Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-00-32-420-005-A00 LPC/Intermediate Case Module - Install The Hydraulic Tubes, Thermal Anti-ice Duct, Starter Air Duct, And EEC Cooling Ducts, Installation-005

General

This TASK gives the procedure to install the hydraulic tubes, the thermal anti-ice (TAI) duct,the thermal anti-ice (TAI) insulation, the pneumatic starter duct and the EEC cooling ducts/hoses.

It also gives the TASKS to install the external gearbox module and the air intake cowl.

Refer to the TASKS which follow for the other related procedures.

Install the LP compressor/intermediate case brackets and the bifurcation panel by TASK 72-00-32-420-001.

Install the LP compressor/intermediate case components by TASK 72-00-32-420-002.

Install the LP compressor/intermediate case tubes and the electrical harness raceways by TASK 72-00-32-420-003.

Install the LP compressor/intermediate case electrical harnesses by TASK 72-00-32-420-004.

Fig/item numbers in parentheses in the procedure agree with those used in the EIPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the EIPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Lubricate all the bolt shanks given in this procedure with CoMat 10-073 SYNTHETIC GREASE, MoDISULFIDE. Lubricate all the bolt holes with CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE), unless other lubricants are referred to in the procedure.

Refer to TASK 72-00-32-420-001 for the position on a raft or bracket of a particular clip position.

Transportation covers/blanks must be removed immediately before the installation of the components.

For lockwire data and procedures refer to SPM TASK 70-42-05-400-501.

For safety cable data and procedures refer to SPM TASK 70-42-08-400-501.

Safety the threaded fasteners in the ATA Chapter/Section/Subject 71-51-41 as applicable with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT.

To identify, lubricate and install seal rings refer to SPM TASK 70-44-00-400-501.

For the torque tightening procedures, refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

To install key washer (tab type) refer to SPM TASK 70-42-03-400-501.

Refer to SPM TASK 70-47-01-420-501 for the data on the installation of the V-band clamps.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. Refer to SPM TASK 70-38-21-380-501.

Do not remove the special plastic caps from the electrical connectors until immediately before they are installed. This will give protection from unwanted fluids or materials.

For the data on the electrical connectors refer to SPM TASK 70-43-00-400-501 and SPM TASK 70-43-01-400-501.

Special torque data and assembly tolerances are included in this procedure.

Special torque data is identified with the symbol * after the torque value.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 02-274 SAFETY CABLE KIT | LOCAL | CoMat 02-274 | ||

| CoMat 02-275 SAFETY CABLE KIT | LOCAL | CoMat 02-275 | ||

| CoMat 06-086 TIES | 18992 | CoMat 06-086 | ||

| CoMat 07-038 AIR DRYING ENAMEL | k3504 | CoMat 07-038 | ||

| CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) | K6835 | CoMat 10-072 | ||

| CoMat 10-073 SYNTHETIC GREASE, MoDISULFIDE | LOCAL | CoMat 10-073 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Tab washer | 1 | |||

| Tab washer | 1 | |||

| Tab washer | 1 | |||

| Tab washer | 1 | |||

| Tab washer | 1 |

Safety Requirements

NONEProcedure

Refer to Figure.

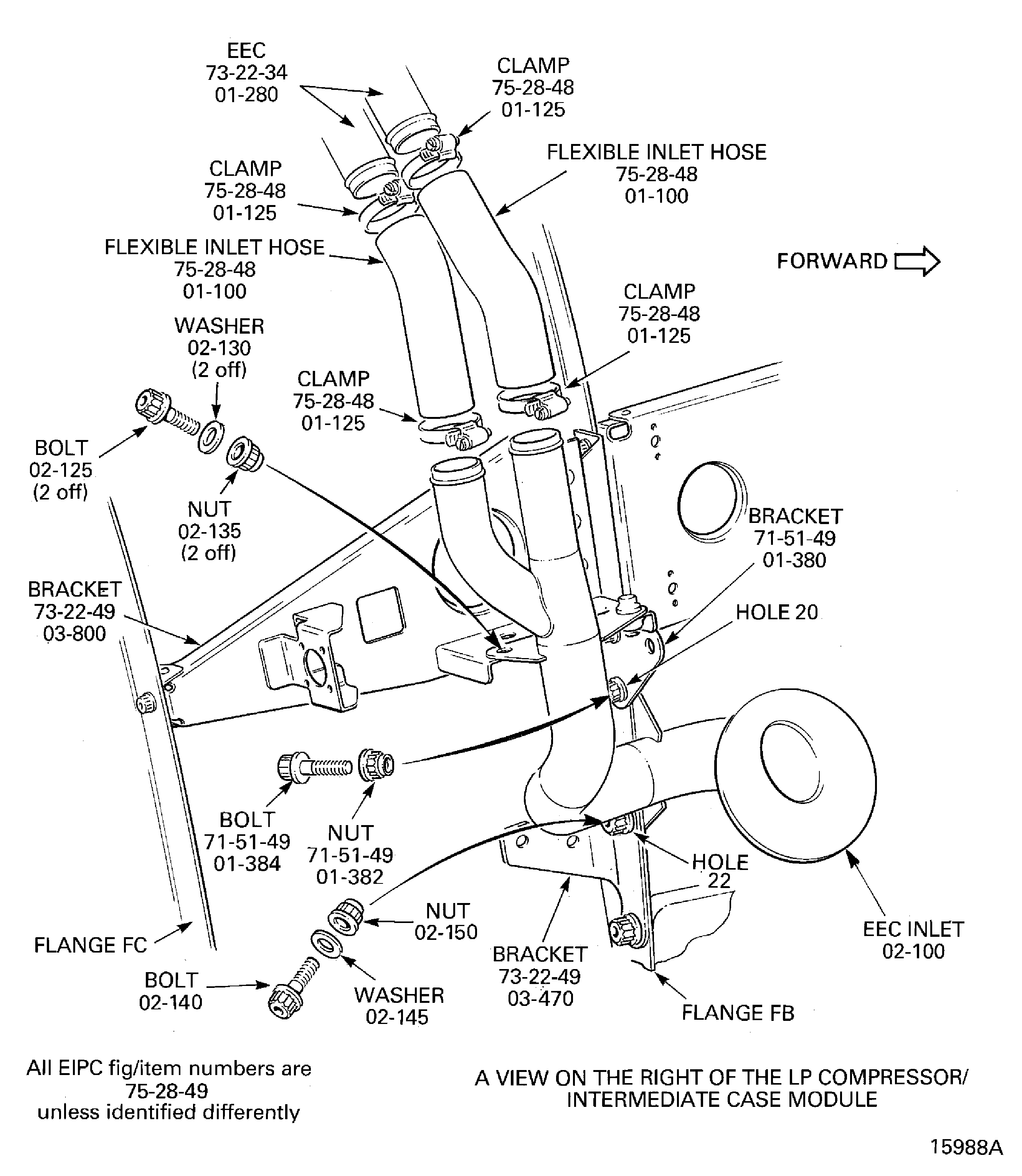

Install the four clamps AIR-EEC COOLING FLEXIBLE TUBES (75-28-48, 01-125) on the two flexible inlet hoses AIR-EEC COOLING FLEXIBLE TUBES (75-28-48, 01-100).

Install the flexible inlet hoses.

Install the EEC inlet to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-800) with the two bolts, the two washers and the two nuts AIR-EEC COOLING DUCTS (75-28-49, 02-125 , AIR-EEC COOLING DUCTS 02-130 and AIR-EEC COOLING DUCTS 02-135).

NOTE

Hole number one is at TDC on the flange FB.The brackets ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-470) and POWER PLANT-RELAY BOX(71-51-49, 01-380) are installed inTASK 72-00-32-420-001 .Install the EEC inlet, to the flange FB at the holes 20 and 22 with the two bolts, the washer and the two nuts POWER PLANT-RELAY BOX (71-51-49, 01-384 and POWER PLANT-RELAY BOX 01-382) and AIR-EEC COOLING DUCTS (75-28-49, 02-140 , AIR-EEC COOLING DUCTS 02-145 and AIR-EEC COOLING DUCTS 02-150).

Adjust the flexible inlet hoses and the four clamps AIR-EEC COOLING FLEXIBLE TUBES (75-28-48, 01-100 and 01-125) as necessary. Torque the four clamps to 18 * lbf.in (2.0 Nm).

Install the EEC inlet AIR-EEC COOLING DUCTS (75-28-49, 02-100).

SUBTASK 72-00-32-420-119 Install the EEC Cooling Ducts/Flexible Hoses (Inlet) (Pre SBN 71-0069 and Pre SBE 71-0070)

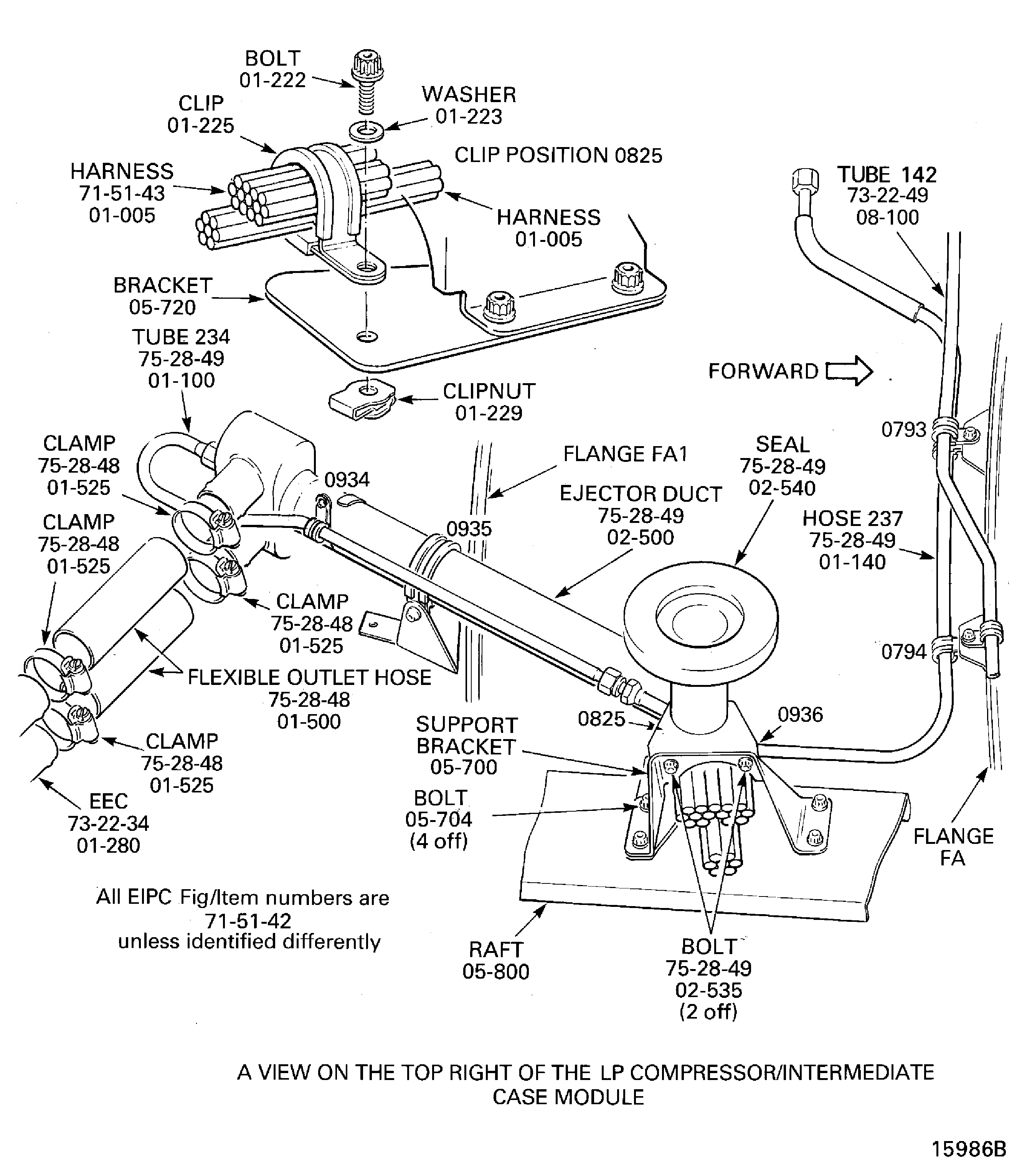

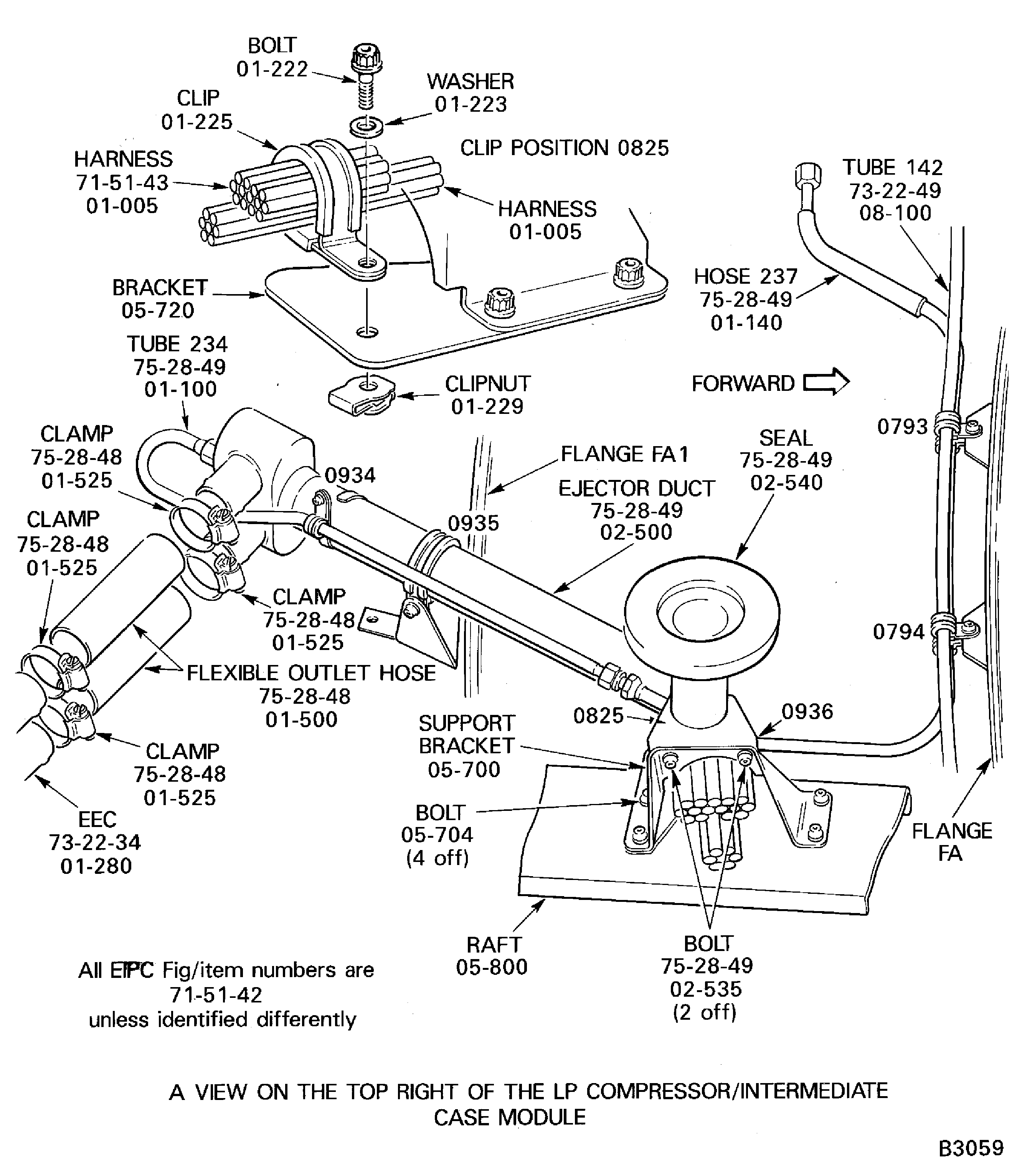

Install the four clamps AIR-EEC COOLING FLEXIBLE TUBES (75-28-48, 01-525) on the two flexible outlet hoses AIR-EEC COOLING FLEXIBLE TUBES (75-28-48, 01-500).

Install the flexible outlet hoses.

Attach the support bracket and the bracket ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-700 and 05-720) to the raft ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-800) with the four bolts ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-704). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

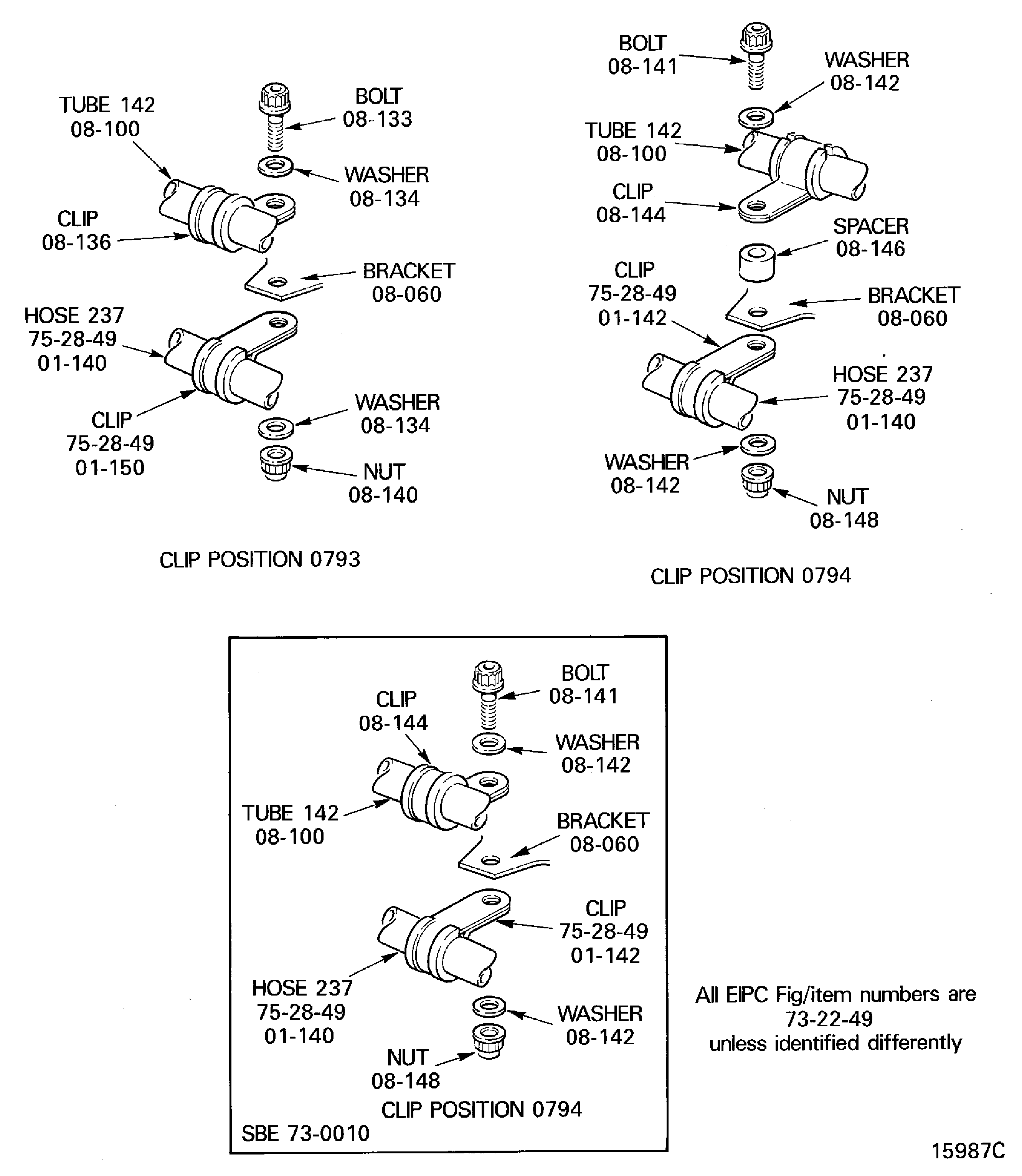

Lubricate the threads and abutment faces of the nuts and the bolts at the clip positions 0936, 0793 and 0794 with CoMat 10-077 APPROVED ENGINE OILS.

Attach the hose 237 to the support bracket ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-700) at the clip position 0936, with the bolt and the clip.

Pre SBE 73-0010 - Install the bolt, the washers, the nut and the clips at the clip position 0793 and the bolt, the washers, the spacer, the nut and the clips at the clip position 0794, to attach the tube 142 and the hose 237 to the flange brackets.

SBE 73-0010 - Install the bolts, the washers, the nuts and the clips at the clip positions 0793 and 0794, to attach the tube 142 and hose 237 to the flange brackets.

Install the hose 237.

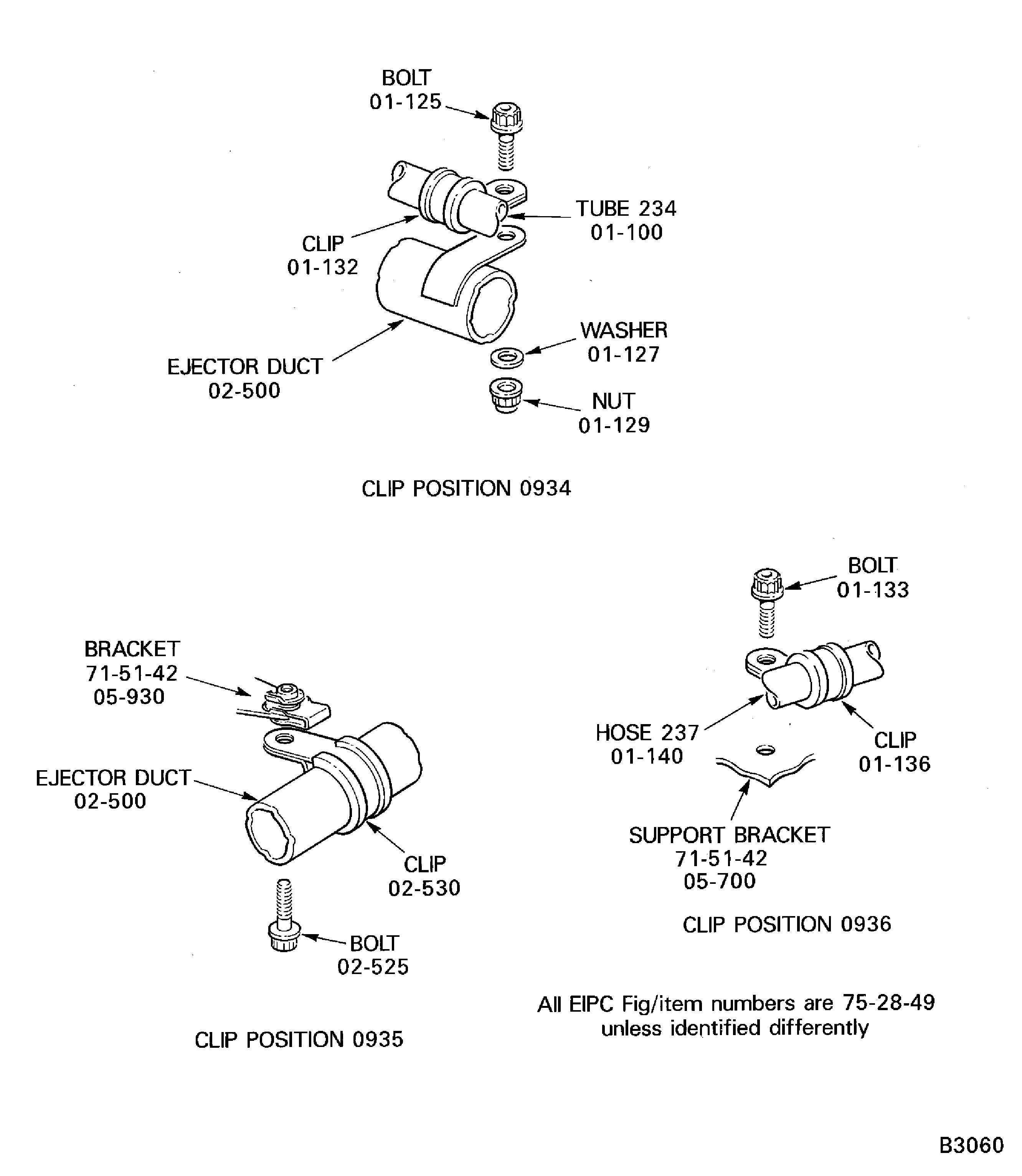

Install the two flexible outlet hoses on the ejector duct AIR-EEC COOLING DUCTS (75-28-49, 02-500).

Install the two bolts AIR-EEC COOLING DUCTS (75-28-49, 02-535) to attach the ejector duct to the support bracket ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-700).

Lubricate the threads and abutment faces of the clip nuts and the bolts at the clip position 0935 and 0825 with CoMat 10-077 APPROVED ENGINE OILS.

Torque the two bolts AIR-EEC COOLING DUCTS (75-28-49, 02-535) to 85 to 105 lbf.in (10 to 12 Nm).

Install the ejector duct.

Lubricate the threads and abutment faces of the nut and the bolt at the clip position 0934 with CoMat 10-077 APPROVED ENGINE OILS.

Attach the tube 234 to the ejector duct AIR-EEC COOLING DUCTS (75-28-49, 02-500) at the clip position 0934.

NOTE

It is not necessary to lubricate the tube 234 nuts.Connect the tube 234 to the ejector duct AIR-EEC COOLING DUCTS (75-28-49, 02-500) and the hose 237. Torque the tube nuts to 175 to 195 * lbf.in (19.78 to 22.0 Nm).

Install the tube 234.

SUBTASK 72-00-32-420-120 Install the EEC Cooling Ducts/Flexible Hoses (Outlet) (Pre SBN 71-0069 and Pre SBE 71-0070)

WARNING

THE AIRCRAFT HYDRAULIC FLUID AND THE VAPOR ARE DANGEROUS THROUGH ABSORPTION AND INGESTION. THE HYDRAULIC FLUID CAN CAUSE EYE, NOSE, AND SKIN IRRITATION. DO NOT BREATHE THE VAPOR.DO NOT GET HYDRAULIC FLUID ON YOUR SKIN OR IN YOUR EYES. YOU MUST USE PROTECTIVE GOGGLES AND GLOVES. YOU MUST OBEY THE MAKERS SPECIAL SAFETY INSTRUCTIONS.CLEAN YOUR EYES IMMEDIATELY WITH CLEAN COLD WATER IF HYDRAULIC FLUID GETS INTO THEM AND GET MEDICAL AID. USE SOAP AND HOT WATER TO IMMEDIATELY CLEAN THE AREA OF SKIN TOUCHED BY THE HYDRAULIC FLUID.

CAUTION

REMOVE THE HYDRAULIC FLUID IMMEDIATELY WITH A DRY CLOTH AND WASH THE AREA OF CONTAMINATION WITH MILD CLEANER, REFER TO THE SPM TASK 70-11-03-300-503. THE HYDRAULIC FLUID USED IN THIS SYSTEM WILL CAUSE DAMAGE TO A LARGE RANGE OF MATERIALS SUCH AS RUBBER, COPPER, DIFFERENT PLASTICS AND PAINT.KEEP LEAKAGE TO A MINIMUM AND INSTALL CLEAN CAPS TO ALL OPEN TUBES AND COMPONENTS AFTER YOU DISCONNECT THEM.Lightly lubricate the threads and abutment faces of the hydraulic system tube/hose nuts, unions and couplings with the hydraulic fluid used in the aircraft hydraulic system.

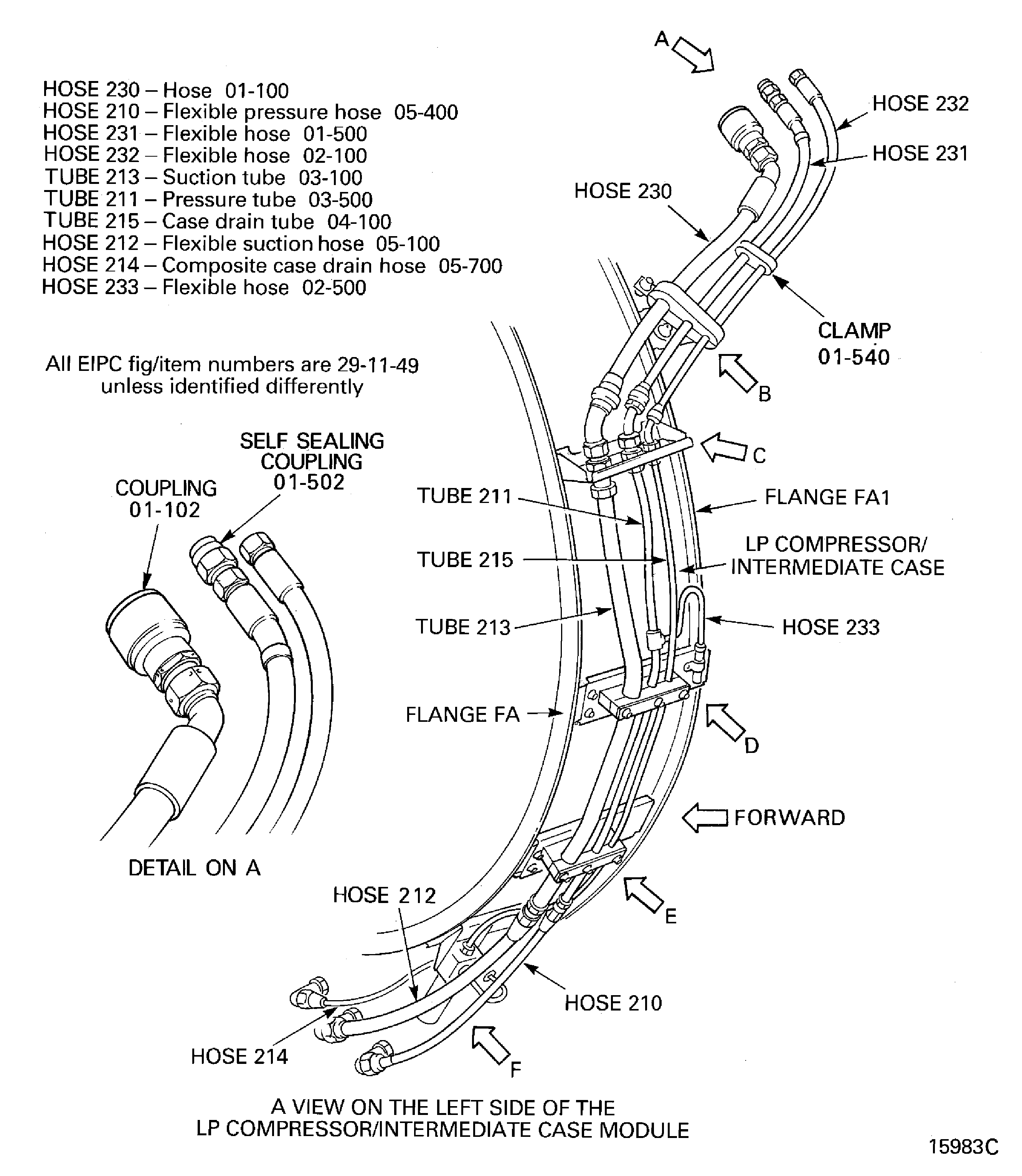

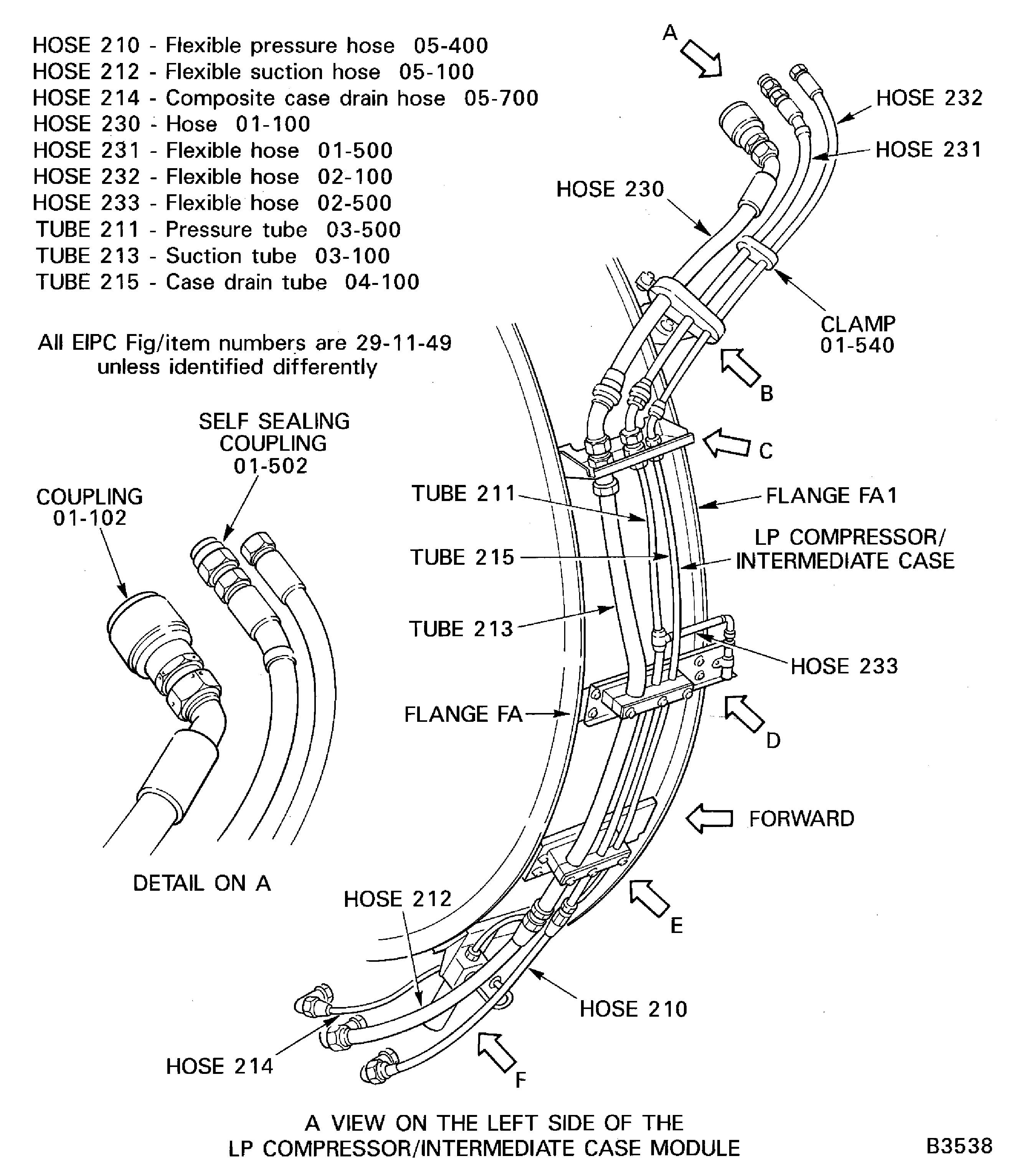

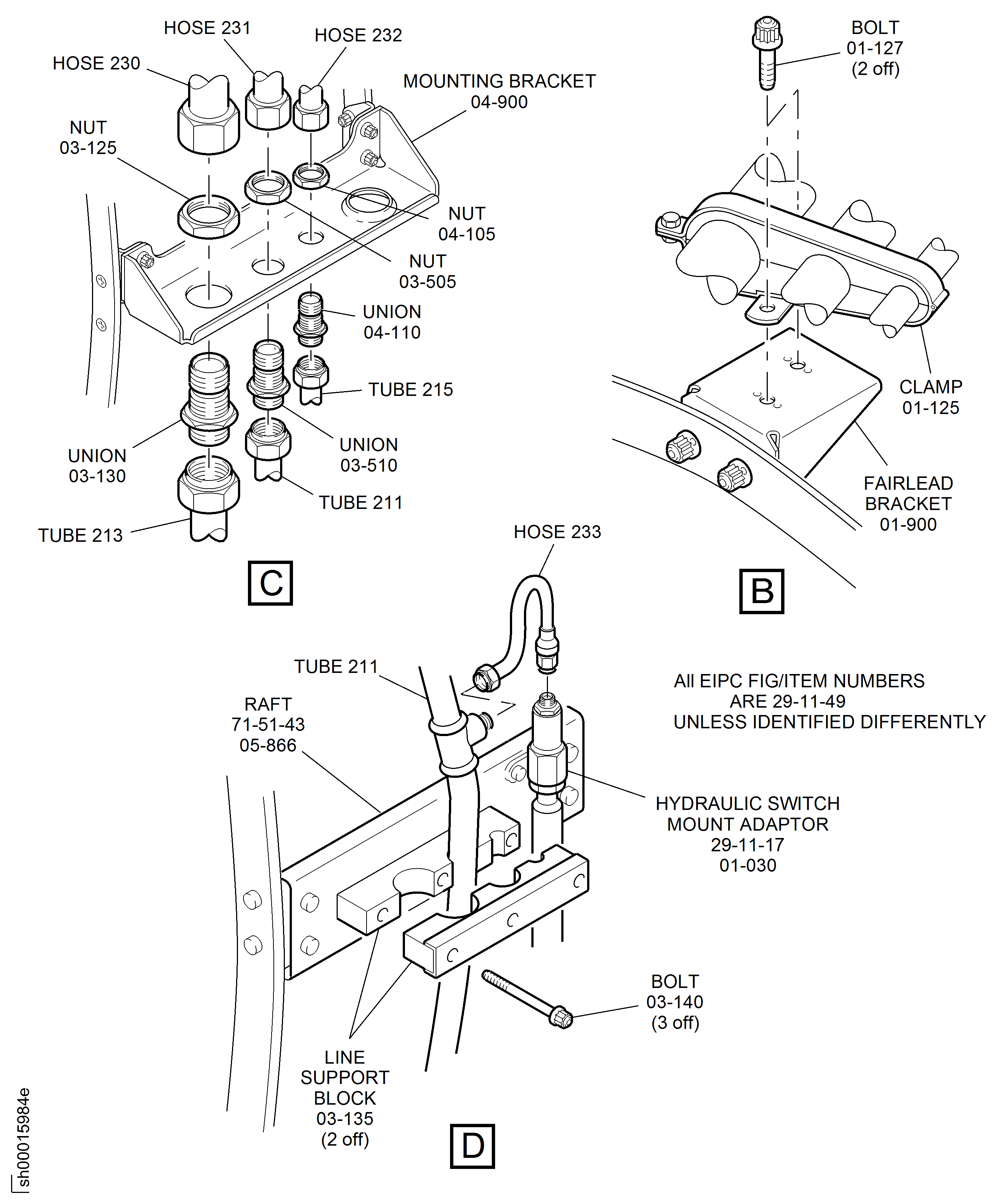

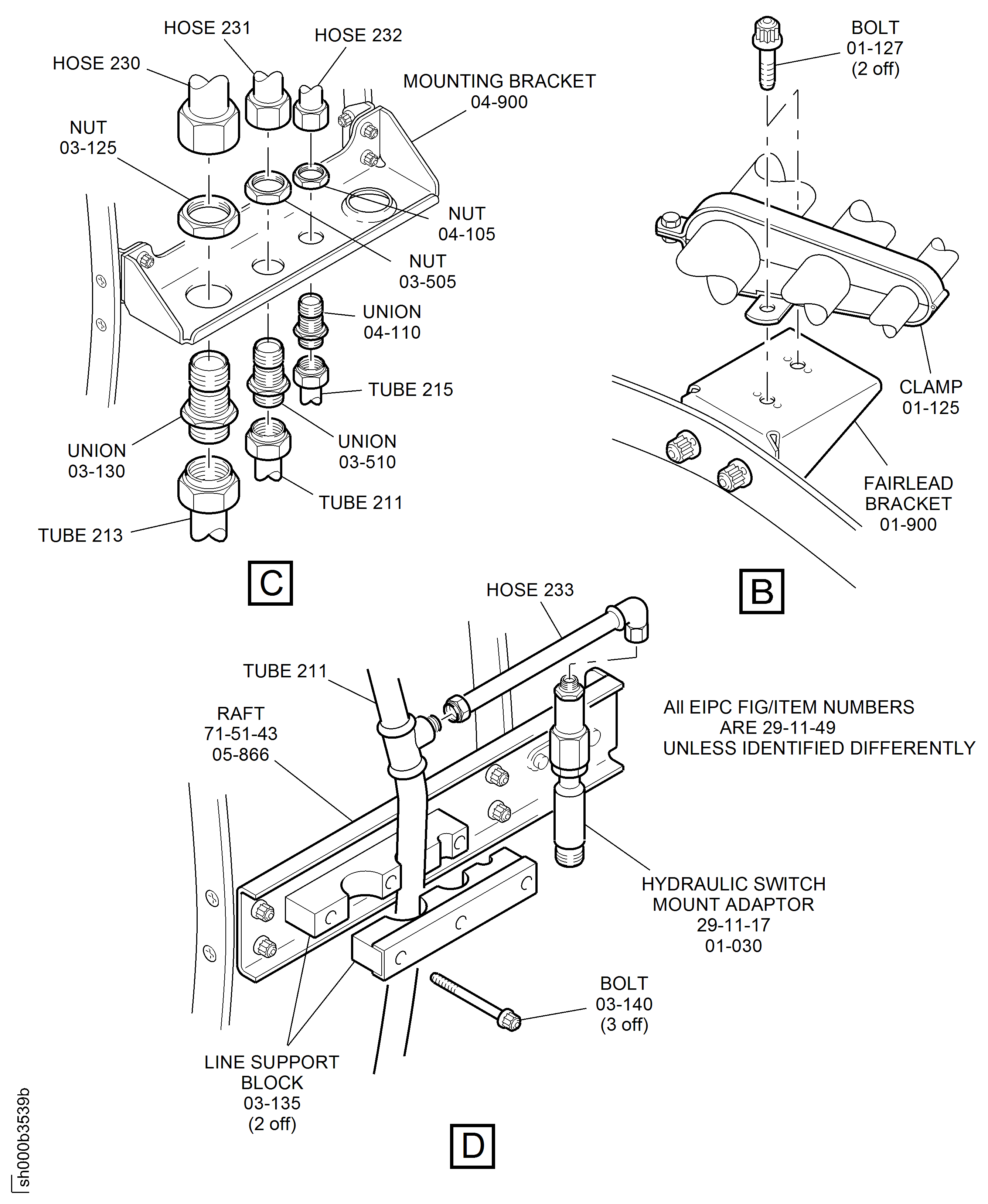

Install the three unions HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 03-130 , HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES 03-510 and HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES 04-110) to the mounting bracket HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-900) with the three nuts HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 03-125), HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 03-505) and HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-105). Refer to Figure. the detail on C.

Hold the union and torque the nut HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 03-125) to 960 to 1200 * lbf.in (108.48 to 135.6 Nm).

Hold the union and torque the nut HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 03-505) to 500 to 600 * lbf.in (56.5 to 67.8 Nm).

Hold the union and torque the nut HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-105) to 120 to 150 * lbf.in (13.56 to 16.95 Nm).

Install the unions to the mounting bracket.

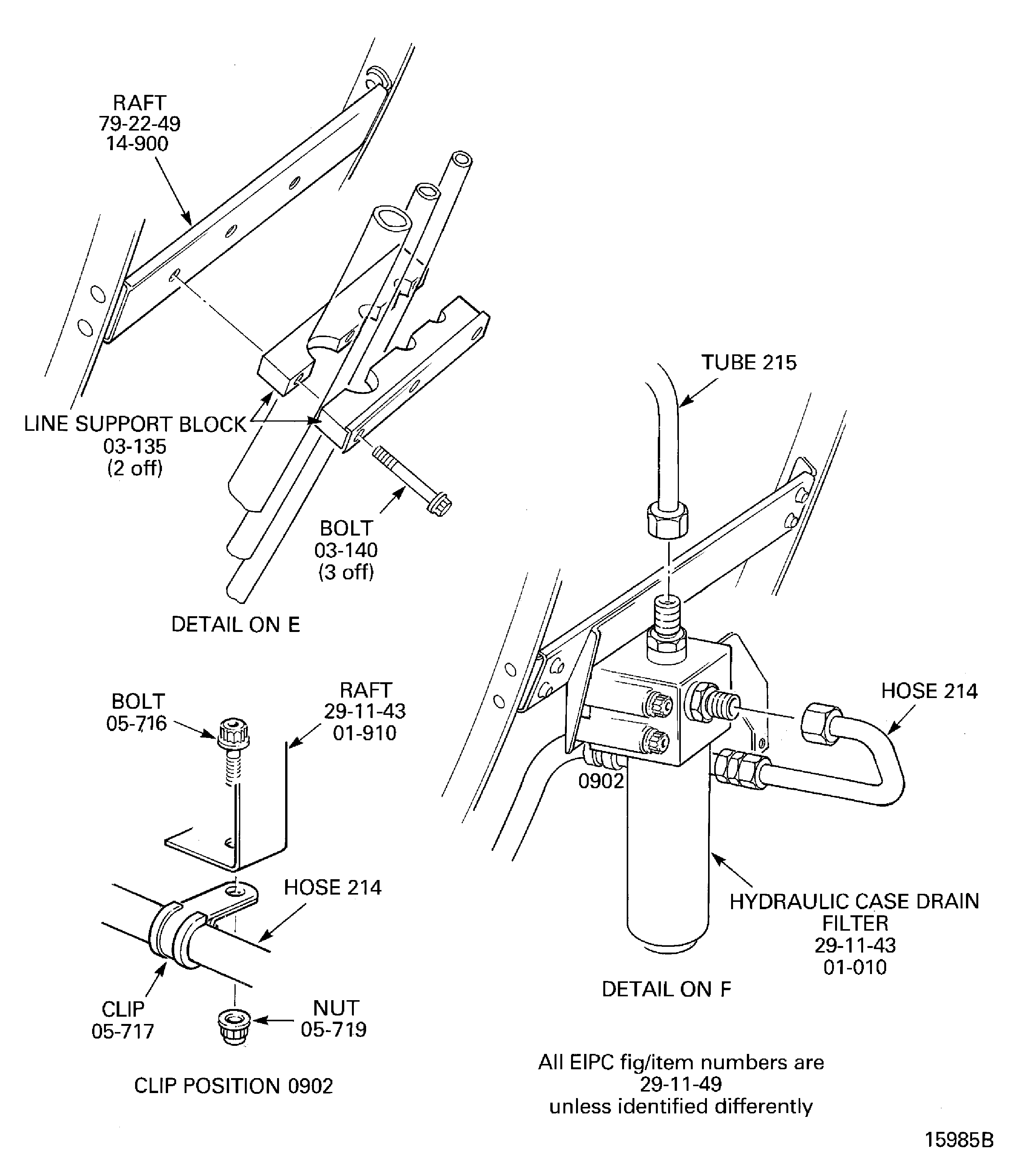

Lubricate the bolt and nut threads at the clip position 0902 with CoMat 10-077 APPROVED ENGINE OILS. Attach the hose 214 to the raft POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 05-710) with the bolt and the nut.

Install the hose 214.

Connect the tube 215 to the hydraulic case drain filter union and the union HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-110). Refer to the details on C and F.

Connect the tube 211 to the union HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 03-510). Refer to the detail on C.

Connect the tube 213 to the union HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 03-130).

Lubricate the six bolts HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 03-140) with CoMat 10-077 APPROVED ENGINE OILS.

Install the four line support blocks HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 03-135) to the rafts ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 05-866) and OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 14-900) and the tubes 213, 211 and 215, with the six bolts HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 03-140). Refer to the details on D and E.

Torque the tube 215 tube nuts at the hydraulic case drain filter union and the union HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-110) to 215 to 245 * lbf.in (24.30 to 27.69 Nm).

Torque the tube 211 nut at the union HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 03-510) to 855 to 945 * lbf.in (96.62 to 106.79 Nm).

Torque the tube 213 tube nut at the union HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 03-130) to 1520 to 1680 * lbf.in (171.76 to 189.84 Nm).

Torque the six bolts HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 03-140) to 85 to 105 lbf.in (10 to 12 Nm).

Install the tubes 213, 211, 215 and the flexible hoses 212 and 210.

Pre SBN 29-0001: Connect the hose 233 to the tube 211 and to the union on the hydraulic switch mount adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030). Torque the hose nuts to 135 to 145 * lbf.in (15.26 to 16.39 Nm).

SBN 29-0001: Connect the hose 233 to the tube 211 and to the elbow connector on the hydraulic switch mount adapter HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17, 01-030). Torque the hose nuts to 135 to 145 * lbf.in (15.26 to 16.39 Nm).

Install the hose 233. Refer to the detail on D.

Lubricate the two bolts HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-127) with CoMat 10-077 APPROVED ENGINE OILS.

Install the clamp HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-125) on the hoses 230, 231 and 232 with the clamp bolt and nut, tighten the nut. Refer to the detail on B.

Attach the hose assemblies and the clamp HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-125) to the fairlead bracket HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-900) with the two bolts HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-127).

Install the clamp HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-540) on the hoses 231 and 232.

Attach the hose 230 nut to the coupling HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-102). Torque the hose nut to 1520 to 1680 * lbf.in (171.76 to 189.84 Nm). Refer to the detail on A.

Attach the hose 231 nut to the self sealing coupling HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-502). Torque the hose nut to 855 to 945 * lbf.in (96.62 to 106.79 Nm).

Connect the hose 230 to the union HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 03-130). Torque the hose nut to 1520 to 1680 * lbf.in (171.76 to 189.84 Nm). Refer to the detail on C.

Connect the hose 231 to the union HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 03-510). Torque the hose nut to 855 to 945 * lbf.in (96.62 to 106.79 Nm).

Connect the hose 232 to the union HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 04-110). Torque the hose nut to 215 to 245 * lbf.in (24.30 to 27.69 Nm).

Torque the two bolts HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-127) and the clamp nut, installed in Step to 85 to 105 lbf.in (10 to 12 Nm).

Torque the captive screw on the clamp HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-540) to 85 to 105 lbf.in (10 to 12 Nm).

Install the hoses 230, 231 and 232.

SUBTASK 72-00-32-420-121 Install the Hydraulic Tubes

NOTE

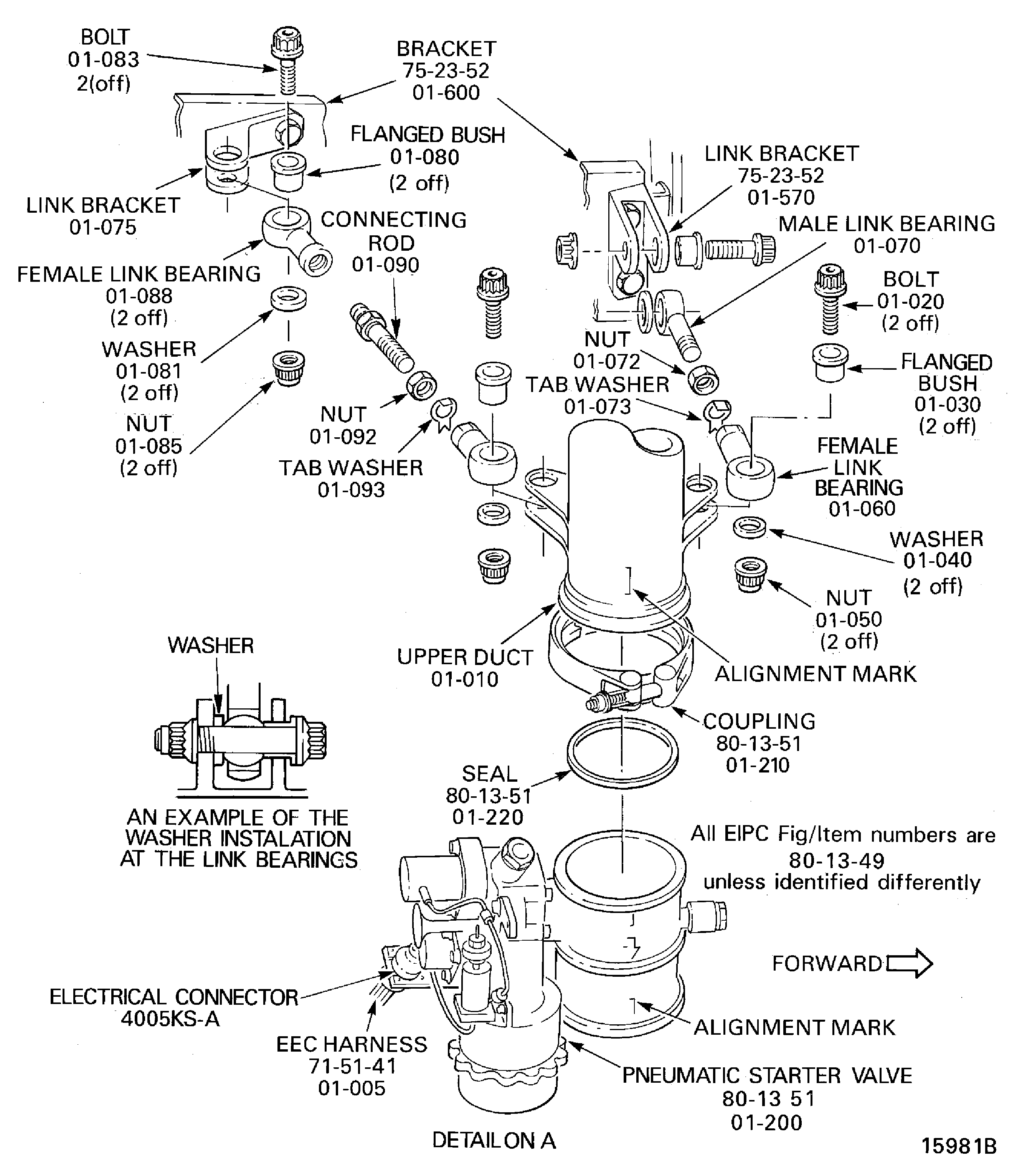

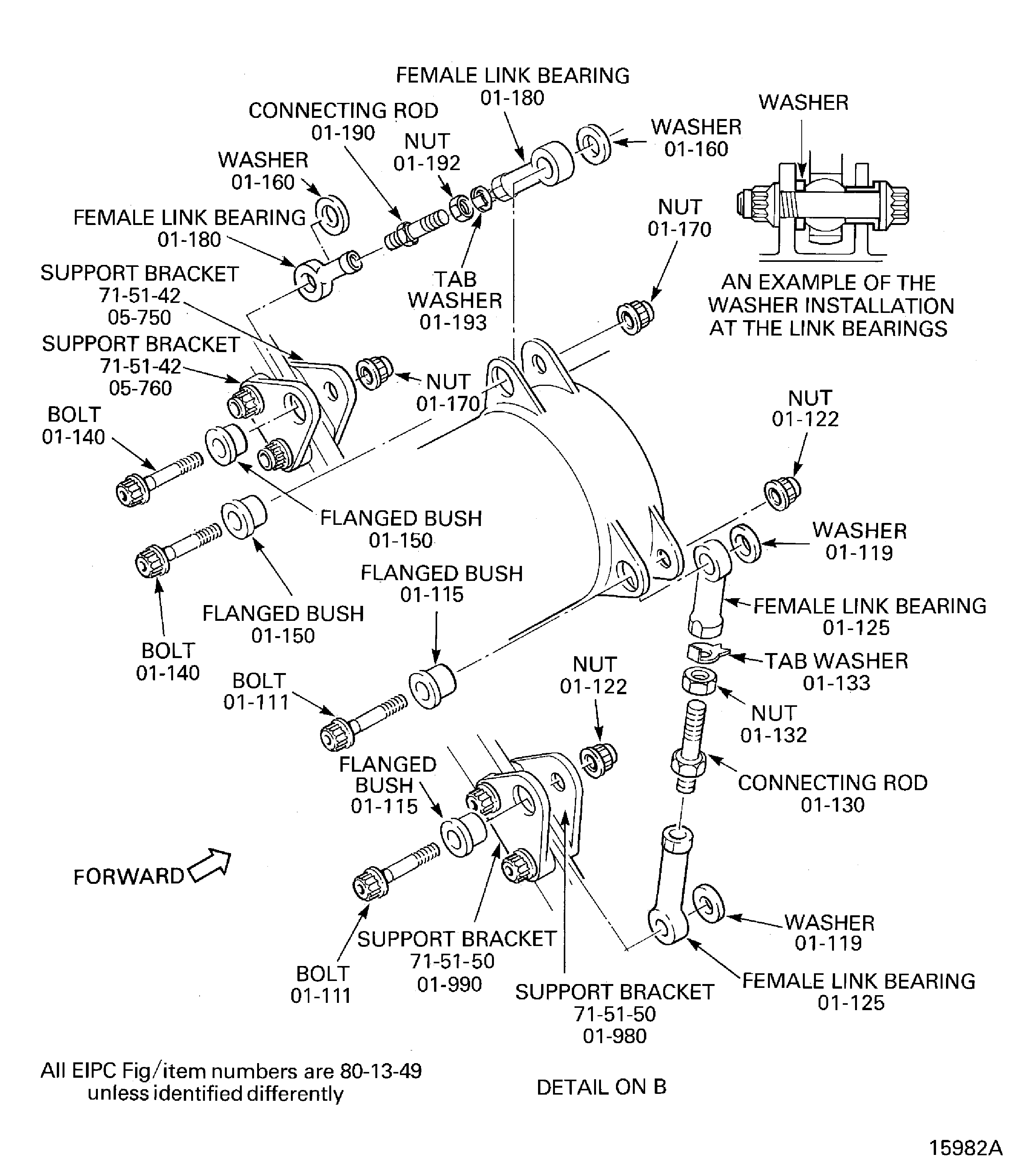

The pre-assembly dimension from the center of the two bearing links is 4.65 in. (118 Nm).Assemble the nut STARTING-STARTER DUCT (80-13-49, 01-192), a new STARTING-STARTER DUCT (80-13-49, 01-193) tab washer 1 off, the two female link bearings STARTING-STARTER DUCT (80-13-49, 01-180) and the connecting rod STARTING-STARTER DUCT (80-13-49, 01-190) together. Install the assembly to the support brackets ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-750 and 05-760) with the bolt, the flanged bush, the washer and the nut STARTING-STARTER DUCT (80-13-49, 01-140), STARTING-STARTER DUCT (80-13-49, 01-150), STARTING-STARTER DUCT (80-13-49, 01-160) and STARTING-STARTER DUCT (80-13-49, 01-170). Refer to the detail on B. Make sure the washer is installed correctly, refer to the example given in Figure.

Assemble the nut STARTING-STARTER DUCT (80-13-49, 01-132), a new STARTING-STARTER DUCT (80-13-49, 01-133) tab washer 1 off, the two female link bearings and the connecting rod STARTING-STARTER DUCT (80-13-49, 01-125 and 01-130) together. Install the female link bearing/connecting rod assembly to the support brackets BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-980 and 01-990). Do the procedure as given in step (1). Make sure the washer is installed correctly.

Assemble the male link bearing, the nut STARTING-STARTER DUCT (80-13-49, 01-070 and STARTING-STARTER DUCT 01-072) and a new STARTING-STARTER DUCT (80-13-49,01-073) tab washer1 off to the female link bearing STARTING-STARTER DUCT (80-13-49, 01-060). Install the assembly to the link bracket AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-570). Do the procedure as given in step (1). Refer to the detail on A.

Assemble the nut STARTING-STARTER DUCT (80-13-49, 01-092), a new STARTING-STARTER DUCT (80-13-49, 01-093) tab washer1 off, the two female link bearings STARTING-STARTER DUCT (80-13-49, 01-088) and the connecting rod STARTING-STARTER DUCT (80-13-49, 01-090) together. Install the assembly to the link bracket STARTING-STARTER DUCT (80-13-49, 01-075). Do the procedure as given in Step

Torque the four nuts STARTING-STARTER DUCT (80-13-49, 01-050), STARTING-STARTER DUCT (80-13-49, 01-085), STARTING-STARTER DUCT (80-13-49, 01-122) and STARTING-STARTER DUCT (80-13-49, 01-170) to 85 to 105 lbf.in (10 to 12 Nm).

Install the link bearings and the connecting rods.

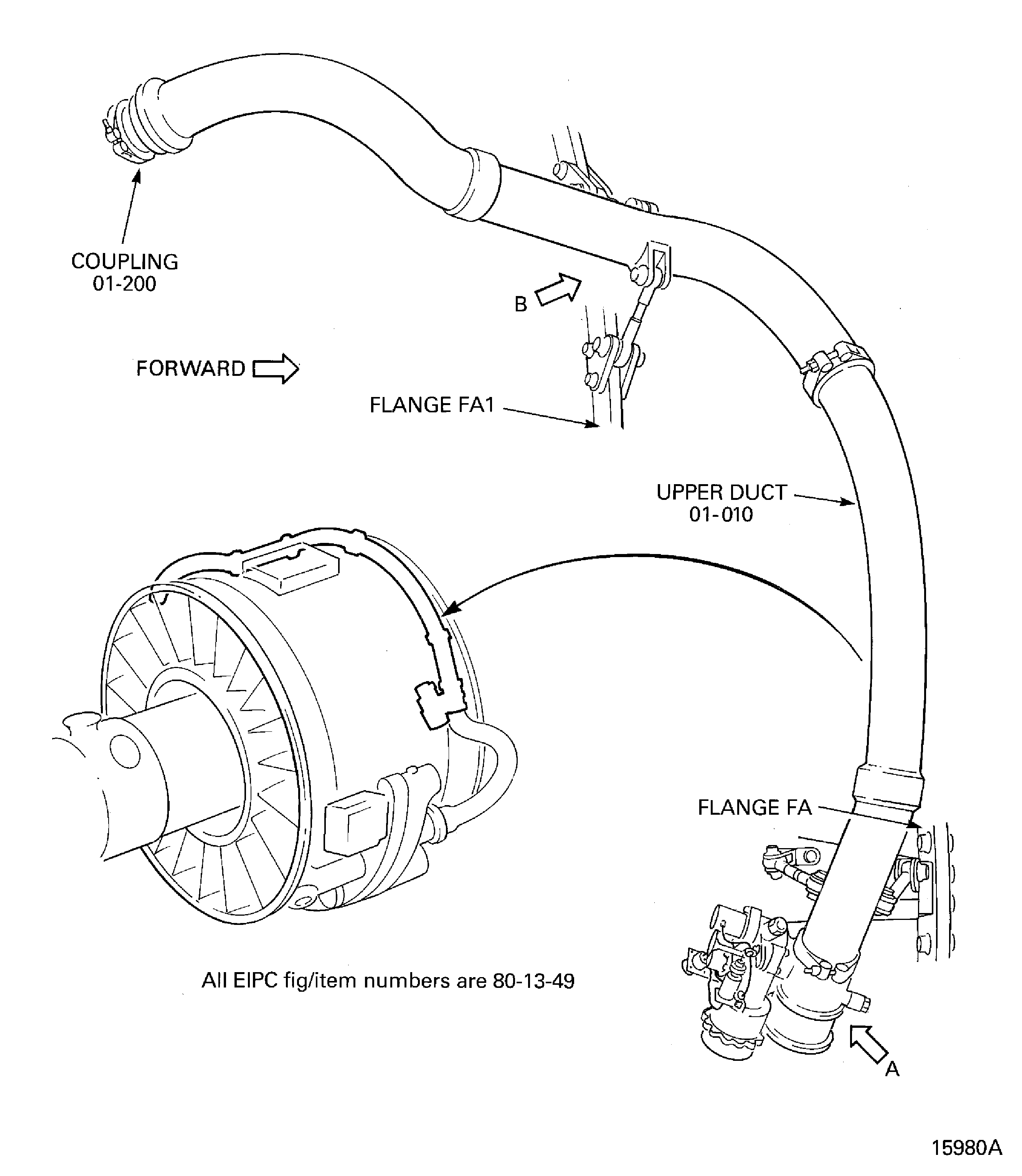

Attach the upper duct STARTING-STARTER DUCT (80-13-49, 01-010) to the two female link bearings STARTING-STARTER DUCT (80-13-49, 01-125) and STARTING-STARTER DUCT (80-13-49, 01-180) with the two bolts, the two flanged bushes, the two washers and the two nuts STARTING-STARTER DUCT (80-13-49, 01-111), STARTING-STARTER DUCT (80-13-49, 01-115), STARTING-STARTER DUCT (80-13-49, 01-119), STARTING-STARTER DUCT (80-13-49, 01-122), STARTING-STARTER DUCT (80-13-49, 01-140), STARTING-STARTER DUCT (80-13-49, 01-150), STARTING-STARTER DUCT (80-13-49, 01-160) and STARTING-STARTER DUCT (80-13-49, 01-170). Refer to the detail on B. Make sure the washers are installed correctly, refer to the example given in Figure.

Attach the upper duct to the female link bearing STARTING-STARTER DUCT (80-13-49, 01-060) with the bolt, the flanged bush, the washer and the nut STARTING-STARTER DUCT (80-13-49, 01-020), STARTING-STARTER DUCT (80-13-49, 01-030), STARTING-STARTER DUCT (80-13-49, 01-040) and STARTING-STARTER DUCT (80-13-49, 01-050). Lubricate the bolt with CoMat 10-077 APPROVED ENGINE OILS. Make sure the washer is installed correctly, refer to the detail on A and the example given in Figure.

Attach the upper duct to the female link bearing STARTING-STARTER DUCT (80-13-49, 01-088) with the bolt, the flanged bush, the washer and the nut STARTING-STARTER DUCT (80-13-49, 01-083), STARTING-STARTER DUCT (80-13-49, 01-080), STARTING-STARTER DUCT (80-13-49, 01-081) and STARTING-STARTER DUCT (80-13-49, 01-085). Make sure the washer is installed correctly.

Torque the four nuts STARTING-STARTER DUCT (80-13-49, 01-072), STARTING-STARTER DUCT (80-13-49, 01-092), STARTING-STARTER DUCT (80-13-49, 01-132) and STARTING-STARTER DUCT (80-13-49, 01-192) to 170 * lbf.in (19.20 Nm). Try to put CoMat 02-126 LOCKWIRE into the safety hole in the female link bearings. The safety holes must be blocked with the connecting rod threads, the safety wire must not go through the safety holes.

Torque the four nuts STARTING-STARTER DUCT (80-13-49, 01-050), STARTING-STARTER DUCT (80-13-49, 01-085), STARTING-STARTER DUCT (80-13-49, 01-122) and STARTING-STARTER DUCT (80-13-49, 01-170) to 85 to 105 lbf.in (10 to 12 Nm).

Install the upper duct.

Install the seal STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-220) in the upper duct groove. Install the pneumatic starter valve to the upper duct. Make sure the alignment marks are opposite each other,align the flow direction arrow on the valve with the yellow paint stripe on the upper duct.

Install the coupling STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-210) around the upper duct/starter valve joint. Make sure the seal in the joint is installed correctly before you tighten the coupling.

NOTE

Refer to TASK 72-00-32-420-004 for the clip position 0529 (during the EEC harness installation).

The remaining procedure for the pneumatic starter ducts is given in the TASK 72-00-60-420-002 Install the tubes and harnesses to the external gearbox.

Connect the electrical connector 4005KS-A to the starter valve. Torque the connector to 21 * lbf.in (2.4 Nm). Remove the CoMat 06-086 TIES and install the datum clip position 0529.

Install the pnuematic starter valve STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-200). Refer to the detail on A.

SUBTASK 72-00-32-420-122 Install the Pneumatic Starter Duct

Install the external gearbox module as given in TASK 72-00-60-420-001-001.

SUBTASK 72-00-32-420-123 Install the External Gearbox Module

Install the tubes and harnesses to the external gearbox module. Refer to TASK 72-00-60-420-002 and TASK 72-00-60-420-003.

SUBTASK 72-00-32-420-124 Install the Tubes and Harnesses to the External Gearbox Module

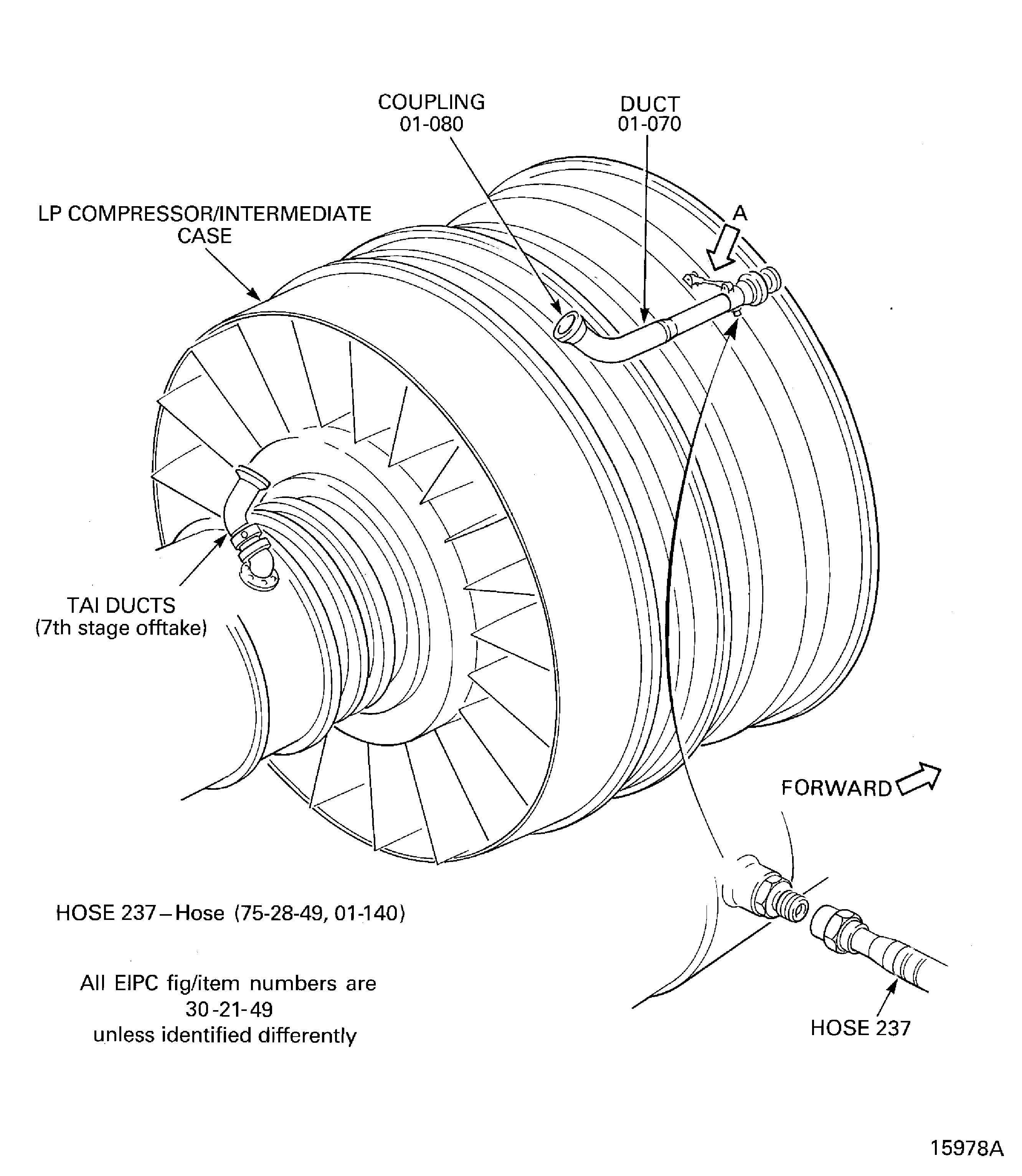

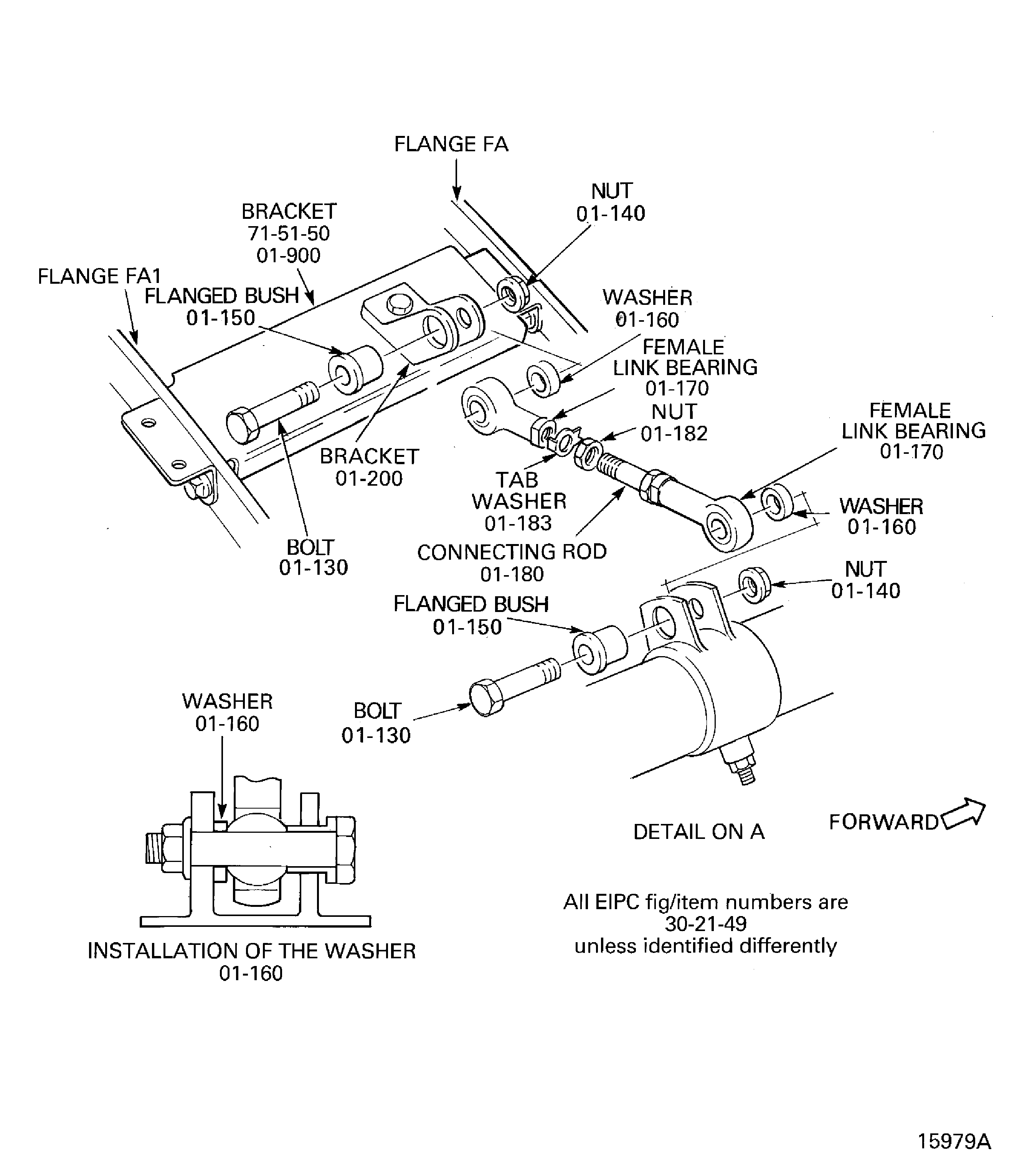

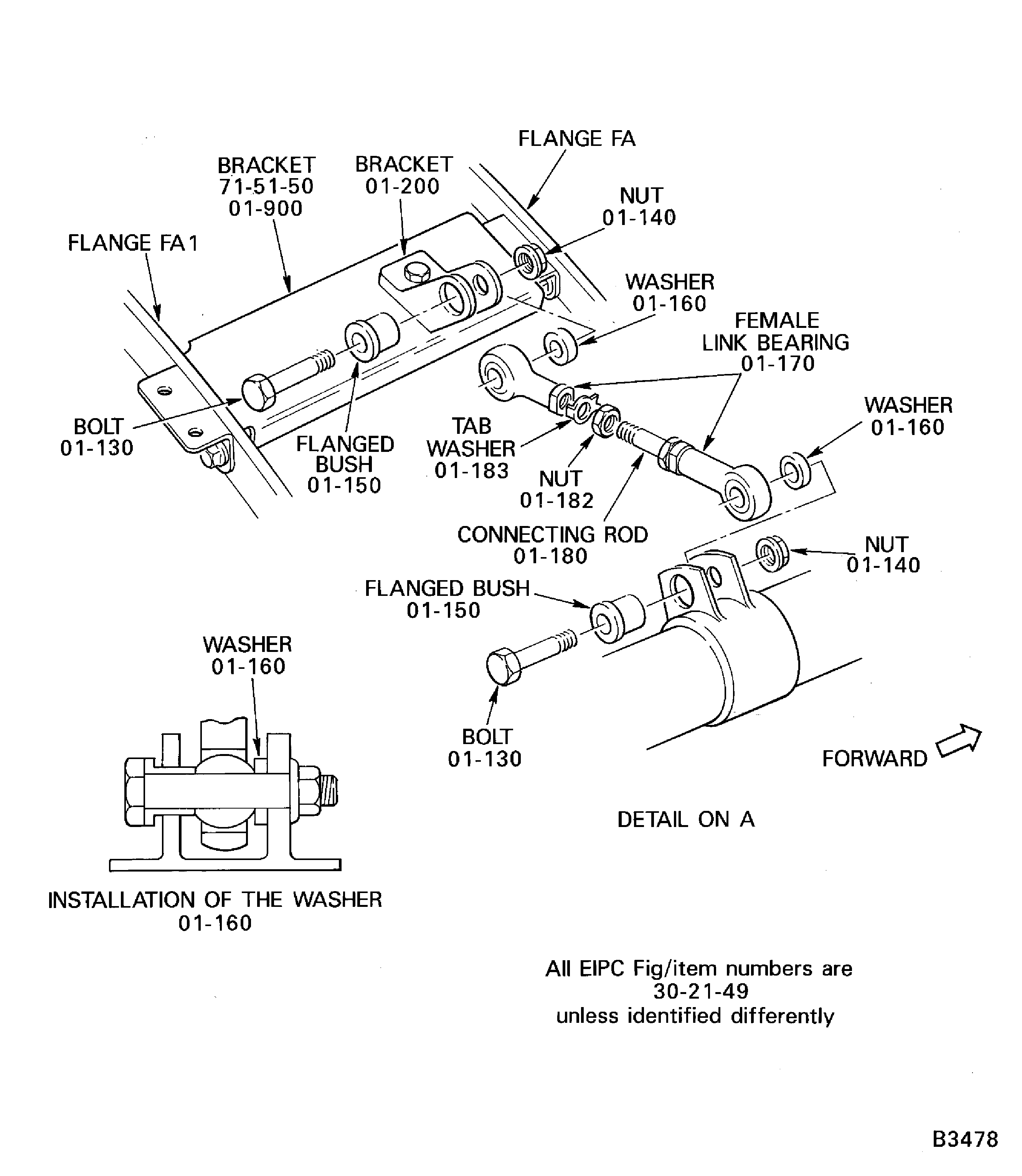

Assemble the nut ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-182), a new ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-183) tab washer1 off and the two female link bearings ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-170) to the connecting rod ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-180).

Install the link bearing/connecting rod assembly to the bracket ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-200) with the bolt, the flanged bush, the washer and the nut ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-130), ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-150), ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-160) and ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-140). Make sure the washer is installed correctly, refer to Figure or Figure, the detail on A.

Torque the nut ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-140) to 85 to 105 lbf.in (10 to 12 Nm).

Install the female link bearings and the connecting rod.

Attach the coupling ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-080) to the duct ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-070). Tighten the coupling.

Install the duct to the female link bearing ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-170) with the bolt, the flanged bush, the washer and the nut ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-130), ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-150), ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-160) and ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-140). Make sure the washer is installed correctly, refer to Figure or Figure, the detail on A.

Torque the nut ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-140) to 85 to 105 lbf.in (10 to 12 Nm).

NOTE

It is not necessary to lubricate the hose 237 nut.Pre SBN 71-0069 and Pre SBE 71-0070: Connect the hose 237 to the duct. Torque the hose nut to 175 to 195 * lbf.in (19.78 to 22.0 Nm).

Install the duct.

Install the TAI duct and the air intake cowl. Refer to CMM-AIC-V2500-1IA and TASK 71-11-11-420-001.

Torque the nut ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-182) to 170 * lbf.in (19.20 Nm). Try to put CoMat 02-126 LOCKWIRE into the safety hole in the female link bearings. The safety holes must be blocked with the connecting rod thread, the safety wire must not go through the safety holes.

NOTE

The procedure for the remaining TAI ducts (7th stage offtake) is given in TASK 72-00-40-420-005.Safety the nut with the tab washer.

Install the remaining TAI duct assembly and the air intake cowl.

Refer to Figure.

Install the inner and outer pipe insulation halves ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-210) and ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-215) to the duct assembly ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-070). Attach the insulation to the duct assembly with the installed clamps.

NOTE

Wrapping or crisscrossing the lockwire around the duct is not necessary.Apply CoMat 02-126 LOCKWIRE between the lacing tags on the inner and outer pipe insulation halves ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-210) and ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-215). Refer to the SPM TASK 70-42-05-400-501.

Install the inner and outer venturi duct insulation halves ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-220) and ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-225) to the venturi duct. Attach the insulation halves to the venturi duct assembly with the installed clamps.

NOTE

Wrapping or crisscrossing the lockwire around the duct is not necessary.Apply CoMat 02-126 LOCKWIRE between the lacing tags on the inner and outer venturi duct insulation halves ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-220) and ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-225). Refer to the SPM TASK 70-42-05-400-501.

Install the TAI insulation.

SUBTASK 72-00-32-420-125 Install the Air Intake Cowl, the Thermal Anti-Ice (TAI) Duct and the Thermal Anti-Ice (TAI) Insulation

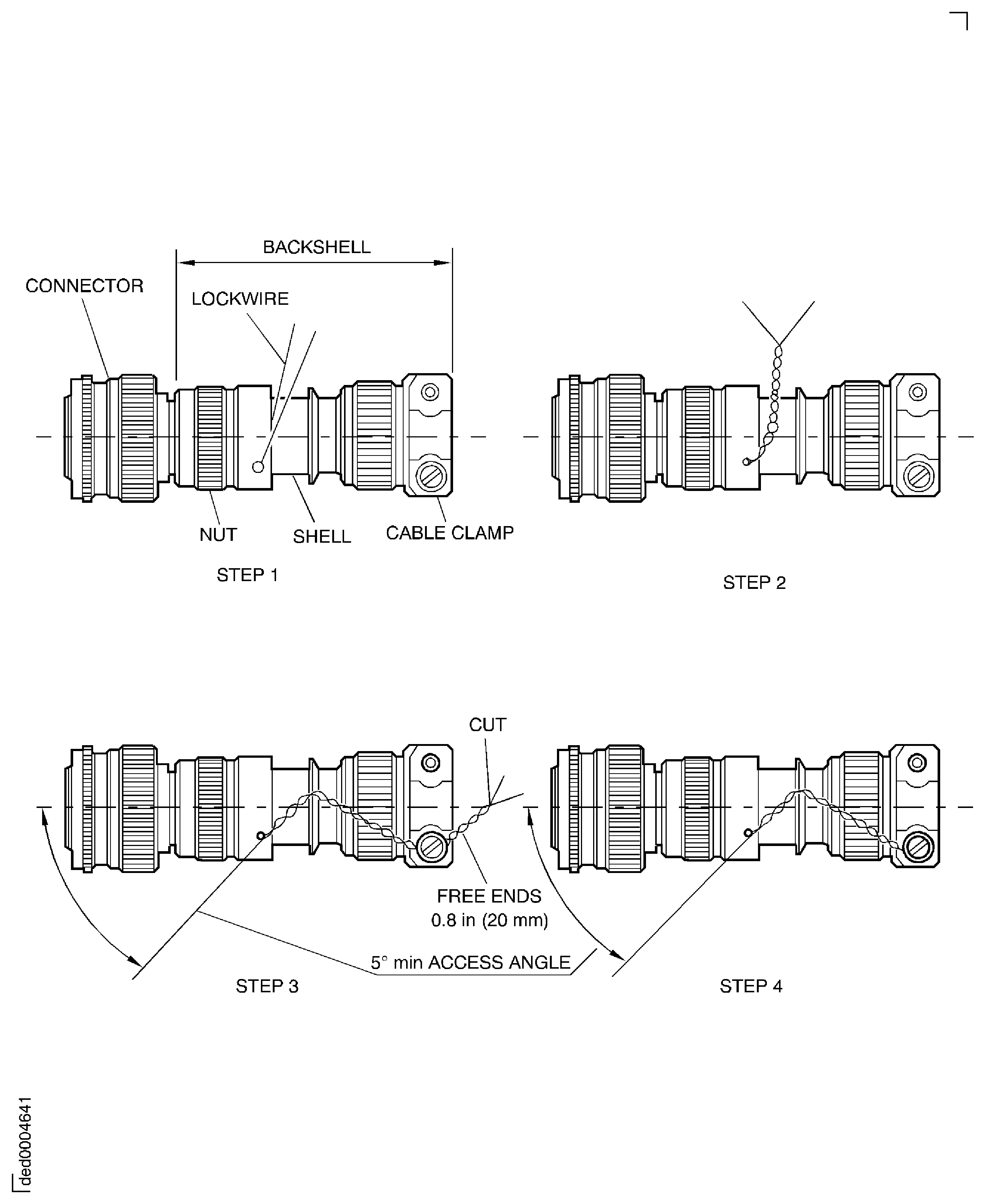

Refer to Figure.

Make sure that all the applicable backshells and cable clamps are safetied with CoMat 02-126 LOCKWIRE. Refer to the SPM TASK 70-42-05-400-501.

SUBTASK 72-00-32-210-079 Visually Inspect the Electrical Backshells and Cable Clamps

NOTE

Use this procedure to safety the EEC harness backshells and cable clamps with safety cable.Refer to Figure.

Make sure that all the EEC harness backshells and cable clamps are safetied. Safety with CoMat 02-274 SAFETY CABLE KIT or with CoMat 02-275 SAFETY CABLE KIT. Refer to the SPM TASK 70-42-08-400-501.

SUBTASK 72-00-32-210-080Visually Inspect the EEC Harness (01-005) Electrical Backshells and Cable Clamps (SBE 70-0813)

SBE 70-0813: Announcement of introduction of safety cable as a preferred method to lockwire.

Figure: Pre SBN 71-0069 and Pre SBE 71-0070: Install the EEC Cooling Ducts/Flexible Hoses (Inlet)

Pre SBN 71-0069 and Pre SBE 71-0070: Install the EEC Cooling Ducts/Flexible Hoses (Inlet)

Figure: Pre SBE 73-0010, Pre SBN 71-0069 and Pre SBE 71-0070: Install the EEC Cooling Ducts/Flexible Hoses (Outlet)

Sheet 1

Figure: SBE 73-0010, Pre SBN 71-0069 and Pre SBE 71-0070: Install the EEC Cooling Ducts/Flexible Hoses (Outlet)

Sheet 2

Figure: Pre SBN 71-0069 and Pre SBE 71-0070: Install the EEC Cooling Ducts/Flexible Hoses (Outlet)

Sheet 3

Figure: Pre SBN 71-0069 and Pre SBE 71-0070: Install the EEC Cooling Ducts/Flexible Hoses (Outlet)

Sheet 4

Figure: Pre SBN 29-0001: Install the Hhydraulic Tubes

Sheet 1

Figure: SBN 29-0001: Install the Hydraulic Tubes

Sheet 2

Figure: Pre SBN 29-0001: Install the Hydraulic Tubes

Sheet 3

Figure: SBN 29-0001: Install the Hydraulic Tubes

Sheet 4

Figure: Install the Hydraulic Tubes

Sheet 5

Figure: Install the Starter Duct

Sheet 1

Figure: Install the Starter Duct

Sheet 2

Figure: Install the Starter Duct

Sheet 3

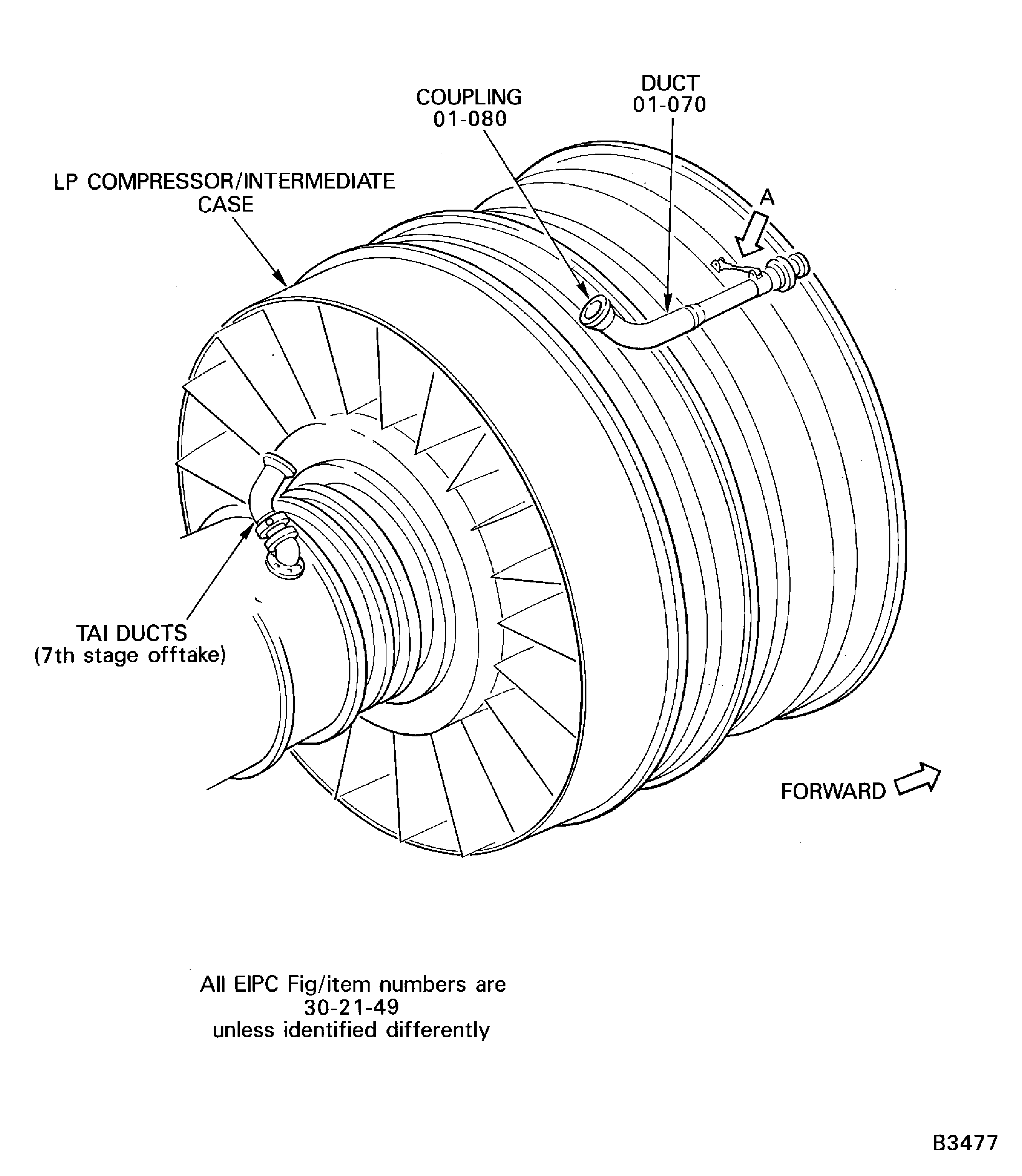

Figure: Pre SBN 71-0069 and SBE 71-0070: Install the Thermal Anti-Ice (TAI) Duct

Sheet 1

Figure: Pre SBN 71-0069 and SBE 71-0070: Install the Thermal Anti-Ice (TAI) Duct

Sheet 2

Figure: SBN 71-0069 and SBE 71-0070: Install the Thermal Anti-Ice (TAI) Duct

Sheet 3

Figure: SBN 71-0069 and SBE 71-0070: Install the Thermal Anti-Ice (TAI) Duct

Sheet 4

Figure: Install Thermal Anti-Ice (TAI) Insulation

Sheet 5

Figure: Visually Inspect the Backshells and Cable Clamps

Visually Inspect the Backshells and Cable Clamps