Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-00-40-420-007-A00 HP System Module - Install The Components, Electrical Harnesses, Tubes, And Brackets To The HPT, Installation-010

General

This TASK gives the procedure to install the components, electrical harnesses, tubes and brackets to the HP turbine module. Refer to the TASKS which follow for other related procedures.

TASK 72-00-40-420-004 (INSTALLATION-007) - Install the initial components, the air off-take ducts and tubes to the HP system module.

TASK 72-00-40-420-005 (INSTALLATION-008) - Install the components, the ducts, the electrical harnesses and the tubes to the HP compressor case vertical splitline.

TASK 72-00-40-420-006 (INSTALLATION-009 CONFIG-001) - Install and connect the components, the electrical harnesses and the tubes to the front of the HP compressor case.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all the parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures refer to the SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501, SPM TASK 70-41-02-400-501 and SPM TASK 70-41-02-410-510.

Special torque data is identified with the symbol * after the torque value. Assembly tolerances are included in this procedure.

If the cotter pin holes do not align within the torque range a different nut must be used. Do not loosen the nut or tighten the nut more than the maximum torque to align the holes.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings refer to the SPM TASK 70-44-01-400-501.

After assembly, apply CoMat 07-038 AIR DRYING ENAMEL to damaged surface protection, joint flanges and attach parts. Use the correct color of air drying enamel. Refer to the SPM TASK 70-38-21-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Transportation covers/blanks must be removed immediately before installation of the components.

Do not remove the special plastic caps from the electrical connections until immediately before installation. This will give protection from unwanted fluids and materials. For the data on the connection of the electrical connectors refer to the SPM TASK 70-43-00-400-501.

For lockwire data and procedures refer to the SPM TASK 70-42-05-400-501.

For safety cable data and procedures refer to the SPM TASK 70-42-08-400-501.

Safety the threaded fasteners in this TASK with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT for the ATA Chapter/Section/Subjects which follow:

A1 series engines: | ||

71-51-41 | 71-52-43 | 72-41-34 |

73-22-49 | 75-23-49 | 75-31-42 |

75-31-43 | 75-32-42 | 75-00-49 |

Refer to the V2500 Illustrated Tool and Equipment Manual (ITE-V2500-1IA) for the illustrations of the special tools used in this procedure.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) | LOCAL | CoMat 02-148 | ||

| CoMat 02-274 SAFETY CABLE KIT | LOCAL | CoMat 02-274 | ||

| CoMat 02-275 SAFETY CABLE KIT | LOCAL | CoMat 02-275 | ||

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Cotter pin | 1 | |||

| Cotter pin | 1 | |||

| Cotter pin | 1 | |||

| Cotter pin | 1 | |||

| Cotter pin | 1 | |||

| Cotter pin | 1 | |||

| Cotter pin | 1 | |||

| Cotter pin | 1 | |||

| Cotter pin | 1 | |||

| Cotter pin | 1 | |||

| Cotter pin | 1 | |||

| Retaining pin | 1 |

Safety Requirements

NONEProcedure

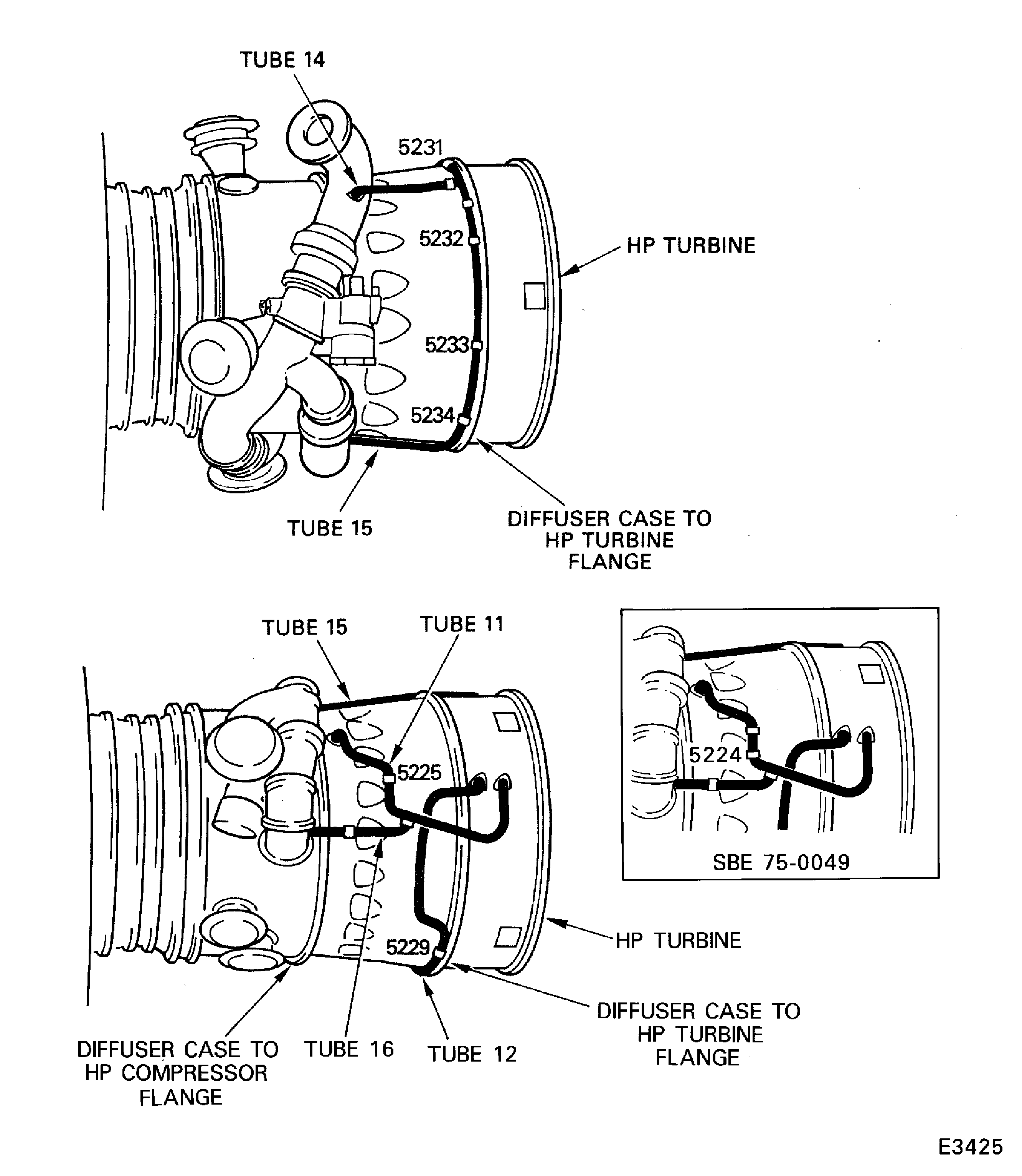

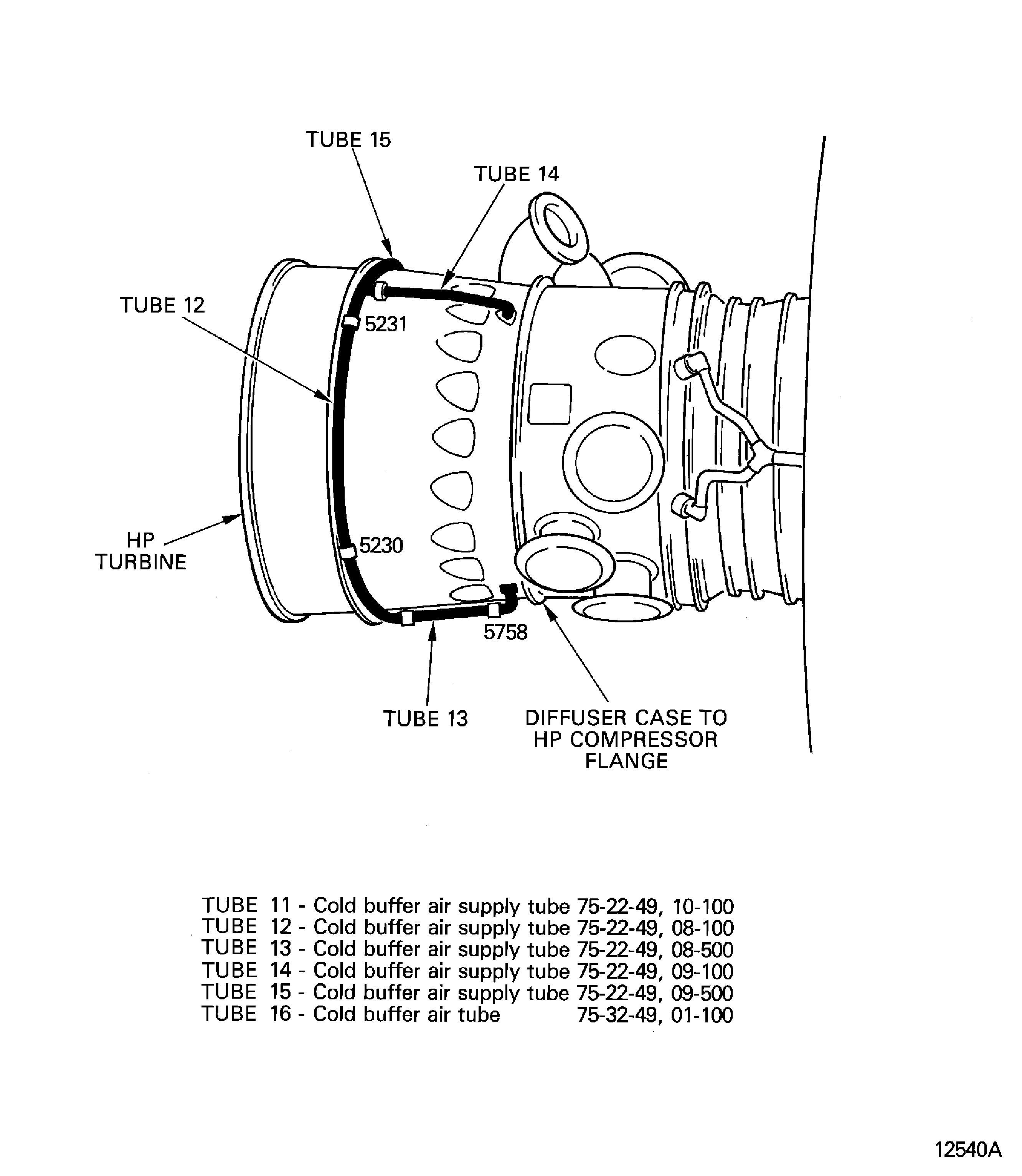

Install the tube 15 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 09-500).

Install the tube 13 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 08-500).

Install the tube 12 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 08-100).

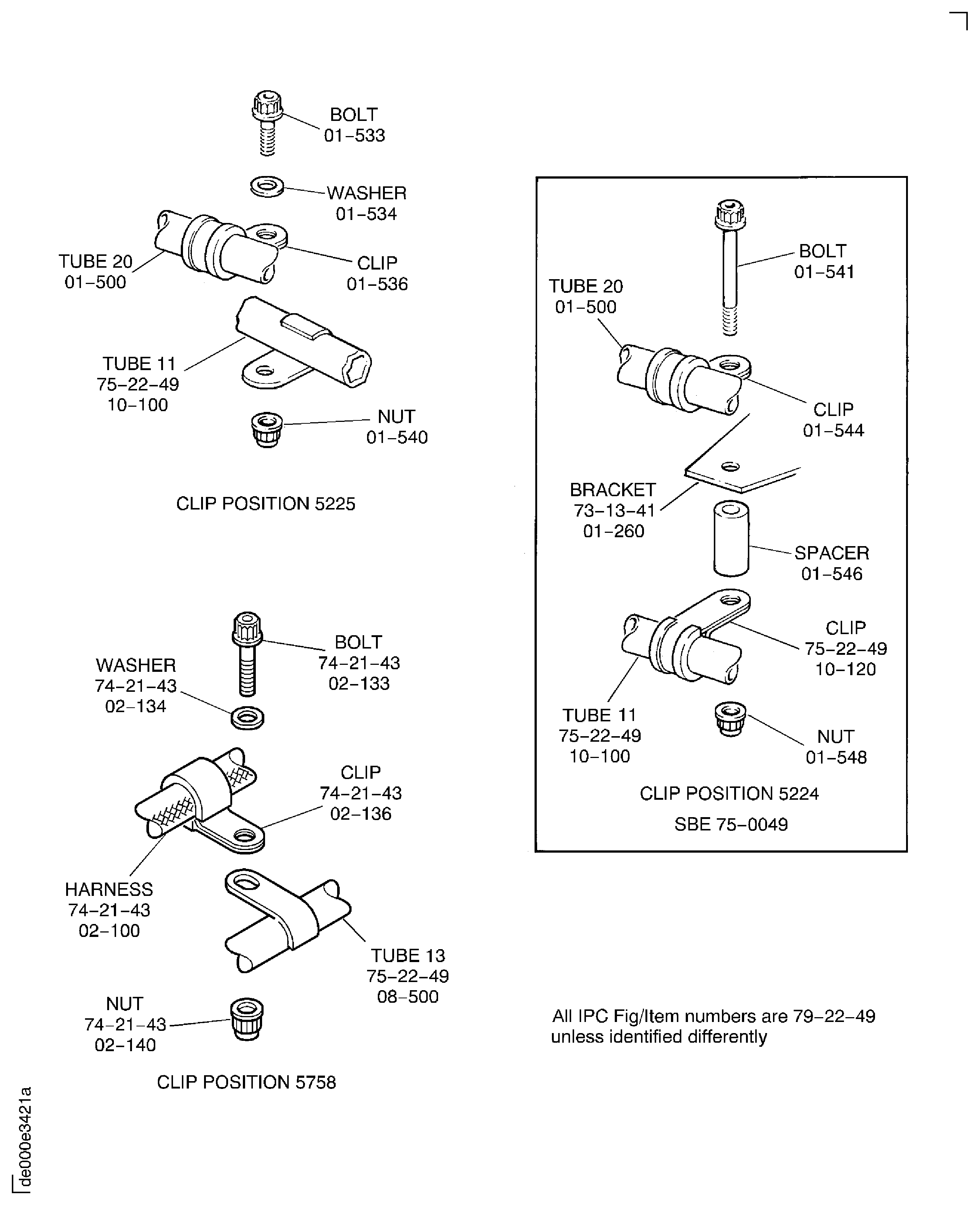

SBE 75-0049: Install the two clips, the bolt, the spacer and the nut at the clip position 5224.

SBE 75-0049: Torque the nut at the clip position 5224 to 36 to 44 lbf.in (4 to 5 Nm).

Install the tube 11 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 10-100).

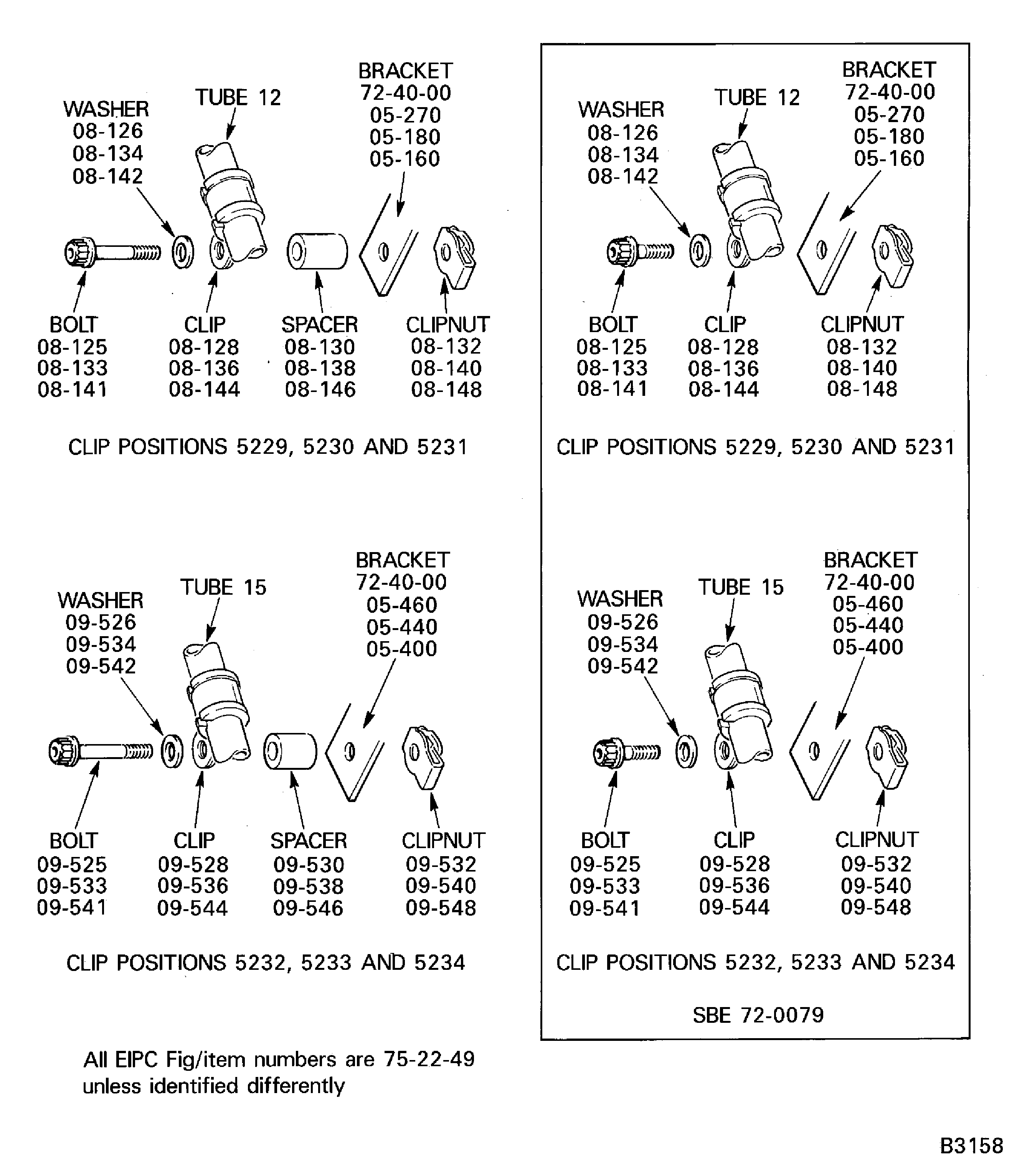

SUBTASK 72-00-40-420-109-A00 Install the Cold Buffer Air Tubes (Pre SBE 72-0079)

Install the tube 15 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 09-500).

Install the tube 13 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 08-500).

Install the tube 12 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 08-100).

SBE 75-0049: Install the two clips, the bolt, the spacer and the nut at the clip position 5224.

SBE 75-0049: Torque the nut at the clip position 5224 to 36 to 44 lbf.in (4 to 5 Nm).

Install the tube 11 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 10-100).

SUBTASK 72-00-40-420-109-B00 Install the Cold Buffer Air Tubes (SBE 72-0079)

SBE 72-0079: Introduce a strengthened number 4 bearing buffer air tube bracket assembly.

Refer to Figure.

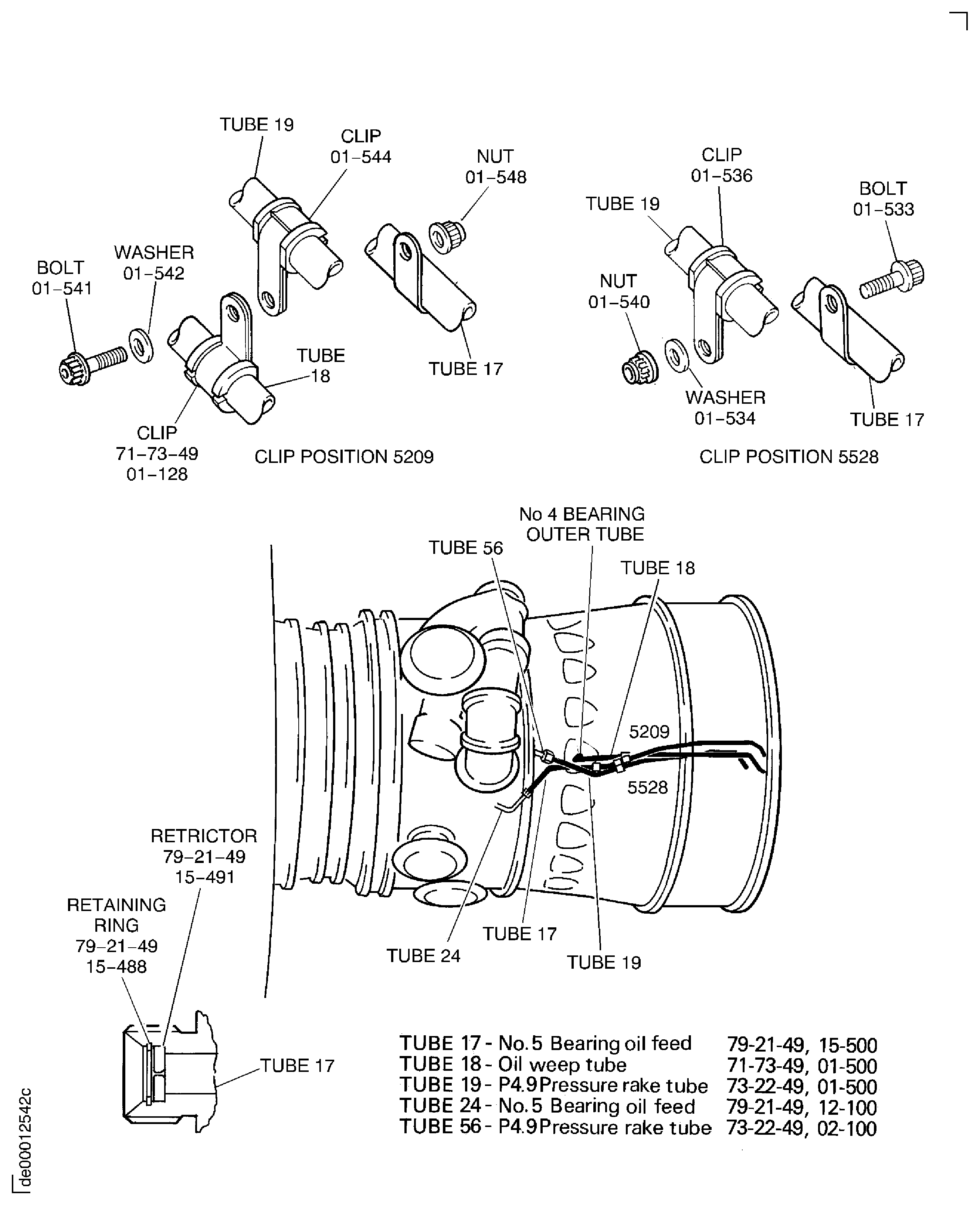

Install the restrictor OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 15-491).

Install the new OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 15-488) retaining ring 1 off.

Connect the tube 17 to the tube 24.

Install the tube 17 OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 15-500).

Connect the tube 18 "OIL,HYDRAULIC AND WATER DRAIN TUBES-ENGINE (71-73-49, 01-100) to the No. 4 bearing outer tube ENGINE-NO.4 BEARING COMPARTMENT TUBES (72-42-20, 03-040).

Install the tube 19 ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 01-500).

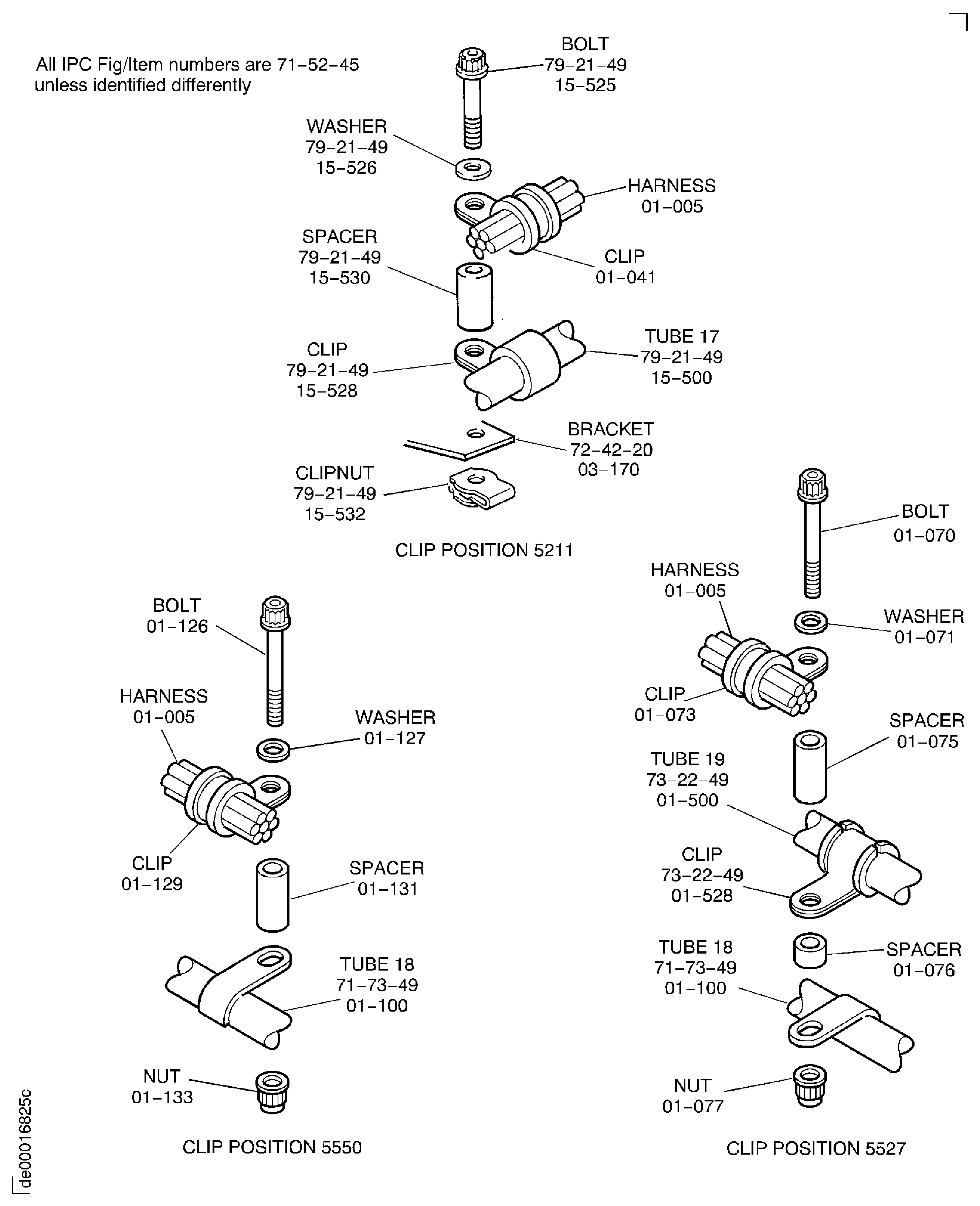

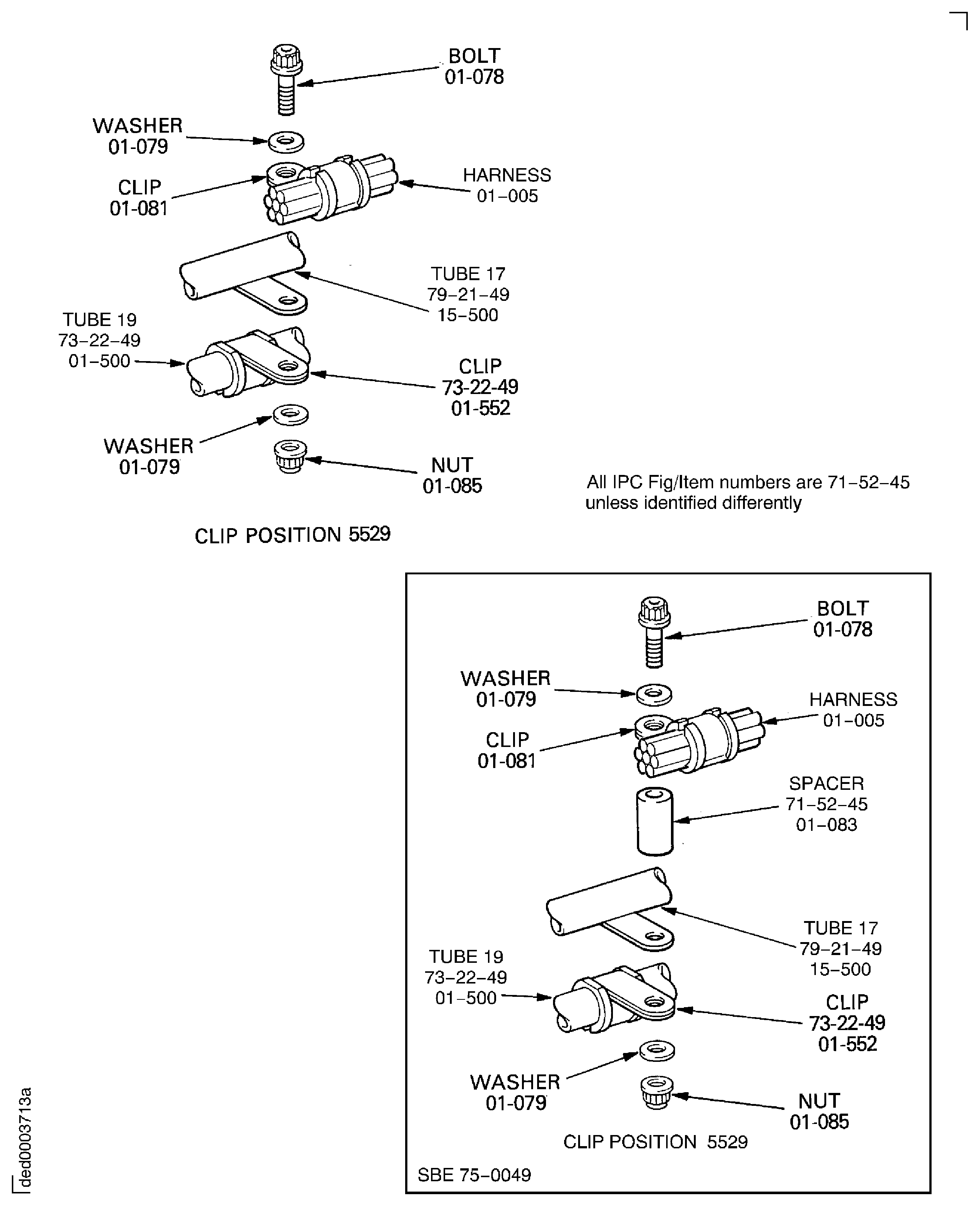

SUBTASK 72-00-40-420-110 Install the Number 5 Oil Feed Tube (17), the Oil Weep Tube (18) and the P4.9 ECC Tube (19)

Refer to Figure

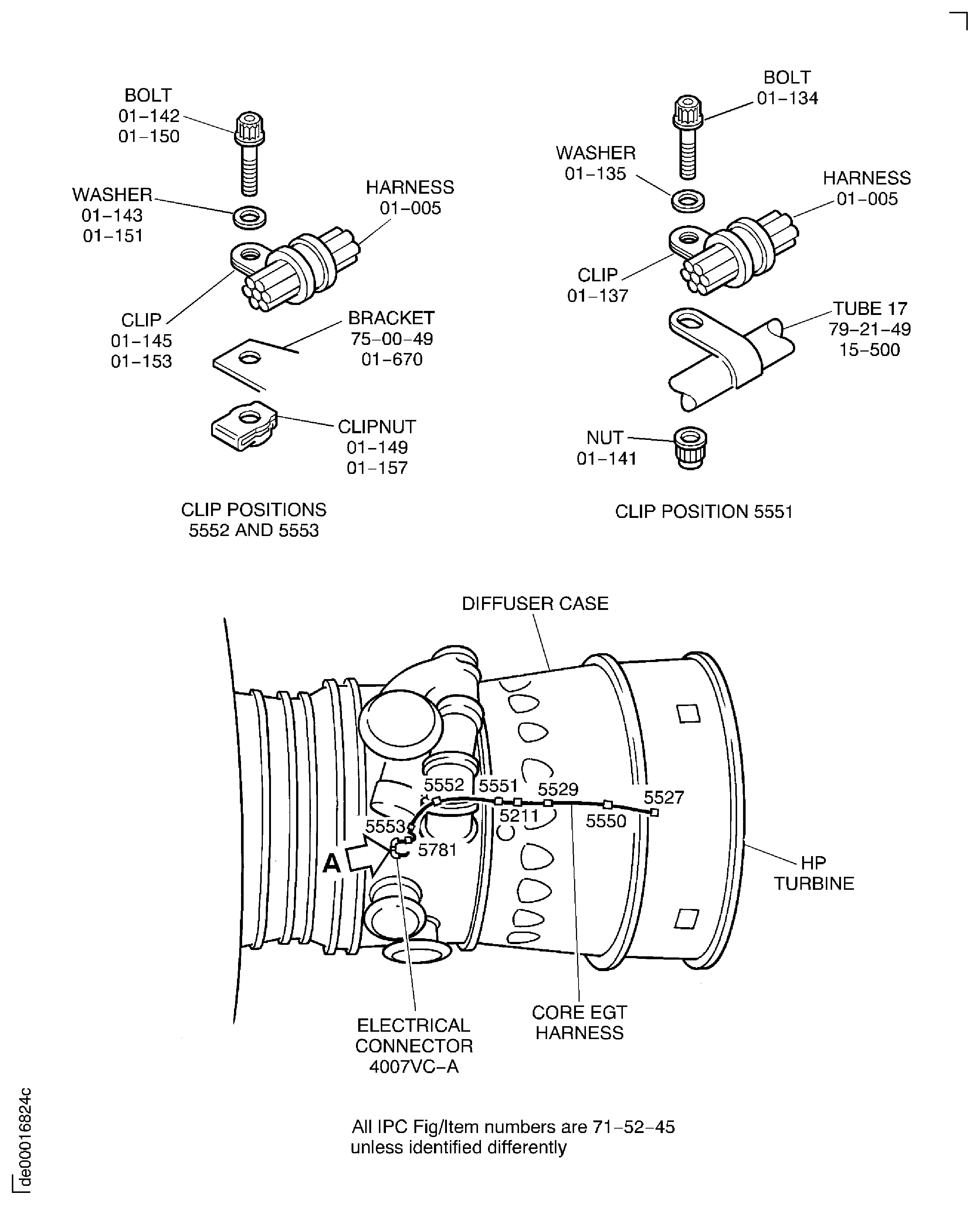

During the installation procedure make sure the harnesses are held temporarily along their different lengths. Always install the datum clip positions when you install each electrical connector. This will give correct installation of the different harnesses, prevent too much strain on the electrical connectors and give the necessary drip loops (the drip loop makes sure moisture or fluids do not go in to the electrical connector).

Because of the differences between the harness diameters, the specified clip could be too large or too small. You can use a clip from a range of six clips that have the same part numbers. If the harness diameter is between two of the clips in the range, use the larger clip. When you do this use CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) to increase the harness diameter.

For the data on the electrical connectors refer to SPM TASK 70-43-00-400-501 and SPM TASK 70-43-01-400-501.

SUBTASK 72-00-40-420-135 Electrical Harness Installation Procedure

Attach the electrical receptacle 4007VC to the bracket ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 03-350) with the four screws ELECTRICAL HARNESS-LIGHT DUTY-EGT HARNESS (71-52-45, 01-022) and the four assembled washer nuts ELECTRICAL HARNESS-LIGHT DUTY-EGT HARNESS (71-52-45, 01-020). Torque the four assembled washer nuts to between 6 and 8 lbf.in (0.68 and 0.90 Nm).

Pre SBE 75-0049: Install the clips, the washers, the bolts and the nuts at the clip positions 5551, 5529 and 5781.

SBE 75-0049: Install the bolt, the washers, the spacer, the clips and the nut at clip position 5529.

NOTE

This procedure will be continued in TASK 72-00-50-420-005-A00 (INSTALLATION-007, CONFIG-001).Temporarily attach the remaining part of the harness to the engine.

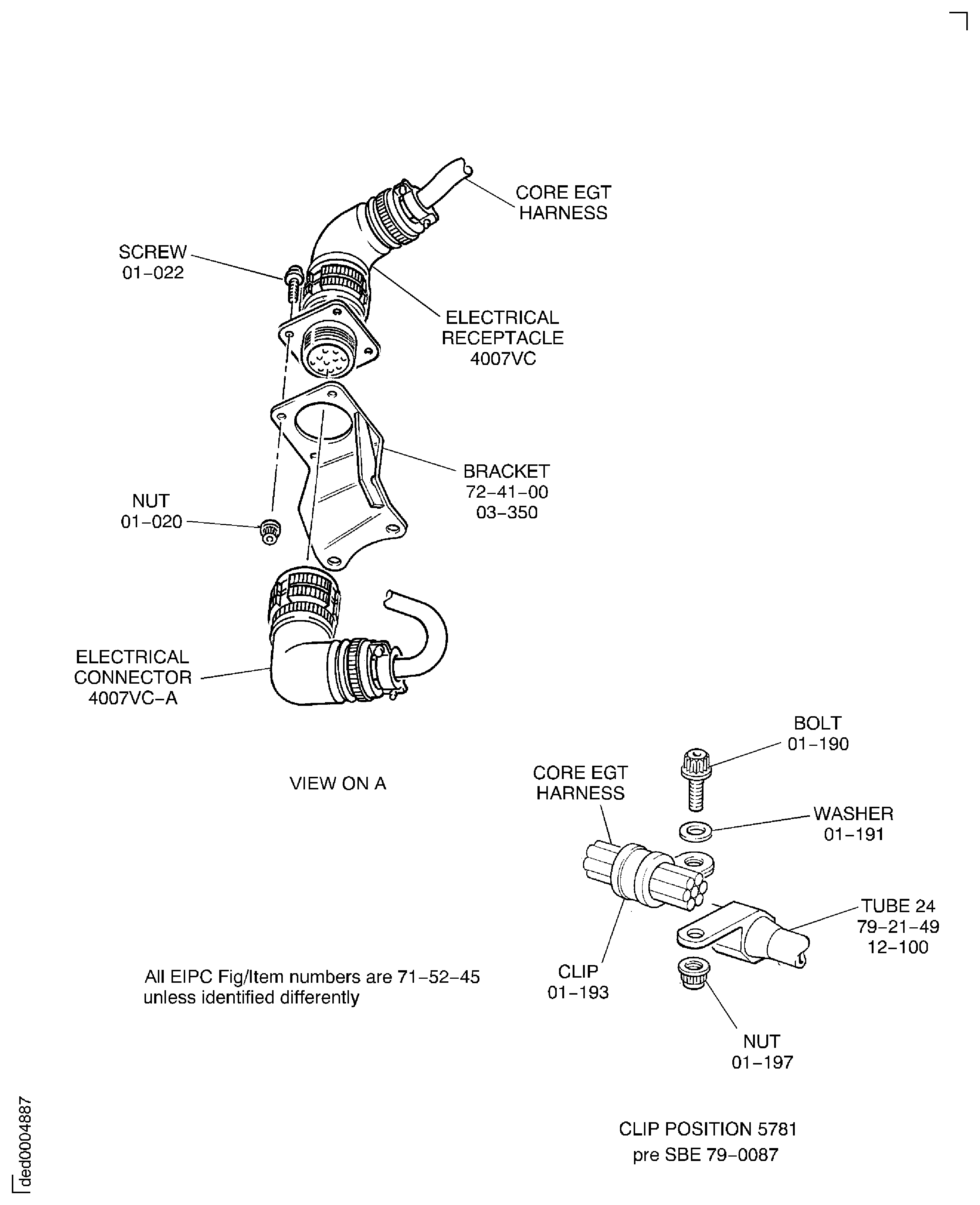

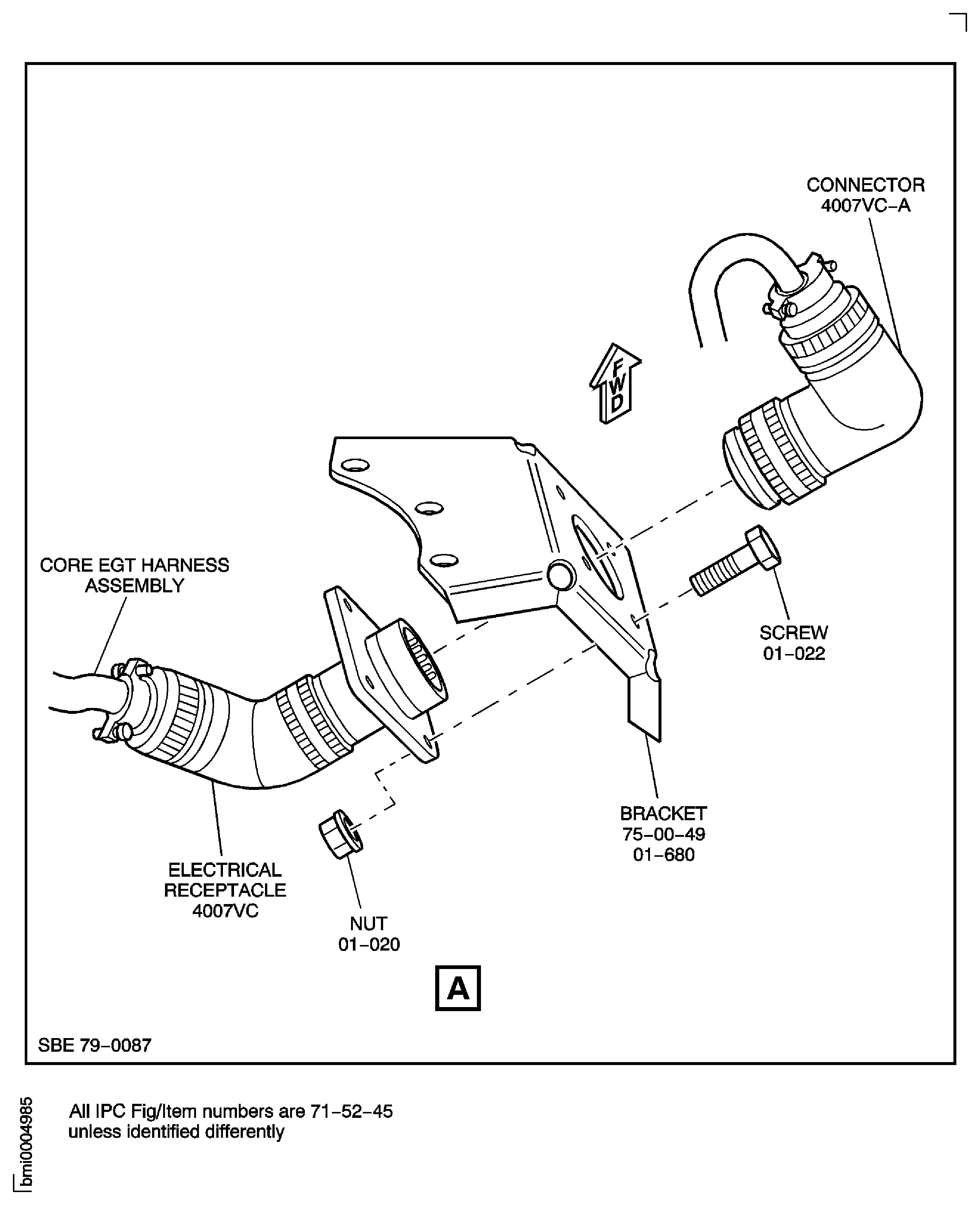

SUBTASK 72-00-40-420-111-A00 Install the Core EGT Harness (Pre SBE 79-0087)

Attach the electrical receptacle 4007VC to the bracket AIR-ENGINE AIR OFFTAKE DUCTS (75-00-49, 01-680) with the four screws ELECTRICAL HARNESS-LIGHT DUTY-EGT HARNESS (71-52-45, 01-022) and the four assembled washer nuts ELECTRICAL HARNESS-LIGHT DUTY-EGT HARNESS (71-52-45, 01-020). Torque the four assembled washer nuts to between 6 and 8 lbf.in (0.68 and 0.90 Nm).

Pre SBE 75-0049: Install the clips, the washers, the bolts and the nuts at the clip positions 5551 and 5529.

SBE 75-0049: Install the bolt, the washers, the spacer, the clips and the nut at clip position 5529.

NOTE

This procedure will be continued in TASK 72-00-50-420-005-A00 (INSTALLATION-007, CONFIG-001).Temporarily attach the remaining part of the harness to the engine.

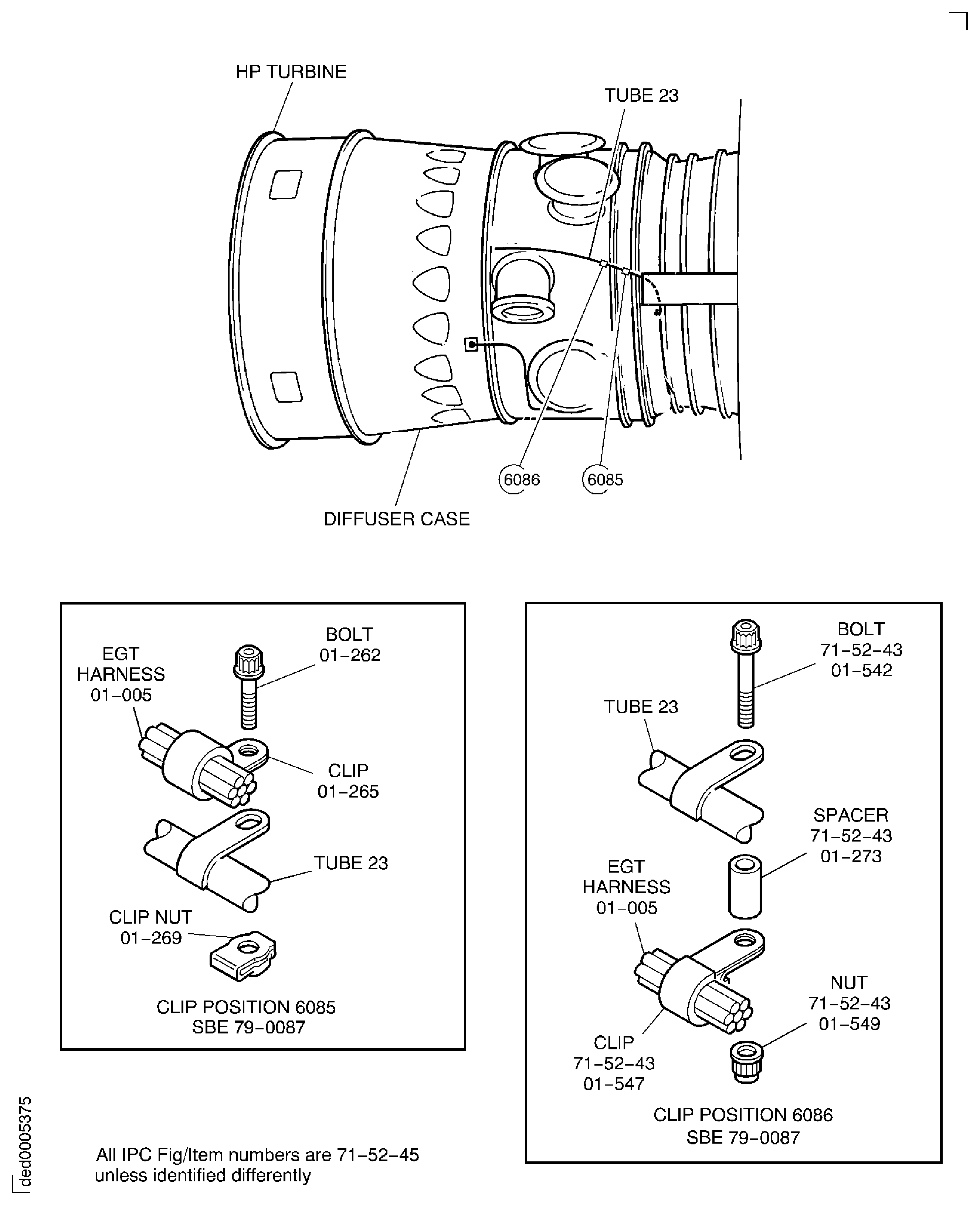

SUBTASK 72-00-40-420-111-B00 Install the Core EGT Harness (SBE 79-0087)

Check configuration as recorded in the removal TASK, refer to TASK 72-00-40-020-001-A00 (REMOVAL-001, CONFIG-001).

NOTE

For in-service engines the same configuration as recorded in the removal TASK, TASK 72-00-40-020-001-A00 (REMOVAL-001, CONFIG-001) should be installed unless the HPT module is new or has been refurbished, if HPT module is new or has been refurbished the plugs must be fitted to the ACC vanes.

SUBTASK 72-00-40-420-199 Check the Configuration of the Valve Vane Removable Plugs (SBE 75-0021)

CAUTION

CONFIGURATIONAL POSITION OF THE PLUGS IS DETERMINED ON THE FOLLOWING CRITERIA.PLUGS ARE REMOVED FROM THE VALVE VANES AND INSTALLED IN THE PLUG STORAGE PLATE AS A RESULT OF THE REQUIREMENT IN SERVICE TO RESTORE EGT MARGINS, REFER TO TASK 71-00-00-810-017 (FAULT ISOLATION-017).PLUGS ARE TO BE INSTALLED IN THE VALVE VANES FOR NEW ENGINES OR ENGINES INCORPORATING REFURBISHED HIGH PRESSURE TURBINE MODULES OR DOUBT AS TO THE CORRECT CONFIGURATION.SBE 75-0021: Valve vane replacement and addition of plug storage plate to HPT/LPT ACC air valve

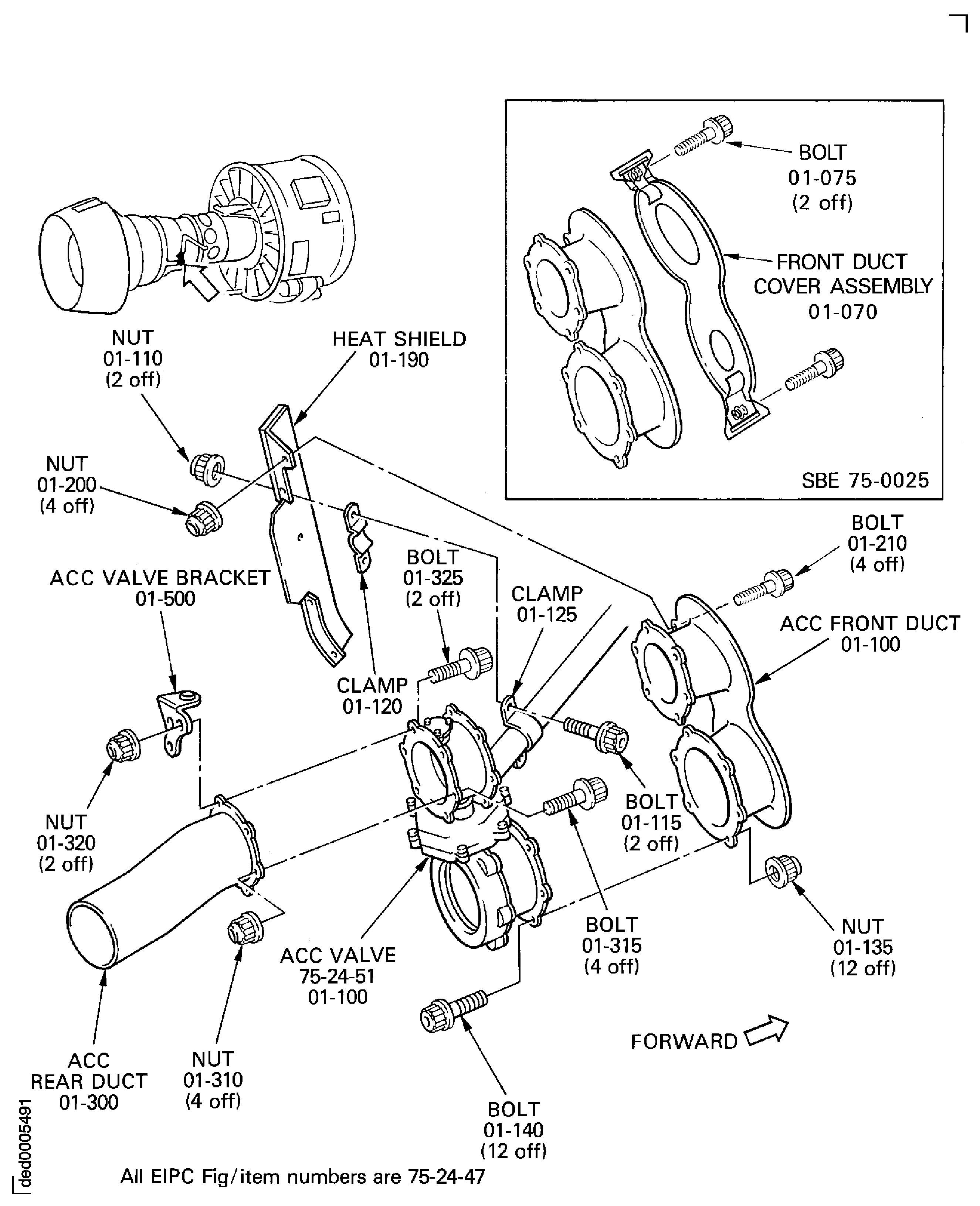

Attach the ACC front duct AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47,01-100) to the ACC valve AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-100) with the 12 bolts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-140) and the 12 nuts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-135). Torque the 12 nuts to 85 to 105 lbf.in (10 to 12 Nm).

Attach the two clamps AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-125 and AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT 01-120) and the heatshield AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-190) to the ACC valve with the two bolts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-115) and the two nuts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-110).

Install the four bolts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-210) and the four nuts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-200).

Attach the rear duct AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-300) to the ACC valve with the four bolts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-315) and the four nuts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-310).

Attach the ACC valve bracket AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-500) to the rear duct with the two bolts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-325) and the two nuts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-320).

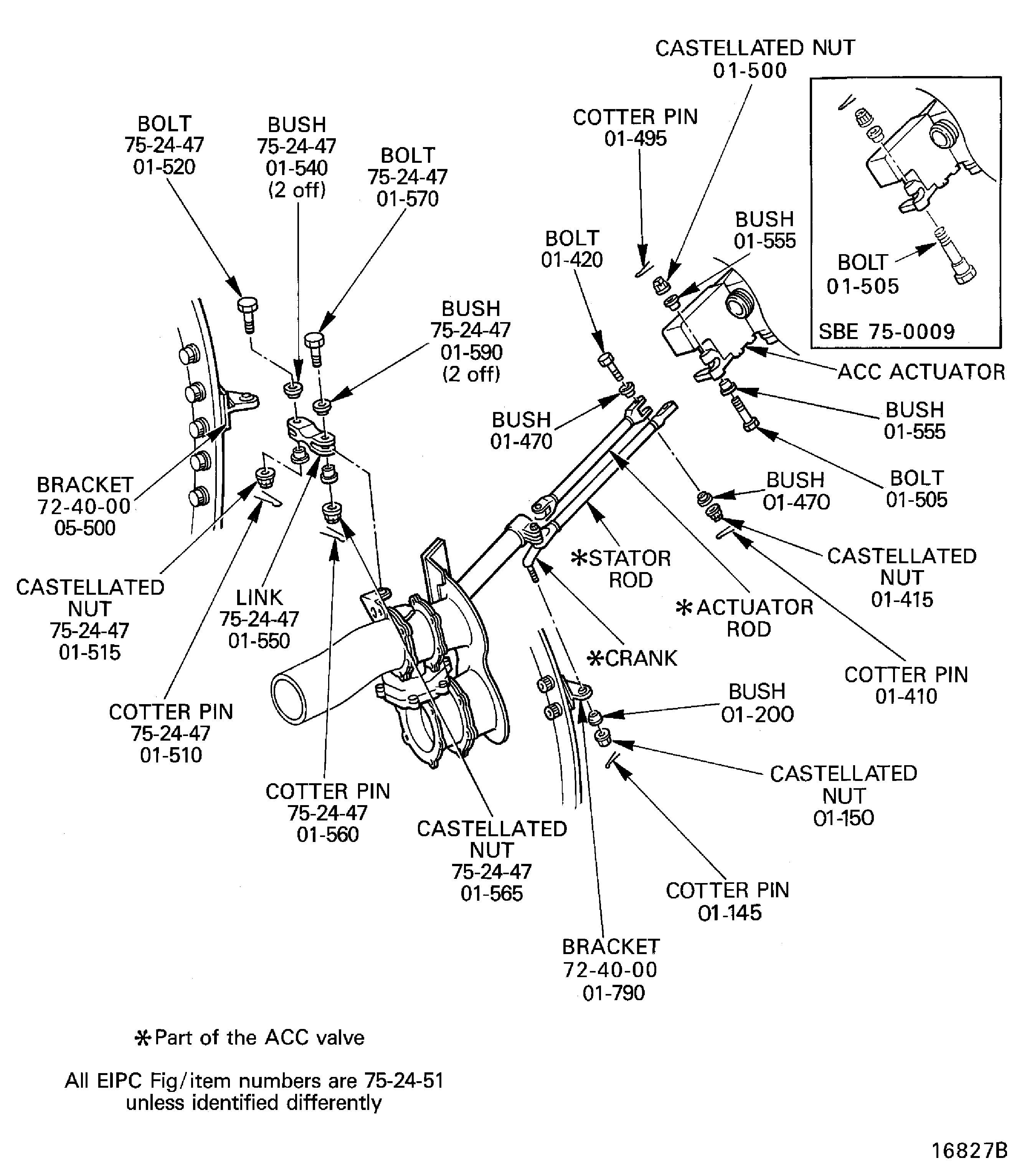

Attach the link AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-550) to the ACC valve bracket with the two bushes AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-590), the bolt AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-570) and the nut AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-565). Torque the nut to 85 to 105 lbf.in (10 to 12 Nm) and align the hole in the bolt with a slot in the castellated nut. Install the new AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-560) cotter pin 1 off.

Attach the ACC valve crank to the bracket HPC Module - Attaching Parts (72-40-00, 01-790) with the bush AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-200) and the nut AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-150).

Attach the link to the bracket HPC Module - Attaching Parts (72-40-00, 05-500) with the two bushes AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-540), the bolt AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-520) and the nut AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-515). Torque the nut to 85 to 105 lbf.in (10 to 12 Nm) and align the hole in the bolt with a slot in the castellated nut. Install and safety the new AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-510) cotter pin1 off.

Torque tighten the nut on the crank to 85 to 105 lbf.in (10 to 12 Nm) and align the hole in the bolt with a slot in the castellated nut. Install and safety the new AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-145) cotter pin 1 off.

Connect the actuator rod to the ACC actuator with the two bushes AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-470), the bolt AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-420) and the nut AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-415). Torque the nut to 22 to 30 lbfin (3 to 3,5 Nm) and align the hole in the bolt with a slot in the castellated nut. Install and safety the new AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-410) cotter pin1 off.

Connect the stator rod to the ACC actuator with the two bushes AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-555), the bolt AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-505) and the nut AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-500). Torque the nut to 36 to 44 lbf.in (4 to 5 Nm) and align the hole in the bolt with a slot in the castellated nut. Install and safety the new AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-495) cotter pin 1 off.

Connect the ACC valve to the ACC actuator.

SUBTASK 72-00-40-420-112-A00 Install the Active Clearance Control (ACC) Valve, the Front Duct and the Rear Duct (Pre SBE 75-0009 and Pre SBE 75-0030)

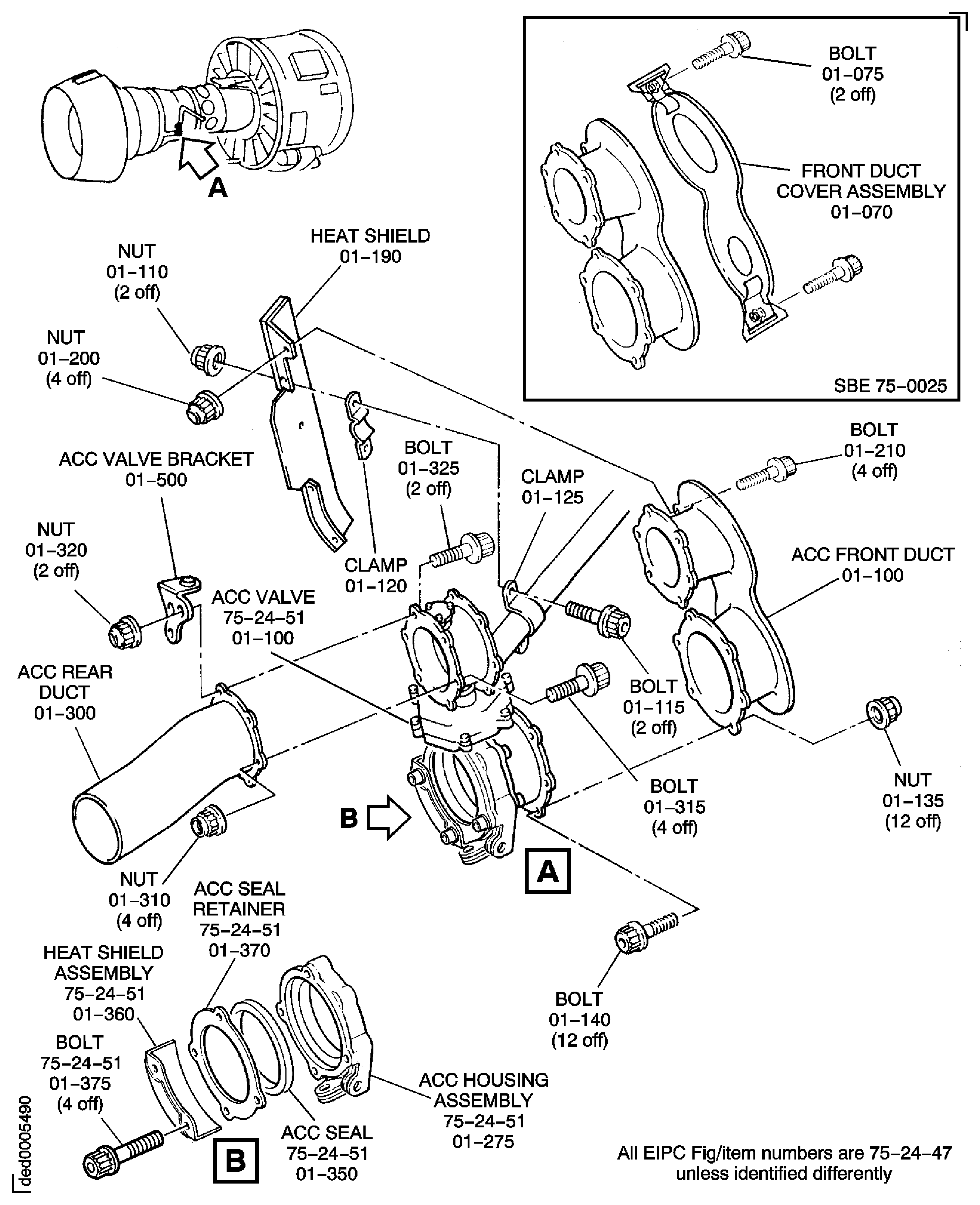

Attach the ACC front duct AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-100) to the ACC valve AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-100) with the 12 bolts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-140) and the 12 nuts V2500-A5-75-24-47-07A-941A-D(75-24-47,07-135). Torque the 12 nuts to 85 to 105 lbfin (10 to 12 Nm).

Attach the two clamps AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-125 and AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT 01-120) to the ACC valve with the two bolts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-115) and the two nuts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-110).

Install the four bolts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-210) and the four nuts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-200) that attach the heatshield AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-190) to the front duct.

Attach the rear duct AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-300) to the ACC valve with the four bolts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-315) and the four nuts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-310).

Attach the ACC valve bracket AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-500) to the rear duct with the two bolts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-325) and the two nuts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-320).

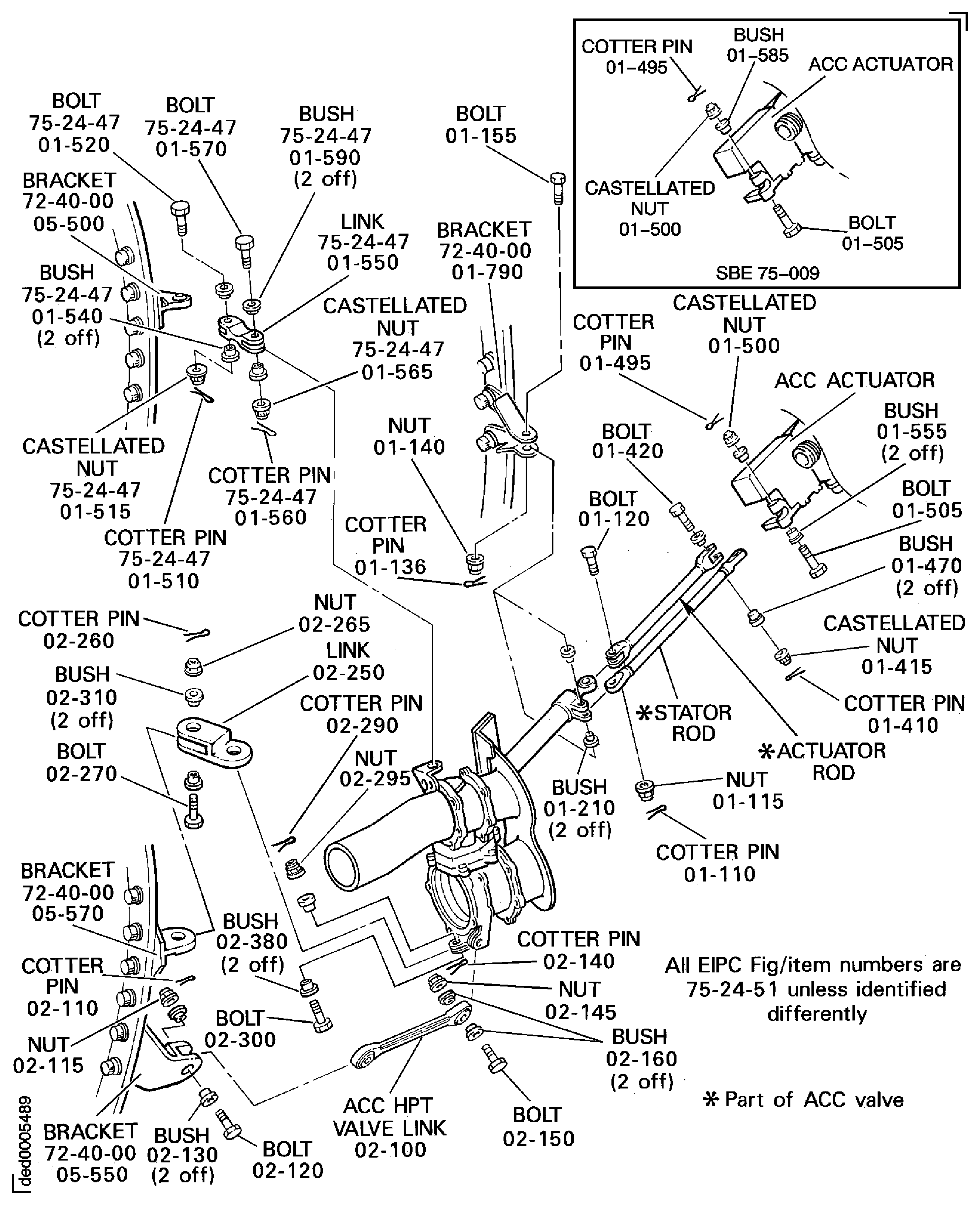

Attach the link AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-550) to the ACC valve bracket with the two bushes AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-590), the bolt AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-570) and the nut AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-565). Torque the nut to 85 to 105 lbf.in (10 to 12 Nm) and align the hole in the bolt with a slot in the castellated nut. Install the new AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-560) cotter pin 1 off.

Connect the stator rod to the ACC valve rod bracket AIR-ACTIVE CLEARANCE CONTROL VALVE (72-40-00, 01-790 installed to the flange FK with the two bushes (75-24-51, 01-210) the bolt AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-155) and the nut AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-140). Torque the nut to 36 to 44 lbf.in (4 to 5 Nm). Align the slot of the nut with the pin hole of the bolt and safety the nut with the new AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-136) cotter pin 1 off.

Connect the actuator rod to the valve rod with the bolt AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-120) and the nut AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-115).

Torque the nut to 22 to 30 lbf.in (3 to 3.5 Nm) and align the slot of the nut with the pin hole of the bolt and safety the nut with the new AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-110) cotter pin 1 off.

Connect the actuator rod to the HPT/LPT ACC air valve.

Attach the link to the bracket HPC Module - Attaching Parts (72-40-00, 05-500) with the two bushes AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-540), the bolt AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-520) and the nut AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-515). Torque the nut to 85 to 105 lbf.in (10 to 12 Nm) and align the hole in the bolt with a slot in the castellated nut. Install and safety the new AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-510) cotter pin 1 off.

Assemble ACC housing AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-275), ACC seal retainer AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-370), ACC seal AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-350) and joint heat shield AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-360) with the four bolts AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-375). Torque the bolts to 36 to 44 lbf.in (4 to 5 Nm).

Attach the ACC HPT valve link AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-100) to the ACC housing AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-275) with the two bushes AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-160), the bolt AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-150) and the nut AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-145). Torque the nut to 36 to 44 lbfin (4 to 5 Nm) and safety with the new AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-140) cotter pin 1 off.

Attach the ACC HPT valve link AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-250) to the ACC housing AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-275) with the two bushes AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-380), the bolt AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-300) and the nut AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-295). Torque the nut to 36 to 44 lbf.in (4 to 5 Nm) and safety with new AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-290) cotter pin 1 off.

Attach the ACC HPT valve bracket HPC Module - Attaching Parts (72-40-00, 05-570) to the ACC HPT valve link AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-250) with the two bushes AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-310), the bolt AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-270) and the nut AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-265). Torque the nut to 36 to 44 lbf.in (4 to 5 Nm) and safety with new AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-260) cotter pin 1 off.

Lightly lubricate the five bolts with CoMat 10-077 APPROVED ENGINE OILS.

Install the five bolts AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-290) and torque tighten to 85 to 105 lbf.in (10 to 12 Nm).

Install the ACC housing assembly to the HPT/LPT ACC air valve.

Install the ACC HPT valve link AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-100) to the ACC HPT valve bracket HPC Module - Attaching Parts (72-40-00, 05-550) installed to the FM flange with the two bushes AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-130), the bolt AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-120) and the nut AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-115). Torque the nut to 36 to 44 lbf.in (4 to 5 Nm) and safety with new AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 02-110) cotter pin 1 off.

Connect the actuator rod to the ACC actuator with the two bushes AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-470), the bolt AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-420) and the nut AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-415). Torque the nut to 22 to 30 lbfin (3 to 3,5 Nm) and align the hole in the bolt with a slot in the castellated nut. Install and safety the new AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-410) cotter pin 1 off.

Connect the stator rod to the ACC actuator with the bush AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-555), the bolt AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-505) and the nut AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-500). Torque the nut to 36 to 44 lbf.in (4 to 5 Nm) and align the hole in the bolt with a slot in the castellated nut. Install and safety the new AIR-ACTIVE CLEARANCE CONTROL VALVE (75-24-51, 01-495) cotter pin 1 off.

Connect the ACC valve to the ACC actuator.

SUBTASK 72-00-40-420-112-B00 Install the Active Clearance Control (ACC) Valve, the Front Duct and the Rear Duct (SBE 75-0009 and SBE 75-0030)

SBE 75-0009: HPT/LPT ACC system - Improved connection of the ACC actuator and the stator rod

SBE 75-0030: HPT/LPT ACC system - Introduction of additional ACC valve supports and new slide type HPT manifold joint

Refer to Figure.

Attach the cover assembly AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-070) to the ACC valve front duct with the two bolts AIR-HP/LP ACTIVE CLEARANCE CONTROL SUPPLY DUCT (75-24-47, 01-075). Torque the bolts to 36 to 44 lbf.in (4 to 5 Nm).

SUBTASK 72-00-40-420-156 Install the Active Clearance Control (ACC) Valve Front Duct Cover Assembly (SBE 75-0025)

SBE 75-0025: HP/LP ACC ducts - To provide a front duct cover assembly for controlled service use

Refer to Figure.

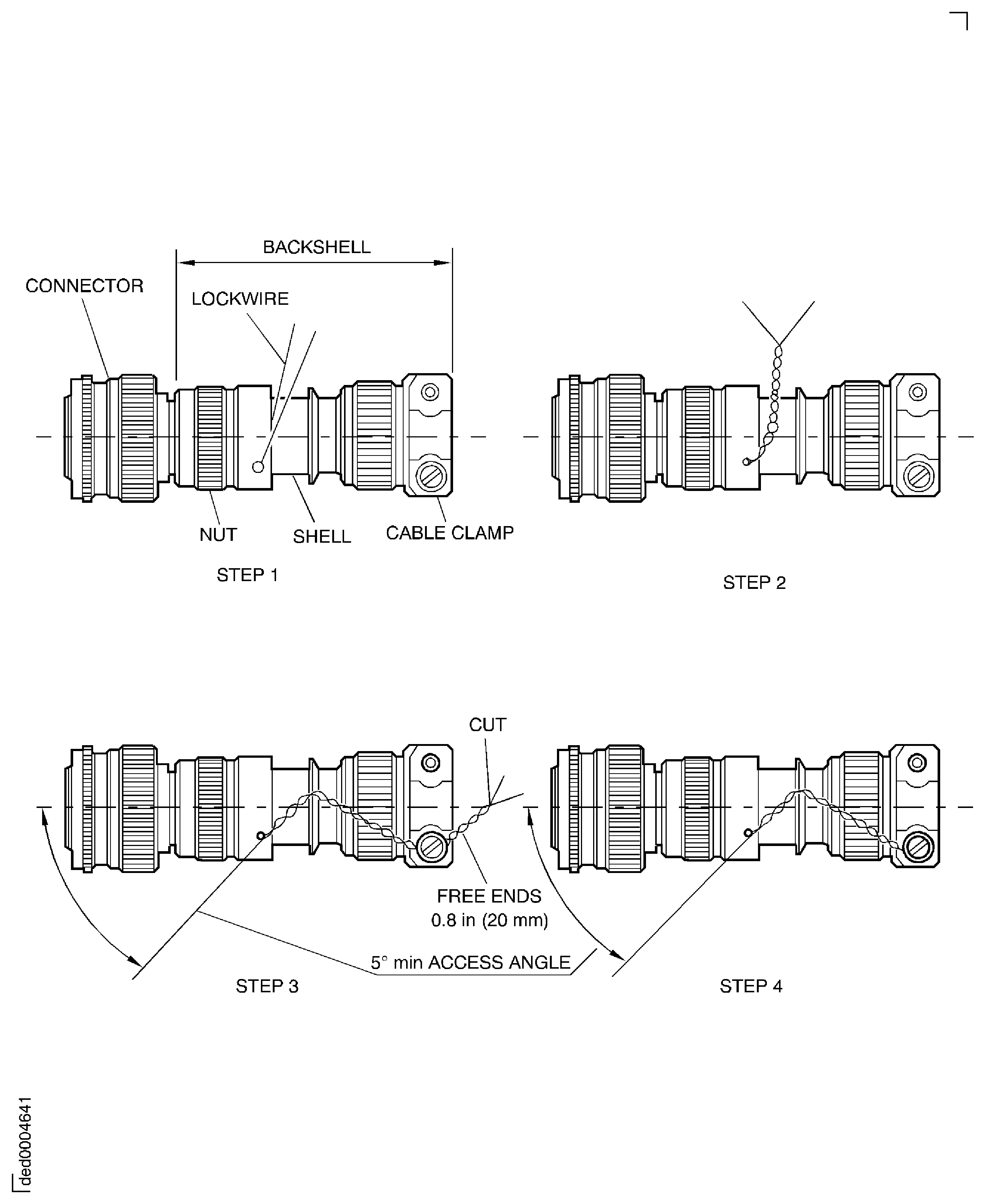

Make sure that all the applicable backshells and cable clamps are safetied with CoMat 02-126 LOCKWIRE. Refer to the SPM TASK 70-42-05-400-501.

SUBTASK 72-00-40-210-059 Visually Inspect the Electrical Backshells and Cable Clamps

Figure: Install the cold buffer air tubes

Sheet 1

Figure: Install the cold buffer air tubes

Sheet 2

Figure: Install the cold buffer air tubes

Sheet 3

Figure: Install the cold buffer air tubes

Sheet 4

Figure: Install the tubes 17, 18 and 19

Install the tubes 17, 18 and 19

Figure: Electrical harnesses installation

Electrical harnesses installation

Figure: Install the core EGT harness

Sheet 1

Figure: Pre SBE 79-0087: Install the Core EGT Harness

Sheet 2

Figure: SBE 79-0087: Install the Core EGT Harness

Sheet 3

Figure: Install the Core EGT Harness

Sheet 4

Figure: Install the Core EGT Harness

Sheet 5

Figure: Install the Core EGT Harness

Sheet 6

Figure: Pre SBE 75-0030: Install the ACC valve, the front duct and rear duct

Sheet 1

Figure: Pre SBE 75-0030: Install the ACC valve, the front duct and the rear duct

Sheet 2

Figure: SBE 75-0030: Install the ACC valve, the front duct and the rear duct

Sheet 3

Figure: SBE 75-0030: Install the ACC valve, the front duct and the rear duct

Sheet 4

Figure: Visually inspect the backshells and cable clamps

Visually inspect the backshells and cable clamps