Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1 and SBE 79-0087

Common Information

TASK 72-00-32-420-004-D00 LPC/Intermediate Case Module - Install The Electrical Harnesses, Installation-004 - SBE 79-0087

General

Refer to the TASKS which follow for the other related procedures.

TASK 72-00-32-420-001 (Page Block-401, INSTALLATION-001): Install the LP compressor/intermediate case brackets and the bifurcation panel

TASK 72-00-32-420-002 (Page Block-401, INSTALLATION-002): Install the LP compressor/intermediate case components

TASK 72-00-32-420-003-D00 (Page Block-401, INSTALLATION-003, CONFIG-004): SBE 79-0087: Install the LP compressor/intermediate case tubes and the electrical harness raceways

TASK 72-00-32-420-005 (Page Block-401, INSTALLATION-005): Install the pneumatic starter duct, the thermal anti-ice (TAI) duct, the hydraulic tubes, and the EEC cooling ducts to the LP compressor/intermediate case module

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

For the lockwire data and procedures refer to the SPM TASK 70-42-05-400-501.

For safety cable data and procedures refer to the SPM TASK 70-42-08-400-501.

Safety the threaded fasteners in the ATA Chapter/Section/Subject 71-51-41 and 73-22-49 as applicable with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT.

To identify, lubricate and install the seal rings refer to the SPM TASK 70-44-00-400-501.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in this procedure.

Special torque data is identified with the symbol * after the torque value.

Transportation covers/blanks must be removed immediately before the connection of the hoses to the components.

For the connection of electrical connectors, refer to the SPM TASK 70-43-01-400-501.

For the installation of open wire harnesses, refer to the SPM TASK 70-43-02-400-501.

NOTE

To identify the consumable materials refer to the PCI.

SBE 70-0813: Announcement of introduction of safety cable as a preferred method to lockwire.

Safety the threaded fasteners in this TASK with safety cable for the ATA Chapter/Section/Subject detailed in 2. General.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1R19416 EEC harness wrench | 0AM53 | IAE 1R19416 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-003 SOLVENT, DELETED | LOCAL | CoMat 01-003 | ||

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) | LOCAL | CoMat 02-148 | ||

| CoMat 02-159 LACING TAPE | LOCAL | CoMat 02-159 | ||

| CoMat 02-184 LACING TAPE | LOCAL | CoMat 02-184 | ||

| CoMat 02-202 GLASS CLOTH TAPE, ADHESIVE | LOCAL | CoMat 02-202 | ||

| CoMat 02-274 SAFETY CABLE KIT | LOCAL | CoMat 02-274 | ||

| CoMat 02-275 SAFETY CABLE KIT | LOCAL | CoMat 02-275 | ||

| CoMat 06-086 TIES | 18992 | CoMat 06-086 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 | ||

| CoMat 01-002 SOLVENT, DELETED. | 0AM53 | CoMat 01-002 | ||

| CoMat 10-039 ENGINE OIL | LOCAL | CoMat 10-039 |

Safety Requirements

NONEProcedure

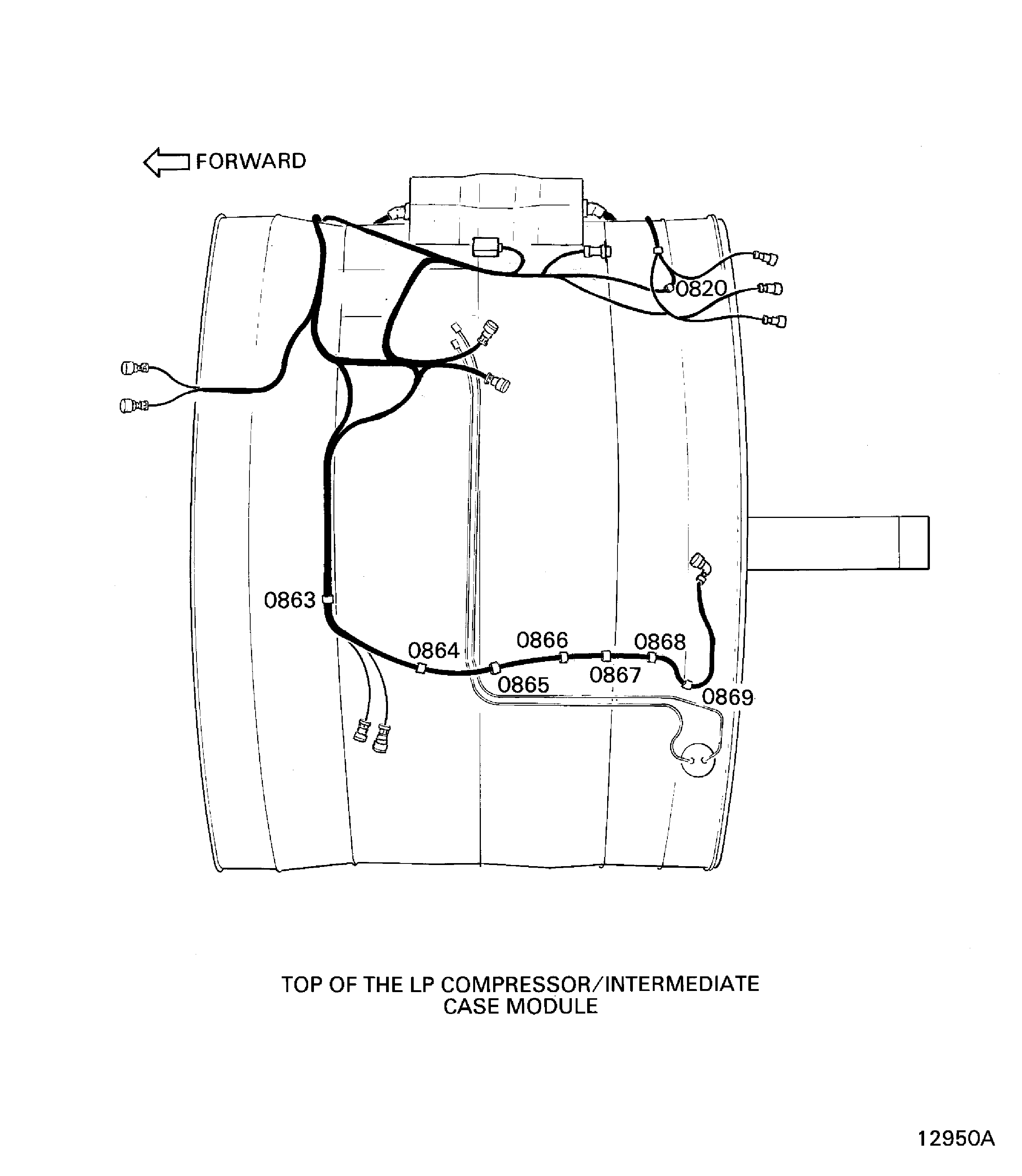

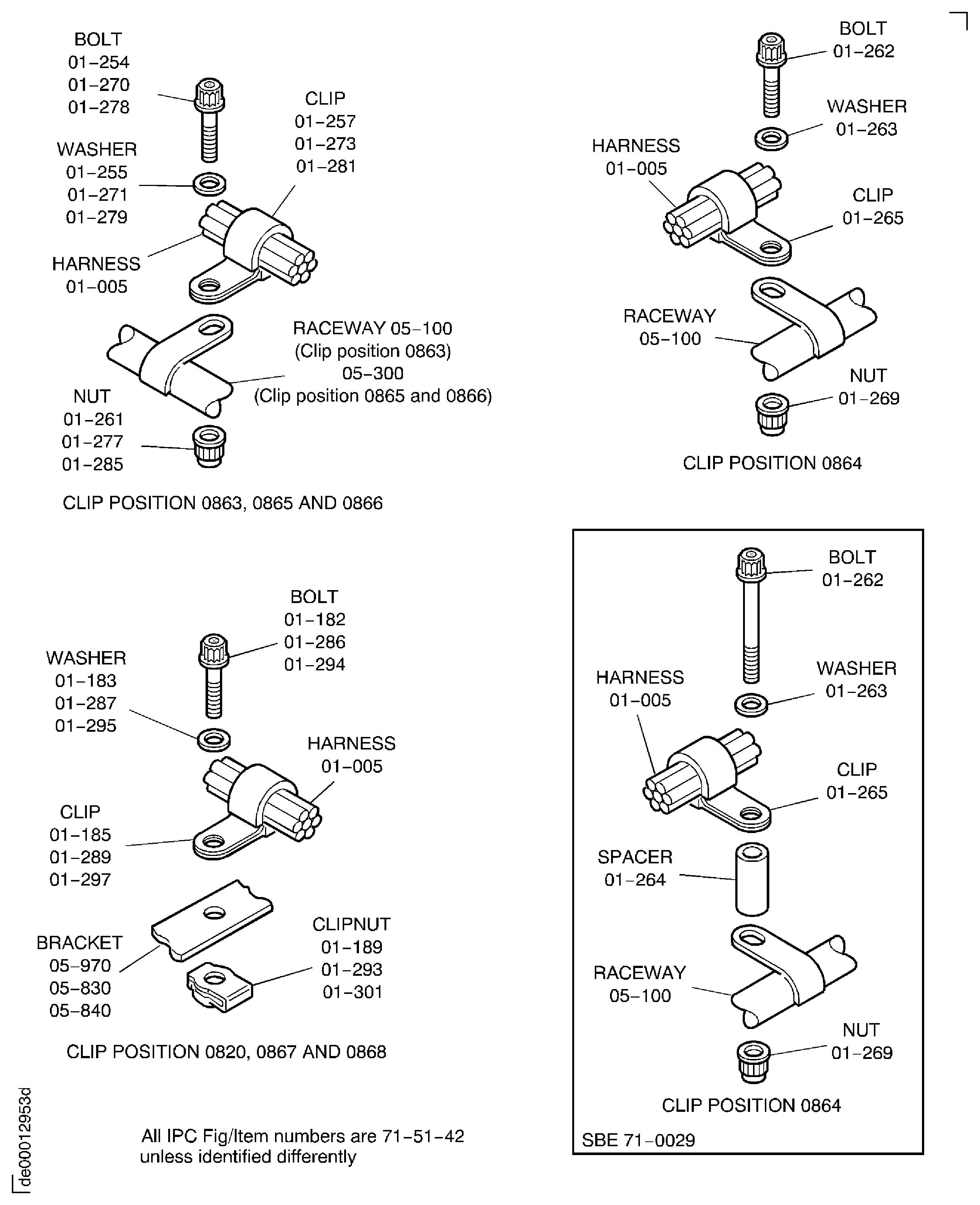

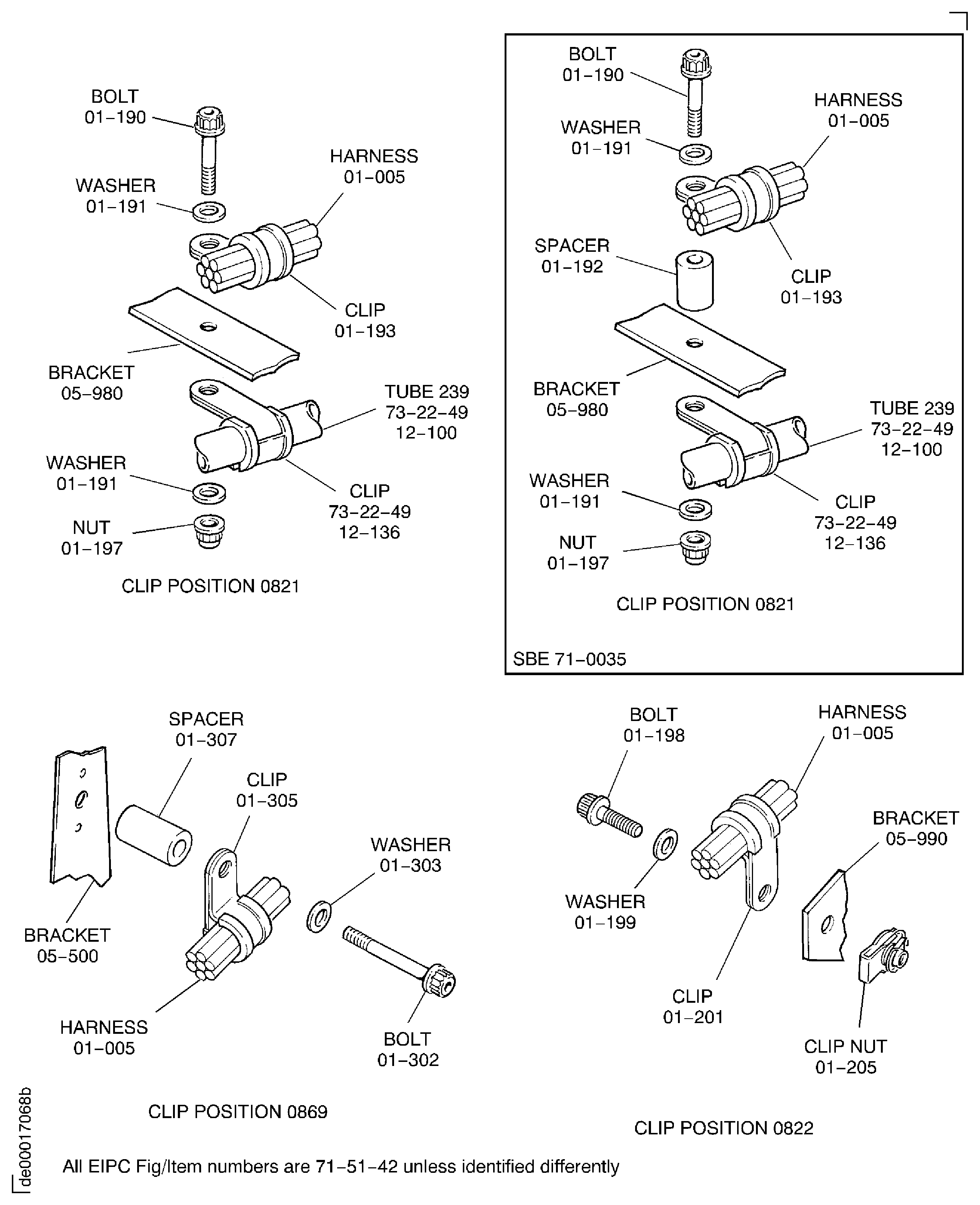

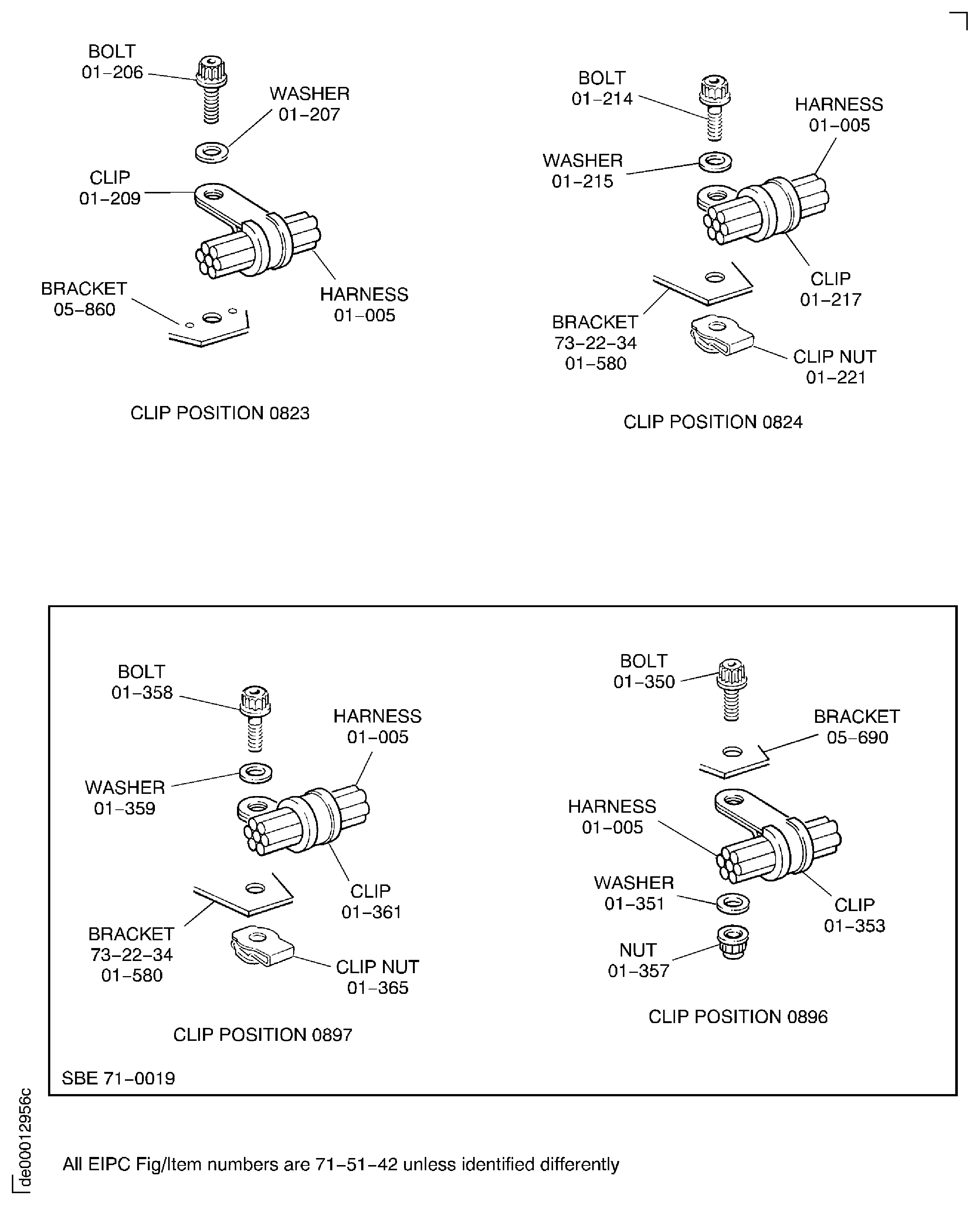

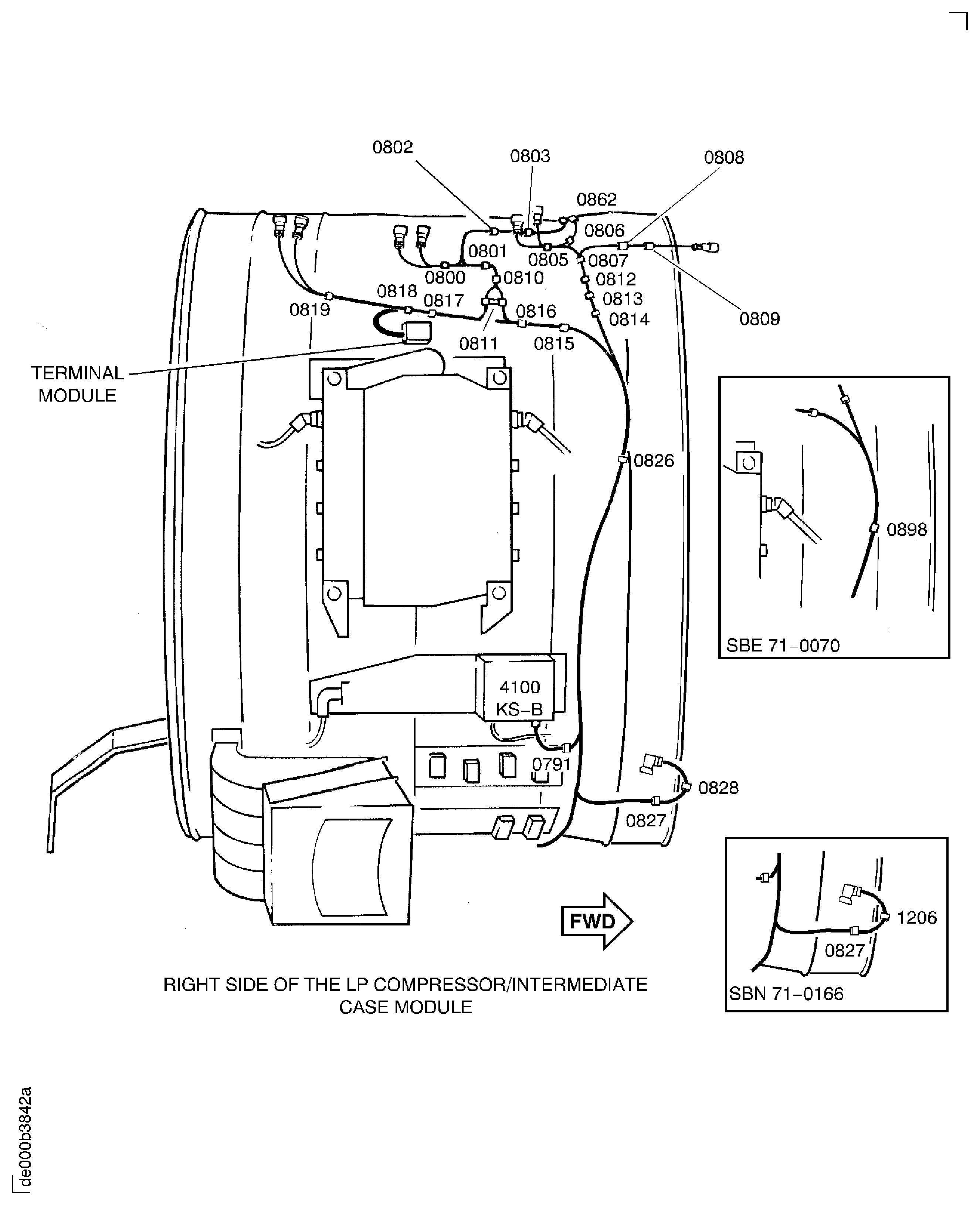

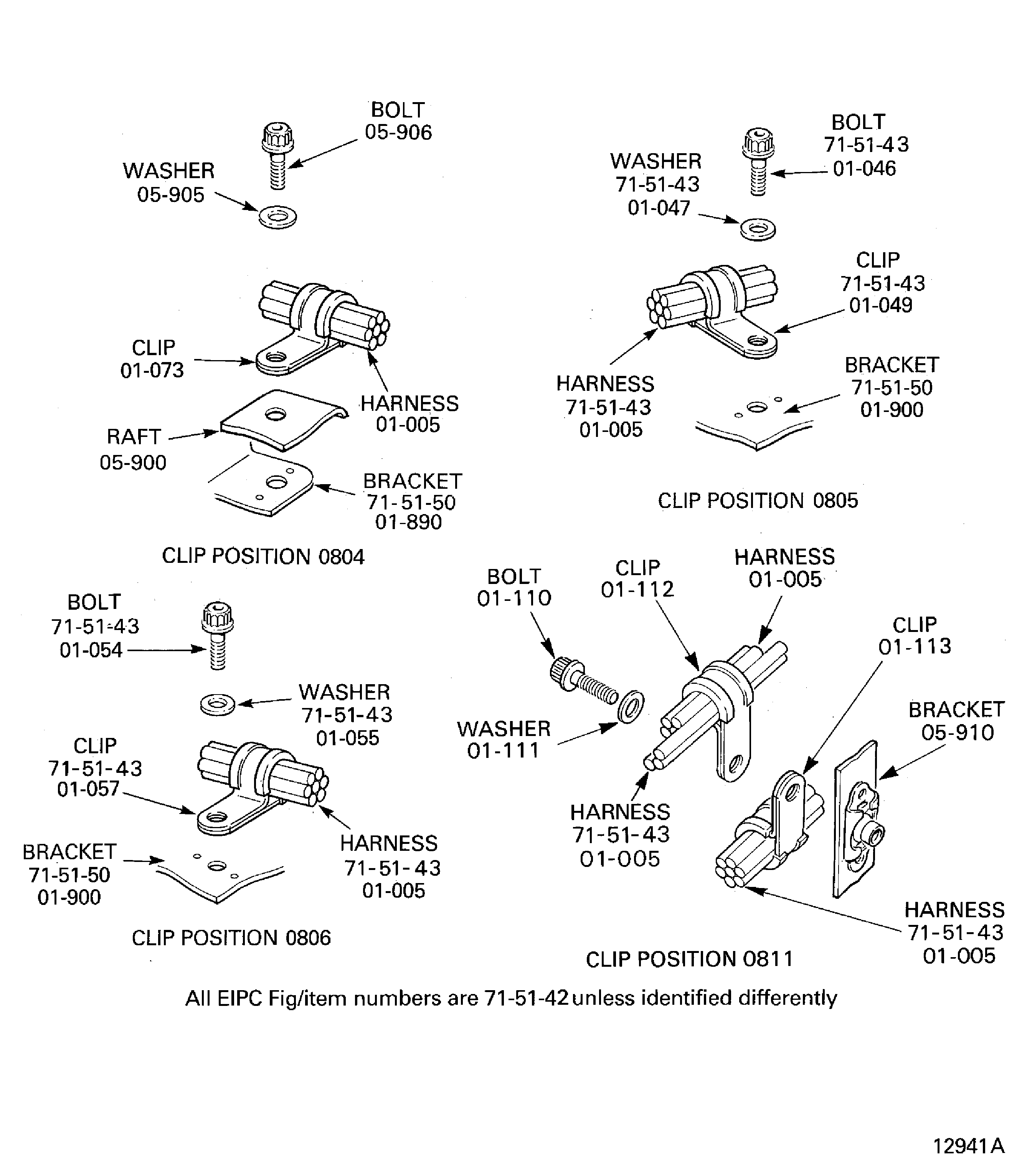

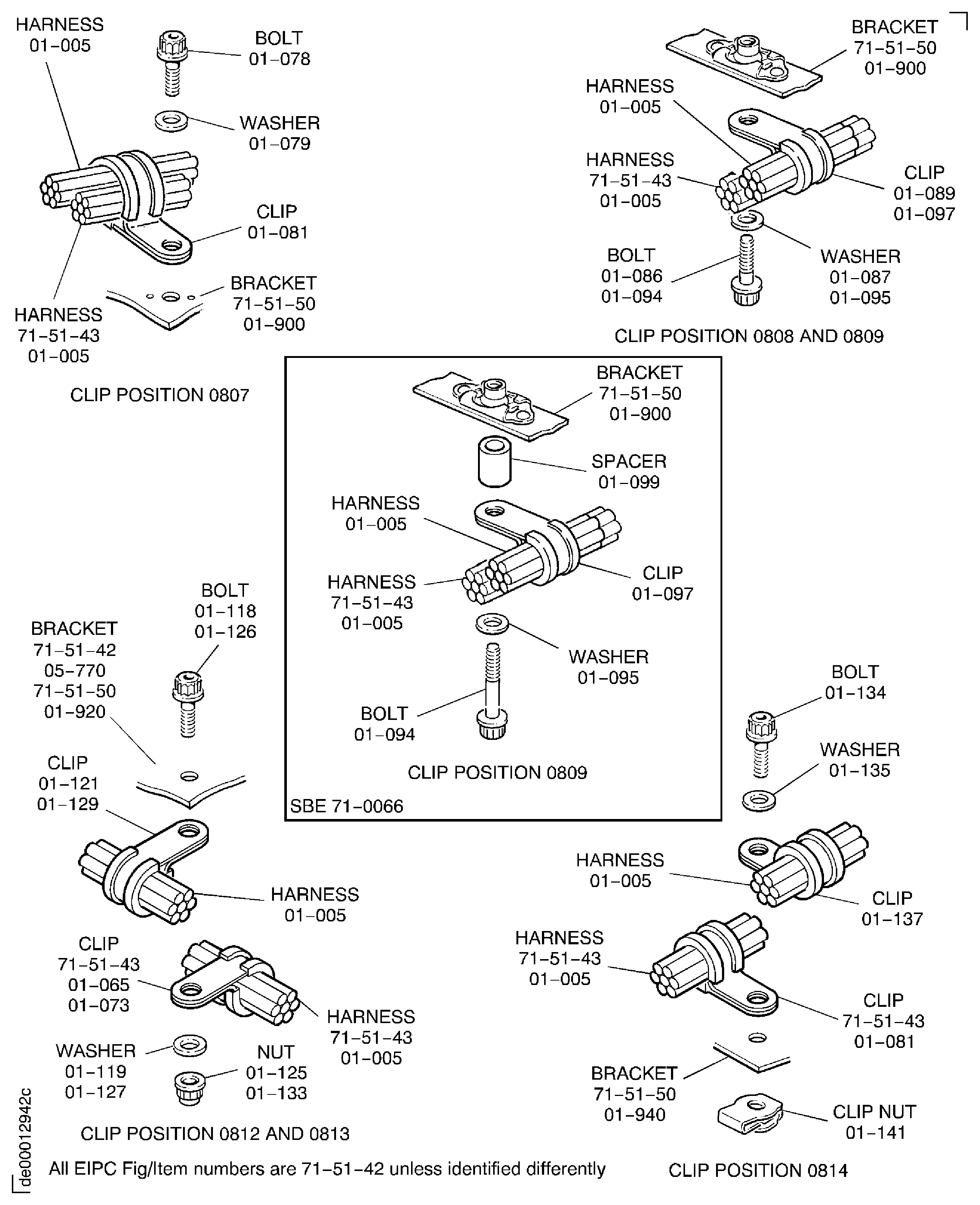

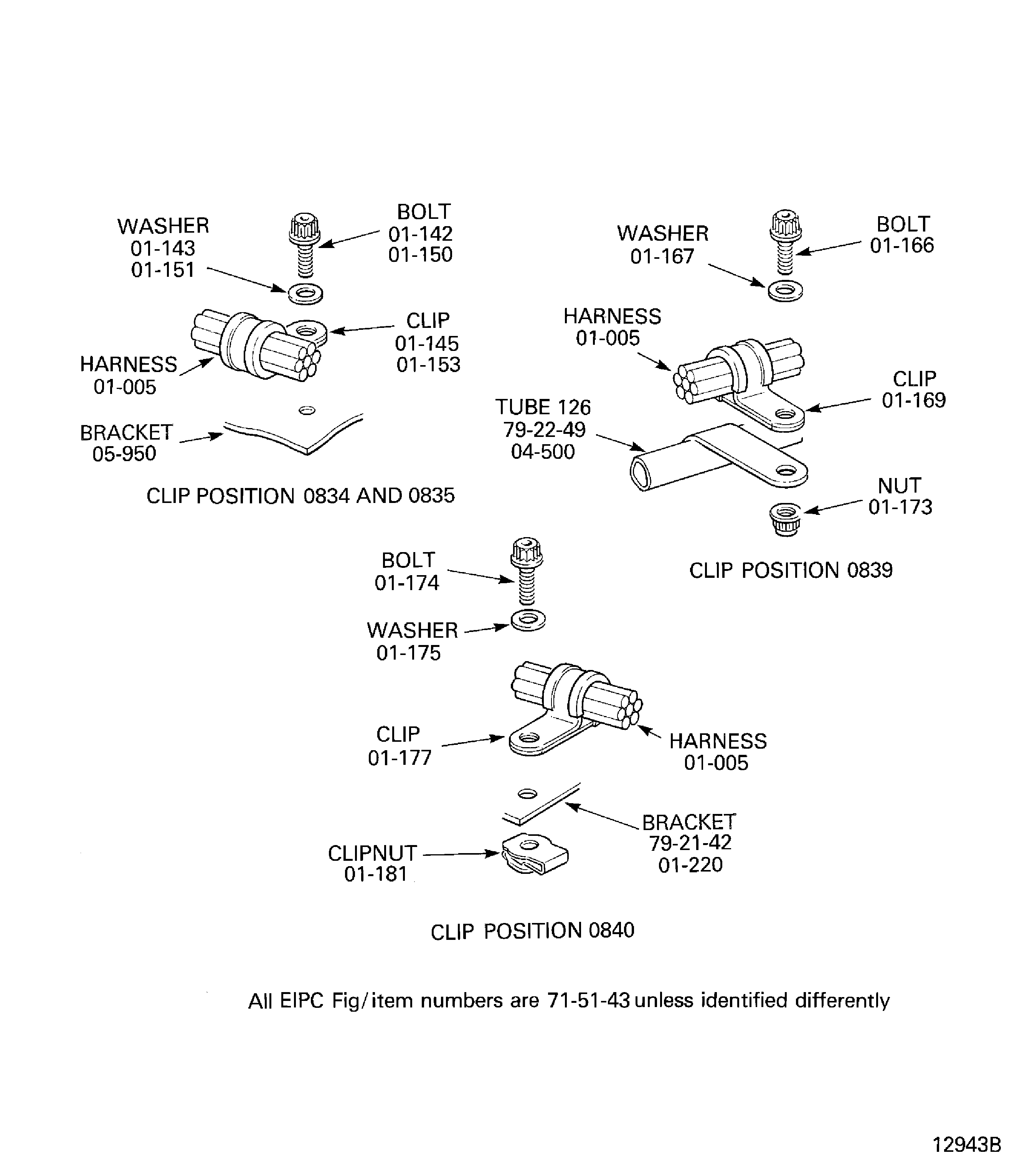

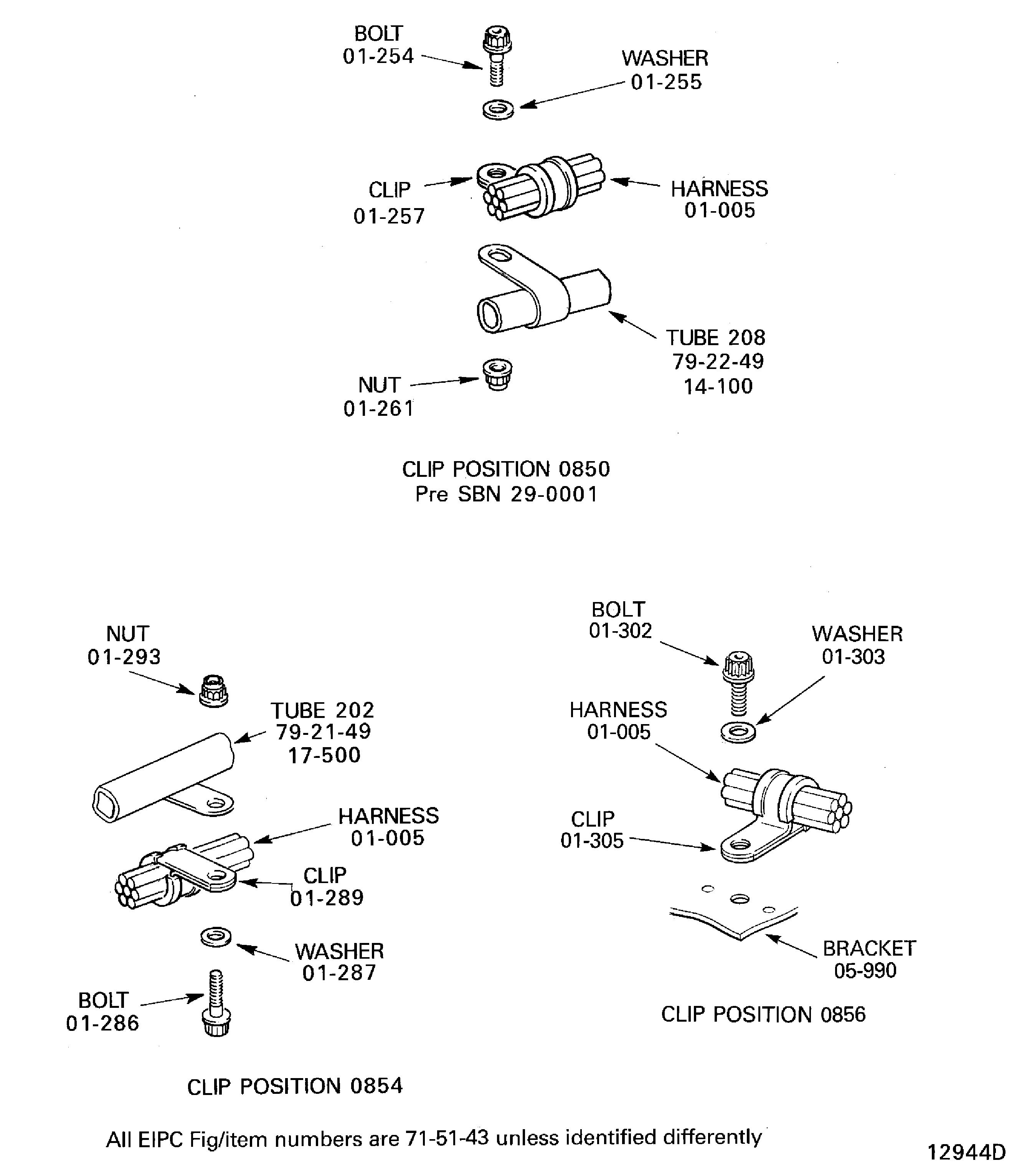

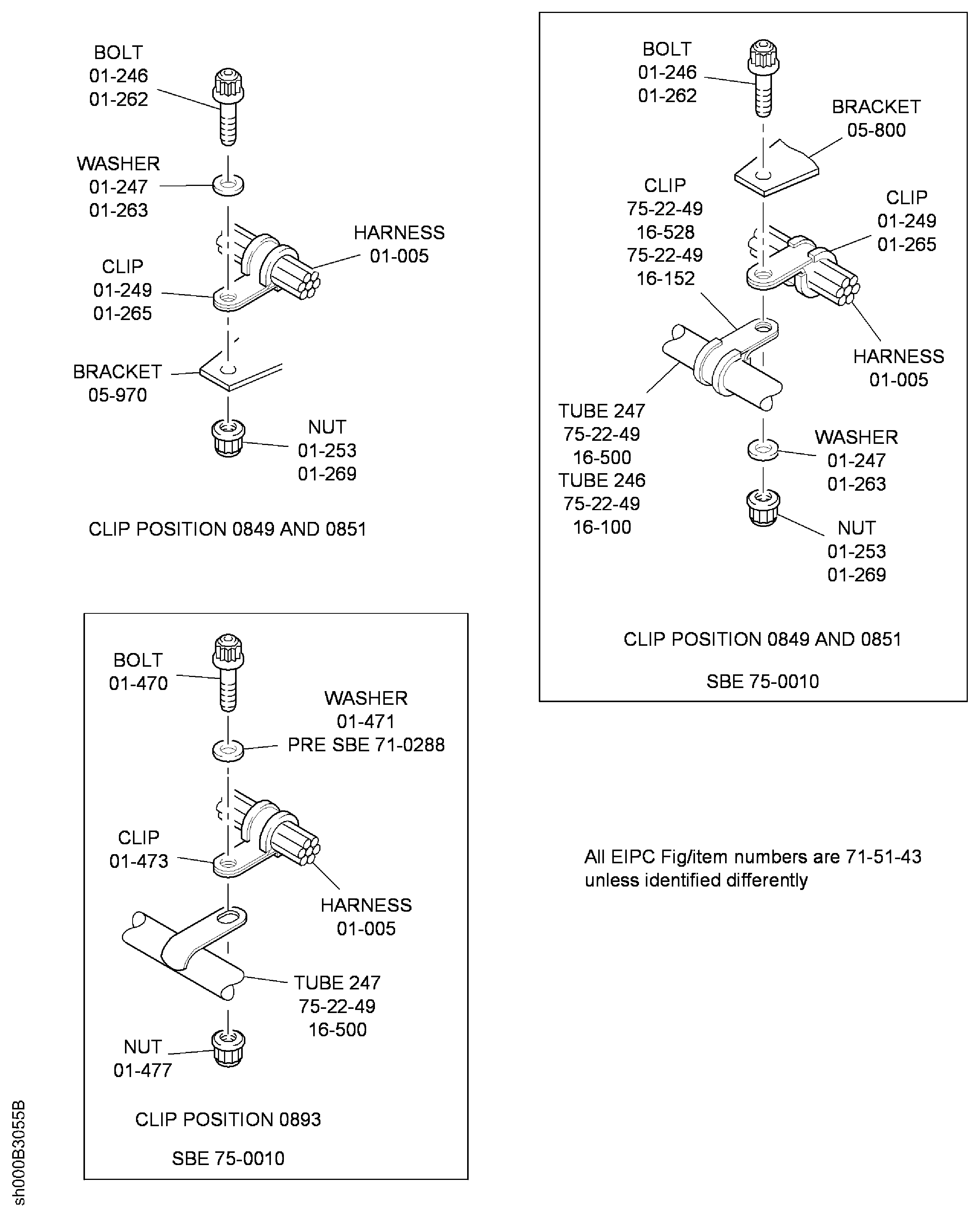

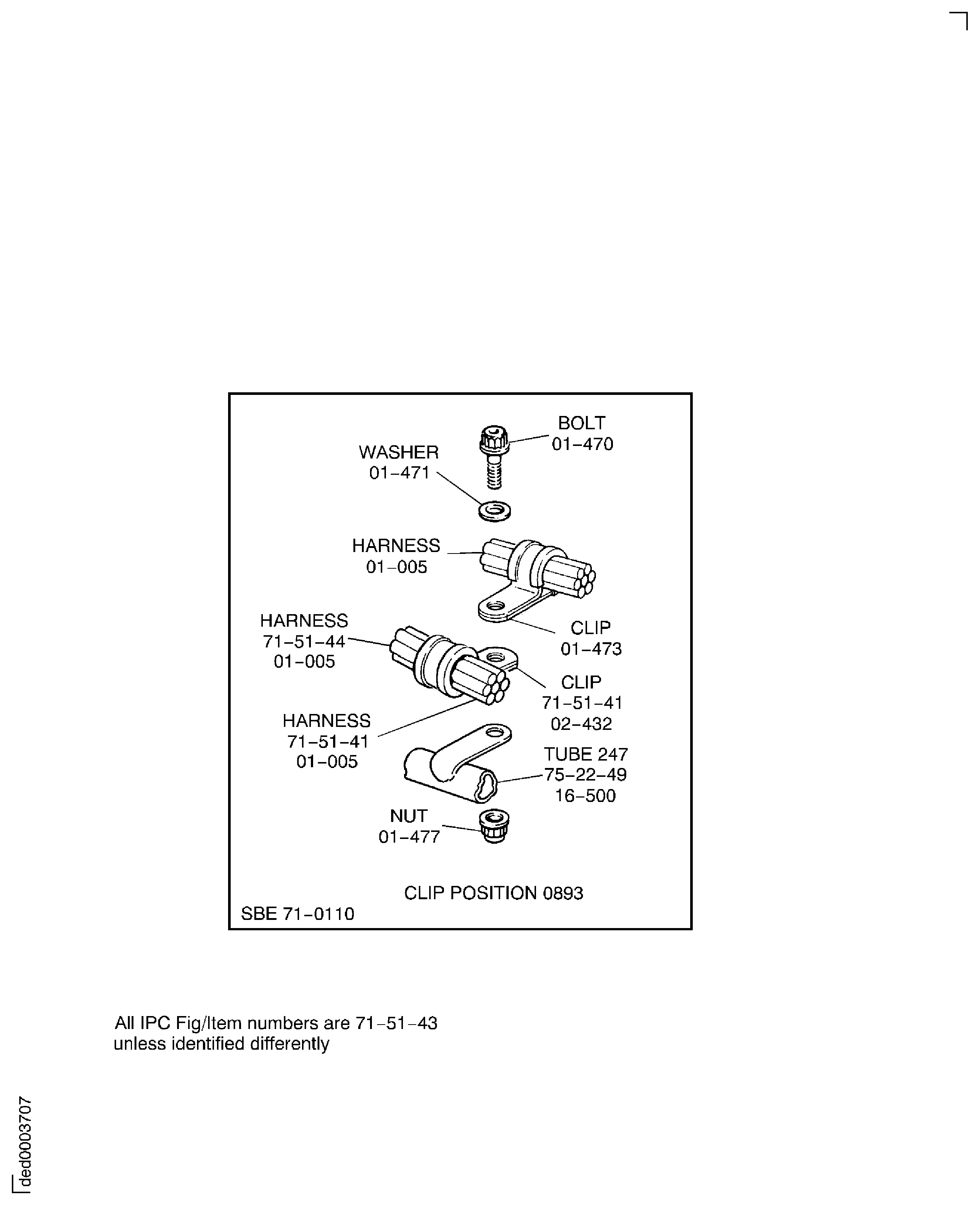

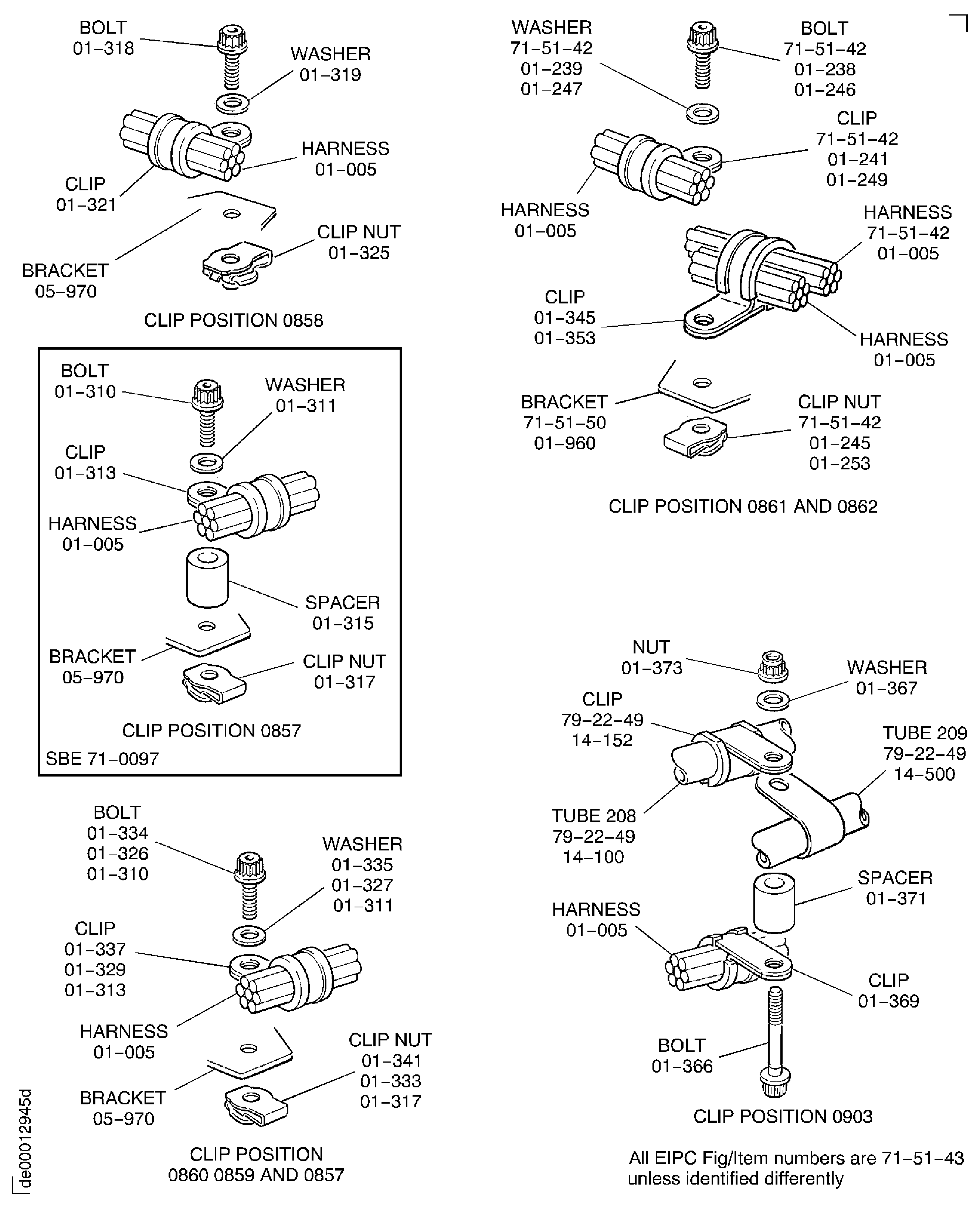

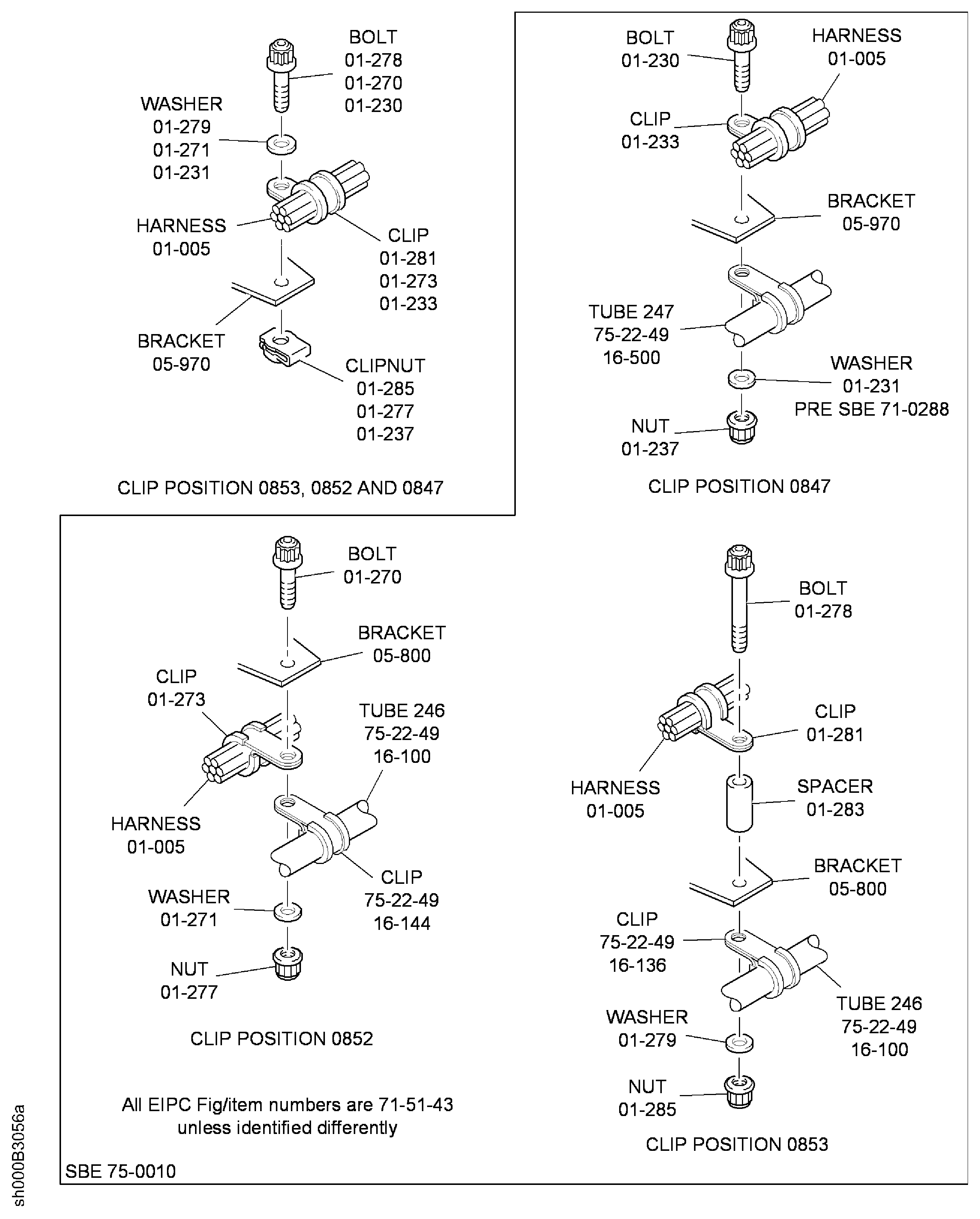

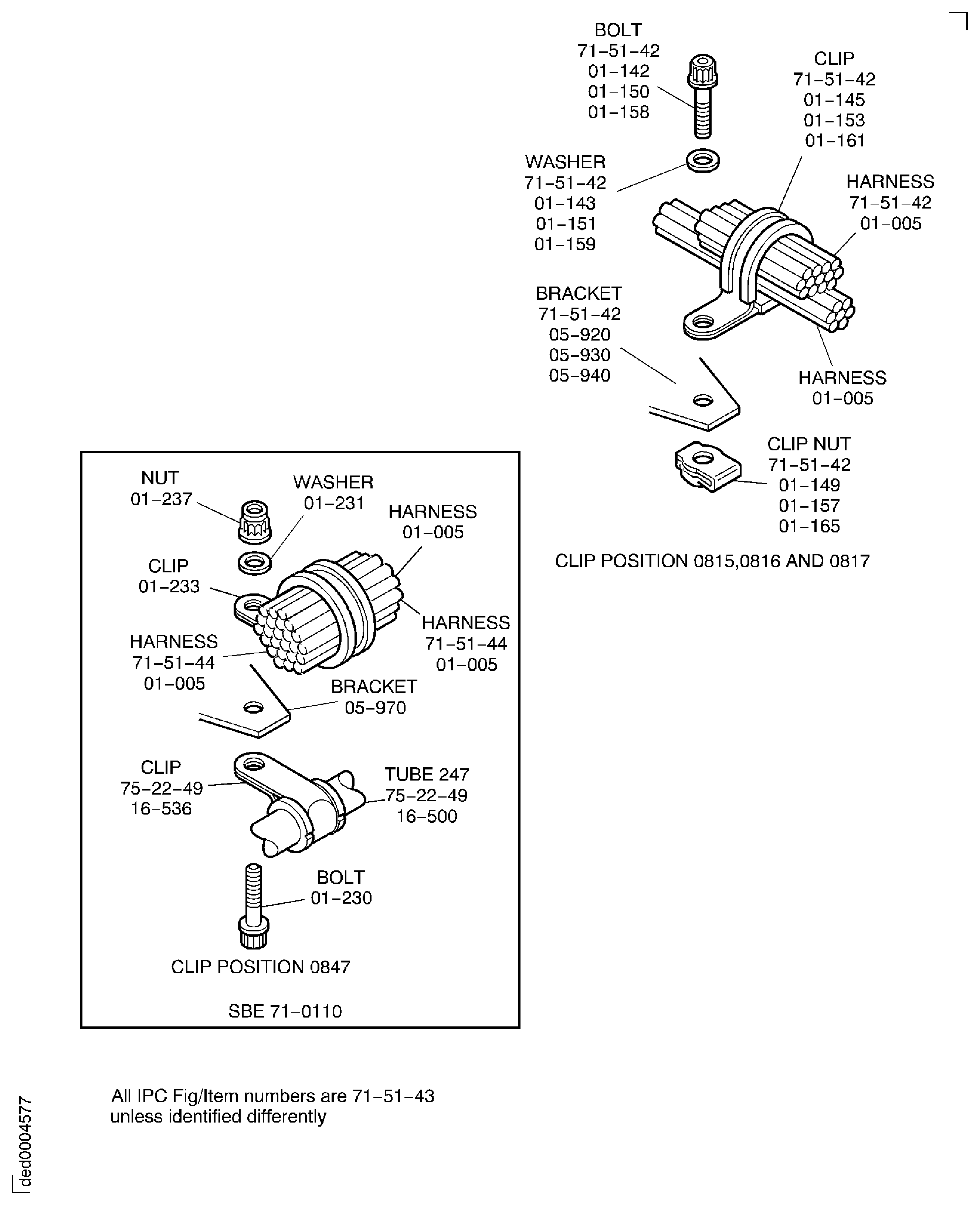

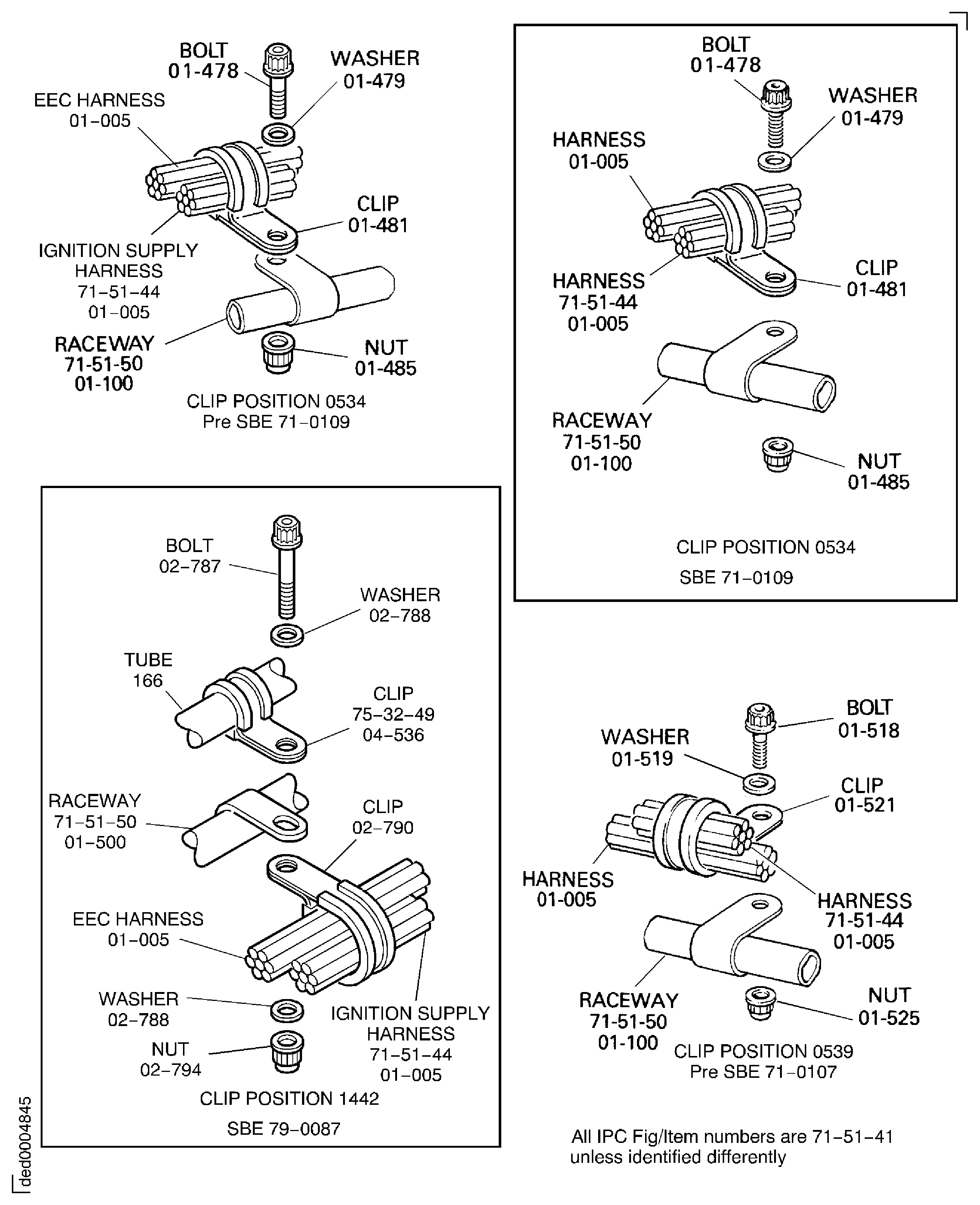

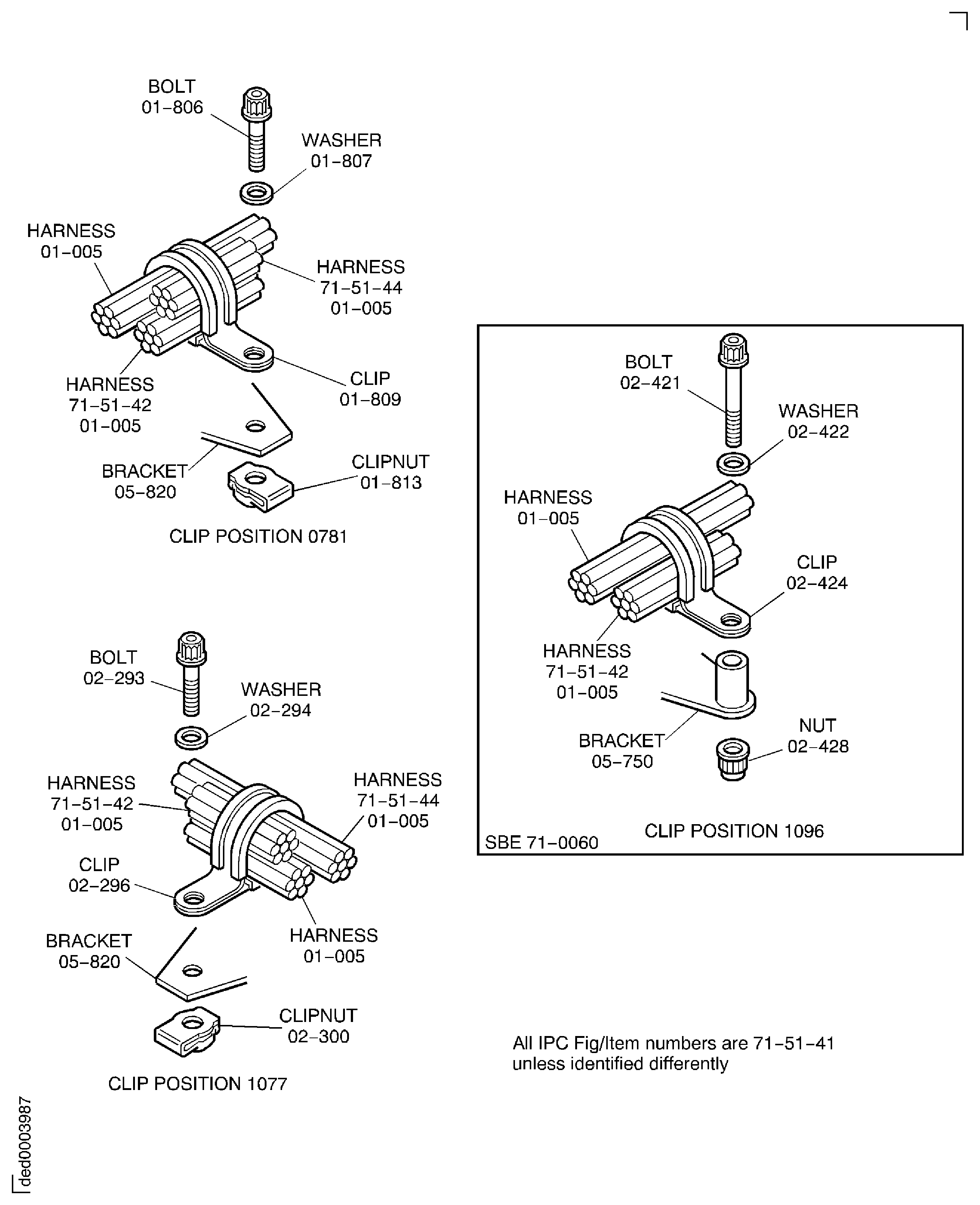

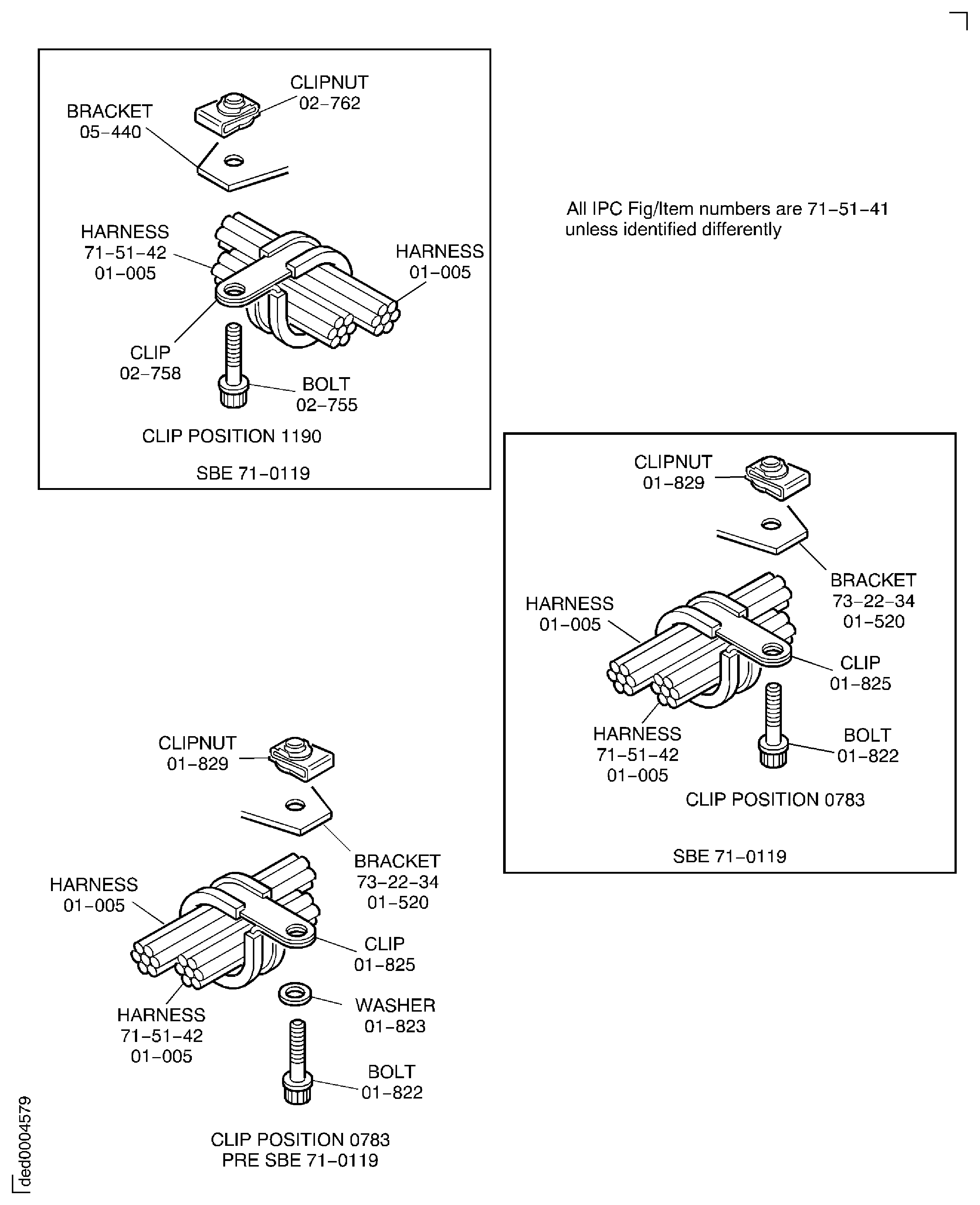

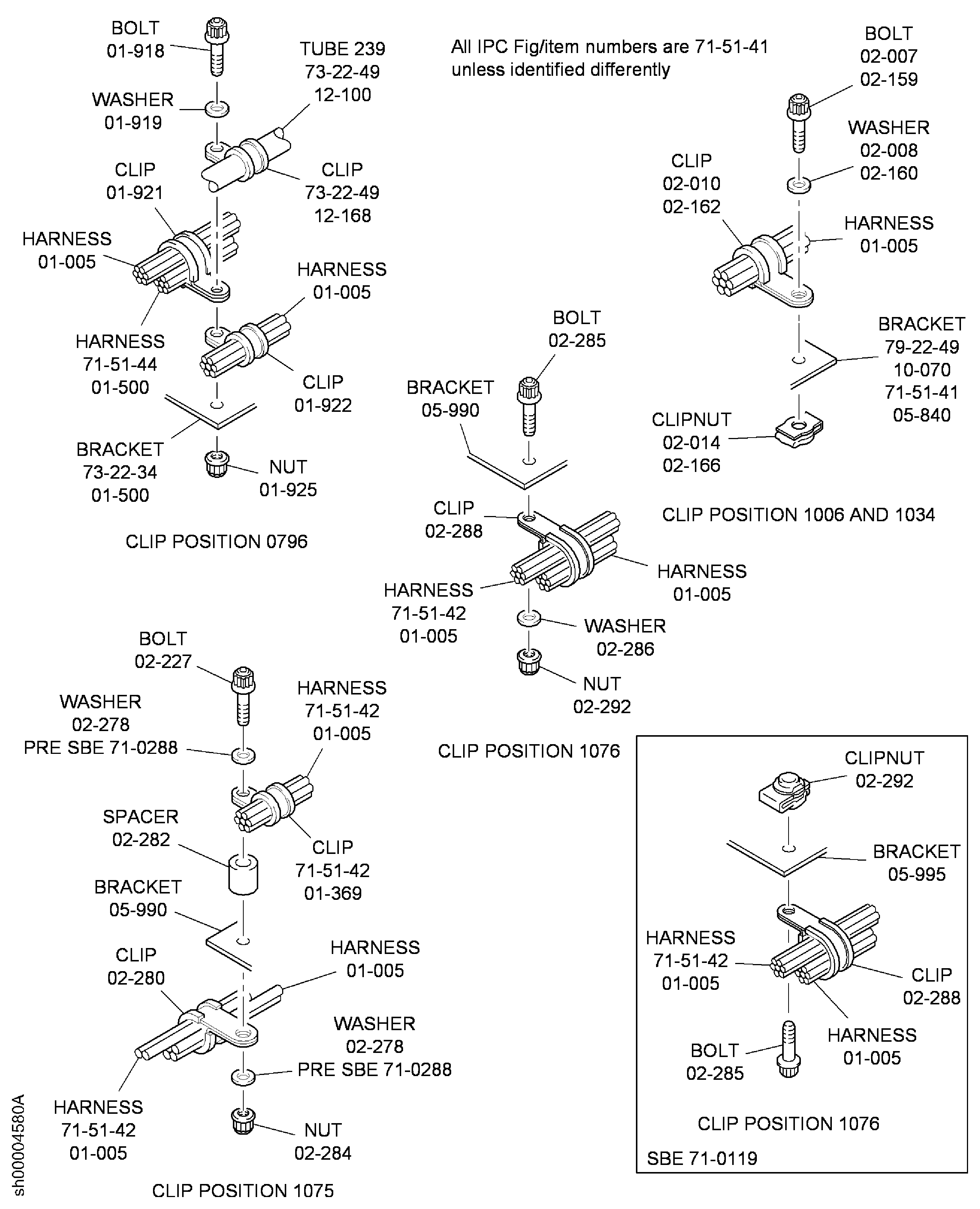

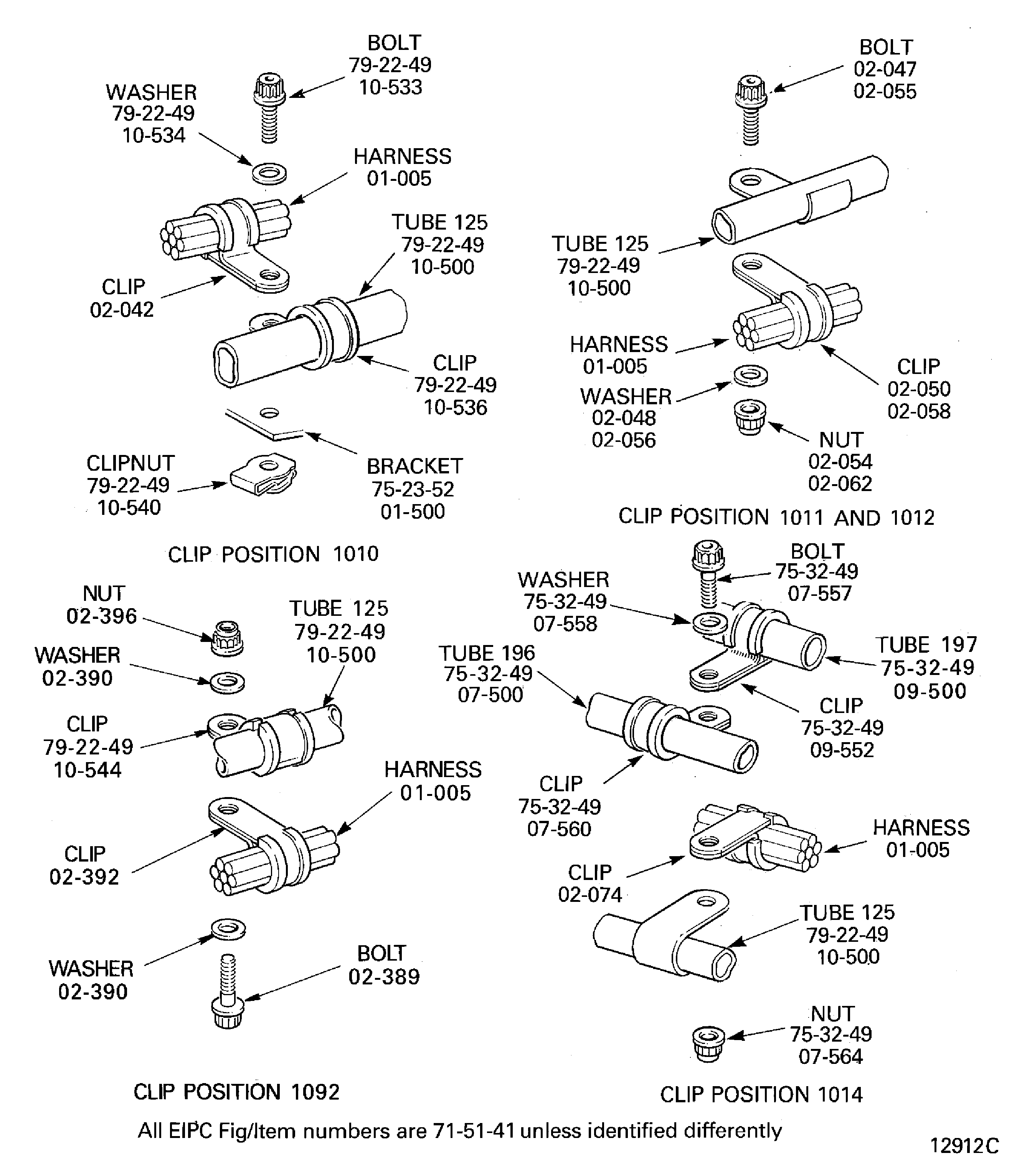

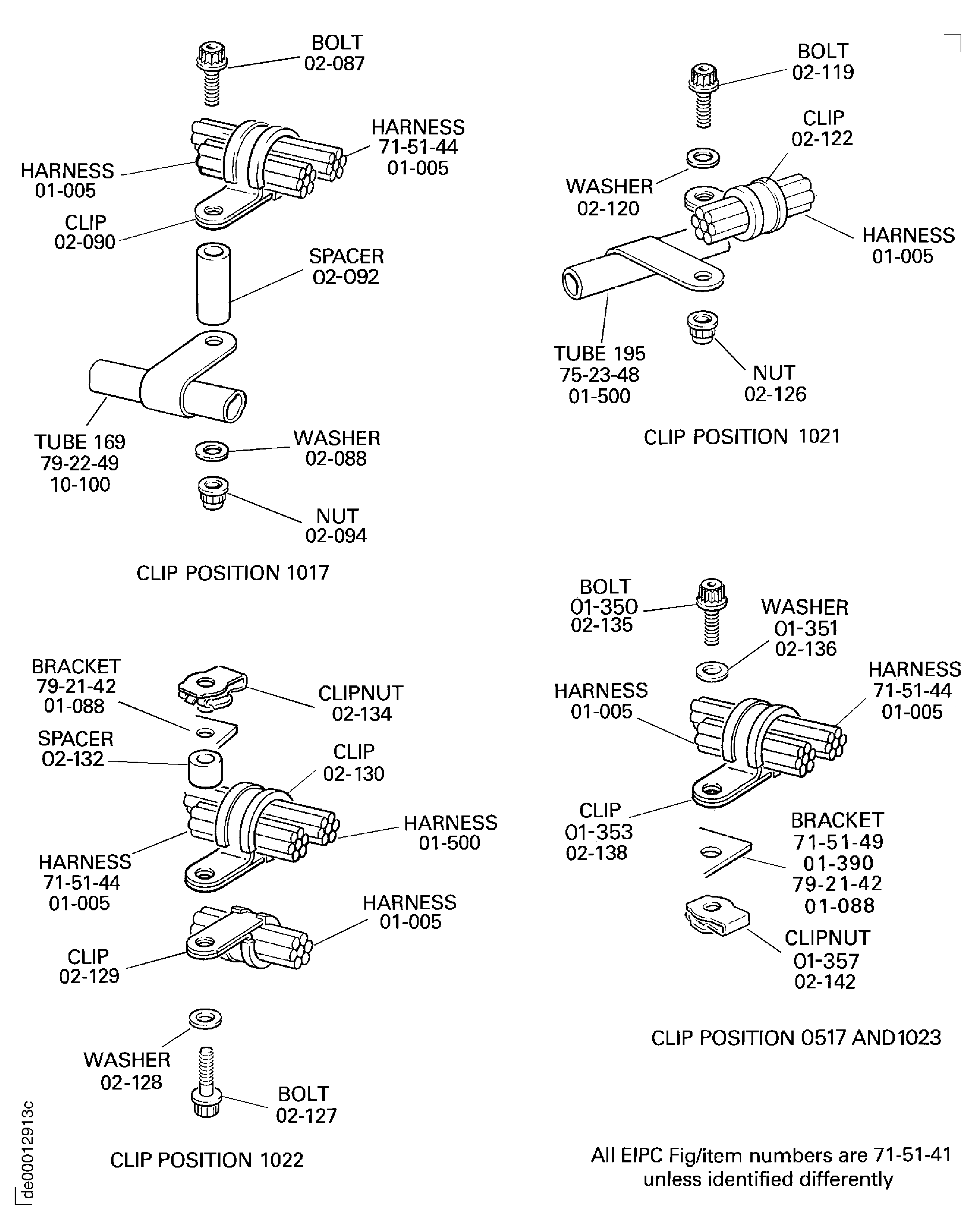

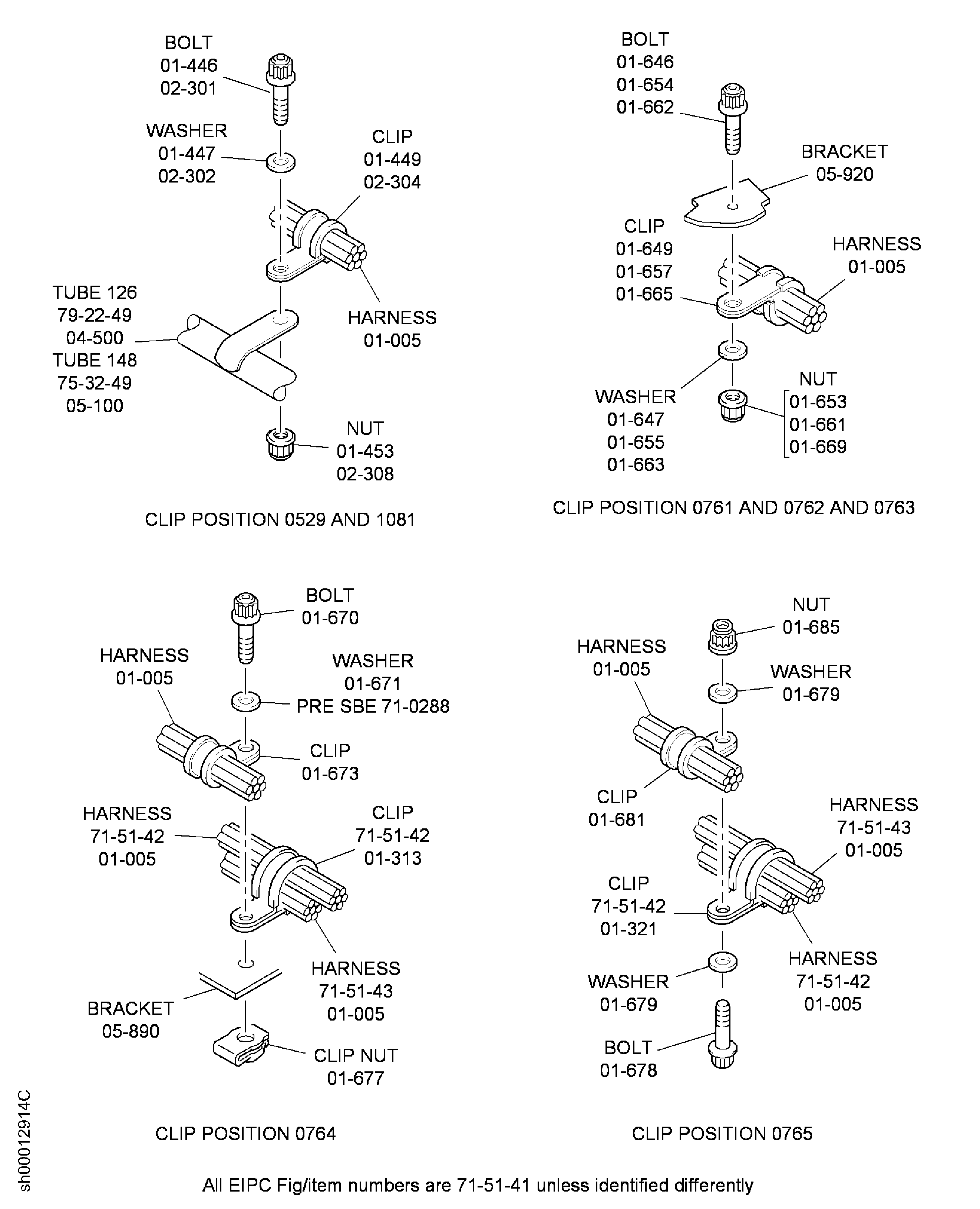

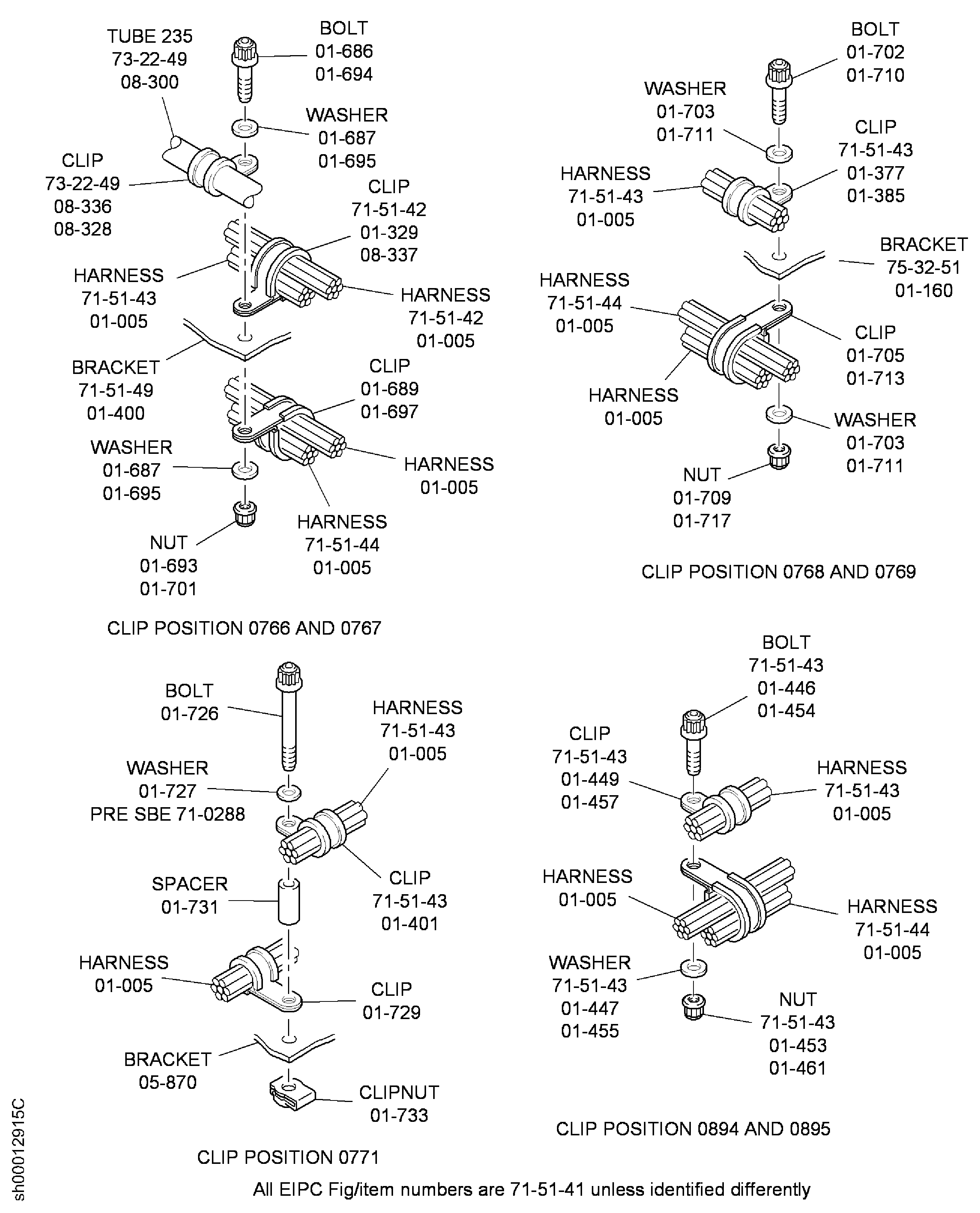

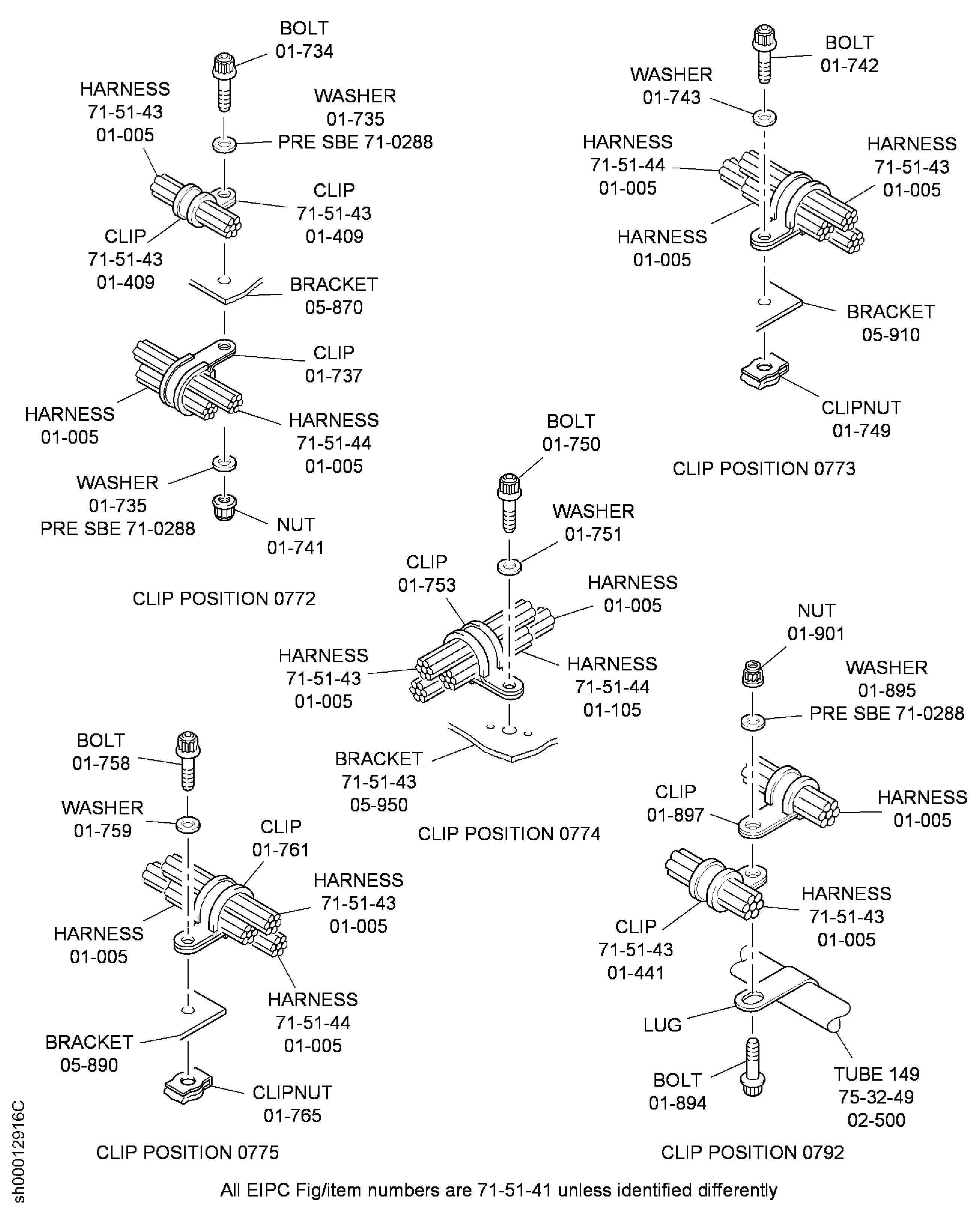

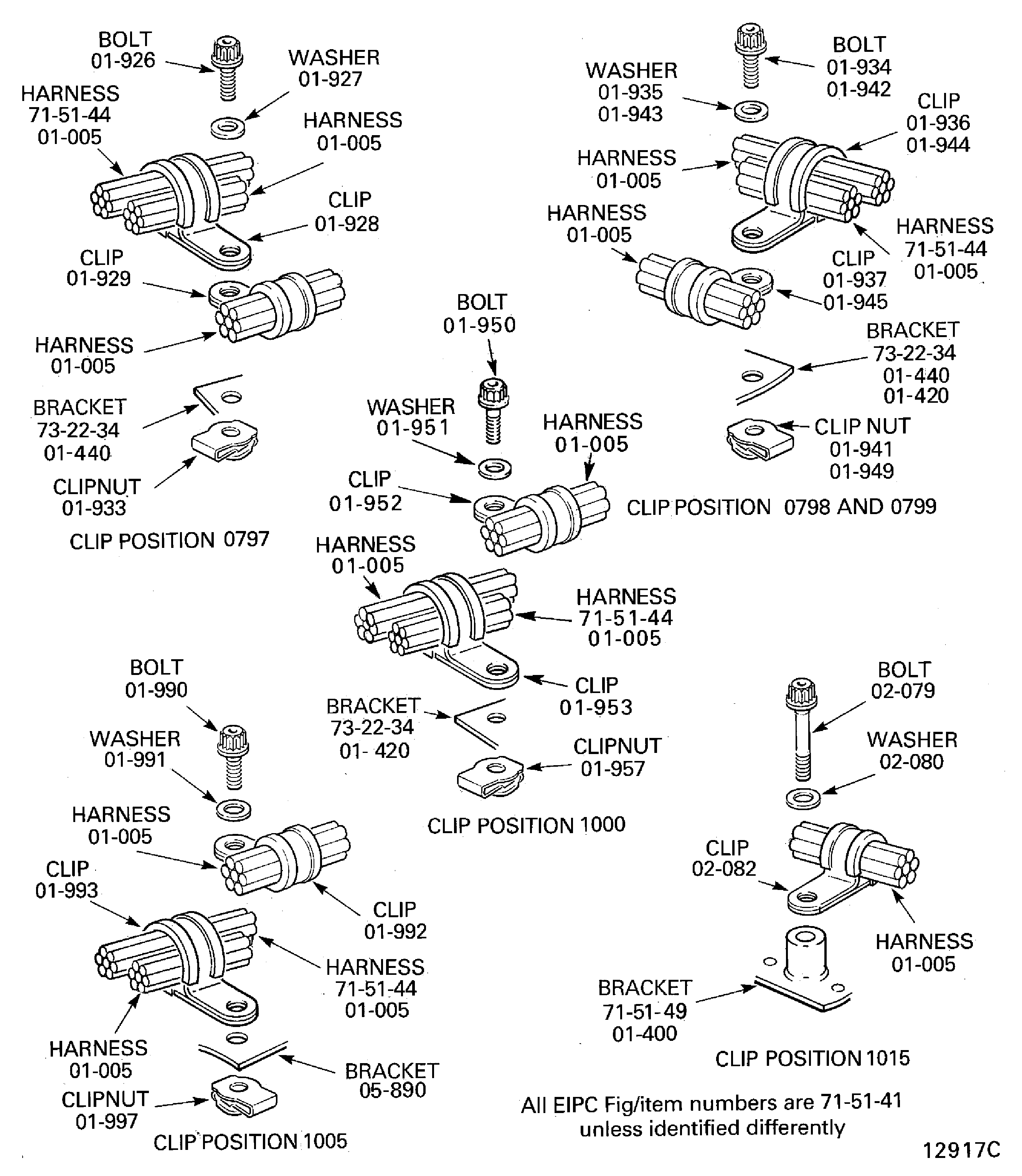

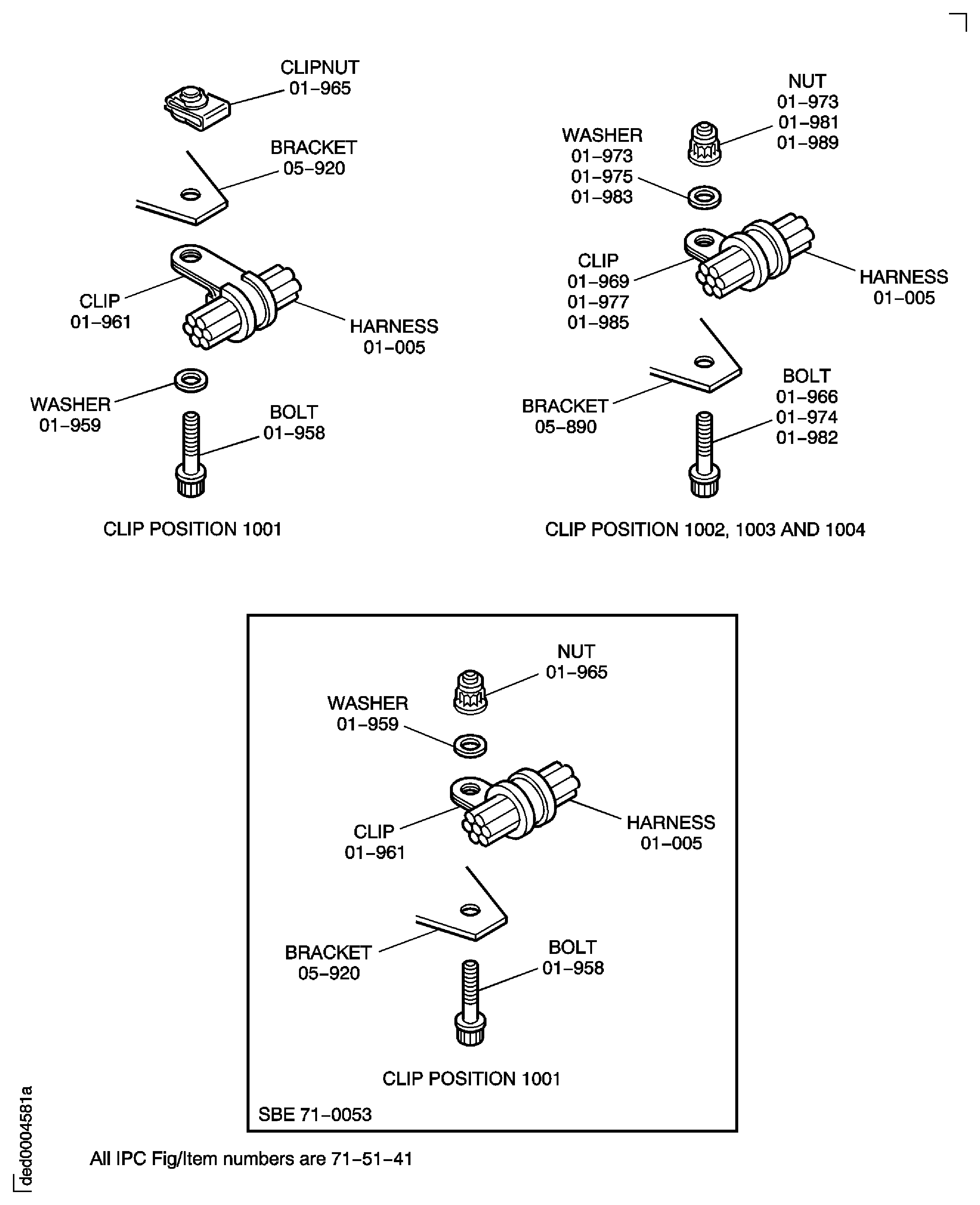

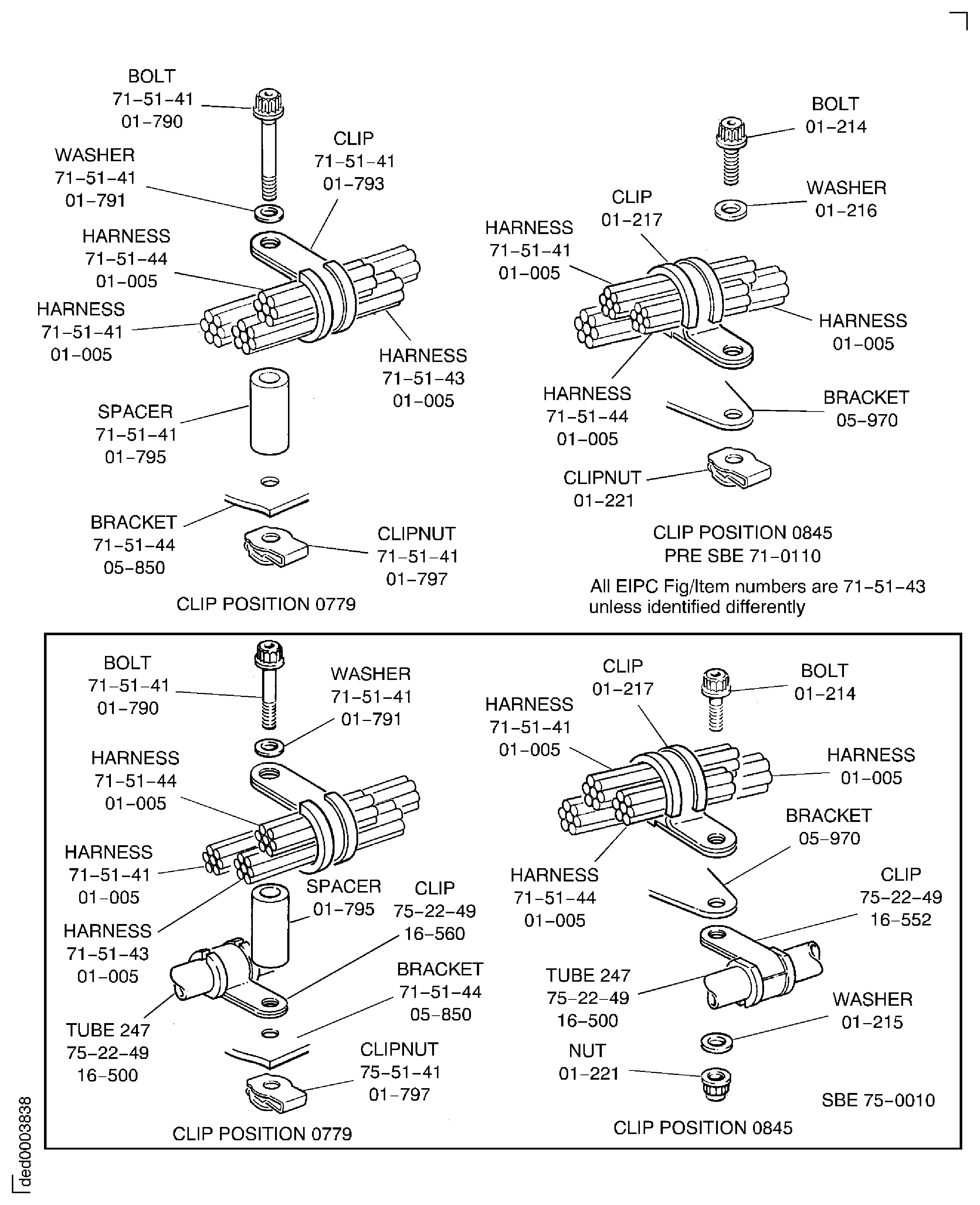

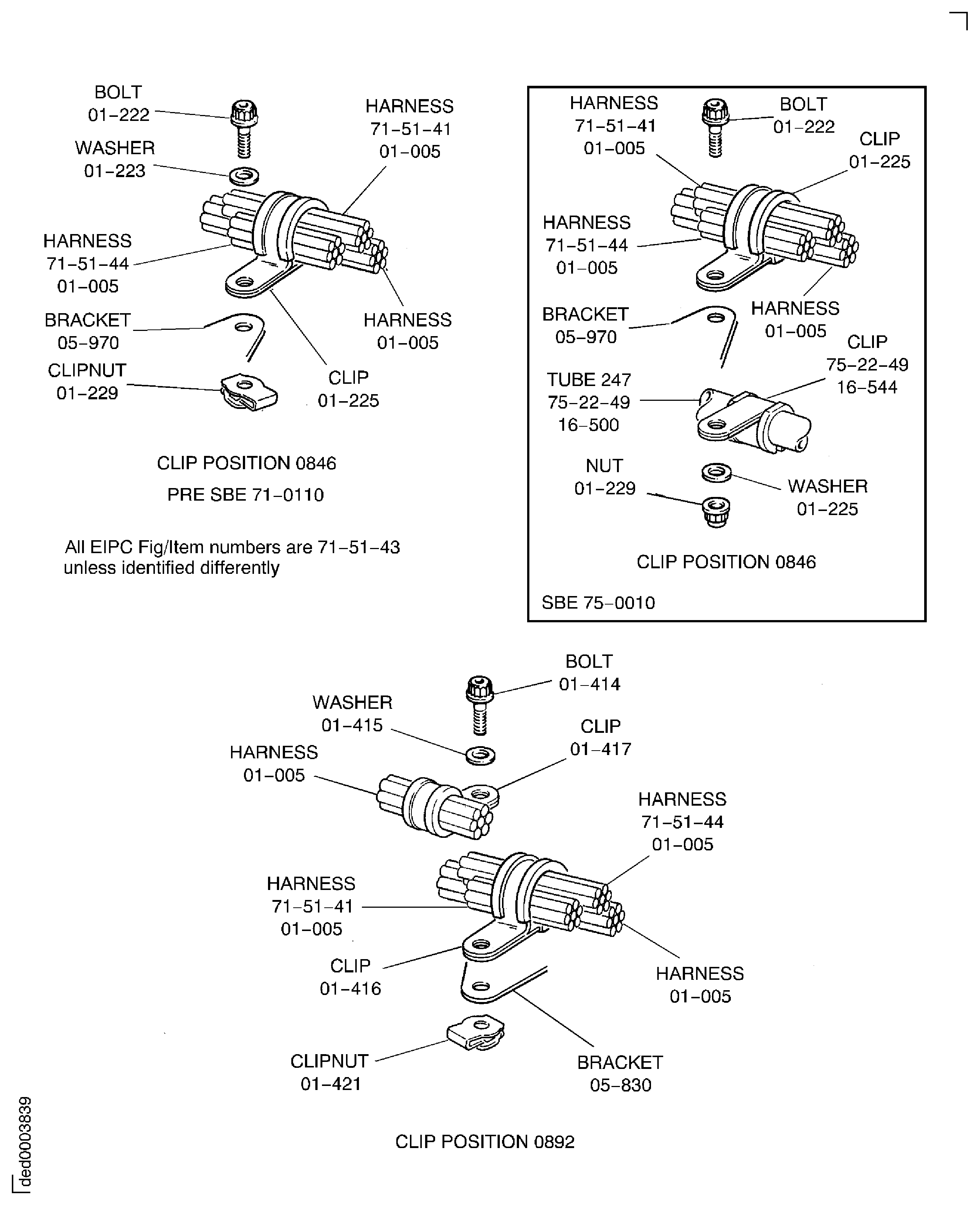

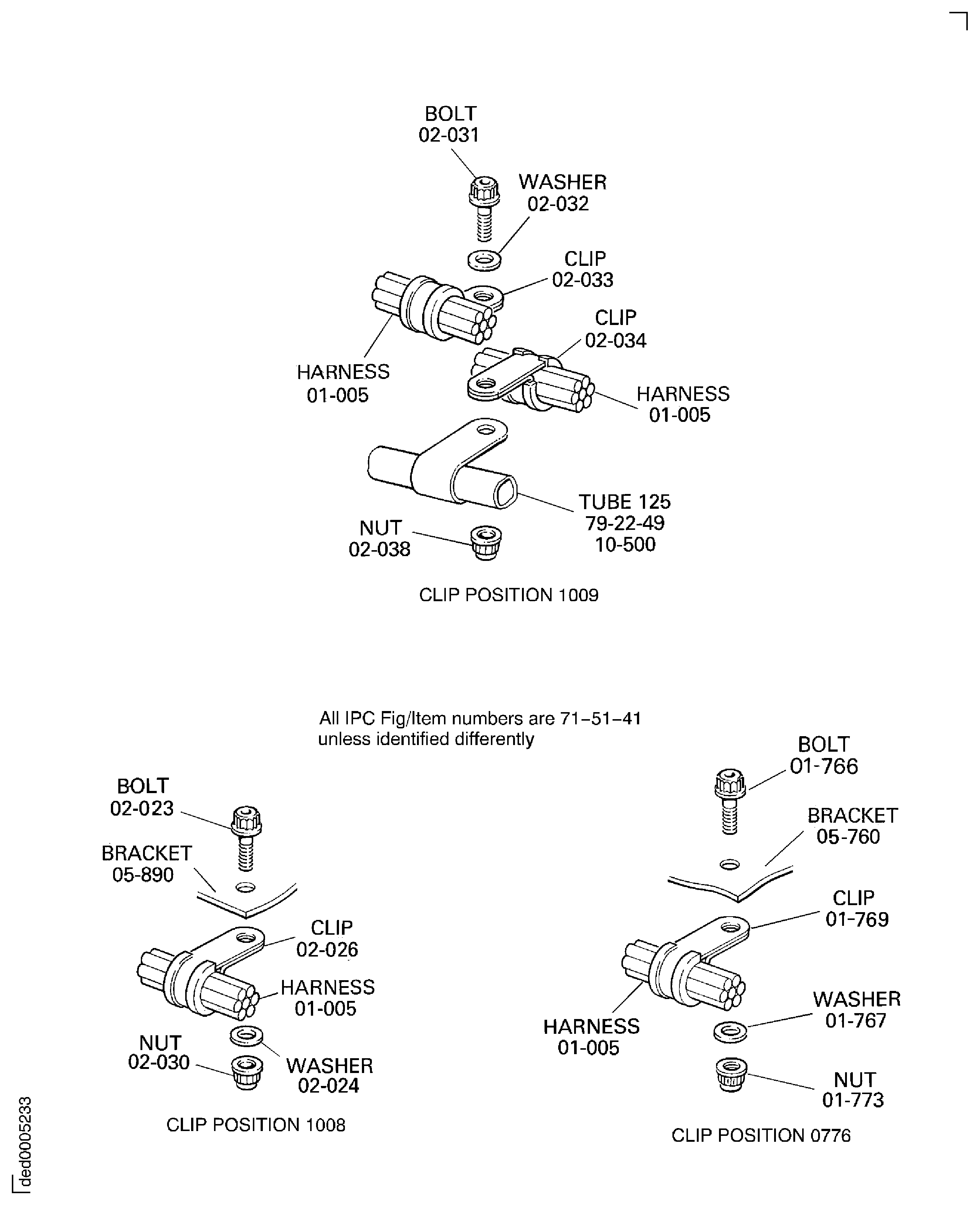

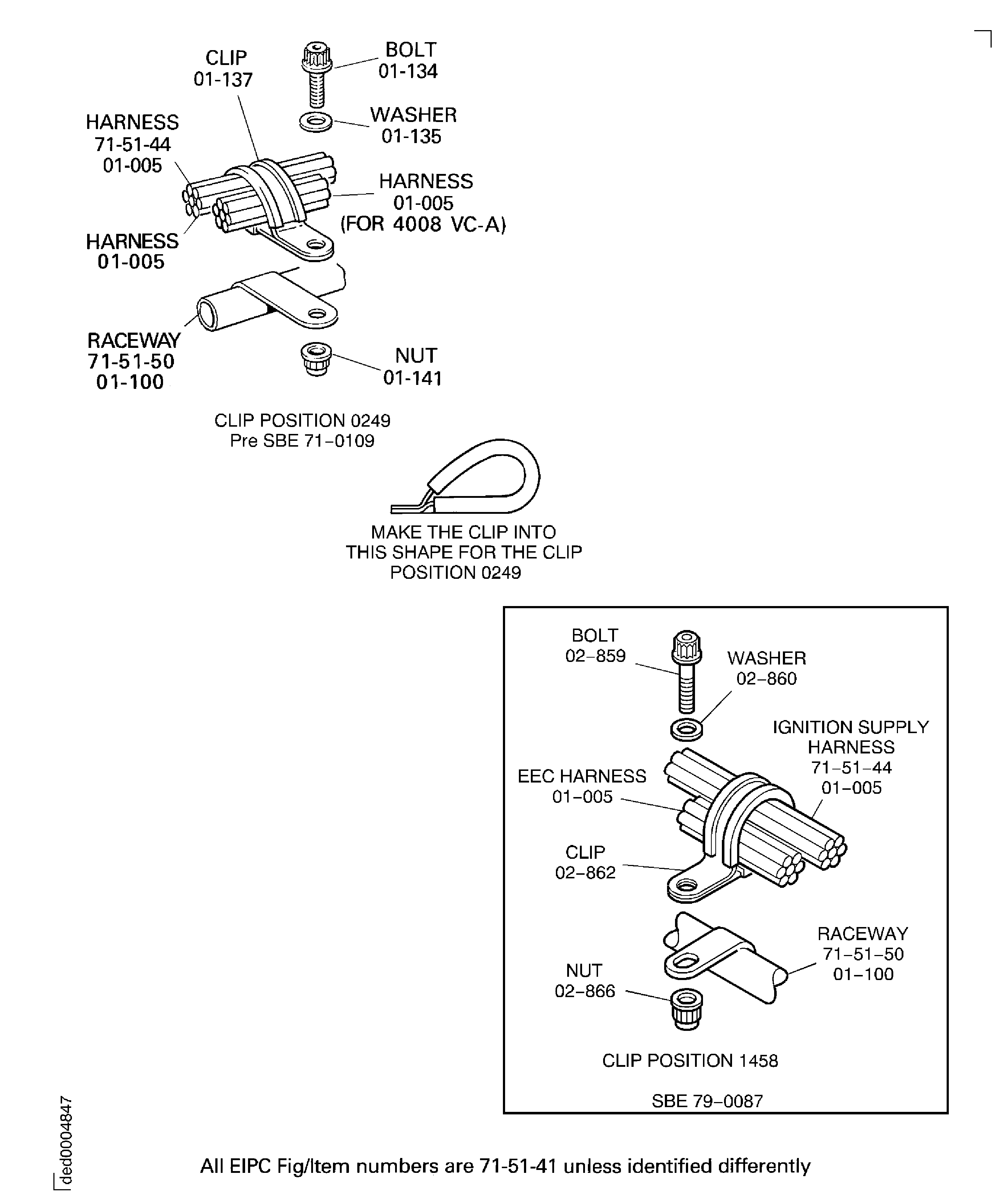

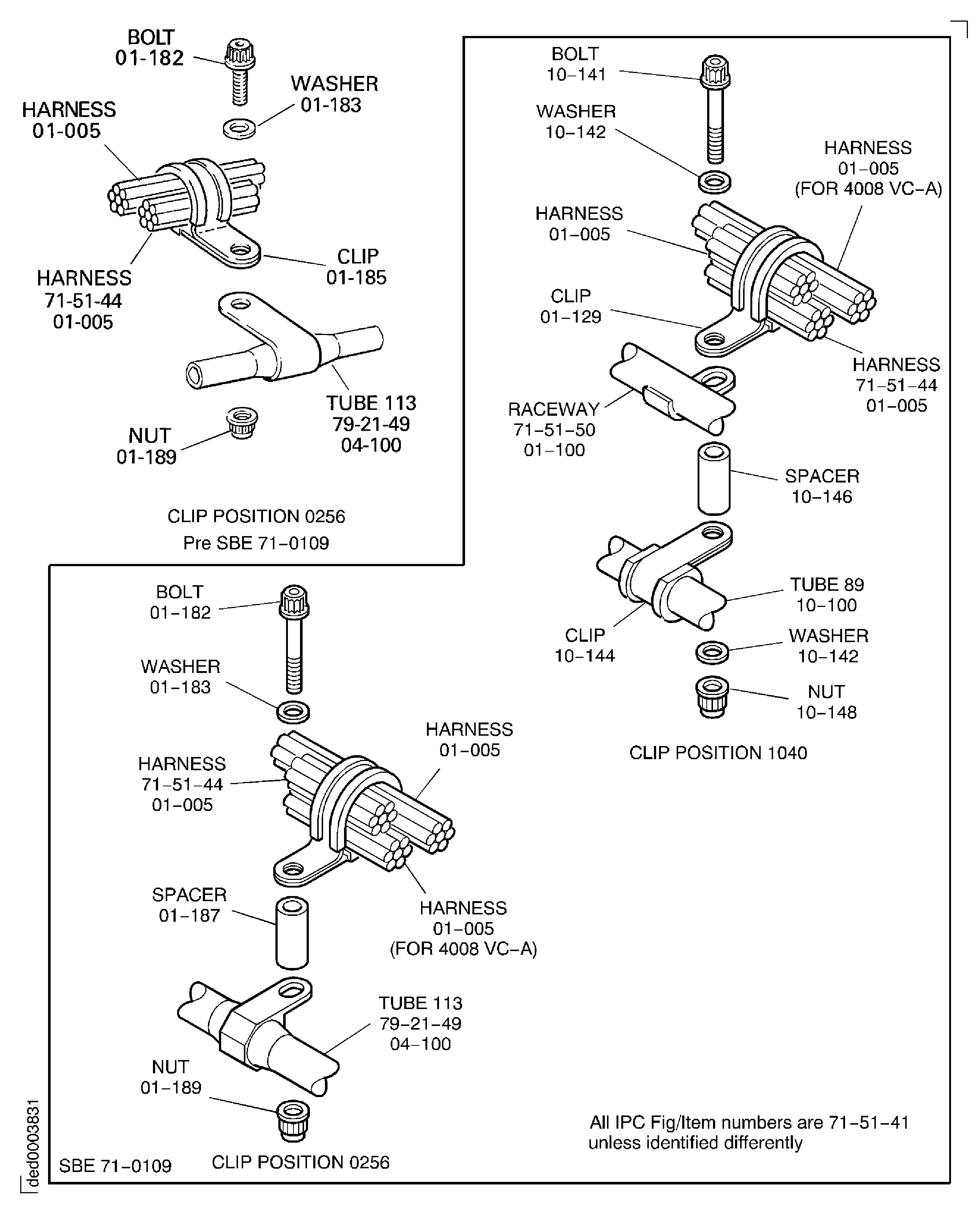

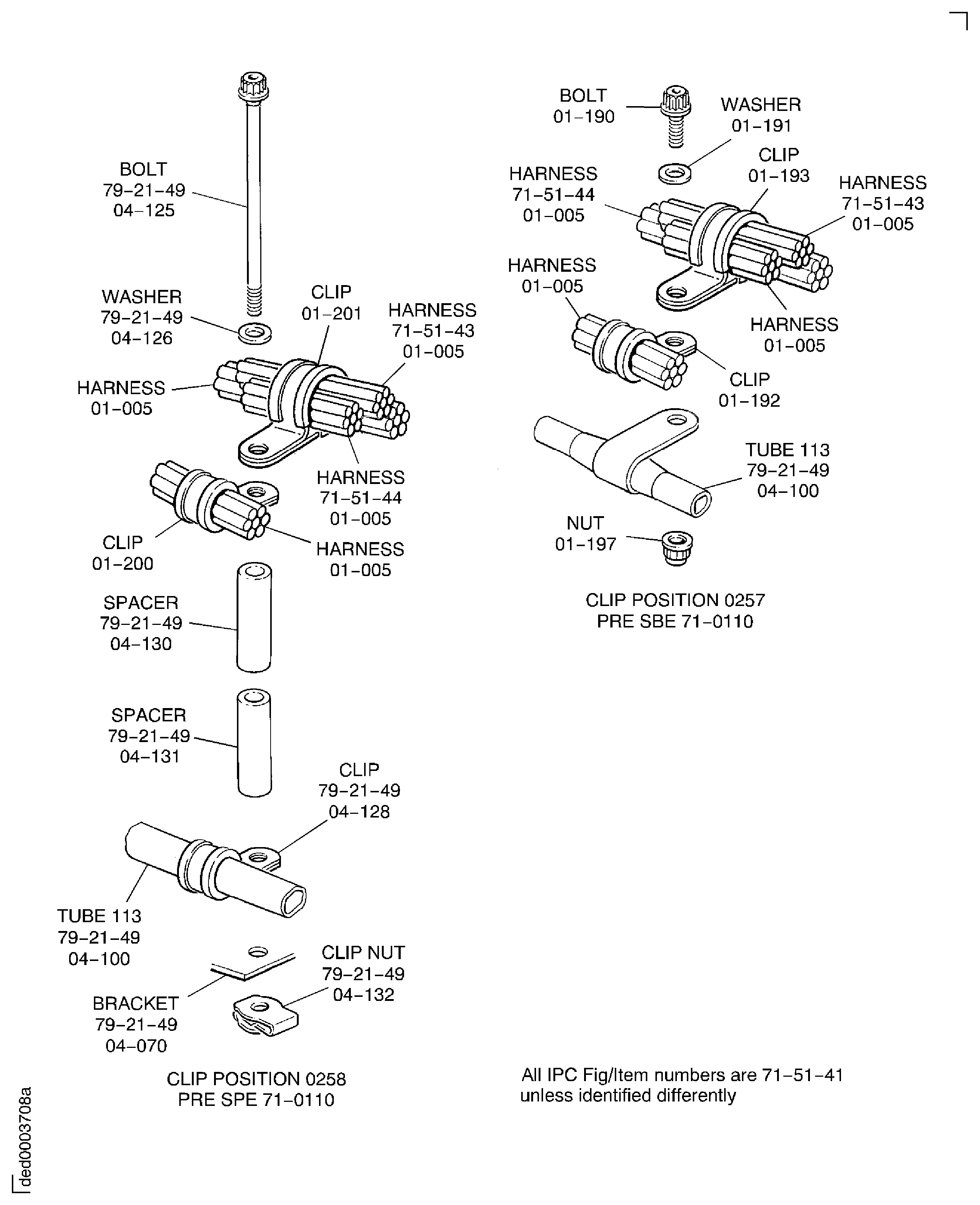

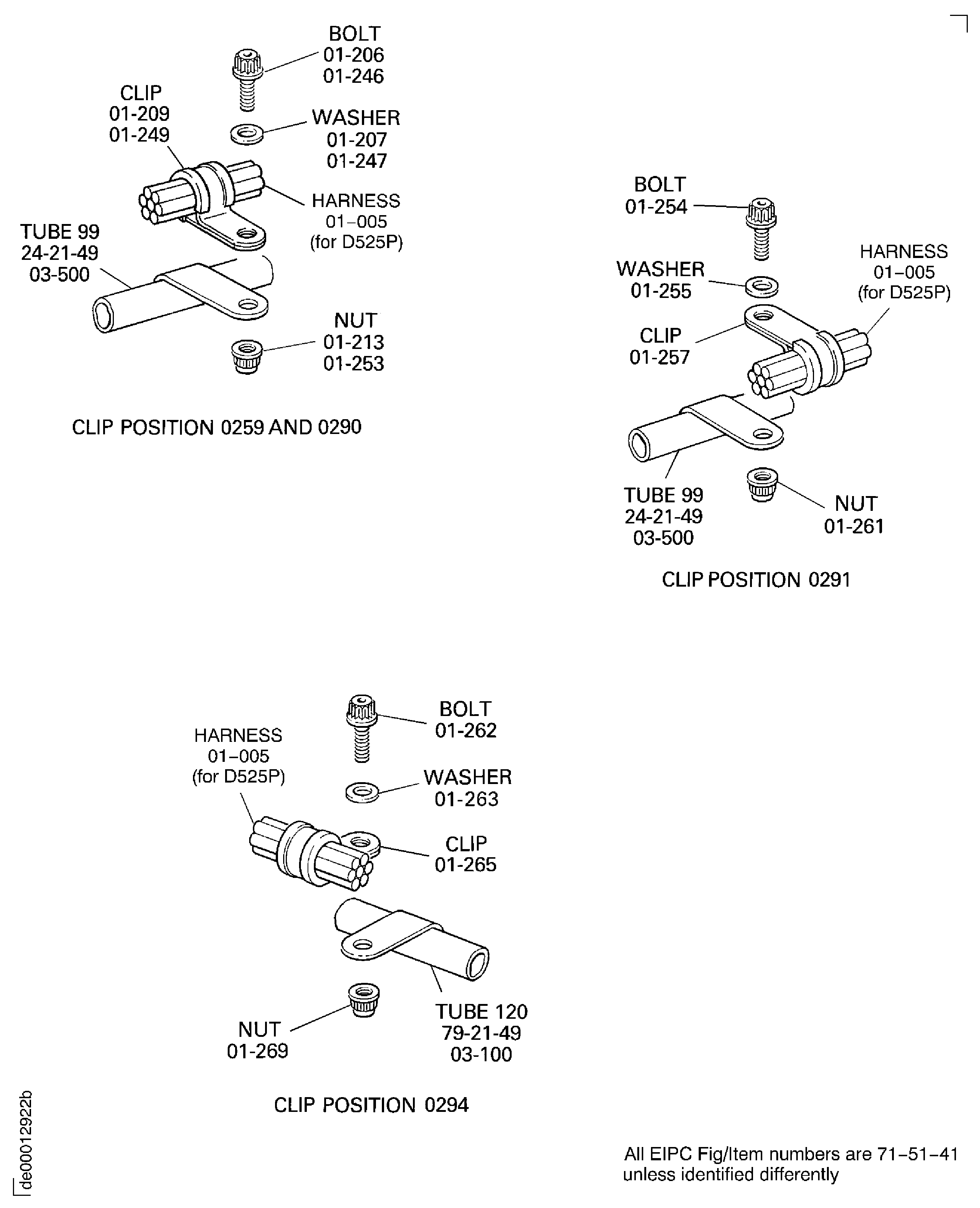

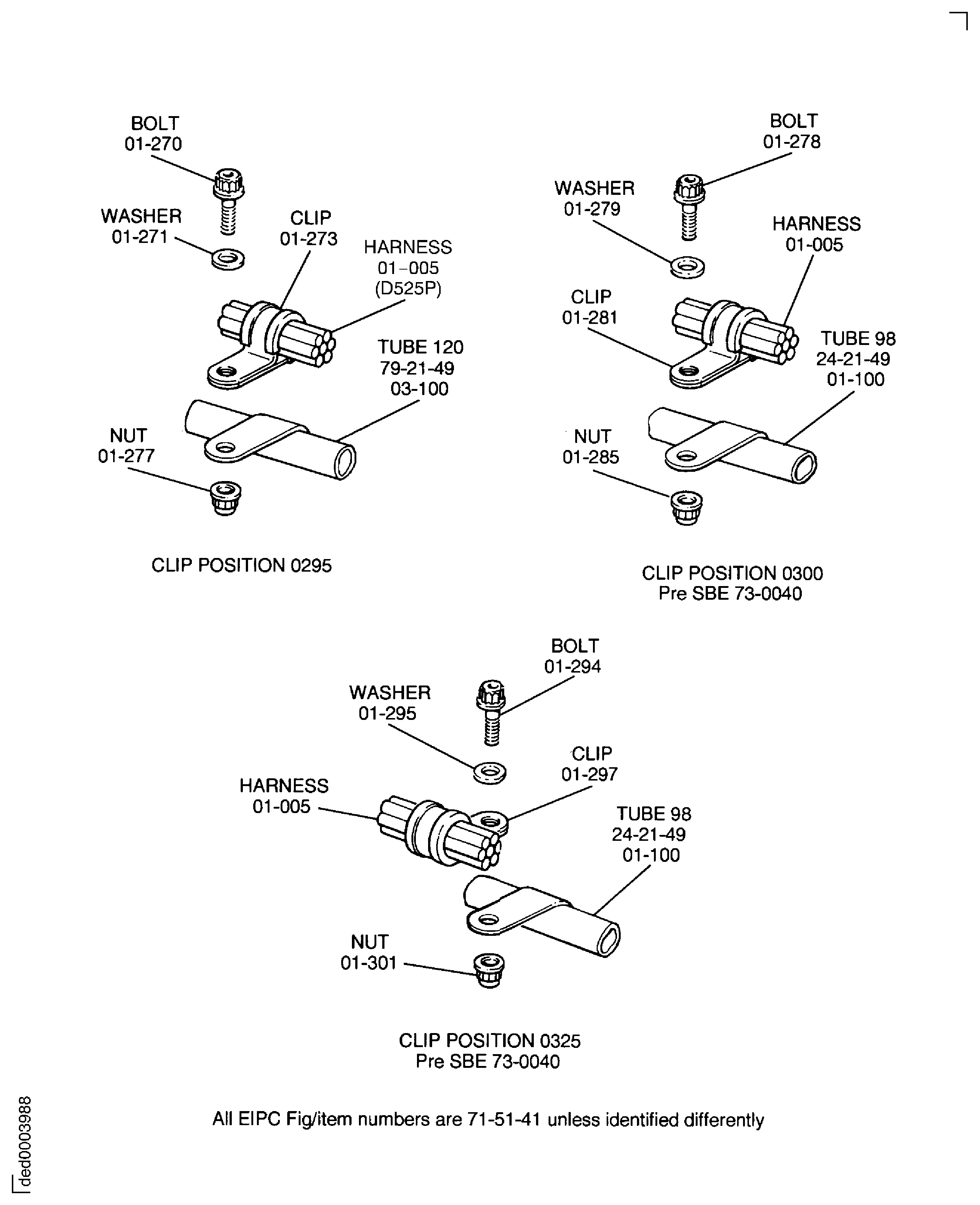

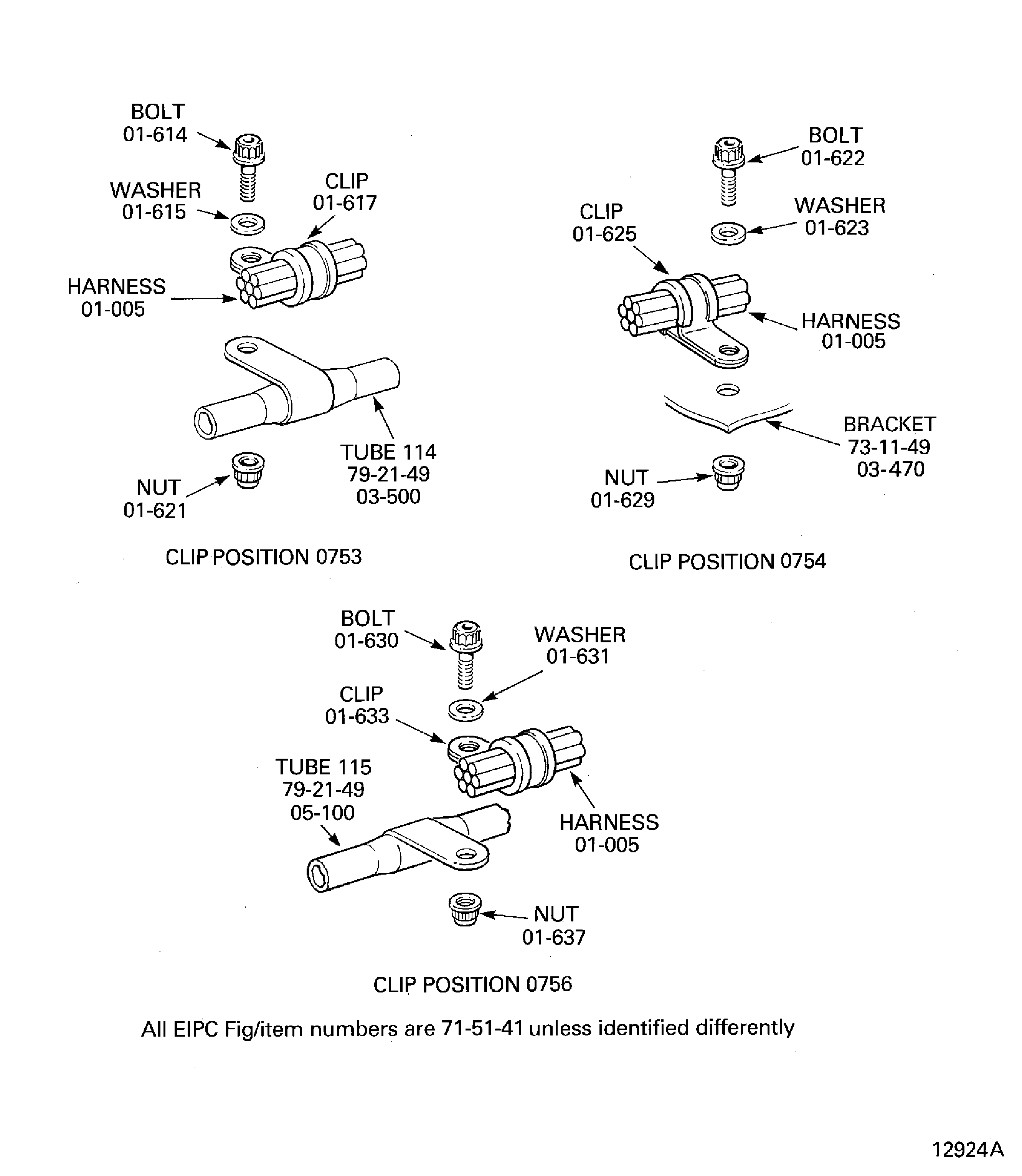

Refer to Figure.

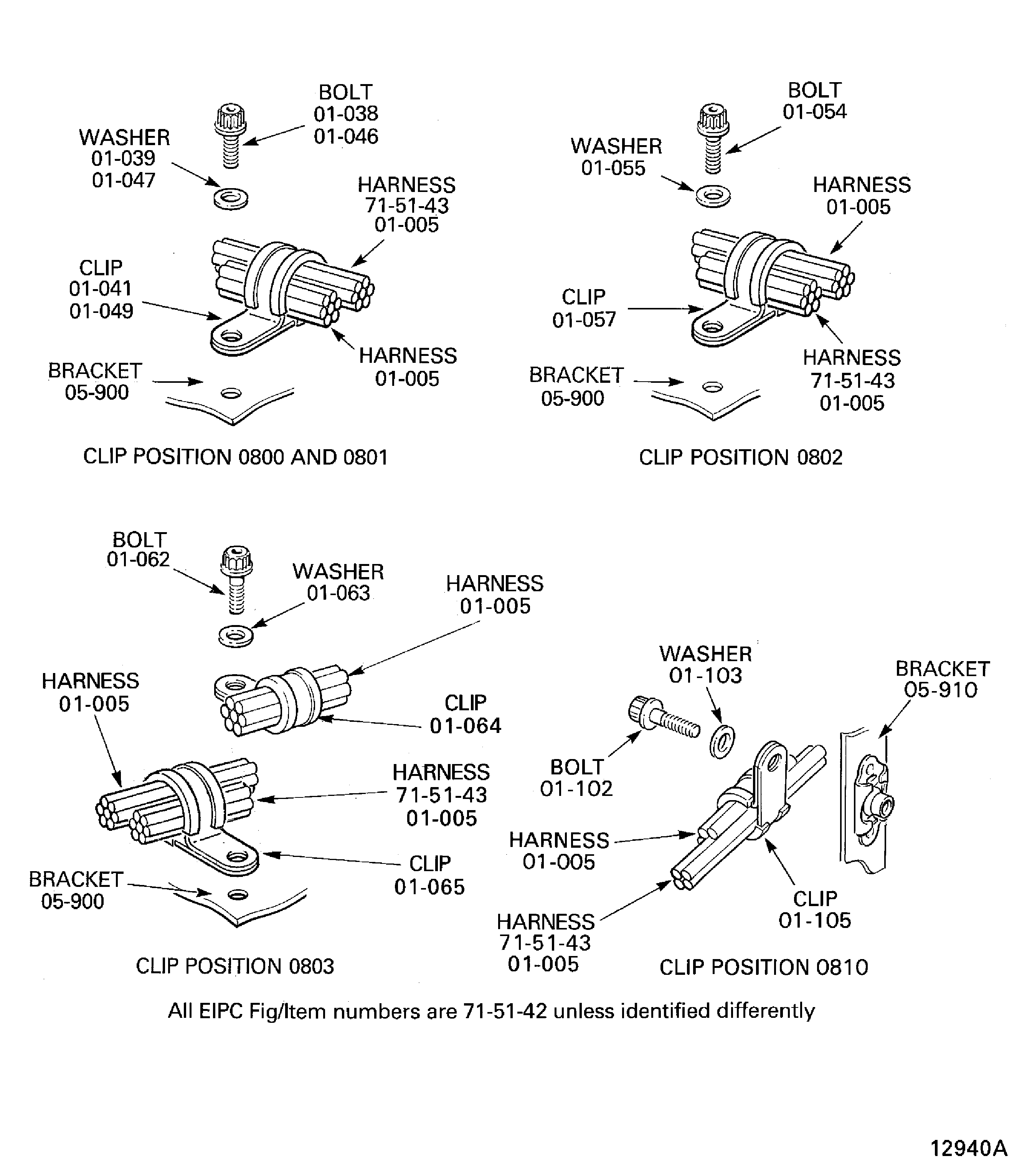

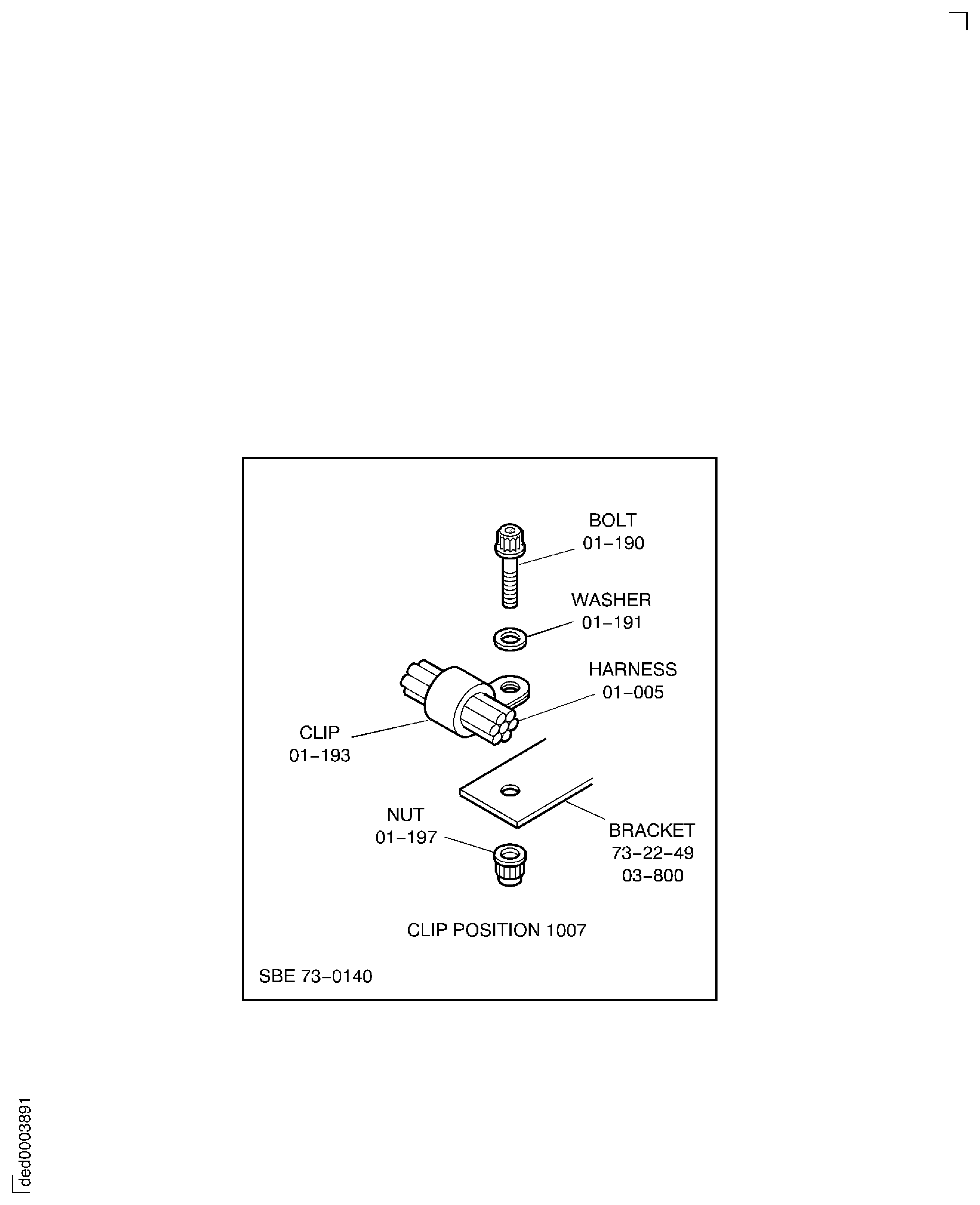

During the installation procedure make sure the harnesses are held temporarily along their different lengths. Always install the datum clip positions when you install each electrical connector. This will give the correct installation of the different harnesses and prevent too much strain on the electrical connectors. It will also give the necessary drip loops (the drip loop makes sure moisture or fluids do not go into the electrical connector).

Refer to TASK 72-00-32-420-001 for the position on a raft or bracket of a particular clip position.

Because of the differences between the harness diameters, the specified clip could be too large or too small. You can use a clip from a range of six clips (that have the same part numbers) refer to the IPC (70-40-10). If the harness diameter is between two of the clips in the range, use the larger clip. When you do this use CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) to increase the harness diameter.

For the data on the electrical connectors refer to the SPM TASK 70-43-00-400-501 and the SPM TASK 70-43-01-400-501.

SUBTASK 72-00-32-420-420 Electrical Harness Installation Procedure

Temporarily attach the IDG cable connector to a safe position on the LP compressor/intermediate case with CoMat 06-086 TIES.

WARNING

WHEN YOU USE CoMat 01-003 SOLVENT, DELETED YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Clean the mating faces of the brackets ELECTRICAL POWER-IDG CABLES (24-21-43,01-950), ELECTRICAL POWER-IDG CABLES (24-21-43,01-952) and the clamp ELECTRICAL POWER-IDG CABLES (24-21-43,01-030) with a clean lint free cloth made moist with CoMat 01-003 SOLVENT, DELETED.

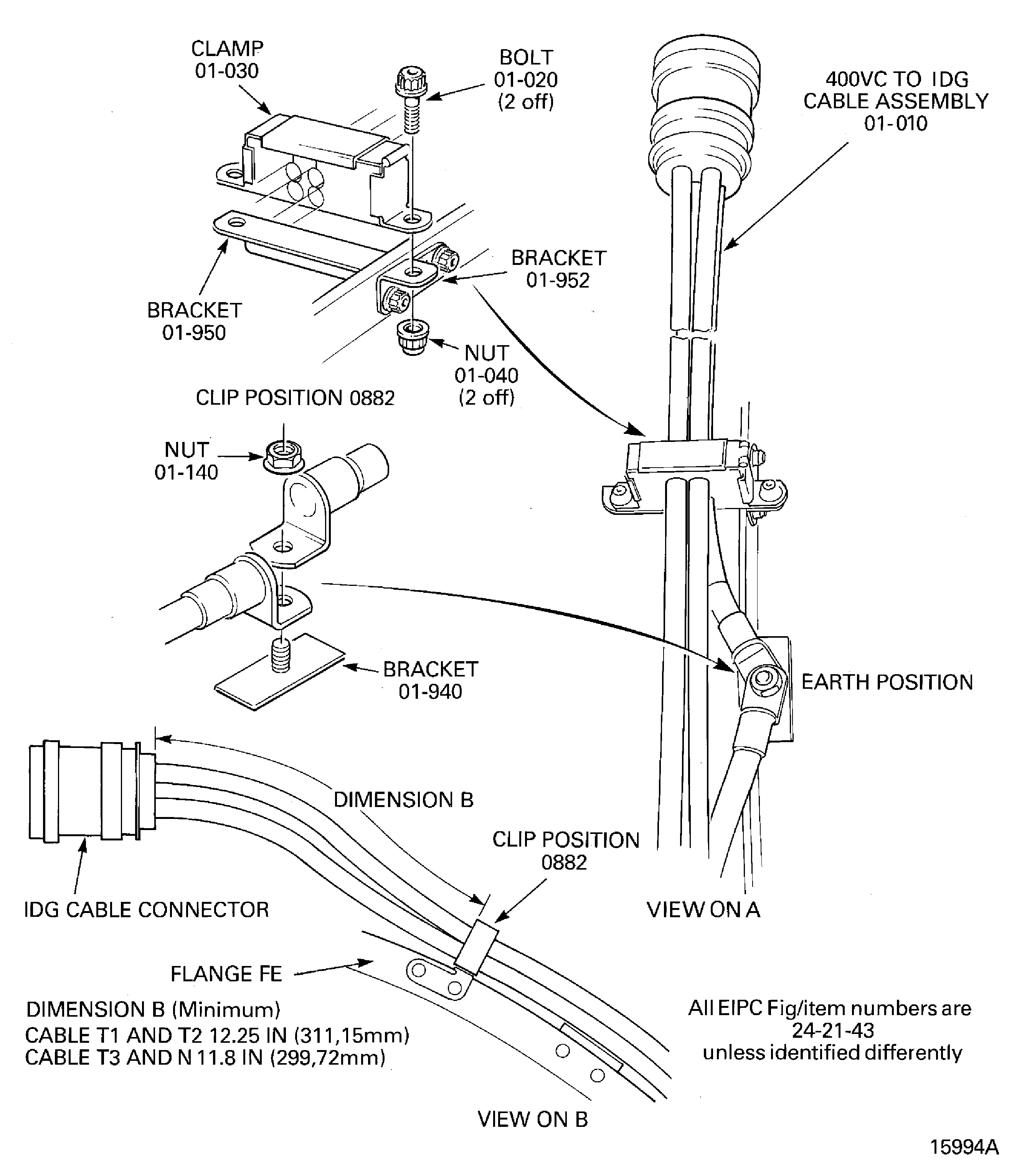

Install the clamp ELECTRICAL POWER-IDG CABLES (24-21-43,01-030) on the cables. Attach the clamp to the brackets ELECTRICAL POWER-IDG CABLES (24-21-43,01-950) and ELECTRICAL POWER-IDG CABLES (24-21-43,01-952) with the two bolts and the two nuts ELECTRICAL POWER-IDG CABLES (24-21-43,01-020) and ELECTRICAL POWER-IDG CABLES (24-21-43,01-040) at the clip position 0882.

Clean the mating faces of the bracket ELECTRICAL POWER-IDG CABLES (24-21-43,01-940) and the cable terminals at the earth position with a clean lint free cloth made moist with CoMat 01-002 SOLVENT, DELETED..

Install the two cable terminals to the earth position on the bracket ELECTRICAL POWER-IDG CABLES (24-21-43,01-940). Install the nut ELECTRICAL POWER-IDG CABLES (24-21-43,01-140) on the bracket. Refer to the view on A.

Remove the CoMat 06-086 TIES which hold the IDG cable connector.

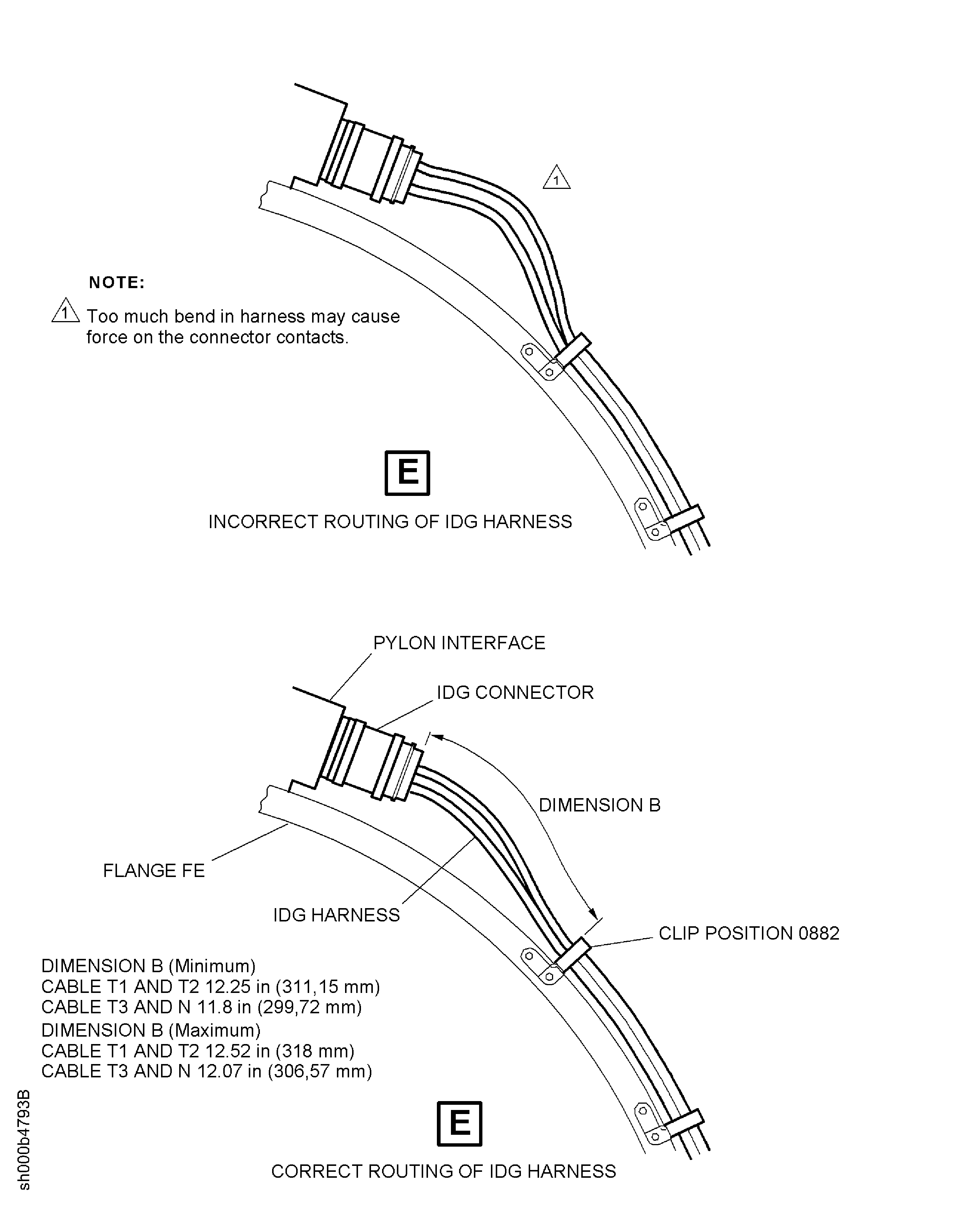

Measure dimension B from the IDG cable connector to the clamp at the clip position 0882. Dimension B must be a minimum of 12.25 in. (311 mm) and a maximum of 12.52 in. (318 mm) for the cables T1 and T2. For the cables T3 and N, the minimum dimension B must be 11.8 in. (300 mm) and the maximum must be 12.07 in. (306 mm). Refer to the view on B.

Torque the nut ELECTRICAL POWER-IDG CABLES (24-21-43,01-140) at the earth position to 110 * lbfin. (12.4 Nm).

SUBTASK 72-00-32-420-421 Install the 400VC to IDG Cable Assembly (24-21-43,01-010)

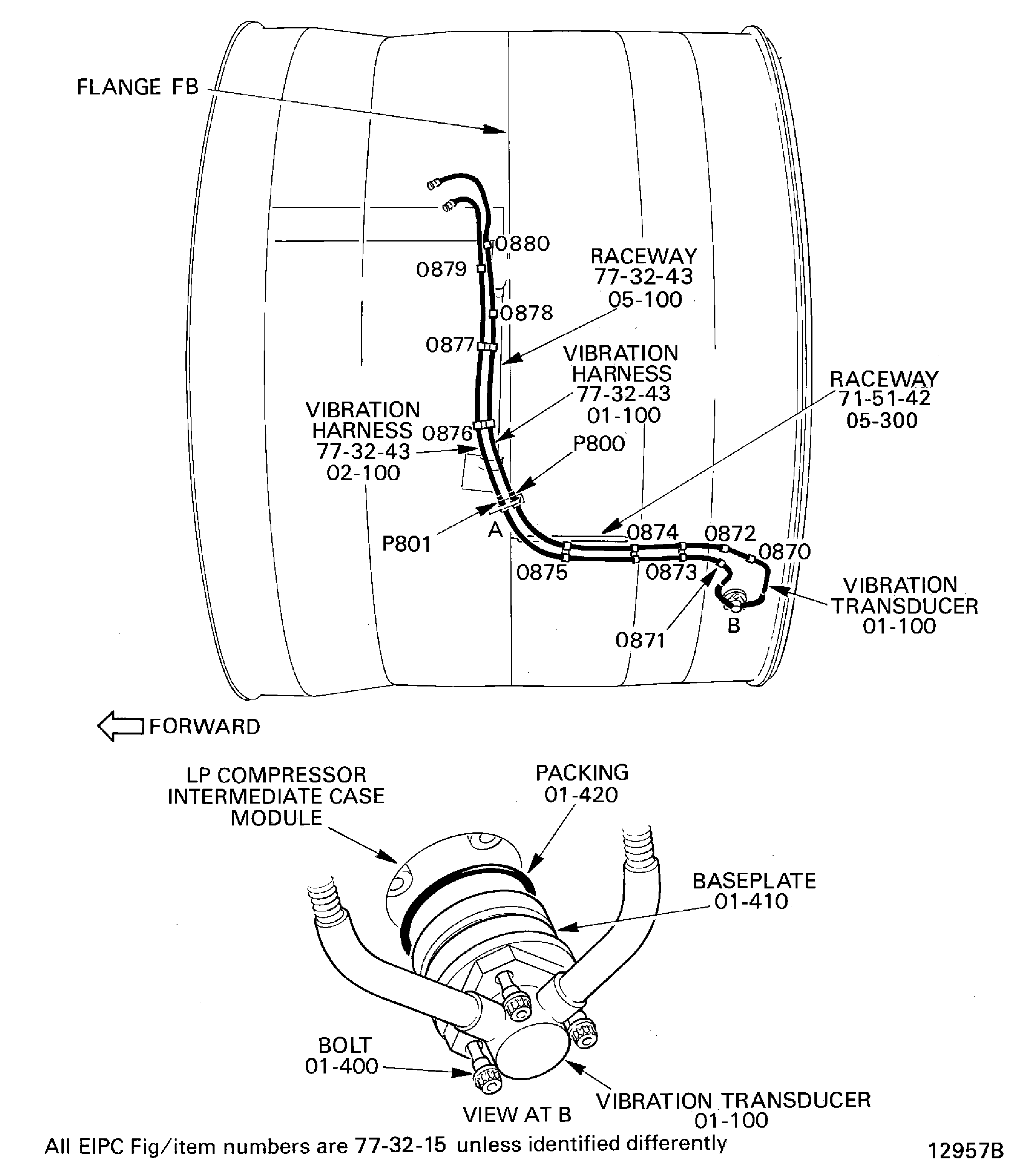

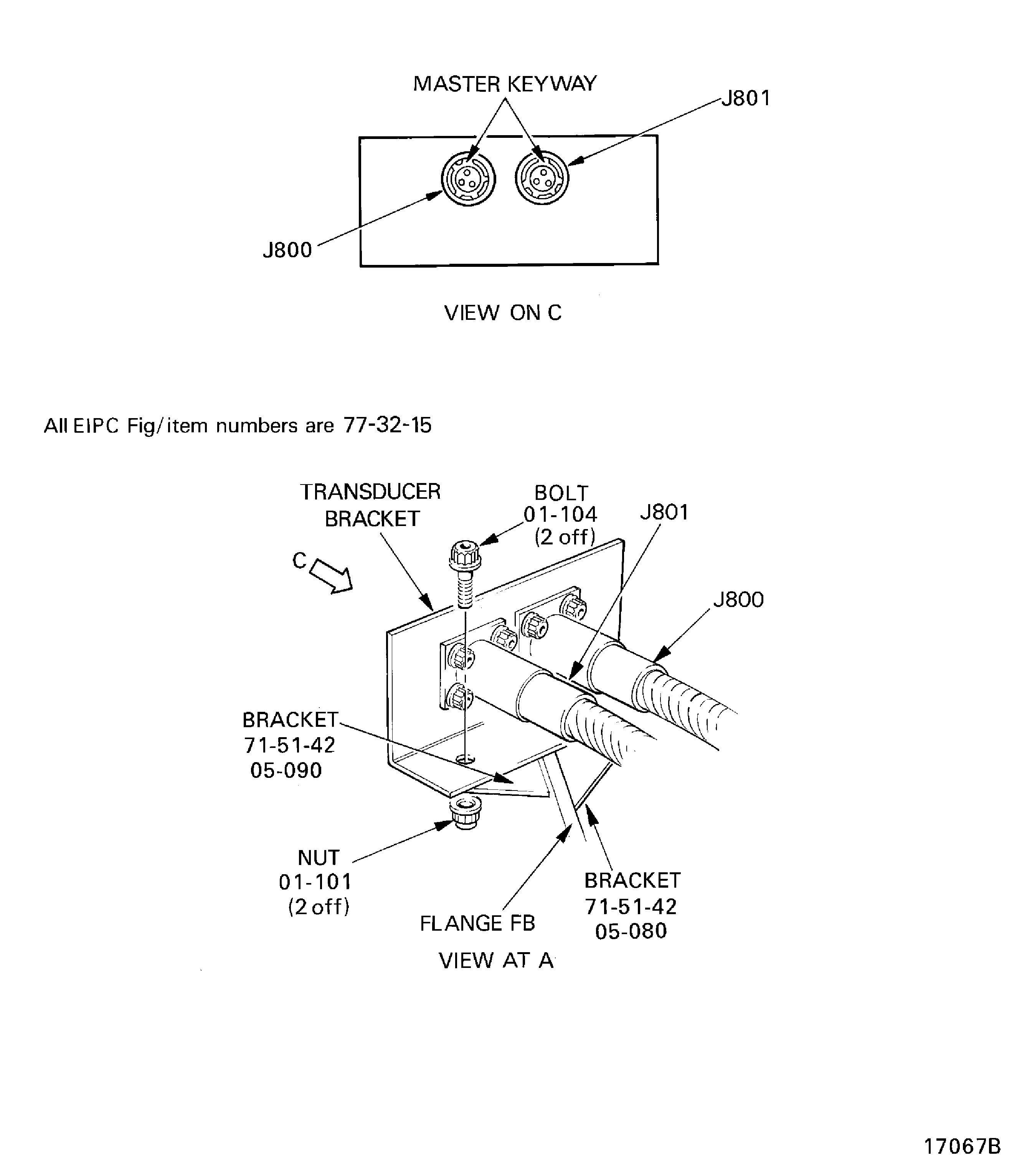

Lightly lubricate a new VIBRATION TRANSDUCER (77-32-15,01-420) packing 1 off with CoMat 10-039 ENGINE OIL.

Install the VIBRATION TRANSDUCER (77-32-15,01-420) Packing 1 off on the baseplate VIBRATION TRANSDUCER (77-32-15,01-410).

Install the three bolts VIBRATION TRANSDUCER (77-32-15,01-400) through the transducer and the baseplate. Install the transducer assembly to the LP compressor/intermediate case. Torque the bolts to 35 to 44 lbfin (3.9 to 4.9 Nm).

Install the transducer bracket to the flange brackets ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42,05-080) and ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42,05-090) with the two bolts and the two nuts VIBRATION TRANSDUCER (77-32-15,01-101) and VIBRATION TRANSDUCER (77-32-15,01-104). Torque the nuts to 36 to 45 lbfin (4 to 5 Nm).

Install the vibration transducer VIBRATION TRANSDUCER (77-32-15,01-100) as follows:

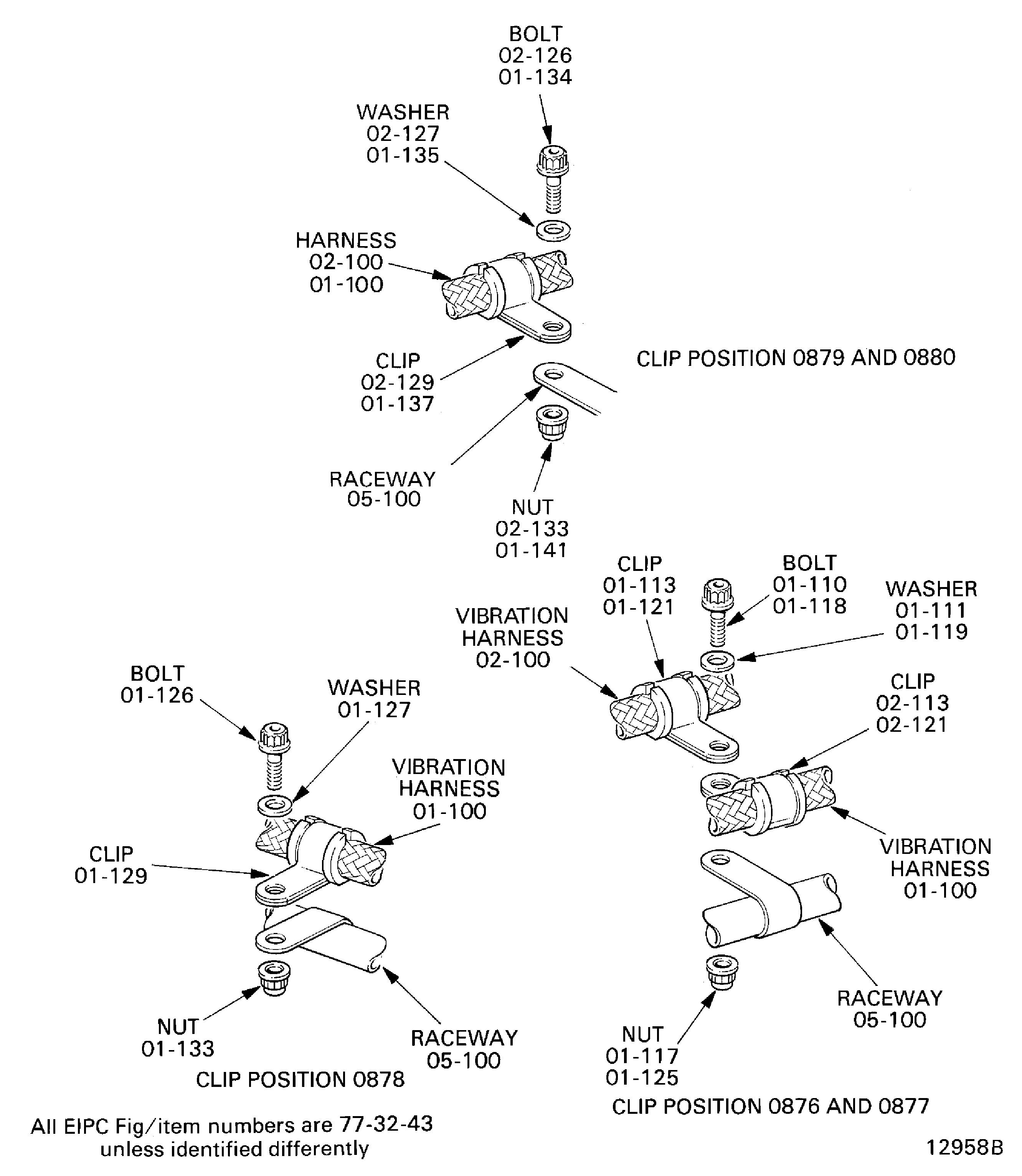

Install the vibration harnesses VIBRATION TRANSDUCER JUNCTION BOX (77-32-43,01-100) and (77-32-15,02-100) as follows:

SUBTASK 72-00-32-420-422 Install the Vibration Harnesses/Transducer

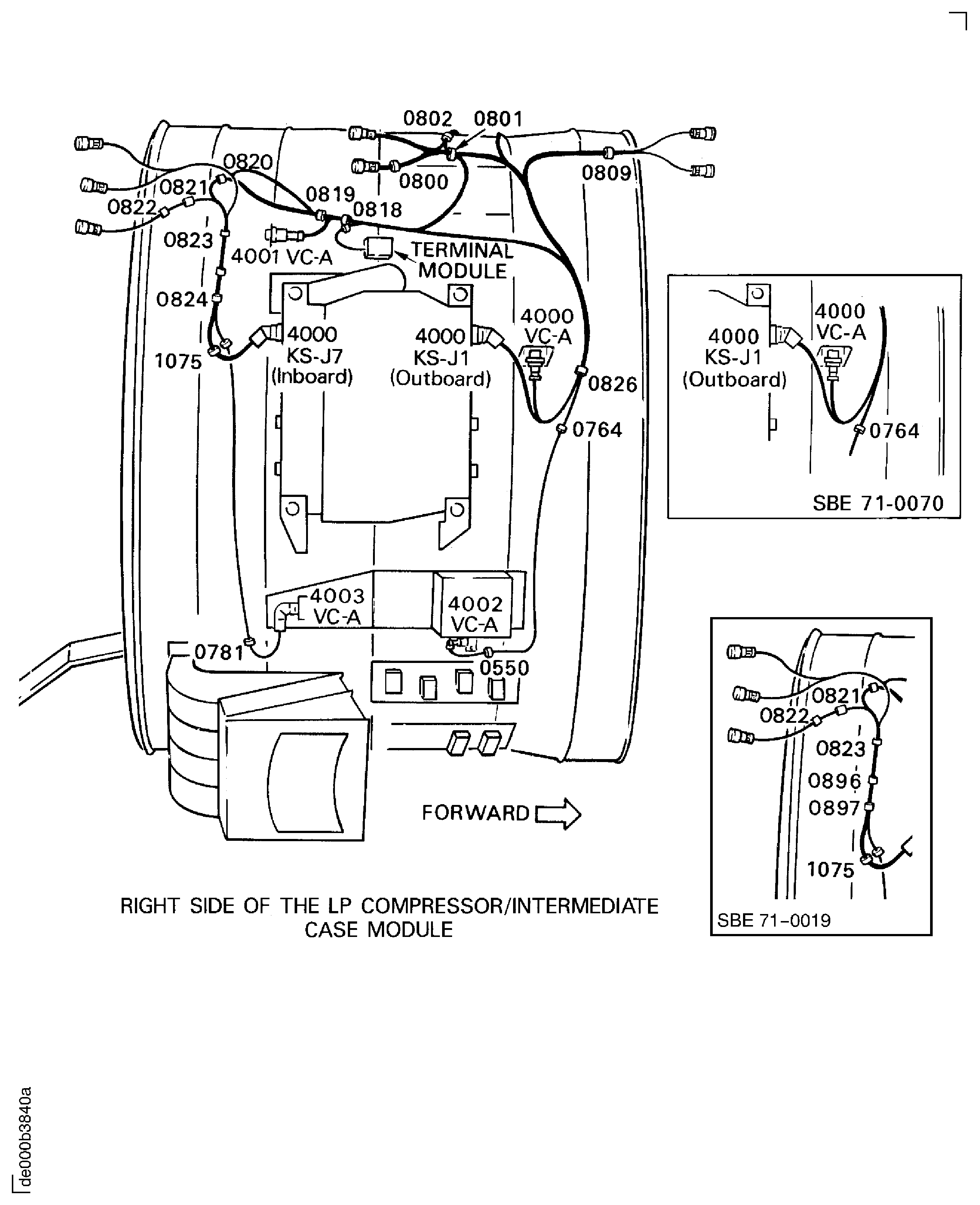

Connect and torque the electrical connectors 4000KS-J1 and 4000KS-J7 to the EEC ELECTRONIC ENGINE CONTROL (EEC) (73-22-34,01-280) with the IAE 1R19416 EEC harness wrench EEC harness wrench 1 off to 32* lbfin (3.6 Nm).

Use CoMat 06-086 TIES and temporarily attach the harness to the applicable brackets at the clip positions that follow:

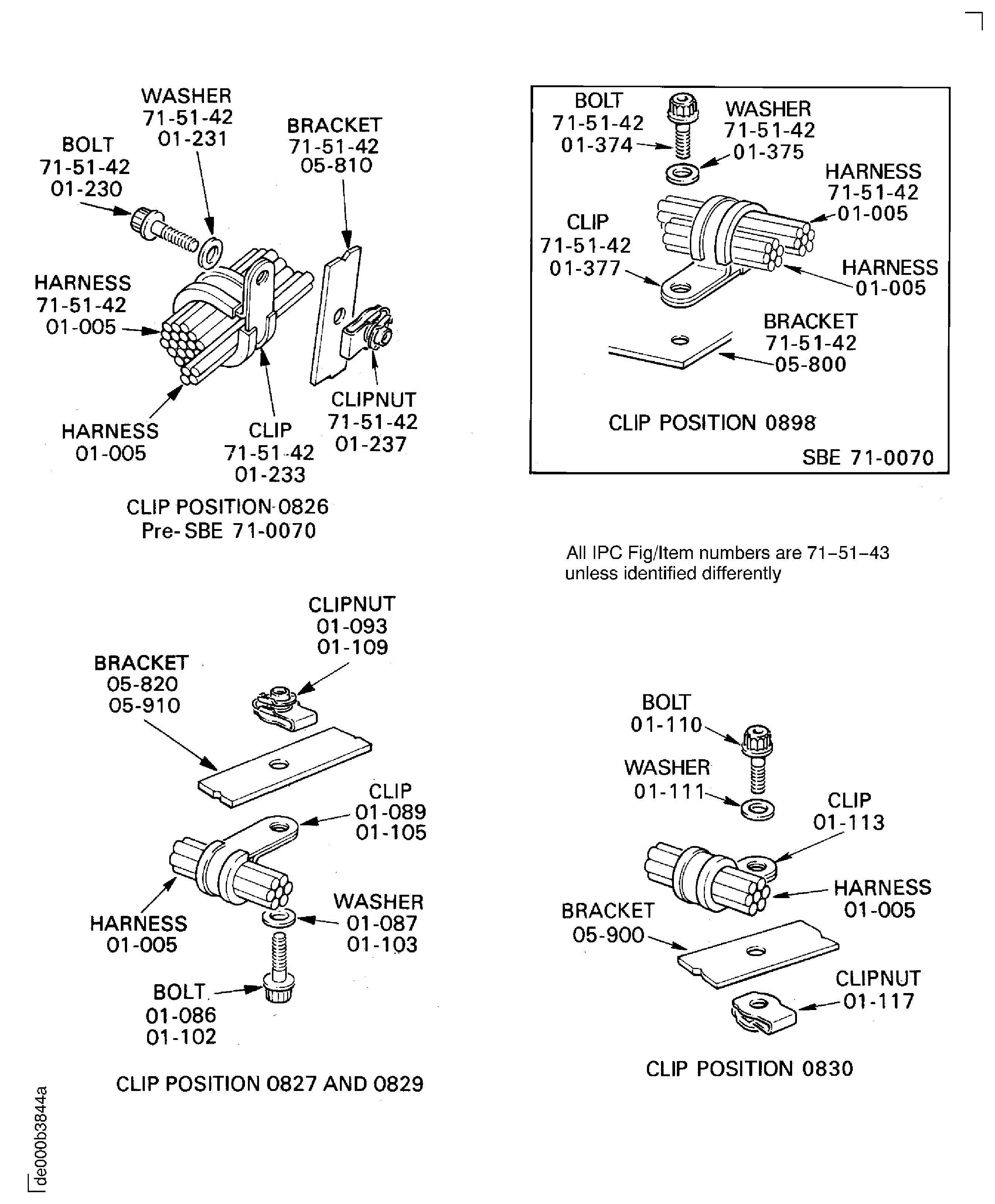

Pre SBE 71-0019: 0550, 0764, 0781, 0800 to 0802, 0809, 0818 to 0823, 0826, 0867 to 0869, 0896, 0897, 1001 and 1075.

SBE 71-0019 and Pre SBE 71-0070: 0550, 0764, 0781, 0800 to 0802, 0809, 0818 to 0823, 0826, 0867 to 0869, 0896, 0897, 1001 and 1075.

SBE 71-0019 and SBE 71-007: 0550, 0764, 0781, 0800 to 0802, 0809, 0818 to 0823, 0867 to 0869, 0896, 0897, 1001 and 1075.

Use CoMat 06-086 TIES and temporarily attach the harness to the applicable tube lugs at clip positions 0550 and 0863 to 0866.

NOTE

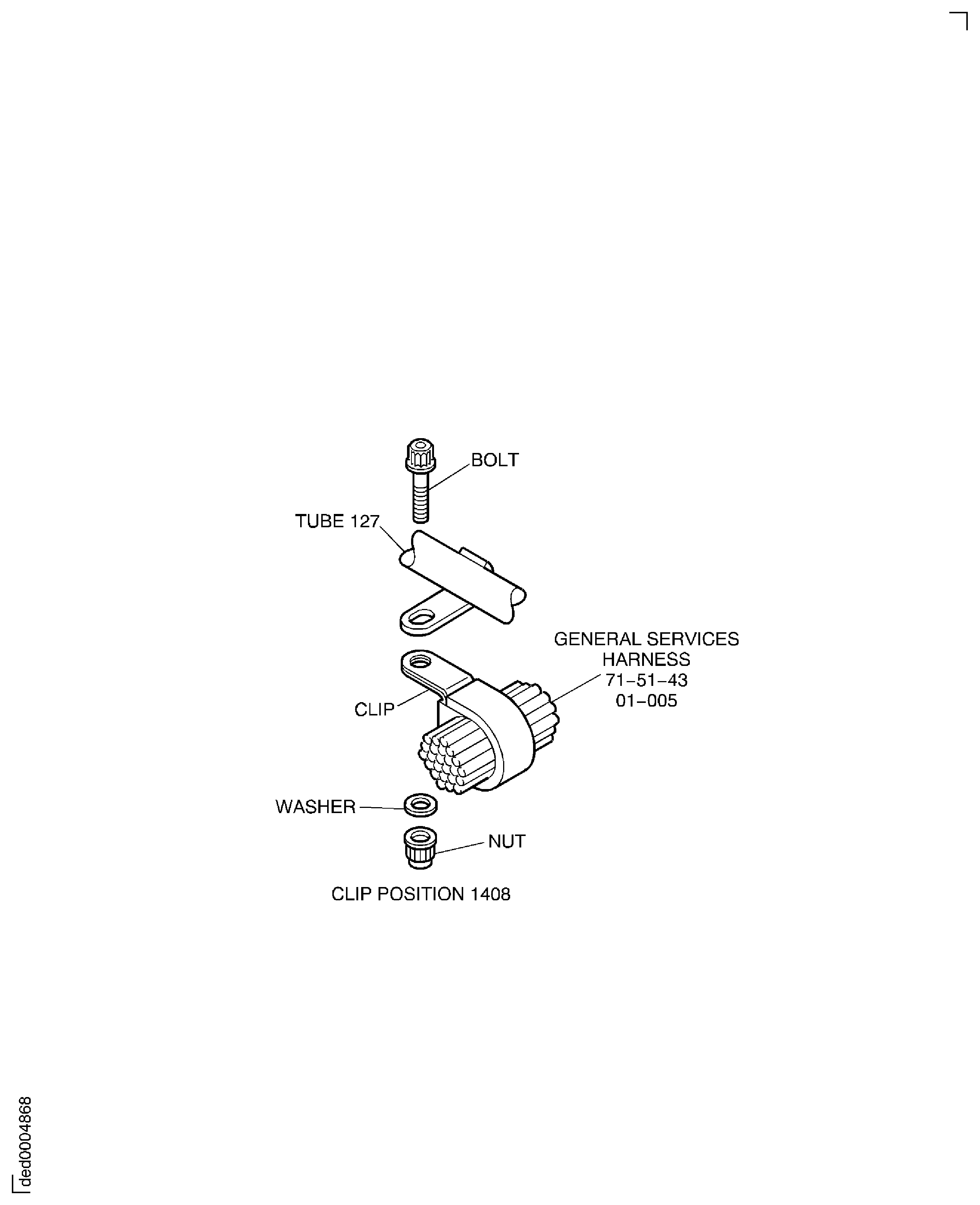

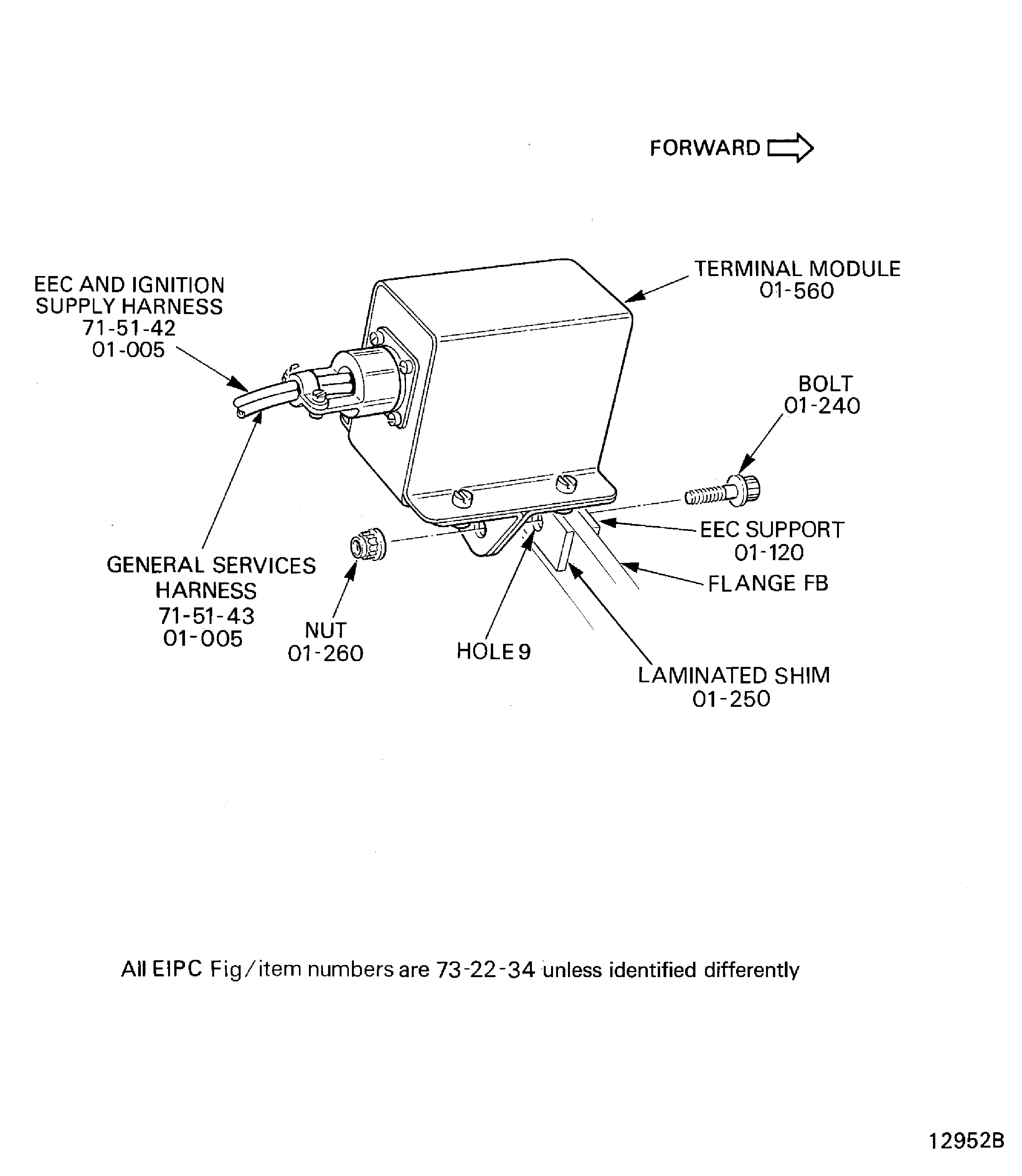

Hole No. 1 is at 12.5 degrees from the engine top position on the flange FB when you look from the rear of the engine.Install the terminal module ELECTRONIC ENGINE CONTROL (EEC) (73-22-34,01-560) to the hole No. 9 on the flange FB with bolt ELECTRONIC ENGINE CONTROL (EEC) (73-22-34,01-240) and nut ELECTRONIC ENGINE CONTROL (EEC) (73-22-34,01-260). Torque the nut to 85 to 105 lbfin (10 to 12 Nm).

SUBTASK 72-00-32-420-423 Install the EEC and Ignition Supply Harness (71-51-42,01-005) (Pre SBE 71-0019, Pre SBE 71-0070, SBE 71-0019 and SBE 71-0070)

SBE 71-0019: Engine - Power Plant - EEC and Ignition Supply Harness, Clipping

SBE 71-0070: Nacelle - Power Plant - EEC Cooling - Support Brackets - Removal/Replacement

NOTE

The EEC and ignition supply harness and the general services harness are previously attached to the terminal module. Refer to the Component Maintenance Manual (CMM-EHC-V2500-1IA) TASK 73-22-34-440-301. Install both these harnesses at the same time. Refer to Step.Pre SBN 71-0166: Identify the correct datum clip positions that follow: 0258, 0786, 0787, 0788, 0790, 0791, 0800, 0805, 0809, 0828, 0830 to 0834, 0848, 0850, 0852 to 0855, 0881, 0892, 0903 and 0922.

SBN 71-0166: Identify the correct datum clip positions that follow: 0258, 0786, 0787, 0788, 0790, 0791, 0800, 0805, 0809, 0830 to 0834, 0848, 0850, 0852 to 0855, 0881, 0892, 0903 and 0922.

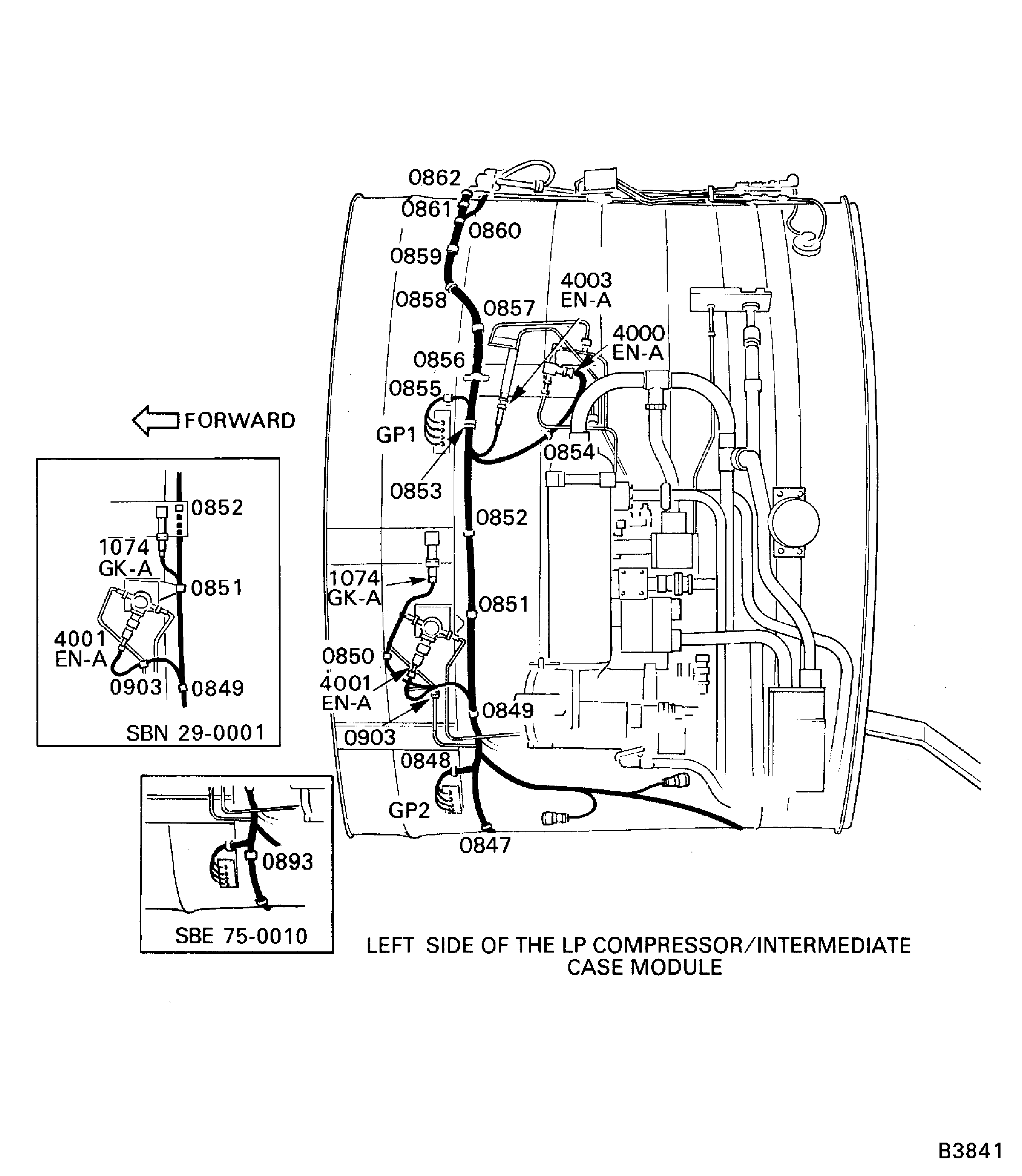

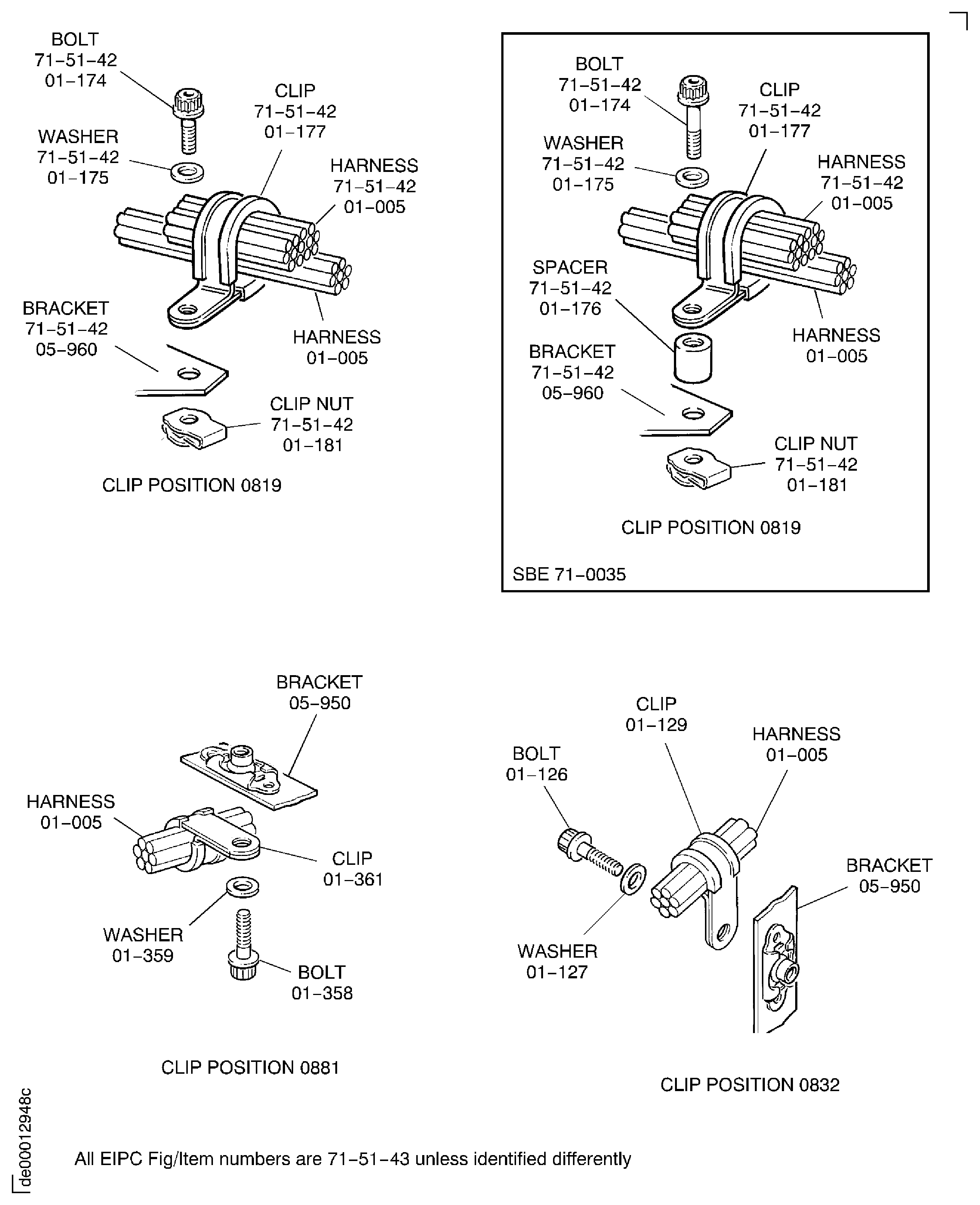

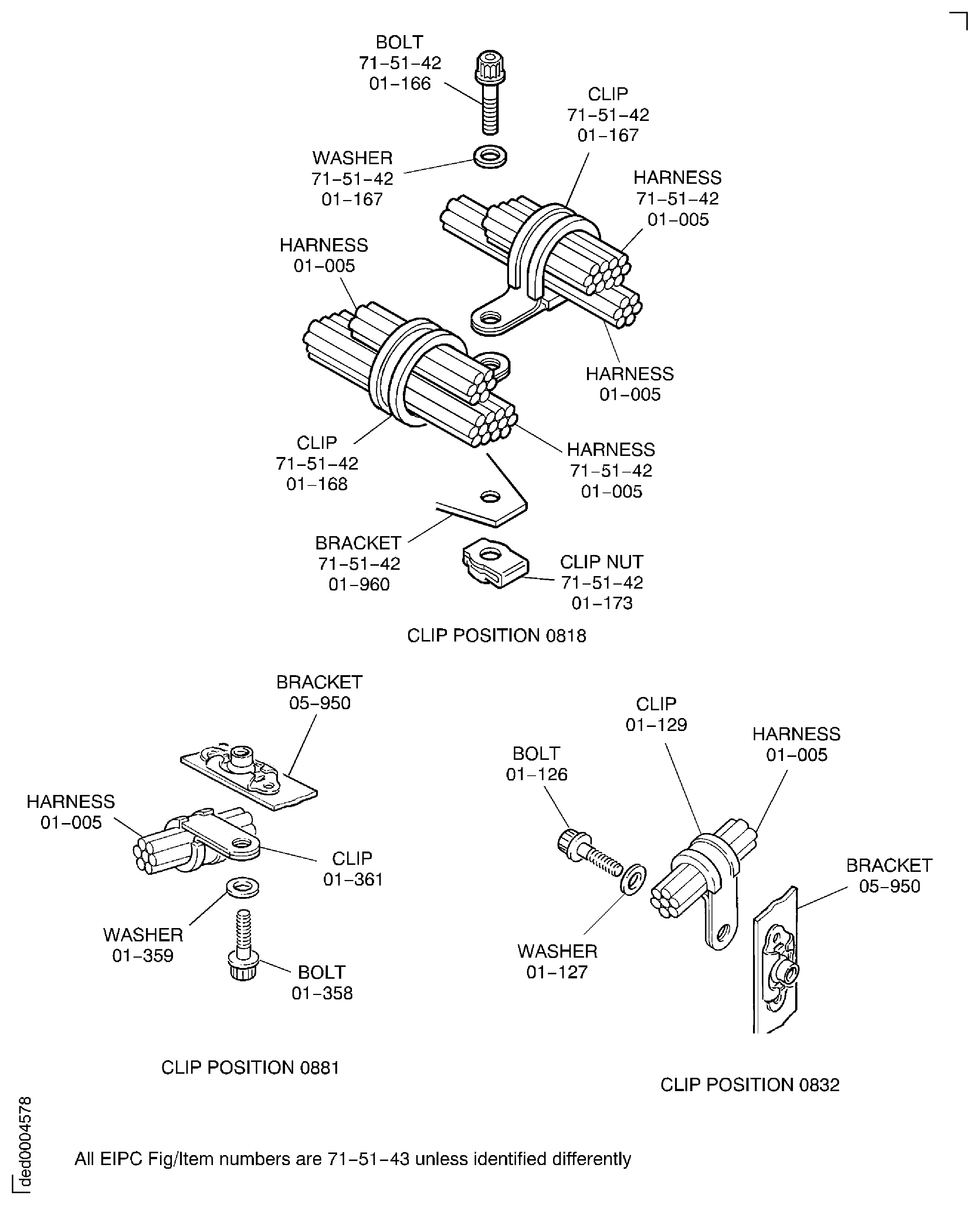

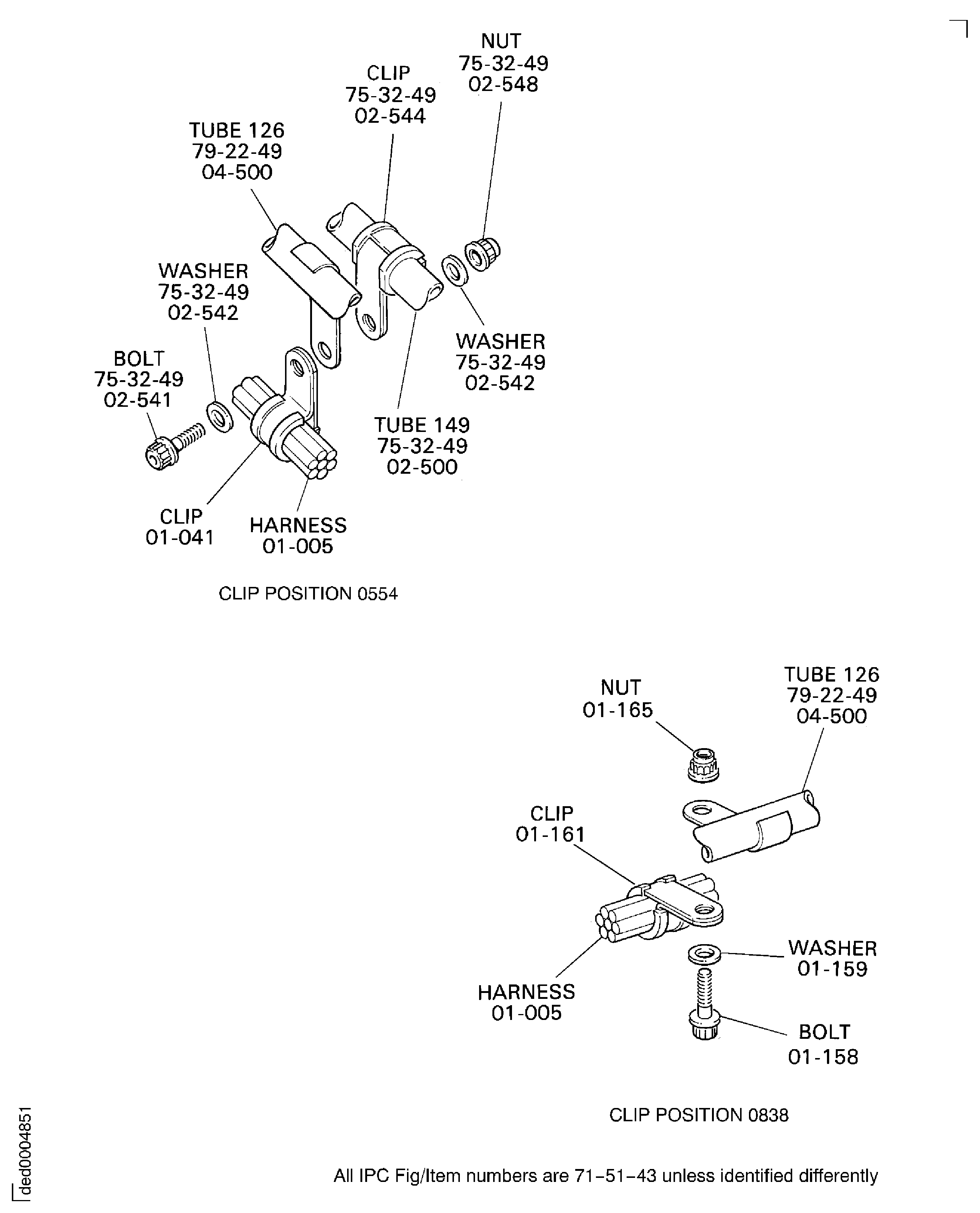

Pre SBN 29-0001, Pre SBE 71-0070, Pre SBE 71-0097 and Pre SBE 75-0010: Identify the correct clip positions that follow: 0800 to 0803, 0805 to 0819, 0826 to 0835, 0791, 0773, 0881 0554, 0838 to 0840, 0892, 0847 to 0862, 0258 and 0903.

SBN 29-0001, SBE 71-0070, SBE 71-0097 and SBE 75-0010: identify the correct clip positions that follow: 0800 to 0803, 0805 to 0819, 0898, 0827 to 0835, 0791, 0773, 0881, 0554, 0838 to 0840, 0892, 0893, 0847 to 0849, 0851 to 0862, 0258 and 0903.

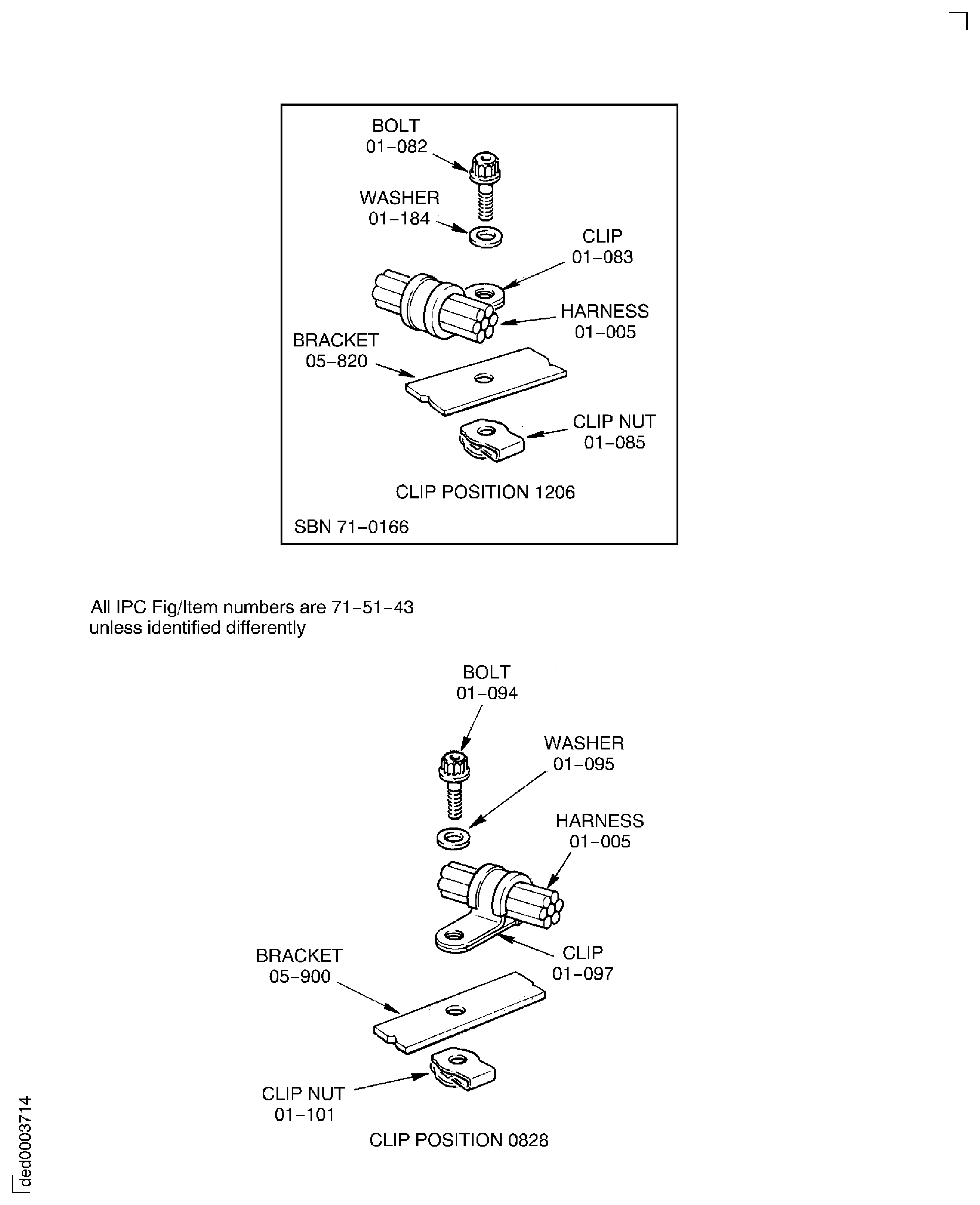

SBN 71-0166: Identify the correct clip positions that follow: 0800, 0805, 0809, 0791, 1206, 0830 to 0834, 0881, 0852 to 0855, 0903, 0848, 0258 and 0892.

Install the general services harness to the LP compressor/intermediate case, connect and torque the electrical connectors:

4005EN-A to the No. 4 bearing pressure transducer OIL-NO.4 BEARING PRESSURE TRANSDUCER (79-33-16,01-100) to 12 * lbfin (1.4 Nm). Install the datum clip position 0881. Refer to Figure.

4100KS-B to the relay box POWER PLANT-RELAY BOX (71-51-49,01-100) to 18 * lbfin (2.0 Nm). Temporarily attach the datum clip position 0791 to the tube lug with CoMat 06-086 TIES. Refer to Figure.

4003EN-A to the oil pressure transmitter OIL-OIL PRESSURE TRANSMITTER (79-33-15,01-010) to 18 * lbfin (2.0 Nm). Install the datum clip positions 0852 and 0853. Refer to Figure.

4000EN-A to the low oil pressure switch LOW OIL PRESSURE SWITCH (79-34-15,01-010) to 14 * lbfin (1.6 Nm). Install the datum clip position 0854. Refer to Figure.

Pre SBN 29-0001: 1074GK-A to the hydraulic pressure switch HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17,01-010) to 14 * lbfin (1.6 Nm). Install the datum clip position 0850. Refer to Figure.

SBN 29-0001: 1074GK-A to the hydraulic pressure switch HYDRAULIC POWER-HYDRAULIC PRESSURE SWITCH (29-11-17,01-010) to 14 * lbfin (1.6 Nm).

4001EN-A to the scavenge filter differential pressure switch OIL-SCAVENGE FILTER DIFFERENTIAL PRESSURE SWITCH (79-35-16, 01-010)to 14 * lbfin (1.6 Nm). Install the datum clip position 0903. Refer to Figure.

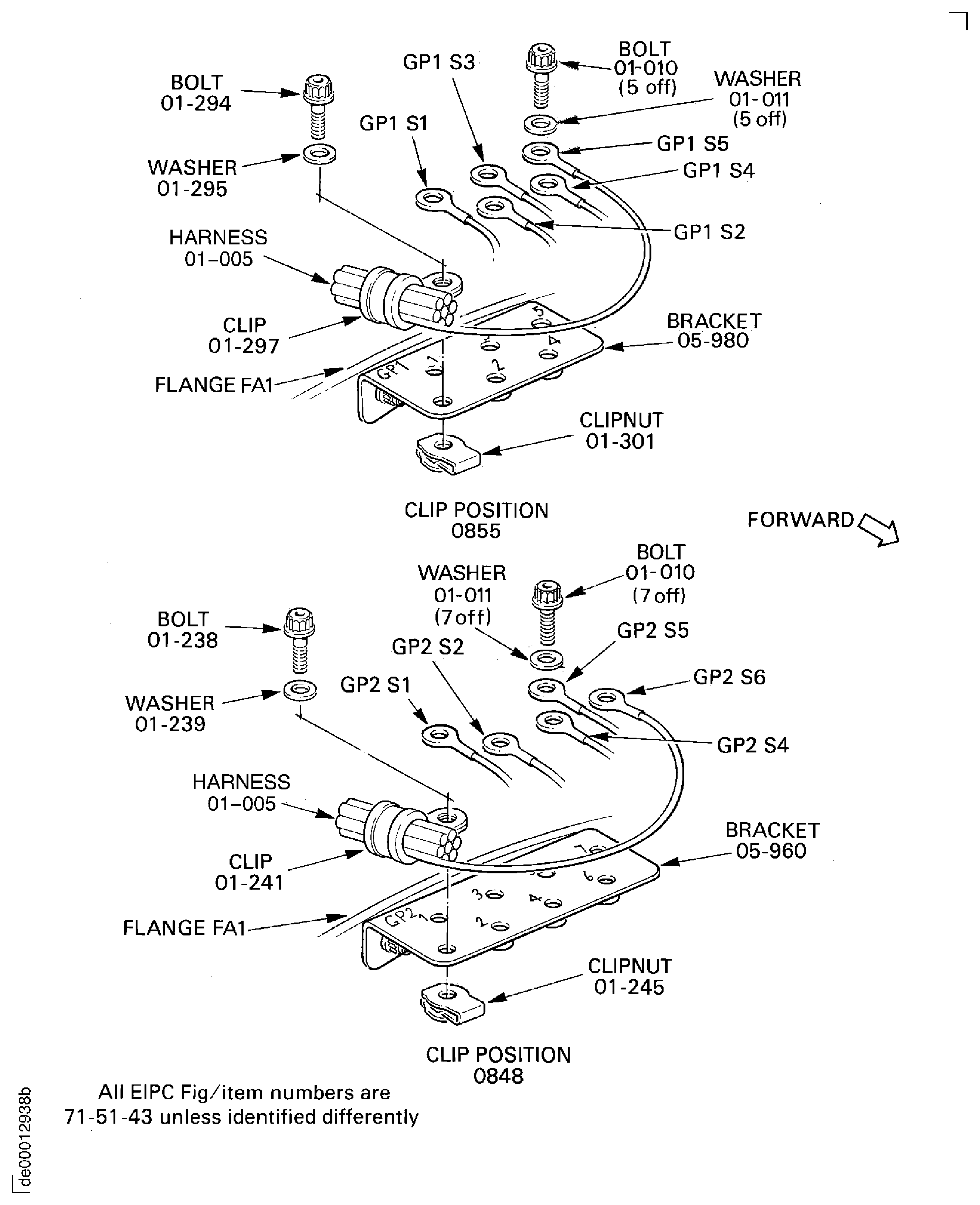

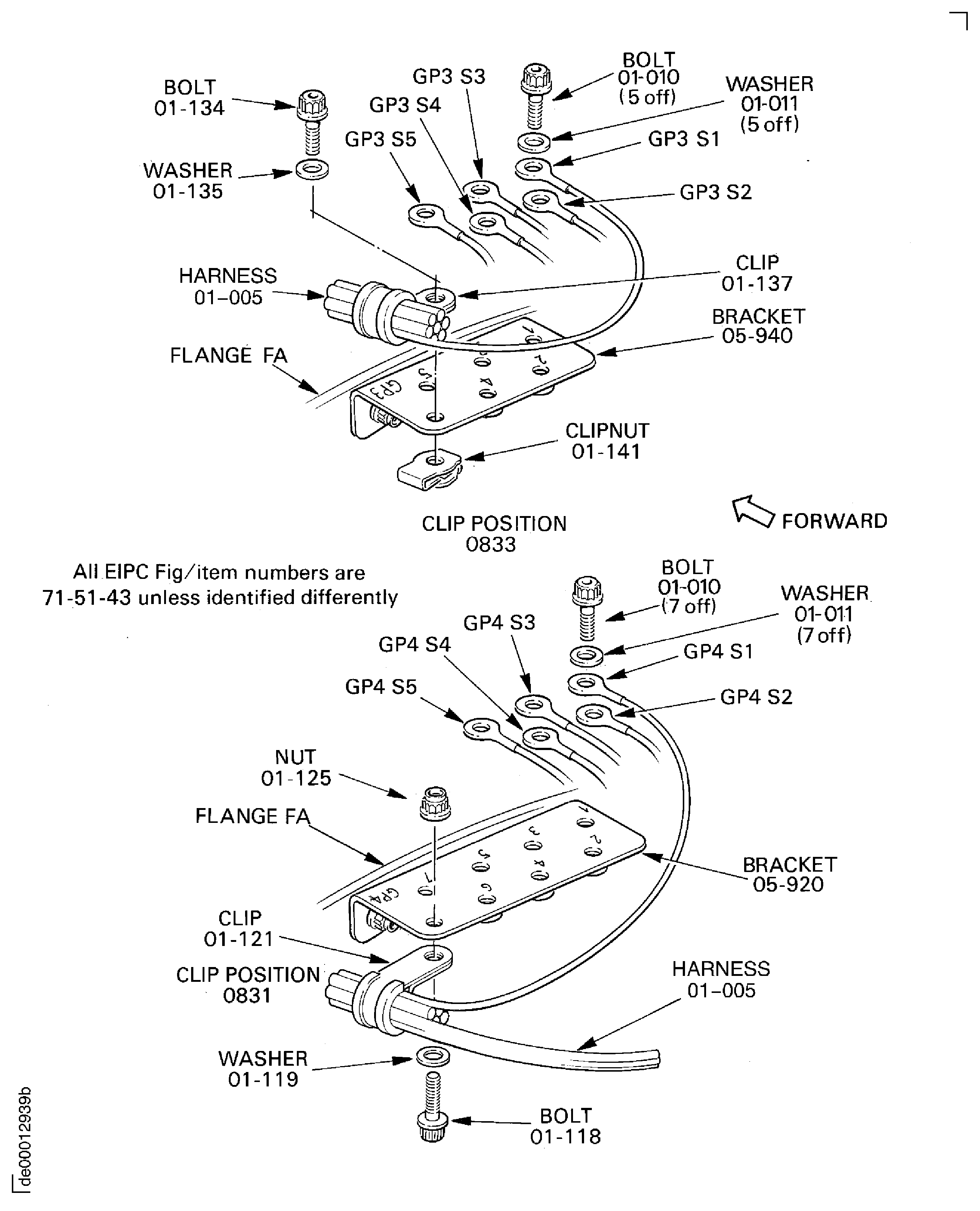

Attach the terminals at GP1, GP2, GP3 and GP4 with the 24 bolts and the 24 washers ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 01-010 and ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS01-011). Install four of the bolts/washers at the positions which are not used. Torque the bolts to 36 to 45 lbfin (4 to 5 Nm). Refer to Figure and Figure.

Pre SBN 26-0005: Install the remaining datum clip positions 0828, 0830, 0832 and 0834.

SBN 26-0005: Install the remaining datum clip positions 0830, 0832, 0834 and 1206.

Temporarily attach the datum clip positions 0892 and 0258 to the applicable brackets with CoMat 06-086 TIES. Refer to Figure.

Install the general services harness ELECT HARNESS-LIGHT DUTY-GEN SERVICES HARNESS (71-51-43, 01-005) as follows:

SUBTASK 72-00-32-420-424 Install the General Services Harness

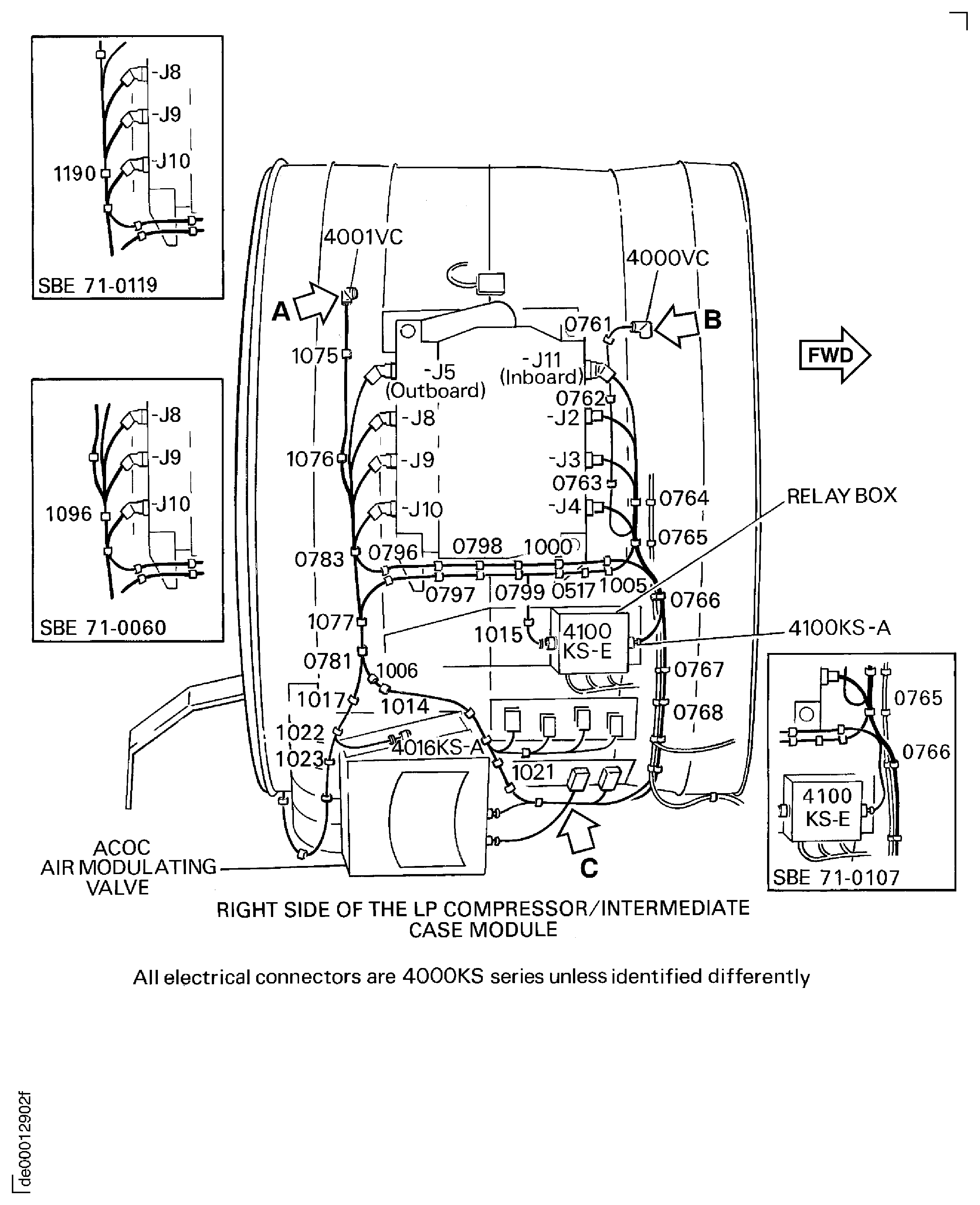

Pre SBE 71-0107: Identify the correct datum clip positions 1075, 0783, 0761, 0764, 1015, 1021, 1022, 0539, 0529, 0792, 1009, 0256, 0325, 0753, 0295, 1032 and 0778.

SBE 71-0107: Identify the correct datum clip positions 1075, 0783, 0761, 0764, 1015, 1021, 1022, 0529, 0792, 1009, 0256, 0325, 0753, 0295, 1032 and 0778.

Pre SBE 73-0040: Identify the correct datum clip positions 1075, 0783, 0761, 0764, 1015, 1021, 1022, 0529, 0792, 1009, 0256, 0753, 0295, 1032 and 0778.

Connect and torque the electrical connectors 4000KS-J2 to -J5 and 4000KS-J8 to -J11 to the EEC ELECTRONIC ENGINE CONTROL (EEC) (73-22-34,01-280) with theIAE 1R19416 EEC harness wrench 1 off to 32* lbfin (3.6 Nm).

Install the datum clip position 0783, refer to Figure. Temporarily attach the harness at the datum clip position 0764 with CoMat 06-086 TIES.

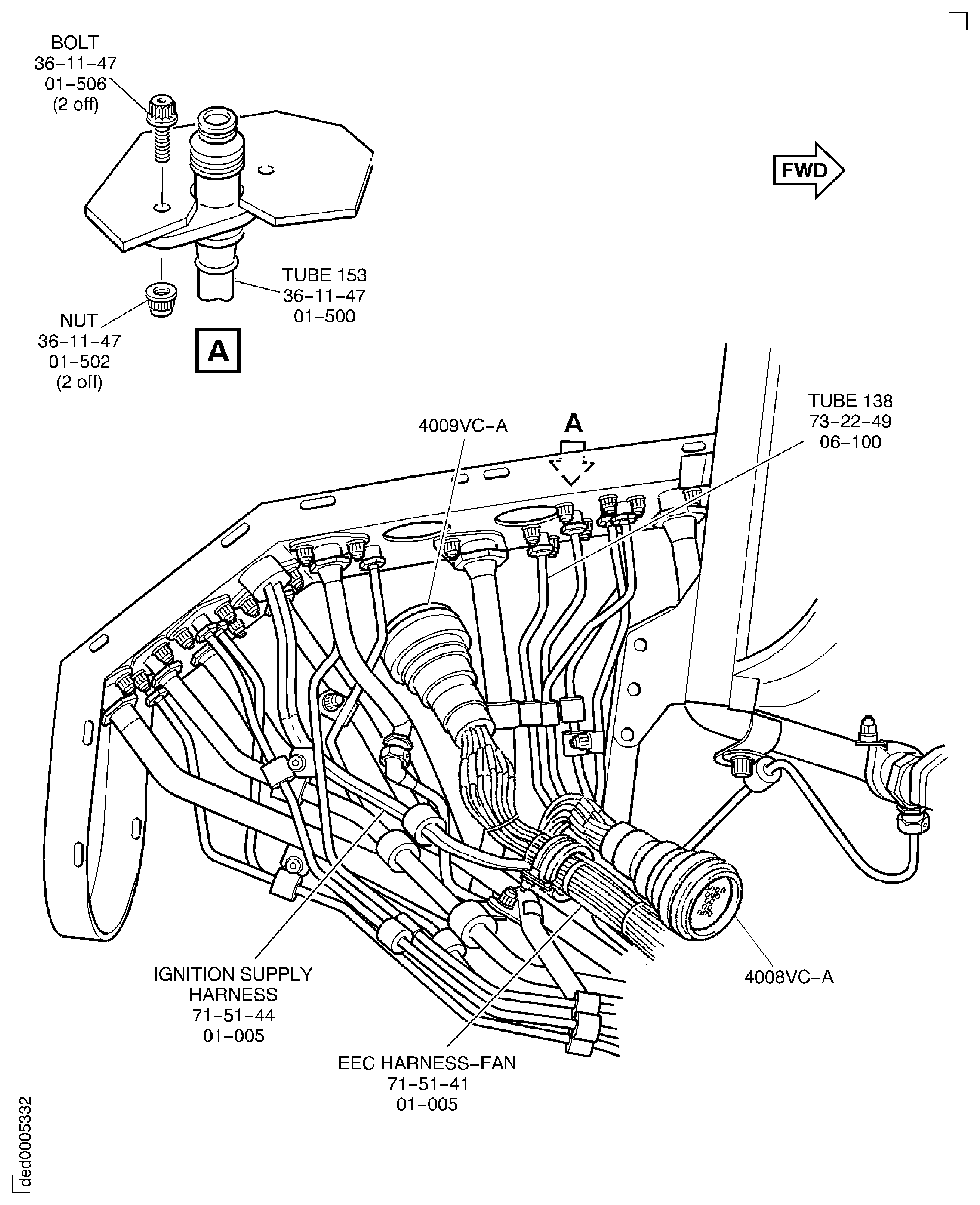

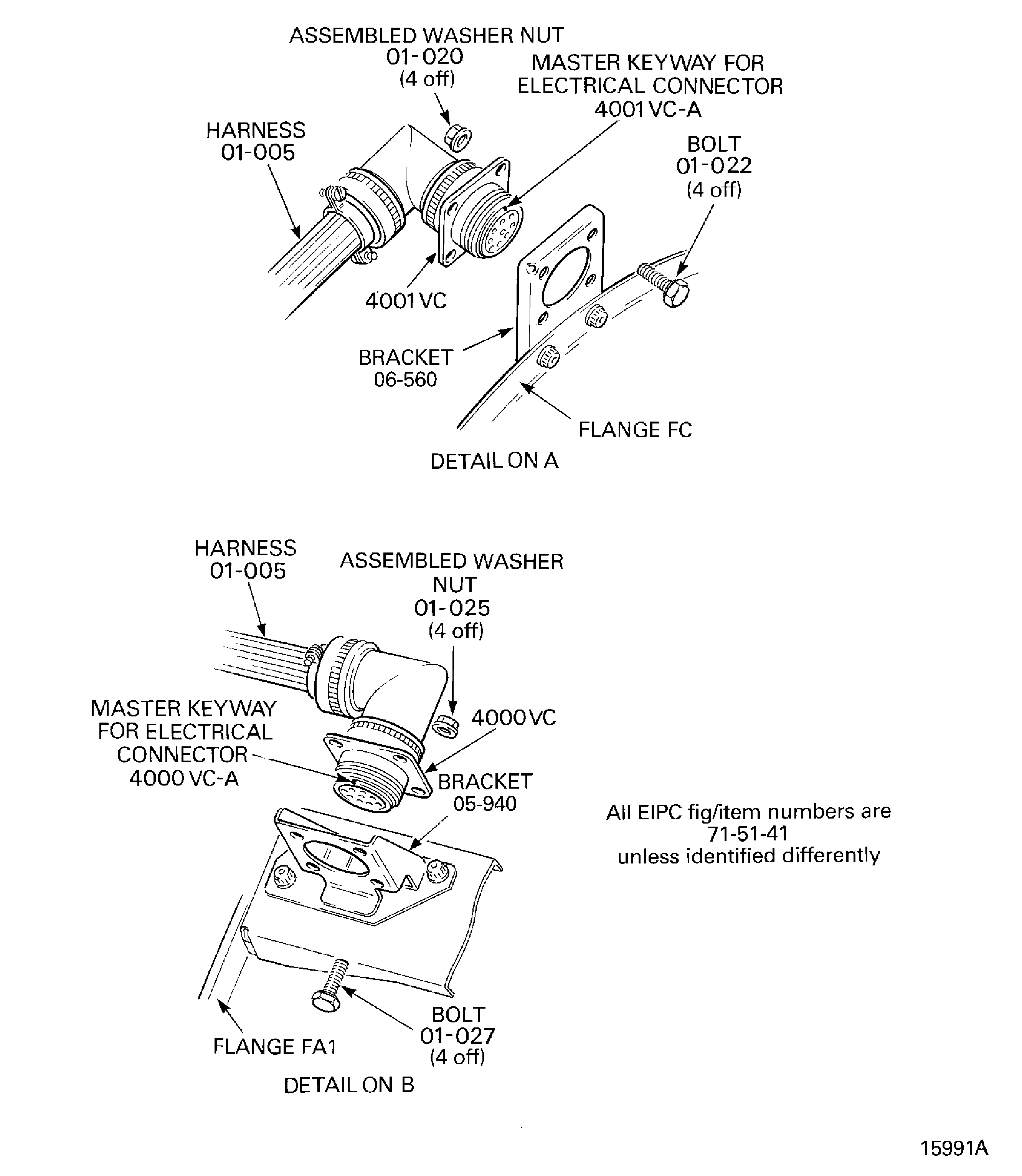

Install the electrical harness receptacle 4000VC, attached to the EEC harness POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41,01-005), to the bracket POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41,05-940) with the four bolts and the four assembled washer nuts POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 01-027 and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN01-025). Make sure the master keyway is in the outboard direction. Refer to the detail on B, refer to Figure. Install the datum clip position 0761, refer to Figure.

Pre SBE 71-0070: Connect the electrical connector 4000VC-A ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42,01-005) to the harness receptacle 4000VC, align the master keyway. Torque the connector to 46 * lbfin (5.2 Nm). Refer to Fig. 72-00-32-990-023-002and Fig. 72-00-32-990-026-011. Remove the temporary ties and install the datum clip positions 0764 and 0826, refer to Figure and Figure.

SBE 71-0070: Connect the electrical connector 4000VC-A ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42,01-005) to the harness receptacle 4000VC, align the master keyway. Torque the connector to 46 * lbfin (5.2 Nm). Refer to Fig. 72-00-32-990-023-002and Fig. 72-00-32-990-026-004. Remove the temporary ties and install the datum clip position 0764, refer to Figure.

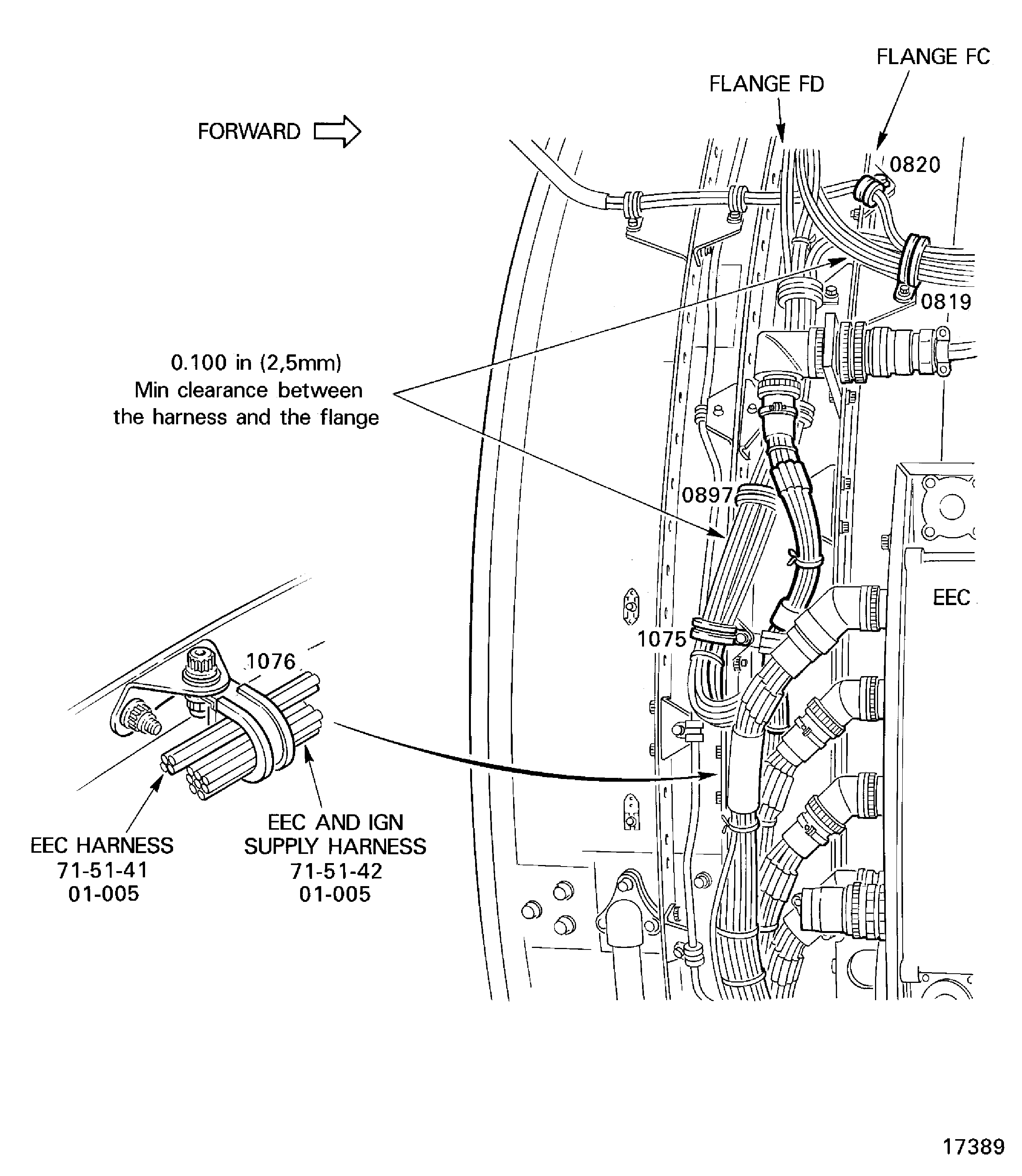

Install the electrical harness receptacle 4001VC, attached to the EEC harness POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41,01-005), to the bracket POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41,06-560) with the four bolts and the four assembled washer nuts POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 01-022 and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN 01-020). Make sure the direction of the master keyway is at the top (in relation to the bracket). Refer to the detail on A, refer to Figure. Remove the temporary ties and install the datum clip position 1075, refer to Figure.

Connect the electrical connector 4001VC-A ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42,01-005) to the harness receptacle 4001VC, align the master keyway. Torque the connector to 46 * lbfin (5.2 Nm). Refer to Figure and Figure.

Remove the temporary ties and install the datum clip position 0819, refer to Figure, Figure and Figure.

NOTE

Refer to TASK 72-00-32-420-005 and TASK 72-00-60-420-003 for the procedure for clip positions 0529 and 0778.

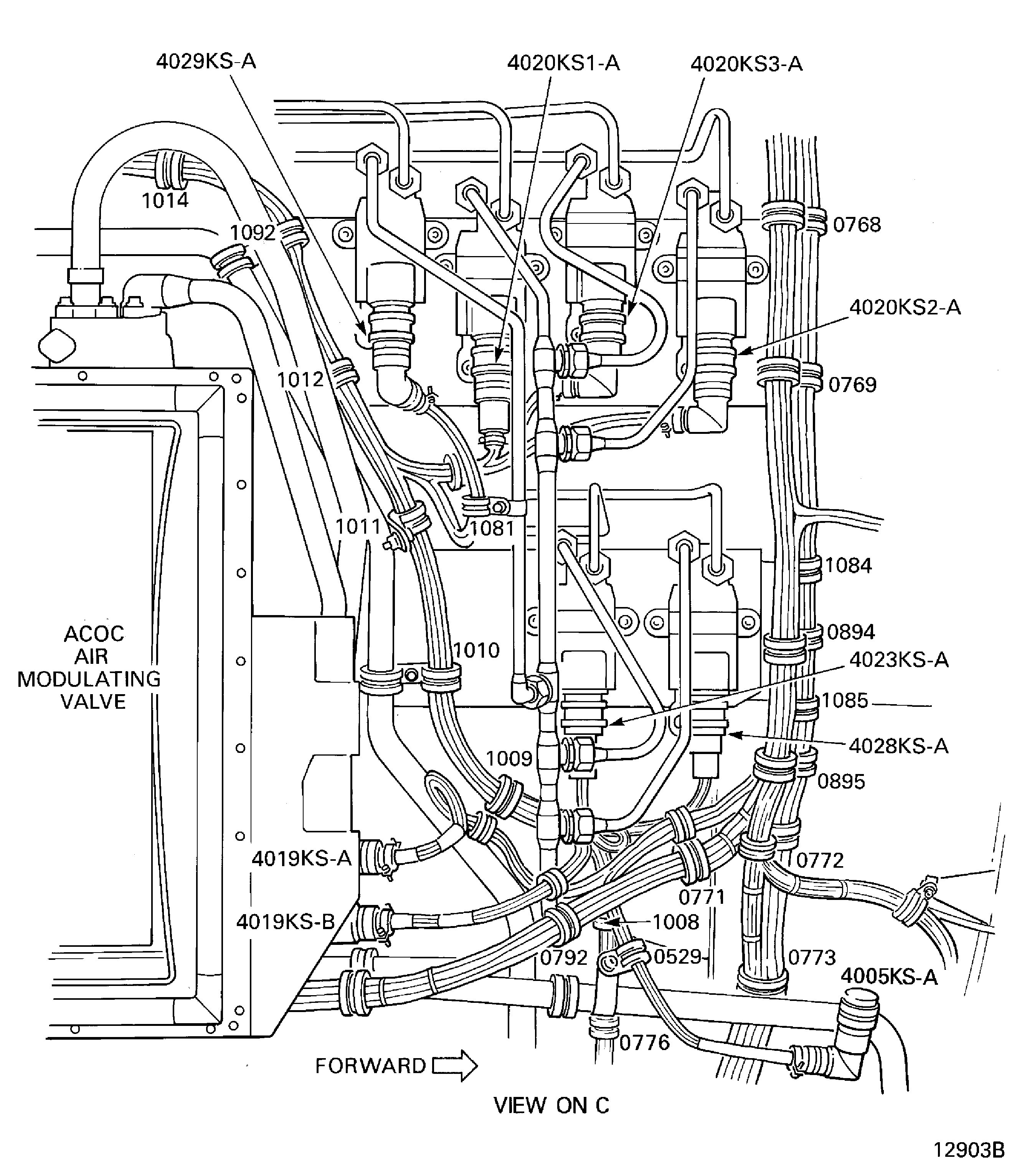

Install the EEC harness POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 01-005) as follows.

Connect and torque the electrical connectors (Right side):

4100KS-E and 4100KS-A to the relay box POWER PLANT-RELAY BOX (71-51-49,01-100) to 21 * lbfin (2.4Nm). Install the datum clip position 1015, refer to Figure.

4016KS-A to the ACOC oil temperature thermocouple OIL-ACOC OIL TEMPERATURE THERMOCOUPLE (79-32-15,01-200) to 18 * lbfin (2.0 Nm). Install the datum clip position 1022, refer to Figure.

4029KS-A to the HP stage 7 and 10 air solenoid valve STAGE 10 AIR SOLENOID VALVE (36-11-57,01-100) to 18 * lbfin (2.0 Nm).

4020KS1-A to the HP compressor stage 7 solenoid valve (51.9 degrees) AIR-HPC STAGE 7 SOLENOID VALVE (75-32-51,01-100) to 18 * lbfin (2.0 Nm). Install the datum clip position 1021, refer to Figure.

4020KS3-A to the HP compressor stage 7 solenoid valve (228 degrees) AIR-HPC STAGE 7 SOLENOID VALVE (75-32-51,01-100) to 18 * lbfin (2.0 Nm).

4020KS2-A to the HP compressor stage 7 solenoid valve (108.8 degrees) AIR-HPC STAGE 7 SOLENOID VALVE (75-32-51,01-100) to 18 * lbfin (2.0 Nm).

4028KS-A to the stage 10 air solenoid valve AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52,01-100) to 18 * lbfin (2.0 Nm).

4023KS-A to the HP compressor stage 10 solenoid valve AIR-HPC STAGE 10 SOLENOID VALVE (75-32-53,01-400) to 18 * lbfin (2.0 Nm).

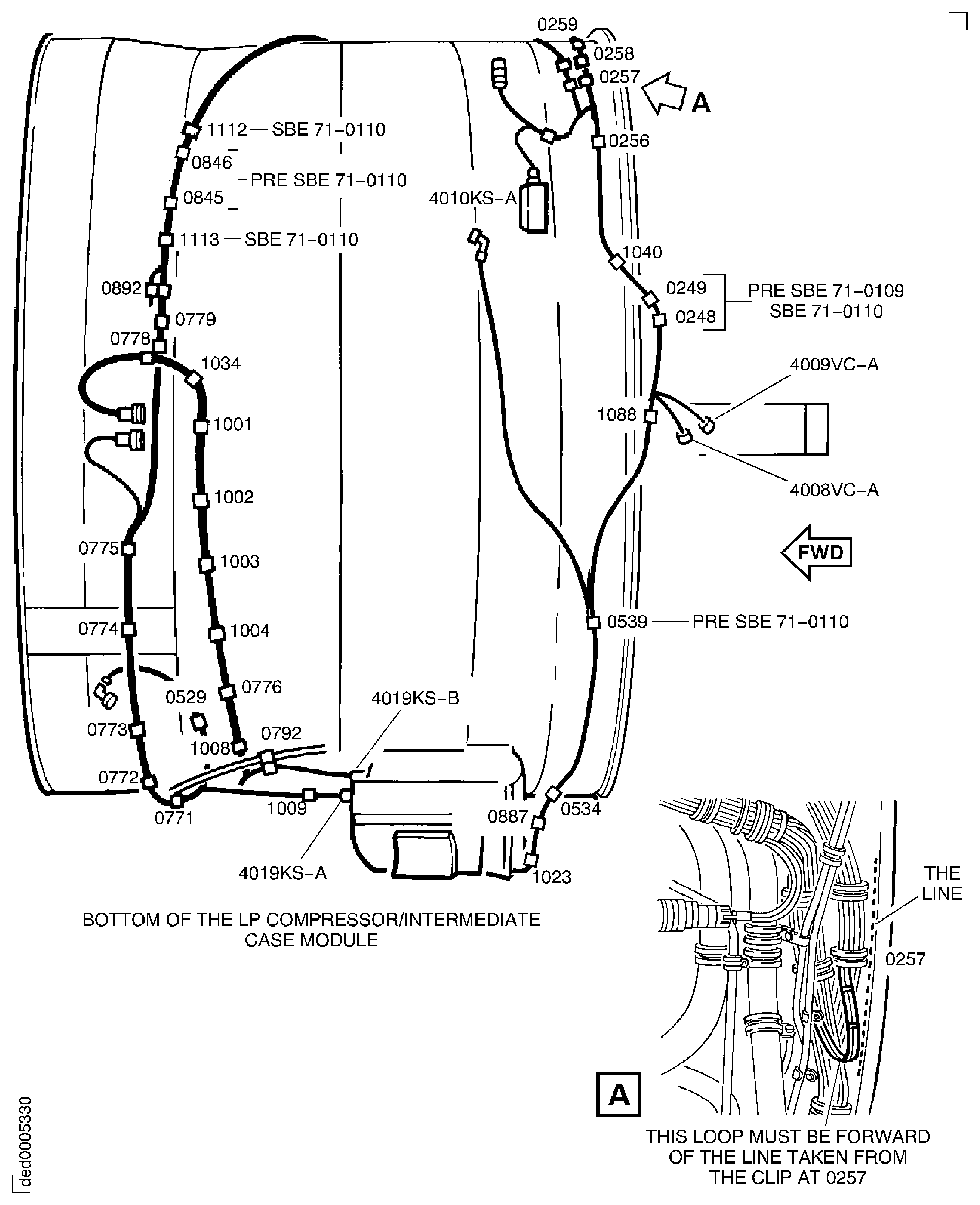

Pre SBE 71-0107 - 4019KS-A and 4019KS-B to the ACOC air modulating valve OIL-AIR COOLED OIL COOLER MODULATING VALVE (79-21-51,01-100) to 18 * lbfin (2.0 Nm). Install the datum clip positions 1009, 0792 and 0539. Temporarily attach the datum clip positions 0529 and 0778 with CoMat 06-086 TIES.

SBE 71-0107 - 4019KSA and 4019KS-B to the ACOC air modulating valve OIL-AIR COOLED OIL COOLER MODULATING VALVE (79-21-51,01-100) to 18 * lbfin (2.0 Nm). Install the datum clip positions 1009, 0792 and 0540. Temporarily attach the datum clip positions 0529 and 0778 with CoMat 06-086 TIES.

Attach the tube 153 to bifurcation panel with the two bolts and the two nuts PNEUMATIC-TUBES-HP BLEED CONTROL AIR (36-11-47, 01-506 and PNEUMATIC-TUBES-HP BLEED CONTROL AIR 01-502).

Torque the tube 236 nut (attached to the tube 153) to 159 to 177 lbfin (18 to 20 Nm). Safety the tube nut with CoMat 02-126 LOCKWIRE.

Torque the two nuts PNEUMATIC-TUBES-HP BLEED CONTROL AIR (36-11-47,01-502) to 85 to 105 lbfin (10 to 12 Nm).

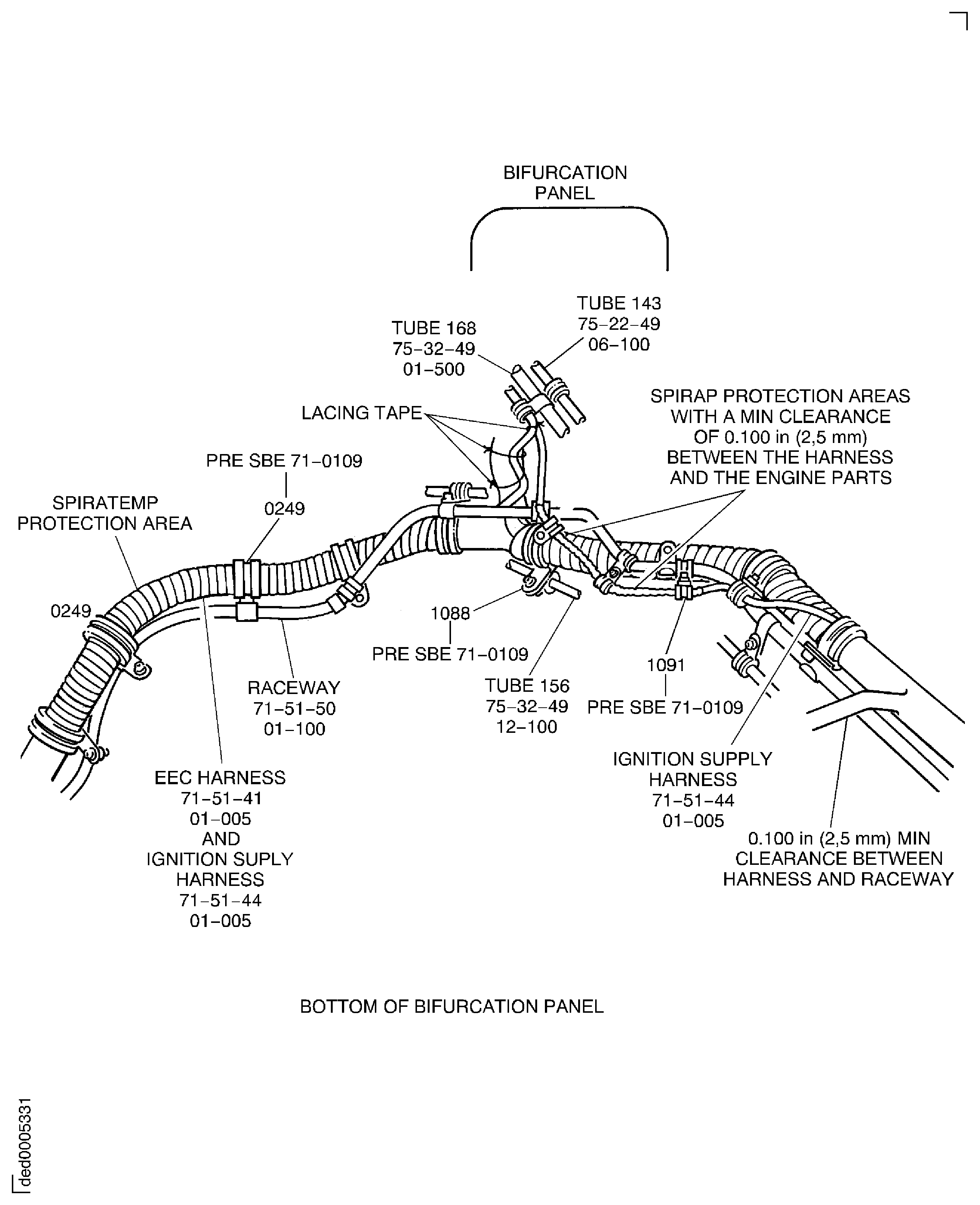

Route the harness at the bifurcation panel.

Connect and torque the electrical connectors (Left side):

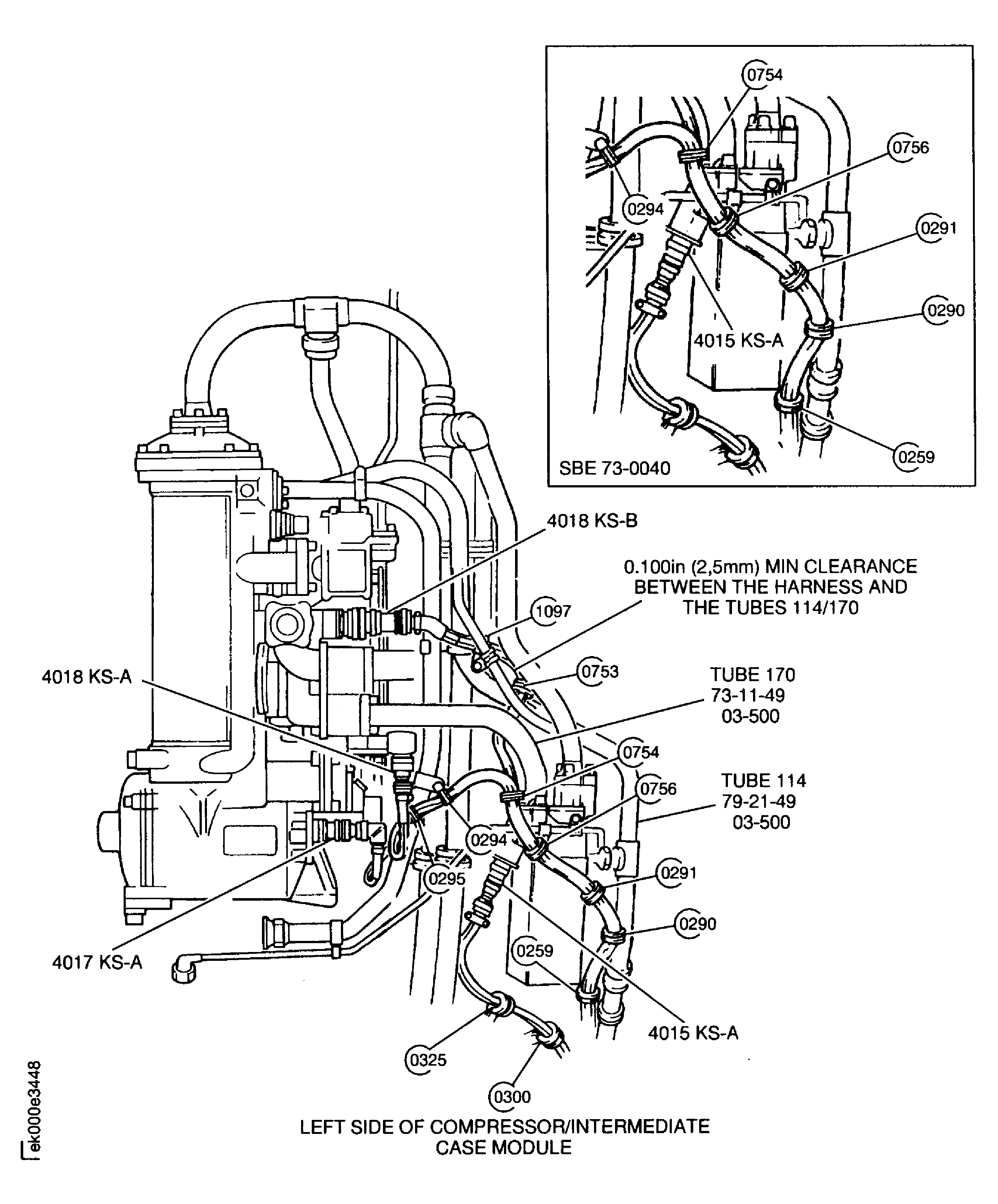

4015KS-A to the IDG FCOC ELECTRICAL POWER-FUEL COOLED IDG OIL COOLER (24-21-42,01-100) to 18 * lbfin (2.0 Nm).

Install the datum clip position 0325, refer to Figure.

4017KS-A to the fuel temperature thermocouple FUEL TEMPERATURE THERMOCOUPLE (73-35-15,01-100) to 18 * lbfin (2.0 Nm).

4018KS-A to the fuel diverter and return valve FUEL DIVERTER AND RETURN VALVE (73-13-42,01-100) to 20 * lbfin (2.3 Nm). Install the datum clip position 0295, refer to Figure.

4018KS-B to the fuel diverter and return valve FUEL DIVERTER AND RETURN VALVE (73-13-42,01-100) to 24 * lbfin (2.7 Nm). Install the datum clip position 0753, refer to Figure.

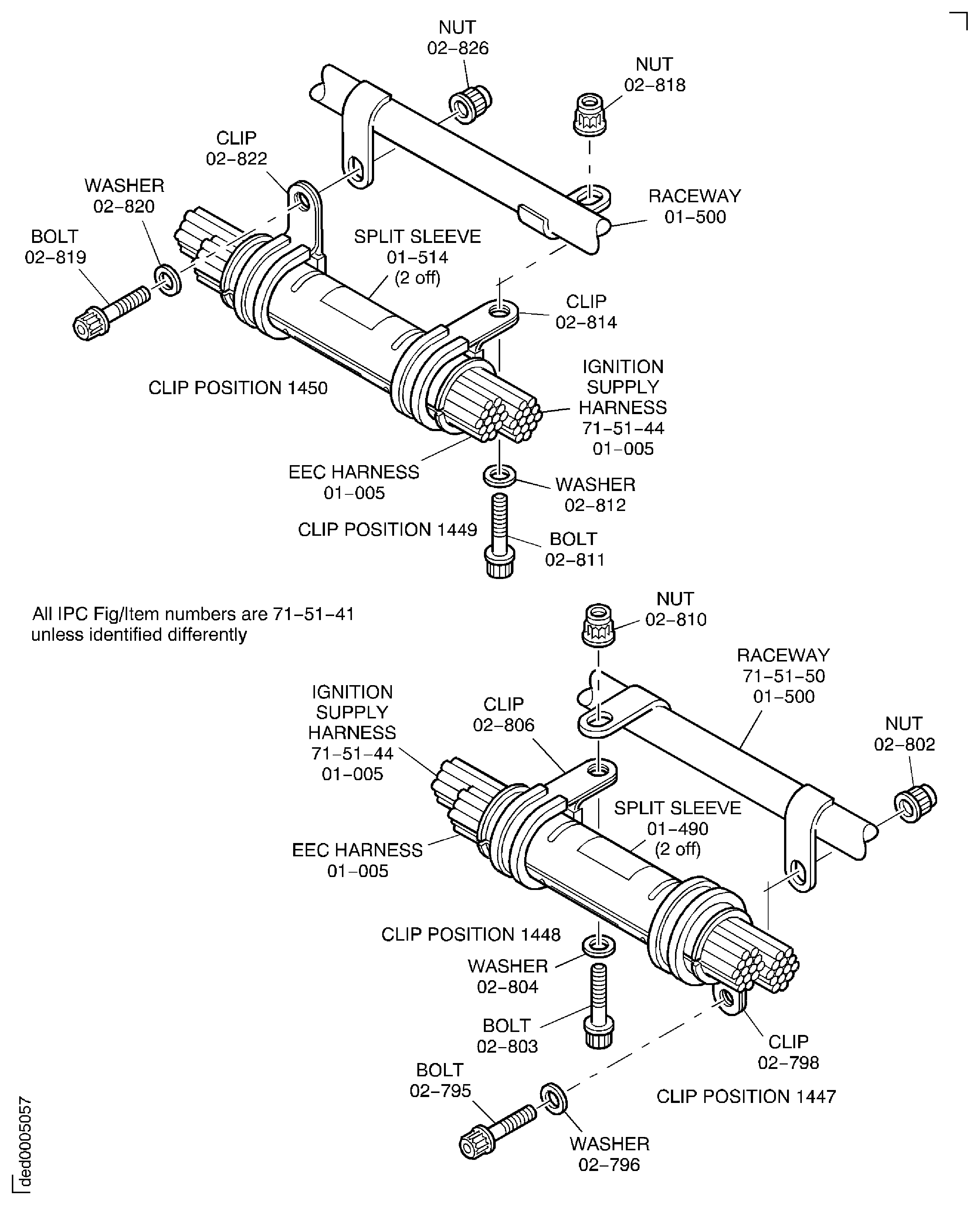

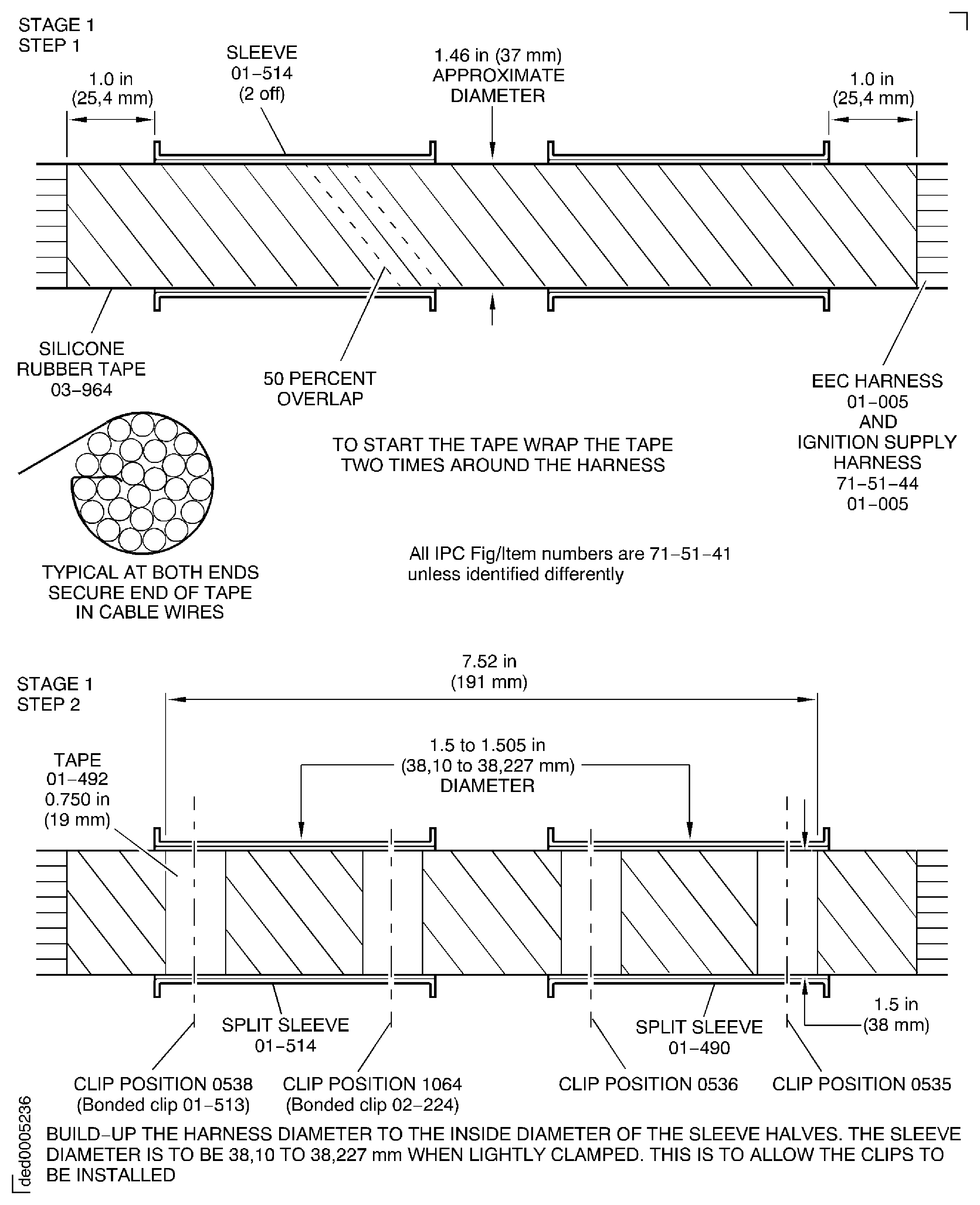

Wind the tape around the harness bundle and along the length of harness. Use a sufficient length of the tape to reduce the diameter of the harnesses to give the dimensions on Figure.

Step 1: Secure the end of the reinforced silicone rubber tape POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 03-964) in the cable wire of the harness.

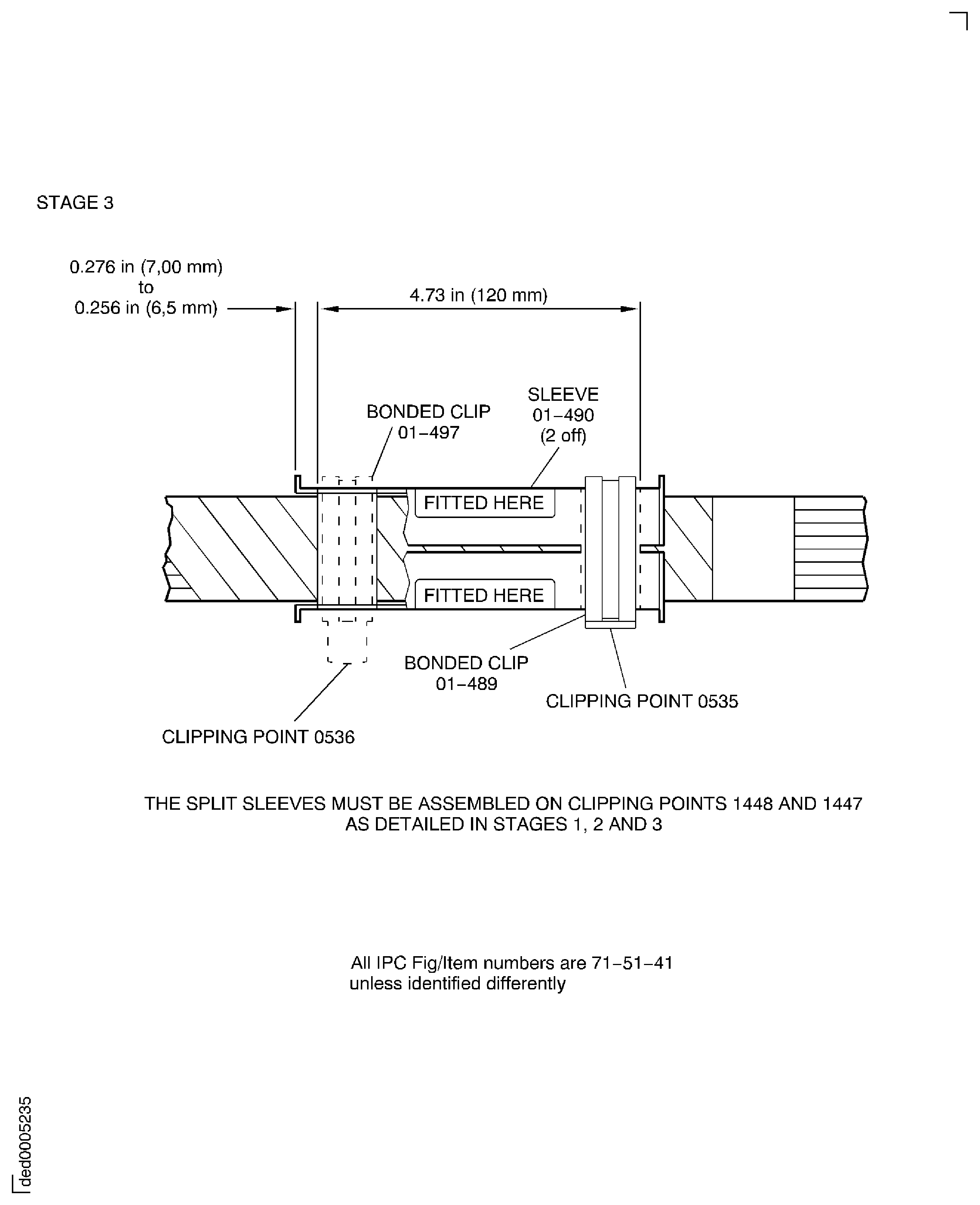

Wrap the 0.750 in. tape POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 01-492) around the harness at the raceway lug clip positions 1450, 1449, 1448 and 1447 to give the dimensions on Figure.

Step 2 : Build-up the harness diameter to match the inside diameter of the split sleeves.

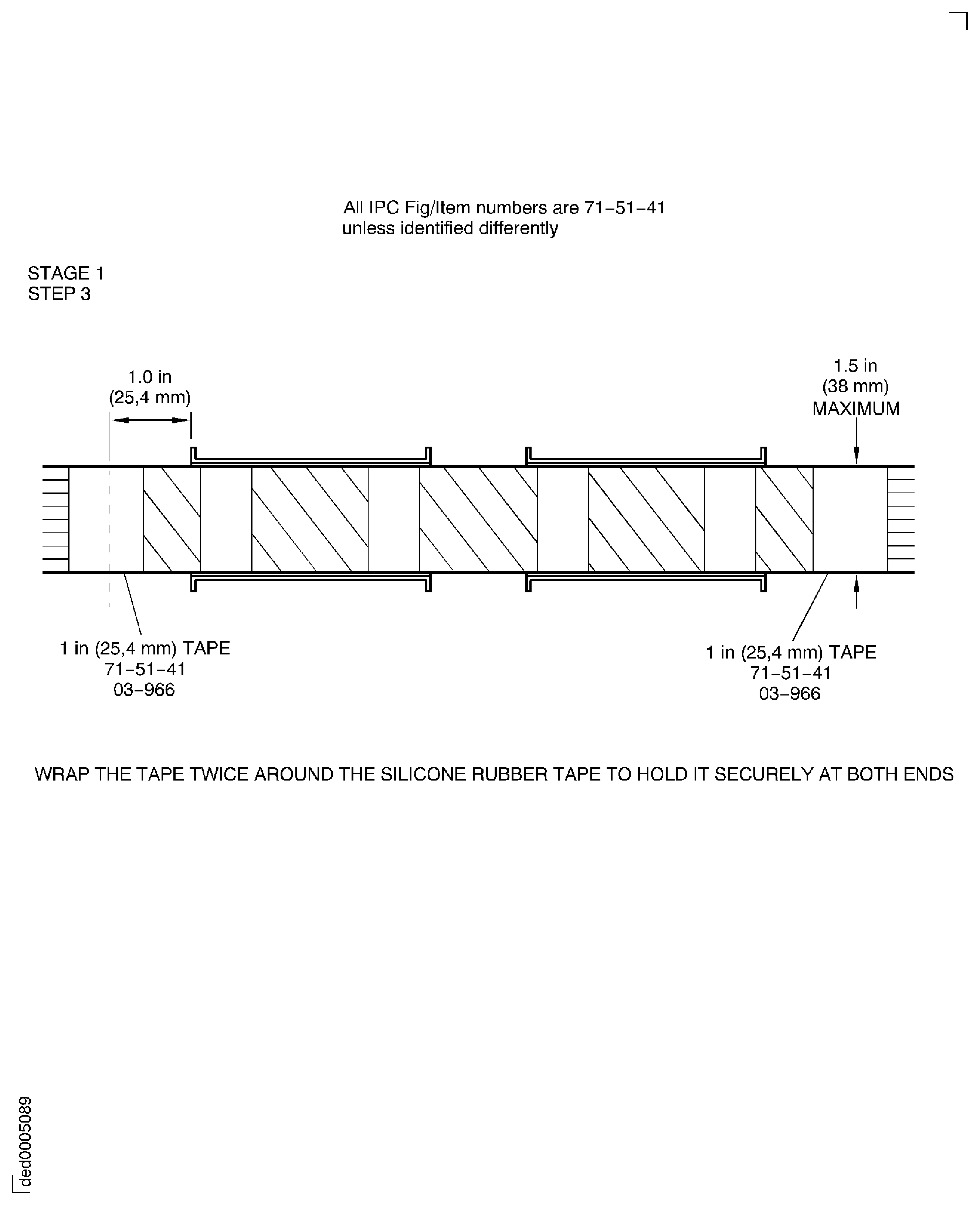

Wrap the 1 in. wide tape POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 03-966) twice around the harness at both ends of the silicone rubber tape to hold it securely to give the dimensions on Figure.

Step 3: Secure the ends of the silicone rubber tape.

Stage 1: Attach the EEC harness and the ignition supply harness ELECT HARNESS-LIGHT DUTY-IGNITION SUPPLY HARNESS (71-51-44, 01-005) together.

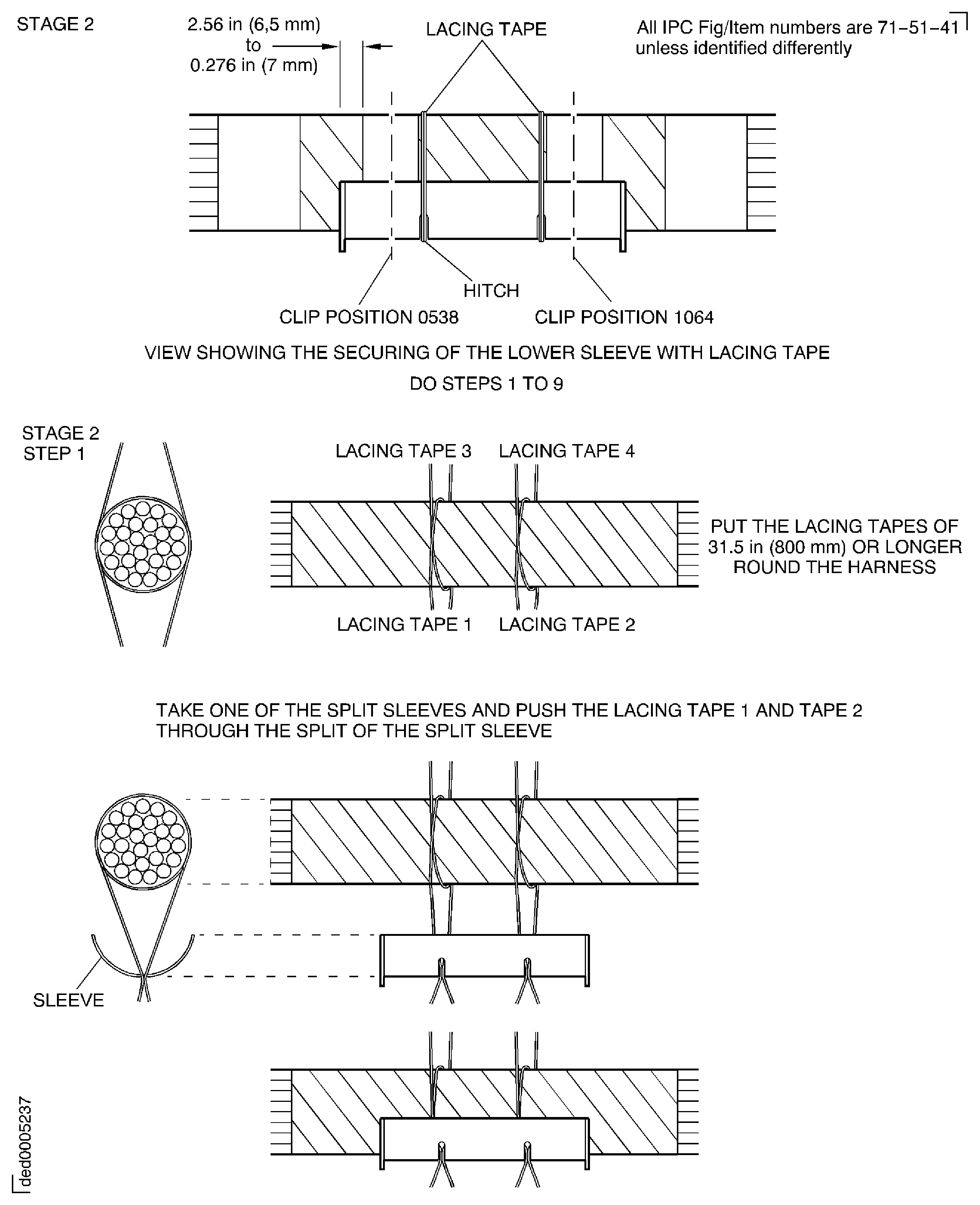

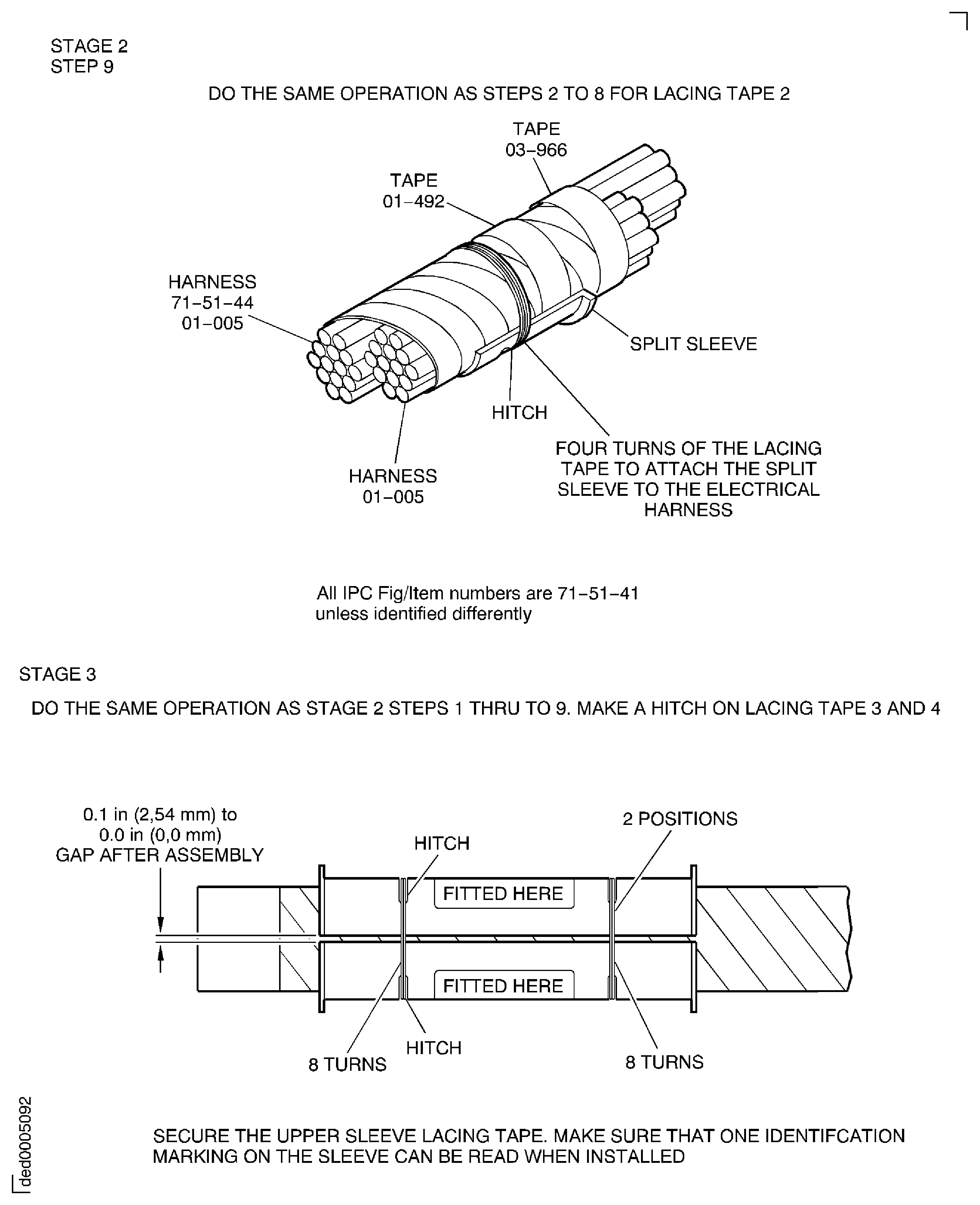

Position and attach the lower split sleeve to the harness with lacing tape number 1 POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 01-491) as given in Figure. Use a length of 31.5 in (800mm) or longer.

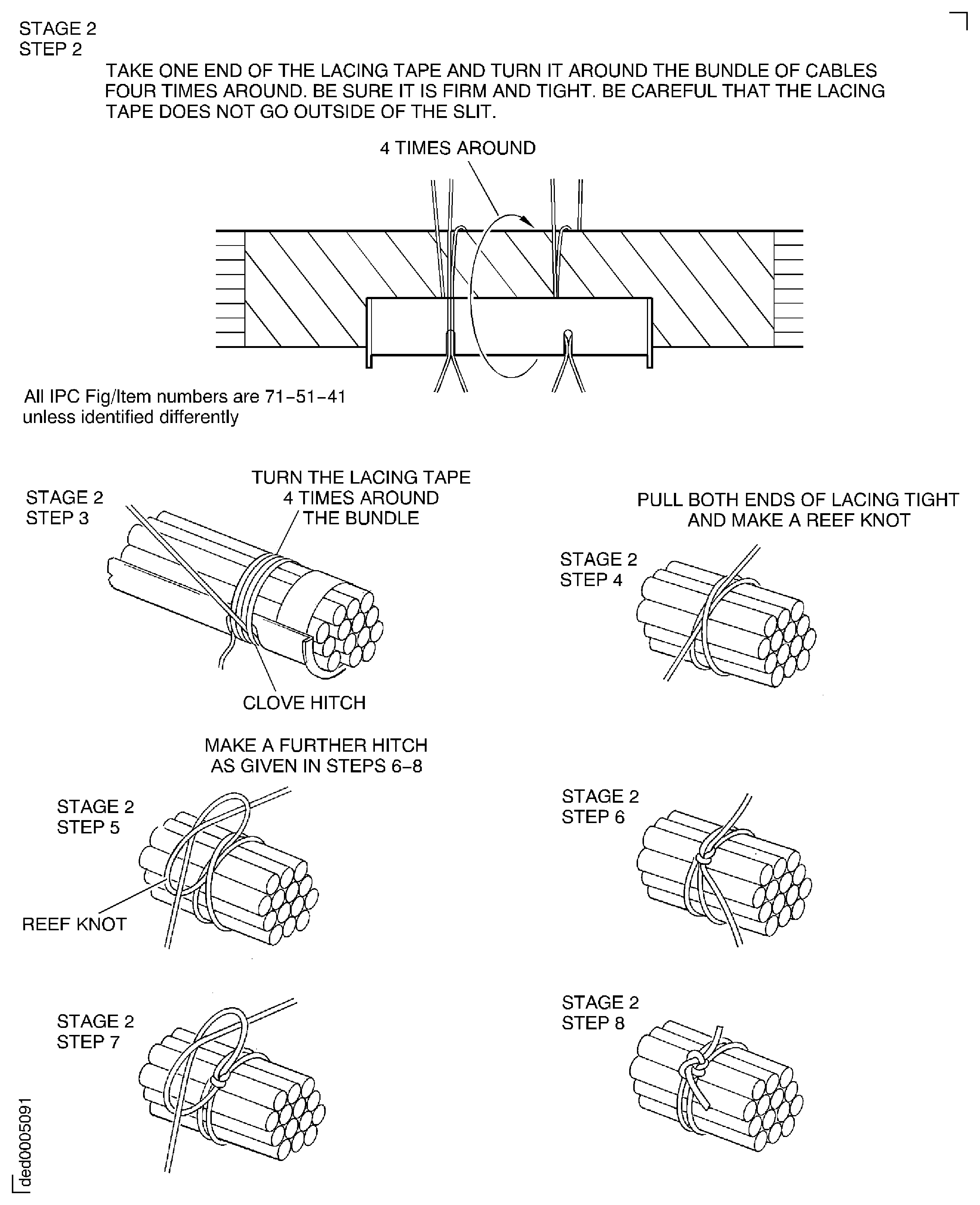

Take one half of the split sleeves and push the lacing tape number 1 and 2 through the slit of the split sleeve, step 1 Figure.

Take one end of the lacing tape and turn it around the harness four times. Make sure the lacing is tight and that it does not go out of the sleeve slit, step 2 Figure.

Steps 1 and 2 :

Steps 3 to 8 : Tie and secure the sleeve half to the harness as shown in Figure.

Step 9 : Do the procedure in steps 2 to 8 for lacing tape number 2, Figure.

Position the sleeve so that at least one CAUTION identification label can be read when it is installed, refer to stage 3 for the completed view, Figure.

Stage 2 : Attach the split sleeves POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 01-514 and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN01-490) to the harness.

WARNING

WHEN YOU USE CoMat 01-003 SOLVENT, DELETED YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Clean the outer surface of the split sleeves POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 01-490 and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN01-514), the bonded clips POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 02-822 , POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN02-814, POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN02-806 and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN02-798) earth fingers, the clip and the raceway lugs with CoMat 01-003 SOLVENT, DELETED. Use a clean cloth made moist with the solvent. Refer to the SPM TASK 70-11-26-300-503 for the procedure to locally swab clean components.

Clean the fayed surfaces, sleeves and bonded clips.

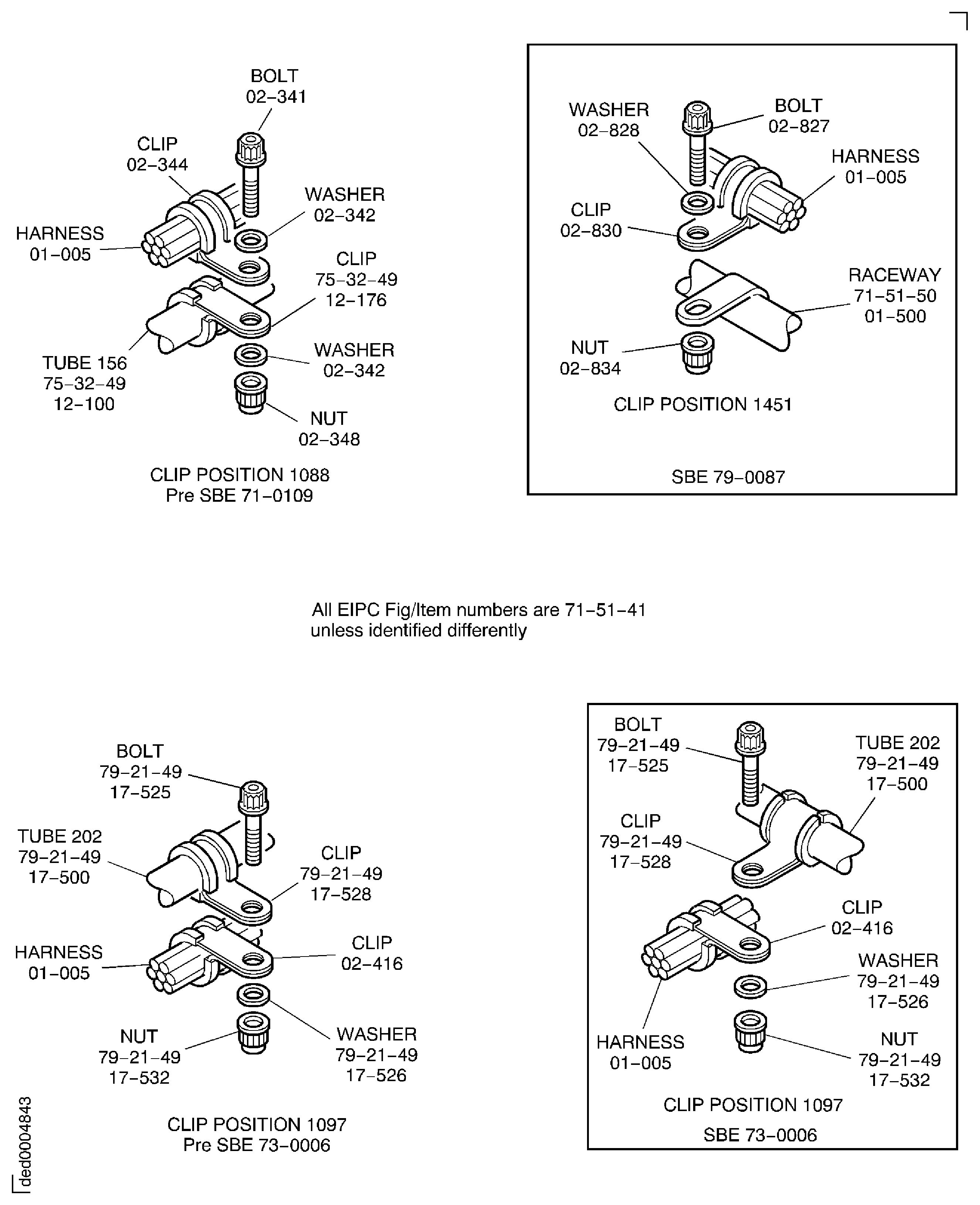

Install split sleeves POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 01-514 and POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN01-490) and the bonded clips at the clip positions 1447, 1448, 1449 and 1450.

WARNING

WHEN YOU USE CoMat 01-003 SOLVENT, DELETED YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Remove the grease, the fingerprints and the unwanted material from the mating surfaces of the raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-100) bonding lug, the fuel flow transmitter bonding lead with CoMat 01-003 SOLVENT, DELETED. Use a clean lint free cloth moistened with the solvent.

Install the bolt, washers, clip, bonding lead and nut to attach the EEC harness POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41,01-005) and the Ignition Supply harness ELECT HARNESS-LIGHT DUTY-IGNITION SUPPLY HARNESS (71-51-44,01-005) to the raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50,01-100) at clip position 1141. Torque the nut to 36 to 45 lbfin (4 to 5 Nm).

Install clip position 1462, refer to Figure.

Install the remaining clip positions.

NOTE

Install the clip positions 0766 and 0767 during the procedure given in Step.

SUBTASK 72-00-32-420-425 Install the EEC Harness (SBE 71-0109)

SBE 71-0109: Provide improved routing and clipping of the EEC and Ignition supply harness and raceway

NOTE

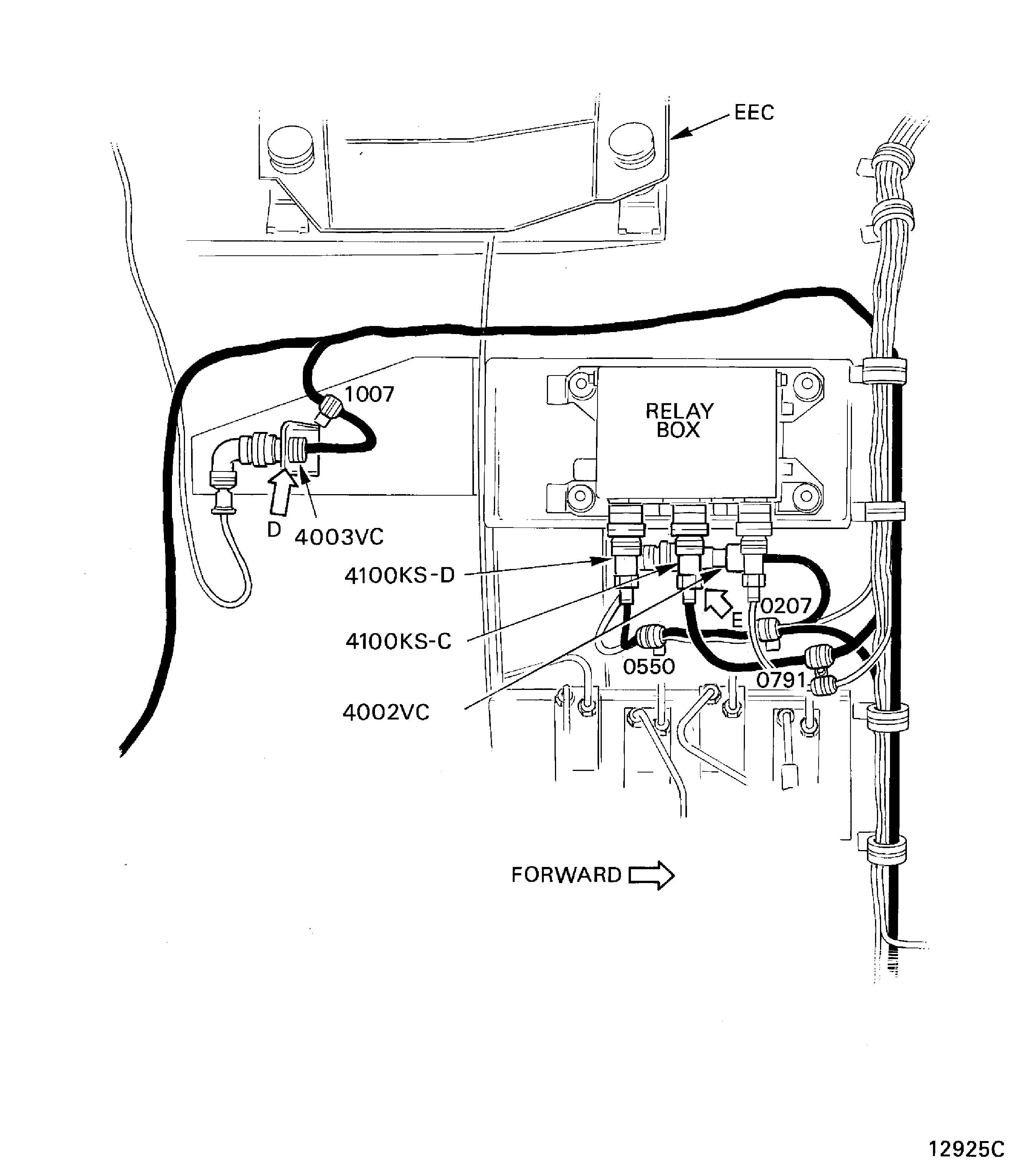

Install the ignition supply harness with the EEC harness. Refer to Step.Connect the electrical connectors 4100KS-D and 4100KS-C to the relay box POWER PLANT-RELAY BOX (71-51-49,01-100). Torque the electrical connectors to 18 * lbfin (2.0 Nm).

Install the ignition supply harness ELECT HARNESS-LIGHT DUTY-IGNITION SUPPLY HARNESS (71-51-44, 01-005) as follows:

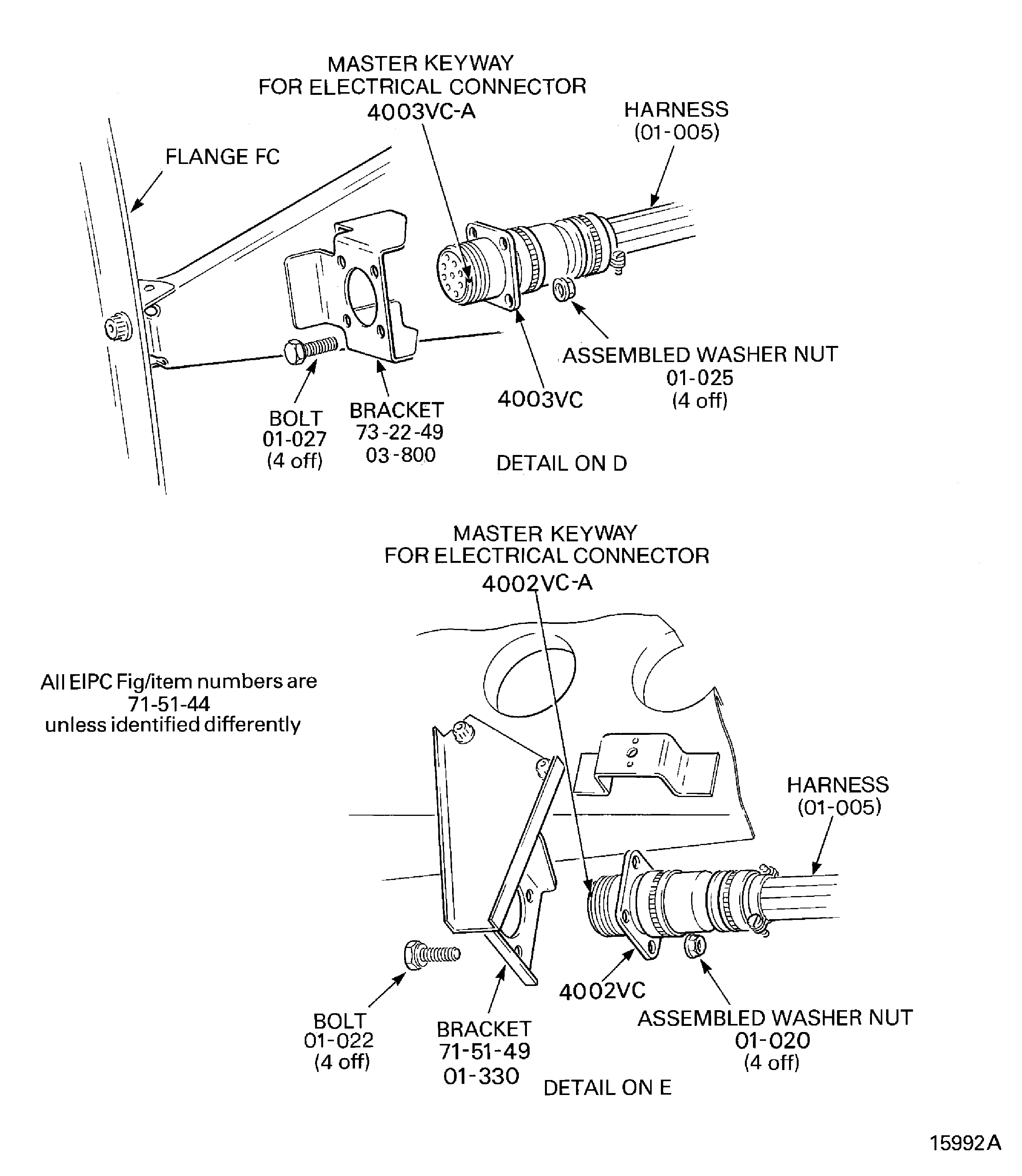

Attach the electrical harness receptacle 4002VC (attached to the ignition supply harness) to the bracket POWER PLANT-RELAY BOX (71-51-49,01-330) with the four bolts and the four assembled washer nuts ELECT HARNESS-LIGHT DUTY-IGNITION SUPPLY HARNESS (71-51-44, 01-022 and ELECT HARNESS-LIGHT DUTY-IGNITION SUPPLY HARNESS01-020). Make sure the master keyway is in the outboard direction, refer to the detail on E. Refer to Figure.

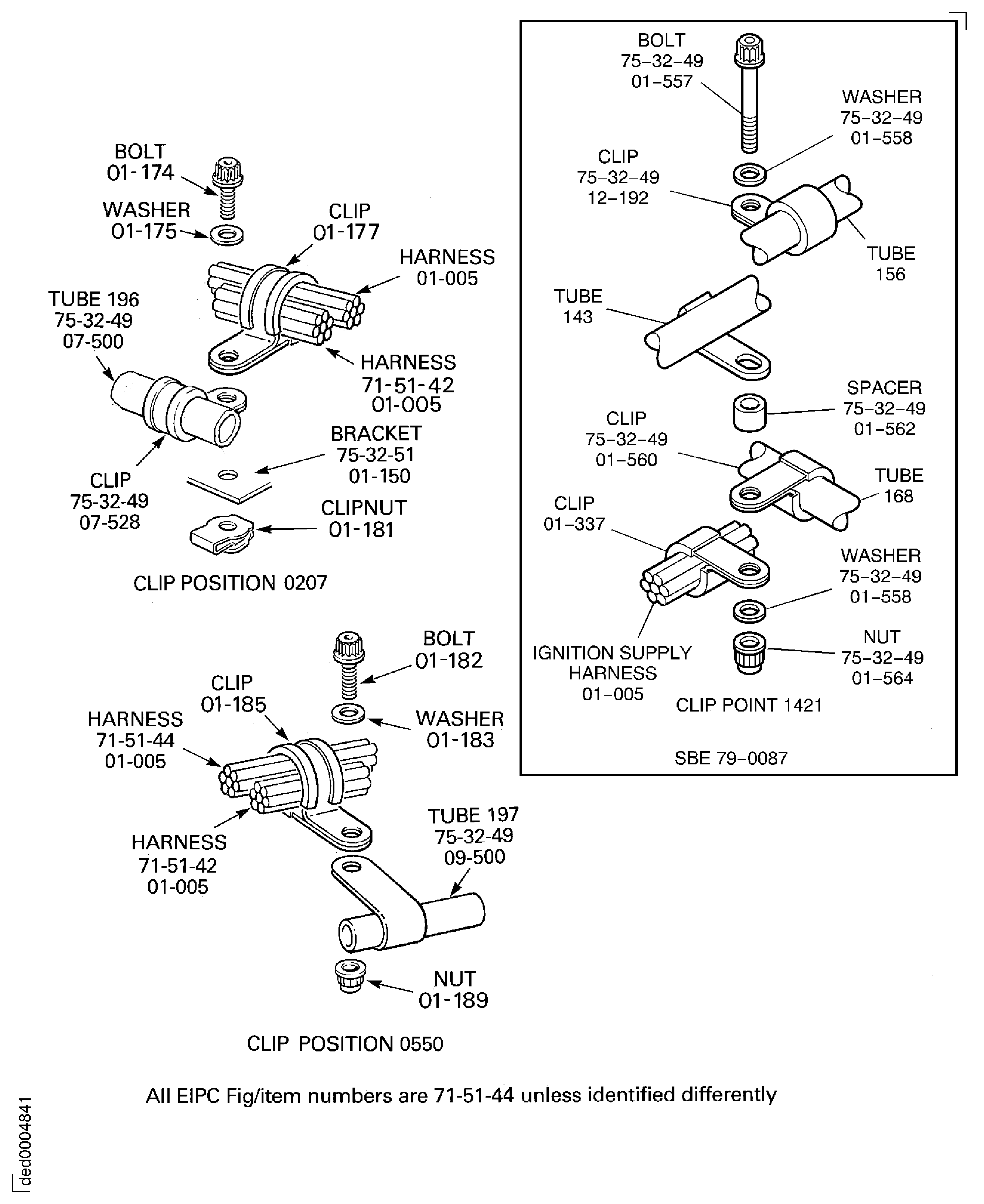

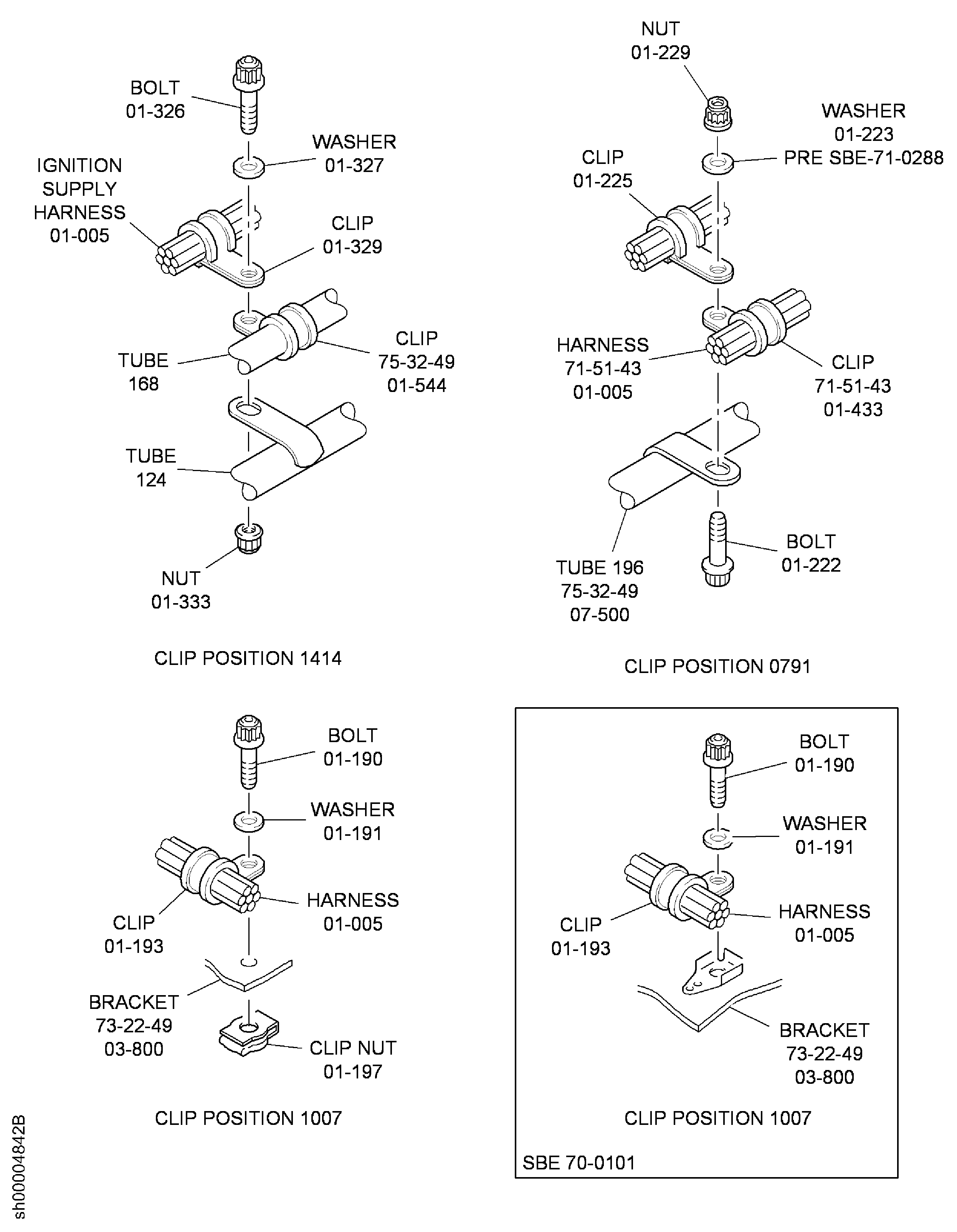

Remove the temporary ties and install the datum clip position 0550 and the clip position 0207. Refer to Figure.

Attach the receptacle 4003VC to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49,03-800) with the four bolts and the four assembled washer nuts ELECT HARNESS-LIGHT DUTY-IGNITION SUPPLY HARNESS (71-51-44, 01-027 and ELECT HARNESS-LIGHT DUTY-IGNITION SUPPLY HARNESS01-025). Make sure the master keyway is in the outboard direction, refer to the detail on D. Refer to Figure.

Install the electrical harness receptacles.

4002VC-A and 4003VC-A ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42,01-005) to the receptacles, align the master keyways. Refer to Figureand Figure. Torque the electrical connectors to 14 * lbfin (1.6 Nm).

Remove the temporary ties and install the datum clip position 0791. Refer to Figure.

Connect and torque the electrical connectors, as follows:

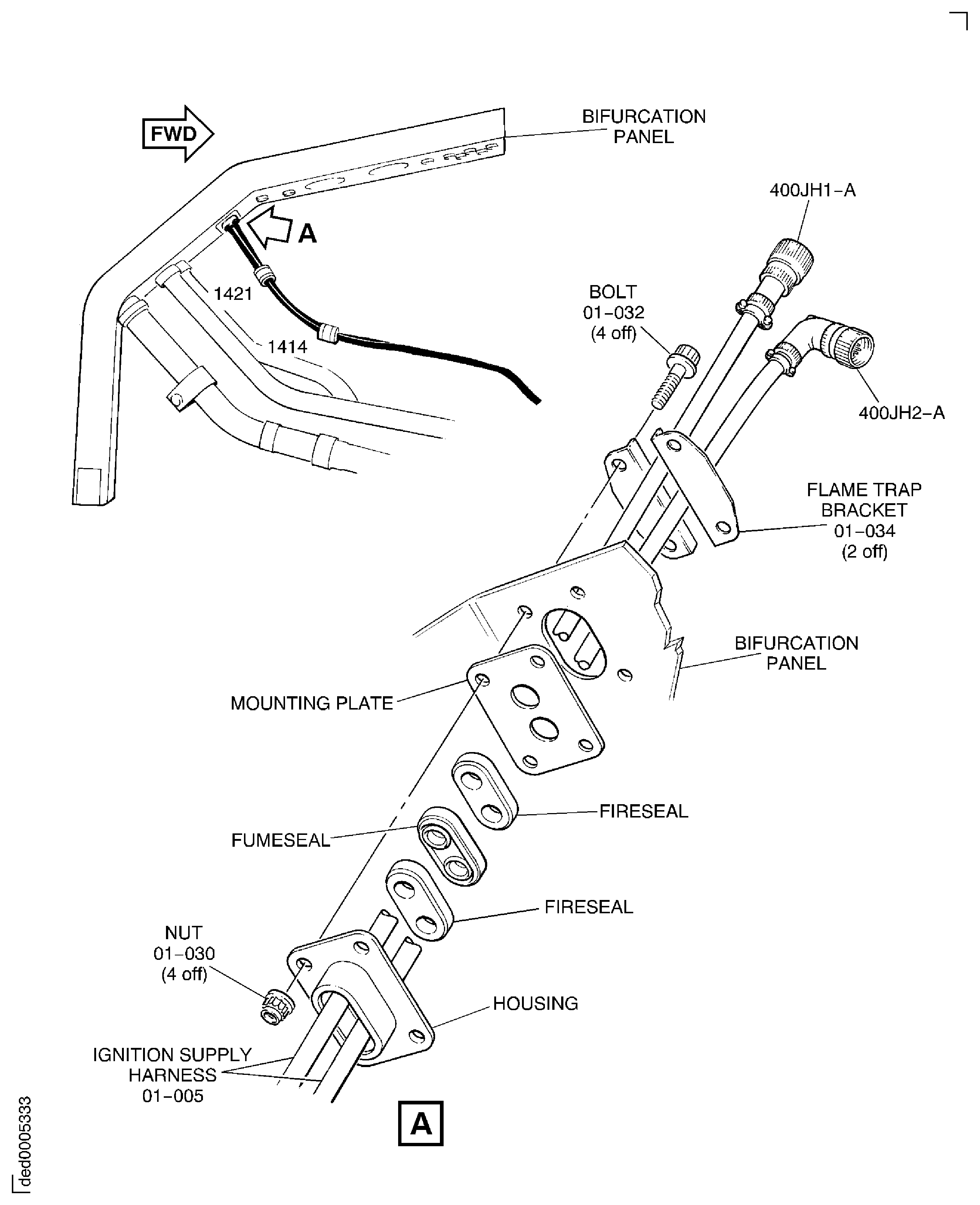

Remove the retaining lockwire from the combined fume and fireseal. Assemble and install the assembly to the bifurcation panel with the four bolts, the four nuts and the two flame trap brackets ELECT HARNESS-LIGHT DUTY-IGNITION SUPPLY HARNESS (71-51-44, 01-032 , ELECT HARNESS-LIGHT DUTY-IGNITION SUPPLY HARNESS01-030 and ELECT HARNESS-LIGHT DUTY-IGNITION SUPPLY HARNESS01-034). Tighten the four nuts to 36 to 45 lbfin (4 to 5 Nm). Refer to Figure.

Torque the bolts at the clip positions to 36 to 45 lbfin (4 to 5 Nm).

NOTE

Refer to TASK 72-00-40-420-006 for the installation of the ignition supply harness to the core engine.

Install the harness at the remaining clip positions.

SUBTASK 72-00-32-420-426 Install the Ignition Supply Harness

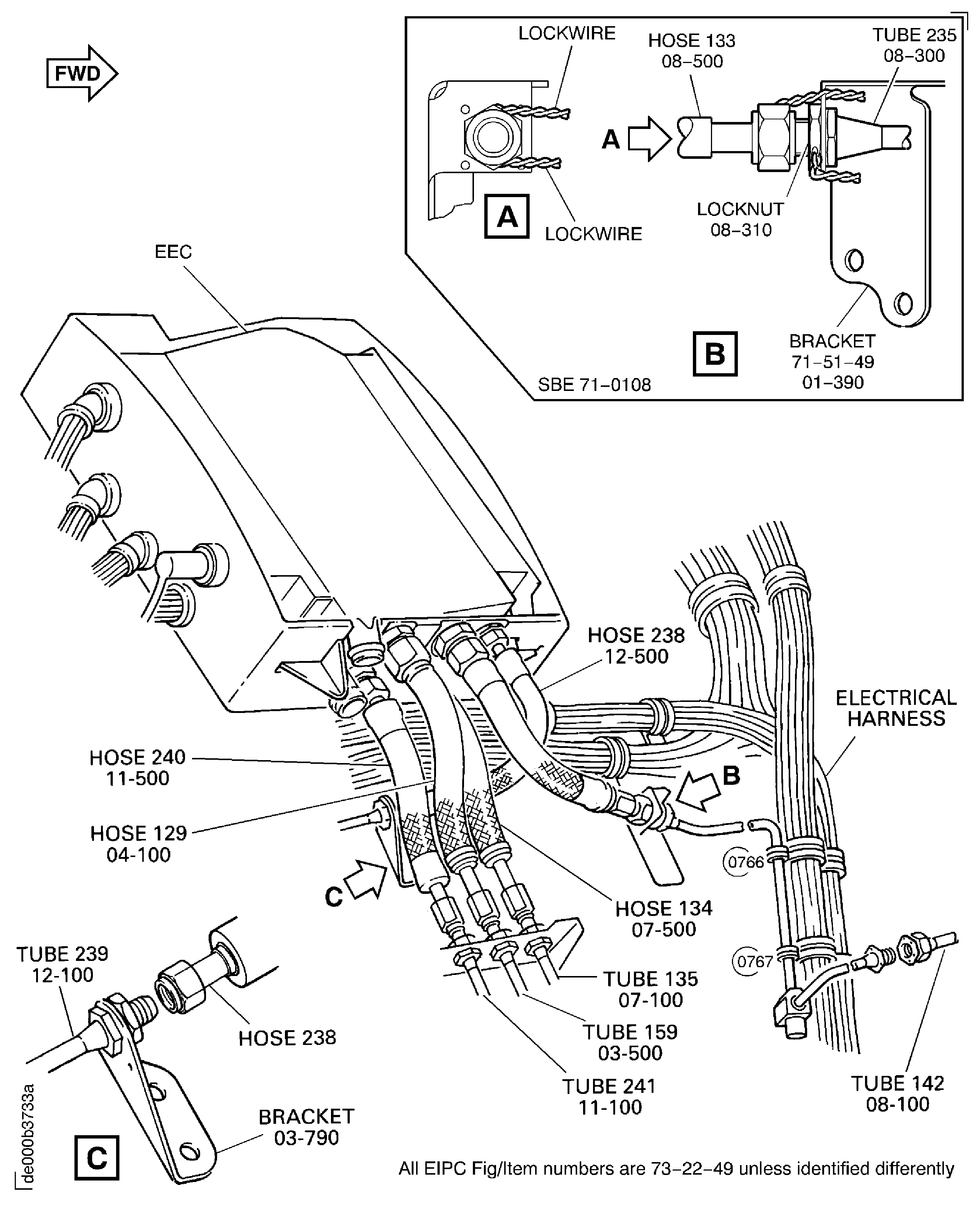

Refer to Figure.

Attach the tube 235 to the bracket POWER PLANT-RELAY BOX (71-51-49,01-390) with the locknut ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49,08-310). Connect the tube 142 to the tube 235. Torque the locknut to 70 to 80 * lbfin (7.9 to 9.0 Nm).

Install the bolts, the washers, the clips and the nuts at the clip positions 0766 and 0767. Refer to Figure.

SBE 71-0108 : Safety the hose 133 and the locknut ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49,08-310) separately to the bracket POWER PLANT-RELAY BOX (71-51-49,01-390) with CoMat 02-126 LOCKWIRE. Refer to the view on A and B, Figure.

Safety the tube/hose nuts with CoMat 02-126 LOCKWIRE.

Safety the hose 238 nut to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49,03-790) with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-427 Install the EEC Flexible Hoses and the Tube 235 (SBE 71-0108)

SBE 71-0108: Provide a P2/T2 line bracket with lockwire holes

Do a check on the clearance. Push the harness with a light pressure of the thumb then release. The harness must spring back and give the minimum clearance. If the pressure moves the harness through the adjacent clips, change the clip or adjust the harness thickness. Refer to Step.

Pre SBE 71-0107 - Between the harness bundle breakout at the clip position 0539 and the raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50,01-100).

A minimum clearance of 0.100in. (2.5 mm) is necessary as follows:

Make sure that the harness loop below the clip position 0257 is forward of a line taken from the rear of the clip. This will prevent a foul of the loop in the left side C-duct door. Attach the loop to the adjacent harness with CoMat 02-159 LACING TAPE to make the loop as small as possible.

Measure the clearance between all the different harnesses and engine parts.

Adjust the harness to get the minimum clearances. Refer to Step.

Adjust the harness.

If the primary harness and the wire bundle breakout touch each other you must attach them together. Both harness bundles must not move in relation to each other. Refer to Step.

Examine the harness wire bundle breakouts.

If one harness goes across or it is parallel with a different harness (and they can touch) you must attach them together. Each harness must not move in relation to each other. Refer to Step.

Examine the harness routing.

SUBTASK 72-00-32-220-126 Measure the Harness Clearance and Examine the Routing

Attach the wire bundle breakout to the primary harness with CoMat 02-159 LACING TAPE to prevent movement of them in relation to each other.

Attach the parallel harnesses and those which go across each other together. If it is necessary wrap CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) around the harness to prevent abrasion. Then attach the harnesses together with the lacing tape.

SUBTASK 72-00-32-420-428 Attach the Harnesses Together

Refer to Figure.

Make sure that all the applicable backshells and cable clamps are safetied with CoMat 02-126 LOCKWIRE. Refer to the SPM TASK 70-42-05-400-501.

SUBTASK 72-00-32-210-089 Visually Inspect the Electrical Backshells and Cable Clamps

Refer to Figure.

Make sure that all the EEC harness backshells and cable clamps are safetied. Safety with CoMat 02-274 SAFETY CABLE KIT or with CoMat 02-275 SAFETY CABLE KIT. Refer to the SPM TASK 70-42-08-400-501.

SUBTASK 72-00-32-210-090 Visually Inspect the EEC Harness (01-005) Electrical Backshells and Cable Clamps (SBE 70-0813)

SBE 70-0813: Announcement of introduction of safety cable as a preferred method to lockwire.

NOTE

Use this procedure to safety the EEC harness backshells and cable clamps with safety cable.

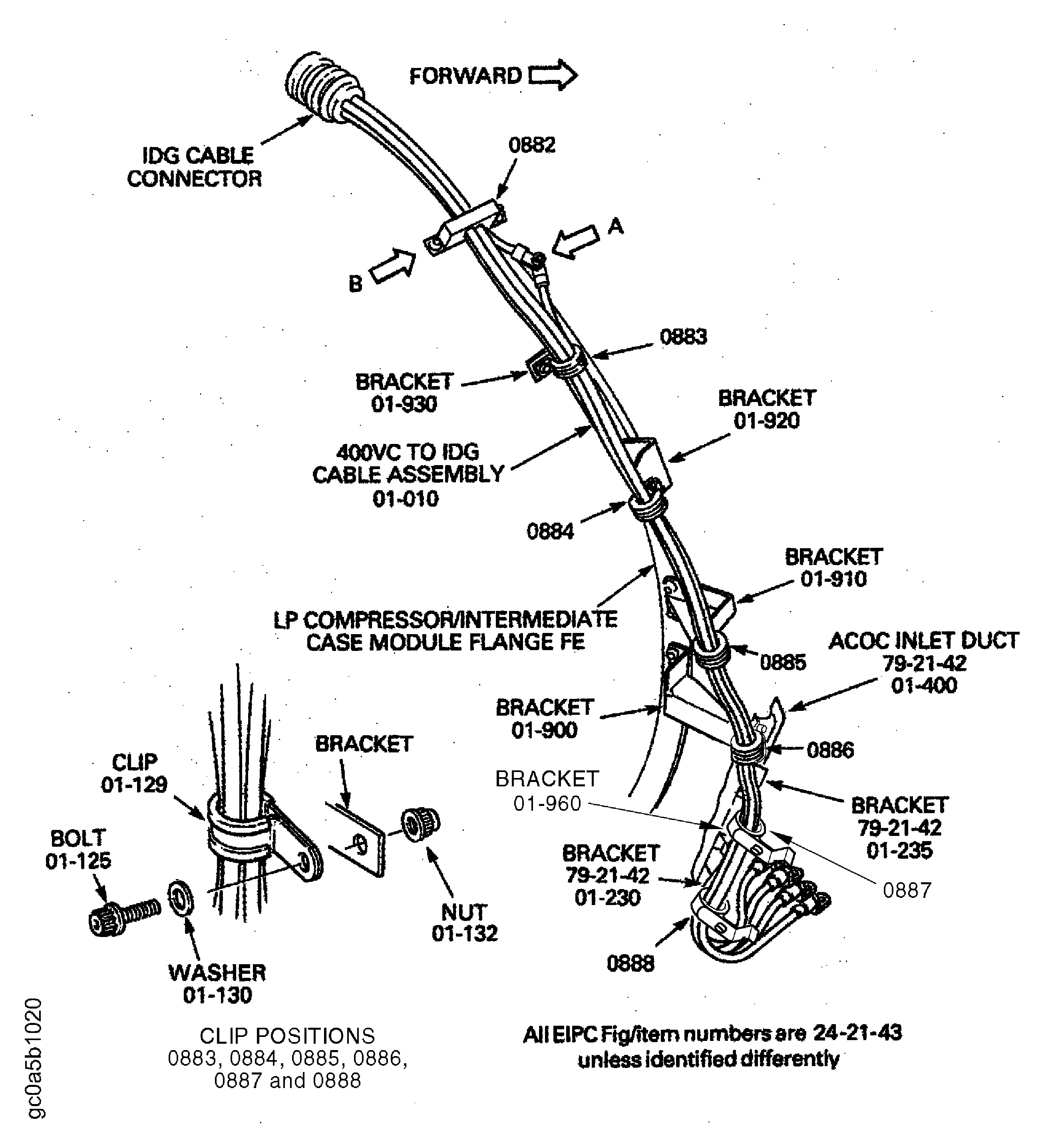

Figure: Electrical Harness Installation Procedure

Electrical Harness Installation Procedure

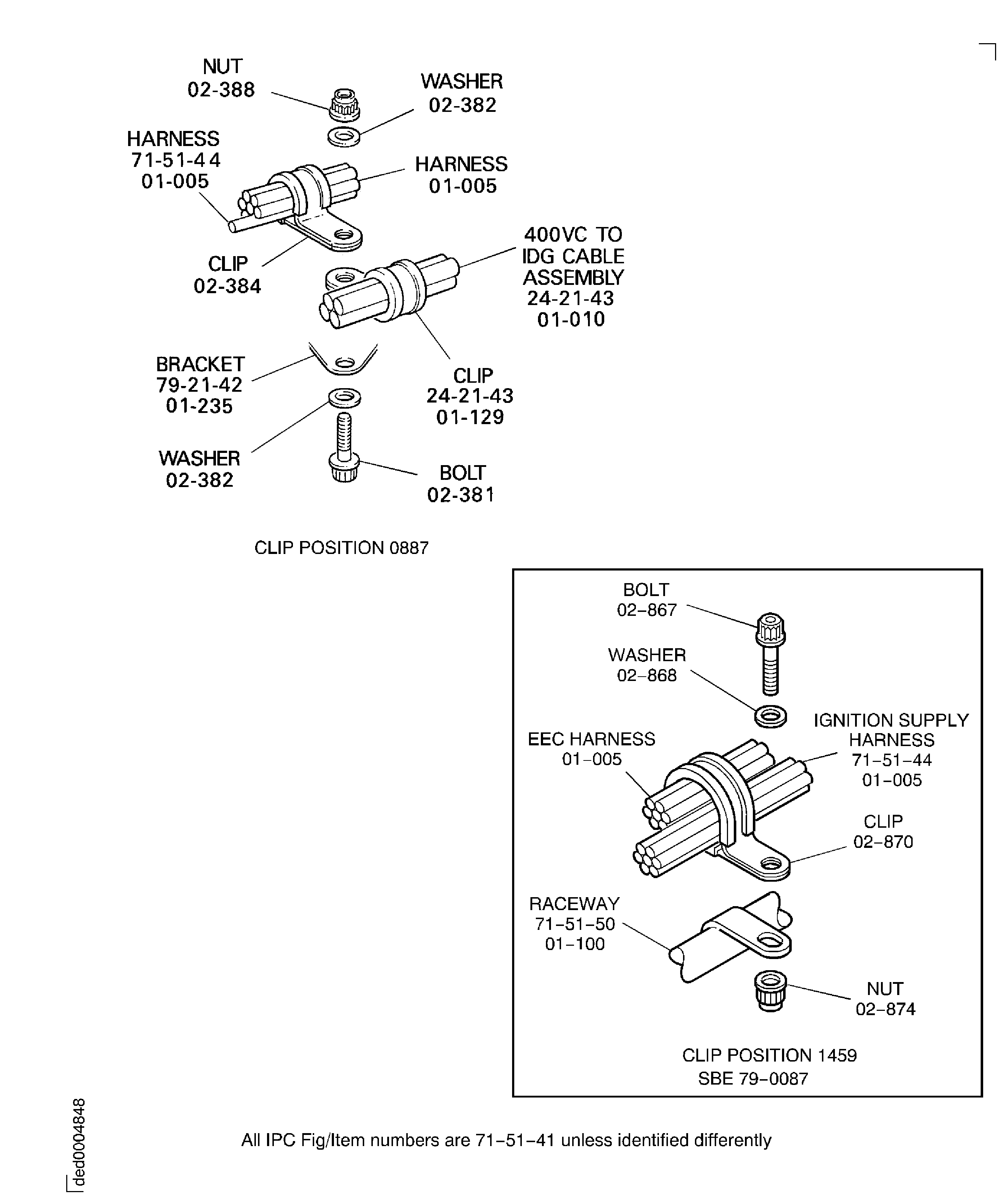

Figure: Install the 400VC to IDG Cable Assembly

Sheet 1

Figure: Install the 400VC to IDG Cable Assembly

Sheet 2

Figure: Install the 400VC to IDG Cable Assembly

Sheet 3

Figure: Install the Vibration Harnesses/Transducer

Sheet 1

Figure: Install the Vibration Harnesses/Transducer

Sheet 2

Figure: Install the Vibration Harnesses/Transducer

Sheet 3

Figure: Install the Vibration Harnesses/Transducer

Sheet 4

Figure: Install the EEC and Ignition Supply Harness

Sheet 1

Figure: Install the EEC and Ignition Supply Harness

Sheet 2

Figure: Install the EEC and Ignition Supply Harness

Sheet 3

Figure: Install the EEC and Ignition Supply Harness

Sheet 4

Figure: Install the EEC and Ignition Supply Harness

Sheet 5

Figure: Install the General Services Harness

Sheet 1

Figure: Install the General Services Harness

Sheet 2

Figure: Install the General Services Harness

Sheet 3

Figure: Install the General Services Harness

Sheet 4

Figure: Install the General Services Harness

Sheet 5

Figure: Install the General Services Harness

Sheet 6

Figure: Install the General Services Harness

Sheet 7

Figure: Install the General Services Harness

Sheet 8

Figure: Install the General Services Harness

Sheet 9

Figure: Install the General Services Harness

Sheet 10

Figure: Install the General Services Harness

Sheet 11

Figure: Install the General Services Harness

Sheet 12

Figure: Install the General Services Harness

Sheet 13

Figure: Install the General Services Harness

Sheet 14

Figure: Install the General Services Harness

Sheet 15

Figure: Install the General Services Harness

Sheet 16

Figure: Install the General Services Harness

Sheet 17

Figure: Install the General Services Harness

Sheet 18

Figure: Install the General Services Harness

Sheet 19

Figure: Install the General Services Harness

Sheet 20

Figure: Install the General Services Harness

Sheet 21

Figure: Install the Terminal Module

Install the Terminal Module

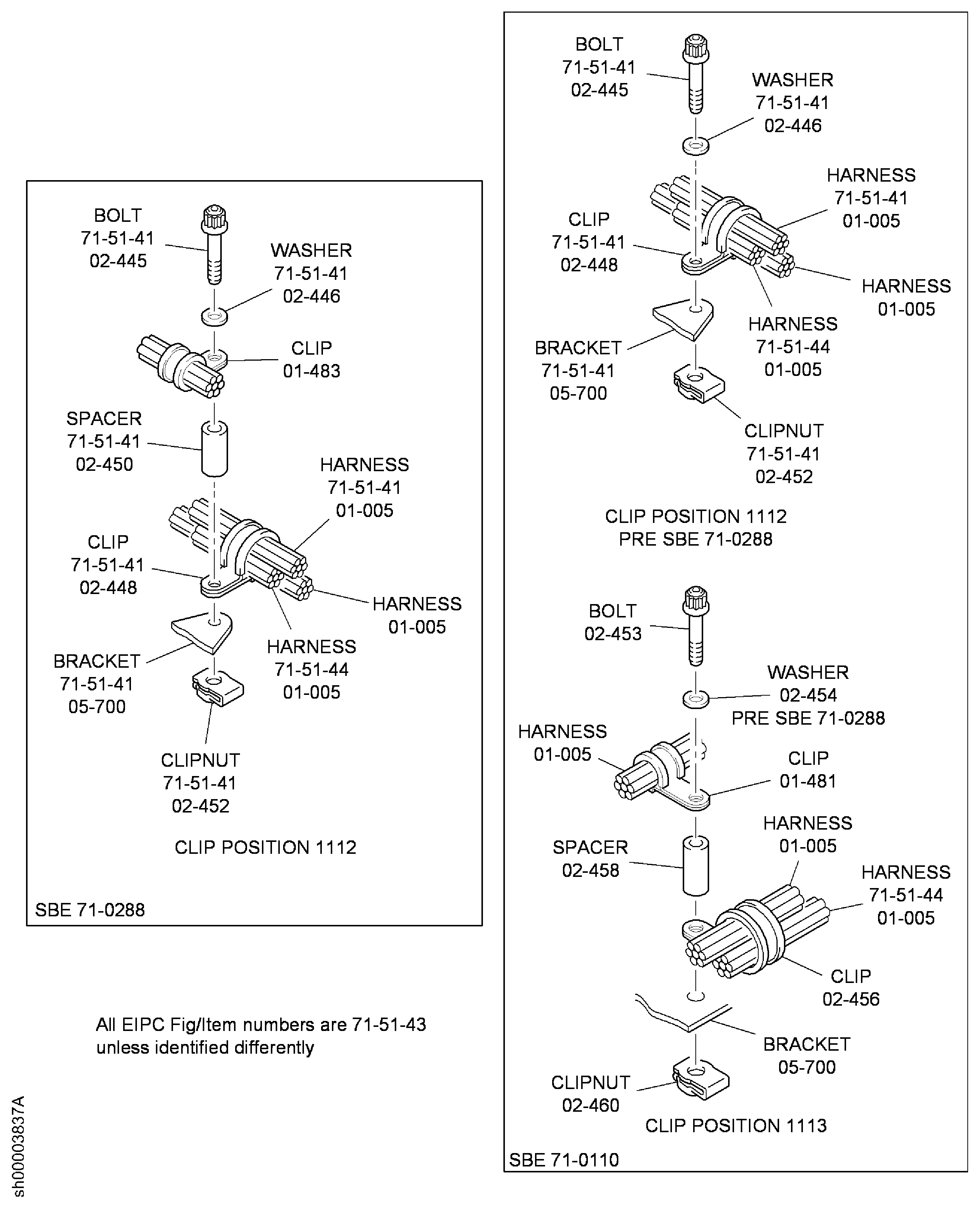

Figure: Install the EEC Harness

Sheet 1

Figure: Install the EEC Harness

Sheet 2

Figure: Install the EEC Harness

Sheet 3

Figure: Install the EEC Harness

Sheet 4

Figure: Install the EEC Harness

Sheet 5

Figure: Install the EEC Harness

Sheet 6

Figure: Install the EEC Harness

Sheet 7

Figure: Install the EEC Harness

Sheet 8

Figure: Install the EEC Harness

Sheet 9

Figure: Install the EEC Harness

Sheet 10

Figure: Install the EEC Harness

Sheet 11

Figure: Install the EEC Harness

Sheet 12

Figure: Install the EEC Harness

Sheet 13

Figure: Install the EEC Harness

Sheet 14

Figure: Install the EEC Harness

Sheet 15

Figure: Install the EEC Harness

Sheet 16

Figure: Install the EEC Harness

Sheet 17

Figure: Install the EEC Harness

Sheet 18

Figure: Install the EEC Harness

Sheet 19

Figure: Install the EEC Harness

Sheet 20

Figure: Install the EEC Harness

Sheet 21

Figure: Install the EEC Harness

Sheet 22

Figure: Install the EEC Harness

Sheet 23

Figure: Install the EEC Harness

Sheet 24

Figure: Install the EEC Harness

Sheet 25

Figure: Install the EEC Harness

Sheet 26

Figure: Install the EEC Harness

Sheet 27

Figure: Install the EEC Harness

Sheet 28

Figure: Install the EEC Harness

Sheet 29

Figure: Install the EEC Harness

Sheet 30

Figure: Install the EEC Harness

Sheet 31

Figure: Install the EEC Harness

Sheet 32

Figure: Install the EEC Harness

Sheet 33

Figure: Install the EEC Harness

Sheet 34

Figure: Install the EEC Harness

Sheet 35

Figure: Install the EEC Harness

Sheet 36

Figure: Install the EEC Harness

Sheet 37

Figure: Install the EEC Harness

Sheet 38

Figure: Install the EEC Harness

Sheet 39

Figure: Install the EEC Harness

Sheet 40

Figure: Install the EEC Harness

Sheet 41

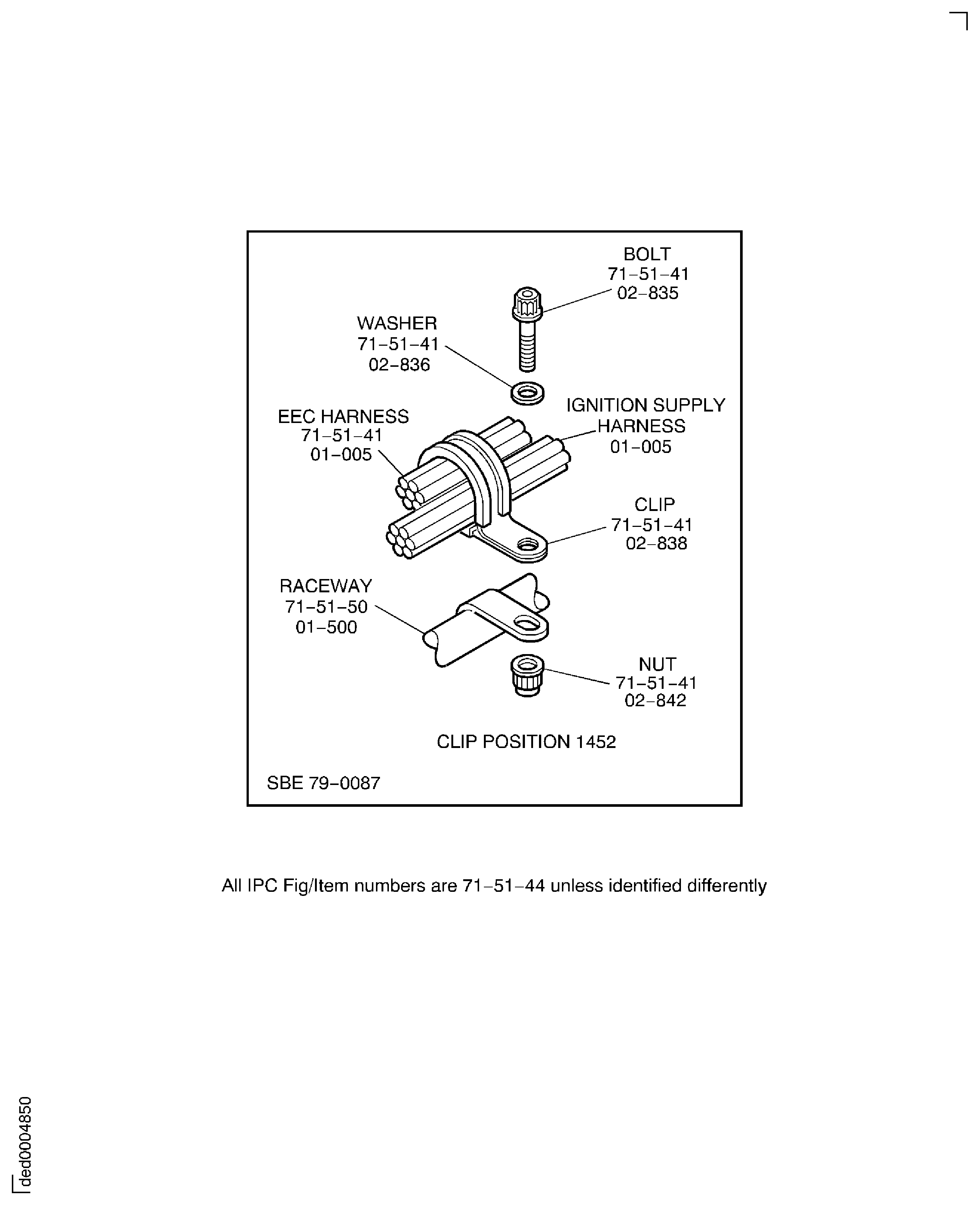

Figure: Install the Ignition Supply Harness

Sheet 1

Figure: Install the Ignition Supply Harness

Sheet 2

Figure: Install the Ignition Supply Harness

Sheet 3

Figure: Install the Ignition Supply Harness

Sheet 4

Figure: Install the EEC Harness

Sheet 5

Figure: Install the Ignition Supply Harness

Sheet 6

Figure: Install the Ignition Supply Harness

Install the Ignition Supply Harness

Figure: Install the Ignition Supply Harness

Install the Ignition Supply Harness