| CoMat 08-074 SEALANT, RTV SILICONE | 01139 | CoMat 08-074 | ||

| CoMat 08-032 PRIMER | LOCAL | CoMat 08-032 | ||

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 |

Spares

Safety Requirements

NONEProcedure

Lightly lubricate a new Control Fuel Tubes(73-11-49, 11-096) preformed packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY.

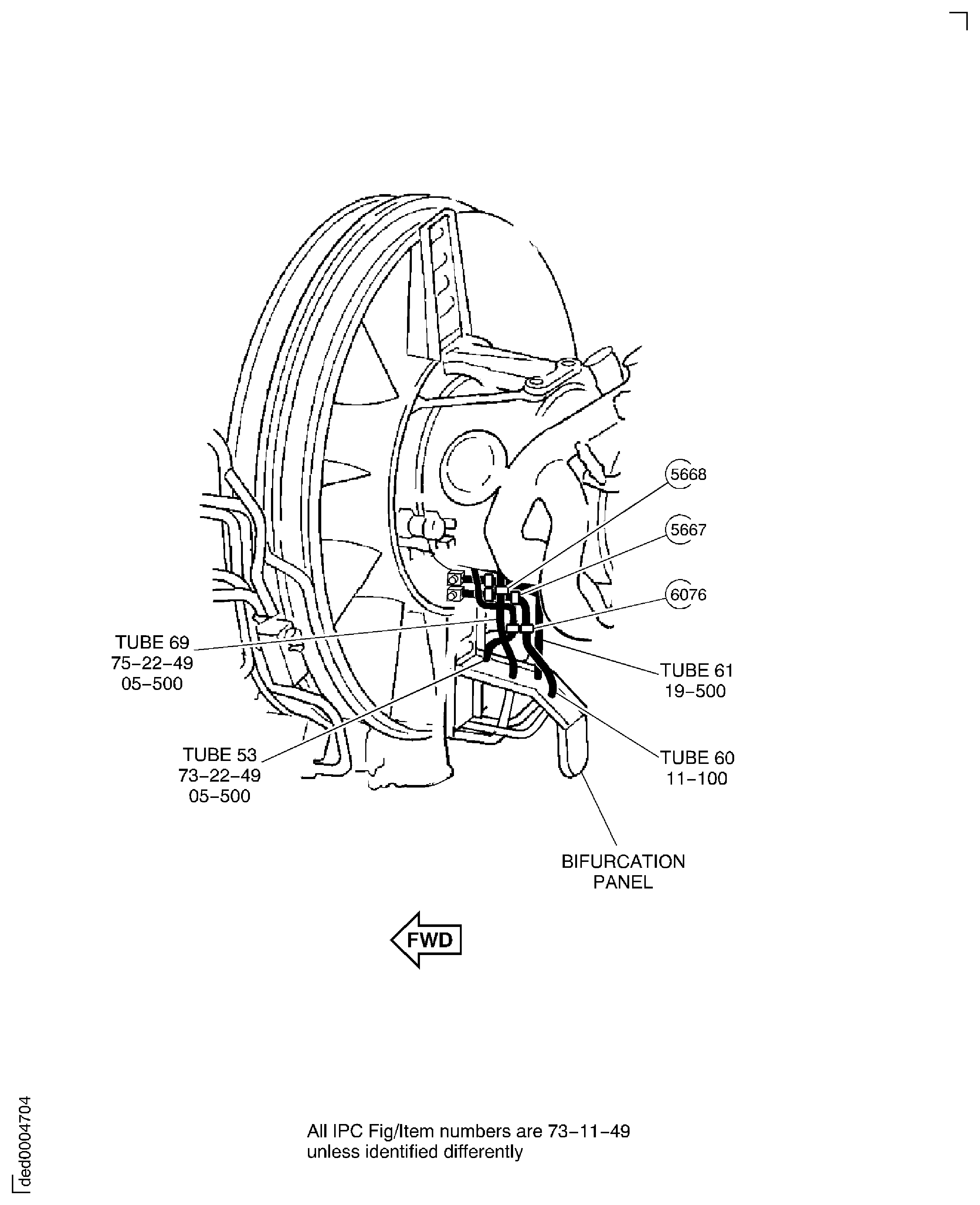

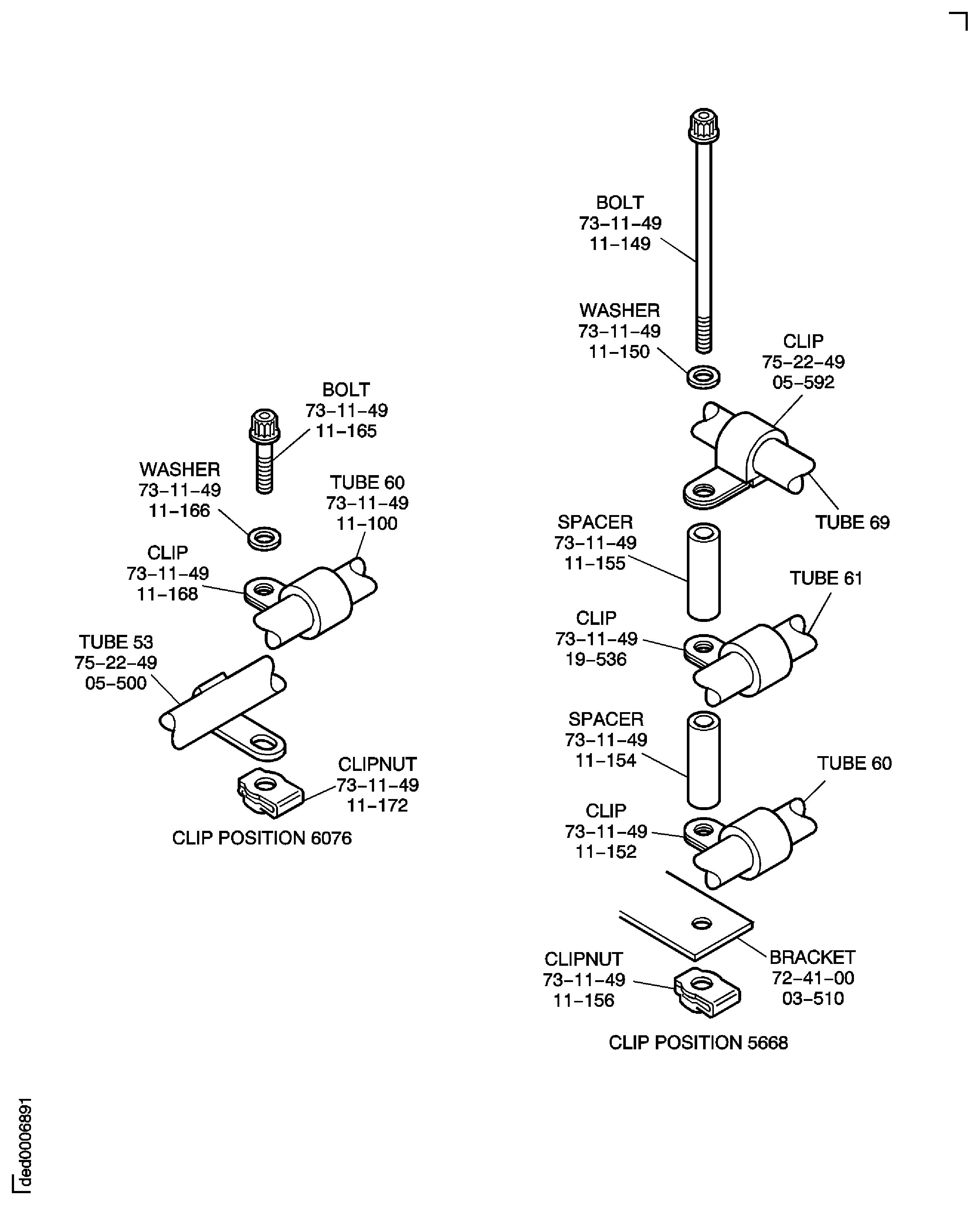

Install the preformed packing on the fuel tube 93 Control Fuel Tubes(73-11-49, 10-500) at the bifurcation panel and loosely connect the tube 60.

Lightly lubricate a new Control Fuel Tubes(73-11-49, 19-498) preformed packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY.

Install the preformed packing on the fuel tube 106 Control Fuel Tubes(73-11-49, 20-100) at the bifurcation panel and loosely connect the tube 61.

NOTE

The installation of the tubes 60 and 61 is completed and the connectors are tightened and safetied in Step.Connect the fuel tubes 60 Control Fuel Tubes(73-11-49, 11-100) and 61 Control Fuel Tubes(73-11-49, 19-500) at the bifurcation panel.

Connect the tube 20 to the oil scavenge tube 124 OIL-SCAVENGE OIL TUBES-ENGINE(79-22-49, 02-100). With the IAE 1R18001 Wrench 1 off, torque the tube connector to 398 to 434 lbfin (45 to 49 Nm) then safety with CoMat 02-126 LOCKWIRE.

With IAE 1R18003 Wrench 1 off torque the tube connector at the bifurcation panel to 566 to 611 lbfin (64 to 69 Nm).

Safety the tube nut and tube connector with CoMat 02-126 LOCKWIRE.

Connect the tube 55:

CAUTION

YOU MUST STOP THE TUBE TURNING WHEN YOU TORQUE THE TUBE NUTS. USE A SPANNER ON THE REAR OF THE MATING UNION. THIS WILL PREVENT ANY STRAIN ON THE TUBES AND HELP PREVENT LEAKS.NOTE

The tubes 20 and 55 were installed in TASK 72-00-40-420-004-B00 (INSTALLATION-007).Connect the oil scavenge tubes 20 Engine Scavenge Oil Tubes(79-22-49, 01-500) and 55 OIL-SCAVENGE OIL TUBES-ENGINE(79-22-49, 03-100) at the bifurcation panel.

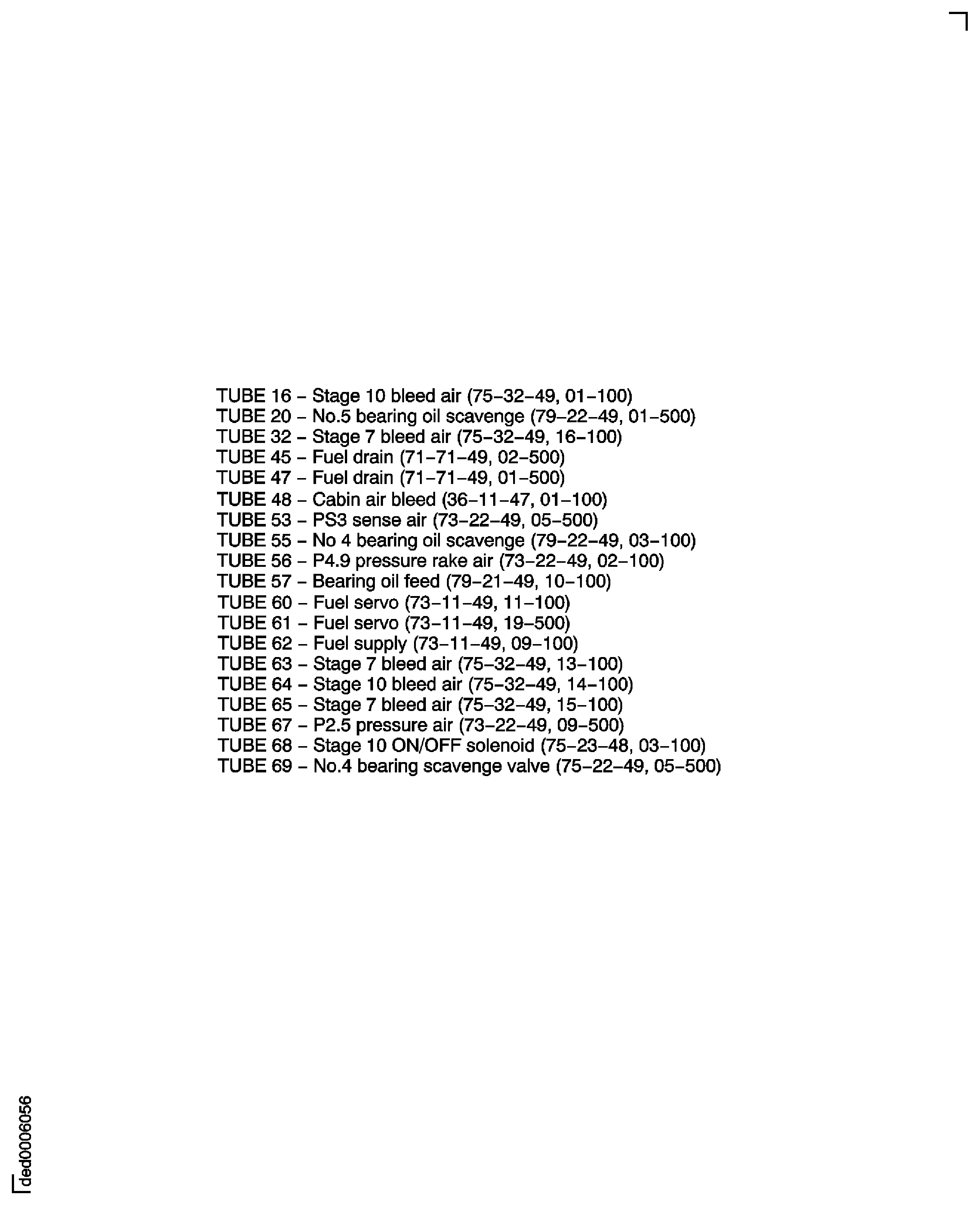

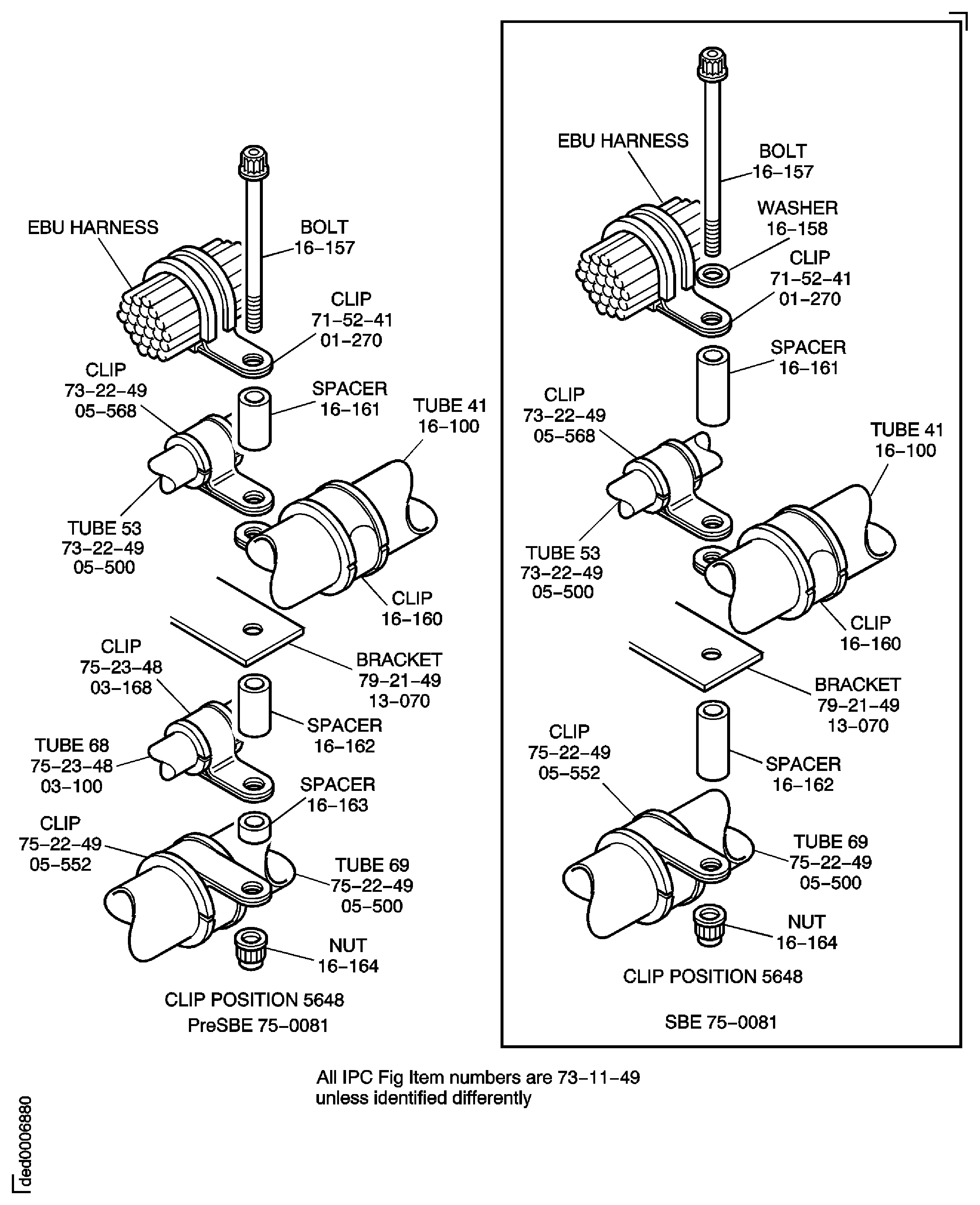

The tubes 16, 53, 56, 68 and 69 were installed in TASK 72-00-40-420-004-B00 (INSTALLATION-007, CONFIG-002).

The tubes 32, 48, 63, 64 and 65 were installed in TASK 72-00-40-420-005-C00 (INSTALLATION-008, CONFIG-003).

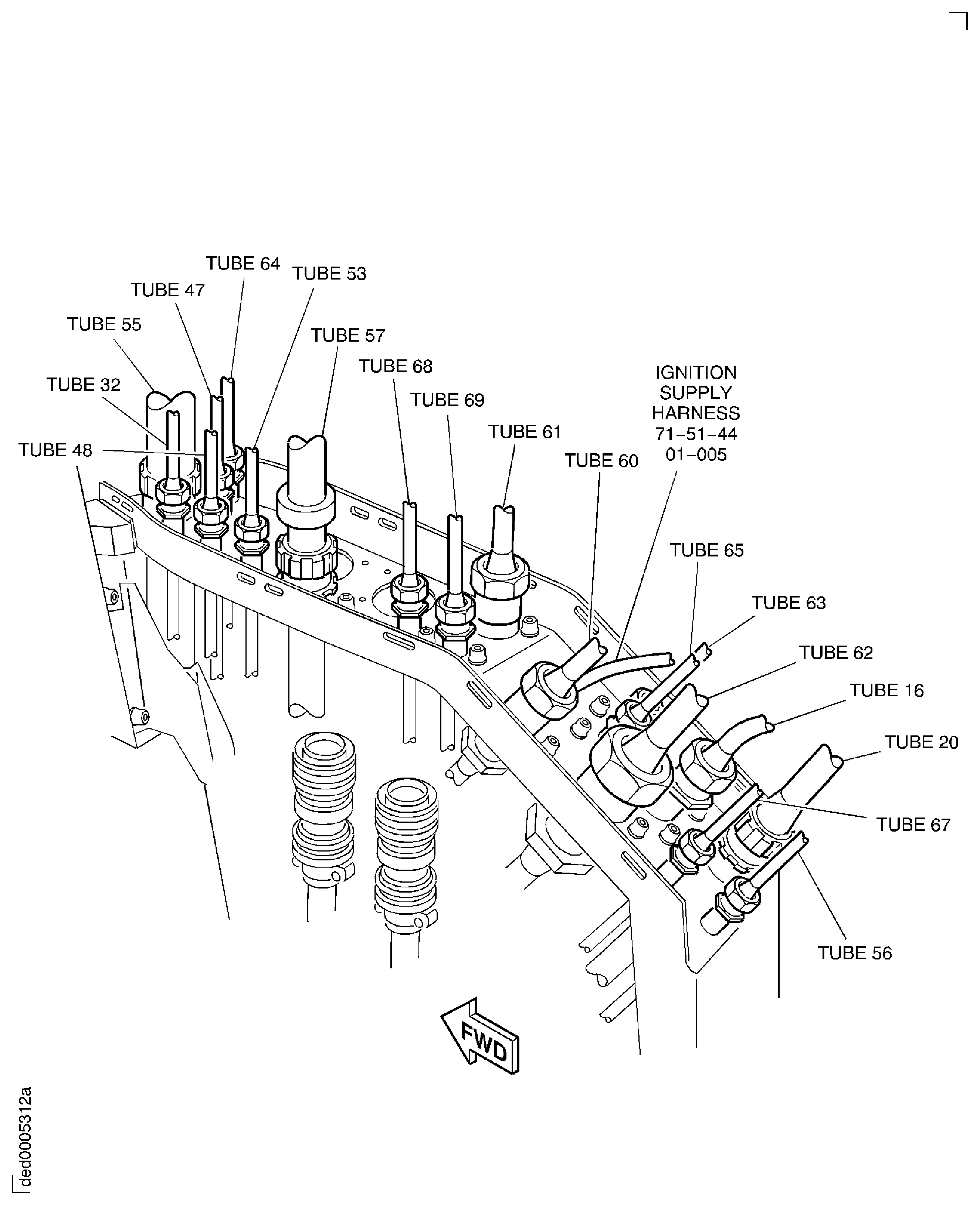

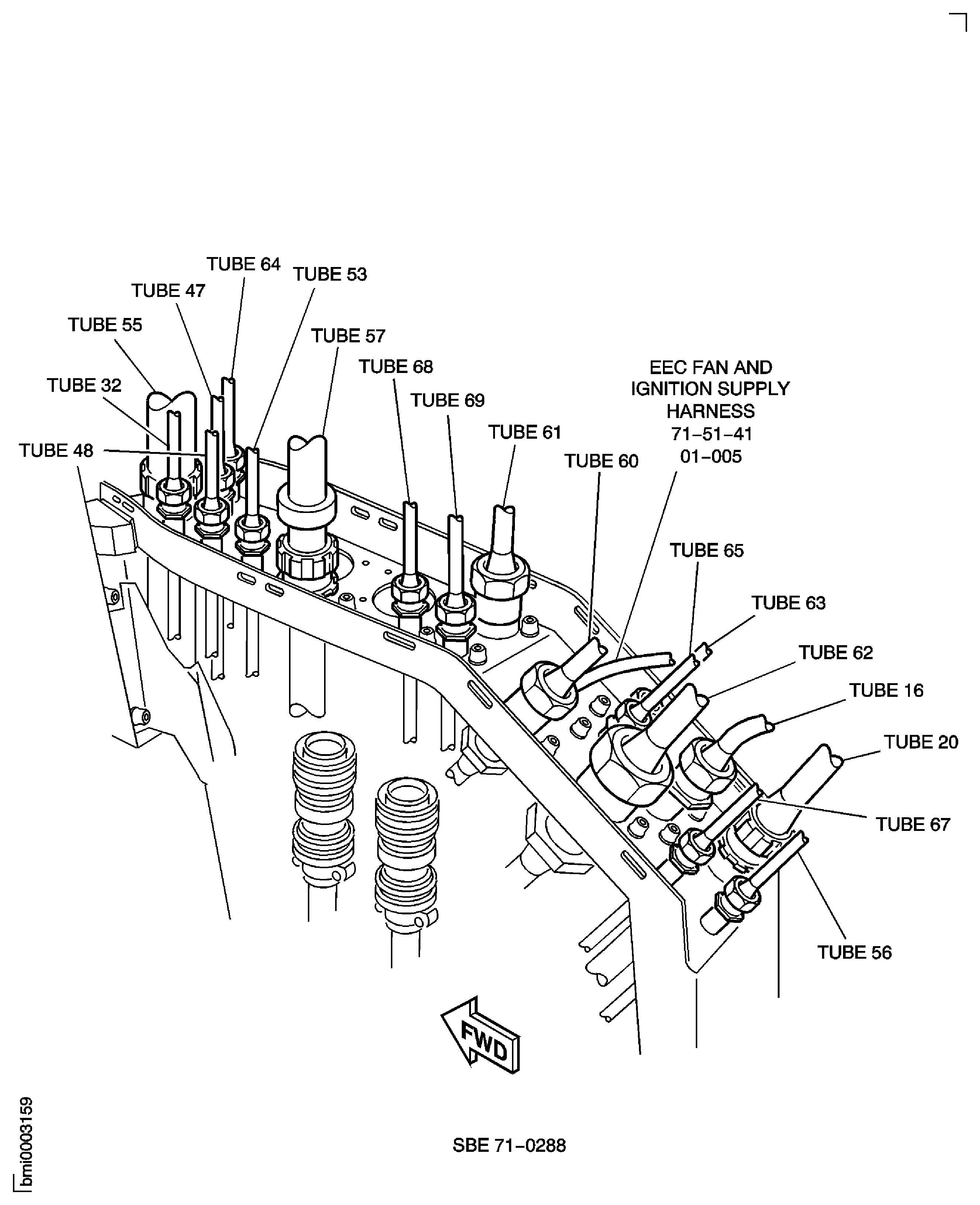

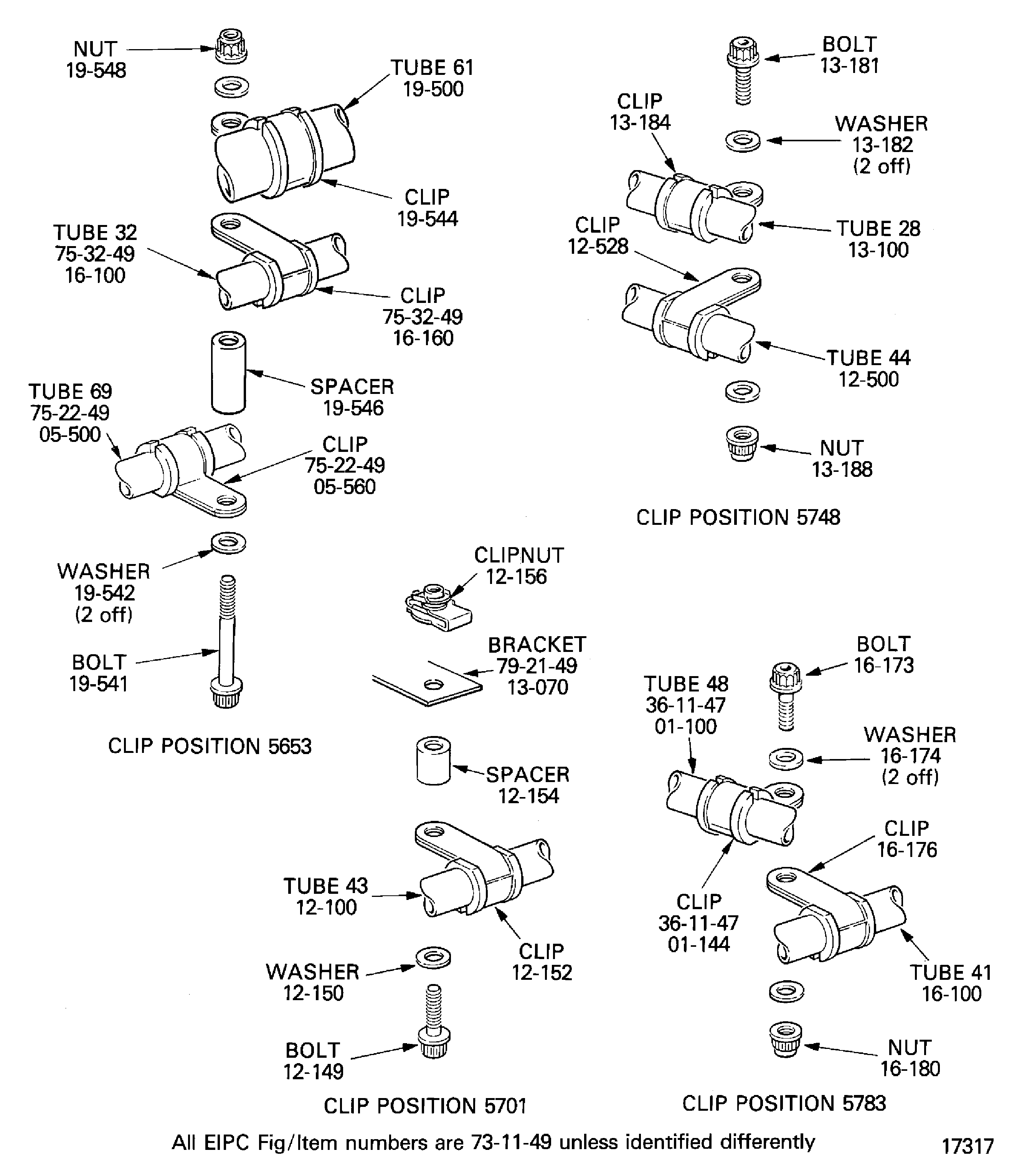

Connect the bleed air tube 16 HPC Bleed Control Air Tubes(75-32-49, 01-100) to the bleed air tube 168 HPC Bleed Control Air Tubes(75-32-49, 01-500). Torque the tube connector to 283 to 310 lbfin (32 to 35 Nm) then safety with CoMat 02-126 LOCKWIRE.

Connect the bleed air tube 32 AIR-HP COMPRESSOR BLEED CONTROL TUBES(75-32-49, 16-100) to the bleed air tube 161 HPC Bleed Control Air Tubes(75-32-49, 10-500). Torque the tube connector to 159 to 177 lbfin (18 to 20 Nm) then safety with CoMat 02-126 LOCKWIRE.

Connect the bleed air tube 48 PNEUMATIC-TUBES-HP BLEED CONTROL AIR(36-11-47, 01-100) to the bleed air tube 153 PNEUMATIC-TUBES-HP BLEED CONTROL AIR(36-11-47, 01-500). Torque the tube connector to 159 to 177 lbfin (18 to 20 Nm) then safety with CoMat 02-126 LOCKWIRE.

Connect the air tube 53 Fuel System Air Tubes(73-22-49, 05-500) to the air tube 138 Fuel System Air Tubes(73-22-49, 06-100). Torque the tube connector to 159 to 177 lbfin (18 to 20 Nm) then safety with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT safety cable.

Connect the air tube 56 Fuel System Air Tubes(73-22-49, 02-100) to the air tube 157 Fuel System Air Tubes(73-22-49, 02-500). Torque the tube connector to 159 to 177 lbfin (18 to 20 Nm) then safety with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT safety cable.

Connect the bleed air tube 63 HPC Bleed Control Air Tubes(75-32-49, 13-100) to the bleed air tube 156 AIR-HP COMPRESSOR BLEED CONTROL TUBES(75-32-49, 12-100). Torque the tube connector to 159 to 177 lbfin (18 to 20 Nm) then safety with CoMat 02-126 LOCKWIRE.

Connect the bleed air tube 64 AIR-HP COMPRESSOR BLEED CONTROL TUBES(75-32-49, 14-100) to the bleed air tube 166 AIR-HP COMPRESSOR BLEED CONTROL TUBES(75-32-49, 04-500). Torque the tube connector to 159 to 177 lbfin (18 to 20 Nm) then safety with CoMat 02-126 LOCKWIRE.

Connect the bleed air tube 65 HPC Bleed Control Air Tubes(75-32-49, 15-100) to the bleed air tube 145 AIR-HP COMPRESSOR BLEED CONTROL TUBES(75-32-49, 08-500). Torque the tube connector to 159 to 177 lbfin (18 to 20 Nm) then safety with CoMat 02-126 LOCKWIRE.

Pre SBE 75-0081: Connect the air tube 68 Bearing Compartment Cooling And Sealing Air Tubes(75-22-49, 05-500) to the air tube 162 Turbine Cooling Air (TCA) Controlled Air Tubes(75-23-48, 03-100). Torque the tube connector to 159 to 177 lbfin (18 to 20 Nm) then safety with CoMat 02-126 LOCKWIRE.

Connect the cooling air tube 69 Bearing Compartment Cooling And Sealing Air Tubes(75-22-49, 05-500) to the cooling air tube 143 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES(75-22-49, 06-100). Torque the tube connector to 204 to 221 lbfin (23 to 25 Nm) then safety with CoMat 02-126 LOCKWIRE.

CAUTION

YOU MUST STOP THE TUBE TURNING WHEN YOU TORQUE THE TUBE NUTS. USE A SPANNER ON THE REAR OF THE MATING UNION. THIS WILL PREVENT ANY STRAIN ON THE TUBES AND HELP PREVENT LEAKS.NOTE

Connect the air tubes at the bifurcation panel.

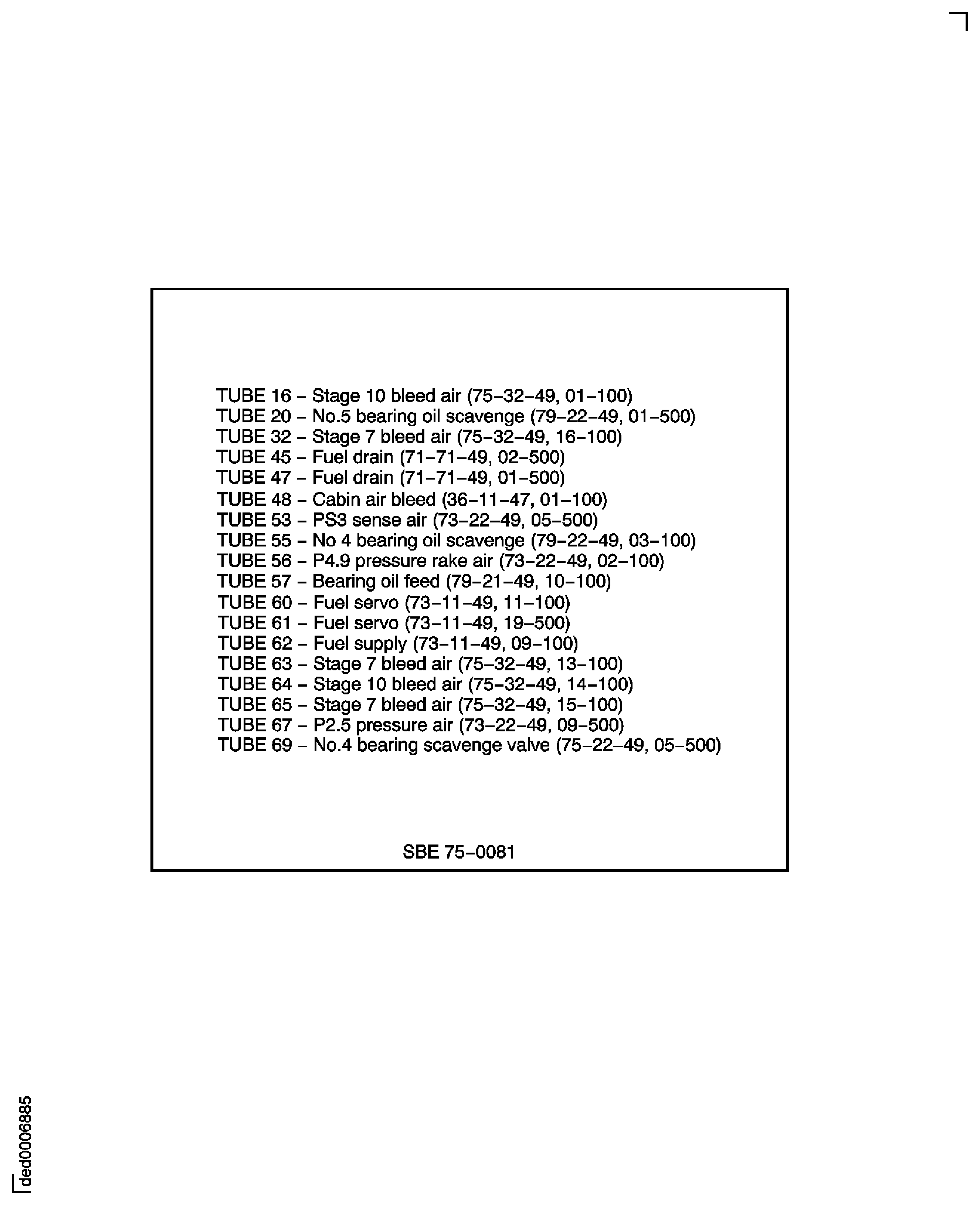

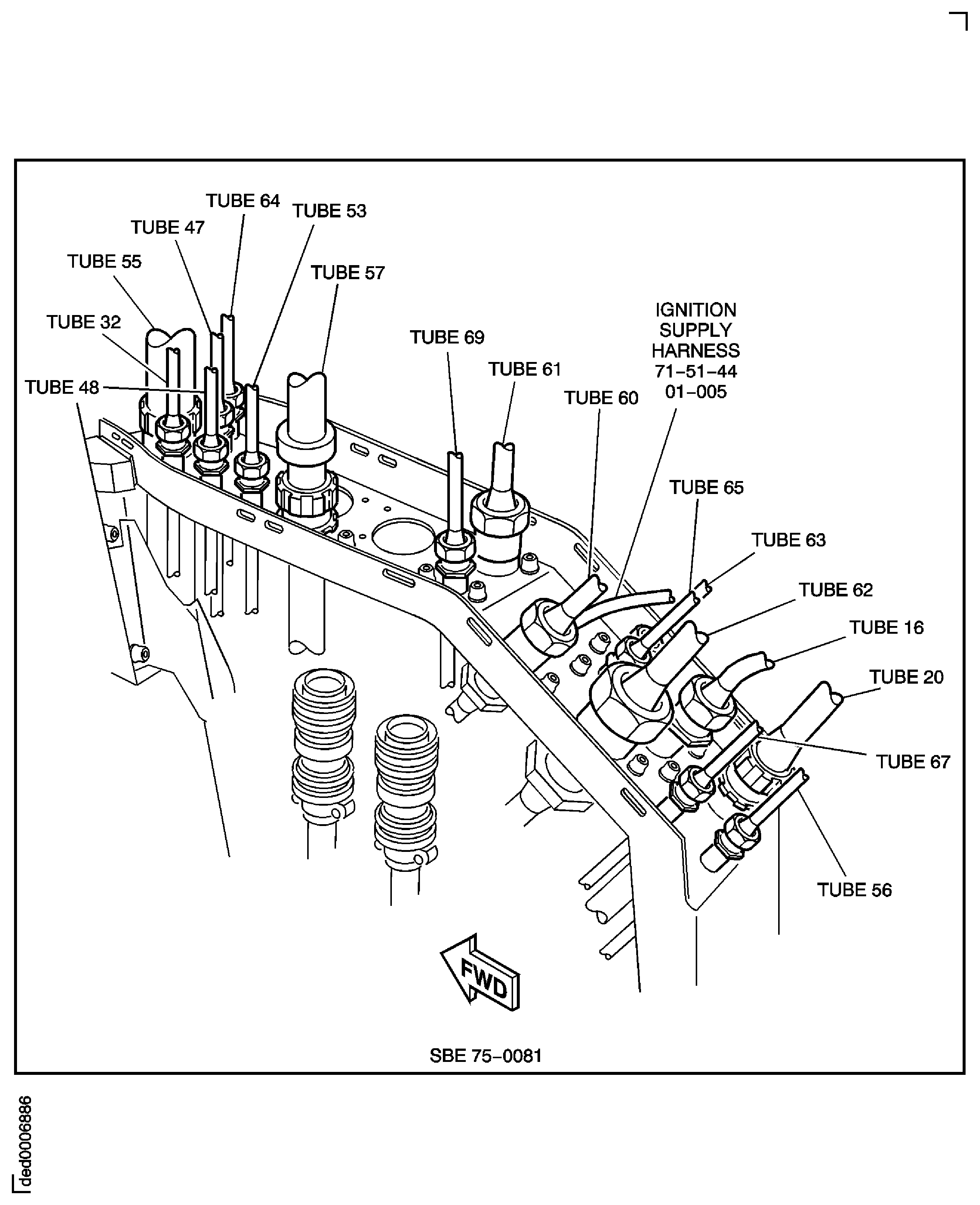

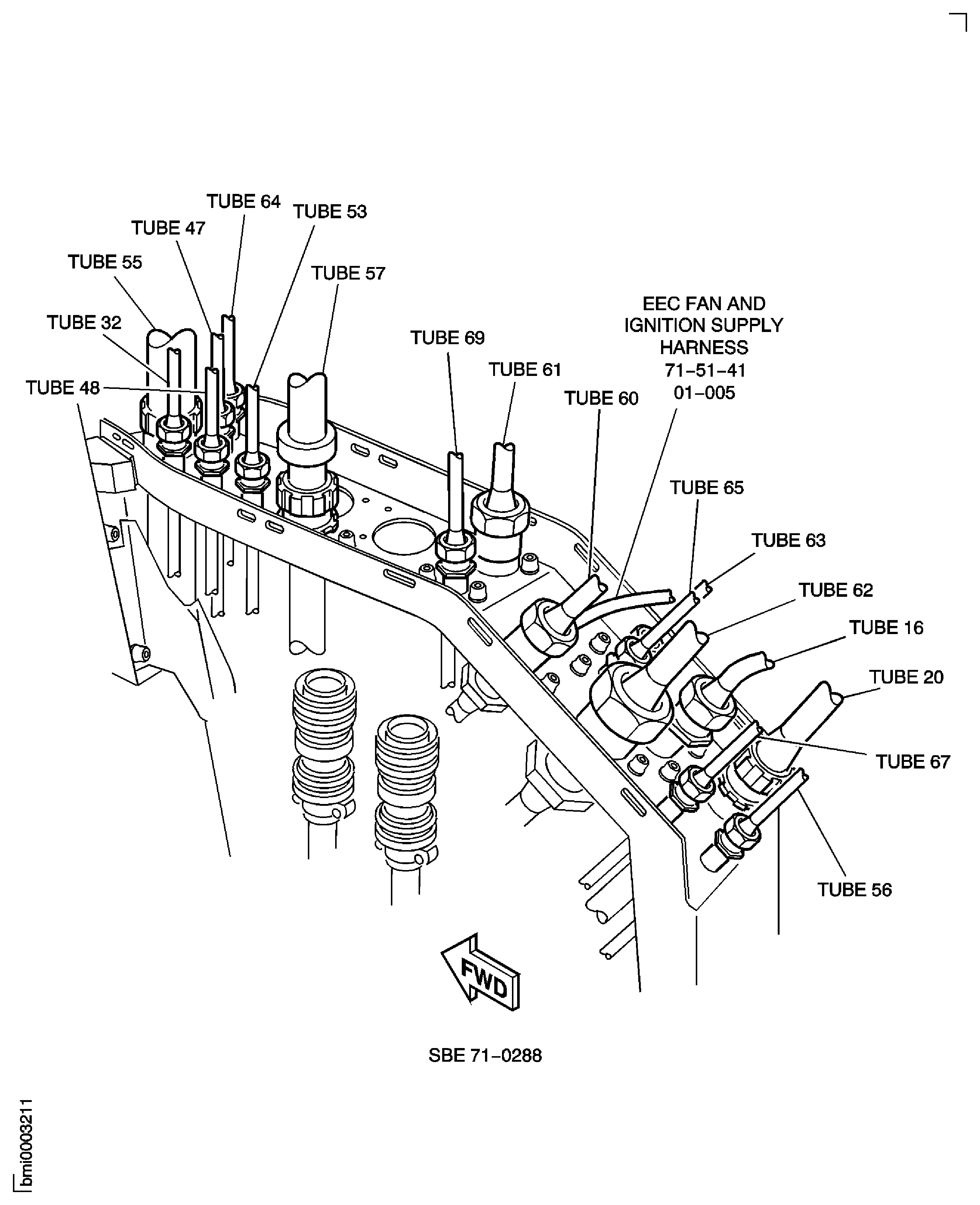

SUBTASK 72-00-40-420-334 Connect the Tubes at the Bifurcation Panel (Pre SBE 75-0081 and SBE 75-0081)

SBE 75-0081: Air - Deletion of the HPC stage 10 make up air valve.

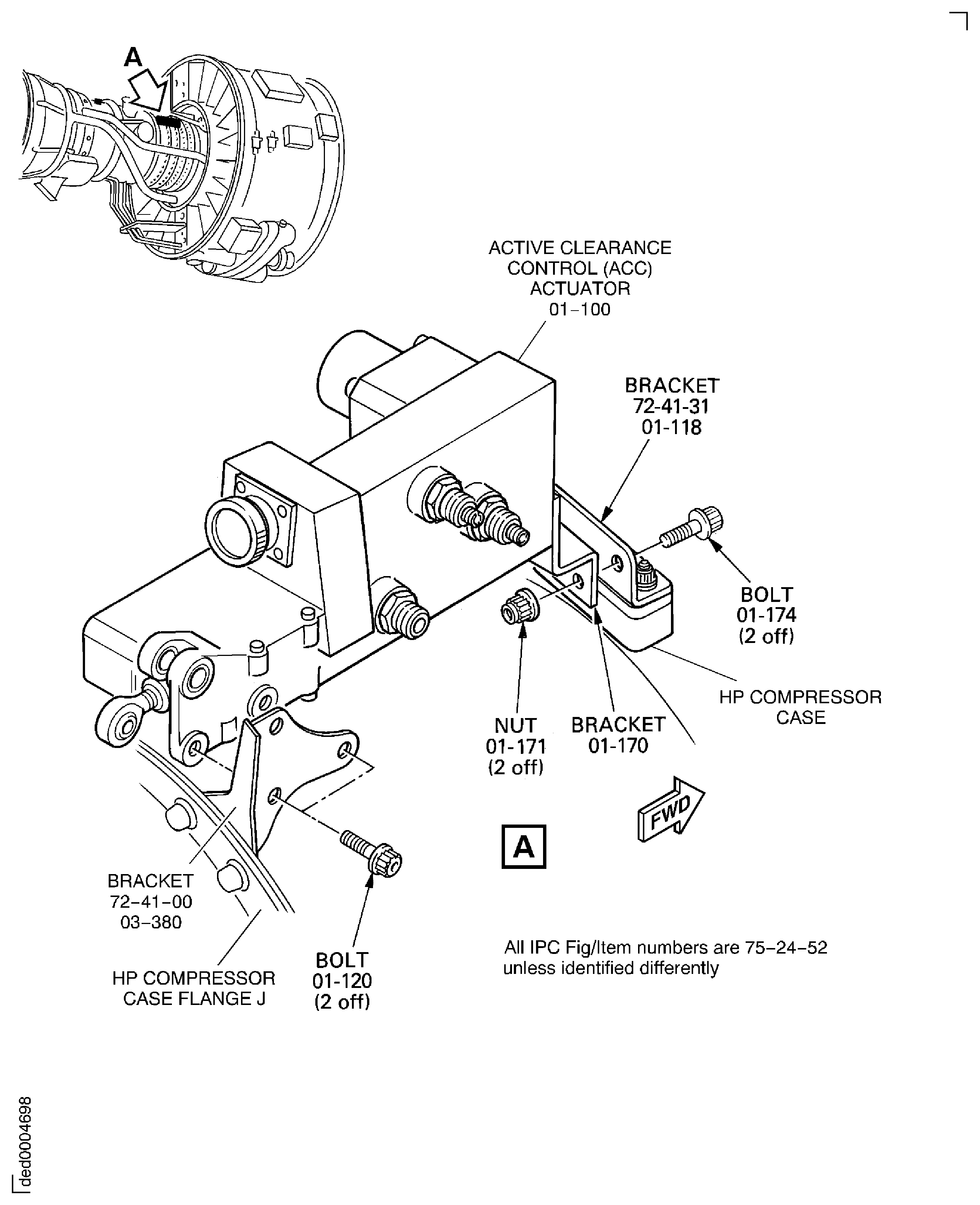

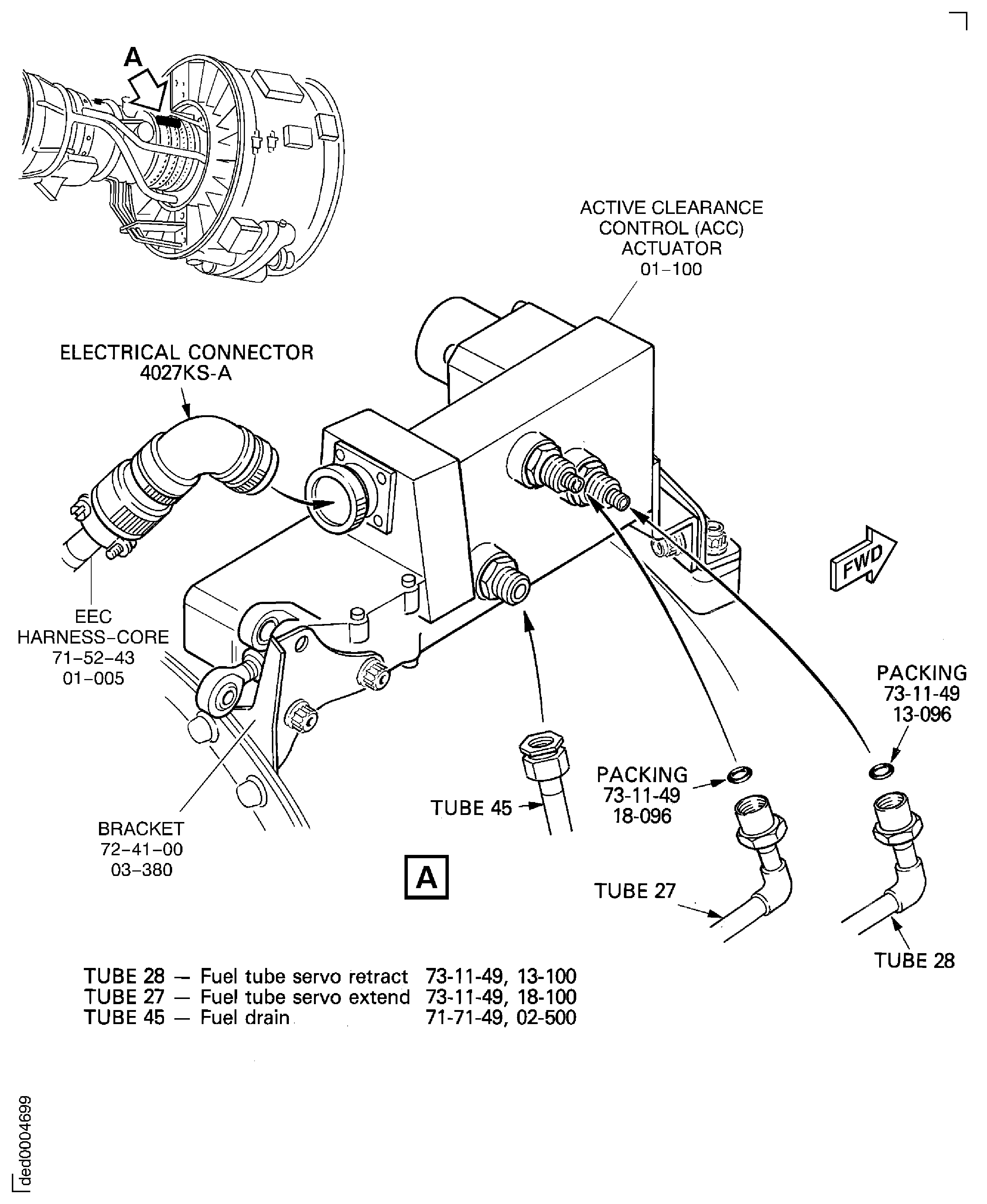

Attach the ACC actuator to the bracket HP COMPRESSOR SPLIT CASE(72-41-31, 01-118) with the two bolts Active Clearance Control (ACC) Actuator(75-24-52, 01-174) and the nuts Active Clearance Control (ACC) Actuator(75-24-52, 01-171).

Install the two bolts Active Clearance Control (ACC) Actuator(75-24-52, 01-120) that attach the ACC actuator to the bracket HPC Assembly(72-41-00, 03-380).

Torque the two nuts Active Clearance Control (ACC) Actuator(75-24-52, 01-171) to 36 to 45 lbfin (4 to 5 Nm).

Torque the two bolts Active Clearance Control (ACC) Actuator(75-24-52, 01-120) to 85 to 105 lbfin (10 to 12 Nm).

SUBTASK 72-00-40-420-335 Install the Active Clearance Control (ACC) Actuator

WARNING

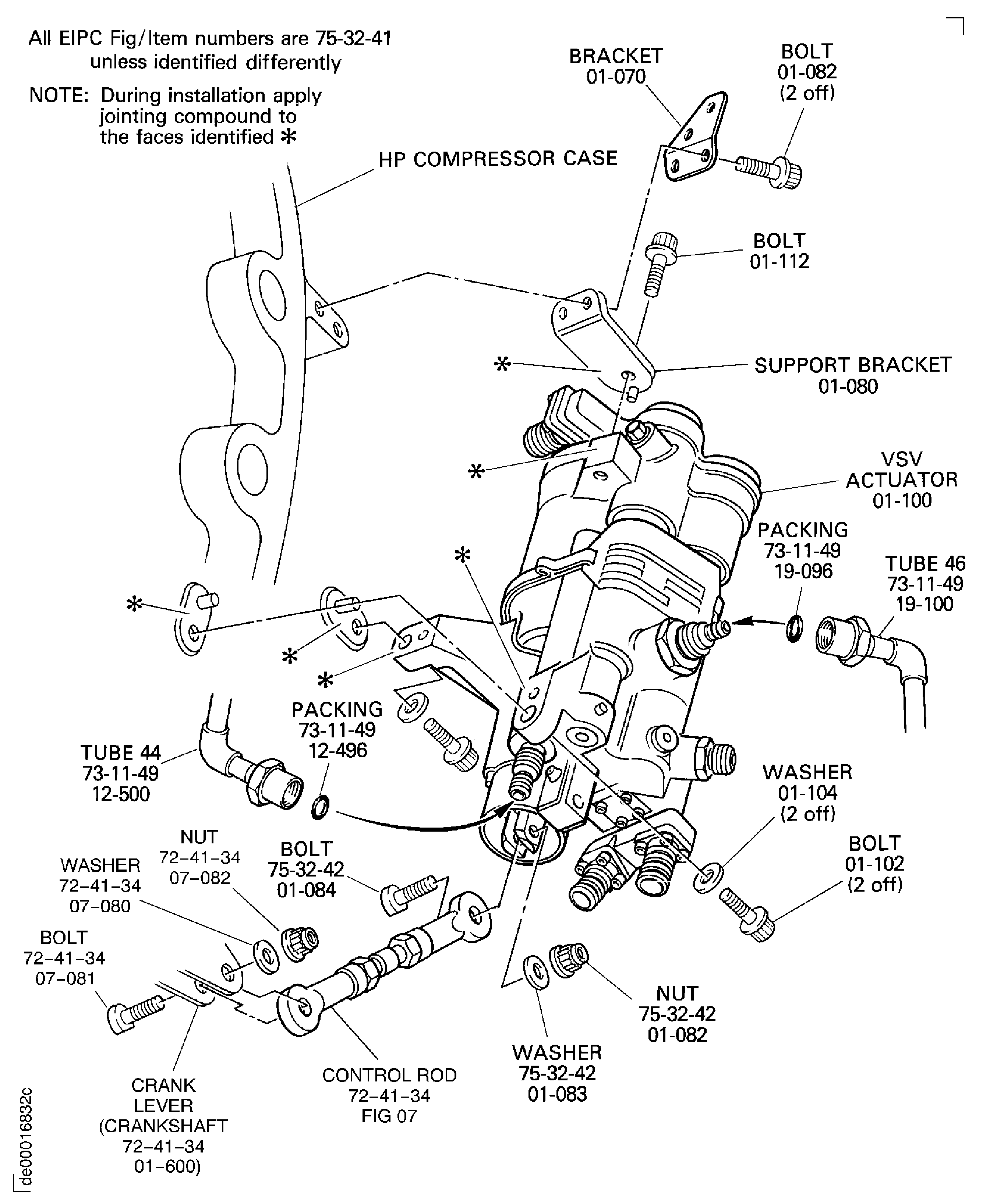

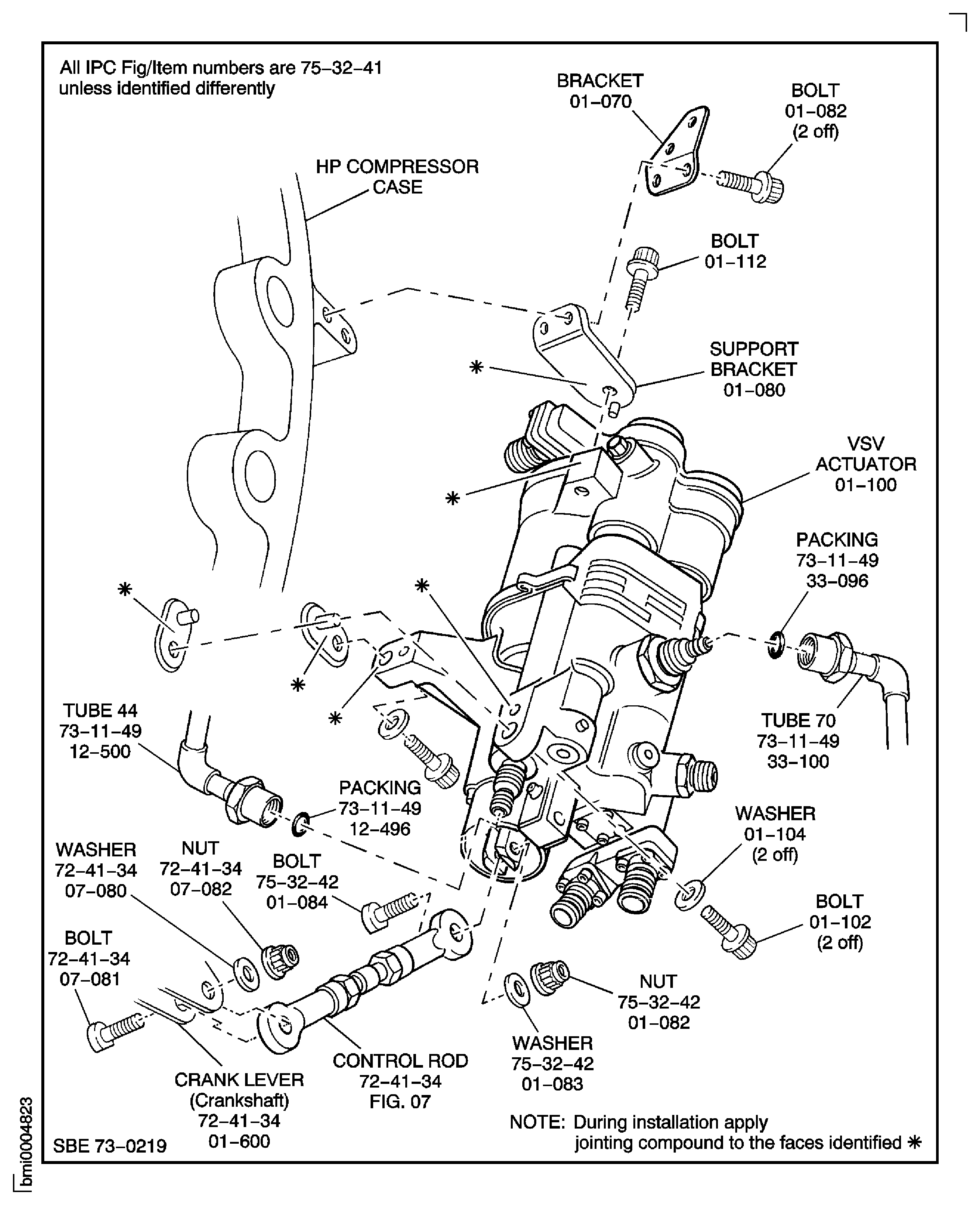

WHEN YOU USE CoMat 01-001 SOLVENT, DELETED INHIBITED AND STABILIZED TRICHLOROETHANE YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.With CoMat 01-001 SOLVENT, DELETED inhibited and stabilized trichloroethane clean the bolts HPC Variable Stator Vane Actuator(75-32-41, 01-082 , HPC Variable Stator Vane Actuator01-102 and HPC Variable Stator Vane Actuator01-112), the brackets HPC Variable Stator Vane Actuator(75-32-41, 01-070 and HPC Variable Stator Vane Actuator01-080) and the attachment faces of the VSV actuator and the HP compressor case. Then apply a layer of CoMat 04-005 JOINTING COMPOUND, MEDIUM GRADE to the surfaces and the bolts.

Attach the support bracket HPC Variable Stator Vane Actuator(75-32-41, 01-080) to the VSV actuator with the bolt HPC Variable Stator Vane Actuator(75-32-41, 01-112) and tighten by hand.

Attach the VSV actuator to the HP compressor case with the four bolts HPC Variable Stator Vane Actuator(75-32-41, 01-102 and 01-082), the two washers HPC Variable Stator Vane Actuator(75-32-41, 01-104) and the bracket HPC Variable Stator Vane Actuator(75-32-41, 01-070). Tighten by hand.

Torque the two bolts HPC Variable Stator Vane Actuator(75-32-41, 01-102) to 180 to 220 lbfin (20 to 25 Nm).

Torque the two bolts HPC Variable Stator Vane Actuator(75-32-41, 01-082) to 180 to 220 lbfin (20 to 25 Nm).

Torque the two bolts HPC Variable Stator Vane Actuator(75-32-41, 01-112) to 180 to 220 lbfin (20 to 25 Nm).

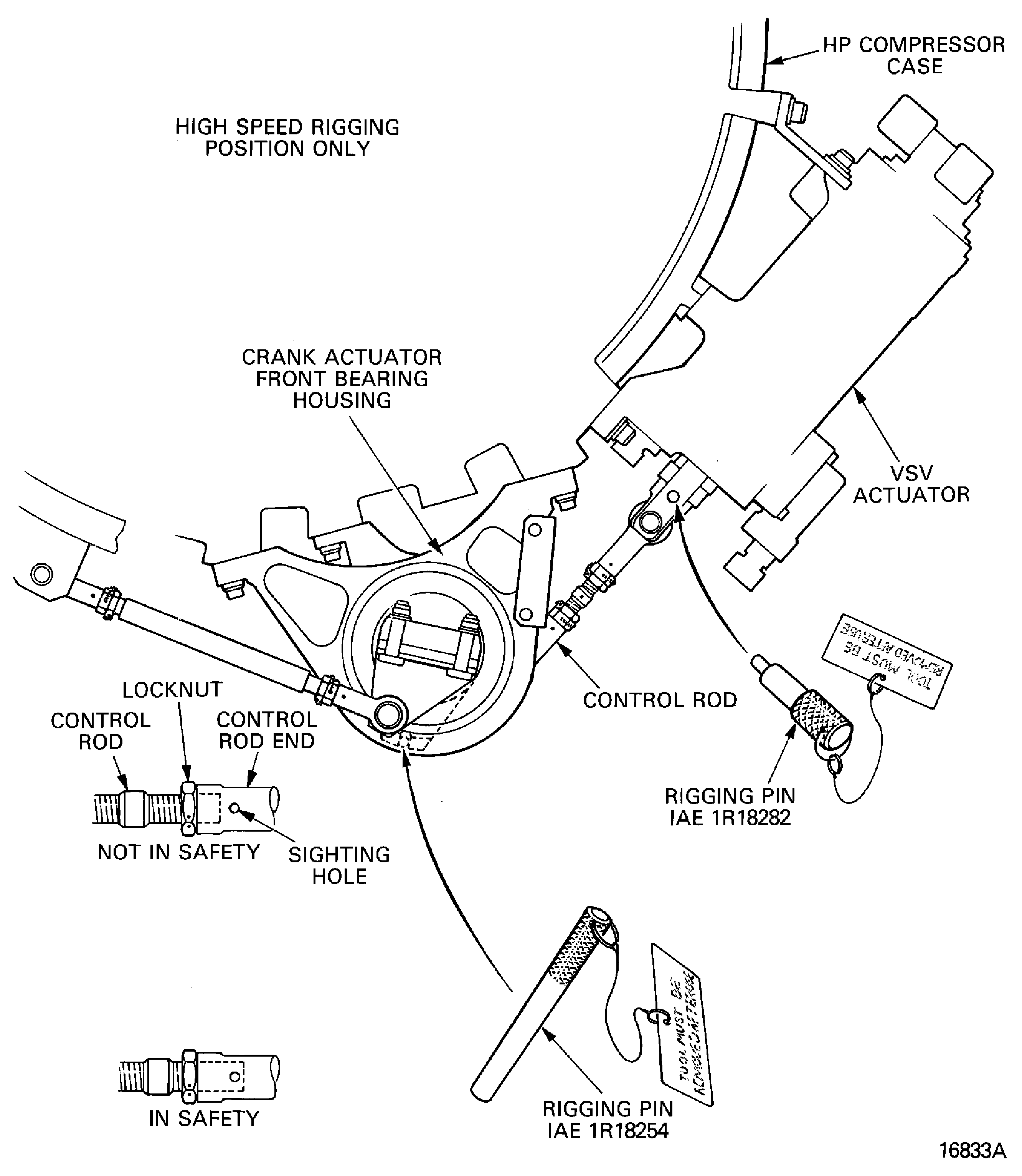

Install IAE 1R18254 Rigging pin 1 off through the front bearing housing and locate in the crankshaft recess.

Install IAE 1R18282 Rigging pin 1 off in the actuating ram.

Loosely assemble the control rod and adjust the length such that the bolt HPC Variable Stator Vane Actuator(75-32-42, 01-084) and the bolt ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES(72-41-34, 07-081) can be installed. Make sure that the control rod ends are in safety with an applicable probe, and lock them with the locknuts. Make sure control rod end alignment is correct.

Install the washer HPC Variable Stator Vane Actuator(75-32-42, 01-083), the washer ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES(72-41-34, 07-080), the nut HPC Variable Stator Vane Actuator(75-32-42, 01-082) and the nut ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES(72-41-34, 07-082) to attach the control rod to the actuator and the ram actuating lever on the crankshaft.

Safety the control rod locknuts with CoMat 02-119 LOCKWIRE.

Connect the VSV actuator to the actuating mechanism.

SUBTASK 72-00-40-420-336 Install the Variable Stator Vane (VSV) Actuator

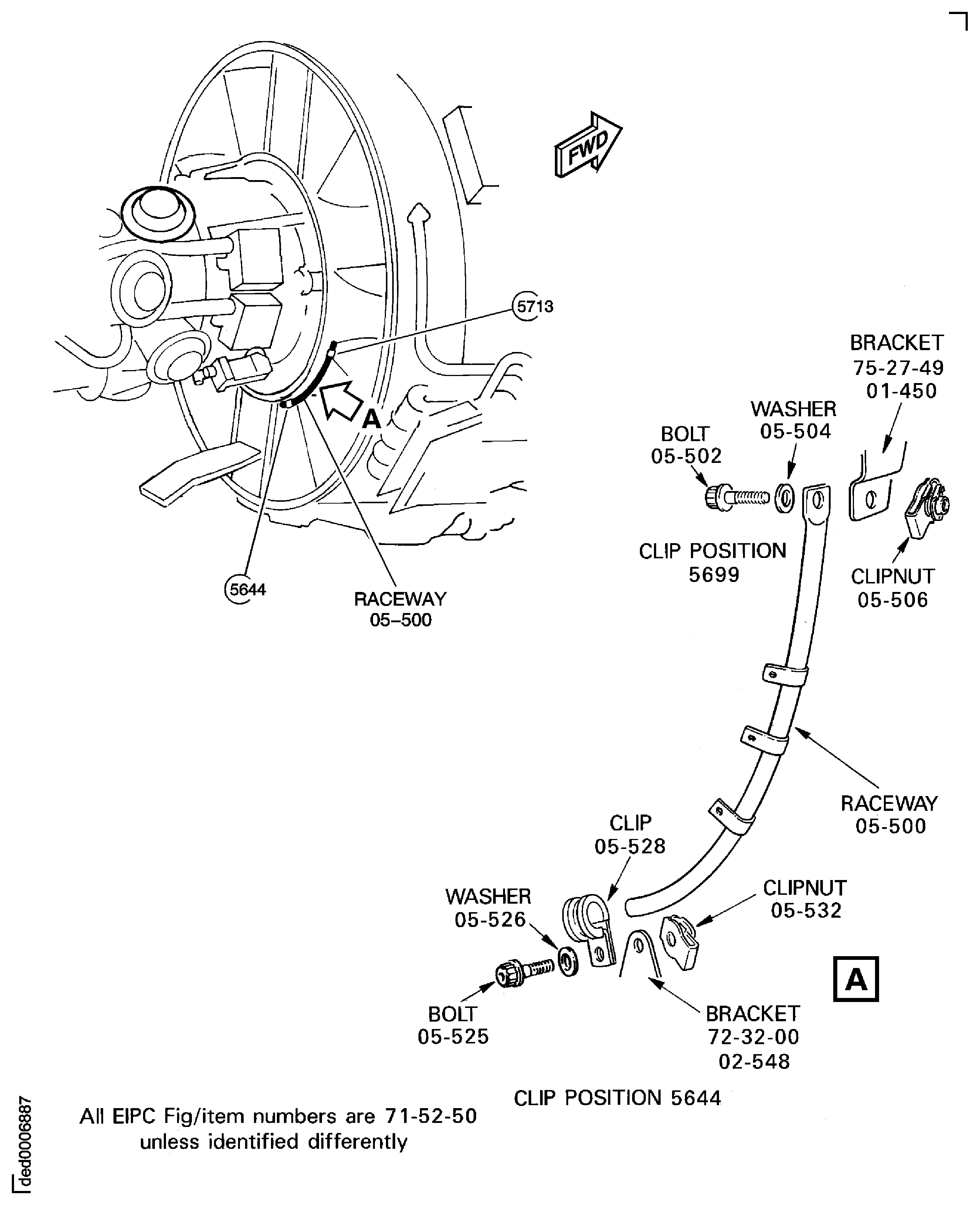

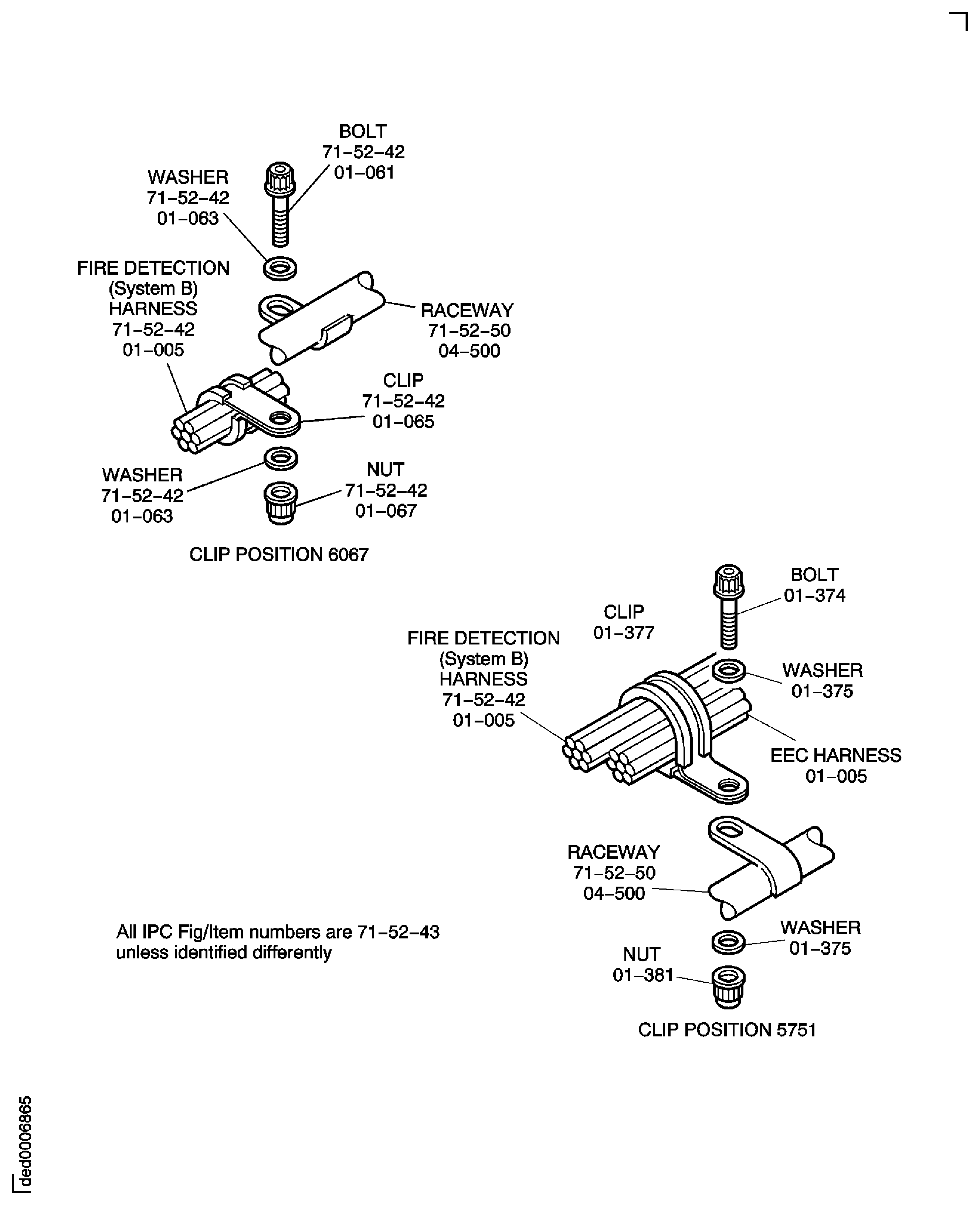

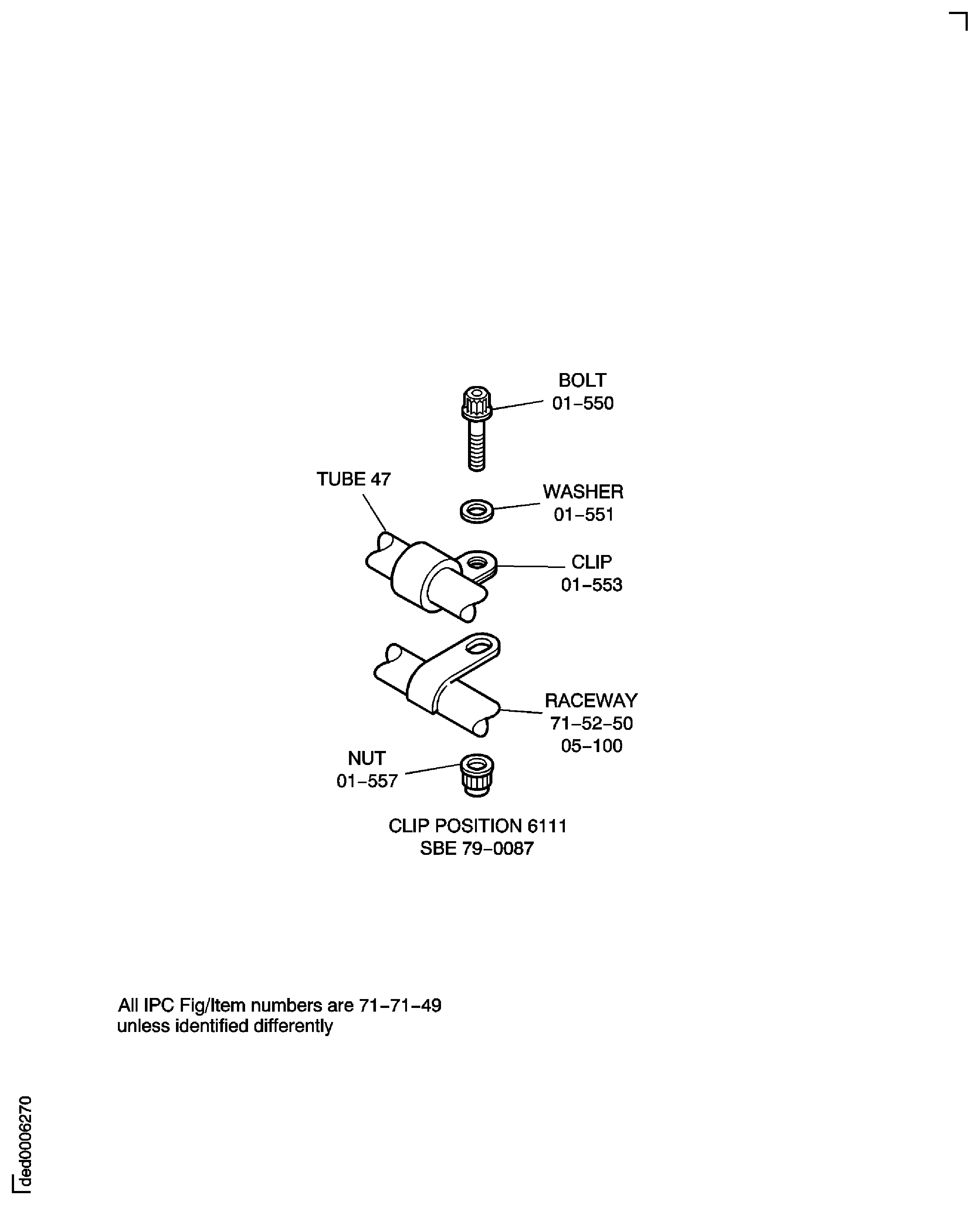

Attach the raceway to the ignition exciter air inlet fitting bracket Igntion Exciter Cooling Air Tubes And Hoses(75-27-49, 01-450) on the inside of the LP compressor/intermediate case with the bolt Core Harness Support Raceways(71-52-50, 05-502), the washer Core Harness Support Raceways(71-52-50, 05-504) and the clipnut Core Harness Support Raceways(71-52-50, 05-506). Torque the bolt to 36 to 45 lbfin (4 to 5 Nm).

Assemble the clip position 5699.

Install the clip Core Harness Support Raceways(71-52-50, 05-528) on the raceway adjacent to the bracket LP Compressor (LPC) - Intermediate Structure Module(72-32-00, 02-548) on the LP compressor/intermediate case rear frame.

Attach the clip to the bracket with the bolt Core Harness Support Raceways(71-52-50, 05-525), the washer Core Harness Support Raceways(71-52-50, 05-526) and the clipnut Core Harness Support Raceways(71-52-50, 05-532). Torque the bolt to 36 to 45 lbfin (4 to 5 Nm).

Assemble the clip position 5644.

Install the raceway Core Harness Support Raceways(71-52-50, 05-500).

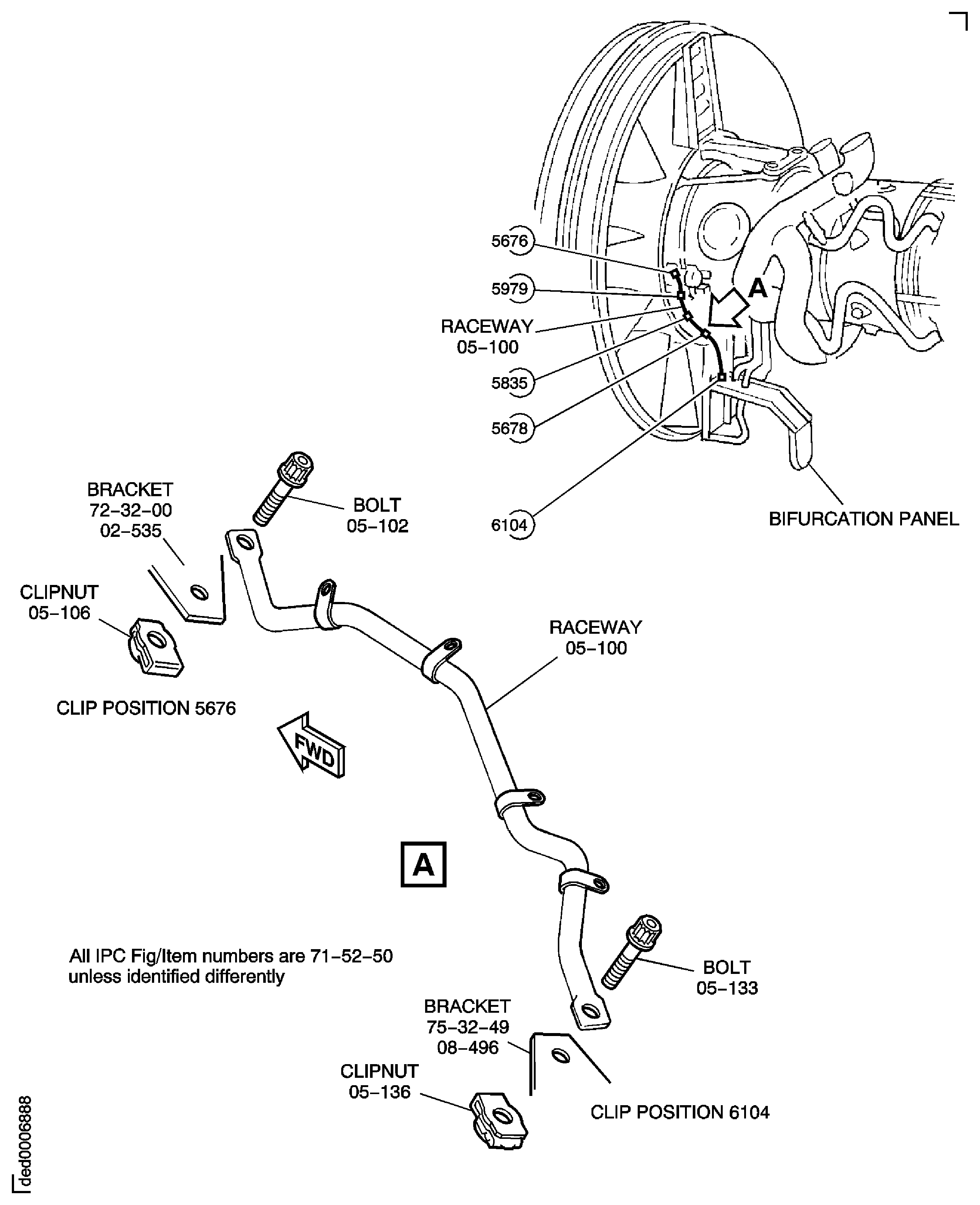

Attach the raceway to the bracket LP Compressor (LPC) - Intermediate Structure Module(72-32-00, 02-535) on the LP compressor/intermediate case rear frame with the bolt Core Harness Support Raceways(71-52-50, 05-102) and the clipnut Core Harness Support Raceways(71-52-50, 05-106). Torque the bolt to 36 to 45 lbfin (4 to 5 Nm).

Assemble the clip position 5676.

Attach the raceway to the bracket AIR-HP COMPRESSOR BLEED CONTROL TUBES(75-32-49, 08-496) at the bifurcation panel with the bolt Core Harness Support Raceways(71-52-50, 05-133) and the clipnut Core Harness Support Raceways(71-52-50, 05-136). Torque the nut to 36 to 45 lbfin (4 to 5 Nm).

Assemble the clip position 6104.

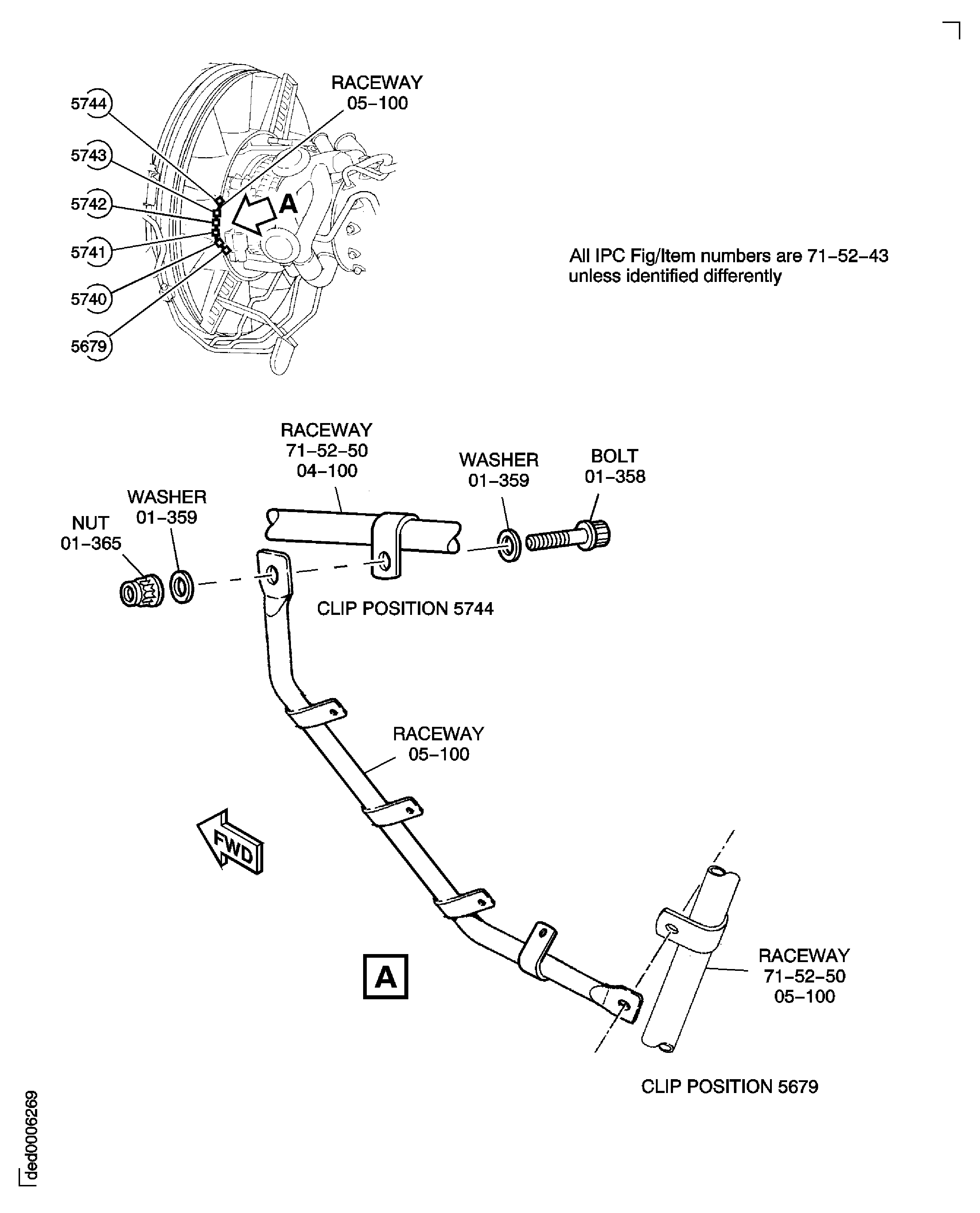

Install the raceway Core Harness Support Raceways(71-52-50, 05-100).

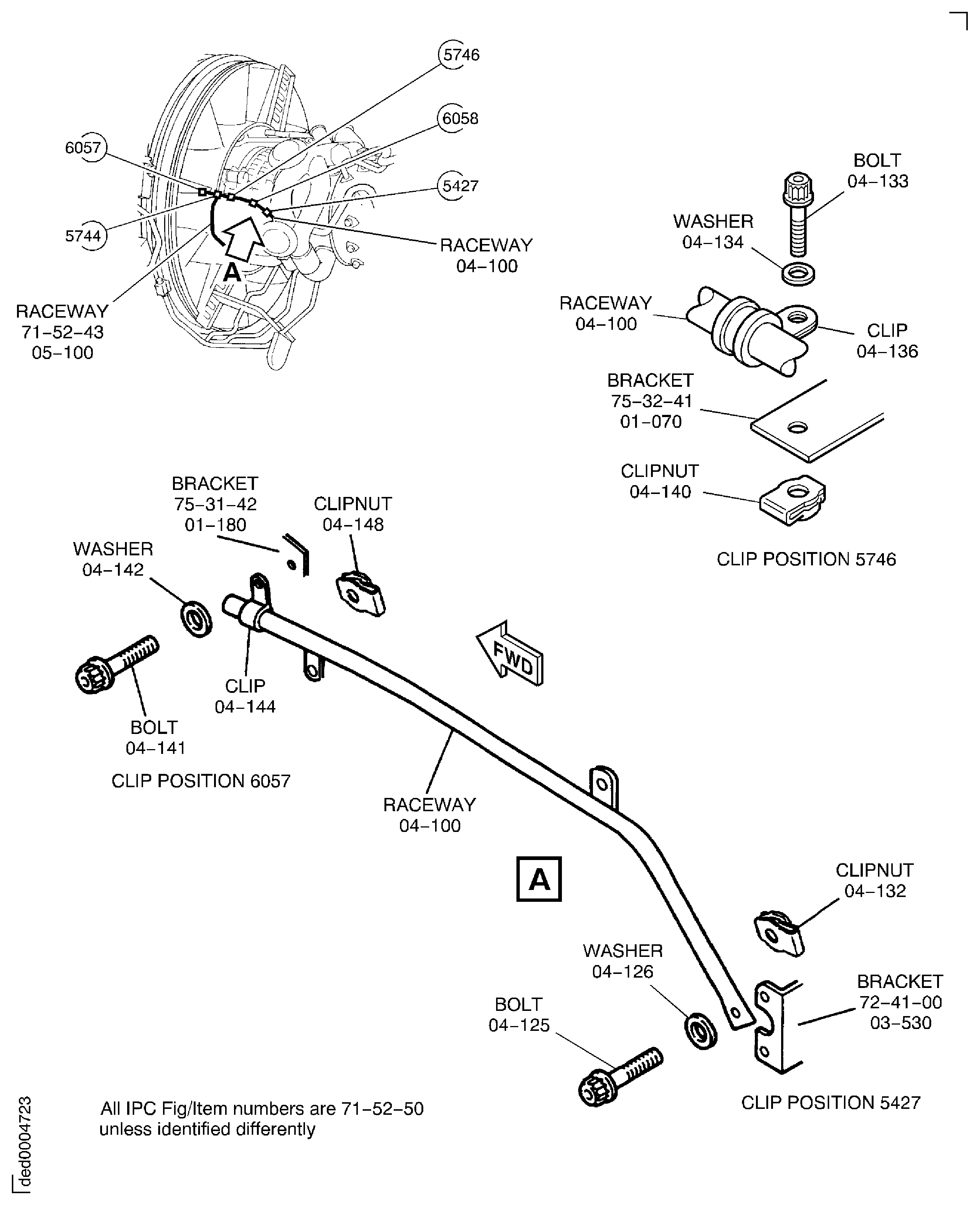

Attach the raceway to the bracket HPC Assembly(72-41-00, 03-530) on flange J, with the bolt BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-125), the washer BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-126) and the clipnut BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-132). Torque the bolt to 36 to 45 lbfin (4 to 5 Nm).

Assemble clip position 5427.

Install the clip BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-144) on the raceway adjacent to the bracket LPC Bleed Master Actuator(75-31-42, 01-180) on the LP compressor bleed valve actuator bracket LPC Bleed Master Actuator(75-31-42, 01-200).

Attach the clip to the bracket LPC Bleed Master Actuator(75-31-42, 01-180) with the bolt BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-141), the washer BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-142) and the clipnut BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-148). Torque the bolt to 36 to 45 lbfin (4 to 5 Nm).

Assemble clip position 6057.

Install the clip BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-136) on the raceway adjacent to the bracket HPC Variable Stator Vane Actuator(75-32-41, 01-070).

Attach the clip to the bracket with the bolt BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-133), the washer BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-134) and the clipnut BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-140). Torque the bolt to 36 to 45 lbfin (4 to 5 Nm).

Assemble clip position 5746.

Install the raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-100).

SUBTASK 72-00-40-420-337 Install the Raceways

NOTE

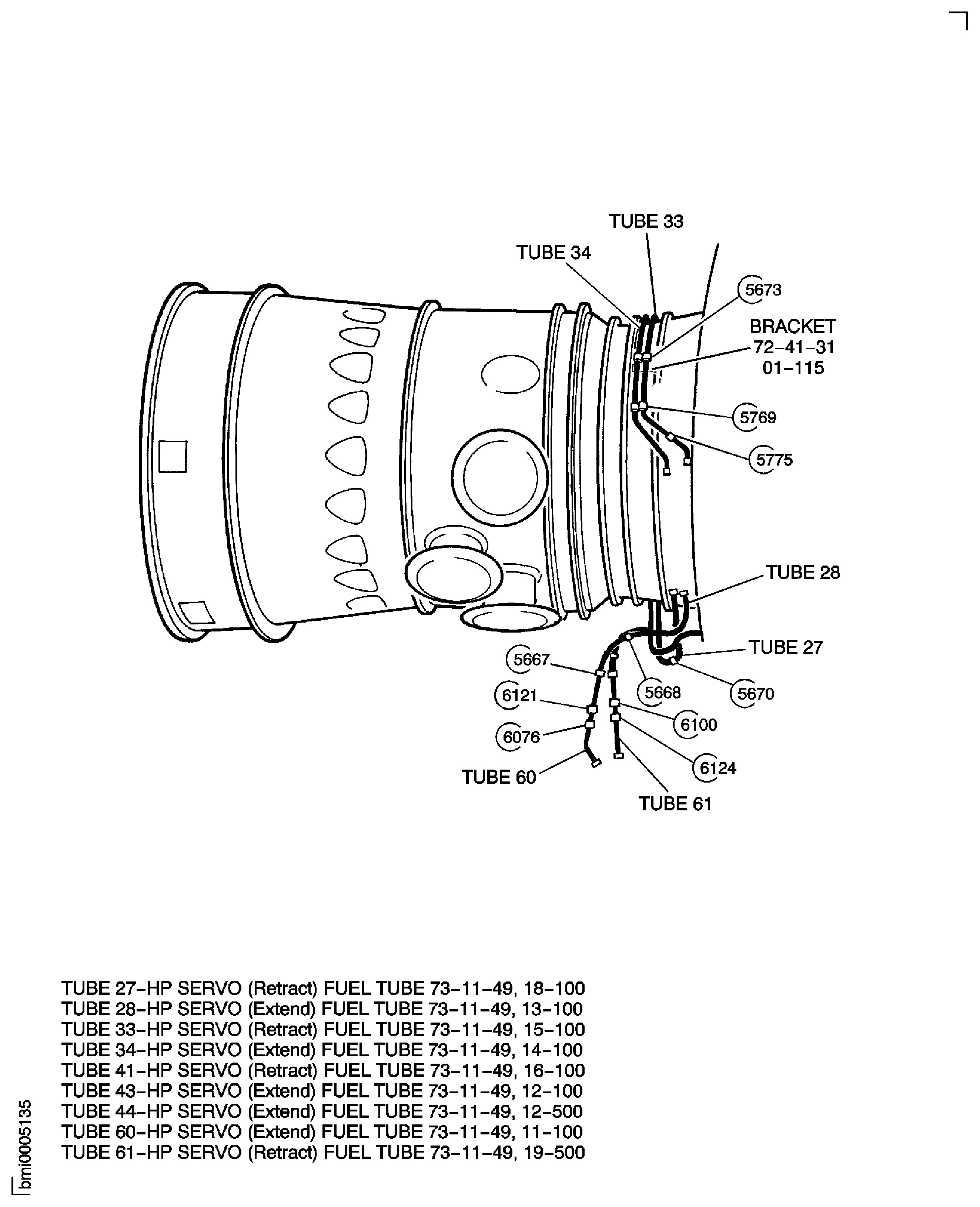

The tubes 60 and 61 are attached to the bifurcation panel in Step, but the connectors were not fully tightened.Install the tubes 60 and 61 Control Fuel Tubes(73-11-49, 11-100 and Control Fuel Tubes19-500).

CAUTION

YOU MUST STOP THE TUBE TURNING WHEN YOU TORQUE THE TUBE NUTS. USE A SPANNER ON THE REAR OF THE MATING UNION. THIS WILL PREVENT ANY STRAIN ON THE TUBES AND HELP PREVENT LEAKS.Torque the tube connectors at the bifurcation panel to 660 to 735 lbfin (74.6 to 83 Nm) and safety with CoMat 02-126 LOCKWIRE.

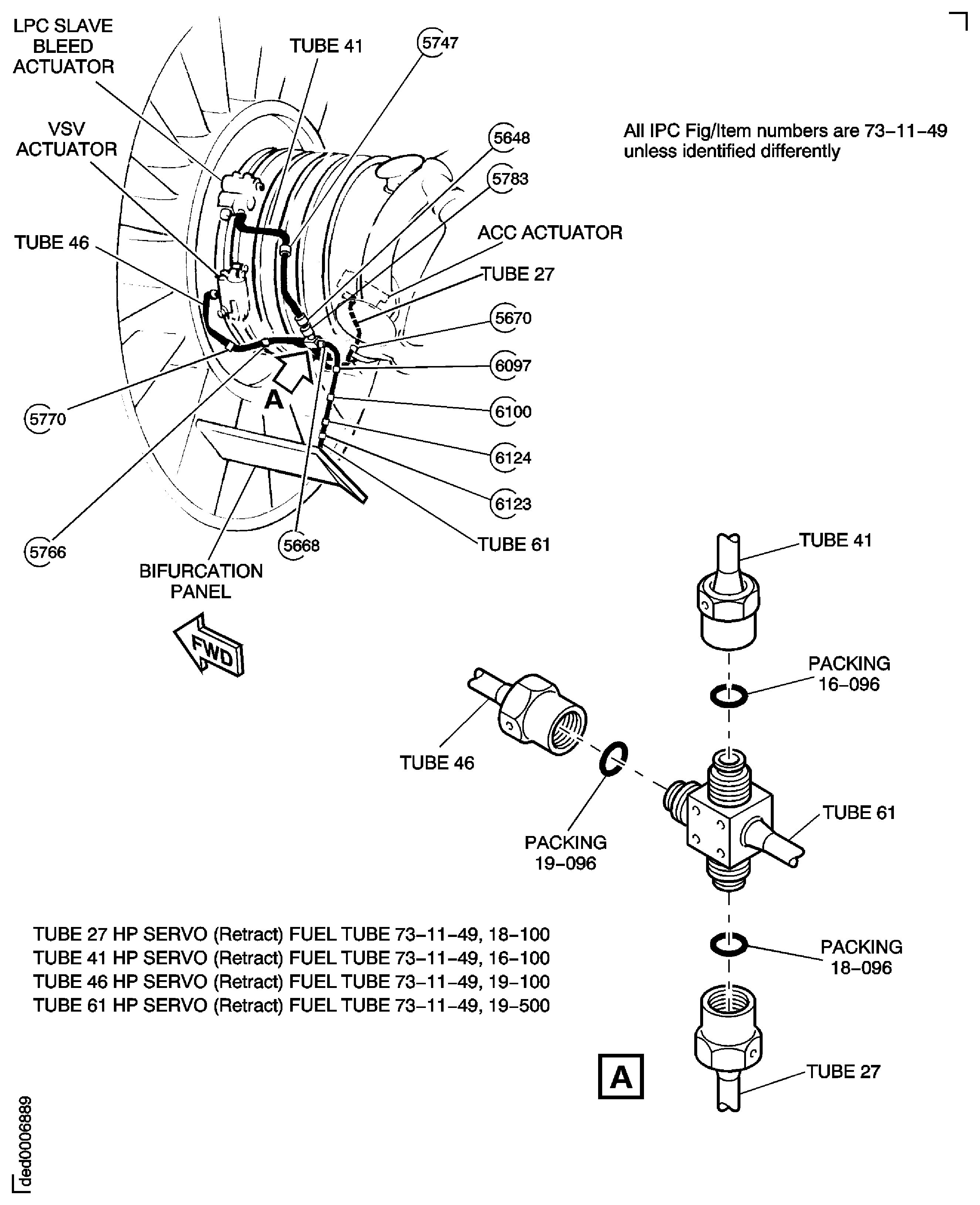

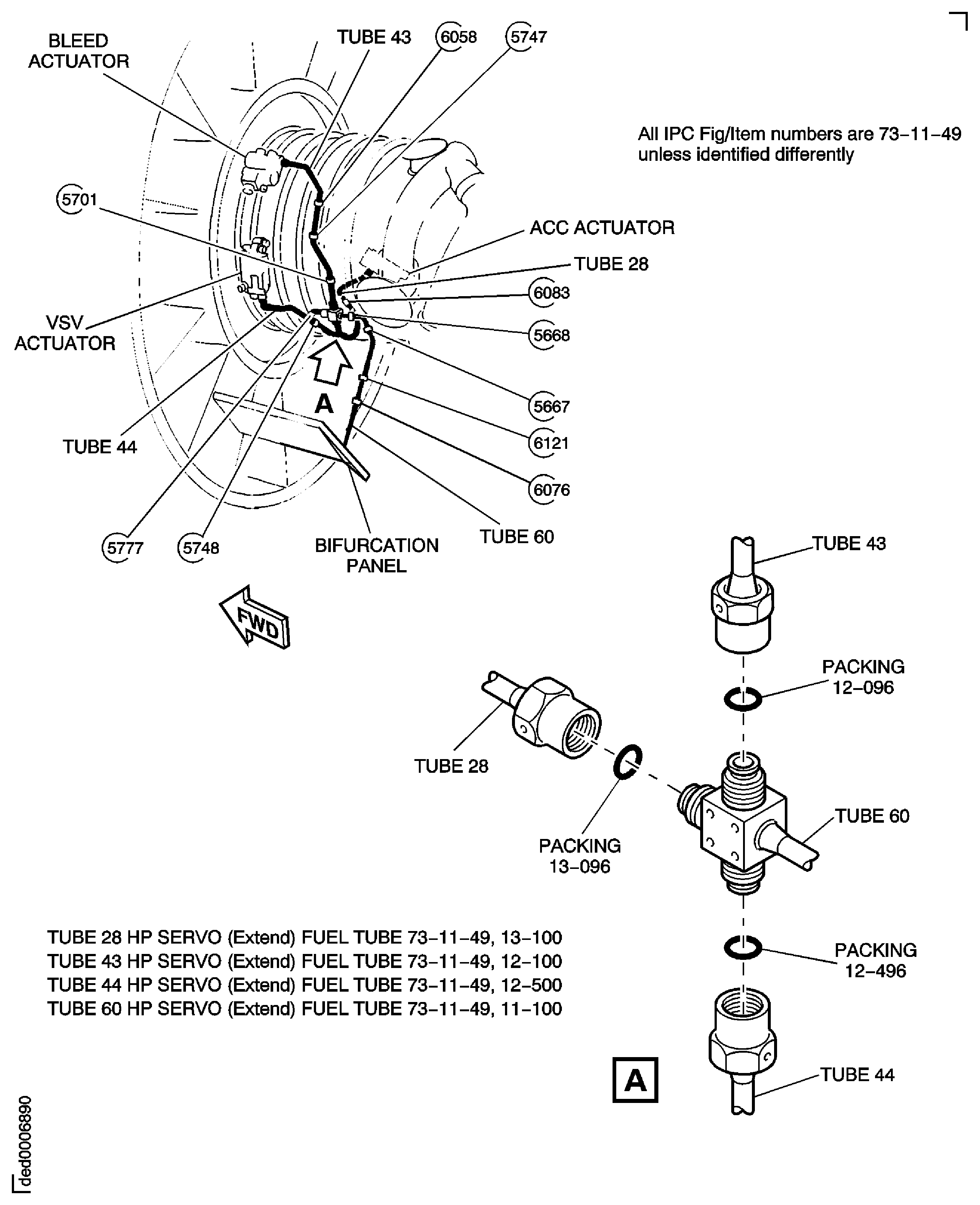

SUBTASK 72-00-40-420-307 Install the Tubes 60 and 61, the HP Servo Fuel Tubes

Lightly lubricate two new Control Fuel Tubes(73-11-49,18-096) packing 2 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install one packing on the lower connection of the tube 61 and one packing on the ACC actuator connection.

Lightly lubricate two new Control Fuel Tubes(73-11-49,13-096) packing 2 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install one packing on the front connection of the tube 60 and one packing on the ACC actuator connection.

Lightly lubricate two new Control Fuel Tubes(73-11-49,12-496) packing 2 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install one packing on the lower connection of the tube 60 and one packing on the VSV actuator connection.

Connect the tube 27 to the tube 61 and to the ACC actuator. Torque the tube connectors to 330 to 360 lbfin (37.3 to 40.7 Nm) and safety with CoMat 02-126 LOCKWIRE.

Connect the tube 28 to the tube 60 and the ACC actuator. Torque the tube connectors to 425 to 475 lbfin (48 to 53.7 Nm) and safety with CoMat 02-126 LOCKWIRE.

Connect the tube 44 to the tube 60 and to the VSV actuator. Torque the tube connectors to 425 to 475 lbfin (48 to 53.7 Nm) and safety with CoMat 02-126 LOCKWIRE. Use a 0.937 in. (24 mm) crowsfoot spanner to torque the VSV tube connector.

Install the tubes 27, 28 and 44 (Control Fuel Tubes(73-11-49,18-100), Control Fuel Tubes(73-11-49,13-100) and Control Fuel Tubes(73-11-49,12-500)).

SUBTASK 72-00-40-420-338 Install the Tubes 27, 28 and 44, the HP Servo Fuel Tubes

Lightly lubricate a new Control Fuel Tubes(73-11-49, 16-096) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the packing on the upper connection of the tube 61.

NOTE

The other end of the tube 41 will be connected to the LP compressor master actuator in Step.Put the tube 41 in position and connect it to the tube 61.

Torque the tube connector to 330 to 360 lbfin (37.3 to 40.7 Nm) and safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-40-420-309 Install the Tube 41, the HP Servo Fuel Tube (12-096)

Lightly lubricate a new Control Fuel Tubes(73-11-49, 12-096) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the packing on the upper connection of the tube 60.

Lightly lubricate a new Control Fuel Tubes(73-11-49, 12-096) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the packing on the bleed actuator. Connect the tube 43 to the bleed actuator.

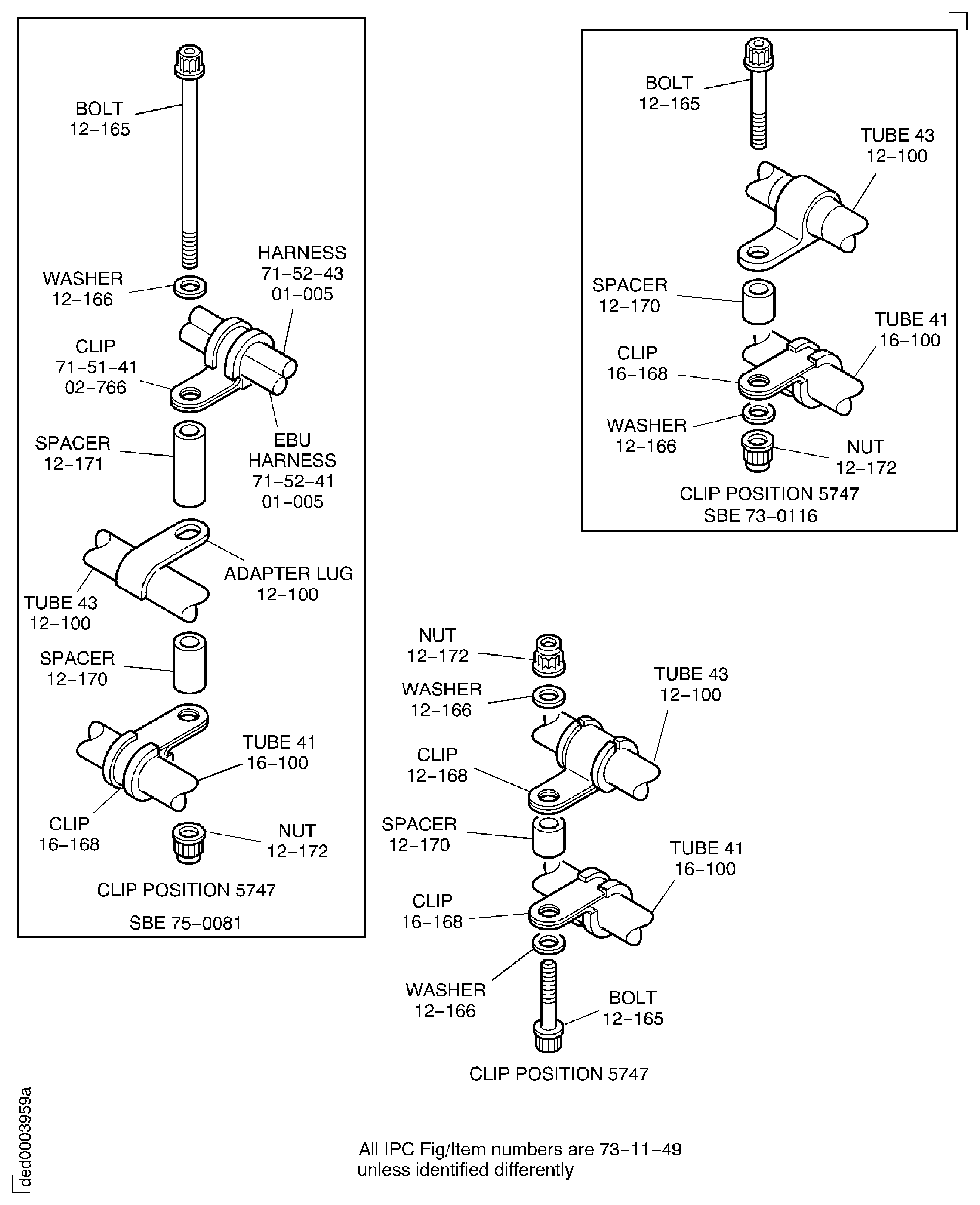

Pre SBE 73-0116 : Install the bolt, two washers, two clips, spacer and nut at the clip position 5747.

SBE 73-0116 : Install the bolt, spacer, clip, washer and nut at the clip position 5747.

SBE 75-0081 : Install the bolt, spacers, clips, washer and nut at the clip position 5747.

Pre SBE 73-0104 and Pre SBE 73-0116 : Install the bolt, two washers, spacer and nut at the clip position 6058.

SBE 73-0104 and SBE 73-0116 : Install the bolt, washer, spacer and nut at the clip position 6058.

SBE 75-0081: Install the bolt, spacers, clips, washer and nut at the clip position 6058.

Torque the tube connector to 425 to 475 lbfin (48 to 53.7 Nm) and safety with CoMat 02-126 LOCKWIRE. Torque the clip position bolt to 36 to 45 lbfin (4 to 5 Nm).

SUBTASK 72-00-40-420-428 Install the Tube 43 (12-100), the HP Servo Fuel Tube (Pre SBE 73-0104, Pre SBE 73-0116, Pre SBE 75-0081, SBE 73-0104, SBE 73-0116 and SBE 75-0081)

SBE 73-0104: Fuel system tubes - Introduction of revised clipping for the HP servo external fuel tube assembly

SBE 73-0116: Fuel system tubes - Introduction of revised HP servo external fuel tube assembly

SBE 75-0081: Air - Deletion of the HPC stage 10 make up air valve

NOTE

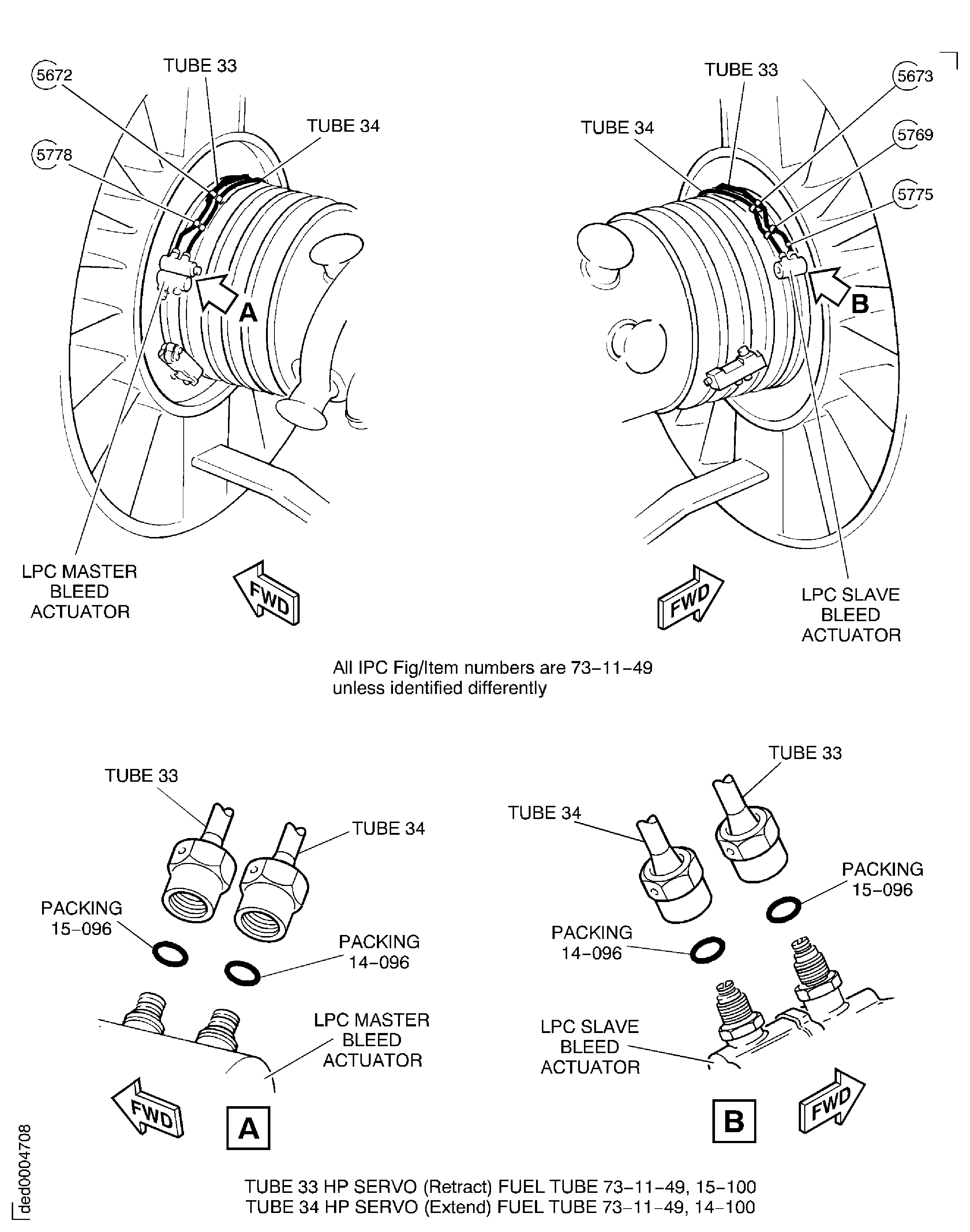

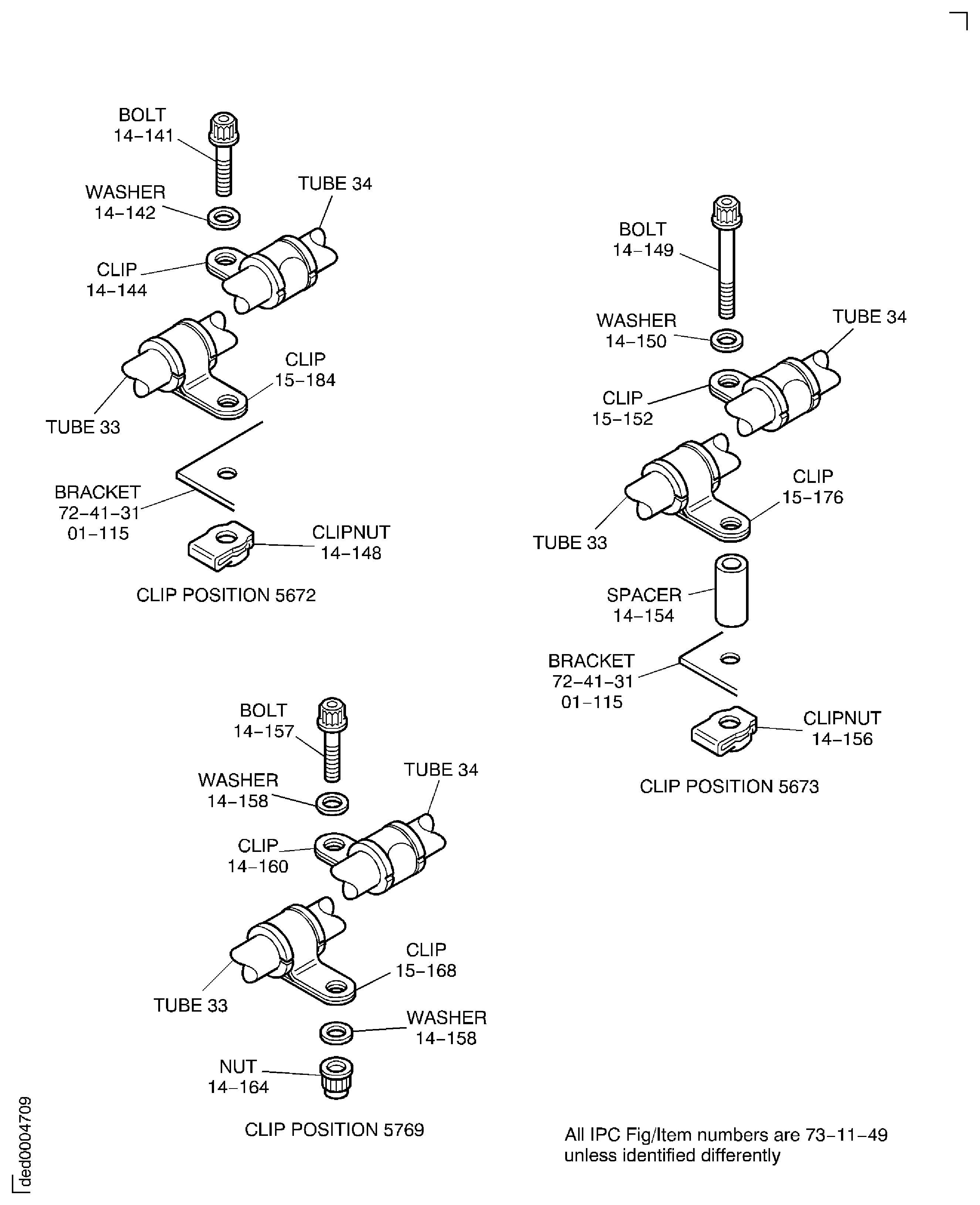

The tubes 33 and 34 are connected in Step.Put the tubes 33 and 34 in position on the HP compressor case.

NOTE

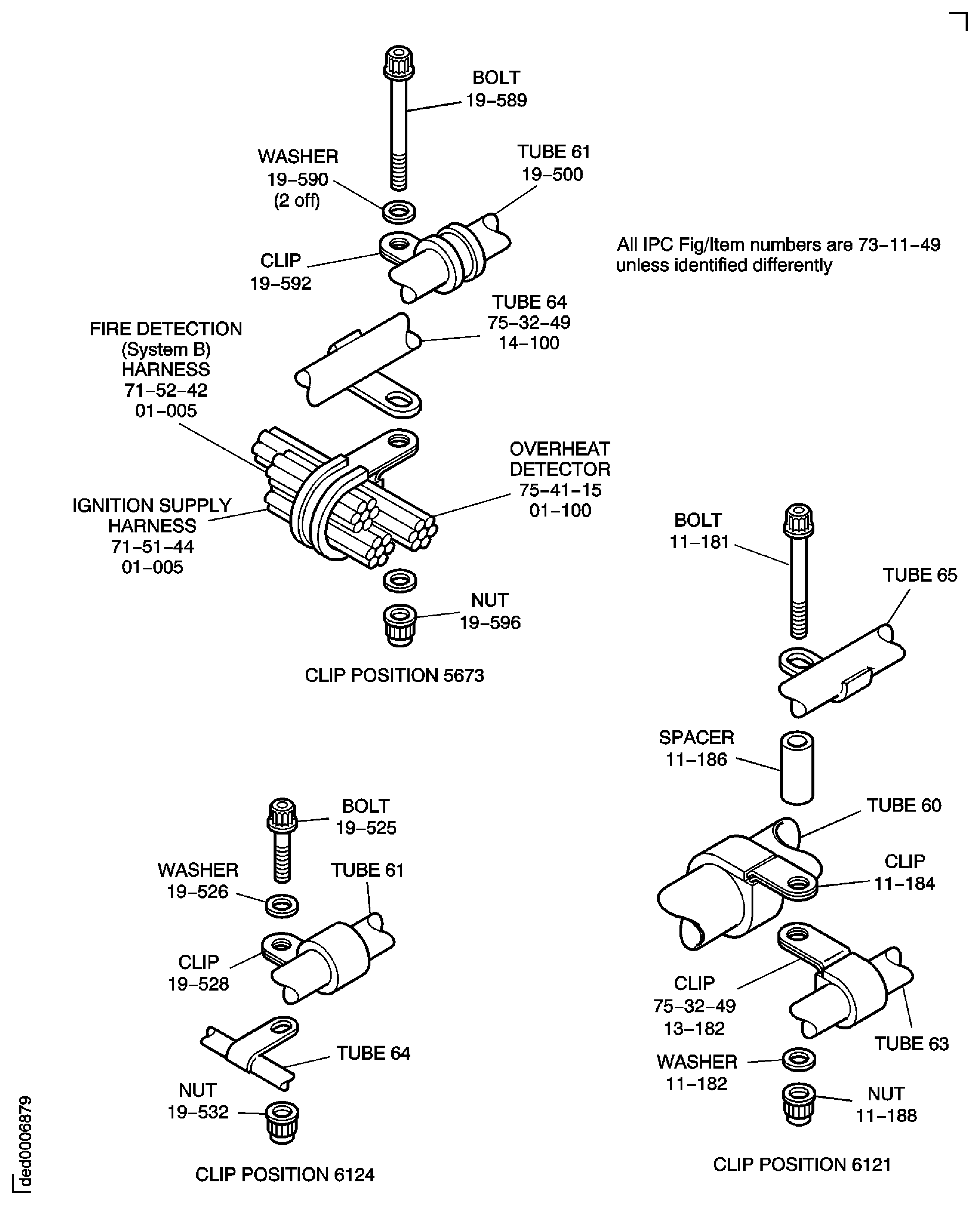

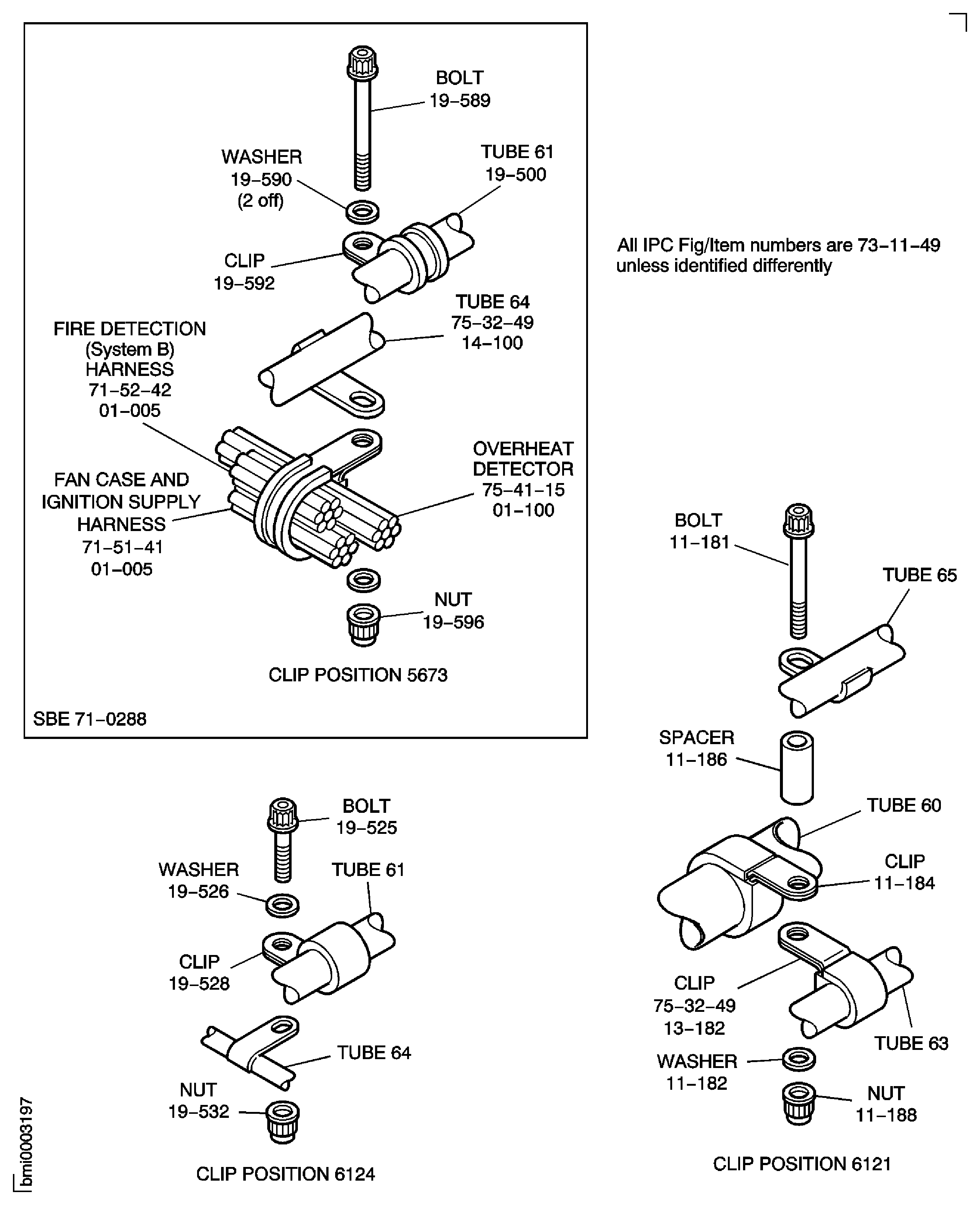

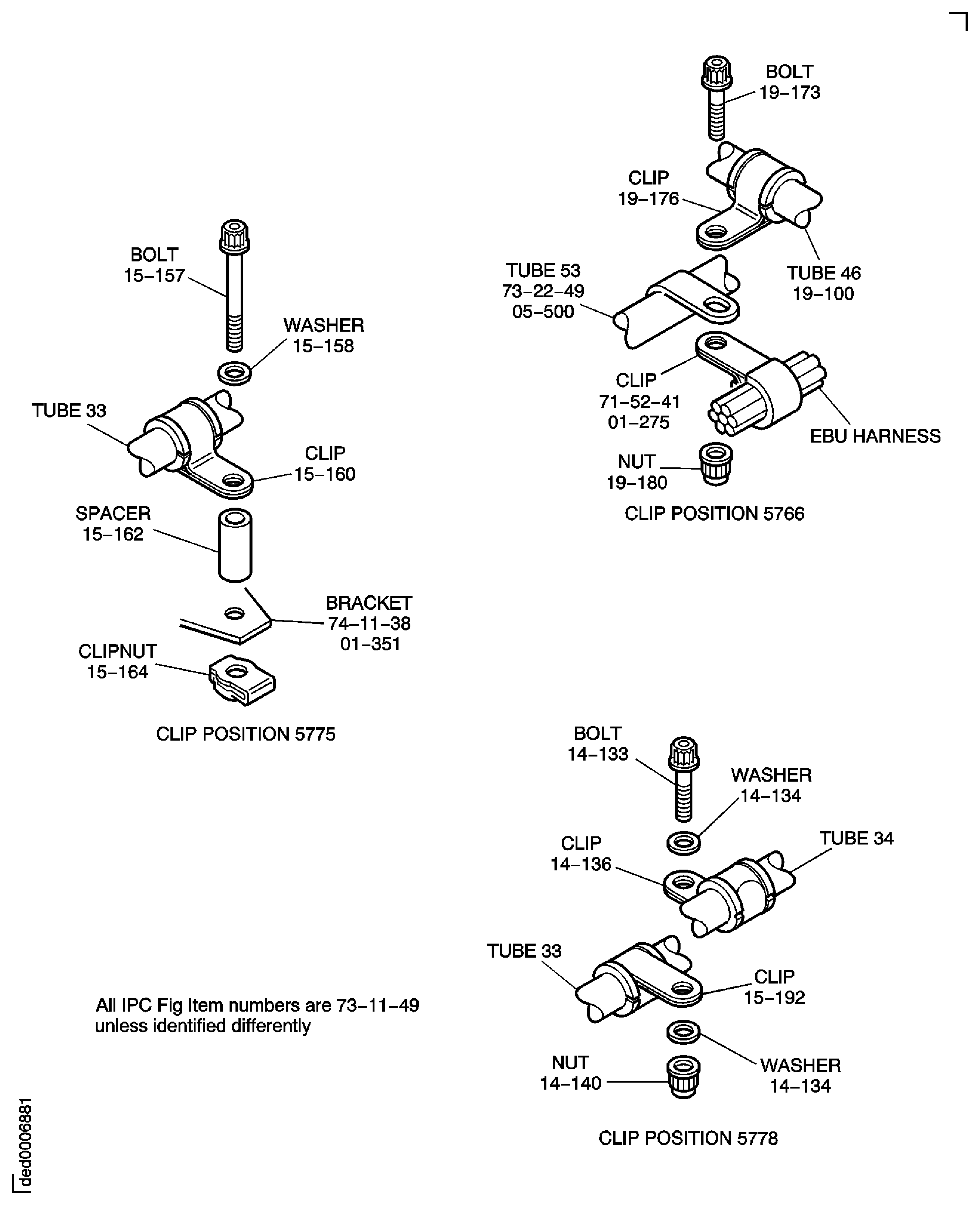

These clip positions are tightened in Step.Loosely assemble the clip positions:

5672, 5673, 5769, 5775 and 5778.

Install the tubes 33 and 34 ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE(73-11-49, 15-100 and ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE14-100).

SUBTASK 72-00-40-420-311 Install the Tubes 33 and 34, the HP Servo Fuel Tubes

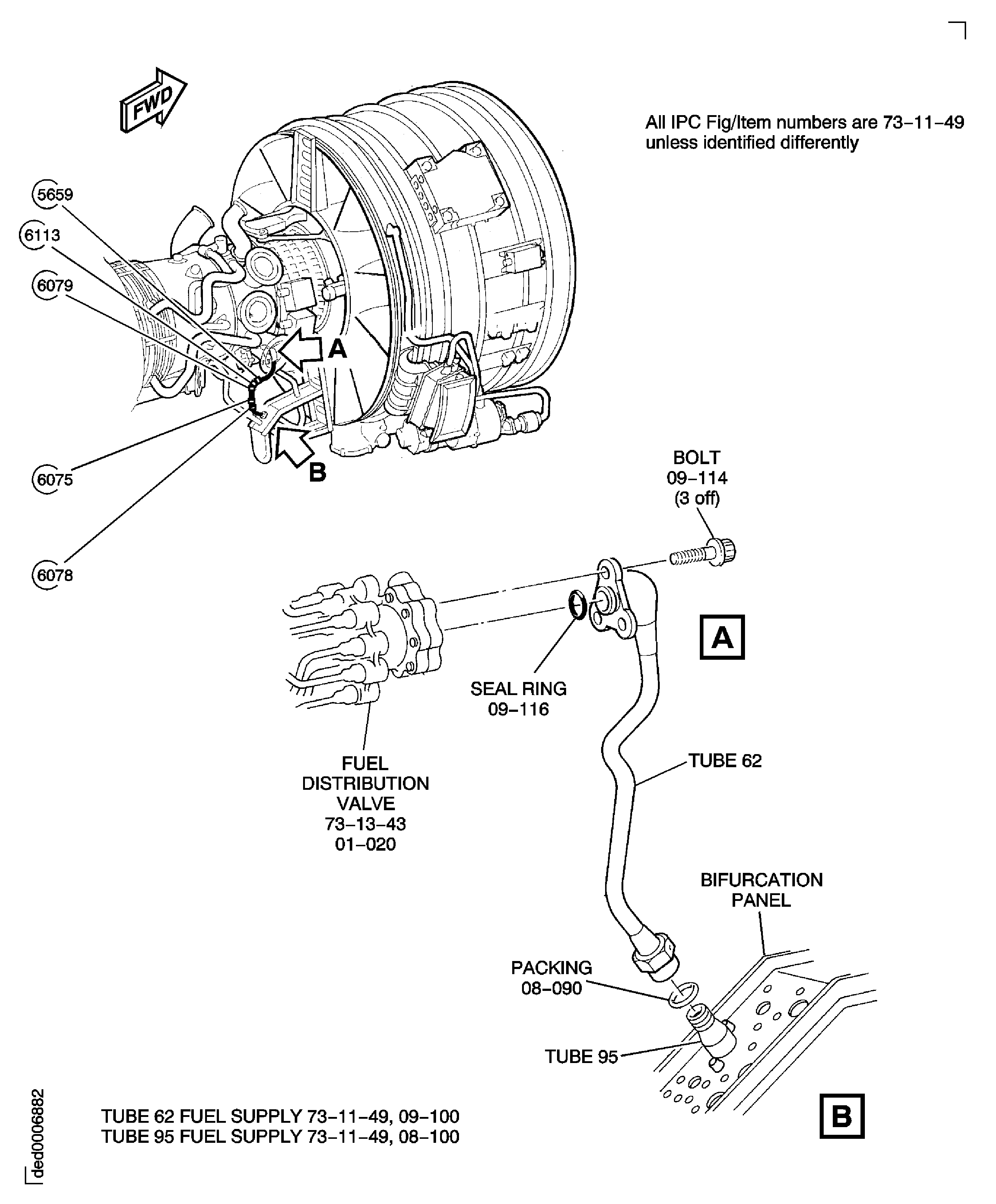

Lightly lubricate a new Control Fuel Tubes(73-11-49, 08-090) seal ring 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the seal ring on the tube 95 at the bifurcation panel.

Lightly lubricate a new Control Fuel Tubes(73-11-49, 09-116) sealing ring 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the sealing ring on the tube 62.

Attach the tube 62 to the fuel distribution valve with the three bolts Control Fuel Tubes(73-11-49, 09-114) and torque them to 85 to 105 lbfin (10 to 12 Nm).

CAUTION

YOU MUST STOP THE TUBE TURNING WHEN YOU TORQUE THE TUBE NUTS. USE A SPANNER ON THE REAR OF THE MATING UNION. THIS WILL PREVENT ANY STRAIN ON THE TUBES AND HELP PREVENT LEAKS.Connect the tube 62 to the tube 95 and torque the tube connector to 1150 to 1250 lbfin (130 to 141 Nm). Safety with CoMat 02-126 LOCKWIRE..

Install the tube 62 Control Fuel Tubes(73-11-49, 09-100).

SUBTASK 72-00-40-420-339 Install the Fuel Distribution Feed Tube (62)

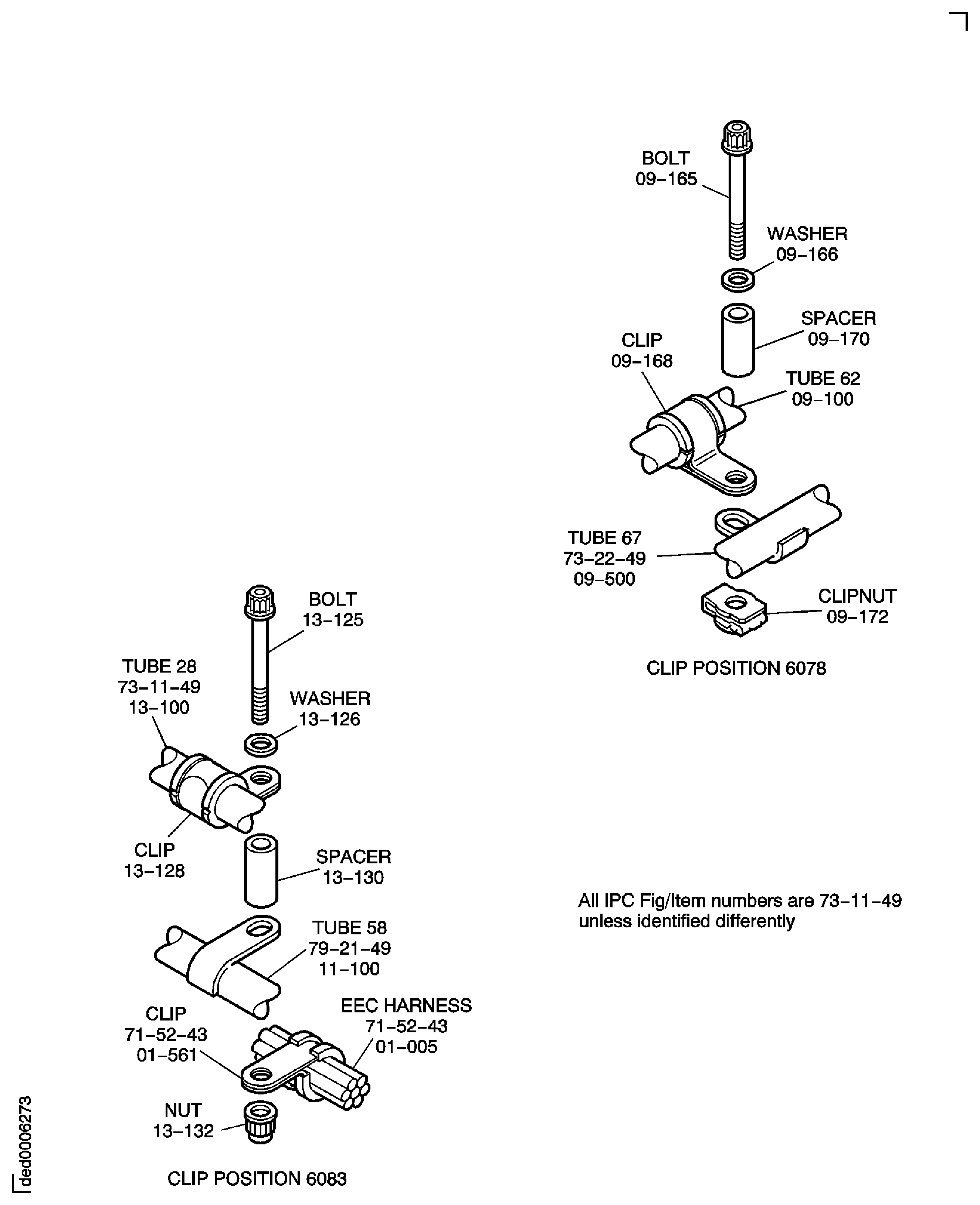

Connect the tube 66 to the air tube Fan Frame Assembly And Related Parts(72-32-03, 01-550) at the LP compressor/intermediate case rear frame.

Torque the tube connector to 159 to 177 lbfin (18 to 20 Nm) and safety with CoMat 02-274 SAFETY CABLE KIT safety cable or CoMat 02-275 SAFETY CABLE KIT safety cable.

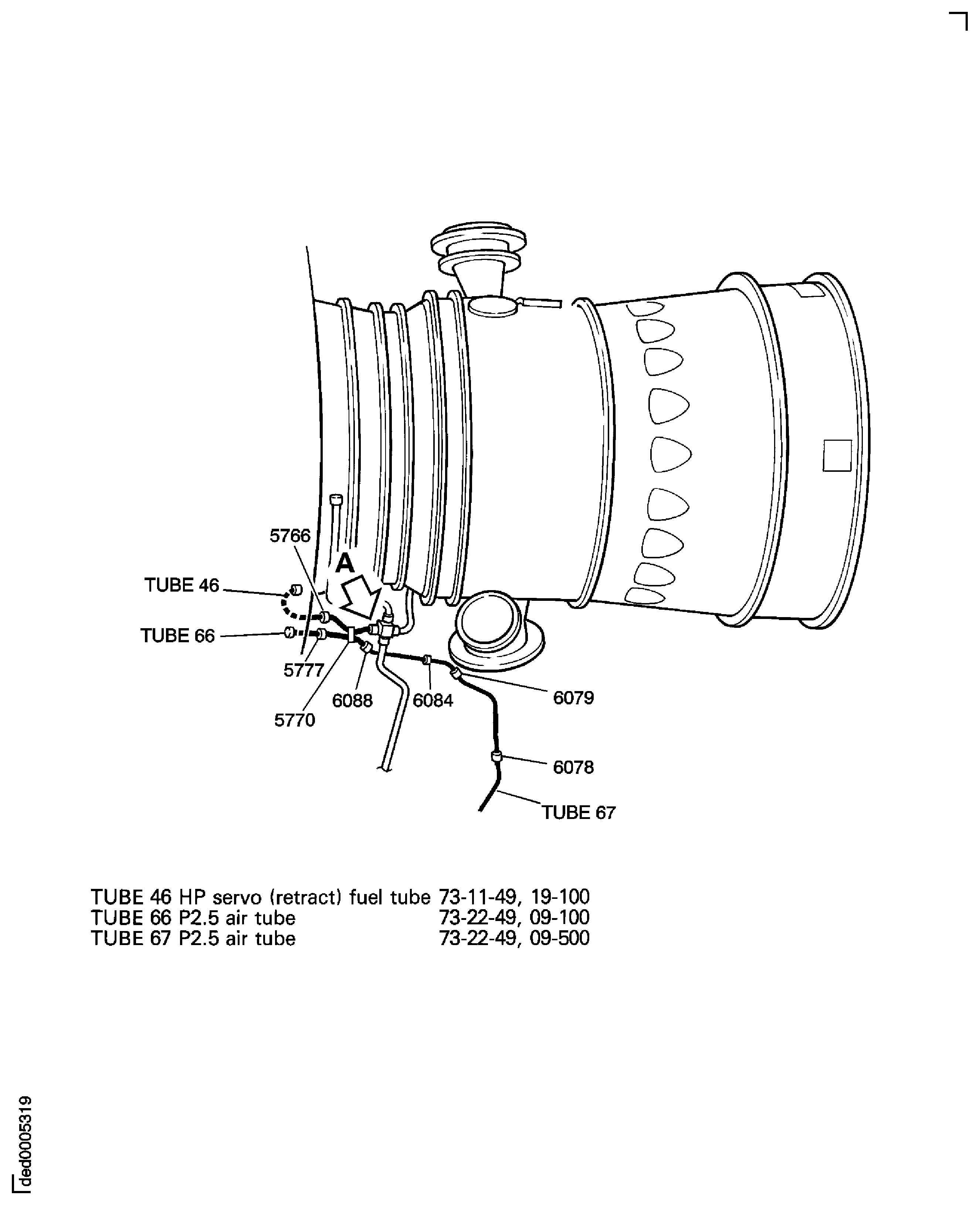

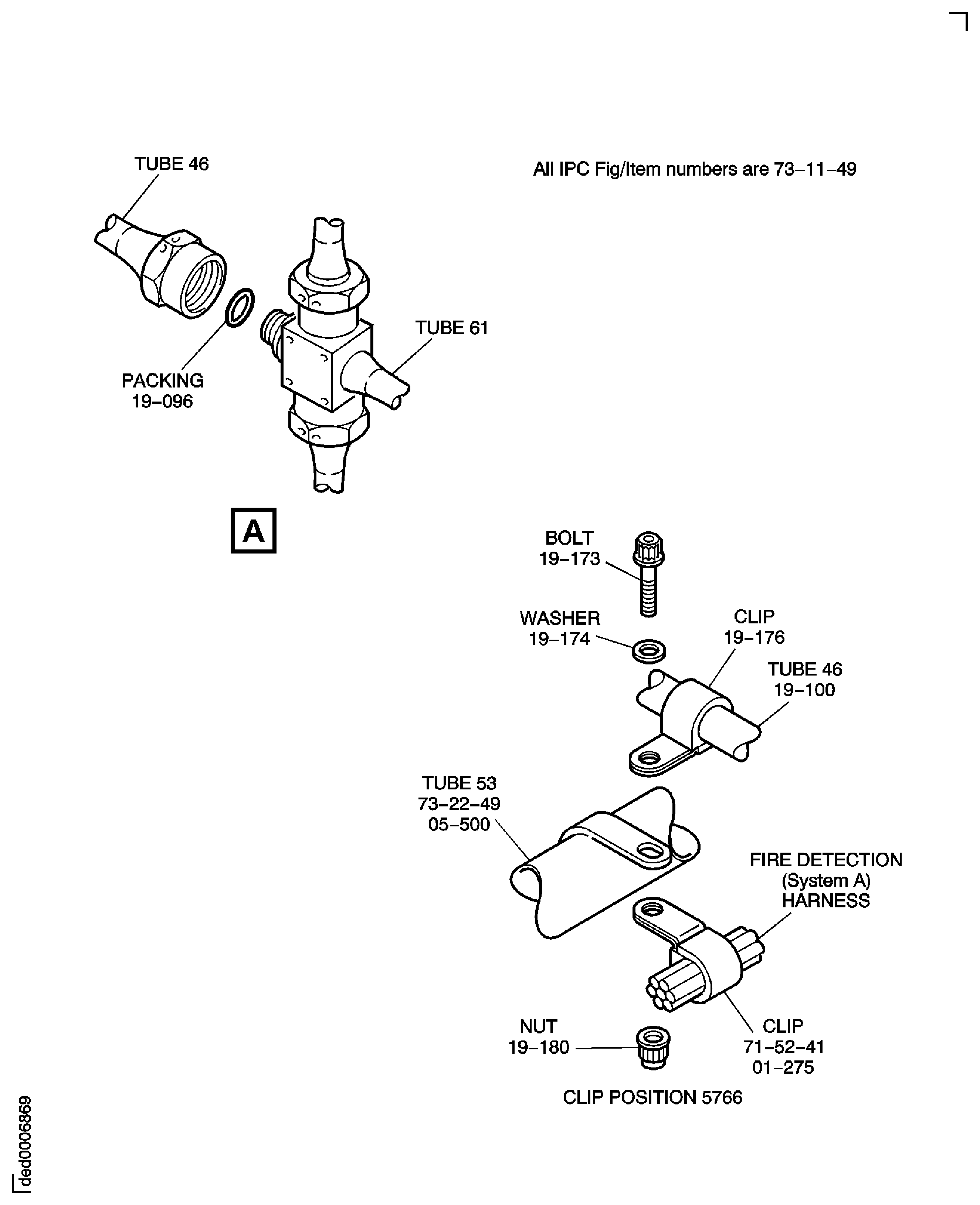

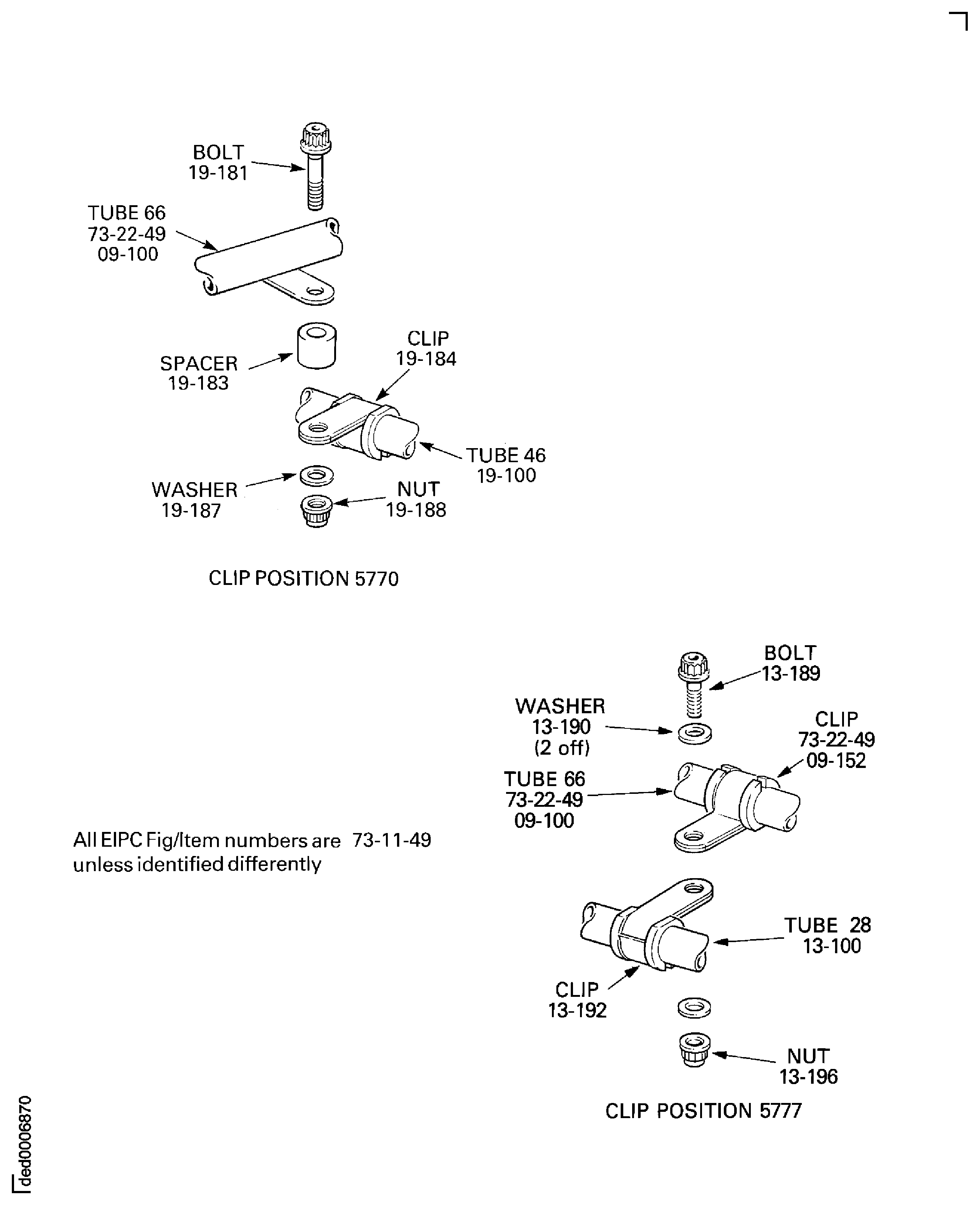

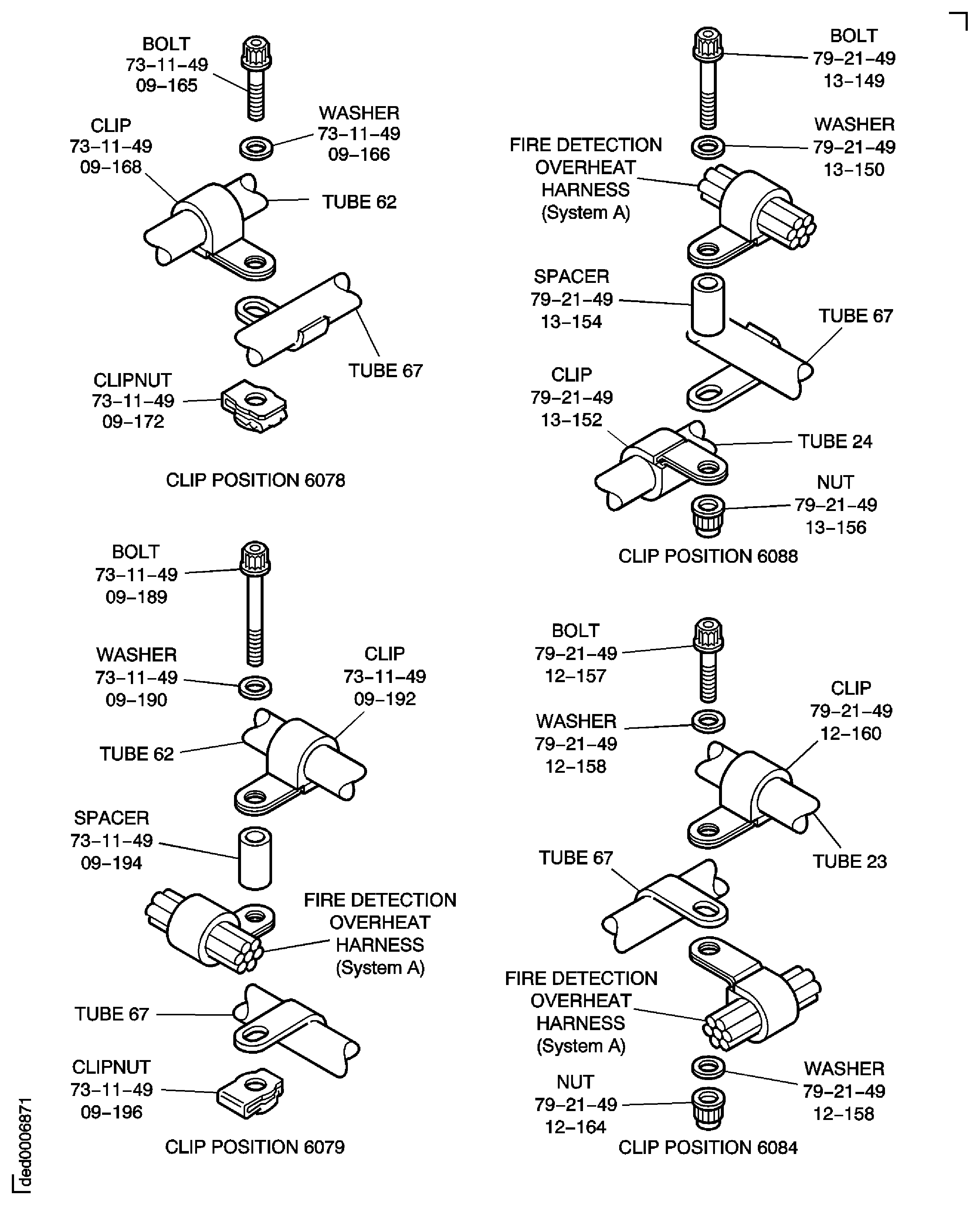

Install the tube 66 Fuel System Air Tubes(73-22-49, 09-100).

CAUTION

YOU MUST STOP THE TUBE TURNING WHEN YOU TORQUE THE TUBE NUTS. USE A SPANNER ON THE REAR OF THE MATING UNION. THIS WILL PREVENT ANY STRAIN ON THE TUBES AND HELP PREVENT LEAKS.Torque the tube connectors to 159 to 177 lbfin (18 to 20 Nm) and safety with CoMat 02-126 LOCKWIRE.

Install the tube 67 Fuel System Air Tubes(73-22-49, 09-500).

Lightly lubricate two new Control Fuel Tubes(73-11-49, 19-096) packing 2 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install one packing on the front connection of the tube 61 and one packing on the VSV actuator connection.

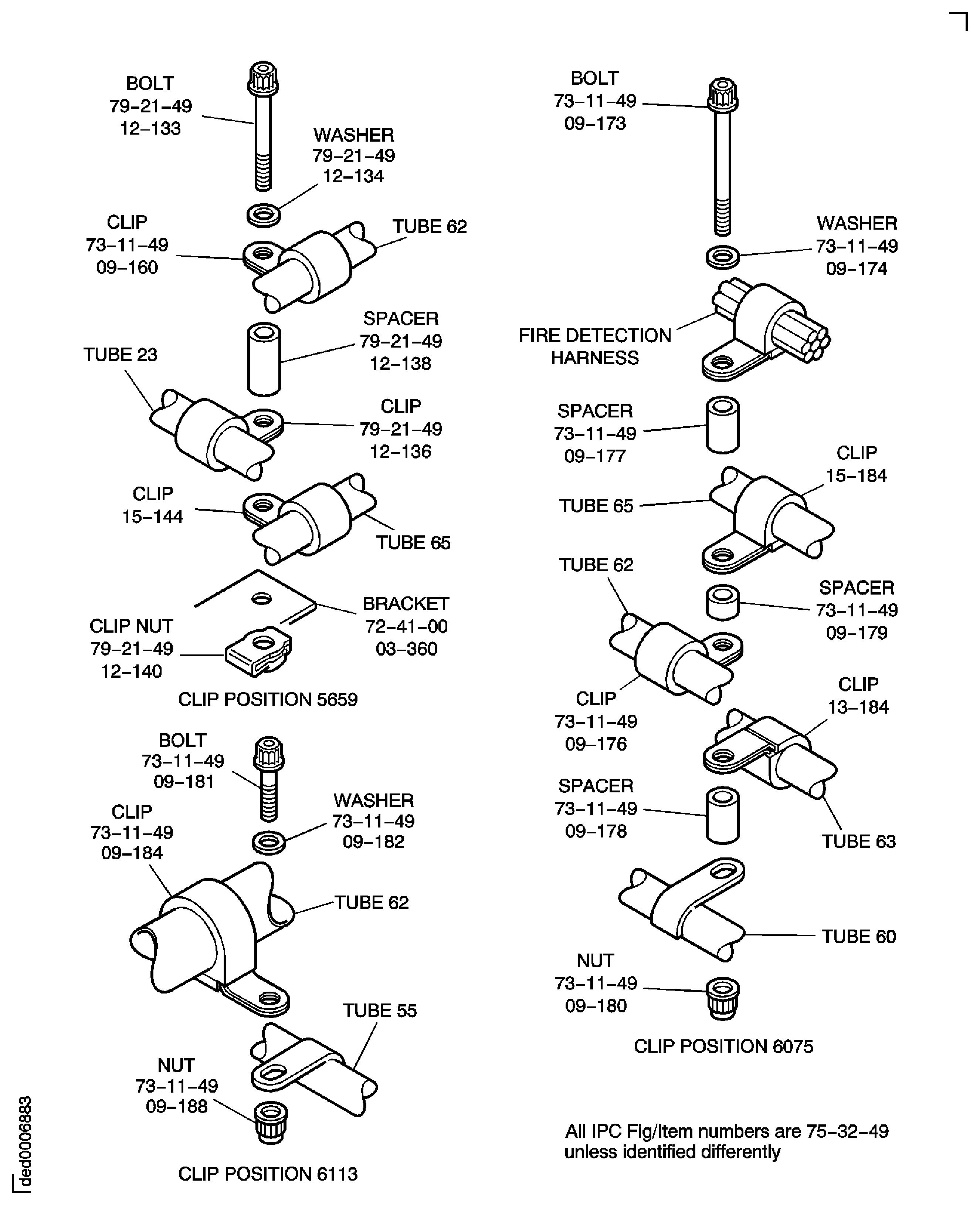

Torque the tube connectors to 425 to 475 lbfin (48 to 53.7 Nm) and safety with CoMat 02-126 LOCKWIRE.

Install the tube 46 Control Fuel Tubes(73-11-49, 19-100).

SUBTASK 72-00-40-420-340 Install the HP Fuel Servo Tube (46) and the P2.5 Air Tubes (66 and 67)

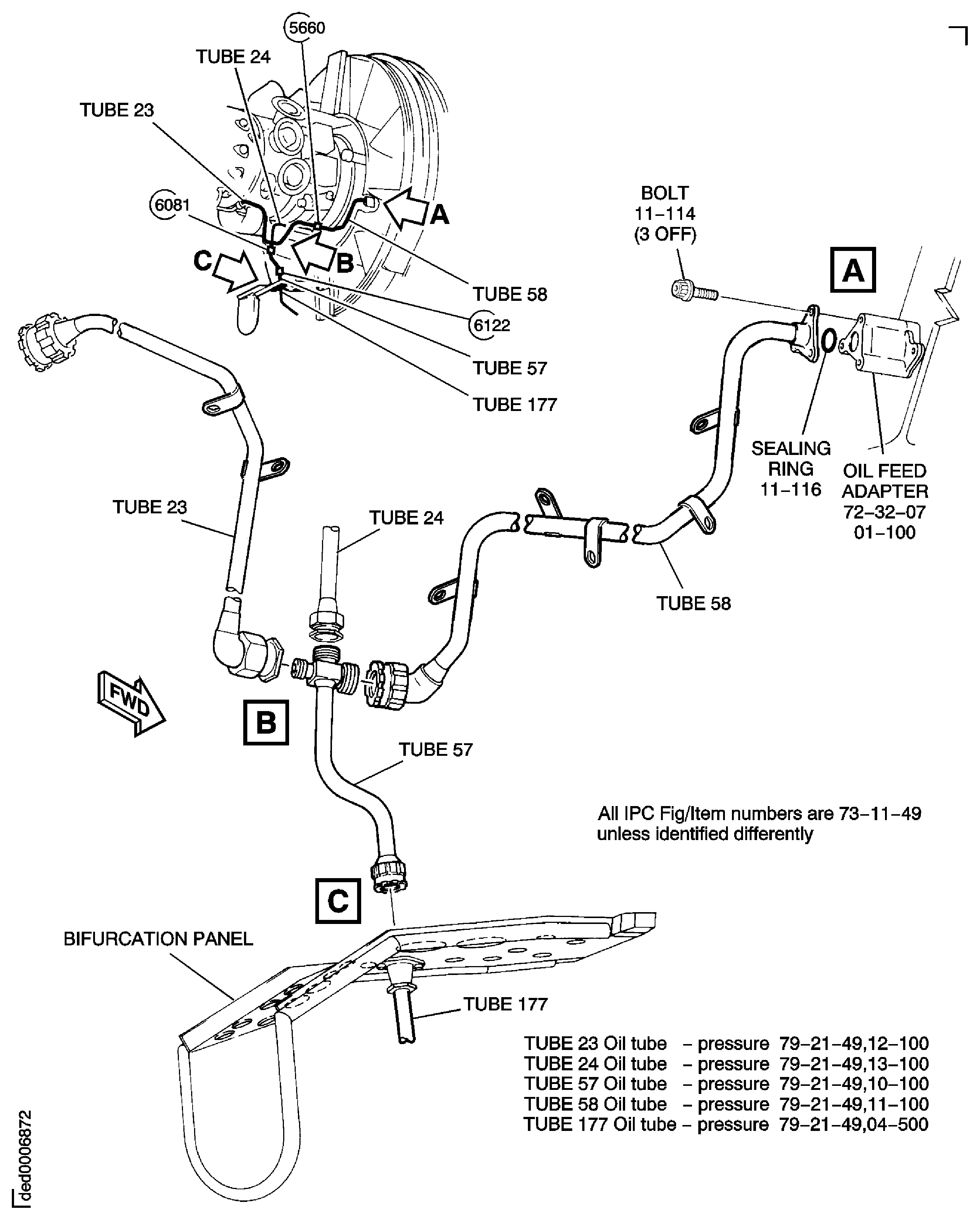

Lightly lubricate a new Engine Pressure Oil Tubes(79-21-49,11-116) packing 1 off with CoMat 10-077 APPROVED ENGINE OILS and install it on the tube 58.

Install the three bolts Engine Pressure Oil Tubes(79-21-49,11-114) that attach the tube 58 to the oil feed adapter and torque to 85 to 105 lbfin (10 to 12 Nm).

NOTE

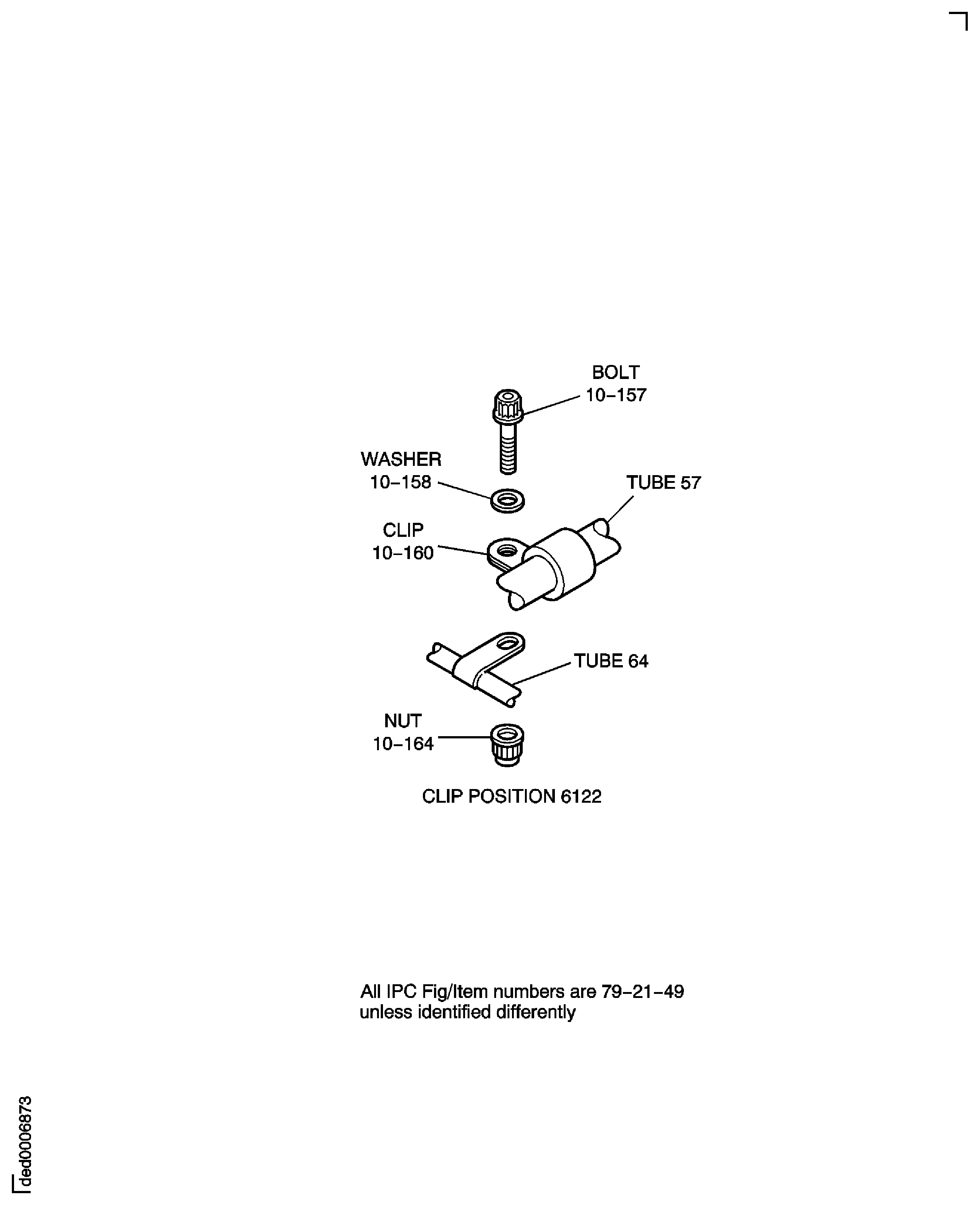

Tubes 23 and 24 are installed in TASK 72-00-40-420-005-B00 (INSTALLATION-008, CONFIG-002).Connect the tube 57 Engine Pressure Oil Tubes(79-21-49,10-100) to the tube 177 at the bifurcation panel and to the tubes 23 Engine Pressure Oil Tubes(79-21-49,12-100), 24 OIL-PRESSURE OIL TUBES-ENGINE(79-21-49,13-100) and 58 Engine Pressure Oil Tubes(79-21-49,11-100).

Torque the tube connector of the tube 24 to 257 to 283 lbfin (29 to 32 Nm) and safety with CoMat 02-126 LOCKWIRE.

Torque the tube connector of the tube 23 to 204 to 221 lbfin (23 to 25 Nm) and safety with CoMat 02-126 LOCKWIRE.

CAUTION

YOU MUST STOP THE TUBE TURNING WHEN YOU TORQUE THE TUBE NUTS. USE A SPANNER ON THE REAR OF THE MATING UNION. THIS WILL PREVENT ANY STRAIN ON THE TUBES AND HELP PREVENT LEAKS.With IAE 1R18001 Wrench 1 off torque the tube connector of the tube 57 to 398 to 434 lbfin (45 to 49 Nm). Safety with CoMat 02-126 LOCKWIRE.

With IAE 1R18000 Wrench 1 off torque the tube connector of the tube 58 to 319 to 345 lbfin (36 to 39 Nm). Safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-40-420-341 Install the No.1, 2 and 3 Bearing Oil Feed Tubes 57 and 58

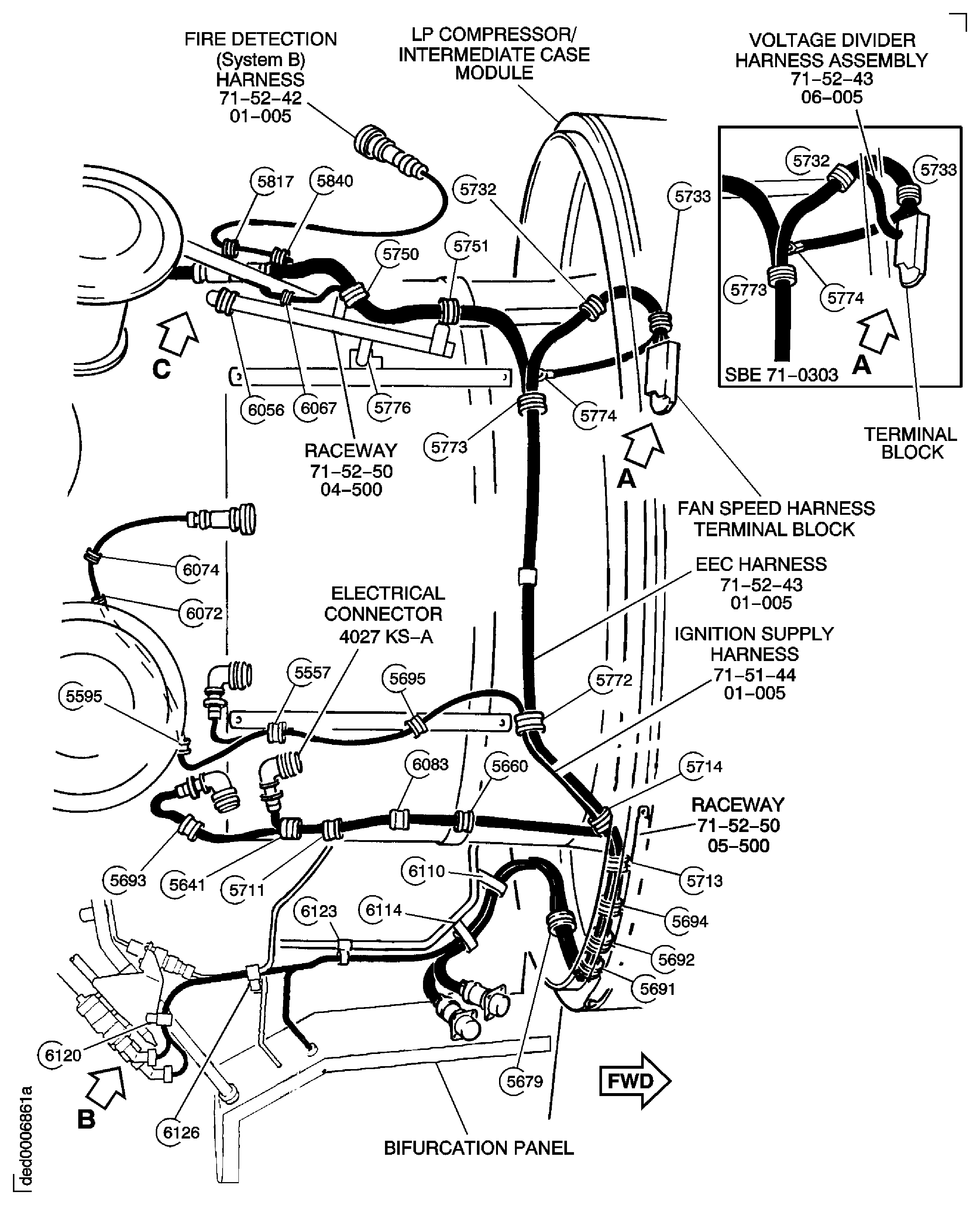

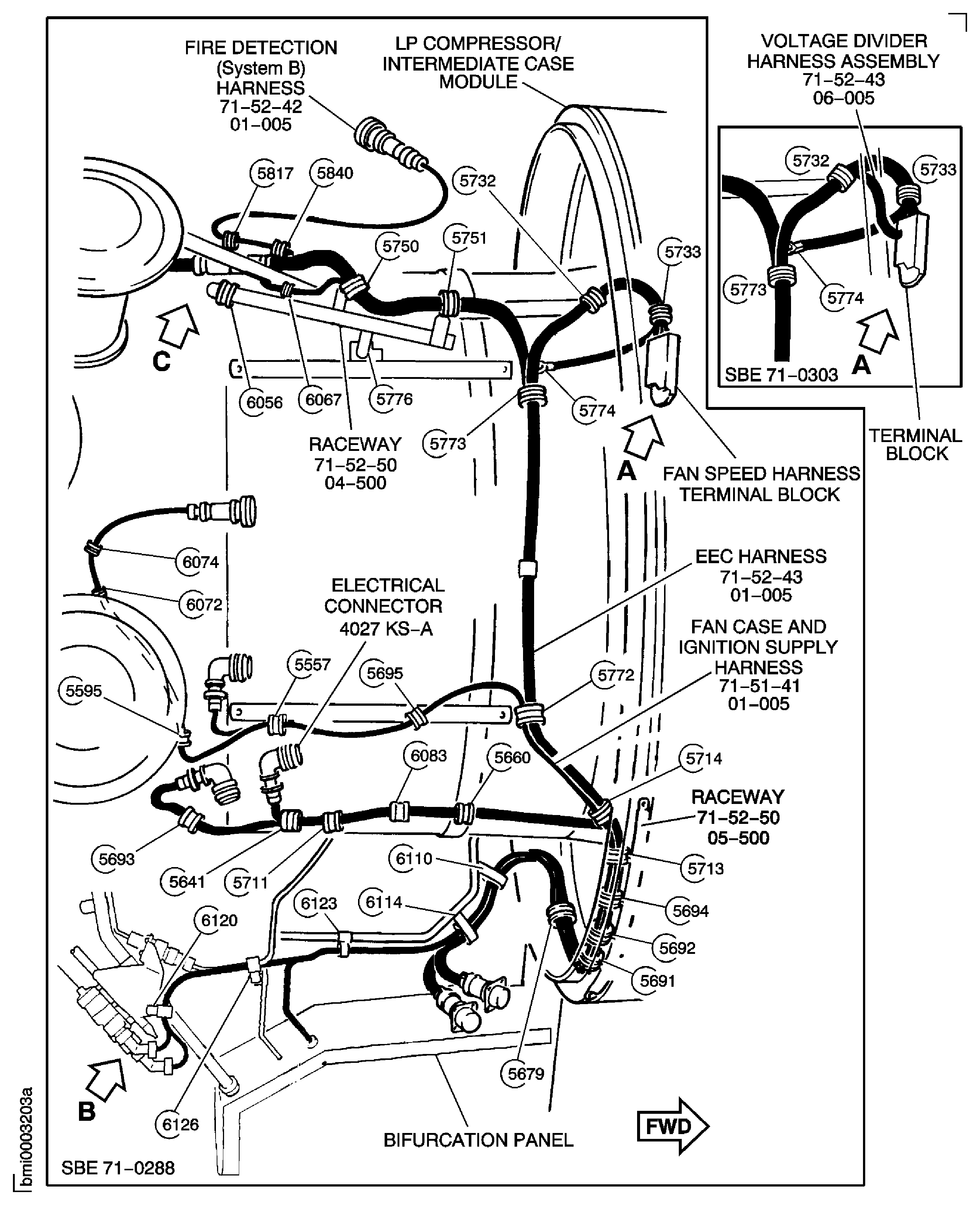

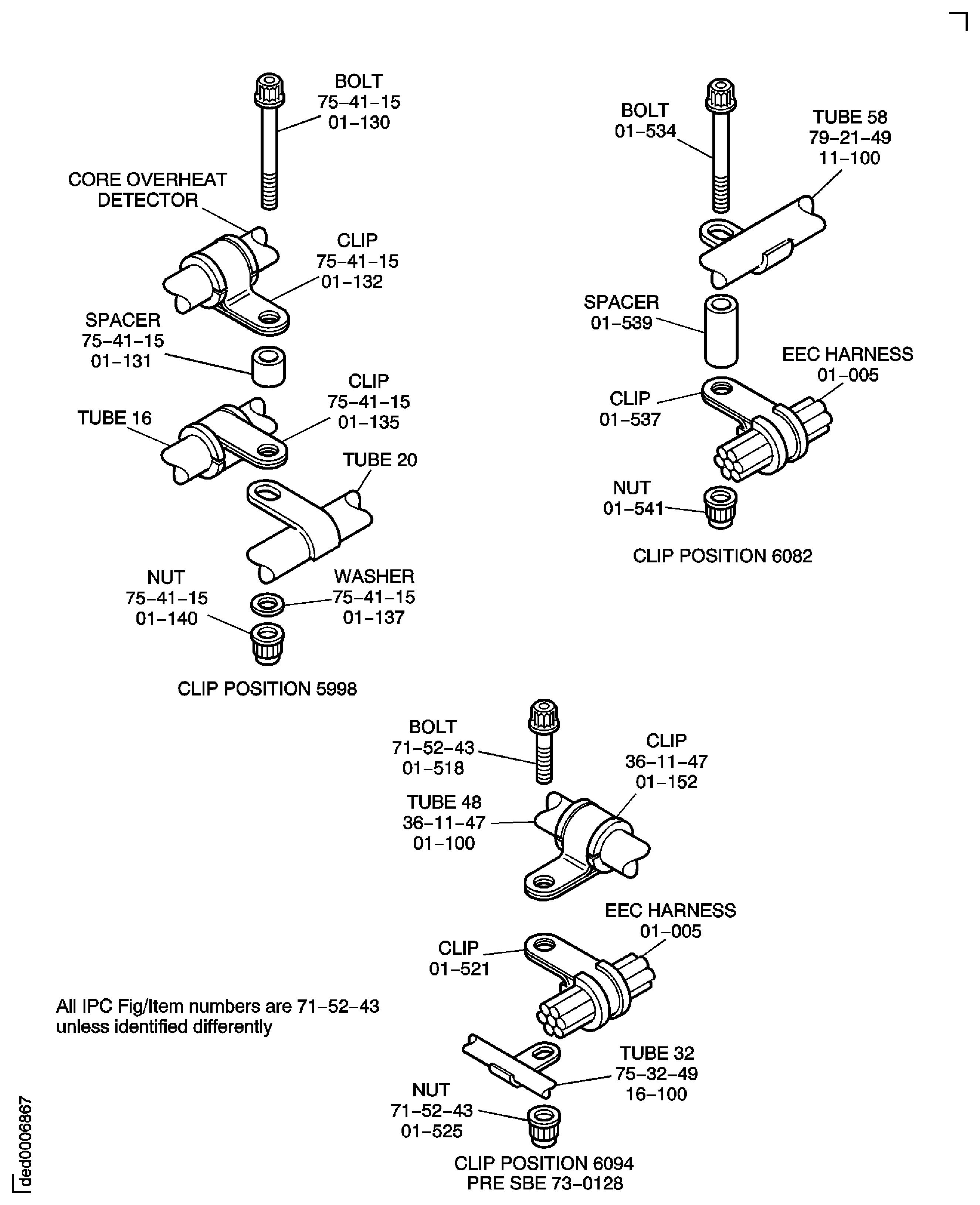

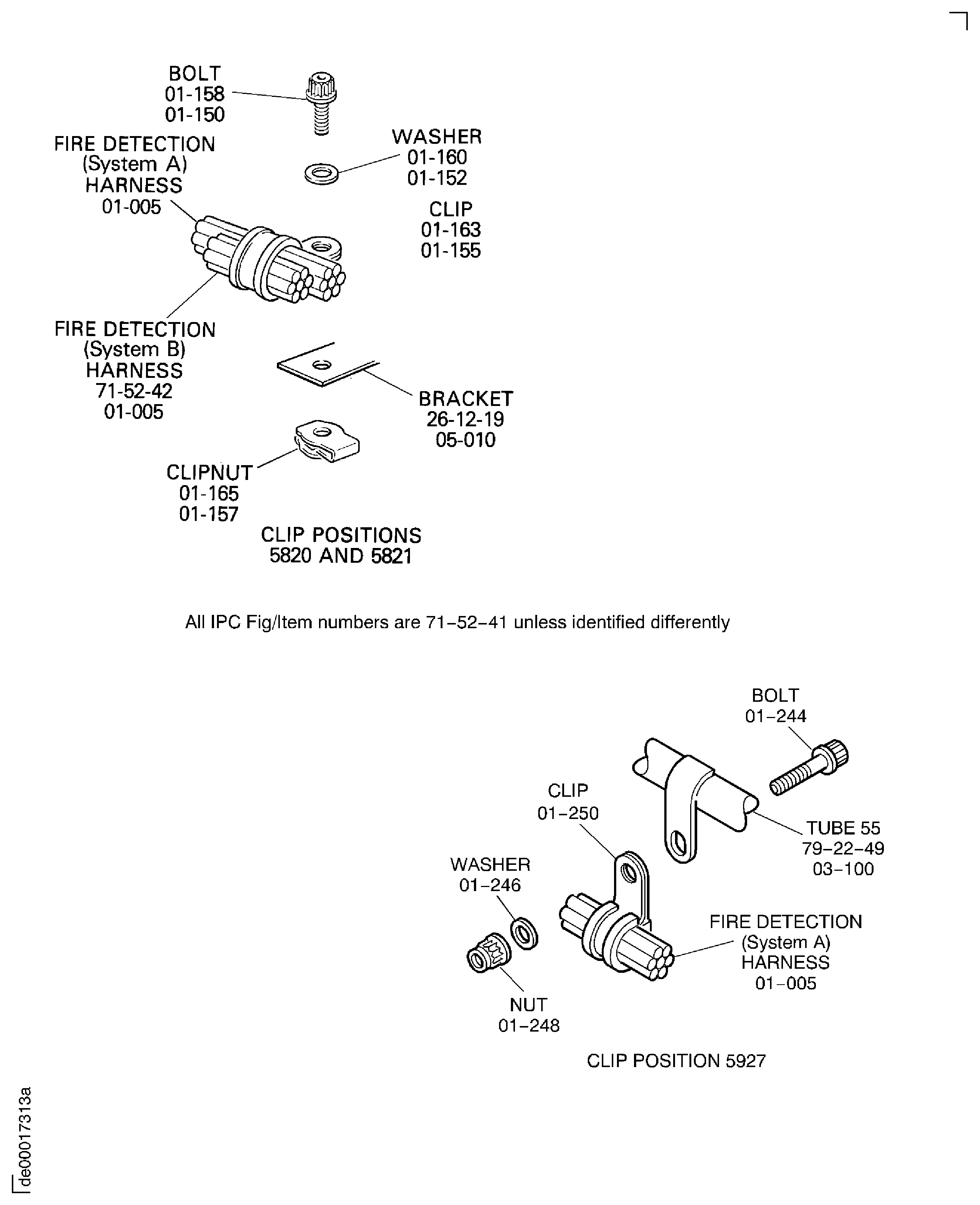

Refer to Figure.

During the installation procedure make sure the harnesses are held temporarily along their different lengths. Always install the datum clip positions when you install each electrical connector. This will give correct installation of the different harnesses, prevent too much strain on the electrical connectors and give the necessary drip loops (the drip loop makes sure moisture or fluids do not go in to the electrical connector).

Because of the differences between the harness diameters, the specified clip could be too large or too small. You can use a clip from a range of six clips that have the same part number. If the harness diameter is between two of the clips in the range, use the larger clip. When you do this use CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) to increase the harness diameter.

For the data on the electrical connectors refer to the SPM TASK 70-43-00-400-501 and SPM TASK 70-43-01-400-501.

For the data on the installation of the open wire harness refer to the SPM TASK 70-43-02-400-501.

Route and attach the right hand side and left hand side EEC harness looms together at the bifurcation panel electrical connectors 4008VC-A and 4009VC-A. Refer to Step.

SUBTASK 72-00-40-420-342 Electrical Harness Installation Procedure

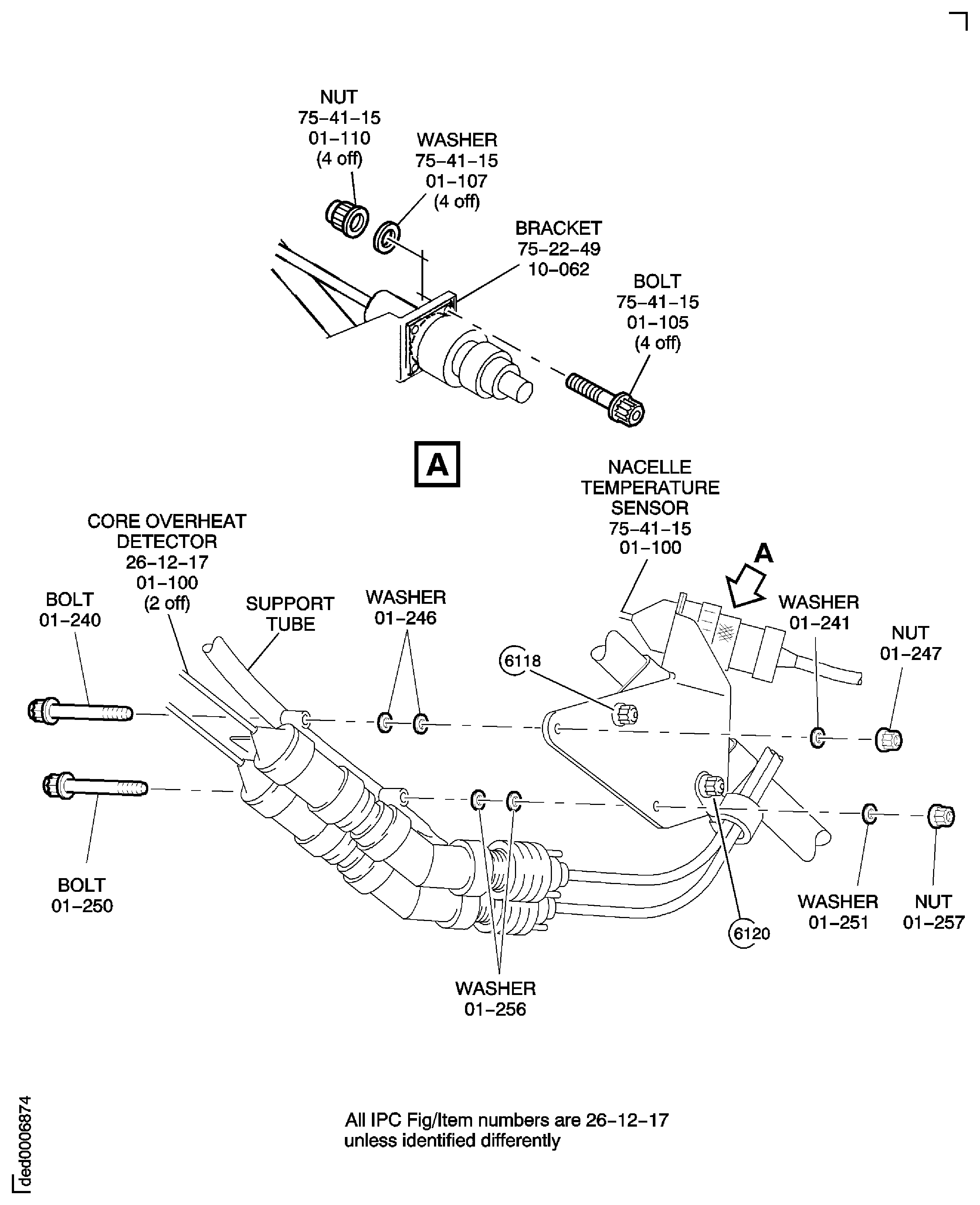

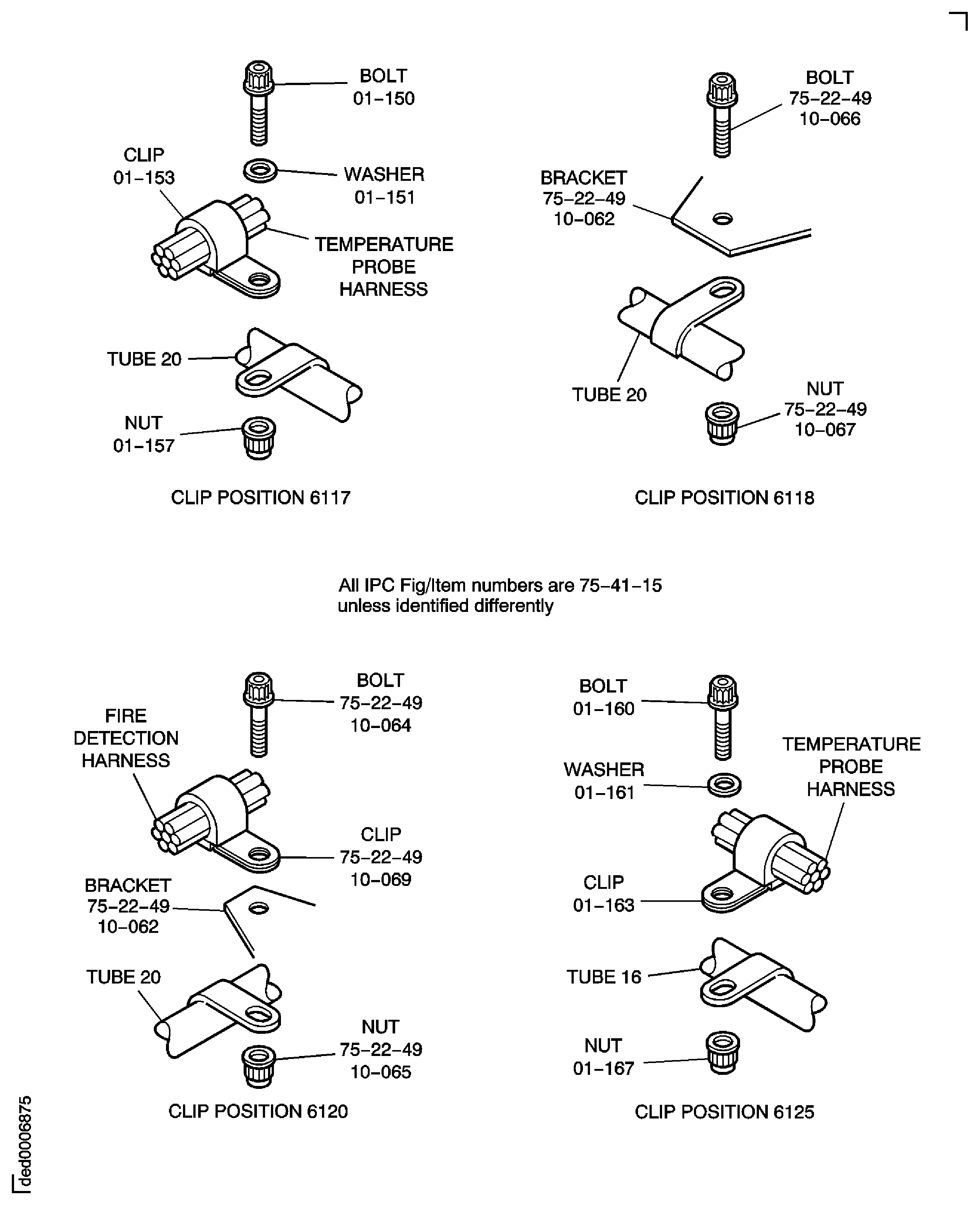

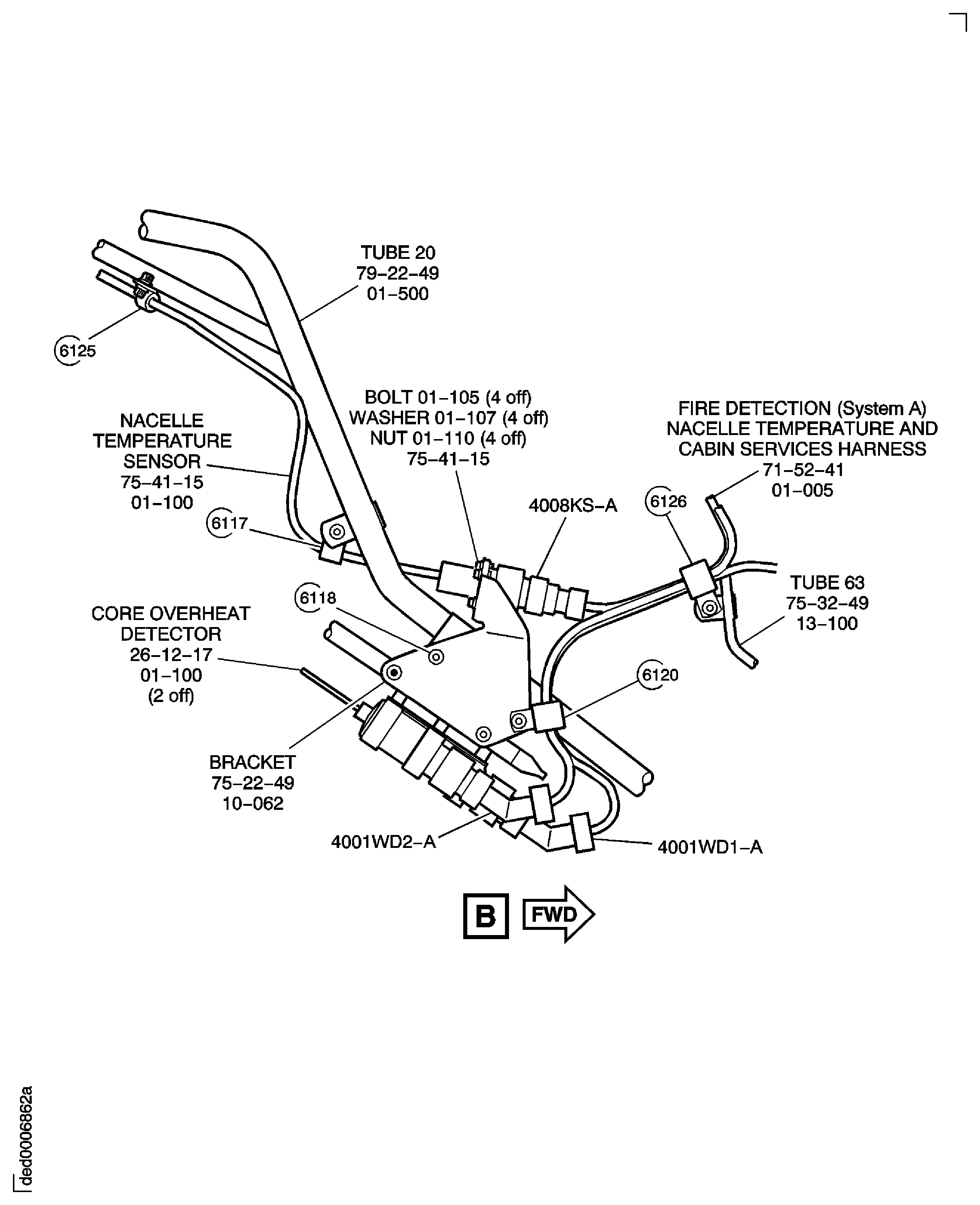

Attach the bracket AIR-BEARING COMPARTMENT COOLING & SEALING TUBES(75-22-49, 10-062) to the tube 20 with the bolts, washers, clips and nuts at the clip positions 6118 and 6120.

Attach the nacelle temperature sensor NACELLE TEMPERATURE SENSOR(75-41-15, 01-100) to the bracket with the four bolts NACELLE TEMPERATURE SENSOR(75-41-15, 01-105), the four washers NACELLE TEMPERATURE SENSOR(75-41-15, 01-107) and the four nuts NACELLE TEMPERATURE SENSOR(75-41-15, 01-110). Torque the nuts to 6 to 8 lbfin (0.68 to 0.90 Nm).

Install the nacelle temperature sensor FIRE PROTECTION-CORE ZONE FIRE DETECTOR(26-12-17, 01-100).

Attach the core overheat detector and support tube assembly to the bracket with the two bolts FIRE PROTECTION-CORE ZONE FIRE DETECTOR(26-12-17, 01-240 and 01-250) and with the six washers FIRE PROTECTION-CORE ZONE FIRE DETECTOR(26-12-17, 01-246 , 01-241, FIRE PROTECTION-CORE ZONE FIRE DETECTOR01-251 and 01-256) and the two nuts FIRE PROTECTION-CORE ZONE FIRE DETECTOR(26-12-17, 01-247 and 01-257).

Install the core overheat detector FIRE PROTECTION-CORE ZONE FIRE DETECTOR(26-12-17, 01-100).

SUBTASK 72-00-40-420-343 Install the Core Overheat Detector and Nacelle Temperature Sensor Electrical Receptacles

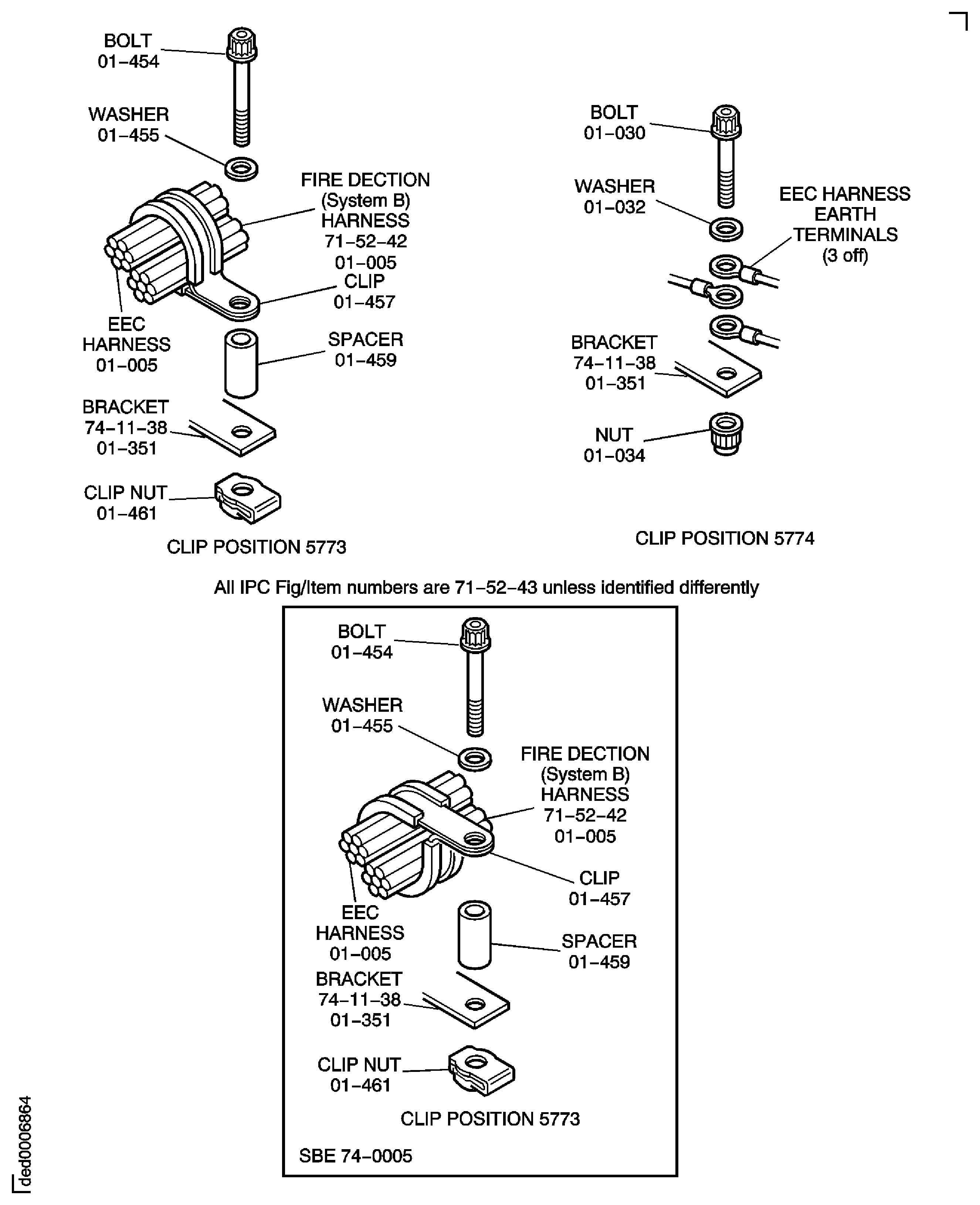

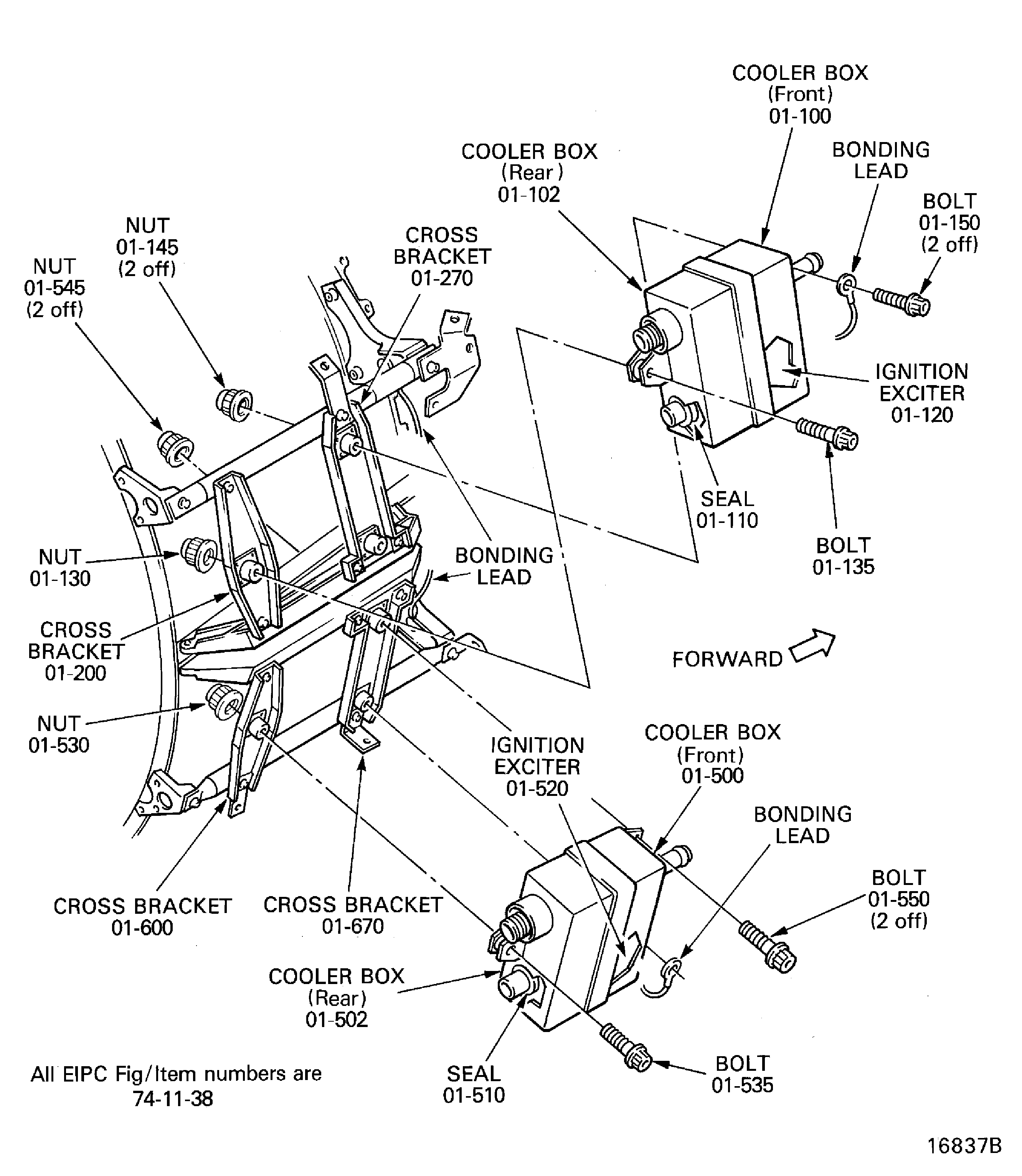

Refer to Figure.

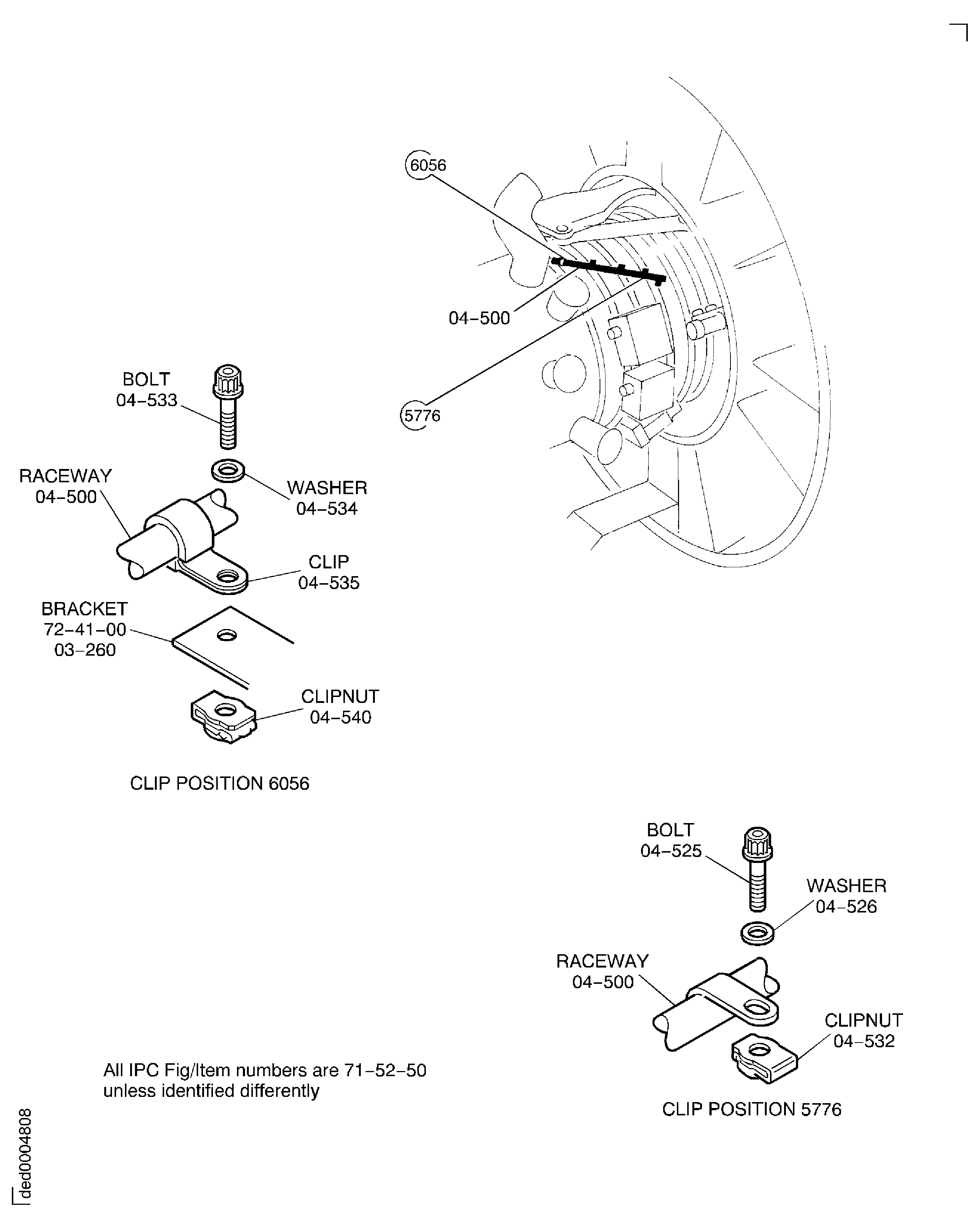

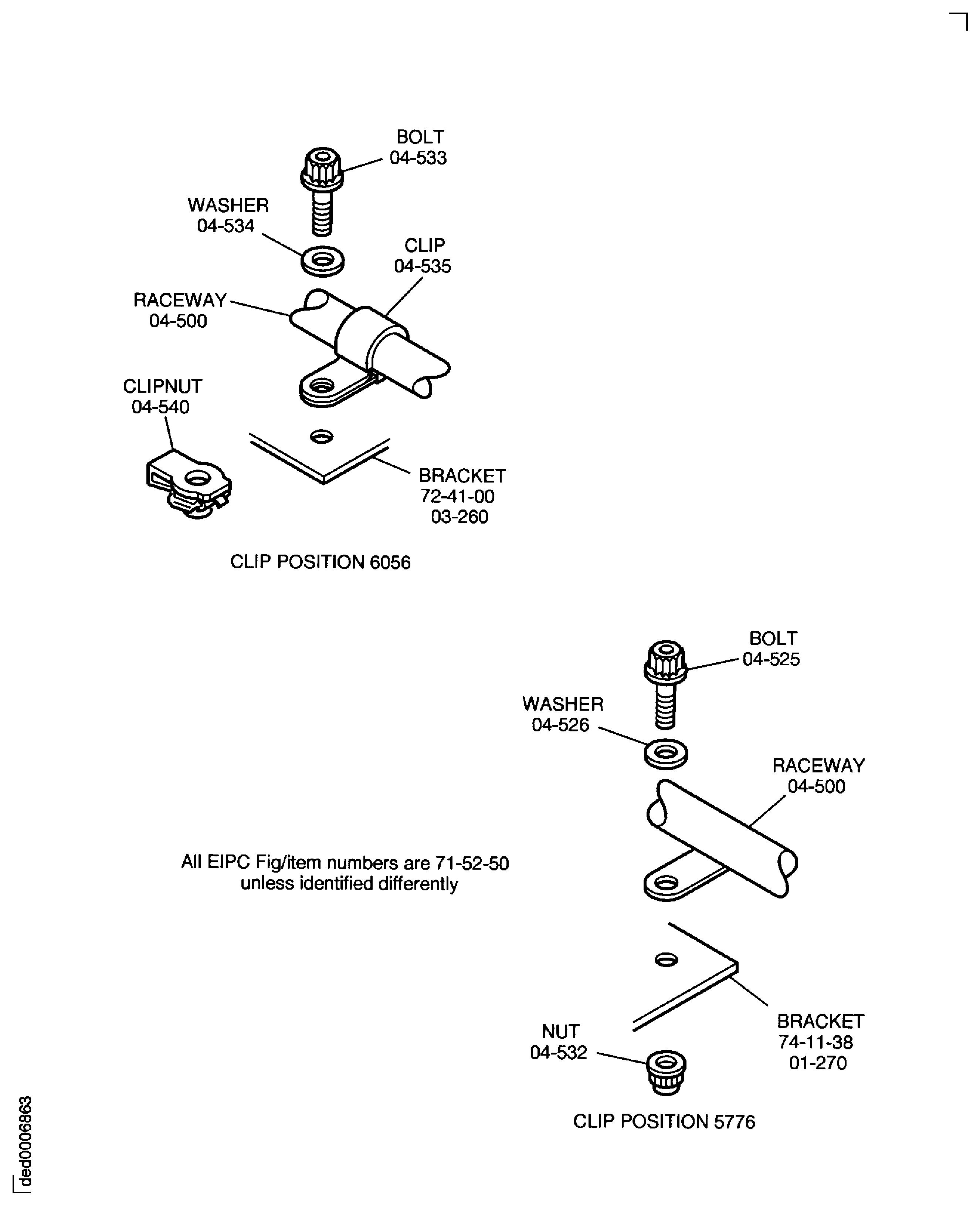

Pre SBE 74-0001: Attach the raceway to the bracket Ignition Exciters(74-11-38, 01-270) with the bolt BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-525), the washer BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-526) and the nut BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-532). Lightly tighten the nut.

SBE 74-0001: Attach the raceway to the bracket Ignition Exciters(74-11-38, 01-200) with the bolt BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-525), the washer BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-526) and the nut BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-532). Lightly tighten the nut.

Assemble the clip position 5776.

Install the clip BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-535) on the raceway, adjacent to the bracket HPC Assembly(72-41-00, 03-260) on flange J.

Attach the clip to the bracket with the bolt BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-533), the washer BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-534) and the clipnut BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-540). Lightly tighten the bolt.

Assemble the clip position 6056.

Install the raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50, 04-500).

SUBTASK 72-00-40-420-429 Install the Raceway (04-500) (Pre SBE 74-0001 and SBE 74-0001)

SBE 74-0001: Engine - Ignition - Introduce a new ignition mounting bracket

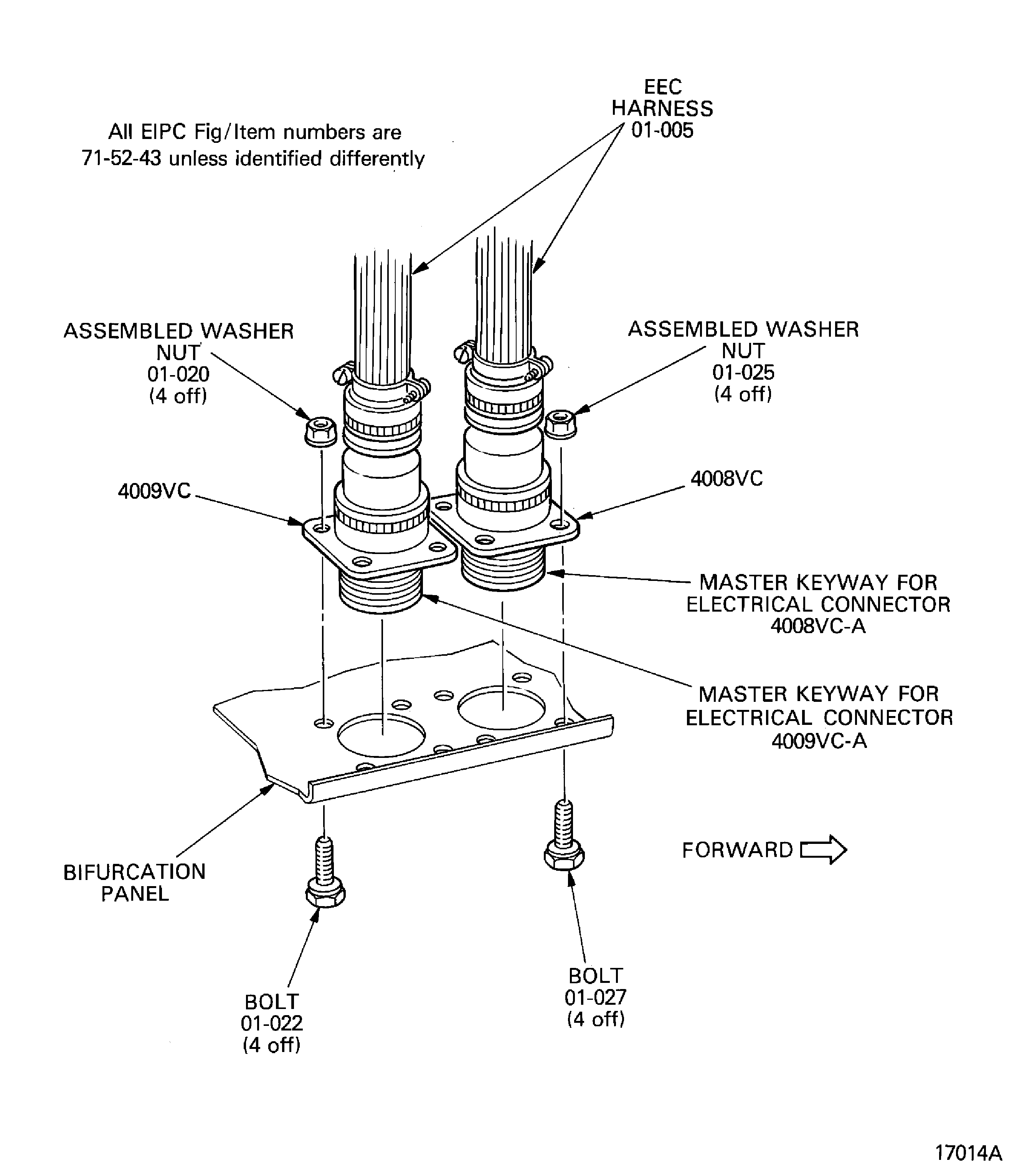

Attach the electrical receptacles 4008VC and 4009VC (with the master keyways to the front) to the bifurcation panel with the eight bolts EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-022), EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-027) and the nuts EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-020), EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-025). Torque the nuts to 10 to 14 lbfin (1.13 to 1.58 Nm). Connect the electrical connectors 4008VC-A and 4009VC-A and torque to 55 * lbfin (6.2 Nm).

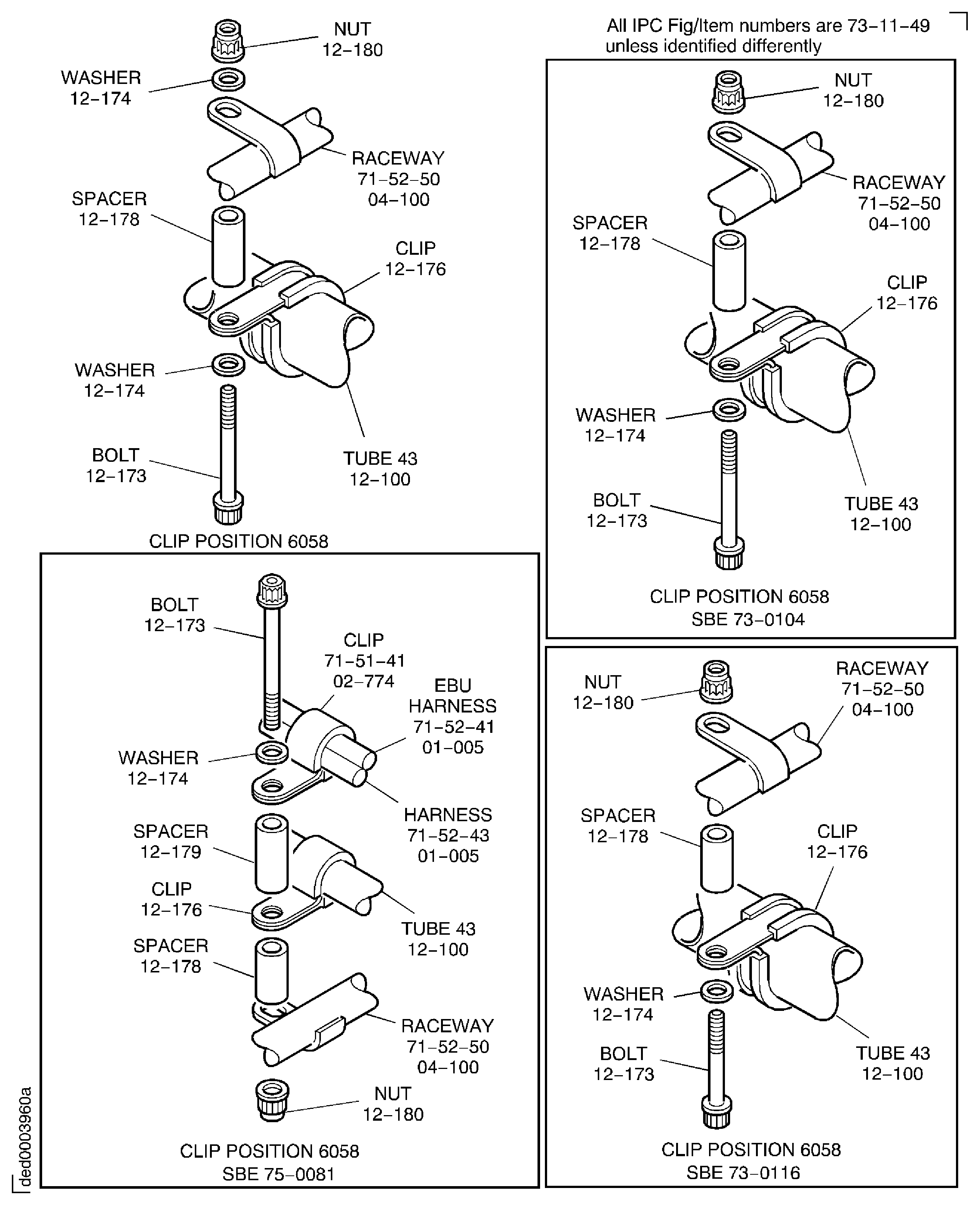

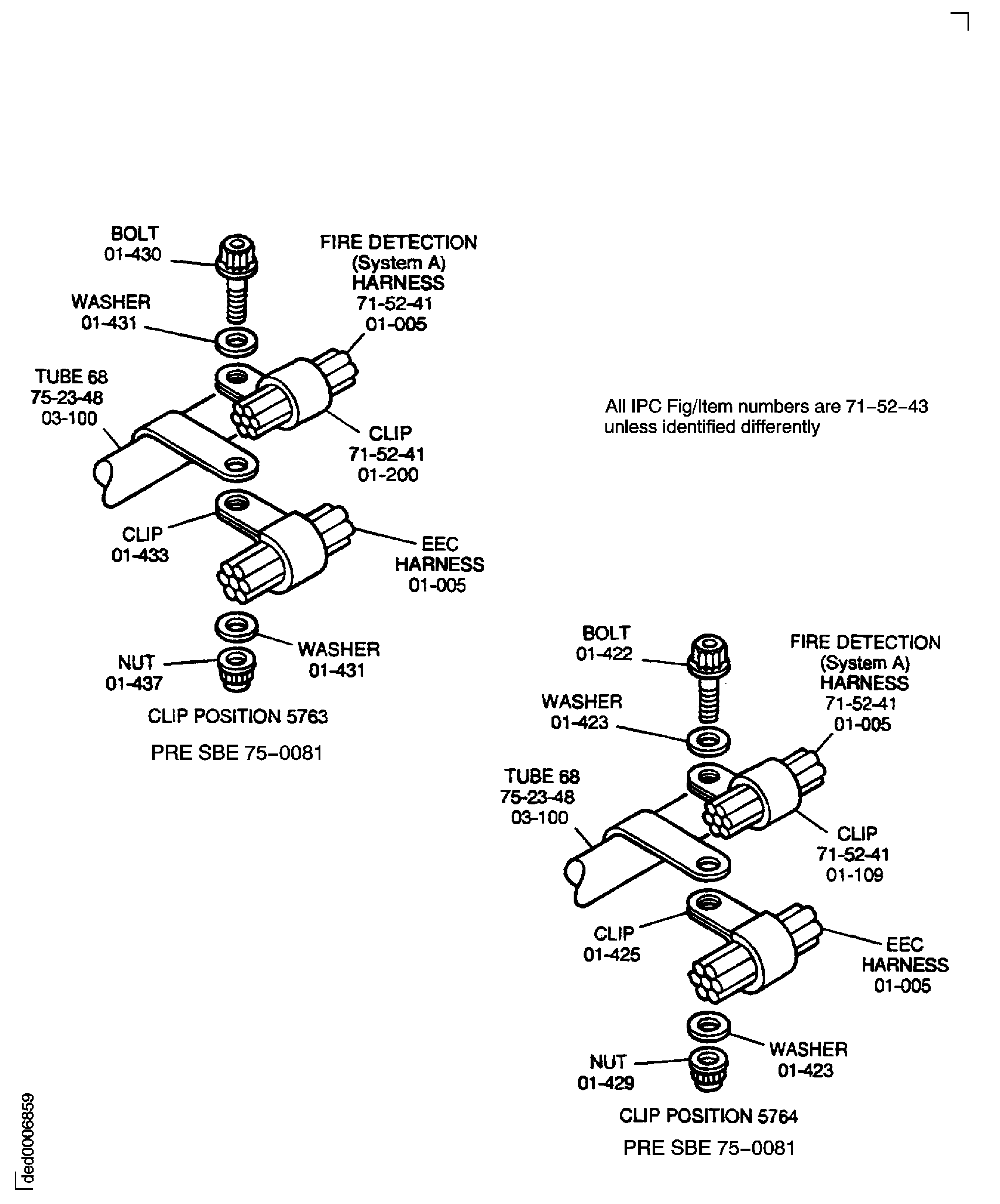

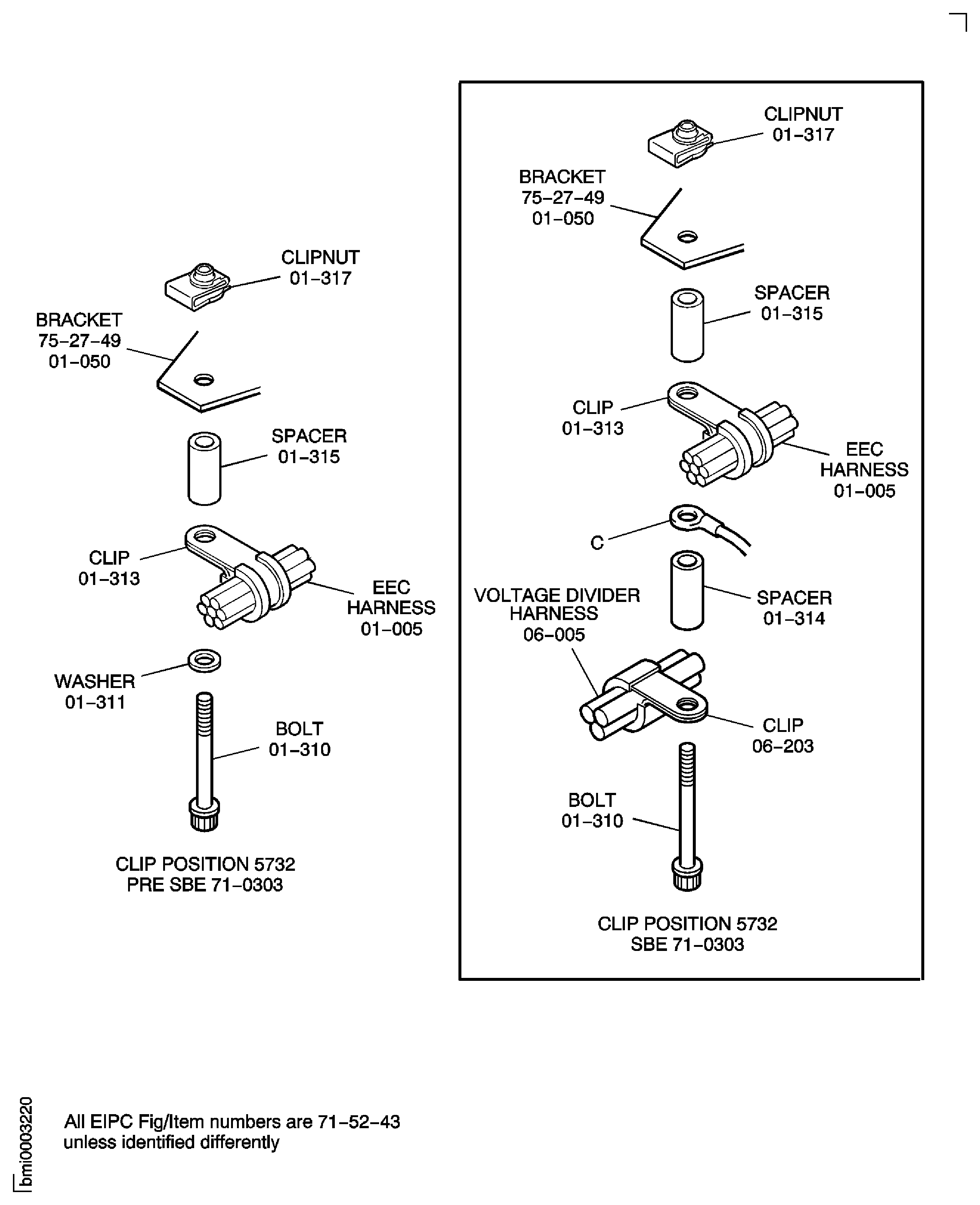

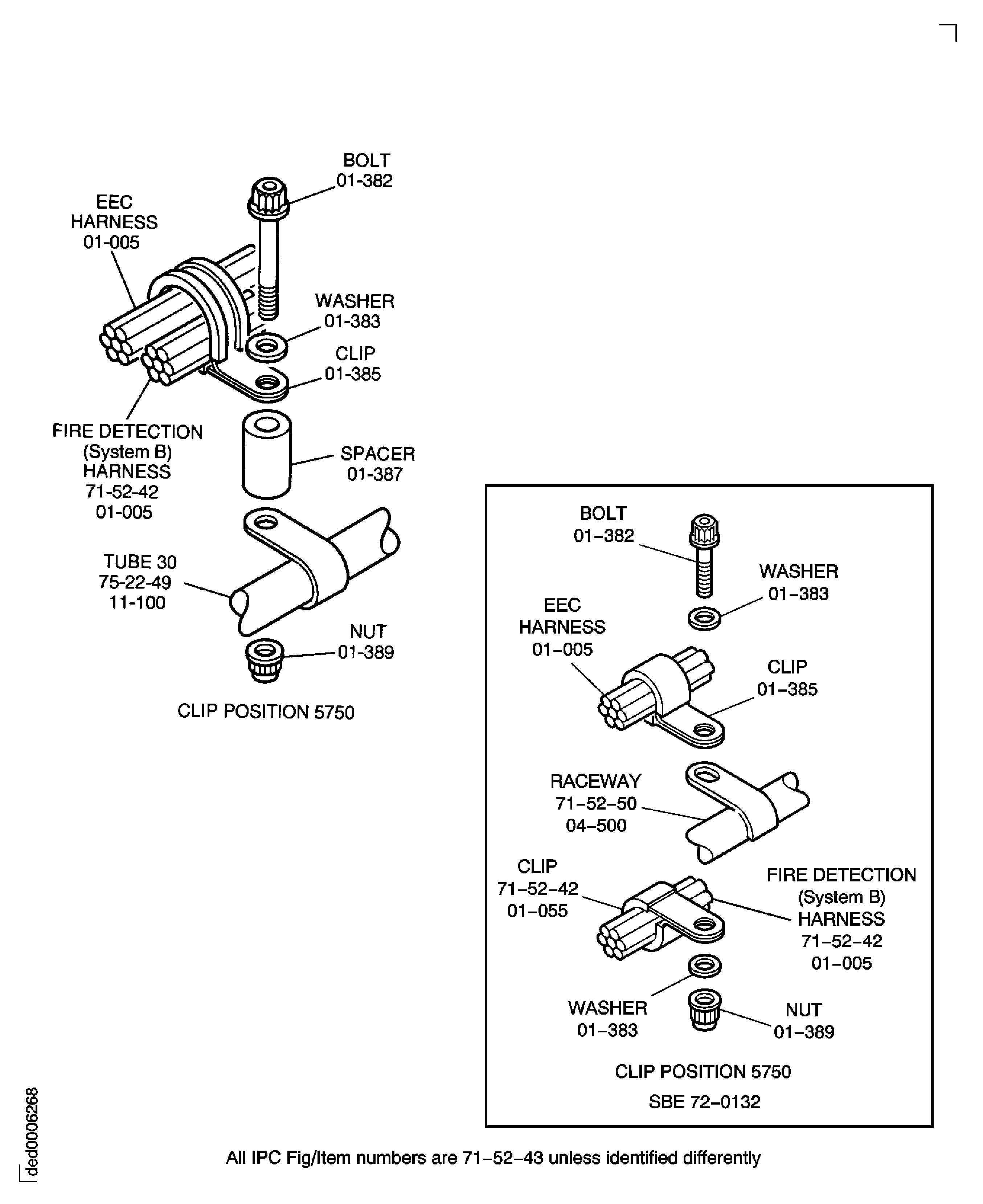

Pre SBE 75-0081: Assemble the datum clip position 5765 and torque the nut to 36 to 45 lbfin (4 to 5 Nm).

Pre SBE 73-0128: Assemble the clip position CP6094.

Pre SBE 75-0081: Assemble the clip positions CP5763 and CP5764.

SBE 75-0081: Assemble the clip positions CP5747 and CP6058.

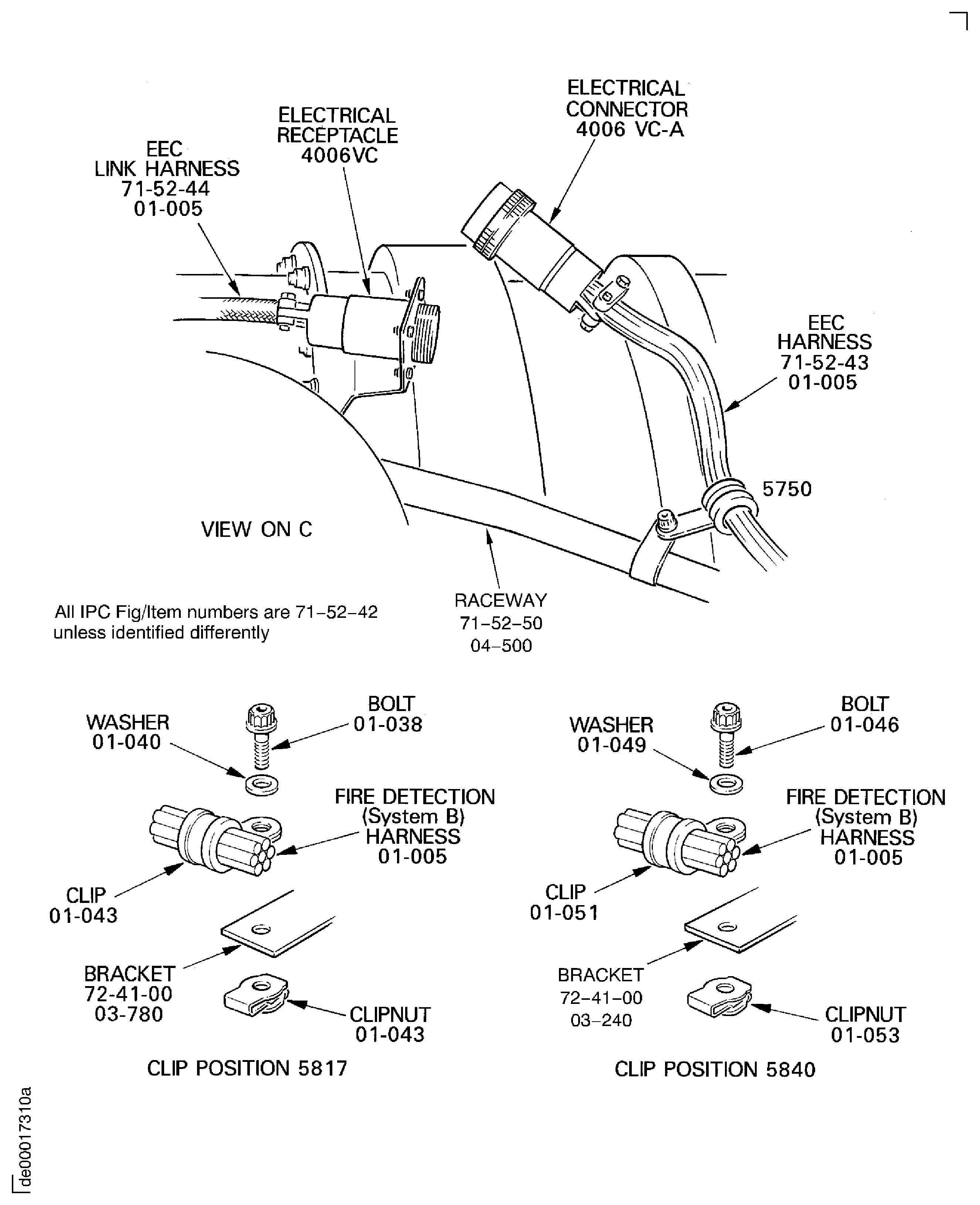

Install the EEC harness EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-005) and the fire detection harness Fire Detection (System B) Harness(71-52-42,01-005).

SUBTASK 72-00-40-420-430-A00 Install the EEC Harness and the Fire Detection Harness (Pre SBE 71-0303, Pre SBE 73-0128, SBE 73-0128, Pre SBE 75-0081 and SBE 75-0081)

SBE 73-0128: Engine fuel and control - Fuel system air tubes - Deletion of a clip at CP6094

SBE 75-0081: Air - Deletion of the HPC stage 10 make up air valve

Attach the electrical receptacles 4008VC and 4009VC (with the master keyways to the front) to the bifurcation panel with the eight bolts EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-022), EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-027) and the nuts EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-020), EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-025). Torque the nuts to 10 to 14 lbfin (1.13 to 1.58 Nm). Connect the electrical connectors 4008VC-A and 4009VC-A and torque to 55 * lbfin (6.2 Nm).

Pre SBE 75-0081: Assemble the datum clip position 5765 and torque the nut to 36 to 45 lbfin (4 to 5 Nm).

Pre SBE 73-0128: Assemble the clip position CP6094.

Pre SBE 75-0081: Assemble the clip positions CP5763 and CP5764.

SBE 75-0081: Assemble the clip positions CP5747 and CP6058.

Install the clip EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-313) on the harness EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-005), the clip ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-203) on the harness ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-005). Assemble the clip ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-203), the spacer EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-314), the clip EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-313) and the spacer EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-315) at the clip position 5732. Temporarily install the bolt EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-310) at the clip position 5732. Lightly tighten the bolt EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-310).

NOTE

Do not torque the bolt EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-310) at the clip position 5732.Torque the nuts and the bolts to 36 to 45 lbfin (4 to 5 Nm).

Install the EEC harness EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-005), the voltage divider harness ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-005) and the fire detection harness Fire Detection (System B) Harness(71-52-42,01-005).

SUBTASK 72-00-40-420-430-B00 Install the EEC Harness, the Voltage Divider Harness and the Fire Detection Harness (SBE 71-0303, Pre SBE 72-0553, Pre SBE 73-0128, SBE 73-0128, Pre SBE 75-0081 and SBE 75-0081)

SBE 71-0303: EEC Harness - Fan Harness Core - Addition of a voltage divider harness assembly

SBE 73-0128: Engine fuel and control - Fuel system air tubes - Deletion of a clip at CP6094

SBE 75-0081: Air - Deletion of the HPC stage 10 make up air valve

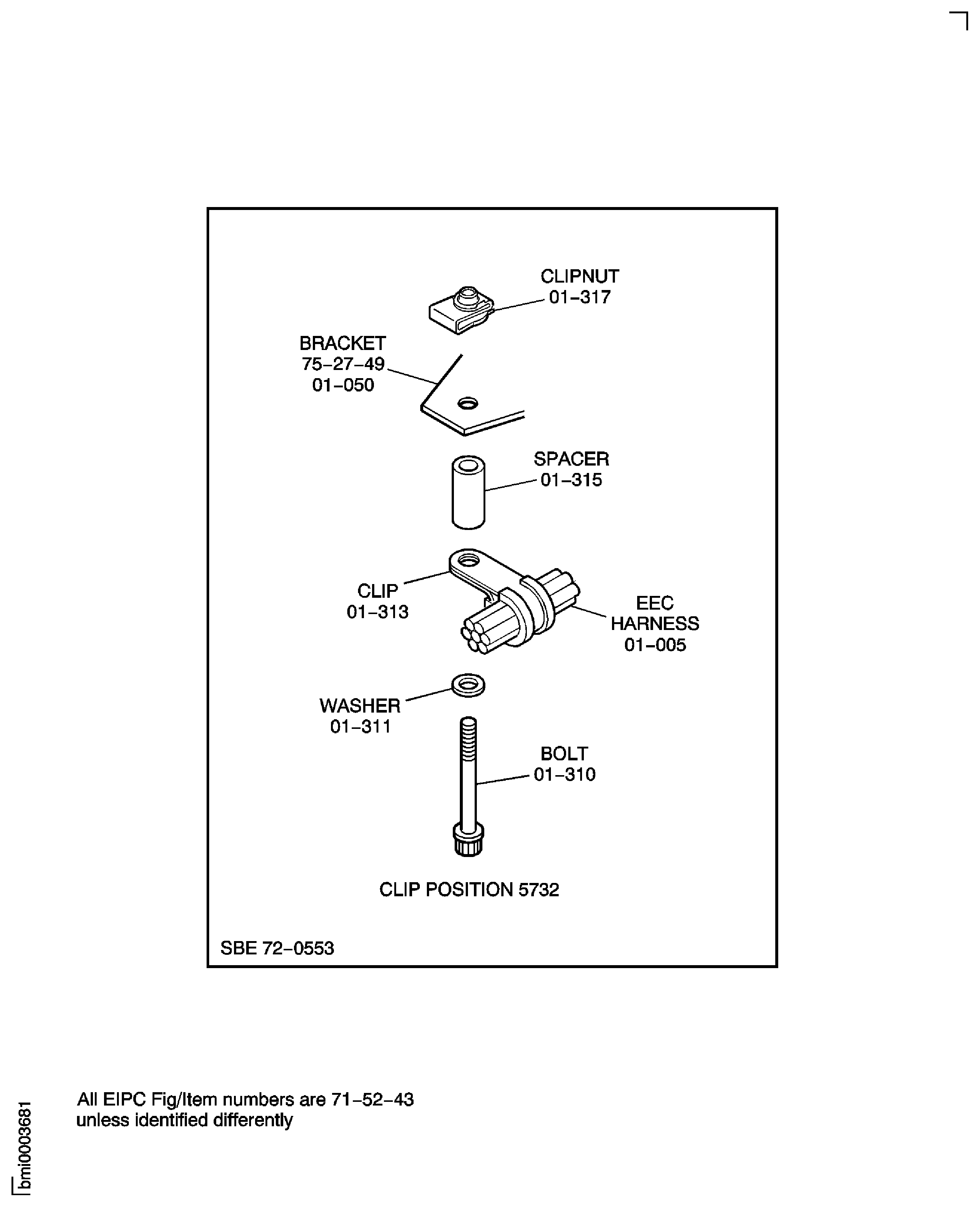

Attach the electrical receptacles 4008VC and 4009VC (with the master keyways to the front) to the bifurcation panel with the eight bolts EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-022), EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-027) and the nuts EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-020), EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-025). Torque the nuts to 10 to 14 lbfin (1.13 to 1.58 Nm). Connect the electrical connectors 4008VC-A and 4009VC-A and torque to 55 * lbfin (6.2 Nm).

Pre SBE 75-0081: Assemble the datum clip position 5765 and torque the nut to 36 to 45 lbfin (4 to 5 Nm).

Pre SBE 73-0128: Assemble the clip position CP6094.

Pre SBE 75-0081: Assemble the clip positions CP5763 and CP5764.

SBE 75-0081: Assemble the clip positions CP5747 and CP6058.

Install the EEC harness EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-005) and the fire detection harness Fire Detection (System B) Harness(71-52-42,01-005).

SUBTASK 72-00-40-420-430-C00 Install the EEC Harness and the Fire Detection Harness (SBE 72-0553, Pre SBE 73-0128, SBE 73-0128, Pre SBE 75-0081 and SBE 75-0081)

SBE 72-0553: Introduction of new trim balance probe and deletion of related powerplant voltage divider harness assembly

SBE 73-0128: Engine fuel and control - Fuel system air tubes - Deletion of a clip at CP6094

SBE 75-0081: Air - Deletion of the HPC stage 10 make up air valve

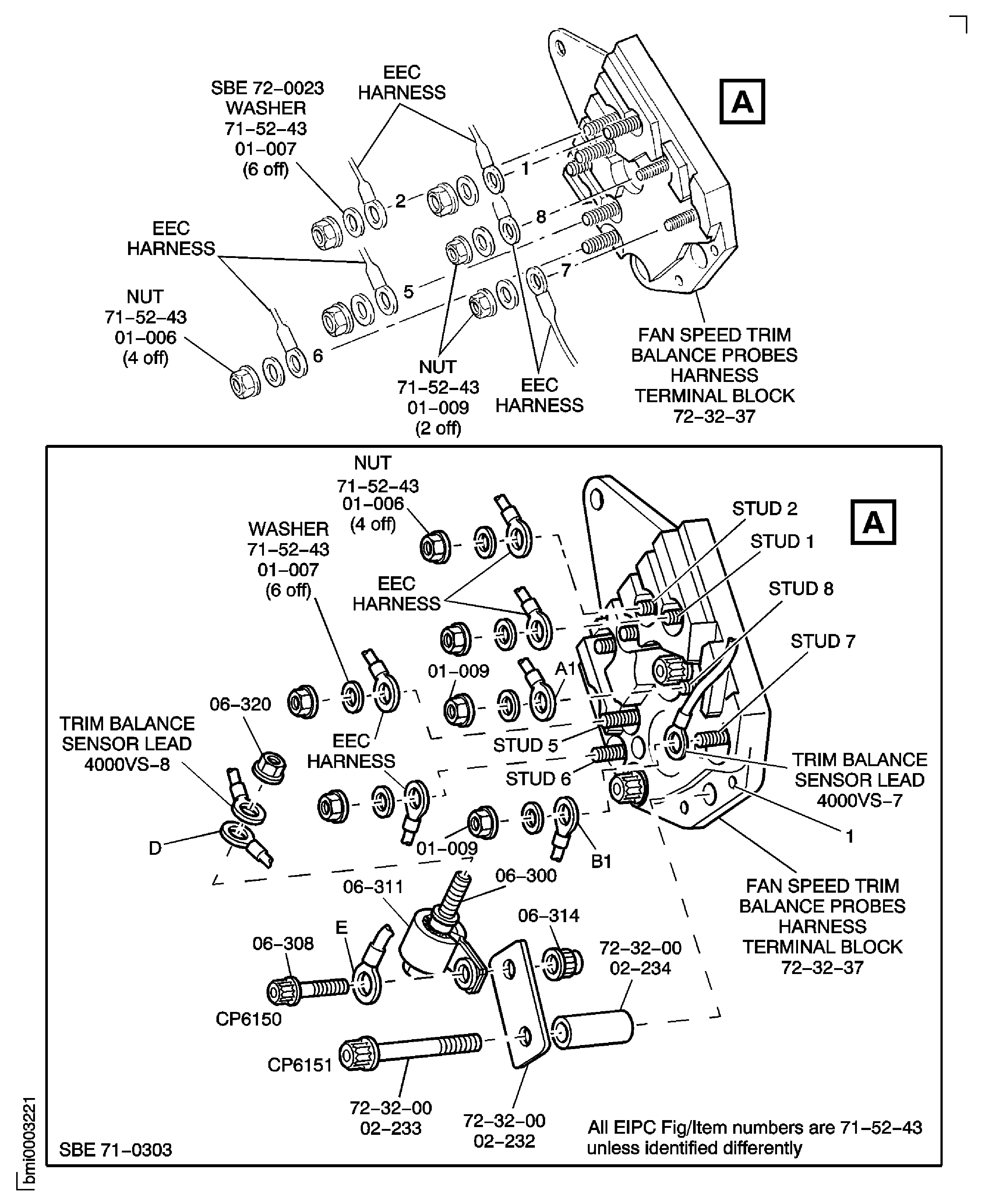

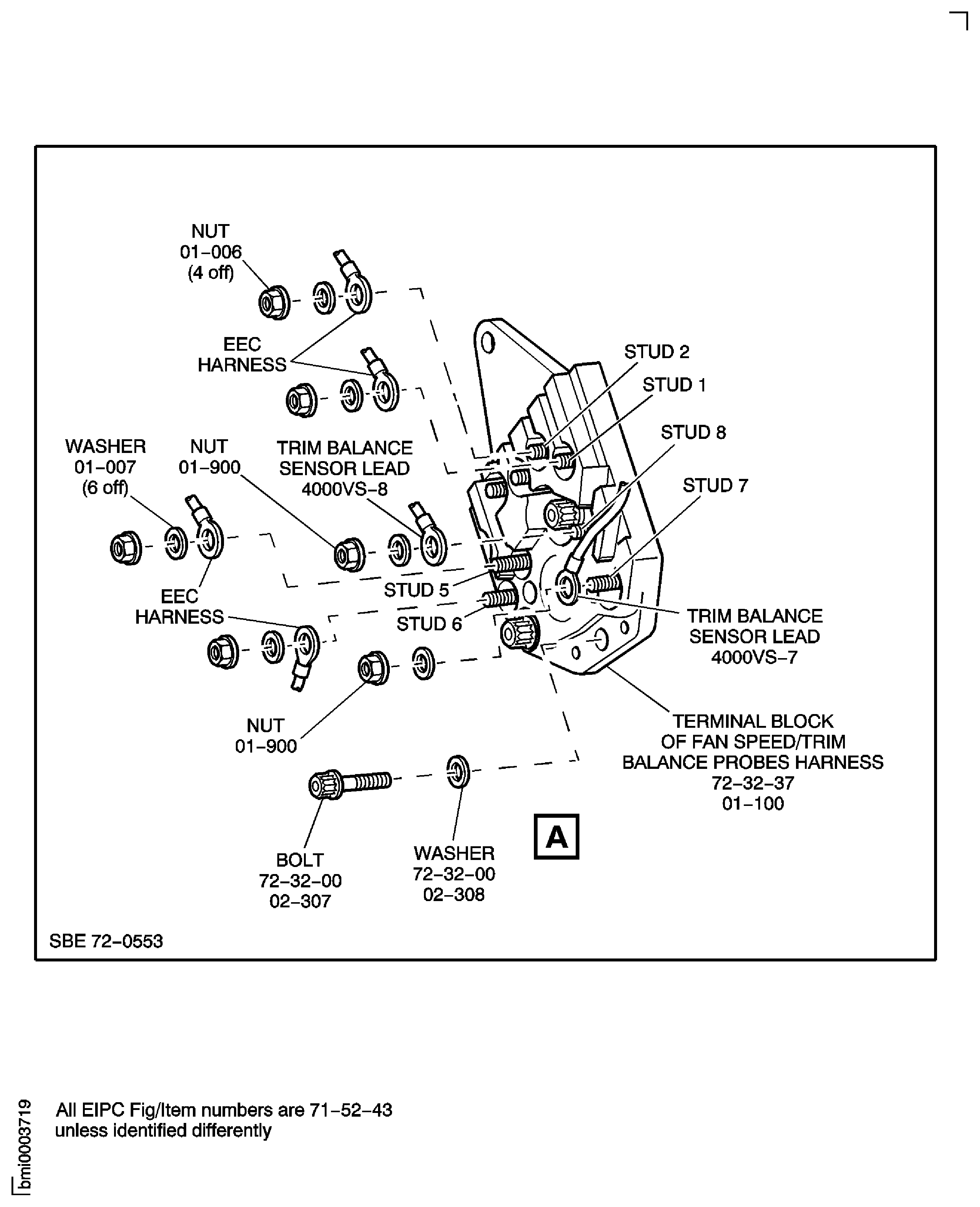

Connect the N1 sensor leads 4000VS-5 and 4000VS-6 to terminals No.5 and No.6. Install the two nuts EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-006) and the two washers EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-007). Torque the nuts to 20 to 26 * lbfin (2.26 to 2.94 Nm).

Connect the N1 sensor leads 4000VS-1 and 4000VS-2 to terminals No.1 and No.2. Install the two nuts EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-006) and the two washers EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-007). Torque the nuts to 20 to 26 lbfin (2.26 to 2.94 Nm).

Connect the trim balance sensor leads 4000VS-7 and 4000VS-8 to terminals No.7 and No.8. Install the two nuts EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-009) and the two washers EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-007). Torque the nuts to 10 to 14 lbfin (1.13 to 1.58 Nm).

Connect the EEC harness EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-005) to the fan speed terminal block.

SUBTASK 72-00-40-420-431-A00 Connect the EEC Harness to the Fan Speed Terminal Block (Pre SBE 71-0303)

Connect the two N1 sensor leads (4000VS-5 and 4000VS-6) to terminals No.5 and No.6. Install the two washers EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-007) and the two nuts EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-006). Torque the nuts to 20 to 22 lbfin (2.26 to 2.48 Nm).

Connect the two N1 sensor leads (4000VS-1 and 4000VS-2) to terminals No.1 and No.2. Install the two washers EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-007) and the two nuts EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-006). Torque the nuts to 20 to 22 lbfin (2.26 to 2.48 Nm).

Connect the terminal lug B1 of the voltage divider harness assembly ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-005) and the trim balance sensor lead (4000VS-7) to terminal No.7. Connect the terminal lug A1 of the voltage divider harness assembly ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-005) to terminal No.8. Install the two washers EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-007) and the two nuts EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-009). Torque the nuts to 10 to 14 lbfin (1.13 to 1.58 Nm).

Install the bolt assembly ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-300) into the clip ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-311) at the clip position 6150. Connect the grounding terminal lug E of the voltage divider harness assembly ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-005) and the clip ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-311) to the bracket LP Compressor (LPC) - Intermediate Structure Module(72-32-00,02-232). Install the bolt ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-308) and the nut ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-314). Torque the nut to 40 lbfin (4.5 Nm).

Attach the terminal lug D of the voltage divider harness assembly ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-005) and the trim balance sensor lead (4000VS-8) to the bolt assembly ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-300). Install the nut ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-320). Torque the nut to 10 to 14 lbfin (1.13 to 1.58 Nm).

Temporarily remove the bolt EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-310) at the clip position 5732. Assemble the grounding terminal lug C of voltage divider harness ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-005), the spacer EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-314), the clip ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-203), the clip EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-313) and the spacer EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-315) at the clip position 5732. Re-install the bolt EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-310). Torque the bolt to 40 lbfin (4.5 Nm).

Connect the EEC harness EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-005) and the voltage divider harness ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE(71-52-43,06-005) to the fan speed terminal block.

SUBTASK 72-00-40-420-431-B00 Connect the EEC Harness and the Voltage Divider Harness to the Fan Speed Terminal Block (SBE 71-0303 and Pre SBE 72-0553)

SBE 71-0303: EEC Harness - Fan Harness Core - Addition of a voltage divider harness assembly

Connect the N1 sensor leads 4000VS-5 and 4000VS-6 to terminals No.5 and No.6. Install the two nuts EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-006) and the two washers EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-007). Torque the nuts to 20 to 26 * lbfin (2.26 to 2.94 Nm).

Connect the N1 sensor leads 4000VS-1 and 4000VS-2 to terminals No.1 and No.2. Install the two nuts EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-006) and the two washers EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-007). Torque the nuts to 20 to 26 lbfin (2.26 to 2.94 Nm).

Connect the trim balance sensor leads 4000VS-7 and 4000VS-8 to terminals No.7 and No.8. Install the two nuts EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-009) and the two washers EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-007). Torque the nuts to 10 to 14 lbfin (1.13 to 1.58 Nm).

Connect the EEC harness EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-005) to the fan speed terminal block.

SUBTASK 72-00-40-420-431-C00 Connect the EEC Harness to the Fan Speed Terminal Block (SBE 72-0553)

SBE 72-0553: Introduction of new trim balance probe and deletion of related powerplant voltage divider harness assembly

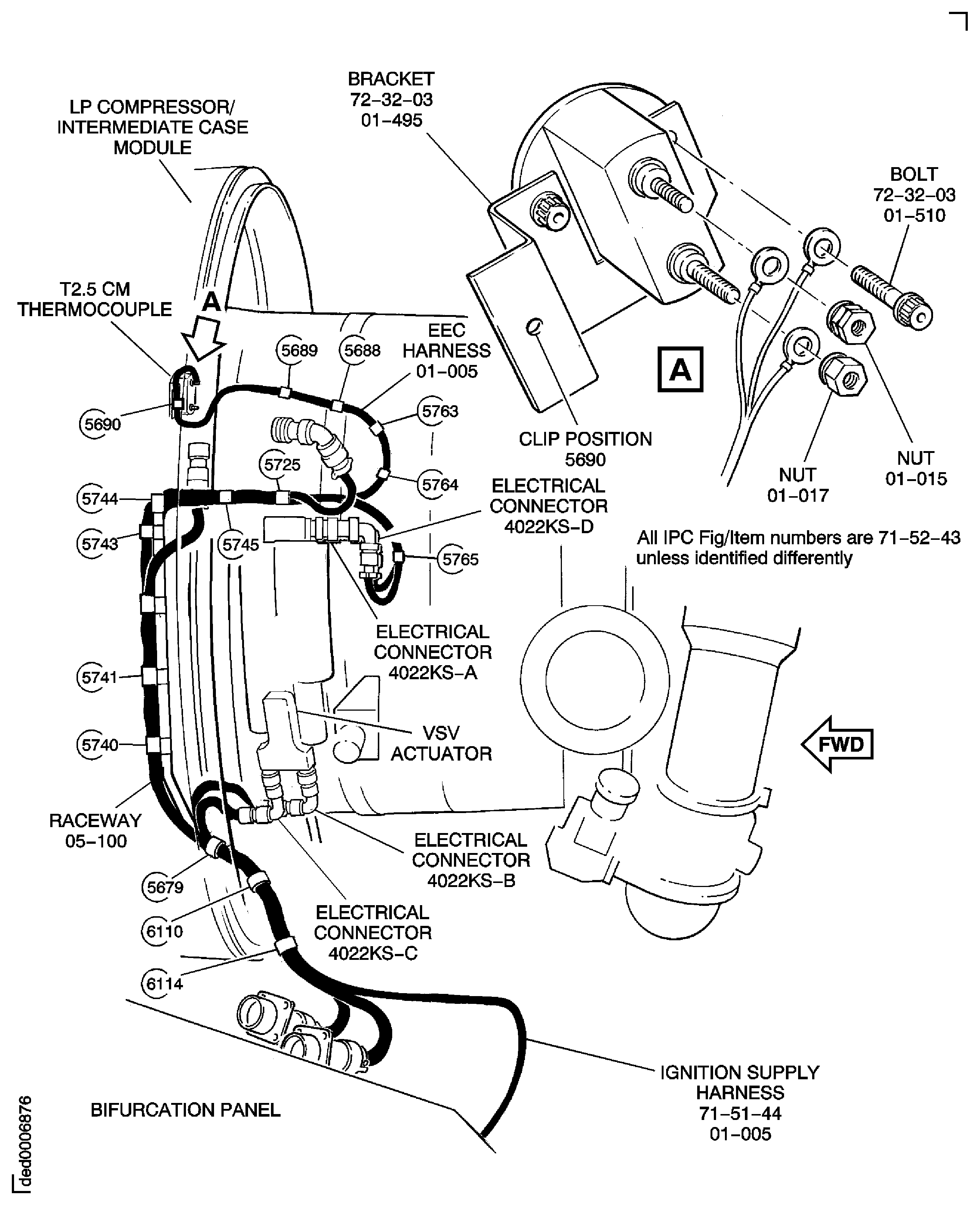

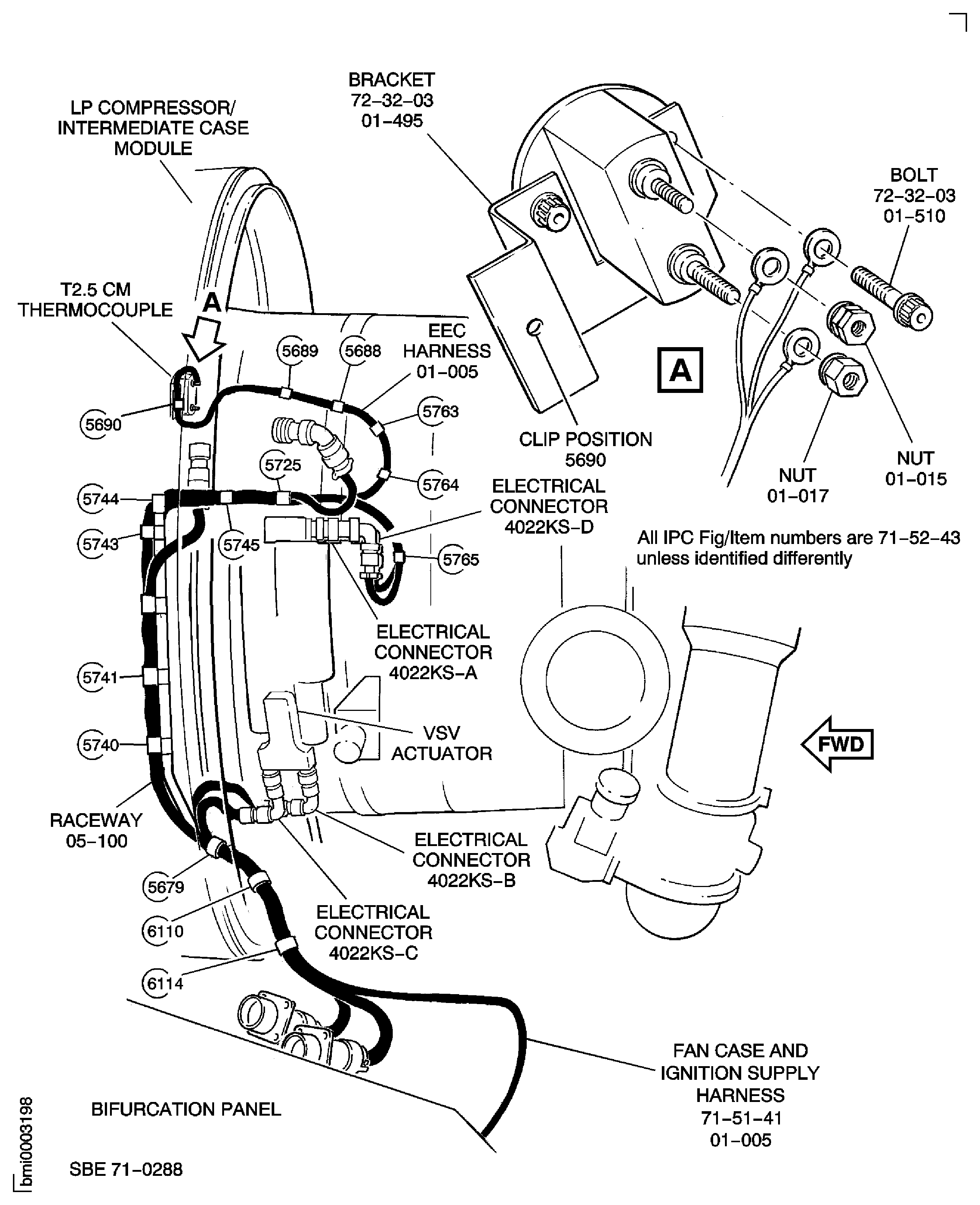

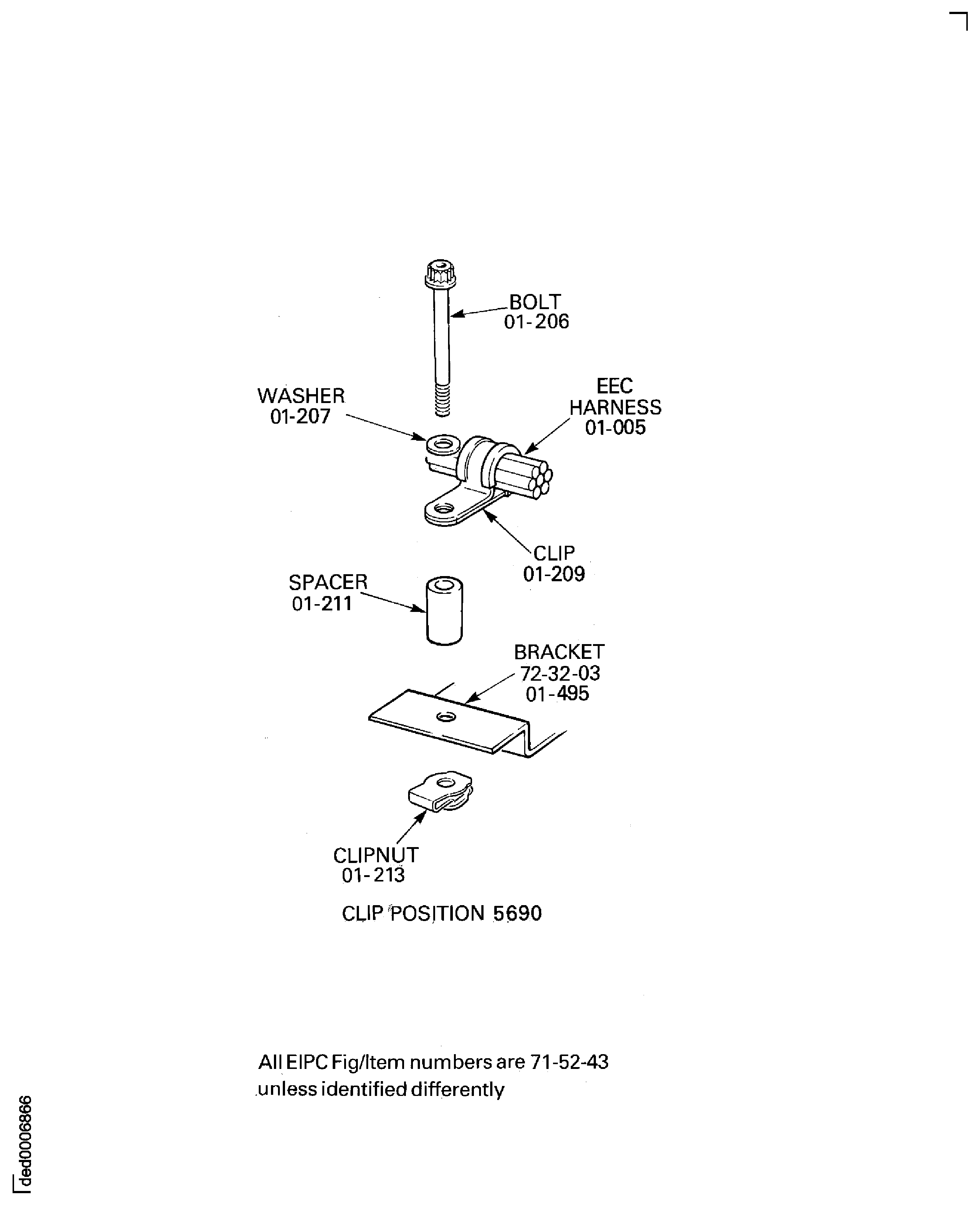

Connect the T2.5 thermocouple leads to the terminal block and install the two nuts EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-015) and EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-017). Torque the top nut EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-015) to 8 to 12 * lbfin. (0.90 to 1.36 Nm.) and the lower nut EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-017) to 10 to 15 * lbfin. (1.13 to 1.69 Nm).

Remove the bolt Fan Frame Assembly And Related Parts(72-32-03,01-510) from the bracket Fan Frame Assembly And Related Parts(72-32-03,01-495) and attach the earth lead to the bracket with the bolt. Torque the bolt to 36 to 45 lbfin. (4 to 5 Nm).

Connect the EEC harness EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-500) to the T2.5 thermocouple terminal block 4026KS-A.

Connect the EEC harness to the T2.5 thermocouple terminal block.

SUBTASK 72-00-40-420-432 Connect the EEC Harness to the T2.5 Thermocouple Terminal Block

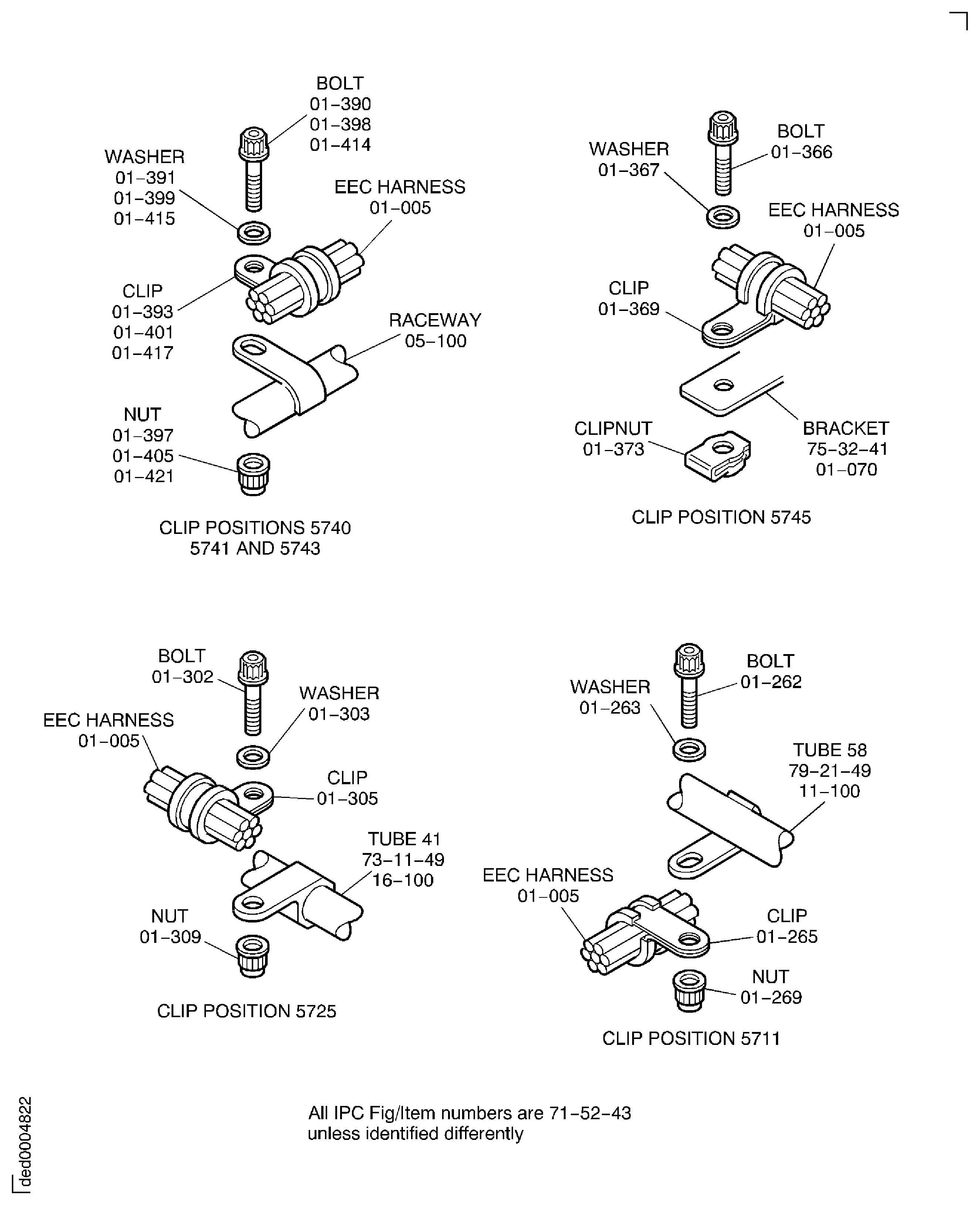

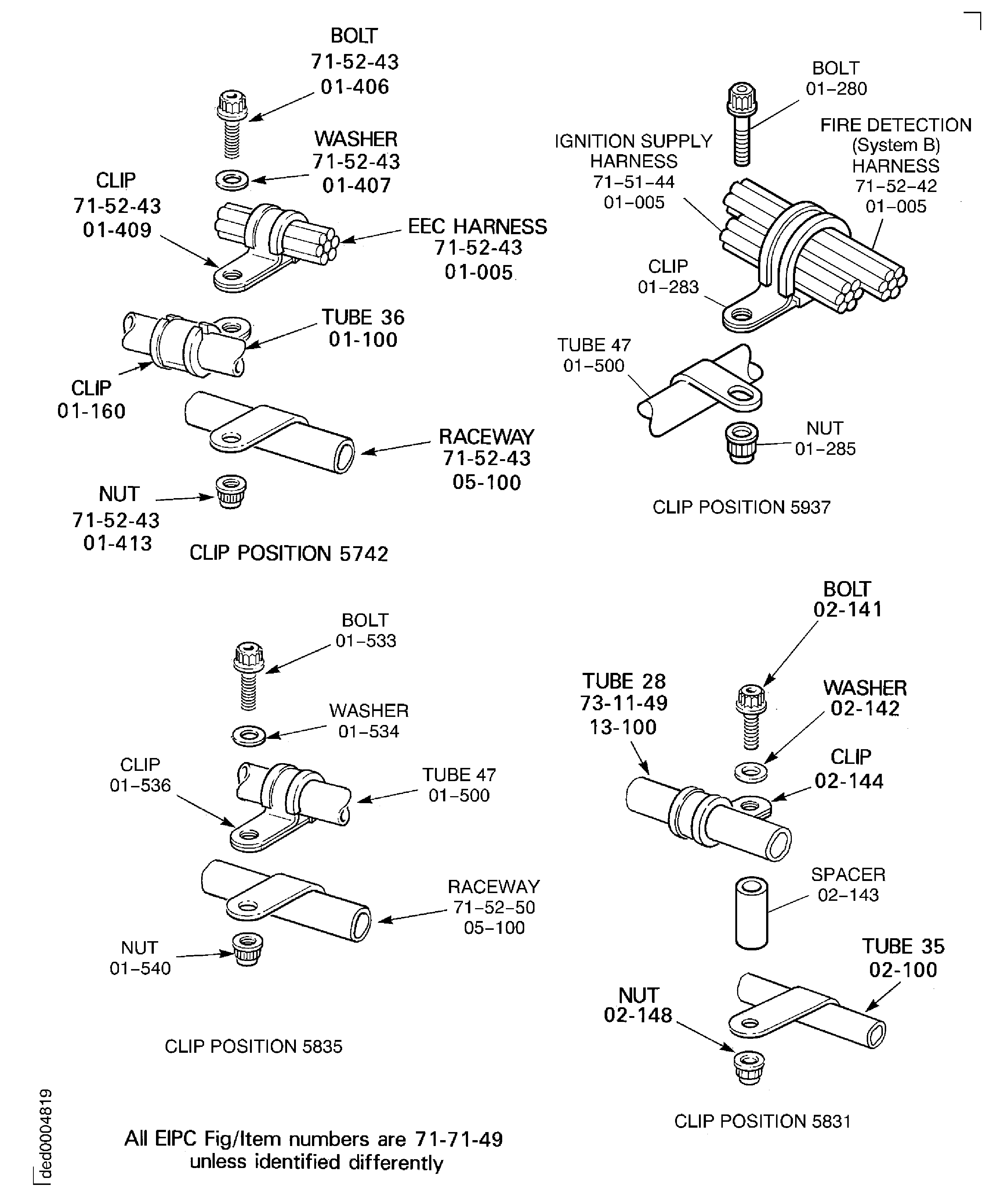

Install the raceway EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,05-100) to the raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50,04-100) at clip position 5744 with the bolt EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-358), the washers EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-359) and the nut EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,01-365).

Install the harness clips and the raceway EEC Core Harness And Voltage Divider Harness Assembly(71-52-43,05-100).

SUBTASK 72-00-40-420-433 Install the Harness Clips and the Raceway (71-52-43,05-100)

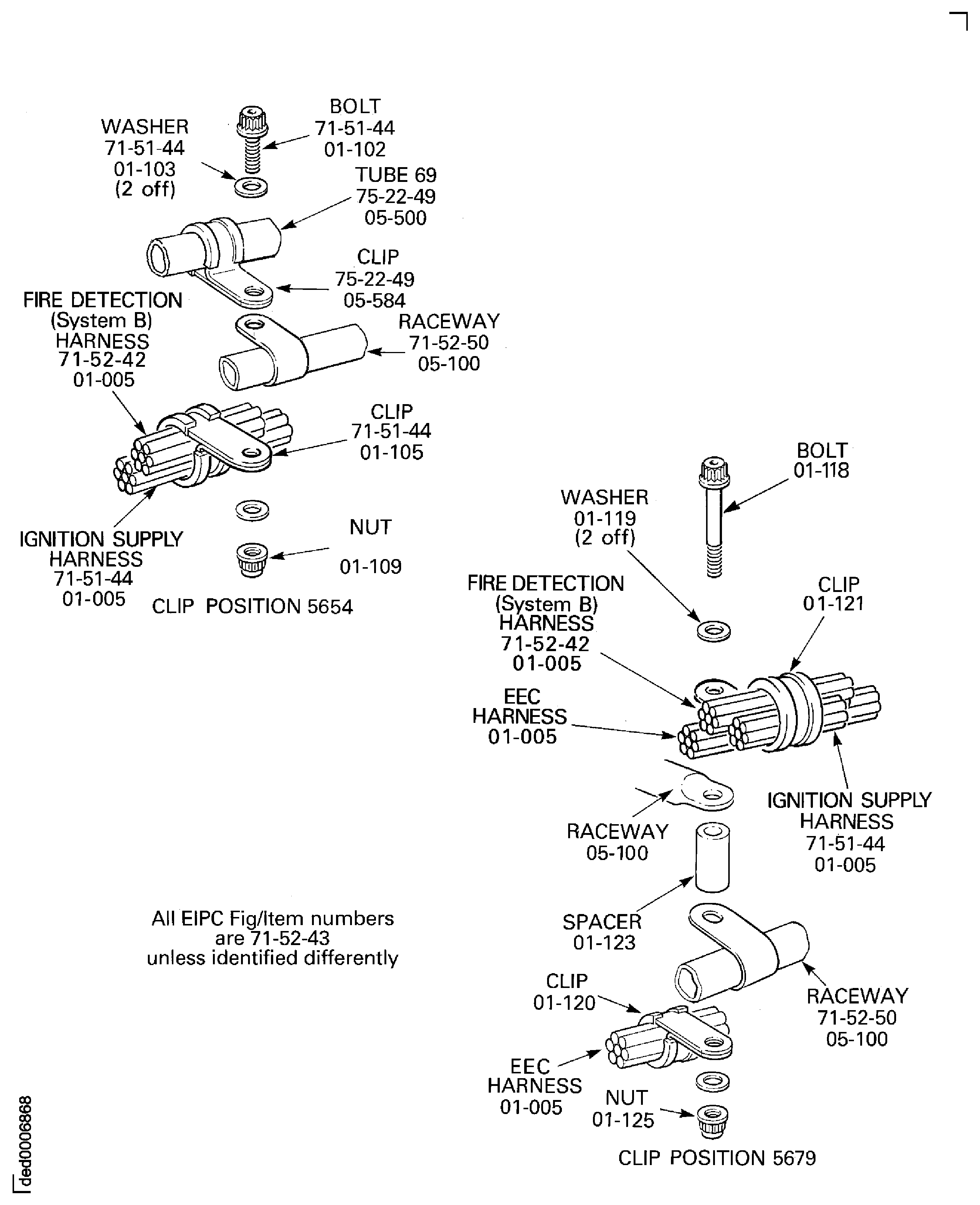

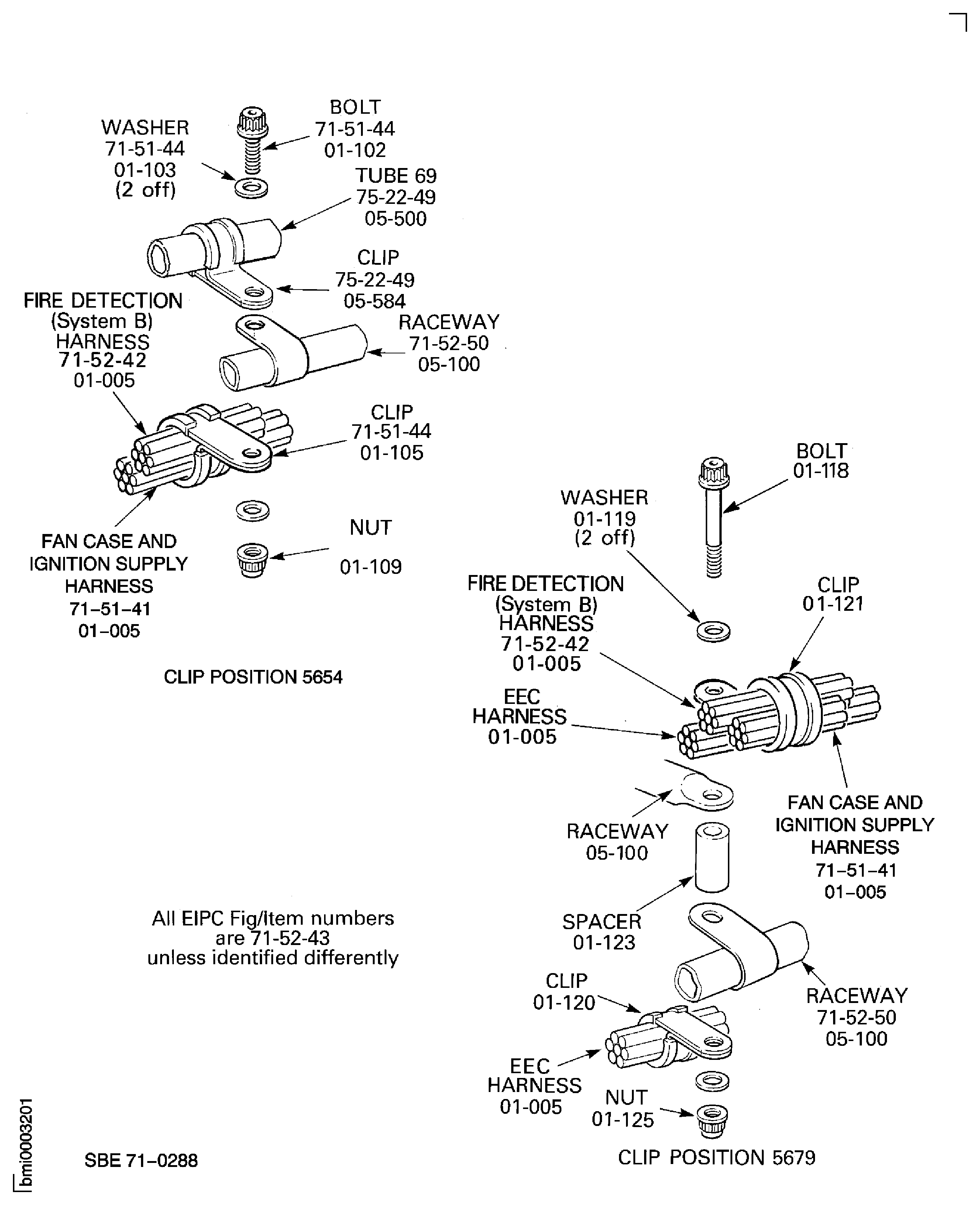

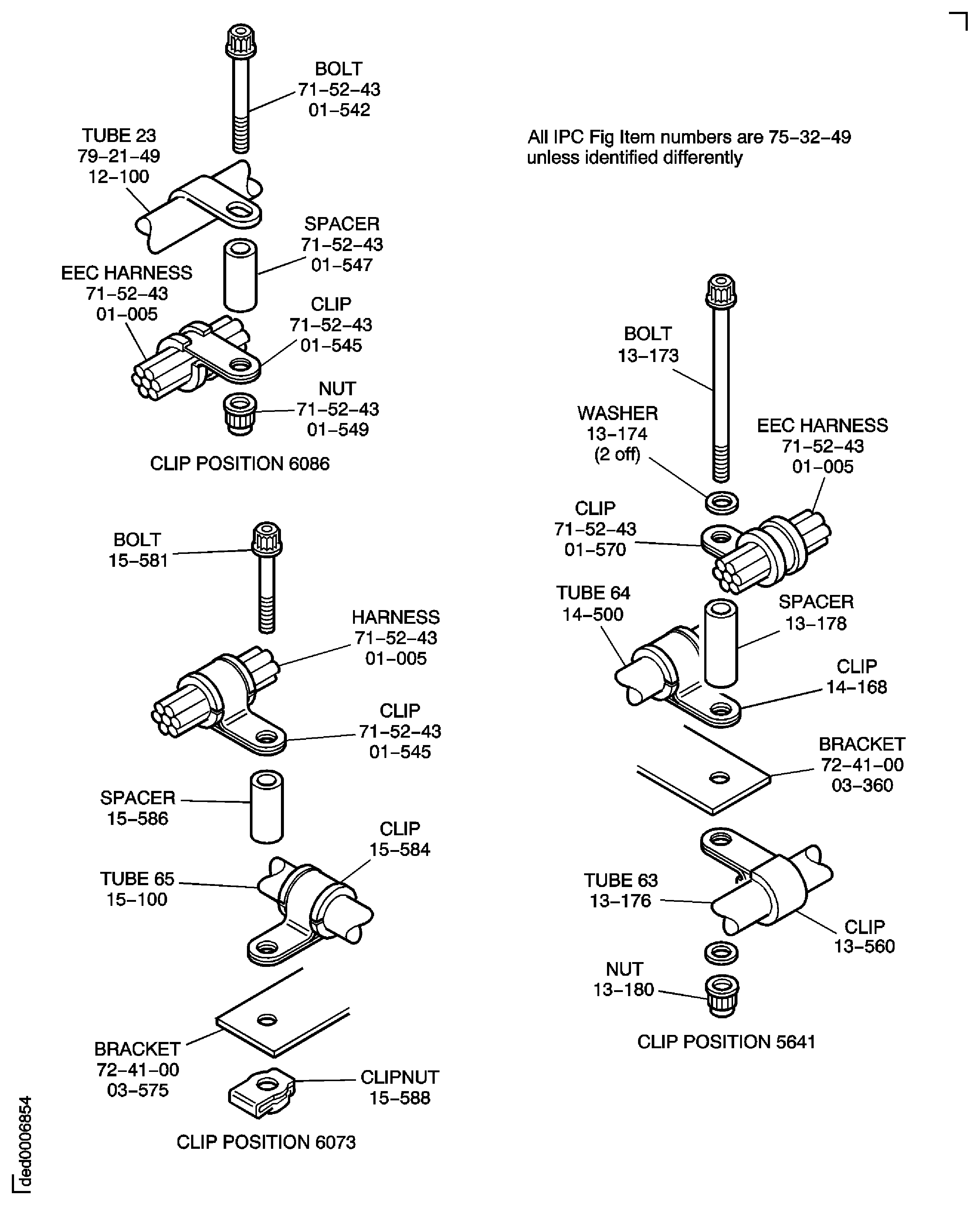

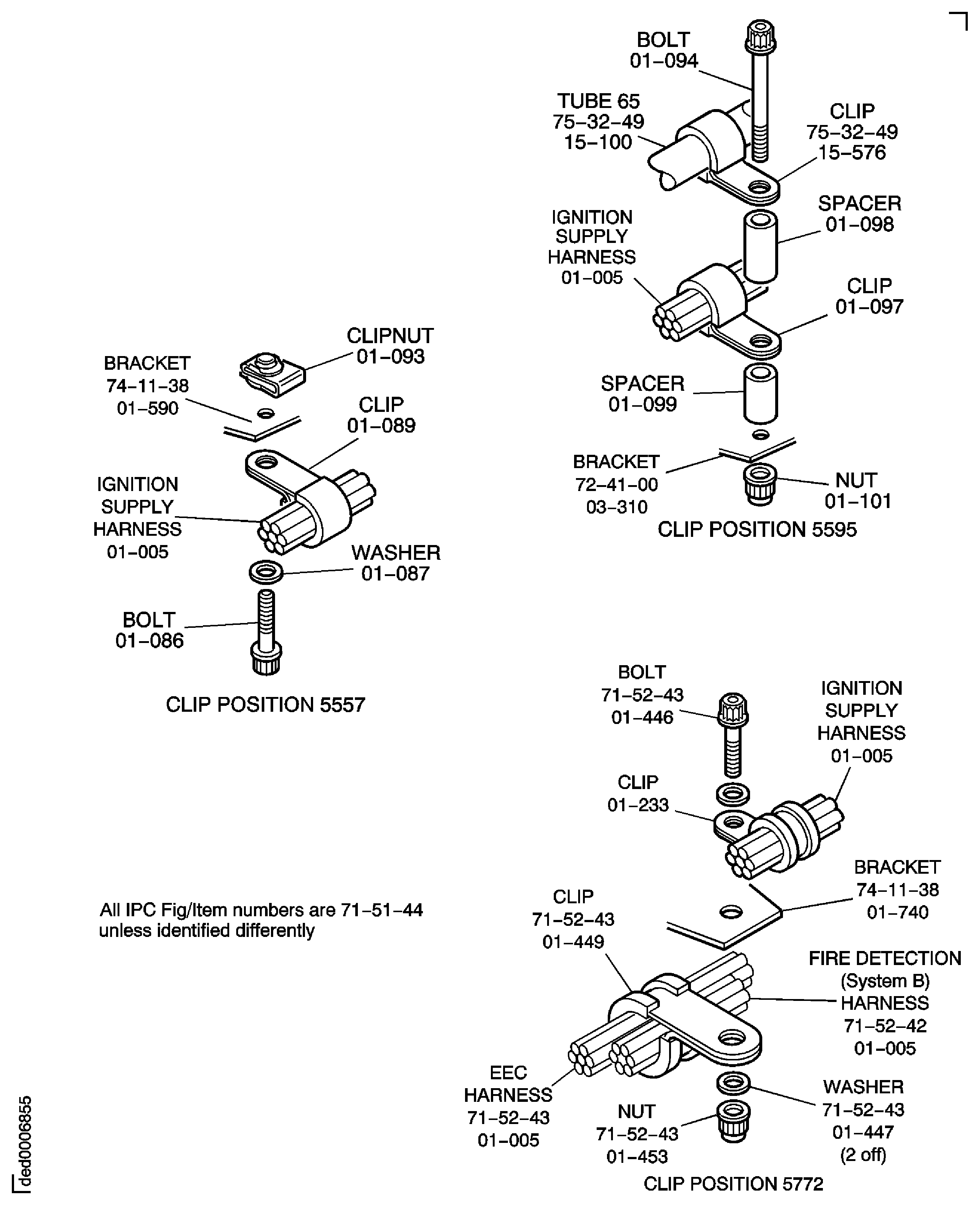

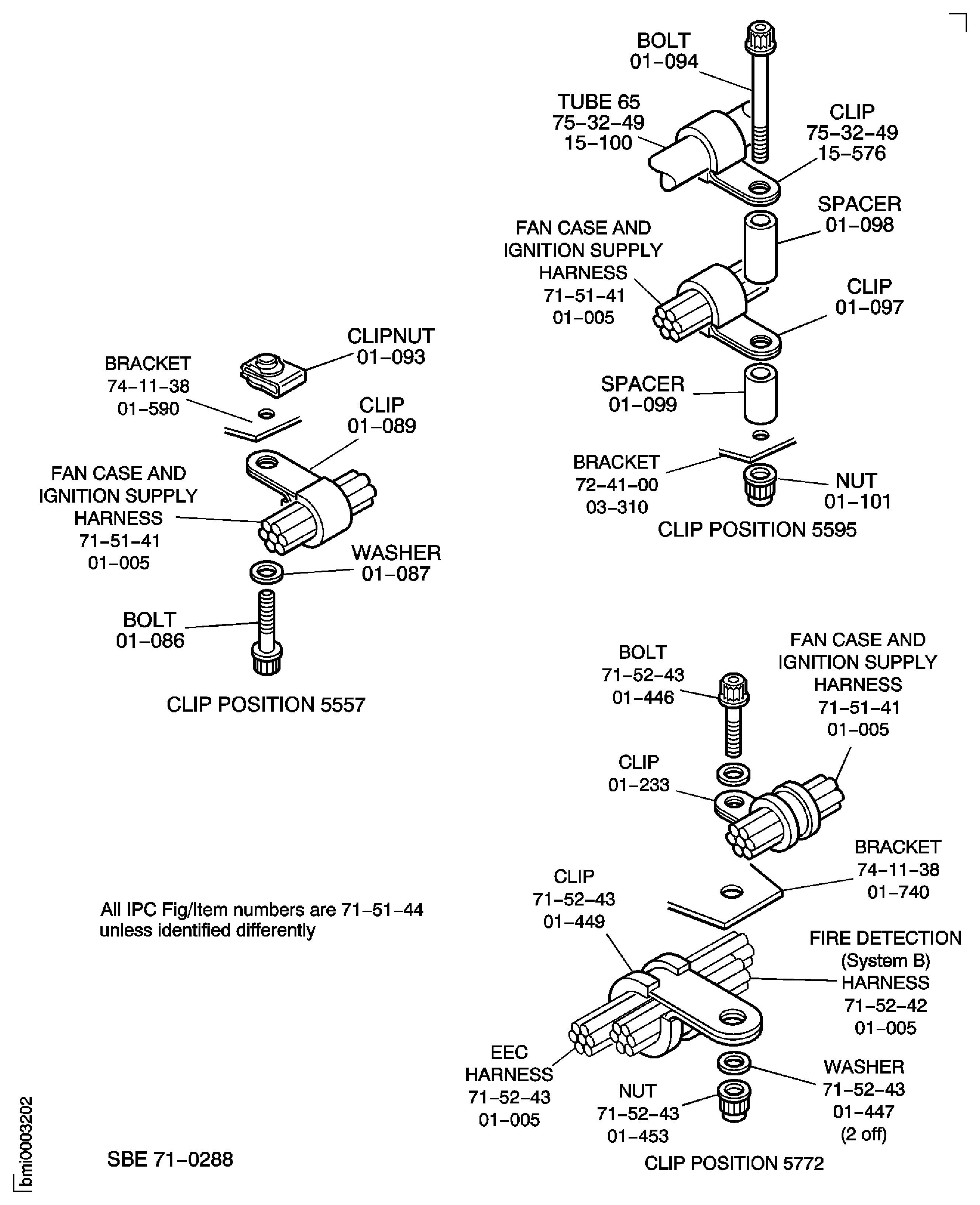

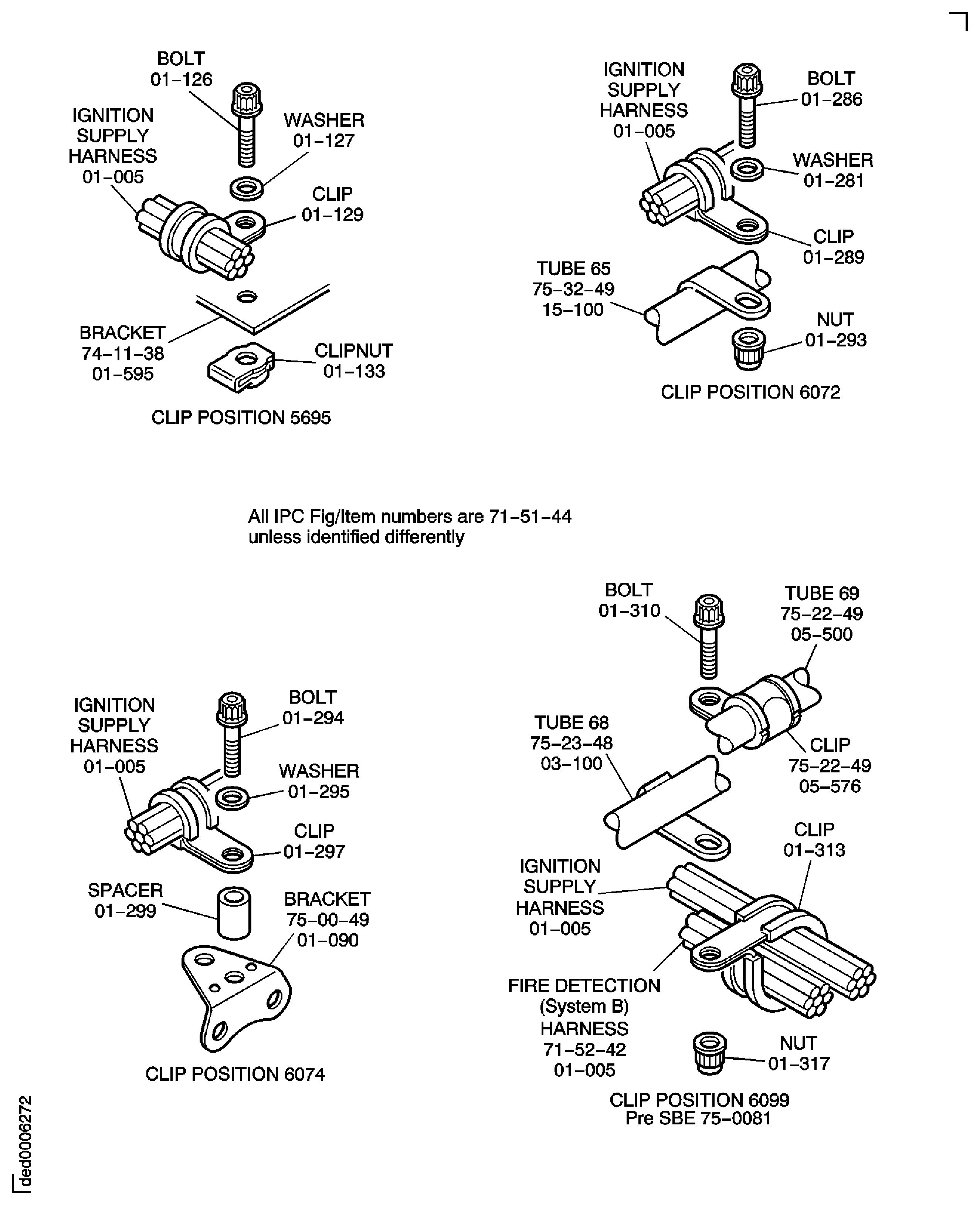

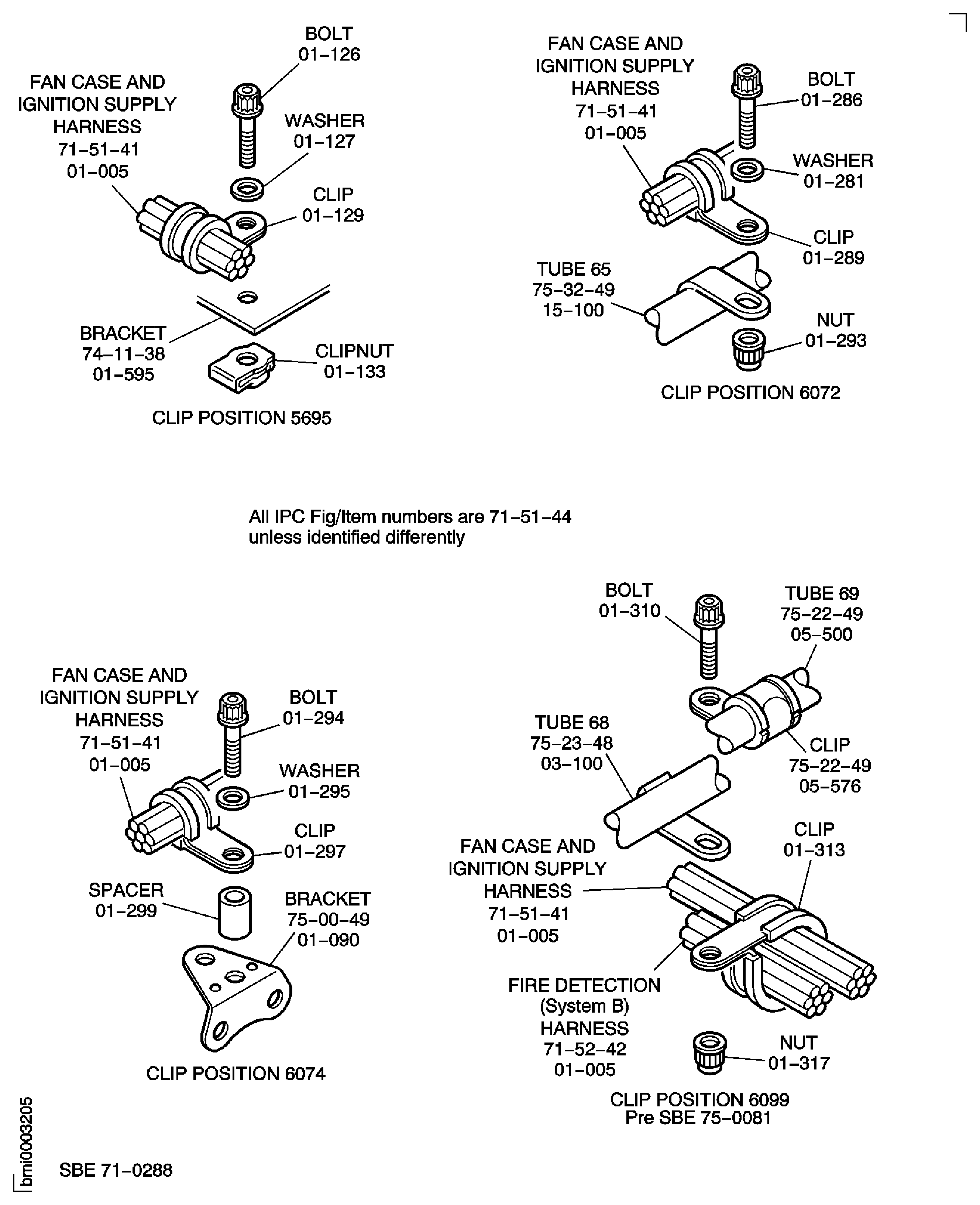

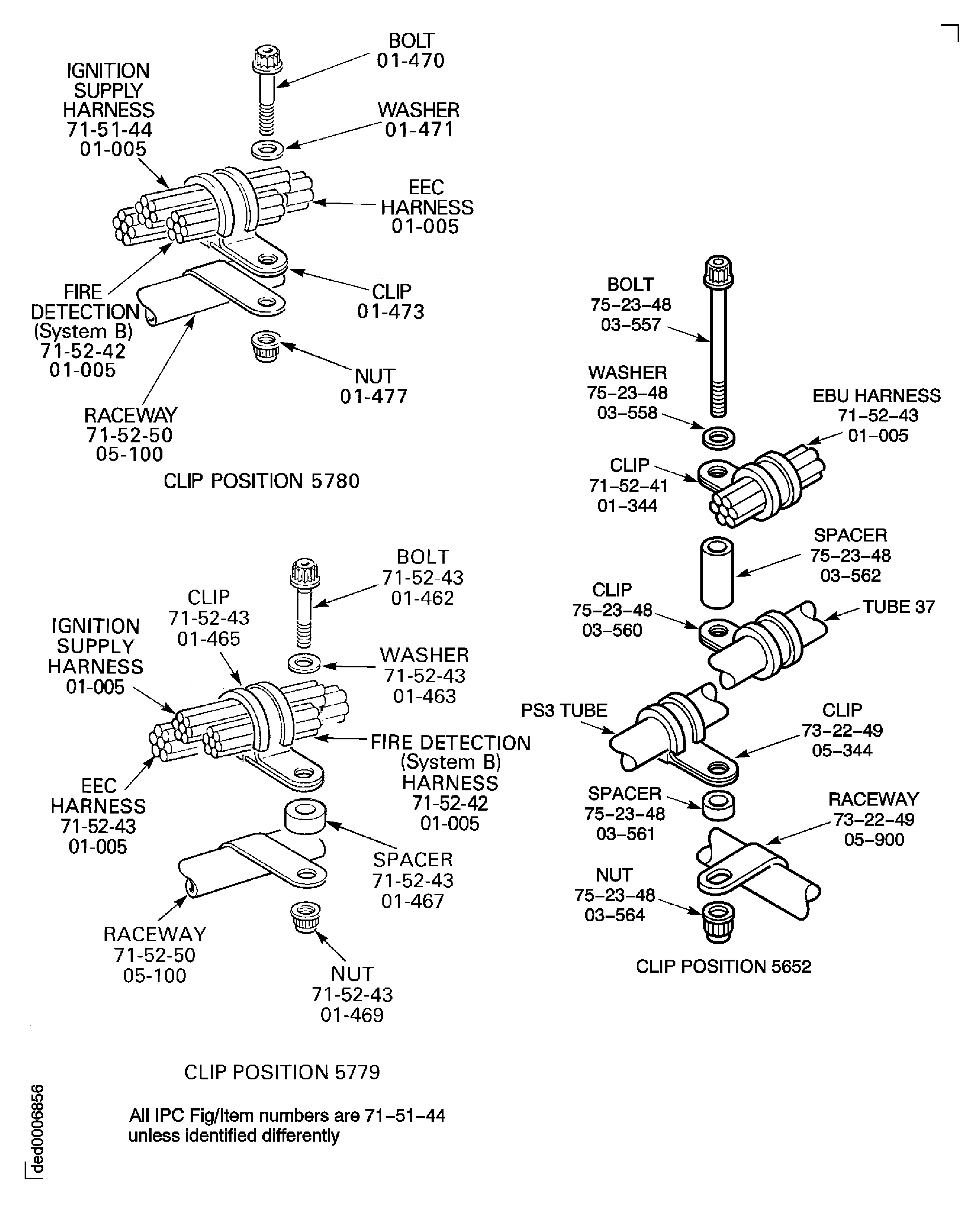

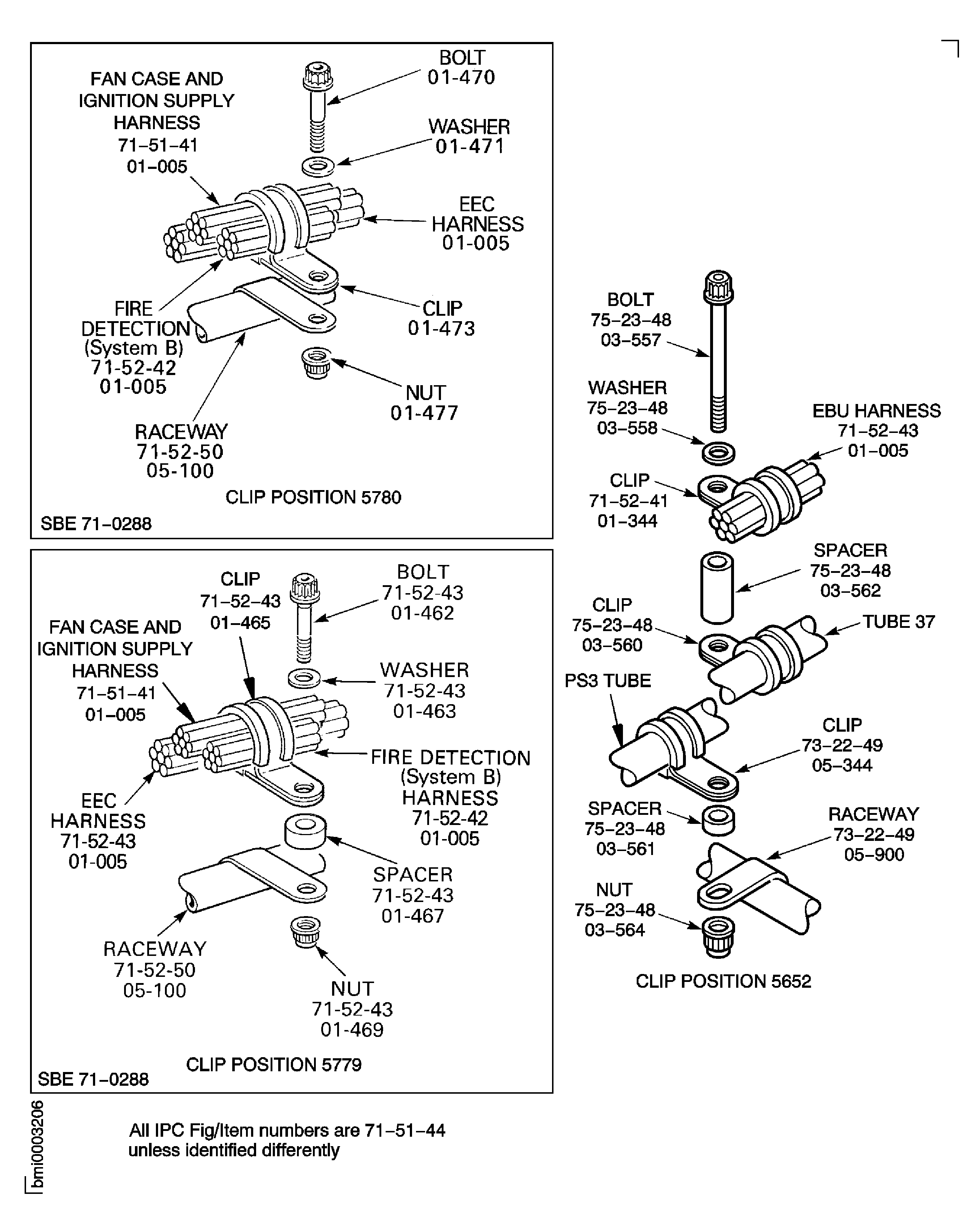

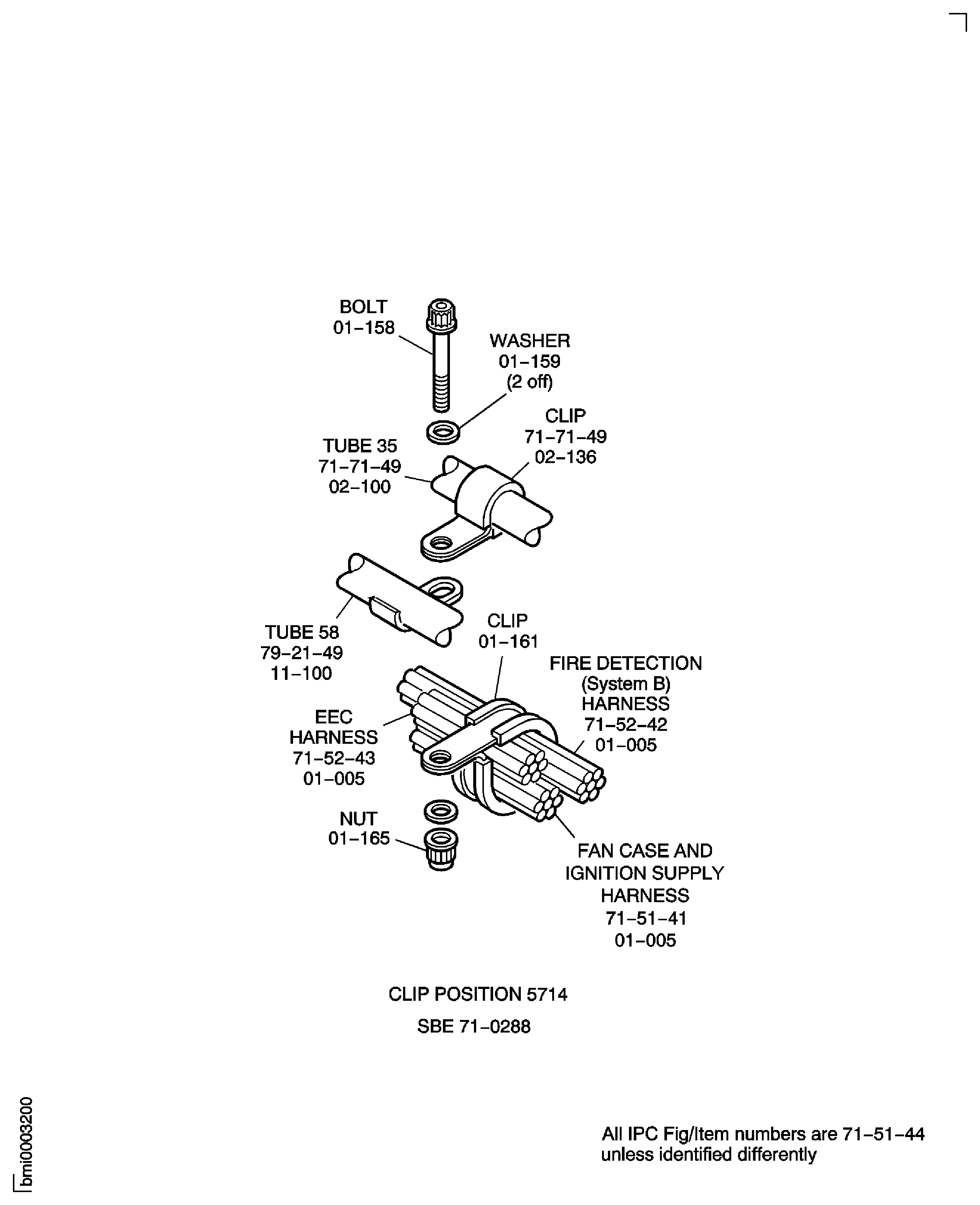

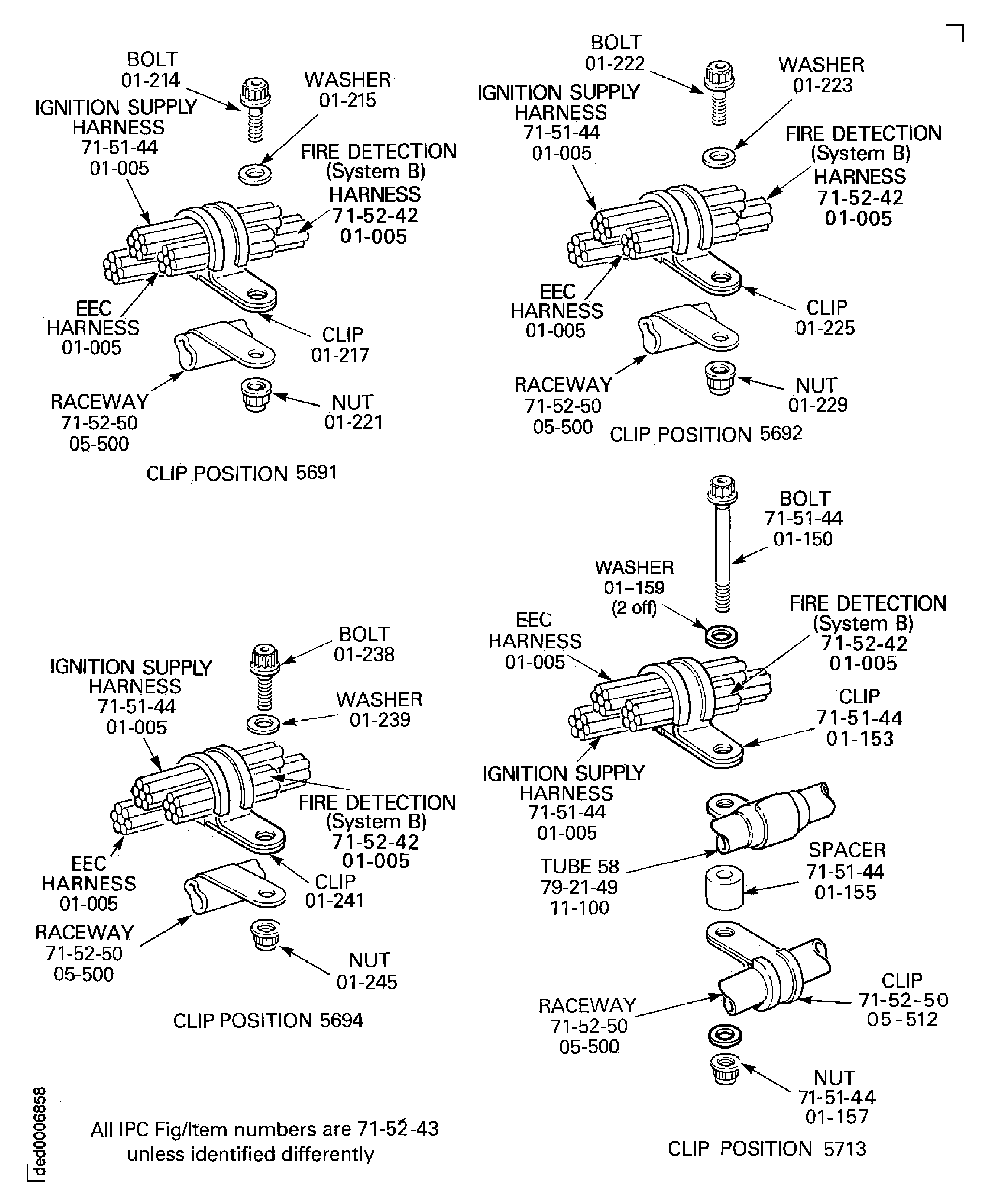

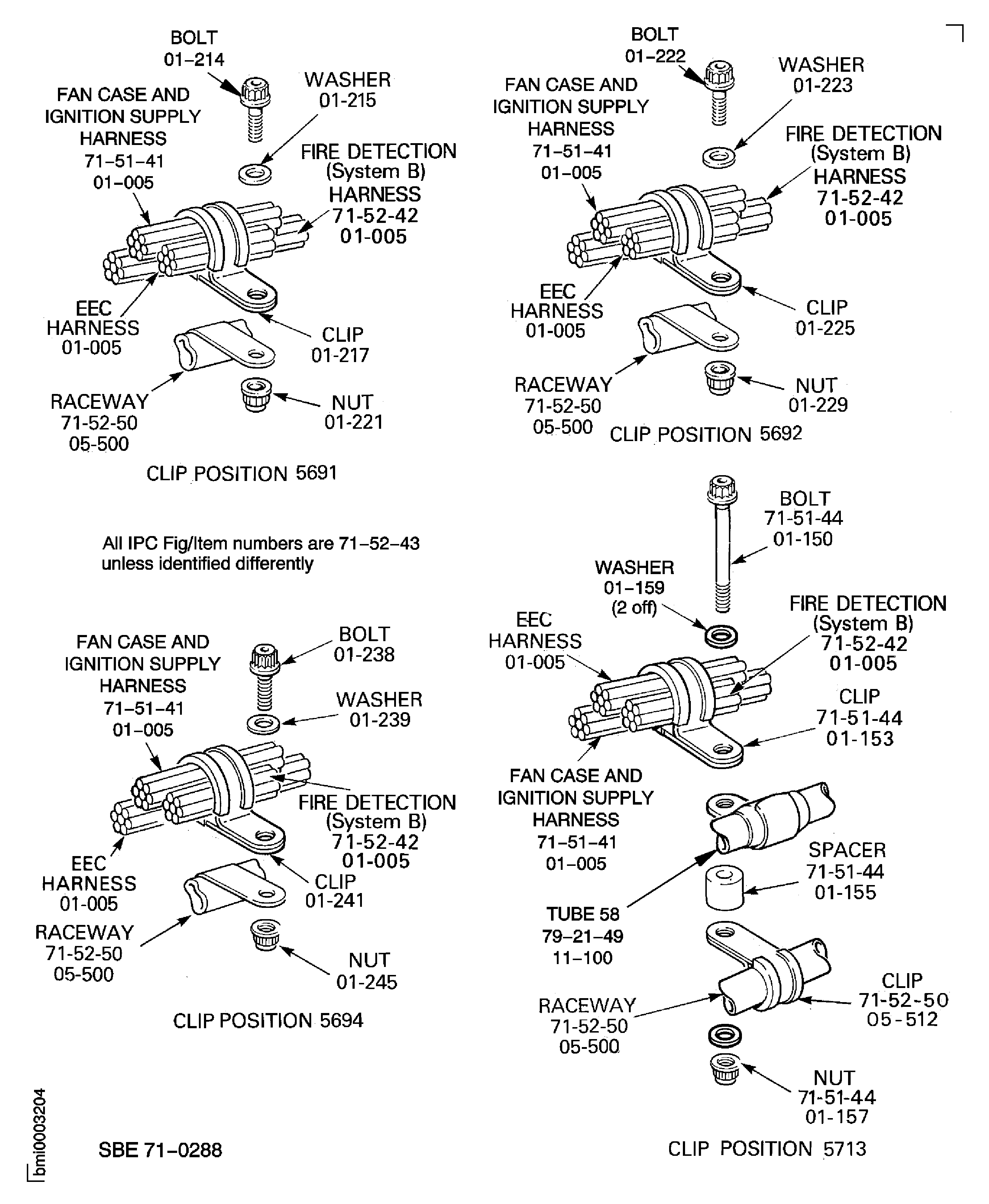

5595, 5695, 5772, 5714, 5713, 5694, 5692, 5691, 5679, 6072, 6074, 6075, 6099, 6110, 6114, 6123, 5643, 5641, 6126 and 6103.

Pre SBE 75-0081: Assemble the clip positions that follow:

5595, 5695, 5772, 5714, 5713, 5694, 5692, 5691, 5679, 6072, 6074, 6075, 6110, 6114, 6123, 5643, 5641, 6126 and 6103.

SBE 75-0081: Assemble the clip positions that follow:

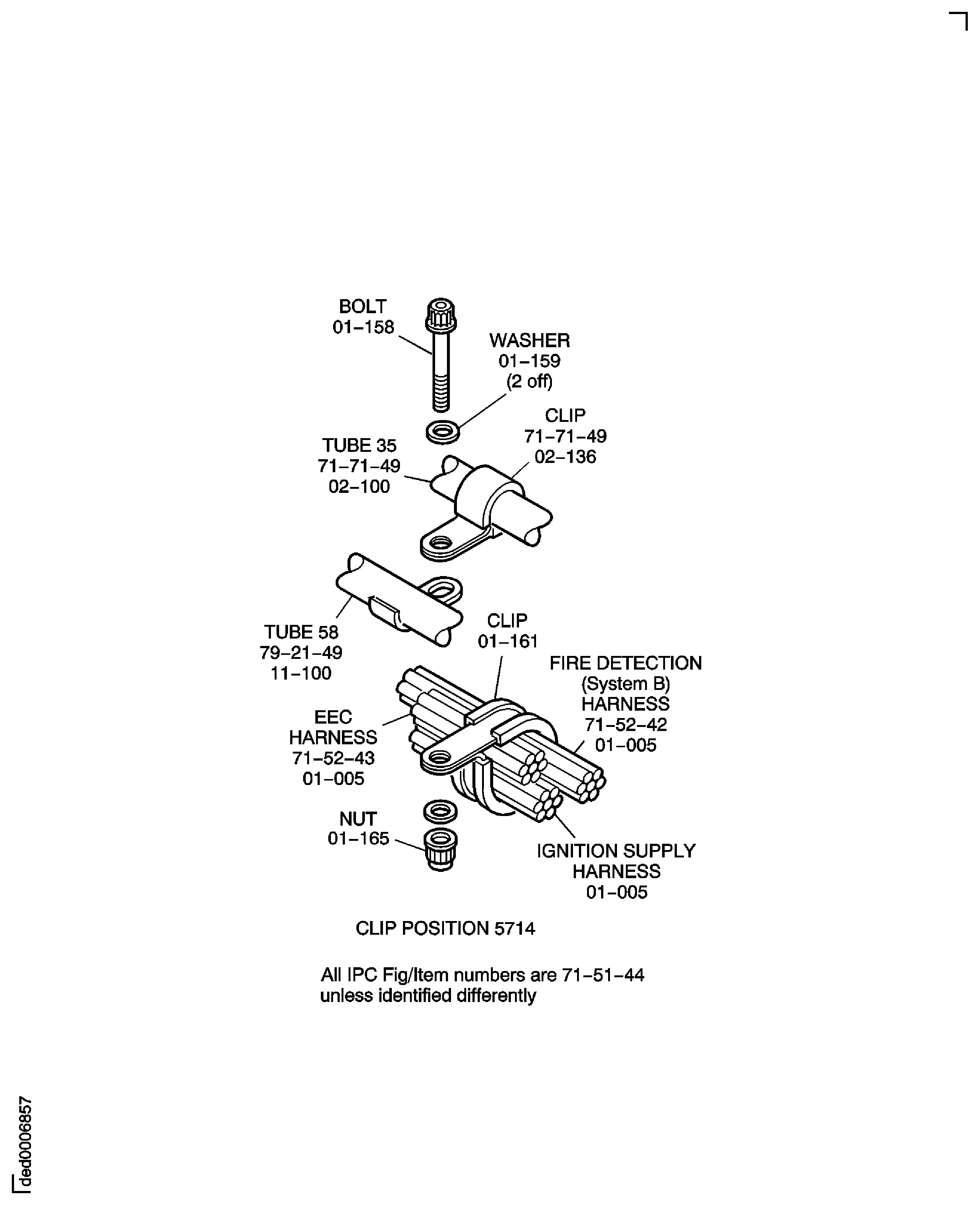

Install the ignition supply harness Ignition Supply Harness(71-51-44,01-005).

SUBTASK 72-00-40-420-434-A00 Install the Ignition Supply Harness (Pre SBE 71-0288, Pre SBE 75-0081 and SBE 75-0081)

SBE 75-0081: Air - Deletion of the HPC stage 10 make up air valve

5595, 5695, 5772, 5714, 5713, 5694, 5692, 5691, 5679, 6072, 6074, 6075, 6099, 6110, 6114, 6123, 5643, 5641, 6126 and 6103.

Pre SBE 75-0081: Assemble the clip positions that follow:

5595, 5695, 5772, 5714, 5713, 5694, 5692, 5691, 5679, 6072, 6074, 6075, 6110, 6114, 6123, 5643, 5641, 6126 and 6103.

SBE 75-0081: Assemble the clip positions that follow:

Install the EEC fan and ignition supply harness EEC Fan Harness(71-51-41,01-005).

SUBTASK 72-00-40-420-434-B00 Install the EEC Fan and Ignition Supply Harness (SBE 71-0288, Pre SBE 75-0081 and SBE 75-0081)

SBE 71-0288: Electrical Harnesses - Introduction of a combined EEC fan and ignition supply harness

SBE 75-0081: Air - Deletion of the HPC stage 10 make up air valve

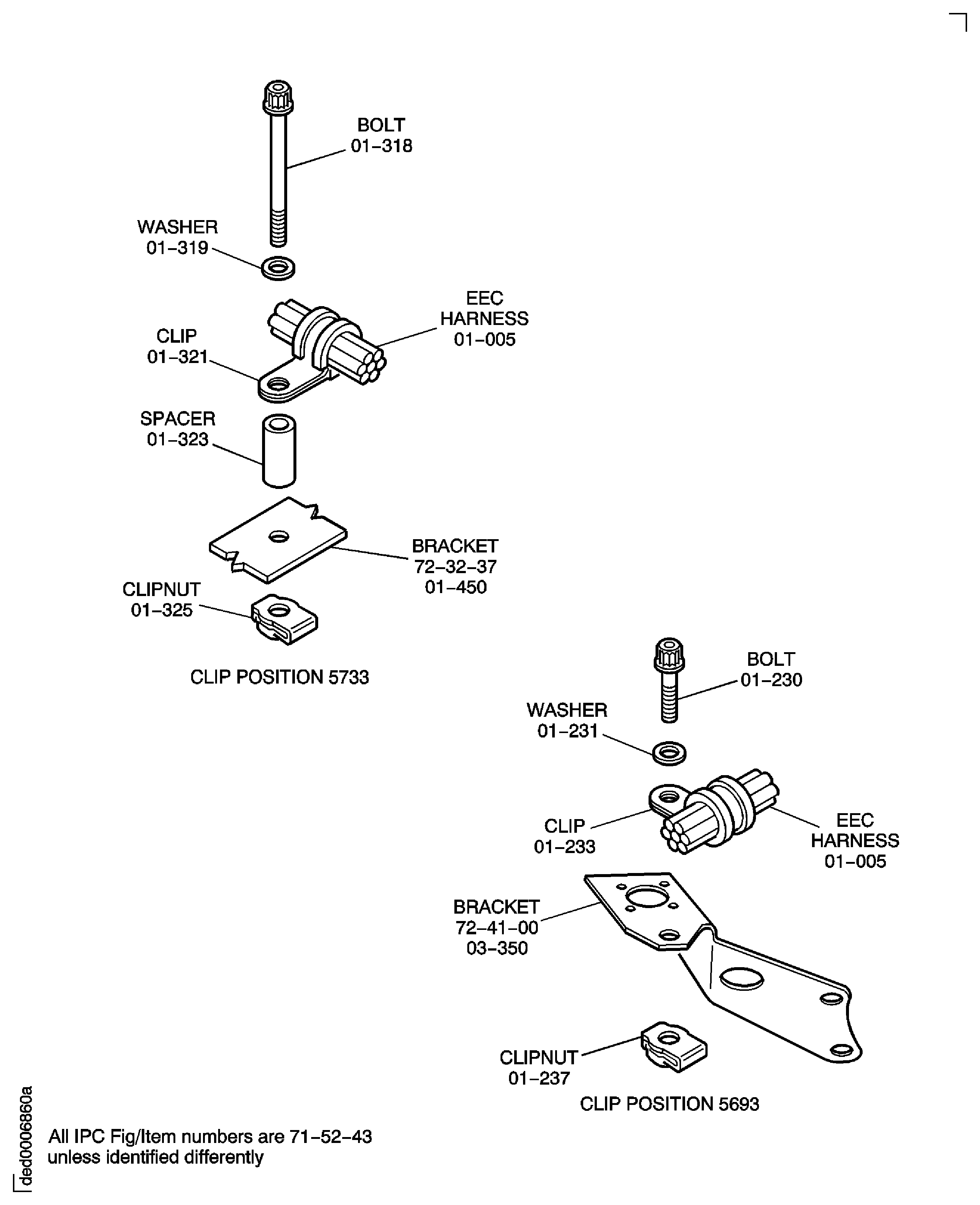

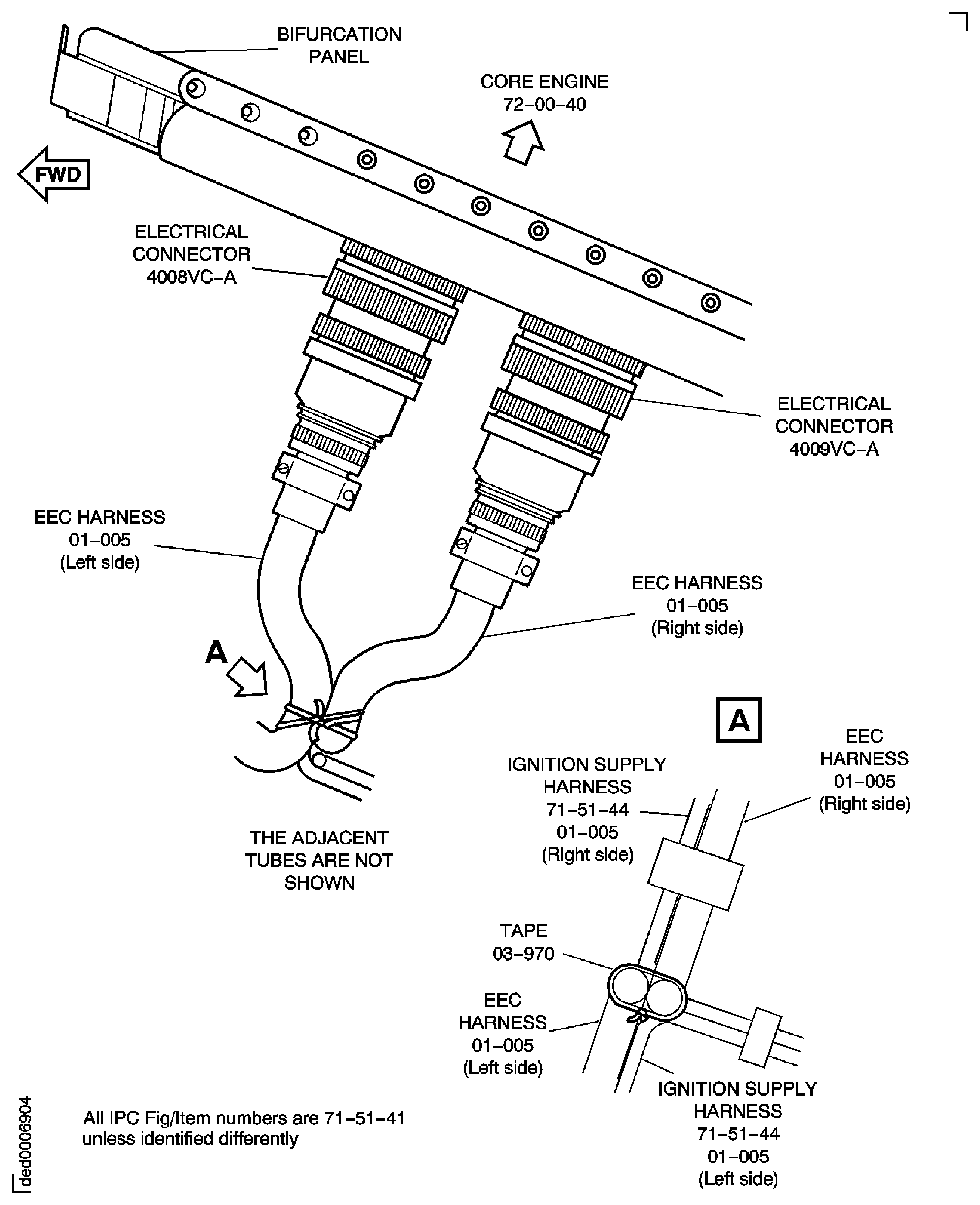

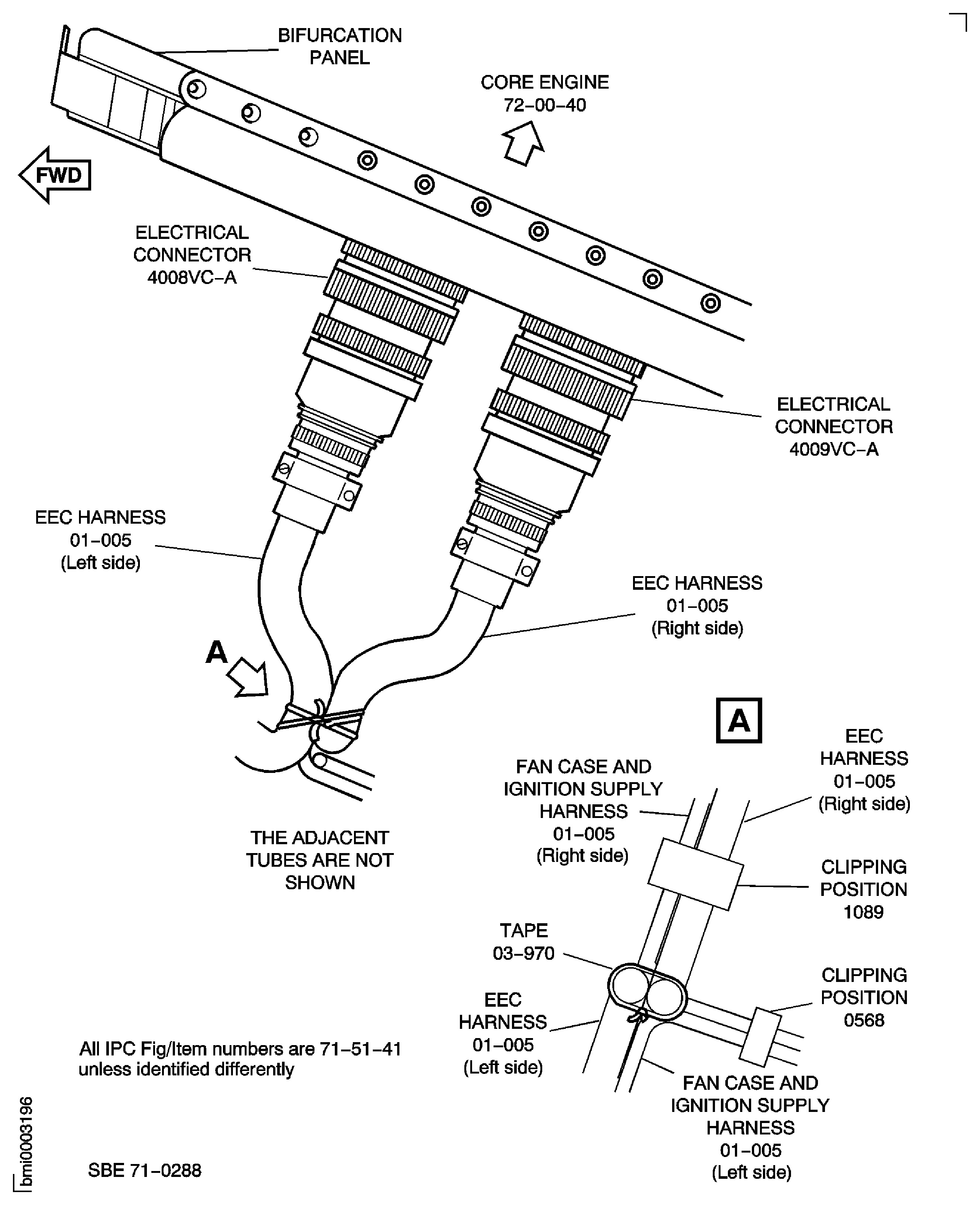

Refer to Figure.

SUBTASK 72-00-40-420-436 Connect the EEC Harness Electrical Connectors to the Master Bleed Actuators

CAUTION

YOU MUST ROUTE THE EEC HARNESS AND THE IGNITION SUPPLY HARNESS NEXT TO EACH OTHER TO THE ELECTRICAL CONNECTOR 4009VC-A. FOLLOW THE ROUTING PROCEDURE TO KEEP THE RIGHT SIDE EEC HARNESS FROM TOUCHING THE RIGHT SIDE C DUCT AND ADJACENT TUBE INSTALLATIONS.NOTE

The EEC harness EEC Fan Harness(71-51-41, 01-005) and the ignition supply harness Ignition Supply Harness(71-51-44, 01-005) are installed in TASK 72-00-32-420-004-C00 (INSTALLATION-004).Pre SBE 71-0288: Make sure the installation of EEC harness EEC Fan Harness(71-51-41, 01-005) and the ignition supply harness Ignition Supply Harness(71-51-44, 01-005) is complete, this includes the installation of all the clip positions and connection of the all the electrical connectors. Make sure the harness routing is correct as follows:

SBE 71-0288: Make sure the installation of the EEC fan and ignition supply harness EEC Fan Harness(71-51-41, 01-005) is complete, this includes the installation of all the clip positions and connection of the all the electrical connectors. Make sure the harness routing is correct.

Attach the EEC harness looms together with lacing tape EEC Fan Harness(71-51-41, 03-970) at the lowest point where the two looms meet (at the bottom dead center position).

Tie the lacing and make secure, refer to the SPM TASK 70-43-02-400-501.

Attach the right hand side and left hand side EEC harness looms together at the bifurcation panel electrical connectors 4008VC-A and 4009VC-A.

SUBTASK 72-00-40-420-345 Route and Attach the Right Hand Side and Left Hand Side EEC Harness Looms Together at the Bifurcation Panel (Pre SBE 71-0288 and SBE 71-0288)

SBE 71-0288: Electrical Harnesses - Introduction of a combined EEC fan and ignition supply harness

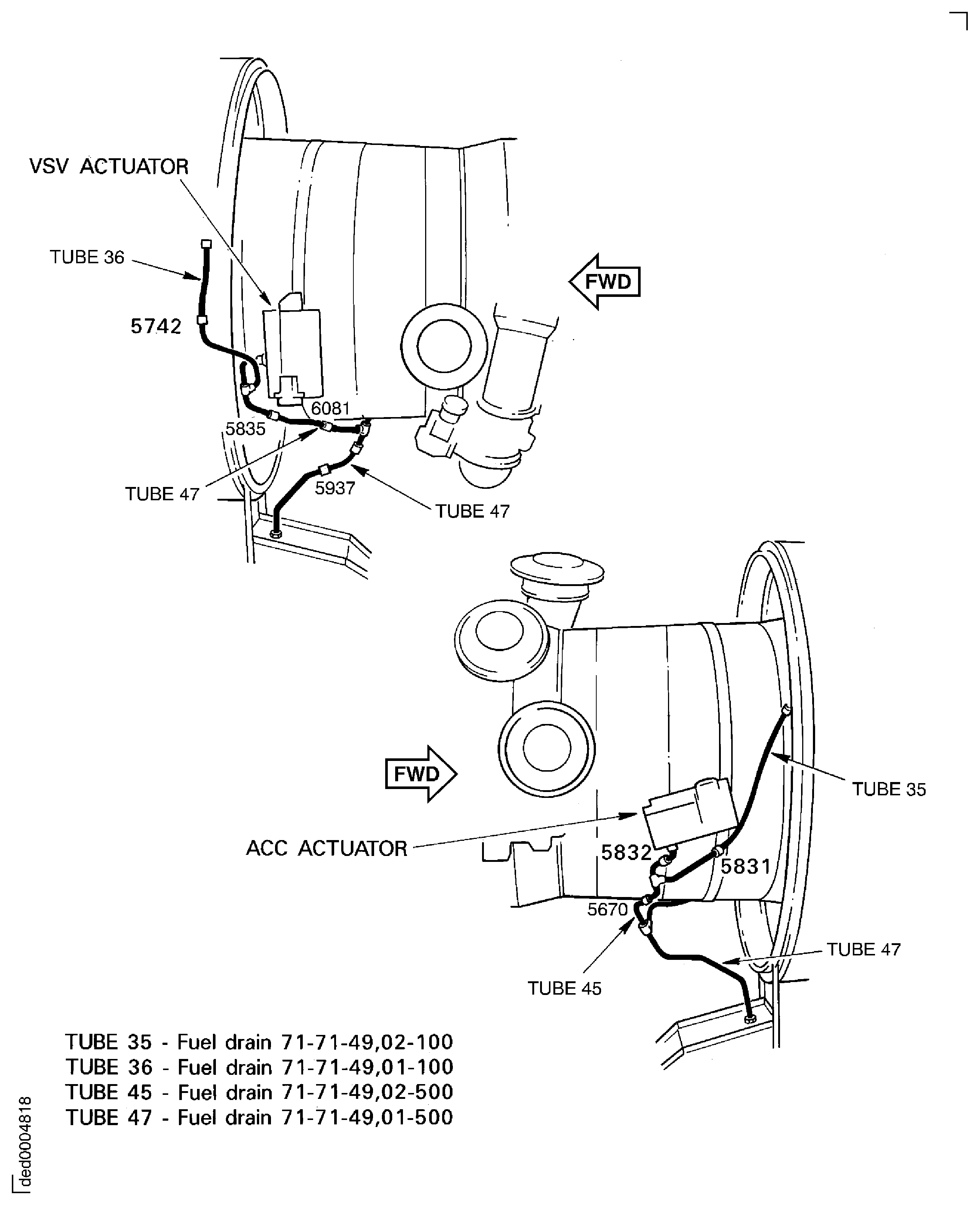

Torque the tube connectors to 159 to 177 lbfin. (18 to 20 Nm) and safety with CoMat 02-126 LOCKWIRE.

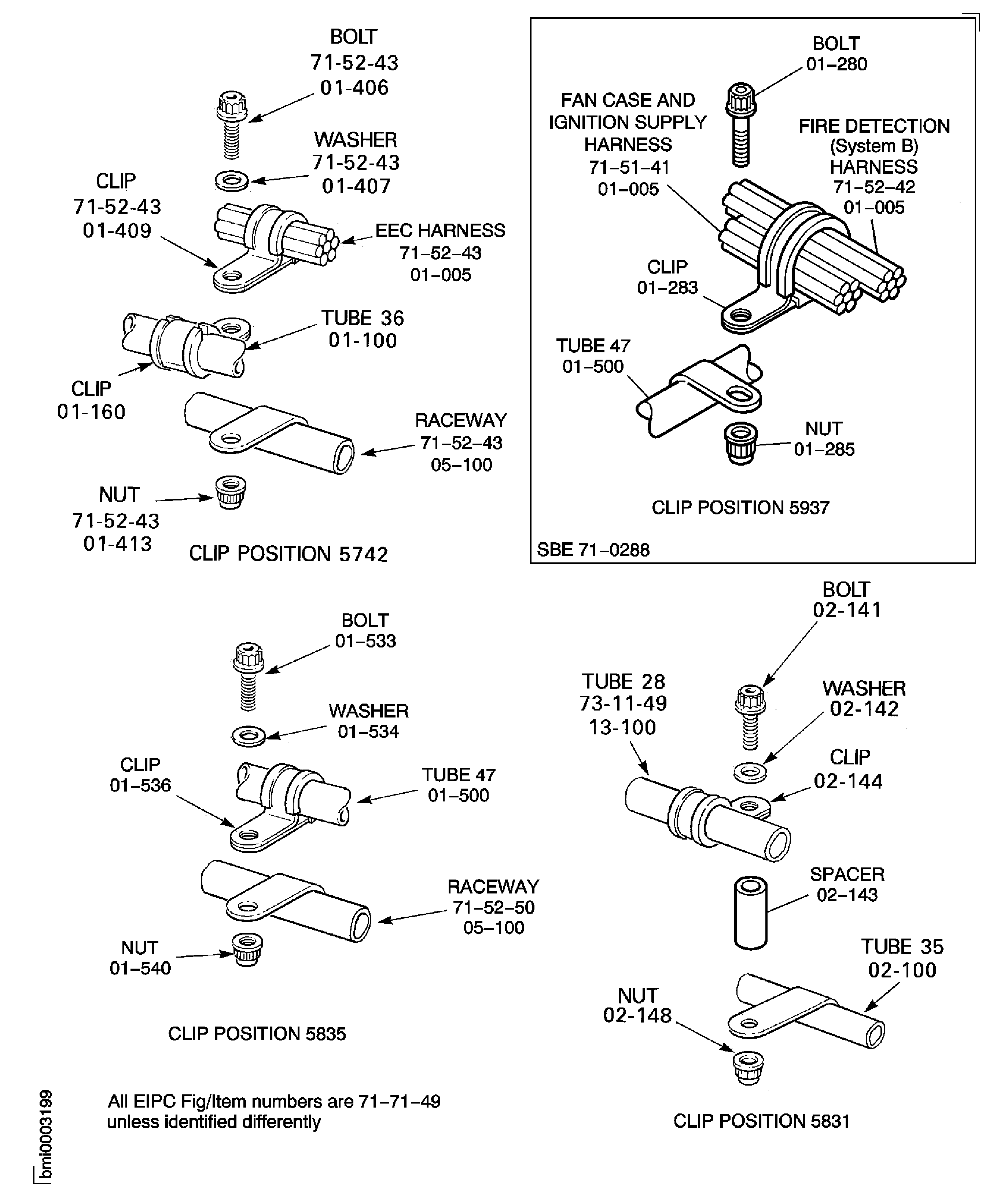

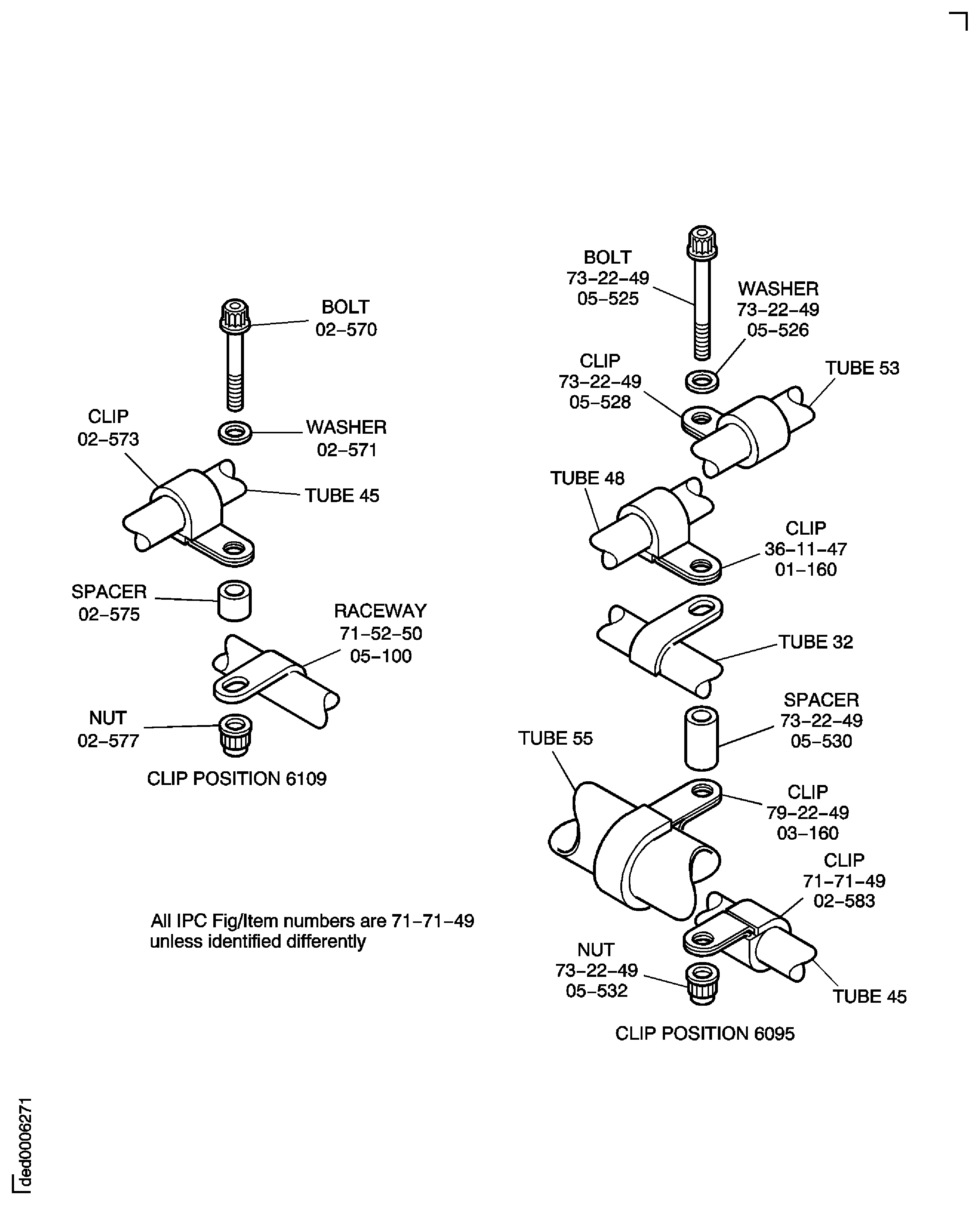

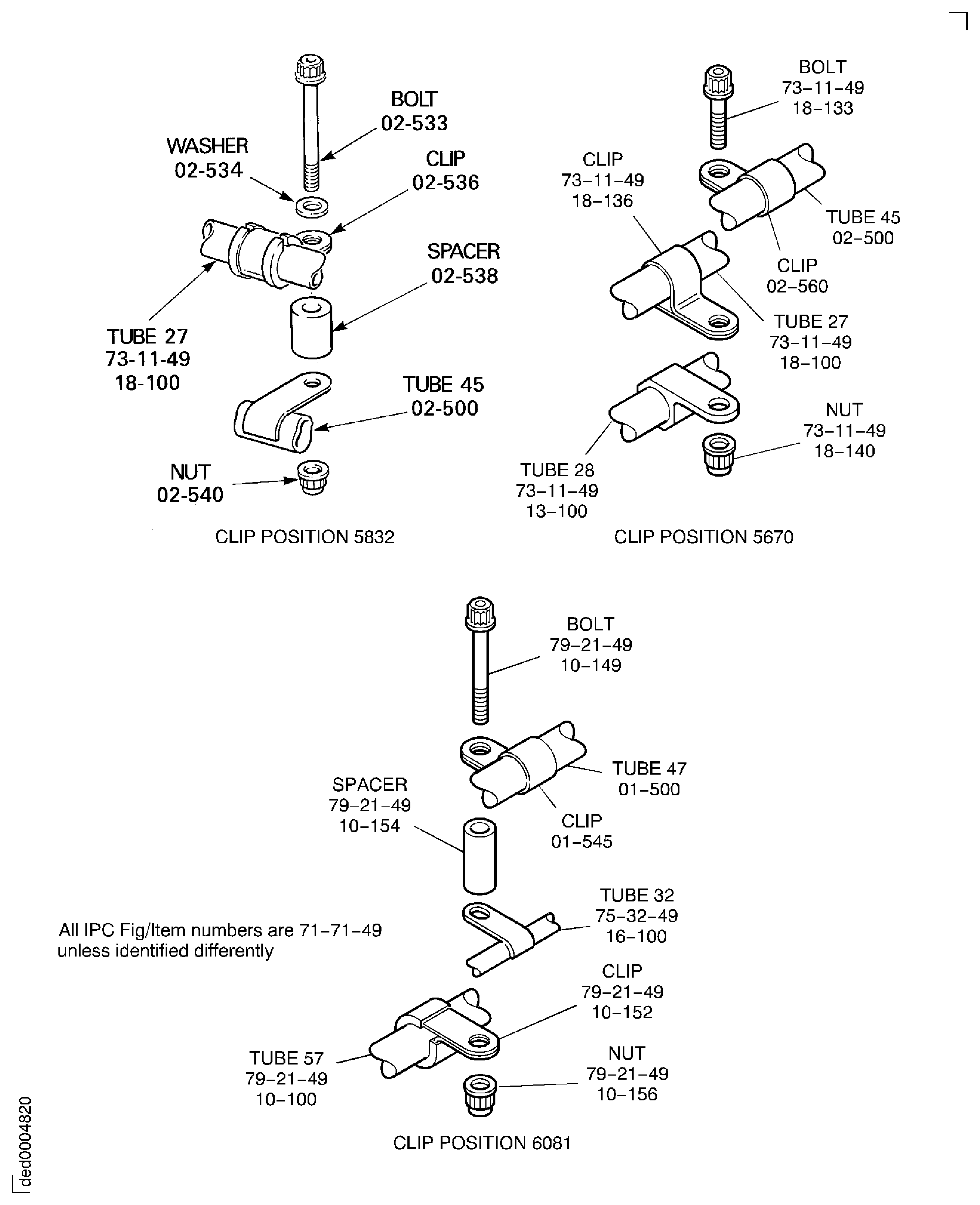

Install the tube 45 POWER PLANT-FUEL DRAIN TUBES-ENGINE(71-71-49, 02-500).

Torque the tube connectors to 159 to 177 lbfin. (18 to 20 Nm) and safety with CoMat 02-126 LOCKWIRE.

Install the tube 47 POWER PLANT-FUEL DRAIN TUBES-ENGINE(71-71-49, 01-500).

Torque the tube connector to 159 to 177 lbfin (18 to 20 Nm) and safety with CoMat 02-126 LOCKWIRE.

Install the tube 36 POWER PLANT-FUEL DRAIN TUBES-ENGINE(71-71-49, 01-100).

Torque the tube connector to 159 to 177 lbfin. (18 to 20 Nm) and safety with CoMat 02-126 LOCKWIRE.

Install the tube 35 POWER PLANT-FUEL DRAIN TUBES-ENGINE(71-71-49, 02-100).

SUBTASK 72-00-40-420-346 Install the Tubes 35, 36, 45 and 47, the Fuel Drain Tubes

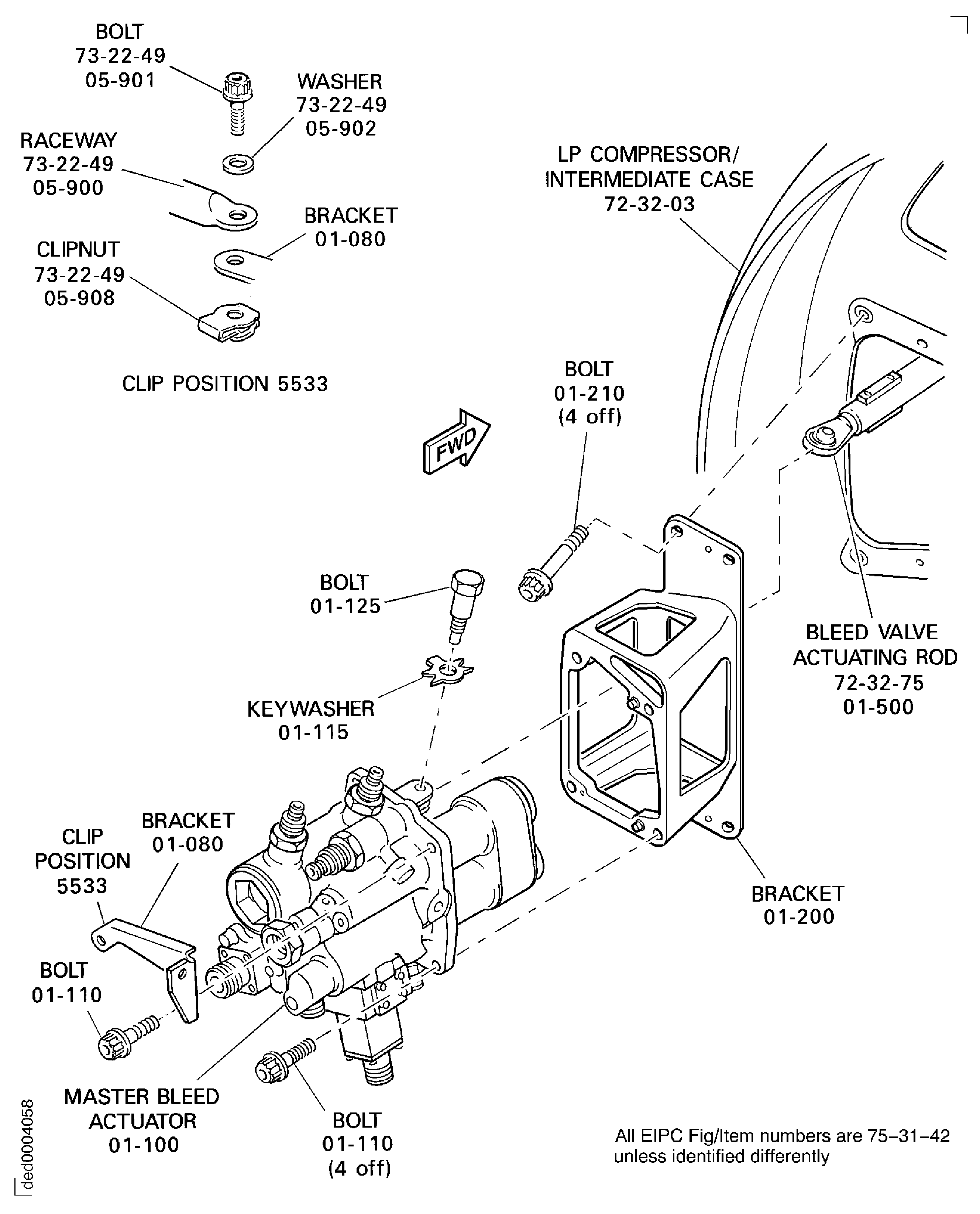

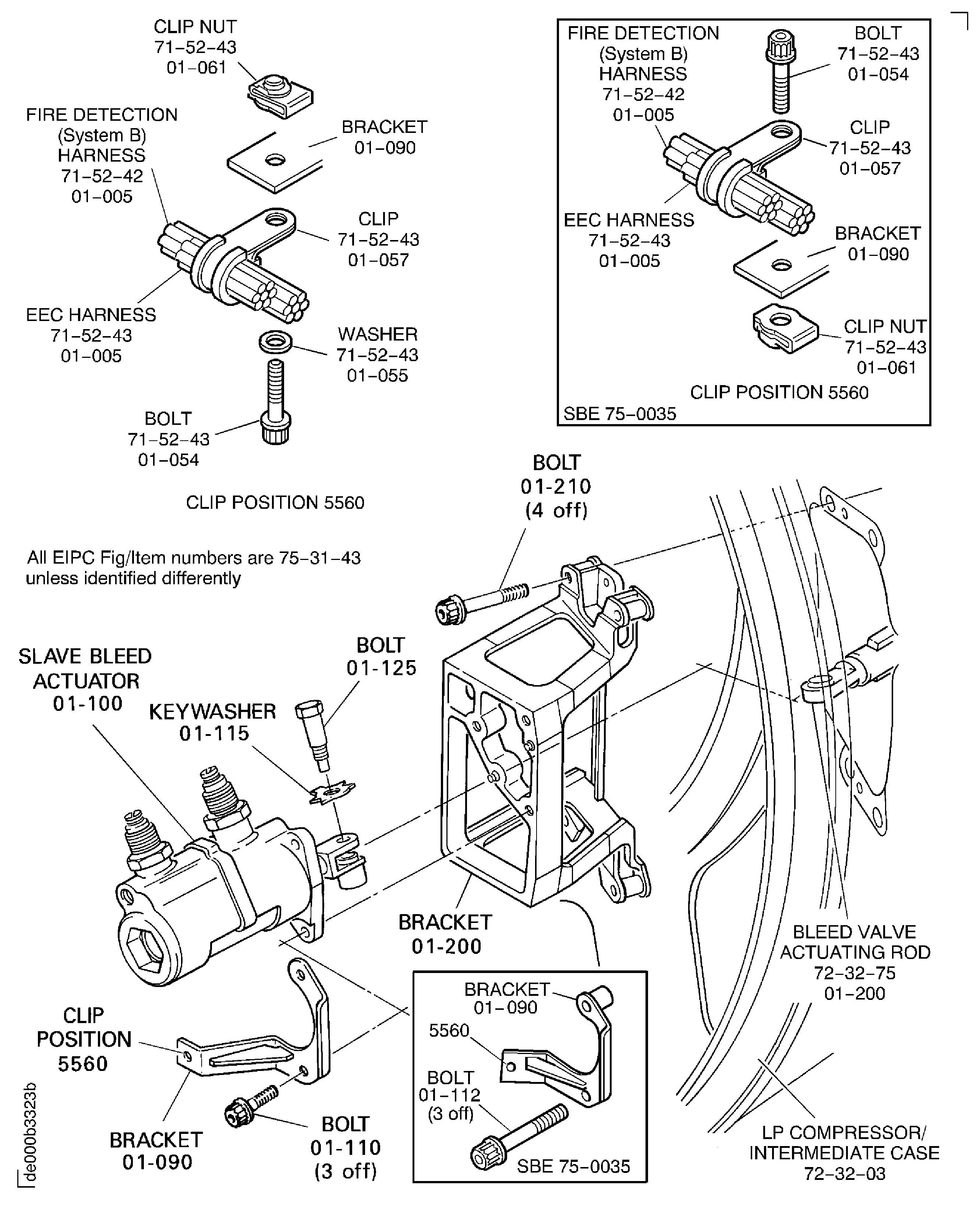

Attach the mount bracket to the LP compressor/intermediate case rear frame with the four bolts LPC Bleed Slave Actuator(75-31-43,01-210). Torque the bolts to 85 to 105 lbfin (10 to 12 Nm). Safety with CoMat 02-141 LOCKWIRE.

Install the slave bleed actuator mount bracket LPC Bleed Slave Actuator(75-31-43,01-200).

Attach the mount bracket to the LP compressor/intermediate case rear frame with the four bolts LPC Bleed Master Actuator(75-31-42,01-210). Torque the bolts to 85 to 105 lbfin (10 to 12 Nm). Safety with CoMat 02-141 LOCKWIRE.

Install the master bleed actuator mount bracket LPC Bleed Master Actuator(75-31-42,01-200).

SUBTASK 72-00-40-420-347 Install the LP Compressor Bleed Actuator Mount Brackets (Pre SBE 75-0080 and SBE 75-0080)

SBE 75-0080: Engine - Air - LP compressor master bleed actuator - Introduction of revised BSBVA master mounting bracket

Attach the bleed actuator to the mount bracket with the three bolts LPC Bleed Slave Actuator(75-31-43, 01-110), together with the bracket LPC Bleed Slave Actuator(75-31-43, 01-090). Torque the bolts to 85 to 105 lbfin (10 to 12 Nm).

Attach the bleed valve actuating rod to the piston jack fork end with the bolt LPC Bleed Slave Actuator(75-31-43, 01-125) and a new LPC Bleed Slave Actuator(75-31-43, 01-115) keywasher 1 off (Refer to SPM TASK 70-42-03-400-501). Torque the bolt to 50 to 60 * lbfin (5.65 to 6.78 Nm).

Install the clip EEC Core Harness And Voltage Divider Harness Assembly(71-52-43, 01-057) on the EEC harness adjacent to the bracket LPC Bleed Slave Actuator(75-31-43, 01-090).

Pre SBE 75-0035 : Attach the clip to the bracket with the bolt EEC Core Harness And Voltage Divider Harness Assembly(71-52-43, 01-054), the washer EEC Core Harness And Voltage Divider Harness Assembly(71-52-43, 01-055) and the clipnut EEC Core Harness And Voltage Divider Harness Assembly(71-52-43, 01-061). Torque the bolt to 36 to 45 lbfin (4 to 5 Nm).

SBE 75-0035 : Attach the clip to the bracket with the bolt EEC Core Harness And Voltage Divider Harness Assembly(71-52-43, 01-054) and the clipnut EEC Core Harness And Voltage Divider Harness Assembly(71-52-43, 01-061). Torque the bolt to 36 to 45 lbfin (4 to 5 Nm).

Assemble the clip position 5560.

Connect the drain tube (35) to the slave bleed actuator and torque the tube connector to 159 to 177 lbfin (18 to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

Lightly lubricate a new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE(73-11-49, 15-096) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the packing on the bleed actuator. Connect the tube 33 to the bleed actuator and torque the tube connector to 204 to 221 lbfin (23 to 25 Nm). Safety with CoMat 02-126 LOCKWIRE.

Connect the servo retract tube (33).

Lightly lubricate a new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE(73-11-49, 14-096) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the packing on the bleed actuator. Connect the tube 34 to the bleed actuator and torque the tube connector to 204 to 221 lbfin (23 to 25 Nm). Safety with CoMat 02-126 LOCKWIRE.

Connect the servo extend tube (34).

Install the LP compressor slave bleed actuator LPC Bleed Slave Actuator(75-31-43, 01-100).

Attach the bleed actuator to the mount bracket with the four bolts LPC Bleed Master Actuator(75-31-42, 01-110), together with the bracket LPC Bleed Master Actuator(75-31-42, 01-080). Torque the bolts to 85 to 105 lbfin (10 to 12 Nm).

Attach the bleed valve actuating rod to the piston jack fork end with the bolt LPC Bleed Master Actuator(75-31-42, 01-125) and a new LPC Bleed Master Actuator(75-31-42, 01-115) keywasher 1 off (Refer to SPM TASK 70-42-03-400-501). Torque the bolt to 50 to 60 * lbfin (5.65 to 6.78 Nm).

Attach the raceway Fuel System Air Tubes(73-22-49, 05-900) to the bracket LPC Bleed Master Actuator(75-31-42, 01-080) with the bolt Fuel System Air Tubes(73-22-49, 05-901), the washer Fuel System Air Tubes(73-22-49, 05-902) and the clipnut Fuel System Air Tubes(73-22-49, 05-908). Torque the bolt to 36 to 45 lbfin (4 to 5 Nm).

Assemble the clip position 5533.

Connect the drain tube (36) to the bleed actuator and torque the tube connector to 159 to 177 lbfin (18 to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

Lightly lubricate a new Control Fuel Tubes(73-11-49, 16-096) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the packing on the bleed actuator. Connect the tube 41 to the bleed actuator and torque the tube connector to 204 to 221 lbfin (23 to 25 Nm). Safety with CoMat 02-126 LOCKWIRE.

Connect the servo return tube (41).

Lightly lubricate a new Control Fuel Tubes(73-11-49, 12-096) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the packing on the bleed actuator. Connect the tube 43 to the bleed actuator and torque the tube connector to 230 to 248 lbfin (26 to 28 Nm). Safety with CoMat 02-126 LOCKWIRE.

Connect the servo supply tube (43).

Lightly lubricate a new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE(73-11-49, 15-096) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the packing on the bleed actuator. Connect the tube 33 to the bleed actuator and torque the tube connector to 204 to 221 lbfin (23 to 25 Nm). Safety with CoMat 02-126 LOCKWIRE.

Connect the servo retract tube (33).

Lightly lubricate a new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE(73-11-49, 14-096) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the packing on the bleed actuator. Connect the tube 34 to the bleed actuator and torque the tube connector to 204 to 221 lbfin (23 to 25 Nm). Safety with CoMat 02-126 LOCKWIRE.

Connect the servo extend tube (34).

Install the LP compressor master bleed actuator LPC Bleed Master Actuator(75-31-42, 01-100).

SUBTASK 72-00-40-420-348 Install the LP Compressor Bleed Actuators (Pre SBE 75-0035 and SBE 75-0035)

SBE 75-0035: Engine - Air - Revise the orientation of clip position 5560

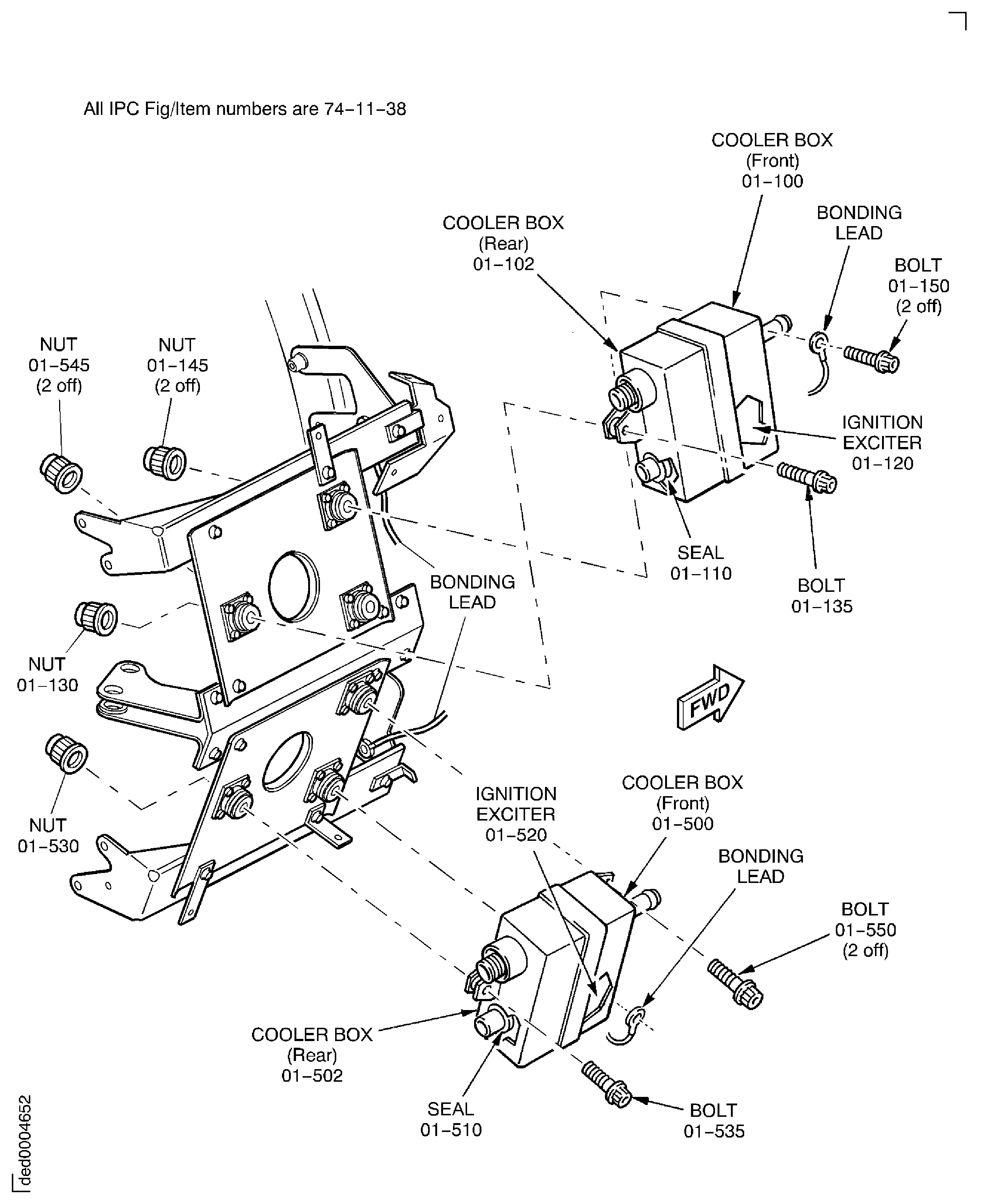

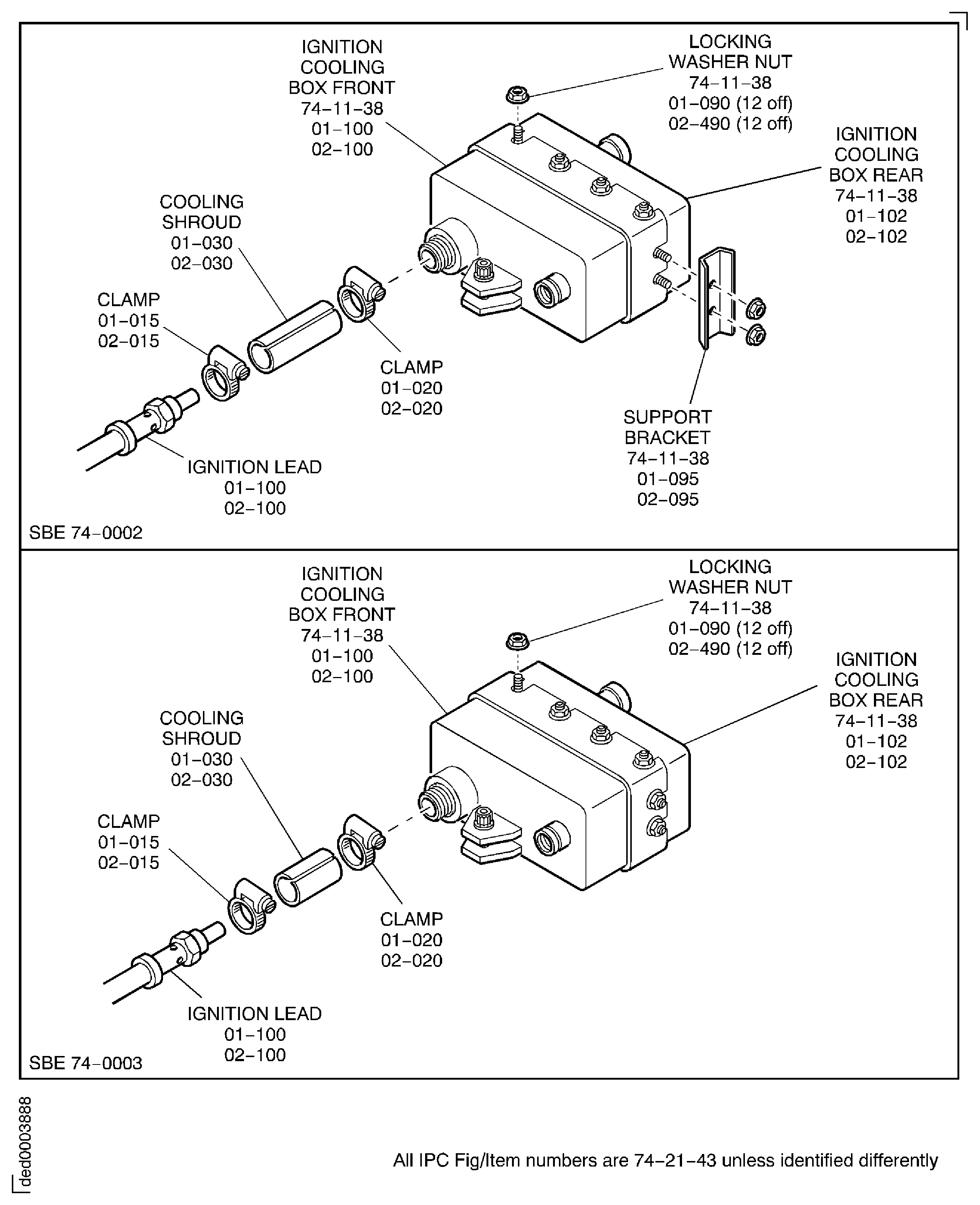

Install the air seal washer Ignition Exciters(74-11-38,01-110) to the top ignition exciter.

SBE 74-0002: Install the front ignition cooling box Ignition Exciters(74-11-38,01-100) and the rear ignition cooling box Ignition Exciters(74-11-38,01-102) to the top ignition exciter Ignition Exciters(74-11-38,01-120).

SBE 74-0002 and Pre SBE 74-0003: Install the support brackets Ignition Exciters(74-11-38,01-095) to the cooling box assembly.

SBE 74-0002: Install the locking washer nuts Ignition Exciters(74-11-38,01-090) to the cooling box assembly.

SBE 74-0002: Torque the 12 nuts to 20 to 26 lbfin (2.26 to 2.94 Nm).

Pre SBE 74-0001: Attach the top ignition exciter to the cross brackets (Ignition Exciters(74-11-38,01-200) and Ignition Exciters(74-11-38,01-270)) with the bolt Ignition Exciters(74-11-38,01-135), the nut Ignition Exciters(74-11-38,01-130), the two bolts Ignition Exciters(74-11-38,01-150) and the two nuts Ignition Exciters(74-11-38,01-145).

SBE 74-0001: Attach the top ignition exciter to the bracket Ignition Exciters(74-11-38,01-200) with the bolt Ignition Exciters(74-11-38,01-135), the nut Ignition Exciters(74-11-38,01-130), the two bolts Ignition Exciters(74-11-38,01-150) and the two nuts Ignition Exciters(74-11-38,01-145).

WARNING

WHEN YOU USE COMAT 01-001 INHIBITED AND STABILIZED TRICHLOROETHANE YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Clean the bonding lead connector and the surface it touches on the exciter box and the remaining bolt Ignition Exciters(74-11-38,01-150) with CoMat 01-001 SOLVENT, DELETED inhibited and stabilized trichloroethane. When the parts are dry install the bolt and the nut Ignition Exciters(74-11-38,01-145).

Install the air seal washer Ignition Exciters(74-11-38,01-510) to the lower ignition exciter end.

SBE 74-0002: Install the front ignition cooling box Ignition Exciters(74-11-38,01-500) and the rear cooling box Ignition Exciters(74-11-38,01-502) to the lower ignition cooling exciter Ignition Exciters(74-11-38,01-520).

SBE 74-0002 and Pre SBE 74-0003: Install the support brackets Ignition Exciters(74-11-38,01-495) to the cooling box assembly.

SBE 74-0002: Install the locking washer nuts Ignition Exciters(74-11-38,01-490) to the cooling box assembly.

Pre SBE 74-0001: Attach the lower ignition exciter to the cross brackets (Ignition Exciters(74-11-38,01-600) and Ignition Exciters(74-11-38,01-670)) with the bolt Ignition Exciters(74-11-38,01-535), the nut Ignition Exciters(74-11-38,01-530), the two bolts Ignition Exciters(74-11-38,01-550) and the two nuts Ignition Exciters(74-11-38,01-545).

SBE 74-0001: Attach the lower ignition exciter to the bracket Ignition Exciters(74-11-38,01-600) with the bolt Ignition Exciters(74-11-38,01-535), the nut Ignition Exciters(74-11-38,01-530), the two bolts Ignition Exciters(74-11-38,01-550) and the two nuts Ignition Exciters(74-11-38,01-545).

WARNING

WHEN YOU USE COMAT 01-001 INHIBITED AND STABILIZED TRICHLOROETHANE YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Clean the bonding lead connector and the surface it touches on the exciter box and the remaining bolt Ignition Exciters(74-11-38,01-550) with CoMat 01-001 SOLVENT, DELETED inhibited and stabilized trichloroethane. When the parts are dry install the bolt and the nut Ignition Exciters(74-11-38,01-545).

Install the ignition exciters.

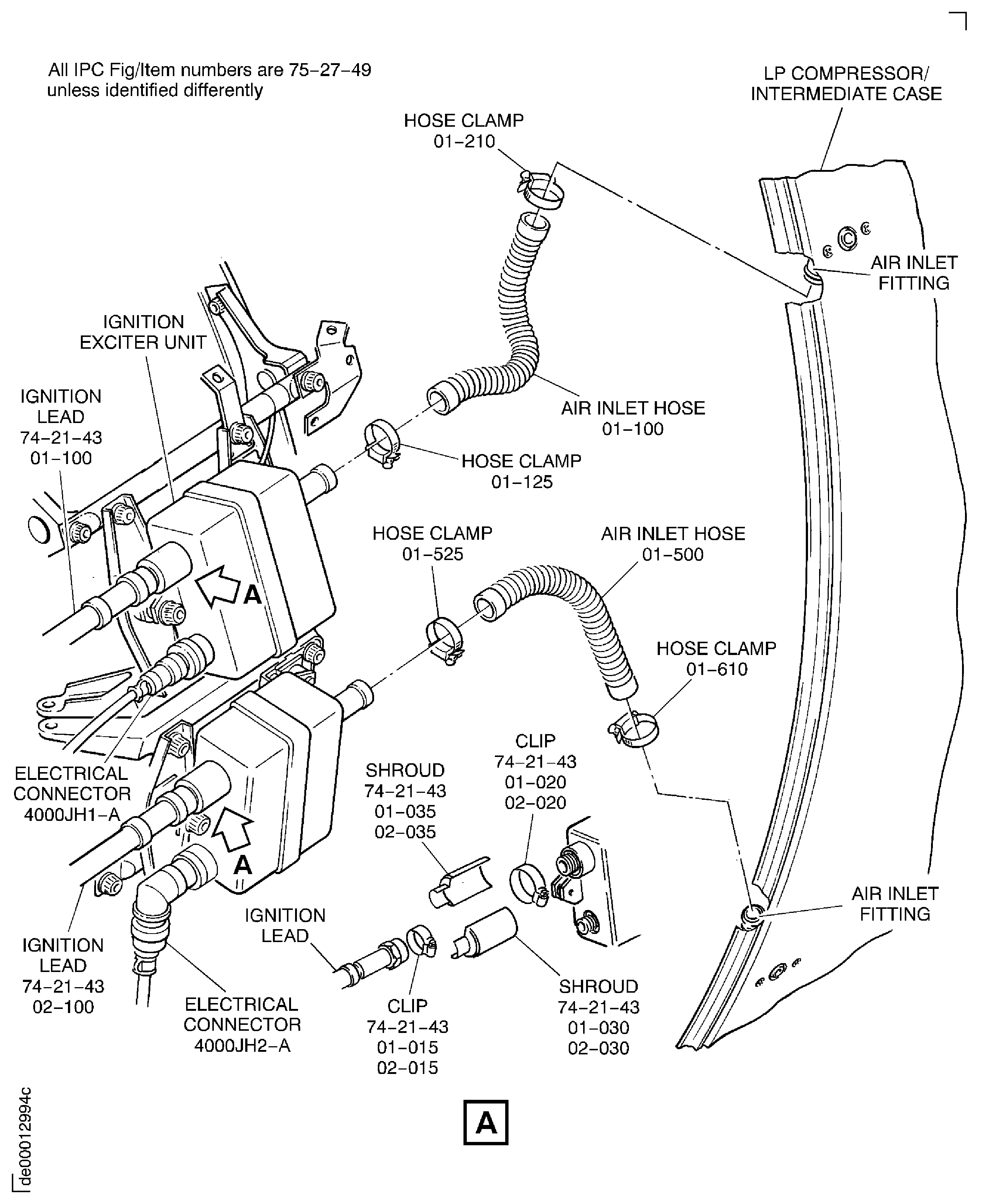

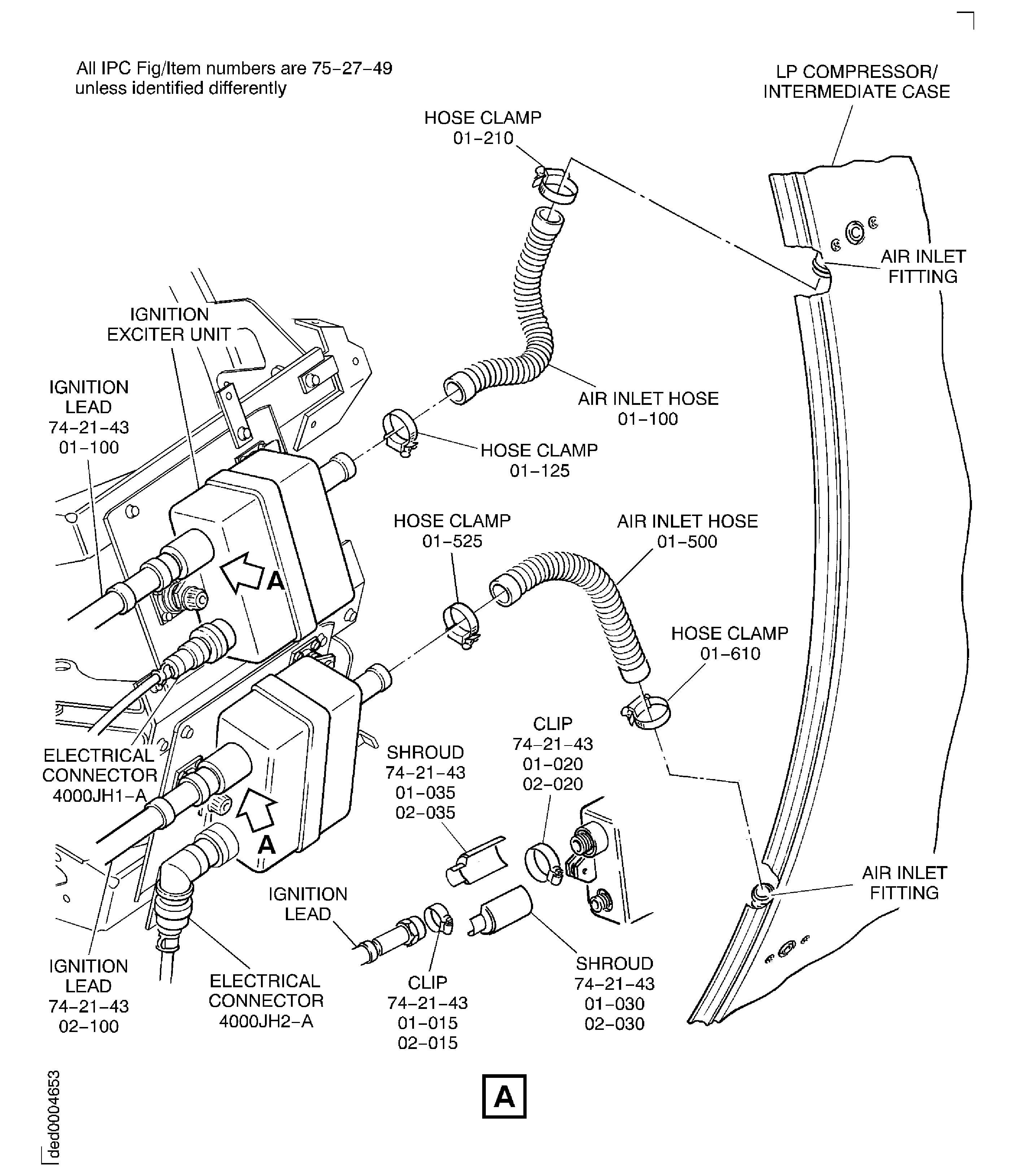

Attach the top air inlet hose Igntion Exciter Cooling Air Tubes And Hoses(75-27-49,01-100) in position with the two hose clamps Igntion Exciter Cooling Air Tubes And Hoses(75-27-49,01-125) and Igntion Exciter Cooling Air Tubes And Hoses(75-27-49,01-210). Tighten the hose clamps finger tight.

Attach the lower air inlet hose Igntion Exciter Cooling Air Tubes And Hoses(75-27-49,01-500) in position with the two hose clamps Igntion Exciter Cooling Air Tubes And Hoses(75-27-49,01-525) and V2500-A5-75-27-19-01A-941A-D (75-27-19,01-610). Tighten the hose clamps finger tight.

Connect the ignition lead IGNITION-IGNITION LEADS(74-21-43,01-100) to the top ignition exciter and torque to 140 to 160 lbfin (15.82 to 18.08 Nm).

Pre SBE 74-0002 and Pre SBE 74-0003: Install the two cooling shrouds IGNITION-IGNITION LEADS(74-21-43,01-030) and IGNITION-IGNITION LEADS(74-21-43,01-035) and the two clamps IGNITION-IGNITION LEADS(74-21-43,01-015) and IGNITION-IGNITION LEADS(74-21-43,01-020).

SBE 74-0002 and SBE 74-0003: Install the cooling shroud IGNITION-IGNITION LEADS(74-21-43,01-030) and the two clamps IGNITION-IGNITION LEADS(74-21-43,01-015) and IGNITION-IGNITION LEADS(74-21-43,01-020).

Connect the ignition lead Ignition Leads(74-21-43,02-100) to the lower ignition exciter and torque to 140 to 160 lbfin (15.82 to 18.08 Nm).

Pre SBE 74-0002 and Pre SBE 74-0003: Install the two cooling shrouds Ignition Leads(74-21-43,02-030) and Ignition Leads(74-21-43,02-035) and the two clamps Ignition Leads(74-21-43,02-015) and Ignition Leads(74-21-43,02-020).

SBE 74-0002 and SBE 74-0003: Install the cooling shroud Ignition Leads(74-21-43,02-030) and the two clamps Ignition Leads(74-21-43,02-015) and Ignition Leads(74-21-43,02-020).

SUBTASK 72-00-40-420-349 Install the Ignition Exciters (Pre SBE 74-0001, SBE 74-0001, Pre SBE 74-0002, SBE 74-0002, Pre SBE 74-0003 and SBE 74-0003)

SBE 74-0001: Engine - Ignition - Introduce new ignition exciter mounting brackets.

SBE 74-0002: Engine - Ignition - Introduction of improved ignition lead, cooling shroud and the ignition cooling box.

SBE 74-0003: Engine - Ignition - Introduction of a redimensioned ignition lead cooling shroud and the deletion of ignition cooling box support bracket.

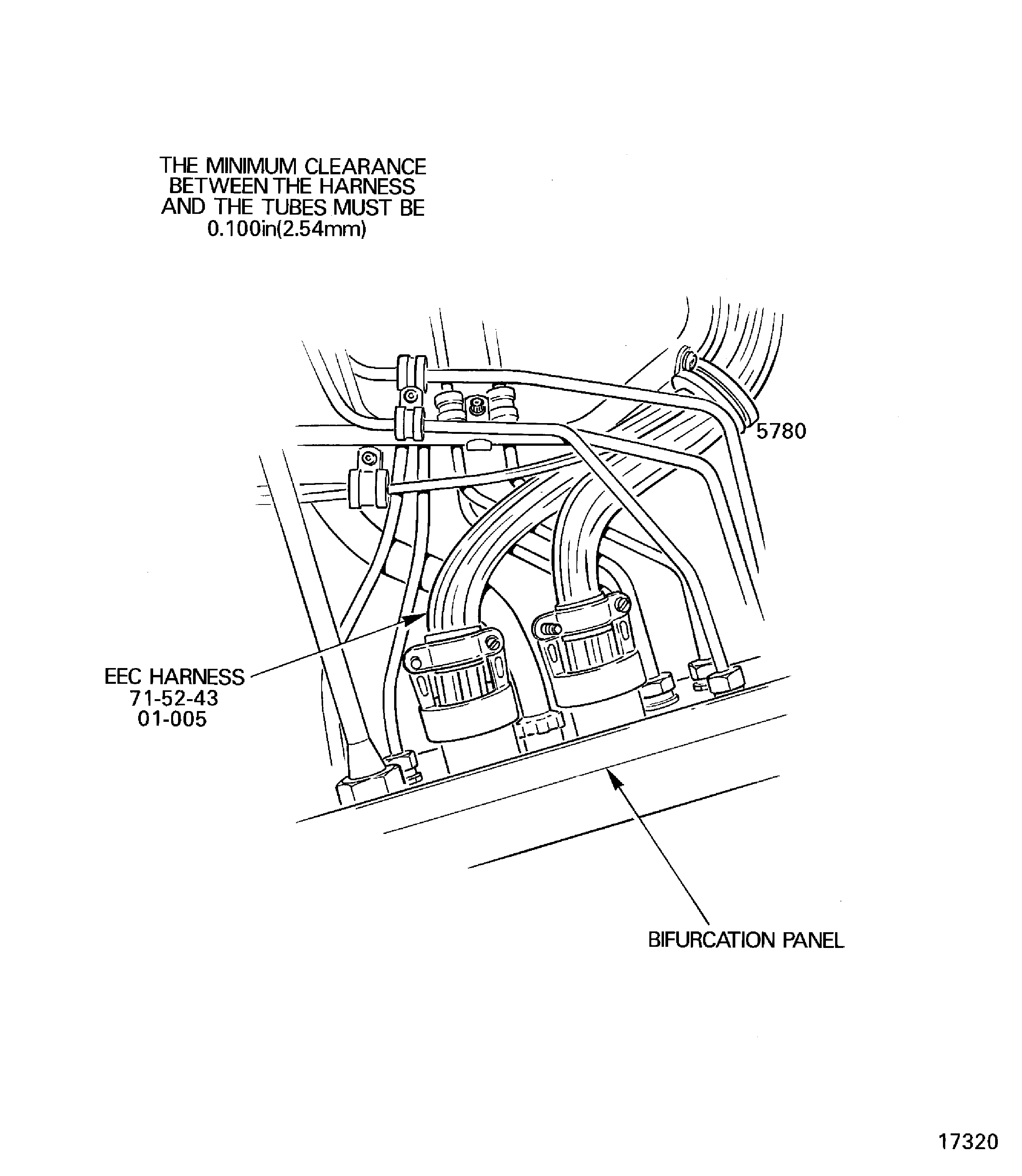

Refer to Figure.

To check the clearance, push the harness with a light pressure of the thumb then release. The harness must spring back and give the minimum clearance. The harness must not move through the adjacent clips (refer to Step).

A minimum clearance of 0.100 in. (2.54 mm) is necessary between the EEC harness EEC Core Harness And Voltage Divider Harness Assembly(71-52-43, 01-005) and the tubes.

Measure the clearance between all the different harnesses and the engine parts.

If the primary harness, the wire bundle breakout or a different harness touch each other they must be attached to each other. Refer to Step. The bundles must not move in relation to each other.

Examine the harness routing.

SUBTASK 72-00-40-220-144 Measure the Harness Clearances and Examine the Harness Routing

Attach the wire bundle breakout to the primary harness with CoMat 02-159 LACING TAPE so they do not move in relation to each other.

Attach the parallel harnesses together and those which go across each other. If it is necessary, put CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) around the harness (to prevent abrasion). Then attach them together with CoMat 02-159 LACING TAPE.

SUBTASK 72-00-40-420-350 Attach the Harness Together

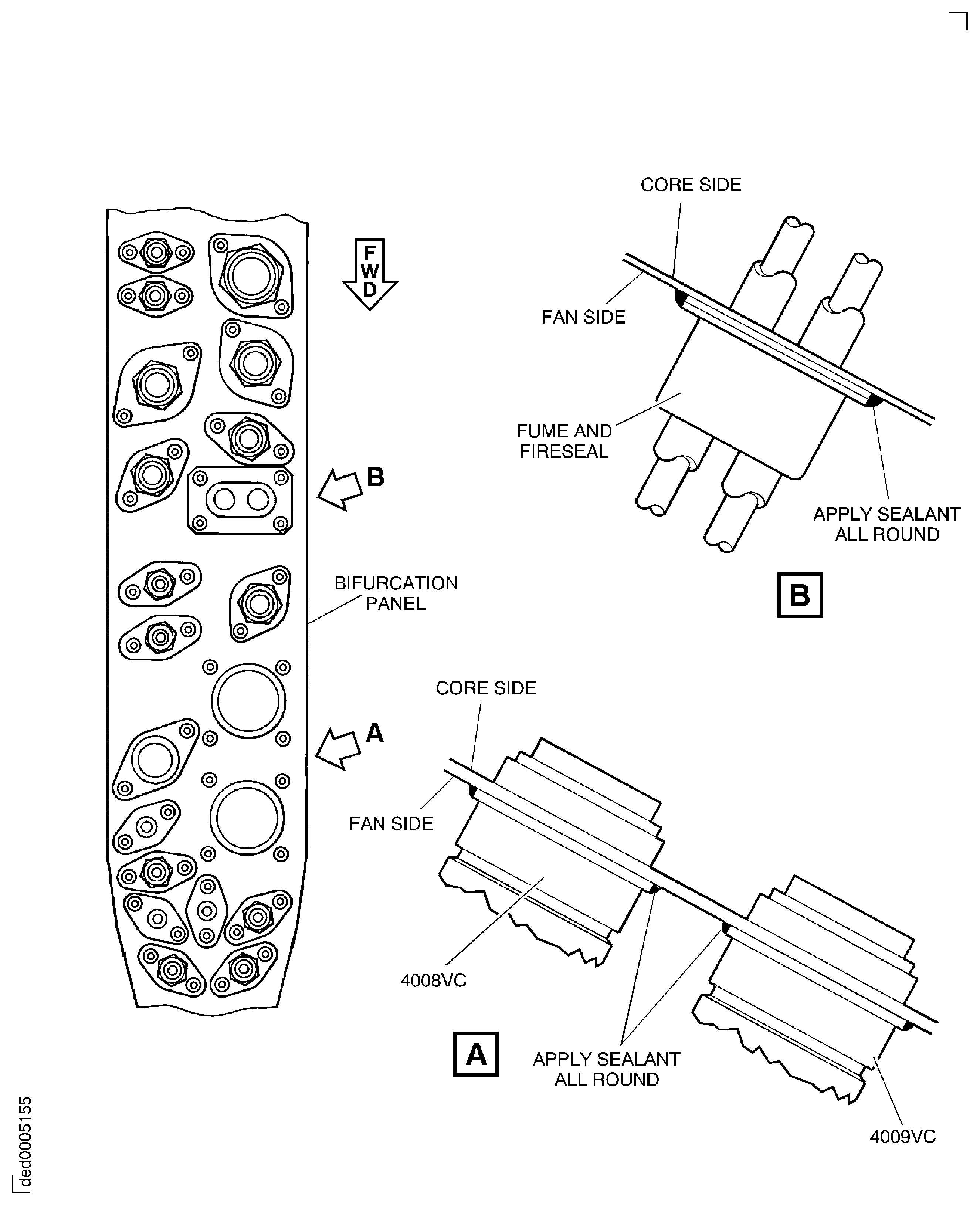

Refer to Figure.

Clean the surface of the joint faces at the electrical connectors and fume and fireseal.

Refer to SPM TASK 70-11-26-300-503 for the procedure to locally swab clean.

Hand clean the specified surfaces with CoMat 05-016 GARNET PAPER, 80-GRIT or CoMat 05-017 GARNET PAPER, 60 GRIT.

Locally swab clean the areas again, refer to SPM TASK 70-11-26-300-503.

Use dry compressed air or CoMat 02-099 LINT-FREE CLOTH to dry the cleaned areas.

For CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT air dry for 30 minutes.

For CoMat 08-032 PRIMER air dry for 60 to 90 minutes.

Dry the primer.

Use a spatula to apply the CoMat 08-013 COLD CURING SILICONE COMPOUND or CoMat 08-074 SEALANT, RTV SILICONE.

Apply the sealant to seal the core receptacle to bifurcation panel joint.

NOTE

The surface of the sealant can be touched after 12 hours.

Do not apply a load during this time.

For CoMat 08-013 COLD CURING SILICONE COMPOUND cold cure at 68 deg F (20 deg C) for 48 hours.

NOTE

The surface of the sealant can be touched after 1 or 2 hours.

Do not apply a load during this time.

For CoMat 08-074 SEALANT, RTV SILICONE cure at 77 deg F (35 deg C) for 24 hours.

Cure the sealant.

SUBTASK 72-00-40-420-351 Seal the Electrical Harness Connections at the Bifurcation Panel (SBE 72-0193)

SBE 72-0193: Core to fancase interface sealing of the bifurcation panel

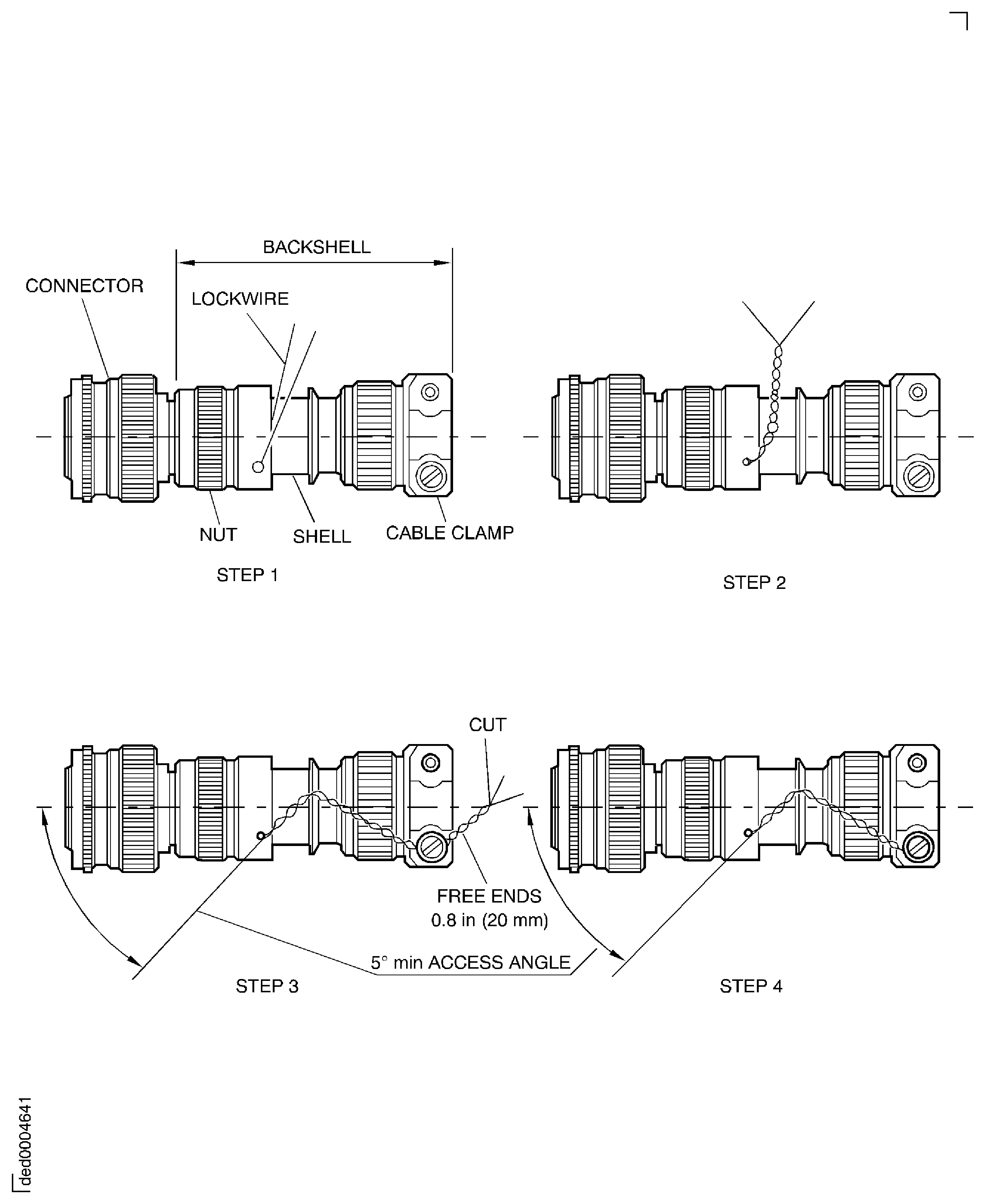

Refer to Figure.

Make sure that all the applicable backshells and cable clamps are safetied with CoMat 02-126 LOCKWIRE. Refer to SPM TASK 70-42-05-400-501.

SUBTASK 72-00-40-210-076 Visually Inspect the Electrical Backshells and Cable Clamps

NOTE

Use this procedure to safety the EEC harness backshells and cable clamps with safety cable.Refer to Figure.

Make sure that all the EEC harness backshells and cable clamps are safetied. Safety with CoMat 02-274 SAFETY CABLE KIT safety cable or with CoMat 02-275 SAFETY CABLE KIT safety cable. Refer to SPM TASK 70-42-08-400-501.

SUBTASK 72-00-40-210-077 Visually Inspect the EEC Harness (01-005) Electrical Backshells and Cable Clamps (SBE 70-0813)

SBE 70-0813: Announcement of introduction of safety cable as a preferred method to lockwire

Install the forward mount assembly as detailed in TASK 71-00-32-450-001 (INSTALLATION).

SUBTASK 72-00-40-420-352 Install the Forward Mount Assembly

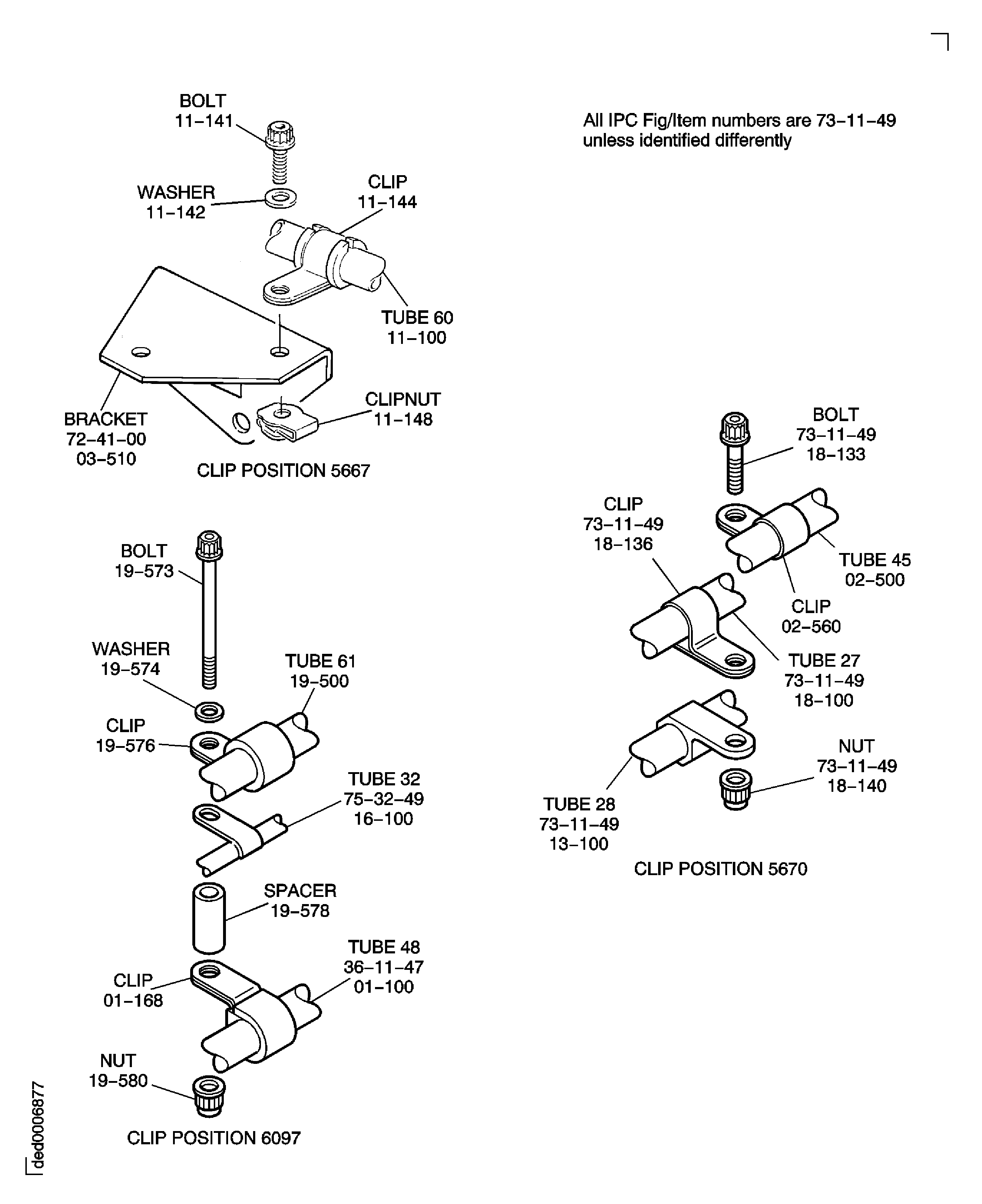

Figure: Pre SBE 75-0081: Connect the Tubes at the Bifurcation Panel

Sheet 1

Figure: Pre SBE 71-0288, Pre SBE 75-0081: Connect the Tubes at the Bifurcation Panel

Sheet 2

Figure: SBE 71-0288, Pre SBE 75-0081: Connect the Tubes at the Bifurcation Panel

Sheet 3

Figure: SBE 75-0081: Connect the Tubes at the Bifurcation Panel

Sheet 4

Figure: Pre SBE 71-0288, SBE 75-0081: Connect the Tubes at the Bifurcation Panel

Sheet 5

Figure: SBE 71-0288, SBE 75-0081: Connect the Tubes at the Bifurcation Panel

Sheet 6

Figure: Install the ACC Actuator

Sheet 1

Figure: Install the ACC Actuator

Sheet 2

Figure: Install the VSV Actuator

Sheet 1

Figure: Install the VSV Actuator

Sheet 2

Figure: Install the Raceways

Sheet 1

Figure: Install the Raceways

Sheet 2

Figure: Install the Raceways

Sheet 3

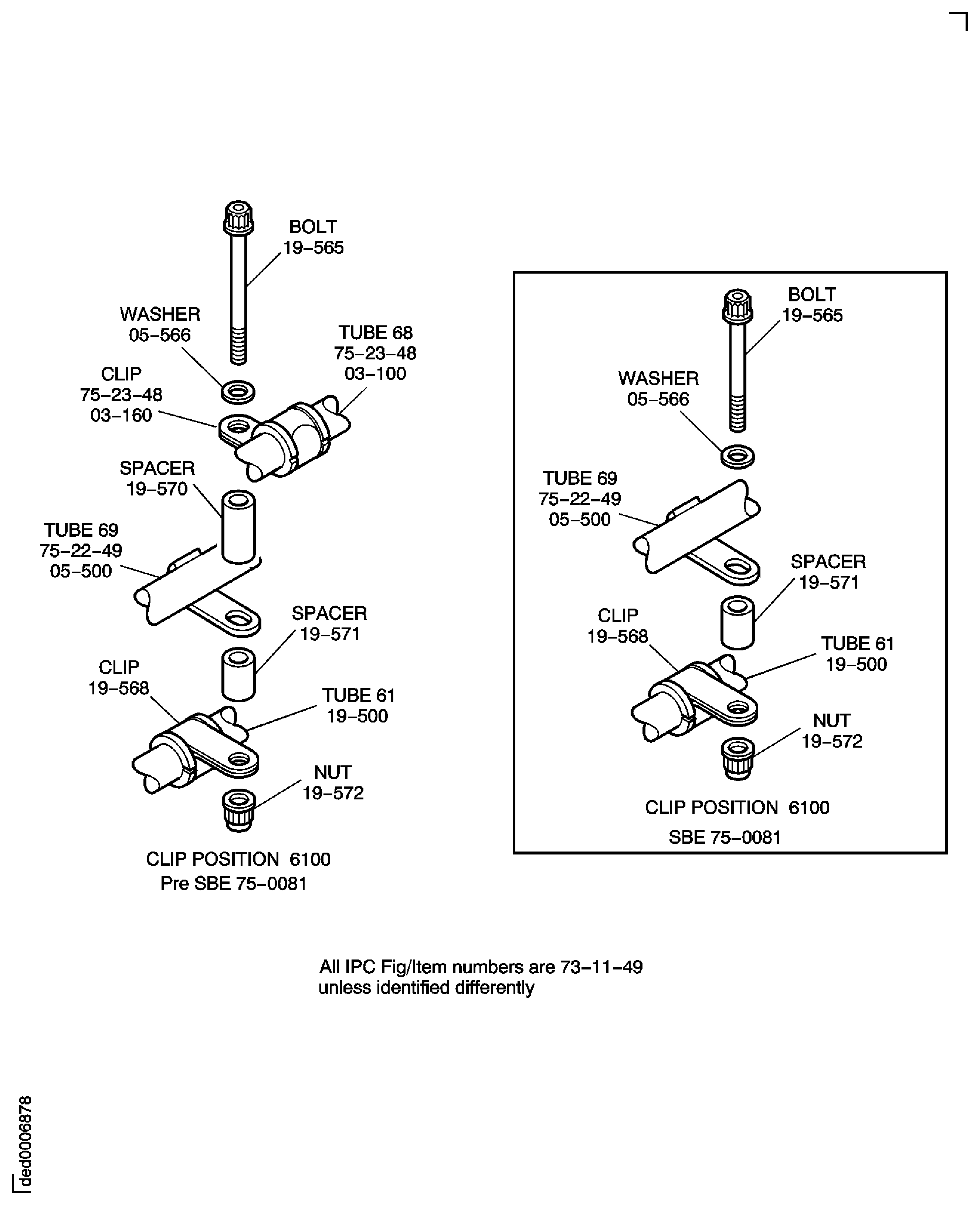

Figure: Install the HP Servo Fuel Tubes

Sheet 1

Figure: Install the HP Servo Fuel Tubes

Sheet 2

Figure: Install the HP Servo Fuel Tubes

Sheet 3

Figure: Install the HP Servo Fuel Tubes

Sheet 4

Figure: Install the HP Servo Fuel Tubes

Sheet 5

Figure: Install the HP Servo Fuel Tubes

Sheet 6

Figure: Install the HP Servo Fuel Tubes

Sheet 7

Figure: Install the HP Servo Fuel Tubes

Sheet 8

Figure: Pre SBE 71-0288: Install the HP Servo Fuel Tubes

Sheet 9

Figure: SBE 71-0288: Install the HP Servo Fuel Tubes

Sheet 10

Figure: SBE 72-0189 : Install the HP Servo Fuel Tubes

Sheet 11

Figure: Install the HP Servo Fuel Tubes

Sheet 12

Figure: Install the HP Servo Fuel Tubes

Sheet 13

Figure: Install the HP Servo Fuel Tubes

Sheet 14

Figure: Install the HP Servo Fuel Tubes

Sheet 15

Figure: Install the HP Servo Fuel Tubes

Sheet 16

Figure: Install the Fuel Distribution Feed Tube (62)

Sheet 1

Figure: Install the Fuel Distribution Feed Tube (62)

Sheet 2

Figure: Install the HP Servo Fuel Tube (46) and the P2.5 Air Tubes (66 and 67)

Sheet 1

Figure: Install the Fuel System Air Tubes (66 and 67)

Sheet 2

Figure: Install the HP Servo Fuel Tube (46) and the P2.5 Air Tubes (66 and 67)

Sheet 3

Figure: Install the HP Servo Fuel Tube (46) and the P2.5 Air Tubes (66 and 67)

Sheet 4

Figure: Install the No.1, 2 and 3 Bearing Oil Feed Tubes (57 and 58)

Sheet 1

Figure: Install the No.1, 2 and 3 Bearing Oil Feed Tubes (57 and 58)

Sheet 2

Figure: Electrical Harness Installation Procedure

Electrical Harness Installation Procedure

Figure: Install the Core Overheat Detector

Sheet 1

Figure: Install the Core Overheat Detector

Sheet 2

Figure: Install the Raceway

Install the Raceway

Figure: Pre SBE 71-0288: Install the Electrical Harnesses

Sheet 1

Figure: SBE 71-0288: Install the Electrical Harnesses

Sheet 2

Figure: Pre SBE 71-0288, Pre SBE 71-0303, SBE 71-0303, Pre SBE 72-0553 and SBE 72-0553: Install the Electrical Harnesses

Sheet 3

Figure: SBE 71-0288, Pre SBE 71-0303, SBE 71-0303, Pre SBE 72-0553 and SBE 72-0553: Install the Electrical Harnesses

Sheet 4

Figure: Pre SBE 71-0303 and SBE 71-0303 and Pre SBE 72-0553: Install the Electrical Harnesses

Sheet 5

Figure: SBE 72-0553: Install the Electrical Harnesses

Sheet 6

Figure: Install the Electrical Harnesses

Sheet 7

Figure: Install the Electrical Harnesses

Sheet 8

Figure: Install the Electrical Harnesses

Sheet 9

Figure: Install the Electrical Harnesses

Sheet 10

Figure: Install the Electrical Harnesses

Sheet 11

Figure: SBE 72-0189: Install the Electrical Harnesses

Sheet 12

Figure: Install the Electrical Harnesses

Sheet 13

Figure: Install the Electrical Harnesses

Sheet 14

Figure: Install the Electrical Harnesses

Sheet 15

Figure: Install the Electrical Harnesses

Sheet 16

Figure: Pre SBE 71-0288: Install the Electrical Harnesses

Sheet 17

Figure: SBE 71-0288: Install the Electrical Harnesses

Sheet 18

Figure: Install the Electrical Harnesses

Sheet 19

Figure: SBE 72-0189: Install the Electrical Harnesses

Sheet 20

Figure: Pre SBE 71-0288: Install the Electrical Harnesses

Sheet 21

Figure: SBE 71-0288: Install the Electrical Harnesses

Sheet 22

Figure: Pre SBE 71-0288: Install the Electrical Harnesses

Sheet 23

Figure: SBE 71-0288: Install the Electrical Harnesses

Sheet 24

Figure: Pre SBE 71-0288: Install the Electrical Harnesses

Sheet 25

Figure: SBE 71-0288: Install the Electrical Harnesses

Sheet 26

Figure: Pre SBE 71-0288: Install the Electrical Harnesses

Sheet 27

Figure: SBE 71-0288: Install the Electrical Harnesses

Sheet 28

Figure: Pre SBE 71-0288: Install the Electrical Harnesses

Sheet 29

Figure: SBE 71-0288: Install the Electrical Harnesses

Sheet 30

Figure: Pre SBE 75-0081: Install the Electrical Harnesses

Sheet 31

Figure: Install the Electrical Harnesses

Sheet 32

Figure: Pre SBE 71-0303, SBE 71-0303 and Pre SBE 72-0553: Install the Electrical Harnesses

Sheet 33

Figure: SBE 72-0553: Install the Electrical Harnesses

Sheet 34

Figure: Install the Electrical Harnesses

Sheet 35

Figure: Install the Electrical Harnesses

Sheet 36

Figure: Install the Electrical Harnesses

Sheet 37

Figure: Install the Fuel Drain Tubes

Sheet 1

Figure: Pre SBE 71-0288: Install the Fuel Drain Tubes

Sheet 2

Figure: SBE 71-0288: Install the Fuel Drain Tubes

Sheet 3

Figure: Install the Fuel Drain Tubes

Sheet 4

Figure: Install the Fuel Drain Tubes

Sheet 5

Figure: Install the Fuel Drain Tubes

Sheet 6

Figure: Install the LP Compressor Bleed Actuators

Sheet 1

Figure: Pre SBE 75-0080: SBE 75-0080: Install the LP Compressor Bleed Actuators

Sheet 2

Figure: Install the LP Compressor Bleed Actuators

Sheet 3

Figure: Install the LP Compressor Bleed Actuators

Sheet 4

Figure: Pre SBE 74-0001, Pre SBE 74-0002 and Pre SBE 74-0003: Install the Ignition Exciters

Sheet 1

Figure: SBE 74-0001, Pre SBE 74-0002 and Pre SBE 74-0003: Install the Ignition Exciters

Sheet 2

Figure: Pre SBE 74-0001: Install the Ignition Exciters

Sheet 3

Figure: SBE 74-0001: Install the Ignition Exciters

Sheet 4

Figure: SBE 74-0002 and SBE 74-0003: Install the Ignition Exciters

Sheet 5

Figure: Examine the Harness Routing

Examine the Harness Routing

Figure: Pre SBE 71-0288: Route and Attach the Right Hand Side and Left Hand Side EEC Harness Looms Together at the Bifurcation Panel

Sheet 1

Figure: SBE 71-0288: Route and Attach the Right Hand Side and Left Hand Side EEC Harness Looms Together at the Bifurcation Panel

Sheet 2

Figure: Seal the Electrical Harness Connections at the Bifurcation Panel

Seal the Electrical Harness Connections at the Bifurcation Panel

Figure: Visually Inspect the Backshells and Cable Clamps

Visually Inspect the Backshells and Cable Clamps