Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-00-60-420-002-A00 External Gearbox Module - Install The Tubes And Electrical Harnesses To The External Gearbox, Installation-003

General

This TASK gives the procedure to install most of the dressings on the external gearbox. For related data refer to:

TASK 72-00-60-420-003 Install the LP compressor intermediate case module drains and fire detector.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all the parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data is identified with the symbol * after the torque value.

Assembly tolerances are included in this procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings refer to the SPM TASK 70-64-02-640-501.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to damaged surface protection, joint flanges and attach parts. Use the correct color of air drying enamel. Refer to the SPM TASK 70-38-21-380-501.

Transportation covers/blanks must not be removed until immediately before installation of the components.

Do not remove the special plastic caps from the electrical connections until immediately before installation. This will give protection from unwanted fluids and materials.

For the data on the installation of V-band clamps refer to the SPM TASK 70-47-01-470-501.

For lockwire data and procedures refer to the SPM TASK 70-42-05-400-501.

For safety cable data and procedures refer to the SPM TASK 70-42-08-400-501.

Safety the threaded fasteners in the ATA Chapter/Section/Subject 71-51-41 as applicable with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT.

Refer to the V2500 Illustrated Tool and Equipment Manual (ITEM) (ITE-V2500-1IA) for the illustrations of special tools used in this procedure.

NOTE

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1R18001 Wrench | 0AM53 | IAE 1R18001 | 1 | |

| IAE 1R18002 Wrench | 0AM53 | IAE 1R18002 | 1 | |

| IAE 1R18003 Wrench | 0AM53 | IAE 1R18003 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) | LOCAL | CoMat 02-148 | ||

| CoMat 02-159 LACING TAPE | LOCAL | CoMat 02-159 | ||

| CoMat 02-274 SAFETY CABLE KIT | LOCAL | CoMat 02-274 | ||

| CoMat 02-275 SAFETY CABLE KIT | LOCAL | CoMat 02-275 | ||

| CoMat 06-086 TIES | 18992 | CoMat 06-086 | ||

| CoMat 07-038 AIR DRYING ENAMEL | k3504 | CoMat 07-038 | ||

| CoMat 10-038 PETROLEUM JELLY | LOCAL | CoMat 10-038 | ||

| CoMat 10-060 LIQUID PARAFFIN | LOCAL | CoMat 10-060 | ||

| CoMat 10-073 SYNTHETIC GREASE, MoDISULFIDE | LOCAL | CoMat 10-073 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

Safety Requirements

NONEProcedure

Remove the two bolts OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 05-540) and the two washers OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 05-550) from the oil inlet manifold flange. Install the bracket OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 05-470) the bolts and the washers. Torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

Remove the two nuts ENGINE FUEL AND CONTROL-LP & HP FUEL PUMPS (73-12-41, 01-120) from the fuel pump mount. Attach the bracket ENGINE FUEL AND CONTROL-LP & HP FUEL PUMPS (73-12-41, 01-080) in position with the two nuts. Torque the nuts to 180 lbfin. to 220 lbfin. (20 Nm to 25 Nm).

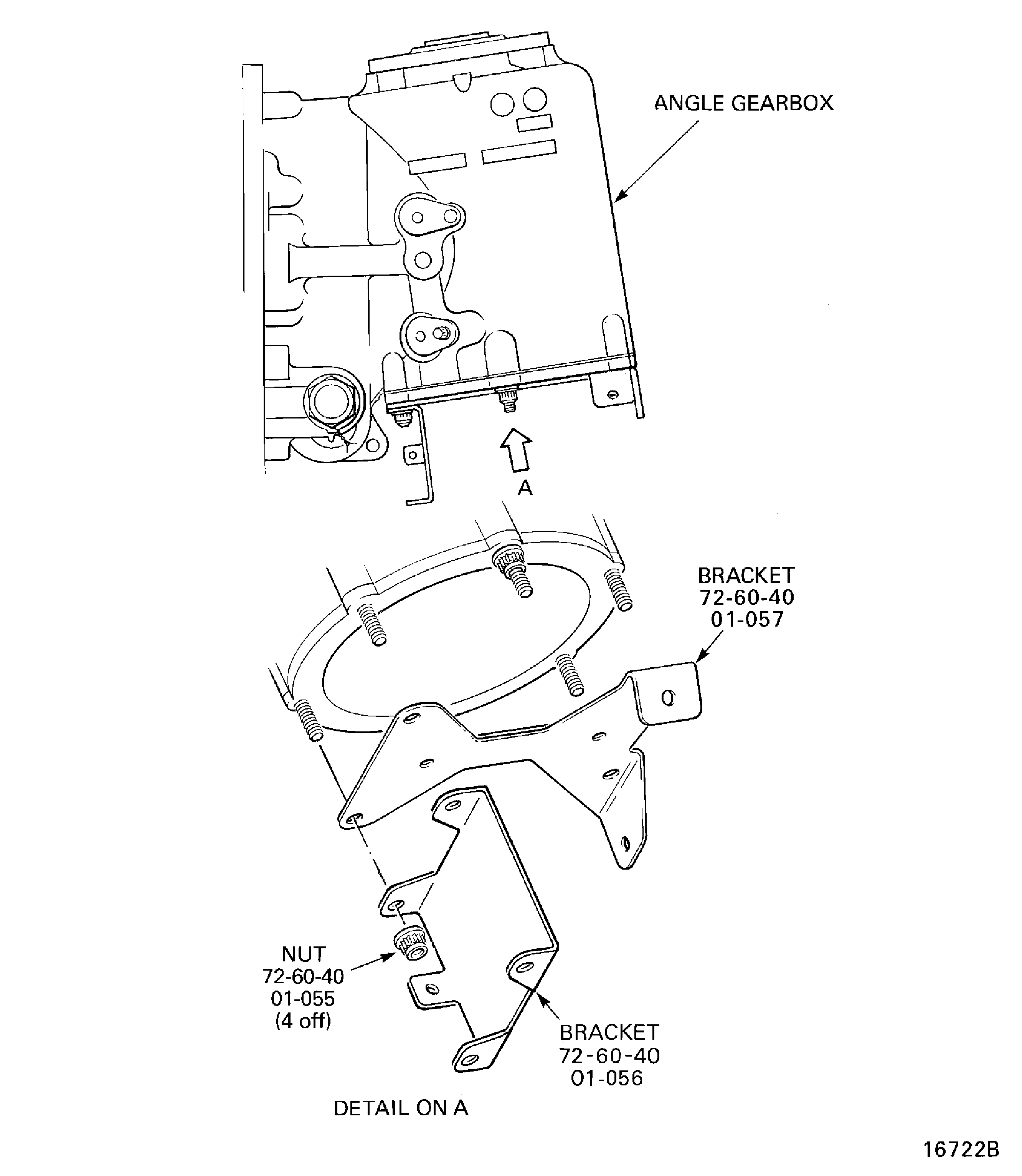

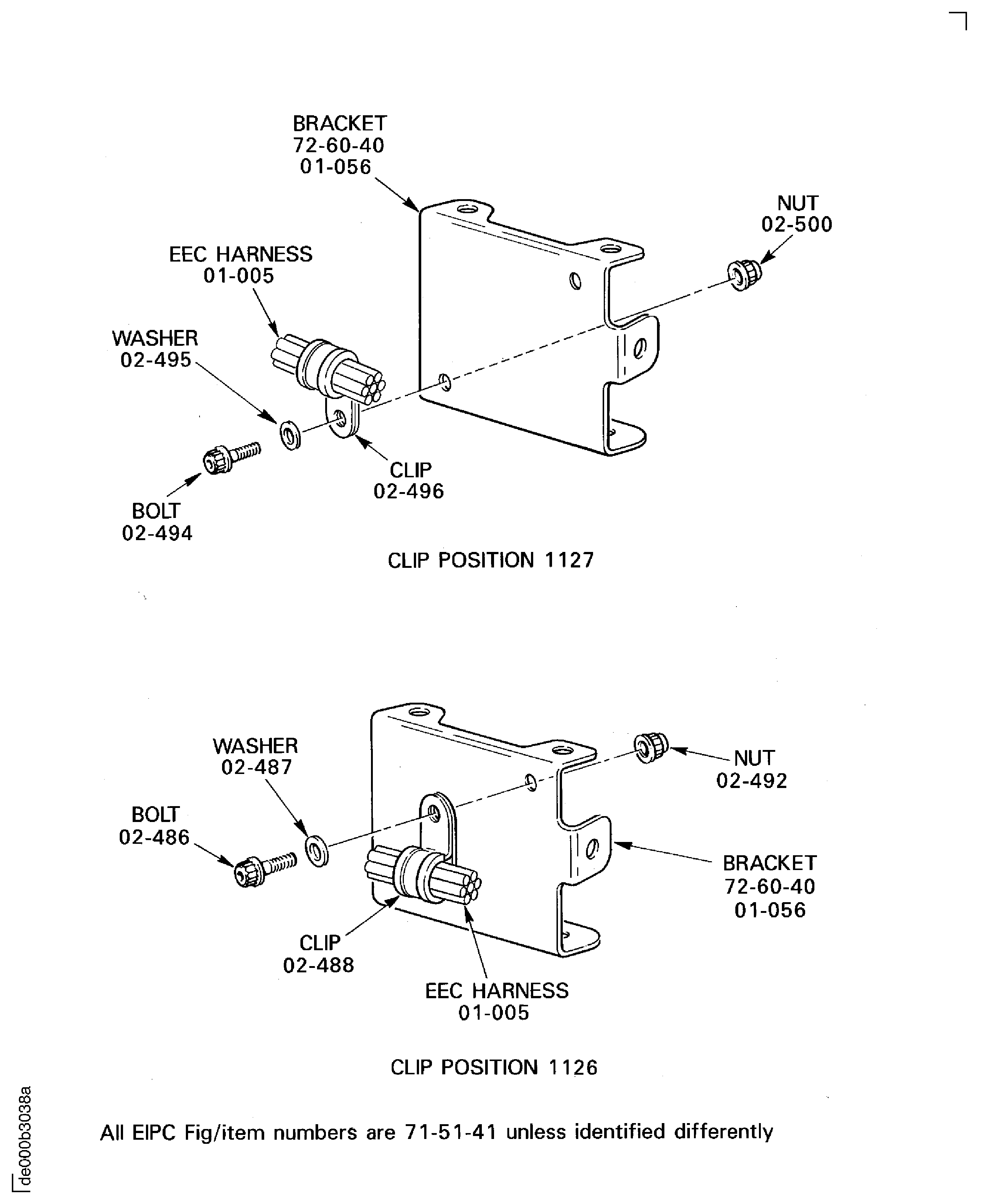

Remove the four nuts ENGINE-ANGLE GEARBOX ASSEMBLY (72-60-40, 01-055), the washers ENGINE-ANGLE GEARBOX ASSEMBLY (72-60-40, 01-060) and the bracket ENGINE-ANGLE GEARBOX ASSEMBLY (72-60-40, 01-056) from the angle gearbox. Attach the bracket ENGINE-ANGLE GEARBOX ASSEMBLY (72-60-40, 01-057) in position with the two rear nuts and install the bracket ENGINE-ANGLE GEARBOX ASSEMBLY (72-60-40, 01-056) and the two forward nuts. Torque the nuts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

SUBTASK 72-00-60-420-063 Install the Non-Modular Brackets on the External Gearbox

Refer to Figure.

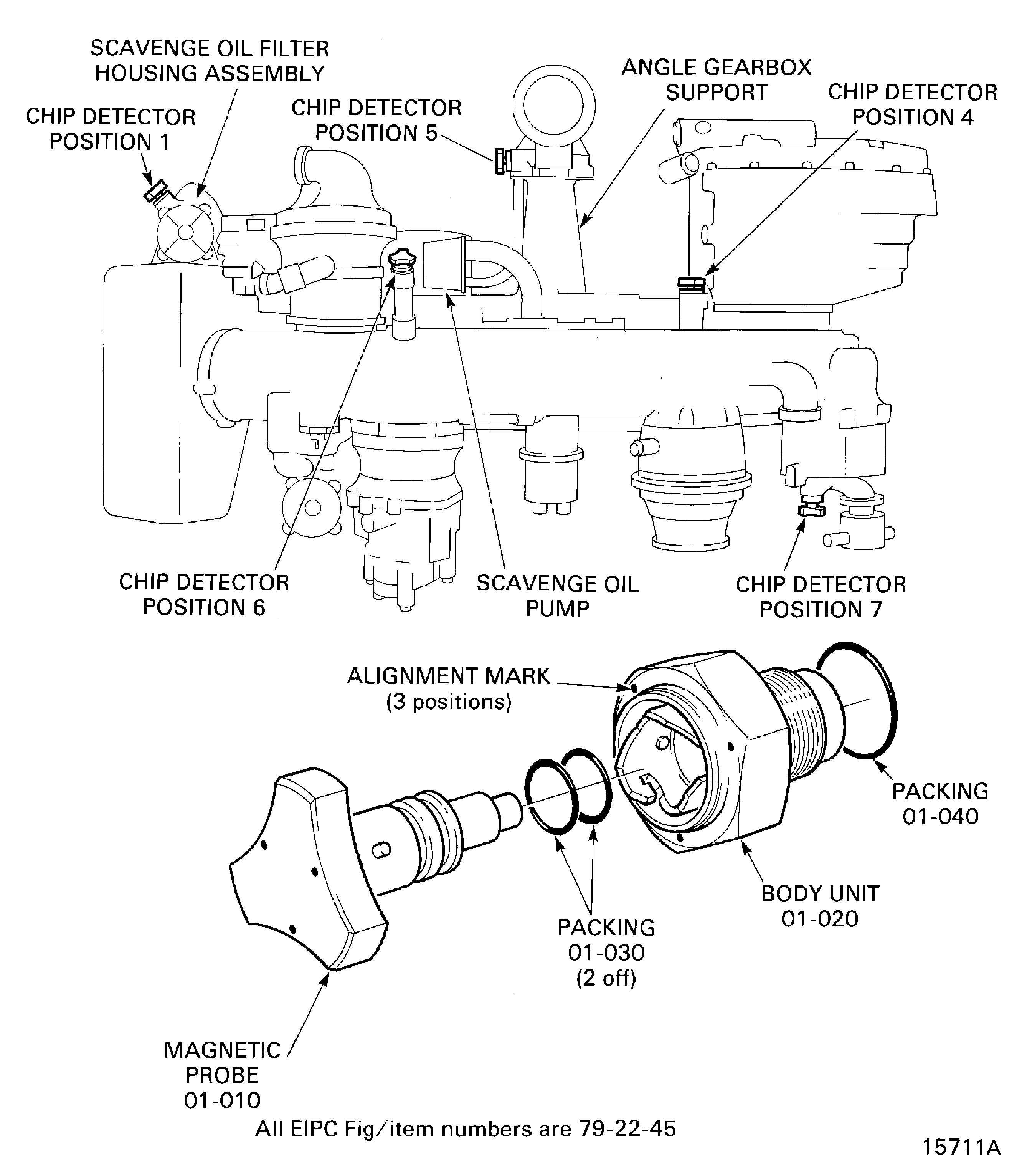

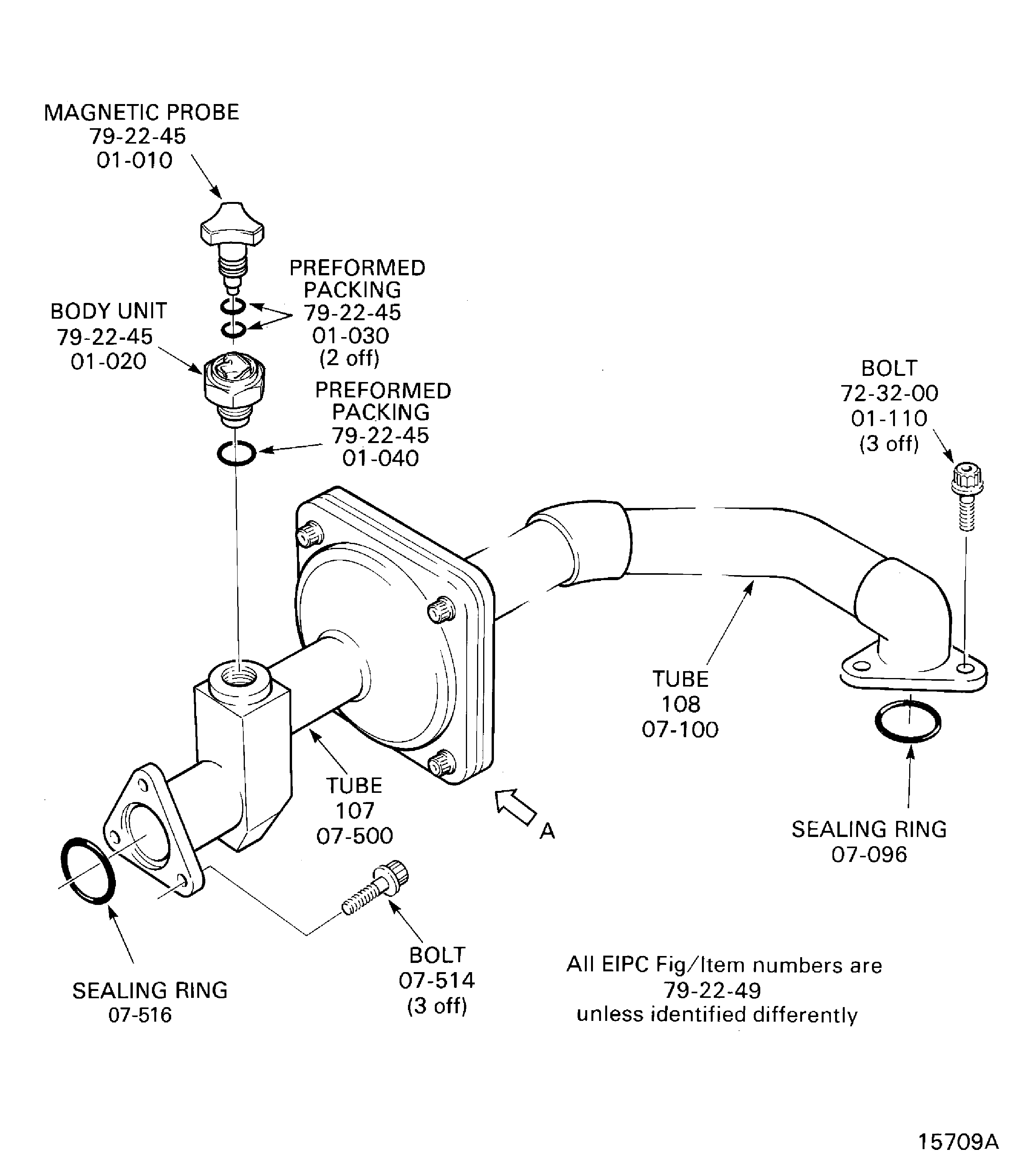

Lightly lubricate the new sealing ring OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-040) 1 off with CoMat 10-077 APPROVED ENGINE OILSs and install it on the body unit OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-020).

Lightly lubricate the threads of the body unit with CoMat 10-077 APPROVED ENGINE OILS. Install the body unit in the scavenge filter housing assembly. Torque the body unit to 160 lbfin. to 180 lbfin. (18 Nm to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

Make sure the two sealing rings OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-030) are correctly installed on the magnetic probe OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-010). Install the magnetic probe in the body unit and make sure the probe is correctly aligned.

Install the magnetic chip detector at position 1:

SUBTASK 72-00-60-420-064-A00 Install the Magnetic Chip Detectors on the External Gearbox (Pre SBE 79-0028)

SBE 79-0028: Replacement of category code 5

Refer to Figure.

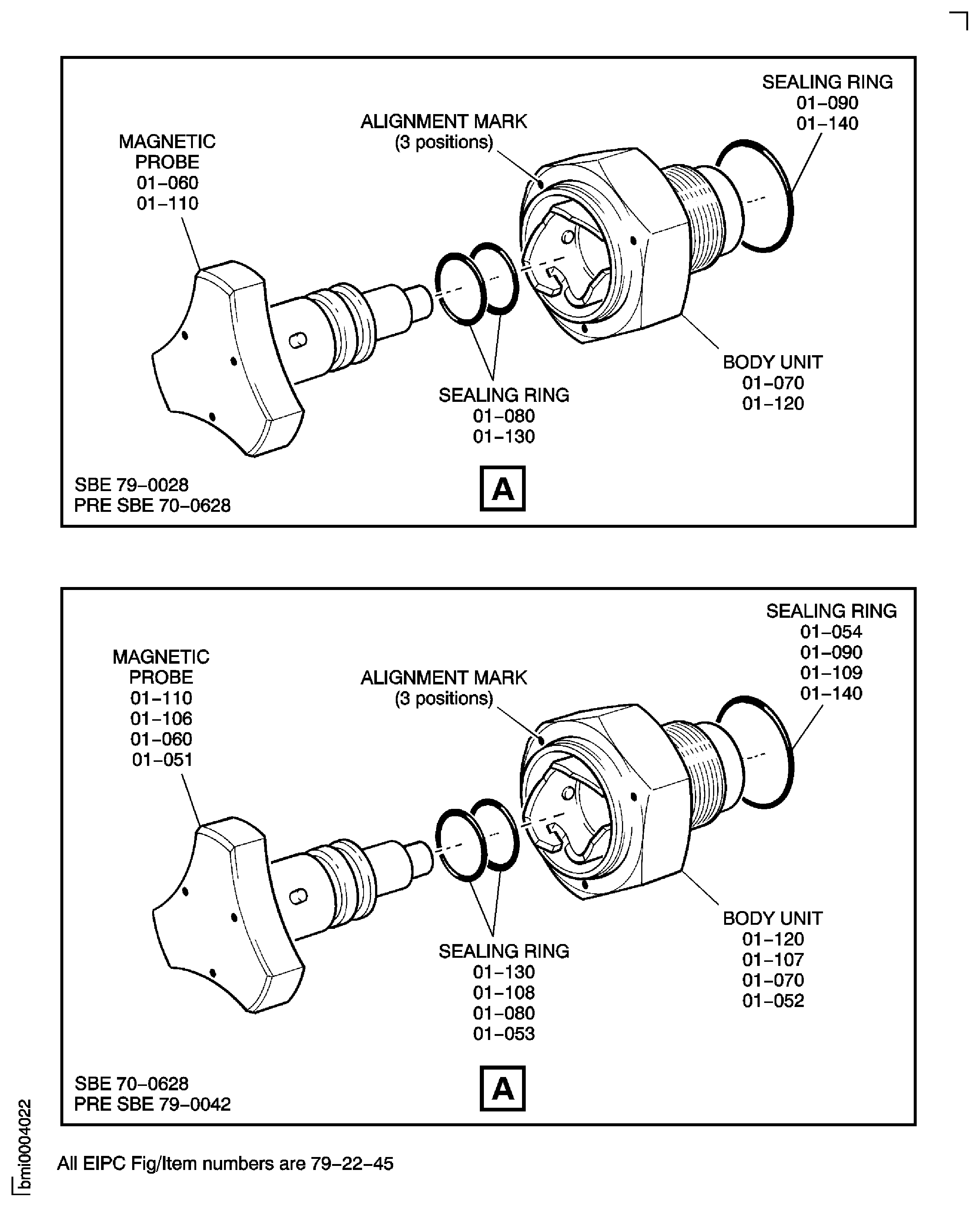

Lightly lubricate the new sealing rings (OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-090) and OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-140)) 1 off with CoMat 10-077 APPROVED ENGINE OILSand install it on the body unit (OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-070) and OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-120)).

Lightly lubricate the threads of the body unit with CoMat 10-077 APPROVED ENGINE OILS. Install the body unit in the scavenge filter housing assembly. Torque the body unit to 160 lbfin. to 180 lbfin. (18 Nm to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

Make sure the two sealing rings (OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-080) and OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-130)) are correctly installed on the magnetic probe (OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-060) and OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-110)). Install the magnetic probe in the body unit and make sure the probe is correctly aligned.

Install the magnetic chip detector at position 1:

SUBTASK 72-00-60-420-064-B00 Install the Magnetic Chip Detectors on the External Gearbox (Pre SBE 70-0628 and SBE 79-0028)

SBE 70-0628: To announce changes to the magnetic chip detector parts called up in the IPC

Refer to Figure.

Lightly lubricate the new sealing rings (OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-054), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-090), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-109) and OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-140)) 1 off with CoMat 10-077 APPROVED ENGINE OILSs and install it on the body unit (OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-120), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-107), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-070) and OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-052)).

Lightly lubricate the threads of the body unit with CoMat 10-077 APPROVED ENGINE OILS. Install the body unit in the scavenge filter housing assembly. Torque the body unit to 160 lbfin. to 180 lbfin. (18 Nm to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

Make sure the two sealing rings (OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-130), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-108), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-080) and OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-053)) are correctly installed on the magnetic probe (OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-110), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-106), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-060) and OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-051)). Install the magnetic probe in the body unit and make sure the probe is correctly aligned.

Install the magnetic chip detector at position 1:

SUBTASK 72-00-60-420-064-C00 Install the Magnetic Chip Detectors on the External Gearbox (Pre SBE 79-0042 and SBE 70-0628)

SBE 79-0042: Introduction of a new magnetic chip detector

Refer to Figure.

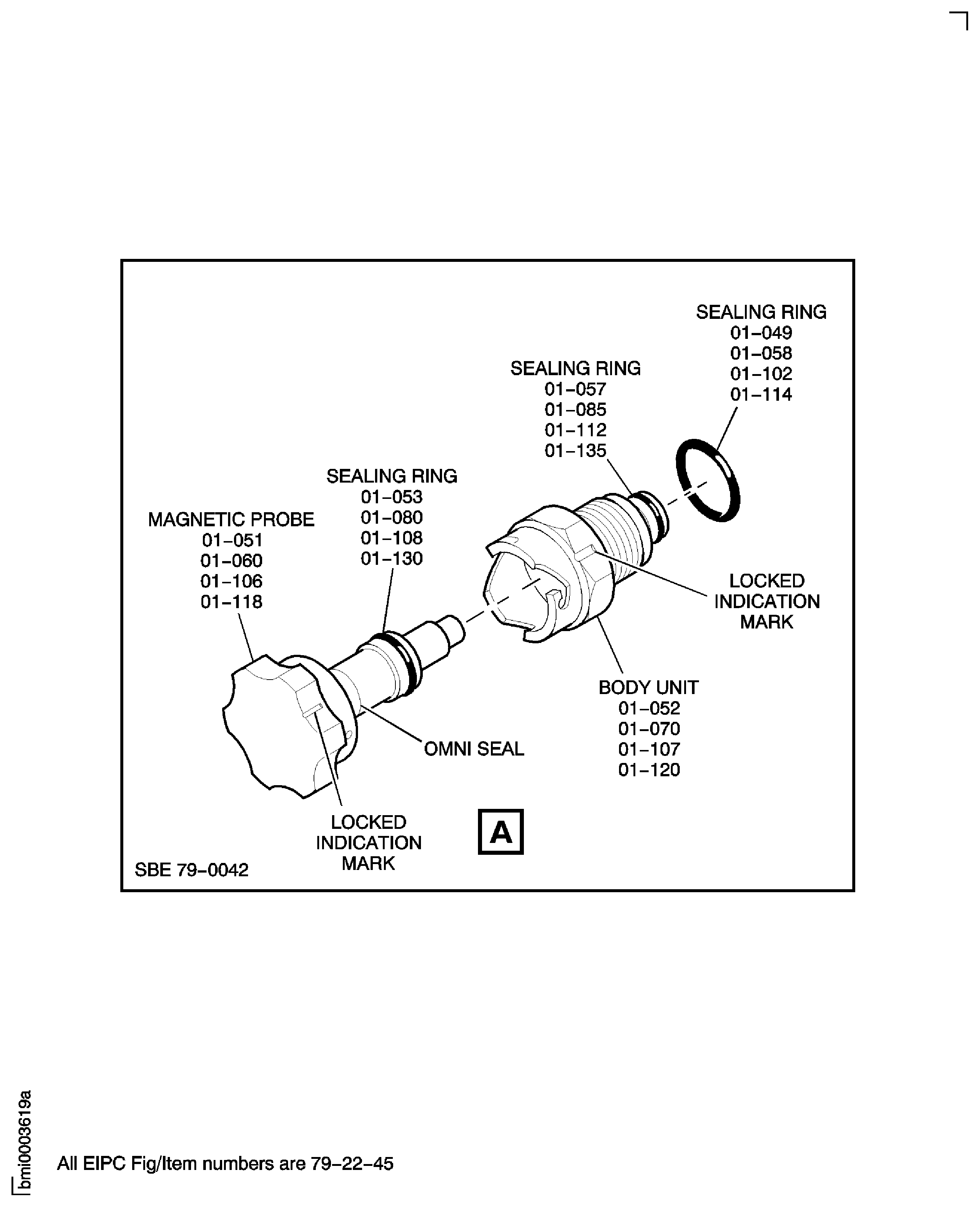

Lightly lubricate the new sealing rings (OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-049), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-058), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-102) and OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-114)) 1 off with CoMat 10-077 APPROVED ENGINE OILSand install it on the body unit (OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-052), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-070), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-107) and OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-120)).

Make sure the sealing rings (OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-057), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-085), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-112) and OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-135)) are correctly installed on the body unit (OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-052), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-070), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-107) and OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-120)).

Lightly lubricate the threads of the body unit with CoMat 10-077 APPROVED ENGINE OILS. Install the MCD housing in the scavenge filter housing assembly. Torque the body unit to 225 lbfin. to 250 lbfin. (25.4 Nm to 28.25 Nm). Safety with CoMat 02-126 LOCKWIRE.

Make sure the sealing rings (OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-053), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-080), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-108) and OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-130)) are correctly installed on the magnetic probe (OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-051), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-060), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-106) and OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-118)).

Install the magnetic probe (OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-051), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-060), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-106) and OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-118)) in the body unit (OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-052), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-070), OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-107) and OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-120)) make sure the probe is correctly aligned.

Install the magnetic chip detector at position 1:

SUBTASK 72-00-60-420-064-D00 Install the Magnetic Chip Detectors on the External Gearbox (SBE 79-0042)

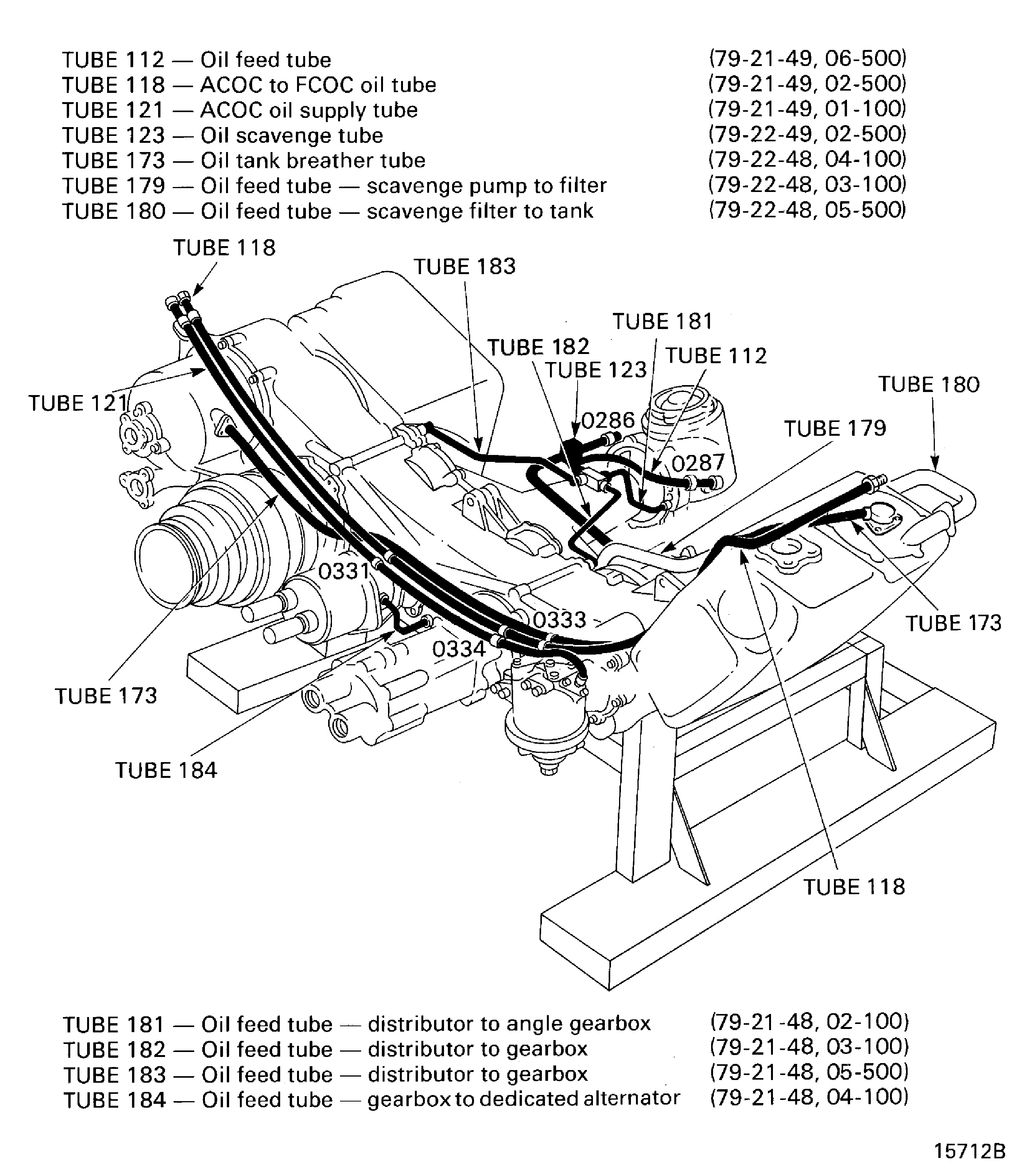

Install the tube 184 on the gearbox between the Dedicated Alternator and the gearbox. Torque the tube connectors to 320 lbfin. to 350 lbfin. (36.2 Nm to 39.6 Nm). Safety with CoMat 02-126 LOCKWIRE.

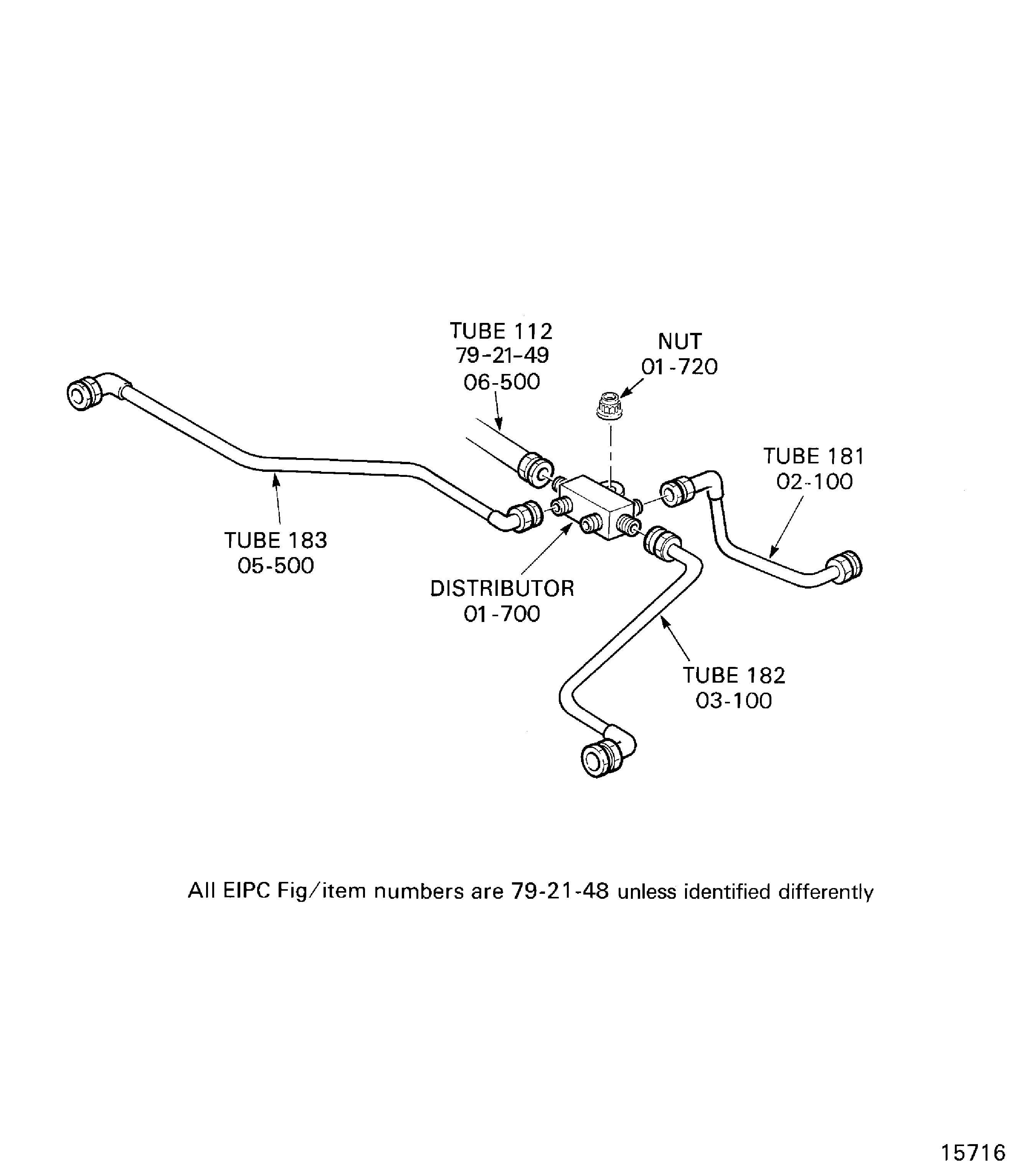

Install the oil pressure distributor OIL-PRESSURE OIL TUBES-GEARBOX (79-21-48, 01-700) on the gearbox and install the nut OIL-PRESSURE OIL TUBES-GEARBOX (79-21-48, 01-720). Torque the nut to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

NOTE

You must line up the correlation marks on the tube and on the oil pressure distributor.Install the tube 183 on the gearbox between the distributor and the gearbox, adjacent to the Integrated Drive Generator (IDG). Torque the gearbox connector to 320 lbfin. to 350 lbfin. (36.2 Nm to 39.6 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the tube 182 on the gearbox between the distributor and the gearbox, adjacent to the scavenge pump. Torque the gearbox connector to 320 lbfin. to 350 lbfin. (36.2 Nm to 39.6 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the tube 181 on the gearbox between the distributor and the angle gearbox. Torque the gearbox connector to 320 lbfin. to 350 lbfin. (36.2 Nm to 39.6 Nm). Safety with CoMat 02-126 LOCKWIRE.

With an applicable tool, hold the distributor to prevent movement while you torque each connector to 320 lbfin. to 350 lbfin. (36.2 Nm to 39.6 Nm). Safety each connector with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-60-420-065-A00 Install the External Gearbox Oil Distribution Tubes (Pre SBE 71-0110)

SBE 71-0110: Engine - Provide rerouted oil tubes for the ACOC and the oil tank assembly.

Install the tube 184 on the gearbox between the Dedicated Alternator and the gearbox. Torque the tube connectors to 320 lbfin. to 350 lbfin. (36.2 Nm to 39.6 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the oil pressure distributor OIL-PRESSURE OIL TUBES-GEARBOX (79-21-48, 01-700) on the gearbox and install the nut OIL-PRESSURE OIL TUBES-GEARBOX (79-21-48, 01-720). Torque the nut to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

NOTE

You must line up the correlation marks on the tube and on the oil pressure distributor.Install the tube 183 on the gearbox between the distributor and the gearbox, adjacent to the Integrated Drive Generator (IDG). Torque the gearbox connector to 320 lbfin. to 350 lbfin. (36.2 Nm to 39.6 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the tube 182 on the gearbox between the distributor and the gearbox, adjacent to the scavenge pump. Torque the gearbox connector to 320 lbfin. to 350 lbfin. (36.2 Nm to 39.6 Nm). Safety with CoMat 02-126 LOCKWIRE.

Install the tube 181 on the gearbox between the distributor and the angle gearbox. Torque the gearbox connector to 320 lbfin. to 350 lbfin. (36.2 Nm to 39.6 Nm). Safety with CoMat 02-126 LOCKWIRE.

With an applicable tool, hold the distributor to prevent movement while you torque each connector to 320 lbfin. to 350 lbfin. (36.2 Nm to 39.6 Nm). Safety each connector with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-60-420-065-B00 Install the External Gearbox Oil Distribution Tubes (SBE 71-0110)

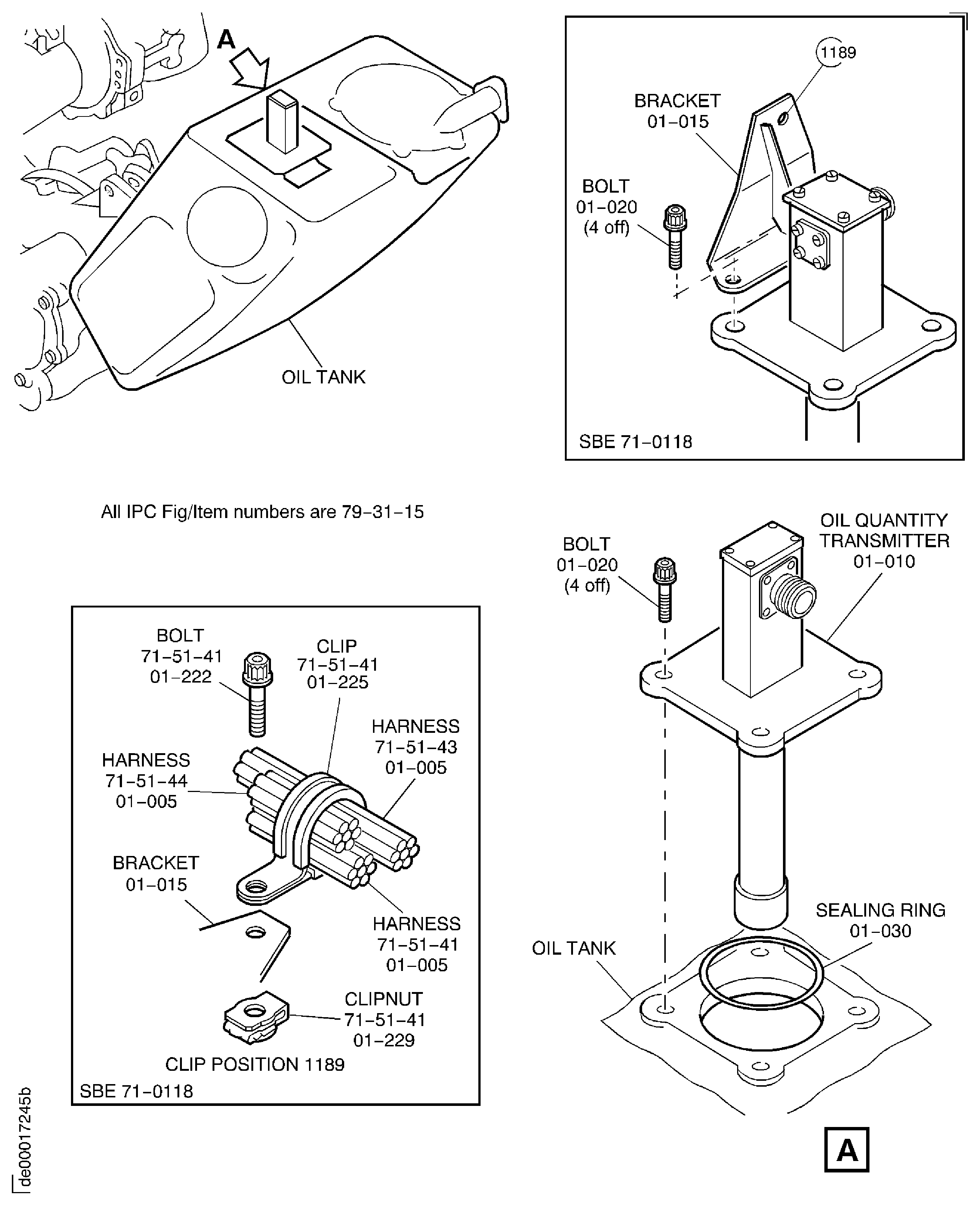

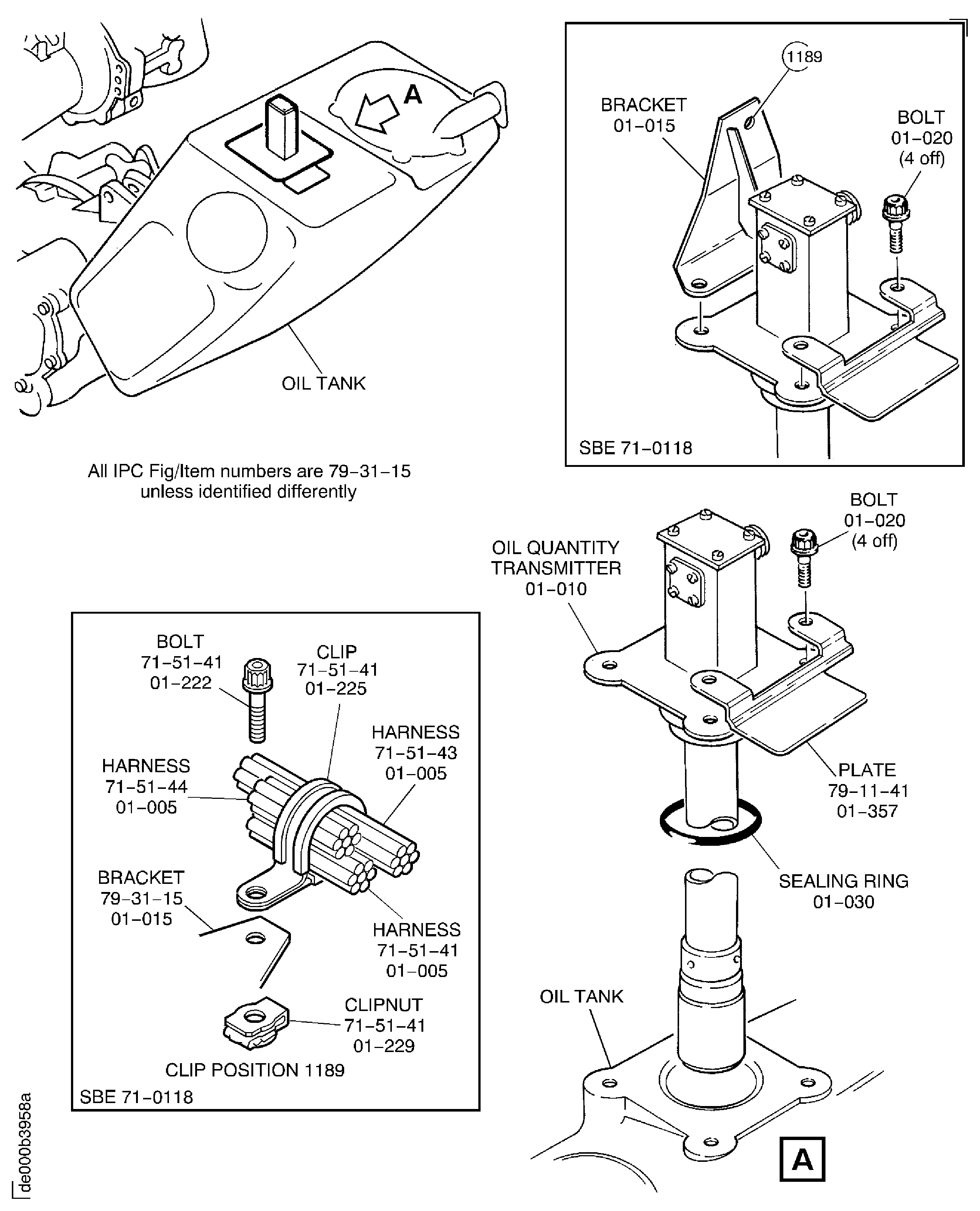

Refer to Figure.

Lightly lubricate the new OIL-OIL QUANTITY TRANSMITTER (79-31-15, 01-030) sealing ring 1 off with CoMat 10-077 APPROVED ENGINE OILS and install it in the oil tank recess.

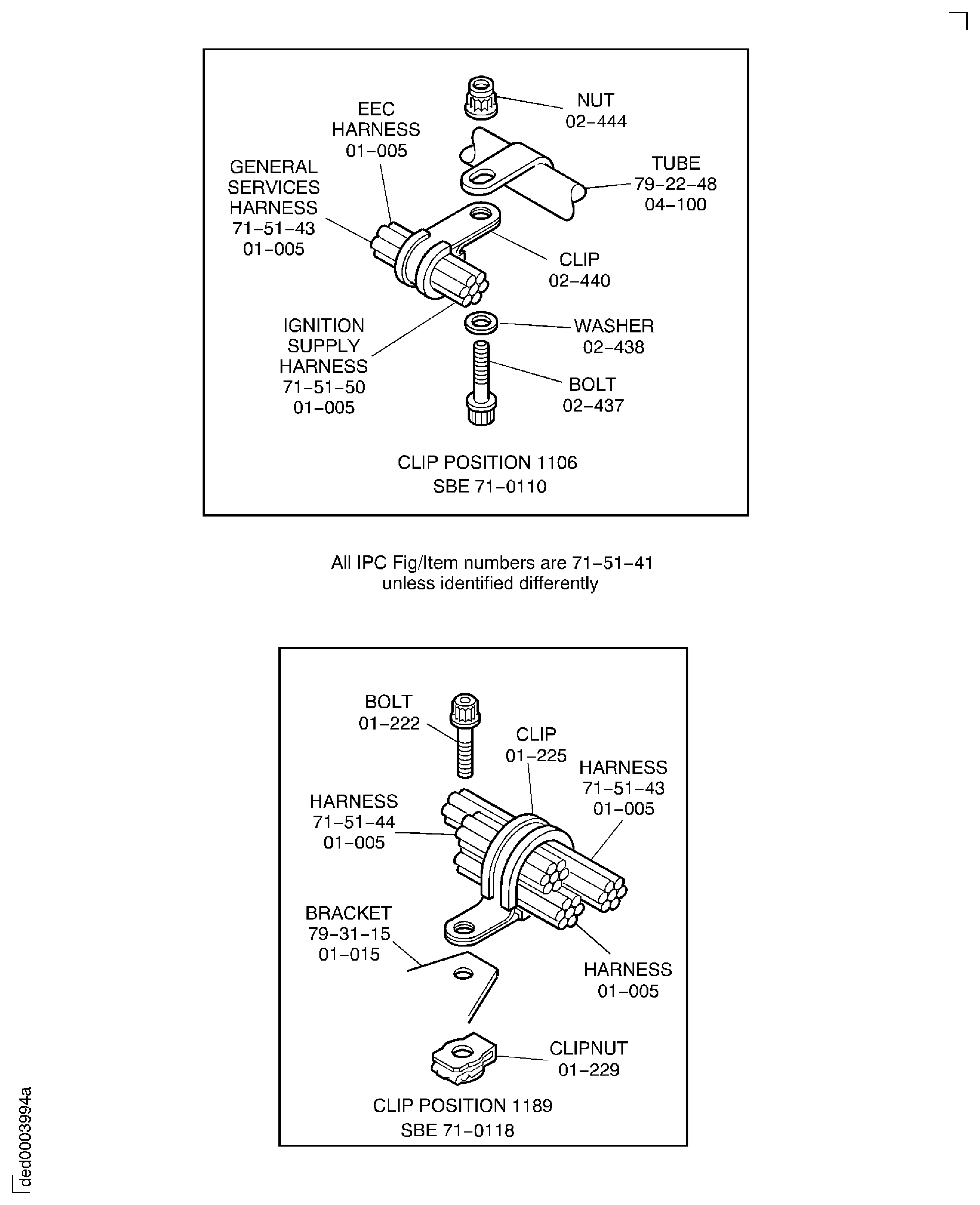

SBE 71-0118: Put the clip bracket OIL-OIL QUANTITY TRANSMITTER (79-31-15, 01-015) over the oil quantity transmitter and align the bolt holes with the two inboard bolt holes in the oil quantity transmitter.

Install the four bolts OIL-OIL QUANTITY TRANSMITTER (79-31-15, 01-020) and torque them to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

SUBTASK 72-00-60-420-095-A00 Install the Oil Quantity Transmitter (01-010) (Pre SBE 79-0023 and SBE 71-0118)

Refer to Figure.

Lightly lubricate the new OIL-OIL QUANTITY TRANSMITTER (79-31-15, 01-030) sealing ring 1 off with CoMat 10-077 APPROVED ENGINE OILS and install it in the oil tank recess.

Install the oil quantity transmitter OIL-OIL QUANTITY TRANSMITTER (79-31-15, 01-010) in the oil tank with the electrical connection to the rear.

SBE 79-0023: Put the overfill warning plate OIL-OIL TANK (79-11-41, 01-357) over the oil quantity transmitter and align the bolt holes with the two outboard bolt holes in the oil quantity transmitter.

SBE 71-0118: Put the clip bracket OIL-OIL QUANTITY TRANSMITTER (79-31-15, 01-015) over the oil quantity transmitter and align the bolt holes with the two inboard bolt holes in the oil quantity transmitter.

Install the four bolts OIL-OIL QUANTITY TRANSMITTER (79-31-15, 01-020) and torque them to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

SUBTASK 72-00-60-420-095-B00 Install the Oil Quantity Transmitter (SBE 79-0023 and SBE 71-0118)

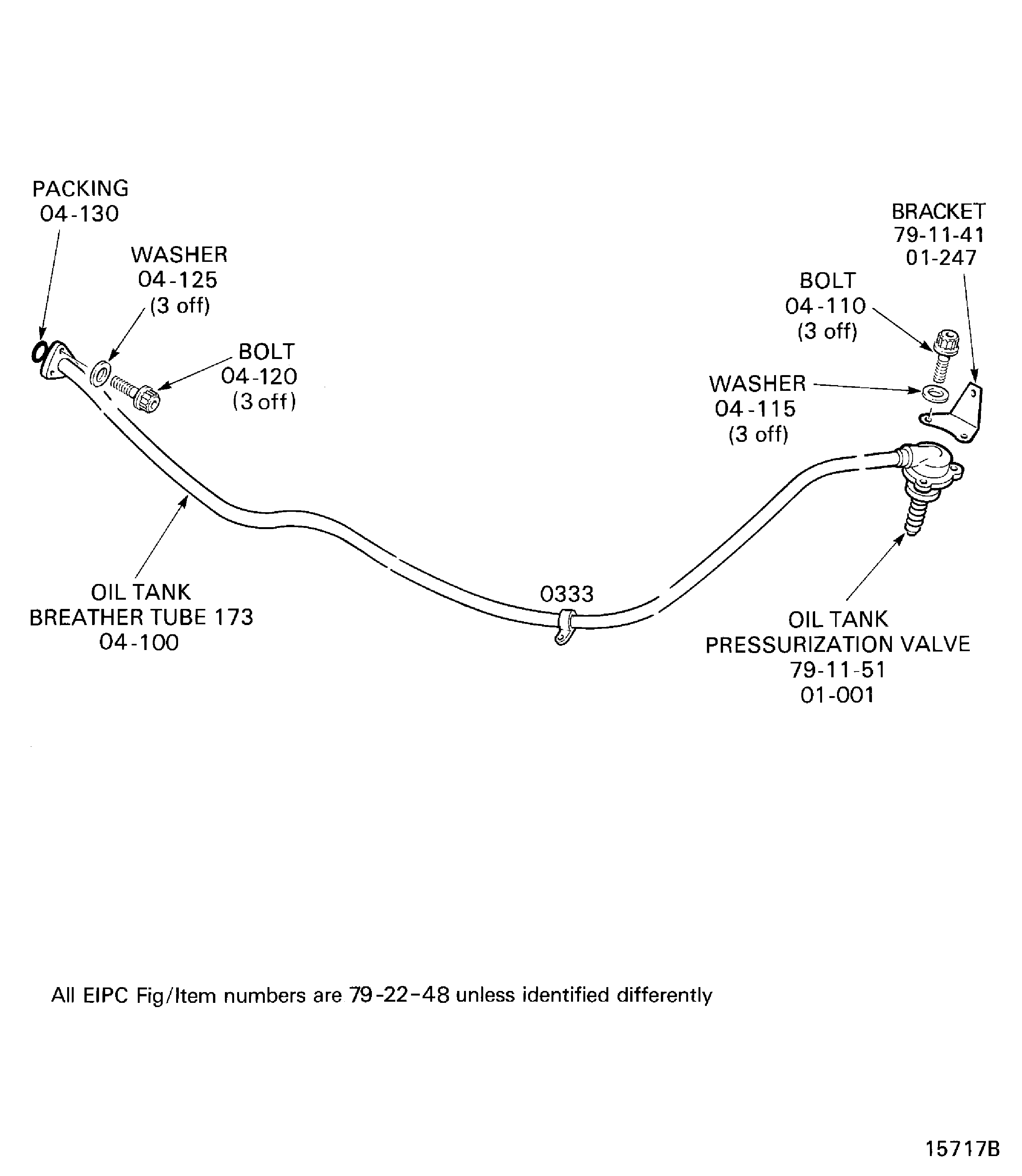

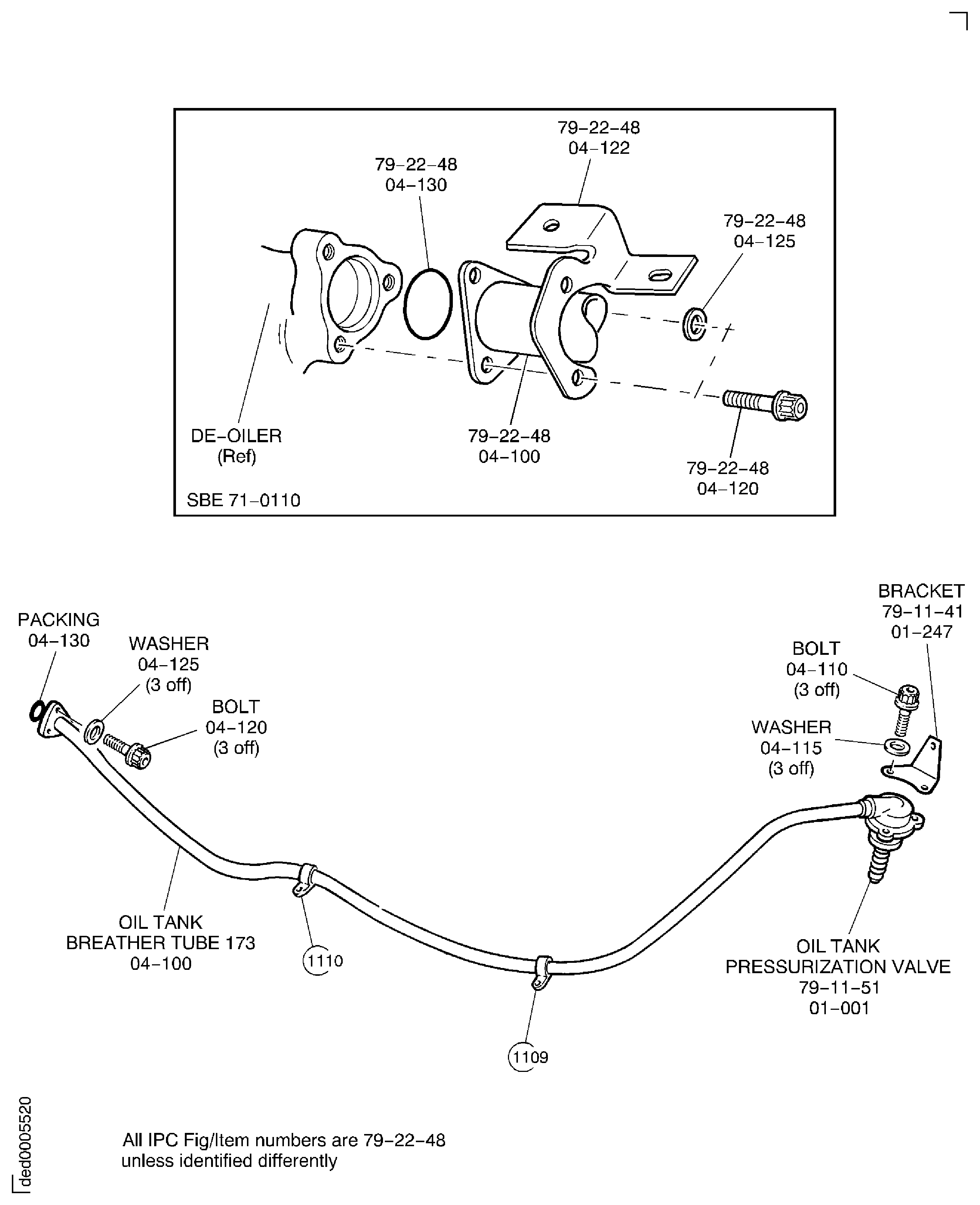

Lightly lubricate the new OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 04-130) packing 1 off with CoMat 10-077 APPROVED ENGINE OILS. Install the packing on the deoiler connector of the tube 173.

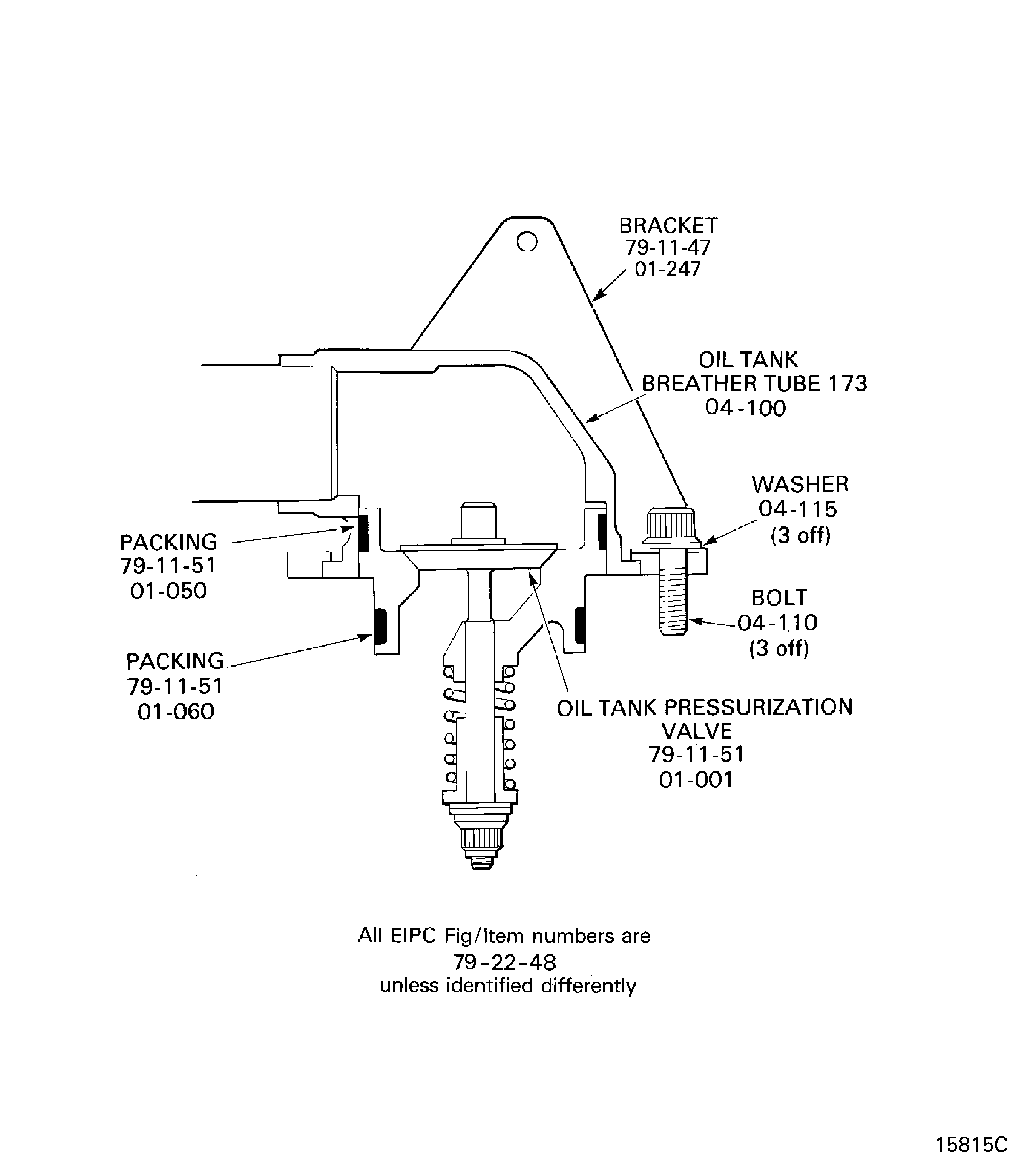

Make sure the two packings OIL-OIL TANK VALVE (79-11-51, 01-050) and OIL-OIL TANK VALVE (79-11-51, 01-060) are correctly installed on the tank pressurization valve OIL-OIL TANK VALVE (79-11-51, 01-001).

Pre SBE 71-0110.

Install the tube 173 in position on the gearbox. Install the three bolts OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 04-120) and washers OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 04-125) that attach the tube 173 to the deoiler. Torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

Install the tube 173 in position on the gearbox. Install the bracket OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 04-122) the three bolts OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 04-120) and washers OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 04-125) that attach the tube 173 to the deoiler. Torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

Together with the bracket OIL-OIL TANK (79-11-41, 01-247), install the three bolts OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 04-110) and washers OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 04-115) that attach the tube 173 to the oil tank. Torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

SUBTASK 72-00-60-420-066 Install the Oil Tank Breather Tube (173)

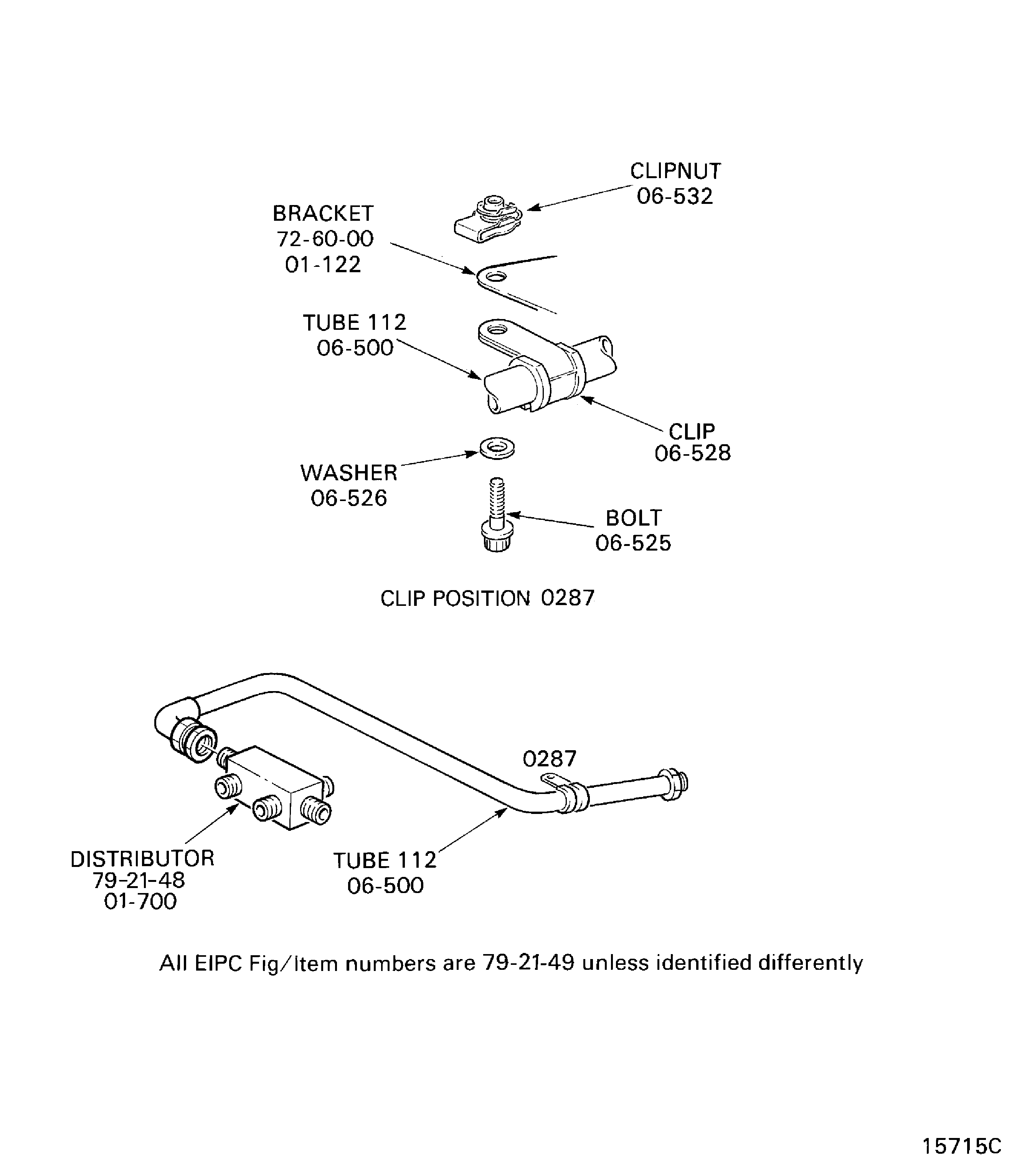

Connect the tube 112 to the oil distributor OIL-PRESSURE OIL TUBES-GEARBOX (79-21-48, 01-700). With an applicable tool hold the distributor to prevent movement and torque the tube connector to 283 lbfin. to 310 lbfin. (32 Nm to 35 Nm).

SUBTASK 72-00-60-420-067 Install the Oil Feed Tube (112) on the External Gearbox

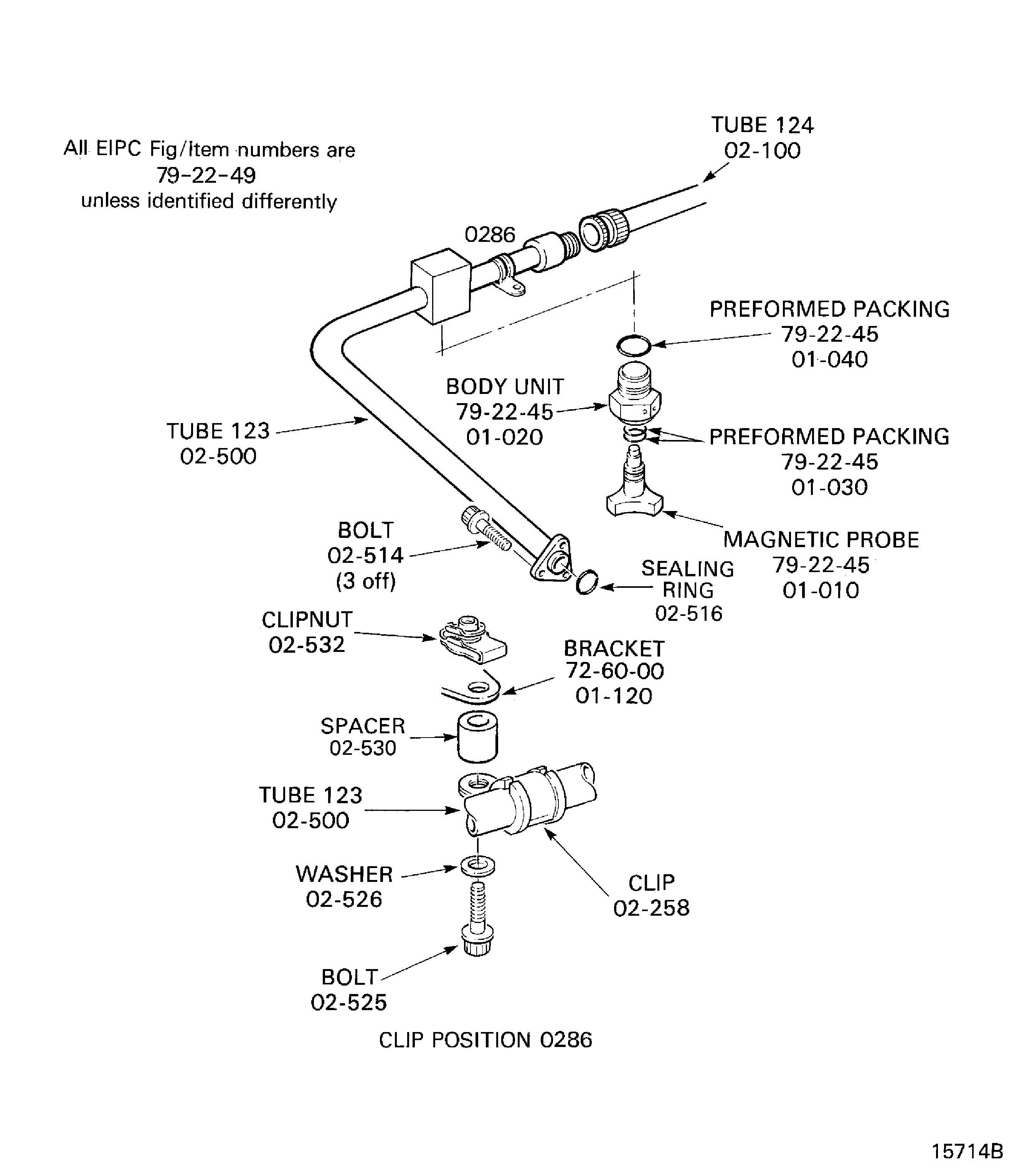

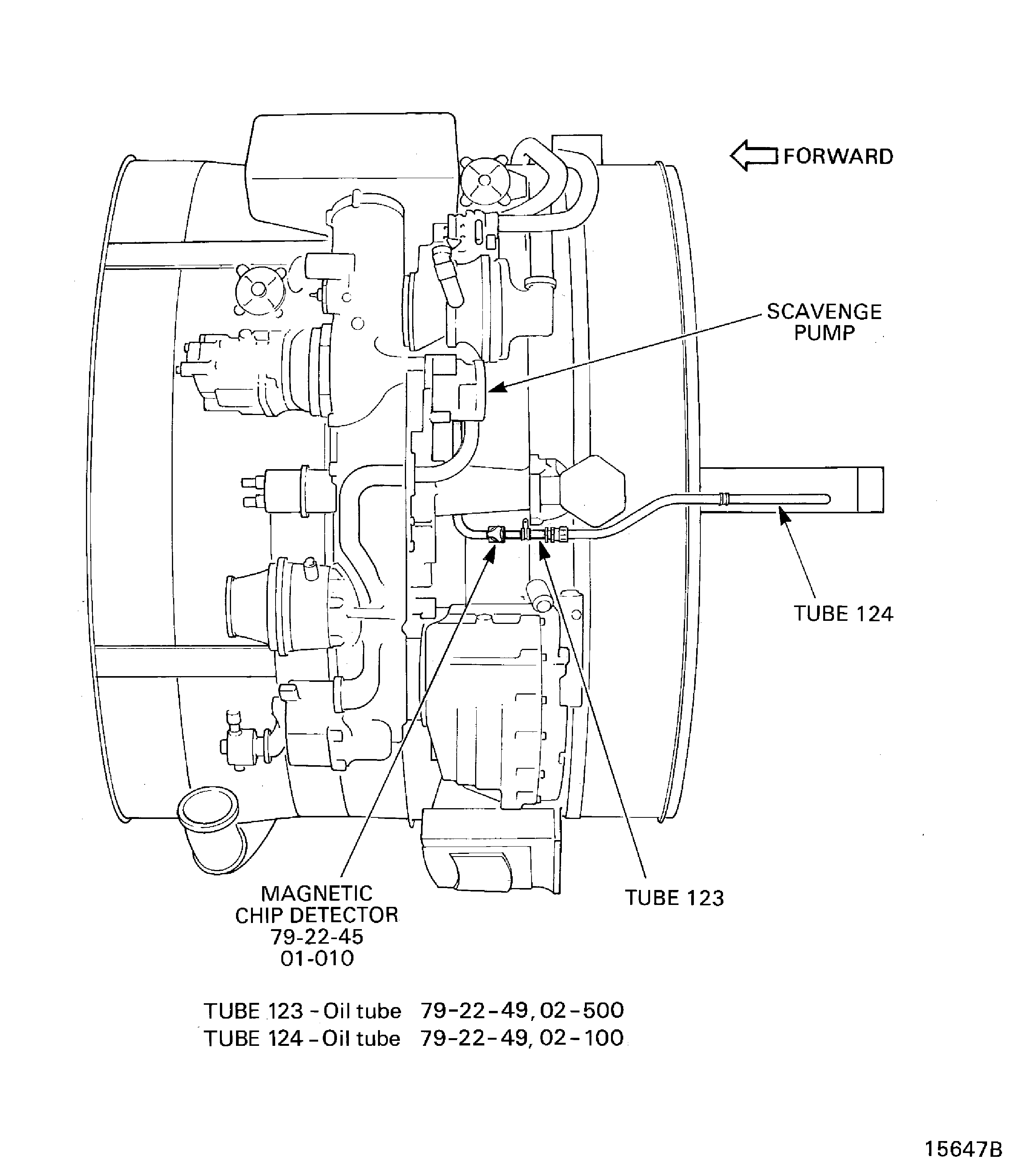

Lightly lubricate the new OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 02-516) seal ring 1 off with CoMat 10-077 APPROVED ENGINE OILS and install it on the tube 123.

Install the tube 123 on the scavenge pump and install the three bolts OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 02-514). Torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

Lightly lubricate the new OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-040) packing 1 off with CoMat 10-077 APPROVED ENGINE OILS and install it on the body unit OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-020).

Lightly lubricate the threads of the body unit with CoMat 10-077 APPROVED ENGINE OILS and install the body unit in the tube 123. Torque the body unit to 160 *lbfin. to 180 *lbfin. (18 Nm to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

Make sure the two packings OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-030) are correctly installed on the magnetic probe OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-010). Install the magnetic probe in the body unit and make sure the probe is correctly aligned.

Install the magnetic chip detector in the tube 123:

SUBTASK 72-00-60-420-068-A01 Install the Oil Scavenge Tube (123) on the External Gearbox

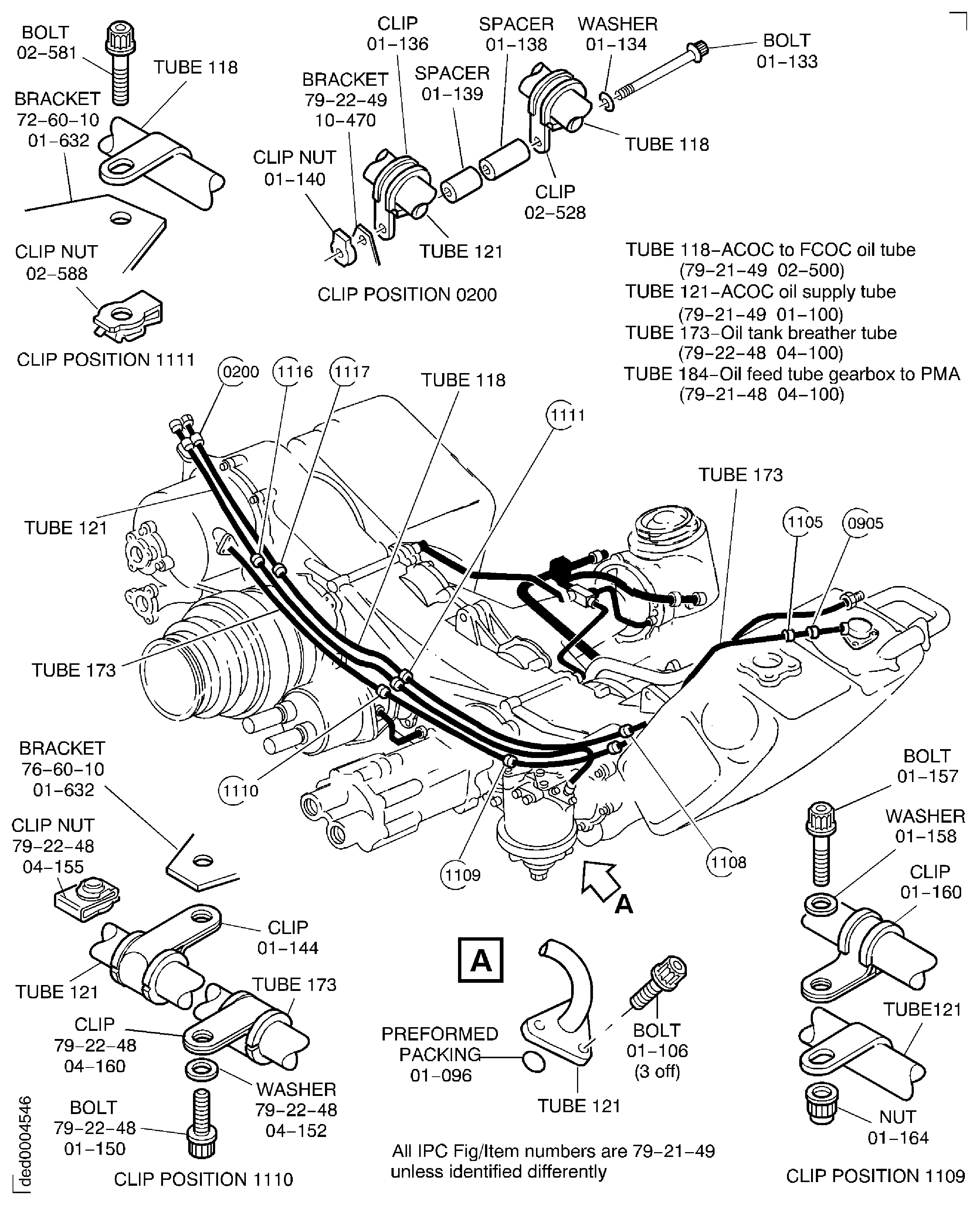

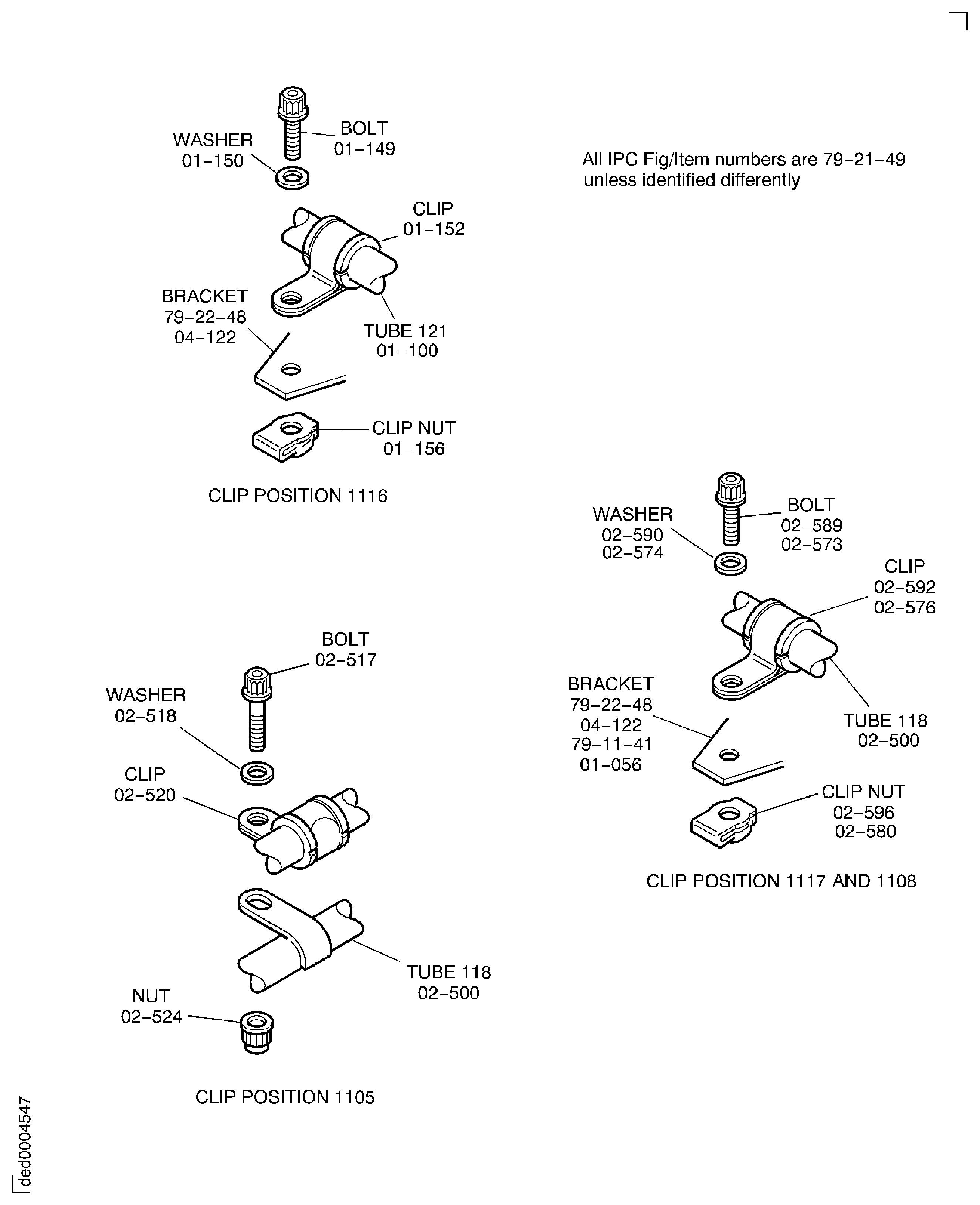

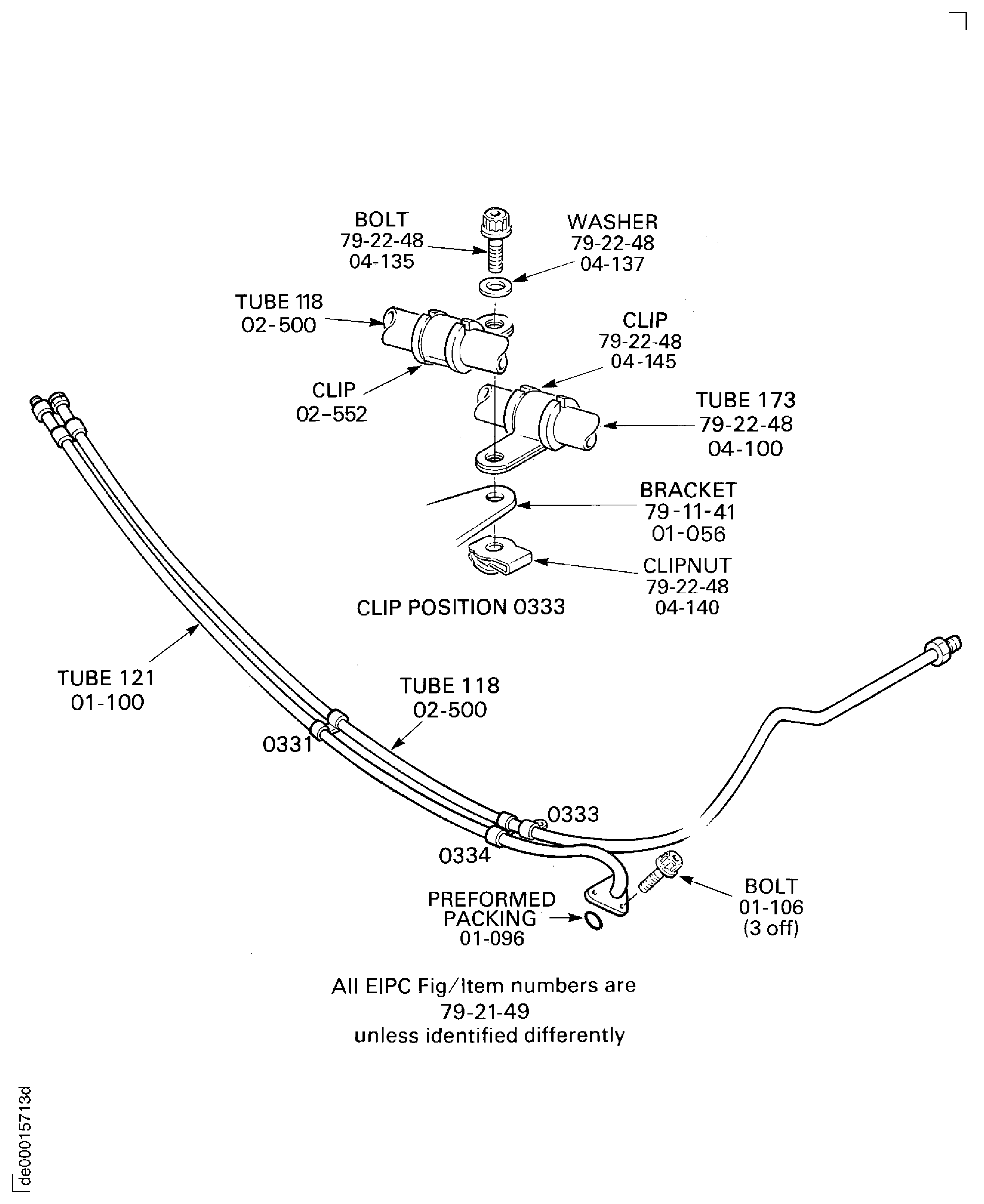

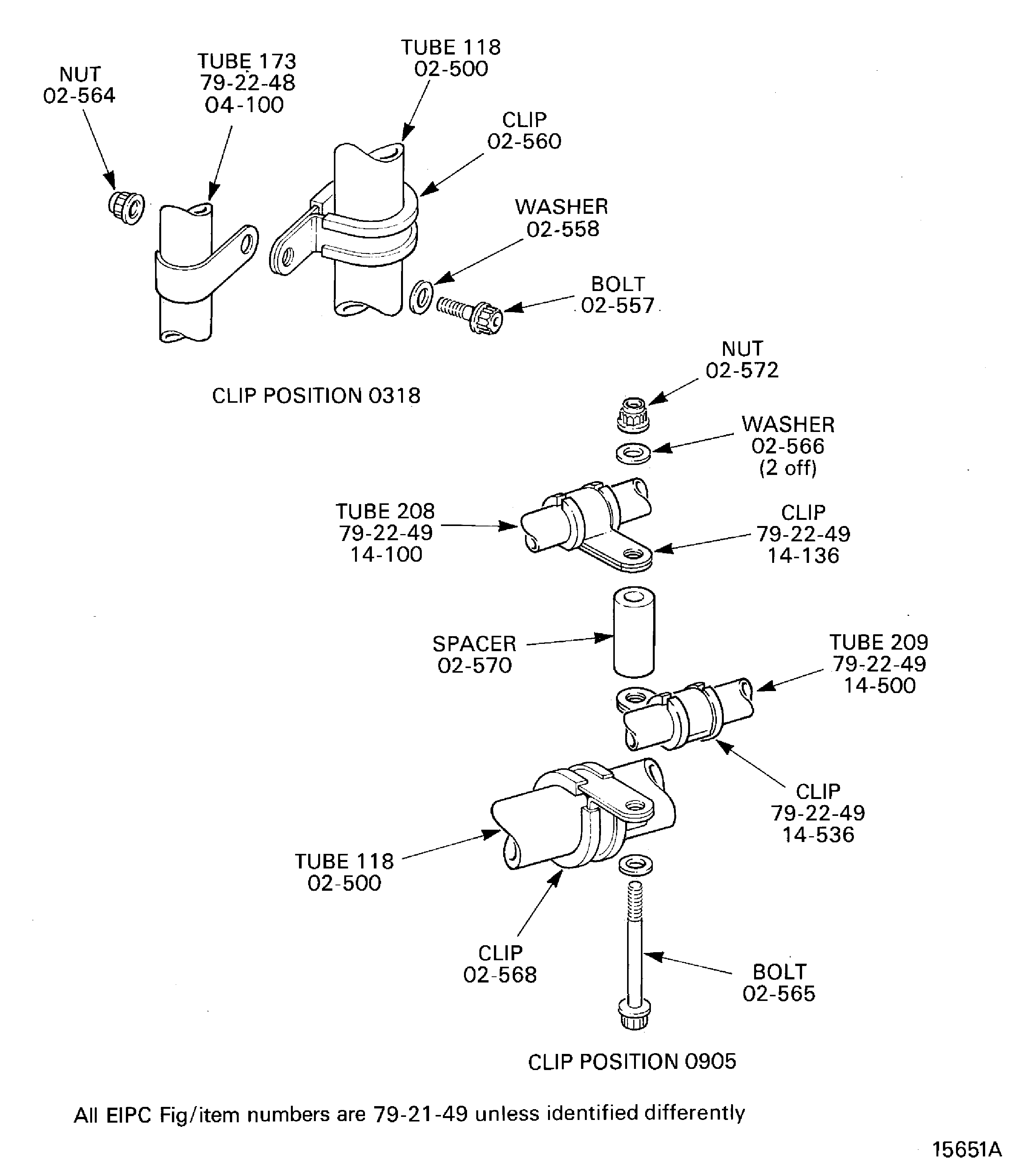

Install the clip OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 04-145) on the tube 173 and the clip OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-552) on the tube 118.

Install the bolt OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 04-135), the washer OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 04-137) and the clipnut OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 04-140) at the bracket OIL-OIL TANK (79-11-41, 01-056). Torque the bolt to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm).

Put the tube 118 forward of, and adjacent to, the tube 173 and assemble clip position 0333:

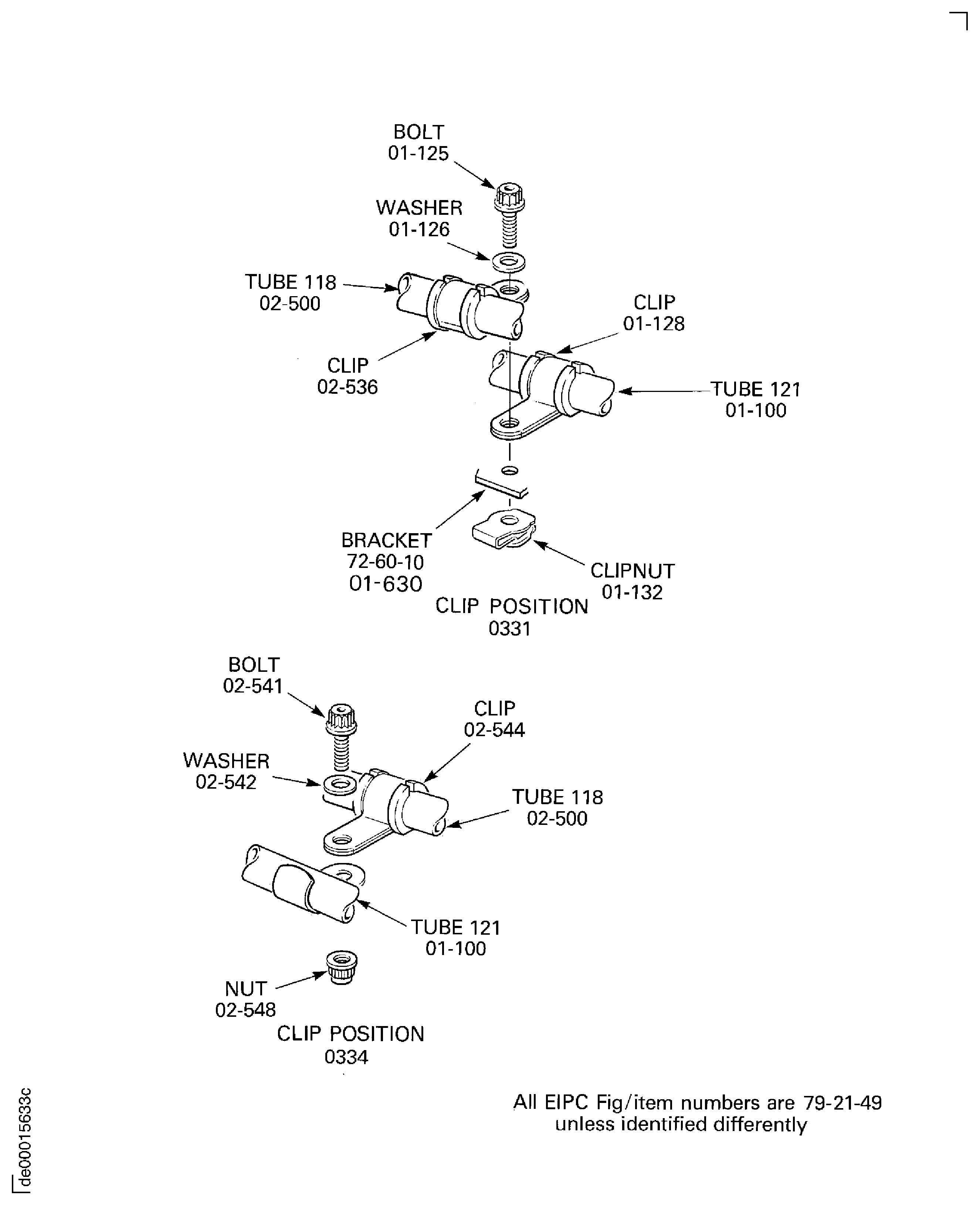

Install the clip OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-544) on the tube 118 adjacent to clip position 0333. Attach the clip to the lug on the tube 121 with the bolt OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-541), the washer OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-542) and the nut OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-548). Tighten the nut by hand.

Install the clip OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-536) on the tube 118. Install clip OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-128) on the tube 121 and attach both clips to the bracket ENGINE-MAIN GEARBOX ASSEMBLY (72-60-10, 01-630) at the Dedicated Alternator interface. Install the bolt OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-125), the washer OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-126) and the clipnut OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-132). Tighten the bolt by hand.

Put the tube 121 forward of, and adjacent to, the tube 118 and loosely assemble the clip positions 0331 and 0334:

Lightly lubricate the new OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-096) preformed packing 1 off with CoMat 10-077 APPROVED ENGINE OILS and install it on the tube 121.

Install the three bolts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-106) that attach the tube 121 to the oil pump. Torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

SUBTASK 72-00-60-420-069 Attach the ACOC Oil Tubes (118 and 121) to the External Gearbox (Pre SBE 71-0110)

SBE 71-0110: Engine - Provide rerouted oil tubes for the ACOC and the oil tank assembly

SBE 79-0069: Introduction of re-routed oil tubes and revised clipping above the external gearbox

Install the clip OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-592) on the tube 118 adjacent to clip position 1117. Attach the clip to the bracket OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 04-122) with the bolt OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-589), the washer OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-590) and the nut OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-596). Tighten the nut by hand.

Install the clip OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-152) on the tube 121 adjacent to clip position 1116. Attach the clip to the bracket OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 04-122) with the bolt OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-149), the washer V2500-A5-72-21-49-01A-941A-D (72-21-49, 01-150) and the nut OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-156). Tighten the bolt by hand.

Attach the lug at clip position 1111 to the bracket V2500-A5-79-60-10-01A-941A-D (79-60-10, 01-632) with the bolt OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-581) and the clipnut OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-588).Tighten the bolt by hand.

Put the tube 121 forward of, and adjacent to, the tube 118 and loosely assemble the clip positions 1116, 1117 and 1111:

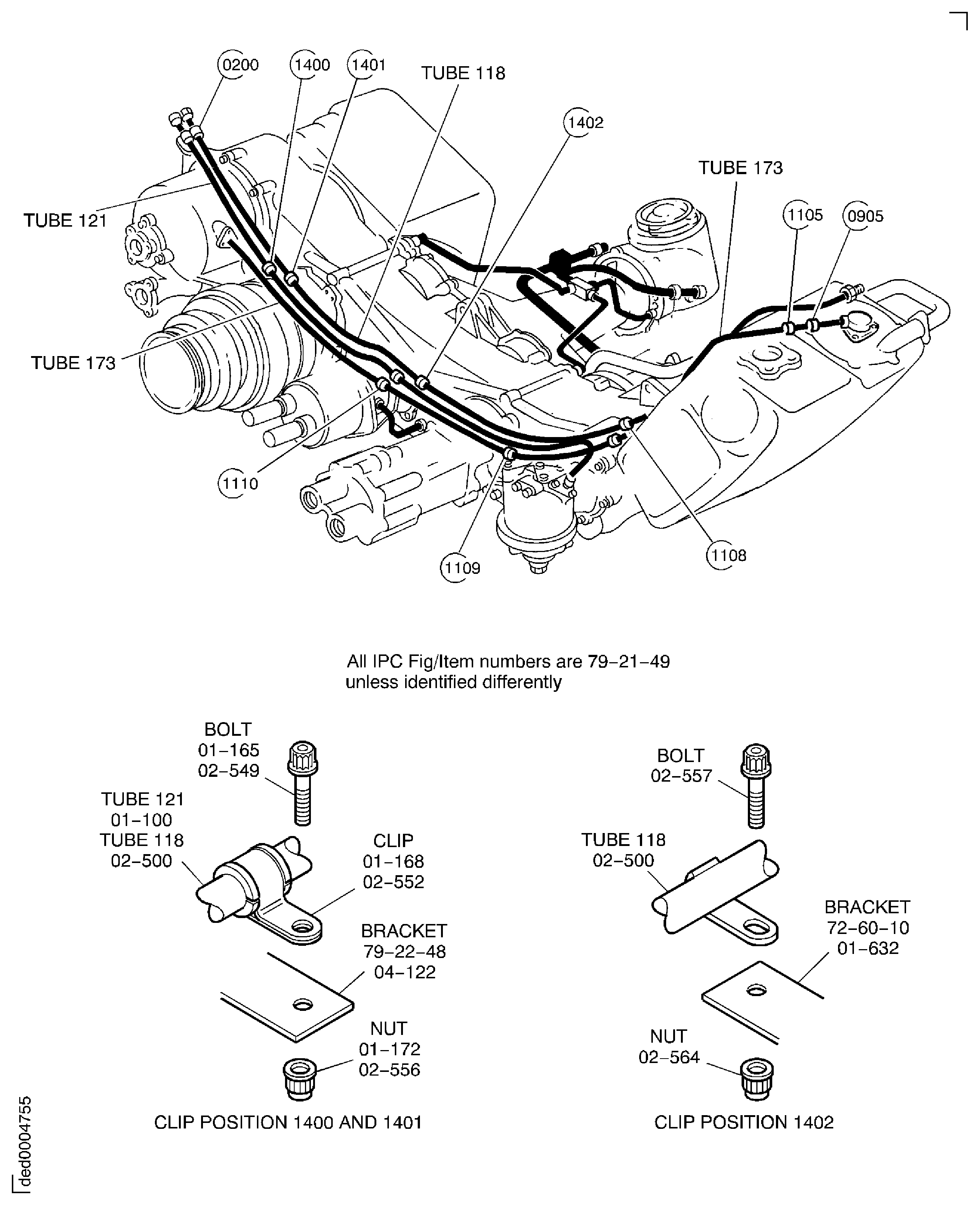

Install the clip OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-552) on the tube 118 adjacent to clip position 1401. Attach the clip to the bracket OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 04-122) with the bolt OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-549) and the nut OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-556). Tighten the nut by hand.

Install the clip OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-168) on the tube 121 adjacent to clip position 1400. Attach the clip to the bracket OIL-SCAVENGE OIL TUBES-GEARBOX (79-22-48, 04-122) with the bolt OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-165) and the nut OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-172). Tighten the nut by hand.

Attach the lug at clip position 1402 to the bracket V2500-A5-79-60-10-01A-941A-D (79-60-10, 01-632) with the bolt OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-557) and the nut OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-564). Tighten the nut by hand.

SBE 79-0069: Put the tube 121 forward of, and adjacent to, the tube 118 and loosely assemble the clip positions 1400, 1401 and 1402:

Lightly lubricate the new OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-096) preformed packing 1 off with CoMat 10-077 APPROVED ENGINE OILS and install it on the tube 121.

Install the three bolts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-106) that attach the tube 121 to the oil pump. Torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

SBE 79-0069: Torque the nuts at clip positions 1400, 1401 and 1402 to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm).

SUBTASK 72-00-60-420-196 Attach the ACOC Oil Tubes (118 and 121) to the External Gearbox (SBE 71-0110 and SBE 79-0069)

Install the external gearbox: Refer to TASK 72-00-60-420-001-001.

SUBTASK 72-00-60-420-070 Install the External Gearbox

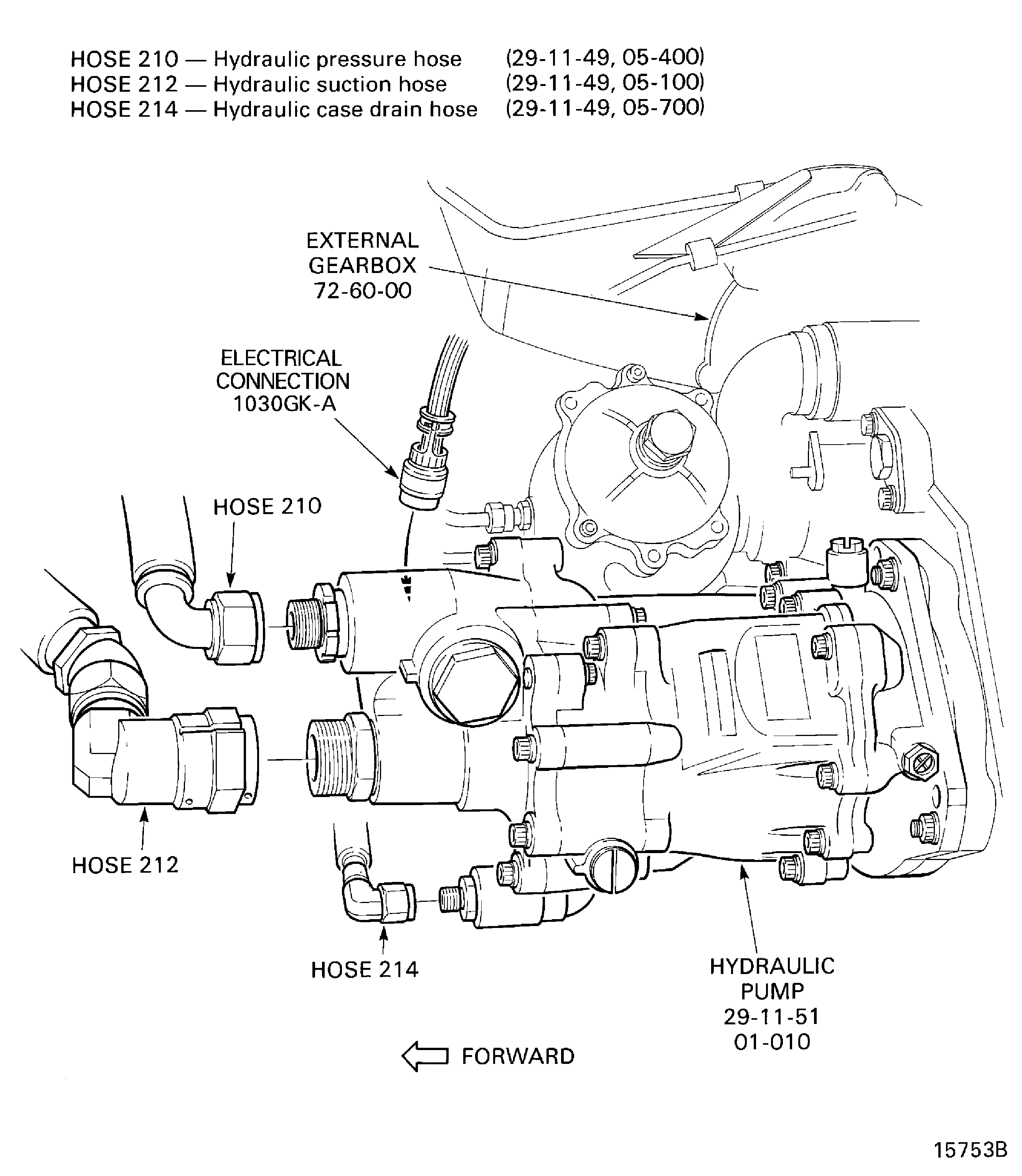

Refer to: Figure.

SUBTASK 72-00-60-420-071 Connect the Hydraulic Pump Hoses

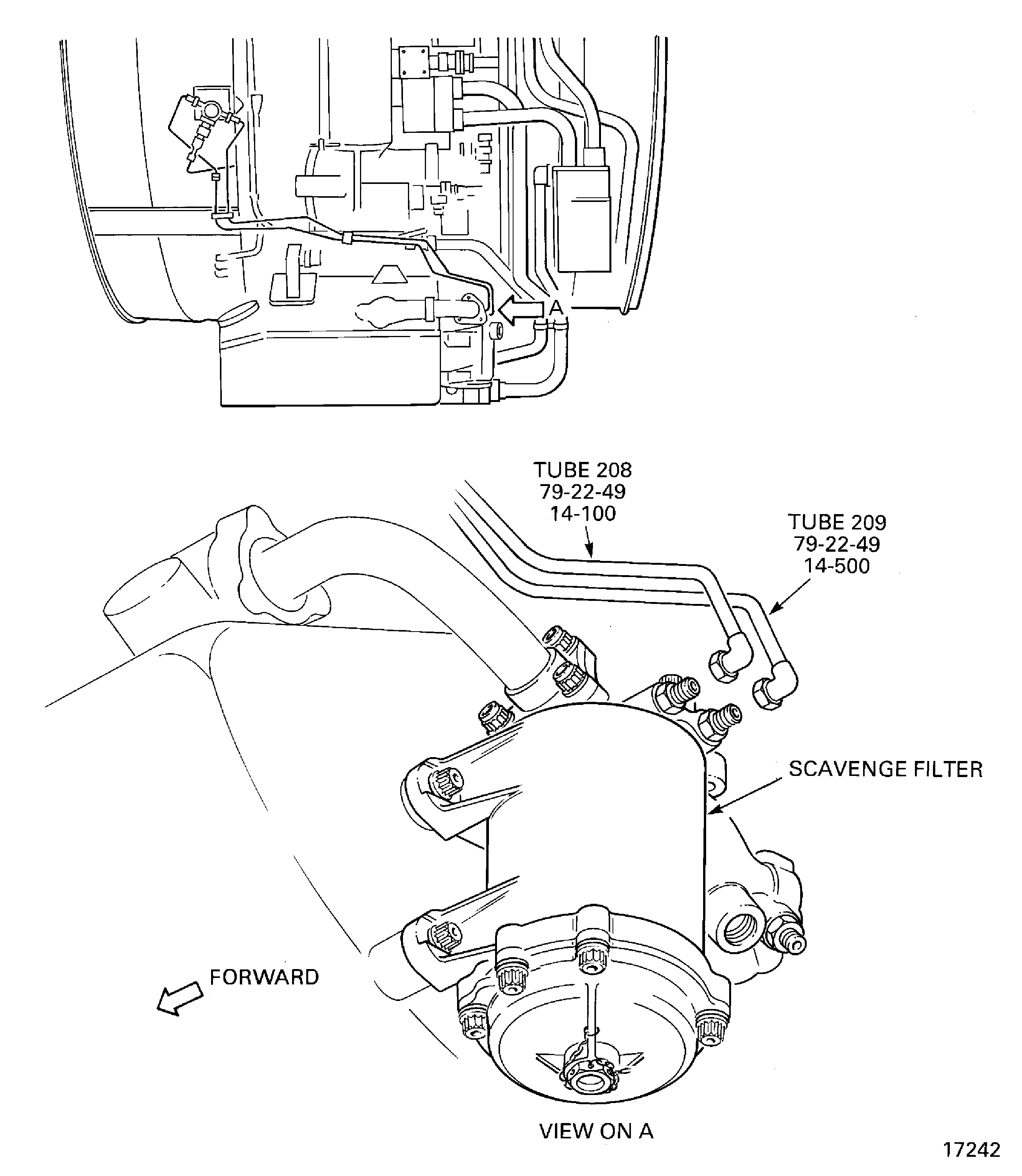

Refer to Figure.

Connect the tubes 208 and 209 to the scavenge filter and torque the tube connectors to 135 *lbfin. to 145 *lbfin. (15 Nm to 16 Nm). Safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-60-420-072 Connect the Scavenge Filter Differential Pressure Switch Tubes (208 and 209)

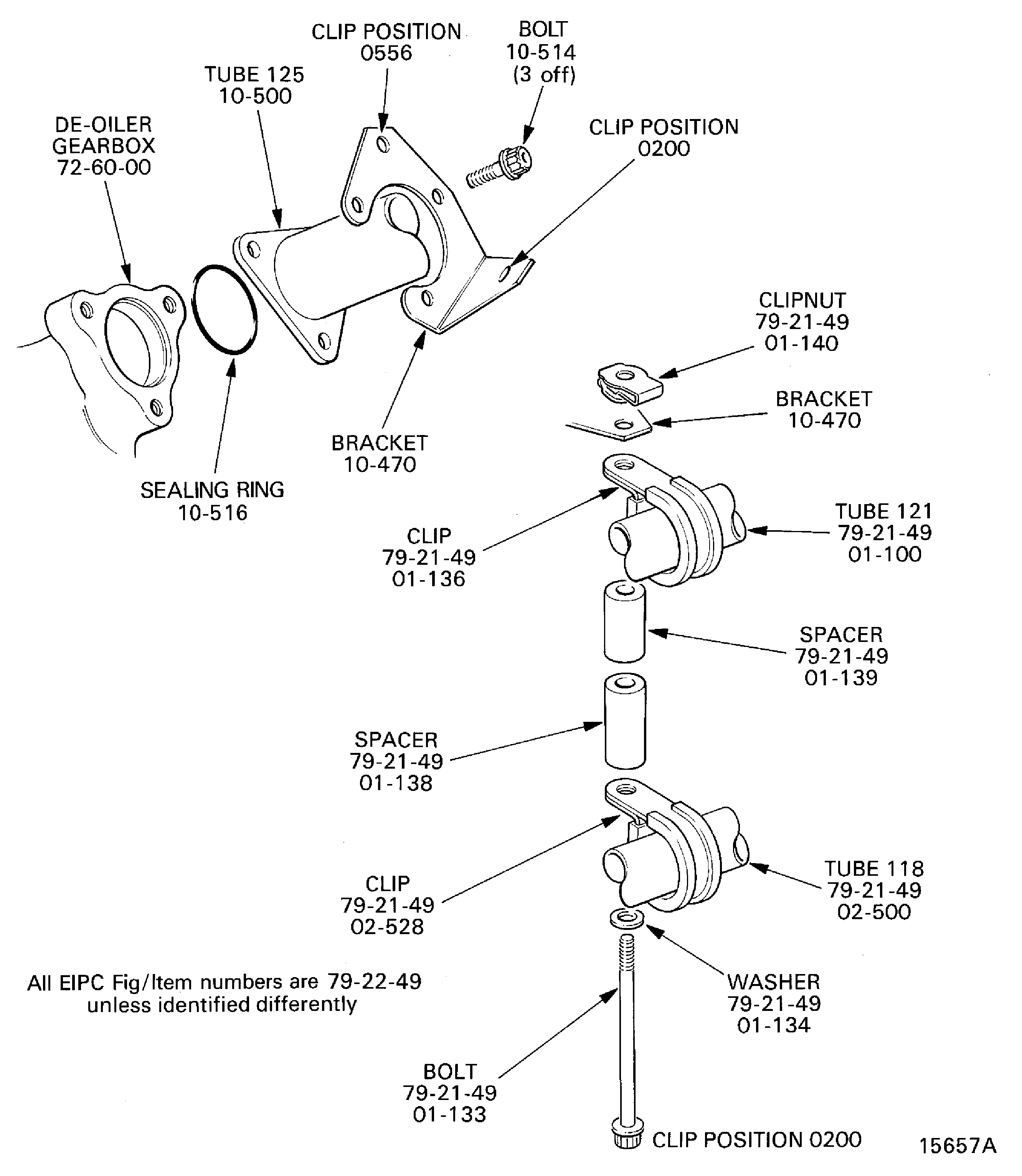

Refer to Figure.

Lightly lubricate the new OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 10-516) sealing ring 1 off with CoMat 10-077 APPROVED ENGINE OILS and install it on the tube 125.

Together with the bracket OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 10-470) install the three bolts OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 10-514) that attach the tube 125 to the gearbox. Torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

SUBTASK 72-00-60-420-073 Connect the No. 1, 2 and 3 Bearing Compartment Vent Tube (125)

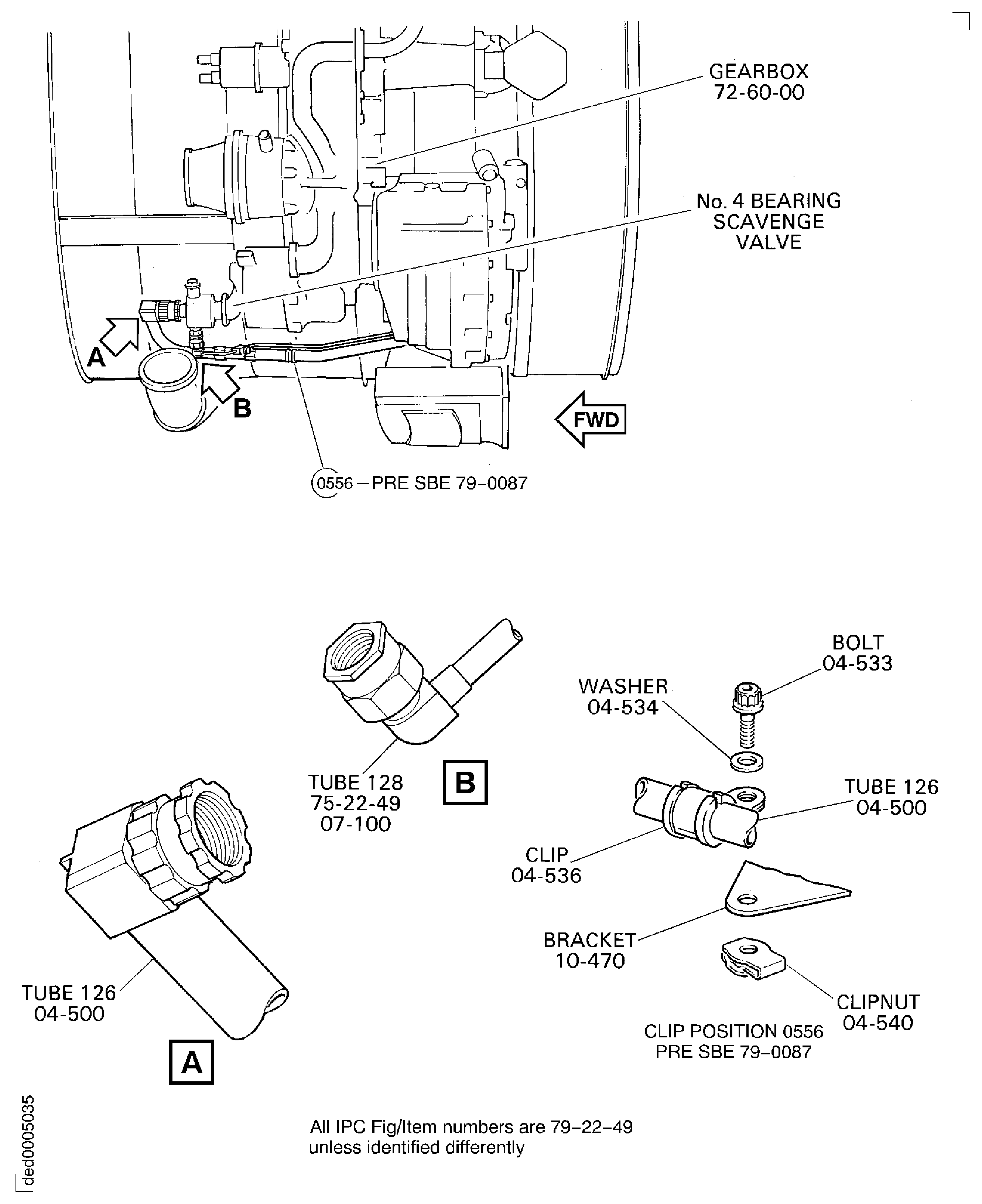

Connect the tube 128 to the No.4 bearing scavenge valve and torque the tube connector to 204 lbfin. to 221 lbfin. (23 Nm to 25 Nm). Safety with CoMat 02-126 LOCKWIRE.

Connect the tube 126 to the No.4 bearing scavenge valve. With IAE 1R18003 Wrench 1 off torque the tube connector to 566 lbfin. to 611 lbfin. (64 Nm to 69 Nm). Safety with CoMat 02-126 LOCKWIRE.

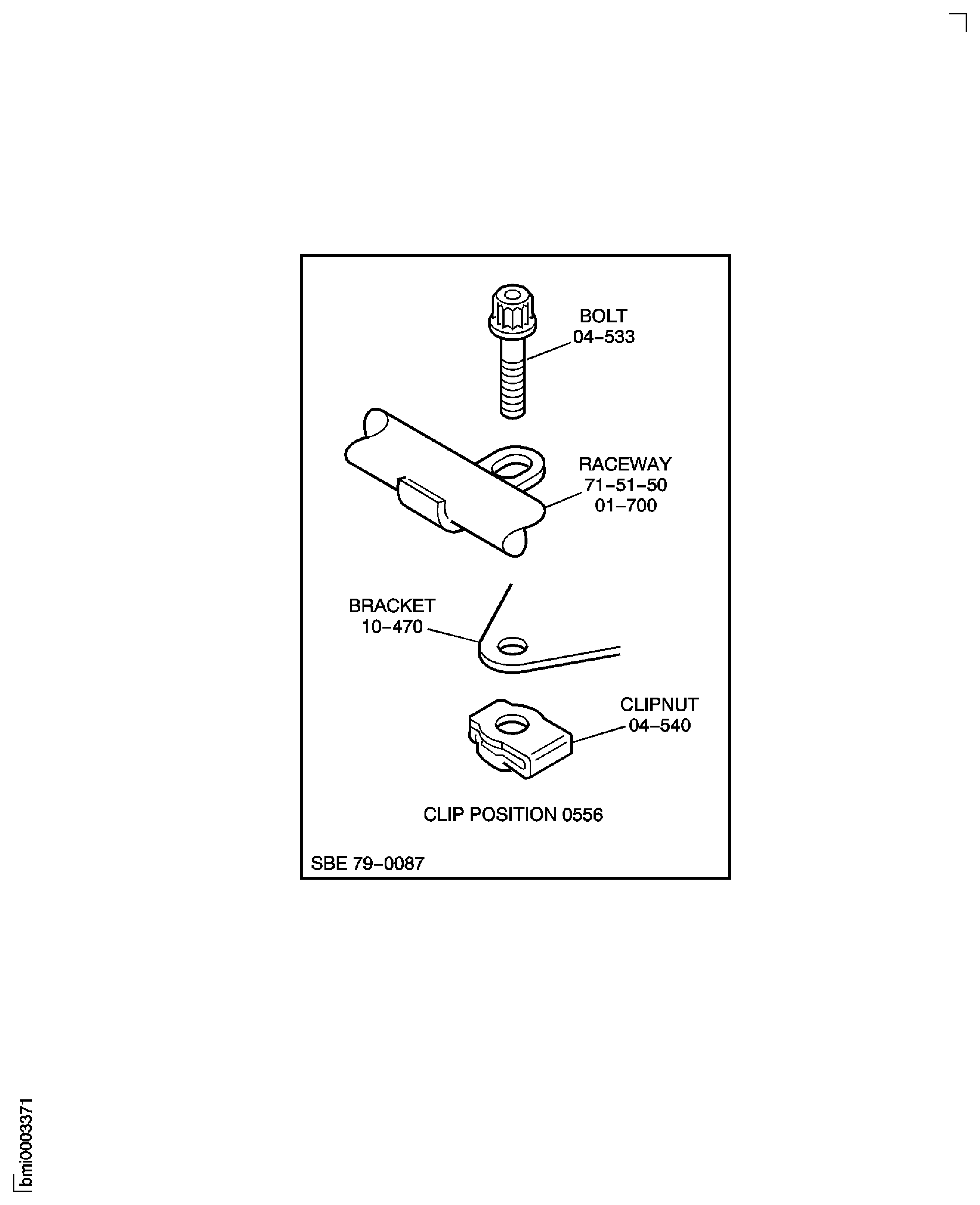

Pre SBE 79-0087: Assemble clip position 0556 and torque the bolt to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm).

SUBTASK 72-00-60-420-074 Connect the No. 4 Bearing Scavenge Tubes (126 and 128) (Pre SBE 79-0087 and SBE 79-0087)

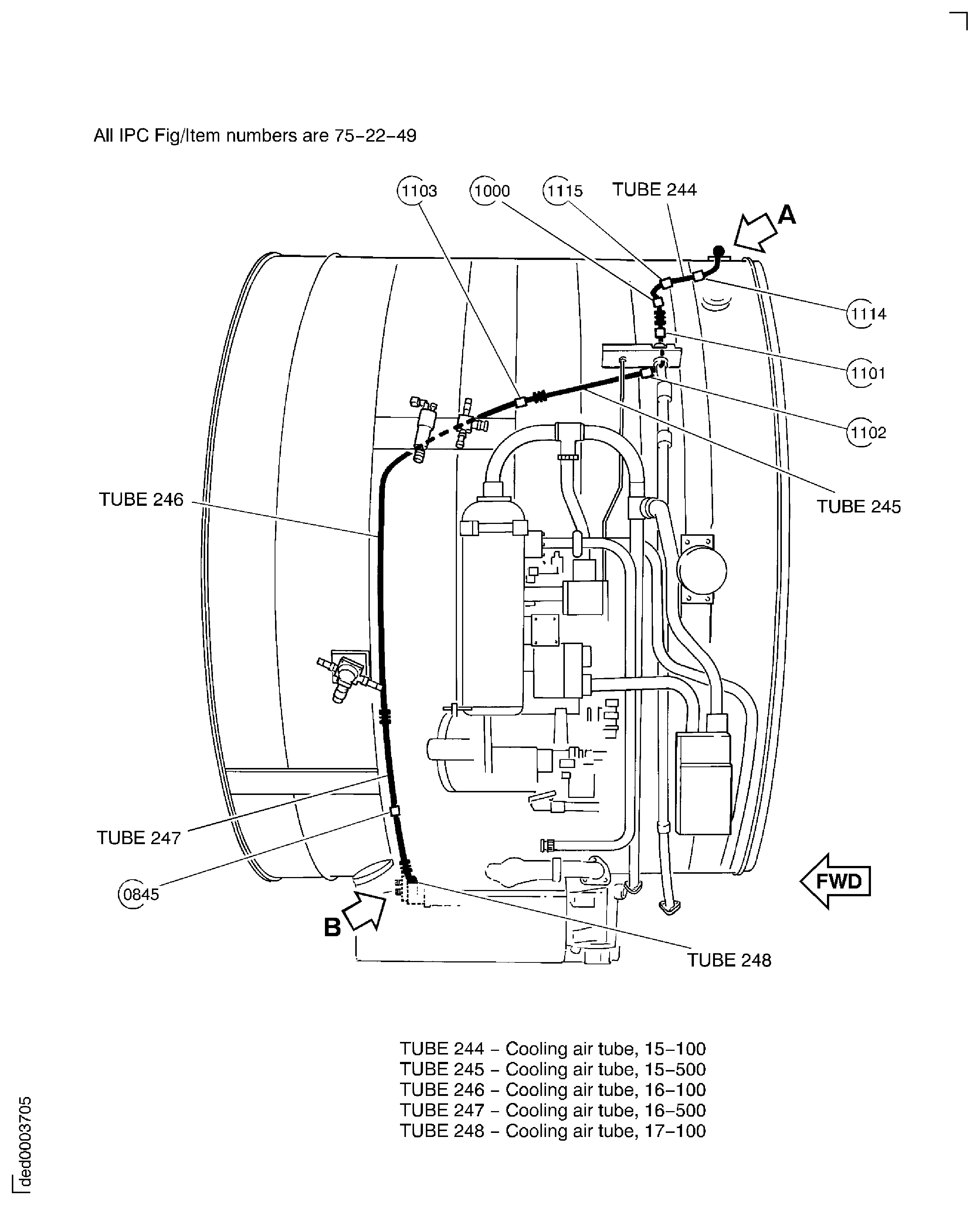

SBE 75-0010: Connect the tube 248 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 17-100) to the dedicated alternator, refer to TASK 72-00-60-450-001-A00 (INSTALLATION-005, CONFIG-001).

SBE 73-0076: Connect the tube 248 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 17-100) to the stator generator, refer to TASK 72-00-60-450-001-A00 (INSTALLATION-005, CONFIG-001).

Connect the tube 247 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 16-500) to the tube 246 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 16-100).

Connect the tube 248 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 17-100) to the tube 247 AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 16-500).

Install the clip positions 0779, 0845, 0846, 0847, 0893 and 0849 which attach the harnesses to the tube 247. Refer to TASK 72-00-32-420-004-A00 (INSTALLATION-004, CONFIG-001).

Safety the tube nuts with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-60-420-205 Install the Tubes 247 and 248, the Dedicated Alternator Cooling Air Tubes (SBE 75-0010 and SBE 73-0076)

Connect the tube 118 to the tube 119 adjacent to the deoiler. With IAE 1R18002 Wrench 1 off torque the tube connector to 478 lbfin. to 513 lbfin. (54 Nm to 58 Nm). Safety with CoMat 02-126 LOCKWIRE.

Connect the tube 118 to the tube 120 adjacent to the oil tank. With IAE 1R18002 Wrench, torque the tube connector to 478 lbfin. to 513 lbfin. (54 Nm to 58 Nm). Safety with CoMat 02-126 LOCKWIRE.

Connect the tube 121 to the tube 122 and with IAE 1R18002 Wrench 1 off torque the tube connector to 478 lbfin. to 513 lbfin. (54 Nm to 58 Nm). Safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-60-420-077 Connect the FCOC Oil Tubes (115 and 118)

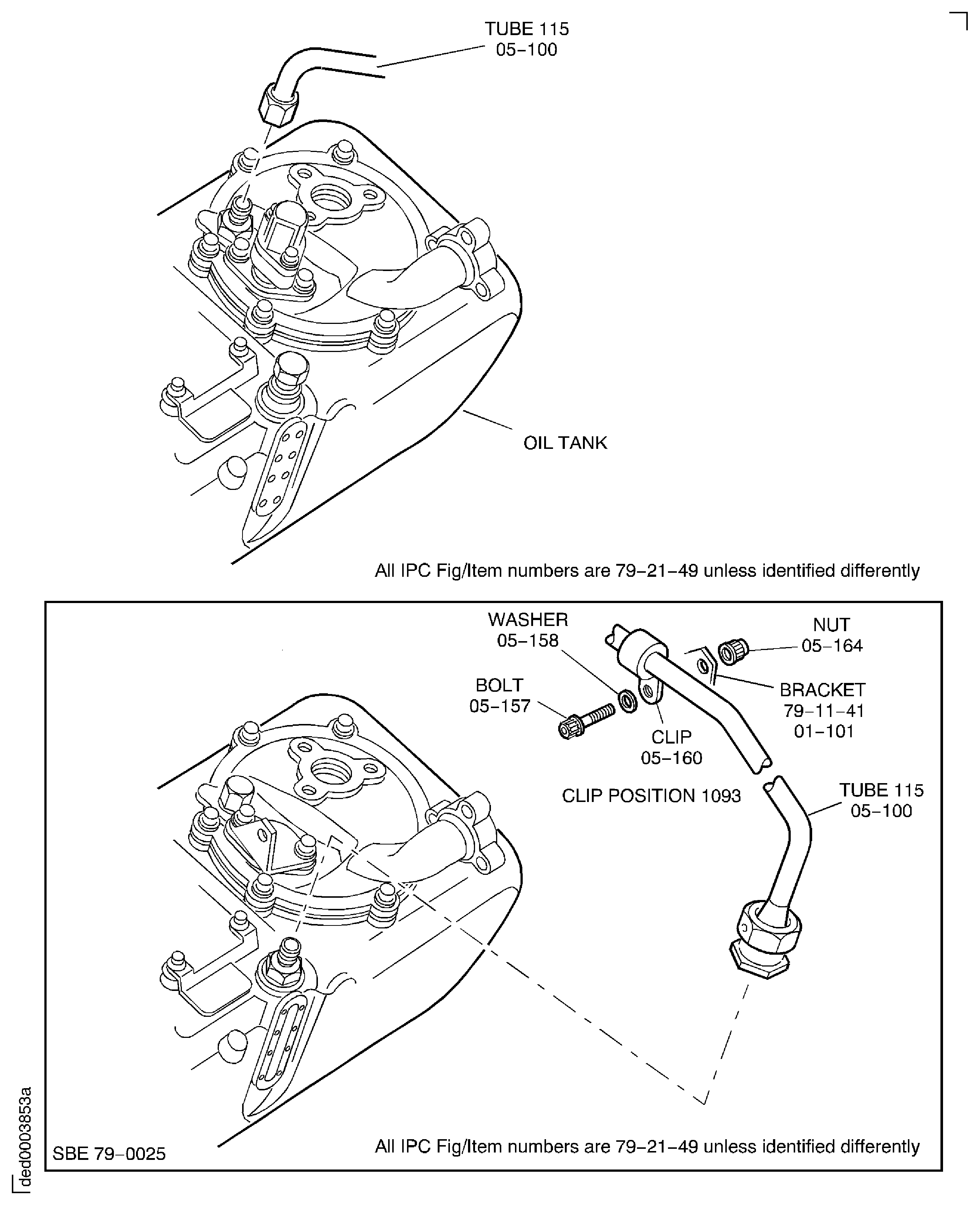

Refer to Figure.

Connect the tube 115 to the oil tank and torque the tube connector to 159 lbfin. to 177 lbfin. (18 Nm to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-60-420-079 Connect the Oil Spill Tube (115) (Pre SBE 79-0025)

Connect the tube 115 to the oil tank and torque the tube connector to 159 lbfin. to 177 lbfin. (18 Nm to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-60-420-197 Connect the Oil Spill Tube (115) (SBE 79-0025)

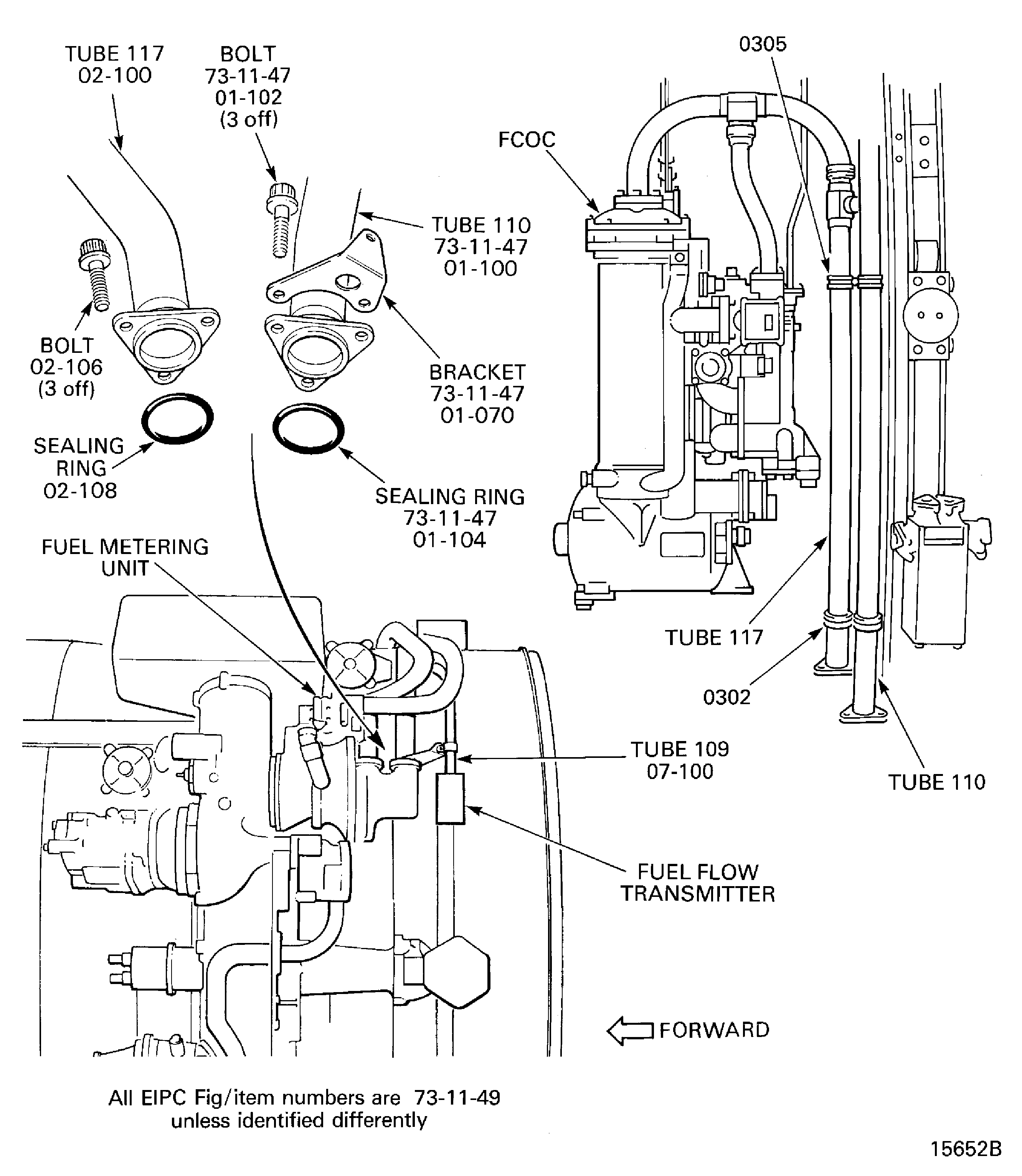

Refer to Figure.

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-108) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY and install it on the tube 109.

Install the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-106) that attach the tube 109 to the Fuel Metering Unit (FMU). Torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm). Safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-60-420-076 Connect the Fuel Flow Transmitter Inlet Tube (109)

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-108) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the packing on the tube 117 and install the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-106) that attach the tube 117 to the fuel pump. Torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

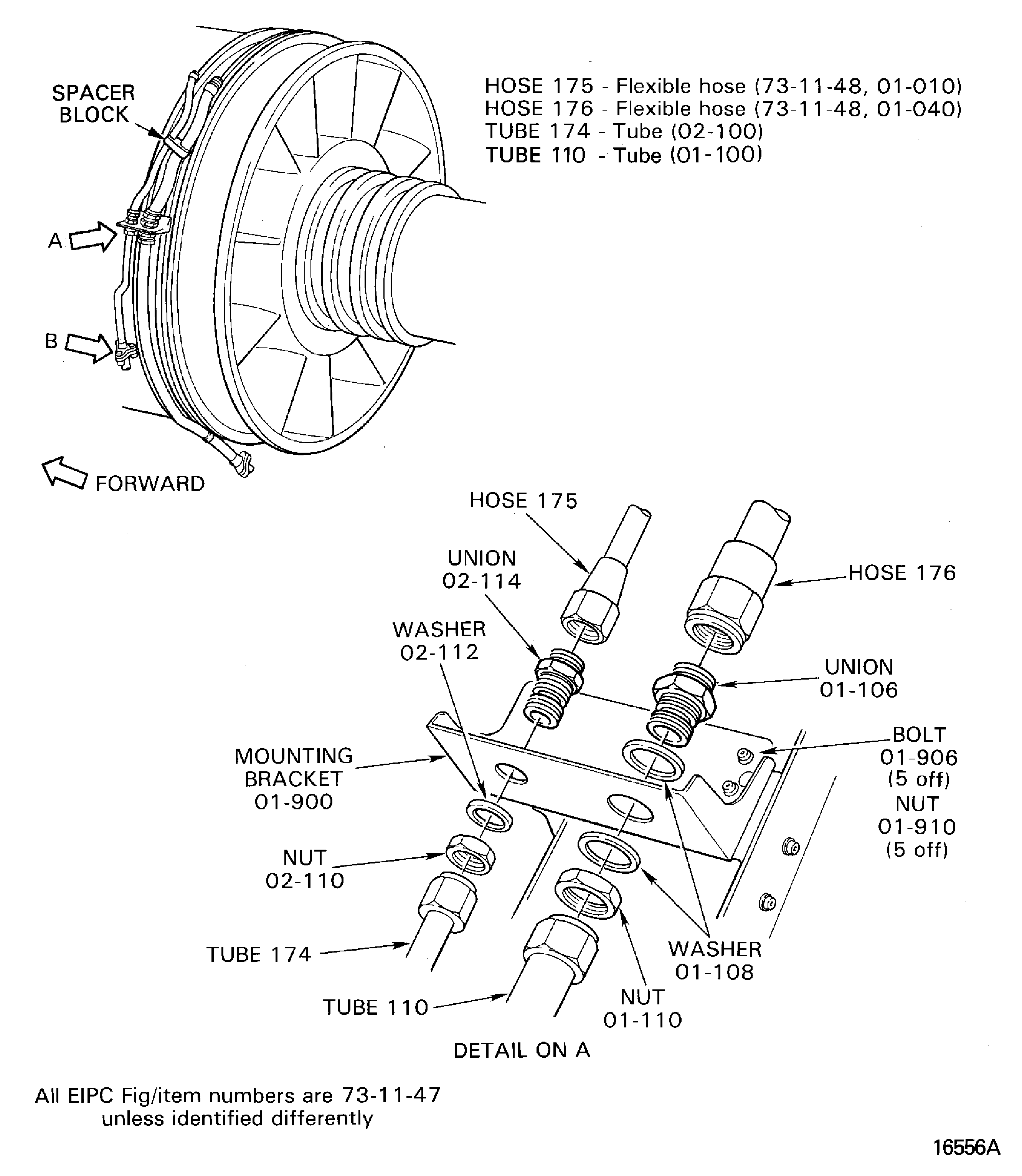

Loosen the five bolts FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-906) and the nuts FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-910) that attach the bracket FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-900) to the two angles on the LP compressor intermediate case. This is to permit adjustment of tube length.

Lightly lubricate the new FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-104) sealing ring 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the sealing ring on the tube 110 and install the three bolts FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-102) that attach the tube 110 to the fuel pump, together with the bracket FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-070). Torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

Disconnect the connectors of tubes 110 and 174 and remove the two nuts FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-110) and FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-110).

Install the washer FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-108) between the union FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-106) and the mounting bracket.

Install the correct thickness of washer FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-112) between the nut FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-110) and the mounting bracket.

Tighten the five nuts FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-910). Tighten the two nuts FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-110) and FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-110).

Adjust the mounting bracket.

Examine the mounting bracket installation. Make sure there is no clearance between the mounting bracket FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-900) and the union FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-106). Also make sure the mounting bracket is horizontal. If there is a clearance at the mounting bracket do the procedure that follows:

Torque the nut FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-110) to 960 *lbfin. to 1120 *lbfin. (108 Nm to 135 Nm).

Torque the nut FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-110) to 240 *lbfin. to 280 *lbfin. (27 Nm to 32 Nm).

Torque the five nuts FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-910) to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

Connect the hose 175 to the union FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-114) and torque to 470 *lbfin. to 510 *lbfin. (53 Nm to 58 Nm).

Connect the hose 176 to the union FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-106) and torque to 1000 *lbfin. to 1100 *lbfin. (113 Nm to 124 Nm).

SUBTASK 72-00-60-420-078 Connect the LP Fuel Tubes (110 and 117) to the Fuel Pump

Refer to Figure.

Connect the tube 123 to the tube 124. With IAE 1R18001 Wrench wrench 1 off torque the tube connector to 398 lbfin. to 434 lbfin. (45 Nm to 49 Nm). Safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-60-420-081 Connect the Oil Scavenge Tube (123)

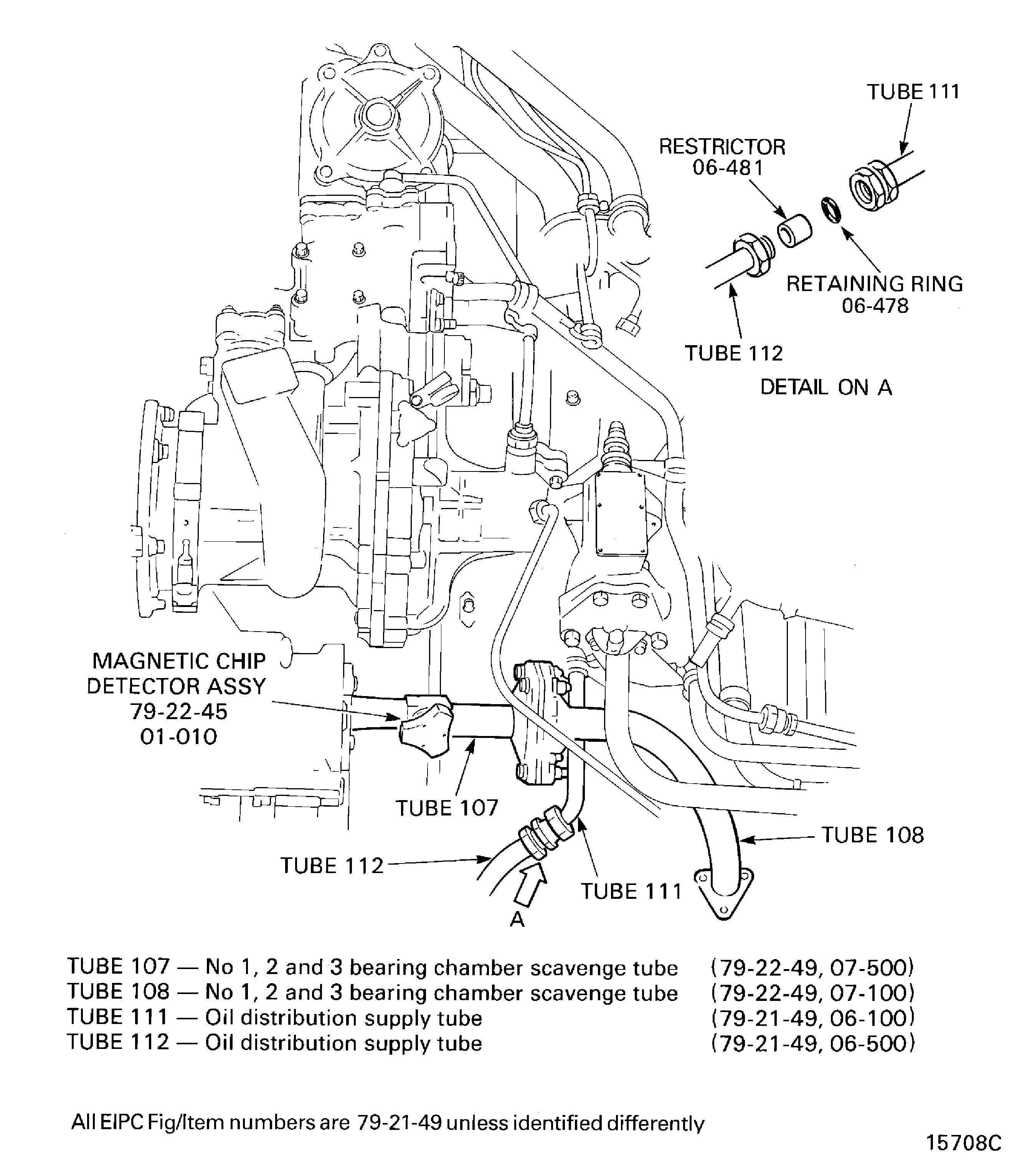

Refer to Figure.

Install the restrictor OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 06-481) and a new OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 06-478) retaining ring 1 off in the tube 112.

Connect the tube 112 to the tube 111. Torque the tube connector to 283 lbfin. to 310 lbfin. (32 Nm to 35 Nm). Safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-60-420-082 Connect the Oil Feed Tube (112)

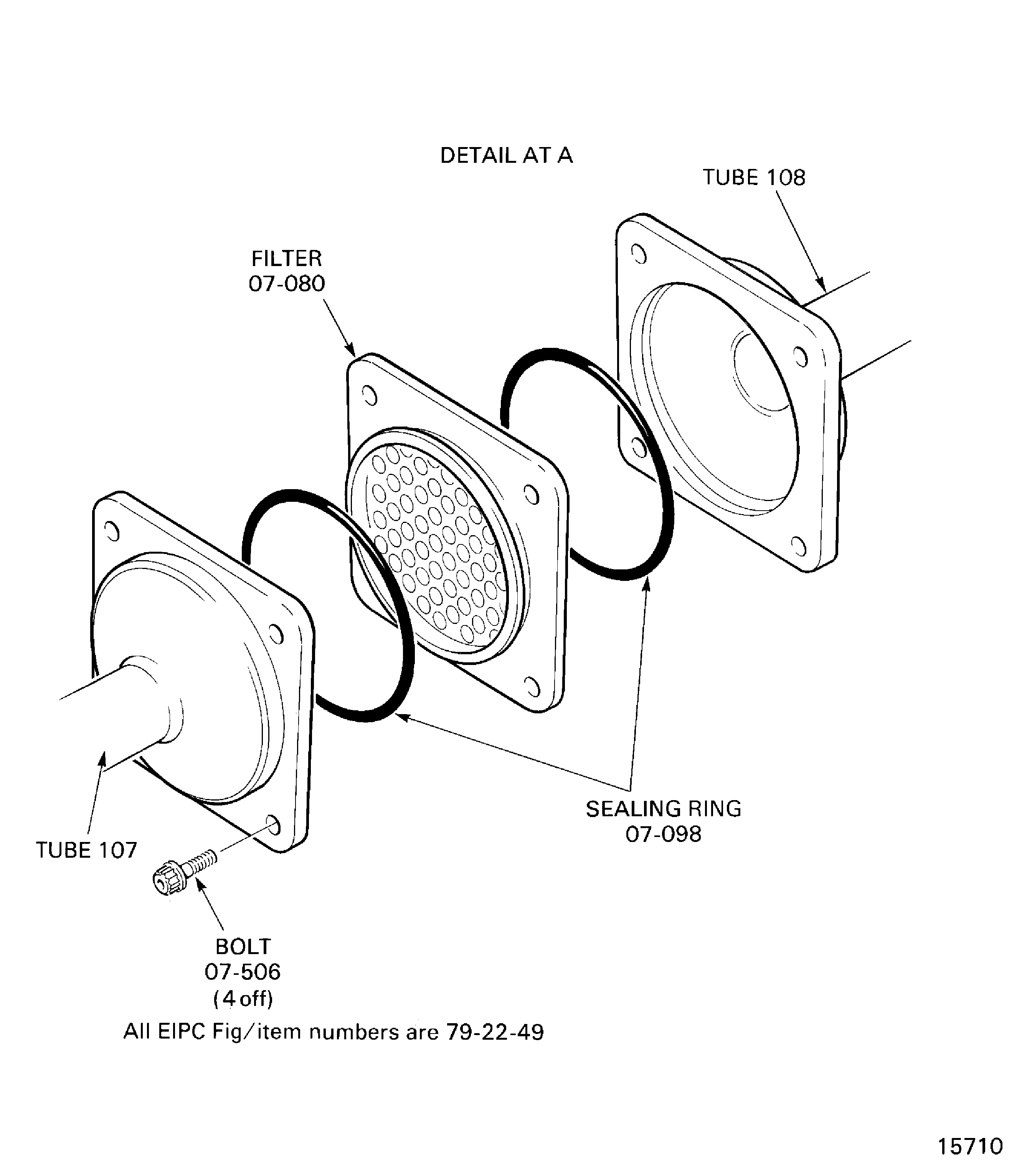

Lightly lubricate the new OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 07-098) sealing rings 2 off with CoMat 10-077 APPROVED ENGINE OILS. Install the two seals on the filter OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 07-080).

Connect the two tubes together with the filter between them. Install the four bolts OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 07-506) in the captive nuts and torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

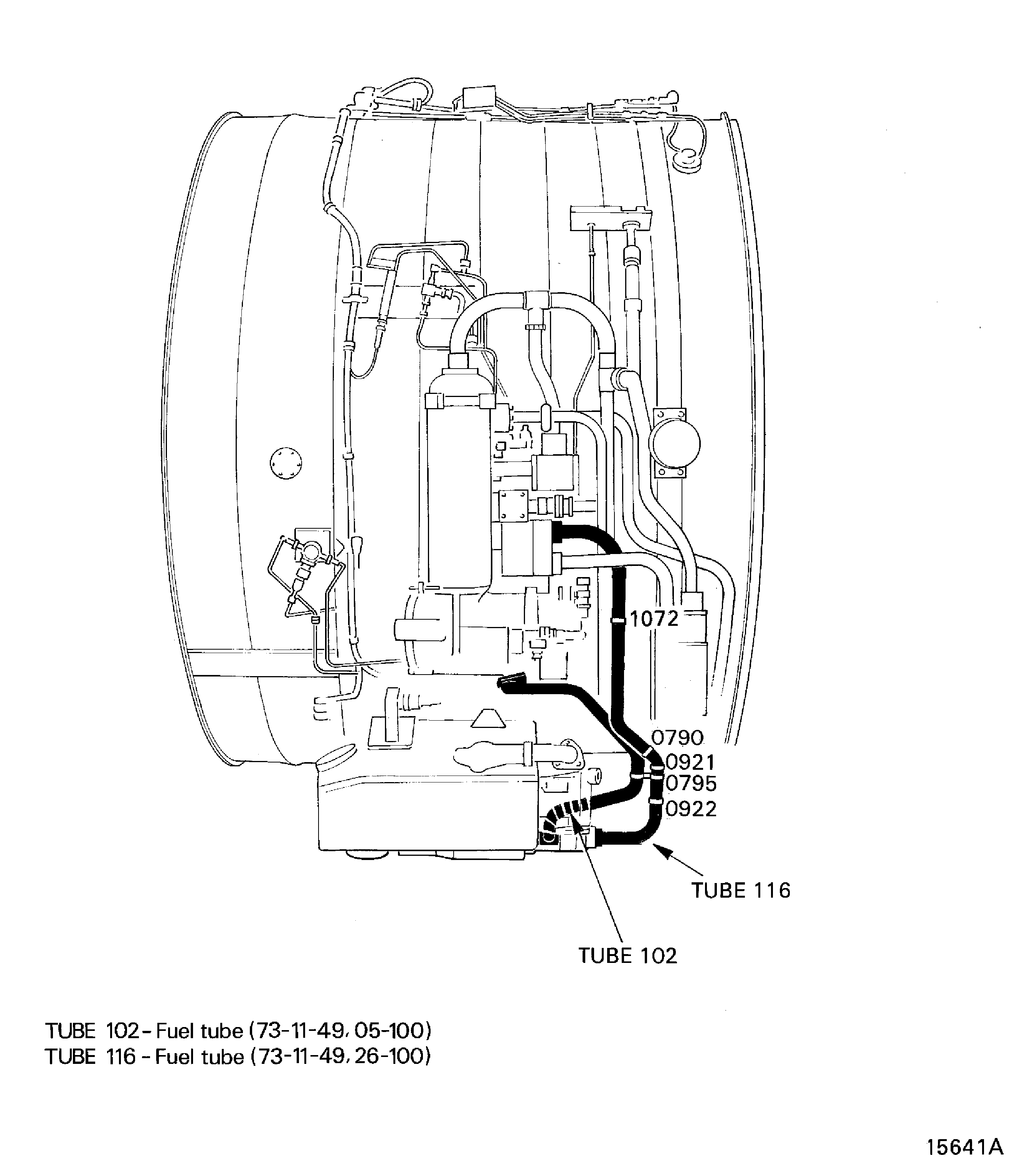

Connect the tube 107 to the tube 108:

Lightly lubricate the new OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 07-096) sealing ring 1 off with CoMat 10-077 APPROVED ENGINE OILS. Install the seal on the tube 108.

Lightly lubricate the new OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 07-516) sealing ring 1 off with CoMat 10-077 APPROVED ENGINE OILS. Install the seal on the tube 107.

Install the three bolts OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 07-514) that attach the tube 107 to the scavenge pump. Torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

Install the three bolts ENGINE-LP COMP/INTERMEDIATE CASE MODULE (72-32-00, 01-110) that attach the tube 108 to the LP compressor/intermediate case. Torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

Install the scavenge tube assembly between the scavenge pump and the LP compressor/intermediate case:

Lightly lubricate the new OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-040) packing 1 off with CoMat 10-077 APPROVED ENGINE OILS and install it in the body unit OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-020).

Lightly lubricate the threads of the body unit with CoMat 10-077 APPROVED ENGINE OILS. Install the body unit in the tube 107 and torque to 160 *lbfin. to 180 *lbfin. (18 Nm to 20 Nm).

Make sure the two packings OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-030) are correctly installed on the magnetic probe OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-010). Install the probe in the body unit and make sure the probe is correctly aligned.

Install the magnetic chip detector in the tube 107:

SUBTASK 72-00-60-420-083 Install the No. 1, 2 and 3 Bearing Compartment Scavenge Tube Assembly Tubes (107 and 108)

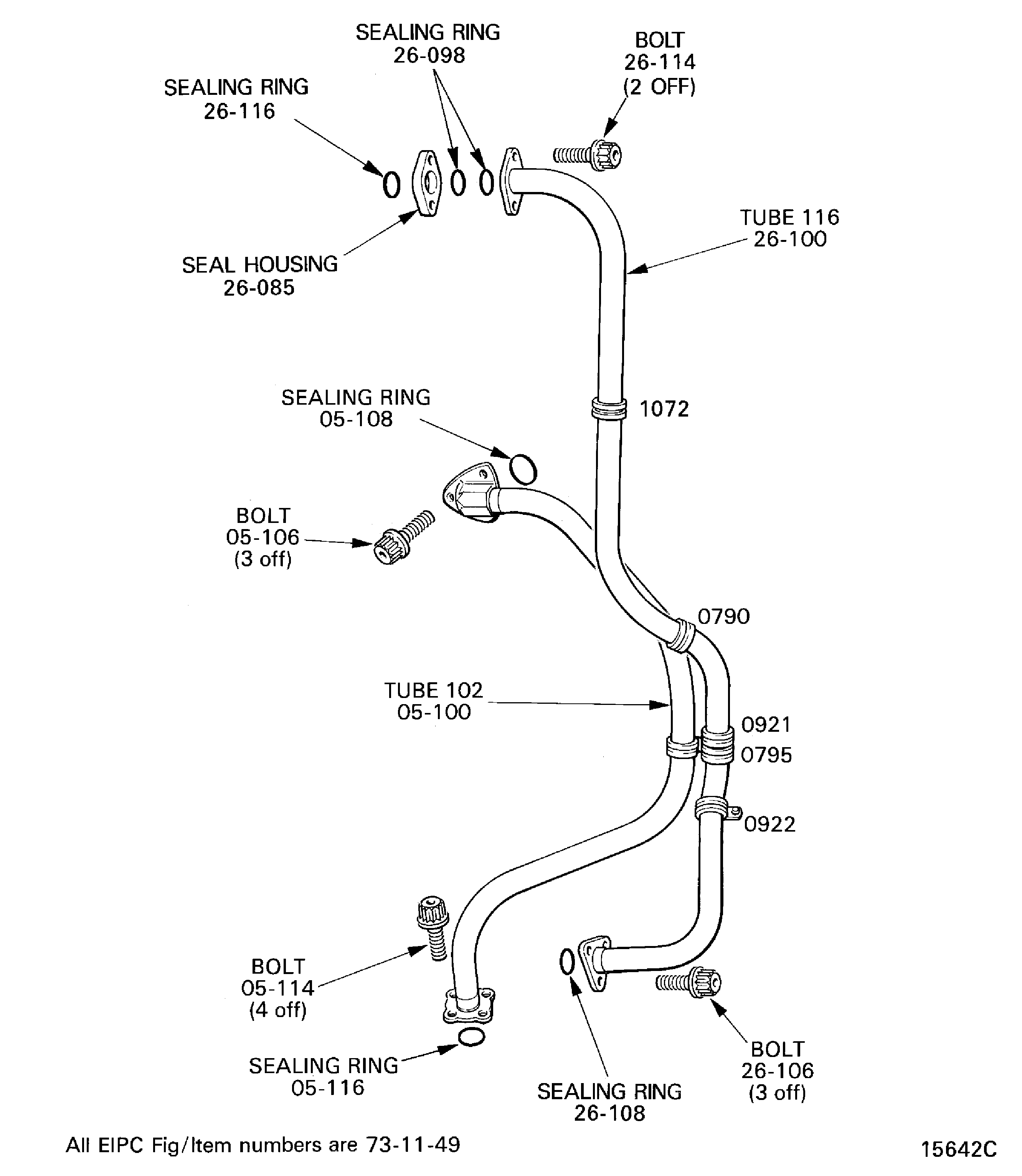

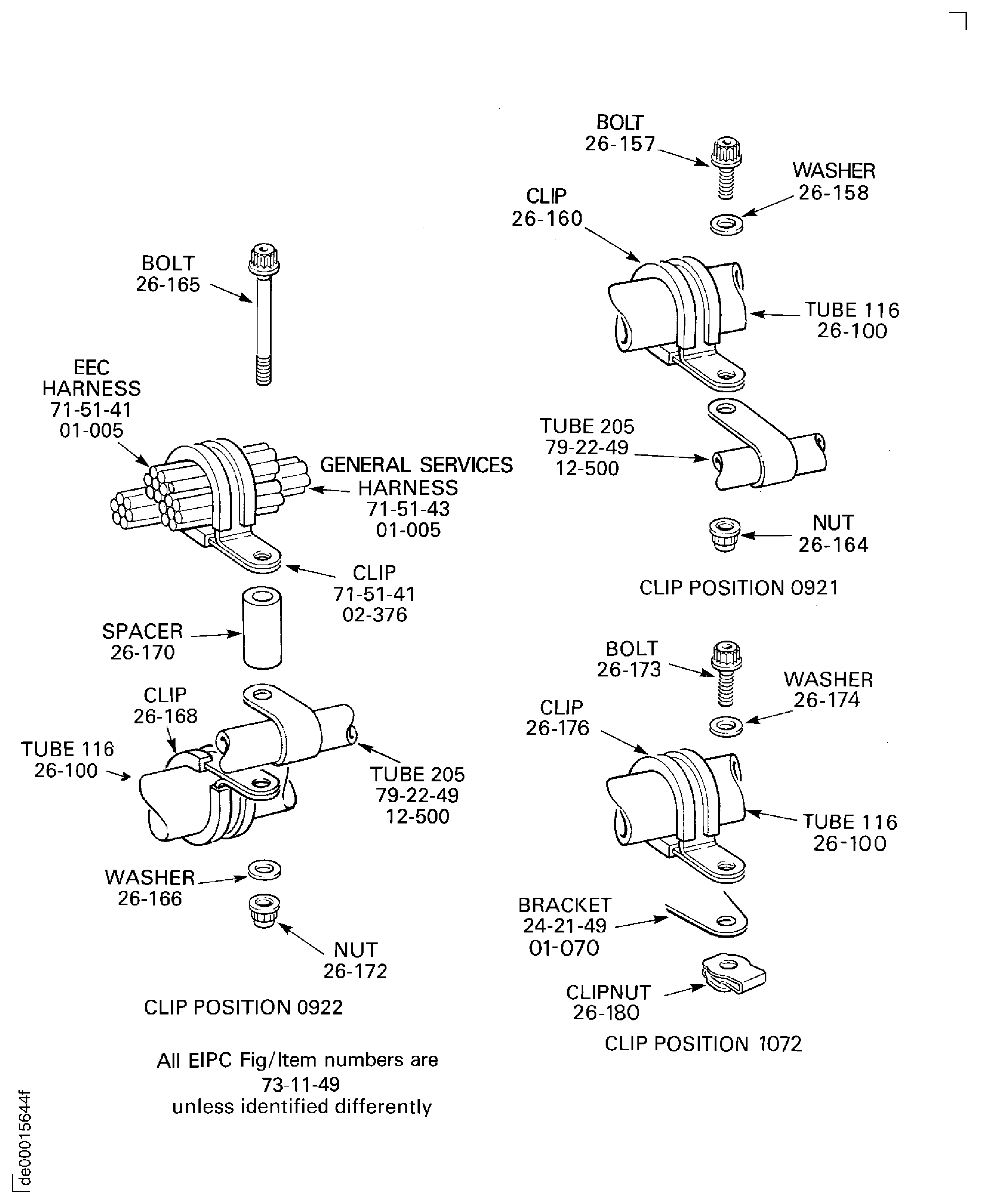

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 26-108) sealing ring 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the seal on the tube 116.

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 26-116) sealing ring 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the seal on the seal housing ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 26-085).

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 26-098) sealing rings 2 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the seals on the tube 116 and the seal housing.

Install the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 26-106) that attach the tube 116 to the FMU. Install the two bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 26-114) that attach the tube 116 to the Fuel Diverter Valve. Torque the five bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

SUBTASK 72-00-60-420-084 Install the FMU Spill Tube (116)

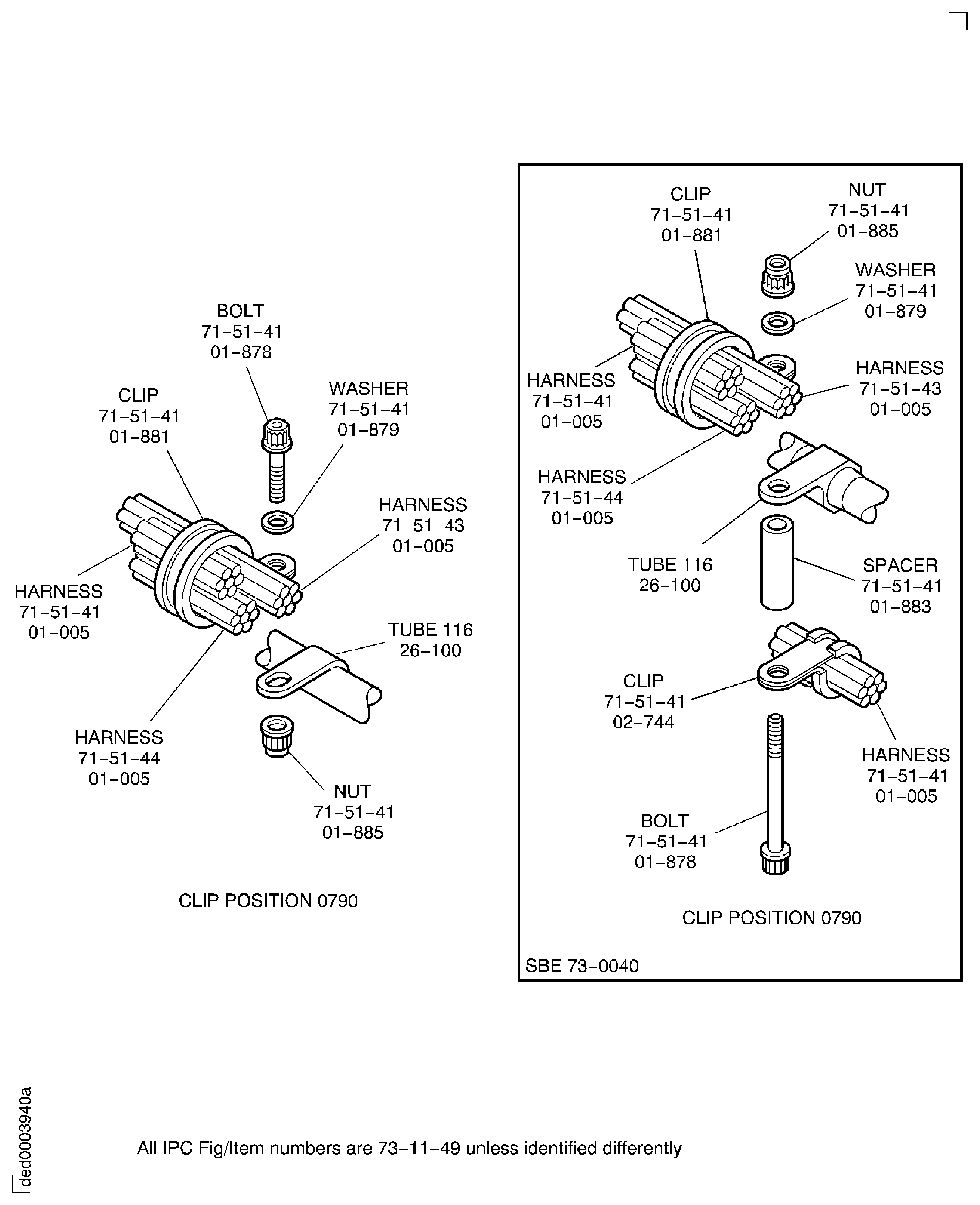

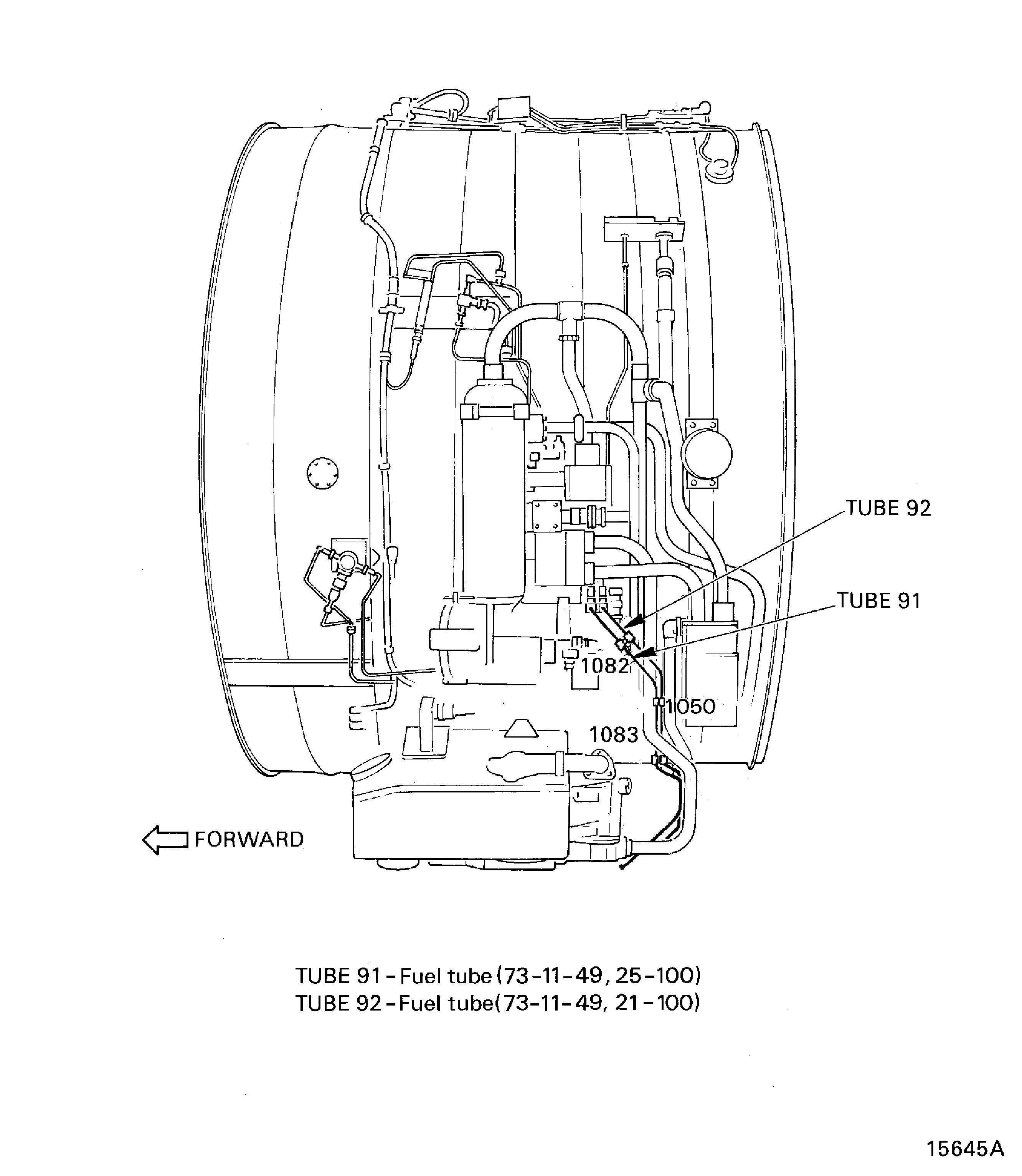

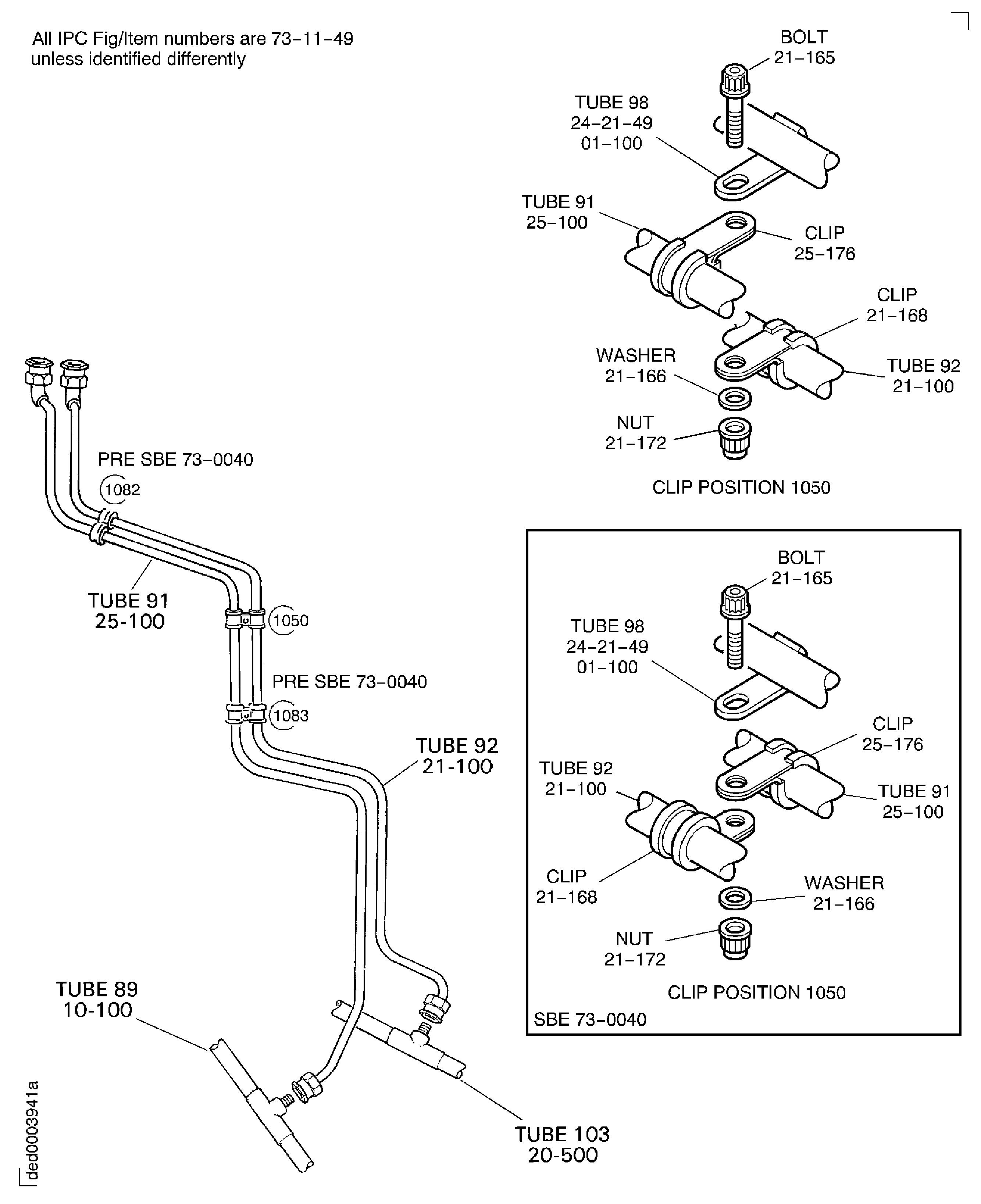

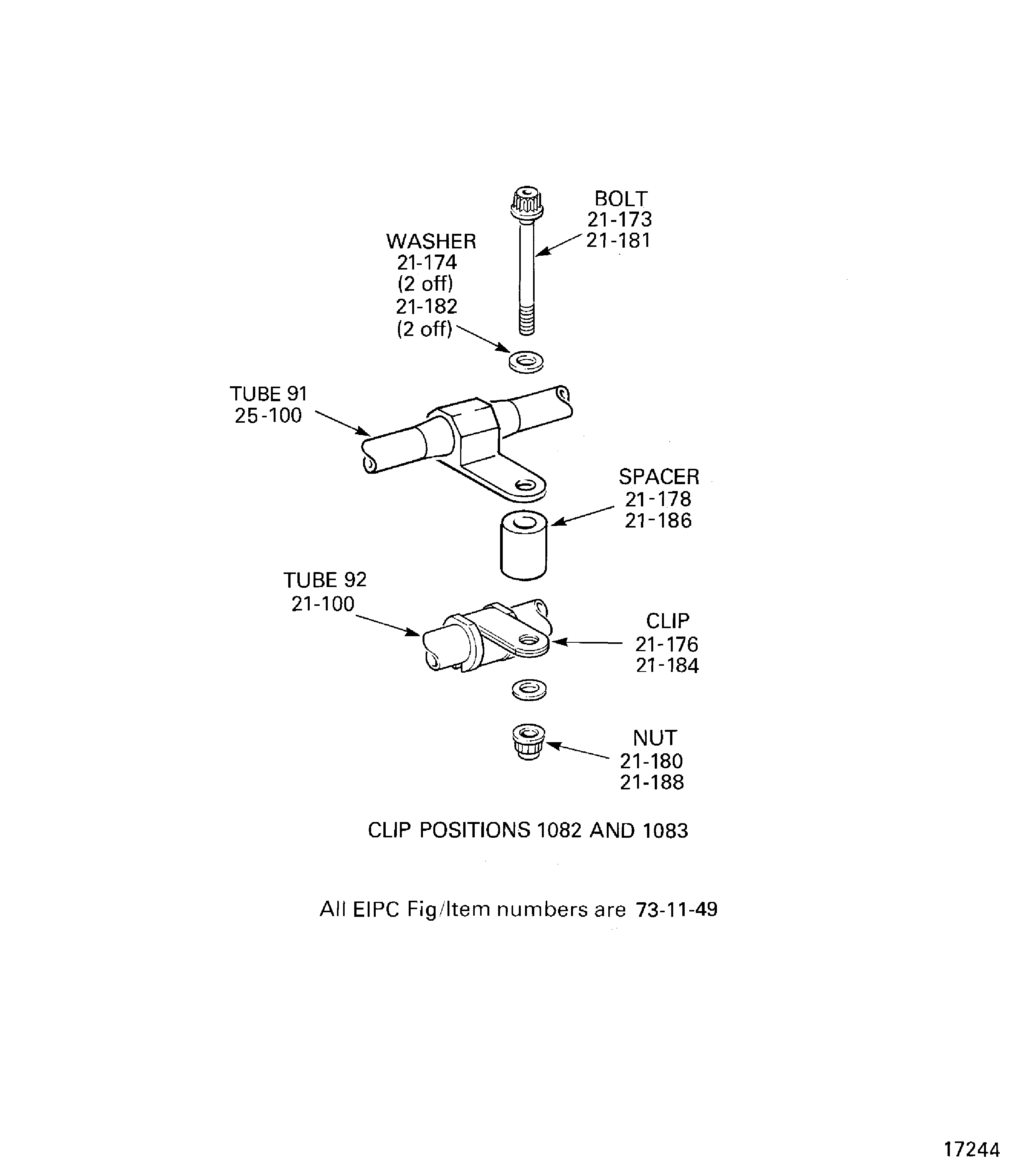

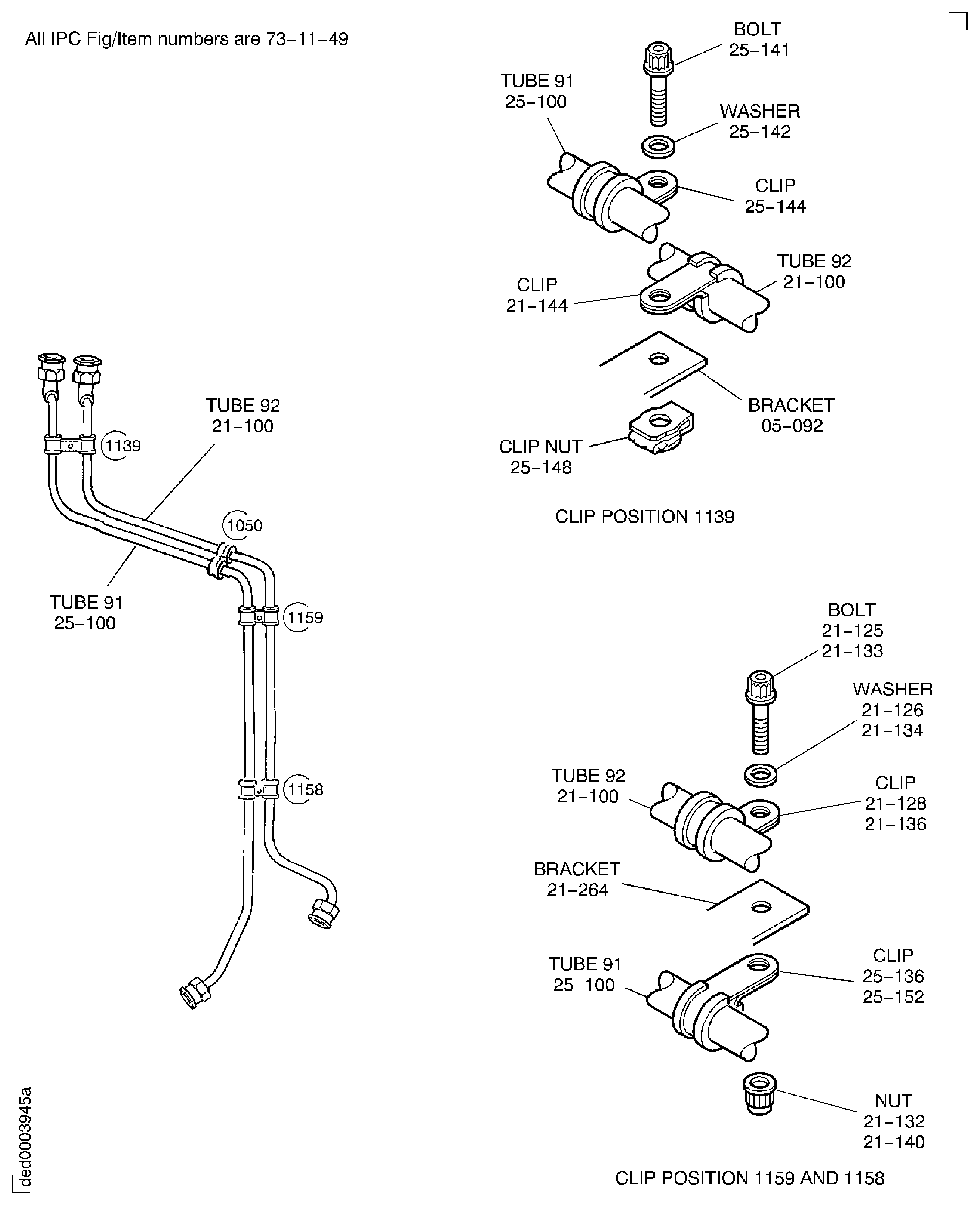

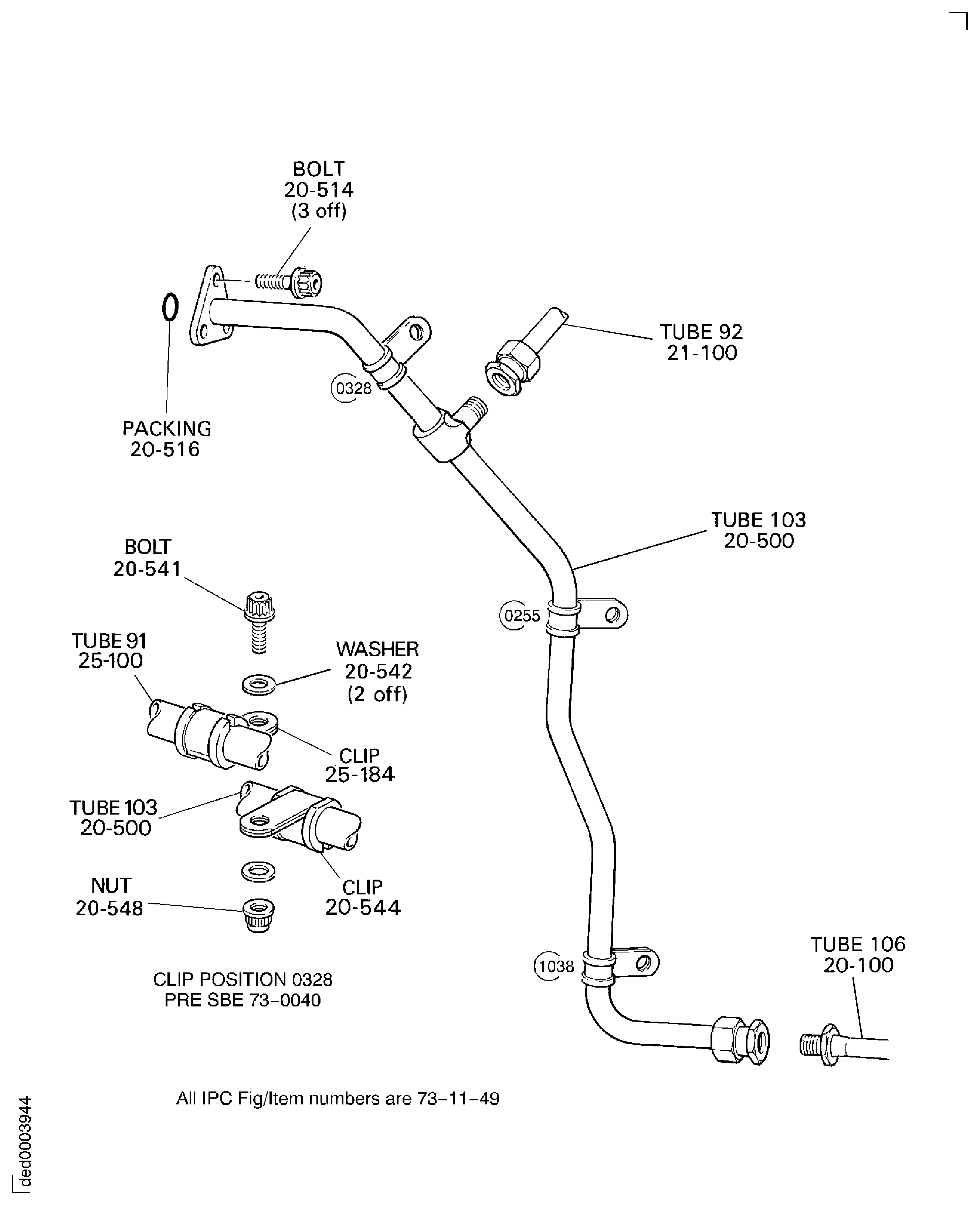

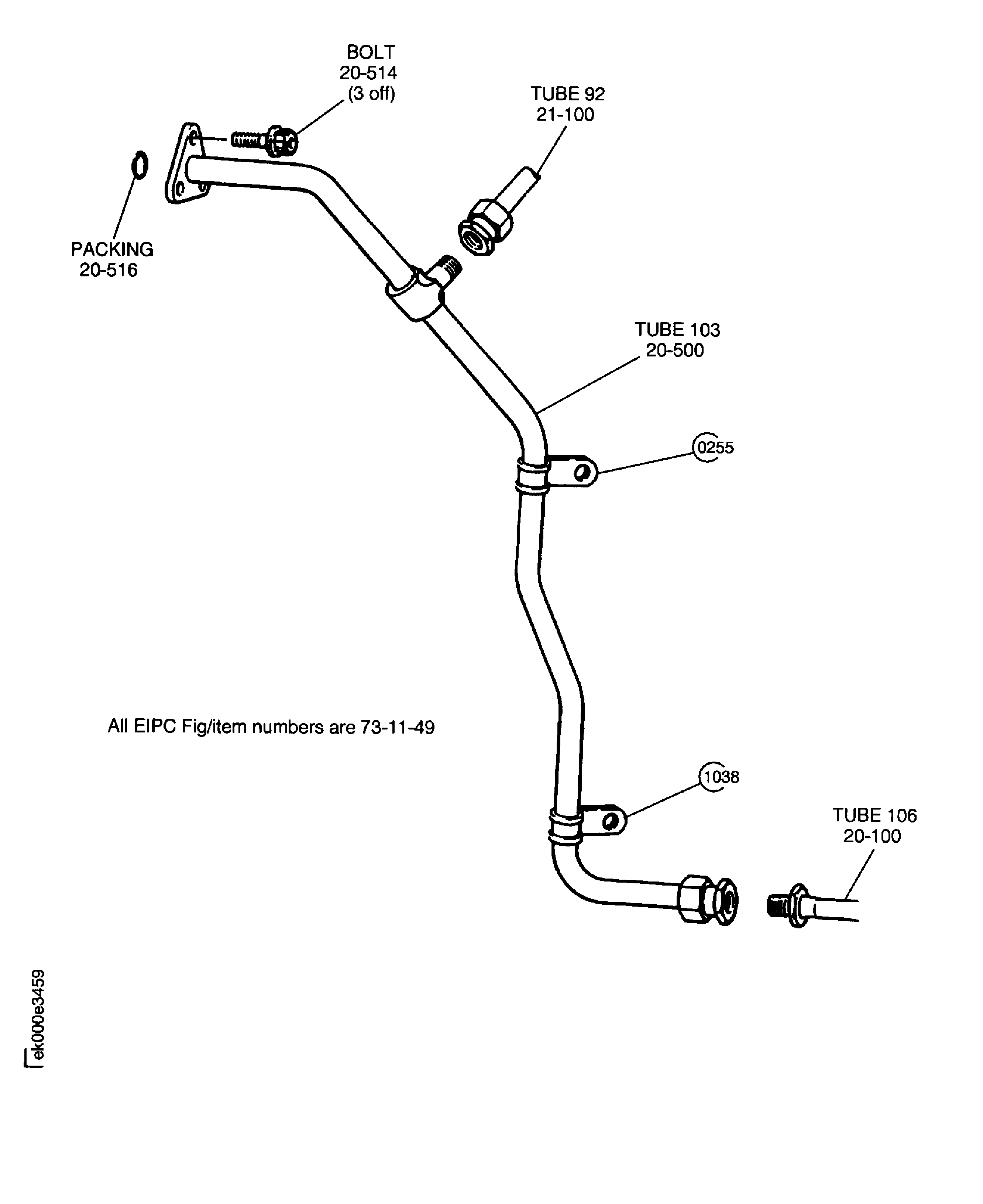

Torque the connector of the tube 92 to 204 lbfin. to 221 lbfin. (23 Nm to 25 Nm) and the connector of tube the 91 to 159 lbfin. to 177 lbfin. (18 Nm to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-60-420-085-A00 Install the Fuel Servo Tubes (91 and 92) (Pre SBE 73-0040)

Torque the connector of the tube 92 to 204 lbfin. to 221 lbfin. (23 Nm to 25 Nm) and the connector of tube the 91 to 159 lbfin. to 177 lbfin. (18 Nm to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-60-420-085-B00 Install the Fuel Servo Tubes (91 and 92) (SBE 73-0040)

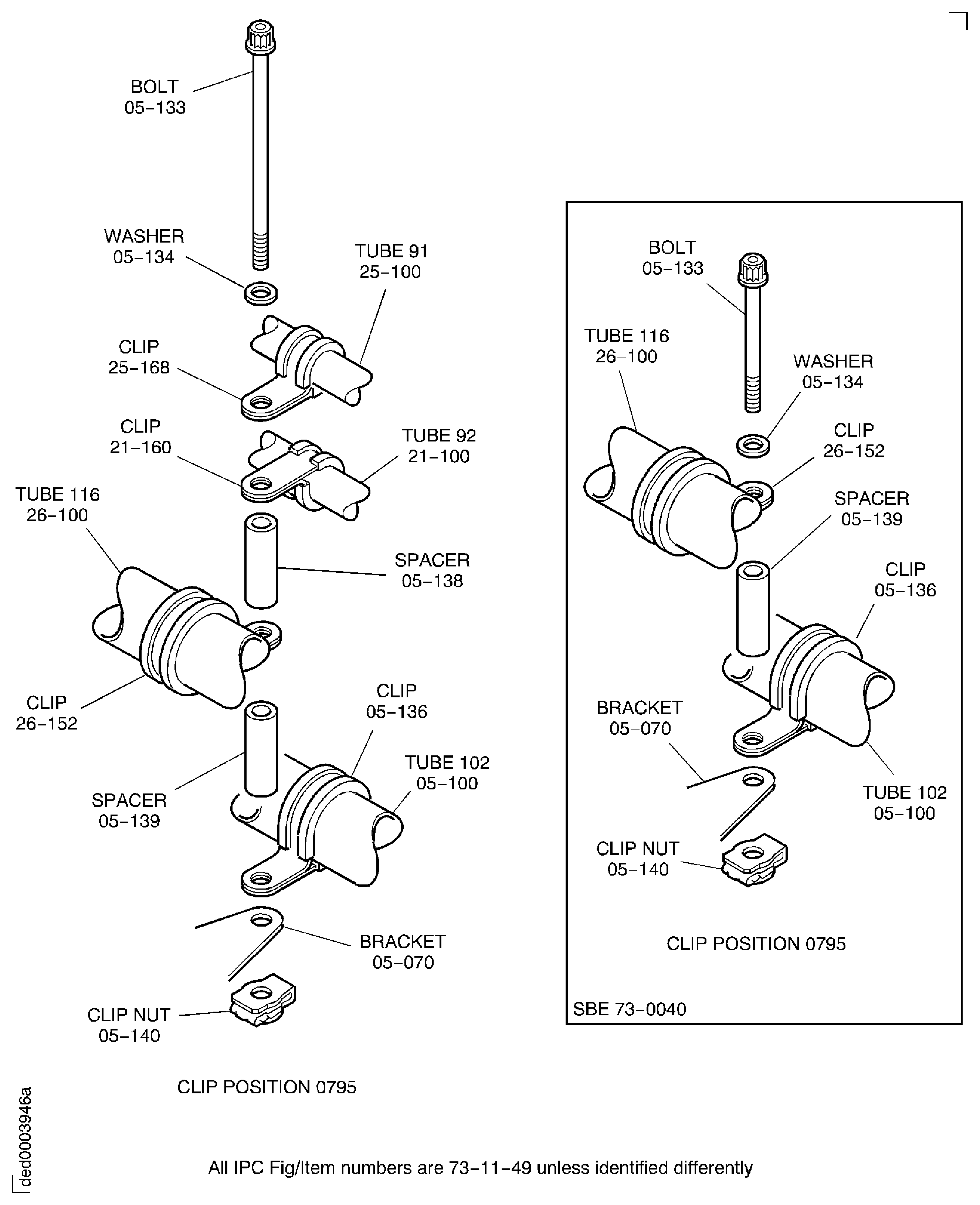

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 05-108) sealing ring 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the seal on the tube 102.

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 05-116) sealing ring 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the seal on the tube 102.

With the tube 102 in position, install the seven bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 05-106 and ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE 05-114) that attach the tube 102 to the fuel pump and the FCOC. Torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

SUBTASK 72-00-60-420-086 Install the LP Fuel Tube (102)

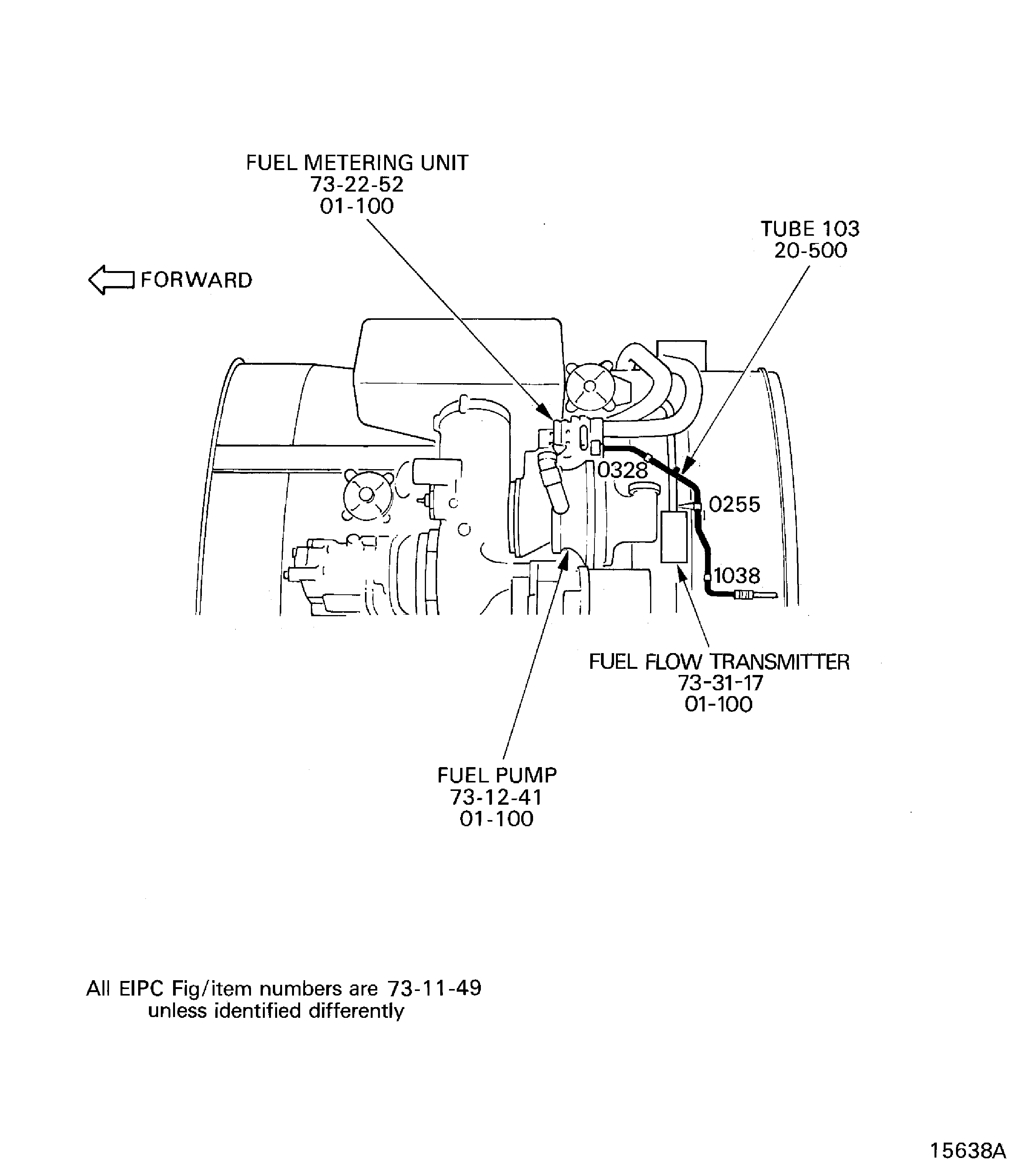

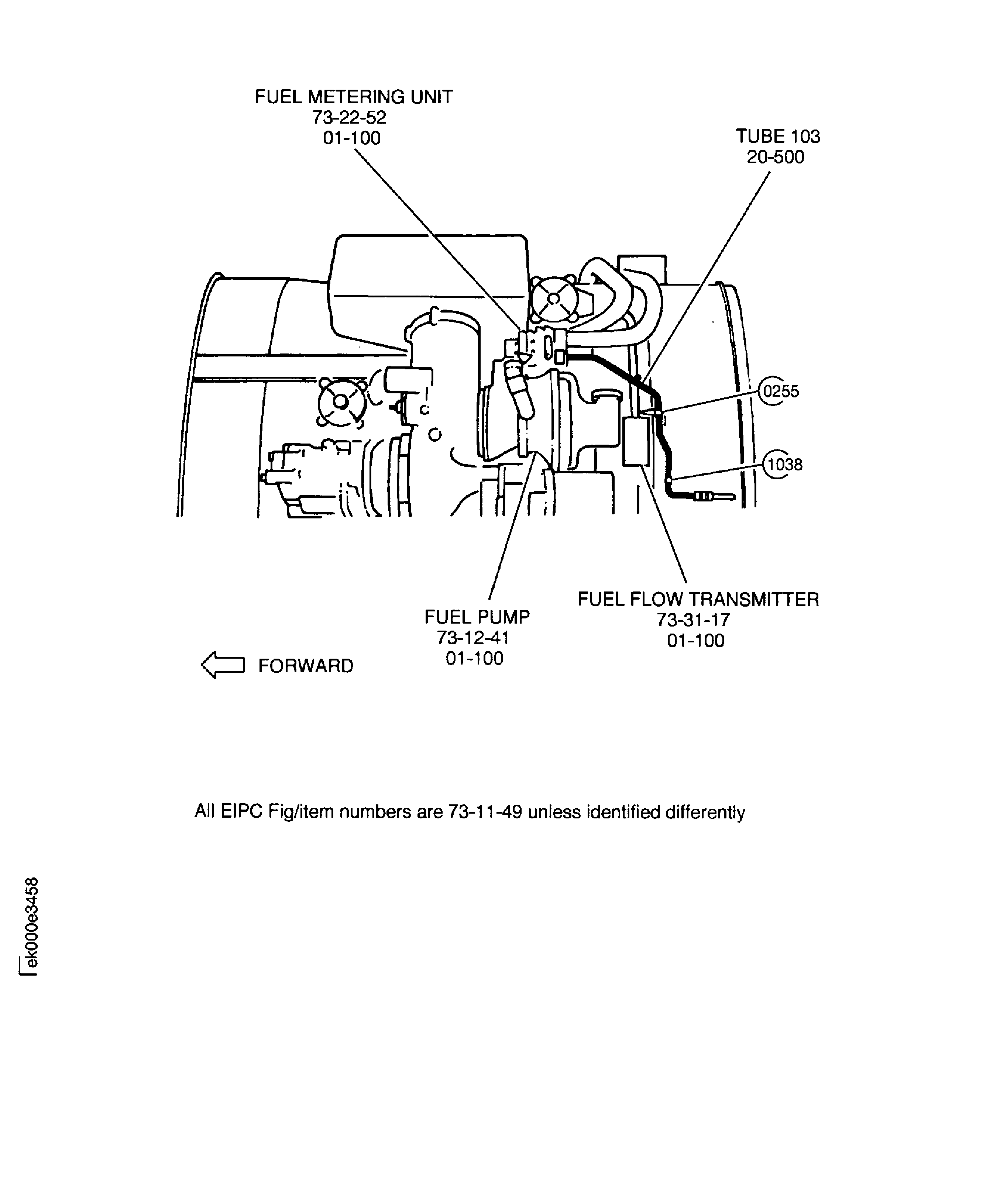

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 20-516) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the packing on the FMU connector of the tube 103.

Install the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 20-514) that attach the tube 103 to the FMU. Torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

Torque the connector of the tube 103 to 283 lbfin. to 310 lbfin. (32 Nm to 35 Nm). Safety with CoMat 02-126 LOCKWIRE.

Connect the tube 92 to the tube 103 and torque to 159 lbfin. to 177 lbfin. (18 Nm to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-60-420-087-A00 Install the Fuel Servo Return Tube (103) (Pre SBE 73-0040)

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 20-516) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the packing on the FMU connector of the tube 103.

Install the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 20-514) that attach the tube 103 to the FMU. Torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm).

Torque the connector of the tube 103 to 283 lbfin. to 310 lbfin. (32 Nm to 35 Nm). Safety with CoMat 02-126 LOCKWIRE.

Connect the tube 92 to the tube 103 and torque to 159 lbfin. to 177 lbfin. (18 Nm to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-60-420-087-B00 Install the Fuel Servo Return Tube (103) (SBE 73-0040)

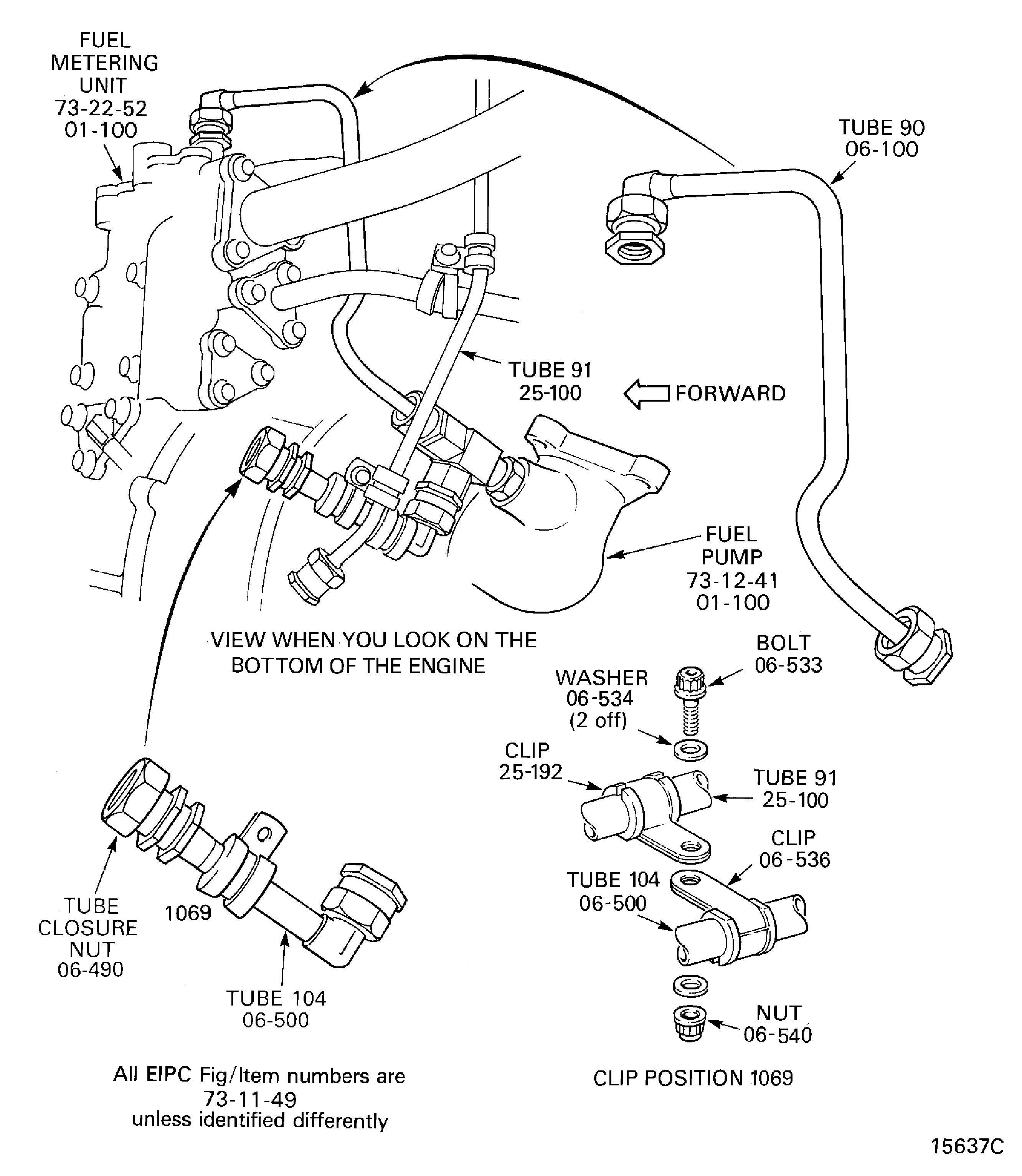

Refer to Figure.

Connect the tube 90 to the LP fuel pump and the FMU. Torque the tube connectors to 159 lbfin. to 177 lbfin. (18 Nm to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

NOTE

Make sure the closure nut ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 06-490) is also safetied with lockwire.Connect the tube 104 to the fuel pump and torque the tube connector to 230 lbfin. to 248 lbfin. (26 Nm to 28 Nm). Safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-60-420-088 Install the LP Fuel Tube (90) and the Fuel Pump Drain Tube (104)

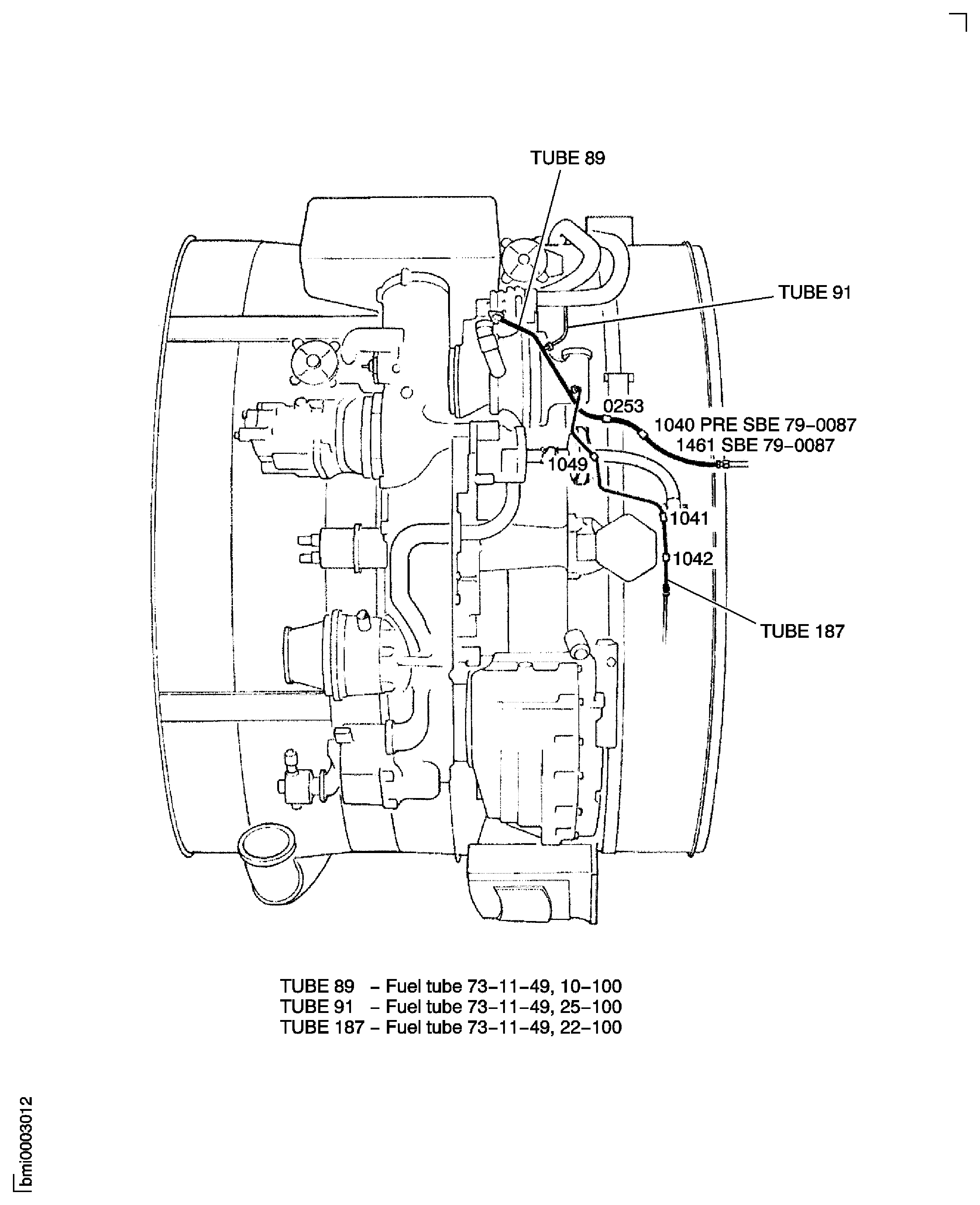

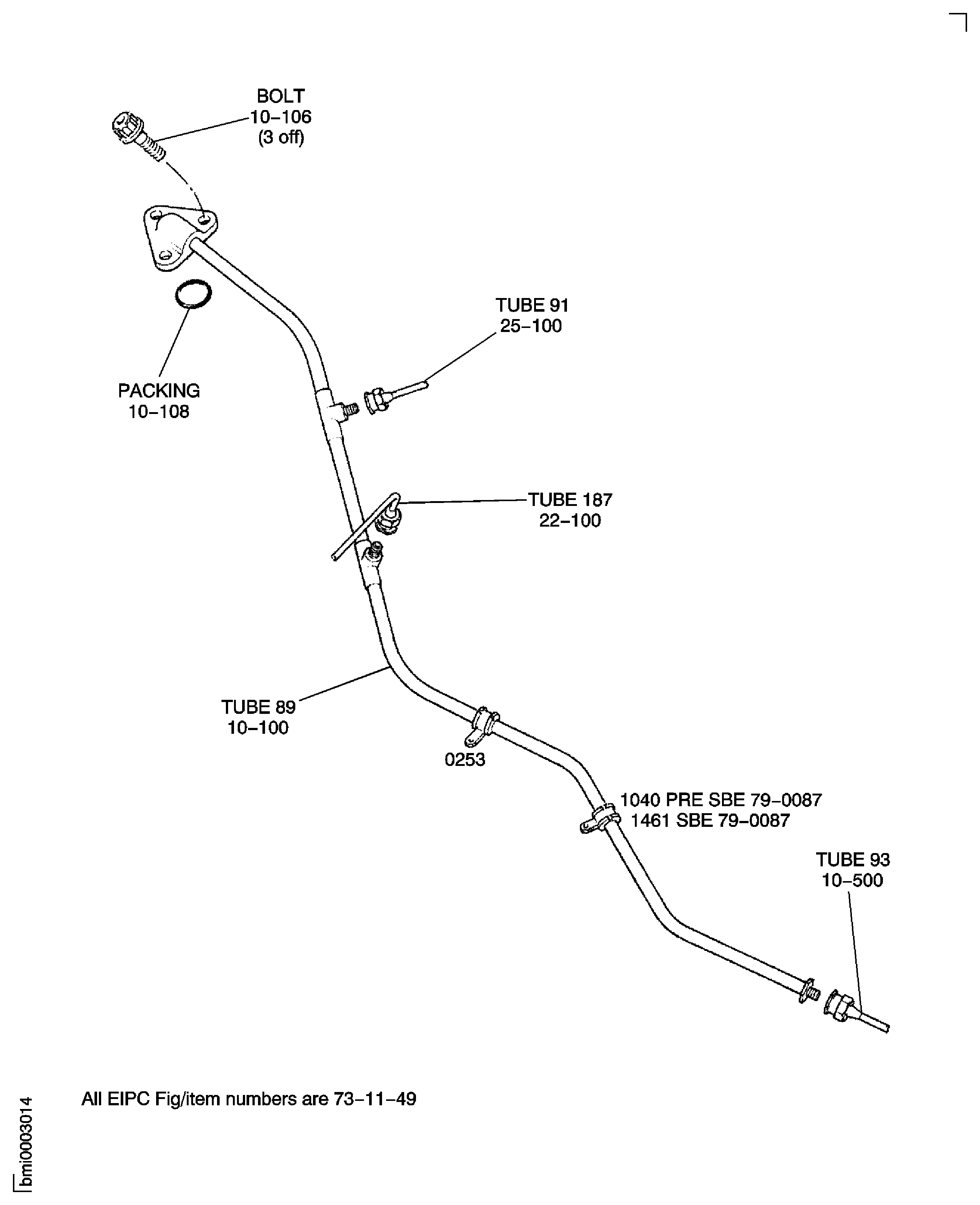

Lightly lubricate the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 10-108) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the packing on the FMU connector of the tube 89.

Loosely connect the tube 89 to the tube 93 then connect the tube 89 to the FMU. Install the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 10-106) that attach the tube 89 to the FMU. Torque the bolts to 85 lbfin. to 105 lbfin. (10 Nm to 12 Nm). Torque the tube connector to 283 lbfin. to 310 lbfin. (32 Nm to 35 Nm). Safety with CoMat 02-126 LOCKWIRE.

Connect the tube 91 to the tube 89. Torque the tube connector to 159 lbfin. to 177 lbfin. (18 Nm to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

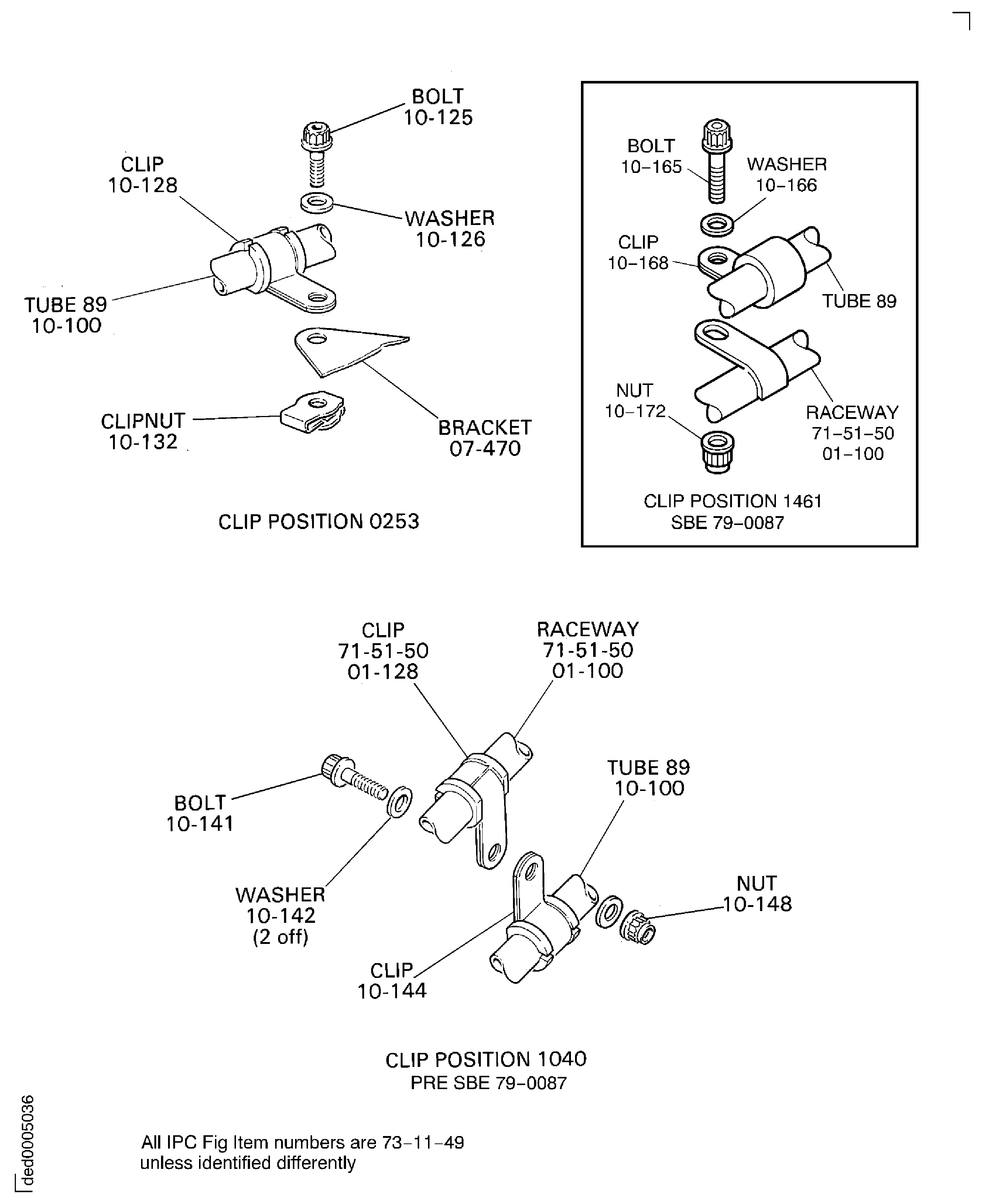

Pre SBE 79-0087: Assemble clip positions 0253 and 1040 and torque the nut and the bolt to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm).

SBE 79-0087: Assemble clip position 0253 and torque the nut and the bolt to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm).

SUBTASK 72-00-60-420-089 Install the HP Servo Fuel Tube (89) (Pre SBE 79-0087 and SBE 79-0087)

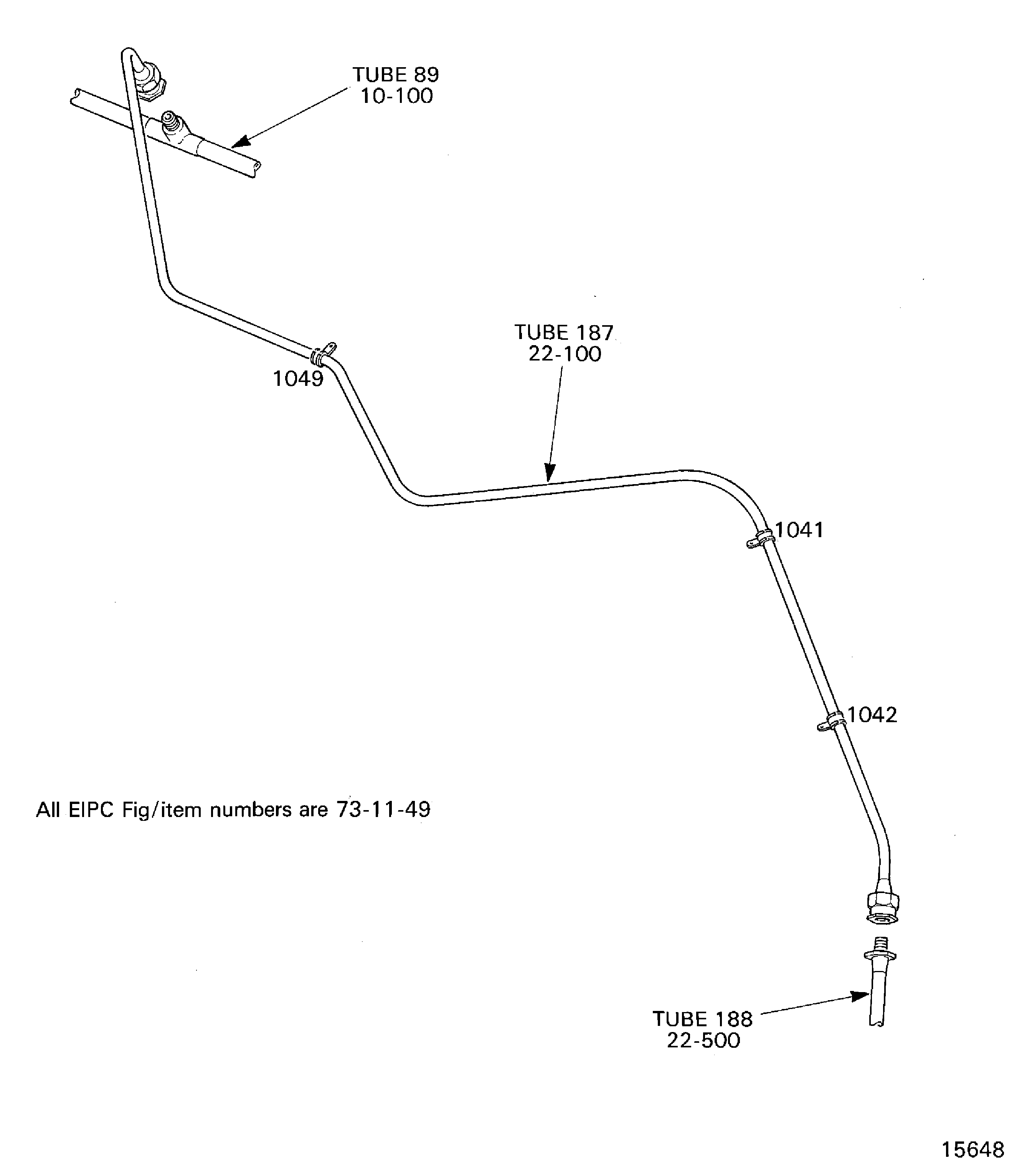

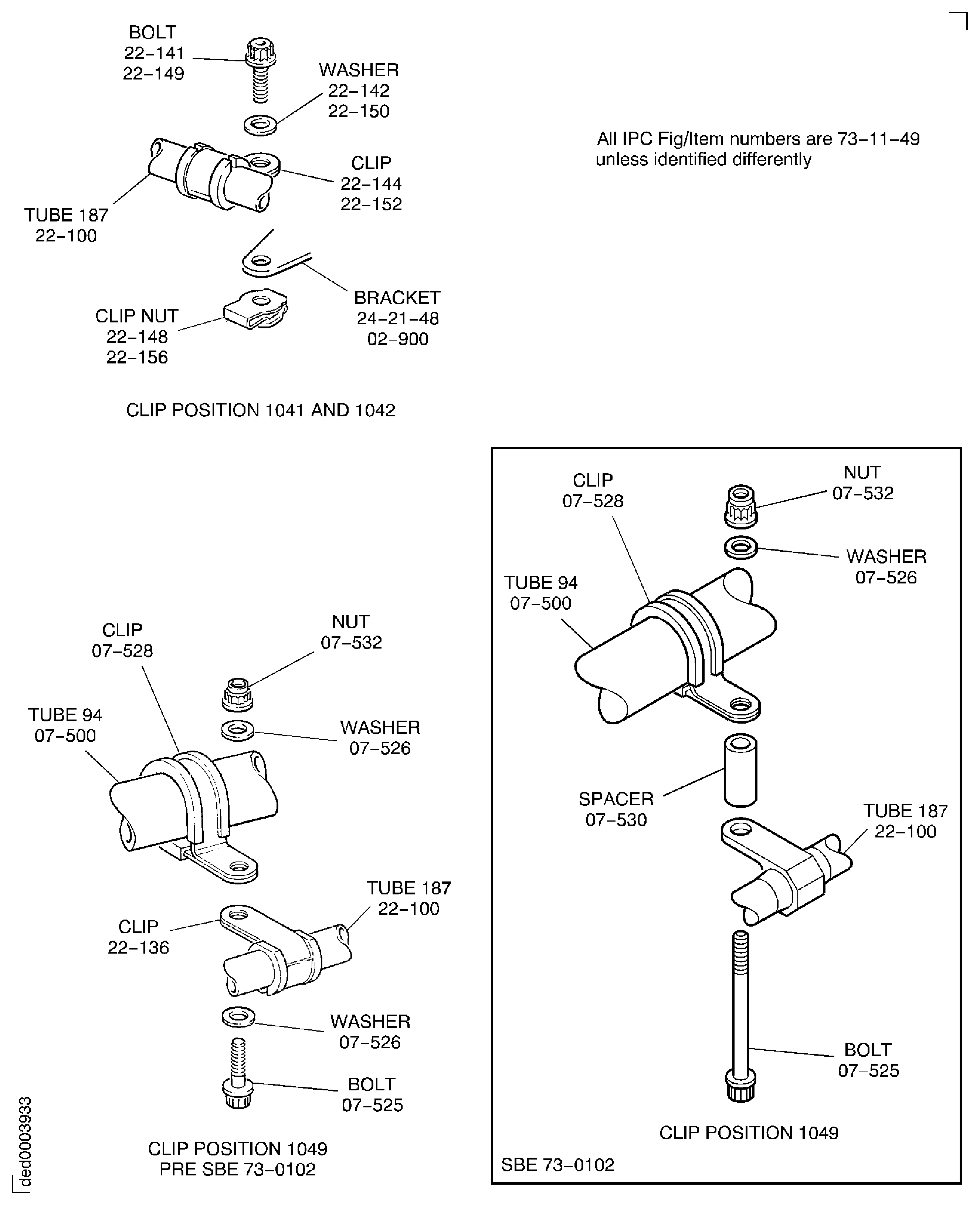

Torque the connectors of the tube 187 to 159 lbfin. to 177 lbfin. (18 Nm to 20 Nm). Safety with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-60-420-080 Install the Air Modulating Valve Supply Tube (187)

Refer to Figure.

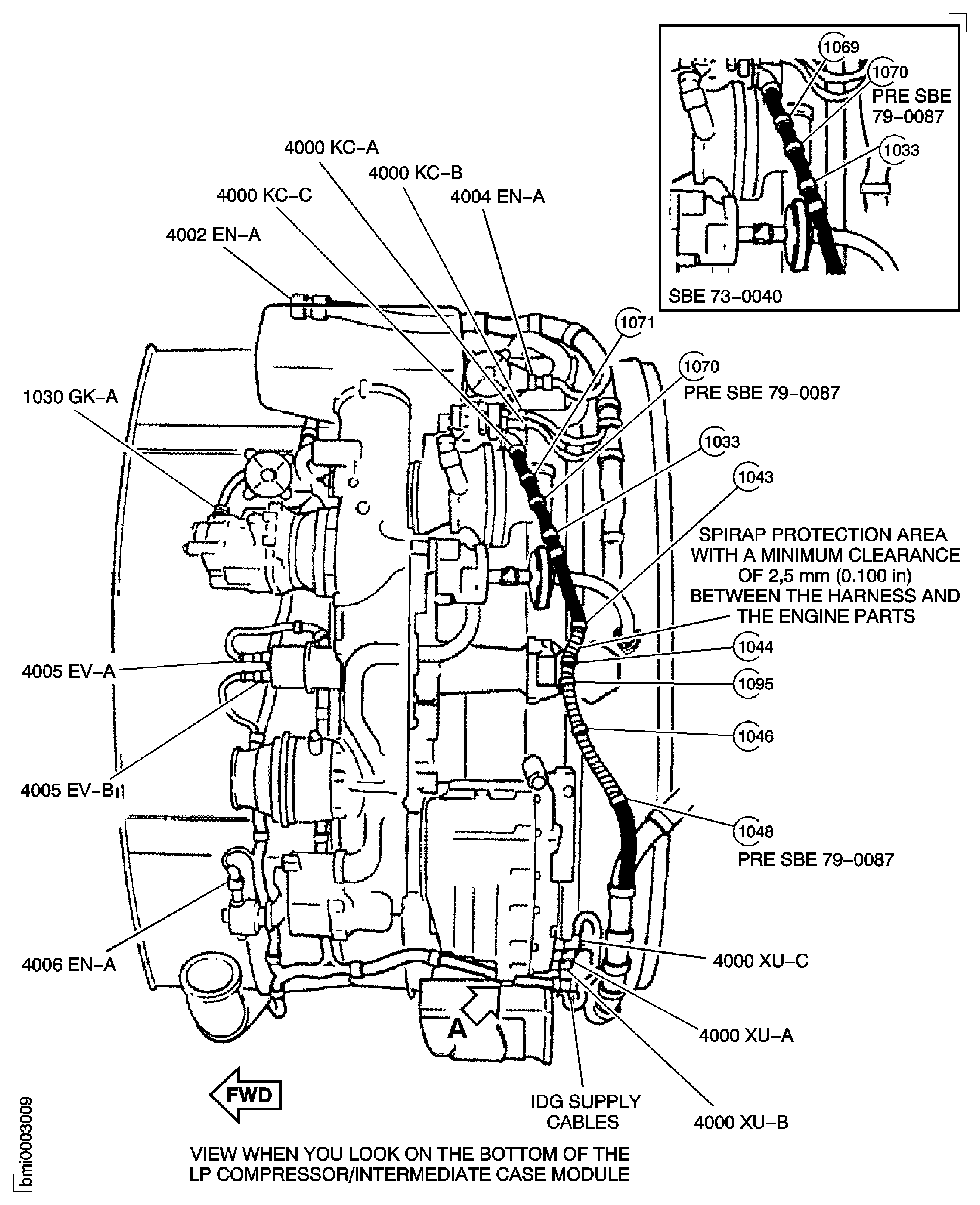

During the installation procedure make sure the harnesses are held temporarily along their different lengths. Always install the datum clip positions when you install each electrical connector. This will give correct installation of the different harnesses, prevent too much strain on the electrical connectors and give the necessary drip loops (the drip loop makes sure moisture or fluids do not go in the electrical connector).

Because of the differences between the harness diameters, the specified clip could be too large or too small. You can use a clip from a range of six clips that have the same part number. If the harness diameter is between two of the clips in the range, use the larger clip. When you do this use CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) to increase the harness diameter.

For the data on the electrical connectors refer to the SPM TASK 70-43-00-400-501 and TASK 70-43-01-400-501.

SUBTASK 72-00-60-420-100 Electrical Harness Installation Procedure

NOTE

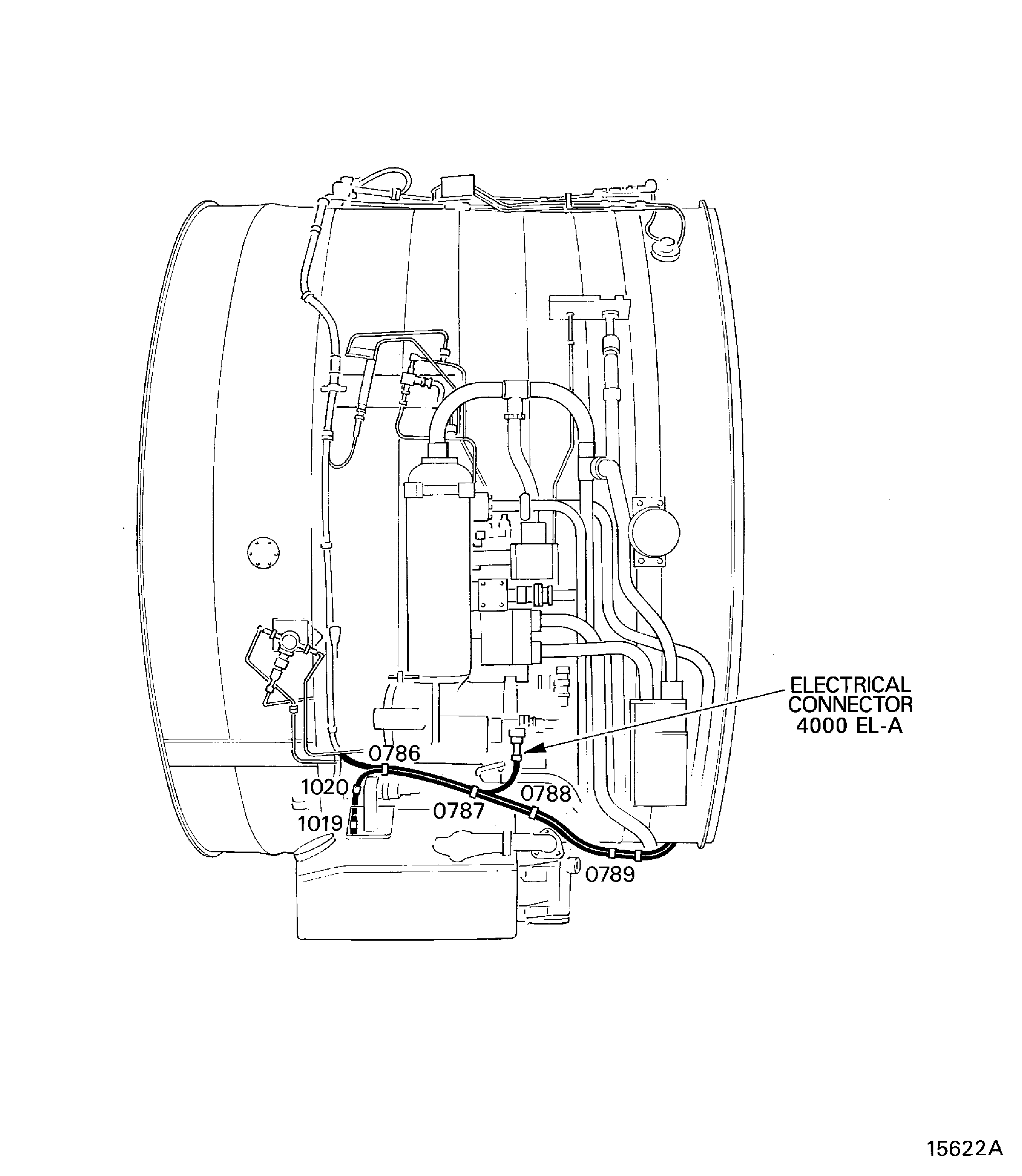

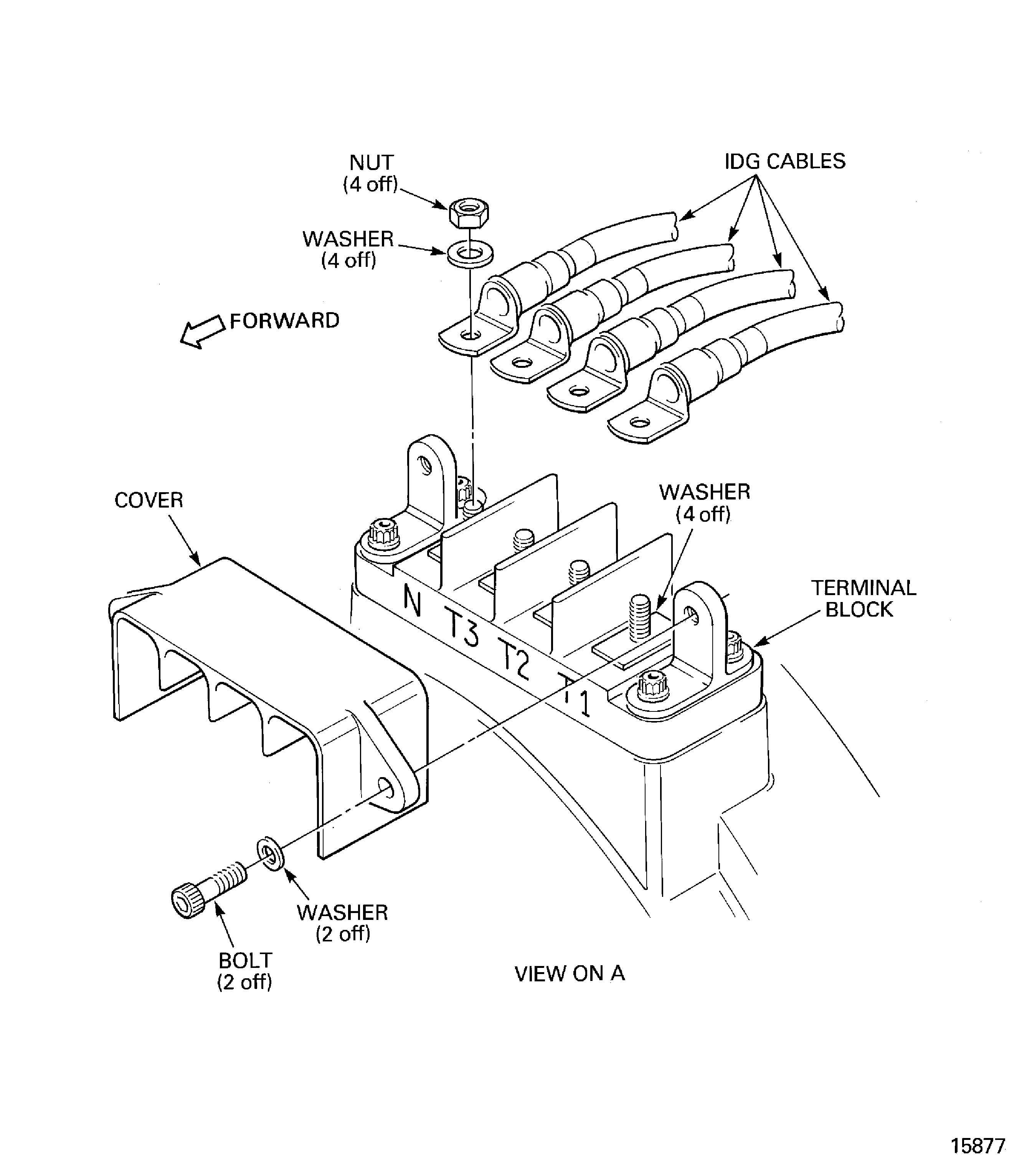

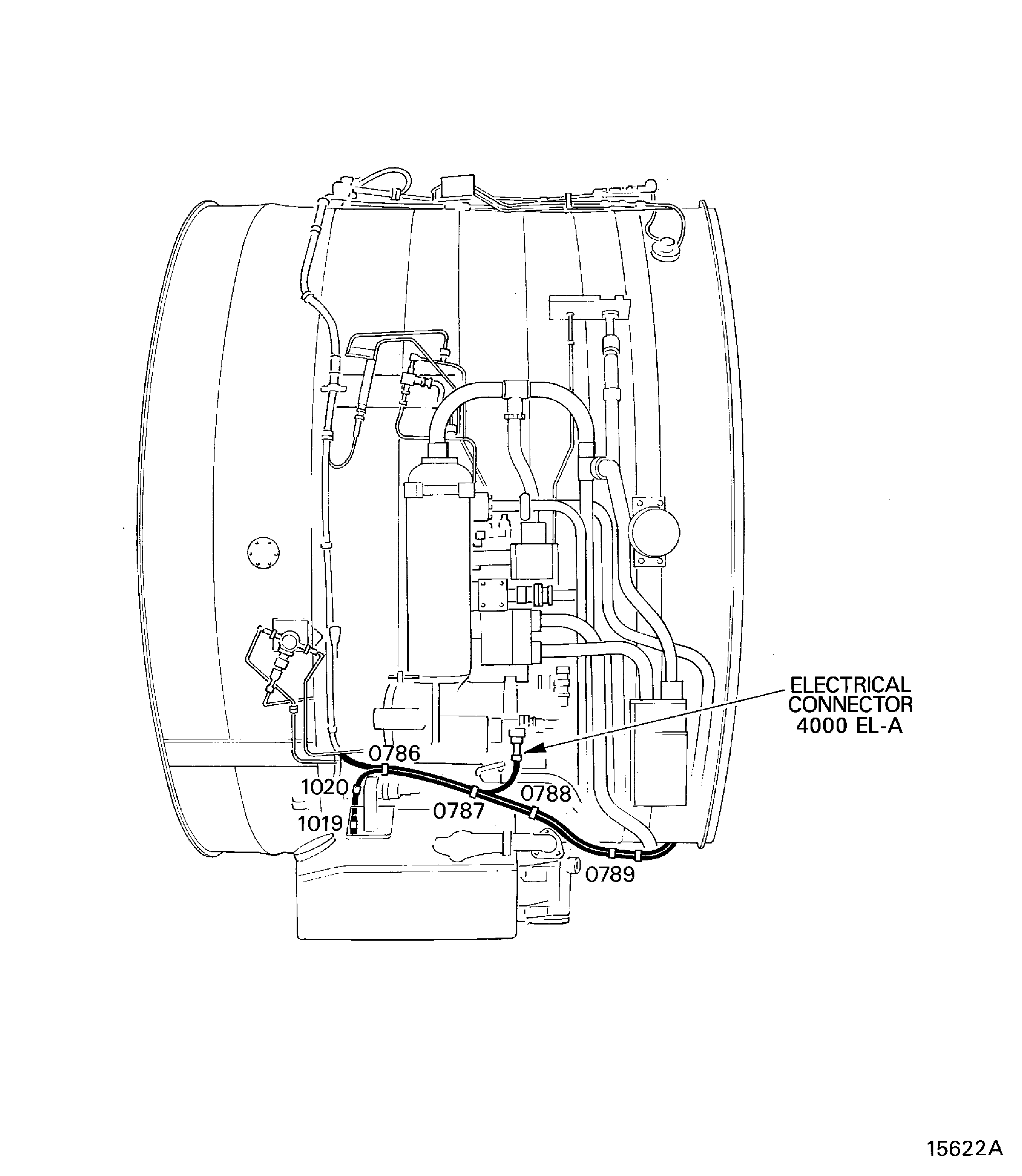

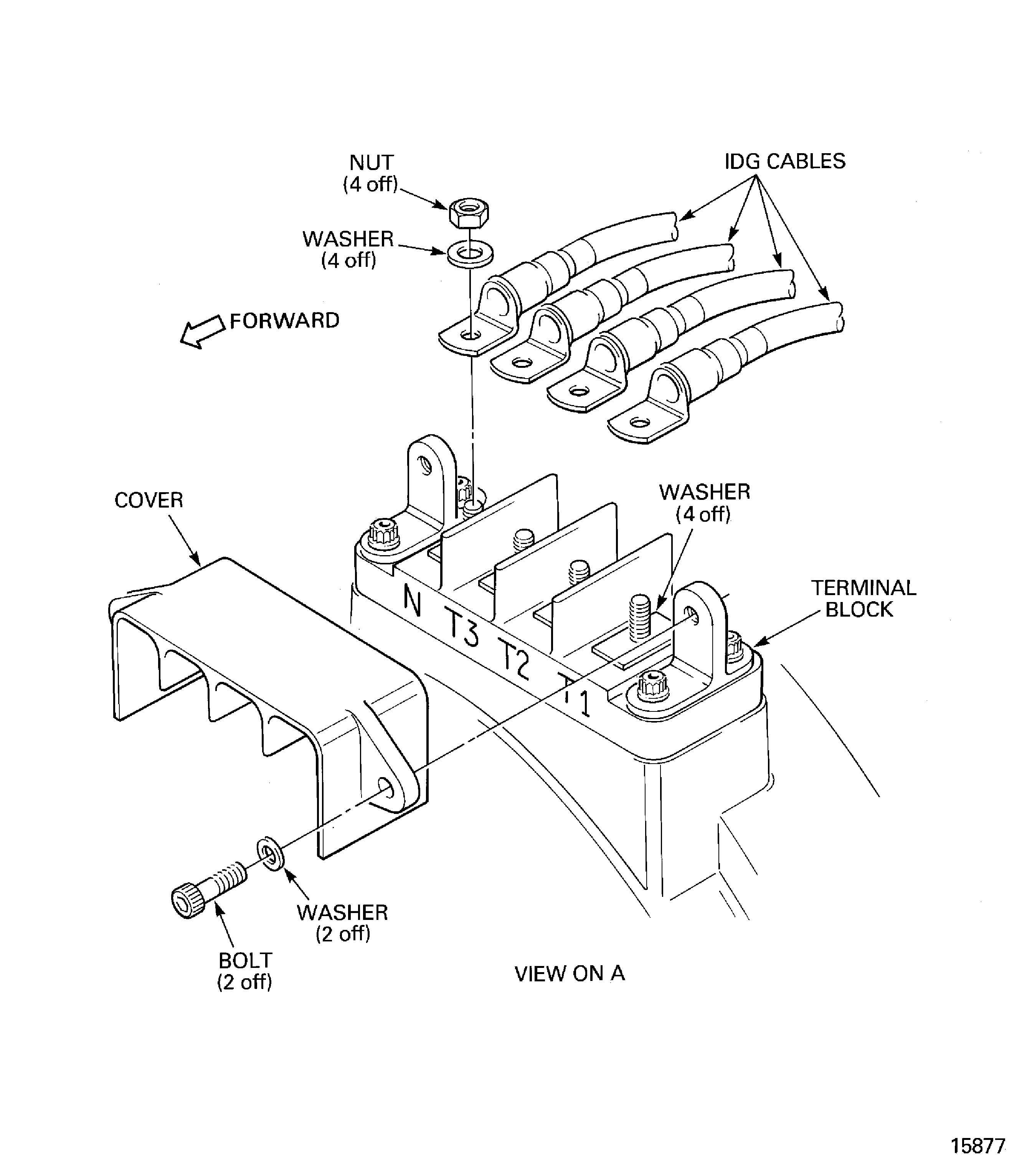

The terminal size used on the cables is the same at all four locations. To avoid incorrect cable installation, it is necessary to carefully check that the identification codes on the cables match with the codes on the IDG mounting bracket.Remove the cover from the IDG cable assembly terminals and connect the four cables to their correct terminals. Install the four nuts and torque them to 144 *lbfin. to 168 *lbfin. (16 Nm to 19 Nm). Install the terminal cover and torque the two bolts to 20 *lbfin. to 22 *lbfin. (2.25 Nm to 2.5 Nm). Remove the temporary identification tags.

NOTE

A EEC harness incorporating SBE 71-0219 or SBE 71-0221 can only be installed to a SBE 73-0138 dedicated alternator stator with revised electrical connectors.Connect the two EEC harness electrical connectors 4005EV-A and 4005EV-B to the Dedicated Alternator and torque to 16 * lbfin. (1.8 Nm). Temporarily support the harness with CoMat 06-086 TIES.

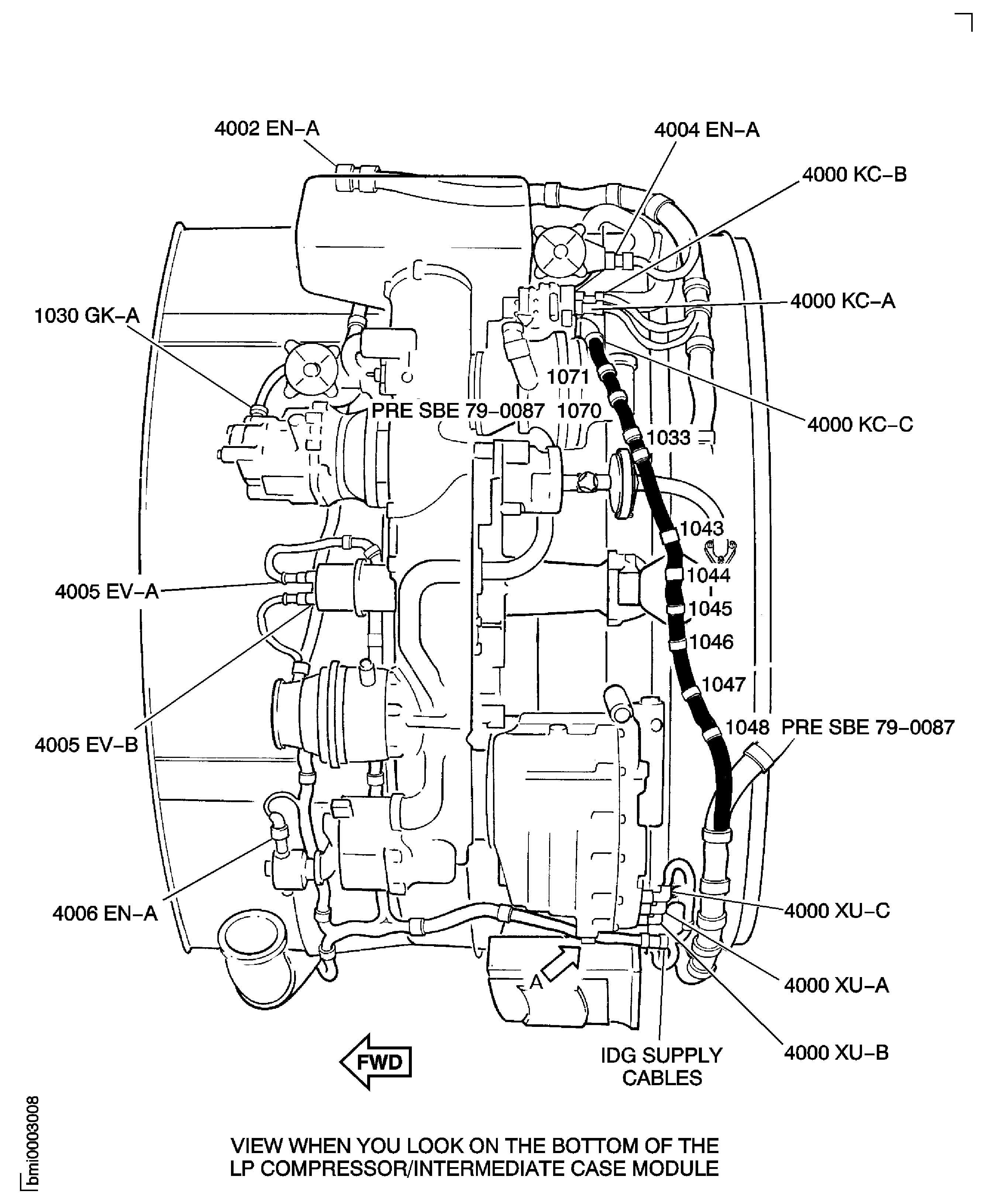

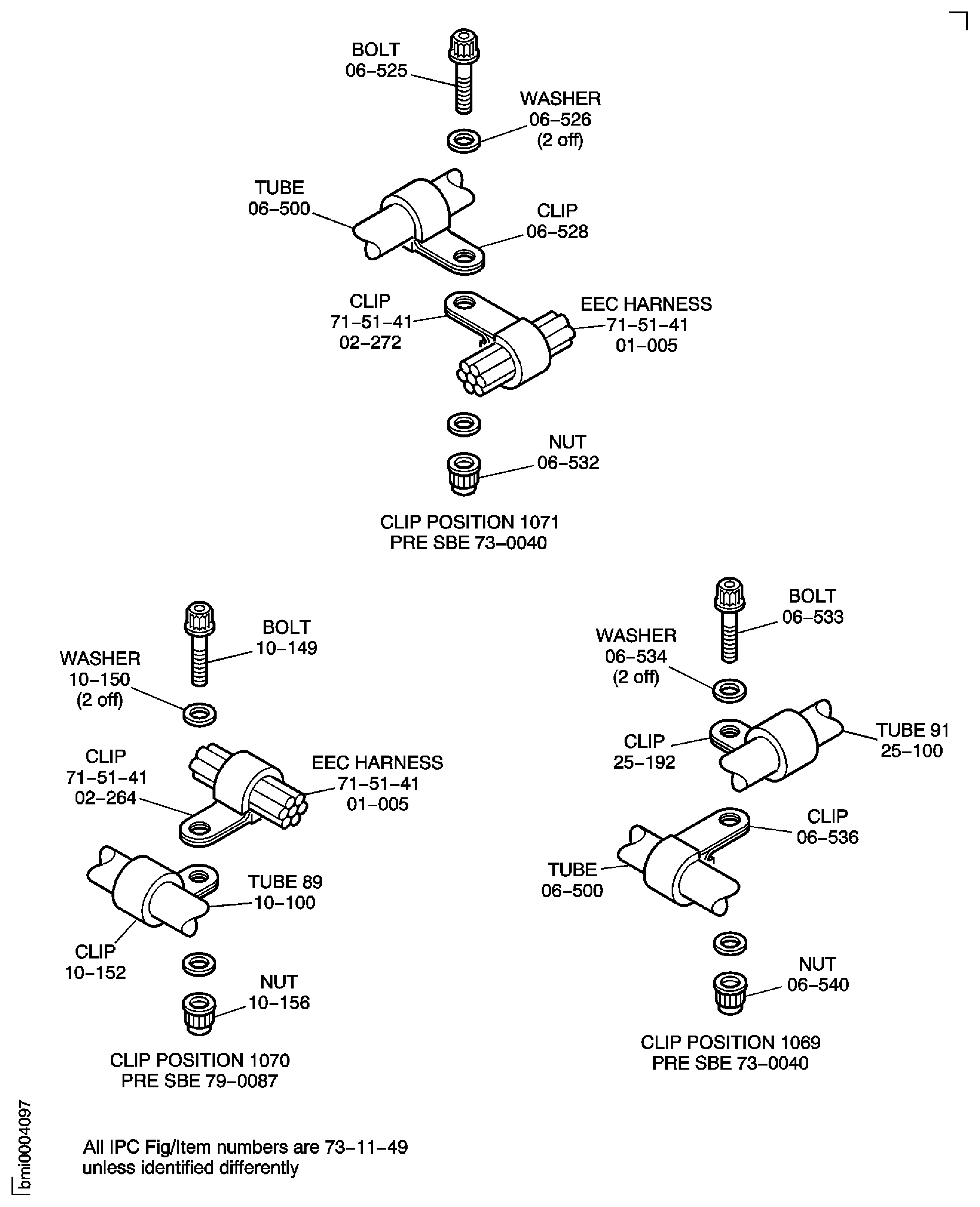

Connect the general services electrical connector 4000KC-A to the FMU and torque to 13 * lbfin. (1.5 Nm). Connect the two EEC harness electrical connectors 4000KC-B and 4000KC-C to the FMU and torque to 20 * lbfin. (2.3 Nm). Assemble clip position 1071 and torque the nut to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm).

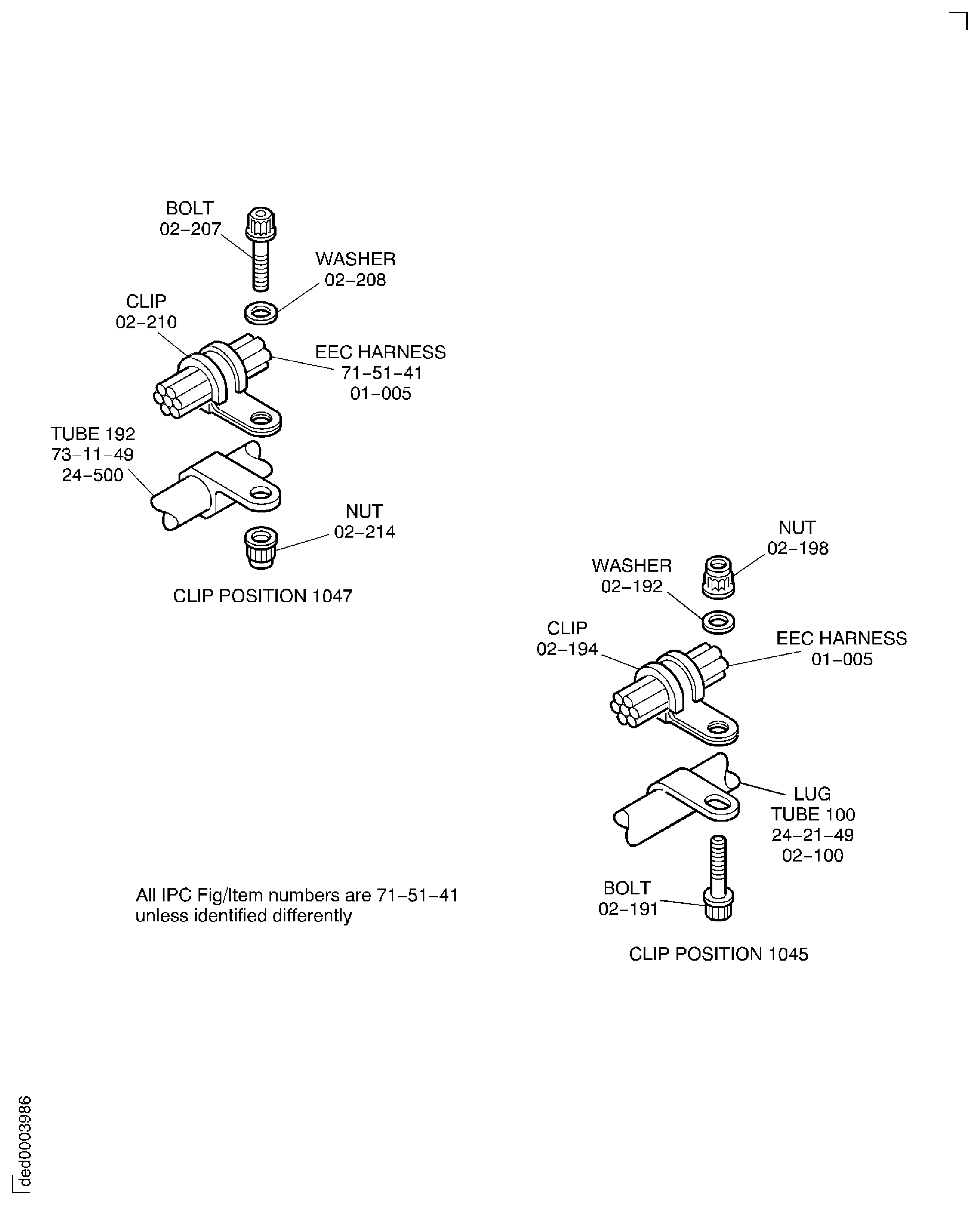

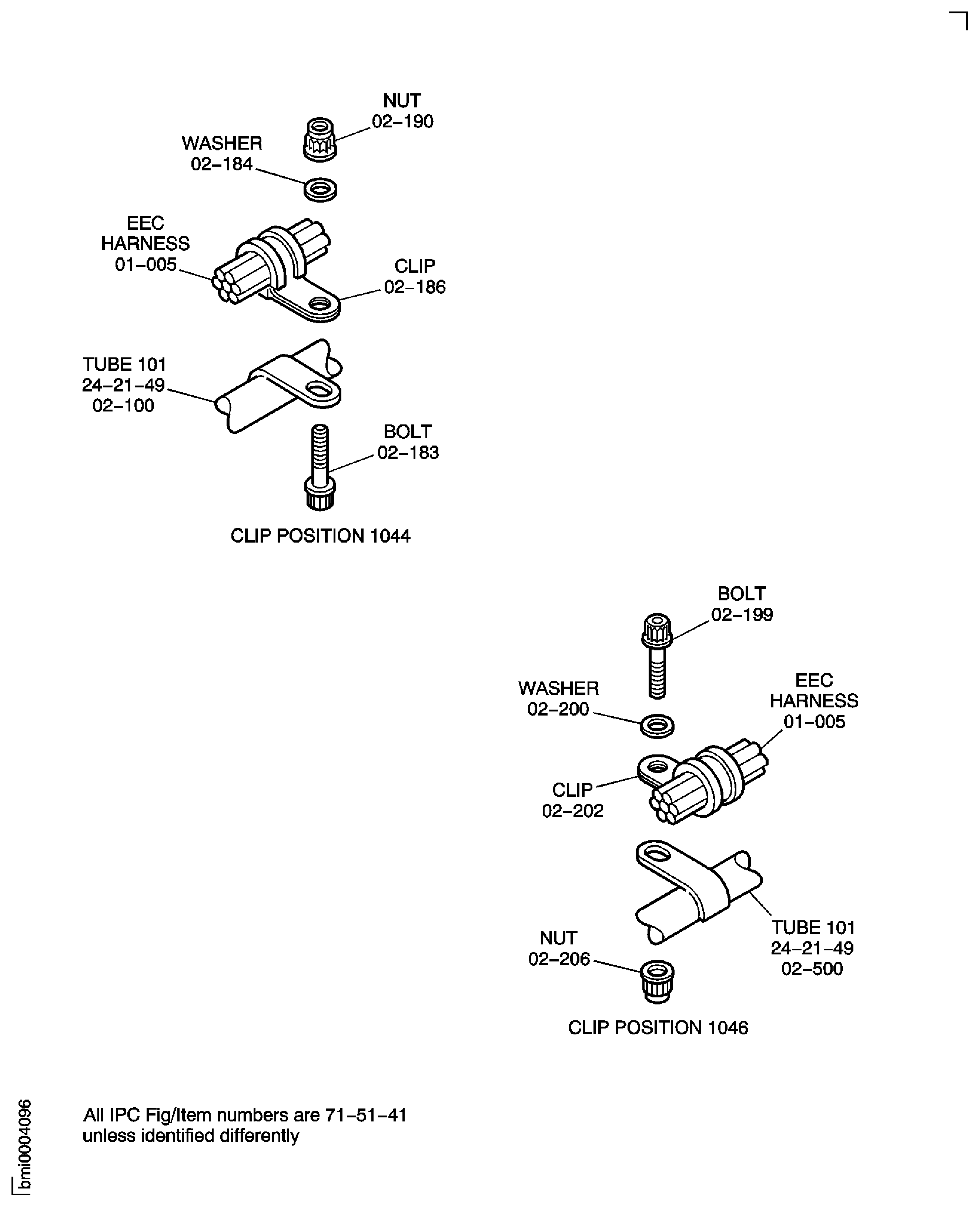

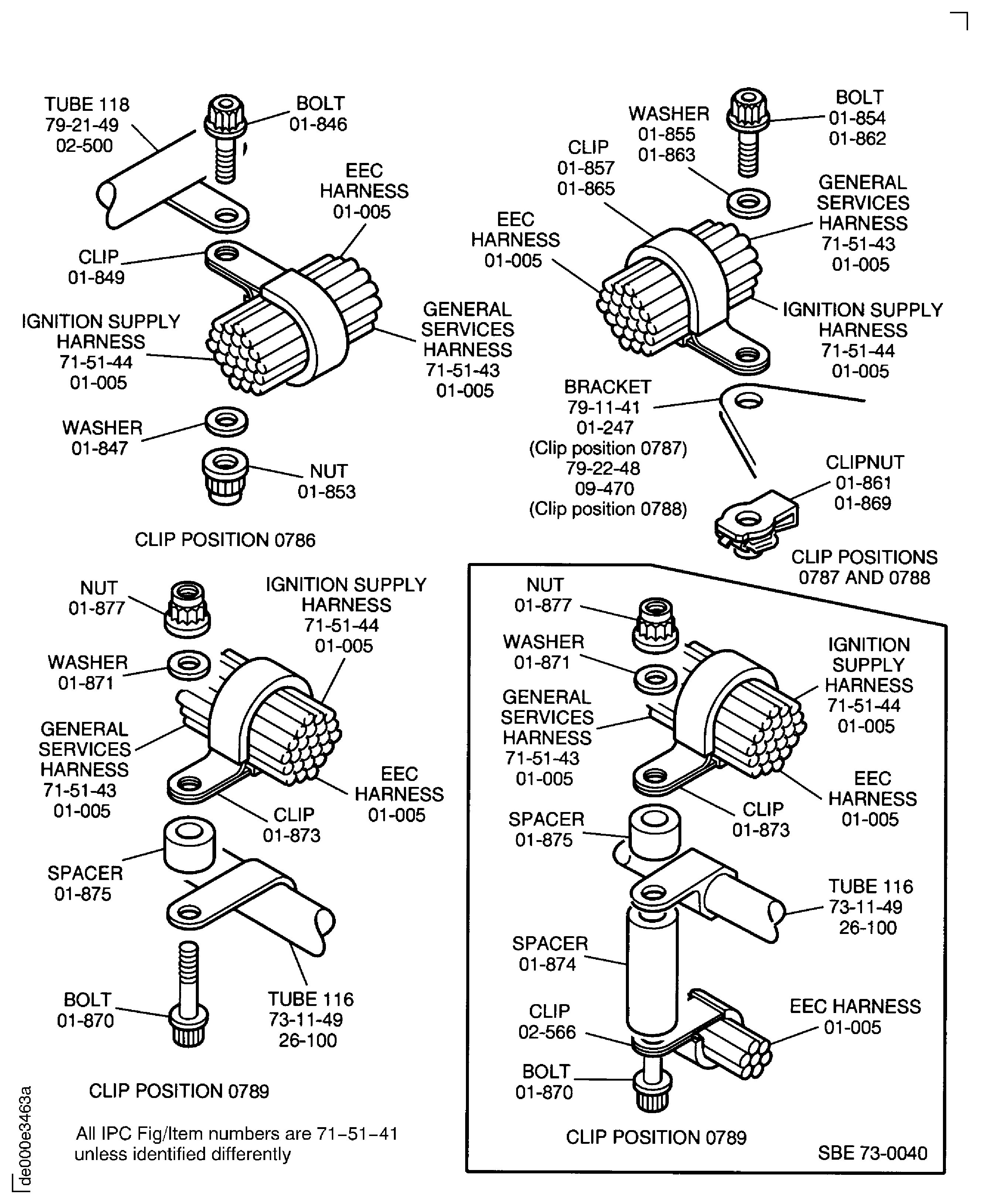

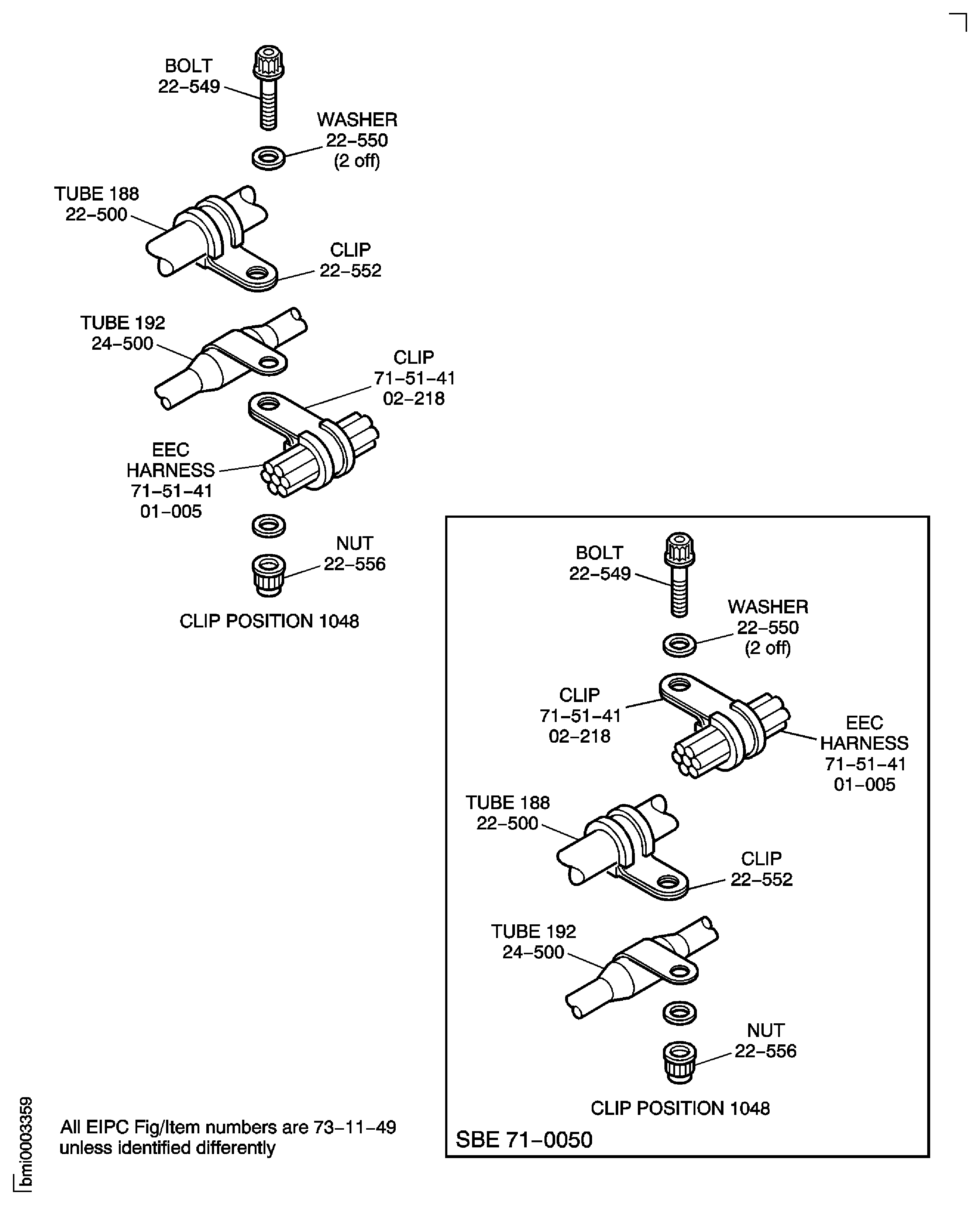

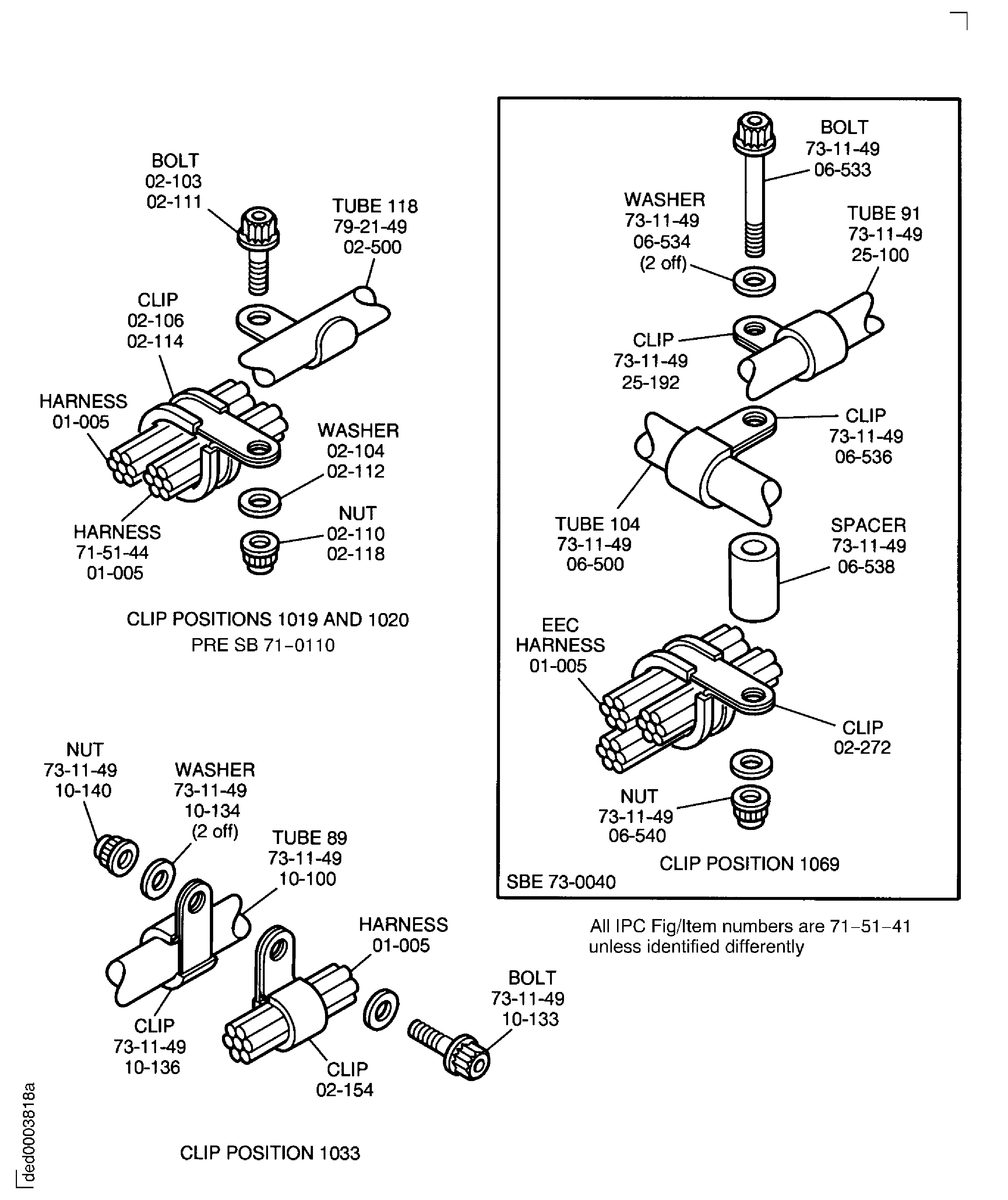

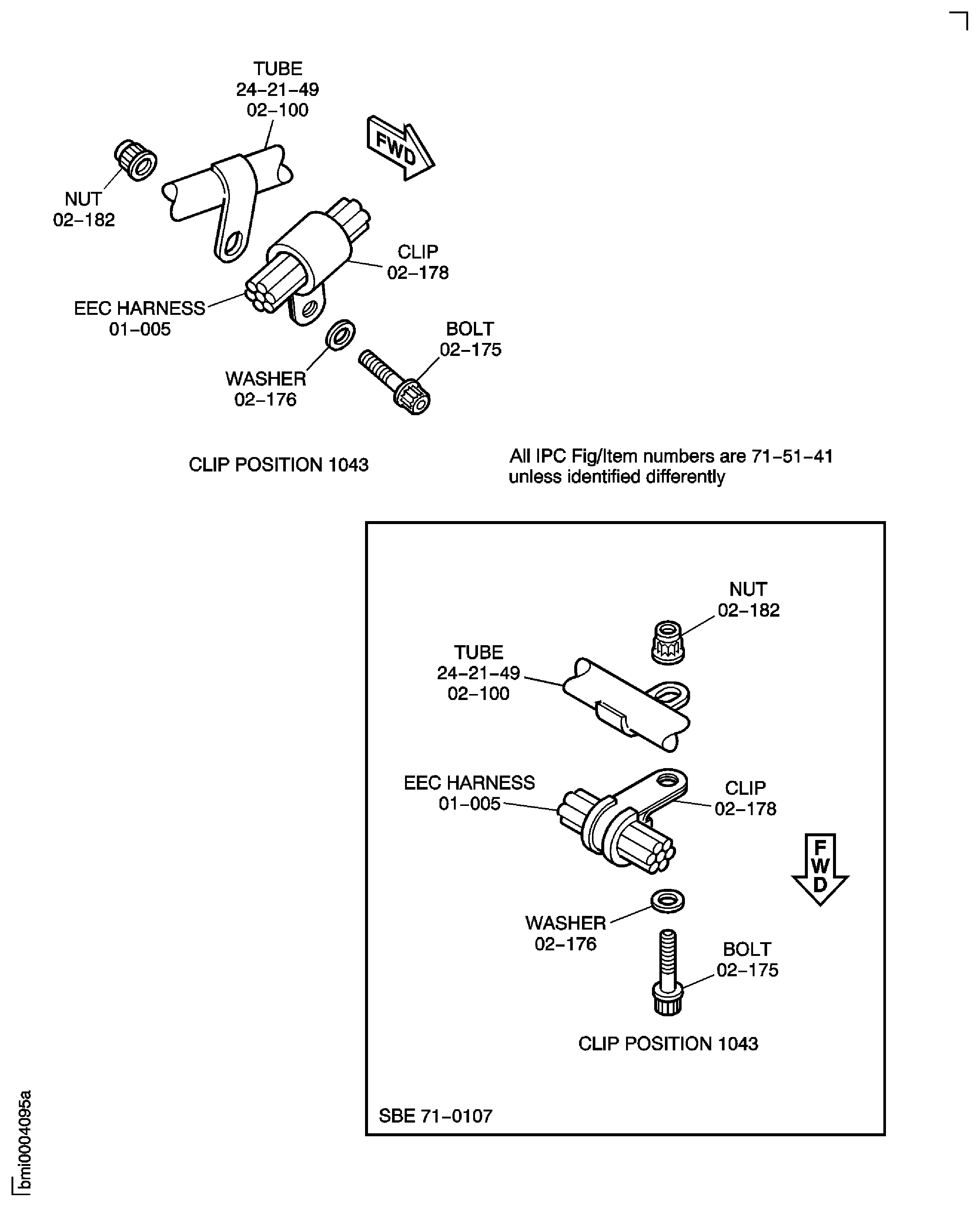

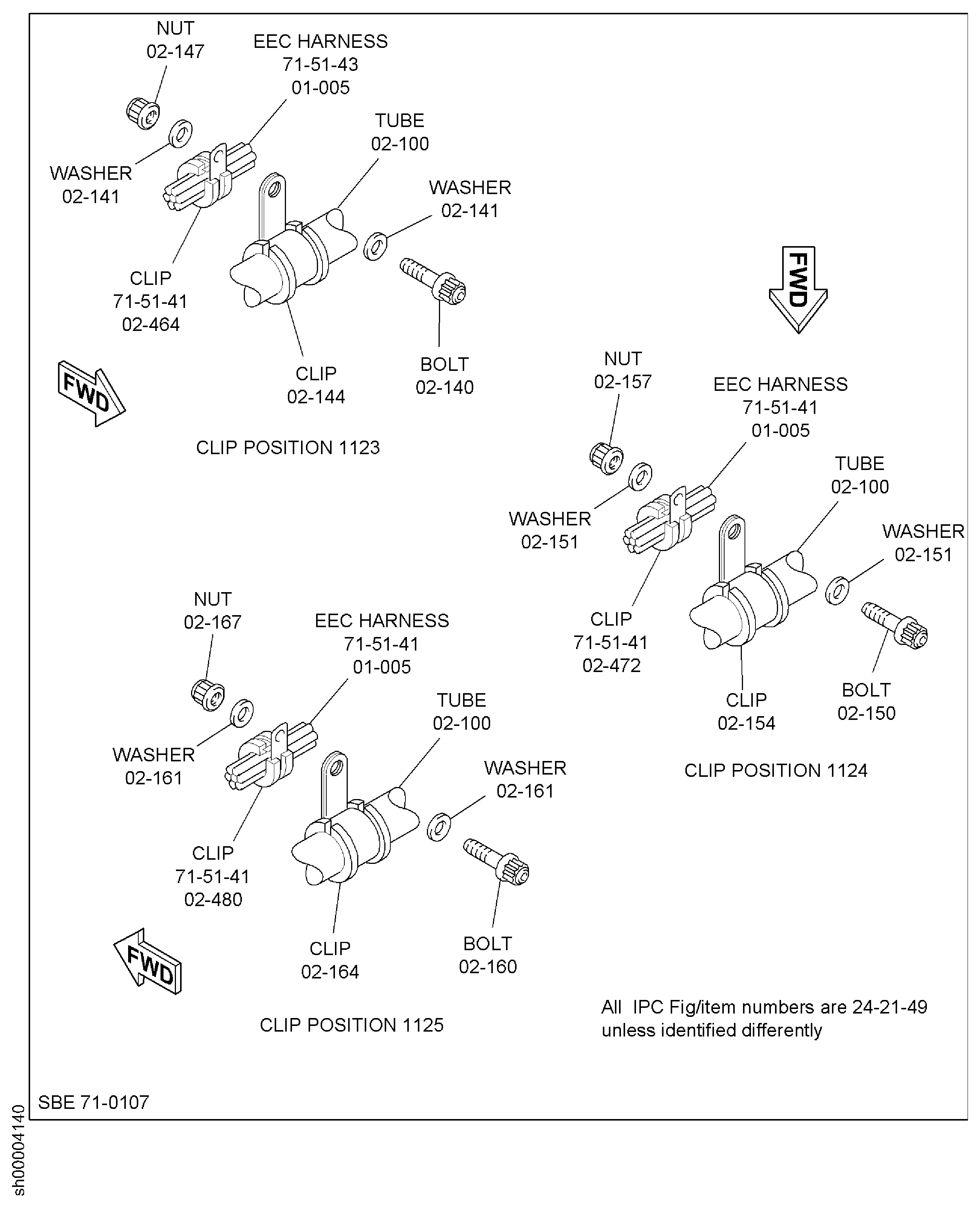

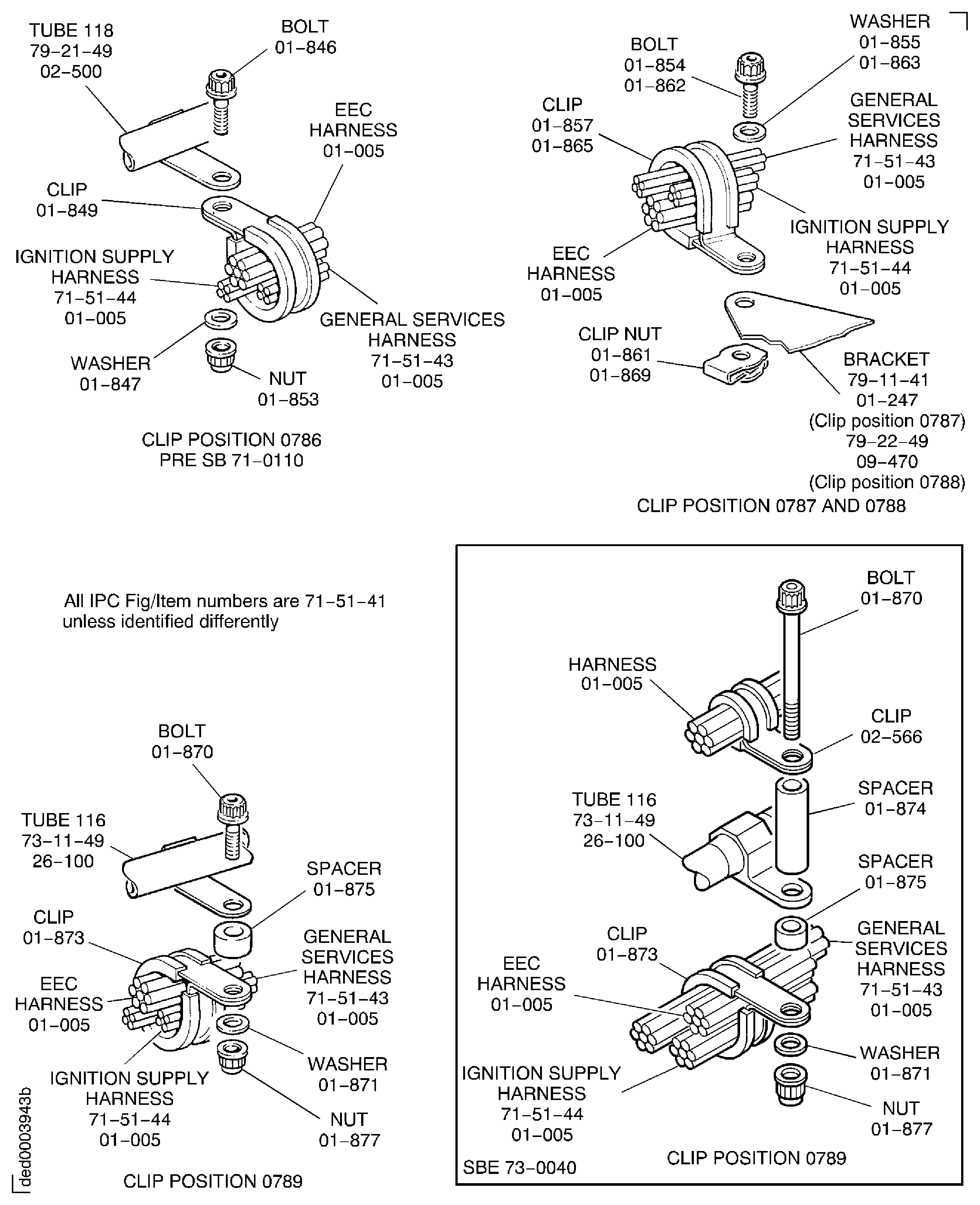

Pre SBE 79-0087: Assemble the clip positions 0788, 0789, 1019, 1020, 1033, 1043, 1044, 1045, 1046, 1047, 1048 and 1070 and torque the nuts or bolts to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm).

SBE 79-0087: Assemble the clip positions 0788, 0789, 1019, 1020, 1033, 1043, 1044, 1045 and 1046 and torque the nuts or bolts to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm).

SUBTASK 72-00-60-420-092-A00 Connect the Electrical Harness to the External Gearbox (Pre SBE 71-0050, Pre SBE 79-0087 and SBE 79-0087)

Remove the cover from the IDG cable assembly terminals and connect the four cables to their correct terminals. Install the four nuts and torque them to 144 *lbfin. to 168 *lbfin. (16 Nm to 19 Nm). Install the terminal cover and torque the two bolts to 20 *lbfin. to 22 * lbfin. (2.25 Nm to 2.5 Nm). Remove the temporary identification tags.

NOTE

A EEC harness incorporating SBE 71-0219 or SBE 71-0221 can only be installed to a SBE 73-0138 dedicated alternator stator with revised electrical connectors.Connect the two EEC harness electrical connectors 4005EV-A and 4005EV-B to the Dedicated Alternator and torque to 16 * lbfin. (1.8 Nm). Temporarily support the harness with CoMat 06-086 TIES.

Pre SBE 73-0040: Connect the general services electrical connector 4000KC-A to the FMU and torque to 13 * lbfin. (1.5 Nm). Connect the two EEC harness electrical connectors 4000KC-B and 4000KC-C to the FMU and torque to 20 * lbfin. (2.3 Nm). Assemble clip position 1071 and torque the nut to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm).

SBE 73-0040: Connect the general services electrical connector 4000KC-A to the FMU and torque to 13 * lbfin. (1.5 Nm). Connect the two EEC harness electrical connectors 4000KC-B and 4000KC-C to the FMU and torque to 20 * lbfin. (2.3 Nm). Assemble clip position 1069 and torque the nut to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm).

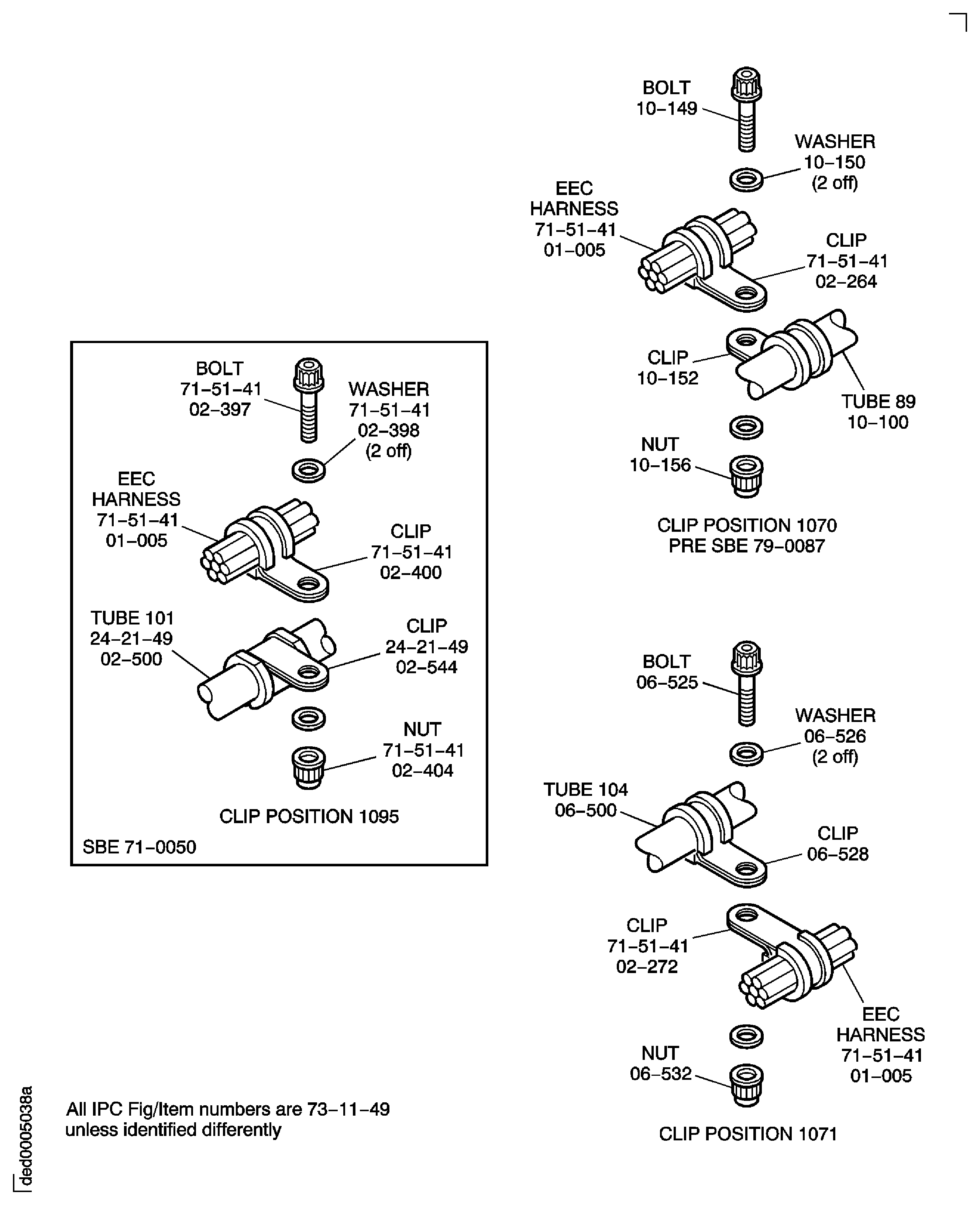

Pre SBE 79-0087: Assemble the clip positions 0788, 0789, 1019, 1020, 1033, 1043, 1044, 1095, 1046, 1048 and 1070 and torque the nuts or bolts to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm). Make sure the clip positions 1043 and 1048 hold the spirap protective tape.

SBE 79-0087: Assemble the clip positions 0788, 0789, 1019, 1020, 1033, 1043, 1044, 1095 and 1046 and torque the nuts or bolts to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm). Make sure the clip position 1043 hold the spirap protective tape.

SUBTASK 72-00-60-420-092-B00 Connect the Electrical Harness to the External Gearbox (SBE 71-0050, Pre SBE 71-0107, SBE 73-0040, Pre SBE 79-0087 and SBE 79-0087)

Remove the cover from the IDG cable assembly terminals and connect the four cables to their correct terminals. Install the four nuts and torque them to 144 *lbfin. to 168 *lbfin. (16 Nm to 19 Nm). Install the terminal cover and torque the two bolts to 20 *lbfin. to 22 *lbfin. (2.25 Nm to 2.5 Nm). Remove the temporary identification tags.

NOTE

A EEC harness incorporating SBE 71-0219 or SBE 71-0221 can only be installed to a SBE 73-0138 dedicated alternator stator with revised electrical connectors.Connect the two EEC harness electrical connectors (4005EV-A and 4005EV-B to the Dedicated Alternator and torque to 16 * lbfin. (1.8 Nm). Temporarily support the harness with CoMat 06-086 TIES.

Pre SBE 73-0040: Connect the general services electrical connector 4000KC-A to the FMU and torque to 13 * lbfin. (1.5 Nm). Connect the two EEC harness electrical connectors 4000KC-B and 4000KC-C to the FMU and torque to 20 * lbfin. (2.3 Nm). Assemble clip position 1071 and torque the nut to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm).

SBE 73-0040: Connect the general services electrical connector 4000KC-A to the FMU and torque to 13 * lbfin. (1.5 Nm). Connect the two EEC harness electrical connectors 4000KC-B and 4000KC-C to the FMU and torque to 20 * lbfin. (2.3 Nm). Assemble clip position 1069 and torque the nut to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm).

Pre SBE 79-0087: Assemble the clip positions 0788, 0789, 1019, 1020, 1033, 1043 and 1070 and torque the nuts or bolts to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm). Make sure the clip position 1043 holds the spirap protective tape.

SBE 79-0087: Assemble the clip positions 0788, 0789, 1019, 1020, 1033 and 1043 and torque the nuts or bolts to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm). Make sure the clip position 1043 holds the spirap protective tape.

SUBTASK 72-00-60-420-092-C00 Connect the Electrical Harness to the External Gearbox (SBE 71-0107, SBE 73-0040, Pre SBE 79-0087 and SBE 79-0087)

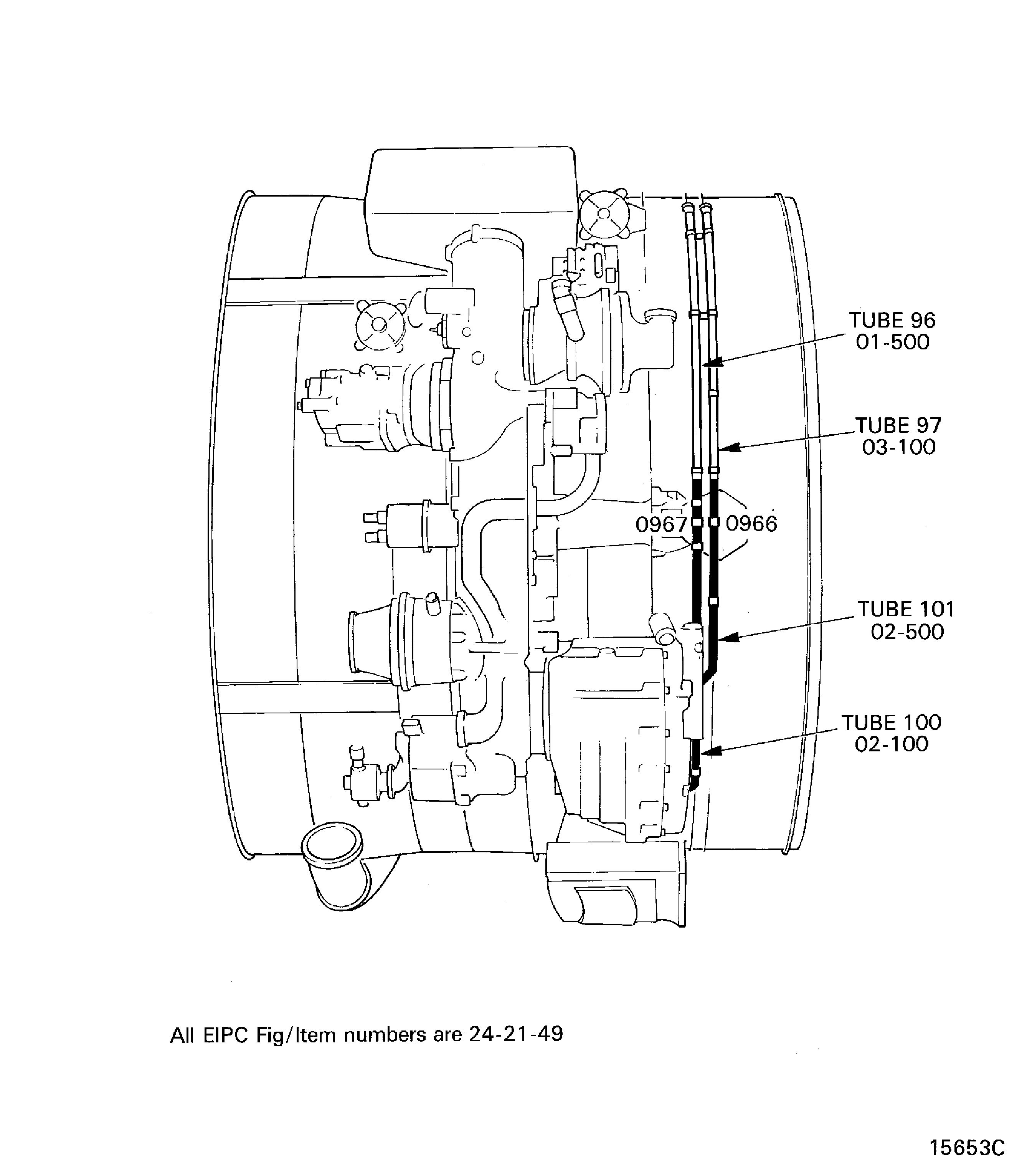

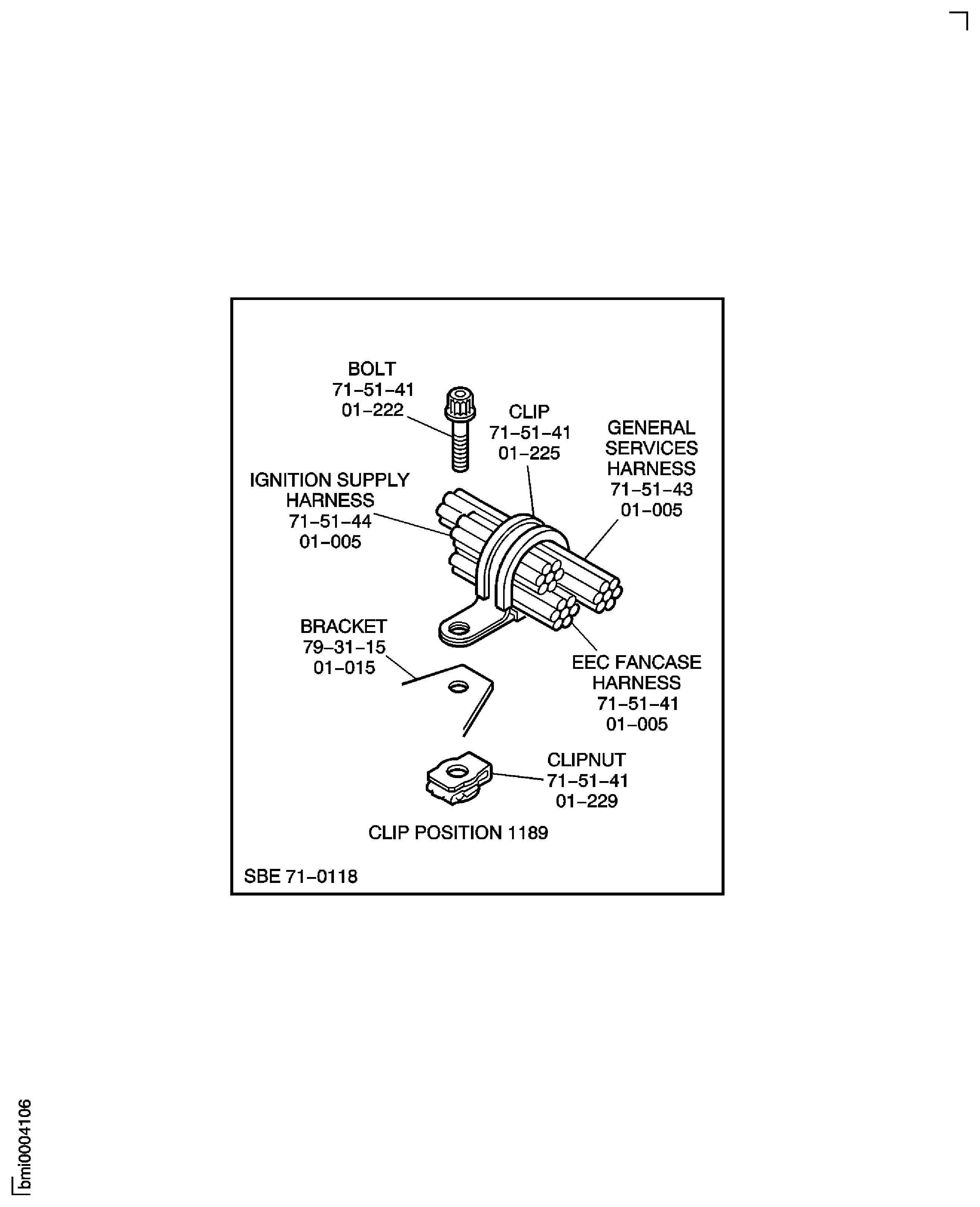

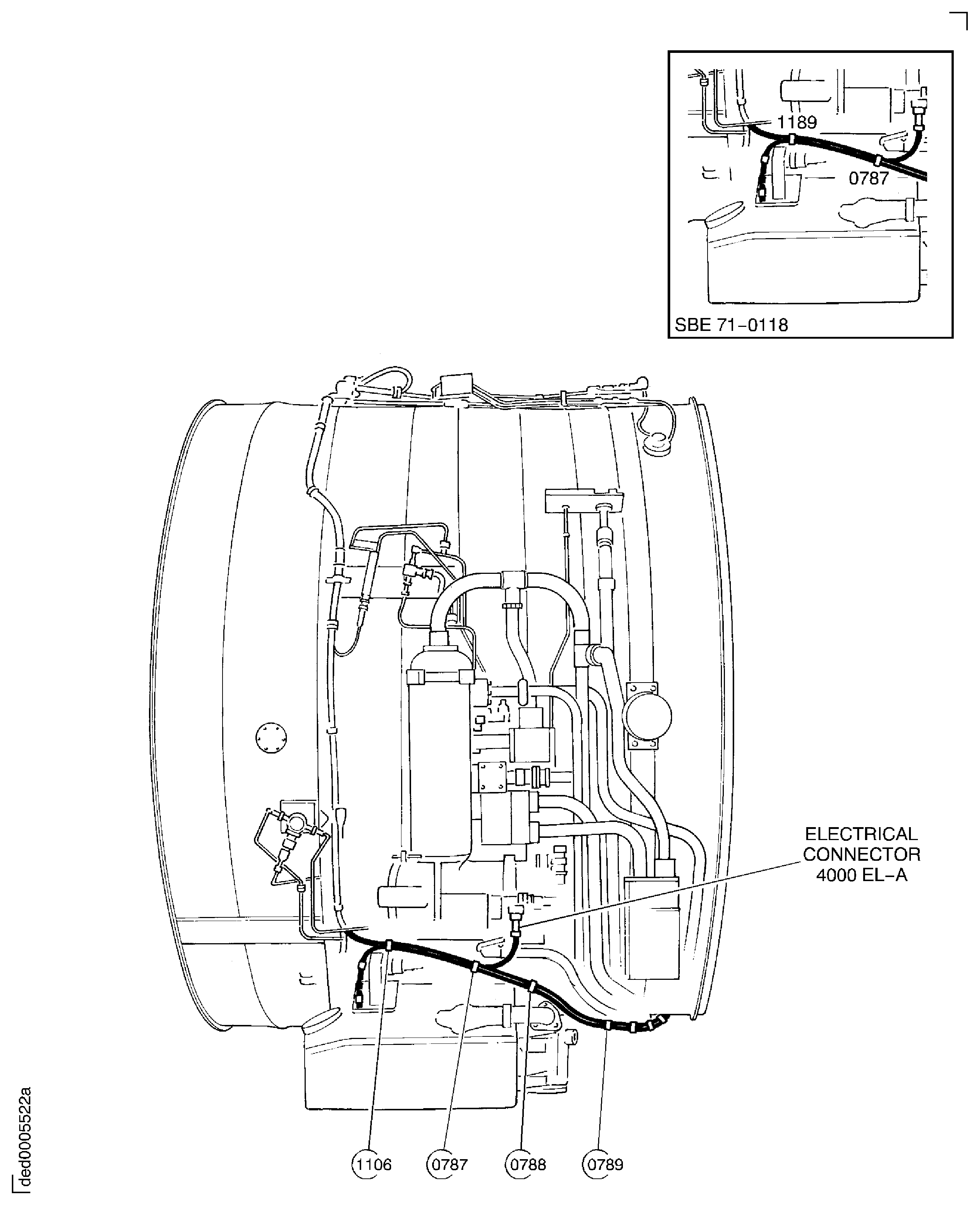

SBE 71-0110: Assemble the clip positions 0788, 0789 and 1106 torque the nuts or bolts to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm). Refer to Figure and Figure.

SBE 71-0118: Assemble the clip positions 0788, 0789 and 1189 torque the nuts or bolts to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm). Refer to Figure and Figure.

SUBTASK 72-00-60-420-092-D00 Connect the Electrical Harness to the External Gearbox (SBE 71-0110 and SBE 71-0118)

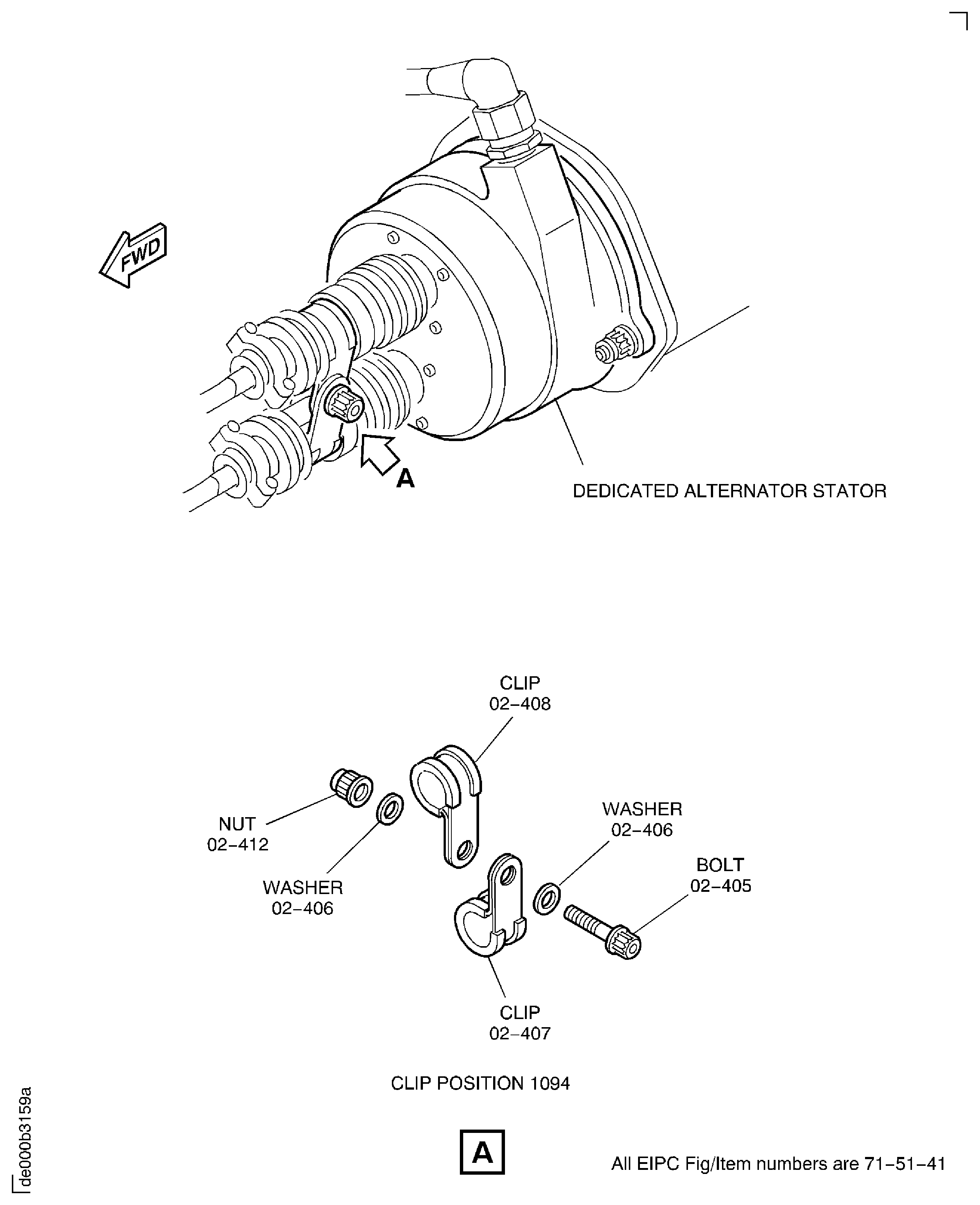

Refer to Figure.

Install the bolt POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 02-405), the nut V2500-A5-72-51-41-02A-941A-D (72-51-41, 02-402), the washers POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 02-406) and the clips POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 02-407) andPOWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 02-408) at clip position 1094 to secure the backshells of the electrical connectors 4005EV-A and 4005EV-B. Torque the nut POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 02-412) to 36 lbfin. to 45 lbfin. (4 Nm to 5 Nm).

SUBTASK 72-00-60-420-204-A00 Install the Clips on the Electrical Connectors 4005EV-A and 4005EV-B (SBE 71-0063 and Pre SBE 71-0111)

SBE 71-0111: Power plant - EEC harness fan/core - deletion of clipping at VSVA and PMA harness connectors and introduction of wire locking to secure the connectors.

Safety the electrical connectors 4005EV-A and 4005EV-B with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-60-420-204-B00 Safety the Electrical Connectors 4005EV-A and 4005EV-B (SBE 71-0111)

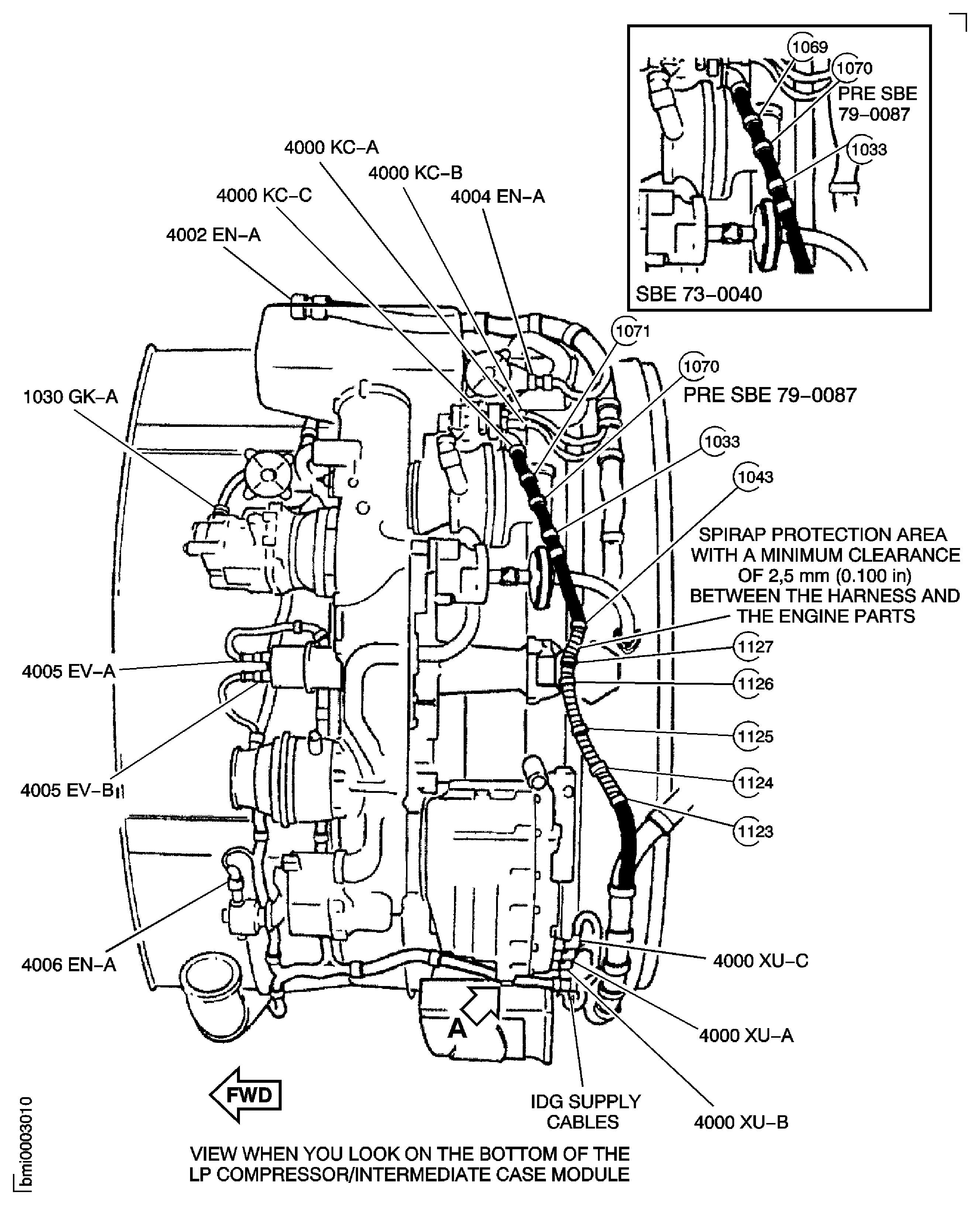

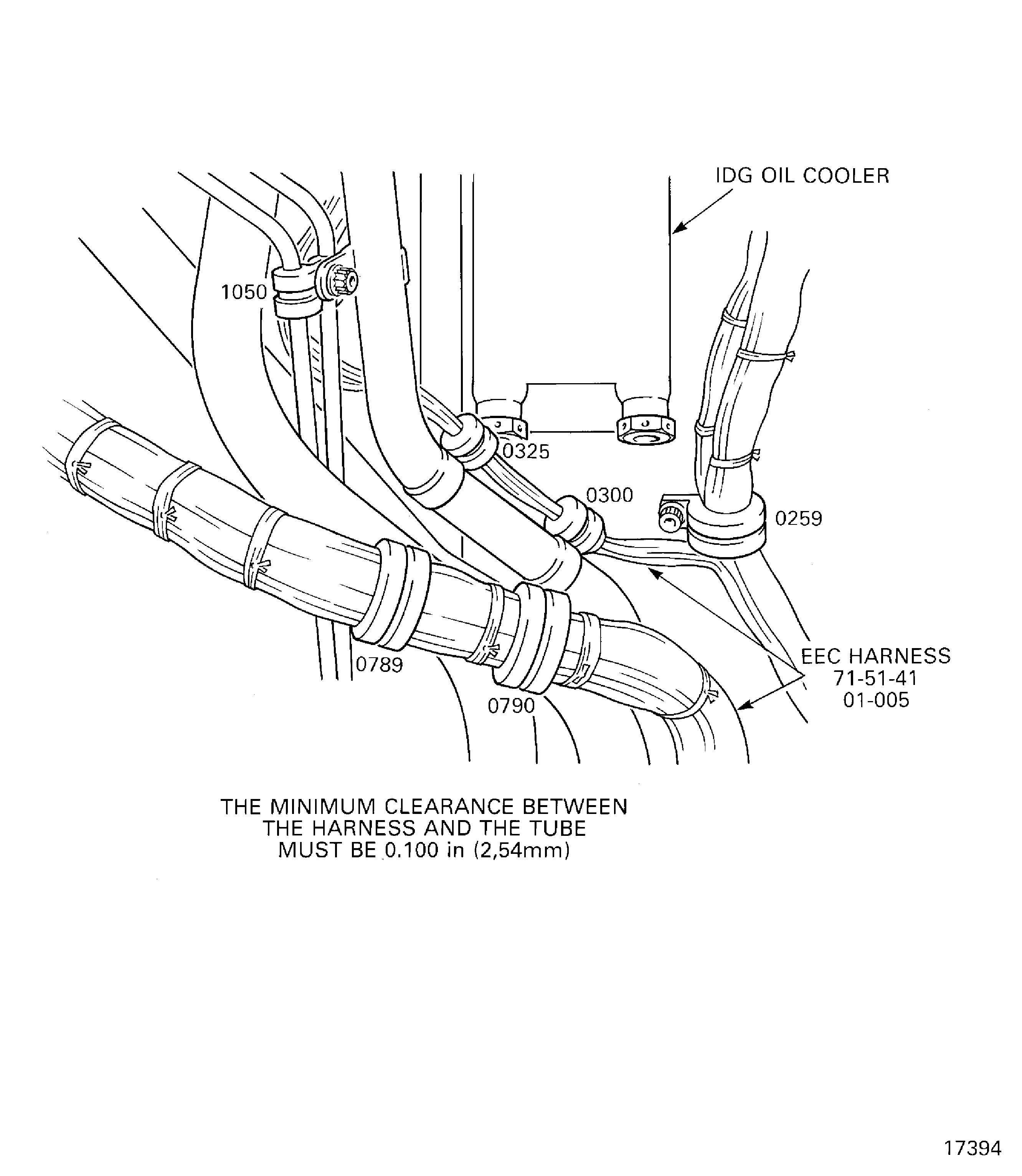

Pre SBE 73-0040: A minimum clearance of 0.100 in. (2.54 mm) is necessary between the EEC harness POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 01-005), the IDG oil cooler and the tubes in the area shown in Figure.

SBE 73-0040: A minimum clearance of 0.100 in. (2.54 mm) is necessary between the EEC harness POWER PLANT-ELECTRICAL HARNESS-EEC HARNESS-FAN (71-51-41, 01-005), the IDG oil cooler and the tubes in the area shown in Figure.

To check the clearance, push the harness with a light pressure of the thumb then release. The harness must spring back and give the minimum clearance. The harness must not move through the adjacent clips (refer to Step).

Measure the clearance between all the different harnesses and the engine parts:

If the primary harness, the wire bundle breakout or a different harness touch each other they must be attached to each other. Refer to Step. The bundles must not move in relation to each other.

Examine the harness routing.

SUBTASK 72-00-60-220-068 Measure the Harness Clearances and Examine the Harness Routing

Attach the wire bundle breakout to the primary harness with CoMat 02-159 LACING TAPE so they do not move in relation to each other.

Attach the parallel harnesses and those which go across each other together. If it is necessary, wrap CoMat 02-148 ADHESIVE TAPE (ELECTRICAL) around the harness (to prevent abrasion). Then attach them together with CoMat 02-159 LACING TAPE.

SUBTASK 72-00-60-420-101 Attach the Harness Together

Refer to Figure.

Install the seal STARTING-STARTER DUCT (80-13-49, 01-520) at the starter and the seal STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-220) at the starter valve STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-200).

With the two seals in position, put the lower duct STARTING-STARTER DUCT (80-13-49, 01-500) between the starter and the starter valve. Make sure the duct is aligned with the starter valve and install the two couplings STARTING-STARTER DUCT (80-13-49, 01-510) and STARTING-PNEUMATIC STARTER VALVE (80-13-51, 01-210). Torque the couplings to 75 *lbfin. to 85 *lbfin. (8.5 Nm to 9.6 Nm).

SUBTASK 72-00-60-420-093 Install the Pneumatic Starter Lower Duct Assembly

Refer to TASK 71-00-02-400-005-A00.

SUBTASK 72-00-60-420-094 Install the Deoiler Breather Duct

Refer to Figure.

Make sure that all the applicable backshells and cable clamps are safetied with CoMat 02-126 LOCKWIRE. Refer to the SPM TASK 70-42-05-400-501.

SUBTASK 72-00-60-210-055 Visually Inspect the Electrical Backshells and Cable Clamps

NOTE

Use this procedure to safety the EEC harness backshells and cable clamps with safety cable.Refer to Figure.

Make sure that all the EEC harness backshells and cable clamps are safetied. Safety with CoMat 02-274 SAFETY CABLE KIT or with CoMat 02-275 SAFETY CABLE KIT. Refer to the SPM TASK 70-42-08-400-501.

SUBTASK 72-00-60-210-056 Visually Inspect the EEC Harness (01-005) Electrical Backshells and Cable Clamps (SBE 70-0813)

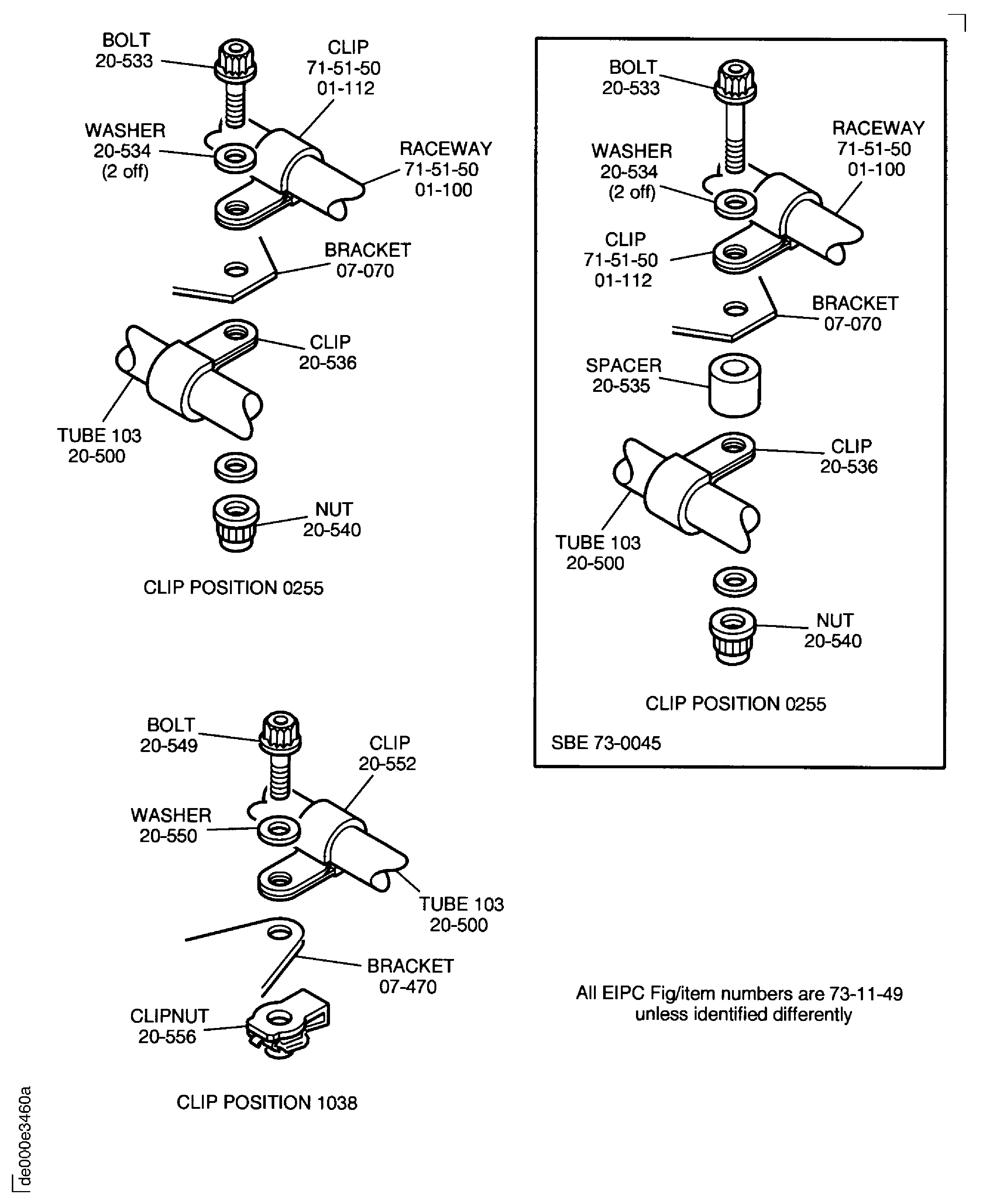

Figure: Install the Non-modular Brackets on the External Gearbox

Sheet 1

Figure: Install the Non-modular Brackets on the External Gearbox

Sheet 2

Figure: Pre SBE 79-0028: External Gearbox Magnetic Chip Detectors - Location and Installation

Sheet 1

Figure: SBE 79-0028, Pre SBE 70-0628, SBE 70-0628 and Pre SBE 79-0042 External Gearbox Magnetic Chip Detectors - Location and Installation

Sheet 2

Figure: SBE 79-0042: External Gearbox Magnetic Chip Detectors - Location and Installation

Sheet 3

Figure: Pre SBE 71-0110: Install the External Gearbox Oil Distribution Tubes

Sheet 1

Figure: SBE 71-0110: Install the External Gearbox Oil Distribution Tubes

Sheet 2

Figure: SBE 79-0069: Install the External Gearbox Oil Distribution Tubes

Sheet 3

Figure: SBE 71-0110: Install the External Gearbox Oil Distribution Tubes

Sheet 4

Figure: Install the External Gearbox Oil Distribution Tubes

Sheet 5

Figure: Pre SBE 79-0023: Install the Oil Quantity Transmitter

Sheet 1

Figure: SBE 79-0023: Install the Oil Quantity Transmitter

Sheet 2

Figure: Pre SBE 71-0110: Install the Oil Tank Breather Tube (173) on the External Gearbox

Sheet 1

Figure: SBE 71-0110: Install the Oil Tank Breather Tube (173) on the External Gearbox

Sheet 2

Figure: Install the Oil Tank Breather Tube (173) on the External Gearbox

Sheet 3

Figure: Install the Gearbox Oil Feed Tube (112) on the External Gearbox

Install the Gearbox Oil Feed Tube (112) on the External Gearbox

Figure: Install the Oil Scavenge Tube (123) on the External Gearbox

Install the Oil Scavenge Tube (123) on the External Gearbox

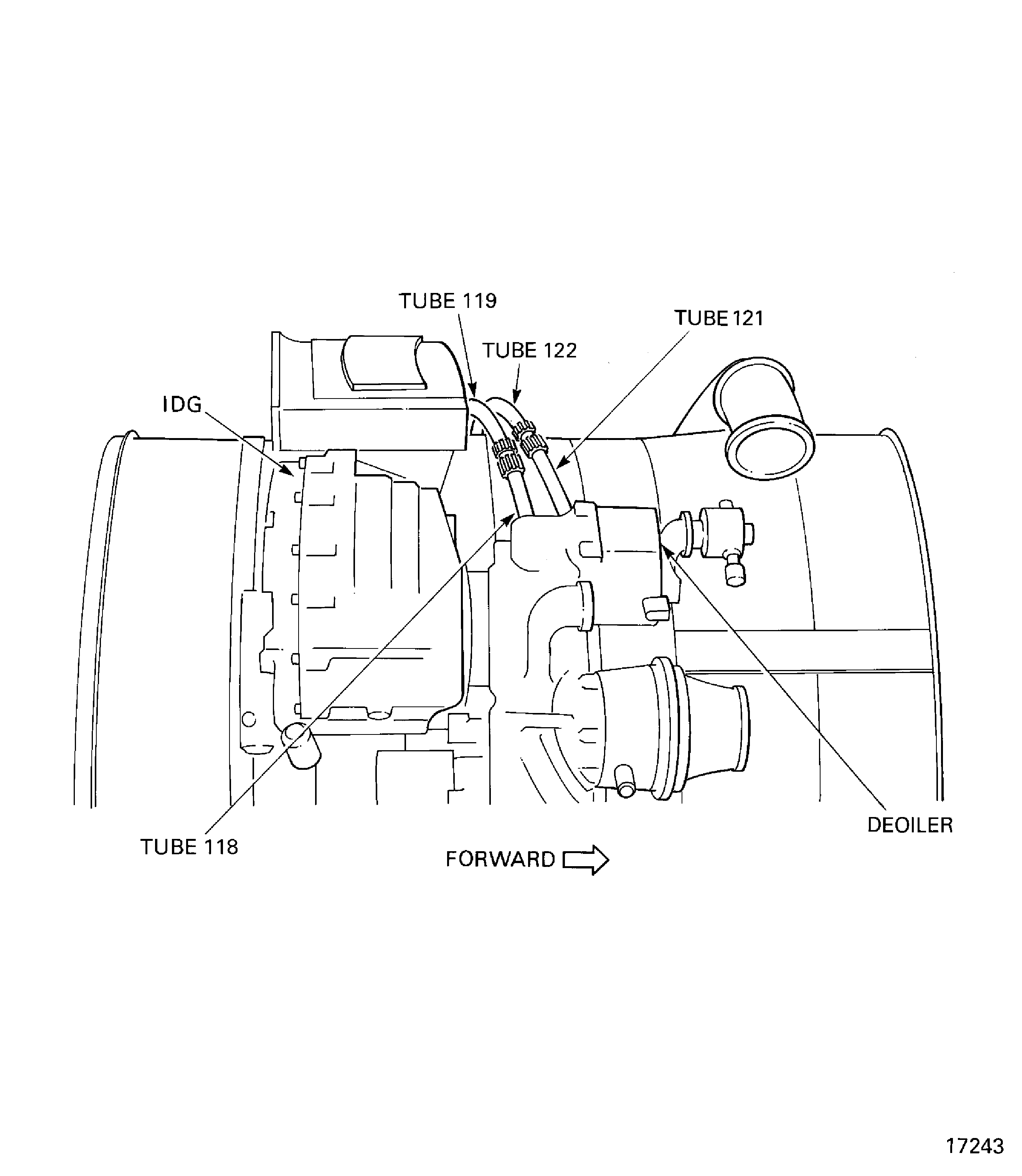

Figure: Install the ACOC Oil Tubes (118 and 121) on the External Gearbox

Sheet 1

Figure: Install the ACOC Oil Tubes (118 and 121) on the External Gearbox

Sheet 2

Figure: Connect the Hydraulic Pump Hoses

Connect the Hydraulic Pump Hoses

Figure: Connect the Scavenge Filter Differential Pressure Switch tubes (208 and 209)

Connect the Scavenge Filter Differential Pressure Switch tubes (208 and 209)

Figure: Connect the No.1, 2 and 3 Bearing Compartment Vent Tube (125)

Connect the No.1, 2 and 3 Bearing Compartment Vent Tube (125)

Figure: Pre SBE 79-0087: Connect the No.4 Bearing Scavenge Valve Tubes (126 and 128)

Sheet 1

Figure: SBE 79-0087: Connect the No.4 Bearing Scavenge Valve Tubes (126 and 128)

Sheet 2

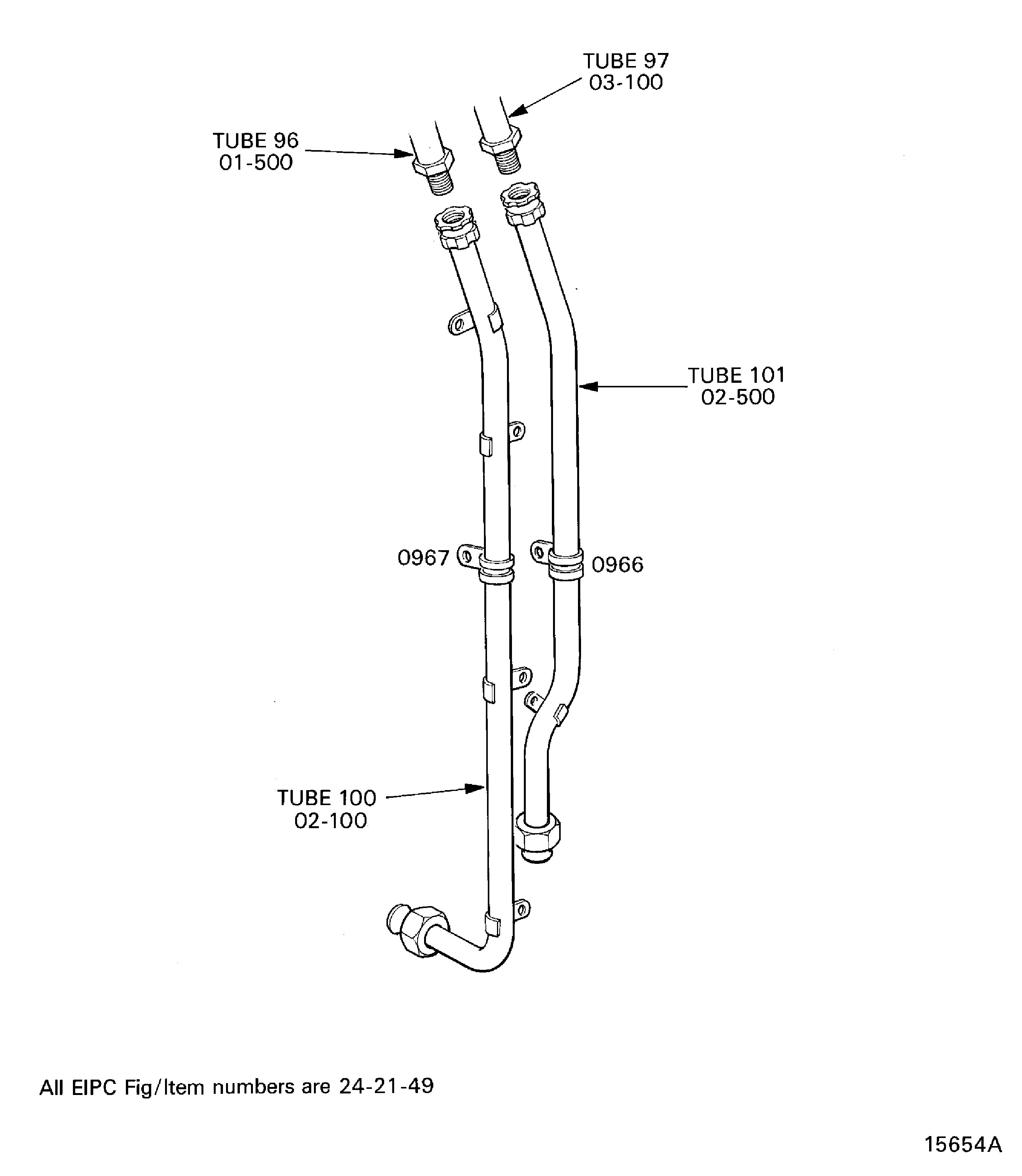

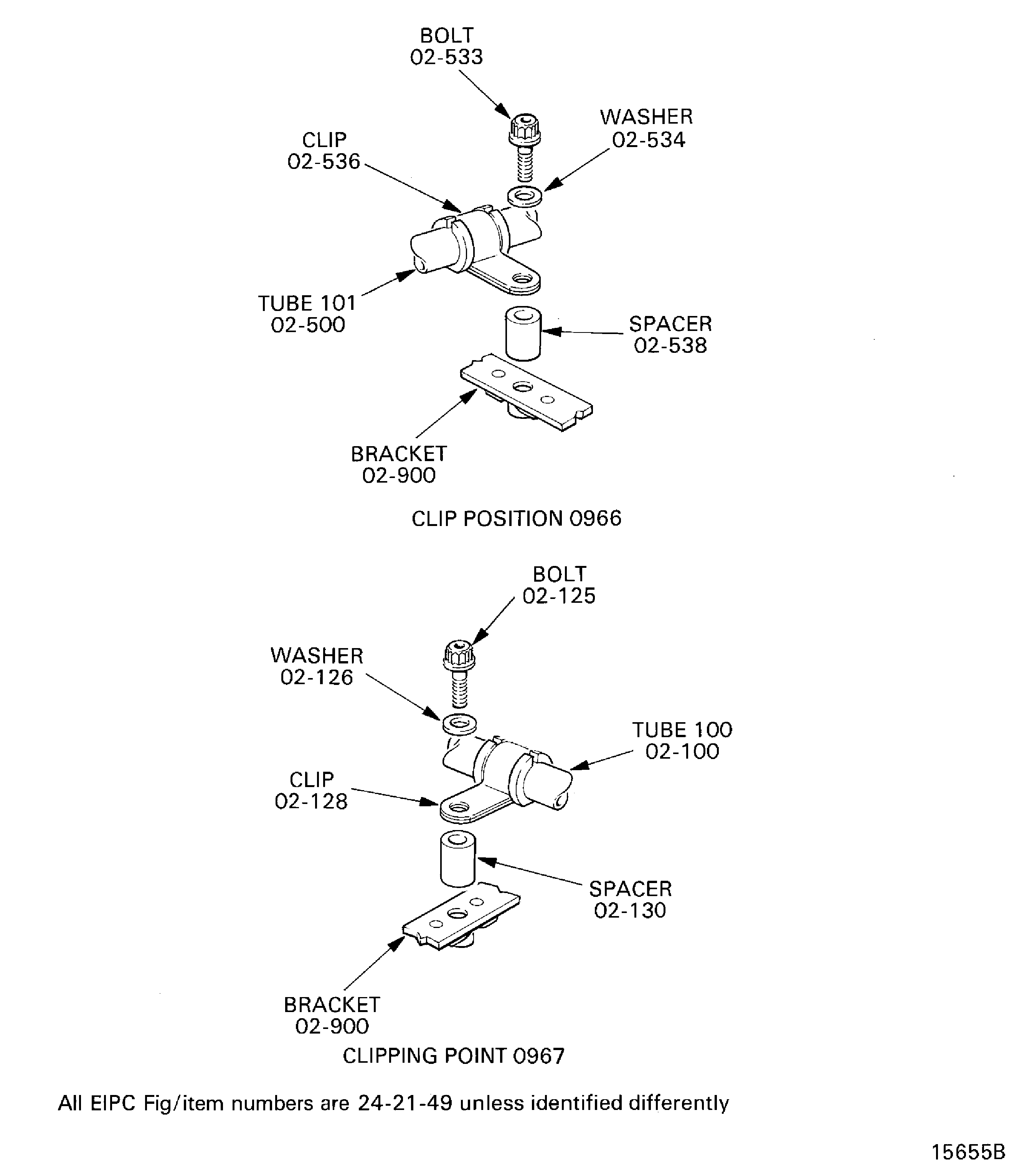

Figure: Install the IDG Oil Cooling Tubes (100 and 101)

Sheet 1

Figure: Install the IDG Oil Cooling Tubes (100 and 101)

Sheet 2

Figure: Install the IDG Oil Cooling Tubes (100 and 101)

Sheet 3

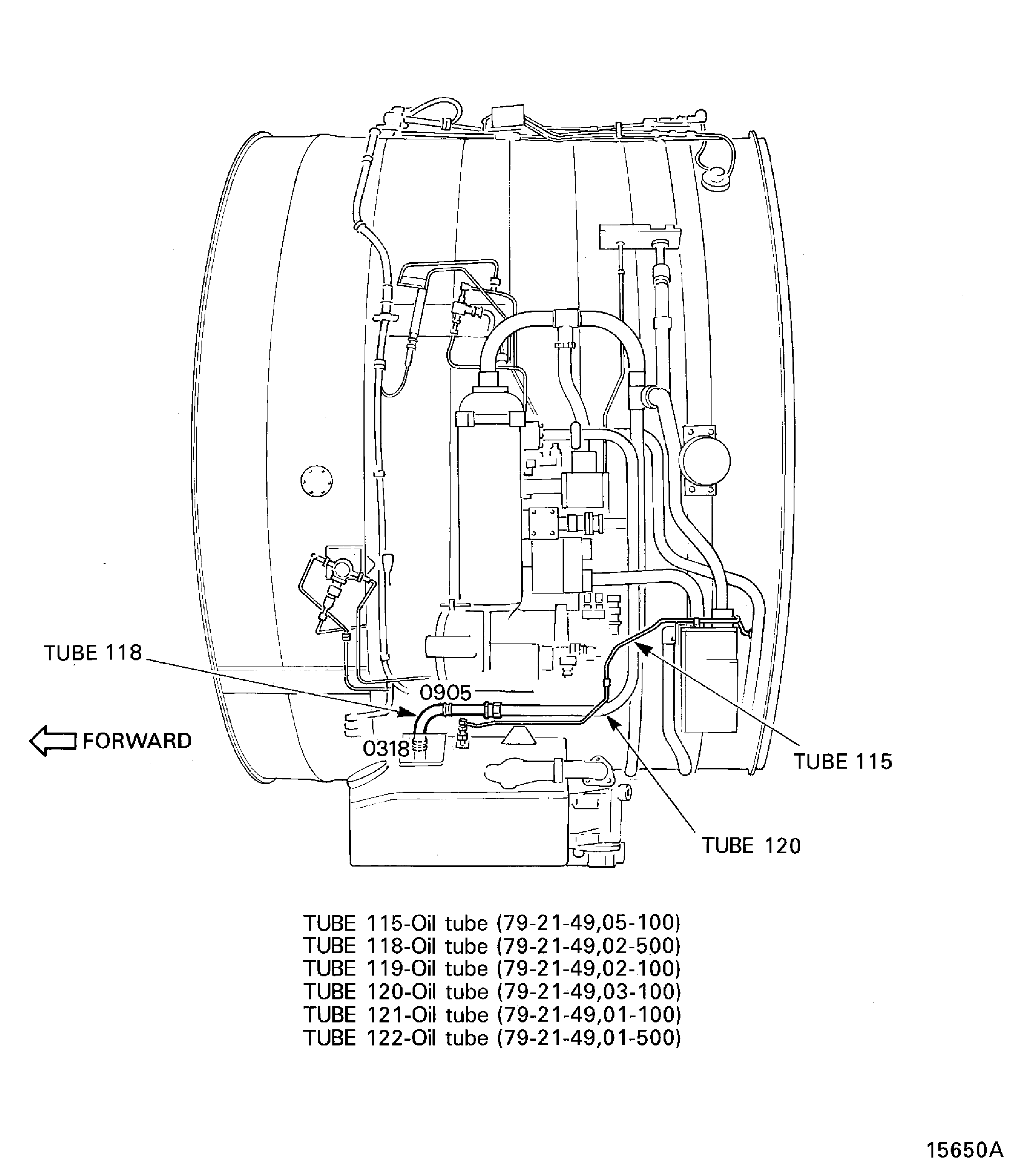

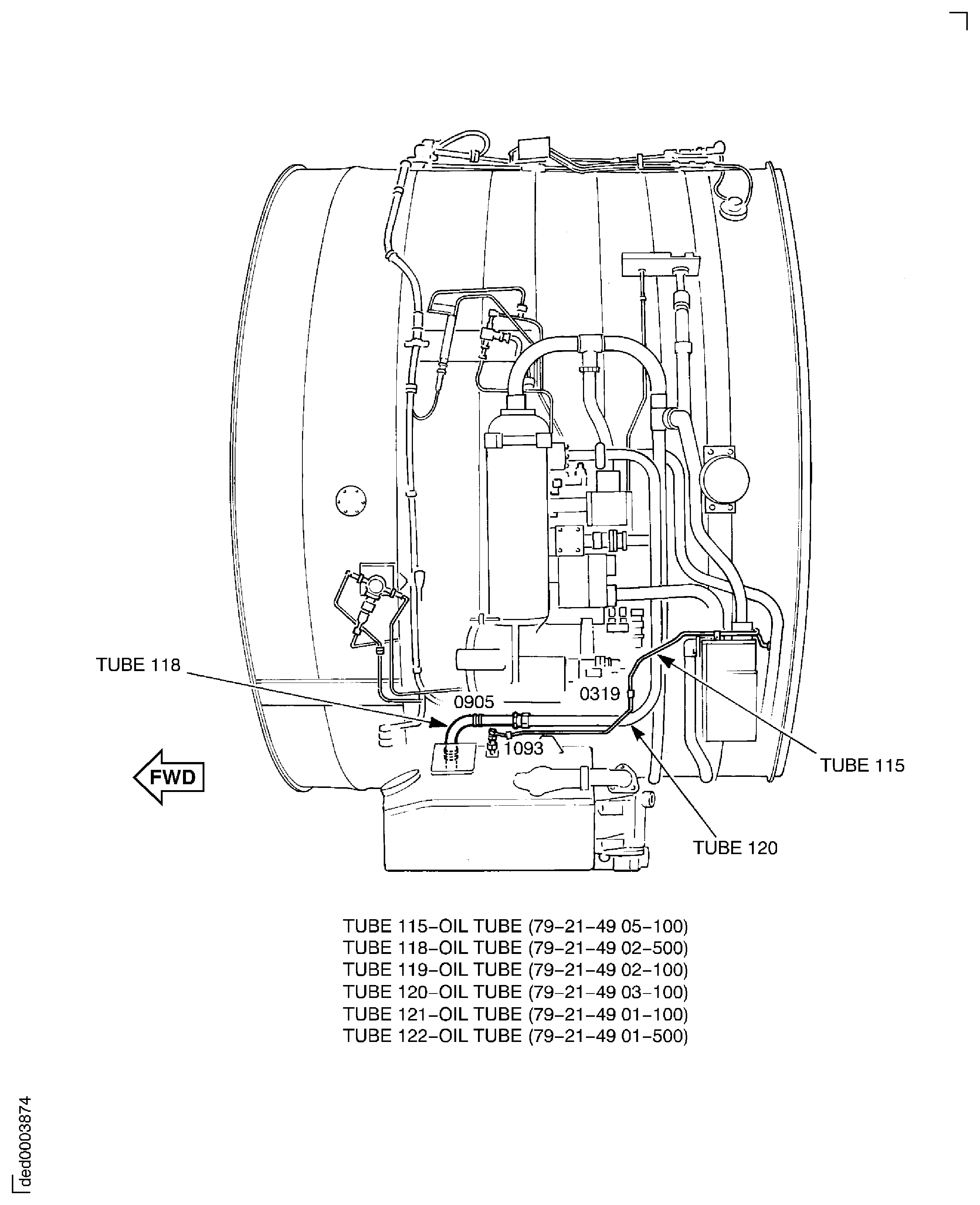

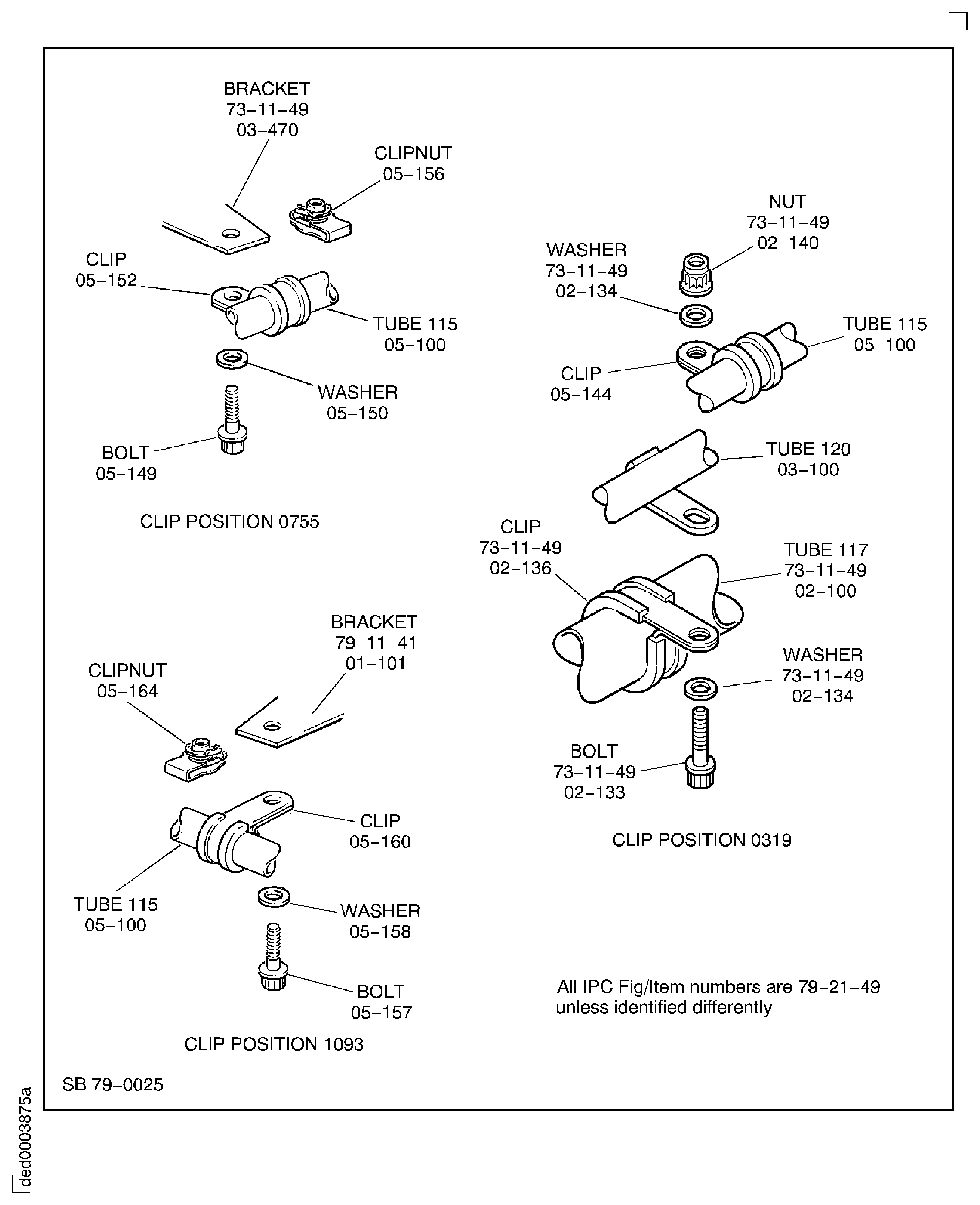

Figure: Pre SBE 79-0025: Connect the FCOC Oil Tubes (115 and 118)

Sheet 1

Figure: SBE 79-0025: Connect the FCOC Oil Tubes (115 and 118)

Sheet 2

Figure: Connect the FCOC Oil Tubes (115 and 118)

Sheet 3

Figure: Connect the FCOC Oil Tubes (115 to 118)

Sheet 4

Figure: Connect the FCOC Oil Tubes (115 to 118)

Sheet 5

Figure: Connect the FCOC Oil Tubes (115 to 118)

Sheet 6

Figure: Connect the FCOC LP Fuel Tubes (110 and 117)

Sheet 1

Figure: Connect the FCOC LP Fuel Tubes (110 and 117)

Sheet 2

Figure: Connect the Oil Pump Scavenge Tube (123)

Connect the Oil Pump Scavenge Tube (123)

Figure: Install the No.1, 2 and 3 Bearing Compartment Scavenge Tube Assembly

Sheet 1

Figure: Install the No.1, 2 and 3 Bearing Compartment Scavenge Tube Assembly

Sheet 2

Figure: Install the No.1, 2 and 3 Bearing Compartment Scavenge Tube Assembly

Sheet 3

Figure: Install the LP Fuel Tubes (102 and 116)

Sheet 1

Figure: Install the LP Fuel Tubes (102 and 116)

Sheet 2

Figure: Install the LP Fuel Tubes (102 and 116)

Sheet 3

Figure: Install the LP Fuel Tubes (102 and 116)

Sheet 4

Figure: Install the LP Fuel Tubes (102 and 116)

Sheet 5

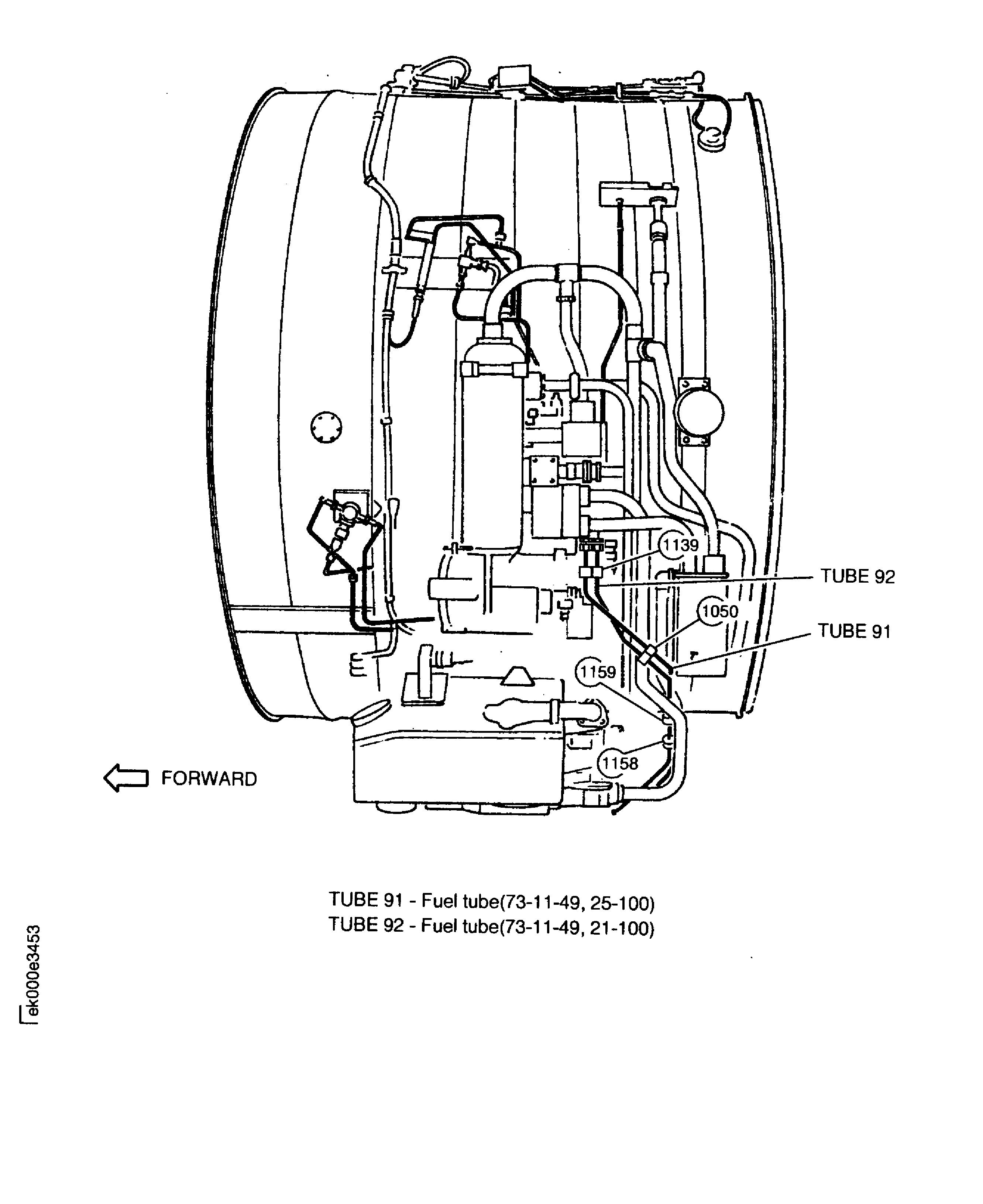

Figure: Pre SBE 73-0040: Install the HP Fuel Tubes (91 and 92)

Sheet 1

Figure: SBE 73-0040: Install the HP Fuel Tubes (91 and 92)

Sheet 2

Figure: Install the HP Fuel Tubes (91 and 92)

Sheet 3

Figure: Pre SBE 73-0040: Install the HP Fuel Tubes (91 and 92)

Sheet 4

Figure: SBE 73-0040: Install the HP Fuel Tubes (91 and 92)

Sheet 5

Figure: Pre SBE 73-0040: Install the Fuel Servo Return Tube (103)

Sheet 1

Figure: SBE 73-0040: Install the Fuel Servo Return Tube (103)

Sheet 2

Figure: Install the Fuel Servo Return Tube (103)

Sheet 3

Figure: SBE 73-0040: Install the Fuel Servo Return Tube (103)

Sheet 4

Figure: Install the Fuel Servo Return Tube (103)

Sheet 5

Figure: Install the LP Fuel Tube (90) and the Fuel Pump Drain Tube (104)

Install the LP Fuel Tube (90) and the Fuel Pump Drain Tube (104)

Figure: Pre SBE 79-0087 and SBE 79-0087: Install the HP Servo Fuel Tube (89)

Sheet 1

Figure: Pre SBE 79-0087 and SBE 79-0087: Install the HP Servo Fuel Tube (89)

Sheet 2

Figure: Pre SBE 79-0087 and SBE 79-0087: Install the HP Servo Fuel Tube (89)

Sheet 3

Figure: Install the Air Modulating Valve Fuel Supply Tube (187)

Sheet 1

Figure: Install the Air Modulating Valve Fuel Supply Tube (187)

Sheet 2

Figure: Electrical Harness Installation Procedure

Electrical Harness Installation Procedure

Figure: Pre SBE 71-0050 and Pre SBE 79-0087: Connect the Electrical Harness to the External Gearbox

Sheet 1

Figure: SBE 71-0050, Pre SBE 71-0107 and Pre SBE 79-0087: Connect the Electrical Harness to the External Gearbox

Sheet 2

Figure: Pre SBE 71-0107: Connect the Electrical Harness to the External Gearbox

Sheet 3

Figure: Pre SBE 71-0107: Connect the Electrical Harness to the External Gearbox

Sheet 4

Figure: Pre SBE 71-0050: Connect the Electrical Harness to the External Gearbox

Sheet 5

Figure: Pre SBE 71-0107: Connect the Electrical Harness to the External Gearbox

Sheet 6

Figure: Pre SBE 71-0107 and SBE 73-0040: Connect the Electrical Harness to the External Gearbox

Sheet 7

Figure: SBE 71-0050, Pre SBE 71-0107 and Pre SBE 79-0087: Connect the Electrical Harness to the External Gearbox

Sheet 8

Figure: Pre SB 71-0050, SBE 71-0050 and Pre SBE 79-0087: Connect the Electrical Harness to the External Gearbox

Sheet 9

Figure: Pre SBE 71-0107 and SBE 73-0040: Connect the Electrical Harness to the External Gearbox

Sheet 10

Figure: SBE 71-0107, SBE 73-0040 and Pre SBE 79-0087: Connect the Electrical Harness to the External Gearbox

Sheet 1

Figure: SBE 71-0107: Connect the Electrical Harness to the External Gearbox

Sheet 2

Figure: SBE 71-0107: Connect the Electrical Harness to the External Gearbox

Sheet 3

Figure: Pre SBE 73-0040 and Pre SBE 79-0087: Connect the Electrical Harness to the External Gearbox

Sheet 4

Figure: SBE 71-0118: Connect the Electrical Harness to the External Gearbox

Sheet 5

Figure: Pre SBE 71-0107 and SBE 71-0107: Connect the Electrical Harness to the External Gearbox

Sheet 6

Figure: SBE 71-0107: Connect the Electrical Harness to the External Gearbox

Sheet 7

Figure: SBE 71-0107: Connect the Electrical Harness to the External Gearbox

Sheet 8

Figure: SBE 71-0110: Connect the Electrical Harness to the External Gearbox

Sheet 1

Figure: SBE 71-0110: Connect the Electrical Harness to the External Gearbox

Sheet 2

Figure: SBE 71-0110 and SBE 71-0118 : Connect the Electrical Harness to the External Gearbox

Sheet 3

Figure: Examine the Harness Routing

Sheet 1

Figure: Examine the Harness Routing

Sheet 2

Figure: Install the Pneumatic Starter Lower Duct Assembly

Install the Pneumatic Starter Lower Duct Assembly

Figure: Install the Gearbox Deoiler Breather Duct

Install the Gearbox Deoiler Breather Duct

Figure: SBE 71-0063 and Pre SBE 71-011: Install the Clips at the Electrical Connectors

SBE 71-0063 and Pre SBE 71-011: Install the Clips at the Electrical Connectors

Figure: SBE 75-0010: Install the Dedicated Alternator Cooling Air Tubes

Sheet 1

Figure: SBE 71-0110: Install the Dedicated Alternator Cooling Air Tubes

Sheet 2

Figure: Visually Inspect the Backshells and Cable Clamps

Visually Inspect the Backshells and Cable Clamps