Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-00-40-420-004-A00 HP System Module - Install The Initial HP System Module Components And Air Off-Take Ducts, Installation-007

General

This TASK gives the procedure to install the components and the air off take ducts on the HP compressor/diffuser case assembly. Refer to the TASKS which follow for other related procedures:

TASK 72-00-40-420-005-A00 (INSTALLATION-008, CONFIG-001) or TASK 72-00-40-420-005-B00 (INSTALLATION-008, CONFIG-002). Install the components, the ducts, the electrical harnesses and the tubes on to the HP compressor case vertical split line.

TASK 72-00-40-420-006-A00 (INSTALLATION-009, CONFIG-001) or TASK 72-00-40-420-006-B00 (INSTALLATION-009, CONFIG-002). Install and connect the components, the electrical harnesses and the tubes on to the front of the HP compressor case.

TASK 72-00-40-420-007-A00 (INSTALLATION-010, CONFIG-001) or TASK 72-00-40-420-007-B00. Install the components, the electrical harnesses and the tubes on to the HP turbine.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

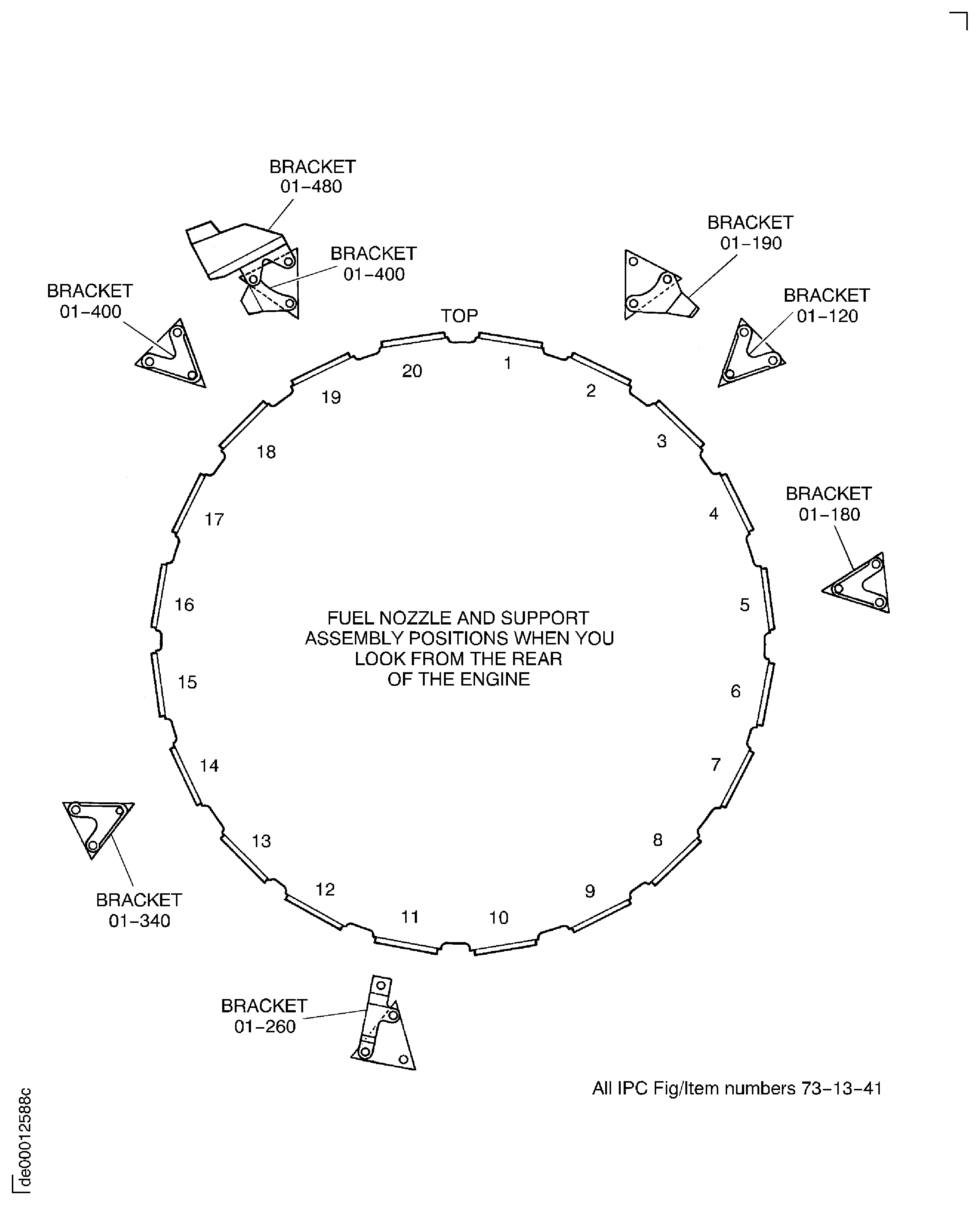

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

For standard torque data and procedures refer to SPM TASK 70-41-01-400-501.

Special torque data is identified with the symbol * after the torque value.

Assembly tolerances are included in this procedure.

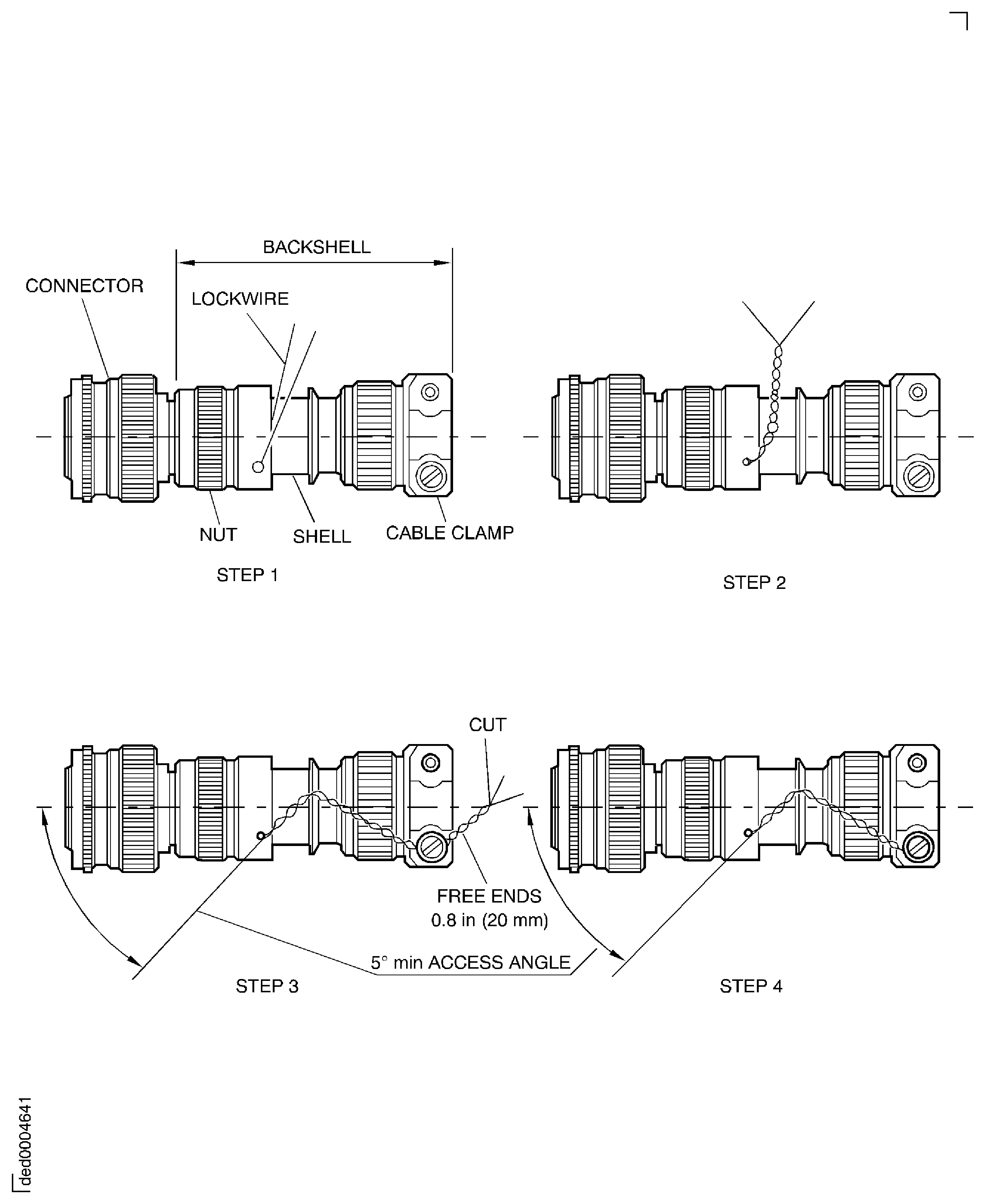

For lockwire data and procedures refer to SPM TASK 70-42-05-400-501.

Safety the threaded fasteners in this TASK with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT for the ATA Chapter/Section/Subjects which follow:

For safety cable data and procedures refer to SPM TASK 70-42-08-400-501.

Refer to the V2500 Illustrated Tool and Equipment Manual (ITE-V2500-1IA) for the illustrations of the special tools used in this procedure.

Transportation covers/blanks must not be removed until immediately before installation of the components.

Do not remove the special plastic caps from electrical connections or tube connections which are not applicable in this procedure. This will give protection from unwanted material.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS unless other lubricants are referred to in this procedure.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL damaged surface protection, joint flanges and attach parts. Use the correct color of air drying enamel. Refer to SPM TASK 70-38-21-380-501.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1P16092 Igniter immersion gage | 0AM53 | IAE 1P16092 | 1 | |

| IAE 1P16139 Wrench | 0AM53 | IAE 1P16139 | 1 | |

| IAE 1R18001 Wrench | 0AM53 | IAE 1R18001 | 1 | |

| IAE 1R18003 Wrench | 0AM53 | IAE 1R18003 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| DELETED | LOCAL | DELETED | ||

| CoMat 01-573 WAX BLEND, PARAFFIN | 24269 | CoMat 01-573 | ||

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 02-141 LOCKWIRE | LOCAL | CoMat 02-141 | ||

| CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) | LOCAL | CoMat 02-148 | ||

| CoMat 02-274 SAFETY CABLE KIT | LOCAL | CoMat 02-274 | ||

| CoMat 02-275 SAFETY CABLE KIT | LOCAL | CoMat 02-275 | ||

| CoMat 07-038 AIR DRYING ENAMEL | k3504 | CoMat 07-038 | ||

| CoMat 10-003 COLLOIDAL GRAPHITE DRY FILM LUBRICANT | LOCAL | CoMat 10-003 | ||

| CoMat 10-038 PETROLEUM JELLY | LOCAL | CoMat 10-038 | ||

| CoMat 10-060 LIQUID PARAFFIN | LOCAL | CoMat 10-060 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Preformed packing | 18 | |||

| Gasket | 3 | |||

| Gasket | 6 | |||

| Preformed packing | 18 | |||

| Gasket | 3 | |||

| Gasket | 6 | |||

| Preformed packing | 24 | |||

| Gasket | 4 | |||

| Gasket | 8 |

Safety Requirements

NONEProcedure

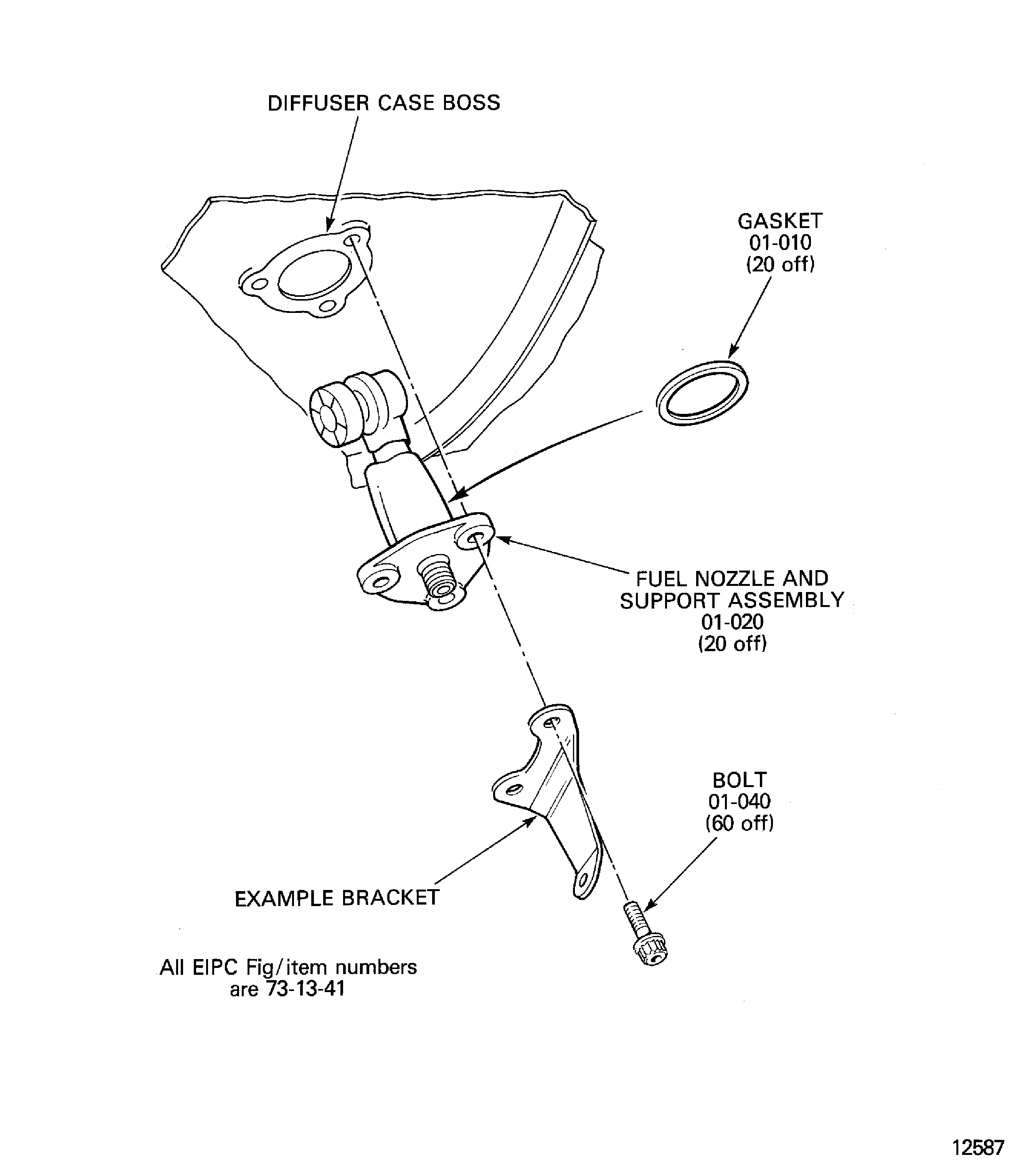

Install the 20 gaskets ENGINE FUEL AND CONTROL-FUEL NOZZLE (73-13-41, 01-010) in to the recesses on the diffuser case. Use CoMat 01-573 WAX BLEND, PARAFFIN to hold the gaskets in position.

Install 13 of the fuel nozzles ENGINE FUEL AND CONTROL-FUEL NOZZLE (73-13-41, 01-020) at assembly positions 1, 4, 6, 7, 8, 9, 10, 12, 13, 15, 16, 17 and 20. Attach each fuel nozzle to the diffuser case with three bolts ENGINE FUEL AND CONTROL-FUEL NOZZLE (73-13-41, 01-040). Torque the bolts to 65 * lbf.in to 85 * lbf.in (7.3 Nm to 10 Nm) and safety with CoMat 02-141 LOCKWIRE.

Position 2 - Install the fuel nozzle, the bracket ENGINE FUEL AND CONTROL-FUEL NOZZLE (73-13-41, 01-190) and three bolts.

NOTE

Refer to Step (SBE 73-0139) which gives the procedure to install the bracket ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 01-258) on top of bracket ENGINE FUEL AND CONTROL-FUEL NOZZLE (73-13-41, 01-120).Position 3 - Install the fuel nozzle, the bracket ENGINE FUEL AND CONTROL-FUEL NOZZLE (73-13-41, 01-120) and three bolts.

Position 5 - Install the fuel nozzle, the bracket ENGINE FUEL AND CONTROL-FUEL NOZZLE (73-13-41, 01-180) and three bolts.

Position 11 - Install the fuel nozzle the bracket ENGINE FUEL AND CONTROL-FUEL NOZZLE (73-13-41, 01-260) and three bolts.

Position 14 - Install the fuel nozzle, the bracket ENGINE FUEL AND CONTROL-FUEL NOZZLE (73-13-41, 01-340) and three bolts.

Position 18 - Install the fuel nozzle, the bracket ENGINE FUEL AND CONTROL-FUEL NOZZLE (73-13-41, 01-400) and three bolts.

Position 19 - Install the fuel nozzle, the two brackets ENGINE FUEL AND CONTROL-FUEL NOZZLE (73-13-41, 01-450) and ENGINE FUEL AND CONTROL-FUEL NOZZLE (73-13-41, 01-480) and three bolts.

Torque all the bolts to 65 * lbf.in to 85 * lbf.in (7.3 Nm to 10 Nm) and safety with CoMat 02-141 LOCKWIRE.

Install the remaining seven fuel nozzles together with their applicable brackets at the assembly positions that follow:

SUBTASK 72-00-40-420-071 Install the Fuel Nozzles

Install the two threaded inserts IGNITION-IGNITER PLUGS (74-21-41, 01-020) in the diffuser case until the bottom of the flange of the insert touches the diffuser case.

With the IAE 1P16092 Igniter immersion gage 1 off; measure the distance E, from the top of the insert, to the point L on the outer combustion chamber nearest the fuel nozzle.

NOTE

Refer to EIPC 74-21-41 Fig. 01 for the applicable range of spacers available.Use initial immersion depth F and, if required, one or two spacers. Make a selection from the available spacers IGNITION-IGNITER PLUGS (74-21-41, 01-042) thru IGNITION-IGNITER PLUGS (74-21-41, 01-076) to get an immersion depth of 0.040 to 0.080 in. (1.02 to 2.03 mm). A maximum of two spacers can be used at each igniter location. The total thickness of the two spacers must not be more than 0.300in. (7.62 mm).

Torque the insert to 600 to 700 * lbf.in (68 to 79 Nm). Safety the insert to the bolt on the adjacent fuel nozzle with CoMat 02-141 LOCKWIRE.

CAUTION

APPLY ANTI-SEIZE COMPOUND MODERATELY TO THE PLUG THREAD. YOU MUST NOT APPLY TOO MUCH COMPOUND, AS IT CAN GO IN TO THE ENGINE.Apply CoMat 10-003 COLLOIDAL GRAPHITE DRY FILM LUBRICANT to the plug thread.

Install the two igniter plugs and torque to 300 to 360 * lbf.in (34 to 41 Nm). Safety the igniter plug and the insert with CoMat 02-141 LOCKWIRE.

SUBTASK 72-00-40-420-072 Install the Igniter Plugs

Refer to Figure.

Install the gasket ENGINE FUEL AND CONTROL-P3/T3 SENSOR (73-22-15, 01-010) on to the diffuser case and install the P3/T3 sensor ENGINE FUEL AND CONTROL-P3/T3 SENSOR (73-22-15, 01-030) with the tube connection to the left.

Install the three bolts ENGINE FUEL AND CONTROL-P3/T3 SENSOR (73-22-15, 01-050) and torque to 85 to 105 lbf.in (10 to 12 Nm).

SUBTASK 72-00-40-420-073 Install the P3/T3 Sensor

Refer to Figure.

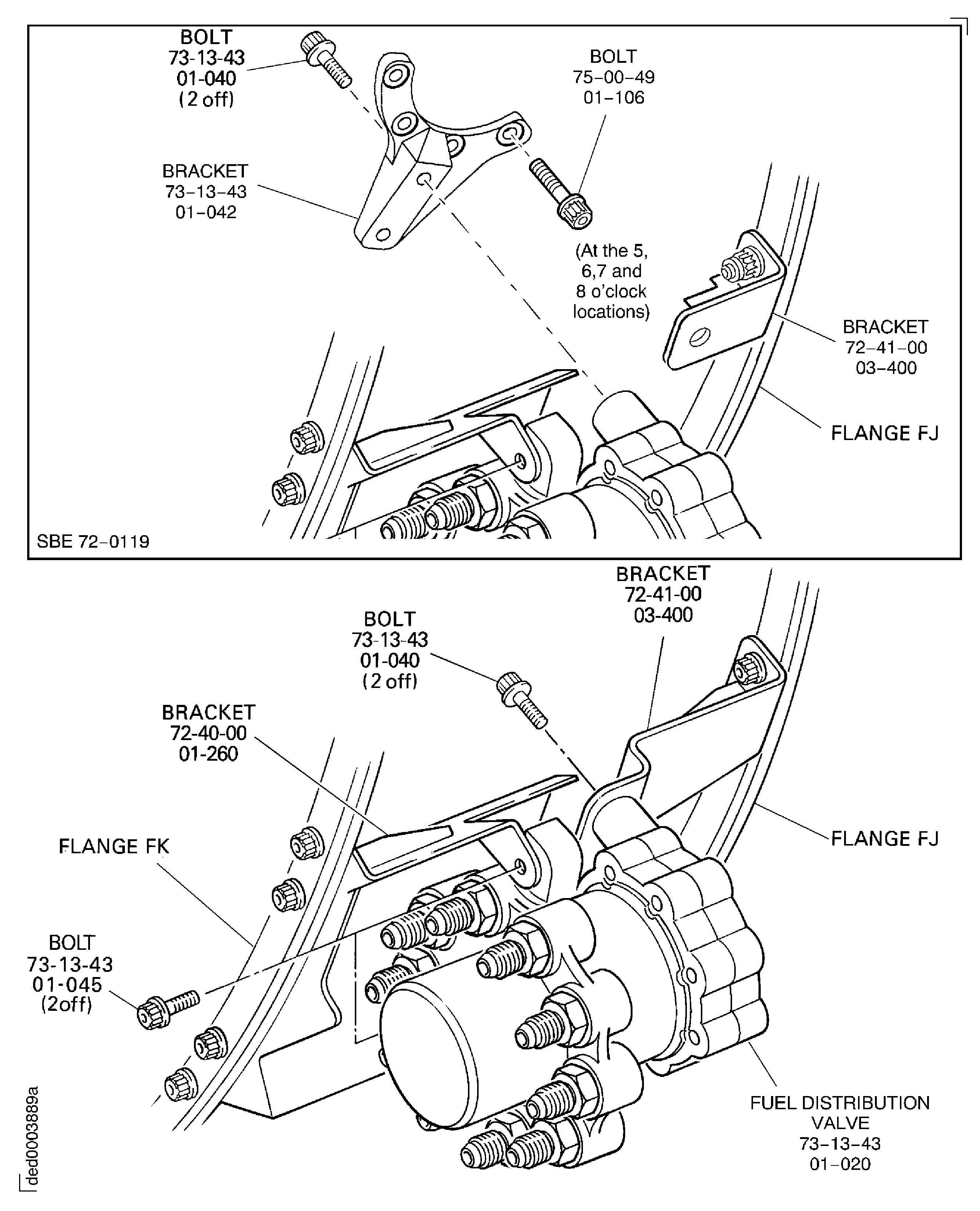

Attach the fuel distribution valve to the brackets ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 03-400) and ENGINE-DIFFUSER AND COMBUSTION GROUP (72-42-00, 01-260) with the four bolts ENGINE FUEL AND CONTROL-FUEL DISTRIBUTION VALVE (73-13-43, 01-040) and ENGINE FUEL AND CONTROL-FUEL DISTRIBUTION VALVE (73-13-43, 01-045). Torque the bolts to 125 to 170 * lbf.in (14 to 19 Nm).

SUBTASK 72-00-40-420-075-A00 Install the Fuel Distribution Valve (Pre SBE 72-0119)

Refer to Figure.

Attach the fuel distribution valve to the bracket HPC Module - Attaching Parts (72-40-00, 01-260) with the two bolts ENGINE FUEL AND CONTROL-FUEL DISTRIBUTION VALVE (73-13-43, 01-045). Torque the bolts to 125 to 170 * lbf.in (14 to 19 Nm).

Attach the fuel distribution valve support bracket ENGINE FUEL AND CONTROL-FUEL DISTRIBUTION VALVE (73-13-43, 01-042) with the two bolts ENGINE FUEL AND CONTROL-FUEL DISTRIBUTION VALVE (73-13-43, 01-040) to the fuel distribution valve. Torque the bolts to 180 to 200 lbf.in (20 to 24 Nm). Refer to TASK 72-00-40-420-005-A00 (72-00-40, INSTALLATION-08, CONFIG-1) SUBTASK 72-00-40-420-079-B00 for installation of upper part of bracket.

SUBTASK 72-00-40-420-075-B00 Install the Fuel Distribution Valve (SBE 72-0119)

SBE 72-0119: Provide new brackets and clamping at flange K and new fuel flow divider valve brackets

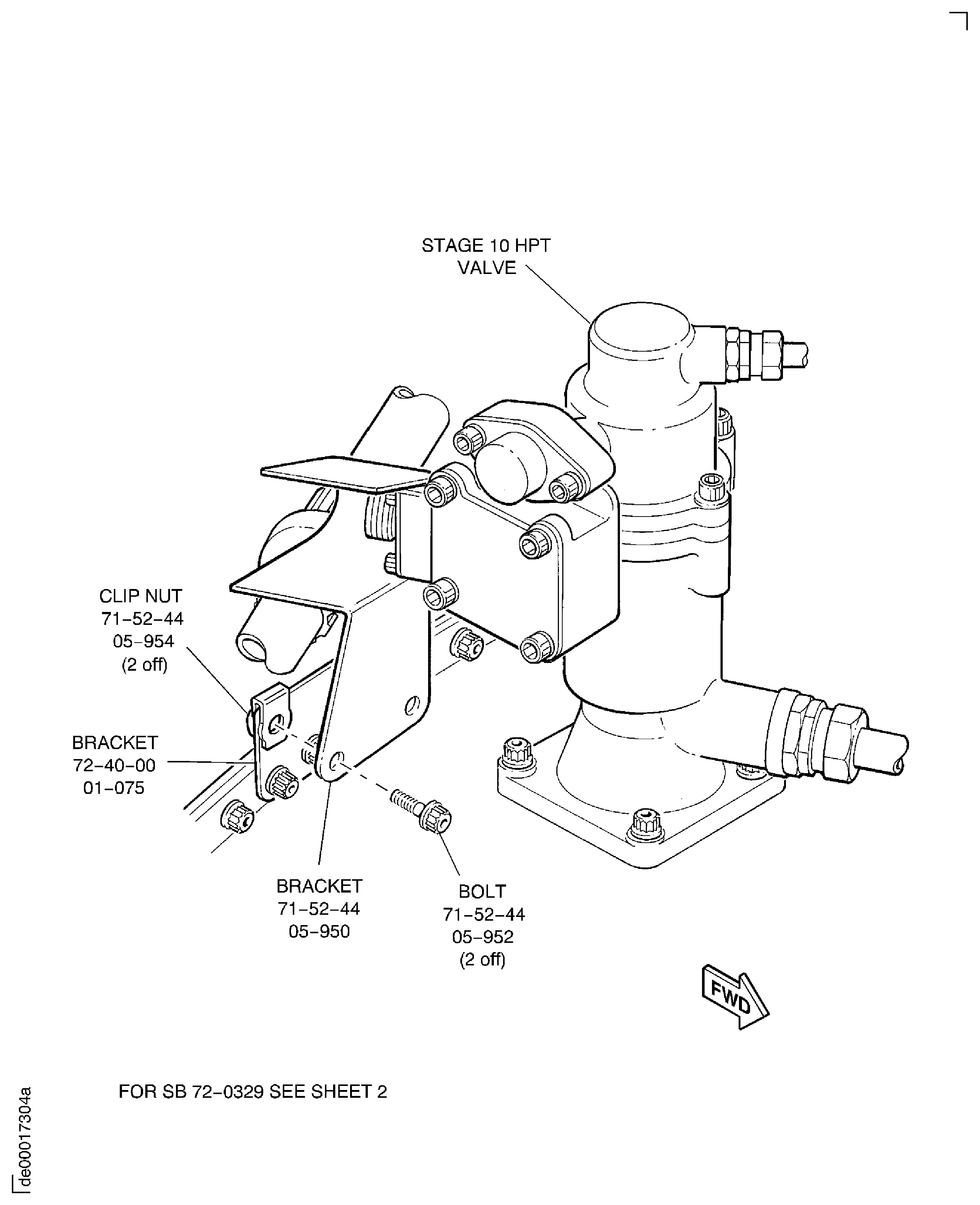

Refer to Figure.

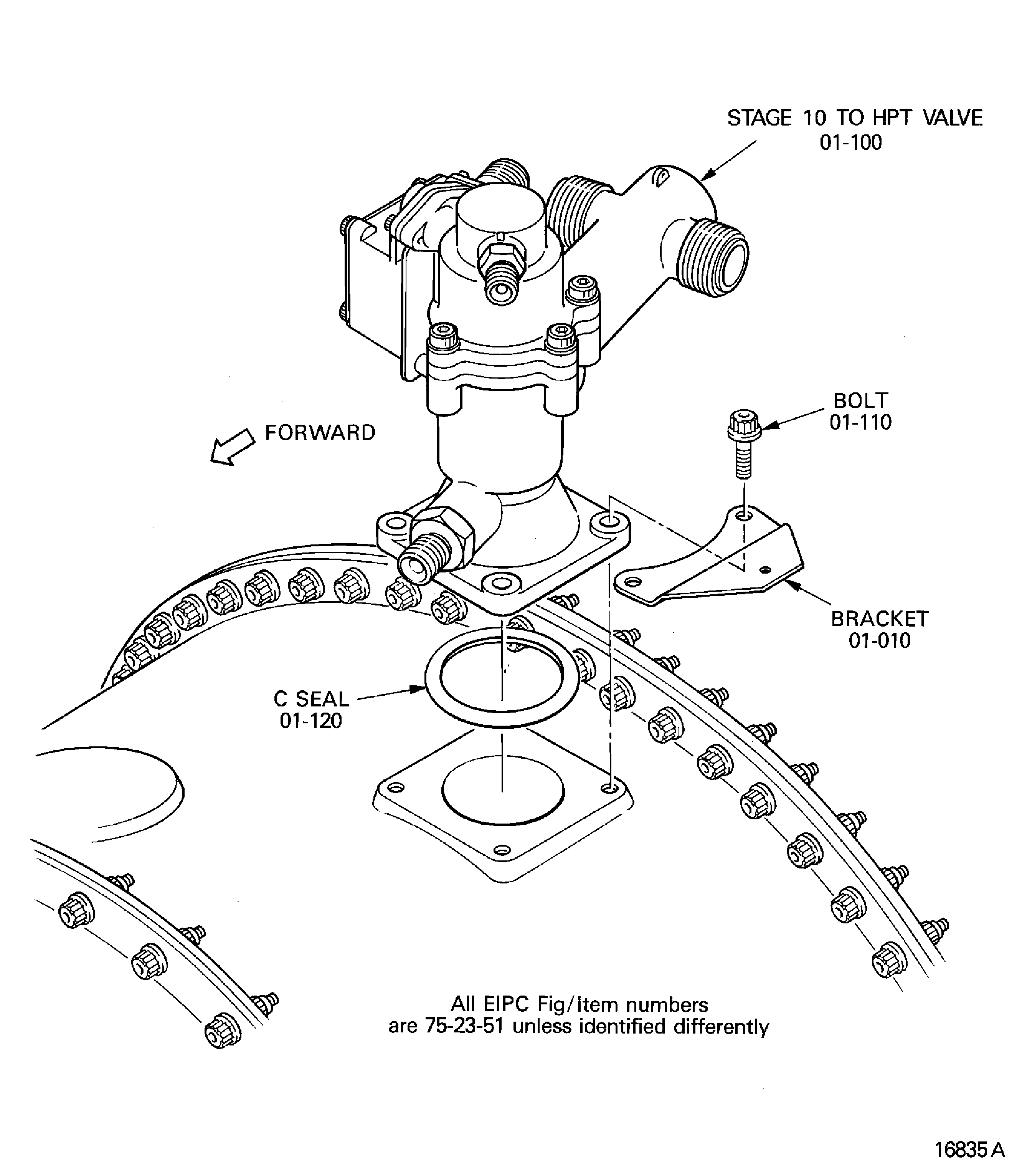

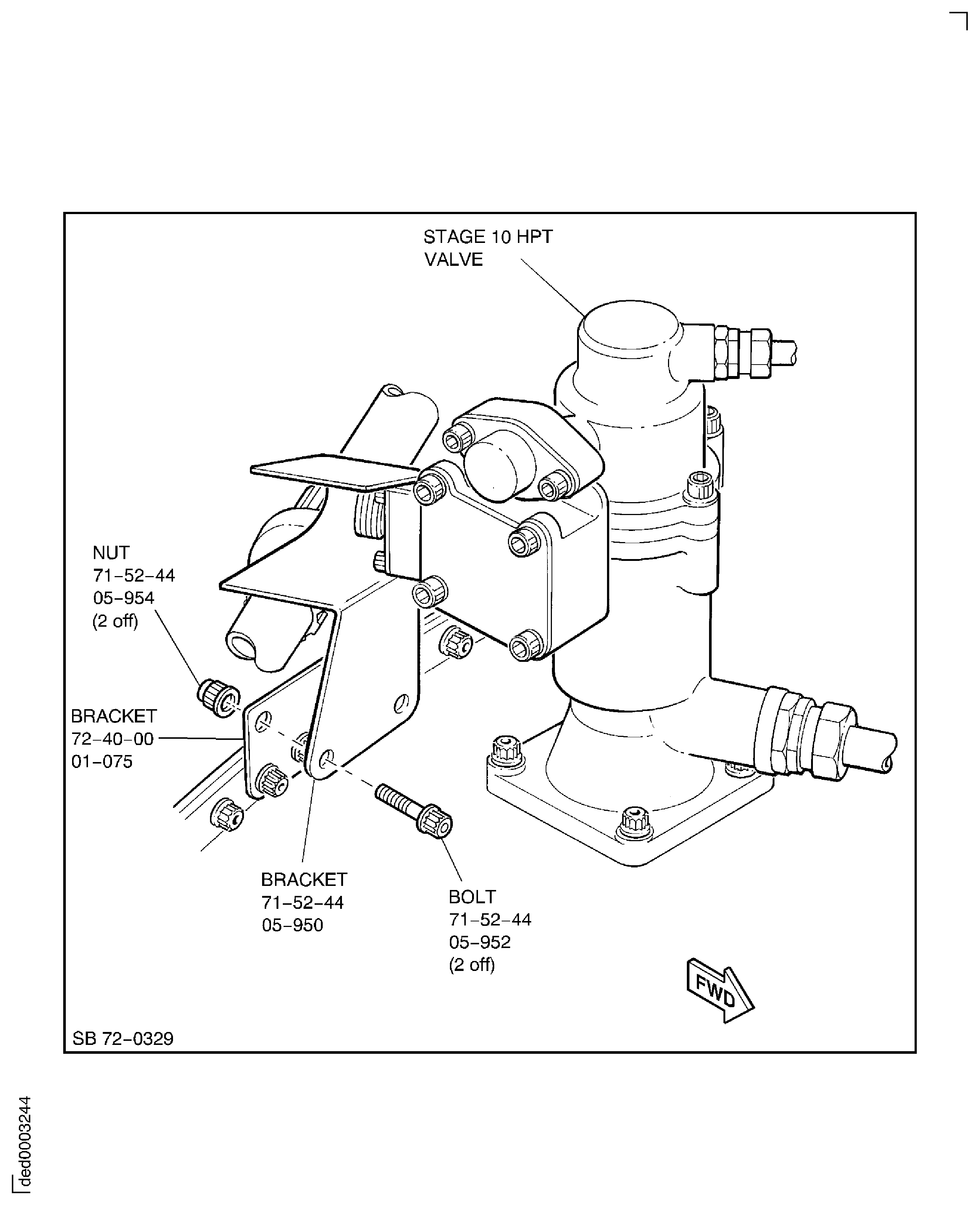

Install the C seal AIR-STAGE 10 TO HPT AIR VALVE (75-23-51, 01-120) in the recess in the stage 10 to HPT air valve AIR-STAGE 10 TO HPT AIR VALVE (75-23-51, 01-100).

Attach the stage 10 to HPT air valve to the HP compressor case with the four bolts AIR-STAGE 10 TO HPT AIR VALVE (75-23-51, 01-110), together with the bracket AIR-STAGE 10 TO HPT AIR VALVE (75-23-51, 01-010). Torque the bolts to 180 to 220 lbf.in (20 to 25 Nm).

SUBTASK 72-00-40-420-076 Install the Stage 10 to HPT Air Valve

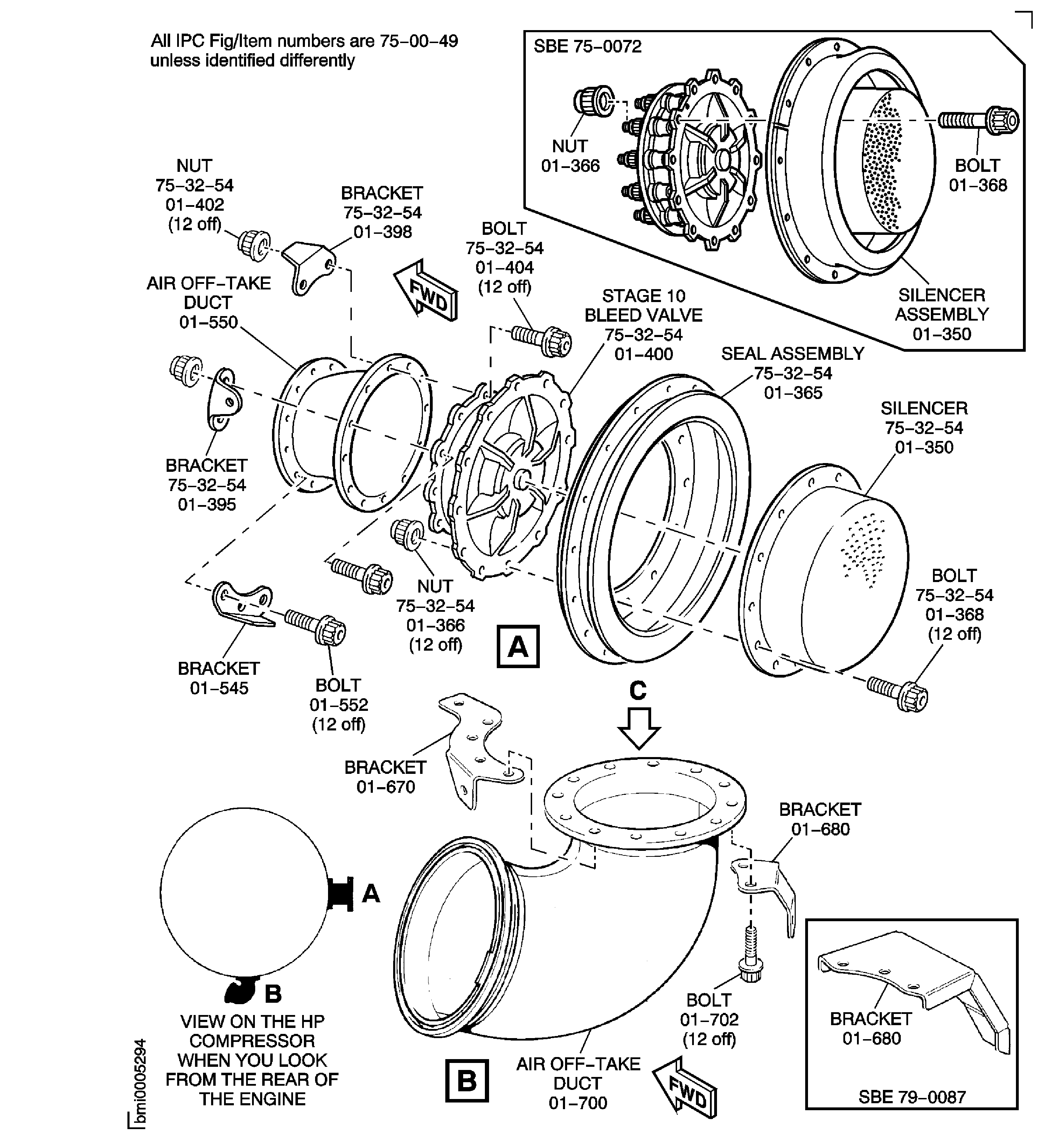

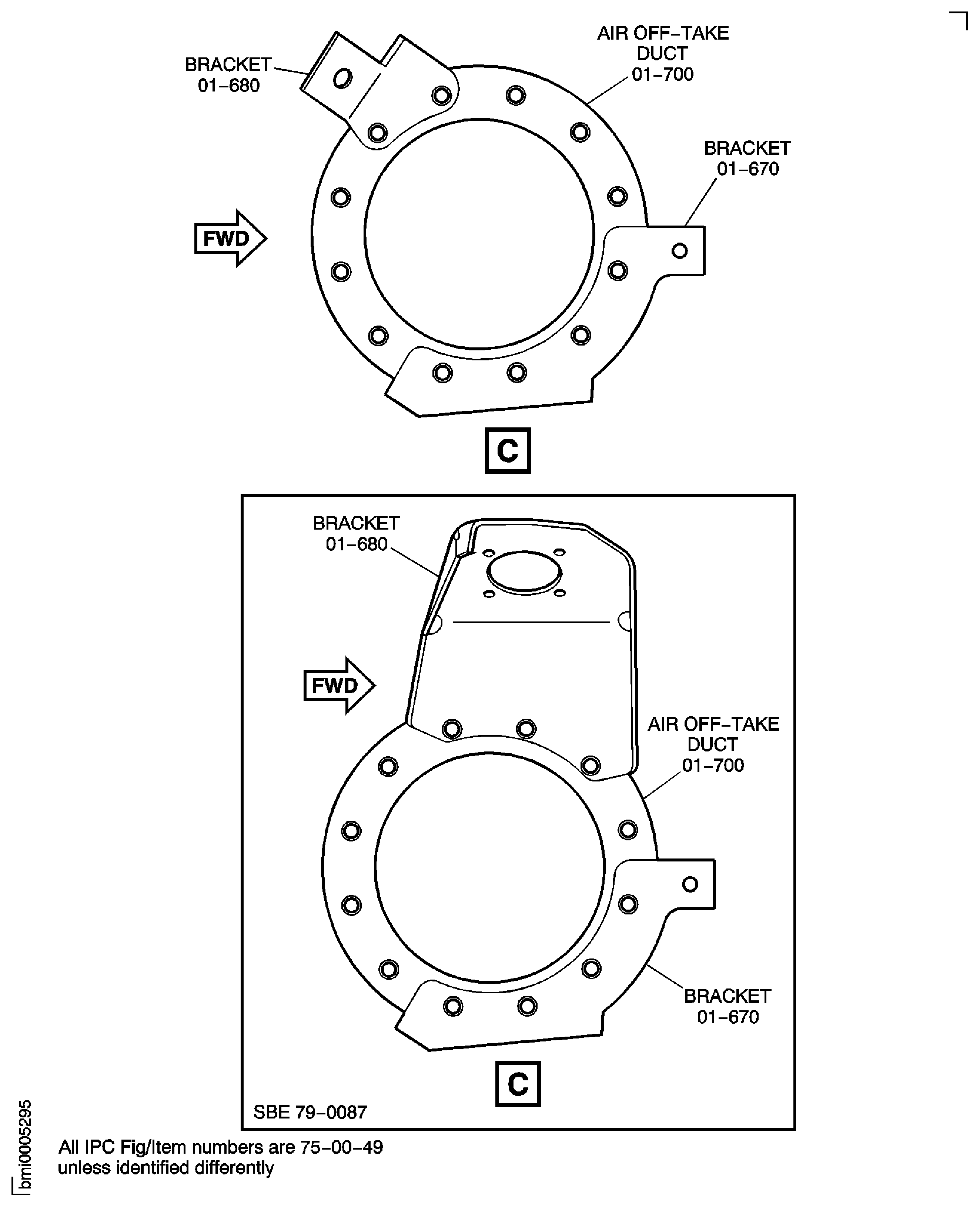

Install the 12 bolts AIR-ENGINE AIR OFFTAKE DUCTS (75-00-49, 01-702), together with the two brackets AIR-ENGINE AIR OFFTAKE DUCTS (75-00-49, 01-670) and AIR-ENGINE AIR OFFTAKE DUCTS (75-00-49, 01-680). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

Install the cabin air off-take duct AIR-ENGINE AIR OFFTAKE DUCTS (75-00-49, 01-700).

Install the 12 bolts AIR-ENGINE AIR OFFTAKE DUCTS (75-00-49, 01-552) together with the bracket AIR-ENGINE AIR OFFTAKE DUCTS (75-00-49, 01-545). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

Install the stage 10 air off-take duct AIR-ENGINE AIR OFFTAKE DUCTS (75-00-49, 01-550).

SUBTASK 72-00-40-420-079 Install the Air Off-Take Ducts (Pre SBE 79-0087 and SBE 79-0087)

Refer to Figure.

Put the bleed valve AIR-HPC STAGE 10 BLEED VALVE (75-32-54, 01-400) in position on the air off-take duct AIR-ENGINE AIR OFFTAKE DUCTS (75-00-49, 01-550) and align the bolt holes. Make sure the bleed valve actuation connection is at the 12 o'clock position.

Install the 12 bolts AIR-HPC STAGE 10 BLEED VALVE (75-32-54, 01-404), the two brackets AIR-HPC STAGE 10 BLEED VALVE (75-32-54, 01-395) and AIR-HPC STAGE 10 BLEED VALVE (75-32-54, 01-398) and the 12 nuts AIR-HPC STAGE 10 BLEED VALVE (75-32-54, 01-402). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Attach the silencer AIR-HPC STAGE 10 BLEED VALVE (75-32-54, 01-350) and the seal assembly AIR-HPC STAGE 10 BLEED VALVE (75-32-54, 01-365) to the bleed valve with the 12 bolts AIR-HPC STAGE 10 BLEED VALVE (75-32-54, 01-368) and the nuts AIR-HPC STAGE 10 BLEED VALVE (75-32-54, 01-366). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

SUBTASK 72-00-40-420-080-A00 Install the Stage 10 Bleed Valve, the Seal Assembly and the Silencer (Pre SBE 75-0072)

Refer to Figure.

Put the bleed valve AIR-HPC STAGE 10 BLEED VALVE (75-32-54, 01-400) in position on the air off-take duct AIR-ENGINE AIR OFFTAKE DUCTS (75-00-49, 01-550) and align the bolt holes. Make sure the bleed valve actuation connection is at the 12 o'clock position.

Install the 12 bolts AIR-HPC STAGE 10 BLEED VALVE (75-32-54, 01-404), the two brackets AIR-HPC STAGE 10 BLEED VALVE (75-32-54, 01-395) and AIR-HPC STAGE 10 BLEED VALVE (75-32-54, 01-398) and the 12 nuts AIR-HPC STAGE 10 BLEED VALVE (75-32-54, 01-402). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Attach the silencer assembly AIR-HPC STAGE 10 BLEED VALVE (75-32-54, 01-350) to the bleed valve with the 12 bolts AIR-HPC STAGE 10 BLEED VALVE (75-32-54, 01-368) and the nuts AIR-HPC STAGE 10 BLEED VALVE (75-32-54, 01-366). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

SUBTASK 72-00-40-420-080-B00 Install the Stage 10 Bleed Valve and the Silencer Assembly (SBE 75-0072)

Refer to Figure

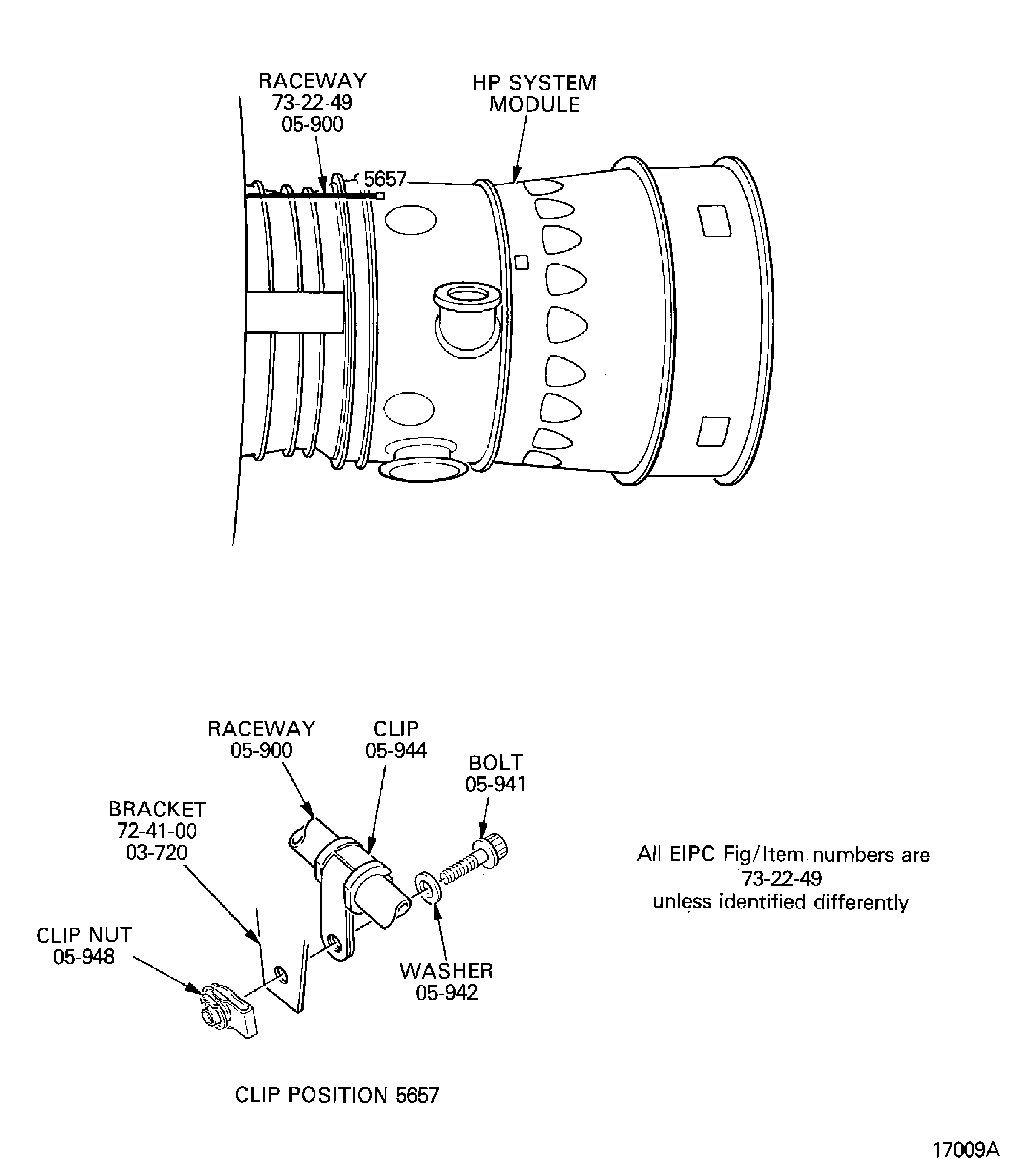

Install the raceway ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 05-900).

SUBTASK 72-00-40-420-084 Install the Tube Raceway

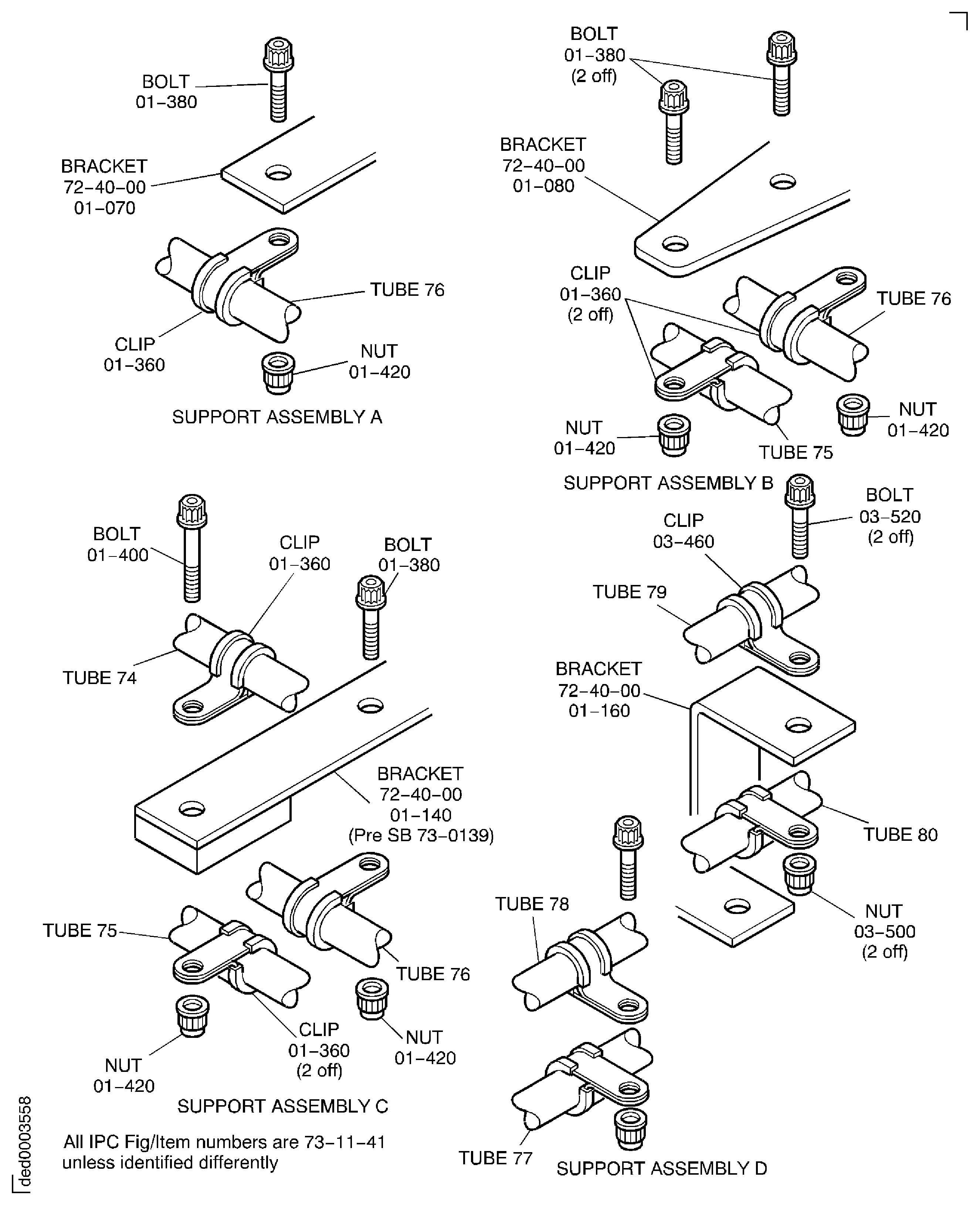

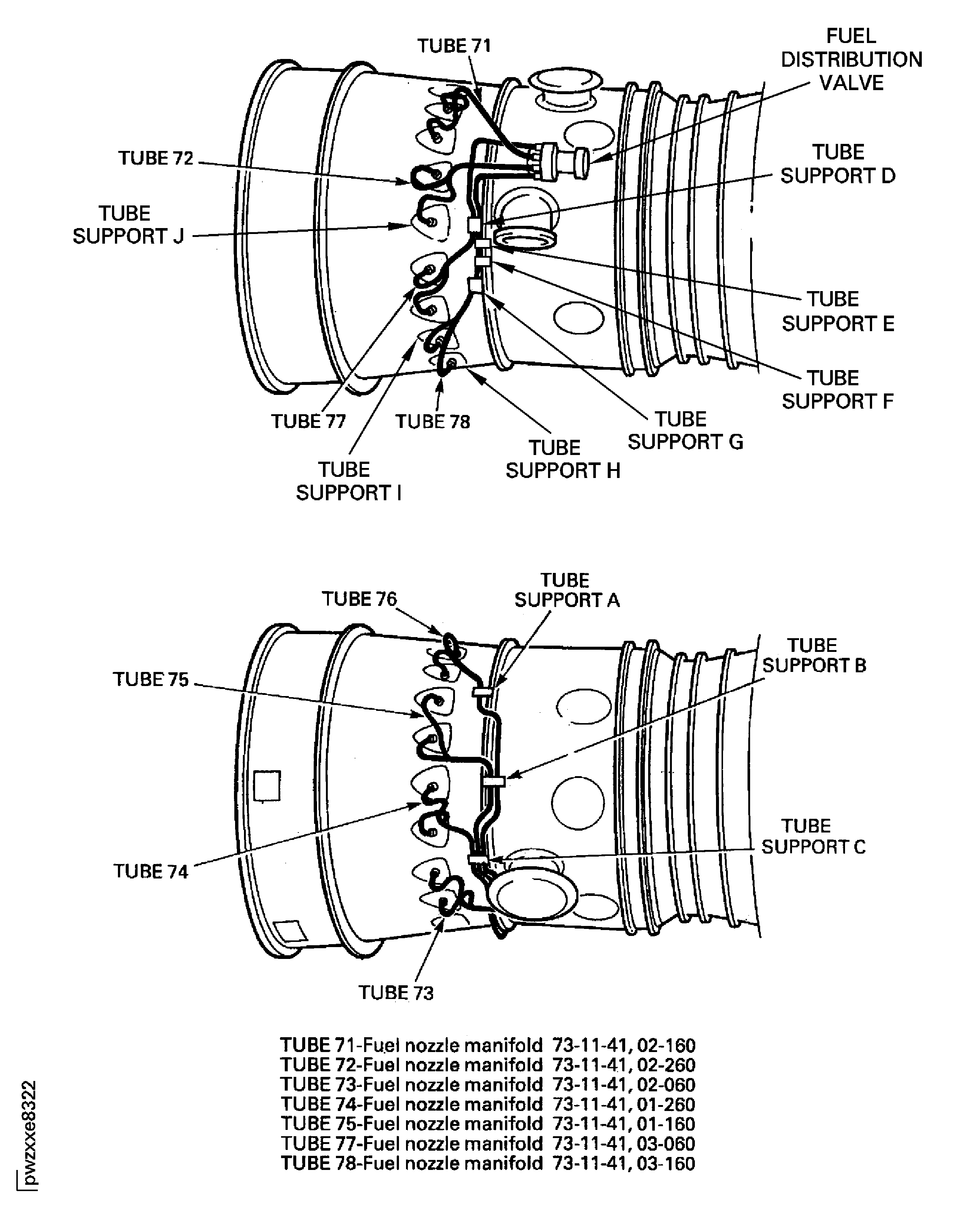

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 03-001) preformed packing 24 off, with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY and install two on to each of the 12 transfer tubes ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 03-020).

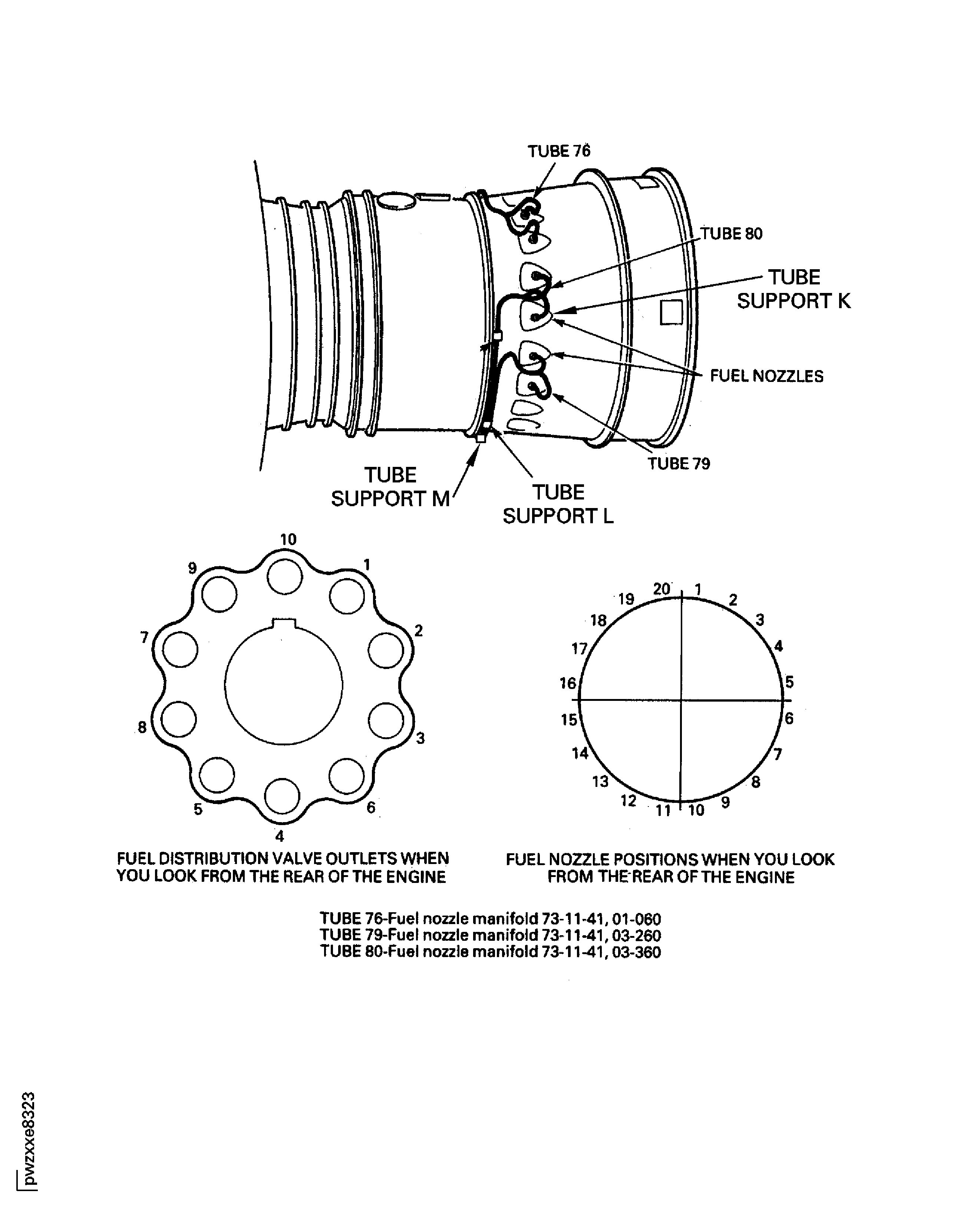

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 03-040) gasket 4 off, with CoMat 10-038 PETROLEUM JELLY and install them on to the fuel distribution valve at the positions 6, 7, 8 and 9.

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 03-050) gasket 8 off, with CoMat 10-038 PETROLEUM JELLY and install them on the fuel nozzles, numbers 11 thru 18.

CAUTION

WHEN YOU USE THE IAE 1P16139 Wrench, THE CORRECT TORQUE WILL HAVE TO BE CALCULATED USING THE FORMULA IN THE STANDARD PRACTICES MANUAL (TASK 70-41-01-400-501).

CAUTION

MAKE SURE THAT YOU DO THE PROCEDURE THAT FOLLOWS: TO CORRECTLY TORQUE THE FUEL MANIFOLD COUPLING NUTS. INCORRECT TORQUE COULD RESULT IN DAMAGE TO THE ENGINE PARTS.Torque the tube nuts at the fuel distribution valve with the IAE 1P16139 Wrench 1 off to between 85 and 95* lbf.in (9.604 and 10.734 Nm).

Do Step again until all the tube nuts are at the correct torque. Do not torque the tube nuts more than four times. If the tube nuts can not be torqued to the correct value then replace the fuel manifold or seals.

Do Step again until all the tube nuts are at the correct torque. Do not torque the tube nuts more than four times. If the tube nuts can not be torqued to the correct value then replace the fuel manifold or seals.

Safety the tube nuts with CoMat 02-126 LOCKWIRE.

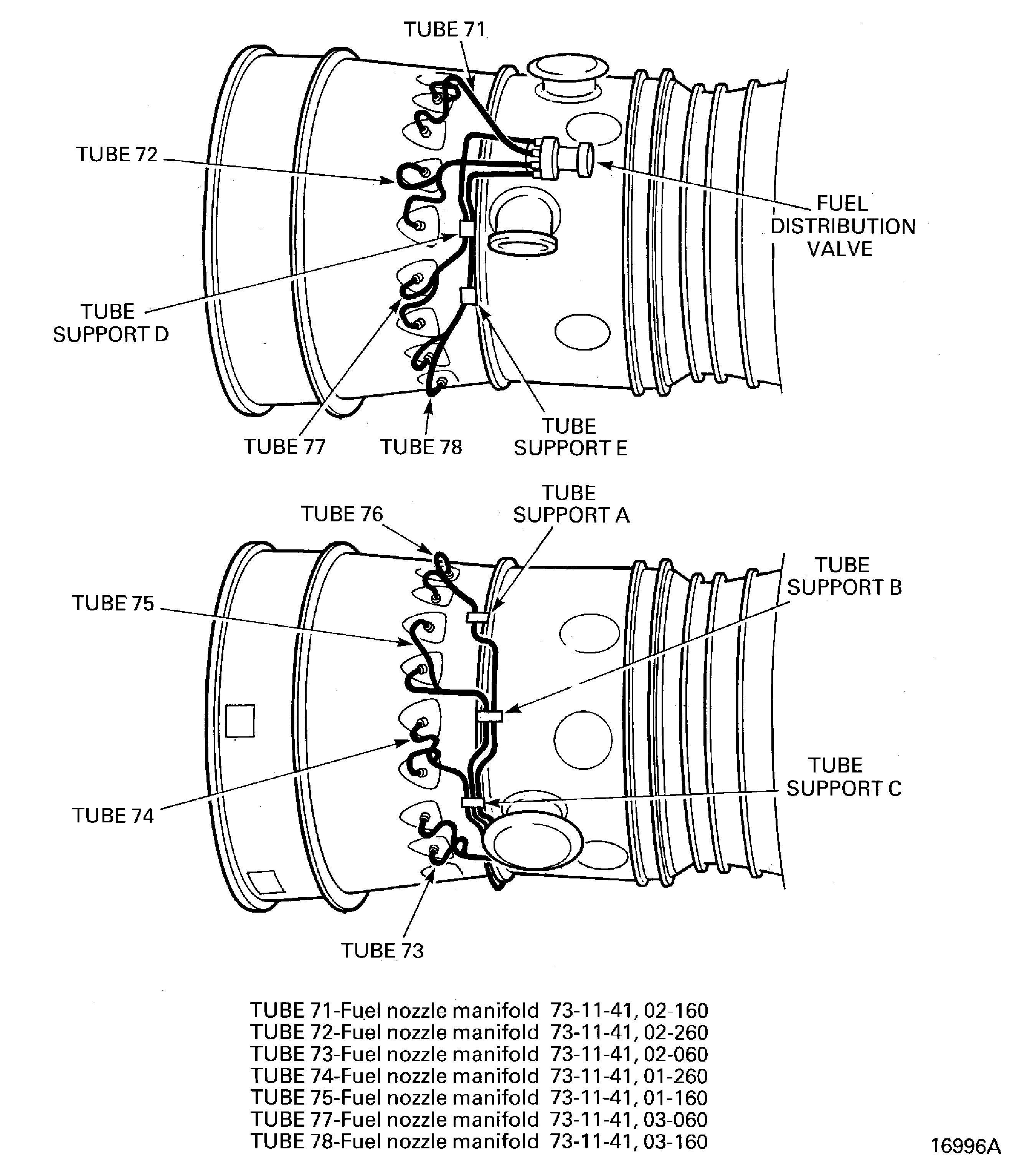

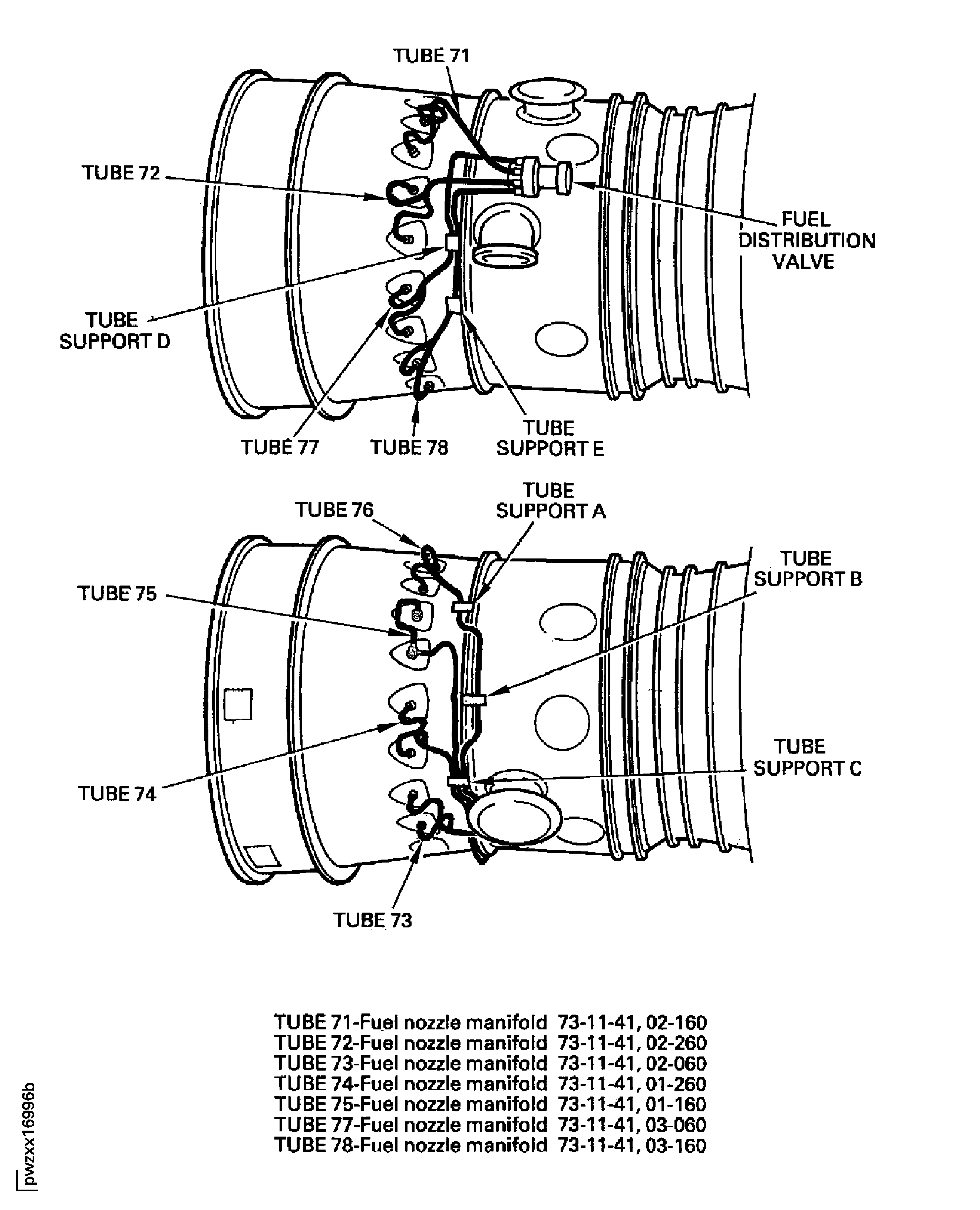

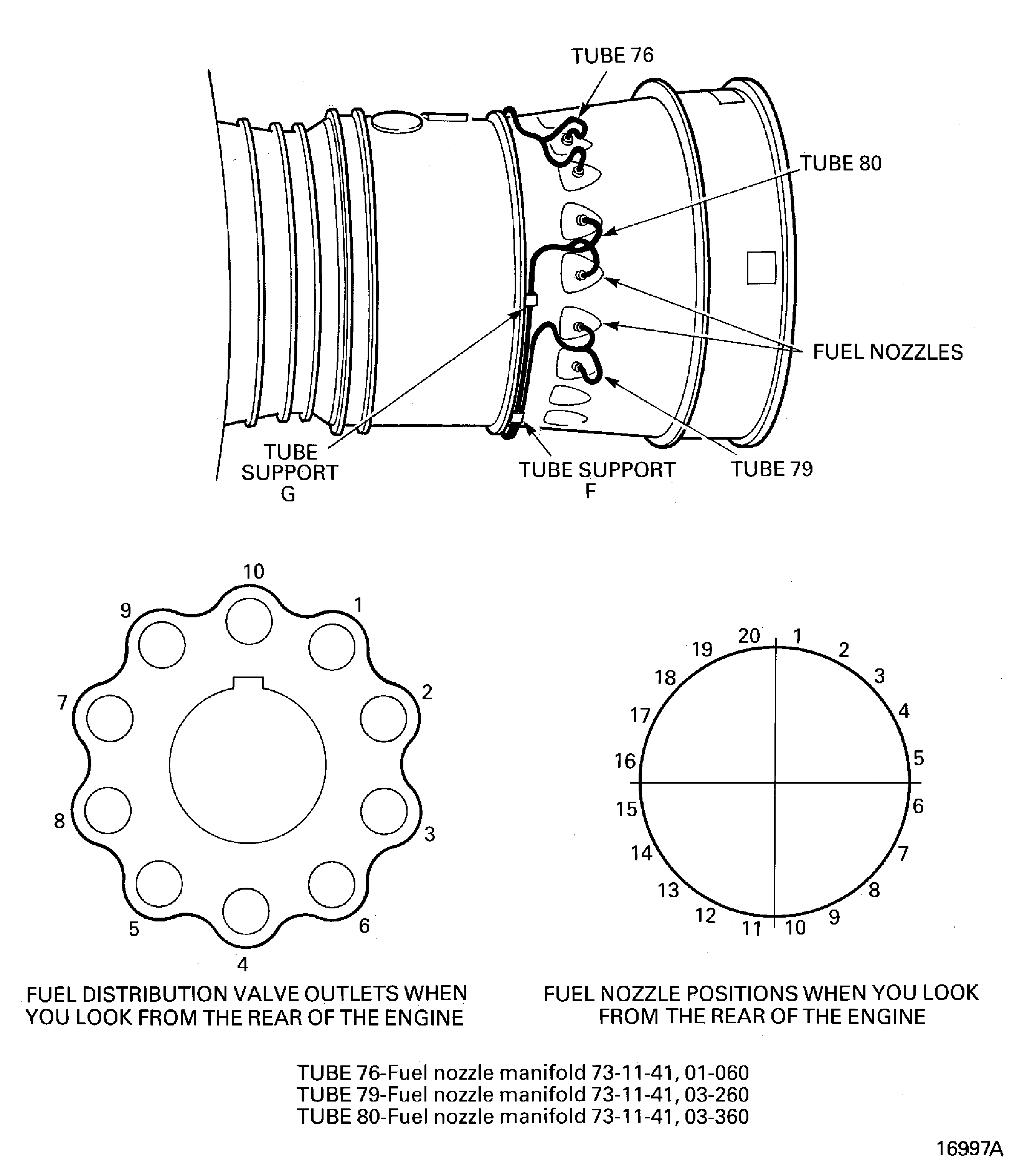

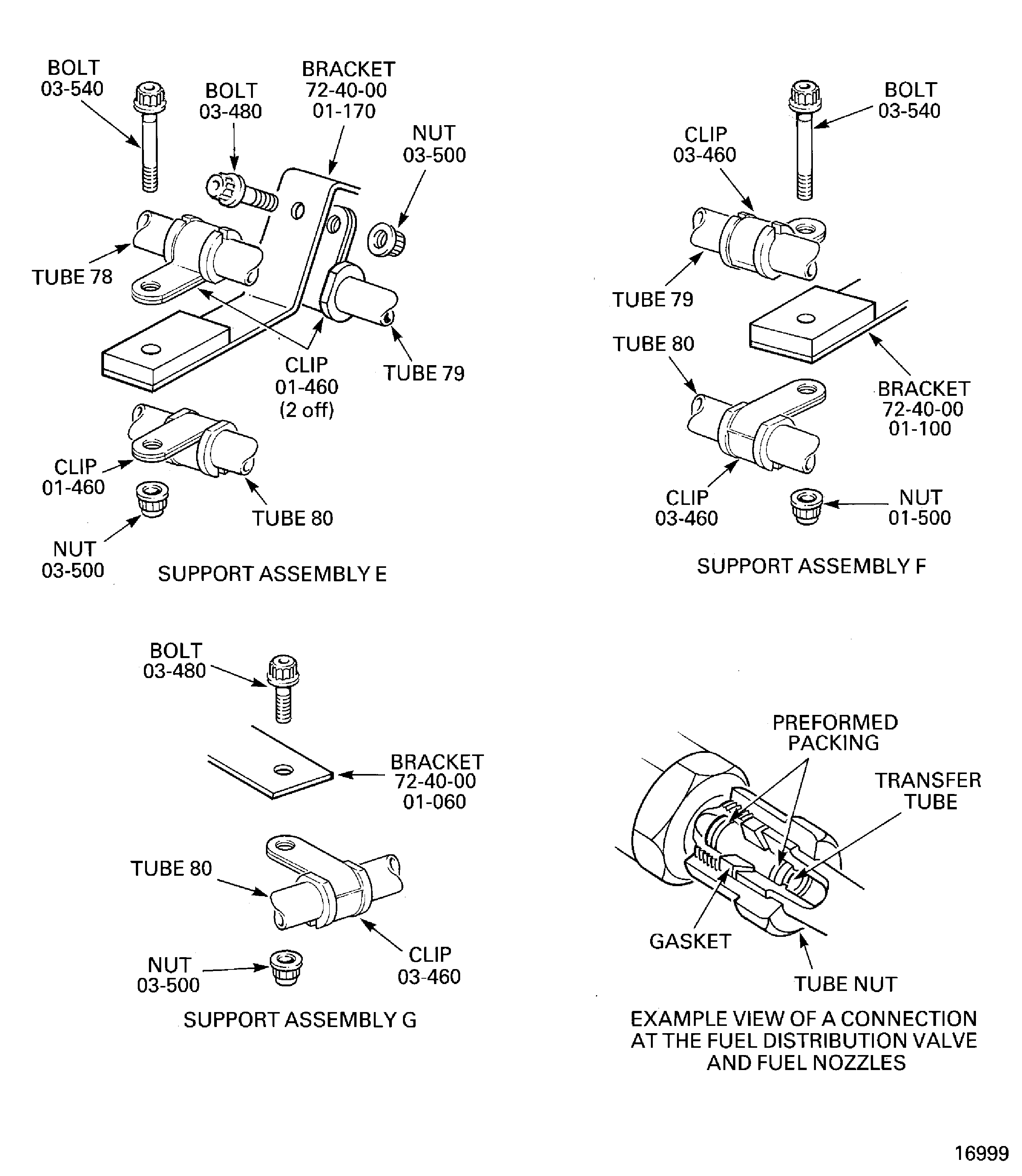

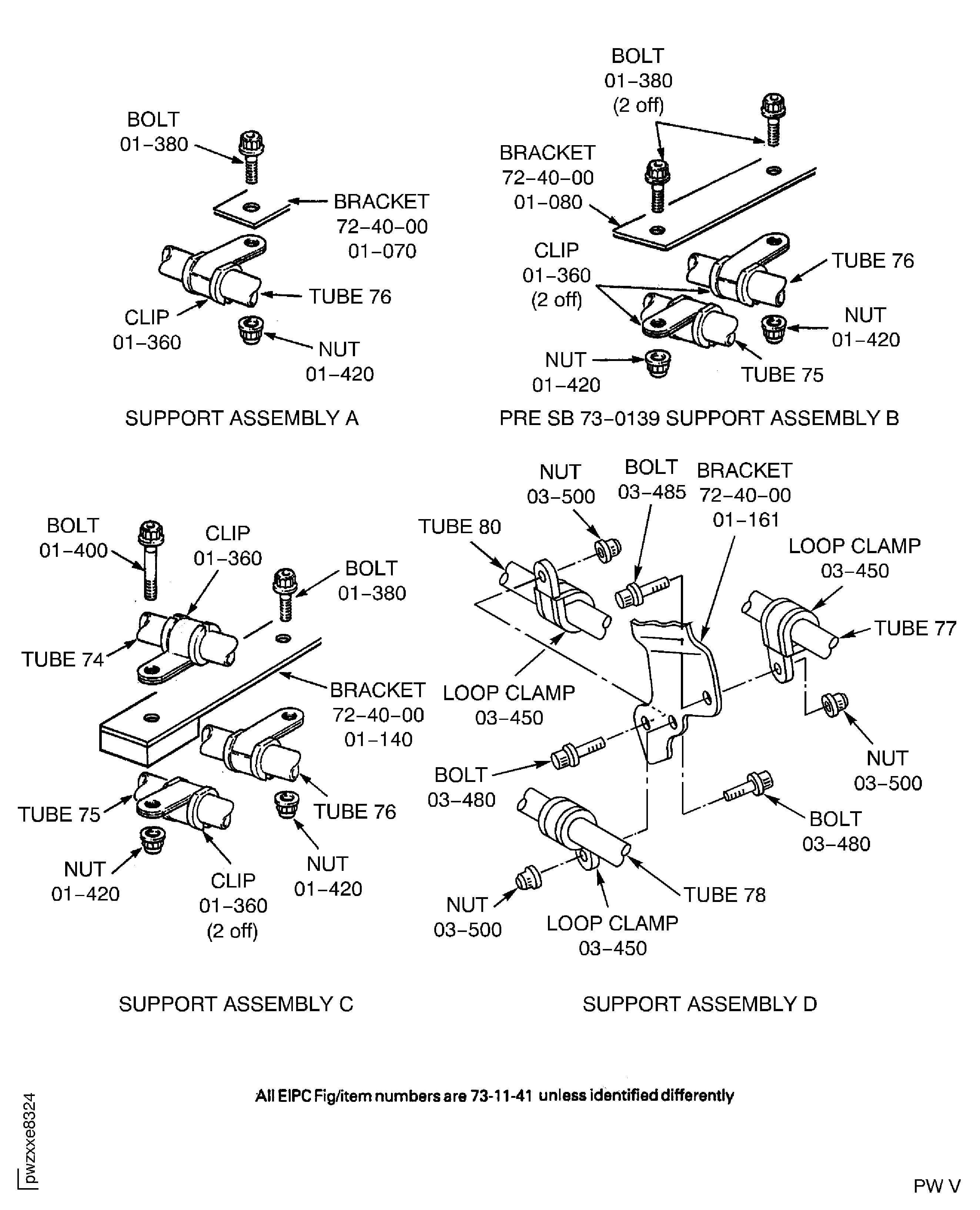

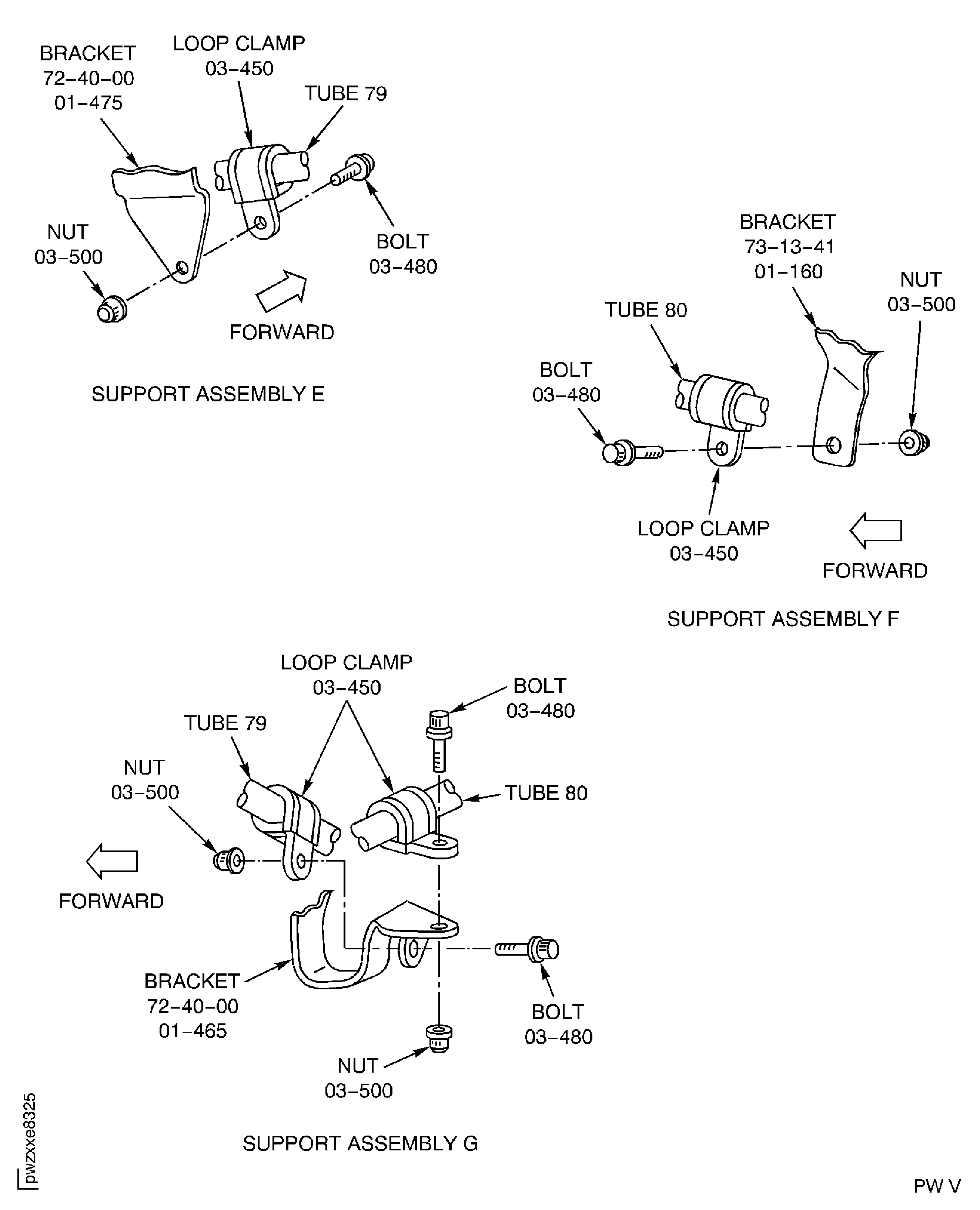

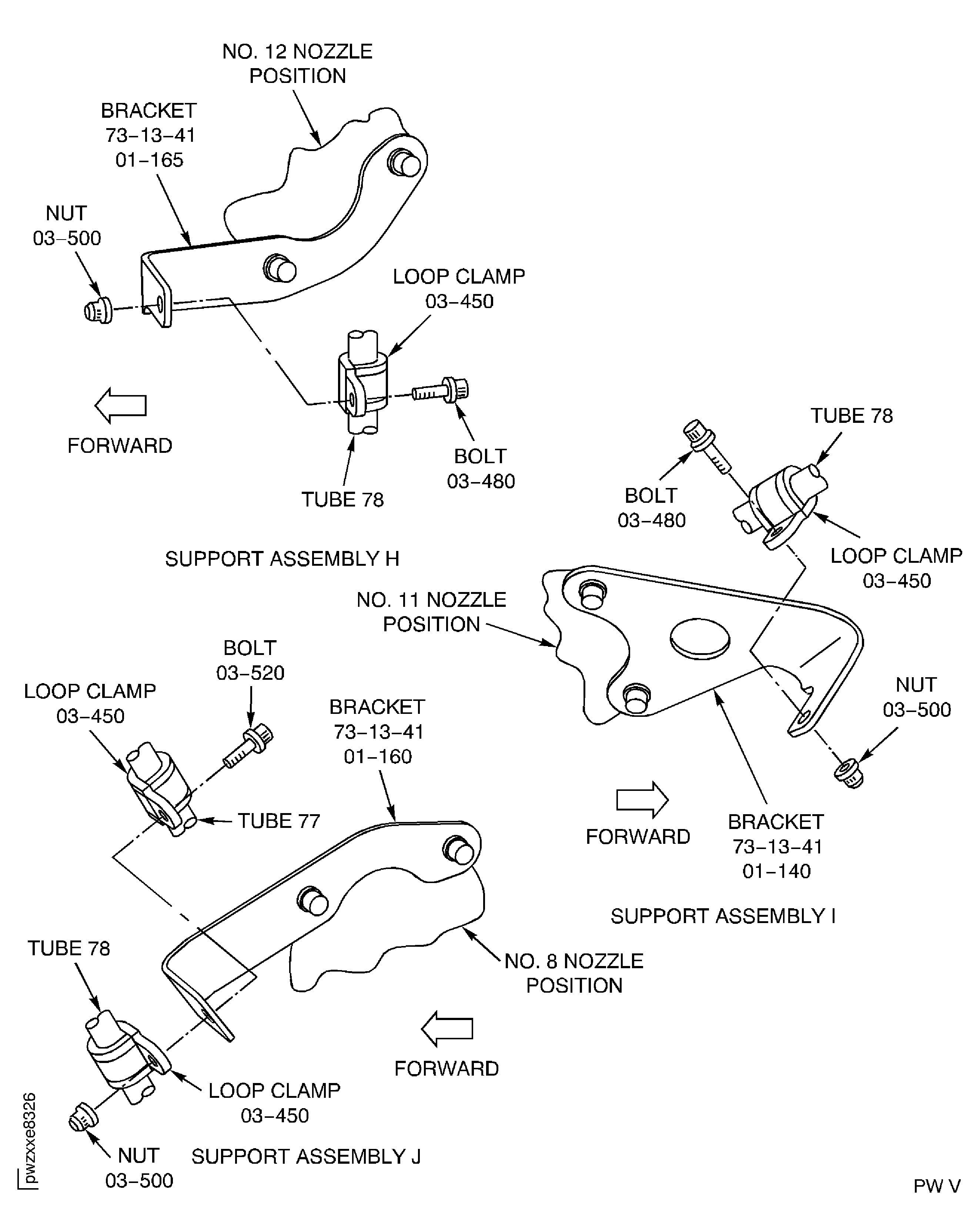

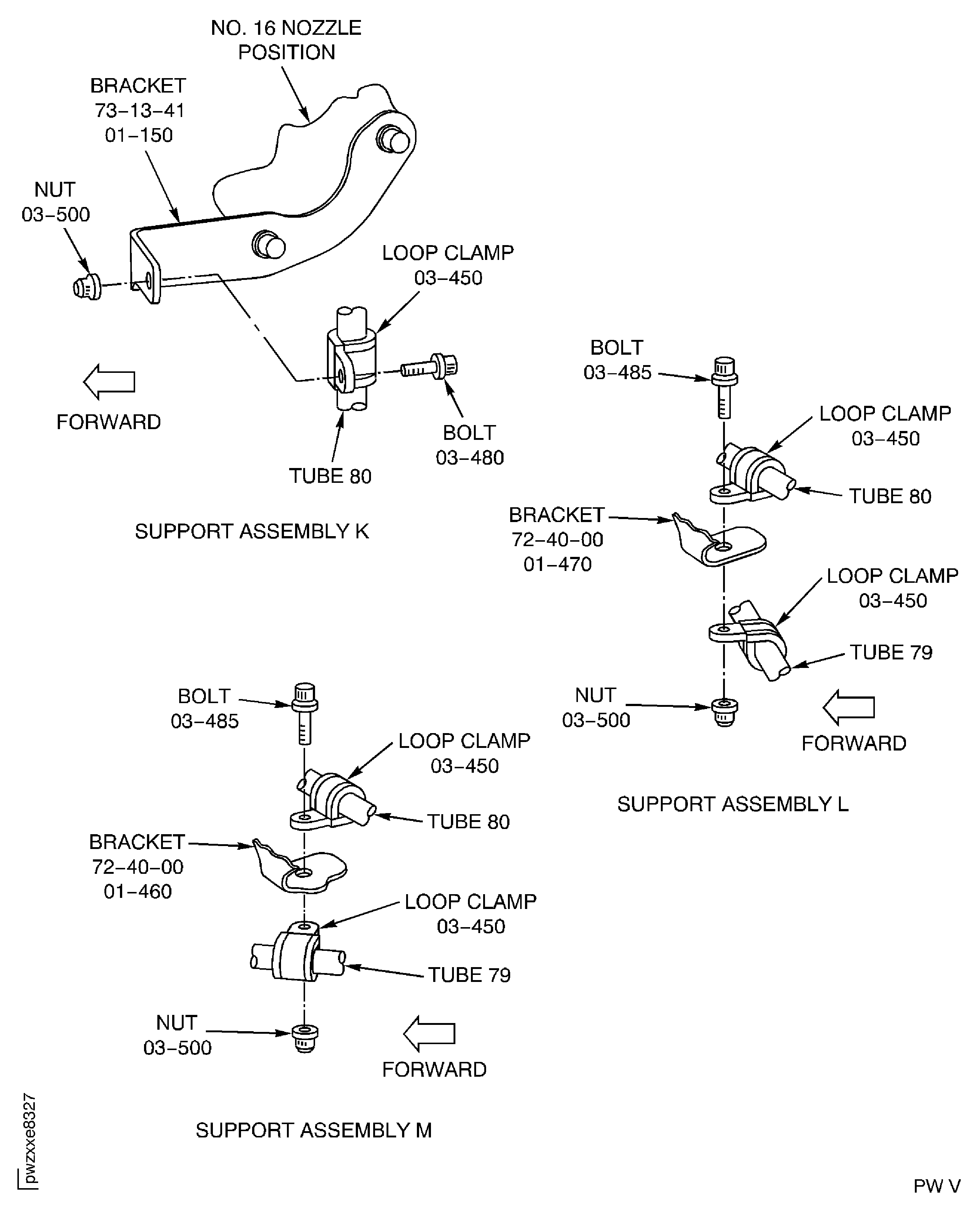

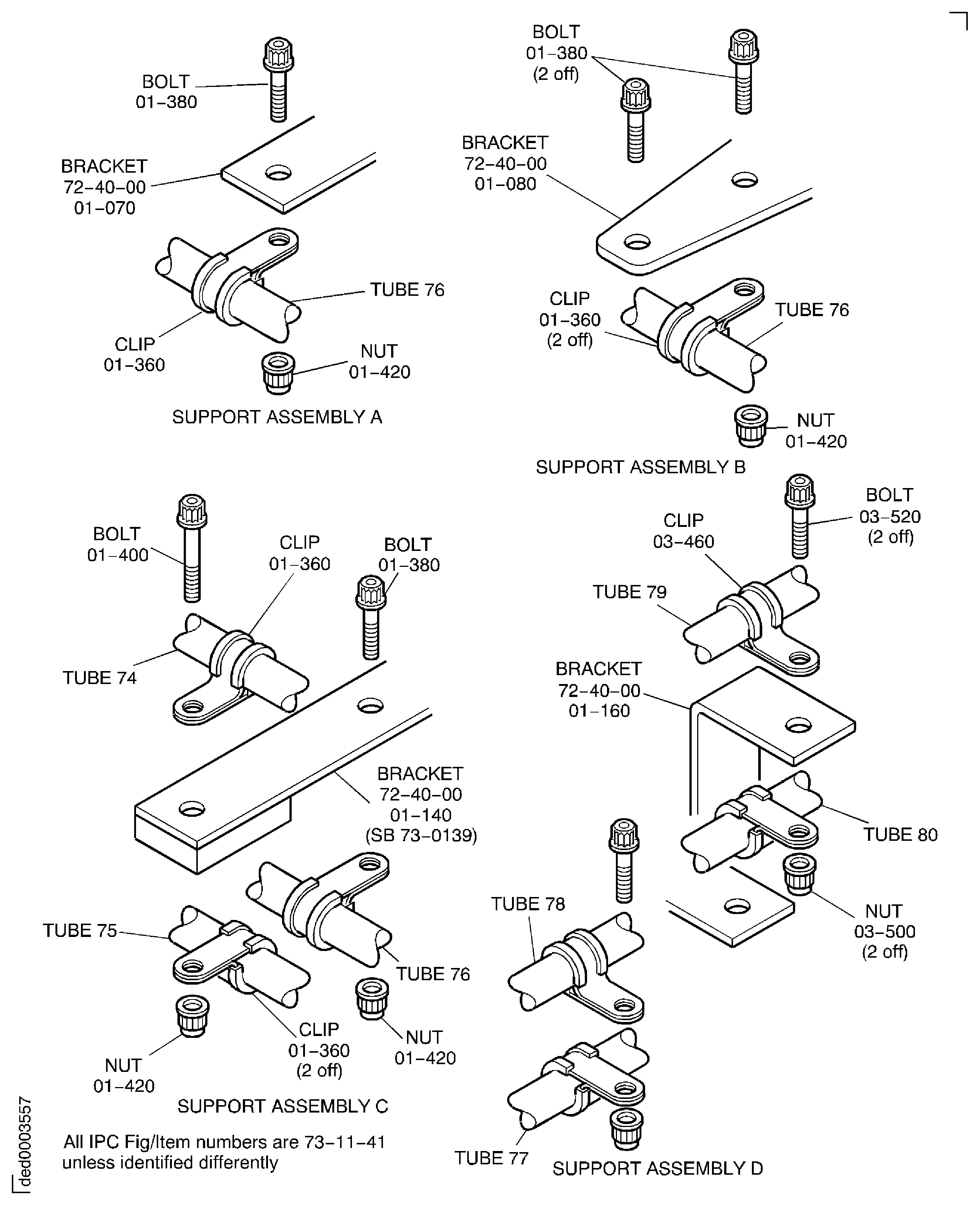

Install the tubes 77 thru 80 ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 03-060), ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 03-160), ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 03-260) and ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 03-360).

SUBTASK 72-00-40-420-087-A00 Install the Fuel Nozzle Manifolds - Tubes 77 thru 80. (Pre SBE 73-0147)

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 03-001) preformed packing 24 off, with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY and install two on to each of the 12 transfer tubes ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 03-020).

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 03-040) gasket 4 off, with CoMat 10-038 PETROLEUM JELLY and install them on to the fuel distribution valve at the positions 6, 7, 8 and 9.

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL MANIFOLD(73-11-41,03-050) gasket 8 off, with CoMat 10-038 PETROLEUM JELLY and install them on the fuel nozzles, numbers 11 thru 18.

NOTE

The installation of tube 80 is completed during installation of the cabin air sense tubes (36-21-49) refer to TASK 72-00-40-420-005-A00 (72-00-40 Installation-08 Config-01) SUBTASK 72-00-40-420-242-A00 or SUBTASK 72-00-40-420-242-B00 (-A1 series engines).Install the clamps, bolts and nuts at the support assemblies D, E, F, G, H, J, I, K, L and M. Torque the nuts to 36 to 45 lbf.in (4 to 5 Nm).

CAUTION

WHEN YOU USE THE IAE 1P16139 Wrench, THE CORRECT TORQUE WILL HAVE TO BE CALCULATED USING THE FORMULA IN THE STANDARD PRACTICES MANUAL (TASK 70-41-01-400-501).

CAUTION

MAKE SURE THAT YOU DO THE PROCEDURE THAT FOLLOWS: TO CORRECTLY TORQUE THE FUEL MANIFOLD COUPLING NUTS. INCORRECT TORQUE COULD RESULT IN DAMAGE TO THE ENGINE PARTS.Torque the tube nuts at the fuel distribution valve with the IAE 1P16139 Wrench 1 off to between 85 and 95* lbf.in (9.604 and 10.734 Nm).

Do Step again until all the tube nuts are at the correct torque. Do not torque the tube nuts more than four times. If the tube nuts can not be torqued to the correct value then replace the fuel manifold or seals.

Do Step again until all the tube nuts are at the correct torque. Do not torque the tube nuts more than four times. If the tube nuts can not be torqued to the correct value then replace the fuel manifold or seals.

Safety the tube nuts with CoMat 02-126 LOCKWIRE.

Install the tubes 77 thru 80 ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 03-060), ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 03-160), ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 03-260) and ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 03-360).

SUBTASK 72-00-40-420-087-B00 Install the Fuel Nozzle Manifolds - Tubes 77 thru 80. (SBE 73-0147)

SBE 73-0147: Replace the Fuel Manifolds

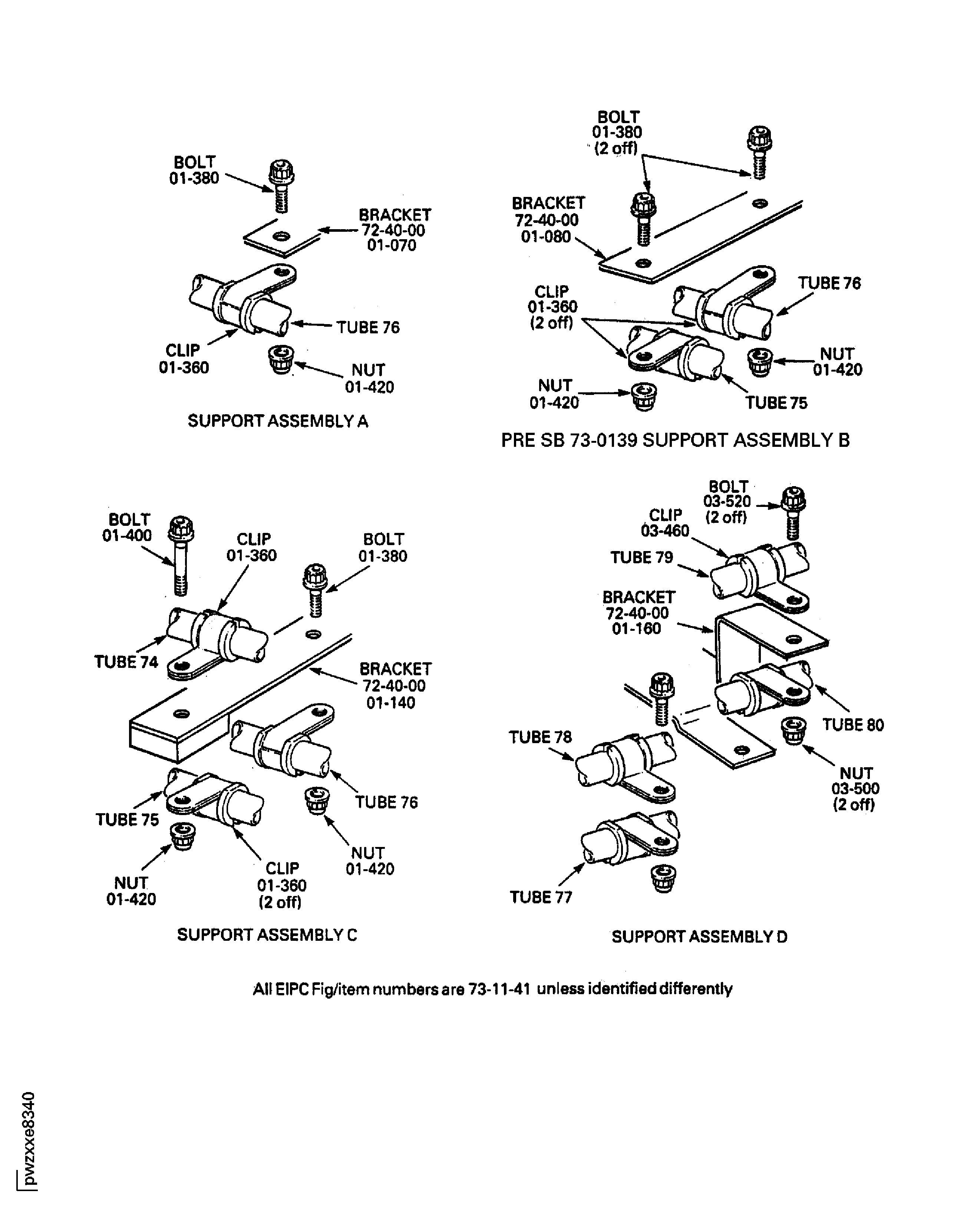

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 01-010) preformed packing 18 off, with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY and install two on to each of the nine transfer tubes ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 01-020).

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 01-040) gasket 3 off, with CoMat 10-038 PETROLEUM JELLY and install them on to the fuel distribution valve at the positions 1, 2 and 10.

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 01-050) gasket 6 off, with CoMat 10-038 PETROLEUM JELLY and install them on to the fuel nozzles Numbers 1 thru 4, 19 and 20.

CAUTION

WHEN YOU USE THE IAE 1P16139 Wrench, THE CORRECT TORQUE WILL HAVE TO BE CALCULATED USING THE FORMULA IN THE STANDARD PRACTICES MANUAL (TASK 70-41-01-400-501).

CAUTION

MAKE SURE THAT YOU DO THE PROCEDURE THAT FOLLOWS: TO CORRECTLY TORQUE THE FUEL MANIFOLD COUPLING NUTS. INCORRECT TORQUE COULD RESULT IN DAMAGE TO THE ENGINE PARTS.Torque the tube nuts at the fuel distribution valve with the IAE 1P16139 Wrench 1 off to between 85 and 95* lbf.in (9.604 and 10.734 Nm).

Do Step again until all the tube nuts are at the correct torque. Do not torque the tube nuts more than four times. If the tube nuts can not be torqued to the correct value then replace the fuel manifold or seals.

Do Step again until all the tube nuts are at the correct torque. Do not torque the tube nuts more than four times. If the tube nuts can not be torqued to the correct value then replace the fuel manifold or seals.

Safety the tube nuts with CoMat 02-126 LOCKWIRE.

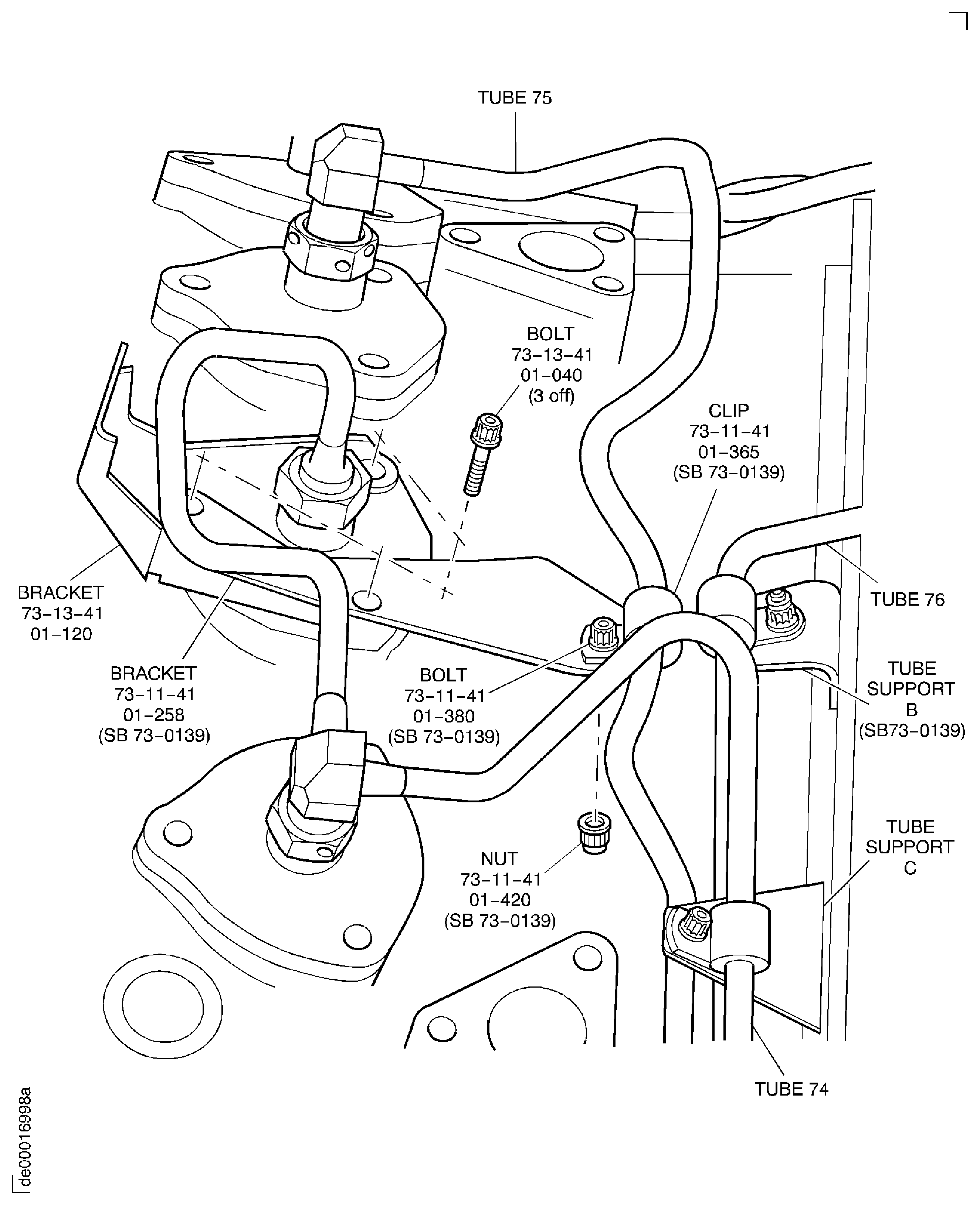

Install the tubes 74, 75 and 76 ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 01-260), ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 01-160) and ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 01-060).

SUBTASK 72-00-40-420-208-A00 Install the Fuel Nozzle Manifolds - Tubes 74, 75 and 76 (Pre SBE 73-0139)

Refer to Step for the procedure to install bracket ENGINE FUEL AND CONTROL-FUEL NOZZLE (73-13-41, 01-120) to fuel nozzle assembly position 3.

Install the bracket ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 01-258) at the number 3 fuel nozzle with the three bolts ENGINE FUEL AND CONTROL-FUEL NOZZLE (73-13-41, 01-040). Locate bracket ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 01-258) on top of bracket ENGINE FUEL AND CONTROL-FUEL NOZZLE (73-13-41, 01-120).

Torque the three bolts ENGINE FUEL AND CONTROL-FUEL NOZZLE (73-13-41, 01-040) to 65 to 85 * lbf.in (7.3 to 10 Nm) and safety with CoMat 02-141 LOCKWIRE.

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 01-010) preformed packing 18 off, with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY and install two on to each of the nine transfer tubes ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 01-020).

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 01-040) gasket 3 off, with CoMat 10-038 PETROLEUM JELLY and install them on to the fuel distribution valve at the positions 1, 2 and 10.

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 01-050) gasket 6 off, with CoMat 10-038 PETROLEUM JELLY and install them on to the fuel nozzles Numbers 1 thru 4, 19 and 20.

CAUTION

WHEN YOU USE THE IAE 1P16139 Wrench, THE CORRECT TORQUE WILL HAVE TO BE CALCULATED USING THE FORMULA IN THE STANDARD PRACTICES MANUAL (TASK 70-41-01-400-501).

CAUTION

MAKE SURE THAT YOU DO THE PROCEDURE THAT FOLLOWS: TO CORRECTLY TORQUE THE FUEL MANIFOLD COUPLING NUTS. INCORRECT TORQUE COULD RESULT IN DAMAGE TO THE ENGINE PARTS.Torque the tube nuts at the fuel distribution valve with the IAE 1P16139 Wrench 1 off to between 85 and 95* lbf.in (9.604 and 10.734 Nm).

Do Step again until all the tube nuts are at the correct torque. Do not torque the tube nuts more than four times. If the tube nuts can not be torqued to the correct value then replace the fuel manifold or seals.

Do Step again until all the tube nuts are at the correct torque. Do not torque the tube nuts more than four times. If the tube nuts can not be torqued to the correct value then replace the fuel manifold or seals.

Safety the tube nuts with CoMat 02-126 LOCKWIRE.

Install the tubes 74, 75 and 76 ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 01-260), ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 01-160) and ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 01-060).

SUBTASK 72-00-40-420-208-B00 Install the Fuel Nozzle Manifolds - Tubes 74, 75 and 76, , and (SBE 73-0139)

SBE 73-0139: Fuel and Control - Replace a fuel nozzle supply manifold assembly and the related attaching parts

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 02-001) preformed packing 18 off, with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install two preformed packing on to each of the nine transfer tubes ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 02-020).

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 02-040) gasket 3 off, with CoMat 10-038 PETROLEUM JELLY and install them on to the fuel distribution valve at the positions 3, 4 and 5.

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 02-050) gasket 6 off, with CoMat 10-038 PETROLEUM JELLY and install them on to the fuel nozzles Numbers 5 thru 10.

CAUTION

WHEN YOU USE THE IAE 1P16139 Wrench, THE CORRECT TORQUE WILL HAVE TO BE CALCULATED USING THE FORMULA IN THE STANDARD PRACTICES MANUAL (TASK 70-41-01-400-501).

CAUTION

MAKE SURE THAT YOU DO THE PROCEDURE THAT FOLLOWS: TO CORRECTLY TORQUE THE FUEL MANIFOLD COUPLING NUTS. INCORRECT TORQUE COULD RESULT IN DAMAGE TO THE ENGINE PARTS.Torque the tube nuts at the fuel distribution valve with the IAE 1P16139 Wrench 1 off to between 85 and 95* lbf.in (9.604 and 10.734 Nm).

Do Step again until all the tube nuts are at the correct torque. Do not torque the tube nuts more than four times. If the tube nuts can not be torqued to the correct value then replace the fuel manifold or seals.

Do Step again until all the tube nuts are at the correct torque. Do not torque the nuts more than four times. If the tube nuts can not be torqued to the correct value then replace the fuel manifold or seals.

Safety the tube nuts with CoMat 02-126 LOCKWIRE.

Install the tubes 71, 72 and 73 ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 02-160), ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 02-260) and ENGINE FUEL AND CONTROL-FUEL MANIFOLD (73-11-41, 02-060).

SUBTASK 72-00-40-420-209 Install the Fuel Nozzle Manifolds - Tubes 71, 72 and 73

Refer to Figure.

Torque the tube nut in Step to 159 to 177 lbf.in (18 to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

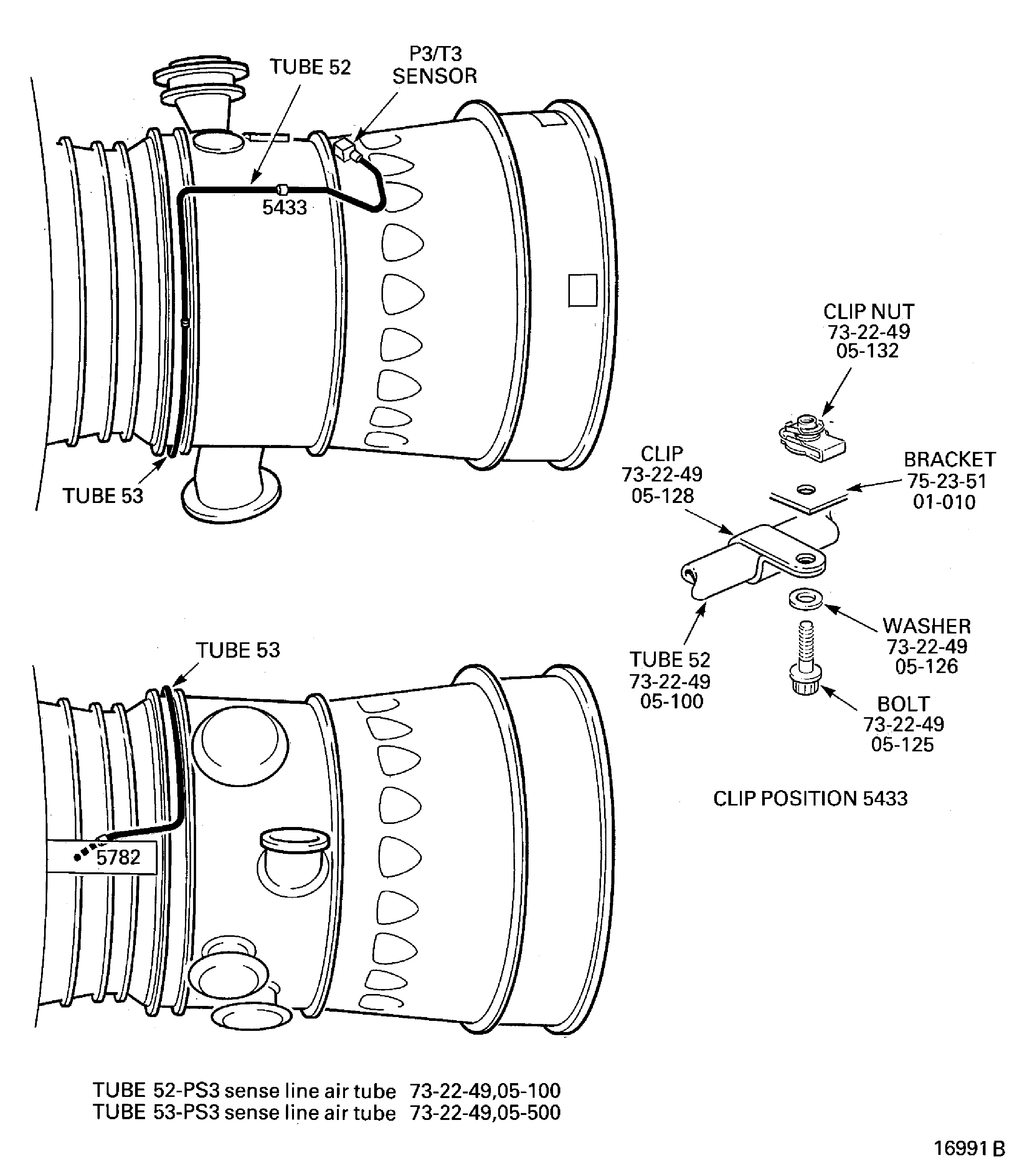

Install the tube 52 ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 05-100).

Temporarily install the attaching parts at clip positions 5650 and 5766. The installation of these clip positions is completed during installation of raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE (71-52-50, 05-100) for clip position 5650 and tube 46 (CP 5766) refer to TASK 72-00-40-420-006-A00 (72-00-40 Installation 09, CONFIG-1).

Temporarily install the clip position 5782. The installation of this clip position is completed during installation of tube 48, refer to TASK 72-00-40-420-005-A00 (72-00-40 Installation 08, CONFIG-1).

Torque the tube nut in Step to 159 to 177 lbf.in (18 to 20 Nm).

Safety the tube nut with CoMat 02-126 LOCKWIRE.

The installation of tube 53 is completed during TASK 72-00-40-420-006-A00 (72-00-40 Installation 09, CONFIG-1).

Install the tube 53 ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 05-500).

SUBTASK 72-00-40-420-089-A00 Install the PS3 Sensor Line Air Tubes (52 and 53) (Pre SBE 79-0087)

SBE 79-0087: Oil - Scavenge oil tubes - Re-route of No.4 bearing scavenge tube.

Refer to Figure.

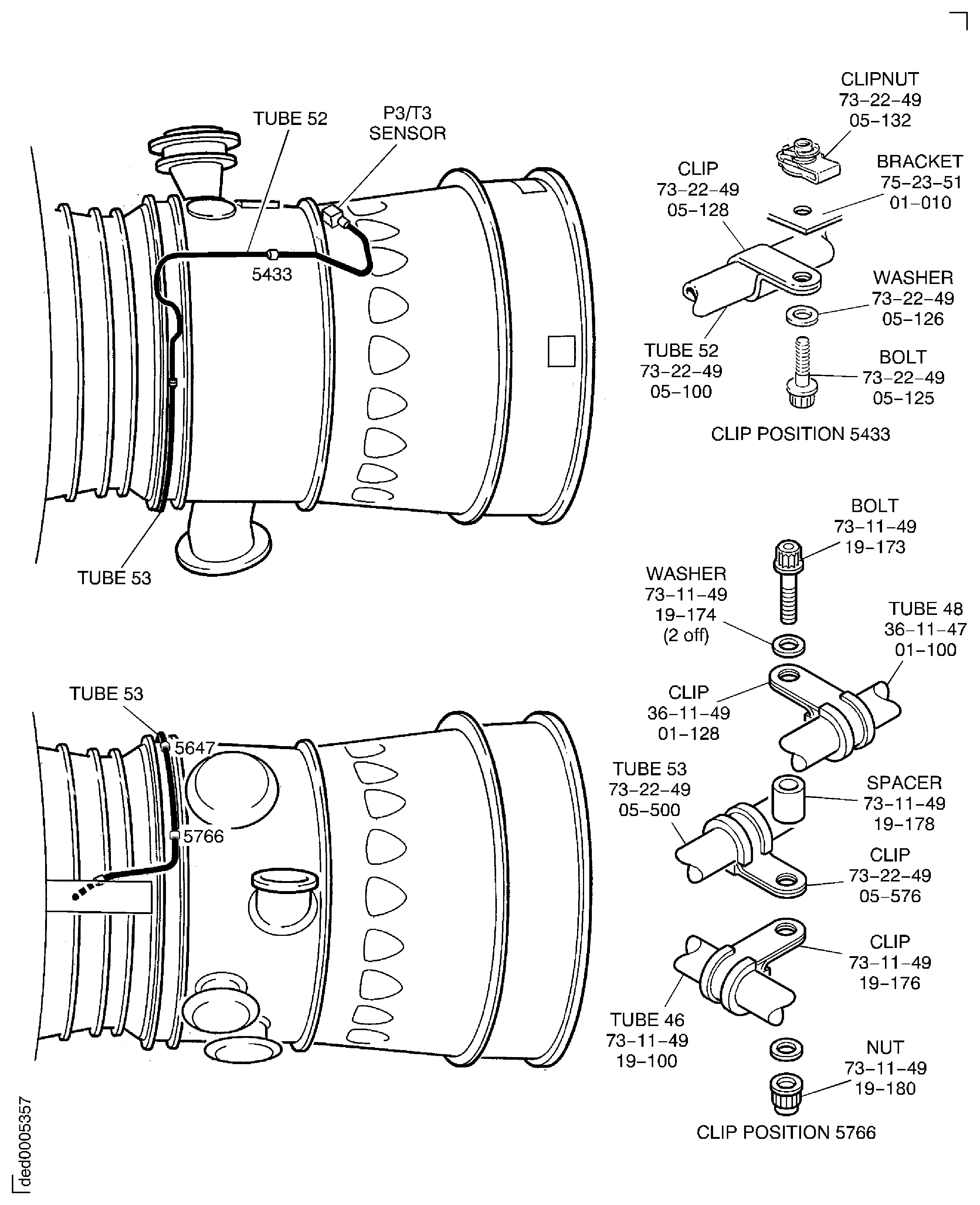

Torque the tube nut in Step to 159 to 177 lbf.in (18 to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the tube 52 ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 05-100).

Temporarily install the attaching parts at clip position 5766. The installation of this clip position is completed during installation of tube 46, refer to TASK 72-00-40-420-006-A00 (72-00-40 Installation 09, CONFIG-1).

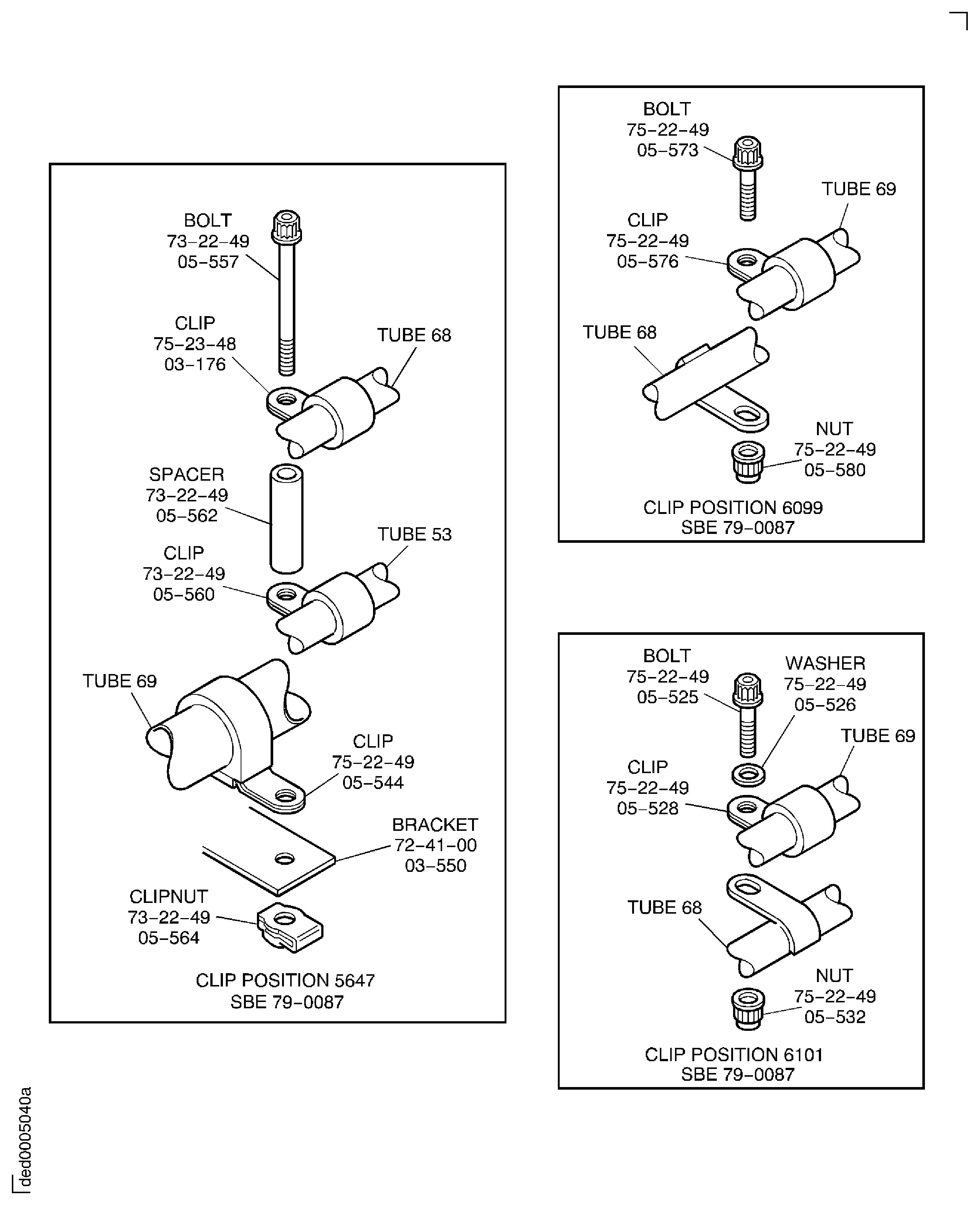

Temporarily install the clip position 5647, refer to Figure. The installation of this clip position is completed during installation of tube 68, refer to SUBTASK 72-00-40-420-091-E00.

Torque the tube nut in Step to 159 to 177 lbf.in (18 to 20 Nm).

Safety the tube nut with CoMat 02-126 LOCKWIRE.

The installation of tube 53 is completed during TASK 72-00-40-420-006-A00 (72-00-40 Installation 09, CONFIG-1).

Install the tube 53 ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 05-500).

SUBTASK 72-00-40-420-089-B00 Install the PS3 Sensor Line Air Tubes (52 and 53) (SBE 79-0087)

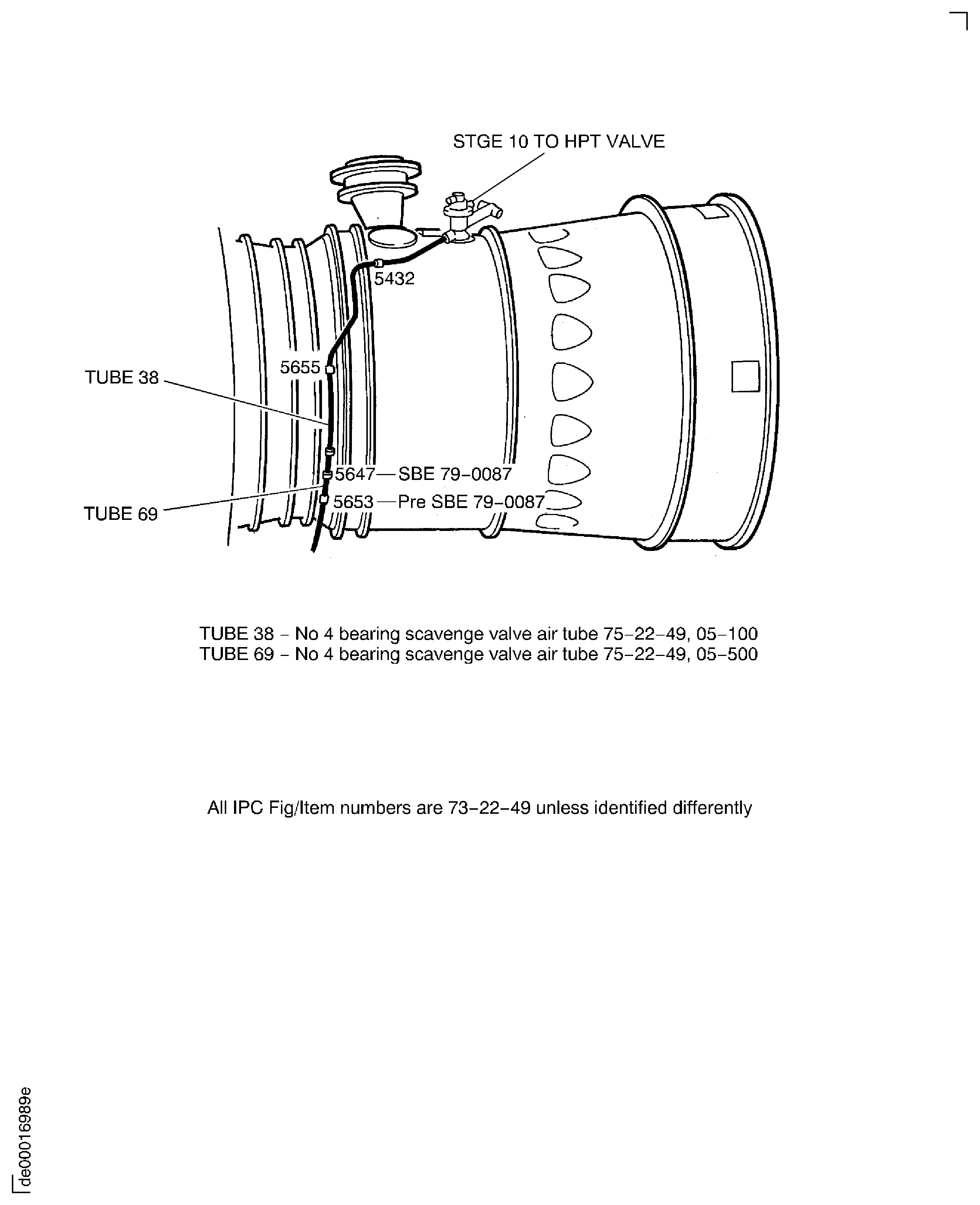

Torque the tube nut in Step to 204 to 221 lbf.in (23 to 25 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the tube 38 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 05-100).

NOTE

The installation of clip position 5653 is completed in TASK 72-00-40-420-006-A00.Assemble the clips, the spacer, the washer, the bolt and the nut at the clip position 5653. Tighten but do not apply the full torque loading.

Torque the tube nut in Step to 204 to 221 lbf.in (23 to 25 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the tube 69 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 05-500).

SUBTASK 72-00-40-420-090-A00 Install the No. 4 Bearing Scavenge Air Tubes (38 and 69) (Pre SBE 79-0087)

Torque the tube nut in Step to 204 to 221 lbf.in (23 to 25 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the tube 38 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 05-100).

Torque the tube nut in Step to 204 to 221 lbf.in (23 to 25 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the tube 69 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 05-500).

SUBTASK 72-00-40-420-090-B00 Install the No. 4 Bearing Scavenge Air Tubes (38 and 69) (SBE 79-0087)

SBE 79-0087: Oil - Scavenge oil tubes - Re-route of No.4 bearing scavenge tube.

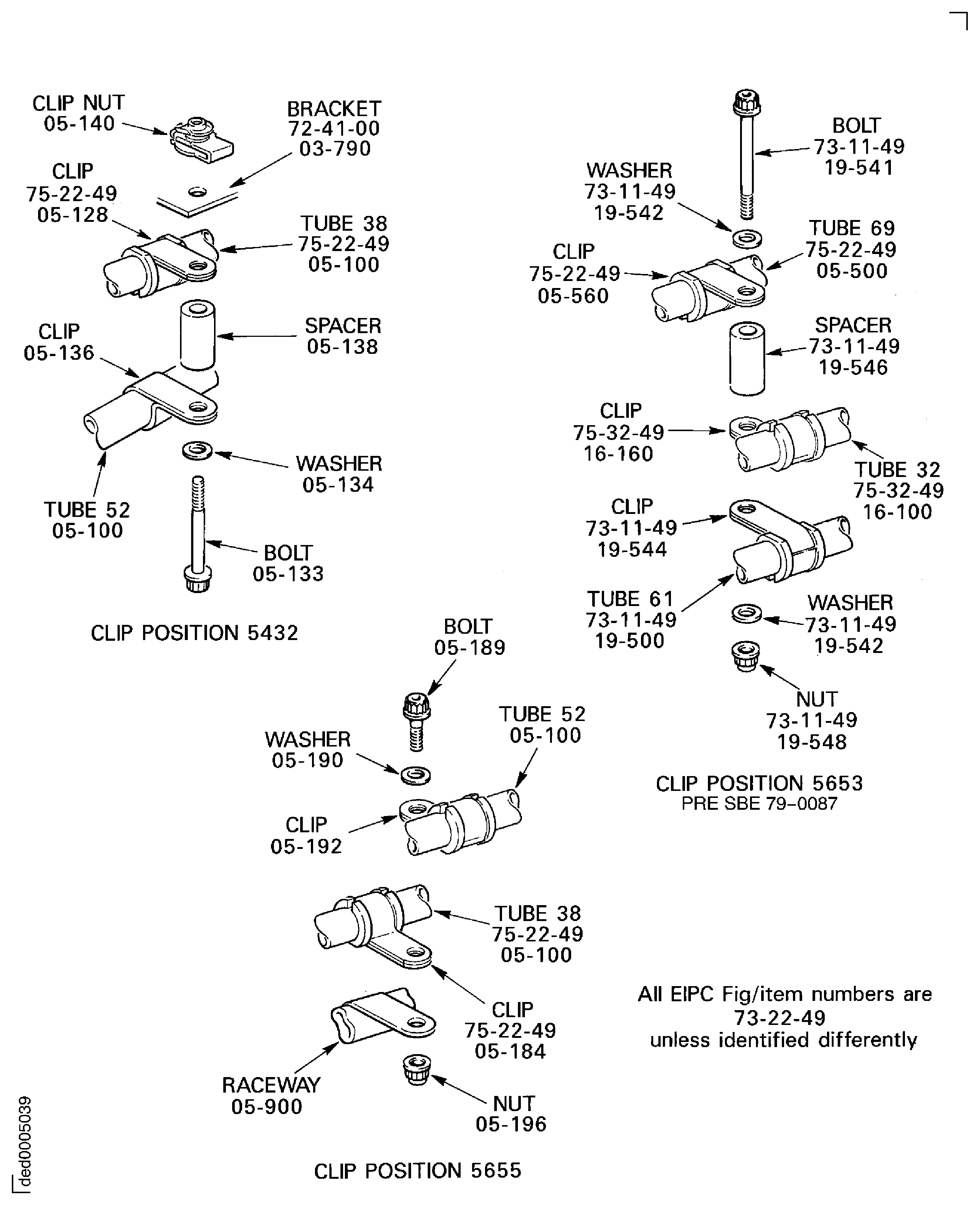

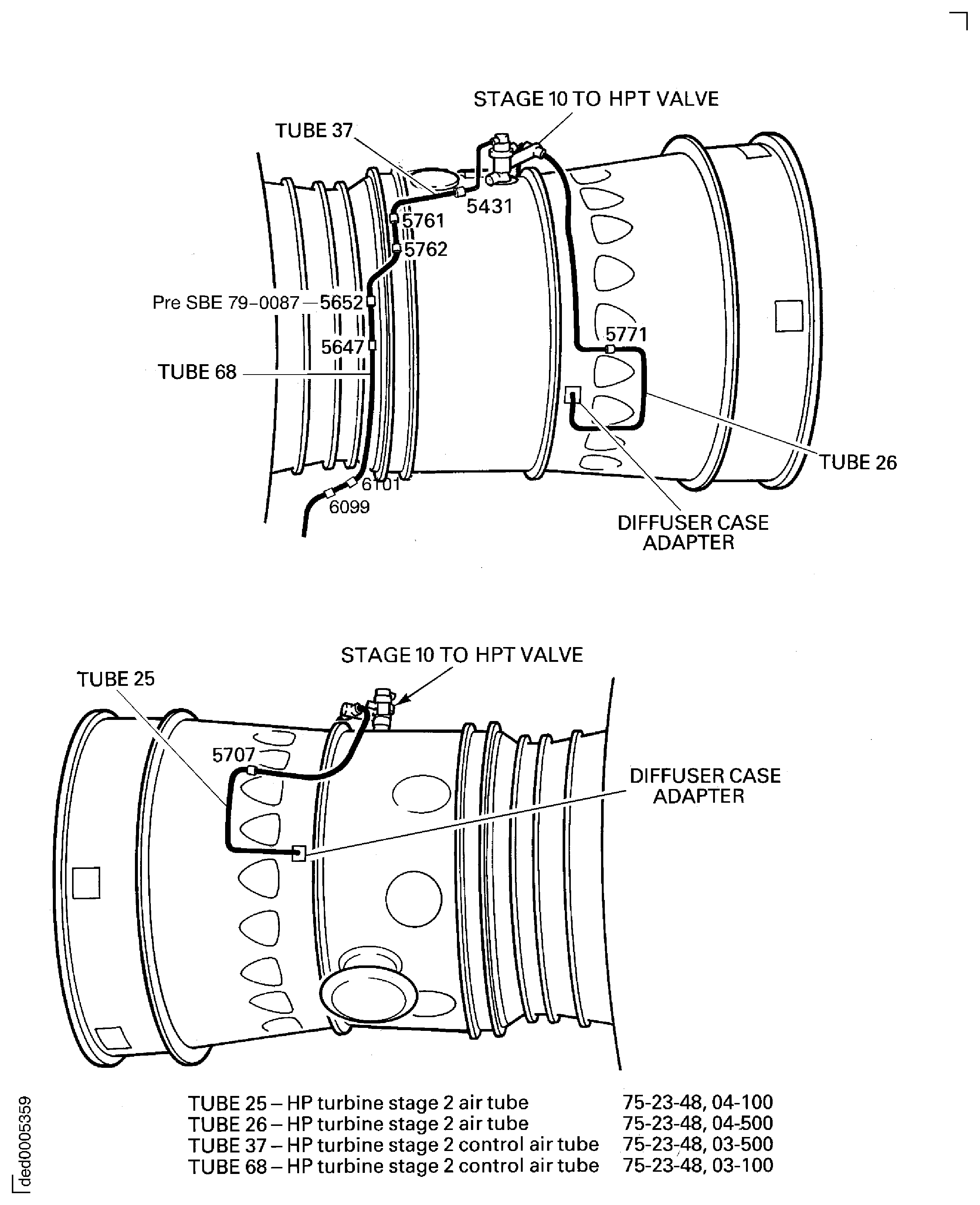

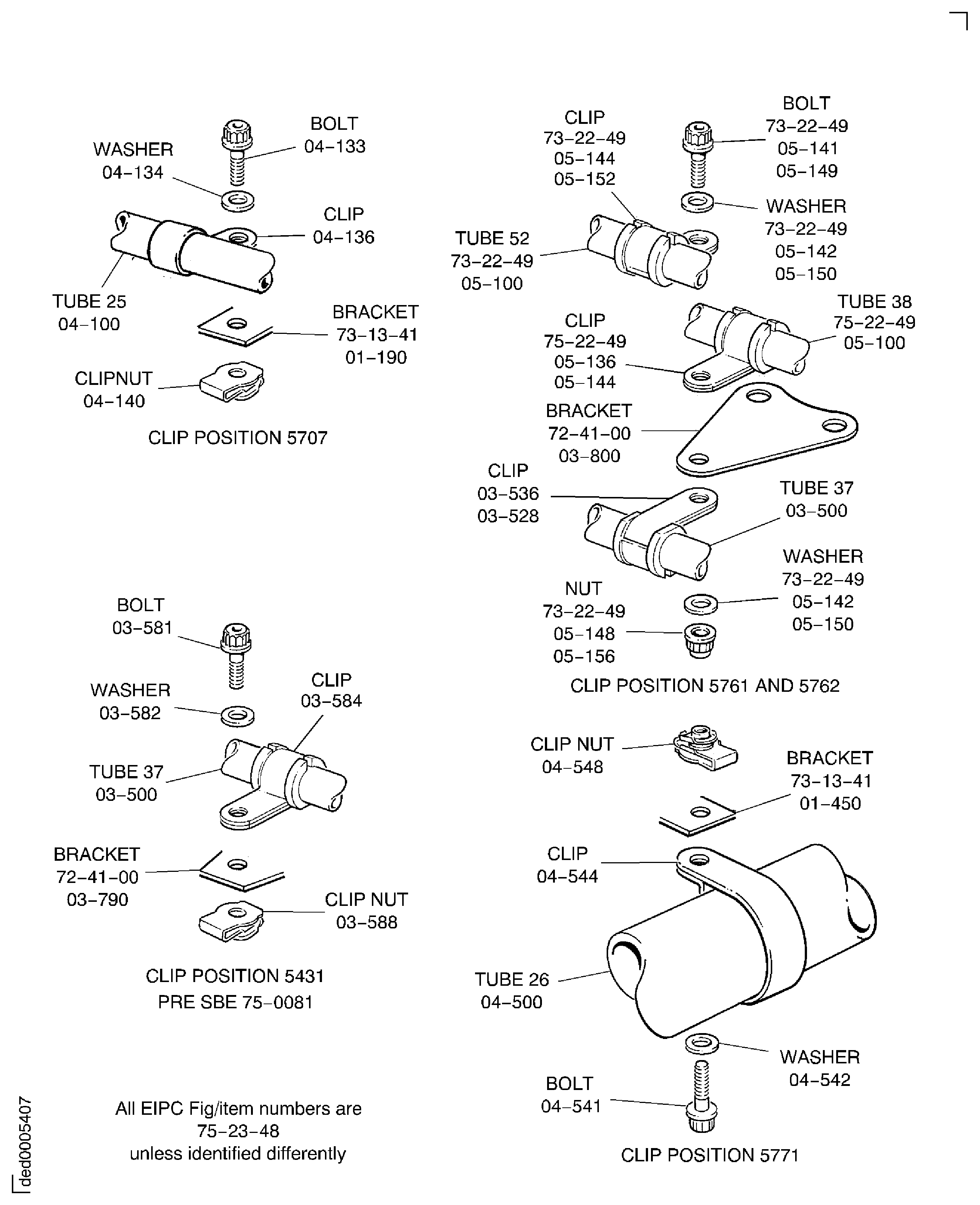

Install the clip, the clipnut, the washer and the bolt at the clip position 5707. Torque the bolt to 36 to 45 lbf.in (4 to 5 Nm).

Refer to Figure.

Use IAE 1R18003 Wrench 1 off to torque the tube nut at the stage 10 to HPT turbine air valve to 566 to 611 lbf.in (64 to 69 Nm).

Use IAE 1R18001 Wrench 1 off to torque the tube nut on the diffuser case adapter to 398 to 434 lbf.in (45 to 49 Nm).

Safety the tube nuts with CoMat 02-126 LOCKWIRE.

Install the tube 25 AIR-TURBINE COOLING CONTROLLED AIR TUBES (75-23-48, 04-100).

Install the clip, the clipnut, the washer and the bolt at the clip position 5771, Figure. Torque the bolt to 36 to 45 lbf.in (4 to 5 Nm).

Use IAE 1R18003 Wrench 1 off to torque the tube nut at the stage 10 to HPT air valve to 566 to 611 lbf.in (64 to 69 Nm).

Use IAE 1R18001 Wrench 1 off to torque the tube nut on the diffuser case adapter to 398 to 434 lbf.in (45 to 49 Nm).

Safety the tube nuts with CoMat 02-126 LOCKWIRE.

Install the tube 26 AIR-TURBINE COOLING CONTROLLED AIR TUBES (75-23-48, 04-500).

Install the clip, the clipnut, the washer and the bolt at the clip position 5431, Figure. Torque the bolt to 36 to 45 lbf.in (4 to 5 Nm).

Torque the tube nut in Step to 159 to 177 lbf.in (18 to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the tube 37 AIR-TURBINE COOLING CONTROLLED AIR TUBES (75-23-48, 03-500), Figure.

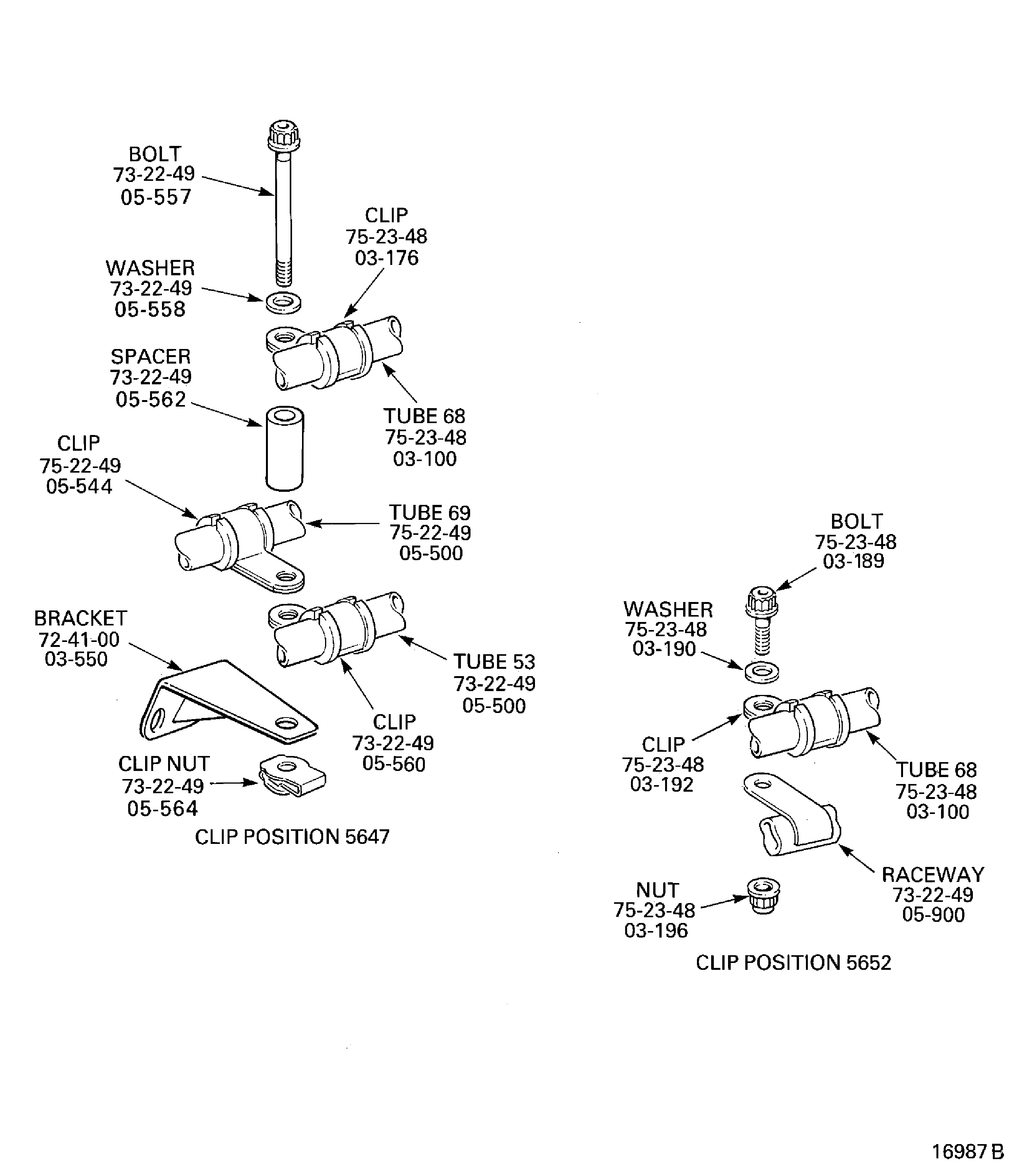

Install the clips, the clipnut, the spacer, the washer and the bolt at the clip position 5647, Figure. Torque the bolt to 36 to 45 lbf.in (4 to 5 Nm).

Torque the tube nut in Step to 159 to 177 lbf.in (18 to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the tube 68 AIR-TURBINE COOLING CONTROLLED AIR TUBES (75-23-48, 03-100).

SUBTASK 72-00-40-420-091-A00 Install the HP Turbine Stage 2 Control Air Tubes (25, 26, 37 and 68) (Pre SBE 79-0087)

Install the clip, the clipnut, the washer and the bolt at the clip position 5707. Torque the bolt to 36 to 45 lbf.in (4 to 5 Nm).

Refer to Figure.

Use IAE 1R18003 Wrench 1 off to torque the tube nut at the stage 10 to HPT turbine air valve to 566 to 611 lbf.in (64 to 69 Nm).

Use IAE 1R18001 Wrench 1 off to torque the tube nut on the diffuser case adapter to 398 to 434 lbf.in (45 to 49 Nm).

Safety the tube nuts with CoMat 02-126 LOCKWIRE.

Install the tube 25 AIR-TURBINE COOLING CONTROLLED AIR TUBES (75-23-48, 04-100).

Install the clip, the clipnut, the washer and the bolt at the clip position 5771, Figure. Torque the bolt to 36 to 45 lbf.in (4 to 5 Nm).

Use IAE 1R18003 Wrench 1 off to torque the tube nut at the stage 10 to HPT air valve to 566 to 611 lbf.in (64 to 69 Nm).

Use IAE 1R18001 Wrench 1 off to torque the tube nut on the diffuser case adapter to 398 to 434 lbf.in (45 to 49 Nm).

Safety the tube nuts with CoMat 02-126 LOCKWIRE.

Install the tube 26 AIR-TURBINE COOLING CONTROLLED AIR TUBES (75-23-48, 04-500).

Install the clip, the clipnut, the washer and the bolt at the clip position 5431, Figure. Torque the bolt to 36 to 45 lbf.in (4 to 5 Nm).

Torque the tube nut in Step to 159 to 177 lbf.in (18 to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the tube 37 AIR-TURBINE COOLING CONTROLLED AIR TUBES (75-23-48, 03-500), Figure.

Install the clips, the clipnut, the spacer, the washer and the bolt at the clip position 5647, Figure. Torque the bolt to 36 to 45 lbf.in (4 to 5 Nm).

Install the clips, the washer, the bolts and the nuts at the clip positions 6099 and 6101, Figure. Torque the nuts to 36 to 45 lbf.in (4 to 5 Nm).

Torque the tube nut in Step to 159 to 177 lbf.in (18 to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the tube 68 AIR-TURBINE COOLING CONTROLLED AIR TUBES (75-23-48, 03-100).

SUBTASK 72-00-40-420-091-B00 Install the HP Turbine Stage 2 Control Air Tubes (25, 26, 37 and 68) (SBE 79-0087)

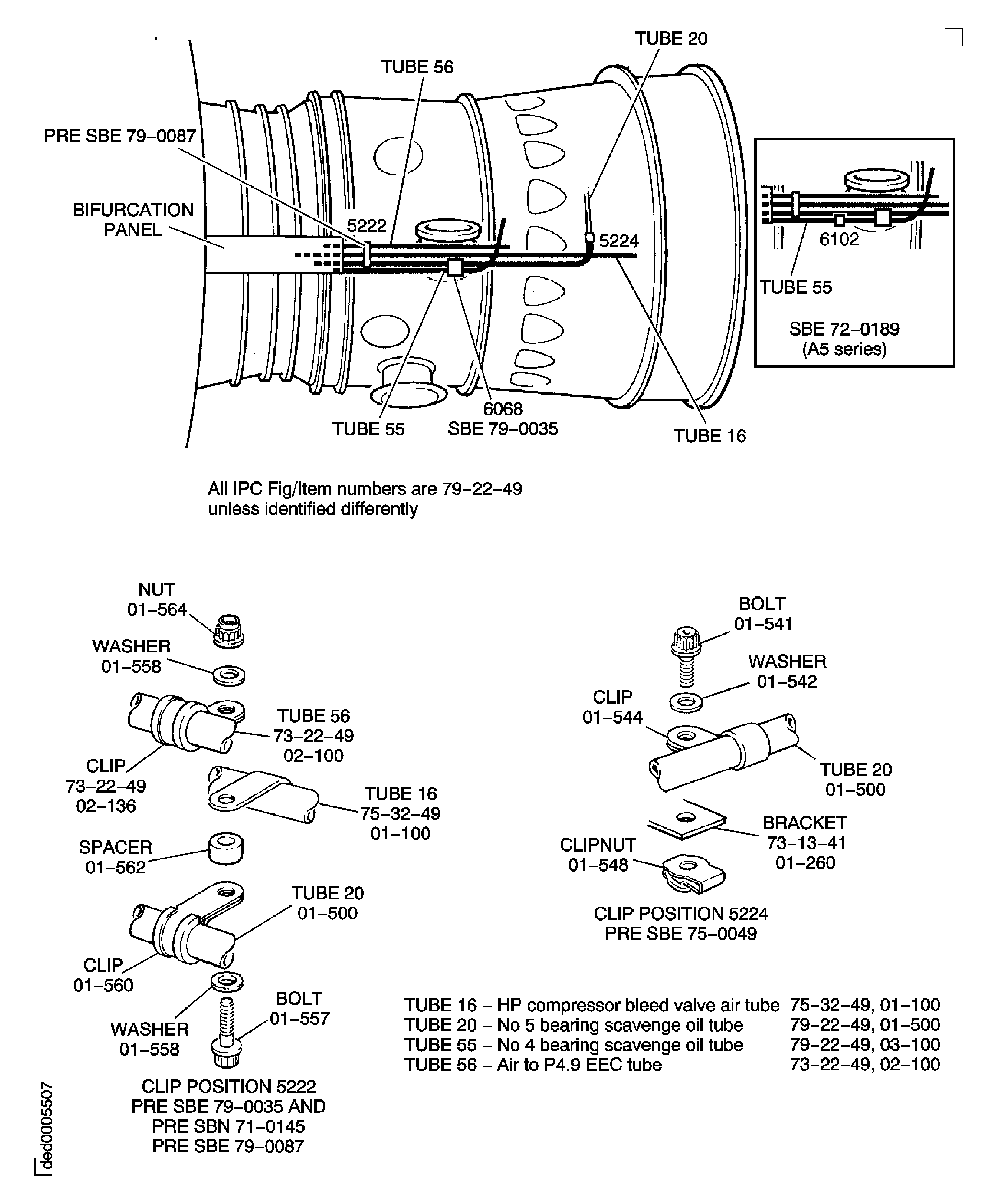

Refer to Figure.

NOTE

The tube nut will be torque tightened when the tube is connected at the bifurcation panel.Attach the tube 55 OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 03-100) to the diffuser case adapter. Hand tighten the tube nut but do not torque tighten at this time.

NOTE

Installation of tube 20 is completed in TASK 72-00-50-420-005-A00 (Installation-007, Config-001) A1 series and TASK 72-00-50-420-005-B00 (Installation-007, Config-002) for A5 series.Put the tube 20 OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 01-500) in to position.

NOTE

For SBE 75-0049, clip position 5224: Refer to TASK 72-00-40-420-007-A00 (Installation-0010, Config-001) and TASK 72-00-40-420-007-B00 (Installation-010, Config-002).Pre SBE 75-0049: Install the clip, the clipnut, the washer and the bolt at the clip position 5224. Torque the bolt to 36 to 45 lbf.in (4 to 5 Nm).

Put the tube 16 AIR-HP COMPRESSOR BLEED CONTROL TUBES (75-32-49, 01-100) in to position.

Put the tube 56 ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 02-100) in to position.

Pre SBE 79-0087: Install the clips, the washers, the bolt and the nut at the clip position 5222, refer to Figure and Figure. Torque the nut to 36 to 45 lbf.in (4 to 5 Nm).

Install the tubes 16, 20 and 56 in to position for installation procedures.

SUBTASK 72-00-40-420-092-A00 Install the HP Compressor Bleed Valve Air Tube (16), the Oil Scavenge Tubes (20 and 55) and the P.49/EEC Tube (56) (Pre SBE 79-0035, Pre SBN 71-0145, Pre SBE 75-0049 and Pre SBE 79-0087)

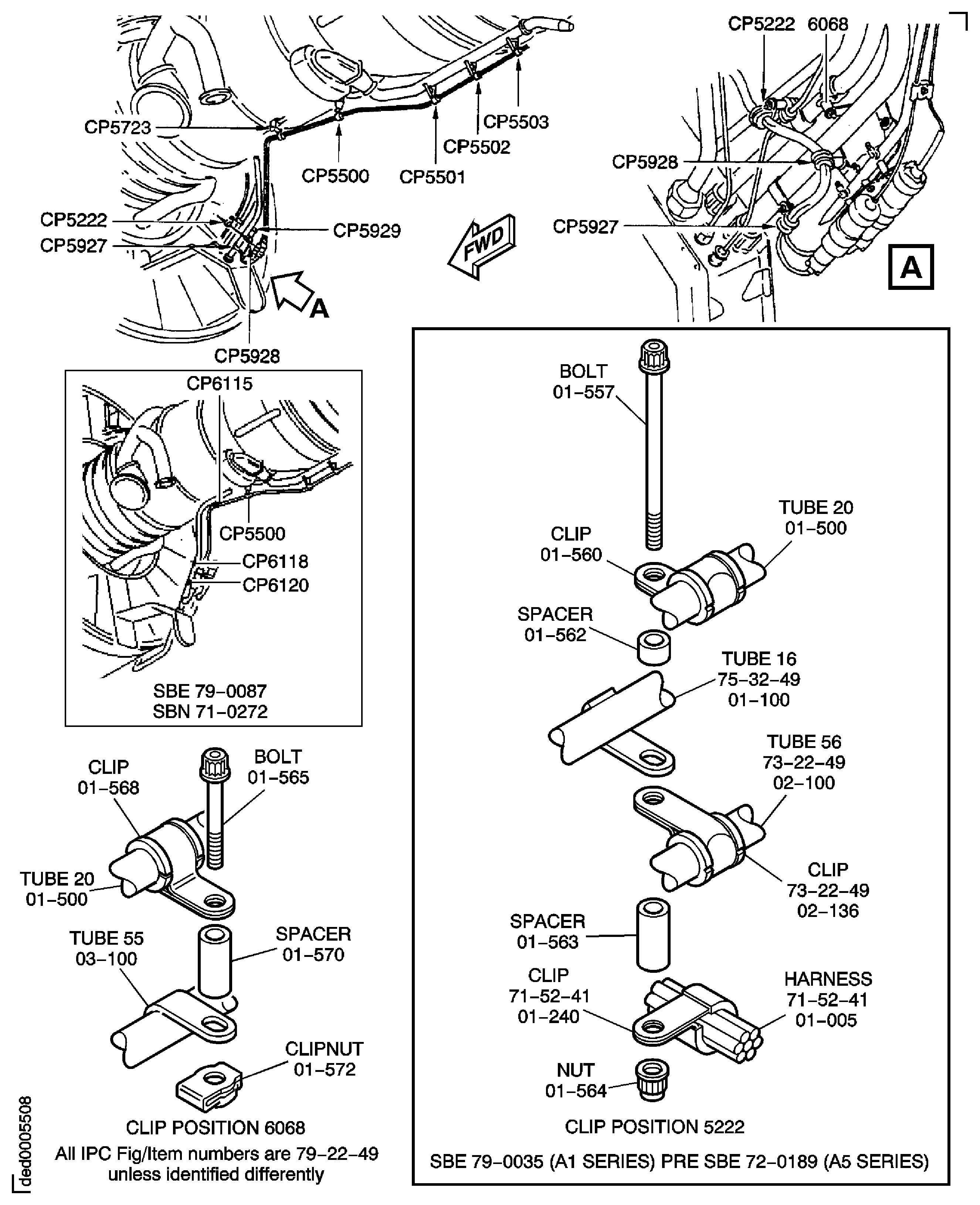

NOTE

The tube nut will be torque tightened when the tube is connected at the bifurcation panel.Attach the tube 55 OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 03-100) to the diffuser case adapter. Hand tighten the tube nut but do not torque tighten at this time.

NOTE

Installation of tube 20 is completed in TASK 72-00-50-420-005-A00 (Installation-007, Config-001) A1 series.Put the tube 20 OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 01-500) in to position.

Pre SBE 79-0087: Install the clip, the clipnut, the spacer and the bolt at the clip position 6068, refer to Figure. Torque the bolt to 36 to 45 lbf.in (4 to 5 Nm).

NOTE

For SBE 75-0049, clip position 5224: Refer to TASK 72-00-40-420-007-A00 (Installation-0010, Config-001) and TASK 72-00-40-420-007-B00 (Installation-010, Config-002).Pre SBE 75-0049: Install the clip, the clipnut, the washer and the bolt at the clip position 5224. Torque the bolt to 36 to 45 lbf.in (4 to 5 Nm).

Put the tube 16 AIR-HP COMPRESSOR BLEED CONTROL TUBES (75-32-49, 01-100) in to position.

Put the tube 56 ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 02-100) in to position.

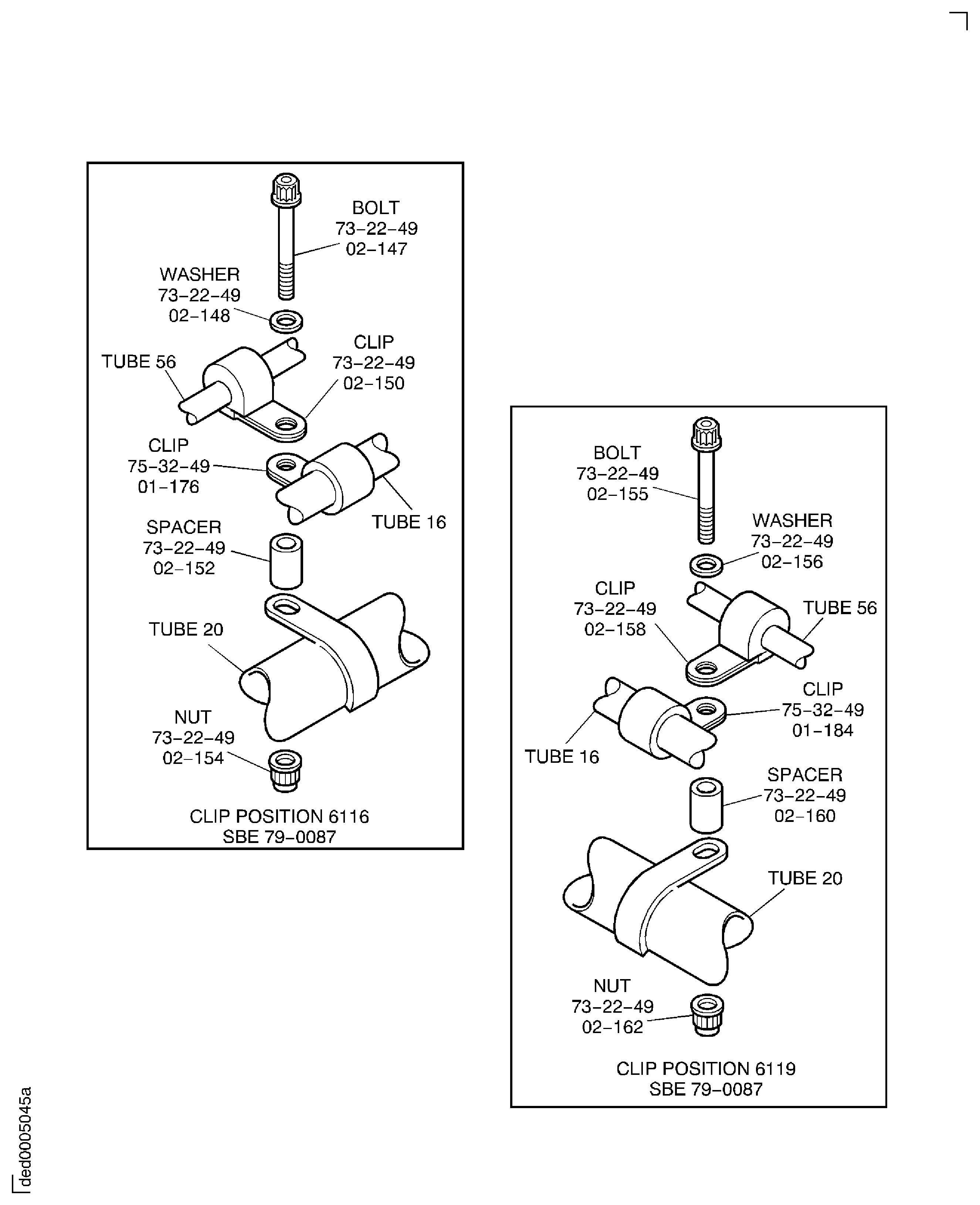

SBE 79-0087: Assemble the clips, the spacers, the washers, the bolts and the nuts at the clip positions 6116 and 6119. Torque the nuts to 36 to 45 lbf.in (4 to 5 Nm).

Put the harness Fire Detection (System A) And Core Services Harness (71-52-41, 01-005) in to position.

SBE 79-0035 and Pre SBE 79-0087 - A1 series: Assemble the clips, the spacers, the bolt and the nut at the clip position 5222, refer to Figure. Tighten but do not fully torque the nut.

Install the tubes 16, 20 and 56.

SUBTASK 72-00-40-420-092-B00 Install the HP Compressor Bleed Valve Air Tube (16), the Oil Scavenge Tubes (20 and 55) and the P.49/EEC Tube (56) (SBE 79-0035, SBN 71-0145, Pre SBE 75-0049, Pre SBE 79-0087 and SBE 79-0087)

SBN 71-0145: Nacelle - core fire detector - rework

SBE 79-0087: Oil - Scavenge oil tubes - Re-route of No.4 bearing scavenge tube.

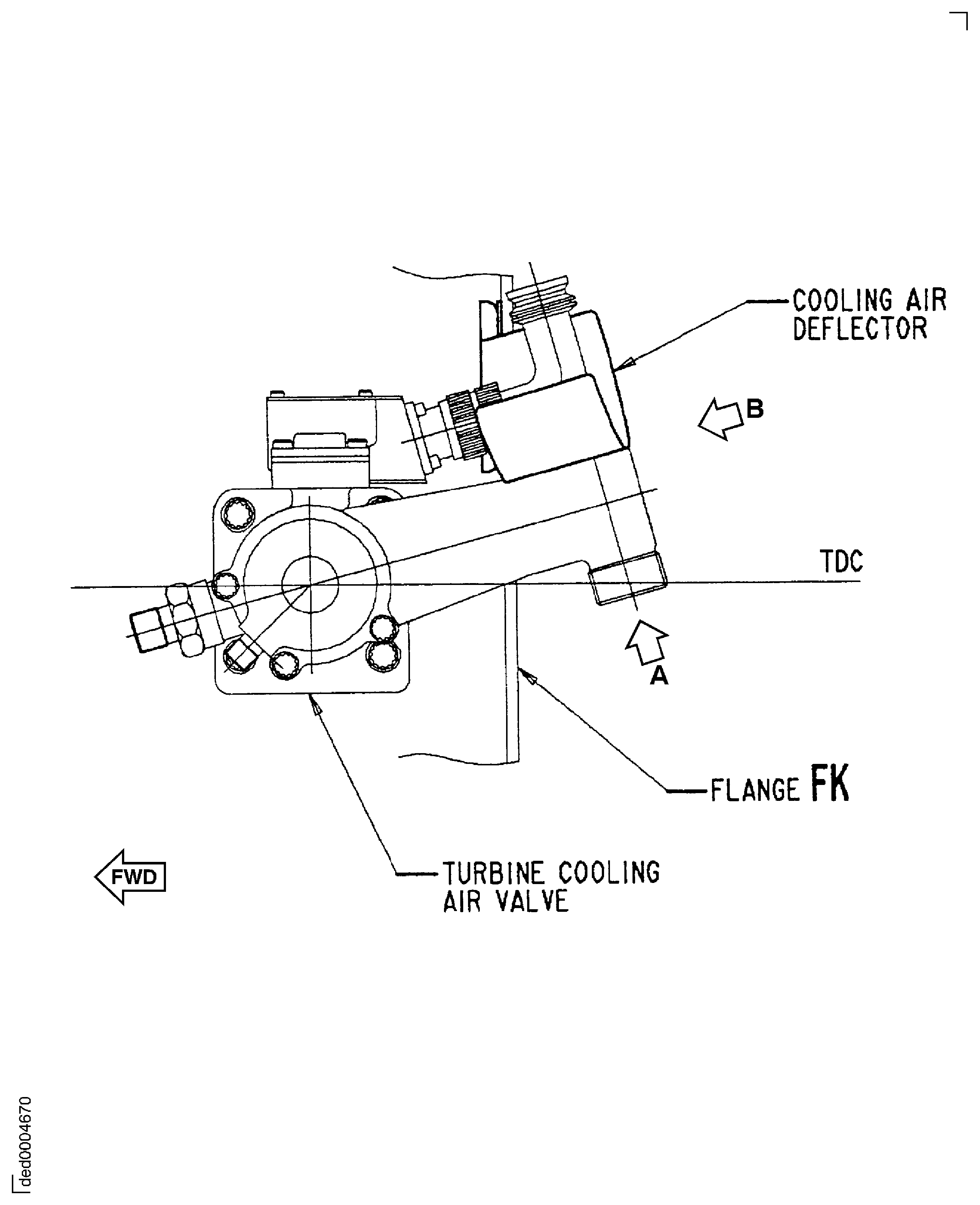

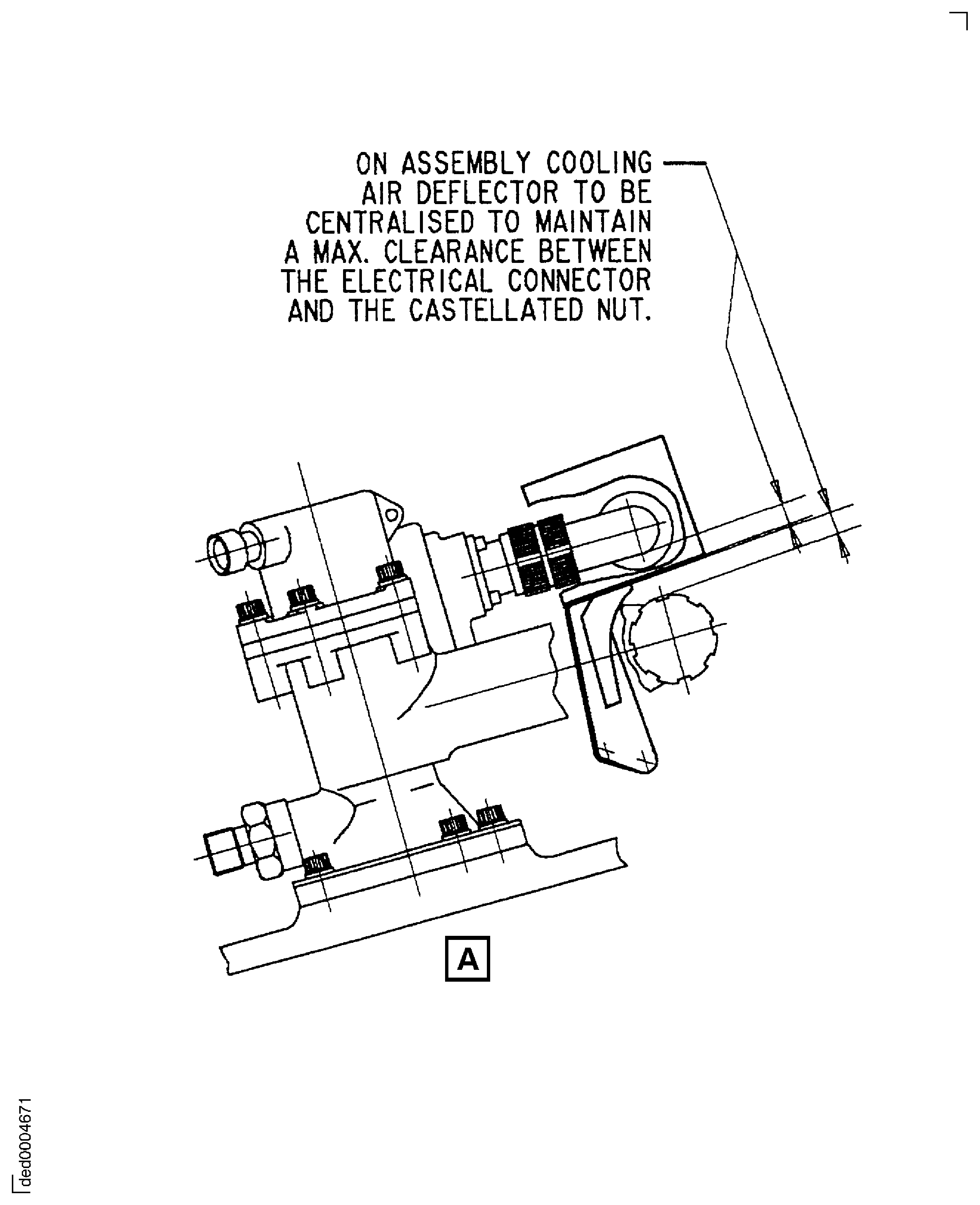

Refer to Figure.

Adjust the position of the deflector bracket so it is in the middle of the space between the electrical connector 4025KS-A and the castellated nut of tube 25 AIR-TURBINE COOLING CONTROLLED AIR TUBES (75-23-48, 04-100).

Torque the bolts ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 05-952) to 36 to 45 lbf.in (4 to 5 Nm).

Attach the air deflector bracket ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 05-950) to the bracket HPC Module - Attaching Parts (72-40-00, 01-075) with the two clip nuts ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 05-954) and the two bolts ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 05-952).

SUBTASK 72-00-40-420-086-A00 Install the Air Deflector Bracket (Pre SBE 72-0329 and Pre SBE 71-0162)

Refer to Figure.

Adjust the position of the deflector bracket so it is in the middle of the space between the electrical connector 4025KS-A and the castellated nut of tube 25 AIR-TURBINE COOLING CONTROLLED AIR TUBES (75-23-48, 04-100).

Torque the bolts ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 05-952) to 36 to 45 lbf.in (4 to 5 Nm).

Attach the air deflector bracket ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 05-950) to the bracket HPC Module - Attaching Parts (72-40-00, 01-075) with the two nuts ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 05-954) and the two bolts ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 05-952). Torque the bolts to 36 to 45 lbf.in (4 to 5 Nm).

SUBTASK 72-00-40-420-086-B00 Install the Air Deflector Bracket (SBE 72-0329 and SBE 71-0162)

SBE 72-0329: HP system - Introduction of revised brackets to provide increased clearance with fuel manifolds.

SBE 71-0162: Power Plant - EEC link harness core - Improved stage 10 on/off valve cooling air deflector for electrical connector

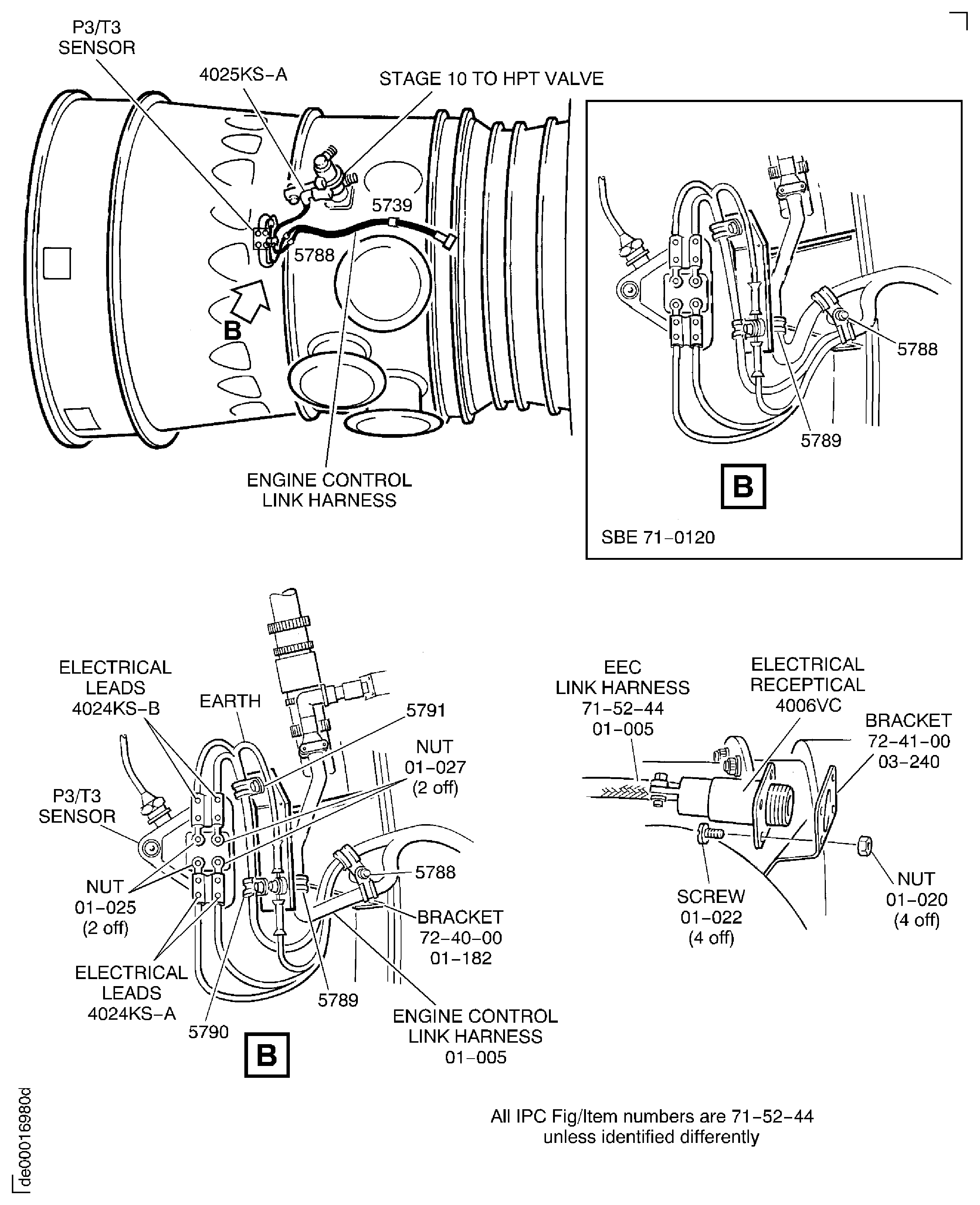

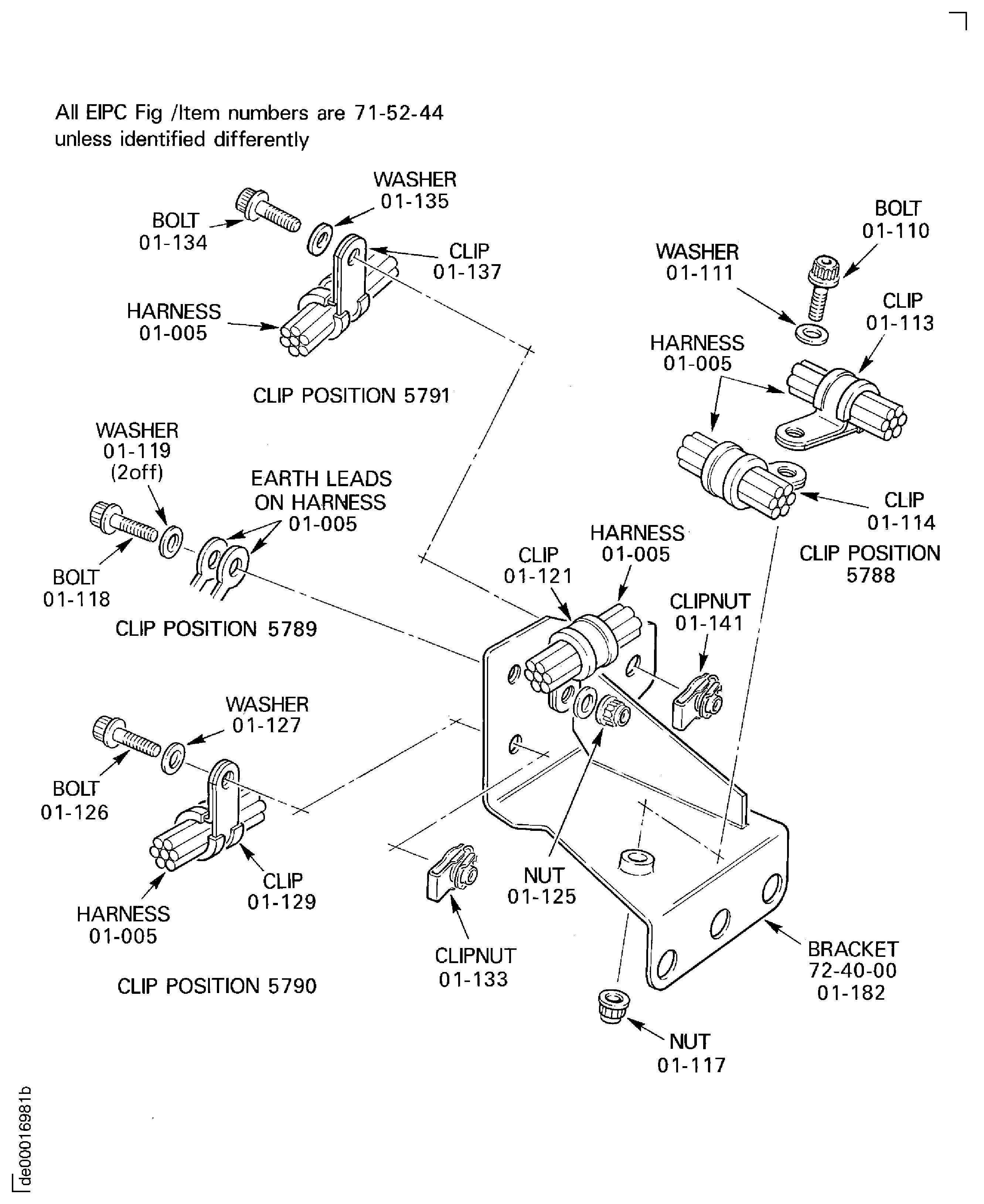

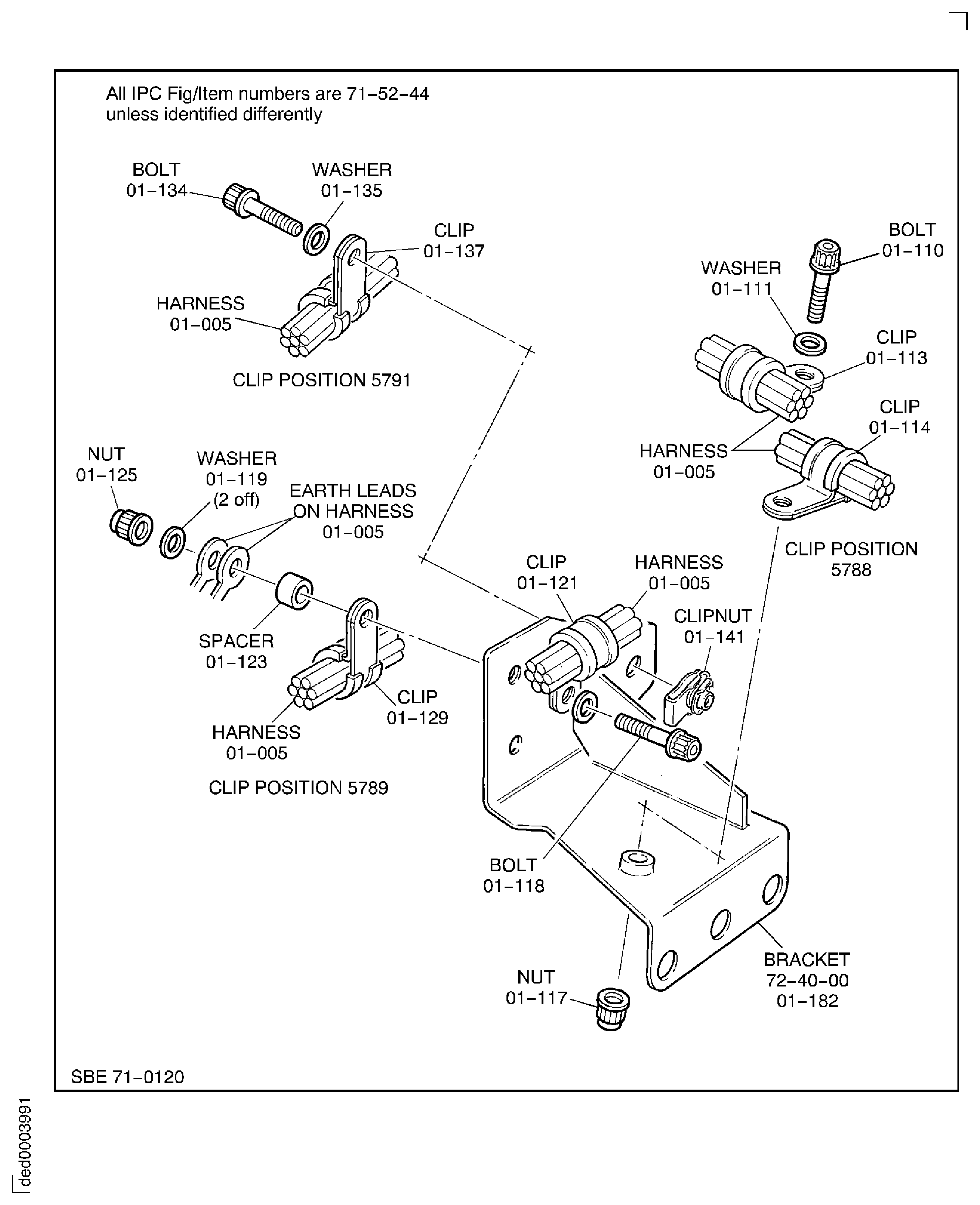

Refer to Figure.

During the installation procedure make sure the harnesses are held temporarily along their different lengths. Always install the datum clip positions when you install each electrical connector. This will give correct installation of the different harnesses, prevent too much strain on the electrical connectors and give the necessary drip loops. The drip loop makes sure moisture of fluids do not go in to the electrical connector.

Because of the differences between the harness diameters, the specified clip could be too large or too small. You can use a clip from a range of six clips that have the same part numbers. If the harness diameter is between two of the clips in the range, use the larger clip. When you do this use CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) to increase the harness diameter.

SUBTASK 72-00-40-420-134 Electrical Harness Installation Procedure

Put the Engine Control Link Harness ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 01-005) into position.

Install the four screws ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 01-022) and the four assembled washer nuts ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 01-020). Torque the assembled washer nut to 6 to 8 lbf.in (0.68 to 0.9 Nm).

Connect the electrical receptacle 4006VC to the bracket ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 03-240).

Install the two nuts ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 01-025) on to the smaller (Chromel) terminals. Torque the nuts to 8 to 12 * lbf.in (0.9 to 1.36 Nm).

Install the two nuts ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 01-027) on to the larger (Alumel) terminals. Torque the nuts to 10 to 15 * lbf.in (1.13 to 1.69 Nm).

Connect the four leads to the four terminals on the P3/T3 diffuser case probe.

SUBTASK 72-00-40-420-094-A00 Install the Engine Control Link Harness (Pre SBE 71-0120 and Pre SBE 71-0162)

Put the Engine Control Link Harness ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 01-005) into position.

Install the four screws ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 01-022) and the four assembled washer nuts ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 01-020). Torque the assembled washer nut to 6 to 8 lbf.in (0.68 to 0.9 Nm).

Connect the electrical receptacle 4006VC to the bracket ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 03-240).

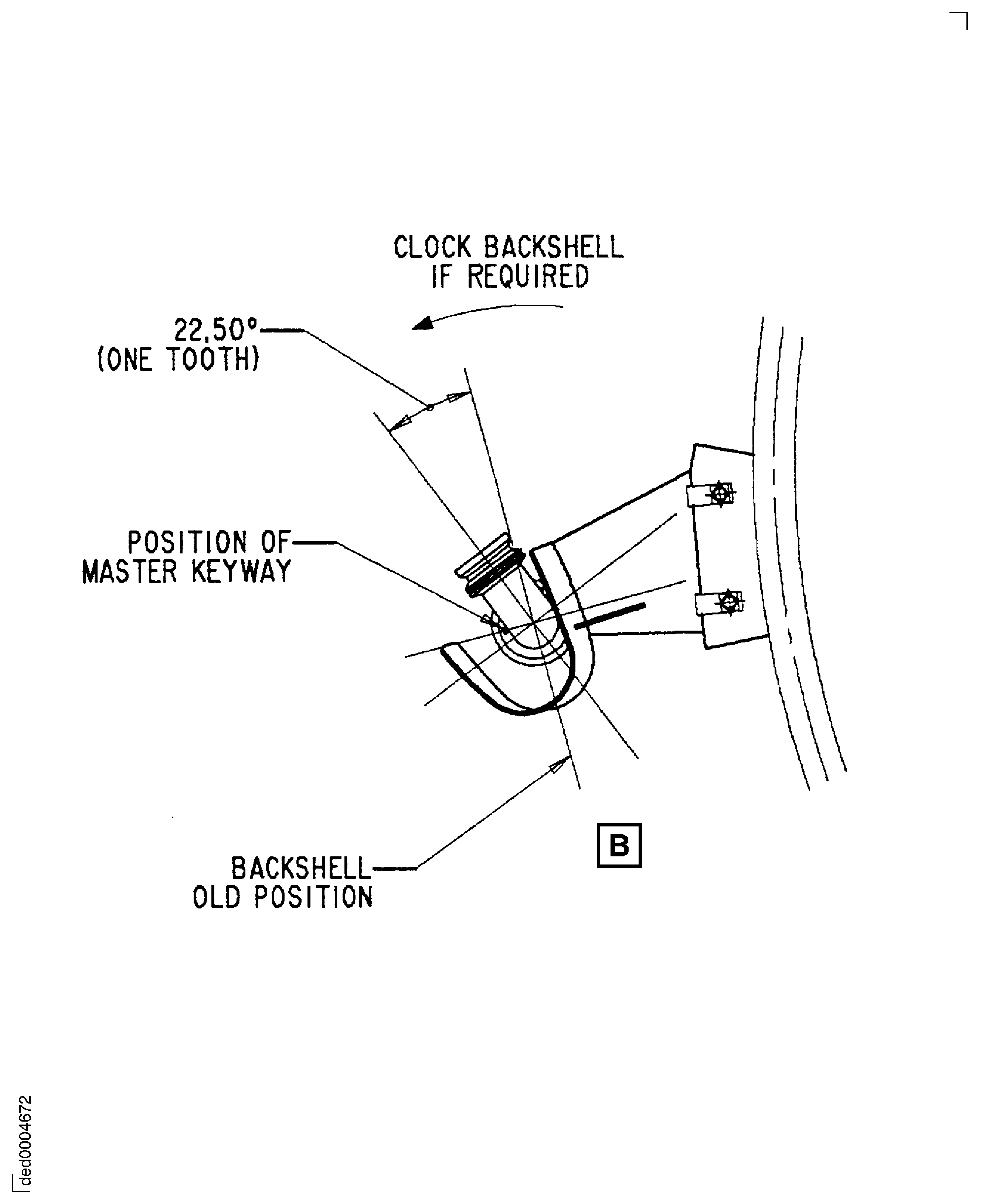

Make sure the electrical connector and elbow do not touch the air deflector bracket ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 05-950), refer to Figure and Figure. Do the procedure in the next step if the connector or elbow touch the bracket.

Adjust the backshell one tooth (22.5 degrees) in a counter clockwise direction to give additional clearance between the connector and the bracket, refer to Figure.

Connect the electrical connector 4025KS-A to the stage 10 to HPT air valve and torque to 12 * lbf.in (1.4 Nm).

Install the two nuts ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 01-025) on to the smaller (Chromel) terminals. Torque the nuts to 8 to 12 * lbf.in (0.9 to 1.36 Nm).

Install the two nuts ELECT HARNESS-LIGHT DUTY-EEC LINK HARNESS-CORE (71-52-44, 01-027) on to the larger (Alumel) terminals. Torque the nuts to 10 to 15 * lbf.in (1.13 to 1.69 Nm).

Connect the four leads to the four terminals on the P3/T3 diffuser case probe.

SUBTASK 72-00-40-420-094-B00 Install the Engine Control Link Harness (SBE 71-0120 and SBE 71-0162)

SBE 71-0120: Power Plant - Reroute the core harness to ensure adequate clearance between the harness the various tubes

SBE 71-0162: Power Plant - EEC link harness core - Improved stage 10 on/off valve cooling air deflector for electrical connector

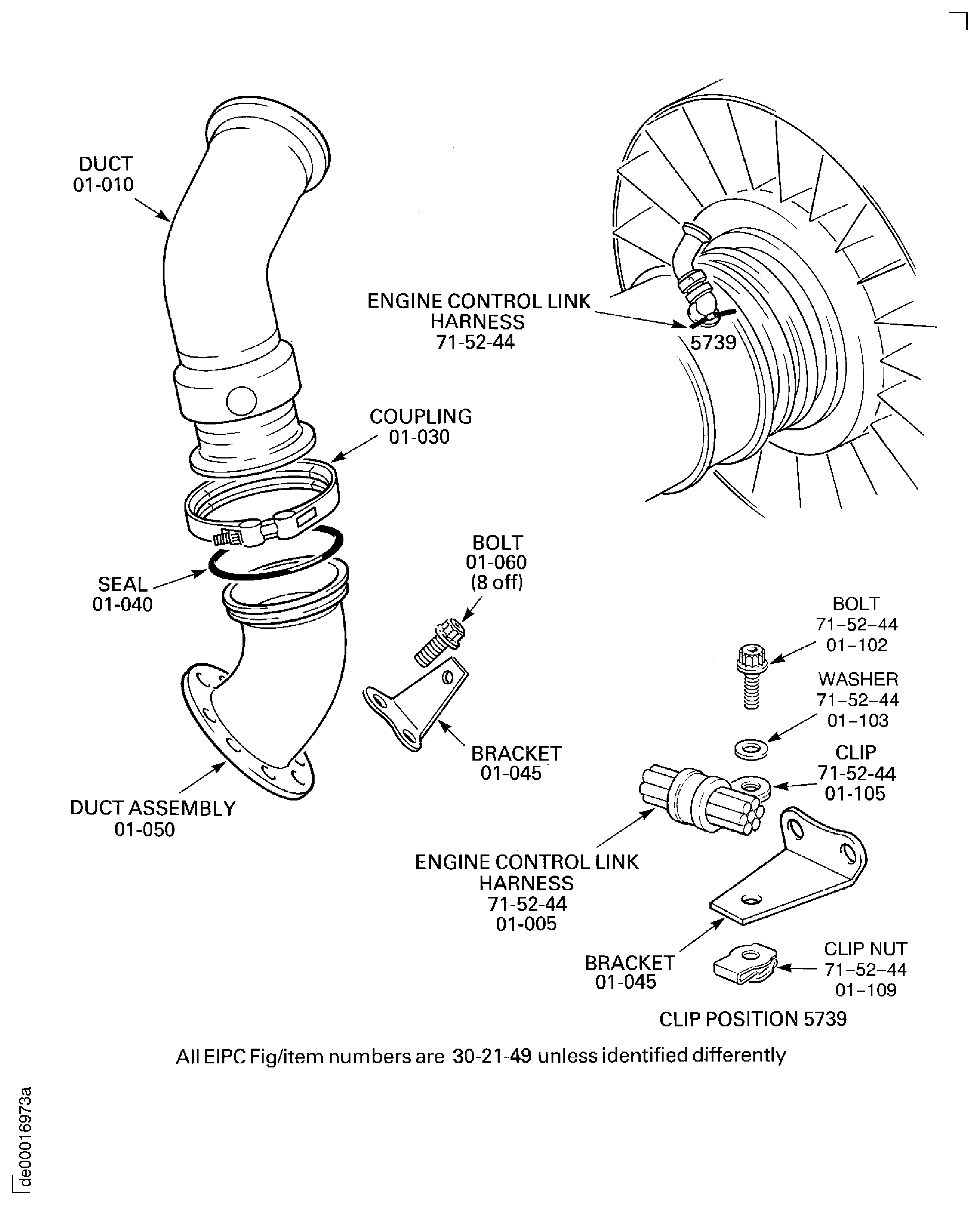

Refer to Figure.

Attach the duct assembly ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-050) and the bracket ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-045) to the HP compressor case with the eight bolts ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-060). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

Install the seal ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-040).

Attach the duct to the duct assembly with the coupling ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-030). Torque the coupling nut to 45 to 55 * lbf.in (5.1 to 6.2 Nm).

Install the duct ICE AND RAIN PROTECTION-ANTI-ICE DUCTS (30-21-49, 01-010).

SUBTASK 72-00-40-420-097 Install the Thermal Anti-Icing Ducts

Refer to Figure.

Make sure that all the applicable backshells and cable clamps are safetied with CoMat 02-126 LOCKWIRE. Refer to SPM TASK 70-42-05-400-501.

SUBTASK 72-00-40-210-053 Visually Inspect the Electrical Backshells and Cable Clamps

Figure: Install the Fuel Nozzles

Sheet 1

Figure: Install the Fuel Nozzles

Sheet 2

Figure: Install the Igniter Plugs

Sheet 1

Figure: Install the Igniter Plugs

Sheet 2

Figure: Install the P3/T3 Sensor

Install the P3/T3 Sensor

Figure: Install the Fuel Distribution Valve

Install the Fuel Distribution Valve

Figure: Install the Stage 10 to HPT Air Valve

Install the Stage 10 to HPT Air Valve

Figure: Install the HP Compressor Stage 10 Air Off-Take Ducts and the Bleed Valve Assemblies

Sheet 1

Figure: Pre SBE 79-0087 and SBE 79-0087: Install the HP Compressor Stage 10 Air Off-Take Ducts

Sheet 2

Figure: Install the Tube Raceway

Install the Tube Raceway

Figure: Pre SBE 73-0139 and Pre SBE 73-0147: Install the Fuel Nozzle Manifolds

Sheet 1

Figure: SBE 73-0139 and Pre SBE 73-0147: Install the Fuel Nozzle Manifolds

Sheet 2

Figure: Pre SBE 73-0147: Install the Fuel Nozzle Manifolds

Sheet 3

Figure: Pre SBE 73-0139: Install the Fuel Nozzle Manifolds

Sheet 4

Figure: Pre SBE 73-0147: Install the Fuel Nozzle Manifolds

Sheet 5

Figure: Pre SBE 73-0147: Install the Fuel Nozzle Manifolds

Sheet 6

Figure: SBE 73-0147: Install the Fuel Nozzle Manifolds

Sheet 7

Figure: SBE 73-0147: Install the Fuel Nozzle Manifolds

Sheet 8

Figure: SBE 73-0147: Install the Fuel Nozzle Manifolds

Sheet 9

Figure: SBE 73-0147: Install the Fuel Nozzle Manifolds

Sheet 10

Figure: SBE 73-0147: Install the Fuel Nozzle Manifolds

Sheet 11

Figure: SBE 73-0147: Install the Fuel Nozzle Manifolds

Sheet 12

Figure: Pre SBE 79-0087: Install the PS3 Sensor Line Air Tubes

Sheet 1

Figure: SBE 79-0087: Install the PS3 Sensor Line Air Tube

Sheet 2

Figure: Install the No.4 Bearing Scavenge Air Tubes (38 and 69)

Sheet 1

Figure: Install the No.4 Bearing Scavenge Air Tubes (38 and 69)

Sheet 2

Figure: Install the No.4 bBaring Scavenge Air Tubes (53, 68 and 69)

Sheet 3

Figure: Install the HP Turbine Stage 2 Control Air Tubes (25, 26, 37 and 68)

Sheet 1

Figure: Install the HP Turbine Stage 2 Control Air Tubes (25, 26, 37 and 68)

Sheet 2

Figure: Install the HP Turbine Stage 2 Control Air Tubes

Sheet 3

Figure: Pre SBE 79-0087: Install the Tubes 16, 20, 55 and 56

Sheet 1

Figure: Pre SBE 79-0087 and Pre SBN 71-0272: Install the Tubes 16, 20, 55 and 56

Sheet 2

Figure: Install the Tubes 16, 20 and 56

Sheet 3

Figure: Install the Air Deflector Bracket

Sheet 1

Figure: Install the Air Deflector Bracket

Sheet 2

Figure: Electrical Harness Installation

Electrical Harness Installation

Figure: Install the Engine Control Link Harness

Sheet 1

Figure: Install the Engine Control Link Harness

Sheet 2

Figure: SBE 71-0120 : Install the Engine Control Link Harness

Sheet 3

Figure: Install the Thermal Anti-Icing Ducts

Install the Thermal Anti-Icing Ducts

Figure: SBE 73-0139: Install the Fuel Nozzle Manifolds

Sheet 1

Figure: SBE 73-0139: Install the Fuel Nozzle Manifolds

Sheet 2

Figure: SBE 71-0162: Connect the Electrical Connector 4025KS-A to the Stage 10 to HPT Air Valve

Sheet 1

Figure: SBE 71-0162: Connect the Electrical Connector 4025KS-A to the Stage 10 to HPT Air Valve

Sheet 2

Figure: SBE 71-0162: Connect the Electrical Connector 4025KS-A to the Stage 10 to HPT Air Valve

Sheet 3

Figure: Visually Inspect the Backshells and Cable Clamps

Visually Inspect the Backshells and Cable Clamps