Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 71-00-02-400-001-A00 (A1-PPBU) - Install The LP Compressor/Intermediate Case Brackets, Installation-001

General

Fig./item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig./item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig./item number.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

For the torque tightening procedures, refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. Refer to SPM TASK 70-38-21-380-501.

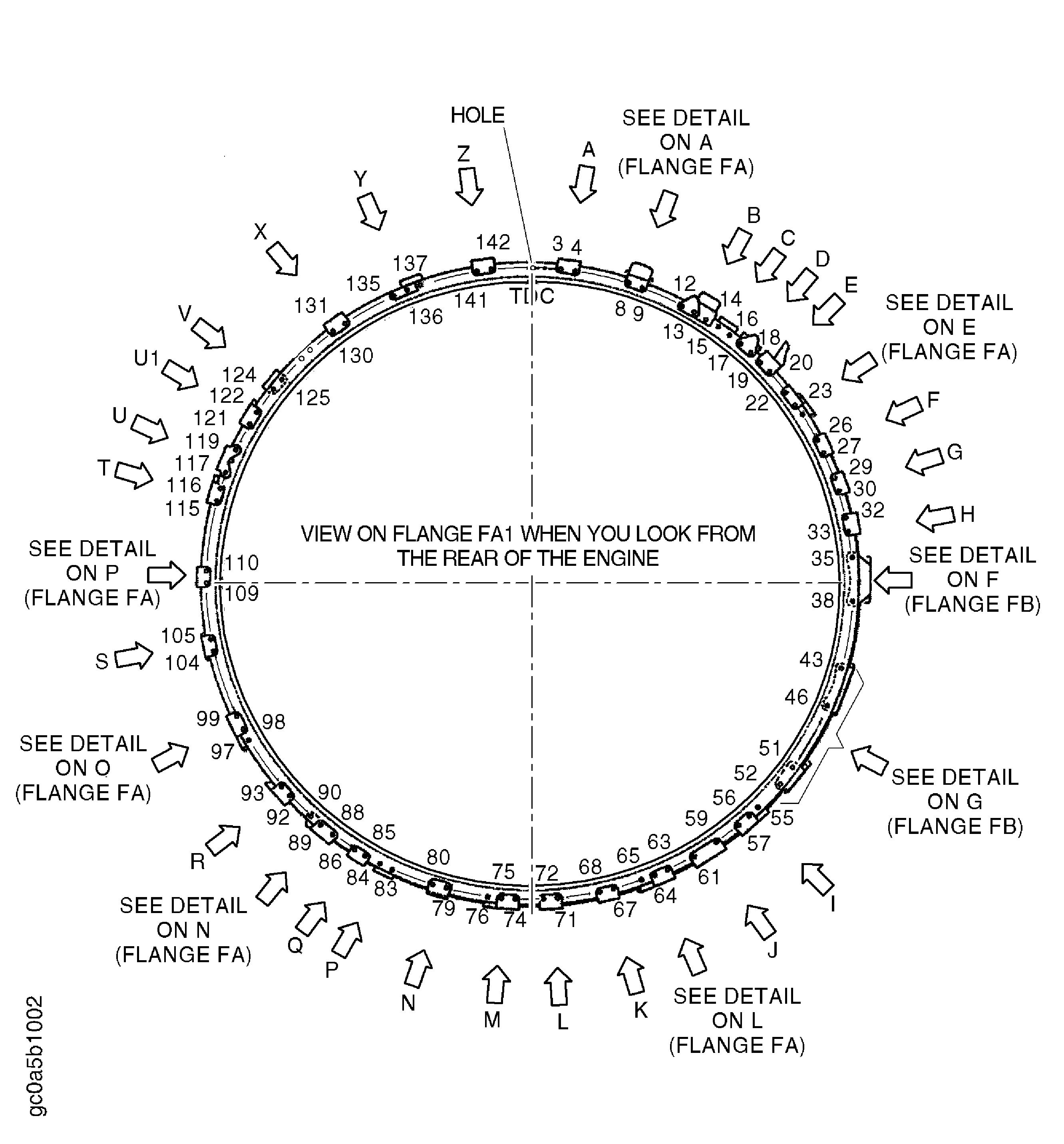

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

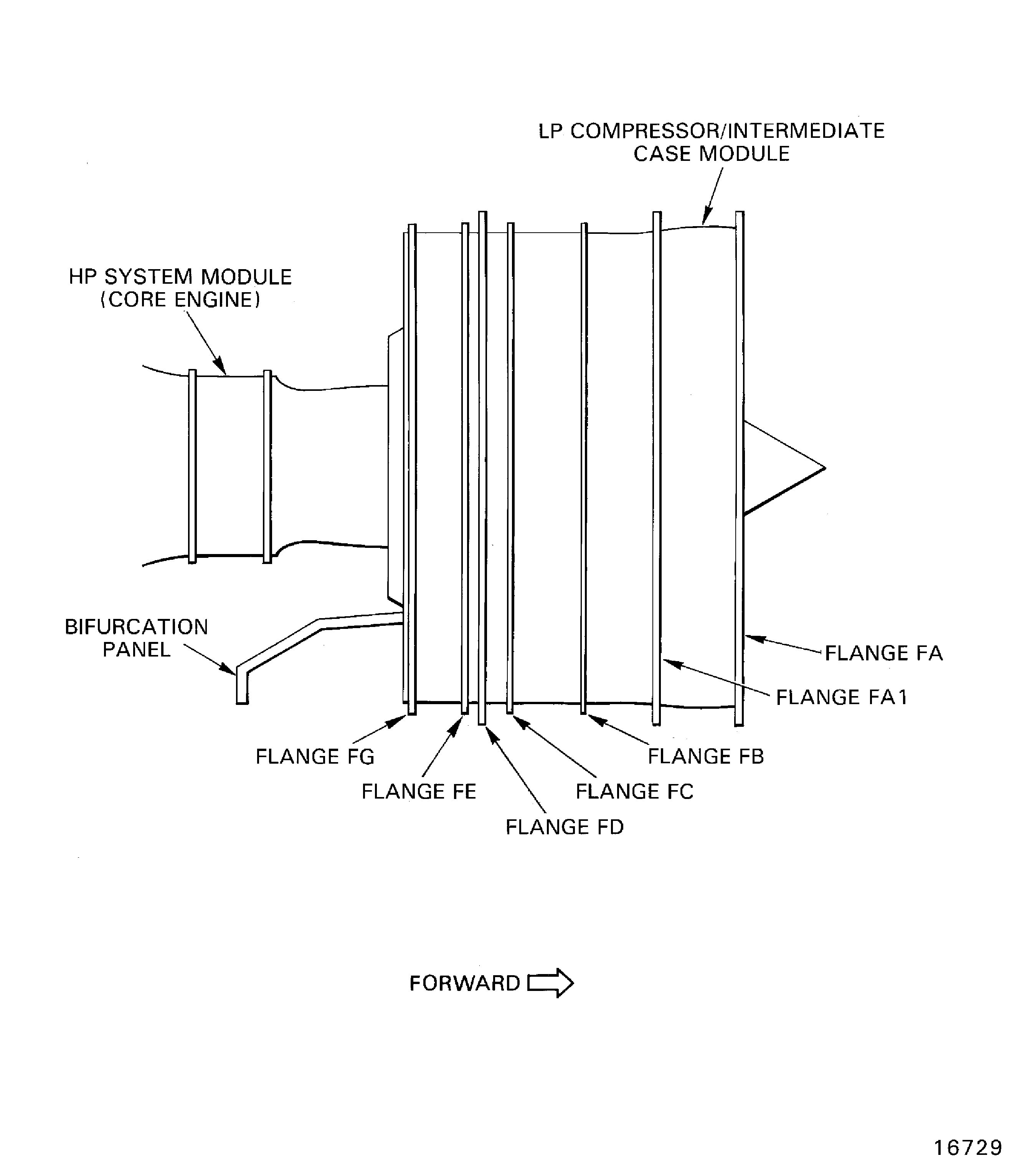

Refer to Figure for details of the module flanges given in this procedure.

Refer to the applicable Figure for each raft or bracket clip position.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| ACR Torq-Set bit 212-1/4-ACR | LOCAL | Torq-Set |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) | K6835 | CoMat 10-072 | ||

| CoMat 10-073 SYNTHETIC GREASE, MoDISULFIDE | 0AM53 | CoMat 10-073 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Install the two brackets ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-980) and ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-990) at the holes 11 and 12 with the two bolts and two nuts ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-984) and ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-981). Torque the nuts 85 to 105 lbf.in. (10 to 12 Nm).

Install the brackets at A.

Install the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 12-060) at the holes 23 and 24 with the two bolts and two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 12-064) and ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 12-062). Refer to the detail on B.

Install the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 12-055) at the holes 28 and 29 with two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 12-059) and ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 12-057). Refer to the detail on C.

Install the brackets at B to C.

NOTE

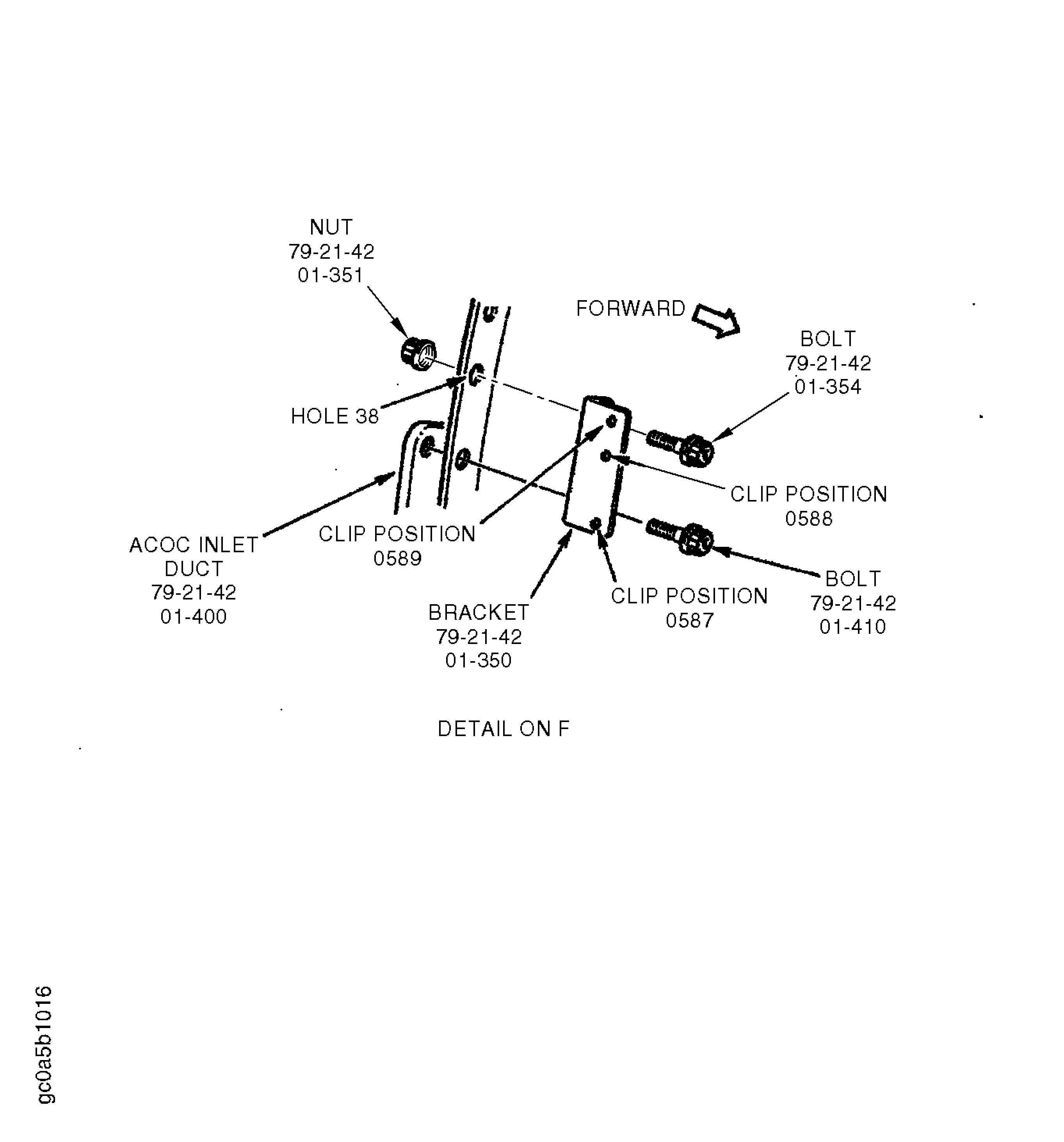

The remaining bolt OIL-AIR COOLED OIL COOLER (79-21-42, 01-410) for the installation of the bracket OIL-AIR COOLED OIL COOLER (79-21-42, 01-350) at the hole 39, is installed during TASK 72-00-32-420-002.Install the bracket OIL-AIR COOLED OIL COOLER (79-21-42, 01-350) at hole 38 with the bolt OIL-AIR COOLED OIL COOLER (79-21-42, 01-354) and the nut OIL-AIR COOLED OIL COOLER (79-21-42, 01-351). Torque the nuts to 85 to 105 lbf.in. (10 to 12 Nm).

Install the LH bracket POWER PLANT-F/C ROD SUPPORT BKTS (71-00-24, 01-010) at the holes 76 and 77 with the two bolts, the two washers and the two nuts POWER PLANT-F/C ROD SUPPORT BKTS (71-00-24, 01-040), POWER PLANT-F/C ROD SUPPORT BKTS (71-00-24, 01-030) and POWER PLANT-F/C ROD SUPPORT BKTS (71-00-24, 01-020). Torque the nuts to 85 to 105 lbf.in. (10 to 12 Nm). Refer to the detail on L.

Install the brackets at F.

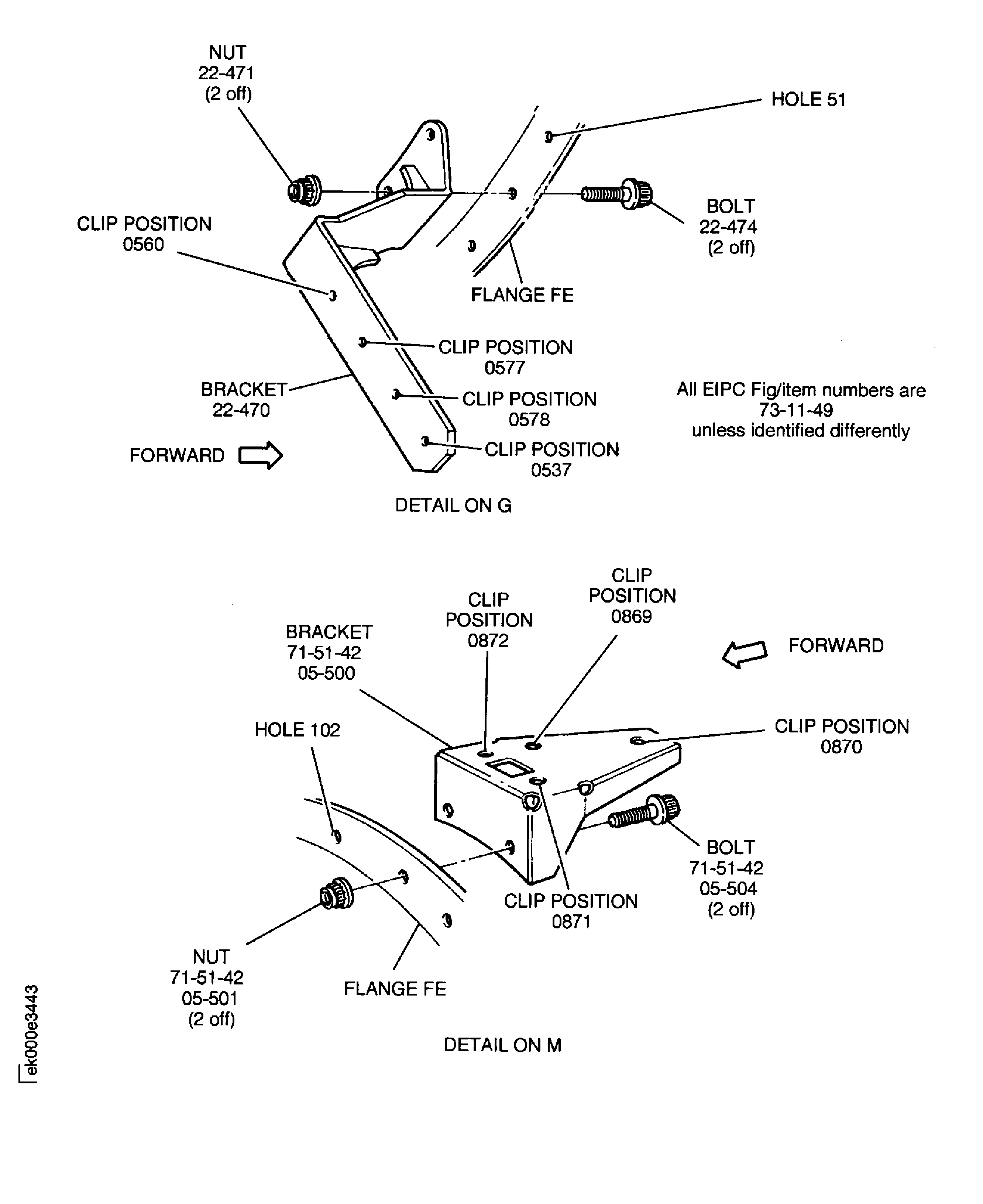

Install the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 22-470) at the holes 51 and 52 with the two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 22-474) and ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 22-471). Refer to the detail on G.

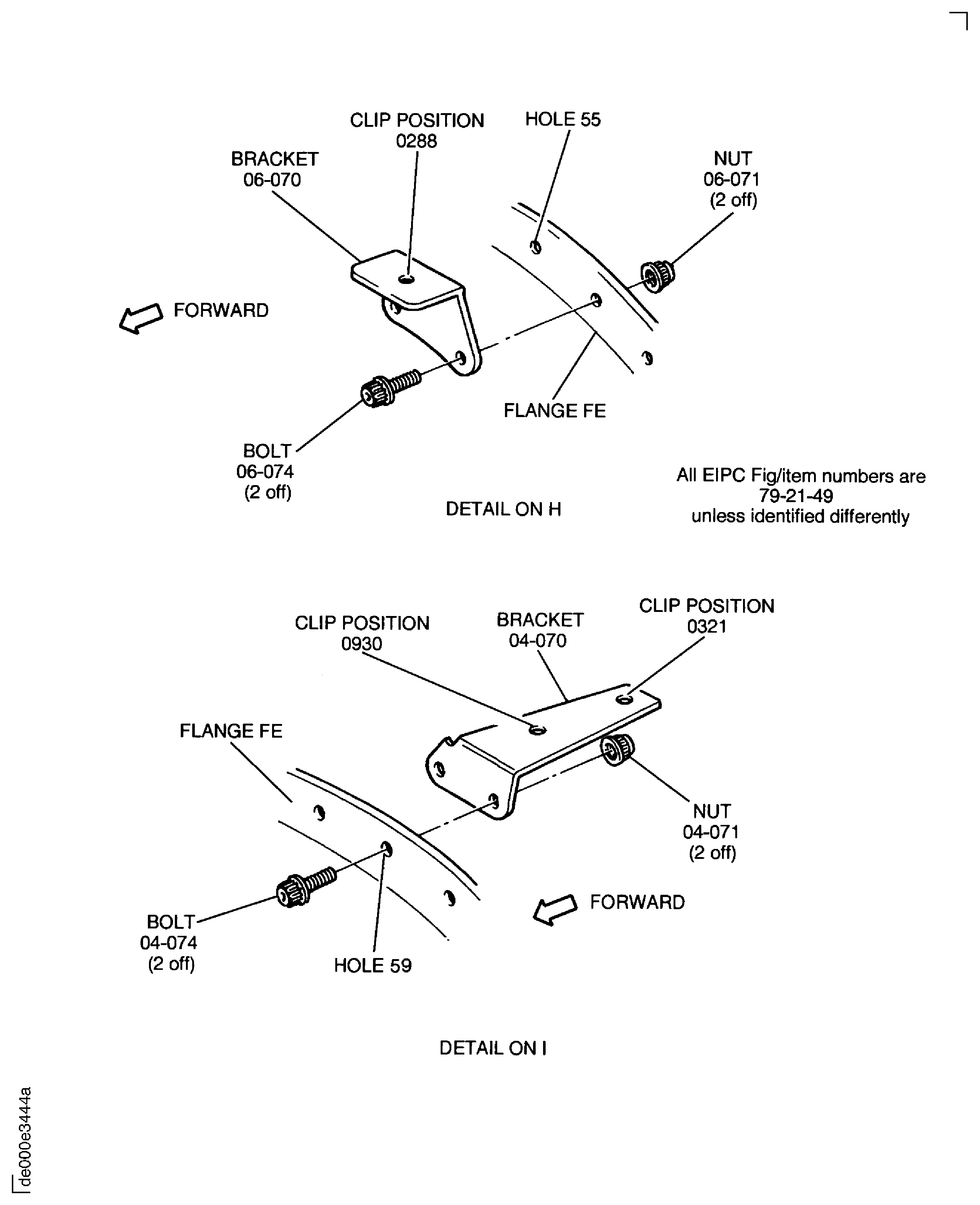

Install the bracket OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 06-070) at the holes 54 and 55 with the two bolts and the two nuts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 06-074) and OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 06-071). Refer to the detail on H.

Install the bracket OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 04-070) at the holes 59 and 60 with the two bolts and the two nuts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 04-074) and OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 04-071). Refer to the detail on I.

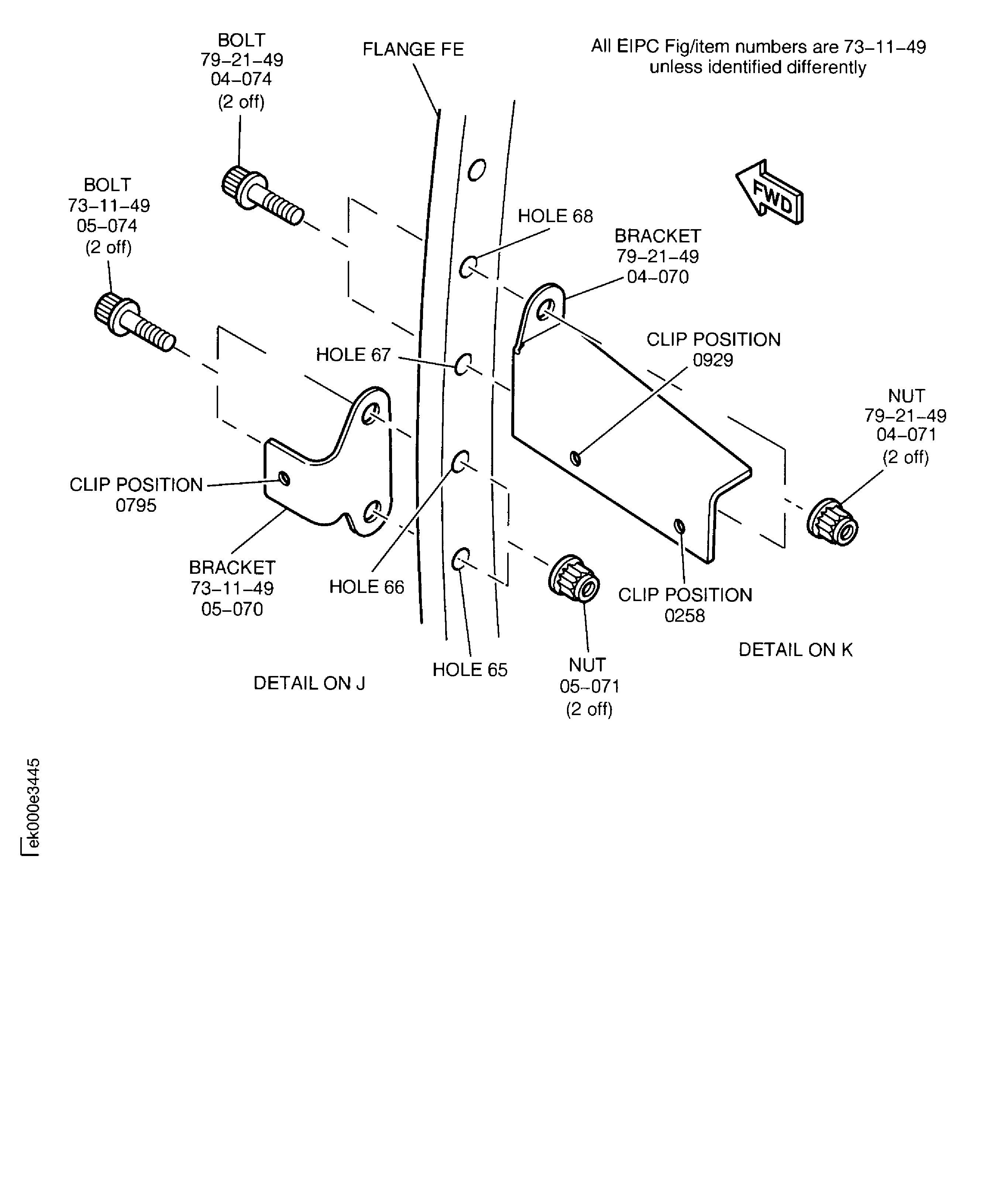

Install the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE(73-11-49, 05-070) at the holes 65 and 66 with the two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE(73-11-49, 05-074) and ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE(73-11-49, 05-071). Refer to the detail on J.

Pre SBE 73-0040: Install the bracket OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 04-070) at the holes 67 and 68 with the two bolts and the two nuts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 04-074) and OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 04-071). Refer to the detail on K.

SBE 73-0040: Install the two brackets OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 04-070) and ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 21-264) at the holes 67 and 68 with the two bolts, the four washers and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 21-267), ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 21-269) and ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 21-270). Refer to the detail on K.

SBE 73-0040: Install the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 21-264) at the holes 63 and 64 with the two bolts, the two washers and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 21-266), ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 21-268) and ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 21-270). Refer to the detail on I.

Install the brackets at G to K.

Install the bracket ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-500) at the holes 101 and 102 with the two bolts and the two nuts ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-504) and ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-501). Torque the nuts to 85 to 105 lbfin. (10 to 12 Nm).

Install the bracket at M.

SUBTASK 71-00-02-420-002 Install the Brackets at the Flange FE (Pre SBE 73-0040 and SBE 73-0040)

Install the bracket BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-960) at the holes 3 and 4 with the two bolts and the two nuts BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-964) and BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-961). Refer to the detail on A.

Install the bracket BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-920) at the holes 15 and 16 with the two bolts and the two nuts BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-924) and BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-921). Refer to the detail on C.

Lightly lubricate the holes 17 and 18 with CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE).

Lightly lubricate the bolt shanks BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-944) with CoMat 10-073 SYNTHETIC GREASE, MoDISULFIDE.

Install the two support brackets and the bracket BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-990), BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-980) and BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-940) at the holes 17 and 18 with the two bolts, the two washers and the two nuts BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-944), BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-945) and BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-941). Torque the nuts to 85 to 105 lbf.in. (10 to 12 Nm). Refer to the detail on D.

Install the brackets at A, C and D.

Attach the bracket ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-890) to the raft ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-910) with the two bolts and the two washers ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-912) and ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-914). Torque the bolts to 36 to 45 lbf.in. (4 to 5 Nm).

Lightly lubricate the holes 12 to 14 with CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE).

Lightly lubricate the bolt shanks ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-754) and ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-774) with CoMat 10-073 SYNTHETIC GREASE, MoDISULFIDE, Mo disulphide.

Install the raft assembly and the three brackets ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-750), ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-760) and ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-770) at the holes 12 to 14 with the three bolts, the two washers, the spacer and the three nuts ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-774), ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-754), ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-755), ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-752), ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-772), ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-771) and ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-751). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Attach the raft assembly at the holes 5 and 6 on the flange FB with the two bolts and the two nuts ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-915) and ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-911). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the brackets at B.

Install the two brackets ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-920) and ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-930) at the holes 19 and 20 with the two bolts and the two nuts ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-934) and ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-931).

Install the brackets at E.

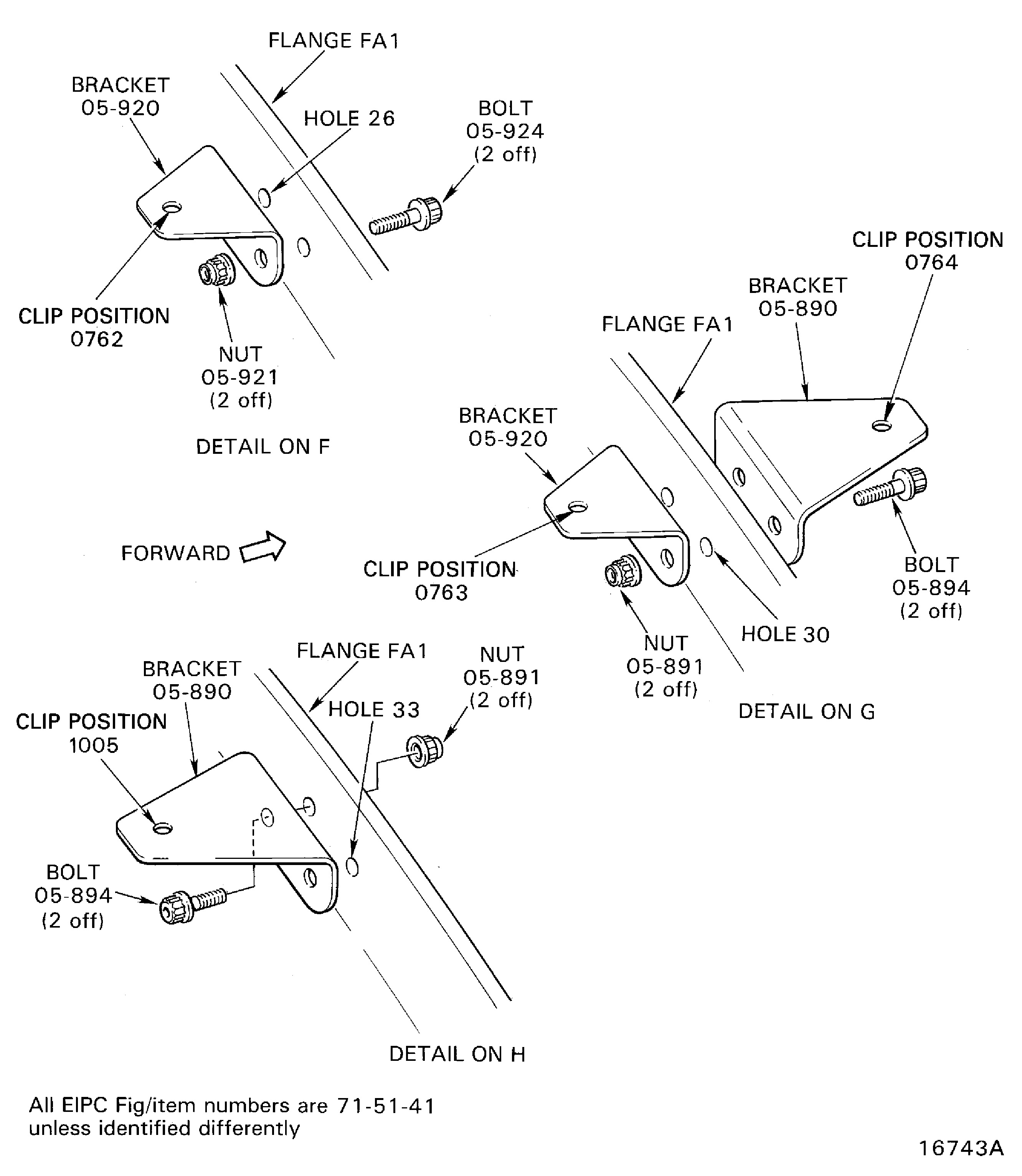

Install the bracket POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-920) at the holes 26 and 27 with the two bolts and the two nuts POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-924) and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-921). Refer to the detail on F.

Install the two brackets POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-890 and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN 05-920) at the holes 29 and 30 with the two bolts and the two nuts POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-894) and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-891). Refer to the detail on G.

Install the bracket POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-890) at the holes 32 and 33 with the two bolts and the two nuts POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-894) and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-891). Refer to the detail on H.

Install the brackets at F, G and H.

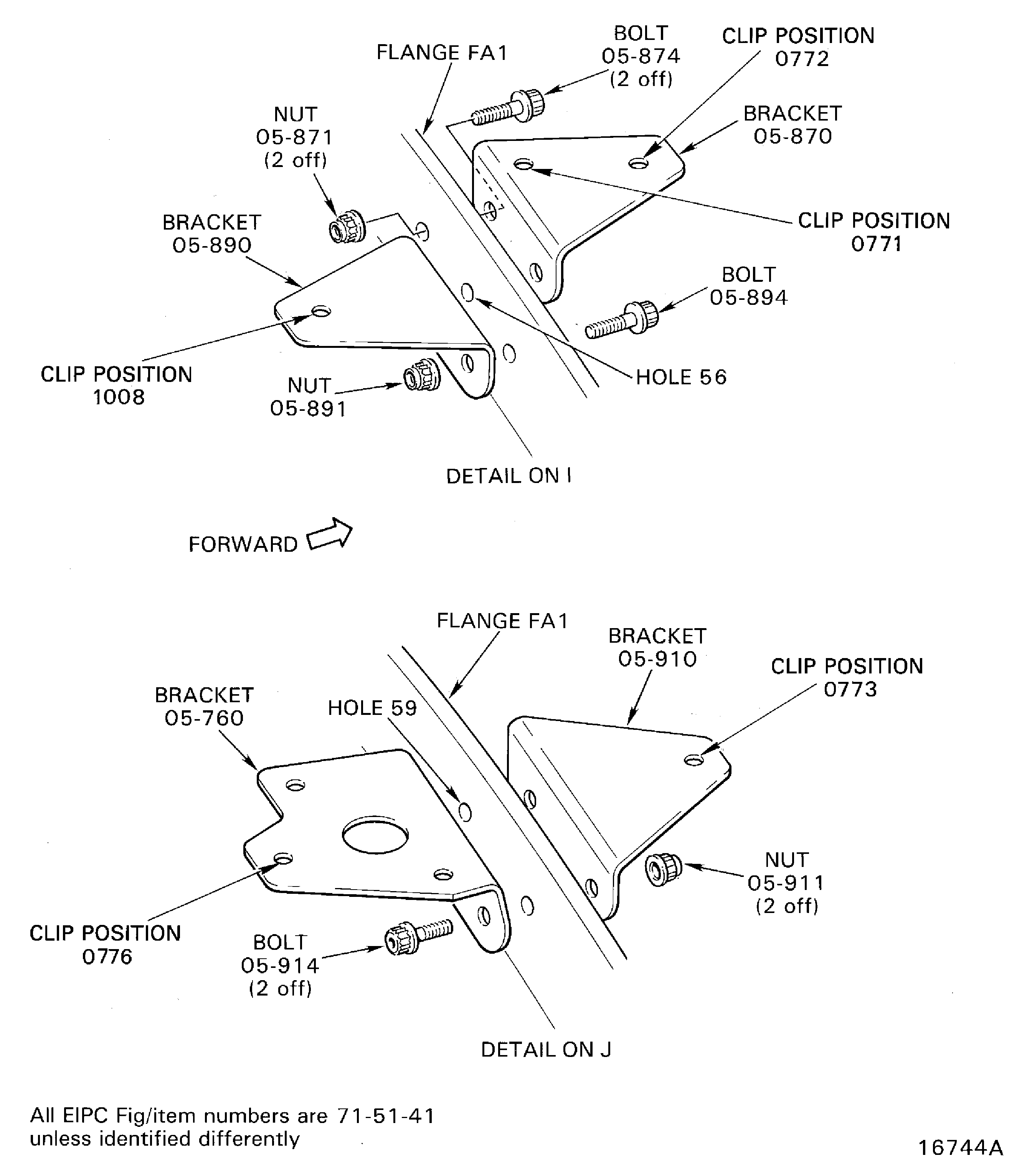

Install the bracket POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-870) and the bracket POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-890) at the holes 55 to 57 with the three bolts and the three nuts POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN(71-51-41, 05-874), POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-871) and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-894), POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-891). Refer to the detail on I.

Install the two brackets POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-760 and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN 05-910) at the holes 59 and 61 with the two bolts and the two nuts POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-914) and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-911). Refer to the detail on J.

Install the brackets at I and J.

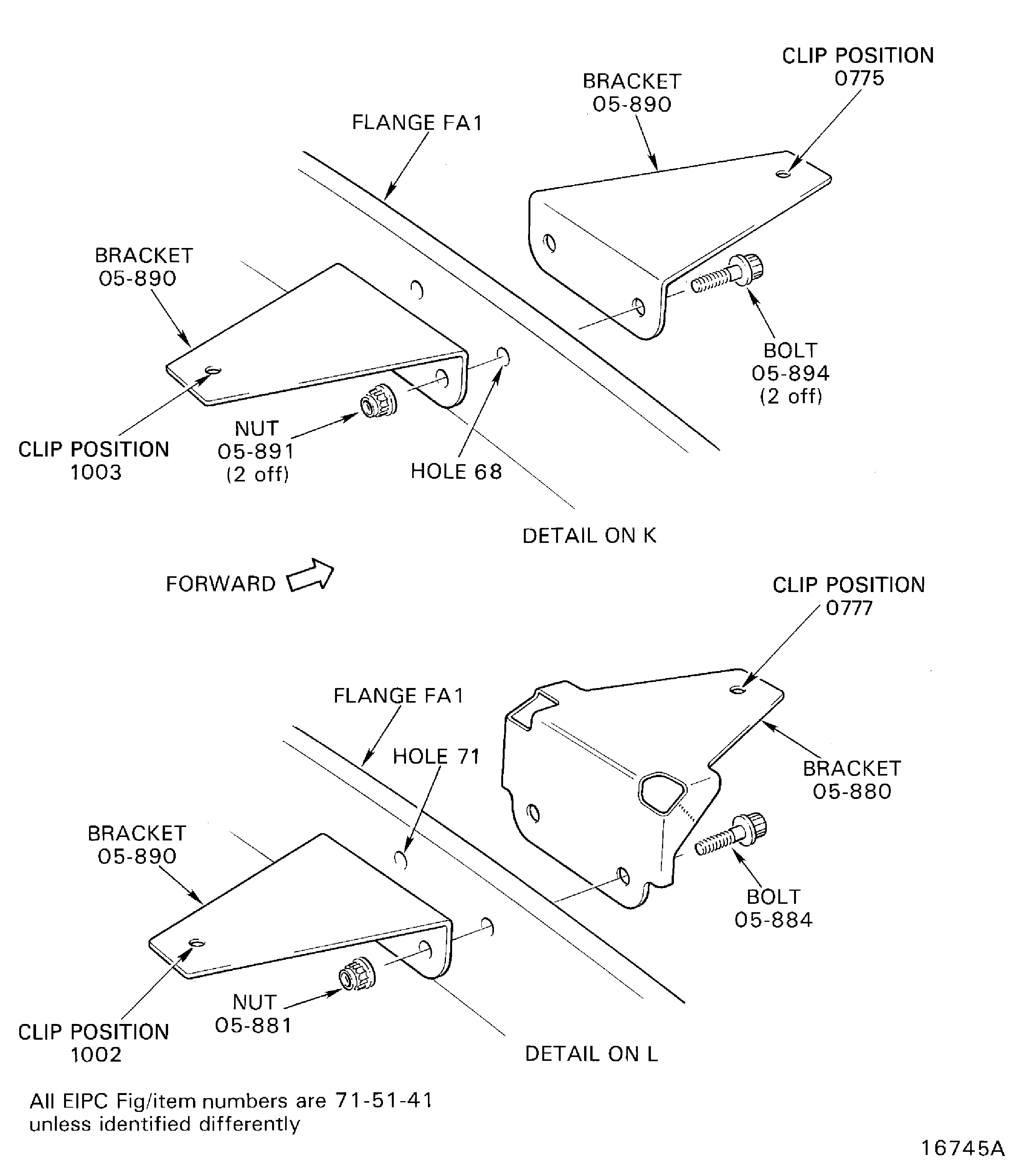

Install the two brackets POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-890) at the holes 67 and 68 with the two bolts and the two nuts POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-894) and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-891). Refer to the detail on K.

Install the two brackets POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-880) and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-890) at the holes 71 and 72 with the two bolts and the two nuts POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-884) and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-881). Refer to the detail on L.

Install the brackets at K and L.

Install the two brackets POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-840) and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-920) at the holes 74 to 76 with the three bolts and the three nuts POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-844), POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-841) and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-924), POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-921). Refer to the detail on M.

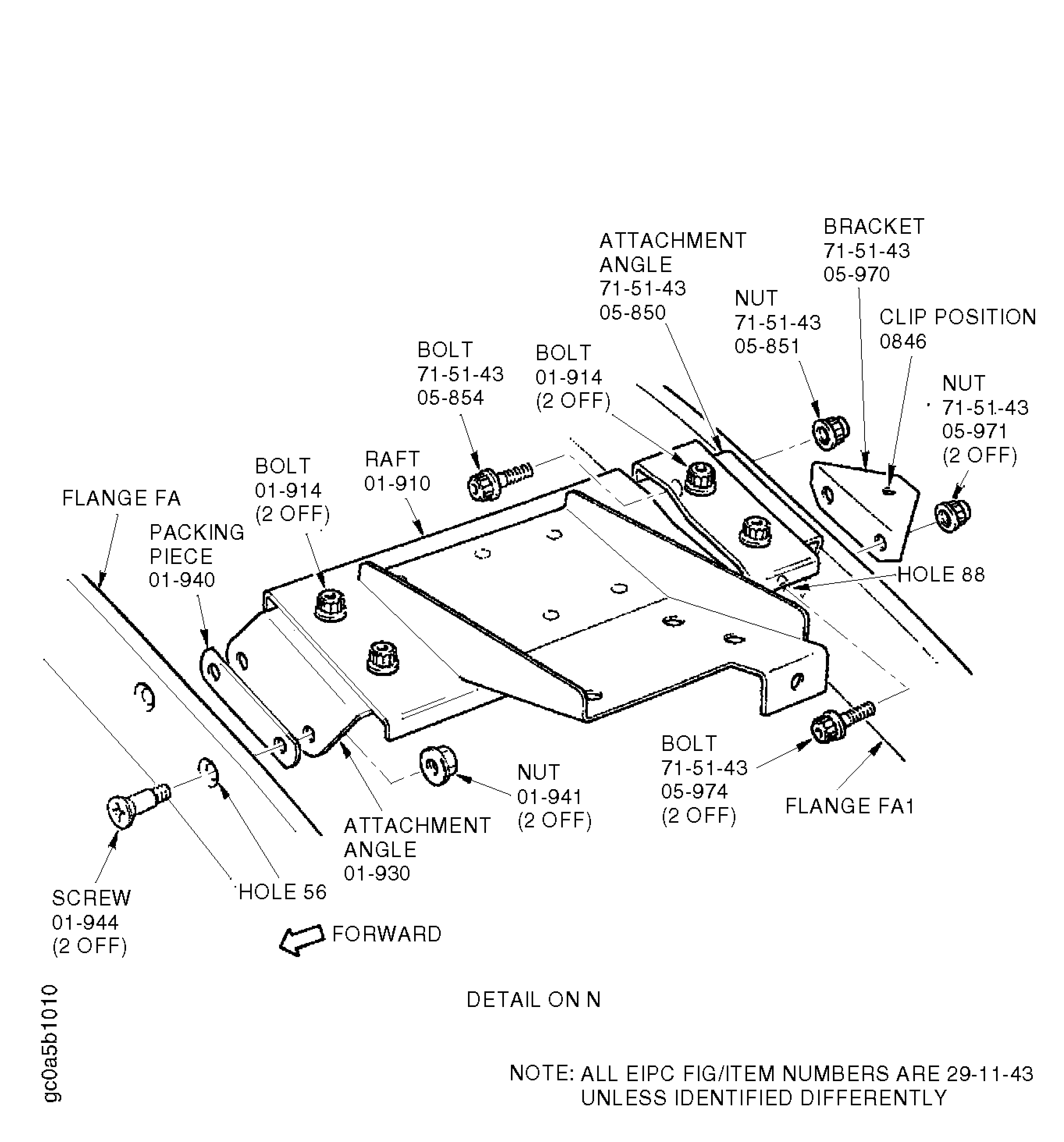

Install the bracket POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-850) at the holes 79 and 80 with the two bolts and the two nuts POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-854) and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-851). Refer to the detail on N.

Install the brackets at M and N.

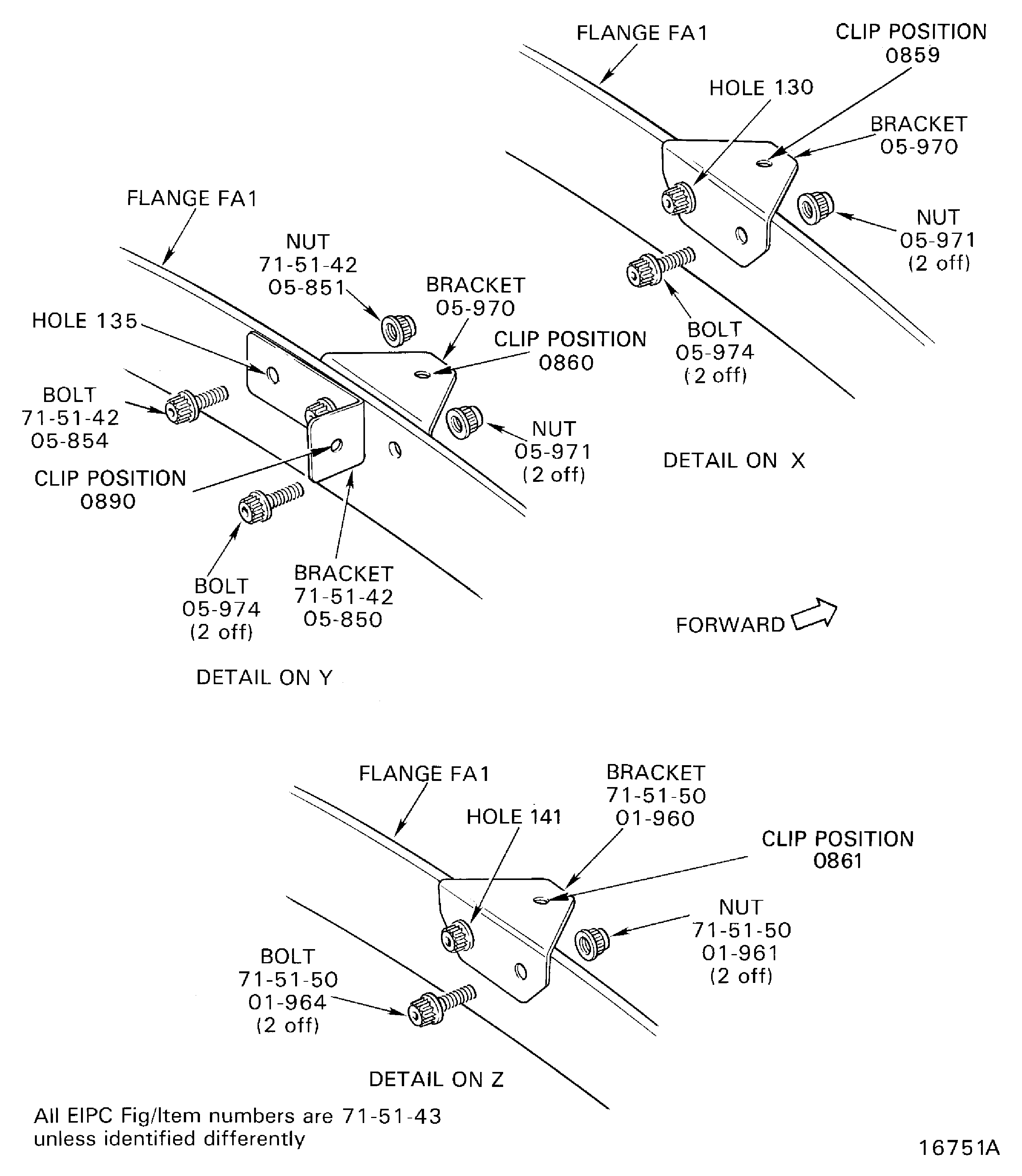

Install the bracket ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-970) at the holes 85 and 86, with the two bolts and the two nuts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-974) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-971). Refer to the detail on Q.

Install the bracket ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-830) at the holes 83 and 84 with the two bolts and the two nuts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-834) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-831). Refer to the detail on P.

Install the brackets at Q and P.

Install the bracket (GP2) and the bracket ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-960) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-970) at the holes 92 and 93 with the two bolts and the two nuts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-964) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-961). Refer to the detail on R.

Measure the electrical resistance between the bracket (GP2) and the flange FA1, it must not be more than 0.005 ohms. If the electrical resistance is more than 0.005 ohms, clean the area again as necessary, refer to TASK 72-00-32-420-001-A00, SUBTASK 72-00-32-160-052.

Install the brackets at R.

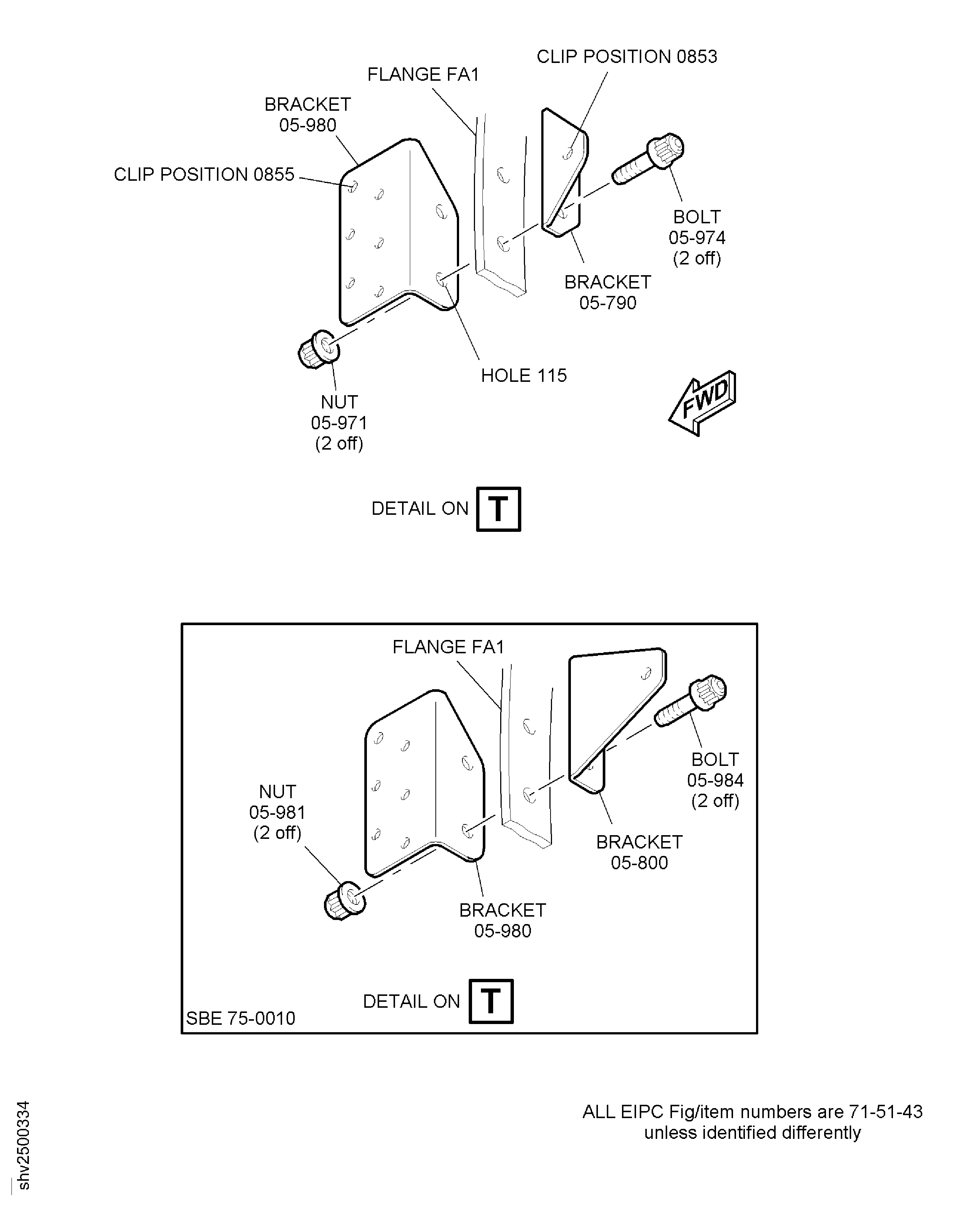

Pre SBE 75-0010: Install the bracket (GP1) and the bracket ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-970) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS(71-51-43, 05-980) at the holes 115 and 116 with the two bolts and the two nuts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS(71-51-43, 05-974) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS(71-51-43, 05-971). Refer to the detail on T.

SBE 75-0010: Install the bracket (GP1) and the bracket ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-800) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-980) at the holes 115 and 116 with the two bolts and the two nuts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-984) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-981). Refer to the detail on T.

Measure the electrical resistance between the bracket (GP1) and the flange FA1, it must not be more than 0.005 ohms. If the electrical resistance is more than 0.005 ohms, clean the area again as necessary, refer to TASK 72-00-32-420-001-A00, SUBTASK 72-00-32-160-052.

Install the brackets at T.

Install the attachment angle, the bracket ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-840) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-970) at the holes 121 and 122 with the two bolts and the two nuts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-974) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-971).

Install the bracket at U1.

Install the two brackets ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-970) at the holes 124, 125 and 130, 131 with the four bolts and the four nuts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-974) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-971). Refer to the details on V and X.

Install the bracket ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-970) and the bracket ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-850) at the holes 135 to 137 with the three bolts and the three nuts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-974), ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-971) and ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-854), ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-851). Refer to the detail on Y.

Install the bracket BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-960) at the holes 141 and 142 with the two bolts and the two nuts BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-964) and BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-961). Refer to the detail on Z.

Install the brackets at V, X, Y and Z.

SUBTASK 71-00-02-420-003 Install the Brackets at the Flange FA1 (Pre SBE 75-0010 and SBE 75-0010)

Lightly lubricate the bracket ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-200) bolt holes with CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE).

Lightly lubricate the bolt ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-205) shanks with CoMat 10-073 SYNTHETIC GREASE, MoDISULFIDE.

Attach the bracket ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-200) to the raft BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-900) with the two bolts ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-205).

Attach the bracket BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-880) to the raft with the two bolts BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-904). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

NOTE

There are two type of nuts for BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-881) and BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-891) bihexagon and hexagon. The hexagon nut has a dry film lubricant, it is not necessary to lubricate their bolts.Install the raft assembly and the packing piece BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-883) at the holes 3 and 4 with the two screws, the two washers and the two nuts BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-884), BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-882) and BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-881).

Attach the raft assembly and the bracket BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-890) at the holes 8 and 9 on the flange FA1 with the two bolts and the two nuts BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-894) and BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-891).

Install the brackets at A.

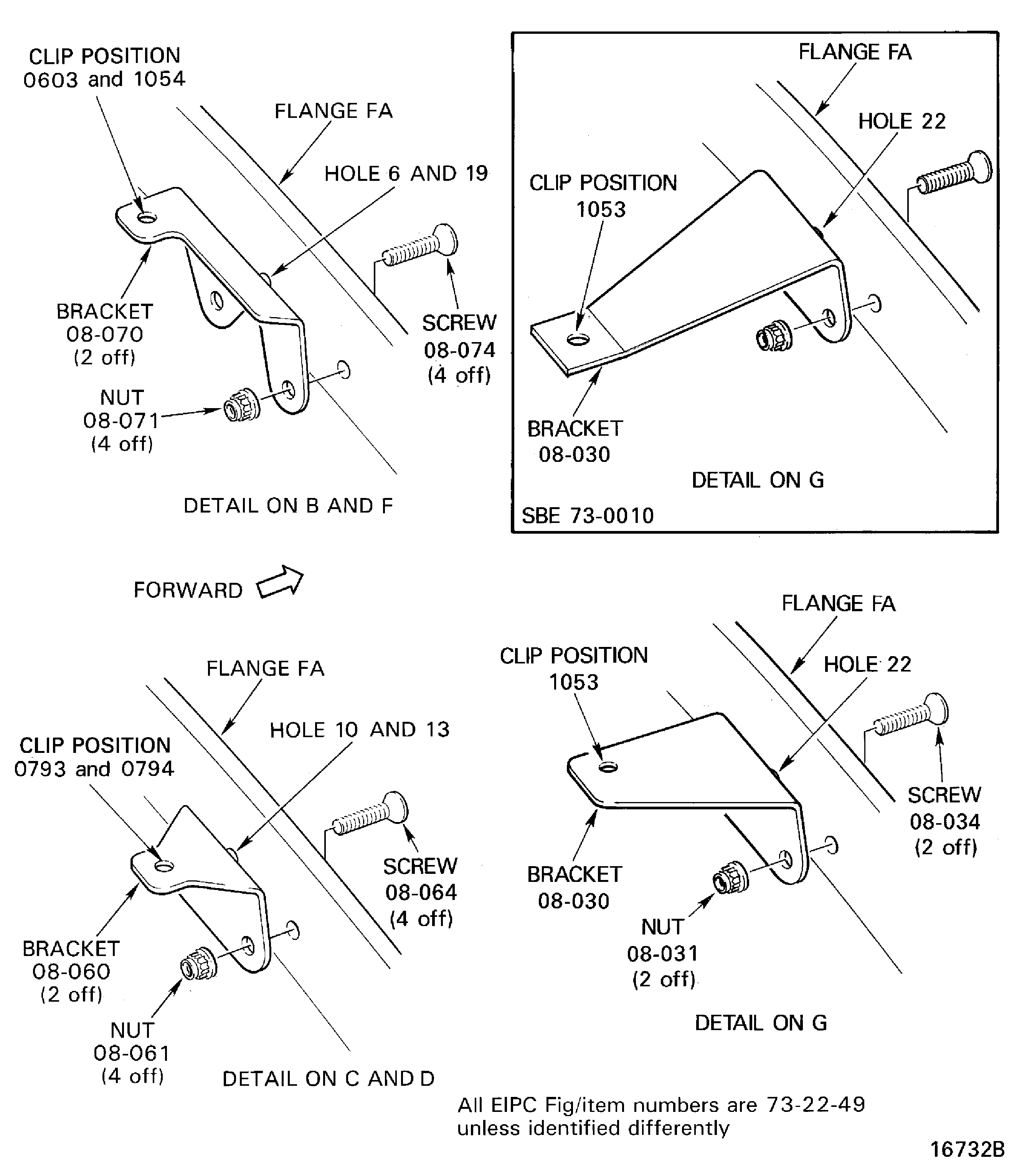

Install the two brackets ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 08-070) at the holes 6, 8 and 19, 20 with the four screws and the four nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 08-074) and ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 08-071). Hold the four screws with the ACR Torq-Set bit 212-1/4-ACR and torque the four nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the brackets at B and F.

Install the two brackets ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 08-060) at the holes 10, 11 and 13, 14 with the four screws and the four nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 08-064) and ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 08-061). Hold the four screws with the ACR Torq-Set bit 212-1/4-ACR and torque the four nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the brackets at C and D.

Install the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 08-030) at the holes 22 and 23 with the two screws and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 08-034) and ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 08-031). Hold the two screws with the ACR Torq-Set bit 212-1/4-ACR and torque the two nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the bracket at G.

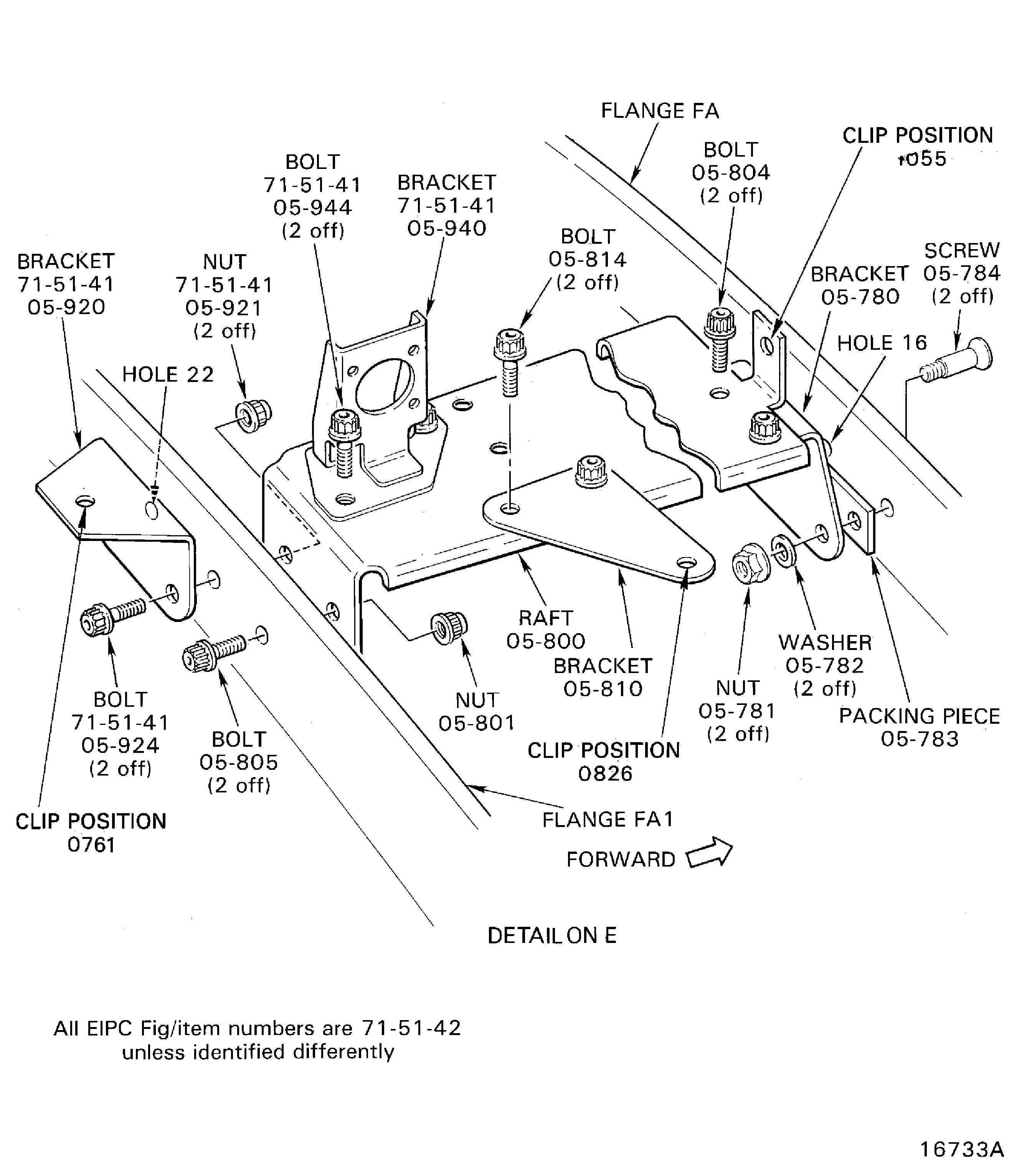

Install the bracket POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-940) to the raft ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-800) with the two bolts POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-944) and torque the two bolts to 36 to 45 lbfin. (4 to 5 Nm).

Pre SBE 71-0070: Attach the bracket ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-810) to the raft with the two bolts ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-814) and torque the two bolts to 36 to 45 lbf.in (4 to 5 Nm).

NOTE

There are two type of nuts for ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-781) bihexagon and hexagon. The hexagon nut has a dry film lubricant, it is not necessary to lubricate their bolts.Install the bracket ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-780) and the packing piece ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-783) at the holes 22 and 23 with the two screws, the two washers and the two nuts ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-784), ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-782) and ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-781). Torque the nuts 85 to 105 lbf.in. (10 to 12 Nm).

Attach the raft assembly to the bracket ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-780) with the two bolts ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-804).

Attach the raft assembly and the bracket POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-920) at the holes 22 to 24 on the flange FA1 with the three bolts and the three nuts ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-805), ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-801) and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-924), POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-921).

Install the brackets at E.

NOTE

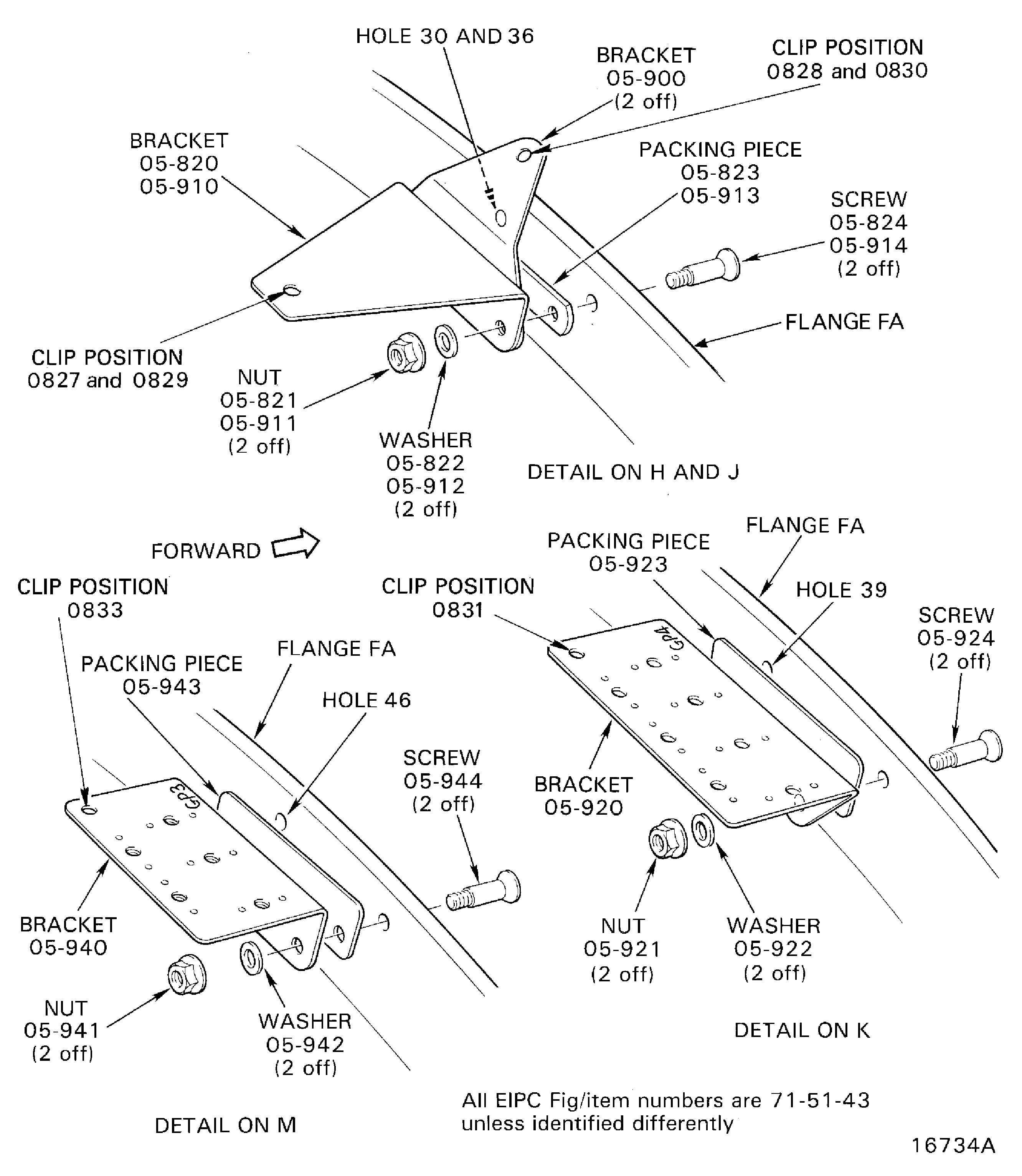

There are two type of nuts for ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-821 and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS 05-911) bihexagon and hexagon. The hexagon nut has a dry film lubricant, it is not necessary to lubricate their bolts.Install the bracket ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-900) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-820) and the packing piece ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-823) at the holes 30 and 31 with the two screws, the two washers and the two nuts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-824), ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-822) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-821). Refer to the detail on H.

Install the bracket ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-910) and the packing piece ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-913) at the holes 36 and 37 with the two screws, the two washers and the two nuts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-914), ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-912) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-911). Refer to the detail on J.

Install the brackets at H and J.

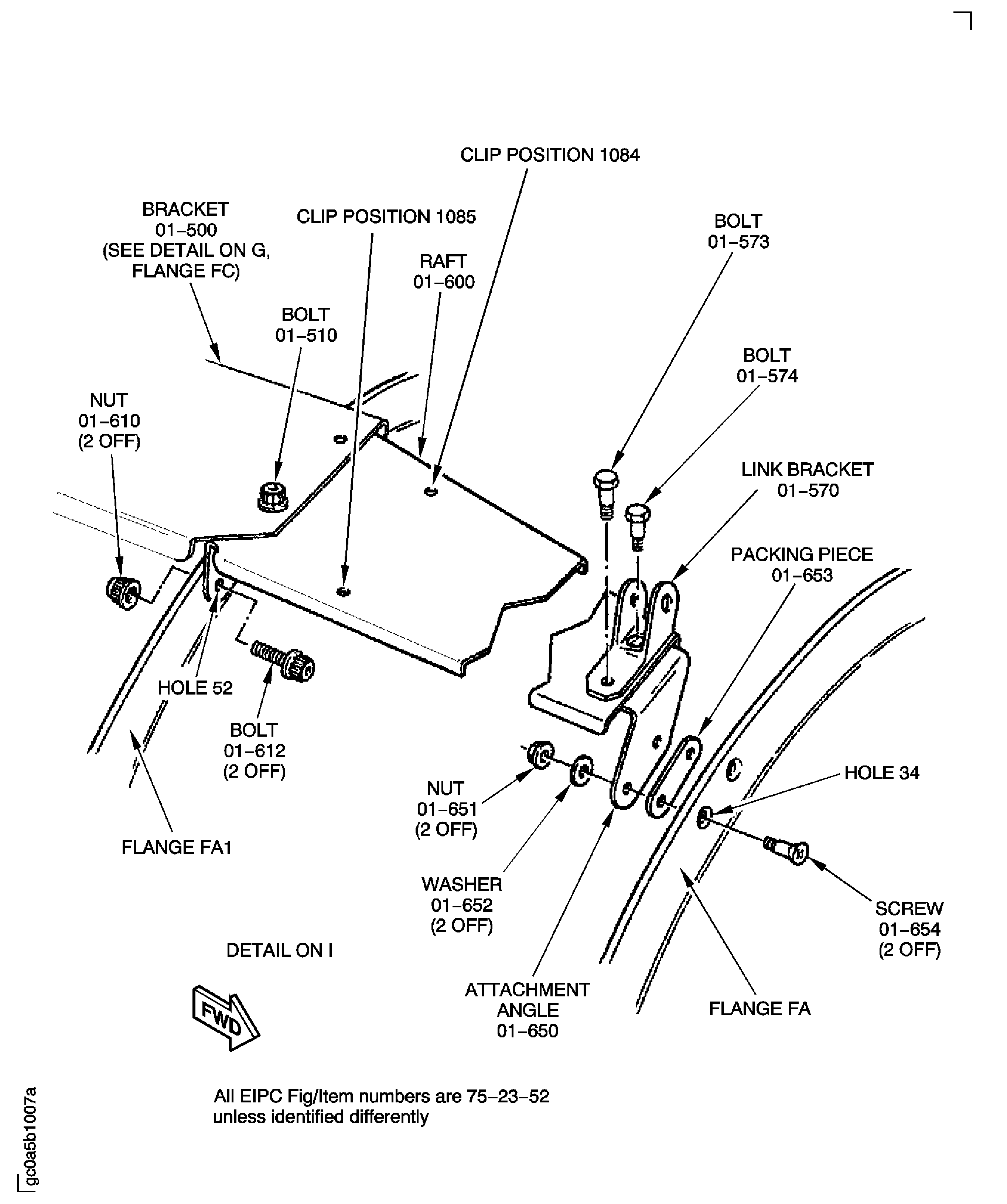

Install the attachment angle and the packing pieces AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-653) to the holes 33 and 34 with the two screws and the two nuts AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-654) and AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-651). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm). Refer to the detail on I.

Attach the link bracket and the raft AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-570) and AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-600) to the attachment angle with the two bolts AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-573) and AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-574).

Attach the raft AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-600) to the holes 51 and 52 on the flange FA1 with the two bolts and the two nuts AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-612) and AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-610).

Install the bracket AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-500). Refer to TASK 72-00-32-420-001-A00, SUBTASK 72-00-32-420-179-A00 or SUBTASK 72-00-32-420-179-B00, at the detail G.

Install the brackets at I.

NOTE

There are two type of nuts for ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-921) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-941) bihexagon and hexagon. The hexagon nut has a dry film lubricant, it is not necessary to lubricate their bolts.Install the bracket (GP4) ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-920) and the packing piece ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-923) at the holes 39 and 41 with the two screws, the two washers and the two nuts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-924), ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-922) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-921). Refer to the detail on K.

Install the bracket (GP3) ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-940) and the packing piece ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-943) at the holes 46 and 47 with the two screws, the two washers and the two nuts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-944), ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-942) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-941). Refer to the detail on M.

Measure the electrical resistance between the brackets (GP3 and GP4) and the flange FA, it must not be more than 0.005 ohms. If the electrical resistance is more than 0.005 ohms, clean the area again as necessary, refer to TASK 72-00-32-420-001-A00, SUBTASK 72-00-32-160-052.

Install the brackets at K and M.

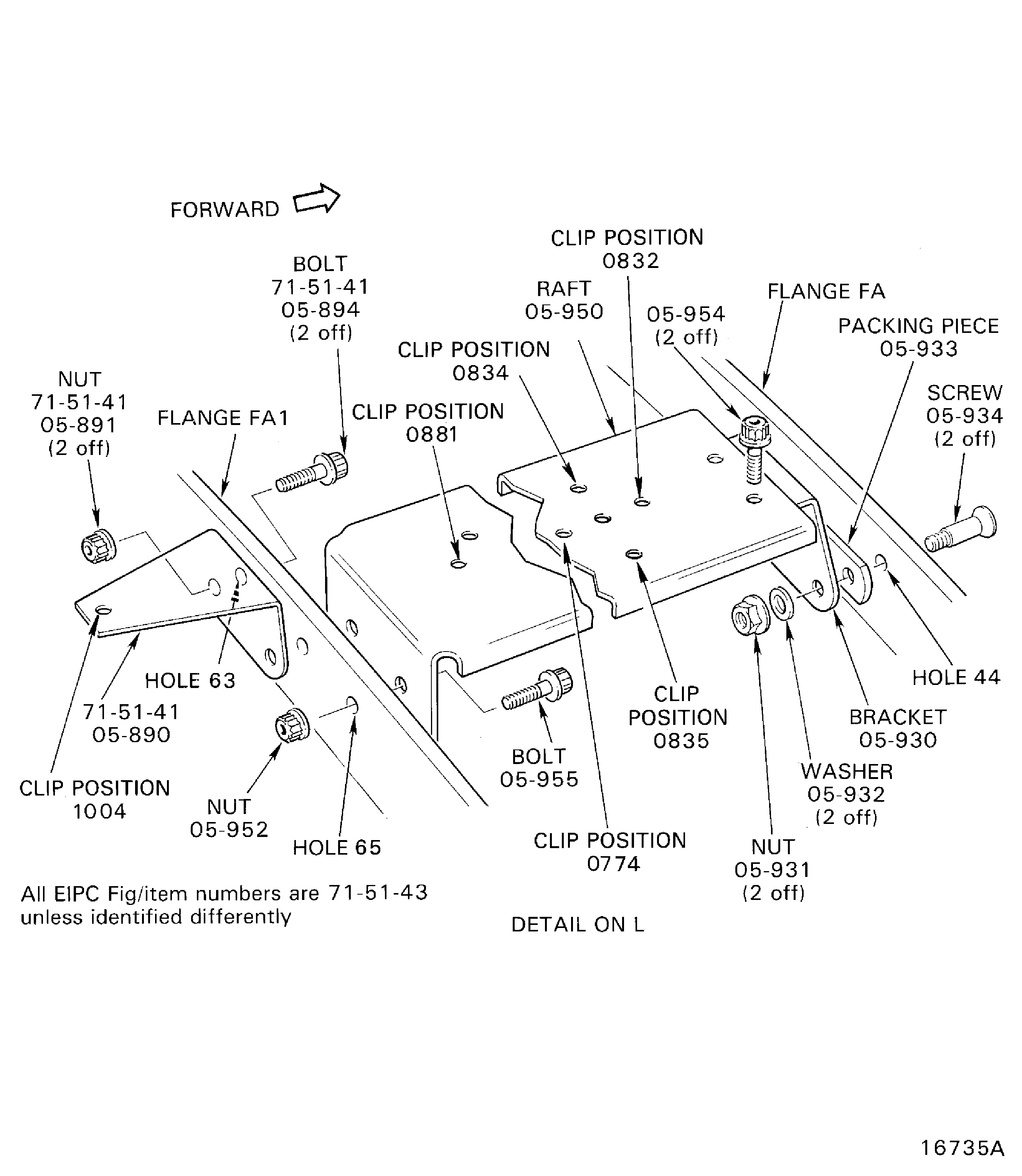

NOTE

There are two type of nuts for ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-931) bihexagon and hexagon. The hexagon nut has a dry film lubricant, it is not necessary to lubricate their bolts.Install the bracket ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-930) and the packing piece ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-933) at the holes 43 and 44 with the two screws, the two washers and the two nuts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-934), ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-932) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-931).

Attach the raft ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-950) to the bracket ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-930) with the two bolts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-954). Torque the bolts to 36 to 45 lbf.in (4 to 5 Nm).

Install the raft and the bracket POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-890) at the holes 63 to 65 on the flange FA1 with the three bolts and the three nuts POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-894), POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-891), ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-955) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-952).

Install the brackets at L.

NOTE

There are two type of nuts for CASE DRAIN HYDRAULIC FILTER ASSEMBLY (29-11-43, 01-941) bihexagon and hexagon. The hexagon nut has a dry film lubricant, it is not necessary to lubricate their bolts.Install the attachment angle CASE DRAIN HYDRAULIC FILTER ASSEMBLY (29-11-43, 01-930) and the packing piece CASE DRAIN HYDRAULIC FILTER ASSEMBLY (29-11-43, 01-940) at the holes 56 and 57 with the two screws and the two nuts CASE DRAIN HYDRAULIC FILTER ASSEMBLY (29-11-43, 01-944 and CASE DRAIN HYDRAULIC FILTER ASSEMBLY 01-941).

Install the attachment angle ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-850) and the bracket ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-970) at the holes 88 to 90 on the flange FA1 with the three bolts and the three nuts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-854), ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-851), ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-974) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-971).

Attach the raft CASE DRAIN HYDRAULIC FILTER ASSEMBLY (29-11-43, 01-910) to the two attachment angles with the four bolts CASE DRAIN HYDRAULIC FILTER ASSEMBLY (29-11-43, 01-914). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

Pre SBE 71-0110: Install the brackets at N.

Install the attachment angle POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-730) and the packing piece POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-733) at the holes 56 and 57 with the two screws, two washers and the two nuts POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-734), POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-732) and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-731).

Install the attachment angle POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-720) at the holes 88 and 89 on the flange FA1 with the two bolts and the two nuts POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-724) and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-721).

Attach the raft POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-710) to the two attachment angles with the four bolts POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-714) and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-715). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

SBE 71-0110: Install the brackets at N.

NOTE

There are two type of nuts for OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 14-901) and OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 14-881) bihexagon and hexagon. The hexagon nut has a dry film lubricant, it is not necessary to lubricate their bolts.Install the attachment angle OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 14-880) and the packing piece OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 14-883) at the holes 60 and 61 with the two screws, the two washers and the two nuts OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 14-884), OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 14-882) and OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 14-881). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Attach the raft OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 14-900) to the attachment angle with the two bolts OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 14-904). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

Attach the raft and install the bracket ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-970) at the holes 97 to 99 on the flange FA1 with the three bolts and the three nuts OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 14-903), OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 14-901) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-974), ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-971). Torque the nut OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 14-901) and the nuts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-971) to 85 to 105 lbf.in (10 to 12 Nm).

Install the brackets at O.

NOTE

There are two type of nuts for HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-956) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-861) bihexagon and hexagon. The hexagon nut has a dry film lubricant, it is not necessary to lubricate their bolts.Install the attachment angle HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-950) and the packing piece HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-952) at the holes 65 and 66 with the two screws, the two washers, and the two nuts HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-954), HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-955) and HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-956).

Install the attachment angle and the bracket ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-860) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-970) at the holes 109 and 110 on the flange FA1 with the two bolts and the two nuts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-864) and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-861).

Attach the raft HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-930) to the two attachment angles with the four bolts HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-935). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

Install the brackets at P.

SUBTASK 71-00-02-420-004 Install the Brackets at the Flange FA (Pre SBE 71-0110 and SBE 71-0110)

Figure: The LP Compressor/Intermediate Case Module Flanges

The LP Compressor/Intermediate Case Module Flanges

Figure: Install the Brackets at the Flange FE

Sheet 1

Figure: Install the Brackets at the Flange FE

Sheet 2

Figure: Install the Brackets at the Flange FE

Sheet 3

Figure: Install the Brackets at the Flange FE

Sheet 4

Figure: Install the Brackets at the Flange FE

Sheet 5

Figure: Install the Brackets at the Flange FE

Sheet 6

Figure: Pre SBE 73-0040: Install the Brackets at the Flange FE

Sheet 7

Figure: SBE 73-0040: Install the Brackets at the Flange FE

Sheet 8

Figure: Install the Brackets at the Flange FA1

Sheet 1

Figure: Install the Brackets at the Flange FA1

Sheet 2

Figure: Install the Brackets at the Flange FA1

Sheet 3

Figure: Install the Brackets at the Flange FA1

Sheet 4

Figure: Install the Brackets at the Flange FA1

Sheet 5

Figure: Install the Brackets at the Flange FA1

Sheet 6

Figure: Install the Brackets at the Flange FA1

Sheet 7

Figure: Install the Brackets at the Flange FA1

Sheet 8

Figure: Install the Brackets at the Flange FA1

Sheet 9

Figure: Install the Brackets at the Flange FA1

Sheet 10

Figure: Install the Brackets at the Flange FA1

Sheet 11

Figure: Install the Brackets at the Flange FA1

Sheet 12

Figure: Install the Brackets at the Flange FA1

Sheet 13

Figure: Install the Brackets at the Flange FA

Sheet 1

Figure: Install the Brackets at the Flange FA

Sheet 2

Figure: Install the Brackets at the Flange FA

Sheet 3

Figure: Pre SBE 71-0070: Install the Brackets at the Flange FA

Sheet 4

Figure: SBE 71-0070: Install the Brackets at the Flange FA

Sheet 5

Figure: Install the Brackets at the Flange FA

Sheet 6

Figure: Install the Brackets at the Flange FA

Sheet 7

Figure: Install the Brackets at the Flange FA

Sheet 8

Figure: Install the Brackets at the Flange FA

Sheet 9

Figure: Install the Brackets at the Flange FA

Sheet 10

Figure: Install the Brackets at the Flange FA

Sheet 11

Figure: Install the Brackets at the Flange FA

Sheet 12