Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-41-30-440-008-A00 HPC Front Case And Vane Assembly - Install The Variable Inlet Guide Vane And The Stage 3 To 6 Connectors, Assembly-008

General

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and touch faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to the SPM TASK 70-44-01-400-501.

For lockwire data and procedures refer to the SPM TASK 70-42-05-400-501.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and parts used to attach. Use the correct colour of the air drying enamel. Refer to the SPM TASK 70-63-02-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

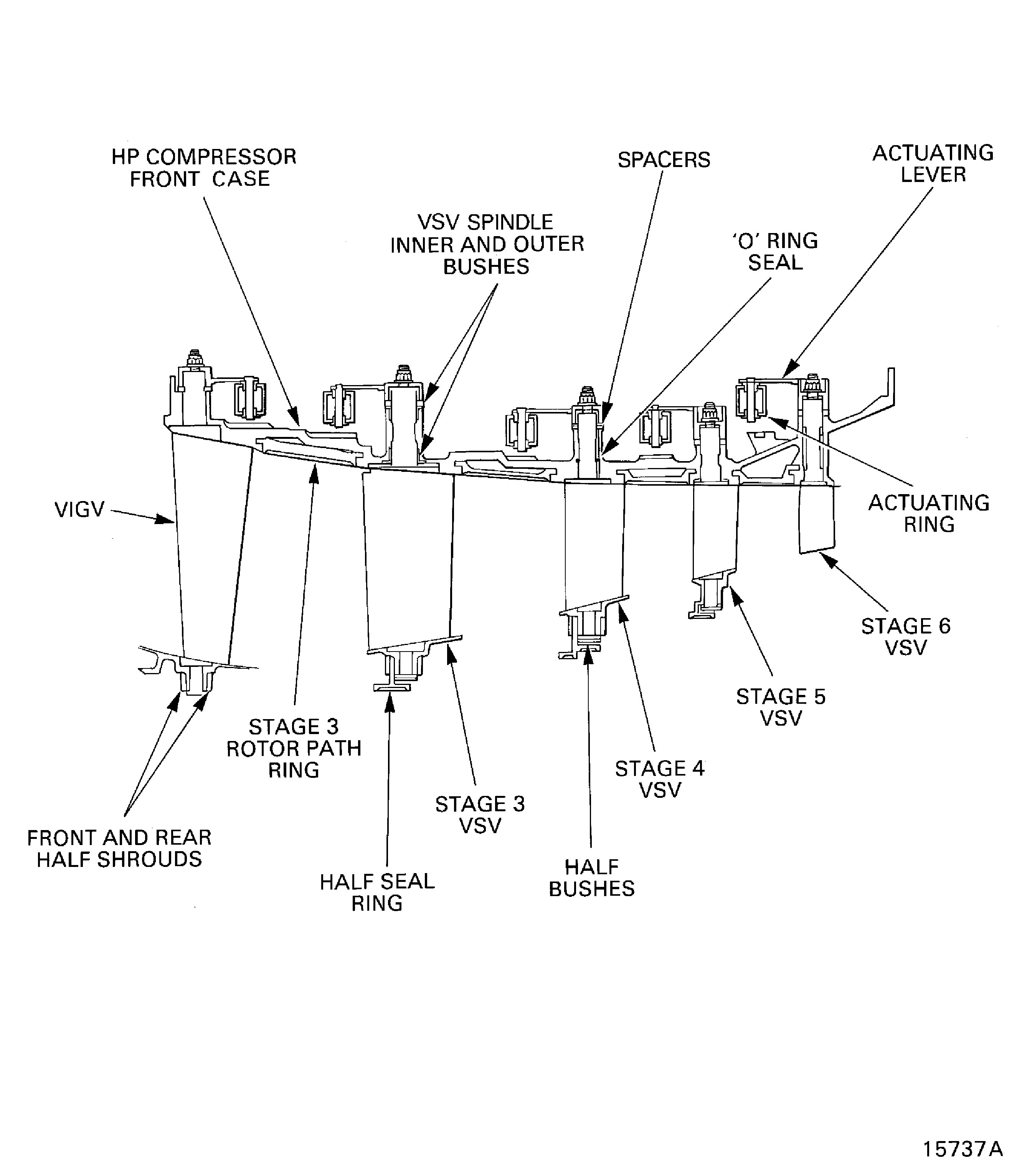

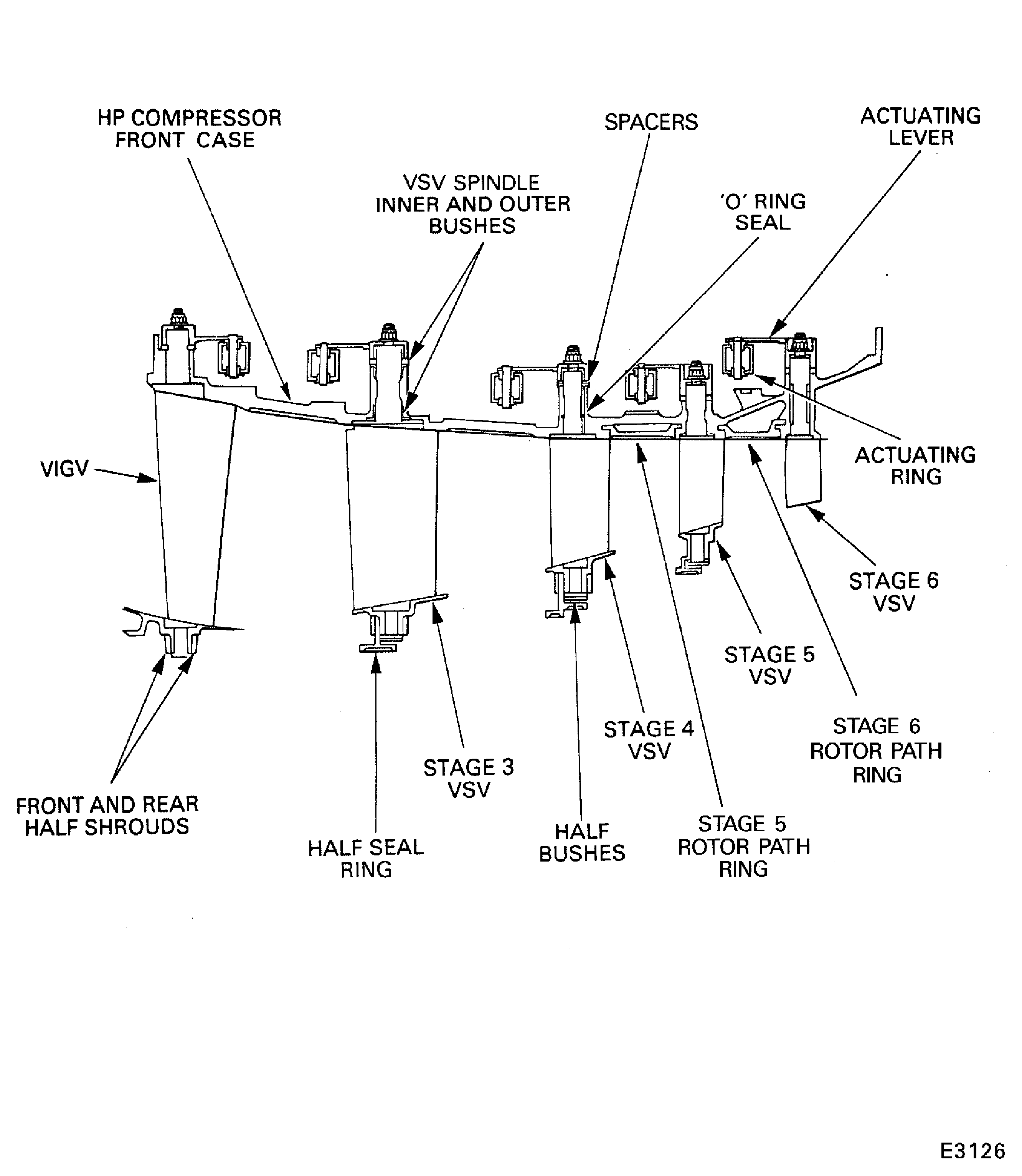

Pre SBE 72-0027: Refer to Figure for a sectional view of the HP compressor front case.

SBE 72-0027: Refer to Figure for a sectional view of the HP compressor front case.

The Fits and Clearances, NEW PART DIMENSIONS and REJECT IF MORE THAN columns will be used by most operators. This permits the full use of the maximum wear allowance and a reduction in the number of parts which are rejected, is possible.

As long as REJECT IF MORE THAN columns do not include reject values, NEW PART DIMENSIONS do not have to be measured before assembly, as there are no reject-if criteria. Values are only valid for new parts, not for worn parts.

The column WORN PART DIMENSIONS (Non-Select) is included for operators who want to have full interchangeability. If this column is used an increase in the number of parts which are rejected is possible.

After the part has been in service for some time the REJECT IF MORE THAN and WORN PART DIMENSIONS could be changed. The operator must tell IAE and if agreed the manual will be changed.

The abbreviation Intf shows an interference or tight fit. This causes REJECT IF MORE THAN to become REJECT IF LESS THAN.

The abbreviation clear shows a clearance fit.

This TASK gives the procedure to install the variable inlet guide vane and stage 3 to 6 connector assemblies. The subsequent TASK gives the procedure to assemble the HP compressor front cases.

TASK 72-41-30-440-001-A00 (ASSEMBLY-001, CONFIG-001) Install the Stage 3 to 6 Rotor Path Rings Pre SBE 72-0027.

TASK 72-41-30-440-001-B00 (ASSEMBLY-001, CONFIG-002) Install the Stage 5 and 6 Rotor Path Rings SBE 72-0027.

TASK 72-41-30-440-002-A00 (ASSEMBLY-002, CONFIG-001) Measure and then Machine the Stage 6 VSV and the Stage 3 to 6 Rotor Path Linings.

TASK 72-41-30-440-003-A00 (ASSEMBLY-003, CONFIG-001) Install the Variable Inlet Guide Vanes.

TASK 72-41-30-440-004-A00 (ASSEMBLY-004, CONFIG-001) Install the Stage 3 Stator Vanes.

TASK 72-41-30-440-005-A00 (ASSEMBLY-005, CONFIG-001) Install the Stage 4 Stator Vanes.

TASK 72-41-30-440-006-A00 (ASSEMBLY-006, CONFIG-001) Install the Stage 5 Stator Vanes.

TASK 72-41-30-440-007-A00 (ASSEMBLY-007, CONFIG-001) Install the Stage 6 Stator Vanes.

TASK 72-41-30-440-009-A00 (ASSEMBLY-009, CONFIG-001) Measure the HP Compressor Front Cases.

TASK 72-41-30-440-010-A00 (ASSEMBLY-010, CONFIG-001) Disassemble the HP Compressor Front Cases.

TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001) Check and Set VSV System with Optimised Build and Setting Clearances - SBE 72-0402.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Inspection table | LOCAL | Inspection table | ||

| IAE 1R18205 Lifting tool | 0AM53 | IAE 1R18205 | 1 | |

| IAE 1R18207 Support stand | 0AM53 | IAE 1R18207 | 1 | |

| IAE 1R18249 Lifting tool | 0AM53 | IAE 1R18249 | 2 | |

| IAE 1R18423 Rigging pin | 0AM53 | IAE 1R18423 | 6 | |

| IAE 1R18892 Rigging pin | 0AM53 | IAE 1R18892 | 6 | |

| IAE 1R18423 Rigging pin | 0AM53 | IAE 1R18423 | 6 per stage | |

| IAE 1R18893 Riggingpin | 0AM53 | IAE 1R18893 | 6 | |

| IAE 1R18894 Rigging pin | 0AM53 | IAE 1R18894 | 6 | |

| IAE 1R18895 Rigging pin | 0AM53 | IAE 1R18895 | 6 | |

| IAE 1R18896 Rigging pin | 0AM53 | IAE 1R18896 | 6 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 | ||

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 |

Spares

NONESafety Requirements

NONEProcedure

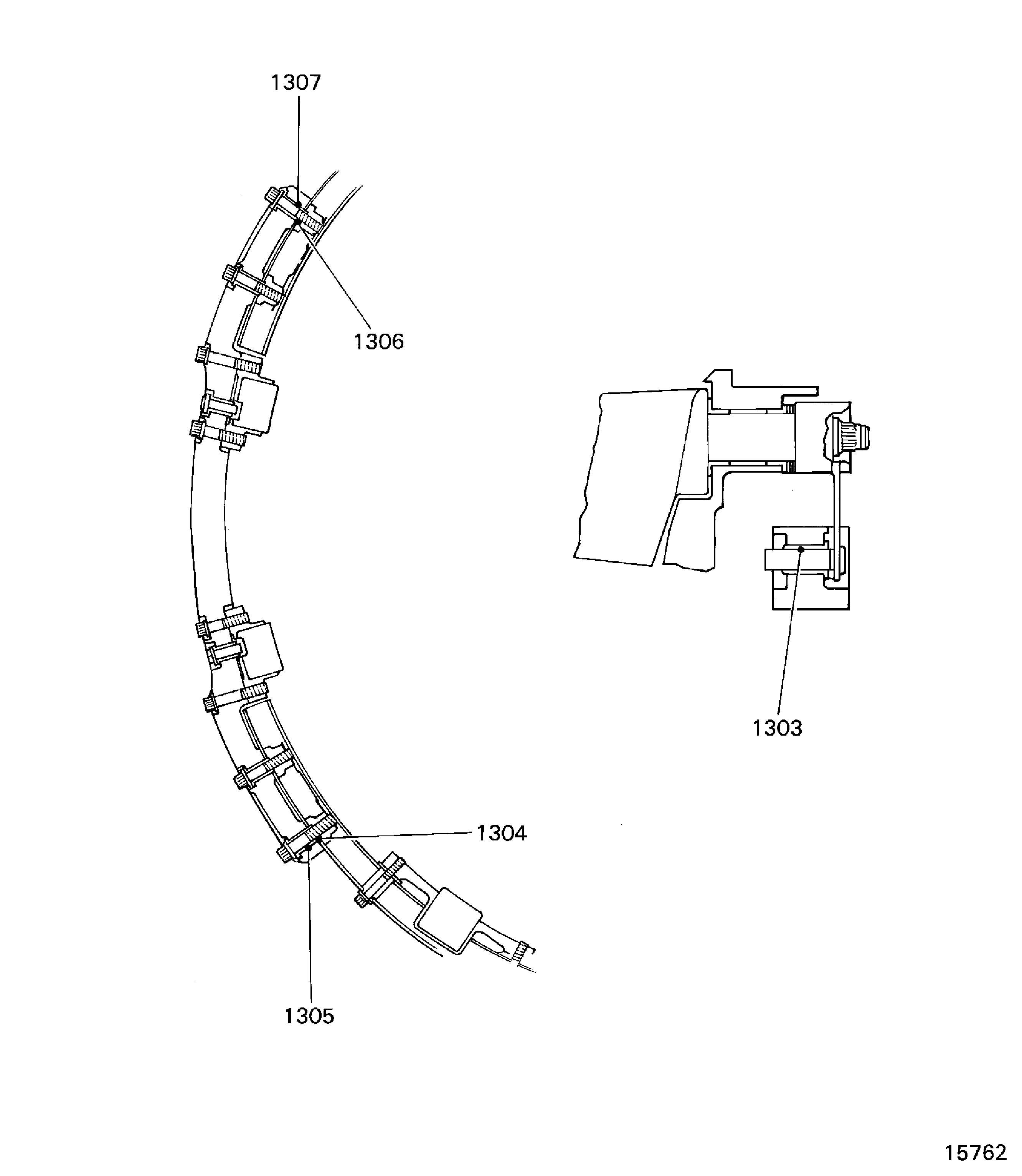

Refer to Figure.

Reference dimensions at location 1303. If required use the data written as a note in TASK 72-41-34-200-000.

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1303

VIGV lever assembly (72-41-34,

02-120) location in the bush

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-220)

VIGV lever pin dia

0.2353

0.2358

0.0004

Bush inner bore

0.2362

0.0016

0.2369

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1303

VIGV lever assembly (72-41-34,

02-120) location in the bush

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-220)

VIGV lever pin dia

5.978

5.990

0.01

Bush inner bore

6.000

0.04

6.018

SUBTASK 72-41-30-220-103 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1303

Refer to Figure.

Reference dimensions at location 1304. If required use the data written as a note in TASK 72-41-34-200-000.

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1304

VIGV upper ring (72-41-34,

02-440) and the VIGV lower ring

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-540) locations for

the hollow dowel

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-208)

VIGV upper and lower ring

0.4762

locations for the hollow dowel

0.4779

0.0023

Hollow dowel outer dia

0.4731

0.0048

0.4739

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1304

VIGV upper ring (72-41-34,

02-440) and the VIGV lower

ring ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-540)

locations for the hollow dowel

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-208)

VIGV upper and lower ring

12.095

location for the hollow dowel

12.138

0.059

Hollow dowel outer dia

12.018

0.121

12.036

SUBTASK 72-41-30-220-104 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1304

Refer to Figure.

Reference dimensions at location 1305. If required use the data written as a note in TASK 72-41-34-200-000.

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1305

VIGV actuating ring connector

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-200) location for

the hollow dowel (72-41-34,

02-208)

VIGV actuating ring connector

location bore for the hollow

0.4762

dowel

0.4779

0.0023

Hollow dowel outer dia

0.4731

0.0048

0.4739

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1305

VIGV actuating ring connector

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-200) location for

the hollow dowel (72-41-34,

02-208)

VIGV actuating ring connector

location bore for the hollow

12.095

dowel

12.138

0.059

Hollow dowel outer dia

12.018

0.121

12.036

SUBTASK 72-41-30-220-105 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1305

Refer to Figure.

Reference dimensions at location 1306. If required use the data written as a note in TASK 72-41-34-200-000.

Table 7. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1306

Upper VIGV ring (72-41-34,

02-440) and the lower VIGV ring

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-540) locations for

the hollow dowel (72-41-34,

02-206)

Upper and lower VIGV ring

location bores for the hollow

0.3969

dowel

0.3983

0.002

Hollow dowel outer dia

0.3943

0.004

0.3949

Table 8. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1306

Upper VIGV ring (72-41-34,

02-440) and the lower VIGV ring

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-540) locations for

the hollow dowel (72-41-34,

02-206)

Upper and lower VIGV ring

location bores for the hollow

10.080

dowel

10.116

0.050

Hollow dowel outer dia

10.015

0.101

10.030

SUBTASK 72-41-30-220-106 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1306

Refer to Figure.

Reference dimensions at location 1307. If required use the data written as a note in TASK 72-41-34-200-000.

Table 9. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1307

VIGV actuating ring connector

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-200) locations for

the hollow dowel (72-41-34,

02-206)

VIGV actuating ring connector

location bores for the hollow

0.3969

dowel

0.3983

0.002

Hollow dowel outer dia

0.3943

0.004

0.3949

Table 10. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1307

VIGV actuating ring connector

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-200) locations for

the hollow dowel (72-41-34,

02-206

VIGV actuating ring connector

location bores for the hollow

10.080

dowel

10.116

0.050

Hollow dowel outer dia

10.015

0.101

10.030

SUBTASK 72-41-30-220-107 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1307

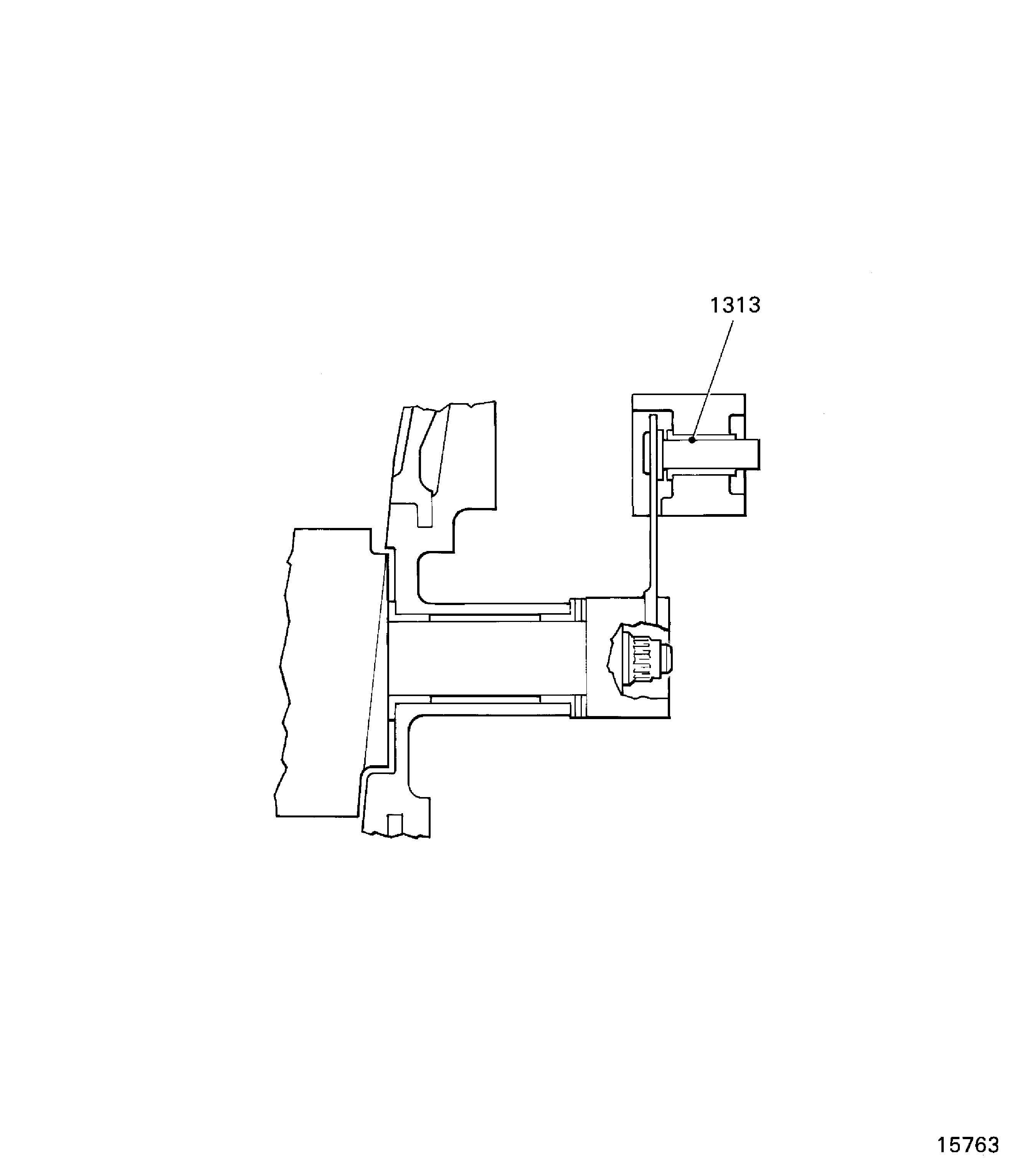

Refer to Figure.

Reference dimensions at location 1313. If required use the data written as a note in TASK 72-31-34-200-000.

Table 11. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1313

Stage 3 VSV lever (72-41-34,

03-120) location in the bushes

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-220 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES03-300)

Stage 3 VSV lever pin dia

0.2353

0.2358

0.0004

Bush bore

0.2362

0.0016

0.2369

Table 12. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1313

Stage 3 VSV lever (72-41-34,

03-120) location in the bushes

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-220 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES03-300)

Stage 3 VSV lever pin dia

5.978

5.990

0.010

Bush bore

6.000

0.040

6.018

SUBTASK 72-41-30-220-108 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1313

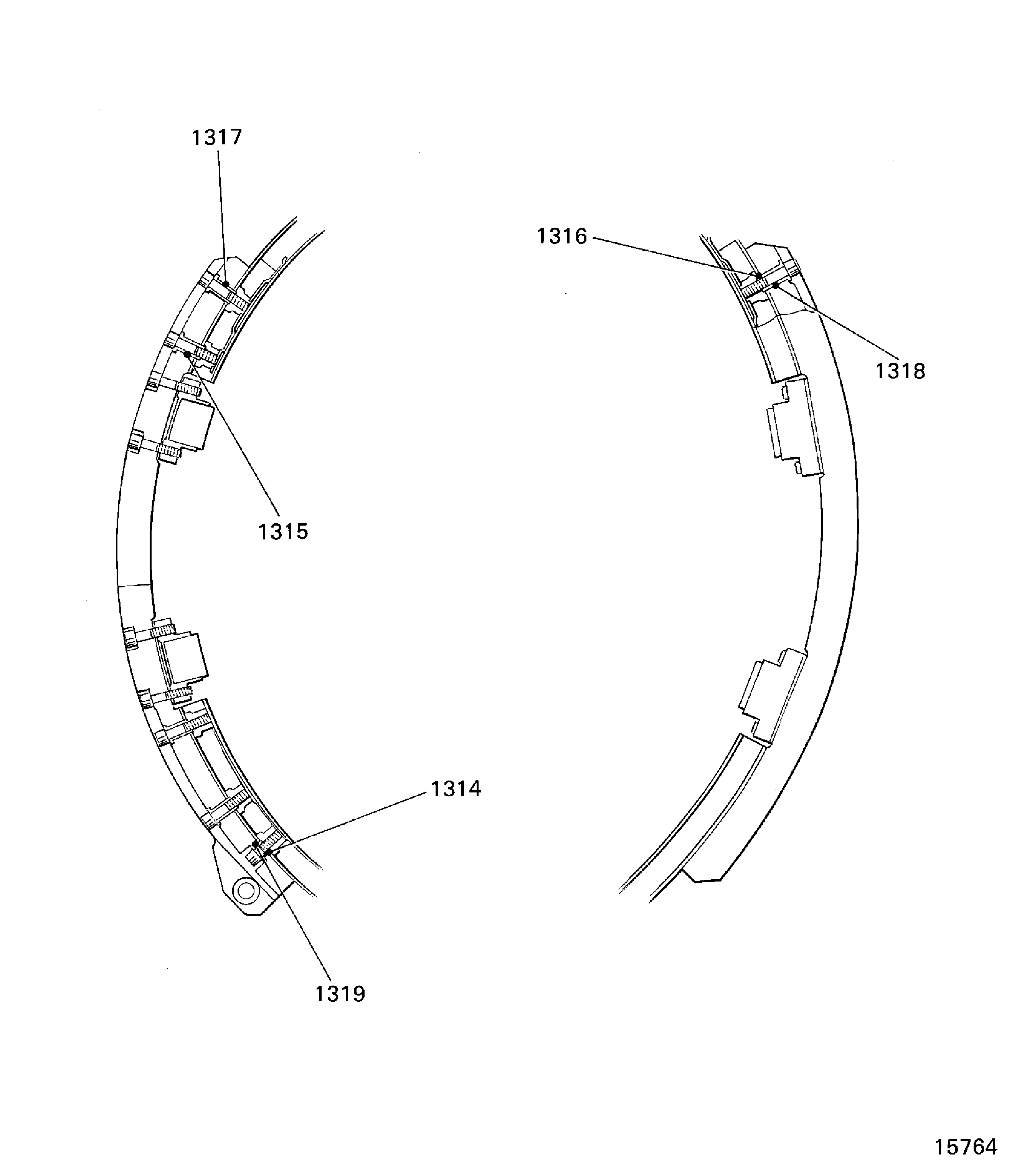

Refer to Figure.

Reference dimensions at location 1314. If required use the data written as a note in TASK 72-41-34-200-000.

Table 13. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1314

Stage 3 lower ring (72-41-34,

03-540) location for the hollow

dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-288)

Stage 3 lower ring location

0.3969

bore for the hollow dowel

0.3983

0.002

Dowel external dia

0.3943

0.004

0.3949

Table 14. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1314

Stage 3 lower ring (72-41-34,

03-540) location for the hollow

dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-288)

Stage 3 lower ring location

10.080

bore for the hollow dowel

10.116

0.050

Dowel external dia

10.015

0.101

10.030

SUBTASK 72-41-30-220-109 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1314

Refer to Figure.

Reference dimensions at location 1315. If required use the data written as a note in TASK 72-41-34-200-000.

Table 15. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1315

Upper and lower stage 3 rings

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-440 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES03-540)

locations for the hollow dowel

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-286)

Upper and lower stage 3 rings

location bore for the hollow

0.3969

dowel

0.3983

0.002

Hollow dowel outer dia

0.3943

0.004

0.3949

Table 16. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1315

Upper and lower stage 3 rings

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-440 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES03-540)

locations for the hollow dowel

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-286)

Upper and lower stage 3 rings

location bore for the hollow

10.080

dowel

10.116

0.050

Hollow dowel outer dia

10.015

0.101

10.030

SUBTASK 72-41-30-220-110 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1315

Refer to Figure.

Reference dimensions at location 1316. If required use the data written as a note in TASK 72-41-34-200-000.

Table 17. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1316

Upper and lower stage 3 rings

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-440 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES03-540)

locations for the sleeve dowel

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-206)

Upper and lower stage 3 rings

location bore for the sleeve

0.3969

dowel

0.3983

0.002

Sleeve dowel outer dia

0.3943

0.004

0.3949

Table 18. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1316

Upper and lower stage 3 rings

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-440 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES03-540)

locations for the sleeve dowel

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-206)

Upper and lower stage 3 rings

location bore for the sleeve

10.080

dowel

10.116

0.050

Sleeve dowel outer dia

10.015

0.101

10.030

SUBTASK 72-41-30-220-111 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1316

Refer to Figure.

Reference dimensions at location 1317. If required use the data written as a note in TASK 72-41-34-200-000.

Table 19. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1317

Stage 3 connector (72-41-34,

03-280) location for the hollow

dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-286)

Stage 3 connector location bore

0.3969

for the hollow dowel

0.3983

0.002

Hollow dowel outer dia

0.3943

0.004

0.3949

Table 20. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1317

Stage 3 connector (72-41-34,

03-280) location for the hollow

dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-286)

Stage 3 connector location bore

10.080

for the hollow dowel

10.116

0.050

Hollow dowel outer dia

10.015

0.101

10.030

SUBTASK 72-41-30-220-112 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1317

Refer to Figure.

Reference dimensions at location 1318. If required use the data written as a note in TASK 72-41-34-200-000.

Table 21. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1318

Stage 3 connector (72-41-34,

03-200) location for the hollow

dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-206)

Stage 3 connector location bore

0.3969

for the hollow dowel

0.3983

0.002

Hollow dowel outer dia

0.3943

0.004

0.3949

Table 22. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1318

Stage 3 connector (72-41-34,

03-200) location for the hollow

dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-206)

Stage 3 connector location bore

10.080

for the hollow dowel

10.116

0.050

Hollow dowel outer dia

10.015

0.101

10.030

SUBTASK 72-41-30-220-113 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1318

Refer to Figure.

Reference dimensions at location 1319. If required use the data written as a note in TASK 72-41-34-200-000.

Table 23. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1319

Stage 3 connector (72-41-34,

03-280) location for the hollow

dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-288)

Stage 3 connector location bore

0.3969

for the hollow dowel

0.3983

0.002

Hollow dowel outer dia

0.3943

0.004

0.3949

Table 24. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1319

Stage 3 connector (72-41-34,

03-280) location for the hollow

dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-288)

Stage 3 connector location bore

10.080

for the hollow dowel

10.116

0.050

Hollow dowel outer dia

10.015

0.101

10.030

SUBTASK 72-41-30-220-114 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1319

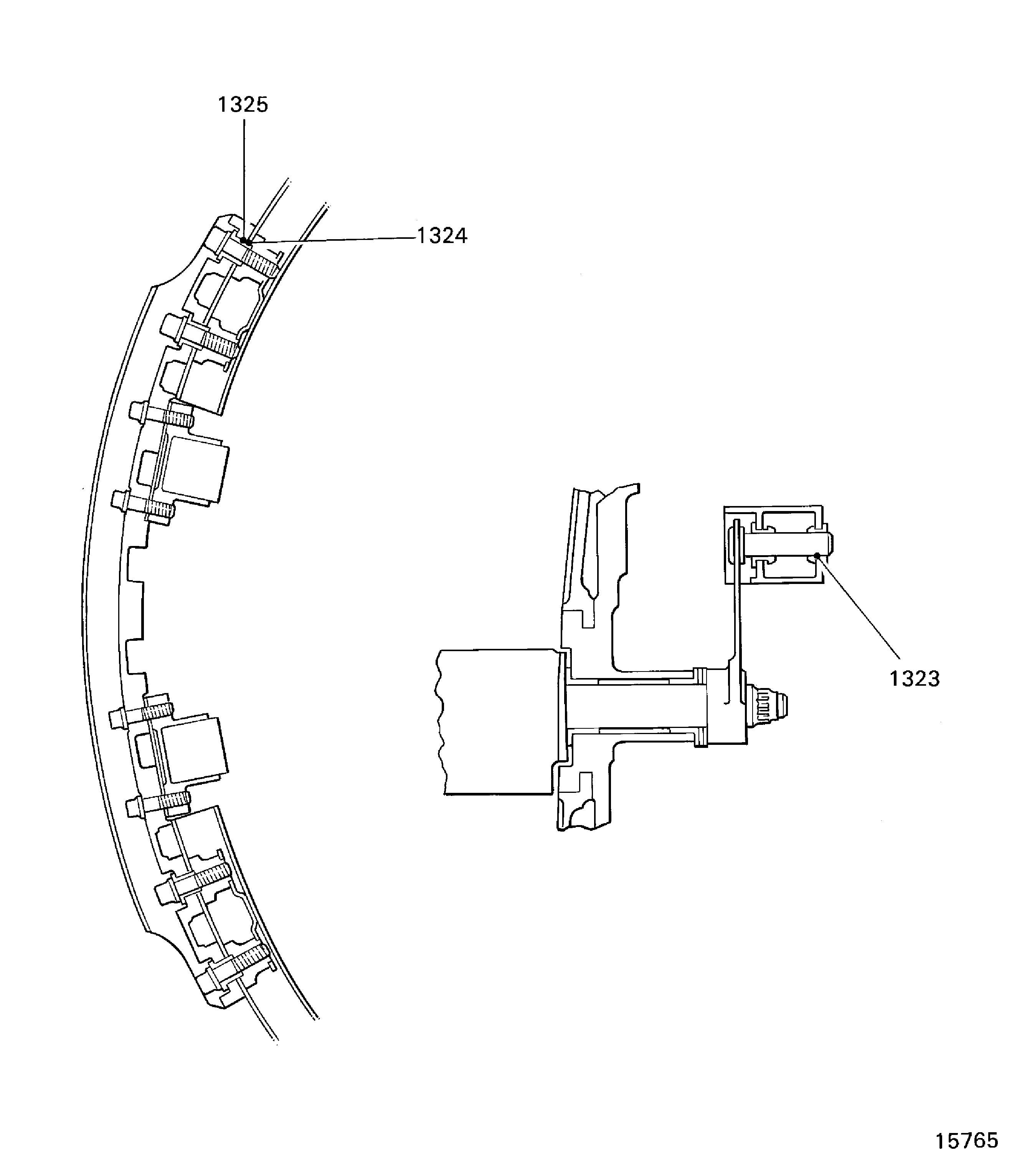

Refer to Figure.

Reference dimensions at location 1323. If required use the data written as a note in TASK 72-41-34-200-000.

Table 25. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1323

Stage 4 VSV lever (72-41-34,

04-120) location for the bush

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-220)

Stage 4 VSV lever pin dia

0.1960

0.1965

0.0004

Bush inner bore

0.1969

0.0016

0.1976

Table 26. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1323

Stage 4 VSV lever (72-41-34,

04-120) location for the bush

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-220)

Stage 4 VSV lever pin dia

4.978

4.990

0.01

Bush inner bore

5.000

0.04

5.018

SUBTASK 72-41-30-220-115 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1323

Refer to Figure.

Reference dimensions at location 1324. If required use the data written as a note in TASK 72-41-34-200-000.

Table 27. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1324

Upper and lower stage 4 rings

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-440 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES04-540)

location for the sleeve dowel

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-206)

Upper and lower stage 4 ring

location bore for the sleeve

0.3969

dowel

0.3983

0.002

Sleeve dowel outer dia

0.3943

0.004

0.3949

Table 28. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1324

Upper and lower stage 4 rings

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-440 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES04-540)

location for the sleeve dowel

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-206)

Upper and lower stage 4 ring

location bore for the sleeve

10.080

dowel

10.116

0.050

Sleeve dowel outer dia

10.015

0.101

10.030

SUBTASK 72-41-30-220-116 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1324

Refer to Figure.

Reference dimensions at location 1325. If required use the data written as a note in TASK 72-41-34-200-000.

Table 29. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1325

Stage 4 connector (72-41-34,

04-200) location for the sleeve

dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-206)

Stage 4 connector location bore

0.3969

for the sleeve dowel

0.3983

0.002

Sleeve dowel outer dia

0.3943

0.004

0.3949

Table 30. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1325

Stage 4 connector (72-41-34,

04-200) location for the sleeve

dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-206)

Stage 4 connector location bore

10.080

for the sleeve dowel

10.116

0.050

Sleeve dowel outer dia

10.015

0.101

10.030

SUBTASK 72-41-30-220-117 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1325

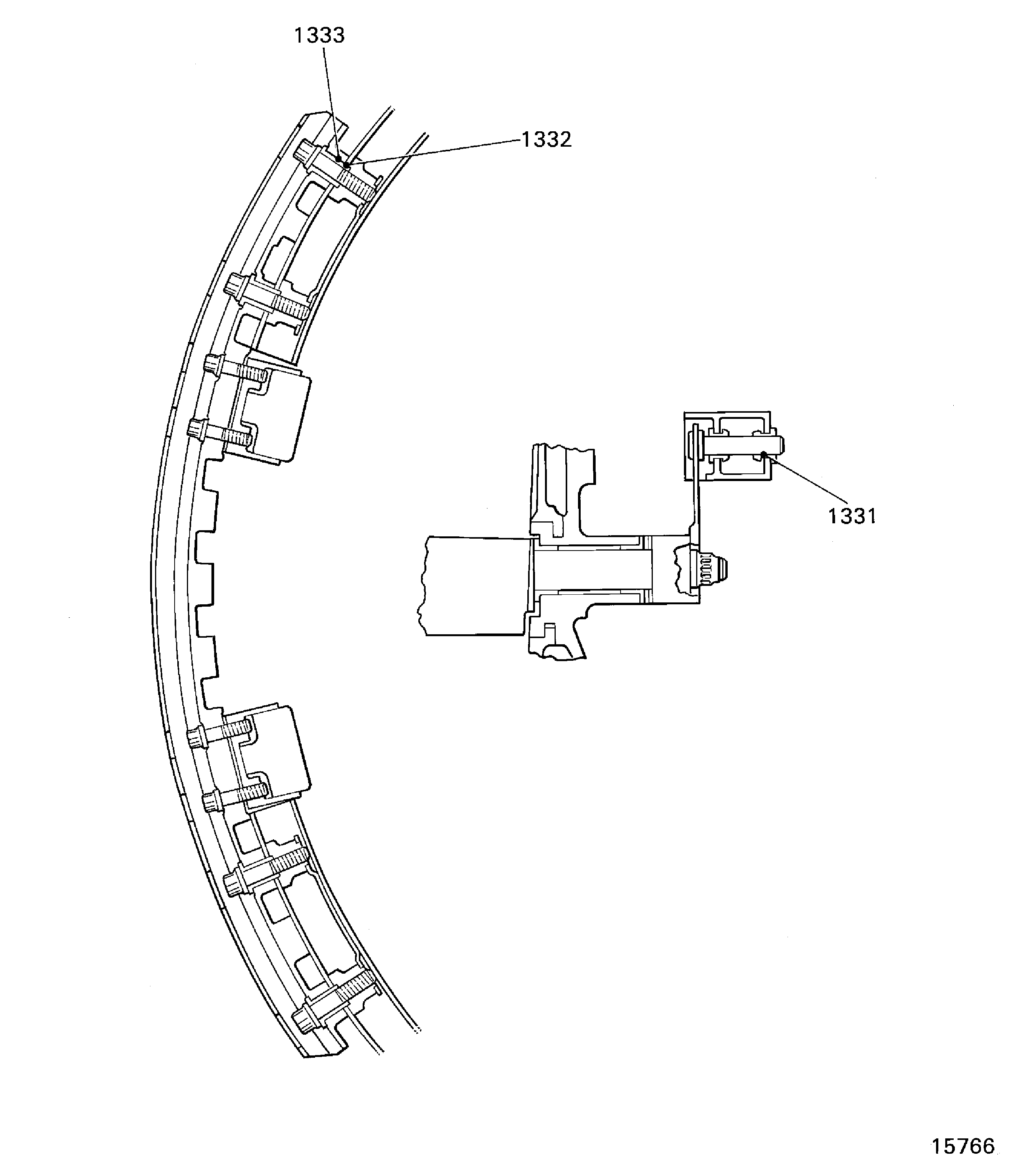

Refer to Figure.

Reference dimensions at location 1331. If required use the data written as a note in TASK 72-41-34-200-000.

Table 31. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1331

Stage 5 VSV lever (72-41-34,

05-120 and 05-140) location in

the bush ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-220)

Stage 5 VSV lever pin dia

0.1960

0.1965

0.0004

Bush inner bore

0.1969

0.0016

0.1976

Table 32. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1331

Stage 5 VSV lever (72-41-34,

05-120 and 05-140) location in

the bush ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-220)

Stage 5 VSV lever pin dia

4.978

4.990

0.01

Bush inner bore

5.000

0.04

5.018

SUBTASK 72-41-30-220-118 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1331

Refer to Figure.

Reference dimensions at location 1332. If required use the data written as a note in TASK 72-41-34-200-000.

Table 33. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1332

Upper and lower stage 5 actuating

rings (72-41-34, 05-440 and

05-540) locations for the sleeve

dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-206)

Upper and lower stage 5

actuating rings location bores

0.3969

for the sleeve dowel

0.3983

0.002

Sleeve dowel outer dia

0.3943

0.004

0.3949

Table 34. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1332

Upper and lower stage 5 actuating

rings (72-41-34, 05-440 and

05-540) locations for the sleeve

dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-206)

Upper and lower stage 5

actuating rings location bores

10.080

for the sleeve dowel

10.116

0.050

Sleeve dowel outer dia

10.015

0.101

10.030

SUBTASK 72-41-30-220-119 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1332

Refer to Figure.

Reference dimensions at location 1333. If required use the data written as a note in TASK 72-41-34-200-000.

Table 35. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1333

Stage 5 connector (72-41-34,

05-200) location for the sleeve

dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-206)

Stage 5 connector location bore

0.3969

for the sleeve dowel

0.3983

0.002

Sleeve dowel outer dia

0.3943

0.004

0.3949

Table 36. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1333

Stage 5 connector (72-41-34,

05-200) location for the sleeve

dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-206)

Stage 5 connector location bore

10.080

for the sleeve dowel

10.116

0.050

Sleeve dowel outer dia

10.015

0.101

10.030

SUBTASK 72-41-30-220-120 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1333

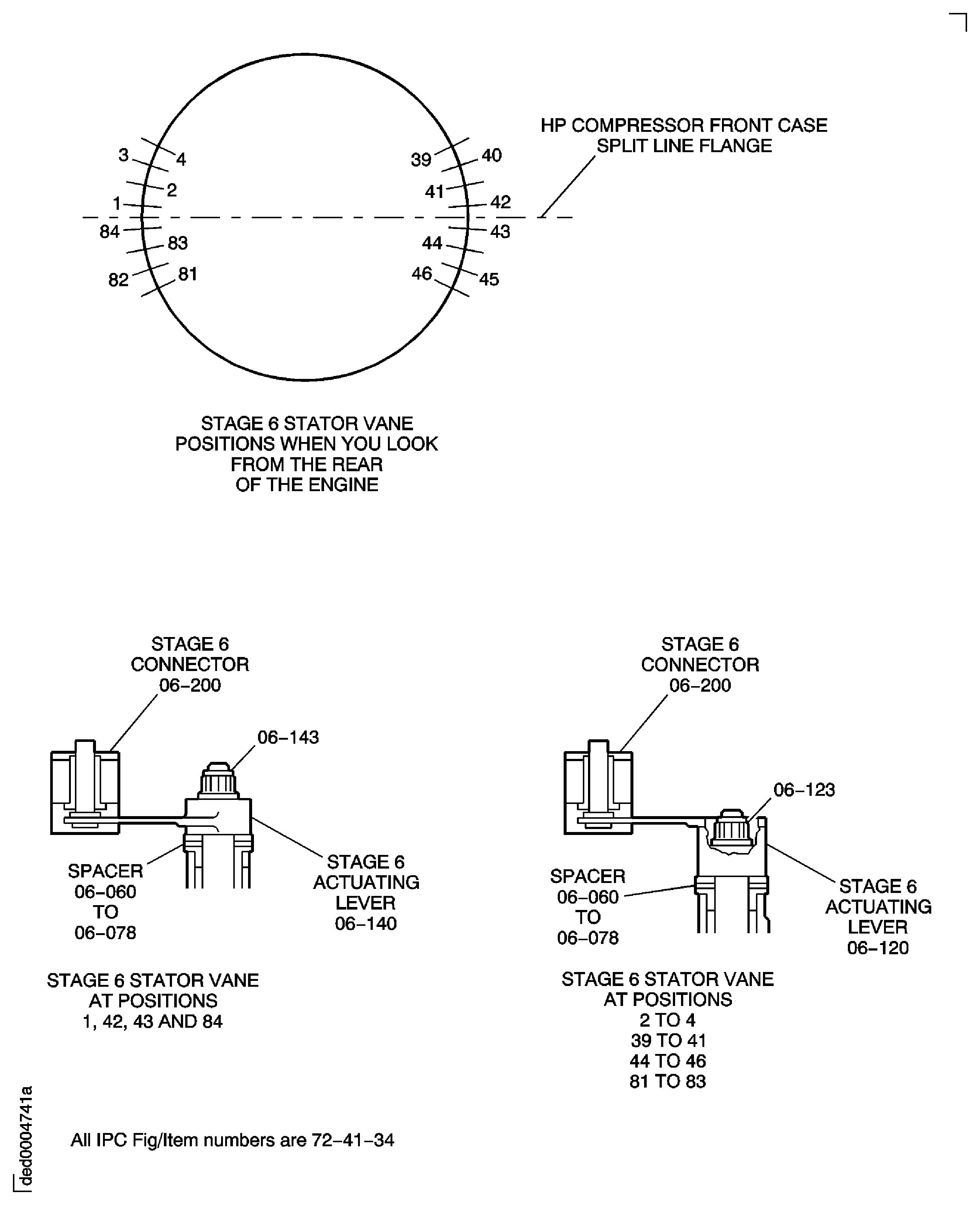

Refer to Figure.

Reference dimensions at location 1339. If required use the data written as a note in TASK 72-41-34-200-000.

Table 37. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1339

Stage 6 VSV lever (72-41-34,

06-120 and 06-140) location for

the bush ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 06-220)

Stage 6 VSV lever pin dia

0.1960

0.1965

0.0002

Bush inner bore

0.1966

0.0018

0.1978

Table 38. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1339

Stage 6 VSV lever (72-41-34,

06-120 and 06-140) location for

the bush ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 06-220)

Stage 6 VSV lever pin dia

4.978

4.990

0.004

Bush inner bore

4.994

0.046

5.024

SUBTASK 72-41-30-220-121 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1339

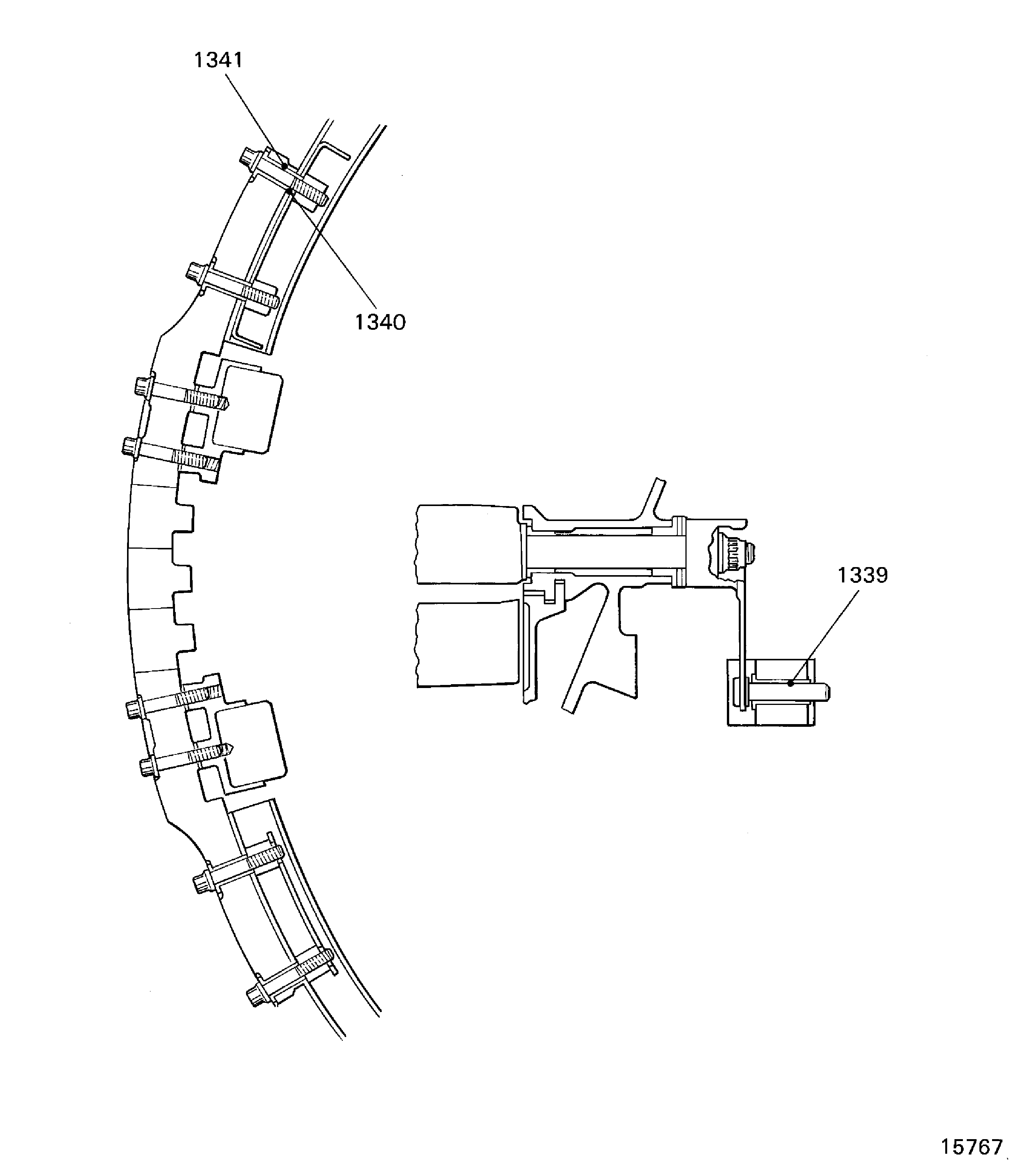

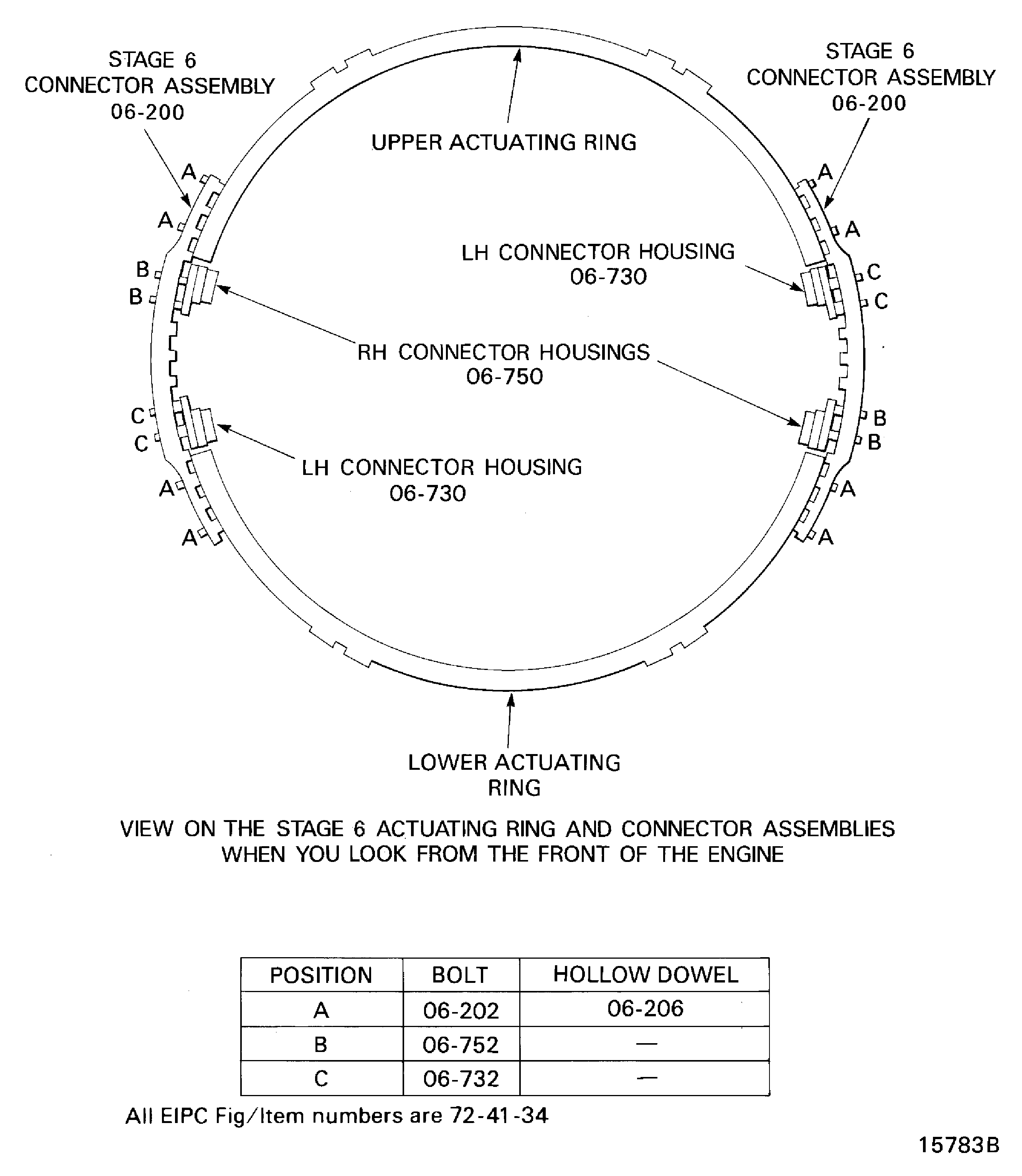

Refer to Figure.

Reference dimensions at location 1340. If required use the data written as a note in TASK 72-41-34-200-000.

Table 39. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1340

Upper and lower stage 6 rings

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 06-440 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES06-540)

location for the hollow dowel

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 06-206)

Upper and lower stage 6 ring

location bore for the hollow

0.2984

dowel

0.2998

0.002

Hollow dowel outer dia

0.2958

0.004

0.2964

Table 40. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1340

Upper and lower stage 6 rings

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 06-440 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES06-540)

location for the hollow dowel

ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 06-206)

Upper and lower stage 6 ring

location bore for the hollow

7.580

dowel

7.616

0.050

Hollow dowel outer dia

7.515

0.101

7.530

SUBTASK 72-41-30-220-122 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1340

Refer to Figure.

Reference dimensions at location 1341. If required use the data written as a note in TASK 72-41-34-200-000.

Table 41. Fits and Clearances (all dimensions are in inches) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1341

Stage 6 connector (72-41-34,

06-200) location for the hollow

dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 06-206)

Stage 6 connector location bore

0.2984

for the hollow dowel

0.2998

0.002

Hollow dowel outer dia

0.2958

0.004

0.2964

Table 42. Fits and Clearances (all dimensions are in millimeters) NEW PART WORN PART

DIMENSIONS DIMENSIONS REJECT IF

PART IDENT Size Clearance (Non-select) MORE THAN

LOCATION 1341

Stage 6 connector (72-41-34,

06-200) location for the hollow

dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 06-206)

Stage 6 connector location bore

7.580

for the hollow dowel

7.616

0.050

Hollow dowel outer dia

7.515

0.101

7.530

SUBTASK 72-41-30-220-123 Reference Fits and Clearances of the HP Compressor Front Cases and Vanes at Location 1341

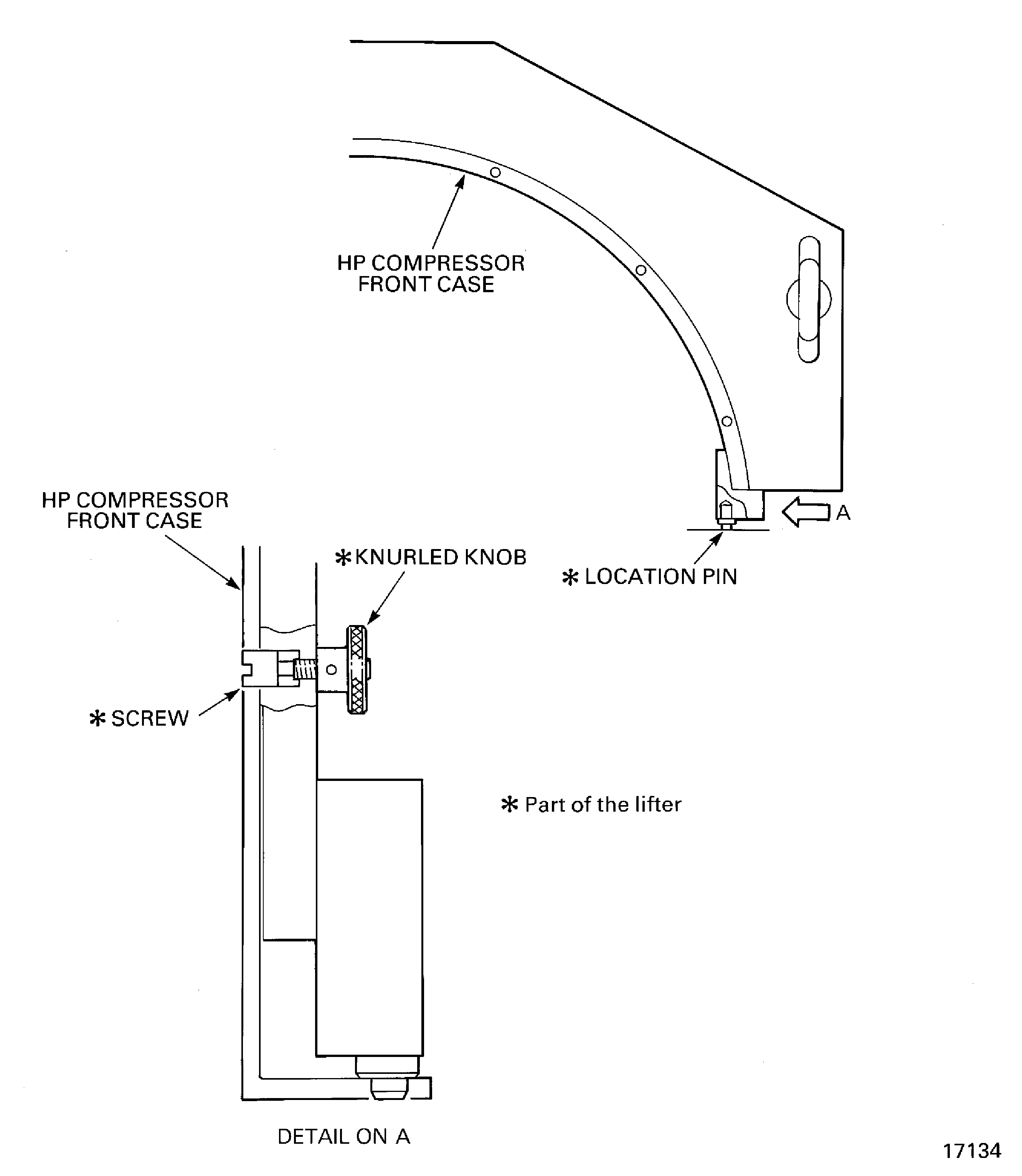

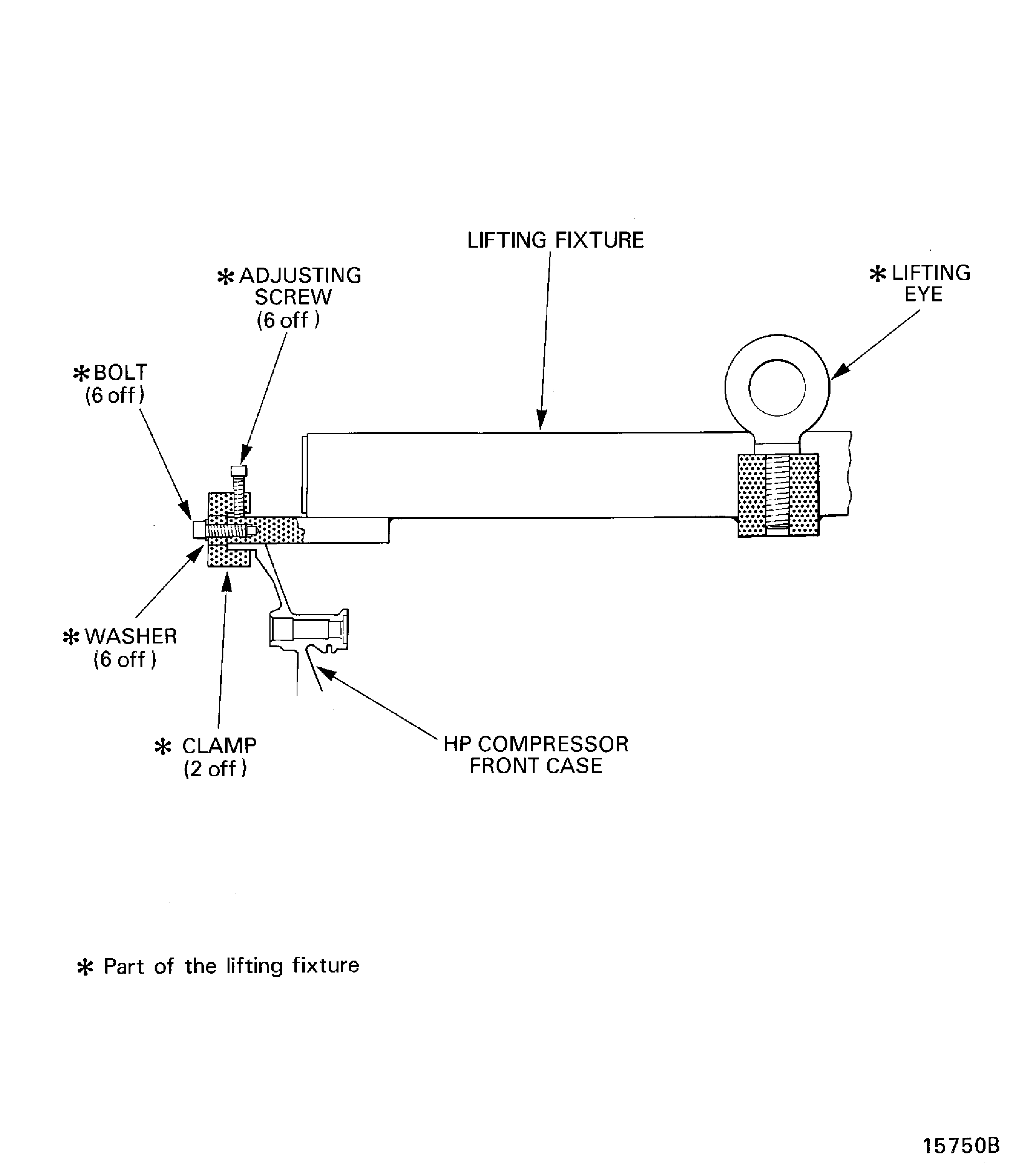

Install the IAE 1R18249 Lifting tool 2 off on to the HP compressor upper and lower half front cases rear flanges. Refer to Figure.

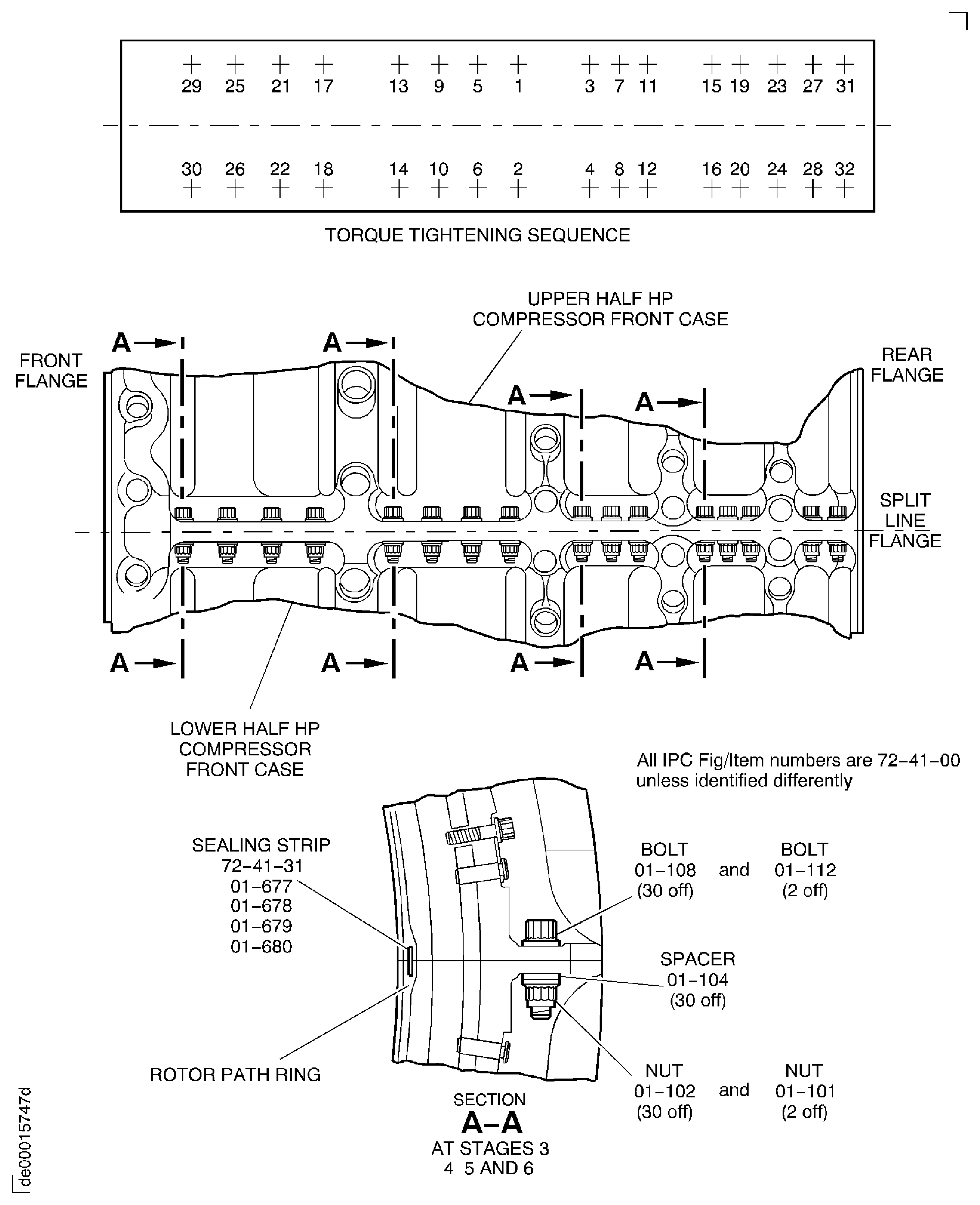

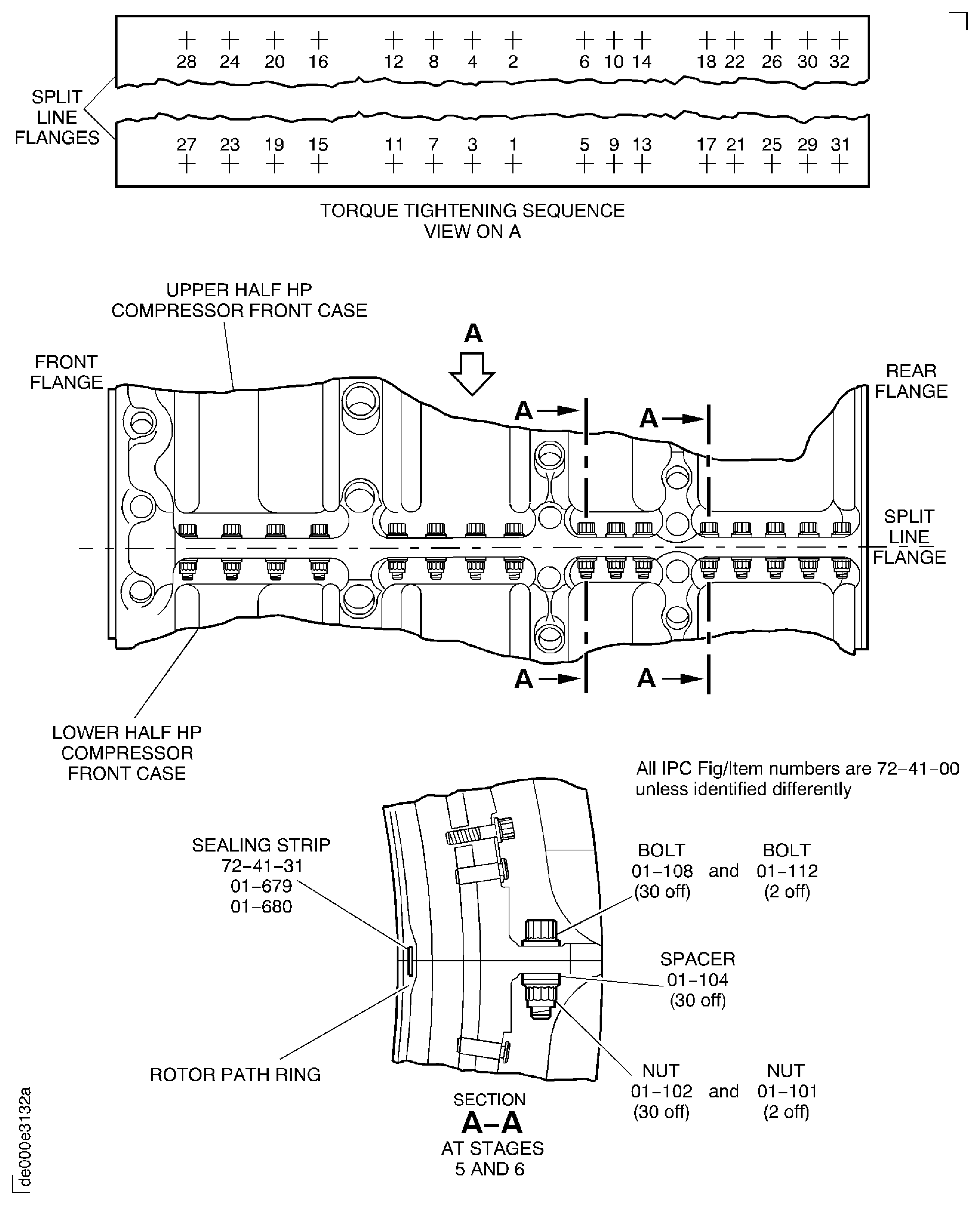

Pre SBE 72-0027: Install the two sealing strips ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-677) into the slots in the stage 3 rotor path ring at the split line flanges.

Pre SBE 72-0027: Install the two stage 4 sealing strips ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-678) in to the slots in the stage 4 rotor path ring at the split line flanges.

Install the two stage 5 sealing strips ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-679) in to the slots in the stage 5 rotor path ring at the split line flanges.

Install the two stage 6 sealing strips ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-680) in to the slots in the stage 6 rotor path ring at the split line flanges.

CAUTION

YOU MUST NOT LET THE BOLTS TURN WHEN YOU INSTALL THEM AND WHEN YOU TORQUE THE NUTS. THE BOLTS ARE A CLOSE TOLERANCE FIT.Install the two bolts ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 01-112) and nuts ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 01-101) at the split line positions 12 and 32. Install 32 bolts ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 01-108), spacers ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 01-104) and nuts ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 01-102) at the remaining split line flange positions. Refer to Figure and Figure.

Install the six bolts and washers to attach the two clamps to the lifting tool. Refer to Figure. Do not tighten the six bolts.

Install IAE 1R18205 Lifting tool 1 off on the HP compressor front case rear flange. Refer to Figure.

Lower the HP compressor front case on to IAE 1R18207 Support stand 1 off.

SUBTASK 72-41-30-440-090 Install the Front Cases Split Line Nuts, Bolts and Spacers

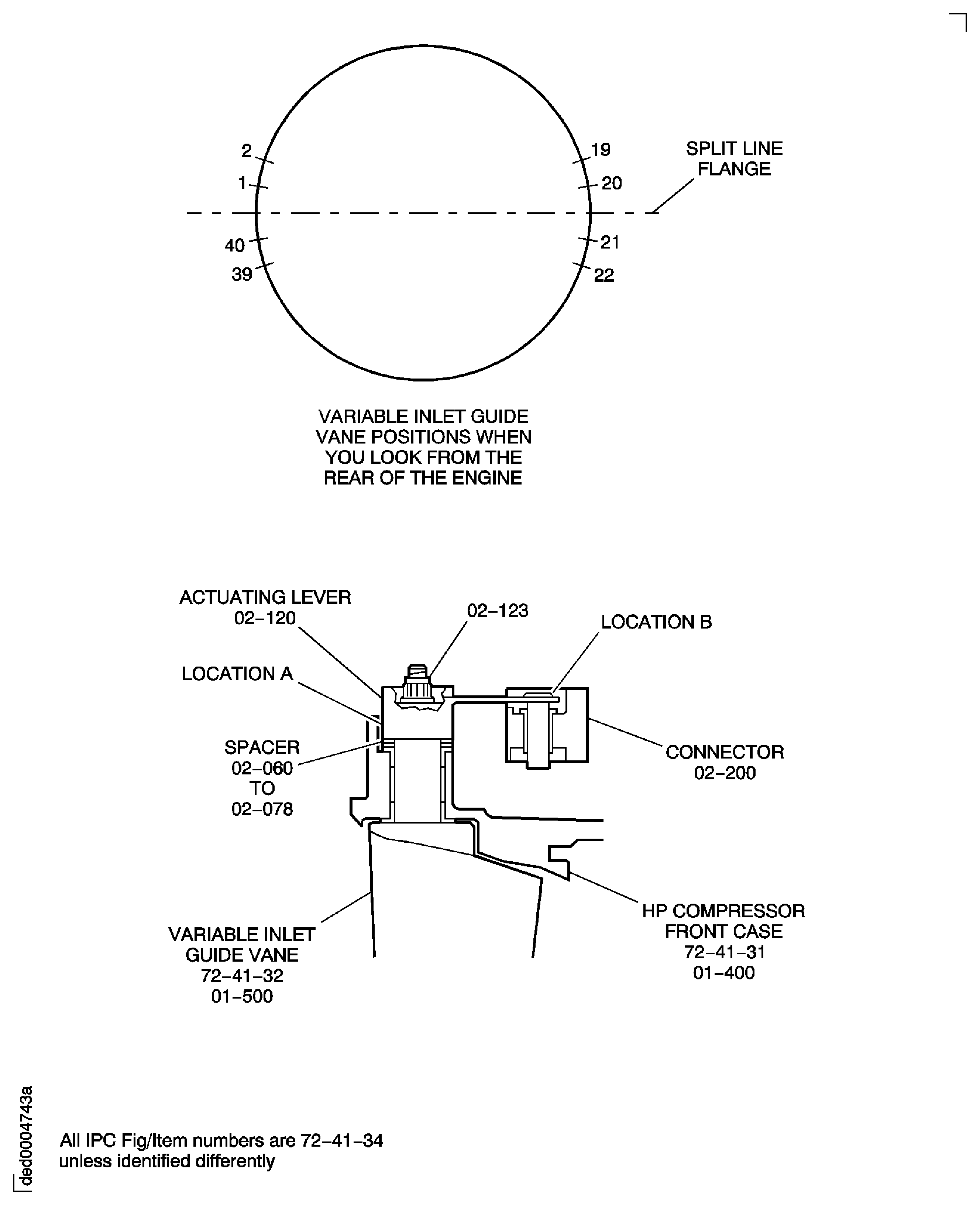

Remove the eight nuts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-123) from the eight inlet guide vanes at the positions 1, 2, 19 to 22, 39 and 40.

Remove the eight actuating levers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-120) from the eight inlet guide vanes. Identify each actuating lever with its position number.

Remove the variable inlet guide vane actuating levers.

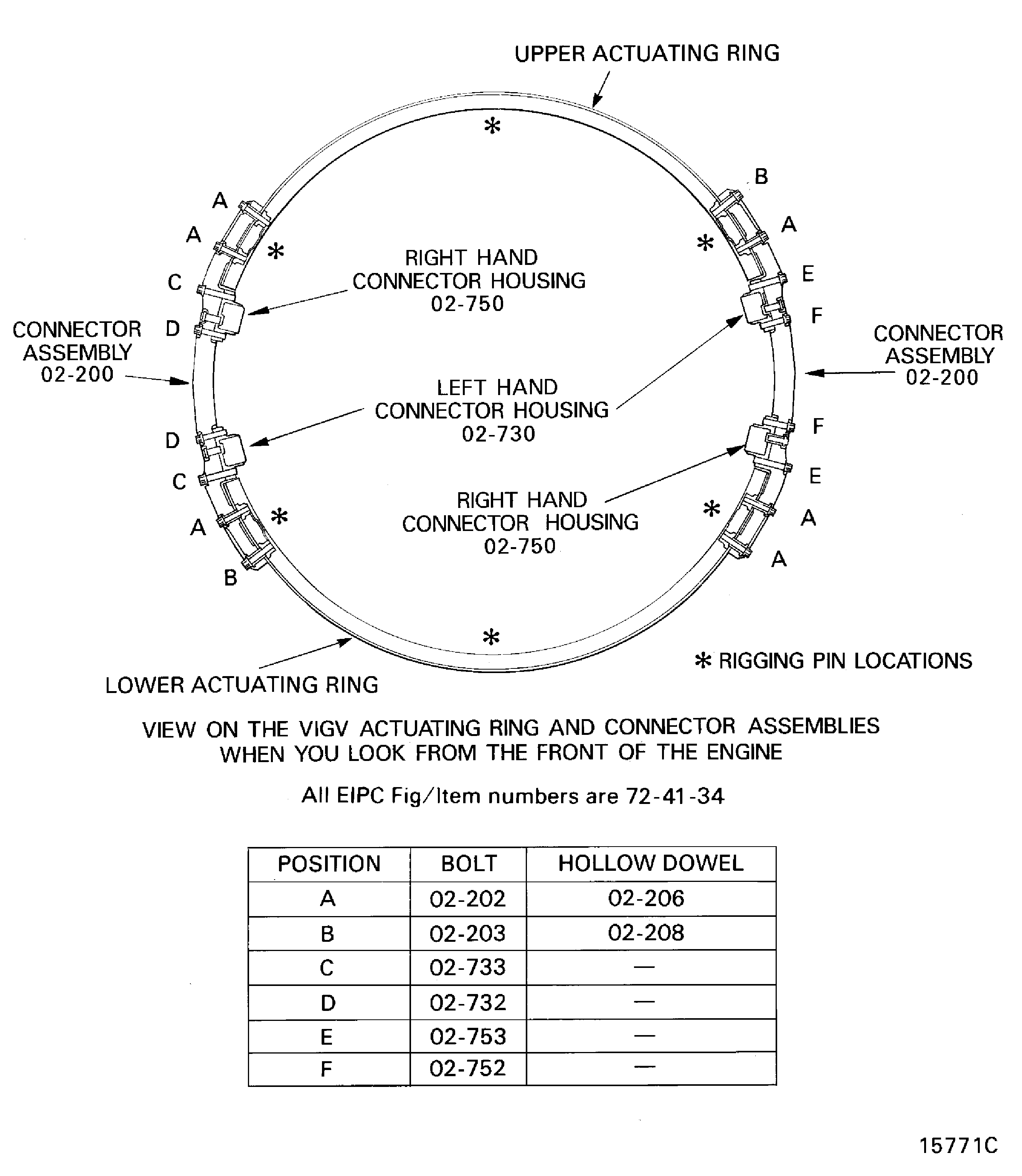

Install the two bolts (ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-732) and V2500-A5-72-41-24-02A-941A-D (72-41-24,02-733)) to attach the left hand connector housing to the left hand connector.

Install the left hand connector housing ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-730) in to the left hand connector ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-200).

Install the two bolts (ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-732) and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,04-733)) to attach the right hand connector housing to the left hand connector.

Install the right hand connector housing ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-750) in to the left hand connector.

Put the left hand connector in to position on the upper and lower actuating rings. Install one of IAE 1R18423 Rigging pin 2 off or IAE 1R18892 Rigging pin 2 off to hold the connector to the upper actuating ring.

Pre SBE 72-0385 or SBE 72-0416: Install the three hollow dowels ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-206) and the three bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-202), which attach the left hand VIGV connector to the upper and lower actuating rings. Torque the bolts to 85 to 105 lbfin (10.00 to 12.00 Nm).

SBE 72-0385: Install the three bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-202), which attach the left hand VIGV connector to the upper and lower actuating rings. Torque the bolts to 85 to 105 lbfin (10.00 to 12.00 Nm).

SBE 72-0416: Install the three bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-202) and the washer ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-205) which attach the left hand VIGV connector to the upper and lower actuating rings. Torque the bolts to 85 to 105 lbfin (10.00 to 12.00 Nm).

Pre SBE 72-0385 or SBE 72-0416: Install the hollow dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-208) and the bolt ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-203), which attach the left hand VIGV connector to the lower actuating ring. Torque the bolt to 180 to 220 lbfin (20 to 25 Nm).

SBE 72-0385: Install the bolt ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-203), which attach the left hand VIGV connector to the lower actuating ring. Torque the bolt to 180 to 220 lbfin (20 to 25 Nm).

SBE 72-0416: Install the bolt ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-203) and the washer ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-207) which attach the left hand VIGV connector to the lower actuating ring. Torque the bolt to 180 to 220 lbfin (20 to 25 Nm).

Pre SBE 72-0402: Install the left hand connectors on to the VIGV upper and lower actuating rings ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-440) and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-540).

Install the left hand connectors on to the VIGV upper and lower actuating rings ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-440) and V2500-A5-72-41-30-02A-941A-D (72-41-30,02-540).

Pre SBE 72-0385 or SBE 72-0416: Install the three hollow dowels ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-206) and the three bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-202), which attach the left hand VIGV connector to the upper and lower actuating rings. Torque the bolts to 85 to 105 lbfin (10.00 to 12.00 Nm).

SBE 72-0385: Install the three bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-202), which attach the left hand VIGV connector to the upper and lower actuating rings. Torque the bolts to 85 to 105 lbfin (10.00 to 12.00 Nm).

SBE 72-0416: Install the three bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-202) and the washer ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-205) which attach the left hand VIGV connector to the upper and lower actuating rings. Torque the bolts to 85 to 105 lbfin (10.00 to 12.00 Nm).

Pre SBE 72-0385 or SBE 72-0416: Install the hollow dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-208) and the bolt ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-203), which attach the left hand VIGV connector to the lower actuating ring. Torque the bolt to 180 to 220 lbfin (20 to 25 Nm).

SBE 72-0385: Install the bolt ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-203), which attach the left hand VIGV connector to the lower actuating ring. Torque the bolt to 180 to 220 lbfin (20 to 25 Nm).

SBE 72-0416: Install the bolt ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-203) and the washer ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-207) which attach the left hand VIGV connector to the lower actuating ring. Torque the bolt to 180 to 220 lbfin (20 to 25 Nm).

SBE 72-0402: Install the left and right hand connectors and connector housings to the upper and lower actuating rings, follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001) and this SUBTASK.

SUBTASK 72-41-30-440-091 Install the Connector Housings and the Variable Inlet Guide Vane Connector Assemblies (Pre SBE 72-0402, SBE 72-0402, Pre SBE 72-0385or SBE 72-0416: and SBE 72-0385or SBE 72-0416:)

Refer to Figure.

Remove the two installed spacers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-060) from the spindles of the eight guide vanes. Measure and write down the total thickness of the two spacers.

Install the two spacers on to the spindles of the eight guide vanes. The thickness of the spacers that are to be installed is equal to:

The total thickness of the two spacers removed in step (2) plus the end float minus 0.003 to 0.005in. (0.08 to 0.13 mm).

Refer to TASK 72-41-30-440-003 where the end float was measured and written down.

Install the spacers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-060 to ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES 02-078) on to the variable inlet guide vanes at the positions 1, 2, 19 to 22, 39 and 40.

Install the eight nuts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-123) removed in step A.(1). Tighten the eight nuts.

CAUTION

MAKE SURE THE CORRECT VARIABLE INLET GUIDE VANE ACTUATING LEVER IS INSTALLED ON THE CORRECT VARIABLE INLET GUIDE VANE.Install the eight variable inlet guide vane actuating levers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-120).

SUBTASK 72-41-30-440-092 Install the Variable Inlet Guide Vane Actuating Levers at the Connectors

Install IAE 1R18423 Rigging pin 4 off or IAE 1R18892 Rigging pin 4 off to set the VIGVs in the correct position.

CAUTION

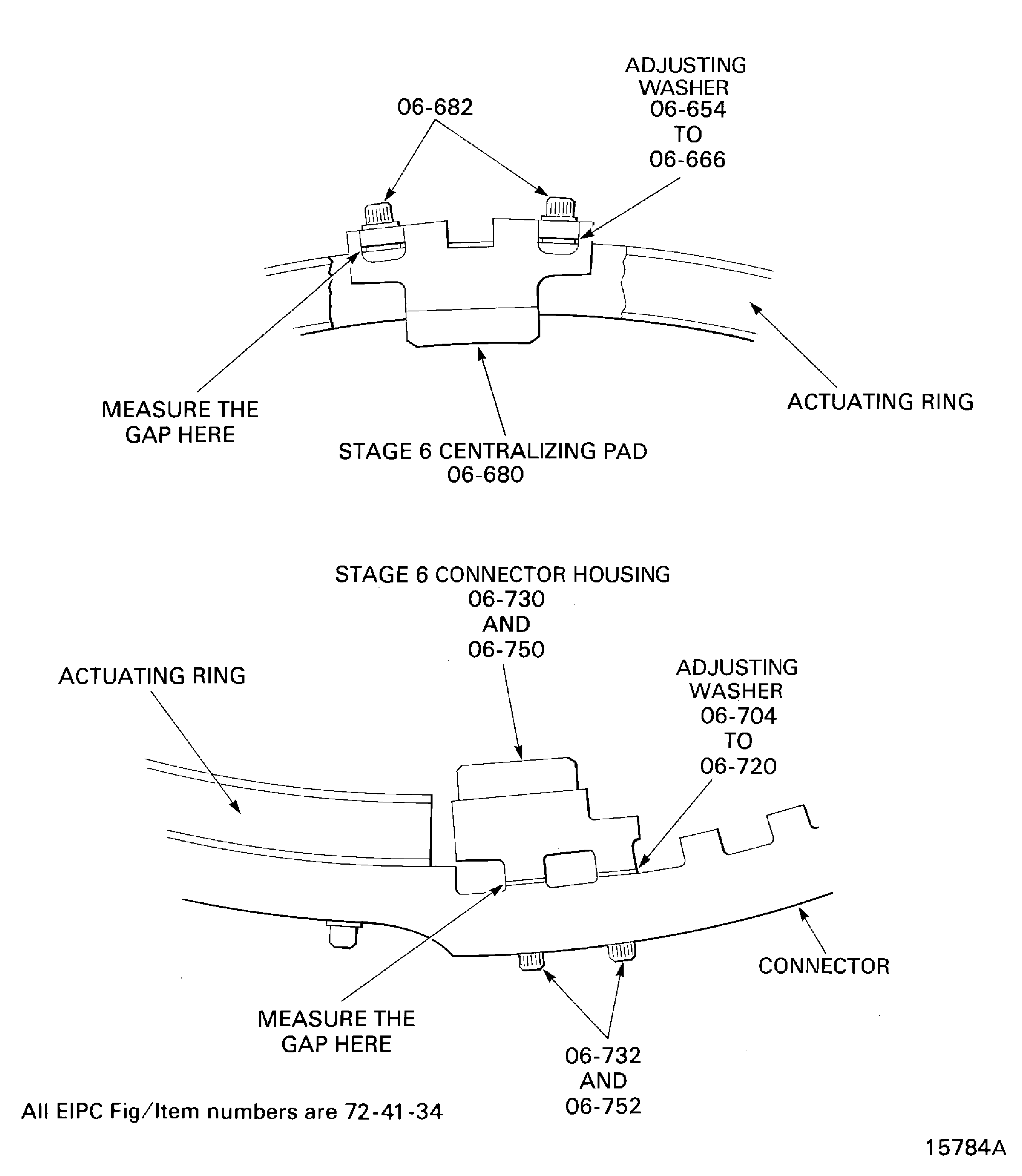

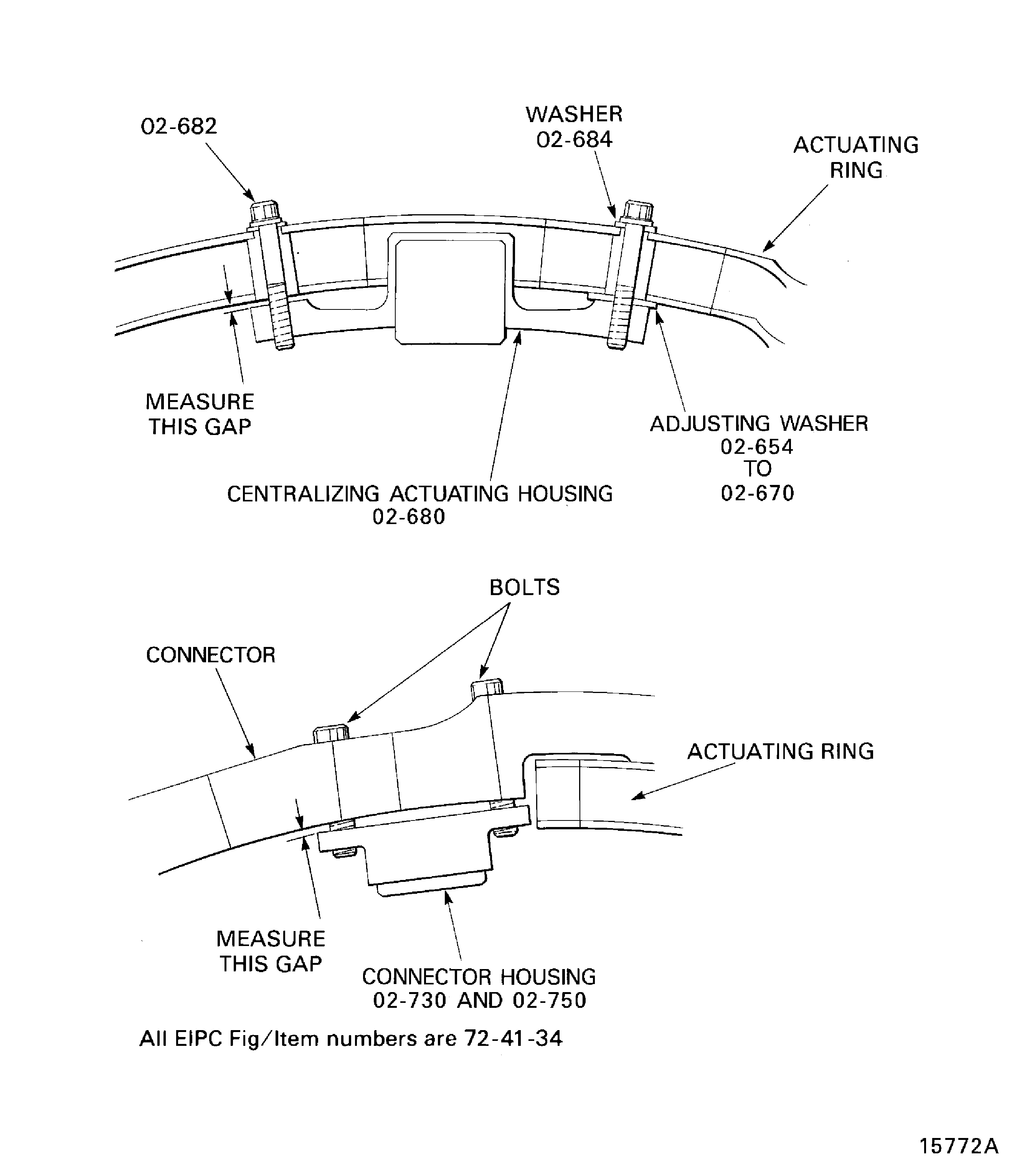

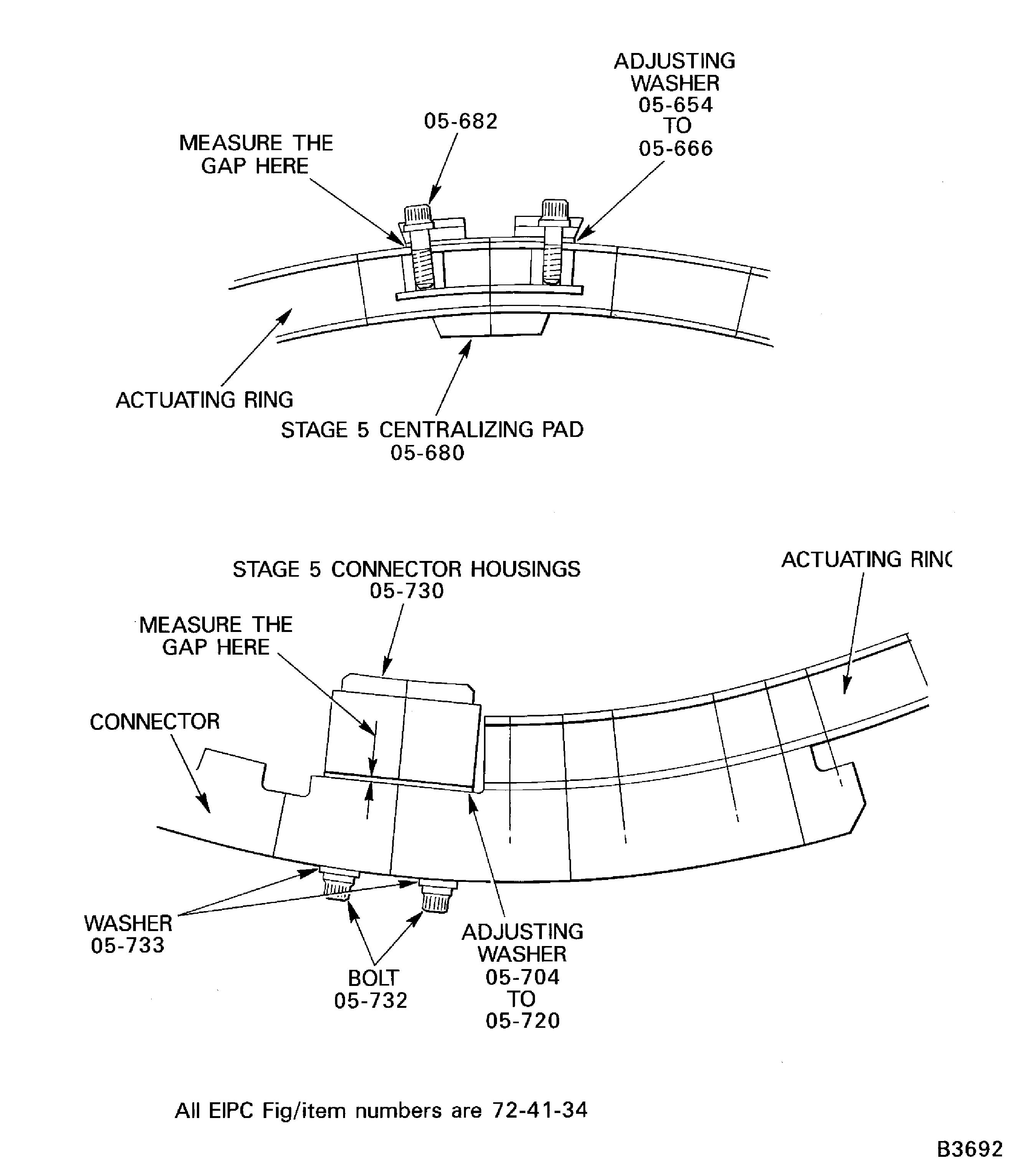

IT IS VERY IMPORTANT TO FULLY INSERT ALL BUILD PINS.Loosen the two bolts which attach a centralizing pad ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-680) to the actuating ring.

NOTE

REMOVE ANY ADJUSTING WASHERS THAT ARE CURRENTLY FITTED BEFORE PROCEEDING.

Install the centralizing pad adjusting washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-654) thru ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-670).

Loosen the two bolts which attach a connector housing ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-730) and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-750) to the connector.

NOTE

REMOVE ANY ADJUSTING WASHERS THAT ARE CURRENTLY FITTED BEFORE PROCEEDING.

Install the connector housing adjusting washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-704) thru ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,02-720).

Remove the four rigging pins and remove all the feeler gauges.

Table 43. TABLE A - PAD CLEARANCES STAGE

PRE SBE 72-0027

POST SBE 72-0027

VIGV

0.003 in (0.08 mm) to 0.004 in (0.10 mm)

0.003 in (0.08 mm) to 0.004 in (0.10 mm)

3

0.003 in (0.08 mm) to 0.004 in (0.10 mm)

0.004 in (0.10 mm) to 0.005 in (0.13 mm)

4

0.004 in (0.10 mm) to 0.005 in (0.13 mm)

0.008 in (0.20 mm) to 0.009 in (0.23 mm)

5

0.004 in (0.10 mm) to 0.005 in (0.13 mm)

0.007 in (0.18 mm) to 0.008 in (0.20 mm)

6

0.003 in (0.08 mm) to 0.004 in (0.10 mm)

0.008 in (0.20 mm) to 0.009 in (0.23 mm)

SUBTASK 72-41-30-440-093-A00 Install the VIGV Centralizing Pad and the Connector Housing Adjusting Washers (Pre SBE 72-0402)

SBE 72-0402: HP compressor variable vanes - inlet guide vane and stages 3 to 6 with optimised build and setting instructions.

Set the pad clearances, follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001).

Install the centralizing pad adjusting washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-654 to ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES02-670).

Install the connector housing adjusting washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-704 to ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES02-720).

Install the VIGV centralizing pad and connector housing adjusting washers, follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001) and this SUBTASK.

Torque the six bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-202), which attach the left and right hand VIGV connectors to the upper and lower actuating ring to 85 to 105 lbfin (10 to 12 Nm).

Torque the two bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-203), which attach the left and right hand VIGV connectors to the upper and lower actuating ring to 180 to 220 lbfin (20 to 25 Nm). Safety the bolts with CoMat 02-126 LOCKWIRE.

Torque the eight bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-682) which attach the centralizing pads to 36 to 45 lbfin (4 to 5 Nm).

Torque the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-732 and , ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES02-733), and the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 02-752 and , ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES02-753) which attach the left and right hand VIGV connector housings to LH and RH connectors to 85 to 105 lbfin (10 to 12 Nm).

Torque tighten the bolts.

Check the pad clearances, follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001).

SUBTASK 72-41-30-440-093-B00 Install the VIGV Centralizing Pad and the Connector Housing Adjusting Washers (SBE 72-0402)

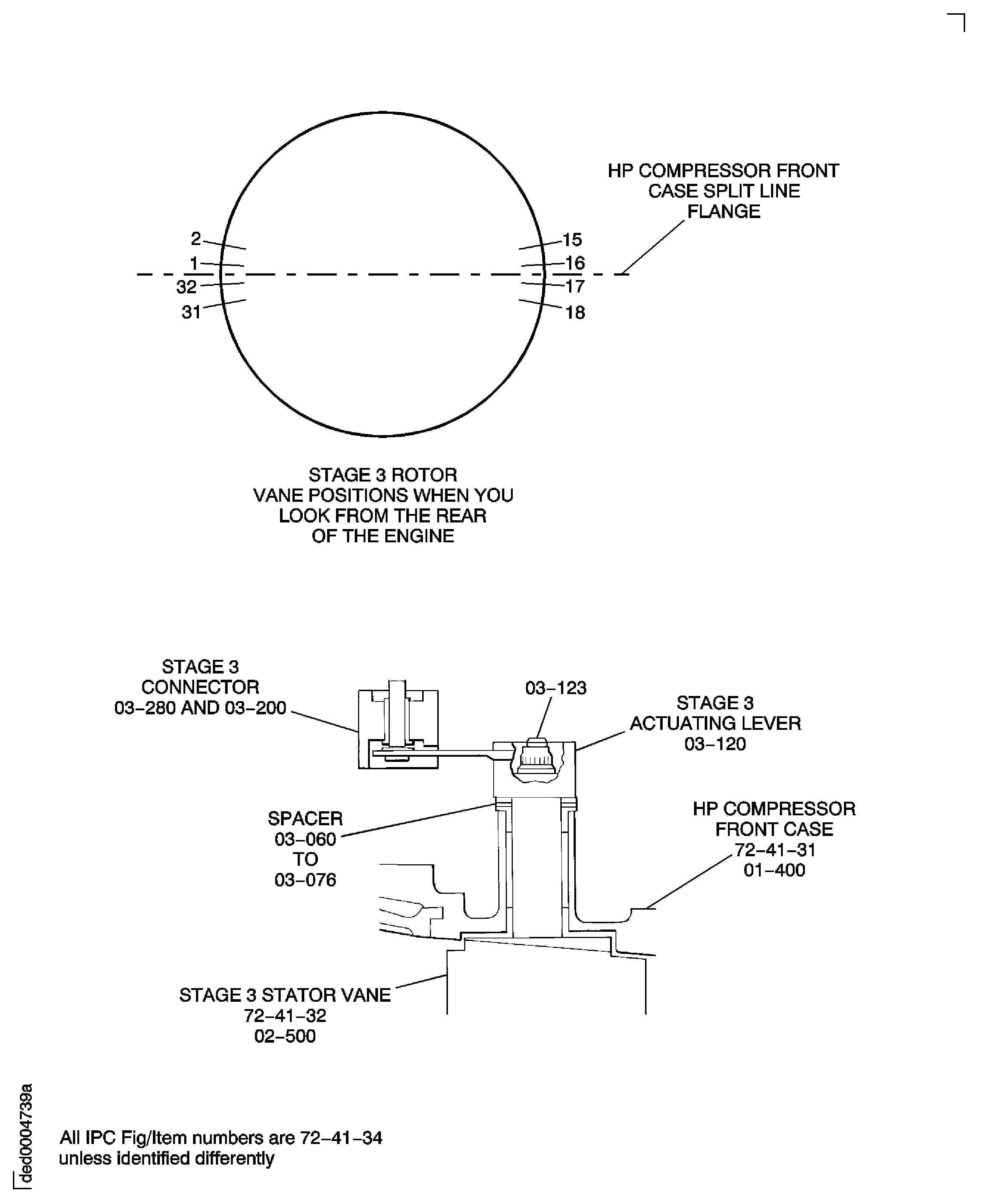

Refer to Figure.

Remove the eight connector actuating levers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-120) from the eight stage 3 stator vanes. Identify each actuating lever with its position number.

Install two spacers on to the spindle of the eight stage 3 stator vanes. The thickness of the spacers that are to be installed is equal to:

The total thickness of the two spacers removed in step (3) plus the end float minus 0.003 to 0.005 (0.08 to 0.13 mm).

The end float was measured and written down in TASK 72-41-34-440-004-A00.

Install the spacers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-060 to ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES03-076) on to the stage 3 stator vanes at the positions 1, 2, 15 to 18, 31 and 32.

Install the eight nuts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-123). Tighten the eight nuts.

CAUTION

MAKE SURE THE CORRECT STAGE 3 ACTUATING LEVER IS INSTALLED ON THE CORRECT STAGE 3 STATOR VANE.Install the eight stage 3 actuating levers at the connectors.

SUBTASK 72-41-30-440-094 Install the Stage 3 Actuating Levers at the Connectors

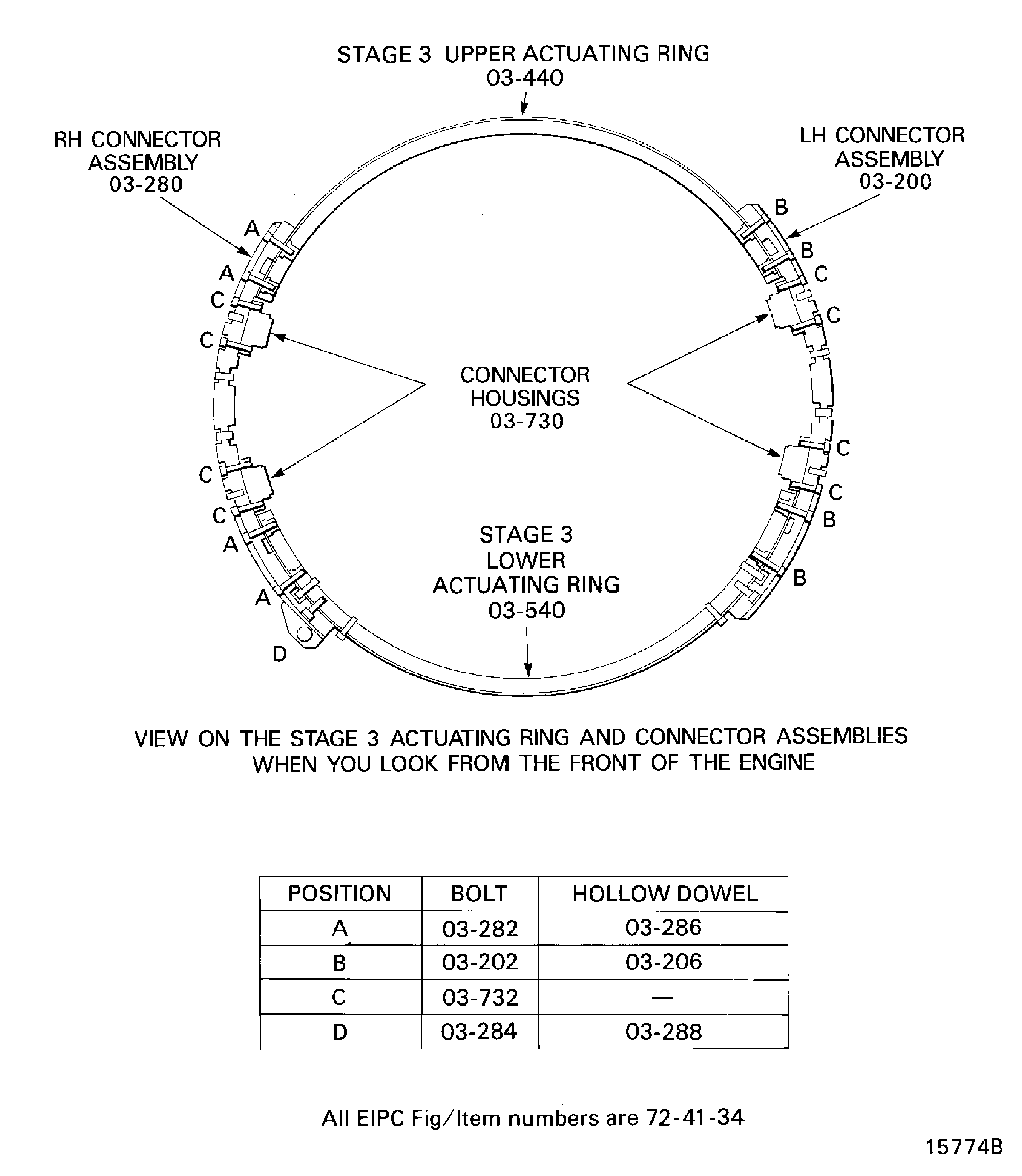

Refer to Figure.

SBE 72-0402: HP compressor variable vanes - inlet guide vane and stages 3 to 6 with optimised build and setting instructions.

SBE 72-0385or SBE 72-0416: Introduction of revised actuation ring connectors and unison ring assemblies.

Install the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-732) which attach the two connector housings to the RH stage 3 connector.

Install the two connector housings ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-730) in to the RH stage 3 connector ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-280).

Install the two connector housings in to the LH stage 3 connector ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-200).

Pre SBE 72-0385 or SBE 72-0416: Install the four hollow dowels ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-286) and four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-282) which attach the RH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

SBE 72-0385: Install the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-282) which attach the RH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

SBE 72-0416: Install the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-282) and the four washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-285) which attach the RH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

Pre SBE 72-0385 or SBE 72-0416: Install the bolt ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-284) and dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-288) which attaches the RH stage 3 connector to the stator vane lower actuating rings.

SBE 72-0385 or SBE 72-0416: Install the bolt ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-284) and washer ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-287) which attaches the RH stage 3 connector to the stator vane lower actuating rings.

Pre SBE 72-0402 : Install the RH stage 3 connector and connector housings on to the stage 3 stator vane upper and lower actuating rings ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-440 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES03-540).

Pre SBE 72-0385 or SBE 72-0416: Install the four hollow dowels ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,03-206) and four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,03-202) which attach the LH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

SBE 72-0385: Install the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,03-202) which attach the LH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

SBE 72-0416: Install the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,03-202) and the four washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-205) which attach the LH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

Install the LH stage 3 connector and connector housings on to the stage 3 stator vane upper and lower actuating rings ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-440 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES03-540).

Torque the eight nuts installed in Step to 85 to 105 lbfin (10.00 to 12.00 Nm).

Torque the actuating lever nuts.

Pre SBE 72-0385 or SBE 72-0416: Install the four hollow dowels ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-286) and four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-282) which attach the RH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

SBE 72-0385: Install the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-282) which attach the RH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

SBE 72-0416: Install the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-282) and the four washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-285) which attach the RH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

Pre SBE 72-0385 or SBE 72-0416: Install the hollow dowel ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-288) and the bolt ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-284) which attaches the RH stage 3 connector to the stator vane lower actuating rings.

Pre SBE 72-0385 or SBE 72-0416: Install the bolt ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-284) and washer ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-287) which attaches the RH stage 3 connector to the stator vane lower actuating rings.

Install the LH stage 3 connector and connector housings on to the stage 3 stator vane upper and lower actuating rings ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-440 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES03-540).

Pre SBE 72-0385 or SBE 72-0416: Install the four hollow dowels ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,03-206) and four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,03-202) which attach the LH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

SBE 72-0385: Install the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,03-202) which attach the LH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

SBE 72-0416: Install the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,03-202) and the four washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-205) which attach the LH stage 3 connector to the stage 3 stator vane upper and lower actuating rings.

SBE 72-0402 : Install the RH and LH stage 3 connector and connector housings on to the stage 3 stator vane upper and lower actuating rings ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-440 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES03-540). Follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001) and this SUBTASK.

Torque the eight nuts installed in Step to 85 to 105 lbfin (10.00 to 12.00 Nm).

Torque the actuating lever nuts.

SUBTASK 72-41-30-440-095 Install the Stage 3 Connector Housings and the Connectors (Pre SBE 72-0402, SBE 72-0402, Pre SBE 72-0385 or SBE 72-0416: and SBE 72-0385 or SBE 72-0416:)

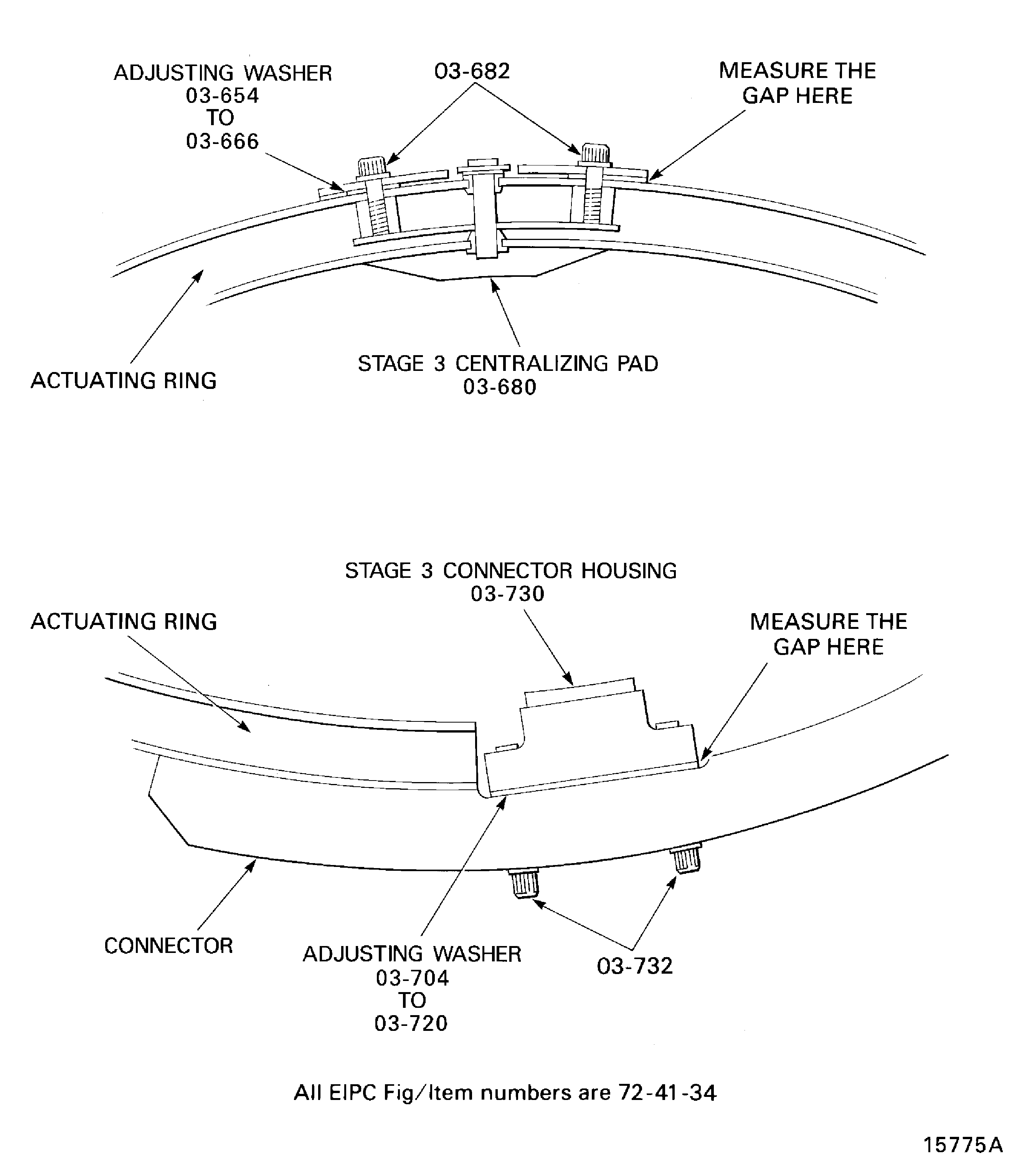

Refer to Figure.

Install IAE 1R18423 Rigging pin 6 off or IAE 1R18893 Riggingpin 6 off to set VSV's in the correct position.

CAUTION

IT IS VERY IMPORTANT TO FULLY INSERT ALL BUILD PINS.Loosen the two bolts which attach a centralizing pad ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,03-680) to the actuating ring.

NOTE

REMOVE ANY ADJUSTING WASHERS THAT ARE CURRENTLY FITTED BEFORE PROCEEDING.Measure and write down the gap between the centralizing pad and the actuating ring.

NOTE

A maximum of two adjusting washers can be installed. On SBE 72-0277 pads a maximum of 3 washers can be installed.

Install the centralizing pad adjusting washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,03-654) thru ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,03-666).

Loosen the two bolts which attach a connector housing ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,03-730) to the connector.

NOTE

REMOVE ANY ADJUSTING WASHERS THAT ARE CURRENTLY FITTED BEFORE PROCEEDING.

Install the connector housing adjusting washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,03-704) thru ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,03-720).

Remove the six rigging pins and remove all feeler gauges.

Table 44. TABLE A - PAD CLEARANCES STAGE

PRE SBE 72-0027

POST SBE 72-0027

VIGV

0.003 in (0.08 mm) to 0.004 in (0.10 mm)

0.003 in (0.08 mm) to 0.004 in (0.10 mm)

3

0.003 in (0.08 mm) to 0.004 in (0.10 mm)

0.004 in (0.10 mm) to 0.005 in (0.13 mm)

4

0.004 in (0.10 mm) to 0.005 in (0.13 mm)

0.008 in (0.20 mm) to 0.009 in (0.23 mm)

5

0.004 in (0.10 mm) to 0.005 in (0.13 mm)

0.007 in (0.18 mm) to 0.008 in (0.20 mm)

6

0.003 in (0.08 mm) to 0.004 in (0.10 mm)

0.008 in (0.20 mm) to 0.009 in (0.23 mm)

SUBTASK 72-41-30-440-096-A00 Install the Stage 3 Centralizing Pad and Connector Housing Adjusting Washers (Pre SBE 72-0402, Pre SBE 72-0277 and SBE 72-0277)

Refer to Figure.

SBE 72-0402: HP compressor variable vanes - inlet guide vane and stages 3 to 6 with optimised build and setting instructions.

SBE 72-0277: Centralising pads with revised method of manufacture.

Set the pad clearances, follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001).

Install the centralizing pad adjusting washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-654 to ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES03-666).

Install the connector housing adjusting washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-704 to ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES03-720).

Install the stage 3 centralizing pad and connector housing washers, follow this procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001) and this SUBTASK.

NOTE

On SBE 72-0277 pads a maximum of 3 washers can be installed.Torque the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-282) which attach the RH stage 3 connectors to the stage 3 upper and lower actuating rings and the bolt ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-284) which attaches the two brackets ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-328) to the upper and lower actuating rings to 85 to 105 lbfin (10 to 12 Nm).

Torque the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-202) which attach the LH stage 3 connector to the upper and lower stage 3 actuating rings to 85 to 105 lbfin (10 to 12 Nm).

Torque the eight bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-682) which attach the centralizing pads to the upper and lower actuating rings to 36 to 45 lbfin (4 to 5 Nm).

Torque the eight bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 03-732) which attach the stage 3 connector housings to the LH and RH connectors to 85 to 105 lbfin (10 to 12 Nm).

Torque tighten the bolts.

Check the pad clearances, follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001).

SUBTASK 72-41-30-440-096-B00 Install the Stage 3 Centralizing Pad and Connector Housing Adjusting Washers (SBE 72-0402, Pre SBE 72-0277: and SBE 72-0277:)

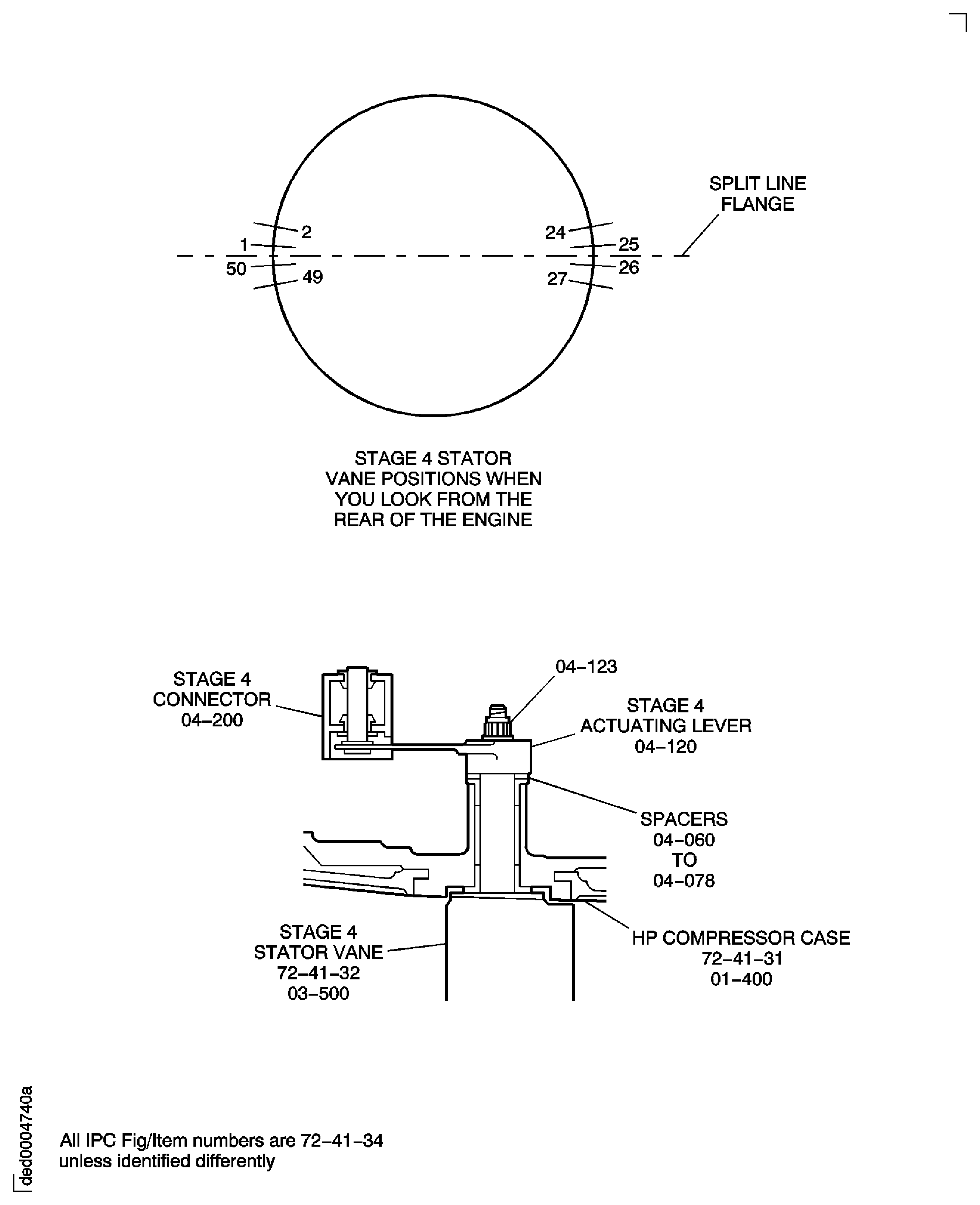

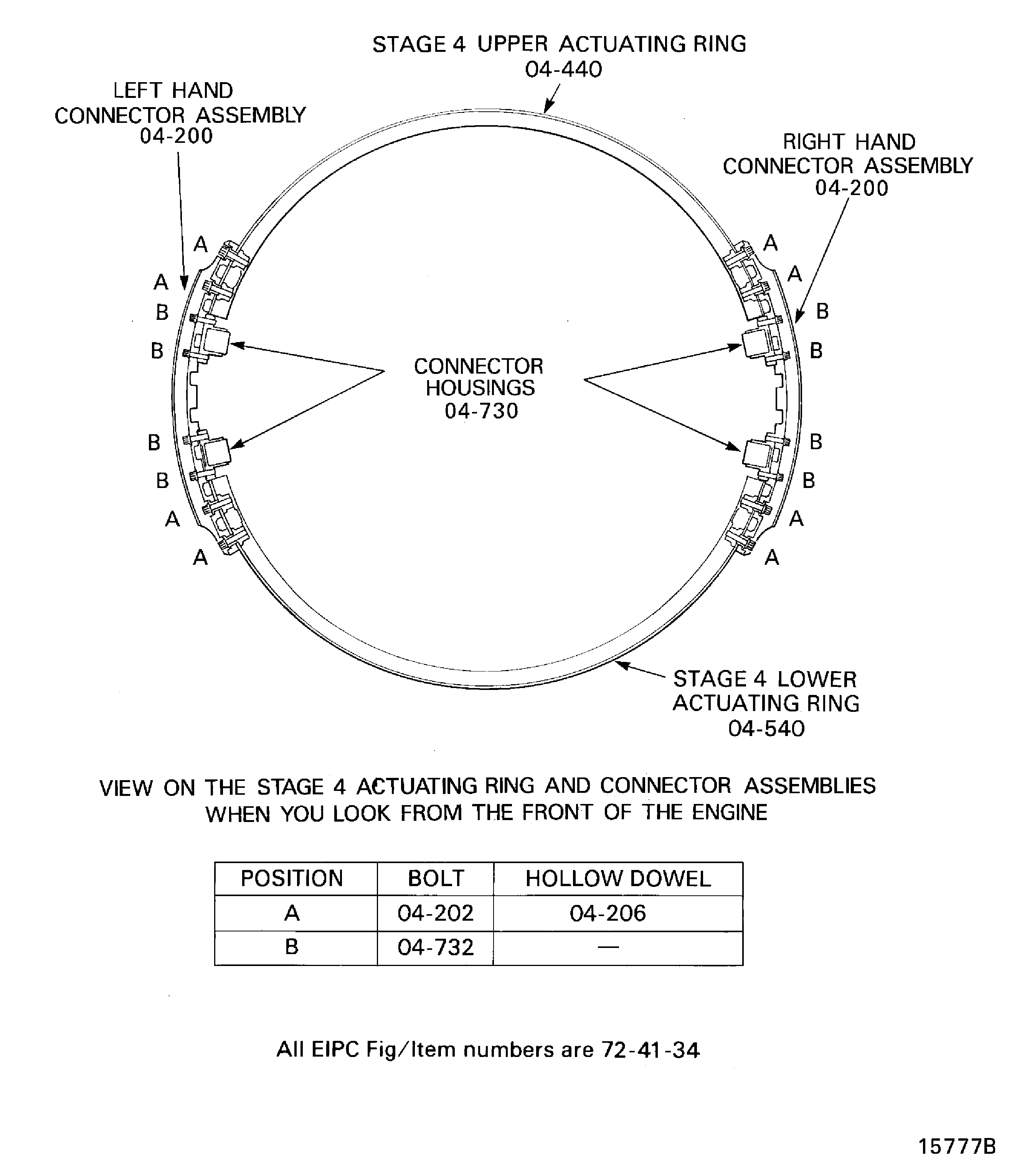

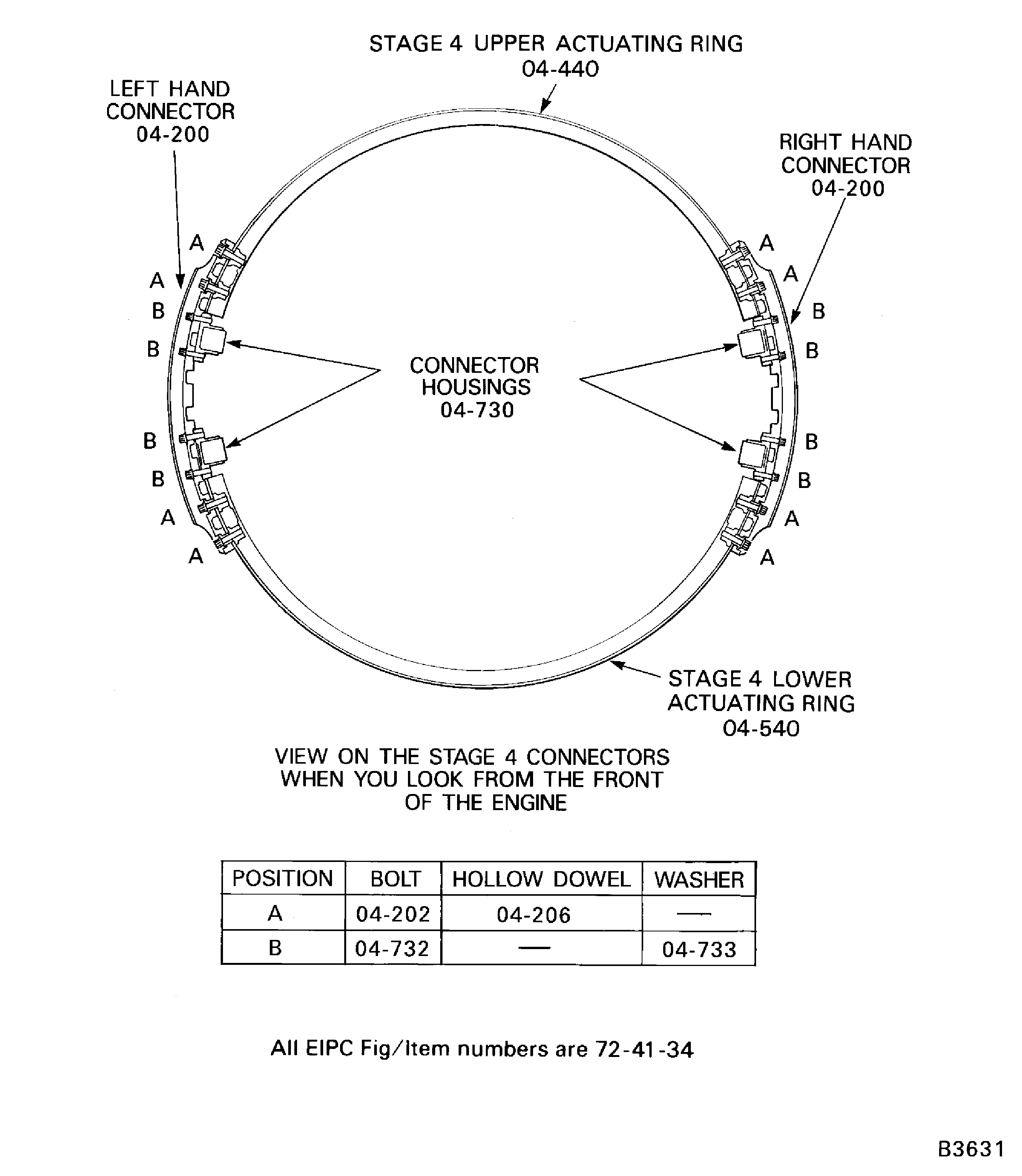

Refer to Figure.

Remove the eight slave nuts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-123) from the eight stage 4 stator vanes.

Remove the eight connector actuating levers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-120) from the eight stage 4 stator vanes. Identify each actuating lever with its position number.

Install two spacers on to the spindle of the eight stage 4 stator vanes. The thickness of the spacers that are to be installed is equal to:

The total thickness of the two spacers removed in step (3) plus the end float minus 0.003 to 0.005in. (0.08 to 0.13 mm).

The end float was measured and written down in TASK 72-41-30-440-005.

Install the spacers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-060 to ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES04-078) on to the stage 4 stator vanes at the positions 1, 2, 24 to 27, 49 and 50.

Install the eight nuts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-123). Tighten the eight nuts.

CAUTION

MAKE SURE THE CORRECT STAGE 4 ACTUATING LEVER IS INSTALLED ON THE CORRECT STAGE 4 STATOR VANE.Install the eight stage 4 connector actuating levers.

SUBTASK 72-41-30-440-097 Install the Stage 4 Actuating Levers at the Connectors

SBE 72-0402: HP compressor variable vanes - inlet guide vane and stages 3 to 6 with optimised build and setting instructions.

SBE 72-0348: Introduction of revised actuation ring connectors.

SBE 72-0385or SBE 72-0416: Introduction of revised actuation ring connectors and unison ring assemblies.

Pre SBE 72-0027: Install the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-732) which attach the two connector housings to the left hand stage 4 connector.

SBE 72-0027: Install the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,04-732) and the four washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,04-733) which attach the two connector housings to the left hand stage 4 connector.

Install the two connector housings ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-730) in to the left hand stage 4 connector ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-200).

Pre SBE 72-0348: Install the four hollow dowels ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-206) and the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-202), which attach the left hand stage 4 connector and connector housings to the stage 4 upper and lower actuating rings.

SBE 72-0348: Install the four washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-204) and the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-202), which attach the left hand stage 4 connector and connector housings to the stage 4 upper and lower actuating rings.

Pre SBE 72-0385 or SBE 72-0416: Install the four washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-204) and the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-202), which attach the left hand stage 4 connector and connector housings to the stage 4 upper and lower actuating rings.

SBE 72-0385 or SBE 72-0416: Install the two washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-204) and the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-202), which attach the left hand stage 4 connector and connector housings to the stage 4 upper and lower actuating rings.

Pre SBE 72-0402 : Install the left hand stage 4 connector on to the upper and lower stage 4 actuating rings ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-440 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES04-540).

Torque the eight nuts installed in Step to 85 to 105 lbfin (10.00 to 12.00 Nm).

Torque the actuating lever nuts.

Pre SBE 72-0348: Install the four hollow dowels ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-206) and the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-202), which attach the left hand stage 4 connector and connector housings to the stage 4 upper and lower actuating rings.

SBE 72-0348: Install the four washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-204) and the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-202), which attach the left hand stage 4 connector and connector housings to the stage 4 upper and lower actuating rings.

Pre SBE 72-0385 or SBE 72-0416: Install the four washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-204) and the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-202), which attach the left hand stage 4 connector and connector housings to the stage 4 upper and lower actuating rings.

SBE 72-0385 or SBE 72-0416: Install the two washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-204) and the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-202), which attach the left hand stage 4 connector and connector housings to the stage 4 upper and lower actuating rings.

SBE 72-0402 : Install the left hand stage 4 connector and connector housings on to the upper and lower stage 4 actuating rings ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-440 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES04-540), follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001) and this SUBTASK.

Torque the eight nuts installed in Step to 85 to 105 lbfin (10.00 to 12.00 Nm).

Torque the actuating lever nuts.

SUBTASK 72-41-30-440-098 Install the Connector Housings and the Stage 4 Connectors (Pre SBE 72-0348, Pre SBE 72-0385 or SBE 72-0416:, SBE 72-0348, SBE 72-0385 or SBE 72-0416:, Pre SBE 72-0402 and SBE 72-0402)

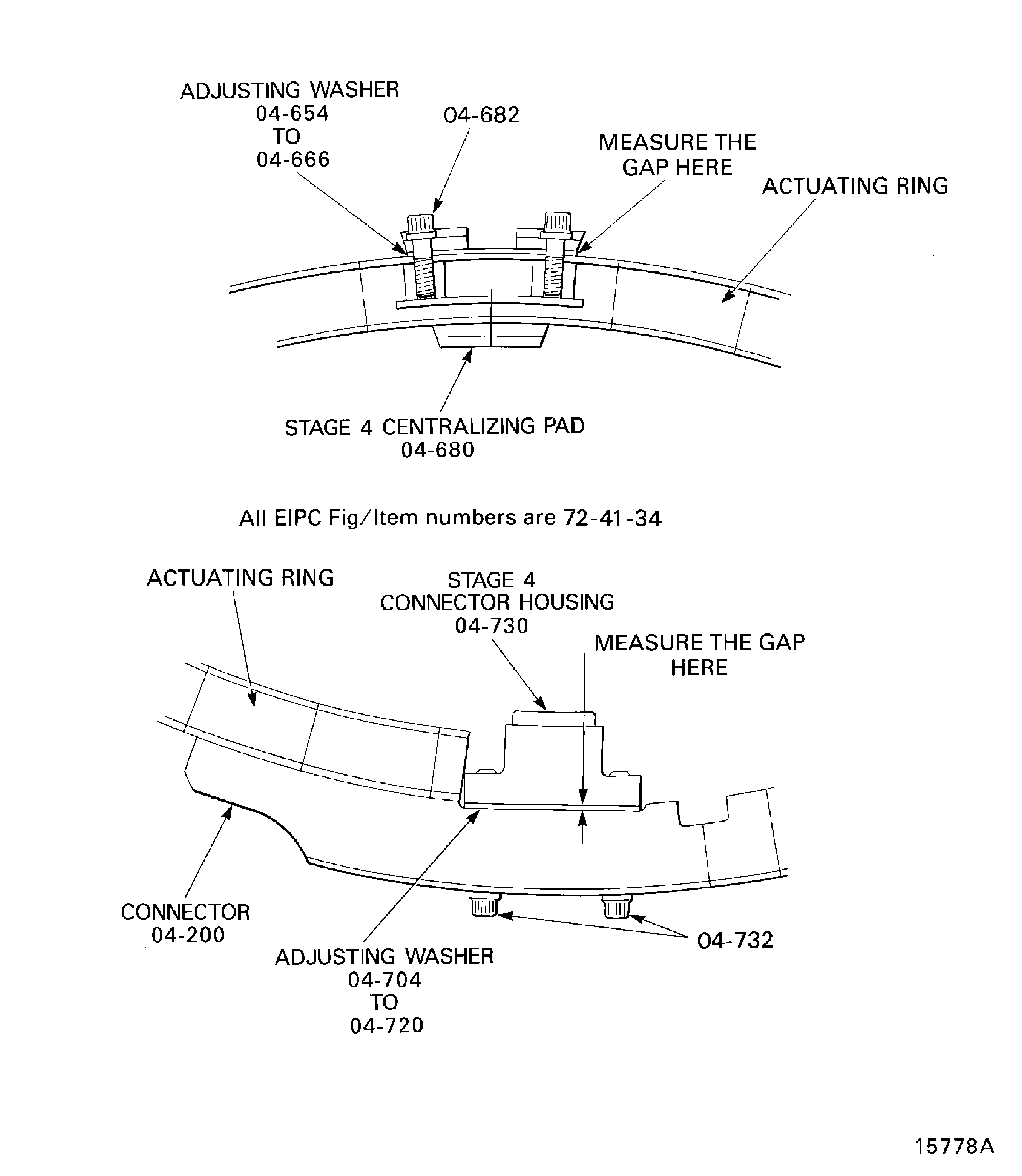

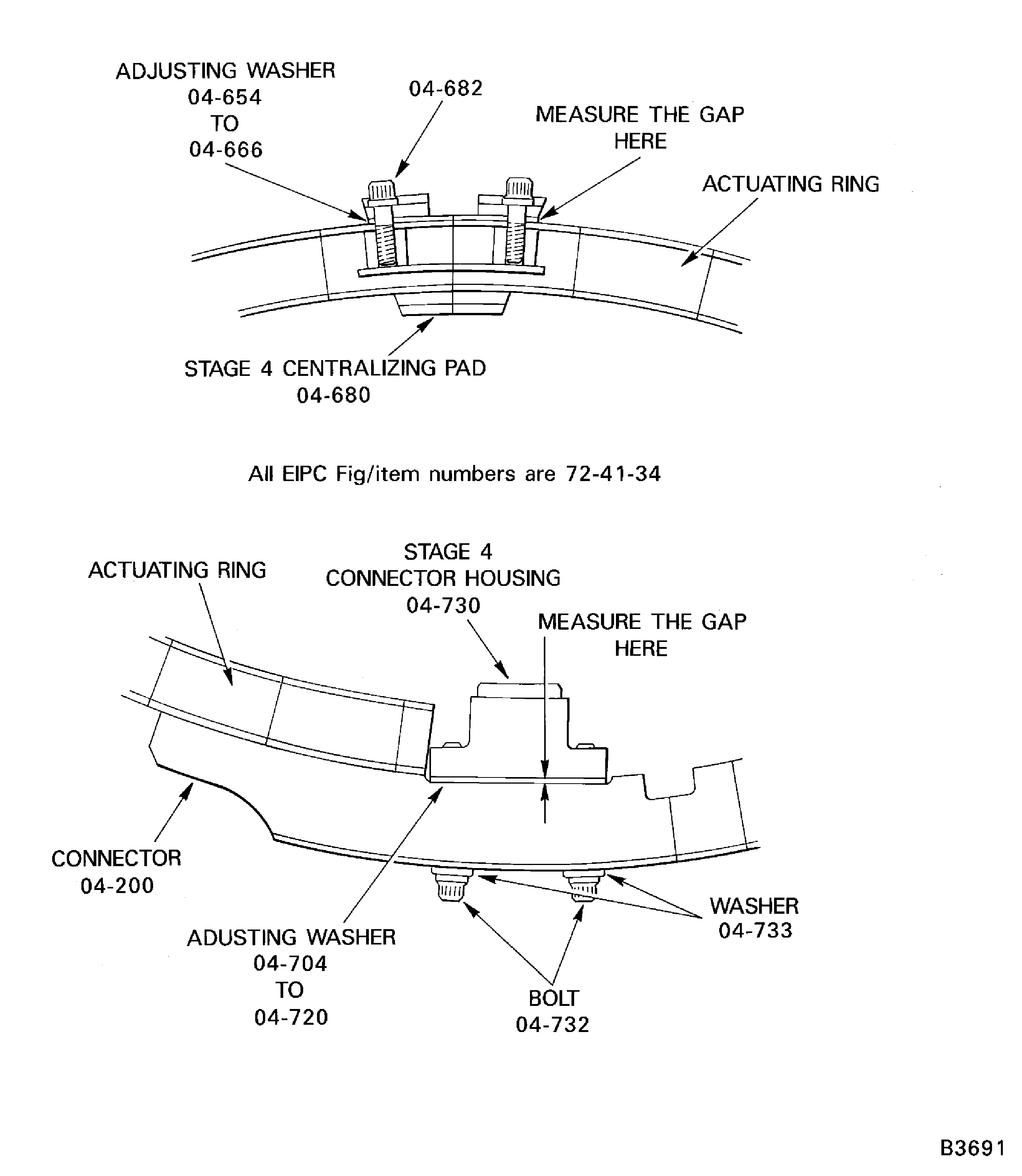

Install IAE 1R18423 Rigging pin 6 off or IAE 1R18894 Rigging pin 6 off to set the VSV's in the correct position.

CAUTION

IT IS VERY IMPORTANT TO FULLY INSERT ALL BUILD PINS.Loosen the two bolts which attach a centralizing pad ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,04-680) to the actuating ring.

NOTE

REMOVE ANY ADJUSTING WASHERS THAT ARE CURRENTLY FITTED BEFORE PROCEEDING.

Install the centralizing pad adjusting washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,04-654) thru ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,04-666).

Loosen the two bolts which attach a connector housing ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,04-730) to the connector.

NOTE

REMOVE ANY ADJUSTING WASHERS THAT ARE CURRENTLY FITTED BEFORE PROCEEDING.

Install the connector housing adjusting washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,04-704) thru ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,04-720).

Remove the six rigging pins and remove all the feeler gauges.

Table 45. TABLE A - PAD CLEARANCES STAGE

PRE SBE 72-0027

POST SBE 72-0027

VIGV

0.003 in (0.08 mm) to 0.004 in (0.10 mm)

0.003 in (0.08 mm) to 0.004 in (0.10 mm)

3

0.003 in (0.08 mm) to 0.004 in (0.10 mm)

0.004 in (0.10 mm) to 0.005 in (0.13 mm)

4

0.004 in (0.10 mm) to 0.005 in (0.13 mm)

0.008 in (0.20 mm) to 0.009 in (0.23 mm)

5

0.004 in (0.10 mm) to 0.005 in (0.13 mm)

0.007 in (0.18 mm) to 0.008 in (0.20 mm)

6

0.003 in (0.08 mm) to 0.004 in (0.10 mm)

0.008 in (0.20 mm) to 0.009 in (0.23 mm)

SUBTASK 72-41-30-440-099-A00 Install the Stage 4 Centralizing Pads and Connector Housing Adjusting Washers (Pre SBE 72-0402)

SBE 72-0402: HP compressor variable vanes - inlet guide vane and stages 3 to 6 with optimised build and setting instructions.

Set the pad clearances, follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001).

Install the centralizing pad adjusting washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-654 to ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES04-666).

Install the connector housing adjusting washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-704 to ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES04-720).

Install the stage 4 centralizing pad and connector housing adjusting washers, follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001) and this SUBTASK.

Torque the eight bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-202), which attach the left and right hand stage 4 connectors to the upper and lower actuating ring to 85 to 105 lbfin (10 to 12 Nm).

Torque the eight bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-682) which attach the centralizing pads to 36 to 45 lbfin (4 to 5 Nm).

Torque the eight bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 04-732) which attach the left and right hand stage 4 connector housings to LH and RH connectors to 36 to 45 lbfin (4 to 5 Nm).

Torque tighten the bolts.

Check the pad clearances, follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001).

SUBTASK 72-41-30-440-099-B00 Install the Stage 4 Centralizing Pads and Connector Housing Adjusting Washers (SBE 72-0402)

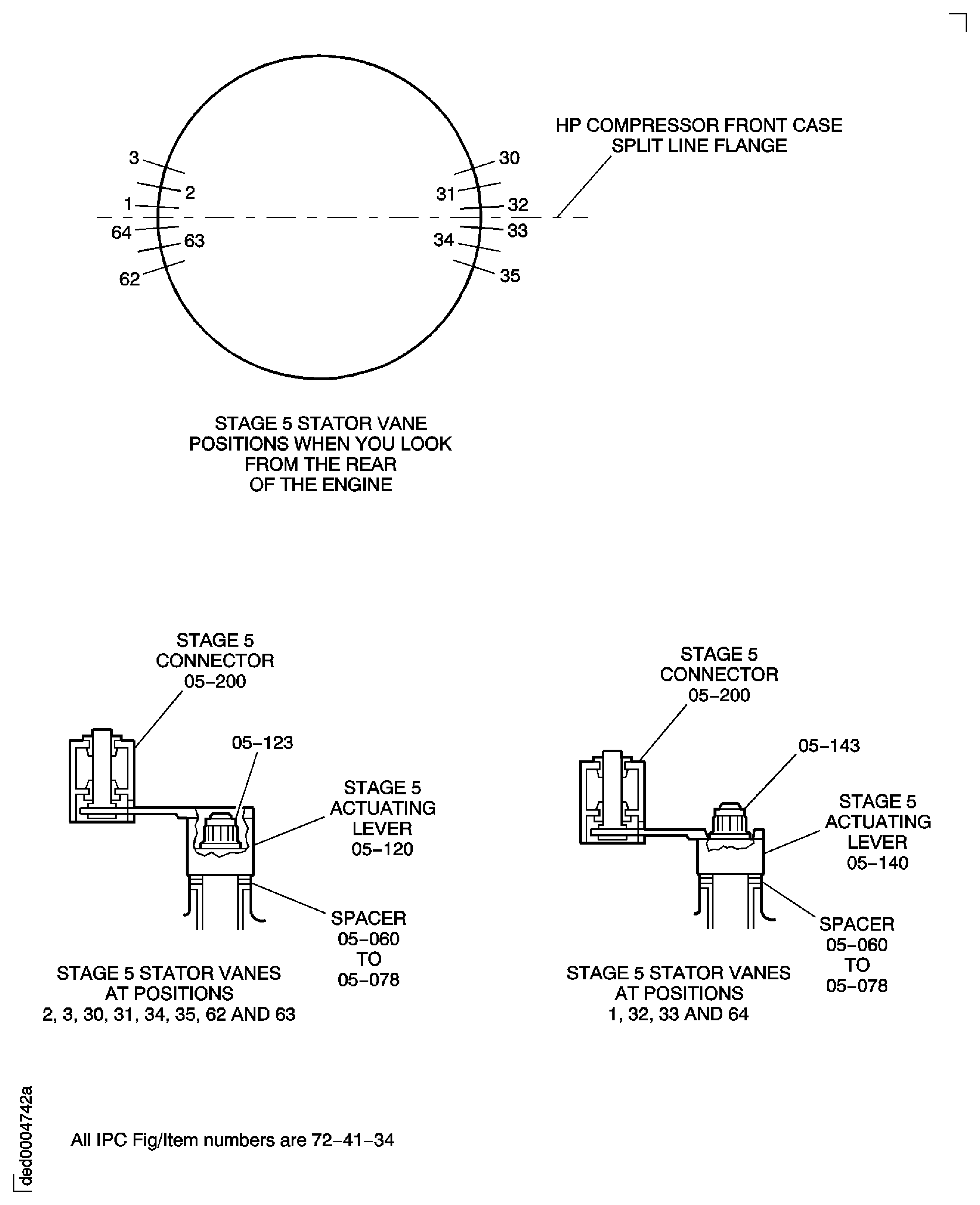

Refer to Figure.

Remove the 12 connector actuating levers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-120 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES05-140) from the 12 stage 5 stator vanes. Identify each actuating lever with its position number.

Install two spacers on to the spindle of the 12 stage 5 stator vanes. The thickness of the spacers that are to be installed is equal to:

The total thickness of the two spacers removed in step (3) plus the end float minus 0.003 to 0.005in. (0.08 to 0.13 mm).

The end float was measured and written down in TASK 72-41-30-440-006.

Install the spacers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-060 to ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES05-078) on to the stage 5 stator vanes at the positions 1 to 3, 30 to 35 and 62 to 64.

Install the four stage 5 stator vane actuating levers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-140) on to the stator vanes at the positions 1, 32, 33 and 64. Make sure the correct actuating levers are installed on the correct stator vane.

Install the eight stage 5 actuating levers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-120) on to the stator vanes at the positions 2, 3, 30, 31, 34, 35, 62 and 63. Make sure the correct actuating levers are installed on the correct stator vane.

Install the 12 nuts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-123 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES05-143). Tighten the 12 nuts.

CAUTION

MAKE SURE THE CORRECT STAGE 5 ACTUATING LEVER IS INSTALLED ON THE CORRECT STAGE 5 STATOR VANE.Install the 12 stage 5 connector actuating levers.

SUBTASK 72-41-30-440-100 Install the Stage 5 Actuating Levers at the Connectors

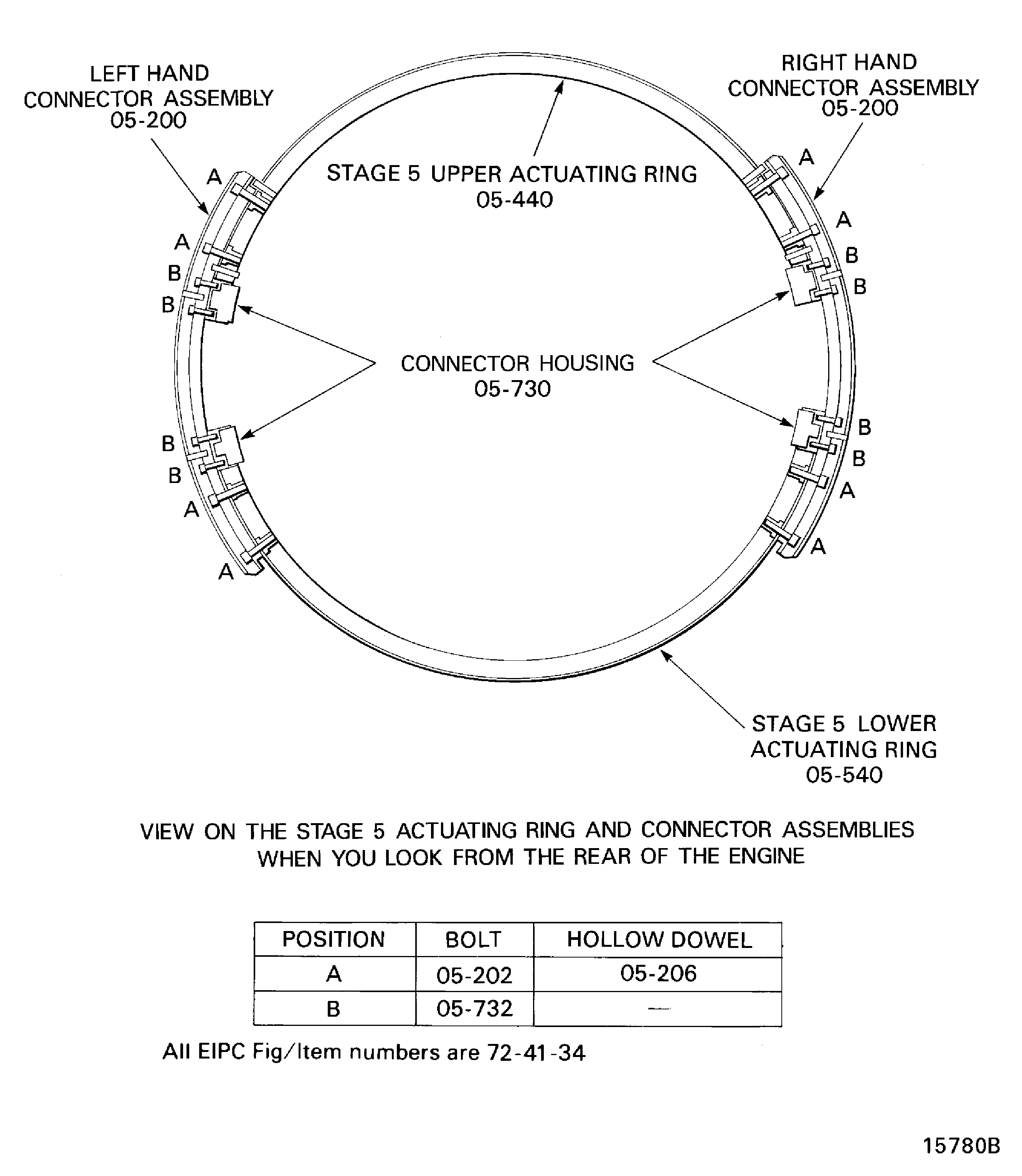

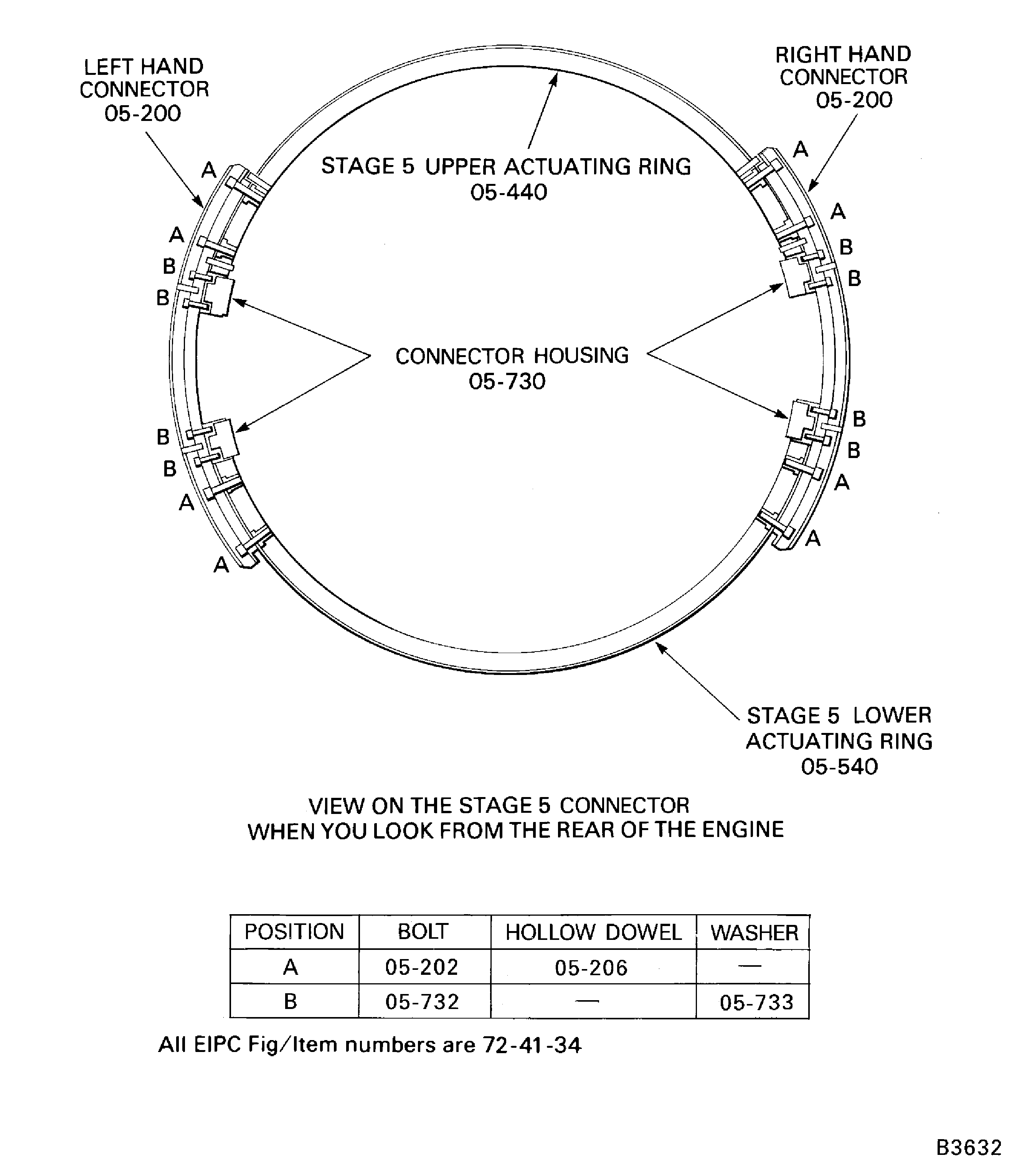

SBE 72-0402: HP compressor variable vanes - inlet guide vane and stages 3 to 6 with optimised build and setting instructions.

SBE 72-0348: Introduction of revised actuation ring connectors.

SBE 72-0385or SBE 72-0416: Introduction of revised actuation ring connectors and unison ring assemblies.

Pre SBE 72-0027: Install the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-732) to attach the two connector housings to the left hand stage 5 connector.

SBE 72-0027: Install the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,05-732) and the four washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,05-733) to attach the two connector housings to the left hand stage 5 connector.

Install the two connector housings ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-730) in to the left hand stage 5 connector ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-200).

Pre SBE 72-0348: Install the four hollow dowels ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-206) and the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-202), which attach the left hand stage 5 connector and connector housings to the stage 5 upper and lower actuating ring.

SBE 72-0348: Install the four washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-204) and the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-202), which attach the left hand stage 5 connector and connector housings to the stage 5 upper and lower actuating ring.

Pre SBE 72-0385 or SBE 72-0416: Install the four washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-204) and the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-202), which attach the left hand stage 5 connector and connector housings to the stage 5 upper and lower actuating ring.

SBE 72-0385 or SBE 72-0416: Install the two washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-204) and the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-202), which attach the left hand stage 5 connector and connector housings to the stage 5 upper and lower actuating ring.

Pre SBE 72-0402 : Install the left hand stage 5 connector and connector housings in to the stage 5 upper and lower actuating rings ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-440 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES05-540).

Torque the 12 nuts installed in Step to 85 to 105 lbfin (10.00 to 12.00 Nm).

Torque the actuating lever nuts.

Pre SBE 72-0348: Install the four hollow dowels ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-206) and the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-202), which attach the left hand stage 5 connector and connector housings to the stage 5 upper and lower actuating ring.

SBE 72-0348: Install the four washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-204) and the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-202), which attach the left hand stage 5 connector and connector housings to the stage 5 upper and lower actuating ring.

Pre SBE 72-0385 or SBE 72-0416: Install the four washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-204) and the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-202), which attach the left hand stage 5 connector and connector housings to the stage 5 upper and lower actuating ring.

SBE 72-0385 or SBE 72-0416: Install the two washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-204) and the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-202), which attach the left hand stage 5 connector and connector housings to the stage 5 upper and lower actuating ring.

SBE 72-0402 : Install the left hand stage 5 connector and connector housings in to the stage 5 upper and lower actuating rings ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-440 and ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES05-540). Follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001) and this SUBTASK.

Torque the 12 nuts installed in Step to 85 to 105 lbfin (10.00 to 12.00 Nm).

Torque the actuating lever nuts.

SUBTASK 72-41-30-440-101 Install the Connector Housings and the Stage 5 Connectors (Pre SBE 72-0402, SBE 72-0402, Pre SBE 72-0348, Pre SBE 72-0385or SBE 72-0416:, SBE 72-0348 and SBE 72-0385or SBE 72-0416)

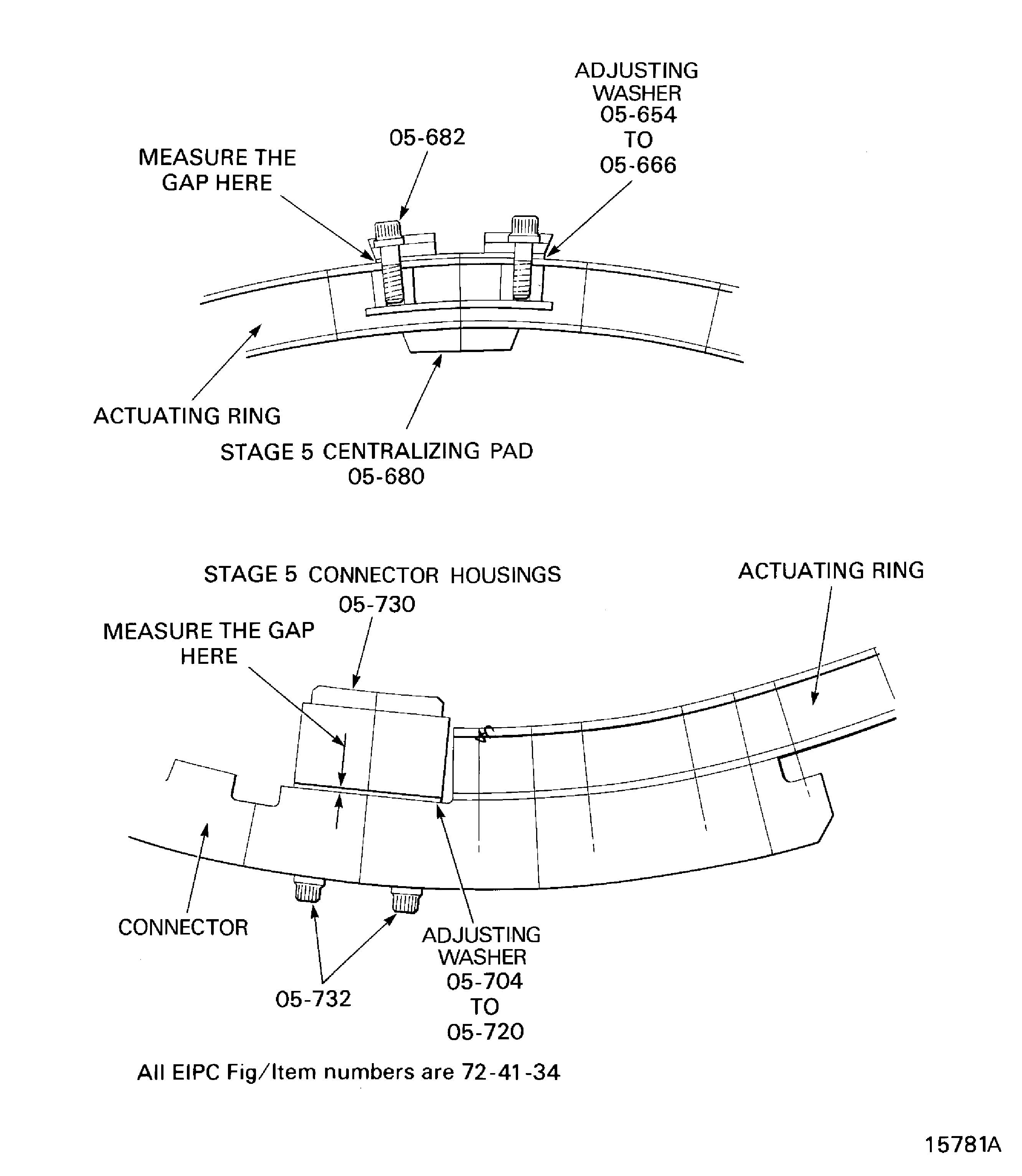

Install IAE 1R18423 Rigging pin 6 off or IAE 1R18895 Rigging pin 6 off to set the VSV's in the correct positions.

CAUTION

IT IS VERY IMPORTANT TO FULLY INSERT ALL BUILD PINS.Loosen the two bolts which attach a centralizing pad ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,05-680) to the actuating ring.

NOTE

REMOVE ANY ADJUSTING WASHERS THAT ARE CURRENTLY FITTED BEFORE PROCEEDING.

Install the centralizing pad adjusting washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,05-654) thru ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,05-666).

Loosen the two bolts which attach a connector housing ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,05-730) to the connector.

NOTE

REMOVE ANY ADJUSTING WASHERS THAT ARE CURRENTLY FITTED BEFORE PROCEEDING.

Install the connector housing adjusting washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,05-704) thru ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34,05-720).

Remove the six rigging pins and remove all feeler gauges.

Table 46. TABLE A - PAD CLEARANCES STAGE

PRE SBE 72-0027

POST SBE 72-0027

VIGV

0.003 in (0.08 mm) to 0.004 in (0.10 mm)

0.003 in (0.08 mm) to 0.004 in (0.10 mm)

3

0.003 in (0.08 mm) to 0.004 in (0.10 mm)

0.004 in (0.10 mm) to 0.005 in (0.13 mm)

4

0.004 in (0.10 mm) to 0.005 in (0.13 mm)

0.008 in (0.20 mm) to 0.009 in (0.23 mm)

5

0.004 in (0.10 mm) to 0.005 in (0.13 mm)

0.007 in (0.18 mm) to 0.008 in (0.20 mm)

6

0.003 in (0.08 mm) to 0.004 in (0.10 mm)

0.008 in (0.20 mm) to 0.009 in (0.23 mm)

SUBTASK 72-41-30-440-102-A00 Install the Stage 5 Centralizing Pads and Connector Housing Adjusting Washers (Pre SBE 72-0402)

SBE 72-0402: HP compressor variable vanes - inlet guide vane and stages 3 to 6 with optimised build and setting instructions.

Set the pad clearances, follow the procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001).

Install the centralizing pad adjusting washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-654 to ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES05-666).

Install the connector housing adjusting washers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-704 to ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES05-720).

Install the stage 5 centralizing pad and connector housing washers, follow this procedure in TASK 72-41-30-440-011-A00 (ASSEMBLY-011, CONFIG-001) and this SUBTASK.

NOTE

A maximum of two adjusting washers can be installed.Torque the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-202) which attach the RH stage 5 connectors to the stage 5 upper and lower actuating rings to the upper and lower actuating rings to 85 to 105 lbfin (10 to 12 Nm).

Torque the four bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-202) which attach the LH stage 5 connector to the upper and lower stage 5 actuating rings to 85 to 105 lbfin (10 to 12 Nm).

Torque the eight bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-682) which attach the centralizing pads to the upper and lower actuating rings to 36 to 45 lbfin (4 to 5 Nm).