Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-53-200-003-A00 Turbine Exhaust Case (TEC) - Examine, Inspection-003

General

This TASK gives the procedure for the inspection of the turbine exhaust case assembly. For the other parts of the turbine exhaust case assembly refer to TASK 72-50-53-200-000 (INSPECTION/CHECK-000).

Fig/item numbers in parentheses in the procedure agree with those used in the IPC.

The policy that is necessary for inspection is given in the SPM TASK 70-20-01-200-501.

All the parts must be cleaned before any part is examined. Refer to the SPM TASK 70-11-03-300-503.

If the instrumentation bushing, PN 4P8009 (02-140), is not loose, inspection of the Turbine Exhaust Case is permitted with the instrumentation bushing in position.

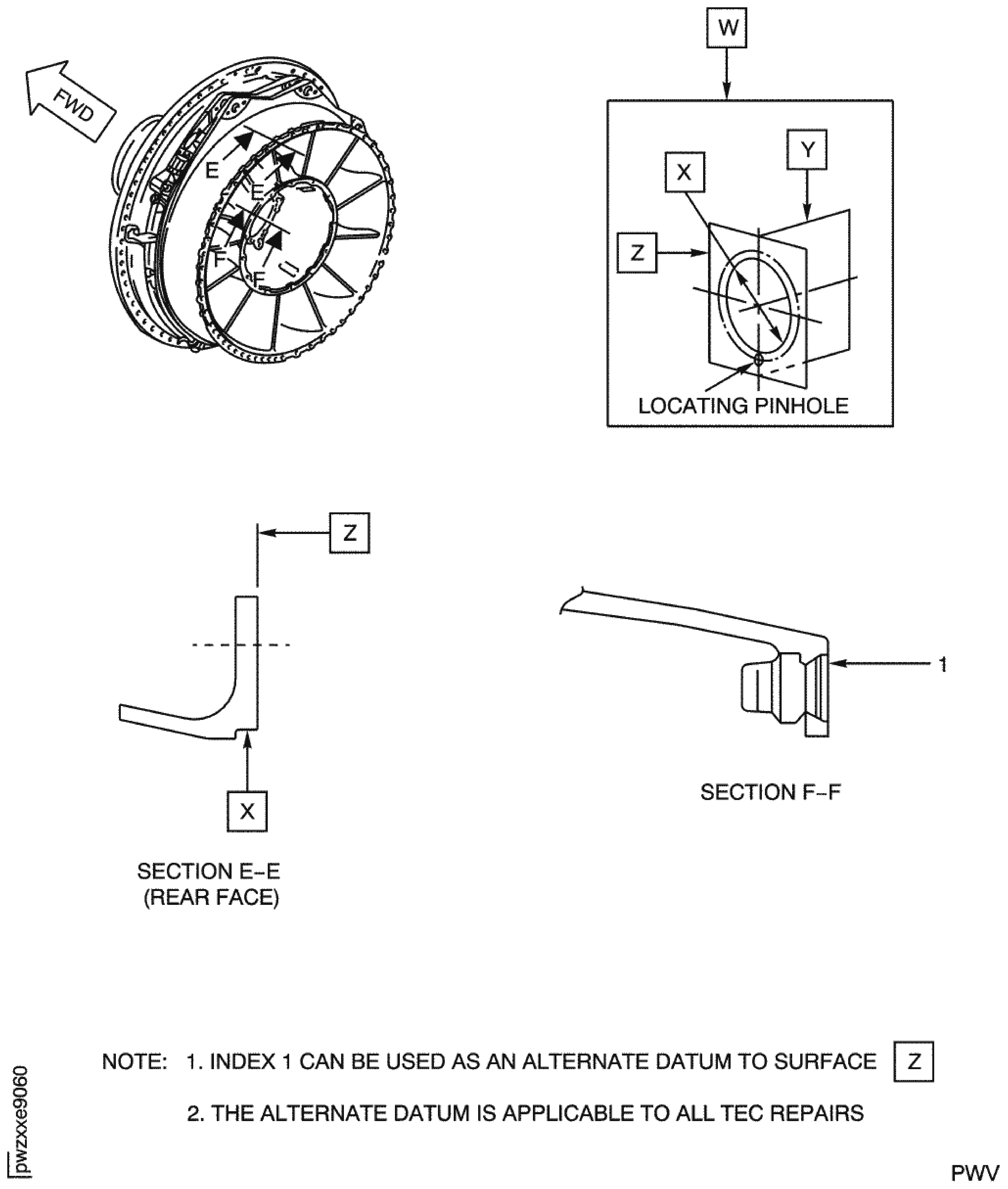

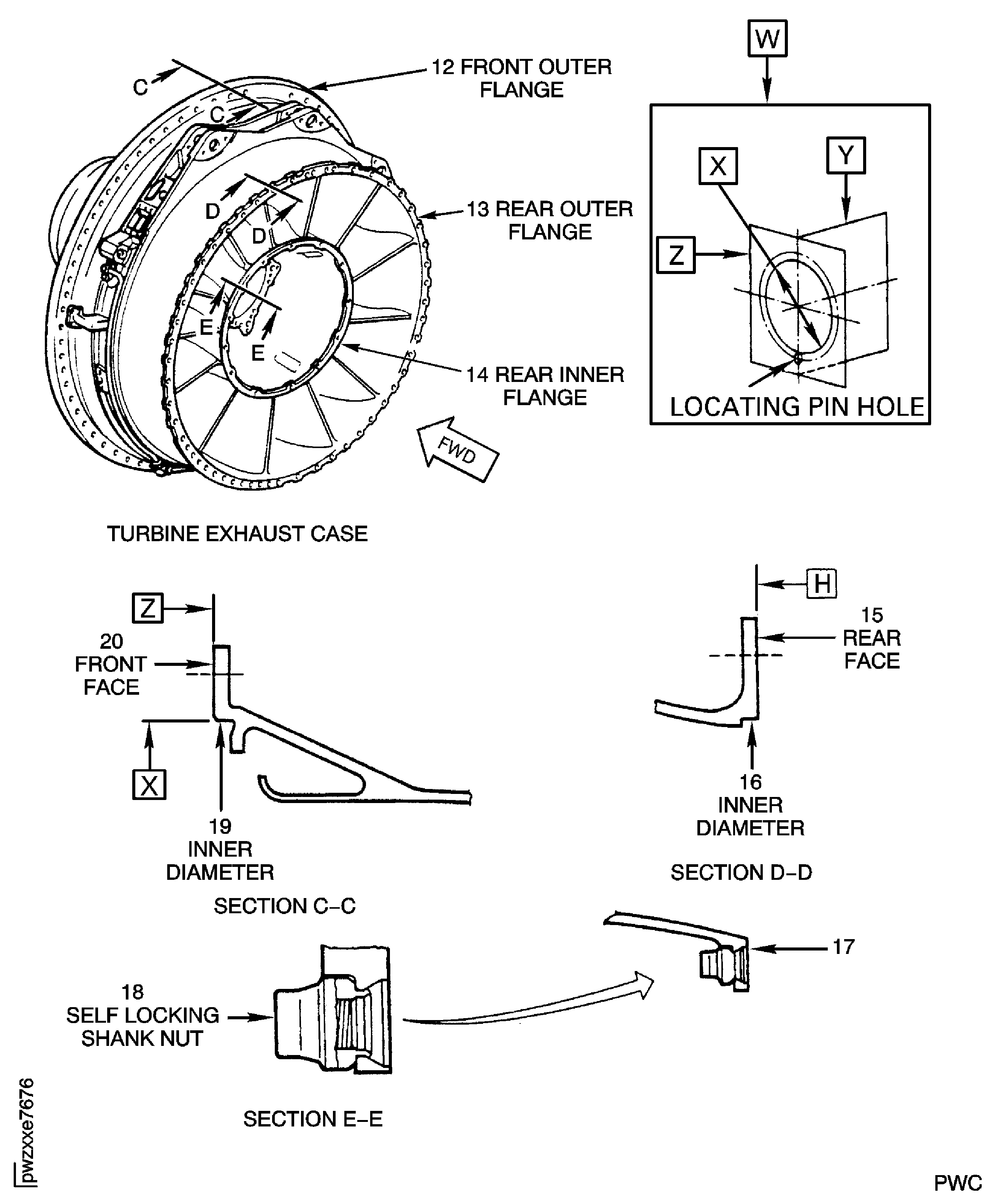

Alternate datum to Surfaces X and Z are available. Refer to Figure.

All parts must be visually examined for damage, corrosion and wear. Any defects that are not identified in the procedure must be referred to IAE.

The procedure for those parts which must have a crack test is given in Step. Do the test before the part is visually examined.

A ** following a repair referenced in this inspection indicates that the repair is not yet published in the current revision of the manual and the part must be rejected. Contact IAE for additional information concerning FAA approved repair data.

Do not discard any part until you are sure there are no repairs available. Refer to the instructions in repair before a discarded part is used again or oversize parts are installed.

Parts which should be discarded can be held although no repair is available. The repair of a discarded part could be shown to be necessary at a later date.

All parts must be examined to make sure that all the repairs have been completed satisfactorily.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

References

Refer to SPM for data on these items.

Definitions of Damage SPM TASK 70-02-02-350-501

Record and Control of the Lives of Parts, SPM TASK 70-05-00-220-501

Inspection of Parts, SPM TASK 70-20-00-200-501

Some data on these items is contained in this TASK. For more data on these items refer to the SPM.

Methods of Testing for Crack Indications

Chemical Processes

Surface Protection

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Workshop Inspection Equipment | 0AM53 | Workshop Inspection Equipment | ||

| Hydraulic test pump | LOCAL | Hydraulic test pump | ||

| IAE 2F10183 Fixture | 0AM53 | IAE 2F10183 | 1 | |

| IAE 2F10330 Adapter,leak test Scavenge tube | 0AM53 | IAE 2F10330 | 1 | |

| IAE 2F10331 Plug | 0AM53 | IAE 2F10331 | 1 | |

| IAE 2F10332 Bracket | 0AM53 | IAE 2F10332 | 1 | |

| IAE 6F10056 Borescope equipment, 4 mm or 6 mm, video borescope | 0AM53 | IAE 6F10056 | 1 | |

| IAE 6F10029 Air flow test cart | 0AM53 | IAE 6F10029 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Clean the parts. Refer to TASK 72-50-53-100-000 (CLEANING-000).

Repair, VRS3522 TASK 72-50-53-300-073 (REPAIR-073)

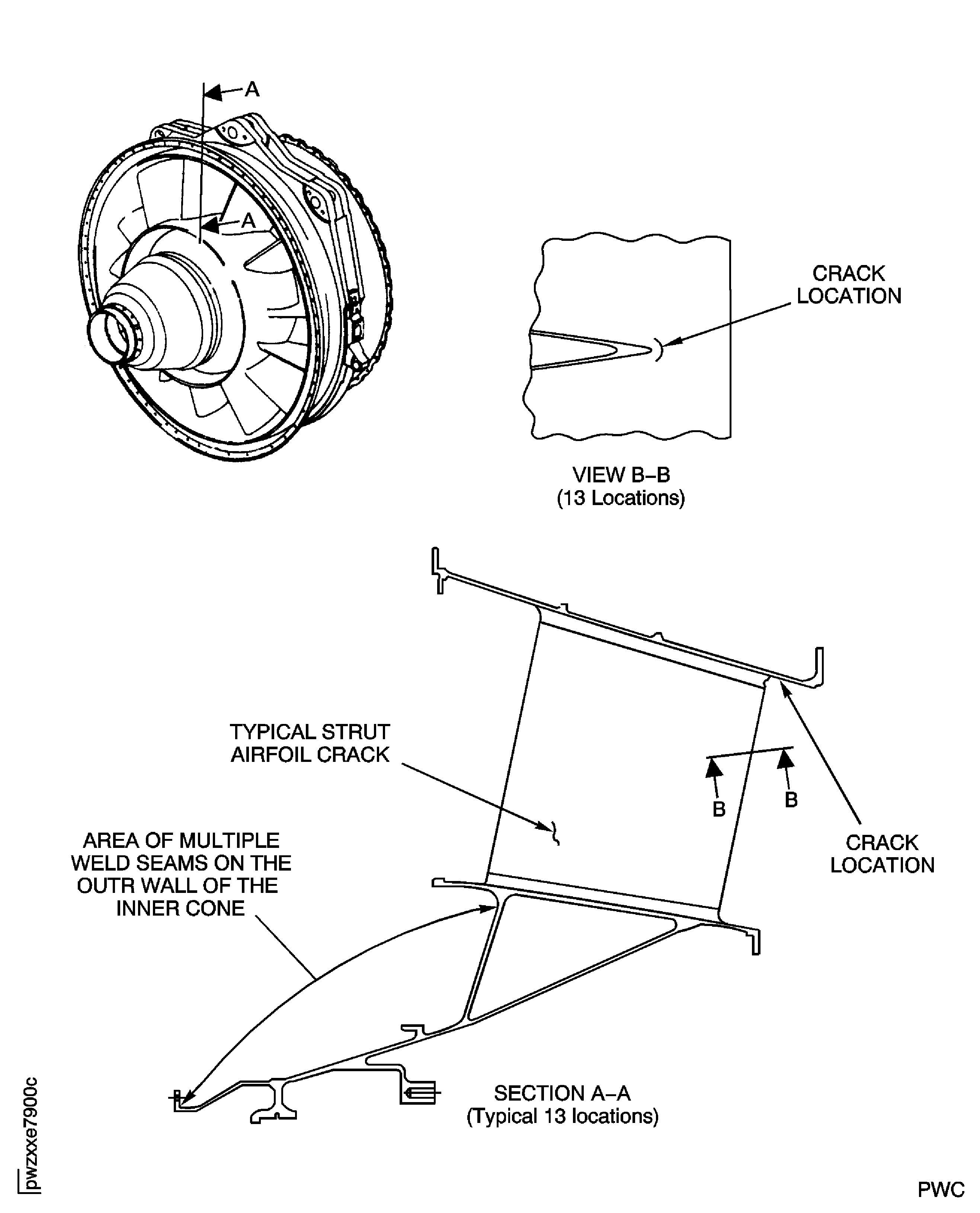

Not more than two strut airfoil cracks that are not more than 0.500 in. (12.70 mm) each in length. Cracks must be separated by a minimum of 2.00 in. (50.8 mm). Cracks on solid leading edges of instrumented struts are not permitted

Repair, VRS3641 TASK 72-50-53-300-074 (REPAIR-074)

Strut trailing edge cracks

Repair, VRS3522 TASK 72-50-53-300-073 (REPAIR-073)

U-shaped cracks around the trailing edge strut stand-ups not more than 1.00 in. (25.4 mm) per side. Cracks must be non-linear and a minimum of 1.00 in. (25.4 mm) from the rear flange

Repair, VRS3522 TASK 72-50-53-300-073 (REPAIR-073)

Outer case cracks not more than 1.000 in. (25.40 mm) in length. Cracks must not be on or between upper stiffening rails. Cracks must be a minimum of 2.500 in. (63.50 mm) from the front flange and a minimum of 1.000 in. (25.40 mm) from the rear flange

Repair, VRS3522 TASK 72-50-53-300-073 (REPAIR-073)

Inner case cracks not more than 1.00 in. (25.4 mm) in length. Cracks must not be more than 1.300 in. (33.02 mm) from forward edge of inner case wall

Repair, VRS3522 TASK 72-50-53-300-073 (REPAIR-073)

Cracks on the ID and/or OD weld bead of struts not more than 5.250 in. (133.35 mm) in length

Repair, VRS3641 TASK 72-50-53-300-074 (REPAIR-074)

Strut trailing edge cracks not more than 1.250 in. (31.75 mm) in length

Repair, VRS3522 TASK 72-50-53-300-073 (REPAIR-073)

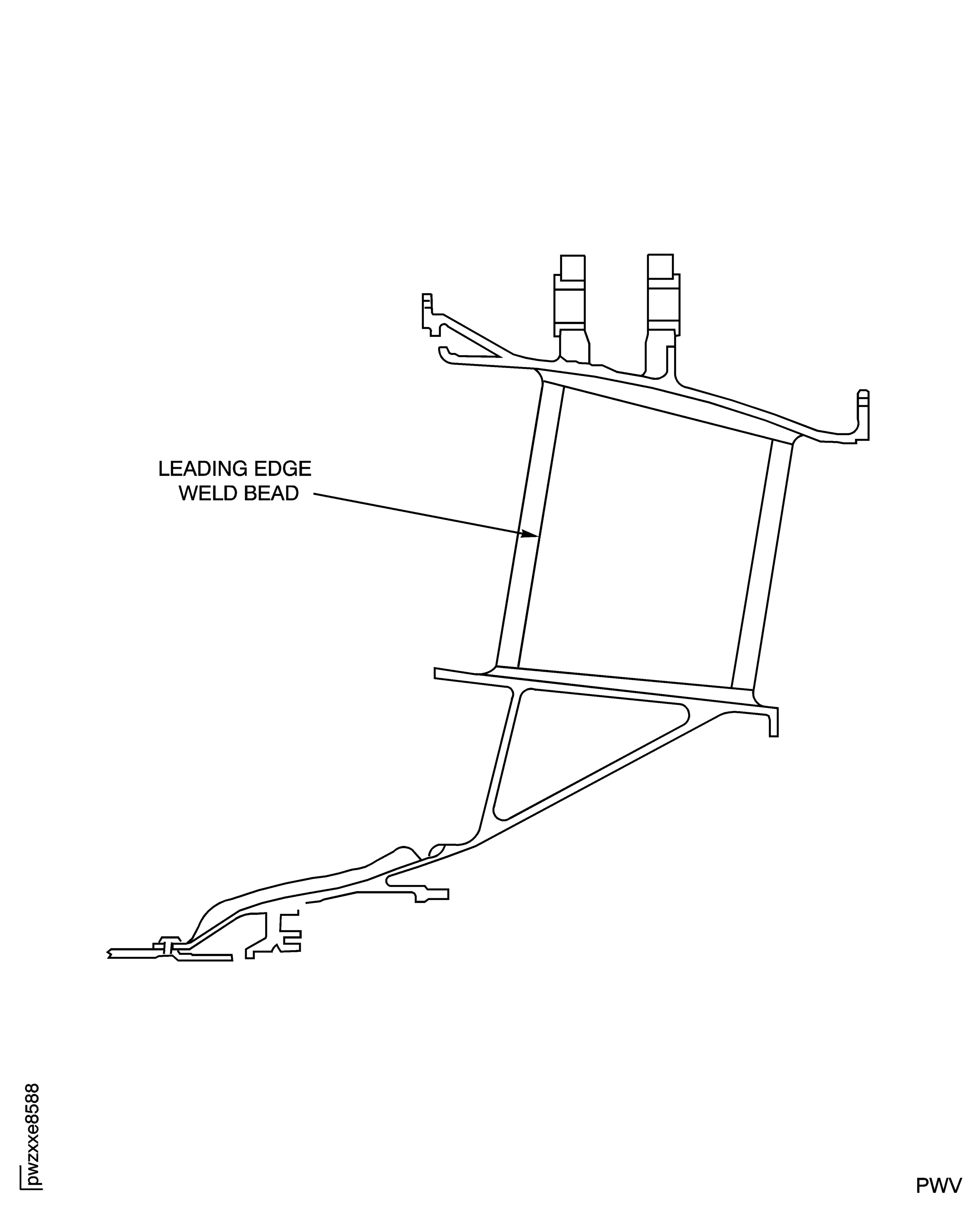

Strut cracks not more than 3.50 in. (88.9 mm) along the heat affected zone of the leading edge weld bead. Refer to Figure

Repair, VRS3522 TASK 72-50-53-300-073 (REPAIR-073)

NOTE

Bolt hole cracks which go into the case wall are not permitted.

Flange bolt hole cracks which go from the bolt hole to the flange OD

Repair, VRS3522 TASK 72-50-53-300-073 (REPAIR-073)

Inner cone weld seam cracks not more than 1.00 in. (25.4 mm). Cracks must be in the initial weld seams.

Repair, VRS3522 TASK 72-50-53-300-073 (REPAIR-073)

Rear inner flange cracks that are not more than 1.00 in. (25.4 mm) in length

Repair, VRS3743 TASK 72-50-53-300-083 (REPAIR-083)

Strut airfoil cracks that are more than 0.50 in. (12.7 mm) in length. Cracks on solid leading edges of instrumented struts are not permitted

Repair, VRS3522 TASK 72-50-53-300-073 (REPAIR-073)

Front outer fairing cracks along weld bead not more than 6.00 in. (152.4 mm) long with 1.00 in. (25.2 mm) minimum separation between cracks. Refer to Location 12 on Figure

Cracks.

Through porosity

Do the test for cracks on the parts that are given below. Use the applicable penetrant procedure.

PART IDENT TASK/SUBTASK

Turbine exhaust case

Repair, VRS3655 TASK 72-50-53-300-076 (REPAIR-076)

Drain the fluorescent penetrant from the struts

SUBTASK 72-50-53-230-052 Do a Crack Test on the Turbine Exhaust Case (01-001) (Fluorescent Penetrant)

NOTE

Do Repair, VRS3655 TASK 72-50-53-300-076 (REPAIR-076) after you do full turbine exhaust case or local fluorescent penetrant inspections.Repair, VRS5389 TASK 72-50-53-300-005 (REPAIR-005)

More than Step

Examine the external surfaces and the gaspath surfaces including the inner/outer case walls and struts for corrosion pits, dents, nicks or surface corrosion.

SUBTASK 72-50-53-220-056 Examine the External and Internal Surfaces of the Turbine Exhaust Case Assembly (01-001)

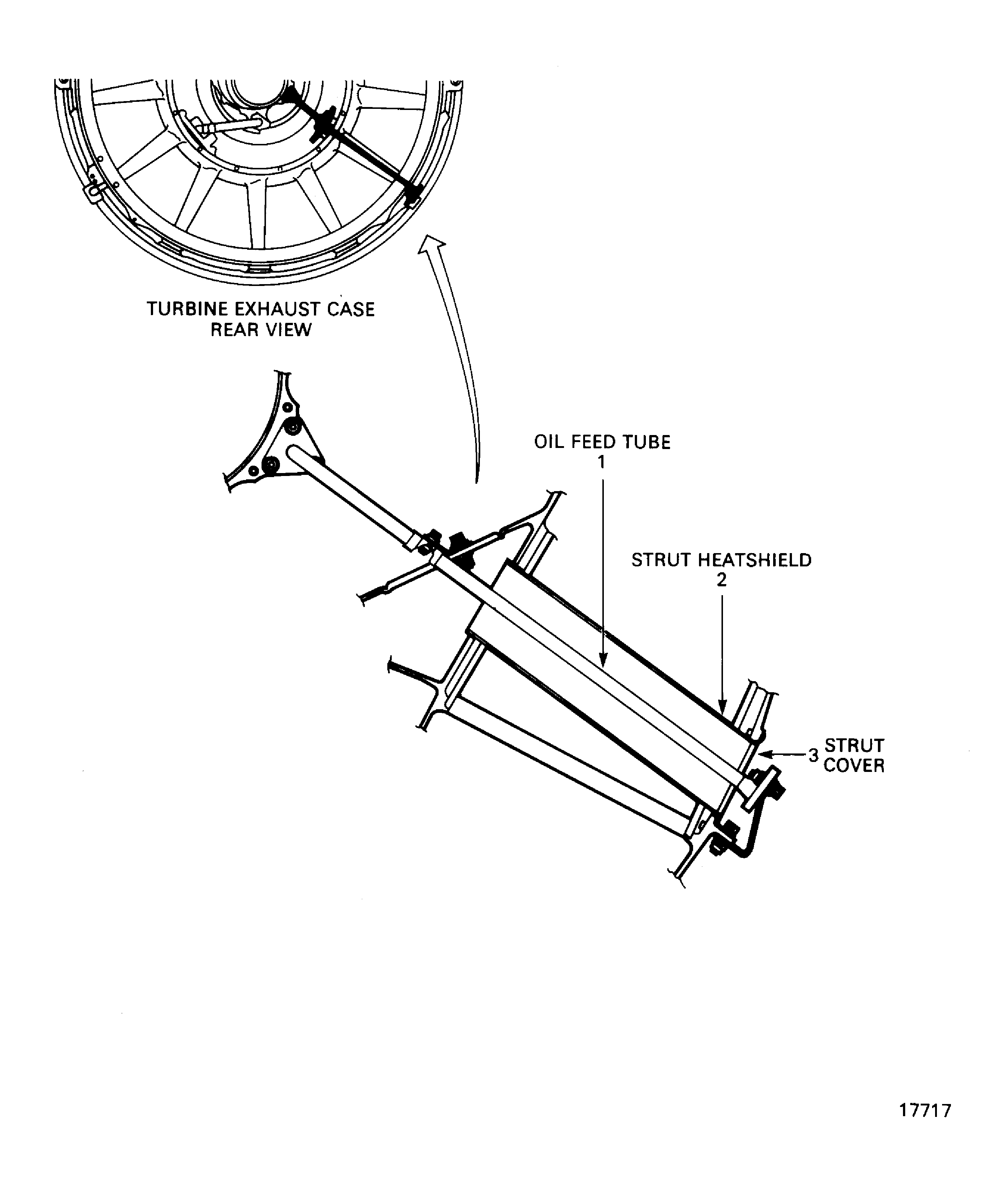

Refer to Figure.

Repair, VRS5390 TASK 72-50-53-300-006 (REPAIR-006)

Evident chafing wear

Chafing wear at the point where it penetrates the strut cover.

Install IAE 2F10183 Fixture 1 off to the oil feed tube

Do a pressure leak check as follows:

Repair, VRS5390 TASK 72-50-53-300-006 (REPAIR-006)

Leakages not because of malfitting of blanking

Pressure leak.

SUBTASK 72-50-53-220-057 Examine the Turbine Exhaust Case (01-001) Oil Feed Tube at Location 1

Refer to Figure.

Repair, VRS5391 TASK 72-50-53-300-007 (REPAIR-007)

Evident chafing wear

Chafing wear.

Install IAE 2F10331 Plug 1 off into the oil scavenge tube hole into No. 5 bearing compartment.

Install IAE 2F10332 Bracket 1 off into the No. 5 bearing compartment.

Attach IAE 2F10330 Adapter,leak test Scavenge tube 1 off to the outer oil scavenge tube flange.

Connect IAE 6F10029 Air flow test cart 1 off to the adapter.

Do a pressure leak check as follows:

Repair, VRS5391 TASK 72-50-53-300-007 (REPAIR-007)

Leakages not because of malfitting of the plug

Pressure leak.

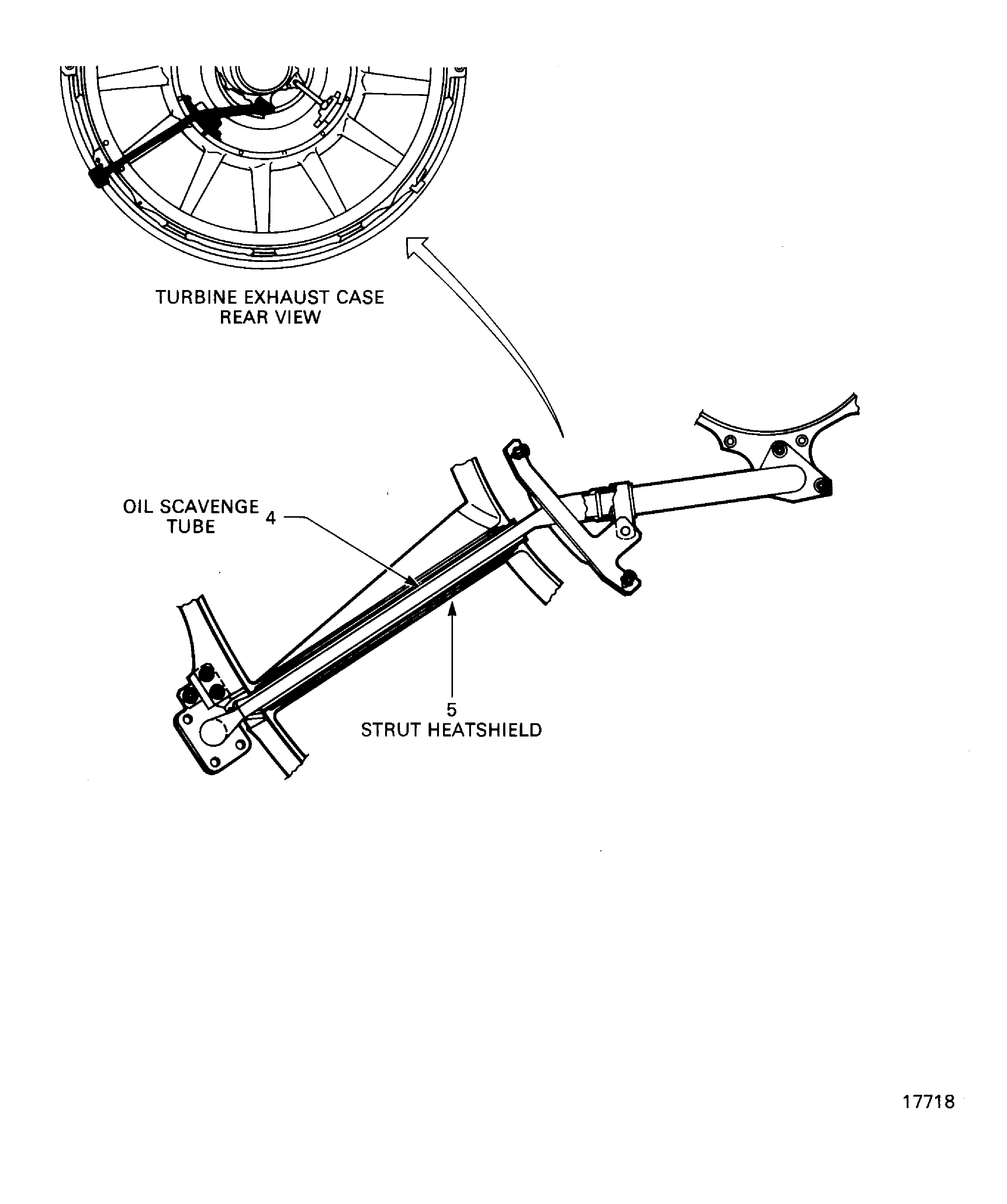

SUBTASK 72-50-53-220-058 Examine the Turbine Exhaust Case (01-001) Oil Scavenge Tube at Location 4

Repair, VRS5389 TASK 72-50-53-300-005 (REPAIR-005)

Worn

SUBTASK 72-50-53-220-059 Examine the Turbine Exhaust Case (01-001) Oil Tubes Flanges

Refer to Figure.

Repair, VRS5389 TASK 72-50-53-300-005 (REPAIR-005)

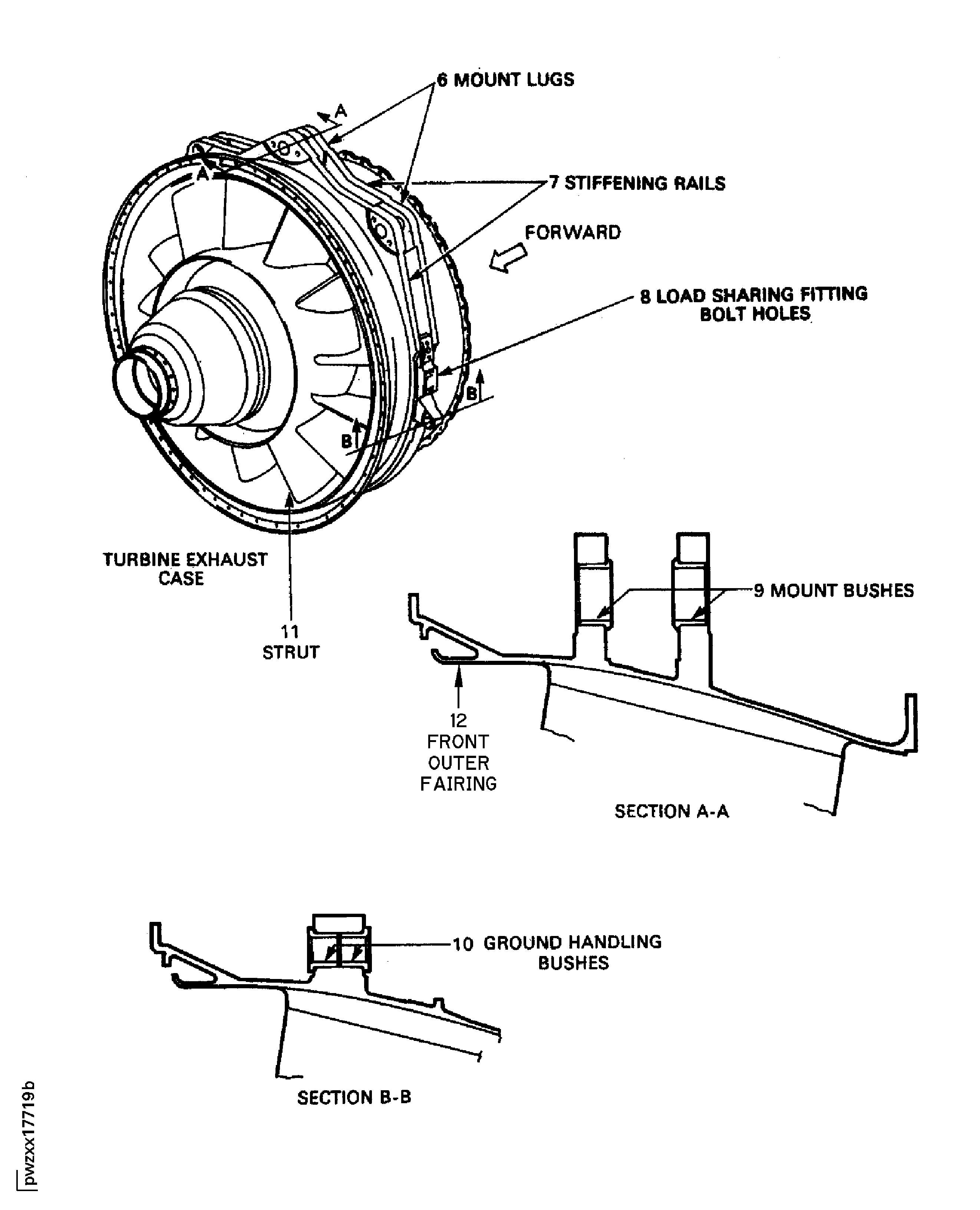

Damaged

SUBTASK 72-50-53-220-060 Examine the Turbine Exhaust Case (01-001) Mount Lugs at Location 6 and the Stiffening Rails at Location 7

Refer to Figure.

SUBTASK 72-50-53-220-080 Examine the Turbine Exhaust Case (01-001) Load Sharing Fitting Bolt Holes at Location 8

Repair, VRS5392 TASK 72-50-53-300-008 (REPAIR-008)

Loose, not there or with internal thread damage

SUBTASK 72-50-53-220-061 Examine the Turbine Exhaust Case (01-001) Helicoils

Refer to Figure.

Repair, VRS5393 TASK 72-50-53-300-009 (REPAIR-009)

More than 1.1885 in. (30.188 mm)

Worn.

Repair, VRS5389 TASK 72-50-53-300-005 (REPAIR-005)

Between 0.004 and 0.008 in. (0.10 and 0.20 mm)

Repair, VRS5393 TASK 72-50-53-300-009 (REPAIR-009)

More than 0.008 in. (0.20 mm)

Scored.

Inner diameter.

SUBTASK 72-50-53-220-062 Examine the Turbine Exhaust Case (01-001) Mount Bushings at Location 9

Refer to Figure.

Repair, VRS5394 TASK 72-50-53-300-010 (REPAIR-010)

More than 0.5912 in. (15.018 mm)

Worn.

Repair, VRS5389 TASK 72-50-53-300-005 (REPAIR-005)

Between 0.004 and 0.008 in. (0.10 and 0.20 mm)

Repair, VRS5394 TASK 72-50-53-300-010 (REPAIR-010)

More than 0.008 in. (0.20 mm)

Scored.

Inner diameter.

SUBTASK 72-50-53-220-063 Examine the Turbine Exhaust Case (01-001) Ground Handling Bushings at Location 10

Refer to Figure.

Repair, VRS5389 TASK 72-50-53-300-005 (REPAIR-005)

More than (a)

Damage.

Leading and trailing edges.

Repair, VRS5389 TASK 72-50-53-300-005 (REPAIR-005)

More than (a)

Nicked or dented.

Repair, VRS3743 TASK 72-50-53-300-083 (REPAIR-083)

Strut airfoil damage that is more than (a), with no damage to the solid leading edges of instrumented struts

Other surfaces.

SUBTASK 72-50-53-220-064 Examine the Turbine Exhaust Case (01-001) Struts at Location 11

Refer to Figure.

Repair, VRS5397 TASK 72-50-53-300-013 (REPAIR-013)

Worn

Front face at location 20.

Repair, VRS5398 TASK 72-50-53-300-014 (REPAIR-014)

More than 38.672 in. (982.28 mm)

Worn.

Inner diameter at location 19.

Repair, VRS3804 TASK 72-50-53-300-087 (REPAIR-087) or Repair, VRS5399 TASK 72-50-53-300-015 (REPAIR-015)

More than 0.330 in. (8.38 mm) in length

Worn or elongated.

Boltholes.

SUBTASK 72-50-53-220-065 Examine the Turbine Exhaust Case (01-001) Front Outer Flange at Location 12

Refer to Figure.

Repair, VRS5400 TASK 72-50-53-300-016 (REPAIR-016) or Repair, VR3732 TASK 72-50-53-300-078 (REPAIR-078).

More than (a)

Parallelism.

Repair, VRS5400 TASK 72-50-53-300-016 (REPAIR-016) or Repair, VR3732 TASK 72-50-53-300-078 (REPAIR-078).

Worn

Rear face at location 15.

Repair, VRS3731 TASK 72-50-53-300-080 (REPAIR-080)

More than 33.0236 in. (838.799 mm)

Worn.

Repair, VRS3731 TASK 72-50-53-300-080 (REPAIR-080)

More than (a)

Concentricity.

Repair, VRS3731 TASK 72-50-53-300-080 (REPAIR-080)

More than (a)

Perpendicularity.

Inner diameter at location 16.

SUBTASK 72-50-53-220-066 Examine the Turbine Exhaust Case (01-001) Rear Outer Flange at Location 13

Refer to Figure.

Repair, VRS5403 TASK 72-50-53-300-019 (REPAIR-019) or Repair, VRS3654 TASK 72-50-53-300-077 (REPAIR-077) or Repair, VRS3799 TASK 72-50-53-300-086 (REPAIR-086)

Less than 0.035 in. (0.89 mm) in depth

Wear or damage.

Repair, VRS5403 TASK 72-50-53-300-019 (REPAIR-019) or Repair, VRS3654 TASK 72-50-53-300-077 (REPAIR-077)

More than (a)

Rear face at location 17.

SUBTASK 72-50-53-220-067 Examine the Turbine Exhaust Case (01-001) Rear Inner Flange at Location 14

Refer to Figure.

Repair, VRS5413 TASK 72-50-53-300-029 (REPAIR-029)

Loose, not there or with internal thread damaged

SUBTASK 72-50-53-220-068 Examine the Turbine Exhaust Case (01-001) Self Locking Shank Nut on Rear Inner Flange at Location 18

Refer to Figure.

Repair, VRS5405, TASK 72-50-53-300-021 (REPAIR-021)

More than 0.125 in. (31.73 mm) deep or with sharp edges, cracks or tears

Nicked or dented.

SUBTASK 72-50-53-220-009 Examine the Turbine Exhaust Case (01-001) Thermal Blanket at Location 21

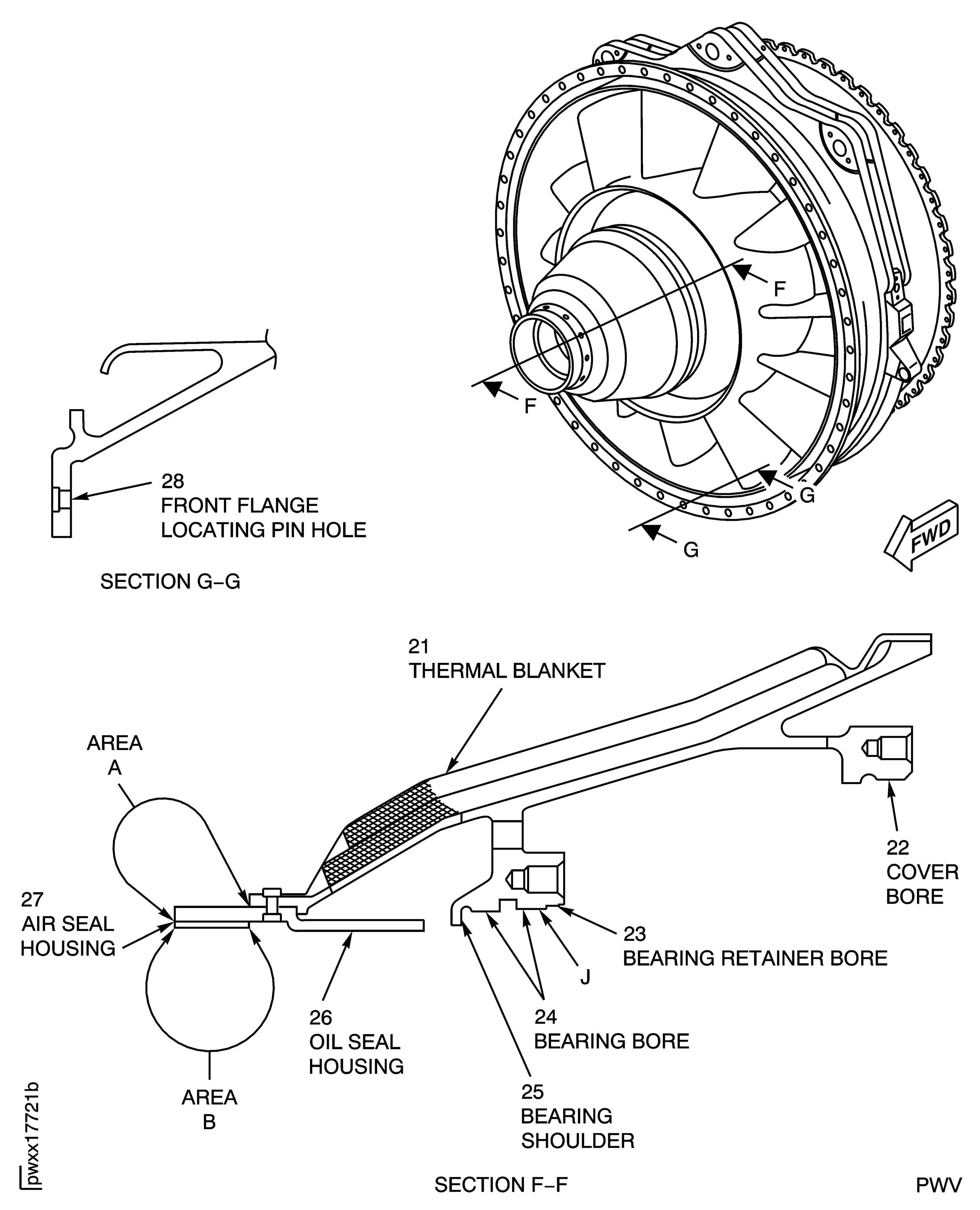

Refer to Figure.

Repair, VRS5406 TASK 72-50-53-300-022 (REPAIR-022)

More than 7.1976 in. (182.818 mm)

Worn.

SUBTASK 72-50-53-220-070 Examine the Turbine Exhaust Case (01-001) Cover Bore at Location 22

Refer to Figure.

Repair, VRS5407 TASK 72-50-53-300-023 (REPAIR-023)

More than 5.5930 in. (142.063 mm)

Worn.

Repair, VRS5407 TASK 72-50-53-300-023 (REPAIR-023)

More than (1)

Concentricity.

SUBTASK 72-50-53-220-071 Examine the Turbine Exhaust Case (01-001) Bearing Retainer Bore at Location 23

Refer to Figure.

Repair, VRS5408 TASK 72-50-53-300-024 (REPAIR-024)

More than 5.5228 in. (140.278 mm)

Worn.

Repair, VRS5408 TASK 72-50-53-300-024 (REPAIR-024)

More than (1)

Runout.

SUBTASK 72-50-53-220-072 Examine the Turbine Exhaust Case (01-001) Bearing Bore at Location 24

Refer to Figure.

Repair, VRS5409 TASK 72-50-53-300-025 (REPAIR-025)

More than (1)

Perpendicularity.

SUBTASK 72-50-53-220-073 Examine the Turbine Exhaust Case (01-001) Bearing Shoulder at Location 25

Refer to Figure.

Repair, VRS5410 TASK 72-50-53-300-026 (REPAIR-026)

More than 5.1984in. (132.040 mm)

Worn.

Repair, VRS5410 TASK 72-50-53-300-026 (REPAIR-026)

More than (1)

Concentricity.

SUBTASK 72-50-53-220-074 Examine the Turbine Exhaust Case (01-001) Oil Seal Housing at Location 26

Refer to Figure.

Repair, VRS5410 TASK 72-50-53-300-026 (REPAIR-026)

More than 5.5551 in. (141.100 mm)

Worn.

Repair, VRS5410 TASK 72-50-53-300-026 (REPAIR-026)

More than (1)

Concentricity.

Repair, VRS5410 TASK 72-50-53-300-026 (REPAIR-026)

More than (1)

Nicked, dented or scratched at area A.

Repair, VRS5410 TASK 72-50-53-300-026 (REPAIR-026)

More than (1)

Grooved circumferentially at area B.

Repair, VRS5410 TASK 72-50-53-300-026 (72-50-53 REPAIR 026)

Raised material at area B

SUBTASK 72-50-53-220-075 Examine the Turbine Exhaust Case (01-001) Air Seal Housing at Location 27

Refer to Figure.

Repair, VRS5411 TASK 72-50-53-300-027 (REPAIR-027) or Repair, VRS3804 TASK 72-50-53-300-087 (REPAIR-087) or Repair, VRS5399 TASK 72-50-53-300-015 (REPAIR-015)

More than 0.2589 in. (6.576 mm)

Worn.

Repair, VRS5411 TASK 72-50-53-300-027 (REPAIR-027) or Repair, VRS3804 TASK 72-50-53-300-087 (REPAIR-087) or Repair, VRS5399 TASK 72-50-53-300-015 (REPAIR-015)

More than 0.004 in. (0.10 mm) diameter in relation to surface W

True position.

SUBTASK 72-50-53-220-076 Examine the Turbine Exhaust Case (01-001) Front Flange Locating Pin Hole at Location 28

Refer to Figure.

Repair, VRS5412 TASK 72-50-53-300-028 (REPAIR-028)

More than (1)

Worn.

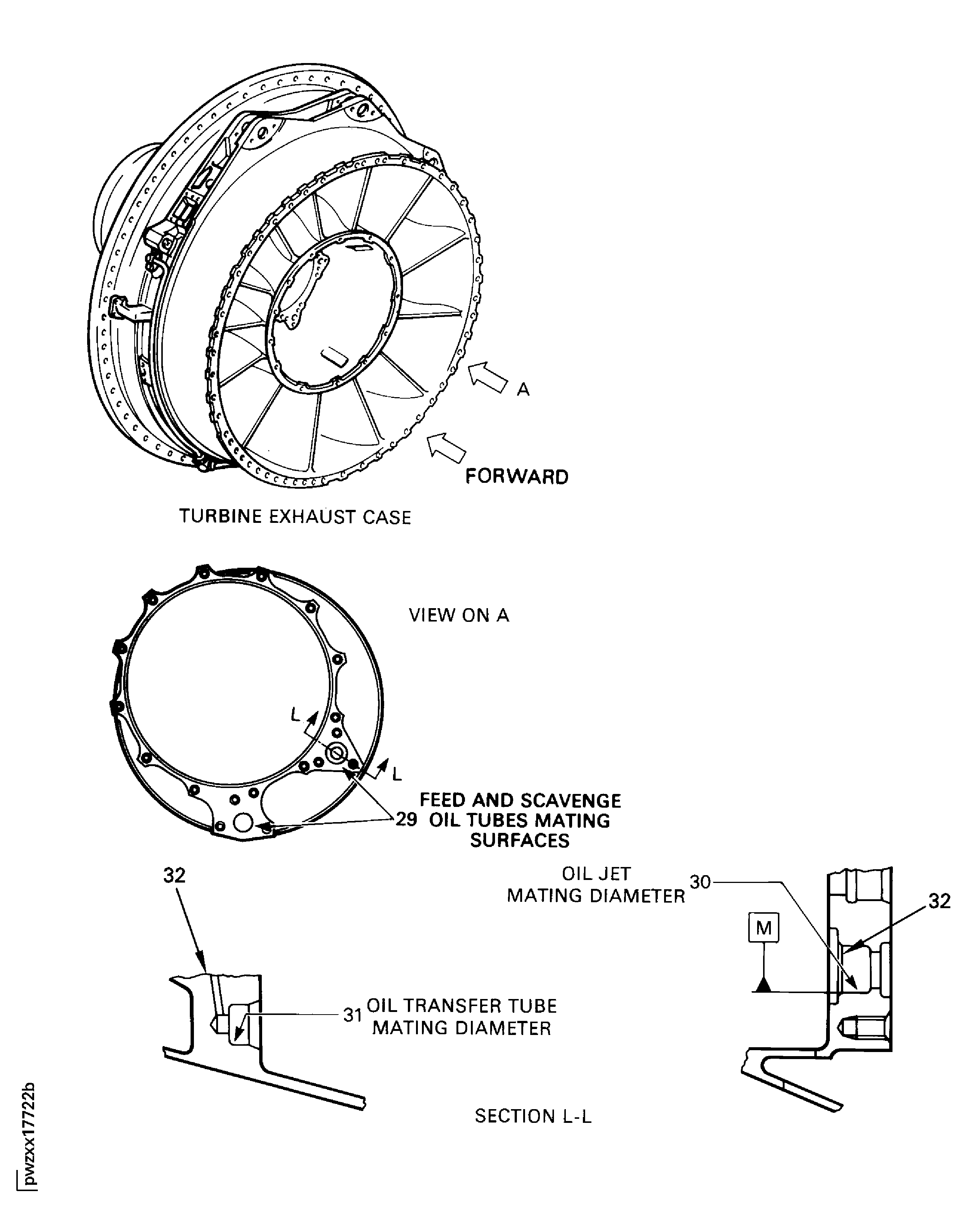

SUBTASK 72-50-53-220-077 Examine the Turbine Exhaust Case (01-001) Feed and Scavenge Oil Tubes Mating Surfaces at Location 29

Refer to Figure.

SUBTASK 72-50-53-220-078 Examine the Turbine Exhaust Case (01-001) Oil Jet Mating Diameter at Location 30

Refer to Figure.

SUBTASK 72-50-53-220-079 Examine the Turbine Exhaust Case (01-001) Oil Transfer Tube Mating Diameter at Location 31

Refer to Figure.

Clean, TASK 72-50-53-100-010

NOTE

The nozzle, elbow and strainer need to be checked. They must be free of any loose coke or particles, which can block all nozzles in operation.

Coke or carbon

SUBTASK 72-50-53-220-238 Examine the Turbine Exhaust Case (01-001) Feed and Scavenge Tube Mating Surfaces and Internal Passages for Coke or Blockages at Location 32

Refer to Figure.

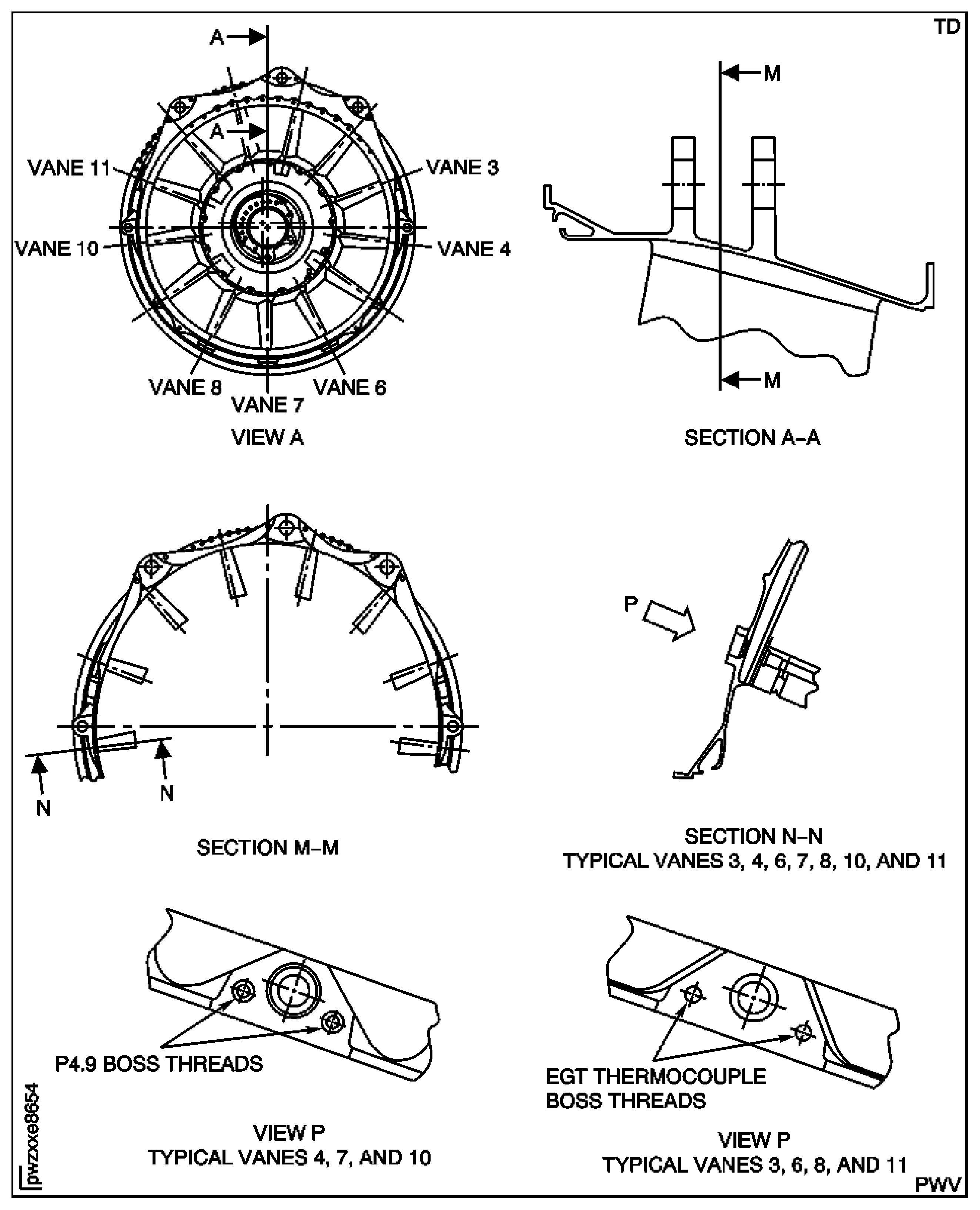

Repair, VRS3763 TASK 72-50-53-300-085 (REPAIR-085)

Thread damage at the 3, 4, 6, 7, 8, 10 and 11 vane locations

SUBTASK 72-50-53-220-260 Examine the Turbine Exhaust Case P4.9 Probe Boss Threads and EGT Thermocouple Boss Threads

Refer to Figure.

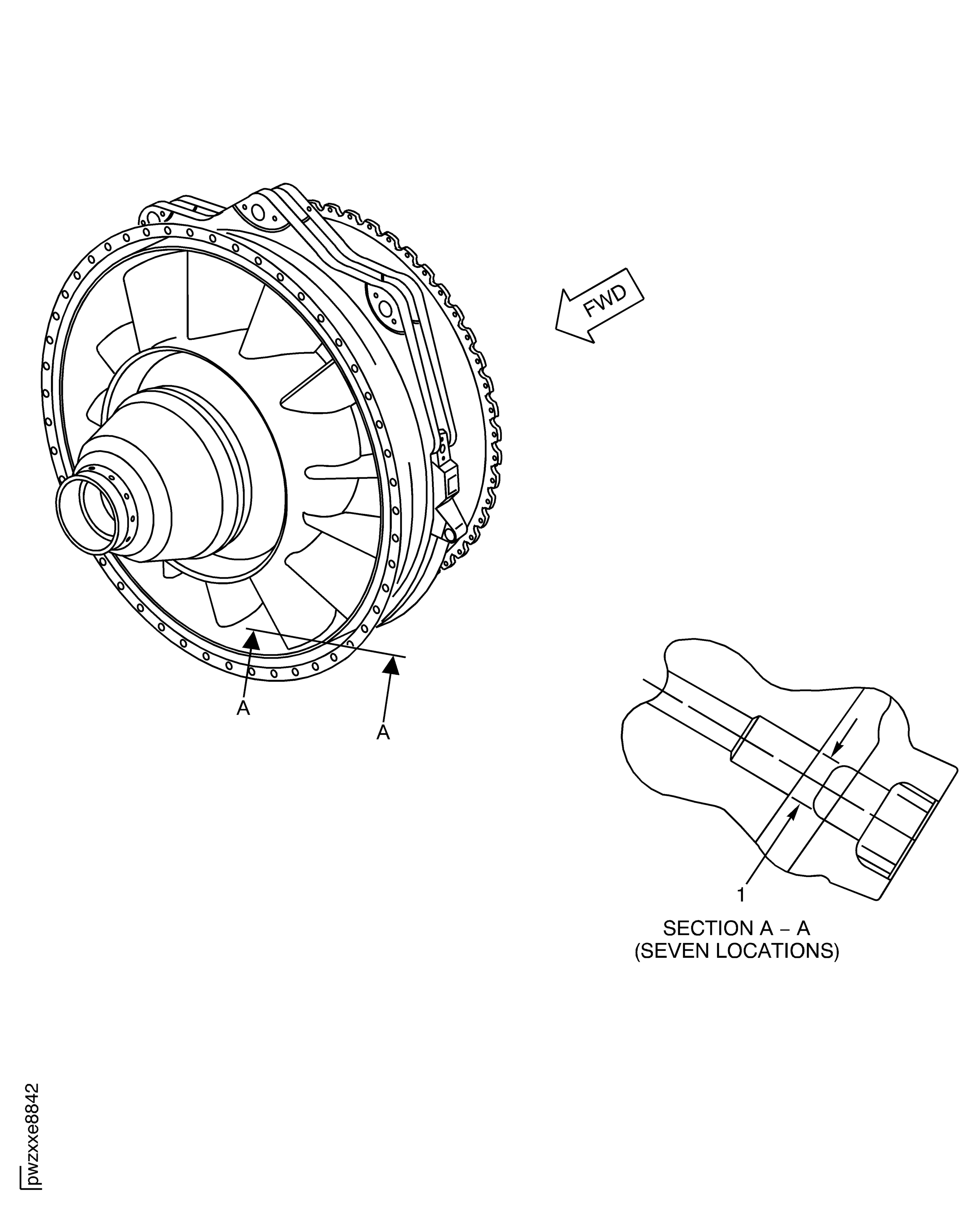

Repair, VRS3068 TASK 72-50-53-300-088 (Repair-088)

More than 0.4338 in. (11.018 mm) and to a maximum of 0.4400 in. (11.176 mm)

Examine the bore at Location 1 for the diameter

SUBTASK 72-50-53-220-274 If You Remove the Instrumentation Bushing (02-140), Examine the Turbine Exhaust Case (02-300) Instrumentation Bushing Bore

Figure: Locations - Turbine Exhaust Case

Sheet 1

Figure: Locations - Turbine Exhaust Case

Sheet 2

Figure: Locations - Turbine Exhaust Case

Sheet 3

Figure: Locations - Turbine Exhaust Case

Sheet 4

Figure: Locations - Turbine Exhaust Case

Sheet 5

Figure: Locations - Turbine Exhaust Case

Sheet 6

Figure: P4.9 Probe Boss and EGT Thermocouple Boss Locations Turbine Exhaust Case

Sheet 7

Figure: Turbine Exhaust Case - Crack Inspection

Turbine Exhaust Case - Crack Inspection

Figure: Turbine Exhaust Case - Leading Edge Weld Area Inspection Location

Turbine Exhaust Case - Leading Edge Weld Area Inspection Location

Figure: Turbine Exhaust Case Instrumentation Bushing Bore Inspection Location

Turbine Exhaust Case Instrumentation Bushing Bore Inspection Location

Figure: Turbine Exhaust Case - Alternate Datum

Turbine Exhaust Case - Alternate Datum