Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-00-32-420-003-A00 LPC/Intermediate Case Module - Install The Tubes And Electrical Harness Raceways, Installation-003

General

Refer to the TASKS which follow for the other related procedures.

TASK 72-00-32-420-001 Install the LP compressor/intermediate case brackets and the bifurcation panel

TASK 72-00-32-420-002 Install the LP compressor/intermediate case components

TASK 72-00-32-420-004 Install the LP compressor/intermediate case electrical harnesses

TASK 72-00-32-420-005 Install the pneumatic starter duct, the thermal anti-ice (TAI) duct, the hydraulic tubes, and the EEC cooling ducts to the LP compressor/intermediate case module

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

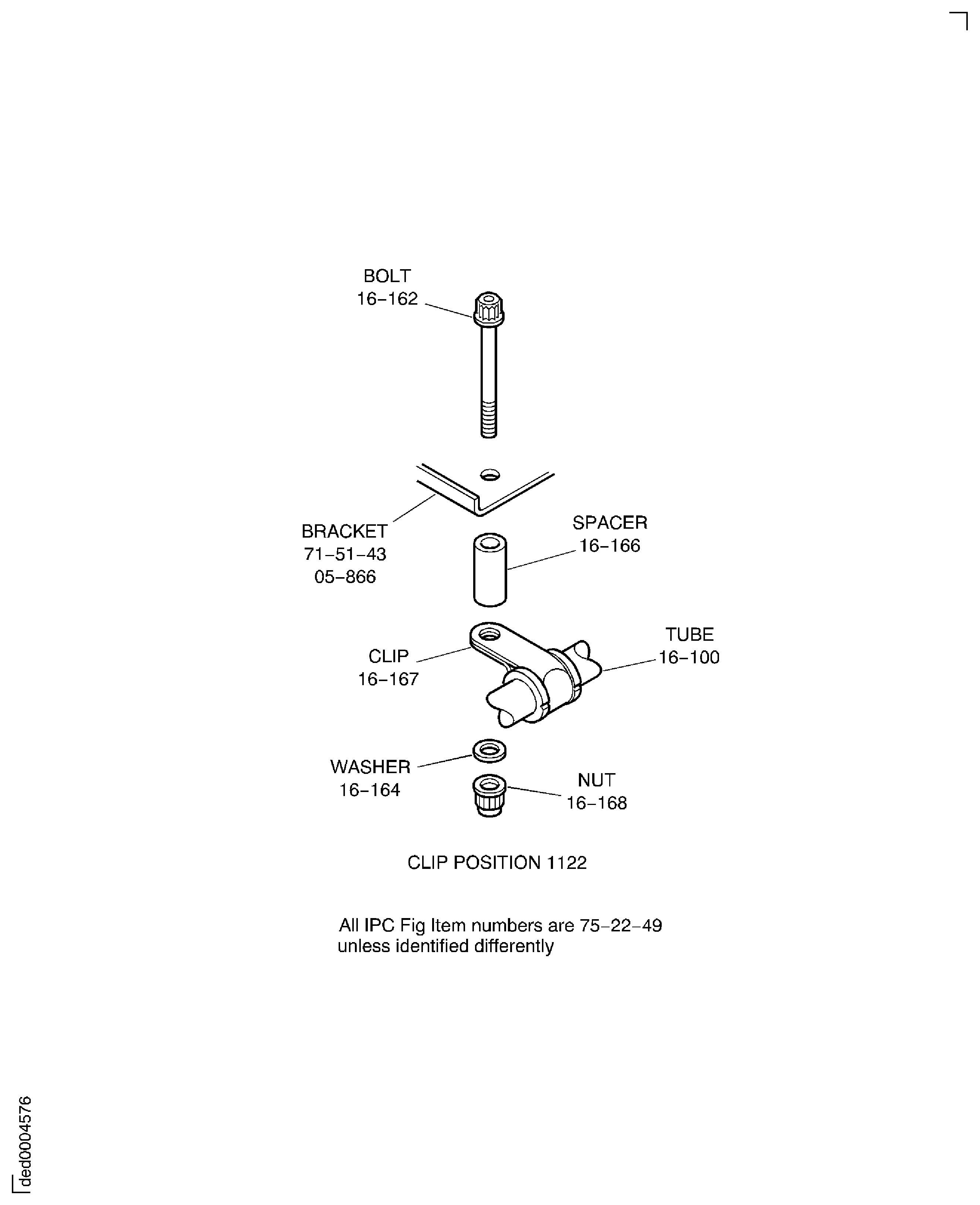

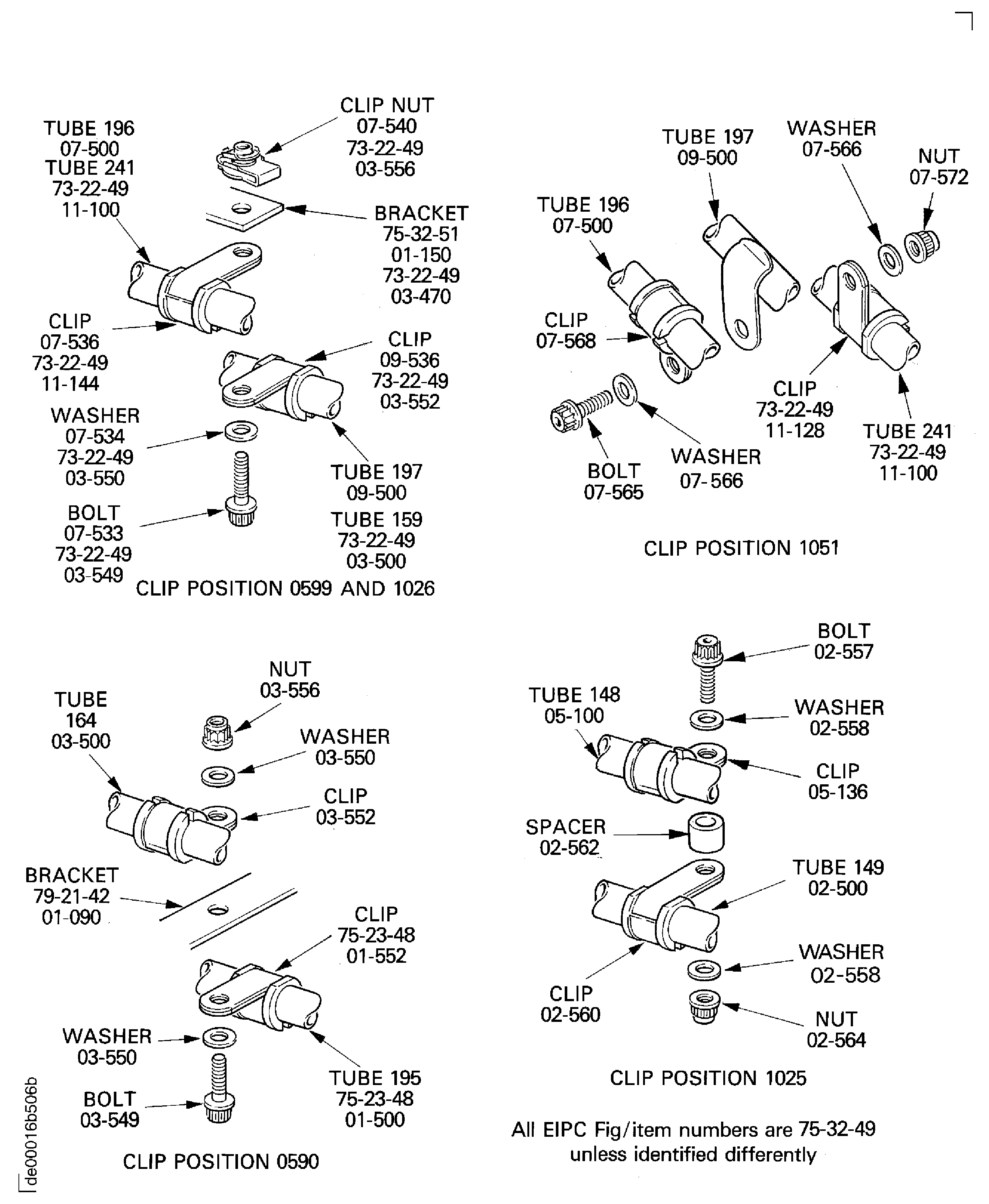

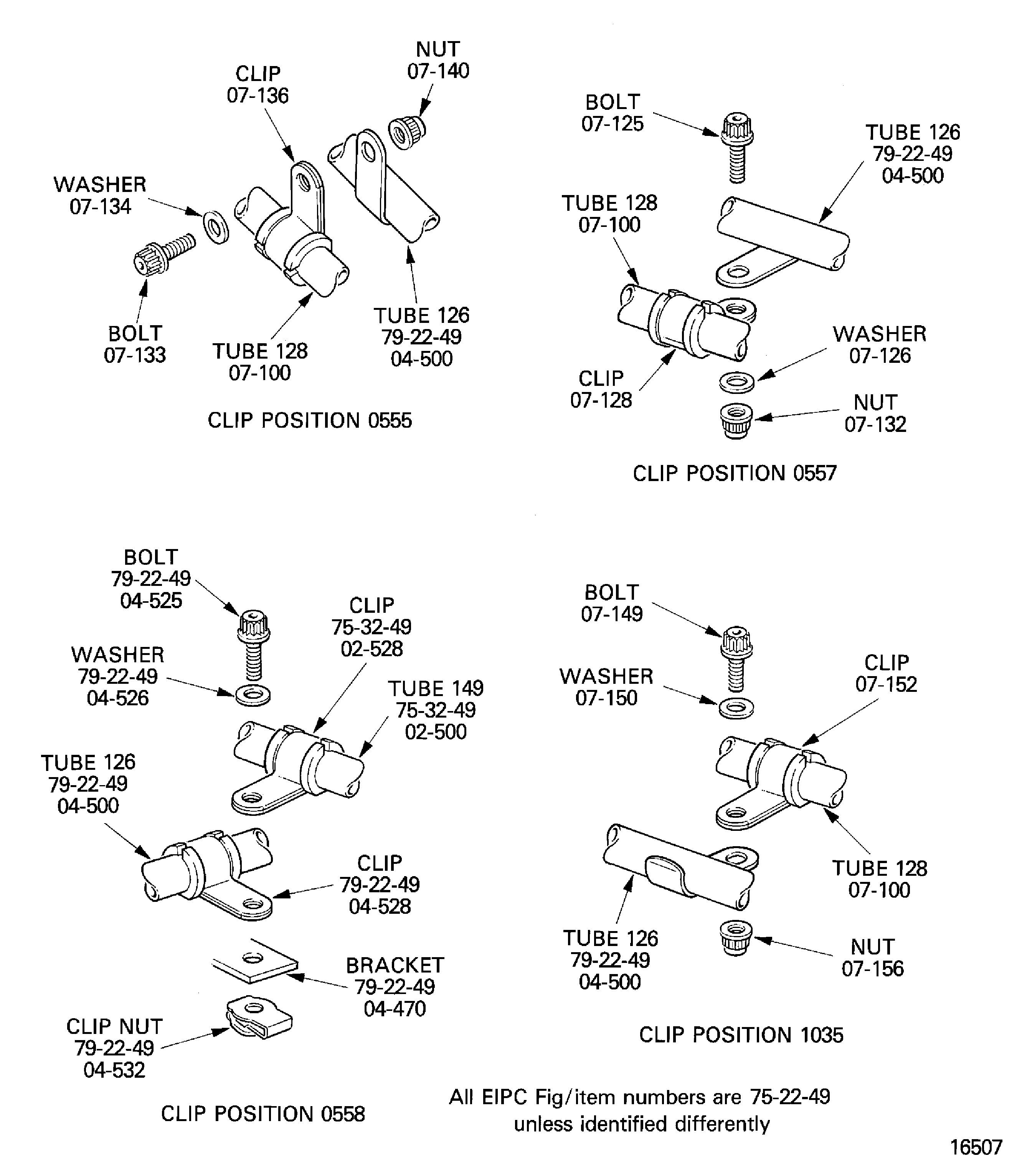

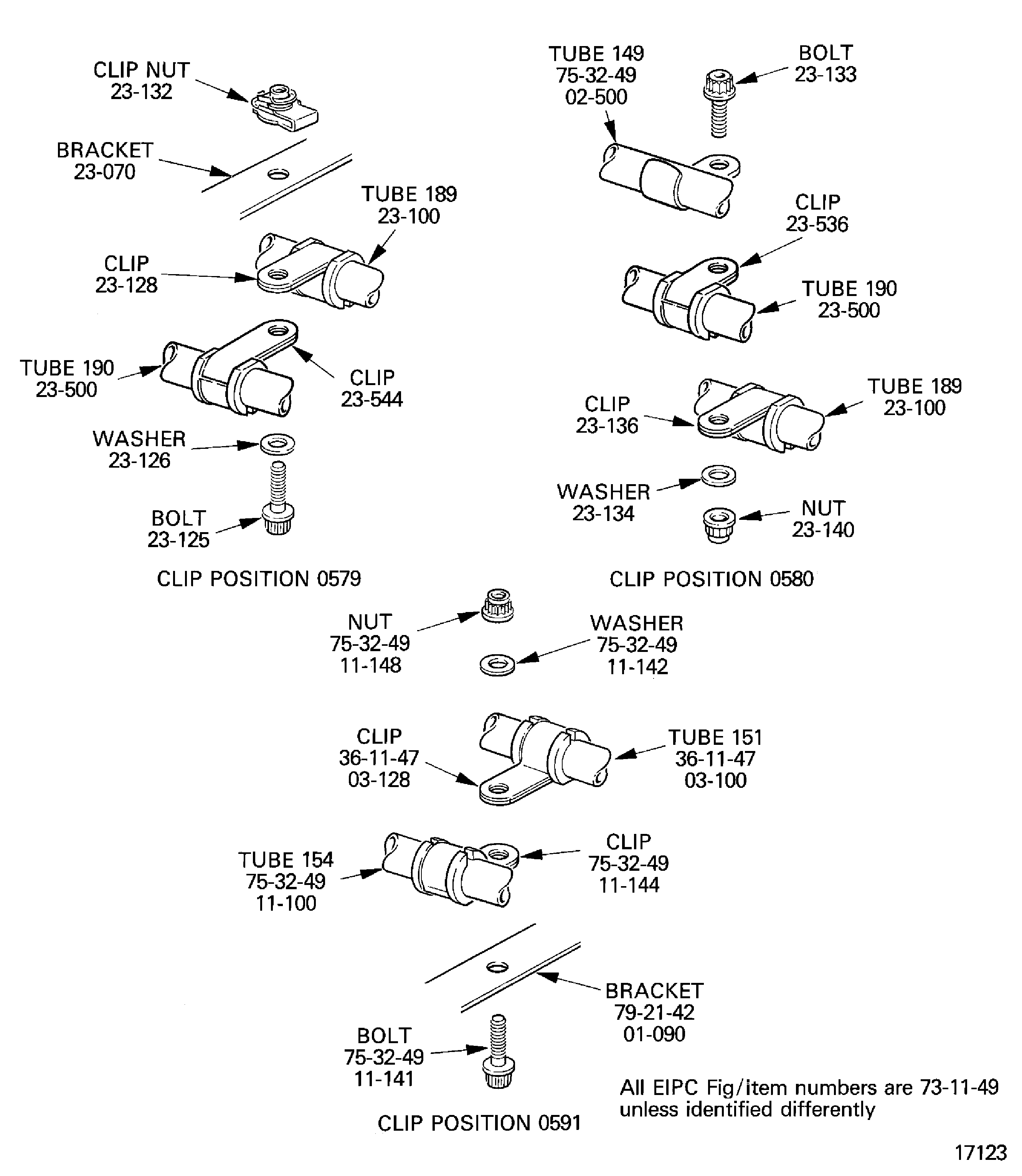

Refer to TASK 72-00-32-420-001 for the position on a raft or bracket of a particular clip position.

Transportation covers/blanks must be removed immediately before the installation of the tubes to the components or the other tubes.

For lockwire data refer to SPM TASK 70-42-05-400-501.

For safety cable data and procedures refer to SPM TASK 70-42-08-400-501.

Safety the threaded fasteners in the ATA Chapter/Section/Subject 73-22-49 as applicable with CoMat 02-274 SAFETY CABLE KIT or CoMat 02-275 SAFETY CABLE KIT.

To identify, lubricate and install seal rings refer to SPM TASK 70-44-00-400-501.

For the torque tightening procedures, refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-01-400-501.

Special torque data and assembly tolerances are included in this procedure.

Special torque data is identified with the symbol * after the torque value.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. Refer to SPM TASK 70-38-21-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1R18001 Wrench | 0AM53 | IAE 1R18001 | 1 | |

| IAE 1R18002 Wrench | 0AM53 | IAE 1R18002 | 1 | |

| IAE 1R18003 Wrench | 0AM53 | IAE 1R18003 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-002 SOLVENT, DELETED. | X111X | CoMat 01-002 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 02-274 SAFETY CABLE KIT | LOCAL | CoMat 02-274 | ||

| CoMat 02-275 SAFETY CABLE KIT | LOCAL | CoMat 02-275 | ||

| CoMat 04-019 Anti-sieze Thread Compound | IE539 | CoMat 04-019 | ||

| CoMat 05-016 GARNET PAPER, 80-GRIT | LOCAL | CoMat 05-016 | ||

| CoMat 05-017 GARNET PAPER, 60 GRIT | LOCAL | CoMat 05-017 | ||

| CoMat 07-038 AIR DRYING ENAMEL | k3504 | CoMat 07-038 | ||

| CoMat 08-013 COLD CURING SILICONE COMPOUND | X222X | CoMat 08-013 | ||

| CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT | LOCAL | CoMat 08-014 | ||

| CoMat 08-032 PRIMER | 71984 | CoMat 08-032 | ||

| CoMat 08-074 SEALANT, RTV SILICONE | 01139 | CoMat 08-074 | ||

| CoMat 10-038 PETROLEUM JELLY | LOCAL | CoMat 10-038 | ||

| CoMat 10-060 LIQUID PARAFFIN | LOCAL | CoMat 10-060 | ||

| CoMat 10-073 SYNTHETIC GREASE, MoDISULFIDE | LOCAL | CoMat 10-073 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

Safety Requirements

NONEProcedure

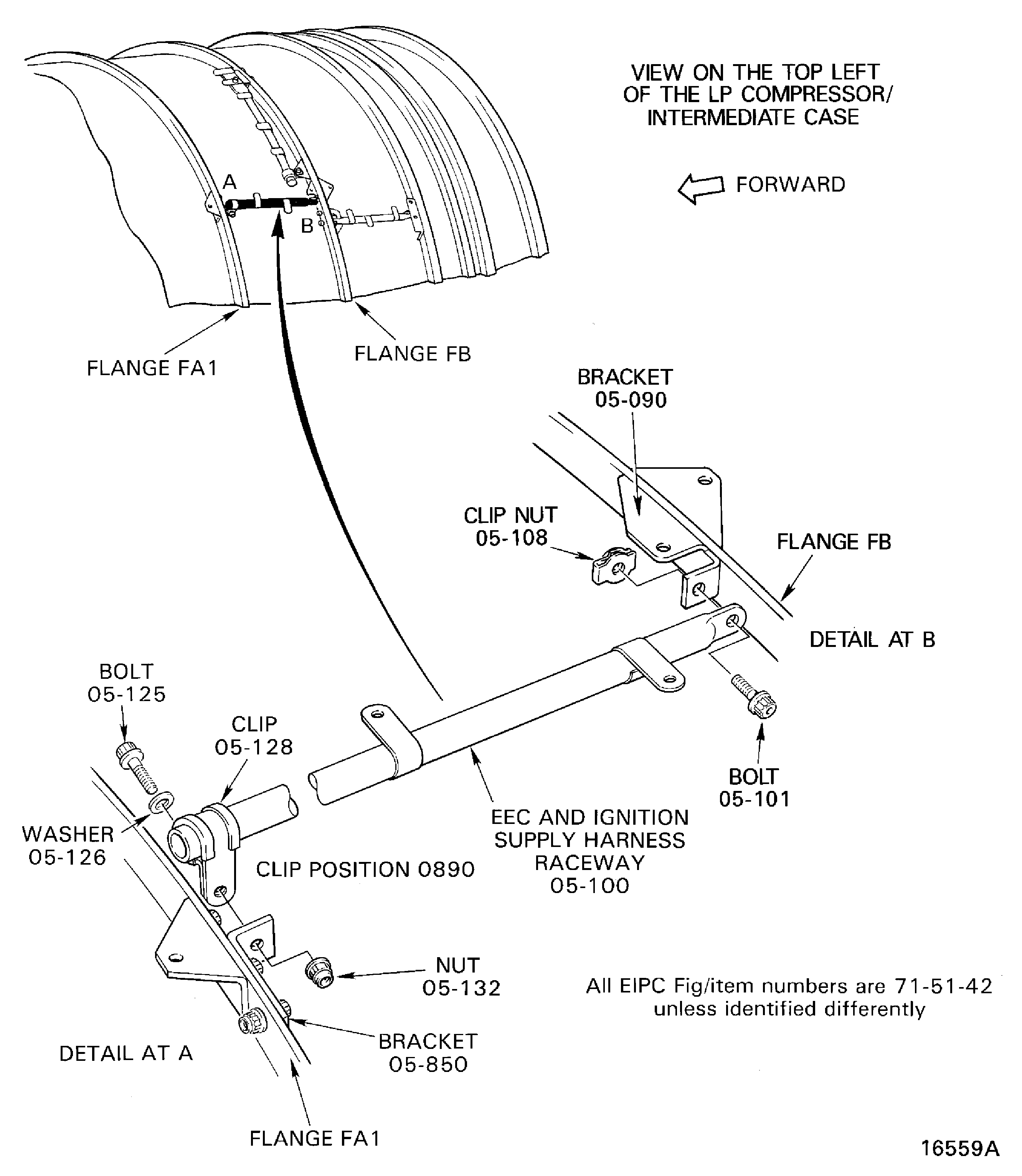

Refer to Figure.

Install the raceway to the bracket ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-090) at the flange FB with the bolt and the clipnut ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-101 and 05-108).

Install the EEC and Ignition Supply Harness Raceway ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-100) as follows:

SUBTASK 72-00-32-420-072 Install the EEC and Ignition Supply Harness Raceway (05-100)

Refer to Figure.

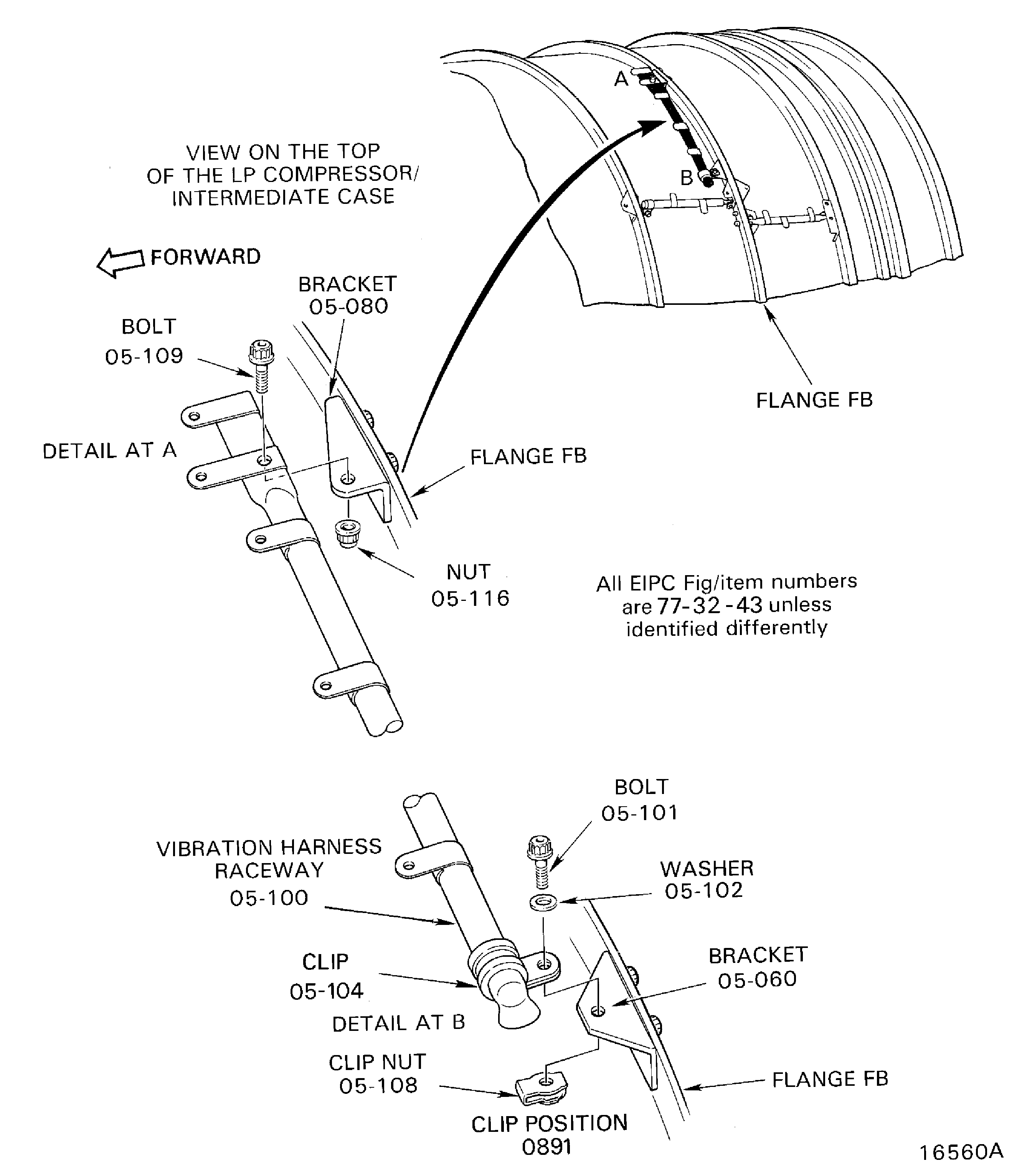

Install the raceway to the bracket VIBRATION TRANSDUCER JUNCTION BOX(77-32-43, 05-080) at the flange FB with the bolt and the nut VIBRATION TRANSDUCER JUNCTION BOX (77-32-43, 05-109 and 05-116).

Install the Vibration Harness Raceway VIBRATION TRANSDUCER JUNCTION BOX (77-32-43, 05-100) as follows:

SUBTASK 72-00-32-420-073 Install the Vibration Harness Raceway (05-100)

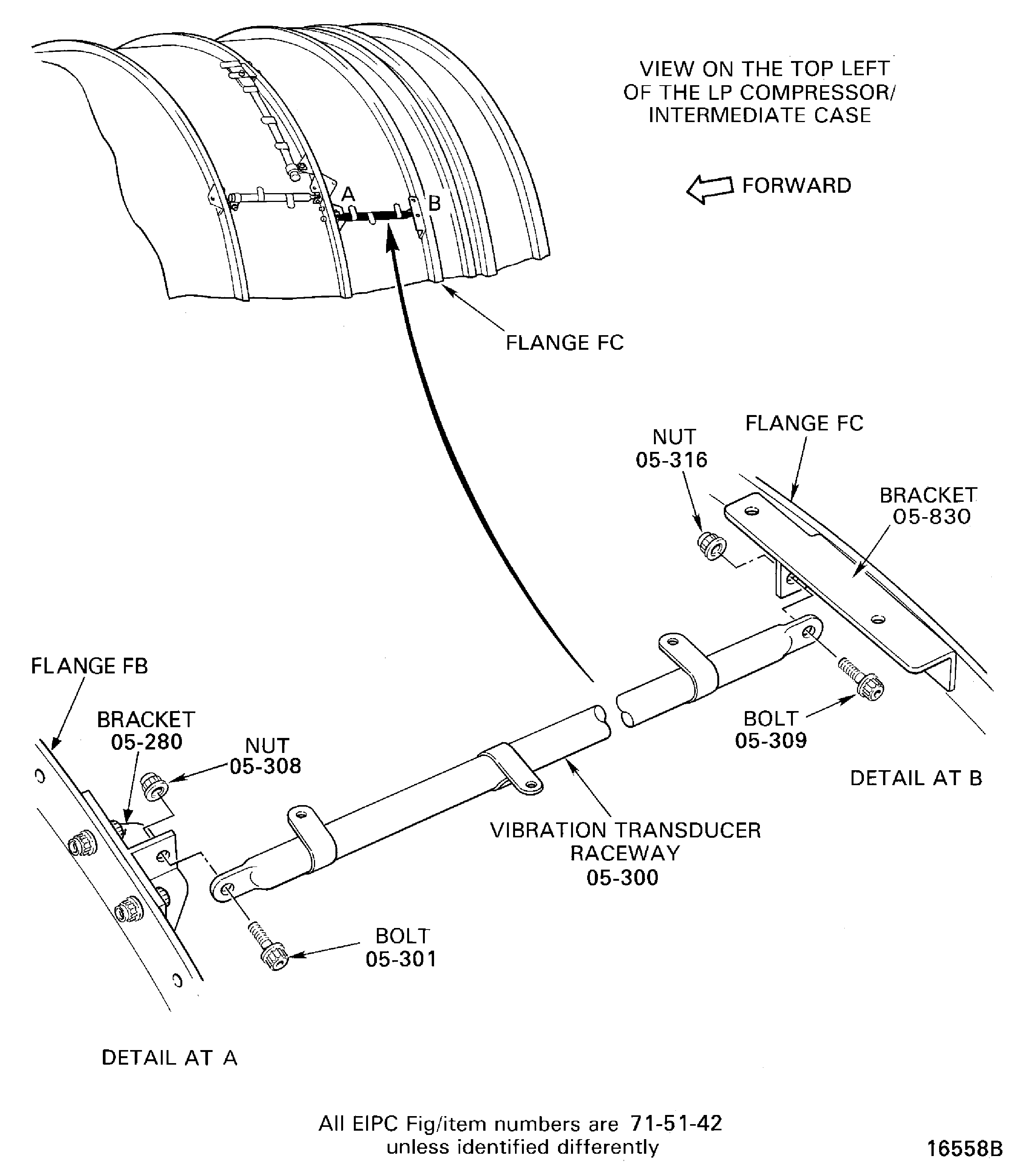

Refer to Figure.

Install the raceway to the bracket ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-830) at the flange FC with the bolt and the nut ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-309 and 05-316).

Install the raceway to the bracket ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-280) at the flange FB with the bolt and the nut ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-301 and 05-308).

Install the Vibration Transducer Raceway ELECT HARNESS-LIGHT DUTY-EEC/IGN SUPPLY HARNESS (71-51-42, 05-300) as follows:

SUBTASK 72-00-32-420-074 Install the Vibration Transducer Raceway (05-300)

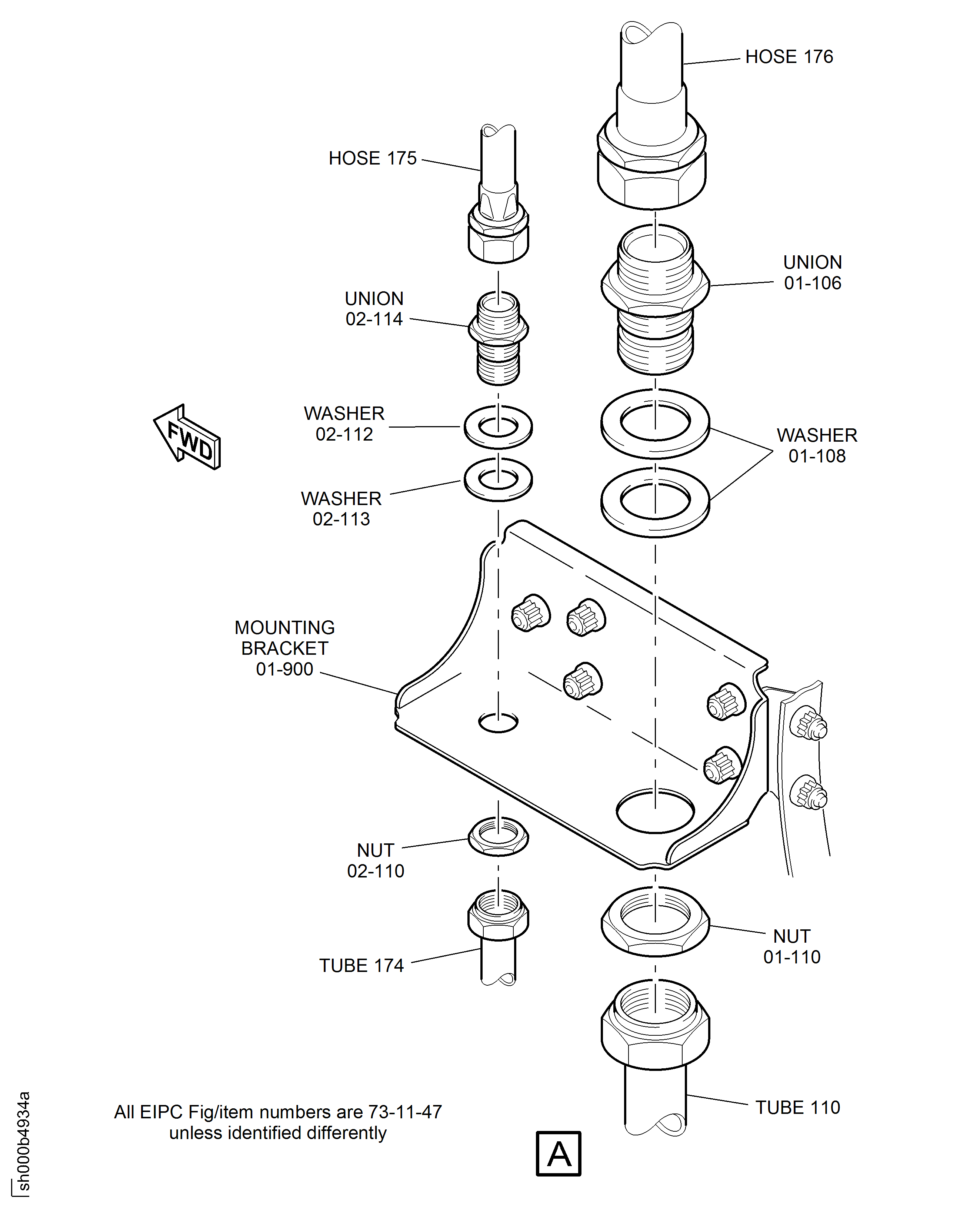

Lubricate the threads on the union FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-106), the tube end of the union FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-114) and the two nuts FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-110) and FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-110) with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY.

NOTE

When the tube 110 is connected to the LP fuel pump (TASK 72-00-60-420-002-A00) it can be necessary to make an adjustment of the bracket position, or install a washer between the mounting bracket and the union.NOTE

The washers are shown above the bracket, but can also be installed on each side of the bracket as necessary.NOTE

FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-106). This is to reduce the possible clearance. Refer to step H. for this procedure.Install the two unions on the mounting bracket with the nuts FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-110) and FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-110). Tighten the two nuts but do not torque them at this time. If necessary install a maximum of two washers FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-108) and FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-112) and FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-113) with one either side of the mounting bracket to make sure the tube and connector are correctly installed or installed as shown.

Connect the tube 110 to the union FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-106). Temporarily attach the tube 110 to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-070) at the clip position 0302 (at the flange FC). Install the bolt, the washer, the clipnut and the clip. Tighten the bolt.

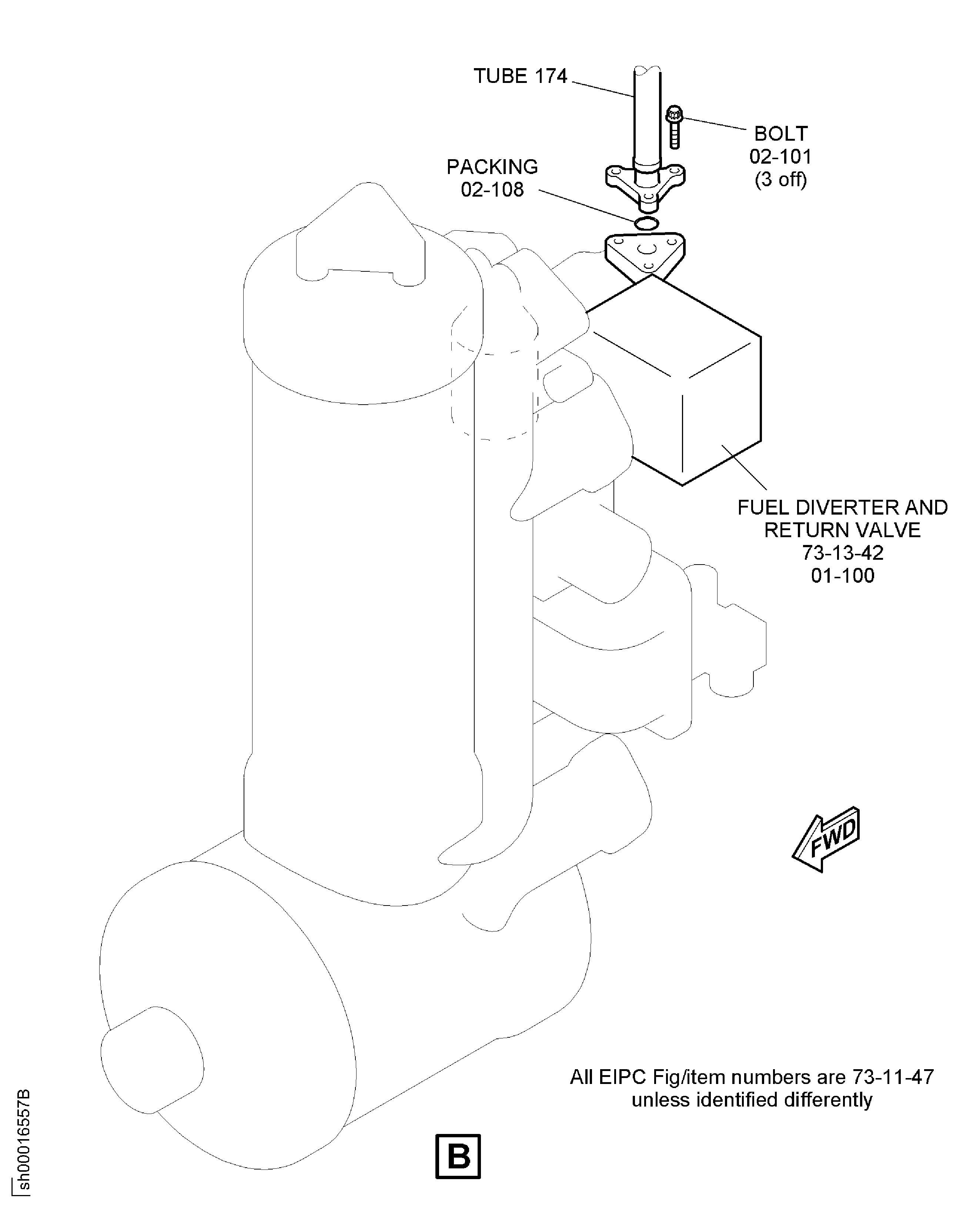

Lubricate a new packing FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-108) 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the packing on the tube 174.

Install the tube 174 to the fuel diverter and return valve FUEL DIVERTER AND RETURN VALVE (73-13-42, 01-100) with the three bolts FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-101). Connect the tube 174 to the union FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-114). Torque the three bolts to 85 to 105 lbf.in ( 10 to 12 Nm).

Install the Tubes 110 and 174, the Power Plant Fuel Tubes as follows:

Lubricate the threads on the hose 175 and the hose end of the union FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-114) with CoMat 04-019 Anti-sieze Thread Compound

Connect the hose 175 to the union FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-114) with the nut FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-110) and washer FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 02-112). Tighten the hose 175 nut but do not torque the nut at this time.

Connect the hose 176 to the union FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-106) with the nut FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-110) and washer FUEL SYSTEM TUBES (RIGID)-POWER PLANT (73-11-47, 01-108). Tighten the tube 176 nut but do not torque the nut at this time.

Attach the hoses 175 and 176 together with the clamp assembly FUEL SYSTEM TUBES (FLEXIBLE)-POWER PLANT (73-11-48, 01-045).

Keep the four bolts FUEL SYSTEM TUBES (FLEXIBLE)-POWER PLANT (73-11-48, 01-020), the four washers FUEL SYSTEM TUBES (FLEXIBLE)-POWER PLANT (73-11-48, 01-021), the gasket FUEL SYSTEM TUBES (FLEXIBLE)-POWER PLANT (73-11-48, 01-030), the four bolts FUEL SYSTEM TUBES (FLEXIBLE)-POWER PLANT (73-11-48, 01-050), the four washers FUEL SYSTEM TUBES (FLEXIBLE)-POWER PLANT (73-11-48, 01-051) and the gasket FUEL SYSTEM TUBES (FLEXIBLE)-POWER PLANT (73-11-48, 01-060) for the installation of the hoses on the pylon.

Install the Hoses 175 and 176 flexible Power Plant Fuel Hoses as follows:

Examine and adjust the mounting bracket installation. Do this step after the tube 110 is connected to the LP fuel pump (TASK 72-00-60-420-002-A00). The remaining procedure to torque and adjust the power plant fuel tubes and hoses is given in TASK 72-00-60-420-002-A00.

SUBTASK 72-00-32-420-075 Install the Tubes 110 and 174, and the Hoses 175 and 176, the Power Plant Fuel Tubes and Hoses

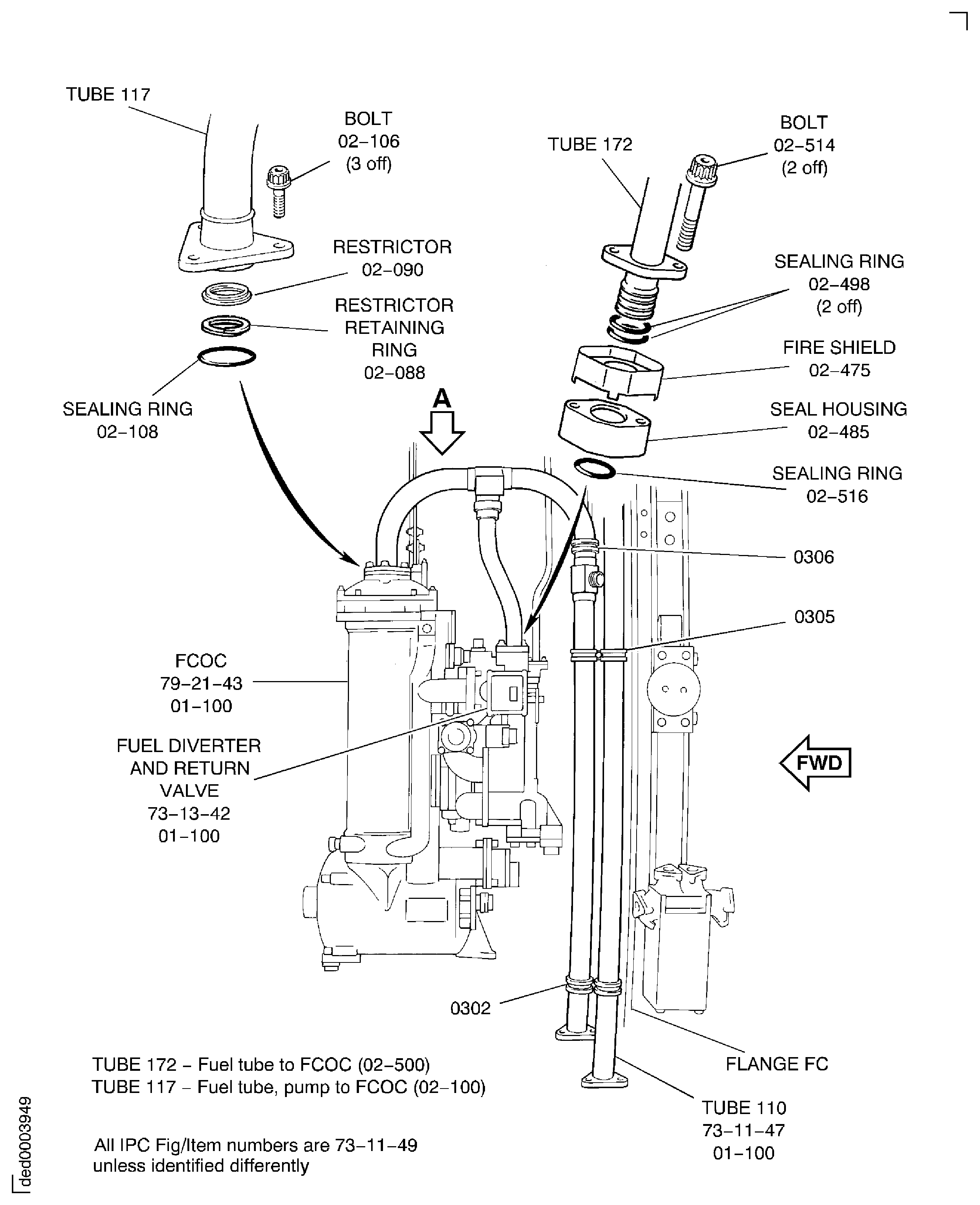

Lubricate the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-498) sealing ring2 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the two sealing rings on the tube 172.

Lubricate a new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-516) sealing ring1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the sealing ring on the seal housing ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-485).

Install the seal housing and the fire shield ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-485 and 02-475) on the tube 172.

Install the tube 172 assembly to the fuel diverter and return valve FUEL DIVERTER AND RETURN VALVE (73-13-42, 01-100) with the two bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-514). Torque the two bolts to 85 to 105 lbf.in (10 to 12 Nm).

Install the restrictor ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-090) and the restrictor retaining ring ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-088) in the tube 117.

Lubricate a new73-11-49,02-108 sealing ring1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the sealing ring on the tube 117.

Install the tube 117 to the FCOC and connect the tube 172 to the tube 117. Install the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-106) which attach the tube 117 to FCOC.

Pre SBE 73-0022 - Install the bolt, the washer, the nut and the clip at the clip position 0306.

SBE 73-0022 - Install the bolt, the nut and the clip at the clip position 0306.

Torque the tube 172 nut to 566 to 611 lbf.in (64 to 69 Nm) with theIAE 1R18003 Wrench 1 off.

NOTE

Refer to TASK 72-00-60-420-002-A00 to torque the clip positions 0302 and 0305 (during the tube 110 installation).Temporarily tighten the two bolts at the clip positions 0302 and 0305.

Safety the tube 172 nut with CoMat 02-126 LOCKWIRE.

Install the Tubes 172 and 117, the Fuel System Tubes as follows:

SUBTASK 72-00-32-420-076-A00 Install the Tubes 172 and 117, the Fuel System Tubes (Pre SBE 73-0058)

Lubricate the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-498) sealing ring 2 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the two sealing rings on the tube 172.

Lubricate a new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-516) sealing ring 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the sealing ring on the seal housing ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-485).

Install the seal housing and the fire shield ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-485 and 02-475) on the tube 172.

Install the tube 172 assembly to the fuel diverter and return valve FUEL DIVERTER AND RETURN VALVE (73-13-42, 01-100) with the two bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-514). Torque the two bolts to 85 to 105 lbf.in (10 to 12 Nm).

Install the restrictor ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-288) and the restrictor retaining ring ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-290) in the tube ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-300) .

Lubricate a new 73-11-49,02-308 sealing ring1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the sealing ring on the tube 117.

Install the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-305) and the three nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-306) which attach the tube ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-300) to the tube 117.

Lubricate a new 73-11-49,02-314 sealing ring 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the sealing ring on the tube ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-300).

Install the tube ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-300) to the FCOC and connect the tube 172 to the tube 117. Install the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-316) which attach the tube ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-300) to FCOC.

Pre SBE 73-0022 - Install the bolt, the washer, the nut and the clip at the clip position 0306.

SBE 73-0022 - Install the bolt, the nut and the clip at the clip position 0306.

Torque the tube 172 nut to 566 to 611 lbf.in (64 to 69 Nm) with theIAE 1R18003 Wrench 1 off.

Torque the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-316) and the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-305) to 85 to 105 lbf.in (10 to 12 Nm).

Safety the tube 172 nut with CoMat 02-126 LOCKWIRE.

Install the Tubes 172, 117 and ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 02-300) the Fuel System Tubes as follows:

NOTE

Refer to TASK 72-00-60-420-002-A00 to torque the clip positions 0302 and 0305 (during the tube 110 installation).

SUBTASK 72-00-32-420-076-B00 Install the Tubes 172, 117 and (02-300) the Fuel System Tubes. (SBE 73-0058)

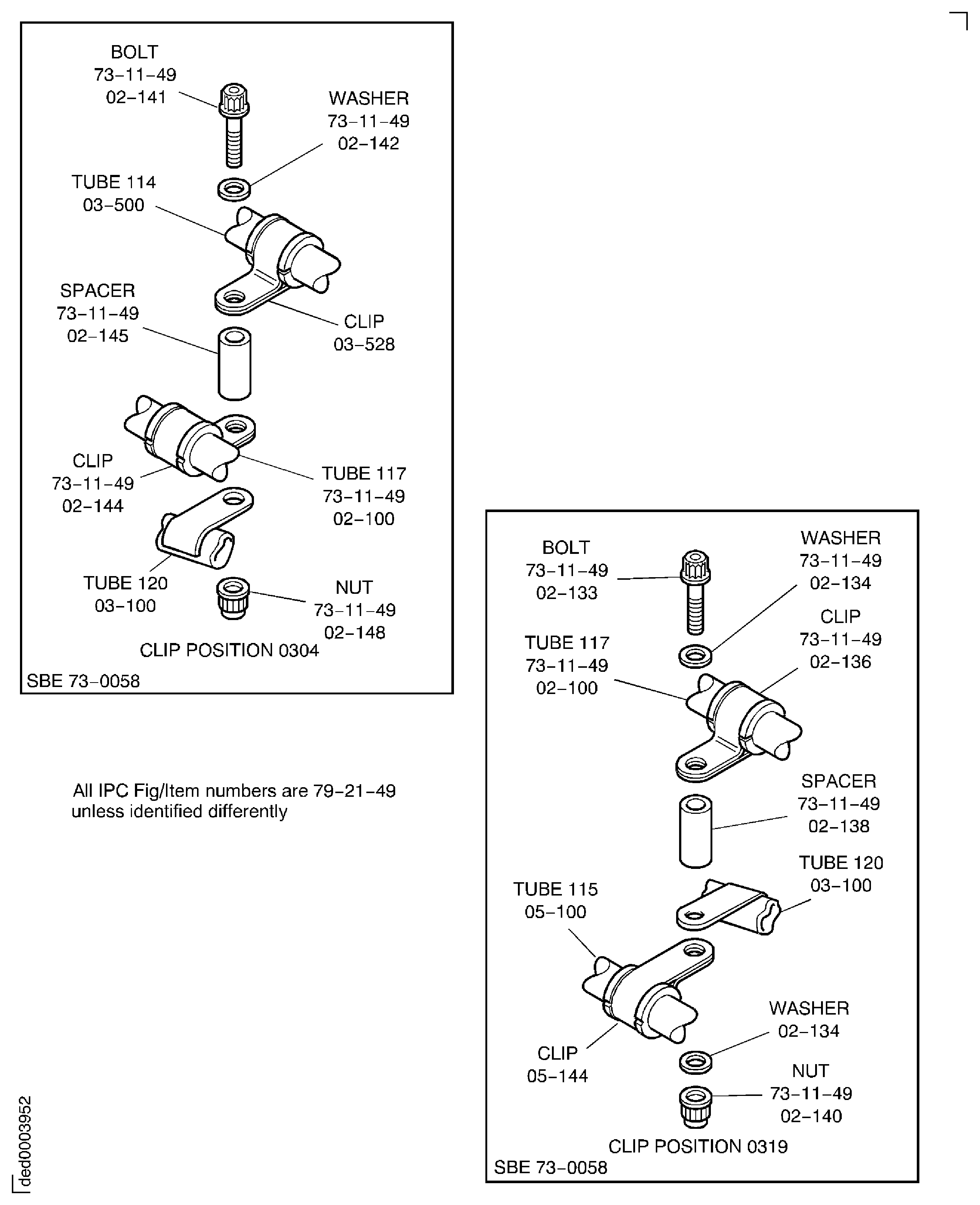

SBE 73-0058: New tubes with a repositioned restrictor orifice.

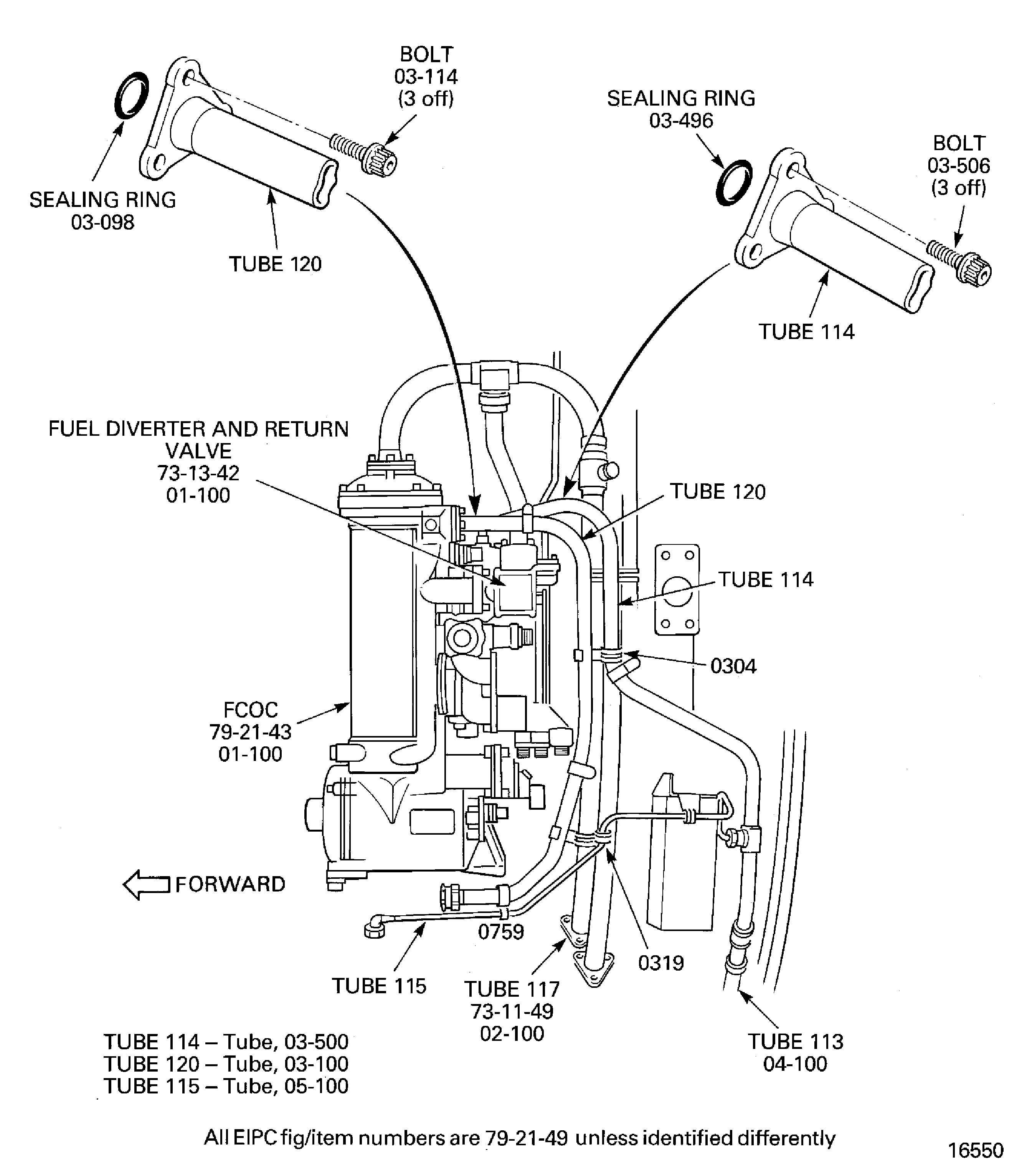

Lubricate a new OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 03-098) sealing ring 1 off with CoMat 10-077 APPROVED ENGINE OILS. Install the sealing ring on the tube 120.

Pre SBE 71-0110 - Install the tube 120 to the FCOC with the three bolts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 03-114). Torque the three bolts to 85 to 105 lbf.in (10 to 12 Nm).

SBE 71-0110 - Install the tube 120 to the FCOC with the three bolts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 03-114). Torque the three bolts to 85 to 105 lbf.in (10 to 12 Nm).

Lubricate a new OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 03-496) sealing ring 1 off with CoMat 10-077 APPROVED ENGINE OILS. Install the sealing ring on the tube 114.

Install the tube 114 to the FCOC with the three bolts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 03-506).

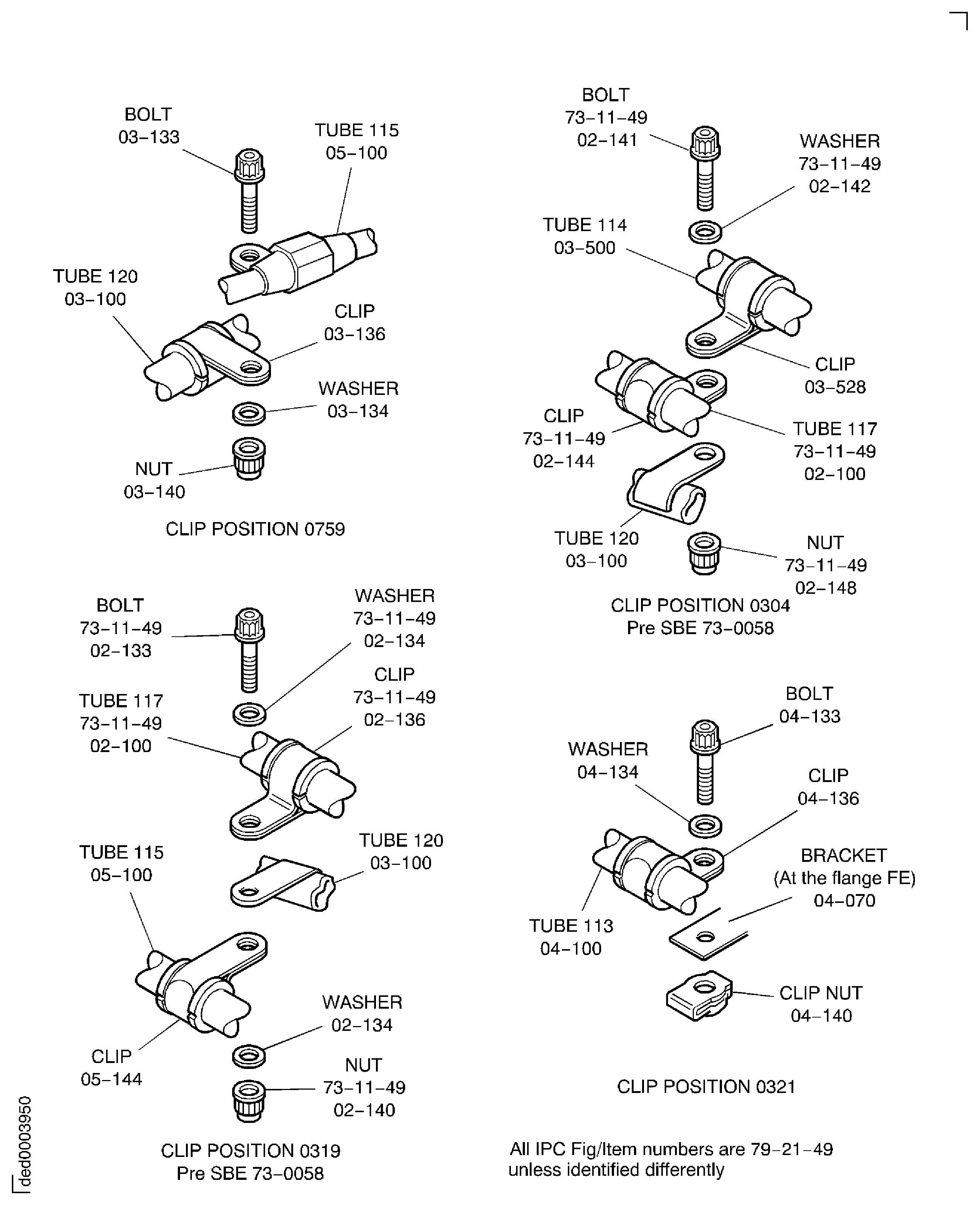

Pre SBE 73-0058 - Install the bolt, the washer, the nut and the clips at the clip positions 0304.

SBE 73-0058 - Install the bolt, the washer, the nut, the spacer and the clips at the clip positions 0304.

Torque the three bolts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 03-506) to 85 to 105 lbf.in (10 to 12 Nm).

Pre SBE 73-0058 - Attach the tube 115 to the tubes 120 and 117 at the clip positions 0319 and 0759 with the bolts, the washers, the nuts and the clips.

SBE 73-0058 - Attach the tube 115 to the tubes 120 and 117 at the clip positions 0319 and 0759 with the bolts, the washers, the spacer, the nuts and the clips.

Connect the tube 115 to the tube 114. Torque the tube 115 nut to 159 to 177 lbf.in (18 to 20 Nm). Safety the tube nut with CoMat 02-126 LOCKWIRE.

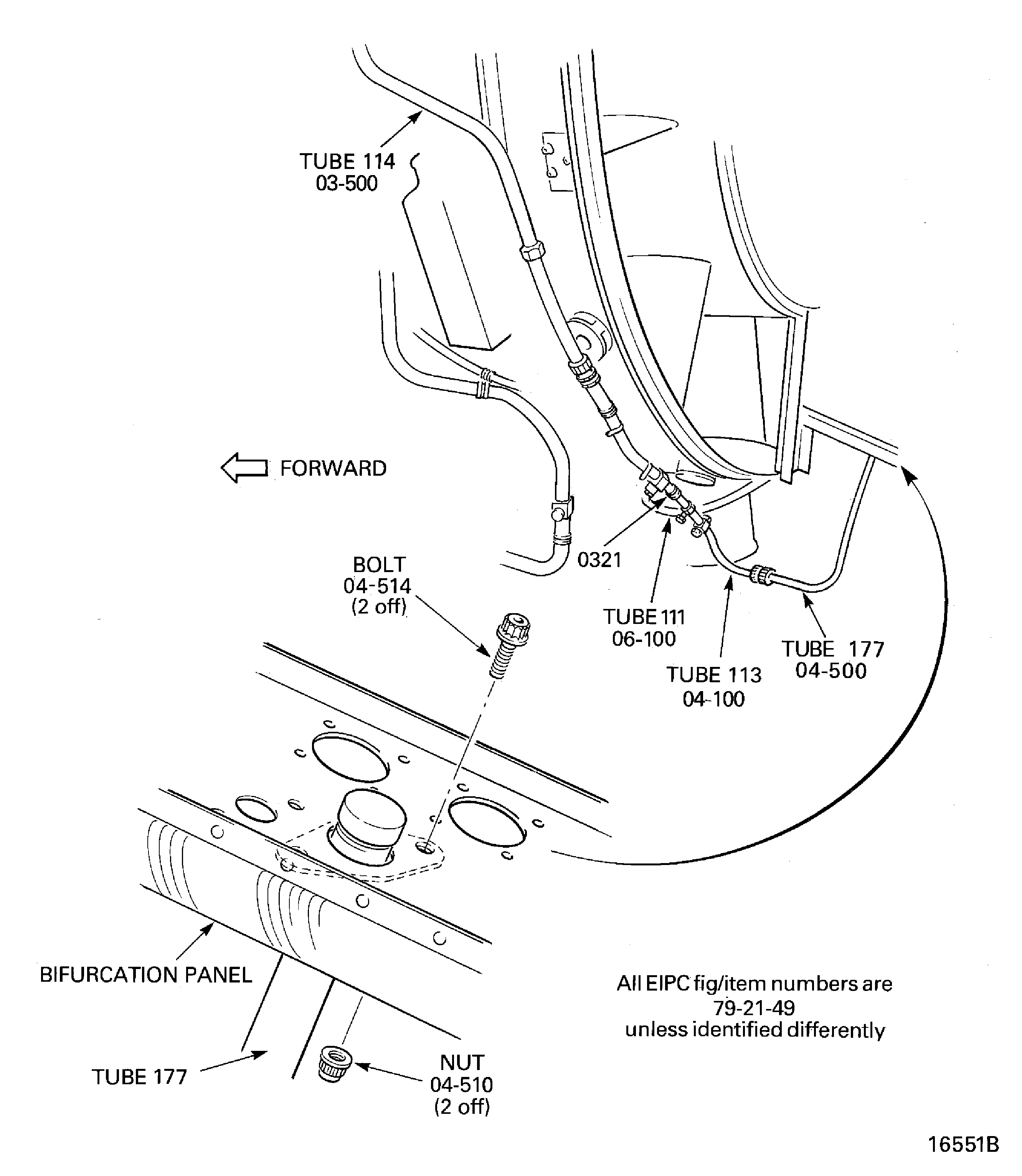

Install the tube 177 to the bifurcation panel with the two bolts and the two nuts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 04-514 and 04-510). Torque the two nuts to 85 to 105 lbf.in (10 to 12 Nm).

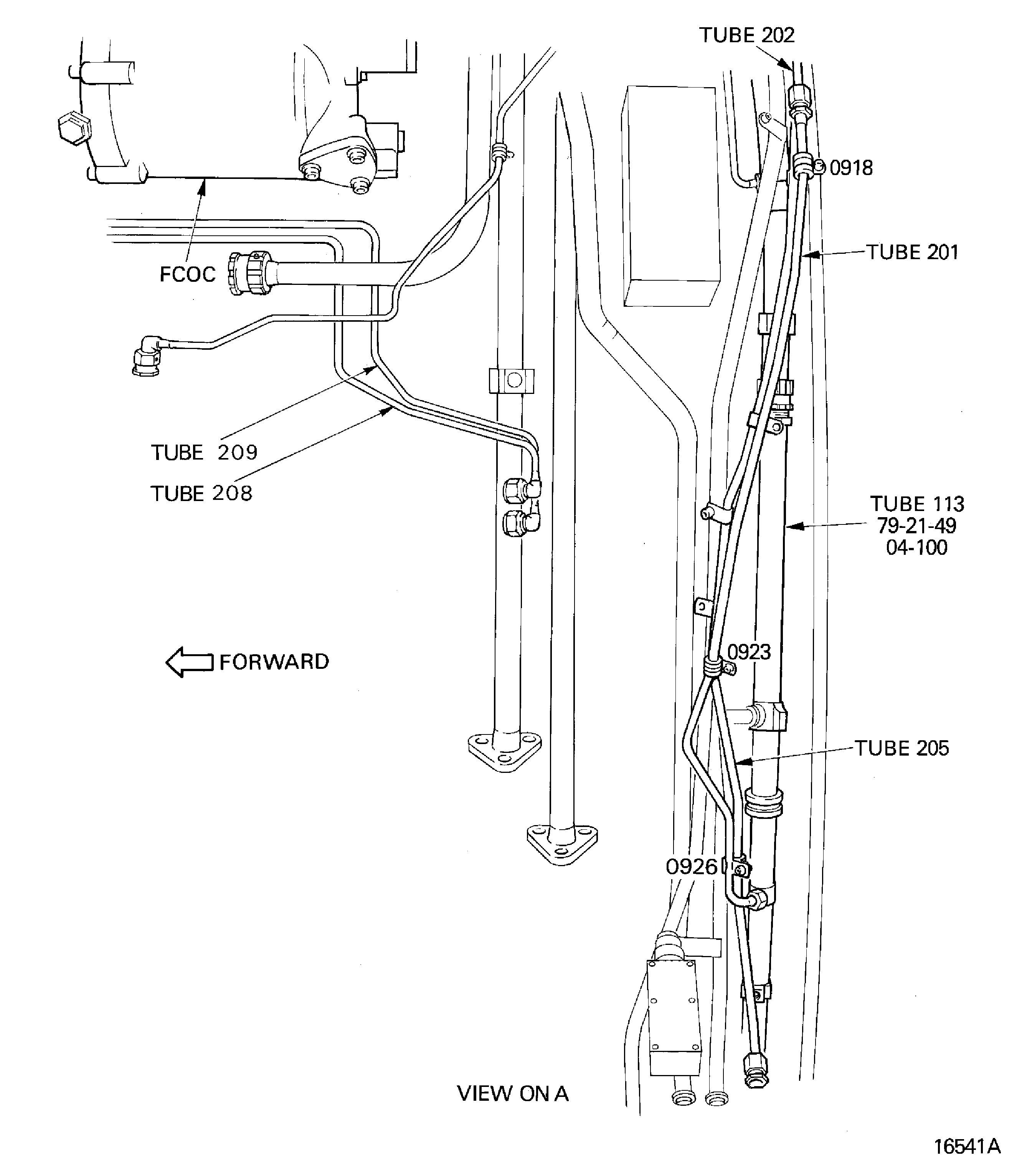

Connect the tube 113 to the tube 177. Torque the tube 113 nut to 398 to 434 lbf.in (45 to 49 Nm) with the IAE 1R18001 Wrench 1 off.

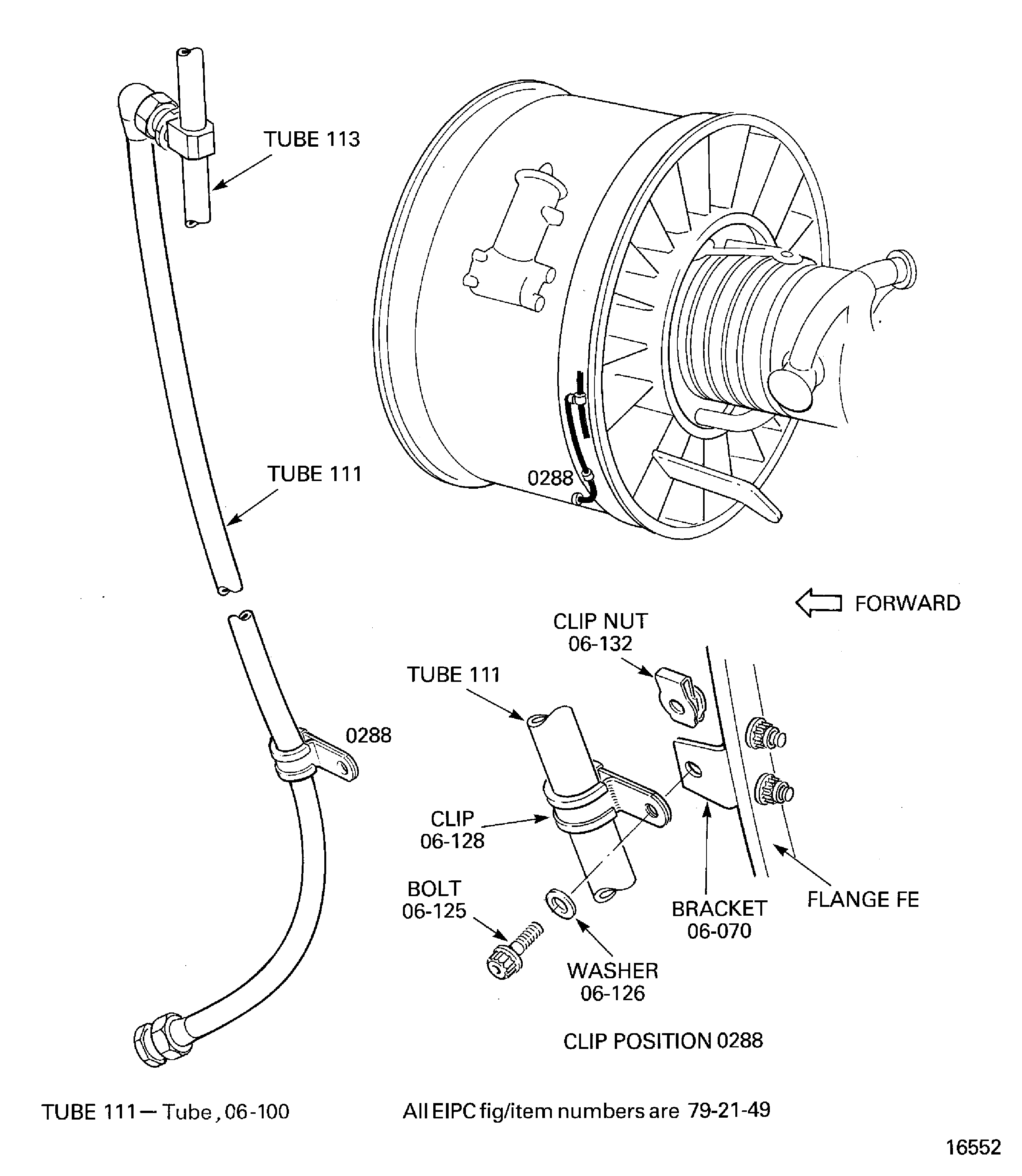

Torque the tube 111 nut to 283 to 310 lbf.in (32 to 35 Nm). Torque the tube 114 nut to 478 to 513 lbf.in (54 to 58 Nm) with the IAE 1R18002 Wrench 1 off. Safety the tube 113, 111 and 114 nuts with CoMat 02-126 LOCKWIRE.

NOTE

The nuts at the clip positions 0319 and 0759 are torque tightened during the procedure given in Step.Torque the bolts and the nut at the clip positions 0321, 0288 and 0304 to 36 to 45 lbf.in (4 to 5 Nm).

SUBTASK 72-00-32-420-077 Install the Tubes 120, 115, 114, 113, 111 and 177, the Pressure Oil Tubes

Lubricate a new ELECTRICAL POWER-IDG OIL COOLING TUBES (24-21-49, 03-514) packing 1 off with CoMat 10-077 APPROVED ENGINE OILS.

Lubricate a new ELECTRICAL POWER-IDG OIL COOLING TUBES (24-21-49, 01-106) packing 1 off with CoMat 10-077 APPROVED ENGINE OILS.

Lubricate the shanks of the six bolts ELECTRICAL POWER-IDG OIL COOLING TUBES (24-21-49, 01-102 and 03-510) with CoMat 10-073 SYNTHETIC GREASE, MoDISULFIDE.

Install the lubricated packing ELECTRICAL POWER-IDG OIL COOLING TUBES (24-21-49, 01-106) on the tube 98. Install the lubricated packing ELECTRICAL POWER-IDG OIL COOLING TUBES (24-21-49, 03-514) on the tube 99.

Install the tube 98 and the bracket ELECTRICAL POWER-IDG OIL COOLING TUBES (24-21-49, 01-070) to the IDG FCOC ELECTRICAL POWER-FUEL COOLED IDG OIL COOLER (24-21-42, 01-100) with the three bolts ELECTRICAL POWER-IDG OIL COOLING TUBES (24-21-49, 01-102). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

Install the tube 99 and the bracket ELECTRICAL POWER-IDG OIL COOLING TUBES (24-21-49, 03-470) to the IDG FCOC with the three bolts ELECTRICAL POWER-IDG OIL COOLING TUBES (24-21-49, 03-510). Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

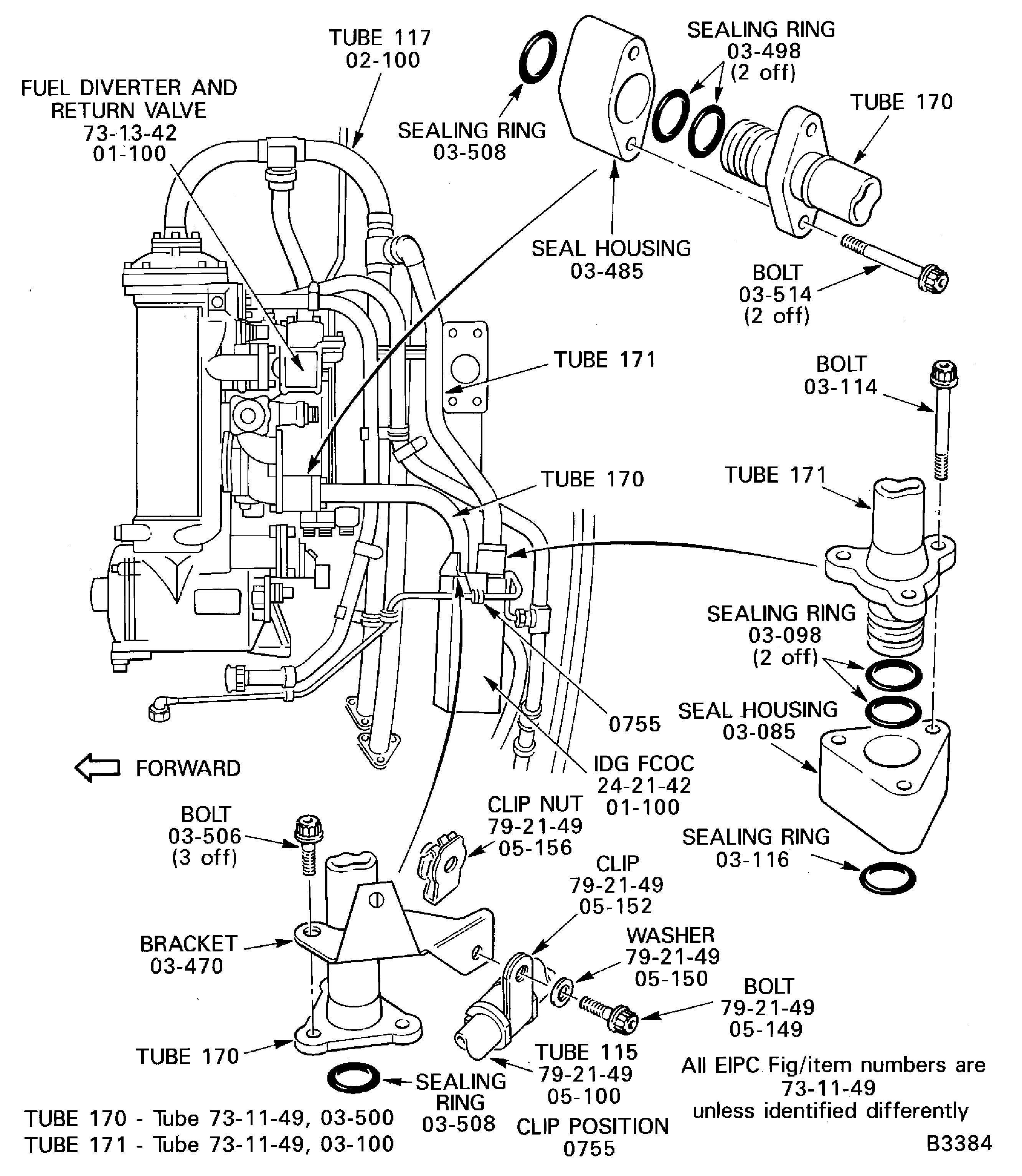

SUBTASK 72-00-32-420-078 Install the Tubes 96, 97, 98 and 99, the IDG Cooling Tubes

Refer to Figure.

Lubricate the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 03-508) sealing ring 2 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install one of the sealing rings on the seal housing ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 03-485). Install the other sealing ring on the tube 170.

Lubricate the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 03-498) sealing ring 2 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the sealing rings on the tube 170.

Install the seal housing ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 03-485) on the tube 170.

Install the tube 170 assembly to the IDG FCOC ELECTRICAL POWER-FUEL COOLED IDG OIL COOLER (24-21-42, 01-100) and the fuel diverter and return valve FUEL DIVERTER AND RETURN VALVE (73-13-42, 01-100).

Install the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 03-506) which attach the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 03-470) and the tube 170 to the IDG FCOC.

Install the two bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 03-514) which attach the seal housing and the tube 170 to the fuel diverter and return valve.

Torque the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 03-506) and the two bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 03-514) to 85 to 105 lbf.in (10 to 12 Nm).

Install the bolt, the washer, the clipnut and the clip at the clip position 0755 to attach the tube 115 to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 03-470). Torque the nuts at the clip positions 0319, 0759 and the bolt at the clip position 0755 to 36 to 45 lbf.in (4 to 5 Nm).

Lubricate the new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 03-098) sealing ring2 off with CoMat to 10-060 liquid paraffin or CoMat 10-038 PETROLEUM JELLY. Install the sealing rings on the tube 171.

Lubricate a new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 03-116) sealing ring1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY. Install the sealing ring on the seal housing ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 03-085).

Install the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 03-114) which attach the tube 171 assembly to the IDG FCOC. Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

Torque the tube 171 nut to 566 to 611 lbf.in (64 to 69 Nm) with the IAE 1R18003 Wrench 1 off. Safety the tube nut with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-079 Install the Tubes 170 and 171, the Fuel System Tubes

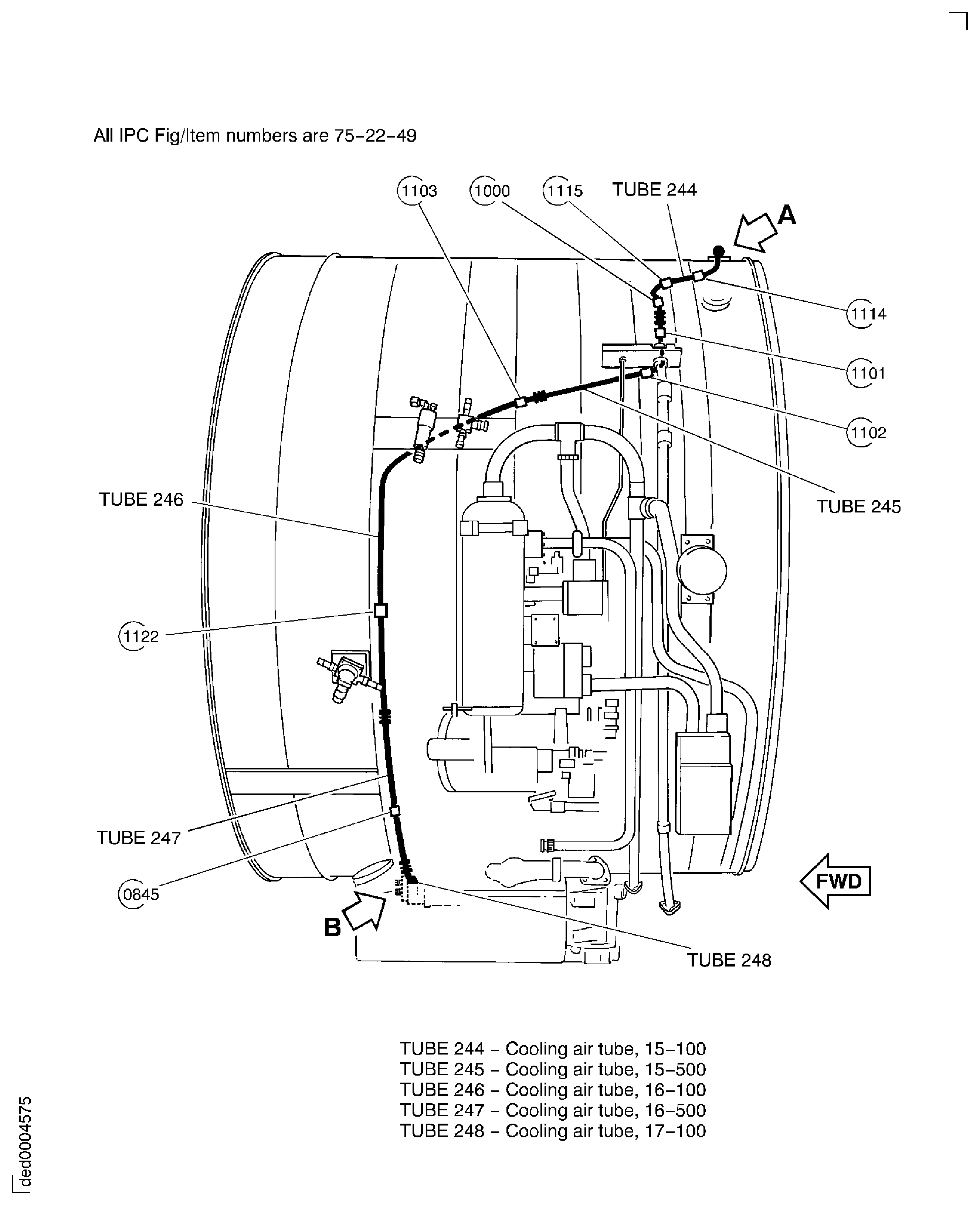

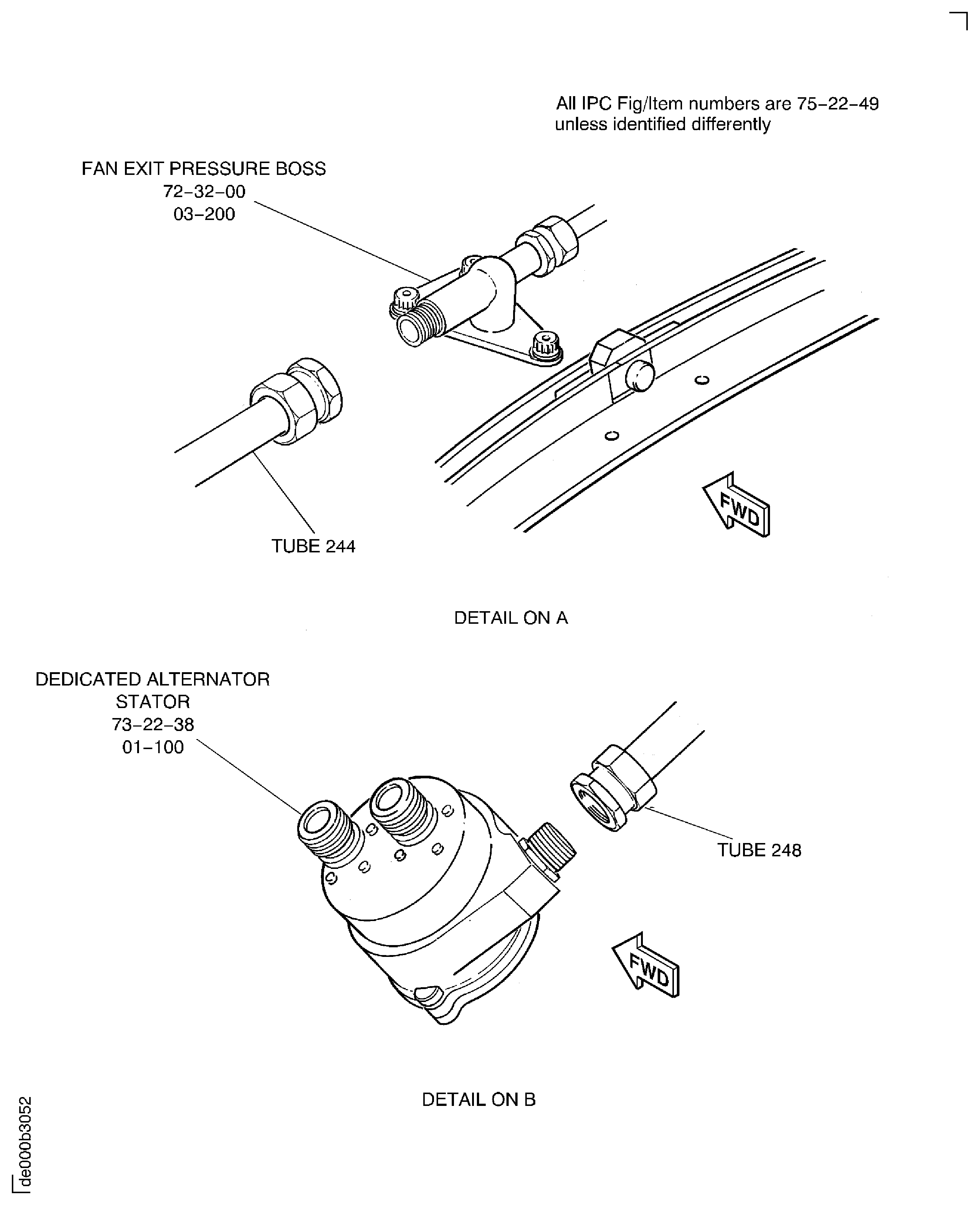

Install the tube 244 to the fan exit pressure boss ENGINE-FAN CASE (72-32-85, 02-100). Hand tighten the tube nut.

Connect the tube 247 to the tube 246 and connect the tube 248 to the tube 247 and to the dedicated alternator stator DEDICATED ALTERNATOR STATOR (73-22-38, 01-100). Torque the tube 247 and the tube 248 tube nuts to 283 to 310 lbf.in (32 to 35 Nm).

SBE 71-0110: Install the bolt, the washer, the nut and the clip at the clip position 0845. Torque the nut to 36 to 45 lbf.in (4 to 5 Nm).

Refer to Figure.

Safety all tube nuts installed in this SUBTASK with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-164 Install the Tubes 244, 245, 246, 247 and 248, the Cooling Air Tubes (SBE 75-0010)

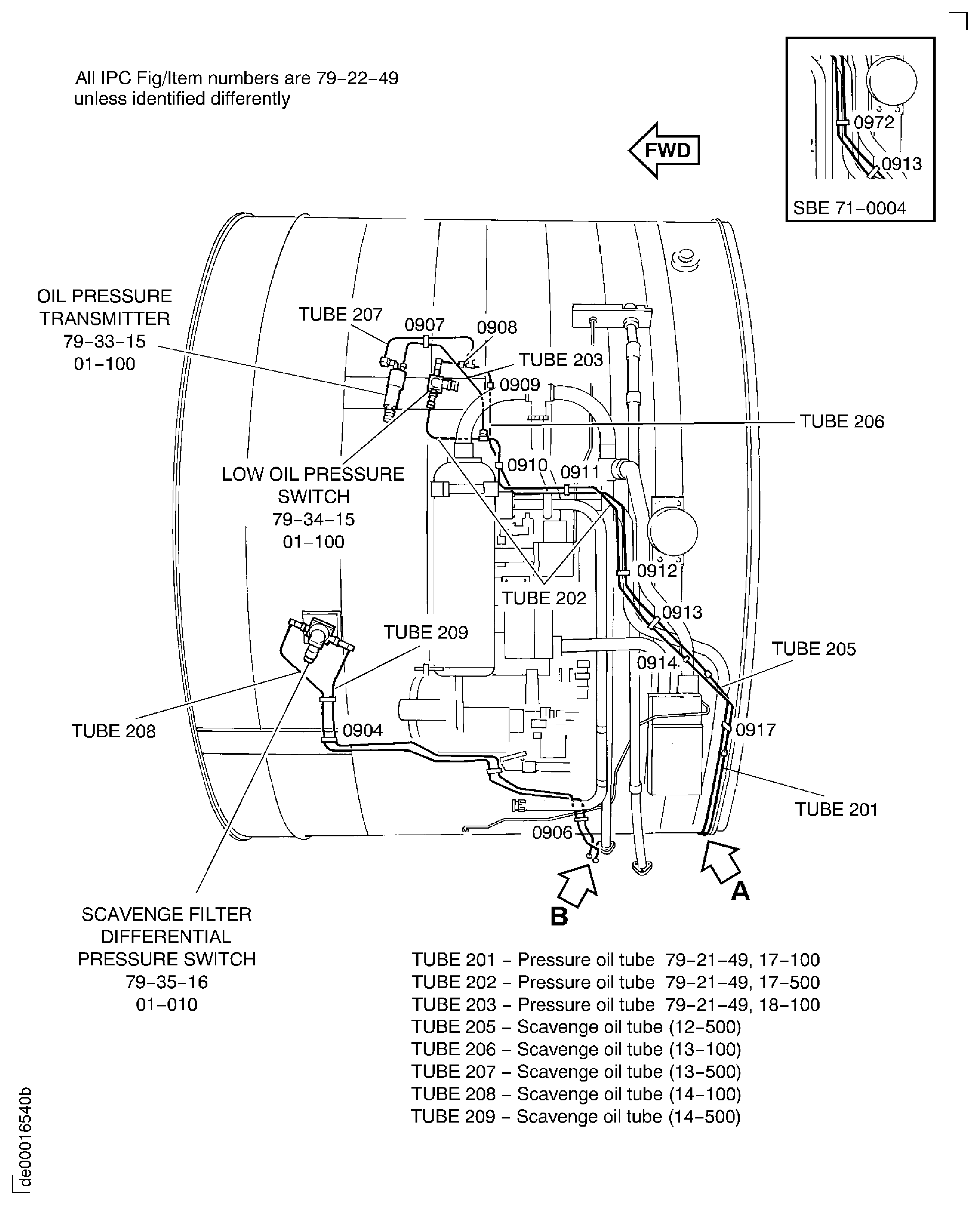

Connect the tube 202 to the low oil pressure switch LOW OIL PRESSURE SWITCH (79-34-15, 01-010).

Torque the tube 201 nut (at the tube 113) to 159 to 177 lbf.in (18 to 20 Nm). Safety the tube 201 nut with CoMat 02-126 LOCKWIRE.

Connect the tube 203 to the oil pressure transmitter OIL-OIL PRESSURE TRANSMITTER (79-33-15, 01-010) and the tube 202.

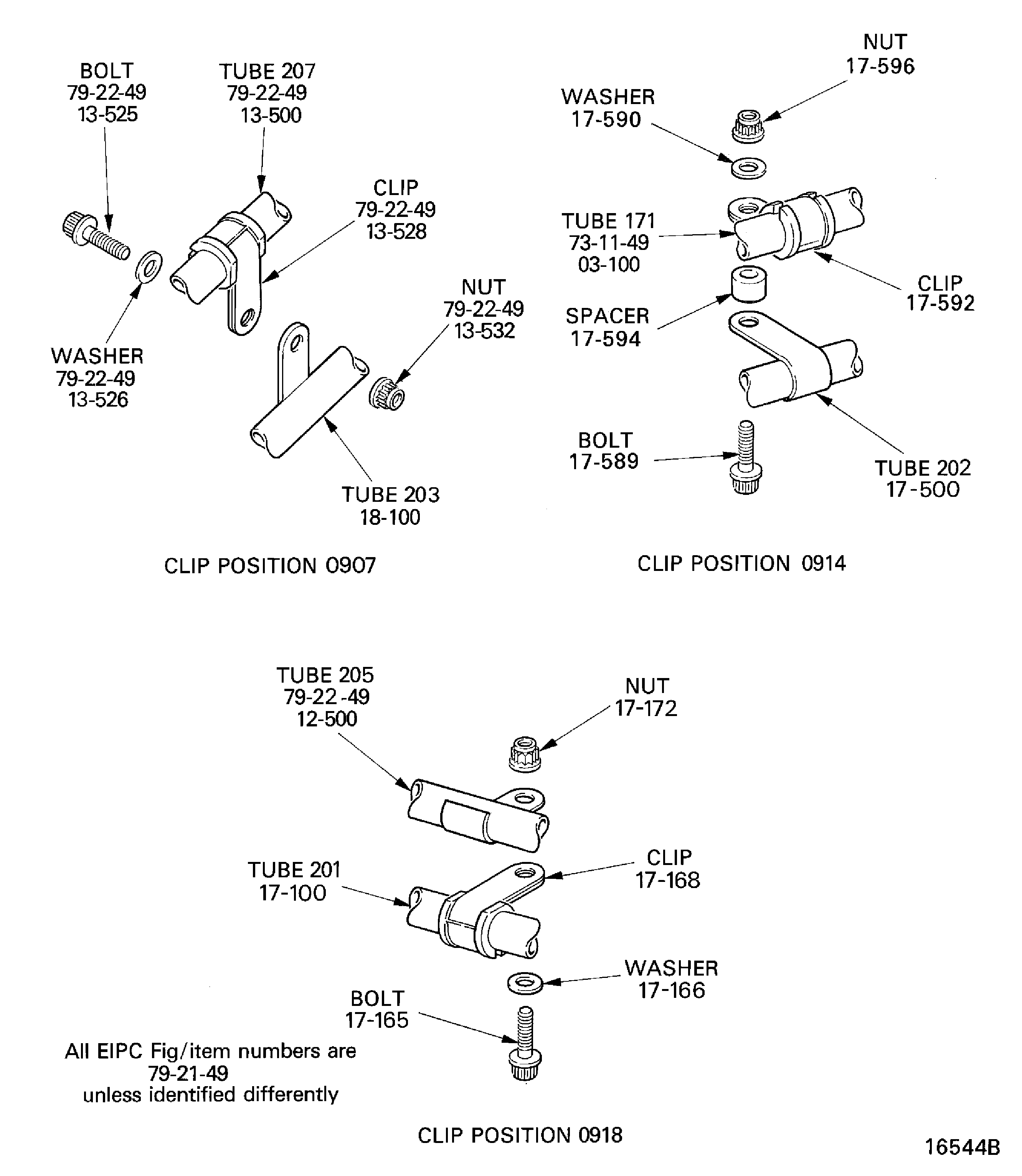

SUBTASK 72-00-32-420-080 Install the Tubes 201, 202 and 203, the Pressure Oil Tubes

Connect the tube 206 to the low oil pressure switch LOW OIL PRESSURE SWITCH (79-34-15, 01-010).

Pre SBE 79-0036: Connect the tube 205 to the tube 206. Install the bolts, the washers, the nuts and the clips at the clip positions 0926, 0923 and 0918.

SBE 79-0036: Connect the tubes 205 to the tube 206. Install the bolts, the washers, the nuts, the spacer and clipss at clip positions 0926,0923 and 0918.

Connect the tube 207 to the tube 206 and the oil pressure transmitter OIL-OIL PRESSURE TRANSMITTER (79-33-15, 01-010).

Pre SBE 71-0004: Install the bolts, the washers, the nuts, the clipnut and the clips at clip positions 0907 to 0913.

SBE 71-0004: Install the bolts, the washers, the nurs, the cipnut and the cips at clip position 0907 to 0911, 0972 and 0913.

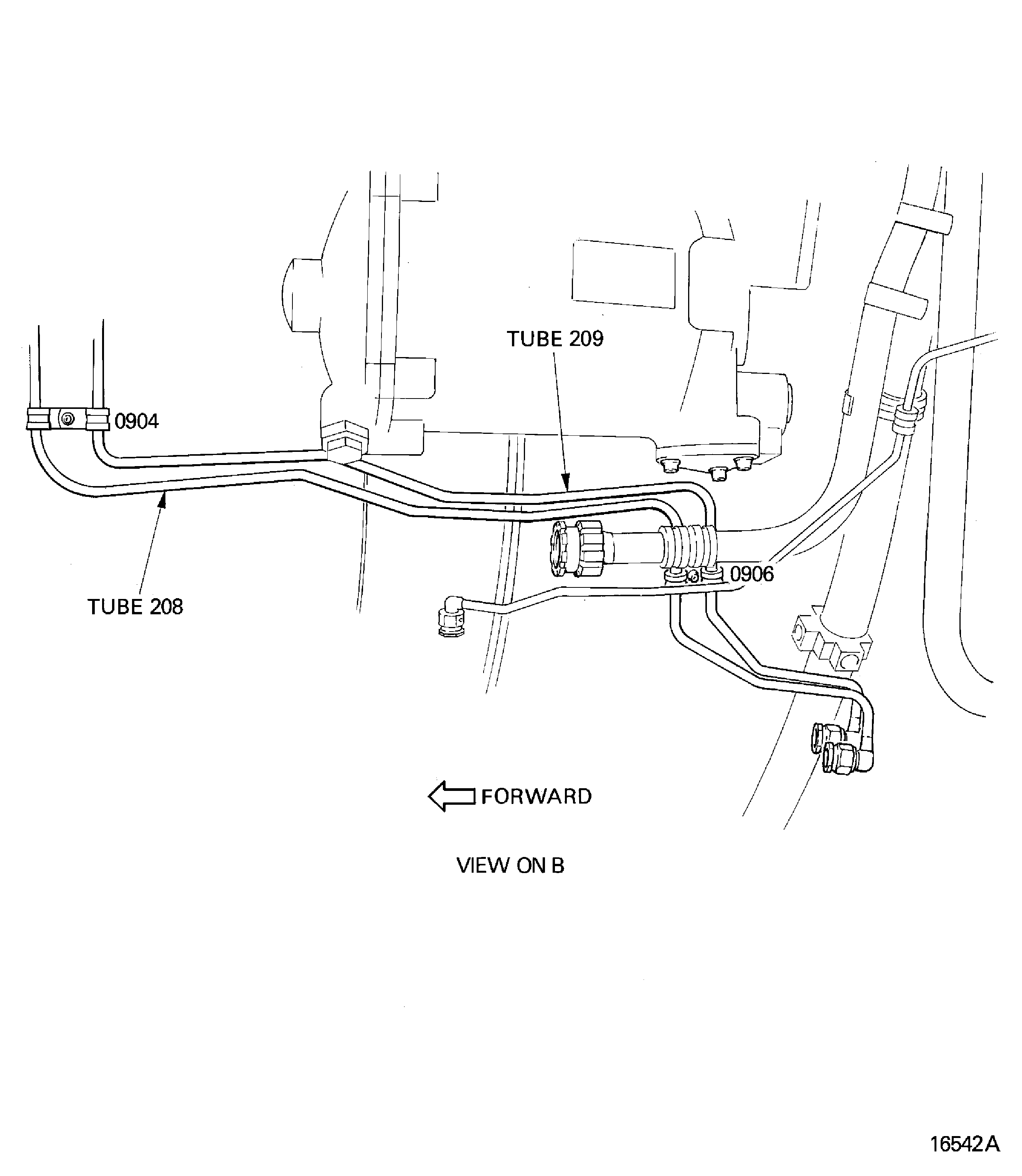

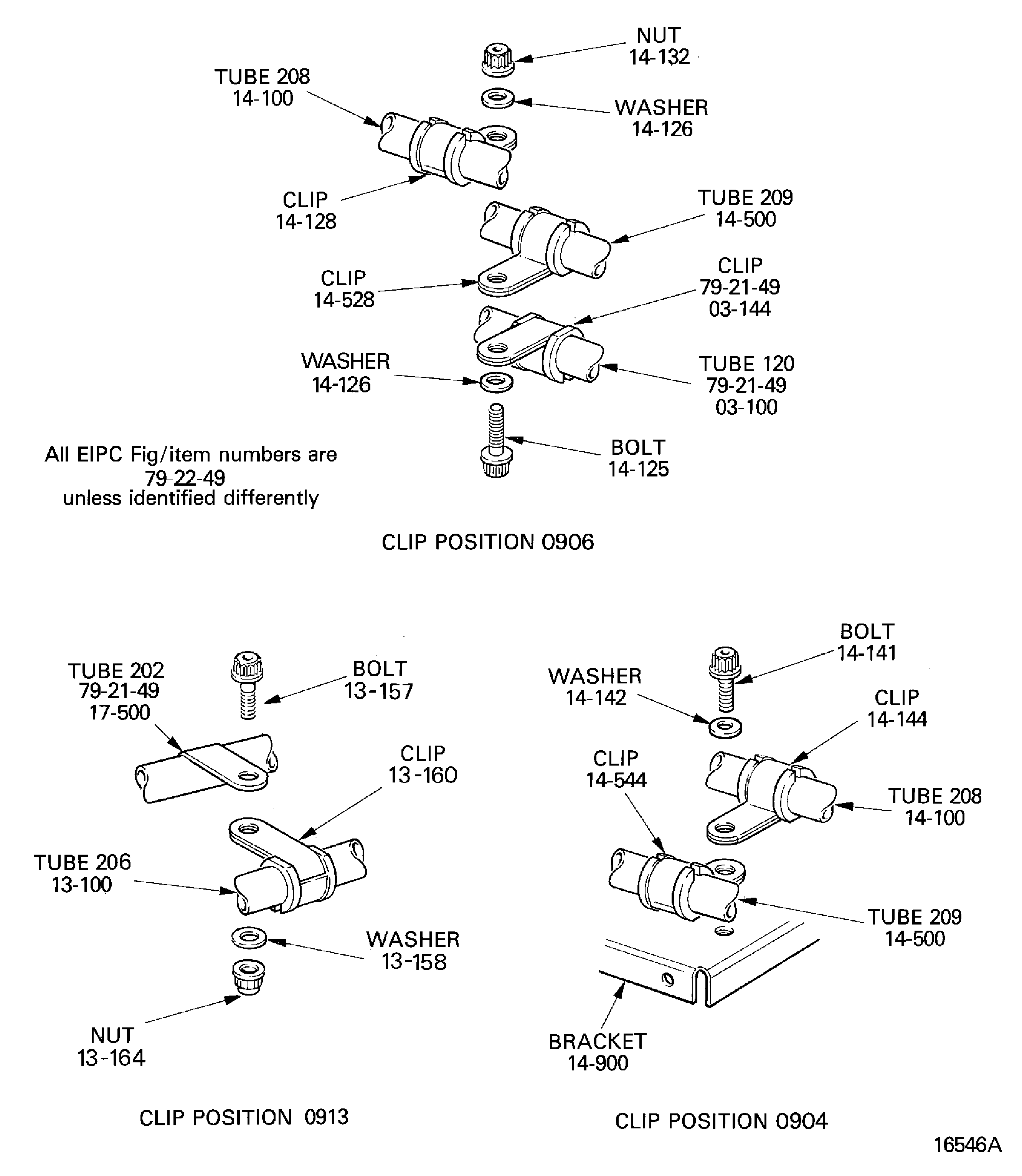

Connect the tubes 208 and 209 to the scavenge filter differential pressure switch OIL-SCAVENGE FILTER DIFFERENTIAL PRESSURE SWITCH(79-35-16, 01-010). Torque the tube nuts to 135 to 145 * lbfin (15.26 to 16.39 Nm).

SUBTASK 72-00-32-420-081 Install the Tubes 205, 206, 207, 208 and 209, the Scavenge Oil Tubes

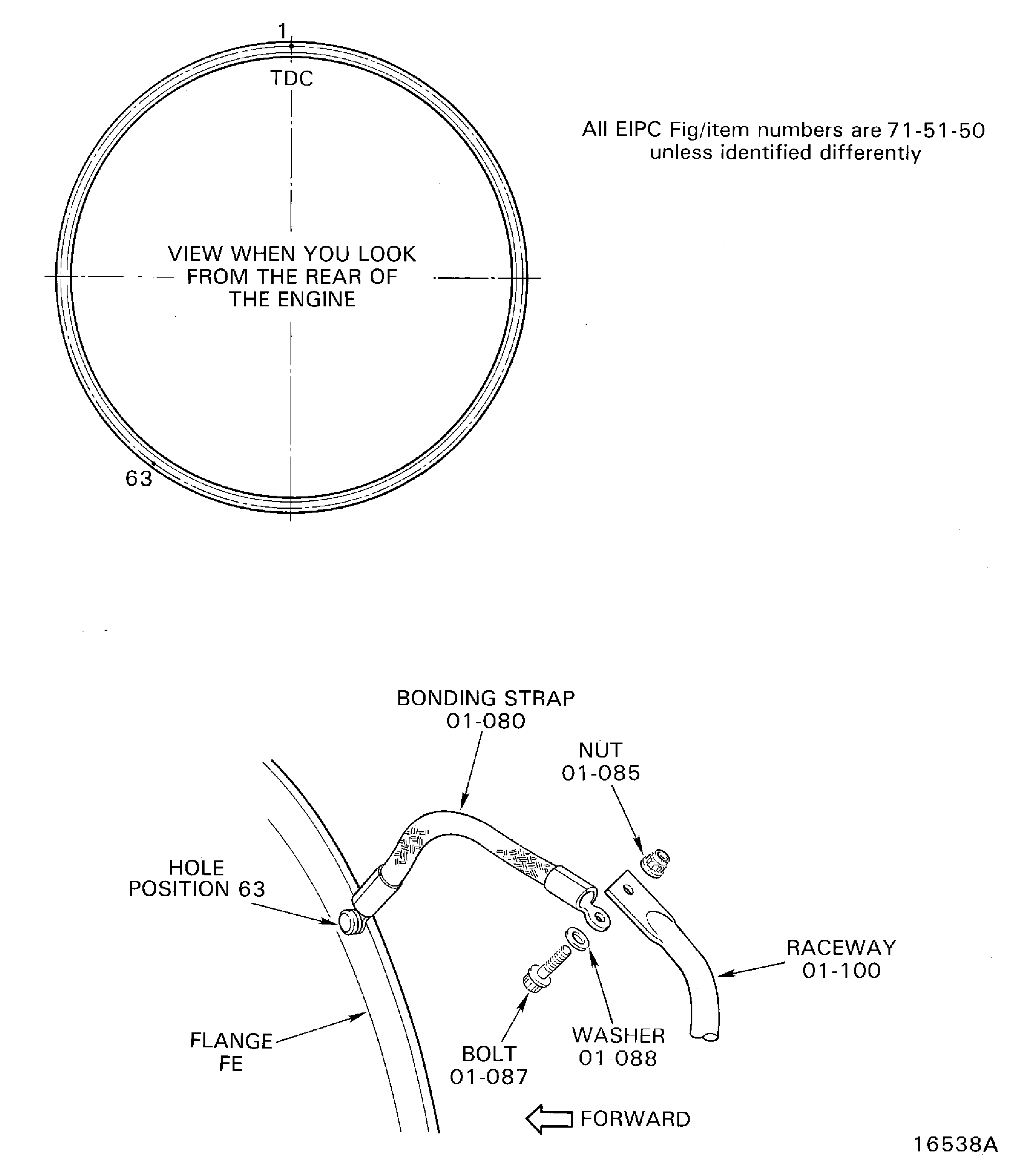

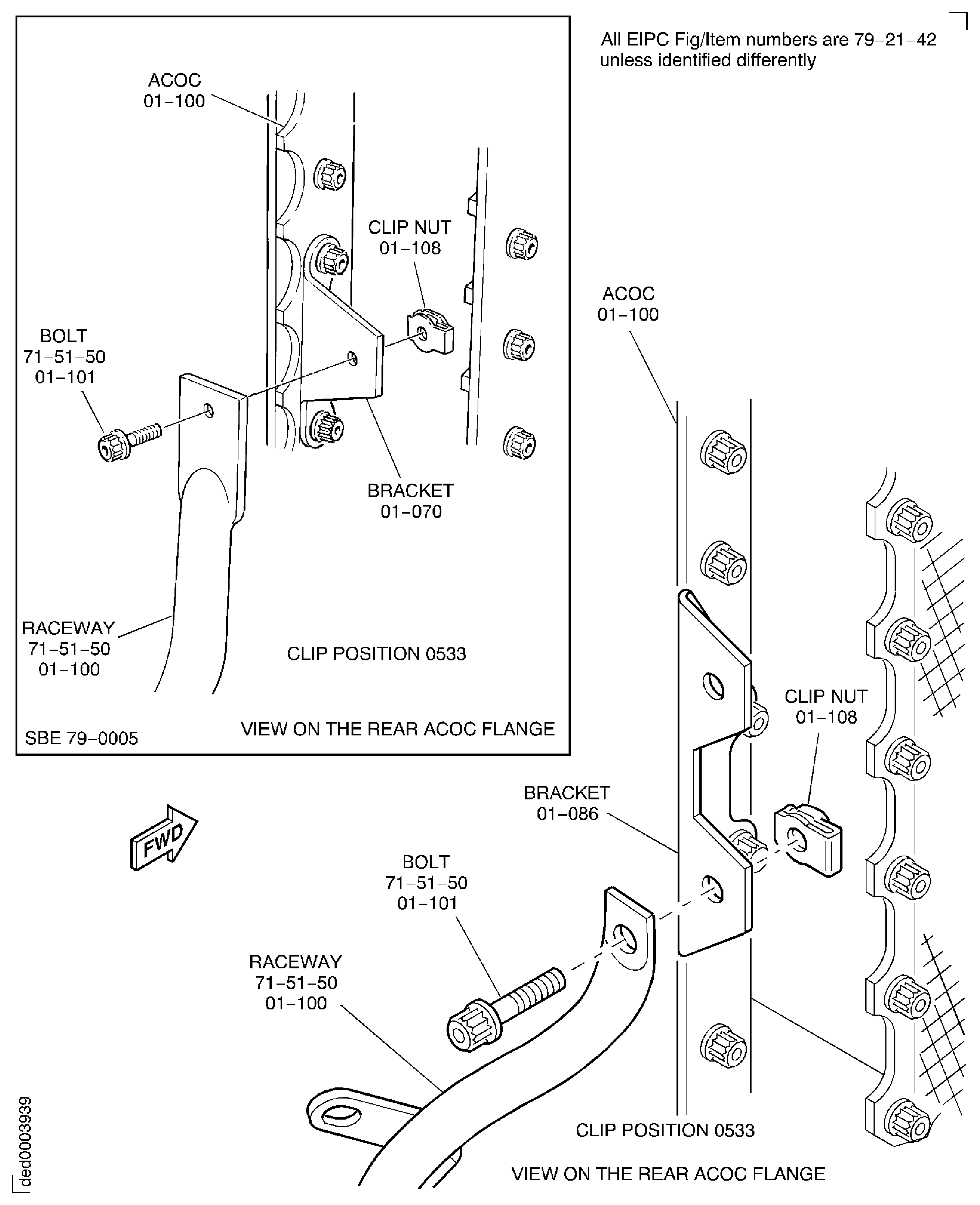

SBE 79-0005: Oil - Replace the clipping bracket on the air cooled oil cooler at CP 0533

Pre SBE 79-0005 : Attach the raceway to the bracket OIL-AIR COOLED OIL COOLER (79-21-42, 01-086) with the bolt and the clipnut.

SBE 79-0005 : Attach the raceway to the bracket OIL-AIR COOLED OIL COOLER (79-21-42, 01-070) with the bolt and the clipnut at the clip position 0533.

NOTE

The installation procedure for the clip position 0246 is given in SUBTASK 72-00-32-420-138, during the installation of the tube 106.Temporarily attach the raceway to the tube 177 with the bolt, the washer and the nut at the clip position 0246. Refer to Figure. Tighten the nut.

WARNING

WHEN YOU USE COMAT 01-002 INHIBITED AND STABILIZED TRICHLOROETHANE YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Remove the grease, the fingerprints and the unwanted material from the mating surfaces of the raceway lug and the bonding strap BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-080) with CoMat 01-002 SOLVENT, DELETED.. Use a clean lint free cloth moistened with the solvent.

Clean the contact (washer) surfaces of the bolt, the nut and the washer BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-087 , BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN 01-085 and BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN 01-088) as given in step C.

Pre SBE 79-0005 : Torque the bolt BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-101) at the bracket OIL-AIR COOLED OIL COOLER (79-21-42, 01-086) to 36 to 45 lbf.in (4 to 5 Nm).

SBE 79-0005 : Torque the bolt BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-101) at the clip position 0533 to 36 to 45 lbf.in (4 to 5 Nm).

SUBTASK 72-00-32-420-082 Install the Electrical Harness Raceway (01-100),. (SBE 79-0005)

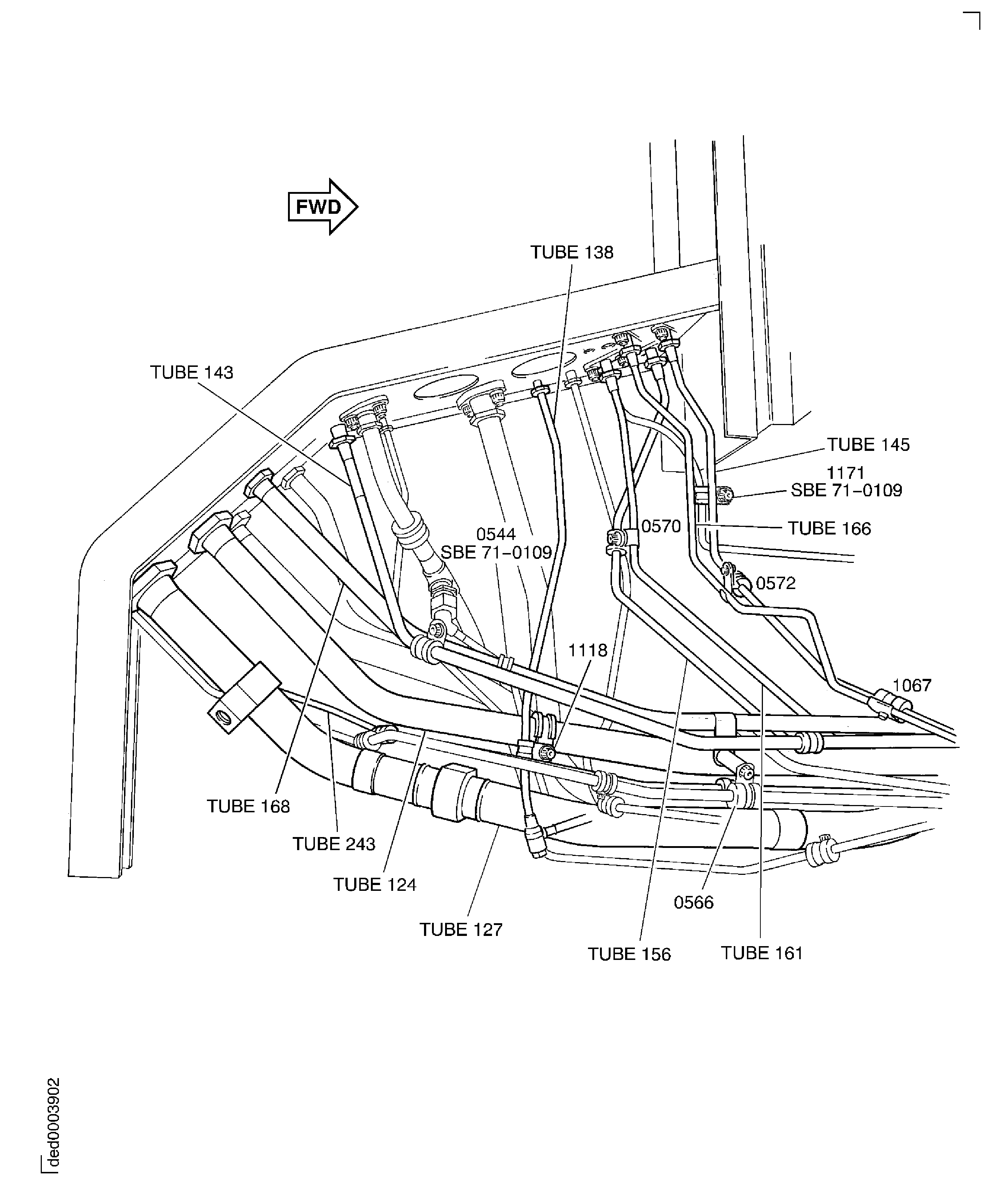

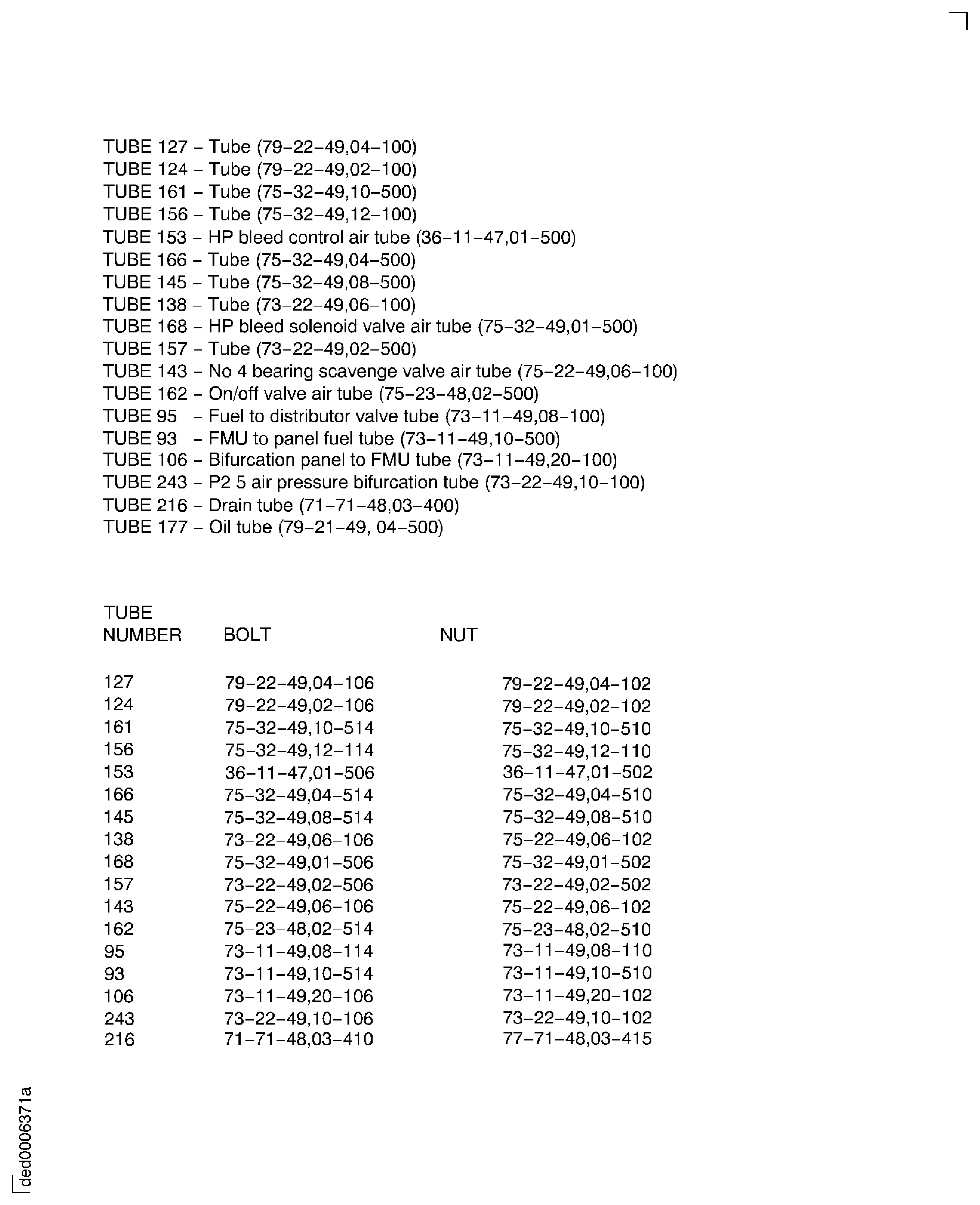

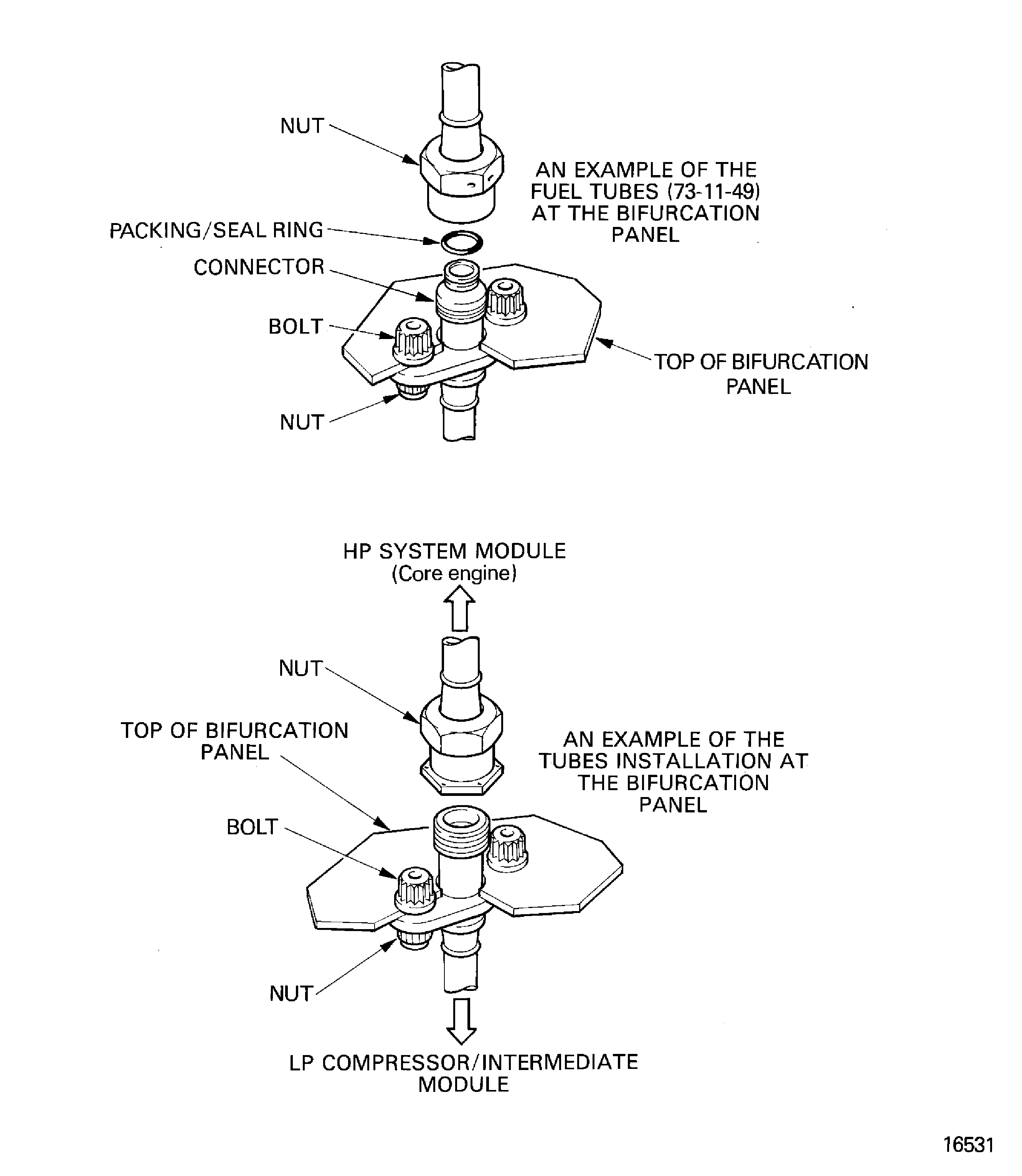

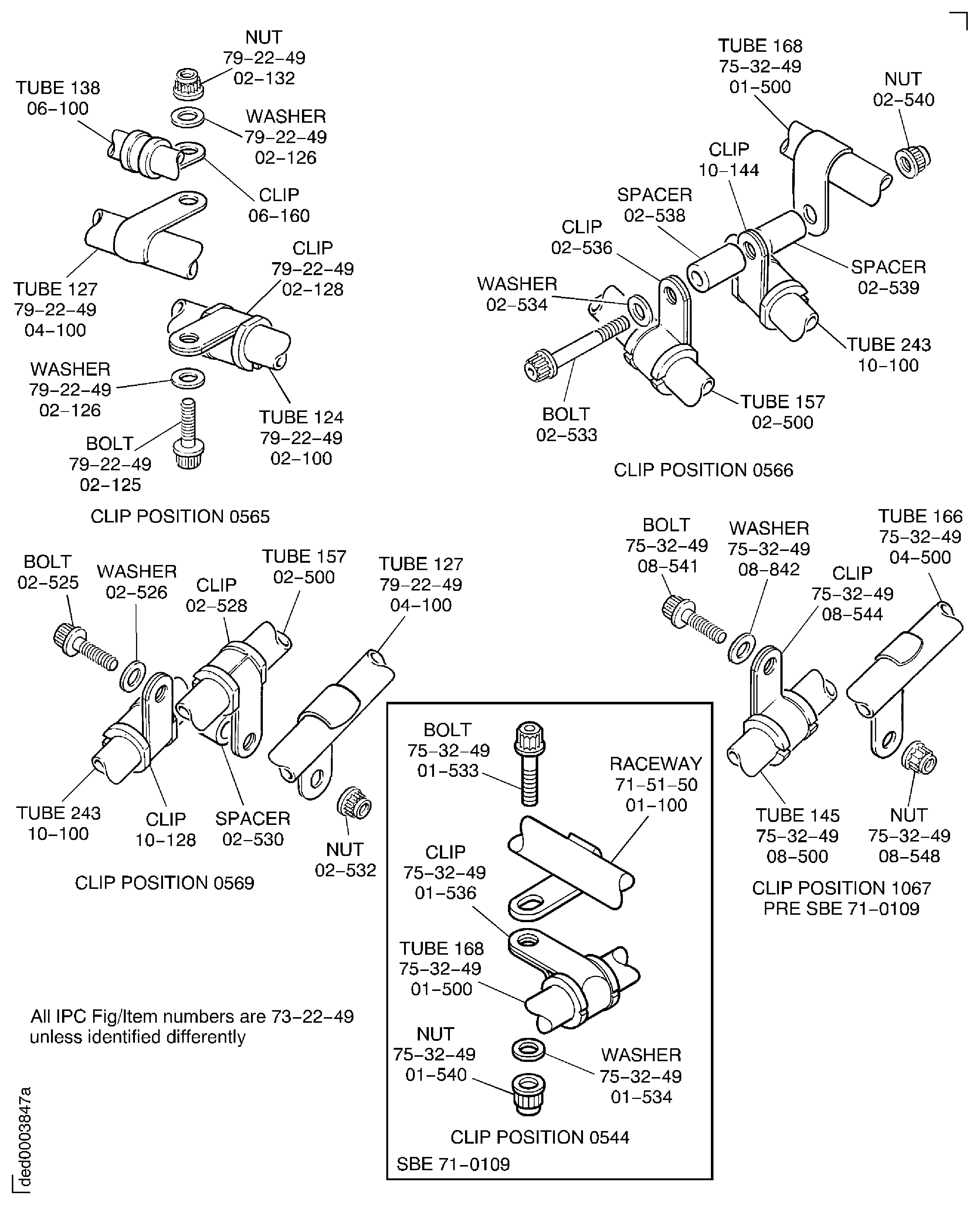

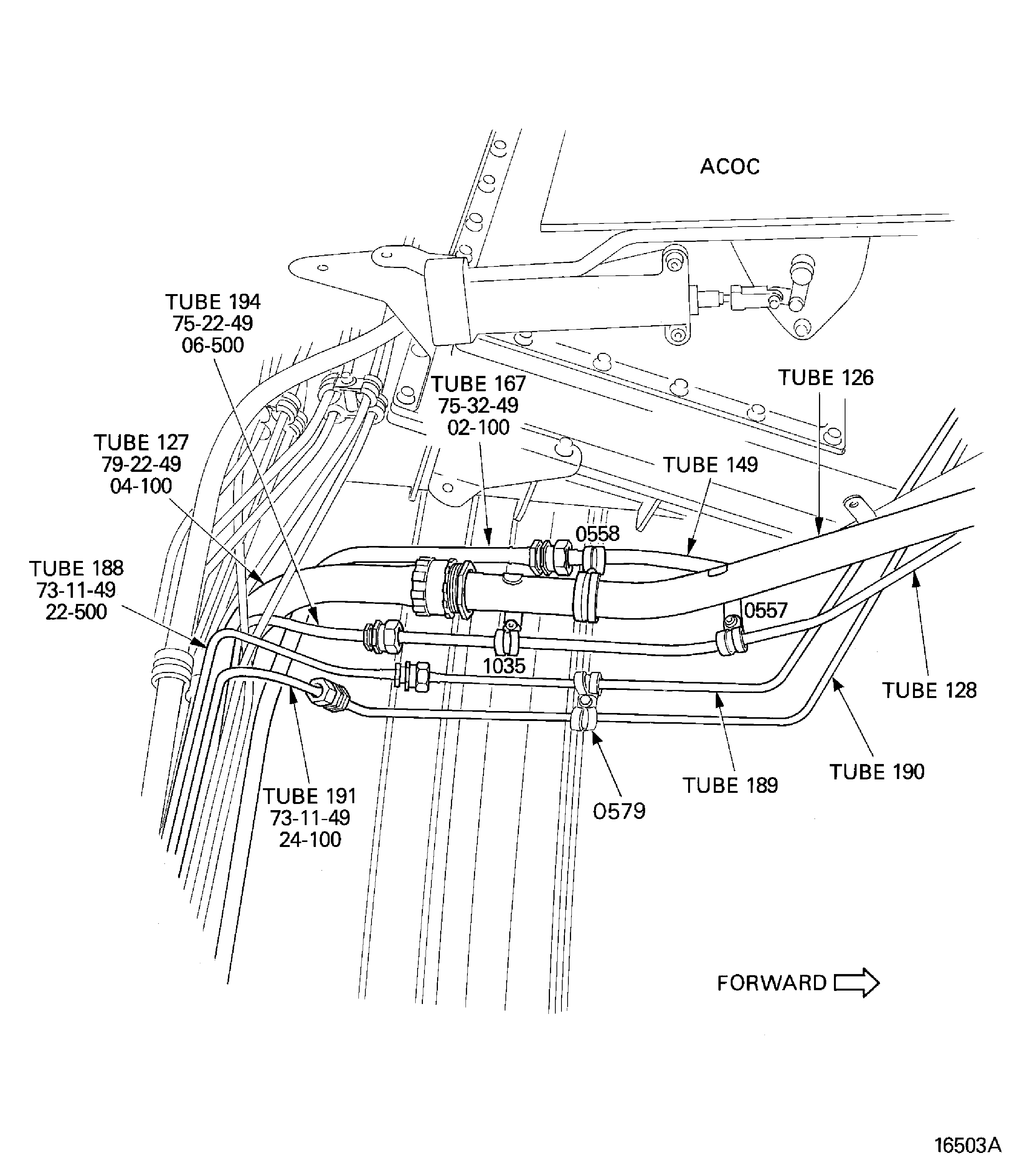

Install the tube 127 to the bifurcation panel with the two bolts and the two nuts OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 04-106 and 04-102). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Temporarily attach the tube 127 to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 22-470) at the clip position 0560, Figure.

Install the tube 124 to the bifurcation panel with the two bolts and the two nuts OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49, 02-106 and 02-102). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

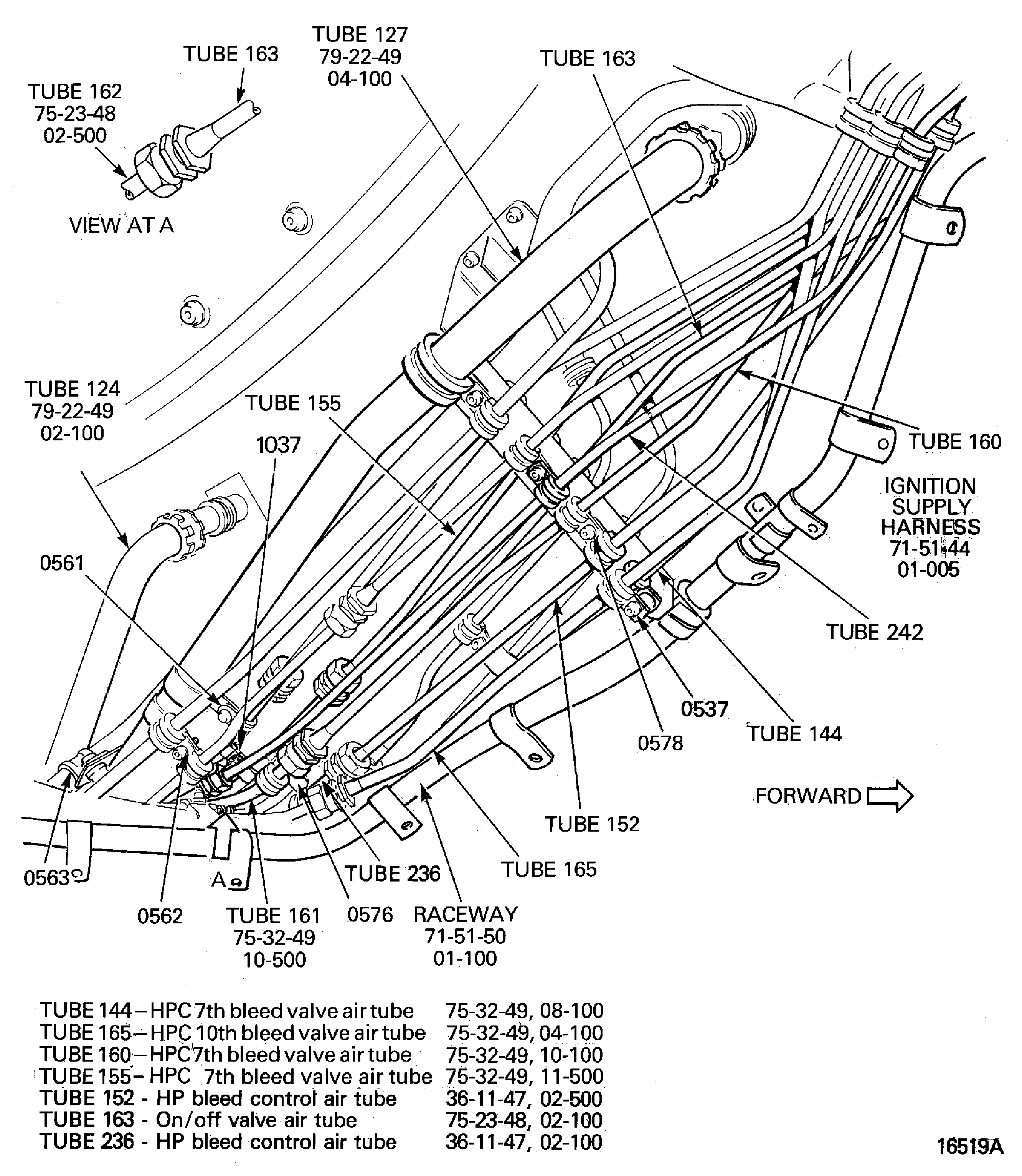

SUBTASK 72-00-32-420-083 Install the Tubes 127 and 124, the Scavenge Oil Tubes

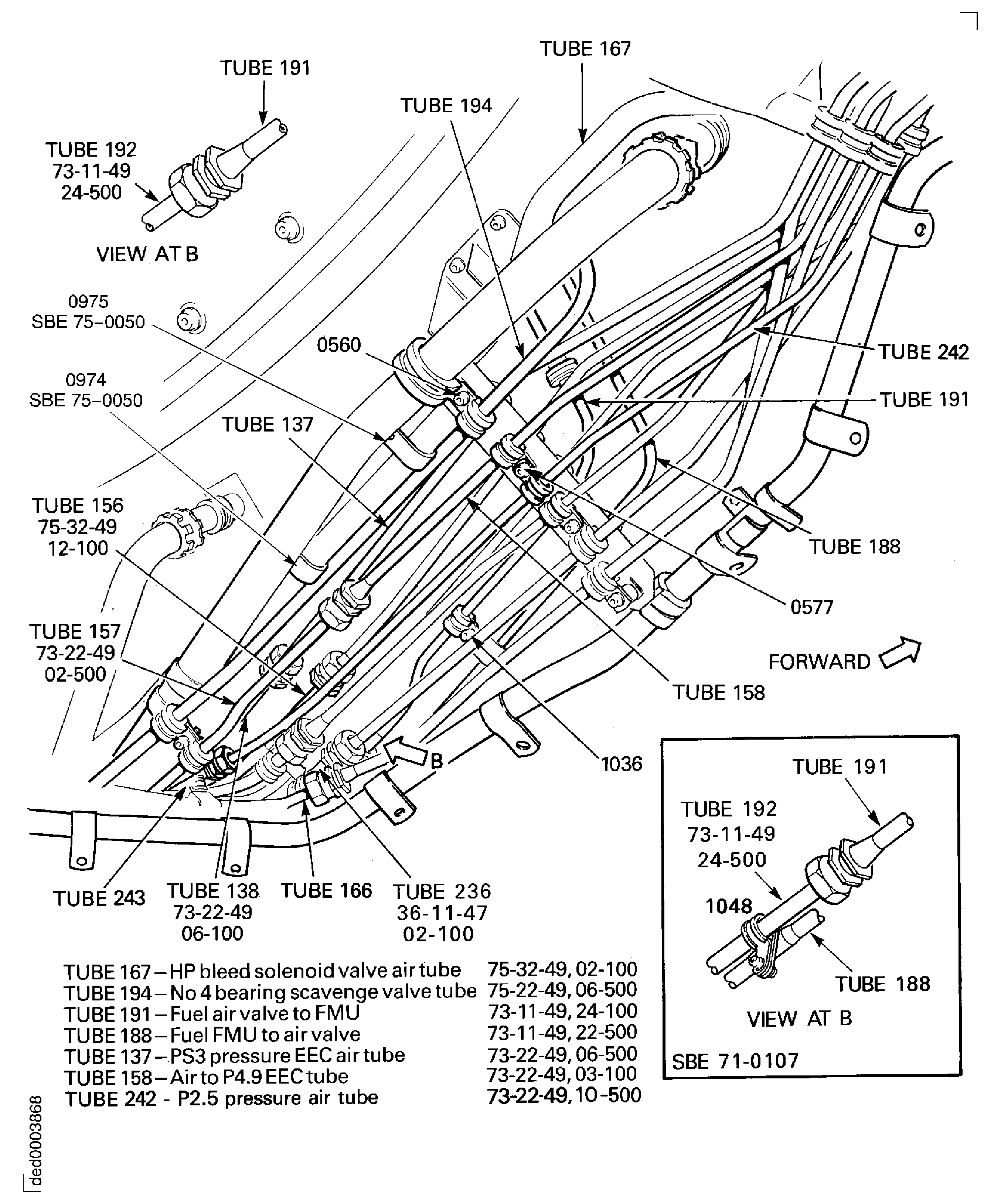

Install the tube 168 to the bifurcation panel with the two bolts and the two nuts AIR-HP COMPRESSOR BLEED CONTROL TUBES (75-32-49, 01-506 and 01-502). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

SBE 71-0109: Install the bolt, the washer and the nut at the clip position 0544. Figure.

Connect the tube 167 to the tube 168. Temporarily attach the tube 167 to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 22-470) at the clip position 0560.

NOTE

The installation procedure for the two bolts and the two nuts which attach the tube 153 to the bifurcation panel and the tube 236 to the tube 153 is given in TASK 72-00-32-420-004.Connect the tube 236 to the tube 153. Temporarily attach the tube 153 to the bifurcation panel with the two bolts and the two nuts PNEUMATIC-TUBES-HP BLEED CONTROL AIR (36-11-47, 01-506 and PNEUMATIC-TUBES-HP BLEED CONTROL AIR 01-502).

Install the tube 138 to the bifurcation panel with the two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 06-106 and 06-102). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the tube 157 to the bifurcation panel with the two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 02-506 and 02-502). Torque the nuts to 85 to 105 lbfin (10 to 12 Nm).

Install the tube 243 to the bifurcation panel with the two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 10-106 and 10-102). Torque the two nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the tube 162 to the bifurcation panel with the two bolts and the two nuts AIR-TURBINE COOLING CONTROLLED AIR TUBES (75-23-48, 02-514 and 02-510). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm). Temporarily attach the tube 162 to the tube 127 at the clip position 0564.

SUBTASK 72-00-32-420-136-A00 Install the Bifurcation Panel Tubes (Pre SBE 73-0019)

Install the tube 168 to the bifurcation panel with the two bolts and the two nuts AIR-HP COMPRESSOR BLEED CONTROL TUBES (75-32-49, 01-506 and 01-502). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

SBE 71-0109: Install the bolt, the washer and the nut at the clip position 0544 Figure.

Connect the tube 167 to the tube 168. Temporarily attach the tube 167 to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 22-470) at the clip position 0560.

NOTE

The installation procedure for the two bolts and the two nuts which attach the tube 153 to the bifurcation panel and the tube 236 to the tube 153 is given in TASK 72-00-32-420-004.Connect the tube 236 to the tube 153. Temporarily attach the tube 153 to the bifurcation panel with the two bolts and the two nuts PNEUMATIC-TUBES-HP BLEED CONTROL AIR (36-11-47, 01-506 and 01-502).

Install the tube 138 to the bifurcation panel with the two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 06-106 and 06-102). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the tube 157 to the bifurcation panel with the two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 02-506 and 02-502). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the tube 243 to the bifurcation panel with the two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 10-106 and 10-102). Torque the two nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the tube 162 to the bifurcation panel with the two bolts and the two nuts AIR-TURBINE COOLING CONTROLLED AIR TUBES (75-23-48, 02-514 and 02-510). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm). Temporarily attach the tube 162 to the tube 127 at the clip position 0564.

SUBTASK 72-00-32-420-136-B00 Install the Bifurcation Panel Tubes (SBE 73-0019)

SBE 73-0019: Fuel and control - Burner pressure (PB) sensor tubes with revised moisture traps

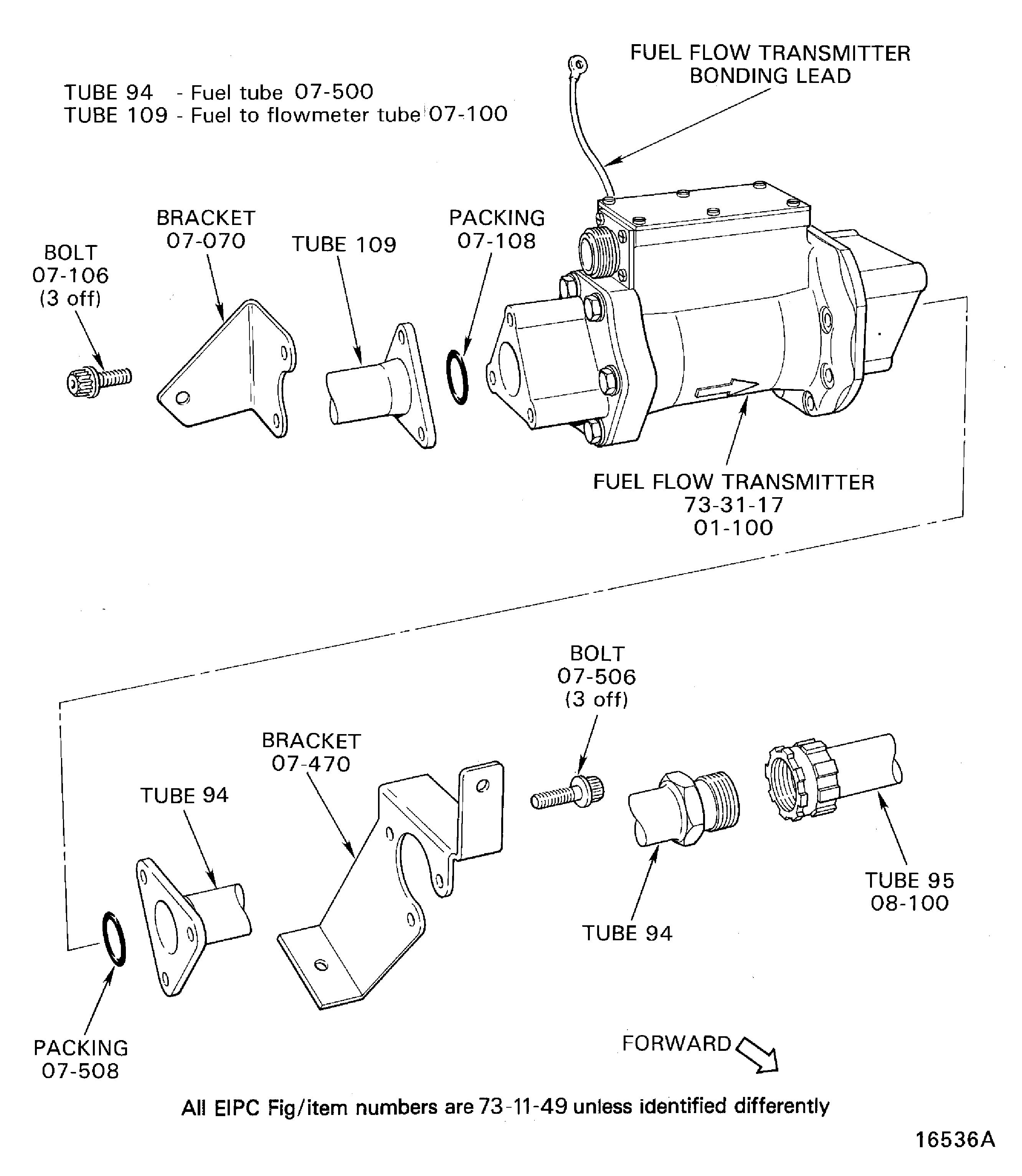

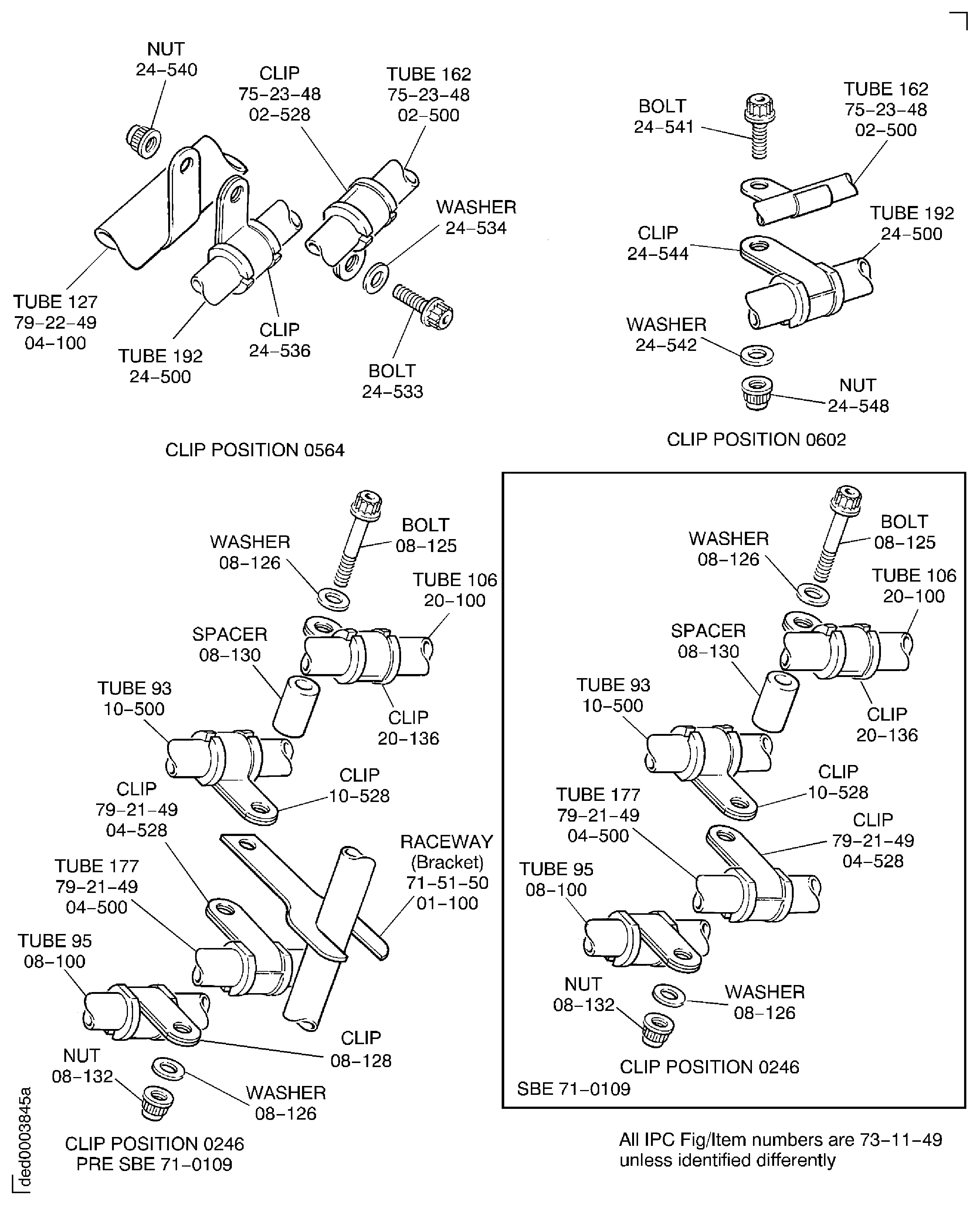

Install the tube 95 to the bifurcation panel with the two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 08-114 and 08-110). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Lubricate a new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-508) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY.

Lubricate a new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-108) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY.

Install the packing ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-508) on the tube 94.

Install the packing ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-108) on the tube 109.

Install the fuel flow transmitter and the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-470) to the tube 94 with the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-506).

Attach the tube 96 and 97 clips to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-470) at the clip position 0965 with the bolt, the washer and the nut, Figure.

Install the tube 109 and the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-070) to the fuel flow transmitter with the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-106).

WARNING

WHEN YOU USE COMAT 01-002 INHIBITED AND STABILIZED TRICHLOROETHANE YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.NOTE

The raceway bonding lug is adjacent to the lug for the clip position 0252.Remove the grease, the fingerprints and the unwanted material from the mating surfaces of the raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-FAN (71-51-50, 01-100) bonding lug and the fuel flow transmitter bonding lead with CoMat 01-002 SOLVENT, DELETED.. Use a clean lint free cloth moistened with the solvent.

Clean the contact (washer) surfaces of the bolt, the nut and the two washers ENGINE FUEL AND CONTROL-FUEL FLOWMETER (73-31-17, 01-125 , ENGINE FUEL AND CONTROL-FUEL FLOWMETER 01-132 and ENGINE FUEL AND CONTROL-FUEL FLOWMETER 01-126) as given in Step.

Attach the fuel flow transmitter bonding lead to the raceway bonding lug with the bolt, the two washers and the nut, refer to Figure. Torque the nut to 36 to 45 lbf.in (4 to 5 Nm).

Torque the six bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-506 and ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE 07-106) to 85 to 105 lbf.in (10 to 12 Nm).

Install the tube 109 and the fuel flow transmitter ENGINE FUEL AND CONTROL-FUEL FLOWMETER (73-31-17, 01-100).

Torque the tube 95 nut to 398 to 434 lbf.in (45 to 49 Nm) with the IAE 1R18001 Wrench 1 off. Safety the tube nut with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-137-A00 Install the Tubes 95, 94, 109 and the Fuel Flow Transmitter to the Fuel System,. (Pre SBE 71-0109)

SBE 71-0109: Fan case - Provide improved routing and clipping of the EEC and ignition harness and raceway

Install the tube 95 to the bifurcation panel with the two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 08-114 and 08-110). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Lubricate a new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-508) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY.

Lubricate a new ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-108) packing 1 off with CoMat 10-060 LIQUID PARAFFIN or CoMat 10-038 PETROLEUM JELLY.

Install the packing ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-508) on the tube 94.

Install the packing ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-108) on the tube 109.

Install the fuel flow transmitter and the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-470) to the tube 94 with the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-506).

Attach the tube 96 and 97 clips to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-470) at the clip position 0965 with the bolt, the washer and the nut, Figure.

Install the tube 109 and the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-070) to the fuel flow transmitter with the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-106).

Torque the six bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 07-506 and 07-106) to 85 to 105 lbf.in (10 to 12 Nm).

NOTE

The fuel flow transmitter bonding lead is attached during installation of the EEC fan harness at the clip position 1141.Refer to TASK 72-00-32-420-004-A00 (INSTALLATION-004, CONFIG-001) for the procedure to install the fuel flow transmitter bonding lead to the raceway bonding lug.

Install the tube 109 and the fuel flow transmitter ENGINE FUEL AND CONTROL-FUEL FLOWMETER (73-31-17, 01-100).

Torque the tube 95 nut to 398 to 434 lbf.in (45 to 49 Nm) with the IAE 1R18001 Wrench 1 off. Safety the tube nut with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-137-B00 Install the Tubes 95, 94, 109 and the Fuel Flow Transmitter to the Fuel System,. (SBE 71-0109)

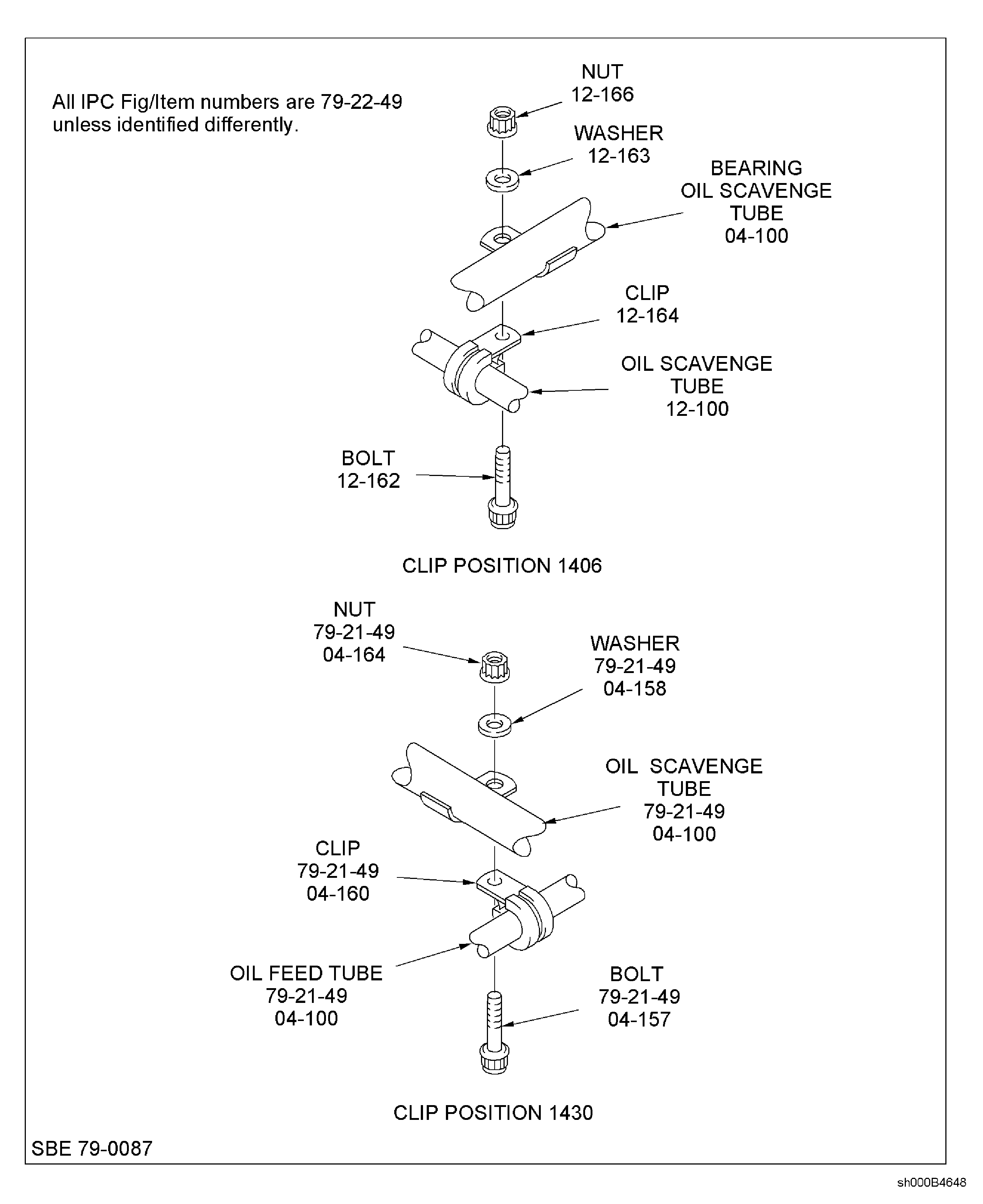

Safety the tube 204 nut (at the tube 127) with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-091-A00 Install the Tube 204, the Scavenge Oil Tube,. (Pre SBE 79-0087)

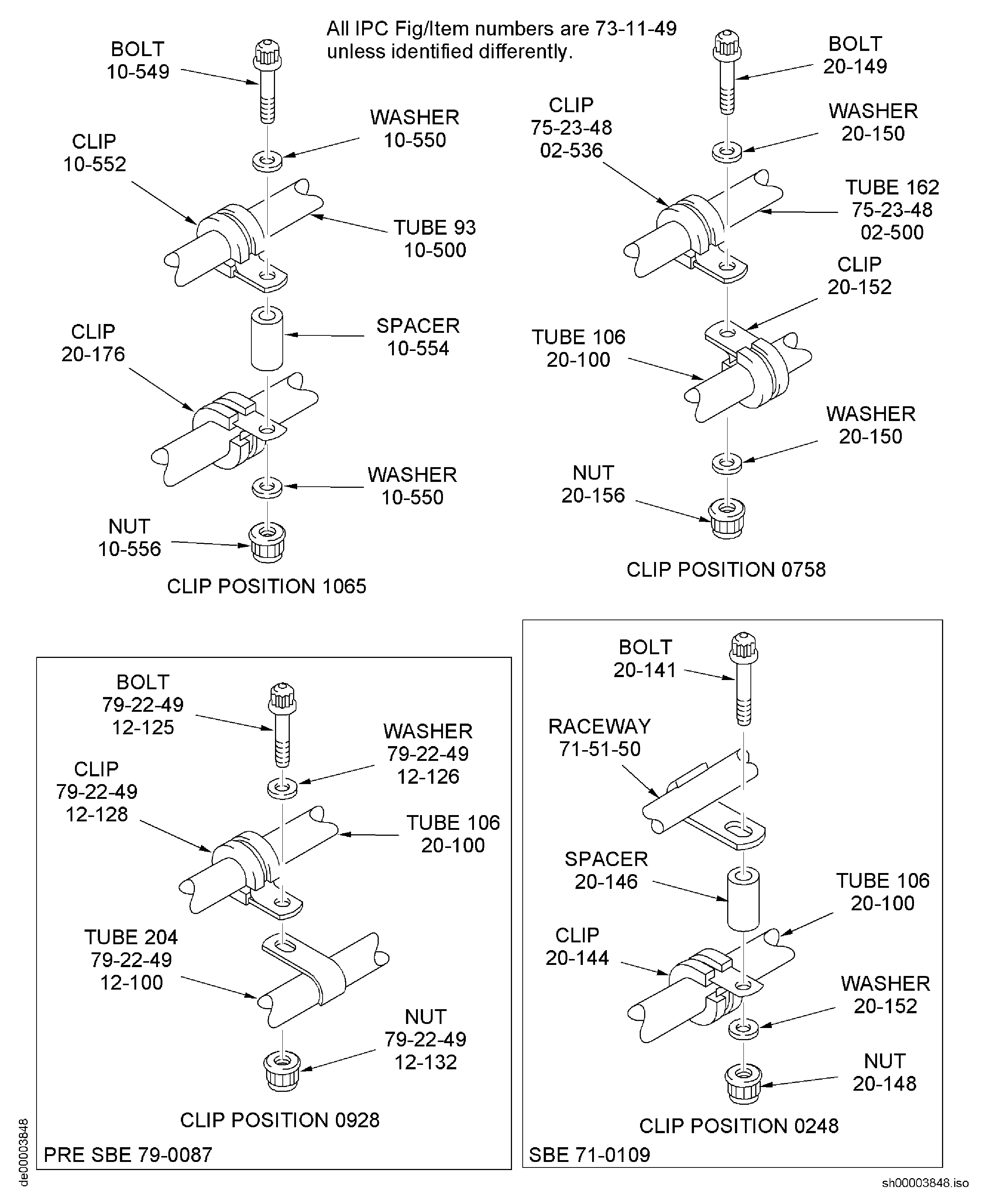

Refer to Figure.

Safety the tube 204 nut (at the tube 127) with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-091-B00 Install the Tube 204, the Scavenge Oil Tube (SBE 79-0087)

Refer to Figure.

Install the tube 106 to the bifurcation panel with the two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 20-106 and 20-102). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the tube 93 to the bifurcation panel with the two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 10-514 and 10-510). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

SBE 71-0109:Install the bolt, the washer, the spacer and the nut at the clip position 0248. Figure.

Connect the tube 192 to the tube 106. Torque the tube 192 nut to 159 to 177 lbf.in (18 to 20 Nm). Safety the tube nut with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-138-A00 Install the Tubes 192, 93 and 106 to the Fuel System (Pre SBE 72-0083 and Pre SBE 79-0087)

Refer to Figure.

Install the tube 106 to the bifurcation panel with the two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 20-106 and 20-102). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the tube 93 to the bifurcation panel with the two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 10-514 and 10-501). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

SBE 71-0109:Install the bolt, the washer, the spacer and the nut at the clip position 0248.Figure.

Connect the tube 192 to the tube 106. Torque the tube 192 nut to 159 to 177 lbf.in (18 to 20 Nm). Safety the tube nut with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-138-B00 Install the Tubes 192, 93 and 106 to the Fuel System (Pre SBE 79-0087)

Refer to Figure.

Install the tube 106 to the bifurcation panel with the two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 20-106 and 20-102). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the tube 93 to the bifurcation panel with the two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 10-514 and 10-501). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the bolt, the washer, the spacer and the nuts at the clip position 0248, Figure.

Connect the tube 192 to the tube 106. Torque the tube 192 nut to 159 to 177 lbf.in (18 to 20 Nm). Safety the tube nut with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-138-C00 Install the Tubes 192, 93 and 106 to the Fuel System (SBE 79-0087)

SBE 71-0109: Engine - Fan case - Provide improved routing and clipping of the ECC and ignition harness and raceway

Install the tube 106 to the bifurcation panel with the two bolts and the two nuts ENGINE FUEL AND CONTROL-FUEL SYSTEM TUBES-ENGINE (73-11-49, 20-106 and 20-102). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

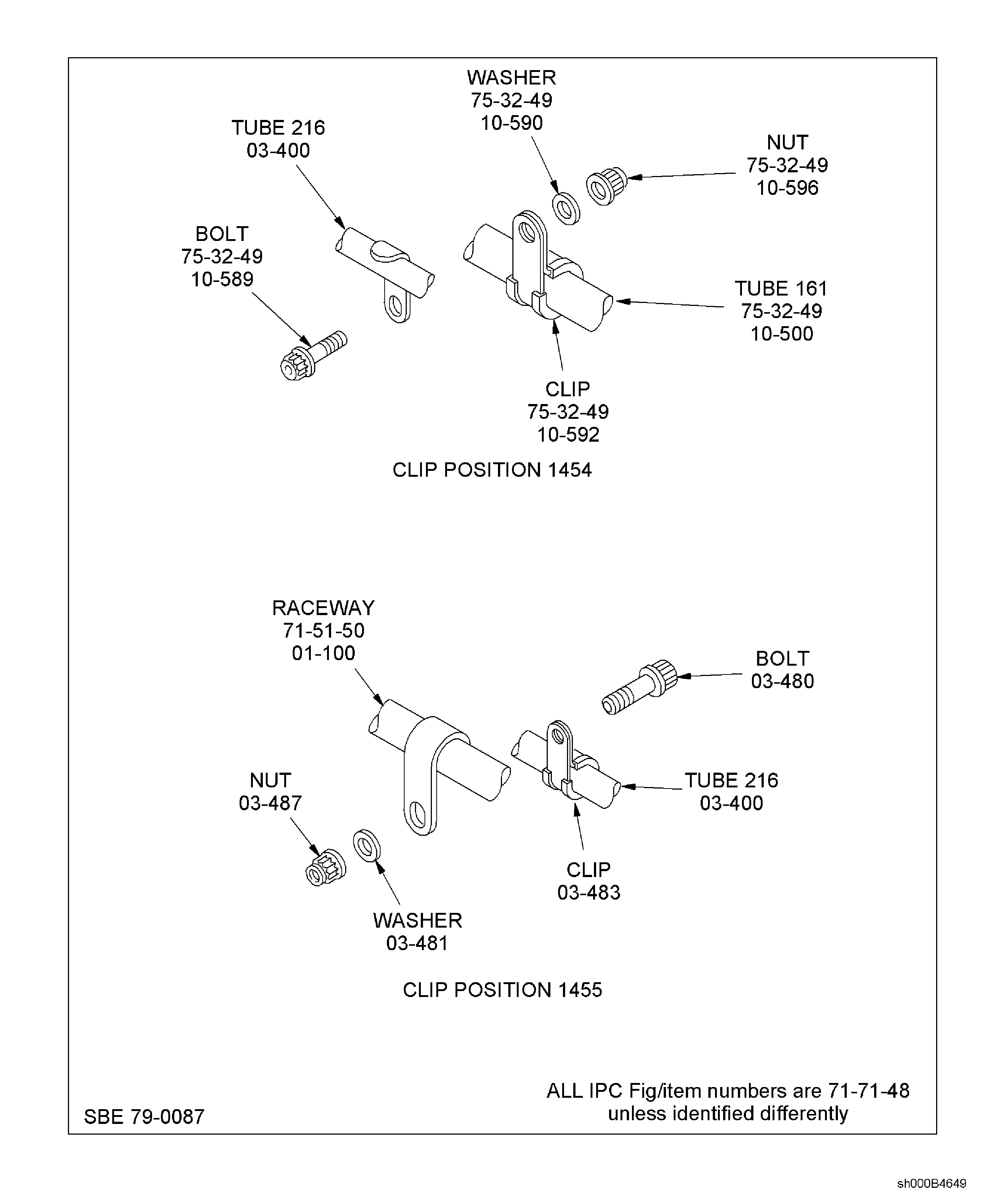

Install the tube 216 to the bifurcation panel with the two bolts and the two nuts POWER PLANT-FUEL DRAIN TUBES-POWER PLANT (71-71-48, 03-410 and 03-415). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Pre SBE 79-0087: Install the bolts, the washers, the spacers, the nuts and the clips at the clip positions 1065, 0246, 1168 and 1169.

SBE 79-0087: Install the bolts, the washers, the spacers, the nuts and the clips at the clip positions 1065, 0246, 1168, 1454 and 1455.

SUBTASK 72-00-32-420-276 Install the Bifurcation Panel Tubes 216 and 106,. 412 sheet 5). 412 sheet 14) (SBE 71-0109)

Refer to Figure.

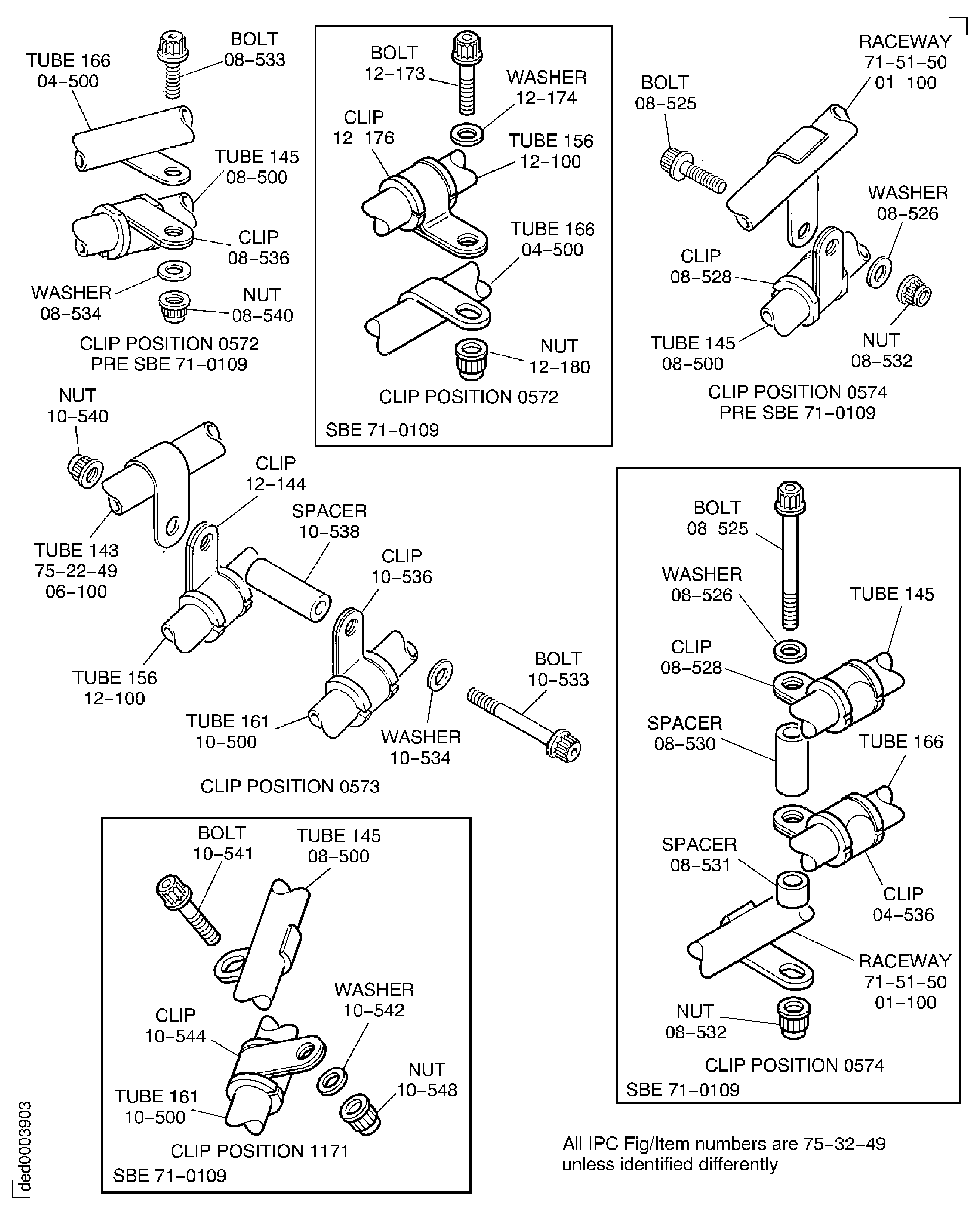

Install the tube 143 to the bifurcation panel with the two bolts and the two nuts AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 06-106 and 06-102). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the tube 161 to the bifurcation panel with the two bolts and the two nuts AIR-HP COMPRESSOR BLEED CONTROL TUBES (75-32-49, 10-514 and 10-510). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the tube 156 to the bifurcation panel with the two bolts and the two nuts AIR-HP COMPRESSOR BLEED CONTROL TUBES (75-32-49, 12-114 and 12-110). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

SBE 71-0109:Install the bolt, the washer, the spacer, the nut and the clip at the clip position 1171.Figure.

Pre SBE 71-0109 and Pre SBE 79-0087: Install the bolts, the washers, the nuts and the clips at the clip positions 0570 and 1037.

SBE 79-0087: Install the bolts, the washers, the nuts and the clips at the clip positions 1454 and 1037.

Install the tube 166 to the bifurcation panel with the two bolts and the two nuts AIR-HP COMPRESSOR BLEED CONTROL TUBES (75-32-49, 04-514 and 04-510). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Install the tube 145 to the bifurcation panel with the two bolts and the two nuts AIR-HP COMPRESSOR BLEED CONTROL TUBES (75-32-49, 08-514 and 08-510). Torque the nuts to 85 to 105 lbf.in (10 to 12 Nm).

Safety the tube 32, 63, 48, 64 and 65 nuts with CoMat 02-126 LOCKWIRE.

Pre SBE 71-0109: Install the bolts, the washers, the nuts and the clips at the clip positions 0572, 0574 and 1067.

SBE 71-0109: Install the bolts, the washers, the nuts and the clips at the clip positions 0572, 0574 and 0570. Figure and Figure.

SUBTASK 72-00-32-420-139 Install the Bifurcation Panel Tubes 143, 161, 156, 166 and 145

Refer to Figure.

SBE 75-0050: Install the bolts, the washers, the nuts and the clips at clip positions 0974 and 0975 EBU harness.

Torque the tube 167 nut to 283 to 310 lbf.in (32 to 35 Nm). Safety the tube nut with CoMat 02-126 LOCKWIRE.

Torque the tube 194 nut to 204 to 221 lbf.in (23 to 25 Nm). Safety the tube nut with CoMat 02-126 LOCKWIRE.

Torque the tube 138 nut to 159 to 177 lbf.in (18 to 20 Nm). Safety the tube nut with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-140 Install the Tubes 137 and 194, the Bottom Right Side Tubes

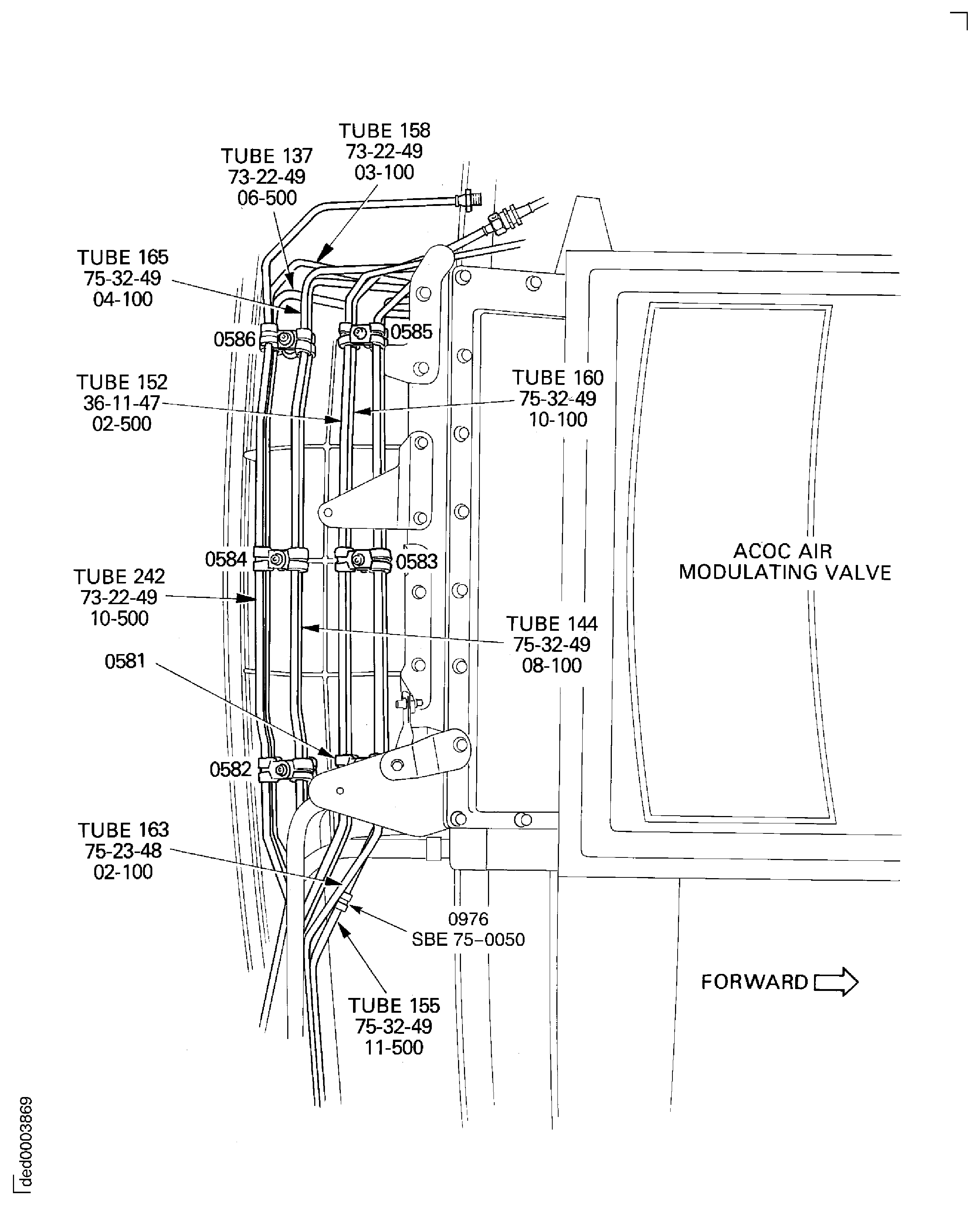

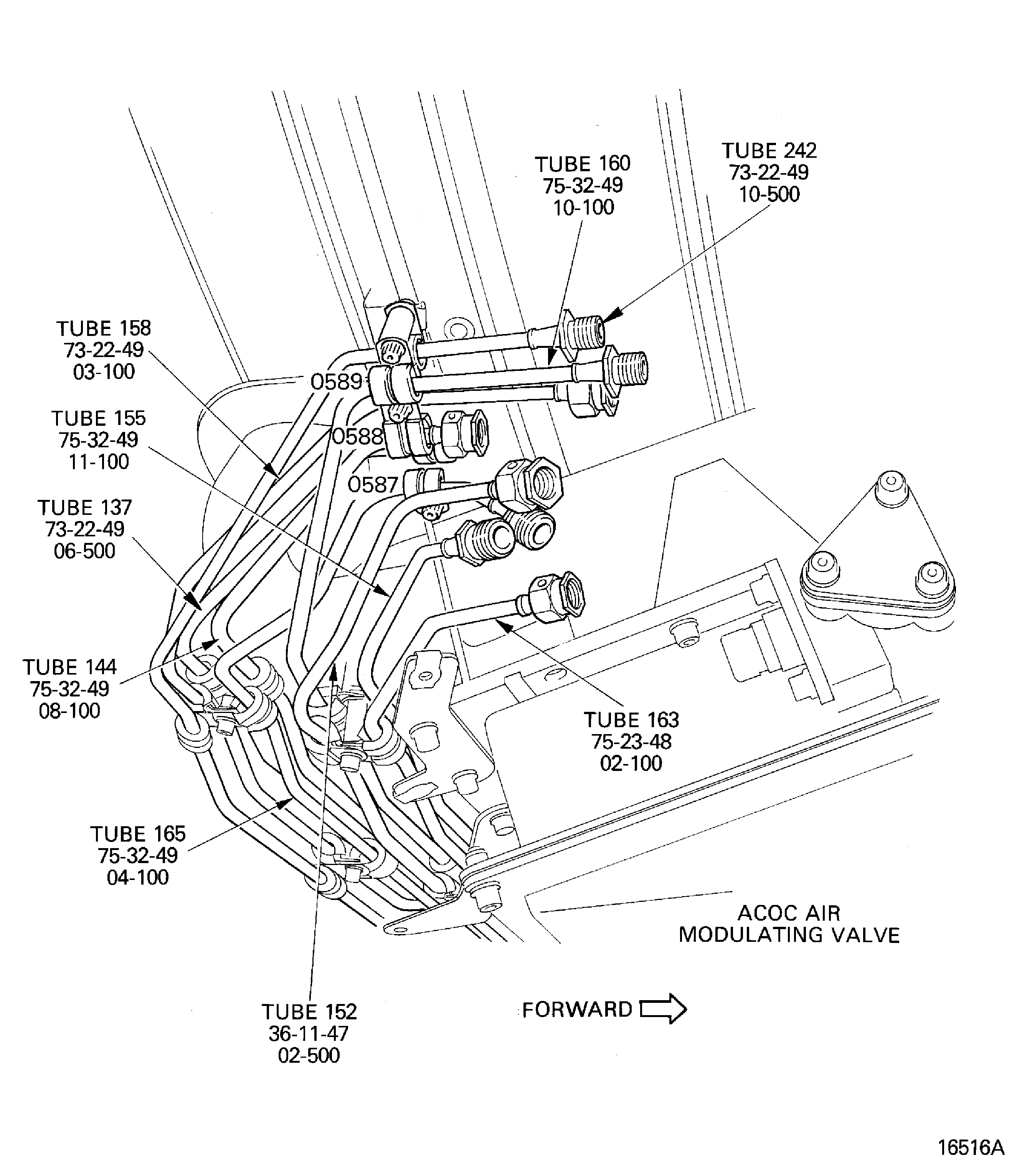

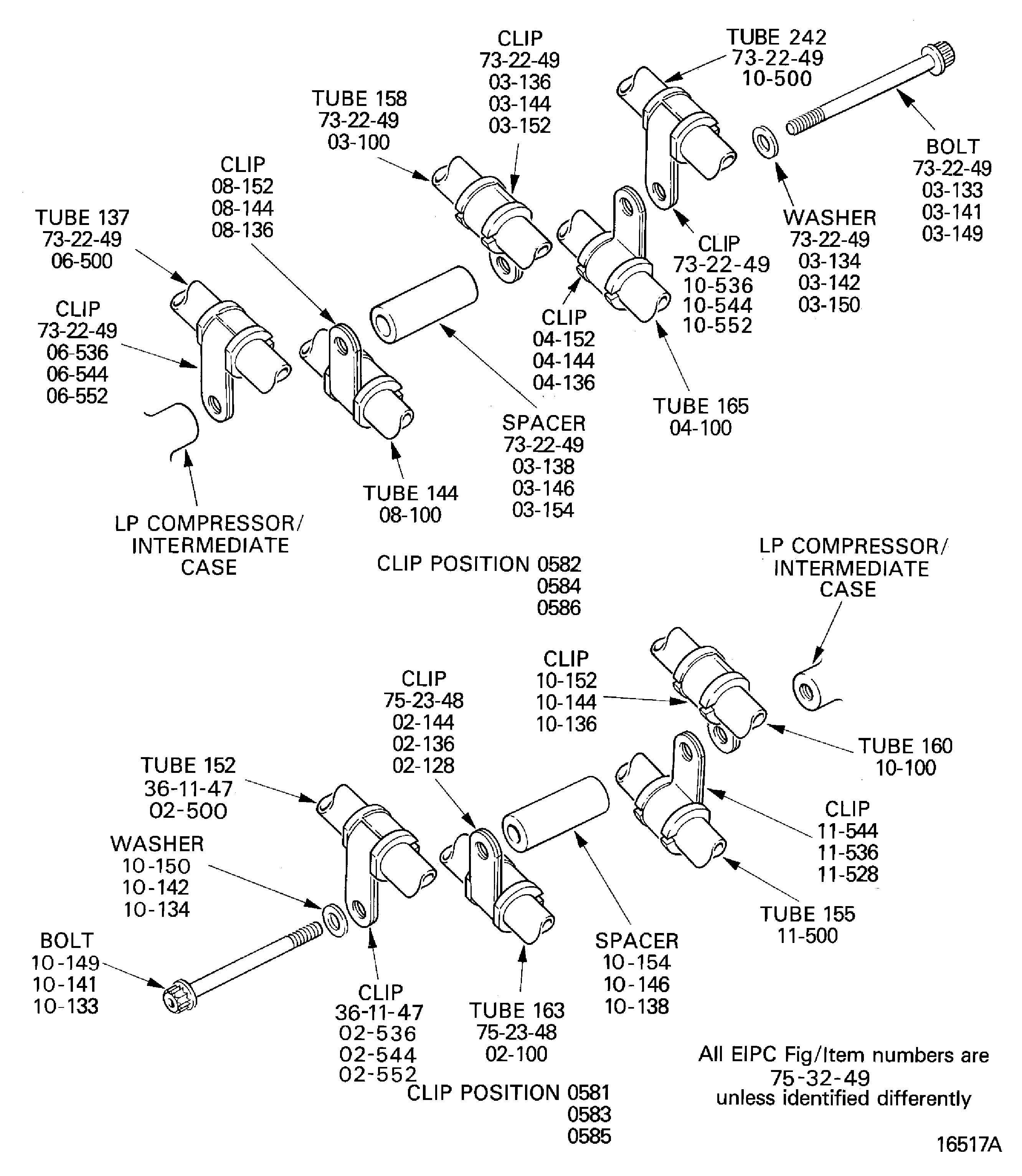

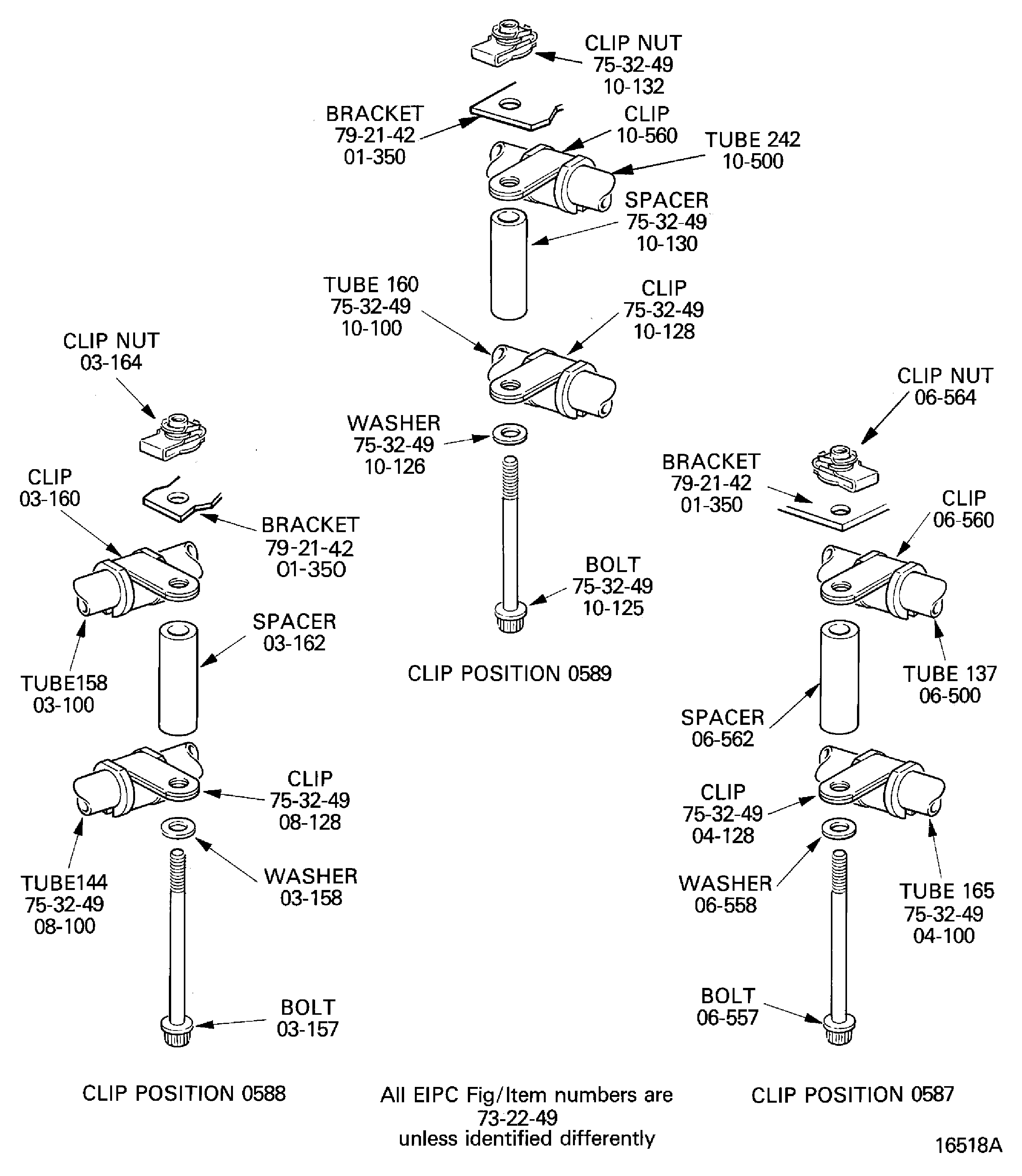

Connect the tube 145 to the tube 144. Temporarily attach the tube 144 clip at the clip position 0586. Refer to Figure.

Connect the tube 157 to the tube 158. Install the bolt, the washer, the spacer, the clipnut and the clips at the clip position 0588. Refer to Figure.

Connect the tube 166 to the tube 165. Temporarily attach the tube 165 clip at the clip position 0586. Refer to Figure.

Pre SBE 71-0109: Install the bolt, the washers,the spacer, the nut and the clips at the clip position 0537.

Connect the tube 242 to the tube 243. Install the bolts, the washers, the spacers and the clips at the clip positions 0586, 0584 and 0582. Refer to Figure.

Connect the tube 161 to the tube 160. Refer to Figure.

Install the bolt, the washer, the spacer, the clipnut and the clip at the clip position 0589. Refer to Figure.

Connect the tube 155 to the tube 156. Refer to Figure.

Connect the tube 162 to the tube 163. Refer to Figure. Temporarily attach the tube 163 at the clip position 0585.

Install the bolts, the washers and the clips at the clip positions 0585, 0583 and 0581. Refer to Figure.

SBE 75-0050: Install the bolt, the washer, the nut, and the clip at clip position 0976 EBU harness.

Torque the tube 145, 157, 166, 242, 161, 155, 152, 192 and 162 nuts to 159 to 177 lbf.in (18 to 20 Nm). Safety the tube nuts with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-141 Install the Right Side Tubes

Refer to Figure.

SBE 71-0107: Incorporation of modification requirements for the EEC and ignition supply harness

SUBTASK 72-00-32-420-165 Install the Clip Position 1048 (SBE 71-0107)

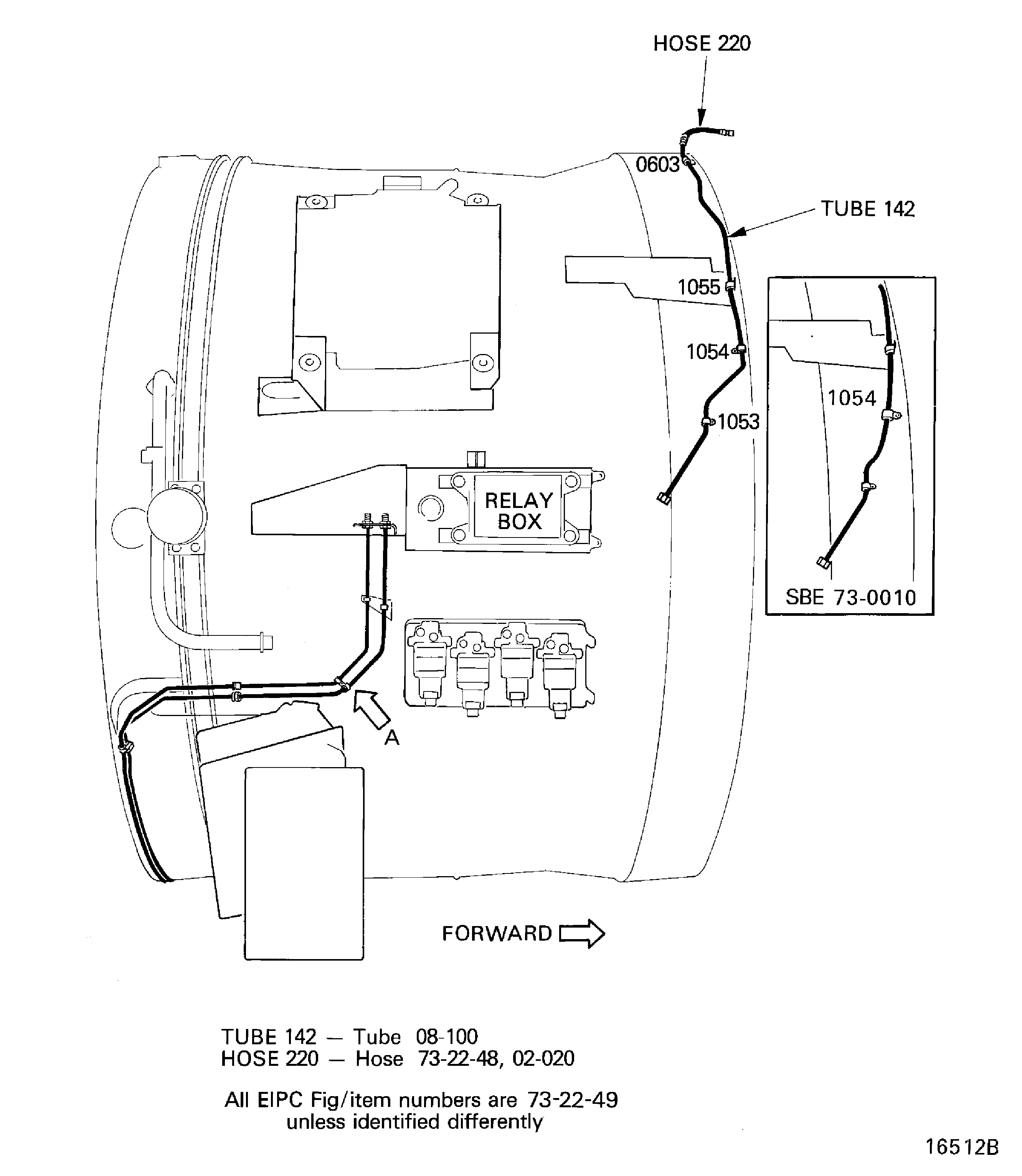

Connect the hose 220 to the tube 142. Torque the hose nut to 135 to 145 * lbf.in (15.26 to 16.39 Nm). Temporarily attach the tube 142 to the flange FA bracket with the clip, the two washers and the nut at the clip position 0793. Refer to TASK 72-00-32-420-005 for the configuration of this clip position.

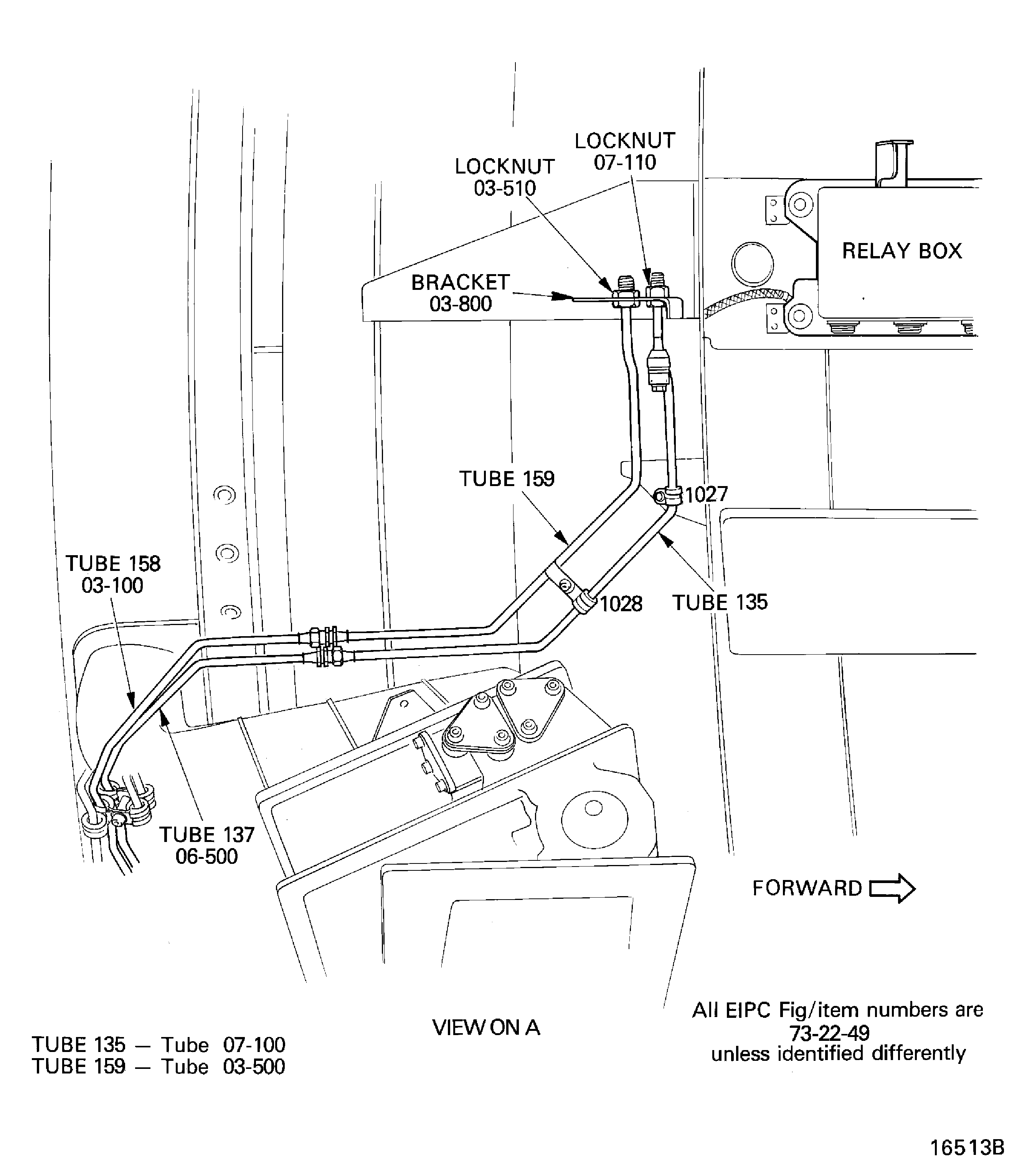

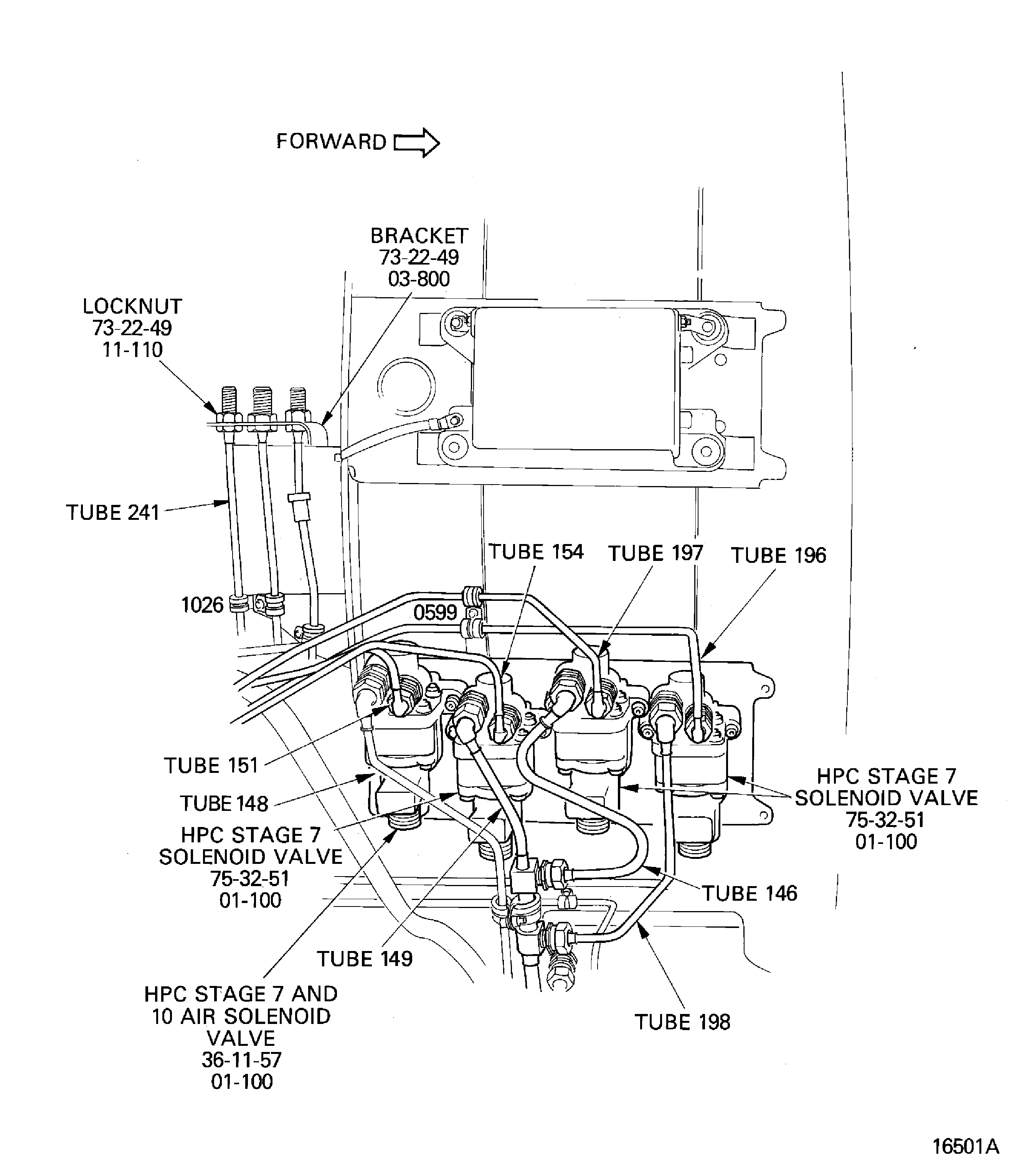

Install the tube 135 to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-800) with the locknut ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 07-110). Connect the tube 135 to the tube 137.

Install the tube 159 to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-800) with the locknut ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-510). Connect the tube 158 to the tube 159.

Torque the locknut ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 07-110) to 38 to 42 * lbf.in (4.3 to 4.7 Nm).

Torque the locknut ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-510) to 58 to 62 * lbf.in (6.5 to 7.0 Nm).

Safety the hose 220, tube 135, 158 nuts and the locknuts ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 07-110 and 03-510) with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-099-A00 Install the Hose 220 and the Tubes 142, 135 and 159 the Fuel System Air Tubes (Pre SBE 73-0010)

Connect the hose 220 to the tube 142. Torque the hose nut to 135 to 145 * lbf.in (15.26 to 16.39 Nm). Temporarily attach the tube 142 to the flange FA bracket with the clip, the two washers and the nut at the clip position 0793. Refer to TASK 72-00-32-420-005 for the configuration of this clip position.

Install the tube 135 to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-800) with the locknut ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 07-110). Connect the tube 135 to the tube 137.

Install the tube 159 to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-800) with the locknut ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-510). Connect the tube 158 to the tube 159.

Torque the locknut ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 07-110) to 38 to 42 * lbf.in (4.3 to 4.7 Nm).

Torque the locknut ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-510) to 58 to 62 * lbf.in (6.5 to 7.0 Nm).

Safety the hose 220, tube 135, 158 nuts and the locknuts ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 07-110 and 03-510) with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-099-B00 Install the Hose 220 and the Tubes 142, 135 and 159, the Fuel System Air Tubes (SBE 73-0010)

SBE 73-0010: Fuel and control - Incorporate a recontoured P2/T2 air tube assembly

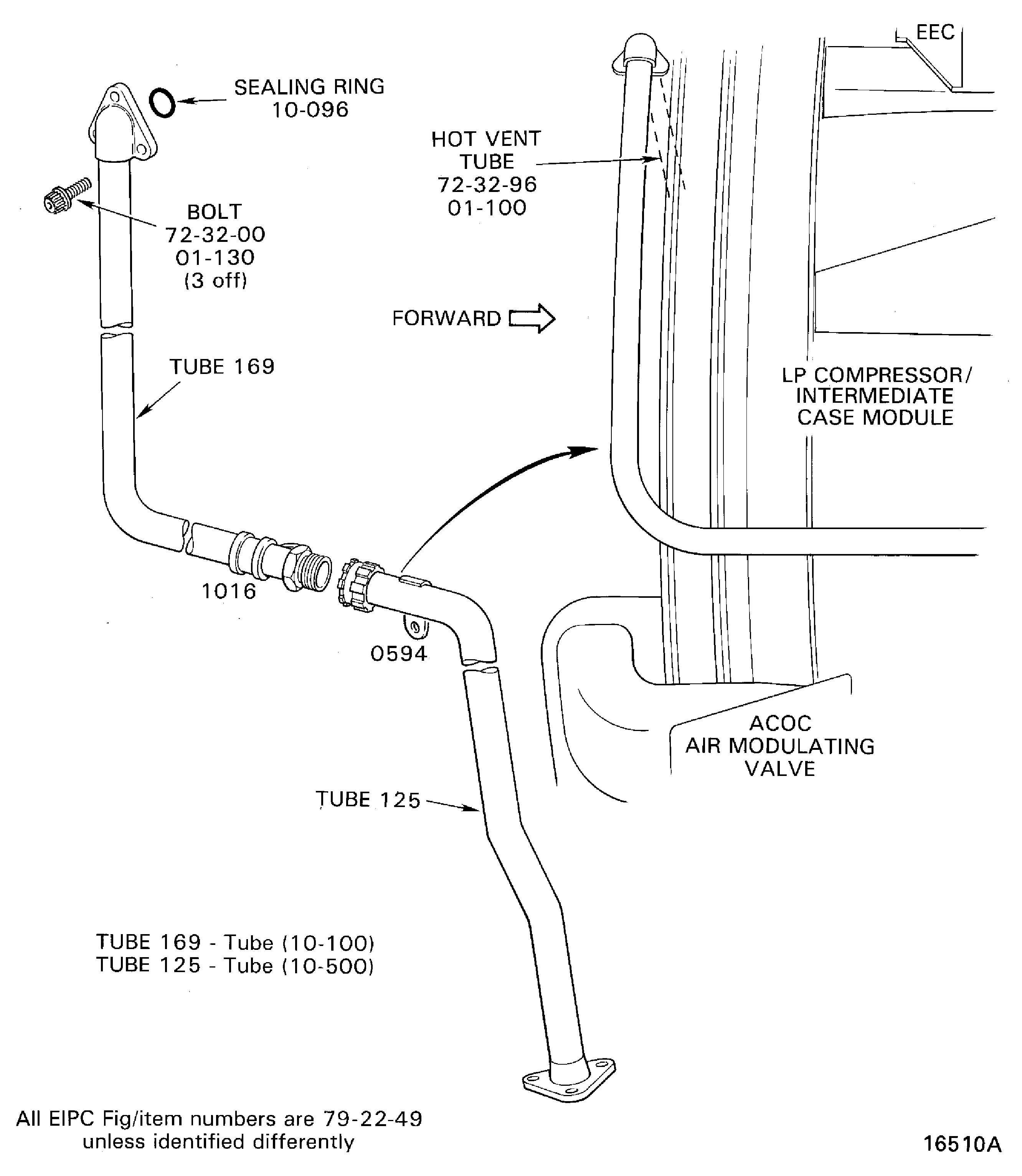

Lubricate a new OIL-SCAVENGE OIL TUBES-ENGINE (79-22-49,10-096) sealing ring 1 off with CoMat 10-077 APPROVED ENGINE OILS. Install the sealing ring on the tube 169.

Remove the three bolts ENGINE-LP COMP/INTERMEDIATE CASE MODULE (72-32-00, 01-130) from the LP compressor/intermediate case module.

Install the tube 169 to the module and the hot vent tube INTERMEDIATE STRUCTURE OIL & AIR TRANSFER TUBES (72-32-96, 01-100) with the three bolts ENGINE-LP COMP/INTERMEDIATE CASE MODULE (72-32-00, 01-130).

Torque the three bolts ENGINE-LP COMP/INTERMEDIATE CASE MODULE (72-32-00, 01-130) to 85 to 105 lbf.in (10 to 12 Nm).

Torque the tube 125 nut to 566 to 611 lbf.in (64 to 69 Nm) with the IAE 1R18003 Wrench 1 off. Safety the tube nut with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-100 Install the Tubes 169 and 125, the Scavenge Oil Tubes

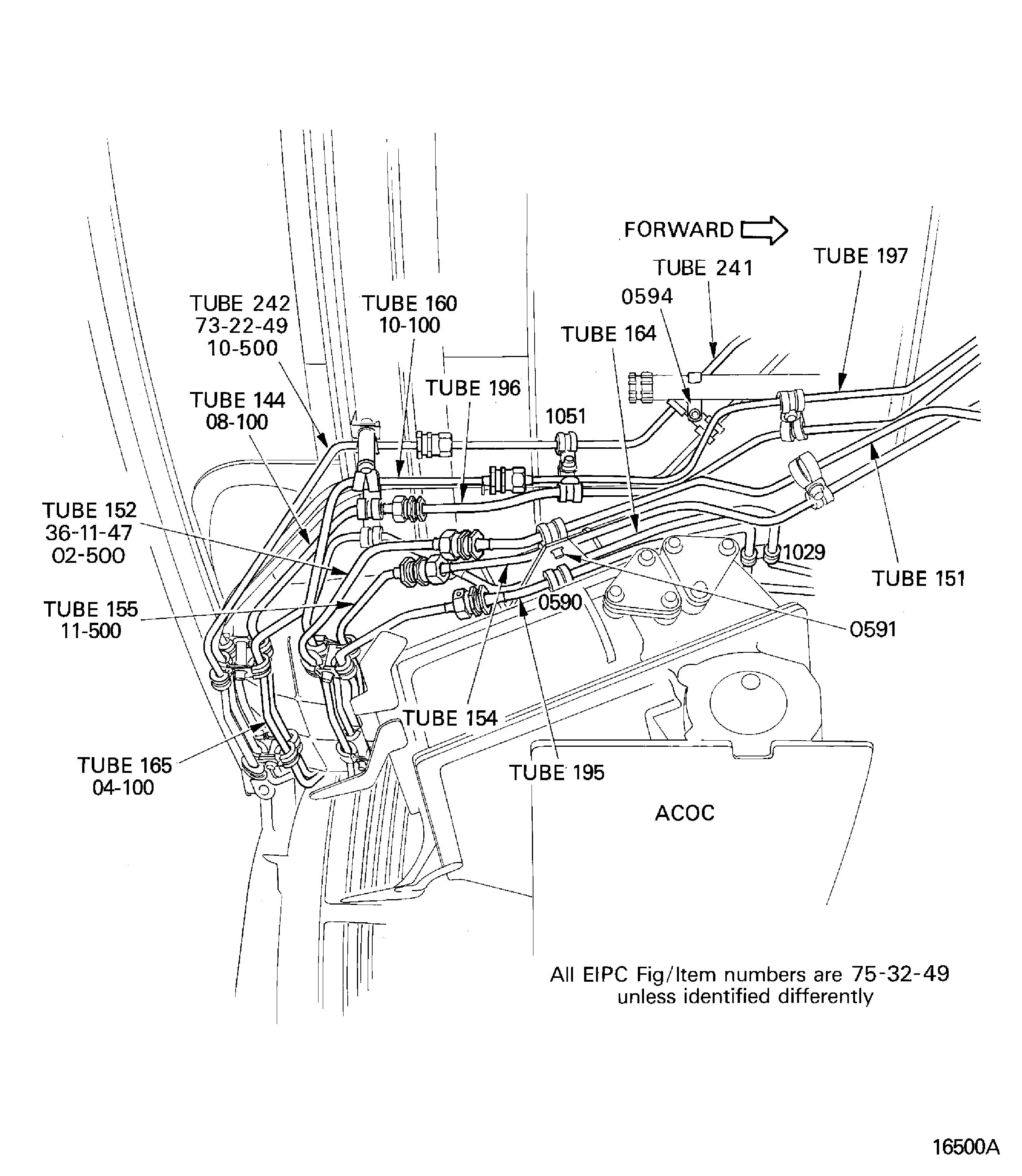

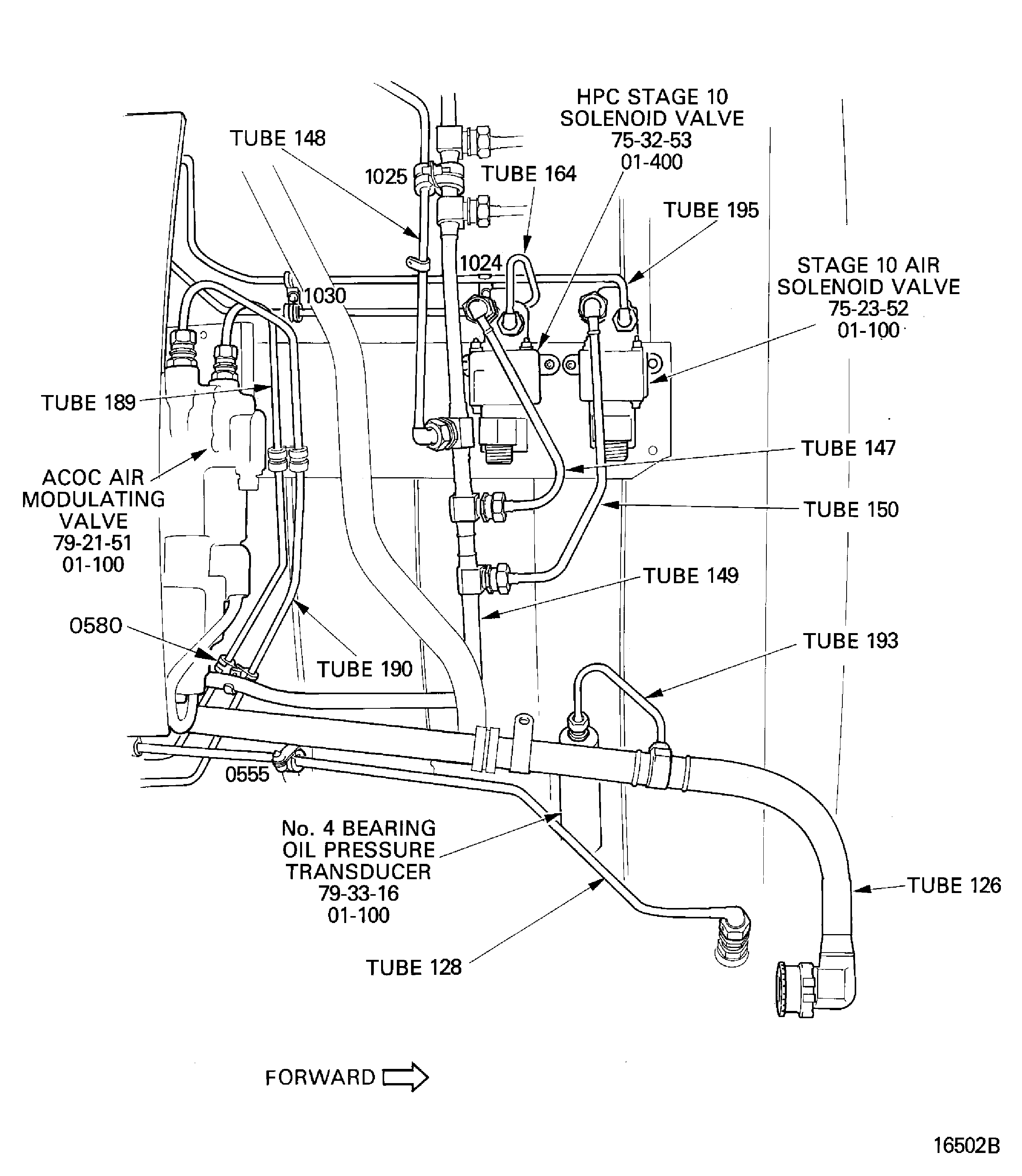

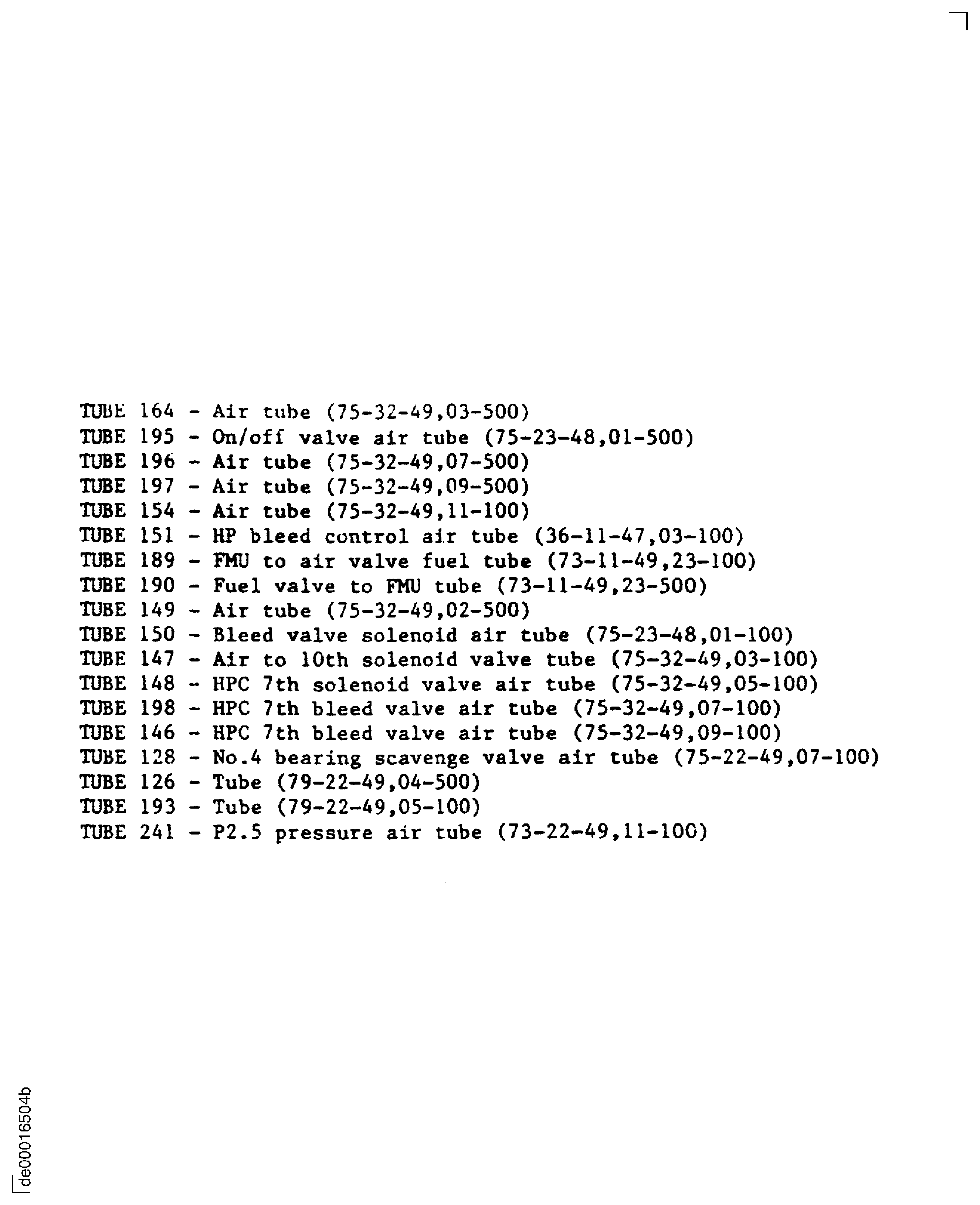

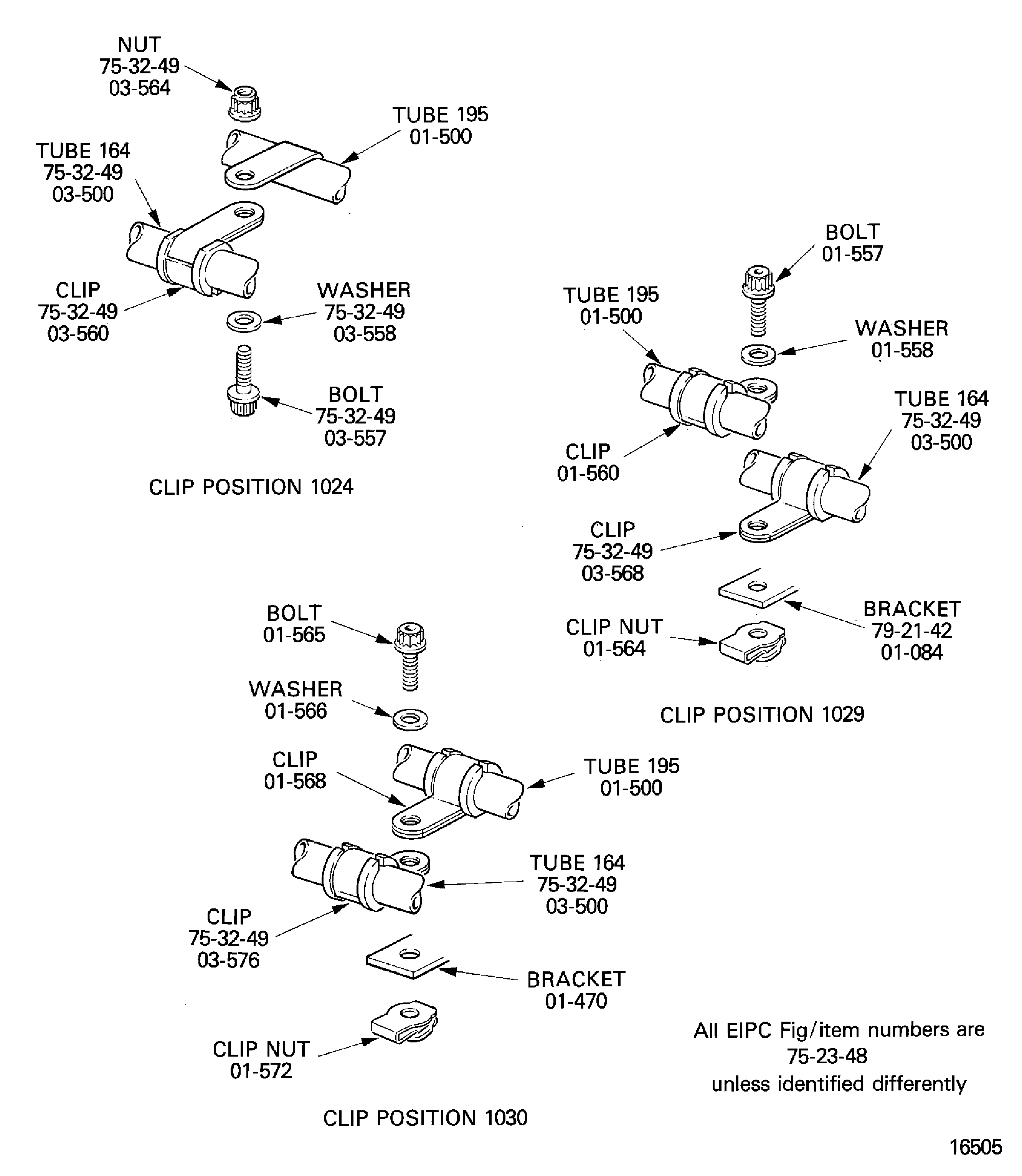

Connect the tube 164 to the tube 165 and the HPC stage 10 solenoid valve (81.9 degrees) AIR-HPC STAGE 10 SOLENOID VALVE (75-32-53, 01-400).

Connect the tube 163 to the tube 195. Connect the tube 195 to the stage 10 air solenoid valve AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-100).

Connect the tube 144 to the tube 196. Connect the tube 196 to the HPC stage 7 solenoid valve (108.8 degrees) AIR-HPC STAGE 7 SOLENOID VALVE (75-32-51, 01-100).

Connect the tube 197 to the tube 160 and the HPC stage 7 solenoid valve (228 degrees) AIR-HPC STAGE 7 SOLENOID VALVE (75-32-51, 01-100).

Connect the tube 154 to the tube 155 and the HPC stage 7 solenoid valve (51.9 degrees) AIR-HPC STAGE 7 SOLENOID VALVE (75-32-51, 01-100).

Connect the tube 152 to the tube 151. Connect the tube 151 to the HPC stage 7 and 10 air solenoid valve STAGE 10 AIR SOLENOID VALVE (36-11-57, 01-100).

Connect the tube 241 to the tube 242, attach the tube 242 to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-800) with the locknut ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 11-110).

Torque the locknut ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 11-110) to 38 to 42 * lbf.in (4.3 to 4.7 Nm).

Torque the tube 164, 163, 195, 144, 196, 197, 154, 152 and 241 nuts to 159 to 177 lbf.in (18 to 20 Nm). Safety the tube nuts and the locknut with CoMat 02-126 LOCKWIRE.

Torque the tube 151 nut to 204 to 221 lbf.in (23 to 25 Nm). Safety the tube nut with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-142 Install the Right Side Tubes

NOTE

It could be necessary to make an adjustment to the position of the tube 188 at the clip positions 1036 and 0578.Connect the tube 189 to the ACOC air modulating valve OIL-AIR COOLED OIL COOLER MODULATING VALVE(79-21-51, 01-100) and the tube 188.

Safety the tube nuts with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-102 Install the Tubes 189 and 190, the Fuel System Tubes

Connect the tube 149 to the tube 167 and the HPC stage 7 solenoid valve (51.9 degrees) AIR-HPC STAGE 7 SOLENOID VALVE (75-32-51, 01-100).

Safety the tube nuts with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-103 Install the Tube 149, the HP Compressor Bleed Air Tube

Refer to Figure

Connect the tube 150 to the tube 149 and the stage 10 air solenoid valve AIR-STAGE 10 AIR SOLENOID VALVE (75-23-52, 01-100). Torque the tube 150 nuts to 204 to 221 lbf.in (23 to 25 Nm).

Safety the tube nuts with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-104 Install the Tube 150 to the Turbine Cooling Controlled Air Tube System

Connect the tube 147 to the HPC stage 10 solenoid valve (81.9 degrees) AIR-HPC STAGE 10 SOLENOID VALVE (75-32-53, 01-400) and the tube 149.

Connect the tube 148 to the HPC stage 7 and 10 air solenoid valve STAGE 10 AIR SOLENOID VALVE (36-11-57, 01-100) and the tube 149.

Connect the tube 198 to the HPC stage 7 solenoid valve (108.8 degrees) AIR-HPC STAGE 7 SOLENOID VALVE (75-32-51, 01-100) and the tube 149.

Connect the tube 146 to the HPC stage 7 solenoid valve (228 degrees) AIR-HPC STAGE 7 SOLENOID VALVE (75-32-51, 01-100) and the tube 149.

Torque the tubes 146 to 148 and 198 nuts to 204 to 221 lbf.in (23 to 25 Nm). Safety the tube nuts with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-105 Install the Tubes 198 and 146 to 148, the HP Compressor (HPC) Bleed Air Tubes

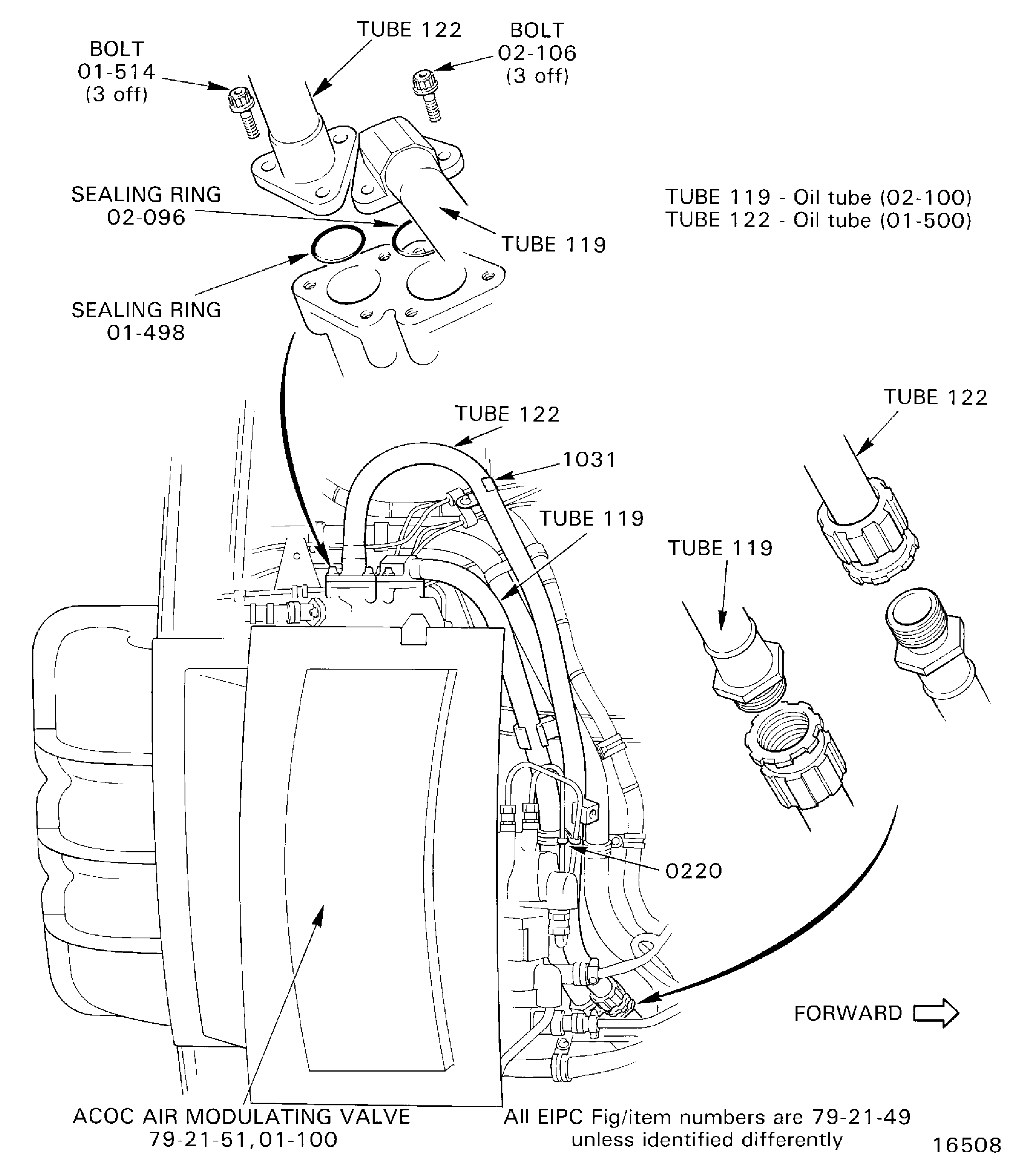

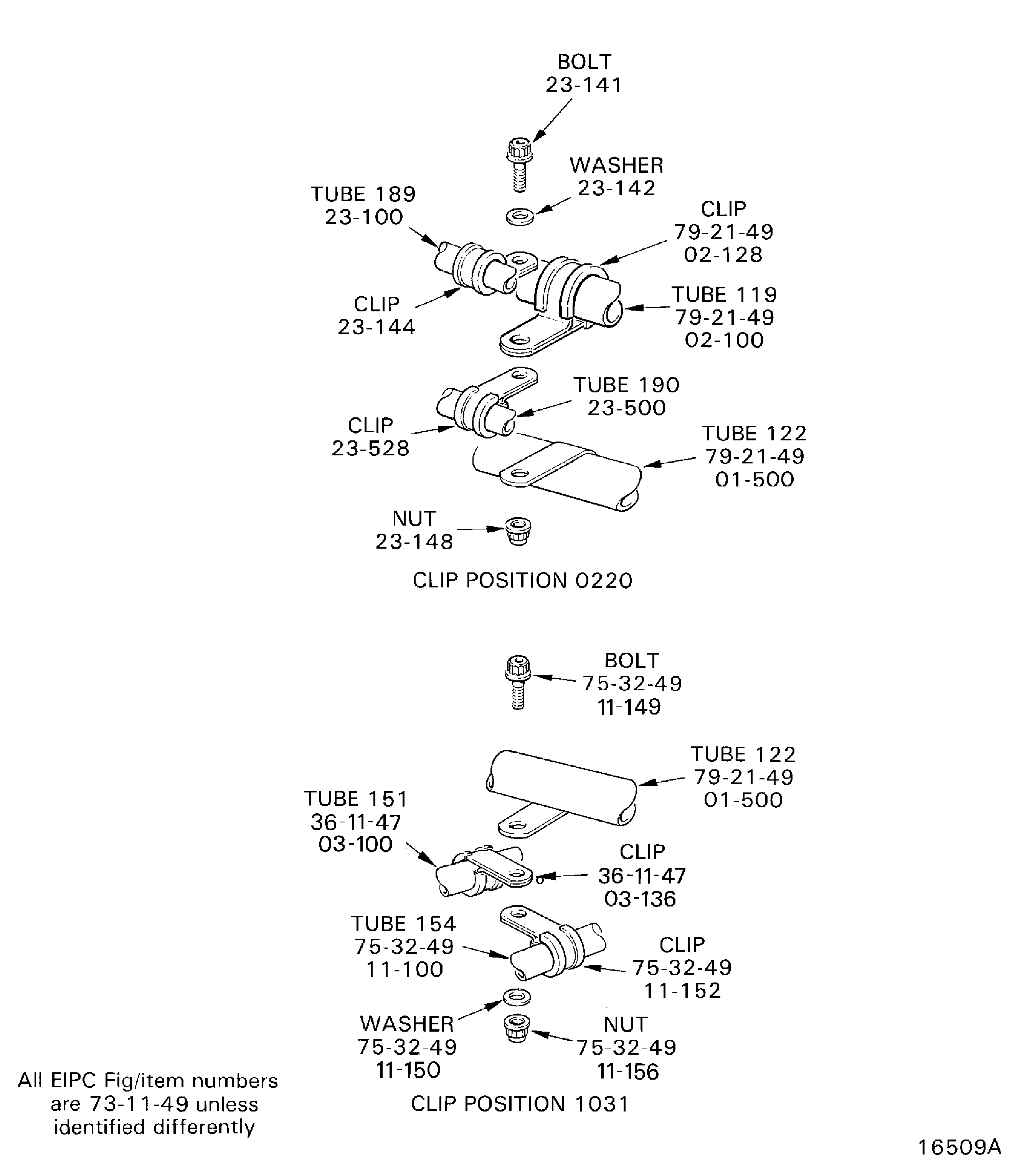

Lubricate a new OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-096) sealing ring 1 off with CoMat 10-077 APPROVED ENGINE OILS. Install the sealing ring on the tube 119.

Lubricate a new OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-498) sealing ring 1 off with CoMat 10-077 APPROVED ENGINE OILS. Install the sealing ring on the tube 122.

Install the tube 119 to the ACOC OIL-AIR COOLED OIL COOLER (79-21-42, 01-100) with the three bolts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-106).

Install the tube 122 to the ACOC with the three bolts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-514).

Torque the six bolts OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 02-106) and OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 01-514) to 85 to 105 lbf.in (10 to 12 Nm).

SUBTASK 72-00-32-420-106 Install the Tubes 119 and 122, the Pressure Oil Tubes

Refer to Figure.

Safety the tube nut with CoMat 02-126 LOCKWIRE.

Connect the tube 193 to the No. 4 bearing oil pressure transducer OIL-NO.4 BEARING PRESSURE TRANSDUCER (79-33-16, 01-100) and the tube 126.

Torque the tube 127 nut to 566 to 611 lbf.in (64 to 69 Nm) with the IAE 1R18003 Wrench 1 off.

Safety the tube nuts with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-143 Install the Tubes 128, 126 and 193, the Scavenge Oil Tubes

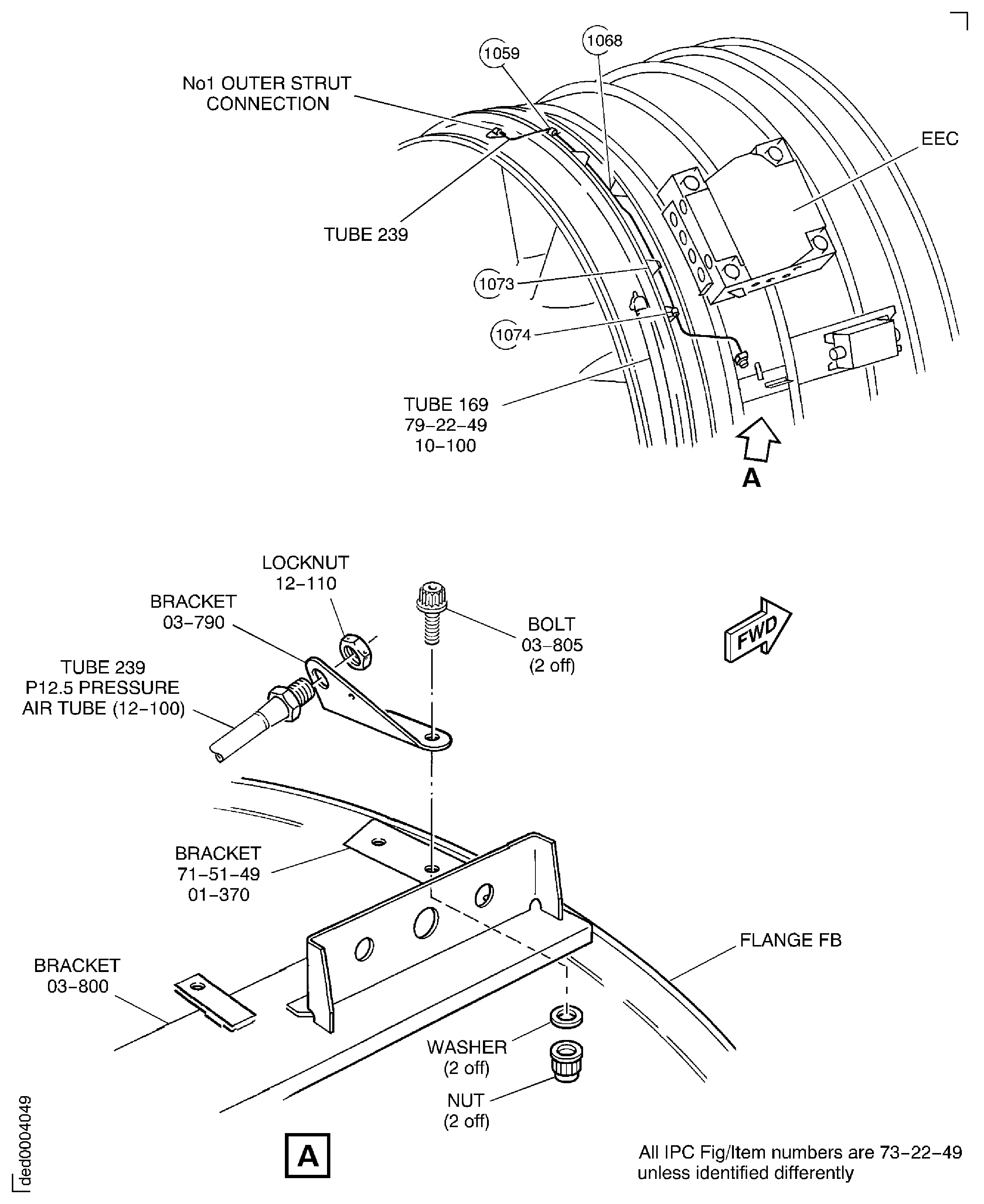

Refer to Figure.

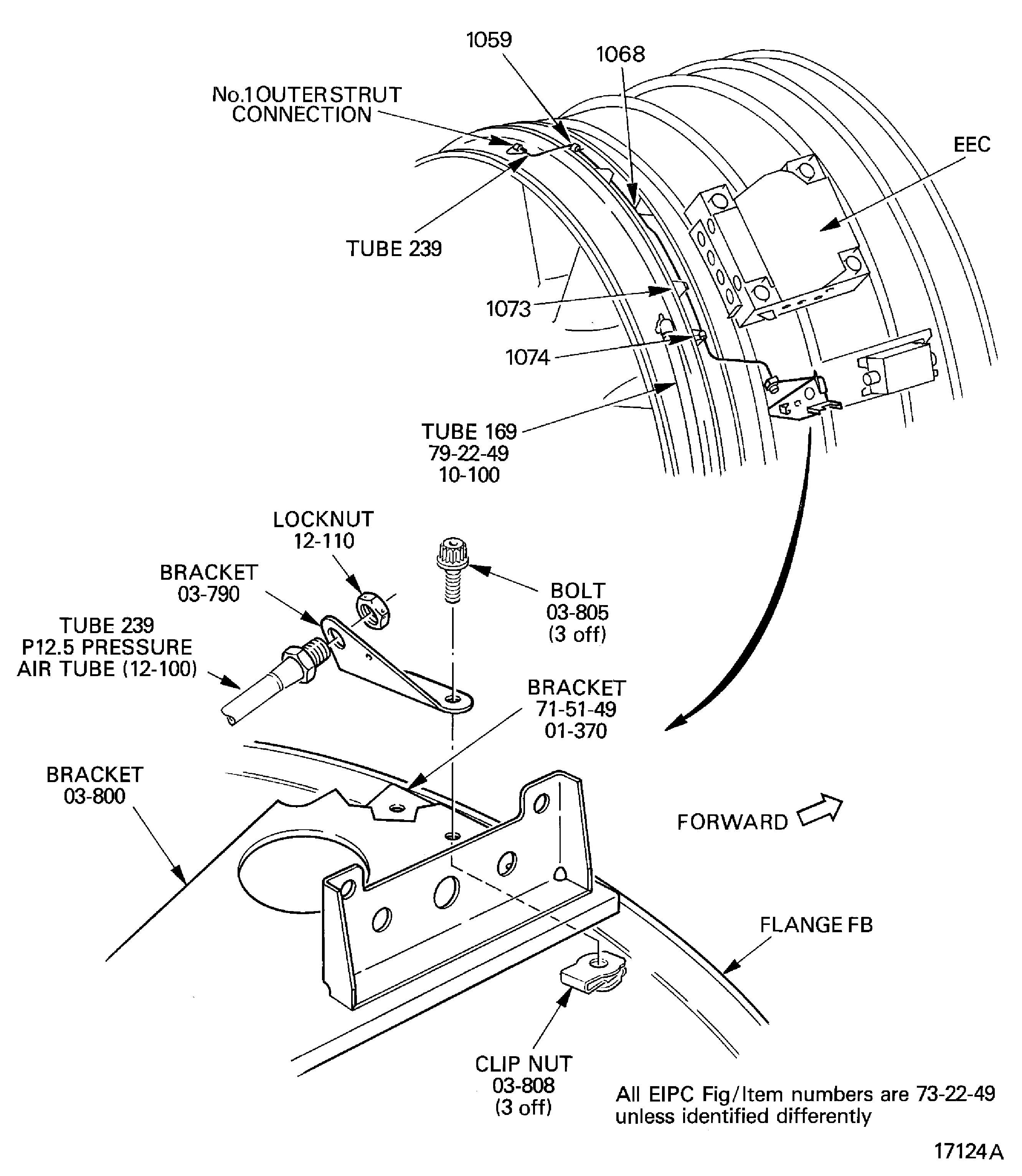

Remove the top two bolts of the three bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-805) which attach the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-800) to the bracket POWER PLANT-RELAY BOX (71-51-49, 01-370).

Attach the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-790) to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-800) with the two bolts ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-805). Torque the two bolts to 85 to 105 lbf.in (10 to 12 Nm).

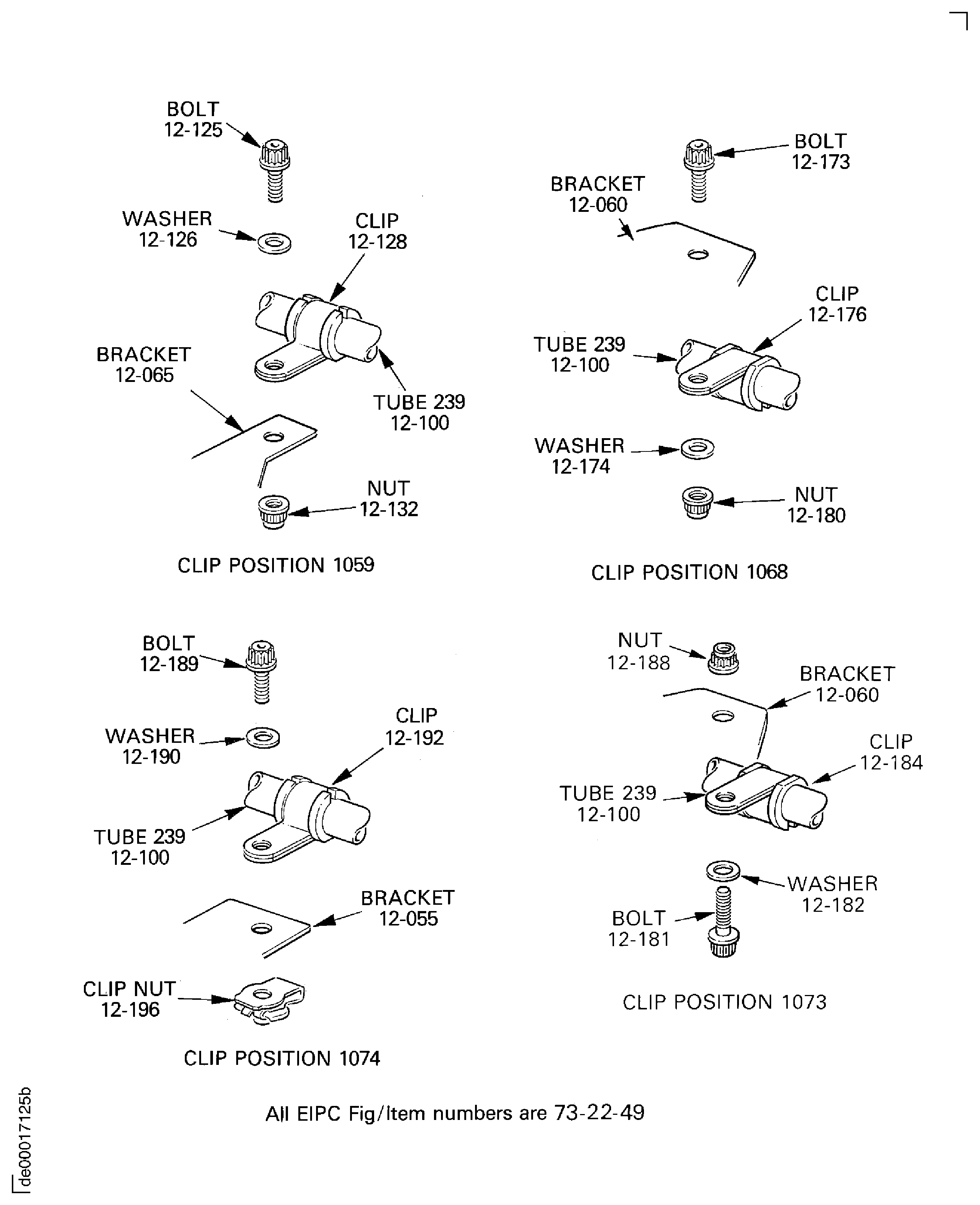

Attach the tube 239 to the flange brackets at the clip positions 1059, 1068, 1073 and 1074 with the bolts, the washers, the nuts and the clipnut.

Refer to Figure.

Attach the tube 239 to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-790) with the locknut ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 12-110).

Torque the tube 239 nut to 159 to 177 lbf.in (18 to 20 Nm). Safety the tube nut with CoMat 02-126 LOCKWIRE.

Torque the locknut ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 12-110) to 38 to 42 * lbf.in (4.3 to 4.7 Nm). Safety the locknut to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-790) with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-144-A00 Install the Tube 239, the Fuel System Air Tube (Pre SBE 73-0140)

Refer to Figure.

SBE 73-0140: Engine fuel and control - Fuel system air tubes - Introduction of revised EEC pipe-support bracket.

Attach the tube 239 to the flange brackets at the clip positions 1059, 1068, 1073 and 1074 with the bolts, the washers, the nuts and the clipnut.

Refer to Figure.

NOTE

Refer to TASK 72-00-32-420-001-A00, SUBTASK 72-00-32-420-279-A00 for the installation of bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-790).Attach the tube 239 to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-790) with the locknut ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 12-110).

Torque the tube 239 nut to 159 to 177 lbf.in (18 to 20 Nm). Safety the tube nut with CoMat 02-126 LOCKWIRE.

Torque the locknut ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 12-110) to 38 to 42 * lbf.in (4.3 to 4.7 Nm). Safety the locknut to the bracket ENGINE FUEL AND CONTROL-FUEL SYSTEM AIR TUBES (73-22-49, 03-790) with CoMat 02-126 LOCKWIRE.

SUBTASK 72-00-32-420-144-B00 Install the Tube 239, the Fuel System Air Tube (SBE 73-0140)

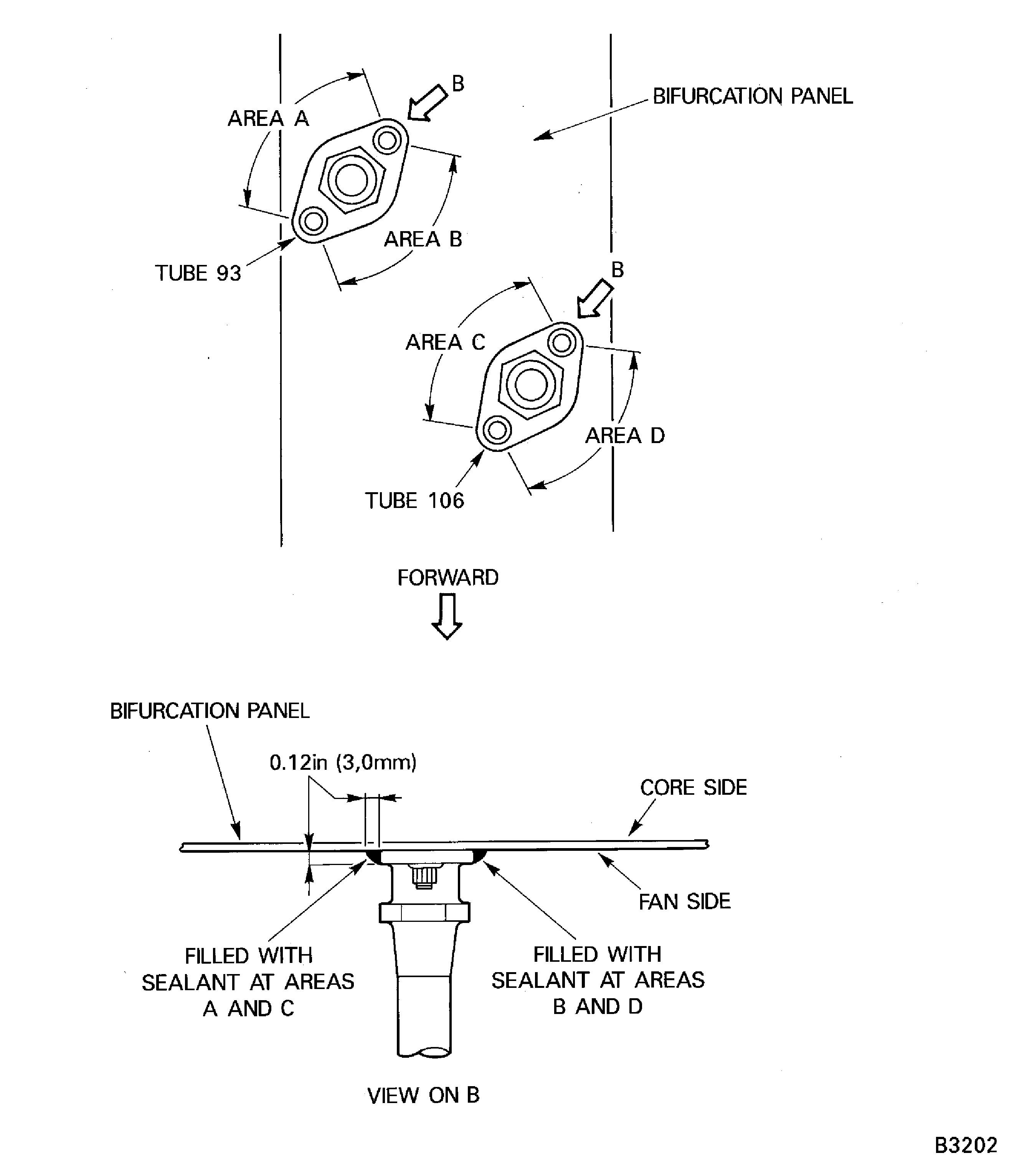

Refer to Figure.

Refer to SPM TASK 70-11-26-300-503 for the procedure to locally swab clean.

Hand clean the specified surfaces with CoMat 05-016 GARNET PAPER, 80-GRIT or CoMat 05-017 GARNET PAPER, 60 GRIT.

Locally swab clean the areas again, refer to the SPM TASK 70-11-26-300-503.

NOTE

Make sure that there are no remaining cleaners in clearances between the bifurcation panel and the fuel tube connectors. The surfaces to be filled must be dry and free from grease, oil and dust.Use dry compressed air or CoMat 02-099 LINT-FREE CLOTH , dry the cleaned areas.

For CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT air dry for 30 minutes.

For CoMat 08-032 PRIMER air dry for 60 to 90 minutes.

Dry the primer:

Use a spatula to apply the CoMat 08-013 COLD CURING SILICONE COMPOUND compound or CoMat 08-074 SEALANT, RTV SILICONE.

Apply the sealant:

NOTE

The surface of the compound can be touched after 12 hours.

Do not apply a load during this time.

For CoMat 08-013 COLD CURING SILICONE COMPOUND cold cure at 68 deg F (20 deg C) for 48 hours.

NOTE

The surface of the sealant can be touched after 1 or 2 hours.

Do not apply a load during this time.

For CoMat 08-074 SEALANT, RTV SILICONE cure at 77 deg F (35 deg C) for 24 hours.

Cure the sealant:

SUBTASK 72-00-32-420-419 Seal the Tube Connections at the Bifurcation Panel. (SBE 72-0193)

SBE 72-0193: Core to fancase interface sealing of the bifurcation panel.

Figure: Install the EEC and Ignition Supply Harness Raceway

Install the EEC and Ignition Supply Harness Raceway

Figure: Install the Vibration Harness Raceway

Install the Vibration Harness Raceway

Figure: Install the Vibration Transducer Raceway

Install the Vibration Transducer Raceway

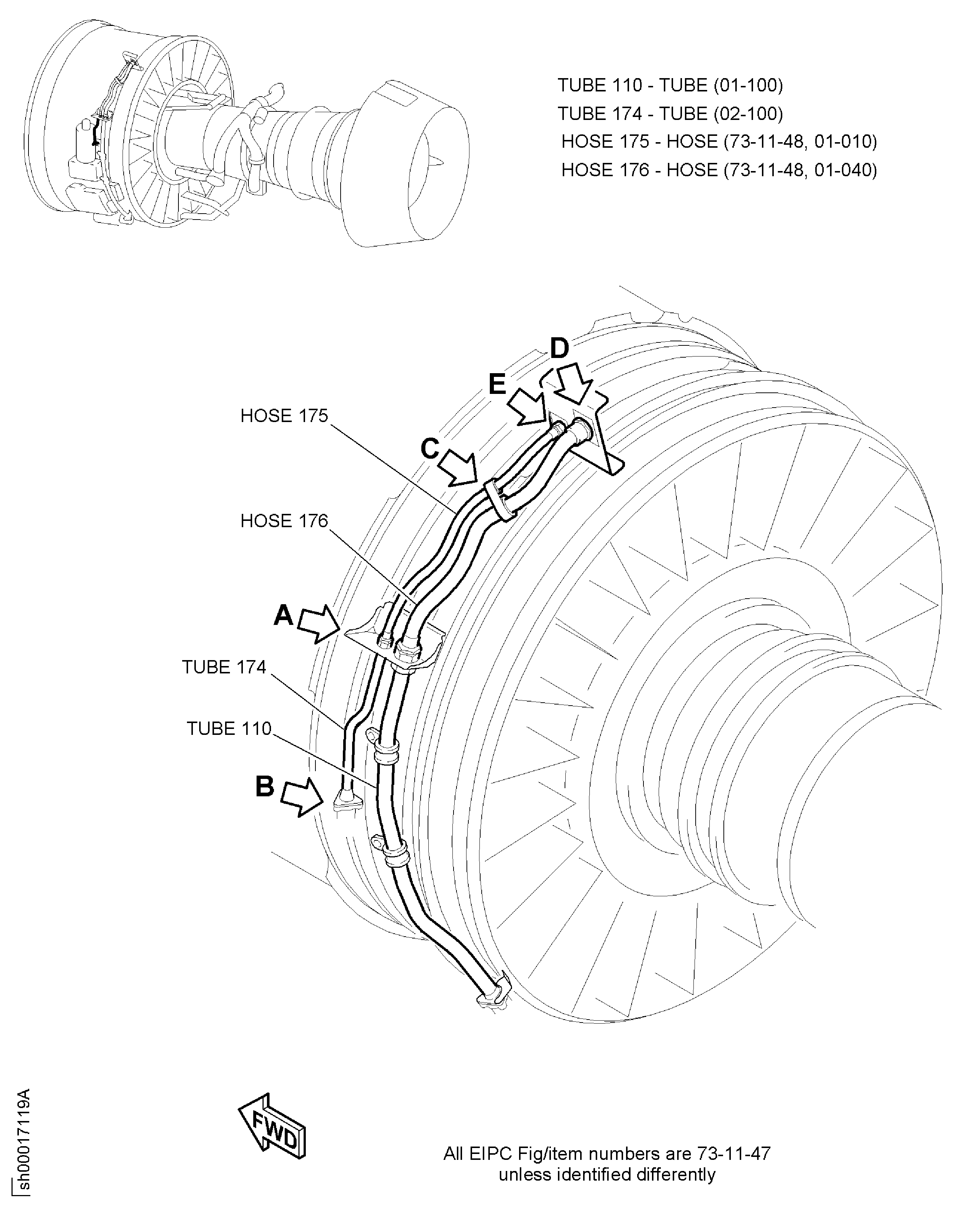

Figure: Install the Tubes 174 and 110, the Power Plant Fuel Tubes

Install the Tubes 174 and 110, the Power Plant Fuel Tubes

Figure: Install the Tubes 174 and 110, the Power Plant Fuel Tubes

Install the Tubes 174 and 110, the Power Plant Fuel Tubes

Figure: Install the Tubes 174 and 110, the Power Plant Fuel Tubes

Install the Tubes 174 and 110, the Power Plant Fuel Tubes

Figure: Install the Tubes 174 and 110, the Power Plant Fuel Tubes

Sheet 4

Figure: Install the Tubes 110, 117 and 172

Sheet 1

Figure: Install the Tubes 110, 117 and 172

Sheet 2

Figure: Install the Tubes 110, 117 and 172

Sheet 3

Figure: Install the Tubes 114, 115, 111, 113, 177 and 120, the Pressure Oil Tubes

Sheet 1

Figure: Install the Tubes 114, 115, 111, 113, 177 and 120, the Pressure Oil Tubes

Sheet 2

Figure: Install the tubes 114, 115, 111, 113, 177 and 120, the Pressure Oil Tubes

Sheet 3

Figure: Install the Tubes 114, 115, 111, 113, 177 and 120, the Pressure Oil Tubes

Sheet 4

Figure: Install the Tubes 114, 115, 111, 113, 177 and 120, the Pressure Oil Tubes

Sheet 5

Figure: Install the Tubes 96 to 98, the IDG Cooling Tubes

Sheet 1

Figure: Install the Tubes 96 to 98, the IDG Cooling Tubes

Sheet 2

Figure: Install the Tubes 170 and 171, the Fuel System Tubes

Install the Tubes 170 and 171, the Fuel System Tubes

Figure: SBE 71-0110: Install the Dedicated Alternator Cooling Air Tubes

Sheet 1

Figure: SBE 75-0010: Install the Dedicated Alternator Cooling Air Tubes

Sheet 2

Figure: SBE 75-0010: Install the Dedicated Alternator Cooling Air Tubes

Sheet 3

Figure: SBE 75-0010: Install the Dedicated Alternator Cooling Air Tubes

Sheet 4

Figure: Install the Dedicated Alternator Cooling Air Tubes

Sheet 5

Figure: Install the Pressure/Scavenge Oil Tubes to the Left Side of the LP Compressor/Intermediate Case

Sheet 1

Figure: Install the Pressure/Scavenge Oil Tubes to the Left Side of the LP Compressor/intermediate Case

Sheet 2

Figure: Install the Pressure/Scavenge Oil Tubes to the Left Side of the LP Compressor/Intermediate Case

Sheet 3

Figure: Install the Pressure/Scavenge Oil Tubes to the Left Side of the LP Compressor/Intermediate Case

Sheet 4

Figure: Install the Pressure/Scavenge Oil Tubes to the Left Side of the LP Compressor/Intermediate Case

Sheet 5

Figure: Install the Pressure/Scavenge Oil Tubes to the Left Side of the LP Compressor/Intermediate Case

Sheet 6

Figure: Install the Pressure/Scavenge Oil Tubes to the Left Side of the LP Compressor/Intermediate Case

Sheet 7

Figure: Install the Electrical Harness Raceway

Sheet 1

Figure: Install the Electrical Harness Raceway

Sheet 2

Figure: Install the Tubes and the Fuel Flow Transmitter to the Bottom of the LP Compressor/Intermediate Case

Sheet 1

Figure: Install the Tubes and the Fuel Flow Transmitter to the Bottom of the LP Compressor/Intermediate Case

Sheet 2

Figure: Pre SBE73-0019: Install the Tubes at the Bifurcation Panel

Sheet 1

Figure: SBE73-0019: Install the Tubes at the Bifurcation Panel

Sheet 2

Figure: Pre SBE 79-0087: Install the Tubes at the Bifurcation Panel

Sheet 3

Figure: Pre SBE 79-0087: Install the Tubes at the Bifurcation Panel

Sheet 4

Figure: Install the Tubes at the Bifurcation Panel

Sheet 5

Figure: Install the Tubes at the Bifurcation Panel

Sheet 6

Figure: Install the Tubes at the Bifurcation Panel

Sheet 7

Figure: Install the Tubes at the Bifurcation Panel

Sheet 8

Figure: Install the Tubes at the Bifurcation Panel

Sheet 9

Figure: Install the Tubes at the Bifurcation Panel

Sheet 10

Figure: Install the Tubes at the Bifurcation Panel

Sheet 11

Figure: Install the Tubes at the Bifurcation Panel

Sheet 12

Figure: Install the Tubes at the Bifurcation Panel

Sheet 13

Figure: Install the Tubes at the Bifurcation Panel

Sheet 14

Figure: Install the Tubes at the Bifurcation Panel

Sheet 15

Figure: Install the Tubes at the Bifurcation Panel

Sheet 16

Figure: Install the LP Compressor/Intermediate Case Bottom Right Side Tubes

Sheet 1

Figure: Install the LP Compressor/Intermediate Case Bottom Right Side Tubes

Sheet 2

Figure: Install the LP Compressor/Intermediate Case Bottom Right Side Tubes

Sheet 3

Figure: Install the LP Compressor/Intermediate Case Bottom Right Side Tubes

Sheet 4

Figure: Install the LP Compressor/Intermediate Case Bottom Right Side Tubes

Sheet 5

Figure: Install the LP Compressor/Intermediate Case Right Rear Side Tubes

Sheet 1

Figure: Install the LP Compressor/Intermediate Case Right Rear Side Tubes

Sheet 2

Figure: Install the LP Compressor/Intermediate Case Right Rear Side Tubes

Sheet 3

Figure: Install the LP Compressor/Intermediate Case Right Rear Side Tubes

Sheet 4

Figure: Install LP Compressor/Intermediate Case Right Rear Side Tubes

Sheet 5

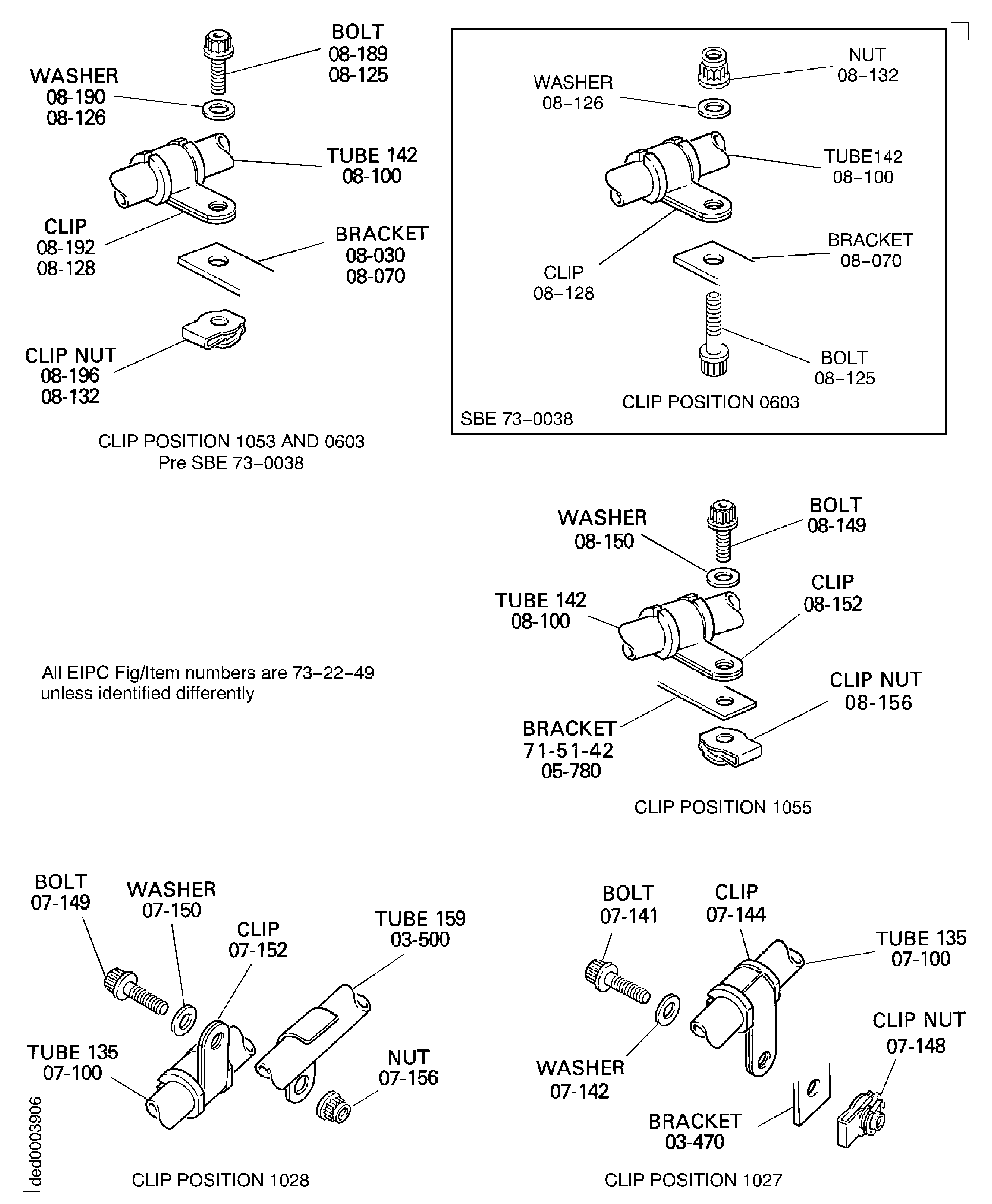

Figure: Install the tubes 159, 135 and 142, the fuel system air tubes and the hose 220

Install the tubes 159, 135 and 142, the fuel system air tubes and the hose 220

Figure: Install the Tubes 159, 135 and 142, the Fuel System Air Tubes and the Hose 220

Sheet 2

Figure: Install the Tubes 159, 135 and 142, the Fuel System Air Tubes and the Hose 220

Sheet 3

Figure: Install the Tubes 159, 135 and 142, the Fuel System Air Tubes and the Hose 220

Sheet 4

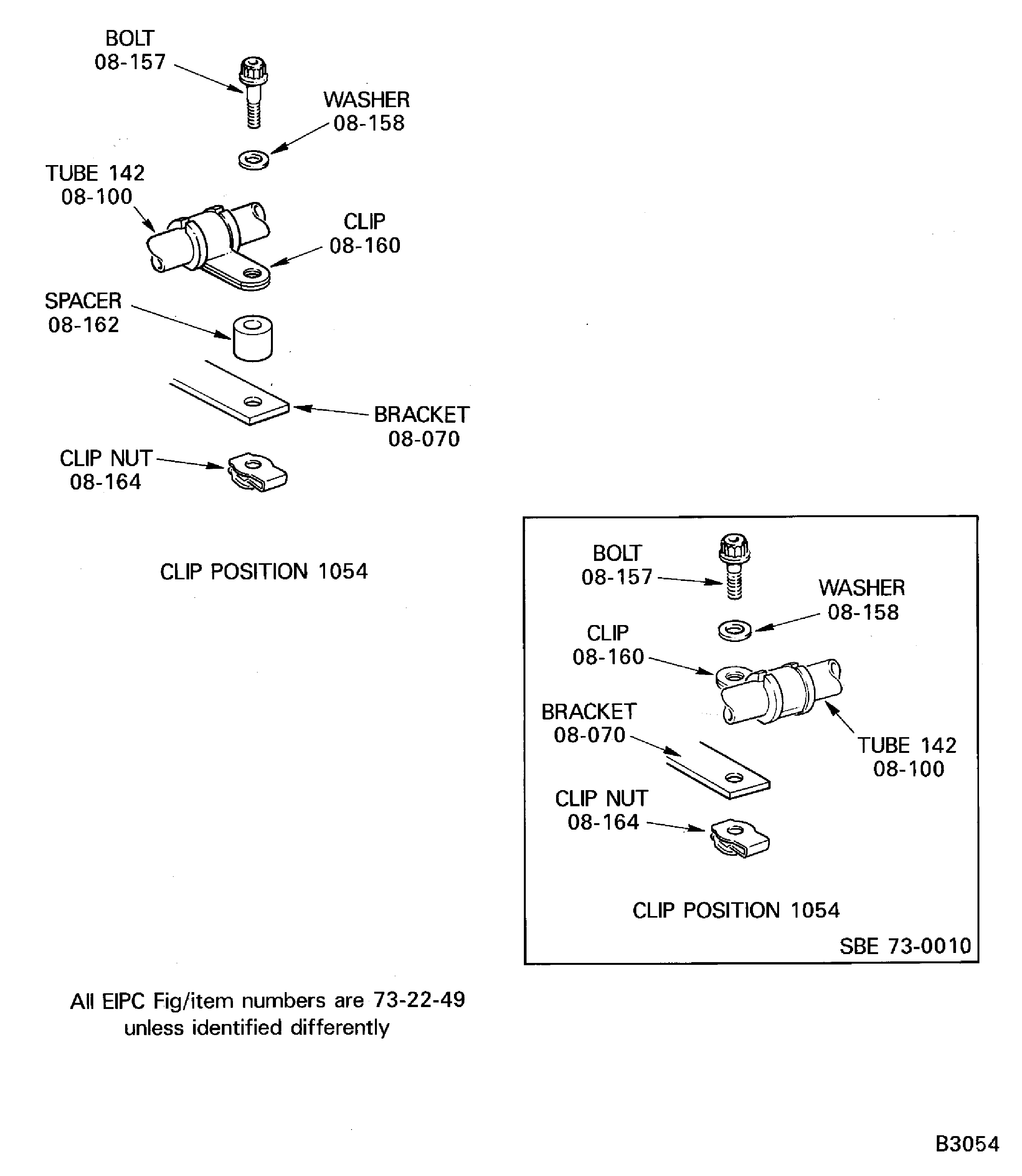

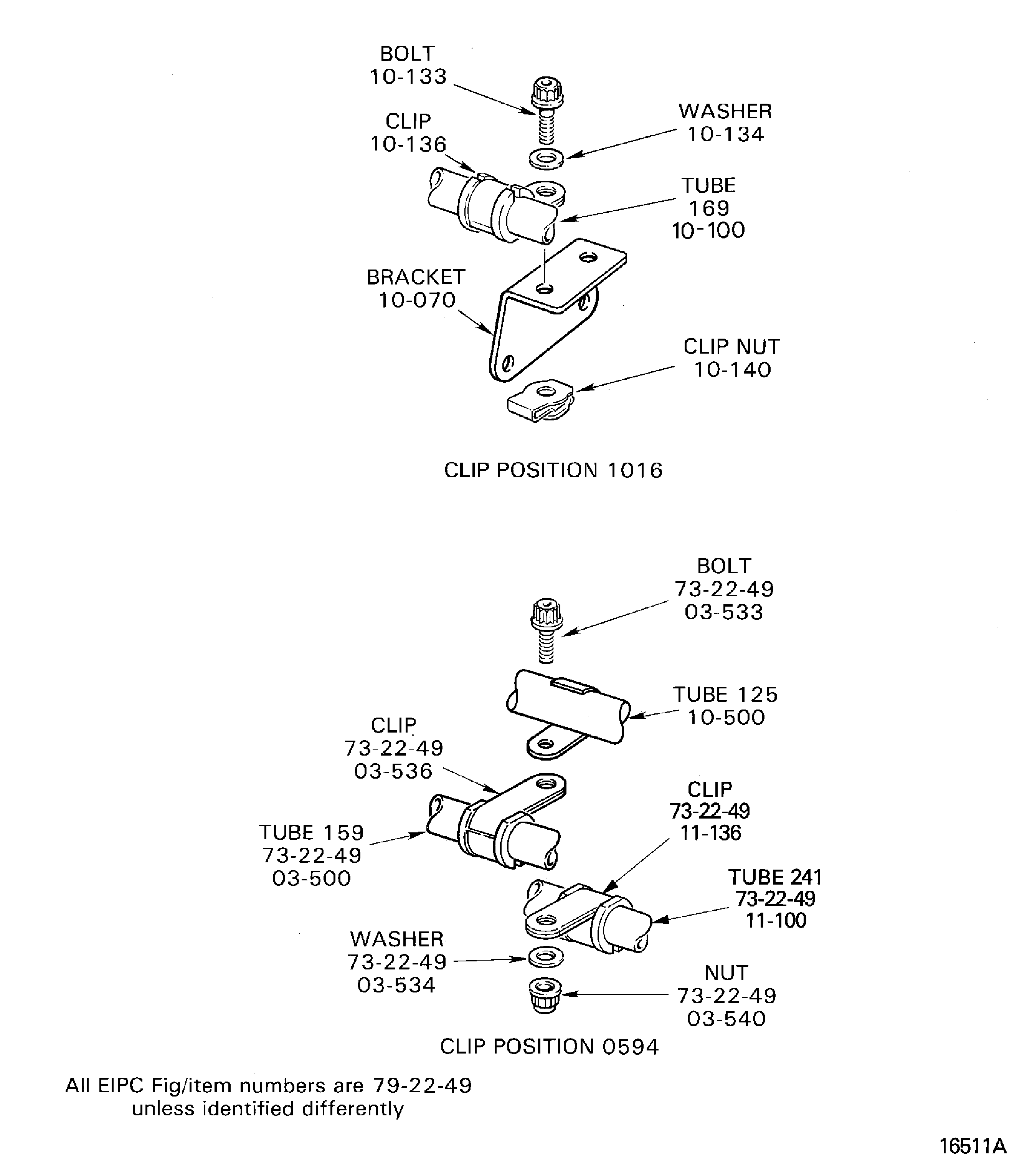

Figure: Install the Tubes 125 and 169, the Scavenge Oil Tubes

Sheet 1

Figure: Install the Tubes 125 and 169, the Scavenge Oil Tubes

Sheet 2

Figure: Install the Tubes 119 and 122, the Pressure Oil Tubes

Sheet 1

Figure: Install the Tubes 119 and 122, the Pressure Oil Tubes

Sheet 2

Figure: Install the LP Compressor/Intermediate Case Right Side Tubes

Sheet 1

Figure: Install the LP Compressor/Intermediate Case Right Side Tubes

Sheet 2

Figure: Install the LP Compressor/Intermediate Case Right Side Tubes

Sheet 3

Figure: Install the LP Compressor/Intermediate Case Right Side Tubes

Sheet 4

Figure: Install the LP Compressor/Intermediate Case Right Side Tubes

Sheet 5

Figure: Install the LP Compressor/Intermediate Case Right Side Tubes

Sheet 6

Figure: Install the LP Compressor/Intermediate Case Right Side Tubes

Sheet 7

Figure: Install the LP Compressor/Intermediate Case Right Side Tubes

Sheet 8

Figure: Install the LP Compressor/Intermediate Case Right Side Tubes

Sheet 9

Figure: Pre SBE 73-0140: Install the Tube 239, the Fuel System Air Tube

Sheet 1

Figure: SBE 73-0140: Install the Tube 239, the Fuel System Air Tube

Sheet 2

Figure: Install the Tube 239, the Fuel System Air Tube

Sheet 3