Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-40-00-430-006-A00 HP System Module - Install The HPT Assembly (Vertical) - Method 2, Assembly-006

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to SPM TASK 70-41-00-400-501, SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

Special torque data and assembly tolerances are included in this procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to SPM TASK 70-44-01-400-501.

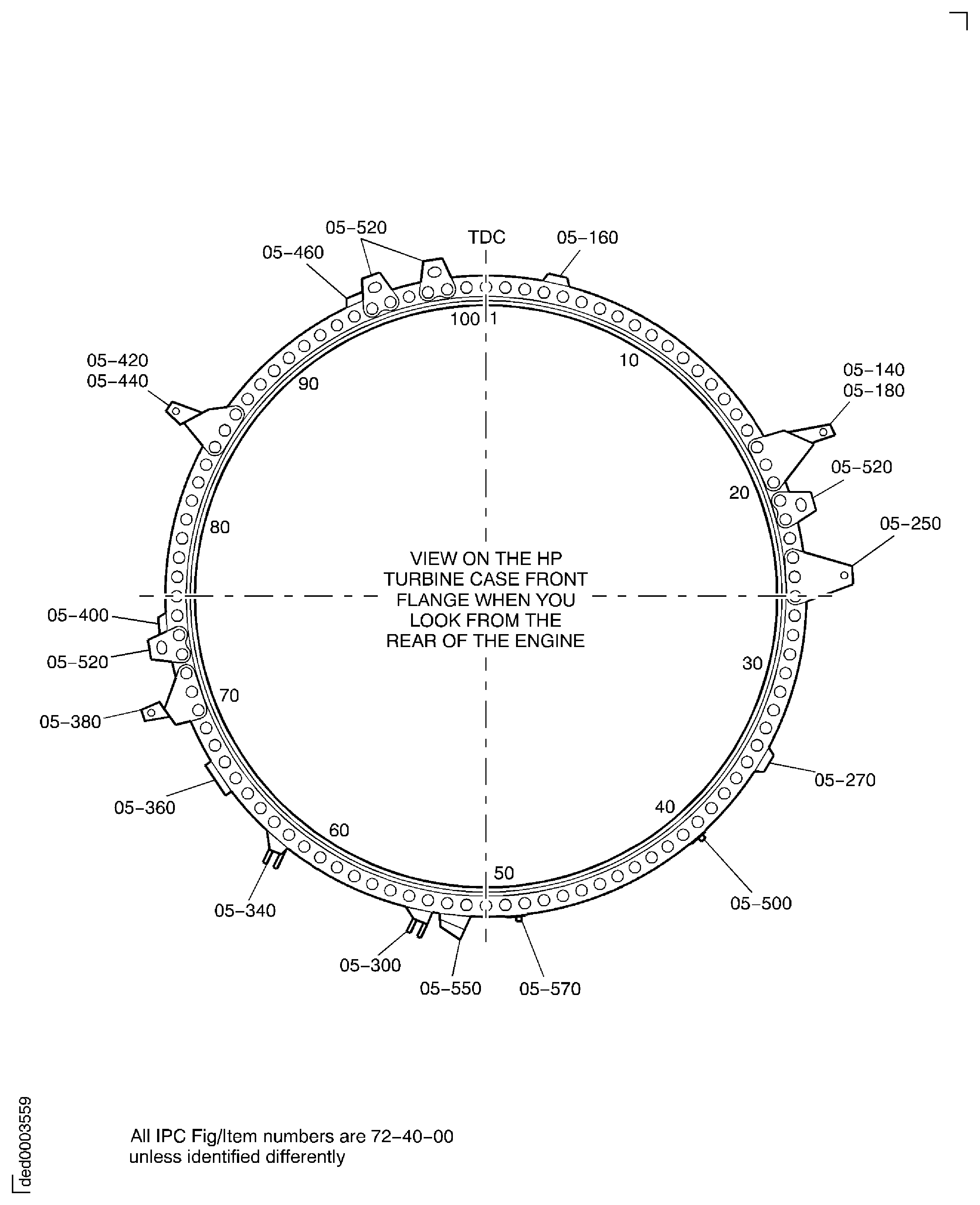

The number for each radial location must be identified in a clockwise direction. Use CoMat 06-153 FELT TIP MARKER, RAPID DRYING or CoMat 06-158 MARKER, EXTRA FINE POINT(BLACK). These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure. Refer to SPM TASK 70-09-00-400-501.

Transportation covers/blanks must be removed immediately before the installation of the components.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1F10015 Hydraulic wrench | 0AM53 | IAE 1F10015 | 1 | (alternative to IAE 1F10016) |

| IAE 1F10016 Mechanical wrench | 0AM53 | IAE 1F10016 | 1 | (alternative to IAE 1F10015) |

| IAE 1F10026 Hydraulic hand pump | 0AM53 | IAE 1F10026 | 1 | |

| IAE 1F10052 Two cables sling | 0AM53 | IAE 1F10052 | 1 | |

| IAE 1P16011 Wrench | 0AM53 | IAE 1P16011 | 1 | |

| IAE 1P16040 Heater | 0AM53 | IAE 1P16040 | 1 | |

| IAE 1P16046 Removal/Installation fixture | 0AM53 | IAE 1P16046 | 1 | |

| IAE 1P16050 Puller | 0AM53 | IAE 1P16050 | 1 | |

| IAE 1P16056 Hand wrench | 0AM53 | IAE 1P16056 | 1 | |

| IAE 1P16058 Removal/installation jaws assembly | 0AM53 | IAE 1P16058 | 1 | |

| IAE 1P16060 Protective cover | 0AM53 | IAE 1P16060 | 1 | (alternative to IAE 1P17758) |

| IAE 1P16123 Drift | 0AM53 | IAE 1P16123 | 1 | (superseded by IAE 1P16470) |

| IAE 1P16186 Gage bar | 0AM53 | IAE 1P16186 | 1 | (alternative to IAE 1P16265) |

| IAE 1P16225 Adapter | 0AM53 | IAE 1P16225 | 1 | |

| IAE 1P16265 Checking fixture | 0AM53 | IAE 1P16265 | 1 | (alternative to IAE 1P16186) |

| IAE 1P16272 Adapter | 0AM53 | IAE 1P16272 | 1 | |

| IAE 1P16470 Drift | 0AM53 | IAE 1P16470 | 1 | |

| IAE 1P16543 Removal/Installation fixture | 0AM53 | IAE 1P16543 | 1 | |

| IAE 1P17509 Protective cover | 0AM53 | IAE 1P17509 | 1 | |

| IAE 1P17515 Gage | 0AM53 | IAE 1P17515 | 1 | |

| IAE 1P17758 Protective cover | 0AM53 | IAE 1P17758 | 1 | (alternative to IAE 1P16060) |

| IAE 6F10027 Heater control unit | 0AM53 | IAE 6F10027 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 06-153 FELT TIP MARKER, RAPID DRYING | LOCAL | CoMat 06-153 | ||

| CoMat 06-153X FELT TIP MARKER, RAPID DRYING, FINE POINT, BLACK, TRACE ELEMENT CERTIFIED | 86874 | CoMat 06-153X | ||

| CoMat 06-158 MARKER, EXTRA FINE POINT(BLACK) | LOCAL | CoMat 06-158 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 | ||

| CoMat 10-129 ANTI-SEIZE PASTE | 34568 | CoMat 10-129 |

Spares

NONESafety Requirements

NONEProcedure

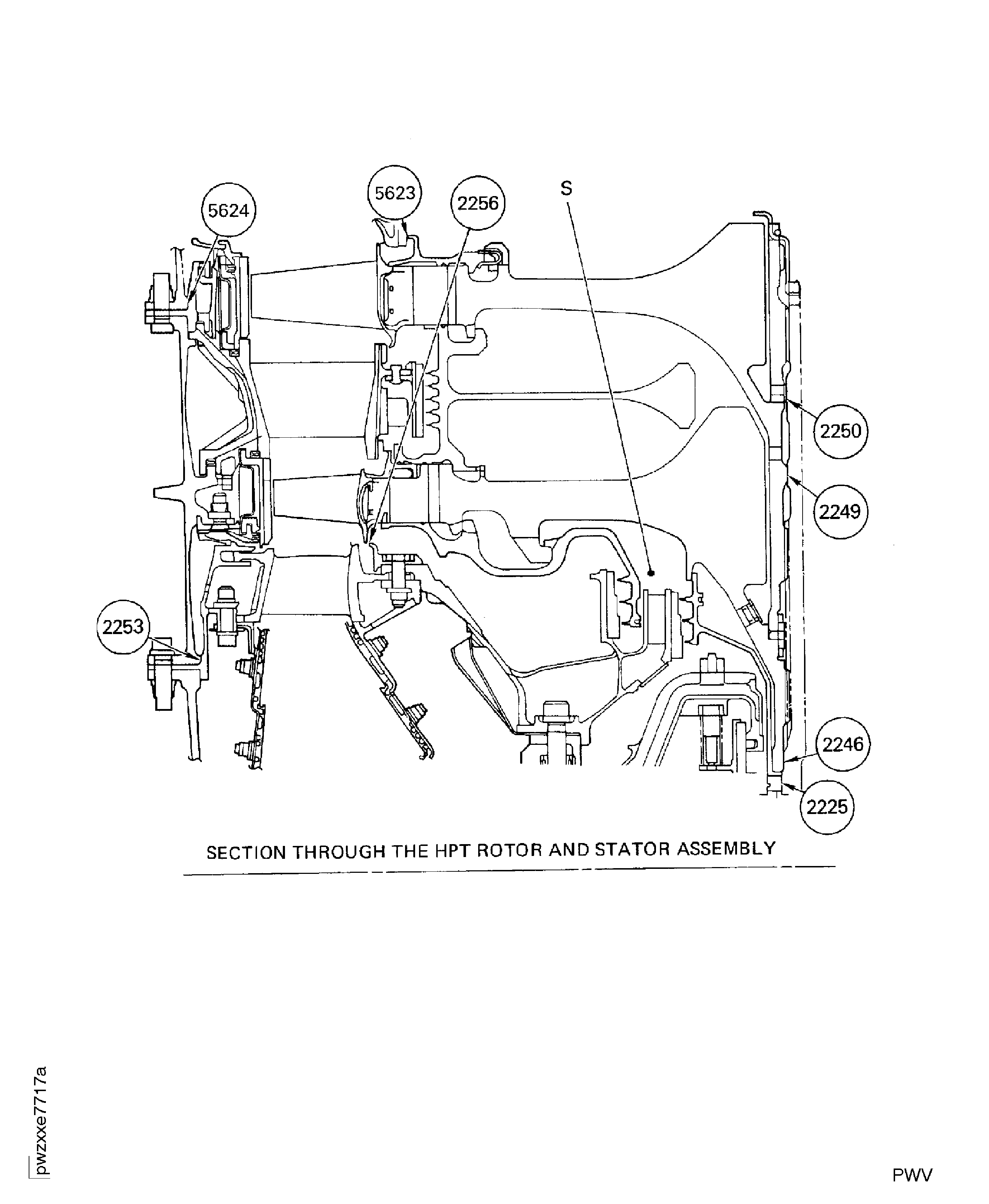

Refer to Figure.

Reference clearance at location 2225. If required, use the data written as a note in TASK 72-41-13-200-001-A00 (INSPECTION-001), TASK 72-41-13-200-001-B00 (INSPECTION-001) and TASK 72-40-00-200-005 (INSPECTION-005).

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2225

HPC Drive Turbine Shaft ENGINE-HP COMPRESSOR SHAFT (72-41-13, 01-850), Journal Diameter

No. 4 Bearing Spacer ENGINE-ATTACH PARTS & FITTINGS-HP SYSTEM (72-40-00, 03-003 Thru 03-035), Bore

HPC Drive Turbine Shaft

5.107

Clear

Journal Diameter Spacer Bore

5.108

0.003

5.111

0.006

5.113

Clear

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2225

HPC Drive Turbine Shaft ENGINE-HP COMPRESSOR SHAFT (72-41-13, 01-850), Journal Diameter

No. 4 Bearing Spacer ENGINE-ATTACH PARTS & FITTINGS-HP SYSTEM (72-40-00, 03-003 Thru 03-035), Bore

HPC Turbine Drive Shaft Journal Diameter

129.718

Clear

129.743

0.077

Spacer Bore

129.819

0.152

129.870

Clear

SUBTASK 72-40-00-220-068 Reference Fits and Clearances of the HP Turbine Rotor and Stator Assembly at Location 2225

Refer to Figure.

Reference interference at location 2246. If required, use the data written as a note in TASK 72-45-11-200-001-A00 (INSPECTION-001), TASK 72-45-11-200-001-B00 (INSPECTION-001), TASK 72-45-11-200-001-C00 (INSPECTION-001), TASK 72-41-13-200-001-A00 (INSPECTION-001) and TASK 72-41-13-200-001-B00 (INSPECTION-001).

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2246

Front Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Bore

HPC Drive Turbine Shaft ENGINE-HP COMPRESSOR SHAFT (72-41-13, 01-850), Location Diameter

Hub Bore

5.102

Intf

5.101

0.005

Shaft Location Diameter

5.108

0.007

5.107

Intf

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2246

Front Turbine Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010), Bore

HPC Drive Turbine Shaft ENGINE-HP COMPRESSOR SHAFT (72-41-13, 01-850), Location Diameter

Hub Bore

129.590

Intf

129.565

0.127

Shaft Location Diameter

129.743

0.177

129.718

Intf

SUBTASK 72-40-00-220-069 Reference Fits and Clearances of the HP Turbine Rotor and Stator Assembly at Location 2246

Refer to Figure.

Reference interference at location 2249. If required, use the data written as a note in TASK 72-41-13-200-001-A00 (INSPECTION-001), TASK 72-41-13-200-001-B00 (INSPECTION-001) and TASK 72-45-31-200-001-A00 (INSPECTION-001).

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2249

HPC Drive Turbine Shaft ENGINE-HP COMPRESSOR SHAFT (72-41-13, 01-850), Location Diameter

Stage 2 Turbine Hub ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-010), Bore

Shaft Location Diameter

4.842

Intf

4.842

Intf

4.841

0.010

4.841

0.010

Hub Bore

4.831

0.012

4.8313

0.012

4.830

Intf

4.830

Intf

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2249

HPC Drive Turbine Shaft ENGINE-HP COMPRESSOR SHAFT (72-41-13, 01-850), Location Diameter

Stage 2 Turbine Hub ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-010), Bore

Shaft Location Diameter

122.987

Intf

122.987

Intf

122.962

0.254

122.962

0.254

Hub Bore

122.707

0.304

122.712

0.304

122.682

Intf

122.682

Intf

SUBTASK 72-40-00-220-072-A00 Reference Fits and Clearances of the HP Turbine Rotor and Stator Assembly at Location 2249 (Pre SBE 72-0075)

Refer to Figure.

Reference interference at location 2249. If required, use the data written as a note in TASK 72-41-13-200-001-A00 (INSPECTION-001), TASK 72-41-13-200-001-B00 (INSPECTION-001), TASK 72-45-31-200-001-B00 (INSPECTION-001), and TASK 72-45-31-200-001-C00 (INSPECTION-001).

Table 7. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Select)

REJECT IF

MORE THAN

LOCATION 2249

HPC Drive Turbine Shaft ENGINE-HP COMPRESSOR SHAFT (72-41-13, 01-850), Location Diameter

Stage 2 Turbine Hub ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-010), Bore

Shaft Location Diameter

4.842

Intf

4.842

Intf

4.841

0.005

4.841

0.005

Hub Bore

4.836

0.007

4.8364

0.007

4.835

Intf

4.8345

Intf

Table 8. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Select)

REJECT IF

MORE THAN

LOCATION 2249

HPC Drive Turbine Shaft ENGINE-HP COMPRESSOR SHAFT (72-41-13, 01-850), Location Diameter

Stage 2 Turbine Hub ENGINE-STAGE 2 TURBINE HUB (72-45-31, 01-010), Bore

Shaft Location Diameter

122.987

Intf

122.987

Intf

122.962

0.125

122.962

0.125

Hub Bore

122.834

0.177

122.844

0.127

122.809

Intf

122.796

Intf

SUBTASK 72-40-00-220-072-B00 Reference Fits and Clearances of the HP Turbine Rotor and Stator Assembly at Location 2249 (SBE 72-0075)

Refer to Figure.

Reference clearance at location 2250. If required, use the data written as a note in TASK 72-41-13-200-001-A00 (INSPECTION-001), TASK 72-41-13-200-001-B00 (INSPECTION-001,) and TASK 72-40-00-200-011 (INSPECTION-011).

Table 9. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2250

HPC Drive Turbine Shaft ENGINE-HP COMPRESSOR SHAFT (72-41-13, 01-850), Thread Diameter

HPC Drive Turbine Nut HPC Module - Attaching Parts (72-40-00, 04-020), Thread Diameter

Shaft Thread Major Diameter

4.819

Clear

4.821

0.002

Nut Thread Minor Diameter

4.823

0.006

4.825

Clear

Table 10. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2250

HPC Drive Turbine Shaft ENGINE-HP COMPRESSOR SHAFT (72-41-13, 01-850), Thread Diameter

HPC Drive Turbine Nut HPC Module - Attaching Parts (72-40-00, 04-020), Thread Diameter

Shaft Thread Major Diameter

122.403

Clear

122.453

0.051

Nut Thread Minor Diameter

122.505

0.152

122.555

Clear

SUBTASK 72-40-00-220-073-A00 Reference Fits and Clearances of the HP Turbine Rotor and Stator Assembly at Location 2250 (Pre SBE 72-0075)

Refer to Figure.

Reference clearance at location 2250. If required, use the data written as a note in TASK 72-41-13-200-001-A00 (INSPECTION-001), TASK 72-41-13-200-001-B00 (INSPECTION-001) and TASK 72-40-00-200-011 (INSPECTION-011).

Table 11. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2250

HPC Drive Turbine Shaft ENGINE-HP COMPRESSOR SHAFT (72-41-13, 01-850), Thread Diameter

HPC Drive Turbine Nut HPC Module - Attaching Parts (72-40-00, 04-020), Thread Diameter

Shaft Thread Major Diameter

4.8020

4.8080

Nut Thread Minor Diameter

4.6939

4.6999

Table 12. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2250

HPC Drive Turbine Shaft ENGINE-HP COMPRESSOR SHAFT (72-41-13, 01-850), Thread Diameter

HPC Drive Turbine Nut HPC Module - Attaching Parts (72-40-00, 04-020), Thread Diameter

Shaft Thread Major Diameter

121.971

122.123

Nut Thread Minor Diameter

119.225

119.377

SUBTASK 72-40-00-220-073-B00 Reference Fits and Clearances of the HP Turbine Rotor and Stator Assembly at Location 2250 (SBE 72-0075)

Refer to Figure.

Reference interference at location 2253. If required, use the data written as a note in TASK 72-45-21-200-001 (INSPECTION-001), TASK 72-44-10-200-001-A00 (INSPECTION-001) and TASK 72-44-10-200-001-B00 (INSPECTION-001).

Table 13. Fits and Clearances (all dimensions are in inches) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 2253

Turbine Case Assembly ENGINE-HP TURBINE CASE ASSEMBLY (72-45-21, 01-010), Location Diameter

Stage 1 HPT Support Assembly ENGINE-STAGE 1 HPT SUPPORT ASSEMBLY (72-44-10, 01-010), Location Diameter

Case Assembly Location Diameter

28.233

28.227

Intf

0.002

28.233

28.222

Intf

0.002

Support Assembly Location Diameter

28.241

28.235

0.014

Intf

28.241

28.230

0.019

Intf

Table 14. Fits and Clearances (all dimensions are in millimeters) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 2253

Turbine Case Assembly ENGINE-HP TURBINE CASE ASSEMBLY (72-45-21, 01-010), Location Diameter

Stage 1 HPT Support Assembly ENGINE-STAGE 1 HPT SUPPORT ASSEMBLY (72-44-10, 01-010), Location Diameter

Case Assembly Location Diameter

717.118

716.966

Intf

0.050

717.118

716.839

Intf

0.050

Support Assembly Location Diameter

717.321

717.169

0.360

Intf

717.321

717.040

0.483

Intf

SUBTASK 72-40-00-220-074 Reference Fits and Clearances of the HP Turbine Rotor and Stator Assembly at Location 2253

Refer to Figure.

Reference interference at location 5624. If required, use the data written as a note in TASK 72-50-21-200-001-A00 (INSPECTION-001) and TASK 72-45-27-200-002-A00 (INSPECTION-002).

Table 15. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 5624

LPT Case Assembly ENGINE-LP TURBINE CASE (72-50-21, 01-010), Location Diameter

Stage 2 HPT Support Assembly ENGINE-STAGE 2 HPT SUPPORT ASSEMBLY (72-45-27, 01-010), Location Diameter

Case Diameter

28.533

Intf

28.533

Clear

28.527

0.002

28.527

0.004

Support Diameter

28.541

0.014

28.541

0.014

28.535

Intf

28.529

Intf

Table 16. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 5624

LPT Case Assembly ENGINE-LP TURBINE CASE (72-50-21, 01-010), Location Diameter

Stage 2 HPT Support Assembly ENGINE-STAGE 2 HPT SUPPORT ASSEMBLY (72-45-27, 01-010), Location Diameter

Case Diameter

724.738

Intf

724.738

Clear

724.586

0.050

724.586

0.102

Support Diameter

724.941

0.356

724.941

0.356

724.789

Intf

724.637

Intf

SUBTASK 72-40-00-220-075 Reference Fits and Clearances of the HP Turbine Rotor and Stator Assembly at Location 5624

Refer to Figure.

Reference clearance at location 5623. If required, use the data written as a note in TASK 72-45-33-200-001-A00 (INSPECTION-001), TASK 72-45-33-200-001-B00 (INSPECTION-001) and TASK 72-50-24-200-001-A00 (INSPECTION-001).

Table 17. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 5623

Stage 2 Blade Retaining Plate ENGINE-STAGE 2 HPT BLADE RETAINING PLATE (72-45-33, 01-020), Knife Edge Outside Diameter

Inner Turbine Duct ENGINE-LP TURBINE INNER STATIC SEALS (72-50-24, 01-010), Inside Diameter

Knife Edge Outside Diameter

19.807

Clear

19.812

0.084

Turbine Duct Inside Diameter

19.896

0.118

19.925

Clear

Table 18. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 5623

Stage 2 Blade Retaining Plate ENGINE-STAGE 2 HPT BLADE RETAINING PLATE (72-45-33, 01-020), Knife Edge Outside Diameter

Inner Turbine Duct ENGINE-LP TURBINE INNER STATIC SEALS (72-50-24, 01-010), Inside Diameter

Knife Edge Outside Diameter

503.098

Clear

503.224

2.135

Turbine Duct Inside Diameter

505.360

3.002

506.100

Clear

SUBTASK 72-40-00-220-076 Reference Fits and Clearances of the HP Turbine Rotor and Stator Assembly at Location 5623

Refer to Figure.

Reference clearance at location 2256. If required, use the data written as a note in TASK 72-44-60-200-002 (INSPECTION-002), TASK 72-45-11-200-001-A00 (INSPECTION-001), TASK 72-45-11-200-001-B00 (INSPECTION-001) and TASK 72-45-11-200-001-C00 (INSPECTION-001).

Table 19. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2256

Radial Clearance Stage 1 HPT Duct Segment ENGINE-STAGE 1 HPT SEGMENT (72-44-60, 01-010)

Stage 1 HPT Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010) And Blade ENGINE-STAGE 1 HPT BLADE ASSEMBLY (72-45-14, 01-010) Assembly

Stage 1 HPT Duct Segment

10.710

Clear

10.720

0.051

Stage 1 HPT Hub And Blade Assembly

10.771

0.071

10.801

Clear

Table 20. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2256

Radial Clearance Stage 1 HPT Duct Segment ENGINE-STAGE 1 HPT SEGMENT (72-44-60, 01-010)

Stage 1 HPT Hub ENGINE-STAGE 1 TURBINE HUB (72-45-11, 01-010) And Blade ENGINE-STAGE 1 HPT BLADE ASSEMBLY (72-45-14, 01-010) Assembly

Stage 1 HPT Duct Segment

272.03

Clear

272.29

1.295

Stage 1 HPT Hub And Blade Assembly

273.58

1.80

274.35

Clear

SUBTASK 72-40-00-220-077 Reference Fits and Clearances of the HP Turbine Rotor and Stator Assembly at Location 2256

Refer to Figure.

Reference clearance at location 2257. If required, use the data written as a note in TASK 72-45-12-200-001-A00 (INSPECTION-001), TASK 72-45-12-200-001-B00 (INSPECTION-001), TASK 72-45-12-200-001-C00 (INSPECTION-001), TASK 72-45-12-200-001-D00 (INSPECTION-001), TASK 72-44-50-200-001-A00 (INSPECTION-001) and TASK 72-44-50-200-001-B00 (INSPECTION-001).

Table 21. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2257

Stage 1 And 2 HPT Air Seal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Knife Edge Outside Diameter

Stage 1 HPT Cooling Duct Assembly ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-010), Seal Land Inside Diameter

Knife Edge OD

11.381

Clear

11.397

0.018

Seal Land ID

11.415

0.064

11.445

Clear

Table 22. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2257

Stage 1 And 2 HPT Air Seal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Knife Edge Outside Diameter

Stage 1 HPT Cooling Duct Assembly ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-010), Seal Land Inside Diameter

Knife Edge OD

289.08

Clear

289.48

0.46

Seal Land ID

289.94

1.63

290.70

Clear

SUBTASK 72-40-00-220-078 Reference Fits and Clearances of the HP Turbine Rotor and Stator Assembly at Location 2257

Refer to Figure.

Reference clearance at location 2258. If required, use the data written as a note in TASK 72-45-12-200-001-A00 (INSPECTION-001), TASK 72-45-12-200-001-B00 (INSPECTION-001), TASK 72-45-12-200-001-C00 (INSPECTION-001), TASK 72-45-12-200-001-D00 (INSPECTION-001), TASK 72-44-50-200-001-A00 (INSPECTION-001) and TASK 72-44-50-200-001-B00 (INSPECTION-001).

Table 23. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2258

Stage 1 And 2 HPT Air Seal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Knife Edge Outside Diameter

Stage 1 HPT Cooling Duct Assembly ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-010), Seal Land Inside Diameter

Knife Edge OD

11.481

Clear

11.497

0.018

Seal Land ID

11.515

0.064

11.545

Clear

Table 24. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2258

Stage 1 And 2 HPT Air Seal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Knife Edge Outside Diameter

Stage 1 HPT Cooling Duct Assembly ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-010), Seal Land Inside Diameter

Knife Edge OD

291.62

Clear

292.02

0.46

Seal Land ID

292.48

1.63

293.24

Clear

SUBTASK 72-40-00-220-079 Reference Fits and Clearances of the HP Turbine Rotor and Stator Assembly at Location 2258

Refer to Figure.

Reference clearance at location 2259. If required, use the data written as a note in TASK 72-45-12-200-001-A00 (INSPECTION-001), TASK 72-45-12-200-001-B00 (INSPECTION-001), TASK 72-45-12-200-001-C00 (INSPECTION-001), TASK 72-45-12-200-001-D00 (INSPECTION-001), TASK 72-44-50-200-001-A00 (INSPECTION-001) and TASK 72-44-50-200-001-B00 (INSPECTION-001).

Table 25. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2259

Stage 1 And 2 HPT Air Seal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Knife Edge Outside Diameter

Stage 1 HPT Cooling Duct Assembly ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-010), Seal Land Inside Diameter

Knife Edge OD

11.581

Clear

11.597

0.018

Seal Land ID

11.615

0.064

11.645

Clear

Table 26. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2259

Stage 1 And 2 HPT Air Seal ENGINE-STAGE 1 HPT AIR SEAL (OUTER) (72-45-12, 01-040), Knife Edge Outside Diameter

Stage 1 HPT Cooling Duct Assembly ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-010), Seal Land Inside Diameter

Knife Edge OD

294.16

Clear

294.56

0.46

Seal Land ID

295.02

1.63

295.78

Clear

SUBTASK 72-40-00-220-080 Reference Fits and Clearances of the HP Turbine Rotor and Stator Assembly at location 2259

Refer to Figure.

Reference clearance at location 2260. If required, use the data written as a note in TASK 72-45-13-200-001-A00 (INSPECTION-001), TASK 72-45-13-200-001-B00 (INSPECTION-001), TASK 72-44-50-200-001-A00 (INSPECTION-001) and TASK 72-44-50-200-001-B00 (INSPECTION-001).

Table 27. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2260

Stage 1 HPT Air Seal ENGINE-STAGE 1 HPT AIR SEAL (INNER) (72-45-13, 01-020), Outside Diameter

Stage 1 HPT Cooling Duct Assembly ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-010), Seal Land Inside Diameter

Knife Edge OD

8.927

Clear

8.921

Clear

8.933

0.022

8.933

0.022

Seal Land ID

8.955

0.038

8.955

0.038

8.965

Clear

8.965

Clear

Table 28. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2260

Stage 1 HPT Air Seal ENGINE-STAGE 1 HPT AIR SEAL (INNER) (72-45-13, 01-020), Outside Diameter

Stage 1 HPT Cooling Duct Assembly ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-010), Seal Land Inside Diameter

Knife Edge OD

226.746

Clear

226.593

Clear

226.898

0.56

226.898

0.56

Seal Land ID

227.46

0.97

227.46

0.97

227.71

Clear

227.71

Clear

SUBTASK 72-40-00-220-081 Reference Fits and Clearances of the HP Turbine Rotor and Stator Assembly at Location 2260

Refer to Figure.

Reference clearance at location 2261. If required, use the data written as a note in TASK 72-45-13-200-001-A00 (INSPECTION-001), TASK 72-45-13-200-001-B00 (INSPECTION-001), TASK 72-44-50-200-001-A00 (INSPECTION-001) and TASK 72-44-50-200-001-B00 (INSPECTION-001).

Table 29. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2261

Stage 1 HPT Air Seal ENGINE-STAGE 1 HPT AIR SEAL (INNER) (72-45-13, 01-020), Outside Diameter

Stage 1 HPT Cooling Duct Assembly ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-010), Seal Land Inside Diameter

Knife Edge OD

9.027

Clear

9.021

Clear

9.033

0.022

9.033

0.022

Seal Land ID

9.055

0.038

9.055

0.038

9.065

Clear

9.065

Clear

Table 30. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2261

Stage 1 HPT Air Seal ENGINE-STAGE 1 HPT AIR SEAL (INNER) (72-45-13, 01-020), Outside Diameter

Stage 1 HPT Cooling Duct Assembly ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-010), Seal Land Inside Diameter

Knife Edge OD

229.286

Clear

229.133

Clear

229.438

0.56

229.438

0.56

Seal Land ID

230.00

0.97

230.00

0.97

230.25

Clear

230.25

Clear

SUBTASK 72-40-00-220-082 Reference Fits and Clearances of the HP Turbine Rotor and Stator Assembly at Location 2261

Refer to Figure.

Reference clearance at location 2262. If required, use the data written as a note in TASK 72-45-13-200-001-A00 (INSPECTION-001), TASK 72-45-13-200-001-B00 (INSPECTION-001), TASK 72-44-50-200-001-A00 (INSPECTION-001) and TASK 72-44-50-200-001-B00 (INSPECTION-001).

Table 31. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2262

Stage 1 HPT Air Seal ENGINE-STAGE 1 HPT AIR SEAL (INNER) (72-45-13, 01-020), Outside Diameter

Stage 1 HPT Cooling Duct Assembly ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-010), Seal Land Inside Diameter

Knife Edge OD

9.127

Clear

9.121

Clear

9.133

0.022

9.133

0.022

Seal Land ID

9.155

0.038

9.155

0.038

9.165

Clear

9.165

Clear

Table 32. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

(Non-select)

REJECT IF

MORE THAN

LOCATION 2262

Stage 1 HPT Air Seal ENGINE-STAGE 1 HPT AIR SEAL (INNER) (72-45-13, 01-020), Outside Diameter

Stage 1 HPT Cooling Duct Assembly ENGINE-STAGE 1 HPT COOLING DUCT ASSEMBLY (72-44-50, 01-010), Seal Land Inside Diameter

Knife Edge OD

231.826

Clear

231.673

Clear

231.978

0.56

231.978

0.56

Seal Land ID

232.54

0.97

232.54

0.97

232.79

Clear

232.79

Clear

SUBTASK 72-40-00-220-083 Reference Fits and Clearances of the HP Turbine Rotor and Stator Assembly at Location 2262

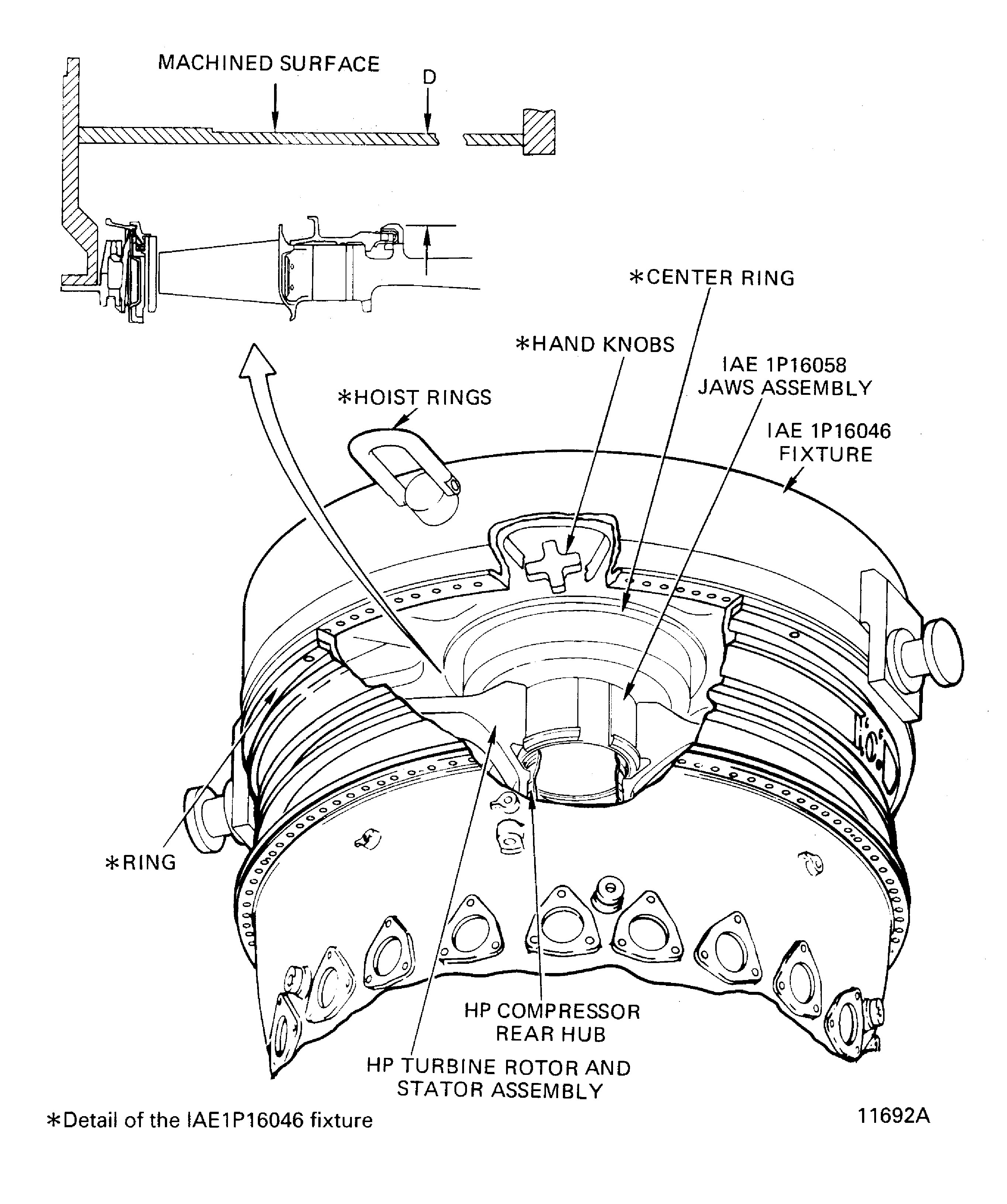

Install the IAE 1P16046 Removal/Installation fixture or IAE 1P16543 Removal/Installation fixture 1 off.

Measure the distance from the two machined areas of the fixture to the rear flange of the stage 2 hub. Use a depth vernier, Figure.

NOTE

Make sure when you take the measurements that the vernier does not go into the slots that are located on the hub flange.

Check to see if the HP Turbine Rotor and Stator Assembly is in the proper running position.

Install the IAE 1P16058 Removal/installation jaws assembly 1 off.

Install the scalloped plate detail of the IAE 1P16272 Adapter 1 off to the rear inner flange of the fixture.

Attach the IAE 1F10052 Two cables sling 1 off to the turning spools on the fixture.

SUBTASK 72-40-00-430-055-A00 Install the Tooling to the HP Turbine Rotor and Stator Assembly (Pre SBE 72-0075)

Install the IAE 1P16046 Removal/Installation fixture or IAE 1P16543 Removal/Installation fixture 1 off.

Measure the distance from the two machined areas of the fixture to the rear flange of the stage 2 hub. Use a depth vernier, Figure.

NOTE

Make sure when you take the measurements that the vernier does not go into the slots that are located on the hub flange.

Check to see if the HP Turbine Rotor and Stator Assembly is in the proper running position.

Install the IAE 1P16058 Removal/installation jaws assembly 1 off.

Install the scalloped plate detail of the IAE 1P16272 Adapter 1 off to the rear inner flange of the fixture.

Attach the IAE 1F10052 Two cables sling 1 off to the turning spools on the fixture.

SUBTASK 72-40-00-430-055-B00 Install the Tooling to the HP Turbine Rotor and Stator Assembly (SBE 72-0075)

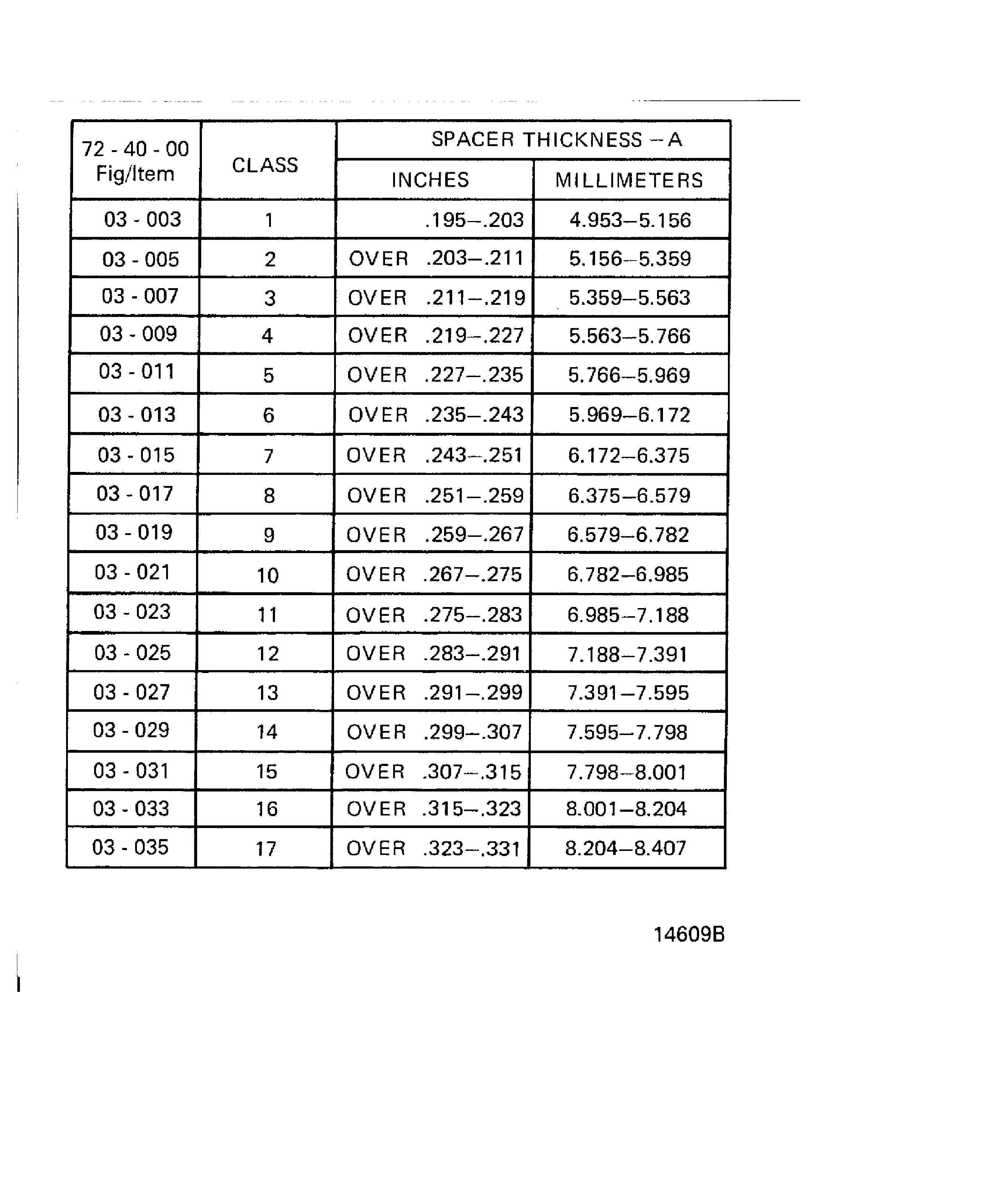

Use the guidelines for correct bearing tolerances that follow so you can meet the final assembly check:

If the C - B calculation results in a class 9 or 10 spacer - Install a class 11 spacer.

If the C - B calculation results in a class spacer that is less than 9 - Install a class 10 spacer.

If the C - B calculation results in a class 13 or 14 spacer - Install a class 12 spacer.

If the C - B calculation results in a class spacer that is more than 14 - Install a class 13 spacer.

Usually, the necessary spacer will be a class 11 or 12. After you subtract dimension B from dimension C, if a different class is necessary, check the measurements and do the calculation again.

Subtract dimension B from dimension C and the result will be the required No. 4 bearing spacer dimension.

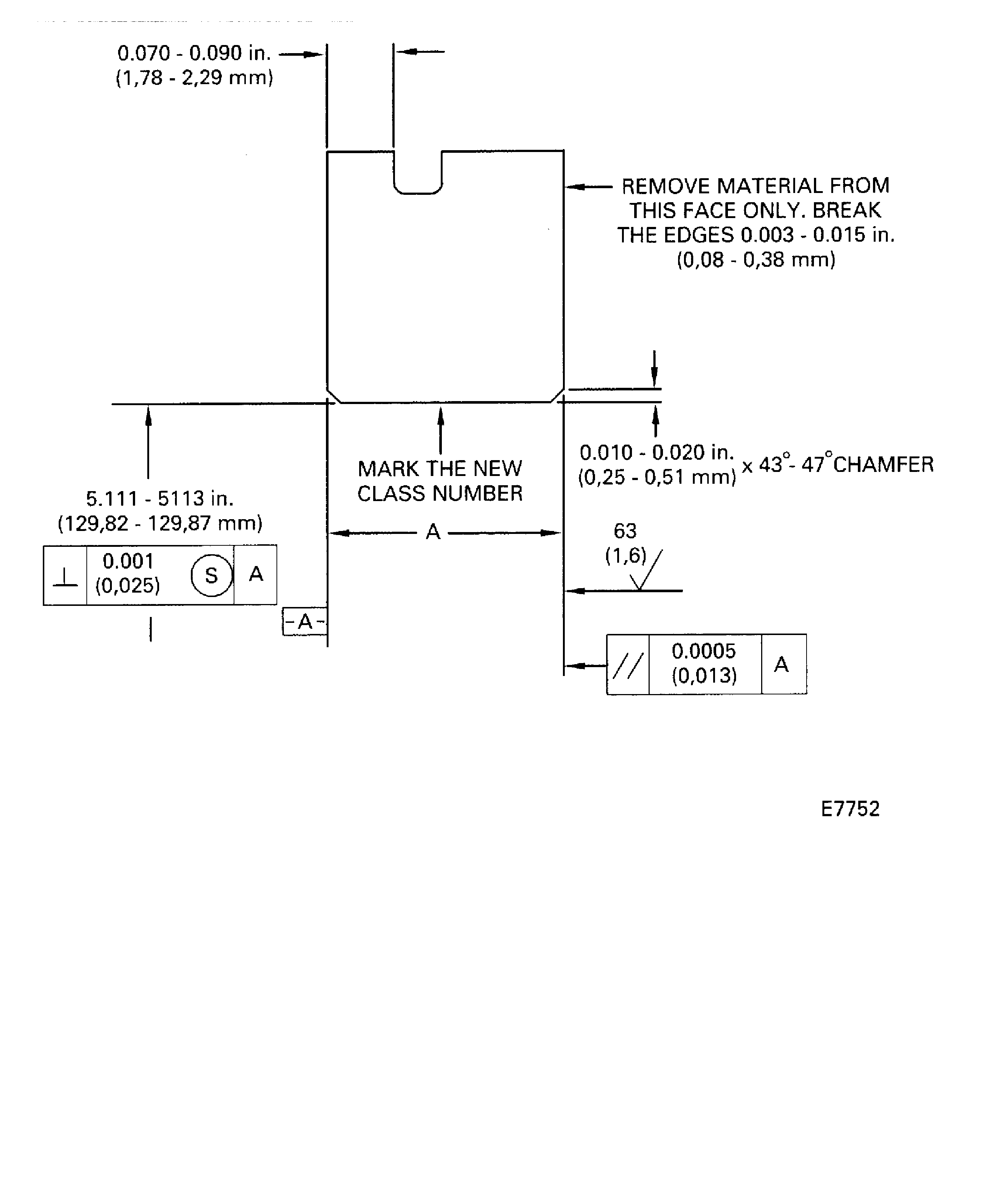

After you have machined the spacer, mark the new class number at the location shown in Figure. Cross off old class marking. Refer to SPM TASK 70-09-00-400-501. Use vibration peen method. Remove high metal.

If the correct class spacer is not available, you can machine a larger (numerically higher) class spacer to a smaller (numerically lower) class spacer as follows:

Find the correct class of the spacer (03-003 thru 03-035) to be used on the table. Refer to Figure.

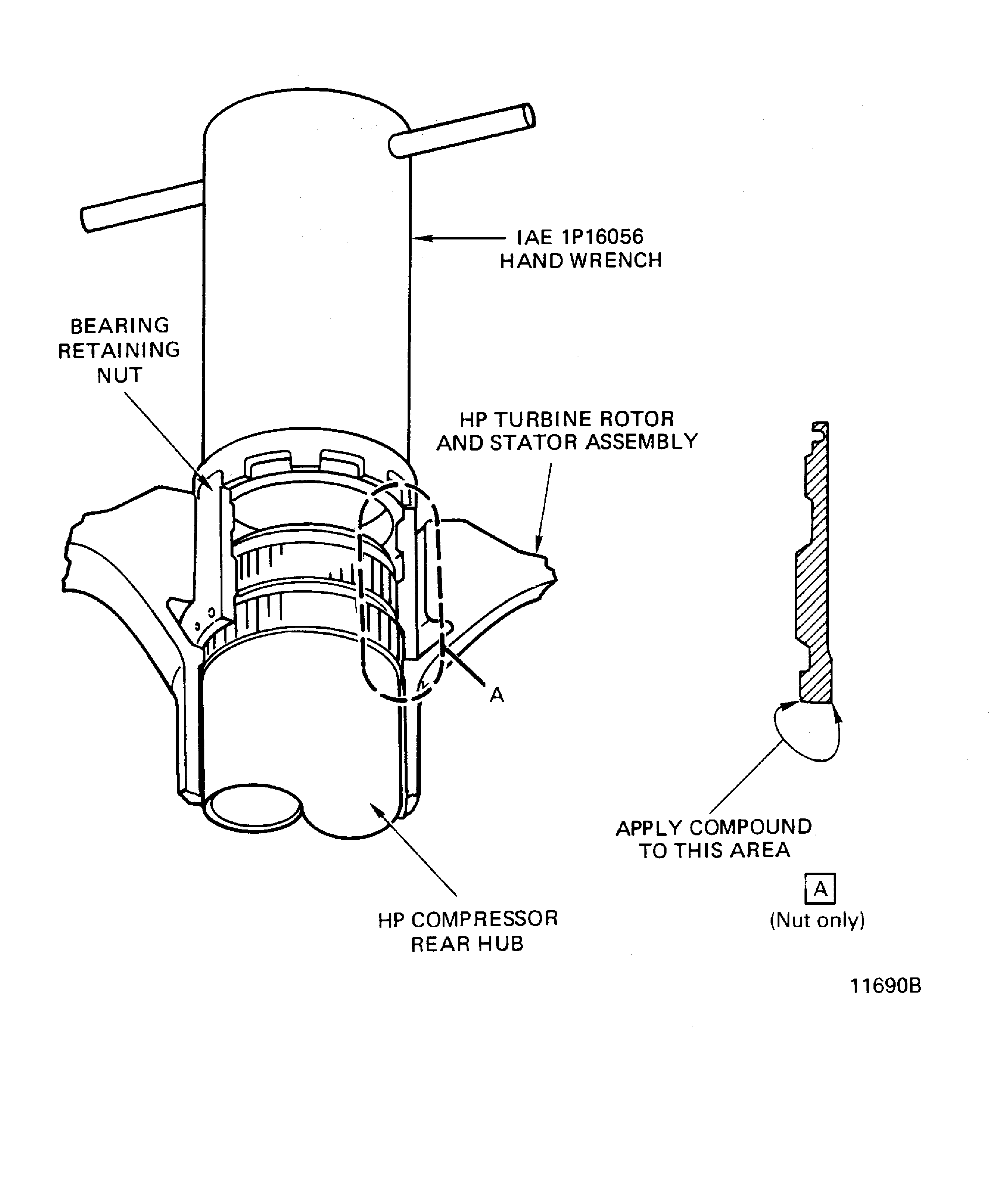

Install the spacer over the HP Compressor rear hub with the puller groove to the rear of the engine. The spacer must touch the No. 4 bearing rear seal seat. Position the spacer with the IAE 1P16470 Drift 1 off. Refer to Figure.

Apply CoMat 10-129 ANTI-SEIZE PASTE to the mating surface on the HP Compressor rear hub, Figure. Wipe off excess paste.

SUBTASK 72-40-00-430-056 Get the No. 4 Bearing Spacer Dimension

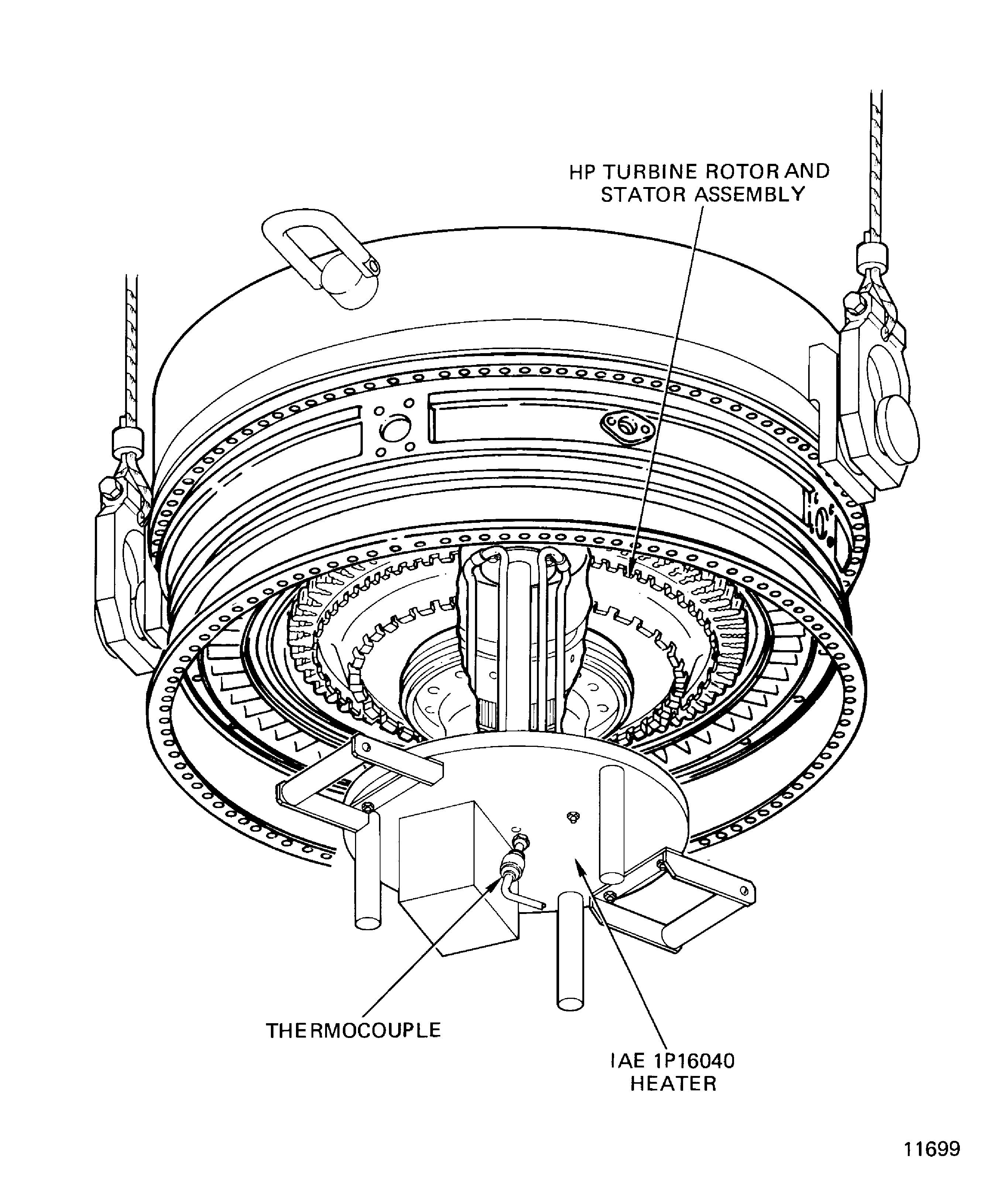

Refer to Figure.

Remove the pin and remove the cover from the IAE 1P16040 Heater 1 off.

CAUTION

REMOVE THE THERMOCOUPLE FROM THE HEATER BEFORE THE HP TURBINE ROTOR AND STATOR ASSEMBLY IS INSTALLED. IF THIS IS NOT DONE, DAMAGE TO THE THERMOCOUPLE MAY RESULT.Turn the HP Turbine Rotor and Stator Assembly to the front end down position and lower on to the heater until the case flange rests on the heater flange.

Attach the heater to the IAE 6F10027 Heater control unit 1 off. Heat the HP Turbine Rotor and Stator Assembly to 400 deg F (204 deg C).

SUBTASK 72-40-00-430-057 Install the HP Turbine Rotor and Stator Assembly on to the Heater

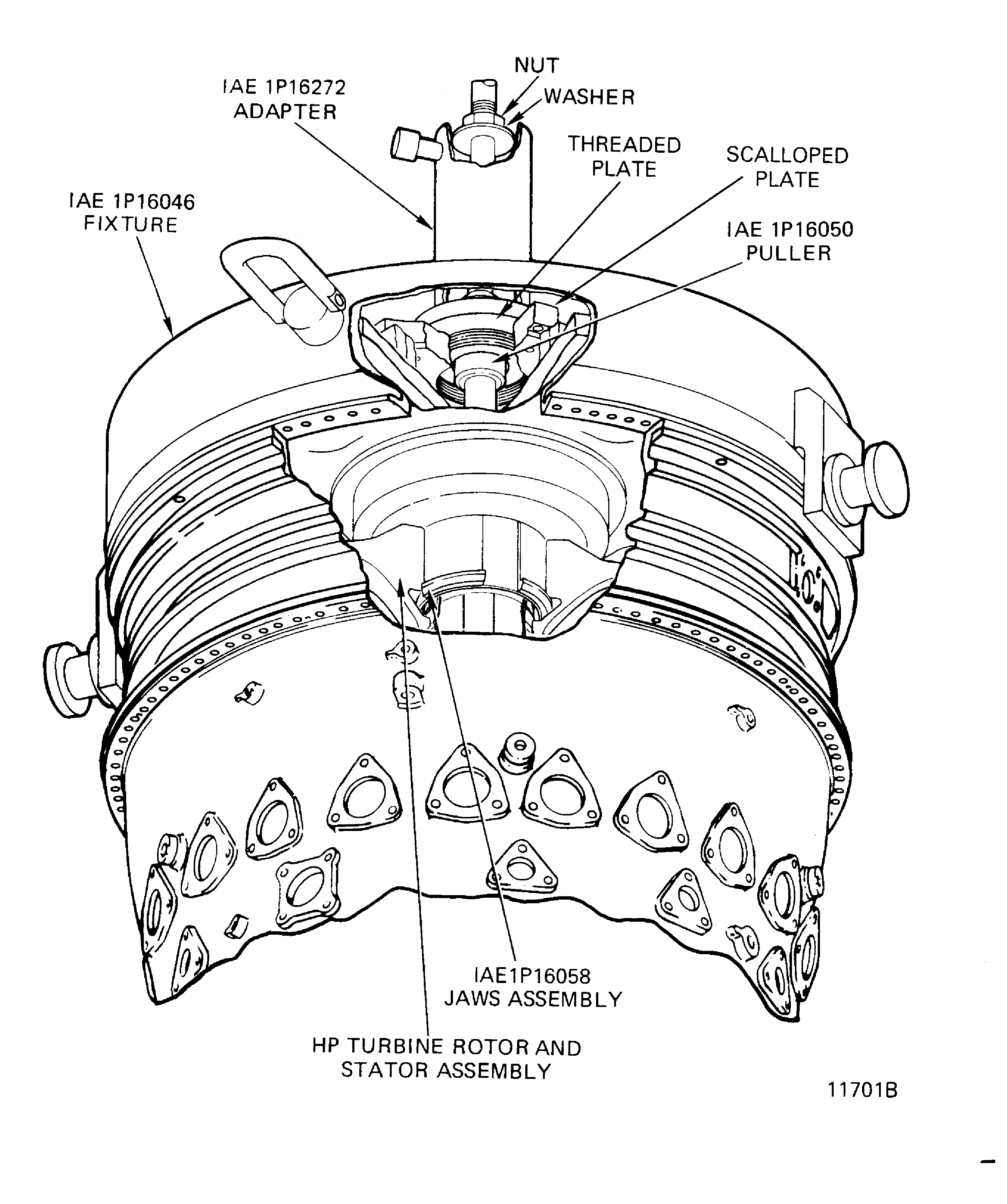

Refer to Figure.

Remove the puller rod if it is on the end of the IAE 1P16050 Puller 1 off.

Install the puller rod on to the puller shaft until the pin in the puller rod touches the capscrew in the puller shaft.

NOTE

The detail 33 puller rod of IAE 1P16050 Puller must be used with IAE 1P16272 Adapter.

Install the puller to the HP Compressor rear hub.

SUBTASK 72-40-00-430-058 Install the Puller in to the HP Compressor Rear Hub

Refer to Figure.

The hub splines are correctly engaged if the distance T is 0.625 in. (15.875 mm) or less, Figure.

Make sure the splines are engaged correctly.

Align the dowel pin in the case flange with the offset hole in the diffuser case flange and the stage 1 HP Turbine support assembly and align the stage 1 turbine hub splines with the splines on the HP Compressor rear hub.

Install the threaded plate detail of the IAE 1P16272 Adapter 1 off over the puller rod and in to the scalloped plate detail of the adapter.

Attach the IAE 1F10026 Hydraulic hand pump 1 off to the hydraulic cylinder.

SUBTASK 72-40-00-430-059 Install the HP Turbine Rotor and Stator Assembly to the HP Compressor Rear Hub

Install the IAE 1P17509 Protective cover 1 off to the rear flange of the HP Turbine Rotor and Stator Assembly.

NOTE

This cover is used to prevent damage to the rotor assembly when the tools are installed to torque the bearing retaining nut.Apply CoMat 10-129 ANTI-SEIZE PASTE to the mating surface of the HP Turbine retaining nut.

NOTE

The bearing retaining nut must be stripped and silver plated when you install or remove the nut more than five times or engine operation has occurred. Refer to Repair, VRS1298 TASK 72-32-54-300-003.Install the bearing retaining nut with the IAE 1P16056 Hand wrench 1 off. Wipe off excess paste.

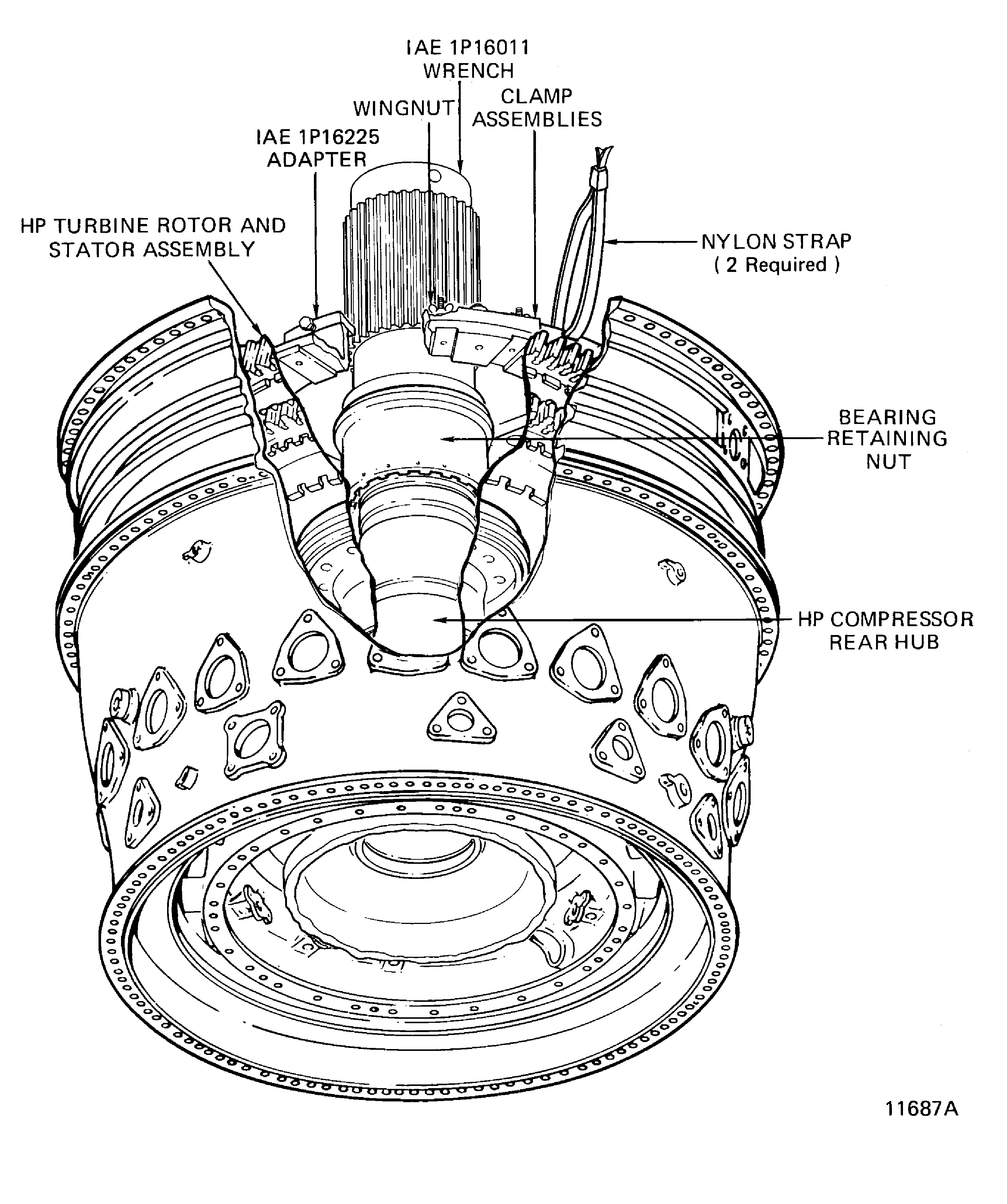

Loosen the wing nuts on all the clamp assemblies on the IAE 1P16225 Adapter 1 off. Move the clamps in the clockwise direction (opposite direction of arrows).

Install the IAE 1P16011 Wrench 1 off through the adapter to engage the retaining nut spline.

Lift the IAE 1F10015 Hydraulic wrench 1 off with a hoist and install over the wrench.

NOTE

You can use IAE 1F10016 Mechanical wrench as an alternative to IAE 1F10015 Hydraulic wrench.

Install the tools to torque the bearing retaining nut.

Make a temporary mark on the shaft and the nut to show the related location with CoMat 06-153 FELT TIP MARKER, RAPID DRYING and CoMat 06-158 MARKER, EXTRA FINE POINT(BLACK). Refer to SPM TASK 70-09-00-400-501.

Torque the bearing retaining nut.

Install the No. 4 bearing lock HPC Module - Attaching Parts (72-40-00, 04-060).

Install the retaining ring HPC Module - Attaching Parts (72-40-00, 04-040) to hold the lock in position.

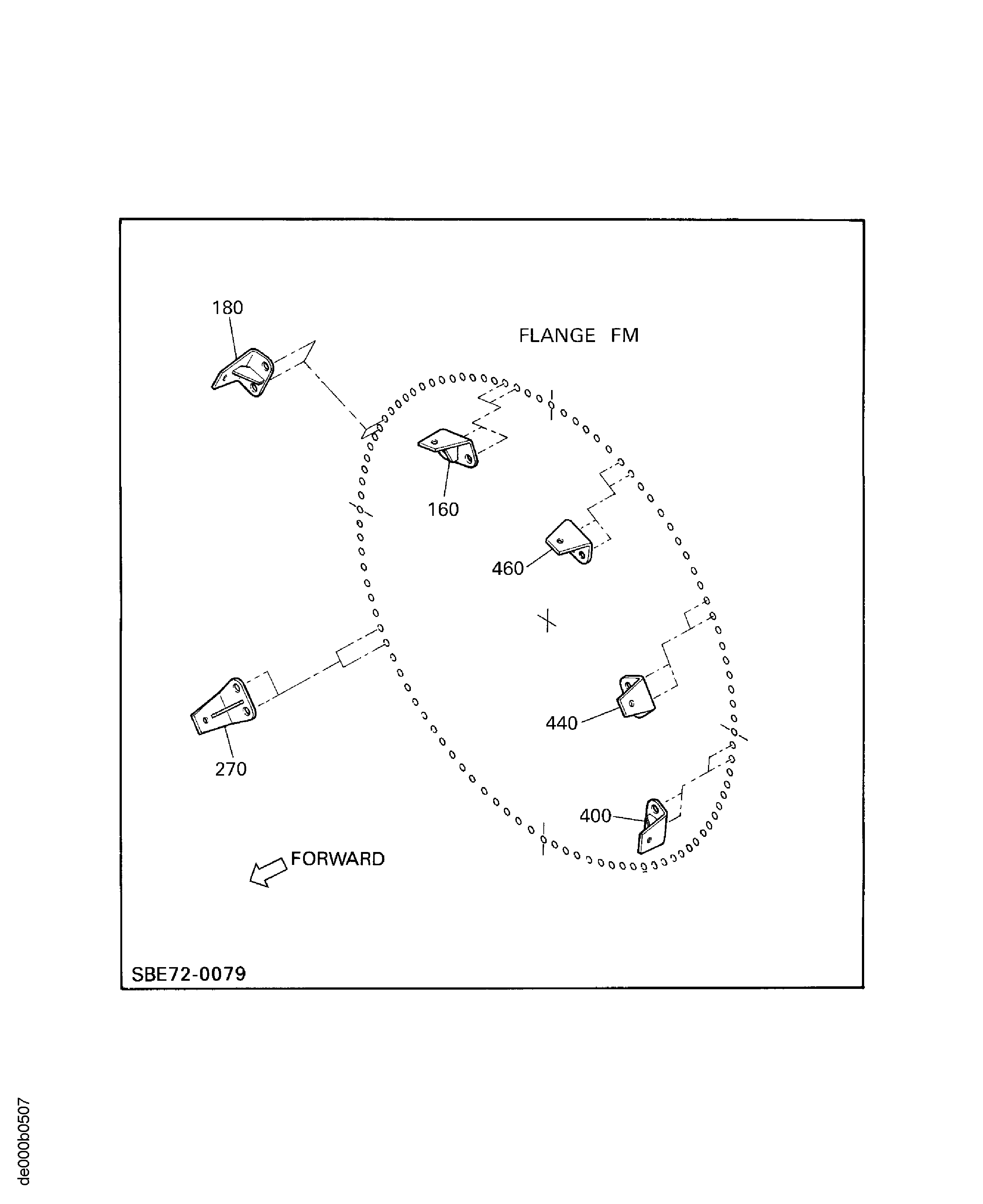

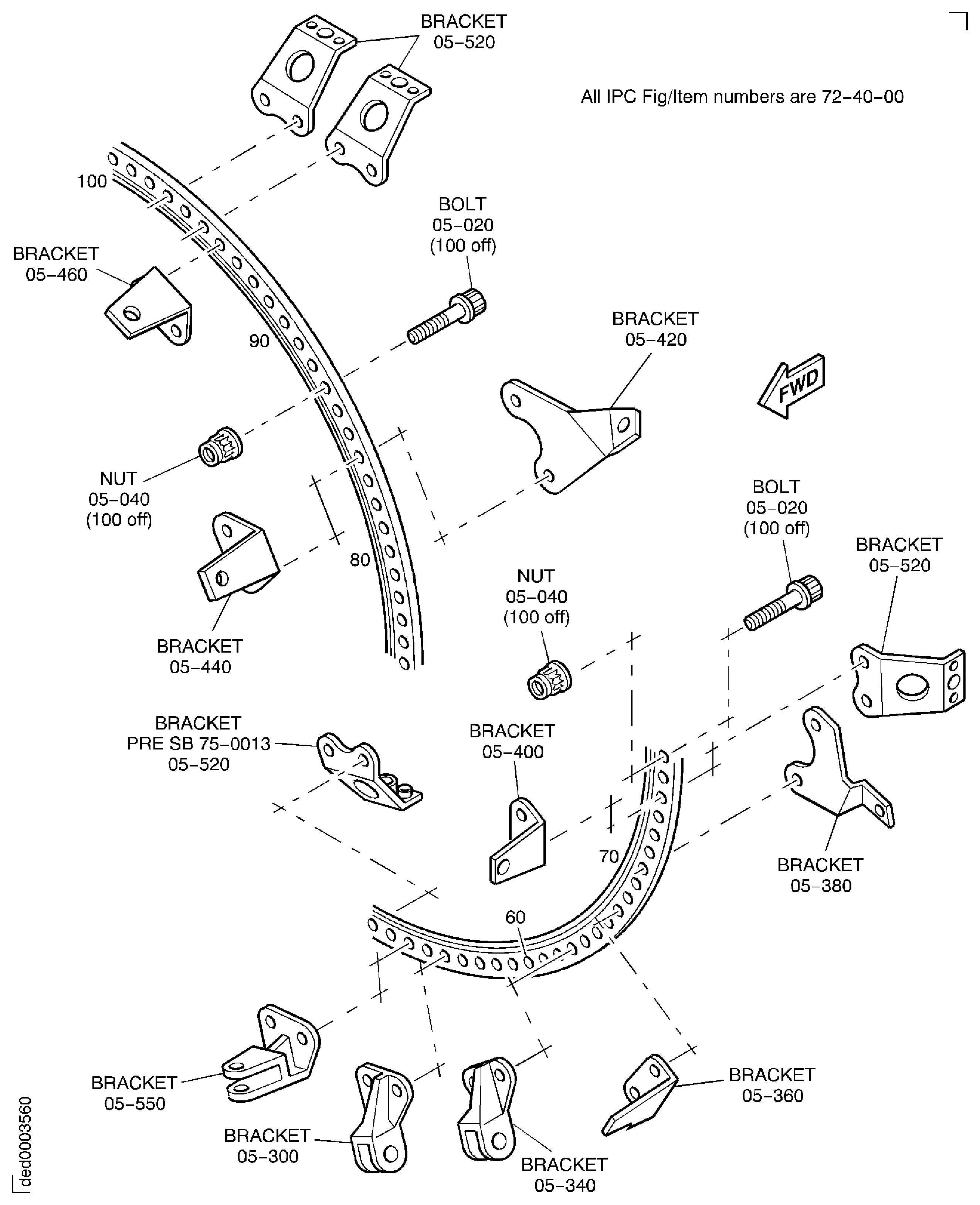

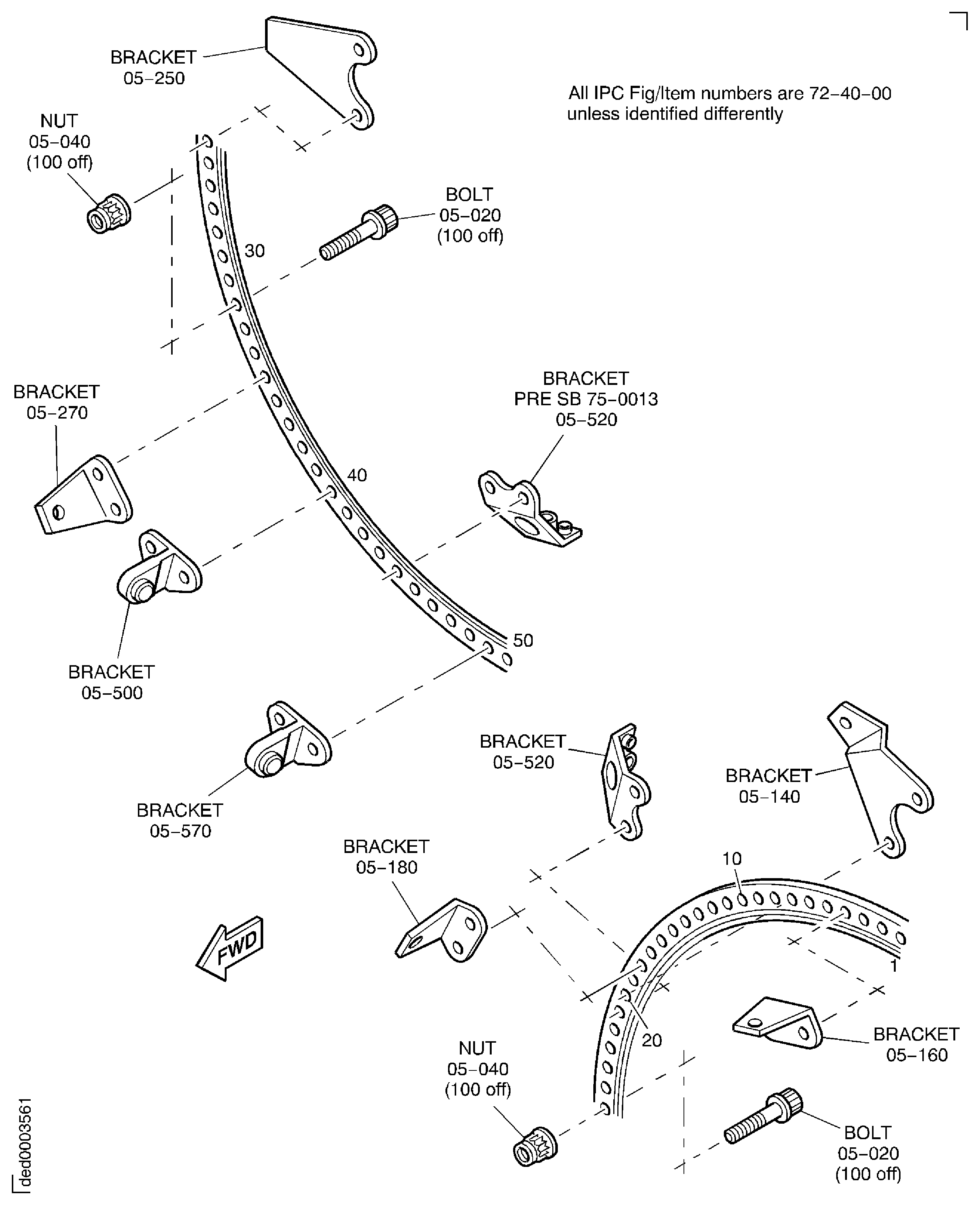

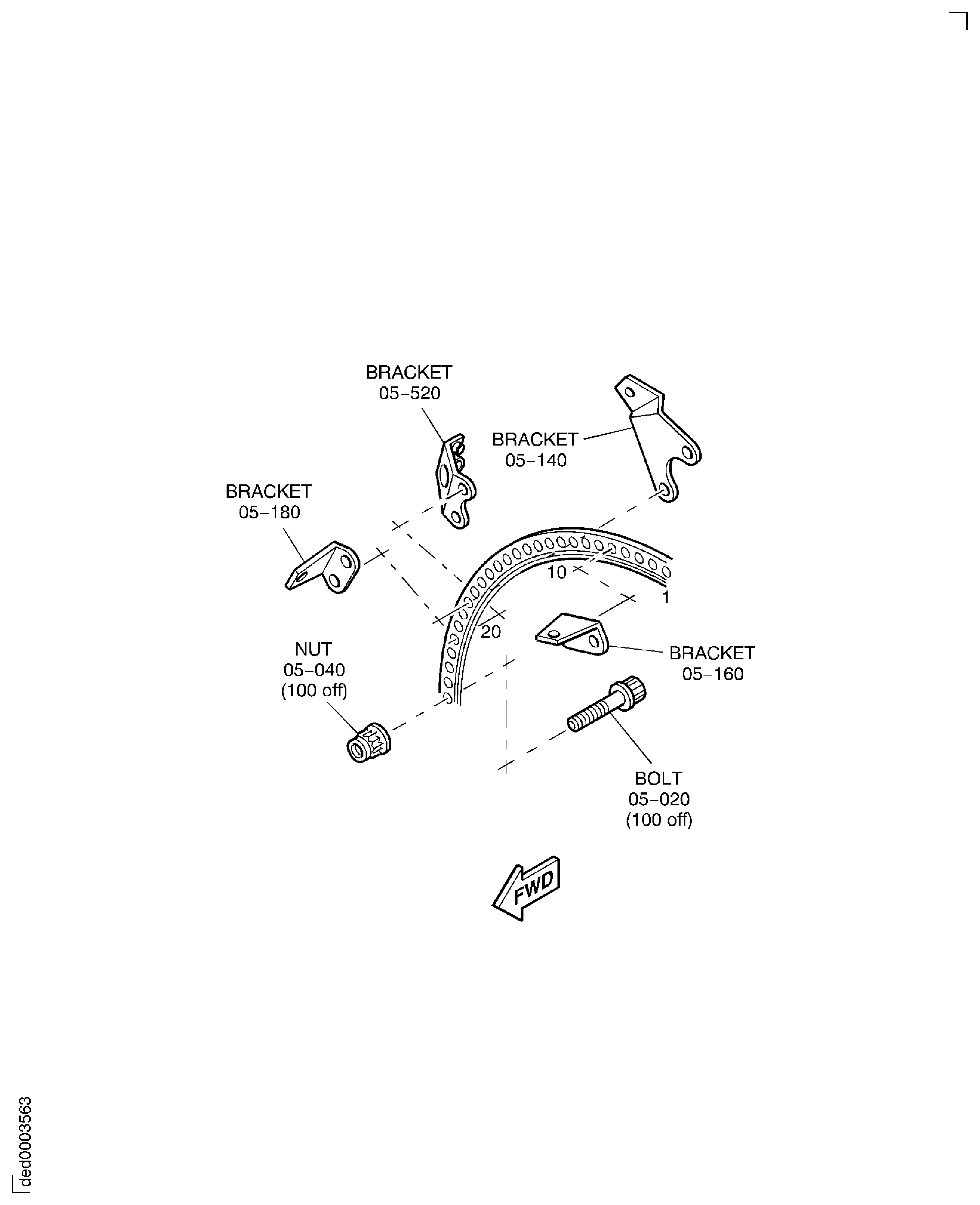

Install the brackets, refer to Figure.

SBE 72-0079 Engine - HP Compressor - Introduce a strengthened No. 4 bearing buffer air tube bracket assembly.

SUBTASK 72-40-00-430-061-A00 Install the Bearing Retaining Nut (Pre SBE 72-0075)

Install the IAE 1P17509 Protective cover 1 off to the rear flange of the HP Turbine Rotor and Stator Assembly.

NOTE

This cover is used to prevent damage to the rotor assembly when the tools are installed to torque the bearing retaining nut.Apply CoMat 10-129 ANTI-SEIZE PASTE to the mating surface of the HP Turbine retaining nut.

NOTE

The bearing retaining nut must be stripped and silver plated when you install or remove the nut more than five times or engine operation has occured. Refer to Repair, VRS1298 TASK 72-32-54-300-003.Install the bearing retaining nut with the IAE 1P16056 Hand wrench 1 off. Wipe off excess paste.

Loosen the wing nuts on all the clamp assemblies on the IAE 1P16225 Adapter 1 off. Move the clamps in the clockwise direction (opposite direction to arrows).

Install the IAE 1P16011 Wrench 1 off through the adapter to engage the retaining nut spline.

Lift the IAE 1F10015 Hydraulic wrench 1 off with a hoist and install over the wrench.

NOTE

You can use IAE 1F10016 Mechanical wrench as an alternative to IAE 1F10015 Hydraulic wrench.

Install the tools to torque the bearing retaining nut.

Make a temporary mark on the shaft and the nut to show the related locations with CoMat 06-153 FELT TIP MARKER, RAPID DRYING and CoMat 06-158 MARKER, EXTRA FINE POINT(BLACK). Refer to SPM TASK 70-09-00-400-501.

Torque the bearing retaining nut.

Install the No. 4 bearing lock HPC Module - Attaching Parts (72-40-00, 04-060).

Install the retaining ring HPC Module - Attaching Parts (72-40-00, 04-040) to hold the lock in position.

SBE 72-0079 Engine - HP Compressor - Introduce a strengthened No. 4 bearing buffer air tube bracket assembly.

Install the brackets.

SUBTASK 72-40-00-430-061-B00 Install the Bearing Retaining Nut (SBE 72-0075)

Refer to Figure.

Install the IAE 1P16186 Gage bar 1 off.

Install the IAE 1P16060 Protective cover 1 off or the IAE 1P17758 Protective cover 1 off to the rear of the HP Turbine Rotor and Stator Assembly.

SUBTASK 72-40-00-430-089-A01 Check the HP Turbine Assembly Running Distance (Pre SBE 72-0075)

Refer to Figure.

Install the IAE 1P16265 Checking fixture 1 off.

Install the IAE 1P16060 Protective cover 1 or the IAE 1P17758 Protective cover 1 off to the rear of the HP Turbine Rotor and Stator Assembly.

SUBTASK 72-40-00-430-089-A02 Check the HP Turbine Assembly Running Distance (Pre SBE 72-0075)

Refer to Figure.

Install the IAE 1P17515 Gage 1 off.

Install the IAE 1P16060 Protective cover 1 off or the IAE 1P17758 Protective cover 1 off to the rear of the HP Turbine Rotor and Stator Assembly.

SUBTASK 72-40-00-430-089-A03 Check the HP Turbine Assembly Running Distance (SBE 72-0075)

Figure: HP Turbine Assembly and Related Parts

HP Turbine Assembly and Related Parts

Figure: Installation Tooling for the HP Turbine Assembly

Installation Tooling for the HP Turbine Assembly

Figure: Engine Dimension

Engine Dimension

Figure: HP Turbine Assembly Dimensions

HP Turbine Assembly Dimensions

Figure: No. 4 Bearing Spacer Installation

No. 4 Bearing Spacer Installation

Figure: Install the HP Turbine Assembly on to the Heater

Install the HP Turbine Assembly on to the Heater

Figure: Puller Installed in HP Compressor Rear Hub

Puller Installed in HP Compressor Rear Hub

Figure: Install the HP Turbine Assembly to the Engine

Install the HP Turbine Assembly to the Engine

Figure: Bearing Retaining Nut

Bearing Retaining Nut

Figure: Retaining nut tooling

Retaining nut tooling

Figure: Hydraulic Wrench Package

Hydraulic Wrench Package

Figure: Thickness of Spacer

Sheet 1

Figure: Machine the Thickness of the Spacer

Sheet 2

Figure: The HP Turbine Rotor and Stator Assembly - Fits and Clearances

Sheet 1

Figure: The HP Turbine Rotor and Stator Assembly - Fits and Clearances

Sheet 2

Figure: Install the Brackets to the HP Turbine Case Front Flange

Sheet 1

Figure: Install the Brackets to the HP Turbine Case Front Flange

Sheet 2

Figure: Install the Brackets to the HP Turbine Case Front Flange

Sheet 3

Figure: Install the Brackets to the HP Turbine Case Front Flange

Sheet 4

Figure: Install the Brackets to the HP Turbine Case Front Flange

Sheet 5

Figure: Install the Brackets to the HP Turbine Case Front Flange SBE 72-0079

Sheet 6