Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-00-60-020-002-A00 External Gearbox Module - Remove The Tubes And Electrical Harnesses From The External Gearbox, Removal-002

General

This TASK gives the procedure to remove the necessary dressings to permit removal of the external gearbox. For related data refer to:

TASK 72-00-60-020-001 Remove the LP compressor/intermediate case module drains and fire detector.

Fig./item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig./item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig./item number.

Apply the approved penetrating oil before the removal of threaded parts and parts with an interference fit. Let the parts soak before removal. For the approved oils and procedures, refer to the SPM TASK 70-64-00-640-501.

Seal all openings when tubes are disconnected, to prevent contamination from unwanted material.

Discard all rubber seal rings removed in this procedure.

Remove and discard the lockwire before the tube or connector is disconnected.

When electrical connectors are disconnected special plastic caps must be installed.

All tubes, hoses and ducts removed in this procedure must have their maintenance completed, as given in the Component Maintenance Manual (CMM-THD-V2500-1IA).

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure.

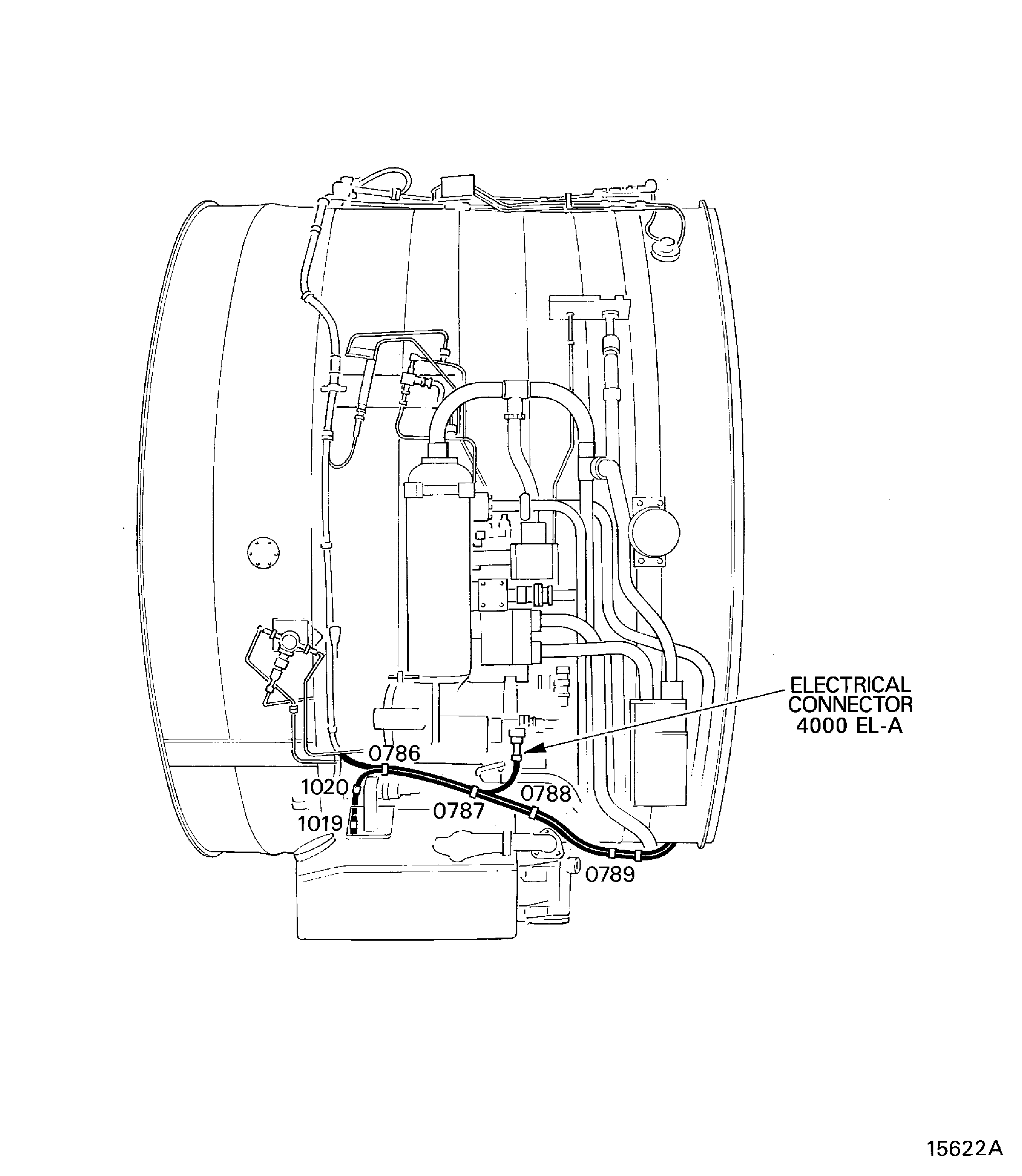

SUBTASK 72-00-60-020-174-A00 Remove the Clips at the Electrical Connectors 4005EV-A and 400EV-B (SBE 71-0063 and Pre SBE 71-0111)

SBE 71-0063: EEC harness - Fan and EEC harness core - Introduction of additional support for electrical connectors

SUBTASK 72-00-60-020-174-B00 Remove the Lockwire at the Electrical Connectors (SBE 71-0111)

SBE 71-0111: Power plant - EEC harness fan/core - deletion of clipping at VSVA and PMA harness connectors and introduction of wire locking to secure the connectors.

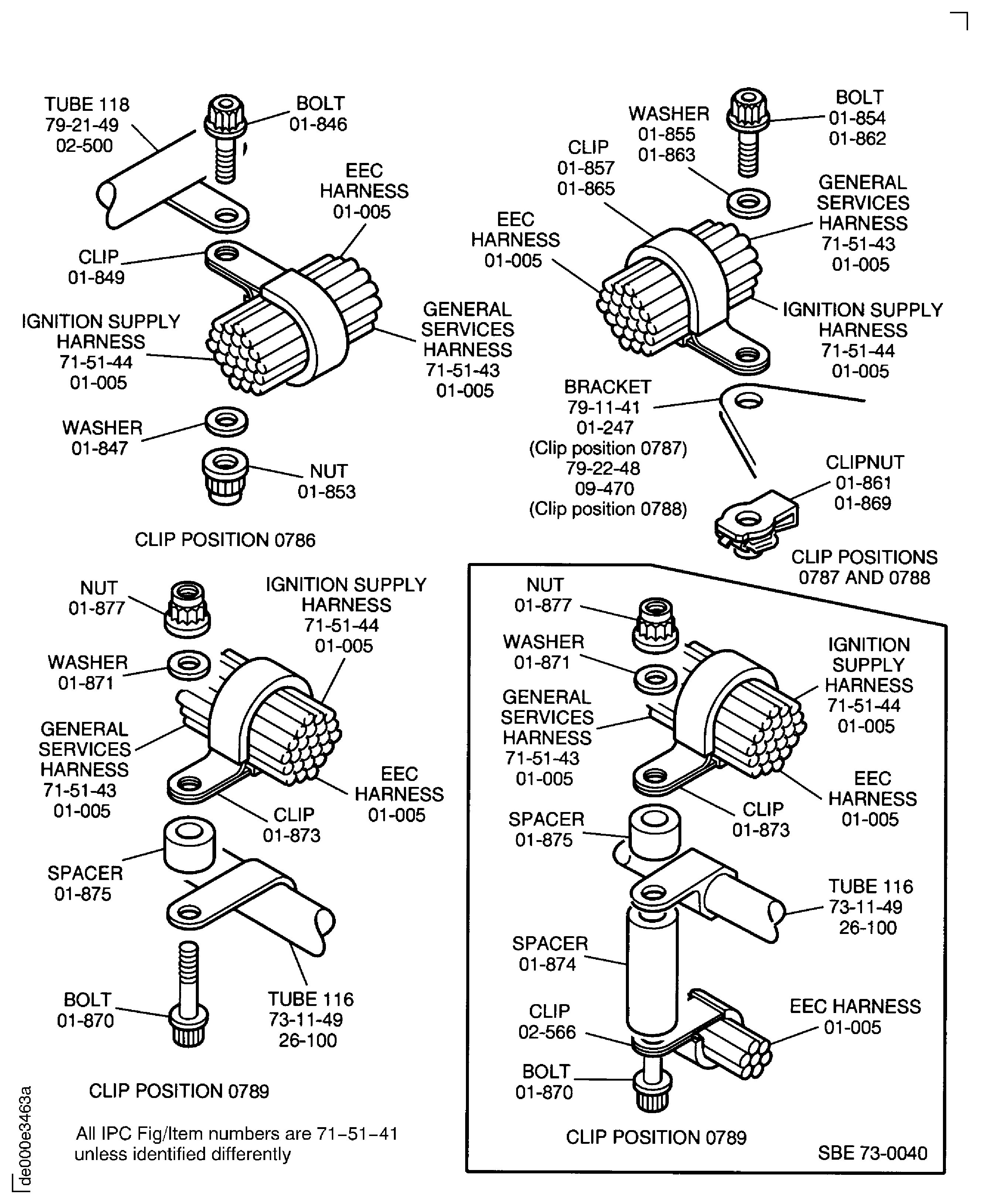

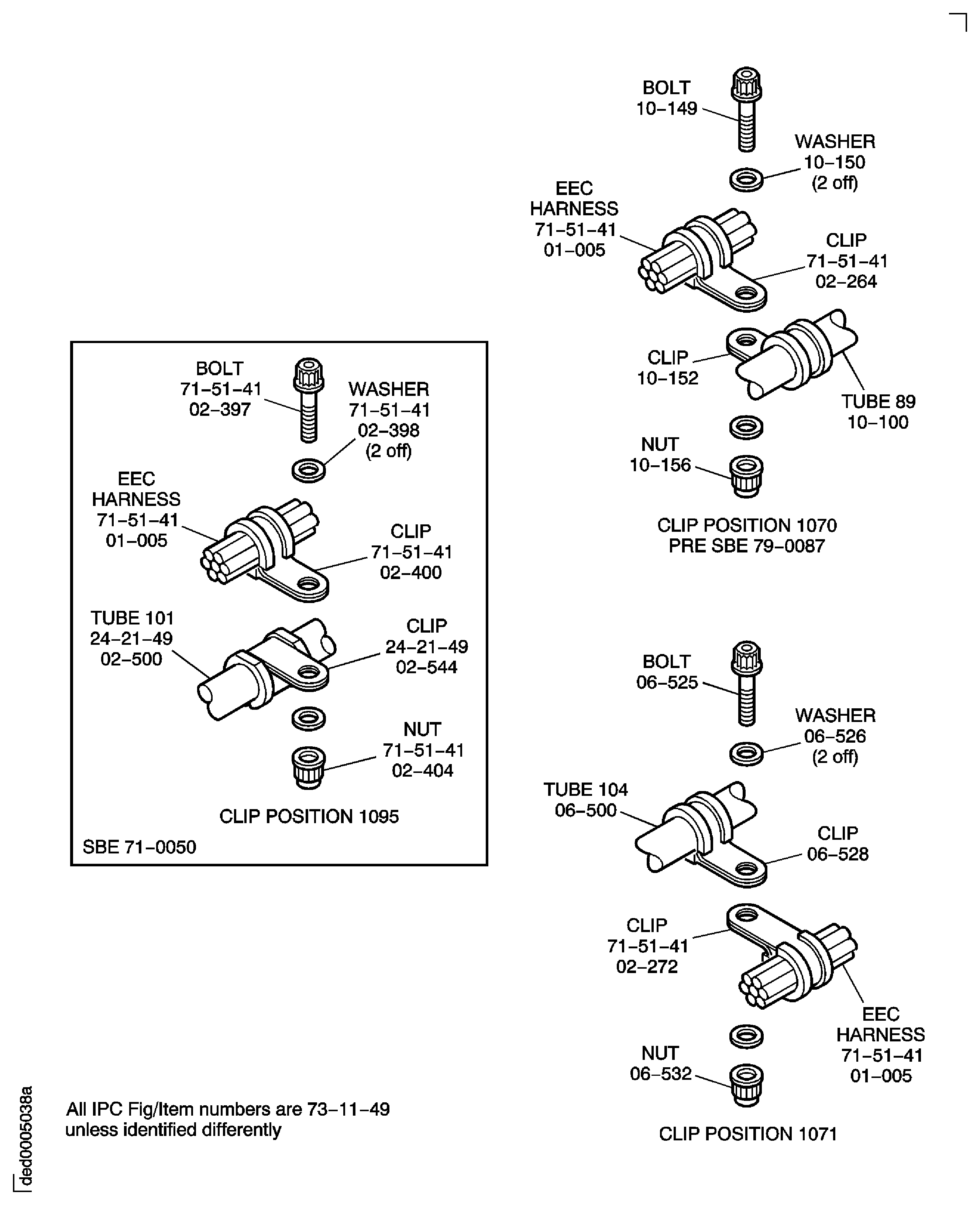

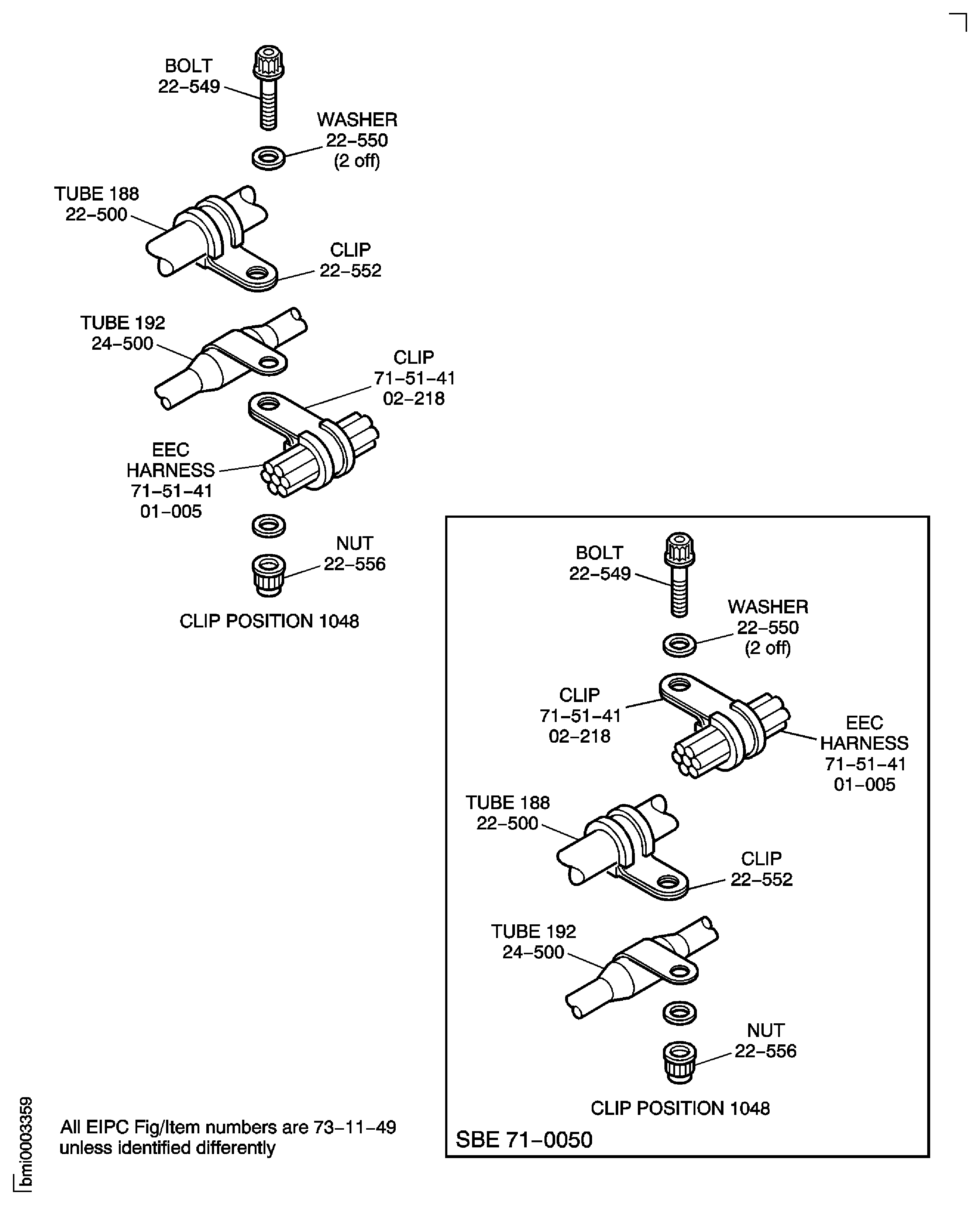

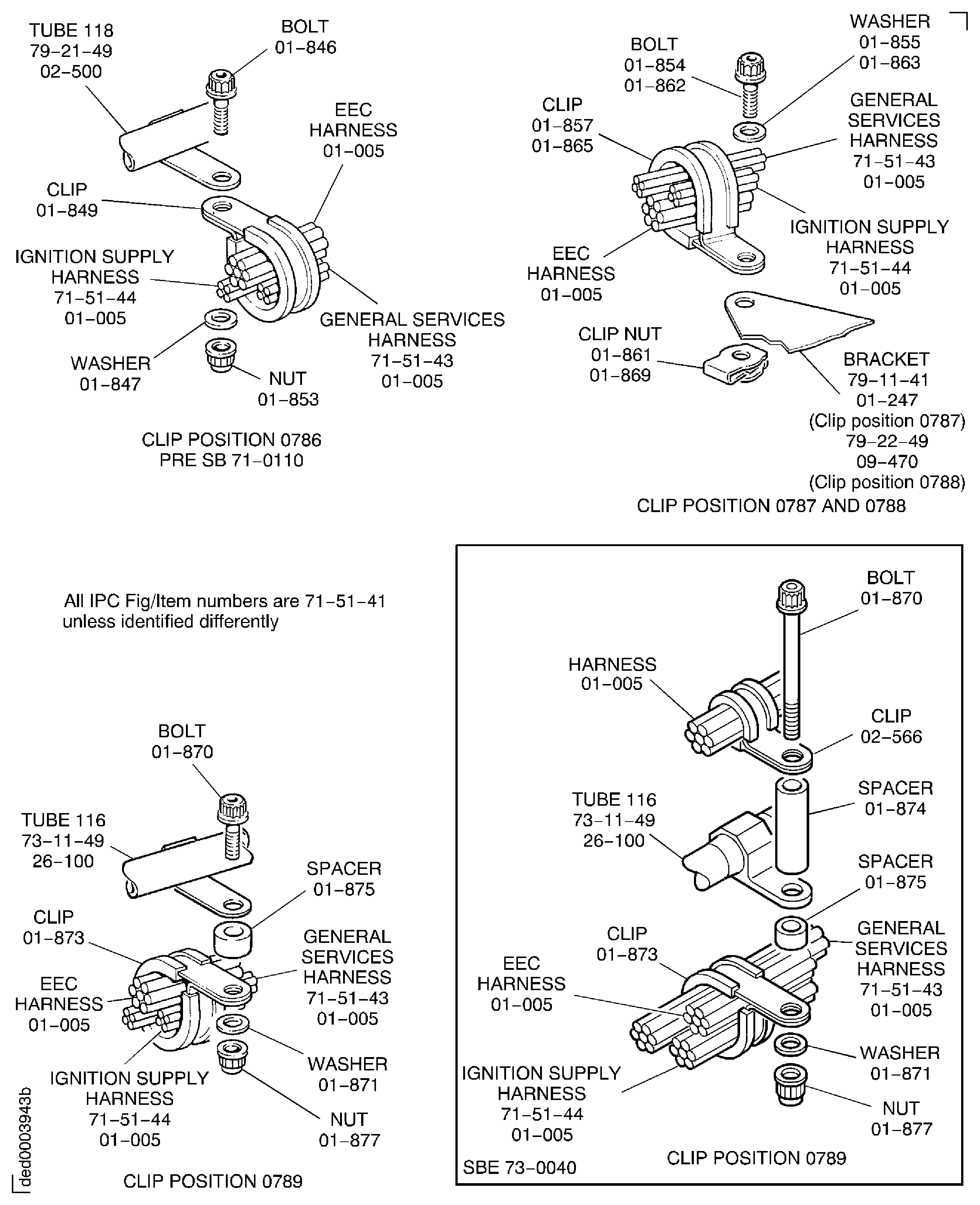

Pre SBE 71-0050, SBE 71-0050 and Pre SBE 71-0107: Refer to Figure, Figure, Figure, Figure.

SBE 71-0107: Refer to Figure, Figure, and Figure.

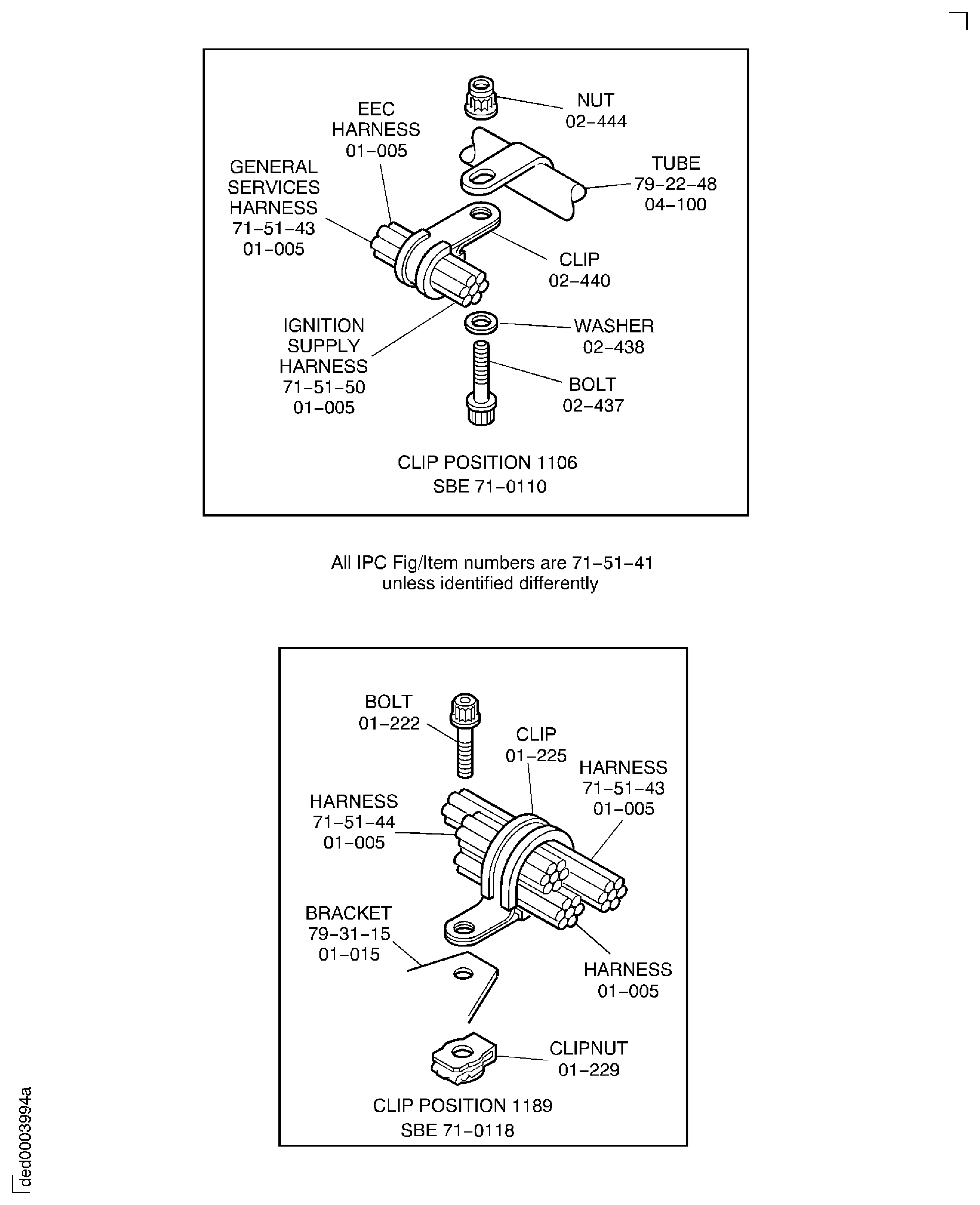

SBE 71-0110: Refer to Figure, Figure, Figure.

SUBTASK 72-00-60-020-065 Disconnect the Electrical Harness Connectors from the External Gearbox

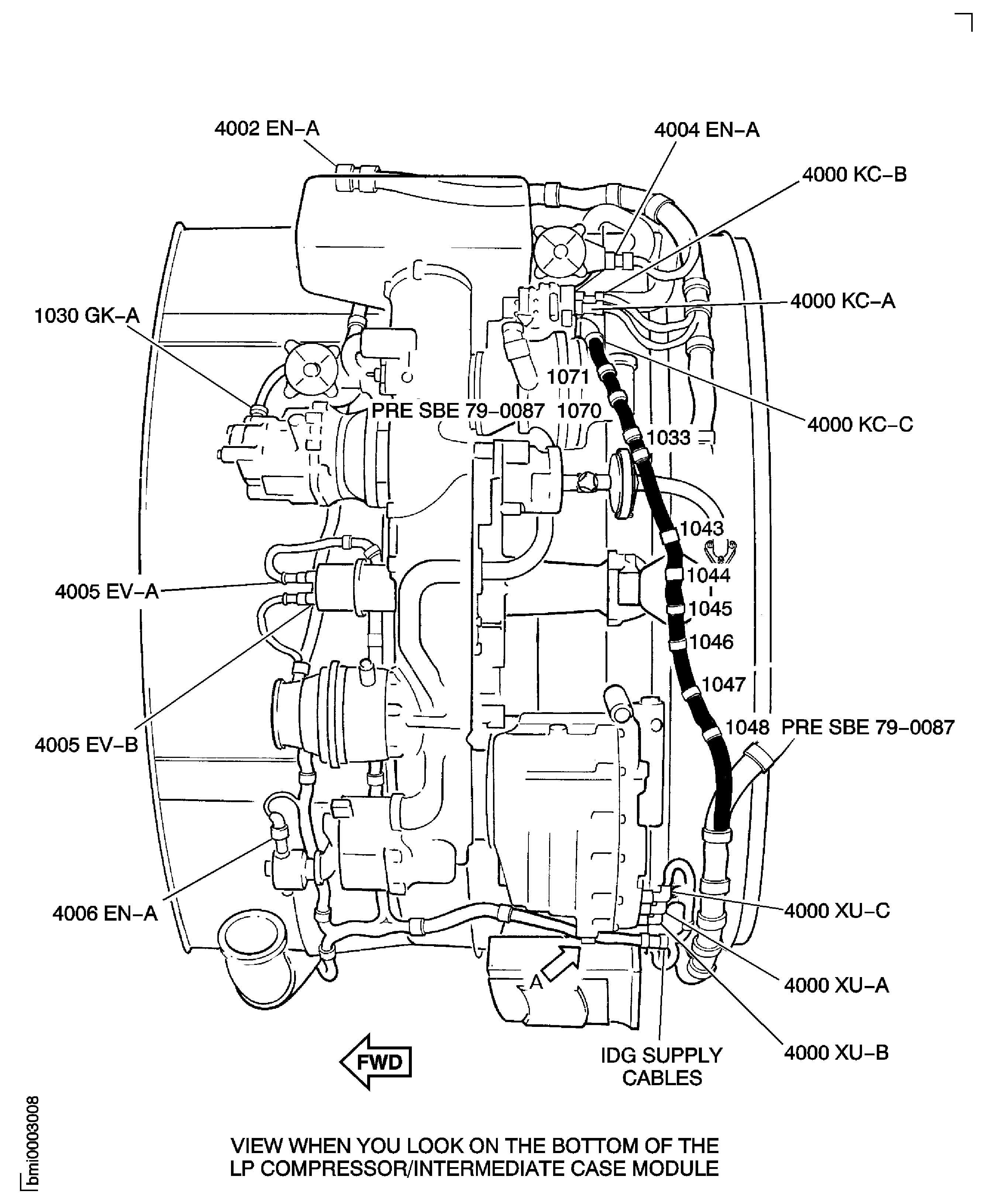

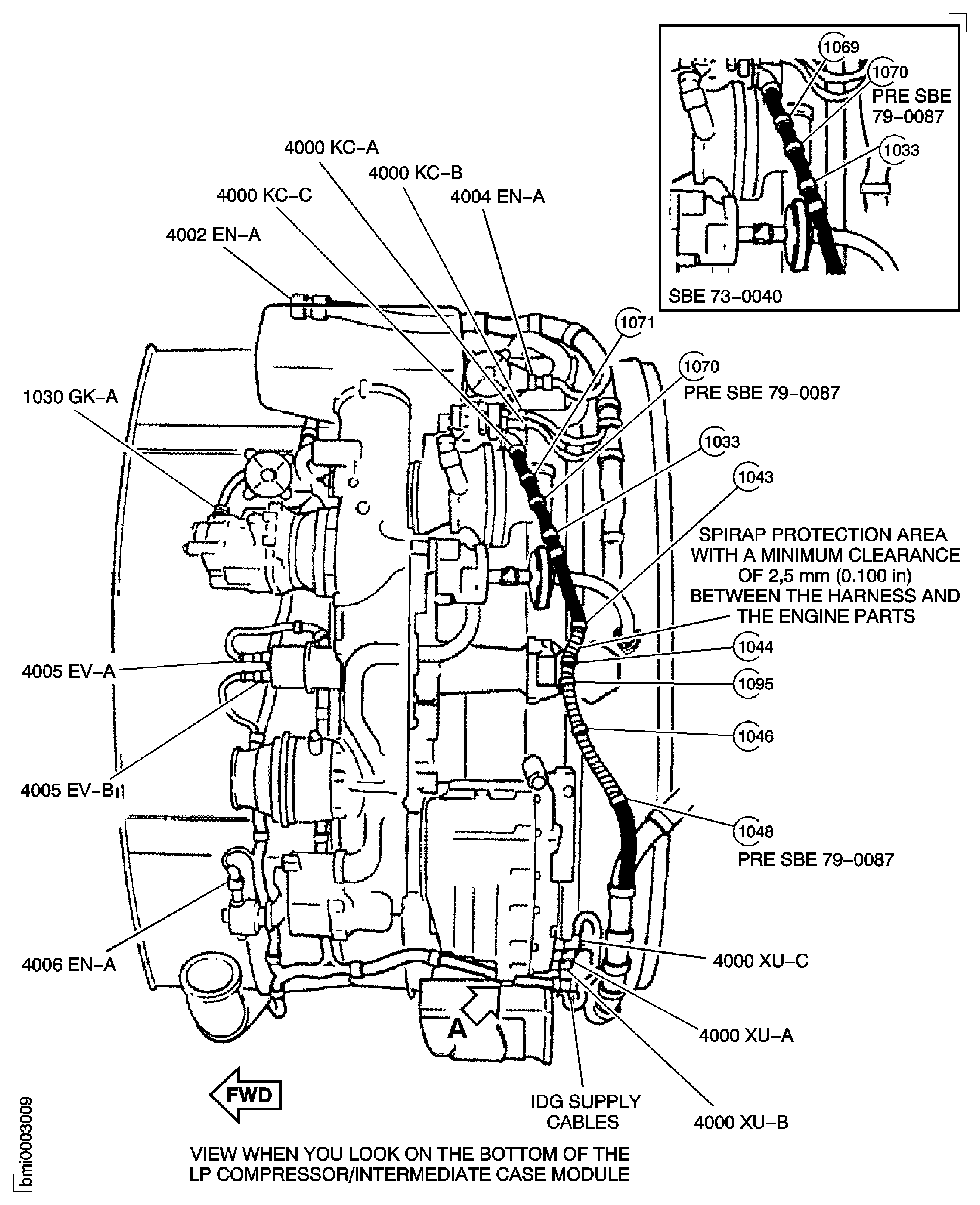

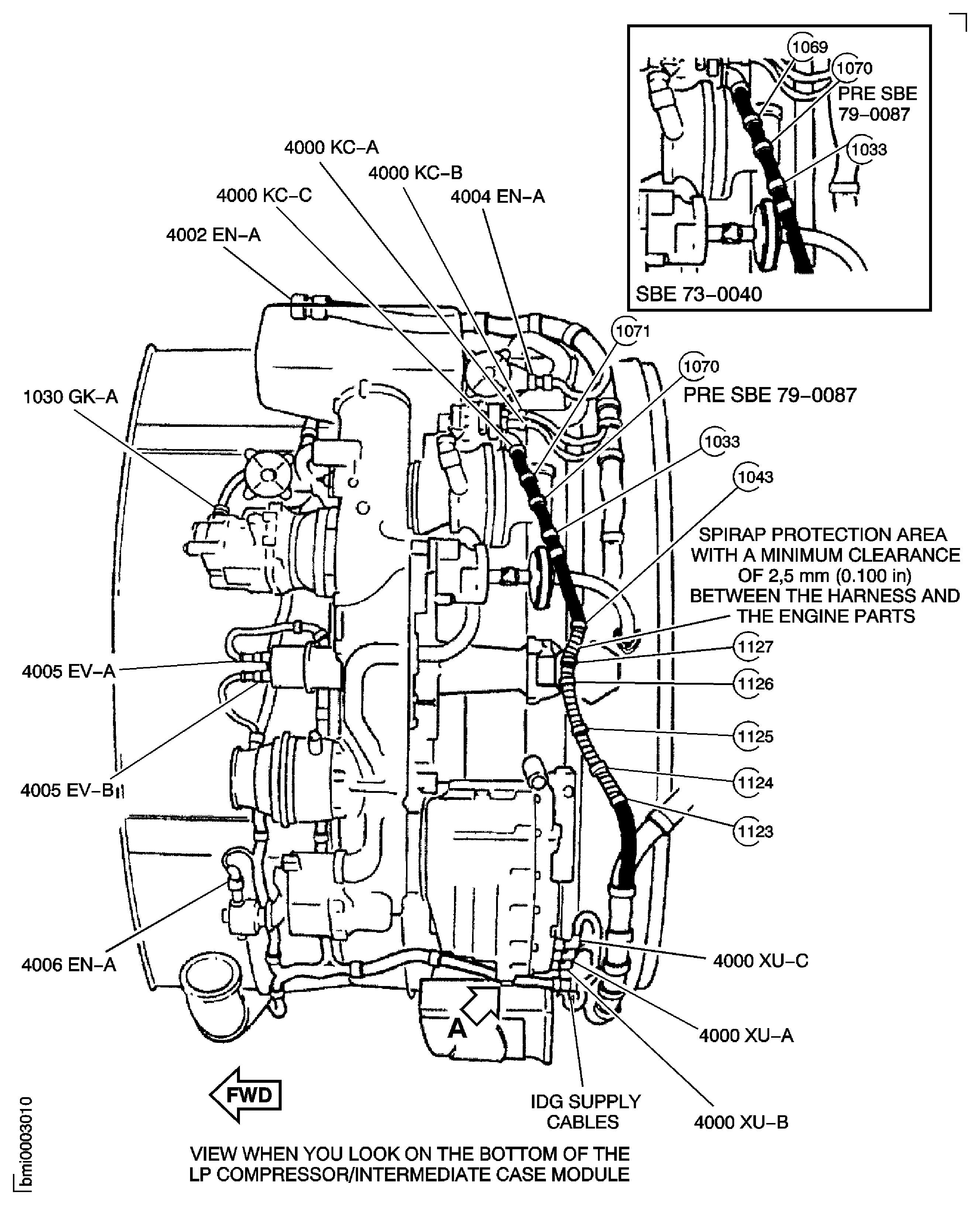

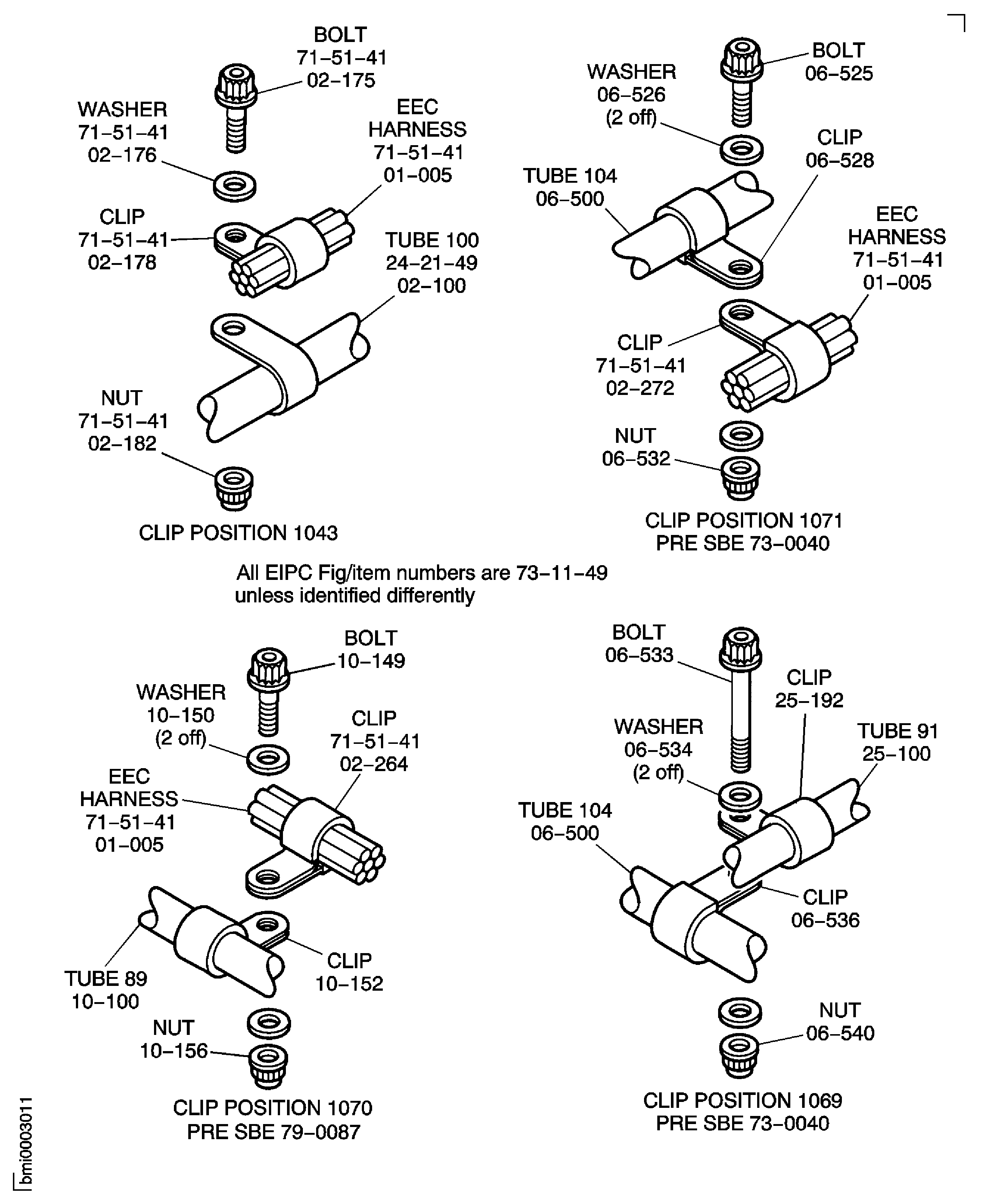

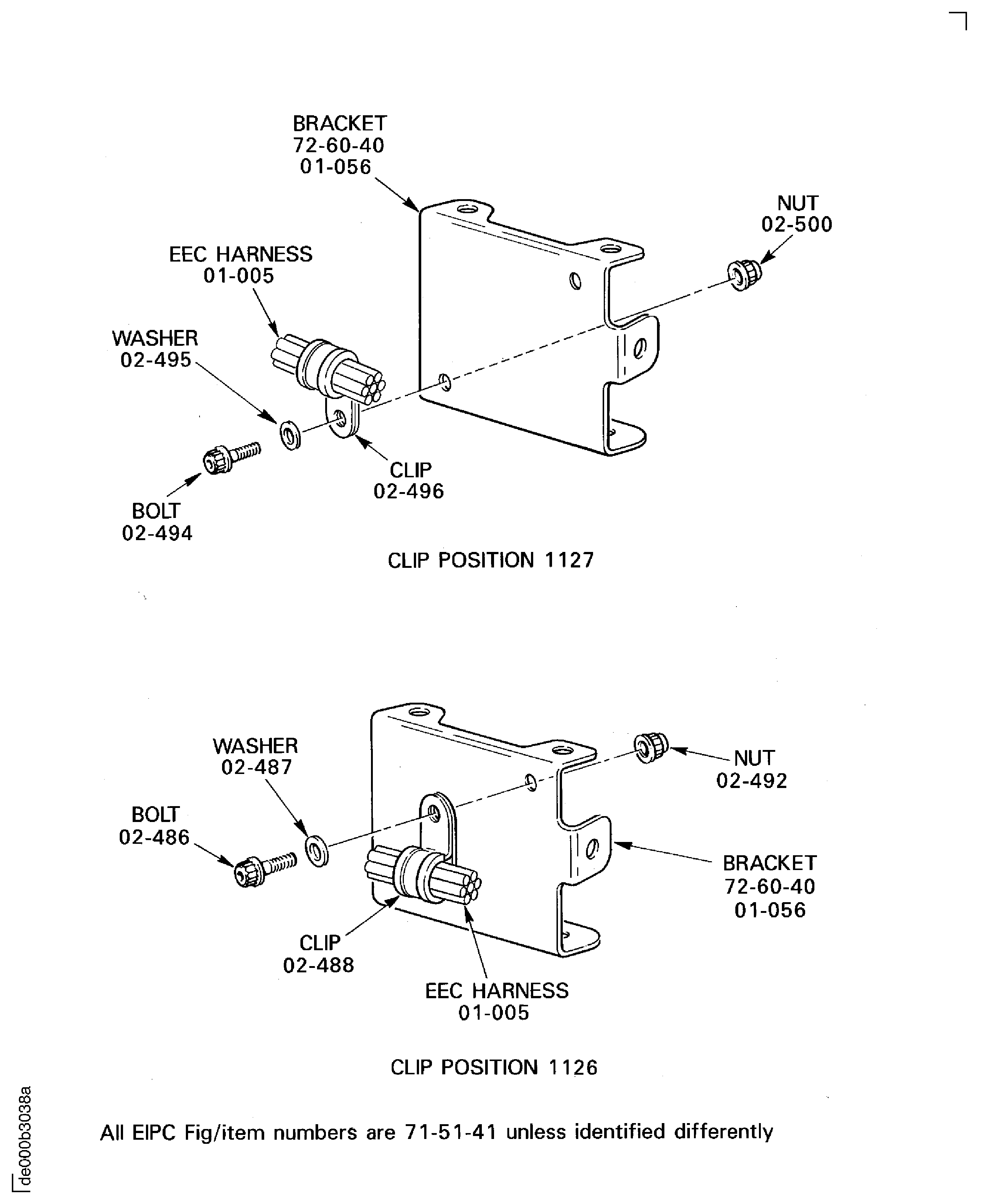

Pre SBE 79-0087: Remove the bolts, washers, nuts, the spacer, clipnuts and clips from the clip positions that follow:

SBE 79-0087: Remove the bolts, washers, nuts, spacer, clipnuts and clips from the clip positions that follow:

SUBTASK 72-00-60-020-066-A00 Move the Electrical Harnesses Clear of the External Gearbox (Pre SBE 71-0050, Pre SBE 79-0087 and SBE 79-0087)

SBE 79-0087: Oil - Scavenge oil tubes - Re-route of No.4 bearing scavenge tube

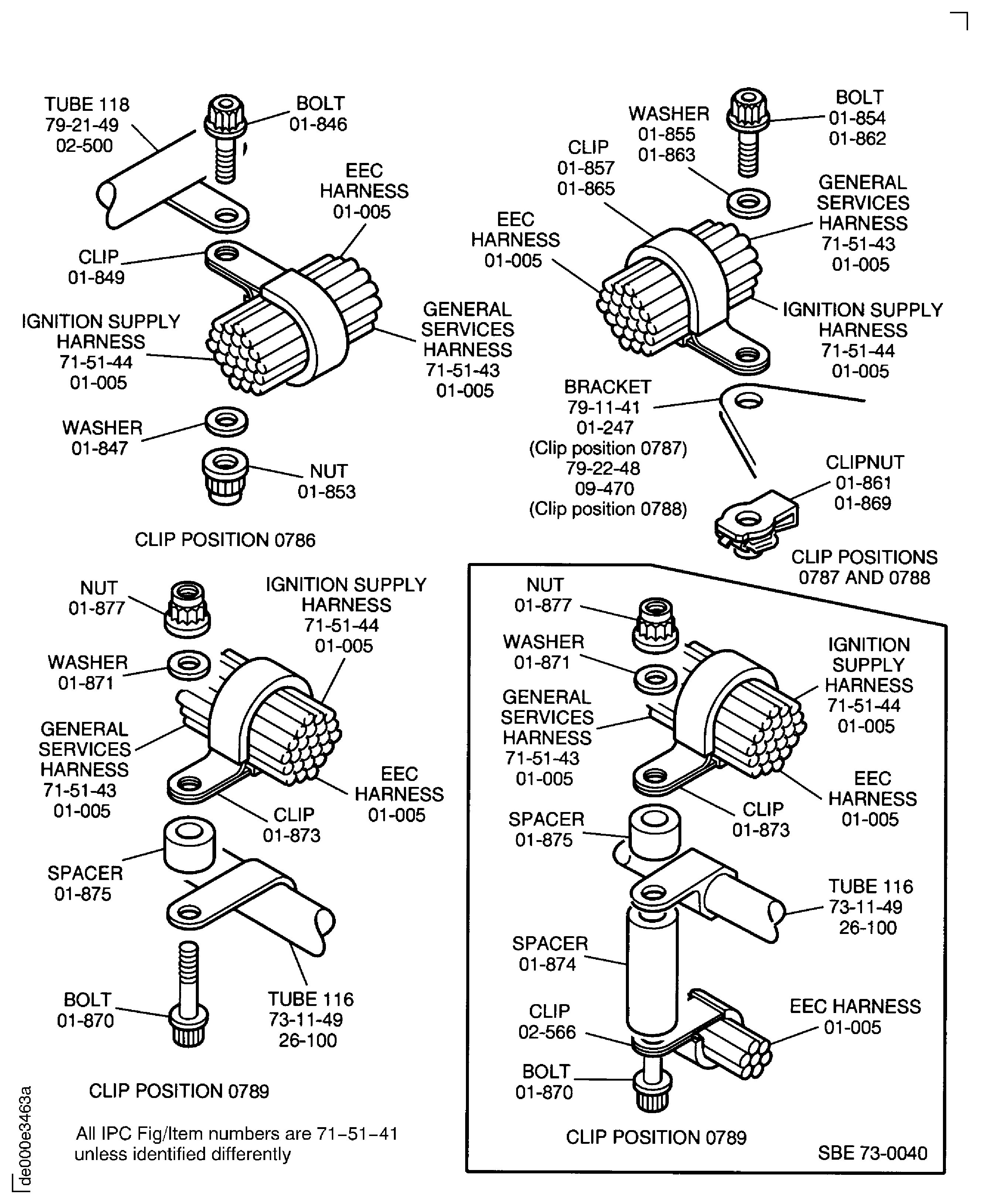

Pre SBE 73-0040 and Pre SBE 79-0087: Remove the bolts, washers, nuts, the spacer, clipnuts and clips from the clip positions that follow:

SBE 73-0040 and Pre SBE 79-0087: Remove the bolts, washers, nuts, the spacer, clipnuts and clips from the clip positions that follow:

Pre SBE 73-0040 and SBE 79-0087: Remove the bolts, washers, nuts, spacer, clipnuts and clips from the clip positions that follow:

SBE 73-0040 and SBE 79-0087: Remove the bolts, washers, nuts, spacer, clipnuts and clips from the clip positions that follow:

SUBTASK 72-00-60-020-066-B00 Move the Electrical Harnesses Clear of the External Gearbox (SBE 71-0050, Pre SBE 71-0107, SBE 73-0040, Pre SBE 79-0087 and SBE 79-0087)

SBE 71-0050: Engine - Incorporation of rerouting and modification requirements for the EEC fan harness

SBE 73-0040: Engine - Fuel and control - Fuel tubes - Fuel metering unit to fuel diverter valve servo tubes re-routed

SBE 79-0087: Oil - Scavenge oil tubes - Re-route of No.4 bearing scavenge tube

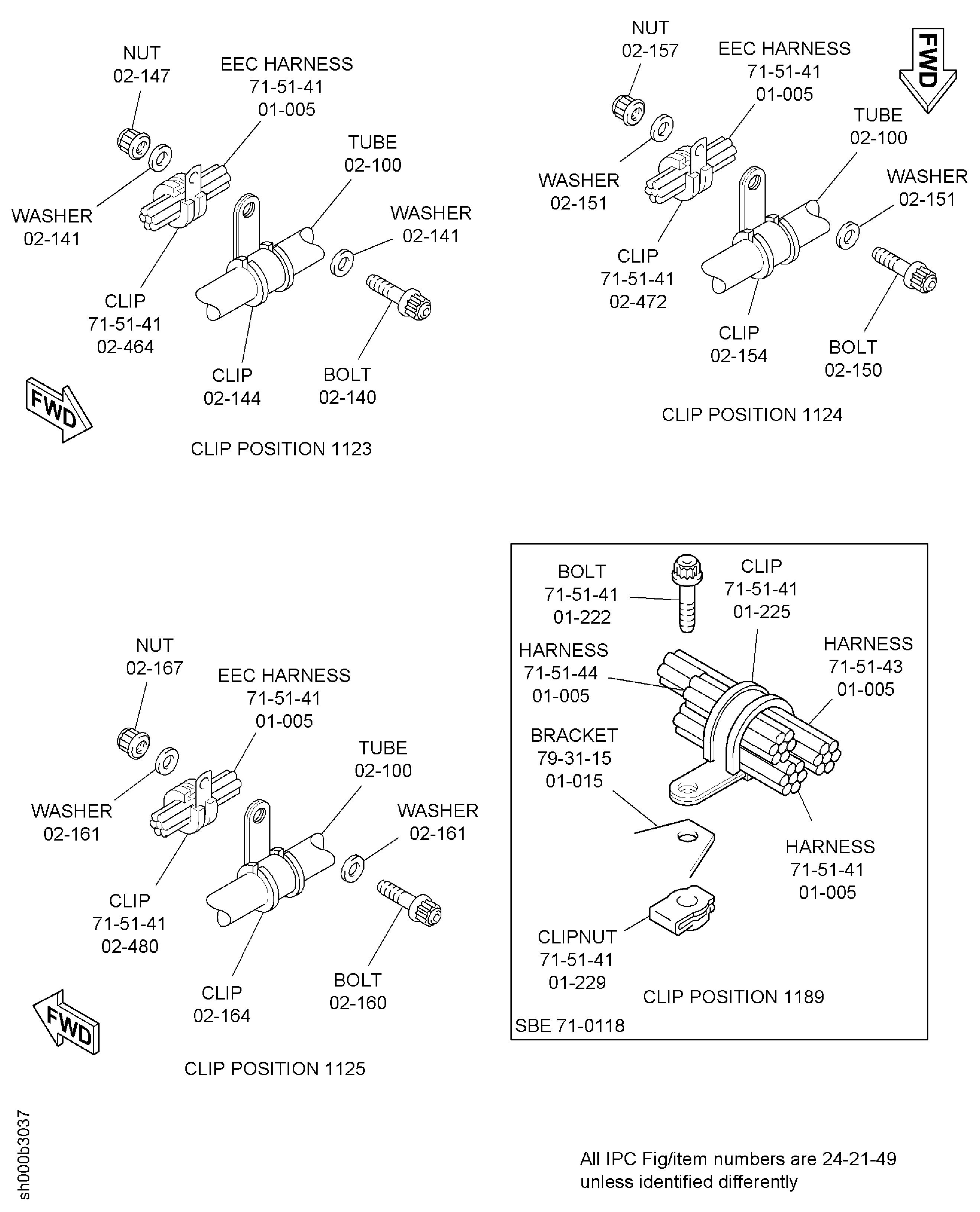

Pre SBE 73-0040 and Pre SBE 79-0087: Remove the electrical harnesses from the clip positions that follow:

SBE 73-0040 and Pre SBE 79-0087: Remove the electrical harnesses from the clip positions that follow:

Pre SBE 73-0040 and SBE 79-0087: Remove the electrical harnesses from the clip positions that follow:

SBE 73-0040 and SBE 79-0087: Remove the electrical harnesses from the clip positions that follow:

SUBTASK 72-00-60-020-066-C00 Move the Electrical Harnesses Clear of the External Gearbox (SBE 71-0107, SBE 73-0040, Pre SBE 79-0087 and SBE 79-0087)

SBE 71-0107: Engine - Power plant - Incorporation of modification requirements for the EEC and ignition supply harness

SBE 73-0040: Engine - Fuel and control - Fuel tubes - Fuel metering unit to fuel diverter valve servo tubes re-routed

SBE 79-0087: Oil - Scavenge oil tubes - Re-route of No.4 bearing scavenge tube

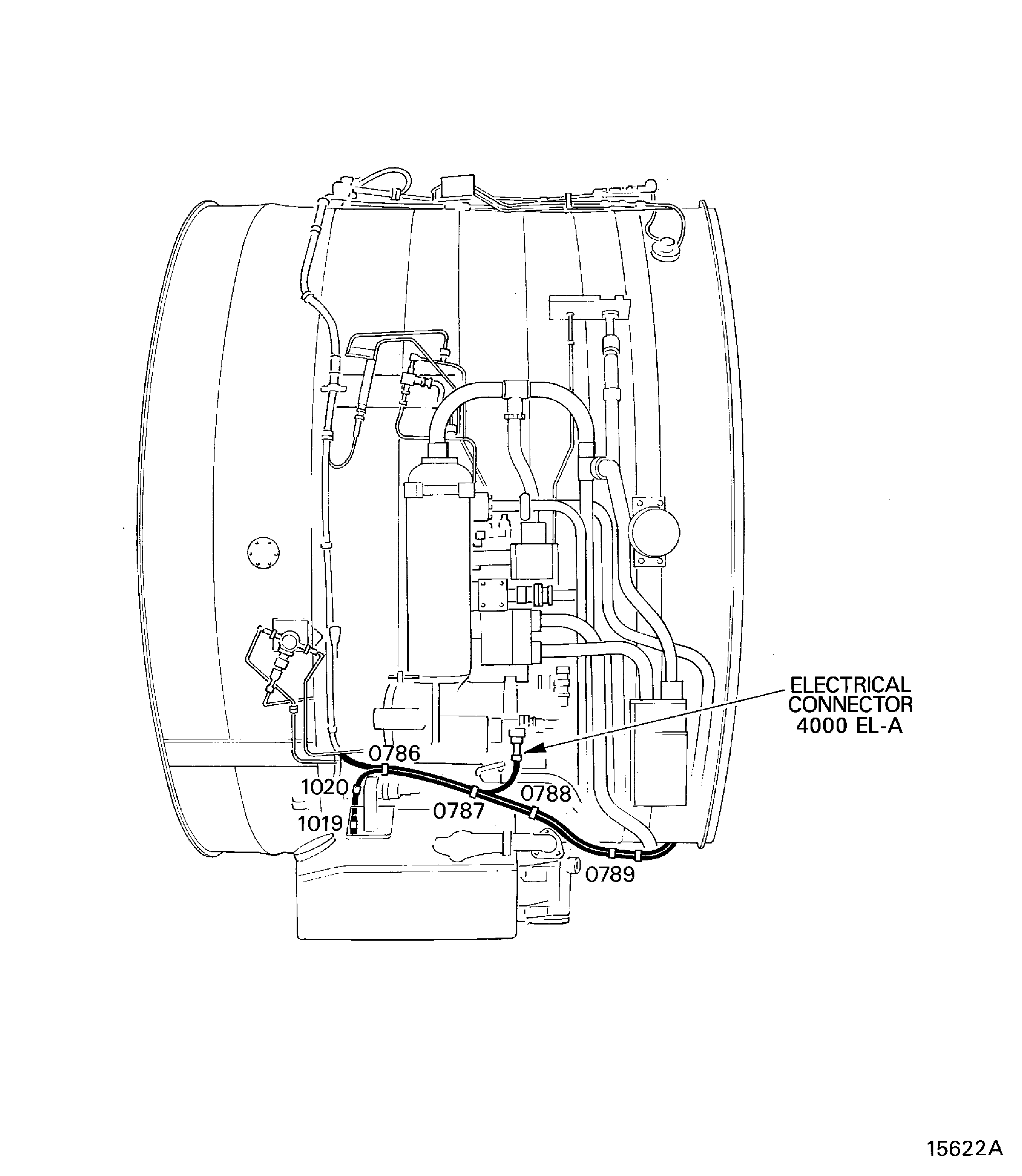

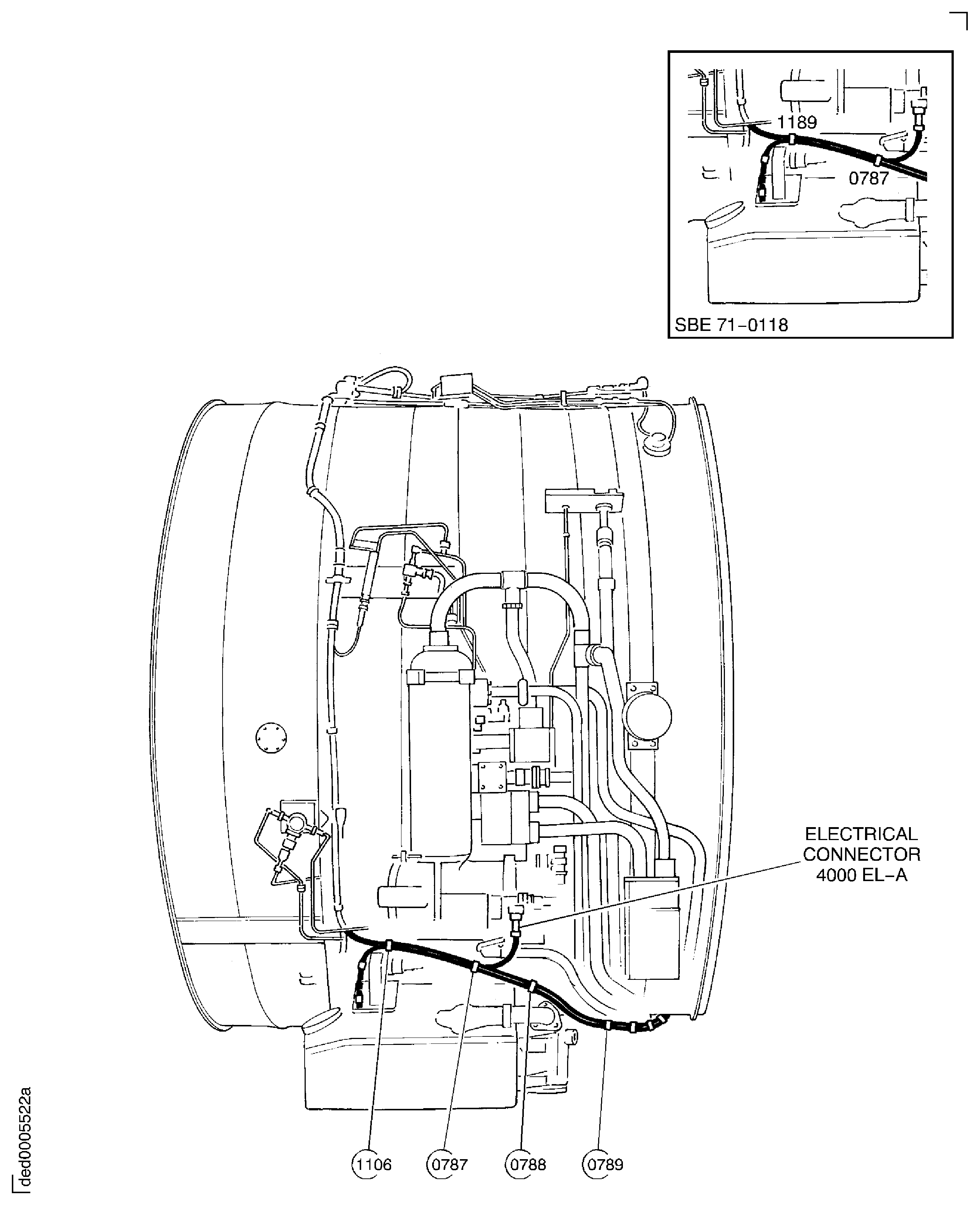

SBE 71-0110 : Remove the bolts, washers, nuts, the spacer, clipnuts and clips from the clip positions 0787, 0788, 0789 and 1106.

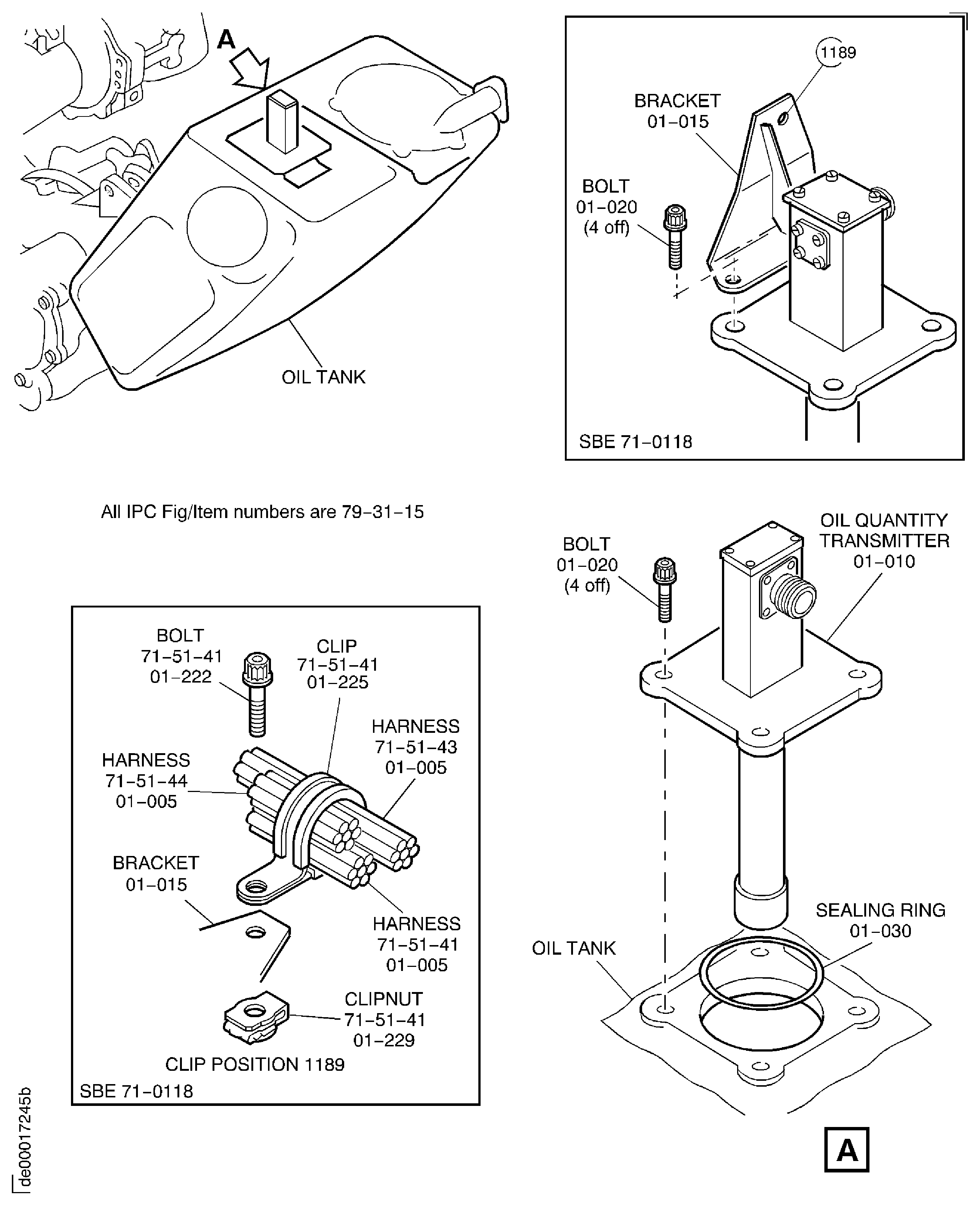

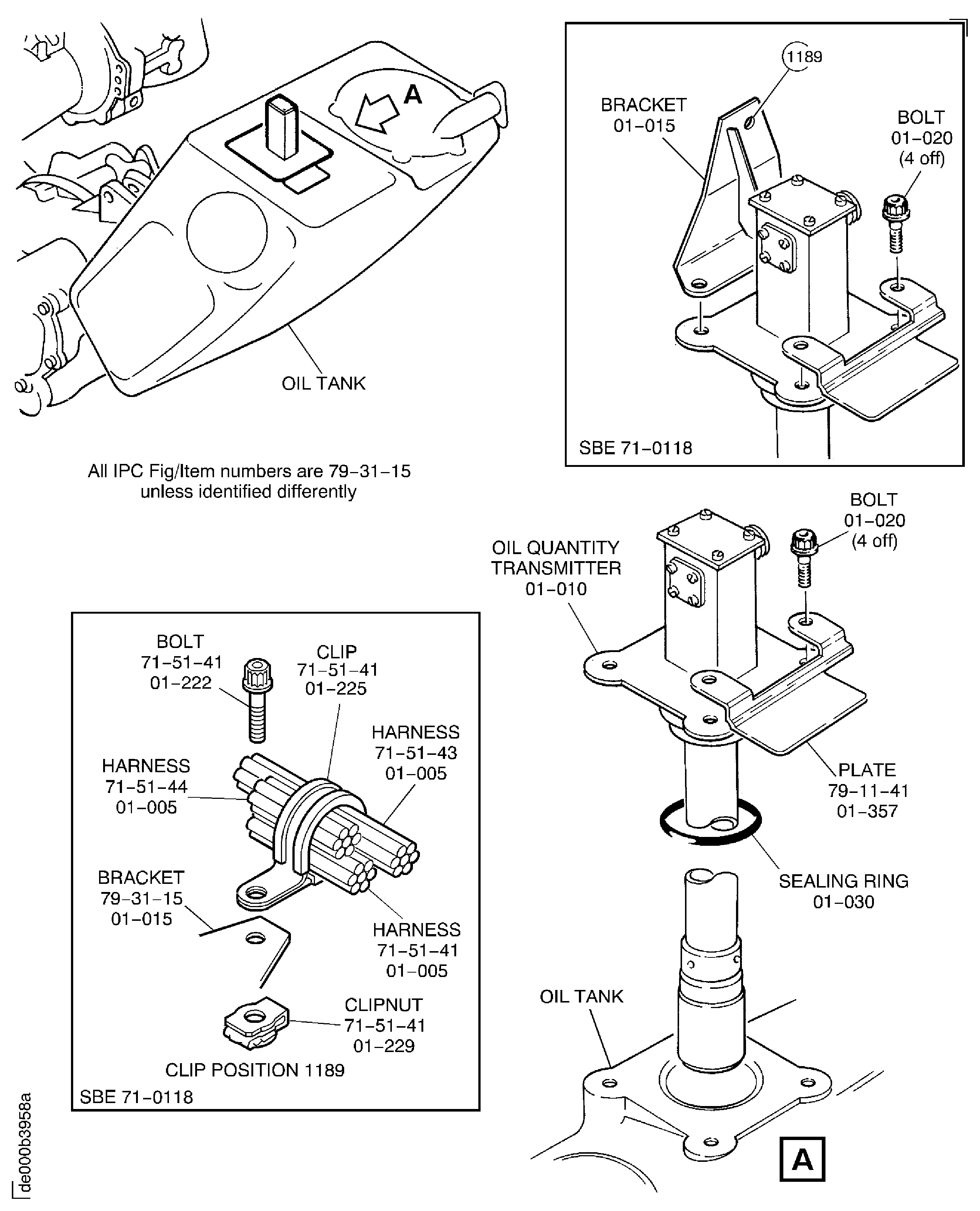

SBE 71-0118 : Remove the bolts, washers, nuts, the spacer, clipnuts and clips from the clip positions 0787, 0788, 0789 and 1189.

Remove the electrical harnesses from the clip positions that follow:

SUBTASK 72-00-60-020-066-D00 Move the Electrical Harness Clear of the External Gearbox (SBE 71-0110 and SBE 71-0118)

SBE 71-0110Engine - Provide rerouted oil tubes for the ACOC and the oil tank assembly

SBE 71-0118: Engine - Revised clipping to provide increased clearance between oil quantity transmitter and EEC harness

Refer to Figure.

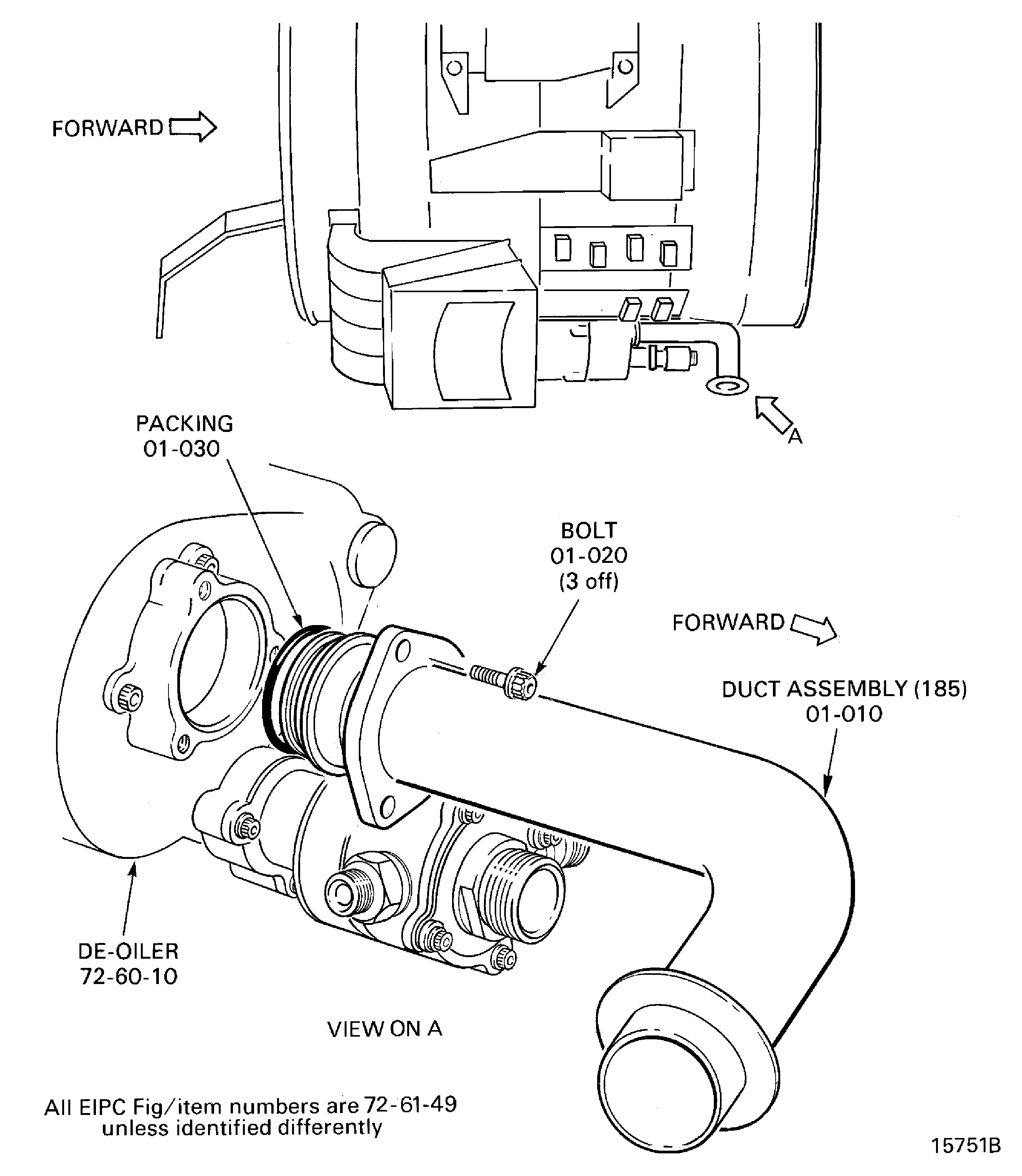

Remove the three bolts that attach the breather duct ENGINE-GEARBOX BREATHER OUTLET DUCT (72-61-49, 01-010) to the deoiler, remove the breather duct and remove the packing.

SUBTASK 72-00-60-020-067 Remove the Deoiler Breather Duct

Refer to Figure.

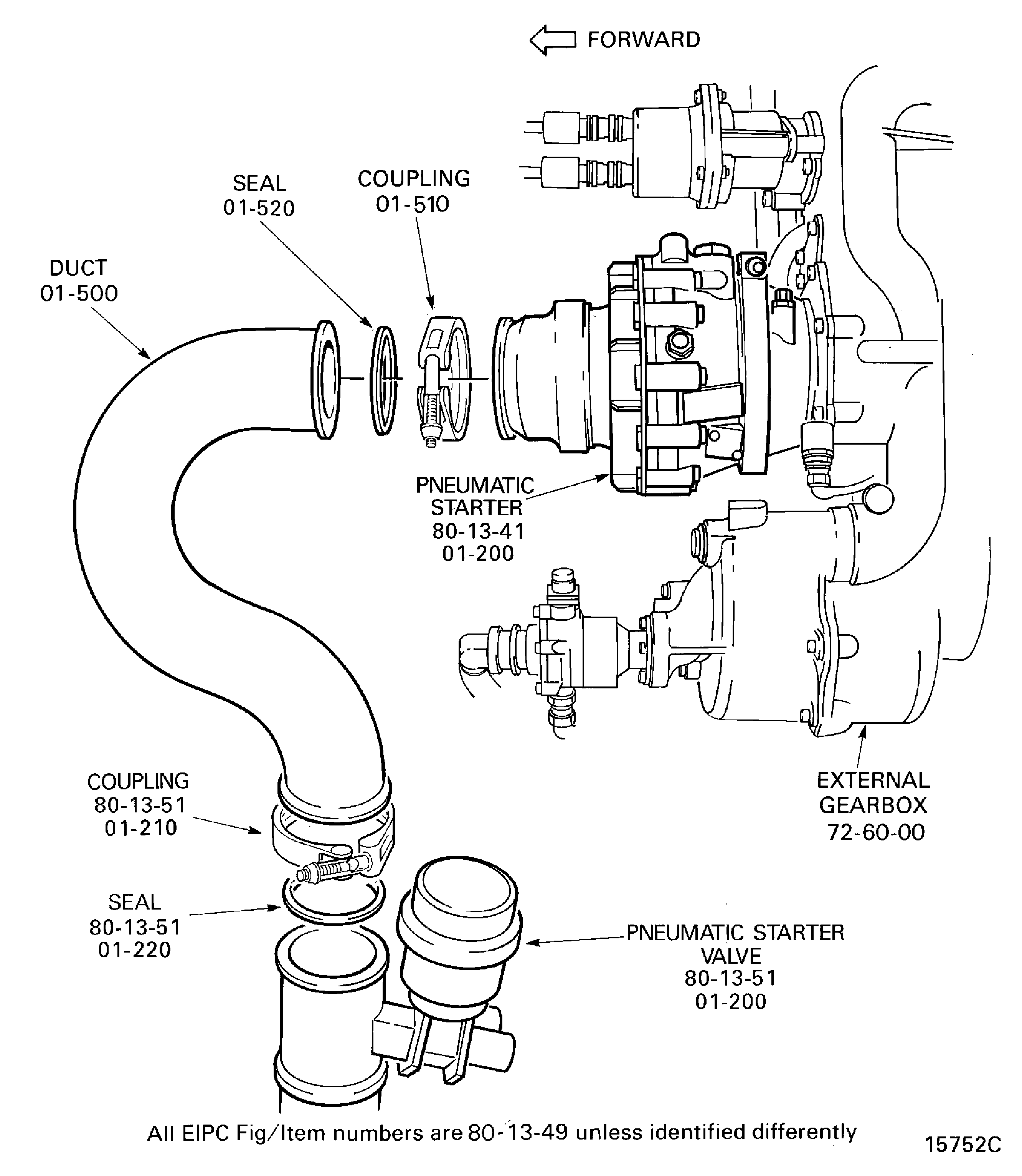

Remove the coupling STARTING-STARTER DUCT (80-13-49, 01-510) from the interface of the lower duct STARTING-STARTER DUCT (80-13-49, 01-500) and the pneumatic starter STARTING-PNEUMATIC STARTER (80-13-41, 01-200).

Hold the lower duct and remove the coupling STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-210) from the interface at the lower duct and the starter valve STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-200).

Remove the lower duct and remove the seals STARTING-STARTER DUCT (80-13-49, 01-520 and STARTING-PNEUMATIC STARTER VALVE 80-13-51, 01-220).

SUBTASK 72-00-60-020-068 Remove the Pneumatic Starter Lower Duct Assembly

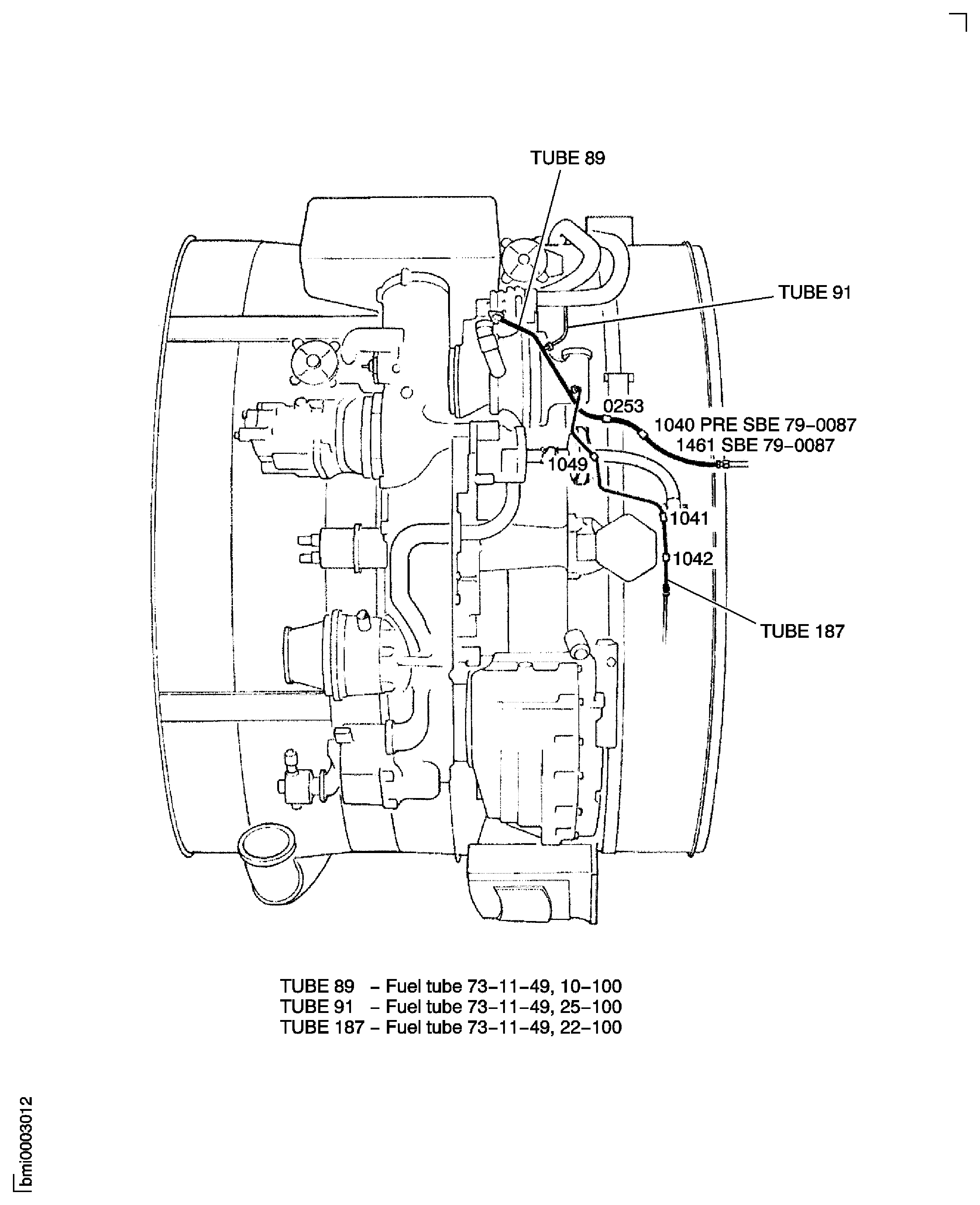

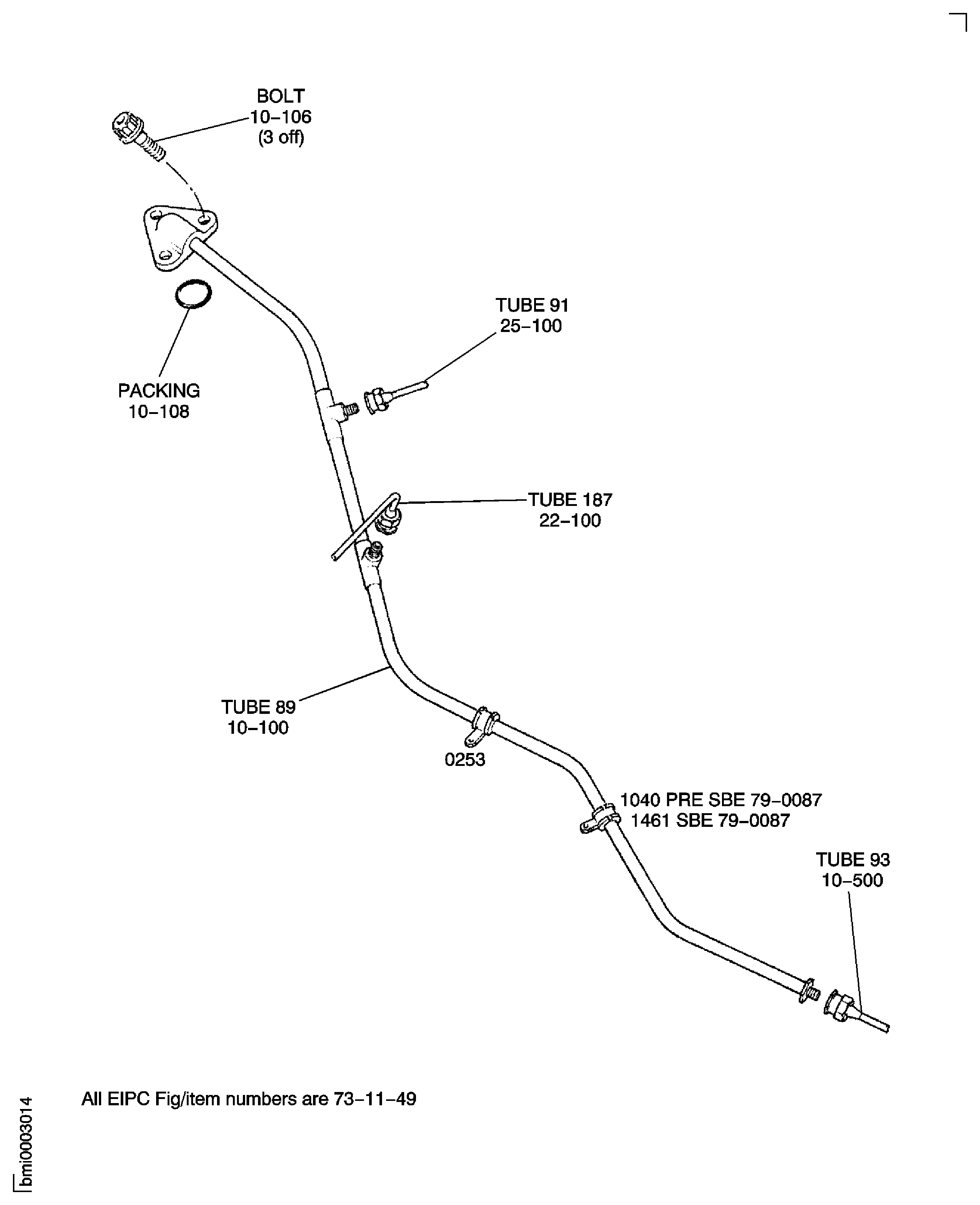

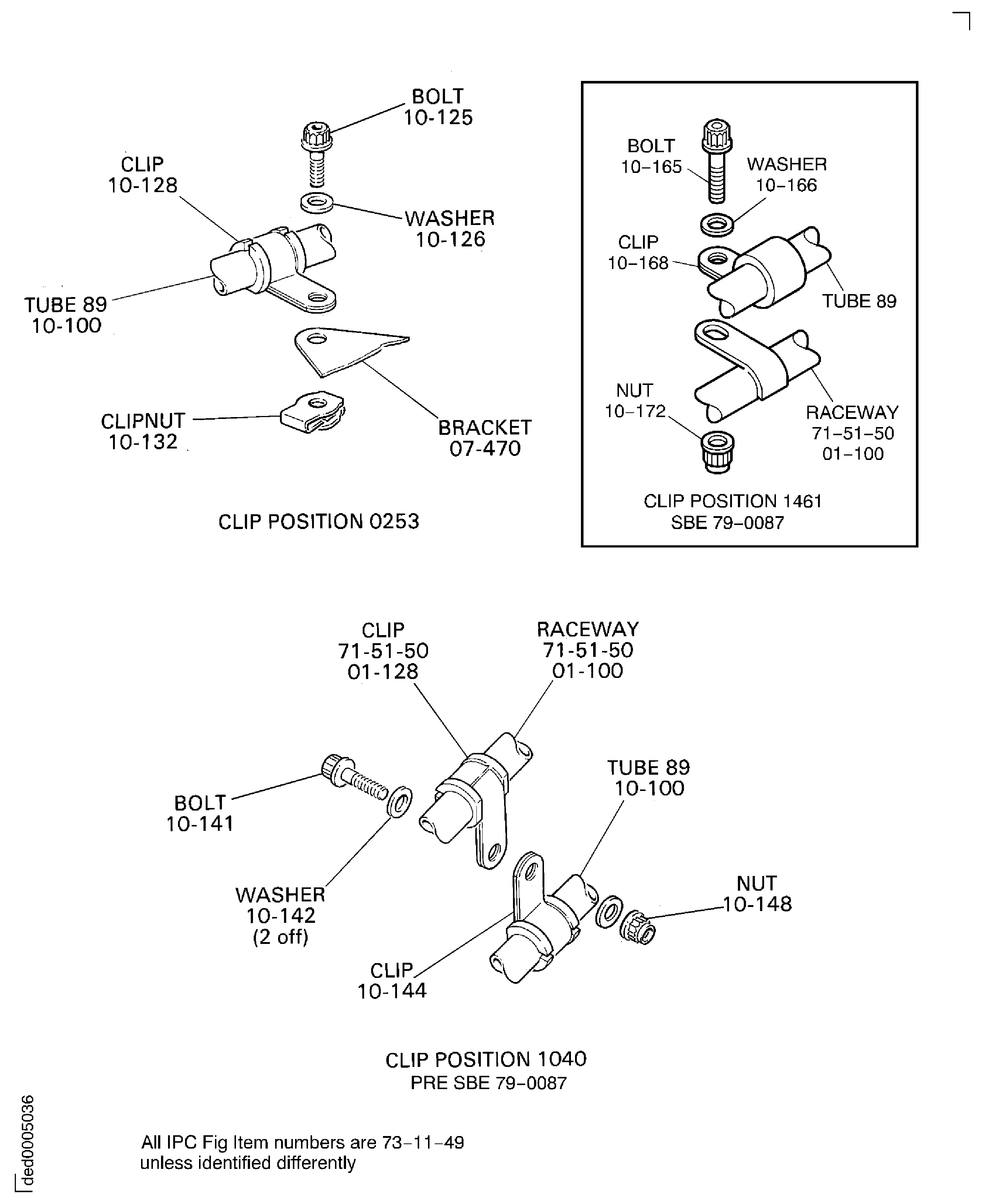

Pre SBE 79-0087: Remove the bolts, washers, nut and clipnut and clips from the clip positions 0253 and 1040. Remove the tube 89.

SBE 79-0087: Remove the bolts, washers, nut and clipnut and clips from the clip positions 0253 and 1461. Remove the tube 89.

SUBTASK 72-00-60-020-069 Remove the HP Servo Fuel Tube (89) (Pre SBE 79-0087 and SBE 79-0087)

SBE 79-0087: Oil - Scavenge oil tubes - Re-route of No.4 bearing scavenge tube

NOTE

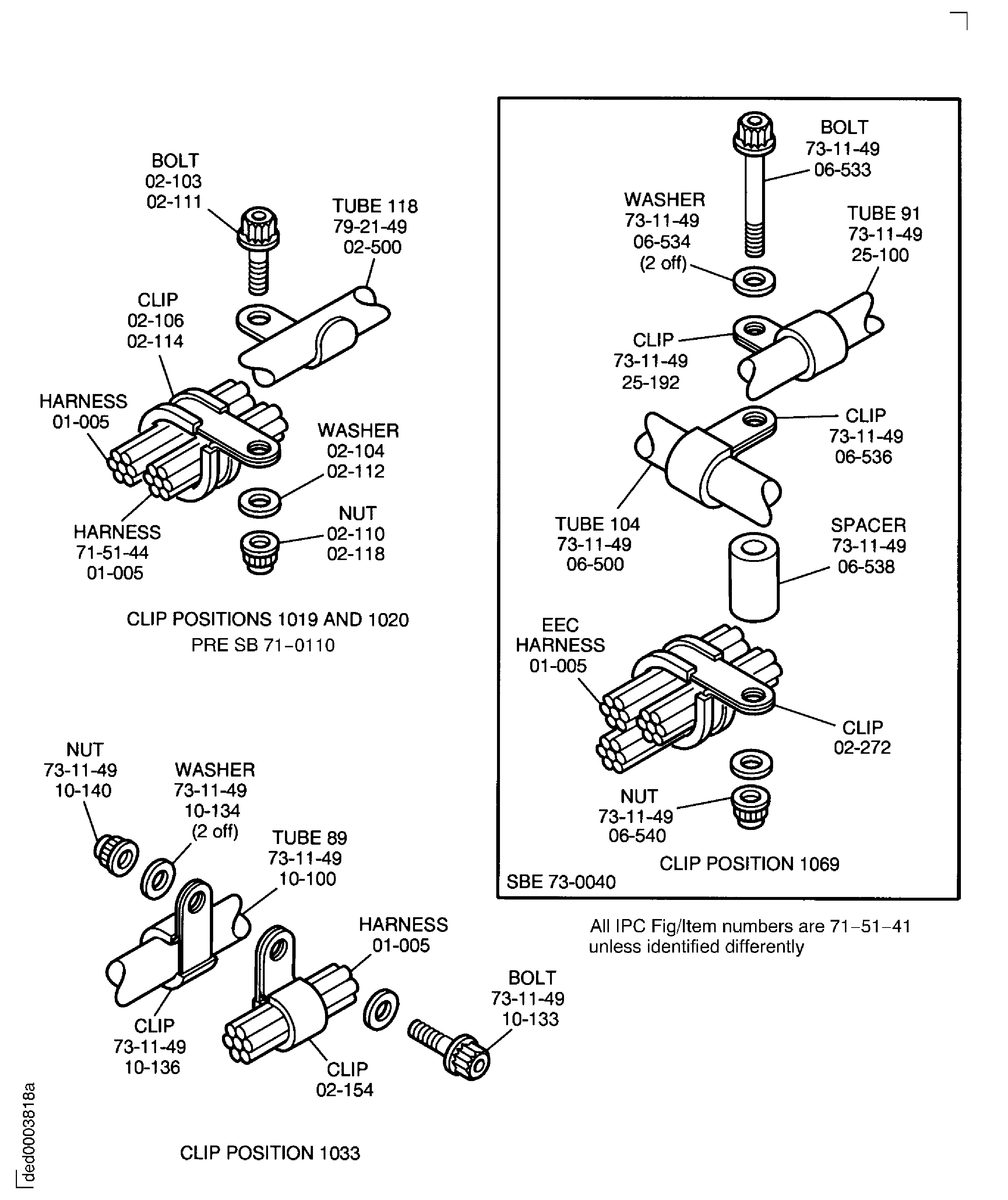

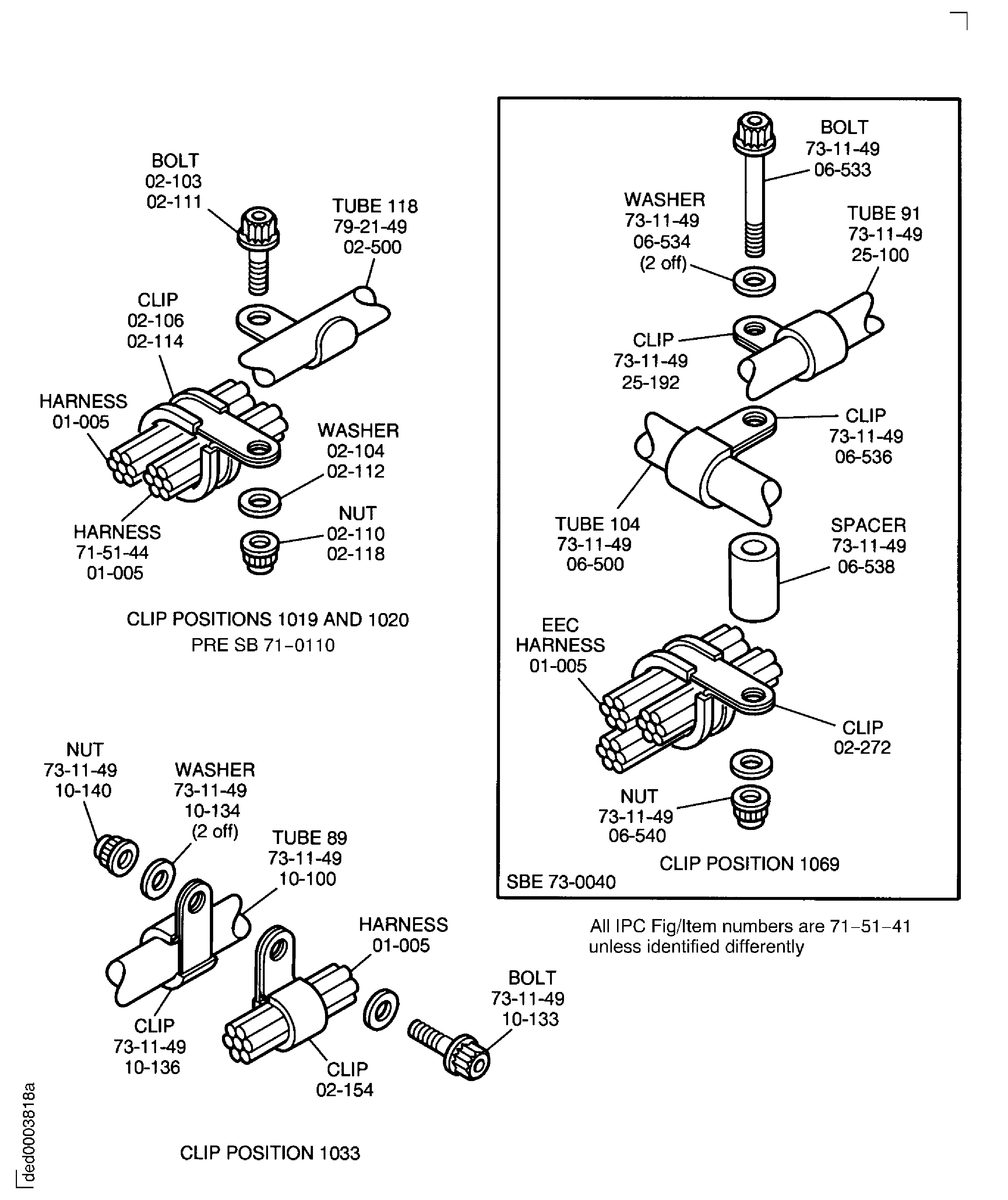

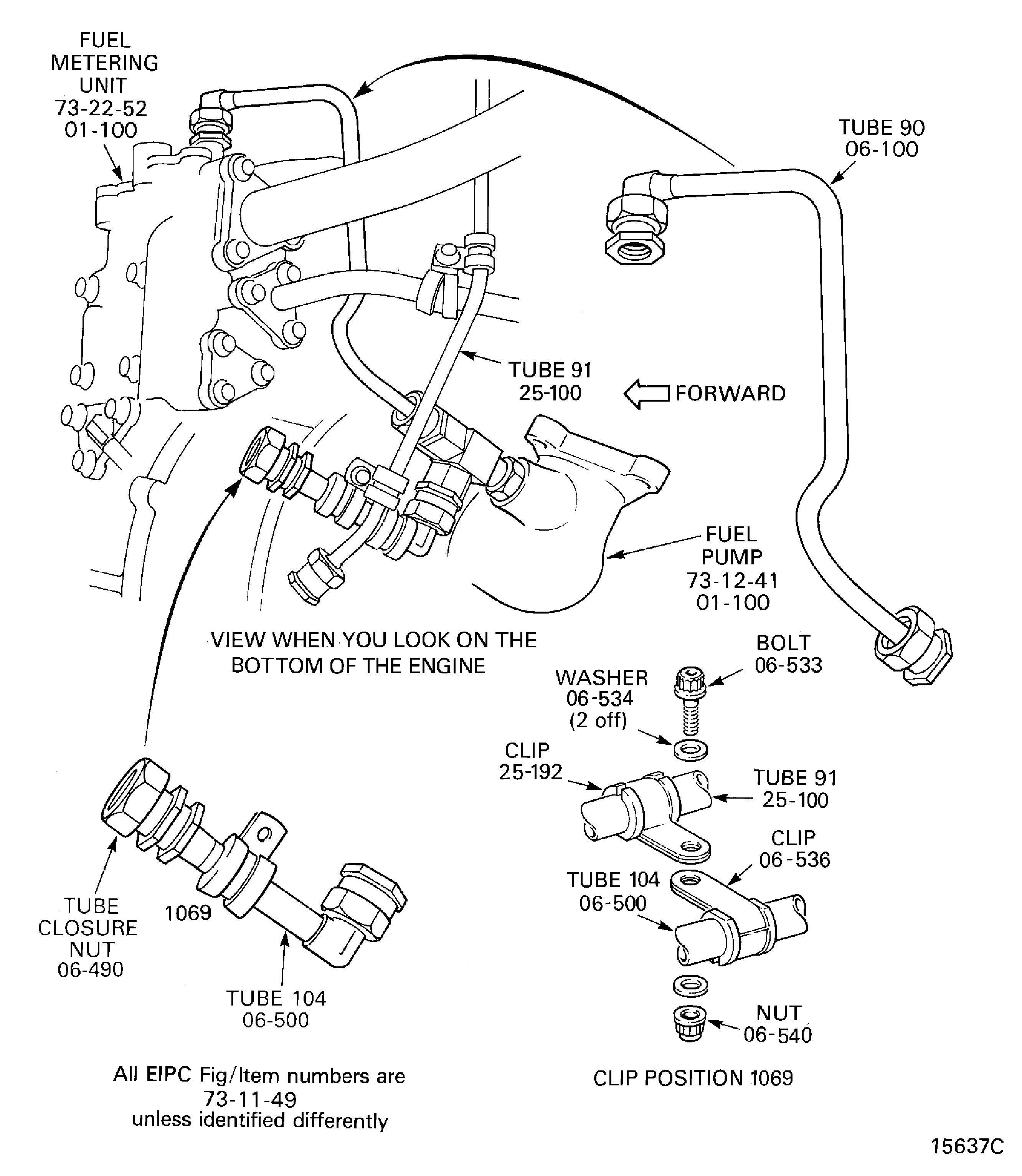

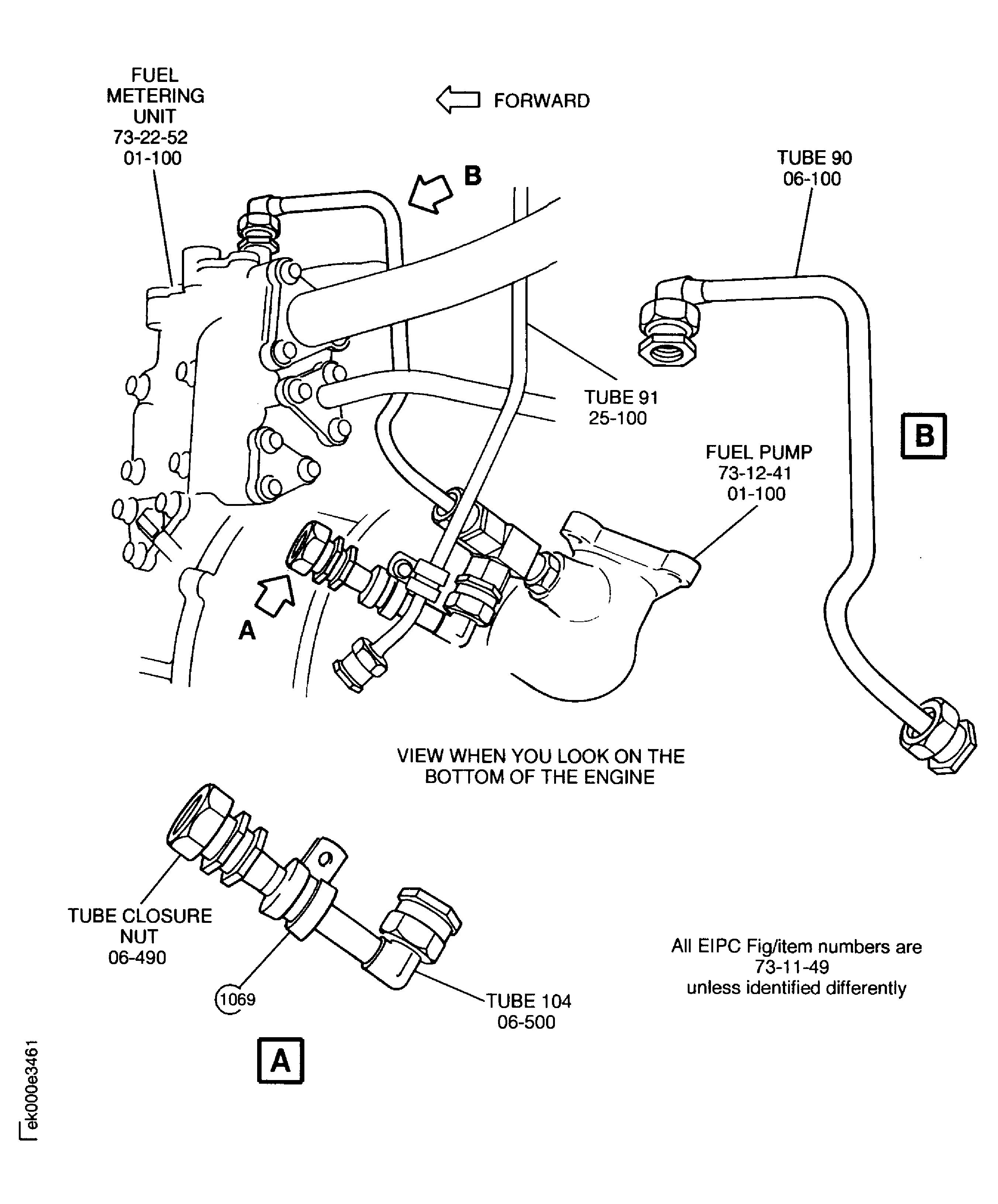

Some fuel drainage could occur during this procedure. It is recommended that an applicable container be available.Pre SBE 73-0040: Remove the bolt, the two washers, the nut and the two clips from clip position 1069.

SBE 73-0040: Remove the bolt, the two washers, the spacer, the nut and the three clips from the clip position 1069.

SUBTASK 72-00-60-020-070 Remove the LP Fuel Tube (90) and the Fuel Pump Drain Tube (104)

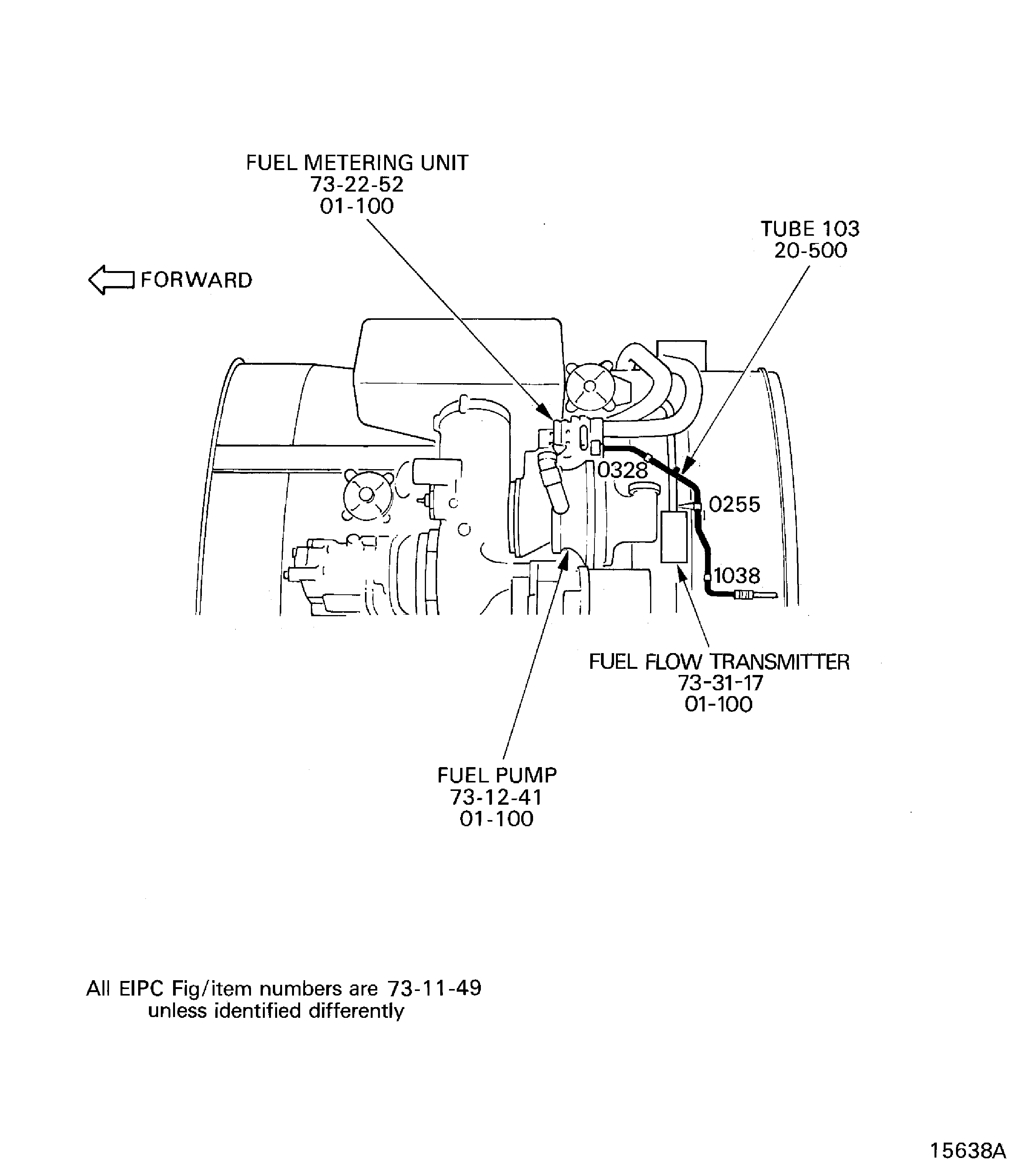

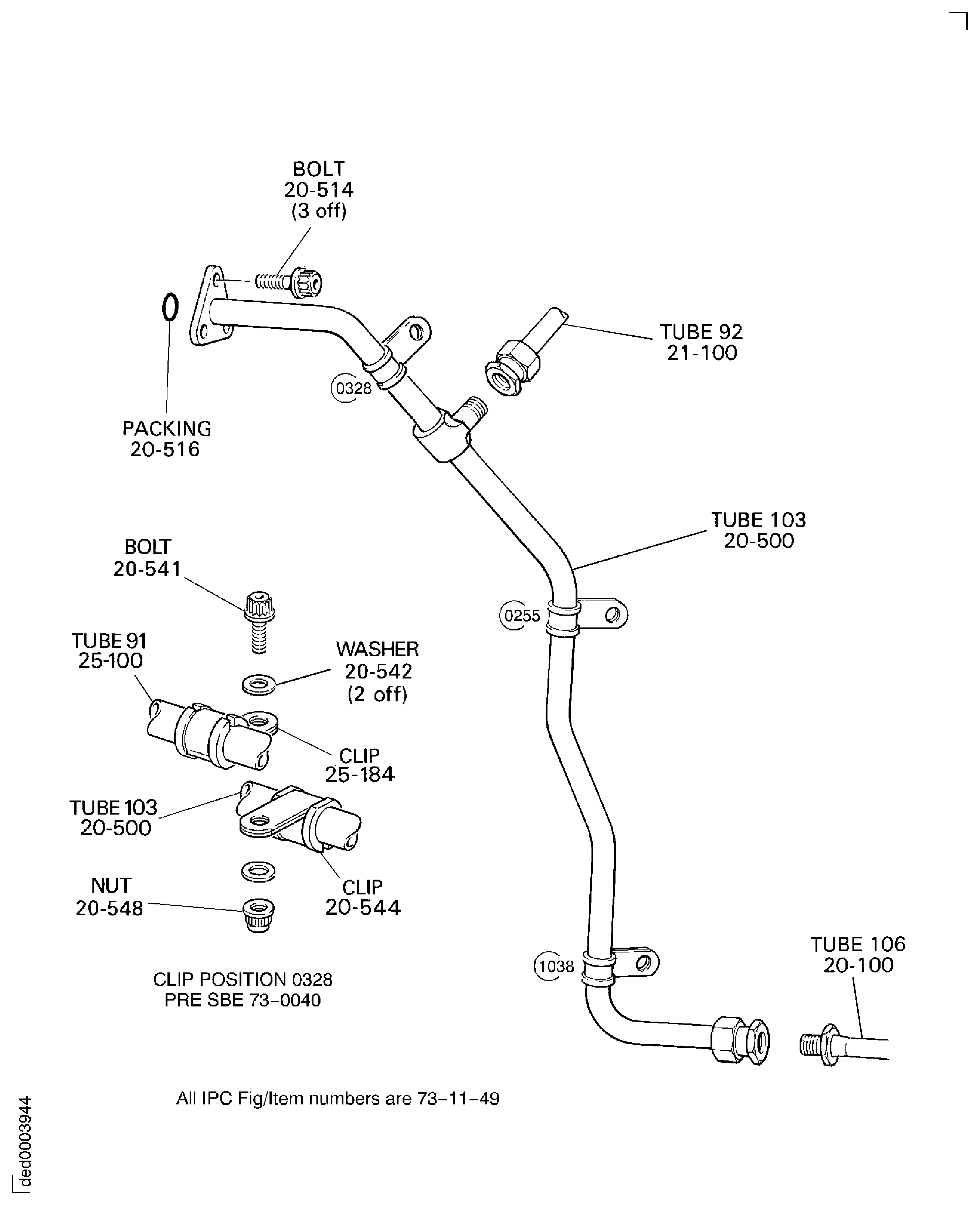

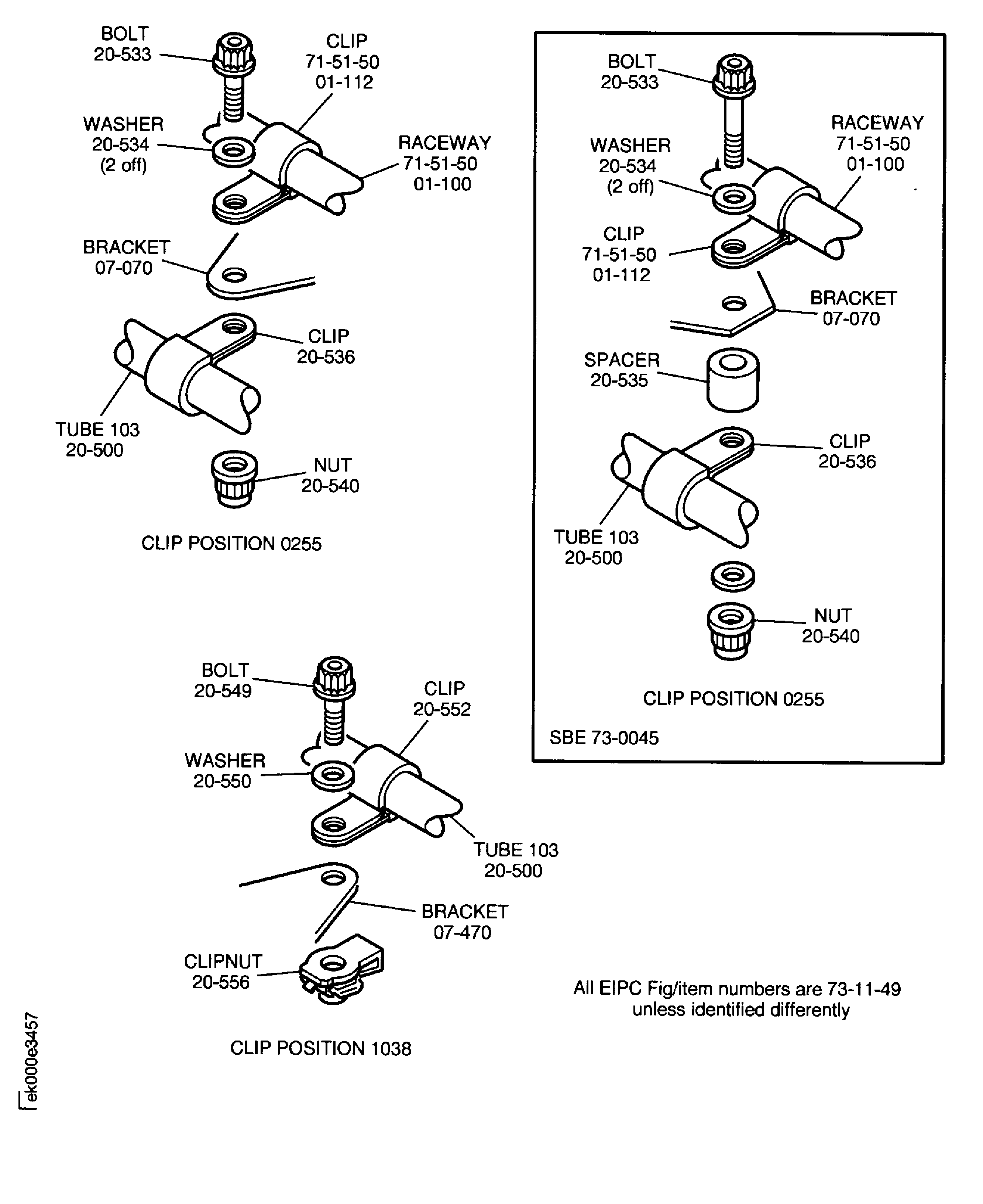

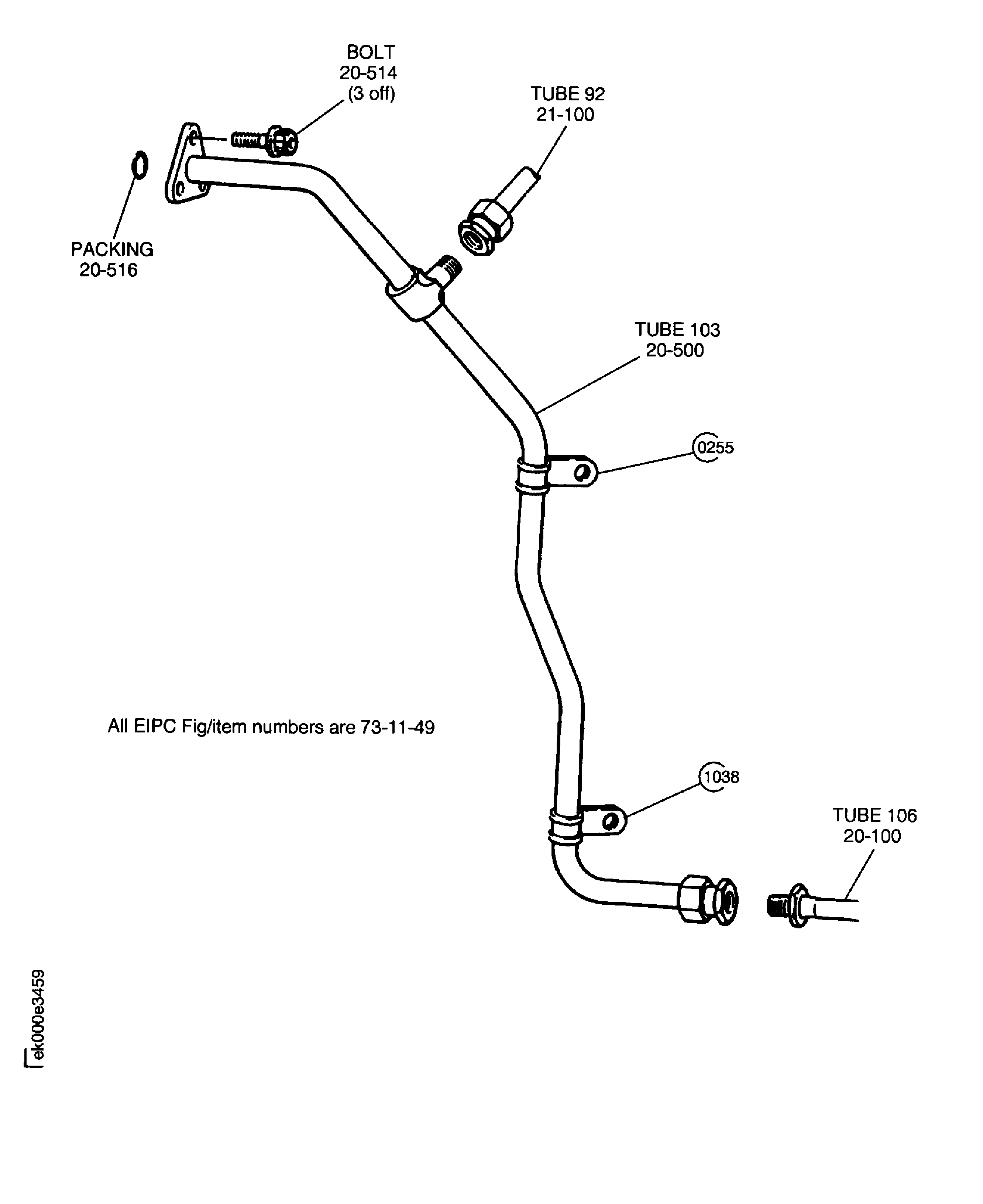

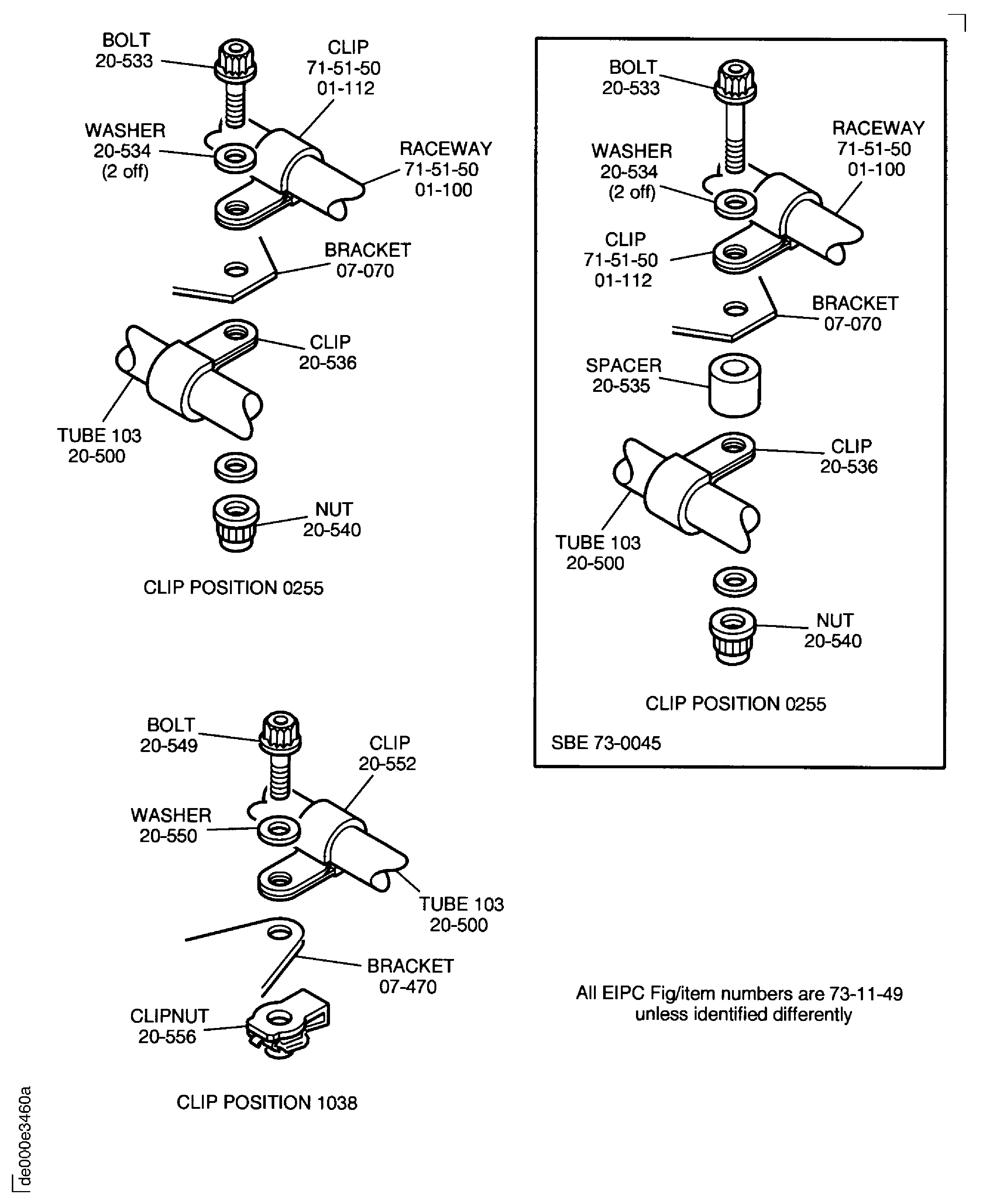

Pre SBE 73-0045: Remove the bolts, the washers, the nuts and clipnut and the clips from the clip positions 0255, 0328 and 1038.

SBE 73-0045: Remove the bolts, the washers, the spacer, the nuts, the clip nut and the clips from the clip positions 0255, 0328 and 1038.

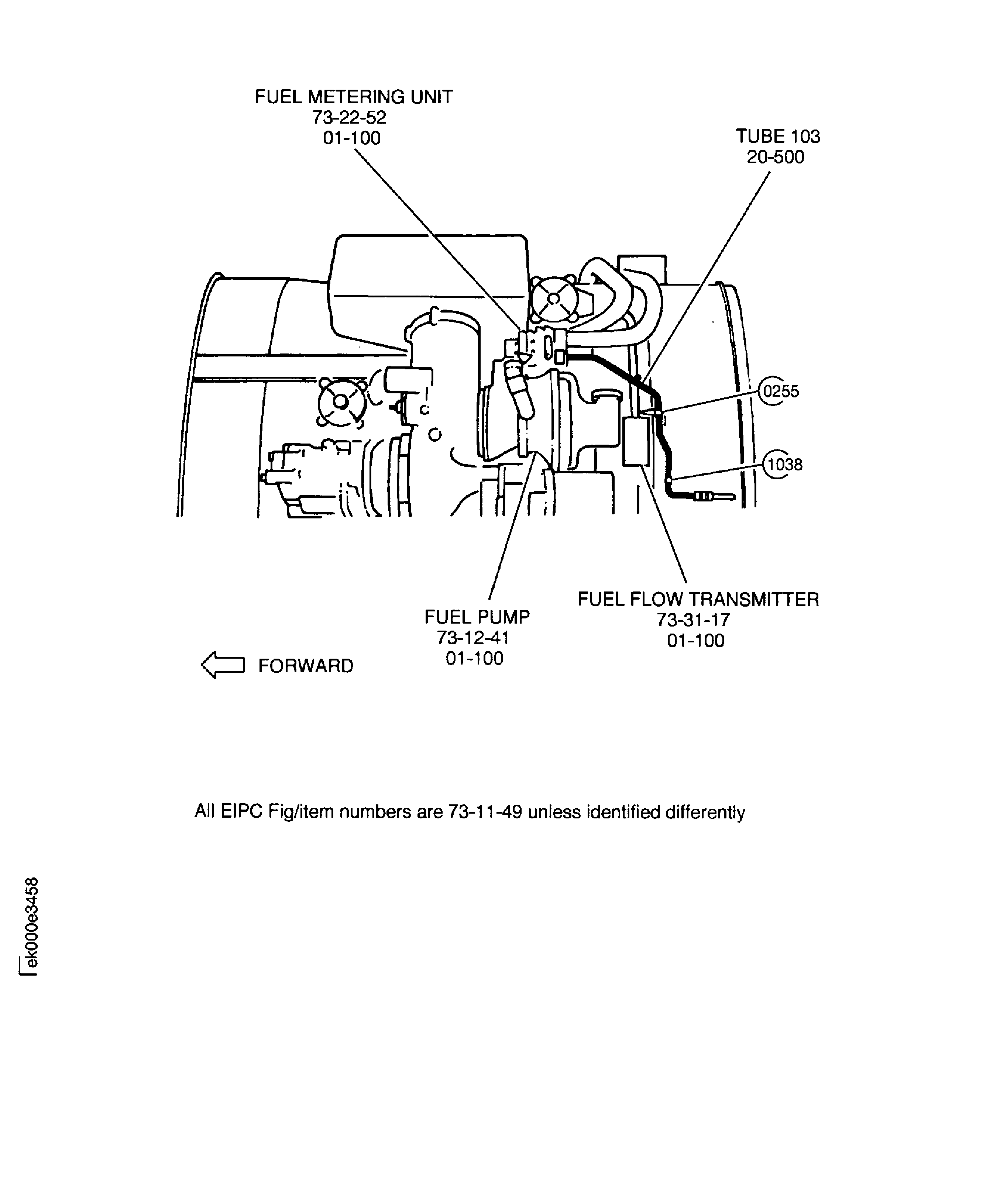

SUBTASK 72-00-60-020-071-A00 Remove the Fuel Servo Return Tube (103) (Pre SBE 73-0040)

NOTE

Some fuel drainage could occur during this procedure. It is recommended that an applicable container be available.SBE 73-0040: Engine - Fuel and control - Fuel tubes - Fuel metering unit to fuel diverter valve servo tubes re-routed

Pre SBE 73-0045: Remove the bolts, the washers, the nuts and clipnut and the clips from the clip positions 0255 and 1038.

SBE 73-0045: Remove the bolts, the washers, the spacer, the clipnut and the clips from the clip positions 0255 and 1038.

SUBTASK 72-00-60-020-071-B00 Remove the Fuel Servo Return Tube (103) (SBE 73-0040)

NOTE

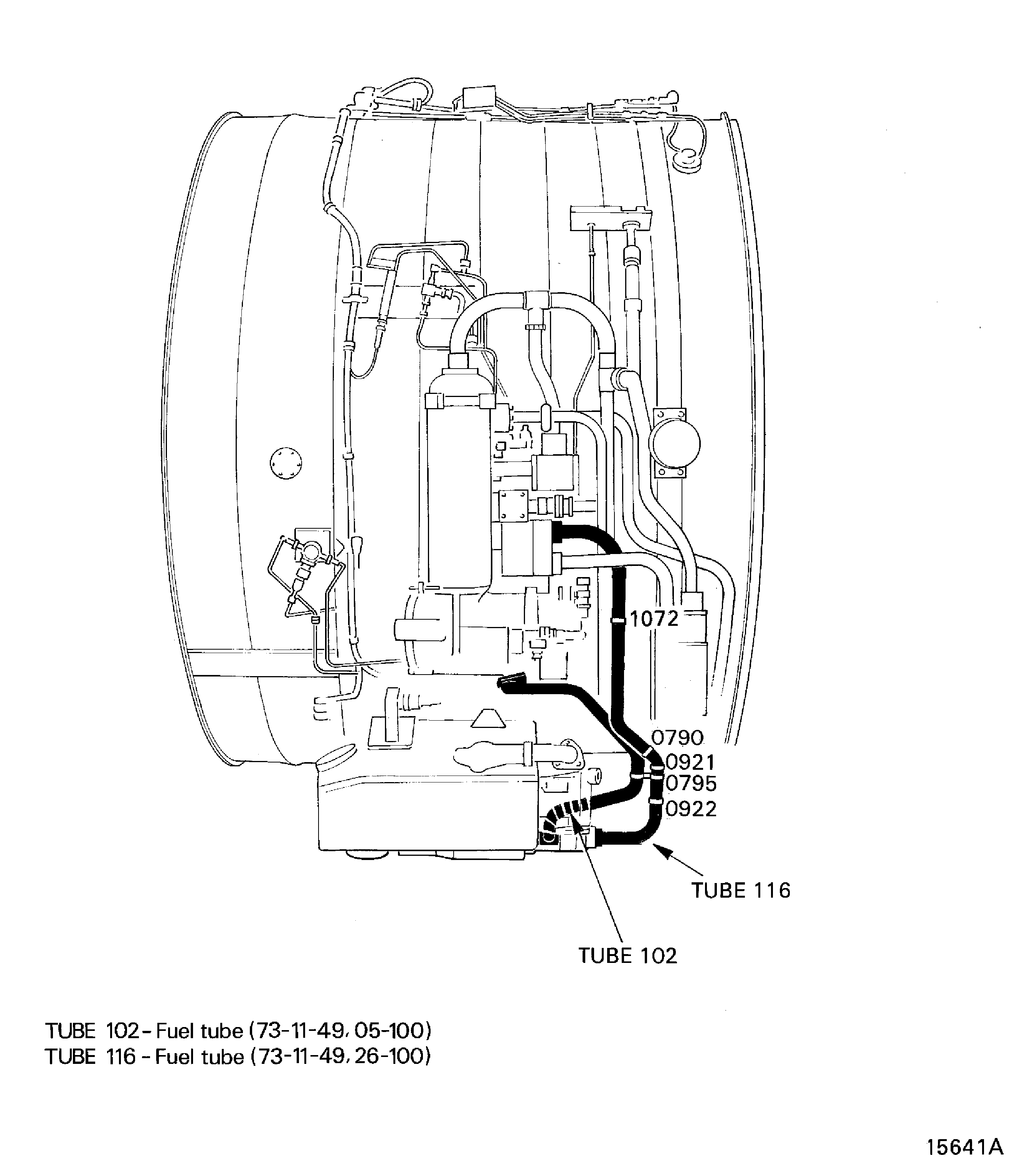

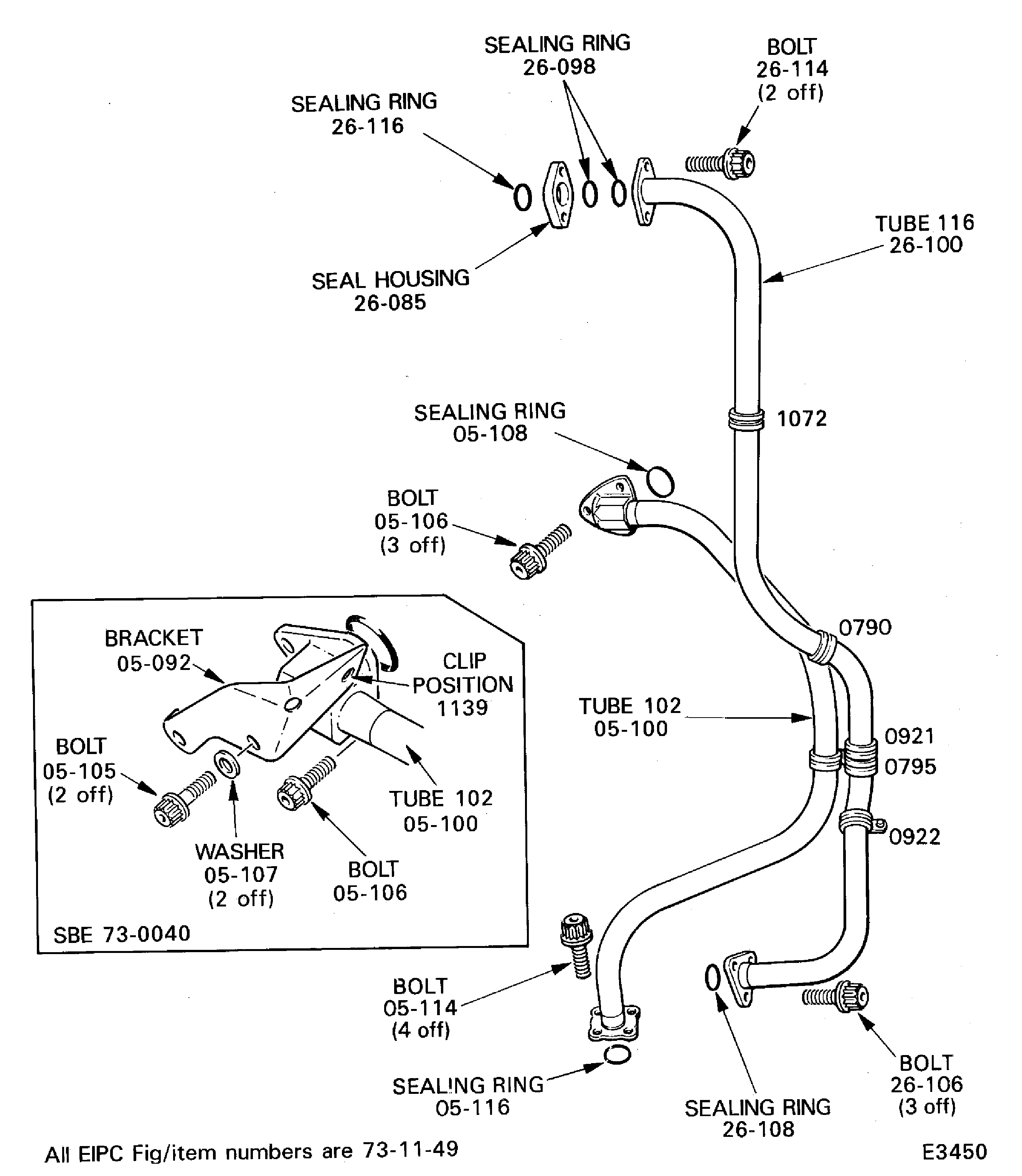

Some fuel drainage could occur during this procedure. It is recommended that an applicable container be available.Remove the seven bolts that attach the tube 102 ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 05-100) to the FCOC and the fuel pump. Remove and discard the two sealing rings from the tube 102.

SUBTASK 72-00-60-020-072-A00 Remove the LP Fuel Tube (102) (Pre SBE 73-0040)

NOTE

Some fuel drainage could occur during this procedure. It is recommended that an applicable container be available.Remove the seven bolts and the washer that attach the tube 102 ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 05-100) and the bracket to the FCOC and the fuel pump. Remove and discard the two sealing rings from the tube 102.

SUBTASK 72-00-60-020-072-B00 Remove the LP Fuel Tube (102) (SBE 73-0040)

SBE 73-0040: Engine - Fuel and control - Fuel tubes - Fuel metering unit to fuel diverter valve servo tubes re-routed

NOTE

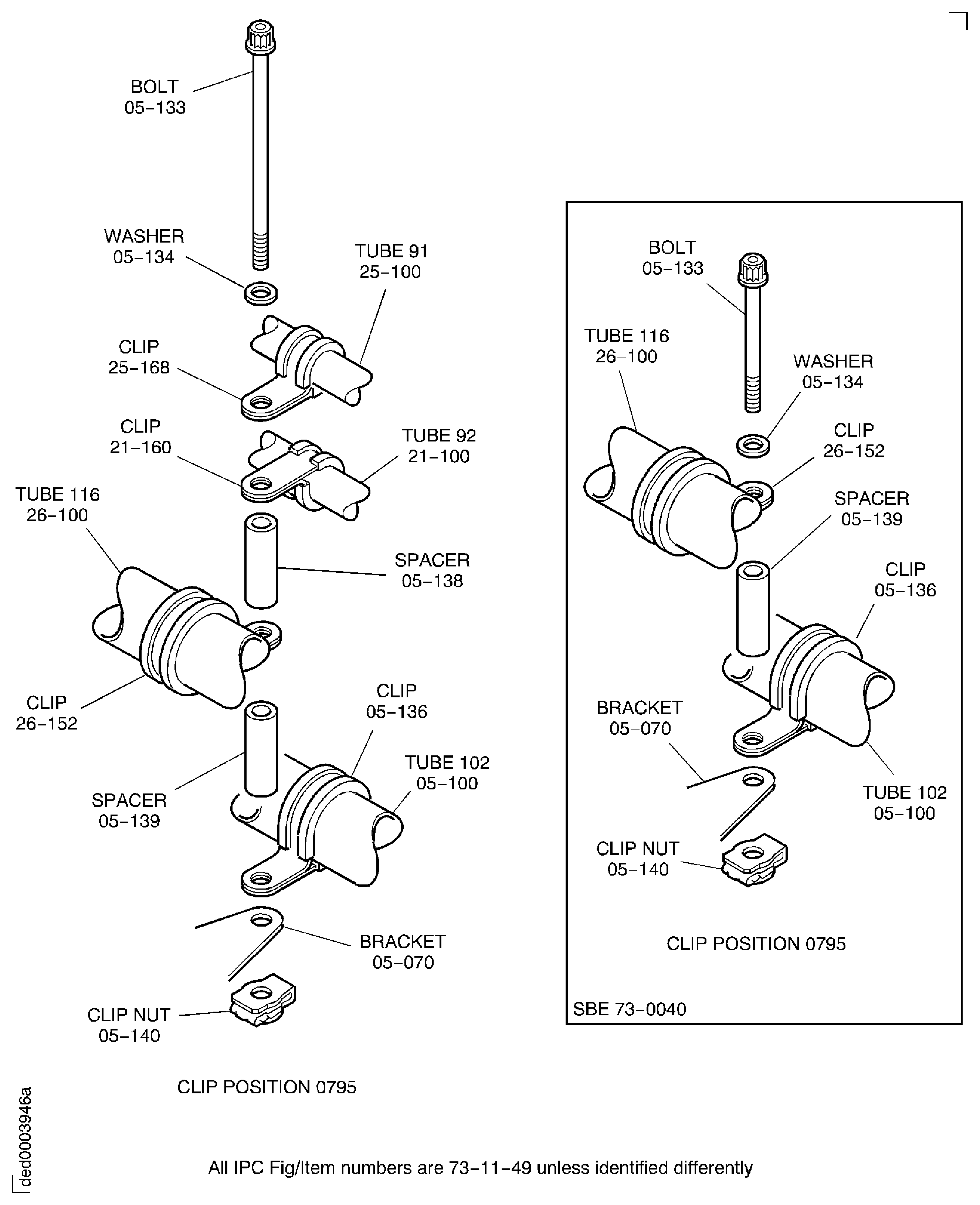

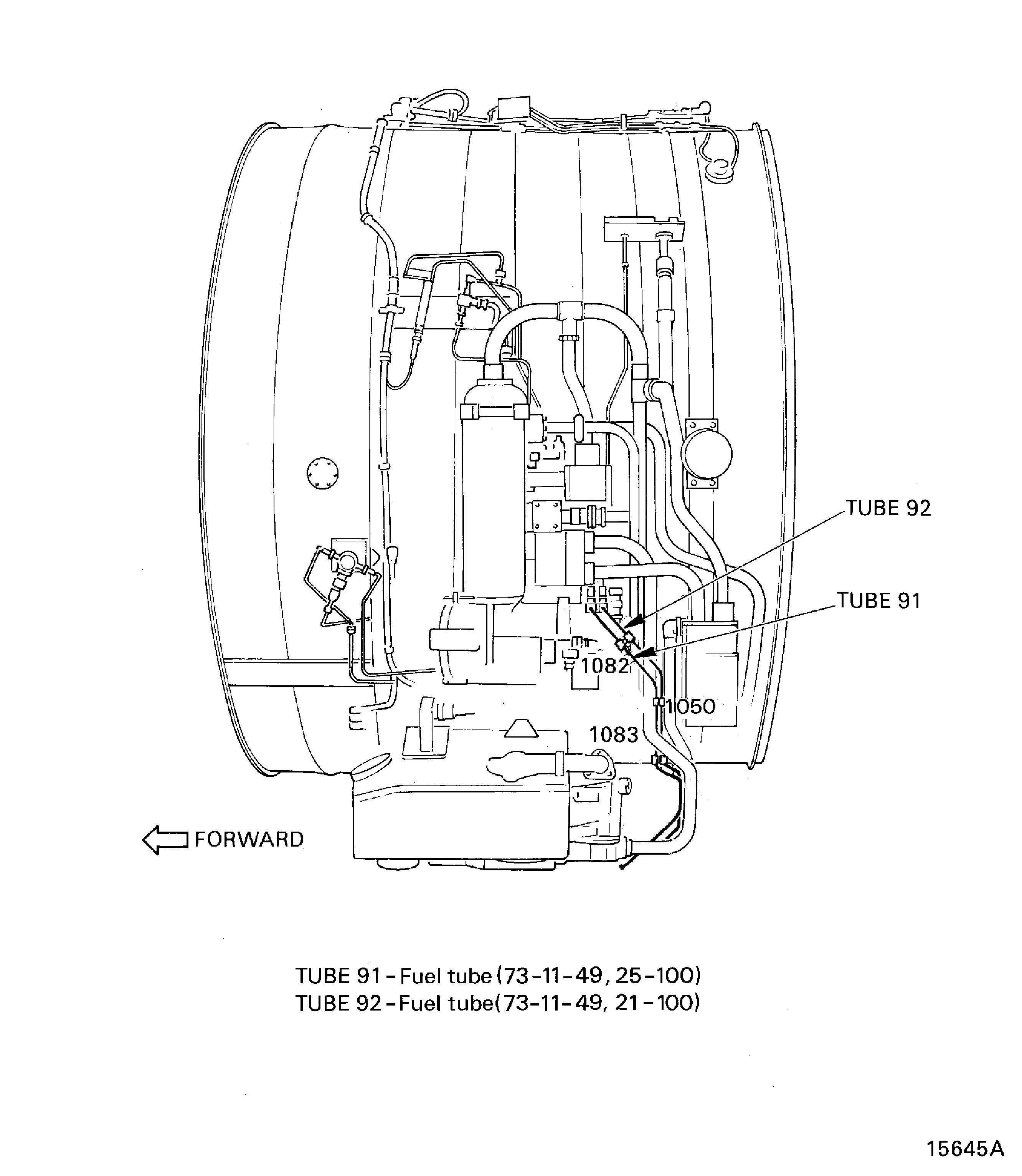

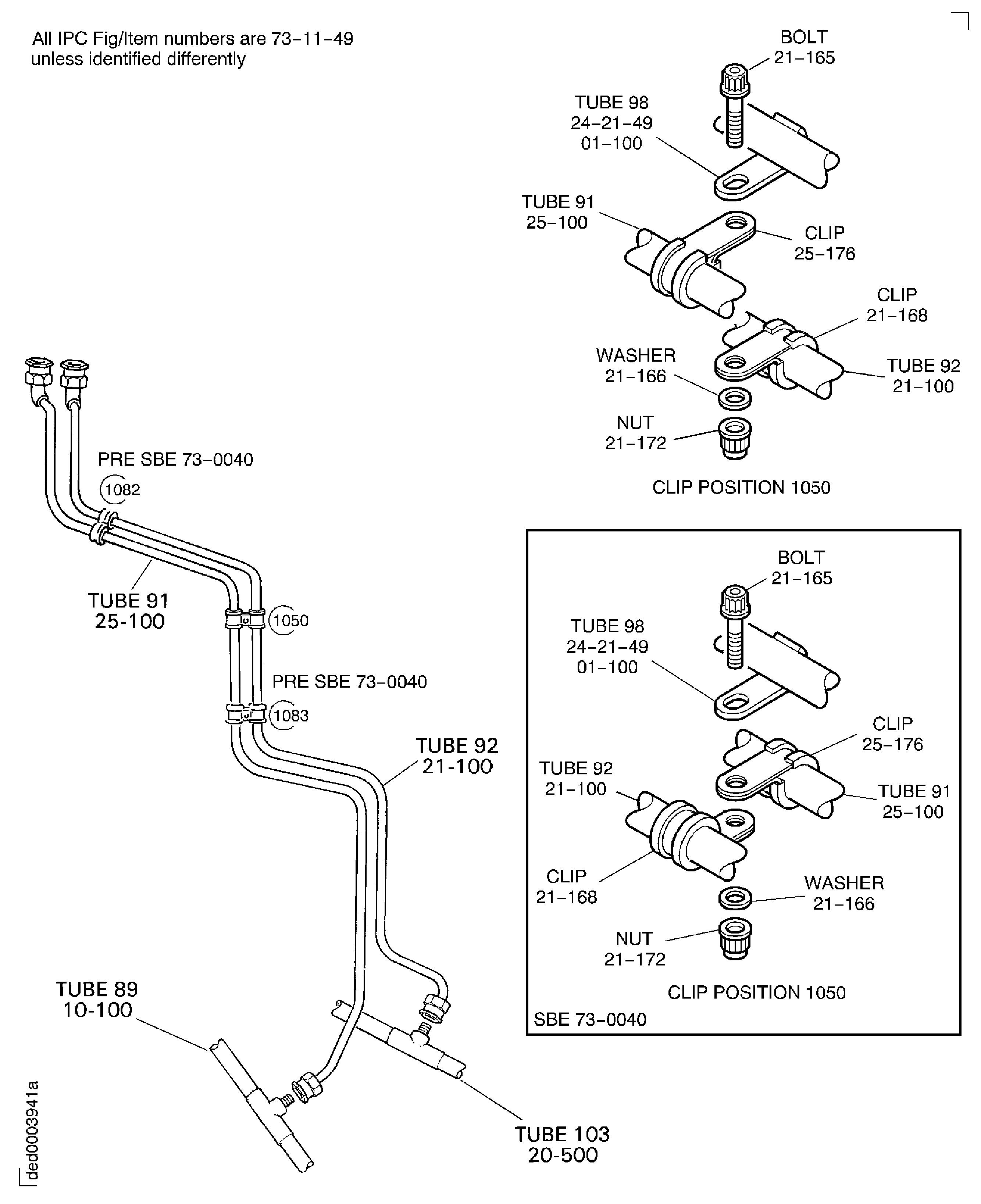

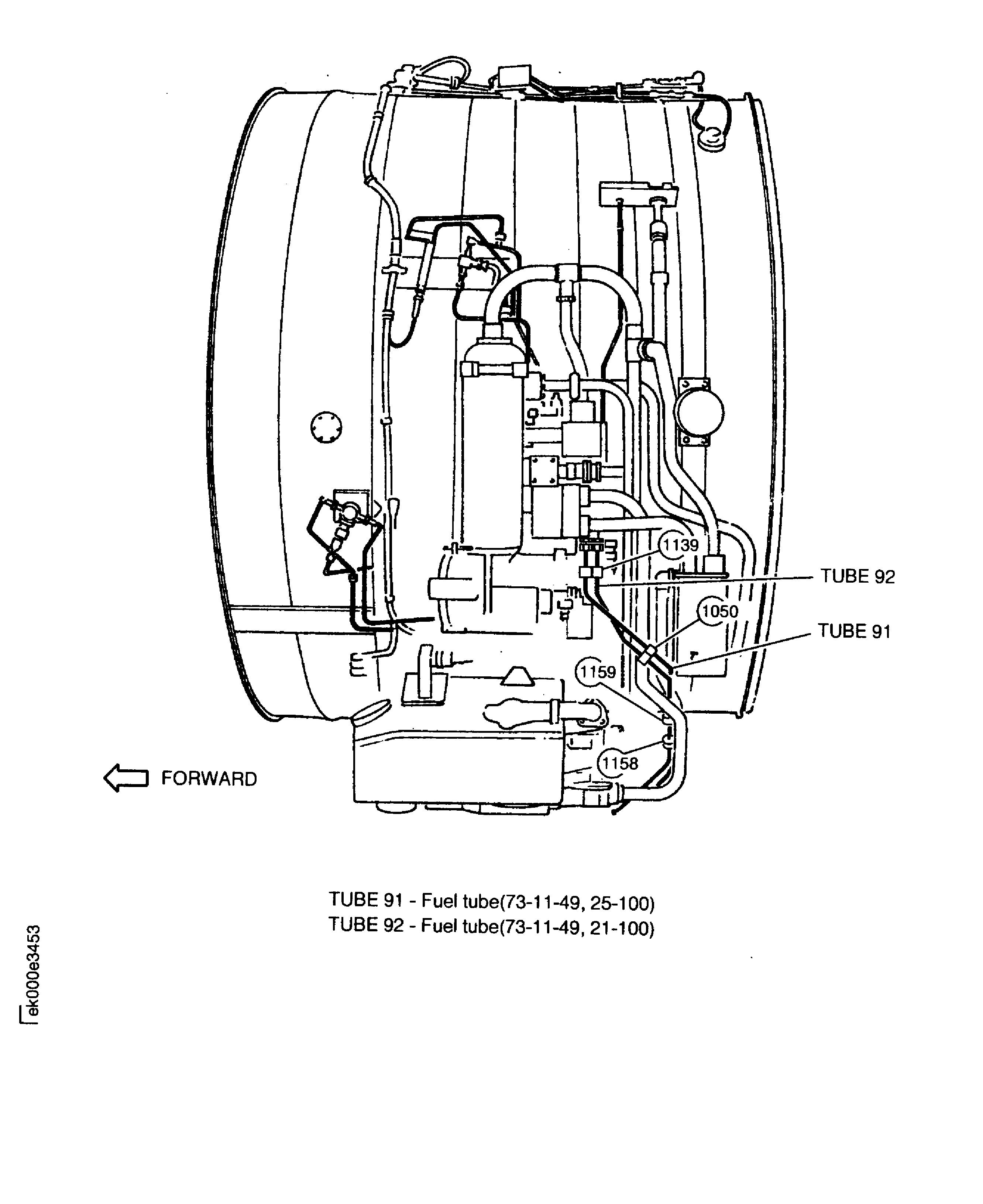

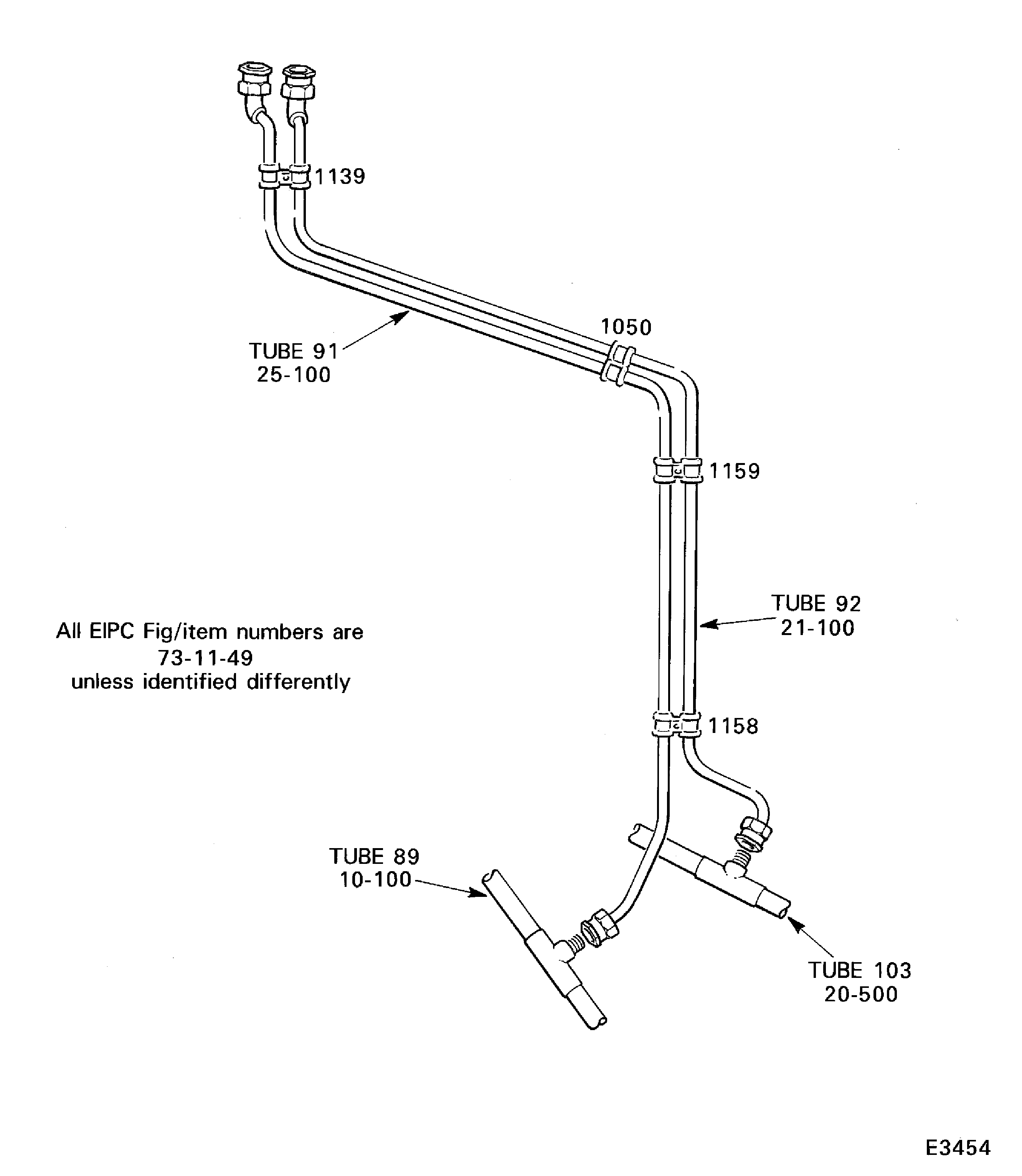

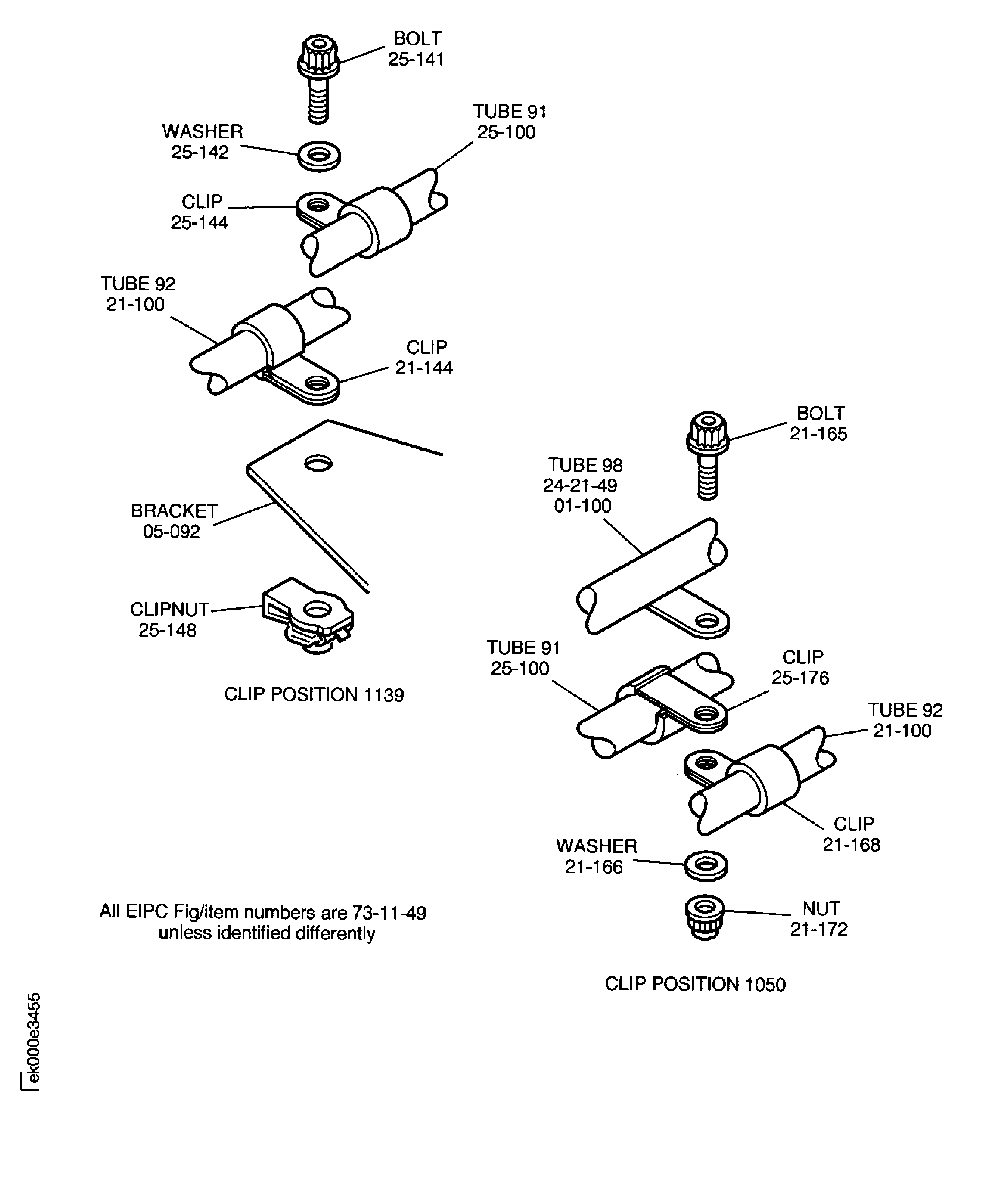

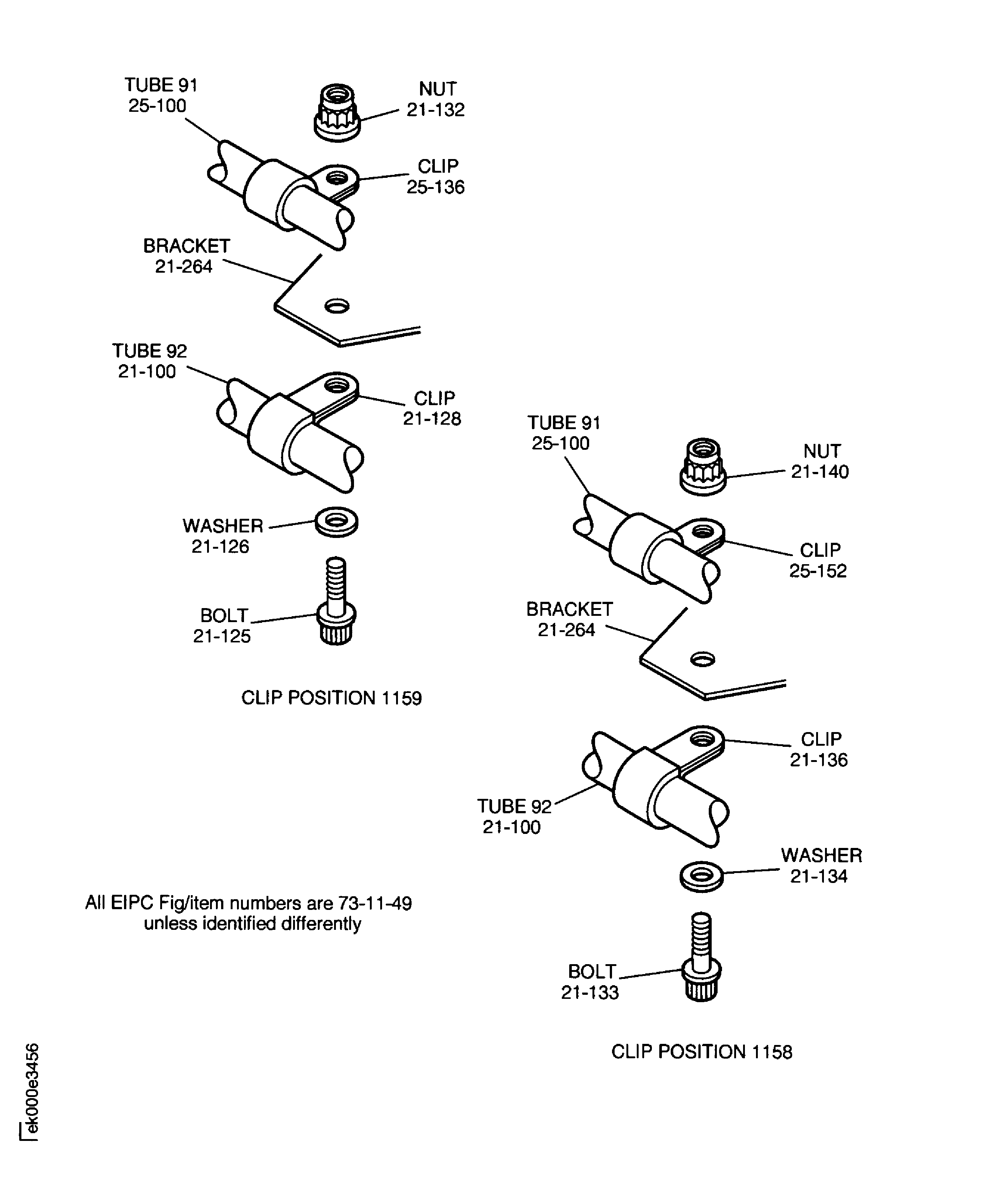

Some fuel drainage could occur during this procedure. It is recommended that an applicable container be available.SUBTASK 72-00-60-020-073-A00 Remove the Fuel Servo Tubes (91 and 92) (Pre SBE 73-0040)

SUBTASK 72-00-60-020-073-B00 Remove the Fuel Servo Tubes (91 and 92) (SBE 73-0040)

SBE 73-0040: Engine - Fuel and control - Fuel tubes - Fuel metering unit to fuel diverter valve servo tubes re-routed

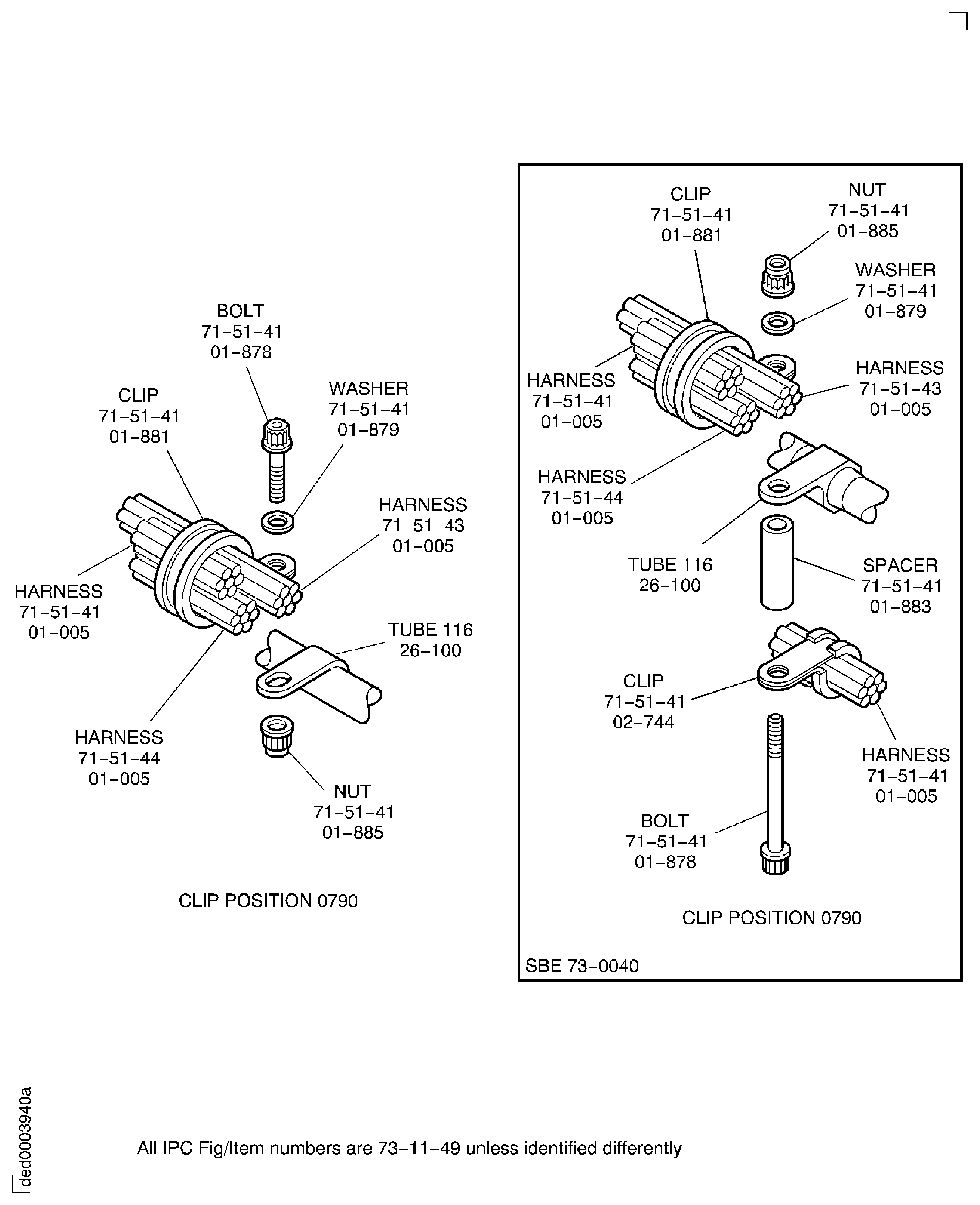

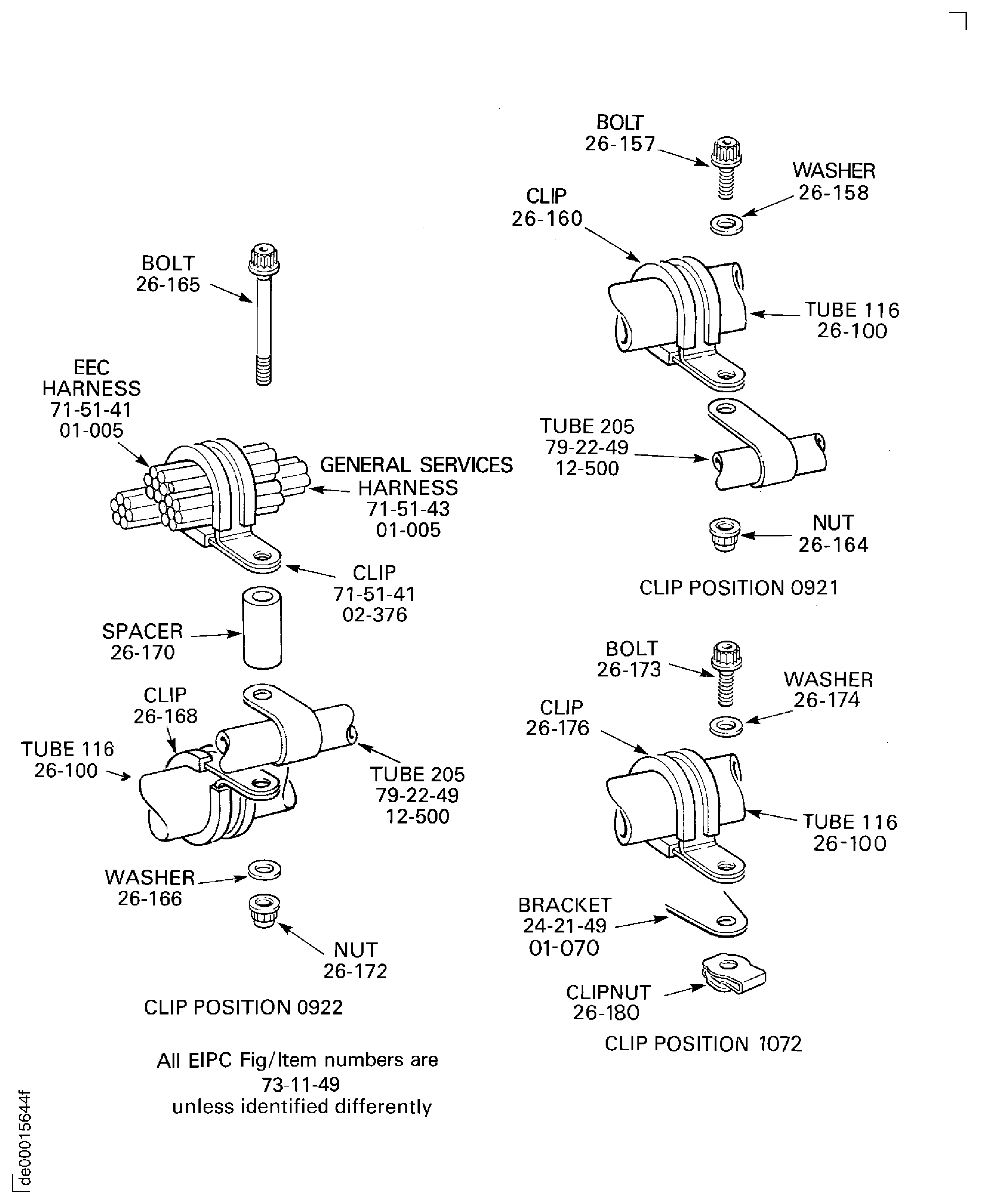

Pre SBE 73-0040: Remove the bolts, washers, nuts and clips from the clip positions 0790, 0921, 0922 and 1072.

SBE 73-0040: Remove the bolts, washers, nuts and clips from the clip positions 0790, 0921, 0922 and 1072.

SUBTASK 72-00-60-020-074 Remove the FMU Spill Tube (116)

NOTE

Some fuel drainage could occur during this procedure. It is recommended that an applicable container be available.Refer to Figure.

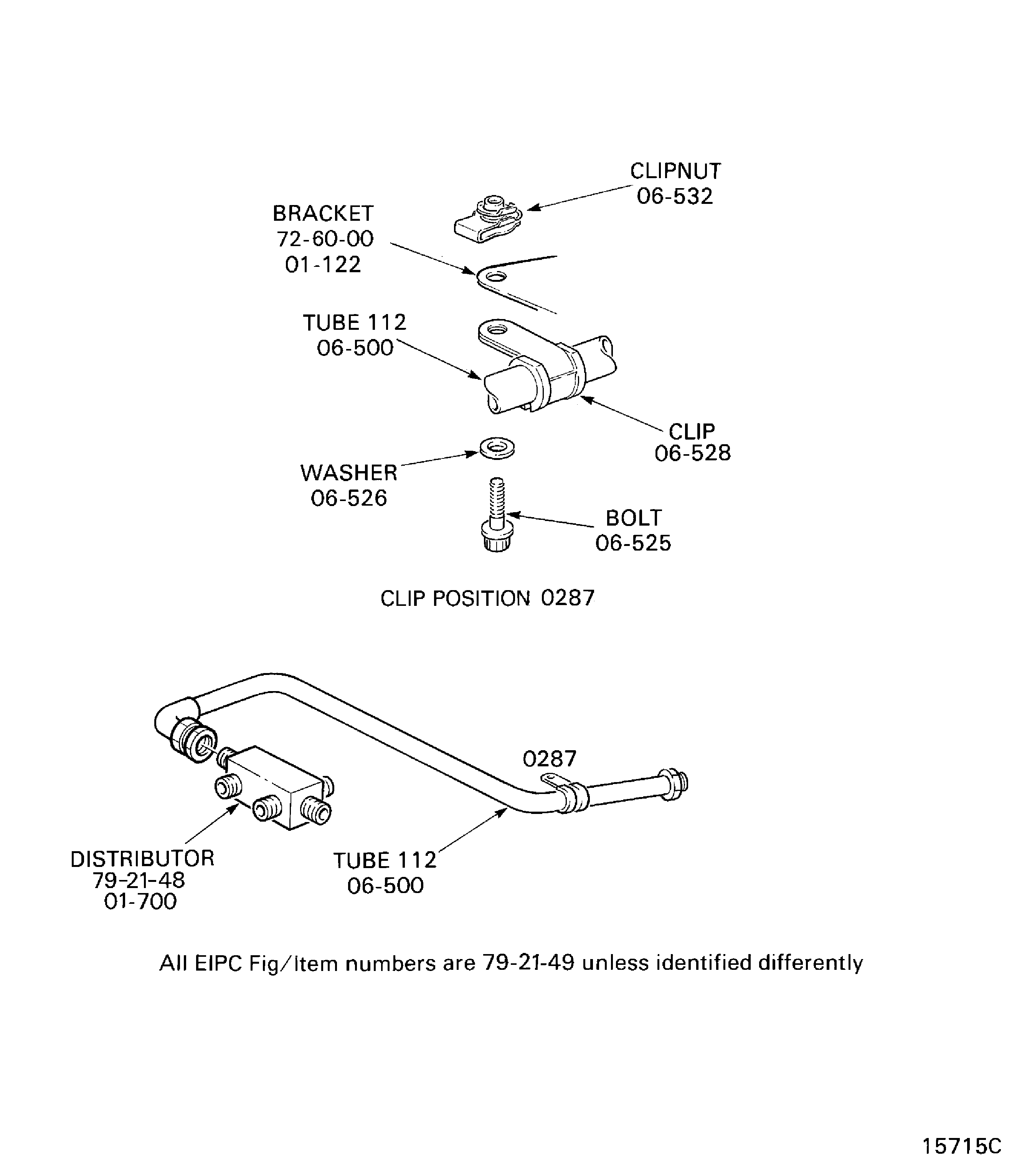

SUBTASK 72-00-60-020-076 Disconnect the Oil Feed Tube (112)

NOTE

Some oil drainage could occur during this procedure. It is recommended that an applicable container be available.Refer to Figure.

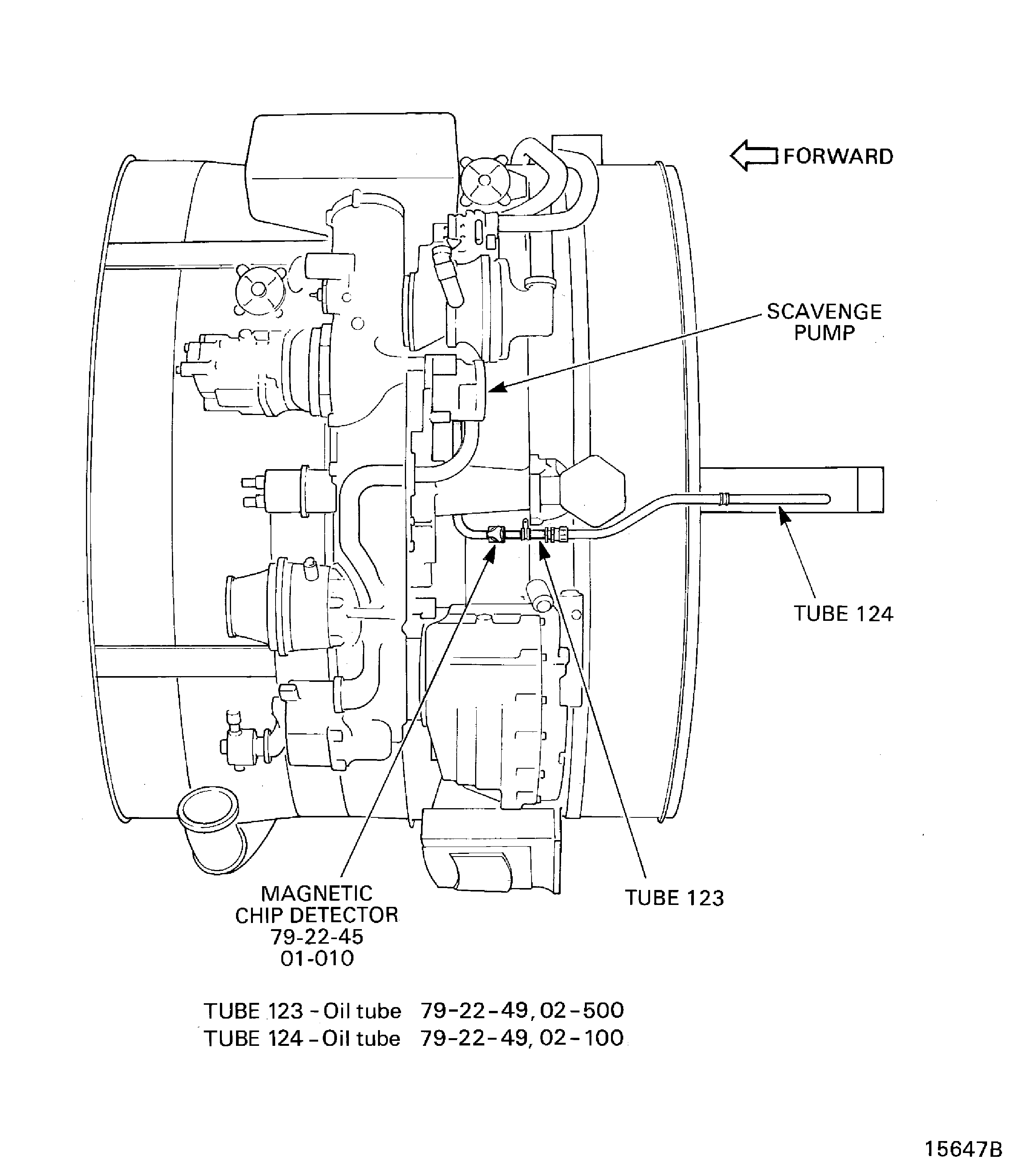

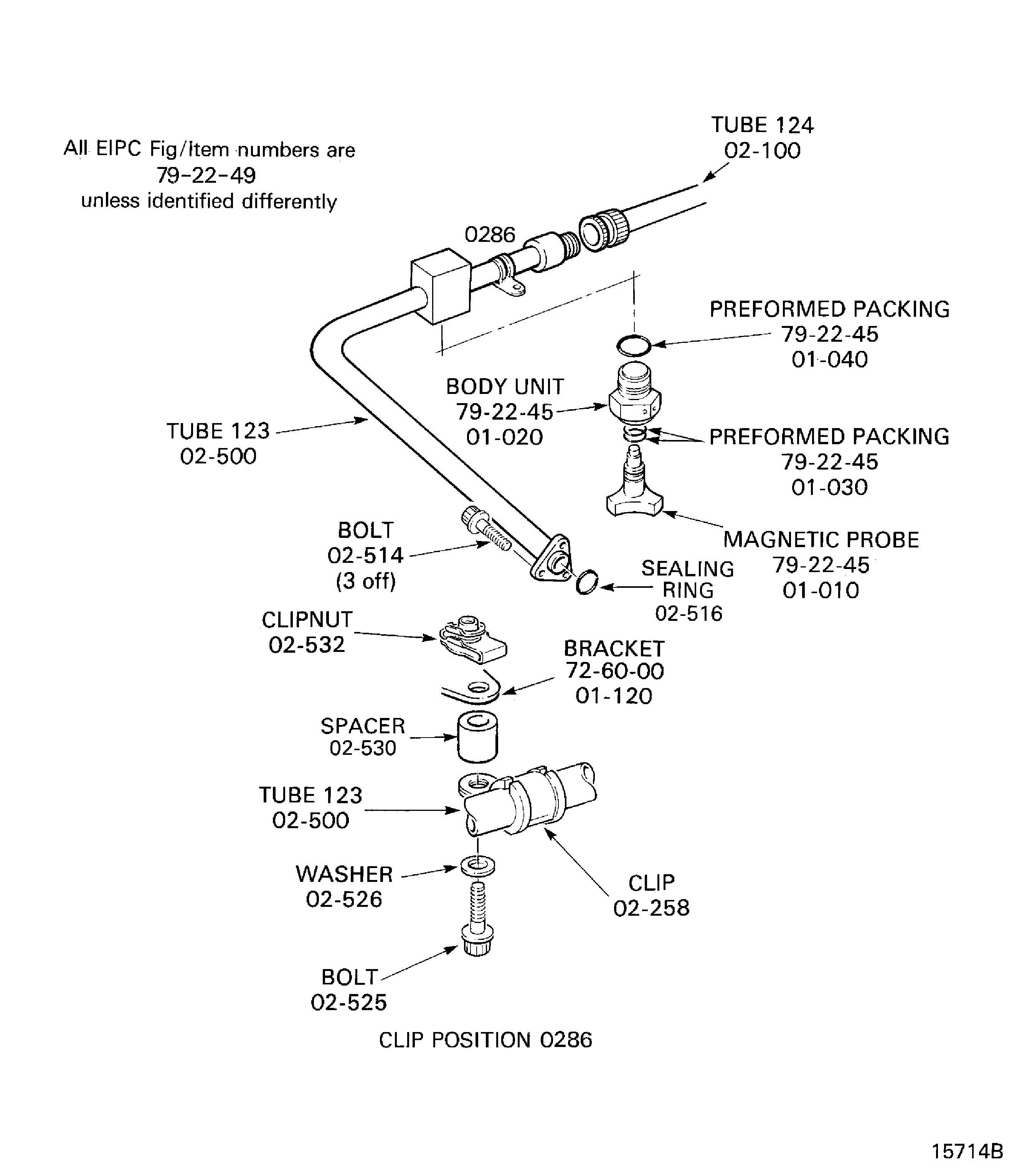

SUBTASK 72-00-60-020-077 Disconnect the Oil Scavenge Tube (123)

NOTE

Some oil drainage could occur during this procedure. It is recommended that an applicable container be available.Refer to Figure.

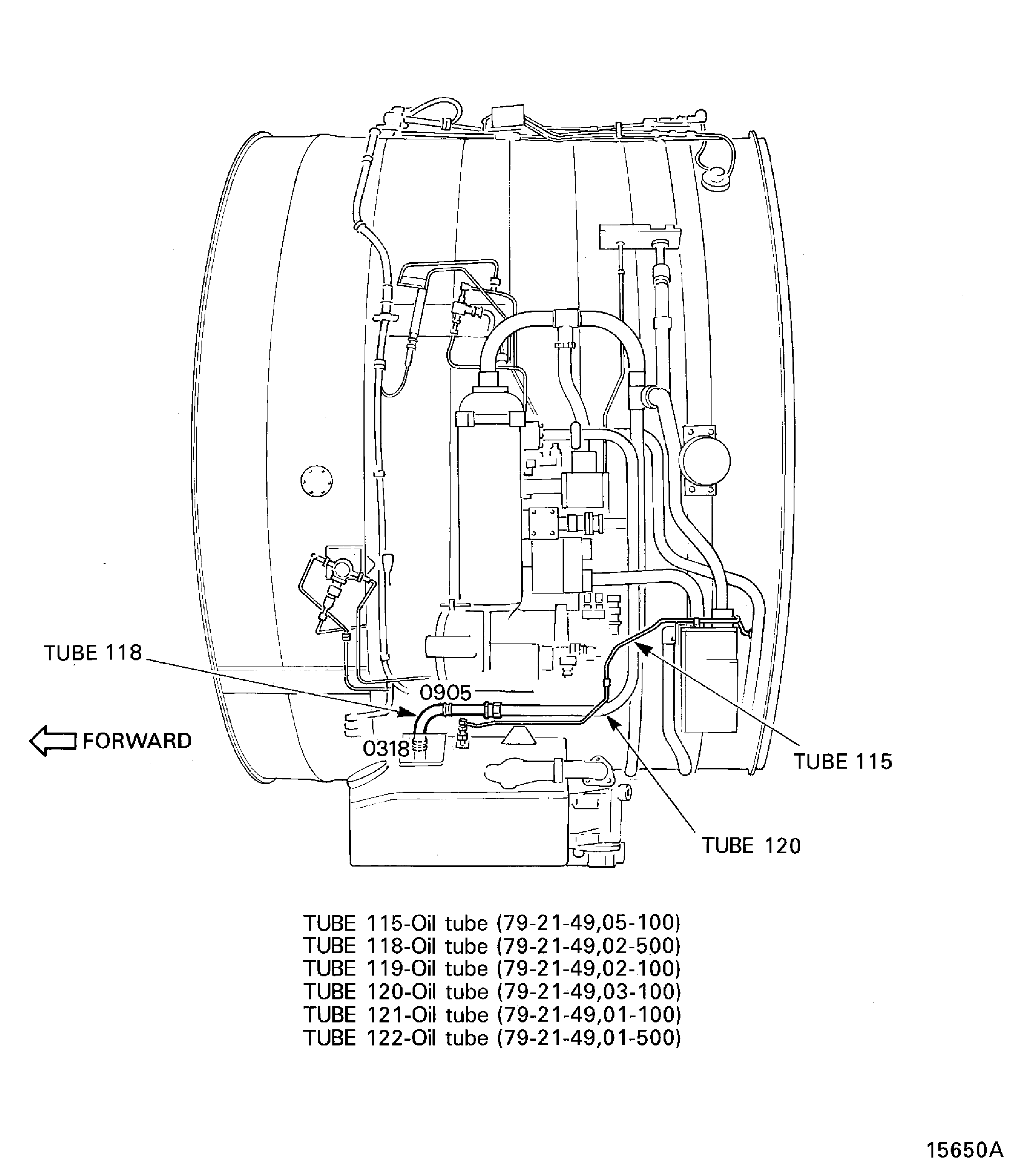

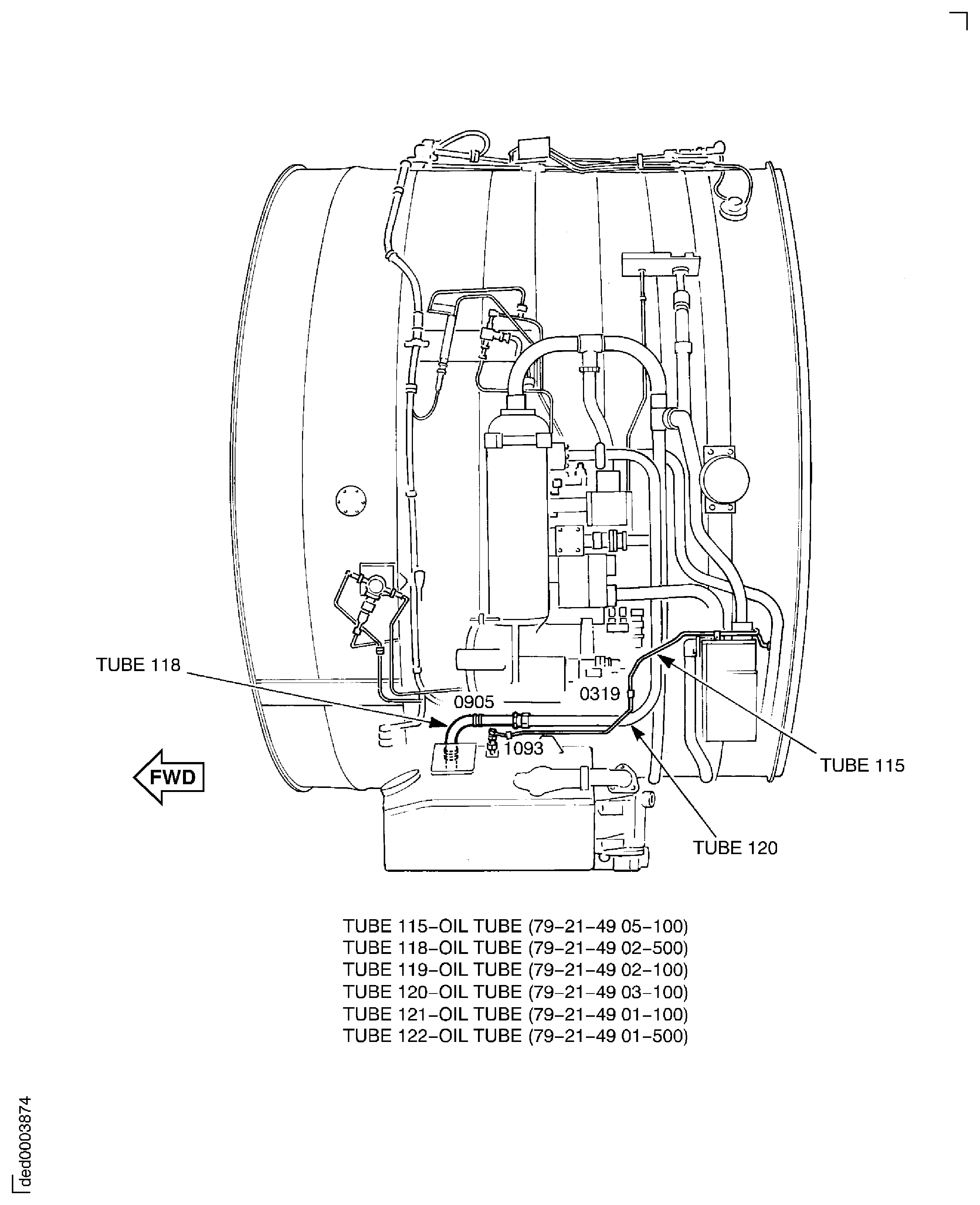

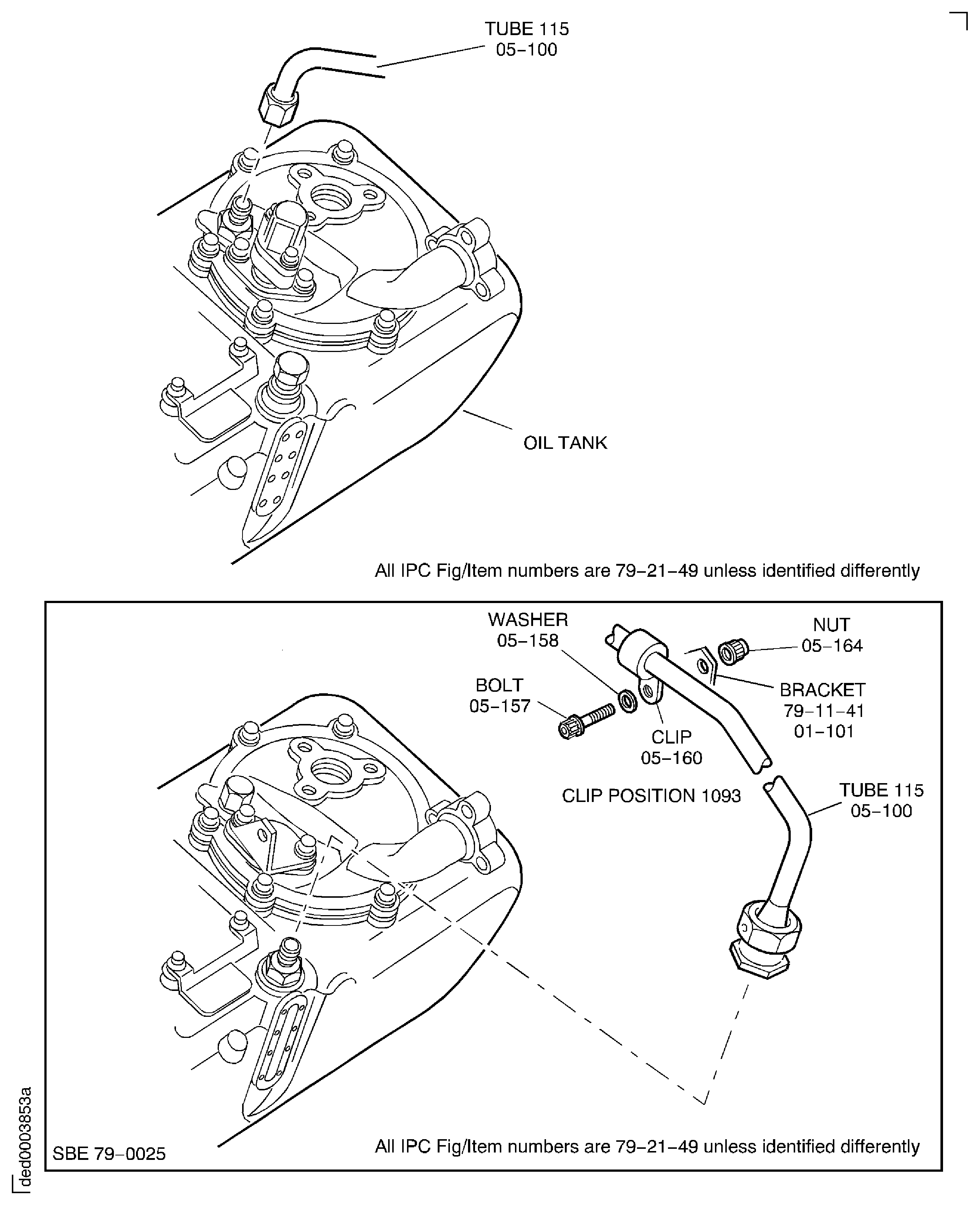

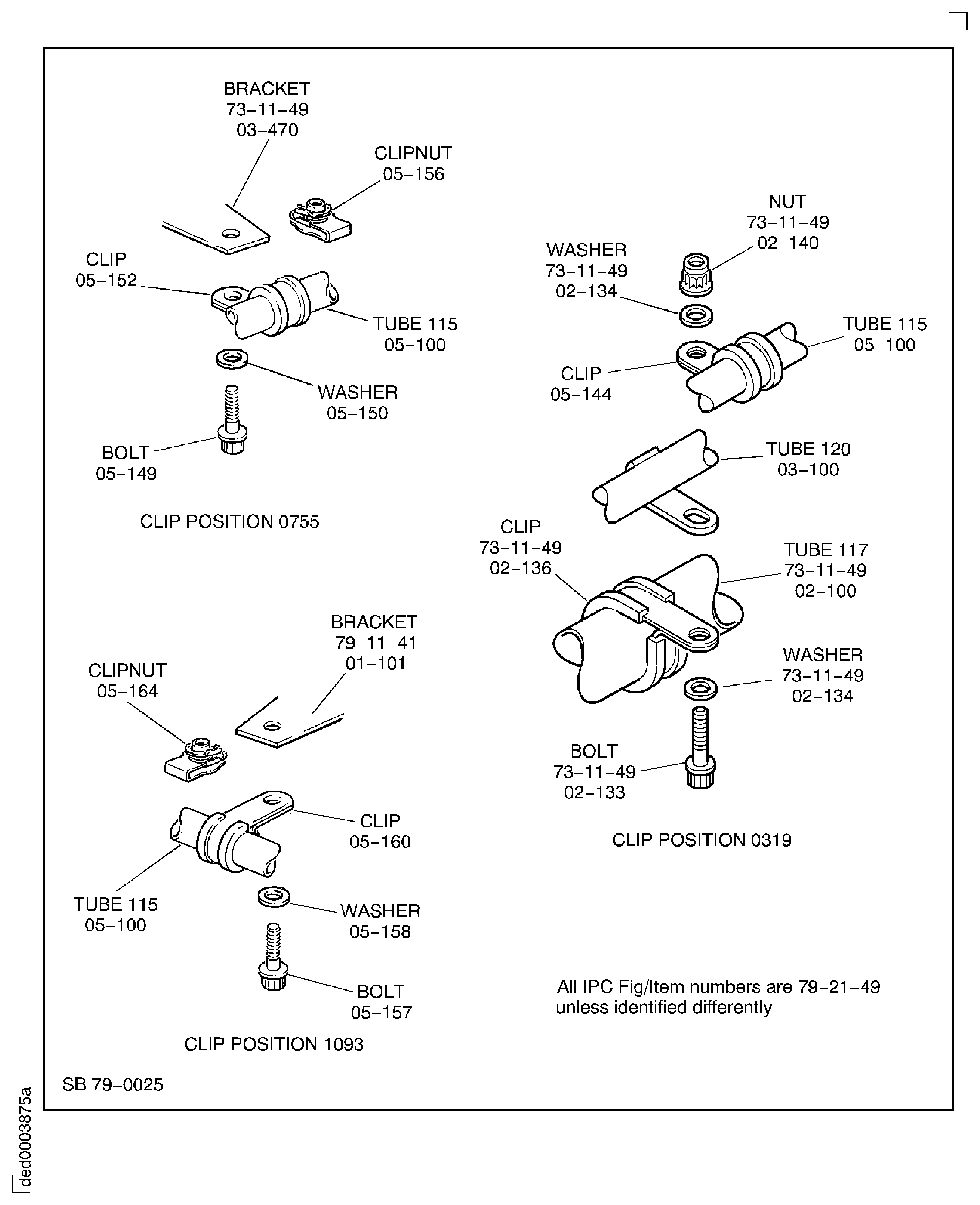

SUBTASK 72-00-60-020-079 Disconnect the Oil Spill Tube (115) (Pre SBE 79-0025)

SUBTASK 72-00-60-020-169 Disconnect the Oil Spill Tube (115) (SBE 79-0025)

SBE 79-0025: Oil - Provide an oil tank sight glass oil level indicator.

Refer to Figure.

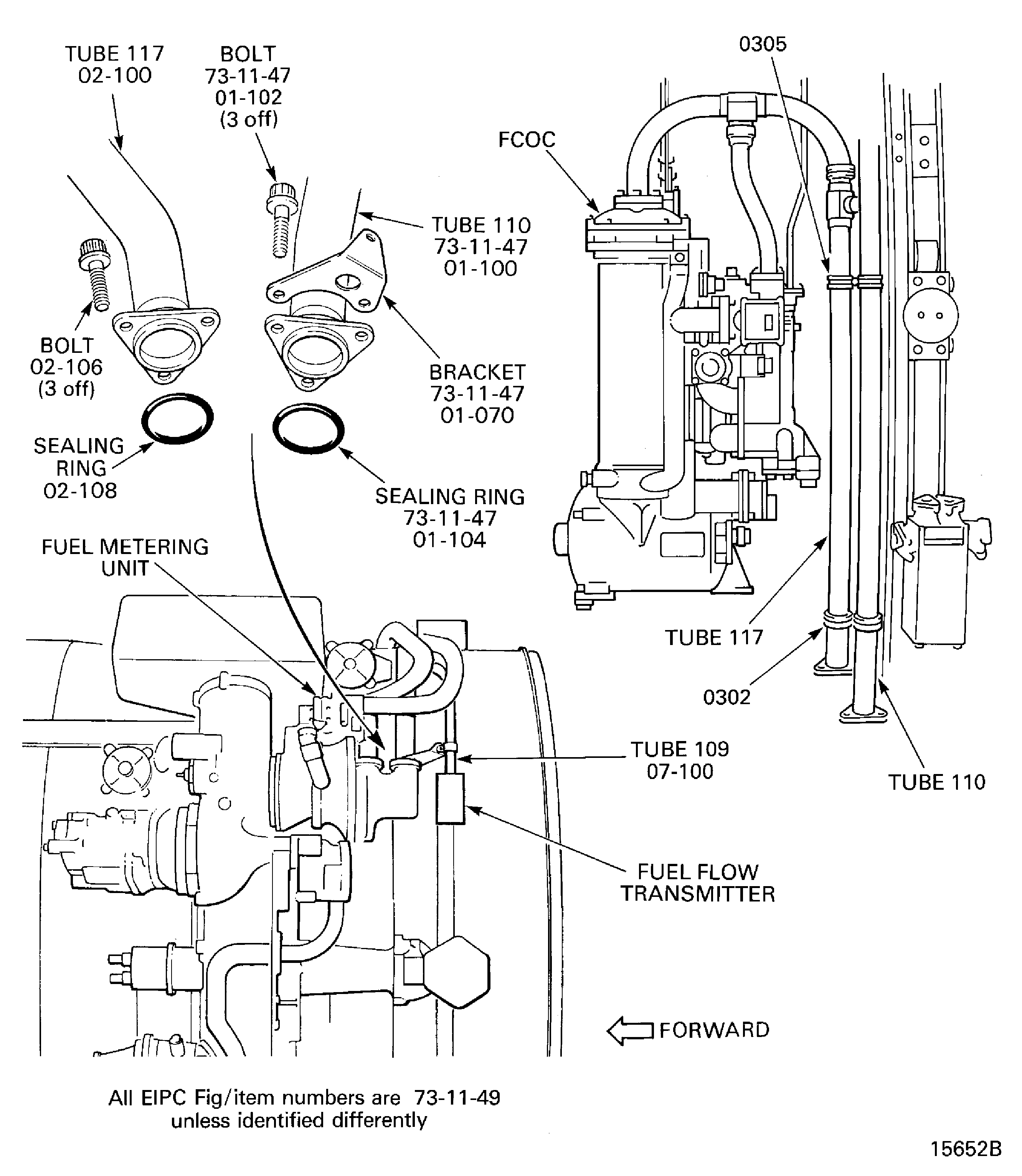

Remove the three bolts that attach the tube 110 to the fuel pump and remove the sealing ring and the bracket FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-070).

SUBTASK 72-00-60-020-080 Disconnect the LP Fuel Tubes (110 and 117)

Refer to Figure.

SUBTASK 72-00-60-020-082 Disconnect the Fuel Flow Transmitter Inlet Tube (109)

NOTE

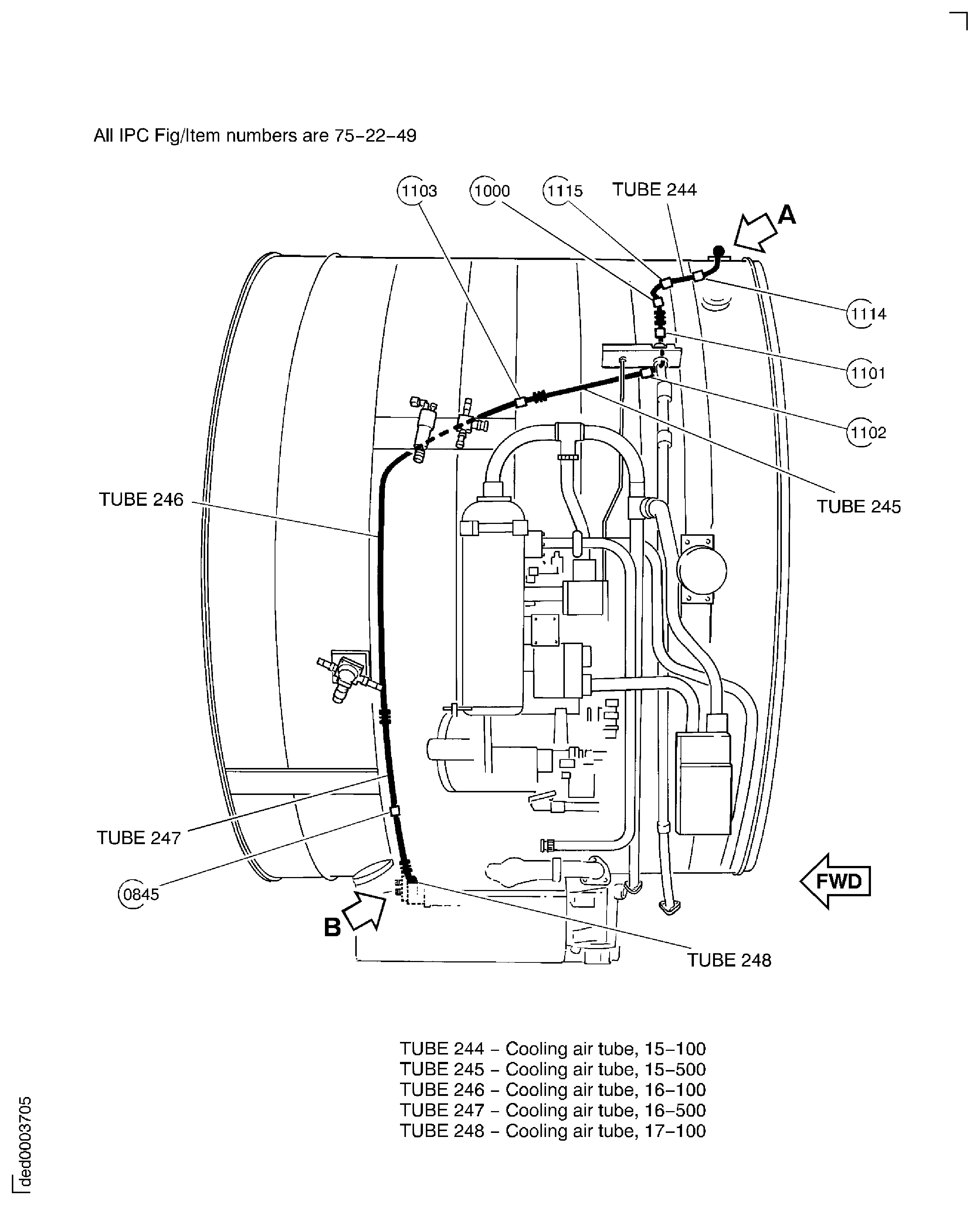

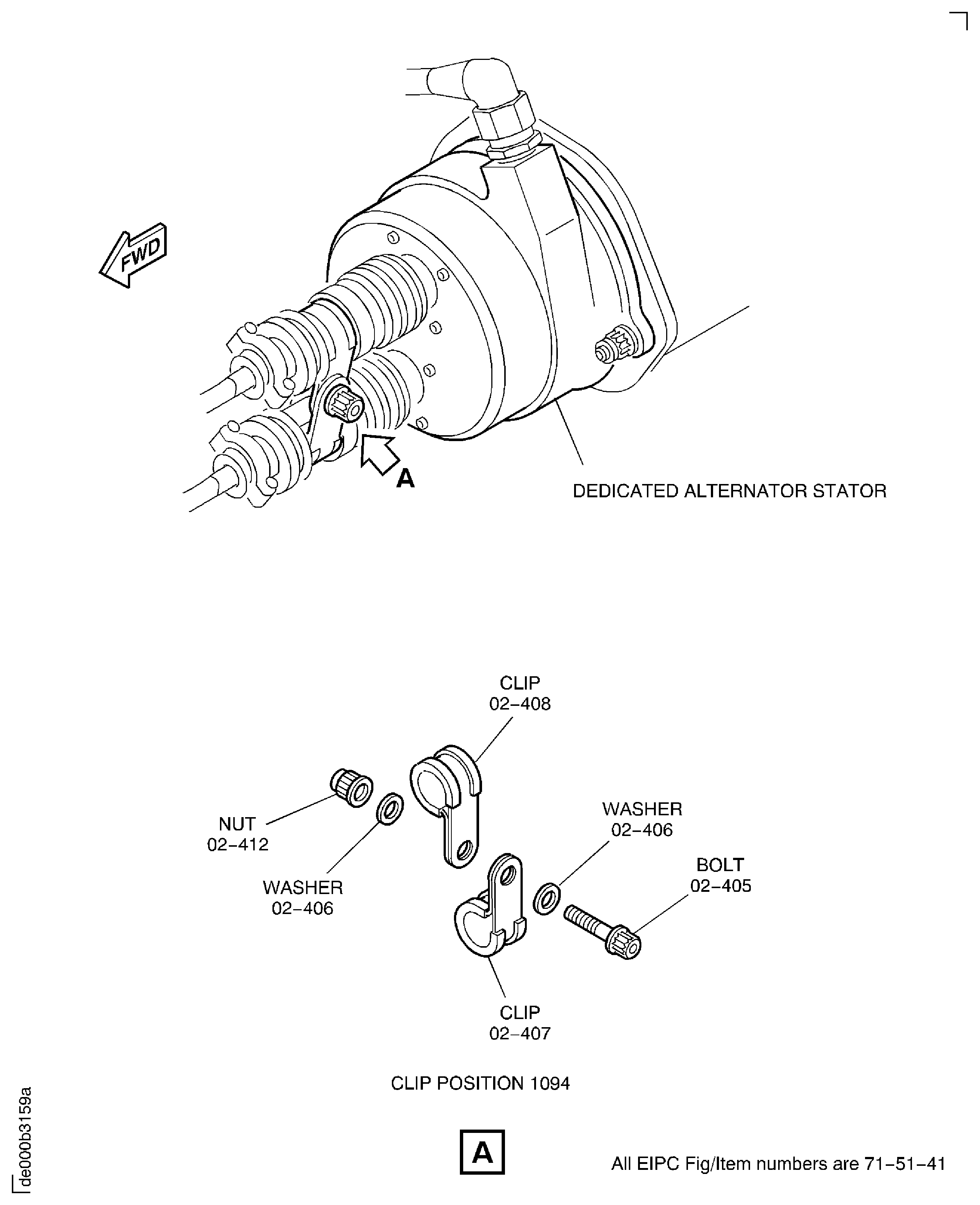

Some fuel drainage could occur during this procedure. It is recommended that an applicable container be available.Disconnect the tube 248 from the dedicated alternator stator. Refer to TASK 72-00-60-050-001-A00 (REMOVAL-005, CONFIG-001).

Disconnect the tube 248 from the tube 247 and remove the tube 248, refer to TASK 72-00-32-020-003-A00 (REMOVAL-003, CONFIG-001).

Remove the clip positions 0779, 0845, 0846, 0847, 0893 and 0849 which attach the harnesses to the tube 247. Refer to TASK 72-00-32-020-002-A00 (REMOVAL-002, CONFIG-001).

Refer to TASK 72-00-32-020-003-A00 (REMOVAL-003, CONFIG-001) for the procedure to remove the remaining cooling air tubes.

SUBTASK 72-00-60-020-175 Remove the Tubes 247 and 248, the Dedicated Alternator Cooling Air Tubes (SBE 75-0010)

SBE 75-0010: Dedicated alternator - Cooling air supply

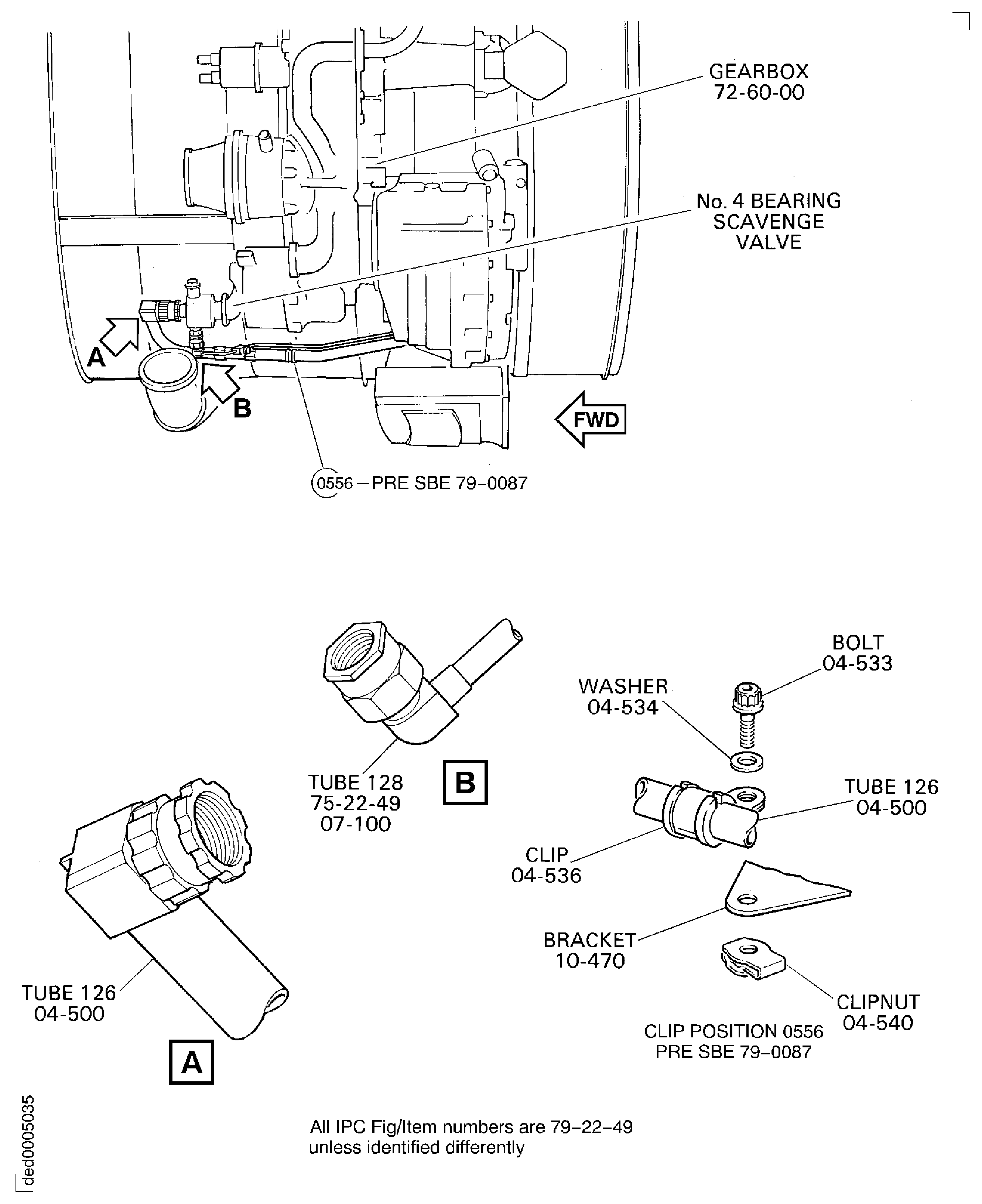

Pre SBE 79-0087: Remove the bolt, washer, clipnut and the clip from the clip position 0556.

SUBTASK 72-00-60-020-084 Disconnect the No. 4 Bearing Scavenge Tubes (126 and 128) (Pre SBE 79-0087)

NOTE

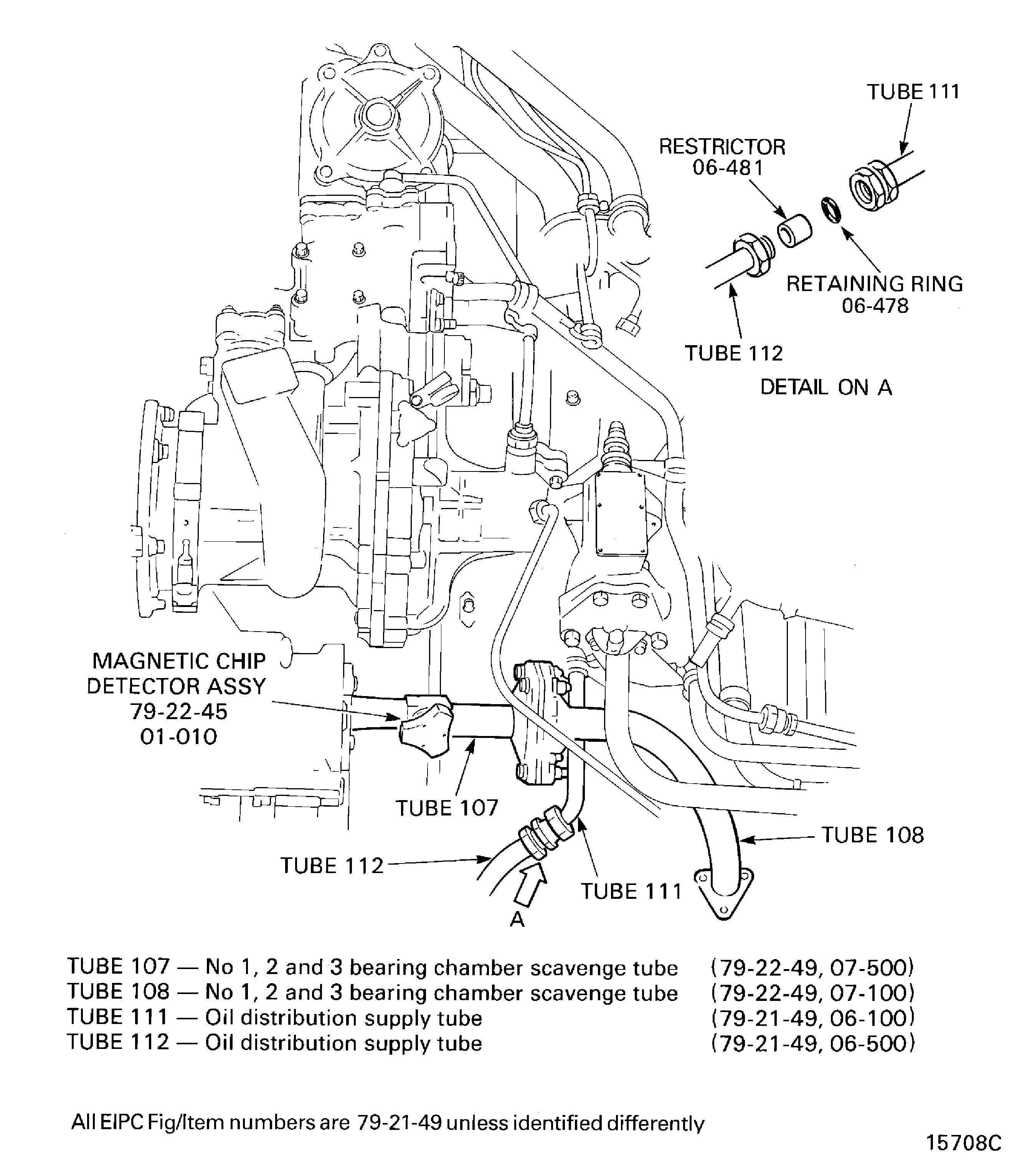

Some oil drainage could occur during this procedure. It is recommended that an applicable container be available.Refer to Figure.

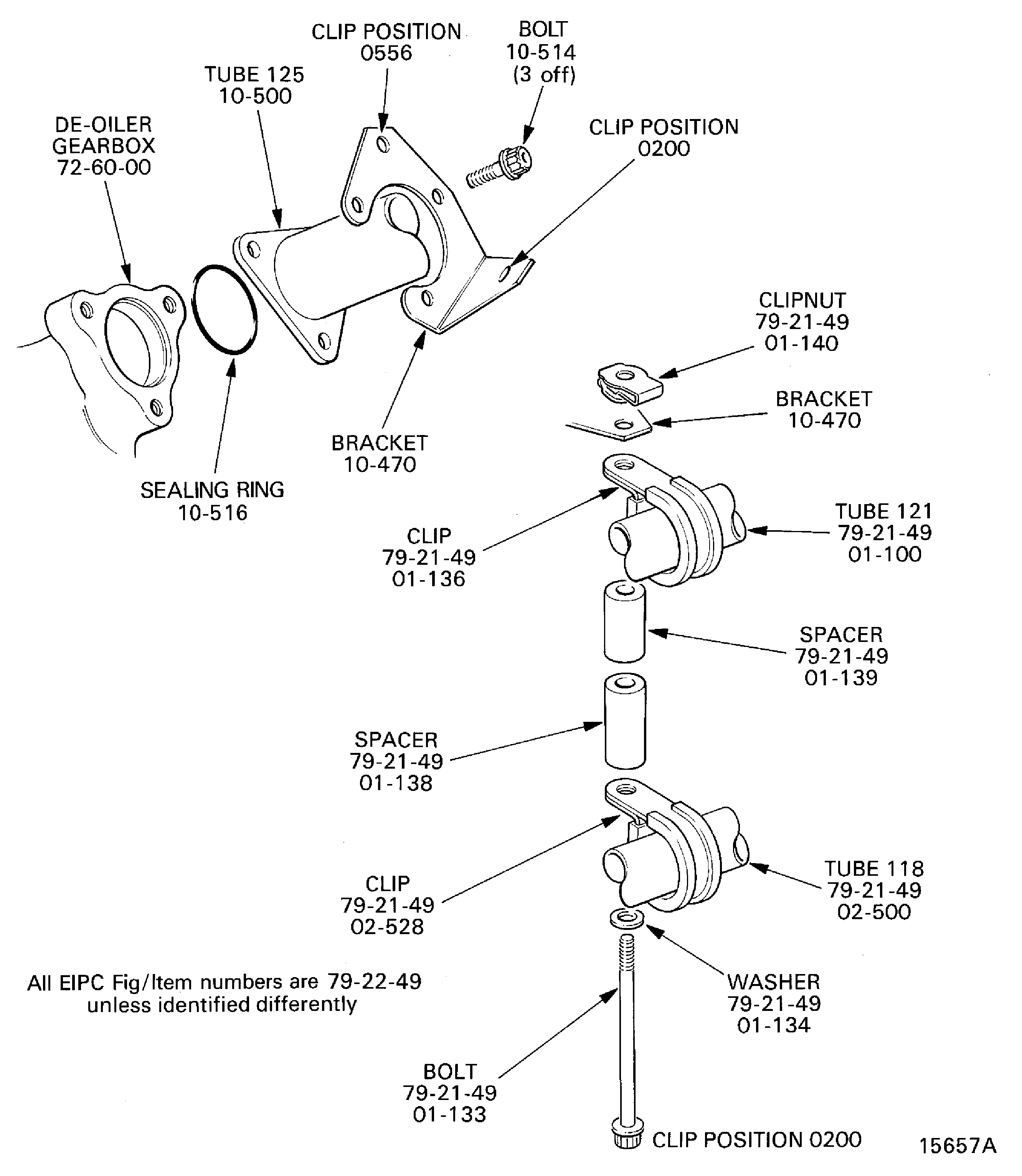

SUBTASK 72-00-60-020-085 Disconnect the No. 1, 2 and 3 Bearing Compartment Vent Tube (125)

NOTE

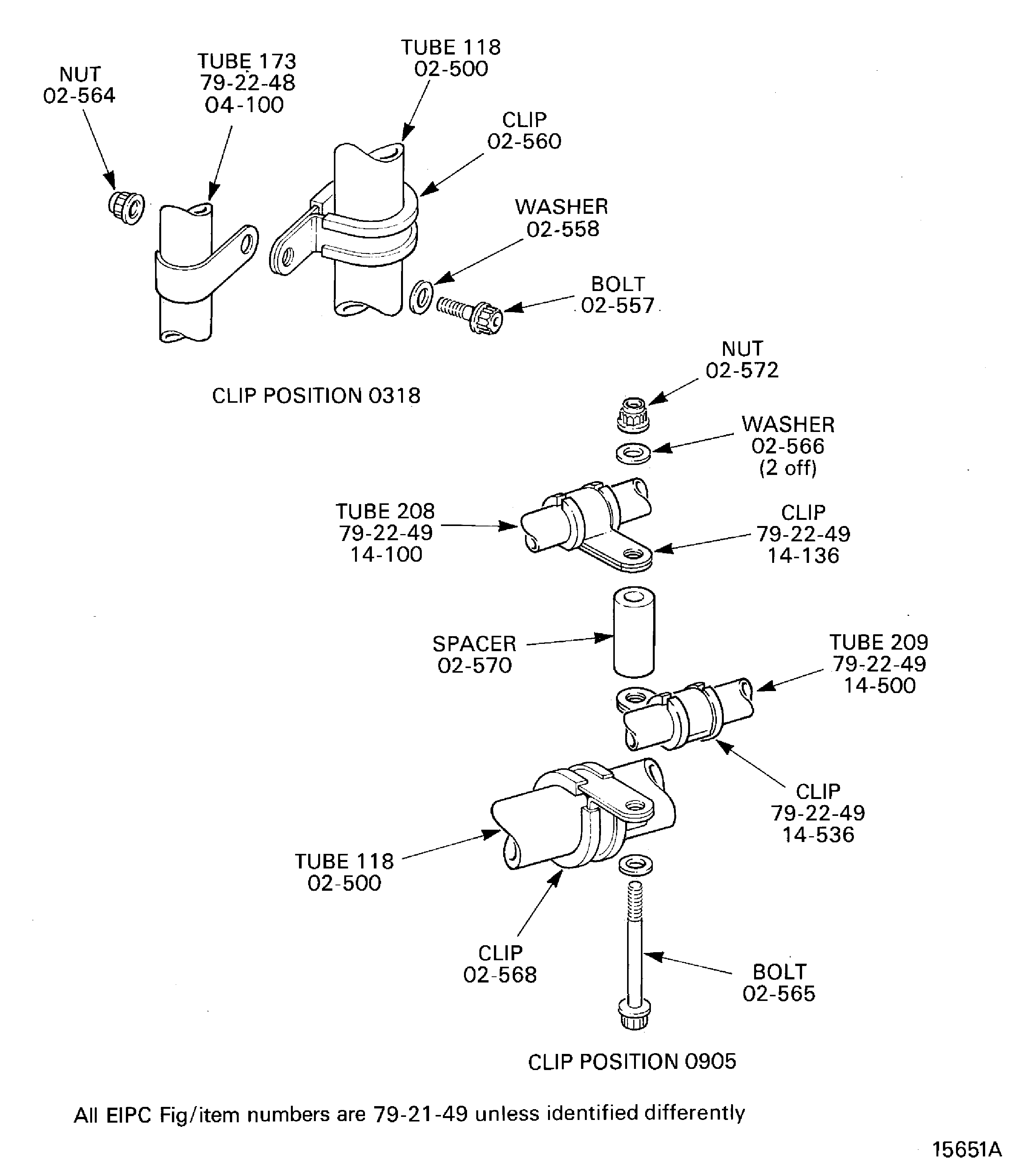

Some oil drainage could occur during this procedure. It is recommended that an applicable container be available.Refer to Figure.

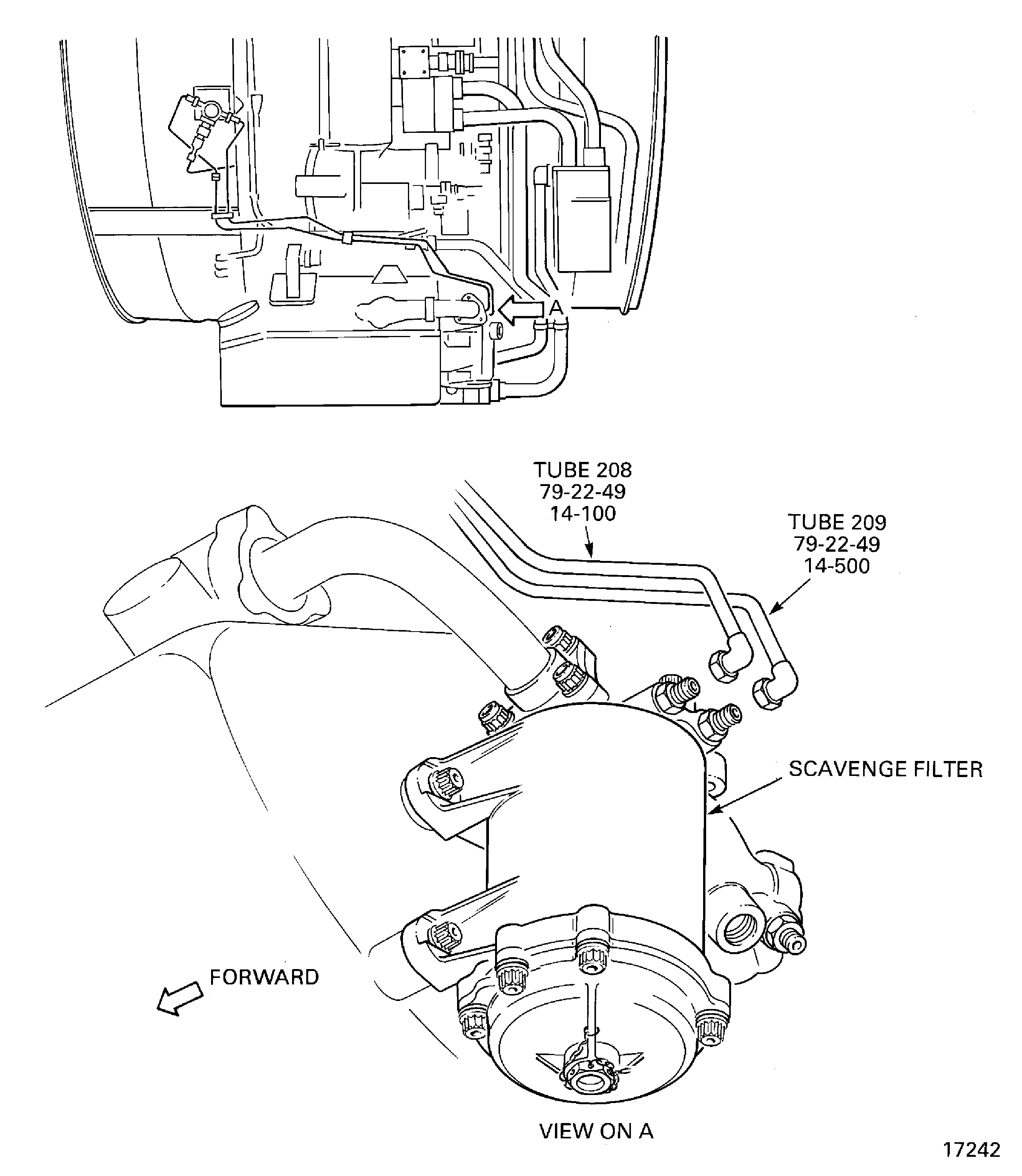

SUBTASK 72-00-60-020-086 Disconnect the Scavenge Filter Differential Pressure Oil Tubes (208 and 209)

Refer to Figure.

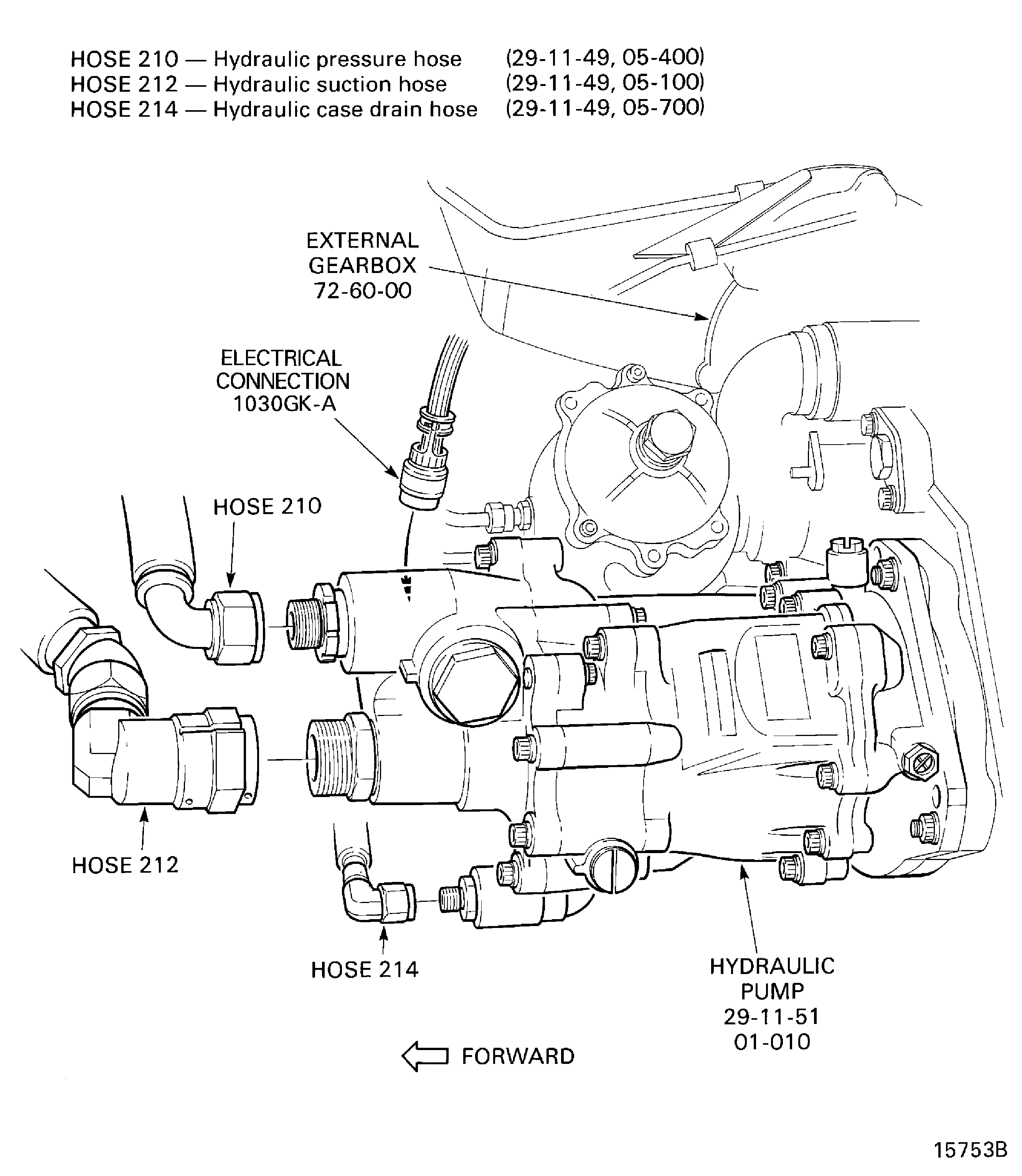

SUBTASK 72-00-60-020-087 Disconnect the Hydraulic Pump Hoses

Refer to TASK 72-00-60-020-003-001 or TASK 72-00-60-020-003-002.

SUBTASK 72-00-60-020-088 Remove the External Gearbox

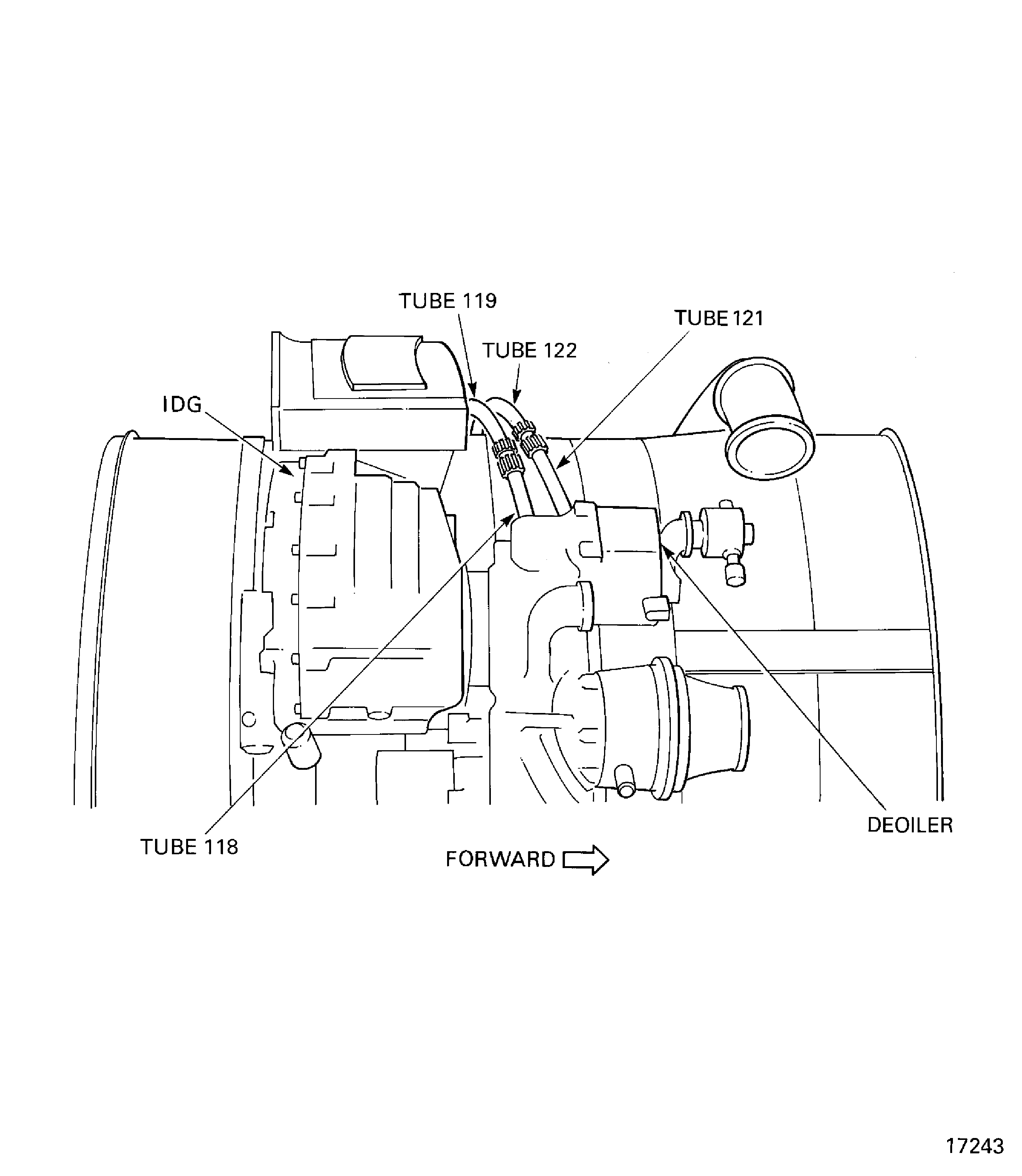

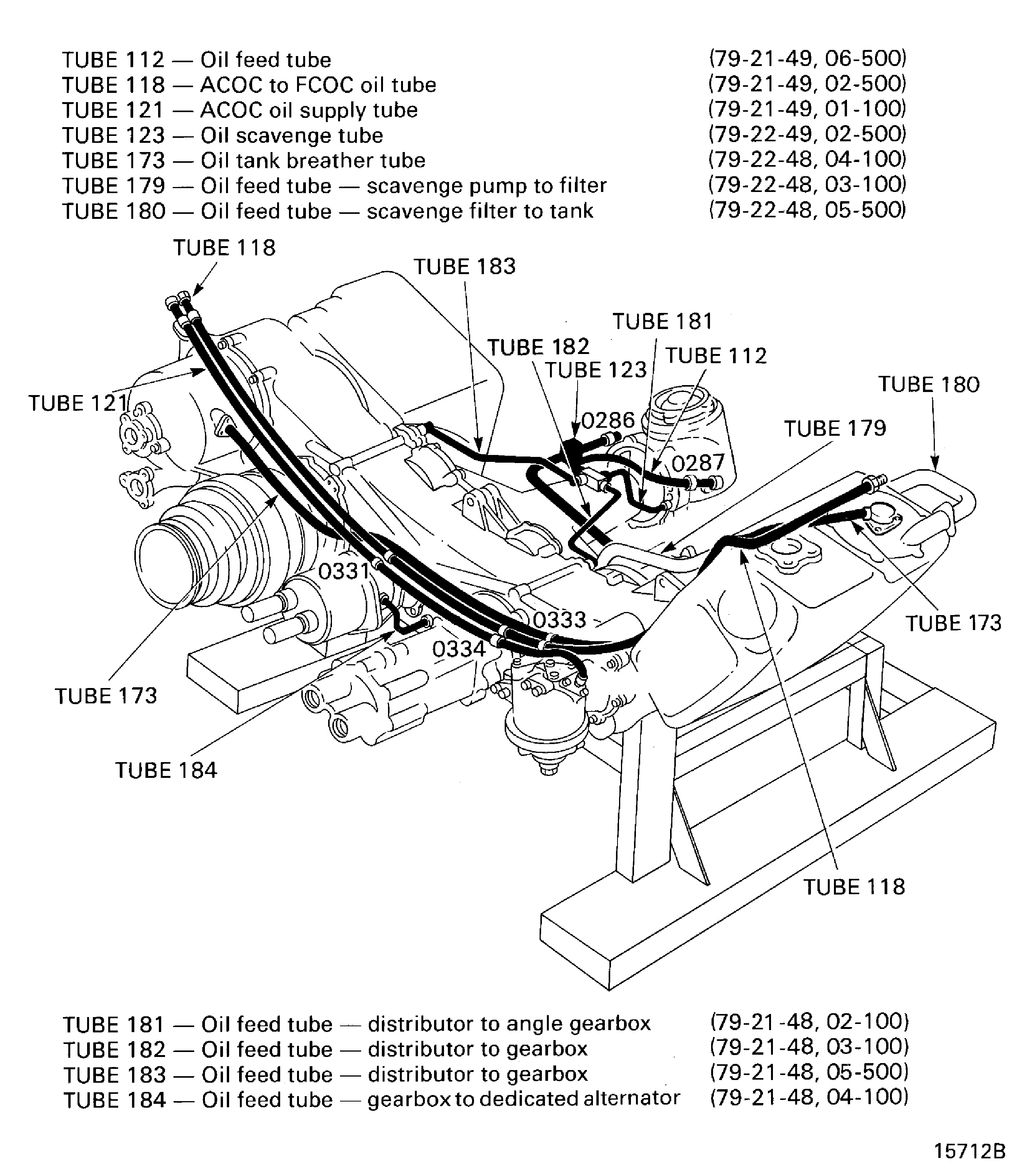

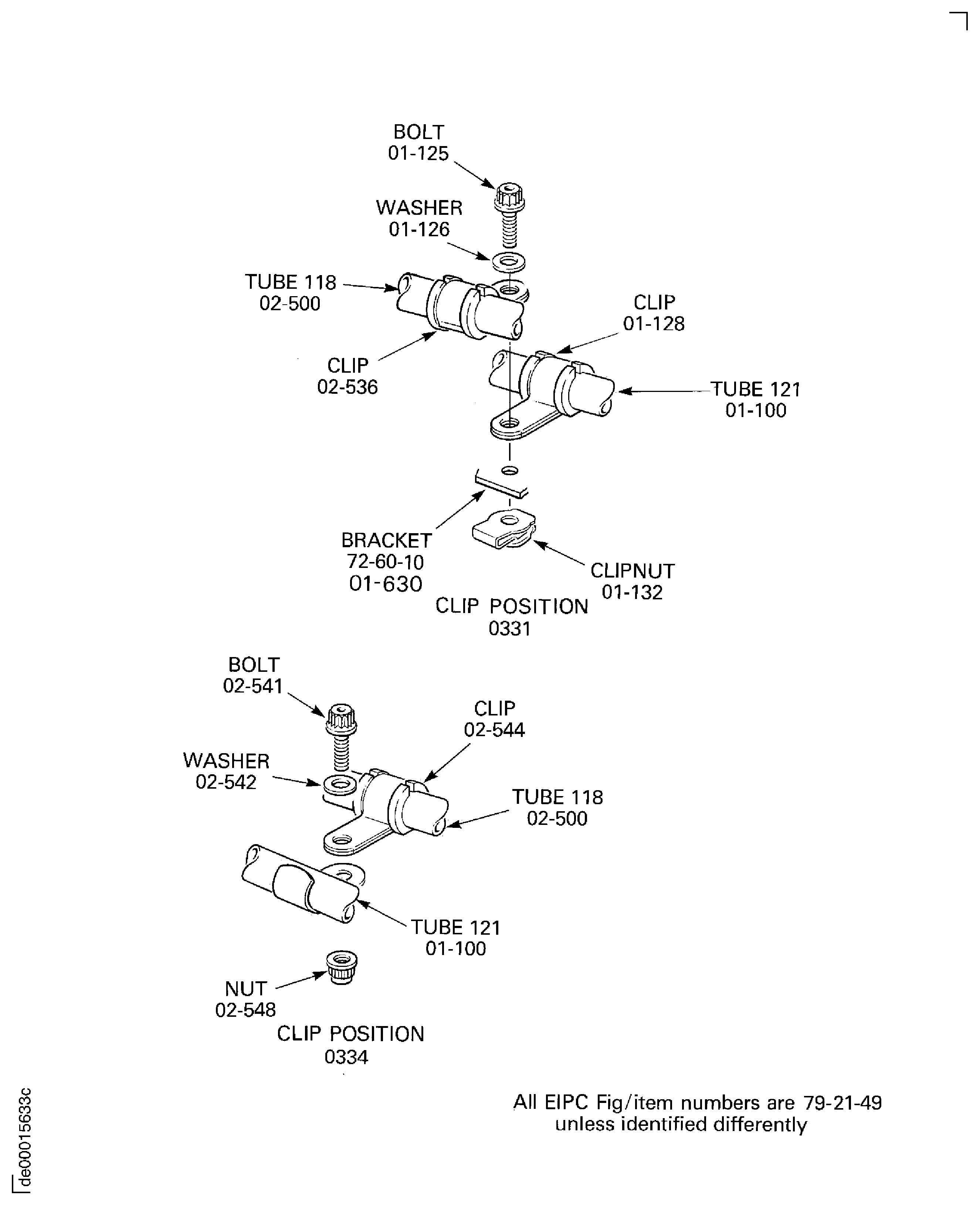

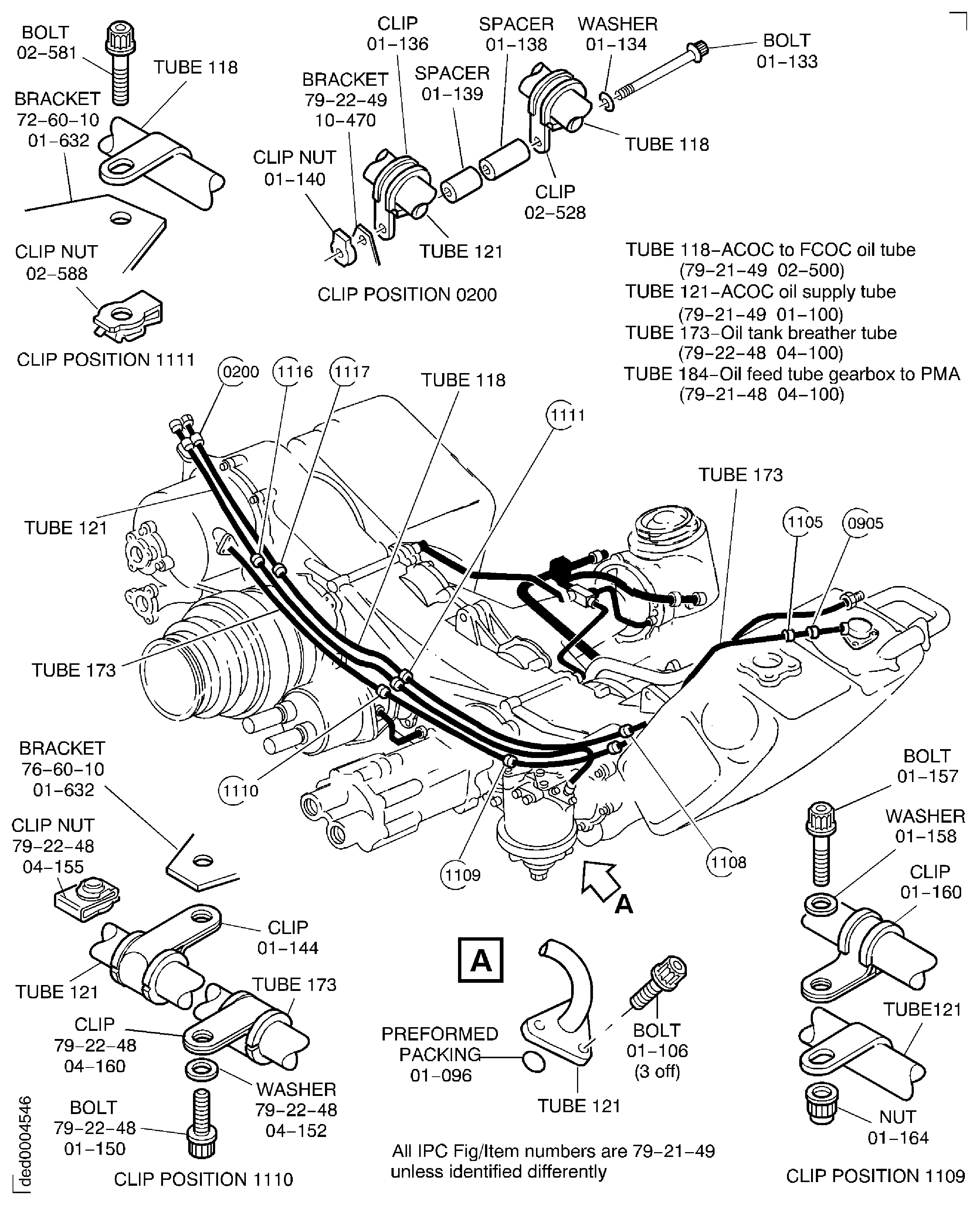

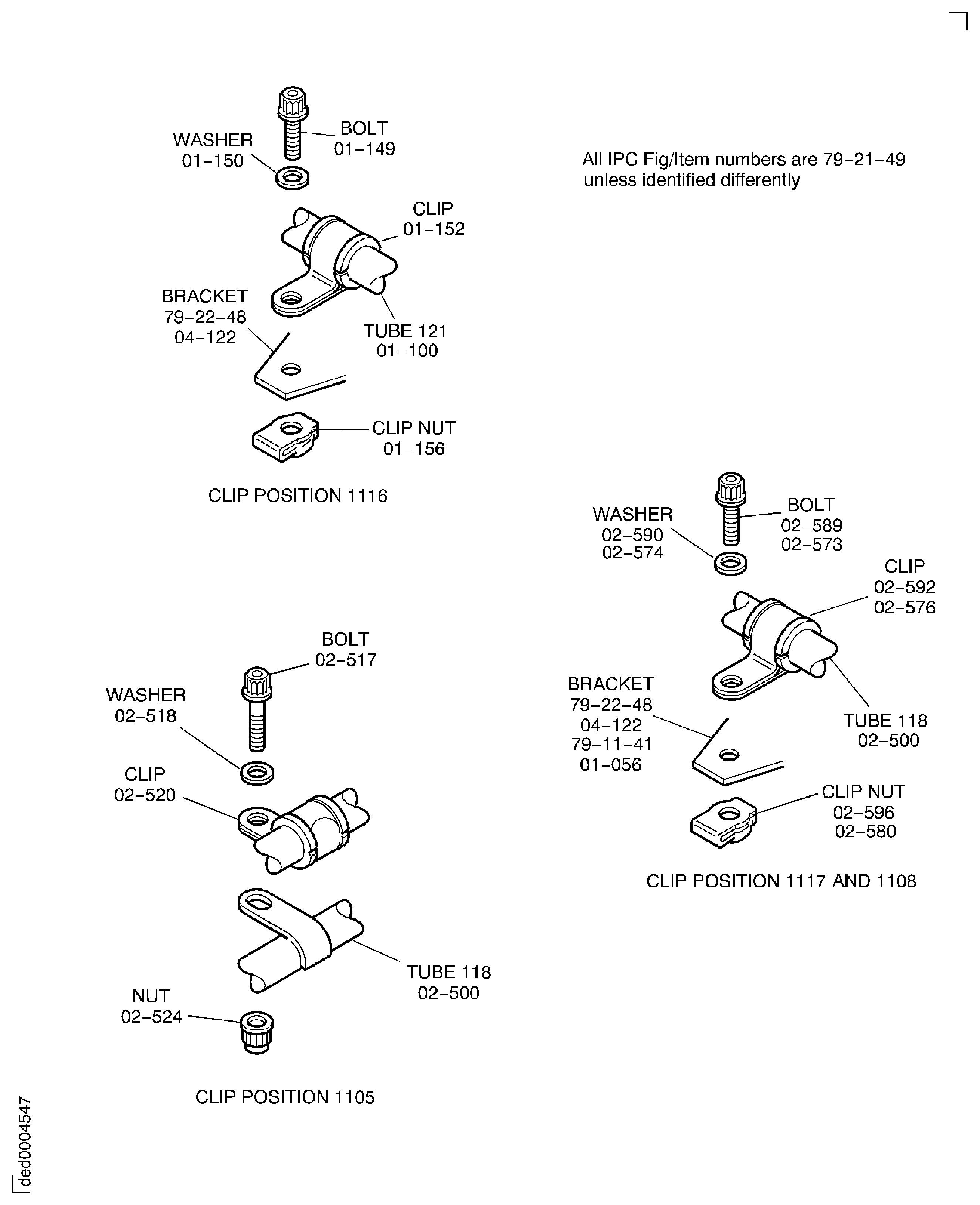

SUBTASK 72-00-60-020-089 Remove the ACOC Oil Tubes (118 and 121) from the External Gearbox (Pre SBE 71-0110)

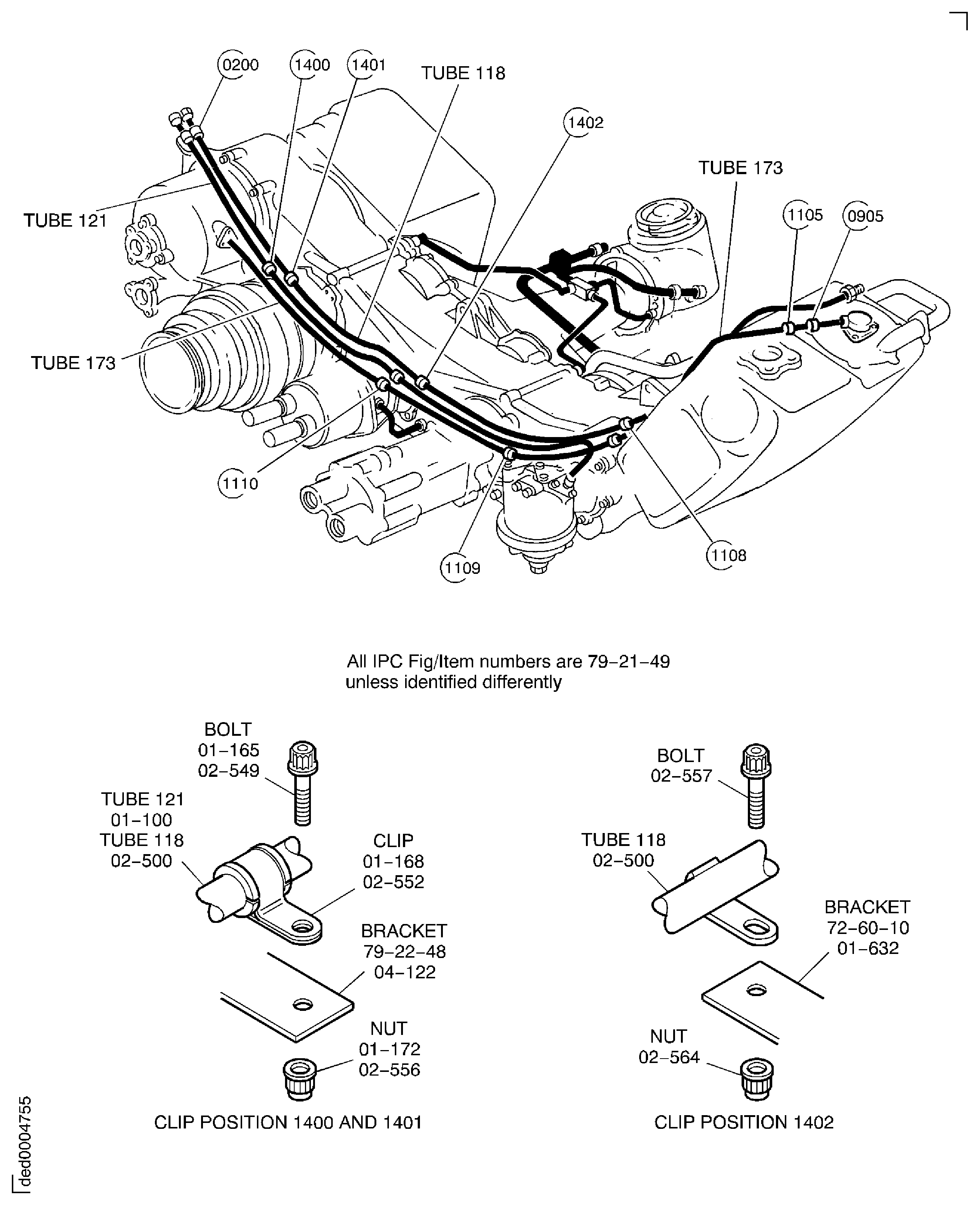

SBE 79-0069: Remove the bolt from clip position 1402.

SBE 79-0069: Remove the bolts and nuts from clip positions 1400 and 1401. Remove the tube 118.

SUBTASK 72-00-60-020-167 Remove the ACOC Oil Tubes (118 and 121) from the External Gearbox (SBE 71-0110 and SBE 79-0069)

SBE 71-0110Engine - Provide rerouted oil tubes for the ACOC and the oil tank assembly

SBE 79-0069: Introduction of re-routed oil tubes and revised clipping above the external gearbox

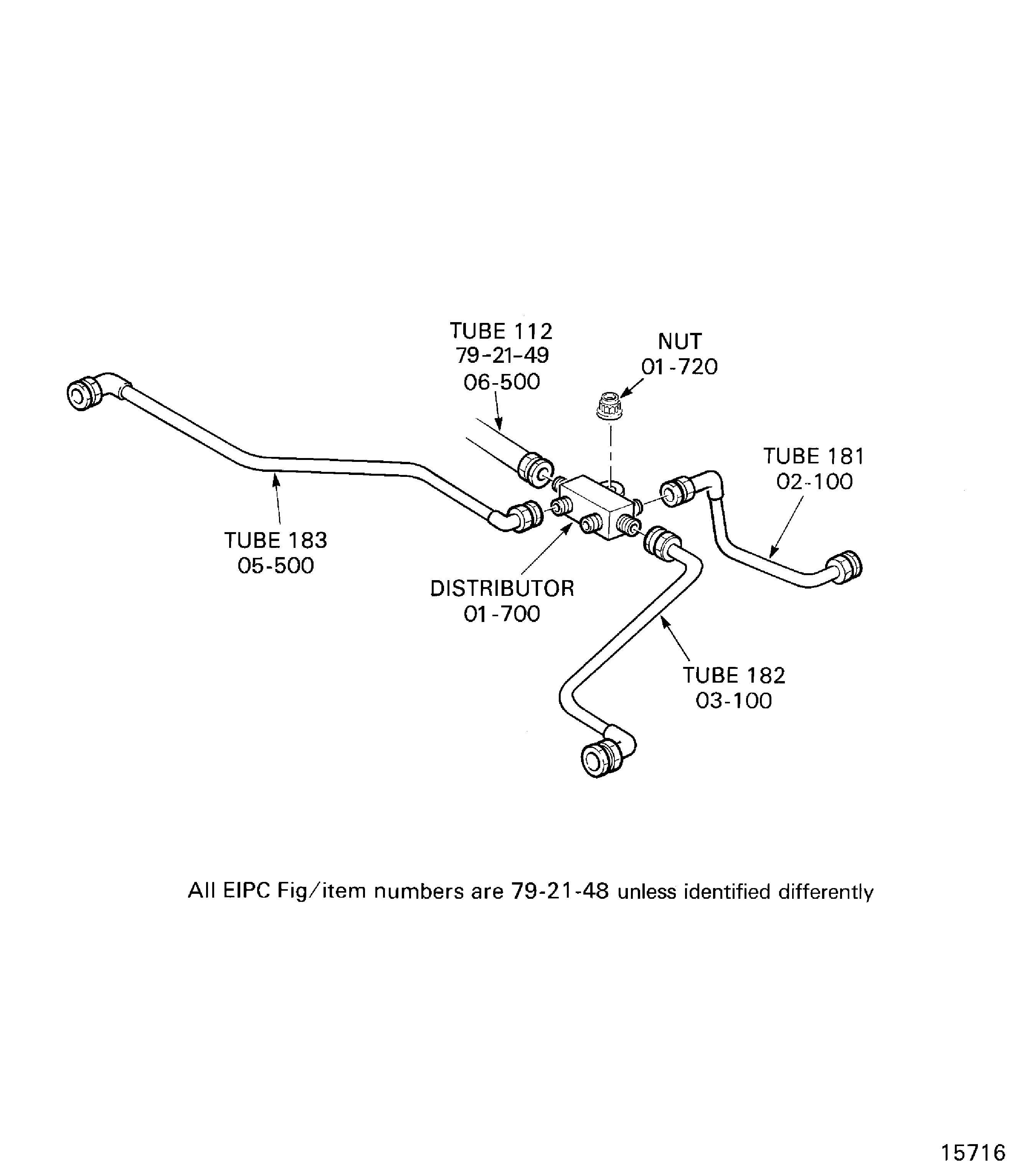

With an applicable tool, hold the oil distributor OIL-PRESSURE OIL TUBES-GEARBOX (79-21-48, 01-700) to prevent movement, disconnect the tube 112 from the oil distributor on the gearbox and remove the tube 112.

SUBTASK 72-00-60-020-091 Remove the Oil Feed Tube (112) from the External Gearbox

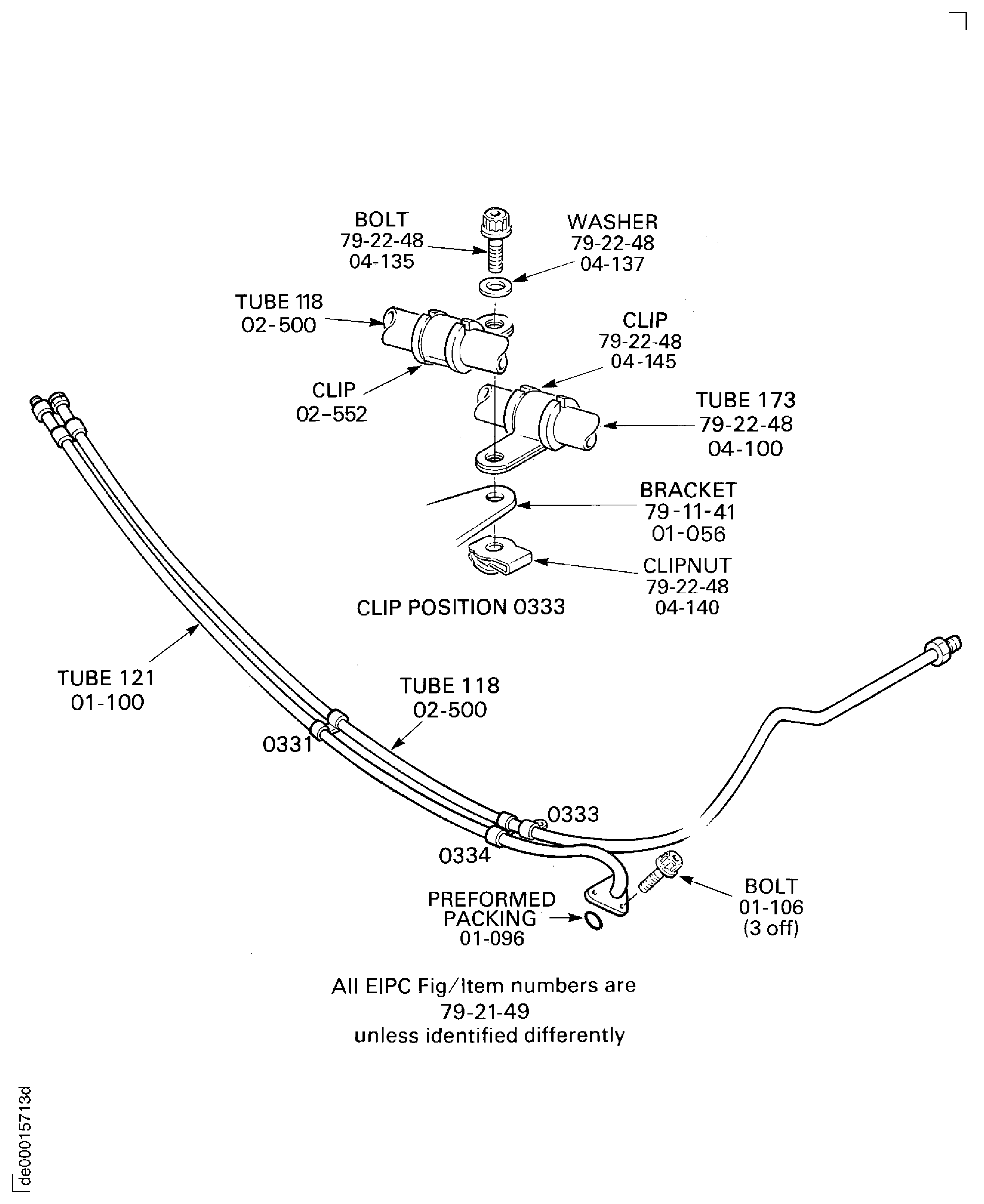

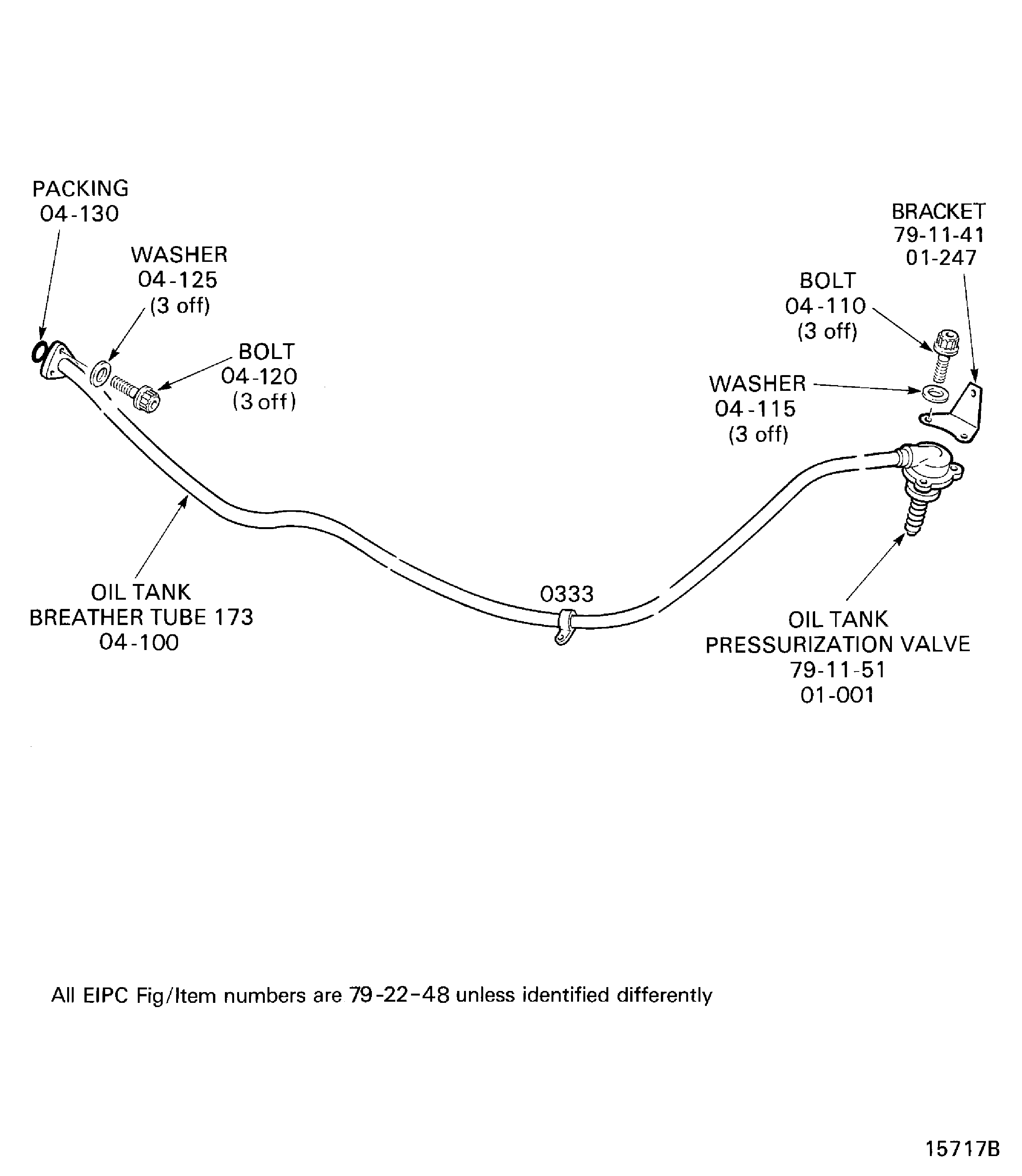

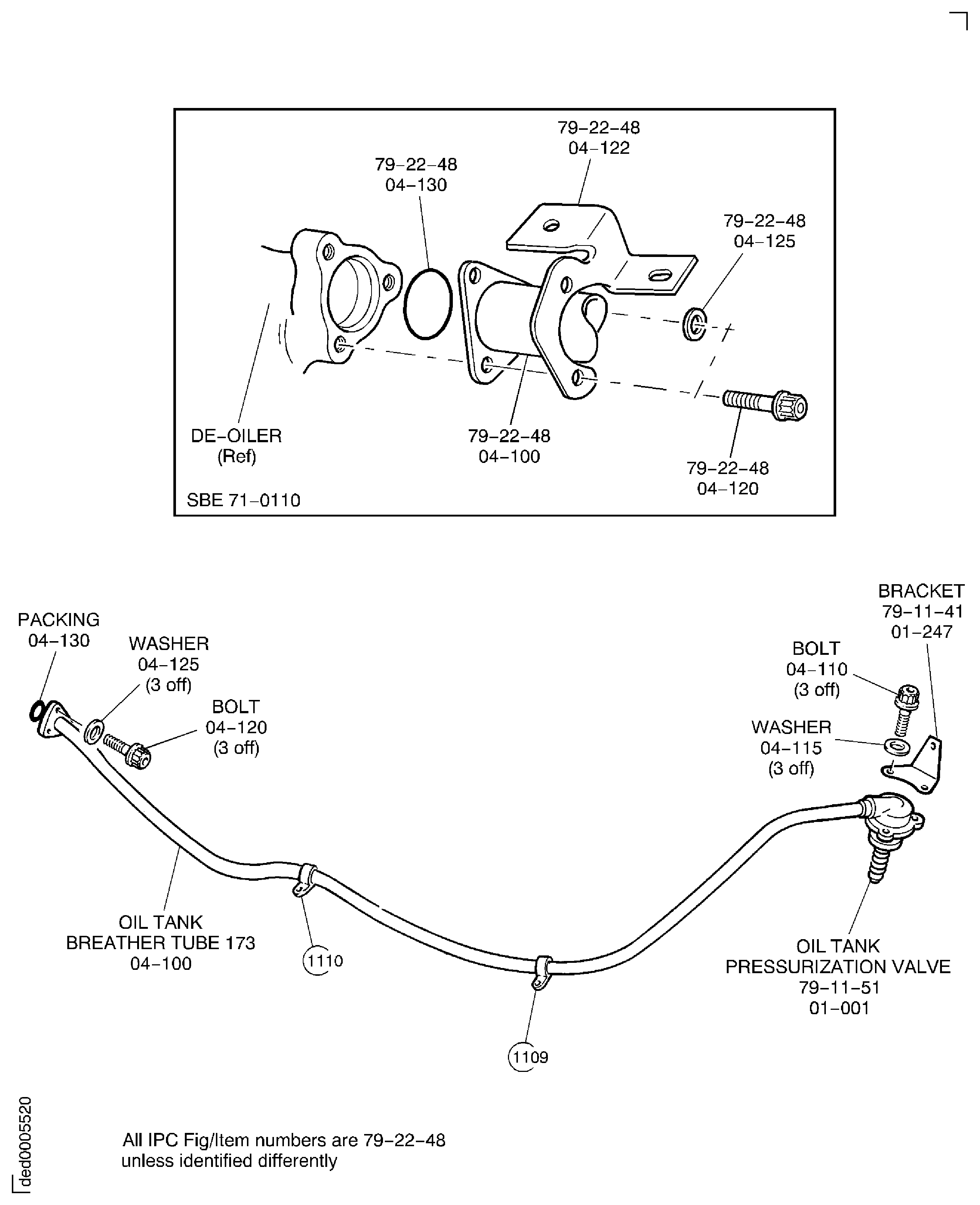

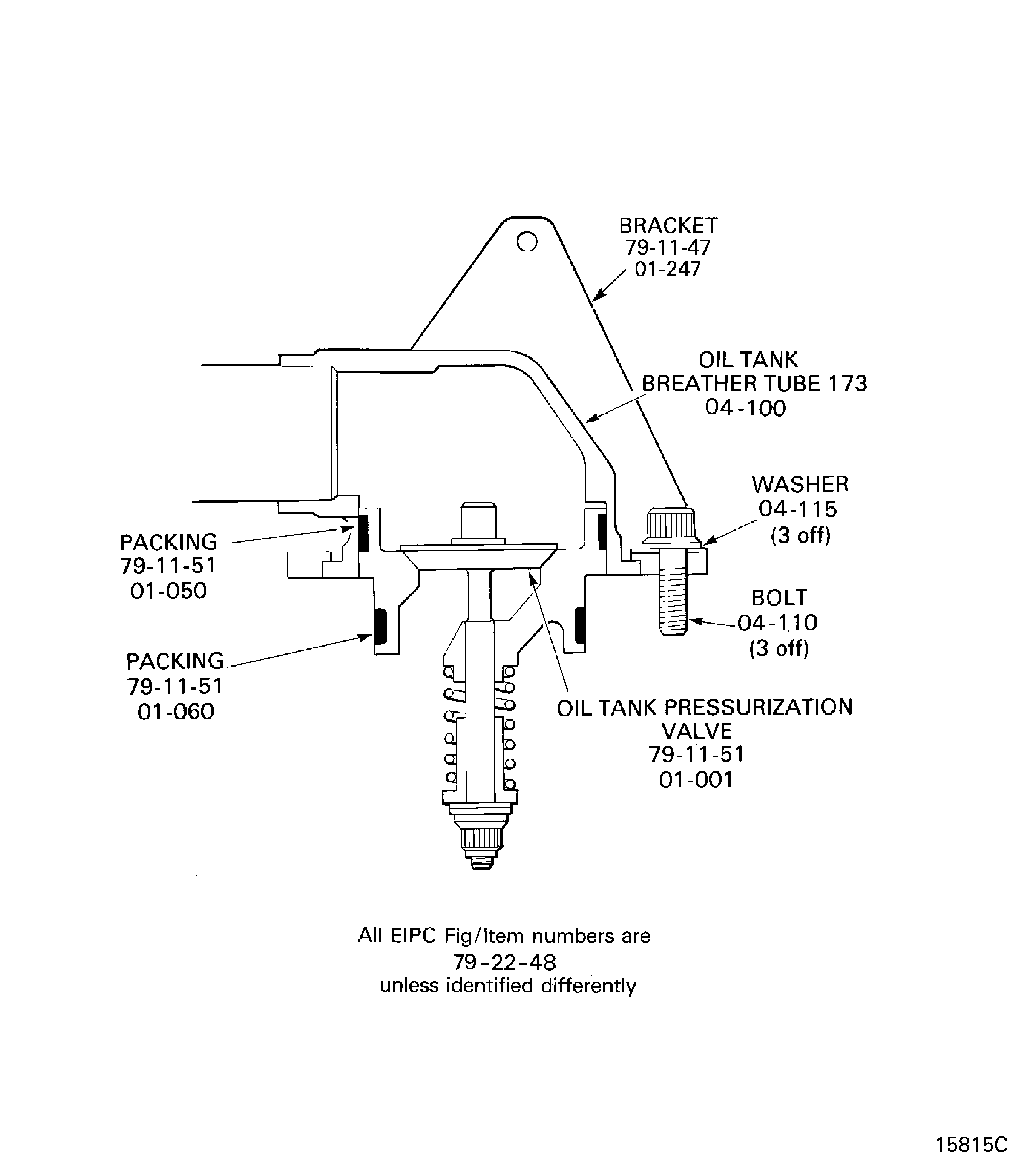

Pre SBE 71-0110 Remove the three bolts and washers that attach the tube 173 to the deoiler. Refer to Figure.

SBE 71-0110 Remove the three bolts and washers that attach the tube 173 to the deoiler and remove the bracket OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 01-122). Refer to Figure.

Remove the three bolts and washers that attach the tube 173 to the oil tank. Remove the tube 173 from the gearbox. Remove the preformed packing from the deoiler tube connection and remove the bracket OIL-OIL TANK (79-11-41, 01-247).

NOTE

The parts of the tank pressurization valve must have their maintenance completed, as given in the Component Maintenance Manual (CMM-MECH-V2500-1IA).Disengage and remove the tank pressurization valve OIL-OIL TANK VALVE (79-11-51, 01-001) from the tube 173. Refer to Figure.

SUBTASK 72-00-60-020-092 Remove the Oil Tank Breather Tube

Disconnect the tube 181 at the angle gearbox and at the oil distributor OIL-PRESSURE OIL TUBES-GEARBOX (79-21-48, 01-700) and remove the tube 181.

With an applicable tool, hold the oil distributor OIL-PRESSURE OIL TUBES-GEARBOX (79-21-48, 01-700) to prevent movement and remove the tubes that follow:

SUBTASK 72-00-60-020-093 Remove the External Gearbox Oil Distribution Tubes

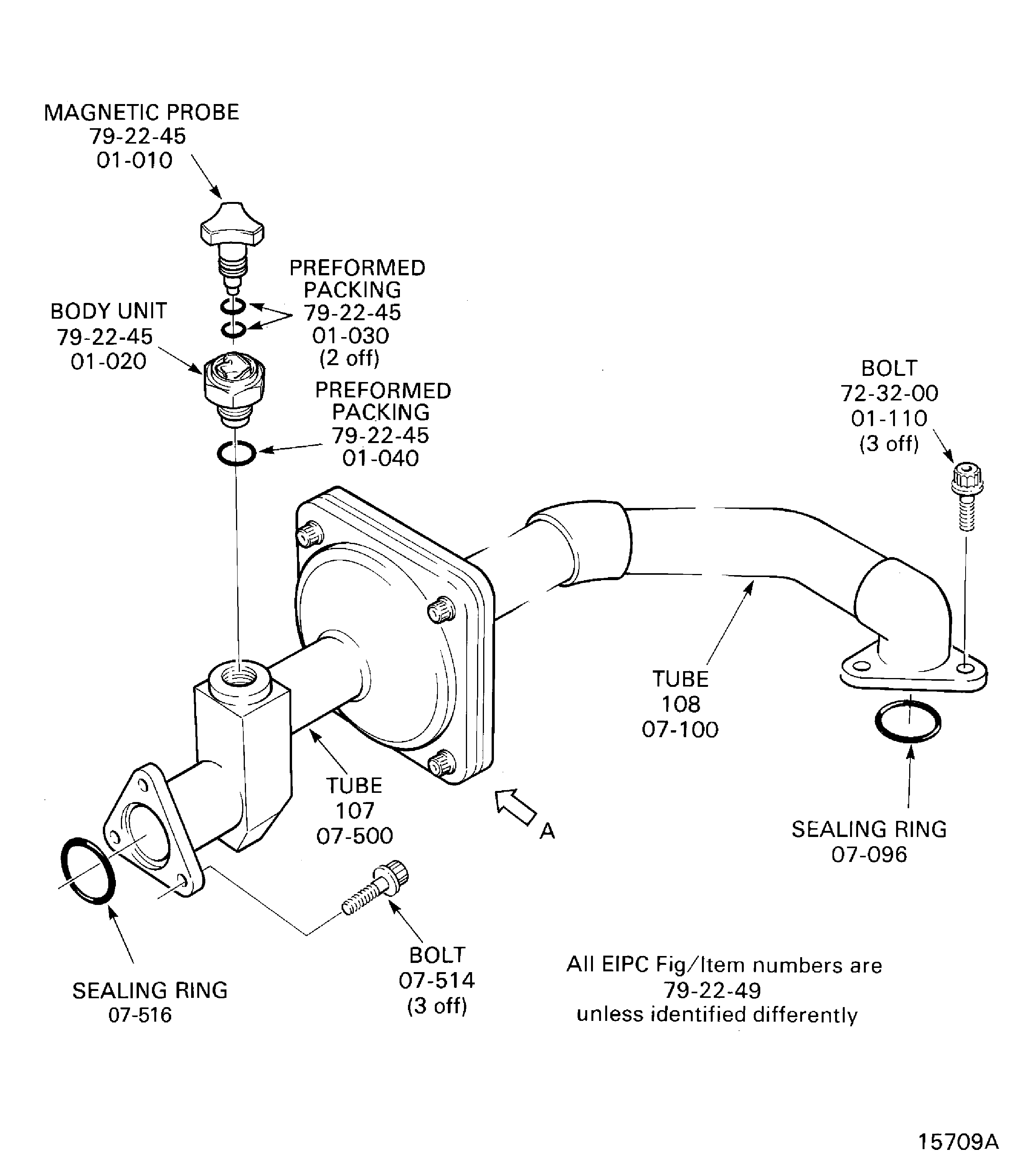

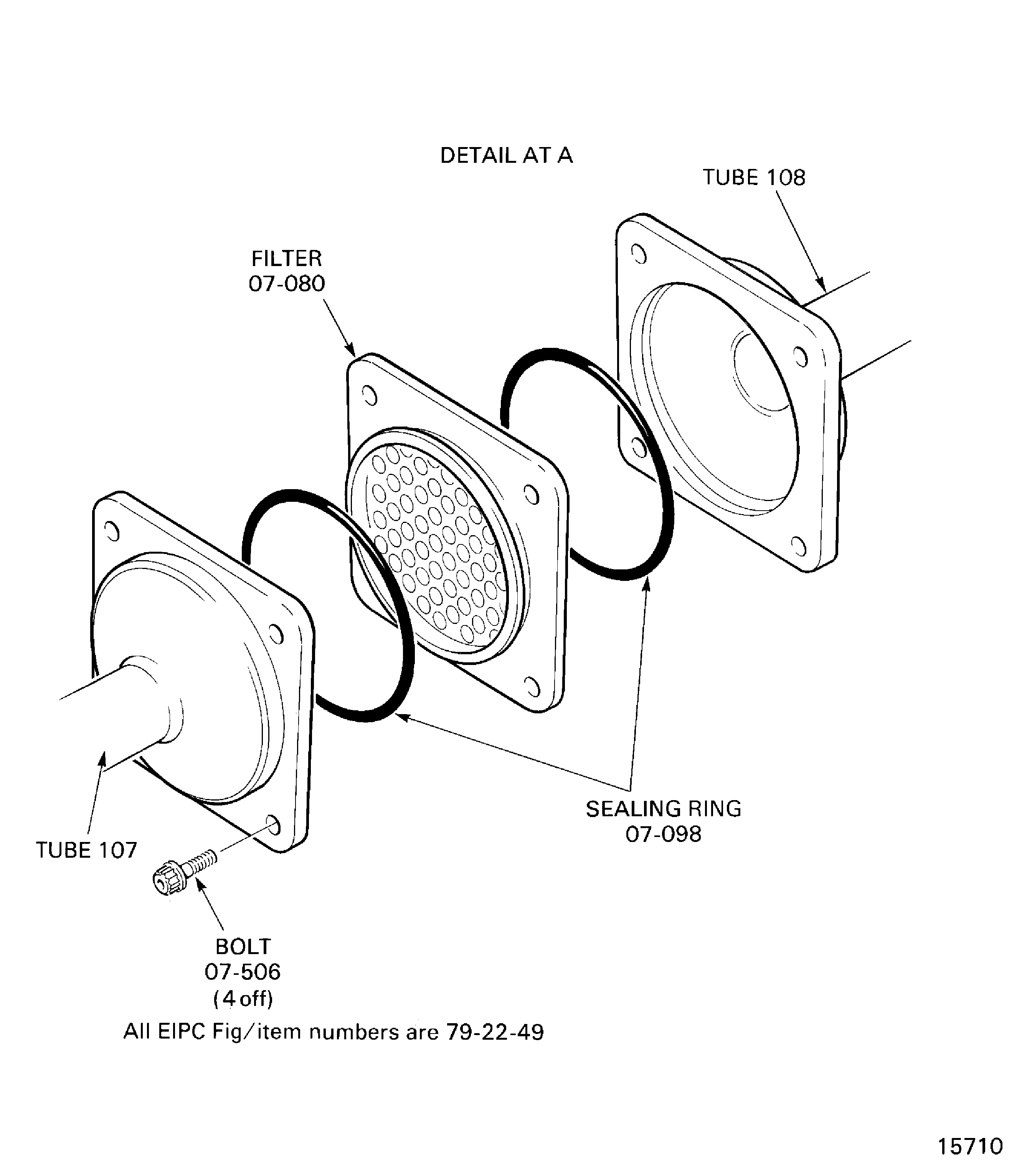

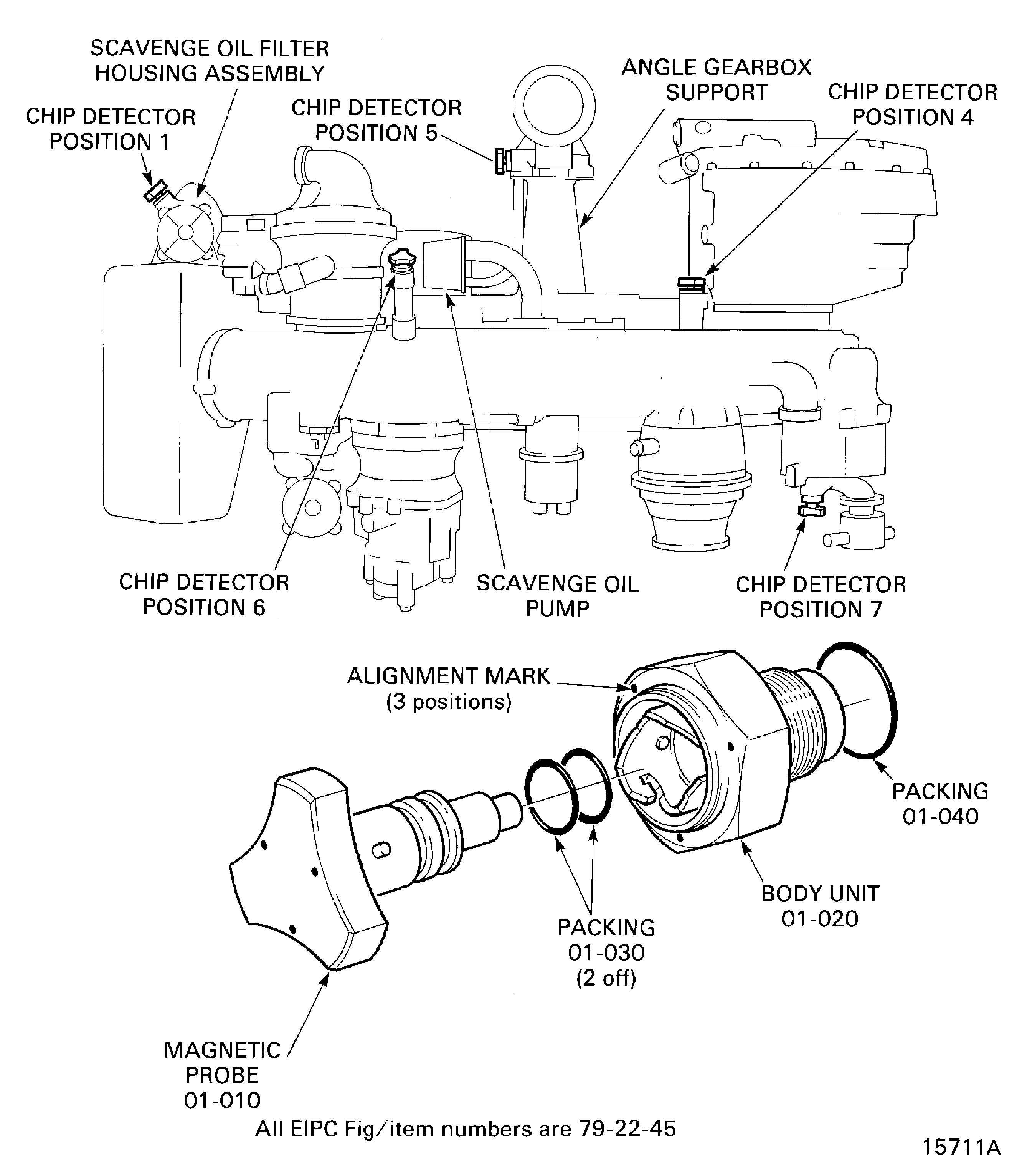

Refer to Figure.

SUBTASK 72-00-60-020-094 Remove the Magnetic Chip Detector Assemblies from the External Gearbox

NOTE

The parts of the magnetic chip detector assemblies must have their maintenance completed, as given in the Component Maintenance Manual (CMM-MECH-V2500-1IA).Remove the two bolts and washers that attach the bracket OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 05-470) to the oil inlet manifold (tube 180). Remove the bracket and install the two bolts and washers again. Tighten by hand.

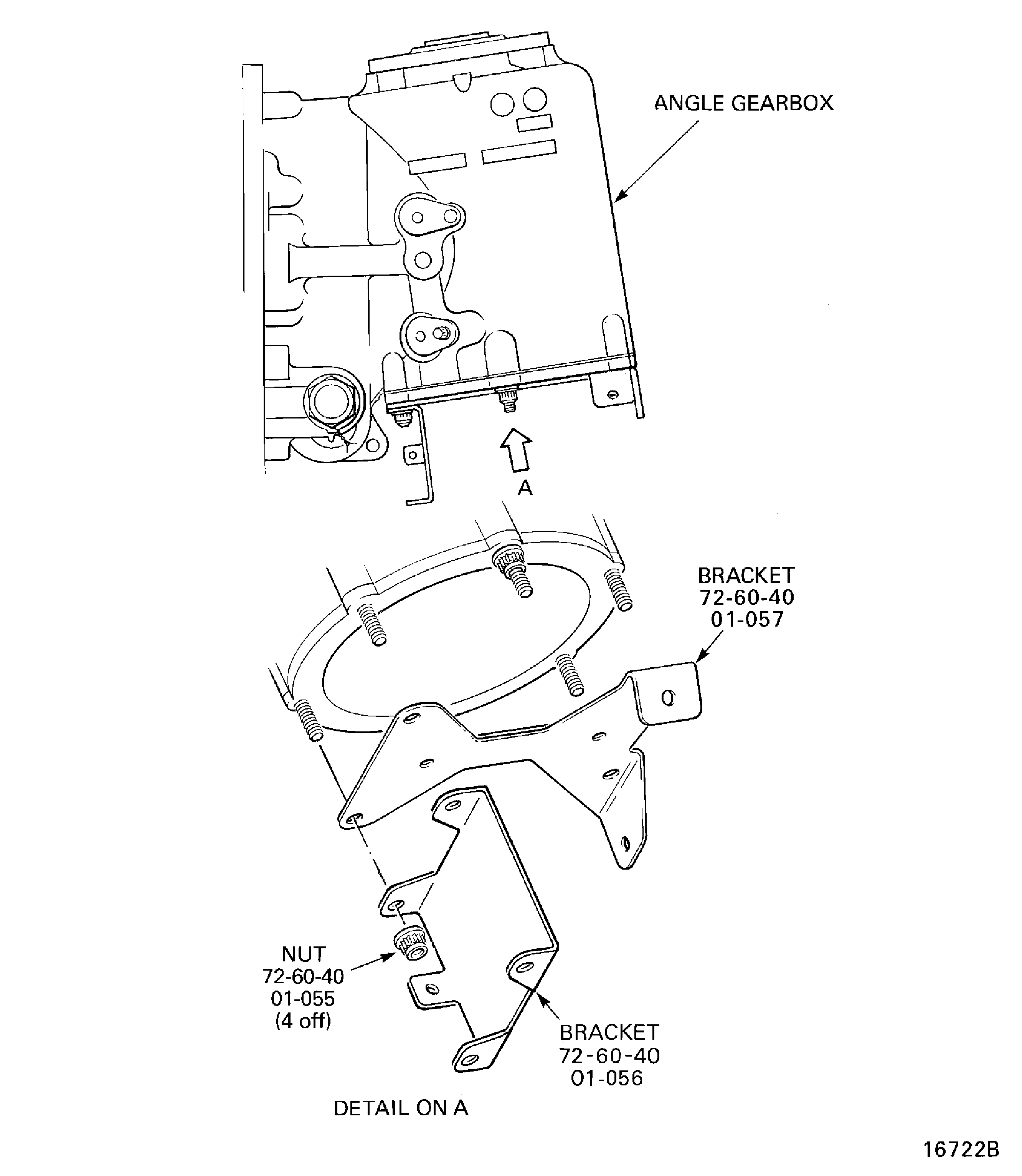

Remove the two nuts that attach the bracket ENGINE FUEL AND CONTROL-LP & HP FUEL PUMPS (73-12-41, 01-080) to the fuel pump mount. Remove the bracket and install the two nuts again. Tighten by hand.

Remove the four nuts that attach the brackets ENGINE-ANGLE GEARBOX ASSEMBLY (72-60-40, 01-057 and ENGINE-ANGLE GEARBOX ASSEMBLY 72-60-40, 01-056) to the angle gearbox. Remove the bracket ENGINE-ANGLE GEARBOX ASSEMBLY (72-60-40, 01-057) and install the bracket ENGINE-ANGLE GEARBOX ASSEMBLY (72-60-40, 01-056) and the four nuts again. Tighten by hand.

SUBTASK 72-00-60-020-095 Remove all the Non-Modular Brackets from the External Gearbox

Refer to Figure.

SBE 71-0118 : Remove the clip bracket OIL-OIL QUANTITY TRANSMITTER (79-31-15, 01-015).

SUBTASK 72-00-60-020-096-A00 Remove the Oil Quantity Transmitter (Pre SBE 79-0023 and SBE 71-0118)

SBE 71-0118: Engine - Revised clipping to provide increased clearance between oil quantity transmitter and EEC harness

Refer to Figure.

SUBTASK 72-00-60-020-096-B00Remove the Oil Quantity Transmitter (SBE 79-0023 and SBE 71-0118)

SBE 79-0023: Provide an oil tank overfill warning plate

SBE 71-0118: Engine - Revised clipping to provide increased clearance between oil quantity transmitter and EEC harness

Figure: Pre SBE 71-0050 and Pre SBE 79-0087: Disconnect the Electrical Harness from the External Gearbox

Sheet 1

Figure: Pre SBE 71-0107, SBE 71-0050, SBE 73-0040 and Pre SBE 79-0087: Disconnect the Electrical Harness from the External Gearbox

Sheet 2

Figure: Pre SBE 71-0107: Disconnect the Electrical Harness from the External Gearbox

Sheet 3

Figure: Pre SBE 71-0107: Disconnect the Electrical Harness from the External Gearbox

Sheet 4

Figure: Pre SBE 71-0050: Disconnect the Electrical Harness from the External Gearbox

Sheet 5

Figure: Pre SBE 71-0107: Disconnect the Electrical Harness from the External Gearbox

Sheet 6

Figure: Pre SBE 71-0107: Disconnect the Electrical Harness from the External Gearbox

Sheet 7

Figure: Pre SBE 71-0107: Disconnect the Electrical Harness from the External Gearbox

Sheet 8

Figure: Pre SBE 71-0107, Pre SBE 79-0087 and SBE 71-0050: Disconnect the Electrical Harness from the External Gearbox

Sheet 9

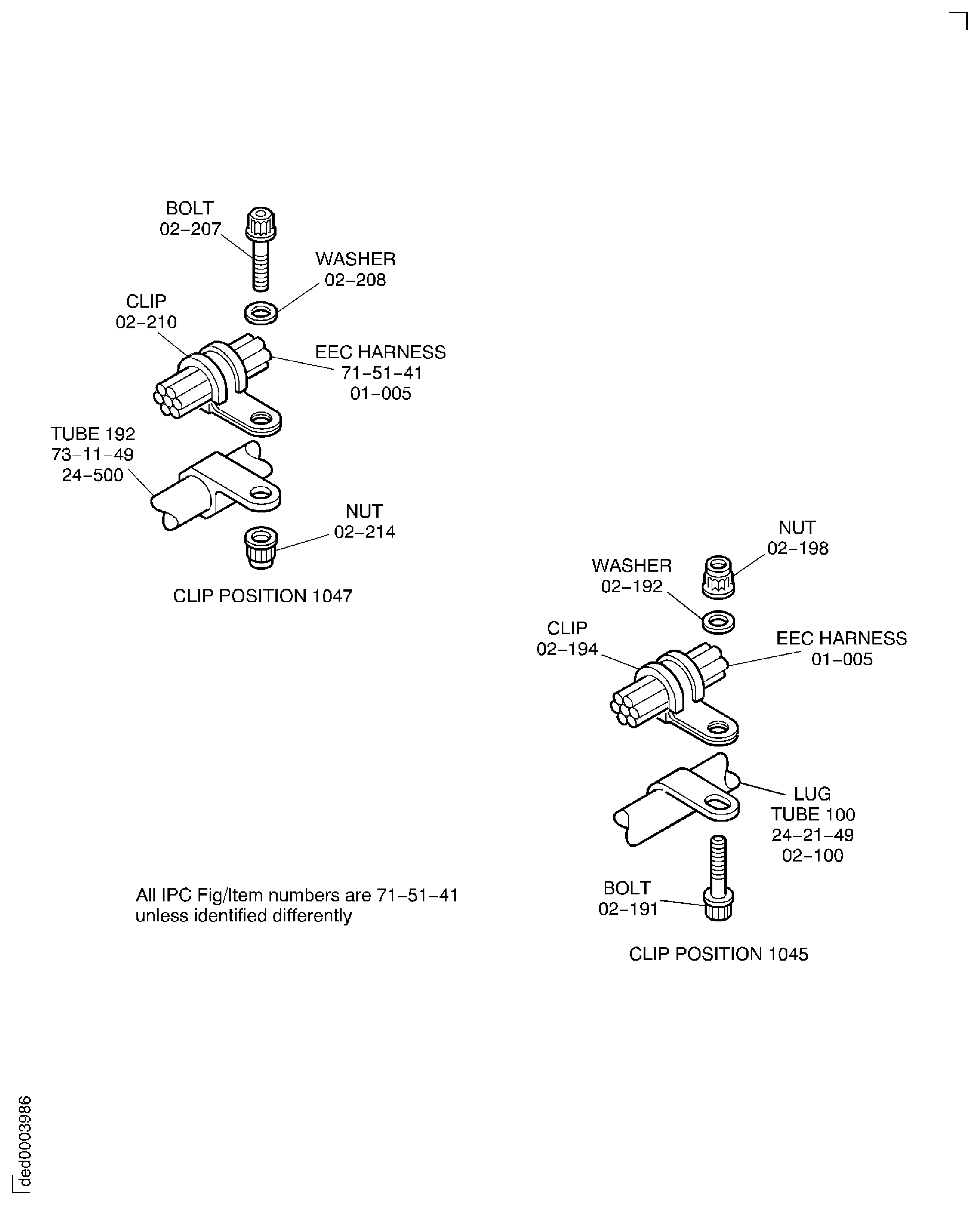

Figure: Pre SB 71-0050, SBE 71-0050 and Pre SBE 79-0087: Disconnect the Electrical Harness from the External Gearbox

Sheet 10

Figure: SBE 71-0107, SBE 73-0040 and Pre SBE 79-0087: Disconnect the Electrical Harness from the External Gearbox

Sheet 1

Figure: SBE 71-0107: Disconnect the Electrical Harness from the External Gearbox

Sheet 2

Figure: SBE 71-0107: Disconnect the Electrical Harness from the External Gearbox

Sheet 3

Figure: SBE 71-0107, Pre SBE 73-0040 and Pre SBE 79-0087: Disconnect the Electrical Harness from the External Gearbox

Sheet 4

Figure: SBE 71-0107: Disconnect the Electrical Harness from the External Gearbox

Sheet 5

Figure: SBE 71-0107: Disconnect the Electrical Harness from the External Gearbox

Sheet 6

Figure: SBE 71-0107: Disconnect the Electrical Harness from the External Gearbox

Sheet 7

Figure: SBE 71-0107: Disconnect the Electrical Harness from the External Gearbox

Sheet 8

Figure: SBE 71-0110: Disconnect the Electrical Harness from the External Gearbox

Sheet 1

Figure: SBE 71-0110: Disconnect the Electrical Harness from the External Gearbox

Sheet 2

Figure: SBE 71-0110 and SBE 71-0118: Disconnect the Electrical Harness from the External Gearbox

Sheet 3

Figure: Pre SBE 79-0023: Remove the Oil Quantity Transmitter

Sheet 1

Figure: SBE 79-0023: Remove the Oil Quantity Transmitter

Sheet 2

Figure: Remove the Gearbox Deoiler Breather Duct

Remove the Gearbox Deoiler Breather Duct

Figure: Remove the Pneumatic Starter Lower Duct Assembly

Remove the Pneumatic Starter Lower Duct Assembly

Figure: Pre SBE 79-0087 and SBE 79-0087: Remove the HP Servo Fuel Tube (89)

Sheet 1

Figure: Pre SBE 79-0087 and SBE 79-0087: Remove the HP Servo Fuel Tube (89)

Sheet 2

Figure: Pre SBE 79-0087 and SBE 79-0087: Remove the HP Servo Fuel Tube (89)

Sheet 3

Figure: Pre SBE 73-0040: Remove the LP Fuel Tube (90) and the Fuel Pump Drain Tube (104)

Sheet 1

Figure: SBE 73-0040: Remove the LP Fuel Tube (90) and the Fuel Pump Drain Tube (104)

Sheet 2

Figure: Pre SBE 73-0040: Remove the Fuel Servo Return Tube (103)

Sheet 1

Figure: Pre SBE 73-0040: Remove the Fuel Servo Return Tube (103)

Sheet 2

Figure: Pre SBE 73-0040: Remove the Fuel Servo Return Tube (103)

Sheet 3

Figure: SBE 73-0040: Remove the Fuel Servo Return Tube (103)

Sheet 1

Figure: SBE 73-0040: Remove the Fuel Servo Return Tube (103)

Sheet 2

Figure: SBE 73-0040: Remove the Fuel Servo Return Tube (103)

Sheet 3

Figure: Remove the LP Fuel Tubes (102 and 116)

Sheet 1

Figure: Remove the LP Fuel Tubes (102 and 116)

Sheet 2

Figure: Remove the LP Fuel Tubes (102 and 116)

Sheet 3

Figure: Remove the LP Fuel Tubes (102 and 116)

Sheet 4

Figure: Remove the LP Fuel Tubes (102 and 116)

Sheet 5

Figure: Pre SBE 73-0040: Remove the HP Fuel Tubes (91 and 92)

Sheet 1

Figure: Pre SB 73-0040: Remove the HP Servo Fuel Tubes (91 and 92)

Sheet 2

Figure: Pre SBE 73-0040: Remove the HP Servo Fuel Tubes (91 and 92)

Sheet 3

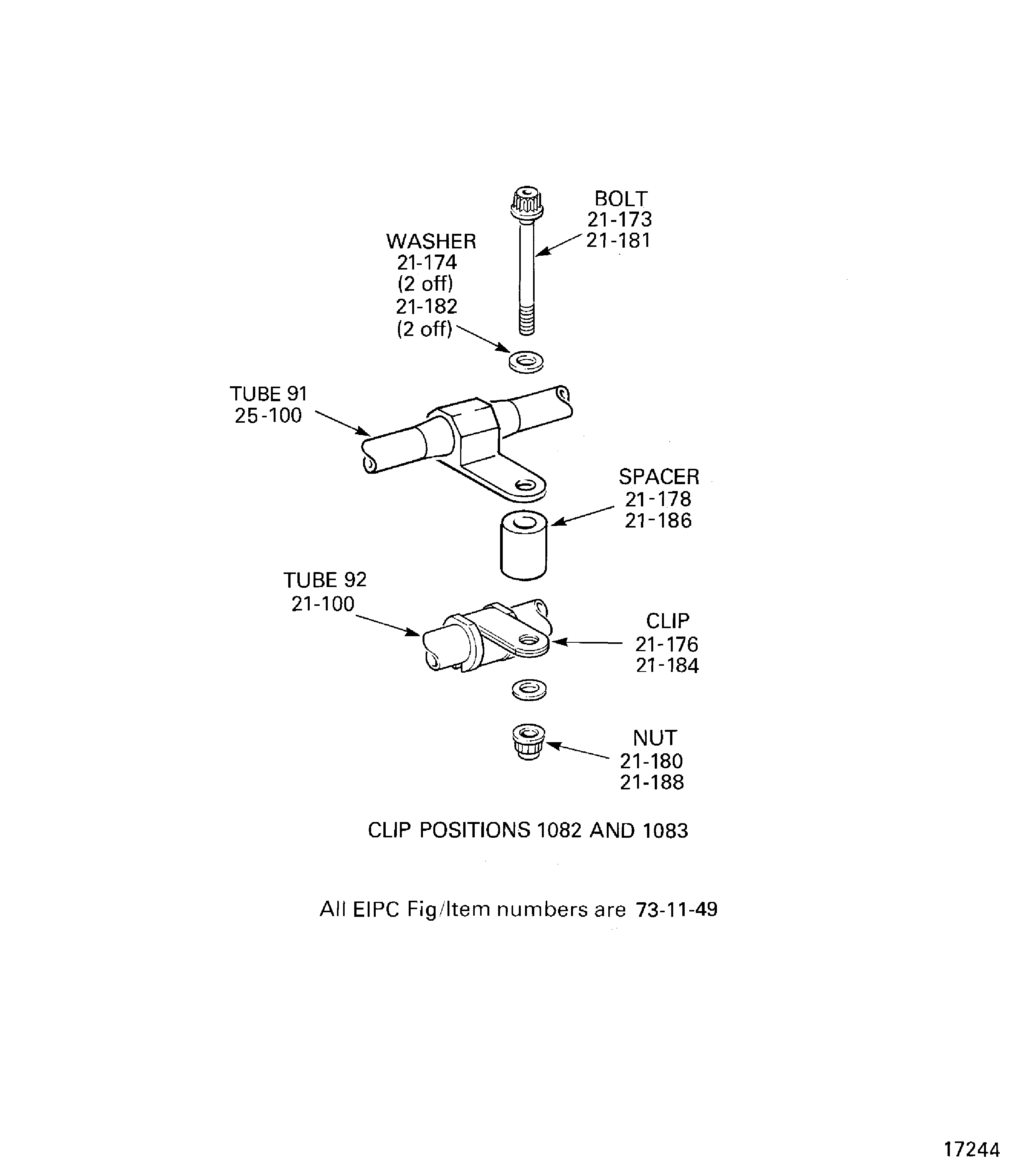

Figure: SBE 73-0040: Remove the HP Servo Fuel Tubes (91 and 92)

Sheet 1

Figure: SBE 73-0040: Remove the HP Servo Fuel Tubes (91 and 92)

Sheet 2

Figure: SBE 73-0040: Remove the HP Servo Fuel Tubes (91 and 92)

Sheet 3

Figure: SBE 73-0040: Remove the HP Servo Fuel Tubes (91 and 92)

Sheet 4

Figure: Remove the No.1, 2 and 3 Bearing Compartment Scavenge Tube Assembly

Sheet 1

Figure: Remove the No.1, 2 and 3 Bearing Compartment Scavenge Tube Assembly

Sheet 2

Figure: Remove the No.1, 2 and 3 Bearing Compartment Scavenge Tube Assembly

Sheet 3

Figure: Disconnect the Oil Pump Scavenge Tube (123)

Disconnect the Oil Pump Scavenge Tube (123)

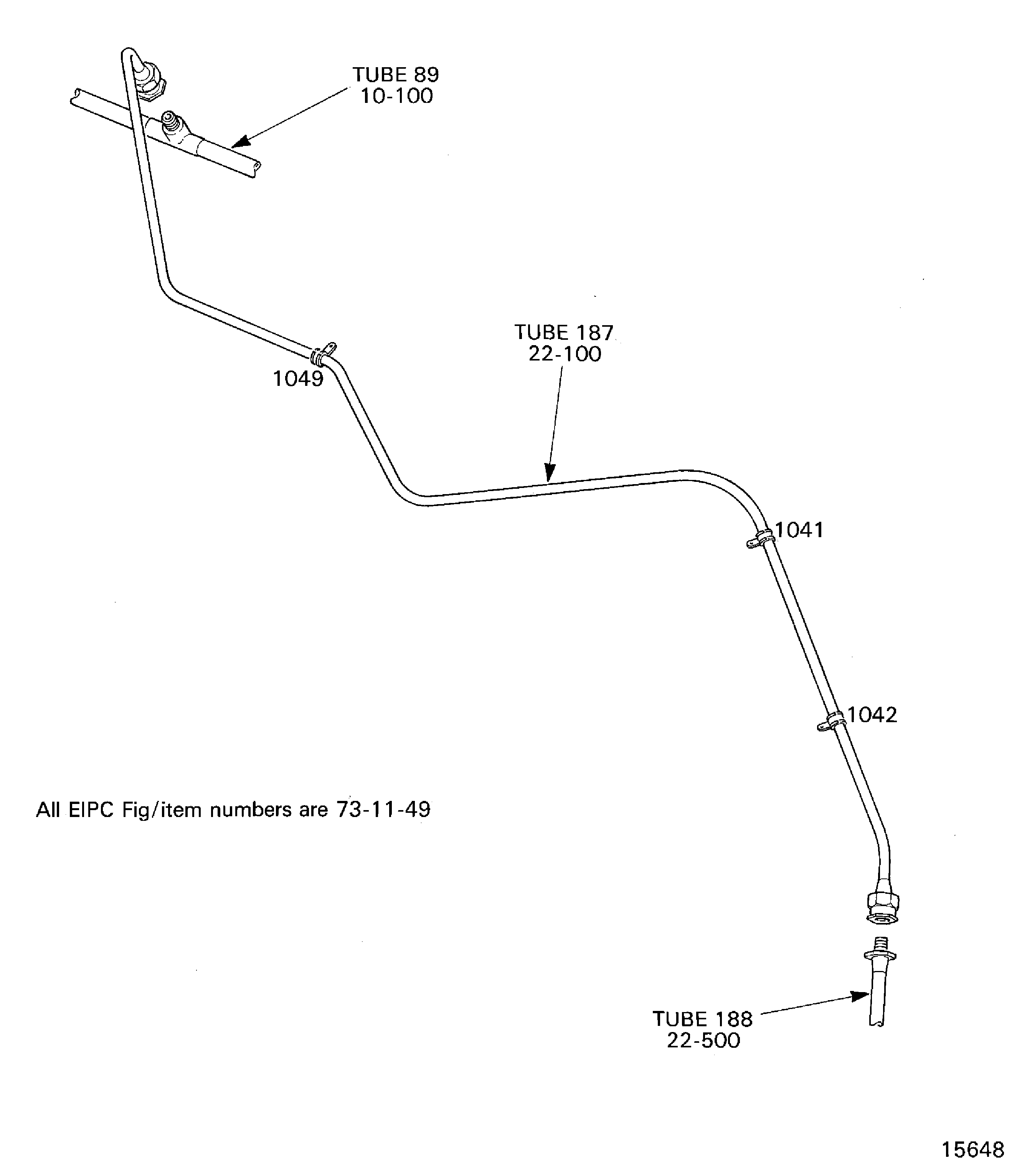

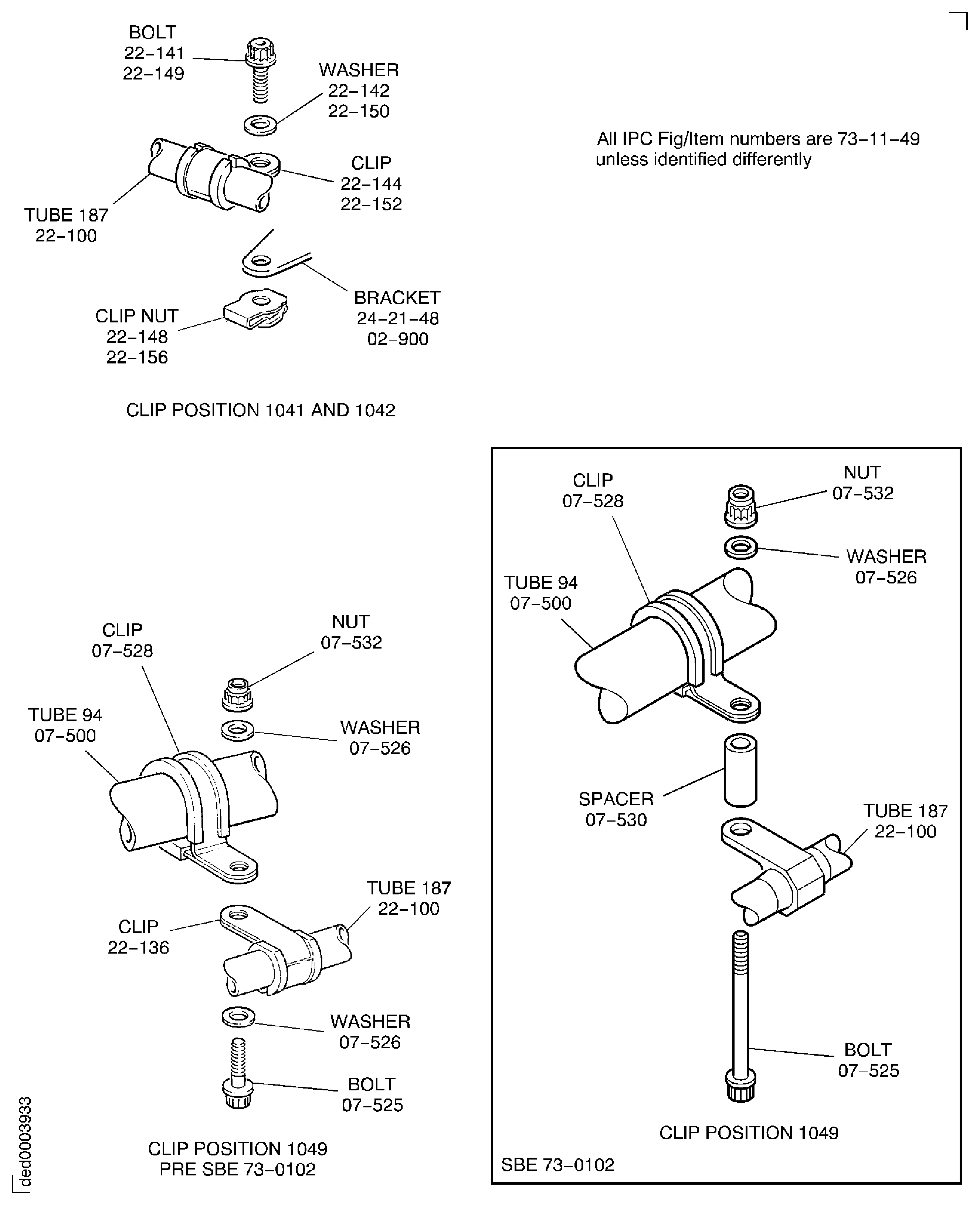

Figure: Remove the Air Modulating Valve Fuel Supply Tube (187)

Sheet 1

Figure: Remove the Air Modulating Valve Fuel Supply Tube (187)

Sheet 2

Figure: Pre SBE 79-0025: Disconnect the FCOC Oil Tubes (115 and 118)

Sheet 1

Figure: SBE 79-0025: Disconnect the FCOC Oil Tubes (115 and 118)

Sheet 2

Figure: Disconnect the FCOC Oil Tubes (115 and 118)

Sheet 3

Figure: Disconnect the FCOC Oil Tubes (115 and 118)

Sheet 4

Figure: Disconnect the FCOC Oil Tubes (115 and 118)

Sheet 5

Figure: Disconnect the FCOC Oil Tubes (115 and 118)

Sheet 6

Figure: Disconnect the FCOC LP Fuel Tubes (110 and 117)

Disconnect the FCOC LP Fuel Tubes (110 and 117)

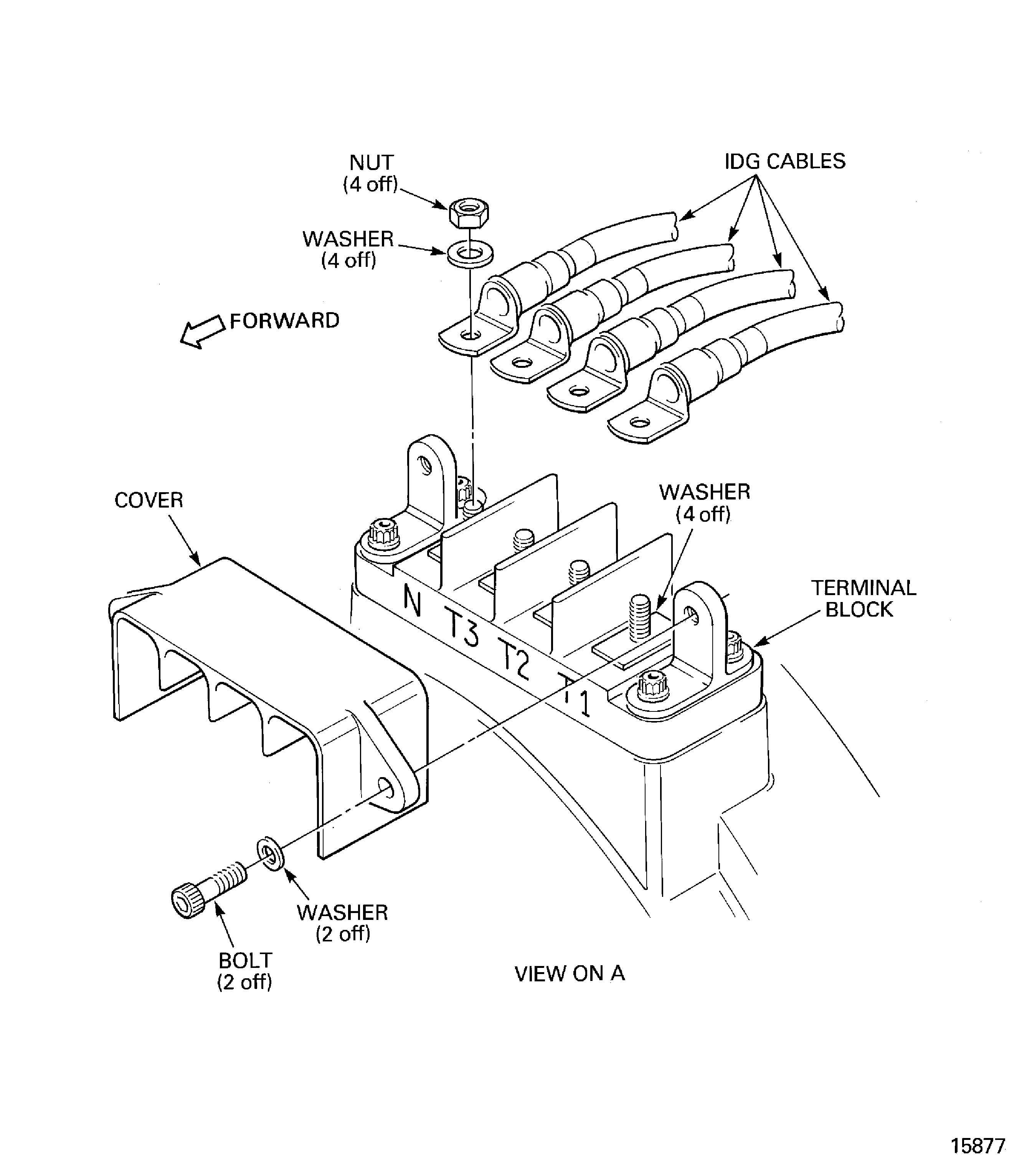

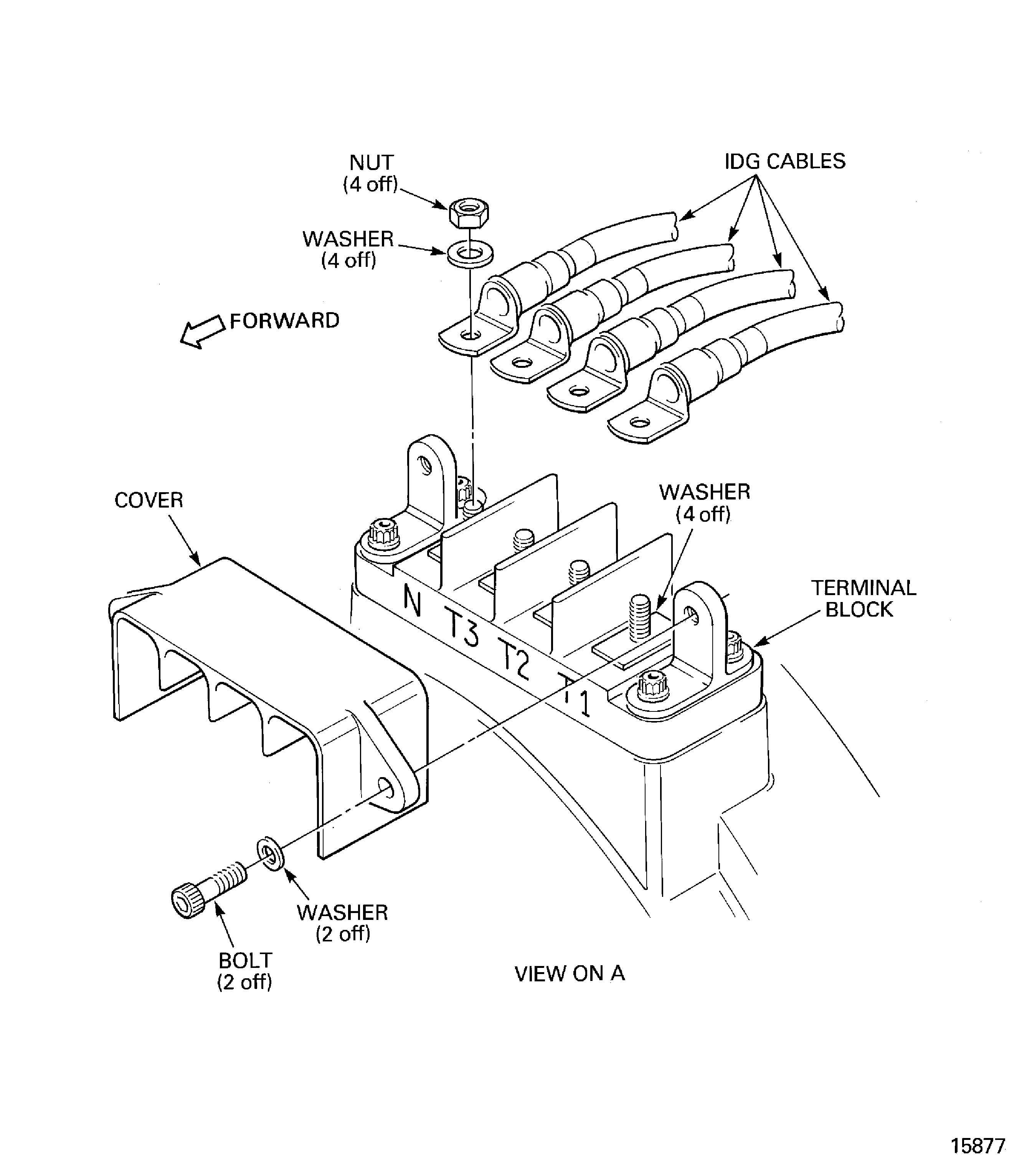

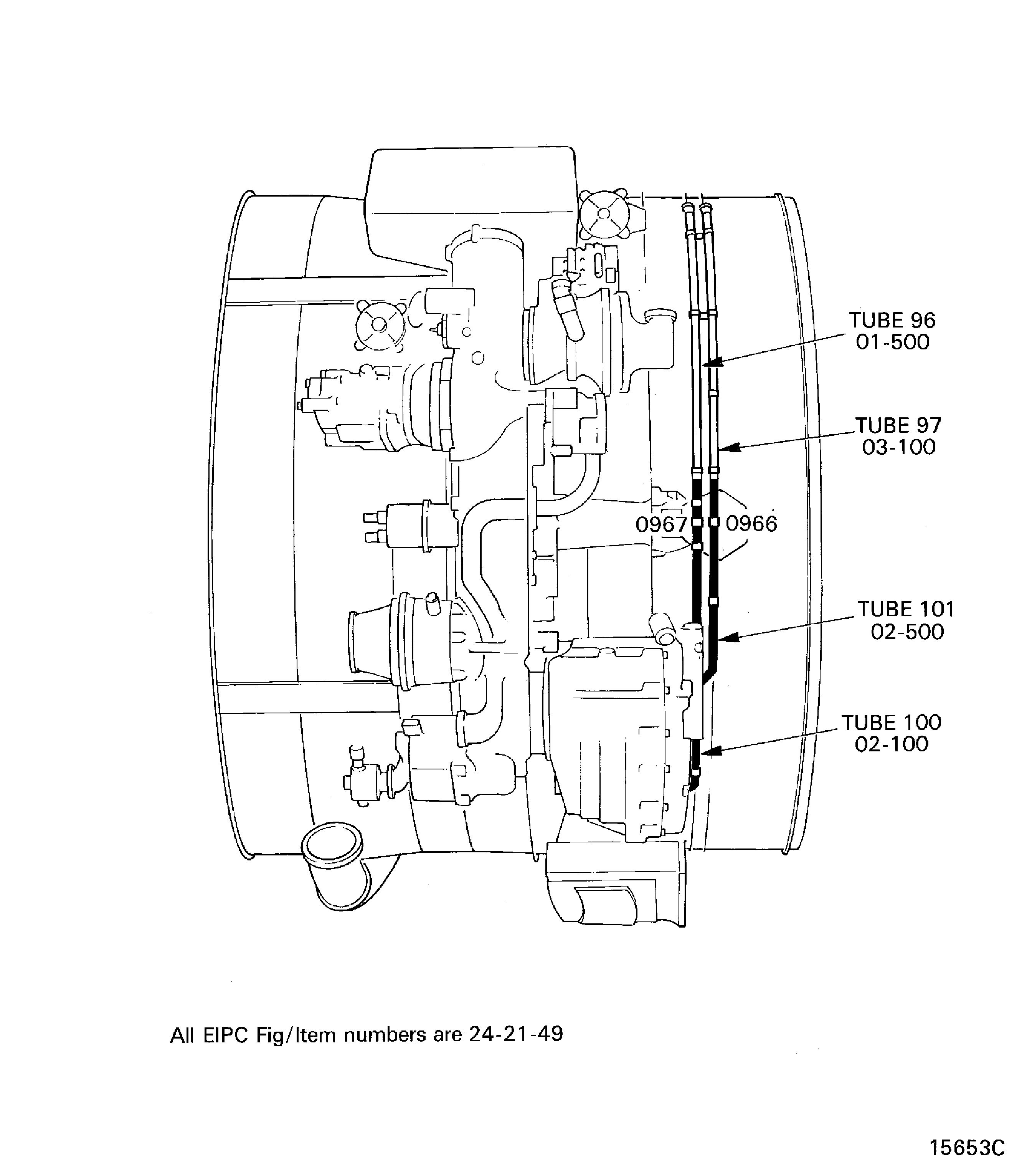

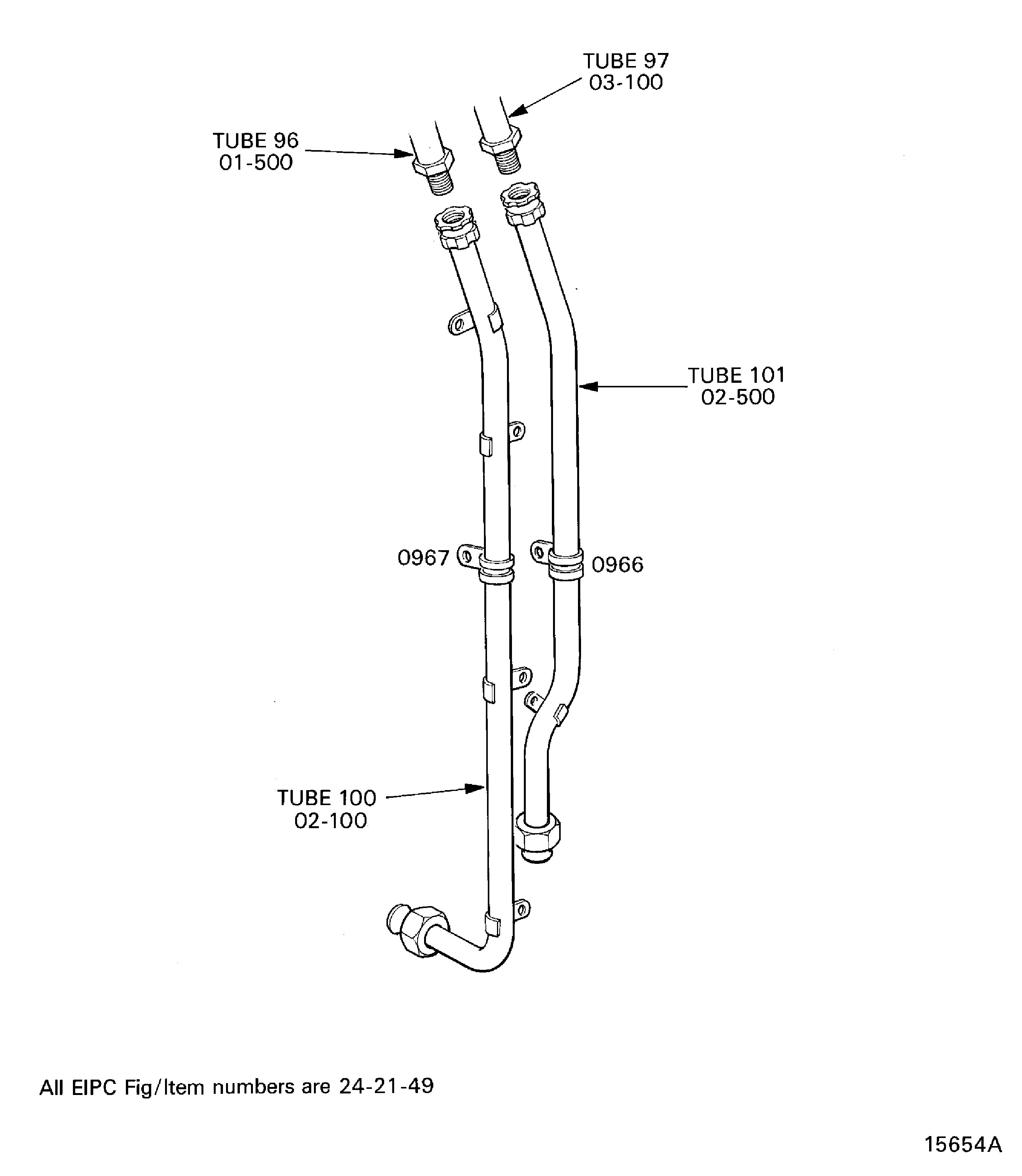

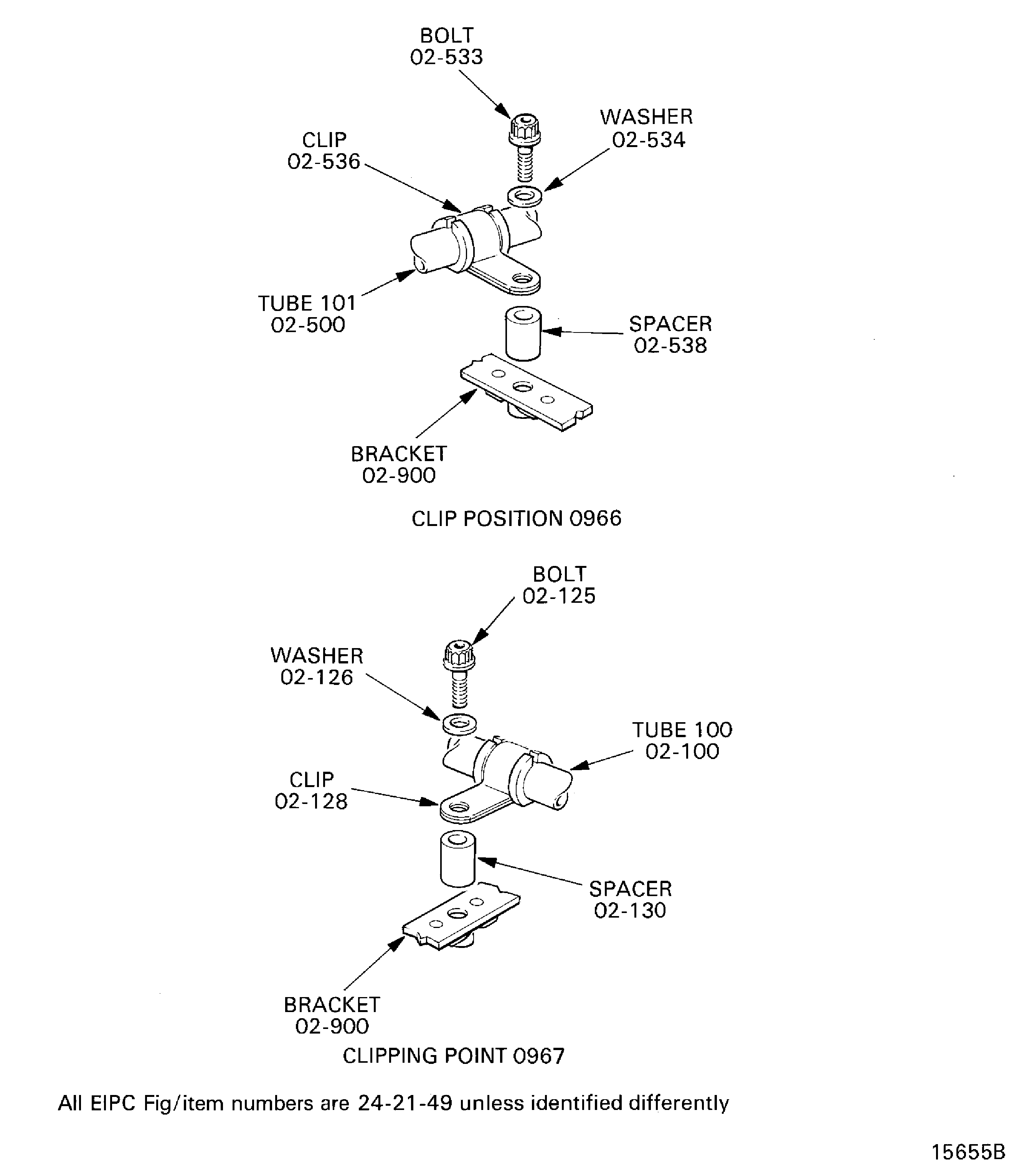

Figure: Remove the IDG Oil Cooling Tubes (100 and 101)

Sheet 1

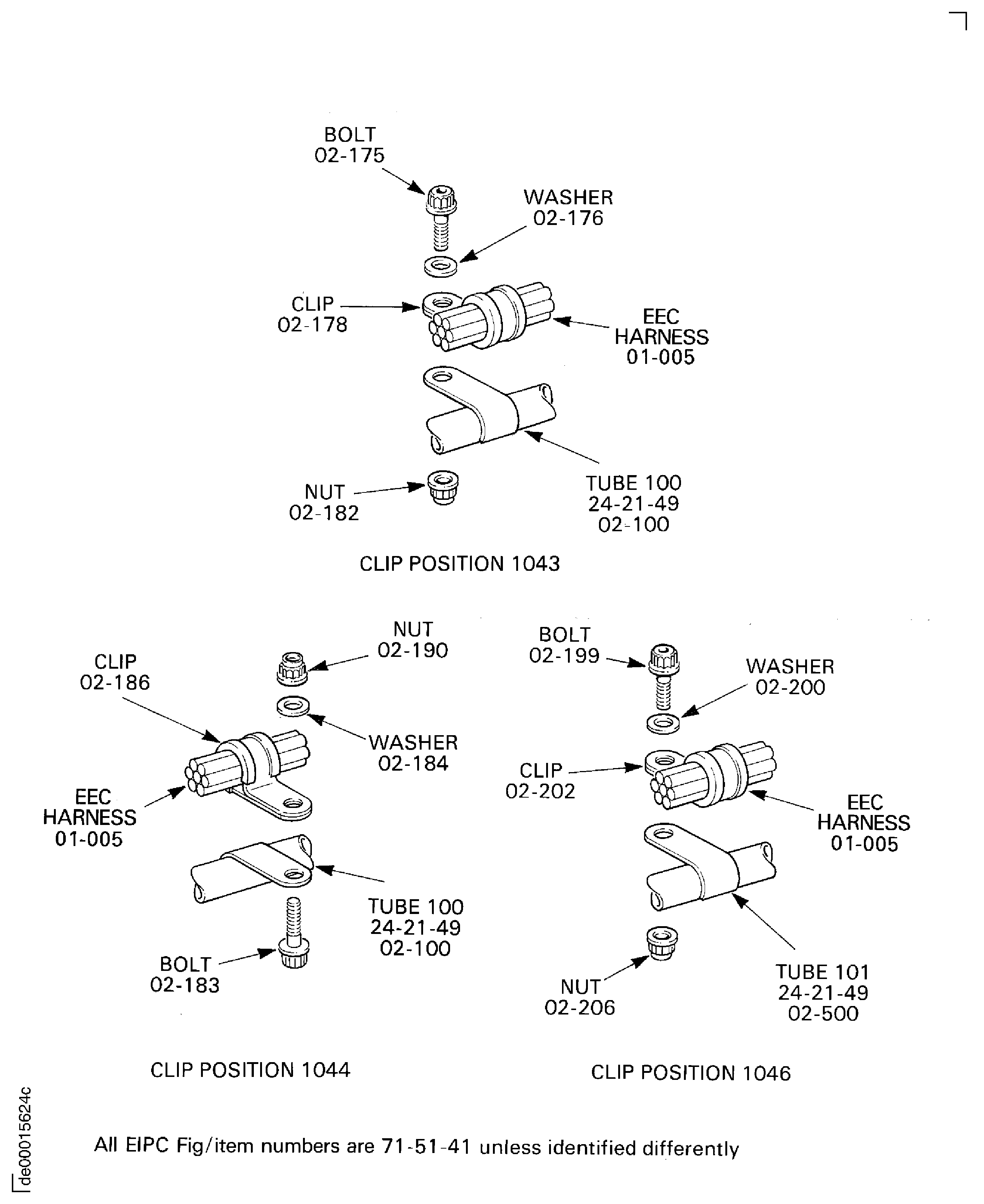

Figure: Remove the IDG Oil Cooling Tubes (100 and 101)

Sheet 2

Figure: Remove the IDG Oil Cooling Tubes (100 and 101)

Sheet 3

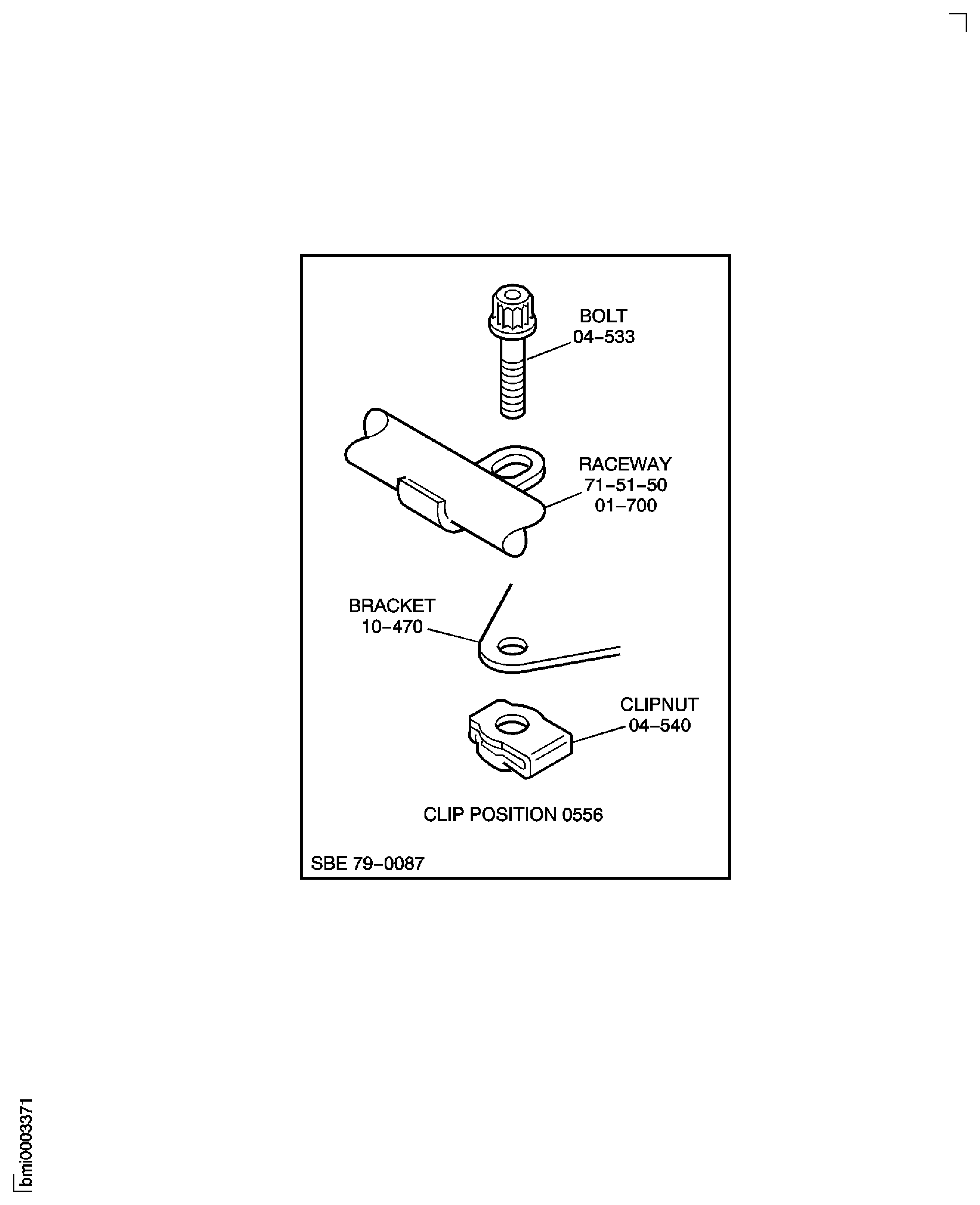

Figure: Pre SBE 79-0087: Disconnect the No.4 Bearing Scavenge Valve Tubes (126 and 128)

Sheet 1

Figure: SBE 79-0087: Disconnect the No.4 Bearing Scavenge Valve Tubes (126 and 128)

Sheet 2

Figure: Disconnect the No.1, 2 and 3 Bearing Compartment Vent Tube (125)

Disconnect the No.1, 2 and 3 Bearing Compartment Vent Tube (125)

Figure: Disconnect the Scavenge Filter Differential Pressure Switch Tubes (208 and 209)

Disconnect the Scavenge Filter Differential Pressure Switch Tubes (208 and 209)

Figure: Disconnect the Hydraulic Pump Hoses

Disconnect the Hydraulic Pump Hoses

Figure: Pre SBE 71-0110: Remove the ACOC Oil Tubes (118 and 121) from the External Gearbox

Sheet 1

Figure: Pre SBE 71-0110: Remove the ACOC Oil Tubes (118 and 121) from the External Gearbox

Sheet 2

Figure: Pre SBE 71-0110: Remove the ACOC Oil Tubes (118 and 121) from the External Gearbox

Sheet 3

Figure: SBE 71-0110: Remove the ACOC Oil Tubes (118 and 121) from the External Gearbox

Sheet 1

Figure: SBE 71-0110: Remove the ACOC Oil Tubes (118 and 121) from the External Gearbox

Sheet 2

Figure: SBE 79-0069: Remove the ACOC Oil Tubes (118 and 121) from the External Gearbox

Sheet 3

Figure: Remove the Oil Scavenge Tube (123) from the External Gearbox

Remove the Oil Scavenge Tube (123) from the External Gearbox

Figure: Remove the Gearbox Oil Feed Tube (112) from the External Gearbox

Remove the Gearbox Oil Feed Tube (112) from the External Gearbox

Figure: Pre SBE 71-0110: Remove the Oil Tank Breather Tube (173) from the External Gearbox

Sheet 1

Figure: SBE 71-0110: Remove the Oil Tank Breather tTbe (173) from the External Gearbox

Sheet 2

Figure: Remove the Oil Tank Breather Tube (173) from the External Gearbox

Sheet 3

Figure: Remove the External Gearbox Oil Distribution Tubes

Remove the External Gearbox Oil Distribution Tubes

Figure: The External Gearbox Magnetic Chip Detectors - Location and Removal

The External Gearbox Magnetic Chip Detectors - Location and Removal

Figure: Remove the None-Modular Brackets from the External Gearbox

Sheet 1

Figure: Remove the Non-Modular Brackets from the External Gearbox

Sheet 2

Figure: SBE 71-0063 and Pre SBE 71-0111: Remove the Clips at the Electrical Connectors

SBE 71-0063 and Pre SBE 71-0111: Remove the Clips at the Electrical Connectors

Figure: SBE 75-0010: Remove the Dedicated Alternator Cooling Air Tubes

Sheet 1

Figure: SBE 71-0110: Remove the Dedicated Alternator Cooling Air Tubes

Sheet 2